Patents

Literature

425results about "Mounting boards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

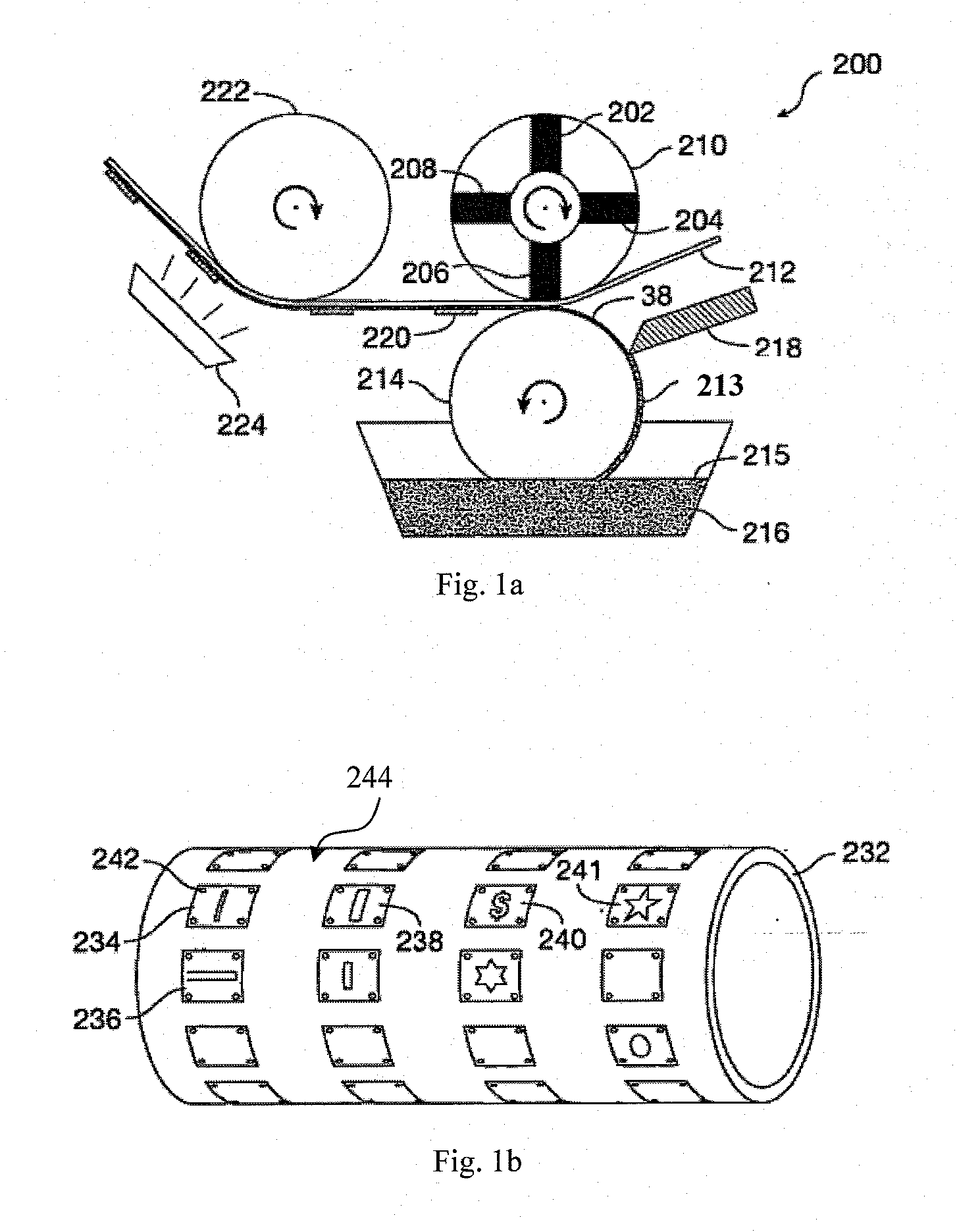

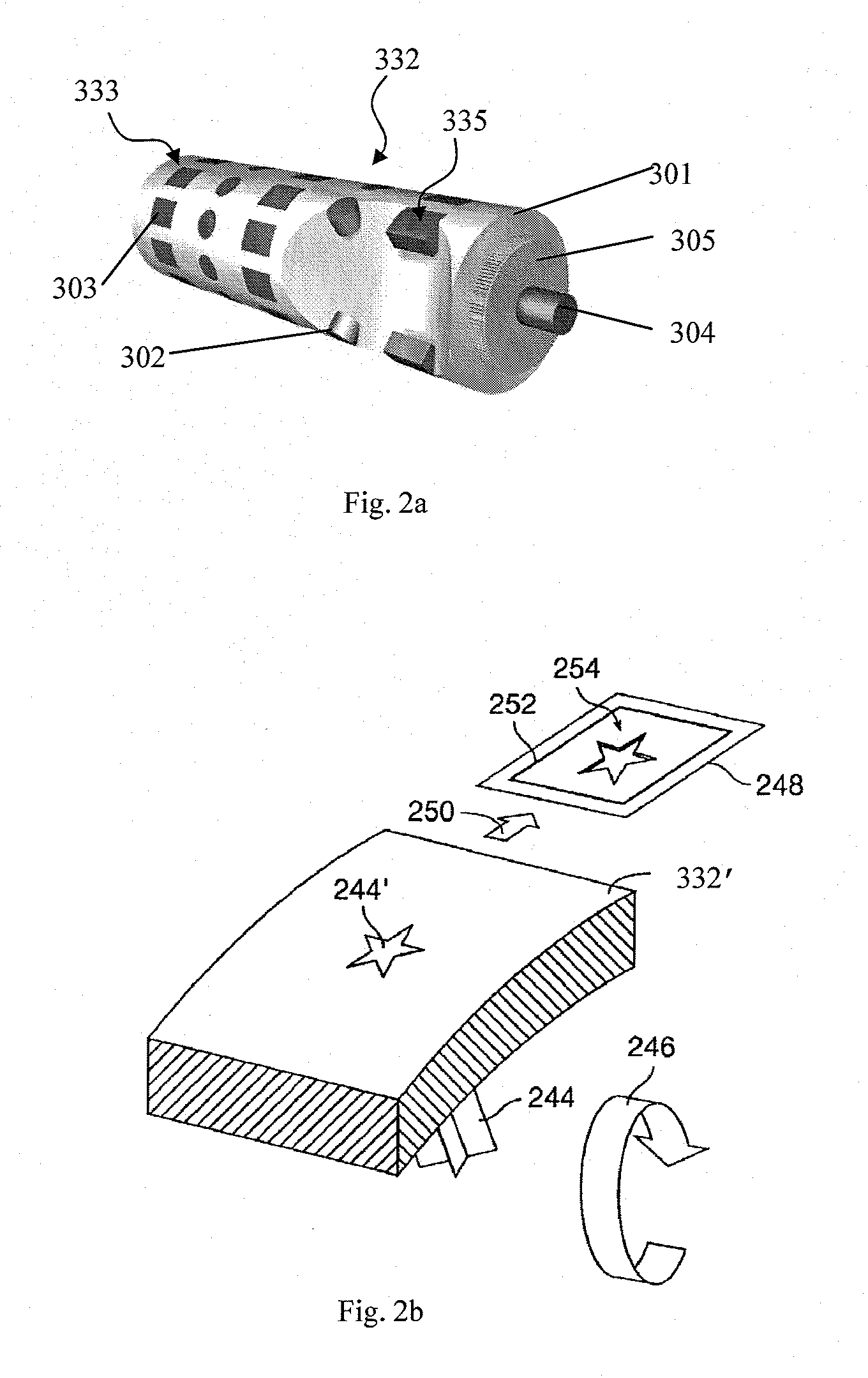

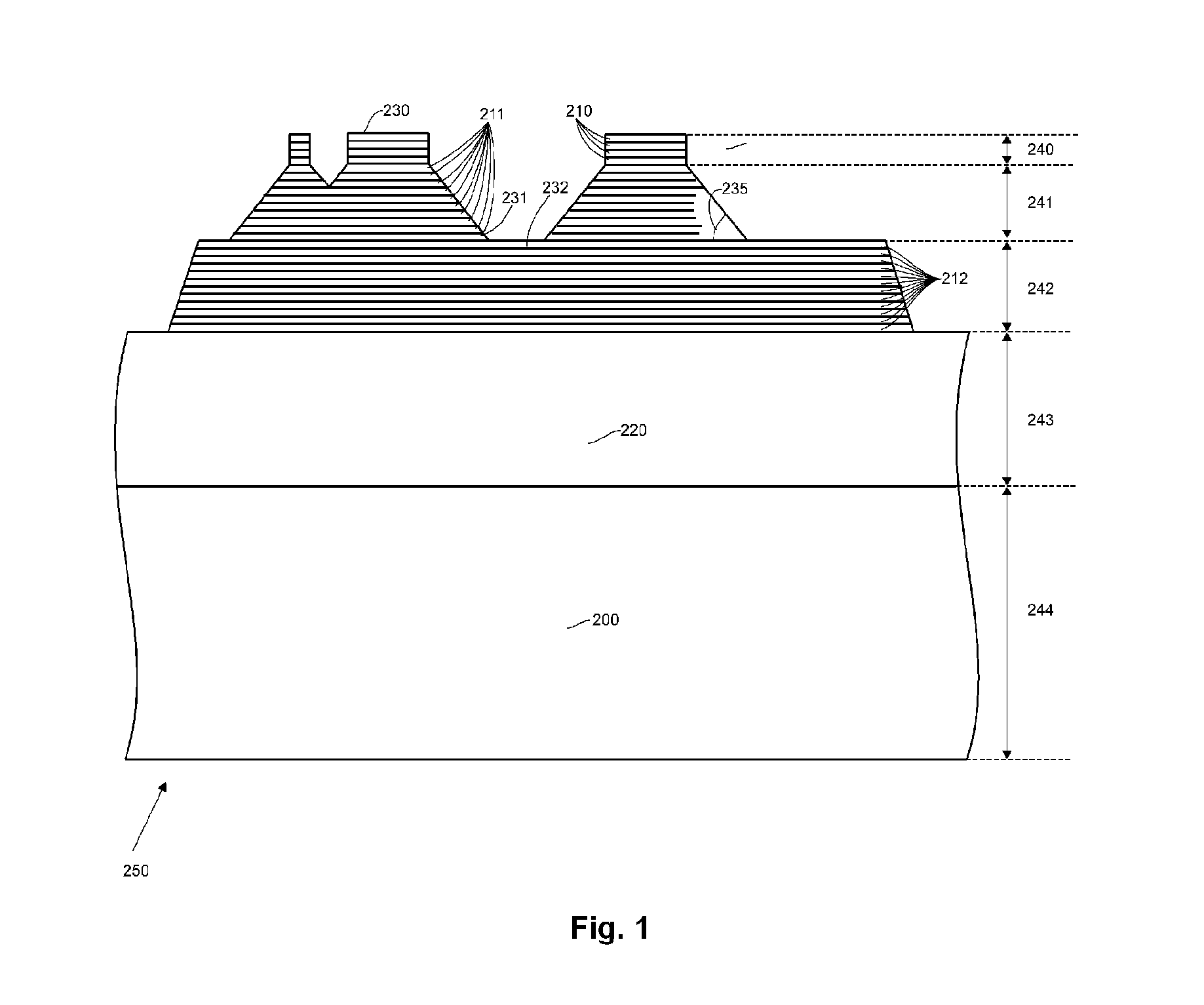

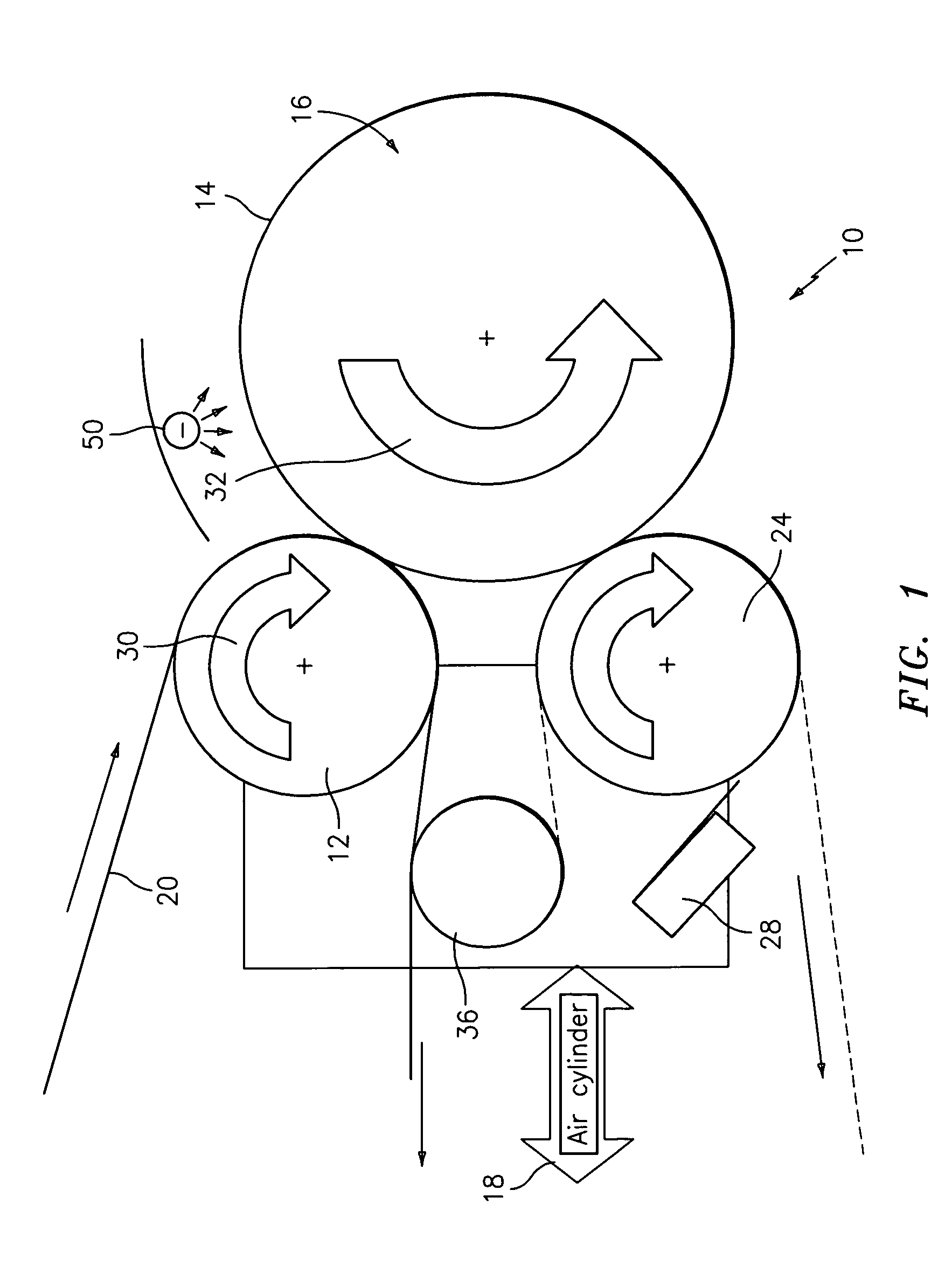

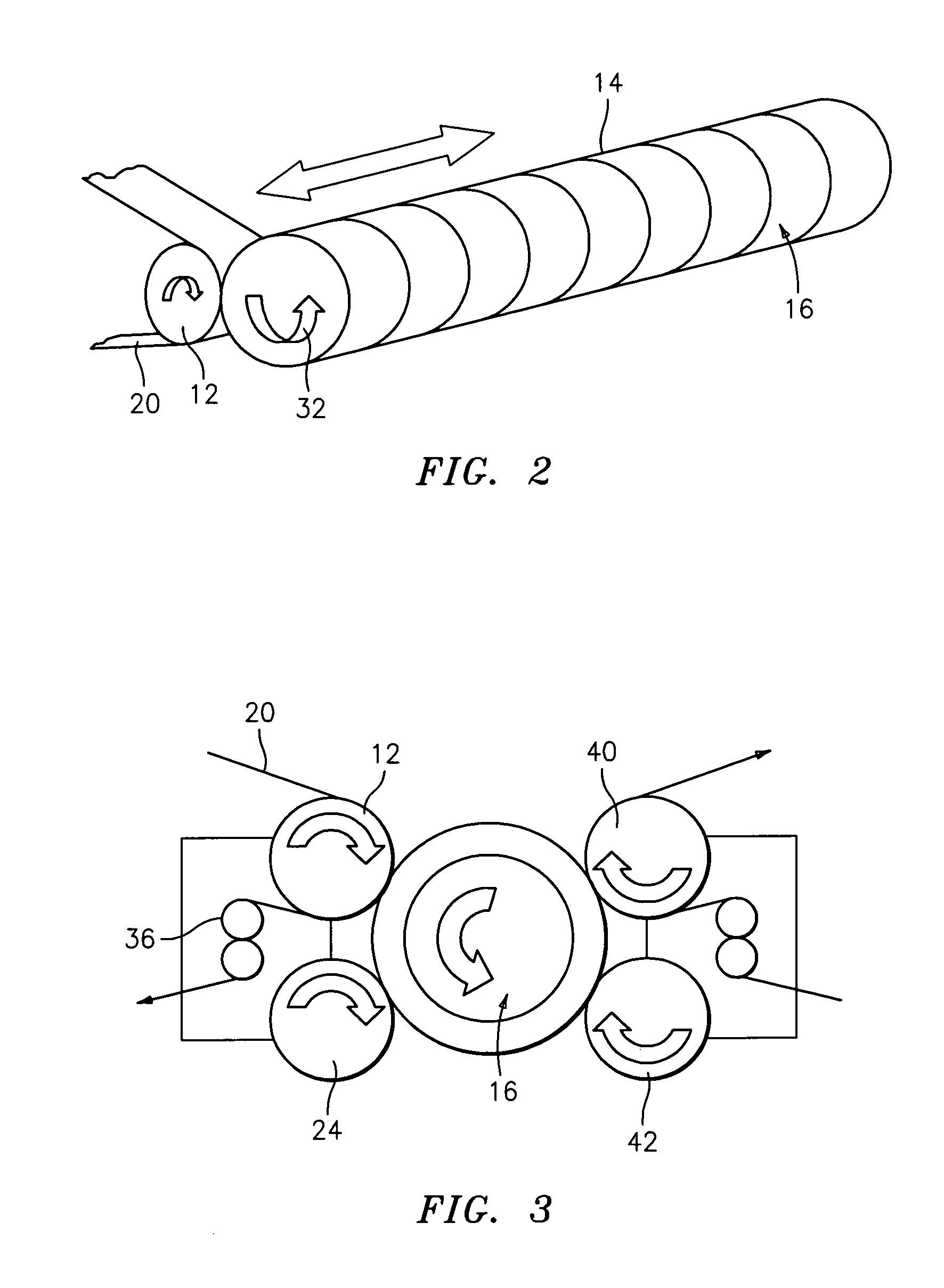

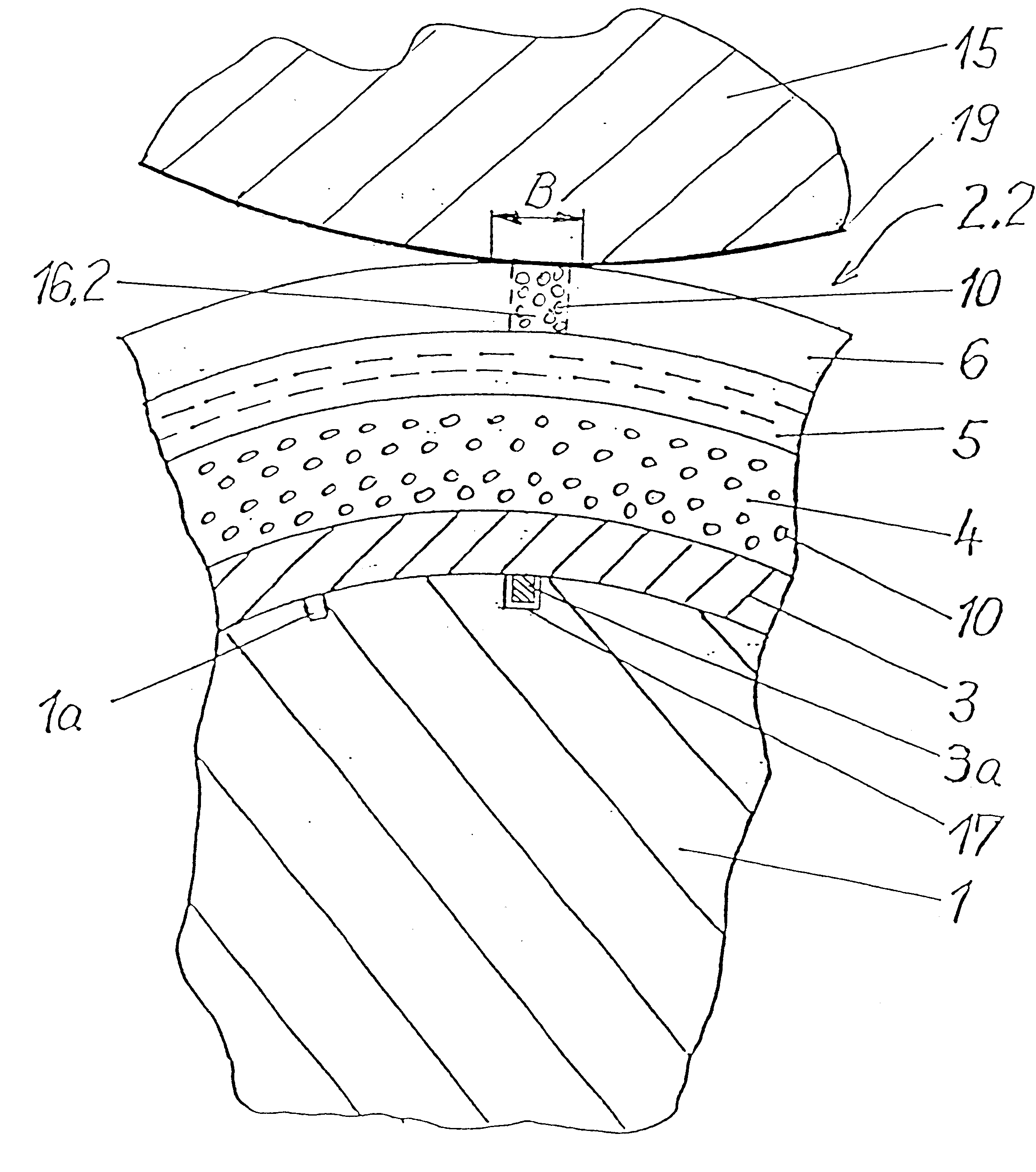

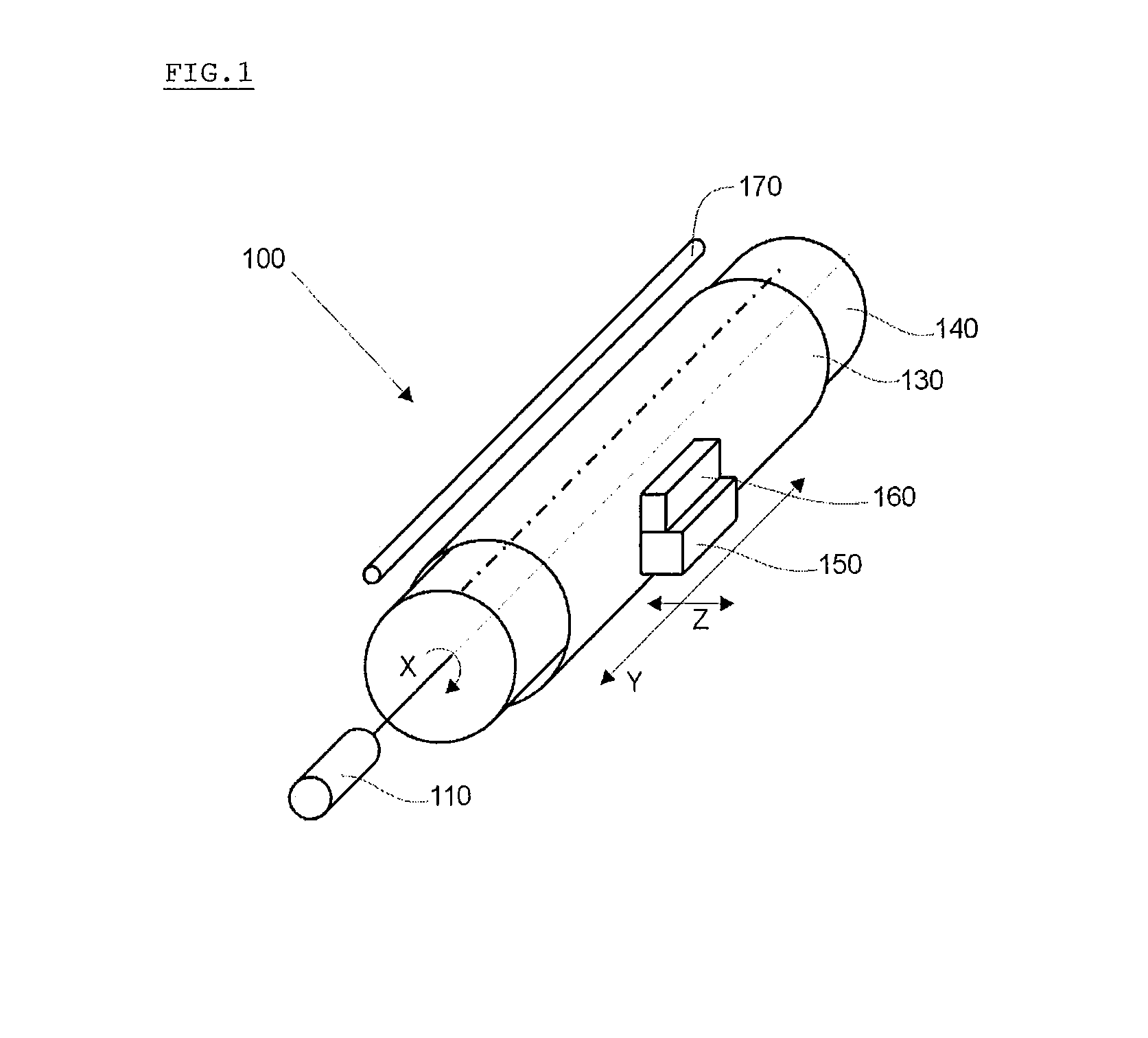

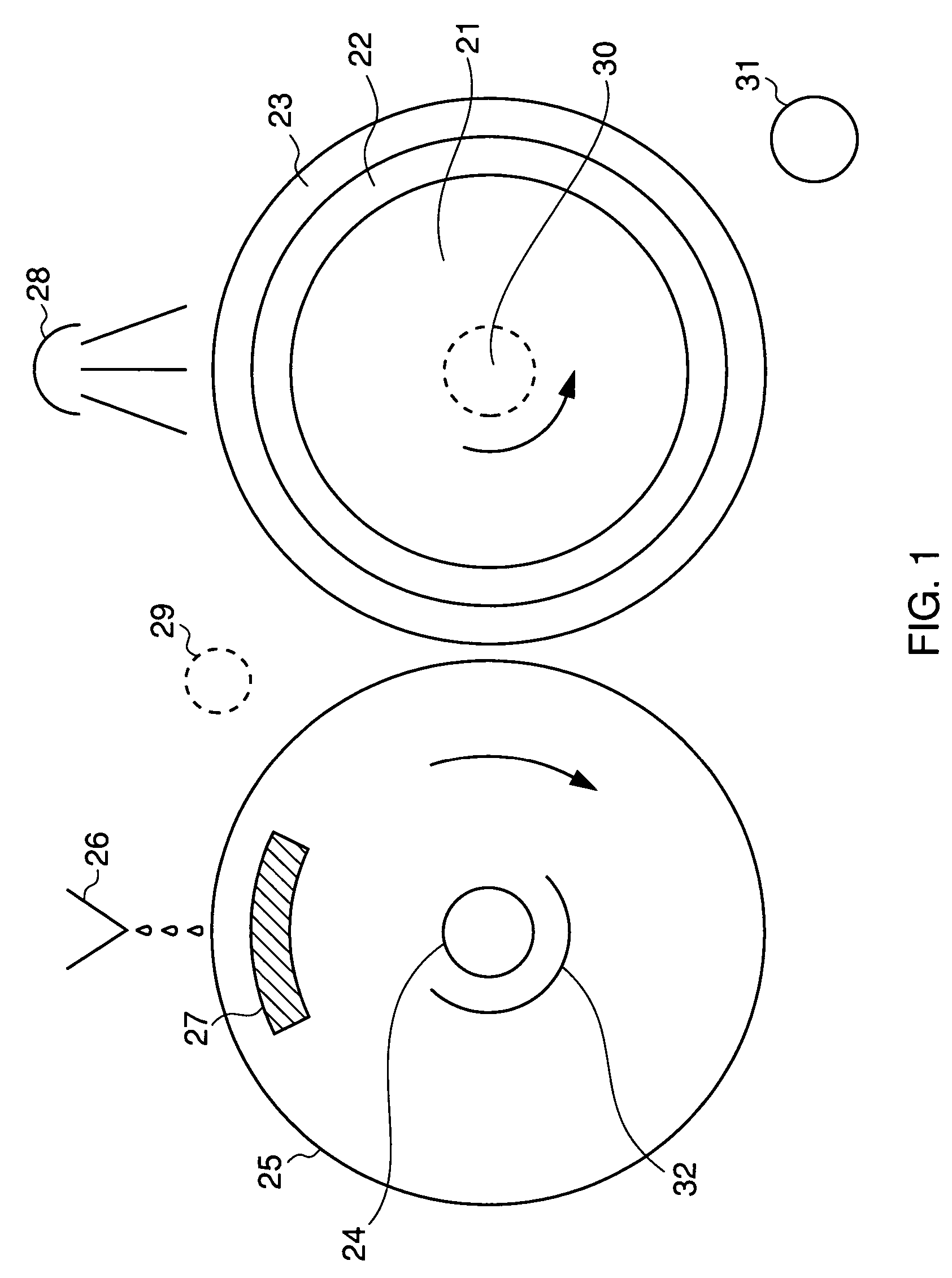

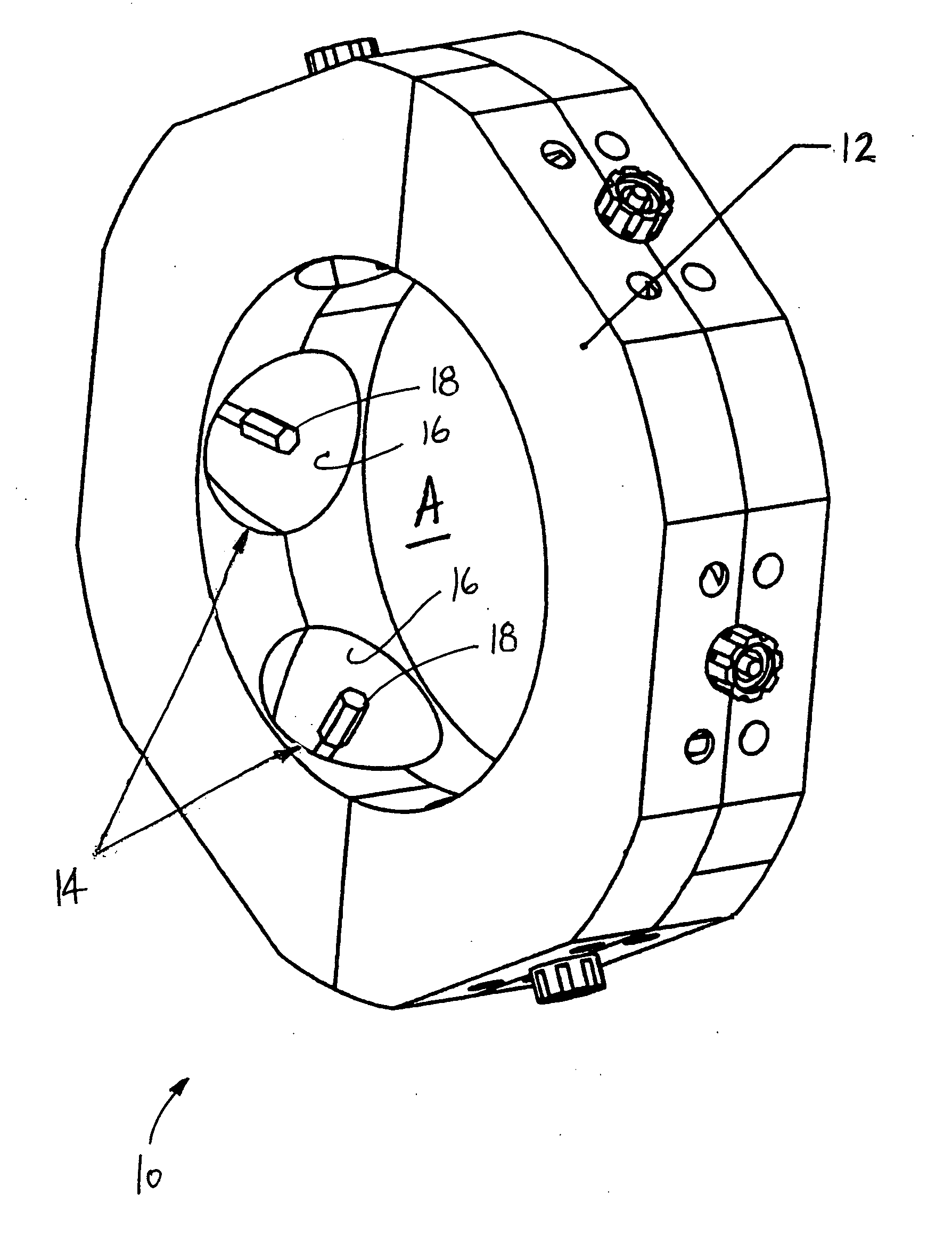

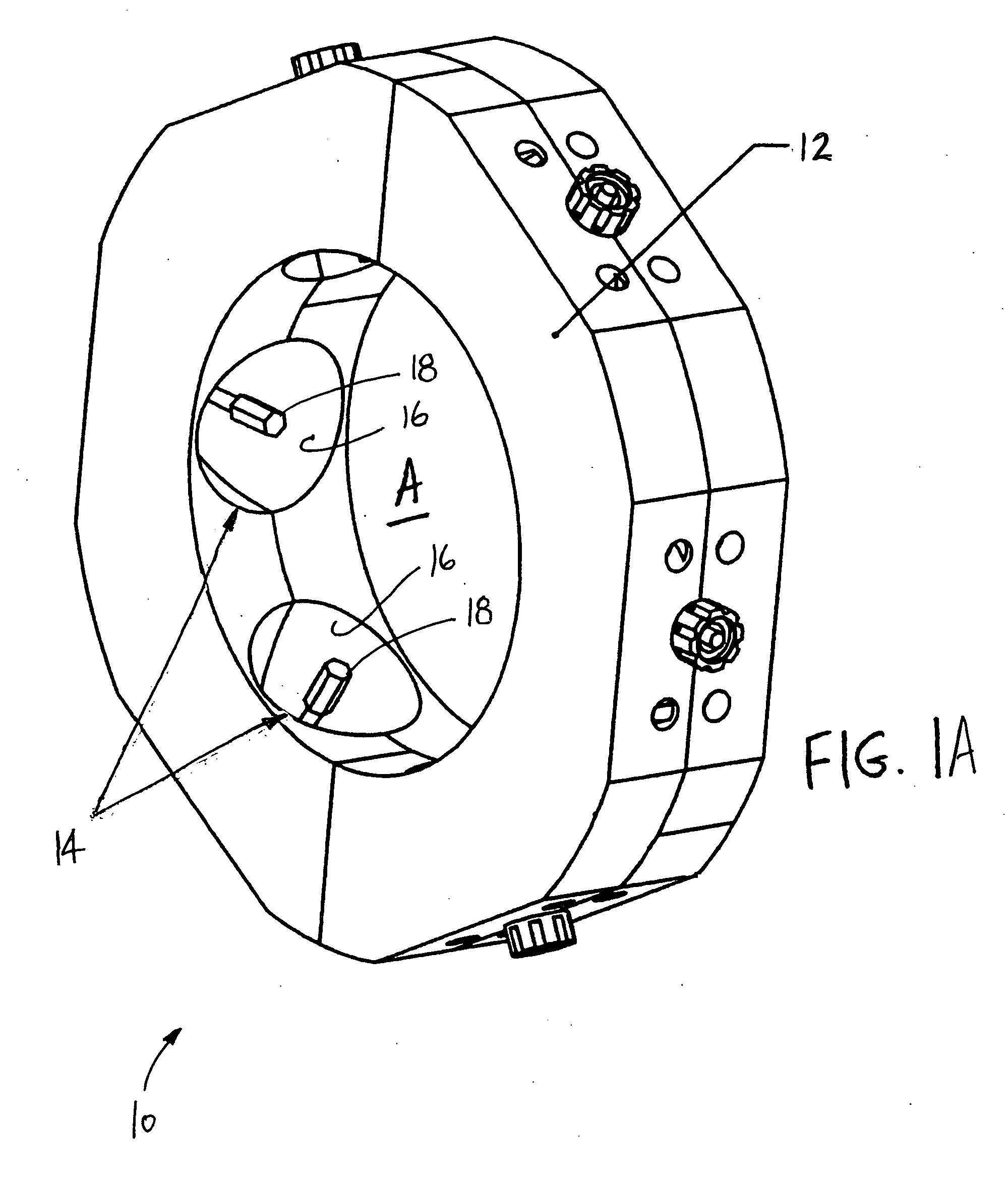

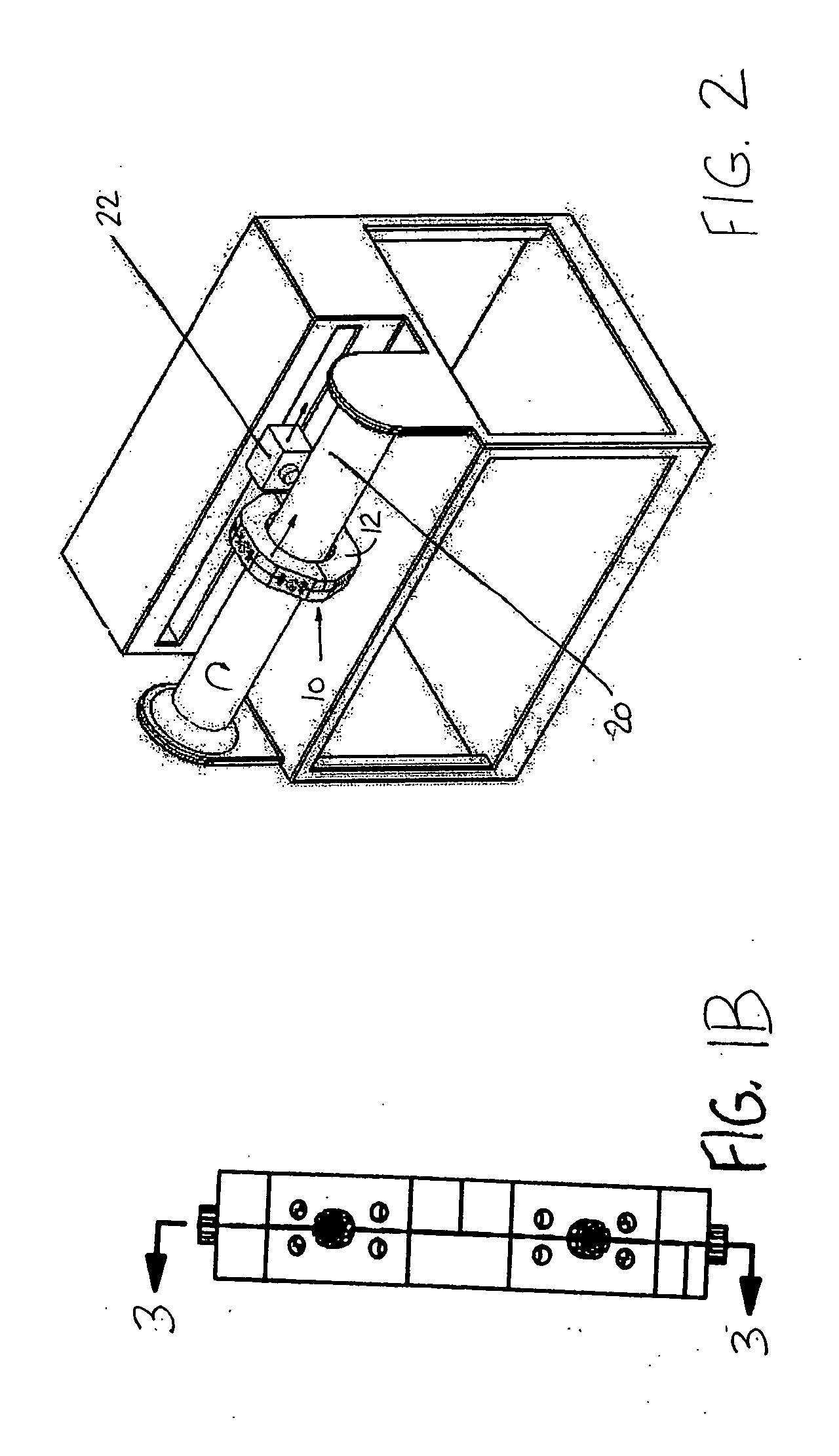

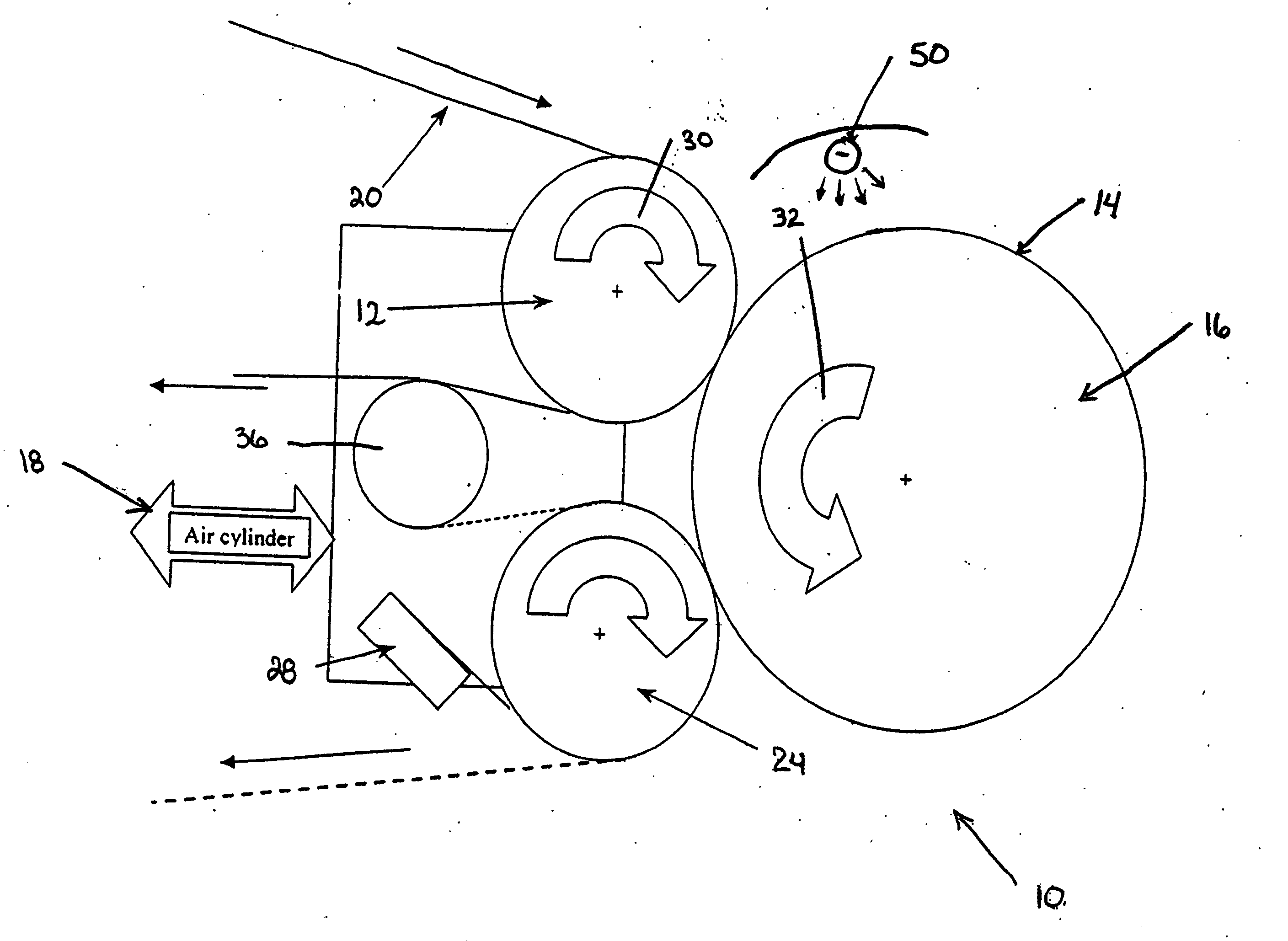

Apparatus For Orienting Magnetic Flakes

A printing apparatus includes a magnetic rotatable roller with a smooth even outer surface for aligning magnetic flakes in a carrier, such as an ink vehicle or a paint vehicle to create optically variable images in a high-speed, linear printing operation. Images can provide security features on high-value documents, such as bank notes. Magnetic flakes in the ink are aligned using magnetic portions of the roller, that can be formed by permanent magnets embedded in a non-magnetic roller body, or selectively magnetized portions of a flexible magnetic cover of the roller. In some embodiments, the roller is assembled for a plurality of interchangeable sections, which can include spinning magnets. Selected orientation of the magnetic pigment flakes can achieve a variety of illusive optical effects that are useful for decorative or security applications.

Owner:VIAVI SOLUTIONS INC

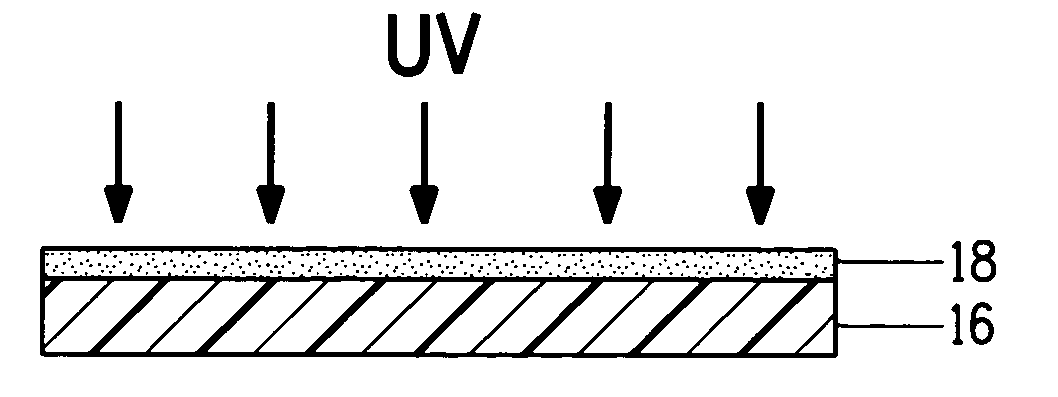

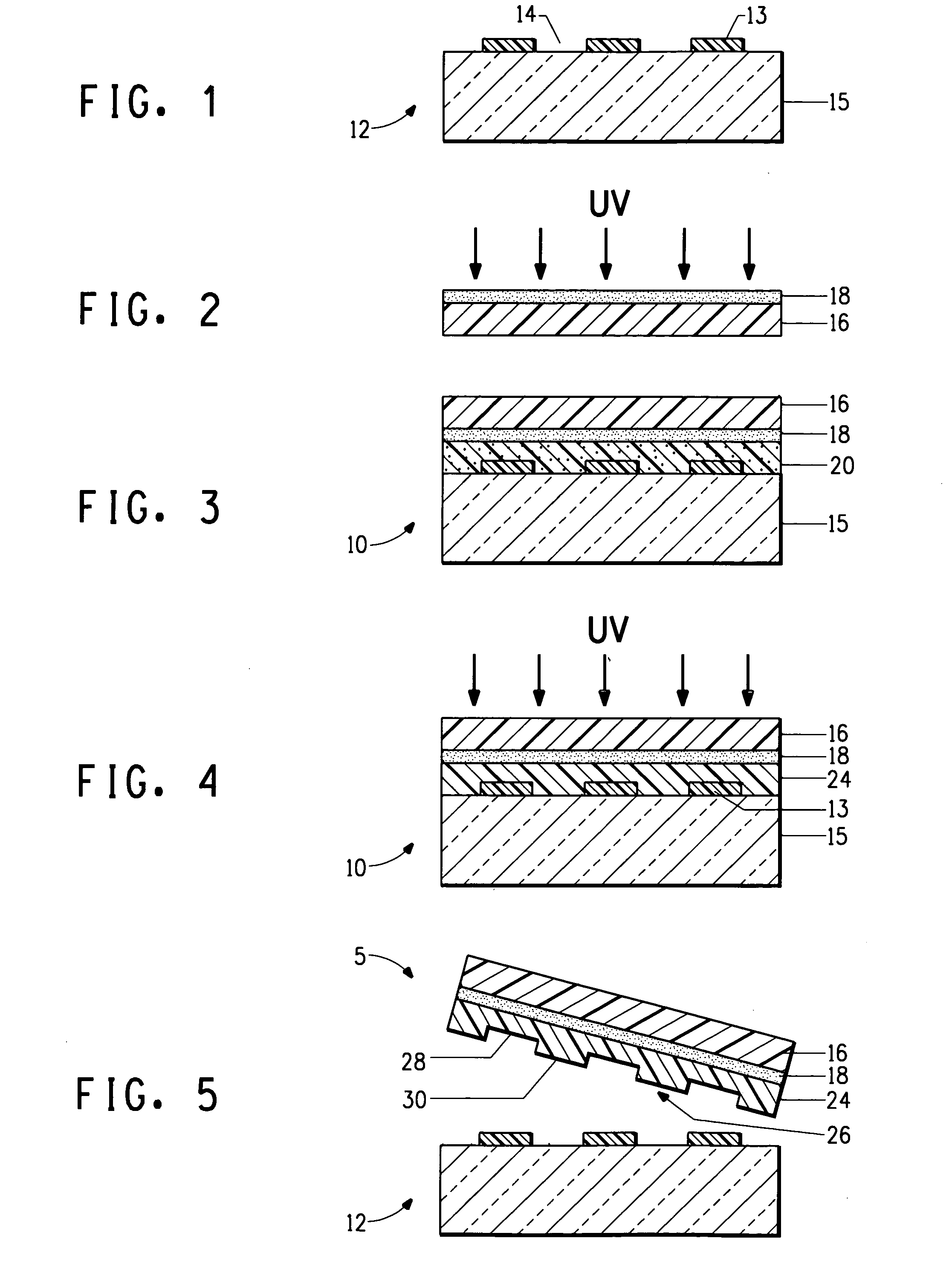

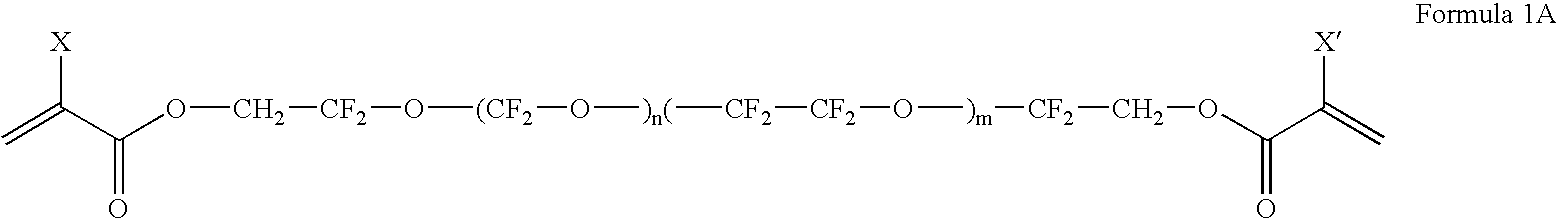

Printing form precursor and process for preparing a stamp from the precursor

The invention pertains to a printing form precursor and a method for preparing a stamp from the precursor for use in soft lithographic applications. The printing form precursor includes a composition layer of a fluorinated compound capable of polymerization upon exposure to actinic radiation and a flexible support transparent to the actinic radiation adjacent the composition layer.

