Method for detecting hydrogen, oxygen and nitrogen in titanium sponge

A technology of sponge titanium and oxyhydrogen, which is applied in the direction of testing metals, material inspection products, etc., can solve the problems of unstable test results, crucible rupture, test failure, etc., so as to avoid test failure phenomenon, improve detection efficiency, and improve detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

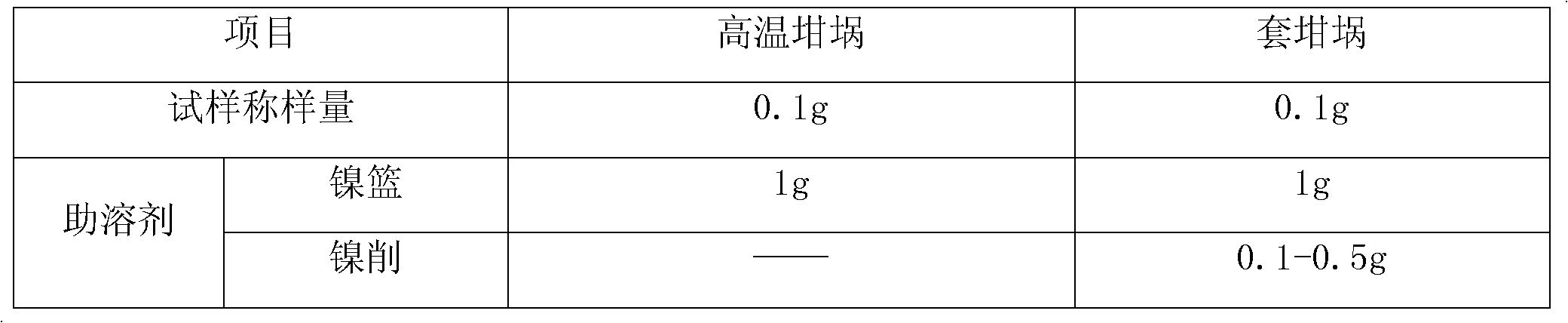

[0025] 1. Sample weight: titanium sponge standard sample 0.0967g, nickel basket 1g, nickel cut 0.2g.

[0026] 2. Melt the sample in step 1 with a set of crucibles (leco, USA).

[0027] 3. Adjust the parameters of the nitrogen, hydrogen and oxygen combined analyzer (lecoTCH600 in the United States), the exhaust low power is 6200W, the exhaust high power is 6200W, the analysis low power is 100W, and the analysis high power is 5500W.

[0028] 4. The test results are shown in Table 3:

[0029] table 3

[0030] Sample container

Embodiment 2

[0032] 1. Sample weight: titanium sponge standard sample 0.1053g, nickel basket 1g, nickel cut 0.2g.

[0033] 2. Melt the sample in step 1 with a set of crucibles.

[0034] 3. Adjust the parameters of the nitrogen, hydrogen and oxygen combined analyzer (lecoTCH600 in the United States), the exhaust low power is 6200W, the exhaust high power is 6200W, the analysis low power is 100W, and the analysis high power is 5500W.

[0035] 4. The test results are shown in Table 4:

[0036] Table 4

[0037] Sample container

Embodiment 3

[0039] 1. Test sample weight: 0.0955g of titanium sponge, 1g of nickel basket, 0.2g of nickel chipping.

[0040] 2. Melt the sample in step 1 with a set of crucibles.

[0041] 3. Adjust the parameters of the nitrogen, hydrogen and oxygen combined analyzer (lecoTCH600 in the United States), the exhaust low power is 6200W, the exhaust high power is 6200W, the analysis low power is 100W, and the analysis high power is 5500W.

[0042] 4. The test results are shown in Table 5:

[0043] table 5

[0044] Sample container

[0045] The above examples illustrate that after adjusting the parameters of the nitrogen-hydrogen-oxygen combined measuring instrument in the present invention, when the hydrogen, oxygen and nitrogen in sponge titanium are measured with the crucible, the error rate of the crucible is small and the measurement result is accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com