Patents

Literature

64results about How to "Avoid test failures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Unattended automatic test system of quartz crystal oscillator

InactiveCN101515009AAvoid fault magnificationAvoid test failuresElectronic circuit testingControl systemMonitoring system

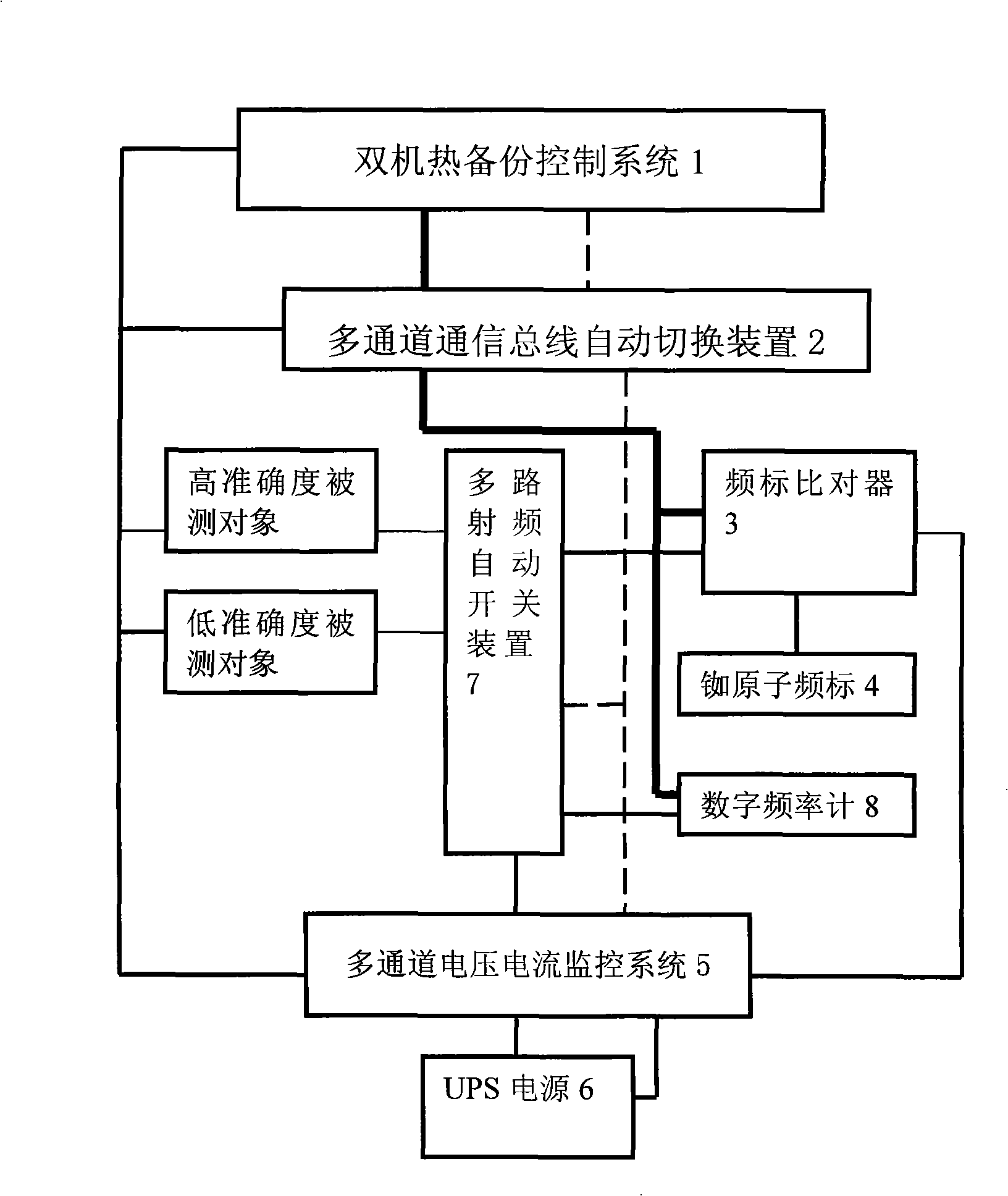

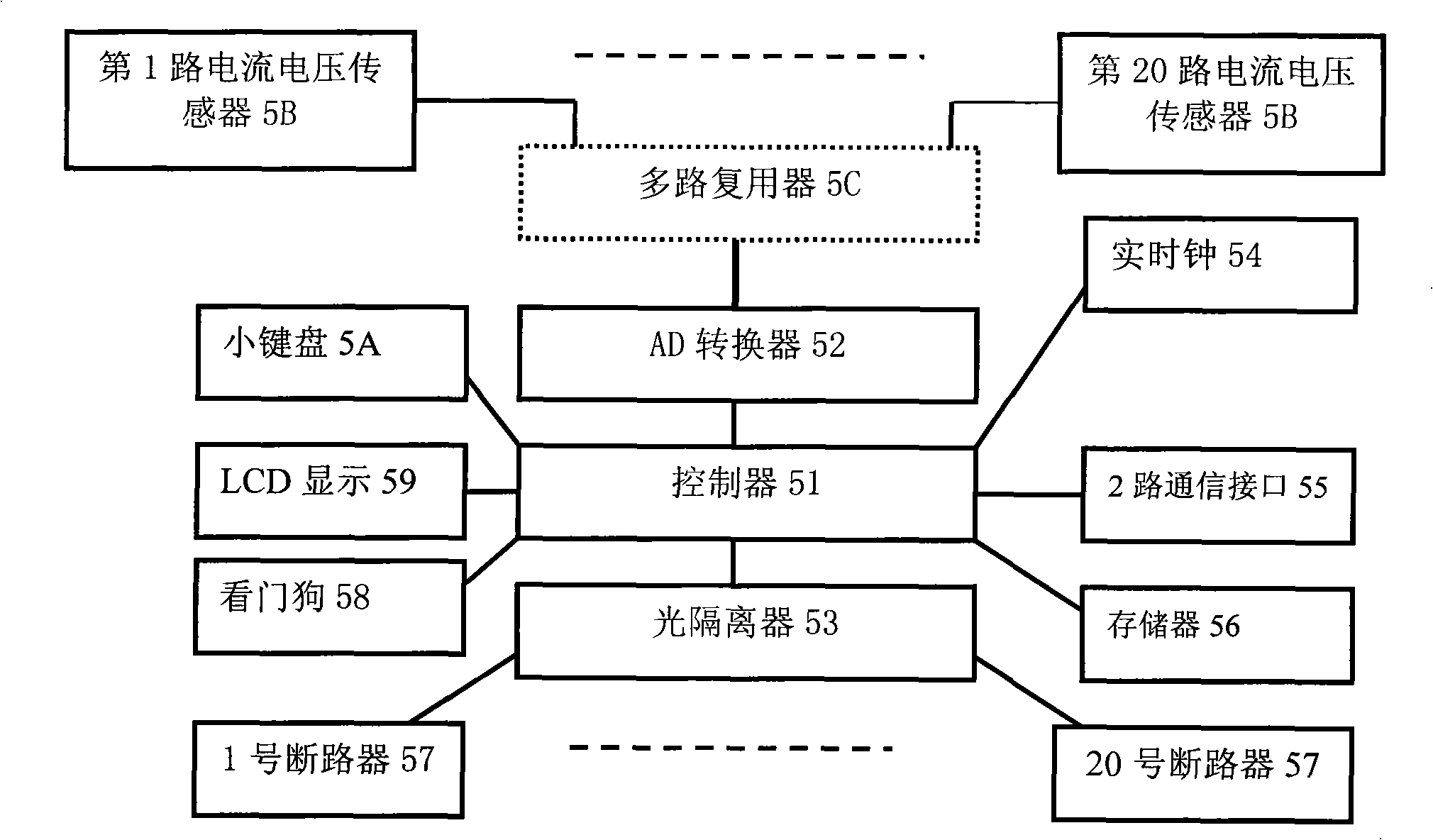

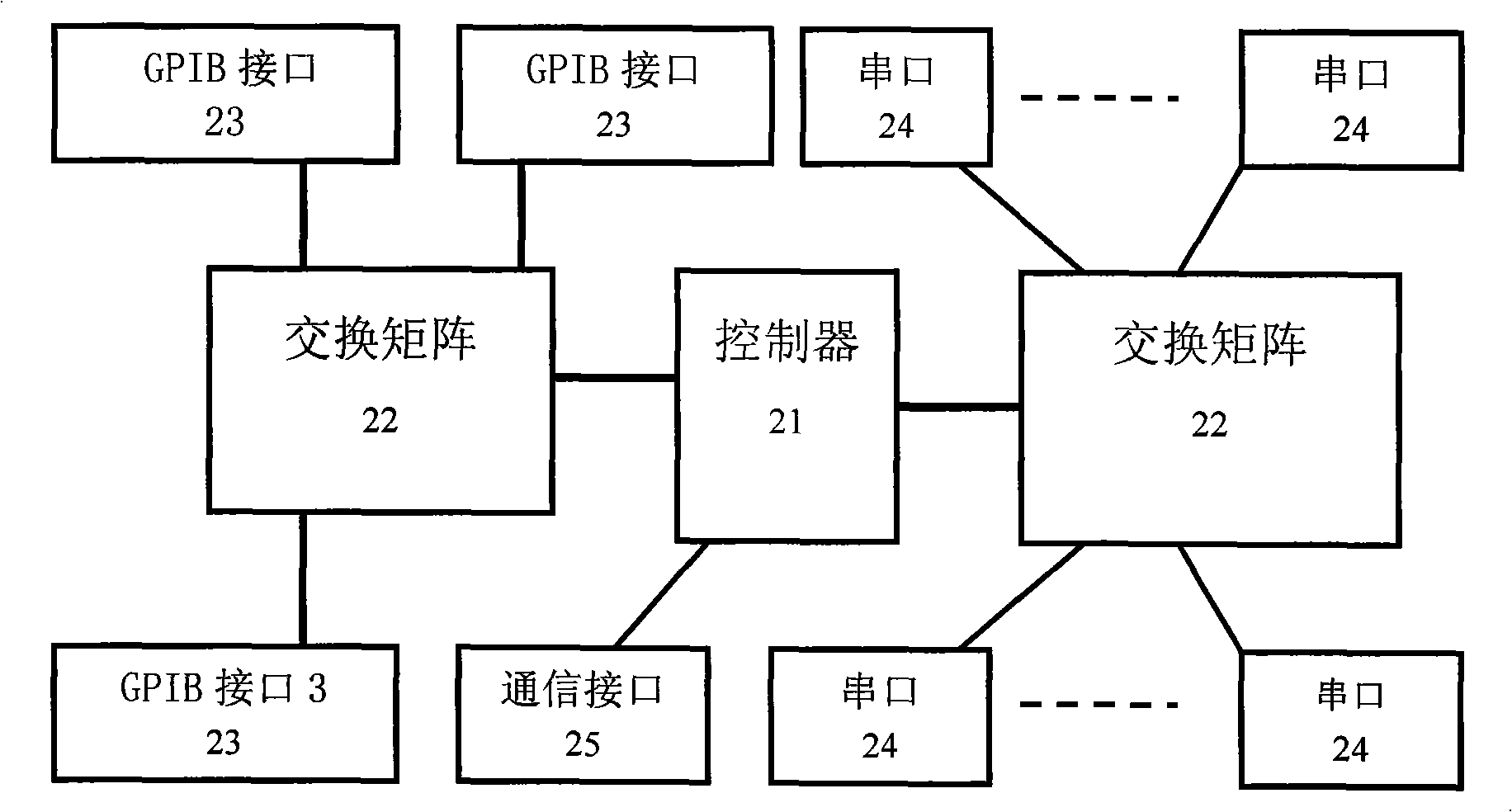

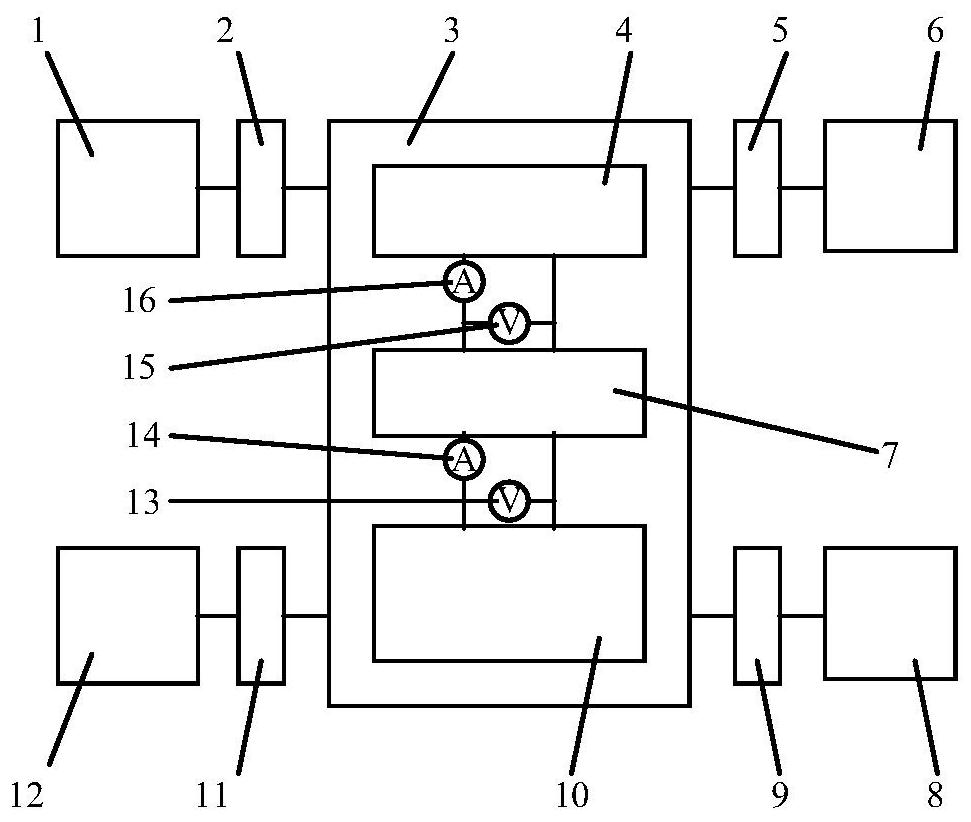

The invention discloses an unattended automatic test system of a quartz crystal oscillator and aims at providing the test system with the safety protection ability and the abilities of self-defining a measurement process, self-setting test parameters and supporting long-time unattended operation. In the test system, a dual-server hot-backup control system is connected with a frequency standard comparator, a multi-channel radio frequency automatic switching device, a digital frequency meter and a multi-channel voltage and current monitoring system through an automatic switchover device of a multi-channel communication bus to form an automatic test loop. The rubidium atomic frequency standard is taken as the benchmark and signals of the tested quartz crystal oscillator are respectively sent to the frequency standard comparator and the digital frequency meter for testing according to the accuracy level thereof by the multi-channel radio frequency automatic switching device under the control of a computer with system control software. The multi-channel voltage and current monitoring system carries out the real-time monitoring of current and voltage states of all the standard devices and the tested devices and receives a command of the dual-server hot-backup control system for turning off or turning on a power supply of any channel.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

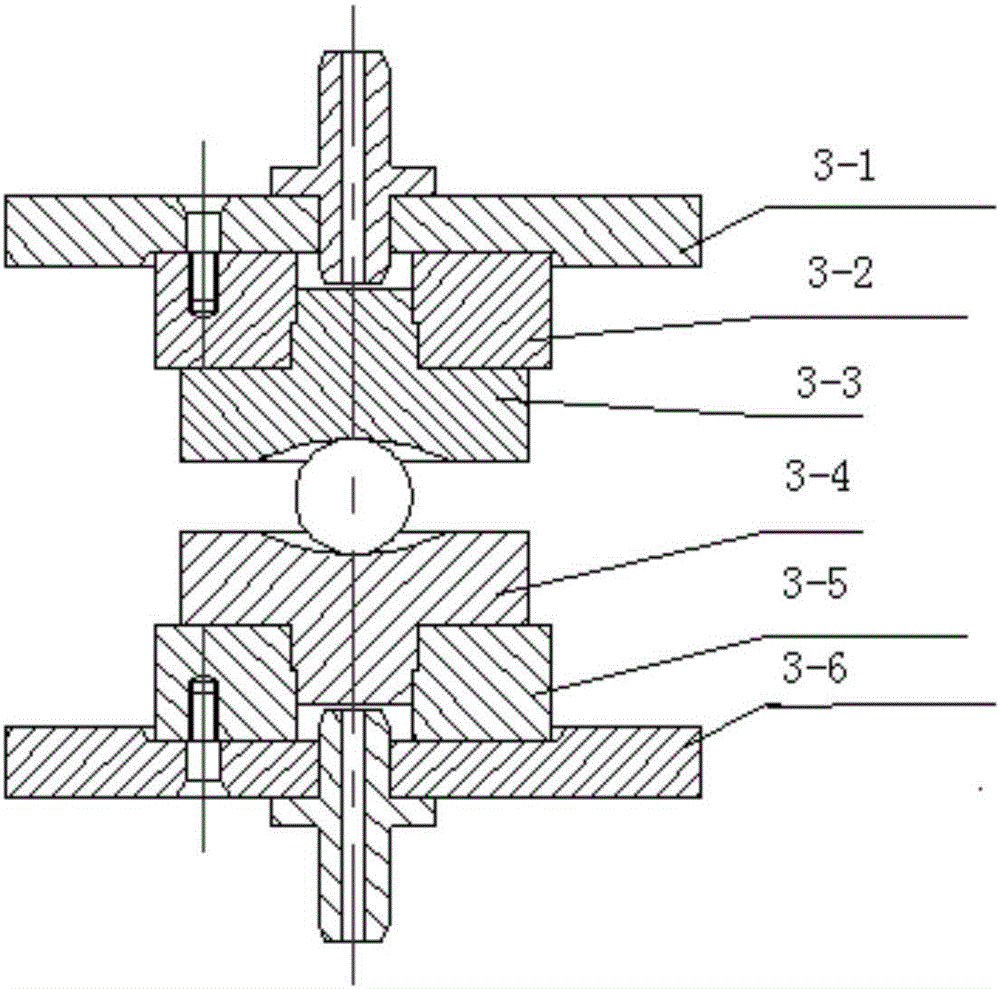

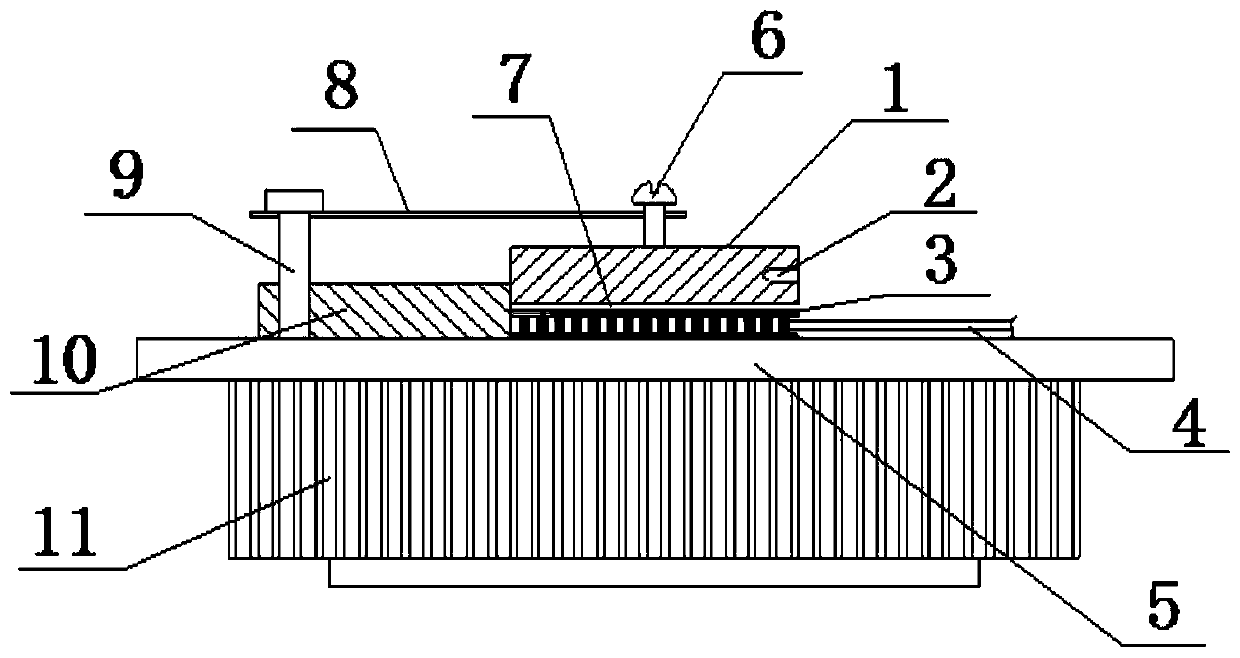

Test device for sealing property of rubber O-shaped ring under high pressure hydrogen environment

ActiveCN106706220AAvoid damageAvoid test failuresDetection of fluid at leakage pointHigh pressure hydrogenEngineering

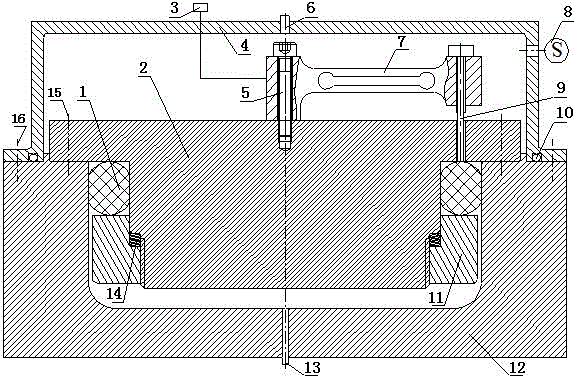

The invention discloses a test device for a sealing property of a rubber O-shaped ring under a high pressure hydrogen environment. The test device mainly comprises a to-be-tested rubber O-shaped ring, a gland, a signal processor, a protecting shell, a bolt, a tapping port, a cantilever type pressure sensor, a hydrogen sensor, a force transferring rod, an O-shaped sealing ring, a pressing ring, a base, a gas inlet / outlet, a gasket, an inner bolt and an outer bolt, wherein the pressing ring has a hollow annular structure; a test chamber is formed between the gland and the base and is sealed by the to-be-tested rubber O-shaped ring; the base is arranged as a drum with an opened upper part and a closed lower part; and the gas inlet / outlet is formed at the center of the bottom end of the base and is used for sucking and discharging the test gas. According to the invention, the measurement for the sealing contact stress and the hydrogen leakage volume of the rubber O-shaped ring under the high pressure hydrogen environment can be realized; the test for the sealing properties of the O-shaped sealing rings in different compression ratios can be realized; and the test device has the advantages of simple and convenient operation, economical effect and reliability.

