Patents

Literature

194results about How to "Reduce aging rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

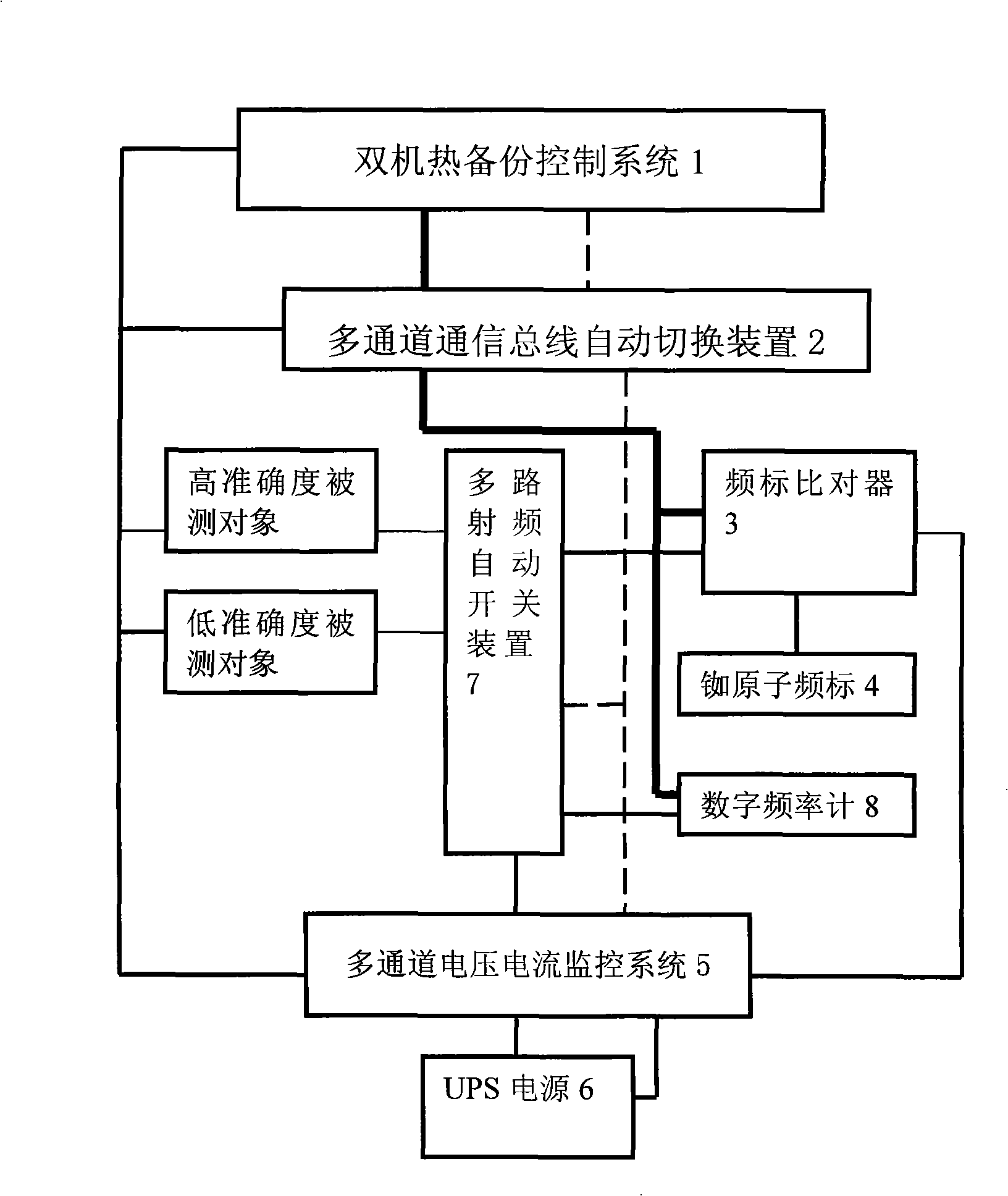

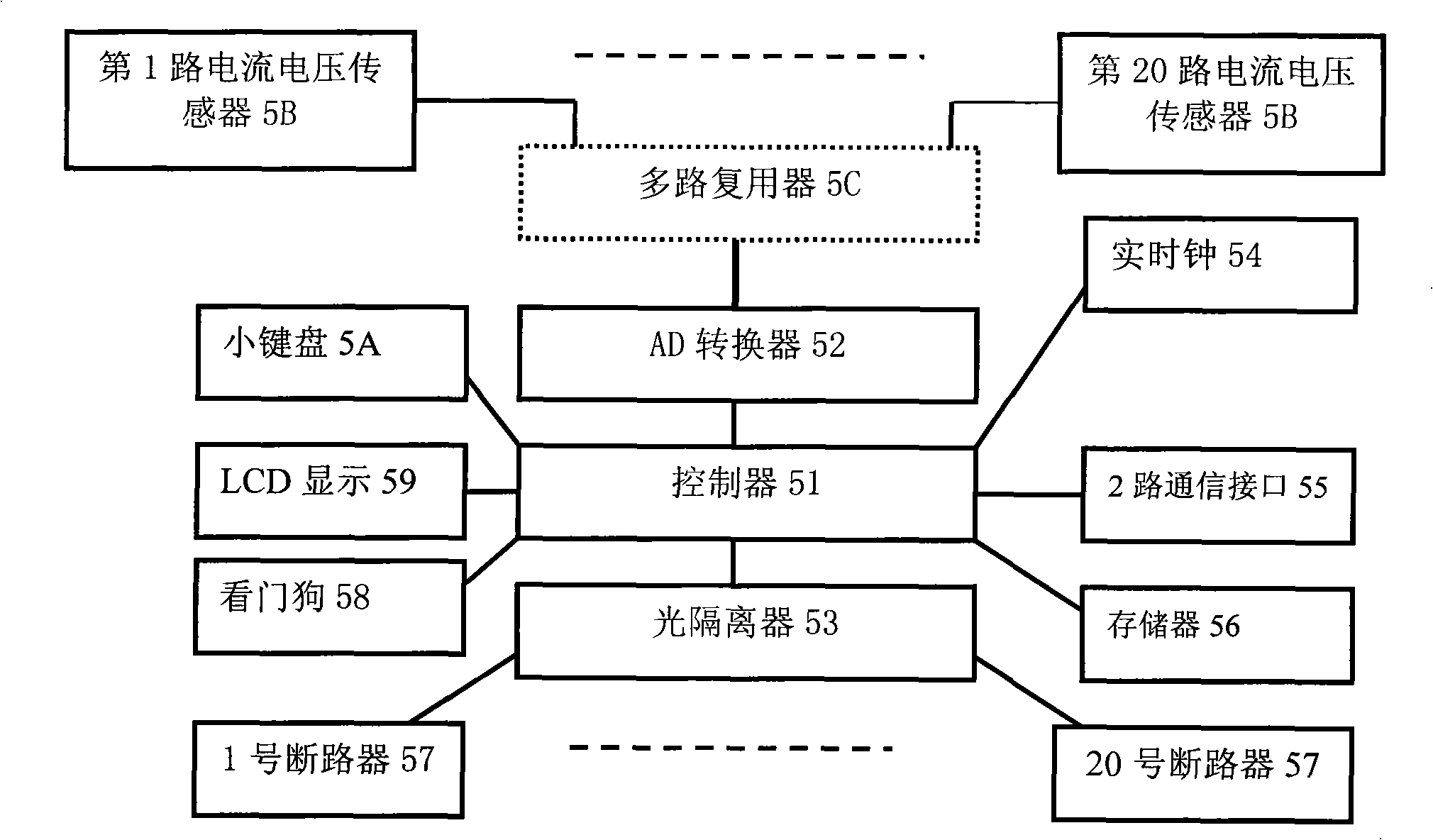

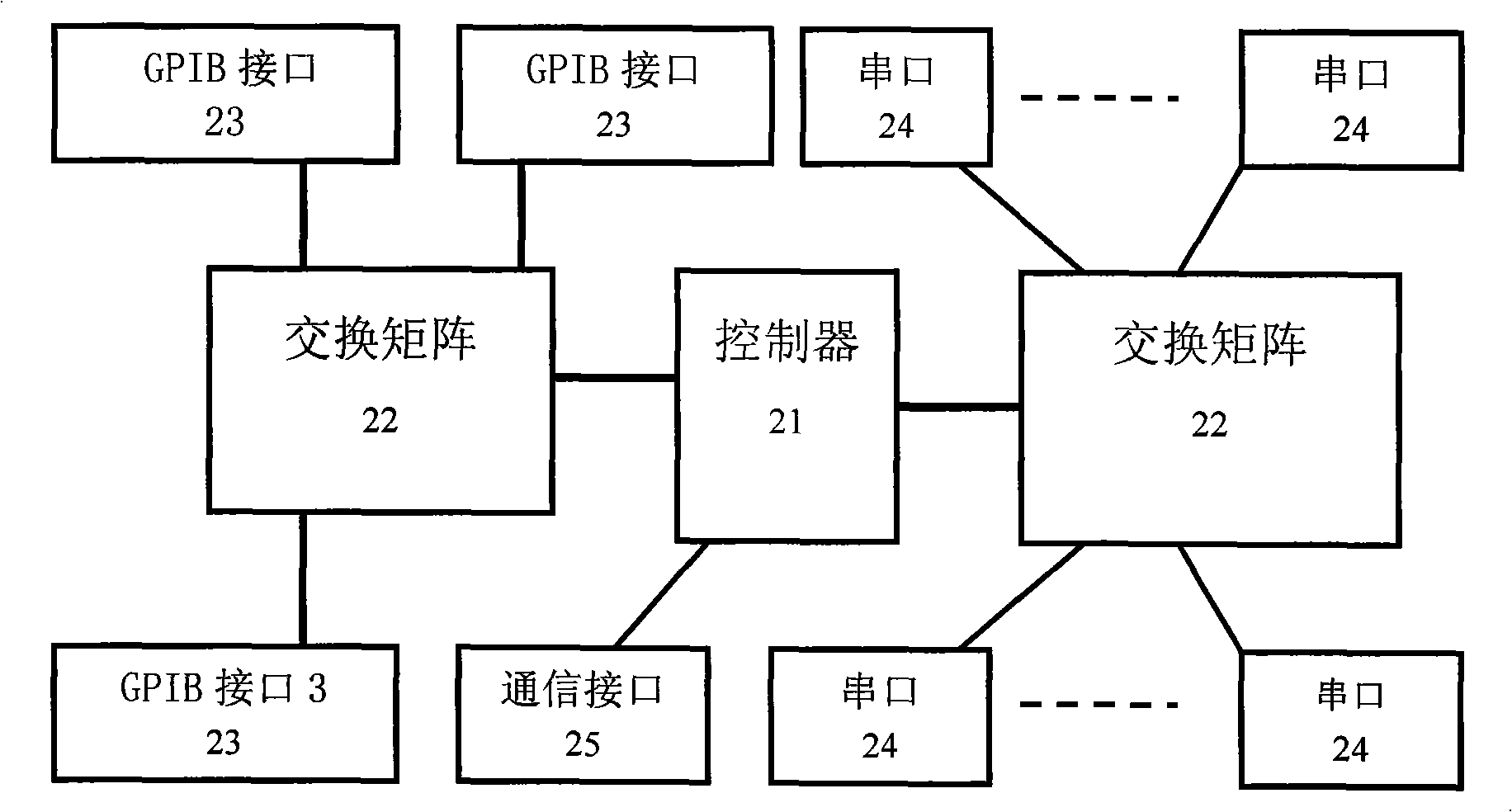

Unattended automatic test system of quartz crystal oscillator

InactiveCN101515009AAvoid fault magnificationAvoid test failuresElectronic circuit testingControl systemMonitoring system

The invention discloses an unattended automatic test system of a quartz crystal oscillator and aims at providing the test system with the safety protection ability and the abilities of self-defining a measurement process, self-setting test parameters and supporting long-time unattended operation. In the test system, a dual-server hot-backup control system is connected with a frequency standard comparator, a multi-channel radio frequency automatic switching device, a digital frequency meter and a multi-channel voltage and current monitoring system through an automatic switchover device of a multi-channel communication bus to form an automatic test loop. The rubidium atomic frequency standard is taken as the benchmark and signals of the tested quartz crystal oscillator are respectively sent to the frequency standard comparator and the digital frequency meter for testing according to the accuracy level thereof by the multi-channel radio frequency automatic switching device under the control of a computer with system control software. The multi-channel voltage and current monitoring system carries out the real-time monitoring of current and voltage states of all the standard devices and the tested devices and receives a command of the dual-server hot-backup control system for turning off or turning on a power supply of any channel.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

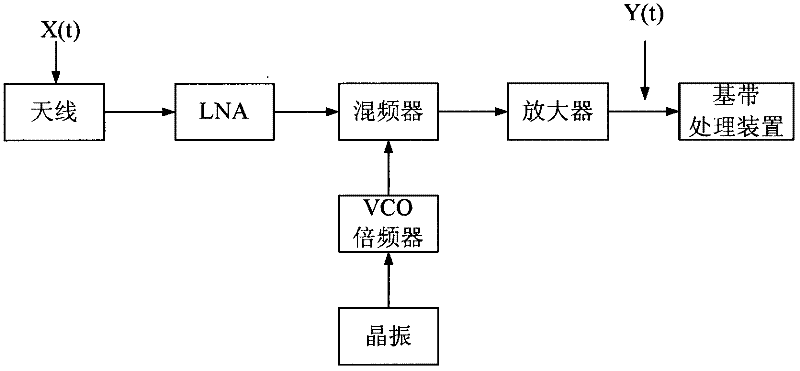

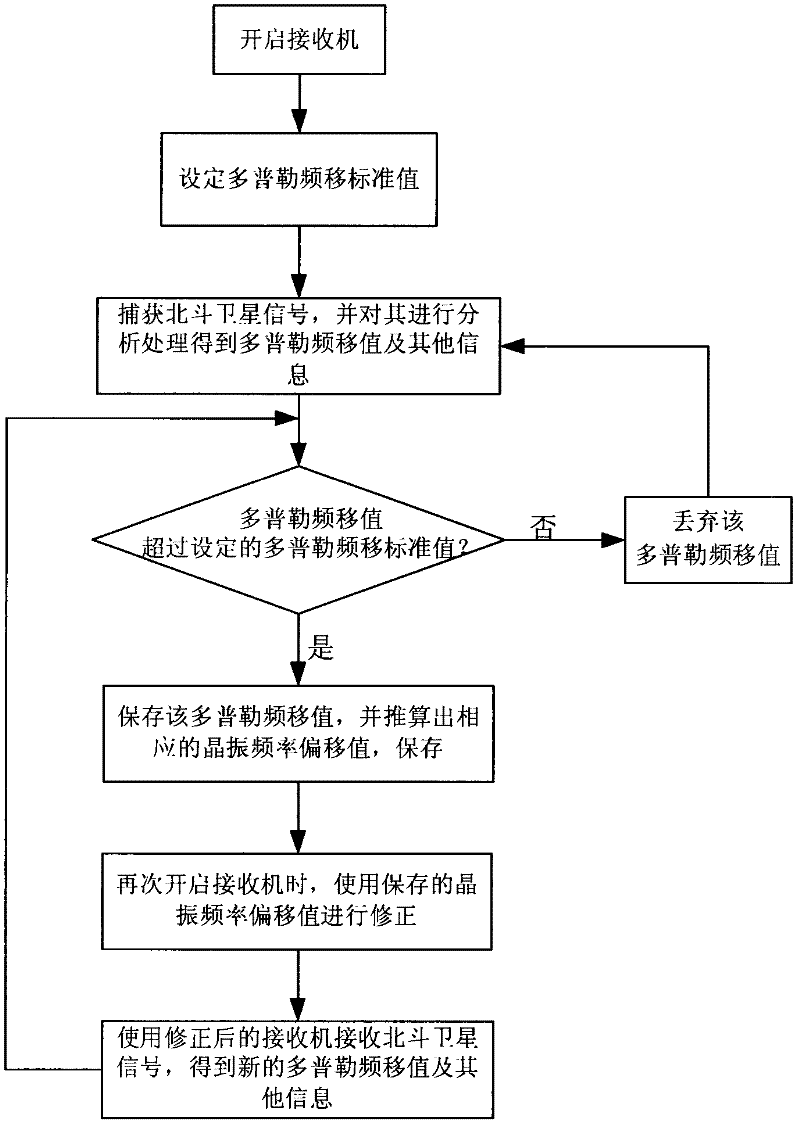

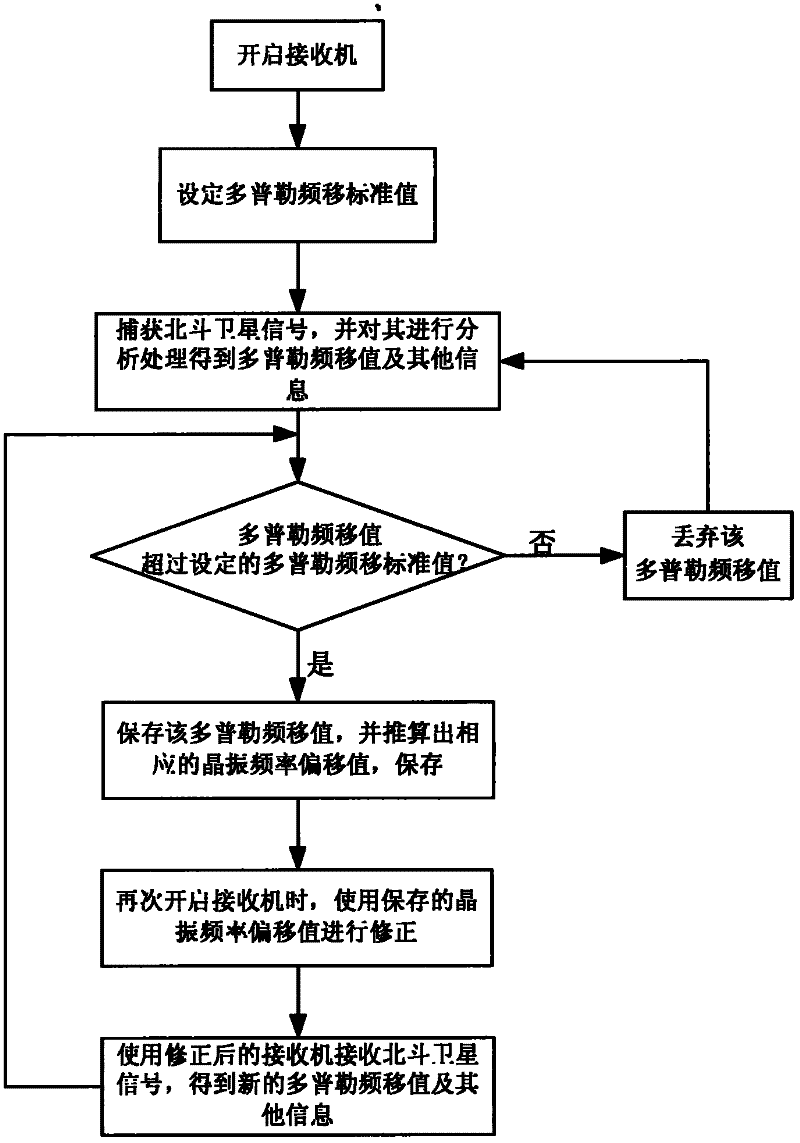

Method for solving crystal oscillator frequency deviation of receiver in receiving big-dipper satellite signals rapidly

ActiveCN102375148AAddressing the Bad Effects of Rapid AcceptanceImprove search efficiencySatellite radio beaconingFrequency shiftCrystal oscillator

The invention discloses a method for solving crystal oscillator frequency deviation of a receiver in receiving big-dipper satellite signals rapidly. The method mainly comprises the following steps: (1) presetting a Doppler frequency shift standard value in a big-dipper satellite receiver; (2) capturing big-dipper satellite signals, and acquiring an initial Doppler frequency shift value; (3) comparing the initial Doppler frequency shift value with the preset Doppler frequency shift standard value, storing the Doppler frequency shift value and the corresponding crystal oscillator deviation value if the preset Doppler frequency shift standard value is exceeded; and discarding the Doppler frequency shift value reversely; and (4) starting up the big-dipper satellite receiver again, and correcting the big-dipper satellite receiver by calling the stored crystal oscillator frequency deviation value. According to the invention, through correcting the crystal oscillator frequency inventively, adverse effects to the rapid receiving of the big-dipper satellite signals by the crystal oscillator frequency deviation are solved effectively.

Owner:CHENGDUSCEON ELECTRONICS

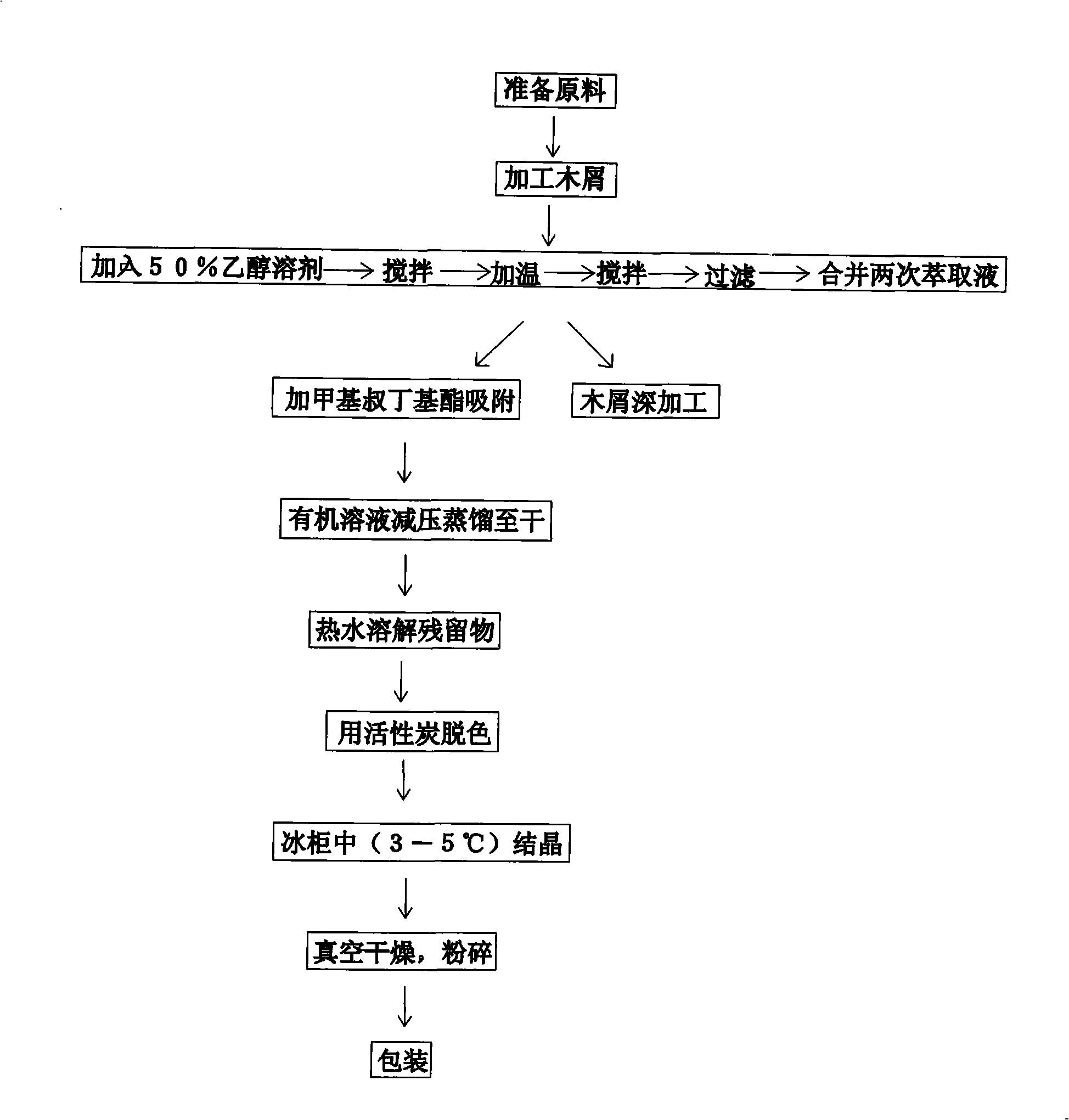

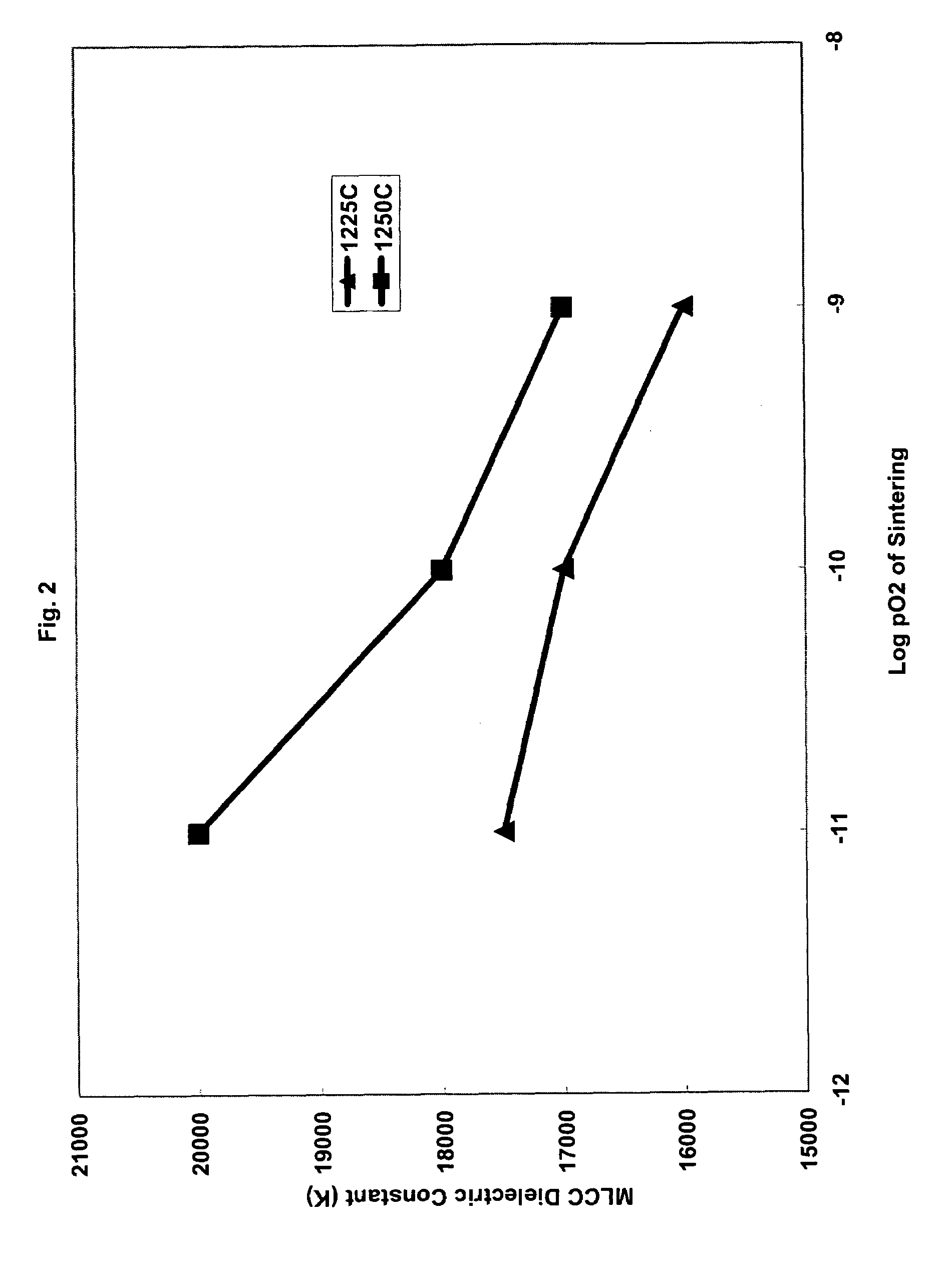

Method for extracting dihydroquercetin form larch

InactiveCN101333203AFree radical scavengingLesion hindranceOrganic chemistryConiferophyta medical ingredientsLarchUnit/Kilogram

