Patents

Literature

40 results about "Flexographic ink" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexographic inks are inks transferred by the process of flexography, primarily used in the printing of packing materials (cardboard boxes, corrugated cardboard, paper bags and plastic bags, food packaging, newspapers, catalogues, etc.). The inks and method of printing continues to grow in popularity due to its low cost and environmentally friendly nature. The most important part of the printing process is the application of the ink.

Hot melt flexographic inks and method of preparing same

Solid, solvent-free inks are provided for use in hot melt flexographic printing. The ink is composed of a pigment; a thermoplastic binder which is an ethylene copolymer, a hydrocarbon resin, or a combination thereof; a wax which is a highly branched hydrocarbon wax, a polyethylene homopolymer wax, an oxidized polyethylene wax, an animal wax, a vegetable wax or combinations thereof; a solid linear alcohol; and, a dispersing agent. The ink may also contain a solid plasticizer. The solid ink has a melting point of about 75° C. or greater, and when heated to a temperature between about 90° C. and about 135° C., a molten ink is formed which has a viscosity between about 100 cps and about 1200 cps. The solid inks are used in melt flexographic printing by heating the ink to a temperature greater than about 90° C. to form a molten ink which has a viscosity between about 100 cps and about 1200 cps; applying the molten ink to the surface of a heated anilox roller in operational contact with a heated flexographic printing plate; and printing the applied molten ink from the printing plate onto a substrate such as conventional print stock, polymeric films, metal sheets, etc.

Owner:SUN CHEM CORP

Water-based flexographic ink system dedicated to dual-PE paper cups

InactiveCN101824246AFulfil requirementsFirmly attachedWax coatingsInksWater basedPulp and paper industry

The invention relates to a water-based flexographic ink system dedicated to dual-PE paper cups. The ink system, which consists of water-based flexographic colored ink dedicated to dual-PE paper cups and varnish capable of being contacted with food, is used for the flexographic printing of dual-PE paper cups, and can effectively meet the printability requirement and the post-press finishing requirement. The varnish can effectively isolate the colored ink from being directly contacted with food and beverage, thus ensuring the hygienic safety of paper cups. The invention has the advantages of excellent properties, no toxin, no smell, safety, environment-friendliness and low overall cost, and has a broad market prospect.

Owner:合肥元和水性化学技术有限公司

Environment-friendly flexographic ink

The invention relates to an environment-friendly flexographic ink, which comprises a coloring agent, a bonding material, a viscosity regulator and a dispersant; the coloring agent is natural plant dye; the weight contents of the compositions are 10 to 30 weight portions of the plant dye, 45 to 70 weight portions of the liquid bonding material, 1 to 5 percent of the viscosity regulator and 1 to 6 weight portions of the dispersant; the bonding material comprises natural plant oil, mineral oil and natural or synthetic resin; and the viscosity regulator is plant oil or viscosity reductant, the plant oil is selected from Chinese wood oil, flax oil or soybean oil, and the viscosity reductant is aluminium salt, low-viscosity alkyd or paraffin oil. The vegetable dye takes pure natural plants as raw materials, has reproducing property and good ecological environmental protection property, and has no harm to human bodies and environment so as to reduce the pollution of the ink to the environment.

Owner:苏州科德教育科技股份有限公司

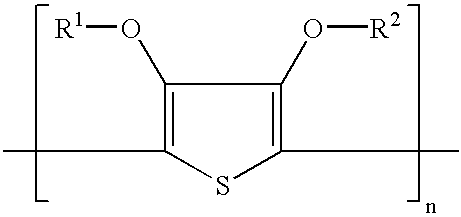

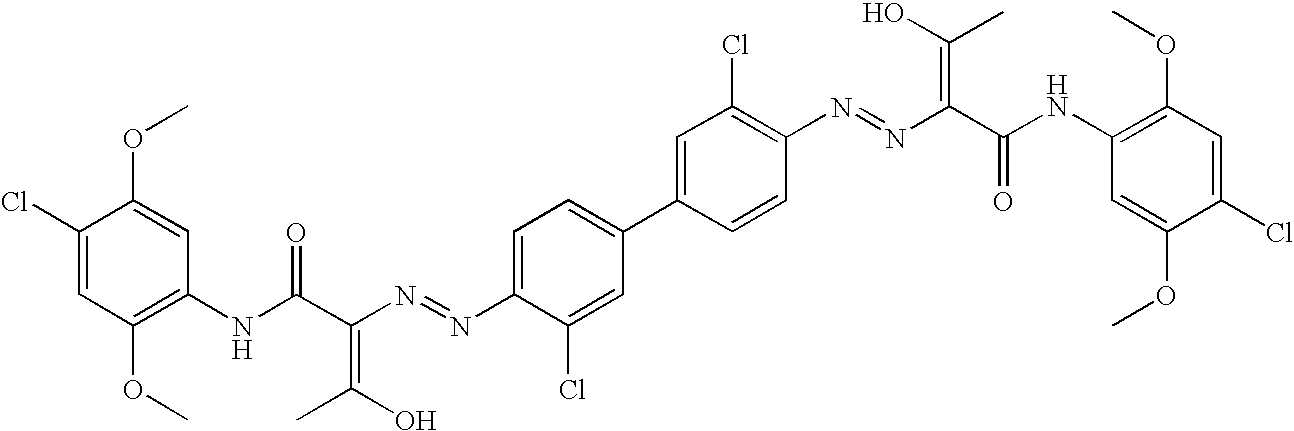

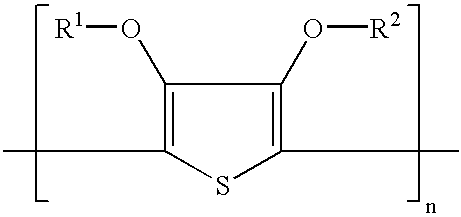

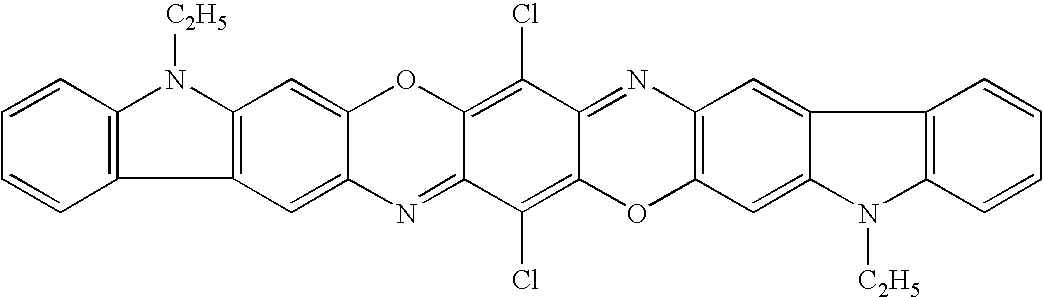

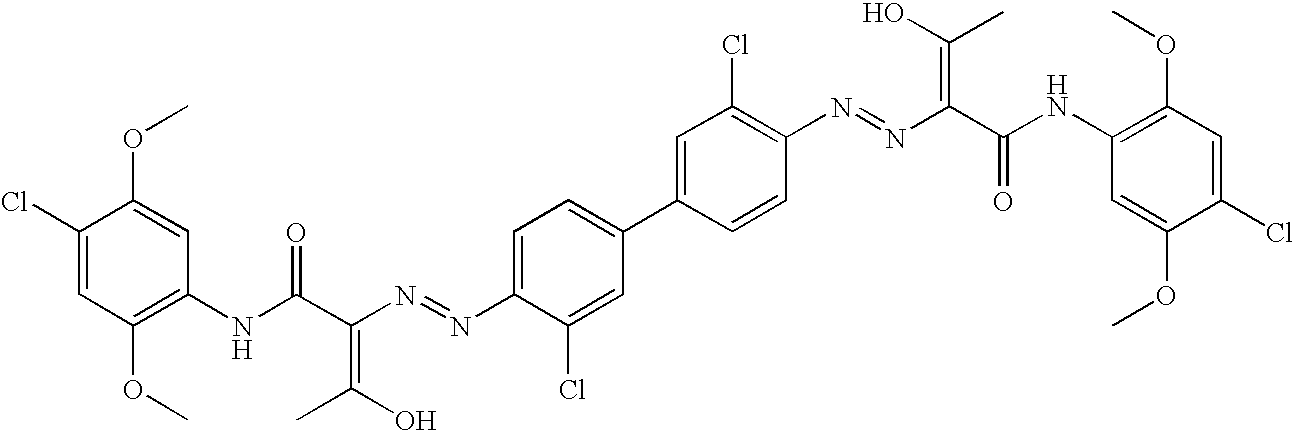

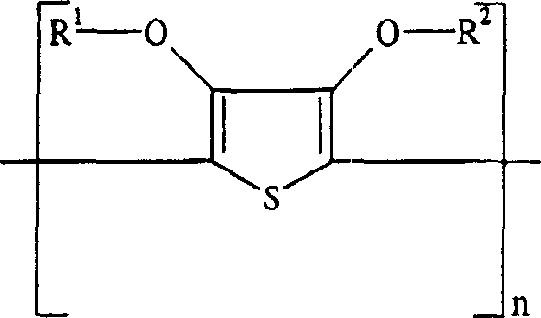

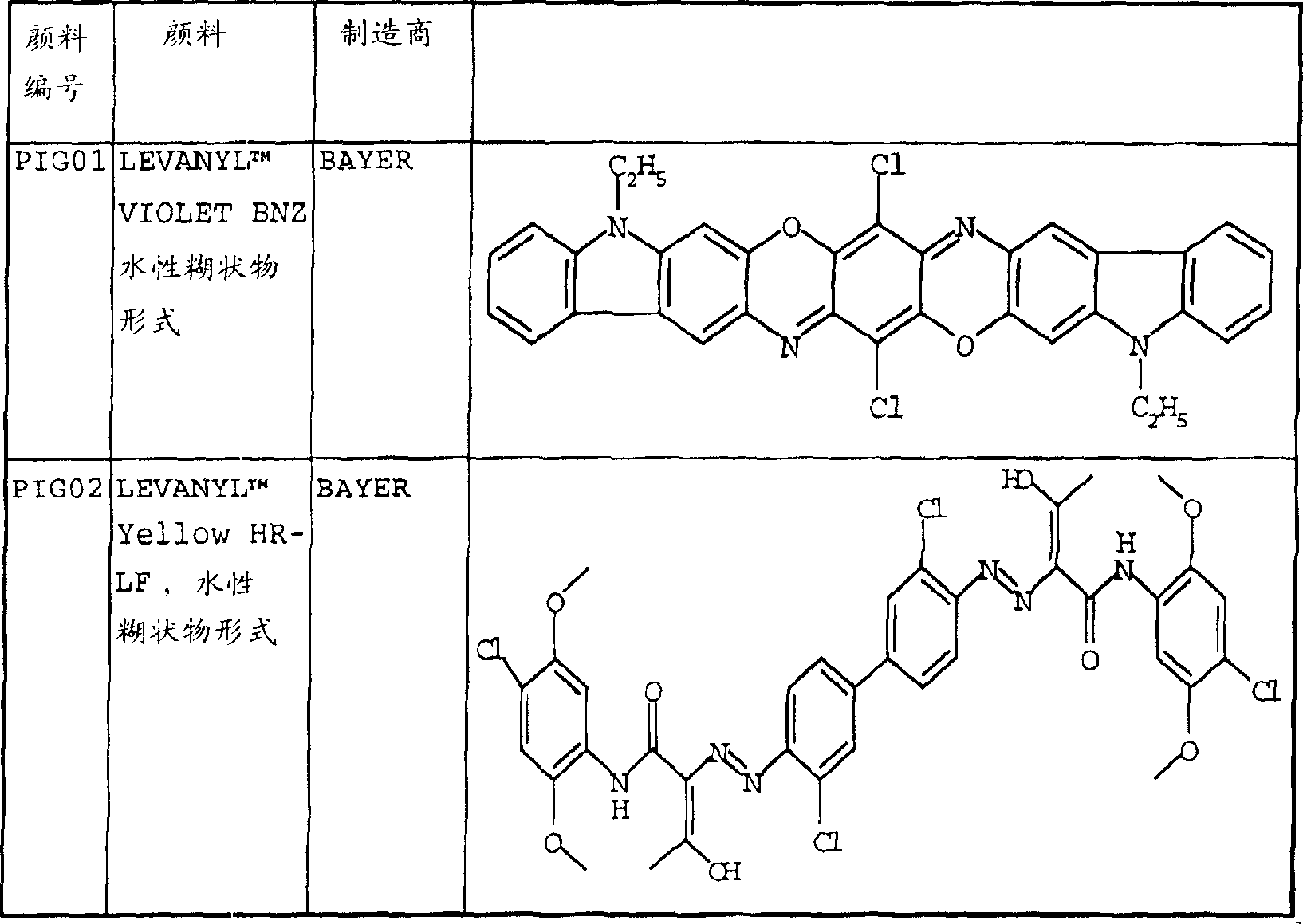

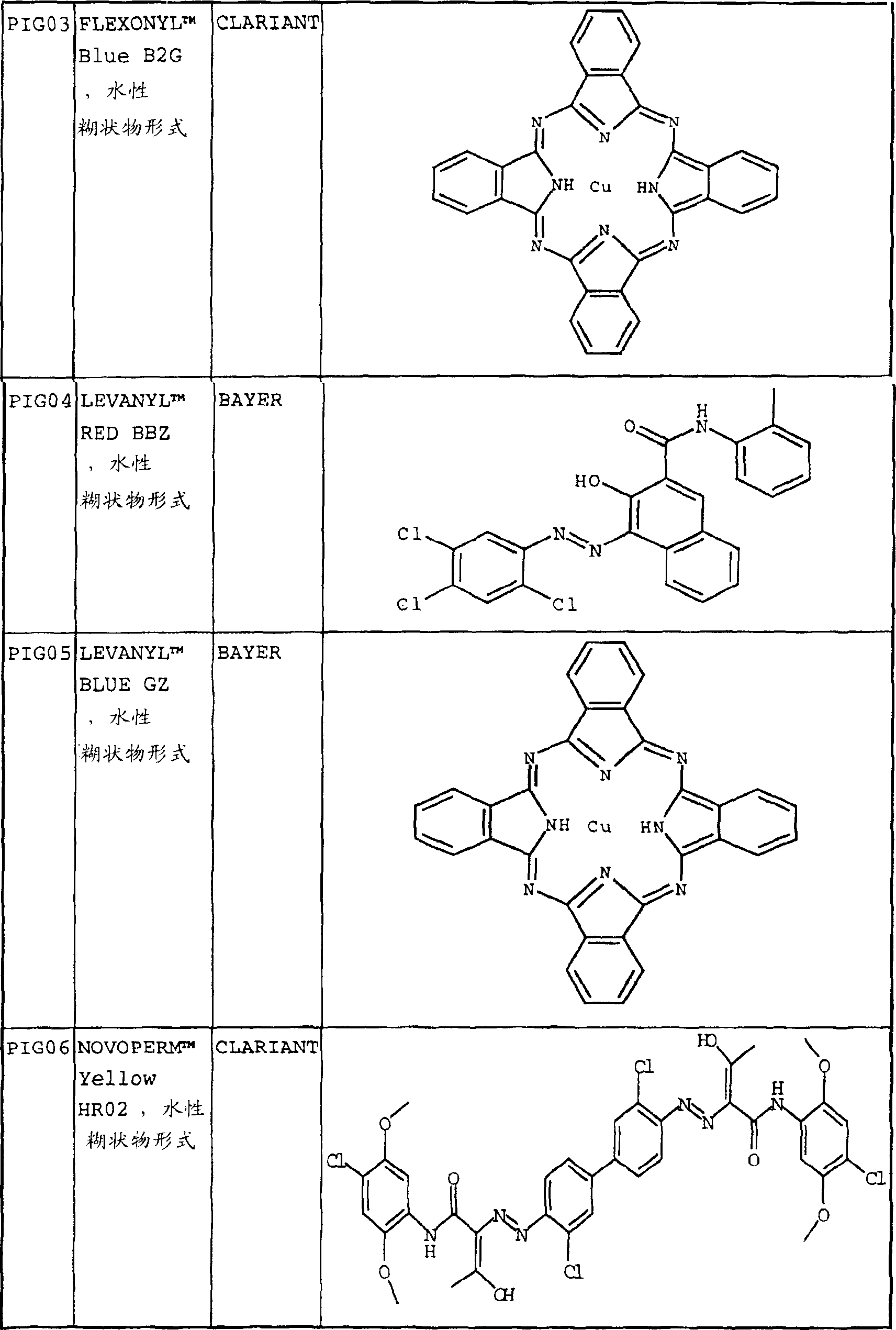

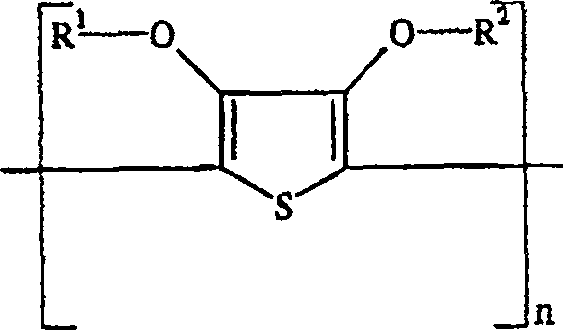

Flexographic ink containing a polymer or copolymer of a 3, 4-dialkoxythiophene

A non-dye containing flexographic ink containing a polymer or copolymer of a 3,4-dialkoxythiophene in which the two alkoxy groups may be the same or different or together represent an optionally substituted oxy-alkylene-oxy bridge, a polyanion and a latex binder in a solvent or aqueous medium, characterized in that the polymer or copolymer of a 3,4-dialkoxythiophene is present in a concentration of at least 0.1% by weight in the ink and that the ink is capable of producing a colorimetrically additive transparent print; a method of preparing the flexographic ink; and a flexographic printing process therewith.