Owner:SOUTH CHINA UNIV OF TECH

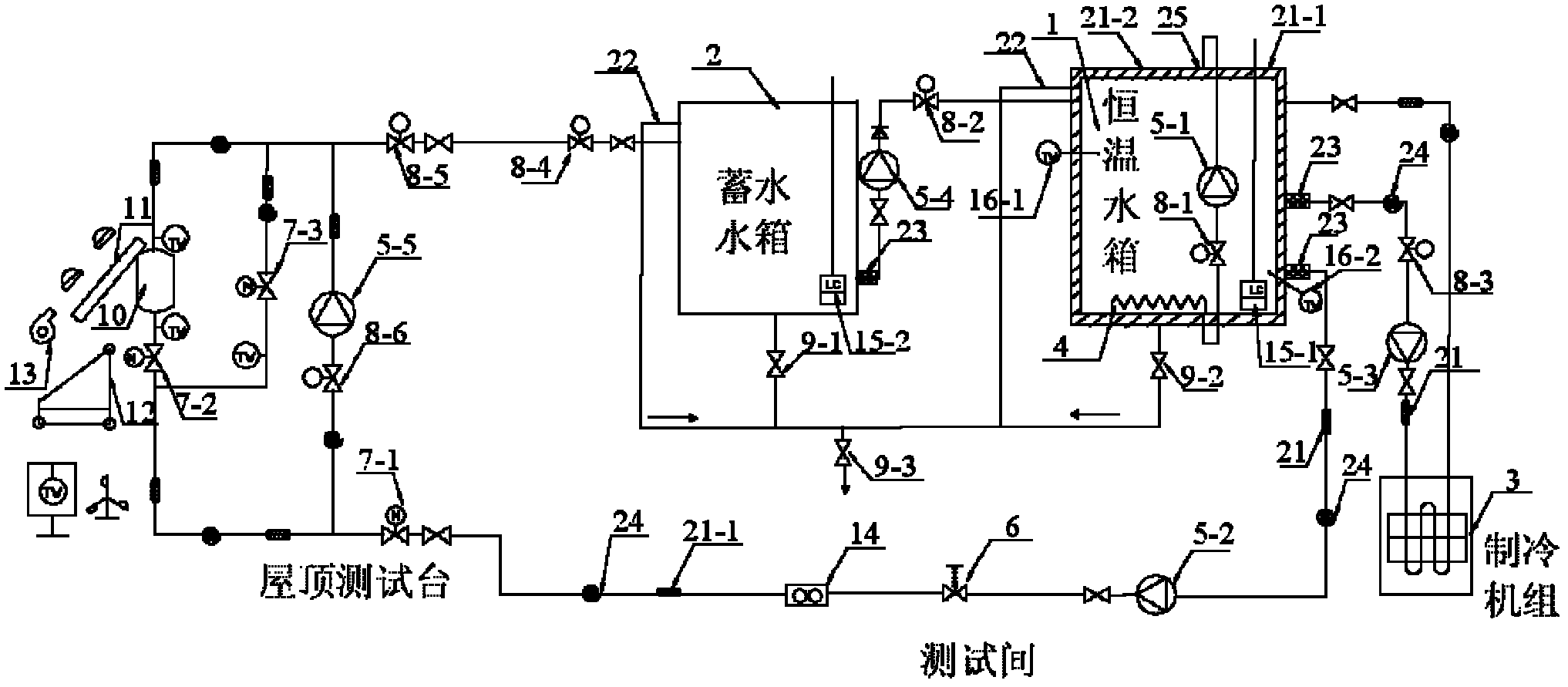

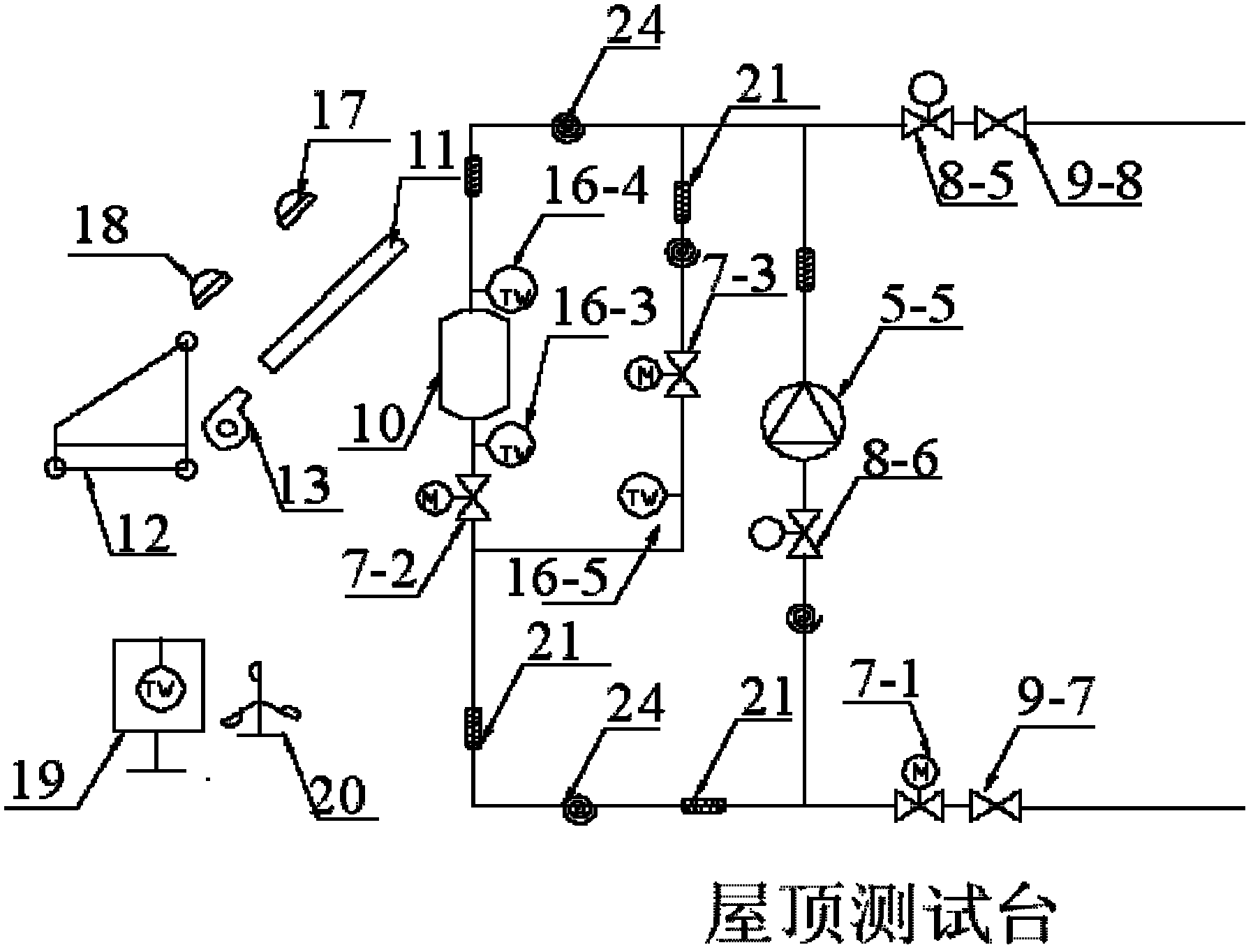

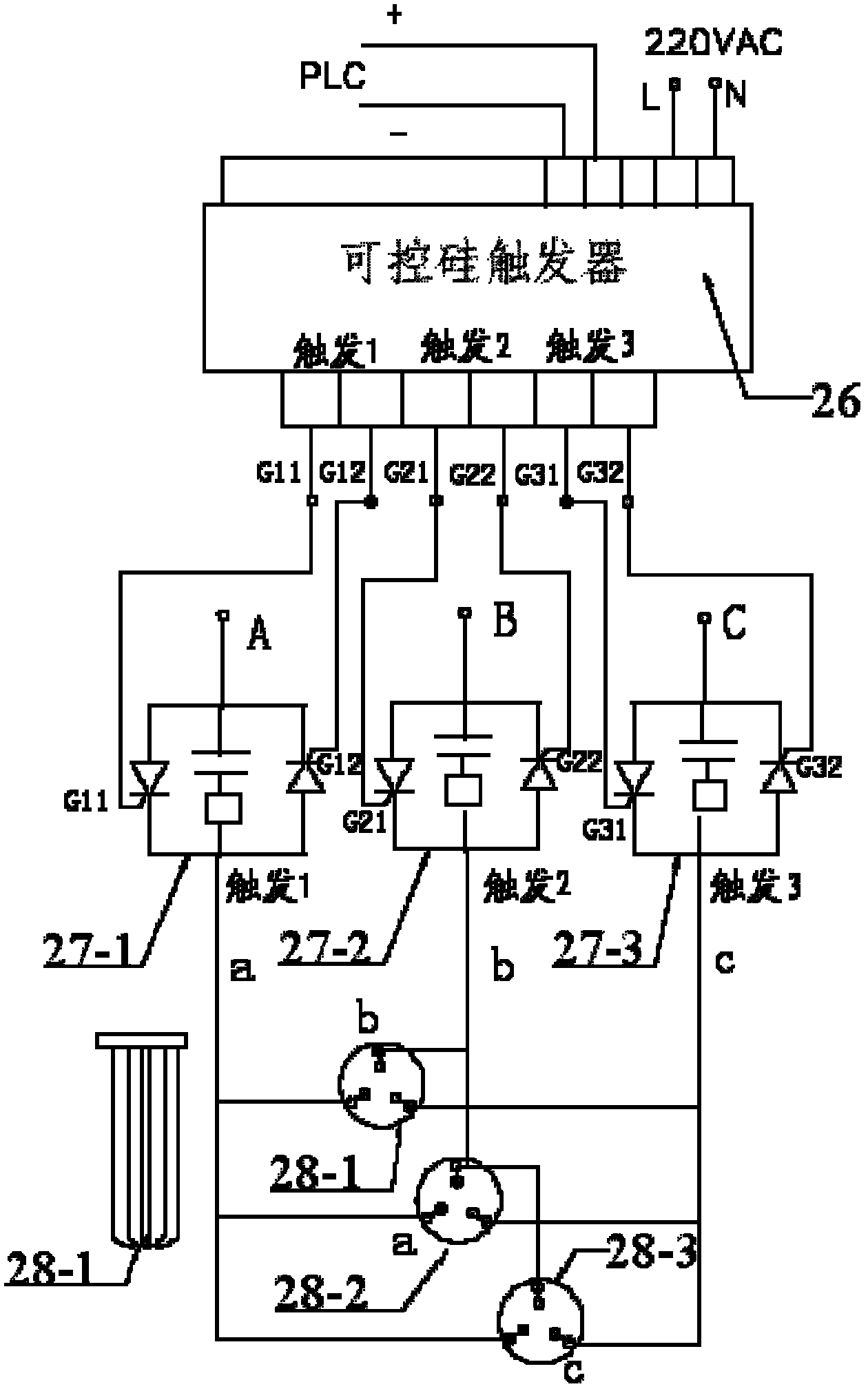

Thermal performance test system of solar water heater

InactiveCN102564783APrevent backflowRealize fully automatic intelligent controlStructural/machines measurementWater storageData acquisition

The invention discloses a thermal performance test system of a solar water heater. The thermal performance test system comprises a pipeline system, a test rack and a full-automatic intelligent control system. The pipeline system comprises a constant-temperature water tank (1), a refrigeration system connected with the constant-temperature water tank (1), a self-circulation system positioned outside the constant-temperature water tank (1), and an electric heating device arranged at the bottom of the constant-temperature water tank; the pipeline system is connected with a thermal storage water tank (10) in a test rack system of the solar water heater; and the pipeline system, the constant-temperature water tank and a water storage water tank form a loop. The full-automatic intelligent control system realizes data acquisition, sequential logic control and real-time regulation and control of temperature and flow by adopting a programmable controller (PLC).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