Disclosed is a method for extracting dihydro quercetin from larch. The invention is an improved production method. Due to different production materials and extraction processes, the dihydro quercetin products in U.S. and European markets are very expensive, at a price of 200-1000 euros per gram. Such a high market price economically limits the wide range of practicability of dihydro quercetin products. During the pretreatment of raw materials, 50 kilograms of larch wood chips and 500-800 liters of 50% ethanol solution are added into a reactor to get fully stirred and mixed; then the mixture is extracted and filtered for the second extraction; the filtrates are combined and adsorbed; the organic solvents are collected and dried by a vacuum evaporator through organic phase vacuum distillation; according to a weight proportion of 10:1, the residues are dissolved with hot water, decolorized with activated carbon and then crystallized at a temperature of 3-5 DEG C to precipitate the dihydro quercetin product which is then crushed after vacuum drying to finished product. The invention is used to extract dihydro quercetin from larch.

Owner:黑龙江花旗科技发展有限公司 +2

Multifunctional peanut growth inhibitor

InactiveCN101213964AEffective growth controlEasy to controlBiocidePlant growth regulatorsGrowth retardantSide effect

The invention relates to a multi-functional peanut growth inhibitor which is composed by the weight ratio of following components, paclobutrazol to prohexadione calcium to uniconazole is 3: 1.2-1.5: 0.8-1.2. The invention not only can effectively control the growth of the vegetative part of the peanut on the ground, can prevent the peanut from overgrowing and lodging, but also can effectively avoid the side effect brought by general growth inhibitor (e.g. paclobutrazol). At the same time, in the growth anaphase of the peanut, the invention can remarkably improve LAI (leaf area index), effective LAI, leaves membrane-lipid protective enzymatic activity (SOD, POD, CAT), Pr (soluble protein) content and so on, can reduce MDA content and can postpone the senescence rate of peanut leaves. More importantly, the invention can remarkably improve the output of pods. The production can be increased by 16.6 percent- 23.0 percent more than the production without spraying any inhibitor, and can be increased by 7.6 percent- 13.7 percent more than the production only spraying paclobutrazol. The invention solves the problem that the overgrowth and presenility can not be prevented synchronously in the production process of the peanuts.

Owner:SHANDONG PEANUT RES INST

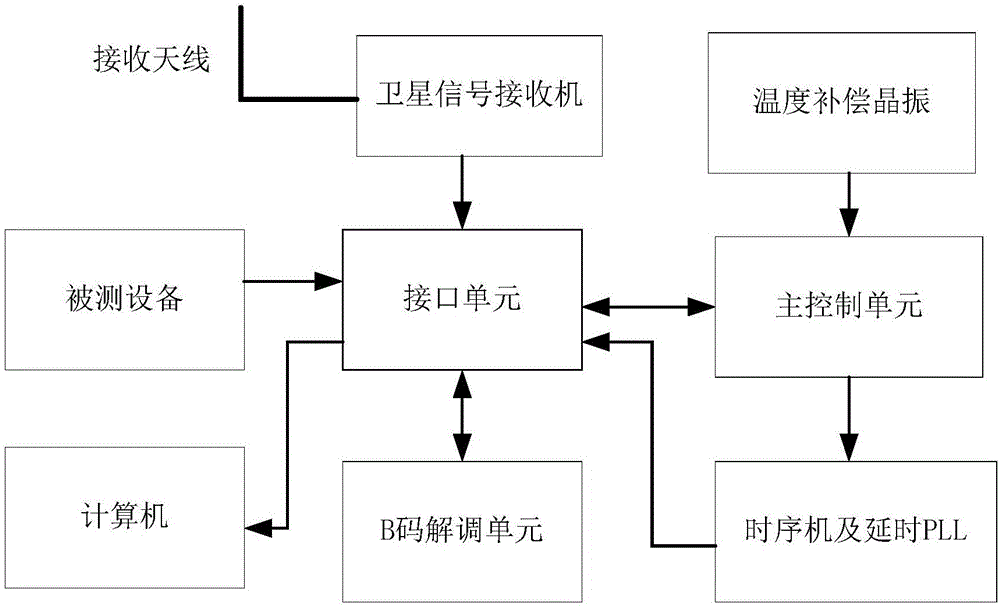

Time-keeping and timing precision test device, time-keeping precision test method and timing precision test method based on satellite timing system

ActiveCN106656451AThe testing process is simpleEasy to implementSynchronisation information channelsRadio-controlled time-piecesSequential machineArrival time

The invention belongs to the field of a photoelectric test and relates to a time-keeping and timing precision test device, time-keeping precision test method and timing precision test method based on the satellite timing system. The device comprises a receiving antenna, a satellite signal receiver, an interface unit, a B code demodulation unit, a master control unit, a sequential machine and delay PLL unit, a computer and a temperature compensation crystal oscillator. The time-keeping precision and timing precision are calculated in a mode of recording arrival time of a to-be-tested signal, and the time-keeping and timing precision test device, the time-keeping precision test method and the timing precision test method based on the GPS / Beidou system are simple in test process and easy in engineering realization.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

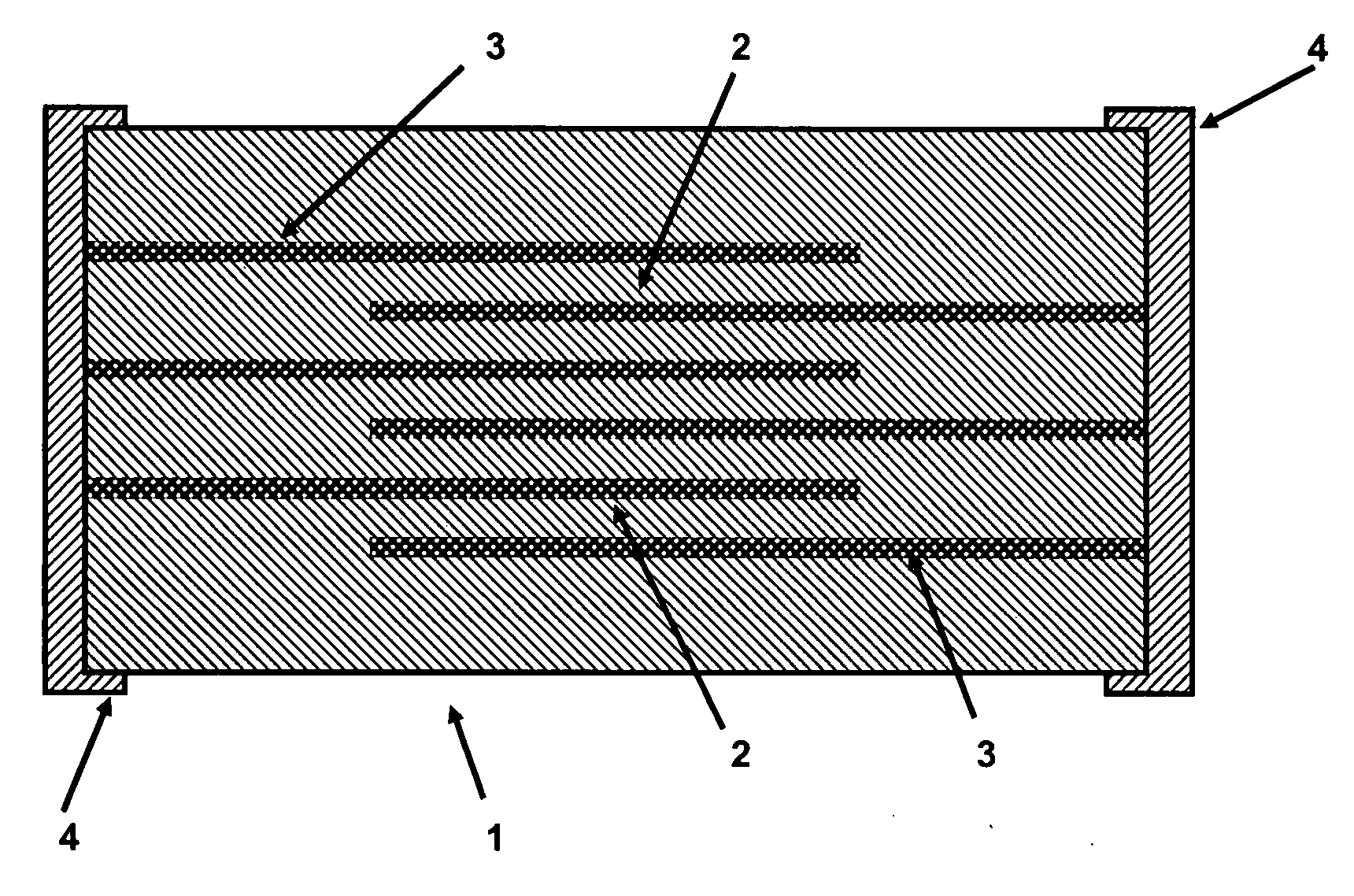

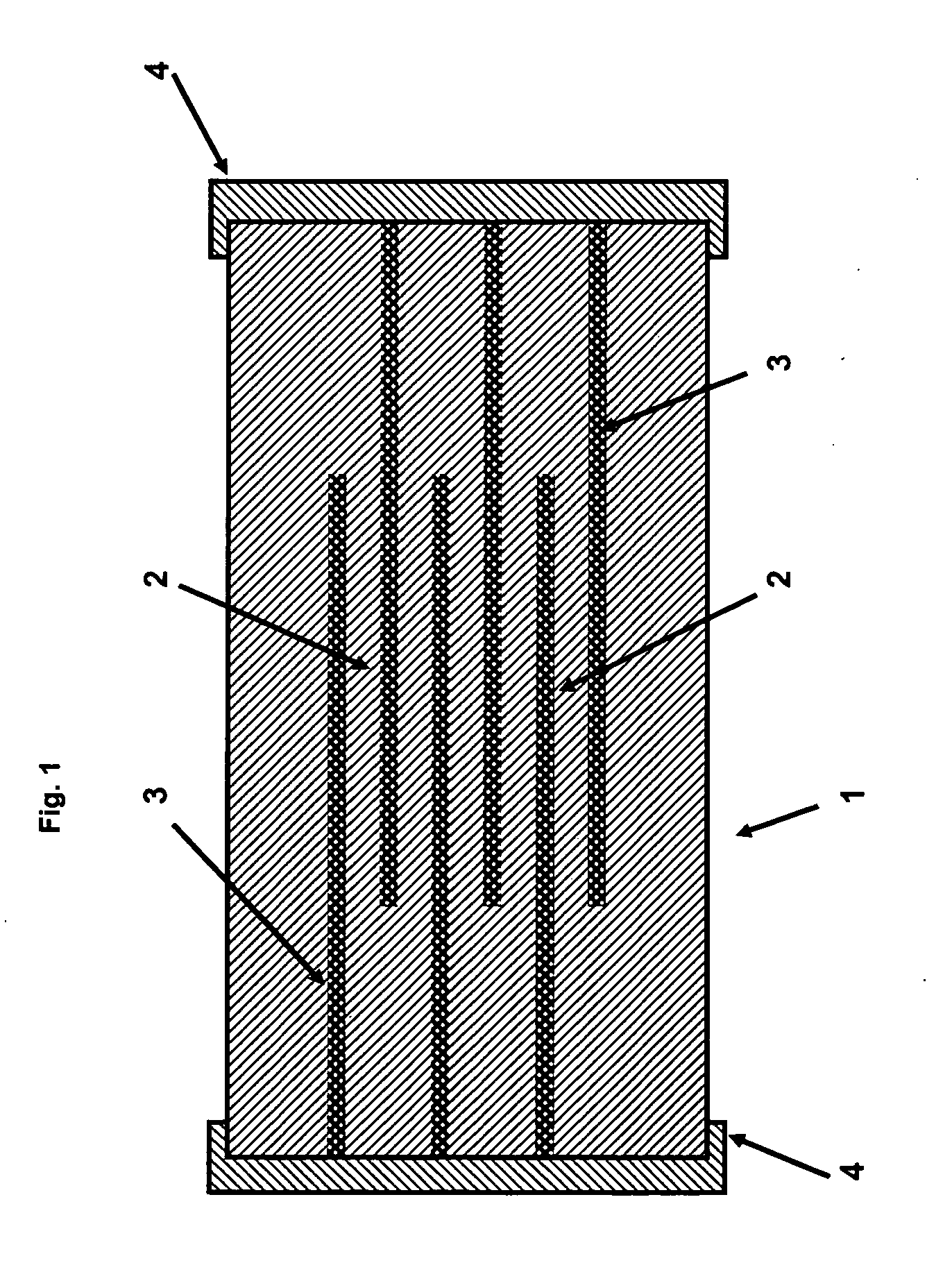

Y5V dielectric composition

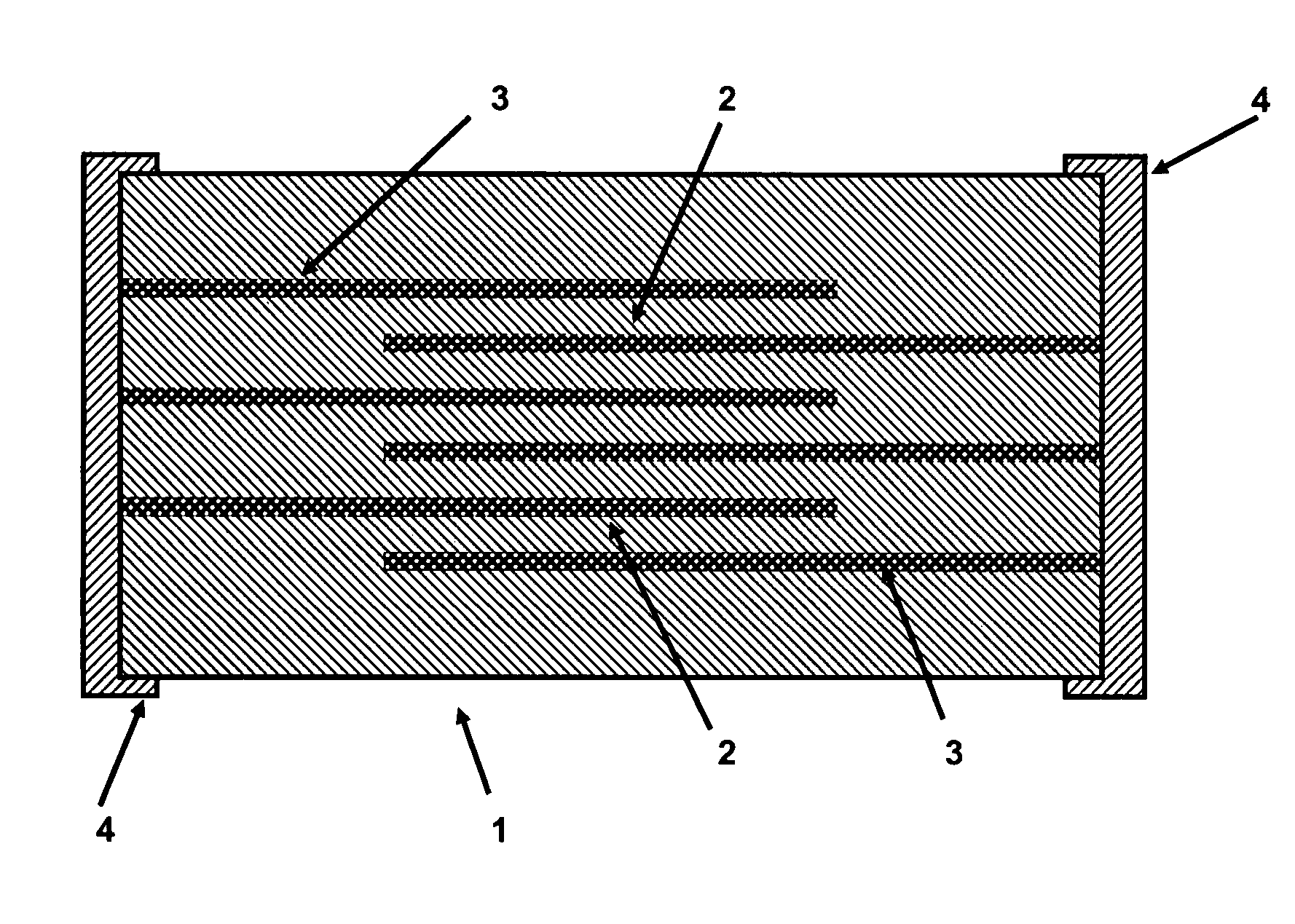

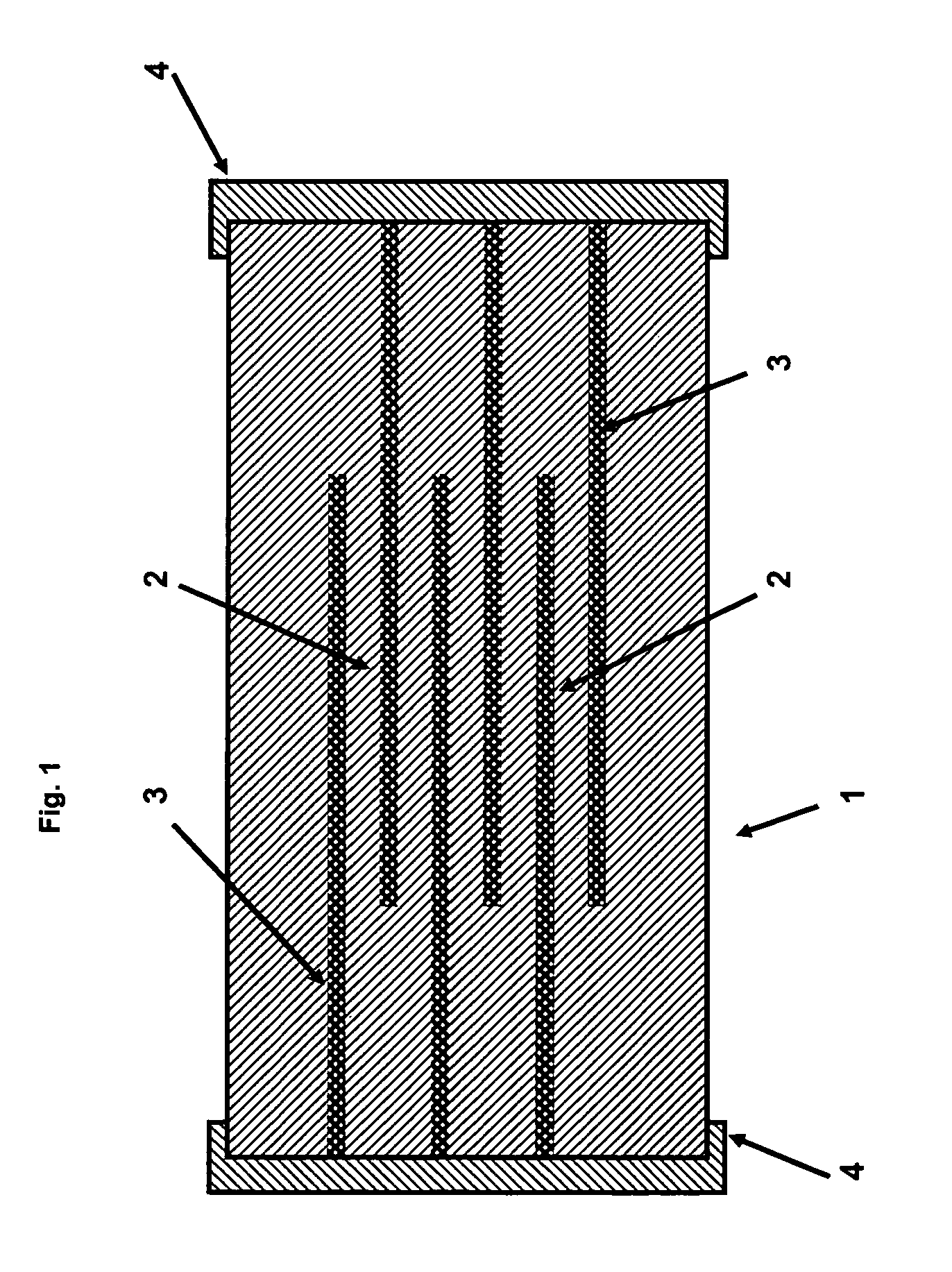

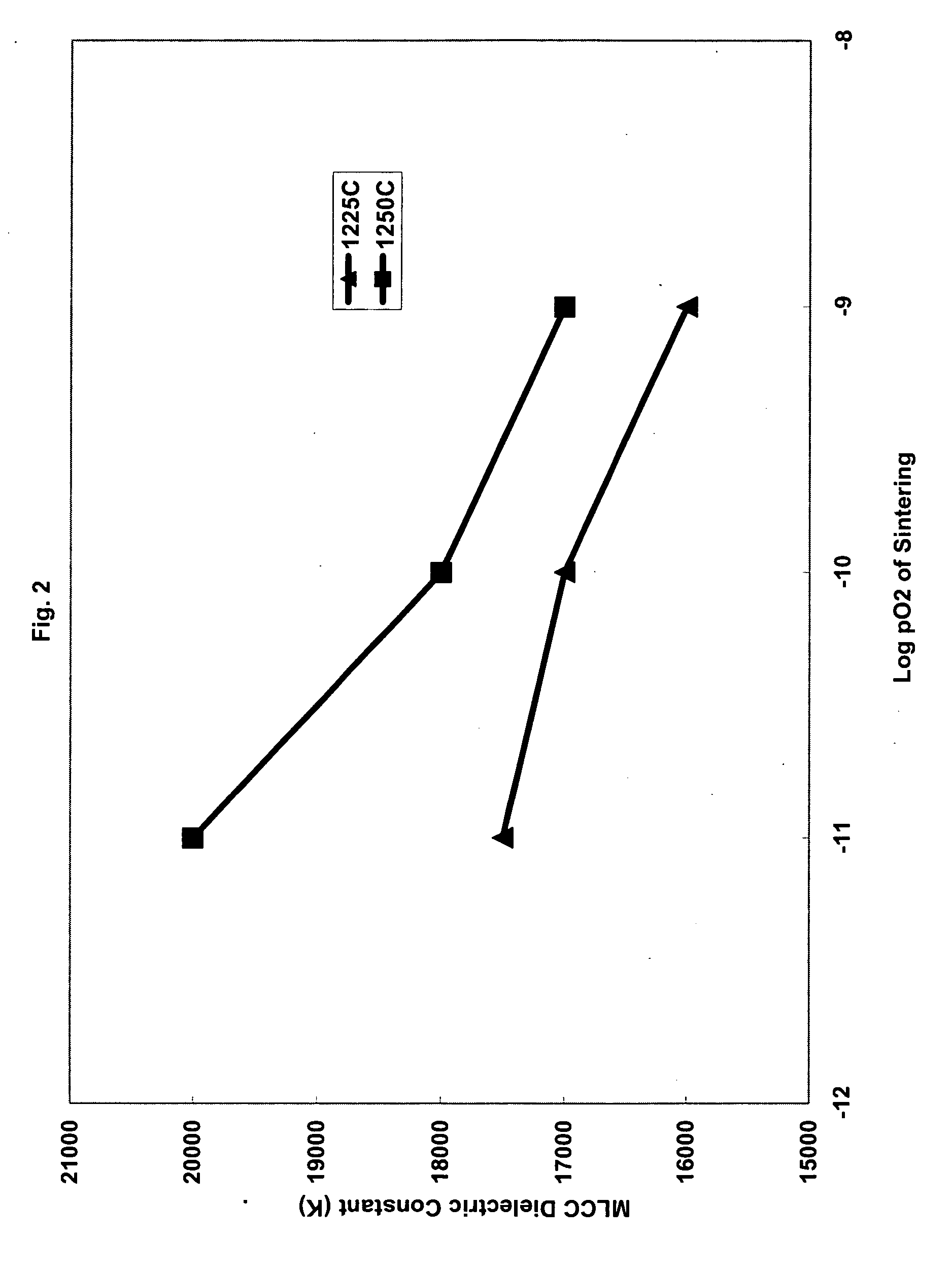

InactiveUS7230817B2Small dielectric lossImprove reliabilityFixed capacitor dielectricStacked capacitorsLow dissipationAlloy

Multilayer ceramic chip capacitors which satisfy Y5V requirements and which are compatible with reducing atmosphere sintering conditions so that non-noble metals such as nickel, copper, and alloys thereof may be used for internal and external electrodes are made in accordance with the invention. The capacitors exhibit desirable dielectric properties (high capacitance, low dissipation factor, high insulation resistance), excellent performance on highly accelerated life testing, and very good resistance to dielectric breakdown. The dielectric layers comprise BaTiO3 doped with other metal oxides such as MgO, CaO, ZnO, MnO2, ZrO2, SiO2, Nd2O3, Nb2O5, and Y2O3.

