Synthetic method and application of active diluent

A reactive diluent and synthesis method technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of reducing construction viscosity, reducing adhesive curing bonding strength, high construction viscosity, etc., and achieve the goal of increasing reaction strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

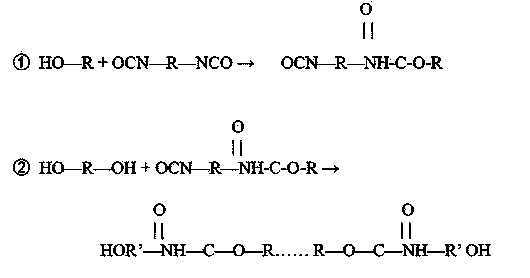

Method used

Image

Examples

Embodiment approach 1

[0015] Add an appropriate amount of molecular sieve to 56.628 grams of methyl ethyl ketone oxime (MEKO) to remove water, the water content is 150ppm, after removing water, fill it with nitrogen and store it for later use;

[0016] Put 77 grams of polyether diol (molecular weight 400) into a three-necked flask, vacuum dehydrate at 120±5°C for 2~3 hours, then cool down and fill with nitrogen to store for later use;

[0017] Put 87.075 grams of toluene diisocyanate (2,4-TDI) into a three-necked flask, fill it with nitrogen, and in a nitrogen atmosphere, after heating the temperature to 40°C, start adding methyl ethyl ketone oxime (MEKO) dropwise with a dropping funnel at a rate of 1 drop / second, during the dropping process, the reaction temperature is controlled at 65±2°C, if it is higher than 70°C, the dropwise addition should be stopped immediately, until the methyl ethyl ketoxime (MEKO) is added, continue to react for 2 hours and then cool down;

[0018] When the temperature d...

Embodiment approach 2

[0020] Others are the same as in Example 1, except that the weight of methyl ethyl ketoxime (MEKO) is 57.272 grams, the weight of polyether diol (molecular weight 400) is 88 grams, and the weight of toluene diisocyanate (2,4-TDI) is 87.075 grams.

[0021]

Embodiment approach 3

[0023] Others are the same as in Example 1, except that the weight of methyl ethyl ketoxime (MEKO) is 60.984 grams, the weight of polyether diol (molecular weight 400) is 66 grams, and the weight of toluene diisocyanate (2,4-TDI) is 87.075 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com