Owner:EI DU PONT DE NEMOURS & CO

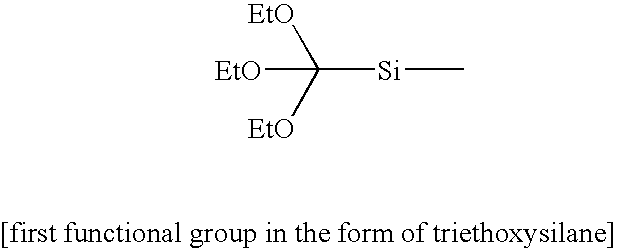

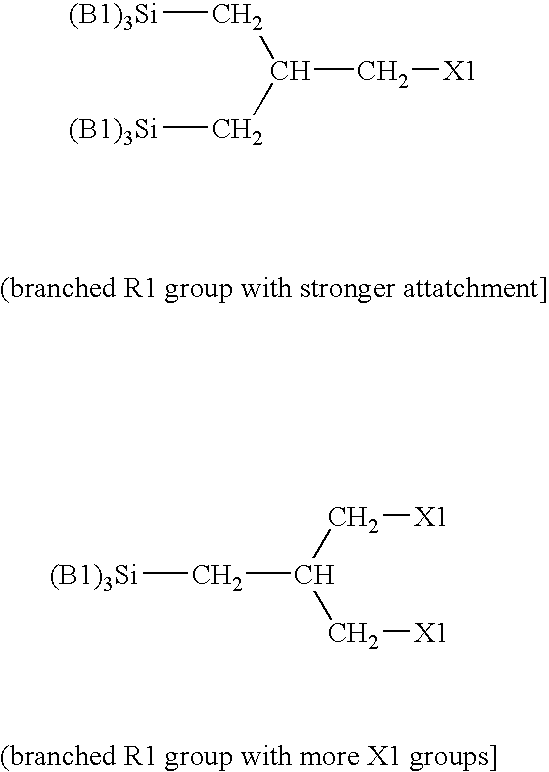

Stamp having an antisticking layer and a method of forming of repairing such a stamp

InactiveUS20050039618A1Good effectStable antisticking layerNanoinformaticsPhotomechanical apparatusCouplingNanoscopic scale

A stamp for use in transferring a pattern in nano-scale has a monomolecular antisticking layer. The anti-sticking layer comprises molecular chains, which are covalently bound to the surface of the stamp and which each comprise at least one fluorine-containing group. Each molecular chain contains a group Q, which comprises a bond which is weaker than the other bonds in the molecular chain as well as the covalent bond that binds the molecular chain to the surface of the stamp. Splitting of said bond in the group Q creates a group Q1, which is attached to the part of the molecular chain being left on the surface of the stamp and which is capable of reacting with a fluorine-containing compound to restore the antisticking layer. In a method of manufacturing a stamp for use in transferring a pattern in nanoscale, the stamp is provided with the above-mentioned molecular chain. In a method of repairing a damaged antisticking layer of the above-mentioned stamp, the stamp is treated with a repairing reagent, which has a coupling end, which is capable of reacting with the group Q1, and a fluorine-containing group located at the other end of the repairing reagent.

Owner:OBDUCAT AB SE

Printing plates comprising modified pigment products

The present invention discloses printing plates comprising a substrate and a radiation-absorptive layer, wherein the radiation-absorptive layer comprises at least one modified pigment product. The modified pigment product comprises a pigment having attached at least one organic group and at least one amphiphilic counterion. Methods of imaging printing plates are also disclosed.

