Patents

Literature

1083 results about "Paper cup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A paper cup is a disposable cup made out of paper and often lined or coated with plastic or wax to prevent liquid from leaking out or soaking through the paper. It may be made of recycled paper and is widely used around the world.

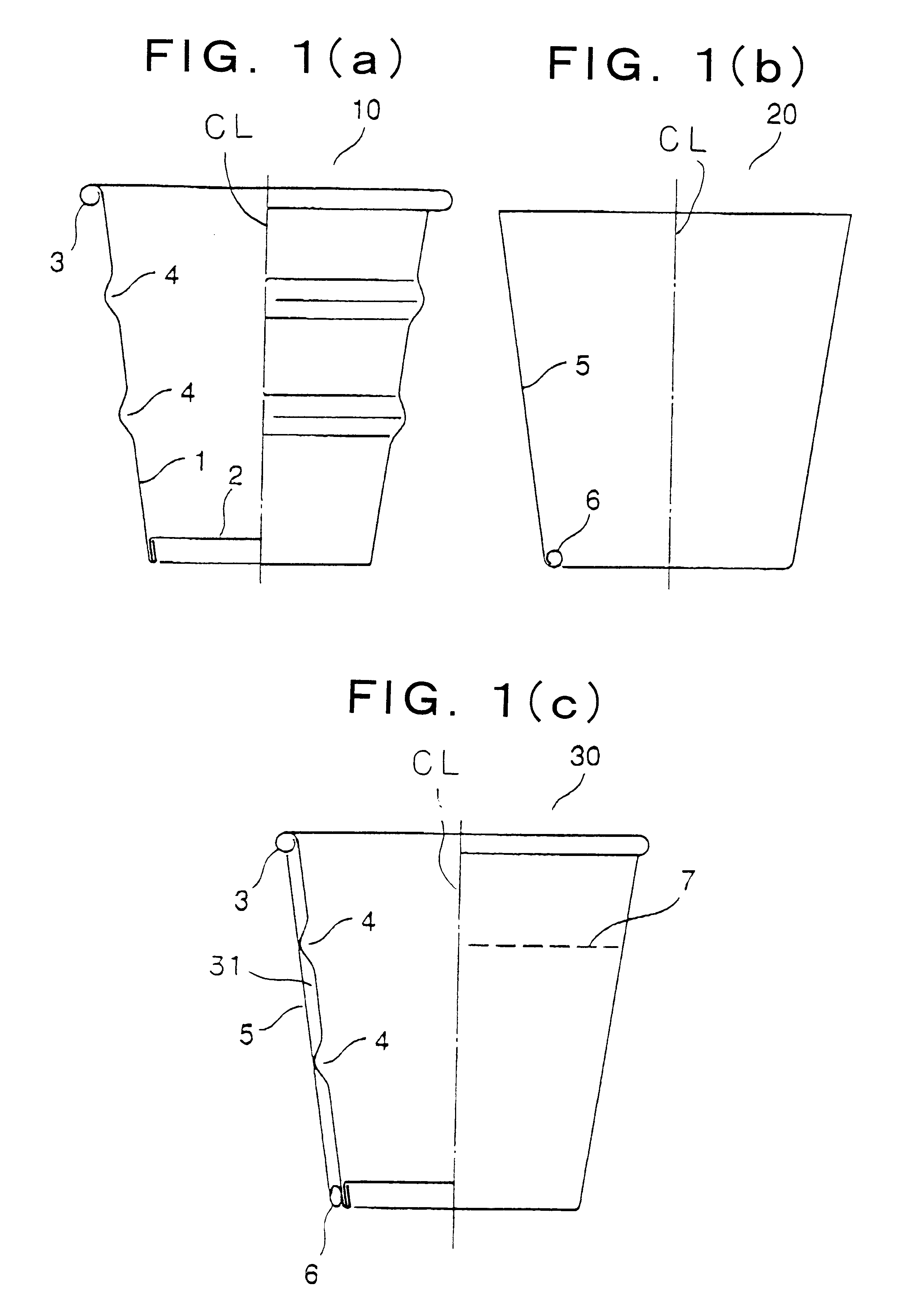

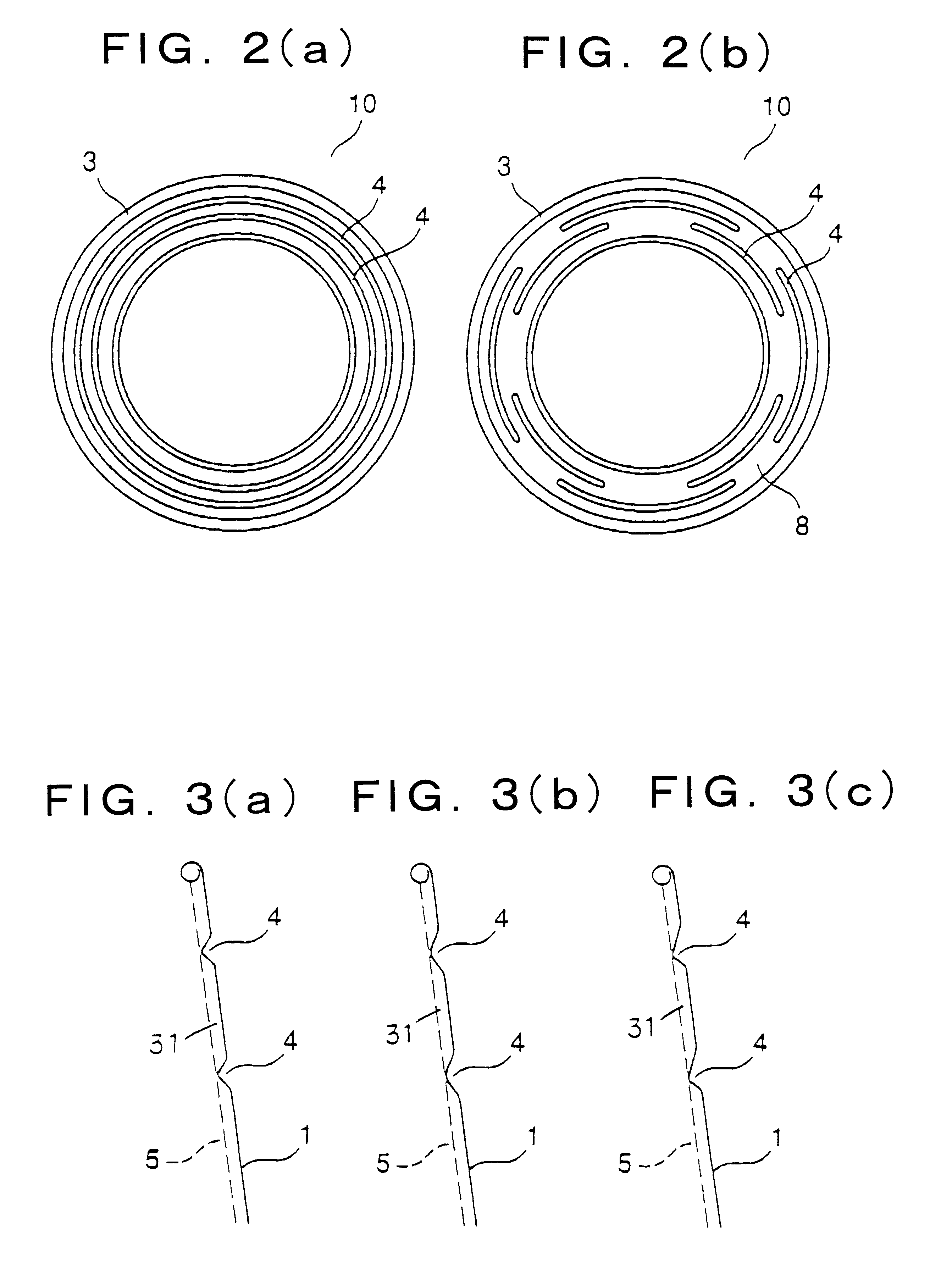

Insulating container

InactiveUS6193098B1Improve insulation performanceImprove securityBoxes/cartons making machineryDomestic cooling apparatusEngineeringPaper cup

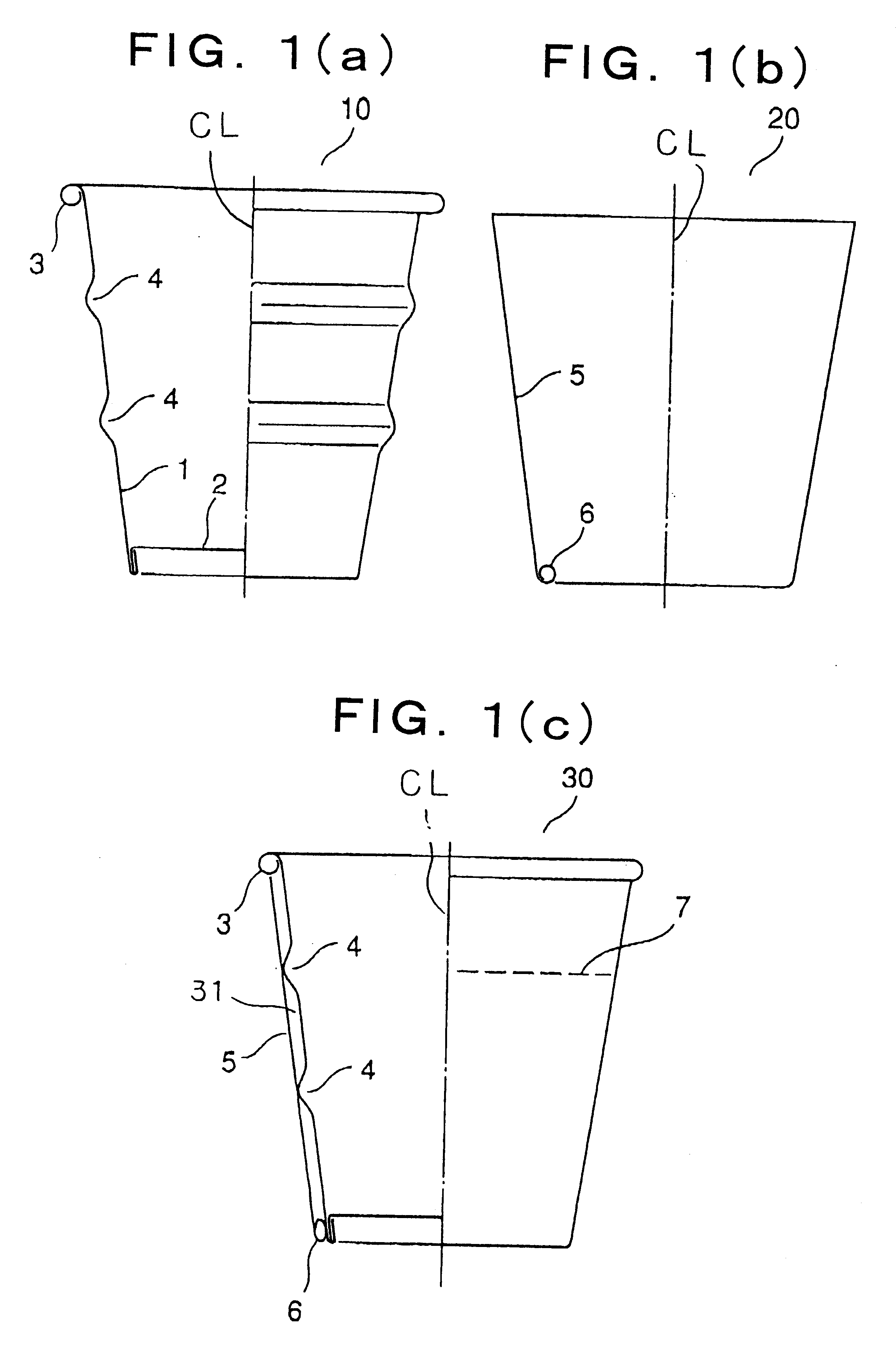

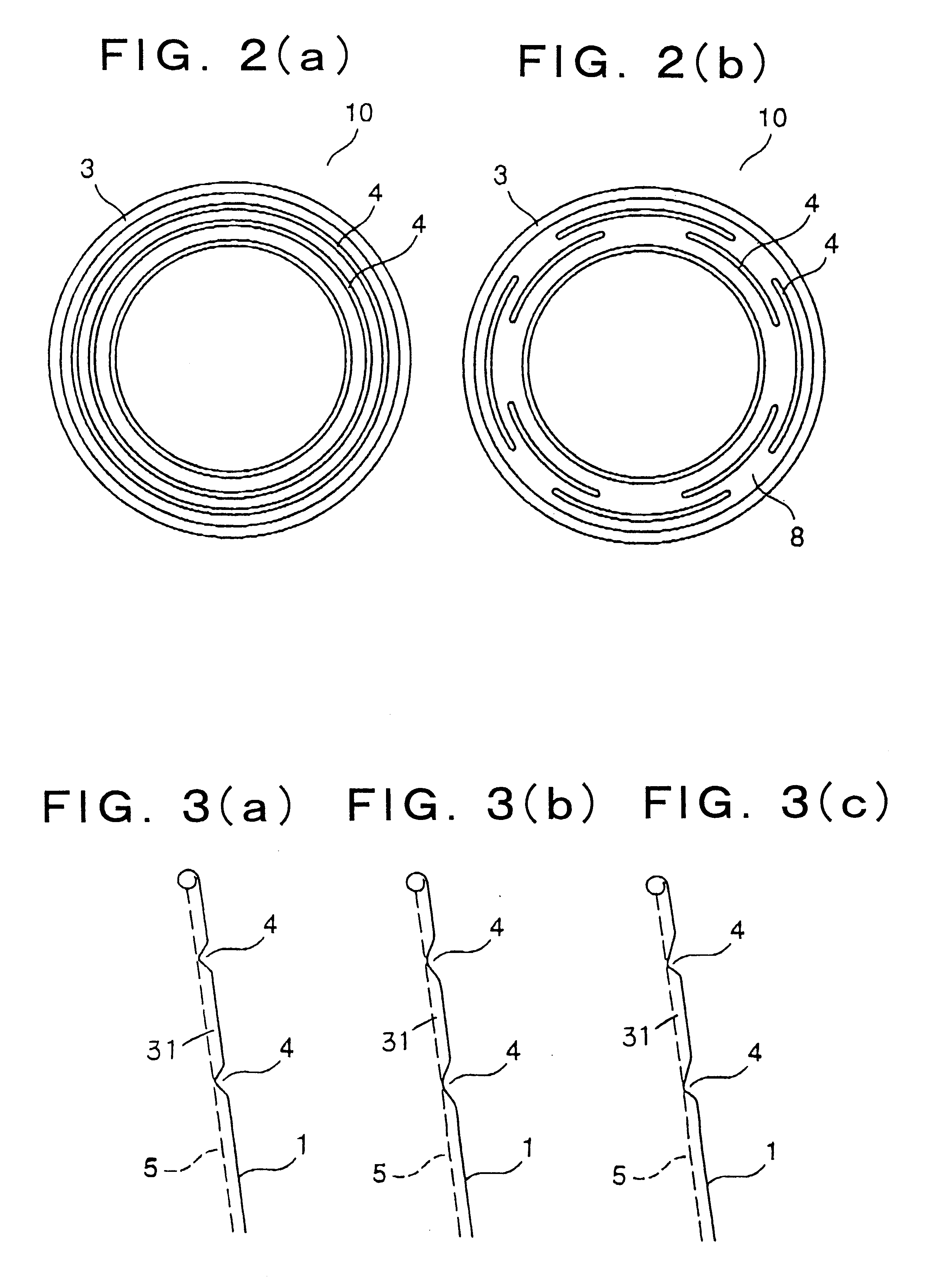

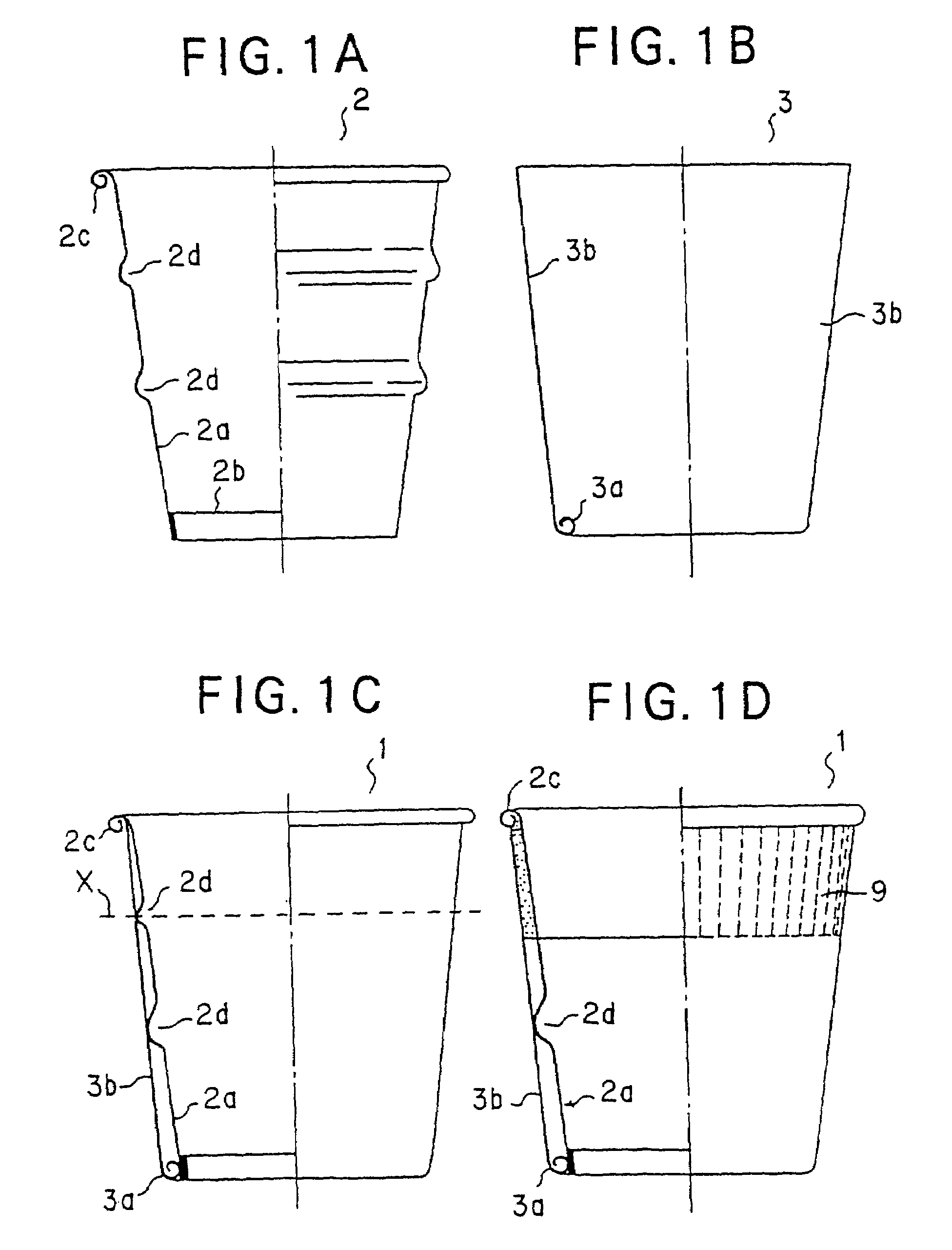

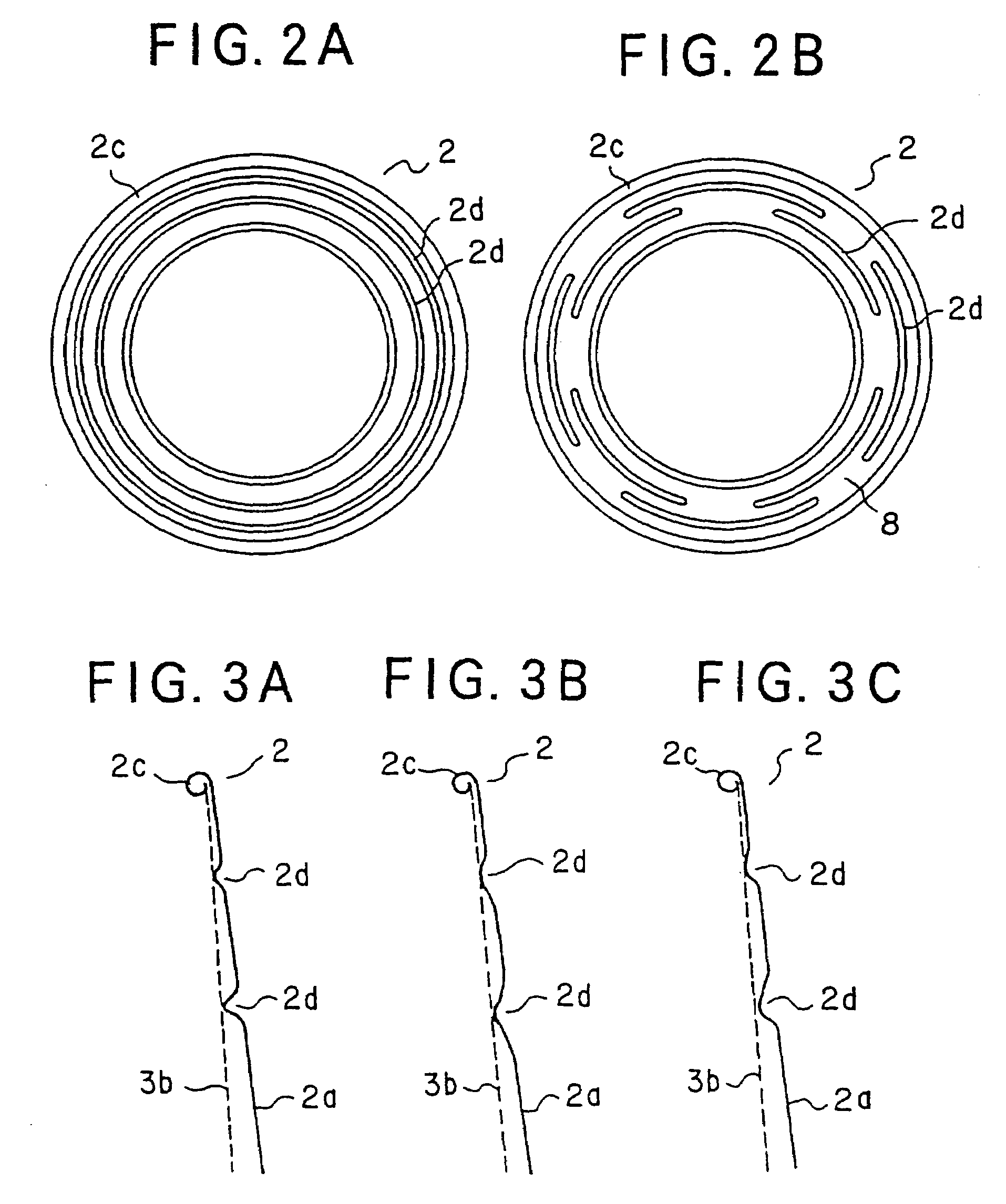

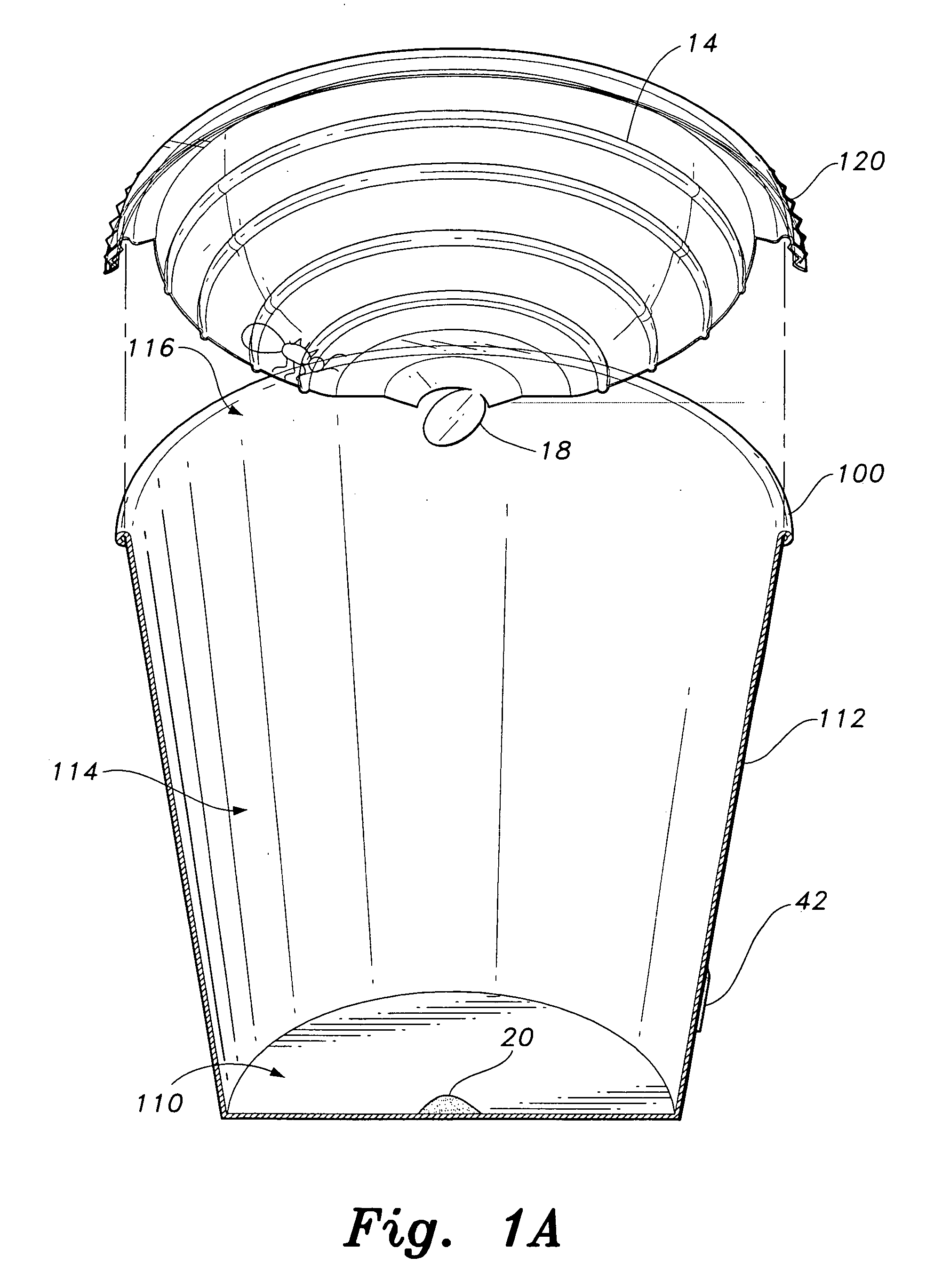

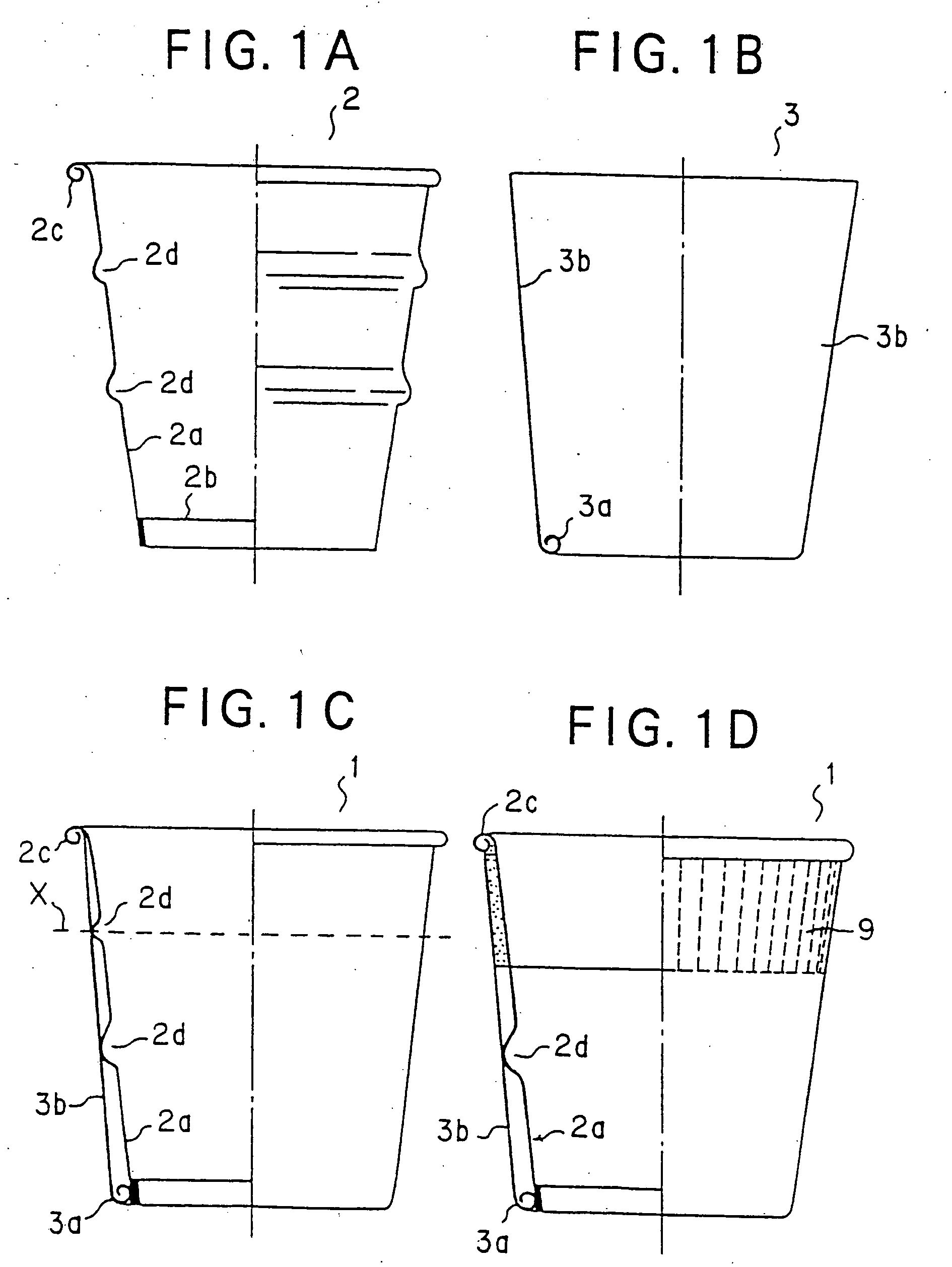

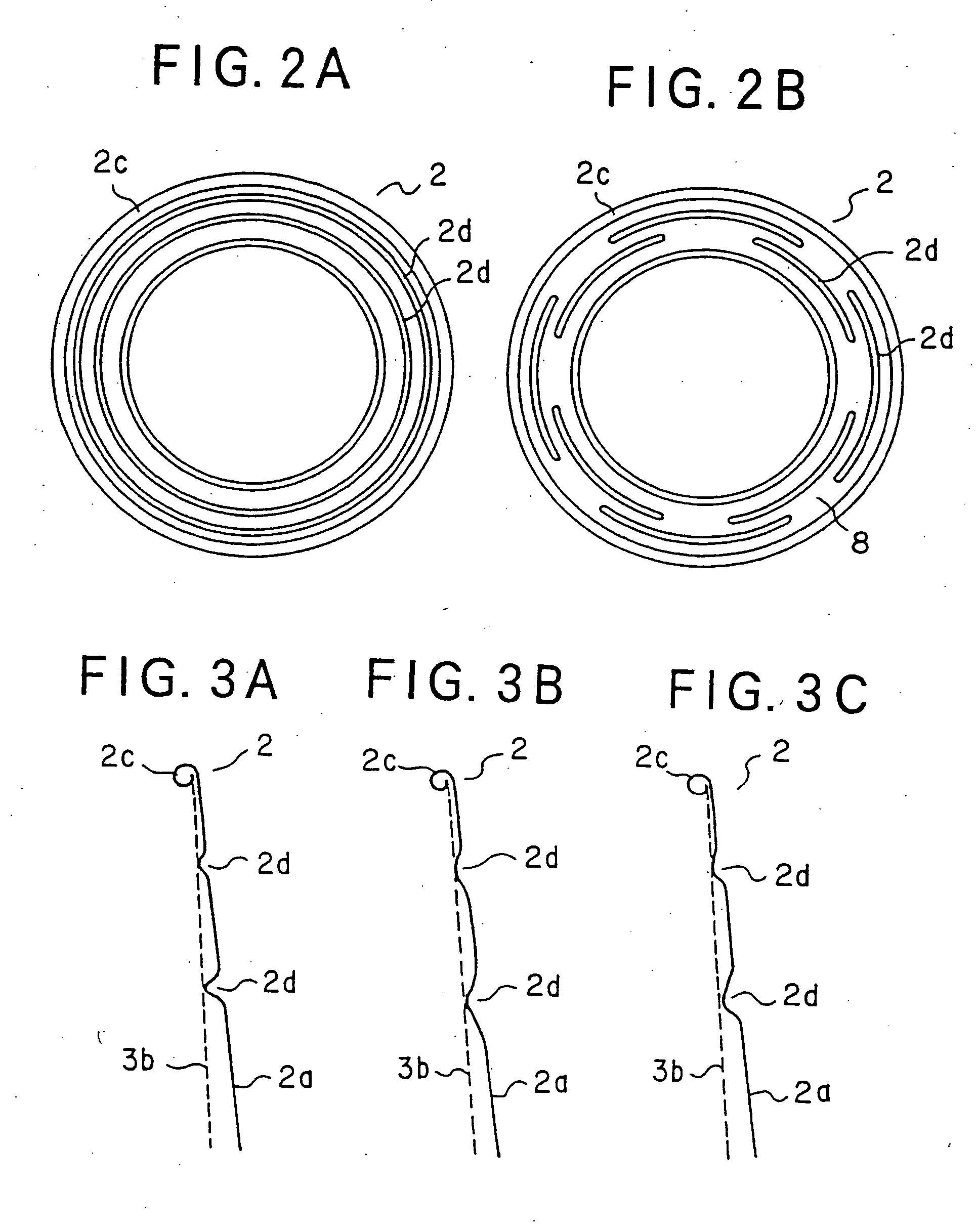

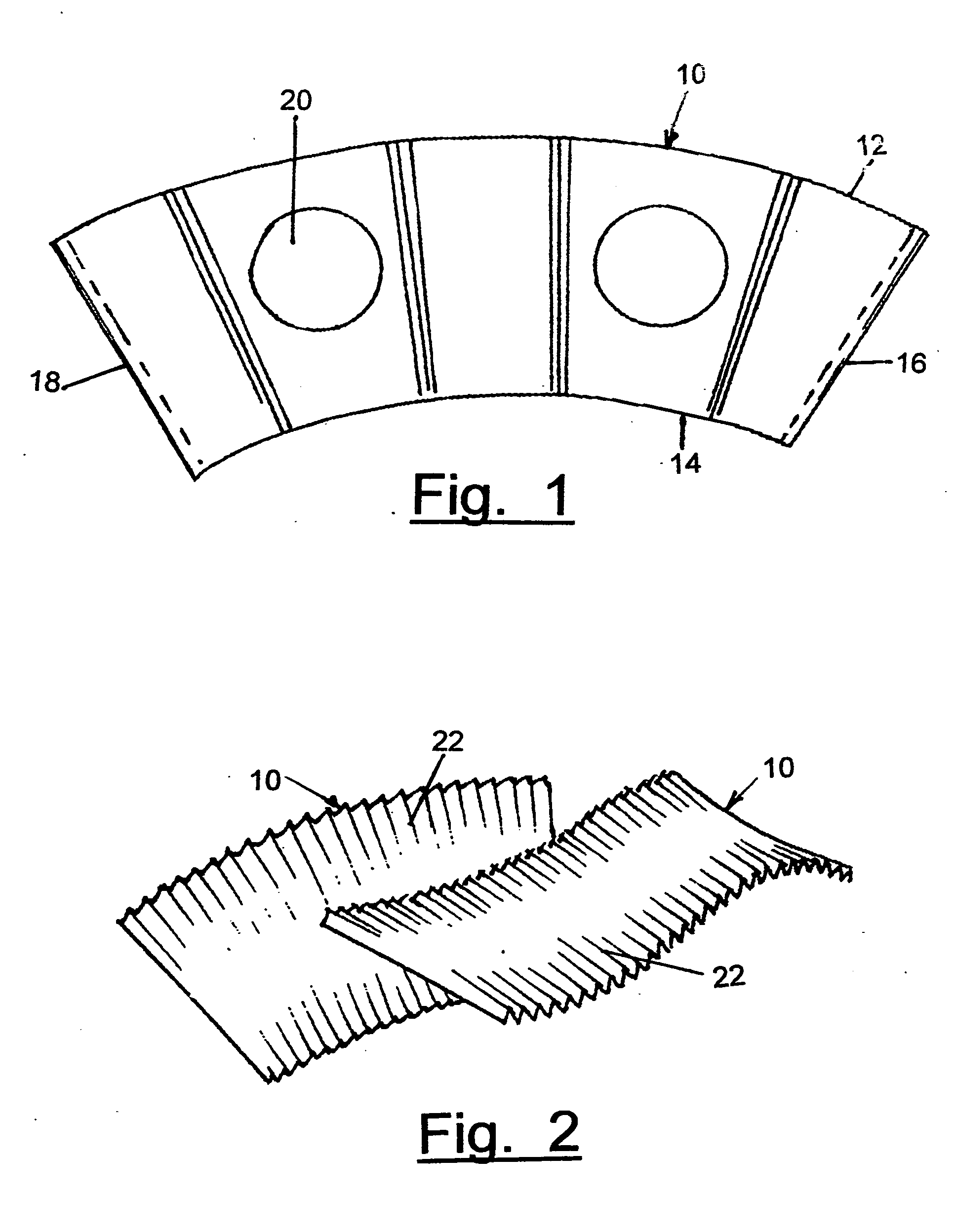

A heat-insulating container comprises a paper cup body having an inner surface, an upper open end, a shell member and a bottom, the inner surface being coated with polyolefine resin, the upper open end having an outward curled portion and the shell member having a side wall on which at least one rib is formed; and a tubular member being formed of paper and having an inverse truncated conical shape, the tubular member having at a lower end thereof an inward curled portion. The tubular member is combined with an outer periphery of the paper cup body so as to come into contact with the paper cup body in contact portions provided on the at least one rib of the paper cup body and on an outer periphery of an lower end of the side wall of the shell member. According to such a structure, it is possible to provide the heat-insulating container, which has a stable heat-insulating property, a high grade design, a high degree of freedom in indication by printing on the outer surface of the container, and a lower production cost.