Owner:FERRO CORP

Method for extracting dihydroquercetin form larch

InactiveCN101333204AFree radical scavengingInhibition of lesionsOrganic chemistryConiferophyta medical ingredientsLarchUnit/Kilogram

Disclosed is a preparation method for extracting dihydro quercetin from larch. The invention is an improved production method. Due to different production materials and extraction processes, the dihydro quercetin products in U.S. and European markets are very expensive, at a price of 200-1000 euros per gram. Such a high market price economically limits the wide range of practicability of dihydro quercetin products. During the pretreatment of raw materials, 50 kilograms of larch wood chips and 500-800 liters of 50% ethanol solution are added into an extractor to get fully stirred and mixed; then the mixture is extracted and filtered for the second extraction; the filtrates are combined and adsorbed; the organic solvents are collected and dried by a vacuum evaporator through organic phase vacuum distillation; according to a weight proportion of 10:1, the residues are dissolved with hot water, decolorized with activated carbon and then crystallized at a temperature of 3-5 DEG C to precipitate the dihydro quercetin product which is then crushed after vacuum drying to finished product. The invention is used to extract dihydro quercetin from larch.

Owner:黑龙江花旗科技发展有限公司 +2

Preparation method of ultravioresistant PVC composite material suitable for plateau environment

InactiveCN104497435AImproves UV resistanceImprove flame retardant performanceChemical solutionPolyvinyl chloride

The invention belongs to the technical field of new material, and concretely relates to an improved preparation technology for enhancing the functionality of a polyvinyl chloride (PVC) material. The preparation technology of the present invention comprises the following steps: 1)preparing a nano reinforcement; and 2)preparing the hybrid PVC functional composite material by a chemical solution method to prepare the hybrid PVC functional composite material. According to the invention, zinc oxide and titanium dioxide are composited for usage, anti ultraviolet performance of the composite material can be greatly increased; nano-sized magnesium hydroxide, zinc oxide and titanium dioxide particles are organically combined to prepare the PVC functional composite material, PVC anti ultraviolet capability can be optimized, aging rate can be reduced, service life is prolonged, flame retardation performance is enhanced, fire hazard generation is reduced, and the external environment adaptation capability of the PVC material at Qinghai-Tibet plateau can be finally increased.

Owner:QINGHAI UNIVERSITY

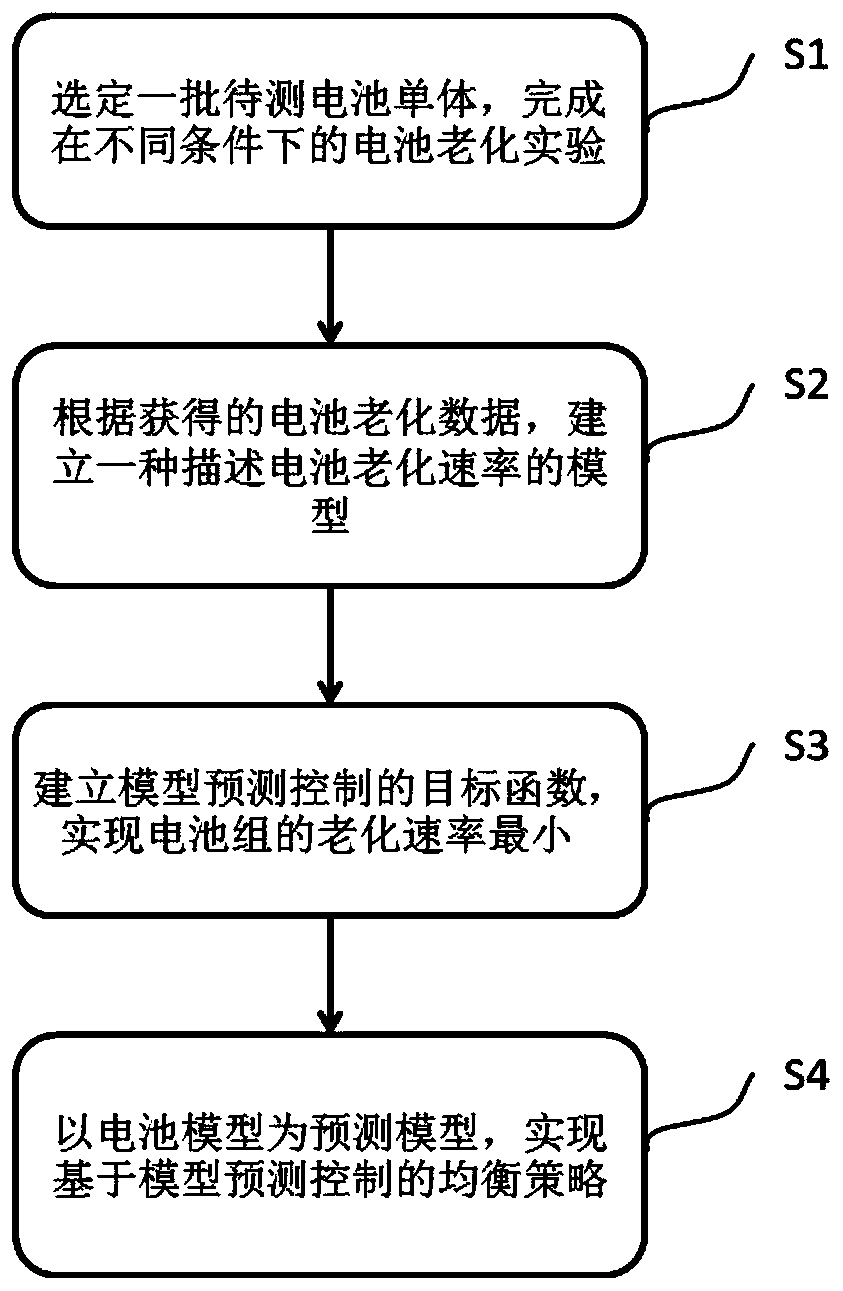

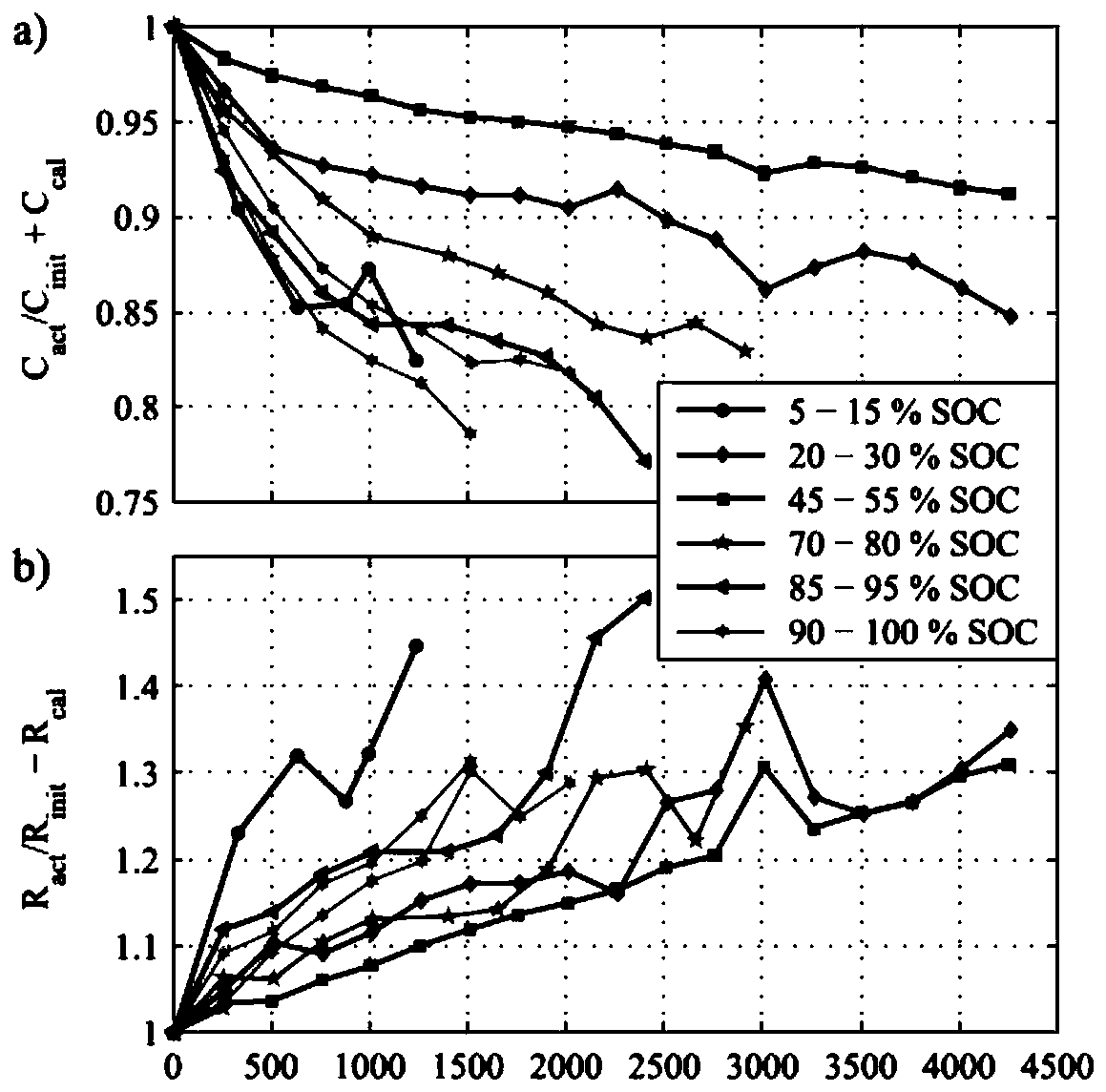

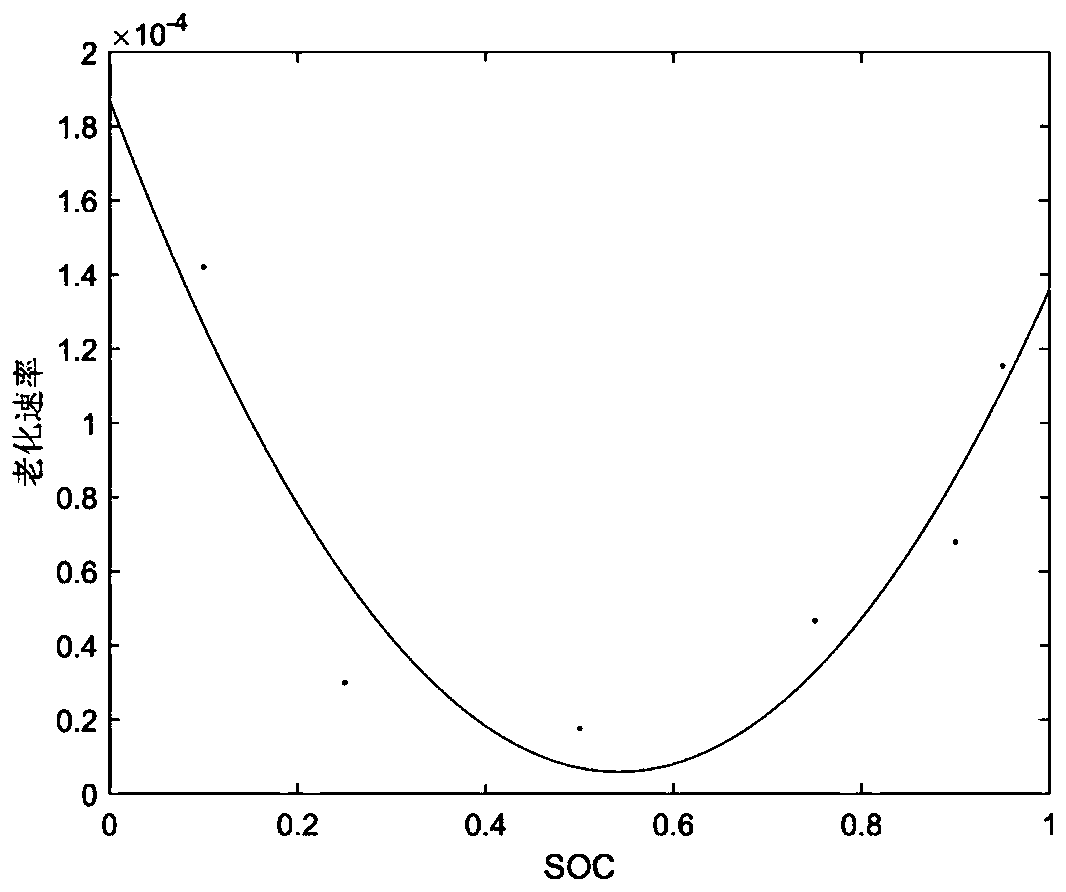

Lithium-ion power battery pack full-life-cycle balance control method

ActiveCN110247451AReduce aging rateExtended service lifeCharge equalisation circuitElectric powerLithiumPower battery

The invention relates to a lithium-ion power battery pack full-life-cycle balance control method, and belongs to the technical field of battery management. The method comprises the following steps: S1, selecting a batch of single batteries to be tested, and completing battery aging experiments under different conditions; s2, establishing a model for describing the aging rate of the battery according to the obtained aging data of the battery; s3, establishing a target function of model prediction control, and realizing the minimum aging rate of the battery pack; and S4, taking the battery model as a prediction model, and realizing an equalization strategy based on model prediction control. The aging rate of the battery pack can be lower, so that the service life of the battery pack is prolonged.

Owner:CHONGQING UNIV

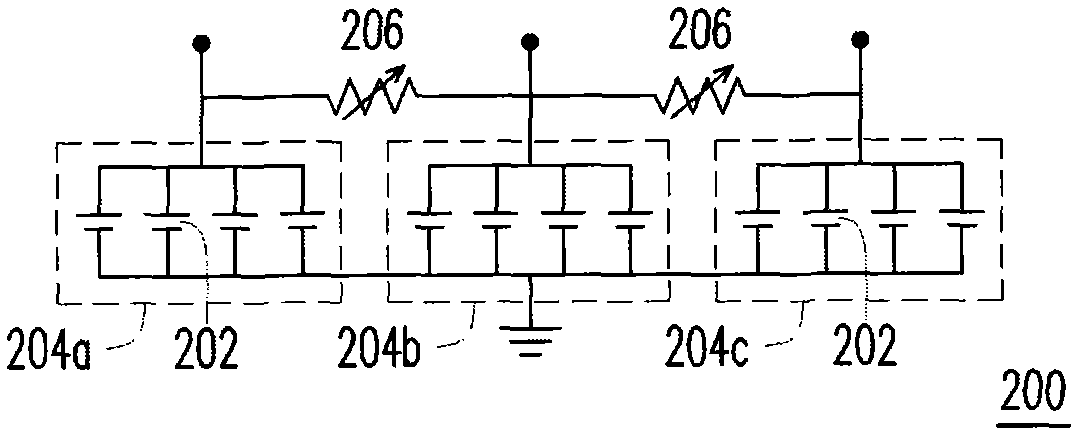

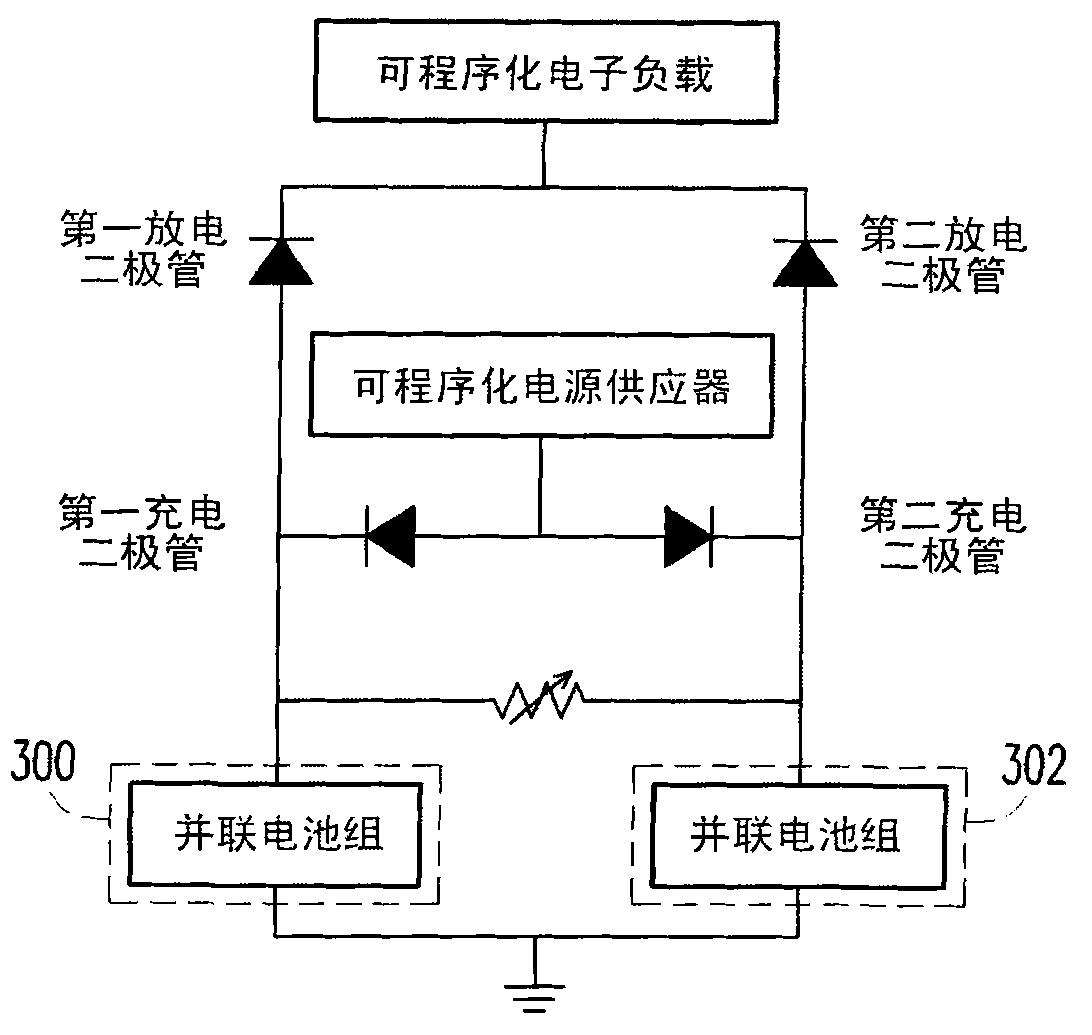

Battery pack and method of controlling charge-and-discharge of battery pack by its thermoelectric property

ActiveCN103123992AImprove toleranceReduce aging rateCharge equalisation circuitSequential battery dischargeBattery packCharge and discharge

A battery pack and a method for controlling charge-and-discharge of the battery pack by its thermoelectric property are provided, in which the battery pack has a plurality of thermal regions divided by different ranges of temperature. The battery pack includes a plurality of parallel-connected battery groups and a plurality of variable resistances. The parallel-connected battery groups are located in the thermal regions respectively, and each of the parallel-connected battery groups includes batteries connected in parallel. The variable resistances are disposed between two parallel-connected battery groups.

Owner:KYMCO

Y5V dielectric composition

InactiveUS20060232910A1Excellent reliabilityLow age rateFixed capacitor dielectricStacked capacitorsInsulation resistanceCapacitance

Multilayer ceramic chip capacitors which satisfy Y5V requirements and which are compatible with reducing atmosphere sintering conditions so that non-noble metals such as nickel, copper, and alloys thereof may be used for internal and external electrodes are made in accordance with the invention. The capacitors exhibit desirable dielectric properties (high capacitance, low dissipation factor, high insulation resistance), excellent performance on highly accelerated life testing, and very good resistance to dielectric breakdown. The dielectric layers comprise BaTiO3 doped with other metal oxides such as MgO, CaO, ZnO, MnO2, ZrO2, SiO2, Nd2O3, Nb2O5, and Y2O3.