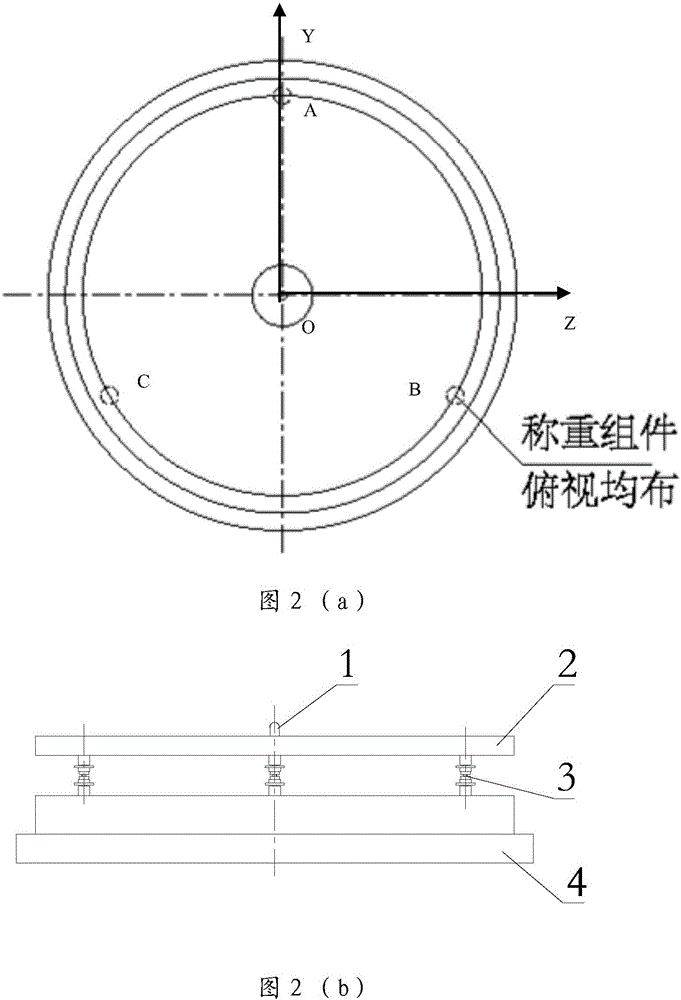

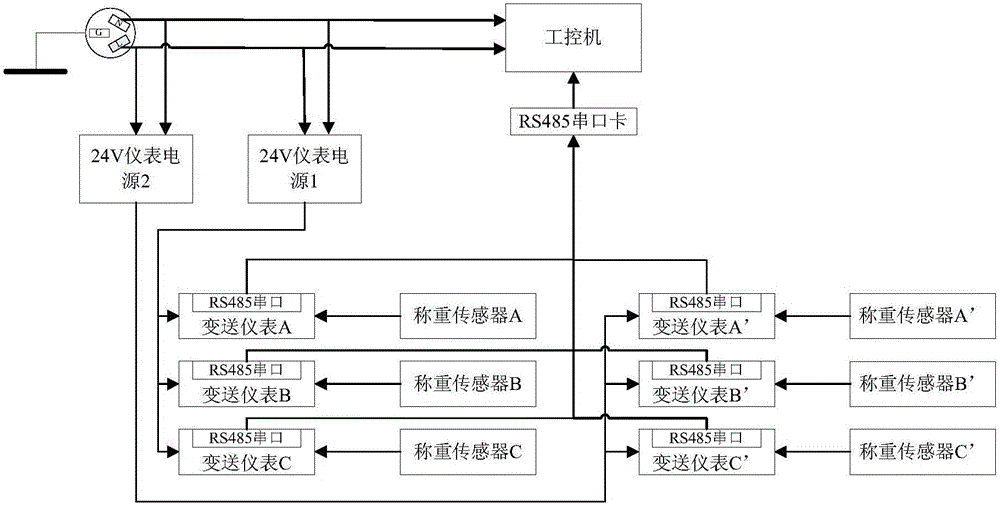

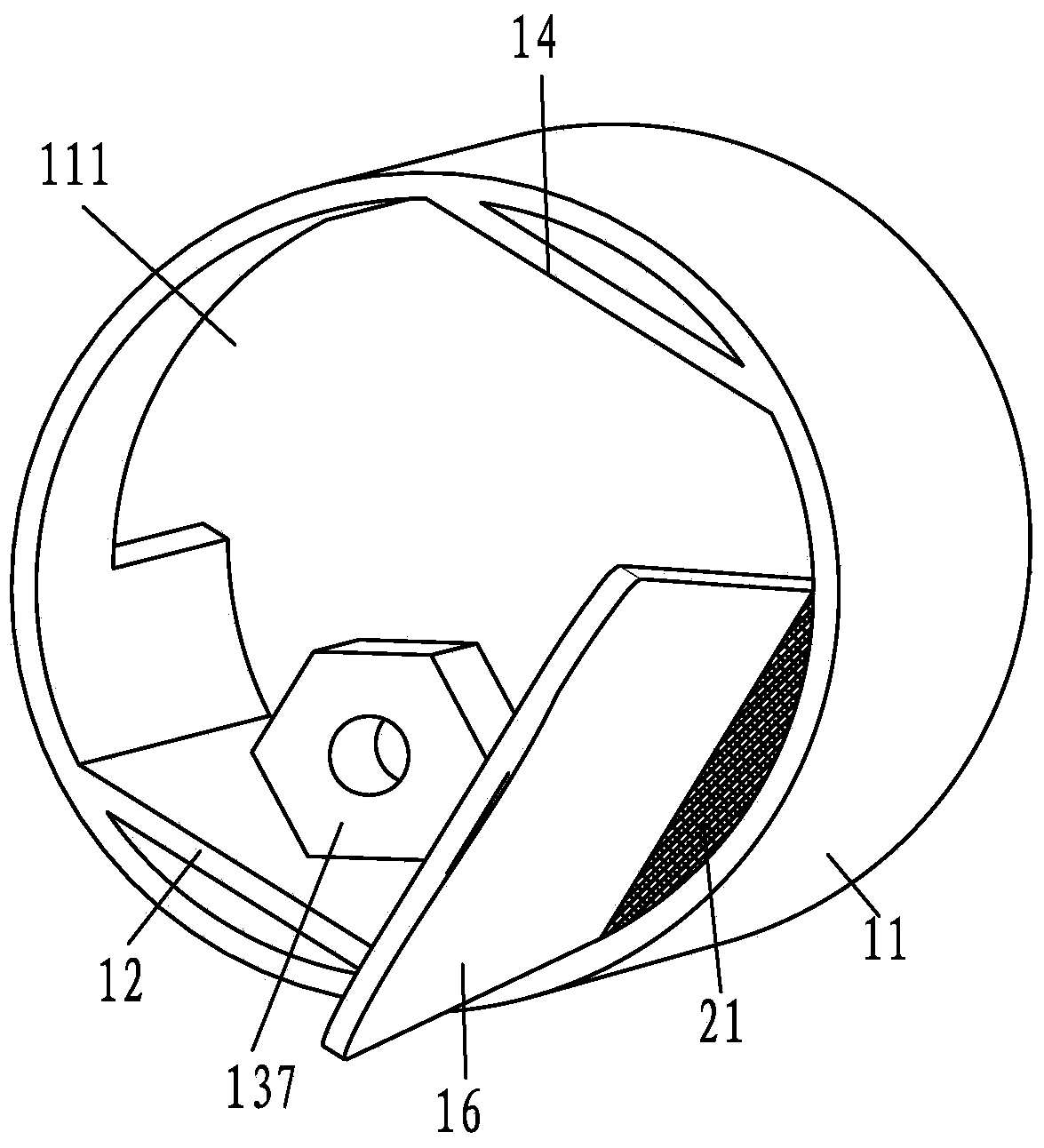

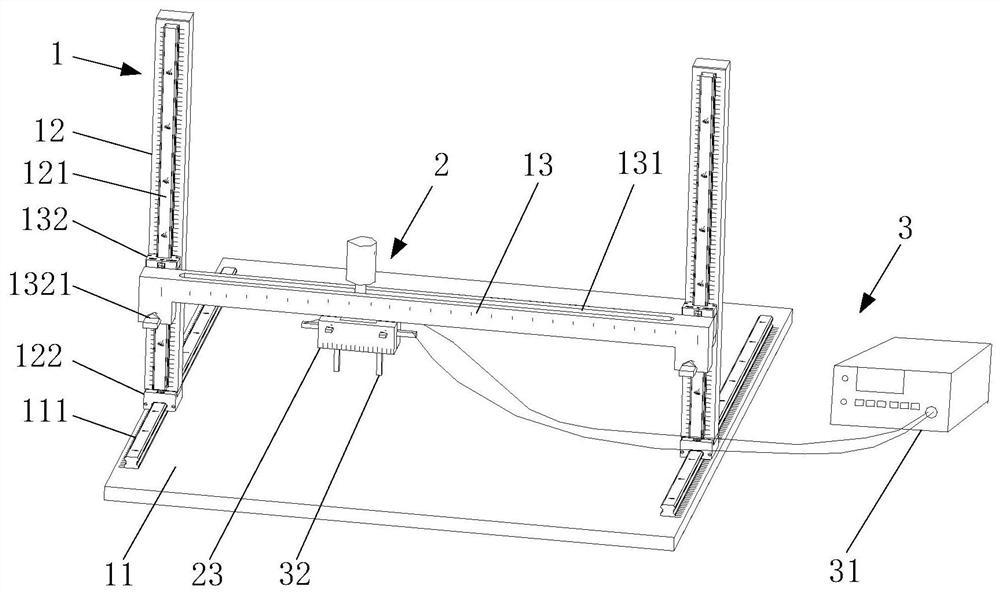

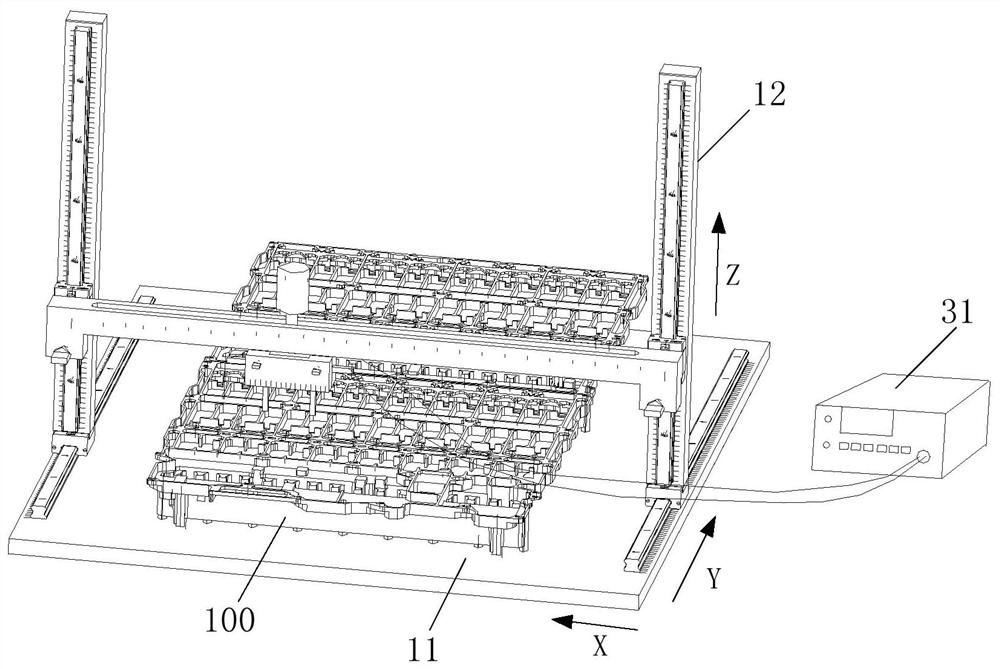

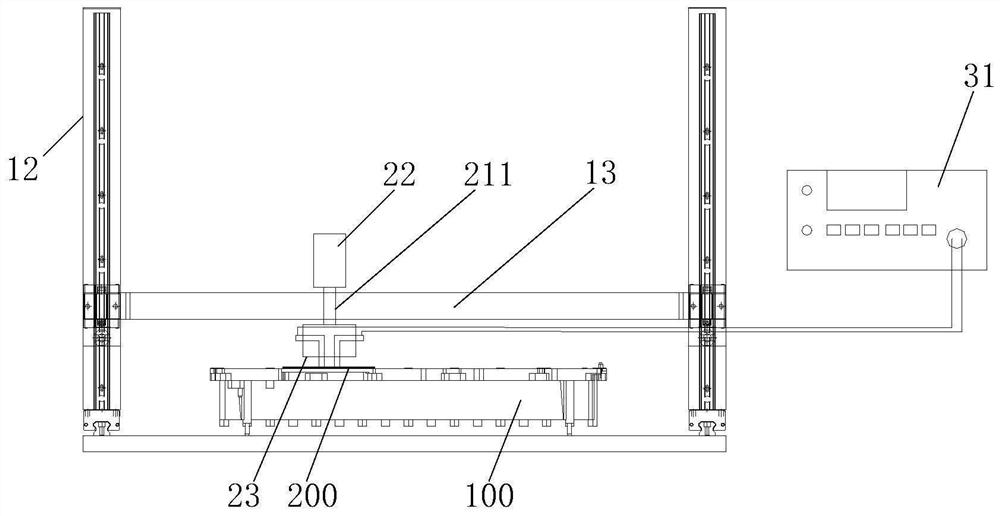

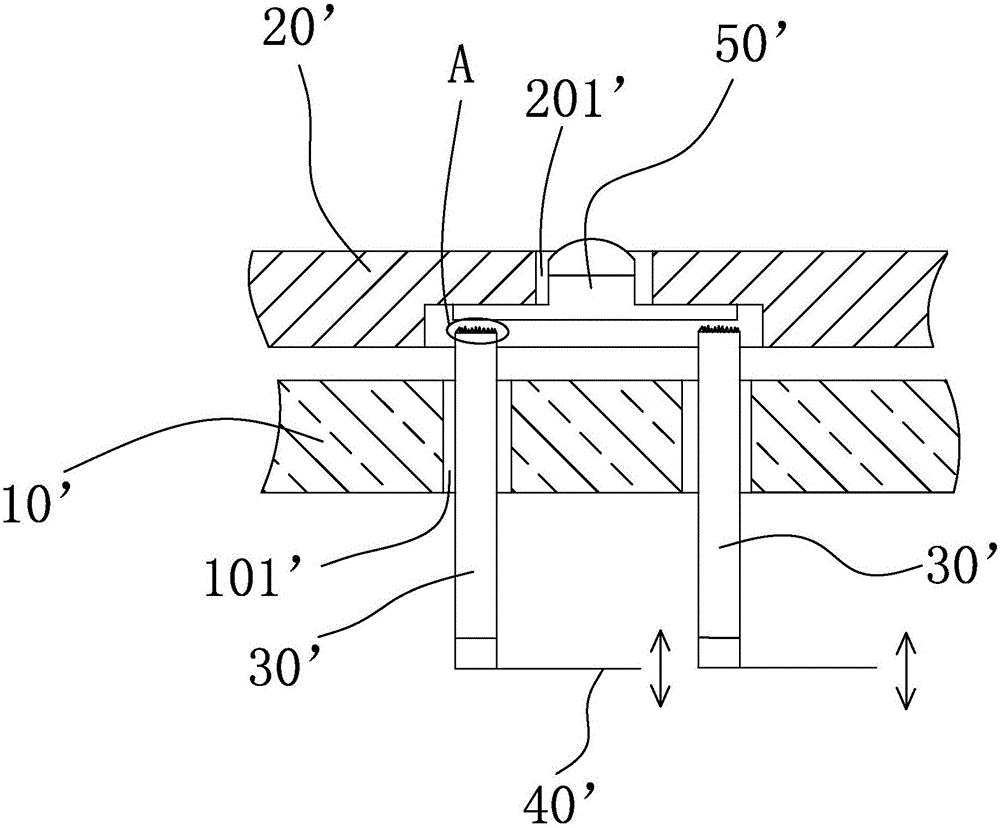

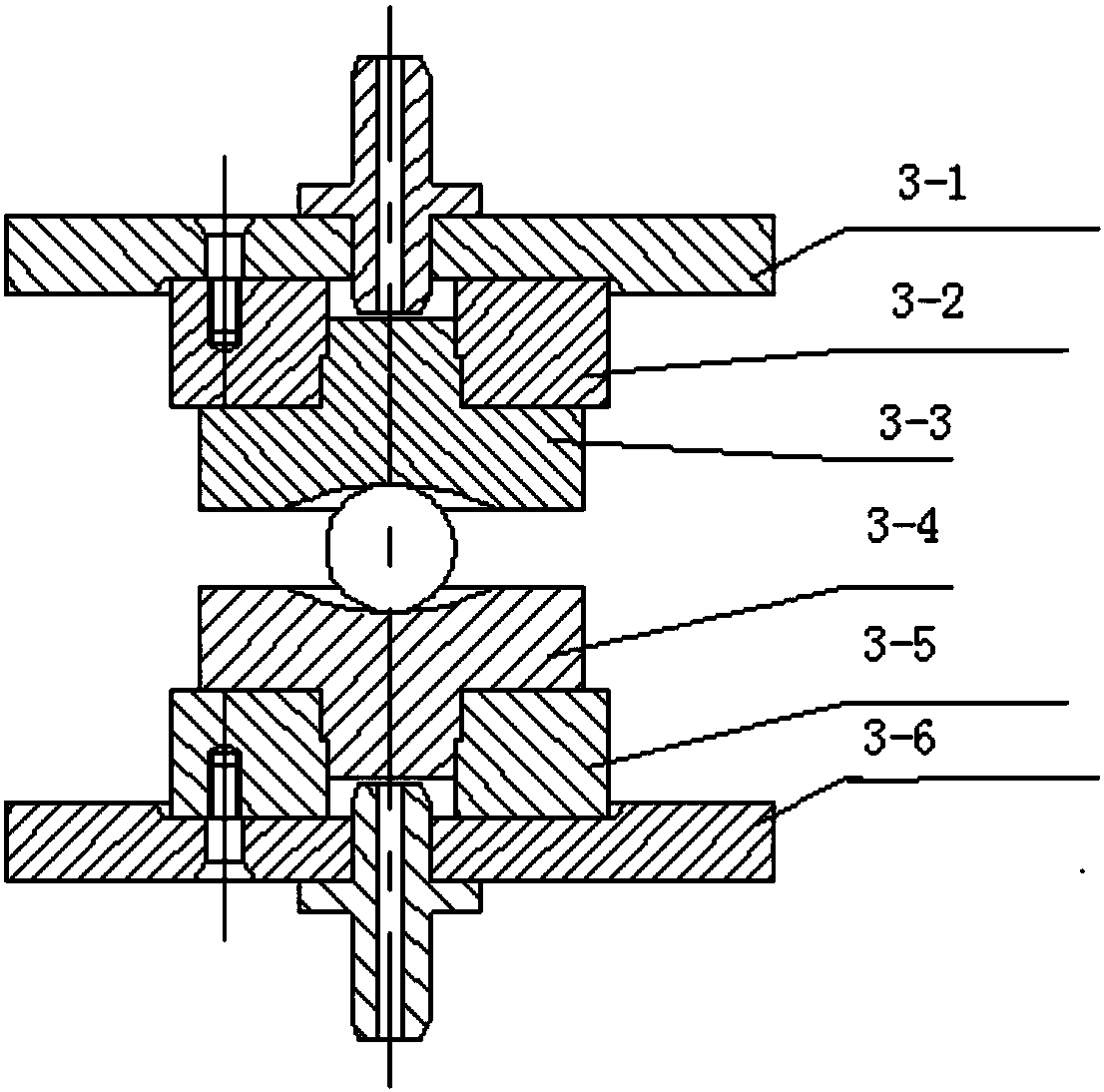

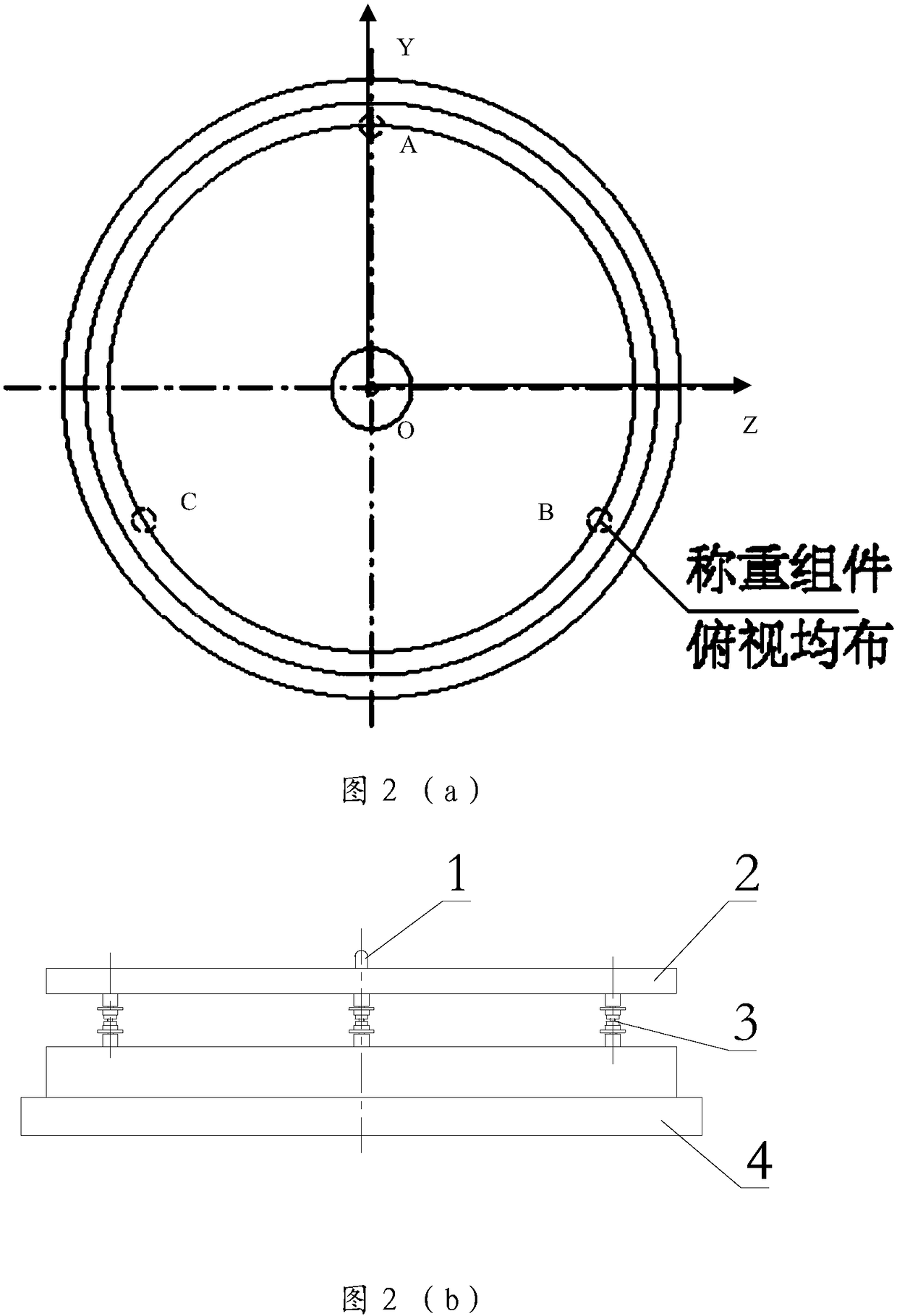

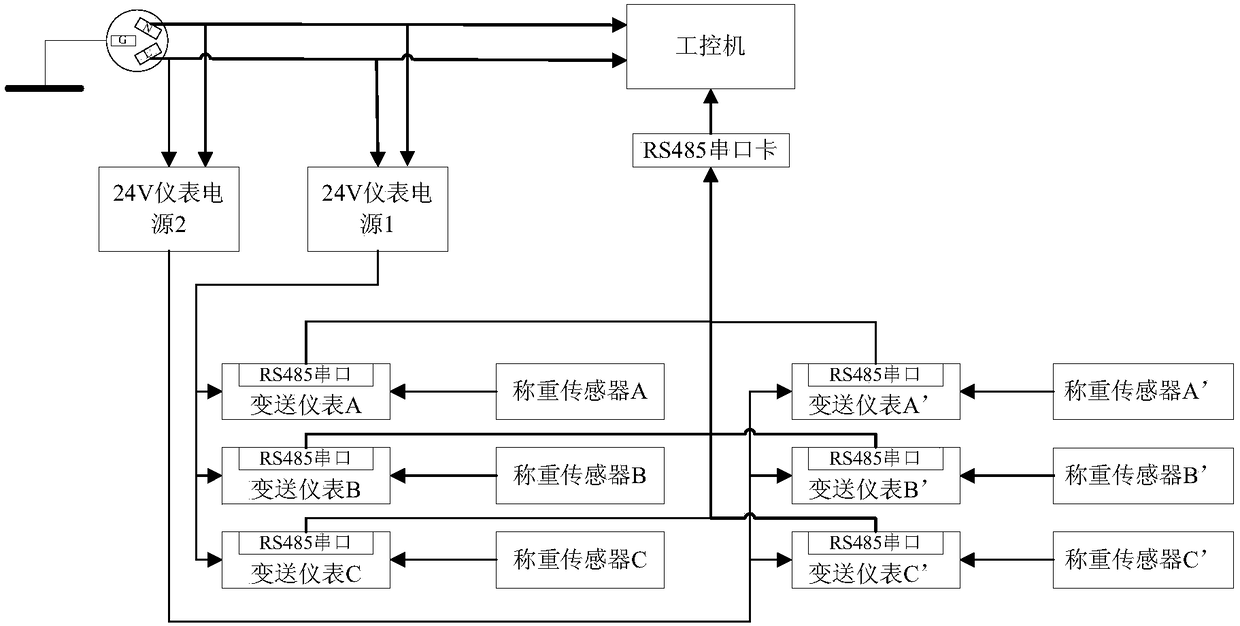

Mass and center three-point supporting redundancy measuring equipment

ActiveCN105806562AAvoid test failuresAvoid interruptionStatic/dynamic balance measurementWeighing apparatus testing/calibrationTest efficiencyLoad cell

The invention relates to mass and center three-point supporting redundancy measuring equipment.The mass and center three-point supporting redundancy measuring equipment comprises three weighing assemblies, a center tray and a base.The center tray is used for carrying a tested object and provided with a positioning part for matched positioning of the tested object.The base supports a mass and center three-point supporting redundancy measuring equipment body.The three weighing assemblies are located between the center tray and the base and are evenly distributed in the circumferential direction.Each weighing assembly comprises an auxiliary weighing sensor, a sphere alignment assembly and a main weighing sensor which are arranged from top to bottom, wherein the auxiliary weighing sensor is stacked on the main weighing sensor through the sphere alignment assembly.According to the measuring equipment, test failures or test interruption caused by failures of weighing sensors is avoided in the process of a three-point supporting method, the other set of sensors can be used for reading numerical values if a certain sensor in one set of sensors breaks down, the phenomenon that the test process needs to be interrupted due to the failure of a certain sensor, and consequently repetition of the processes such as recalibration and reassembling is caused can be avoided, and the testing efficiency is improved.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

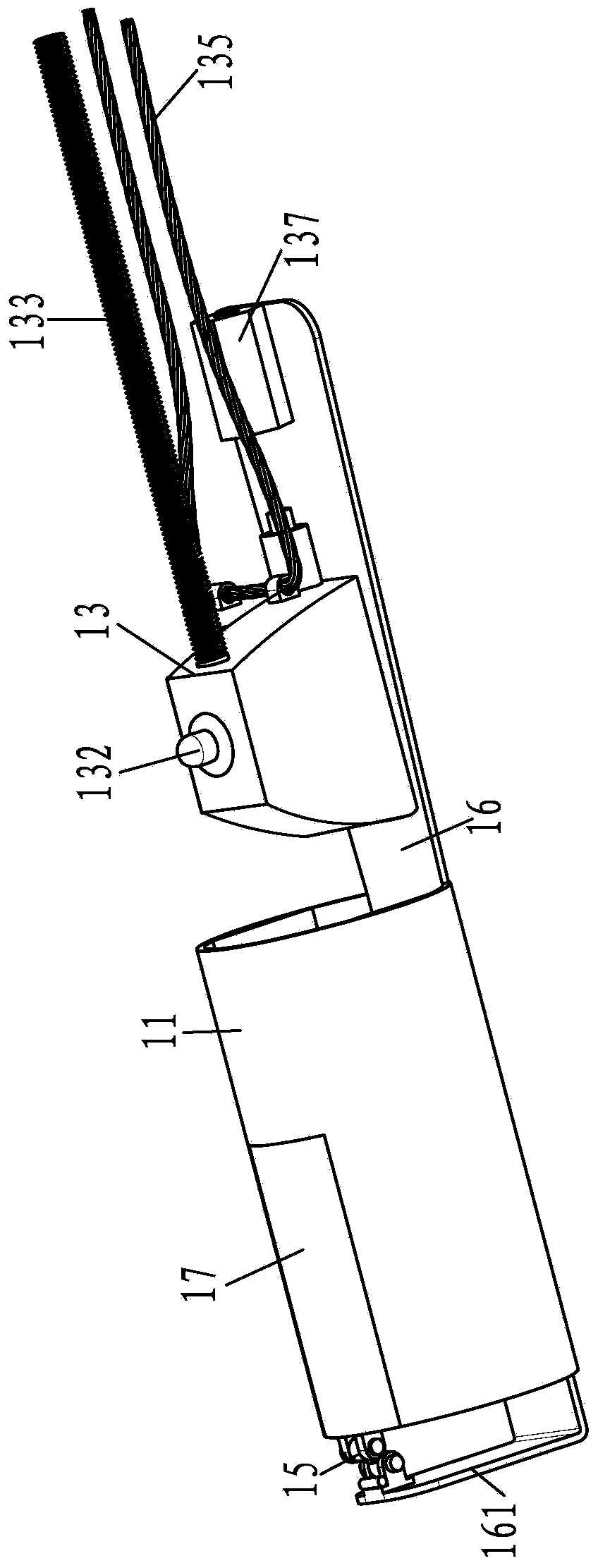

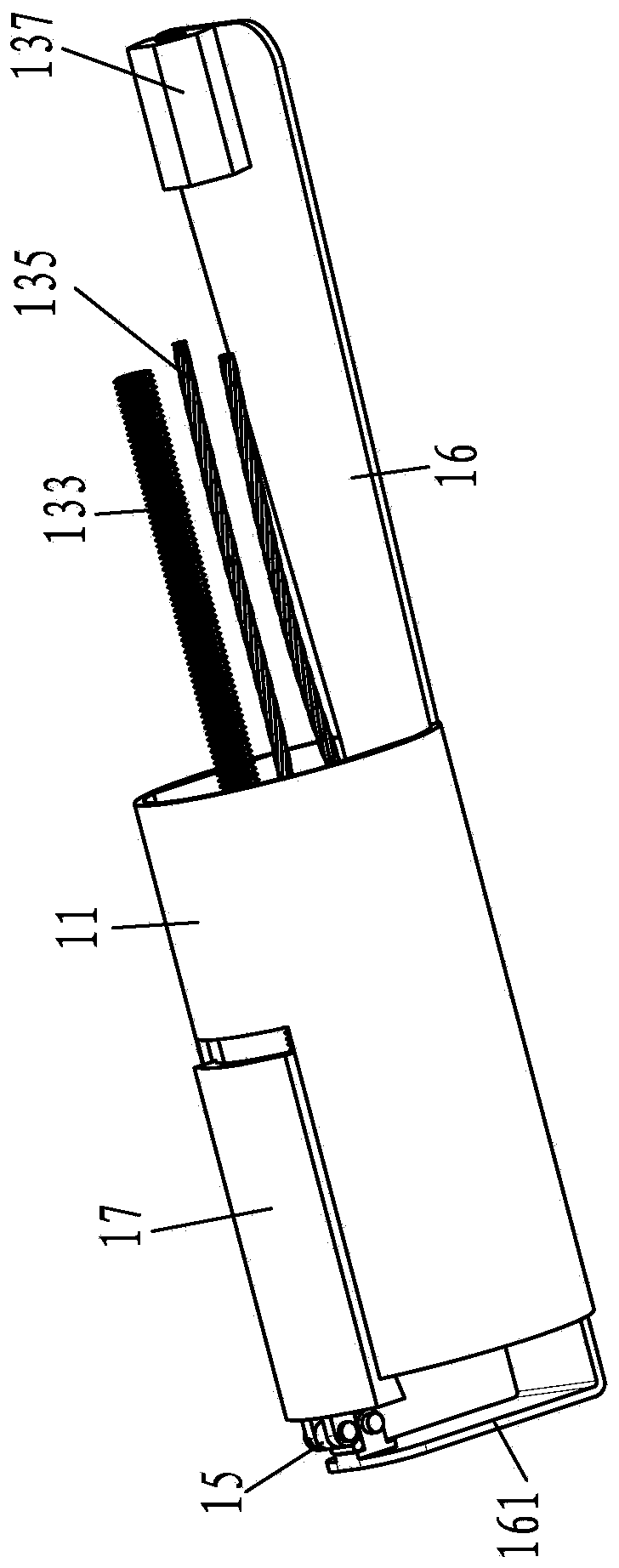

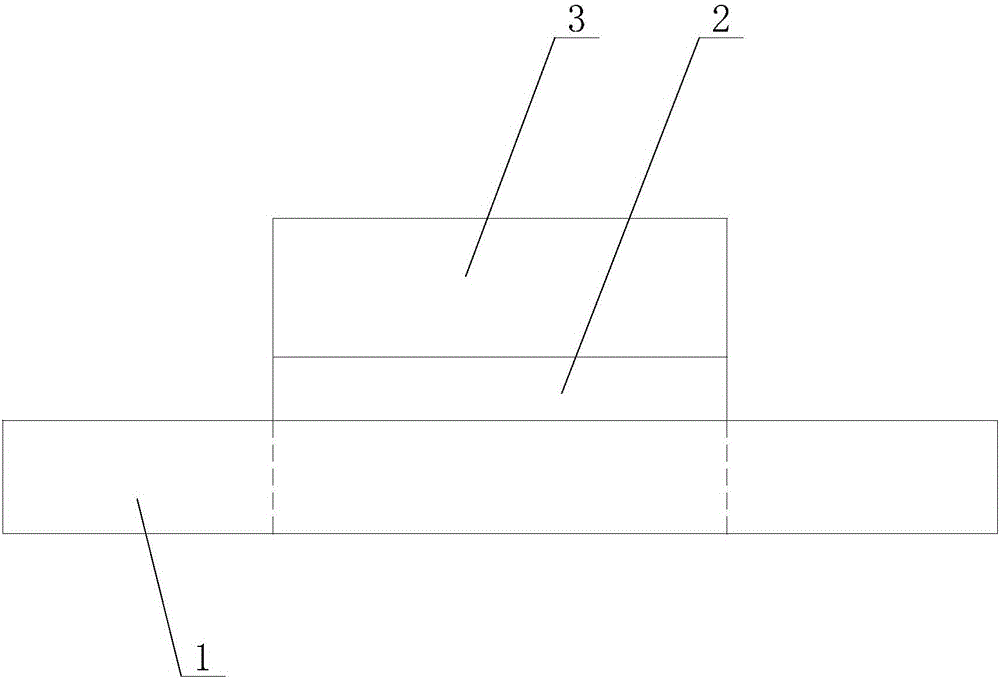

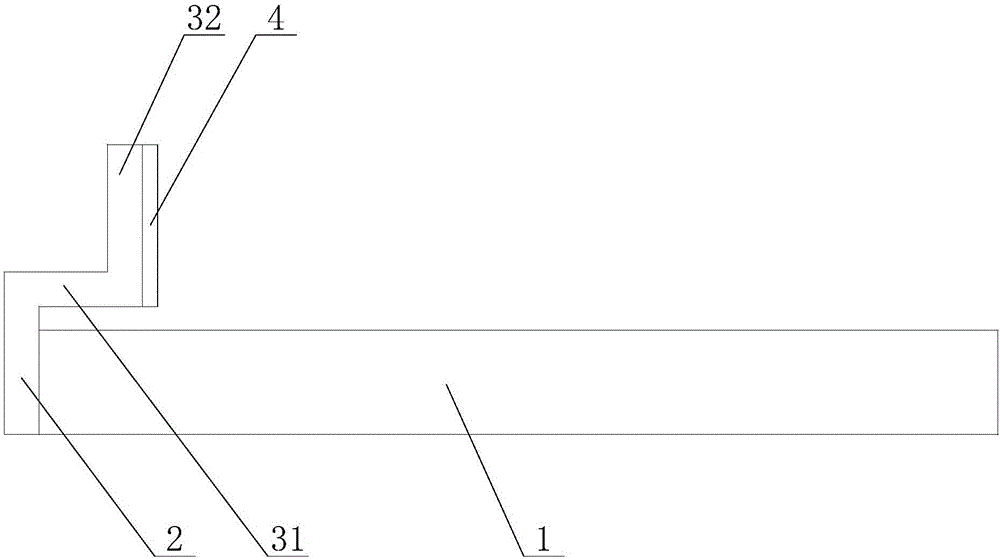

Clamping fixing device for compressing metal sheet

ActiveCN107727489ARealize the quadratic constraintAvoid test failuresStrength propertiesTest sampleMetallic materials

The invention relates to a clamping fixing device for compressing a metal sheet. The device utilizes a base to position and fix clamping blocks and a test sample; vertical trapezoid grooves are processed on contact surfaces of the clamping blocks and the test sample; the gauge length at the width center of the test sample is visible in the middle through slots of the clamping blocks; guiding rodsare arranged on diagonal positions of the clamping blocks so as to align the two clamping blocks; eight full-thread hex head screws are penetrated into the first clamping block and out from the secondclamping block; gaskets and nuts are arranged at the tail ends of the bolts; uniform symmetrical pressure is applied to the clamping blocks, so that the test sample is prevented from being unstable;four half-thread hex head screws are penetrated into four lug bosses on the base, are inserted into the blind holes on the two sides of the middle part of the clamping blocks and are twisted; the clamping blocks are used for clamping the test sample for the second time and supplying effective support, so that the test sample is prevented from bending damage. The clamp is designed according to therequirement of metallic material compression test standard, is convenient and easy in operation and can be applied to the standard compression tests for various metal sheets in various thicknesses.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Efficient interface testing method for Ethernet switch

InactiveCN105337806ADoes not delay the development-to-production cycleSimple configurationNetworks interconnectionEmbedded systemLocal area network

The invention discloses an efficient interface testing method for an Ethernet switch. The method comprises the following steps: 1) the interface quantity of the switch is defined as n, and the interface numbers are defined as E1, E2, E3...En; 2) every two interfaces belong to a VLAN (Virtual Local Area Network), namely, E1 and E2 belong to a VLAN1, E3 and E4 belong to a VLAN2, E5 and E6 belong to a VLAN3, E7 and E8 belong to a VLAN4, and the like, E(n-1) and En belong to a VLAN(n / 2); 3) E2 and E3, E4 and E5, E6 and E7...E(n-2) and E(n-1) are respectively connected with each other by a cable in sequence; 4) except E1 and En, each two of all the rest interfaces are subjected to loopback in sequence, and E1 and En are connected with an Ethernet testing instrument to be tested. As nearly all large switches support the interface VLAN division, the method has the beneficial effects that the configuration is simple, and the operation is convenient; under the condition that the cost of the testing instrument is not increased, the testing time can be greatly saved.

Owner:武汉微创光电股份有限公司

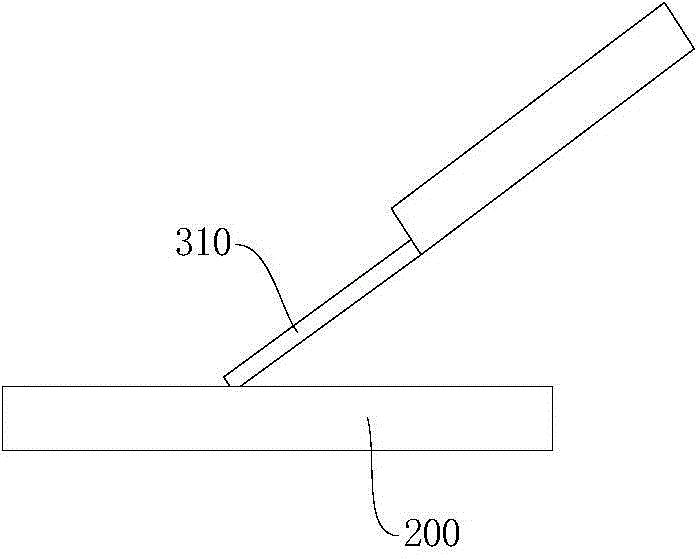

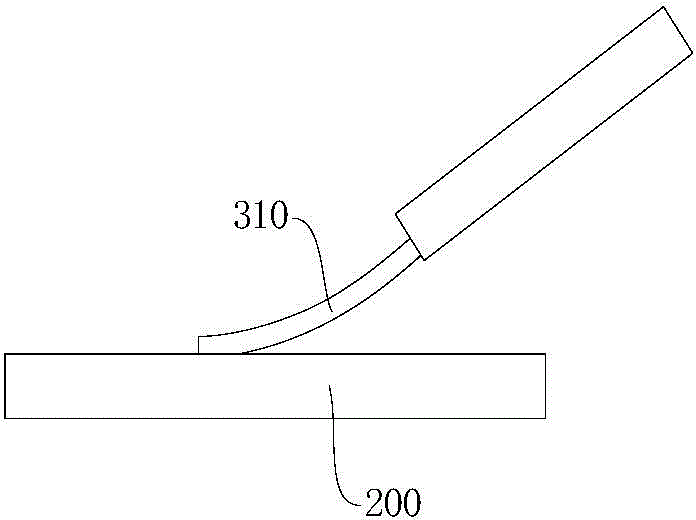

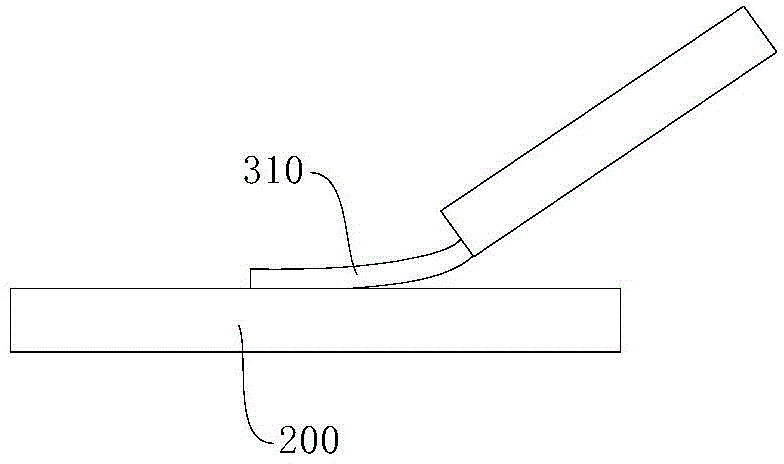

Microprobe and manufacturing method thereof

ActiveCN104931741AExtended service lifeHigh strengthTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamTest sample

The invention provides a microprobe which comprises a body supporting part and a testing probe. The testing probe comprises a testing cantilever beam. The microprobe further comprises a side wing which is fixedly connected with body supporting part. The testing cantilever beam and the side wing are in an integral structure. The microprobe can test the dimension precision of the cantilever beam and a pressure monitoring cantilever beam through the side wing which is fixedly connected with the body supporting part, thereby ensuring elasticity index uniformity of the testing cantilever beam and the pressure monitoring cantilever beam of the microprobe. Furthermore, a pressure monitoring probe can be used for monitoring contact between the testing probe and a tested sample, thereby preventing a testing failure caused by defects such as projection, small hole and stain on the tested sample.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

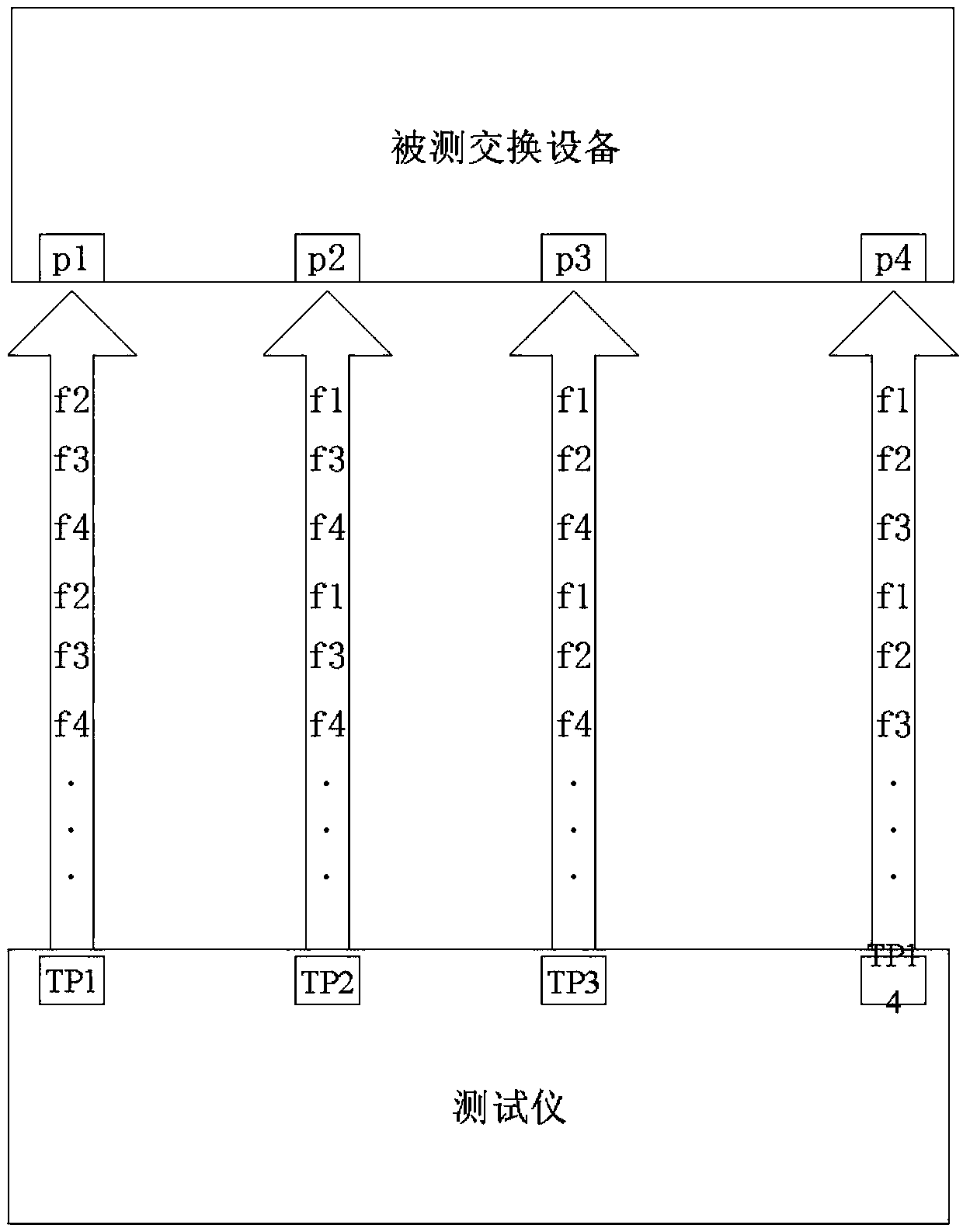

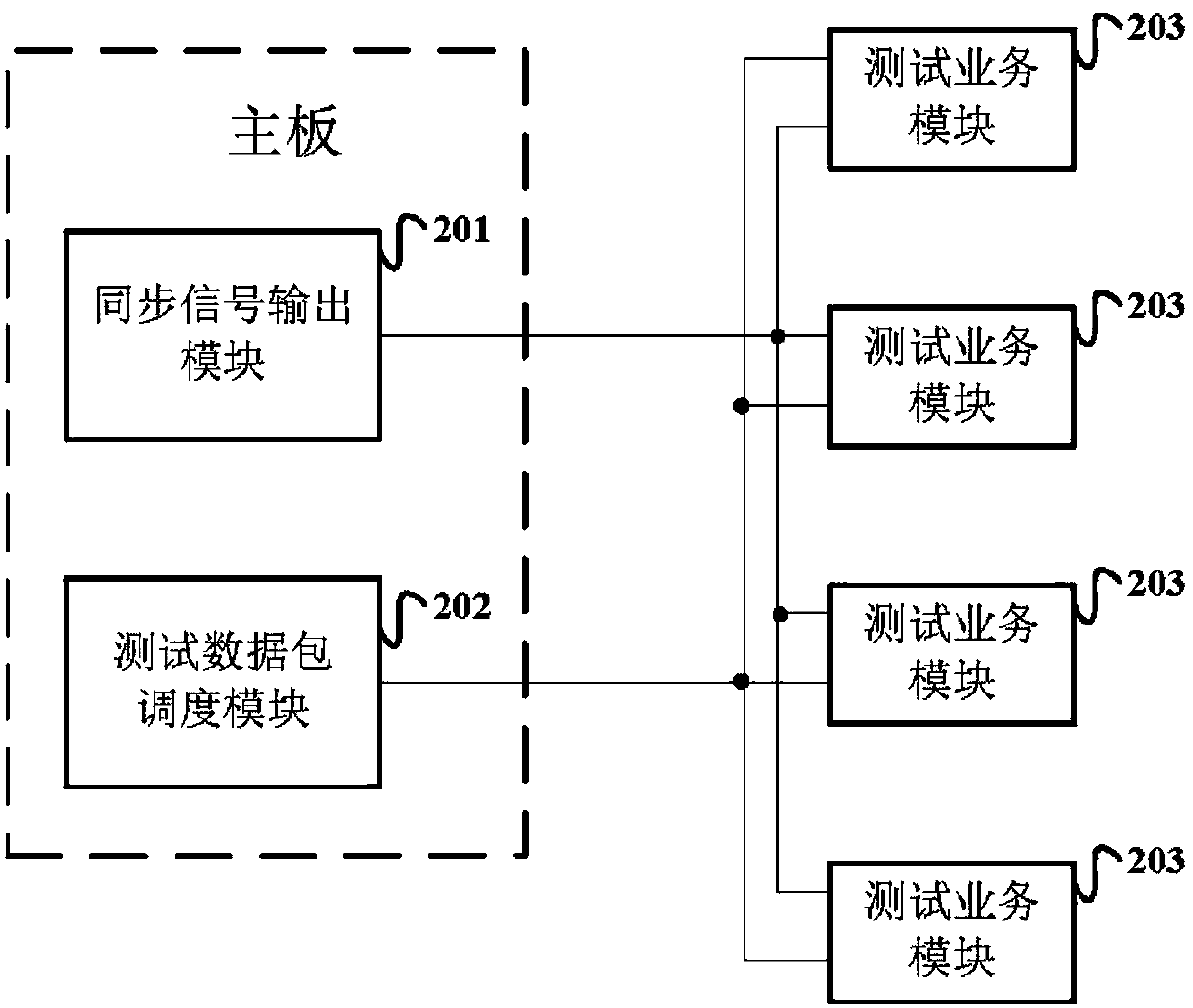

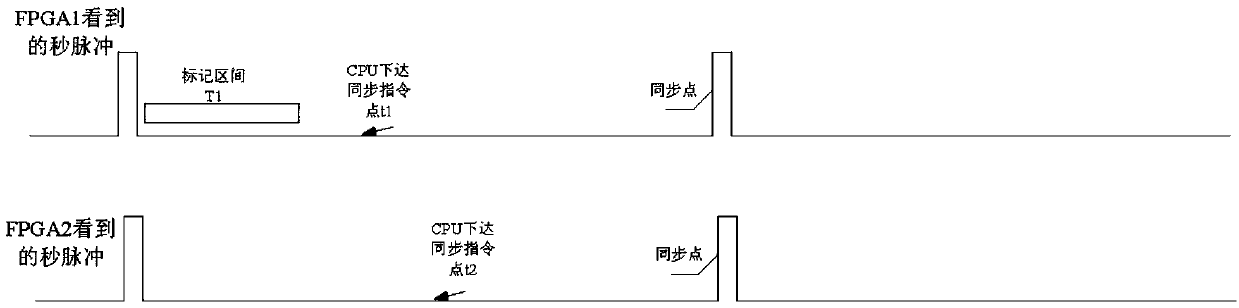

Tester and Ethernet test method of multiport tested device

ActiveCN107864072AAvoid test failuresAvoider exceptionData switching networksNetwork packetTester device

The invention discloses a tester and an Ethernet test method of a multiport tested device. The method comprises the following steps: the tester schedules a destination port which is about to send a test data packet in ports connected with the tested device according to the following principle: no more than one test data packet of the ports is sent to the same destination port at the same moment; each port sends the test data packet to all ports excluding the port connected with the present port of the tested device in a polling manner; and the tester controls the ports to send the test data packets synchronously according to the scheduling result. By application of the Ethernet test method disclosed by the invention, the situation that a plurality of ports send flow to a certain destination port at the same time, resulting in test failure or abnormality, is avoided.

