Patents

Literature

35results about How to "Achieve chemical modification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof

ActiveCN102021819AExcellent water repellencyBasic physical and mechanical propertiesSilicon compoundsVegetal fibresOrganic solventHYDROSOL

The invention relates to a fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof. The finishing agent is prepared by the following steps of: (1) mixing a precursor, an anionic surfactant and water and stirring violently at the temperature of between 20 and 50 DEG C; and (2) slowly adding ammonia water serving as a catalyst dropwise, stirring, adding long-chain alkylsiloxane serving as a modifier and stirring continually so as to obtain modified SiO2 hydrosol. The finishing agent has a stable property, avoids the pollution of an organic solvent and has high water repellency when used for performing superhydrophobic finishing on textiles.

Owner:DONGHUA UNIV +1

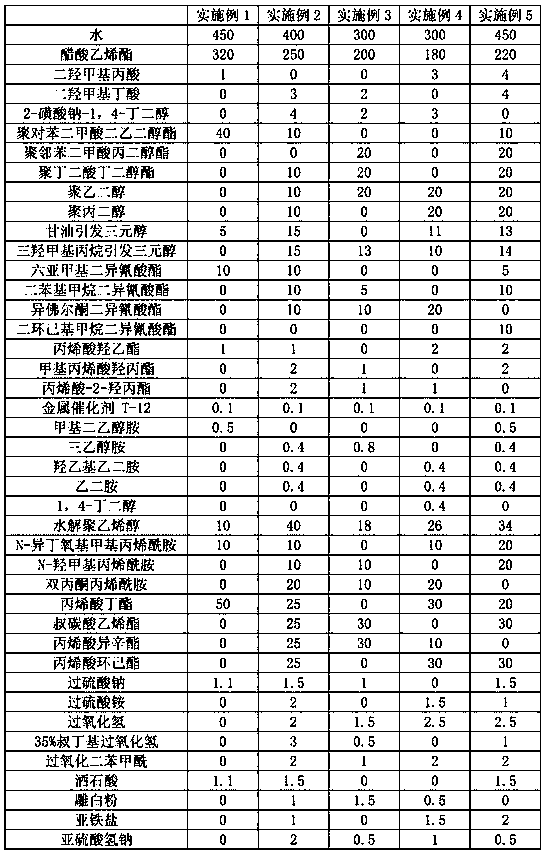

Preparation method of polyester acrylate hybrid aqueous dispersion

InactiveCN101824209AAchieve chemical modificationImprove stabilityPolyurea/polyurethane coatingsPolyesterOrganic solvent

The invention relates to a preparation method of polyester acrylate hybrid aqueous dispersion, which belongs to the field of chemical coatings, and the preparation method comprises four steps of synthesizing hydroxyl acrylate resin, preparing an intermediate, preparing polyester acrylate resin and dispersing with deionized water. The preparation method effectively combines the advantages of polyester and acrylic resin, the prepared stable dispersion can be used as the hydroxyl resin component of a dual-component polyurethane coating for preparing a high-performance waterborne dual-component polyurethane coating with hydrophilic polyisocyanate, and a coating film has excellent performance; in addition, the preparation of the dispersion does not use amine as a neutralizer, thereby avoiding the smell caused by the amine and simplifying the process; and only a small amount of cosolvent is adopted in the dispersion, and the content of an organic solvent in the coating is low.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

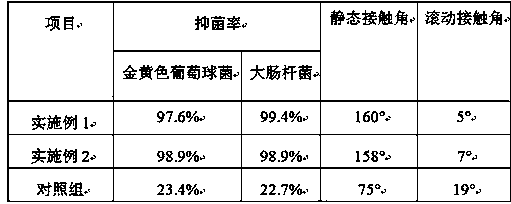

Slow-release fragrance-type antibacterial super-hydrophobic processing method for decorative paper

InactiveCN110777567AMeet the intensitySatisfy breathabilitySurface covering paperReinforcing agents additionCelluloseKaolin clay

The invention discloses a slow-release fragrance-type antibacterial super-hydrophobic processing method for decorative paper. The method comprises the steps: immersing bleached softwood pulp and bleached hardwood pulp in water, performing defibering by using a beater, starting beating, adding a titanium dioxide-kaolin composite suspension, a wet strength agent and a retention aid to the pulp, preparing sheets by using a standard paper sheet former, performing vacuum drying and moisture balancing so as to obtain decorative base paper, immersing the obtained decorative base paper in a slow-release fragrance-type antibacterial microcapsule solution, taking the immersed paper out, performing natural drying so as to obtain slow-release fragrance-type antibacterial processed decorative paper, putting hydrophobic-modification cellulose nanoparticles, methyltrimethoxysilane and water in a closed reactor for a reaction, adding the reaction product into tetrahydrofuran, performing ultrasound treatment so as to obtain a super-hydrophobic coating, spraying the coating uniformly to the slow-release fragrance-type antibacterial processed decorative paper by using a spray gun, and performing curing in an oven so as to obtain the slow-release fragrance-type antibacterial super-hydrophobic decorative paper.

Owner:刘丹丹

Preparation method of green light-cured durable one-way moisture-diversion finishing agent

InactiveCN103276585AAchieve chemical modificationExcellent unidirectional moisture transfer performancePhysical treatmentPotassiumCarbon chain

The invention relates to a preparation method of a green light-cured durable one-way moisture-diversion finishing agent. The preparation method comprises the following steps of 1, adding 3 to 20wt% of sodium or potash water glass into a mixture of water and ethanol, adding greater than or equal to 4wt% of an ammonium salt aqueous solution into the mixed solution, adjusting a pH value, and carrying out stirring at a room temperature, 2, orderly adding 0.5 to 1wt% of gamma-azidopropyltriethoxysilane and 2 to 4wt% of a hydrophobic long-carbon chain alkyl siloxane into the mixed solution obtained by the step 1 with stirring, and sequentially carrying out stirring to obtain a modified nano-SiO2-hydrophobic long-carbon chain alkyl silanol cohydrolyzed solution, and 3, sequentially adding 0.5 to 15wt% of a thickener into the modified nano-SiO2-hydrophobic long-carbon chain alkyl silanol cohydrolyzed solution, and carrying out stirring to obtain the green light-cured durable one-way moisture-diversion finishing agent. The preparation method adopts the raw materials having wide sources and has a low cost. The green light-cured durable one-way moisture-diversion finishing agent has stable properties. A fabric treated by the green light-cured durable one-way moisture-diversion finishing agent has excellent one-way moisture-diversion performance and washing endurance and has wide market application prospects and good social benefits.

Owner:DONGHUA UNIV +1

Fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof

ActiveCN102021819BExcellent water repellencyBasic physical and mechanical propertiesSilicon compoundsVegetal fibresOrganic solventAmmonia

The invention relates to a fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof. The finishing agent is prepared by the following steps of: (1) mixing a precursor, an anionic surfactant and water and stirring violently at the temperature of between 20 and 50 DEG C; and (2) slowly adding ammonia water serving as a catalyst dropwise, stirring, adding long-chain alkylsiloxane serving as a modifier and stirring continually so as to obtain modified SiO2 hydrosol. The finishing agent has a stable property, avoids the pollution of an organic solvent and has high water repellency when used for performing superhydrophobic finishing on textiles.

Owner:DONGHUA UNIV +1

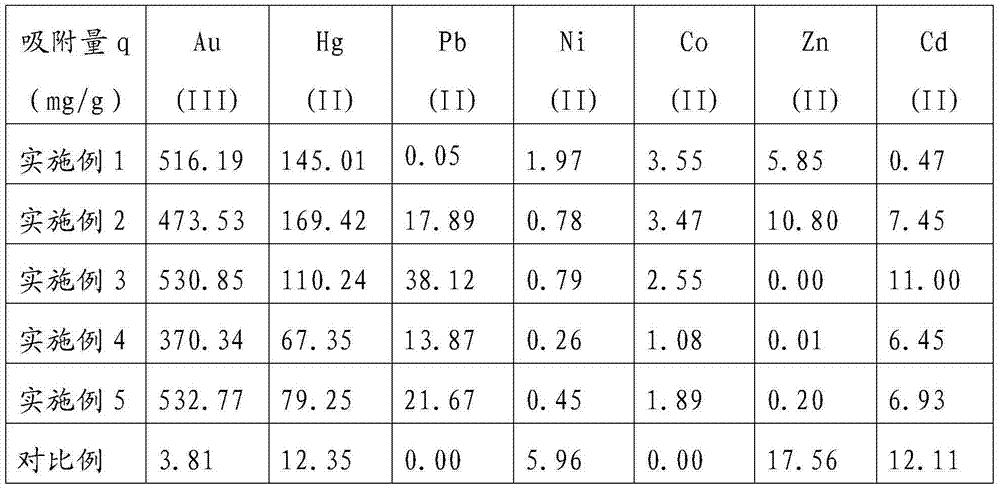

Preparation method and application of porous kieselguhr adsorbing material

InactiveCN104492385AImprove adsorption capacityLarge adsorption capacityOther chemical processesWater/sewage treatment by sorptionAdsorption effectAdsorption separation

The invention discloses a preparation method of a porous kieselguhr adsorbing material which is synergistically modified by hydroxyl and a proline functional group for separating heavy metal ions. According to the preparation method, porous kieselguhr is modified by using the proline functional group at low temperature, and with the synergistic effect with hydroxyl, the adsorption separation property of the adsorbing material to heavy metal ions is effectively improved. The porous kieselguhr adsorbing material which is modified by double functional groups is simple in preparation operation, low in cost, good in adsorption effect on heavy metal ions in water, and can be widely popularized and used in fields such as heavy metal ion separation and recycling.

Owner:LUDONG UNIVERSITY

A kind of coal tar pitch chemical modification method for carbon fiber preparation

InactiveCN102260513AAchieve chemical modificationSimple processWorking-up pitch/asphalt/bitumen by chemical meansFiberCarbon fibers

The invention relates to a chemical modification method of coal tar pitch used for carbon fiber preparation. The operation steps of the method are as follows: dry the coal tar pitch at a temperature of 110-120°C to constant weight; mix the solvent quinoline and coal tar pitch at a volume-to-mass ratio of 3-15:1, and stir for 5-15 hours; solution; filter the mixed solution to obtain the filtrate; pour the filtrate into a reaction vessel, heat it under continuous nitrogen flow and stirring, and when it is heated to 80-120°C, add a catalyst to the filtrate according to 1-16% of the mass of coal tar pitch. The catalyst is The mixture of boron trifluoride diethyl ether and nitroaromatics is reacted at 100-180°C for 5-10 hours, and the solvent quinoline is distilled out by heating, until no quinoline solvent is distilled out, and the viscosity at 190°C is 1000-3400Pa·s Chemically modified coal tar pitch. The present invention can successfully realize the chemical modification of coal tar pitch only by using a chemical reaction catalyst, the process is simple, the modification effect is good, the modified coal tar pitch is easy to spin and carbonize, and the purpose of preparing high-quality coal pitch as a carbon fiber precursor is successfully achieved.

Owner:徐国财

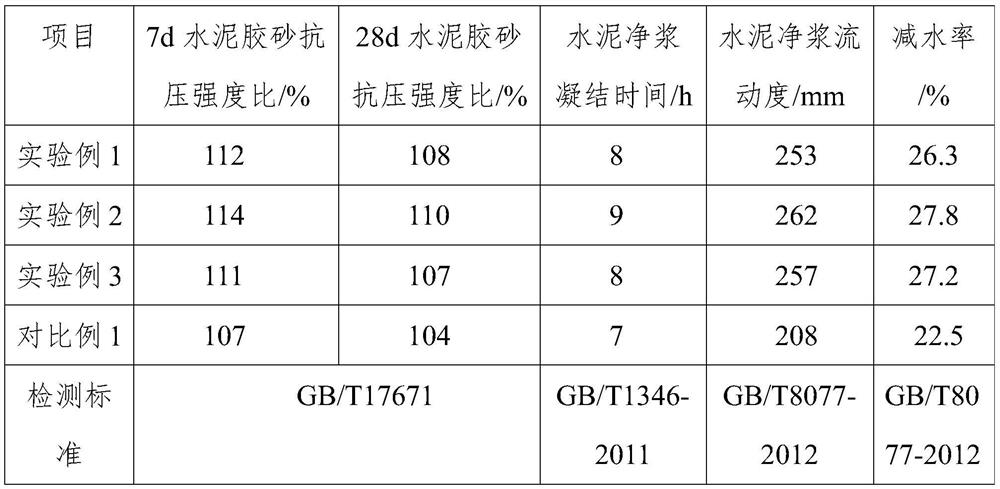

Starch-based water reducing agent and production process thereof

The invention relates to the technical field of building material preparation, in particular to a starch-based water reducing agent and a production process thereof. The starch-based water reducing agent is prepared from the following raw materials in parts by weight: 50-80 parts of starch, 4-8 parts of an oxidation reagent, 5-12 parts of an etherification reagent, 20-45 parts of sodium methallyl sulfonate, 4.5-7.0 parts of an initiator, 2.5-4.0 parts of dihydroxysuccinic acid and a proper amount of distilled water and absolute ethyl alcohol. The starch is used as a raw material for preparing the high-efficiency water reducing agent and is modified, and the modified starch contains rich macromolecular groups, so that a strong steric hindrance effect is easily formed on the surfaces of cement particles, the cement particles are more sufficiently and uniformly dispersed, and re-agglomeration of the dispersed particles is reduced. Compared with a water reducing agent sold in the market at present, the retarding and water reducing effects of the starch-based water reducing agent are more excellent. Moreover, the starch is used as the raw material, so that the production cost can be reduced, the environment can be protected, and the pollution to the environment is reduced.