Owner:CABOT CORP

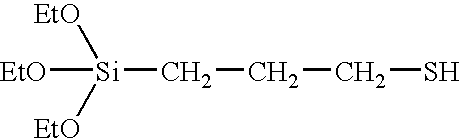

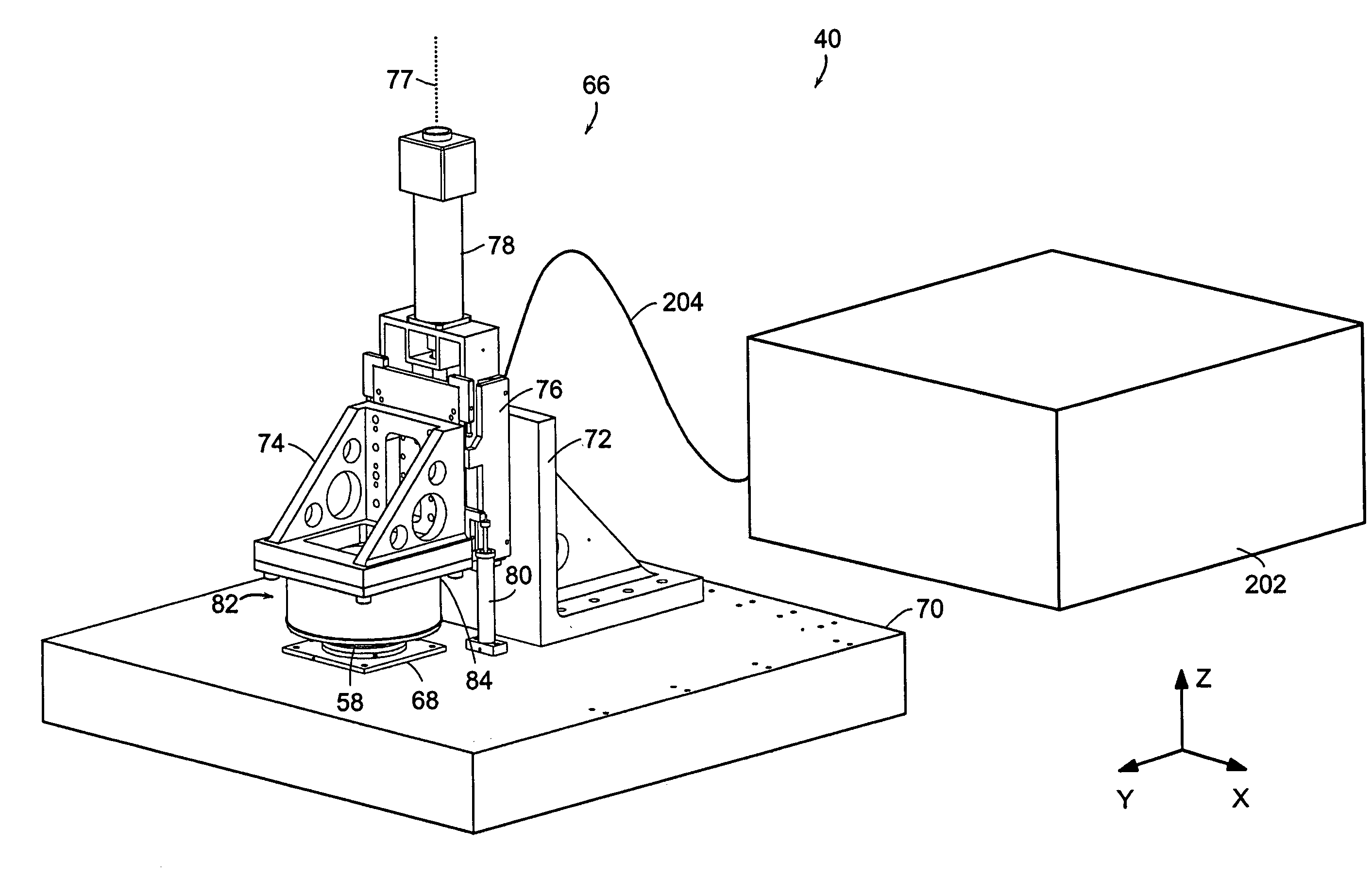

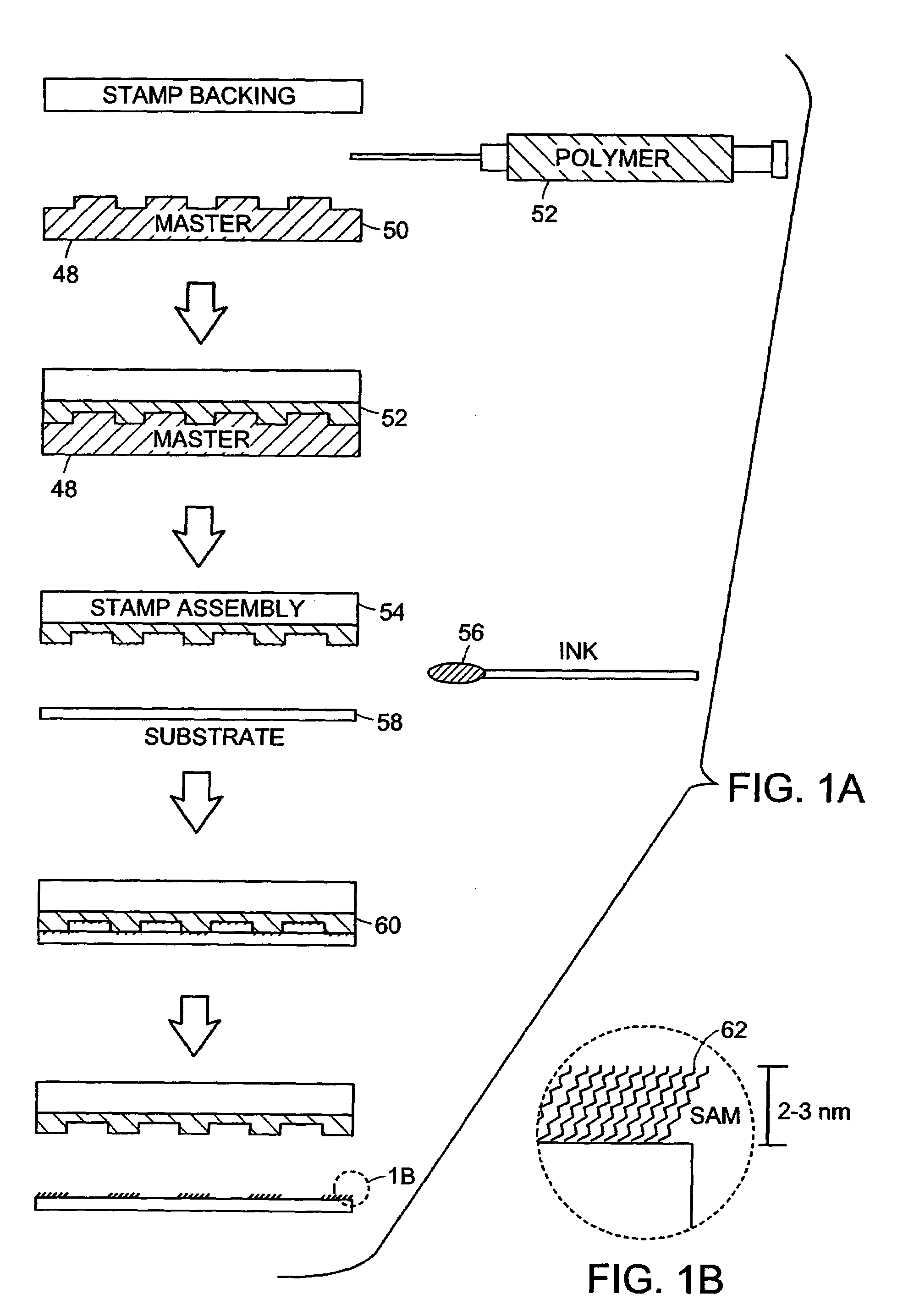

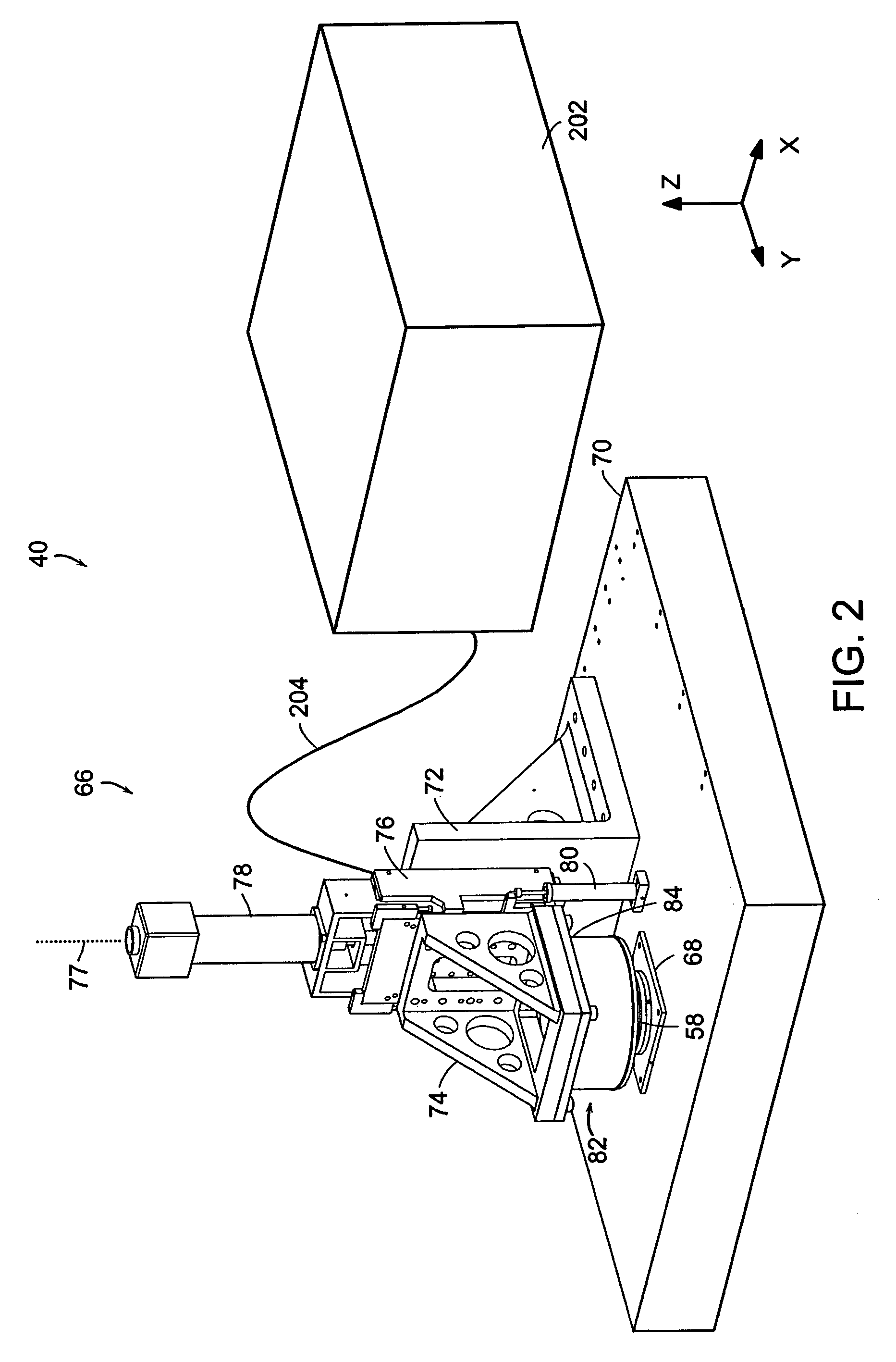

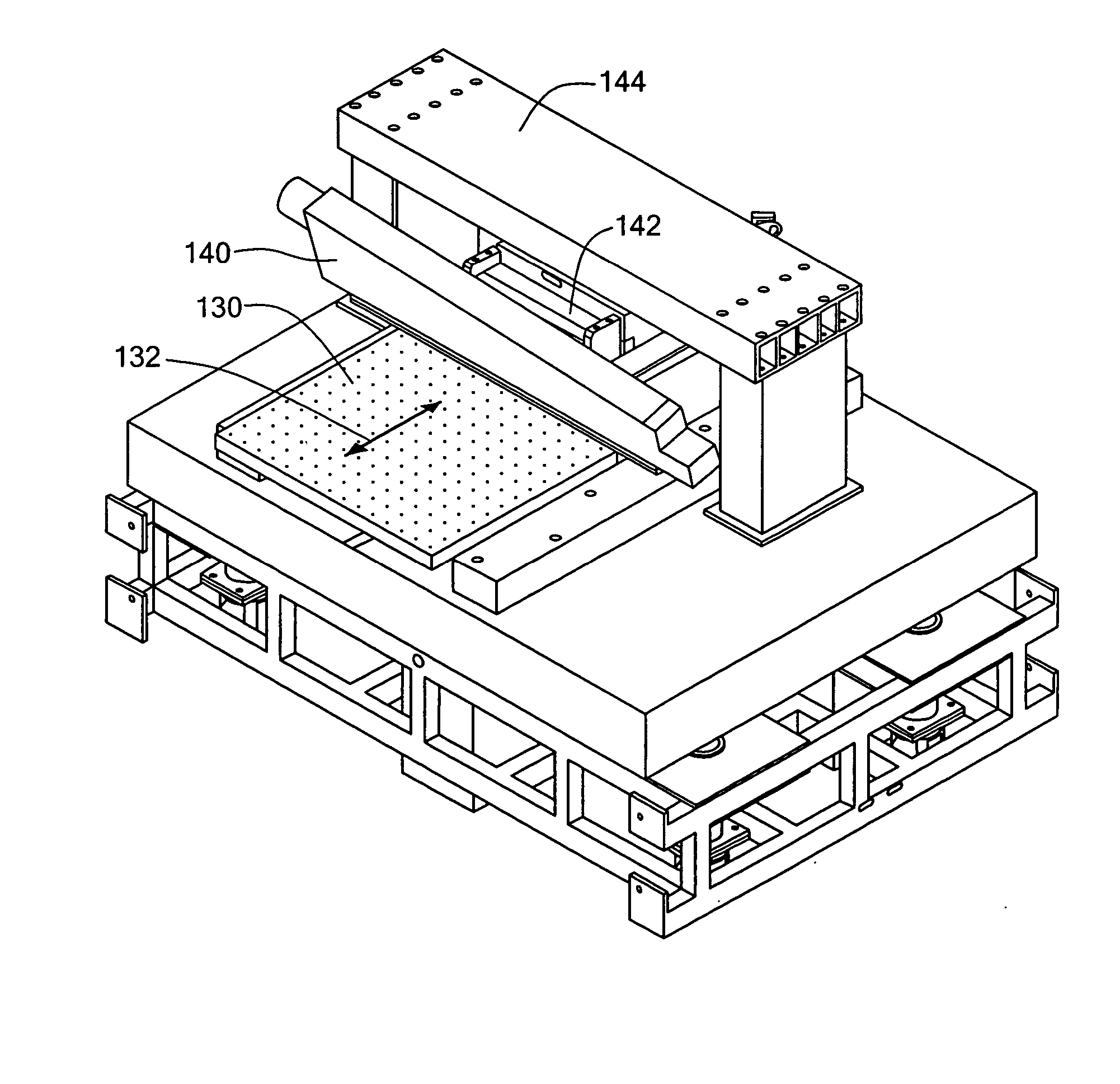

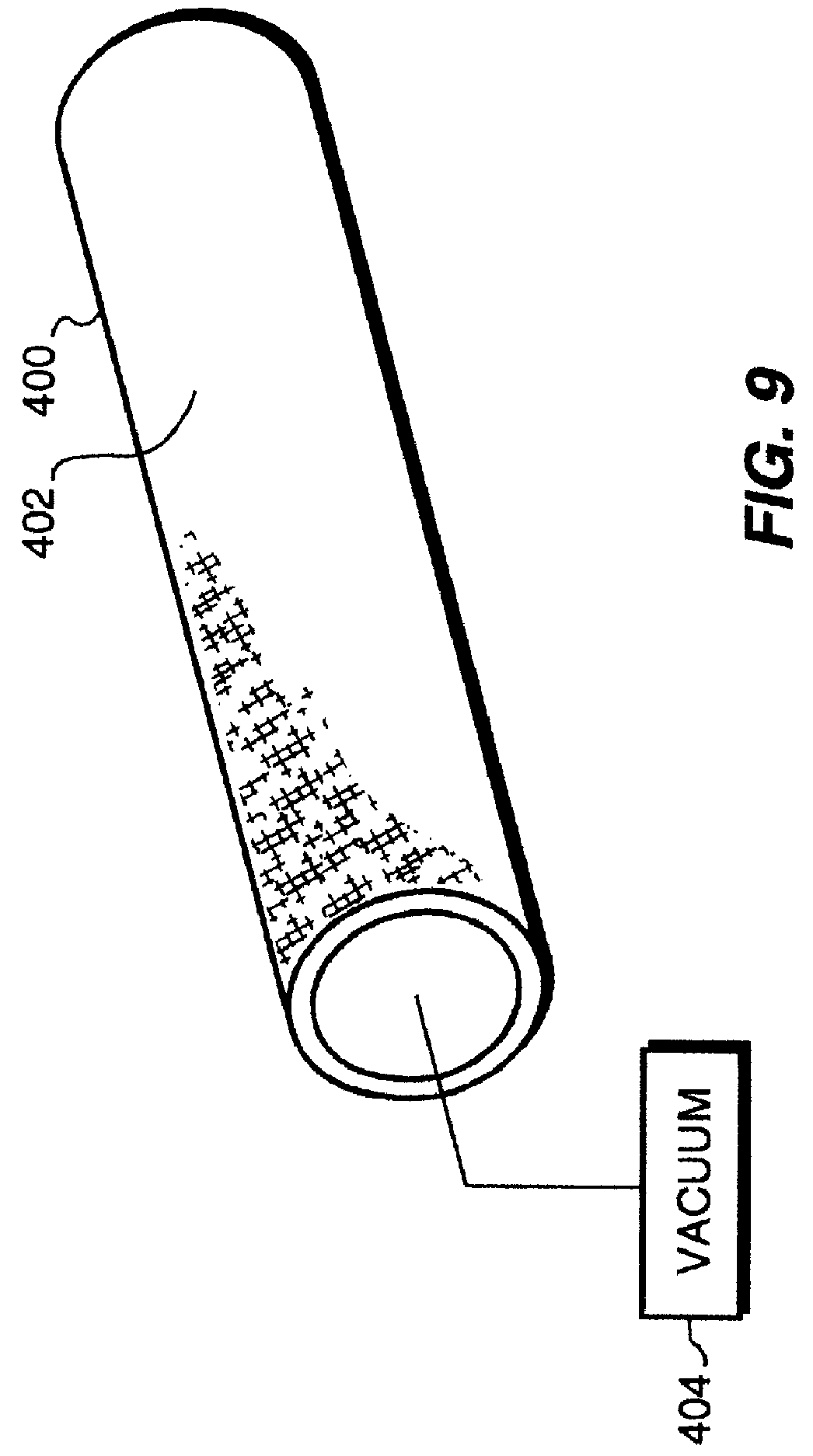

Microcontact printing

InactiveUS7117790B2Generate undesired patterning resultsControl distortionMaterial nanotechnologyNanoinformaticsMicrocontact printingEngineering

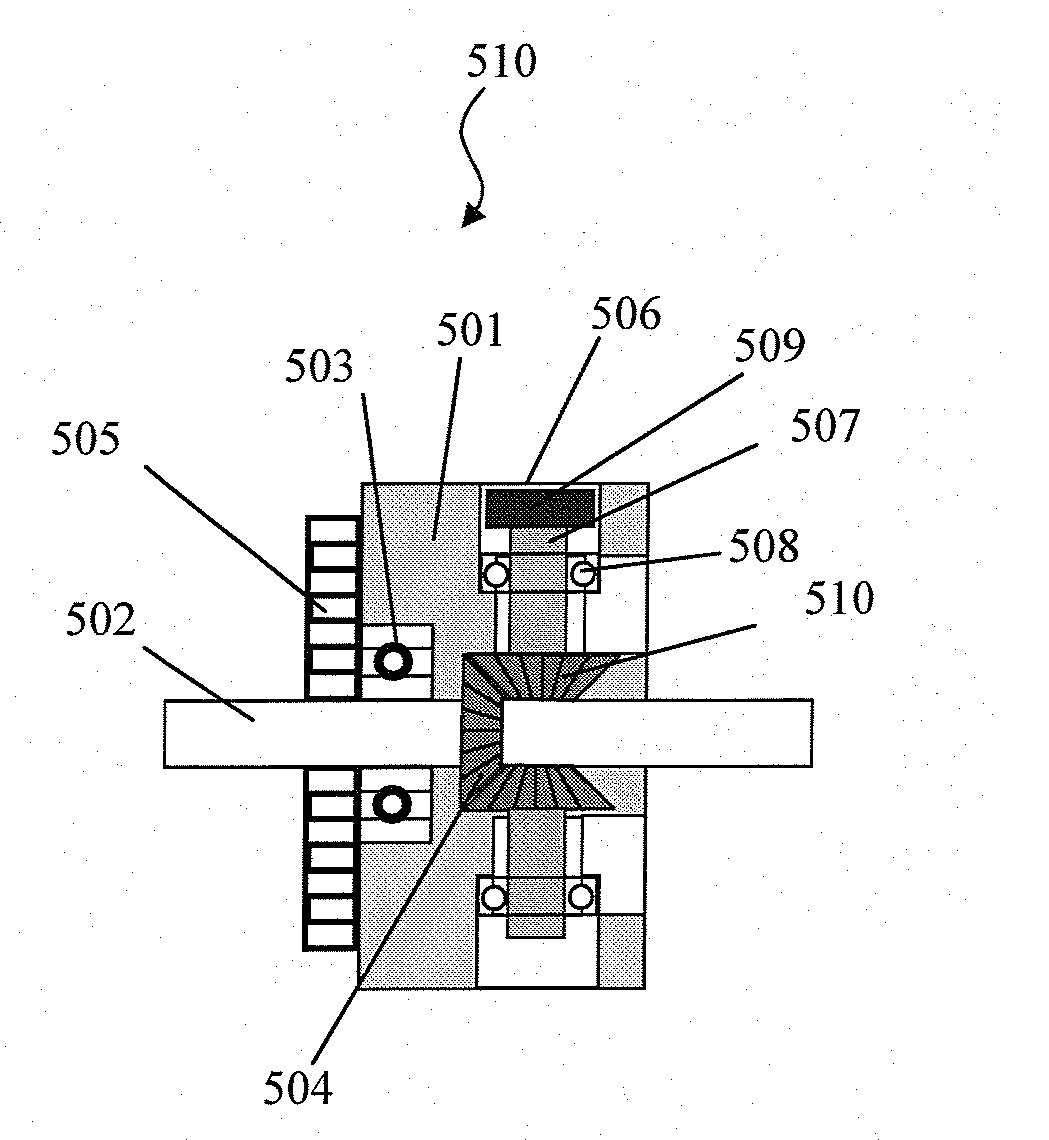

A microcontact printing tool having a print unit including a stamp head with a stamp and a wafer chuck for retaining a substrate. The stamp contained by the stamped head movable relative to the substrate by an actuator and a stage. A plurality of sensors detect the position of the stamp relative to substrate. A method of using the printing tool that includes a real-time feedback for consistent and accurate application of force during the printing of the substrate. The stamp head includes a pressure chamber carrying the stamp. The stamp backing is deflected prior to contact of the stamp with the substrate to form a minimum point and the stamp backing and the stamp is returned to a plane to create a printing propagation contact. An apparatus and method of producing the stamp on a stamp backing. The apparatus has a master backing and a stamping backing in close proximity and the stamp material drawn in through a vacuum. The stamp is separated from the master by use of a parting fluid.

