PVC lamp box film and preparation process thereof

A PVC resin and light box technology, applied in flat products, other household appliances, applications, etc., can solve the problems of PVC film aging and affect the use effect, and achieve the effects of avoiding adhesion, delaying aging, and improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

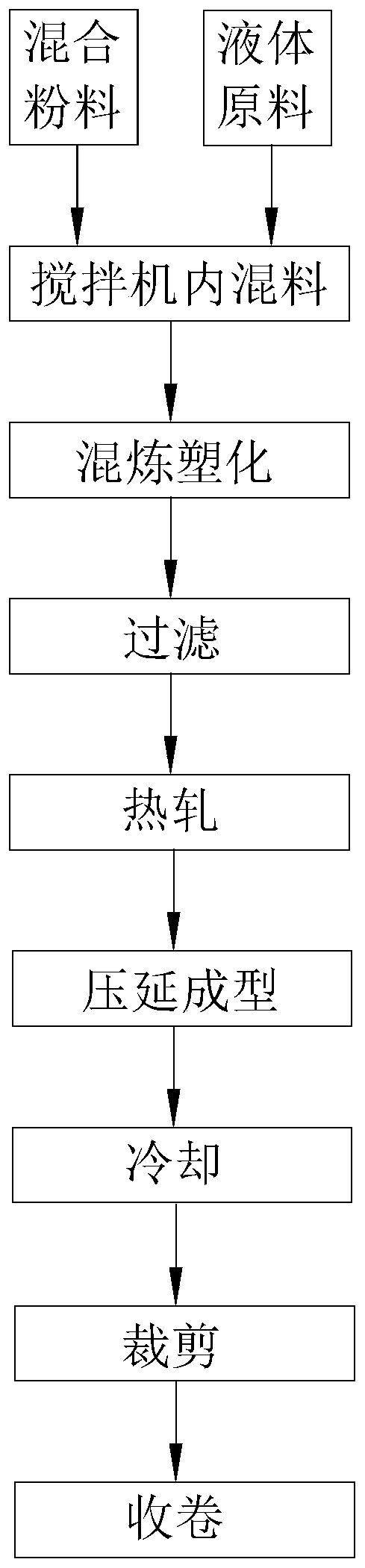

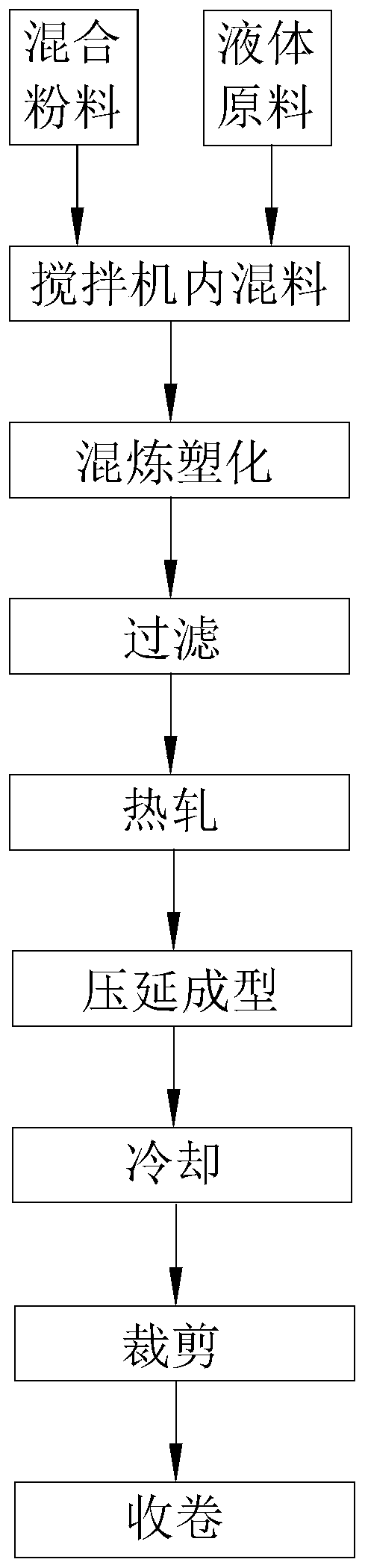

Method used

Image

Examples

Embodiment 1

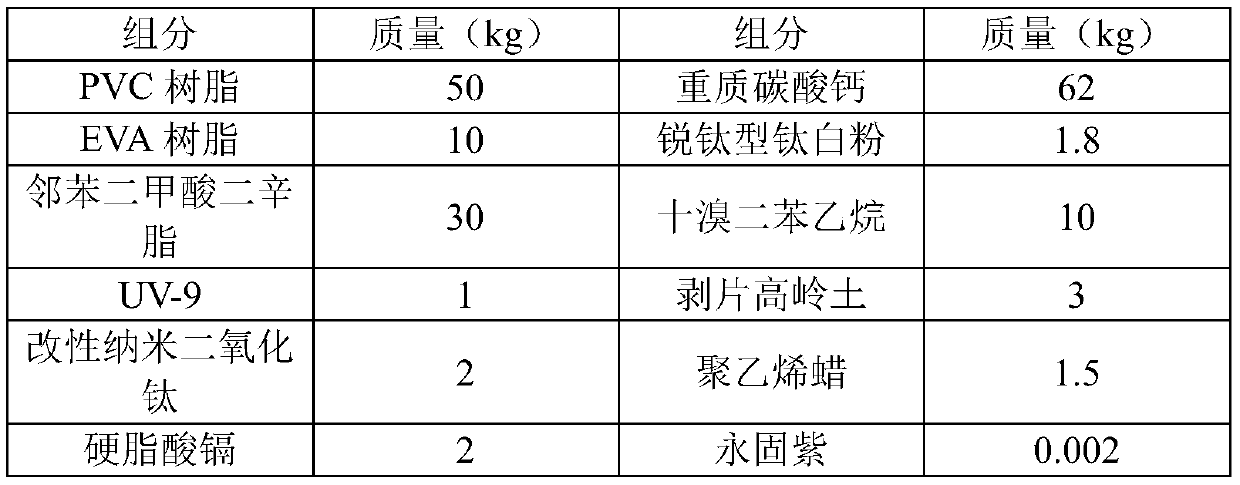

[0045] Table 1 is each component and quality of a kind of PVC light box film of embodiment 1

[0046]

[0047] Wherein, the preparation method of the modified nano-titanium dioxide is as follows: 1) According to the number of parts by mass, 5 kg of nano-titanium dioxide is uniformly dispersed in 30 kg of absolute ethanol, ultrasonicated for 10 min, and then stirred for 40 min; 2) 1 kg of KH570 is added to 1) and stirred evenly Finally, add 10kg of polyethylene glycol, and emulsify the resulting solution for 30 minutes; 3) adjust the pH of the slurry obtained after 2) emulsification to 7.0, then stir the slurry at 60°C for 3 hours, and then ultrasonicate the obtained reaction solution for 30 minutes; 4) The suspension obtained by ultrasound is centrifuged, the supernatant is poured off, the precipitate is washed 3 times with absolute ethanol, and the obtained sample is dried and ground to obtain the modified nano-titanium dioxide.

[0048] A kind of preparation technology of...

Embodiment 2

[0059] Table 2 is each component and quality of a kind of PVC light box film of embodiment 2

[0060]