Owner:DAI NIPPON PRINTING CO LTD

Heat-insulating container

InactiveUS6260756B1Improve insulation performanceIncrease freedomBoxes/cartons making machineryDomestic cooling apparatusPolyolefinEngineering

A heat-insulating container comprises a paper cup body having an inner surface, an upper open end, a shell member and a bottom, the inner surface being coated with polyolefine resin, the upper open end having an outward curled portion and the shell member having a side wall on which at least one rib is formed; and a tubular member being formed of paper and having an inverse truncated conical shape, the tubular member having at a lower end thereof an inward curled portion. The tubular member is combined with an outer periphery of the paper cup body so as to come into contact with the paper cup body in contact portions provided on the at least one rib of the paper cup body and on an outer periphery of an lower end of the side wall of the shell member. According to such a structure, it is possible to provide the heat-insulating container, which has a stable heat-insulating property, a high grade design, a high degree of freedom in indication by printing on the outer surface of the container, and a lower production cost.

Owner:DAI NIPPON PRINTING CO LTD

Insulated beverage or food container

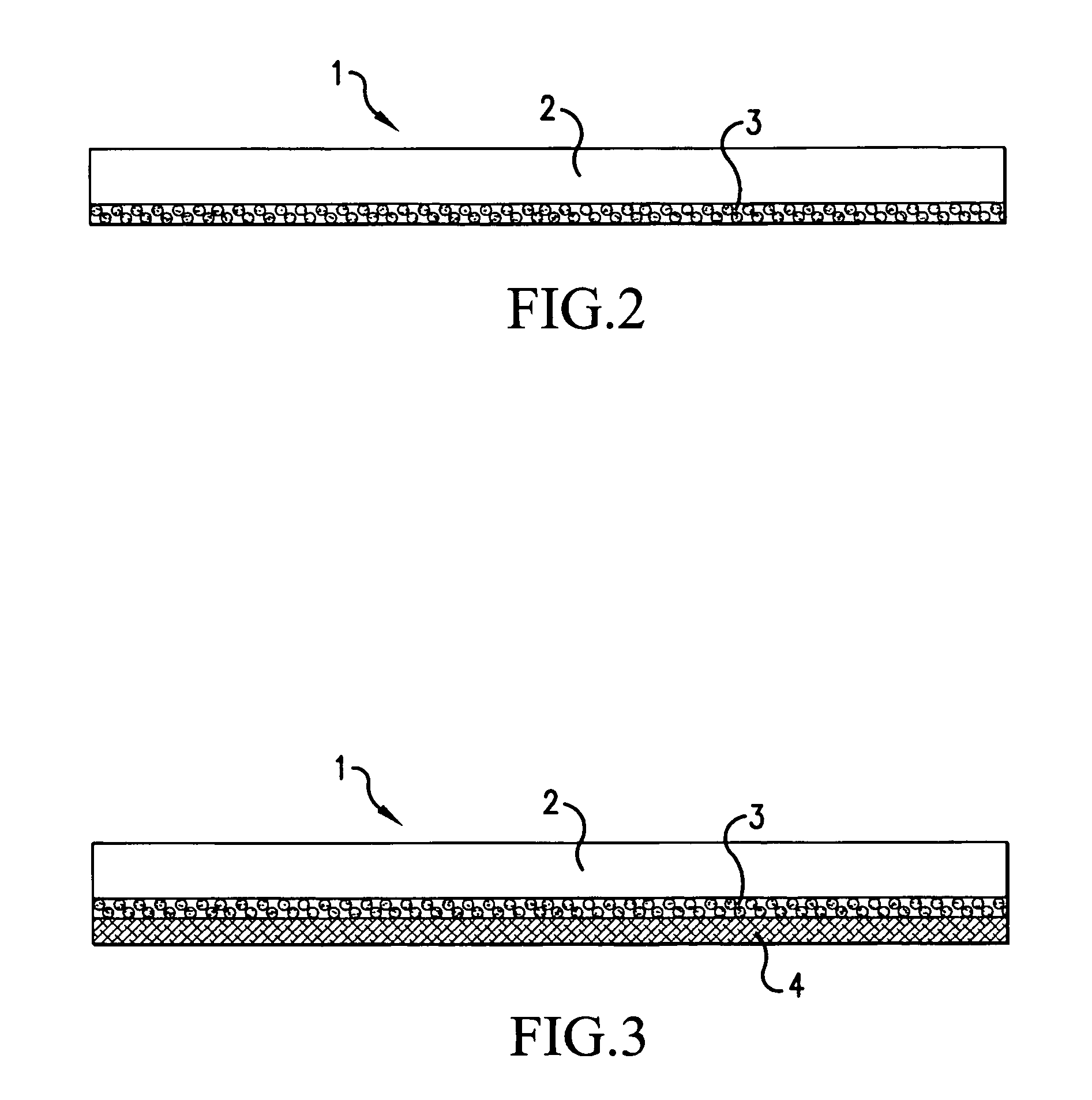

InactiveUS20050003122A1Reduce energy transferImprove functionalityFibreboardWrappersEnergy transferEngineering

An insulating beverage cup or sleeve is produced with a foam layer disposed on an inner surface of a food or beverage paper stock. A polyethylene film layer is arranged in a position between a paper stock layer and an inside surface of the beverage container. The foam layer decreases the energy transfer between the beverage and the user's hands allowing the user to hold onto the cup for an extended period of time without causing user discomfort or pain, e.g. greatly extends the hold time of the paper cup. The exterior surface of the beverage cup remains highly printable and predisposed to high quality graphics both before and after cup manufacture.

Owner:APPLETON PAPERS INC

Two-part recyclable cup

A paper cup or shell with a thin removable liner that is not laminated to the cup or shell such that the liner may be easily disengaged, removed, or separated from the cup or shell prior to disposal or the recycling process. The thin removable or detachable liner is preferably made from aluminum, aluminum alloy, or aluminum foil, as opposed to other recyclable materials. Aluminum is the preferred material for the liner due to the fact that aluminum is infinitely recyclable and can be used over and over again to make recycled aluminum products or recycled detachable cup liners.

Owner:SNACKTOPS

Bio-degradable cup and method for making the same

A bio-degradable cup includes an IXPE foam cup and a paper cup which is securely received in the foam cup. The paper cup includes a bio-degradable film coated to an inside thereof. The paper cup is made from a paperboard with a bio-degradable film coated and the paperboard is cut, folded and heat-pressed to be the paper cup. The foam cup is made from a foam board made by IXPE and the foam board is cut, shaped and folded into pieces and each piece is made to be the foam cup by way of heat pressing. A heat treatment is applied to an inside of the foam cup to obtain a sticky inner surface of the foam cup and the paper cup is securely connected to the sticky inner surface of the foam cup. A lip is made around an outer top edge of the foam cup.

Owner:CHANG HSI CHING

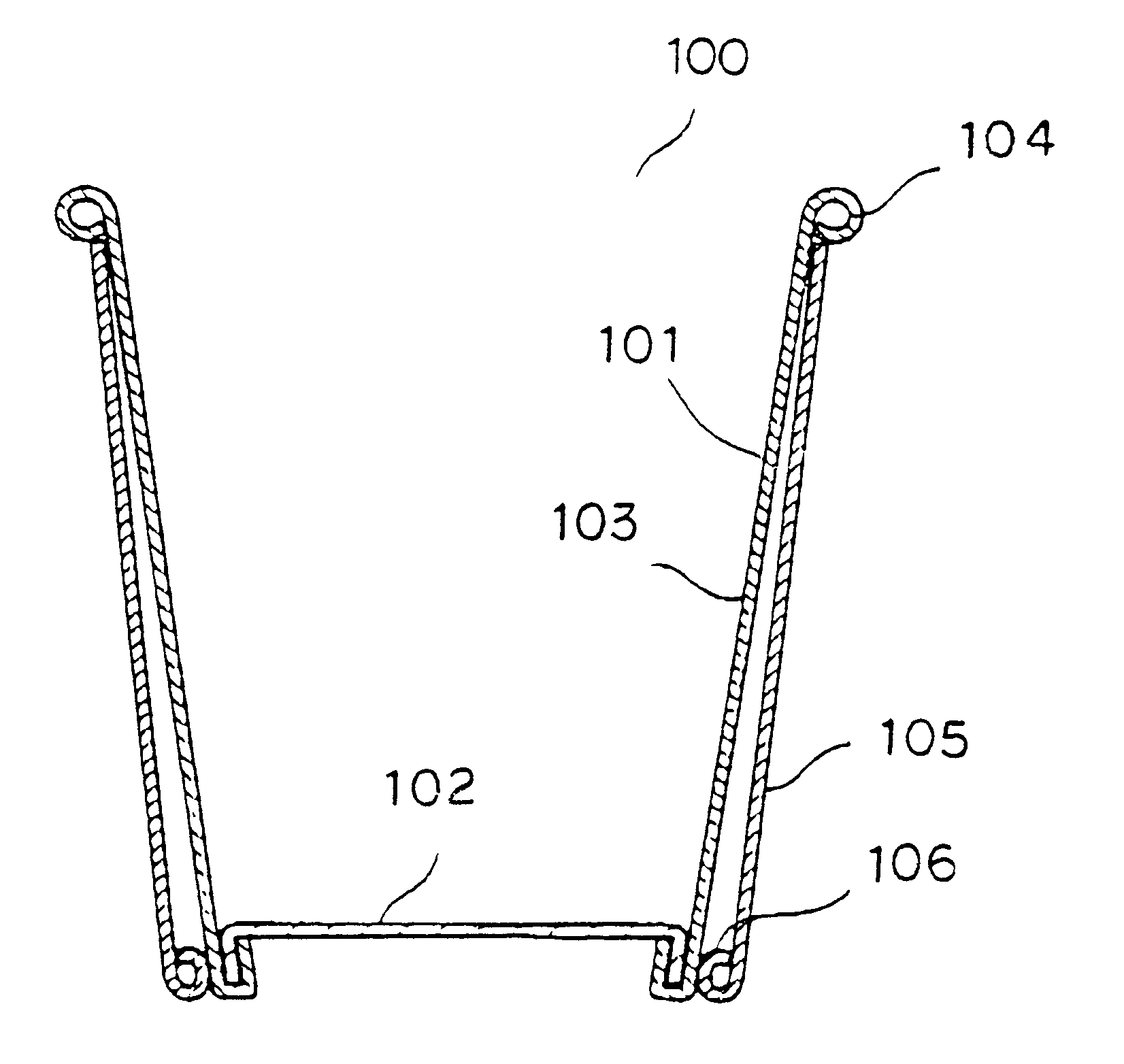

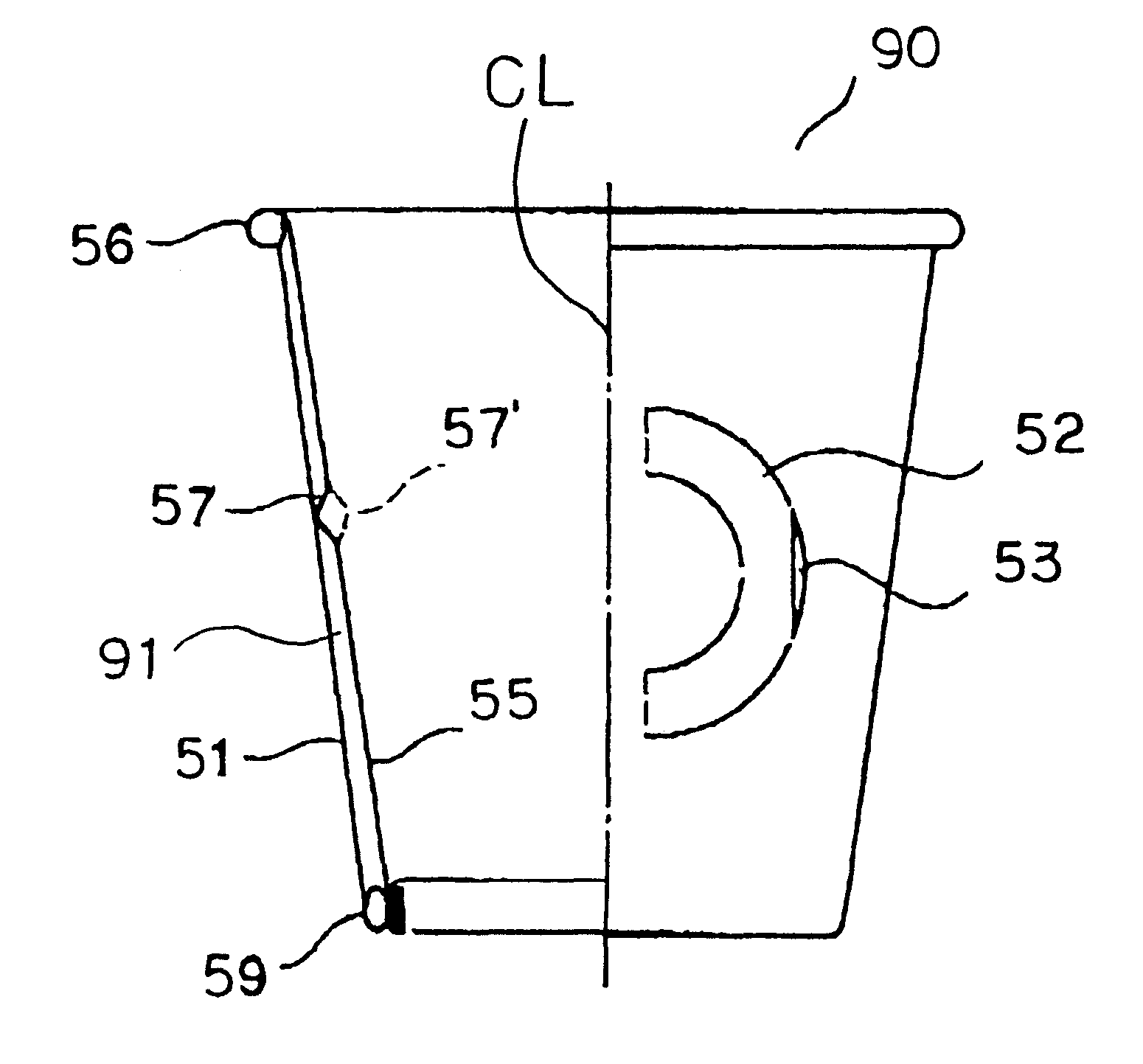

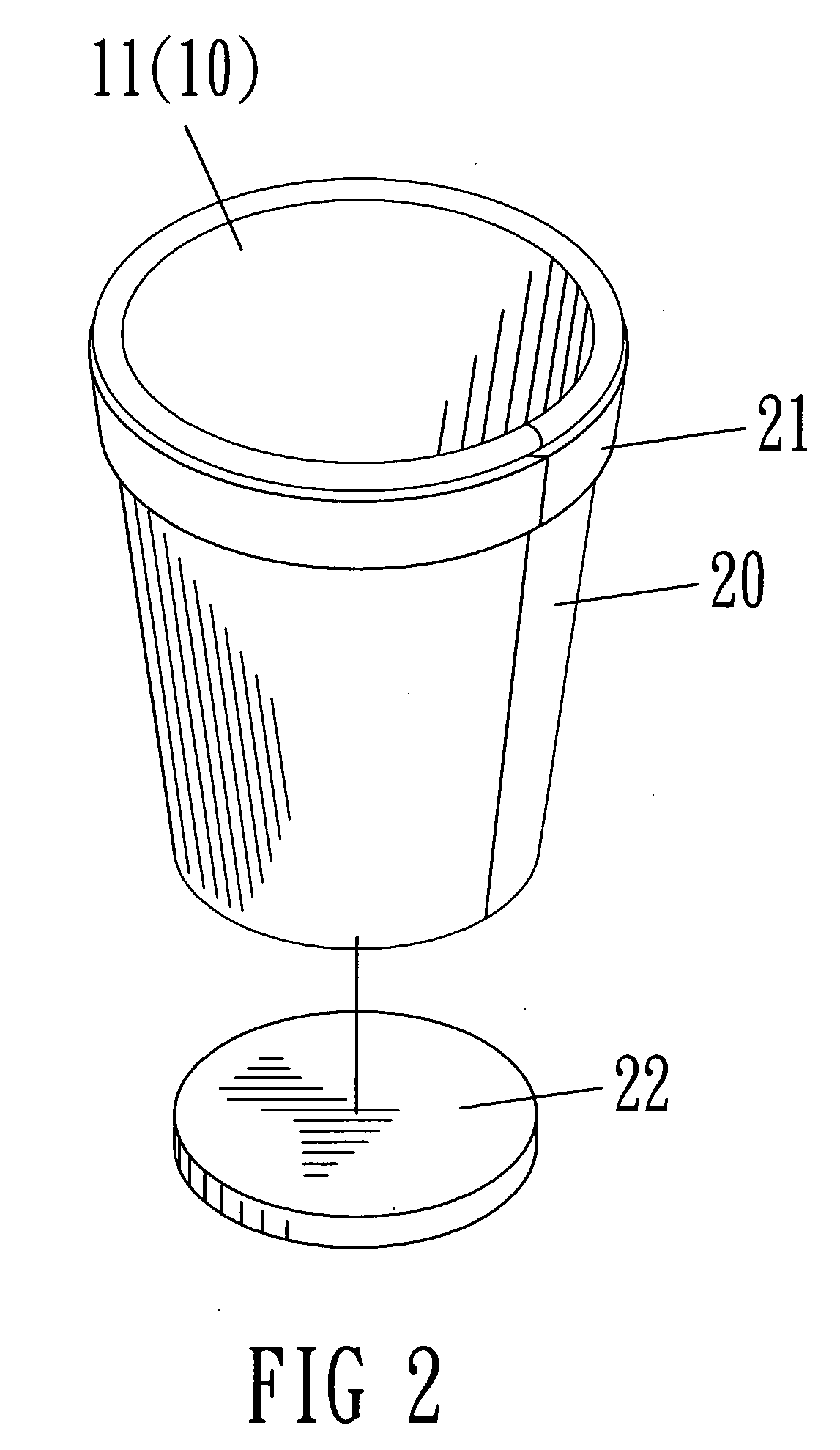

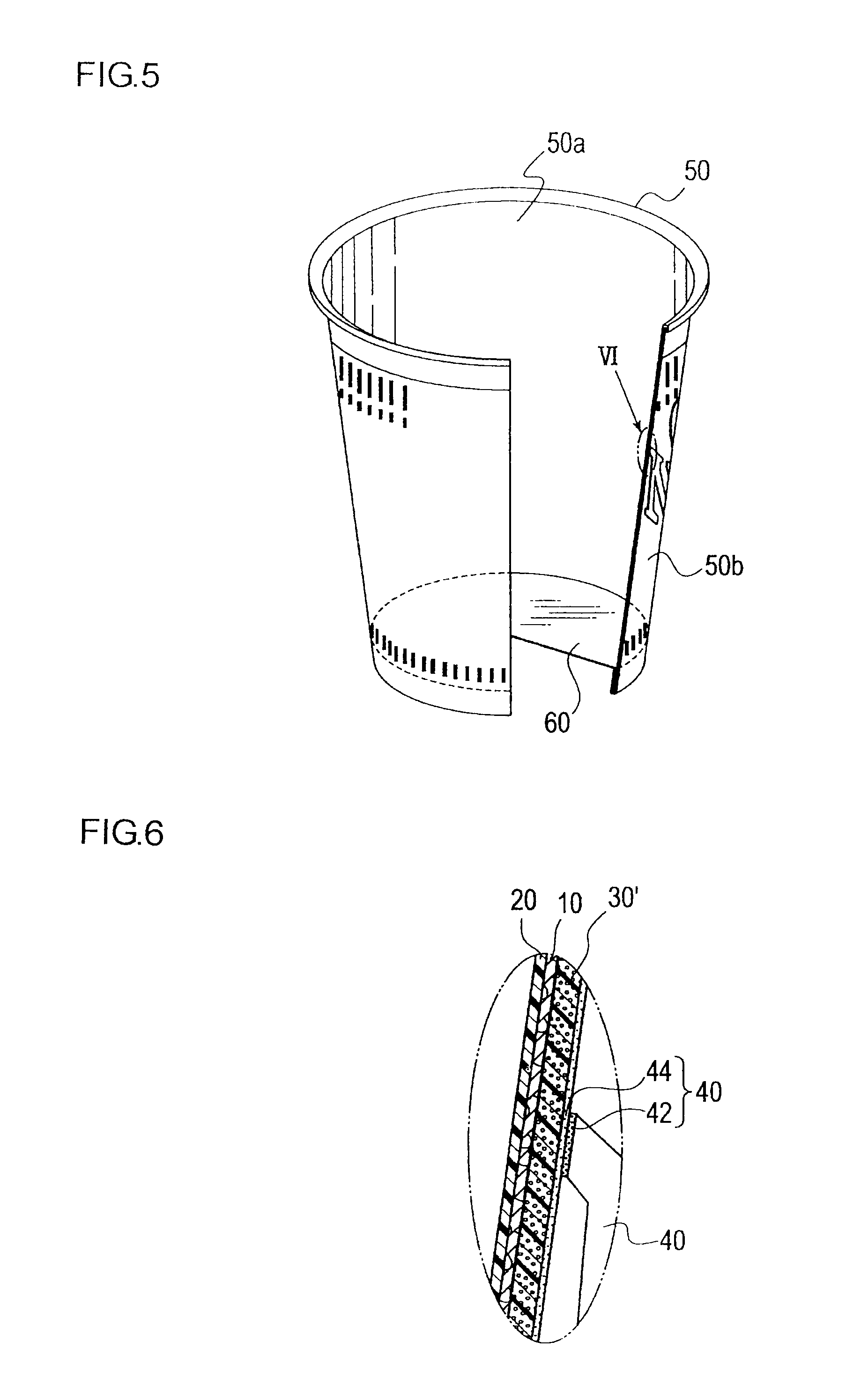

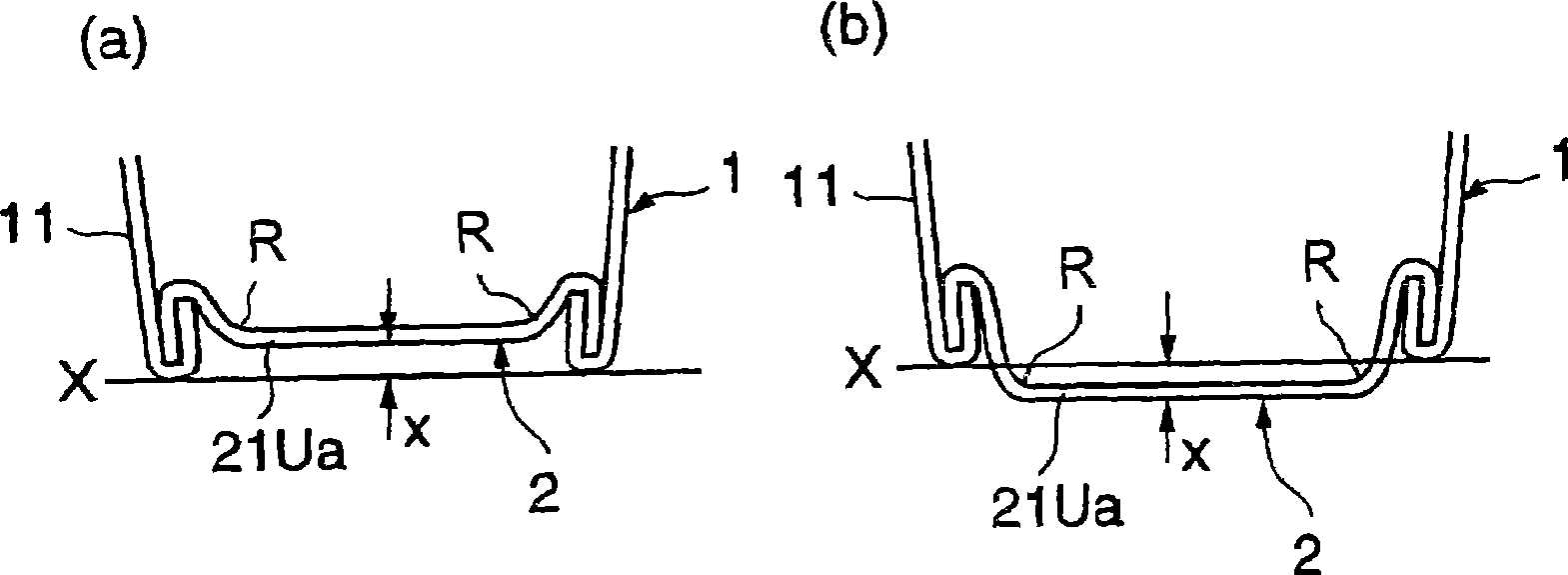

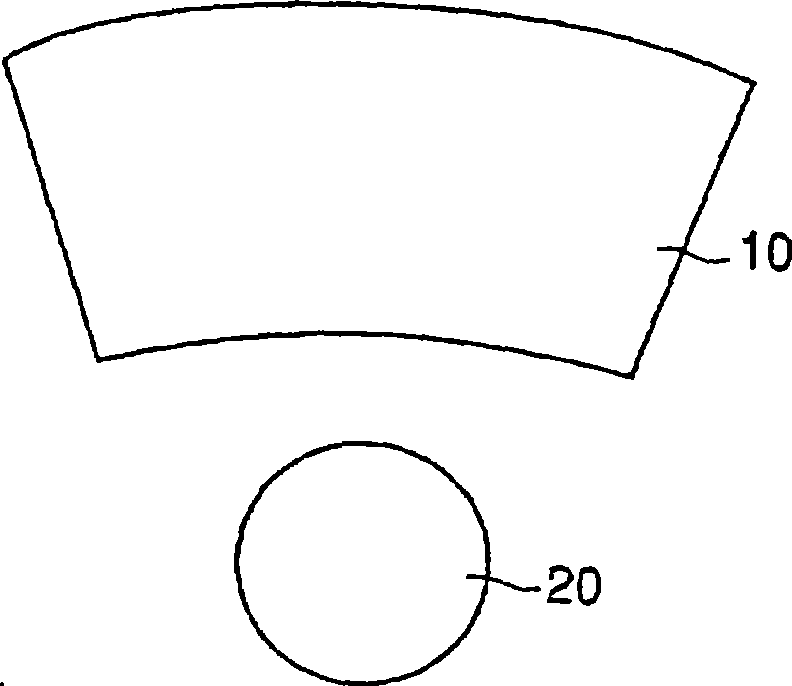

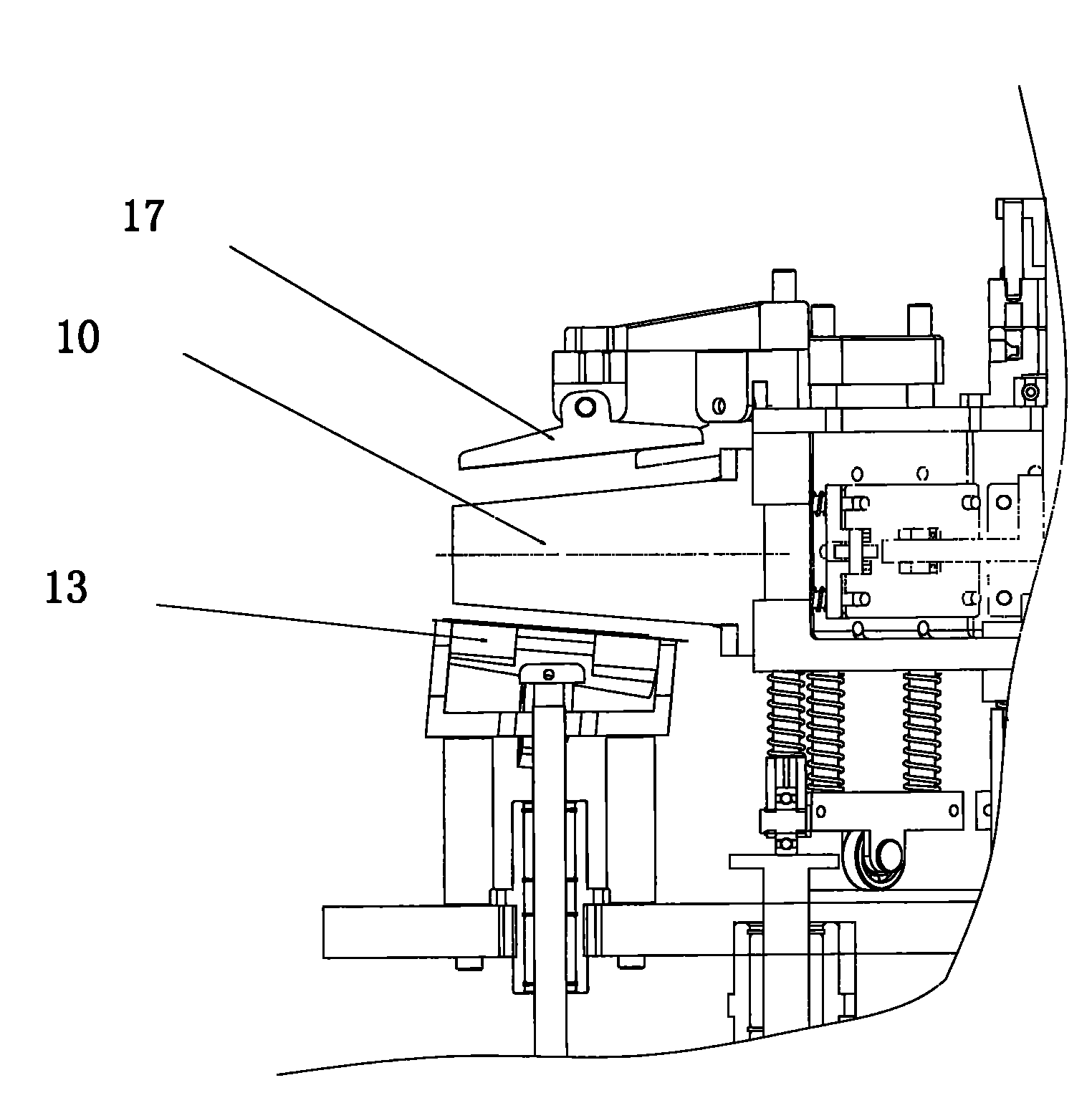

Heat-insulating container and apparatus for producing the same

InactiveUS7175585B2Improve insulation performanceIncrease freedomEnvelopes/bags making machineryMechanical working/deformationPolyolefinConoid

