An electrical test component

A test component and electrical technology, which is applied to the parts of electrical measuring instruments, measuring electricity, measuring devices, etc., can solve the problems of inaccurate connection between test plug components and test sockets, test failures, affecting test work efficiency, etc., to avoid problems such as Inability to accurately connect, avoid test failures, and ensure the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

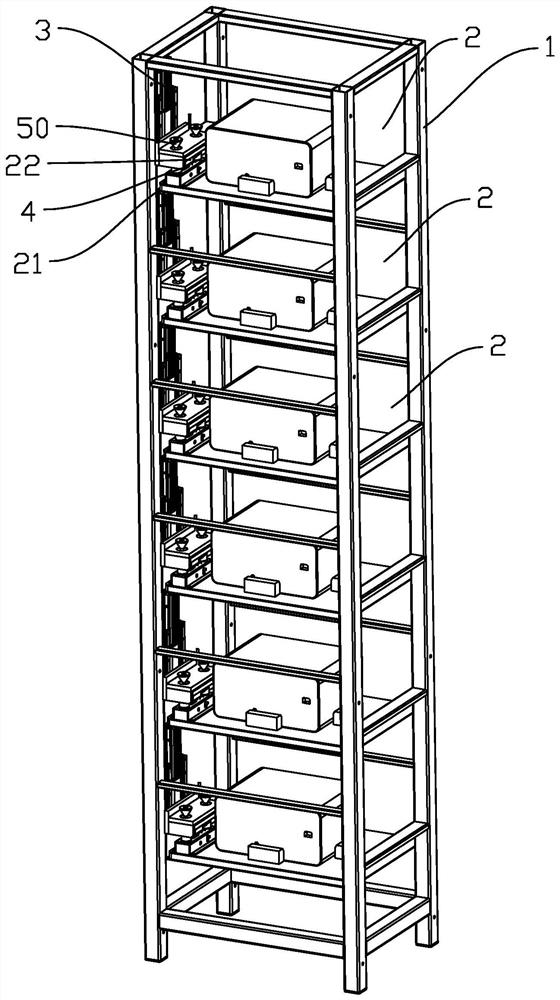

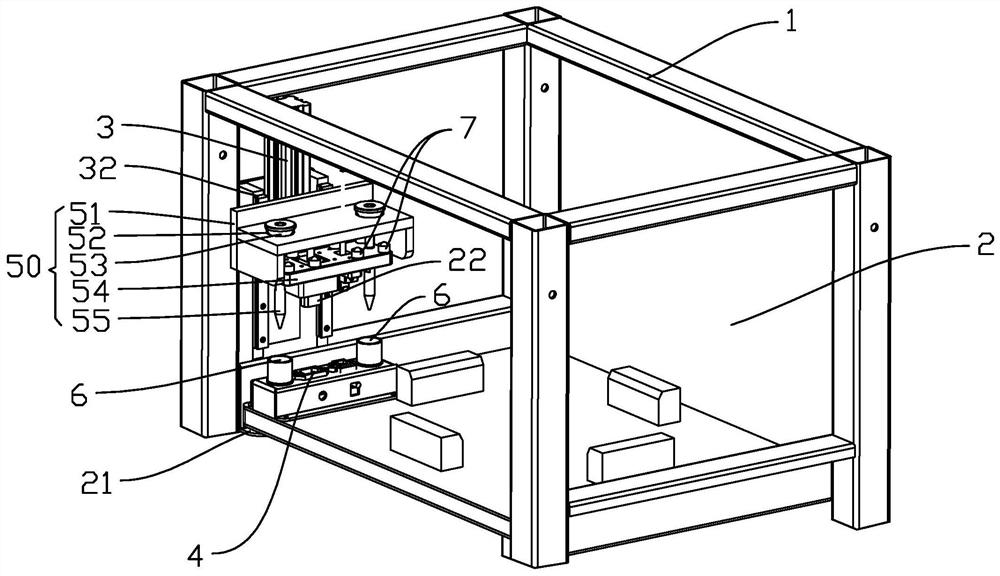

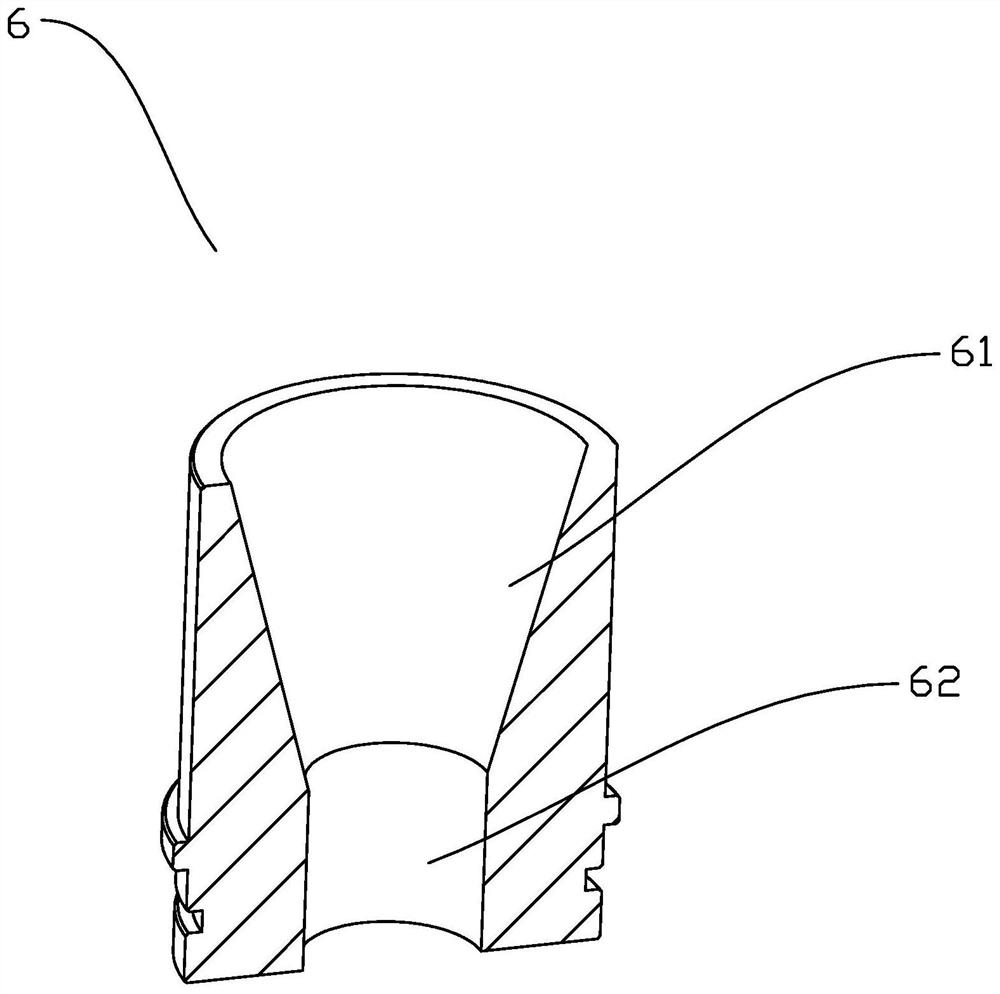

[0017] refer to Figure 1 to Figure 3 , an electrical test assembly of the present invention, comprising: a frame 1, at least one test station 2 is arranged on the frame 1, and the test station 2 has a supporting part 21 for placing a tooling plate with a product A test plug assembly 22 is movable on the test station 2, the test plug assembly 22 is located above the supporting part 21, and the test station 2 is provided with a linear drive for driving the test plug assembly 22 to move up and down relative to the supporting part 21 3. There is a deflection correction structure 50 between the test plug assembly 22 and the test socket 4 on the tooling board for adjusting the relative position of the two. The electrical test assembly of the above structure utilizes the linear driver 3 to drive the test plug assembly 22 to move up and down to approach or stay away from the test socket 4 on the tooling board, and simultaneously utilizes the deviation correction structure 50 to adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com