Owner:ZHEJIANG LAOHUSHAN BUILDING MATERIALS

Metal hydrides coordination catalyst and preparation and application thereof

ActiveCN105820326ANotable featuresSignificant catalytic effectGroup 8/9/10/18 element organic compoundsEnd-groupStructural formula

The invention relates to a catalyst preparation technology and aims at providing a metal hydrides coordination catalyst and preparation and application thereof. The structural formula of an active component of the catalyst is Zn2[Co(CN)6](OR)mXn, wherein R is alkyl, aryl or acyl, X is a single valence anion, m and n are positive numbers, and m plus n is 1. The divalent Zn ions in the activated component are coordinated with inner metal trivalent cobalt ions through cyanide ions and surrounding anions OR and X at the same time to form a Co-CN-Zn-OR structure and a Zn-X structure. The activated triggering center structure of the catalyst is a definite Zn-OR bond; when the catalyst catalyzes a reaction in which epoxyalkane takes participate, due to the fact that one end of the generated polymer is an R group, the chain transfer reaction degree is reduced, and the degradation property of a product is improved; one end of the obtained polymerisate is an OR group, due to the diversity of the R group, functionalization of the end group of the polymer is achieved, and only polymer with the two ends being hydroxyls can be obtained through reported DMCC containing the Zn-OH bond.

Owner:ZHEJIANG UNIV

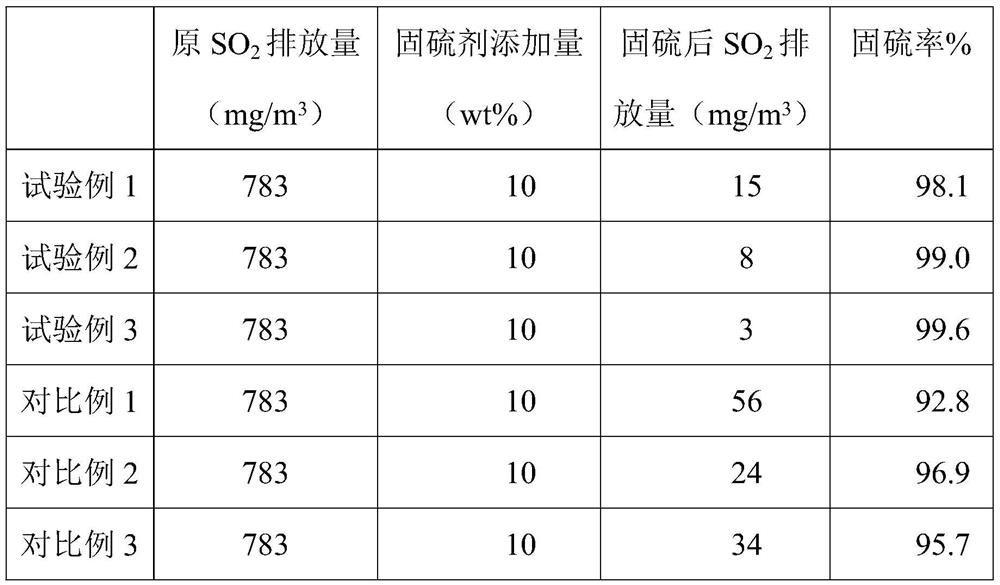

Flue gas sulfur-fixing agent used in sodium sulfide synthesis process and preparation process of flue gas sulfur-fixing agent

ActiveCN112742204ARich in mesoporesHigh porosityGas treatmentDispersed particle separationChemical reactionEngineering

The invention relates to the technical field of preparation of sulfur-fixing agents, in particular to a flue gas sulfur-fixing agent used in a sodium sulfide synthesis process and a preparation process of the flue gas sulfur-fixing agent. The flue gas sulfur-fixing agent comprises the following raw materials in parts by weight: 80-90 parts of modified calcium carbonate powder, 10-13 parts of vermiculite powder, 3.6-4.5 parts of sodium carbonate, 7-12 parts of graphene, 3-5 parts of potassium nitrate, 3.5-4.3 parts of cerium stearate, 8-12 parts of liquid paraffin, 4-6 parts of potassium permanganate, 3-5 parts of sodium lauryl sulfate, 12-15 parts of an activator, 6-10 parts of a stabilizer, 2.2-3.2 parts of an auxiliary agent and a proper amount of deionized water. The sulfur-fixing agent prepared by the invention can ensure that sulfur-containing gas can be subjected to chemical reaction with effective components in the sulfur-fixing agent in time; therefore, the purpose of efficiently fixing sulfur is achieved, the emission amount of sulfur oxides is greatly reduced, and emission of sulfur-containing gas is reduced; the burden in environment-friendly treatment , and meanwhile, the service life of equipment and facilities is effectively prolonged.

Owner:铜陵铜冠环保科技有限公司

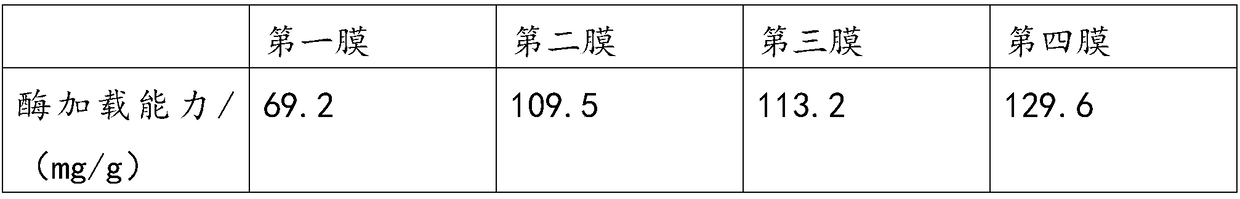

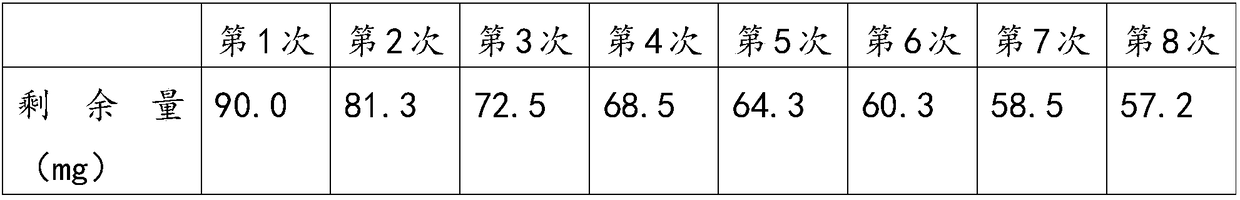

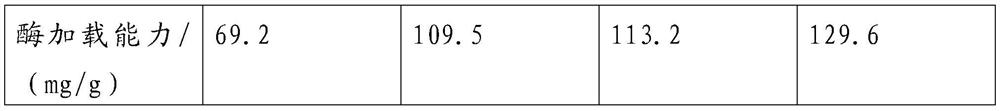

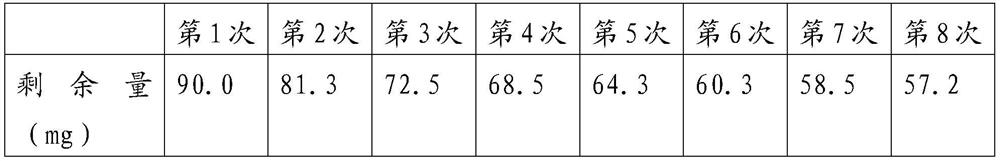

Preparation method of composite nanofiber membrane, composite nanofiber membrane, application of composite nanofiber membrane to enzyme immobilization and immobilized enzyme

ActiveCN108754871AImprove the nano effectGood enzyme loading capacityElectro-spinningOn/in organic carrierComposite nanofibersNanofiber

The invention belongs to the field of nanofiber membranes, and particularly relates to a preparation method of a composite nanofiber membrane, the composite nanofiber membrane, application of the composite nanofiber membrane to enzyme immobilization and an immobilized enzyme. An electrostatic spinning solution containing chitosan is adopted for preparing the nanofiber membrane, and the membrane has a good film-forming property and an enzyme-immobilizing function; meanwhile, polypeptide nanofibers are adopted and loaded onto the membrane, in this way, the property of the membrane is further improved, and the enzyme-immobilizing property of the membrane is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Method for preparing highly grafted silanization modified clay/rubber nanocomposite material

The invention relates to a method for preparing a highly grafted silanization modified clay / rubber nanocomposite material. According to the method, a silane coupling agent is treated with an acid to make a surface have more active silicon hydroxyl groups, and then is added to a clay slurry, the acid in the system can simultaneously activate the surface of clay to produce reactive hydroxyl groups,and a grafting reaction is completed in an aqueous phase; and a aqueous suspension of silane coupling agent-grafted clay is stirred and mixed with rubber latex, and the clay / rubber nanocomposite material is obtained by flocculation, washing, drying, mixing and a vulcanization process. By increasing hydrolysis of the silane coupling agent and increasing the amount of reactive hydroxyl groups on thesurface of the clay, the method enables the grafting amount of the silane coupling agent to be increased, thereby enhancing interaction between the clay and rubber, and mechanical properties of the rubber is increased.