Owner:北京信而泰科技股份有限公司

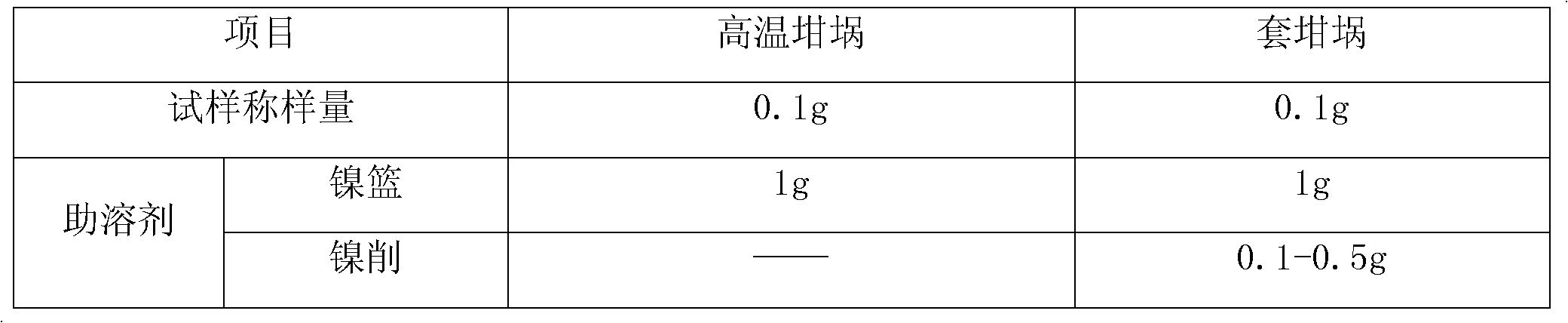

Method for detecting hydrogen, oxygen and nitrogen in titanium sponge

The invention belongs to the technical field of titanium sponge detection, and particularly relates to a method for detecting hydrogen, oxygen and nitrogen in titanium sponge. The invention solves the technical problem by providing the method for detecting hydrogen, oxygen and nitrogen in the titanium sponge, and the method has stable detection result. The method for detecting hydrogen, oxygen and nitrogen in the titanium sponge takes a graphite sleeve crucible as a sample container. As the invention takes the graphite sleeve crucible as the sample container for melting the titanium sponge for detection, the experiment failure caused by the damage of the sample container is effectively avoided, the detection efficiency is improved, and the detecting accuracy is improved at the same time.

Owner:PANZHIHUA GANGCHENG GROUP

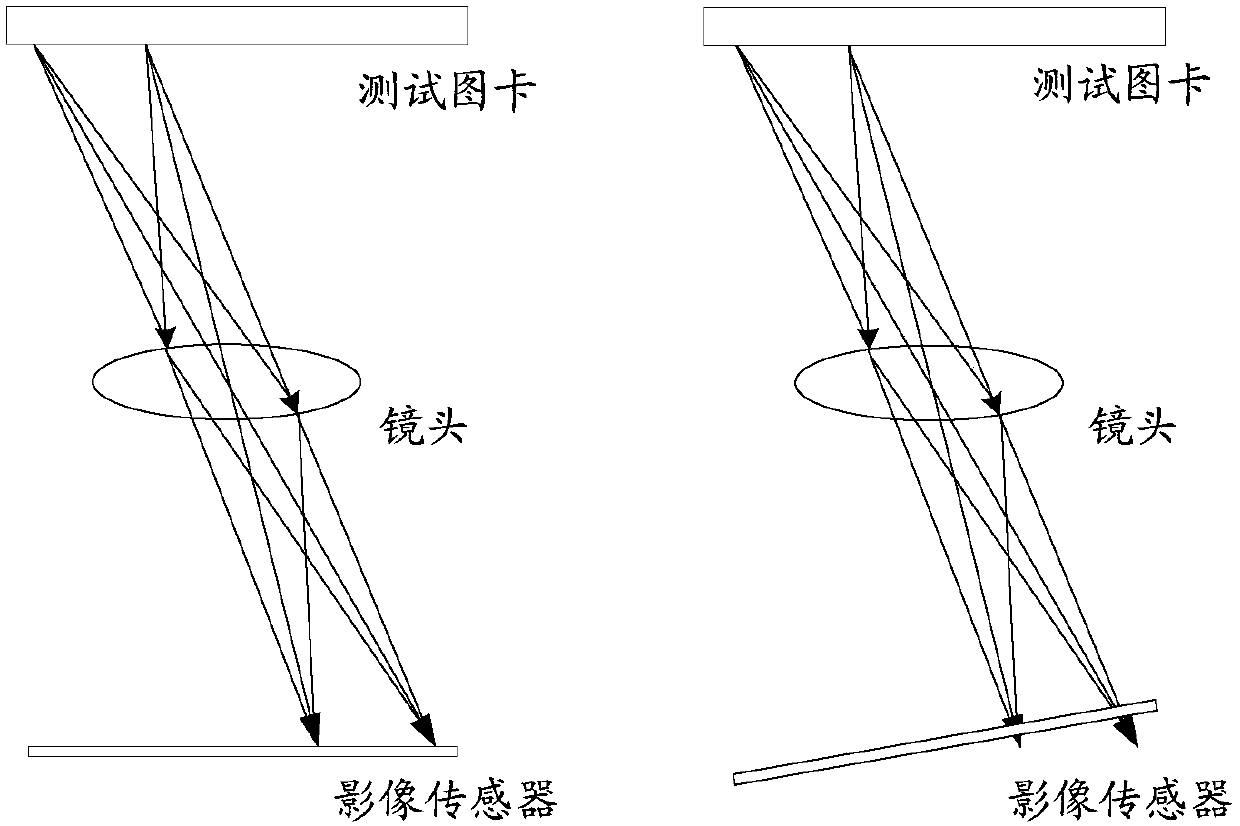

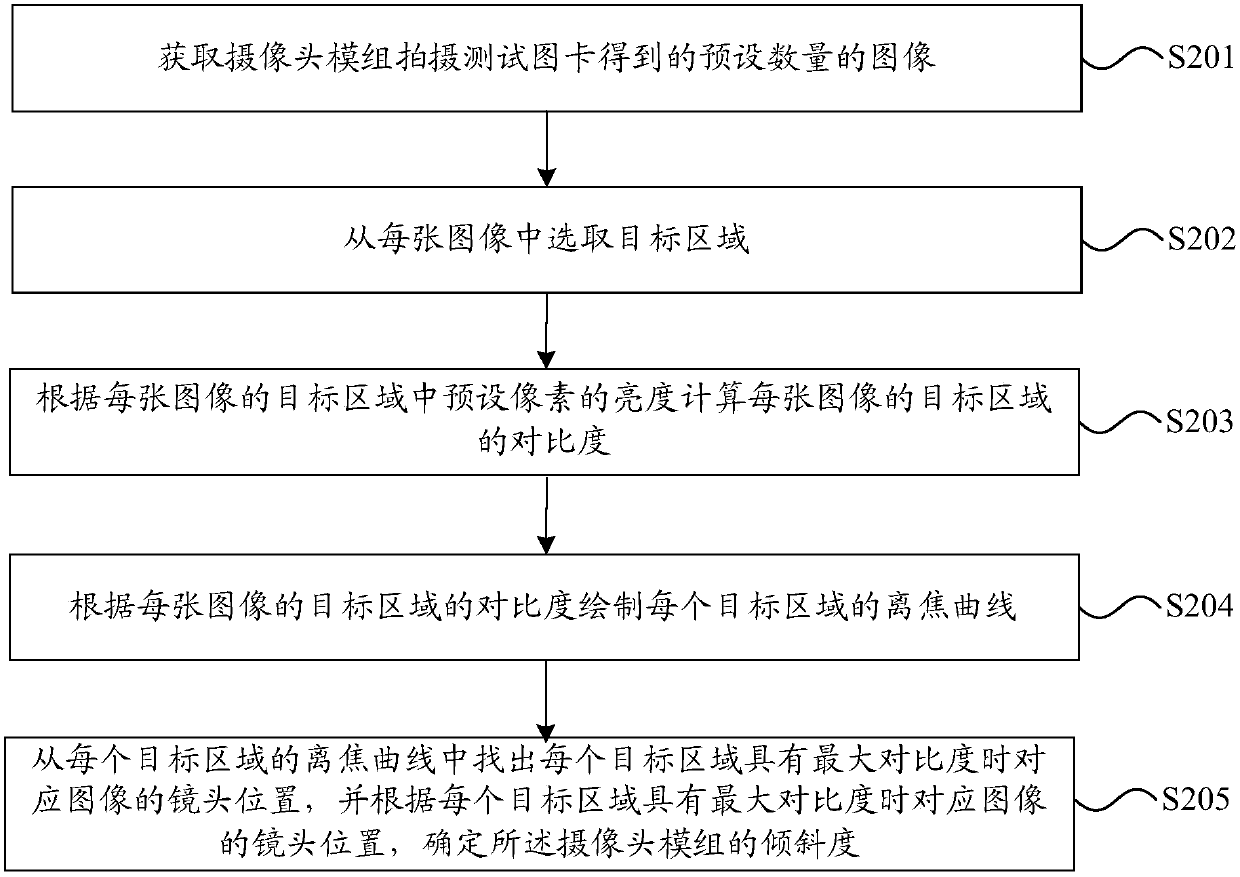

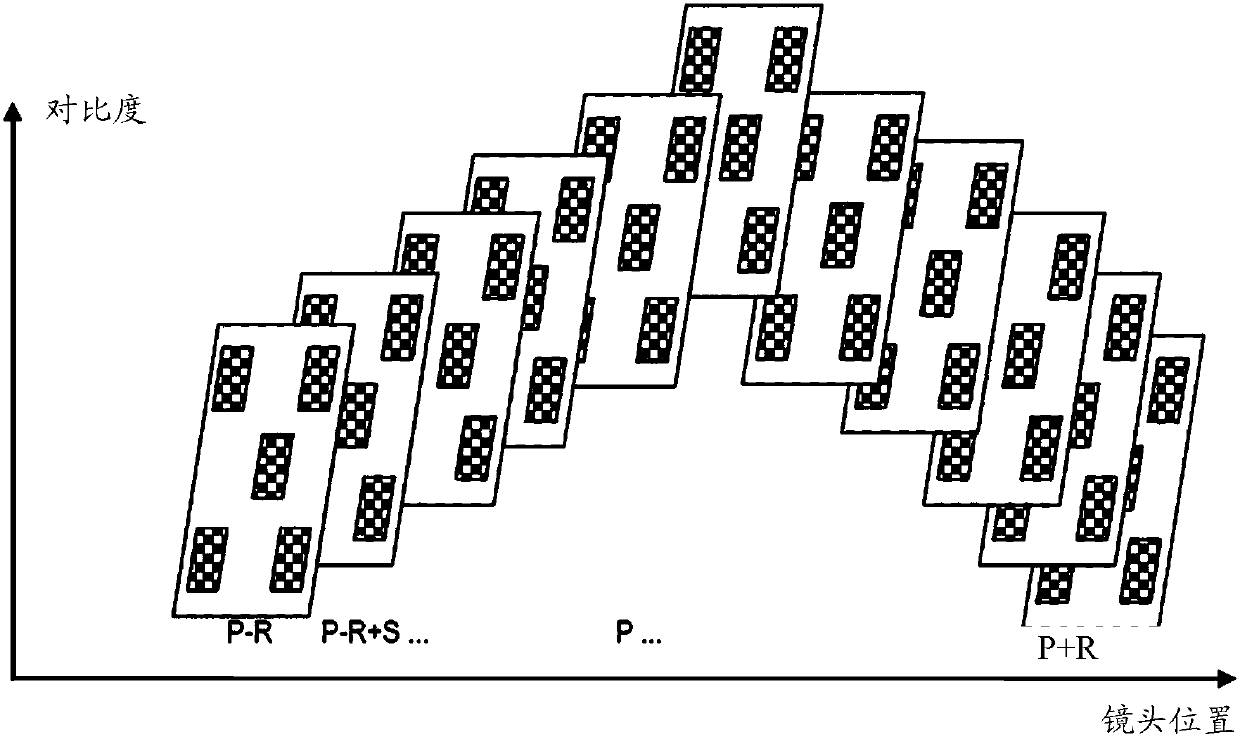

Method and device for testing tilt of camera module

ActiveCN107920246AWide range of test scenariosAvoid mistakes or test failuresTelevision systemsTest sceneCamera module

The embodiment of the invention discloses a method and device for testing the tilt of a camera module. The method for testing the tilt comprises the following steps: obtaining a preset number of images obtained by the camera module by shooting a test picture card; selecting a target area from each image; calculating a contrast ratio of the target area of each image according to the brightness of apreset pixel in the target area of each image; drawing a defocus curve of each target area according to the contrast ratio of the target area of each image; and finding a lens position of corresponding to the image when each target area has the maximum contrast ratio from the defocus curve of each target area, and determining the tilt of the camera module according to the lens position of corresponding to the image when each target area has the maximum contrast ratio. The method provided by the embodiment of the invention is applied to wide test scenes and can improve the accuracy and stability of the test.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

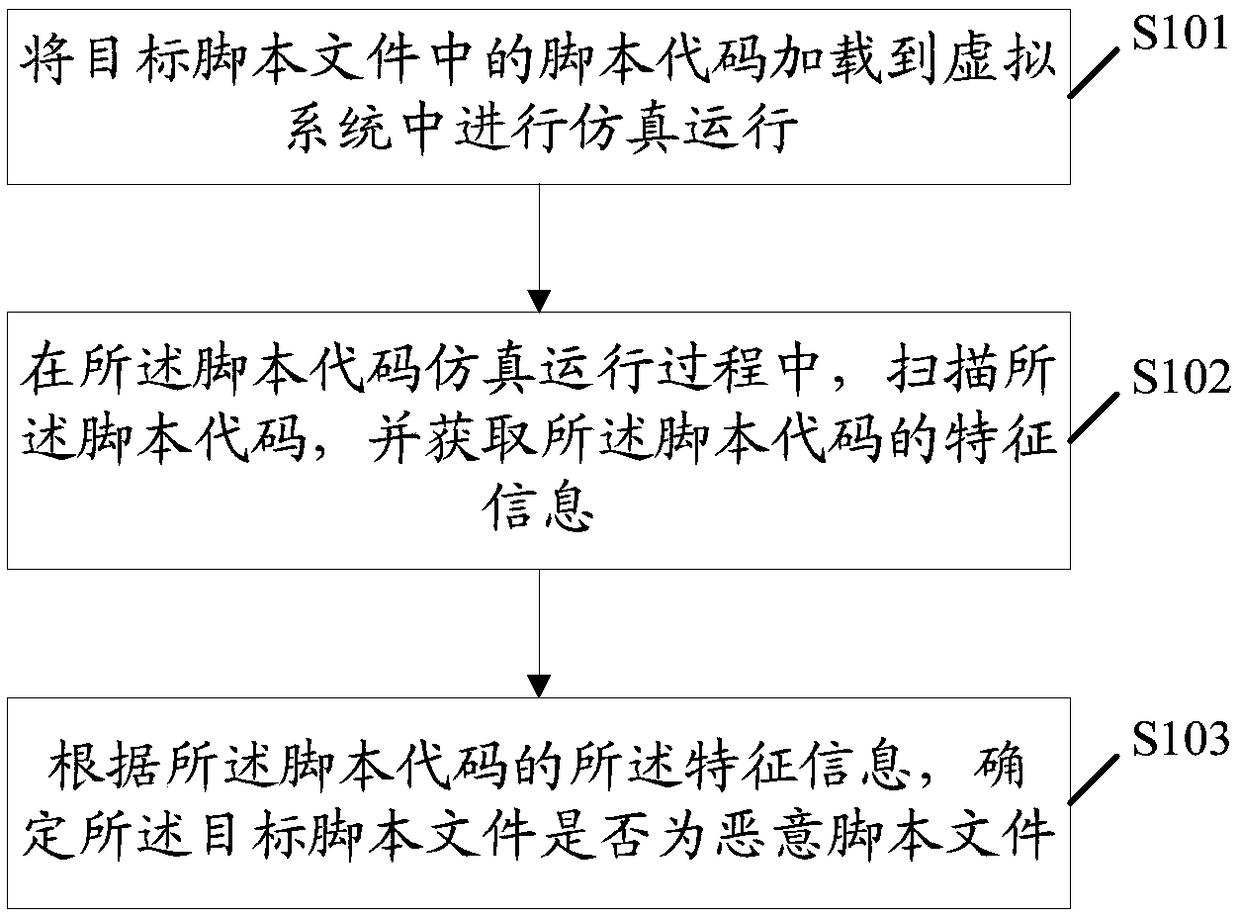

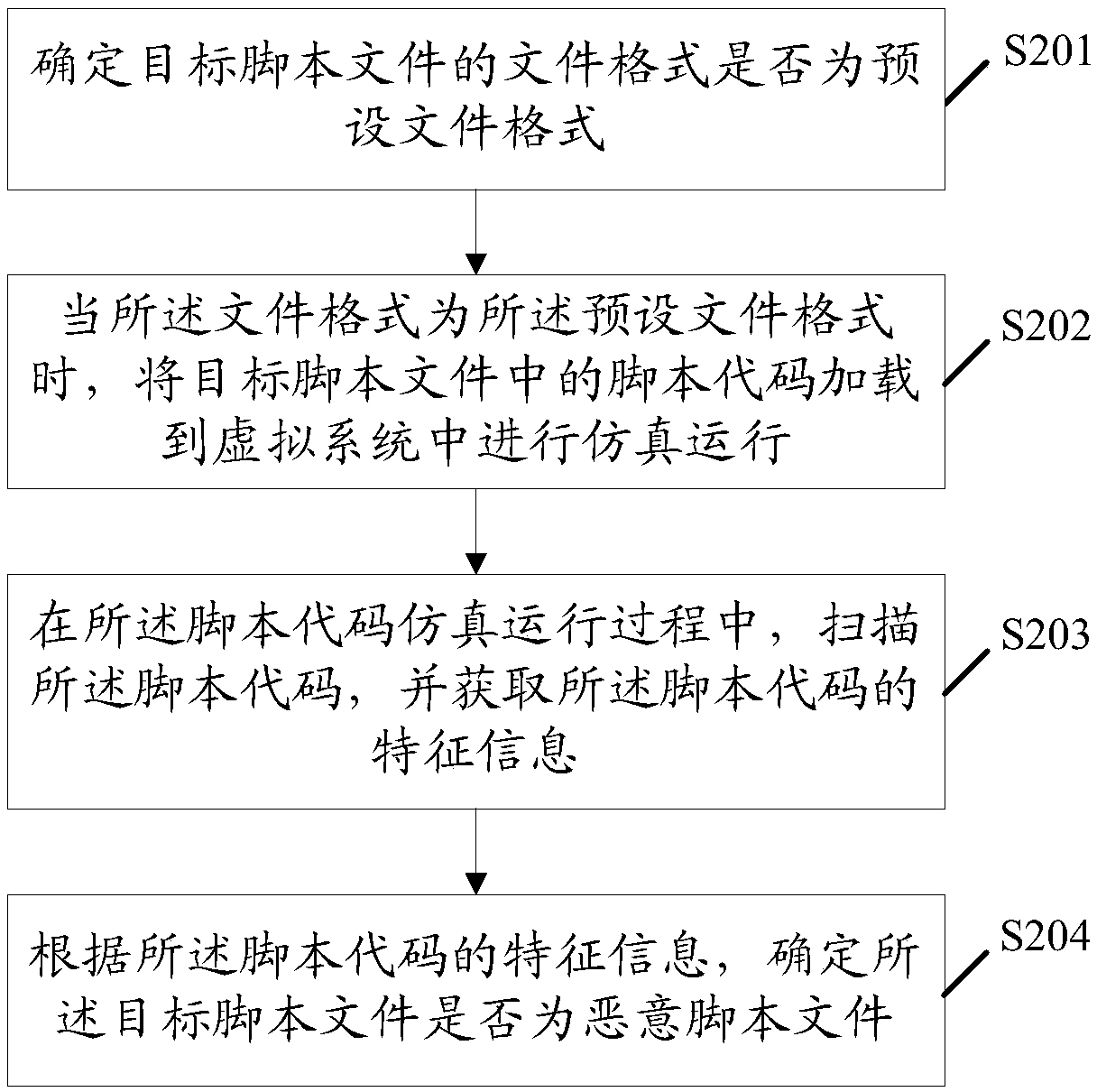

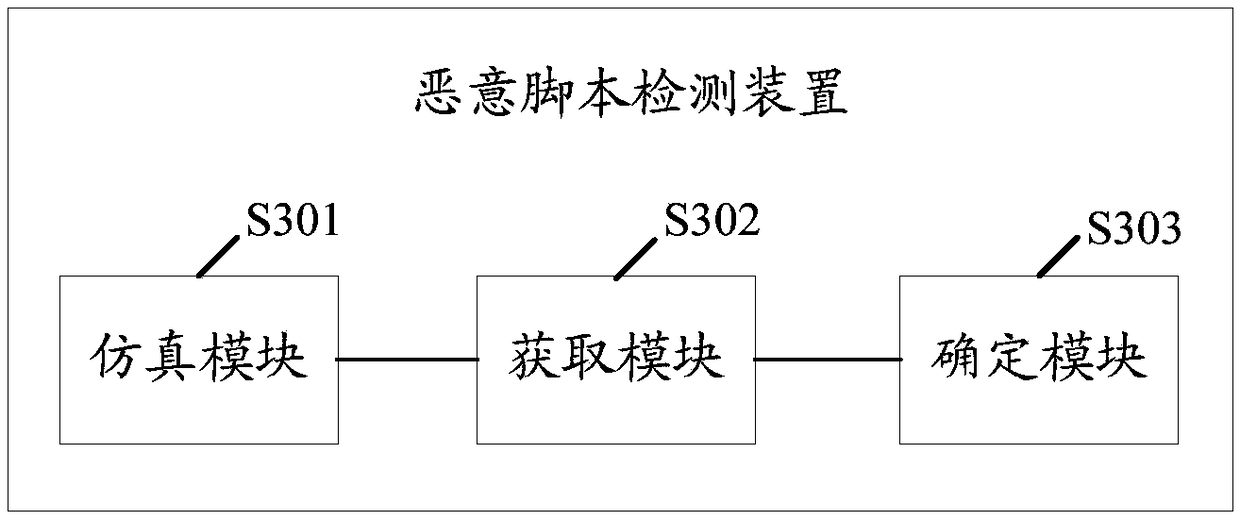

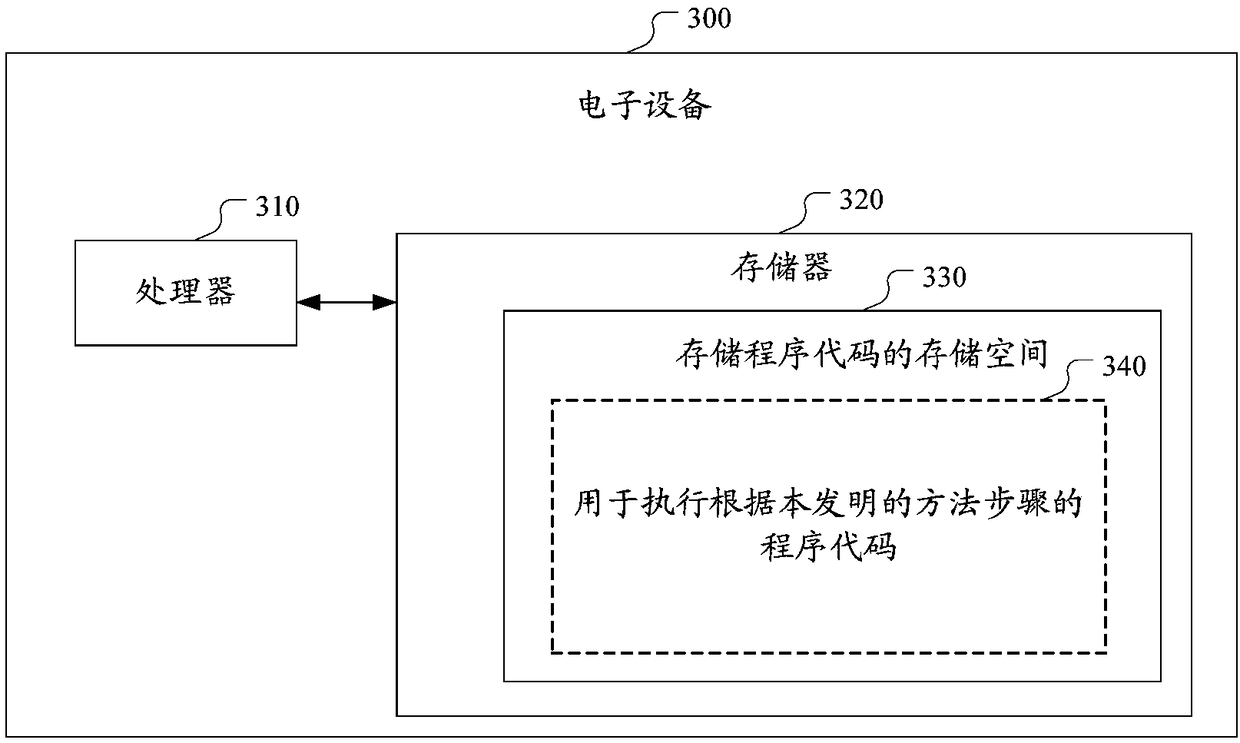

Malicious script detection method and device, electronic device and storage medium

InactiveCN108959925AImprove effectivenessAvoid test failuresPlatform integrity maintainanceOperating systemElectronic equipment

The invention discloses a malicious script detection method and device, an electronic device and a storage medium. The method includes the steps of loading the script code in a target scrip file to avirtual system for simulation running; scanning the script code and obtaining the characteristic information of the script code in the script code simulation running process; according to the characteristic information of the script code, determining whether the target script file is a malicious script file. Through adoption of the embodiment of the invention, the effectiveness of malicious scriptdetection can be improved.

