A kind of centroid three-point support redundant measurement equipment

A measuring equipment and three-point support technology, which is applied in the direction of measuring devices, weighing equipment testing/calibration, testing of machines/structural components, etc., can solve problems such as complicated processes and inability to make timely judgments, reduce the number of calibrations, and realize Automatic centering, avoiding the effect of recalibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

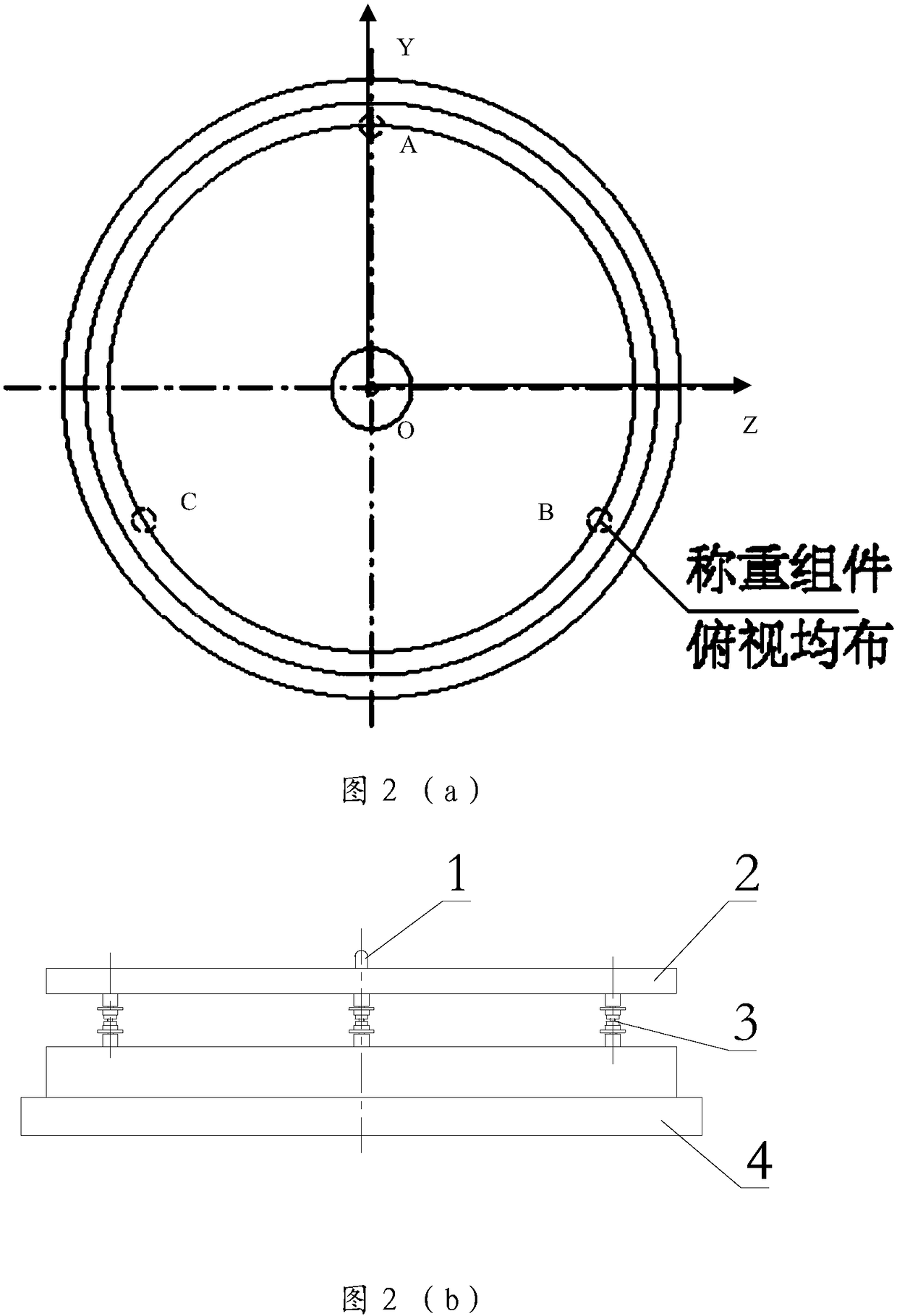

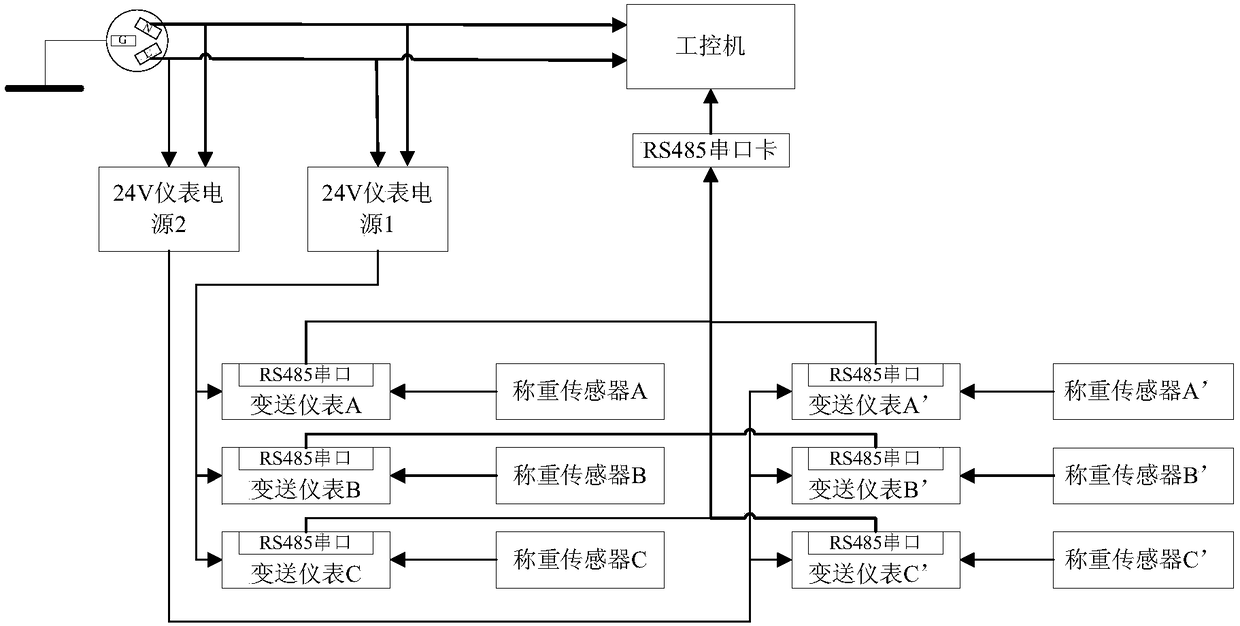

[0026] The mass centroid three-point support redundant measurement equipment includes the mass centroid redundant test bench main structure, control system hardware and software, etc.

[0027] The main structure of the centroid redundant test bench is composed of three weighing components, a centroid disk and a base.