Owner:MASSACHUSETTS INST OF TECH

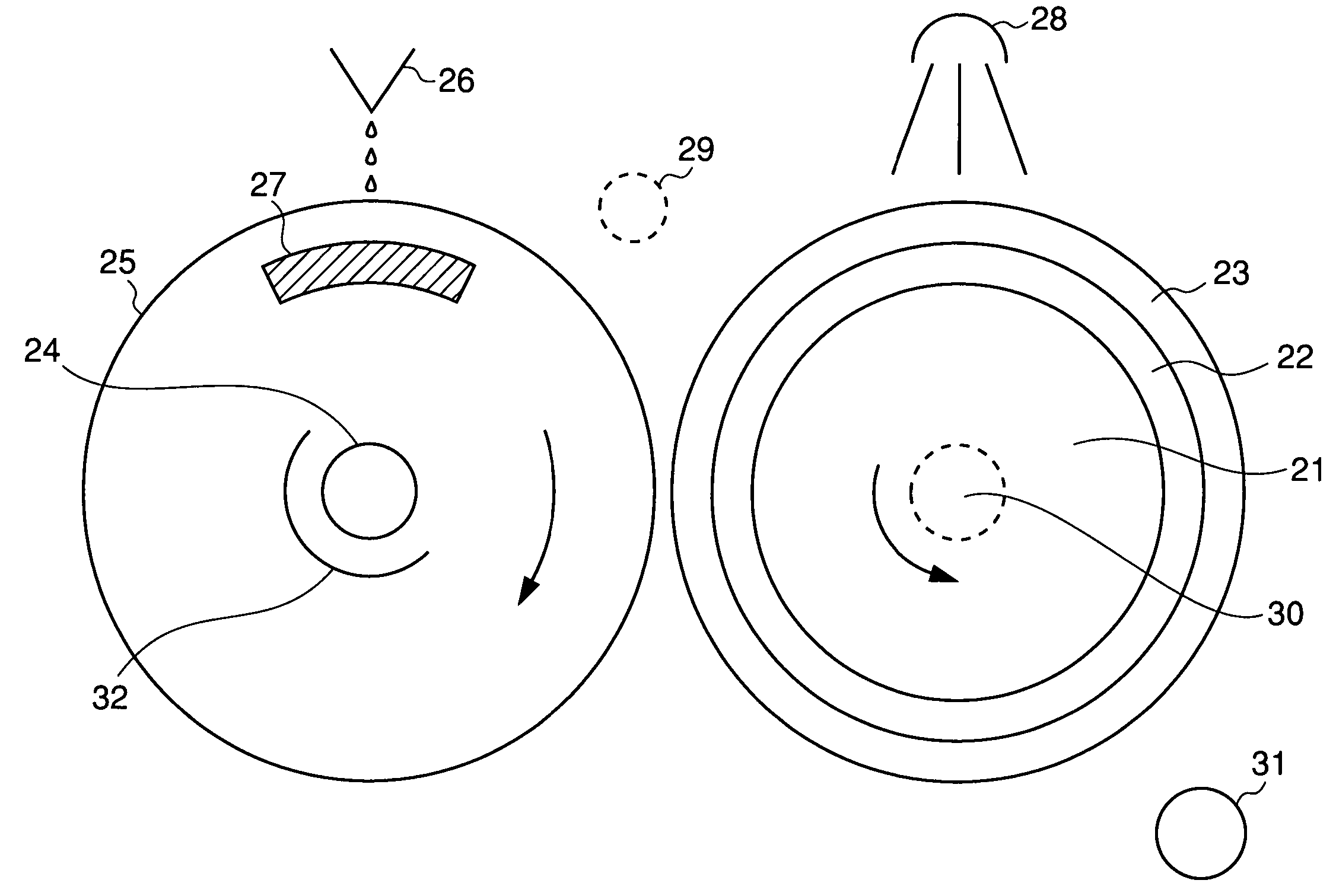

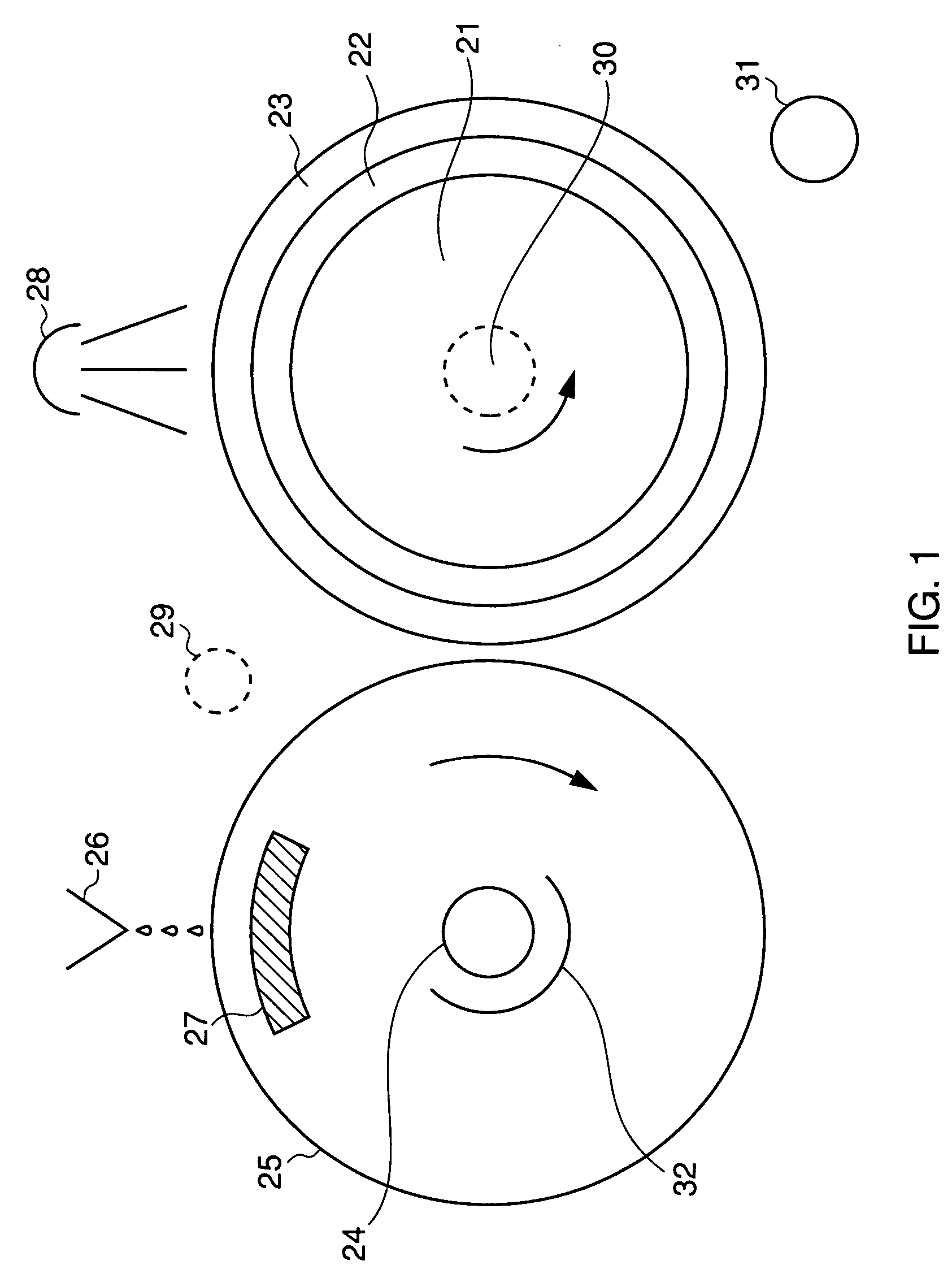

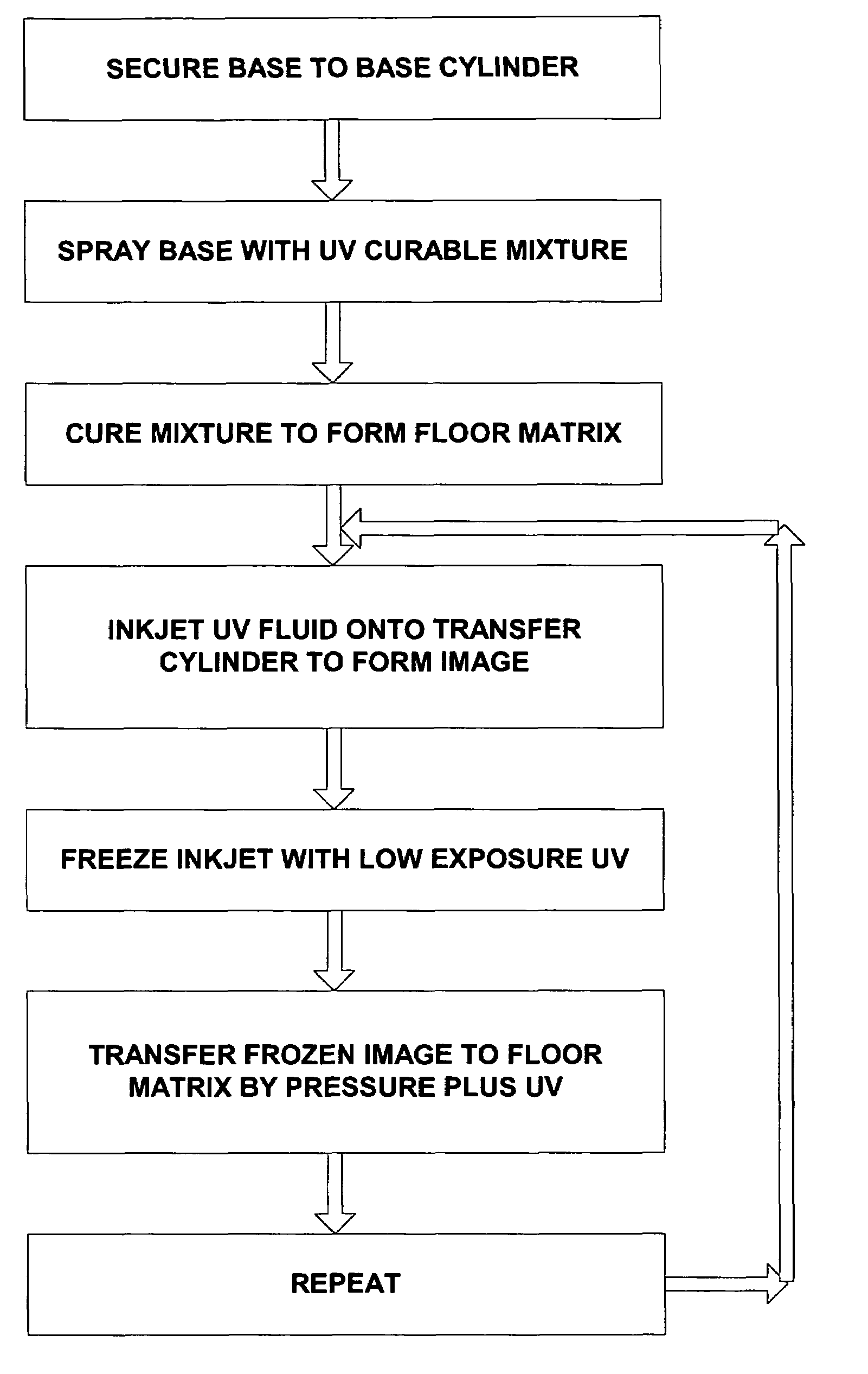

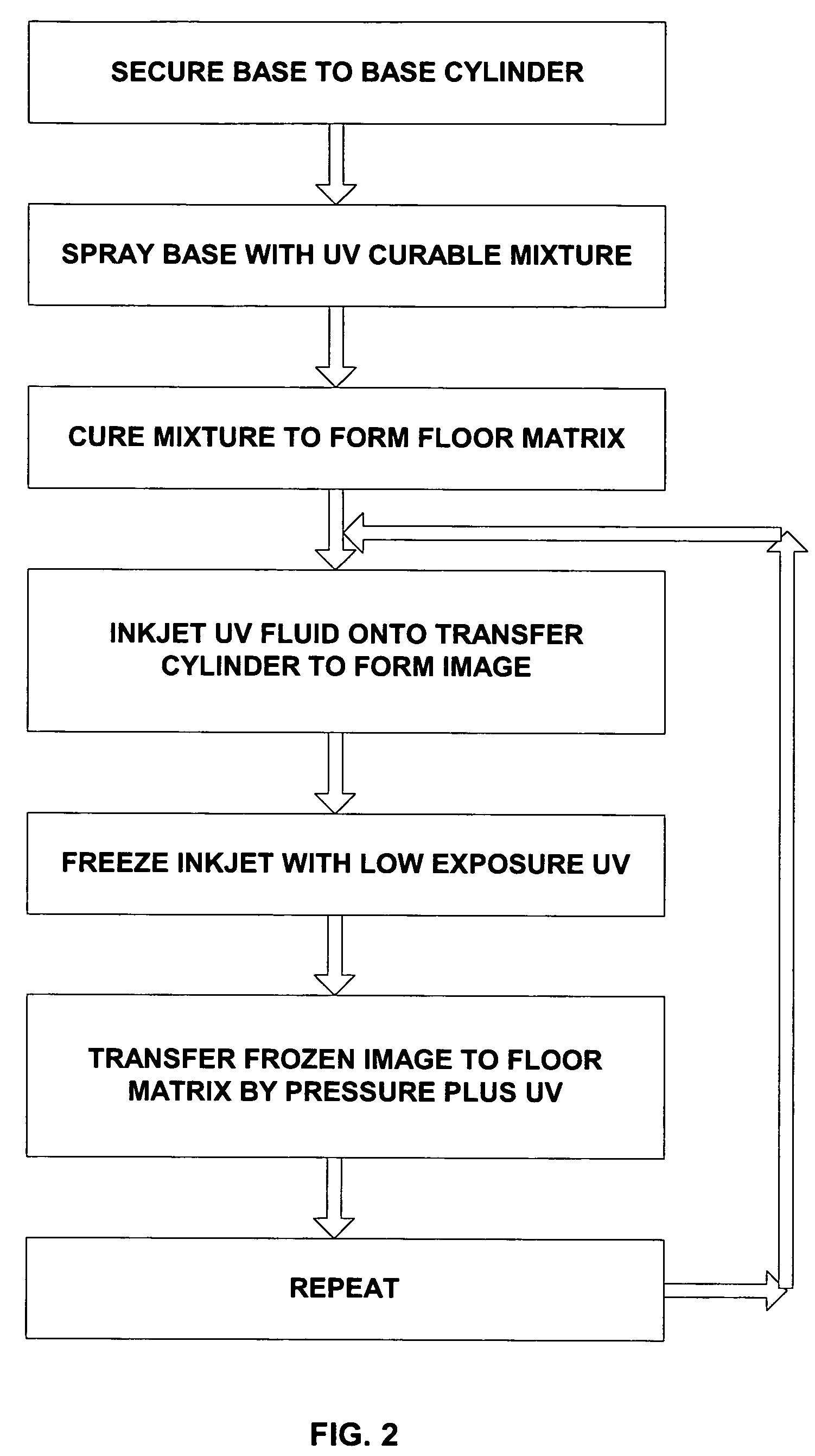

Method for producing a flexographic printing plate formed by inkjetted fluid

InactiveUS20040129158A1Rapid and inexpensive mannerDuplicating/marking methodsMounting boardsEngineeringElectrical and Electronics engineering

Owner:KODAK IL

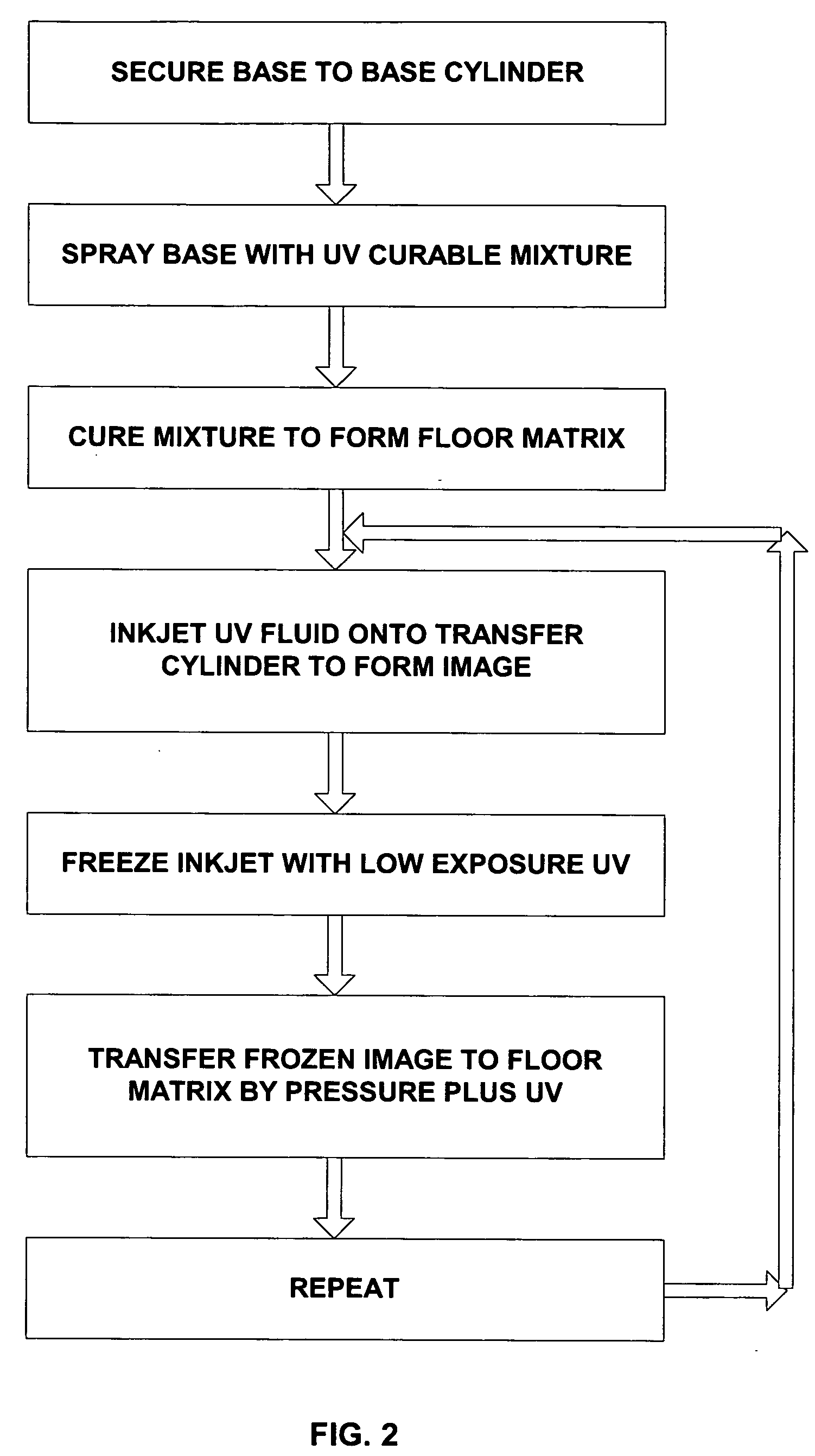

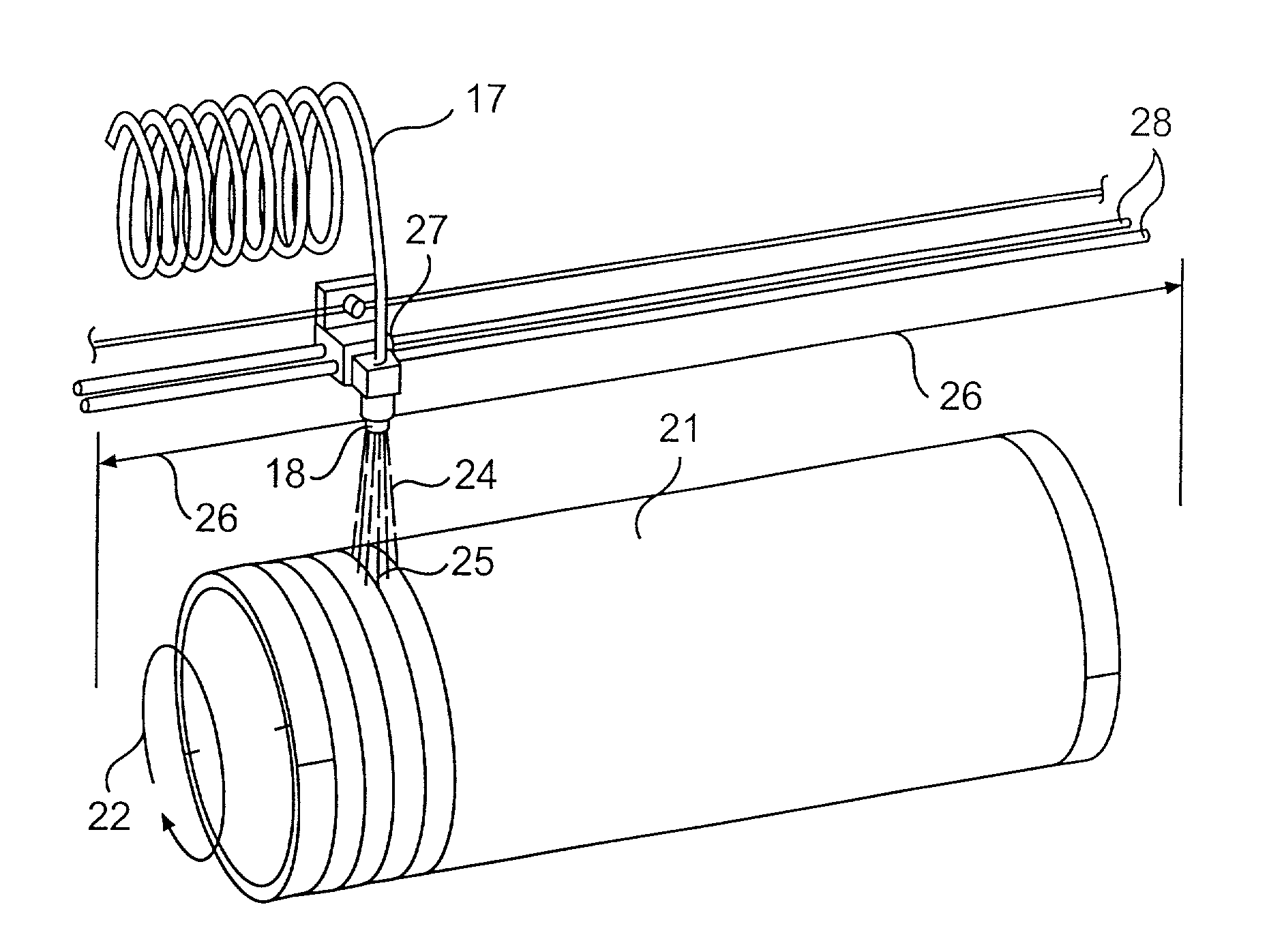

Printing sleeves and cylinders applied with a photopolymer composition

A method of forming a photopolymer layer on a printing substrate (e.g., flexographic printing sleeves and cylinders) is provided. The method includes providing a photopolymer composition that contains a photopolymer and at least one monomer bonded to the photopolymer. The monomer can help reduce the hardness of the resulting photopolymer composition. In addition, the method also includes spraying the photopolymer composition onto a rotating generally cylindrical surface of the printing substrate. In one embodiment, the sprayed photopolymer composition is then cured. The resulting photopolymer layer is seamless and continuous and, in some embodiments, has a hardness of between about 50 to about 70 Shore A.