Owner:ZHUHAI BAOQU TECH CO LTD

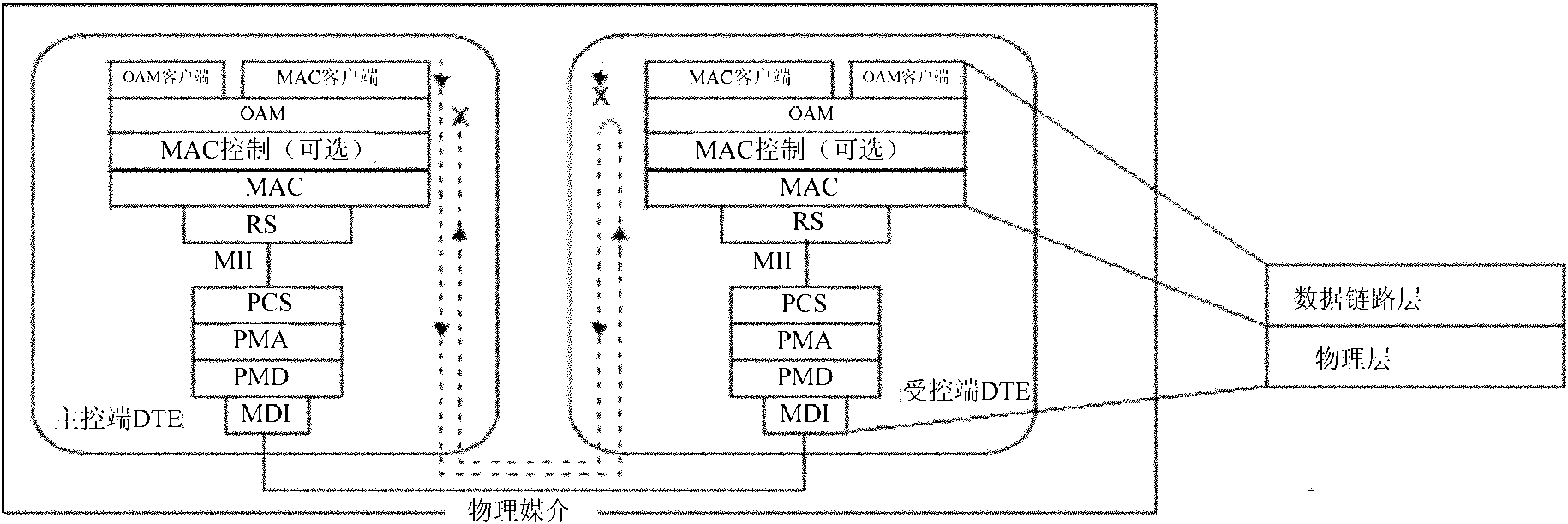

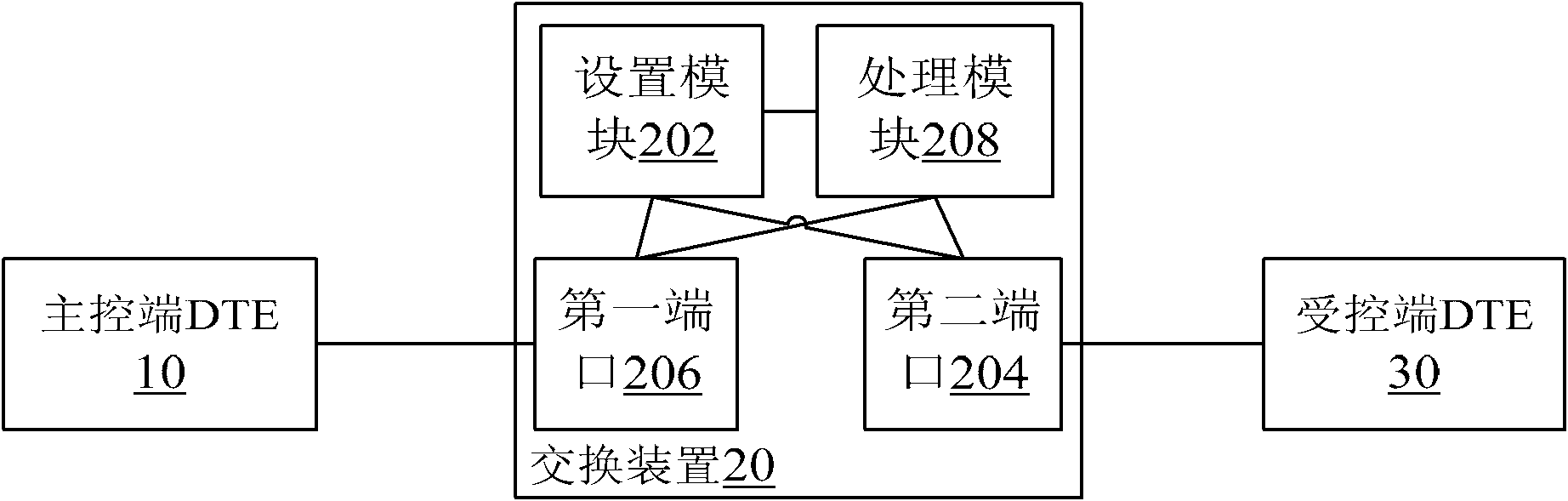

Realization method and system of remote loopback

The invention discloses realization method and system of remote loopback, wherein the realization method of the remote loopback comprises the following steps that: an exchanger receives the test message of controlled end DTE (Data Terminal Equipment) loopback; and the exchanger directly transfers the test message of the loopback to main control end DTE. The invention realizes the far-end loopback test of the Ethernet OAM (Operation and Maintenance) when the exchanger exists between the DTE at both ends of links of 802.3ah protocol, and ensures the successful realization of far-end loopback test when the exchanger exists between the main control end DTE and the controlled end DTE.

Owner:ZTE CORP

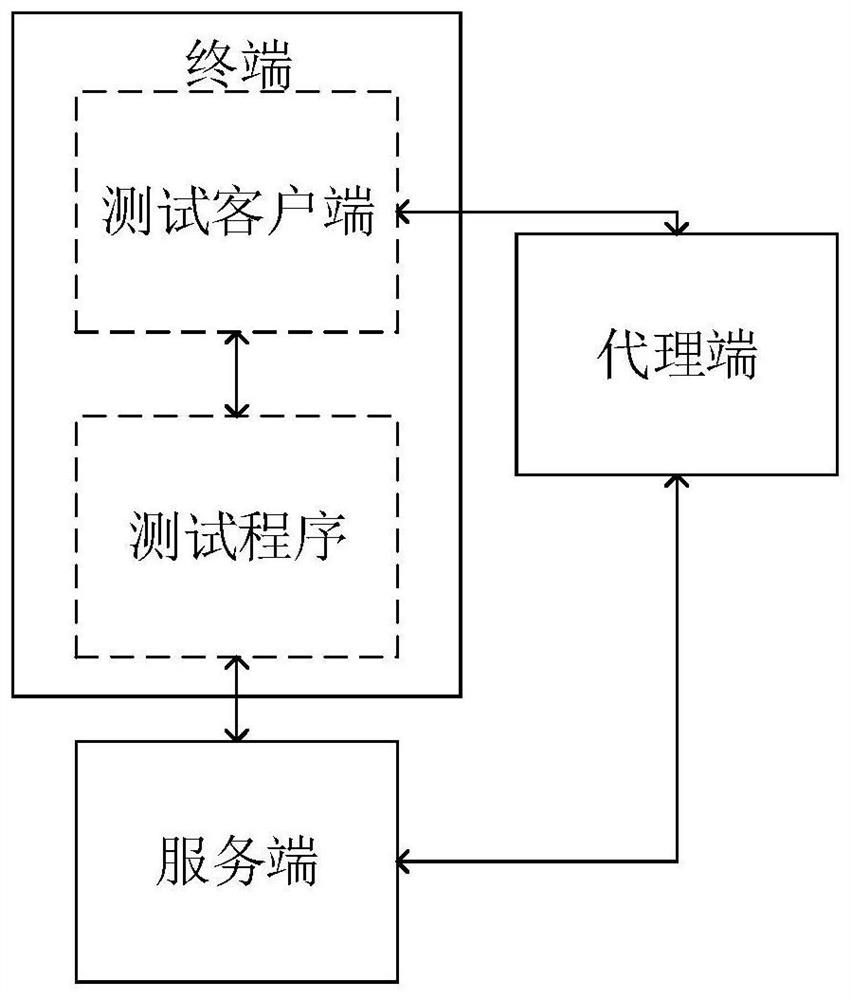

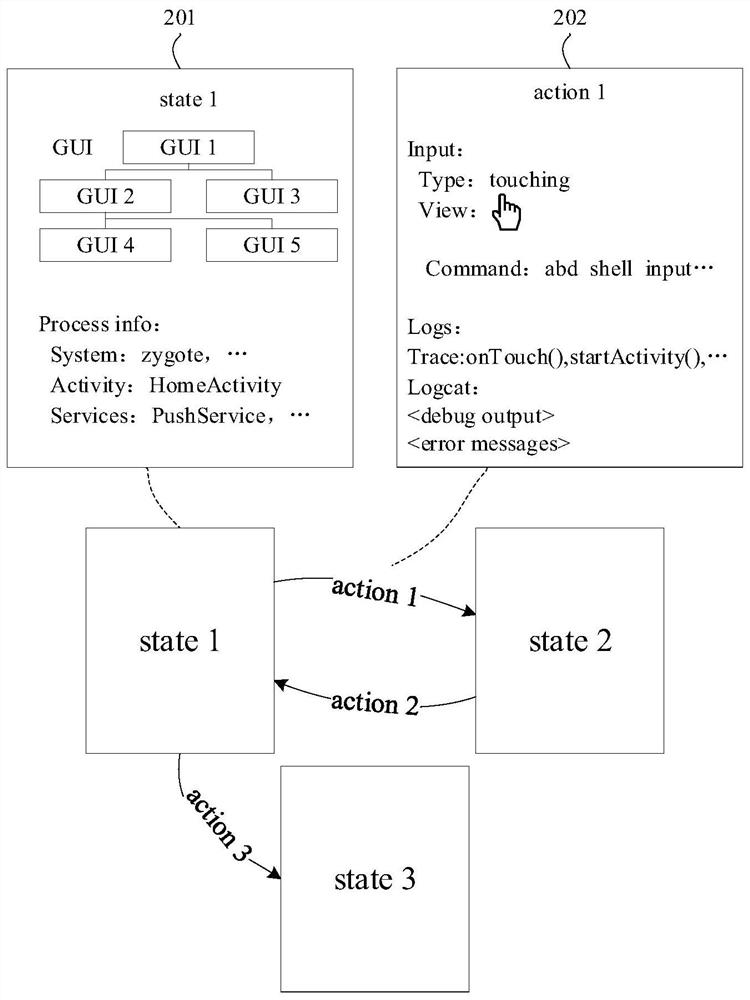

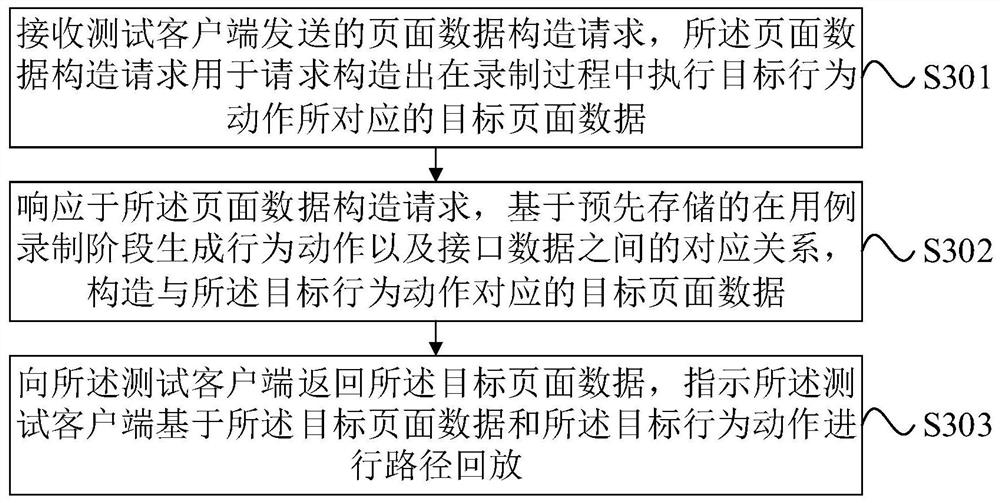

Application program testing method and device, electronic equipment and computer readable storage medium

PendingCN111694757AImprove the success rate of playbackIncrease success rateSoftware testing/debuggingEnergy efficient computingCase recordsPathPing

The invention provides an application program testing method and device, electronic equipment and a computer readable storage medium, and relates to the field of application program testing. The method comprises the steps of receiving a page data construction request sent by a test client, wherein the page data construction request is used for requesting to construct target page data correspondingto a target behavior action executed in a recording process; in response to the page data construction request, constructing target page data corresponding to a target behavior action based on a pre-stored corresponding relationship between the behavior action generated in the case recording stage and the interface data; and returning the target page data to the test client, and indicating the test client to perform path playback based on the target page data and the target behavior action. According to the method and the device, when path playback is carried out on the test client, the original page data can still be constructed even if the original page data does not exist, so that the playback success rate is improved, and the test success rate is further improved.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

Recyclable ground stress testing device

InactiveCN103776575AAvoid force deformationSensitive transferApparatus for force/torque/work measurementEngineeringTest fixture

A recyclable ground stress testing device comprises a pipe body, a probe and a movable plate. A notch is formed in the top of the left end of the pipe body, a first guide plate is fixed at the bottom of the pipe body, the two ends of the first guide plate both extend out of the pipe body, a limit plate is fixed at the left end of the first guide plate, a connection rod is hinged to the limit plate, and the movable plate is hinged to the other end of the connection rod. The inner wall of the movable plate gradually becomes thinner from the hinge end to the free end, the movable plate is located at the notch, a pipe body conveying and recycling device is fixed at the right end of the first guide plate, the probe is provided with a stress sensing column, a probe conveying device and a probe recycling device, and the probe can be conveyed into the pipe body along the first guide plate. The recyclable ground stress testing device can be repeatedly used, and lower the cost of stress testing.

Owner:ANHUI UNIV OF SCI & TECH

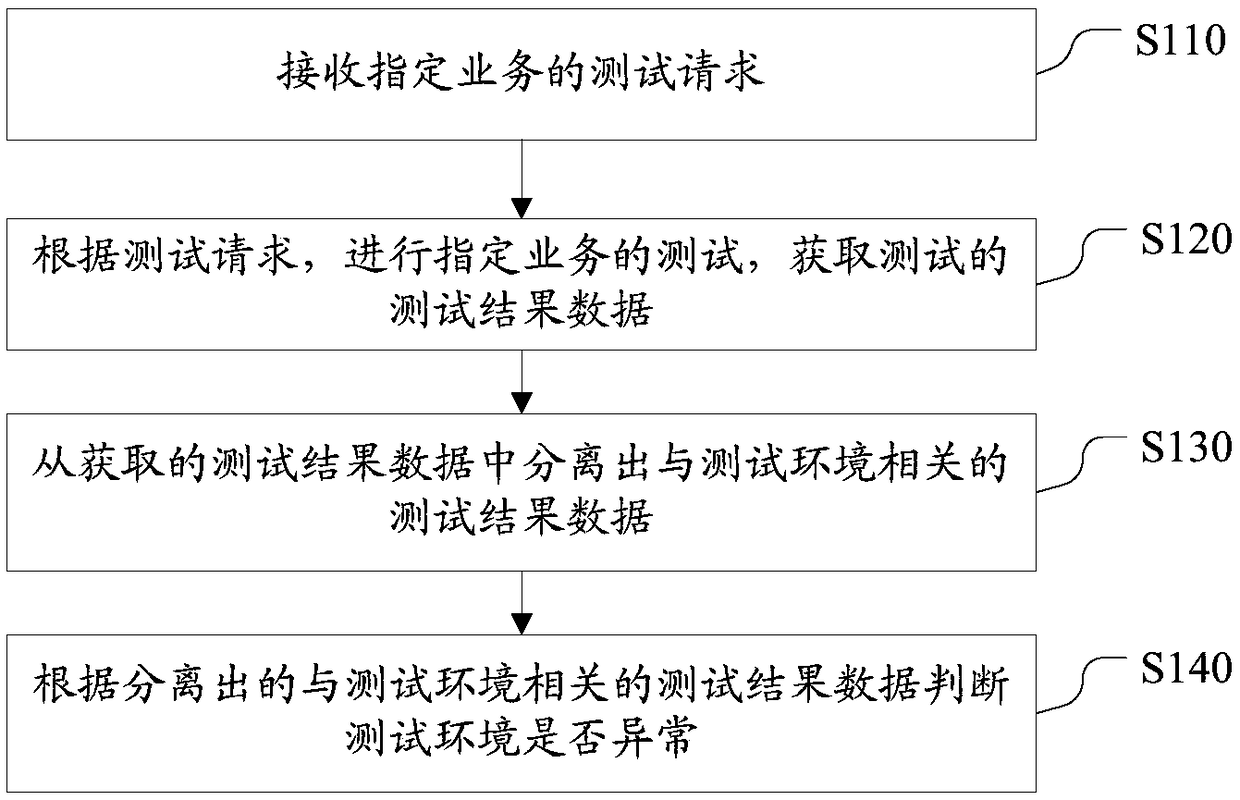

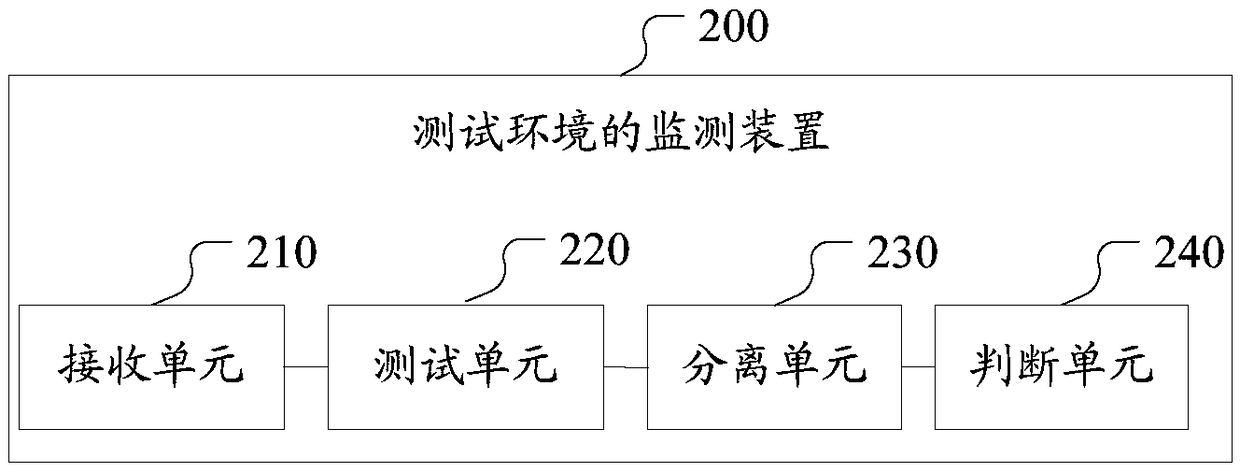

A method and apparatus for monitoring a test environment

ActiveCN109144874ARealize monitoringAvoid test failuresSoftware testing/debuggingTest requirementsTest failure

The invention discloses a monitoring method, an apparatus, an electronic device and a computer-readable storage medium for a test environment. The method comprises the following steps of: receiving atest request of a specified service; according to the test request, carrying out the test of the specified business, and obtaining the test result data of the test; separating the test result data related to the test environment from the acquired test result data; whether the test environment is abnormal or not being judged according to the separated test result data related to the test environment. Visible, through the technical scheme, the test environment can also be monitored in the process of testing, to determine whether the test environment abnormal and to prevent the test failure caused by the test environment abnormal.

Owner:BEIJING QIHOO TECH CO LTD

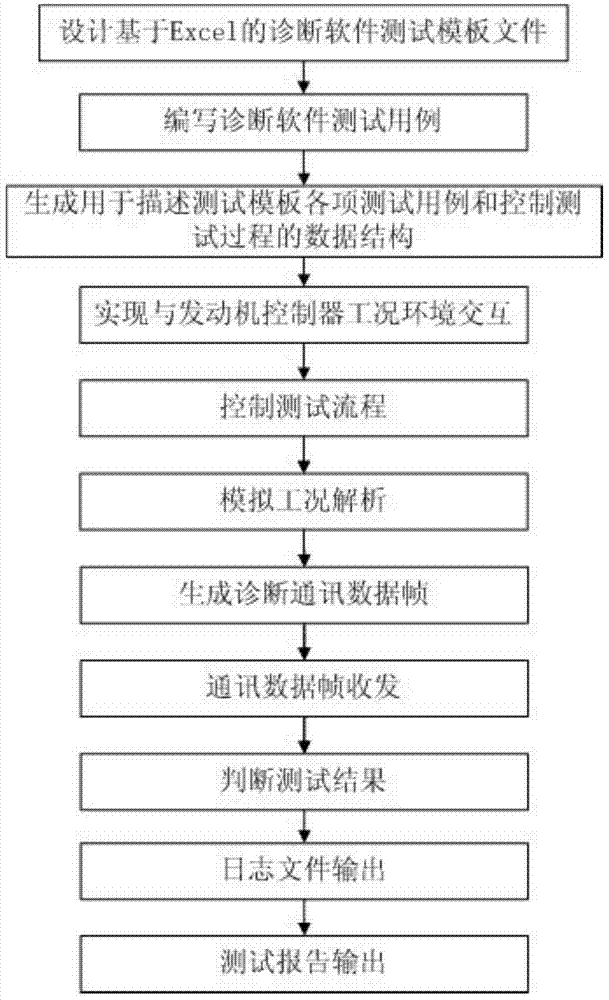

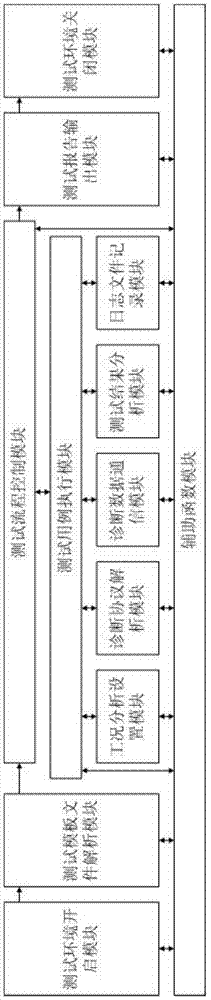

Engine Controller Software Diagnosis Module Test Method and Test System

ActiveCN105224447BReduce manual operationsAvoid test failuresSoftware testing/debuggingArea networkTest quality

The invention discloses a test method of an engine controller software diagnosis module on the basis of the USB-CAN (Universal Serial Bus-Controller Area Network) network communication equipment and the automobile diagnosis instruction set tool of the NI Company (National Instruments). The method comprises the following steps: designing an Excel-based diagnosis software test template file; according to the test template, compiling a diagnosis software test case which conforms to a test template format; obtaining the test template file input by a user, analyzing the test template appointed by the user, and generating a data structure used for describing a test template test case and controlling a test process; controlling a test flow; analyzing a simulation working condition; generating a diagnosis communication data frame; receiving and transmitting the communication data frame; judging a test result; realizing interaction with the working condition environment of an engine controller; and outputting a test report and a log file. The invention also discloses a test system of the engine controller software diagnosis module on the basis of the USB-CAN network communication equipment and the automobile diagnosis instruction set tool of the NI Company. The test method can improve the test efficiency and the test quality of the test work of the engine controller software diagnosis module.