Owner:AGFA GEVAERT AG

Flexographic ink containing a polymer or copolymer of a 3,4-dialkoxythiophene

InactiveUS6890584B2Improve adhesionPoor resistanceFilm/foil adhesivesConductive materialPolymer scienceAqueous medium

A non-dye containing flexographic ink containing a polymer or copolymer of a 3,4-dialkoxythiophene in which the two alkoxy groups may be the same or different or together represent an optionally substituted oxy-alkylene-oxy bridge, a polyanion and a latex binder in a solvent or aqueous medium, characterized in that the polymer or copolymer of a 3,4-dialkoxythiophene is present in a concentration of at least 0.1% by weight in the ink and that the ink is capable of producing a colorimetrically additive transparent print; a method of preparing the flexographic ink; and a flexographic printing process therewith.

Owner:AGFA GEVAERT AG

Flexographic ink with high degradation rate

The invention relates to a flexographic ink with a high degradation rate, which is characterized by comprising the following compositions by weight: 15 to 20 weight portions of coloring agent, 24 to 29 weight portions of resin, 12 to 15 weight portions of dry plant oil, 24 to 29 weight portions of semidry plant oil, 1 to 2 weight portions of drying agent, 2 to 4 weight portions of animal and vegetable wax and 5 to 10 weight portions of auxiliary agent. The ink has greatly improved natural component content, and the degradable components reaching more than 60 percent, and reduces the pollution of the ink to the environment.

Owner:苏州科德教育科技股份有限公司

Flexographic printing inks

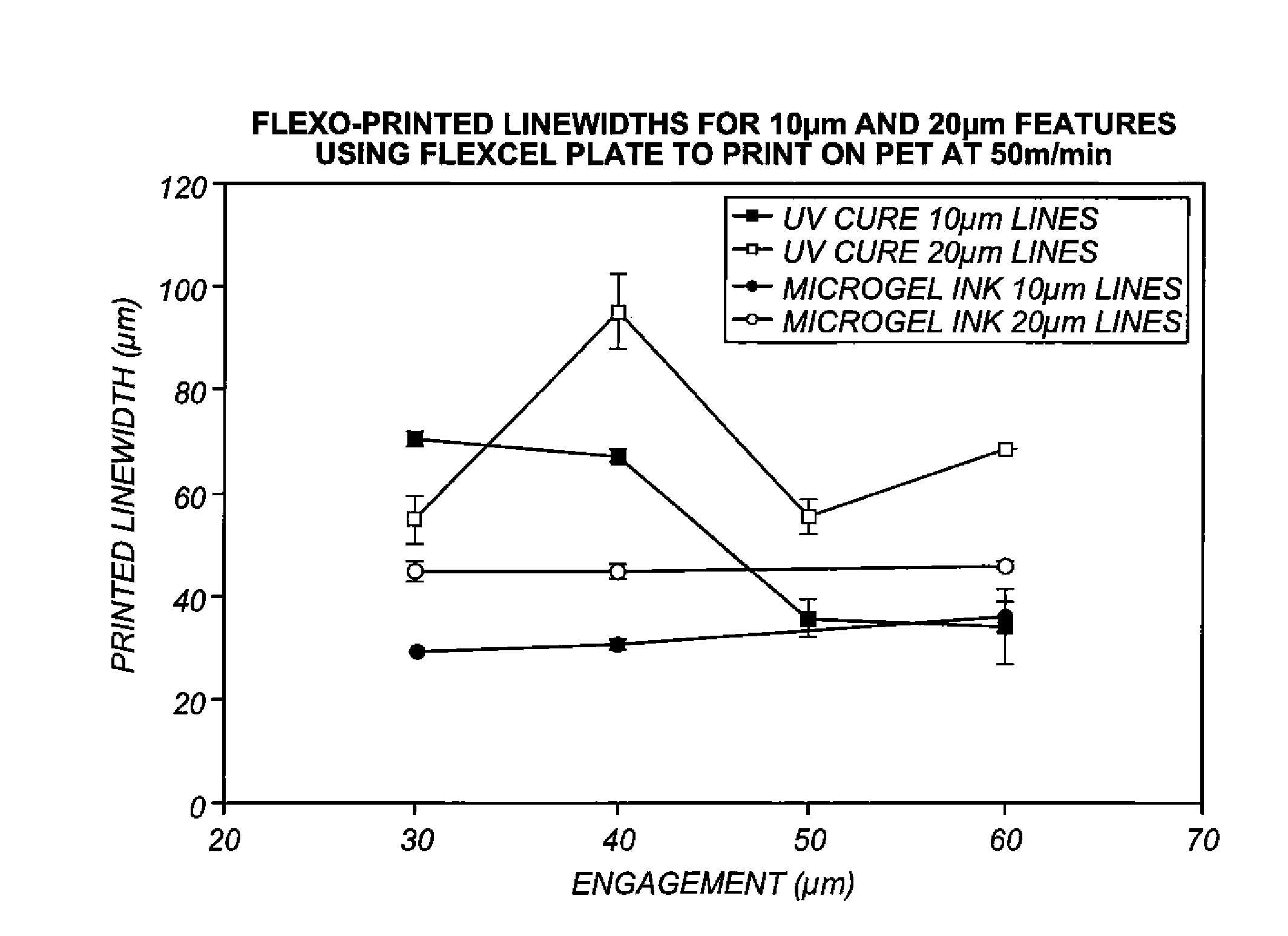

InactiveUS20110041715A1Improve printing effectImprove adhesionGroup 4/14 element organic compoundsInksImage resolutionCorona discharge

A flexographic printing composition which comprises a carrier-swellable particle composition, such as a microgel particle composition, has improved printing performance and printing resolution, especially where the flexographic printing composition is an aqueous printing composition and the carrier is water. The composition is particularly beneficial for flexographic printing of such an aqueous printing ink onto low-energy surface substrates or impermeable substrates, in which the ink has improved adhesion, even in the absence of corona discharge treatment. The use of surfactant in an amount of at least 0.5% by weight of the ink composition enhances printed density and / or reduces mottling in solid printed areas.

Owner:EASTMAN KODAK CO

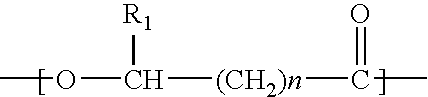

Biodegradable flexographic ink

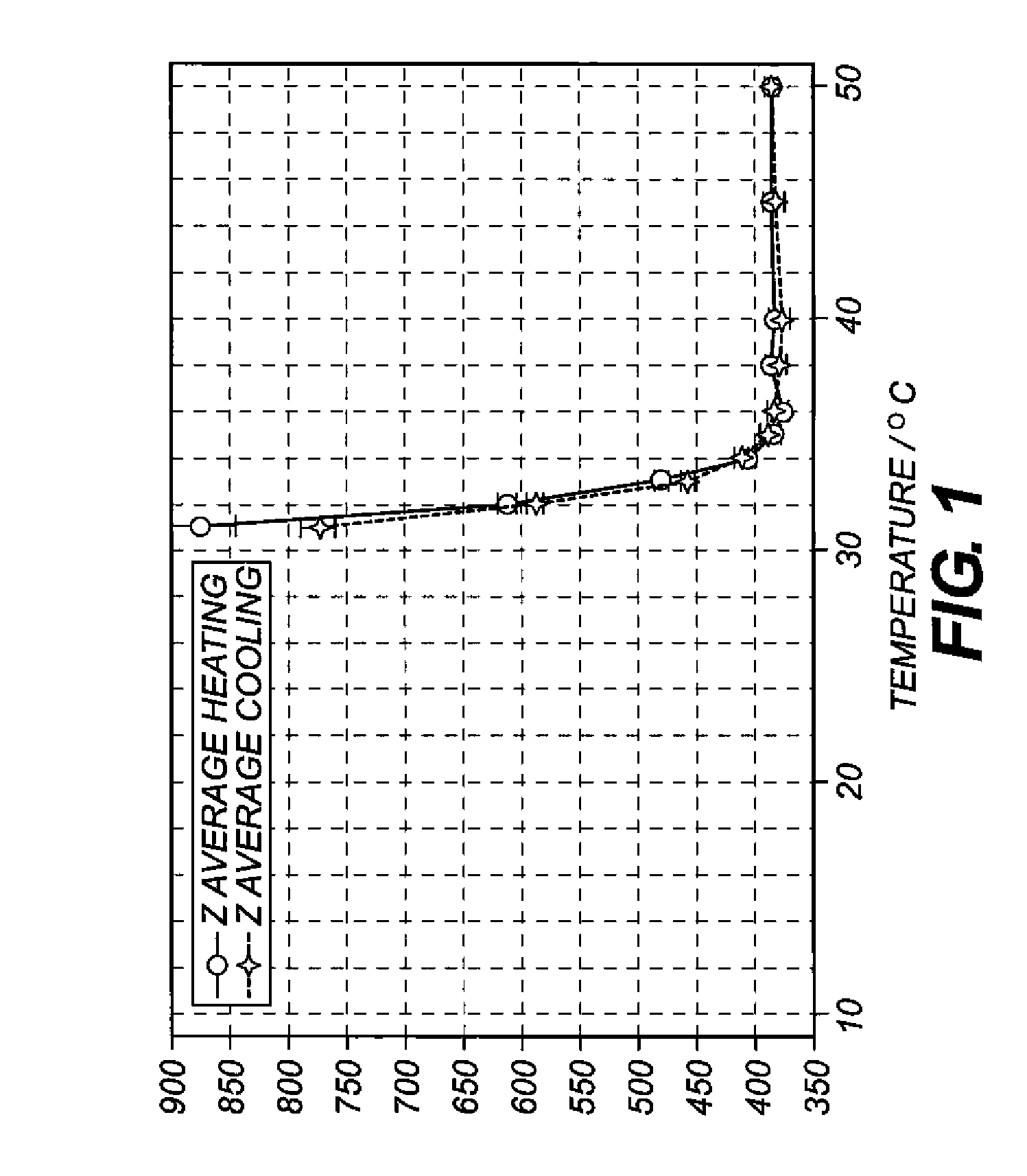

The present invention relates to a flexographic water based ink in which a biodegradable polymer, such a polyhy-droxyalkanoate (PHA), replaces conventional poorly or non-biodegradable organic polymeric resins for example. PHAs are used as a latex suspension in water, thus the present invention relates to a novel pigment / latex mixture. PHA in a latex form is a fluid vehicle in which all the other components necessary to provide a flexographic ink are added, i.e., pigments, wax and / or binder, as well as a solvent, if necessary. The PHAs are mainly responsible for the biodegradability of the flexographic water based ink. The present invention relates also a method to produce a flexographic water based composition with enhanced biodegradability properties.

