Semiconductor refrigeration chip aging test device

A technology of aging test and cooling chip, which is applied in the direction of semiconductor working life test and single semiconductor device testing, etc. It can solve the problems of low test accuracy and low efficiency of semiconductor cooling chip aging test, so as to prevent test failure and prevent test failure. Inefficiency, the effect of guaranteeing the test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

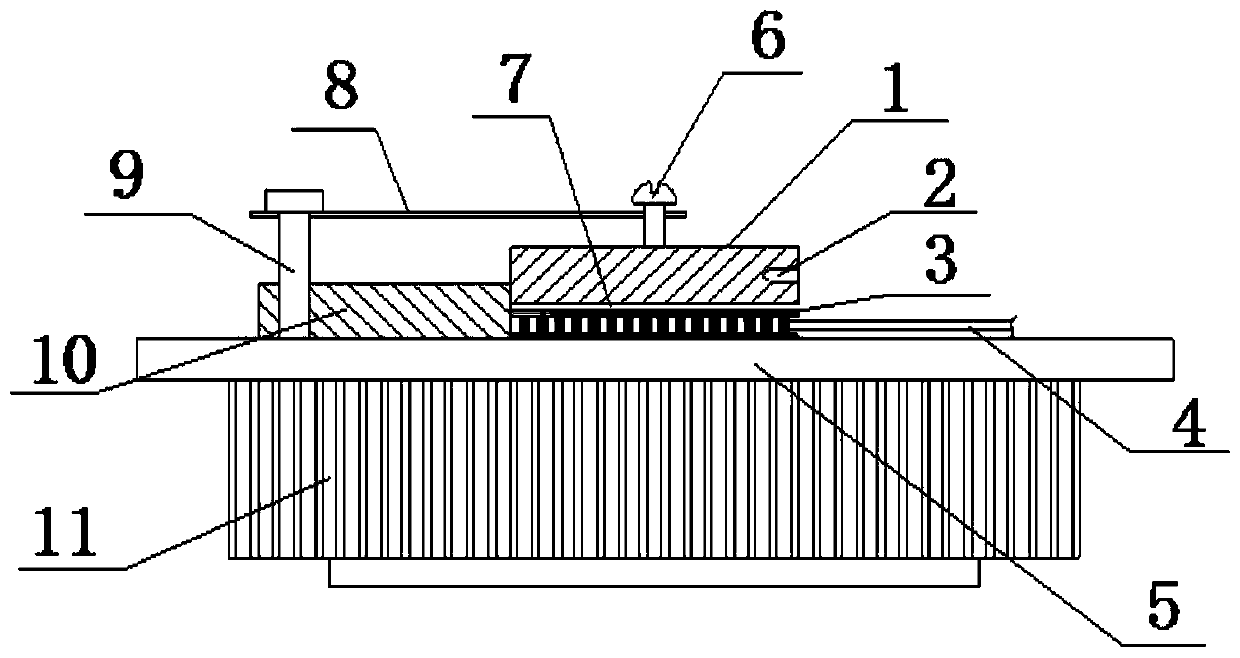

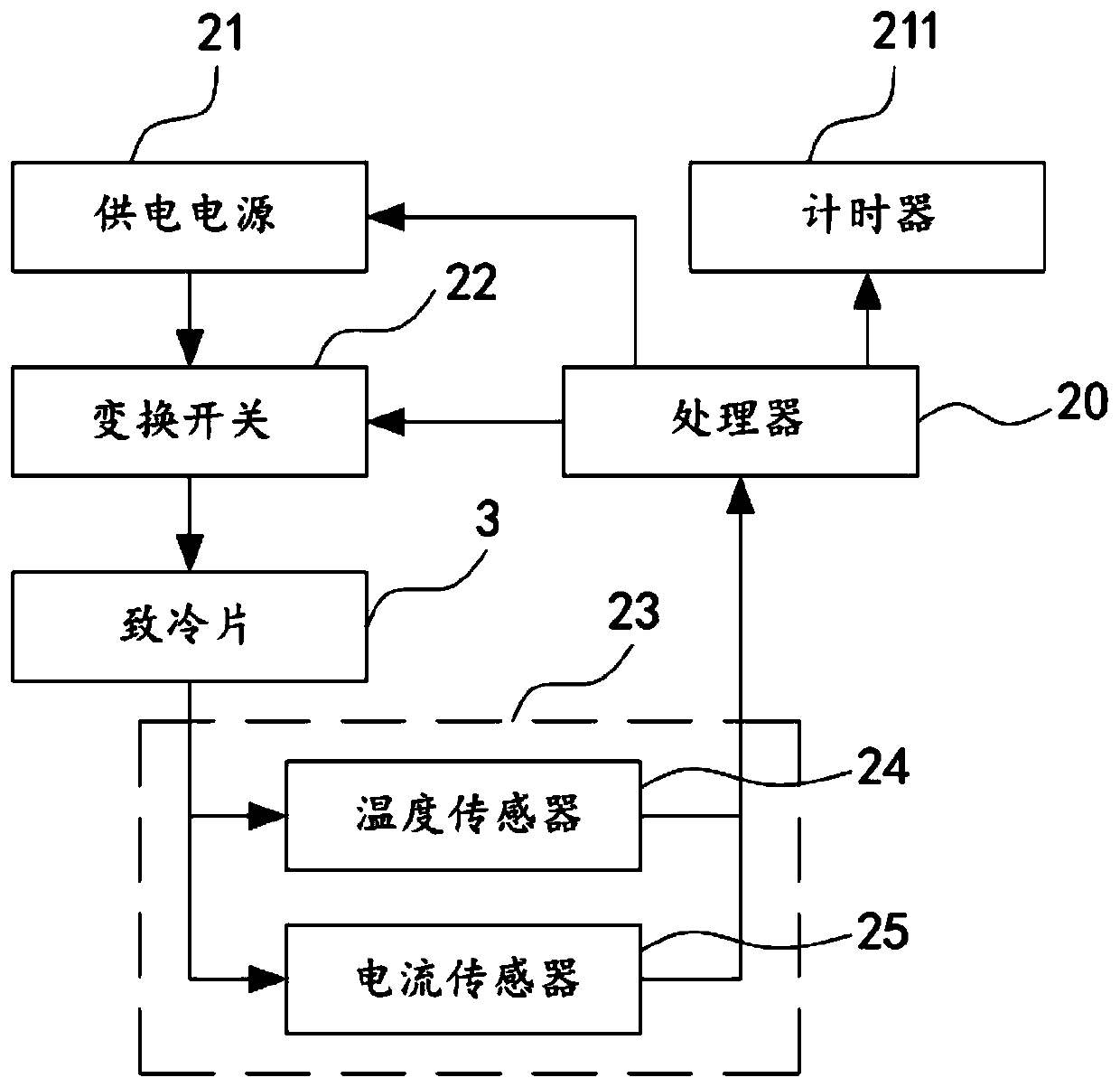

[0027] Example 1, see Figure 1 to Figure 2 , The first embodiment of the present invention provides a semiconductor refrigeration chip aging test device, including a test bench 5, a limit assembly arranged on the test bench 5, a first heat conduction plate 1 connected to the limit assembly, The second heat conduction plate 11 located at the bottom of the test bench 5 and the test controller electrically connected to the refrigerating plate 3 to be tested, the bottom surface of the first heat conducting plate 1 is attached to the top surface of the refrigerating plate 3 to be tested. Together, the test bench 5 is used to play the role of bearing and fixing the limit assembly, the first heat conduction plate 1, the second heat conduction plate 11 and the test controller, so as to improve the aging test of the semiconductor refrigeration plate. The stability of the overall structure of the device, the limit assembly is used to prevent the position of the refrigerating plate 3 to...