Owner:BEIJING UNIV OF CHEM TECH

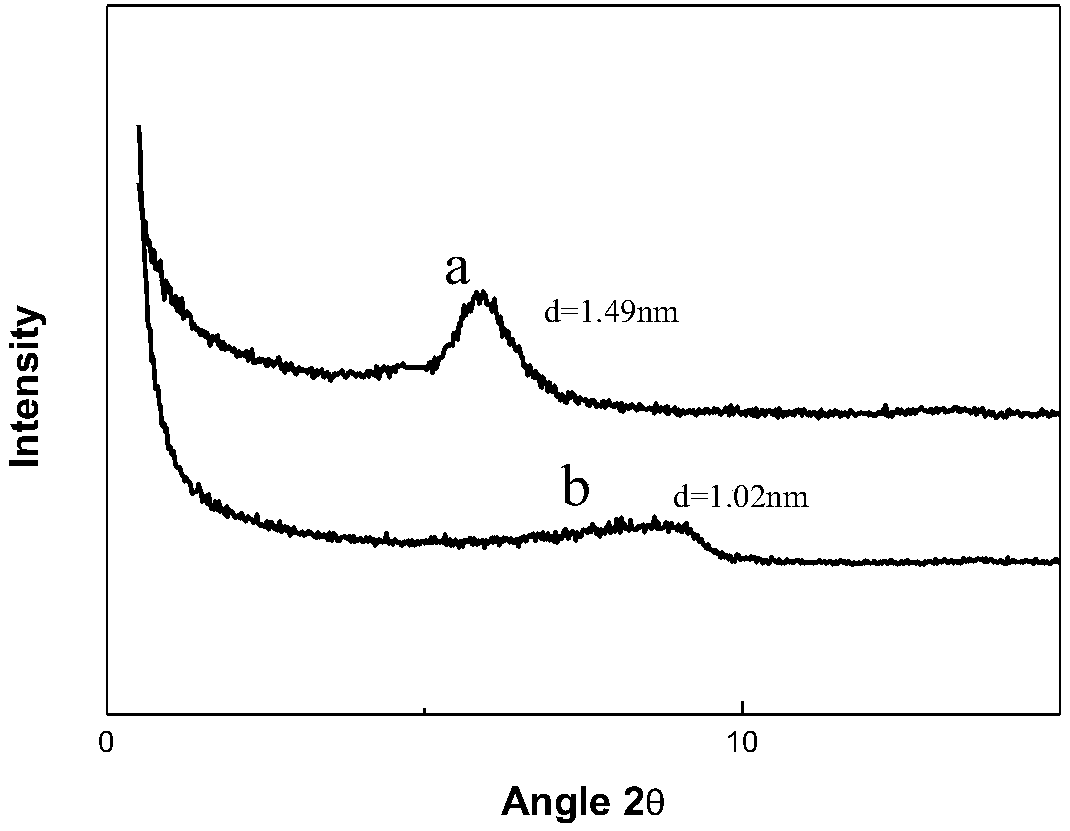

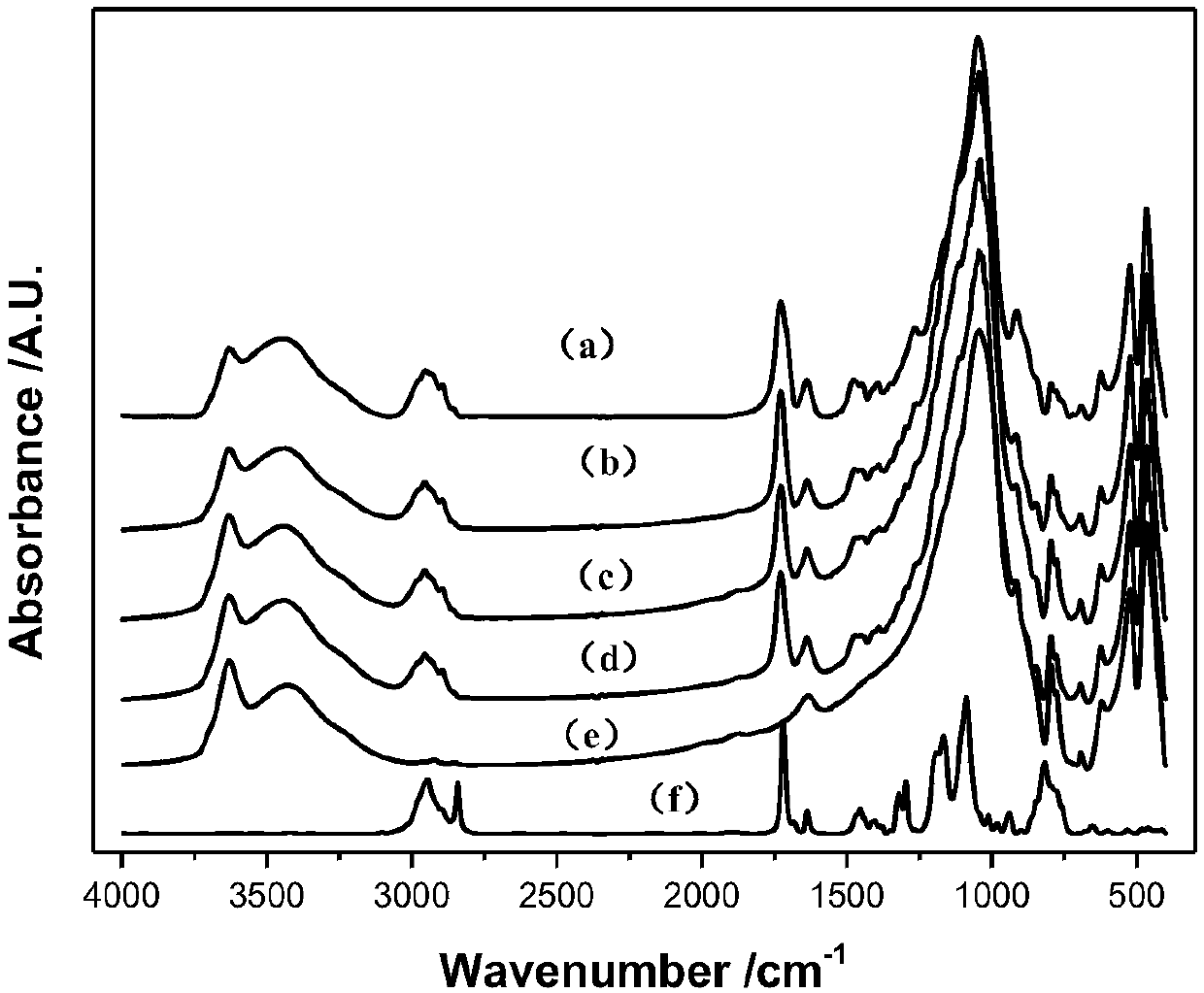

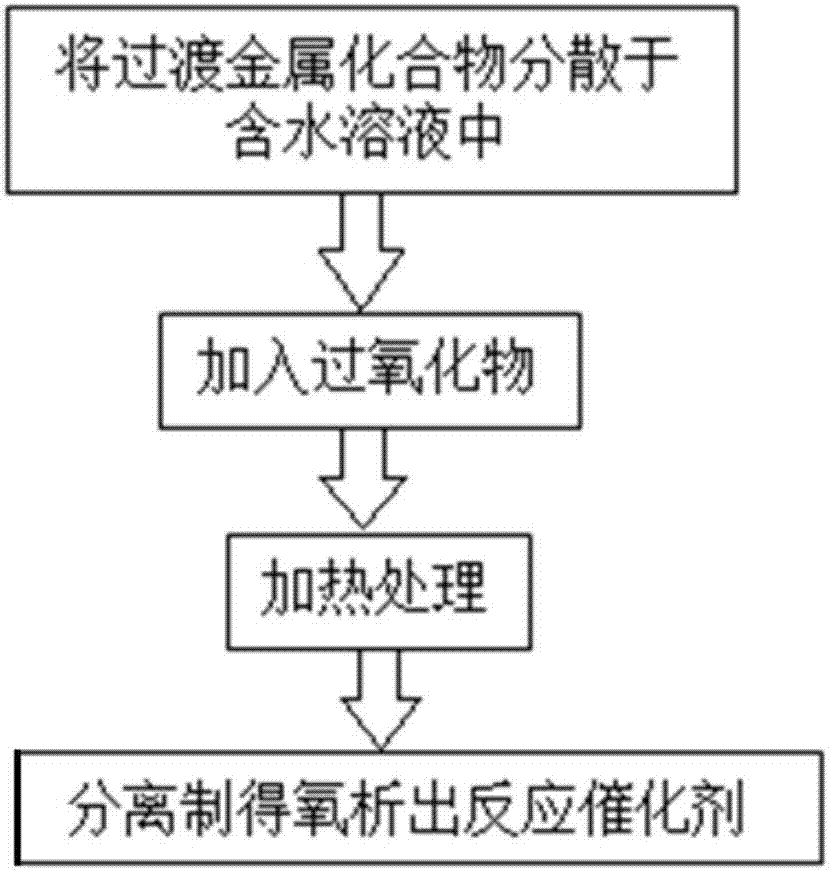

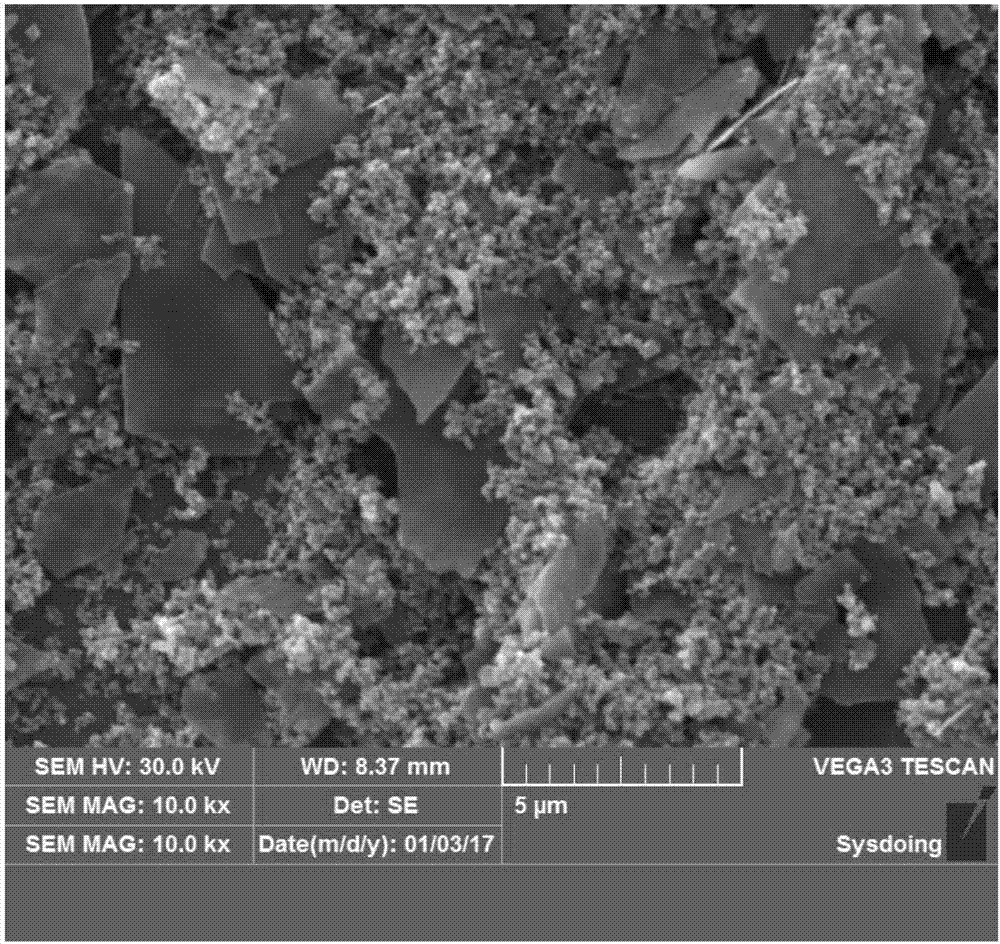

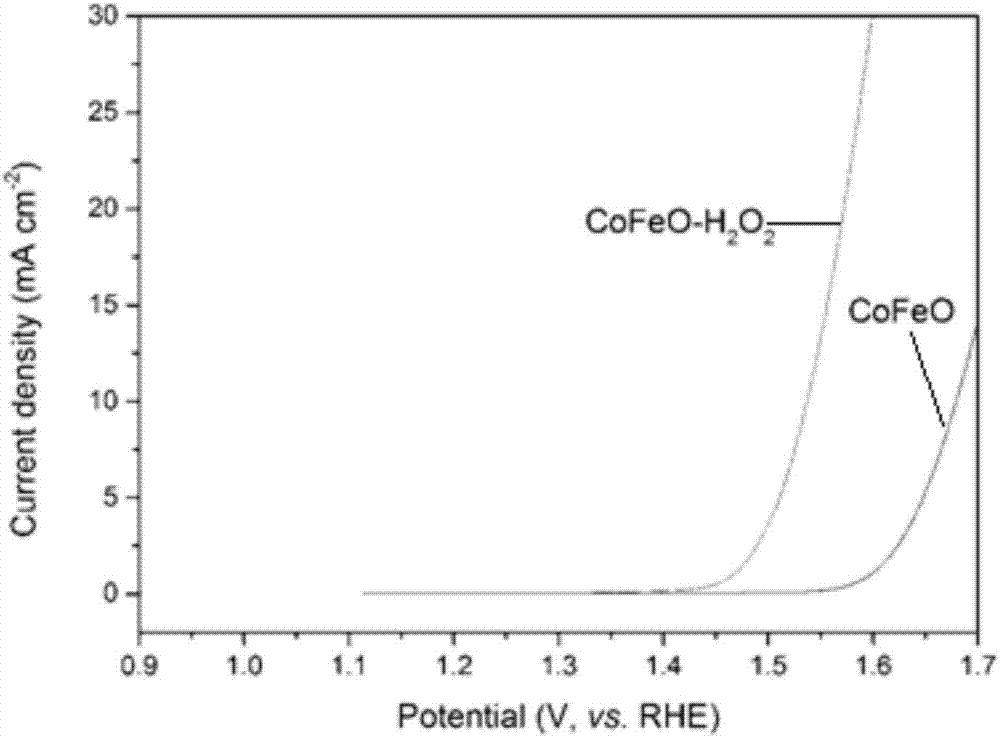

Preparation method of oxygen evolution reaction catalyst

InactiveCN107262098AHigh oxygen evolution reaction catalytic activityHigh activityElectrolysis componentsHeterogenous catalyst chemical elementsPtru catalystOxygen evolution

The invention belongs to the field of electrochemical catalysis, and specifically relates to a preparation method of an oxygen evolution reaction catalyst. The method comprises the following steps: S1, dispersing a compound containing more than two transition metals in an aqueous solution; S2, adding a peroxide; S3, performing heating treatment; and S4, cooling the heated mixture, and performing centrifugation or filtering separation to obtain a solid, which is the oxygen evolution reaction catalyst having high activity. According to the method, a transition metal compound undergoes surface modification through a chemical oxidation manner, so that more active sites are produced on the surface of the transition metal compound, and the catalytic activity of the oxygen evolution reaction is improved. Compared with an electrochemical oxidation method which is mostly adopted at present, chemical oxidation is convenient to operate, and massive application and regulation of surface sites of a material are easy to realize. The preparation method is high in efficiency, quality and purity, low in cost, and convenient to control, and is non-toxic. The preparation method is particularly suitable for application to massive production.

Owner:HUAZHONG UNIV OF SCI & TECH

Chemical synthesizing process of beta-butyrolactone with lactide copolymer

InactiveCN100506878CAchieve chemical modificationHigh crystallinityChemical synthesisPoly-3-hydroxybutyrate

The invention is a chemical synthesis method for synthesizing poly-3-hydroxybutyrate by using the technology of beta-butyrolactone and lactide copolymer. The specific method is: preparing reactants; 1-100 parts by weight of β-butyrolactone and 1-100 parts by weight of lactide; coordination polymerization catalyst or anion polymerization catalyst with a total weight of 0.01-1%; Dry in the reaction container for 0-48 hours; put the reactant into the reaction container and seal the reaction container, and react for 24-720 hours under stirring at 40-150°C to obtain a colorless transparent solid product; dissolve the product in an organic solvent , and then added dropwise to the excess precipitant, the precipitate is poly-3-hydroxybutyrate. Utilizing the preparation method of the β-butyrolactone and L-lactide copolymer of the present invention, the number-average relative molecular mass of the β'-butyrolactone and L-lactide copolymer can reach 1000-40000, and the relative molecular mass The mass distribution is narrow.