Owner:FERRO CORP

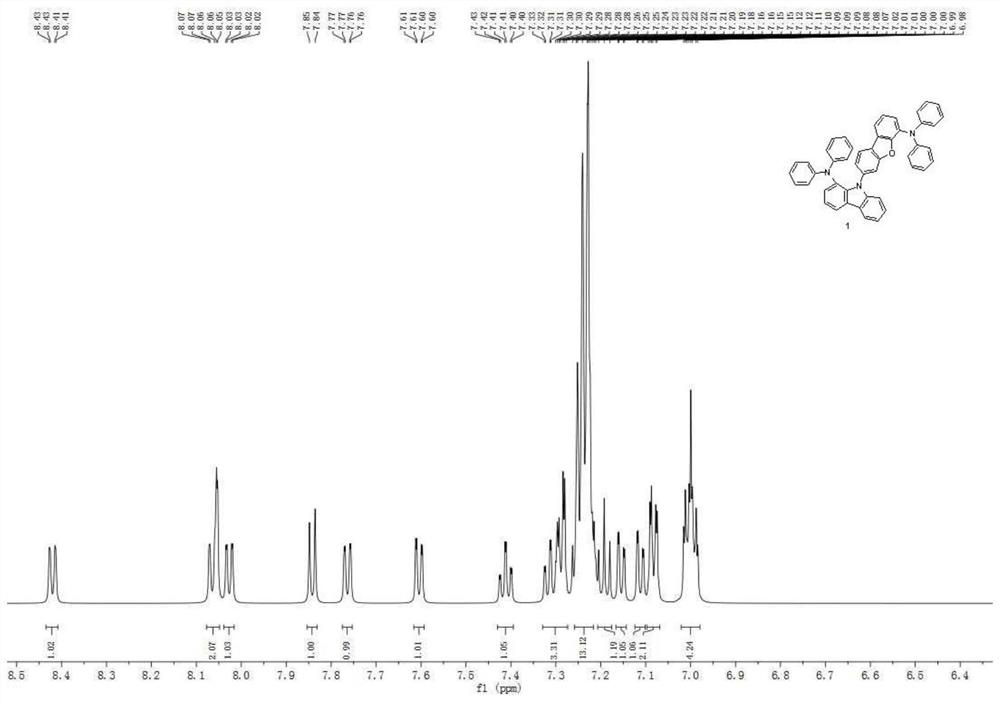

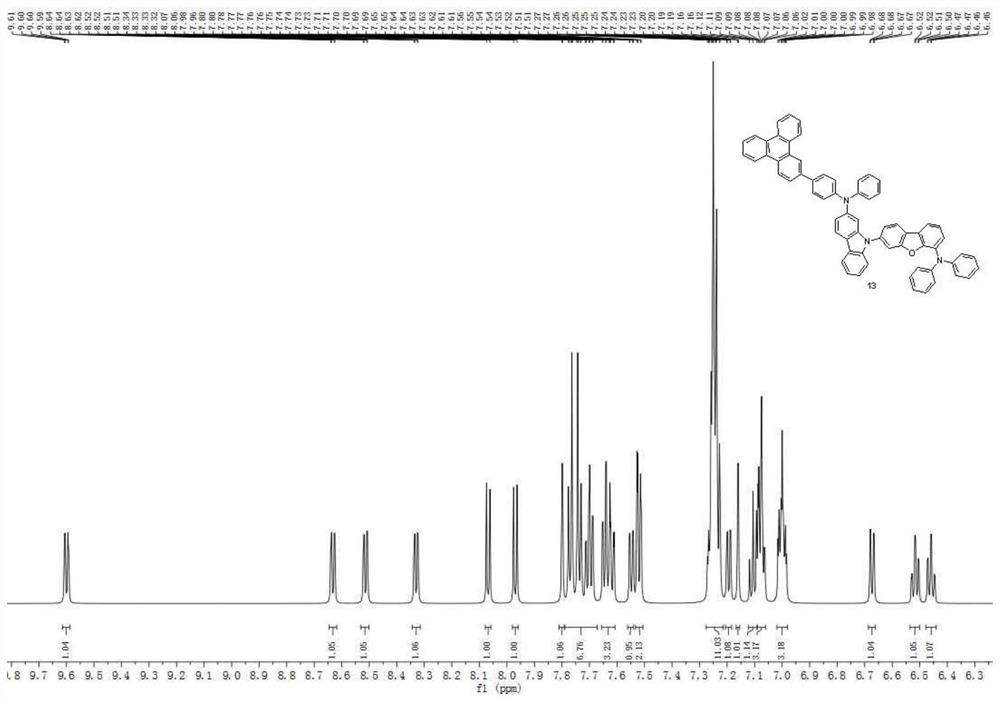

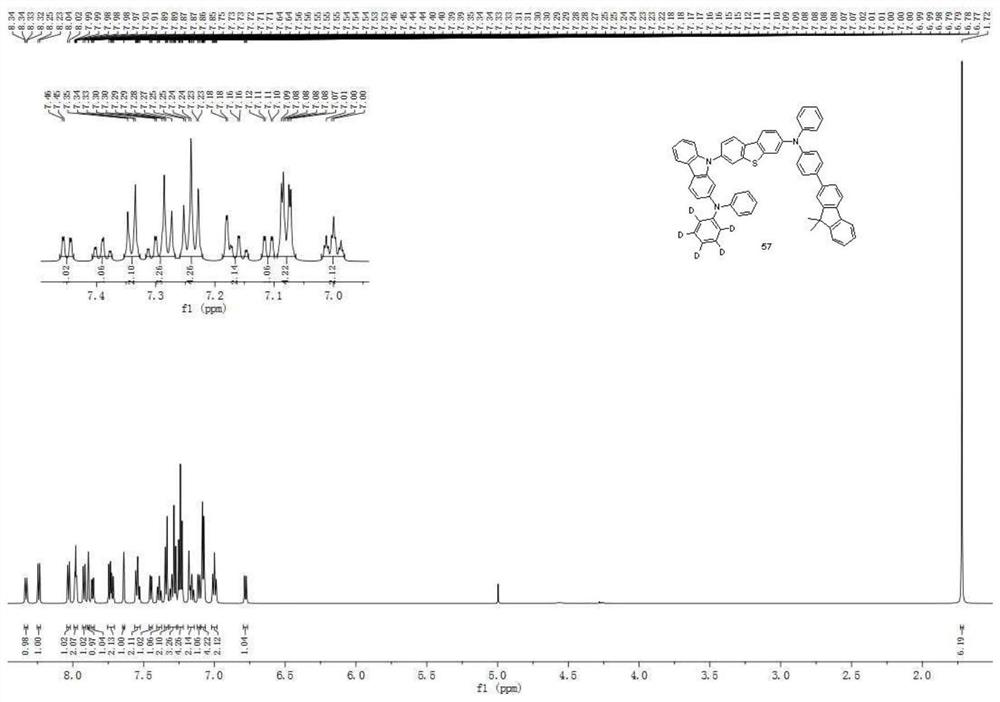

Arylamine compound and organic electroluminescent device thereof

ActiveCN111747938AIncrease the curvatureHigh TgOrganic chemistrySolid-state devicesElectron holeOrganic electroluminescence

The invention provides an arylamine compound and an organic electroluminescent device thereof, and belongs to the technical field of organic photoelectric materials. In order to achieve better light emission inside a light-emitting layer so as to improve the luminous efficiency and the service life of the device, the present invention provides an arylamine compound having a high glass transition temperature, a HOMO value between a light-emitting layer and a hole transport layer, and a high T1 value, when the arylamine compound is applied to the device as a light-emitting auxiliary layer, the light emitting efficiency and the service life of the device are effectively improved, and the driving voltage of the device is also reduced at the same time. Therefore, the arylamine compound providedby the invention is an OLED material with excellent performance.

Owner:CHANGCHUN HYPERIONS TECH CO LTD

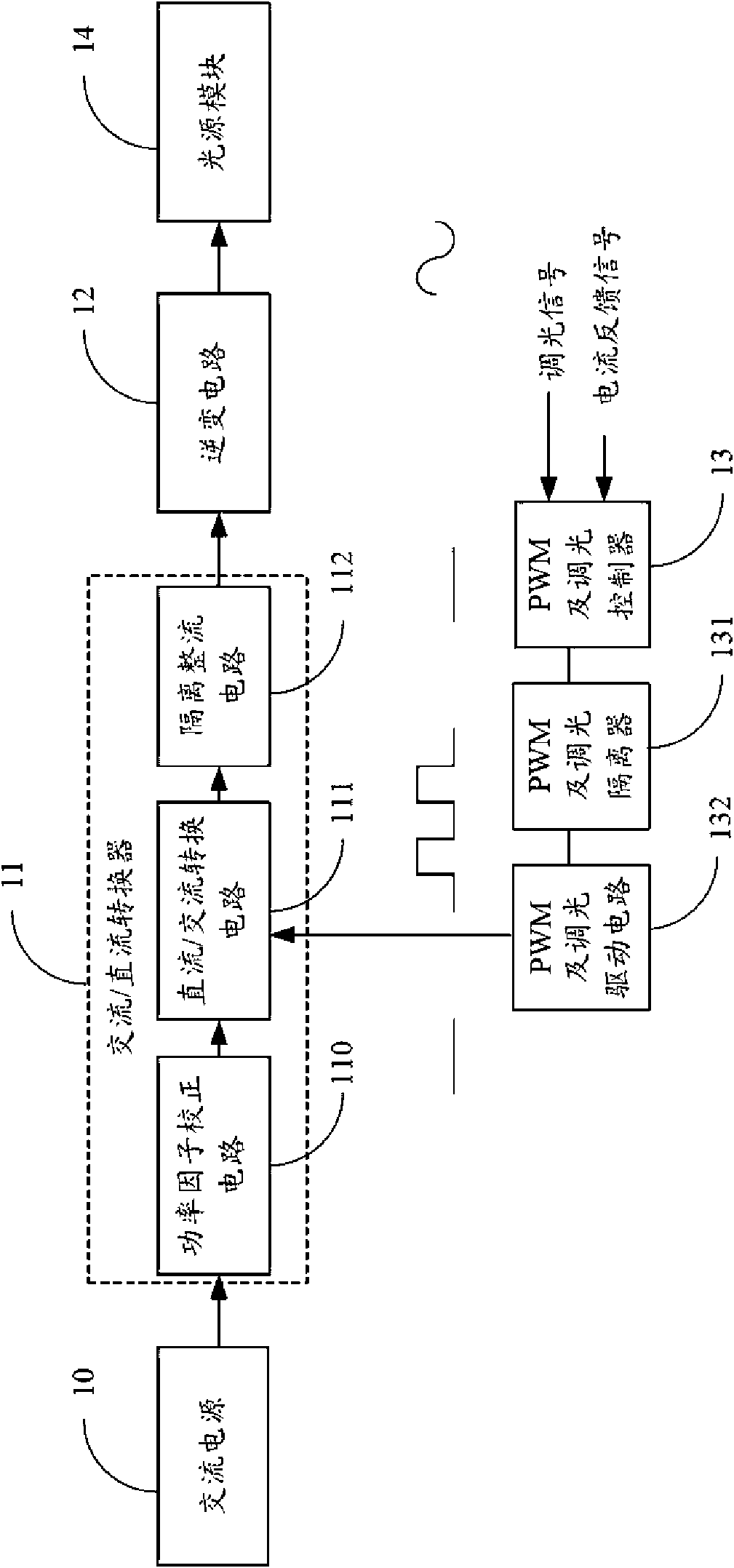

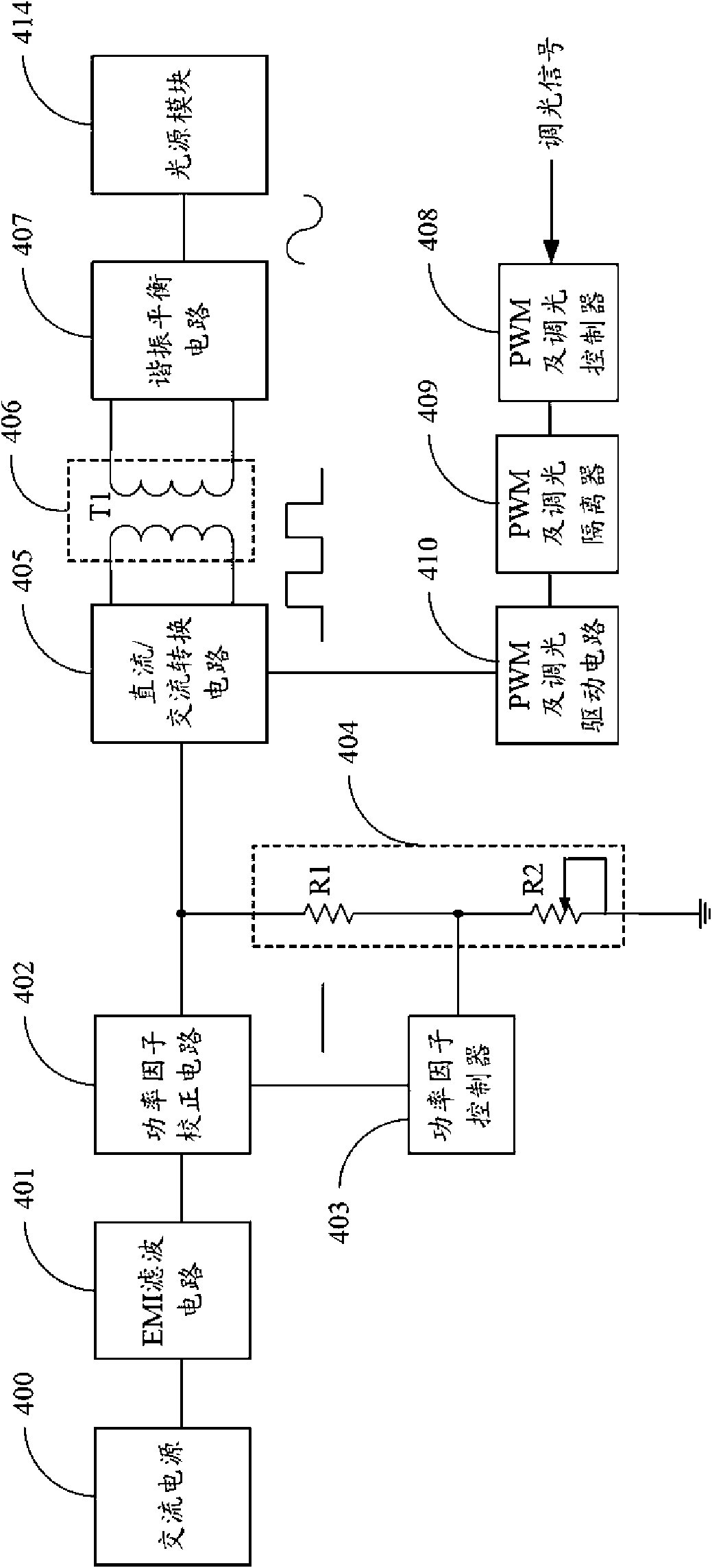

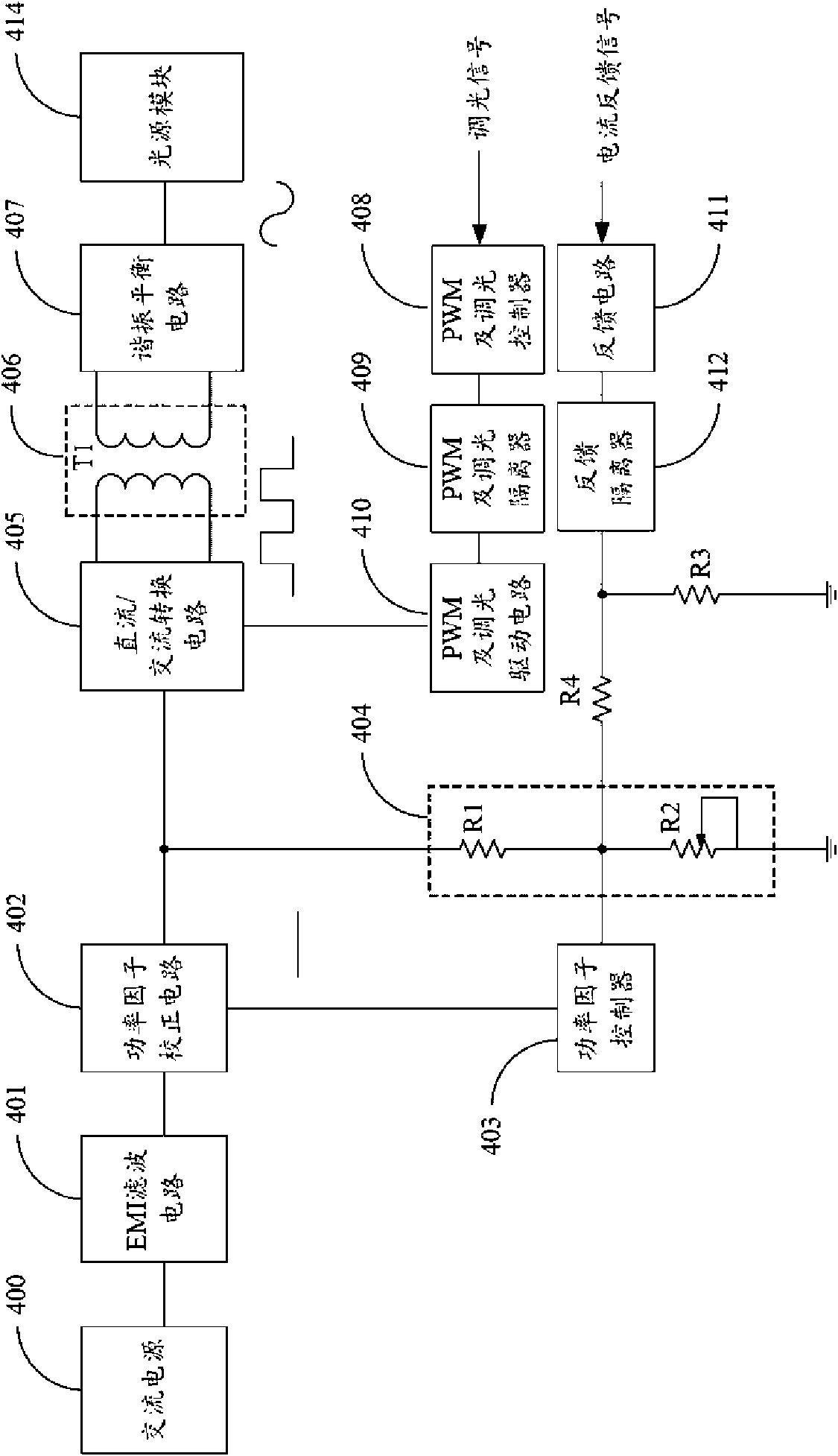

Light source driving device

InactiveCN101568219AReduce aging rateStable currentElectrical apparatusElectric lighting sourcesEngineeringBalanced circuit

The invention discloses a light source driving device, which is used for driving a light source module and comprises a power factor correction circuit, a DC / AC conversion circuit, a variable voltage circuit, a resonance balance circuit, a PWM and dimming controller, an adjustable voltage division circuit and a power factor controller, wherein the DC / AC conversion circuit is connected with output of the power factor correction circuit; the variable voltage circuit is connected with the DC / AC conversion circuit; the resonance balance circuit is connected with the variable voltage circuit; the PWM and dimming controller is connected with the DC / AC conversion circuit and used for outputting a control signal according to a received dimming signal, and the operation cycle of the control signal is a fixed value; the adjustable voltage division circuit is connected between the output of the power factor correction circuit and the ground; and the power factor controller is used for feeding signals after voltage division of the adjustable voltage division circuit back to the power factor correction circuit. The light source driving device can reduce the aging rate of the DC / AC conversion circuit and compensate the deviation of initial elements of the light source driving device.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

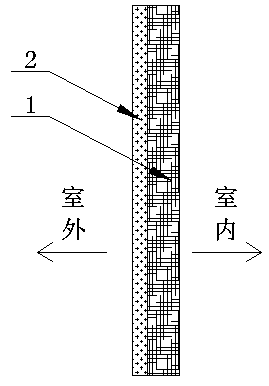

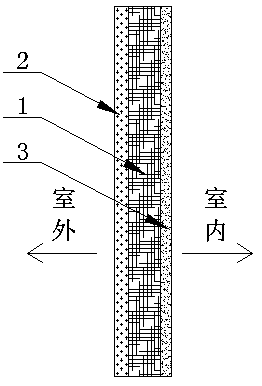

Window screening capable of releasing anion and filtering particle matter (PM) 2.5 particles

InactiveCN104295219AGood light transmissionImprove breathabilityInsect protectionPolyesterGlass fiber

The invention discloses a window screening capable of releasing anion and filtering particle matter (PM) 2.5 particles. The window screening comprises a grid cloth with the aperture of 1-3mm and a microfiltration membrane, wherein the grid cloth provides a framework supporting function and is made from any one of polyester, polypropylene, acrylic fibers 6, acrylic fibers, high strength glass fiber, and inflaming retarding aramid fiber, the microfiltration membrane is used for air ventilation and filtration and made of a Teflon material, the aperture of the microfiltration membrane is 0.2-5.0mm, the thickness of the microfiltration membrane is 0.01-0.05mm, the grid cloth and the microfiltration membrane are laminated, the grid cloth faces towards the indoor, and the microfiltration membrane faces the outdoor. The window screening capable of releasing anion and filtering PM 2.5 particles has functions of existing window screenings and is capable of filtering fine particle pollutants in the air and meeting actual use requirements.

Owner:ANHUI LITE ENVIRONMENTAL PROTECTION TECH

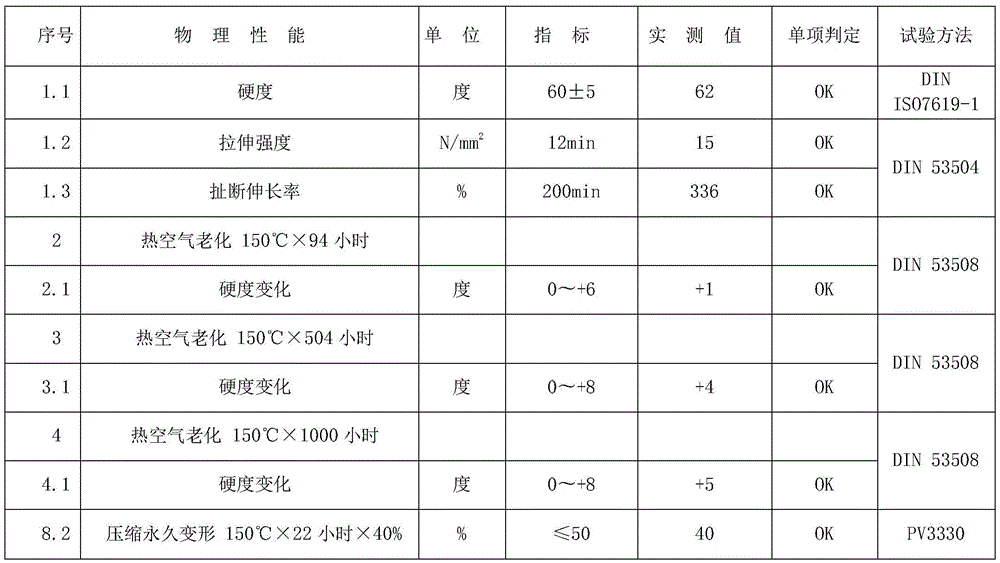

Novel anti-aging compound rubber and preparation method thereof

InactiveCN105566779AIncrease crosslink densityImprove anti-aging propertiesPolymer scienceTriallyl isocyanurate

The invention discloses an anti-aging compound rubber sealing strip. The anti-aging compound rubber sealing strip is prepared from, by weight, 50-200 parts of ethylene propylene rubber, 10-70 parts of fast extruding furnace black, 1-15 parts of indirect zinc oxide, 1-10 parts of antiager, 1-15 parts of paraffin oil, 1-10 parts of lubricant, 1-10 parts of vulcanizing agent and 1-8 parts of accelerant. The accelerant is triallyl isocyanurate and / or trifunctional acrylic ester. The invention further discloses a preparation method of the anti-aging compound rubber sealing strip. The anti-aging compound rubber sealing strip has the advantages of being long in service life, resistant to aging and pressure changes and stable in hardness, and the preparation method is simple and easy to operate.

