Steamed oatmeal buns and processing method thereof

A processing method and technology of oatmeal, which is applied in the field of food processing, can solve the problems of not meeting the needs of diet therapy, the dough cannot be formed, and the content of oats is not high, so as to prevent cardiovascular and cerebrovascular diseases, plump and upright appearance, health care and Both taste and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

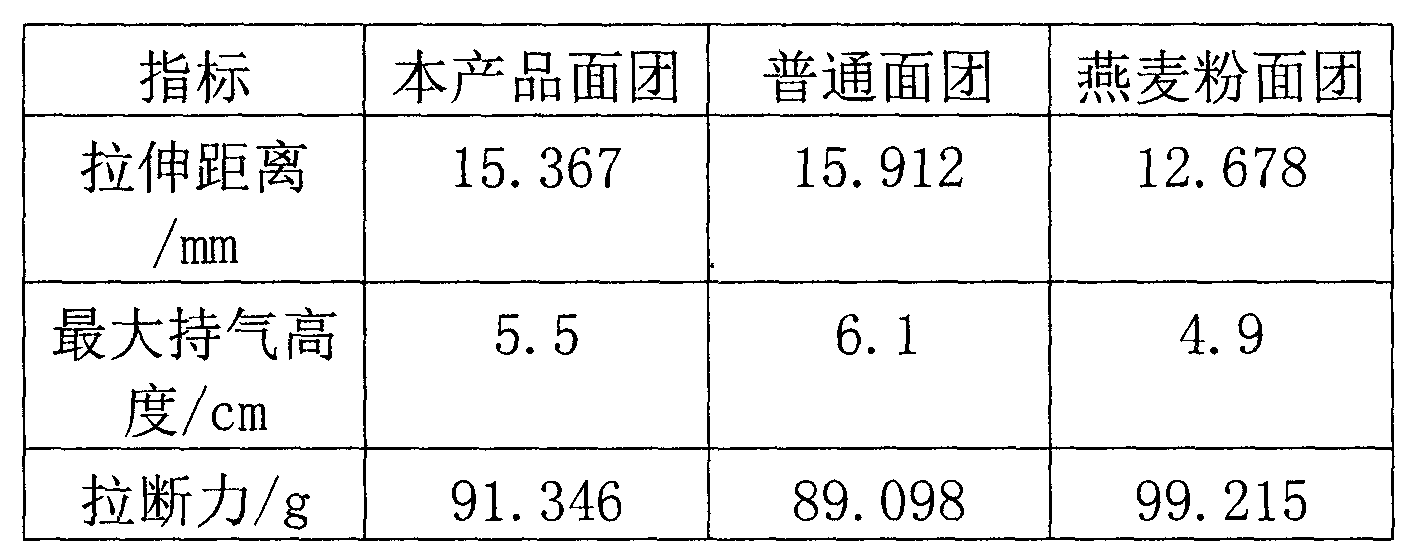

Examples

Embodiment 1

[0031] Embodiment 1: An oatmeal steamed bun is processed by the following ingredients in kilograms: 50 kg of white flour, 30 kg of oatmeal, 1 kg of gluten, 0.4 kg of yeast, 0.5 kg of polydextrose, and 21 kg of water.

[0032] Preparation method: take 30 kg of oatmeal and steam at 90-100°C for 20 minutes, microwave the steamed oatmeal at 1000W for 2 minutes, and then switch to microwave at 600W for 1 minute. Add 50 kg of white flour, 20 kg of processed oatmeal, 1 kg of gluten, 0.4 kg of yeast, 0.5 kg of polydextrose, 18 kg of water into the dough mixer, and knead the dough for 5-6 minutes at 30 rpm until the dough is formed Forming, then add 10 kg of oatmeal, 3 kg of water, and knead the dough for 10 minutes under the condition of 50 rpm. Press the reconciled dough 15 times, make square steamed buns on a knife-cut steamed bun machine, put the formed steamed buns at 38°C and 85% humidity to proof for 40 minutes, and put the proofed steamed buns under a pressure of 0.01MPa Serve...

Embodiment 2

[0033] Embodiment 2: An oatmeal steamed bun is processed by the following ingredients in kilograms: 50 kg of white flour, 30 kg of oatmeal, 2 kg of gluten, 0.4 kg of yeast, 0.5 kg of polydextrose, and 21 kg of water.

[0034] Preparation method: take 30 kg of oatmeal and steam at 90-100°C for 20 minutes, microwave the steamed oatmeal at 1000W for 2 minutes, and then switch to microwave at 600W for 1 minute. Add 50 kg of white flour, 20 kg of processed oatmeal, 2 kg of gluten, 0.4 kg of yeast, 0.5 kg of polydextrose, 18 kg of water into the dough mixer, and knead the dough for 5-6 minutes at 30 rpm until the dough is formed Forming, then add 10 kg of oatmeal, 3 kg of water, and knead the dough for 10 minutes under the condition of 50 rpm. Press the reconciled dough 15 times, make square steamed buns on a knife-cut steamed bun machine, put the formed steamed buns at 38°C and 85% humidity to proof for 40 minutes, and put the proofed steamed buns under a pressure of 0.01MPa Serve...

Embodiment 3

[0035] Embodiment 3: An oatmeal steamed bun is processed by the following ingredients in kilograms: 50 kg of white flour, 30 kg of oatmeal, 5 kg of gluten, 0.4 kg of yeast, 0.5 kg of polydextrose, and 21 kg of water.

[0036] Preparation method: take 30 kg of oatmeal and steam at 90-100°C for 20 minutes, then microwave the steamed oatmeal at 1000W for 2 minutes, then switch to microwave at 600W for 1 minute. Add 50 kg of white flour, 20 kg of processed oatmeal, 5 kg of gluten powder, 0.4 kg of yeast, 0.5 kg of polydextrose, 18 kg of water into the dough mixer, and knead the dough for 5-6 minutes at 30 rpm until the dough is formed Forming, then add 10 kg of oatmeal, 3 kg of water, and knead the dough for 10 minutes under the condition of 50 rpm. Press the reconciled dough 15 times, make square steamed buns on a knife-cut steamed bun machine, put the formed steamed buns at 38°C and 85% humidity to proof for 40 minutes, and put the proofed steamed buns under a pressure of 0.01MP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com