Special additive for machine-made sand plastering mortar and preparation method thereof

A plastering mortar and admixture technology, which is applied in the field of special admixtures for machine-made sand plastering mortar and its preparation, can solve problems such as poor batch scraping, bleeding, and affecting the construction performance of machine-made sand mortar, so as to increase stability, The effect of improving construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

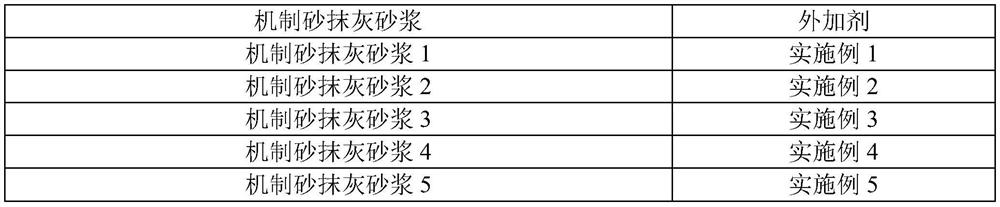

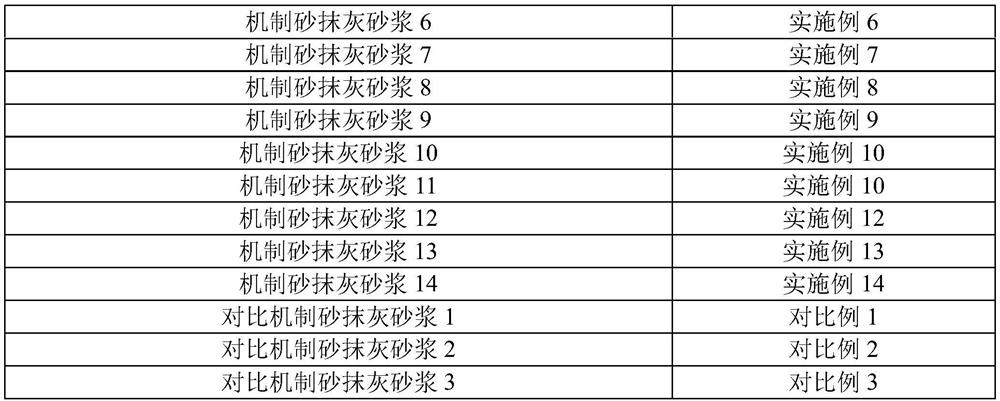

Examples

Embodiment 1

[0041] A preparation method of special admixture for machine-made sand plastering mortar comprises the following steps:

[0042] Mix 0.7kg of polycarboxylate water reducer and 1kg of water uniformly in the first reaction kettle, then add 2kg of cellulose ether and 0.5kg of starch ether into the first reaction kettle under stirring, and stir evenly to obtain mixture I;

[0043] Add 4kg of water into the second reaction kettle, start stirring, and add 0.8kg of maltodextrin, 0.2kg of air-entraining agent AOS, 0.3kg of magnesium aluminum silicate and 0.5kg of tartaric acid into the second reaction kettle under stirring, and stir evenly. Mixture II is obtained;

[0044] Pour the mixture I in the first reaction kettle into the second reaction kettle and mix it with the mixture II, stir for 3 hours, and stir evenly to prepare the special admixture for machine-made sand plastering mortar.

Embodiment 2

[0046] A preparation method of special admixture for machine-made sand plastering mortar comprises the following steps:

[0047]Mix 1.2kg of polycarboxylate water reducer and 1.0kg of water in the first reaction kettle evenly, then add 1.2kg of cellulose ether and 0.3kg of starch ether into the first reaction kettle under stirring, and stir evenly to obtain the mixture I ;

[0048] Add 4kg of water into the second reaction kettle, start stirring, and add 0.8kg of maltodextrin, 0.2kg of air-entraining agent AOS, 0.3kg of magnesium aluminum silicate and 1.0kg of tartaric acid into the second reaction kettle under stirring, and stir evenly. Mixture II is obtained;

[0049] Pour the mixture I in the first reaction kettle into the second reaction kettle and mix it with the mixture II, stir for 3 hours, and stir evenly to prepare the special admixture for machine-made sand plastering mortar.

Embodiment 3

[0051] A preparation method of special admixture for machine-made sand plastering mortar comprises the following steps:

[0052] Mix 1.0kg of polycarboxylate superplasticizer and 1.0kg of water in the first reaction kettle evenly, then add 1.7kg of cellulose ether and 0.3kg of starch ether into the first reaction kettle under stirring, and stir evenly to obtain the mixture I ;

[0053] Add 4.0kg of water into the second reaction kettle, start stirring, add 0.8kg of maltodextrin, 0.2kg of air-entraining agent AOS, 0.3kg of magnesium aluminum silicate and 0.7kg of tartaric acid into the second reaction kettle under stirring, and stir evenly , to obtain mixture II;

[0054] Pour the mixture I in the first reaction kettle into the second reaction kettle and mix it with the mixture II, stir for 3 hours, and stir evenly to prepare the special admixture for machine-made sand plastering mortar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com