Owner:TIANJIN UNIV

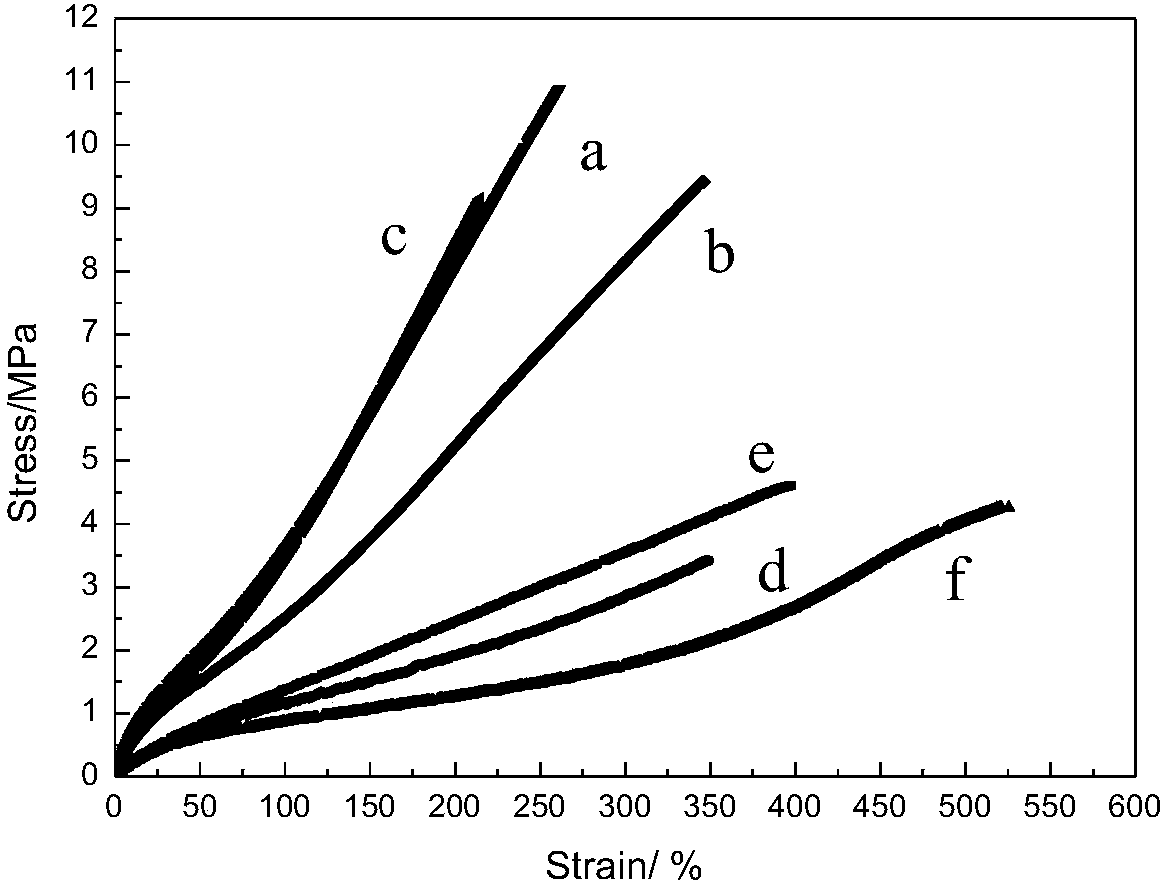

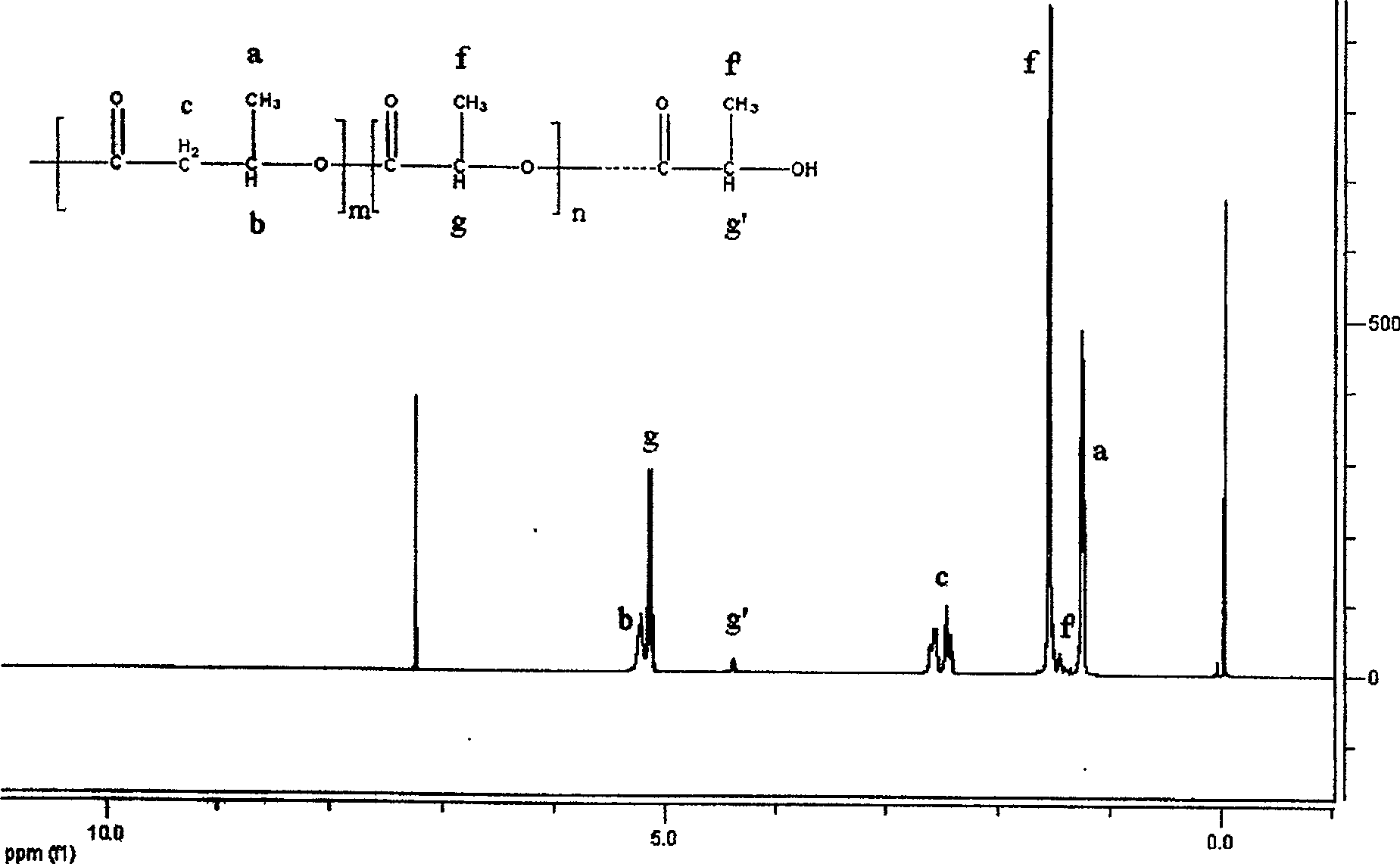

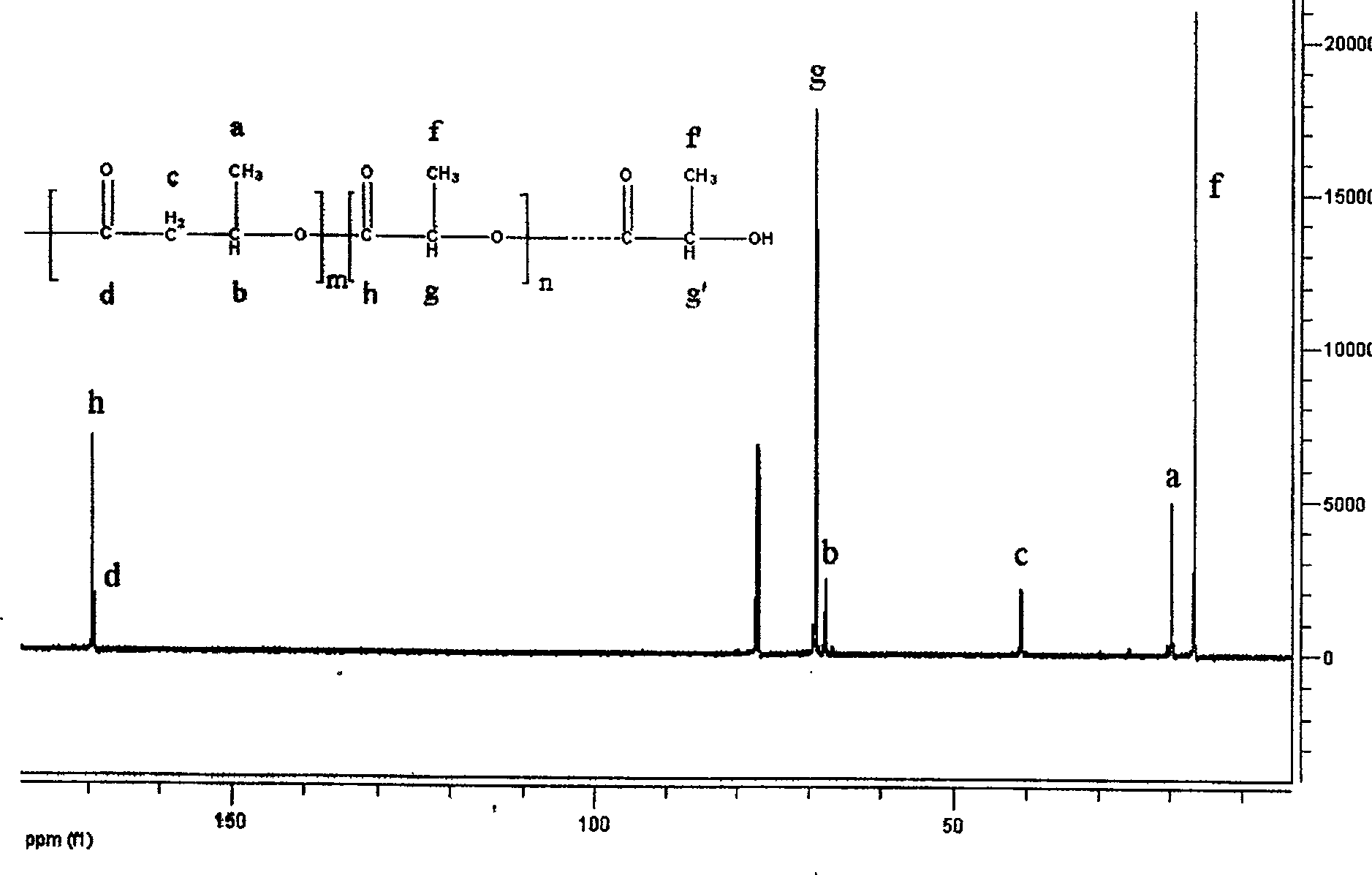

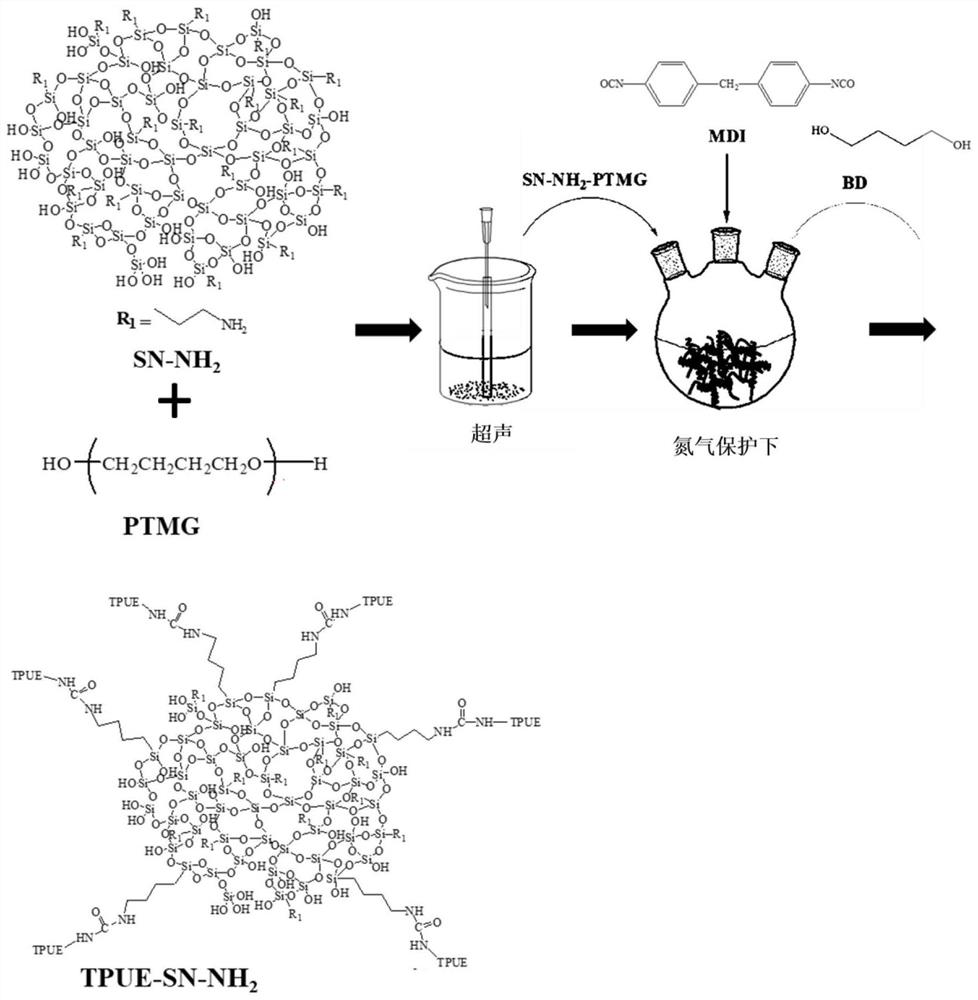

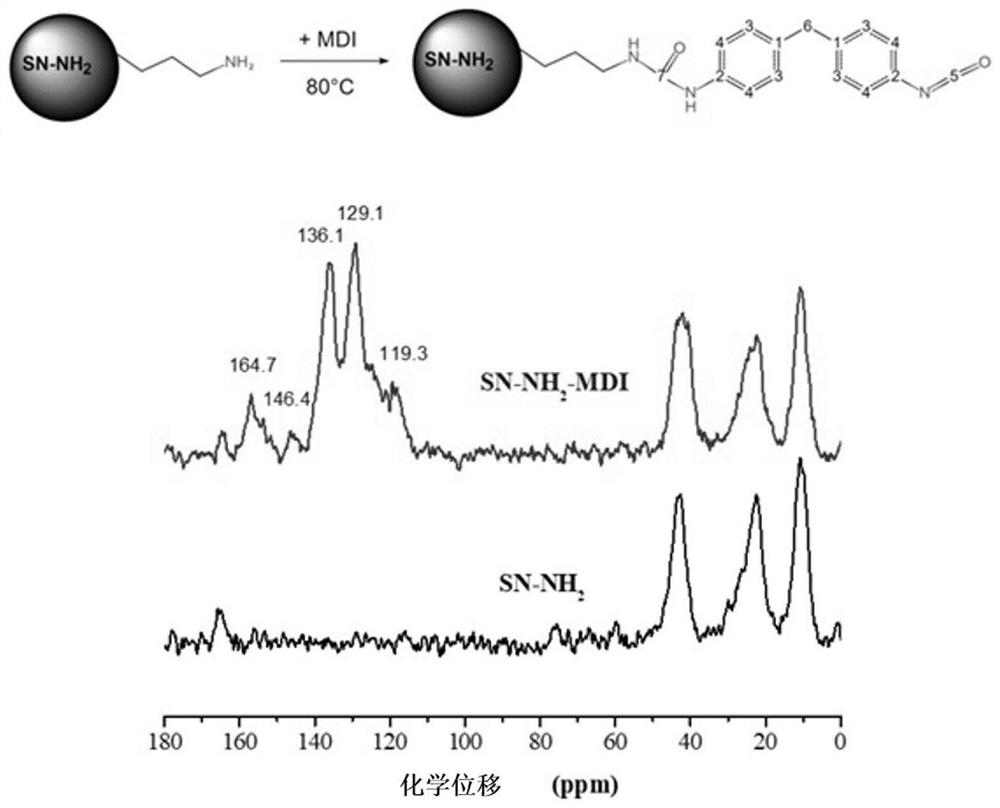

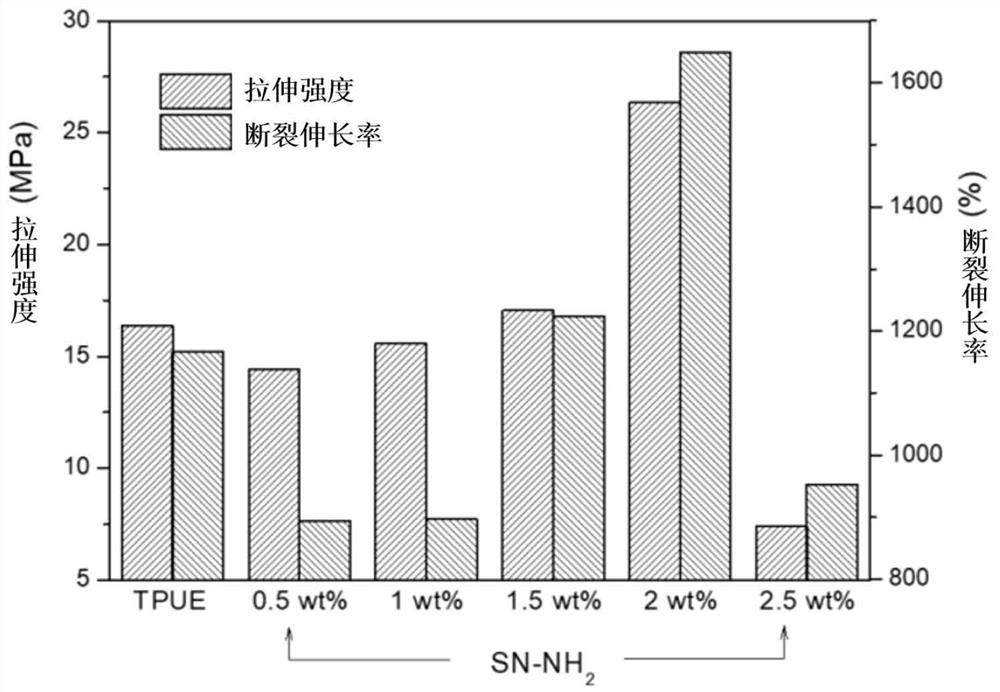

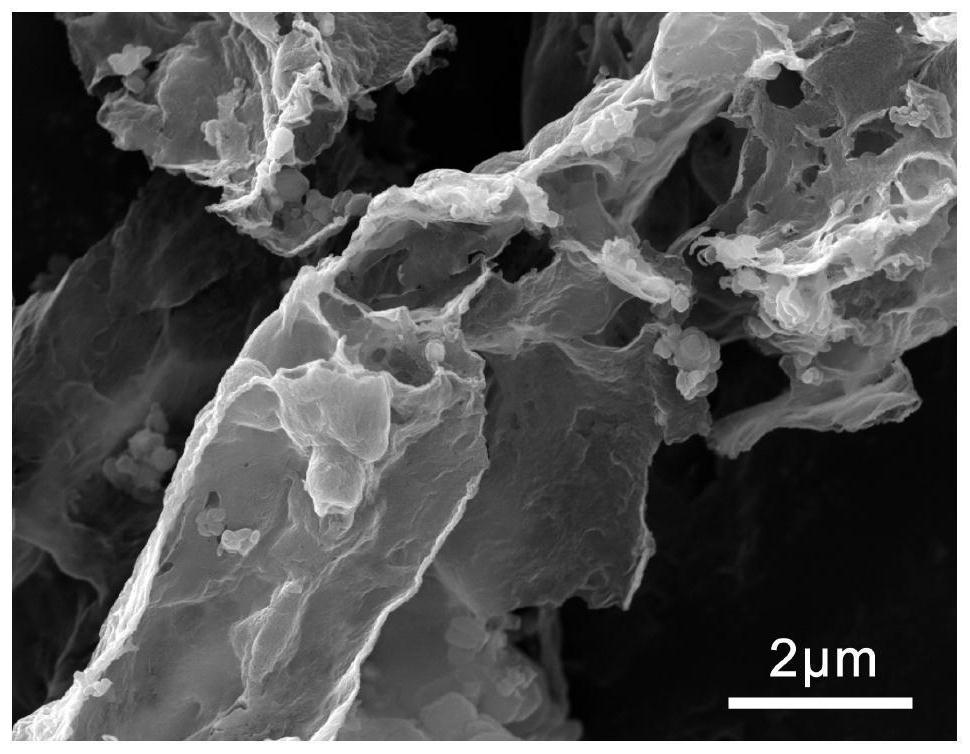

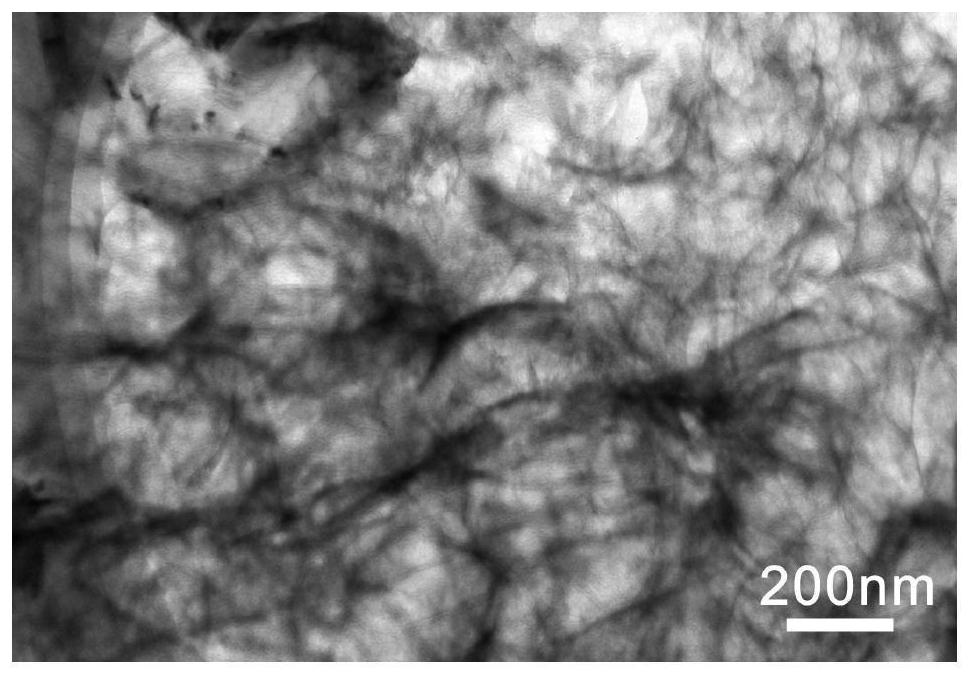

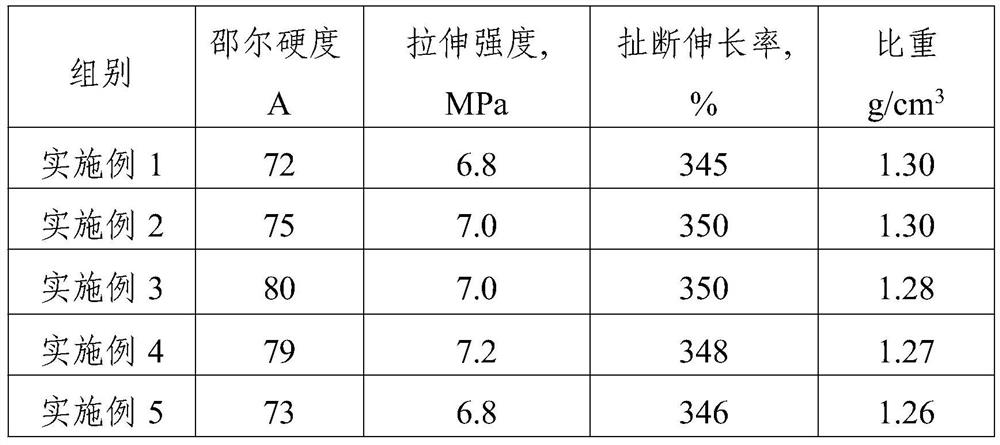

Thermoplastic polyurethane elastomer nanocomposite and preparation method thereof

PendingCN114369220AAchieve chemical modificationHigh strengthPolymer scienceThermoplastic polyurethane

The invention relates to a thermoplastic polyurethane elastomer nanocomposite and a preparation method thereof, belongs to the field of modified polyurethane composites, and solves the problem that the toughness of TPUE cannot be maintained while the strength and wear resistance of TPUE are improved in the prior art. The thermoplastic polyurethane elastomer nano composite material disclosed by the invention is prepared from the following raw materials: reactive nano silicon dioxide introduced in a polymerization process of a thermoplastic polyurethane elastomer, and the reactive nano silicon dioxide is amino nano silicon dioxide nano particles of which the surfaces contain active amino functional groups with reaction capacity. The material is a universal high polymer material and can be widely applied to the fields of shoe materials, cables, automobiles, pipes and films.