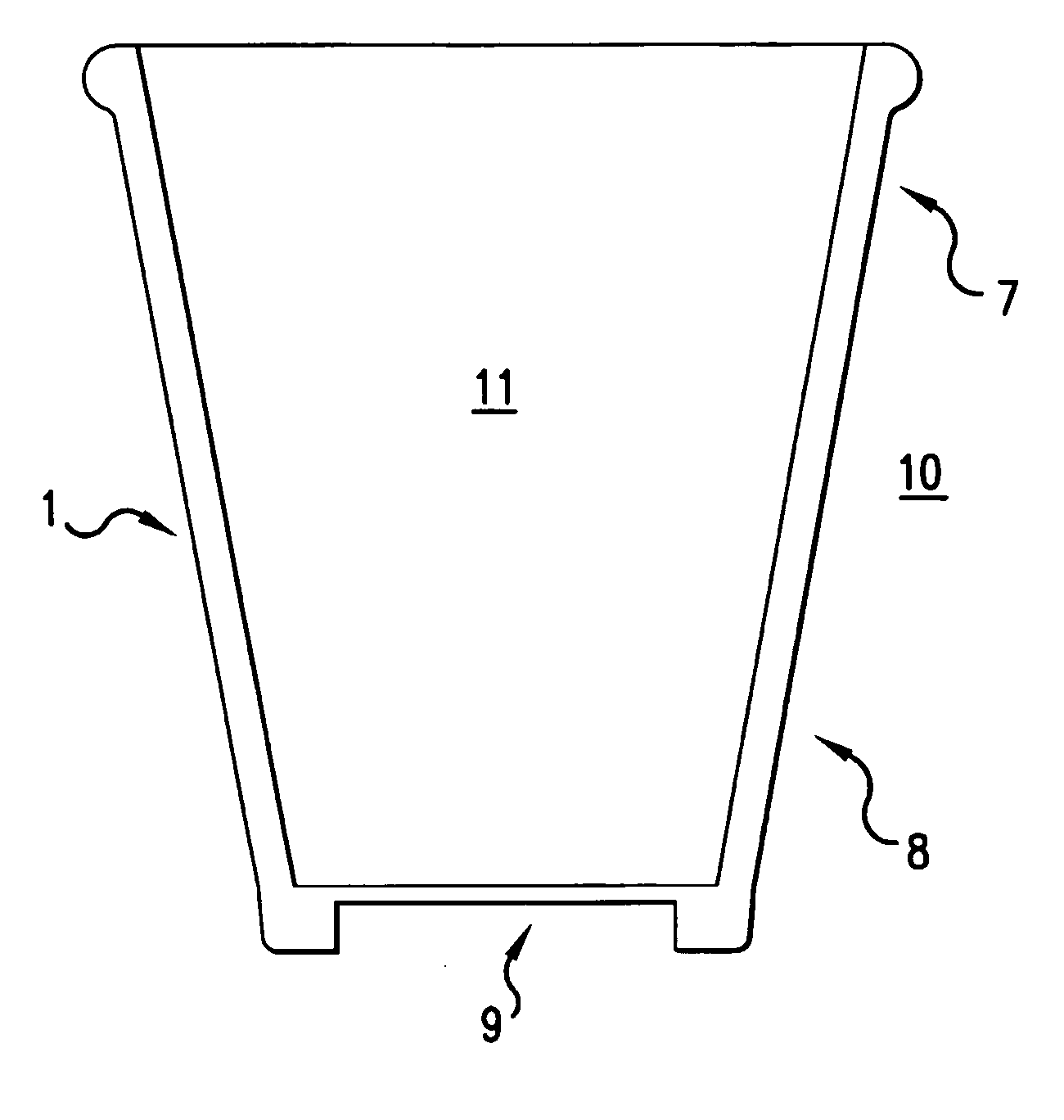

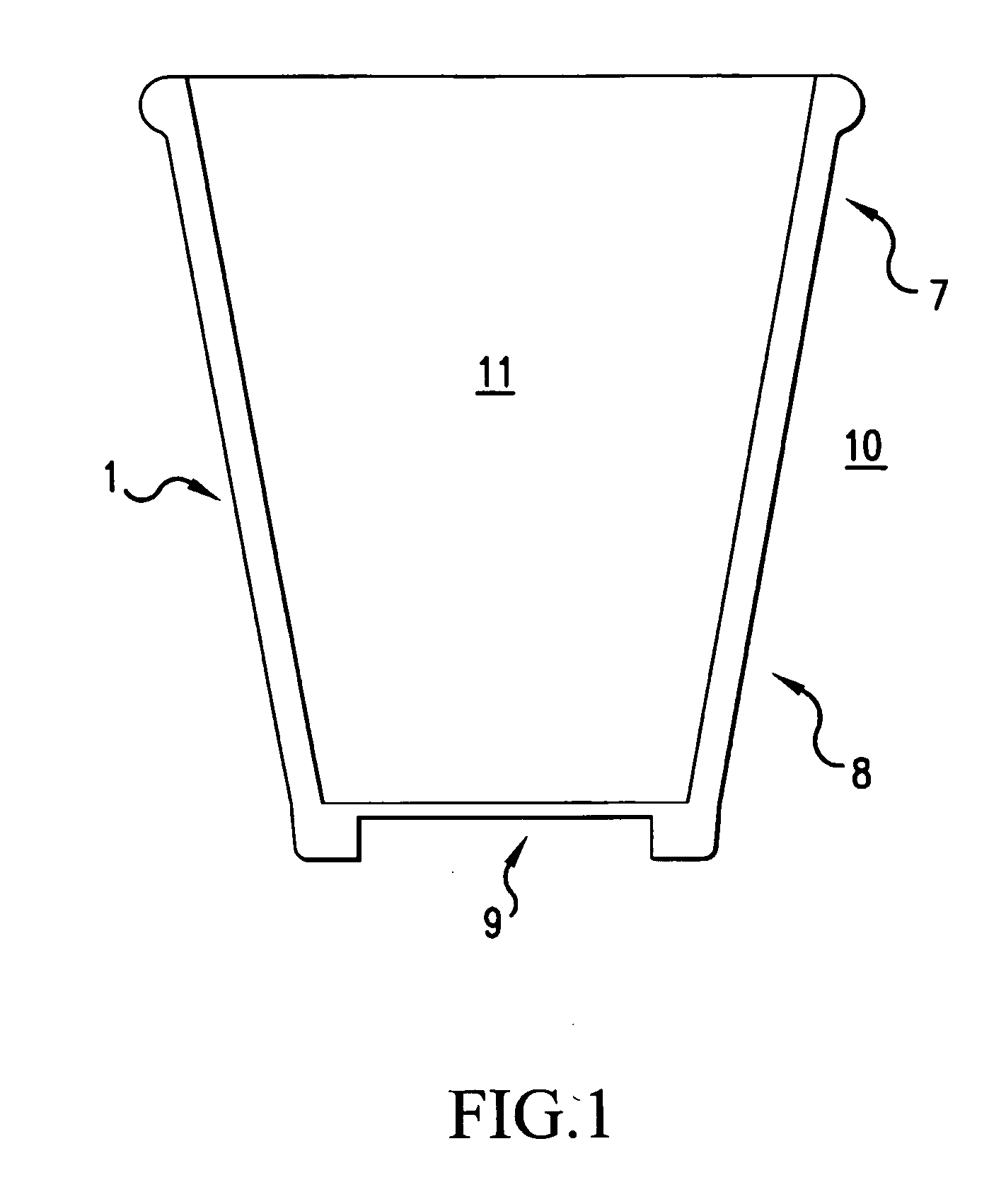

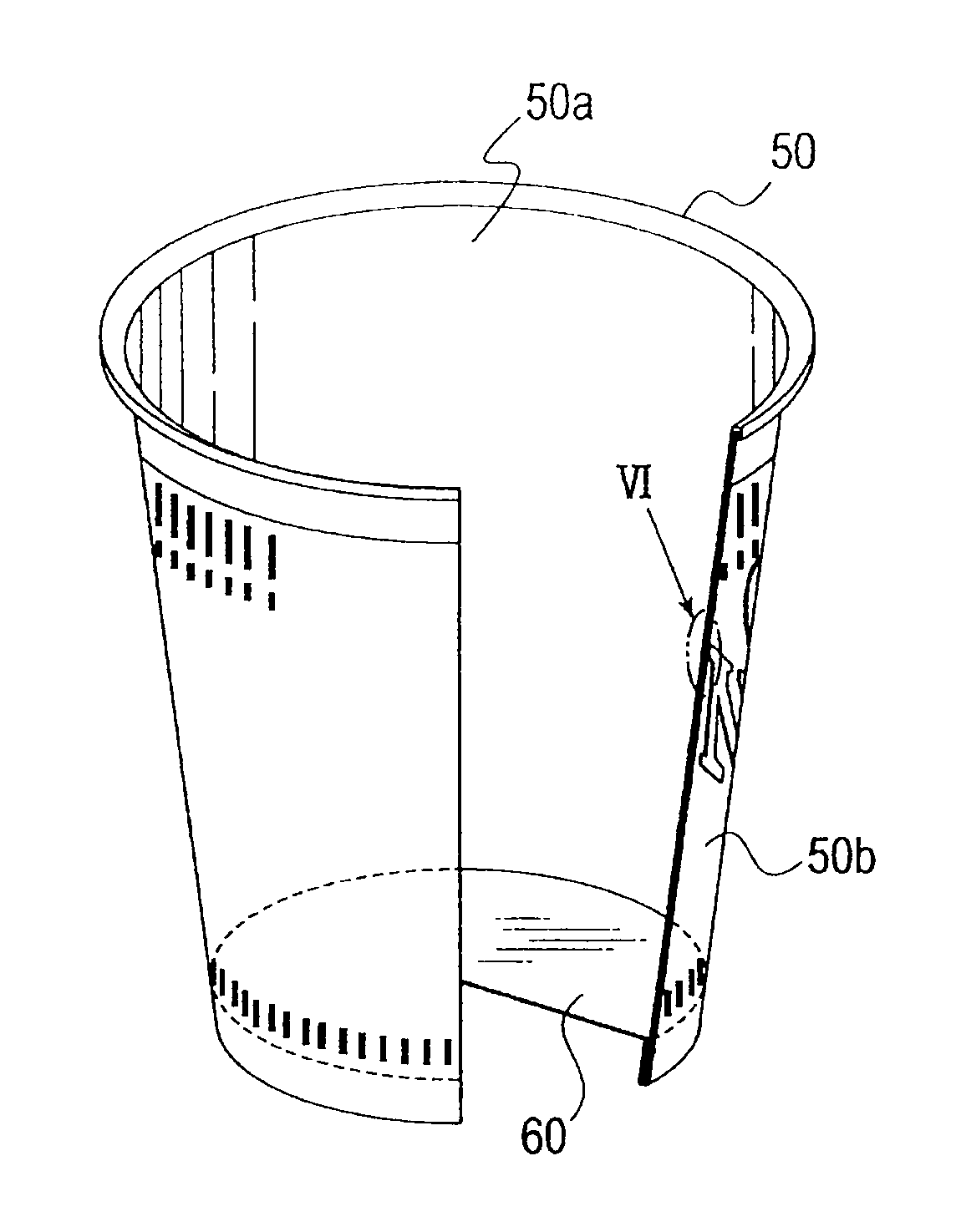

A heat-insulating container is used for an instant dried food and is excellent in heat-insulating property, design and economy. The container comprises a paper cup body with a bottom, which has an inner surface coated with a polyolefin resin and is provided with an outward curled portion formed at an upper opening end of the cup body and at least one horizontal rib formed on a side wall of the cup body so as to project outward therefrom; and an inverse-frustoconical paper sleeve provided with an inward curled portion formed at a lower end of the sleeve. The cup body and the sleeve are integrally combined with each other so that an upper end of the sleeve is joined to an outer periphery of the side wall of the cup body, which is adjacent to the outward curled portion of the cup body, and an inner surface of the inward curled portion of the sleeve is joined to an outer periphery of a lower portion of the side wall of the cup body.

Owner:DAI NIPPON PRINTING CO LTD

Water-based flexographic ink system dedicated to dual-PE paper cups

InactiveCN101824246AFulfil requirementsFirmly attachedWax coatingsInksWater basedPulp and paper industry

The invention relates to a water-based flexographic ink system dedicated to dual-PE paper cups. The ink system, which consists of water-based flexographic colored ink dedicated to dual-PE paper cups and varnish capable of being contacted with food, is used for the flexographic printing of dual-PE paper cups, and can effectively meet the printability requirement and the post-press finishing requirement. The varnish can effectively isolate the colored ink from being directly contacted with food and beverage, thus ensuring the hygienic safety of paper cups. The invention has the advantages of excellent properties, no toxin, no smell, safety, environment-friendliness and low overall cost, and has a broad market prospect.

Owner:合肥元和水性化学技术有限公司

Brightening ink composition for printing, paper container material using the brightening ink composition, and heat insulating foamed paper container

ActiveUS20110111150A1Excellent foaming adaptabilityLess occurrence of crackDomestic cooling apparatusLighting and heating apparatusHeat resistanceEngineering

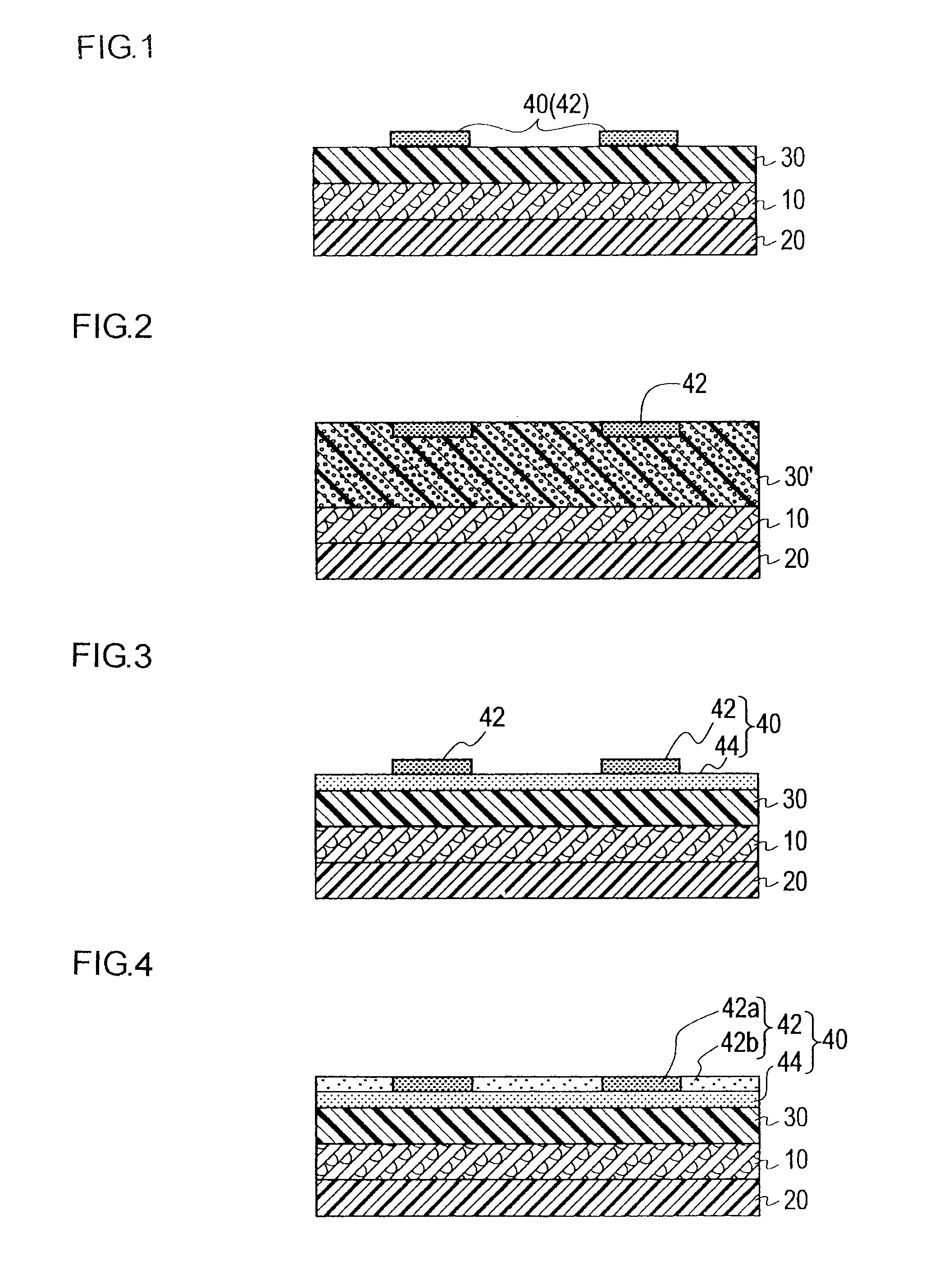

There is provided a brightening ink composition for printing intended for realizing a heat insulating foamed paper container produced by foaming a low-melting point film by a heat treatment, such as a heat insulating foamed paper cup, the brightening ink composition conforming to the foaming without the occurrence of ink splits (cracks) upon foaming, having very small differences in level between the brightening printed areas and other printed areas at the container surface after foaming, making the container surface almost smooth, and having excellent design applicability and aesthetic properties as well as excellent heat resistance and print quality. A brightening ink composition containing a brightening material that imparts a sense of brightness, silicon dioxide, a binder resin and a solvent is prepared, and the brightening ink composition is used to form a printed layer of a paper container material for producing a heat insulating foamed paper container.

Owner:NISSIN YORK +1

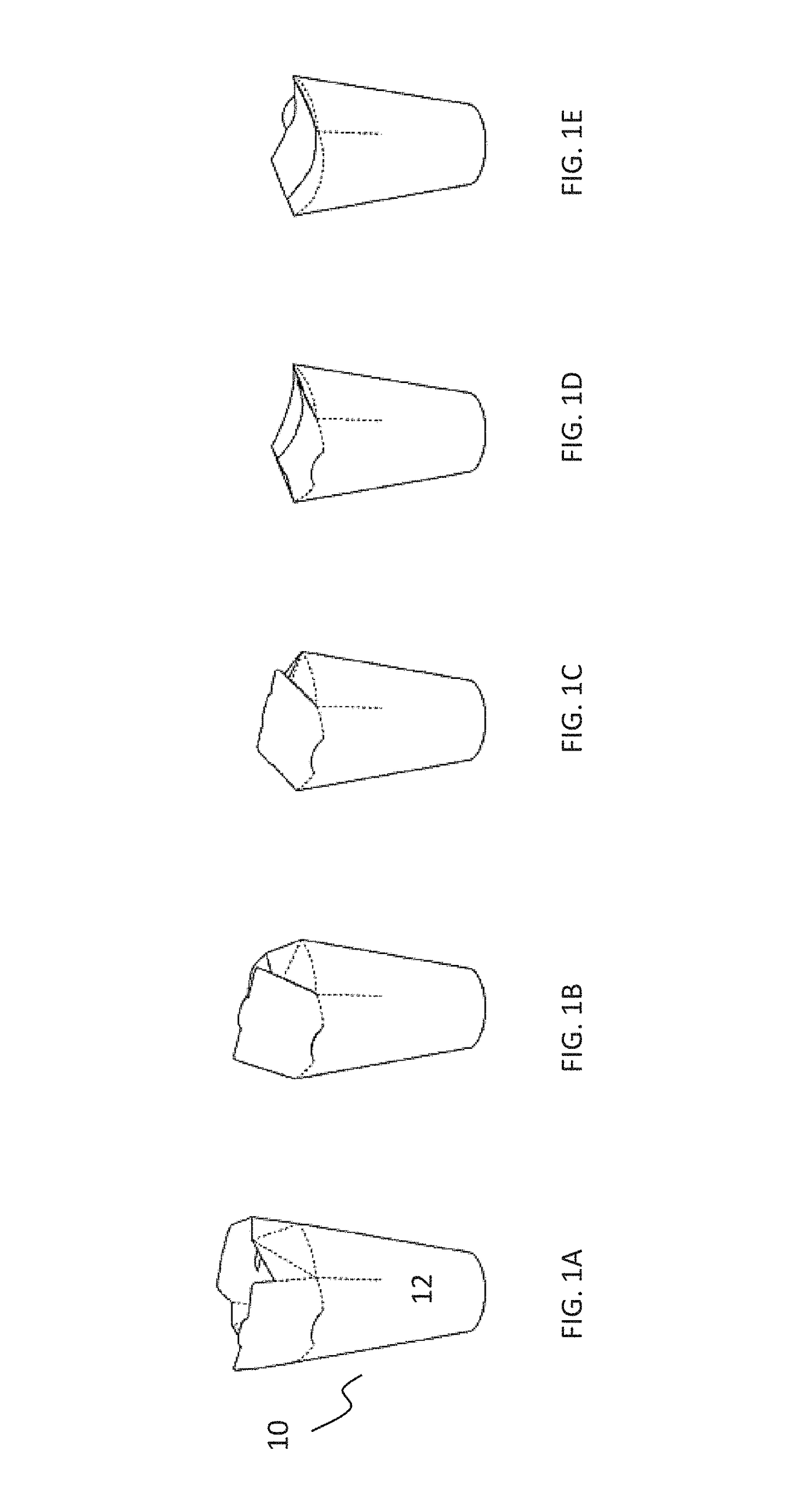

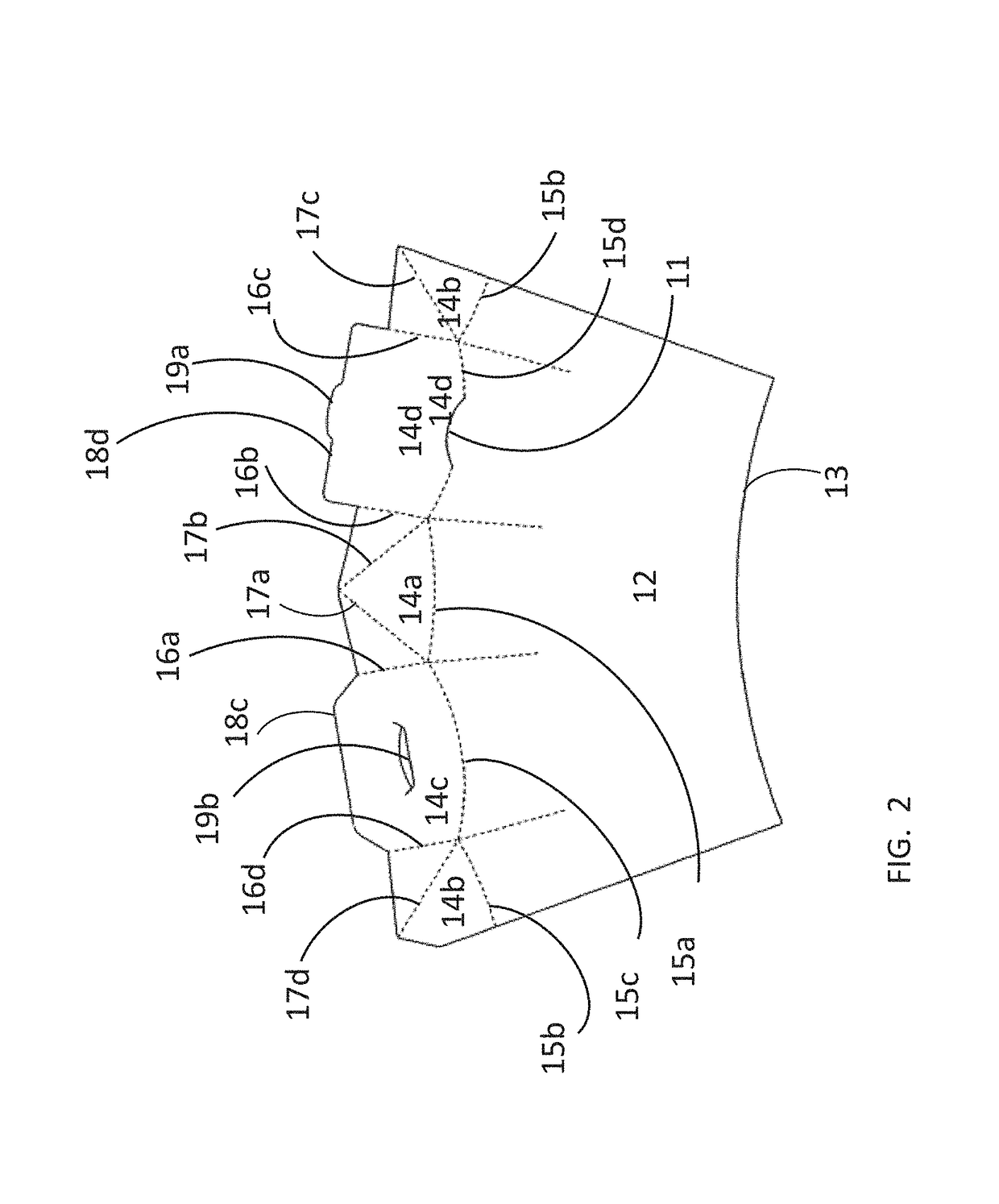

Paper cup, a blank for a paper cup, and use of a paper cup

ActiveUS9737161B1Achieve recyclabilityForce is requiredRigid containersDrinking vesselsEngineeringPaper cup

According to an example aspect of the present invention, there is provided a paper cup comprising: a base; a sidewall; said base and said sidewall together defining a space for receiving liquid or food; an upper end portion of the cup comprising a first and second pair of opposing closure panels, whereby each panel is attached to an upper edge of the sidewall via a respective first folding line and to adjacent panels via respective second folding lines. Said panels are foldable into a closed position to form a lid of the cup. Each panel of said first pair contains two additional folding lines to enable folding inwards. Upon folding to the closed position, a first panel of said second pair is partly inserted below a second panel of said second pair, and the panels of said second pair close the upper end portion.