Owner:BIOMATERA INC

Wet-trapping of energy curable flexographic inks and coatings

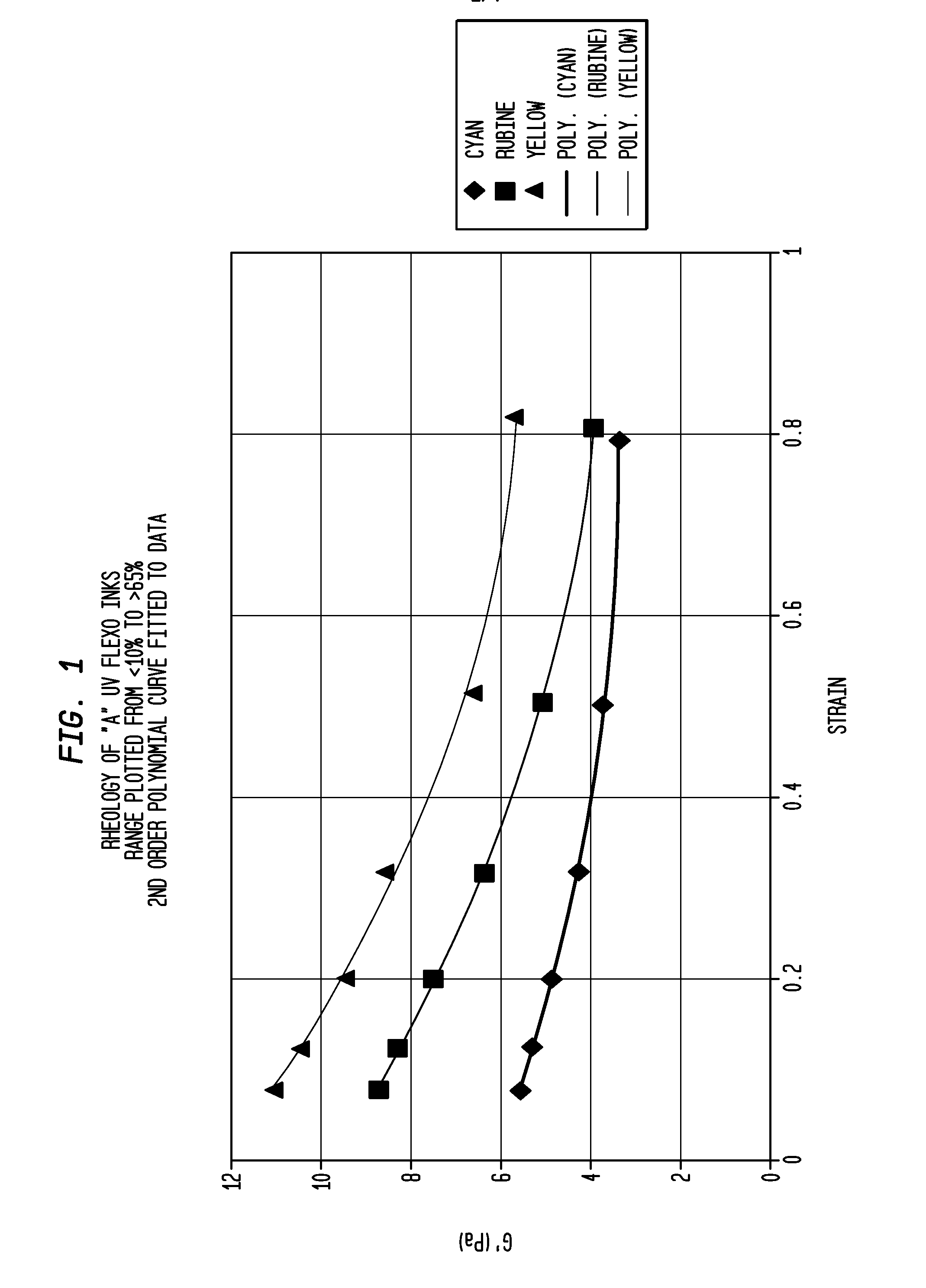

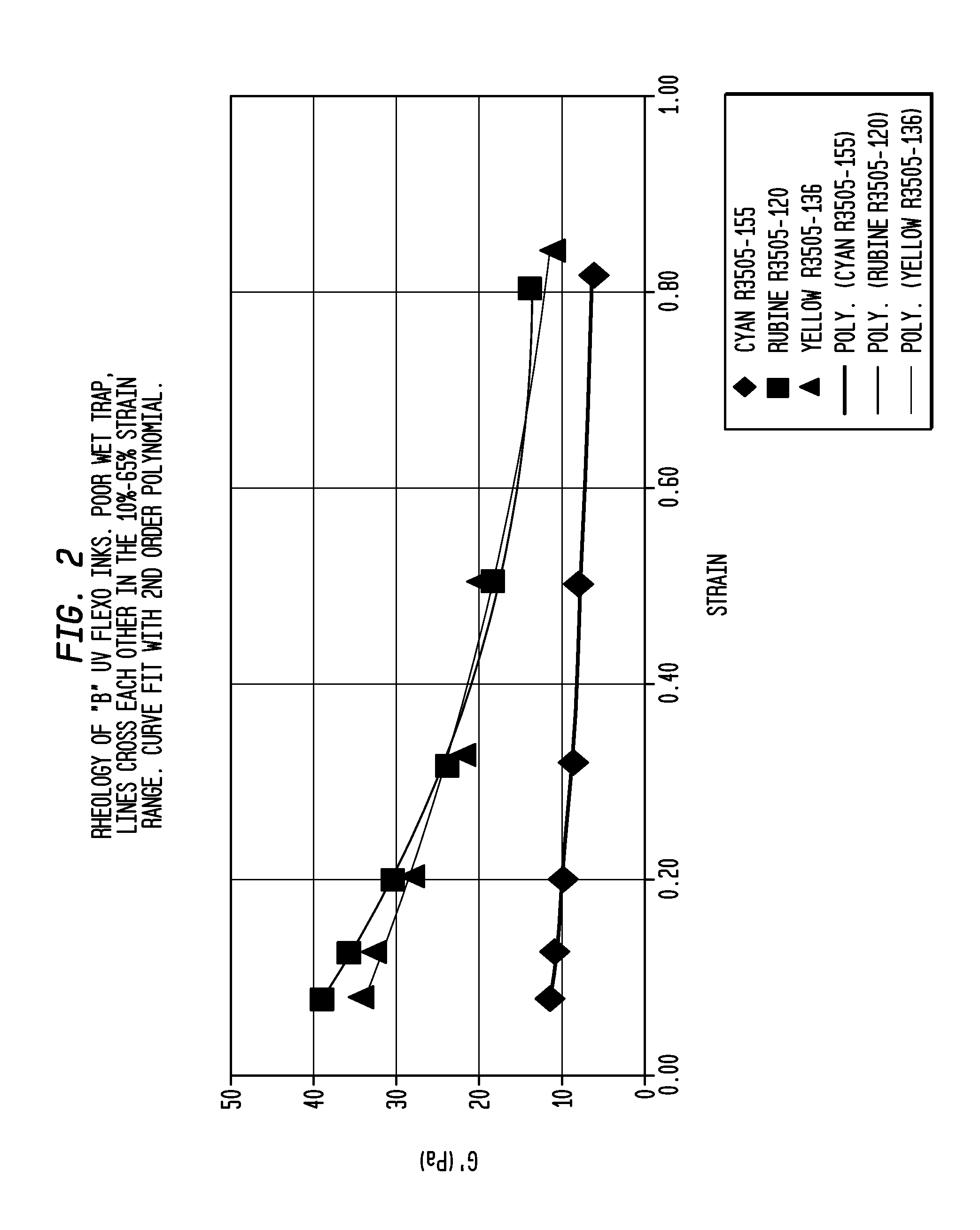

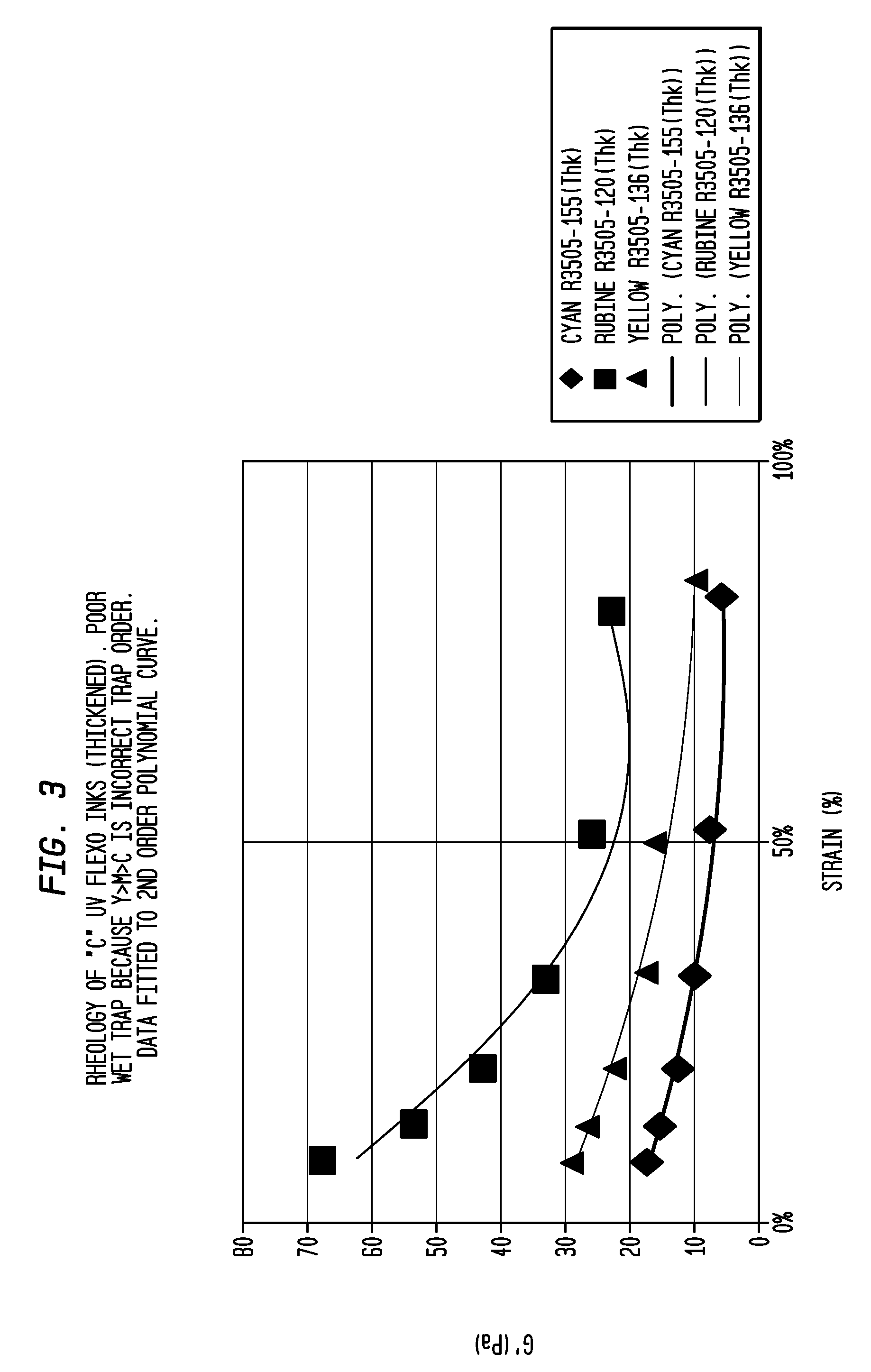

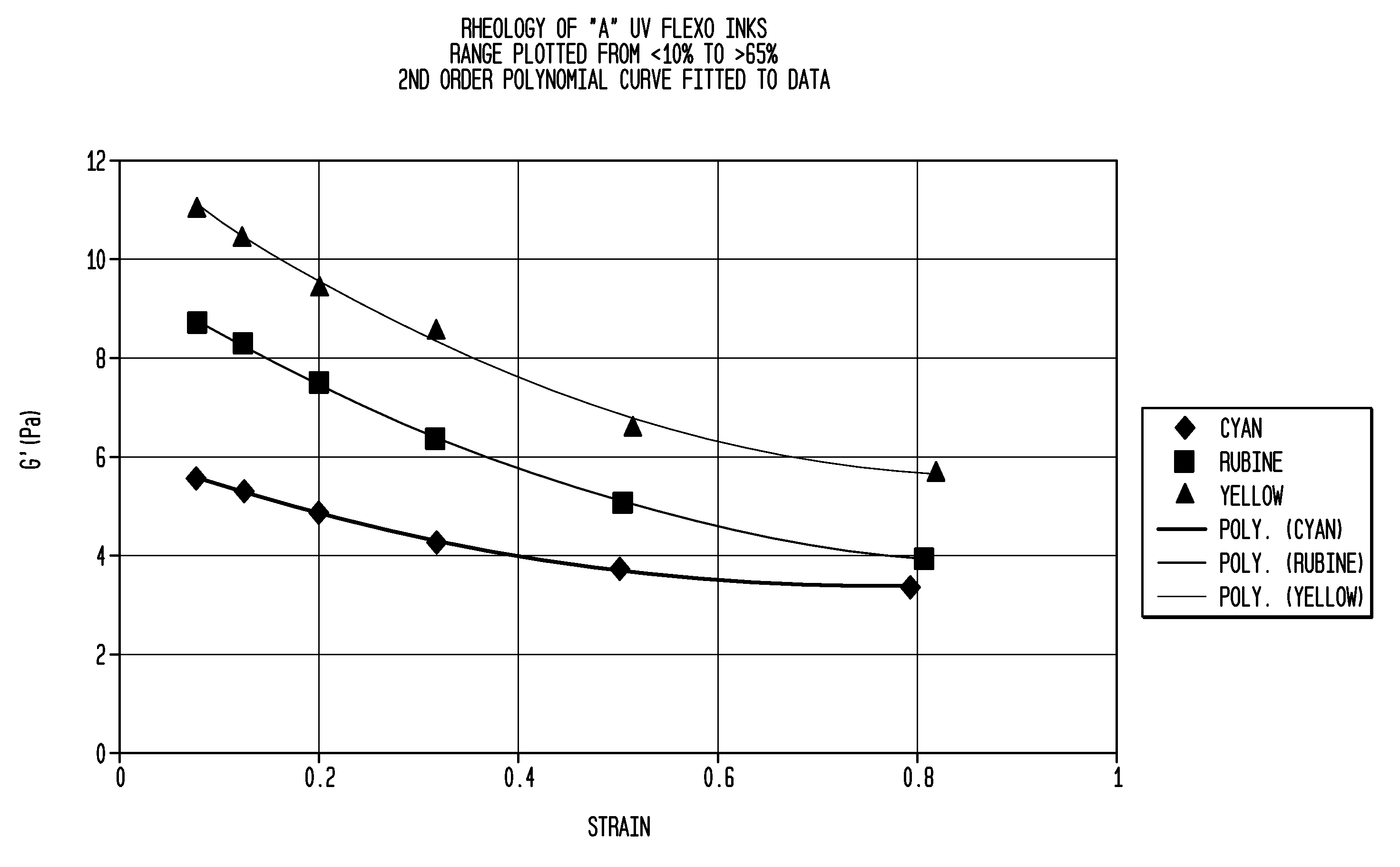

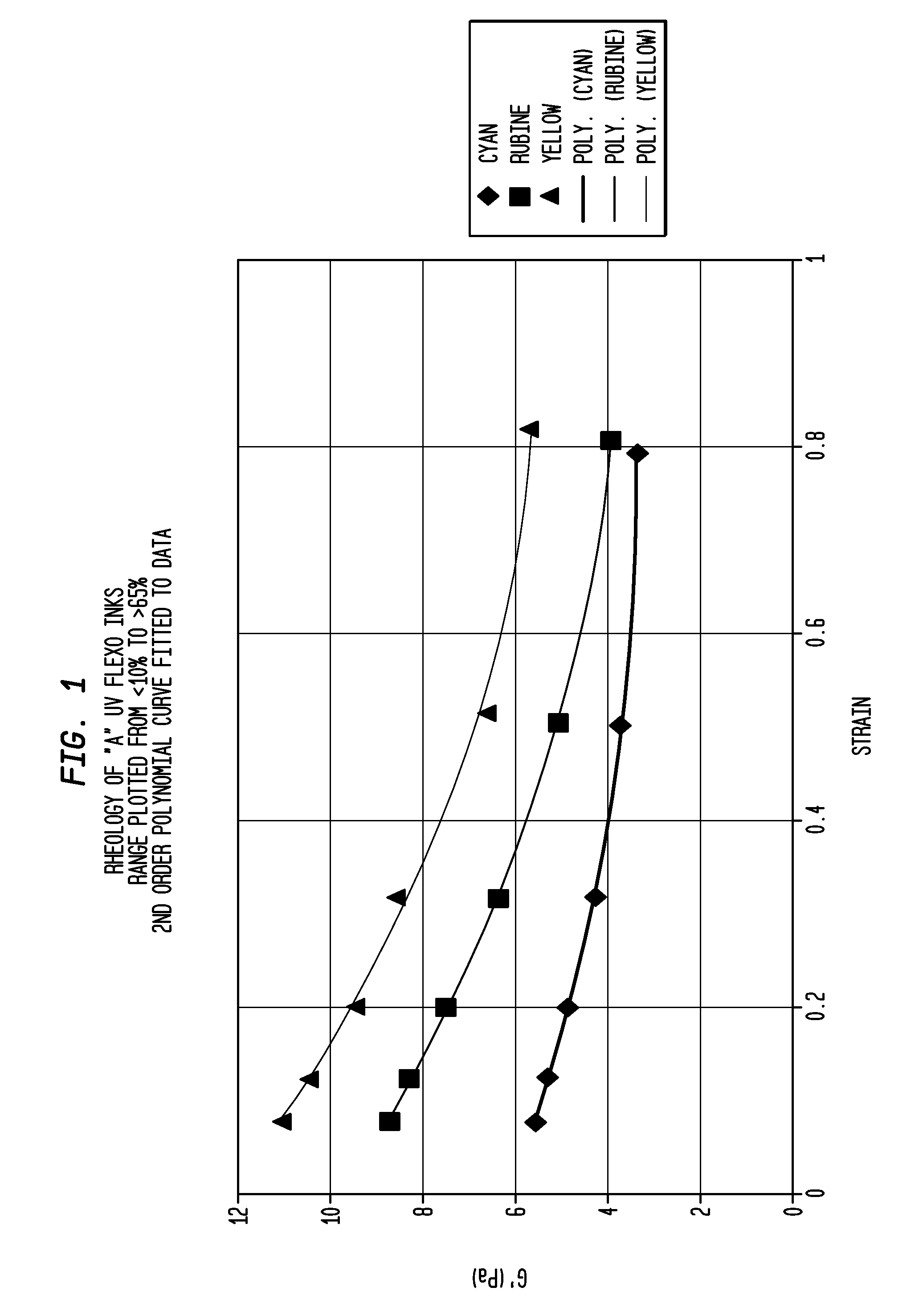

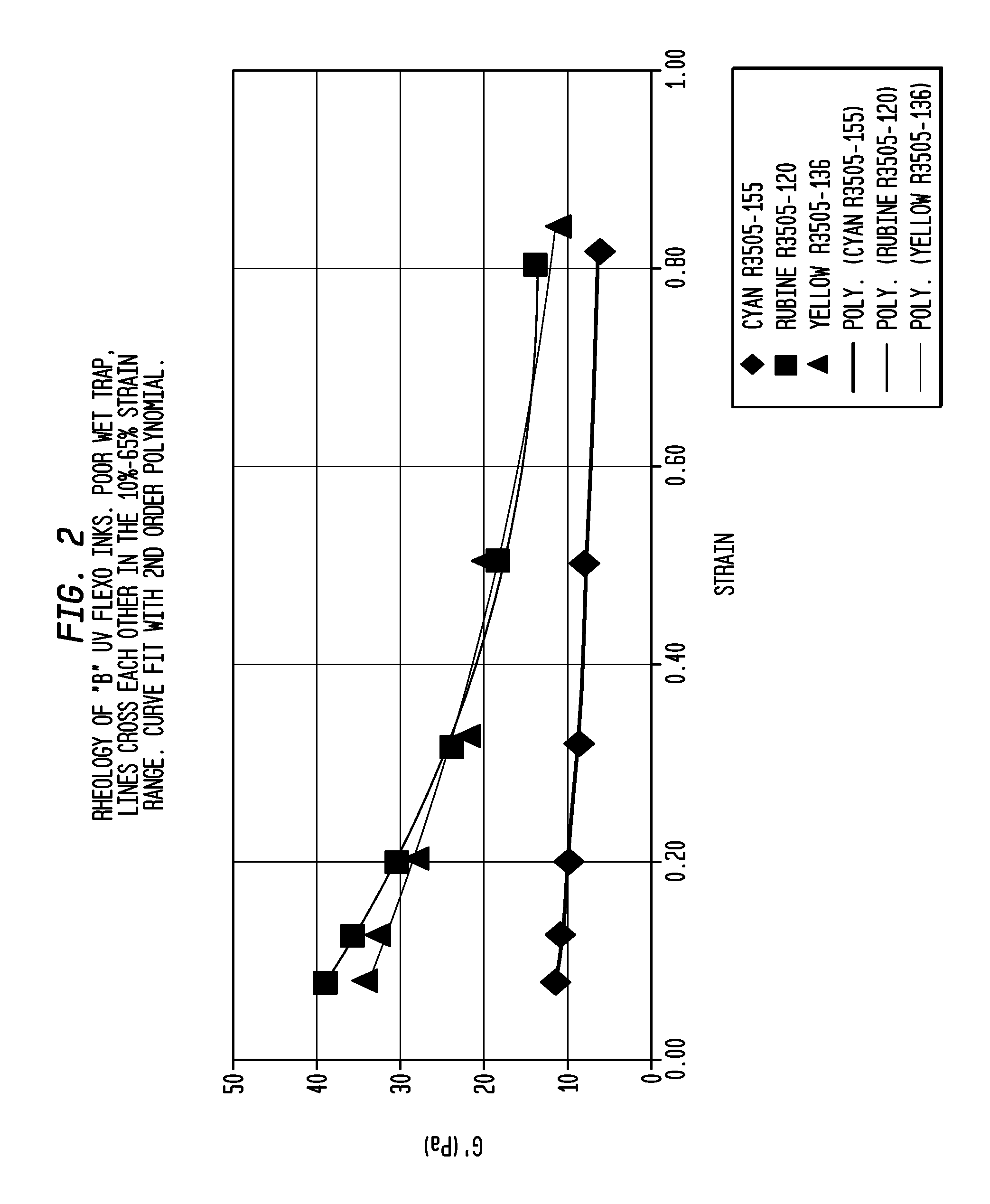

ActiveUS20120304879A1Good trappingEnsure sufficient separationInksOther printing apparatusColor printingTrapping

Methods and apparatus for flexographic color printing, and more particularly for implementing “wet trapping” in flexographic printing using energy curable flexographic liquid inks are presented. Radiation curable inks can be formulated that wet trap over each other without back-trapping onto the plates and anilox units of down-line printing units by controlling the storage modulus of the inklcoating. The storage modulus G′ in the inks can be controlled to ensure that the highest G′ ink is printed ISt down with successive colors being trapped in the order of their (declining) G′ values. An image in wet ink can thus be trapped over a different image in wet ink of a different color without picking the ISt ink back up and redepositing it onto the subsequent plates and rollers in the printing press (back-trapping).