Owner:LIANCHUANG AUTOMOBILE ELECTRONICS

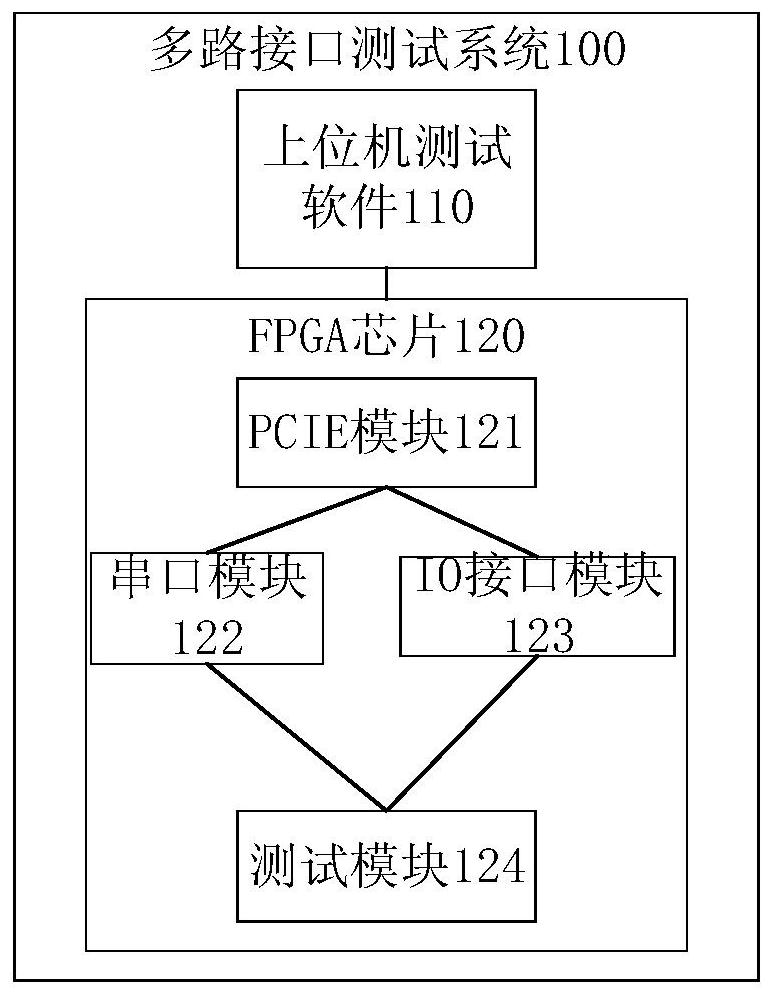

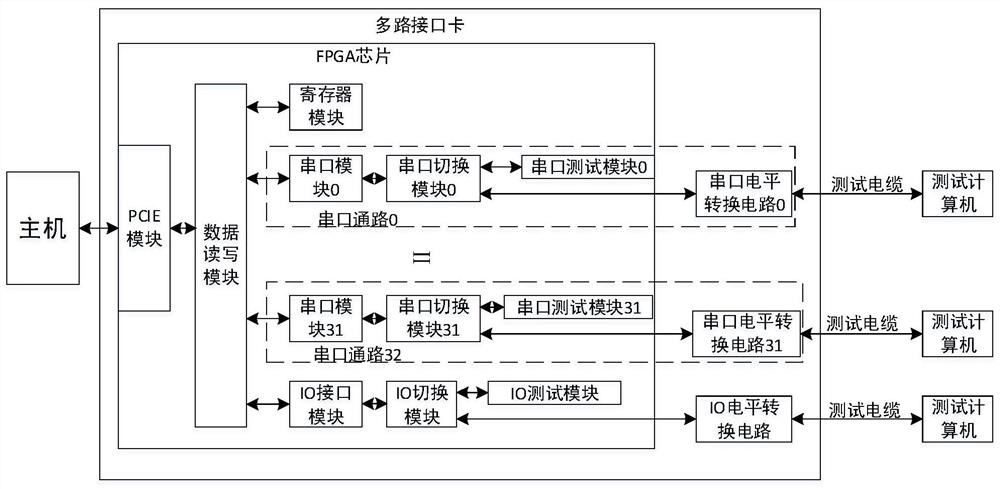

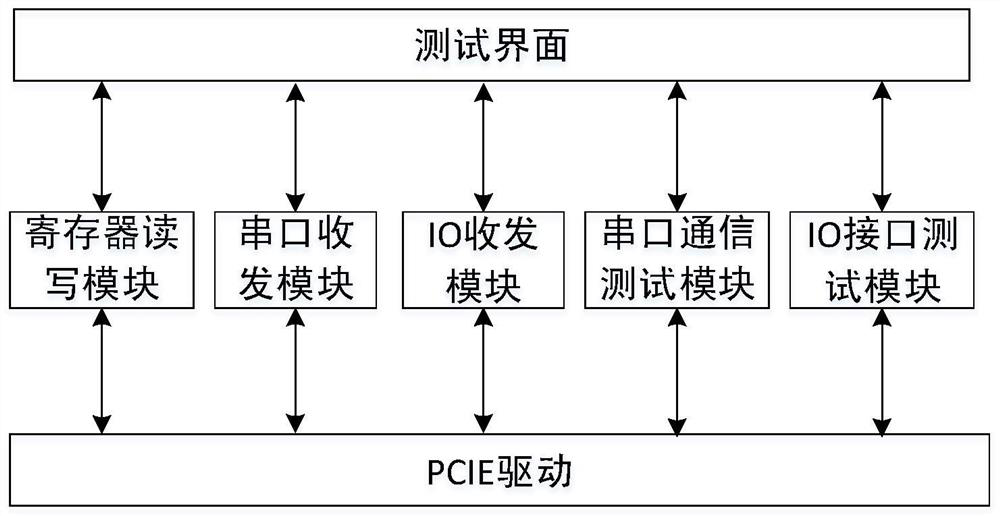

Multi-interface test system and method

PendingCN113608936AAvoid test failuresImprove test efficiencyDetecting faulty computer hardwareTest efficiencyComputer architecture

The invention discloses a multi-interface test system and method. The test system comprises upper computer testing software and an FPGA chip, the FPGA chip comprises a PCIE module, a plurality of serial port modules, an IO interface module and a testing module, wherein the IO interface module comprises a plurality of IO interfaces, the upper computer testing software is in communication connection with the PCIE module, and the PCIE module is connected with the serial port modules and the IO interface module. When a serial port test is carried out, the serial port module is in communication connection with a serial port of a tested computer; when the IO interface is tested, the IO interface is connected with the IO interface of the tested computer; and the testing module is configured to test the interface state of the serial port and / or the IO interface of the tested computer. According to the invention, the test efficiency can be improved, the fault elimination efficiency is improved, and test failure caused by interference data is avoided.

Owner:TIANJIN JINHANG COMP TECH RES INST

Silicon chip electron life tester positioning device

InactiveCN106124959ANo tiltAvoid breakingElectronic circuit testingIndividual semiconductor device testingTester deviceEngineering

The invention discloses a silicon chip electron life tester positioning device, comprising a bottom pallet; one side of the bottom pallet is provided with a positioning baffle plate; the positioning baffle plate comprises an installation part and a positioning part, wherein the positioning part is arranged at the upper end of the installation part, and the positioning part is provided with a cushioning pad. The silicon chip electron life tester positioning device realizes silicon chip positioning by employing the positioning baffle plate, and can guarantee a silicon chip from inclination, and avoid test failure; the positioning part is provided with the cushioning pad so as to effectively avoid breaking caused by direction collision between the silicon chip and the positioning part; the silicon chip electron life tester positioning device has a simple structure and is easy to realize.

Owner:KONCA SOLAR CELL

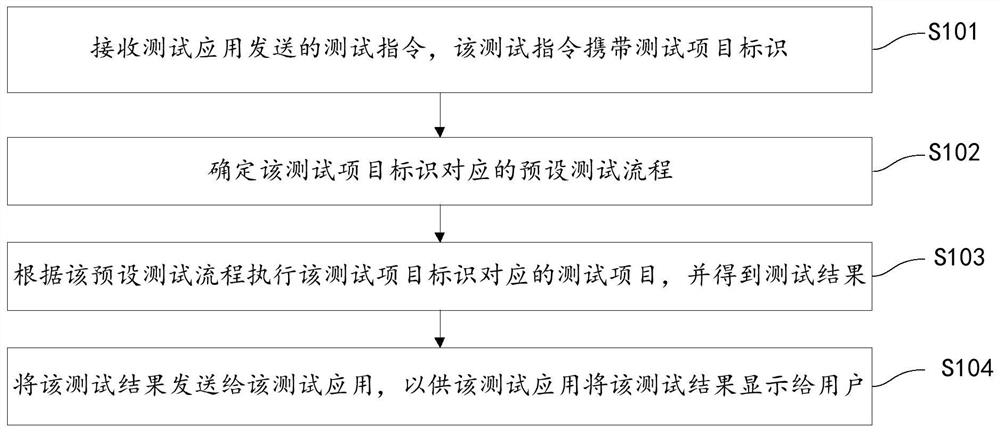

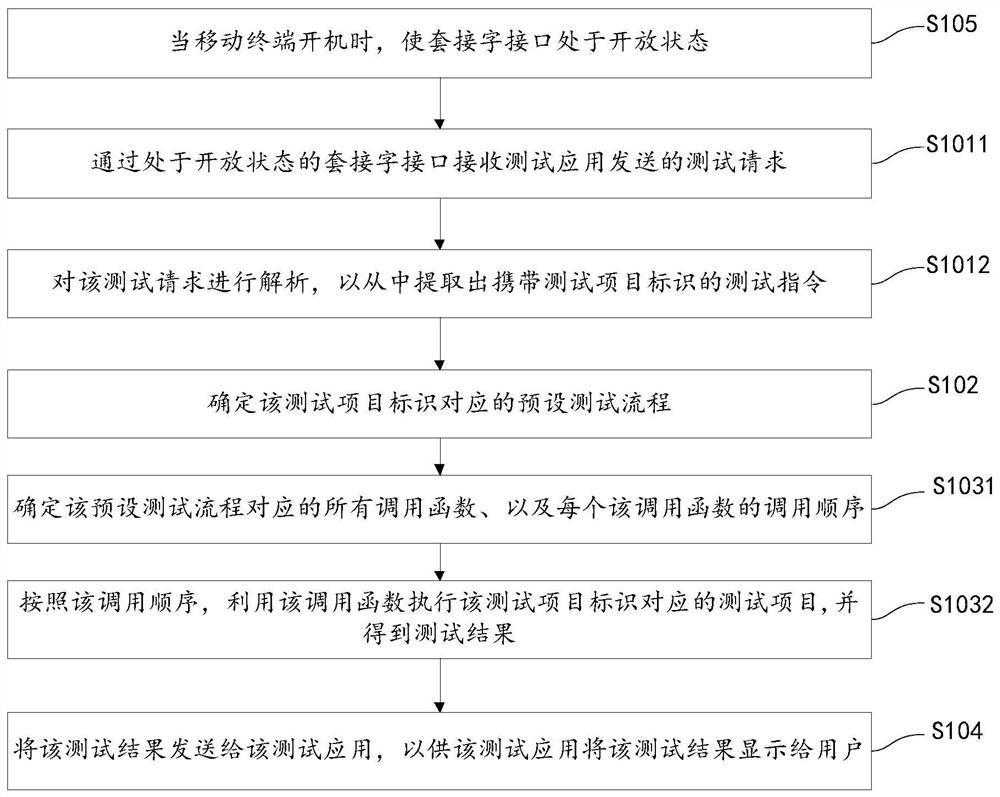

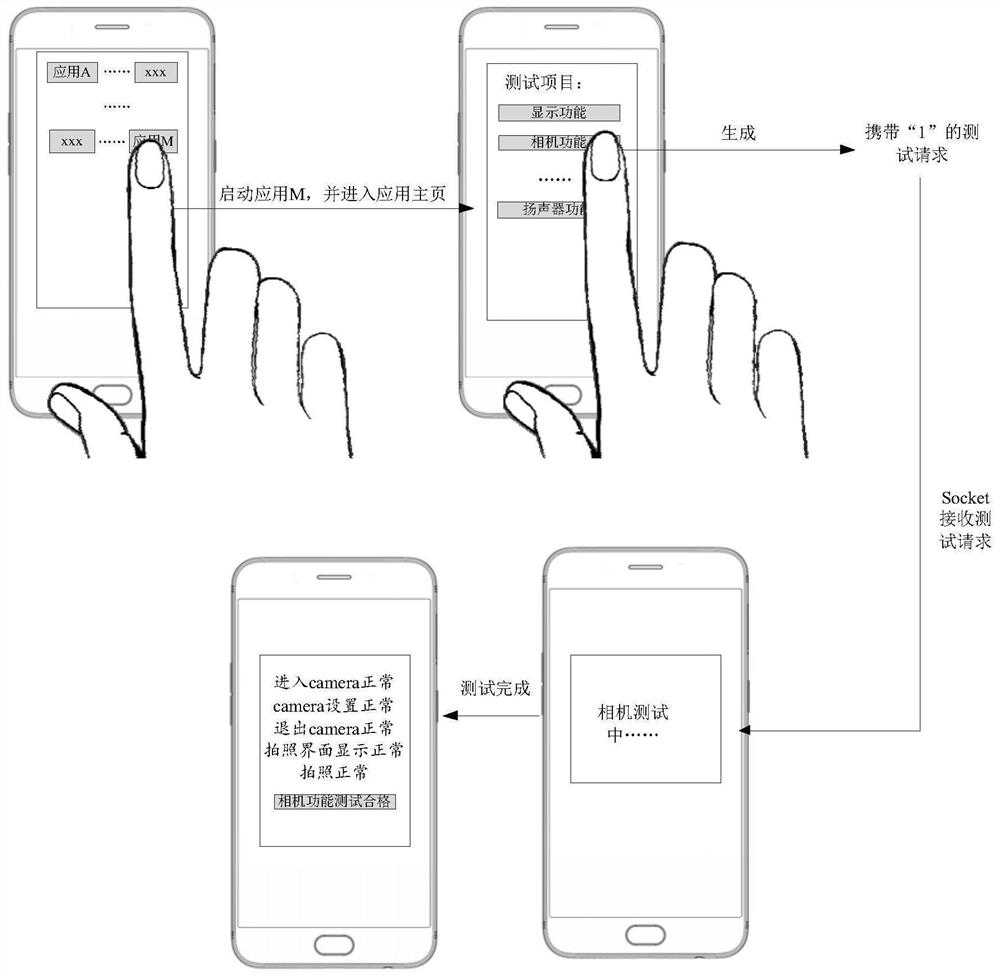

Terminal test method and device, storage medium and mobile terminal

PendingCN112199246AAvoid test failuresImprove test accuracyFaulty hardware testing methodsTest itemComputer engineering

The invention discloses a terminal test method and device, a storage medium and a mobile terminal. The terminal test method comprises the steps of receiving a test instruction sent by a test application, wherein the test instruction carries a test item identifier; determining a preset test process corresponding to the test item identifier; executing a test item corresponding to the test item identifier according to a preset test flow, and obtaining a test result; and sending the test result to the test application, so that the test application displays the test result to the user, thereby realizing independence of application and device interaction in a factory test process, and avoiding a phenomenon of test failure caused by a logic problem of the application.

Owner:TCL COMM NINGBO

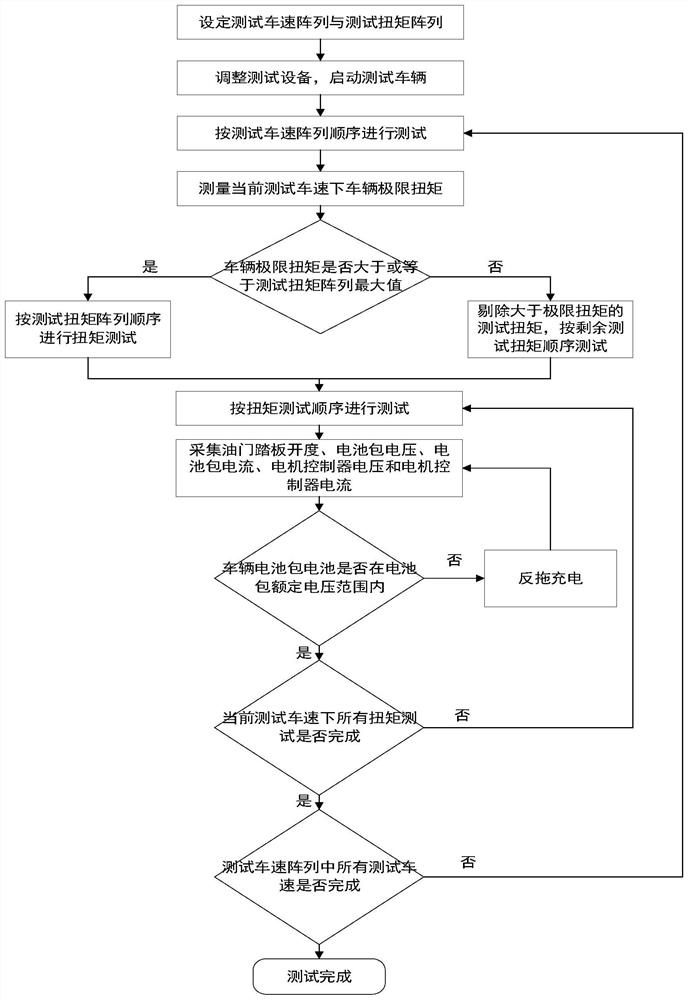

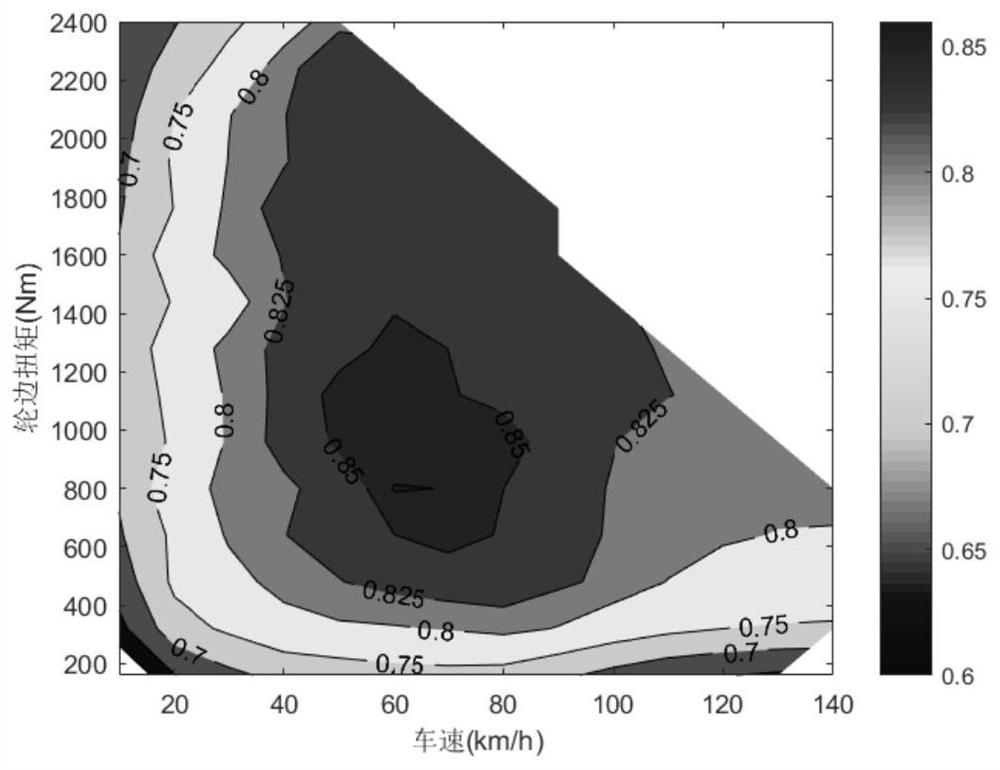

Pure electric vehicle whole vehicle efficiency test method, electronic equipment and medium

PendingCN112781886ASolve the tedious problem of determiningEnough test pointsVehicle testingWork measurementPure electric vehicleControl theory

The invention relates to a pure electric vehicle whole vehicle efficiency test method, electronic equipment and a medium. The method comprises the following steps: a test vehicle speed array and a test torque array of a test vehicle are set; the test vehicle speed array comprises at least two test vehicle speeds; torque testing is carried out at each testing vehicle speed, and the torque testing comprises the steps that the limit torque of the vehicle at the current testing vehicle speed is compared with the maximum value of the testing torque in the testing torque array, the torque testing sequence at the current testing vehicle speed is determined, and torque testing is carried out. According to the method, the test torque sequence at different vehicle speeds can be quickly determined through the relation between the vehicle limit torque and the test torque array at different test vehicle speeds, and the efficiency of the whole vehicle efficiency test of the pure electric vehicle is improved.

Owner:CHINA AUTOMOTIVE TECH & RES CENT +1

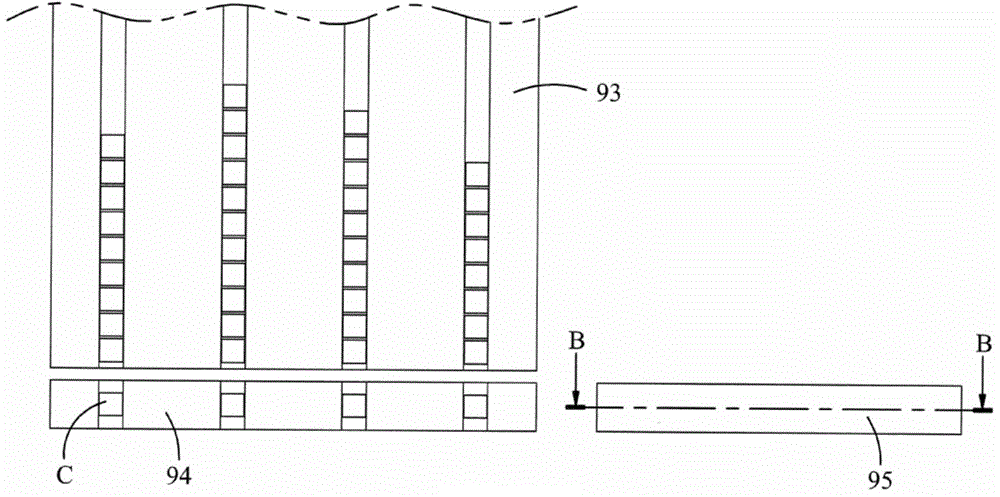

Resistance measuring device for conductive adhesive tape in shielding cover

PendingCN113358936ARealize measurementConsistent spacingResistance/reactance/impedenceElectrical resistance and conductanceEngineering

The invention discloses a resistance measuring device for a conductive adhesive tape in a shielding cover, and belongs to the field of conductive adhesive tape testing. A supporting assembly comprises a bottom plate, a vertical shaft and a transverse shaft. A counterweight assembly comprises a connecting shaft, a counterweight block and an insulating seat; the connecting shaft comprises a first shaft rod and a second shaft rod, the first shaft rod is movably inserted into a strip-shaped hole, one end of the first shaft rod is detachably connected with one end of the counterweight block, the other end of the first shaft rod is coaxially connected with one end of the second shaft rod, and the other end of the second shaft rod is connected with the insulating seat. A testing assembly comprises an ohmic resistance meter and two electrodes, the two electrodes are movably arranged on the insulating seat, and one end, facing the bottom plate, of each electrode protrudes out of the insulating seat. The resistance measuring device provided by the invention not only can realize detection of products of the same type and avoid the problem of test failure caused by large fluctuation of a test result, but also can realize detection of products of different types.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

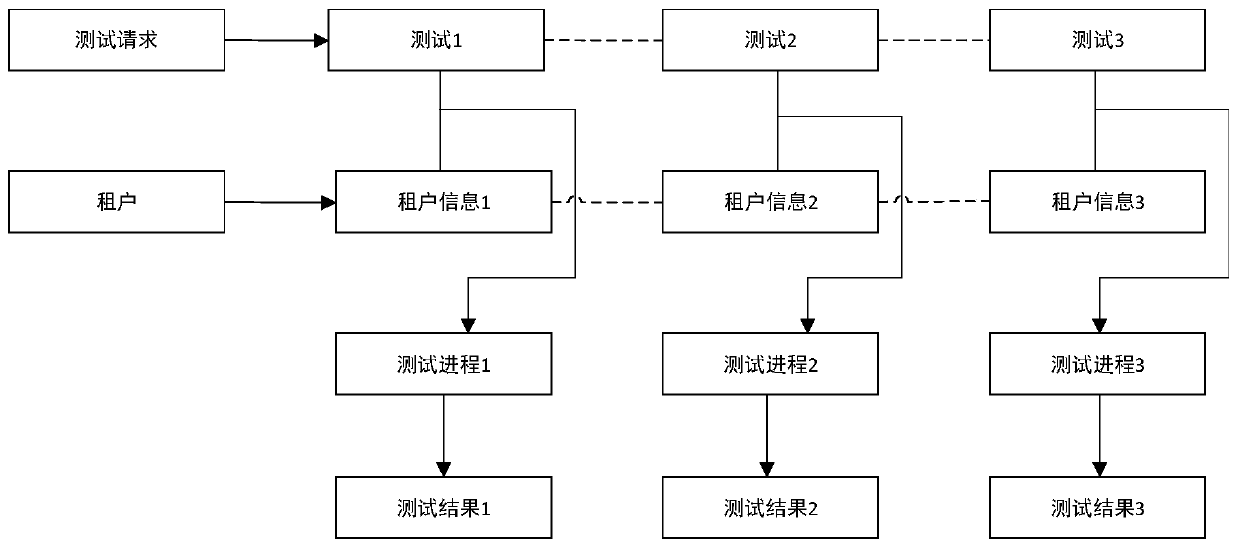

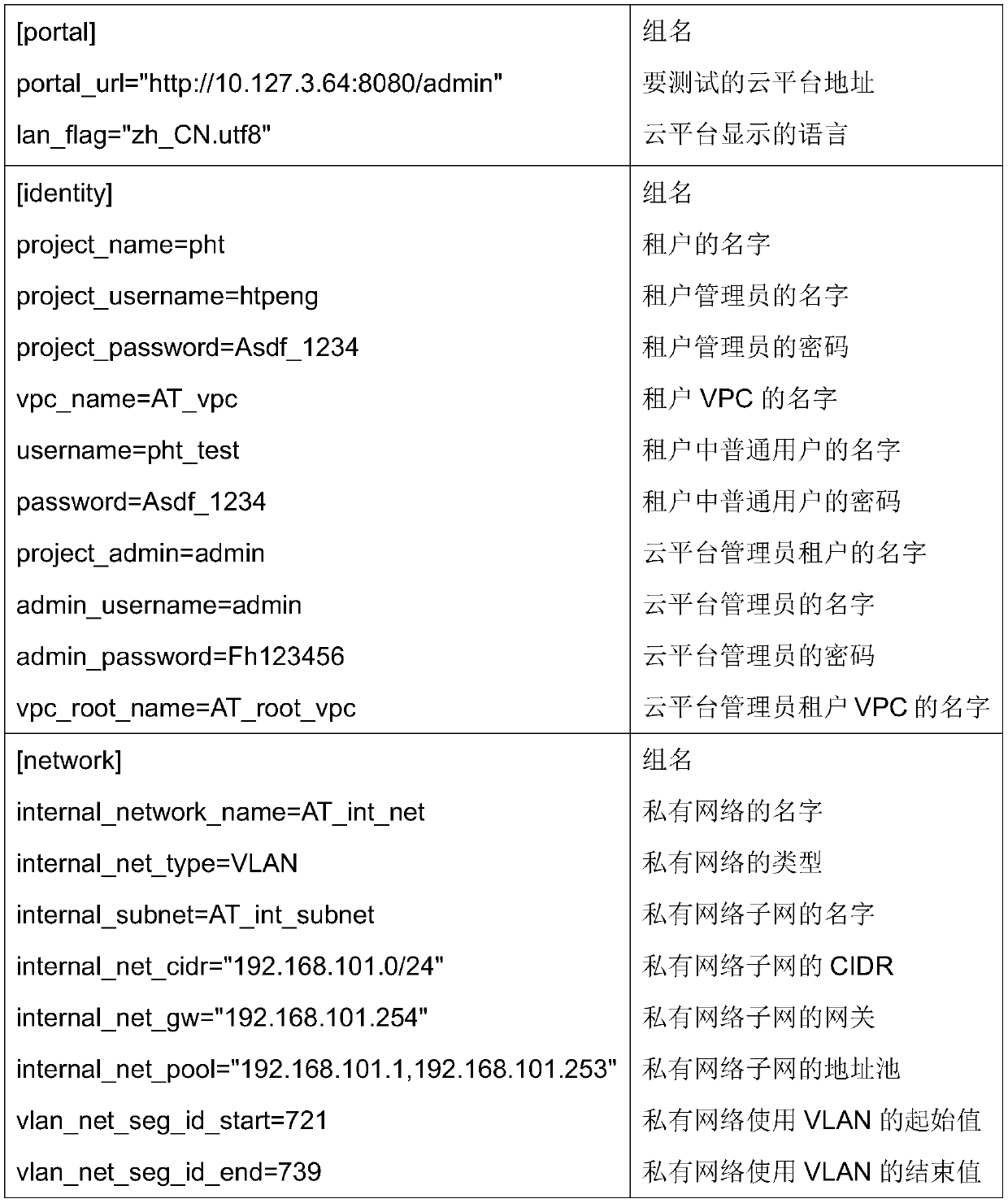

Automatic test system and method based on multiple processes and multiple tenants

InactiveCN111338930AIncrease profitReduce distractionsProgram initiation/switchingSoftware testing/debuggingTest executionTest failure

The invention discloses an automatic test method and system based on multiple processes and multiple tenants. The method comprises the steps: dynamically generating multiple corresponding tenant information configuration files according to test case requirements and tenant information, wherein the tenant information configuration file comprises tenant identity information, tenant network resourceinformation and test case information; creating a corresponding tenant based on the tenant information configuration file, associating the tenant with a corresponding test case resource, and sending atest request, wherein the tenants comprise tenant identities, tenant network resources and test case resources; analyzing the tenant information configuration file according to the test request to form a plurality of corresponding test processes, and executing the test processes; and obtaining a plurality of corresponding test results. Through the scheme of multiple test processes, test failure possibly caused by resource name duplication and quota can be avoided, the test execution time is greatly shortened, the scheme can be closer to the actual use condition of a user, and a better test effect is achieved.