Owner:INST OF CHEM CHINESE ACAD OF SCI

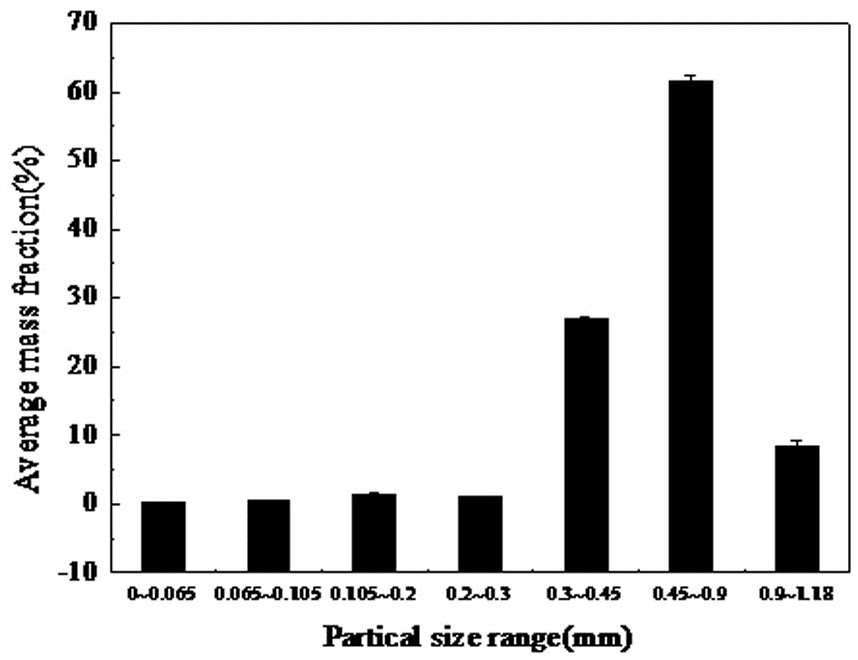

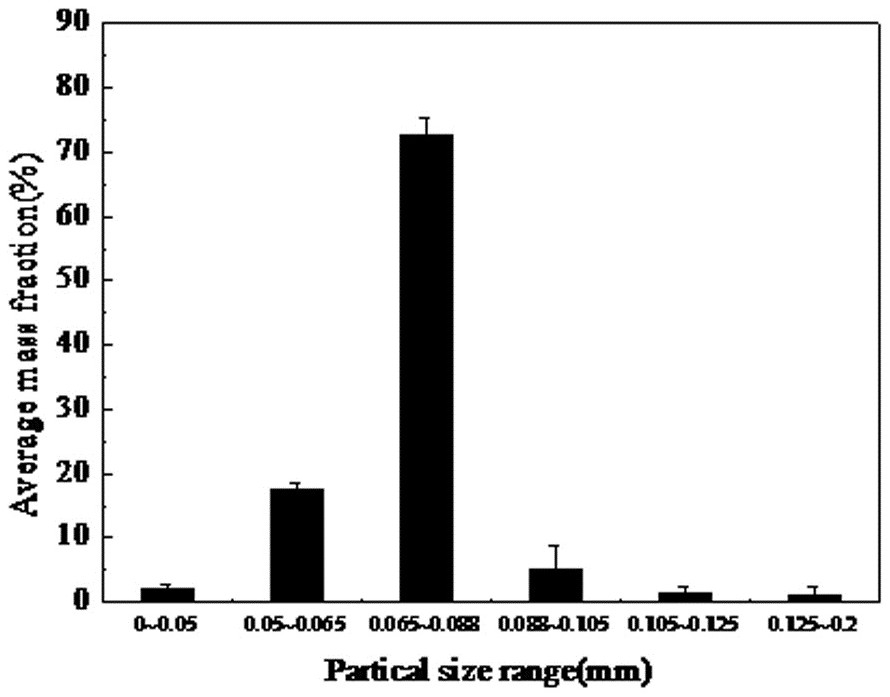

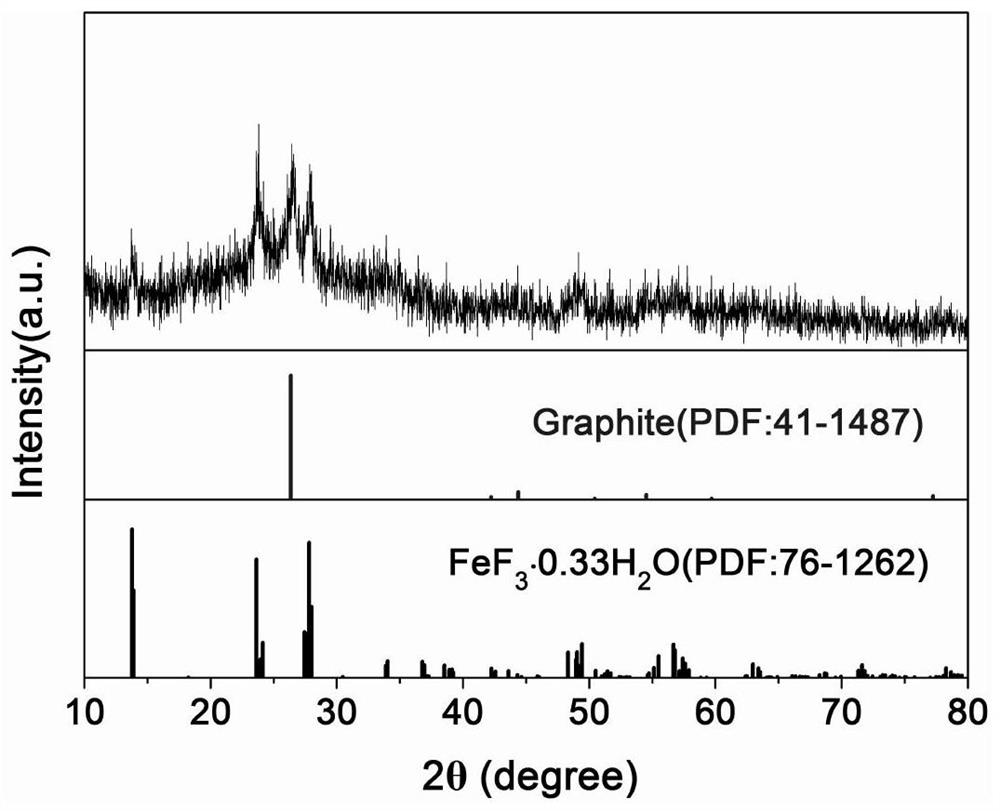

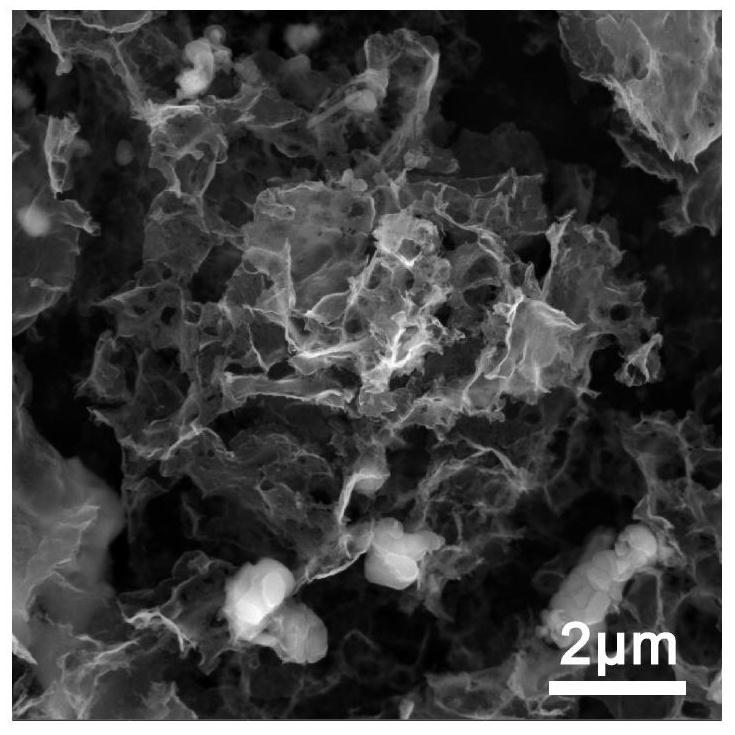

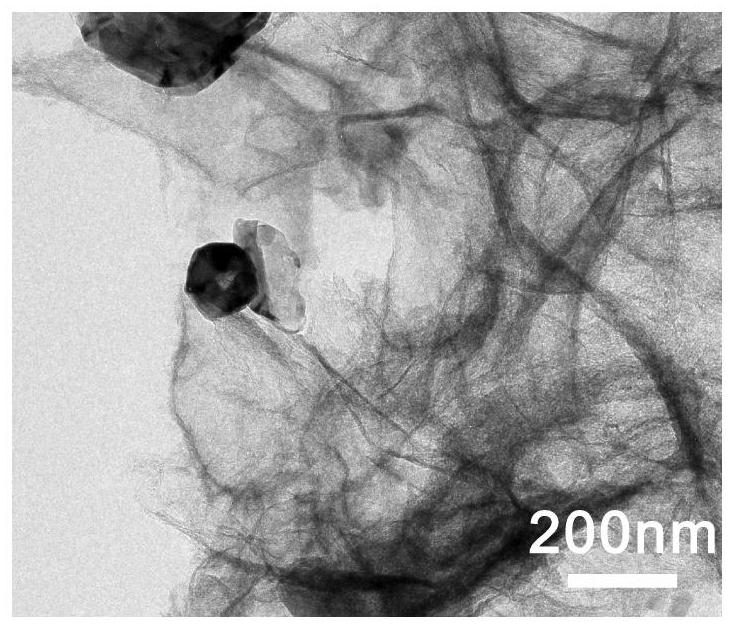

Method for preparing thin-layer graphene negative electrode active material by utilizing antibiotic bacterium dregs

ActiveCN112225203AFill technology gaps in processingImprove electrochemical performanceCell electrodesSecondary cellsLithium-ion batteryAntibiotic drug

The invention belongs to the technical field of waste utilization and lithium ion battery material preparation, and particularly discloses a method for preparing a thin-layer graphene negative electrode active material from antibiotic bacterium dregs, which comprises the following steps of: carrying out hydrothermal liquefaction on an aqueous solution containing antibiotic bacterium dregs and alkali, and carrying out solid-liquid separation to obtain a bacterium dreg solution; adding a transition metal source into the bacterium dreg solution, carrying out dehydration treatment after liquid phase mixing, and then carrying out heat treatment, the heat treatment comprising first-stage heat treatment and second-stage heat treatment which are carried out in sequence, the temperature of the first-stage heat treatment being 400-600 DEG C, the temperature of the second-stage heat treatment being 700-900 DEG C, and the heating rate in the heat treatment process being 2-10 DEG C / min; and washingand drying a product obtained by heat treatment to obtain the thin-wall graphene. According to the invention, efficient utilization of the waste material is realized, and the graphene negative electrode material with high thin wall and high electrochemical performance is co-produced.

Owner:CENT SOUTH UNIV

Method for preparing thin-layer graphene negative electrode active material by using antibiotic bacteria residue

ActiveCN112225203BFill technology gaps in processingImprove electrochemical performanceCell electrodesSecondary cellsElectrochemistryLithium-ion battery

The invention belongs to the technical field of waste material utilization and lithium ion battery material preparation, and specifically discloses a method for preparing a thin-layer graphene negative electrode active material by using antibiotic slag. The aqueous solution containing antibiotic slag and alkali is hydrothermally liquefied, and then solidified. liquid separation to obtain a bacterial residue solution; adding a transition metal source to the bacterial residue solution, mixing the liquid phases, performing dehydration treatment, and then performing heat treatment; the heat treatment includes the first stage of pretreatment and the second stage of heat treatment in sequence; The temperature of the first stage of heat treatment is 400-600°C; the temperature of the second stage of heat treatment is 700-900°C; and the heating rate of the heat treatment process is 2-10°C / min; the product obtained by heat treatment is washed and dried, That is, the thin-walled graphene is obtained. The invention realizes the high-efficiency utilization of the waste materials, and co-produces the graphene negative electrode material with high thin wall and high electrochemical performance.

Owner:CENT SOUTH UNIV

A kind of preparation method of green photocuring durable unidirectional moisture-conducting finishing agent

InactiveCN103276585BAchieve chemical modificationExcellent unidirectional moisture transfer performancePhysical treatmentPotassiumCarbon chain

The invention relates to a preparation method of a green light-cured durable one-way moisture-diversion finishing agent. The preparation method comprises the following steps of 1, adding 3 to 20wt% of sodium or potash water glass into a mixture of water and ethanol, adding greater than or equal to 4wt% of an ammonium salt aqueous solution into the mixed solution, adjusting a pH value, and carrying out stirring at a room temperature, 2, orderly adding 0.5 to 1wt% of gamma-azidopropyltriethoxysilane and 2 to 4wt% of a hydrophobic long-carbon chain alkyl siloxane into the mixed solution obtained by the step 1 with stirring, and sequentially carrying out stirring to obtain a modified nano-SiO2-hydrophobic long-carbon chain alkyl silanol cohydrolyzed solution, and 3, sequentially adding 0.5 to 15wt% of a thickener into the modified nano-SiO2-hydrophobic long-carbon chain alkyl silanol cohydrolyzed solution, and carrying out stirring to obtain the green light-cured durable one-way moisture-diversion finishing agent. The preparation method adopts the raw materials having wide sources and has a low cost. The green light-cured durable one-way moisture-diversion finishing agent has stable properties. A fabric treated by the green light-cured durable one-way moisture-diversion finishing agent has excellent one-way moisture-diversion performance and washing endurance and has wide market application prospects and good social benefits.

Owner:DONGHUA UNIV +1

Modified phosphogypsum and its preparation method

ActiveCN109626850BAchieve chemical modificationAvoid pollutionSolid waste managementO-Phosphoric AcidEnvironmental engineering

The invention discloses a modified phosphogypsum capable of avoiding environmental pollution caused by phosphogypsum produced in the phosphoric acid or phosphate fertilizer industry, and capable of using the phosphogypsum for roadbed materials, turning waste into treasure and a preparation method thereof. The modified phosphogypsum, including 84% to 94% CaSO 4 and 5% to 15% CaCO 3 . The preparation method of the modified phosphogypsum comprises steps, S1, dehydrating the phosphogypsum, the dehydration temperature is 150°C to 200°C; S2, stirring and breaking the phosphogypsum into powder; S3, air cooling the dehydrated phosphogypsum to room temperature ; then add CaCO to the phosphogypsum 3 , and makes CaCO 3 The mass percentage content is 3%; stirring makes phosphogypsum and CaCO 3 Mix well; S4, then to the mixed phosphogypsum and CaCO 3 CaCO 3 ; and make CaCO 3 The mass percentage content is 5% to 15%; stir and mix evenly. The modified phosphogypsum prepared by the modified phosphogypsum preparation method is used as a roadbed material, which can save land and avoid environmental pollution.