Owner:ROSSINI SPA

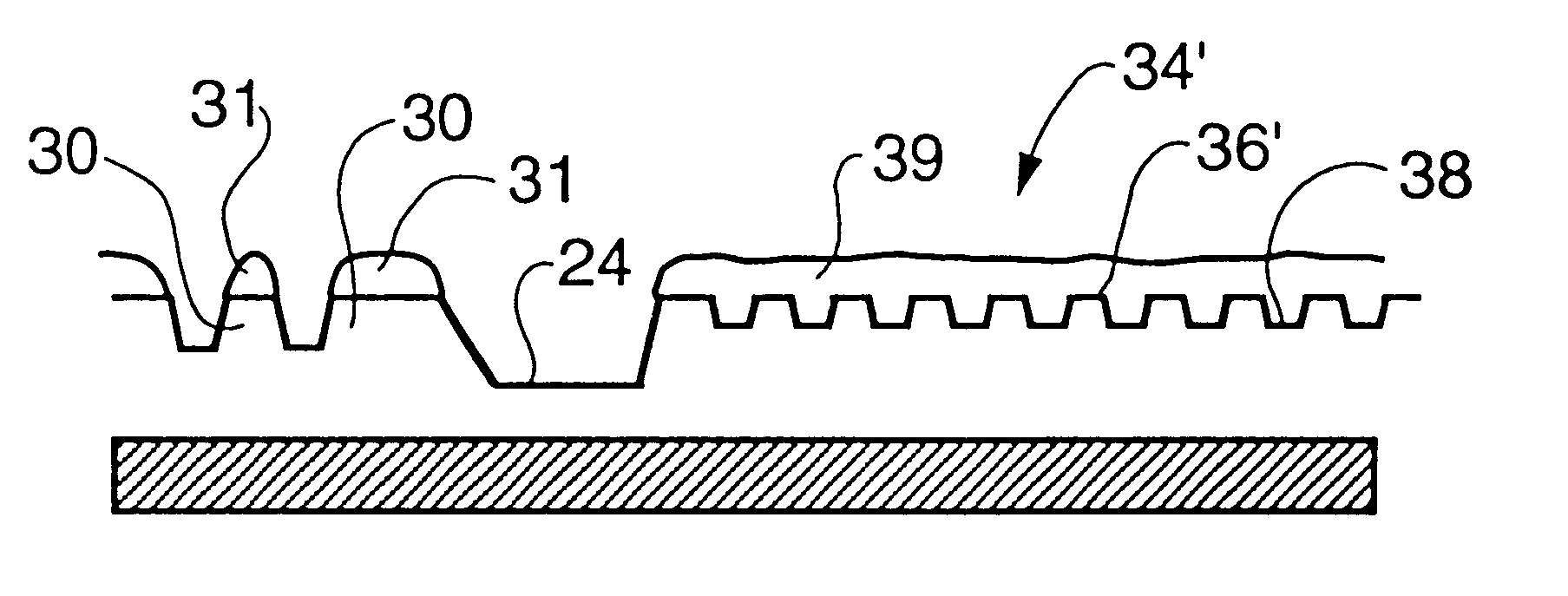

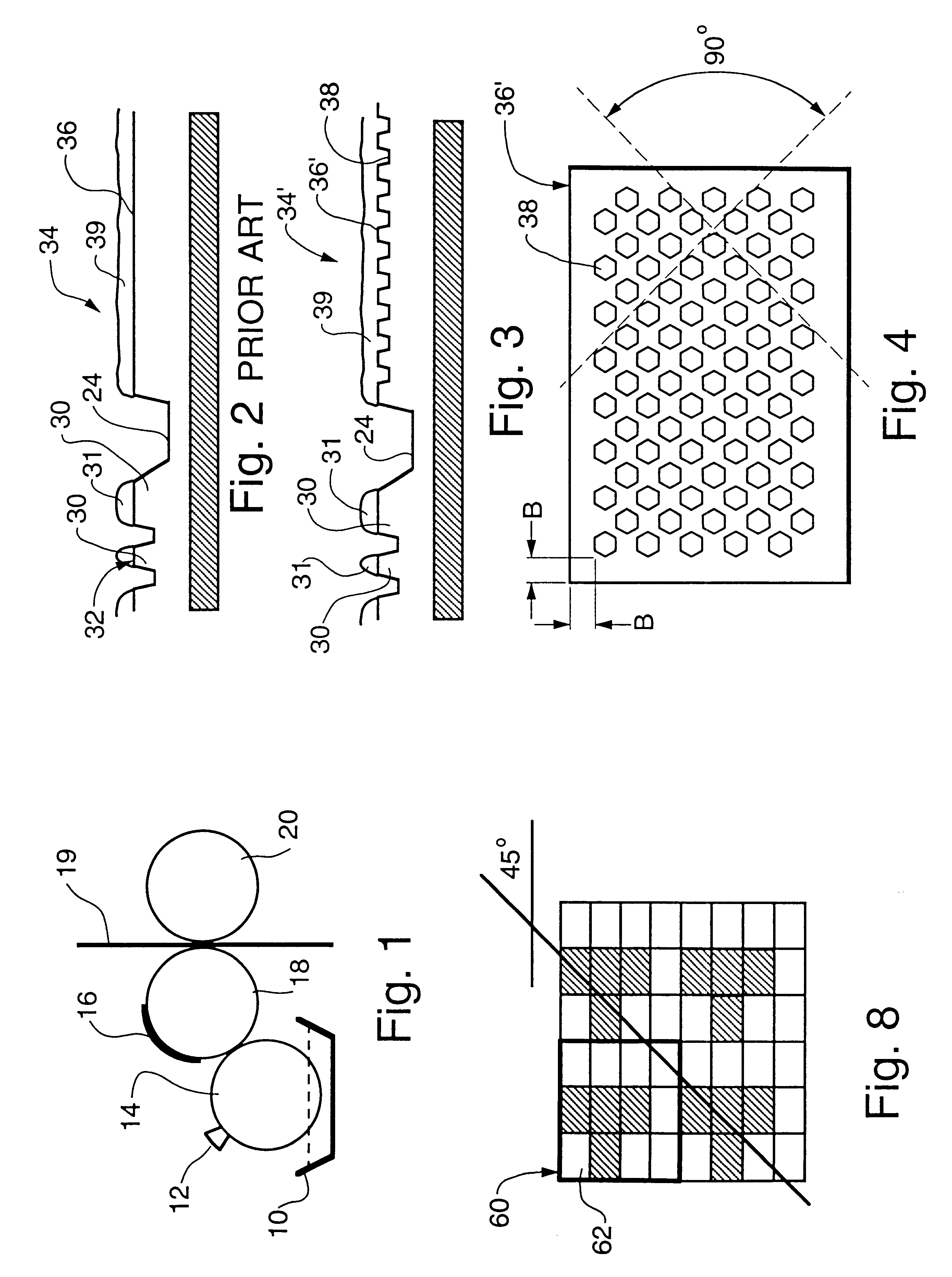

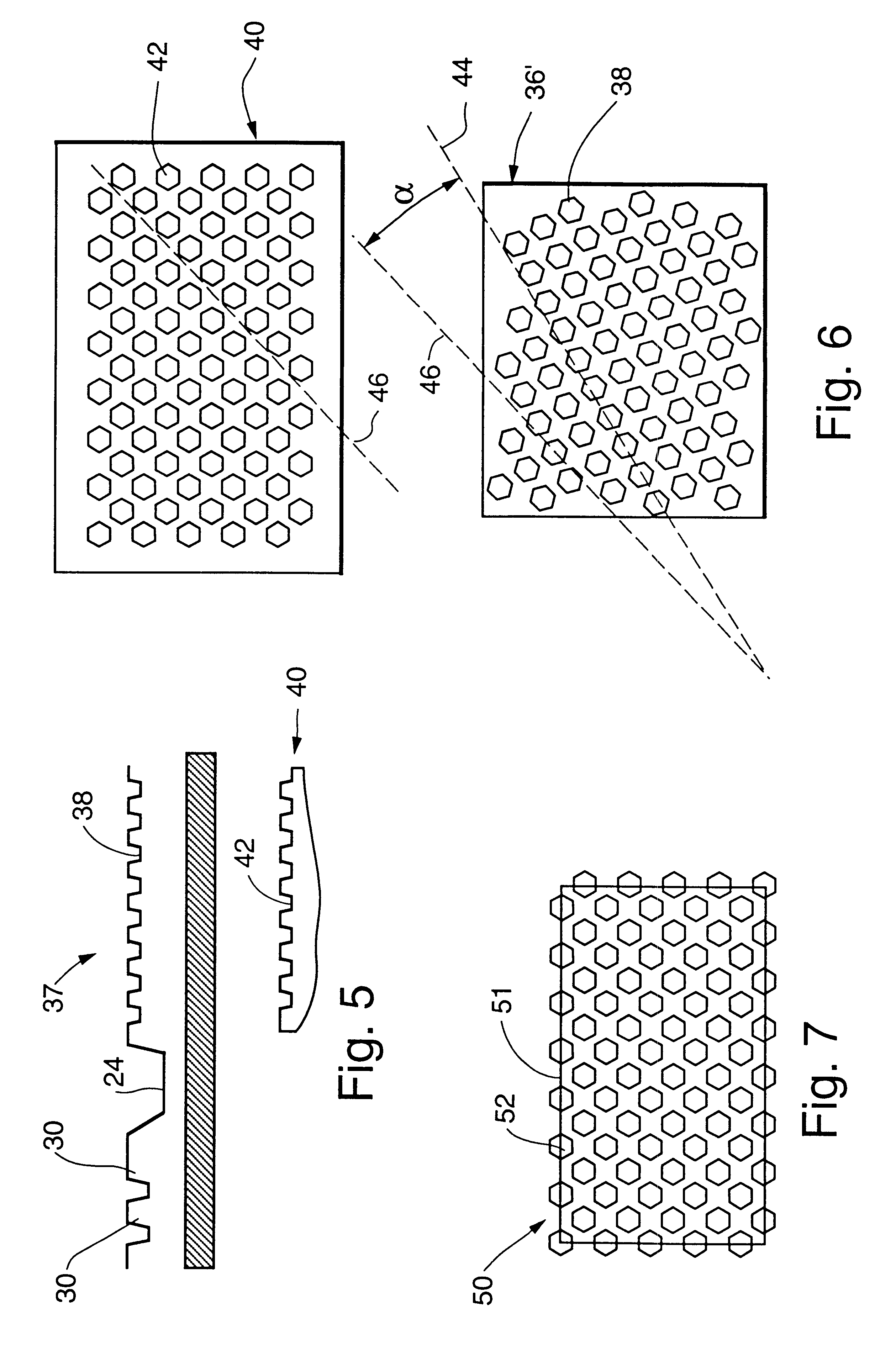

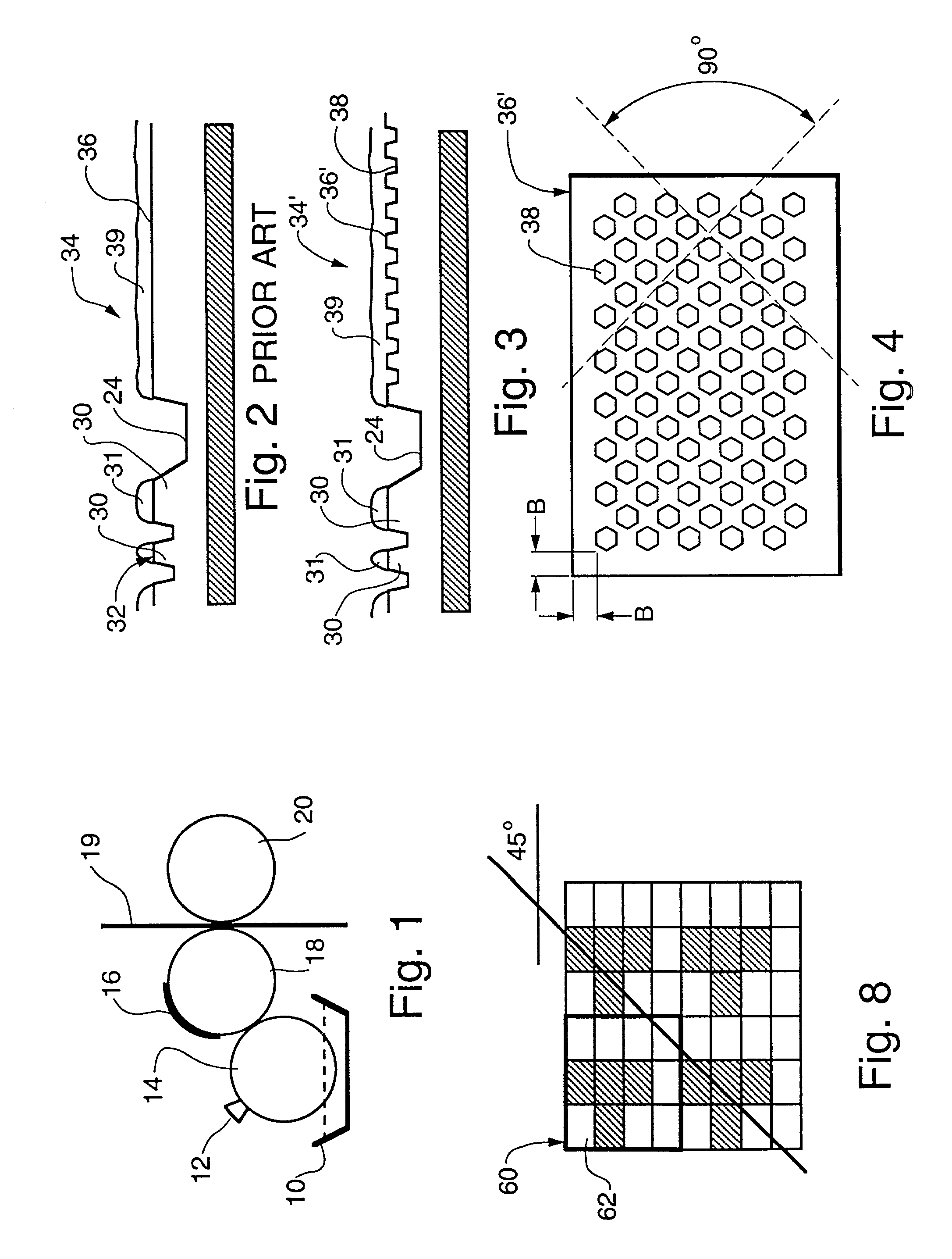

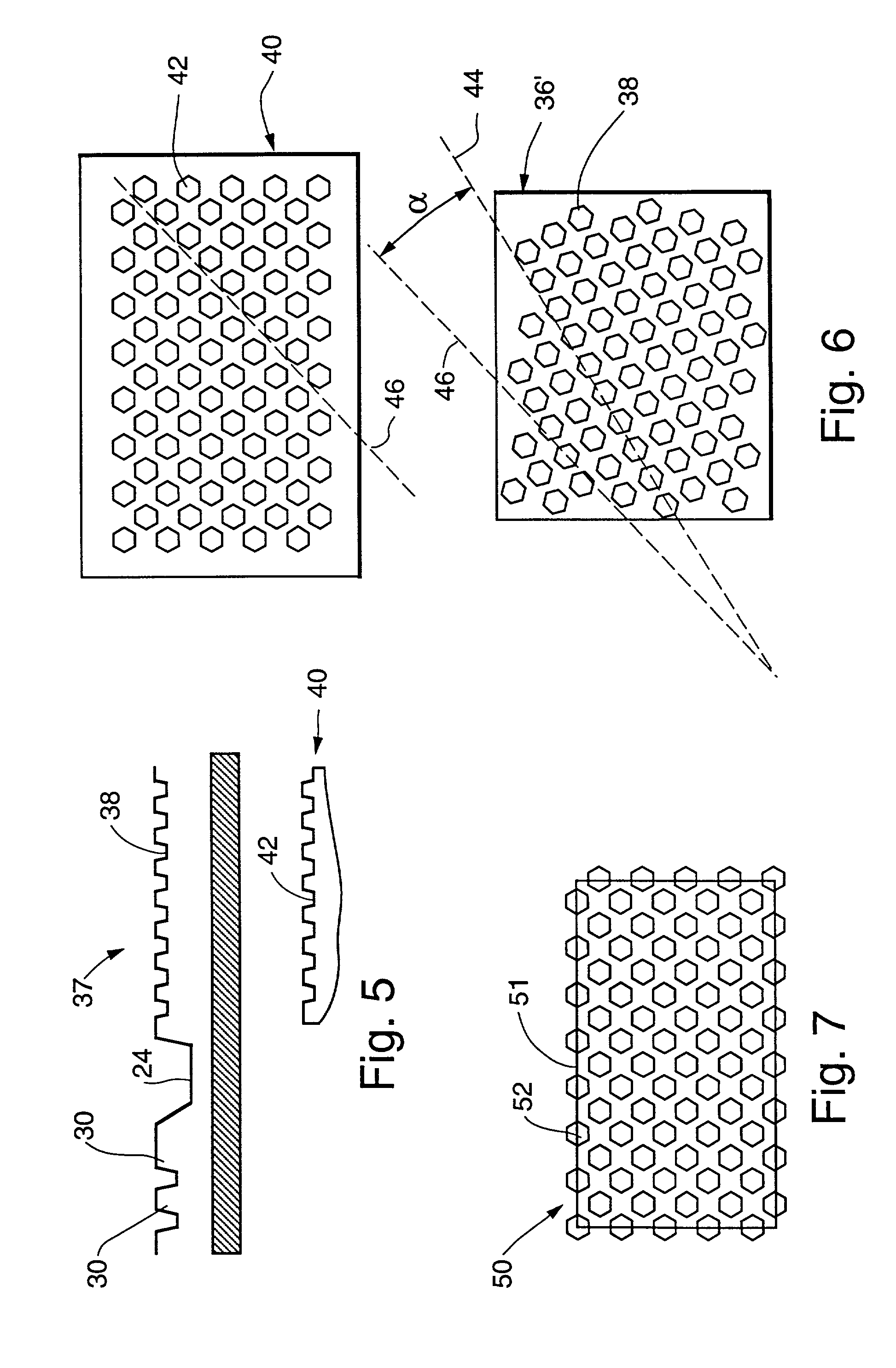

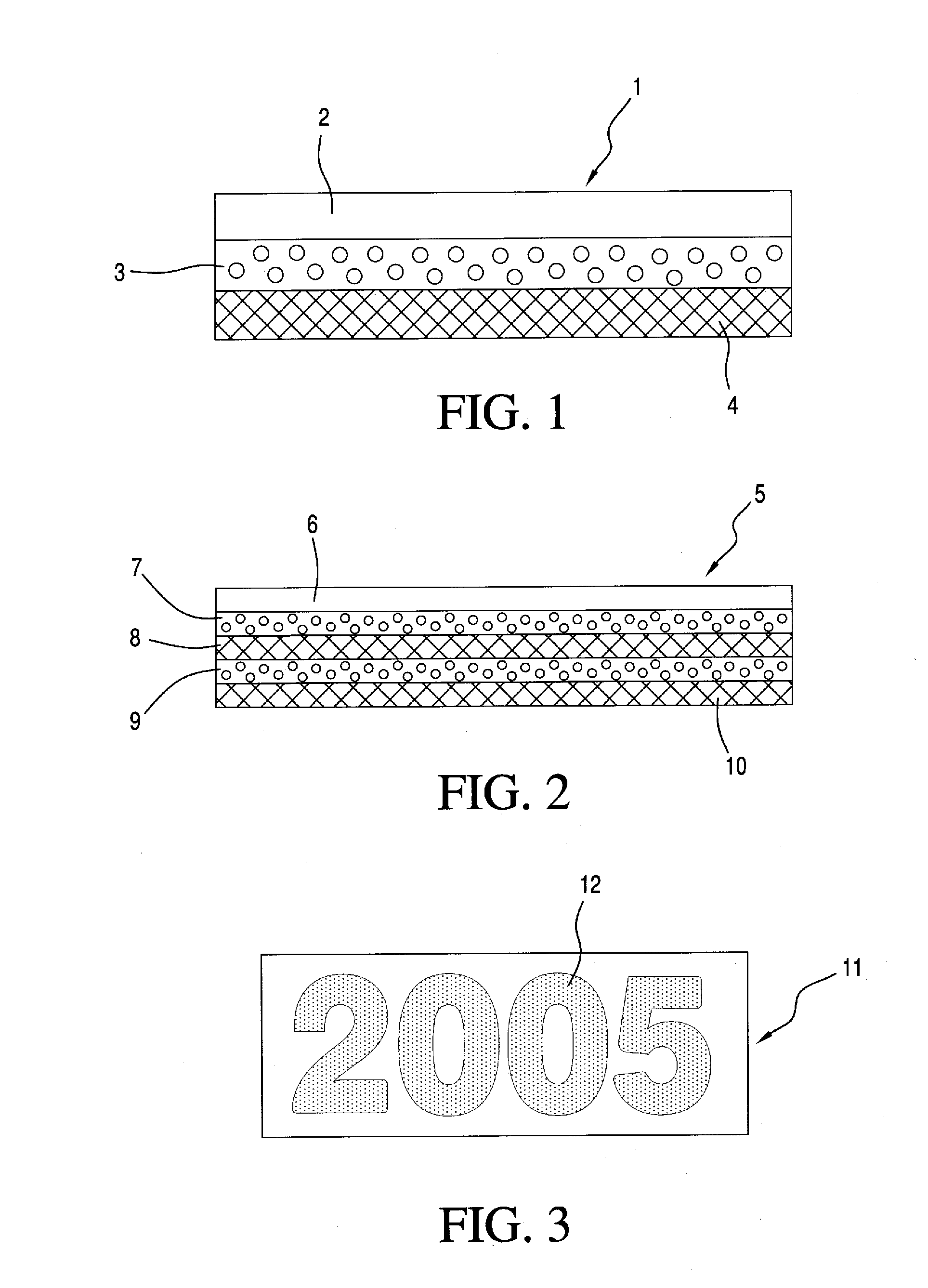

Screened film intermediate for use with flexographic printing plate having improved solids rendition

InactiveUS6492095B2Digitally marking record carriersInking apparatusColor saturationMechanical engineering

flexographic printing plate having solid image areas which are covered by a plurality of very small and shallow cells similar to the ink carrying cells found in anilox ink metering rolls. These cells fill with ink during the plate inking step and reproduce solid image areas with better color saturation while at the same time reducing the halo typical of flexographic printing of solids. Associated with this plate is a method for producing the cells, including the use of an intermediate screened film and of a computer program for generating the film intermediate.

Owner:ESKO SOFTWARE

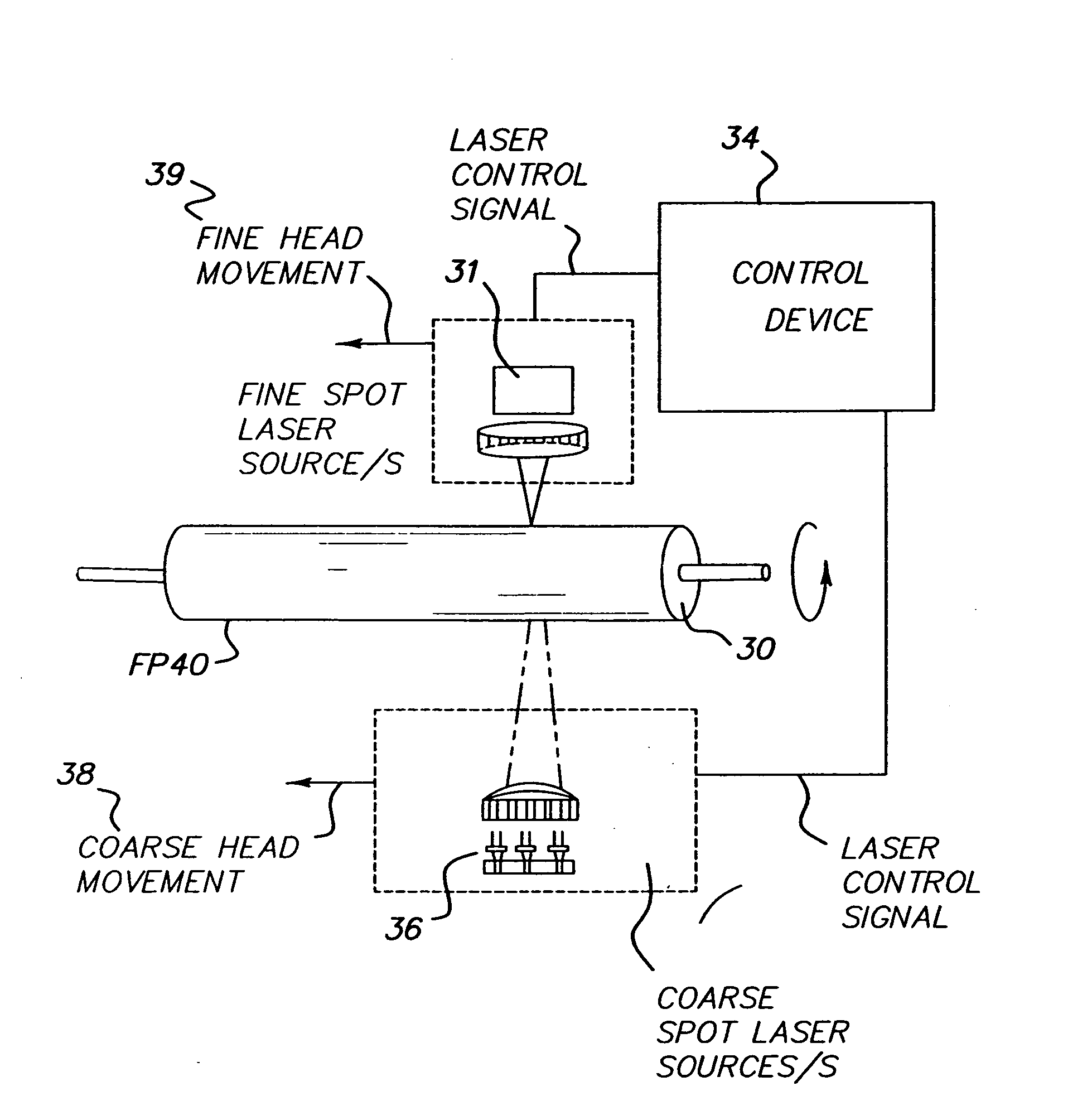

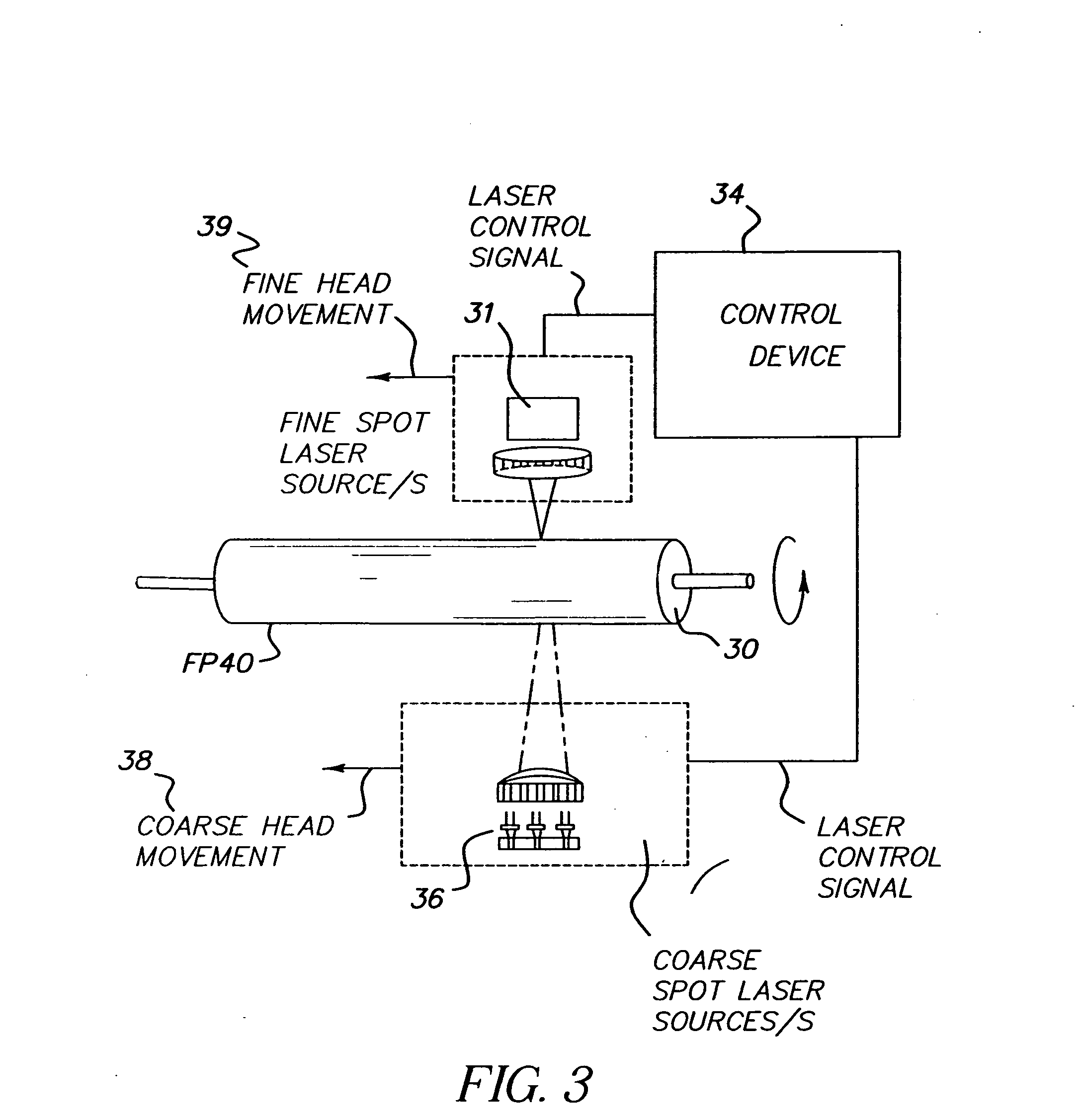

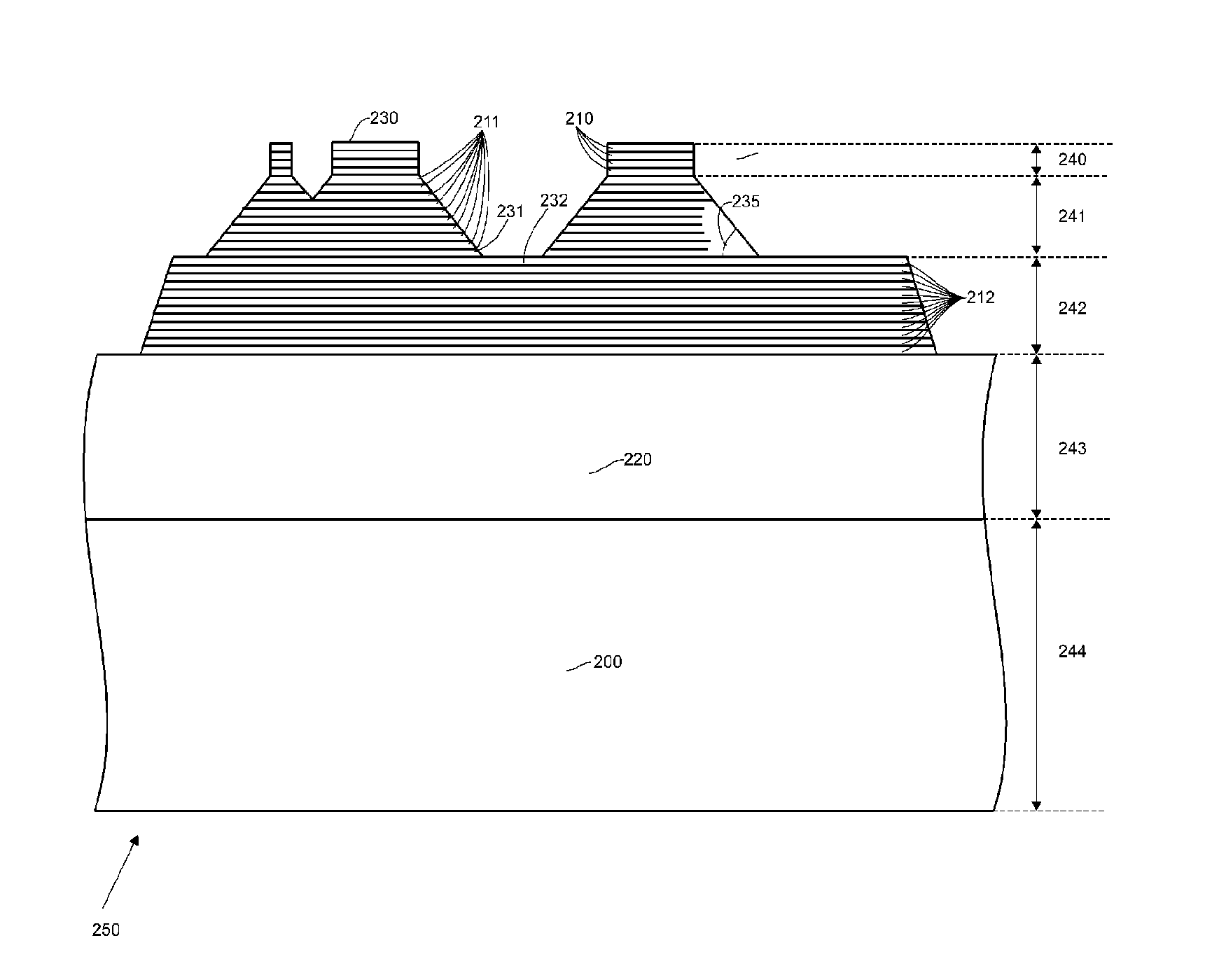

Hybrid optical head for direct engraving of flexographic printing plates

An optical imaging head for direct engraving of flexographic printing plates, comprising: at least two groups of radiation sources, each group comprising at least one radiation source, wherein the radiation sources within each group emit radiation having the same intensity and spot size, different from the intensity and spot size of radiation sources in the other groups, said groups of radiation sources operating simultaneously.

