Low-temperature-sintered BiFeO3-based high-performance negative-temperature-coefficient thermosensitive ceramic material and preparation method thereof

A negative temperature coefficient, heat-sensitive ceramic technology, applied in the field of electronic information functional materials, can solve problems such as hindering application, and achieve the effects of high practicability, high promotion and application prospects, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

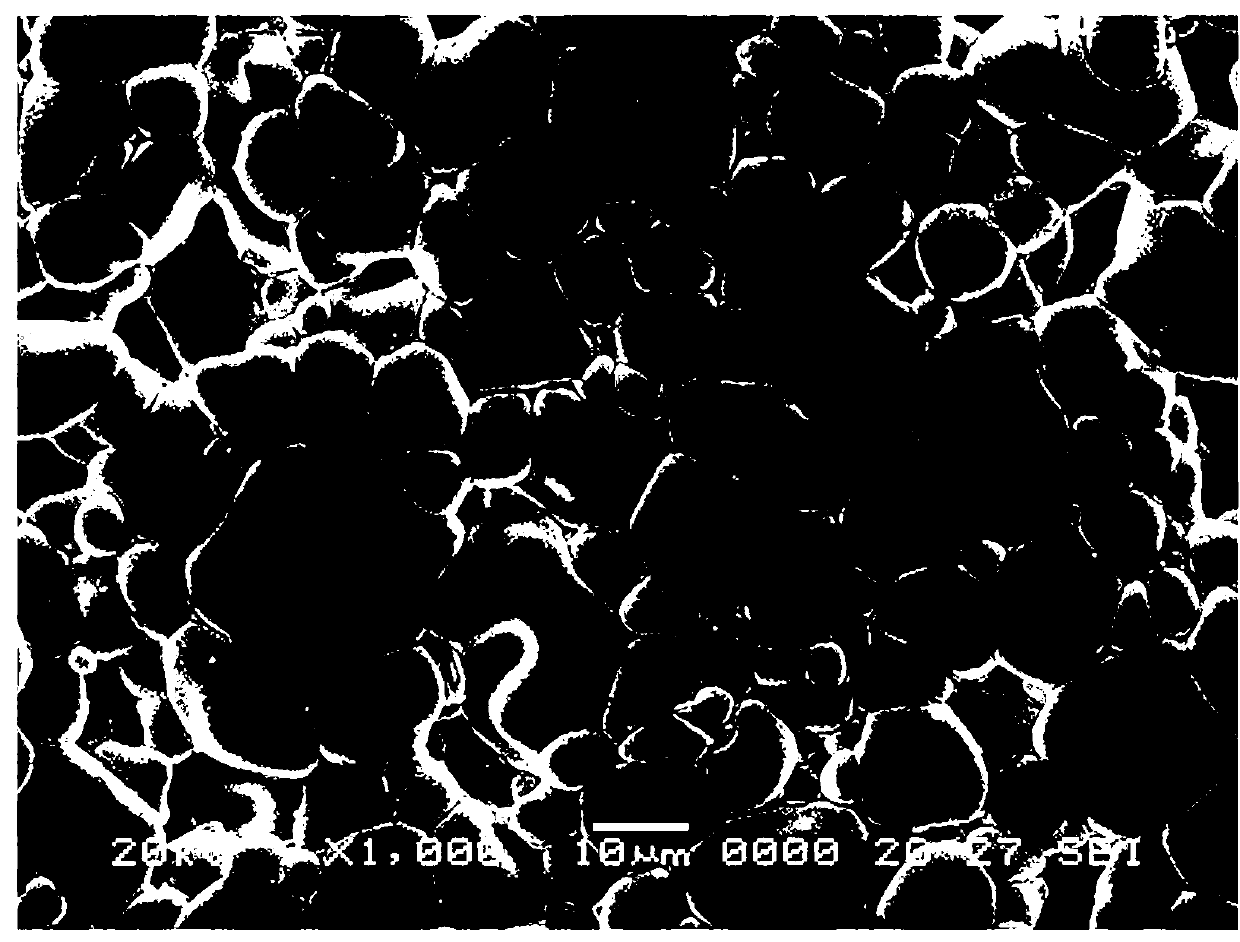

[0019] with BaCO 3 、 Bi 2 o 3 , Fe 2 o 3 and TiO 2 As raw material, according to the chemical formula 0.9BiFeO 3 -0.1BaTiO 3 Proportioning, wet ball milling with anhydrous ethanol as the medium, after drying, synthesize 0.9BiFeO at 750°C for 2 hours 3 -0.1BaTiO 3 Solid solution powder, the obtained solid solution powder is carried out secondary ball milling and sieving, and then in the obtained 0.9BiFeO 3 -0.1BaTiO 3 Add a certain amount of polyvinyl alcohol (PVA) with a mass concentration of 5% to the solid solution powder, mix it evenly, dry it, and then press it into a disc-shaped green body on a molding machine, and put the obtained disc-shaped green body at 905°C Heat preservation for 4 hours and sinter into thermosensitive ceramics. The resulting 0.9BiFeO 3 -0.1BaTiO 3 Thermally sensitive ceramics are polished on both sides and then tested for resistivity-temperature relationship and aging performance.