Owner:SUN CHEM CORP

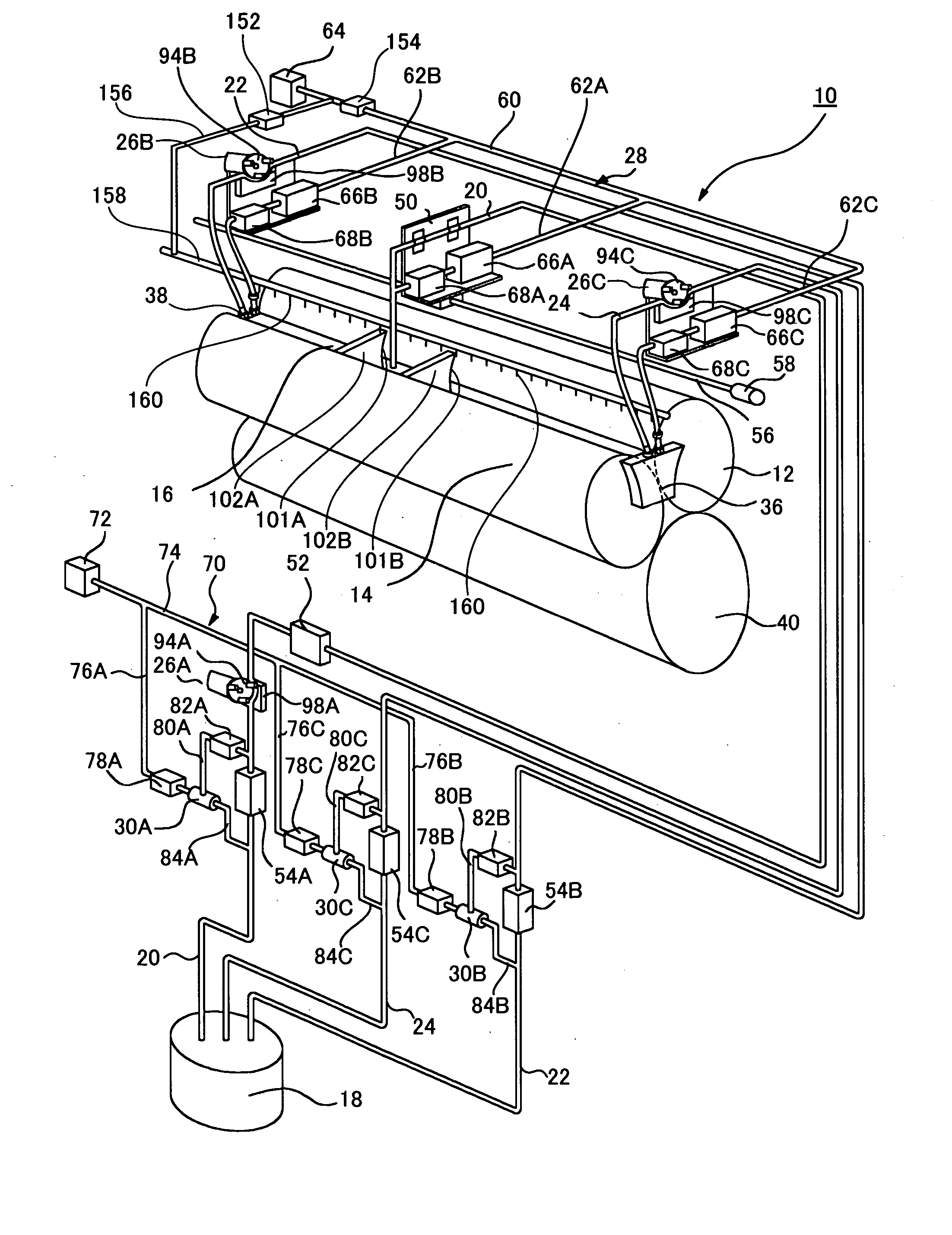

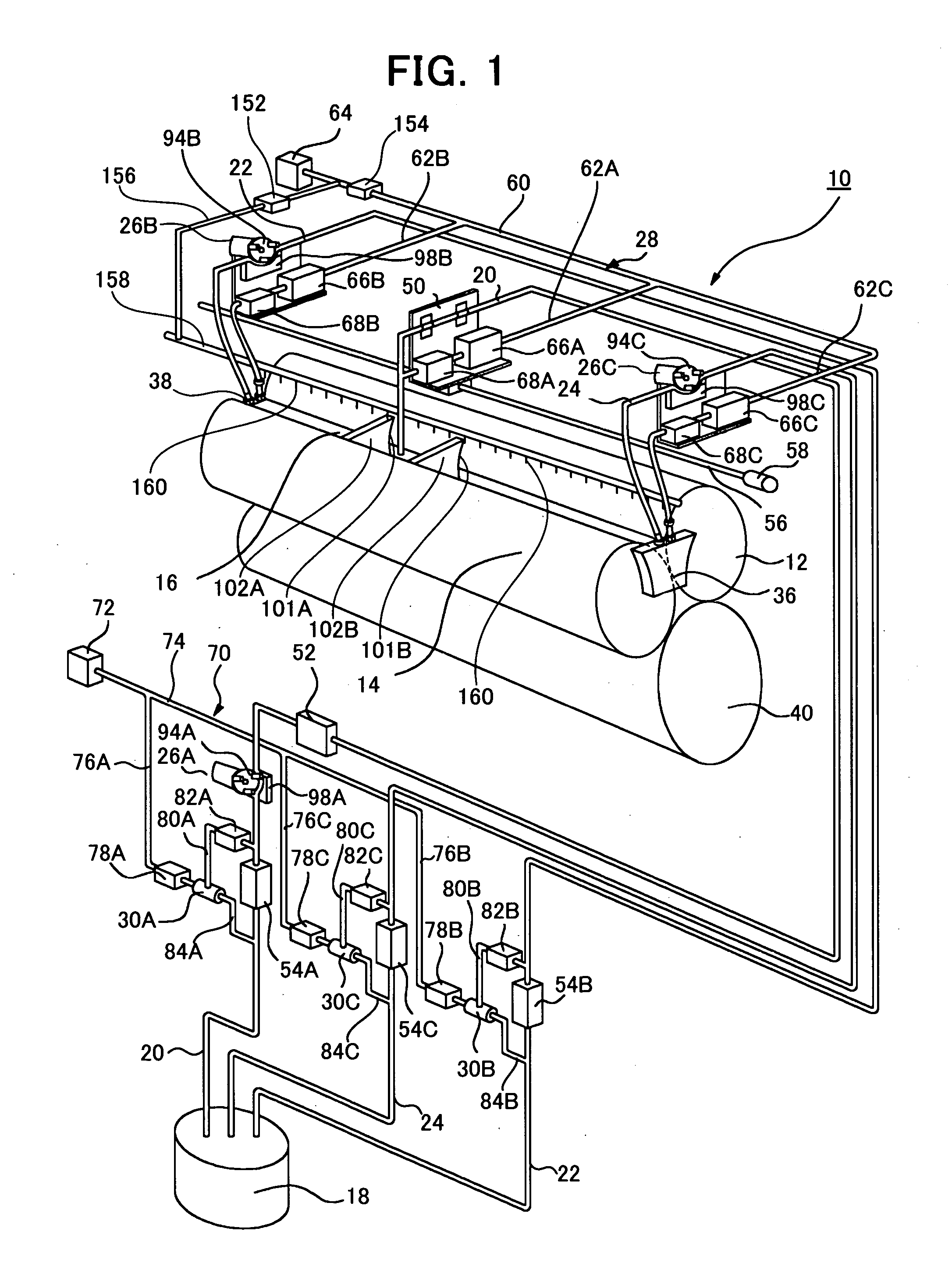

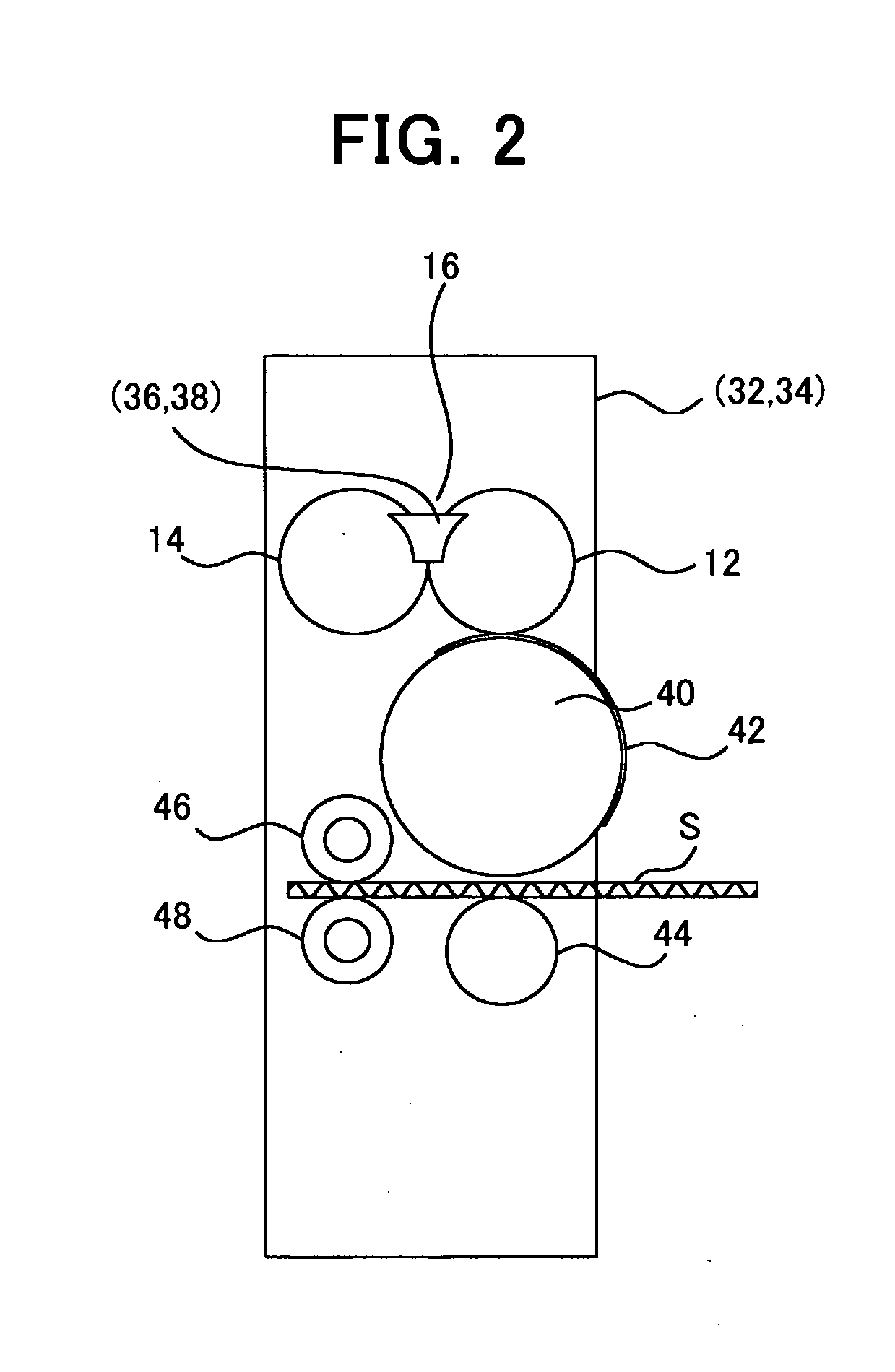

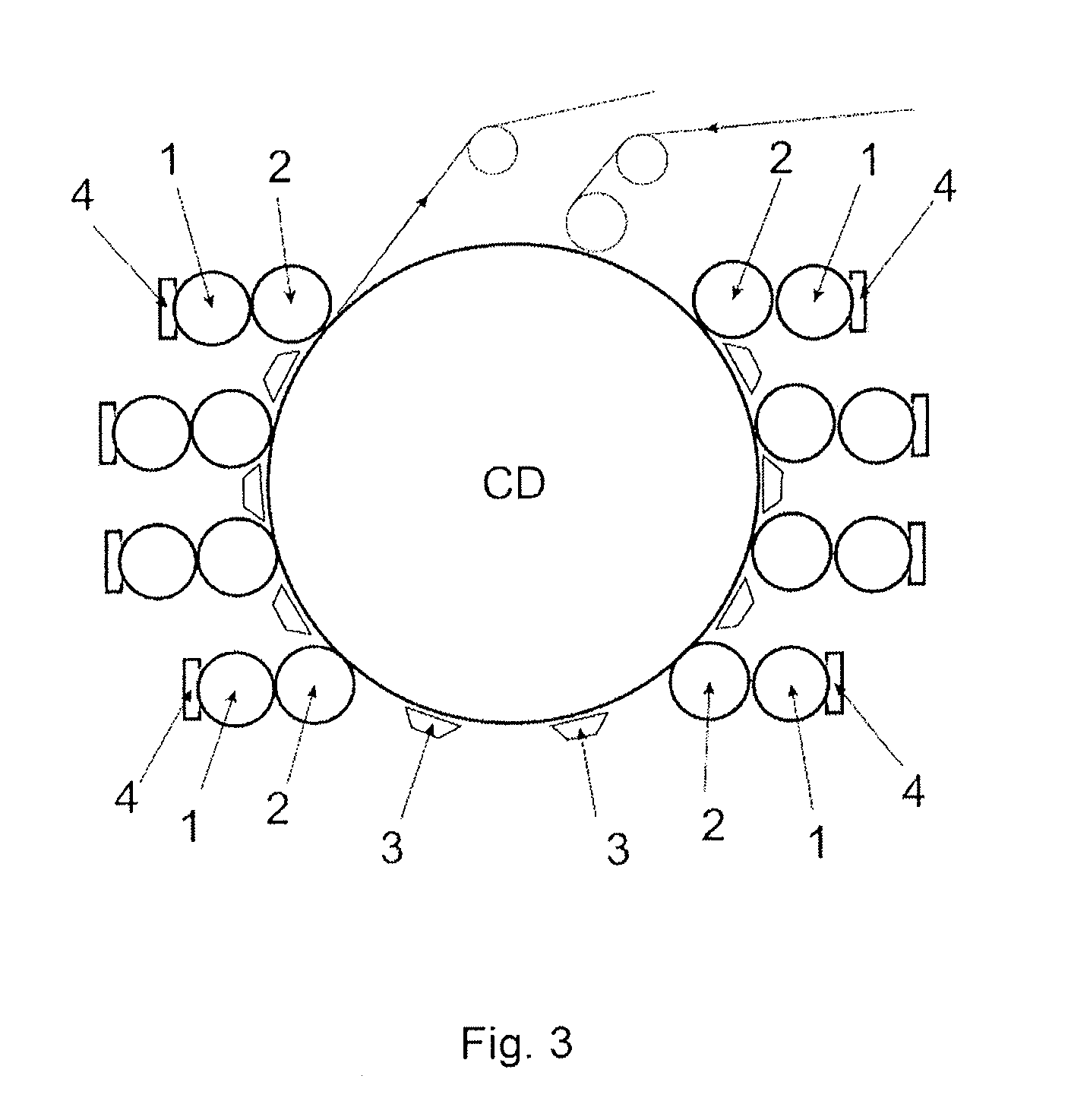

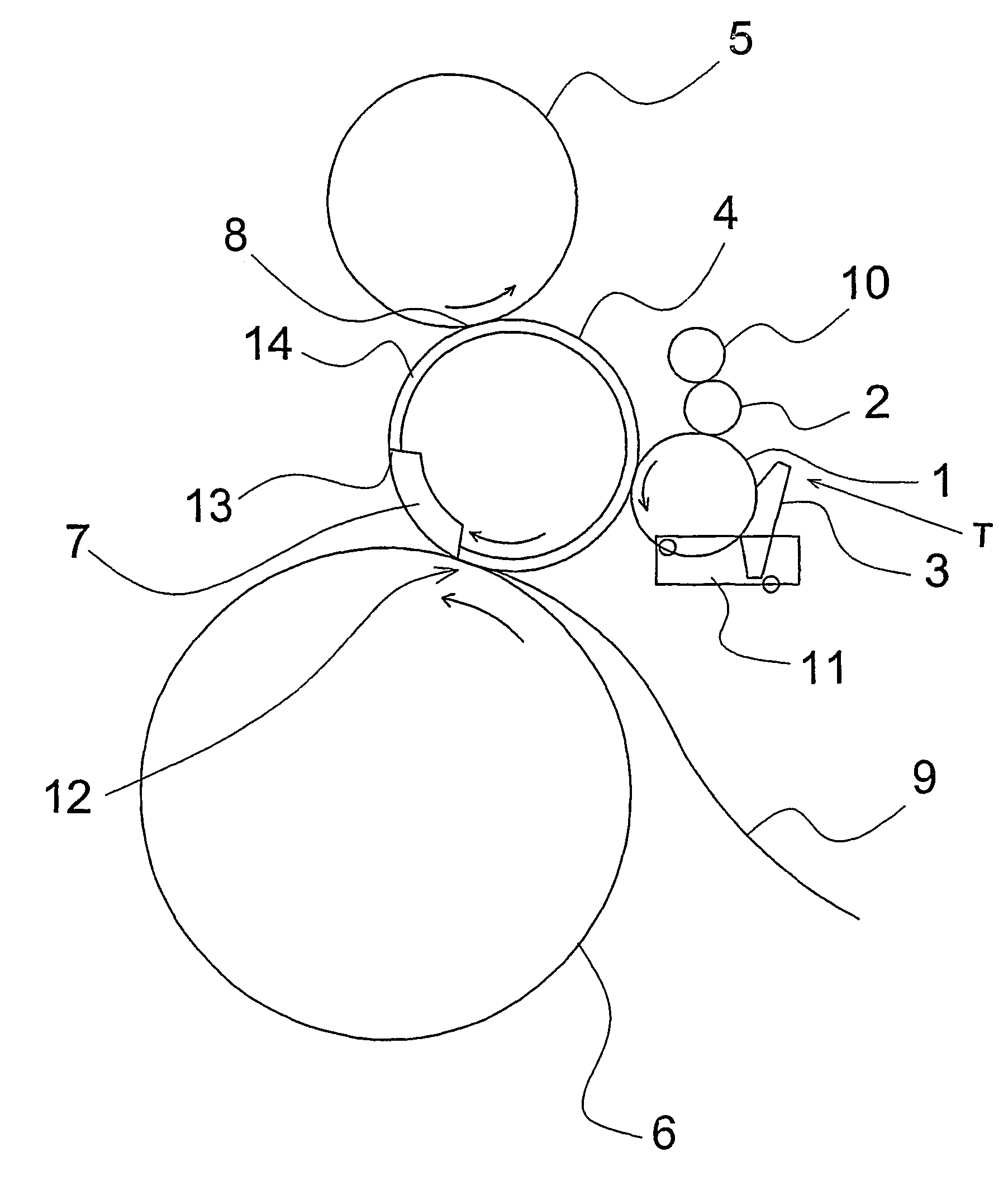

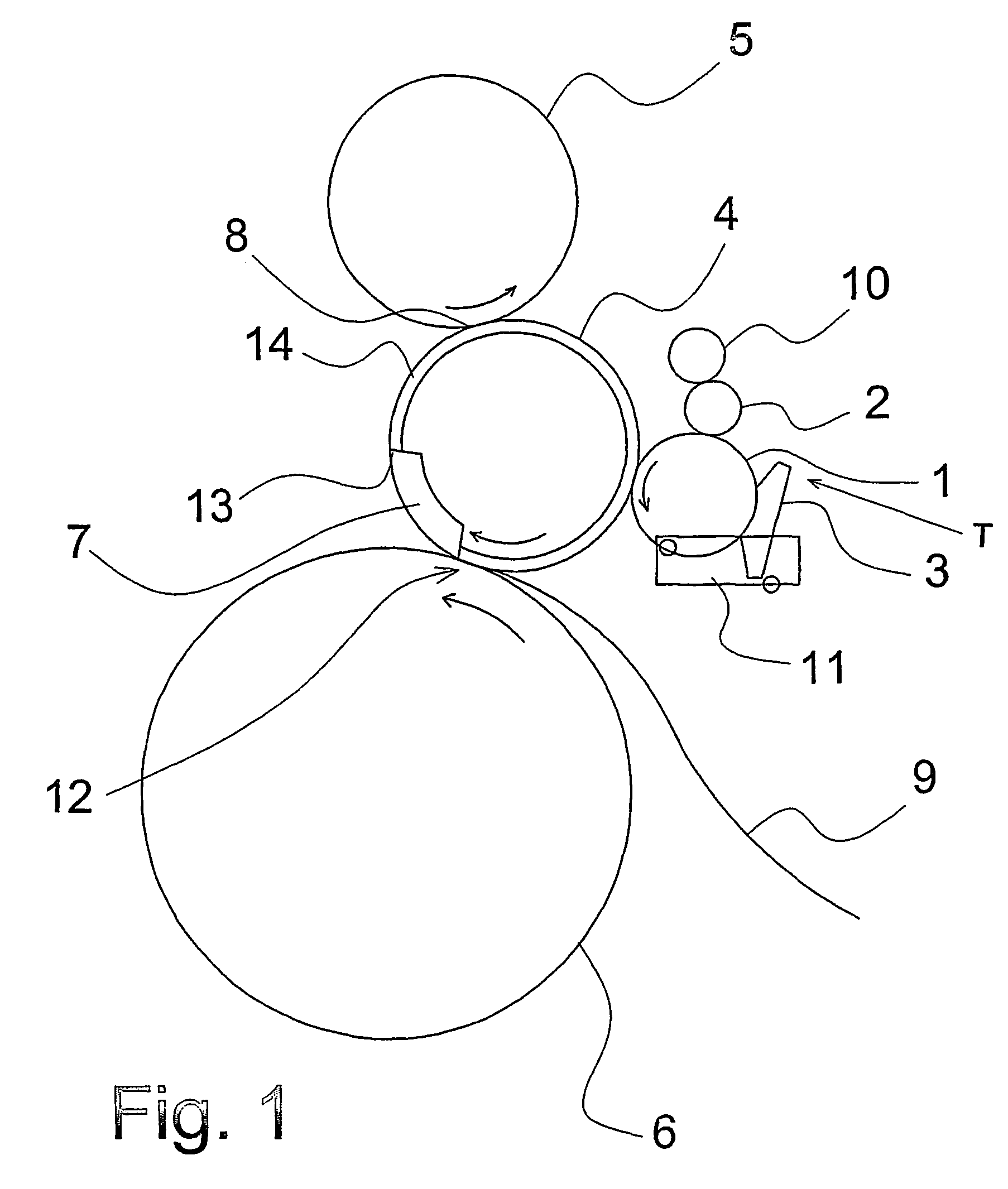

Flexographic ink printing machine

InactiveUS20060032387A1Raise the liquid levelGood adhering conditionRotary letterpress machinesPrinting press partsEngineeringPrinting press

A flexographic ink printing machine is provided in which ink is circulated in order to prevent solidifying of the ink during a printing operation, whereby during ink supplying or ink recovering operations, high efficiency of supplying and recovering the ink can be obtained. A printing machine which includes an ink reservoir, an ink supply source, and ink delivery tubings each connecting said ink reservoir to said ink supply source, whereby the ink supplied from said ink supply source via at least one of said ink delivery tubings to said ink reservoir and accumulated therein is used for printing, said ink delivery tubings including ink recovery tubings for recovering the flexographic ink from said ink reservoir to said ink supply source, said ink recovery tubings having their ink recovery opening ends located within said ink reservoir, said ink delivery tubings including ink supply tubing for supplying the flexographic ink from said ink supply source to said ink reservoir, said ink supply tubing having its ink supply opening end located within said ink reservoir, whereby the ink within said ink reservoir is maintained in a dynamic state by supplying said flexographic ink from said ink supply source to said ink reservoir via said ink supply tubing and by recovering the flexographic ink from said ink reservoir to said ink supply source via said ink recovery tubings during the printing operation of the printing machine, wherein: said ink recovery tubings and said ink supply tubing have ink transfer means which can transfer the ink in both forward and backward directions between said ink supply source and said ink reservoir, wherein the flexographic ink is recovered from said ink reservoir to said ink supply source via said ink recovery tubings and said ink supply tubing now being used as an ink recovery tubing during ink recovering, and wherein the flexographic ink is supplied from said ink supply source to said ink reservoir via said ink supply tubing and said ink recovery tubings now being used as ink supply tubings during ink supplying.