Owner:胡瑾 +1

A low-carbon light-curing one-way moisture-conducting finishing agent and its preparation method and application

InactiveCN103061106BExcellent unidirectional moisture transfer performanceIncreased durabilityPhysical treatmentSocial benefitsChain length

The invention relates to a preparation method for low-carbon photocuring single-side moisture transport finishing agent. The method comprises the following steps: (1) a precursor is poured in a mixture of ethanol and de-ionized water, and is acutely stirred at the temperature of 10-40 DEG C; and (2) catalyst-ammonia water is slowly dripped to stir, then different-chain-length alkyl containing an azide group or siloxane of aromatic hydrocarbon is added to continuously stir in order to obtain low-carbon and energy-conservation single-side moisture transport finishing agent containing an azide functional group. The finishing agent has stable properties; finished fabrics obtain excellent single-side moisture transporting performance and durability, and need no heat baking, so that a large amount of energy is saved; the finishing agent accords with the national modern economic development theme of environmental protection and low energy consumption, and has wide market application prospect and excellent social benefit.

Owner:DONGHUA UNIV +1

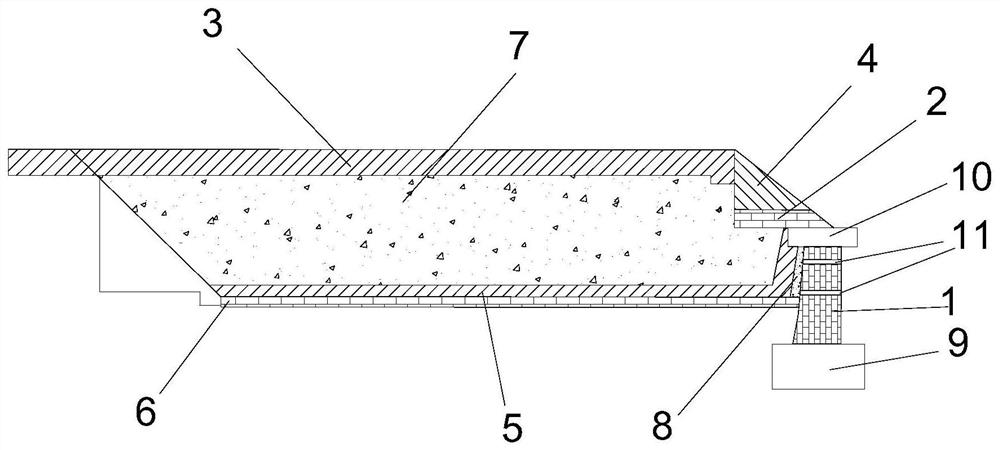

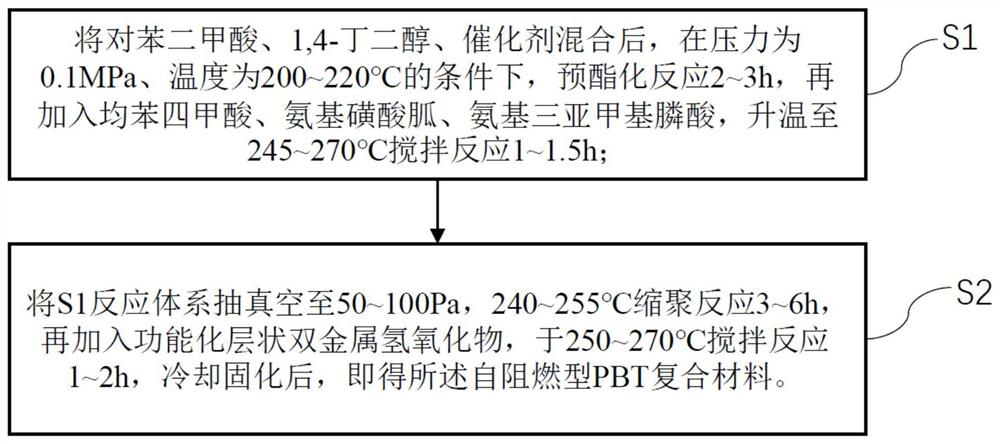

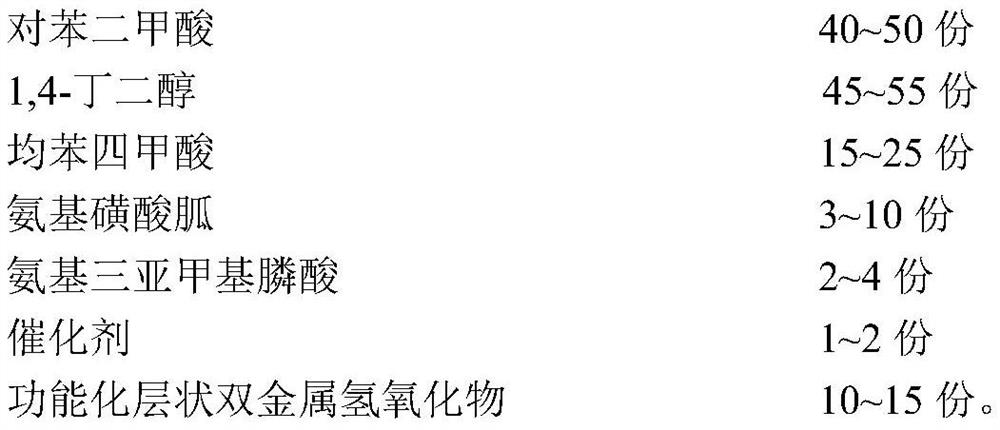

Self-flame-retardant PBT composite material and preparation method thereof

The invention discloses a self-flame retardant PBT composite material and a preparation method thereof. The self-flame-retardant PBT composite material is prepared from the following raw materials in parts by mass: 40 to 50 parts of terephthalic acid, 45 to 55 parts of 1, 4-butanediol, 15 to 25 parts of pyromellitic acid, 3 to 10 parts of guanidine sulfamate, 2 to 4 parts of amino trimethylene phosphonic acid, 1 to 2 parts of a catalyst and 10 to 15 parts of functionalized layered double hydroxides. The preparation method comprises the following steps: S1, mixing terephthalic acid, 1, 4-butanediol and a catalyst, carrying out pre-esterification reaction for 2-3 hours under the conditions of 0.1 MPa and 200-220 DEG C, then adding pyromellitic acid, guanidine sulfamate and amino trimethylene phosphonic acid, heating to 245-270 DEG C, and carrying out stirring reaction for 1-1.5 hours; and S2, vacuumizi1ng the reaction system in the S1 to 50-100 Pa, carrying out condensation polymerization at 240-255 DEG C for 3-6 hours, then adding the functionalized layered double-metal hydroxide, carrying out stirring reaction at 250-270 DEG C for 1-2 hours, and cooling and curing. According to the method disclosed by the invention, a flame-retardant substance is embedded into a PBT molecular chain, so that microcosmic molecular modification is realized, the PBT material is endowed with a self-flame-retardant characteristic, the problem of phase layering is avoided, and the mechanical strength and the mechanical property of the PBT material are greatly improved.

Owner:朱浩

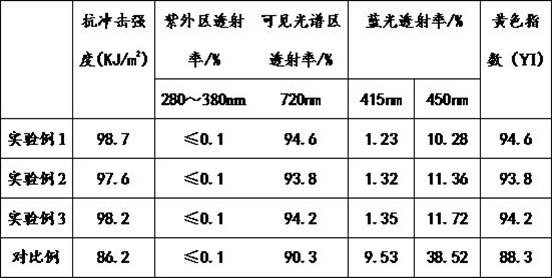

Anti-blue-ray mobile phone camera lens and preparation process thereof

InactiveCN112300557AGood light transmissionReduce aging rateCamera filtersOptical elementsCamera lensUv absorbance

The invention relates to the technical field of optical lens preparation, in particular to an anti-blue-ray mobile phone camera lens and a preparation process thereof. The anti-blue-ray mobile phone camera lens is prepared from the following raw materials in parts by weight: 95 to 100 parts of polycarbonate, 0.16 to 0.38 part of metal oxide, 0.14 to 0.28 part of nano powder, 0.25 to 0.45 part of modified mica powder, 0.025 to 0.032 part of diisopropyl peroxydicarbonate, 0.03 to 0.12 part of ultraviolet absorbent, 0.6 to 1.5 parts of blue light absorbent, 0.03 to 0.08 part of antistatic agent and 0.015 to 0.023 part of toner. The mobile phone camera lens prepared by the preparation method not only has good light transmission, but also has a good absorption effect on ultraviolet rays and blue light; in addition, the anti-blue-ray mobile phone camera lens has good anti-blue-ray performance, the blocking effect of the camera lens on harmful blue ray is effectively improved, and harm of ultraviolet light and blue ray to the body of a user is reduced; in addition, the camera lens also has excellent anti-ultraviolet capability so that the aging rate of the camera lens is effectively reduced, and the service life of the camera lens is prolonged.

Owner:深圳市龙迪光电实业有限公司

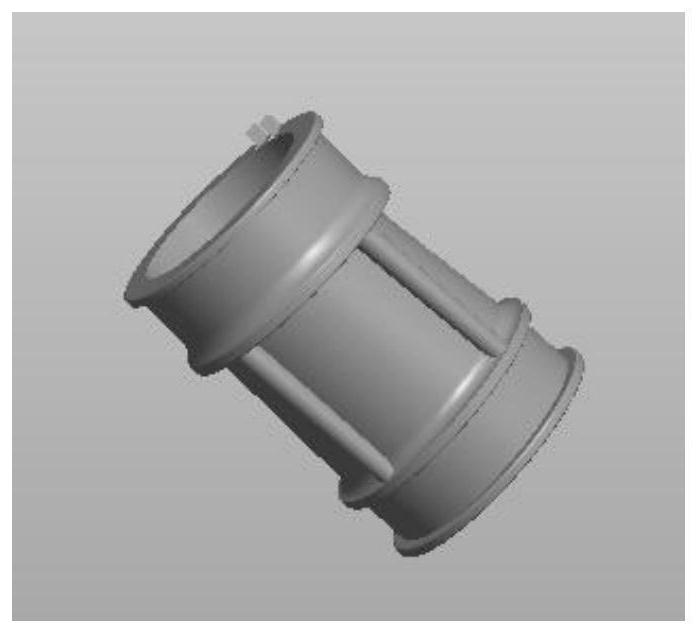

Household dish-washing machine corrosion-resistant medium

PendingCN112592541AHigh modulus of elasticityIncrease crosslink densityVegetable oilMaterials science

The invention discloses a household dish-washing machine corrosion-resistant medium, and belongs to the technical field of dish-washing machines. The household dish-washing machine corrosion-resistantmedium is prepared from the following raw materials in parts by weight: 95-105 parts of raw rubber, 50-60 parts of filler, 20-30 parts of white carbon black, 1-2 parts of S-80, 1-2 parts of N-cyclohexyl-2-benzothiazole sulfonamide, 1-2 parts of 2-mercaptobenzothiazole, 2-5 parts of plasticizer, 2-6 parts of antiager A and 5-8 parts of paraffin. The product has the characteristics of olive oil resistance, excellent electric breakdown performance, high strength, good elasticity and good sealing performance, is already used for water inlet and outlet pipes of dishwashers in batches, is good in formula and structure manufacturability, and meets batch vulcanization production; the electric breakdown performance of the product reaches 7000 V, the effects of medium resistance, water resistance,aliphatic hydrocarbon resistance and aromatic hydrocarbon nonpolar vegetable oil resistance are excellent, and the sealing waterproof grade is IP67.