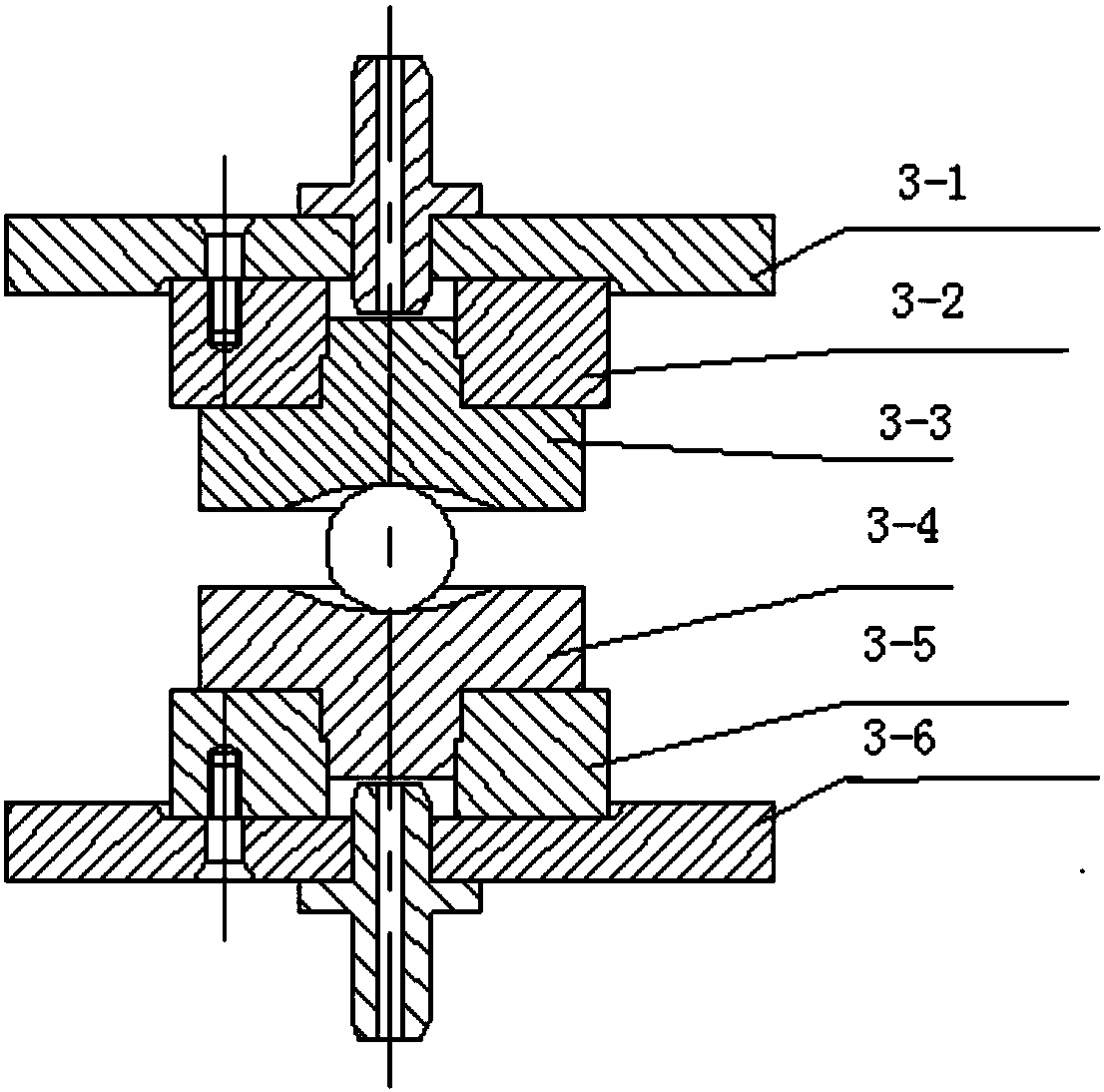

[0028] The 3 weighing components have the same structure, see figure 1 , each weighing assembly includes a top-down auxiliary load cell 3-2, a sphere centering assembly, and a main load cell 3-5, and the auxiliary load cell 3-2 is stacked through a sphere centering assembly To the main load cell 3-5, the sub-load cell 3-2 and the main load cell 3-5 are applied in opposite directions and have the same magnitude. The weighing assembly also includes a secondary load cell mounting plate 3-1, an upper positioning column, a main load cell mounting plate 3-6 and a lower positioning column; the lower surface of the secondary load cell mounting plate 3-1 is used to inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com