Owner:METSA BOARD

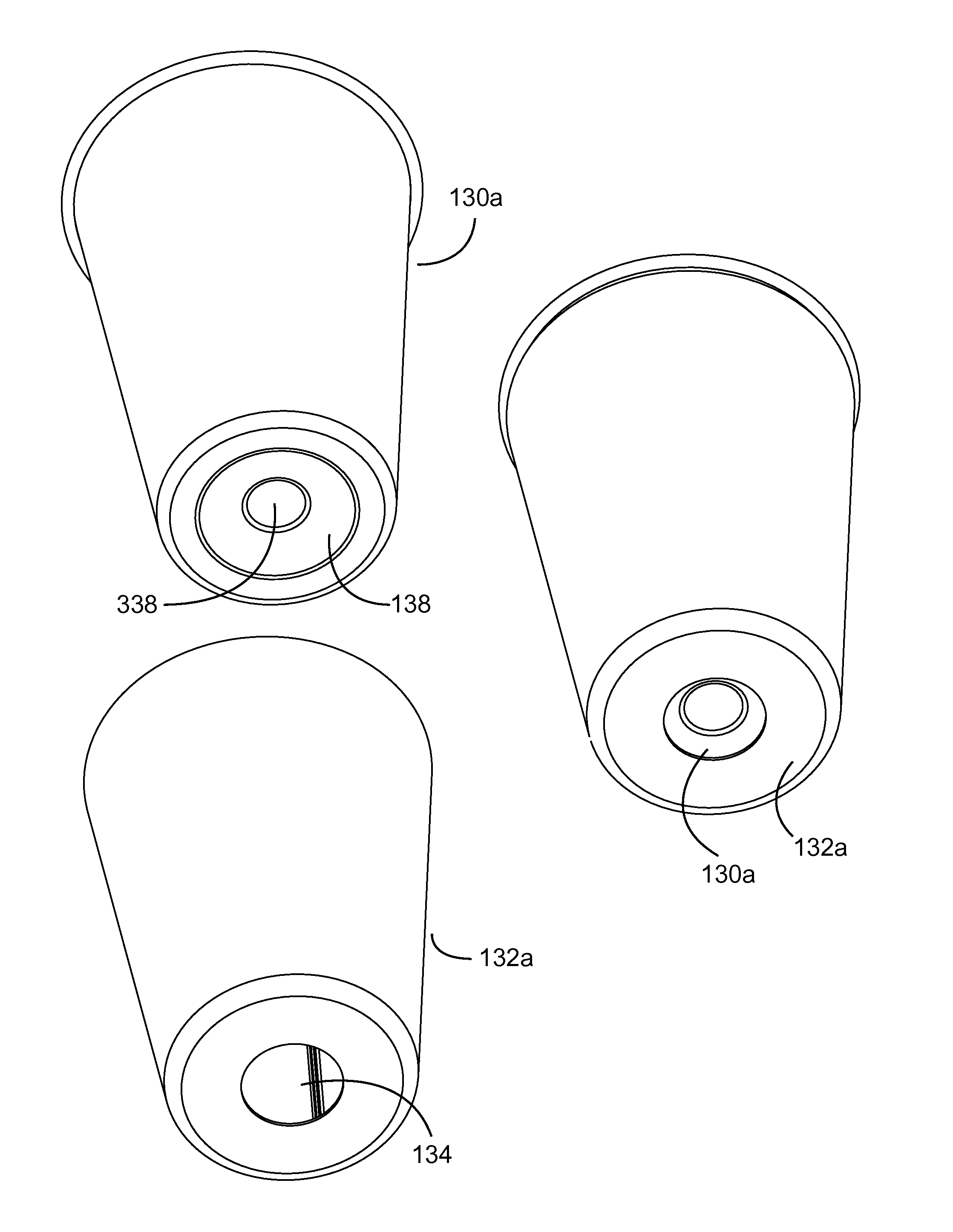

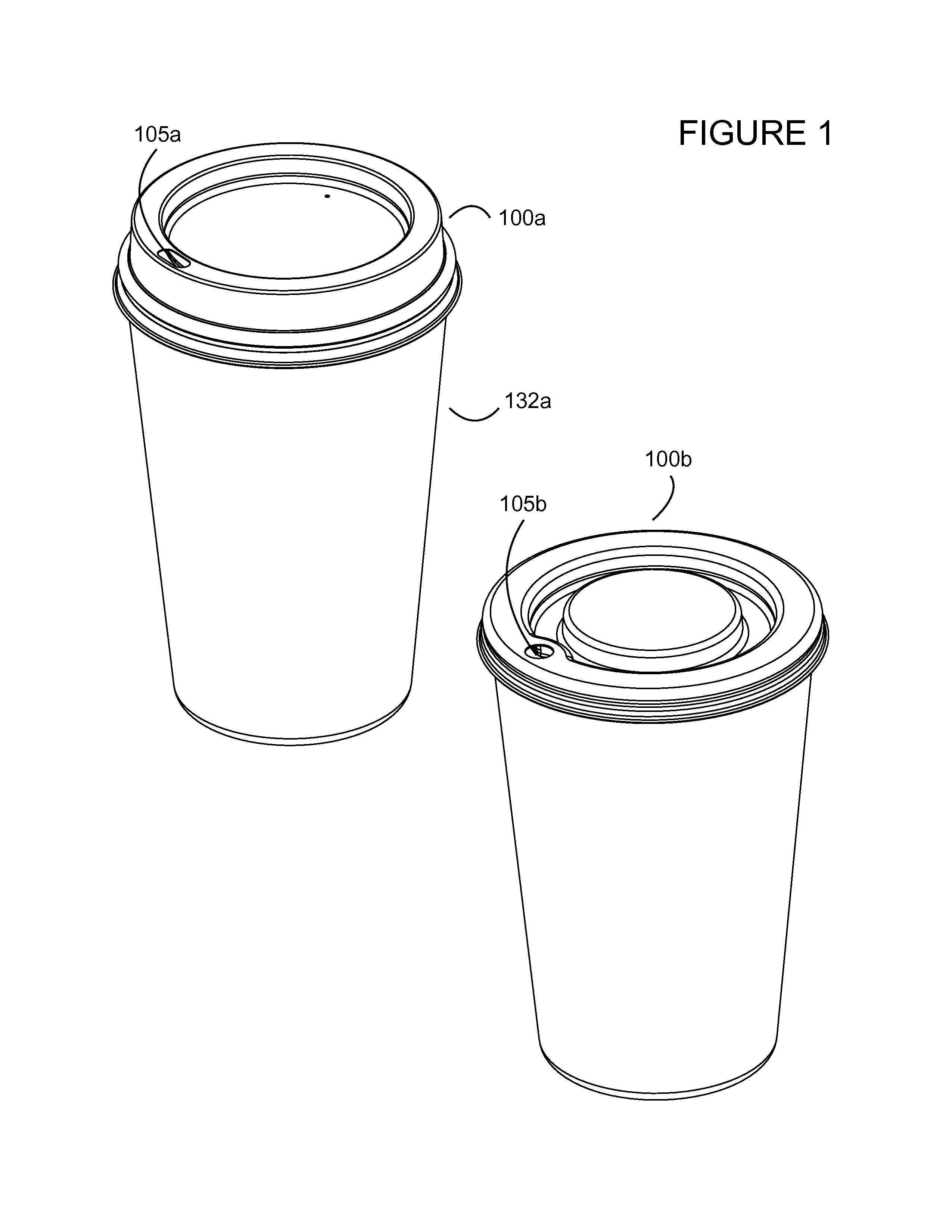

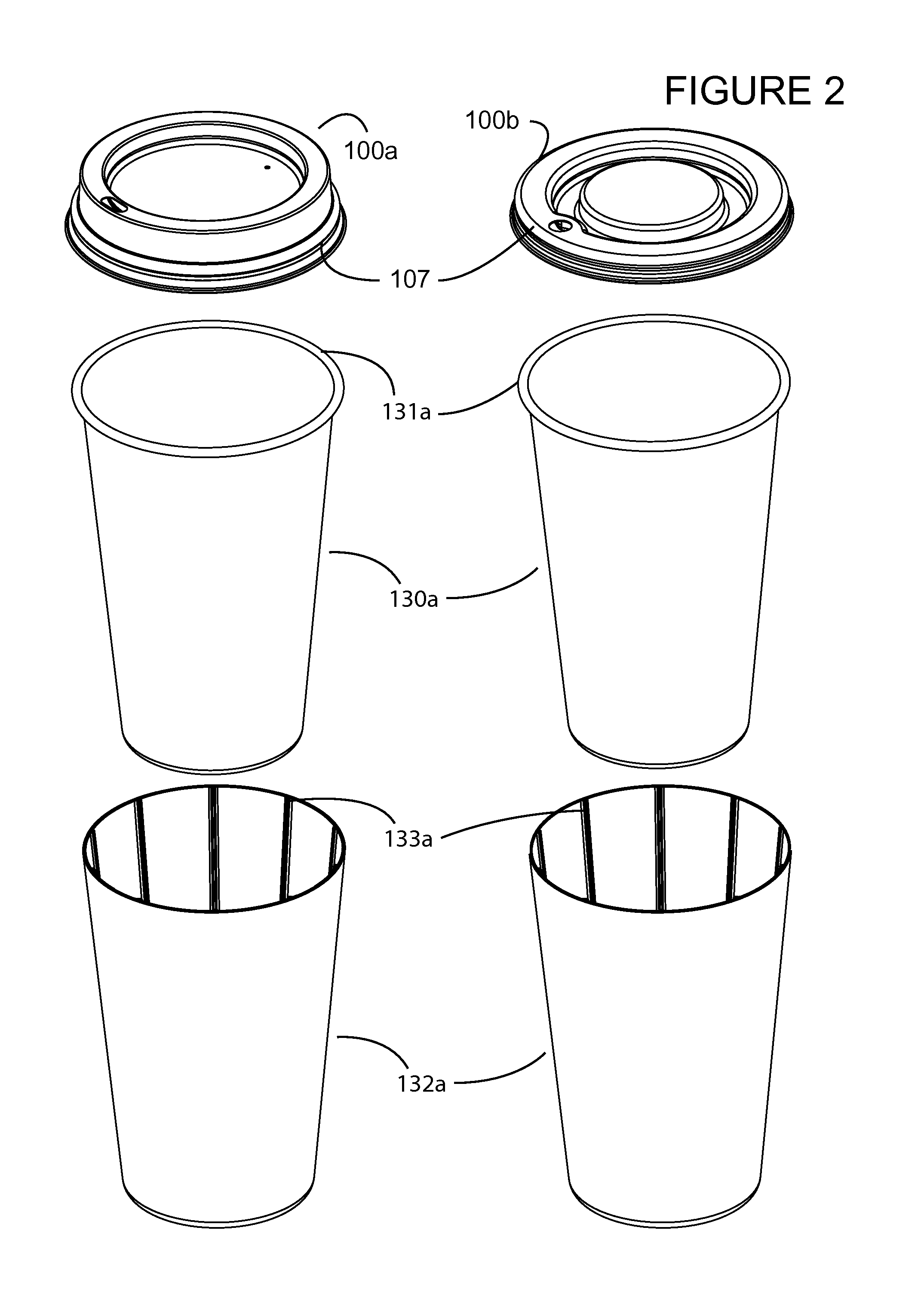

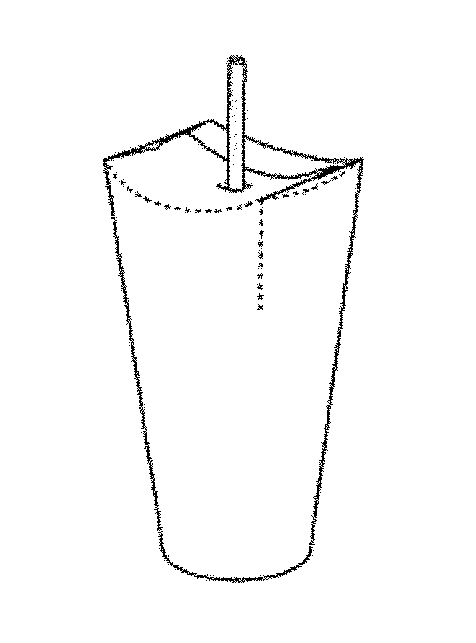

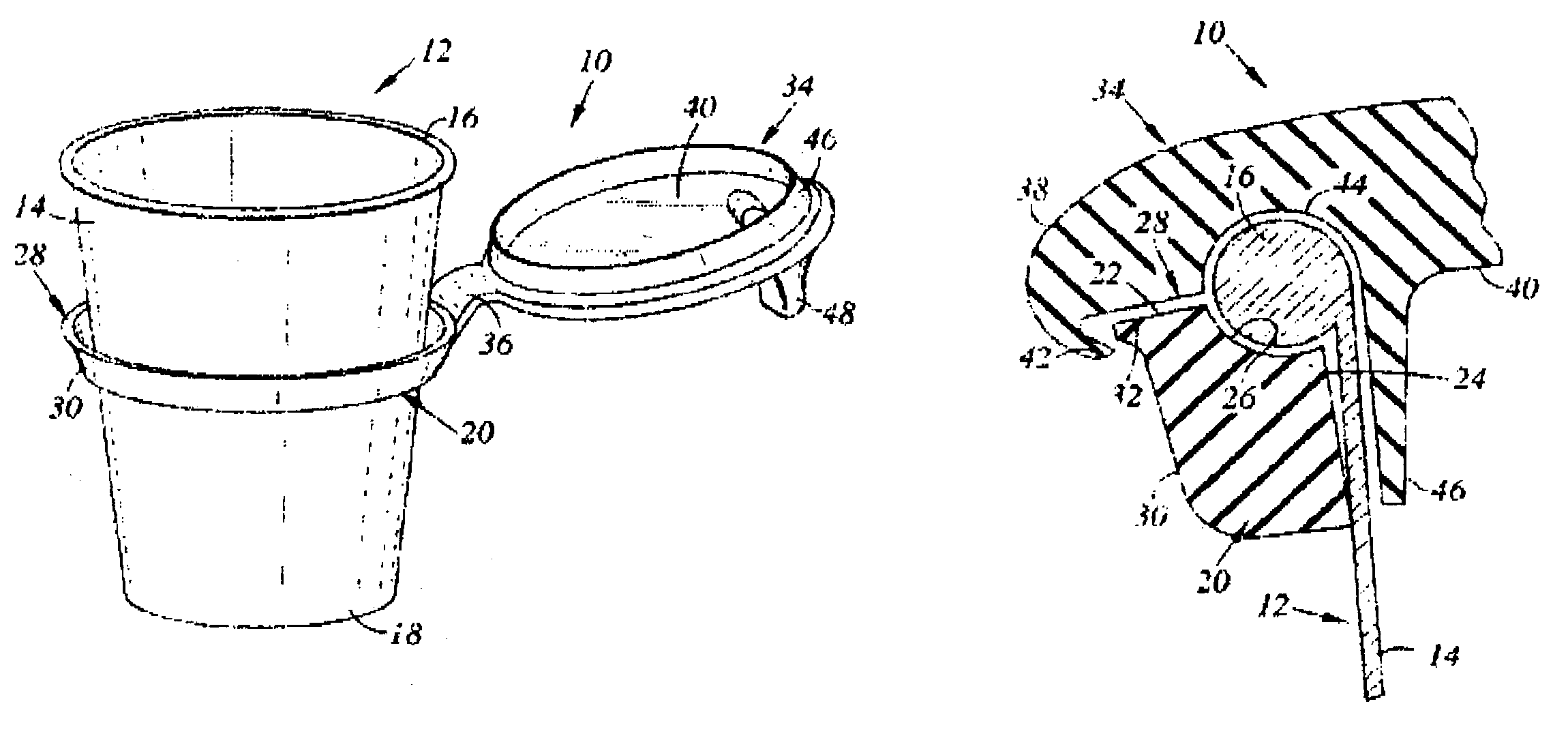

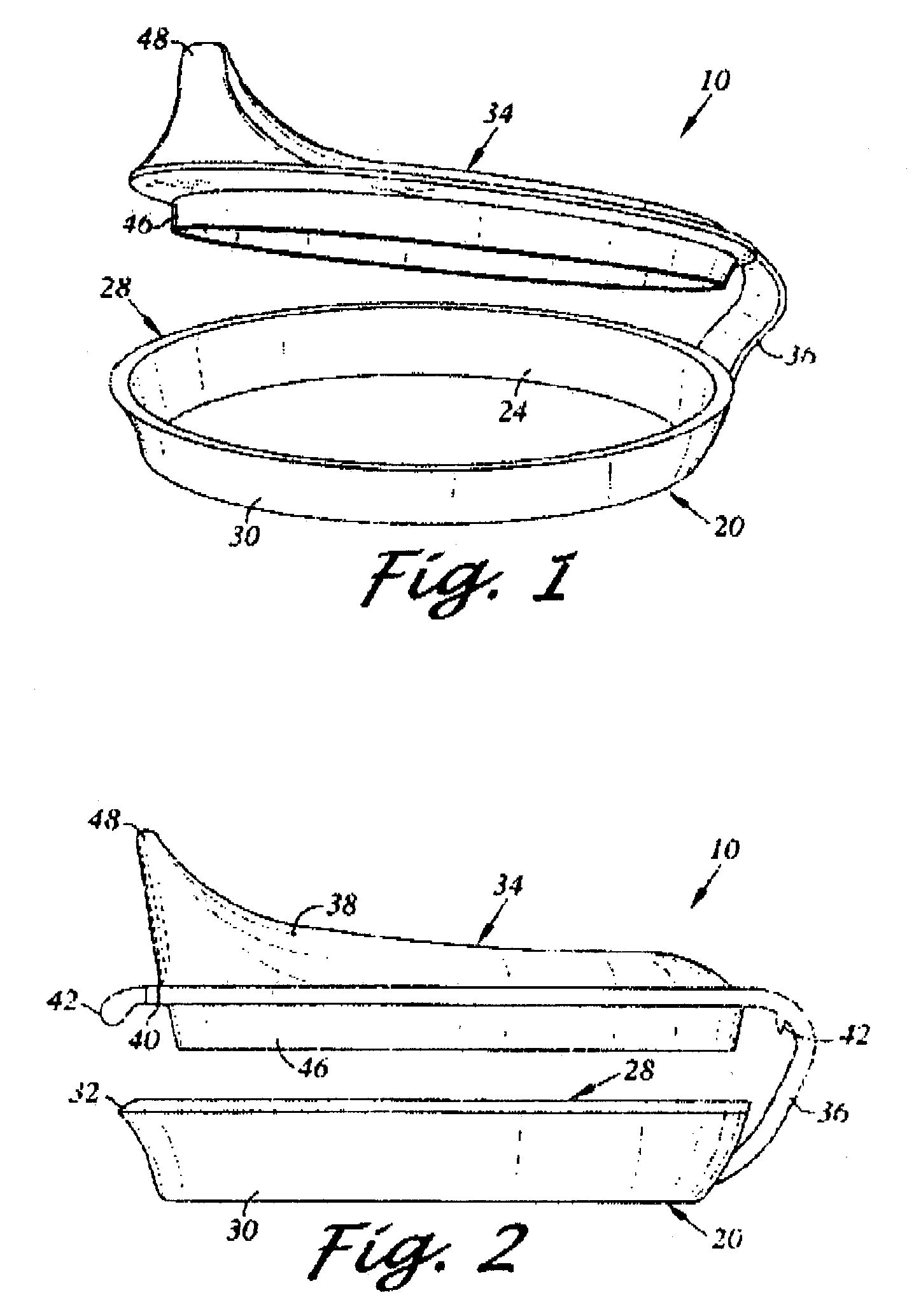

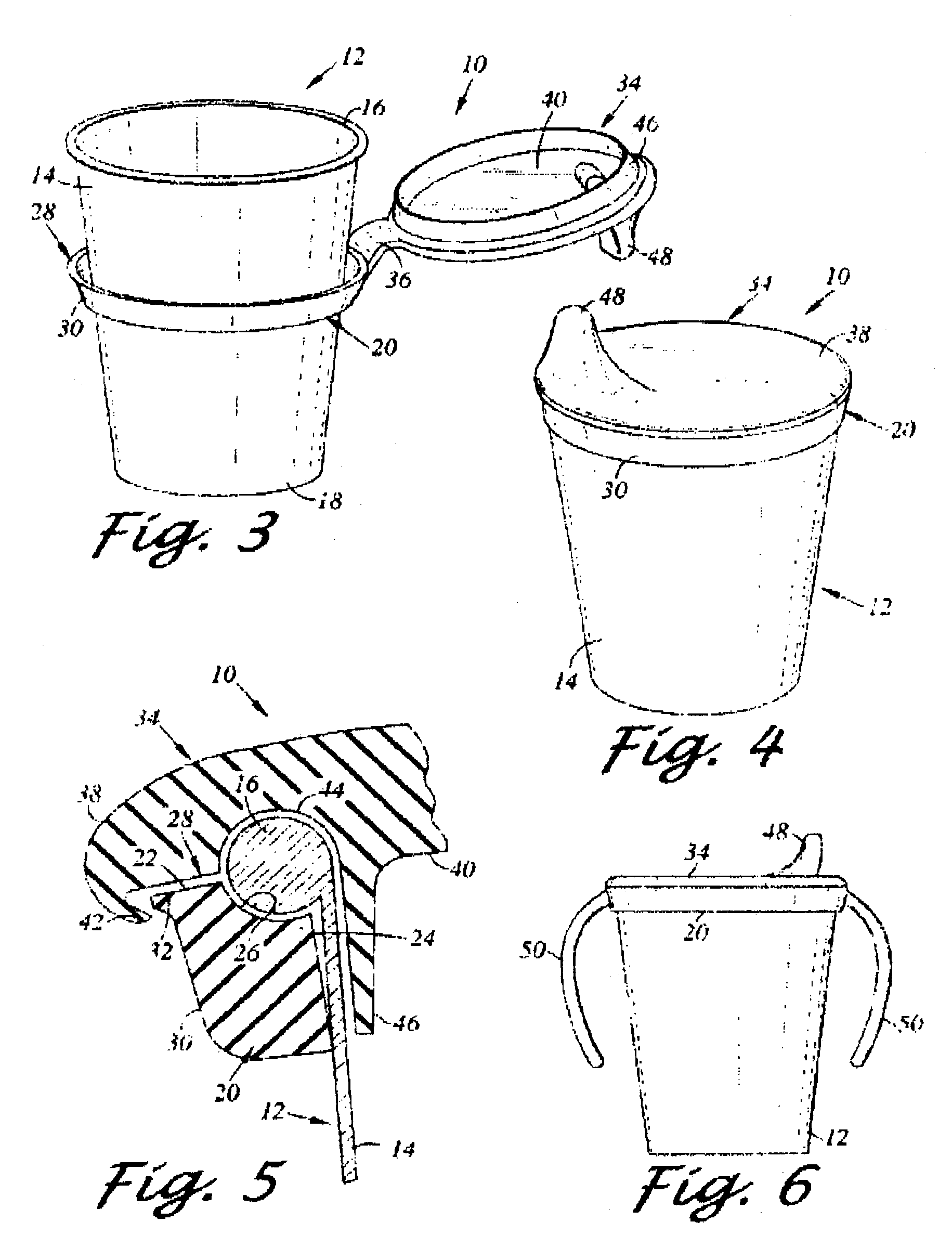

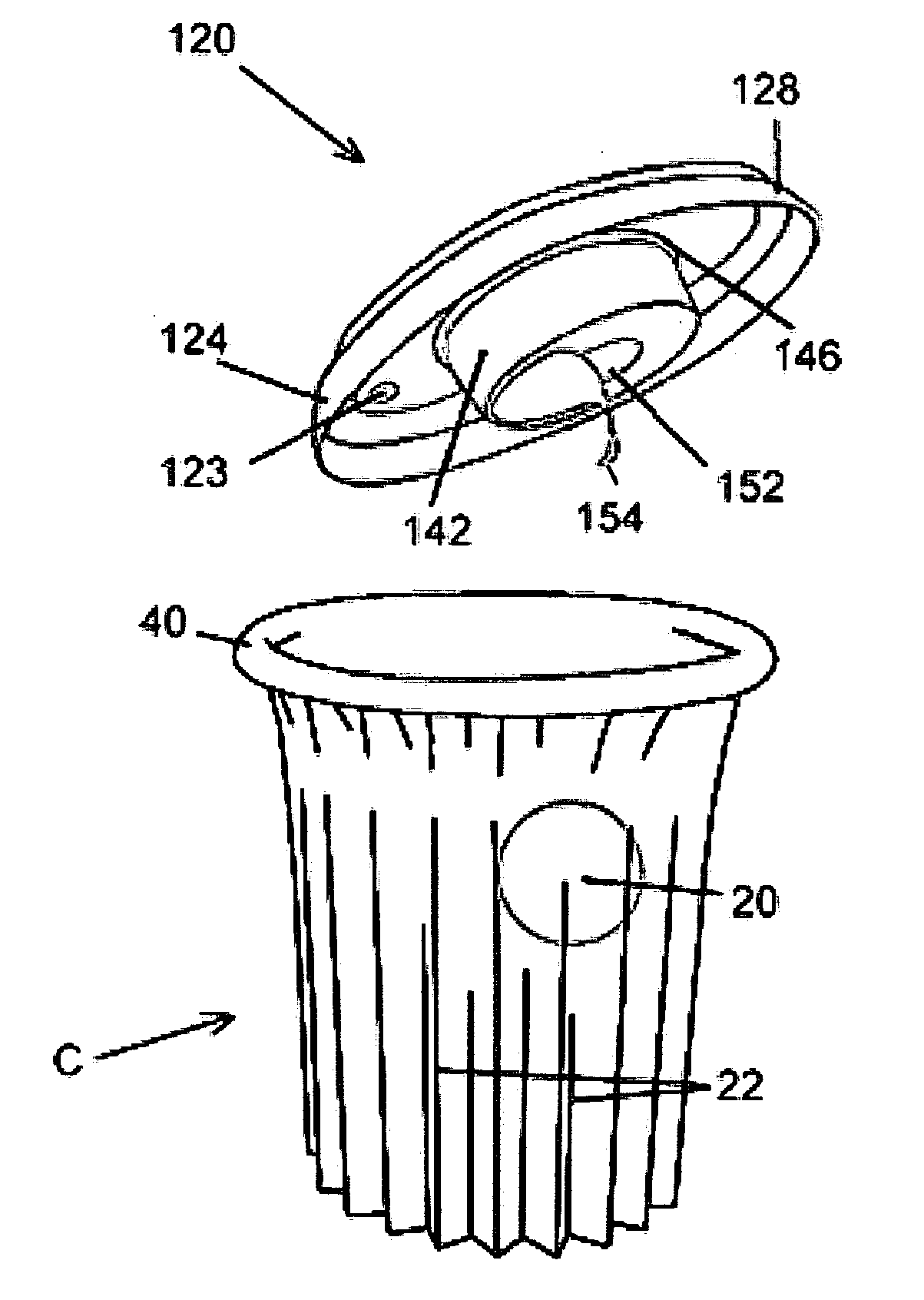

Single-piece paper cup sip adaptor

An adaptor enables a child to drink from a cup having a bead extending around an open end of the cup. The adaptor has an annular collar that supports the cup by engaging a lower portion of a bead of the cup around a substantial portion of a periphery of the bead. A lid is removably engageable with the collar. The lid has an annular flange depending from a lower surface toward the collar with the flange being located to abut an interior side of the wall of the cup when the lid engages the collar to form a fluid seal with the cup. The lid has a channel formed therein and located between the flange and a periphery of the lid and encircling the flange. The channel encloses an upper portion of the bead of the cup. The lid has a child drinking spout on an exterior surface of the lid adjacent a peripheral edge of the lid. The spout is in fluid communication with the cup during use of the adaptor.

Owner:SCOTTY OF CALIFORNIA INC

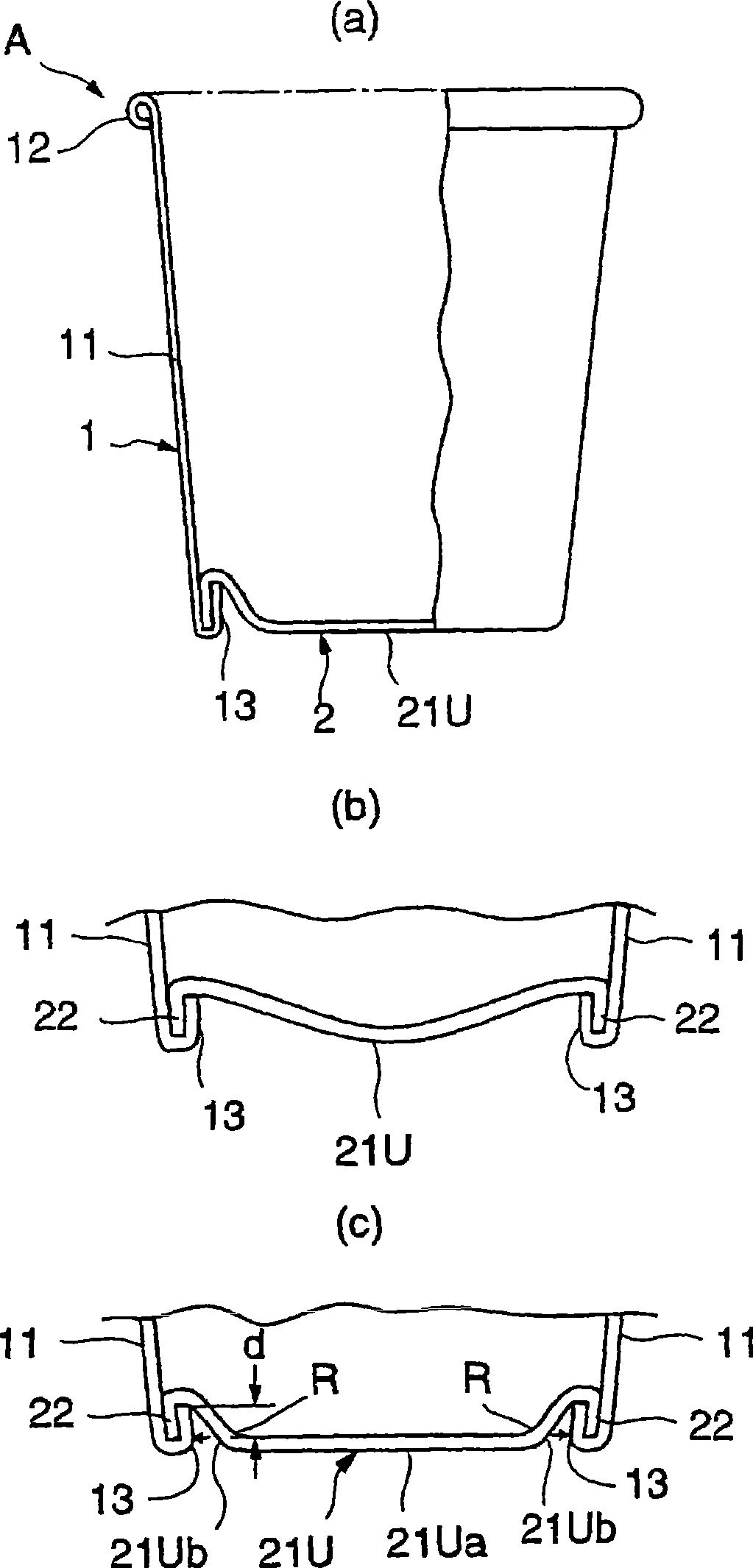

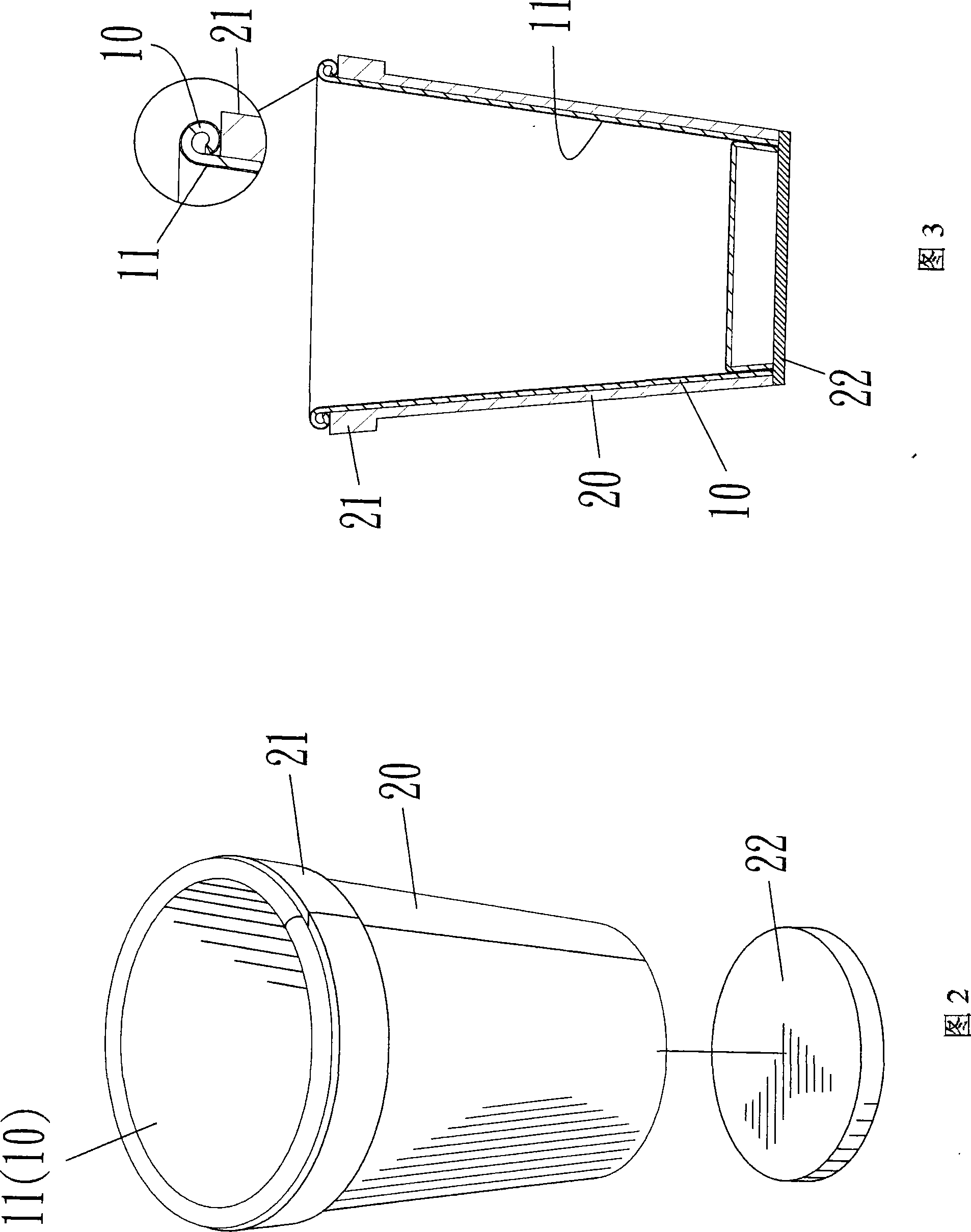

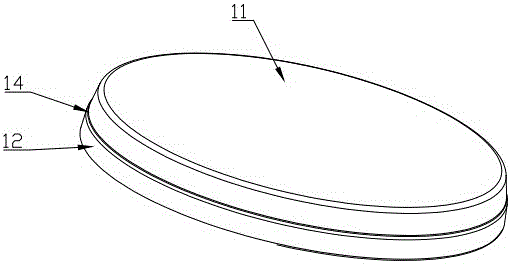

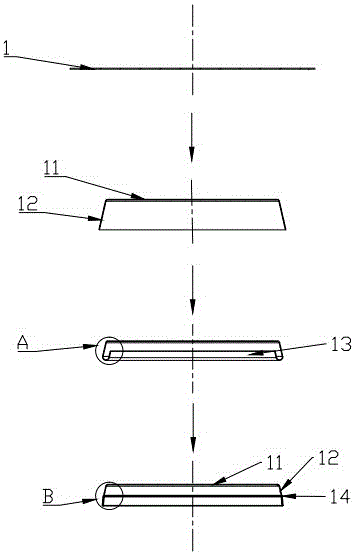

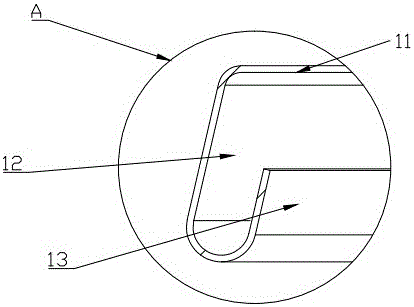

Microwave oven-compatible paper cup

This invention provides a microwave oven-compatible paper cup capable of preventing a thread end part from being burnt when the paper cup containing a content such as beverage and instant food is heated for cooking by a microwave oven, comprising a shell member (1) having a cylindrical shell part (11), a top curl part (12) formed by bending the upper end side of the shell part, and a folded part (13) formed by folding up the lower end of the shell part inward, and a bottom member (2) having a bottom surface part (20) and a bent part (22) formed by bending the outer peripheral edge part of the bottom surface part, wherein the bent part (22) is sandwiched between the shell part (11) and the folded part (13) to connect the shell member (1) to the bottom member (2), and the bottom surface part (20) is formed recessedly downward and including a lower surface section, which is almost flat.

Owner:DAI NIPPON PRINTING CO LTD

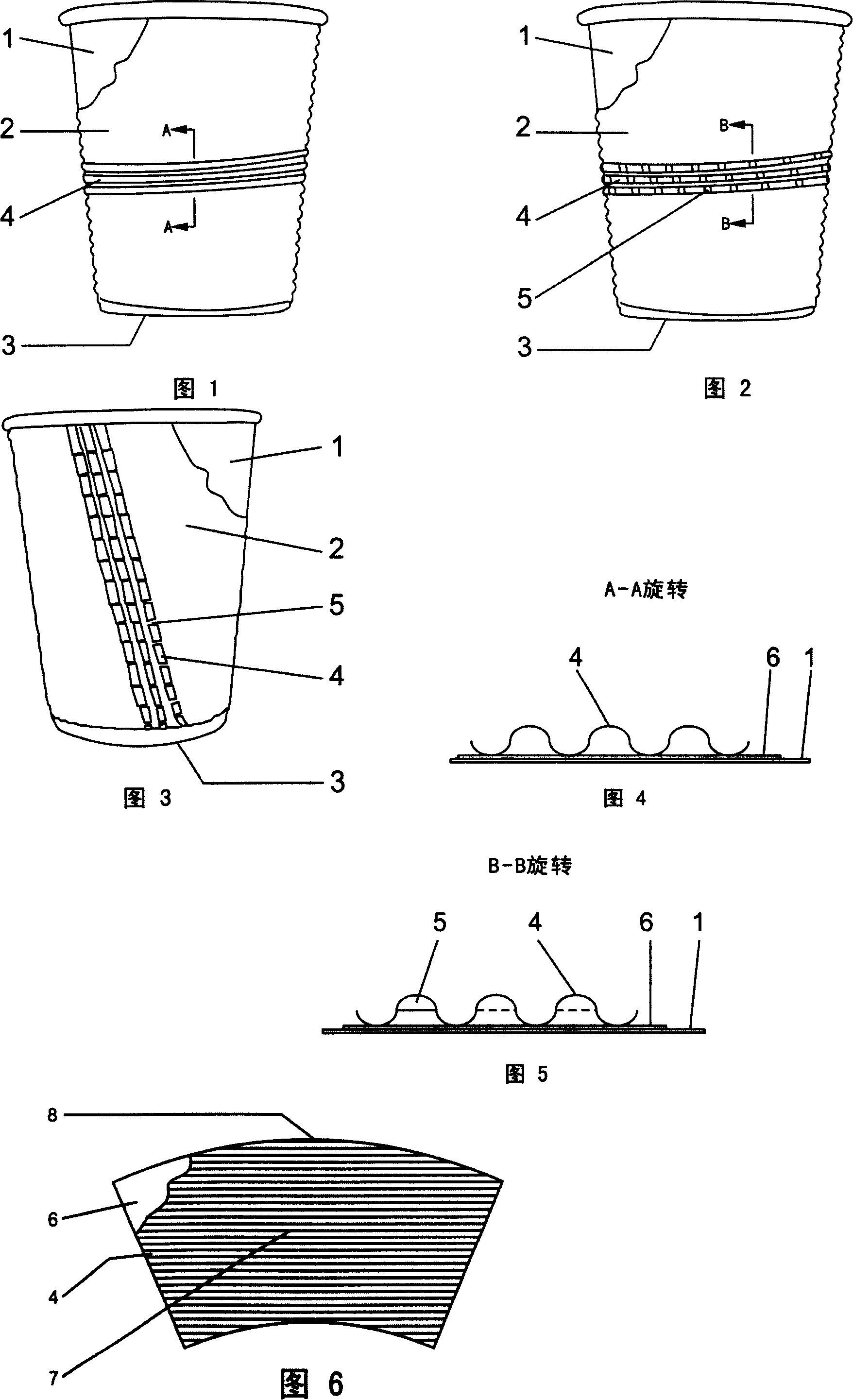

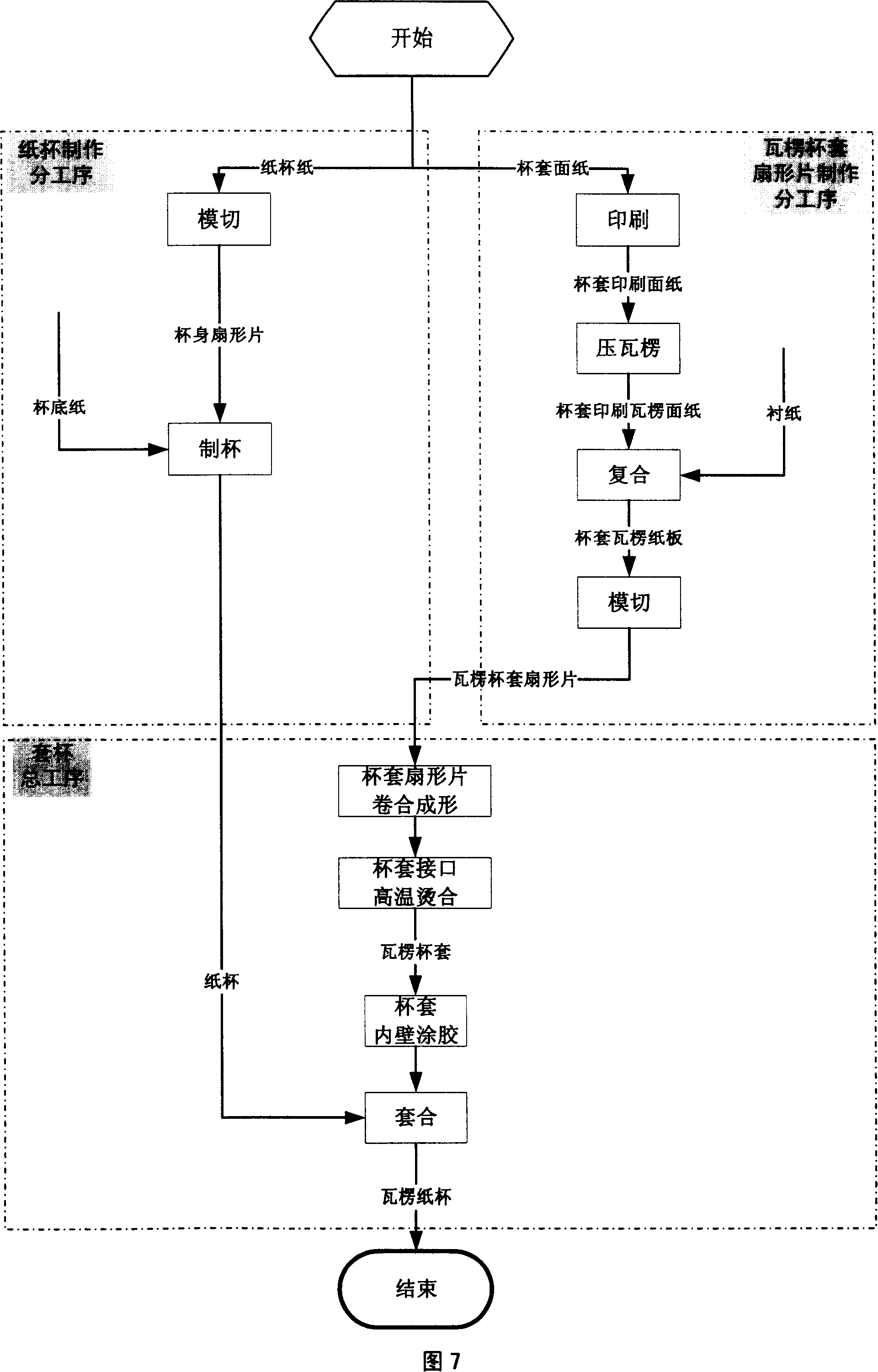

Corrugated paper cup and production method thereof

InactiveCN1961786ANice appearanceModerate stiffnessEnvelopes/bags making machineryBoxes/cartons making machineryAdhesiveEngineering

The invention relates to a corrugated paper cup, wherein it comprises cup body, bottom and sheath; said cup sheath is corrugated paper sheath, whose corrugated bars are transversely arranged; or the corrugated bar has groove; and its production comprises that producing the paper cup, and the corrugated cup sheath arc plates, and sheathing the cup; the arc plates are coiled and shaped, while the interfaces are combined at high temperature by ultrasonic wave; the inner wall is coated with adhesive to combine the cup. The invention has high thermal-insulated property and the batch production ability.

Owner:林泠镪

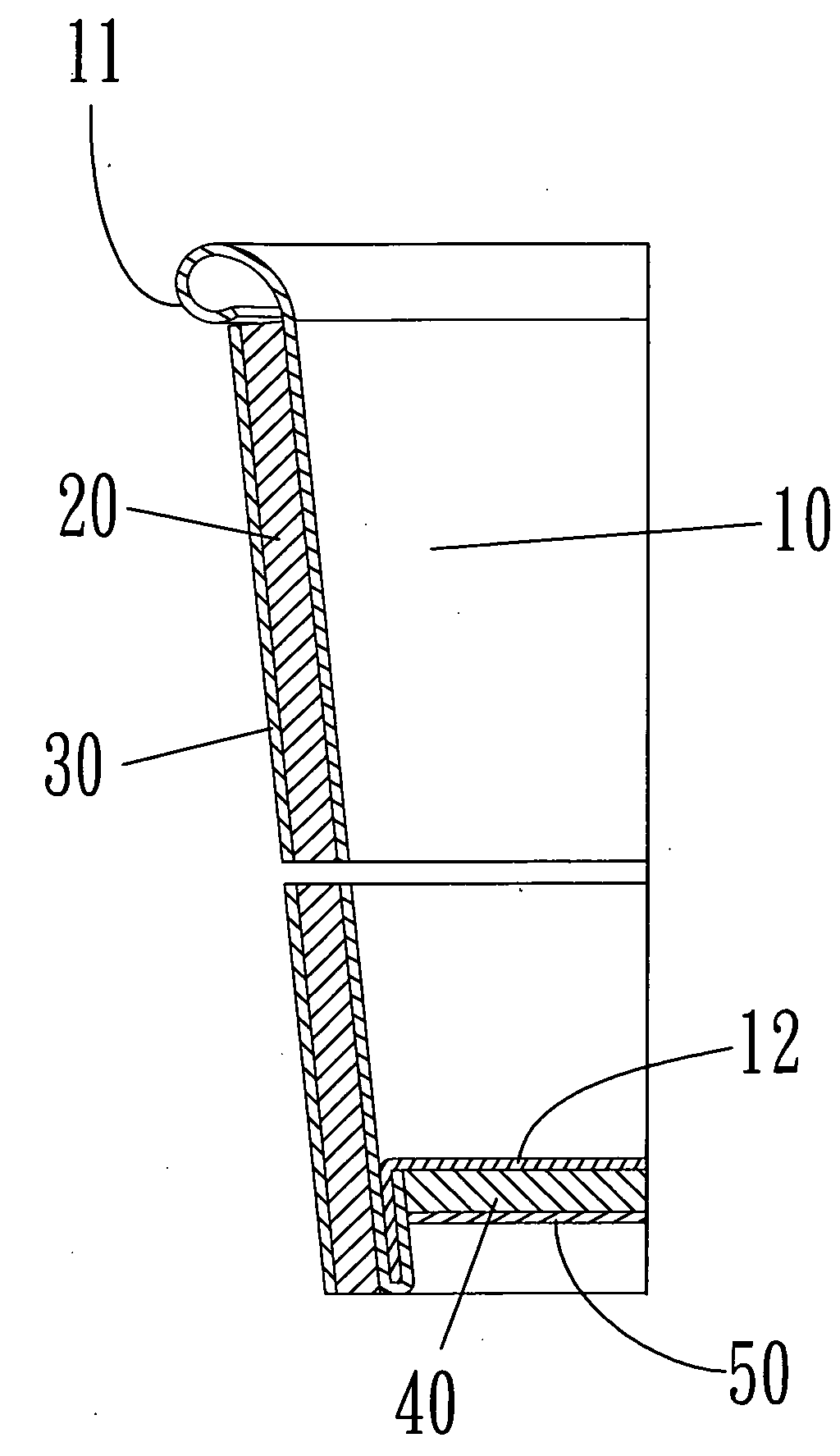

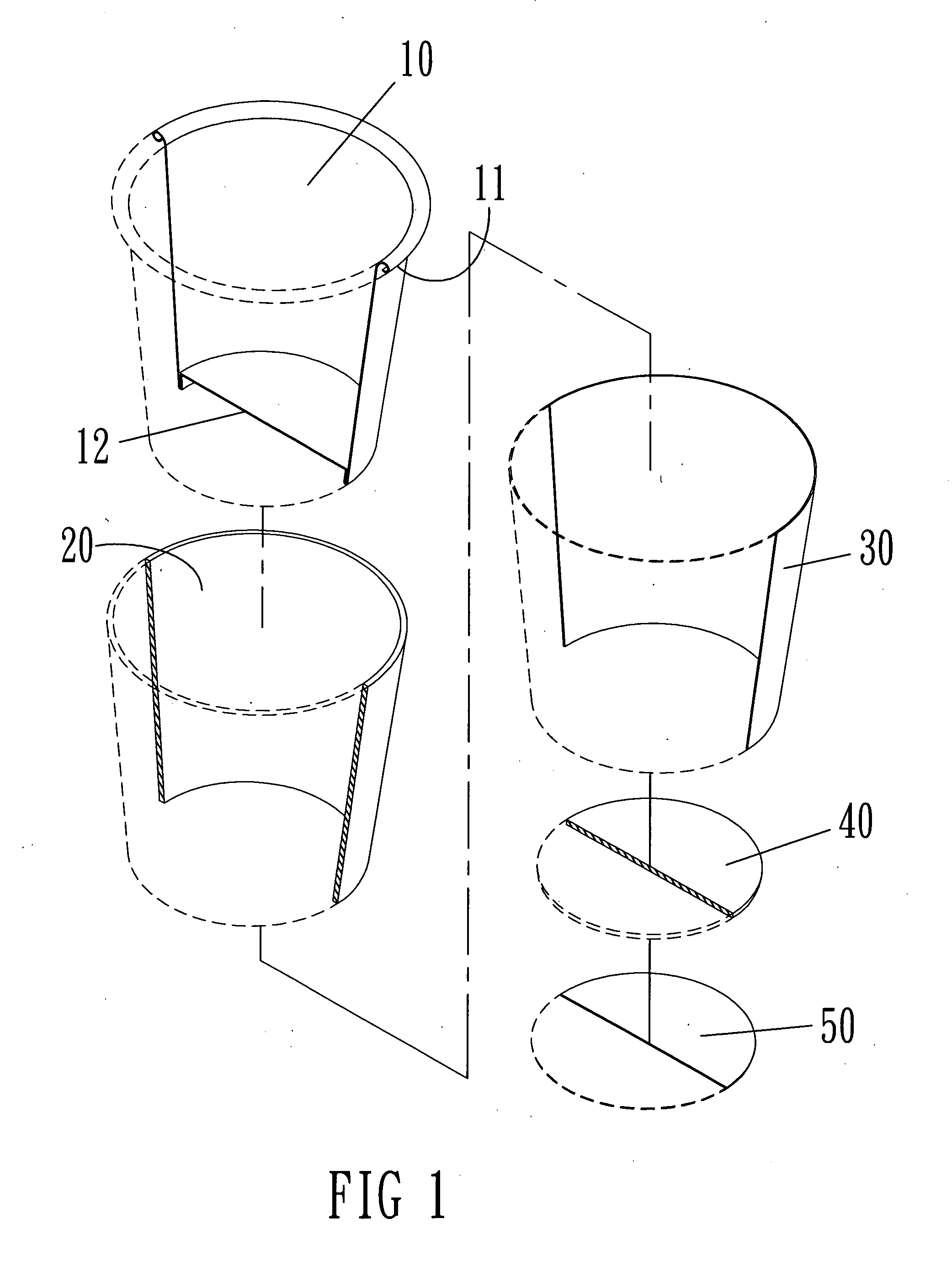

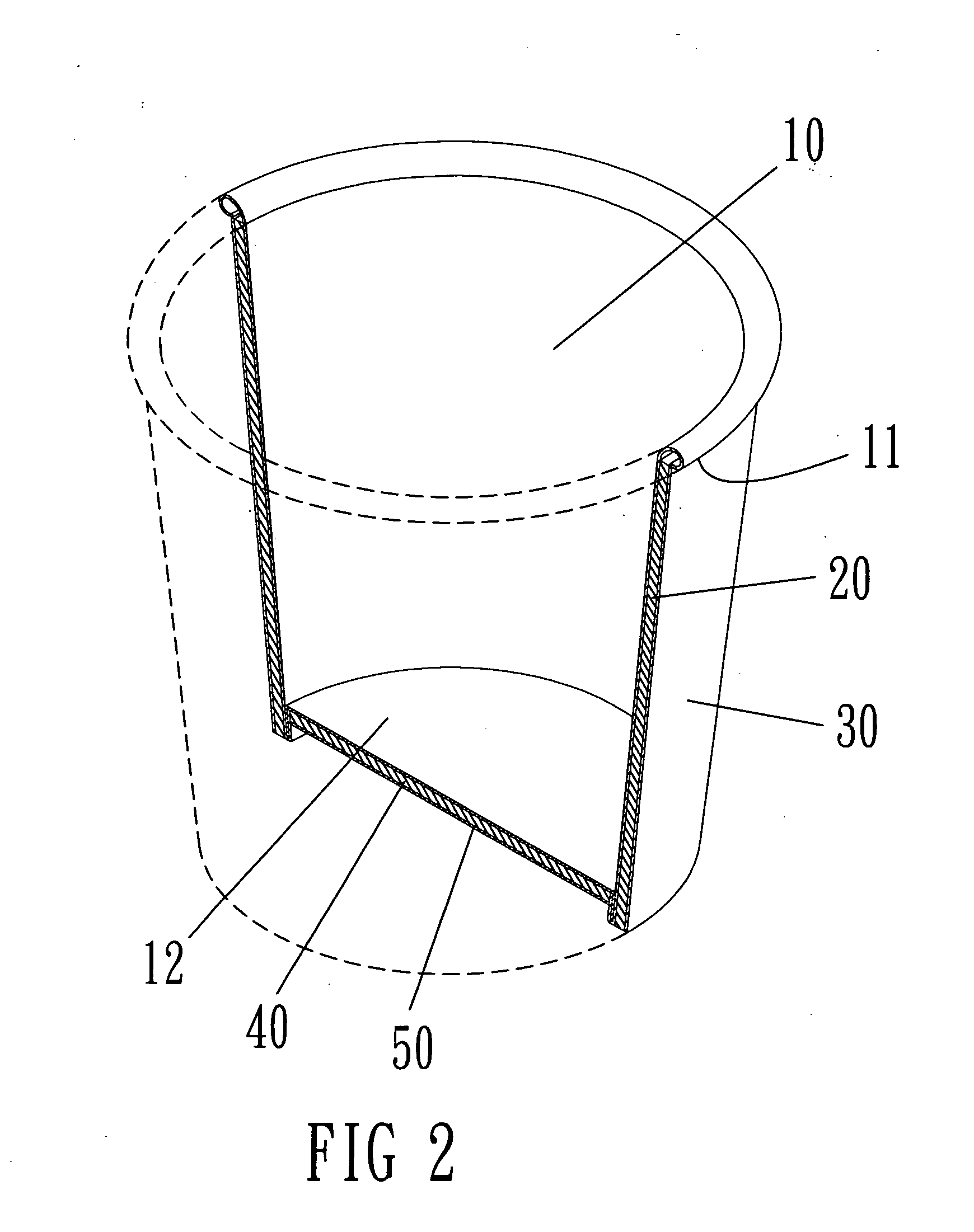

Structural improvement for cup container

InactiveUS20100065622A1Improve efficiencyImprove structural strengthBio-packagingRigid containersPulp and paper industryPaper cup

