Heat radiation layer with phase transition material, preparation method of heat radiation layer and photovoltaic assembly with heat radiation layer

A solar photovoltaic and phase change material technology, applied in the field of photovoltaic power generation, can solve problems such as easy leakage and low thermal conductivity, and achieve the effects of improving power generation, increasing power generation, wide application prospects and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

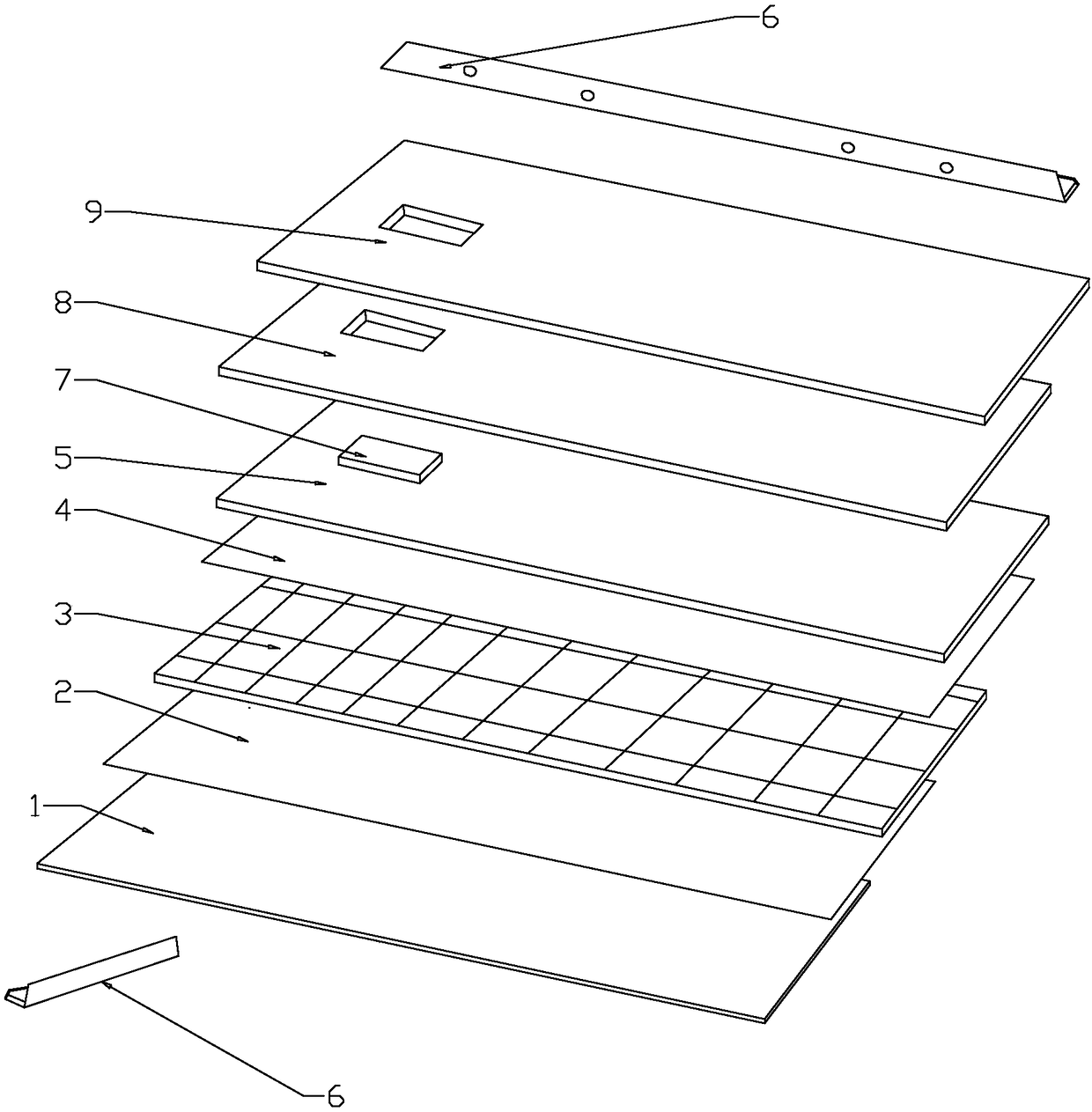

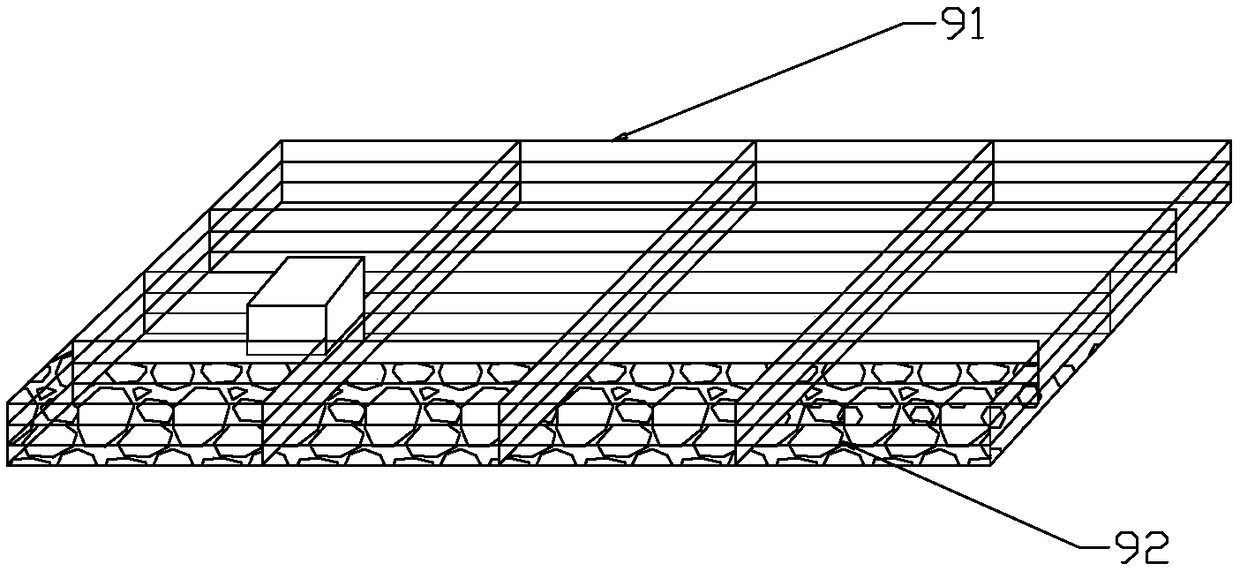

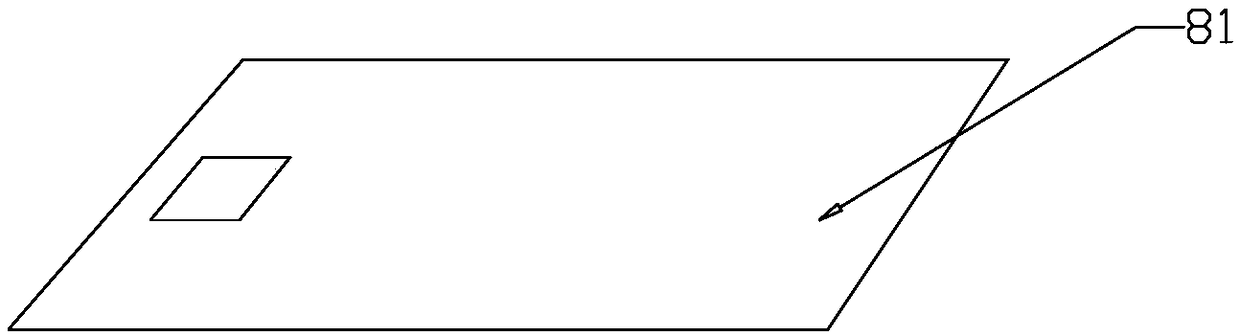

[0033] Such as Figure 1 to Figure 4 The solar photovoltaic module shown includes frame 6, photovoltaic glass 1, upper layer encapsulation EVA2, cell array 3, lower layer encapsulation EVA4, encapsulation backplane 5, junction box 7, heat conduction layer 8 and sheet-shaped material containing phase change material The heat dissipation layer 9, the photovoltaic glass 1, the upper layer encapsulation EVA2, the cell array 3, the lower layer encapsulation EVA4, the encapsulation backplane 5, the heat conduction layer 8 and the heat dissipation layer 9 are arranged sequentially from top to bottom to form a laminated part of the solar photovoltaic module, which conducts heat The layer 8 is respectively bonded to the packaging backplane 5 and the heat dissipation layer 9, the junction box 7 is placed on the back of the packaging backplane 5, and exposed after passing through the heat conduction layer 8 and the heat dissipation layer 9, wherein the heat conduction layer 8 and the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com