Owner:MIRACLON CORP

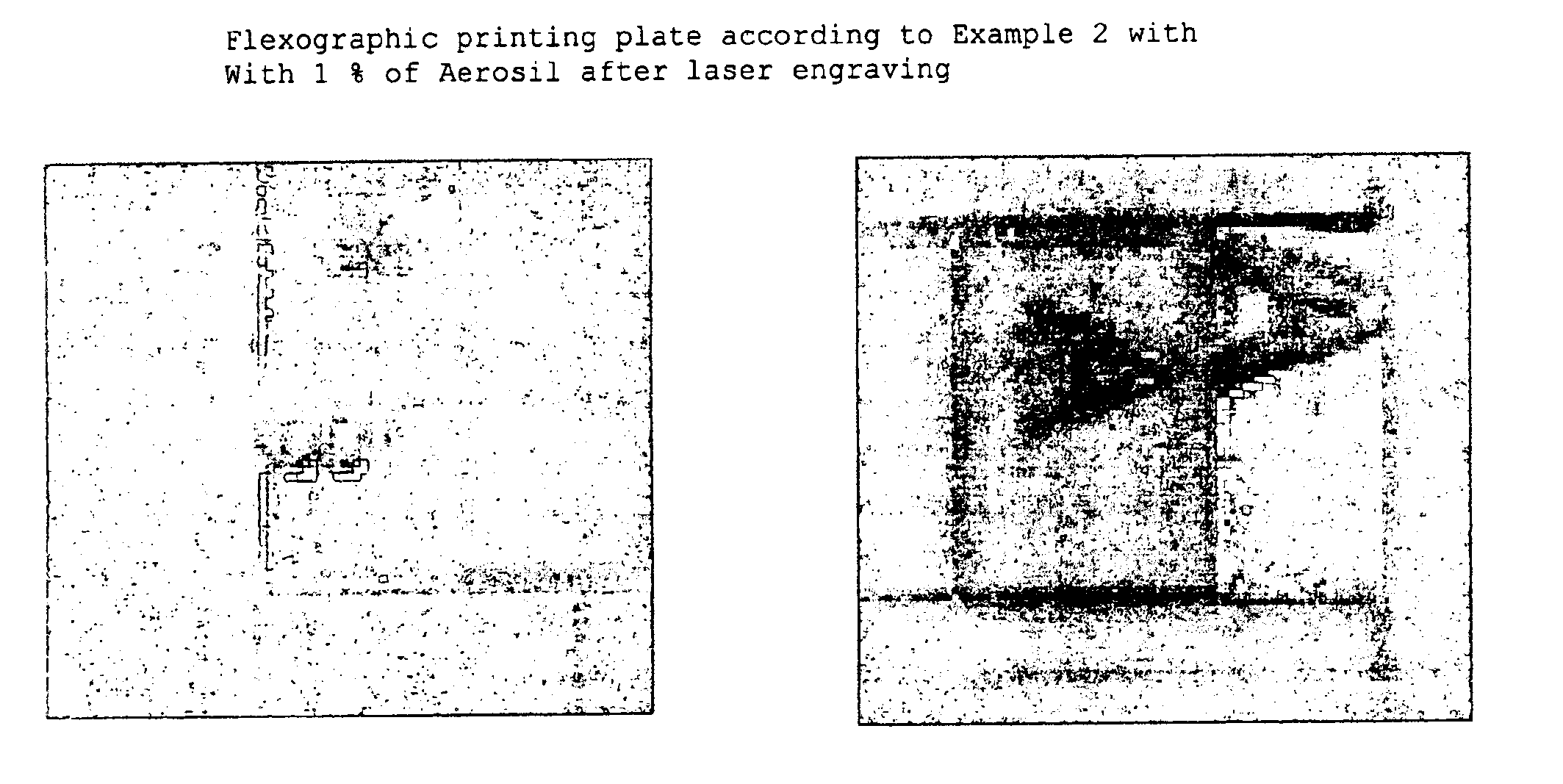

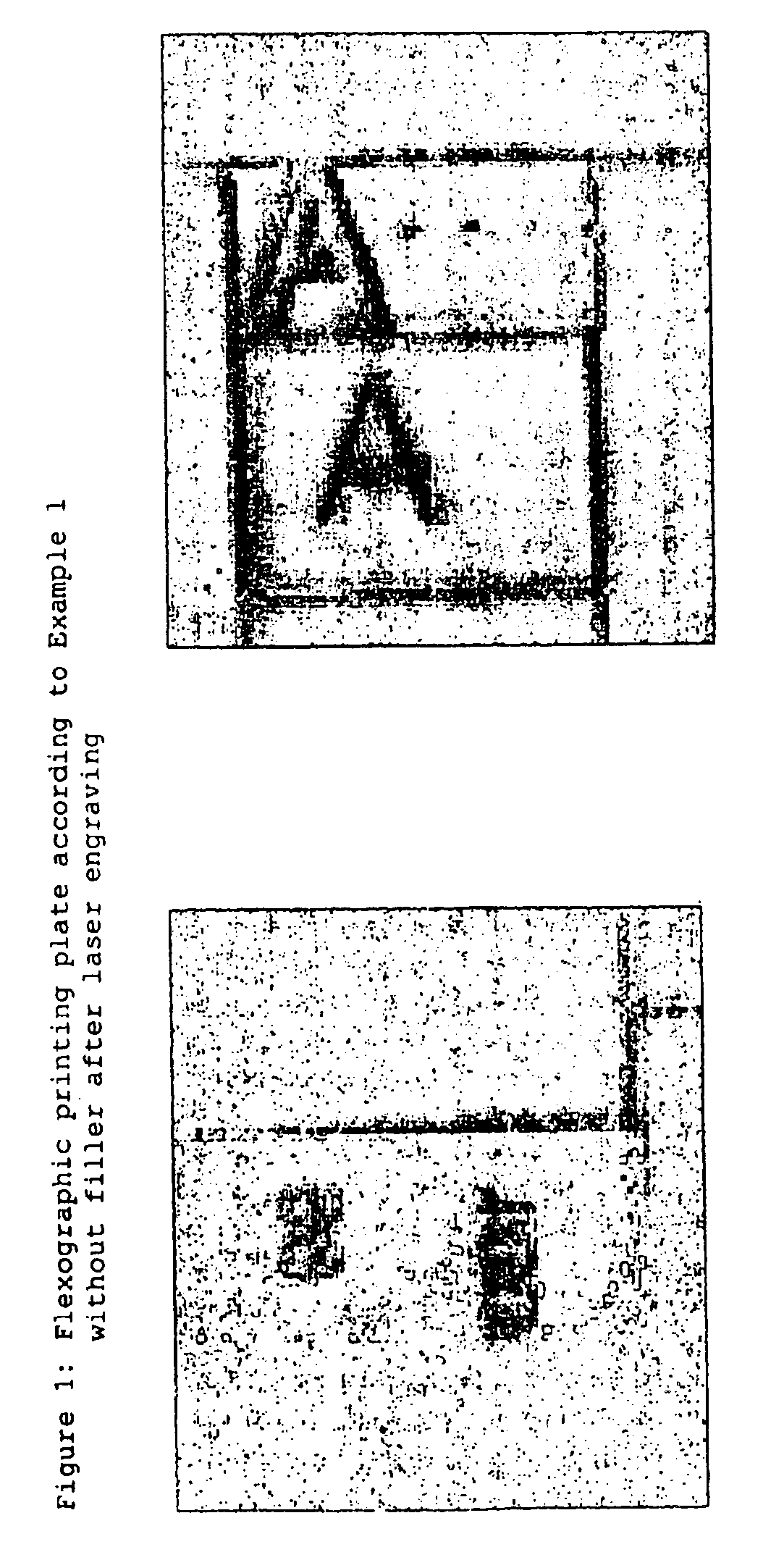

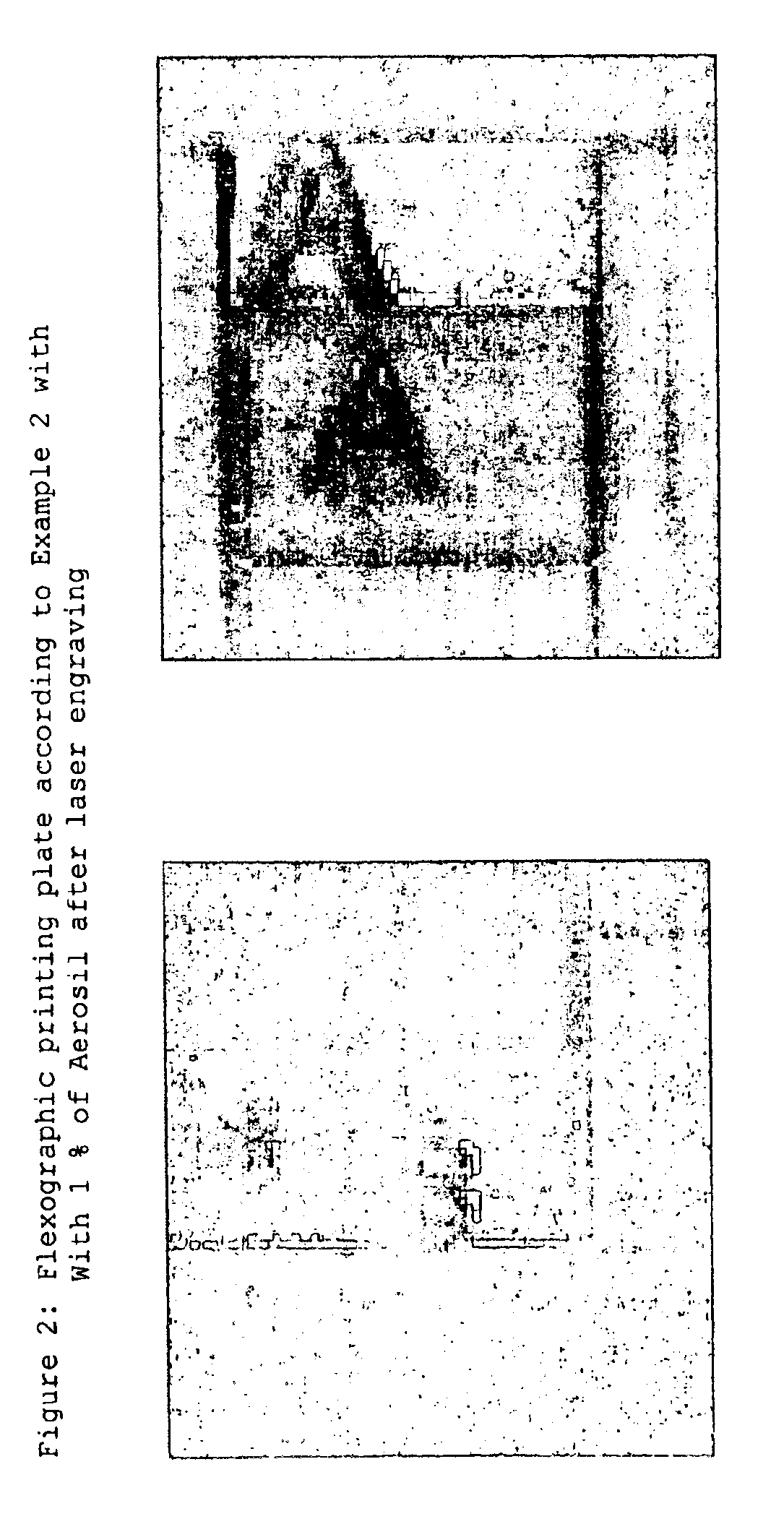

Method for producing flexographic printing plates by means of laser engraving

InactiveUS6935236B2High resolutionAvoid it happening againDuplicating/marking methodsSemiconductor/solid-state device manufacturingCross-linkLaser engraving

The invention relates to a method for producing flexographic printing forms by engraving a printing relief on a flexographic printing element that can be laser engraved, said element having a photochemically cross-linked relief layer. The relief layer is transparent and comprises oxidic, siliceous or zeolitic solid matter with a particle size between 1 and 400 nm in a quantity of between 0.1 and 8 wt. % in relation to the quantity of all components in the relief layer.

Owner:XSYS PRINT SOLUTIONS DEUT GMBH

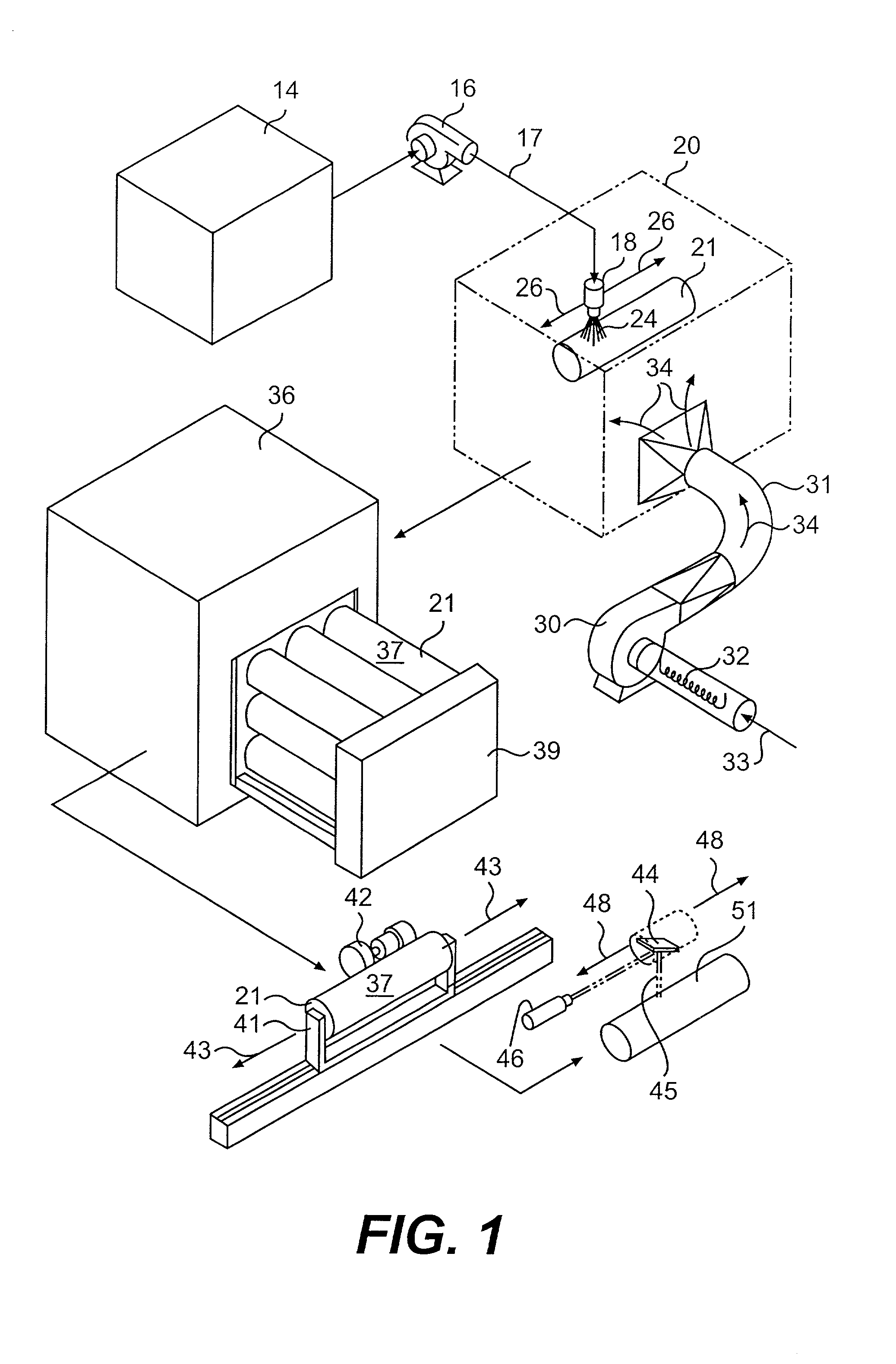

Imaging apparatus and method for making flexographic printing masters

InactiveUS20110219973A1Short manufacturing timeMounting boardsPlate printingEngineeringInkjet printing

A method for making a flexographic printing master includes the steps of providing a flexographic printing support; providing an inkjet printing device; applying a mesa relief on the flexographic printing support with the inkjet printing device; and applying an image relief with the inkjet printing device on the mesa relief. A method for making a flexographic printing master includes the imaging apparatus.

Owner:AGFA NV

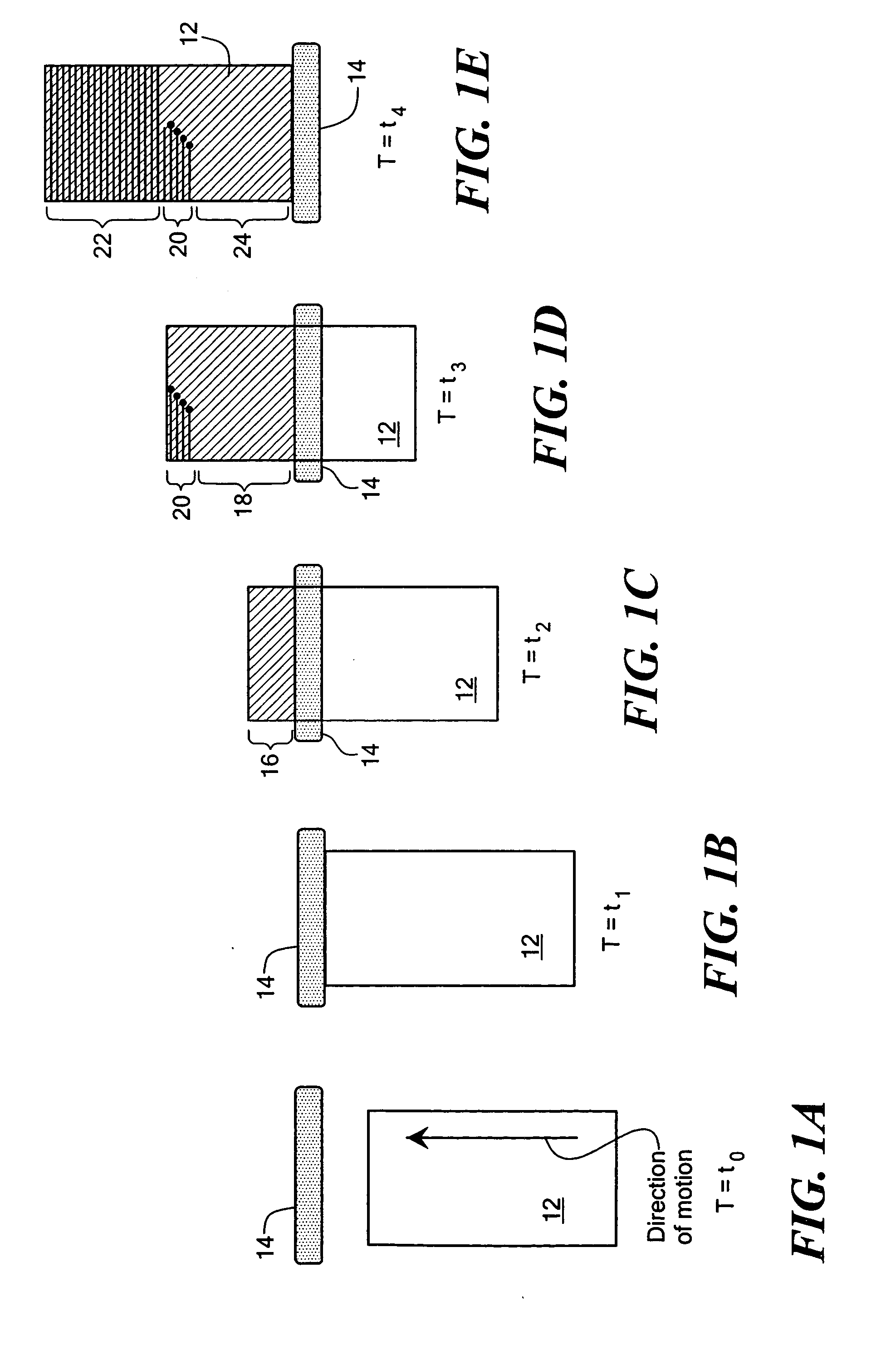

Integrated, in-line bumping and exposure system

ActiveUS20050011382A1Improve image qualityLow costMounting boardsPhotomechanical exposure apparatusGratingSpatial light modulator

An integrated, in-line bumping and exposure system for printing plates or other substrates having a photosensitive layer. A linear illumination source or sources are for bumping the photosensitive material with a band of illumination to consume dissolved oxygen within the photosensitive layer. A raster scan optical assembly or an illuminated and re-imaged spatial light modulator array exposes the photosensitive material with a rasterized beam or beams or an array of modulated electromagnetic radiation located downstream of the bumping illumination. A conveyance mechanism is configured to provide relative continuous motion between one or more substrates and the bands of illumination to continuously bump and pattern one portion of the plate or plates while the other portion of the plate or plates is bumped in anticipation of patterning.

Owner:THE PERKIN ELMER CORP

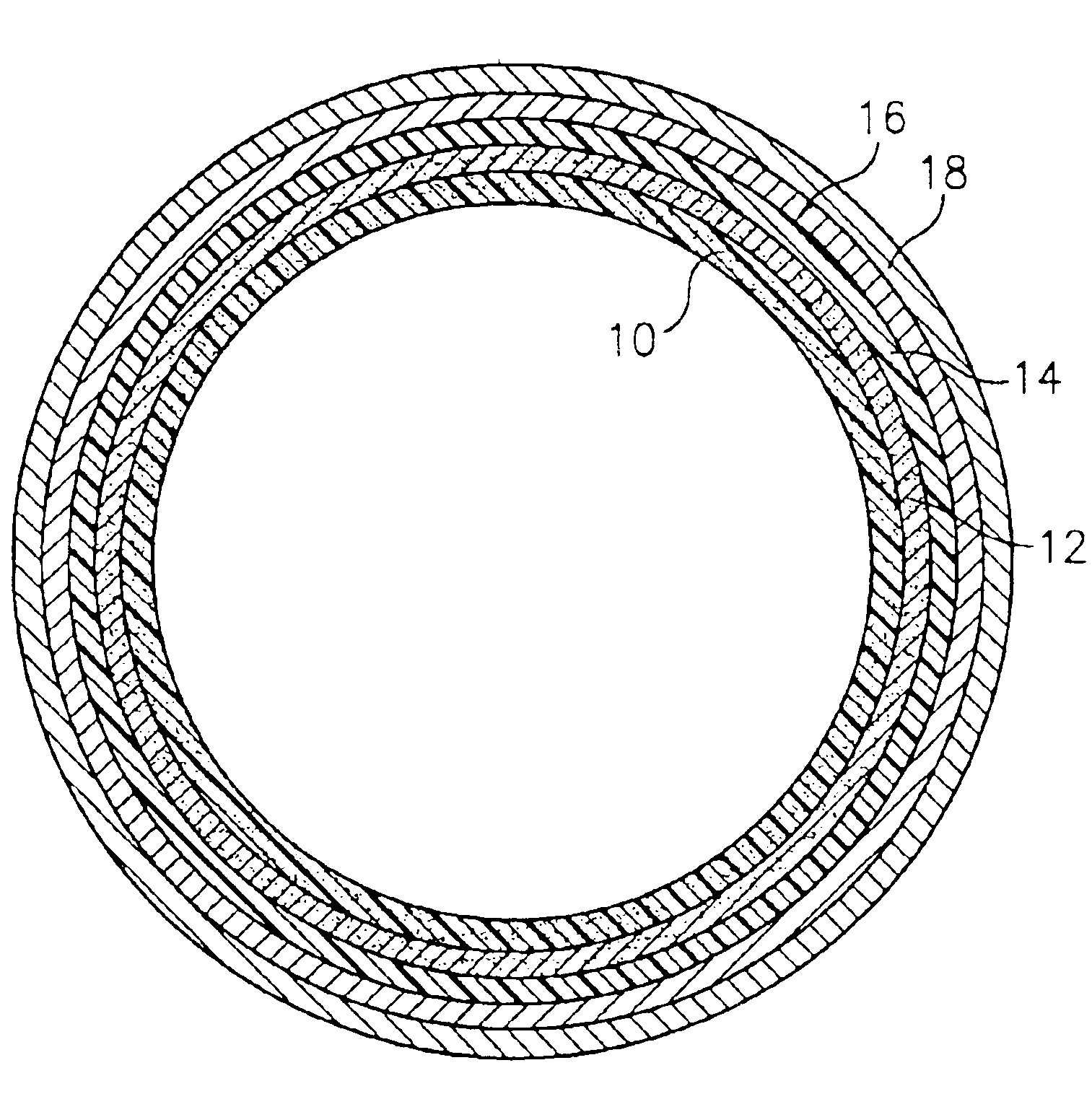

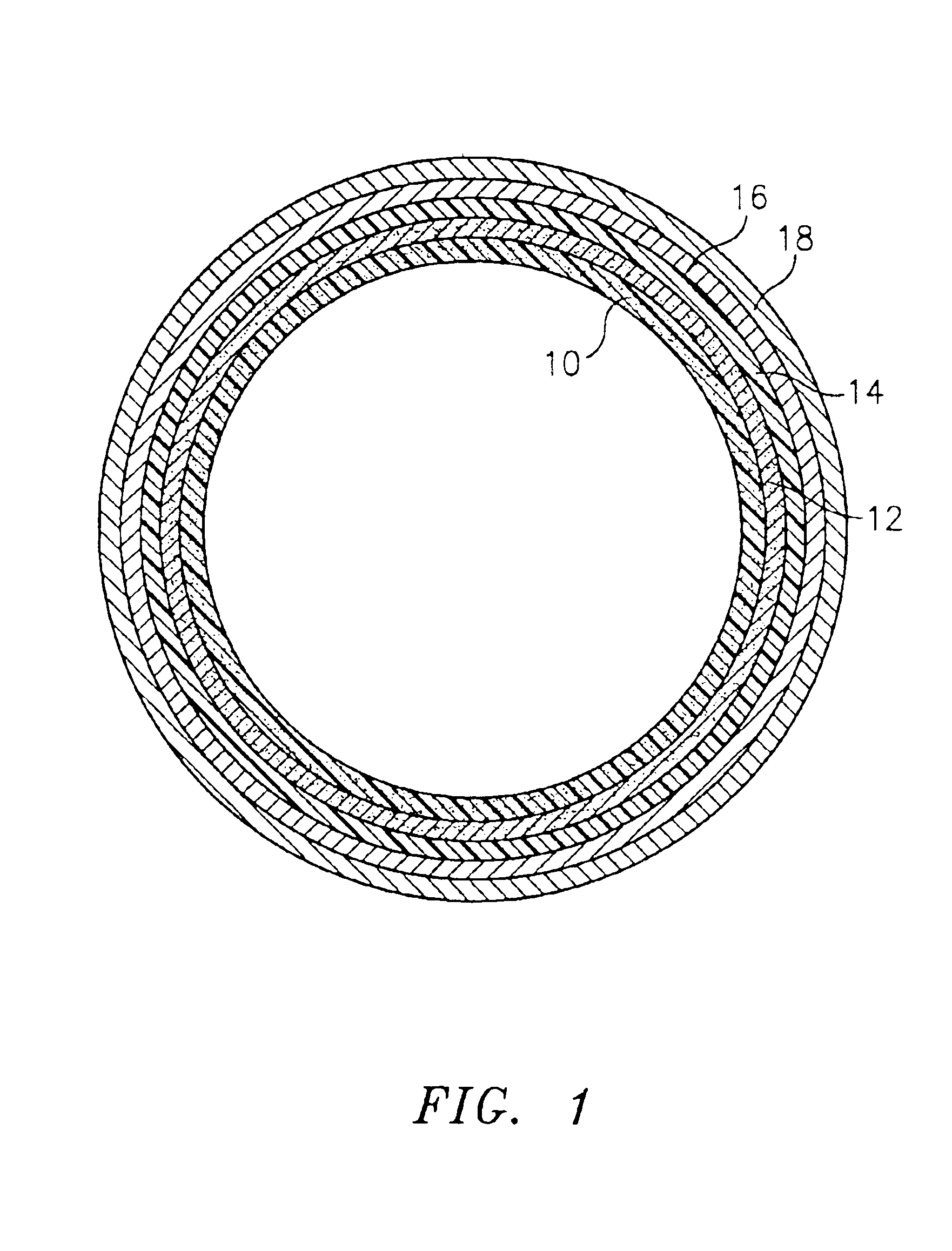

Printing sleeve with an integrated printing surface

ActiveUS6966259B2Improve adhesionQuality improvementElectric discharge tubesStereotype printingPhotopolymerEngineering

A seamless printing sleeve comprising a hollow cylindrical base and a seamless imageable surface as its outermost layer is described. The imageable surface acts as an integral flexographic printing surface. Preferably the printing sleeve comprises an intermediate photopolymer or resilient polymer layer between the outer surface of the base and the imageable surface. Also, preferably the base is uniformly transparent or translucent to actinic radiation.

