High-strength foldable prefabricated floor heating plate and manufacturing method thereof

A floor heating board and high-strength technology, applied in the field of building materials, can solve the problems of inconvenient long-term storage and transportation, poor thermal performance of floor heating boards, poor thermal insulation and sound insulation effects, etc., and achieve easy transportation, long service life, and excellent heat dissipation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] A method for manufacturing a high-strength foldable prefabricated floor heating panel, comprising the following steps:

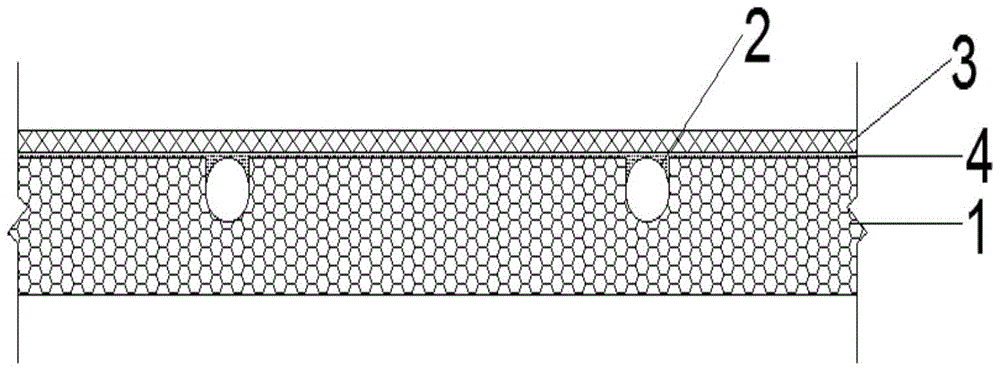

[0106] (1) Cut the cement board 3 (5mm thick) into required specifications and sizes, and polish the edges of the cut cement board 3;