Owner:FENGHUO COMM SCI & TECH CO LTD

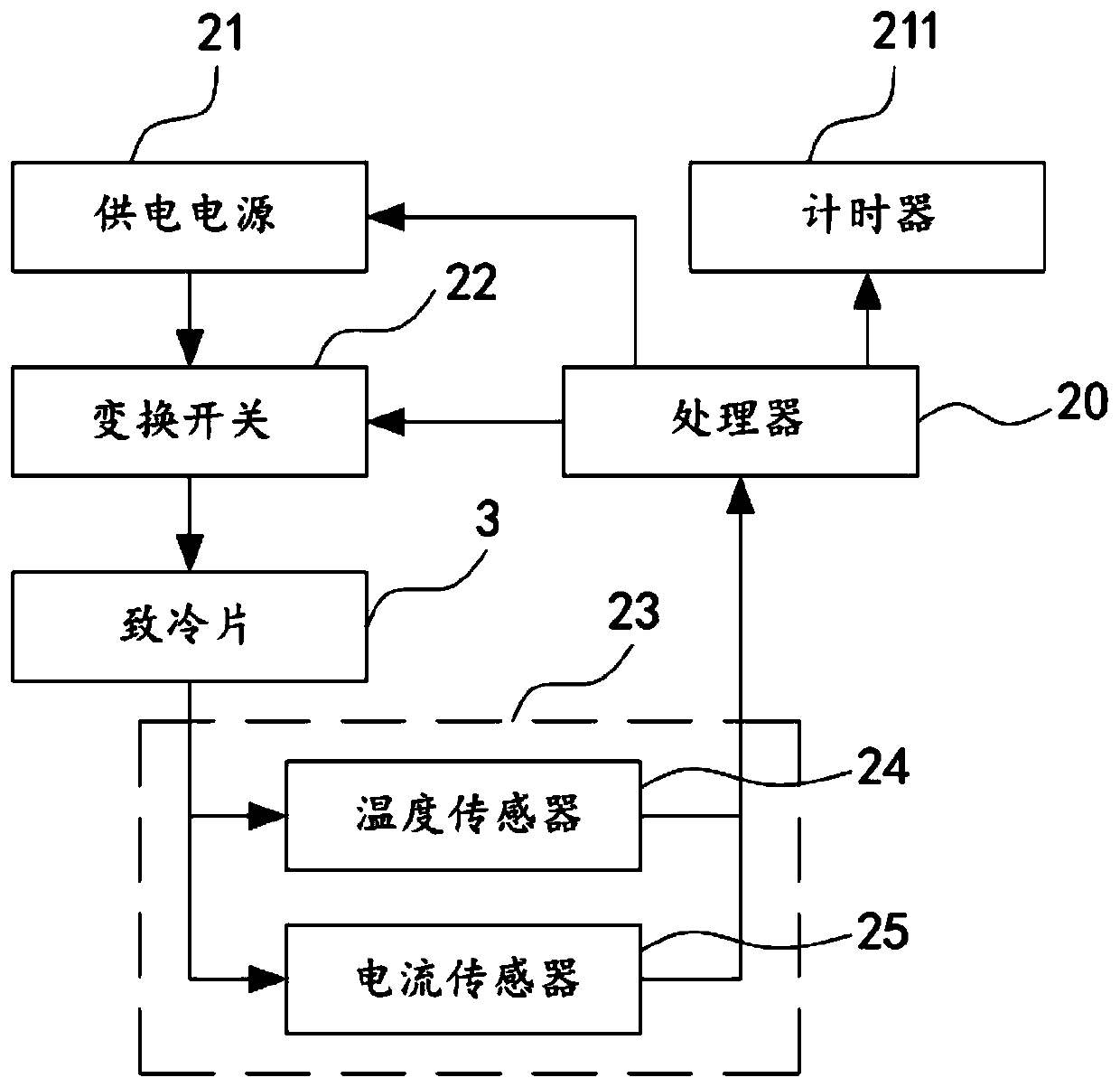

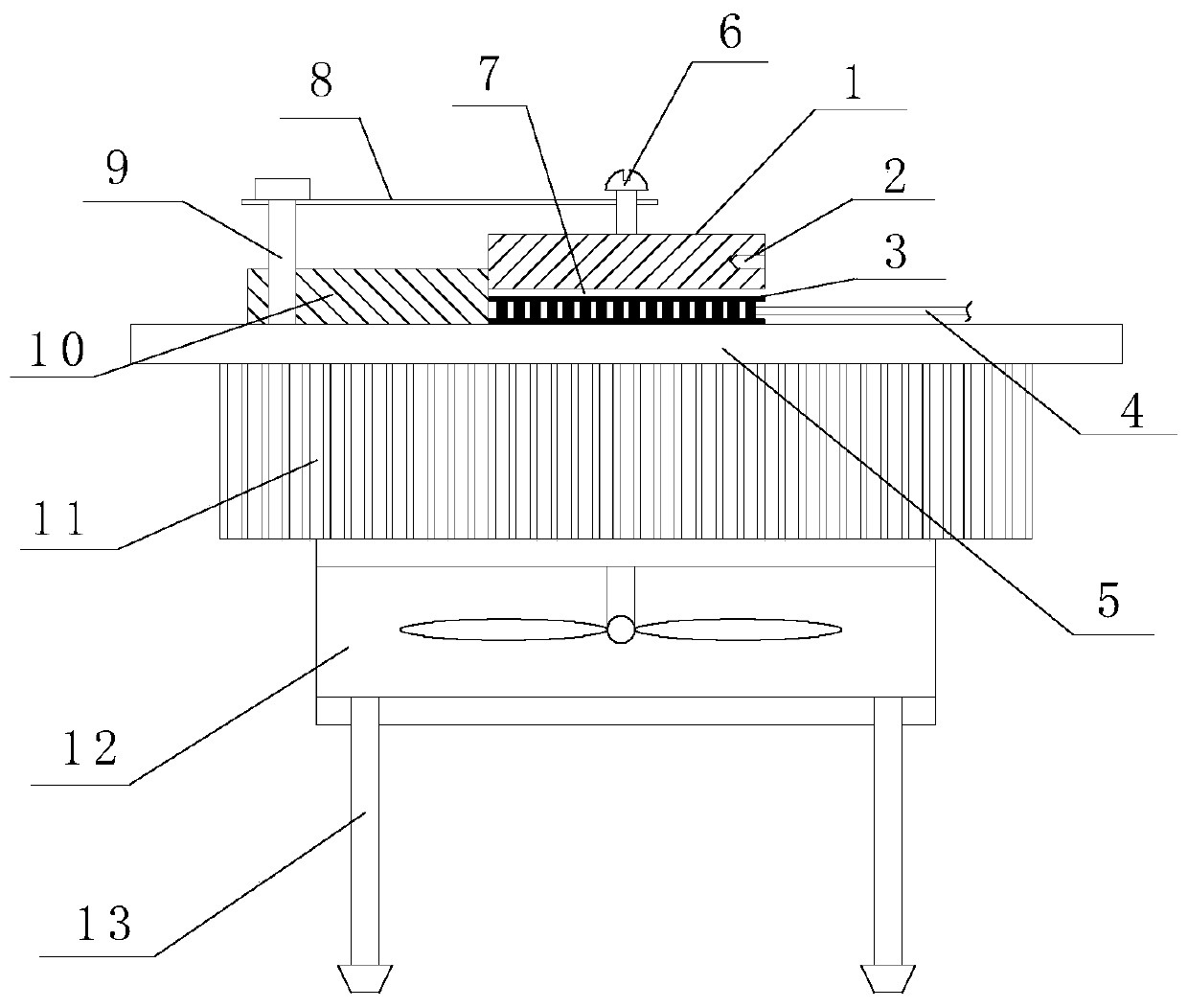

Semiconductor refrigeration chip aging test device

InactiveCN110187252AGuaranteed test resultsGuaranteed test efficiencySemiconductor operation lifetime testingTest efficiencyCurrent sensor

The invention provides a semiconductor refrigeration chip aging test device, and relates to the technical field of semiconductor refrigeration chips. The semiconductor refrigeration chip aging test device comprises a test bench, a limiting component, a first heat conduction plate, a second heat conduction plate and a test controller, a bottom surface of the first heat conduction plate is laminatedwith a cold surface of a refrigeration chip to be tested, the test controller comprises a processor, a power supply, an alteration switch, a detection component and a timing counter, the alteration switch is arranged between the power supply and the refrigeration chip to be tested, the detection component comprises a temperature sensor and a current sensor, and an input end of the current sensoris electrically connected with the refrigeration chip. According to the semiconductor refrigeration chip aging test device provided by the invention, by means of the design of the test controller, anaging test is performed on the refrigeration chip to be tested in an automatic manner to prevent the phenomena of low test efficiency and low test accuracy due to manual test.

Owner:泉州市依科达半导体致冷科技有限公司

High-voltage detection module, device and method for multilayer capacitor

The invention relates to a high-voltage detection module, device and method for a multilayer capacitor, and the device and method mainly employ a first electrode group and a second electrode group of the high-voltage detection module to clamp the multilayer capacitor for testing, and do not need any other mechanism or device to assist the supporting or fixing of the multilayer capacitor for the suspension testing, wherein air is directly used for insulation. Therefore, no metal filing is generated, and no surge can be generated. In addition, the first and second electrode groups can be used for contact testing firstly before the high-voltage detection, i.e., detecting the whether the electrode end faces of the first and second electrode groups and the multilayer capacitor fully contact with each other firstly, and then carrying out the high-voltage detection, so as to guarantee that the detection electrode groups and the multilayer capacitors are connected in advance, and prevent the poor contact from causing a testing failure.