Owner:MACDERMID PRINTING SOLUTIONS

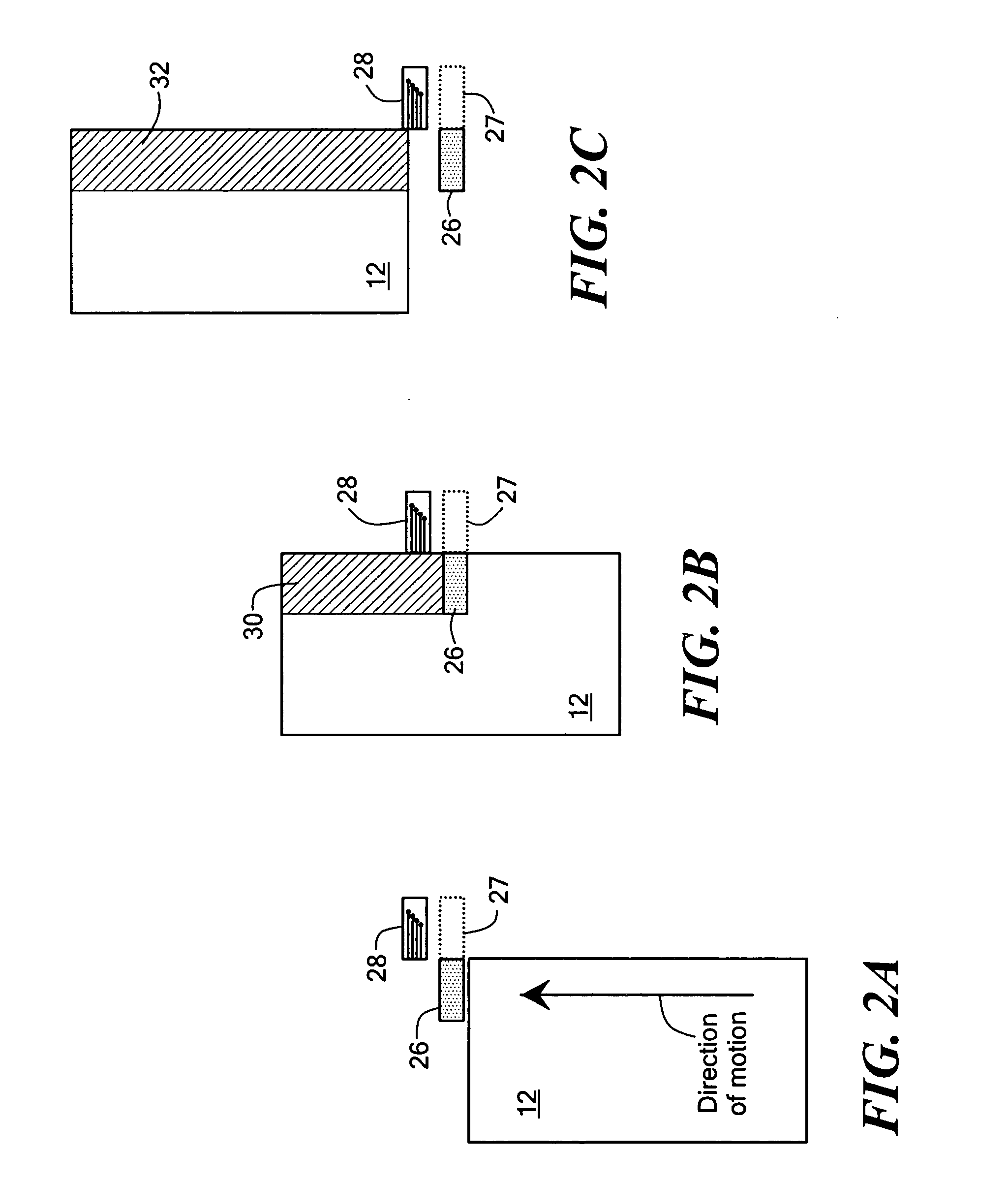

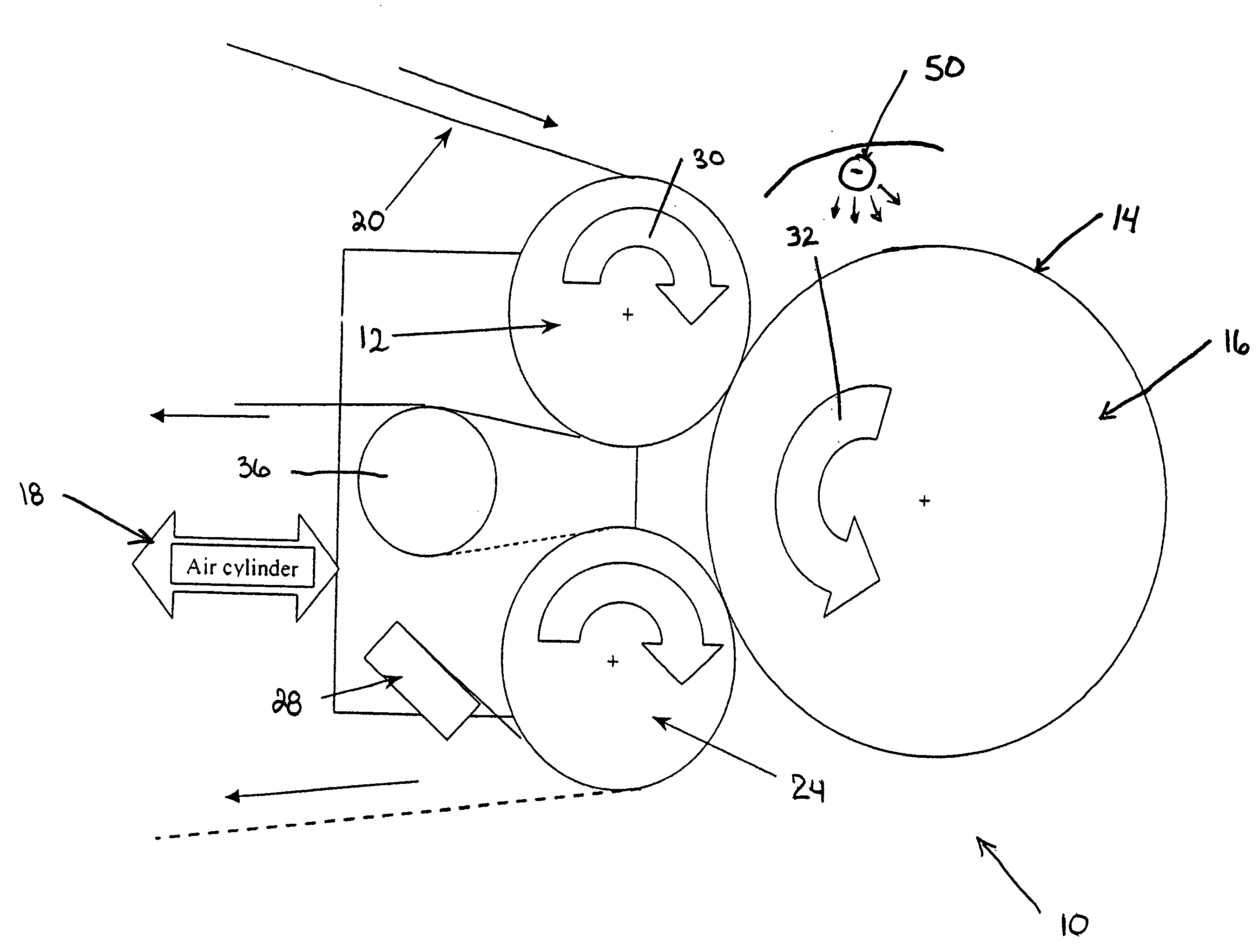

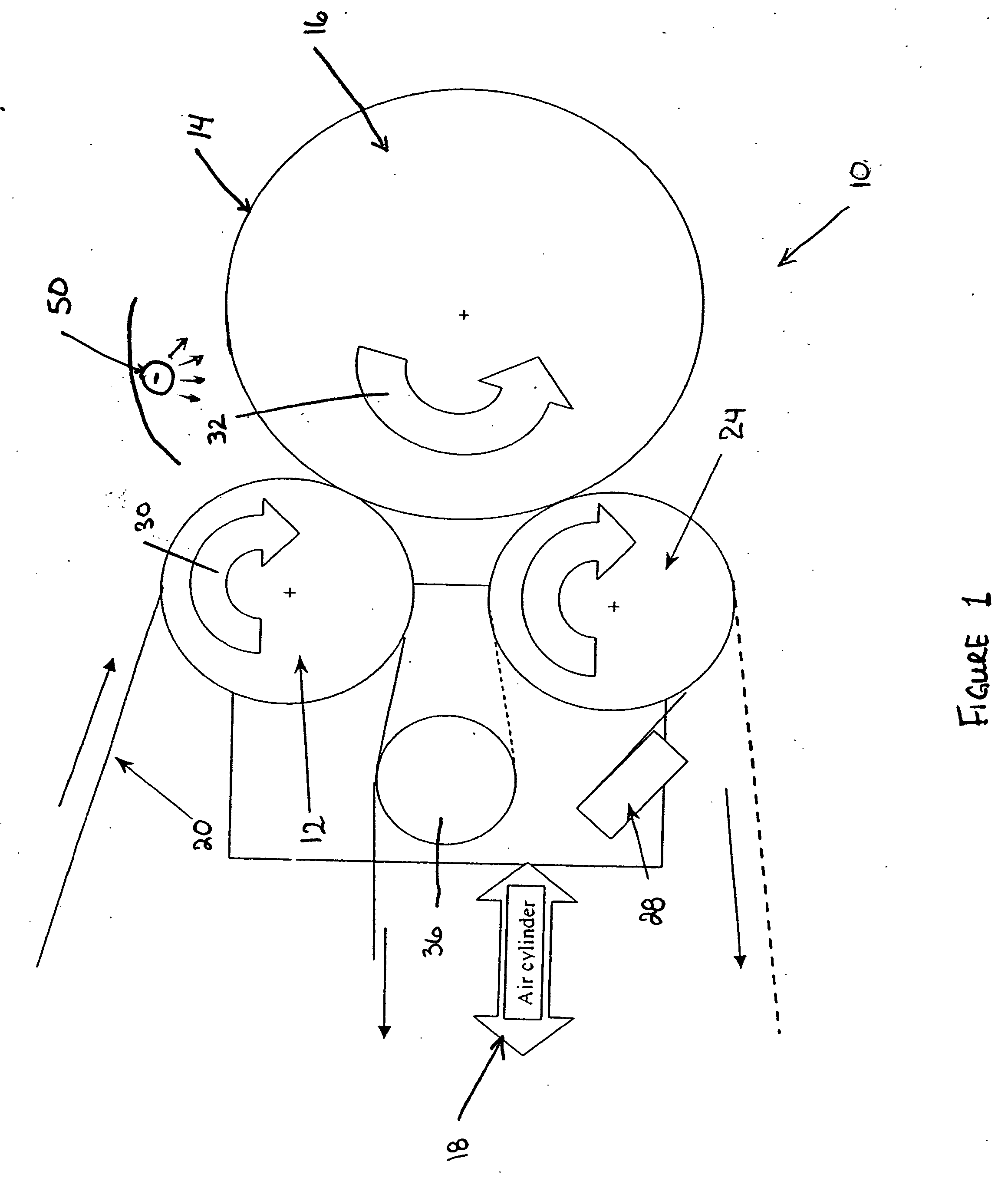

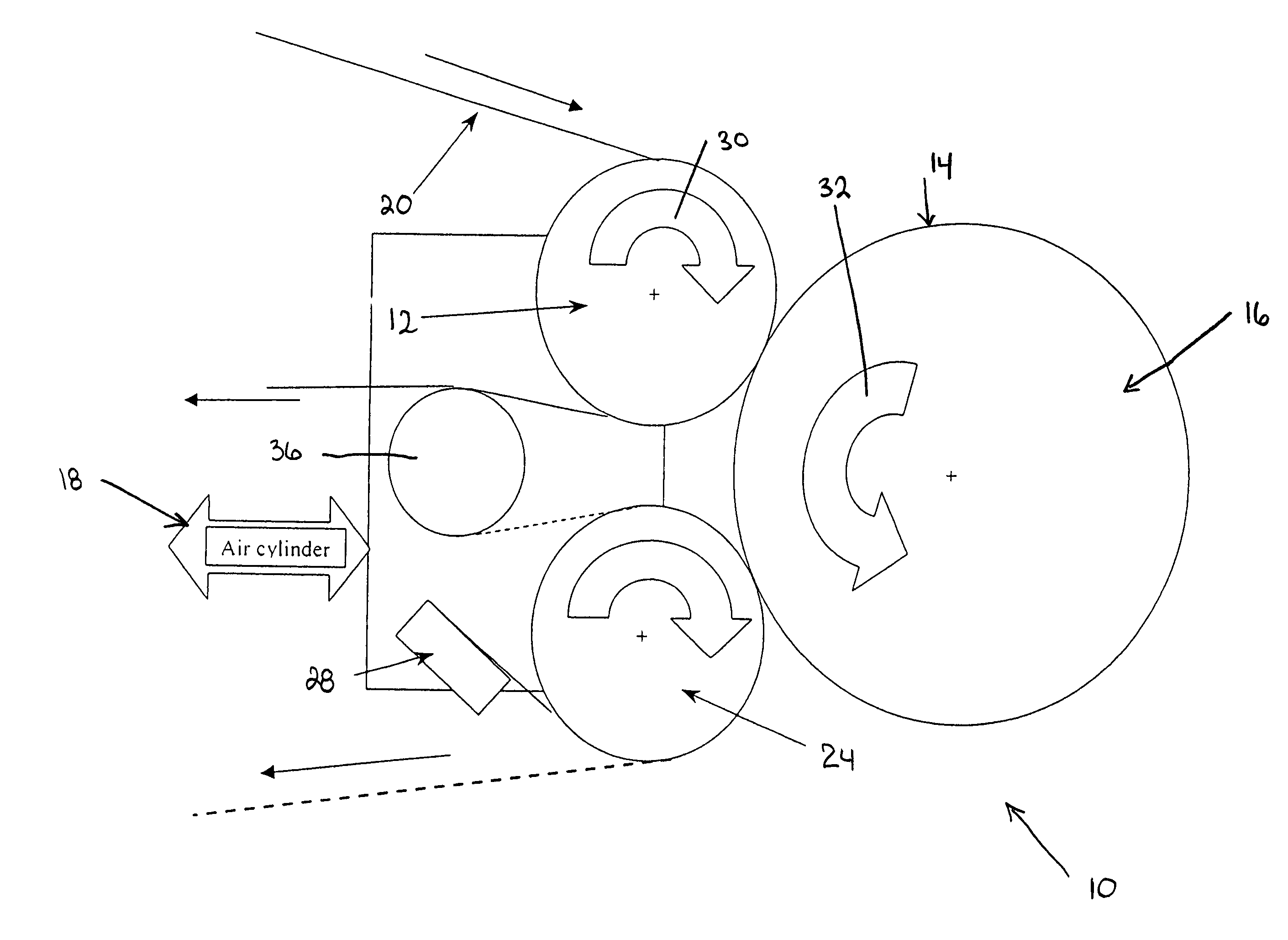

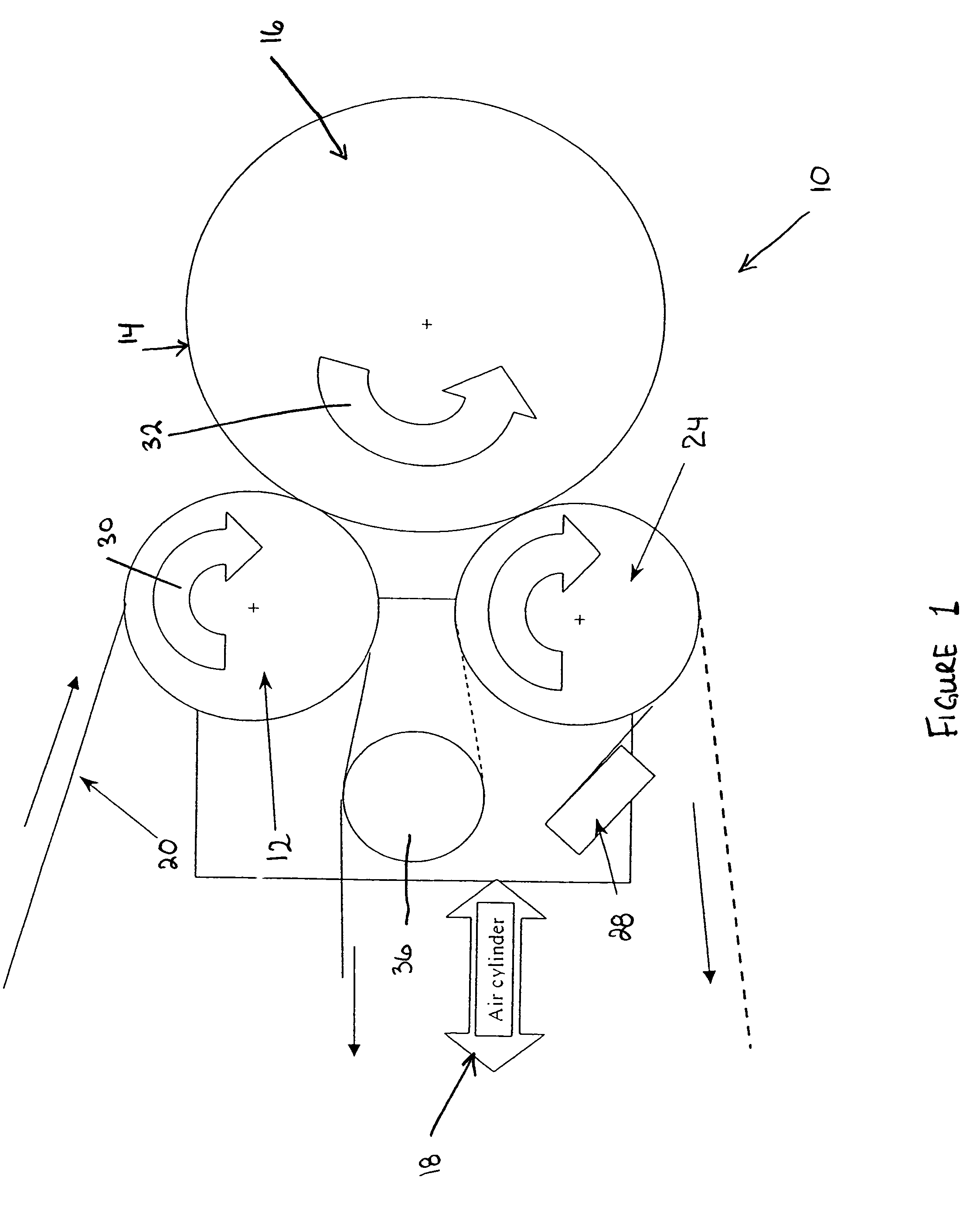

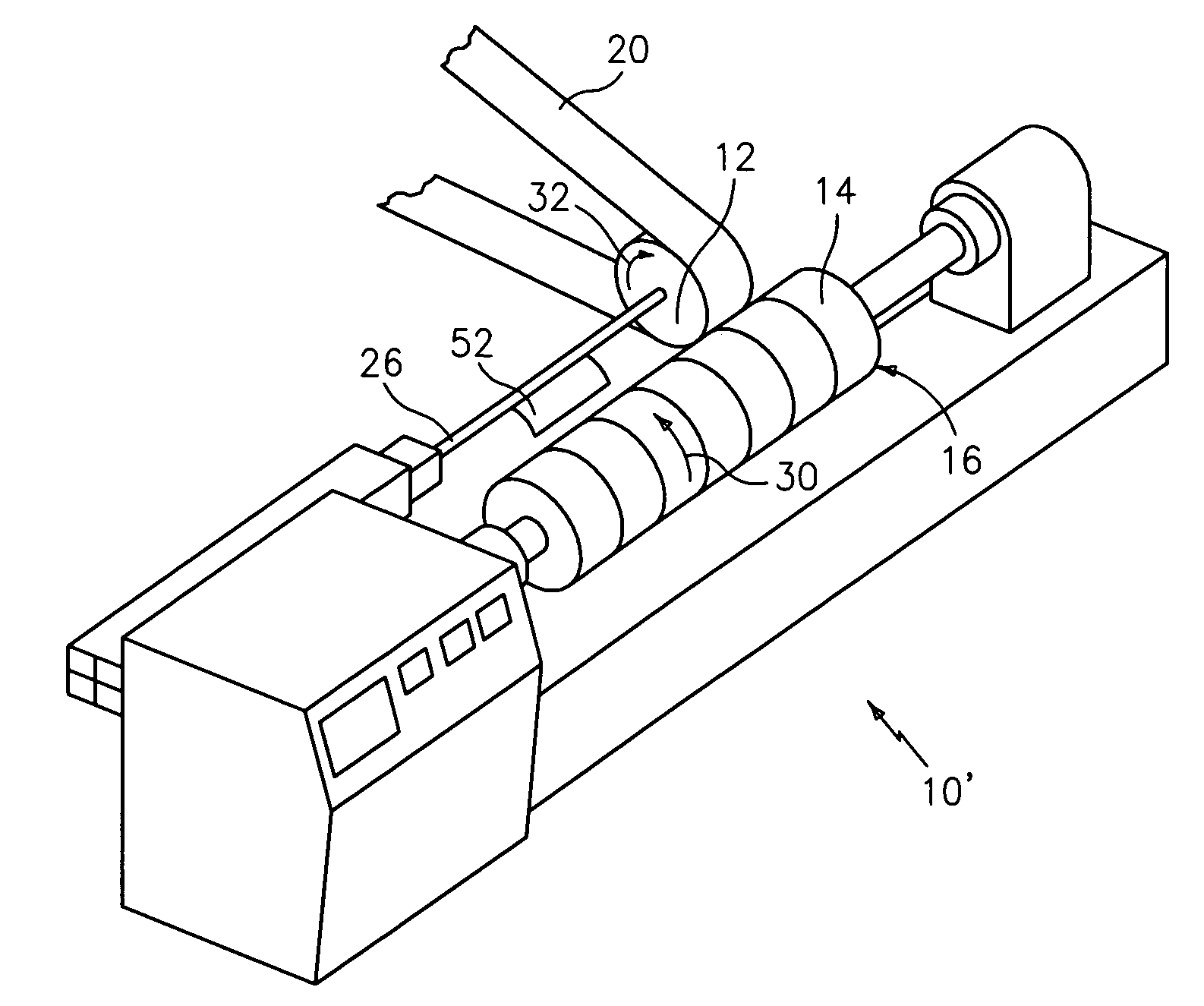

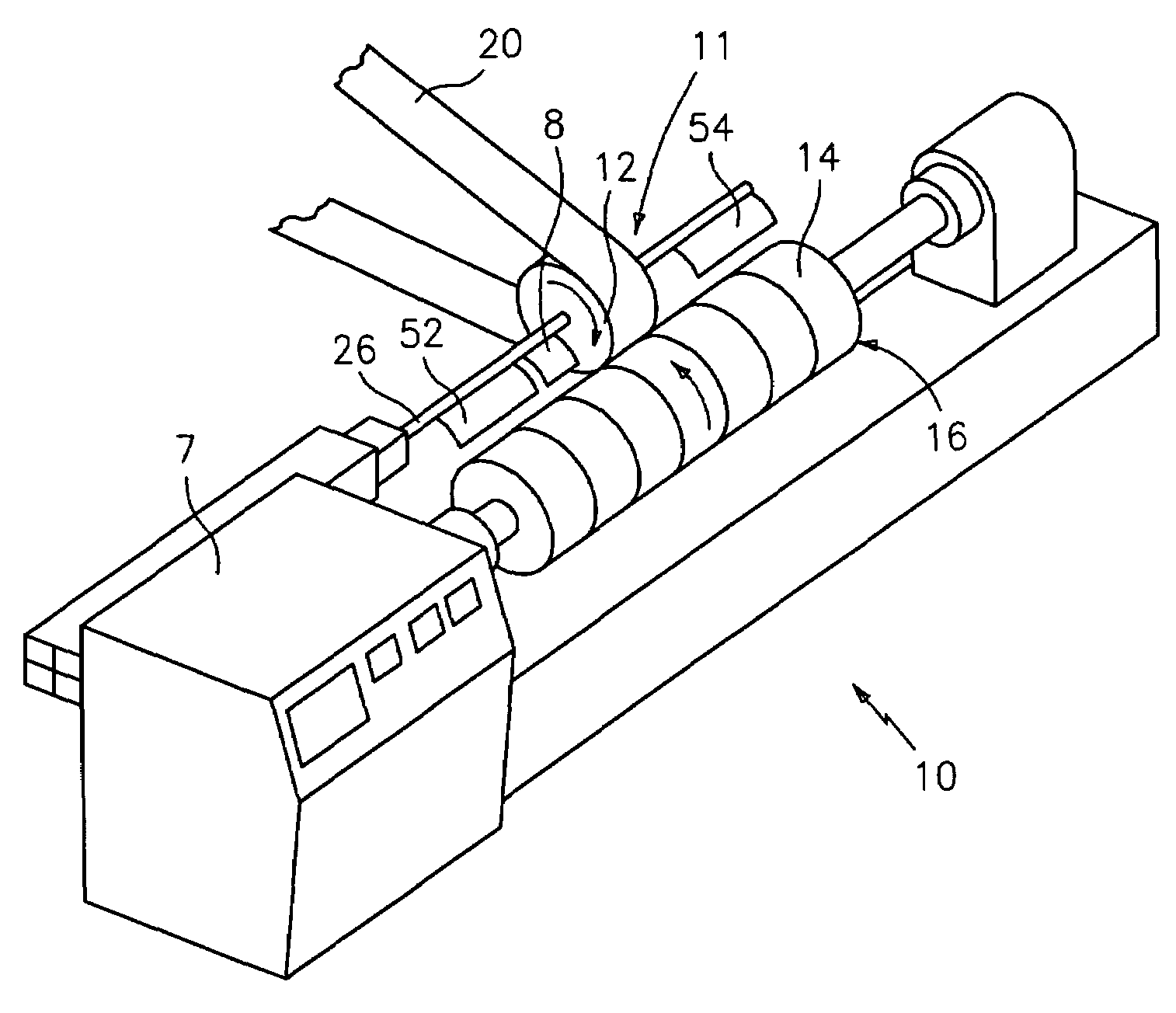

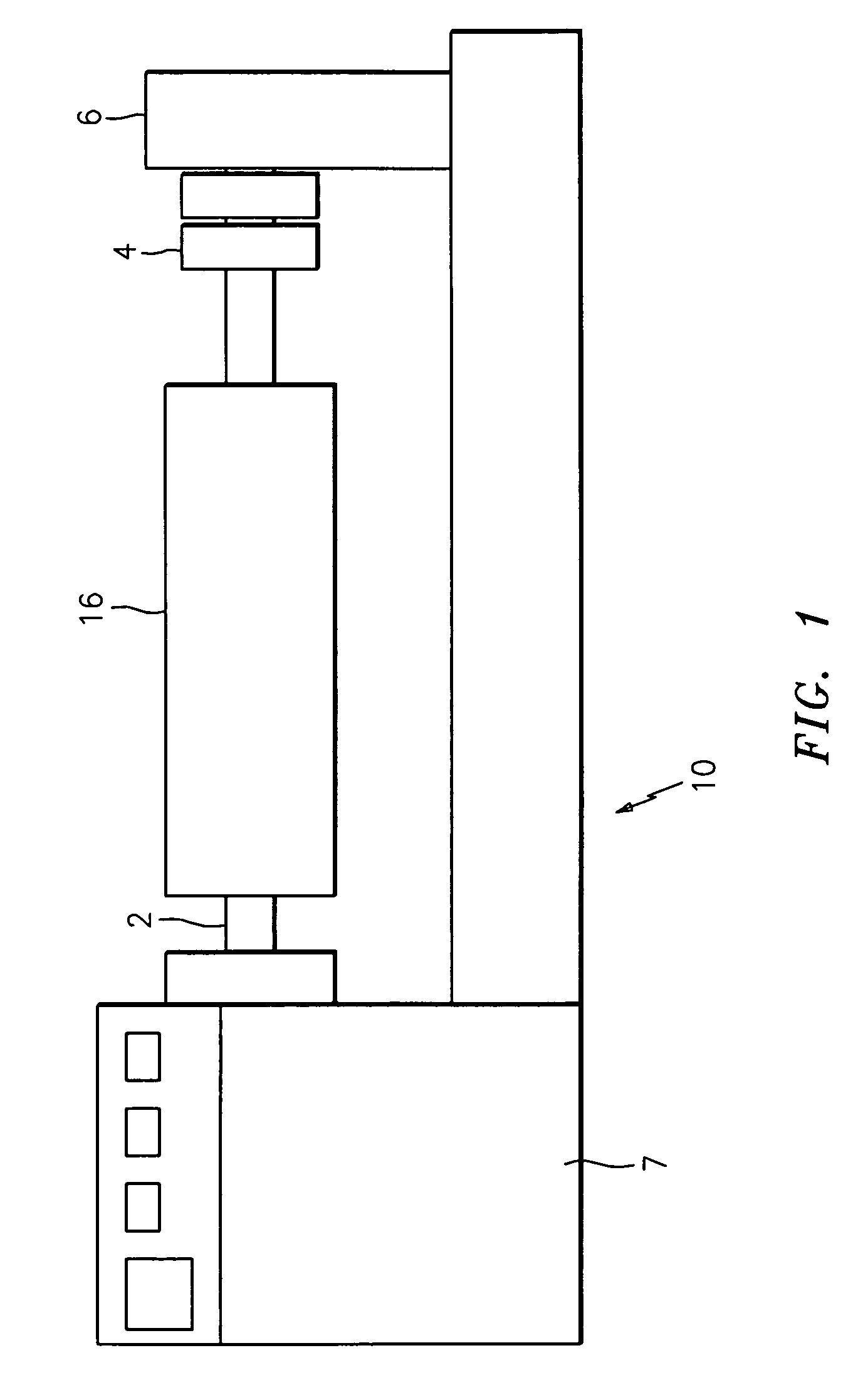

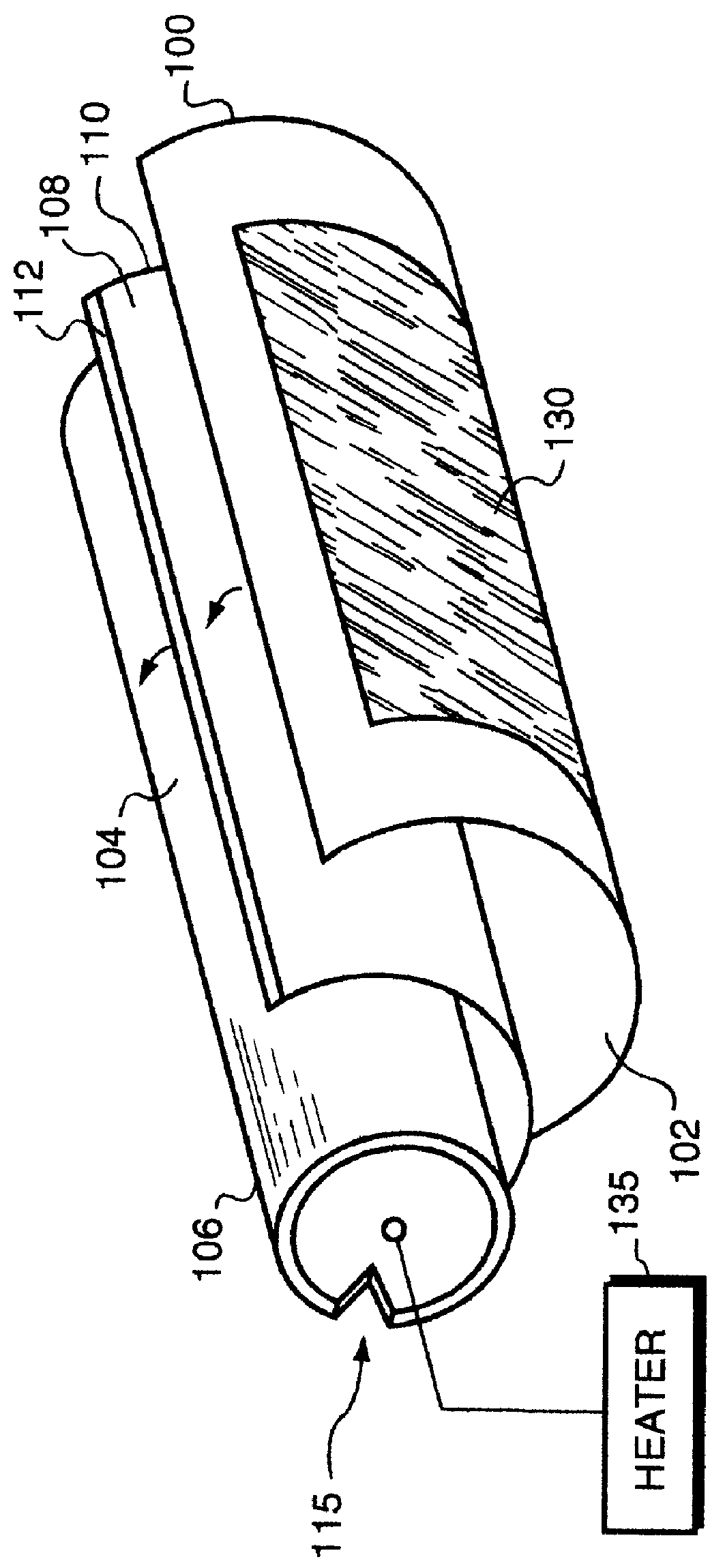

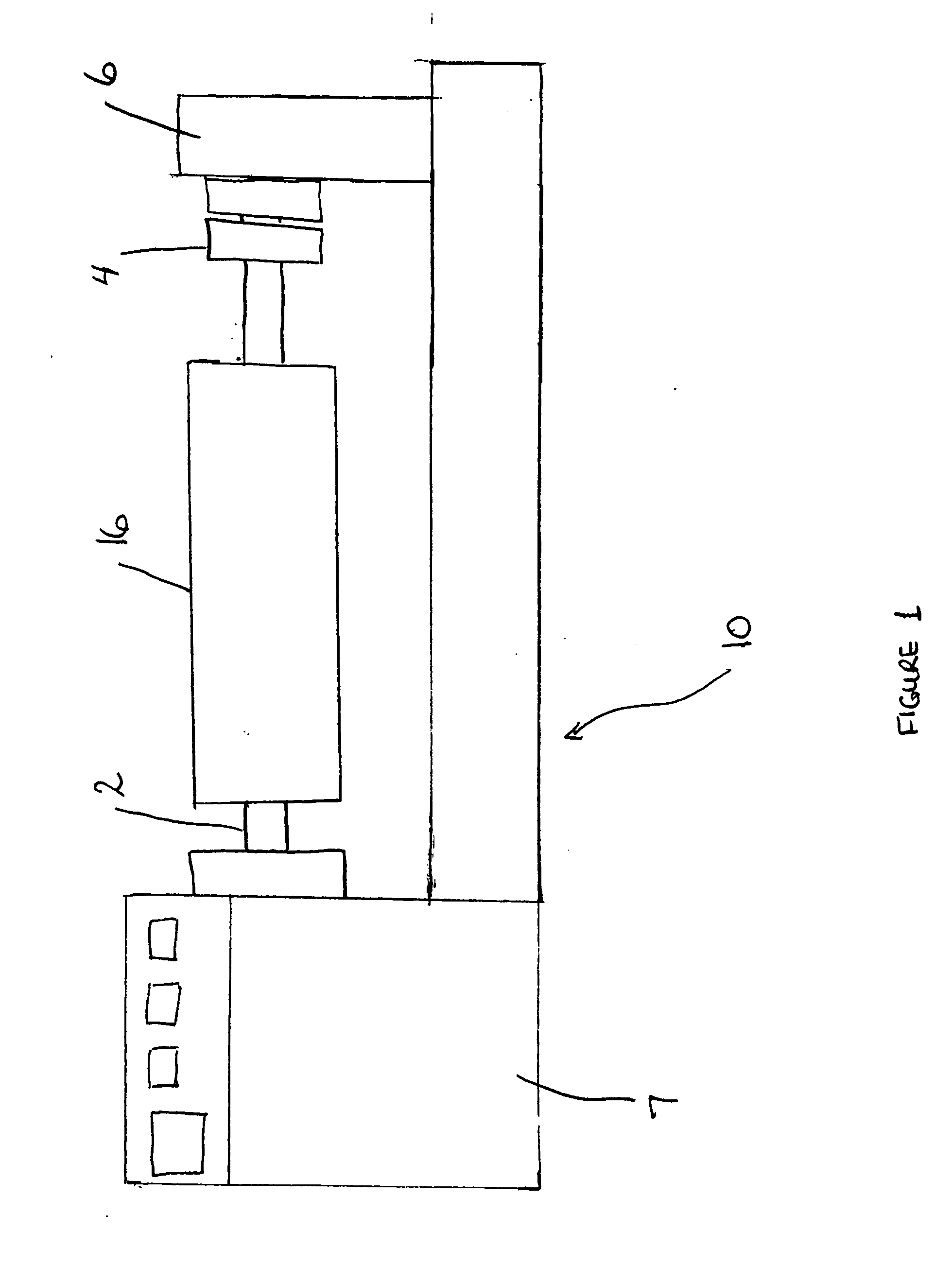

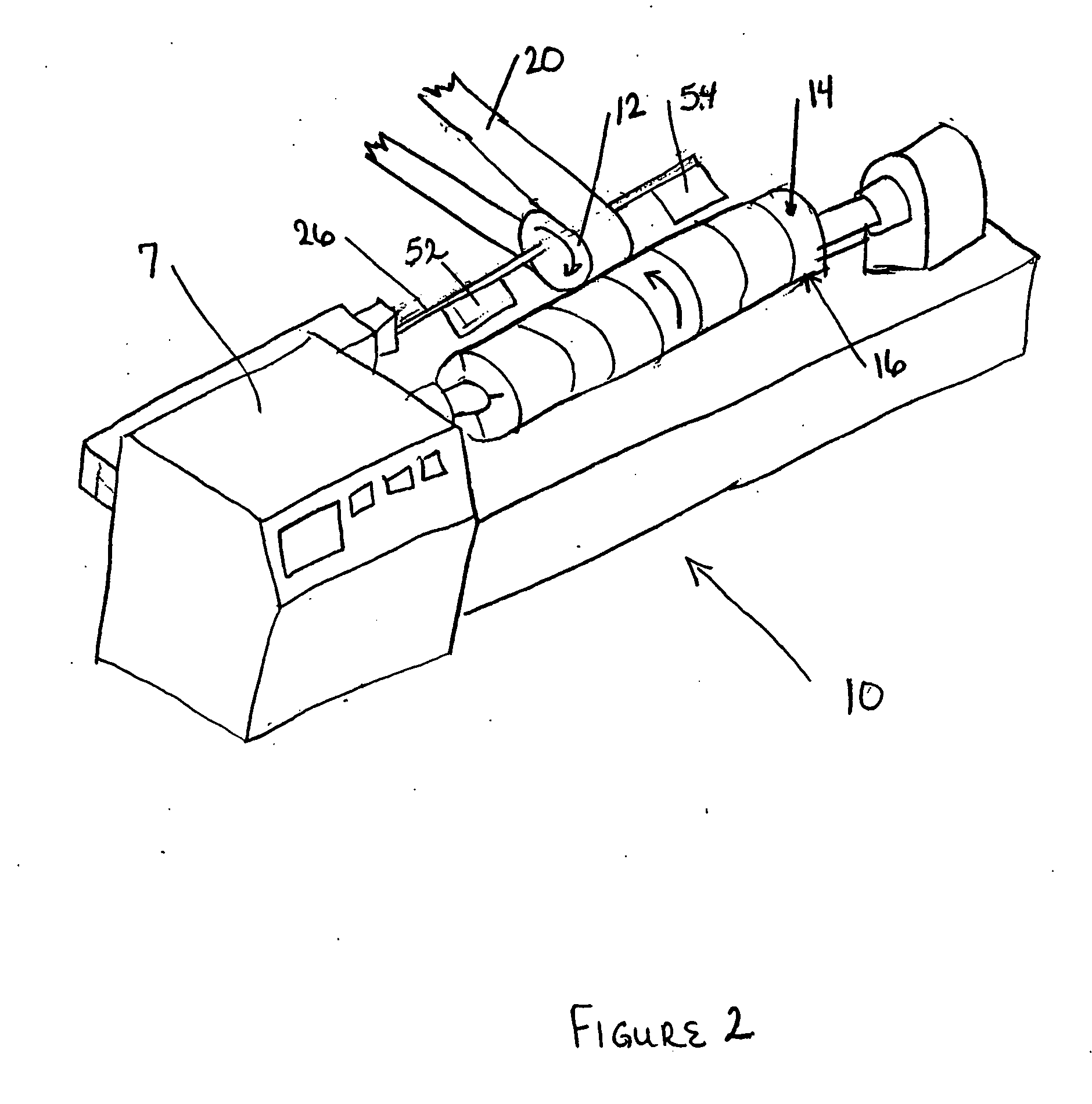

Apparatus and method for thermally developing flexographic printing elements

ActiveUS20050211120A1Improve developmentGood removal effectX-ray/infra-red processesDuplicating/marking methodsPhotopolymerElectrical and Electronics engineering

An improved apparatus for thermally developing a flexographic printing element to reveal a relief image on the surface and a method of using the apparatus to expose and develop a flexographic printing element. The apparatus typically comprises means for softening or melting non-crosslinked photopolymer on the imaged and exposed surface of the flexographic printing element; at least one roll that is contactable with the imaged surface of the flexographic printing element and capable of moving over at least a portion of the imaged surface of the flexographic printing element to remove the softened or melted non-crosslinked photopolymer on the imaged and exposed surface of the flexographic printing element; and means for maintaining contact between the at least one roll and the imaged and exposed surface of the flexographic printing element. The means for softening or melting non-crosslinked photopolymer on the imaged and exposed surface of the flexographic printing element comprise a heater positioned adjacent to the imaged surface of the flexographic printing element and / or heating the at least one roll that contactable with the imaged surface of the flexographic printing element. The apparatus may also contain an exposure device to crosslink and cure the imaged surface of the flexographic printing element prior to thermal development.

Owner:MACDERMID PRINTING SOLUTIONS

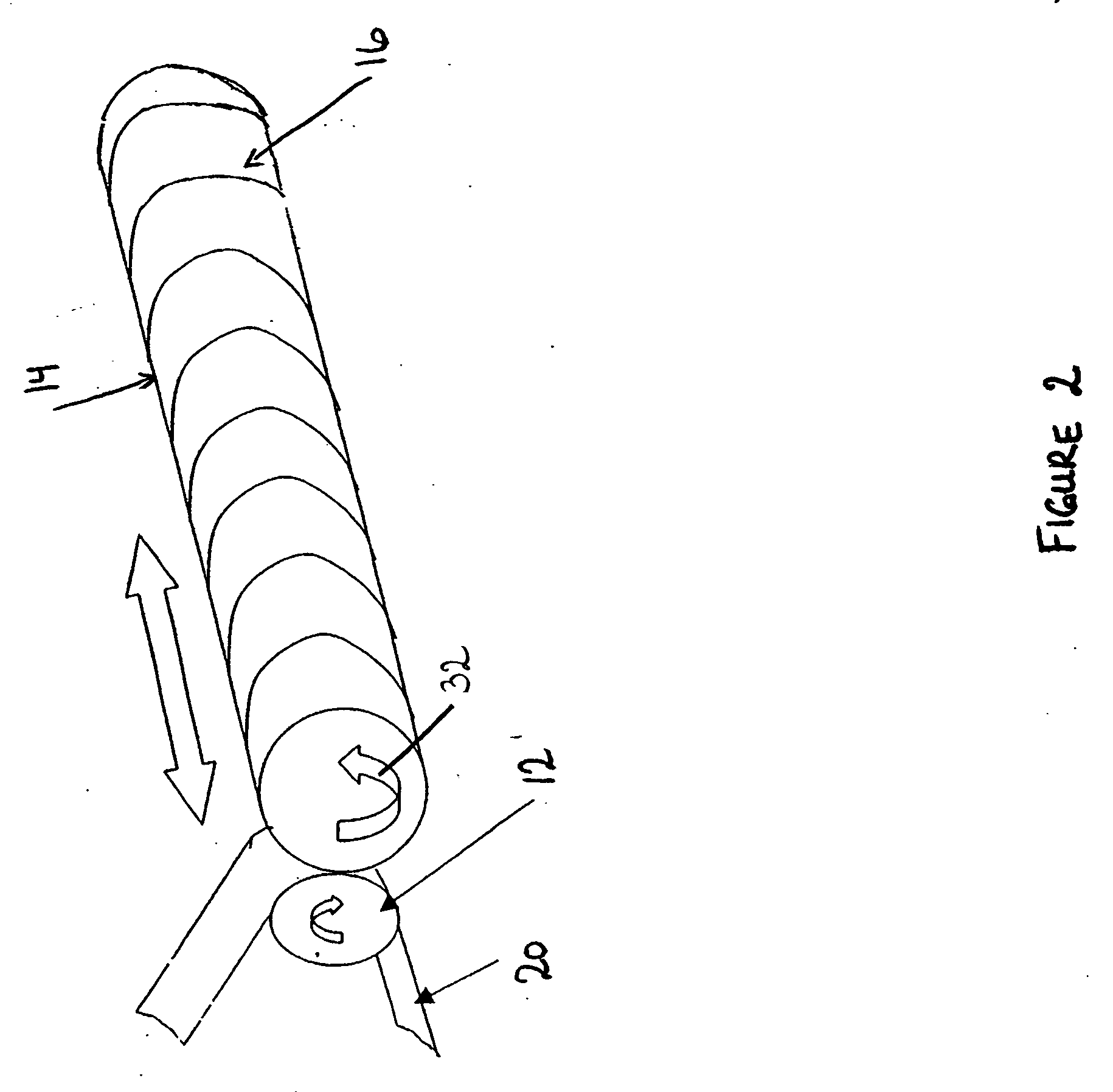

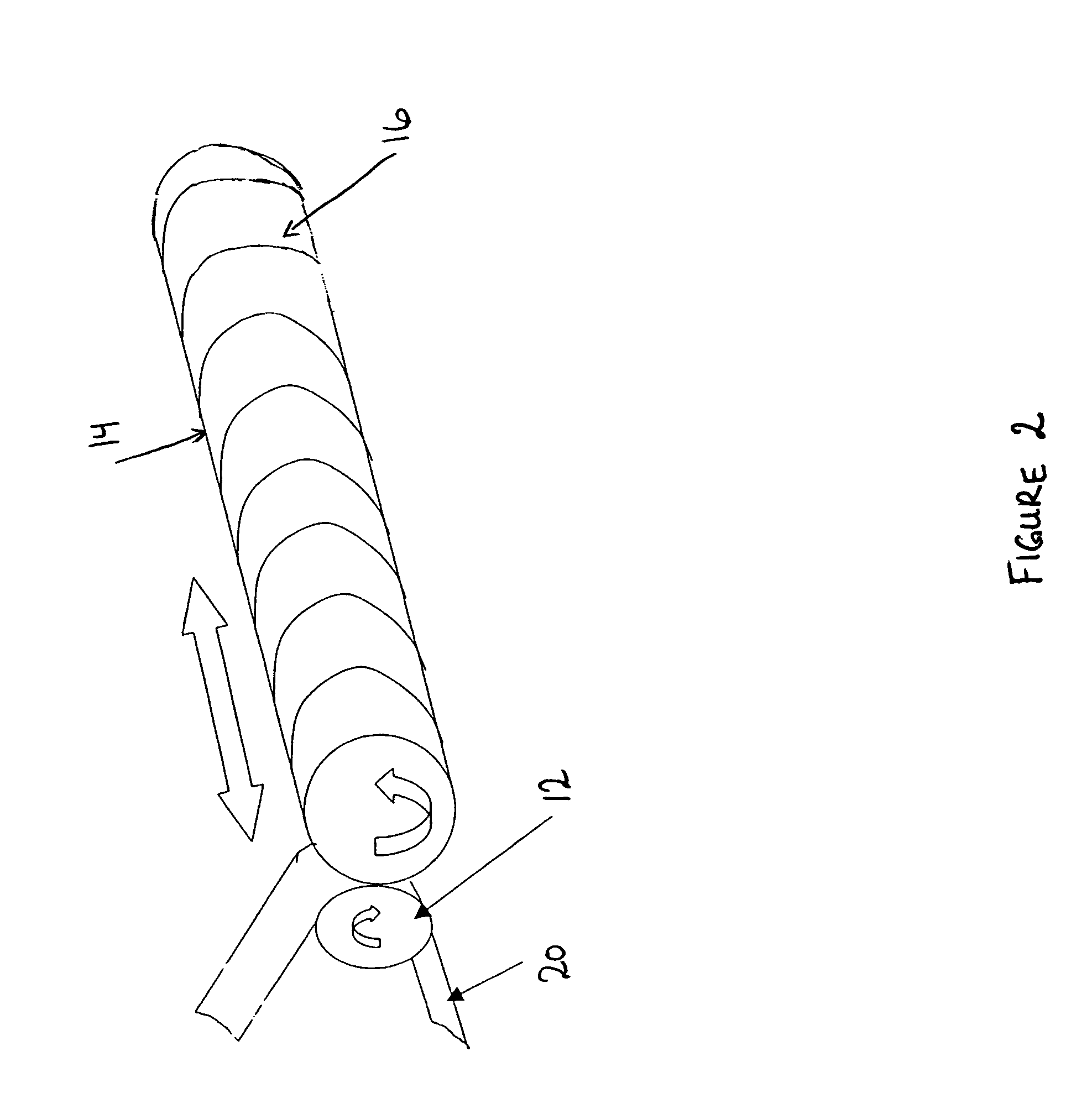

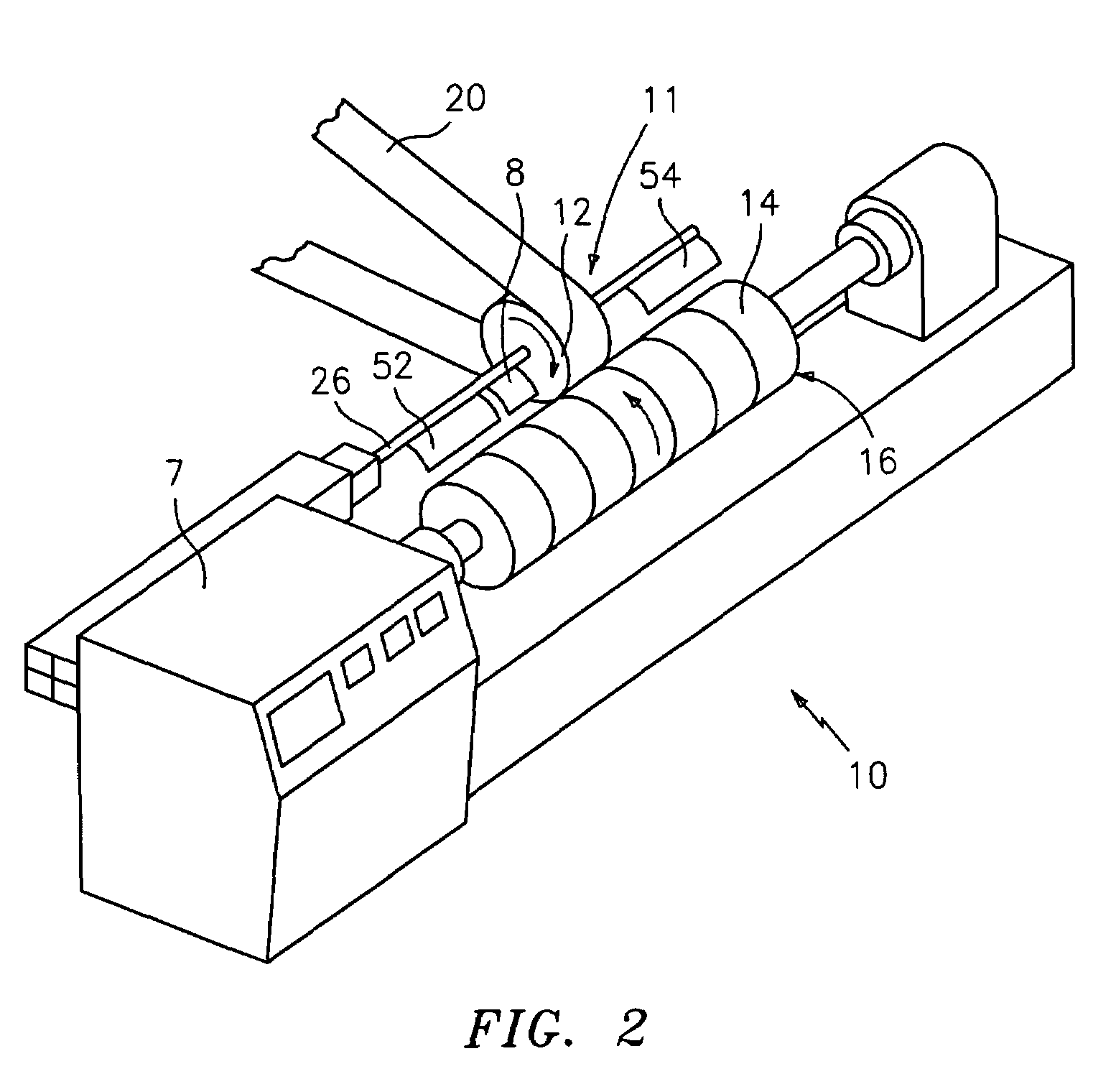

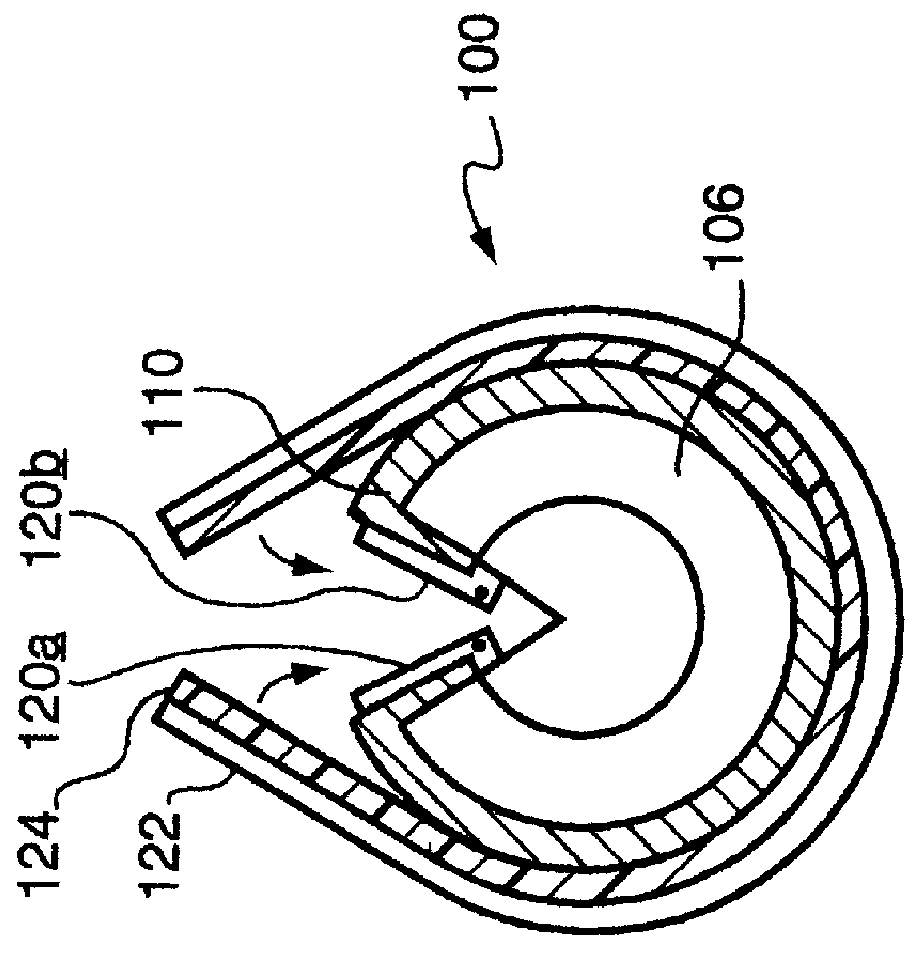

Apparatus and method for thermally developing flexographic printing sleeves

ActiveUS6998218B2Good removal effectIncrease speedMulticolor photographic processingSemiconductor/solid-state device manufacturingPhotopolymerCrosslinked polymers

An improved thermal development apparatus is used to remove uncured photopolymer from the imaged surface of a flexographic printing element. The apparatus typically comprises one or more heatable rolls that are contactable with an imaged surface of a flexographic printing element; and means for maintaining contact between the one or more heatable rolls and the imaged surface of the flexographic printing element. The one or more heatable rolls are heated and is moved over at least a portion of the imaged surface of the flexographic printing element, and non-crosslinked polymer on the imaged surface of the flexographic printing element is melted and removed by the one or more heatable rolls.

Owner:MACDERMID PRINTING SOLUTIONS

Screened film intermediate for use with flexographic printing plate having improved solids rendition