Owner:ANHUI JINGHONG SEAL TECH

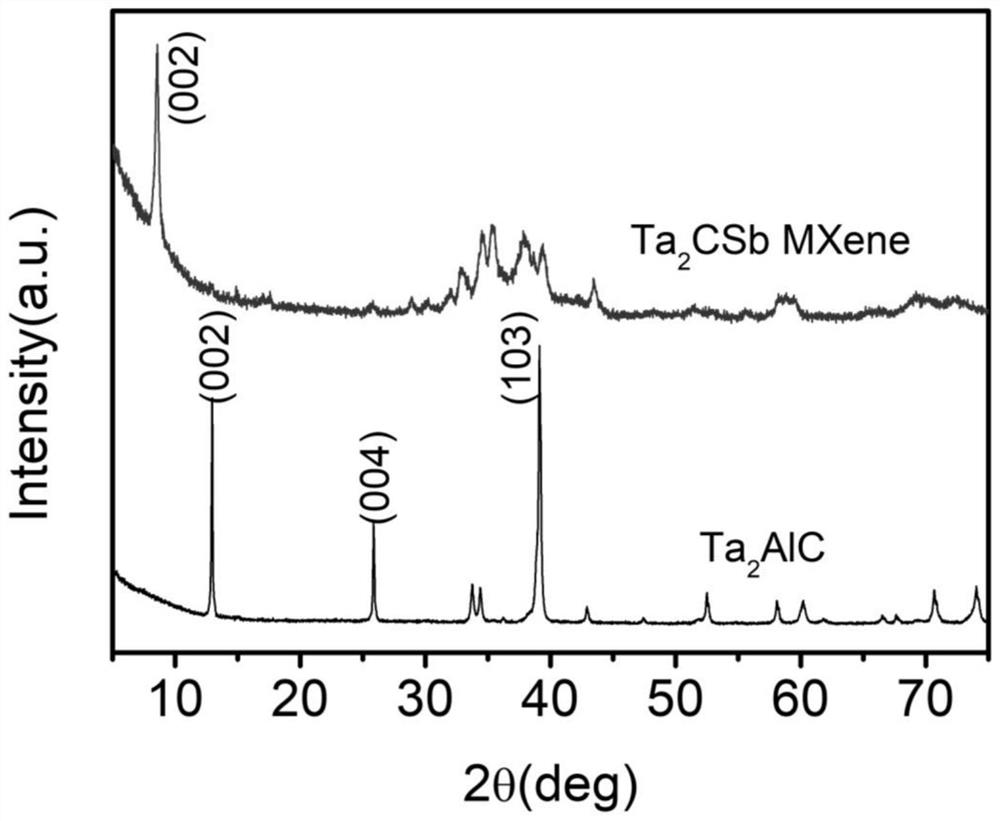

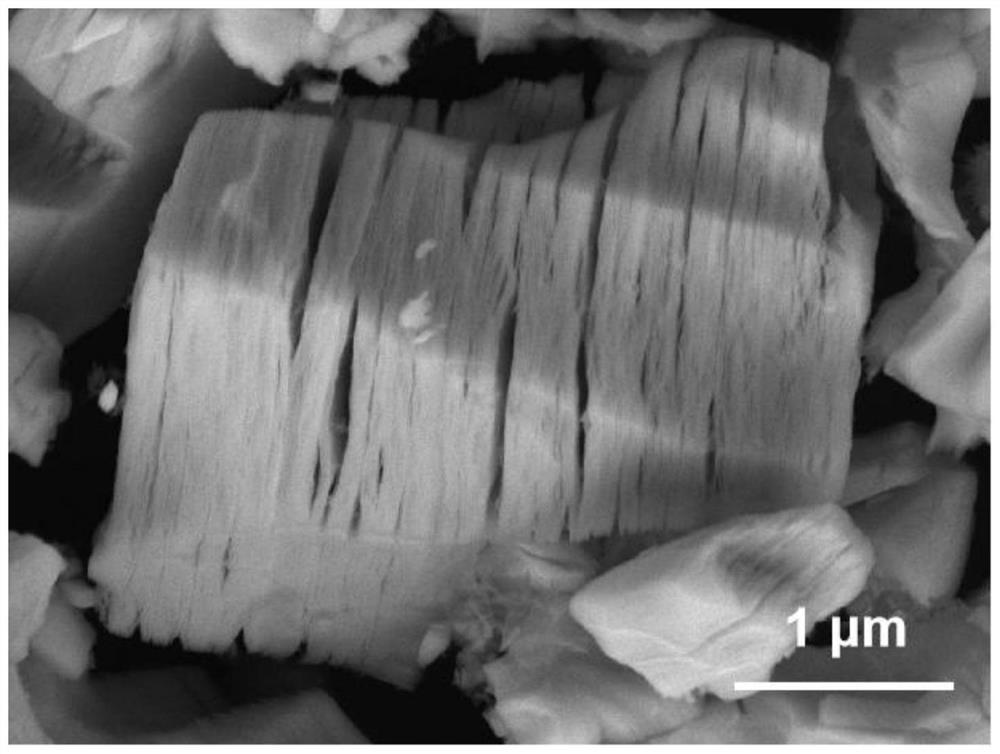

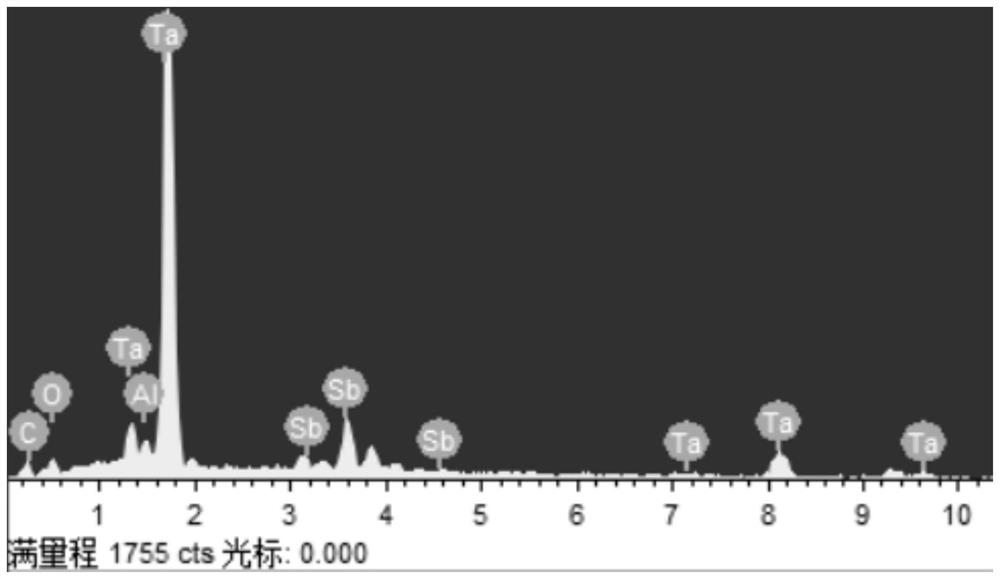

Surface modification method of MXene material

PendingCN114349006AFacilitate functional applicationImprove application functionalityTitanium carbideHydrofluoric acidInorganic salts

The invention belongs to the technical field of two-dimensional nano materials, and particularly relates to a surface modification method of an MXene material, in particular to an MXene surface modification method based on anion coordination competition in a molten salt environment. The preparation method specifically comprises the following steps: mixing a precursor MAX phase material, Lewis acid molten salt, end-group-related elemental element powder or an end-group-related alloy phase and inorganic salt, and carrying out high-temperature reaction to prepare the MXene material. The method disclosed by the invention is simple, efficient and environment-friendly, multiple defects caused by using a hydrofluoric acid solution with high toxicity and high risk as an etching agent to prepare MXene are avoided, meanwhile, chemical modification of the surface of the MXene material is realized, physical and chemical properties of the MXene material can be effectively regulated and controlled through end group modification, and functional application and large-scale preparation of MXene are expected to be further promoted.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

A preparation method of composite nanofiber membrane, composite nanofiber membrane and its application in enzyme immobilization and immobilized enzyme

ActiveCN108754871BLarge specific surface areaHigh chemical activityElectro-spinningOn/in organic carrierPolymer scienceComposite nanofibers

The invention belongs to the field of nanofiber membranes, and particularly relates to a preparation method of a composite nanofiber membrane, the composite nanofiber membrane, application of the composite nanofiber membrane to enzyme immobilization and an immobilized enzyme. An electrostatic spinning solution containing chitosan is adopted for preparing the nanofiber membrane, and the membrane has a good film-forming property and an enzyme-immobilizing function; meanwhile, polypeptide nanofibers are adopted and loaded onto the membrane, in this way, the property of the membrane is further improved, and the enzyme-immobilizing property of the membrane is improved.

Owner:ANHUI POLYTECHNIC UNIV

Novel process for modifying wood through chemical crosslinking of environment-friendly polyester

PendingCN114683365ASimple process preparationAchieve chemical modificationWood treatment detailsPressure impregnationOrganic acidOrganic acid (substance)

The invention discloses a novel process for modifying wood through environment-friendly polyester chemical crosslinking, belongs to the technical field of wood chemical modification, and provides a process for modifying wood through biodegradable elastomer polyester. Organic acid and dihydric alcohol infiltrate wood in a molten state according to the molar ratio of 0.5: 1-1: 3, the two monomers are subjected to a cross-linking reaction under proper conditions, and meanwhile substances in a system and wood hydroxyl are subjected to a chemical reaction and fill wood cell cavities and cell walls. The process method of the environment-friendly polyester chemical crosslinking modified wood comprises the following steps: (1) melting organic acid and dihydric alcohol; (2) synthesis of biodegradable polyester and wood impregnation; and (3) drying the wood. The process method is simple and efficient, and the prepared wood has durability and stability and has extremely high application value.

Owner:NORTHEAST FORESTRY UNIVERSITY

A kind of polyurethane/polyvinyl acetate hybrid emulsion and preparation method thereof

Owner:佛山市顺德区蓝德堡实业有限公司

Flue gas sulfur-fixing agent used in a kind of sodium sulfide synthesis process and preparation technology thereof

ActiveCN112742204BRich in mesoporesHigh porosityGas treatmentDispersed particle separationChemical reactionModified carbon

The invention relates to the technical field of preparation of a sulfur-fixing agent, in particular to a flue gas-sulfur-fixing agent used in a sodium sulfide synthesis process and a preparation process thereof; it is composed of the following raw materials by weight: 80-90 parts of modified calcium carbonate powder, 10 parts of ~13 parts vermiculite powder, 3.6~4.5 parts sodium carbonate, 7~12 parts graphene, 3~5 parts potassium nitrate, 3.5~4.3 parts cerium stearate, 8~12 parts liquid paraffin, 4~6 parts permanganic acid Potassium, 3-5 parts of sodium lauryl sulfate, 12-15 parts of activator, 6-10 parts of stabilizer, 2.2-3.2 parts of auxiliary agent and appropriate amount of deionized water; the sulfur-fixing agent prepared by the present invention can ensure the sulfur-containing gas It can chemically react with the active ingredients in the sulfur-fixing agent in time; thus achieving the purpose of high-efficiency sulfur-fixing, greatly reducing the emission of sulfur oxides and reducing the emission of sulfur-containing gases; while reducing the pressure of environmental protection, it also makes the The life of equipment and facilities is effectively extended.

Owner:铜陵铜冠环保科技有限公司

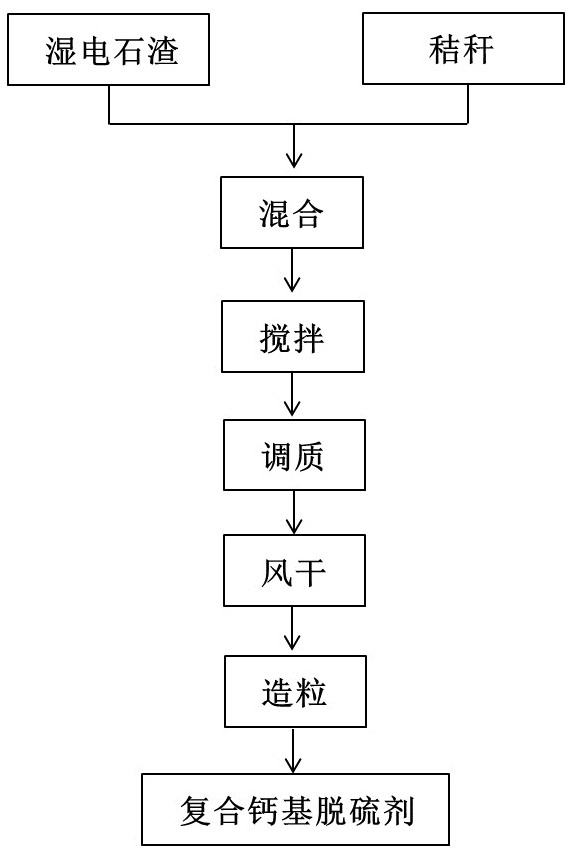

Carbide slag composite calcium-based desulfurizer based on biomass conditioning and preparation method thereof

ActiveCN108704470BSolve the furnace problemAchieve chemical modificationDispersed particle separationSlagFluidized bed

The invention relates to the field of desulfurization in circulating fluidized bed furnace, in particular to a carbide slag composite calcium-based sorbent based on biomass quenching and tempering anda preparation method thereof. According to the sorbent, the biomass is mixed with the wet carbide slag to adjust the moisture in the carbide slag, so that the furnace charging problem of the wet carbide slag can be solved without a heating the drying process; the carbide slag is quenched and tempered by utilizing biomass, chemical modification of carbide slag is realized, rich soluble potassium is contained in the biomass, the migration of potassium in the biomass to the carbide slag surface of solid waste-based calcium-based sorbent can be realized through the quenching and tempering, so that the diffusion capacity of CaO in the CaSO4 dense product layer is improved during the desulfurization process, and the calcium conversion rate of the calcium carbide slag in the furnace when put into the furnace as small particle diameters can still be achieved when the carbide slag is put into the furnace with relatively large particle diameters; the sorbent has the advantages of high utilization efficiency, good desulfurization performance, short preparation process, low production cost and the like. Not only can the synergistic effective utilization of solid waste carbide slag and agricultural biomass be realized, but also the cost of desulfurization in the circulating fluidized bed furnace can be reduced.

Owner:SHANXI UNIV

Method for preparing thin-layer graphene/transition metal fluoride composite positive electrode active material by using antibiotic bacteria residue

ActiveCN112234206BFill technology gapsAchieve chemical modificationSecondary cellsNegative electrodesElectrical batteryElectrochemistry

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com