Owner:ANHUI ZHONGDING SEALING PARTS

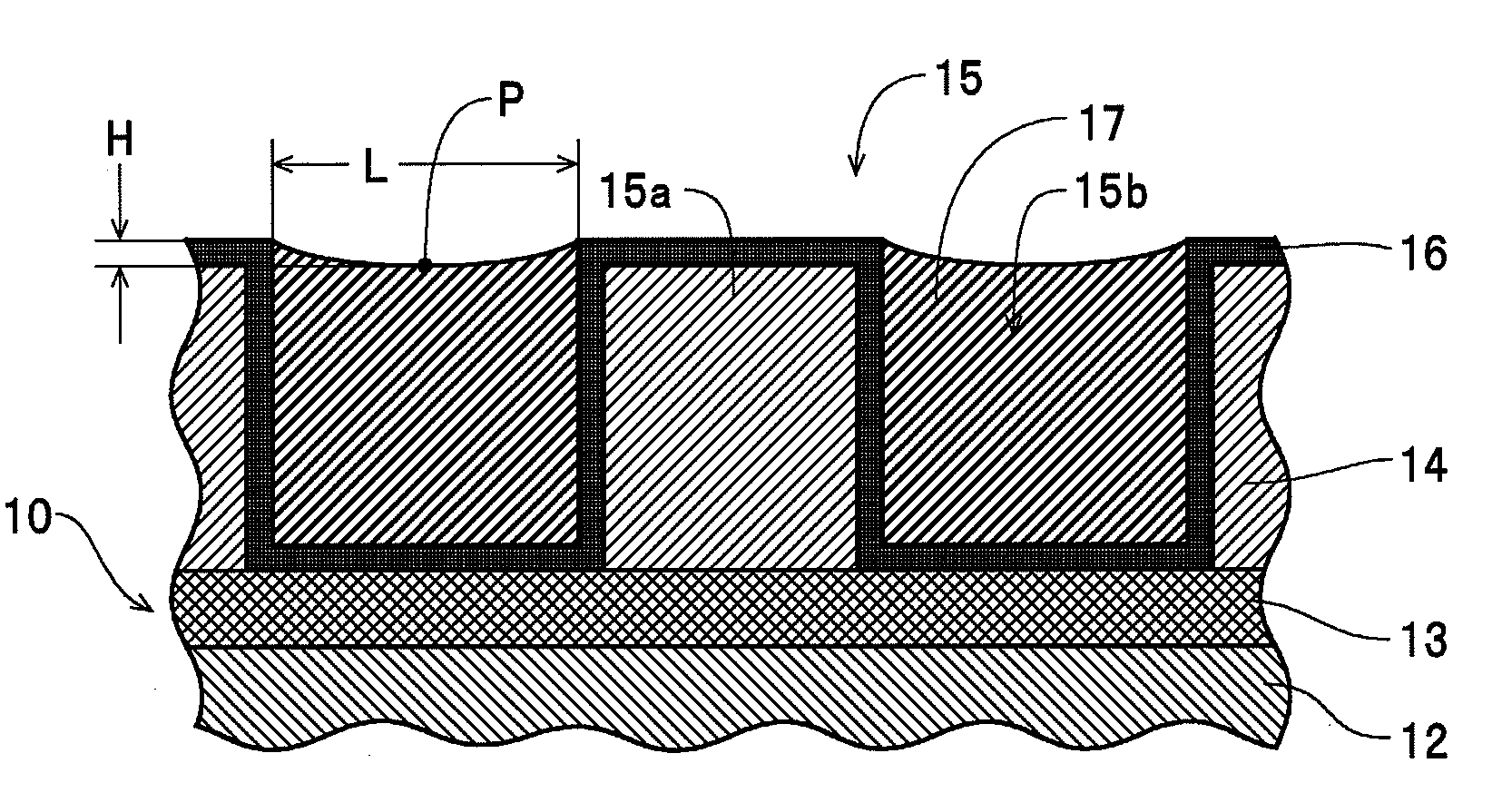

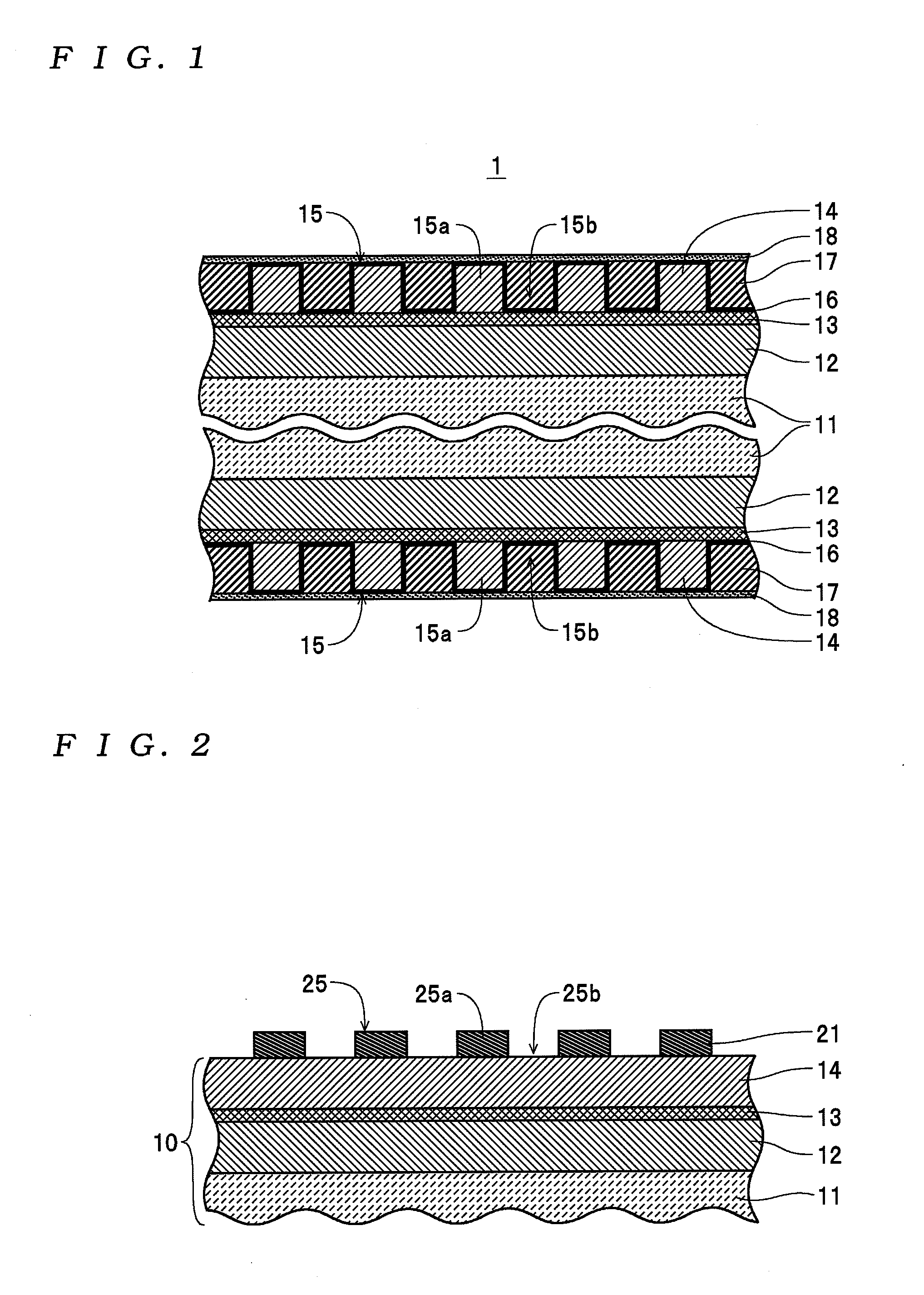

Information medium

InactiveUS20070275270A1Improve protectionReduce the probability of bindingProtective coatings for layersRecord information storageEngineeringRecording layer

An information medium which is capable of maintaining the protection capability by a lubricant for a long term. An information medium has a recording area and a non-recording area disposed on at least one surface of a disk-shaped base plate. The information medium is configured such that a lubricant exists on the one surface of the disk-shaped base plate. The recording area is configured such that a protective film formed of DLC exists above the recording layer. At least a surface-side portion of the non-recording area is formed of a resin material having a higher bonding ratio with respect to the lubricant than that of DLC.

Owner:TDK CORPARATION

Bio-based adhesive and preparation method thereof

InactiveCN107384287AImprove adhesionImprove thermal stabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveHeat stability

The invention provides a bio-based adhesive and a preparation method thereof and belongs to the technical field of high-molecular chemistry. The bio-based adhesive contains the following main components in parts by weight: bio-based starch, lignin, tea polyphenol and isocyanate. The bio-based adhesive and the preparation method provided by the invention have the advantages that the traditional preparation method for the adhesives is changed, and under the condition without adding any organic solvent and aldehyde-containing monomer, the bio-based adhesive with higher adhesiveness and heat stability is prepared by adopting natural biomass starch as a main agent, the lignin and the tea polyphenol as additives, the isocyanate as a crosslinking agent and water as a green solvent as well as a series of environment-friendly paths.

Owner:QILU UNIV OF TECH

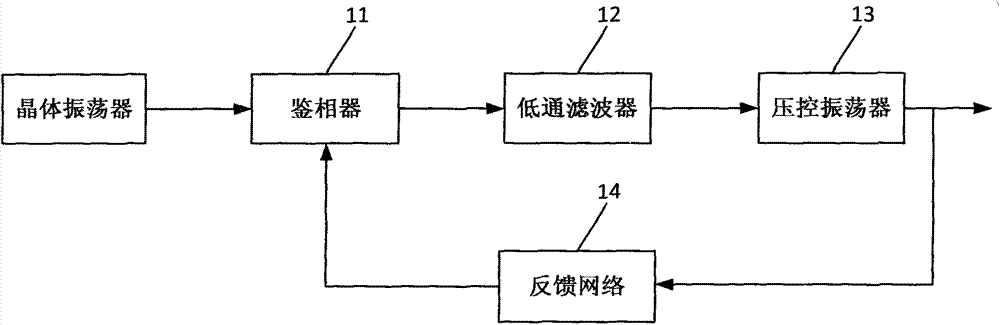

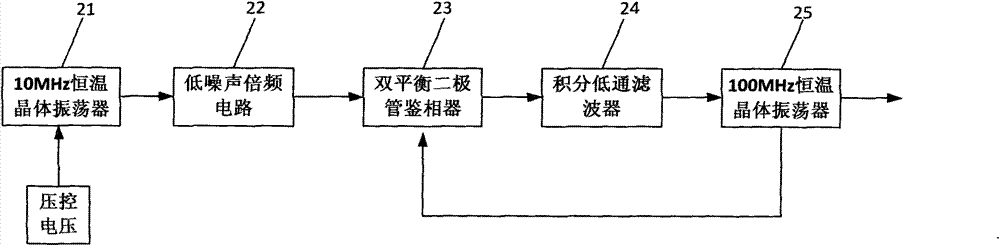

Low-noise reference signal generator and signal generation method

The invention provides a low-noise reference signal generator and a signal generation method. The generator comprises a 10MHz constant-temperature crystal oscillator, a low-noise frequency doubling circuit, a double-balance diode phase discriminator, an integral low-pass filtering circuit and a 100MHz constant-temperature crystal oscillator. A 100MHz reference signal generated by the low-noise reference signal generator has the phase noise starting from 1Hz at the extremely low near end, and has very high frequency accuracy and extremely low aging rate after correction.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

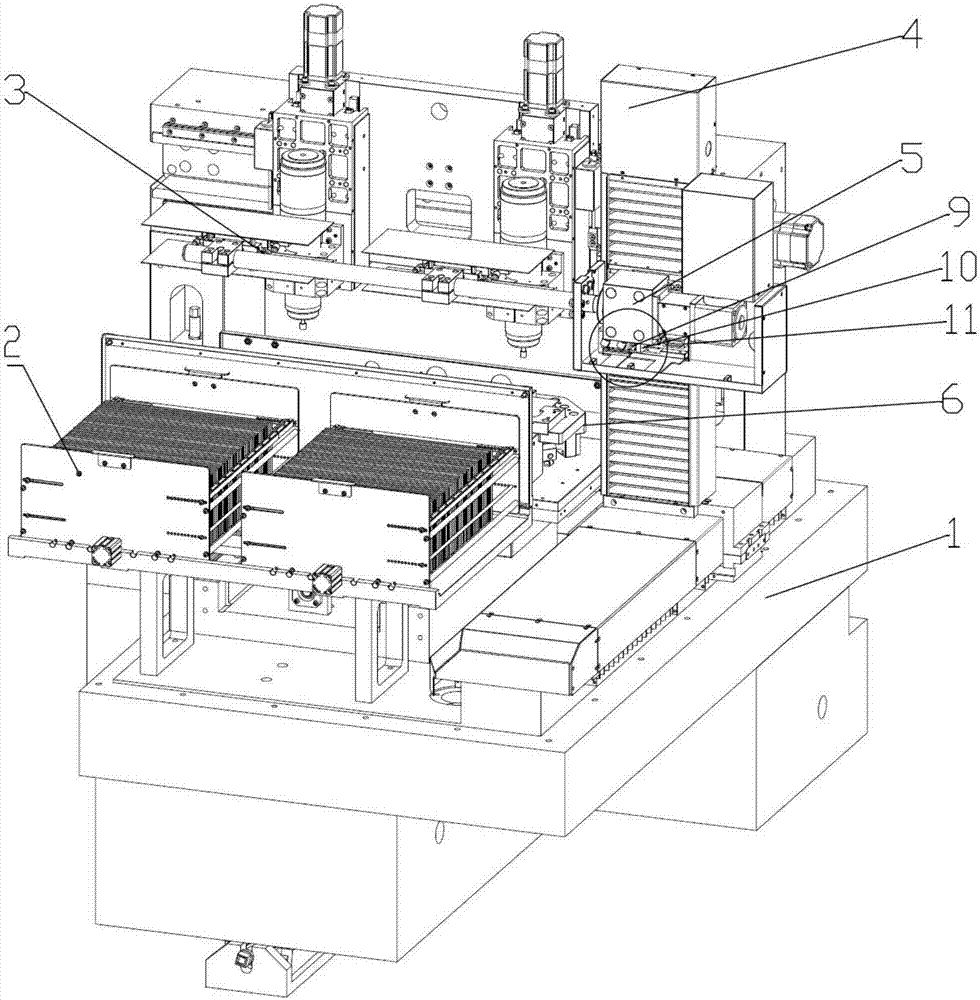

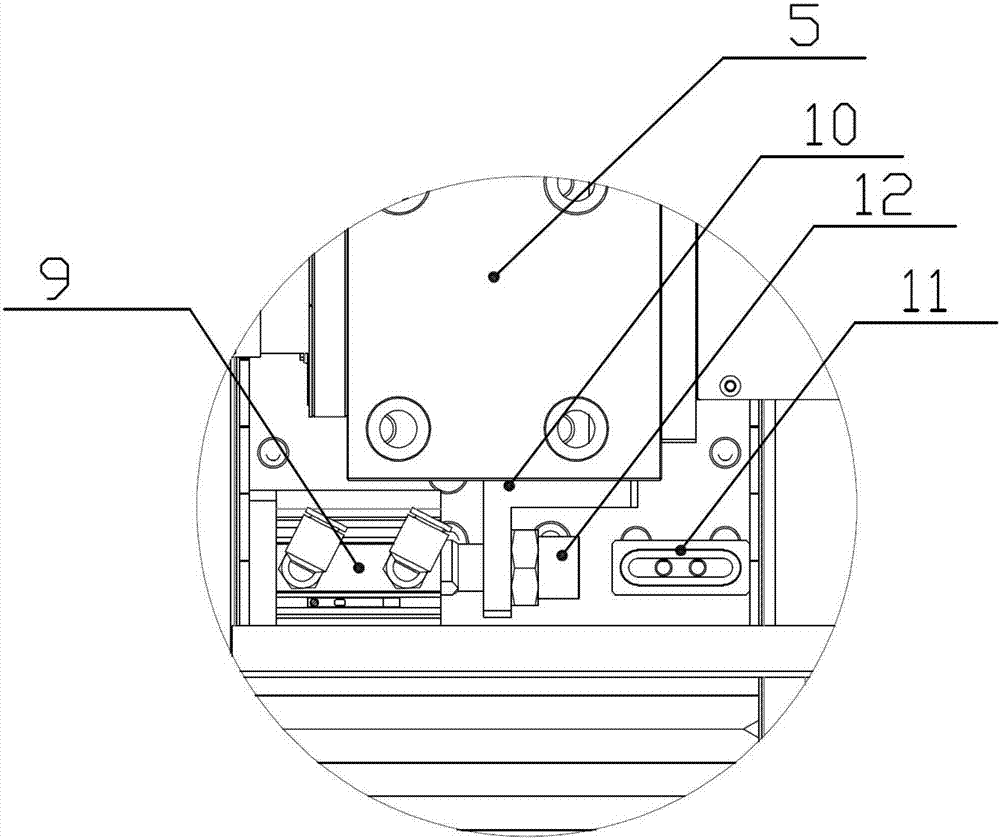

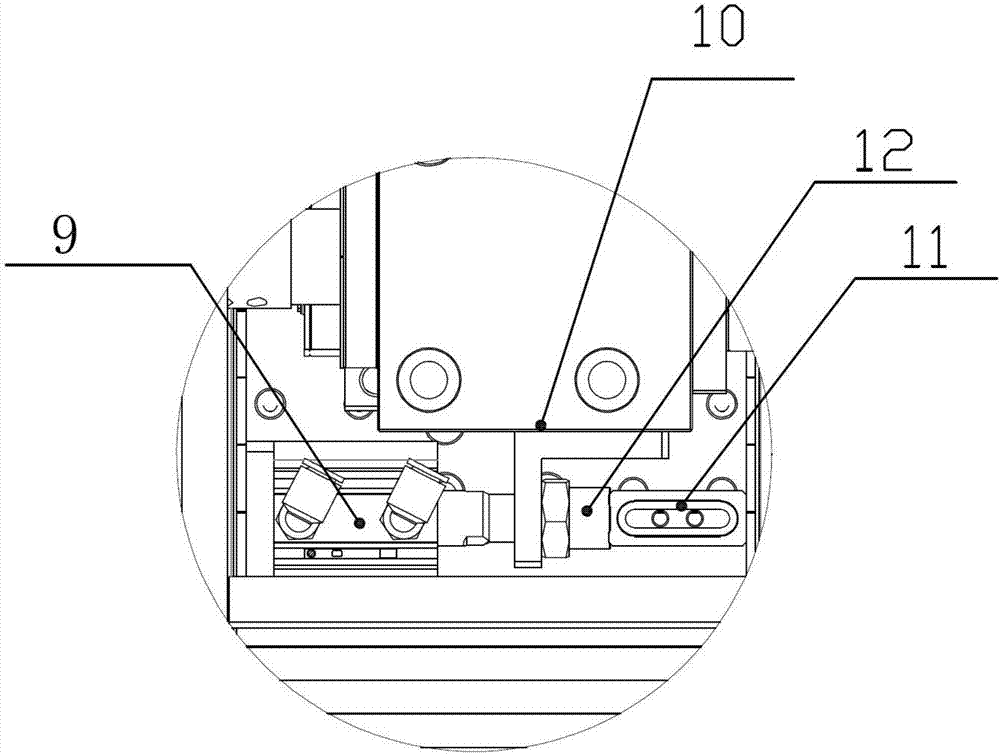

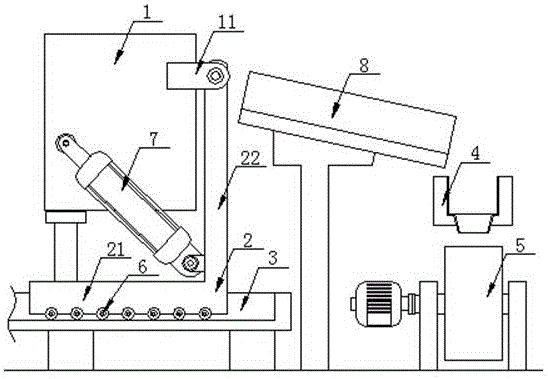

Positioning device of fine glass engraving machine

PendingCN107187257AImproved positioning deviceReduce in quantityOther artistic work equipmentsModel makingPhysicsManipulator

The invention discloses a positioning device of a fine glass engraving machine, and belongs to the technical field of fine glass engraving machines. The positioning device comprises a working platform, and the working platform is provided with material boxes used for storing glass and a manipulator used for grabbing glass from the material boxes; the manipulator is arranged on a mechanical arm perpendicular to the working platform through a fixing base. The positioning device further comprises a square fixing table used for fixing to-be-processed glass taken out of the material boxes, a corner fixture arranged at one corner of the square fixing table and an air cylinder connected with the corner fixture; the air cylinder is arranged under the square fixing table and arranged along the diagonal line where the corner fixture is located; a micro-motion air cylinder is arranged under the fixing base, and when the micro-motion air cylinder is pushed out, the manipulator is driven to move towards the pushing-out direction of the micro-motion air cylinder. The positioning device is compact in structure and accurate in positioning.

Owner:SHENZHEN CREATE CENTURY MACHINERY

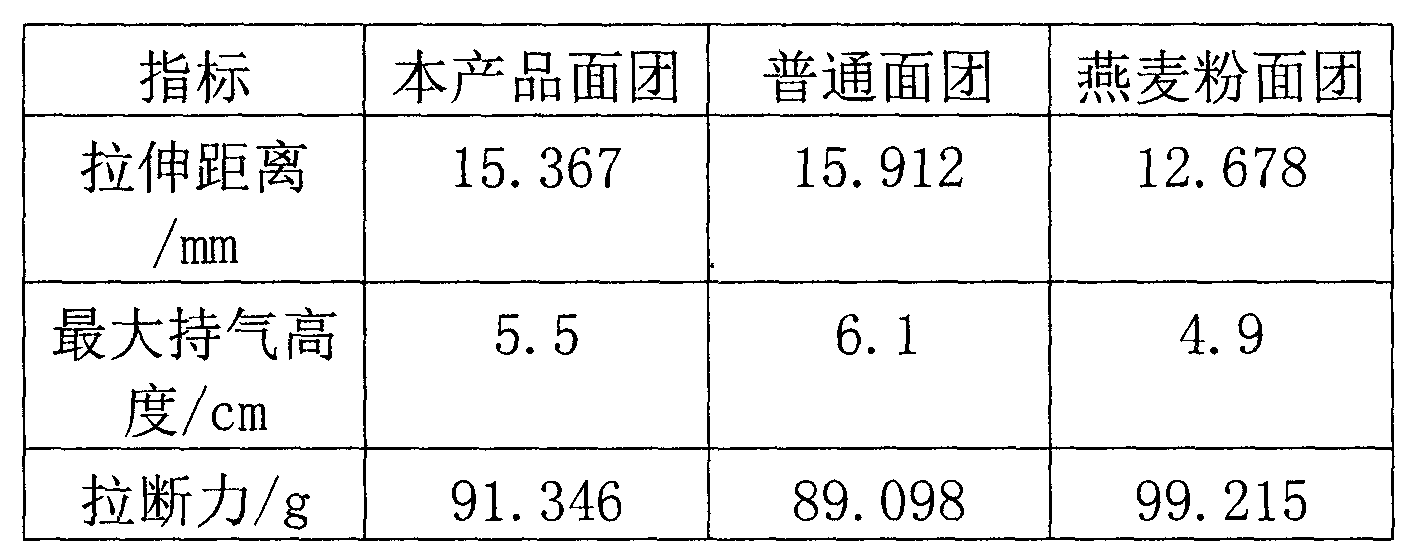

Steamed oatmeal buns and processing method thereof

InactiveCN104286690AImprove propertiesIncreased oat contentDough treatmentYeast food ingredientsPolydextroseGluten

The invention relates to steamed oatmeal buns and a processing method thereof. The steamed oatmeal buns comprise the following components in parts by weight: 50 parts of wheat flour, 30 parts of oatmeal, 1-5 parts of vital gluten, 0.4 part of yeast, 0.5 part of polydextrose and 21 parts of water. The invention further provides the processing method of the steamed oatmeal buns, and the processing method comprises the following steps: carrying out steaming and microwaving to the oatmeal, making a paste, using raw materials such as the vital gluten and the polydextrose to improve the quality of the paste, and increasing the content of oat in the paste through a paste making technology and formula, so as to enable people to intake more oat while a less amount of bud is taken and effectively lower human body blood fat and blood glucose. Due to very high contents of dietary fiber and beta glucosan, the aging speed of the buns is relatively low, and decline in bun quality caused by adding a large amount of oatmeal can be avoided, namely sharp increase of hardness and sharp decrease of specific volume can be avoided; the steamed oatmeal bun is relatively white, and has an acceptable appearance. The steamed oatmeal bun adopts the combination of the formula and the process, so that the processing performance of the past is improved, the content of oat in the buns is increased greatly, the buns are added with nutrients, and the effects of lowering blood fat and blood glucose are enhanced.

Owner:ZHENGZHOU TECHN COLLEGE

Lamp base, LED lamp fixture and LED lamp

InactiveCN104913222AExtended service lifeReduce aging ratePoint-like light sourceElectric circuit arrangementsCapacitanceEngineering

In an LED lamp fixture disclosed in the invention, a communication control circuit and a power source circuit are disposed inside a chamber of a shell body, and a radiator equipped with an LED baseplate and an LED chip is located outside the shell body, so that the space in which the communication control circuit and the power source circuit are located is separated from the space in which the radiator is located, environmental temperature of the communication control circuit and the power source circuit is then reduced, aging of the communication control circuit and the power source circuit caused by a high temperature is prolonged, an aging rate of an electrolytic capacitor in the power source circuit is especially reduced, and thus service life of the LED lamp fixture is increased. In addition, a communication module in the communication control circuit has good working performances and also reduces design difficulty of an optical path. The invention also discloses a lamp base and an LED lamp.