A structural improvement for a cup container includes the following structures. An internal layer paper cup having an internal paper cup bottom is bonded to a bottom of the cup container. A foam layer is bonded to an exterior of the internal layer paper cup. An external layer paper cup then is bonded to an exterior of the foam layer. A foam bottom and an external paper cup bottom are bonded to an external bottom of the internal paper cup bottom in order. The internal surface of the internal layer paper cup and an upper of the internal paper cup bottom are coated with waterproof layers. The foam material of the foam layer can be a biodegradable material, or non-biodegradable materials. The foregoing waterproof layers can be a biodegradable material, or can be a non-biodegradable material.

Owner:CHANG HSI CHING

Paper cup manufacture with microencapsulated adhesive

InactiveUS20100012712A1Improve sealingElimination of glue applicationBoxes/cartons making machineryPaper-makingAdhesivePaperboard

Paper cup manufacture utilizing microencapsulated adhesive typically includes: (a) supplying a paperboard web to a coating line; (b) coating the web in the coating line with a liquid-resistant coating in a first predetermined pattern on a first side thereof corresponding to interior surfaces of sidewalls of paperboard cups formed from the paperboard blanks; (c) coating the web in the coating line with a microencapsulated adhesive in a second predetermined pattern corresponding to seams of paperboard cups formed from the paperboard blanks, the microencapsulated adhesive thereby being applied in common registry with the liquid-resistant coating in the coating line; and (d) cutting paperboard blanks from the web. The paperboard blanks are then (e) formed into the cup sidewall with the adhesive securing a seam.

Owner:DIXIE CONSUMER PROD

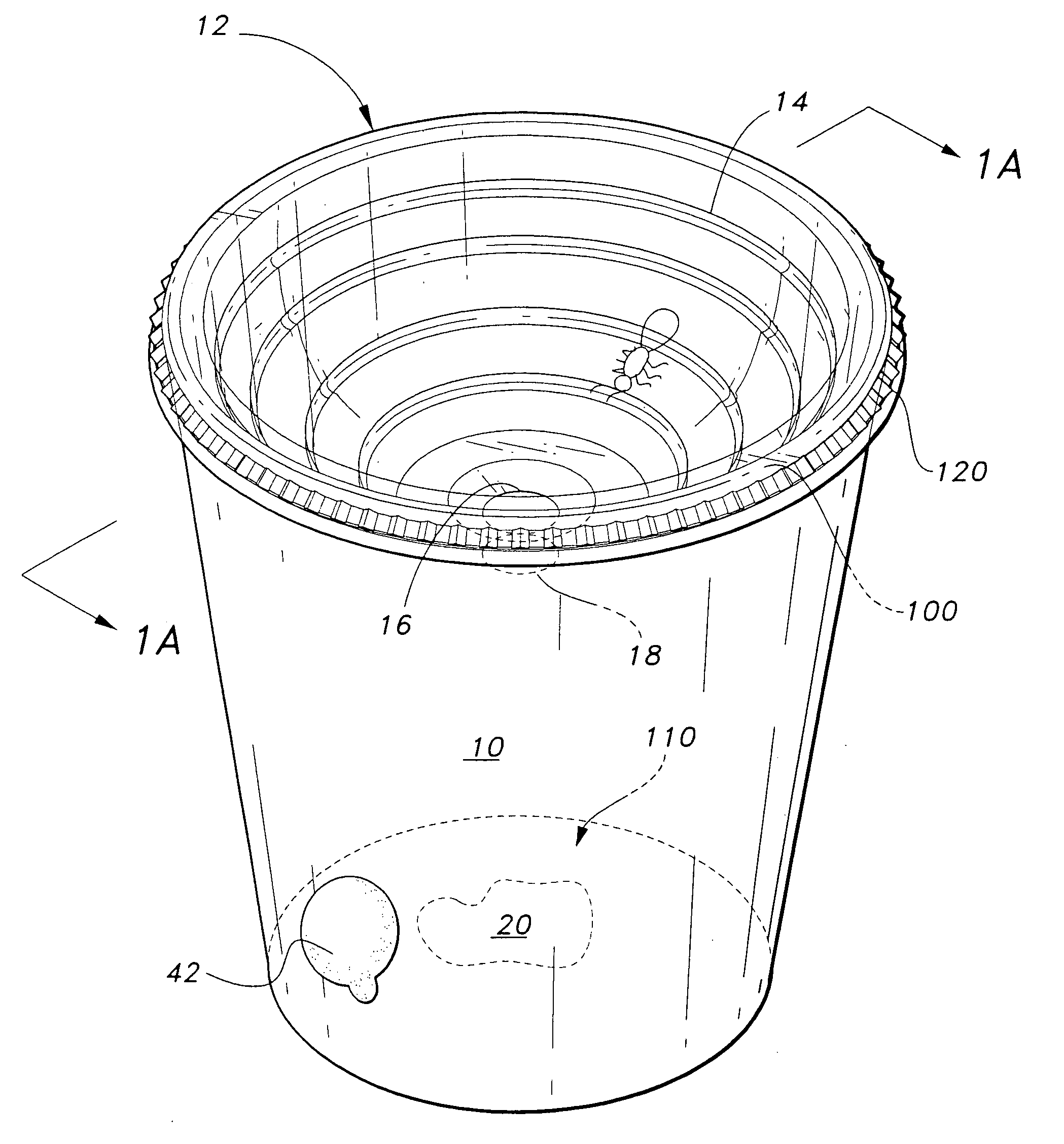

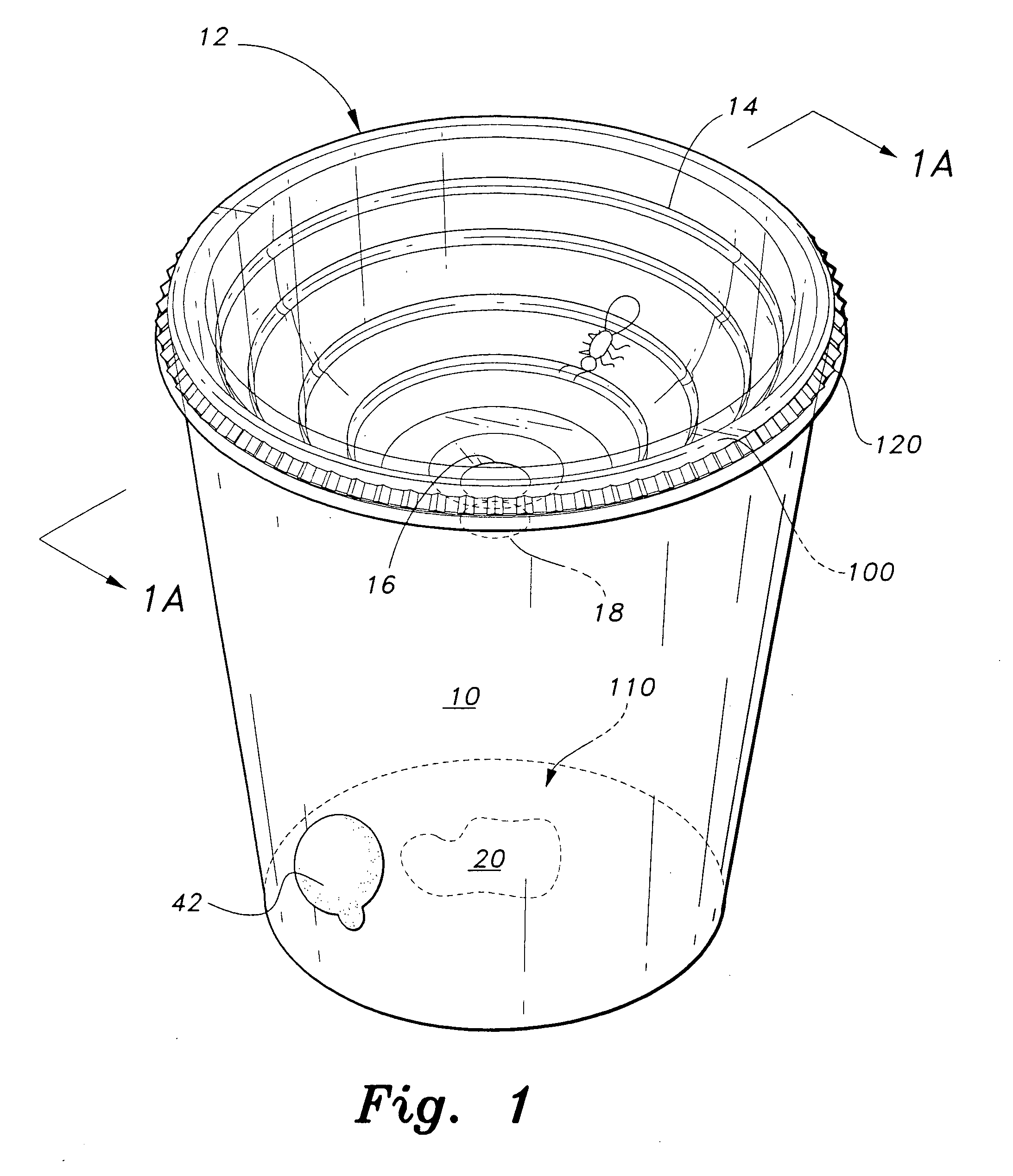

Vehicle roach trap

The vehicle roach trap is an economical and ergonomic paper or plastic cup insect trap containing a bait and which can be placed in the vehicle's cup holder(s). In a first embodiment, a paper cup trap has a lipped transparent plastic concave cover formed by an inverted dome with a small flap at its bottom that will fall open by the insect's weight. A second embodiment has a similar cover, but without the flap, and has at least a portion of the cup interior coated by a sticky, viscous substance. In the latter case, an alternative cover is substantially planar, having a plurality of concave depressions, each depression having a hole defined therein through which the roach may fall. The planar cover may also have resilient, pivotal flaps covering the holes. An adhesive sticker may be provided for sealing the hole(s) for disposal of the trap.

Owner:WONG JOE K

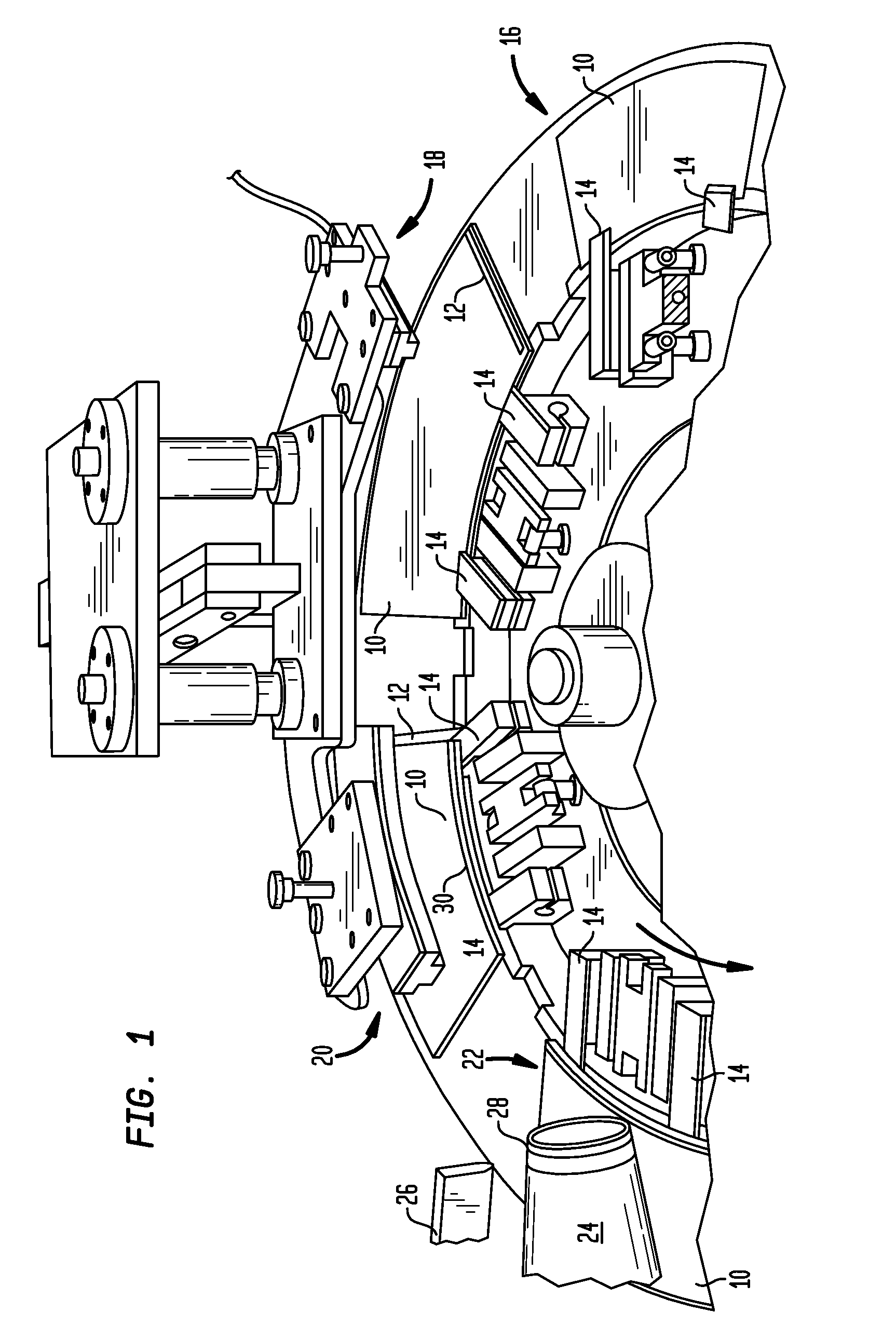

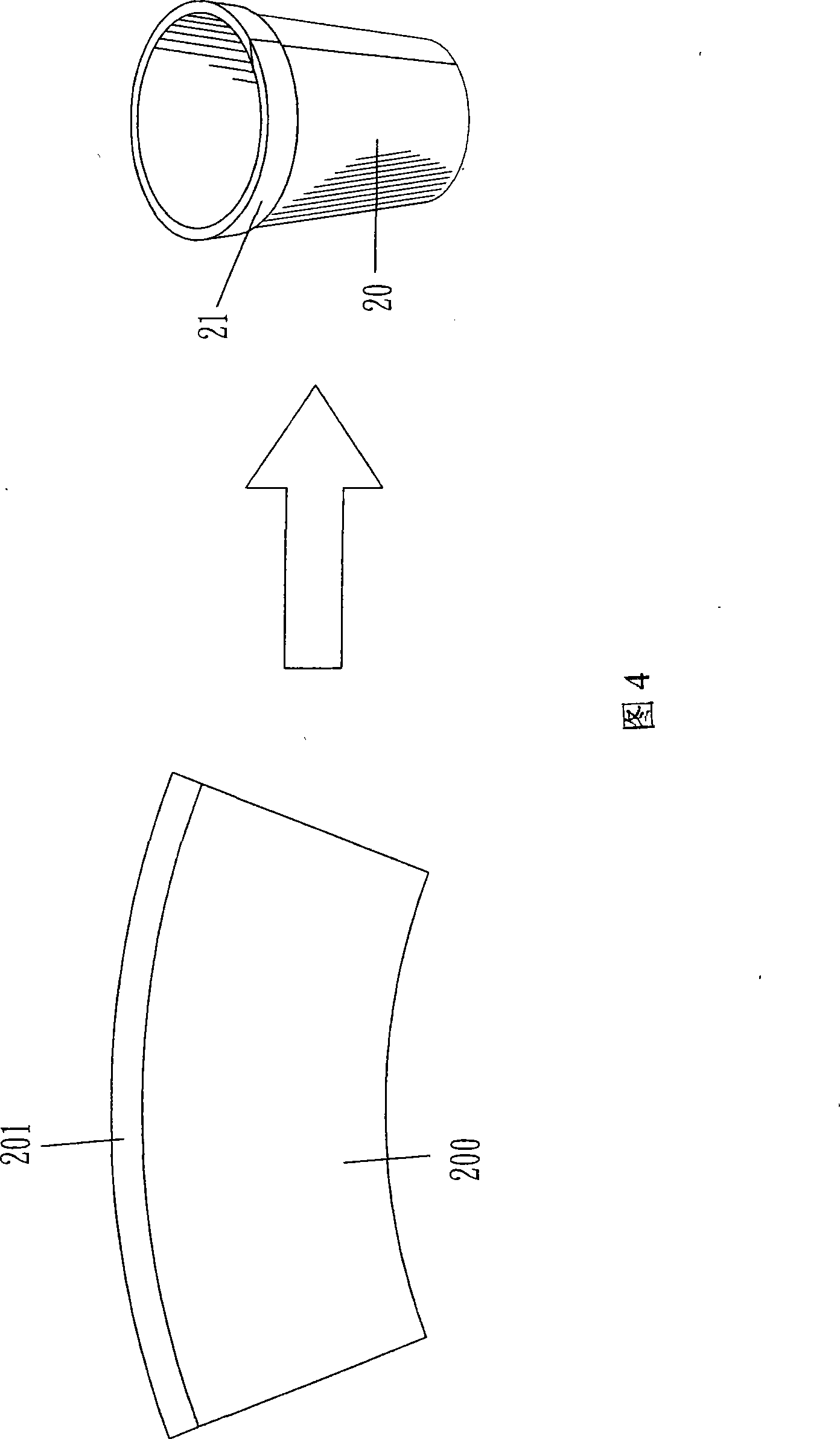

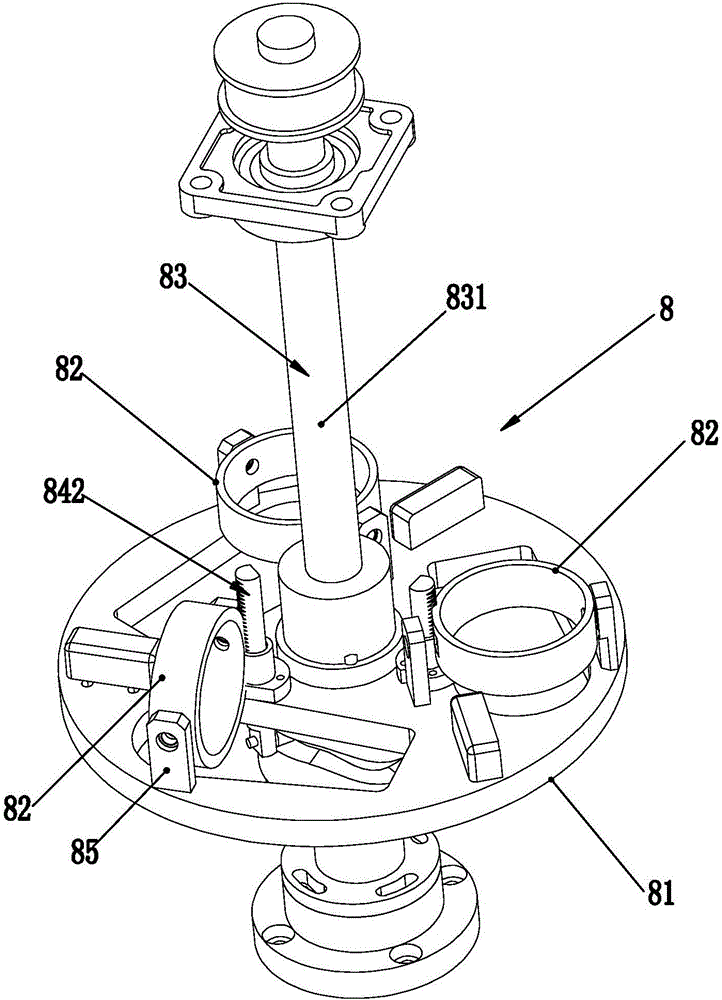

Corrugated insulated paper cup and paper cup forming machine preparing same

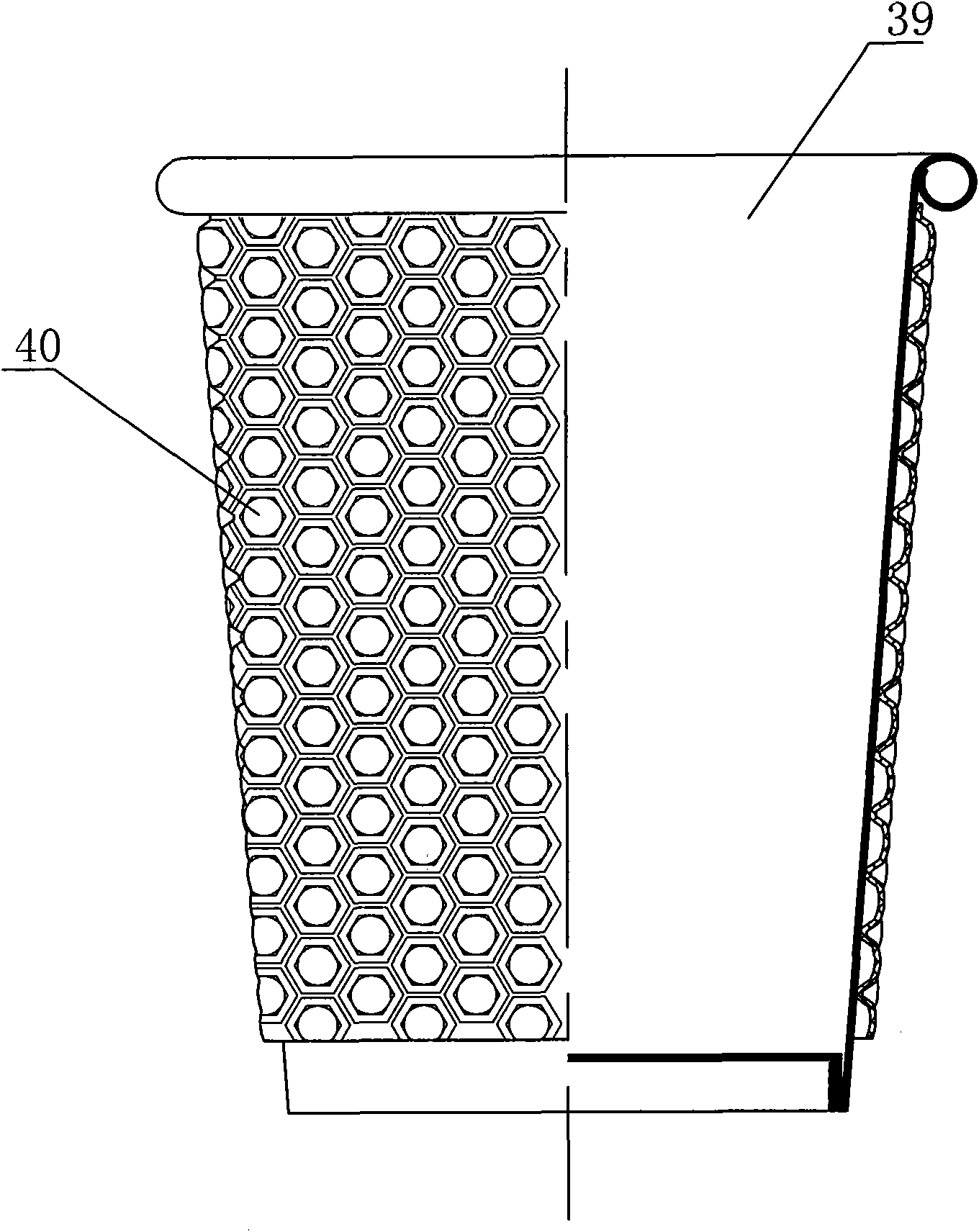

InactiveCN101889806AGood heat insulationLow costBoxes/cartons making machineryDrinking vesselsPulp and paper industryPaper cup

The invention discloses a corrugated insulated paper cup. The paper cup consists of an inner cup and an outer sleeve sleeved together, wherein the outer sleeve is prepared by rolling a single-layer sheet pressed with corrugated grains. The paper cup has a high heat insulation effect and a low cost. Meanwhile, the invention discloses a paper cup forming machine for preparing the paper cup. The paper cup forming machine can realize the automatic, low-cost and efficient production of the paper cup, and the patterns on the outer sleeve of the paper cup can be printed according to the requirements of users per se.

Owner:ZHEJIANG SINI MACHINERY

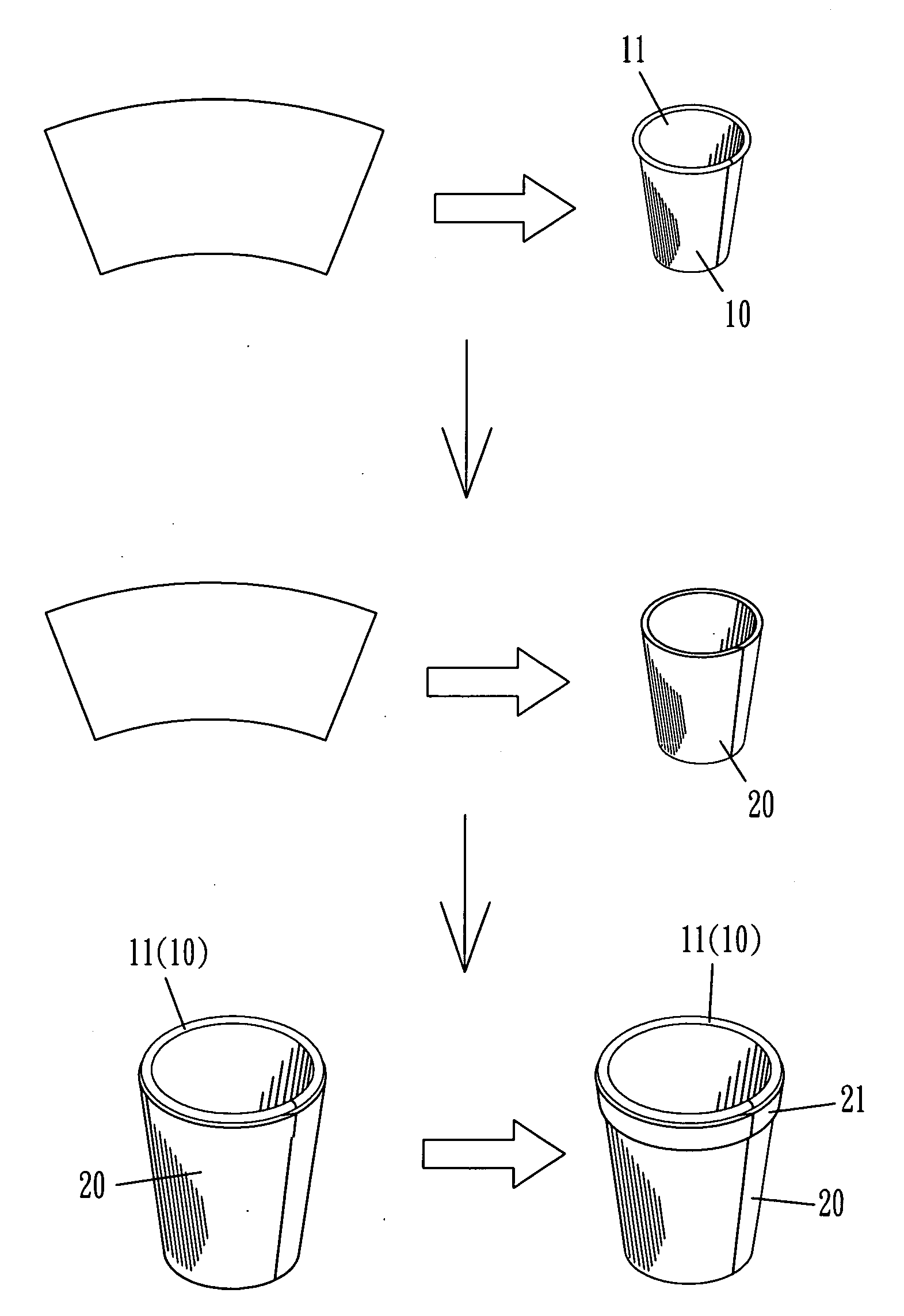

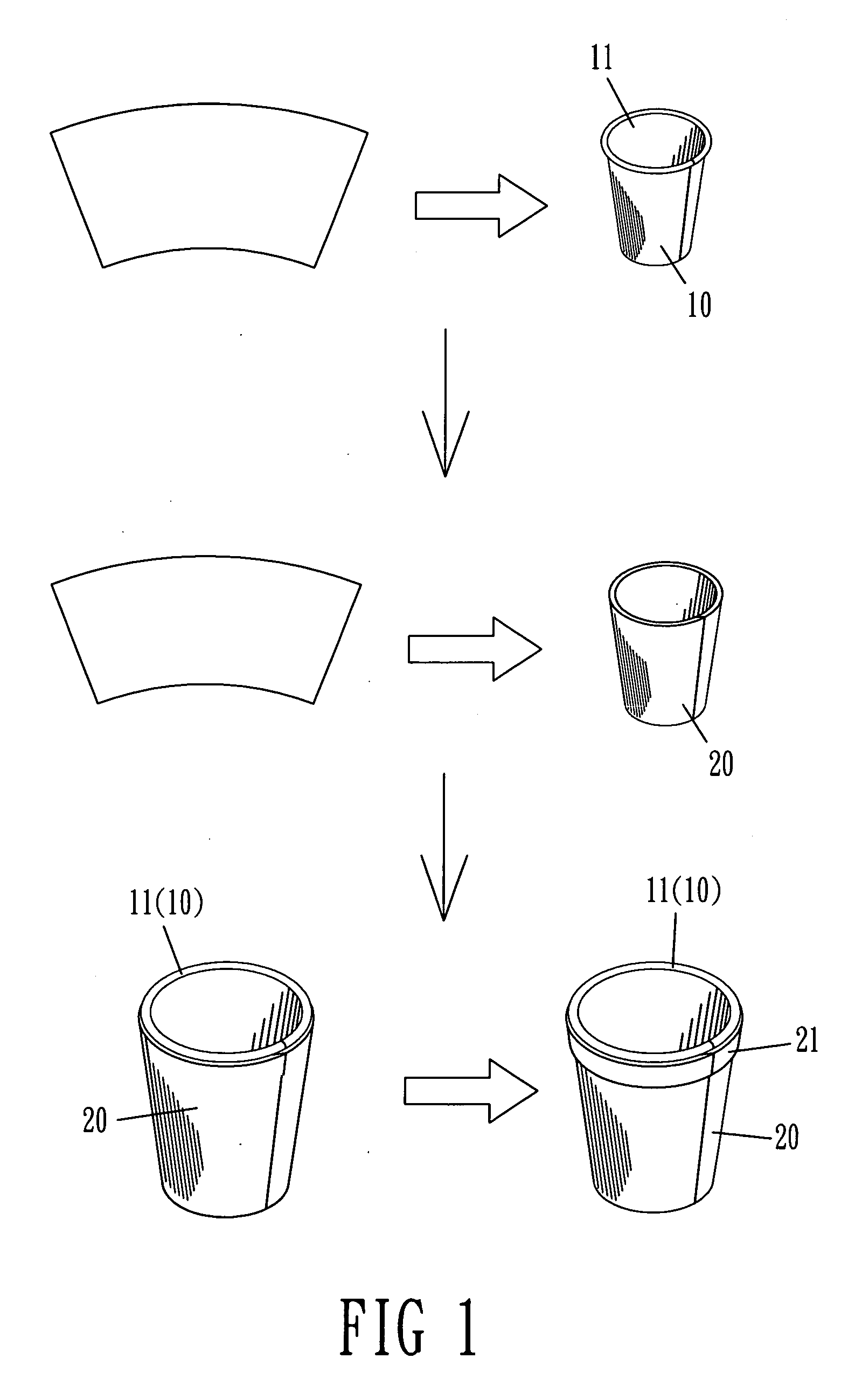

Method for making container cup and structure thereof

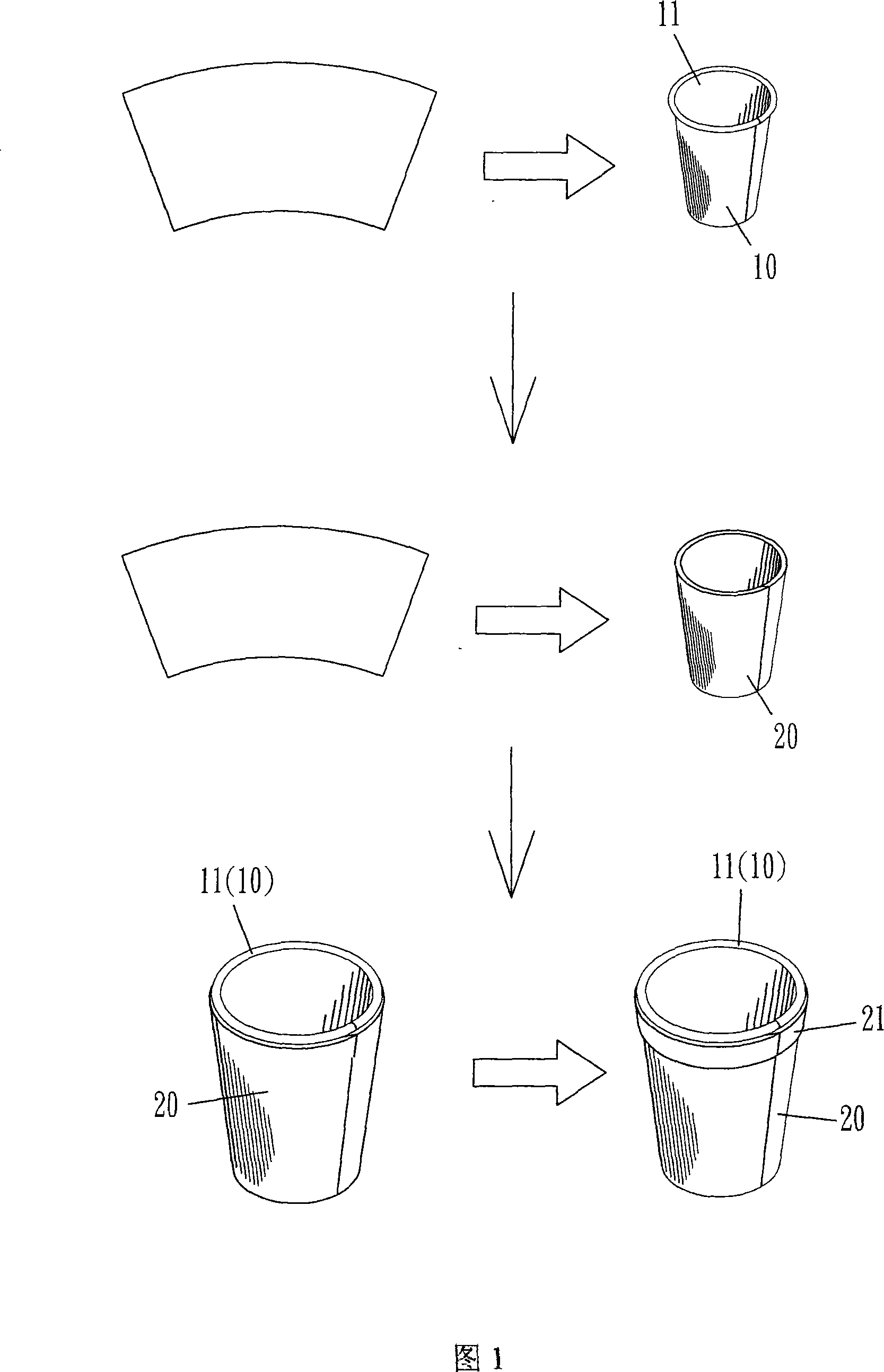

InactiveCN101249732APrevent tight fittingEasy to take outBoxes/cartons making machineryThermal insulationPulp and paper industry

The invention relates to a manufacturing method of a container cup and a structure thereof, which belongs to the daily article class. The invention comprises a paper cup and a cup-shaped electronic bridging foaming body, wherein the inner surface or the outer surface of the paper cup is sprinkled and covered with a film layer, and is pressed into the paper cup through shape cutting; the cup-shaped electronic bridging foaming body is formed by being bonded in a hot pressing way after an electronic bridging foaming plate is manufactured into a sector body through printing, shape cutting and stripe pinching, the inner peripheral of the cup-shaped electronic bridging foaming body is ensured to produce softening viscosity in the hot pressing way, then the paper cup is directly covered on and bonded with the inside of the cup-shaped electronic bridging foaming body, and meanwhile a convex ring with a oversize diameter is formed at the outer part of the paper cup lip where the cup-shaped electronic bridging foaming body is positioned. The structure has the advantages that the protective effect is good, the thermal insulation function is good, the water absorbability is low, the appearance is smooth and artistic, the structure is not easy to be metamorphic, the drug fastness is good, the processing is easy, etc.