Embodiment 2

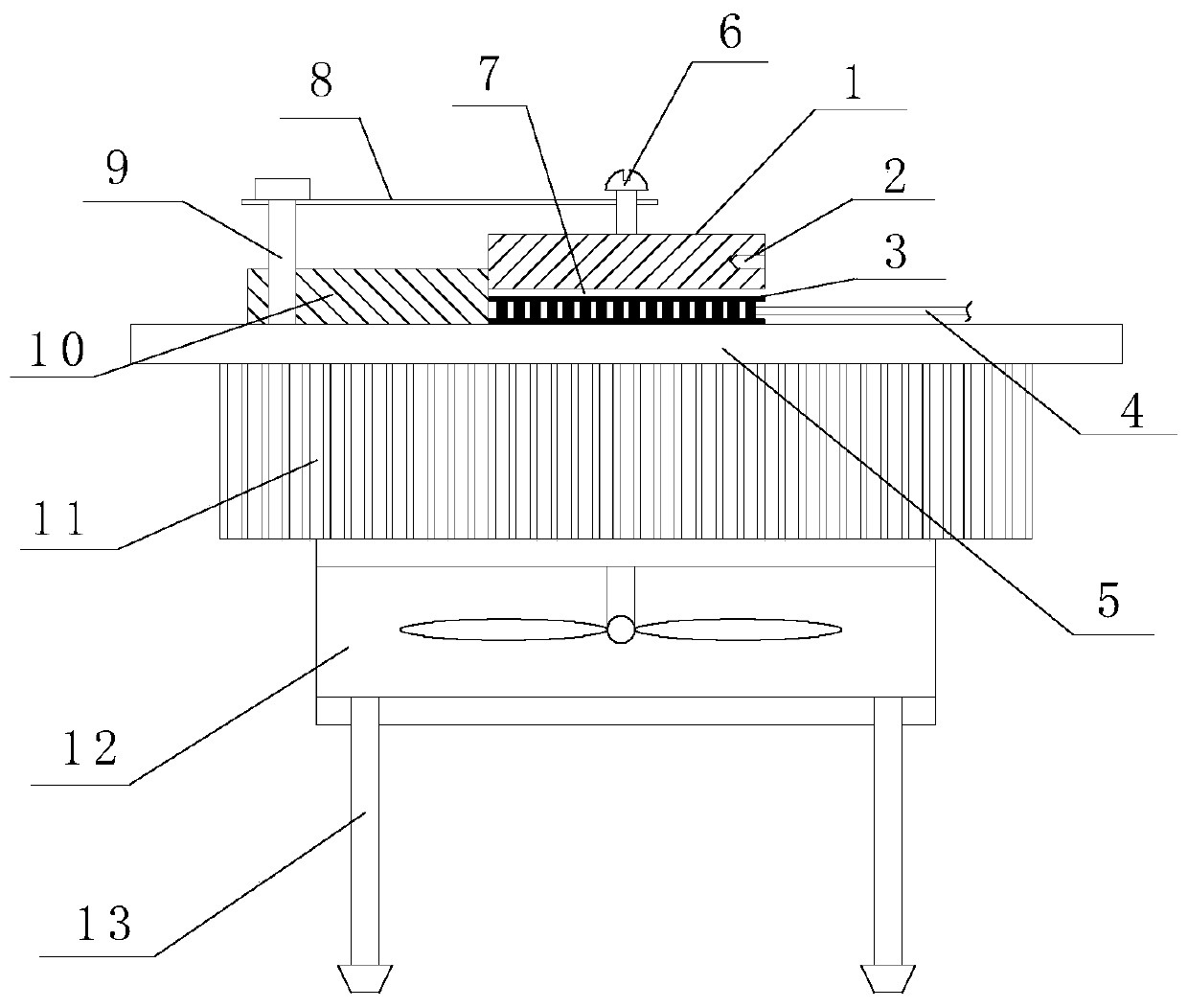

[0042] Embodiment 2, with reference to image 3 It is a schematic structural diagram of a semiconductor refrigeration chip aging test device provided by the second embodiment of the present invention. The structure of the second embodiment is roughly the same as that of the first embodiment. The difference is that in this embodiment, the second heat conducting plate 11 is provided with a ventilation cooling seat 12 on the side facing away from the test bench 5, and a cooling fan is arranged inside the ventilation cooling seating 12, and the cooling fan is used to improve the heat conduction efficiency of the second heat conducting plate 11. The bottom of the ventilation heat dissipation seat 12 is provided with a plurality of support feet 13, and the end of the support feet 13 is provided with a rubber pad, and the rubber pad is used to improve the friction between the support feet 13 and the ground, thereby effectively preventing the The movement of the positions of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com