System and process for continuous industrial preparation of 3-chloropropylchlorosilanes

A technology of allyl chloride and equipment, which is applied in the field of equipment and methods for continuous industrial preparation of 3-chloropropylchlorosilane, and can solve the problems of lacking and unrealized organosilane micro-reactor technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0080] Preparation of 3-Chloropropyltrichlorosilane

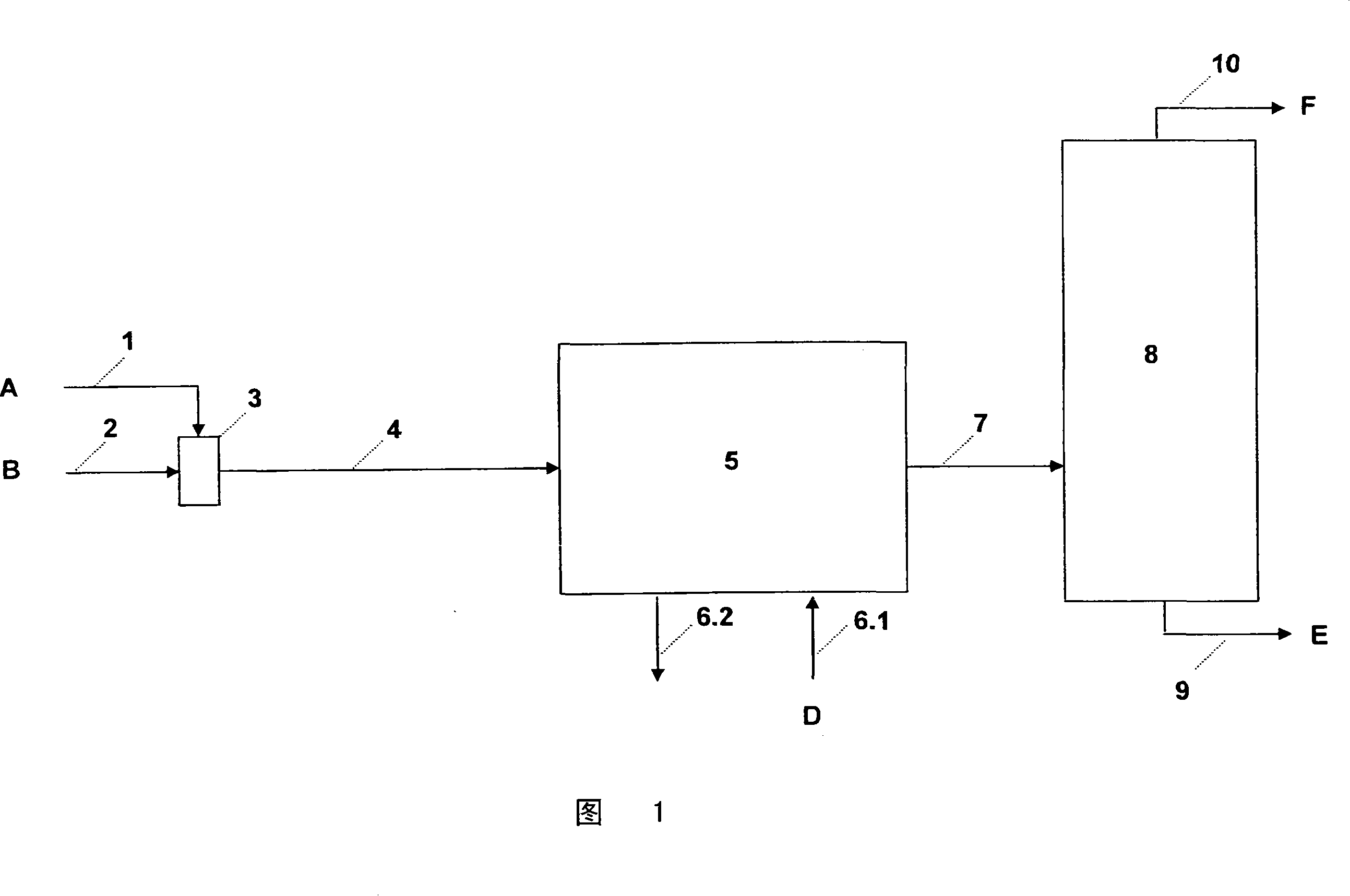

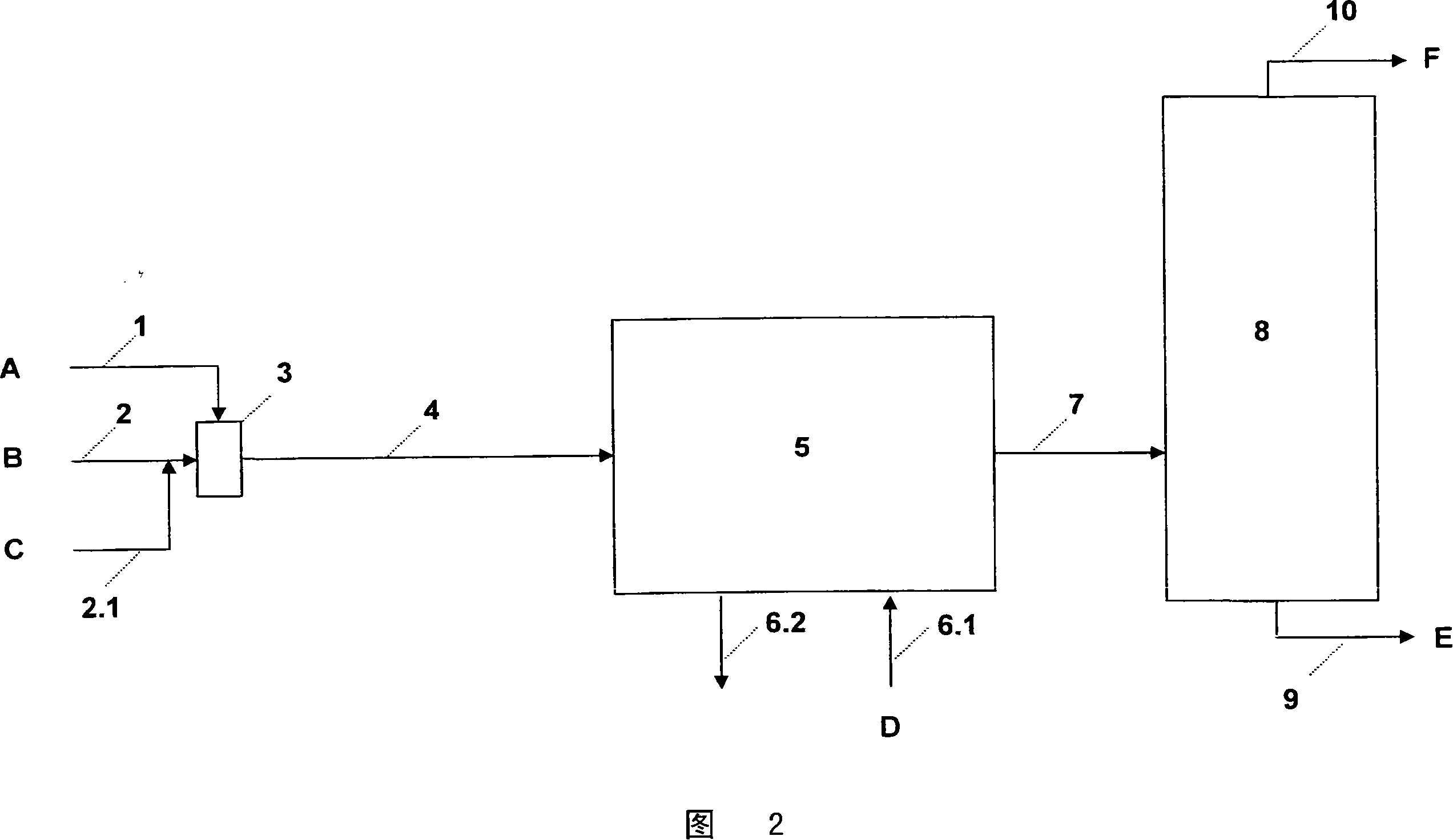

