Reinforced composite thermal insulation template

A composite thermal insulation and reinforced technology, which is applied in the field preparation and construction of formwork/formwork components and building components, can solve the problems of the collapse of the outer cement foundation and other adhesion layers, and the failure to meet the national requirements. Reduce the amount of template, light weight, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

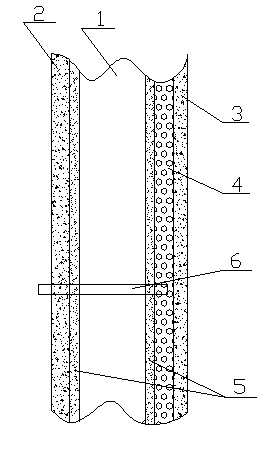

[0019] As shown in the figure, the reinforced composite thermal insulation formwork includes a rock wool or foam thermal insulation board body 1, an interface bonding layer 5 with reinforcing materials is arranged on the inner and outer surfaces of the thermal insulation board body 1, and the interface bonding layer 5 on the inner surface The inner reinforcement layer 2 is arranged, the heat storage transition layer 4 is arranged outside the interface adhesive layer on the outer surface, and the outer reinforcement layer 3 is arranged outside the heat storage transition layer 4 . The inner reinforcement layer 2, the outer reinforcement layer 3 and the interface bonding layer 5 are made of cement-based slurry with reinforcement materials; the reinforcement materials are non-woven fabrics with holes, glass fiber mesh cloth, steel mesh or glass fiber wires; The thermal storage transition layer 4 is made of lightweight aggregate thermal insulation mortar or foamed cement.

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com