Owner:ISOWA IND CO LTD

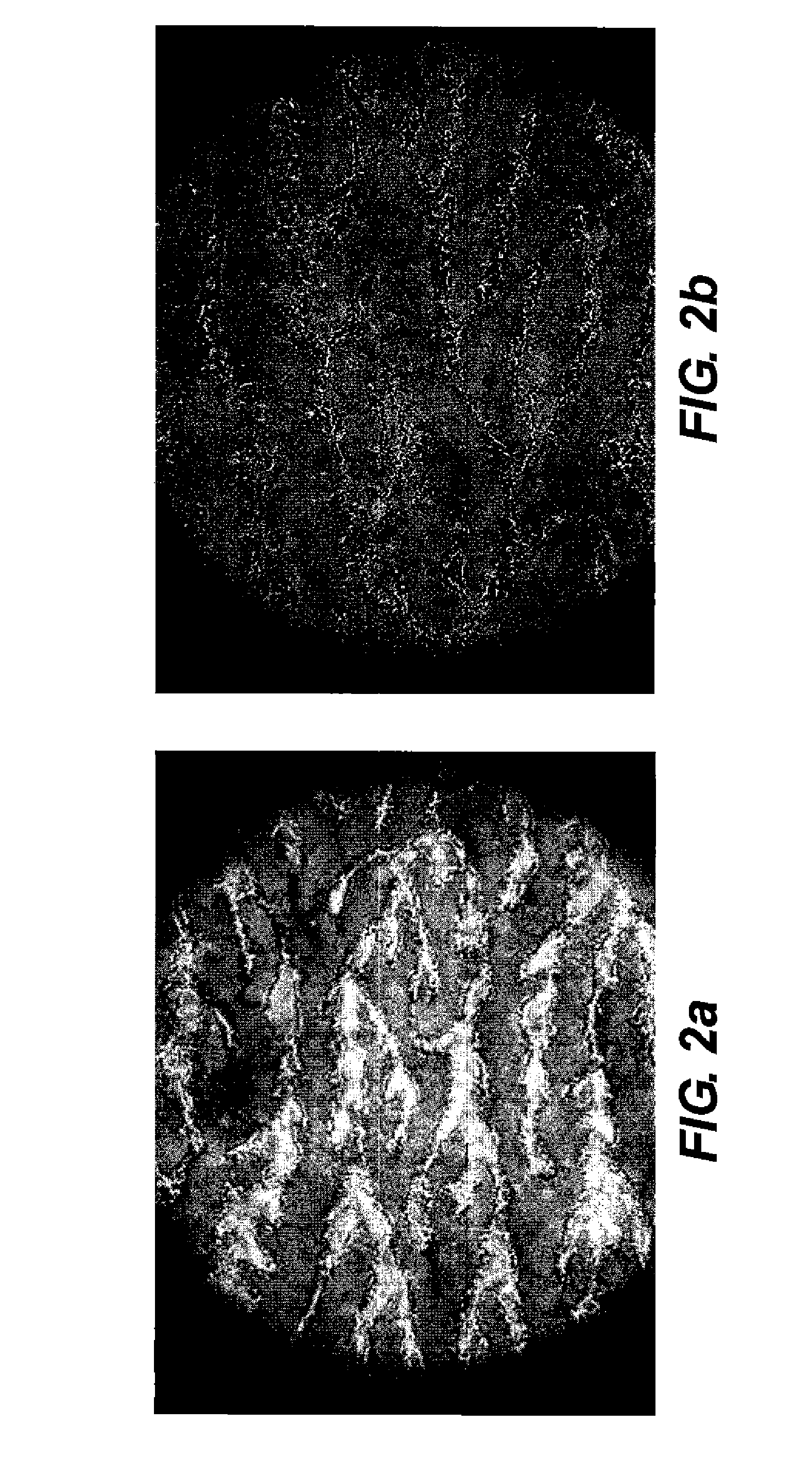

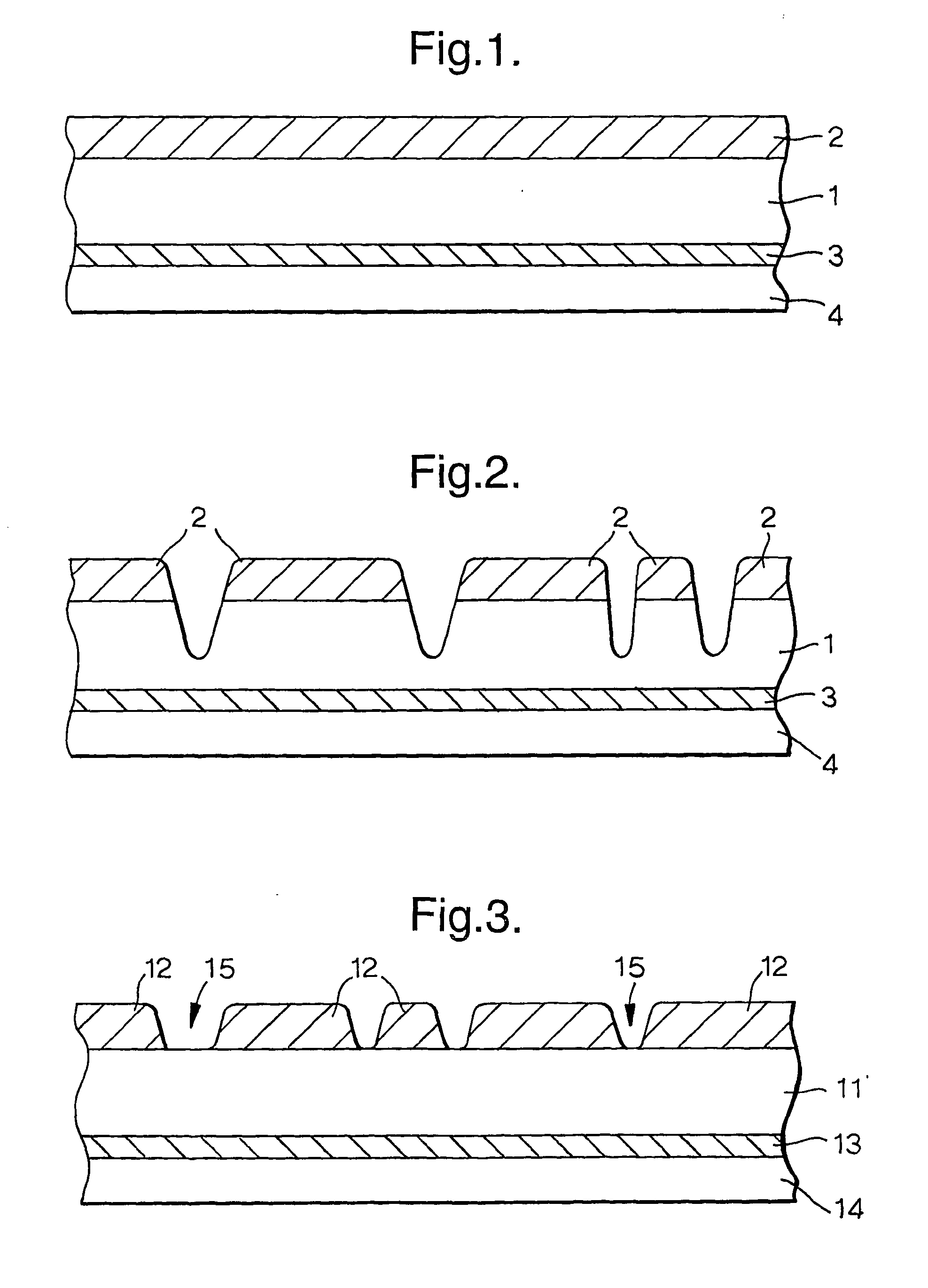

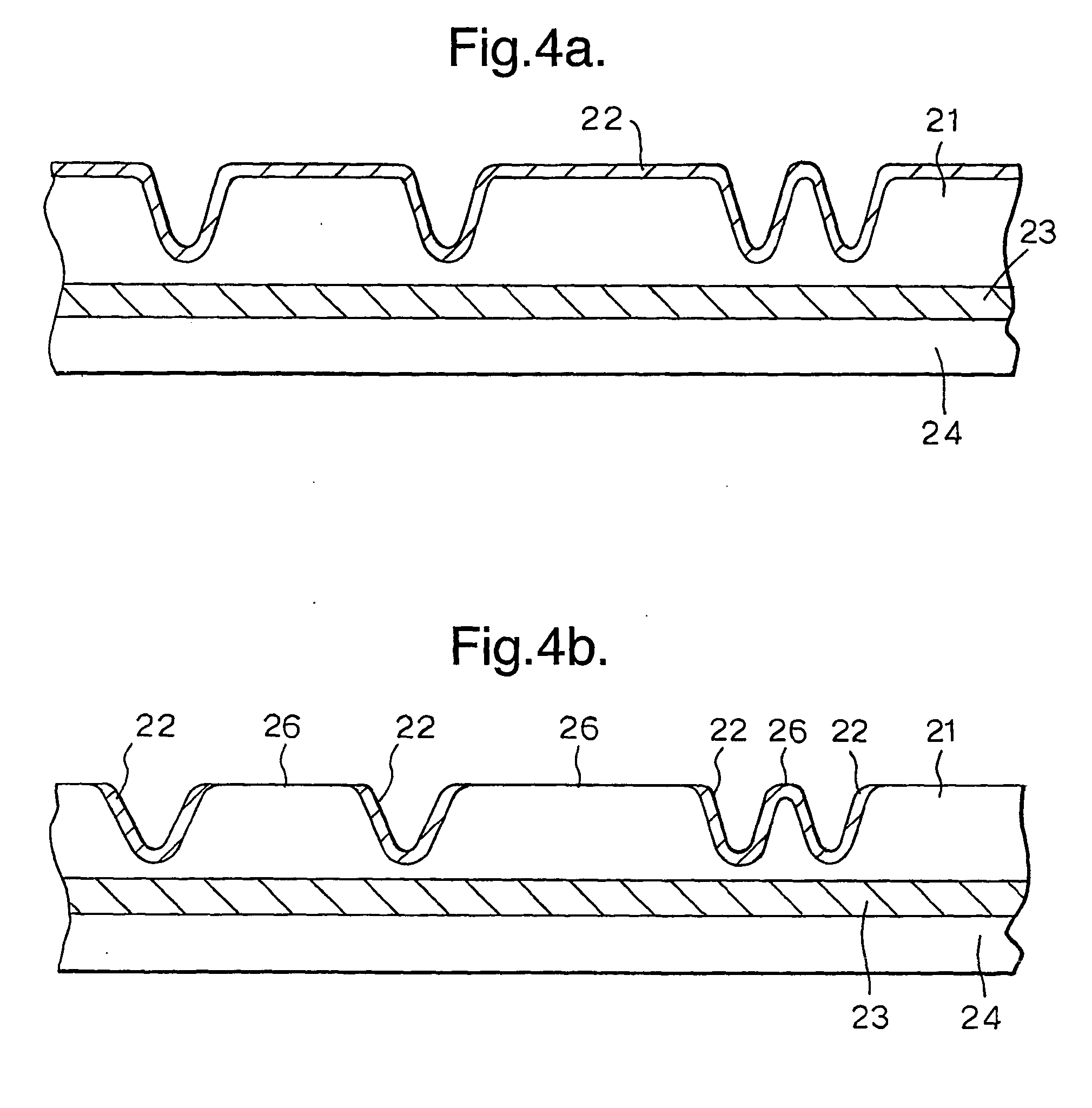

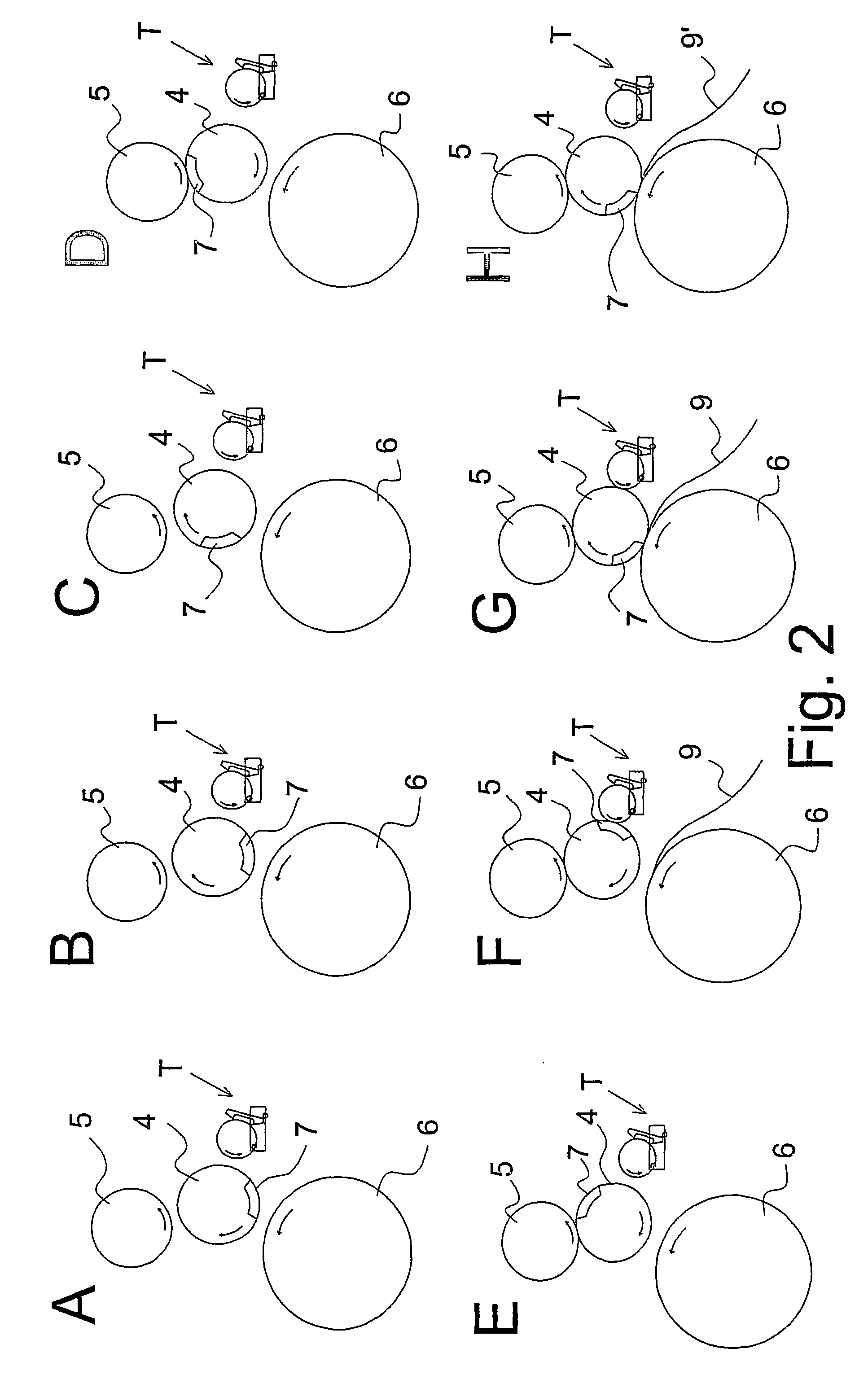

Flexographic printing formes

Elastomeric materials have long been used to produce printing blocks, printing rollers, printing formes and elastomeric covered printing sleeves for flexographic printing. A suitable and commonly used elastomeric material is natural rubber. According to one aspect of the present invention such a flexographic printing member comprises a printing surface having raised regions (2) and sunken regions (1) wherein one of the raised regions or sunken regions (2) is formed of ink accepting material and the other (1) is formed of ink repelling material. The area of the forme onto which the ink is held is therefore limited essentially to the tops of the raised regions (2) since it is repelled by the side walls of the raised regions. This considerably reduces the "dot gain" that otherwise takes place.

Owner:INNOVATIVE ELASTICS

Water-based extender vehicle composition, and method for tinting and use

The present invention relates to the use of esterified tall oil rosin, esterified wood rosin, esterified gum rosin, and mixtures thereof to enhance water-based flexographic ink. The products and methods of the present invention result in enhanced image clarity and resolution; enhanced image clarity and resolution as a result of elimination of most press-side imperfections such as ghosting, inefficient ink transfer and bronzing; increased ink mileage up to three times that of conventional water-based inks; achievement of fine-line details; increased gloss properties on high hold-out liners; and increased color strength and density on most paper and paperboard substrates.

Owner:ALLISON CYNTHIA LOU +1

Aqueous flexographic printing inks

An aqueous flexographic printing ink composition containing a pigment, a styrene:acrylic copolymer and a plasticizer.

Owner:SUN CHEM CORP

Flexographic ink containing polymer or copolymer of 3,4-dialkoxythiophene

A non-dye containing flexographic ink containing a polymer or copolymer of a 3,4-dialkoxythiophene in which the two alkoxy groups may be the same or different or together represent an optionally substituted oxy-alkylene-oxy bridge, a polyanion and a latex binder in a solvent or aqueous medium, characterized in that the polymer or copolymer of a 3,4-dialkoxythiophene is present in a concentration of at least 0.1% by weight in the ink and that the ink is capable of producing a colorimetrically additive transparent print; a method of preparing the flexographic ink; and a flexographic printing process therewith.

Owner:AGFA GEVAERT AG

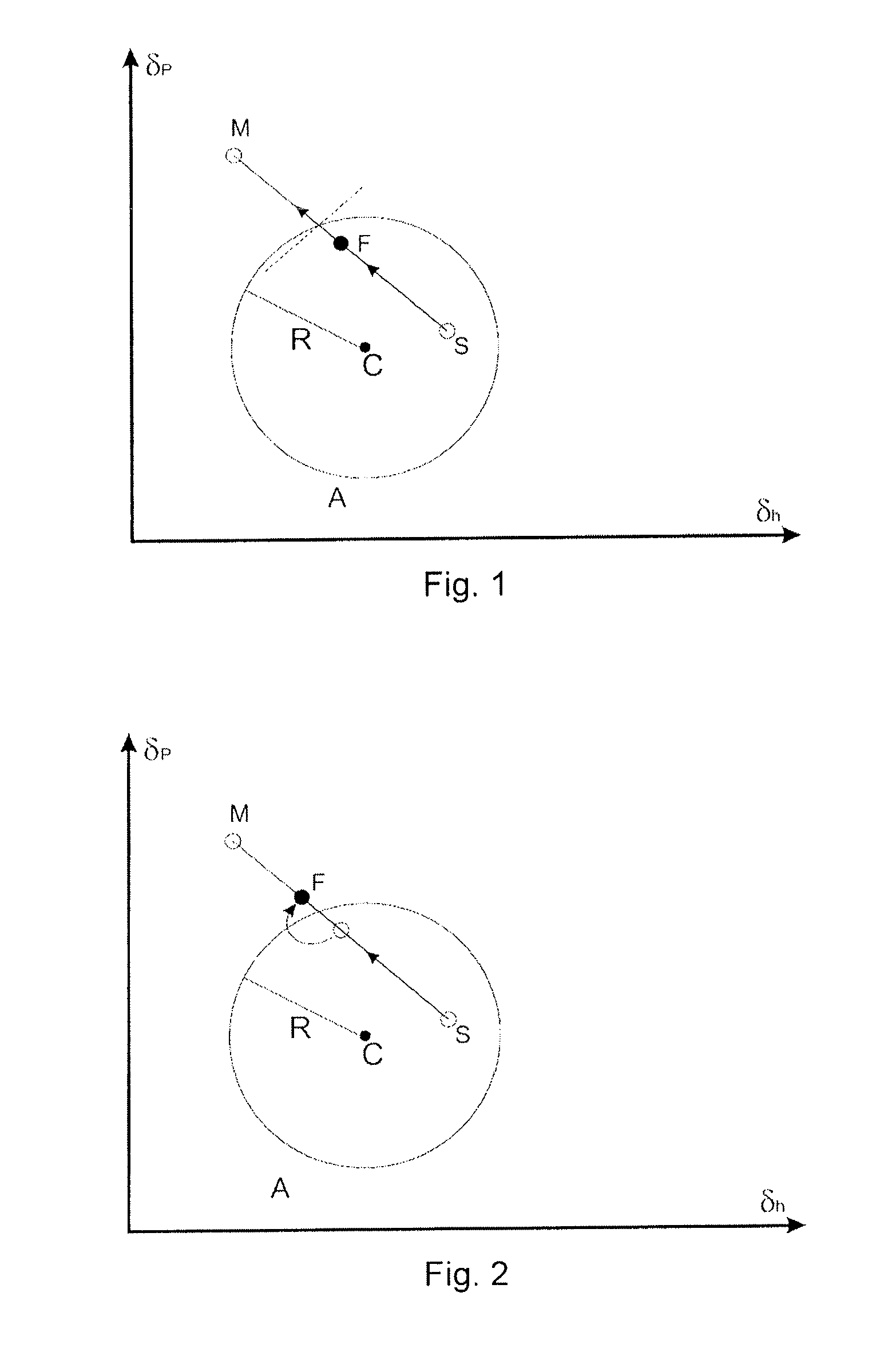

Ink for use in a flexographic printing process with wet on wet capability

ActiveUS20120220683A1Improve adhesionReduce the amount requiredFilm/foil adhesivesInksSolubilityOligomer