Owner:THINK TECH

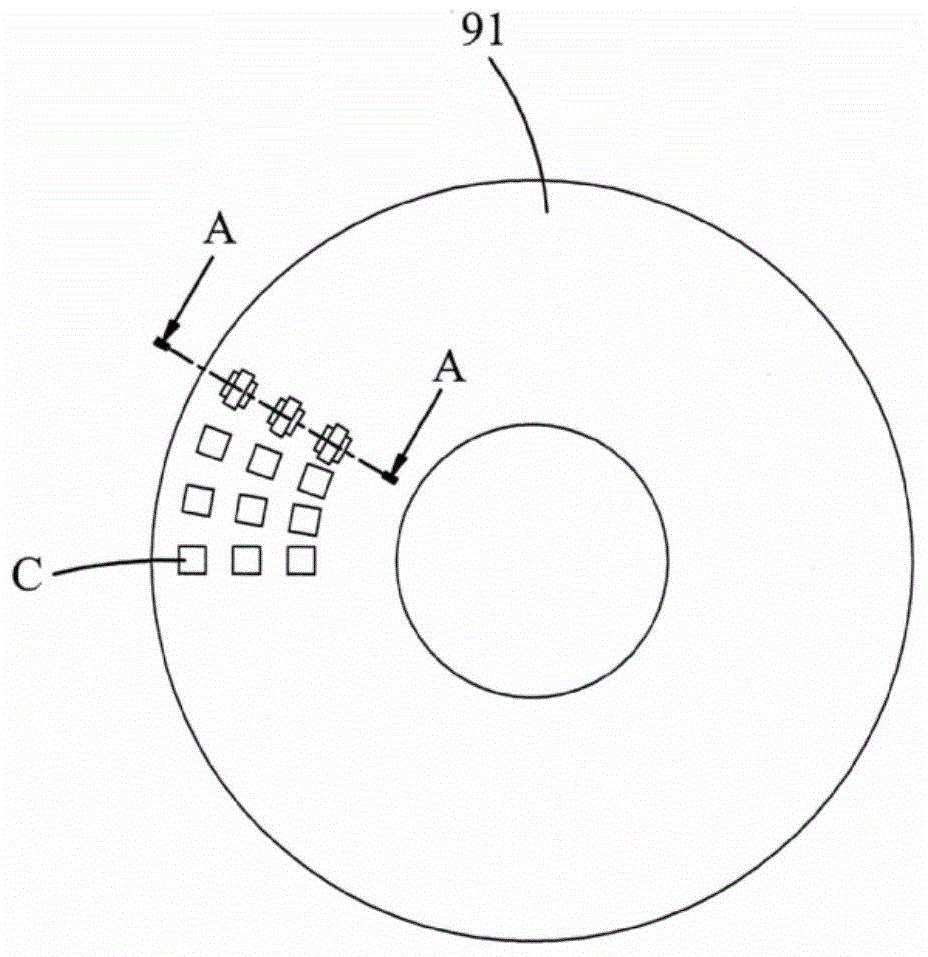

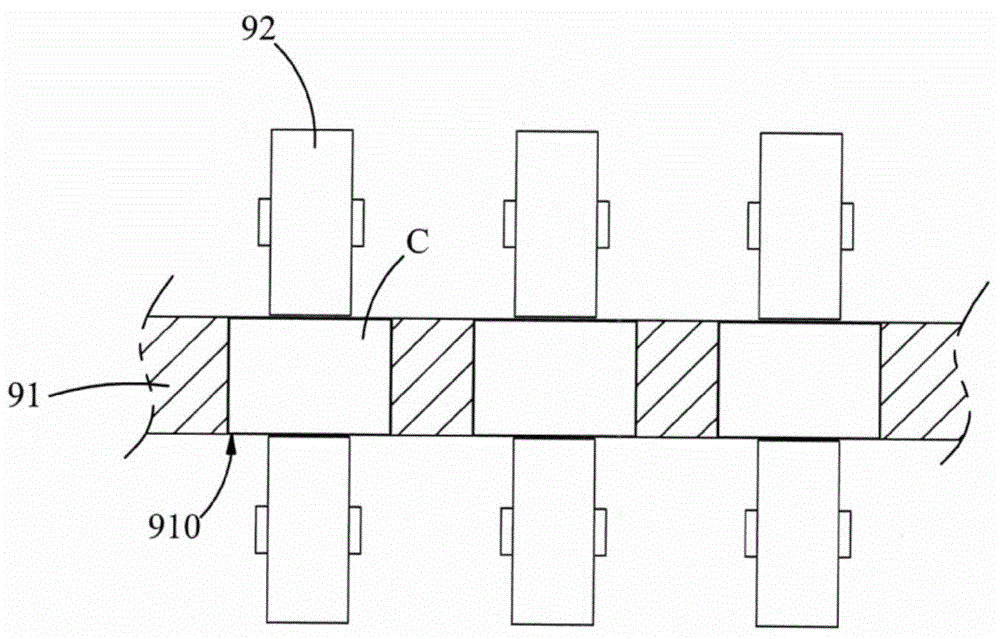

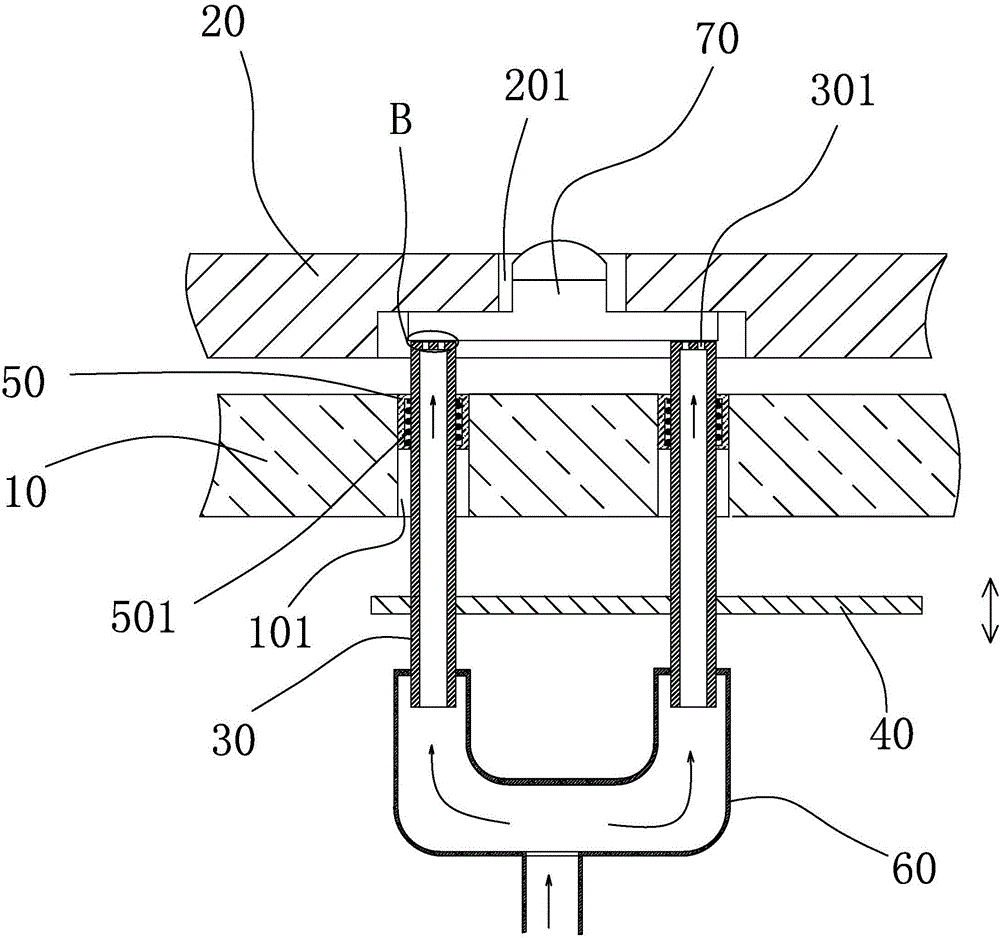

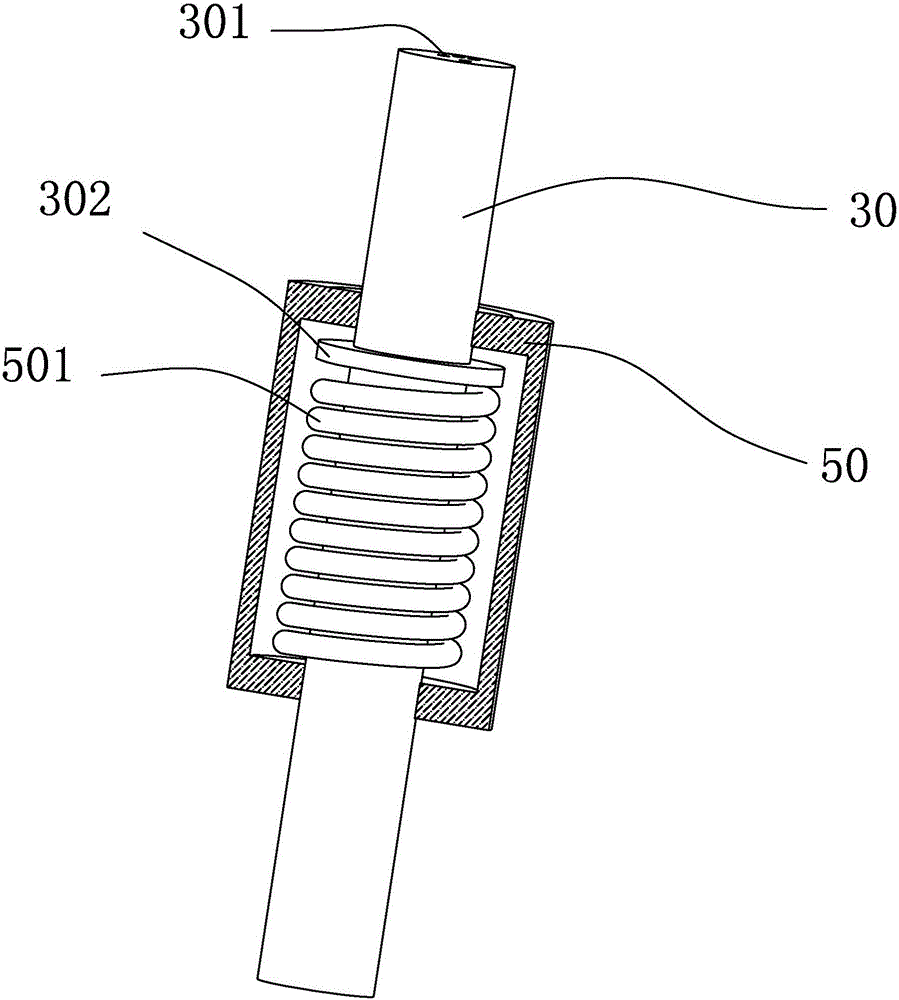

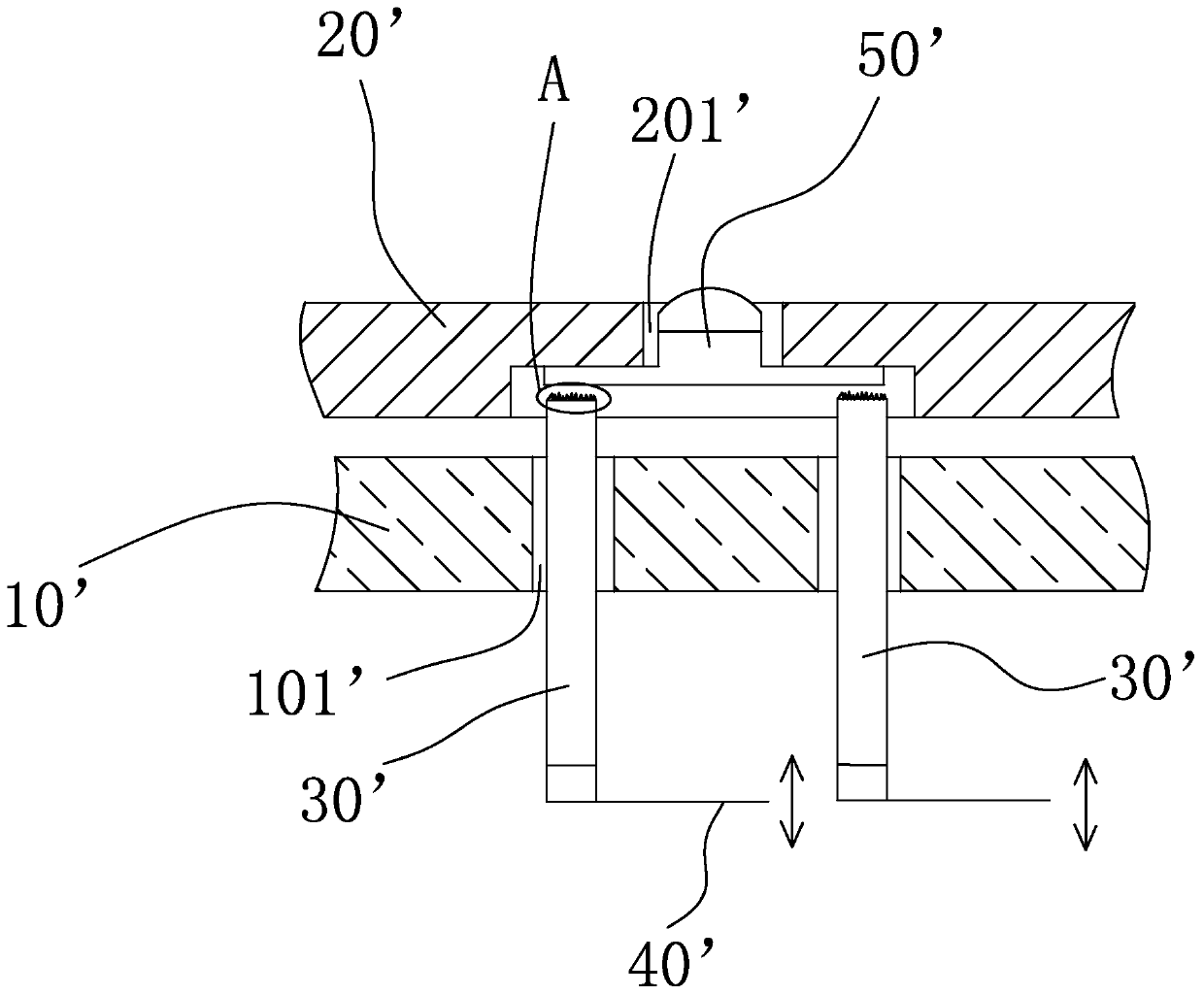

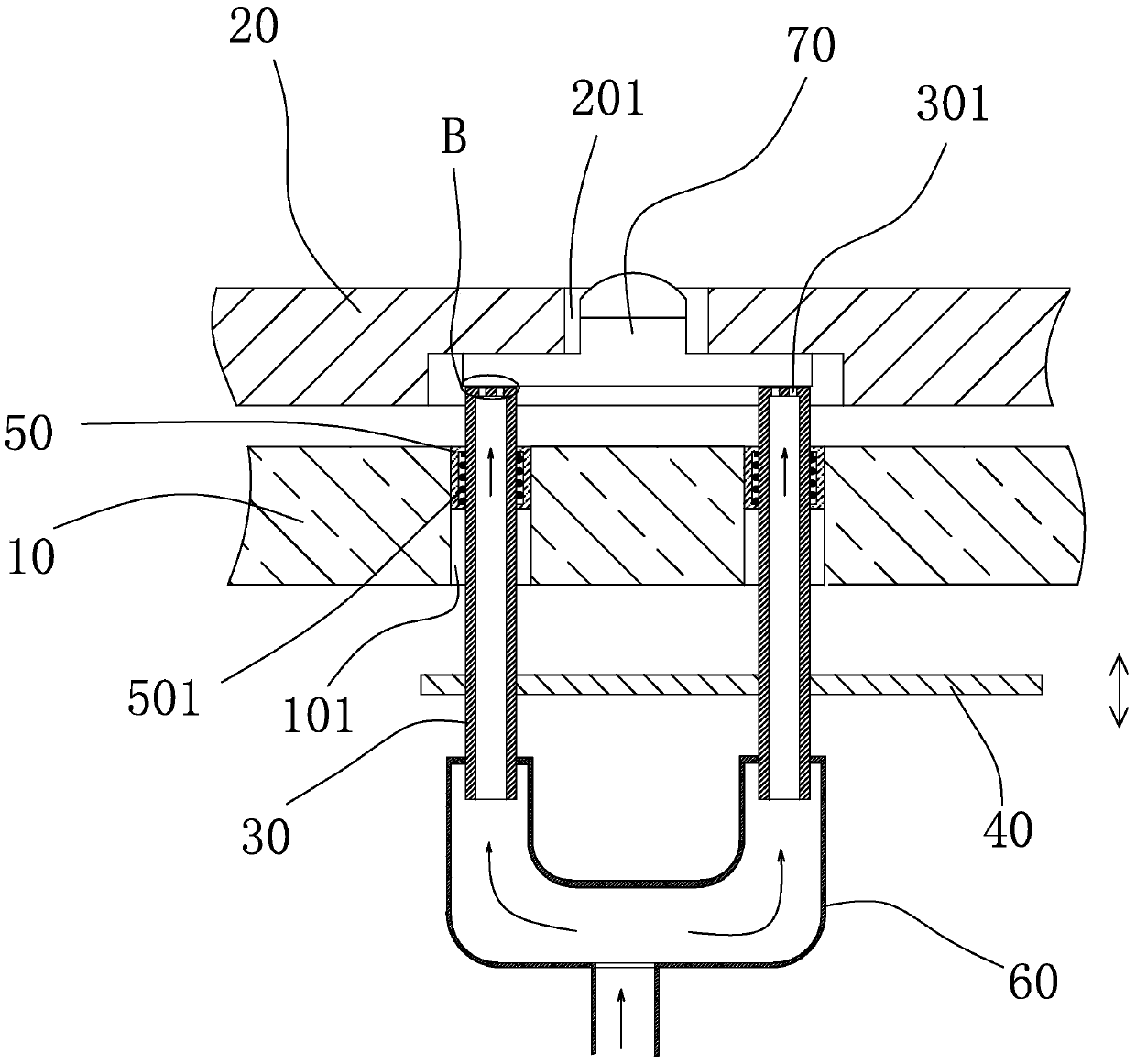

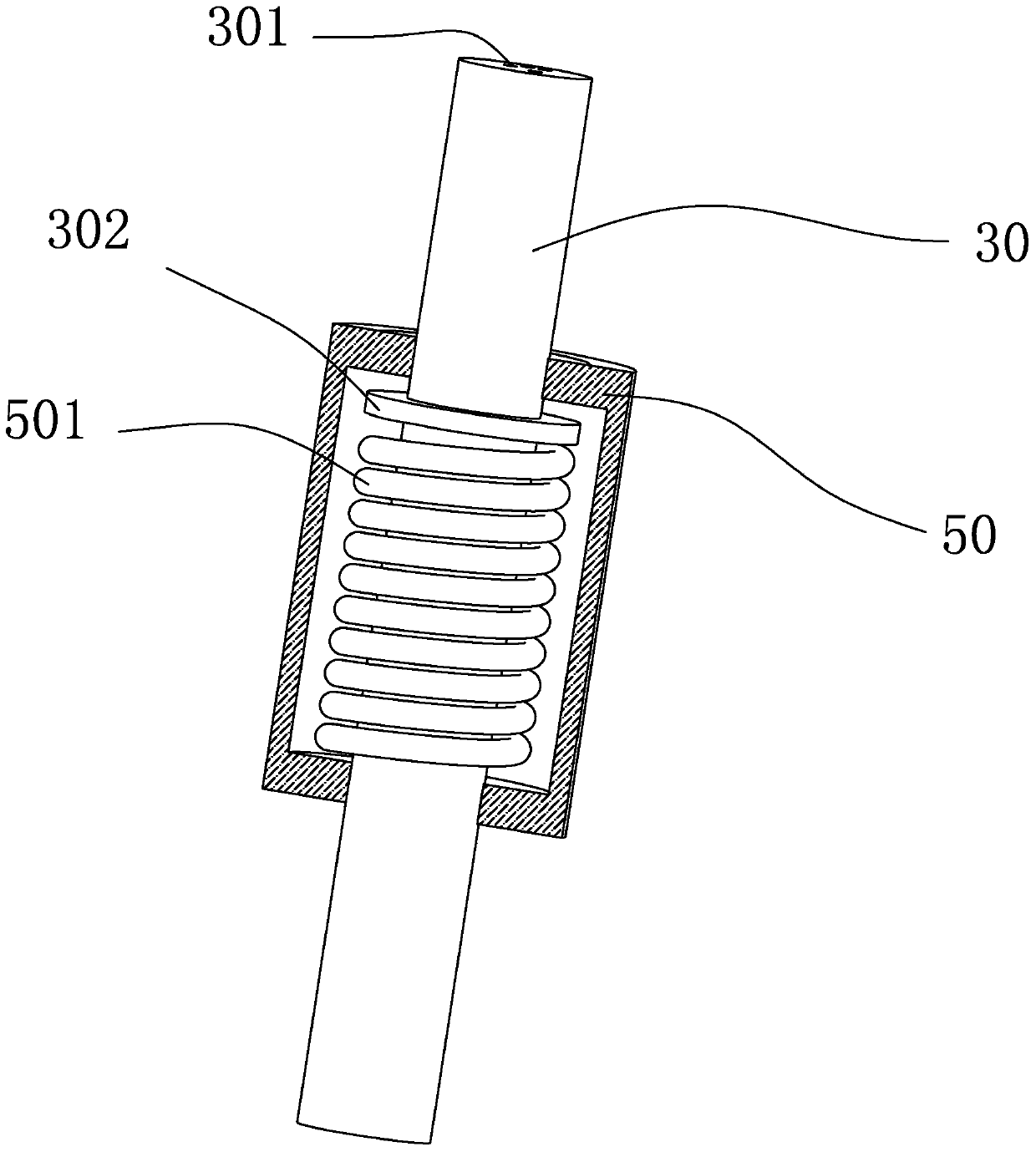

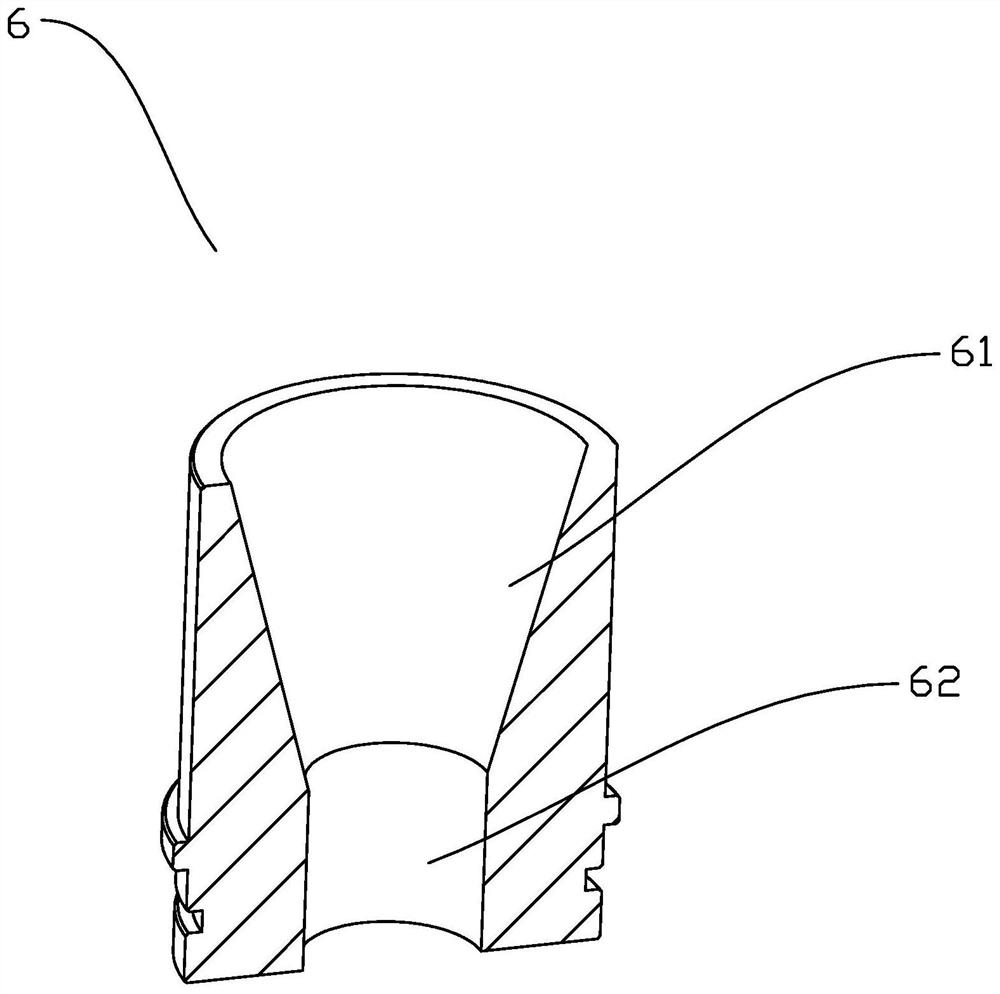

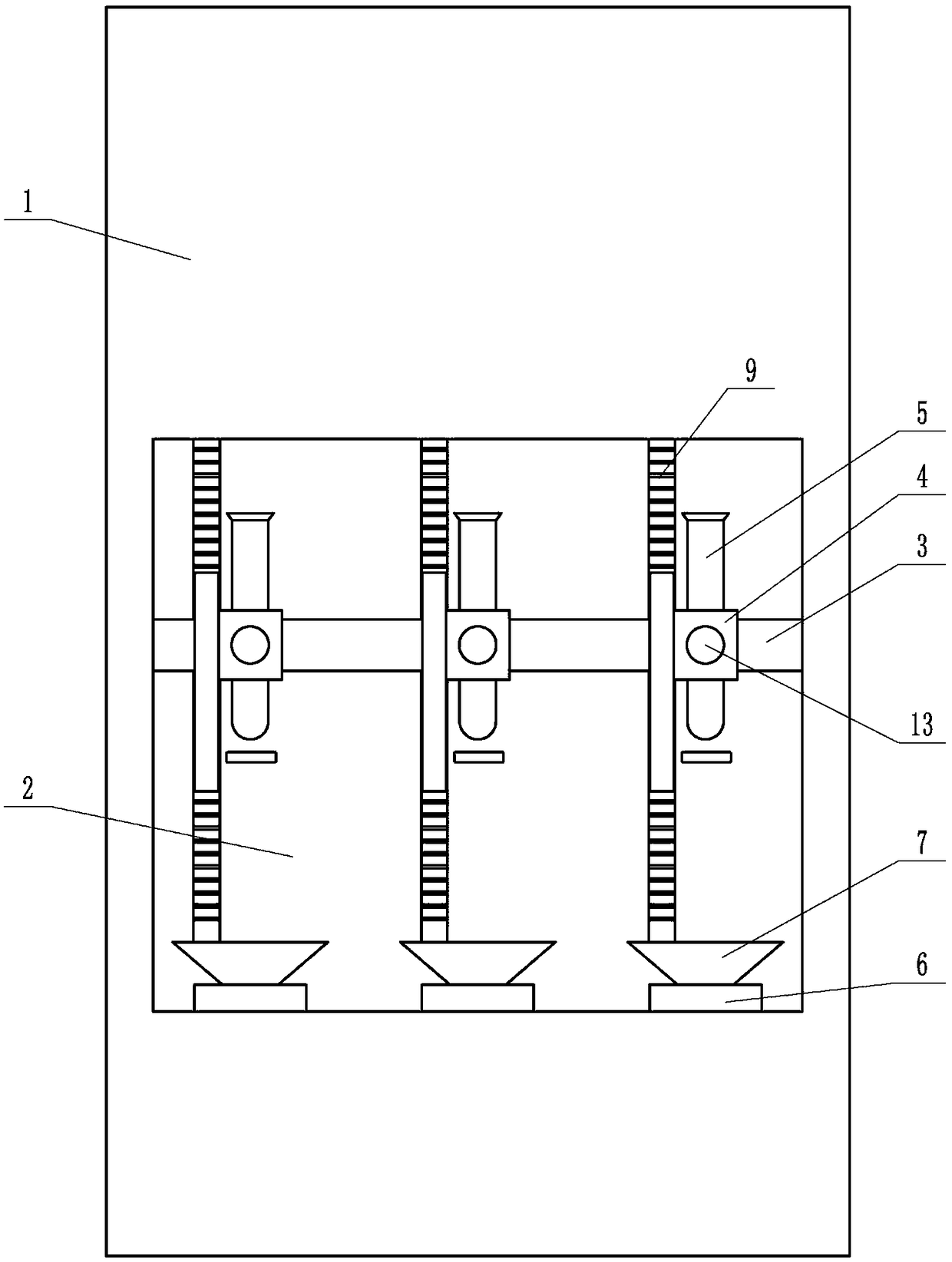

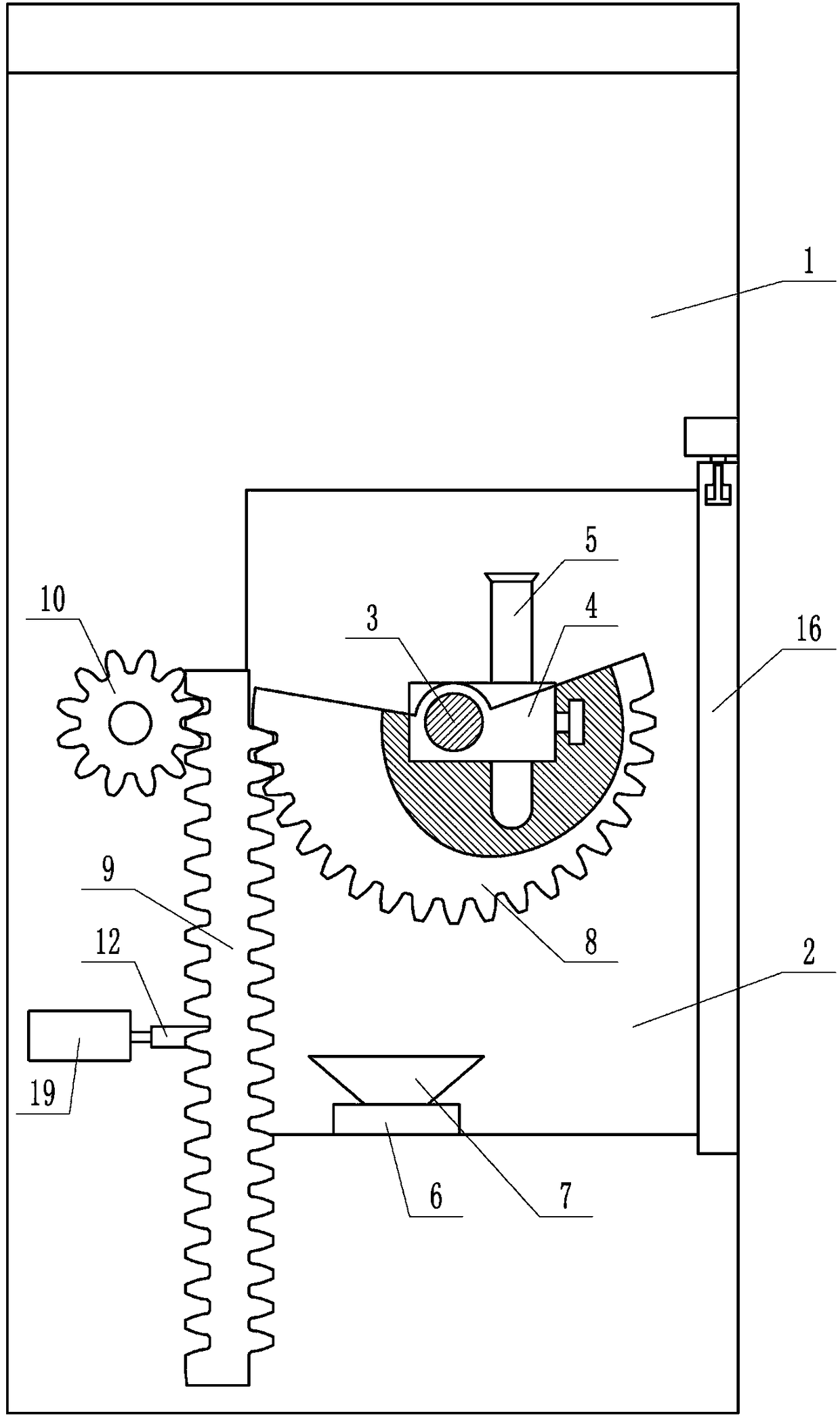

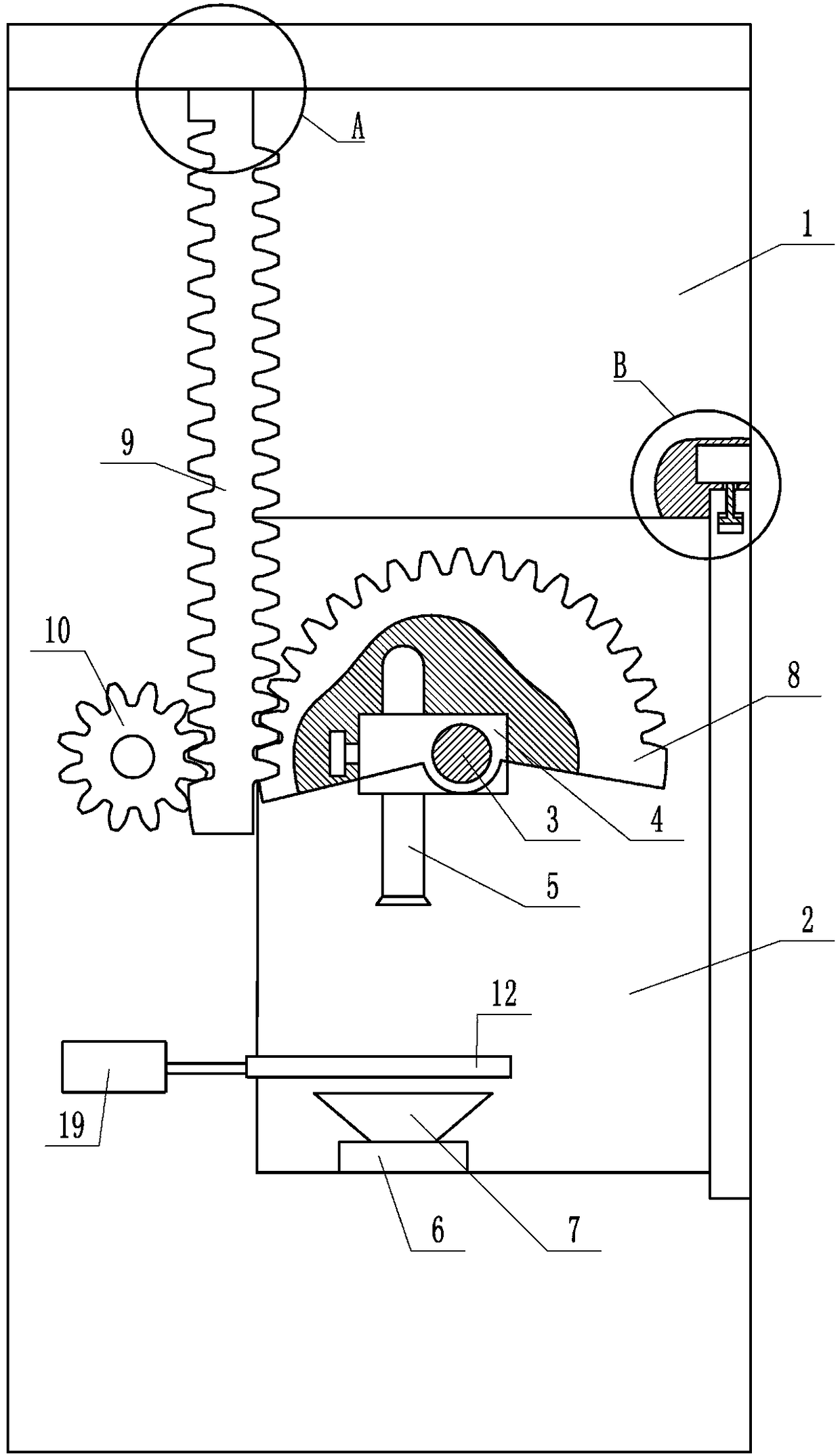

Spot measurement mechanism for LED light sorting machine and LED light sorting machine

ActiveCN105807199AAvoid accumulationIncrease contactDiode testingSortingMeasurement testingEngineering

The invention relates to a spot measurement mechanism for an LED light sorting machine and the LED light sorting machine with the spot measurement mechanism, wherein the spot measurement mechanism is good in probe contact, long in service life, accurate in spot measurement testing and not prone to being stuck.According to the spot measurement mechanism for the LED light sorting machine, probes and an installation structure in the prior art are improved, each probe is provided with an air flow channel, the surface of a probe tip of each probe is provided with vent holes communicated with the corresponding air flow channel, air flow is blown off from the vent holes formed in the surfaces of the probe tips, residual packaging glue remaining on the testing probe tips can be cleaned away, and long-time good contact between the probe tips of the probes and electrode pins of LED lamp beads can be maintained; sleeves are additionally arranged, the sleeves are arranged on the probes in a sleeving mode and fixed in through holes, the probes can move relative to the corresponding sleeves, gaps between a support plate and the probes are filled with the sleeves, the residual packaging glue is prevented from entering the gaps, and contact point deviations caused by transverse displacement of the probes are avoided.The invention further provides the LED light sorting machine with the spot measurement mechanism.

Owner:厦门多彩光电子科技有限公司

A point-measuring mechanism of a led spectrometer and an led spectrometer

The invention relates to a spot measurement mechanism for an LED light sorting machine and the LED light sorting machine with the spot measurement mechanism, wherein the spot measurement mechanism is good in probe contact, long in service life, accurate in spot measurement testing and not prone to being stuck.According to the spot measurement mechanism for the LED light sorting machine, probes and an installation structure in the prior art are improved, each probe is provided with an air flow channel, the surface of a probe tip of each probe is provided with vent holes communicated with the corresponding air flow channel, air flow is blown off from the vent holes formed in the surfaces of the probe tips, residual packaging glue remaining on the testing probe tips can be cleaned away, and long-time good contact between the probe tips of the probes and electrode pins of LED lamp beads can be maintained; sleeves are additionally arranged, the sleeves are arranged on the probes in a sleeving mode and fixed in through holes, the probes can move relative to the corresponding sleeves, gaps between a support plate and the probes are filled with the sleeves, the residual packaging glue is prevented from entering the gaps, and contact point deviations caused by transverse displacement of the probes are avoided.The invention further provides the LED light sorting machine with the spot measurement mechanism.

Owner:厦门多彩光电子科技有限公司

A kind of centroid three-point support redundant measurement equipment

ActiveCN105806562BAvoid test failuresAvoid interruptionWeighing apparatus testing/calibrationStatic/dynamic balance measurementTest efficiencyMeasurement device

The invention relates to mass and center three-point supporting redundancy measuring equipment.The mass and center three-point supporting redundancy measuring equipment comprises three weighing assemblies, a center tray and a base.The center tray is used for carrying a tested object and provided with a positioning part for matched positioning of the tested object.The base supports a mass and center three-point supporting redundancy measuring equipment body.The three weighing assemblies are located between the center tray and the base and are evenly distributed in the circumferential direction.Each weighing assembly comprises an auxiliary weighing sensor, a sphere alignment assembly and a main weighing sensor which are arranged from top to bottom, wherein the auxiliary weighing sensor is stacked on the main weighing sensor through the sphere alignment assembly.According to the measuring equipment, test failures or test interruption caused by failures of weighing sensors is avoided in the process of a three-point supporting method, the other set of sensors can be used for reading numerical values if a certain sensor in one set of sensors breaks down, the phenomenon that the test process needs to be interrupted due to the failure of a certain sensor, and consequently repetition of the processes such as recalibration and reassembling is caused can be avoided, and the testing efficiency is improved.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

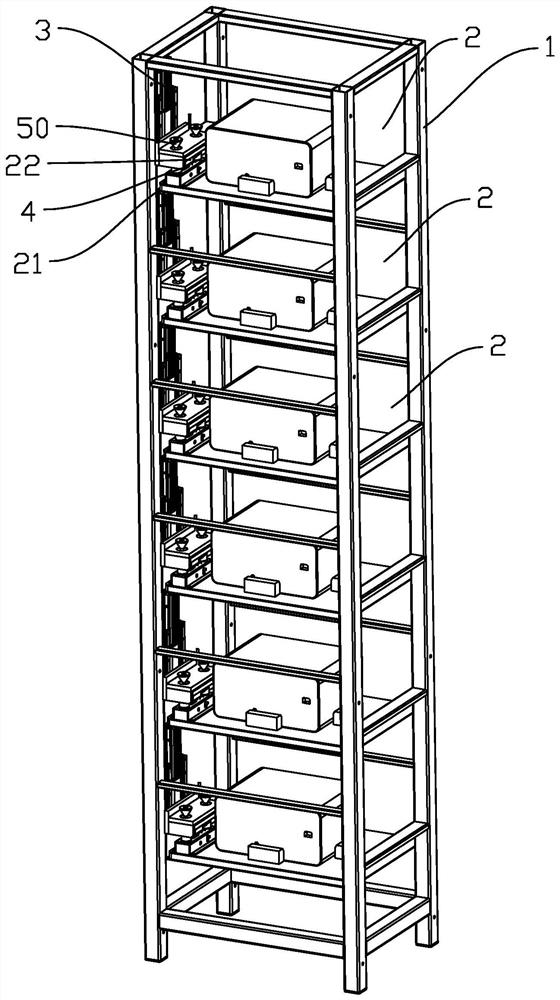

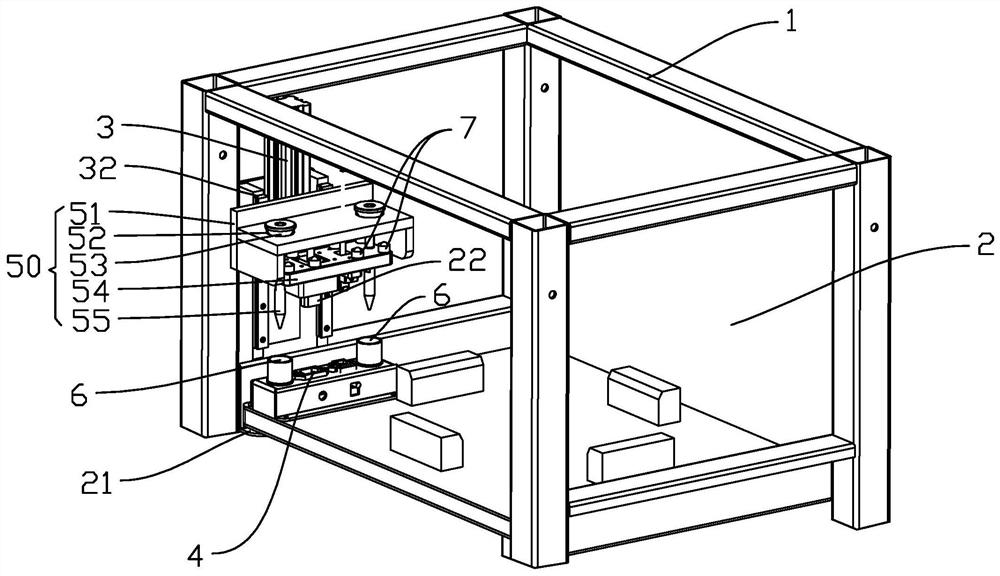

An electrical test component

ActiveCN109655684BAvoid test failuresGuaranteed work efficiencyElectrical testingMeasurement instrument housingDrive by wireControl engineering

The invention discloses an electrical test assembly, which comprises a frame, at least one test station is arranged on the frame, the test station has a supporting part for placing a tooling board with products, and the test station is movable A test plug assembly is provided, the test plug assembly is located above the supporting part, and the test station is provided with a linear driver for driving the test plug assembly to move up and down relative to the supporting part, and the test plug assembly and the test socket on the tooling board There is a deviation correcting structure for adjusting the relative position of the two. The electrical test assembly with the above structure uses a linear driver to drive the test plug assembly up and down to move closer to or away from the test socket on the tooling board, and at the same time uses the correction structure to adjust the relative position between the test plug assembly and the test socket, so as to realize the function of correction and avoid The test plug assembly and the test socket cannot be accurately docked, thereby avoiding test failure and ensuring the working efficiency of the test process.

Owner:ZHONGSHAN TUODIAN ELECTRONICS TECH

Device used for testing asphalt low-temperature flowability

InactiveCN108872015AThe test result is accurateAvoid test failuresDirect flow property measurementAutomatic controlEngineering

The invention provides a device used for testing asphalt low-temperature flowability. The device effectively solves the problem of test result inaccuracy due to cold repairing asphalt dripping in theexisting test process. In order to solve the problems, the device has the technical scheme that the device comprises a box body, wherein a temperature cabin is arranged in the box body; a fixing shaftis transversely arranged at the upper part in the temperature cabin; a plurality of test tube frames are rotationally connected on the fixing shaft; test tubes are arranged on the test tube frames; aplurality of electronic scales positioned right under the test tubes are arranged at the bottom in the temperature cabin; a paper cup for collecting cold repairing asphalt is put on the electronic scale. Compared with the prior art, the device has the advantages that a paper cup sealing and blocking device is added, so that the test result inaccuracy due to cold repairing asphalt dripping in thetest tube rotating process is prevented; in addition, the whole test process is set to be the automatic control; the manual operation is not needed, so that the test failure due to wrong operation isavoided; the test tube rotation and the circuit control are combined; the control is performed through a sensor; higher accuracy and sensitivity are realized.

Owner:张素红 +1

A clamping and fixing device for compressing metal sheets

ActiveCN107727489BRealize the quadratic constraintAvoid test failuresStrength propertiesTest sampleMetallic materials

The invention relates to a clamping fixing device for compressing a metal sheet. The device utilizes a base to position and fix clamping blocks and a test sample; vertical trapezoid grooves are processed on contact surfaces of the clamping blocks and the test sample; the gauge length at the width center of the test sample is visible in the middle through slots of the clamping blocks; guiding rodsare arranged on diagonal positions of the clamping blocks so as to align the two clamping blocks; eight full-thread hex head screws are penetrated into the first clamping block and out from the secondclamping block; gaskets and nuts are arranged at the tail ends of the bolts; uniform symmetrical pressure is applied to the clamping blocks, so that the test sample is prevented from being unstable;four half-thread hex head screws are penetrated into four lug bosses on the base, are inserted into the blind holes on the two sides of the middle part of the clamping blocks and are twisted; the clamping blocks are used for clamping the test sample for the second time and supplying effective support, so that the test sample is prevented from bending damage. The clamp is designed according to therequirement of metallic material compression test standard, is convenient and easy in operation and can be applied to the standard compression tests for various metal sheets in various thicknesses.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com