[0061] Among them, the preparation method of modified nano-titanium dioxide is: 1) According to the number of parts by mass, evenly disperse 8 kg of nano-titanium dioxide into 40 kg of absolute ethanol, and then stir for 50 min after ultrasonication for 15 min; 2) Add 2 kg of KH570 to 1) After stirring evenly, add 12kg of polyethylene glycol, and emulsify the obtained solution for 40 minutes; 3) adjust the pH of the slurry obtained after 2) emulsification to 8.0, then stir the slurry at 80°C for 2 hours, and then sonicate the obtained reaction solution for 30 minutes; 4) The suspension obtained by ultrasound is centrifuged, the supernatant liquid is poured off, the precipitate is washed 5 times with absolute ethanol, and the obtained sample is dried and ground to obtain modified nano-titanium dioxide.

[0062] A kind of preparation technology of PVC light box film, specif...

Embodiment 3

[0073] Table 3 is each component and quality of a kind of PVC light box film of embodiment 3

[0074] components mass (kg) components mass (kg) PVC resin 60 Anatase Titanium Dioxide 2 EVA resin 5 Decabromodiphenylethane 6 Dioctyl phthalate 30.4 Aluminum hydroxide 4 Epoxidized soybean oil 4.4 magnesium hydroxide 5 UV-9 1 Flaked Kaolin 2.5 UV-P 1 polyethylene wax 0.5 Modified Nano Titanium Dioxide 2.8 Oxidized polyethylene wax 0.5 Zinc stearate 2 Everlasting Purple 0.003 Ground calcium carbonate 65 Fluorescent whitening agent FP 0.05

[0075]Wherein, the preparation method of the modified nano-titanium dioxide is as follows: 1) According to the number of parts by mass, 7.5kg of nano-titanium dioxide is evenly dispersed in 40kg of absolute ethanol, ultrasonicated for 15min, and then stirred for 60min; 2) 3kg of KH570 is added to 1). After stirring evenly, add 15kg of polyethylene g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com