Glazing-free double-PE water-based flexible ink and preparation method thereof

A flexographic and ink technology, applied in the field of glazing-free double PE water-based flexographic ink and its preparation, can solve the problems of poor printing ink adhesion, low surface tension of PE film, high and low temperature resistance, etc., to reduce ink cost , The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

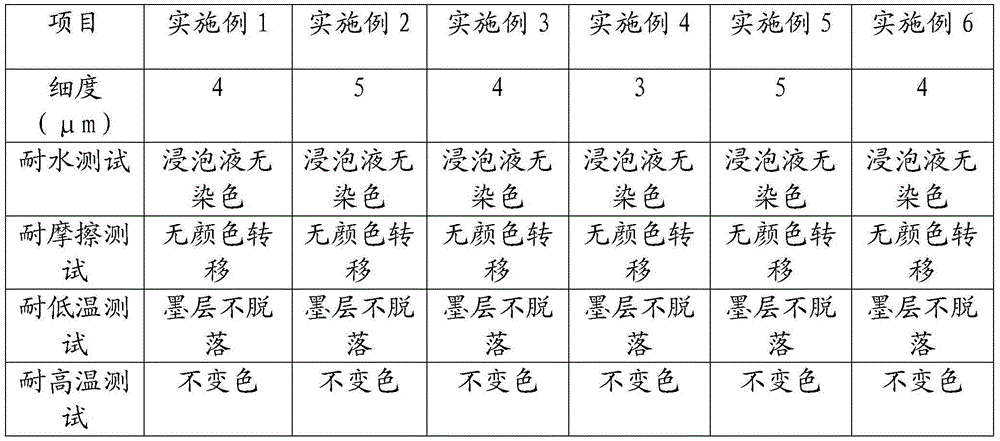

Examples

Embodiment 1

[0029] A coating-free double PE water-based flexographic ink (red)

[0030] It is composed of the following raw materials by weight percentage: varnish 40% and water-based color paste 60%; wherein, the varnish is composed of the following raw materials by weight percentage: JONCRYL 624 60%, JONCRYL 89 10%, JONCRYL HPD96 25%, DC51 1 %, Zinc Oxide Solution#1 1%, DC85 1%, OT-75 0.1%, propylene glycol 1%, DC65 0.1%, deionized water 0.8%; the water-based color paste is composed of the following raw materials in weight percentage: Red HF3S30% and Red FGR 70%.

[0031] Its preparation method is:

[0032] (1) Preparation of varnish: weigh JONCRYL 624, JONCRYL 89, JONCRYL HPD96, DC51, Zinc Oxide Solution#1, DC85, OT-75, propylene glycol, DC65 and deionized water according to the above proportions, add them into the reaction kettle and stir Uniform, spare;

[0033] (2) Preparation of water-based red color paste: take Red HF3S and Red FGR7 according to the above ratio and mix them eve...

Embodiment 2

[0036] A coating-free double PE water-based flexographic ink (yellow)

[0037] It is composed of the following raw materials by weight percentage: 45% of varnish and 55% of water-based color paste; wherein, the varnish is composed of the following raw materials by weight percentage: JONCRYL 617 65%, JONCRYL 90 8%, JONCRYL HPD96MEA 20%, DC51 1.5 %, Zinc Oxide Solution#1 1.5%, Surfynol 104E 0.3%, Diethylene Glycol Ether 2%, TEGO Foamex 825 0.2%, Deionized Water 1.5%; Water-based color paste is composed of the following raw materials in weight percentage: Yellow GR 40% and Yellow HR 60%.

[0038] Its preparation method is:

[0039](1) Preparation of varnish: Weigh JONCRYL 617, JONCRYL 90, JONCRYL HPD96MEA, DC51, Zinc Oxide Solution#1, Surfynol 104E, diethylene glycol ethyl ether, TEGO Foamex 825 and deionized water according to the above ratio, add to the reaction Stir well in the kettle and set aside;

[0040] (2) Preparation of water-based yellow color paste: weigh Yellow GR...

Embodiment 3

[0043] A coating-free double PE water-based flexographic ink (blue)

[0044] It is composed of the following raw materials by weight percentage: varnish 50% and water-based color paste 50%; wherein, the varnish is composed of the following raw materials by weight percentage: JONCRYL 74 70%, JONCRYL 89 3%, JONCRYL 61 15%, DC51 2 %, Zinc Oxide Solution#1 2%, DC85 2%, BYK-301 0.3%, glycerol 3%, DC65 0.3%, deionized water 3.4%; the water-based color paste is composed of the following raw materials in weight percentage: Blue B2G 50 % and LEVANYL Blue G-LF 50%.

[0045] Its preparation method is:

[0046] (1) Preparation of varnish: Weigh JONCRYL 74, JONCRYL 89, JONCRYL61, DC51, Zinc Oxide Solution#1, DC85, BYK-301, glycerol, DC65 and deionized water according to the above ratio, and add them to the reaction kettle stir well, set aside;

[0047] (2) Preparation of water-based blue color paste: weigh Blue B2G and LEVANYL Blue G-LF according to the above proportions and mix well, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com