Owner:唐水 +1

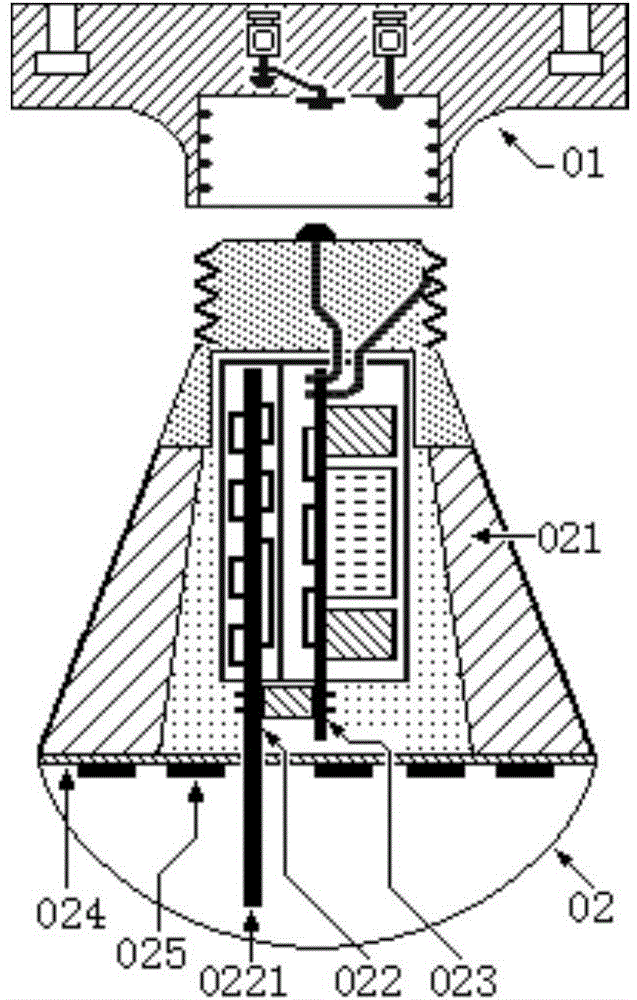

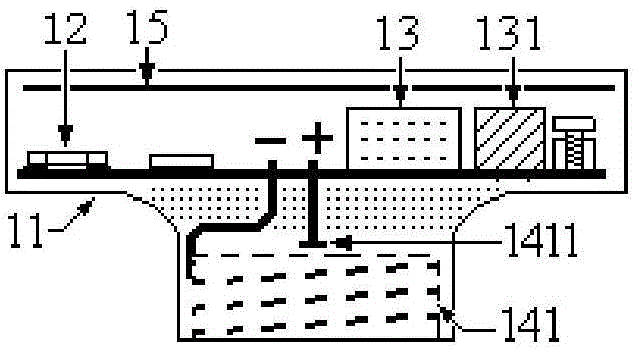

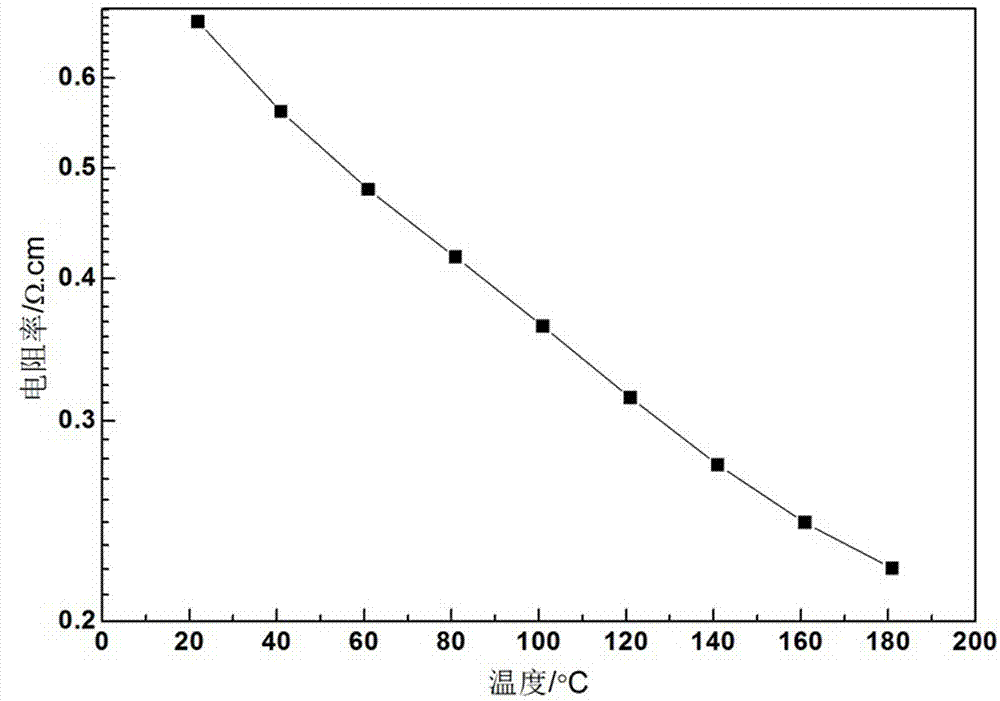

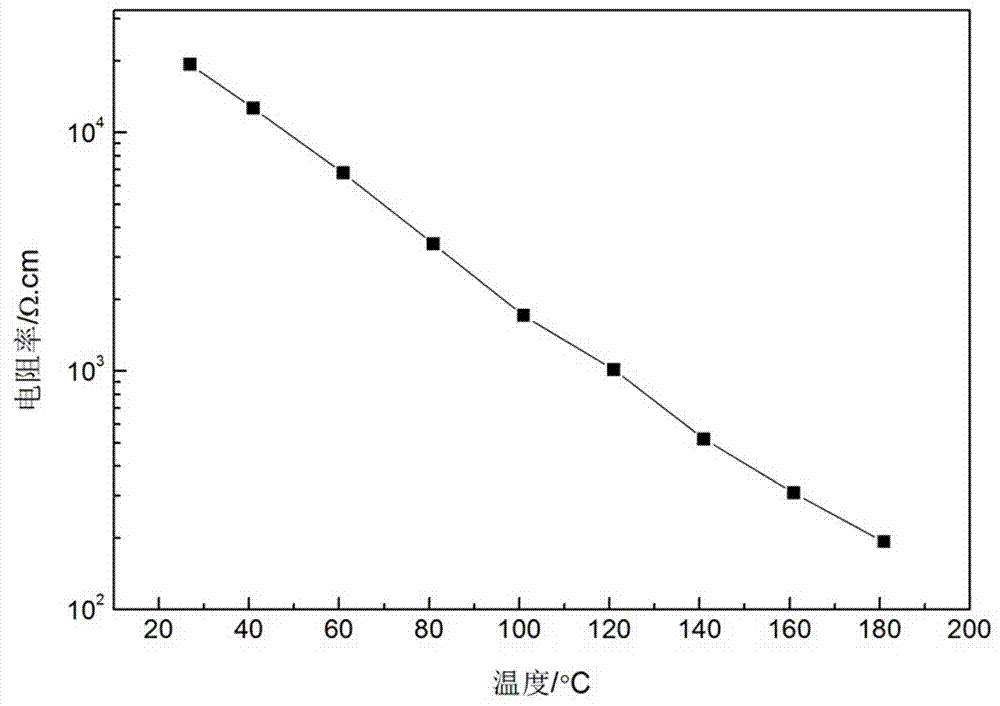

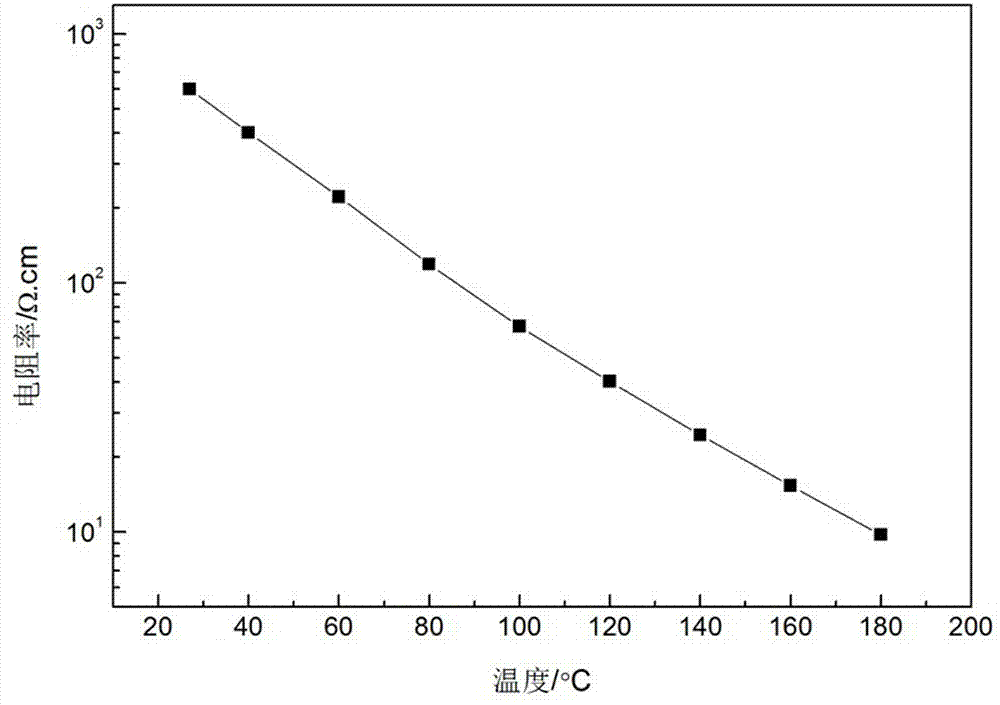

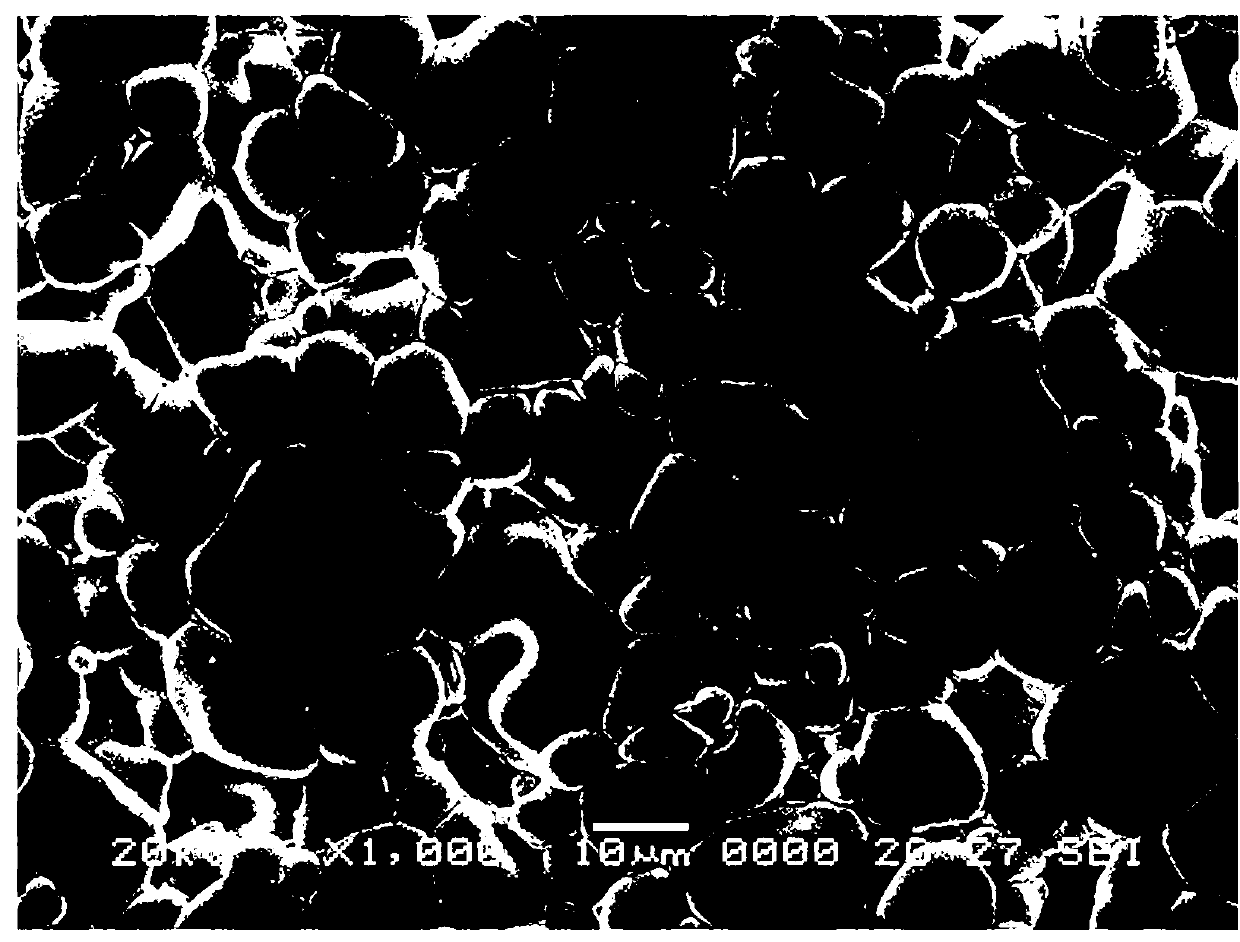

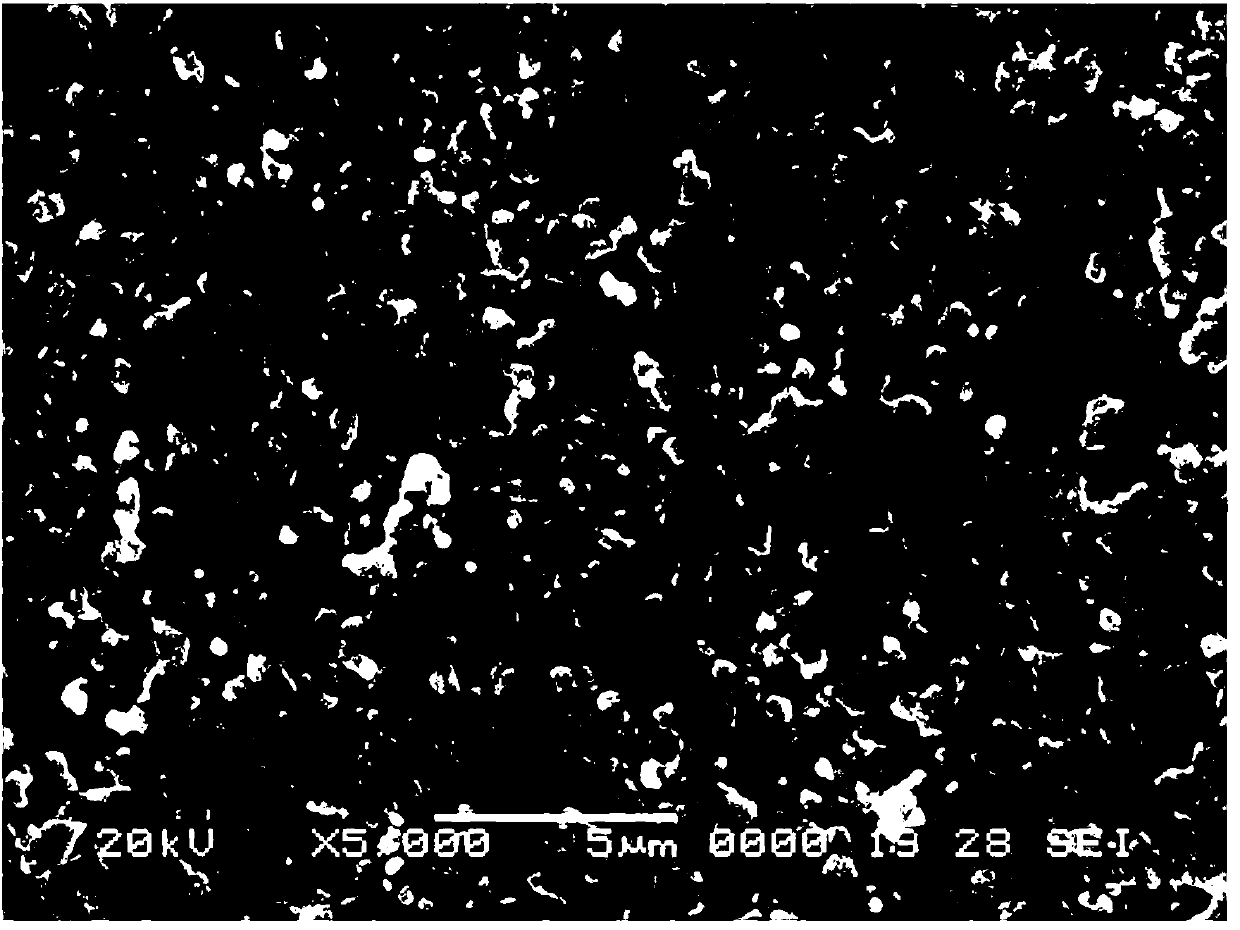

Low-resistance BaM<II><x>Bi<1-x>O3 negative-temperature-coefficient thermosensitive thick-film material and preparation method thereof

InactiveCN103864412ALow room temperature resistivityModerate thermal constantFilm resistanceScreen printing

The invention discloses a low-resistance BaMBi<1-x>O3 negative-temperature-coefficient thermosensitive thick-film material and a preparation method thereof. The main active ingredient of the low-resistance BaMBi<1-x>O3 negative-temperature-coefficient thermosensitive thick-film material is BaMBi<1-x>O3 thermosensitive phase powder, wherein x is more than or equal to 0.01 and less than or equal to 0.05, the M is one of plus 2 oxides of Co, Mn, Ni, Cu and Zn. The preparation method comprises the steps: evenly mixing BaMBi<1-x>O3 thermosensitive phase powder with an organic carrier in the mass ratio of 74:26 to form thick-film resistance paste; printing the resistance paste on a substrate through a silk-screen printing technique, laying flat, drying, pre-roasting and repeatedly printing to obtain the thick-film biscuit with needed thickness; sintering the biscuit at 700-900DEG C, and insulating for 120 minutes to obtain the low-resistance BaMBi<1-x>O3 negative-temperature-coefficient thermosensitive thick-film material. The low-resistance BaMBi<1-x>O3 negative-temperature-coefficient thermosensitive thick-film material is simple in preparation technique, low in film forming temperature, the thickness of the film is within 20-80mu m, the thermosensitive constant value ranges from 1000-4000K, the room-temperature resistivity is within the range of 0.7ohm.cm to 20kohm.cm, and the aging rate under the condition of insulating for 650hours at150DEG C is lower than 2%.

Owner:GUILIN UNIV OF ELECTRONIC TECH

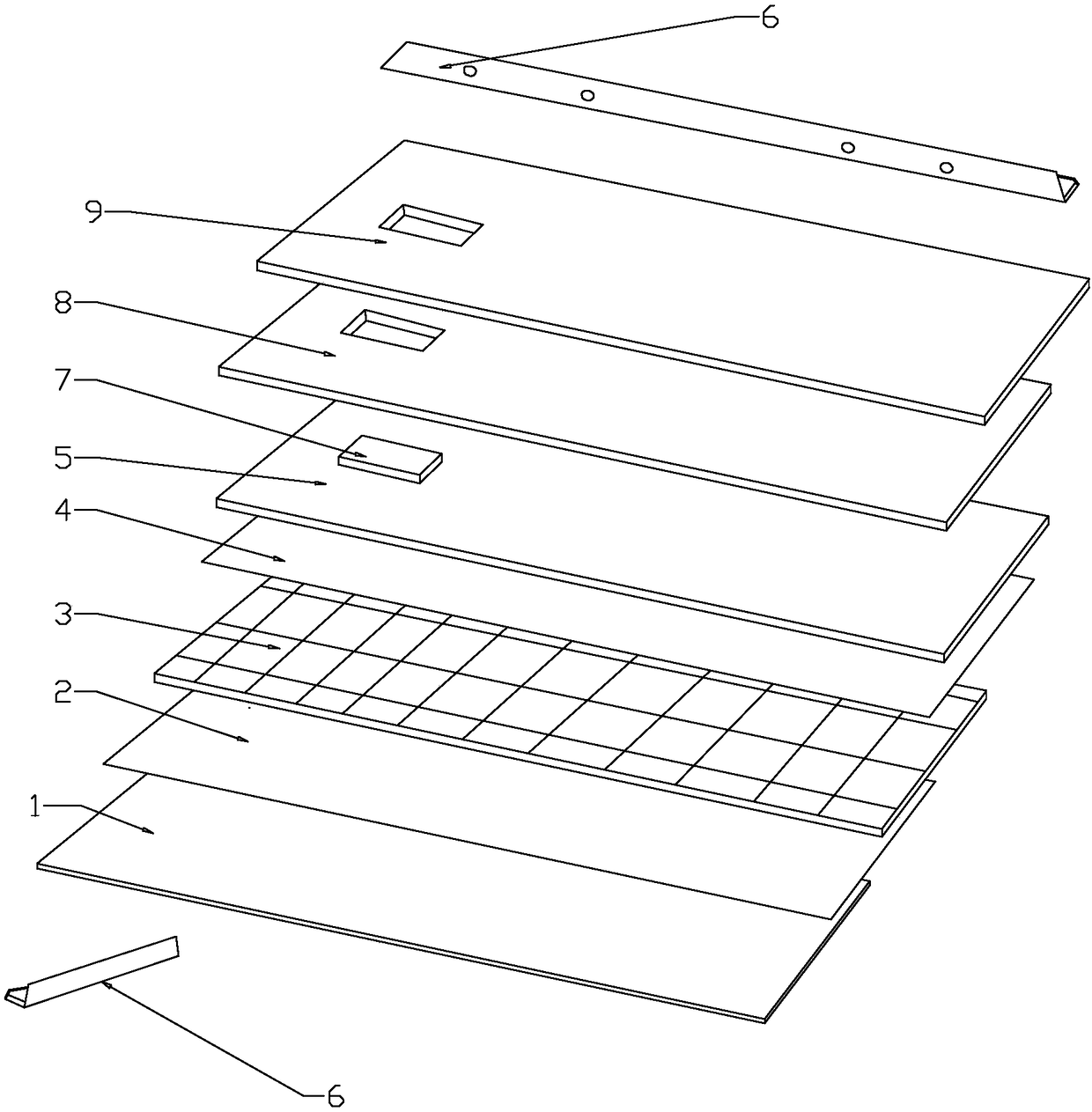

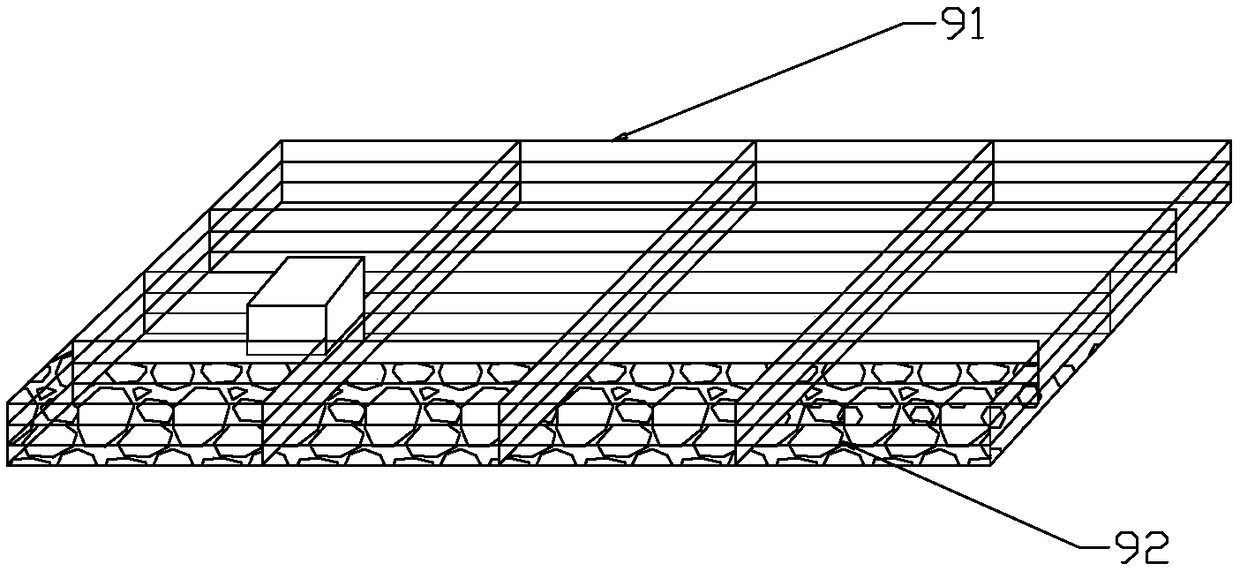

Heat radiation layer with phase transition material, preparation method of heat radiation layer and photovoltaic assembly with heat radiation layer

ActiveCN108365034AReduce power lossIncrease power generationFinal product manufacturePhotovoltaic energy generationWorking temperaturePhase-change material

The invention discloses a heat radiation layer with a phase transition material, a preparation method of the heat transition material and a photovoltaic assembly with the heat transition material. Theheat radiation layer is composed of an internal phase transition composite material and a wrapping material which wraps the phase transition composite material, the phase transition composite material is formed by combining a phase transition material and a support material in a dipping adsorption method, and the phase transition material occupies 80wt%-90wt% of the whole heat radiation layer. The heat radiation layer uses the phase transition layer to release or absorb heat from the environment and thus release or store energy in the phase transition process. The photovoltaic assembly with the heat radiation layer can balance heat generated in the working process of the photovoltaic assembly, power loss caused by too high working temperature of the assembly can be reduced, and thus, thepower generation power of the photovoltaic assembly is improved effectively, and the power generation cost is reduced.