Owner:张锡卿

Heat-insulating container and apparatus for producing the same

InactiveUS20070117702A1Improve insulation performanceIncrease freedomEnvelopes/bags making machineryMechanical working/deformationPolyolefinEngineering

Owner:DAI NIPPON PRINTING CO LTD

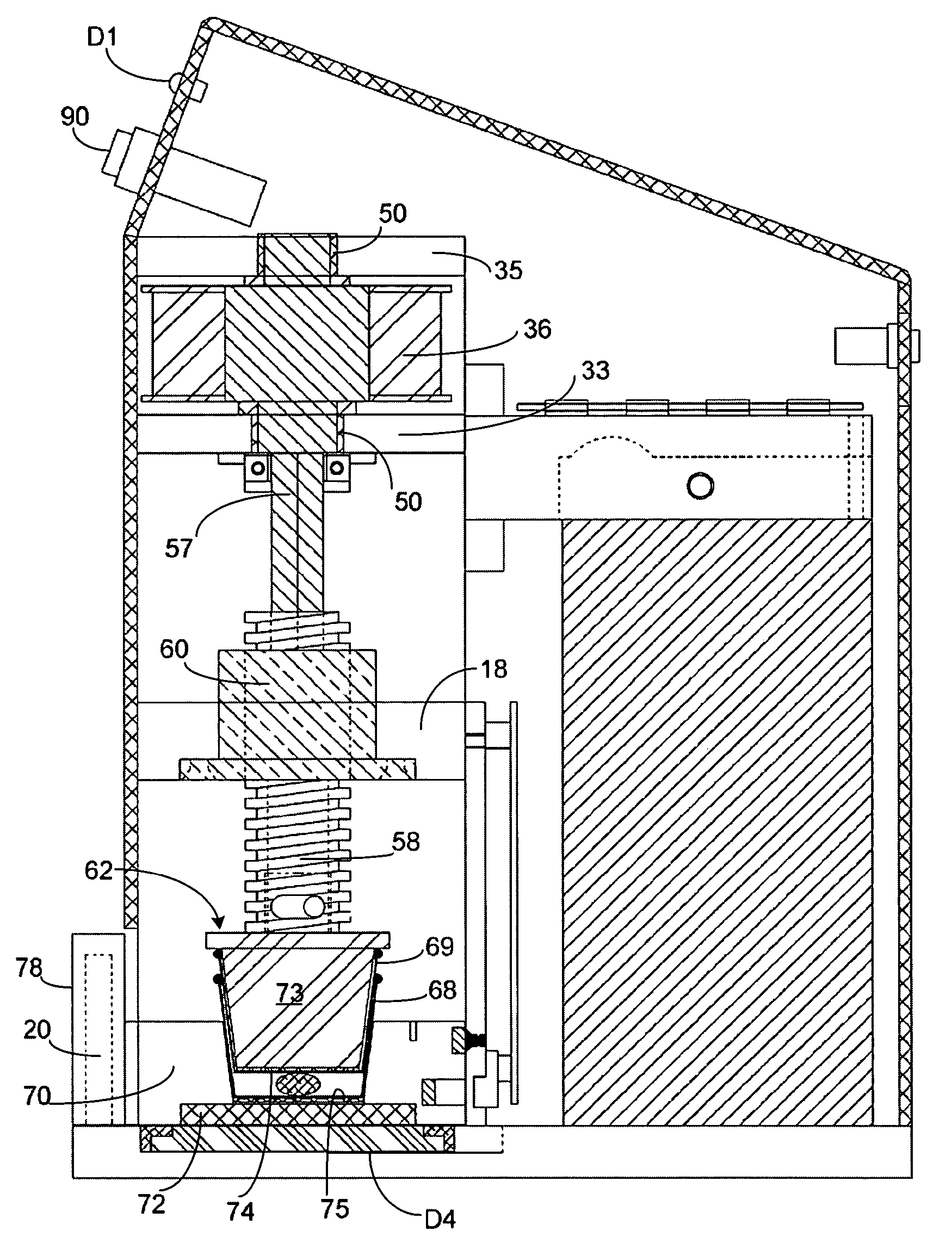

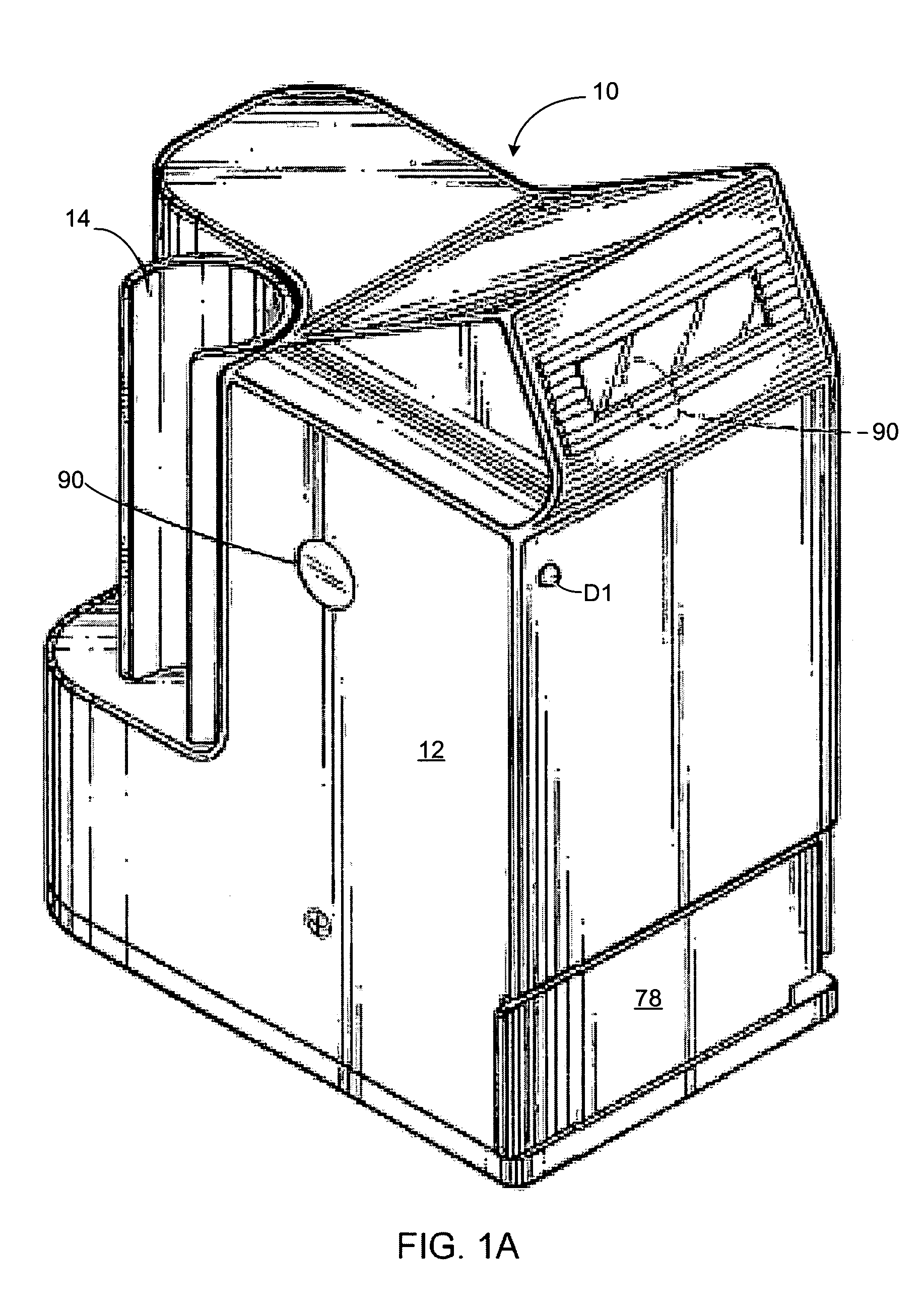

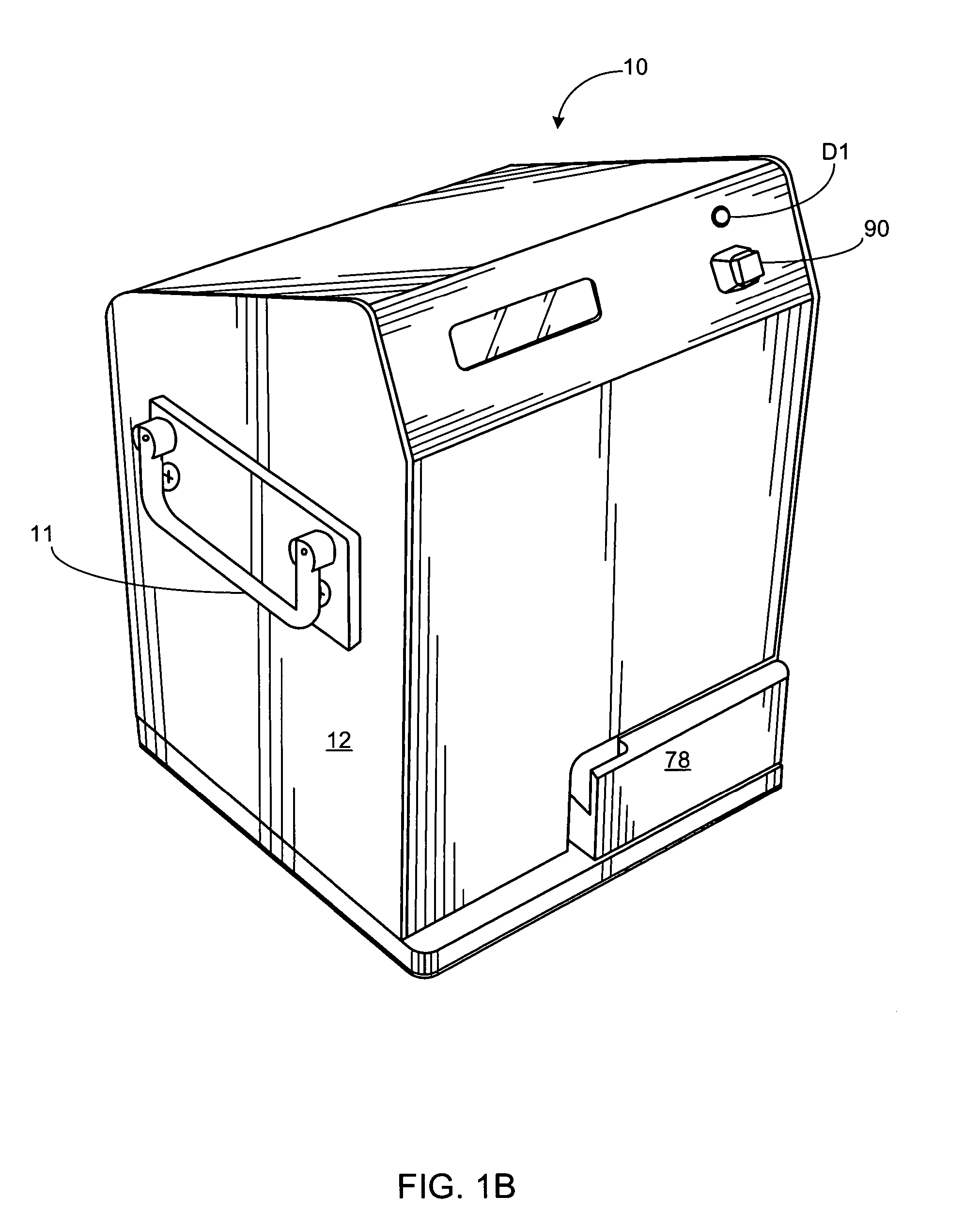

Pill crusher

A pill crusher has a paper cup receptacle having an upwardly open, frusto-conical recess for receiving a paper cup, a plunger having a frusto-conical shape complimentary to that of the recess, the plunger being above and coaxial with the recess, an electric motor and a reciprocating drive transmission between the electric motor and the plunger for displacing the plunger into and out of the recess. The reciprocatory drive transmission comprises a worm and nut drive transmission for rotating the plunger while displacing the plunger into the receptacle. A drive control connected to the electric motor controls the motor so as to displace the plunger into and out of the recess.

Owner:COUGAR MOUNTAIN MARKETING

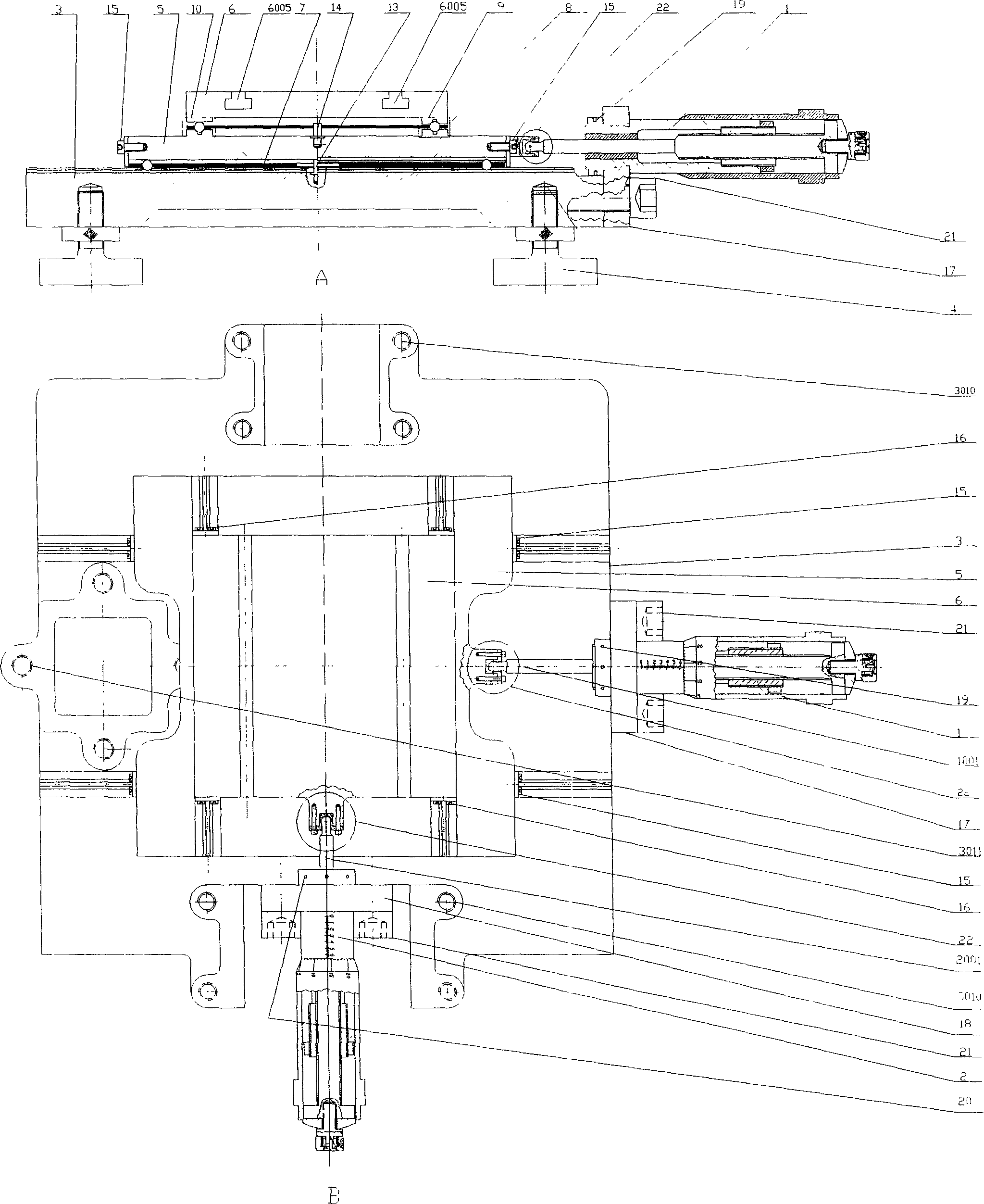

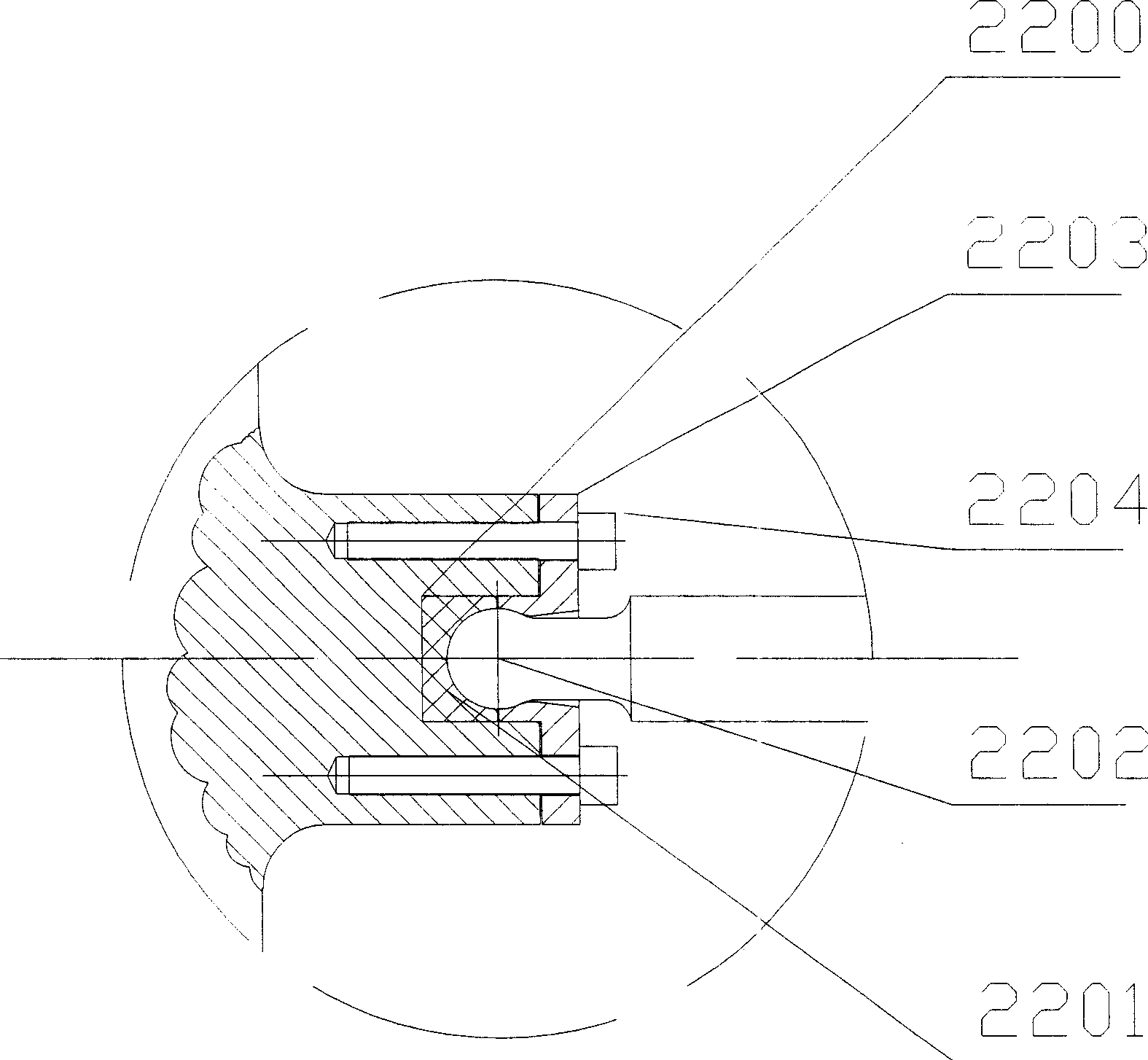

Measuring instrument for paper cup

The invention relates to a non-touch measuring device for the geometry size and tolerance of the paper cup. The feature is that it includes geometry aiming-driving unit, and location detecting and signal collecting processing unit. The geometry aiming-driving unit includes X-Y work platform device, rotating work platform device, X-Y flexible jiggle platform device, Z direction lifting work platform device A that realizes Z shaft direction lifting and Z direction lifting work platform device B that realizes Z shaft direction and horizontal direction adjusting. The location detecting and signal collecting processing unit includes a first laser location sensitive sensor, two second laser location sensitive sensor, two transmission grating rule, closed control circuit formed by measuring and feedback height signal process circuit and step motor server driving signal, diameter signal process circuit, grating process circuit. The invention has advantages of high accuracy, high efficiency, automatic measuring process and data process.

Owner:BEIJING UNIV OF TECH

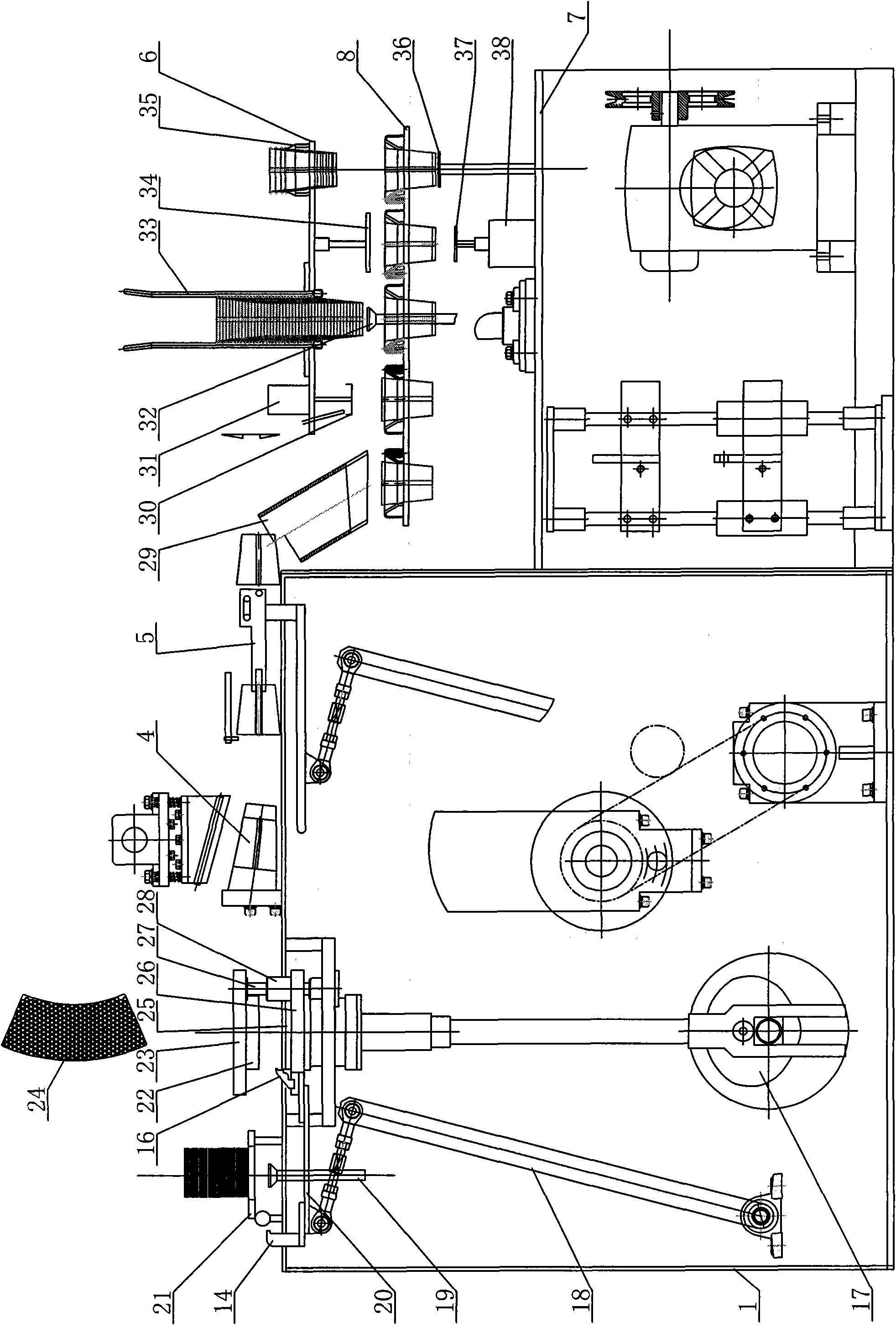

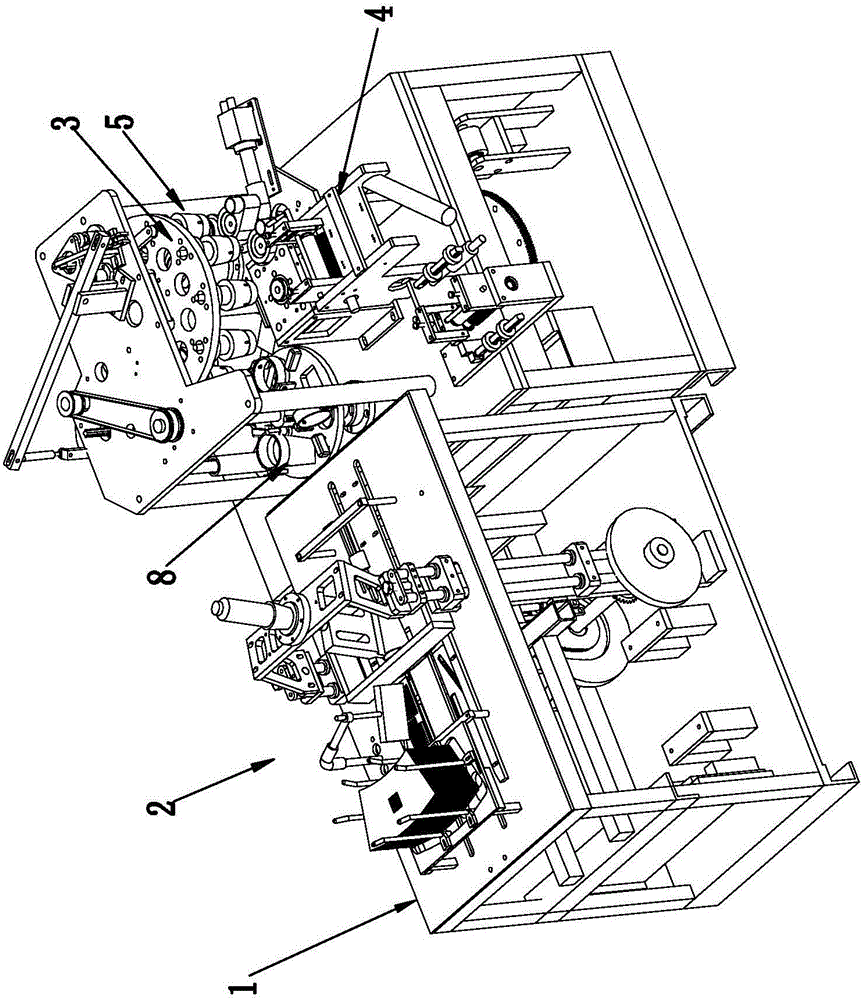

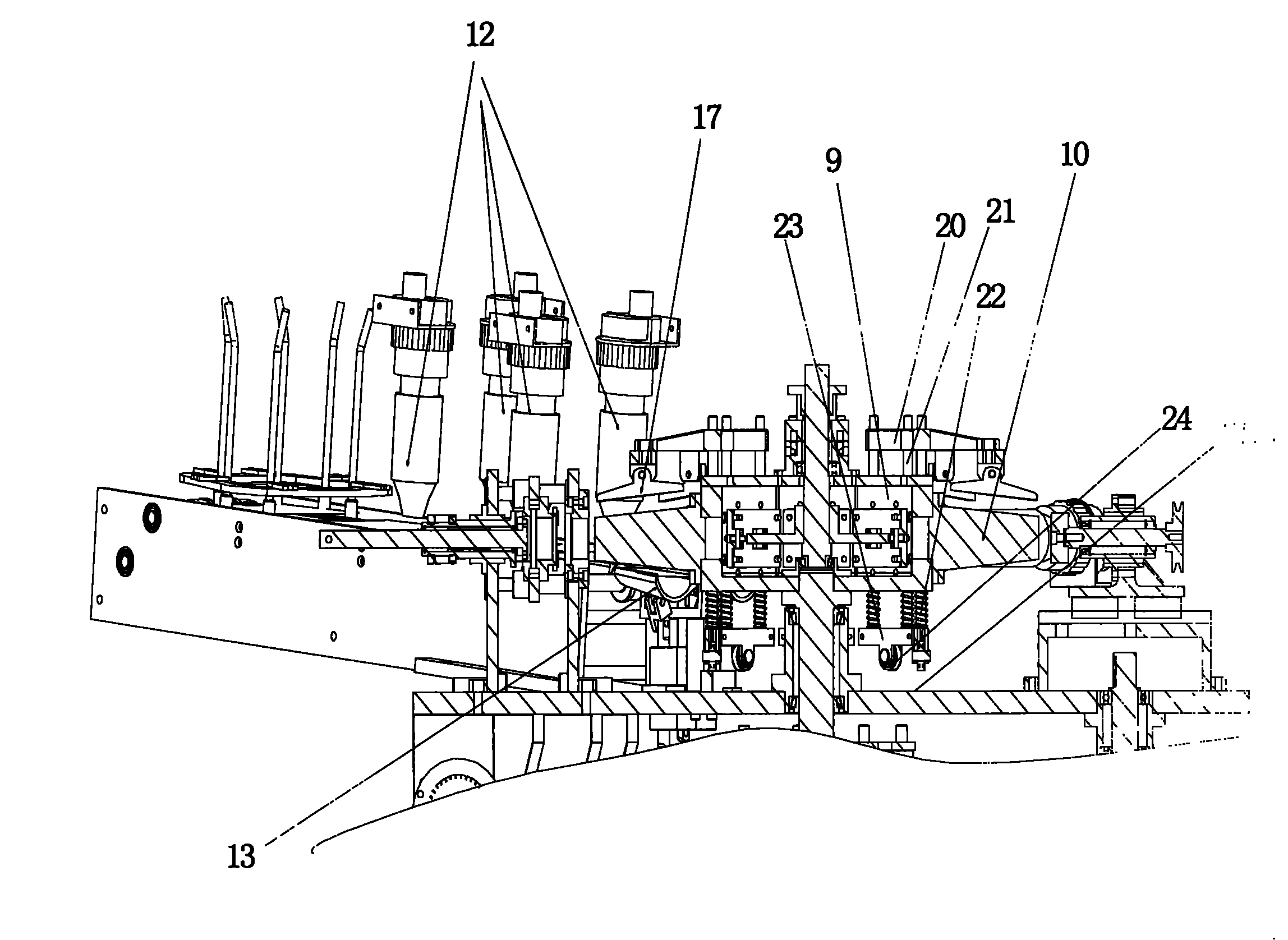

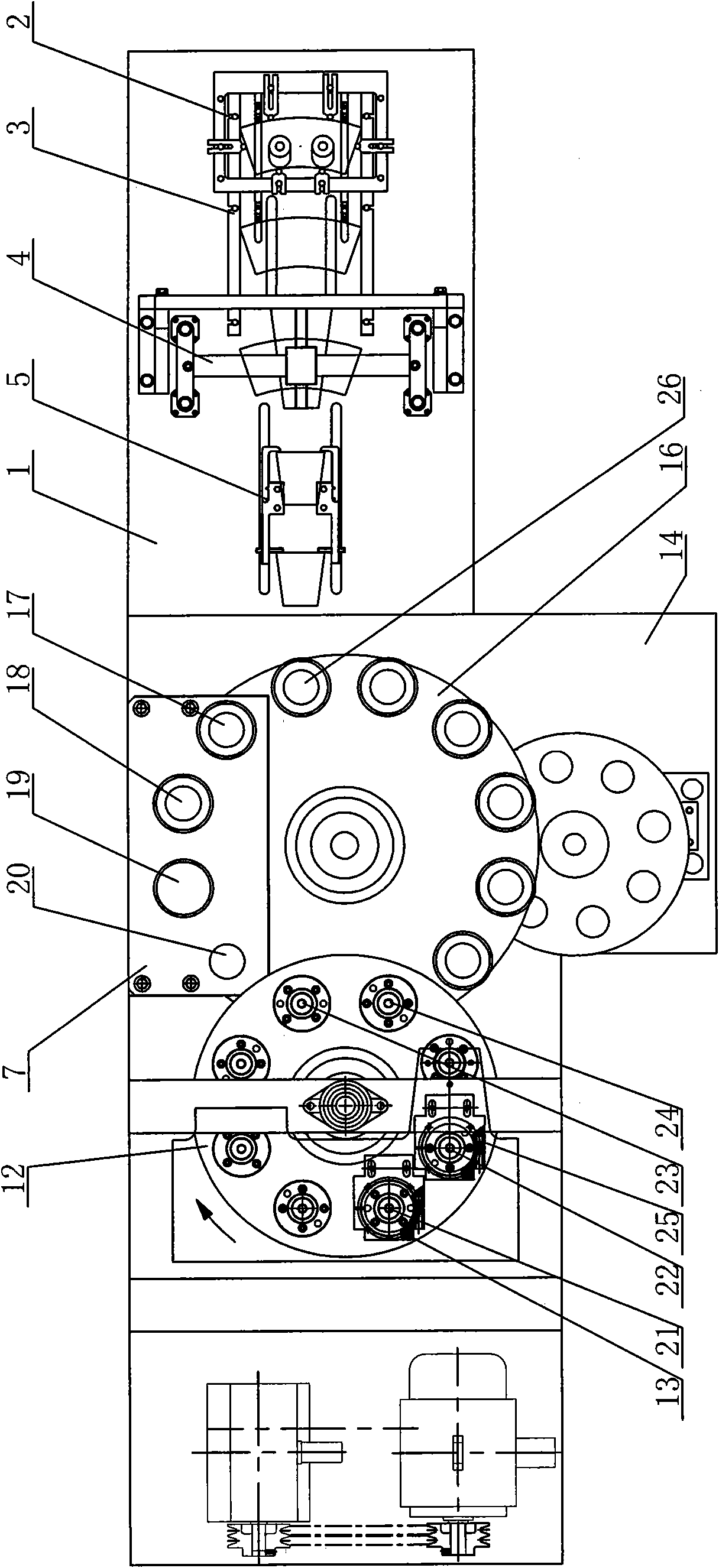

Fully automatic paper cup forming machine

The invention provides a paper cup machining apparatus and specifically provides a fully automatic paper cup forming machine. The fully automatic paper cup forming machine comprises a machine body, a cup body forming mechanism disposed on the machine body, a transfer rotating disc linked to the cup body forming mechanism, a cup bottom conveying mechanism, a cup body and cup bottom combining mechanism, a heating mechanism, a bottom folding mechanism, a knurling mechanism and a crimping assembly, wherein the cup bottom conveying mechanism, the cup body and cup bottom combining mechanism, the heating mechanism, the bottom folding mechanism, the knurling mechanism and the crimping assembly are arranged along the transfer rotating disc successively in order. A cup body steering mechanism is arranged between the cup body forming mechanism and the transfer rotating disc. The cup body steering mechanism comprises an adjusting rotating disc and at least two cup body holding sleeves disposed on the adjusting rotating disc and capable of turning on the adjusting rotating disc. The adjusting rotating disc is driven to rotate by a driving component. The adjusting rotating disc is provided with a turning component driving the cup body holding sleeves to turn. The fully automatic paper cup forming machine increases the machining efficiency, is high in cup body position adjusting speed and is simple in structure.

