Testing system for material erosion resistance

A test system and anti-erosion technology, applied in analytical materials, measuring devices, weather resistance/light resistance/corrosion resistance, etc., can solve the problem of affecting the accuracy and reliability of test results, unfavorable simulation test samples, and insufficient test functions and other problems, to achieve and guarantee the results of test results, flexible test operations, and comprehensive test operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

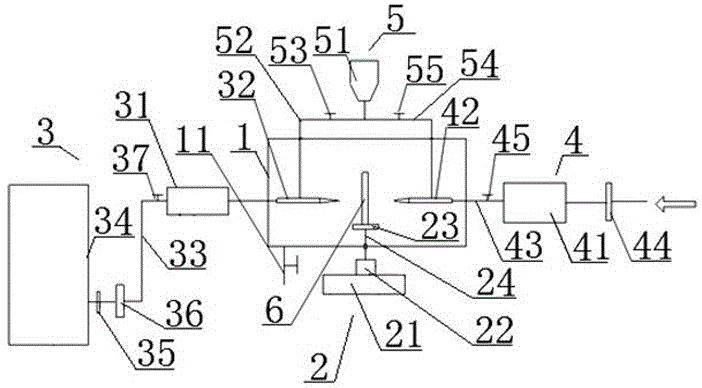

[0023] see figure 1 Shown, the present invention is the test system of material anti-erosion property, and the carrier of this material is the parts and components of industrial equipment, such as steam turbine blade, promptly the surface of blade is provided with the protection material that needs to test, and in test experiment, the steam turbine blade Part of it is sample 6, that is, sample 6 is a sample of the blade. The test system includes a test chamber 1 , a sample control mechanism 2 , a water erosion test part 3 , a cavitation test part 4 and a particle addition part 5 .

[0024] Wherein, the test chamber 1 is a space for the entire test operation, which is in the shape of a box. The center of the test chamber 1 is used to clamp the sample 6 through the sample control mechanism 2; the two opposite side walls of the test chamber 1 are used to arrange the water erosion test part 3 and the cavitation test part 4; There is a sewage outlet, and a sewage valve 11 is seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com