[0020] The performance test shows that the thermosensi...

Embodiment 2

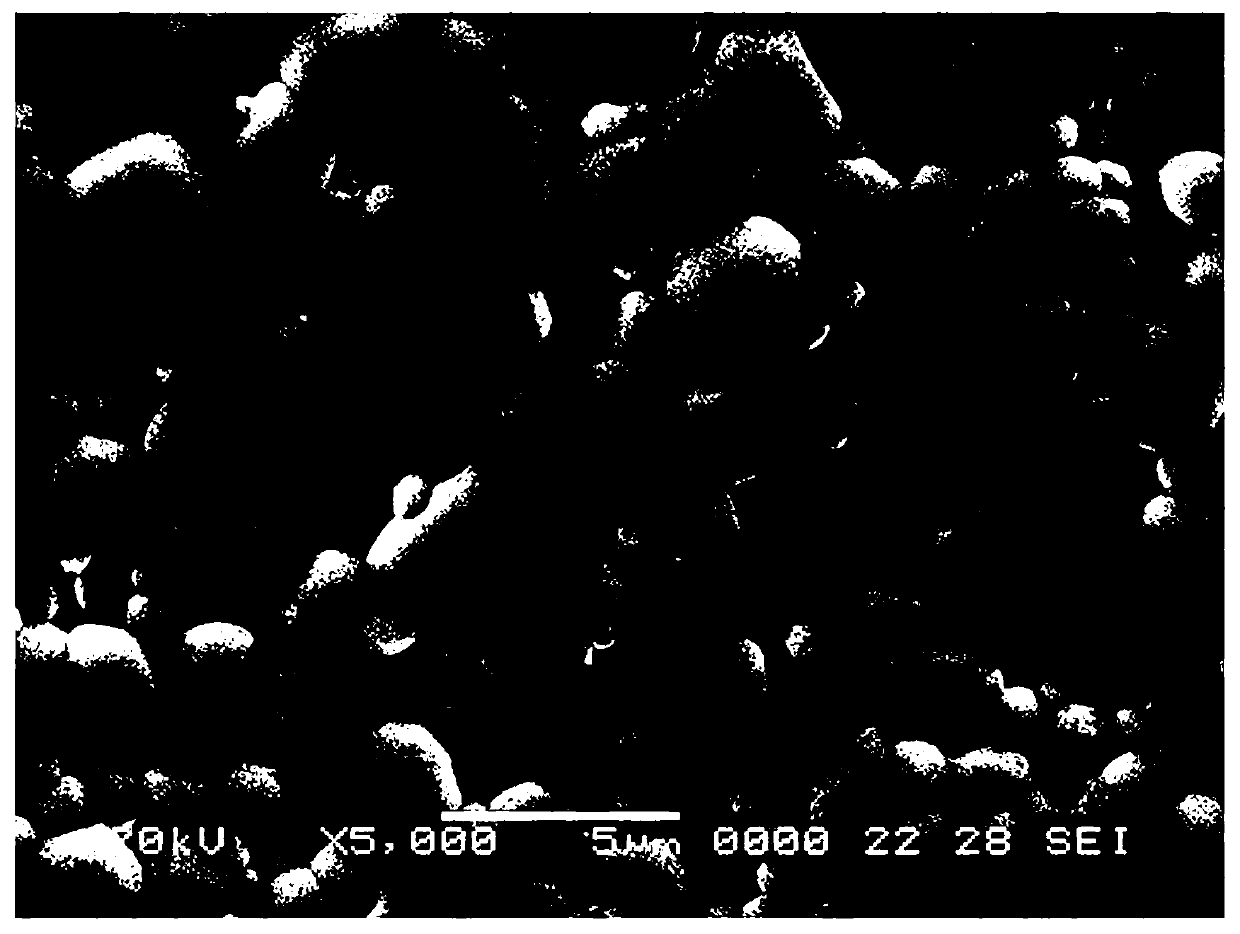

[0022] SrCO 3 、 Bi 2 o 3 , Fe 2 o 3 and TiO 2 As raw material, according to the chemical formula 0.8BiFeO 3 -0.2SrTiO 3 Proportioning, wet ball milling with anhydrous ethanol as the medium, after drying, synthesize 0.8BiFeO at 750°C for 4 hours 3 -0.2SrTiO 3 Solid solution powder, the obtained solid solution powder is carried out secondary ball milling and sieving, and then in the obtained 0.8BiFeO 3 -0.2SrTiO 3 Add a certain amount of polyvinyl alcohol (PVA) with a mass concentration of 5% to the solid solution powder, mix it evenly, dry it, and then press it into a disc-shaped green body on a molding machine, and put the obtained disc-shaped green body at 935°C Heat preservation for 4 hours and sinter into thermosensitive ceramics. The resulting 0.8BiFeO 3 -0.2SrTiO 3 Thermally sensitive ceramics are polished on both sides and then tested for resistivity-temperature relationship and aging performance.