Owner:HEFEI & SOLAR TECH

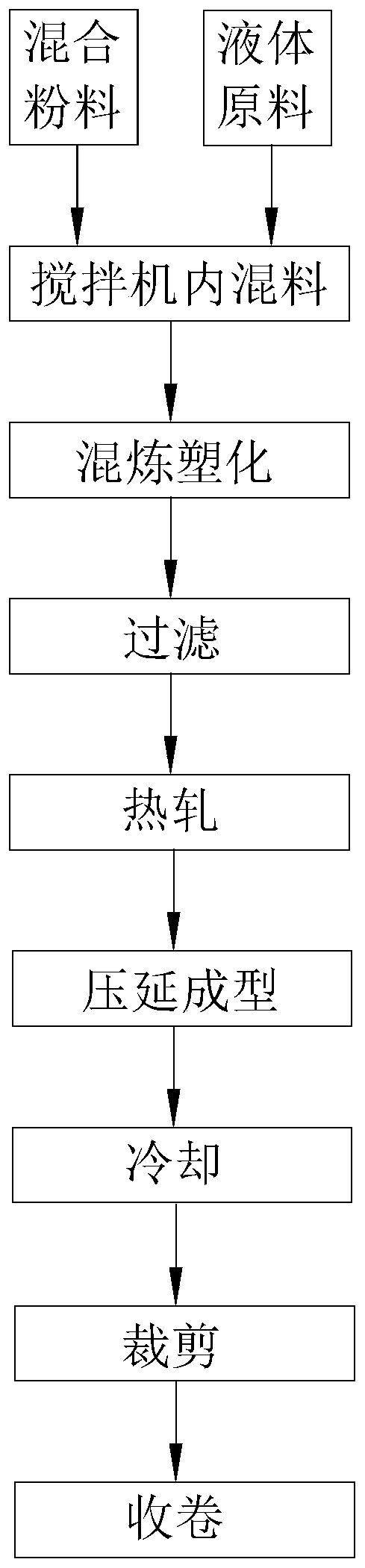

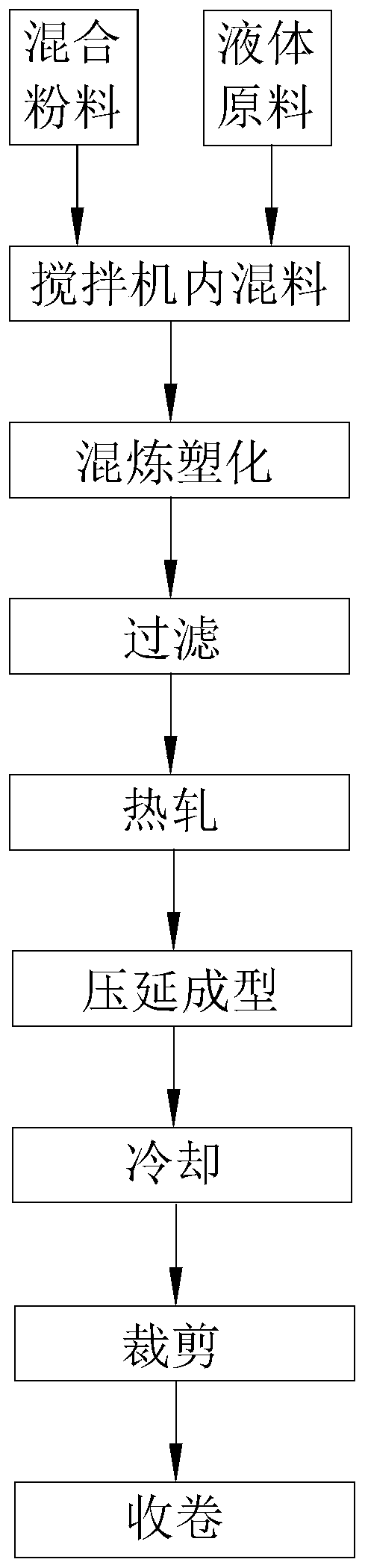

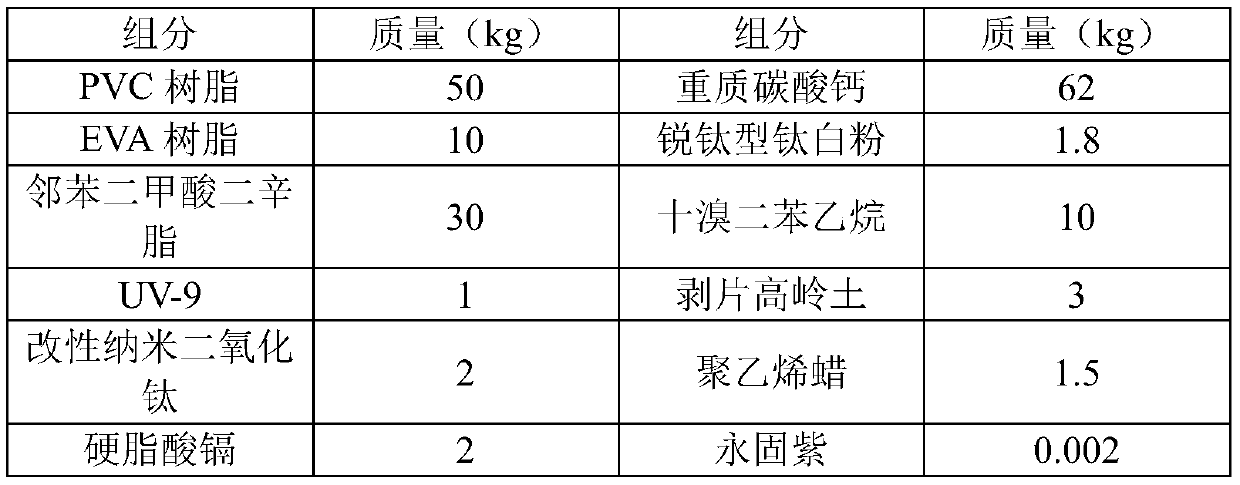

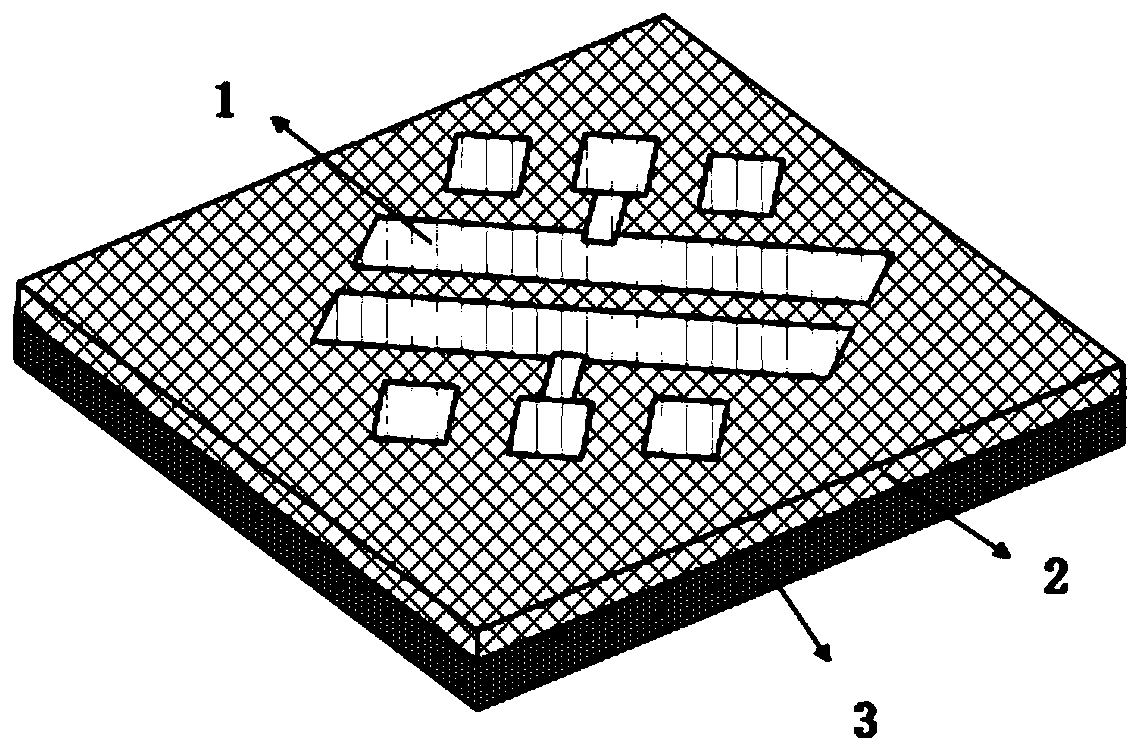

PVC lamp box film and preparation process thereof

The invention relates to a PVC lamp box film and a preparation process thereof, and relates to the technical field of lamp box films. The PVC lamp box film specifically comprises the following components in parts by weight: 50-60 parts of PVC resin, 5-10 parts of EVA resin, 28-35 parts of a plasticizer, 1-3 parts of an ultraviolet light absorber, 2-5 parts of modified nano titanium dioxide, 1-5 parts of a stabilizer, 62-70 parts of ground calcium carbonate, 1.8-2.5 parts of anatase titanium dioxide, 10-15 parts of a flame retardant, 2-3 parts of a flame retardant synergist, 1-3 parts of a lubricant and 0.002-0.007 part of a pigment. The aging of the PVC lamp box film is delayed, and the service life is prolonged.

Owner:上海蓝泉塑料制品有限公司

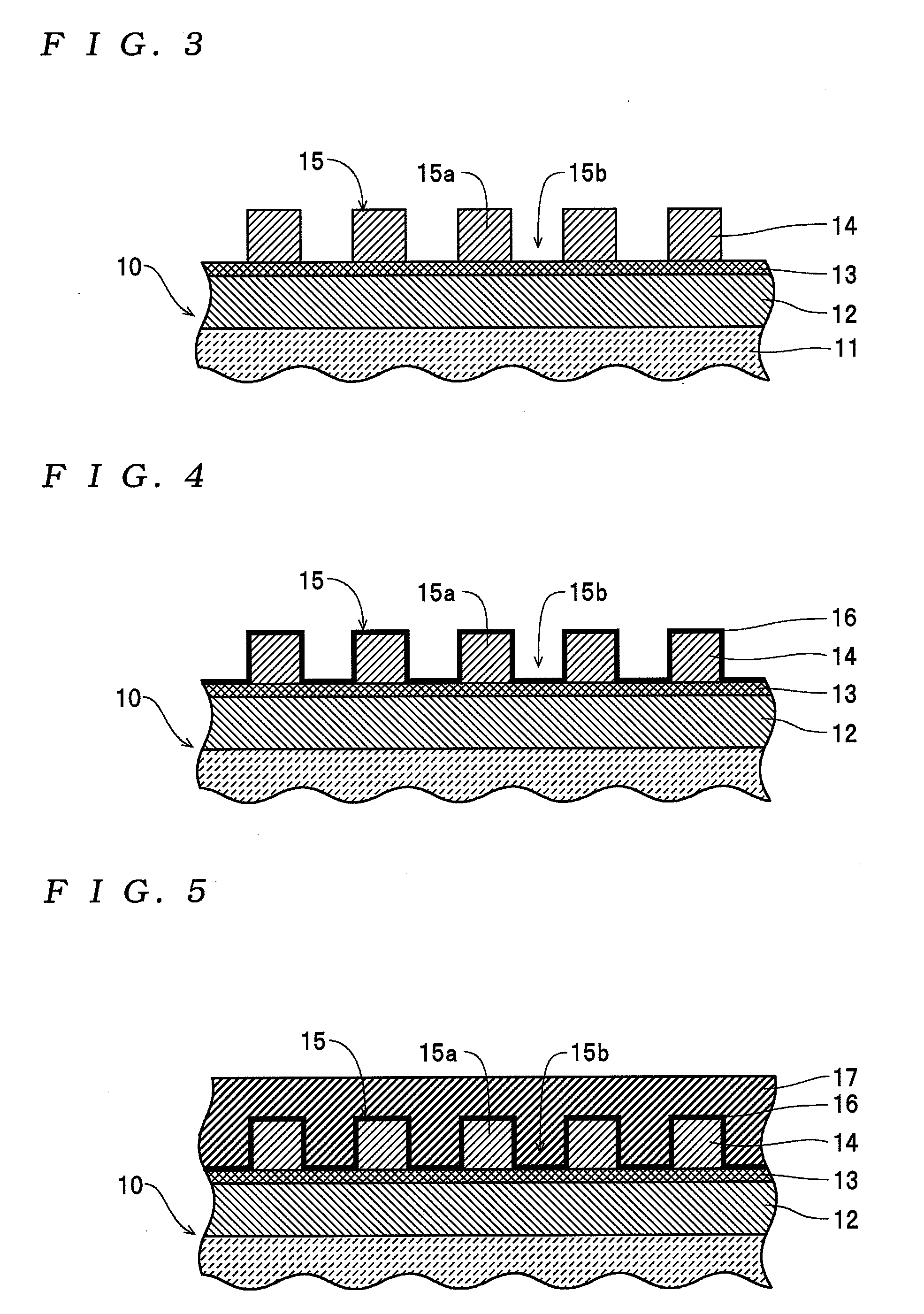

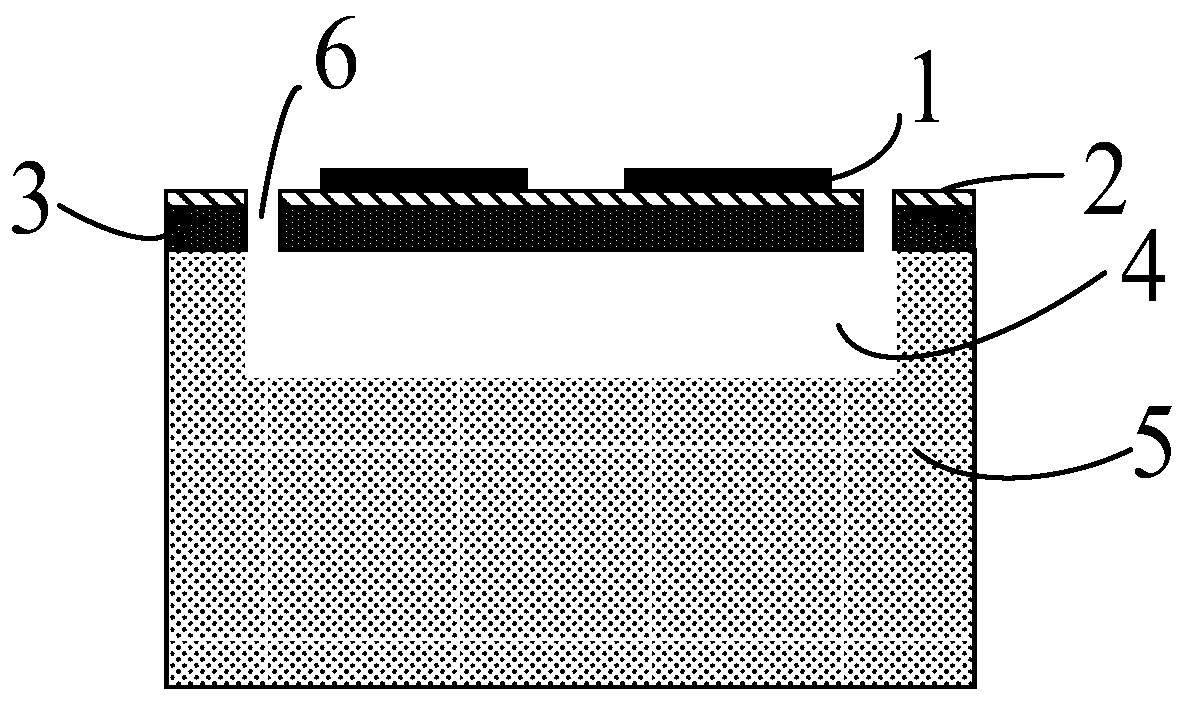

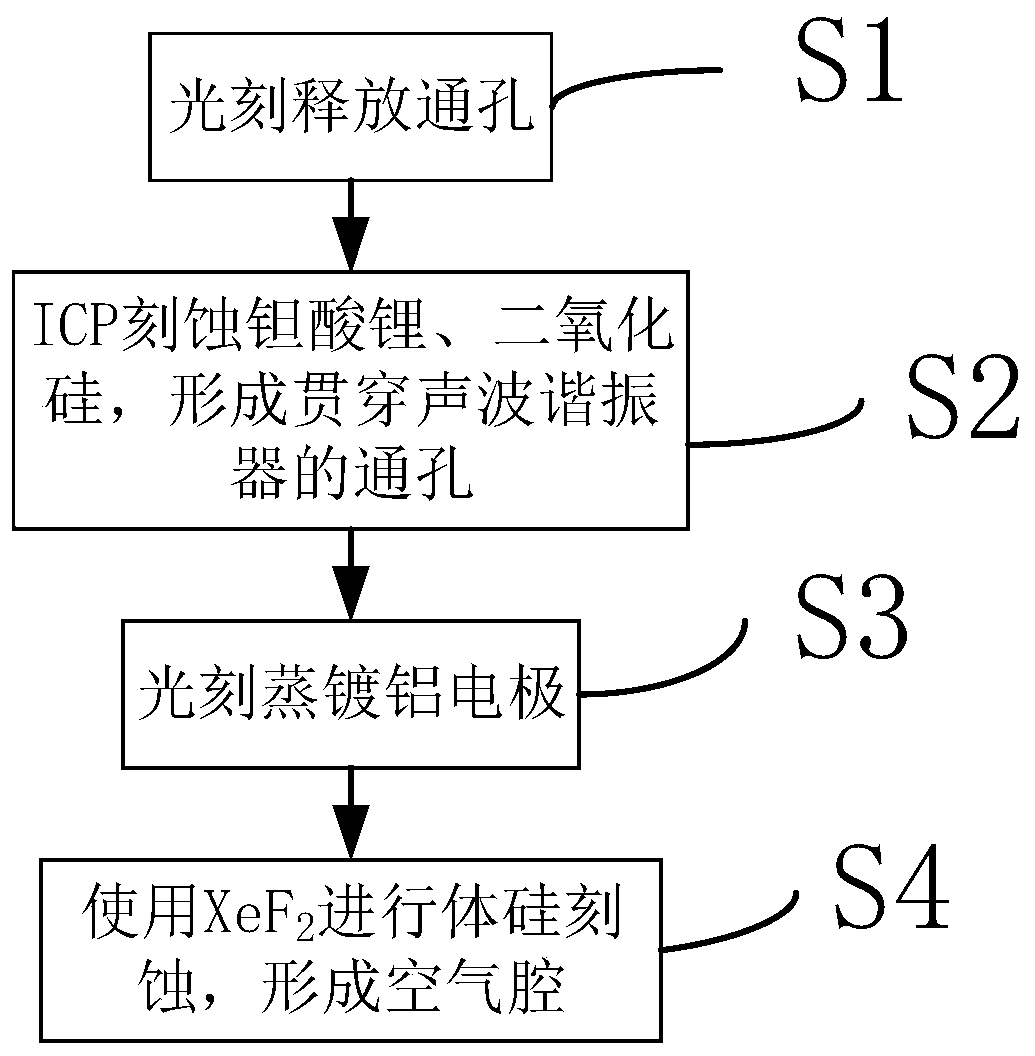

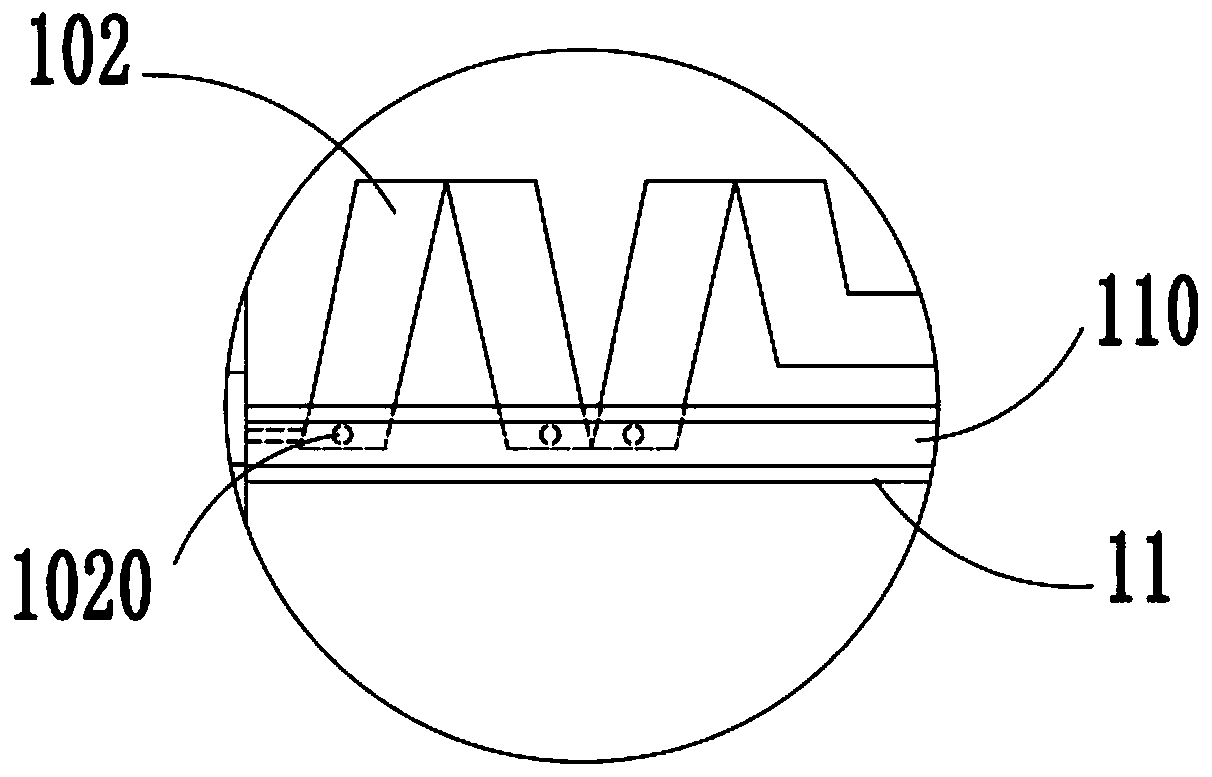

Frequency-adjustable transverse field excitation film bulk acoustic resonator and preparation method thereof

PendingCN110417373AAdjustable resonance frequencyReduce volumeImpedence networksThin-film bulk acoustic resonatorSingle crystal

The invention discloses a frequency-adjustable transverse field excitation film bulk acoustic resonator and a preparation method thereof. The frequency-adjustable transverse field excitation film bulkacoustic resonator sequentially comprises electrode aluminum, a piezoelectric substrate lithium tantalate, temperature compensation layer silicon dioxide and substrate silicon from top to bottom, wherein the substrate is provided with a cavity, the cavity is communicated with a release through hole penetrating through the temperature compensation layer and the piezoelectric substrate, and the piezoelectric substrate is made of a single crystal material. Under the condition that the thickness of the piezoelectric substrate is not changed, the center frequency of the resonator changes along with the change of the excitation direction of the electrode pair.

Owner:SOUTH CHINA UNIV OF TECH

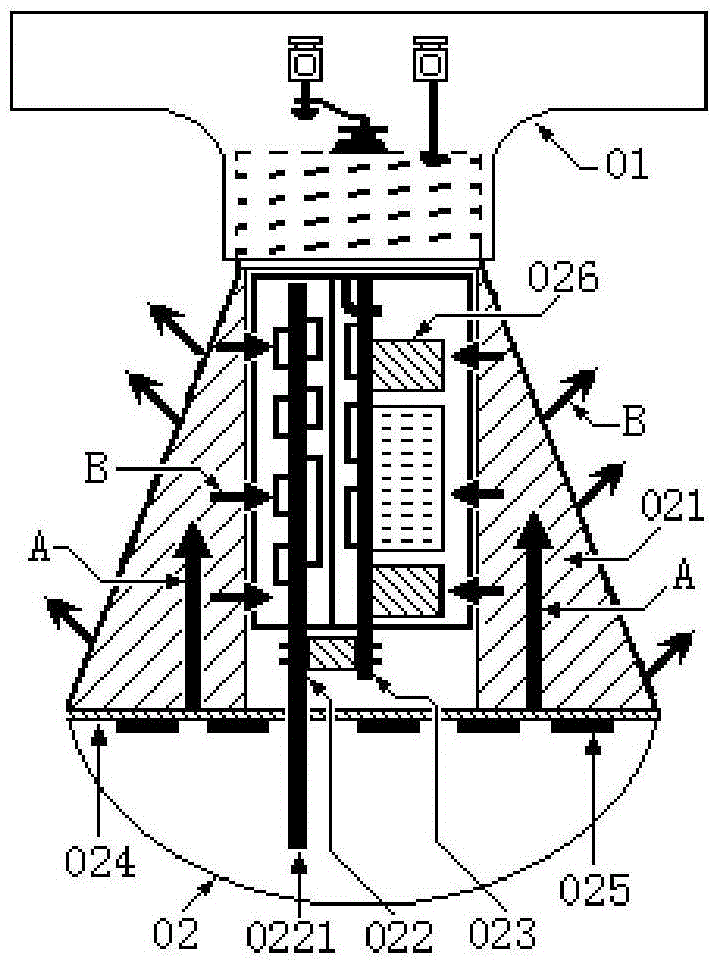

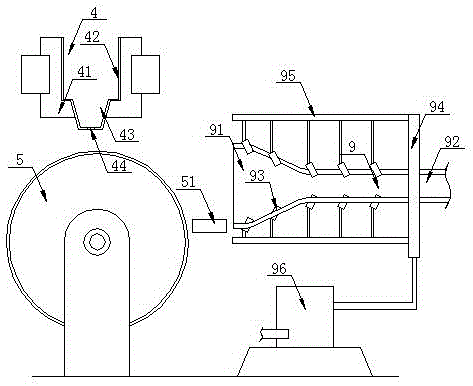

Processing system for amorphous alloy magnetic core belt material of mutual inductor

The invention discloses a processing system for an amorphous alloy magnetic core belt material of a mutual inductor. The processing system comprises an amorphous alloy smelting furnace, a smelting furnace movable support, a smelting furnace sliding guide rail, an amorphous alloy pouring container, an amorphous alloy belt material cooling roller and an amorphous alloy belt material collecting pipe. The amorphous alloy smelting furnace is fixedly arranged on the smelting furnace movable support. A plurality of support movable rolling wheels are arranged at the bottom of the smelting furnace movable support. The multiple support movable rolling wheels are all arranged on the smelting furnace sliding guide rail. The two ends of the amorphous alloy belt material collecting pipe are provided with a belt material collecting inlet end and a belt material collecting outlet end, and a plurality of cooling gas high-speed sprayers are arranged on the inner side wall of the amorphous alloy belt material collecting pipe. Each cooling gas high-speed sprayer obliquely faces the axis of the amorphous alloy belt material collecting pipe and further faces the belt material collecting outlet end. By the adoption of the processing system, the influence on all supporting members by high temperatures can be reduced, and waste of the magnetic core belt material in the collecting operation process can be reduced.