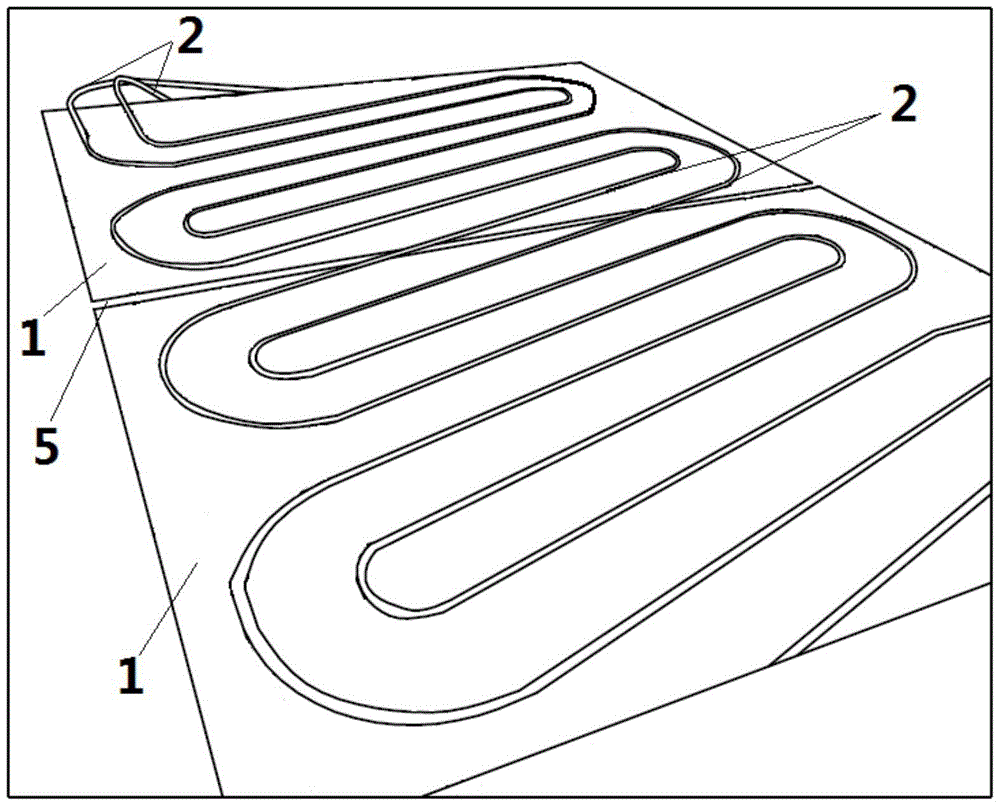

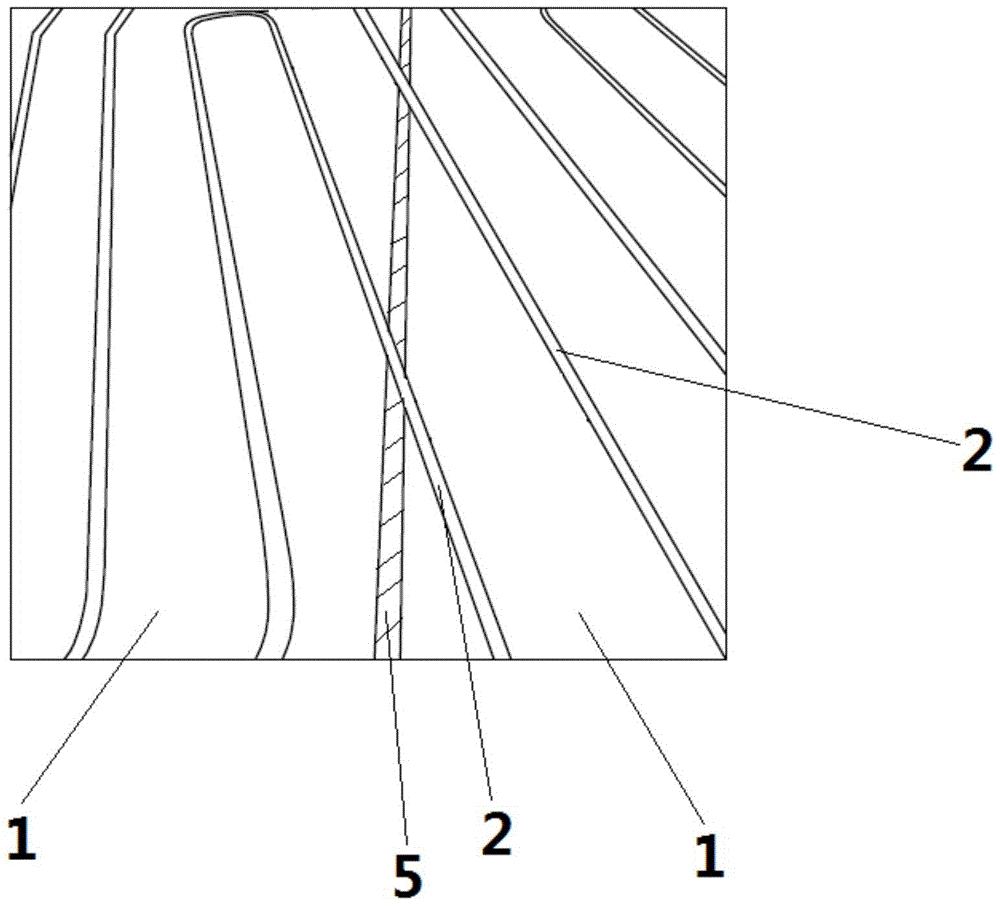

[0107] (2) Splicing together two groups of benzene plates 1 (respectively 20 mm thick) with grooves, leaving a 2-3 cm gap 5 between the benzene plates 1, and fixing the edges of the benzene plates 1 with angle iron;

[0108] (3) Lay the heating pipe 2 along the groove of the benzene plate 1 (the pipe diameter is 10mm), and fix the heating pipe 2 and the benzene plate 1 with aluminum foil at the part where the heating pipe 2 is easy to lift, and leave 5m for the water inlet pipe and the return water pipe ;

[0109] (4) Blend cement, latex powder, and water in a specific ratio, and pour the reconciled mud on the polystyrene board to smooth it;

[0110] (5) Sprinkle water on one side of the cement board 3, and cover th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com