A flexographic printing ink for use in a flexographic printing process with wet on wet capability, comprising a polymer and a combination of liquids comprising radiation curable monomers and / or oligomers, diluents, colorants, additives, and photoinitiators, the components having the Hansen Solubility Parameters adjusted to generate an ink with a capability to form a gel having the required physical characteristics, and that is in a liquid form in the presence of a small quantity of non reactive solvent, or is brought to a liquid state during the printing process. The disclosure is also directed to a flexographic printing process with wet on wet capability based on controlled polymer or polymer segment precipitation that leads to gel formation of ink compounds by controlling the solubility parameter of the ink system.

Owner:TECHNOSOLUTIONS ASSESSORIA

Biodegradable flexographic ink

The present invention relates to a flexographic water based ink in which a biodegradable polymer, such a polyhy-droxyalkanoate (PHA), replaces conventional poorly or non-biodegradable organic polymeric resins for example. PHAs are used as a latex suspension in water, thus the present invention relates to a novel pigment / latex mixture. PHA in a latex form is a fluid vehicle in which all the other components necessary to provide a flexographic ink are added, i.e., pigments, wax and / or binder, as well as a solvent, if necessary. The PHAs are mainly responsible for the biodegradability of the flexographic water based ink. The present invention relates also a method to produce a flexographic water based composition with enhanced biodegradability properties.

Owner:BIOMATERA INC

Wet-trapping of energy curable flexographic inks and coatings

Methods and apparatus for flexographic color printing, and more particularly for implementing “wet trapping” in flexographic printing using energy curable flexographic liquid inks are presented. Radiation curable inks can be formulated that wet trap over each other without back-trapping onto the plates and anilox units of down-line printing units by controlling the storage modulus of the inklcoating. The storage modulus G′ in the inks can be controlled to ensure that the highest G′ ink is printed ISt down with successive colors being trapped in the order of their (declining) G′ values. An image in wet ink can thus be trapped over a different image in wet ink of a different color without picking the ISt ink back up and redepositing it onto the subsequent plates and rollers in the printing press (back-trapping).

Owner:SUN CHEM CORP

High speed printing ink

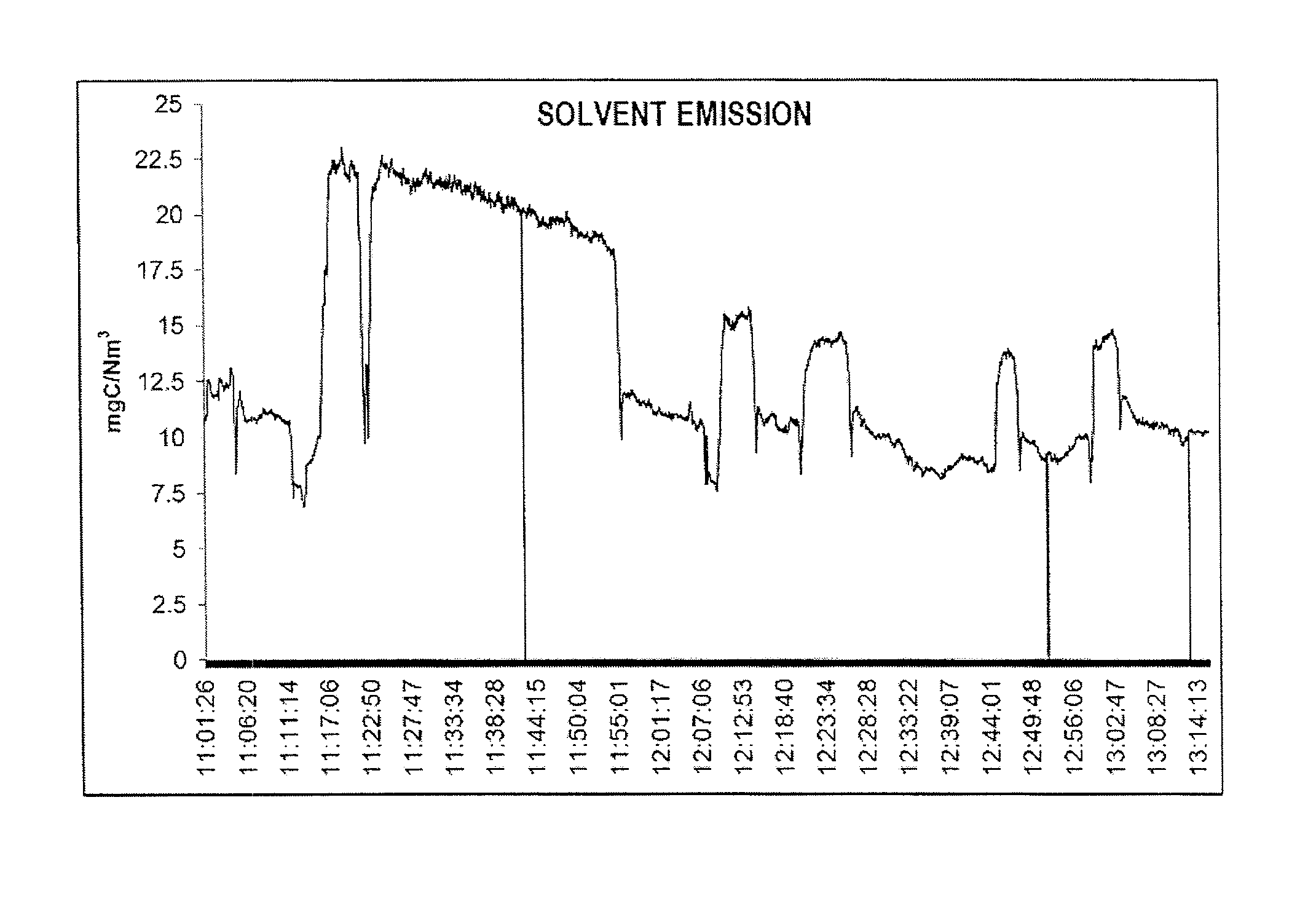

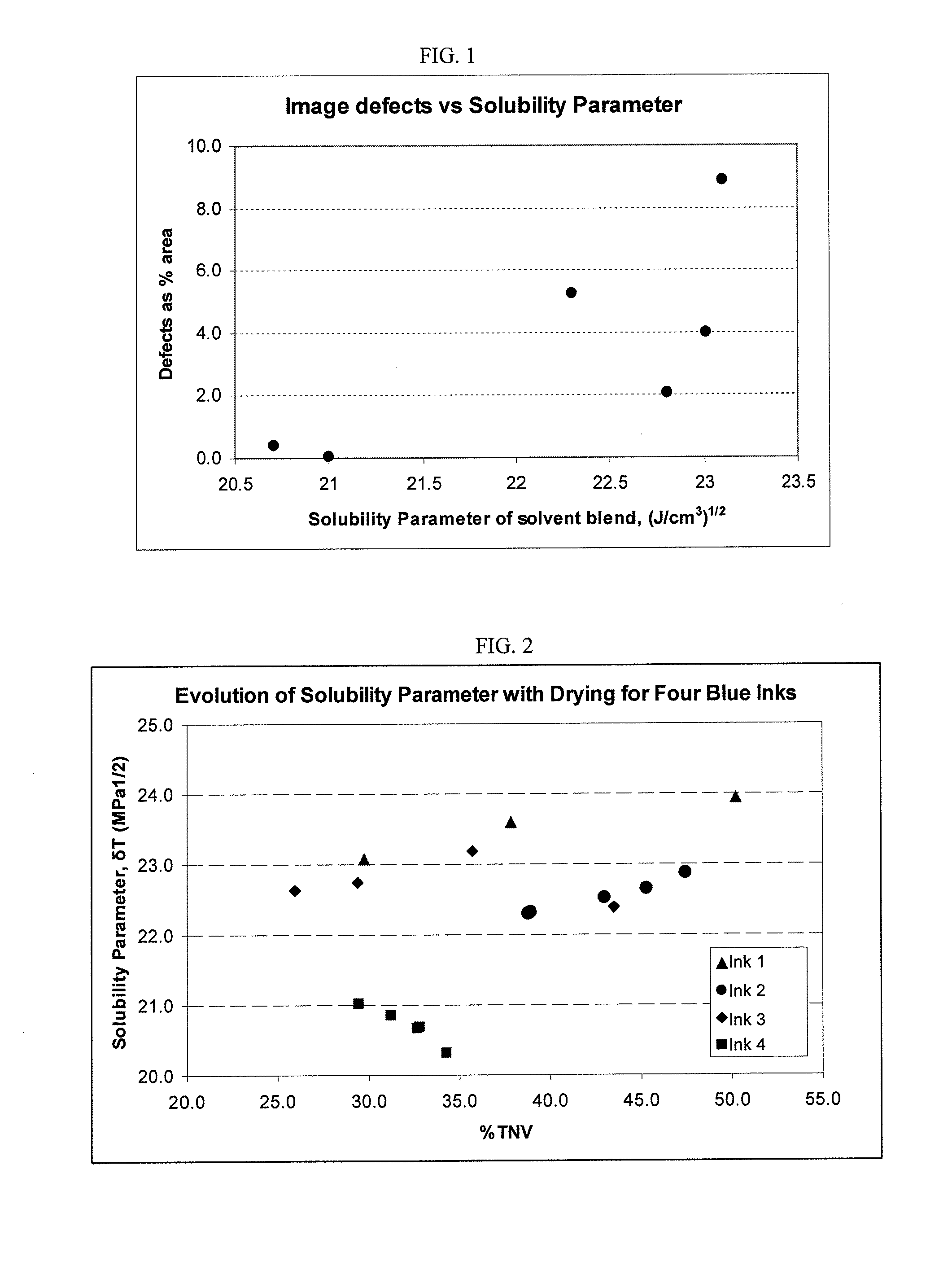

ActiveUS20130149507A1Avoid print qualityImprove printing qualityDecorative surface effectsDuplicating/marking methodsSolubilitySolvent based

Formulations for solvent-based flexographic or rotogravure inks, which are capable high-quality, defect-free printing at high speeds, contain flexographic ink resins solutions and solvent mixtures which are designed to maintain a dynamic solubility parameter in the ink as the dry state is approached during the printing process. The inks described show extremely high quality printing at linear press speeds above 1800 fee per minute (ca 0.549 km / min).