Owner:江苏科兴电器有限公司

Fresh wet rice noodles and preparation method thereof

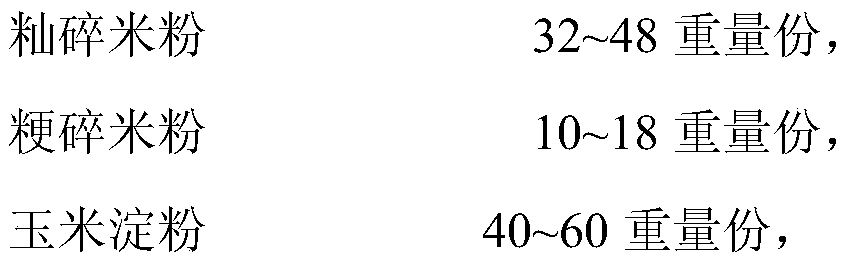

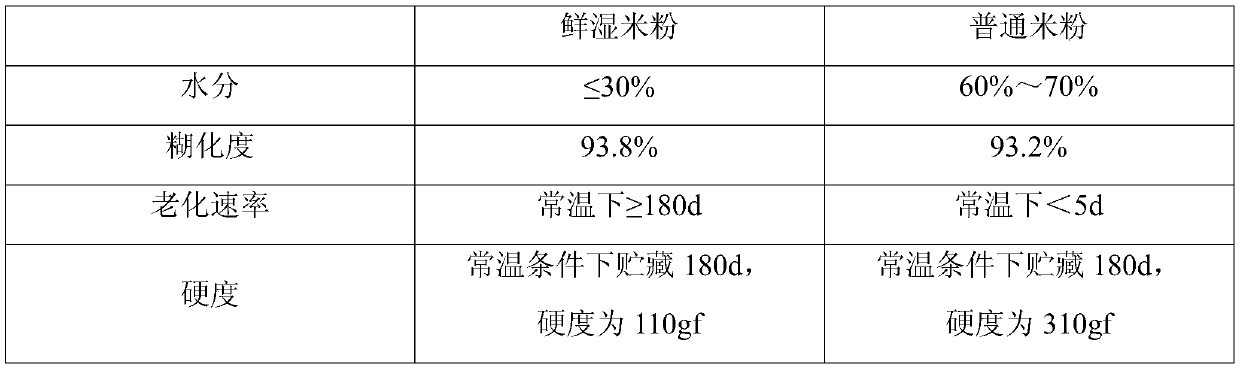

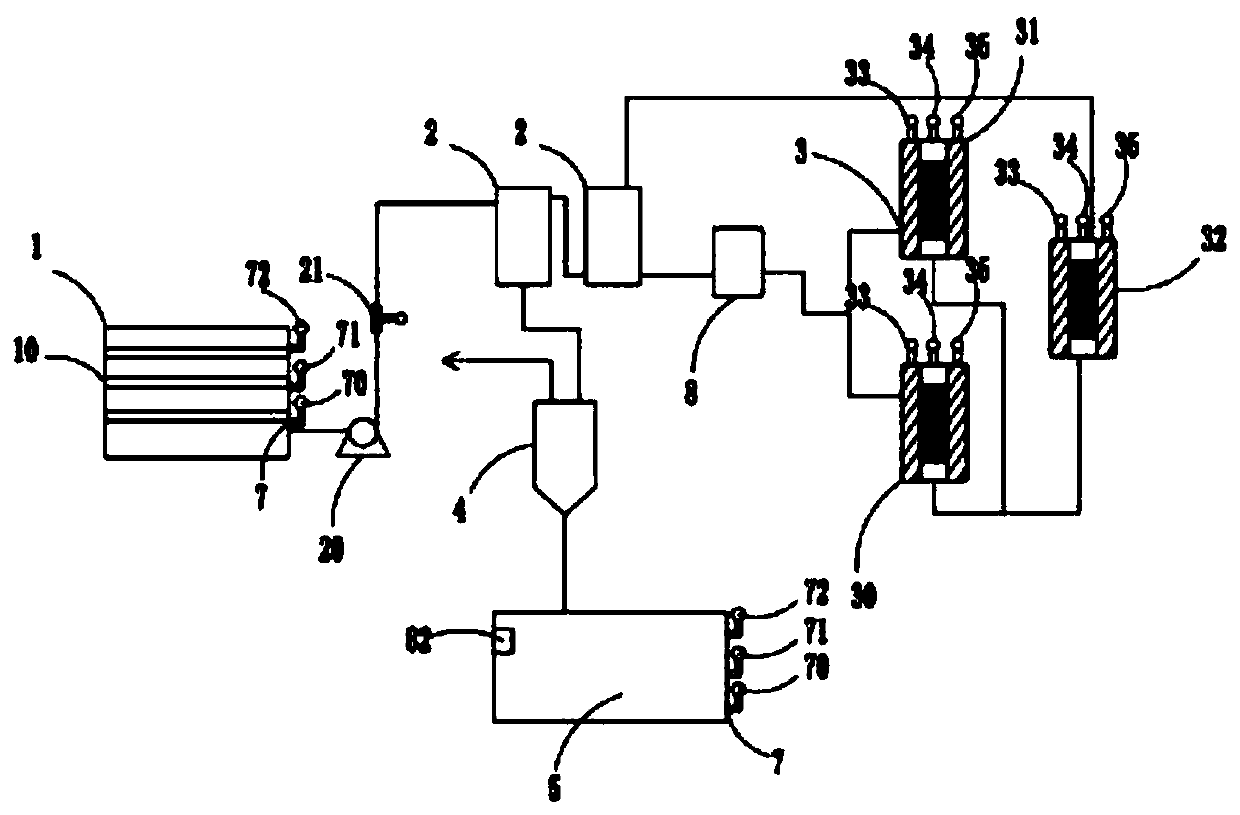

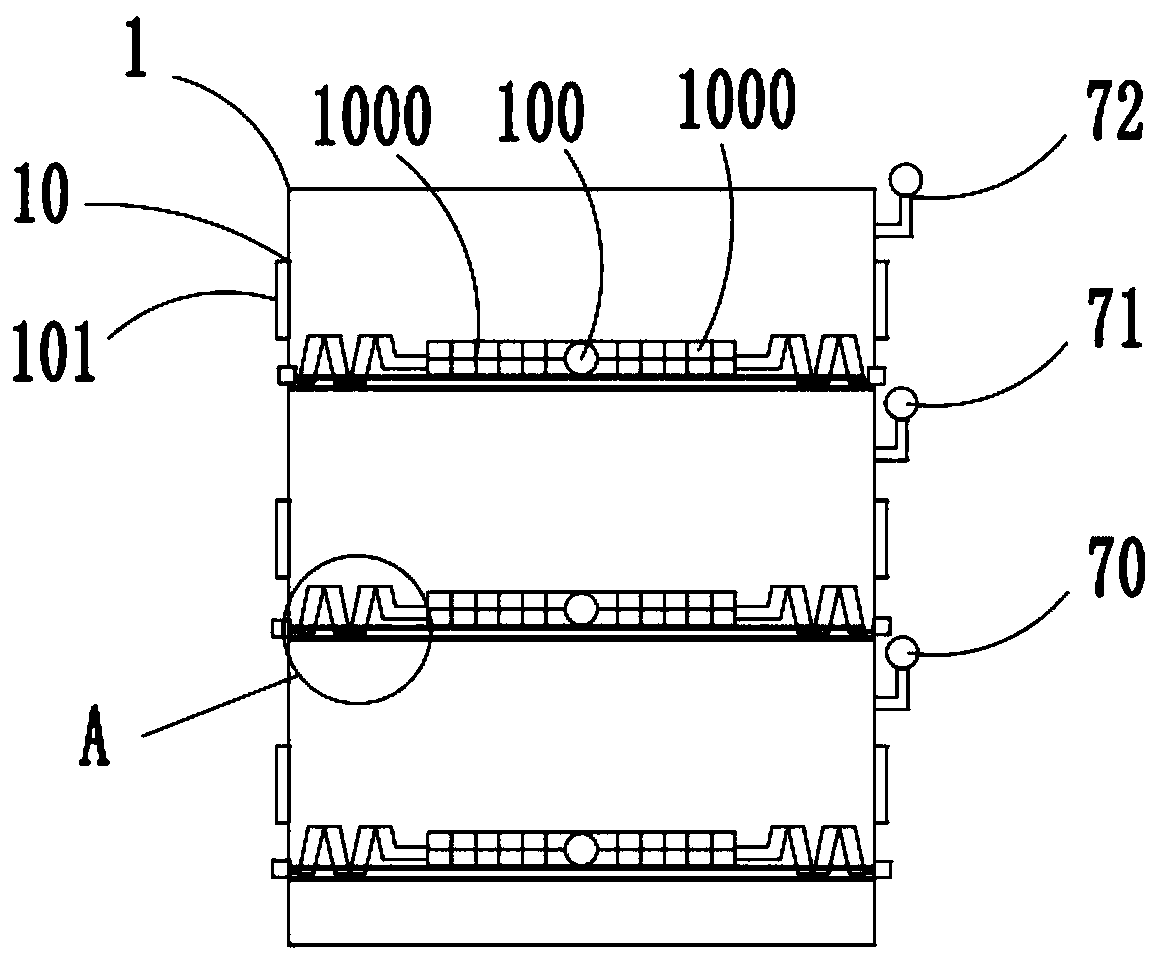

InactiveCN110326741ASolve long-term wasteIncrease added valueFood scienceDegree of polymerizationKonjac glucomannan

The invention relates to the technical field of food processing, in particular to fresh wet rice noodles and a preparation method thereof. The fresh wet rice noodles comprise the following raw materials: 32-48 parts by weight of broken polished long-grained nonglutinous rice flour, 10-18 parts by weight of broken polished round-grained rice, 40-60 parts by weight of corn starch, 1-5 parts by weight of cooked rice flour and 0.2-0.8 part by weight of compound quality modifier, wherein the compound quality modifier comprises sodium carboxymethylcellulose, modified soybean phosphatide, konjac glucomannan, beta-amylase and maltogenic amylase. By use of the fresh wet rice noodles, the broken polished long-grained nonglutinous rice flour, the broken polished round-grained rice, the corn starch and the cooked rice flour are taken as main raw materials, and the compound quality modifier is taken as an auxiliary material. Through the synergistic effect of the beta-amylase and the maltogenic amylase in the compound quality modifier, the gelatinization degree of the rice noodles is improved, in addition, the degree of polymerization of amylose in the rice noodles is lowered, the rice noodle aging rate in a rice noodle storage process is greatly delayed, the rice noodles can keep good elasticity and can maintain proper hardness during shelf life, and the quality of the fresh wet rice noodles is guaranteed to be stable.

Owner:四川东方主食产业技术研究院

Resourceful treatment system and process for high-concentration phenolic resin wastewater

InactiveCN111533377AAdjustable temperatureReduce the temperatureWater treatment parameter controlWater contaminantsIndustrial waste waterPtru catalyst

The invention discloses a resourceful treatment system and process for high-concentration phenolic resin wastewater, and belongs to the technical field of industrial wastewater treatment. The device mainly comprises a wastewater temporary storage tank, a heat exchanger, a reactor, a flow buffer element, a gas-liquid separator, a recycled water temporary storage tank and an intelligent control element. The high-concentration phenolic resin wastewater enters the reactor after multi-stage heat exchange, organic matters in the wastewater can be decomposed and reformed to generate high-added-valueproducts such as CH4 in only 10-15 minutes under the action of the catalyst, the COD removal rate is up to 99.5% or above, and the CH4 yield is up to 98%. In conclusion, the new system and the new process for resourceful treatment of high-concentration phenolic resin wastewate have the advantages of good treatment effect, safety, reliability, high automation degree, energy and water conservation,high resourceful degree and the like, and have good industrial application prospects.

Owner:恩宜瑞(江苏)环境发展有限公司 +1

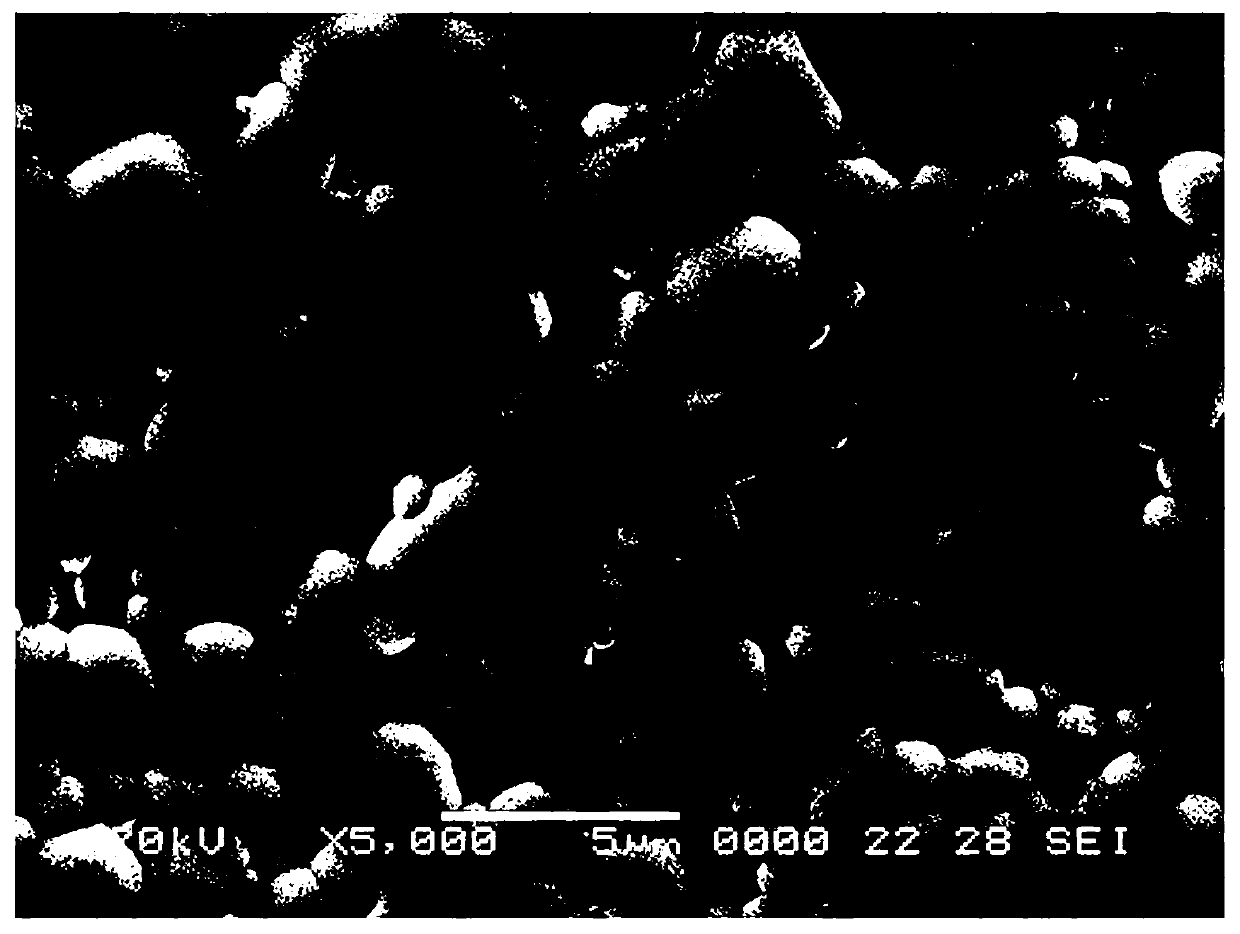

Low-temperature-sintered BiFeO3-based high-performance negative-temperature-coefficient thermosensitive ceramic material and preparation method thereof

The invention discloses a low-temperature-sintered BiFeO3-based high-performance negative-temperature-coefficient thermosensitive ceramic material and a preparation method thereof. According to the preparation method, (1-x)BiFeO3-xMeMO3 powder is firstly synthesized, no SiO2 or a small amount of SiO2 is doped, and the SiO2-doped (1-x)BiFeO3-xMeMO3 thermosensitive ceramic material is formed through compression molding and sintering. According to the low-temperature-sintered BiFeO3-based high-performance negative-temperature-coefficient thermosensitive ceramic material prepared by the preparation method, the sintering temperature is lower than 95 DEG C, the performance is stable, and shown by property tests, the following better comprehensive thermosensitive properties can be obtained: the thermosensitive constant beta25 / 85 is higher than 5,000 K, the room-temperature resistivity rho25 is lower than 1,000,000 ohm.cm, and the aging rate eta is lower than 5%. According to the preparation method, a traditional ceramic solid phase sintering preparation process is adopted, and the adopted process is relatively simple and stable, so that the preparation method has higher practicality and popularization and application prospects.

Owner:GUILIN UNIV OF ELECTRONIC TECH

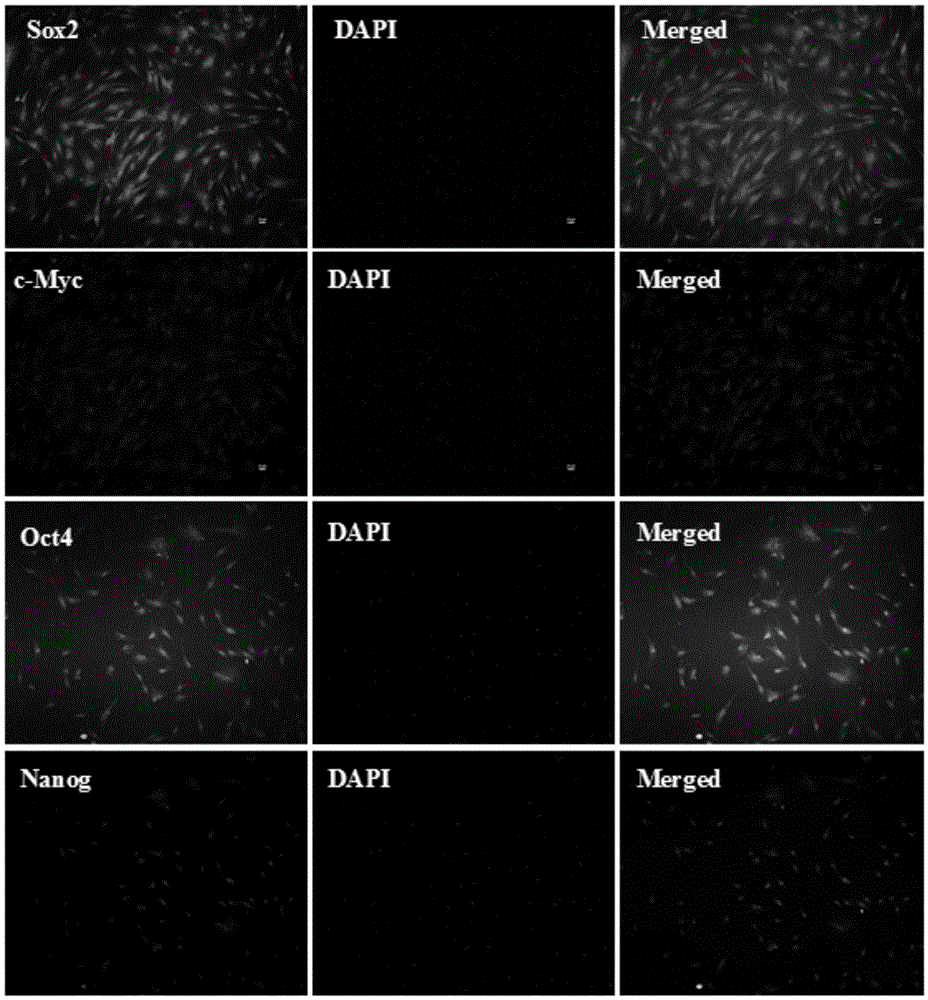

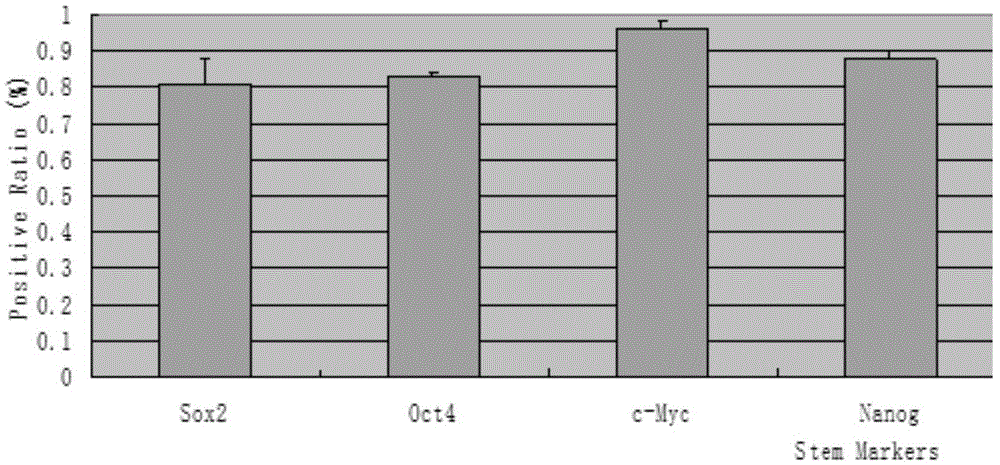

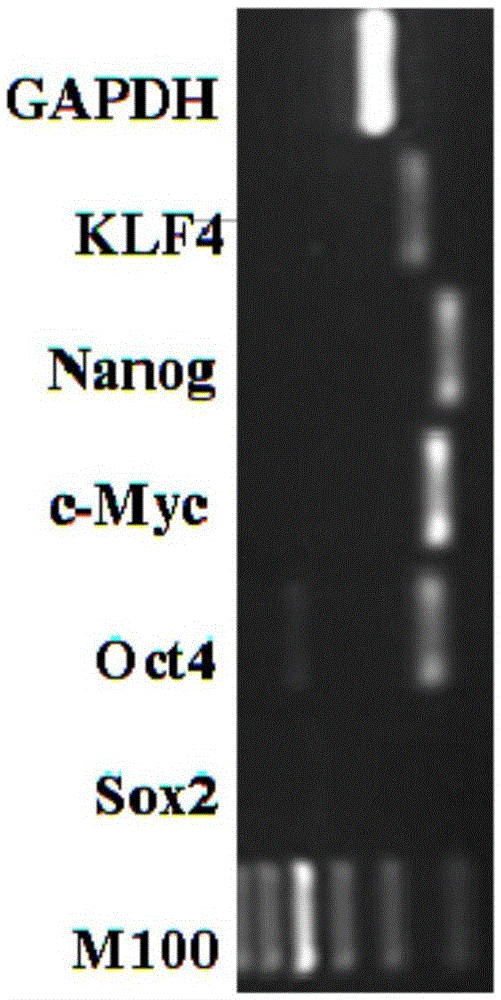

Induced differentiation method for human adipose-derived stem cells

InactiveCN105567637ASimplified quantityEasy to manufactureNervous disorderNervous system cellsTransdifferentiationFunctional movement

The invention relates to an induced differentiation method for human adipose-derived stem cells. The method comprises the following steps: carrying out induced differentiation on the human adipose-derived stem cells by adopting SHH and RA together, so as to obtain motor neurons; carrying out in-vitro culture on the obtained motor neurons, so as to obtain mature functional motor neurons with an electrophysiological function. According to the induced differentiation method provided by the invention, the easy and feasible and high-differentiation-yield preparation of the neurons is achieved, and the transdifferentiation efficiency and specificity of directed differentiation of the adipose-derived stem cells to the motor neurons are improved.

Owner:厚朴生物科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com