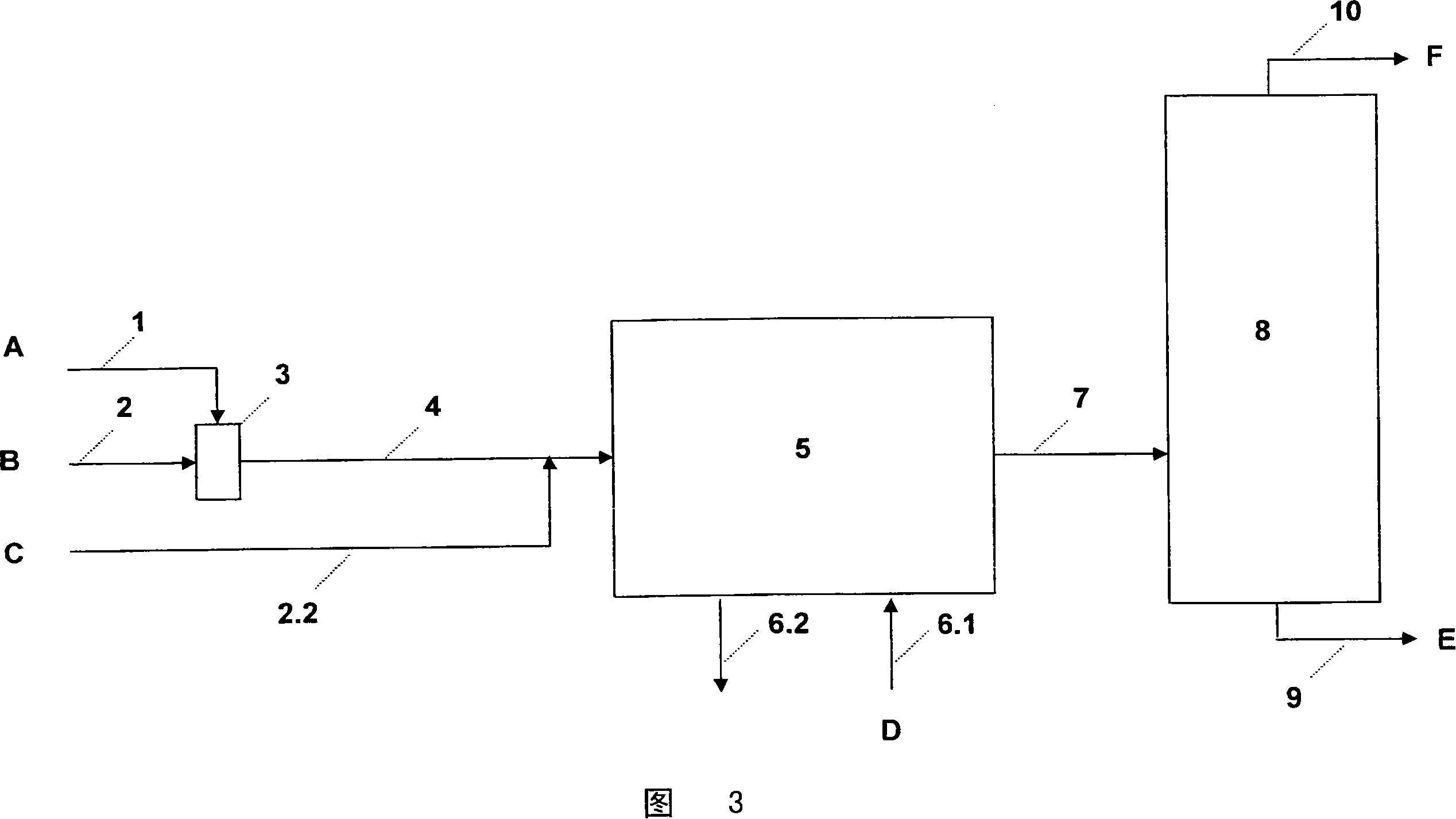

[0081] The equipment used for the preparation of chloropropyltrichlorosilane is mainly composed of educt storage, diaphragm pump, adjustment assembly, measurement assembly and metering assembly, a T-mixer, 2 series replaceable and equipped with packing (average diameter of 1.5mm stainless steel ball), a prereactor (diameter 5cm, length 40mm, stainless steel), a stainless steel capillary (diameter 1mm, length 50m), a constant temperature bath for prereactor and capillary temperature regulation, a pressure stabilization valve, a continuous N2 Operation of the stripping column, and piping required for input of educts and output of products, recycle and waste gases.

[0082] First at room temperature olefin (propenyl chloride) and platinum-catalyst [53 g hexachloroplatinic acid-hexahydrate in 1 L acetone] were metered in molar ratio olefin:Pt=200000:1, mixed, and In the mixer, it is mixed with trichlorosilane (TCS, Degussa Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com