Owner:RUIAN MINGGUO MACHINERY CO LTD

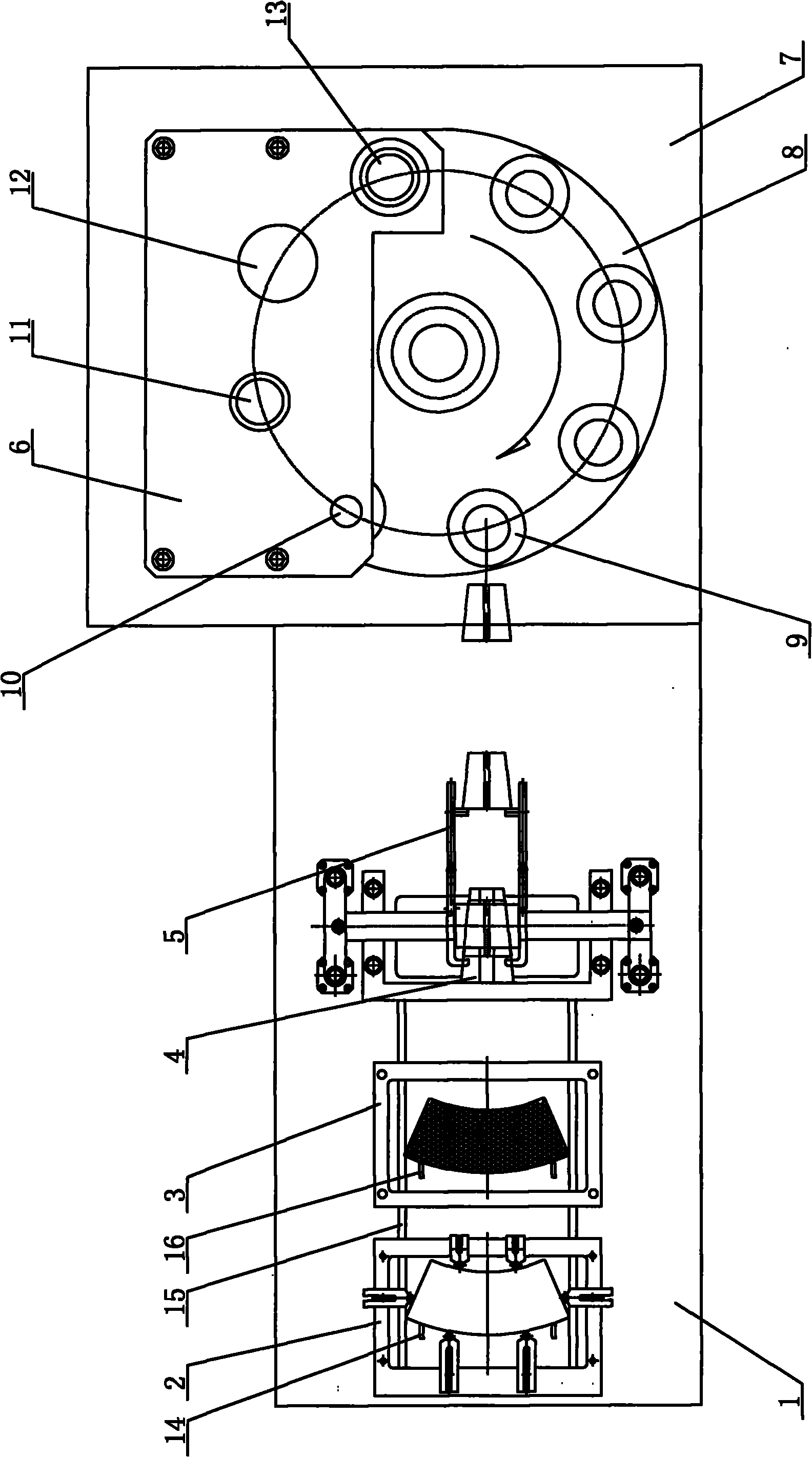

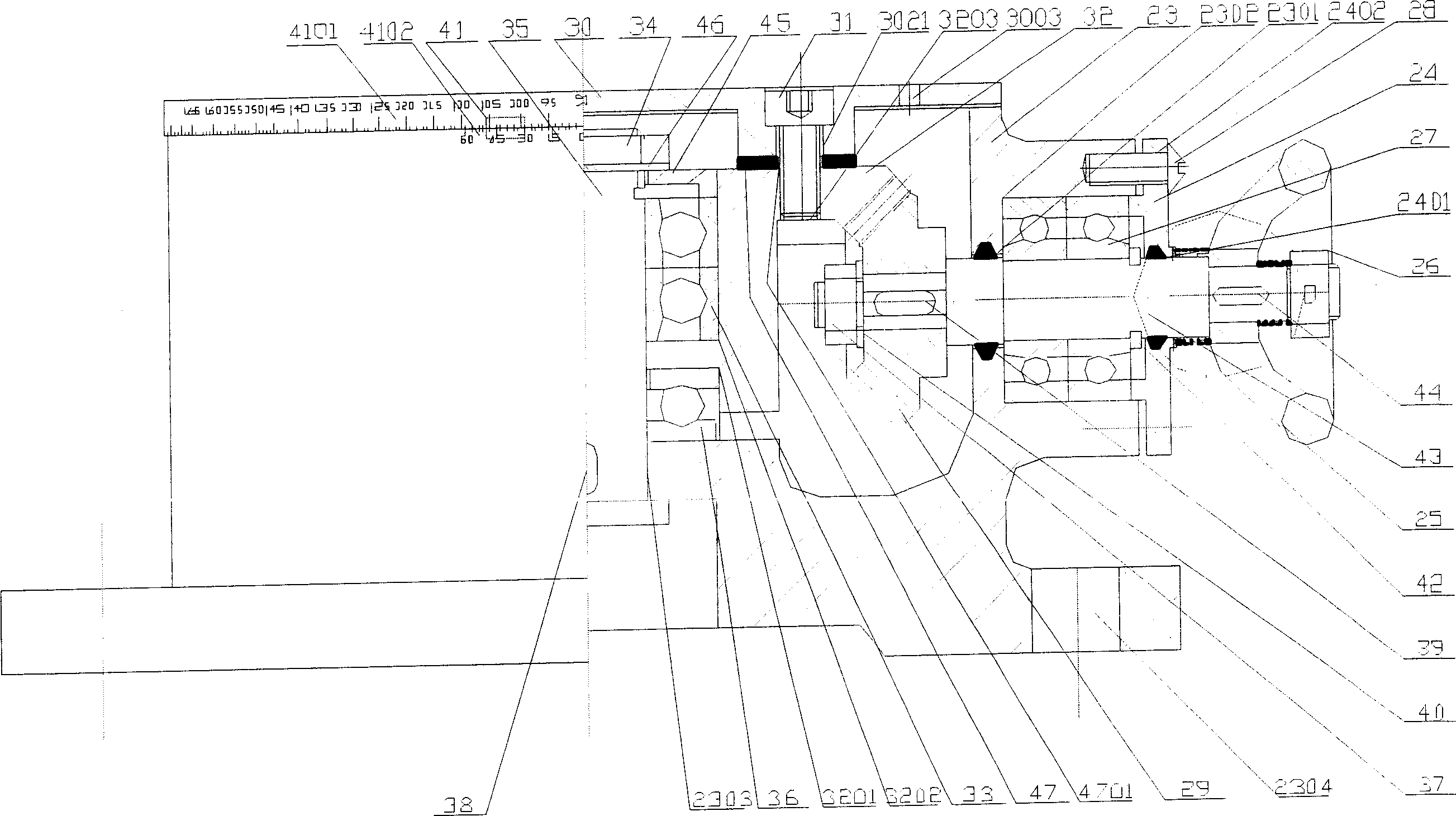

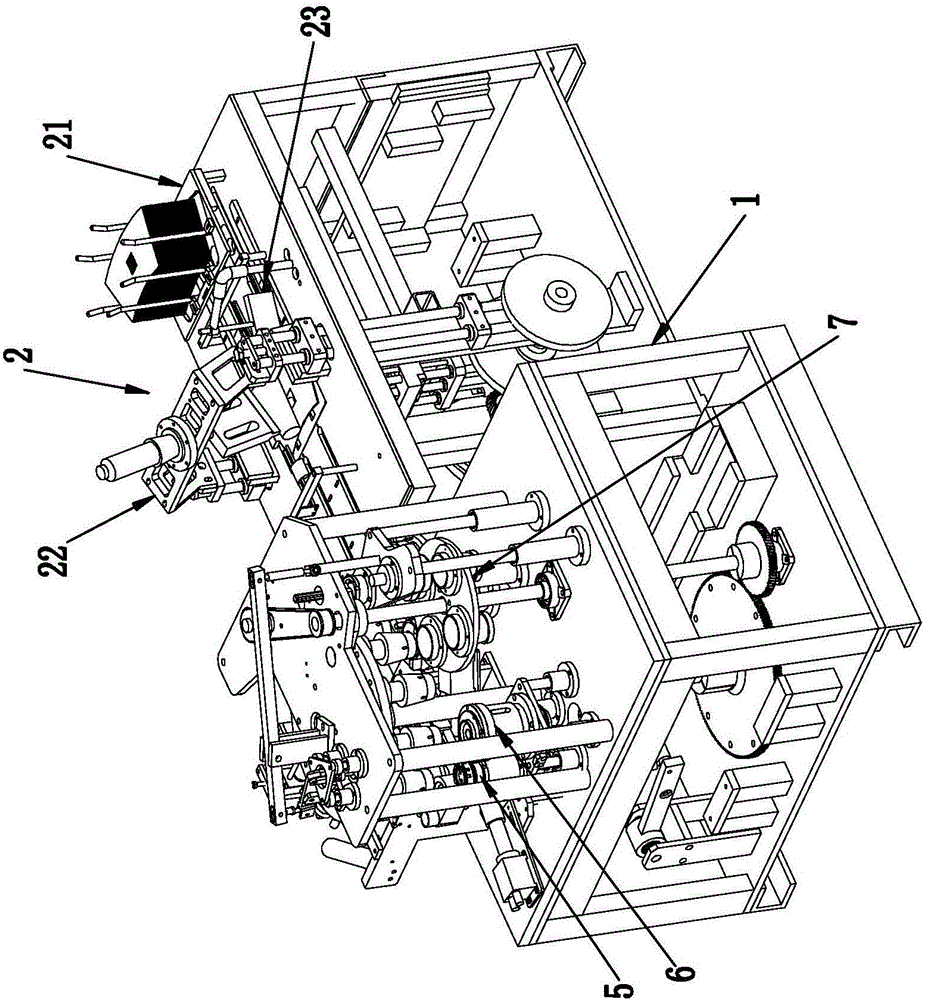

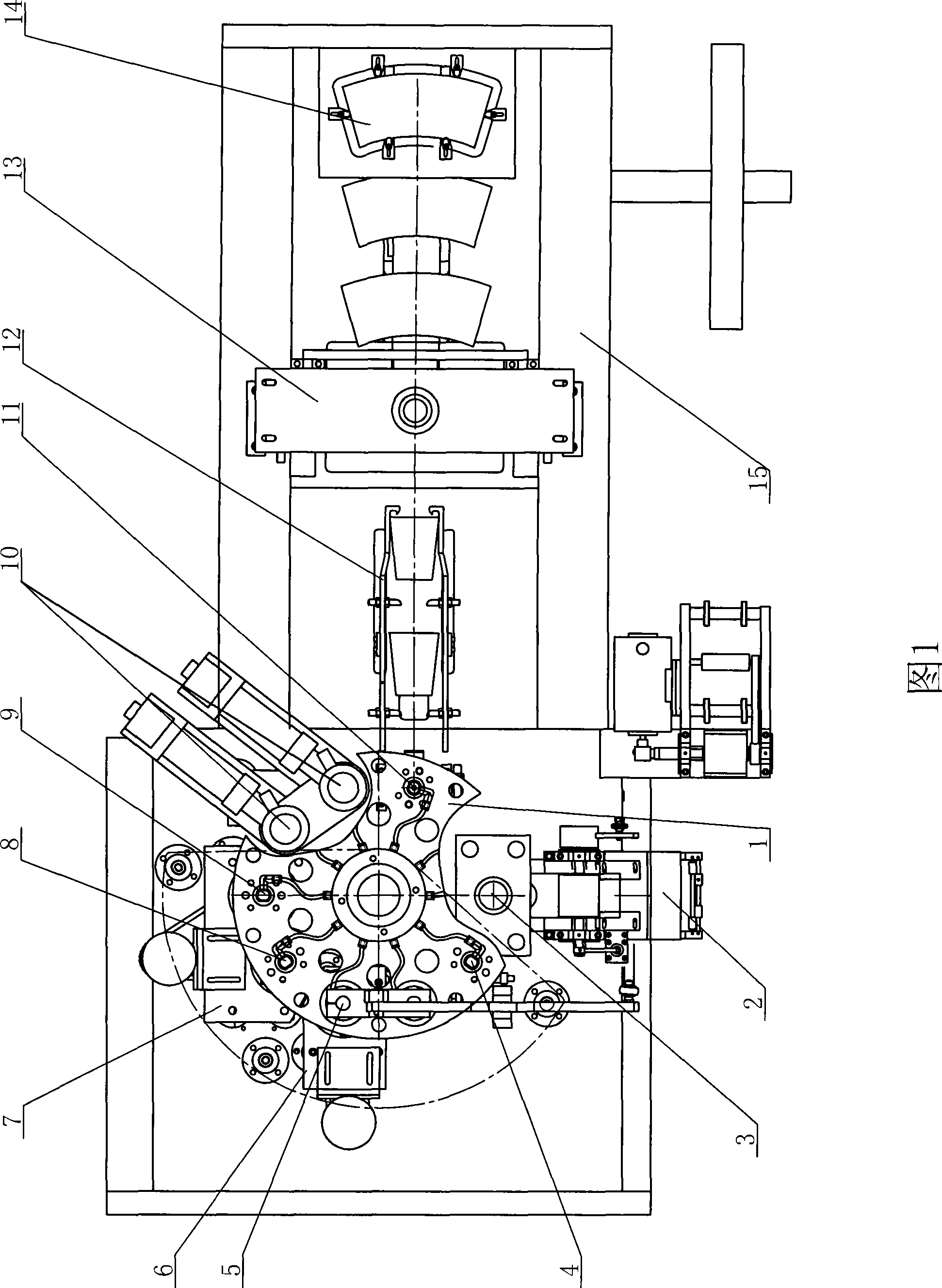

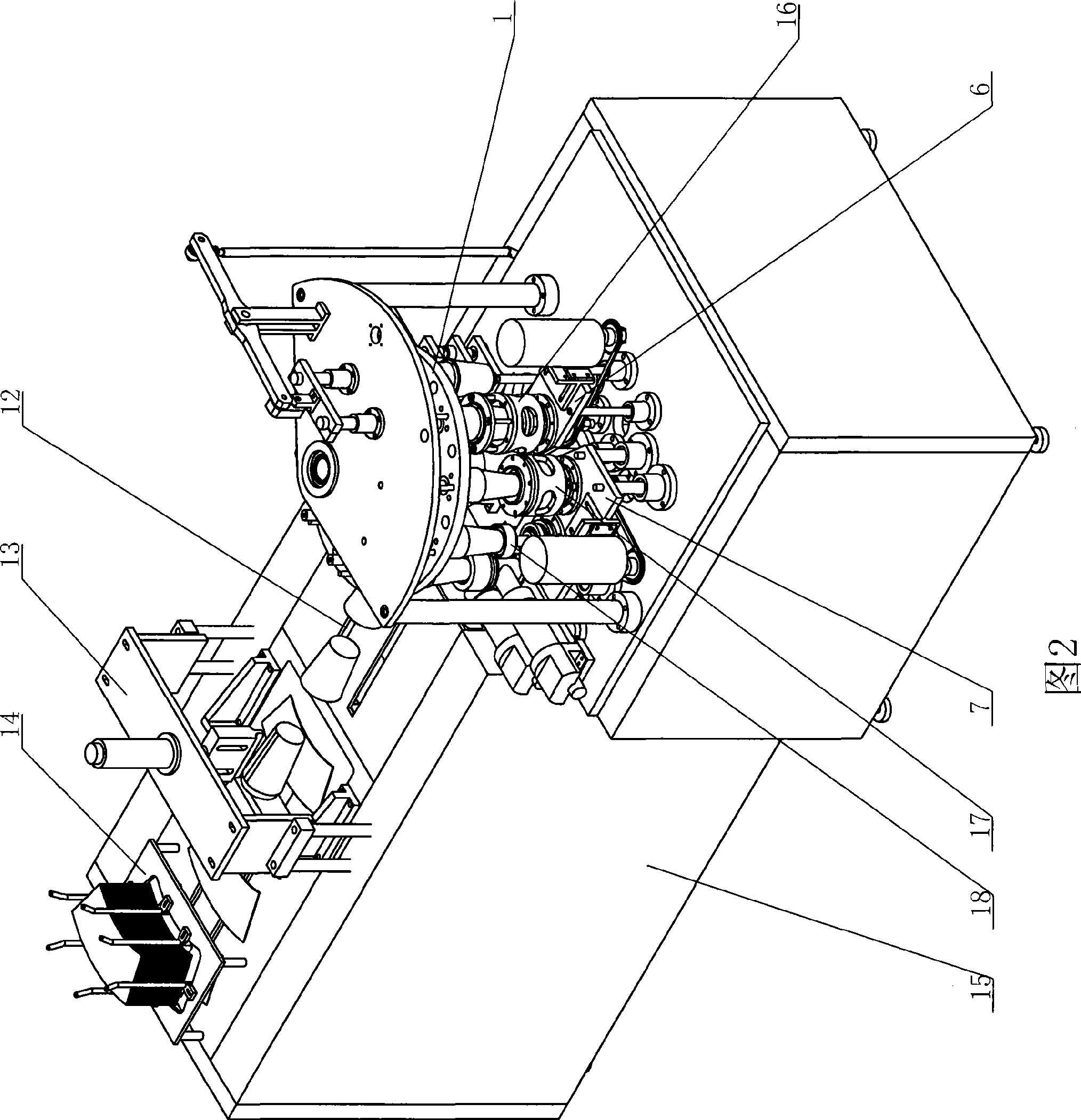

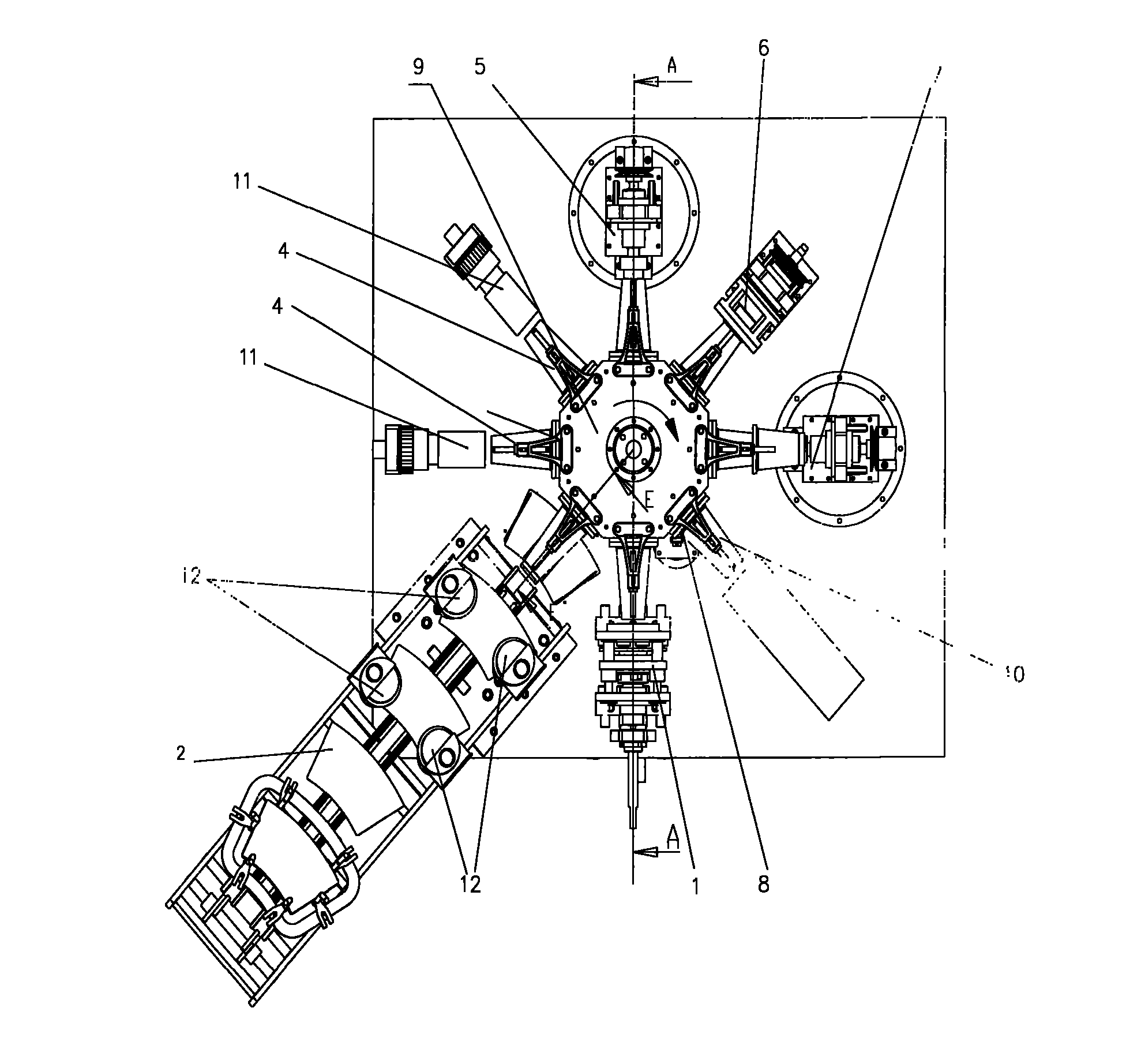

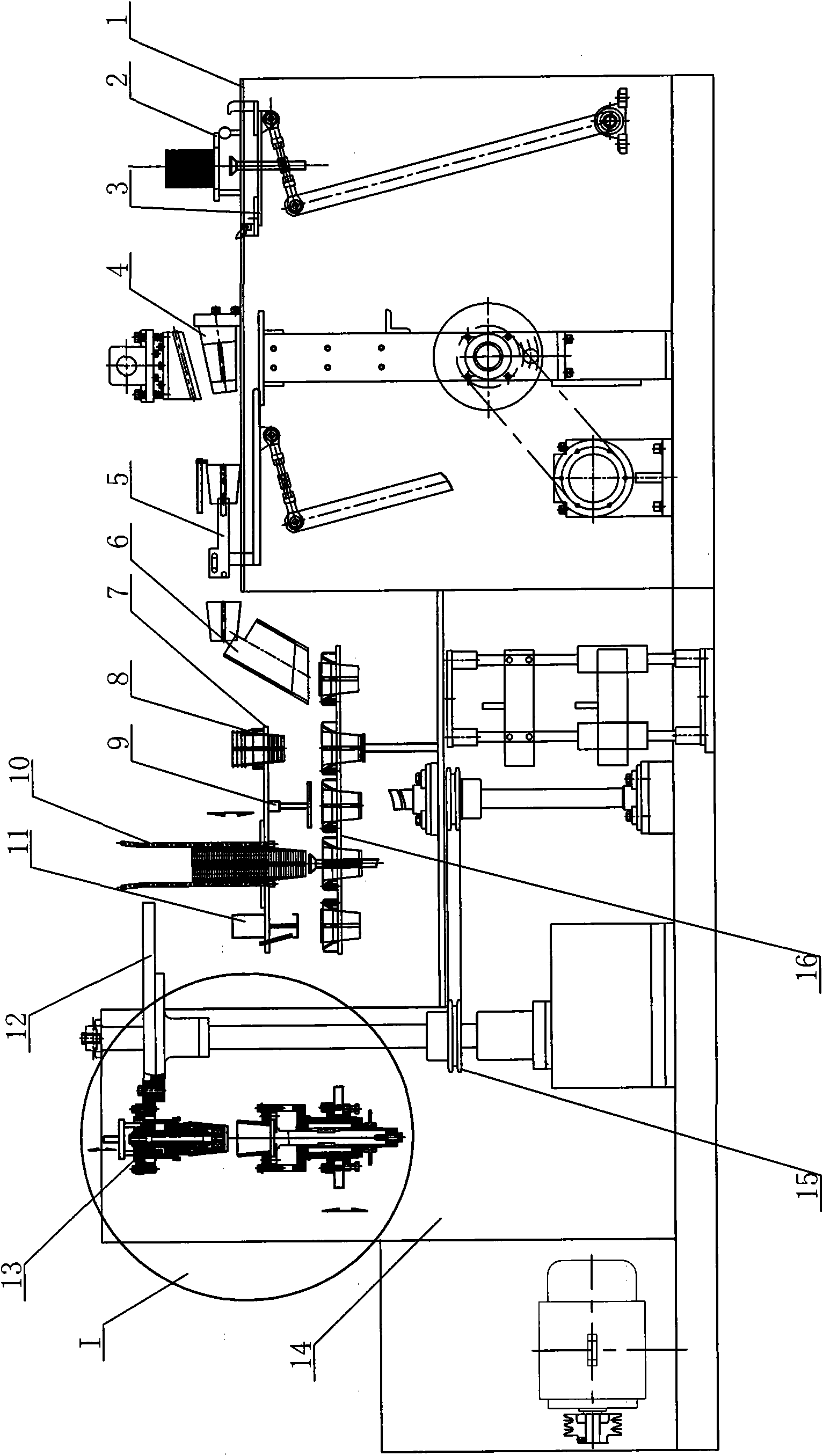

Paper cup making machine

ActiveCN101391493AReduce manufacturing costReduce use and maintenance costsPaper/cardboard wound articlesLow speedEngineering

The invention discloses a paper cup machine, comprising a frame (15), a cup body paper feeding mechanism (14), a cup cylinder forming mechanism (13), a cup cylinder feeding mechanism (12), an indexing turntable (1), a cup bottom paper feeding mechanism (2), a transmission mechanism, a bottom feeding working position (3), a cup receiving working position (11), a heating working position (10), a bottom folding working position (9), a bottom rolling working position (8), a mouth coiling working position (5) and a cup outgoing working position (4); all working positions are provided with corresponding working mechanisms; the paper cup machine is characterized in that the paper cup machine is only provided with an indexing turntable; the bottom feeding working position, the cup receiving working position, the heating working position, a bottom folding working position, a bottom rolling working position, a mouth rolling working position and a cup outgoing working position are all arranged on the indexing turntable. The paper cup machine has the advantages of simple structure, higher speed, stable running, has high speed mode and low speed mode, reduces the preparation cost of the die, shortens the preparation period of the die, reduces the equipment failure rate, reduces the maintenance difficulty and cost and leads the equipment to be easy to be operated.