[0023] The performance test shows that the thermosensitive ...

Embodiment 3

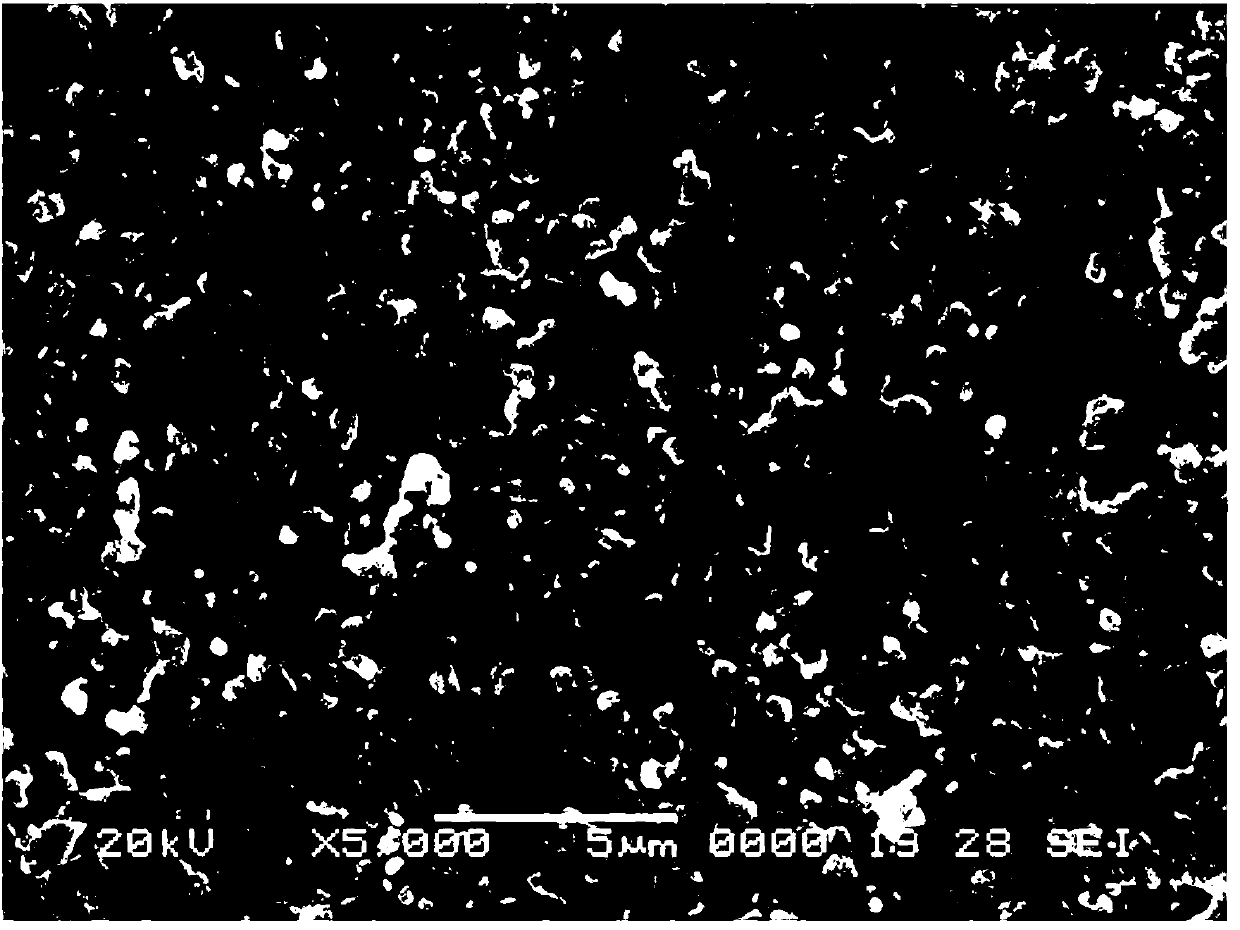

[0025] with BaCO 3 、 Bi 2 o 3 , Sb 2 o 3 , Fe 2 o 3 and SnO 2 As raw material, according to the chemical formula 0.95BiFeO 3 -0.05BaSb 0.04 sn 0.96 o 3Proportioning, wet ball milling with anhydrous ethanol as the medium, after drying, synthesize 0.95BiFeO at 780°C for 2 hours 3 -0.05BaSb 0.04 sn 0.96 o 3 Solid solution powder, the obtained solid solution powder is carried out secondary ball milling and sieving, and then in the obtained 0.95BiFeO 3 -0.05BaSb 0.04 sn 0.96 o 3 Add a certain amount of polyvinyl alcohol (PVA) with a mass concentration of 5% to the solid solution powder, mix it evenly, dry it, and then press it into a disc-shaped green body on a molding machine, and put the obtained disc-shaped green body at 925°C Heat preservation for 2 hours and sinter into heat-sensitive ceramics. The resulting 0.95BiFeO 3 -0.05BaSb 0.04 sn 0.96 o 3 Thermally sensitive ceramics are polished on both sides and then tested for resistivity-temperature relationsh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com