Owner:SUN CHEM CORP

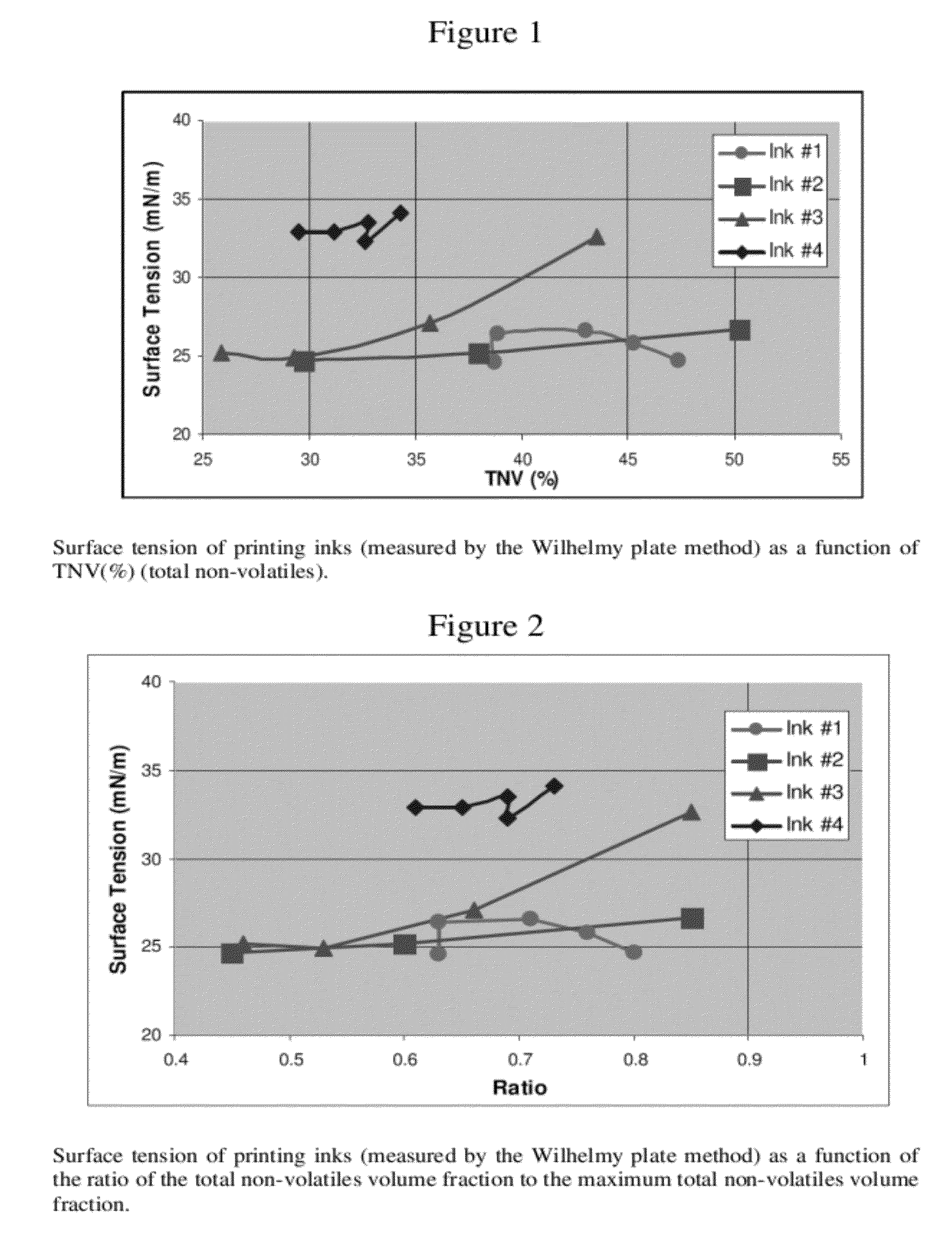

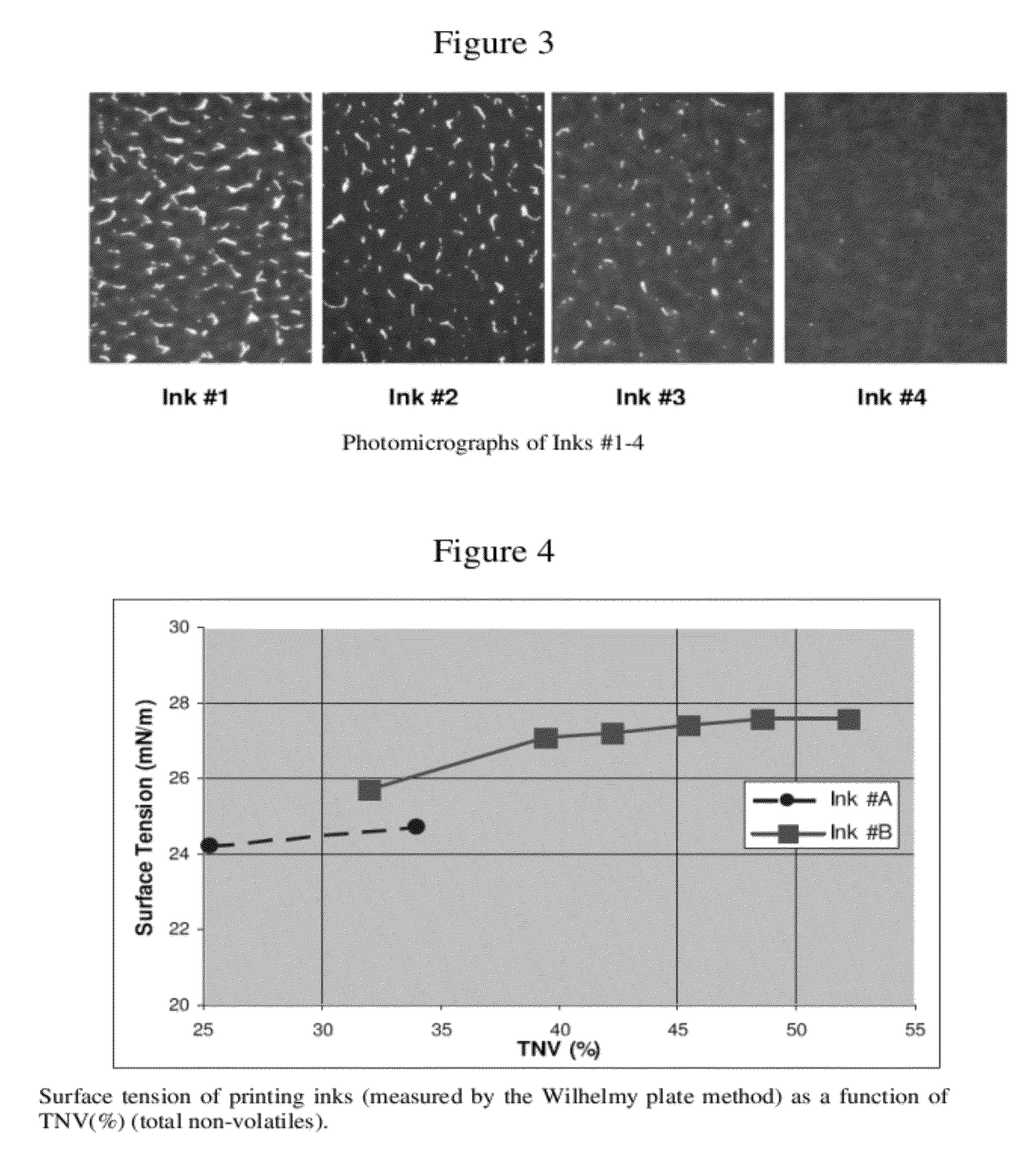

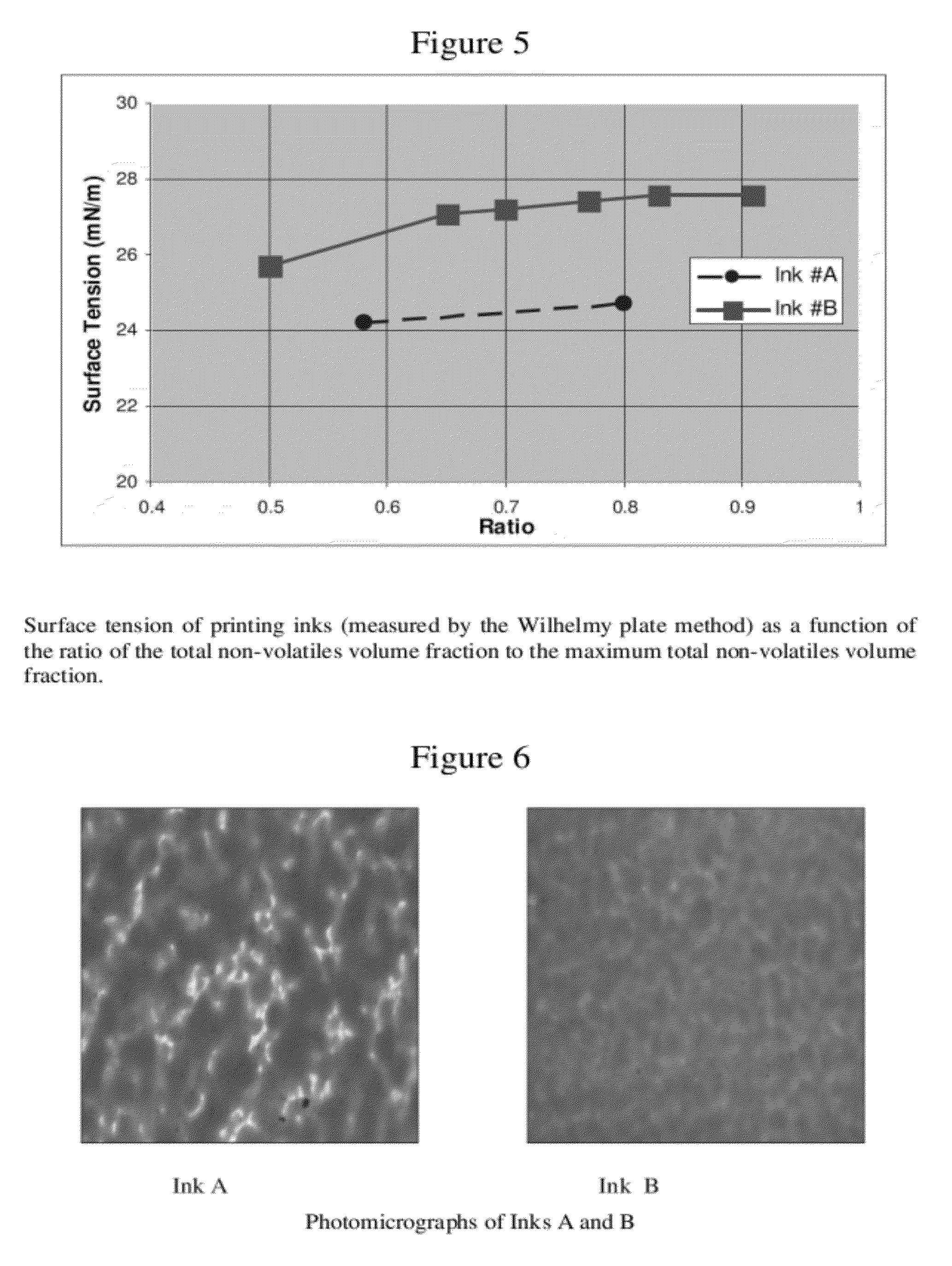

Surface tension of inks for high speeding printing

A method of formulating ink for high-speeding printing includes controlling a surface tension of the ink to equal to or greater than 26 mN / m, equal to or greater than 28 mN / m, or equal to or greater than 30 mN / m. The surface tension is measured when the ratio of the total non-volatiles volume fraction of the ink to the maximum total non-volatiles volume fraction of the ink is a ratio between about 0.40 and about 0.90. An ink for high-speed printing includes one or more resins, one or more colorants, one or more solvents, and one or more additives. The ink can be a flexographic ink, a rotogravure ink, a heatset offset ink, or a publication gravure ink. A print of the ink includes less than 1% of pinholes by area. A method of printing includes preparing an ink and applying the ink to a substrate. The ink has a surface tension of equal to or greater than 26 mN / m, and the substrate moves at a speed of greater than 1200 feet / min.

Owner:SUN CHEM CORP

Carboxylic acid-modified vinylic polymeric compositions

This invention relates to novel carboxylic acid-modified vinylic polymeric compositions and the process for preparing them. In particular, the invention relates to novel carboxylic acid-modified vinylic polymeric compositions which exhibit properties that make them useful as support resins for producing polymer latices which can be employed in the formulation of various water-based coatings and inks, particularly flexographic inks. More particularly, these carboxylic acid-modified vinylic polymeric compositions are produced by the addition polymerization reaction of vinylic monomers in the presence of dimer acids, trimer acids, dimerized rosins, or mixtures thereof.

Owner:美德威斯特瓦克公司

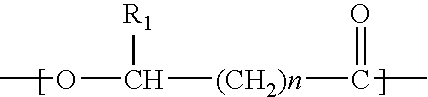

Carboxyester-modified vinylic polymeric compositions

This invention relates to novel carboxyester-modified vinylic polymeric compositions and the process for preparing them. In particular, the invention relates to novel carboxyester-modified vinylic polymeric compositions which exhibit properties that make them useful as support resins for producing polymer latices which can be employed in the formulation of various water-based coatings and inks, particularly flexographic inks. More particularly, these carboxyester-modified vinylic polymeric compositions are produced by the addition polymerization reaction of vinylic monomers in the presence of adducts of hydroxyl-substituted fatty acids and carboxylic anhydrides.

Owner:MEADWESTVACO CORP

High-resolution water-based flexographic ink and preparation method thereof

The invention discloses a high-resolution water-based flexible printing ink comprising ink paste and acrylic emulsion. The ink is characterized in that the ink paste comprises the following components in parts by weight: 20 to 30 parts of water-based acrylic resin, 30 to 60 parts of pigment, 2 to 8 parts of dispersant 760W, 10 to 20 parts of water, 10 to 15 parts of ethanol, and 0.5 to 1 part of defoaming agent. The invention further discloses a preparation method for the ink. The quantity of the pigment is increased in the ink paste of the ink disclosed by the invention, and meanwhile, the dispersant 760W is adopted, so that a large dose of pigment can be well dispersed, and the ink has good stability and good dyeing property. The ink can reach more than 100 resolution cables and can be used for directly printing line boards, and the inking effect is similar to an offset printing effect. The third dimension of printed pictures can be reflected, and the pictures are exquisite and vivid. Moreover, the ink disclosed by the invention is water-based ink, so the ink accords with the national environmental protection policy, and can achieve the printing effect of an oil-based ink.

Owner:CHONGQING HONGYUAN PRINTING INK

Carboxylic acid-modified vinylic polymeric compositions

This invention relates to novel carboxylic acid-modified vinylic polymeric compositions and the process for preparing them. In particular, the invention relates to novel carboxylic acid-modified vinylic polymeric compositions which exhibit properties that make them useful as support resins for producing polymer latices which can be employed in the formulation of various water-based coatings and inks, particularly flexographic inks. More particularly, these carboxylic acid-modified vinylic polymeric compositions are produced by the addition polymerization reaction of vinylic monomers in the presence of dimer acids, trimer acids, dimerized rosins, or mixtures thereof.

Owner:MEADWESTVACO CORP

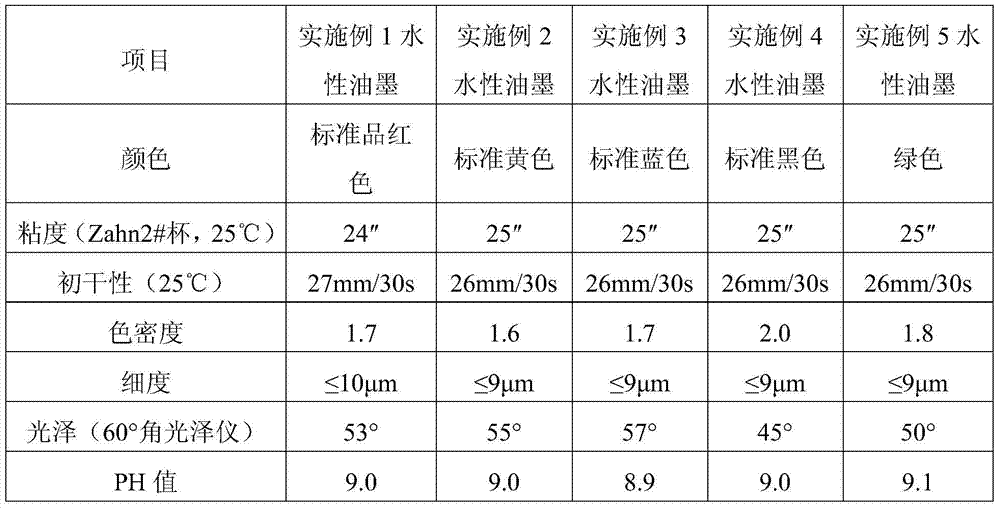

A kind of high-speed printing flexographic water-based ink and preparation method thereof

The invention provides a high-speed printing flexographic water-based ink and a preparation method thereof. The flexographic water-based ink of the present invention comprises the following components by weight: 30-40 parts of acrylic non-film-forming emulsion, 5-10 parts of acrylic film-forming emulsion, 15-20 parts of acrylic resin solution, 30-40 parts of water-based color paste, 1-3 parts of polyethylene wax, 1-2 parts of film-forming aid, 0.3-1 part of leveling agent, 0.1-0.5 part of defoamer, 3-7 parts of deionized water and pH regulator; among them, acrylic acid is not The film emulsion is an acrylic emulsion with a Tg value ≥ 90°C, the acrylic film-forming emulsion is an acrylic emulsion with a Tg value < 30°C, the mass content of the pigment in the water-based color paste is 40-45%, and the pH regulator makes the pH of the flexographic water-based ink The value is 8 to 9.5. The water-based ink can be well adapted to the printing of high-speed satellite printing machines, and has good resolubility and excellent leveling and overprinting effects. The printed products have high color saturation, bright colors, good gloss, and a wide range of applications.