Owner:ZHEJIANG RUIDA MACHINERY

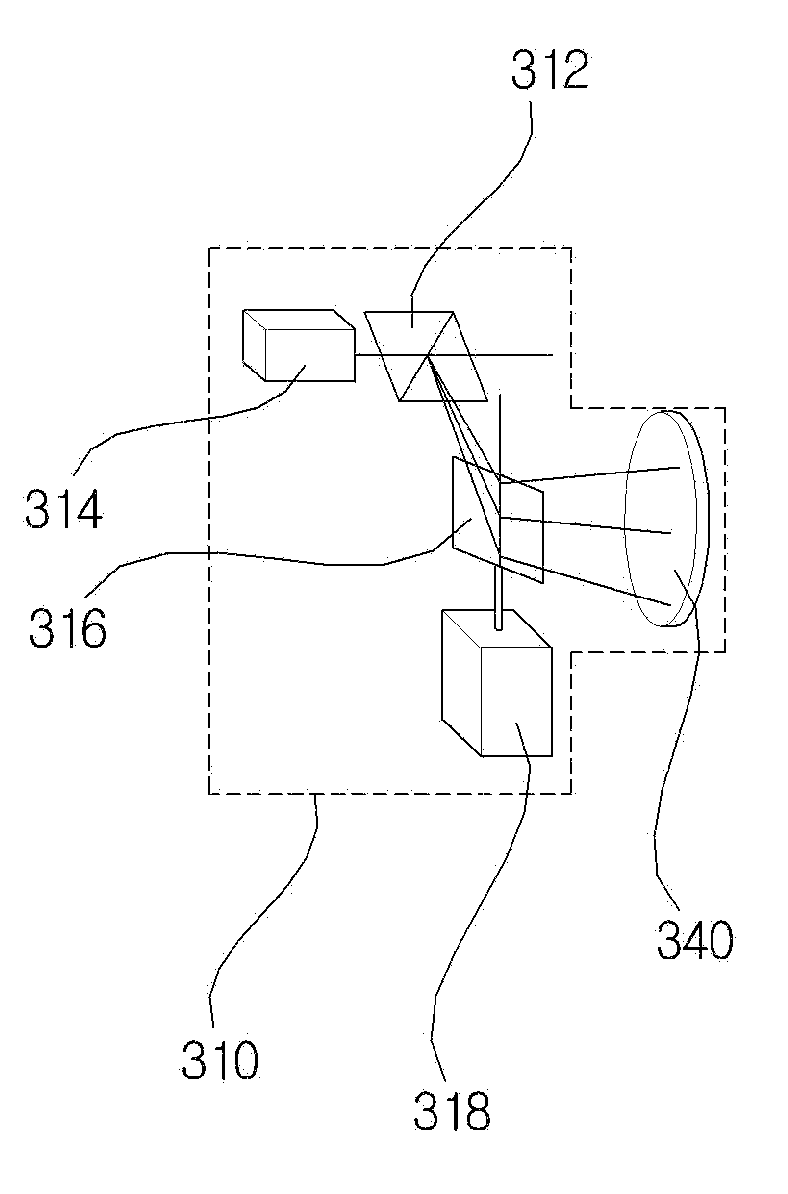

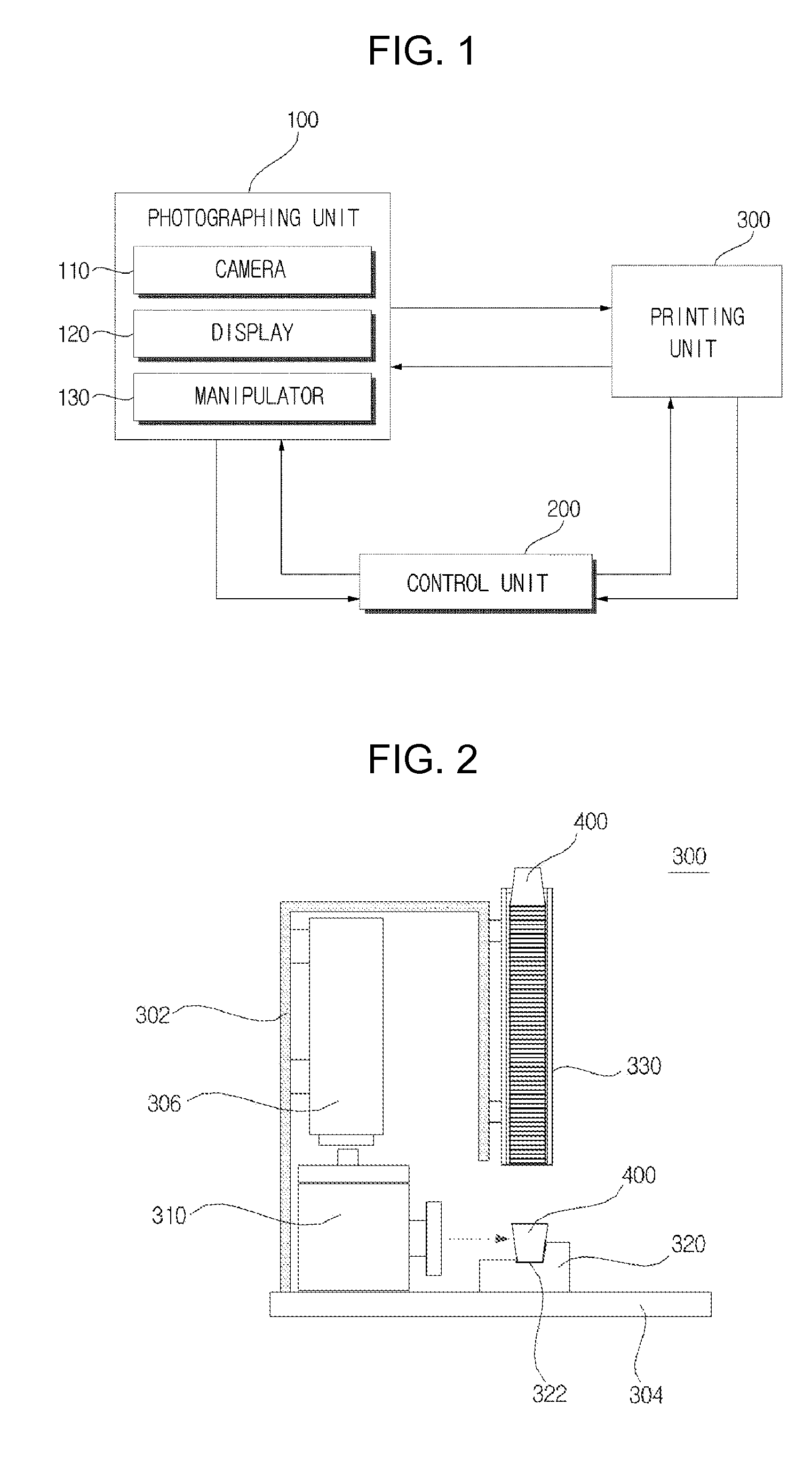

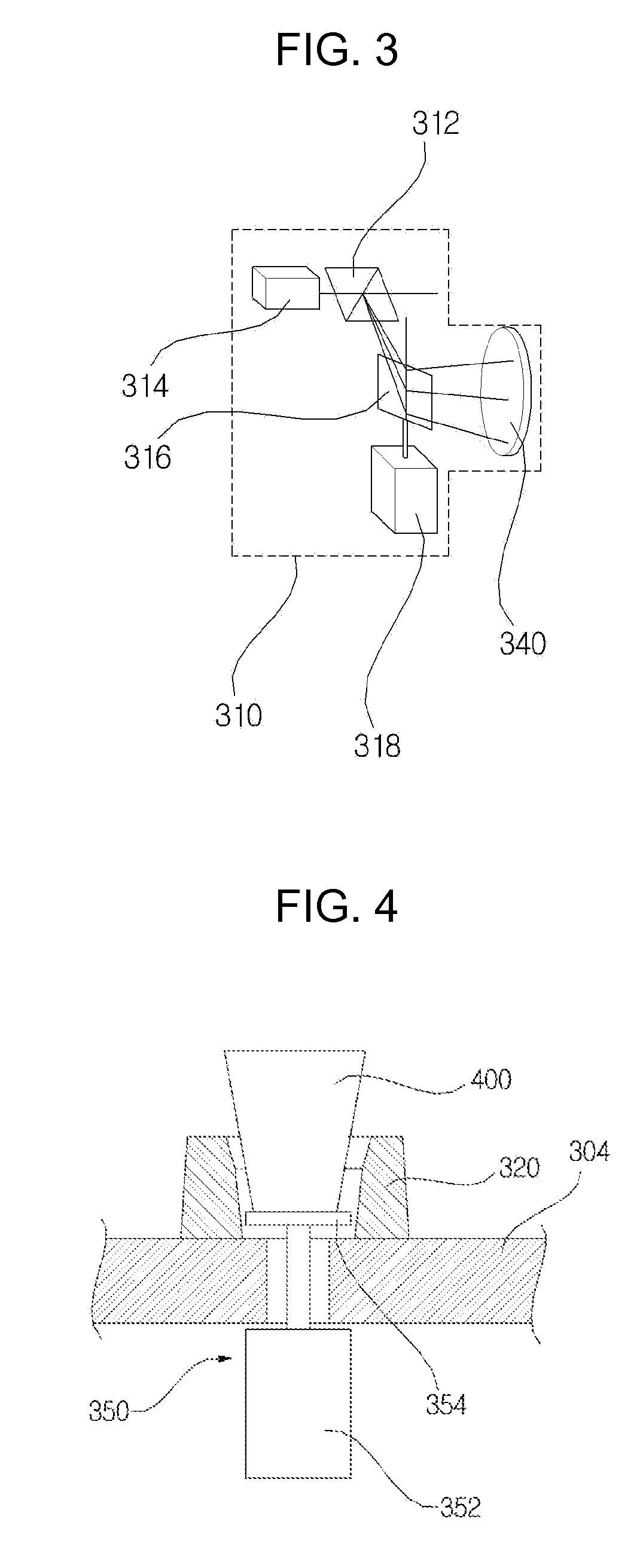

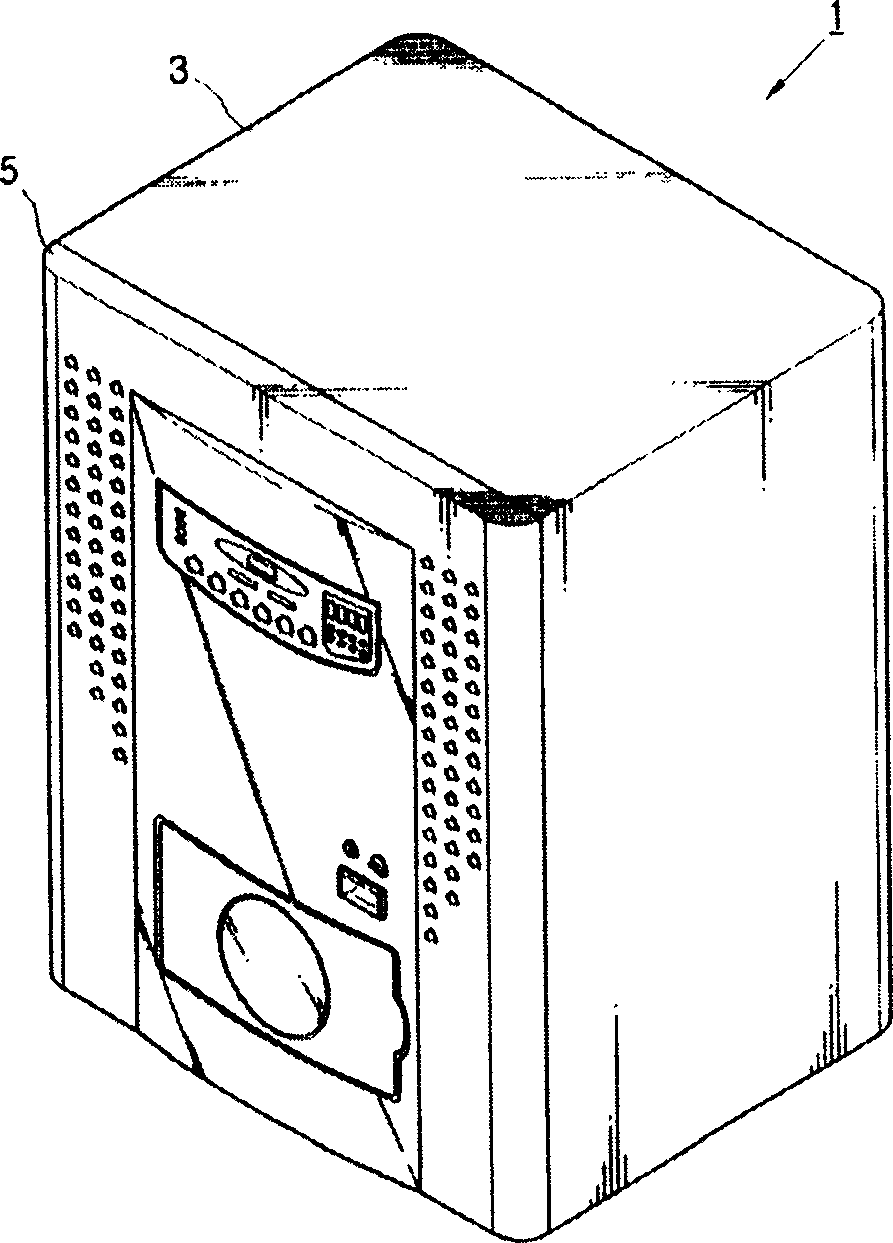

Printing apparatus and method for paper cup

InactiveUS20120306987A1Encourage recyclingEasy to useRecording apparatusTypewritersPulp and paper industryPaper cup

Provided is a paper cup printing apparatus including: a photographing unit that takes a photo; a printing unit that prints the photo taken by the photographing unit on the surface of a paper cup; and a control unit that converts the photo taken by the photographing unit into data for printing, and controls the printing unit to automatically print the photo on the surface of the paper cup. The paper cup printing apparatus prints user's face or favorite image on a paper cup for containing coffee or drink to thus encourage recycling of the paper cup and increase sales of coffee or drink.

Owner:KIM MYEONG JU

Paper cup cover and processing technology thereof

ActiveCN106335702ASimple structureEasy to processPaper/cardboard articlesBox making operationsCompression moldingKnurling

A paper cup cover and a processing technology thereof are characterized in that the paper cup cover is of an integrated structure; the processing technology of the paper cup cover comprises the steps of material taking, compression molding, bottom folding and knurling; the structure of the paper cup cover comprises a circular top part and an annular side part surrounding the bottom; a step is formed in the middle section of the annular side part; and the bottom of the annular side part is provided with a flanging which is folded inwards and tightly attached to the inner wall of the annular side part. The paper cup cover and the processing technology thereof have the advantages that the paper cup cover is integrally formed, the structure and the processing technology are simple, and the paper cup cover can be matched with a paper cup better.

Owner:瑞安市贝斯特机械有限公司

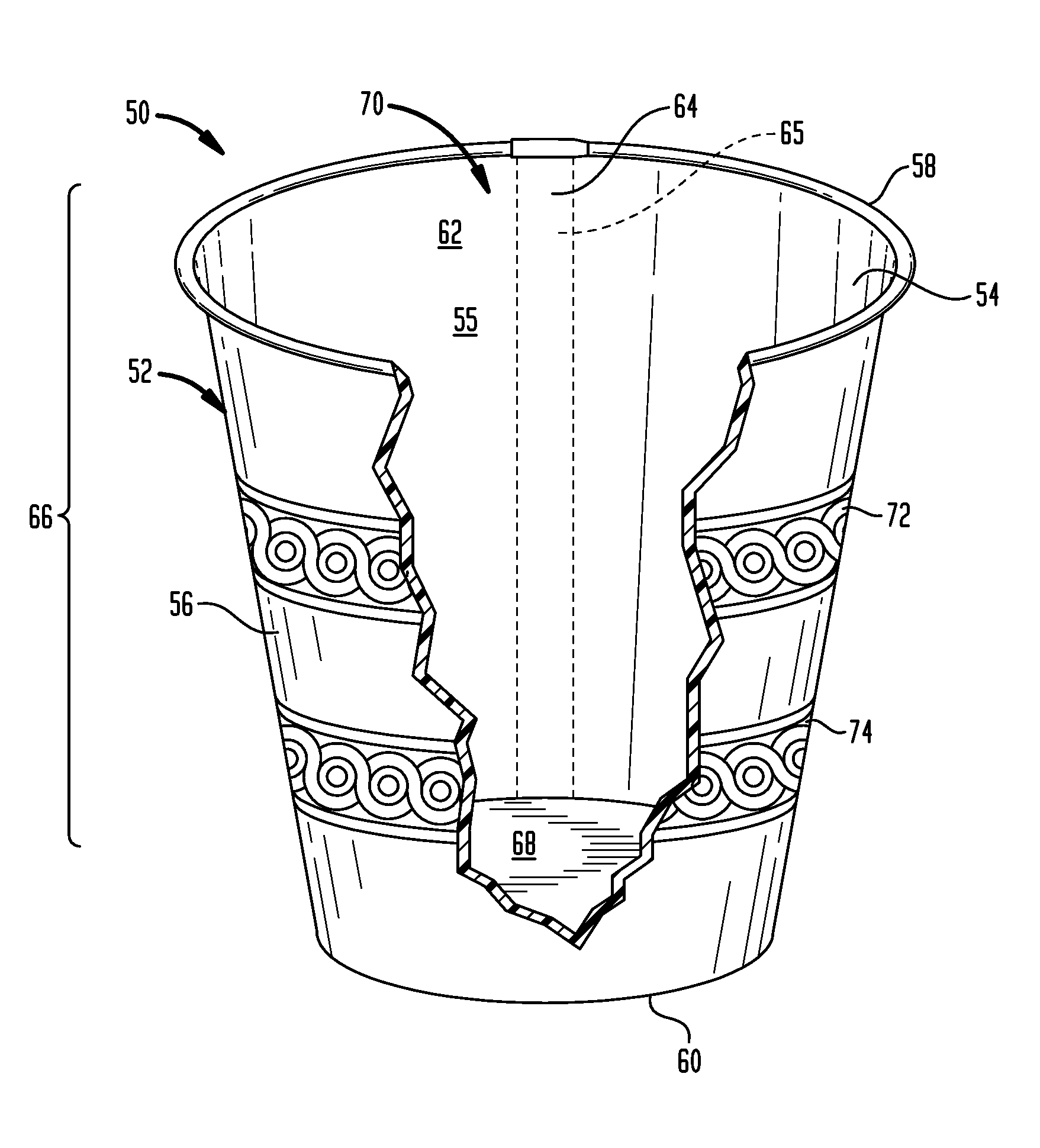

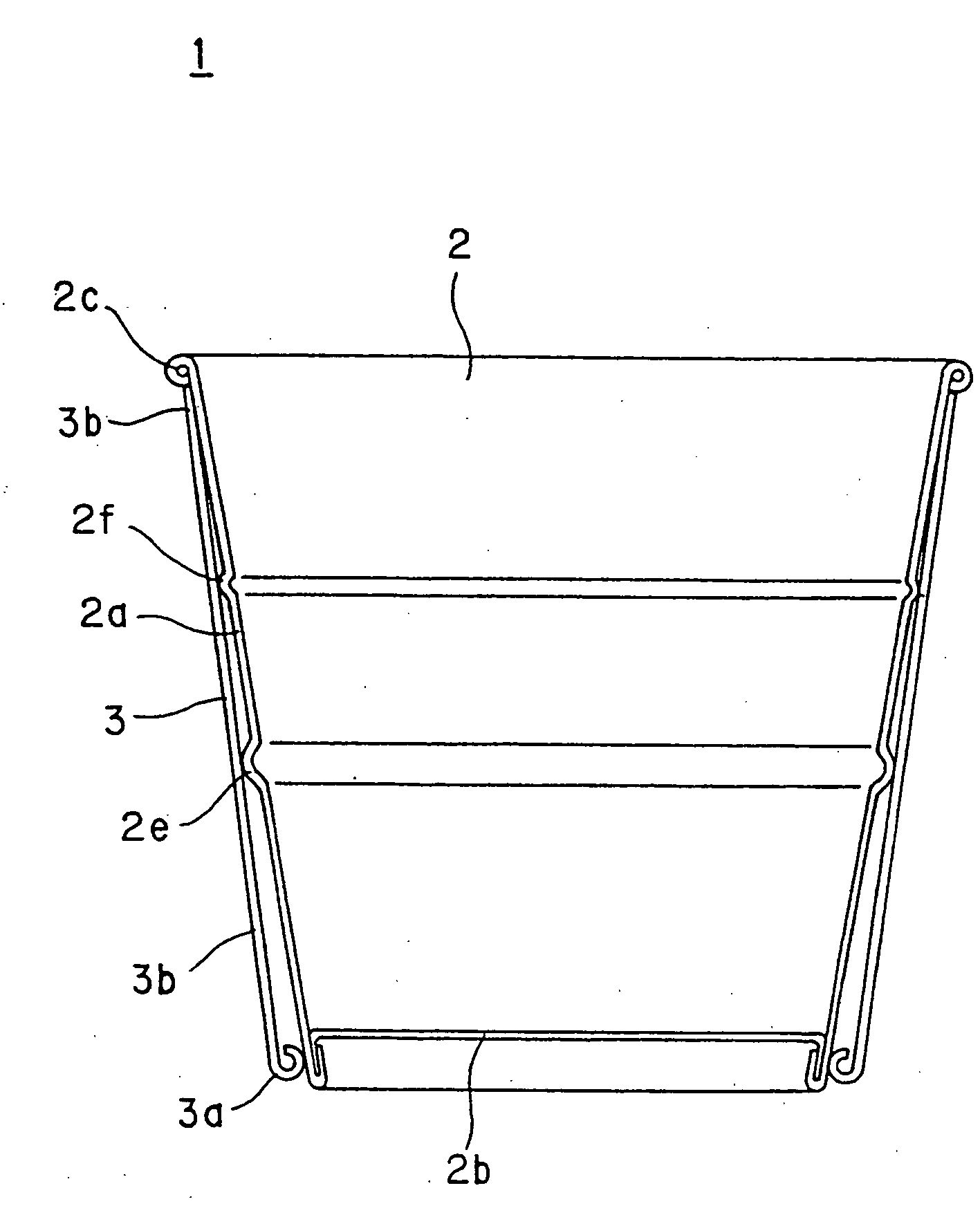

Disposable paper cups, method of making, and handling of such cups

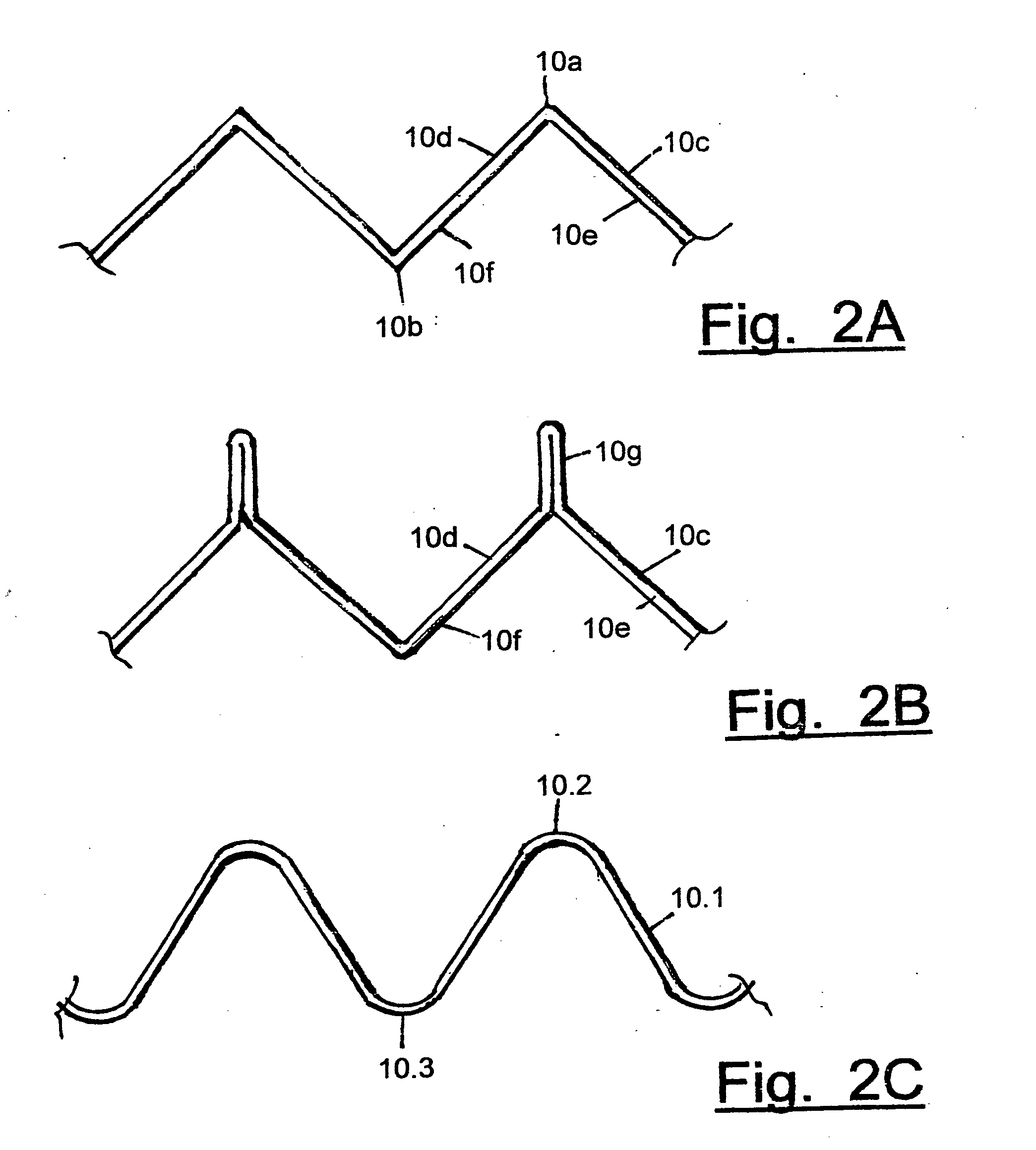

InactiveUS20050269390A1Improve insulation qualitySmall surface areaDomestic cooling apparatusLighting and heating apparatusCard stockTrademark

There are now provided disposable paper cups, method of making, and handling of such cups. The cup may comprise a pleated disposable paper cup with a zigzag shaped, pleated cylindrical body, an open top and closed bottom. The cup may be constructed of a paper card stock evenly folded to create parallel pleats that serve to decrease the energy transfer between hot or cold beverages contained in the cup and a user's hand, enabling the user to hold onto the container for an extended period of time without pain or discomfort. The application further relates to an arrangement configured to prepare a personalized brew of coffee or the like, with a lid that can be punctured to flow hot liquid over a material configured to make a drink and into a disposable cup. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, the abstract is not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:MARTIN CONRAD D

Paper cup machine

The invention discloses an improved invention of a paper cup machine, which is mainly characterized in that the machine body comprises a rotating disc, wherein the periphery of the rotating disc is provided with a horizontal cup mould, a bounding press block is arranged on the position of the horizontal cup mould, when the rotating disc rotates, the cup mould sequentially passes through each station making paper cups, the rolling bottom and the hemming of the invention are formed at one step, and more important, when all the stations work, the cup is always in the bonding state on the cup mould, so that the edge of the heated paper cup has enough time to cool when being bounded, and the paper cup is firmly bounded. The invention has strong movement coherence, can make over 100 paper cups per minute, and can reach the purpose of making the paper cups at a high speed.

Owner:ZHEJIANG NEW DEBAO MACHINERY

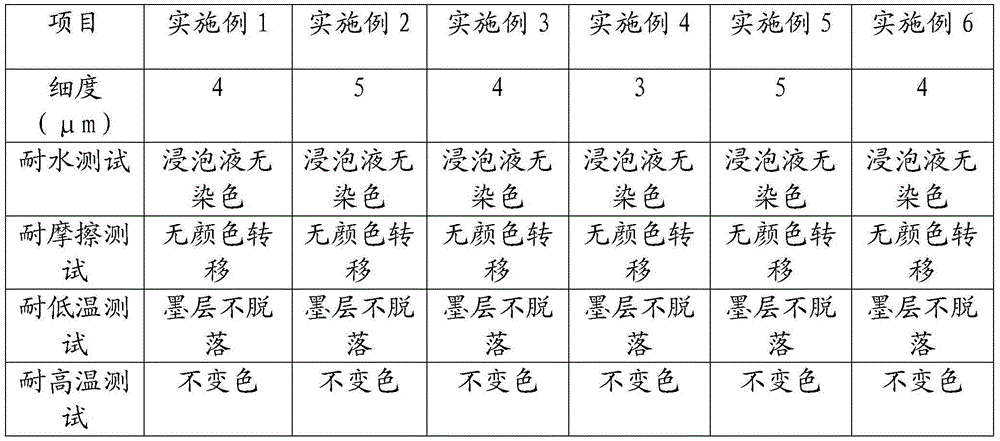

Glazing-free double-PE water-based flexible ink and preparation method thereof

The invention belongs to the technical field of ink preparation, and particularly relates to glazing-free double-PE water-based flexible ink and a preparation method thereof. The glazing-free double-PE water-based flexible ink comprises the following raw materials in percentage by weight: 40-60% of varnish and 40-60% of water-based color paste, wherein the varnish comprises the following raw materials in percentage by weight: 60-80% of soft emulsion, 0-10% of hard emulsion, 0-25% of water-soluble resin liquid, 1-3% of a scratch-resistant agent, 1-3% of a crosslinking agent, 0-3% of a water-resistant agent, 0-1% of a leveling agent, 0-8% of a film-forming auxiliary agent, 0.1-0.5% of a defoaming agent and the balance of deionized water. The glazing-free double-PE water-based flexible ink omits a glazing process in the printing process, so that the cost is saved, and a double-PE paper cup printed by using the ink is high in gloss, colorful, beautiful, water-proof, wear-resistant, high-temperature-resistant and freezing-resistant.

Owner:山东力美喷墨科技有限公司 +1

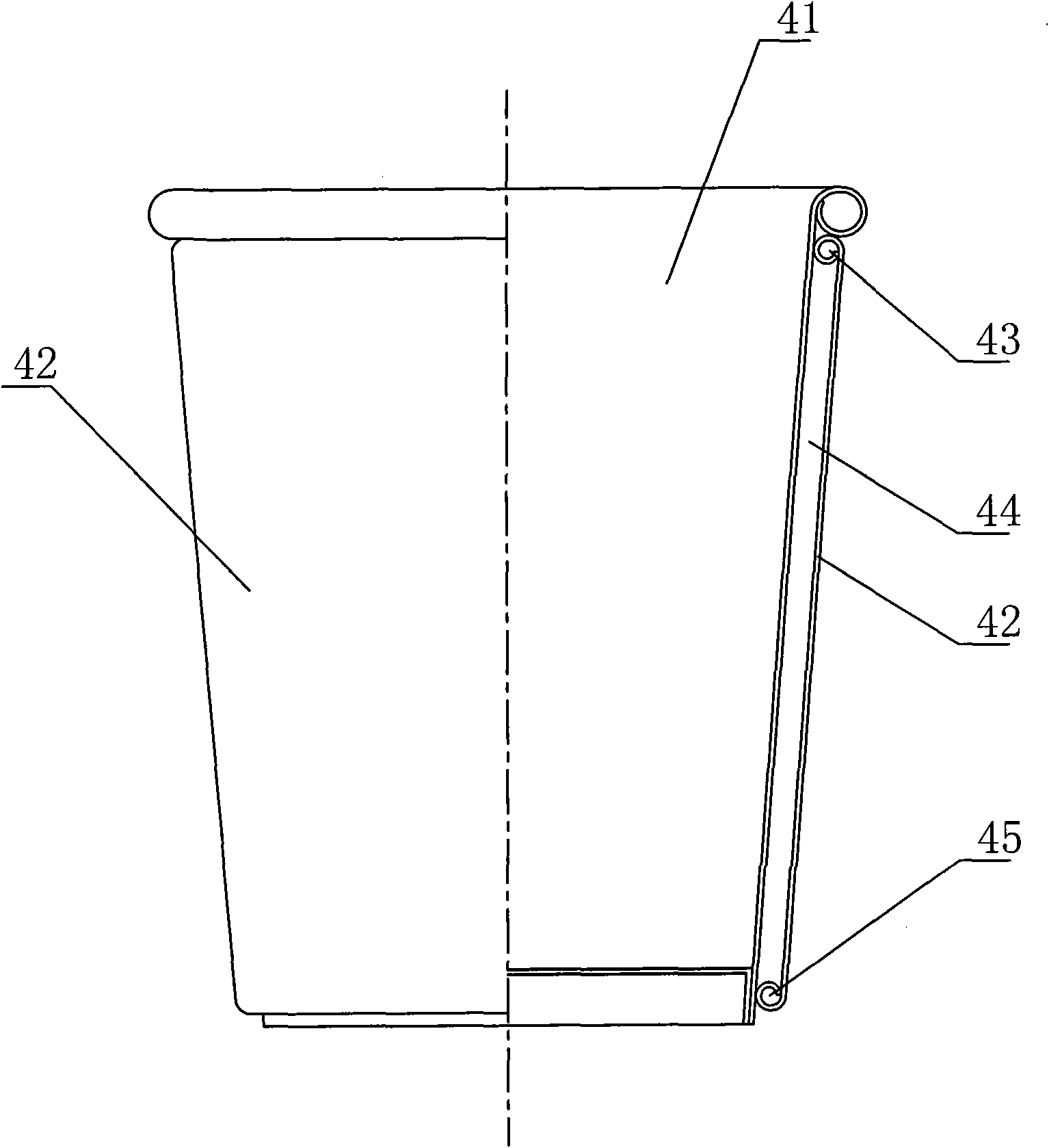

Hollow heat insulation paper cup and paper cup molding machine for manufacturing same

InactiveCN101889805AImprove insulation performanceLow costBoxes/cartons making machineryDrinking vesselsMolding machinePulp and paper industry

The invention discloses a hollow heat insulation paper cup. The paper consists of an outer sleeve and an inner cup which is sleeved into the outer sleeve and is characterized in that: the upper opening of the outer sleeve is inwards turned to form an involute opening; the lower opening of the outer sleeve is inwards turned to form an involute bottom; and a hollow gap is formed between the outer sleeve and the wall of the inner cup. The paper cup has a good heat insulation effect. Simultaneously, the invention also discloses a paper cup molding machine for manufacturing the paper cup.

Owner:ZHEJIANG SINI MACHINERY

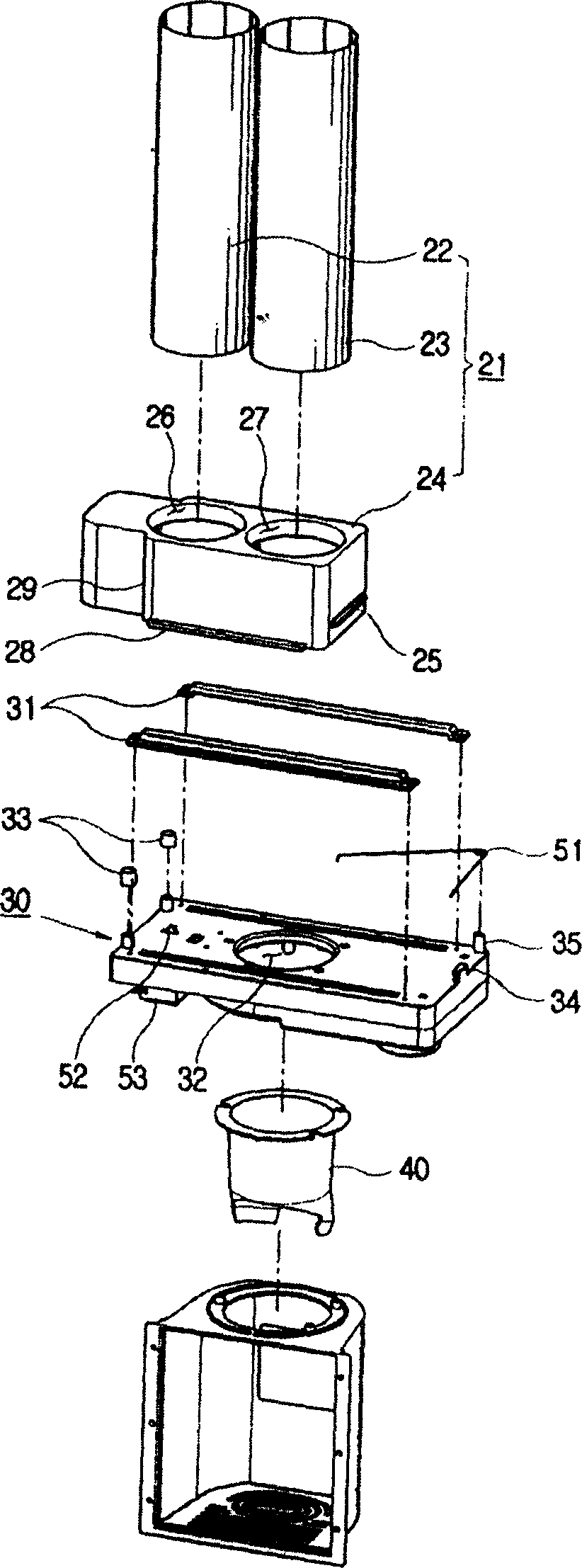

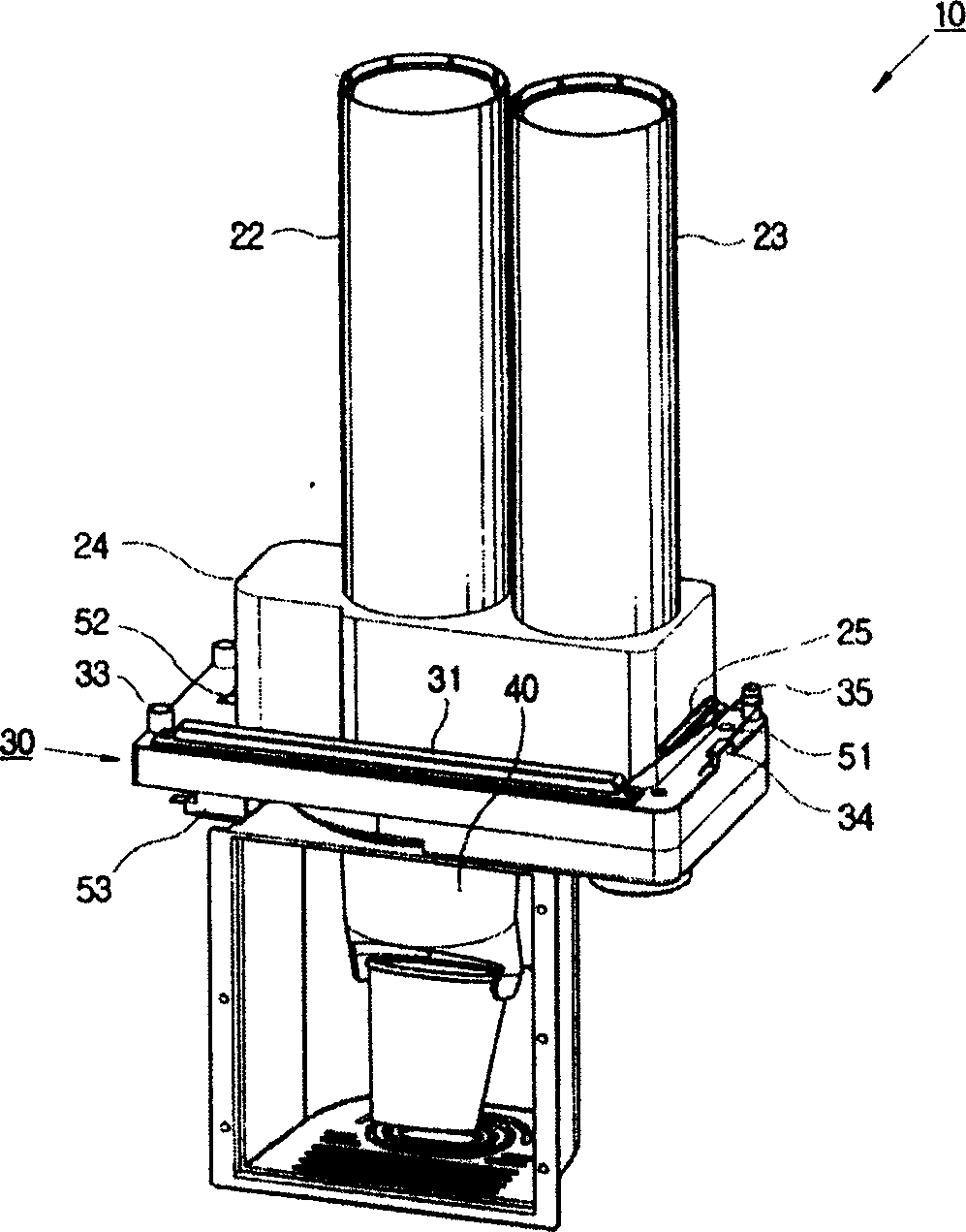

Beverage antomatic vender

InactiveCN1624724AReduce the probability of misuseEasy to operateCoin testingApparatus for dispensing fluids/granular materialsAutomatic controlEngineering

The invention discloses a drink automatic selling machine, including a paper cup supplying device, a drink mixture device and the coin device. The relating paper cup supplying device is composed of two cup channels the glide guide can glide between the primary state and the compensational state, and guide the cup supporter; the driver is in charge of the cup supporter gliding from the above primary state to the compensational state. When the cups in the channel 1 are used up, this machine will accurately provide the cup in the channel 2 to the transmitting place. The operation is simple and low cost.

Owner:进洋食品机械(昆山)有限公司 +1

Preparation technology of disposable paper cup

InactiveCN105342292AImprove qualityGuaranteed bonding qualityDrinking vesselsMolding machinePaperboard

The invention discloses a preparation technology of a disposable paper cup. Before printing, rectangular paper is subjected to corona treatment, the surface tension of the treated rectangular paper is 40-50 nM / m, the surface tension of the rectangular paper can meet requirements of printing during printing, printing quality is guaranteed, adhesion temperature and adhesion temperature of a paper board forming machine can be controlled, adhesion quality of the paper cup can be guaranteed, so that yield of the paper cup is guaranteed, after a finished product is formed, the disposable finished paper cup is placed in a disinfection cabinet and is disinfected for 6-8 hours and at the temperature of 100-120 DEG C, and the quality of the disposable paper cup can be improved. A cup body produced by the method is regular in appearance, market potential is huge, and the prospect is wide.

Owner:ANQING SHENGHUA PAPER PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com