Owner:山东布瑞特油墨有限公司

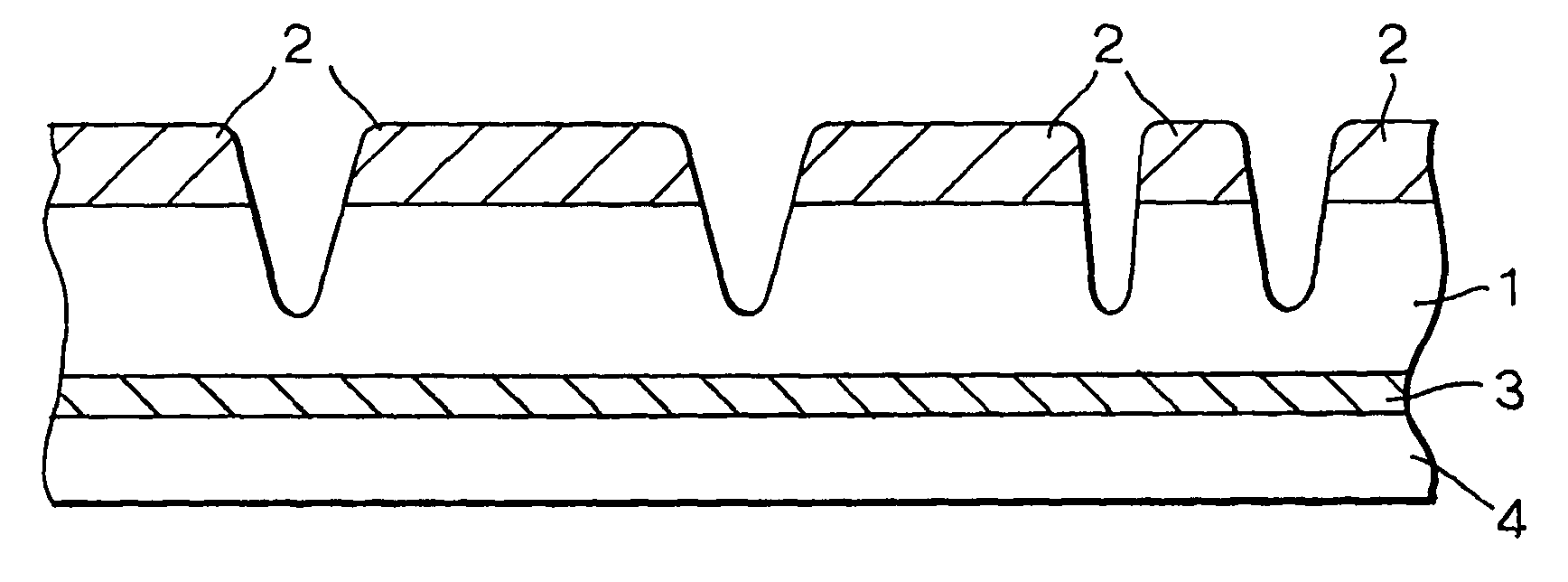

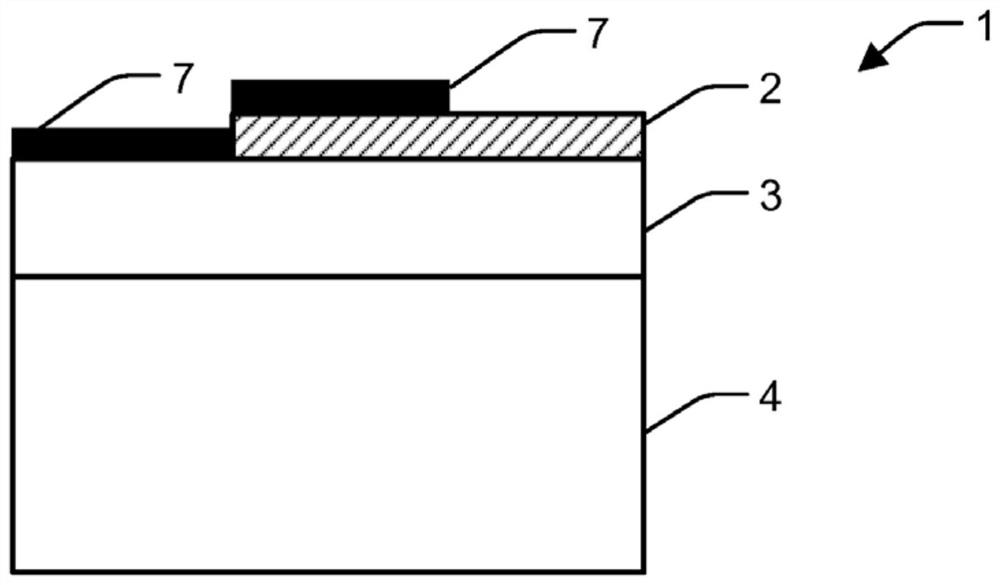

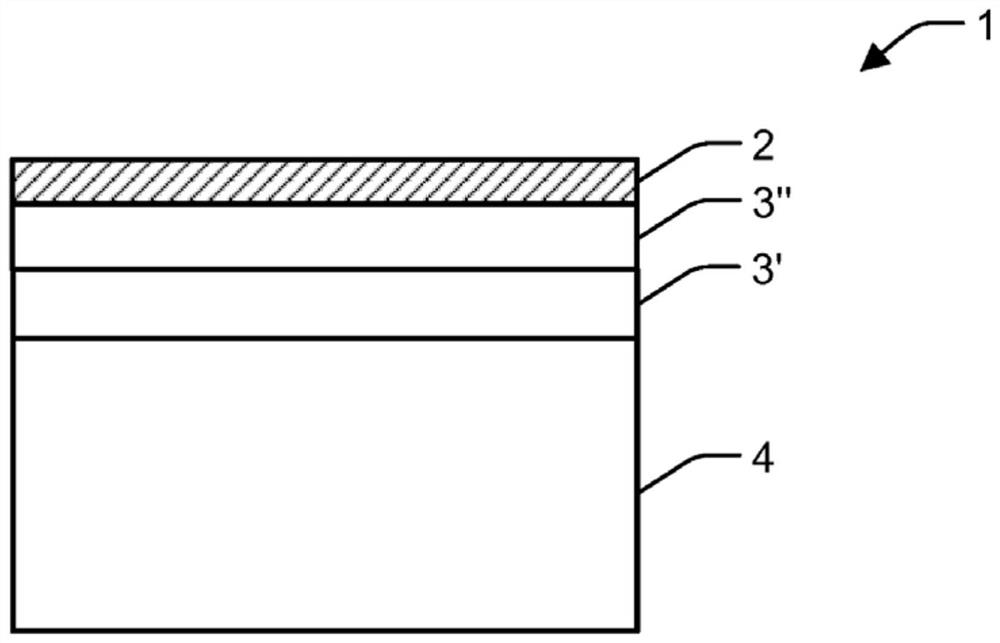

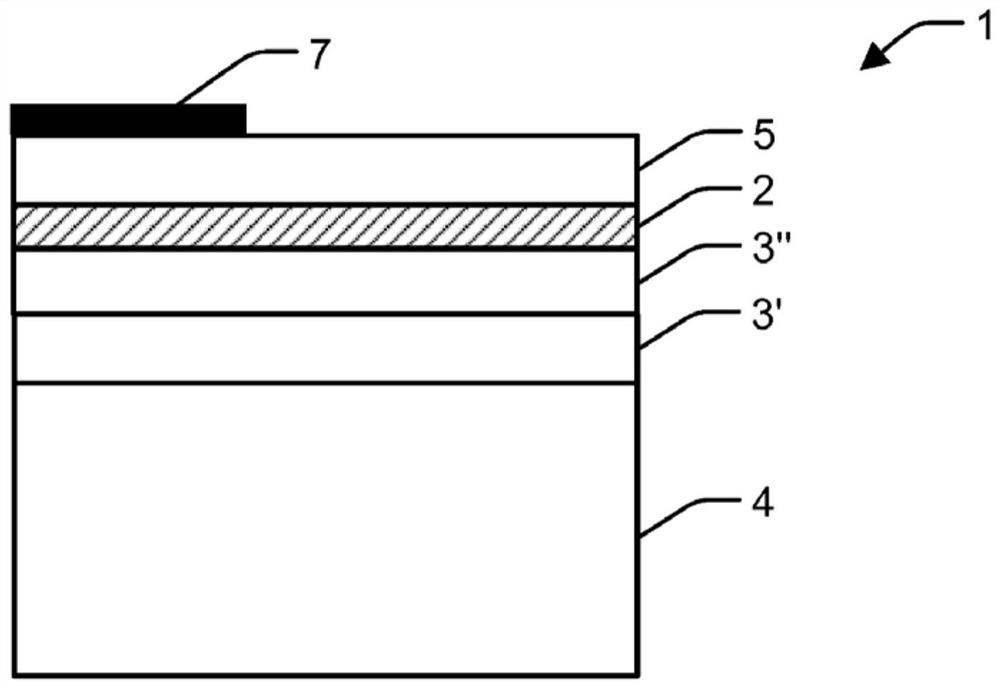

A laminated packaging material for liquid food products, a method for making the same, a method for printing on the same and a package made from the same

ActiveCN112638656AReduce the temperatureReduce risk of defectsLamination ancillary operationsDuplicating/marking methodsCellulosePaperboard

A laminated packaging material (1) for liquid food products comprising, a core layer (4) of paper or paperboard or other cellulose-based material, a laminate portion (3) being arranged on a first side of the core layer (4), a dark colored flexographic ink composition (2) printed onto the free surface of the laminate portion (3), the dark colored ink composition comprises color bases mixed at a ratio such that a total energy absorption by the dark colored flexographic ink composition (2), when provided on the laminated packaging material (1), is below 80%, such as below 70% in an emission spectra from a tungsten light source in the region 250-2500 nm at a temperature of 3000 K, the dark colored flexographic ink composition (2) has a color space lightness value L* <= 25, and a color space difference ([delta]E2000) equal to or lower than 6, with respect to a specified black reference composition.

Owner:TETRA LAVAL HLDG & FINANCE SA

A kind of water-based flexo printing ink for tobacco pine paper printing and preparation method thereof

ActiveCN106928771BGood flexibilityImprove wettability and dispersibilityInksFreeze thawingWater based

The invention discloses a water-based flexographic printing ink for cigarette tipping paper printing and a preparation method thereof. The water-based flexographic printing ink is composed of a modified acrylic emulsion, pigment and filler, a wetting dispersant, a transfer printing agent, a defoaming agent, deionized water, and a cosolvent. The modified acrylic emulsion is a novel acrylic emulsion formed by copolymerization of an imported high quality emulsifier, acrylate and special functional monomers, and has the advantages of fantastic calcium ion stability, dilution stability, mechanical stability and freeze-thaw stability, and small pollution to the environment. The water-based flexographic printing ink for tipping paper printing provided by the invention is non-toxic and tasteless, has quick drying speed and good dispersion stability, the printing product is free of deformation and edge curling, and has bright color and excellent antibacterial properties. The printing product has few residual monomer and low odor, is green and environment-friendly, the printing ink can be used cooperatively with a flexographic press, the printing speed can reach 250-300m / min, and the machine speed is doubled than the traditional intagliotipping paper printing press, thus greatly improving the production efficiency, and saving the production cost.

Owner:JIANGSU TANGCAI PRINTING INK SCI TECH CO LTD

A kind of all-aqueous plastic flexographic printing ink and preparation method thereof

The invention provides full water-based plastic flexible printing ink. The full water-based plastic flexible printing ink is prepared by the following raw materials by weight: 35-70 parts of printing ink connection materials, 25-50 parts of color paste, 1-10 parts of a flatting agent, 1-10 parts of a defoamer, 1-8 parts of wax emulsion, and 5-20 parts of deionized water. The color paste is prepared by mixing the following raw materials by weight: 20-55 parts of printing ink resin, 20-50 parts of organic pigments, 1-8 parts of a wetting dispersant, 1-6 parts of the defoamer, and 20-40 parts of the deionized water. The full water-based printing ink has abroad application range, and has environment-friendly feature compared with the normal water-based printing ink, and is capable of greatly reducing the pollutant residue and volatility gases on the surface of a printed matter, and realizing the zero release of VOC in the printing ink products. The full water-based printing ink has the characteristics of good adhesive force, rub resistance, scratch resistance, weather resistance, water resistance, chemical resistance, resistance and so on, and the high-speed flexible printing is more than 150 m / min.

Owner:中国印刷科学技术研究院有限公司

Printing with flexographic inks and lacquer

InactiveUS7497161B2Rapid and easy changeNo risk damagingOther printing apparatusLithographyLacquerEngineering

There is described a printing unit and a method for printing with flexographic inks. The printing unit includes a screen roller engaging a doctor blade system (3), and which is in continuous operation, either by engaging a motor (10) or by operation by the transmission (2) of the printing machine. The screen roller (1) of the printing unit interacts with a rubber sheet (16) which is disposed on a rubber sheet cylinder (4) at a position between a printing plate cylinder (5) and a back-pressure cylinder (6). A slot (7) is provided in the rubber sheet, used when the screen roller (1) is to be engaged with the rubber sheet (17).

Owner:TRESU ANLAEG

Flexographic ink containing polymer or copolymer of 3,4-dialkoxythiophene

Owner:AGFA GEVAERT AG

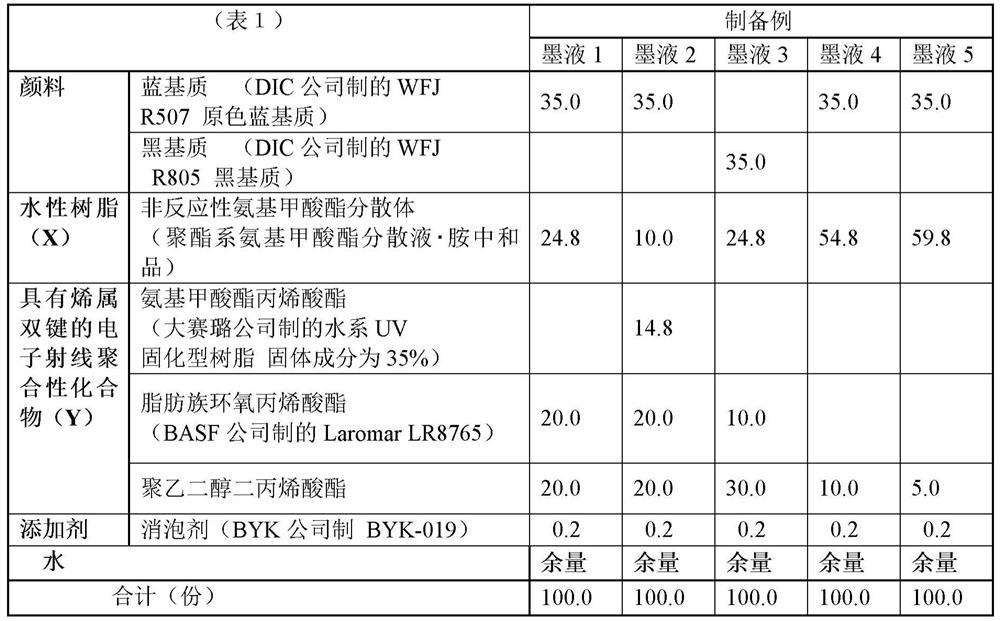

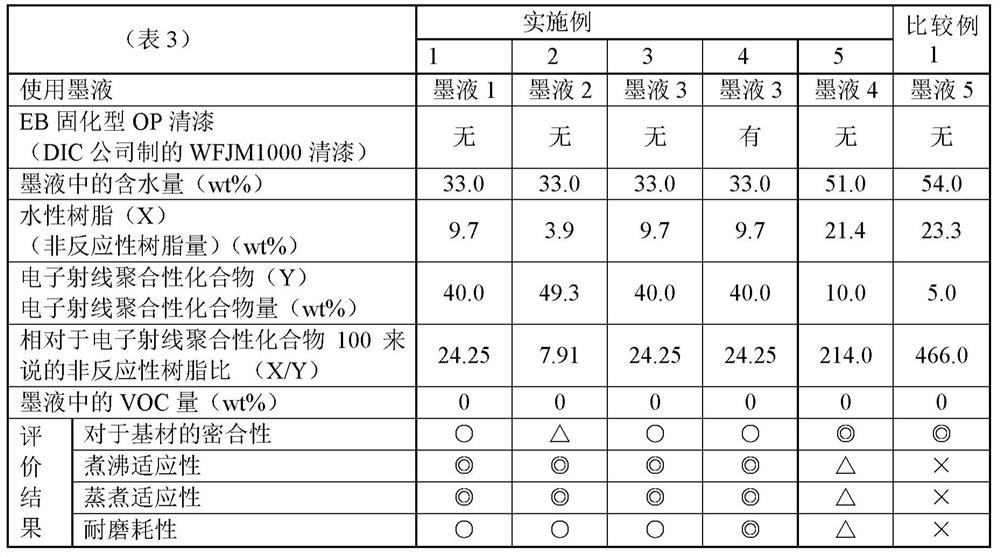

Aqueous flexographic ink for electron beam-curable surface printing and pouches for boiling/retorting using the same

ActiveCN111108159BExcellent adaptability to boiling/steamingSynthetic resin layered productsBagsPolymer scienceSolid content

Owner:DAINIPPON INK & CHEM INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com