A flexographic printing plate having solid image areas which are covered by a plurality of very small and shallow cells similar to the ink carrying cells found in anilox ink metering rolls. These cells fill with ink during the plate inking step and reproduce solid image areas with better color saturation while at the same time reducing the halo typical of flexographic printing of solids. Associated with this plate is a method for producing the cells, including the use of an intermediate screened film and of a computer program for generating the film intermediate.

Owner:ESKO SOFTWARE

Clean Flexographic Printing Plate and Method of Making the Same

ActiveUS20130228086A1Printing cleanly during a print runEasy constructionMounting boardsPlate printingPhotopolymerEngineering

A clean running flexographic relief image printing element and a method of making the same is described. The relief image printing element comprises (a) a backing layer; (b) a floor layer disposed on the backing layer and comprising a photopolymer containing a silicone monomer or silicone oil, wherein the cured floor layer has a surface energy of between about 18 to about 25 dynes / cm; (c) a cap layer disposed on the floor layer and comprising a photocurable composition that is capable of being imagewise exposed to actinic radiation to create a relief image therein, wherein the cap layer has a surface energy of between about 30 and about 40 dynes / cm; and (d) a removable cover sheet. The differential of surface energies between the floor layer and the cap layer increases how clean the plate will print over time.

Owner:MACDERMID PRINTING SOLUTIONS

Apparatus and method for thermally developing flexographic printing elements

ActiveUS7041432B2Good removal effectIncrease speedX-ray/infra-red processesDuplicating/marking methodsPhotopolymerElectrical and Electronics engineering

An improved apparatus for thermally developing a flexographic printing element to reveal a relief image on the surface and a method of using the apparatus to expose and develop a flexographic printing element. The apparatus typically comprises means for softening or melting non-crosslinked photopolymer on the imaged and exposed surface of the flexographic printing element; at least one roll that is contactable with the imaged surface of the flexographic printing element and capable of moving over at least a portion of the imaged surface of the flexographic printing element to remove the softened or melted non-crosslinked photopolymer on the imaged and exposed surface of the flexographic printing element; and means for maintaining contact between the at least one roll and the imaged and exposed surface of the flexographic printing element. The means for softening or melting non-crosslinked photopolymer on the imaged and exposed surface of the flexographic printing element comprise a heater positioned adjacent to the imaged surface of the flexographic printing element and / or heating the at least one roll that contactable with the imaged surface of the flexographic printing element. The apparatus may also contain an exposure device to crosslink and cure the imaged surface of the flexographic printing element prior to thermal development.

Owner:MACDERMID PRINTING SOLUTIONS

Rubber cylinder sleeve, especially for web-fed rotary offset printing machines

InactiveUS6484632B2Produced cost-effectivelyImprove printing qualityMounting boardsPrinting blanketsCompressible materialEngineering

A rubber cylinder sleeve for web-fed rotary offset printing machines has a covering layer which is a finite layer having a joint location, the joint location being filled with a compressible material.

Owner:MANROLANAD AG

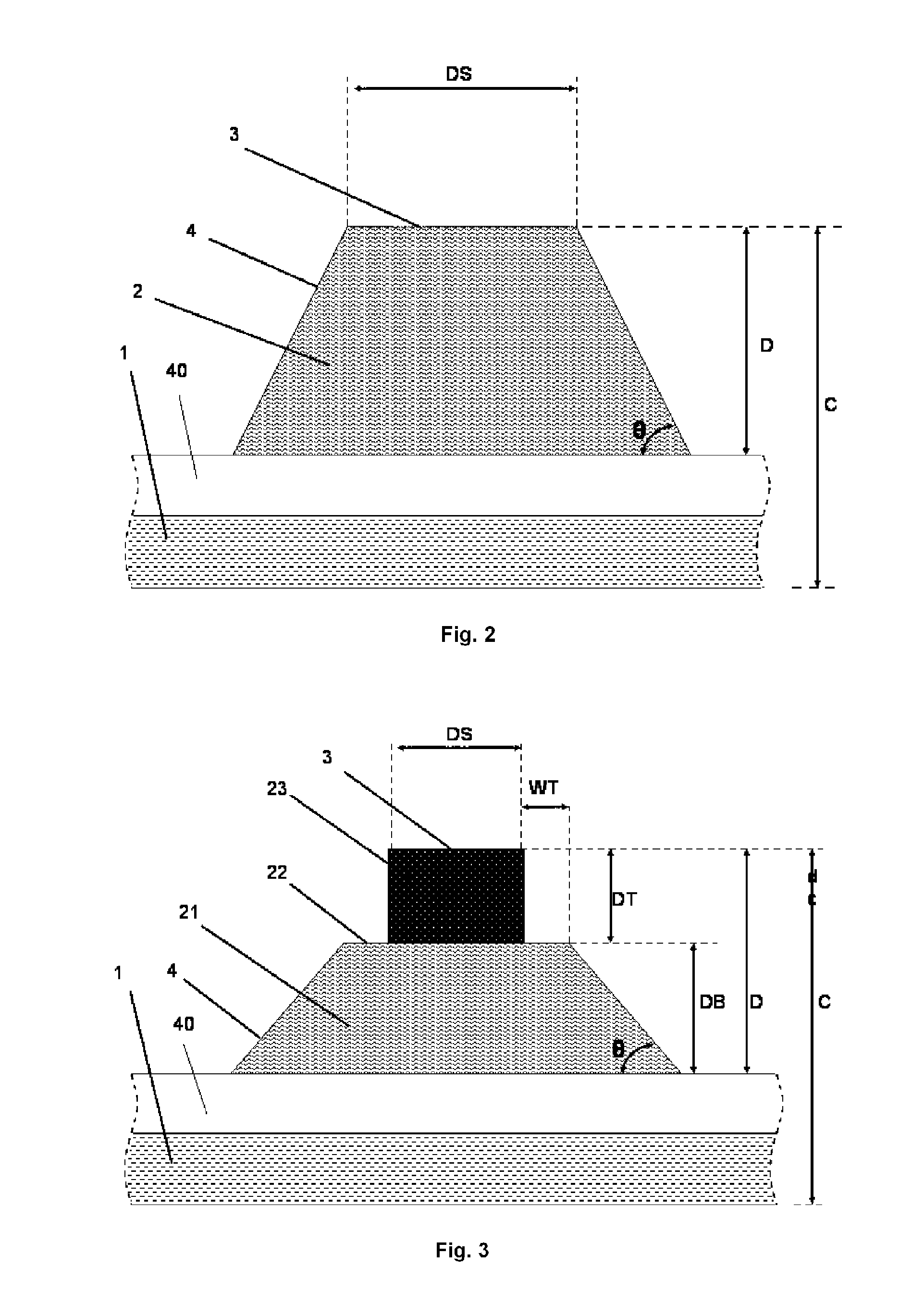

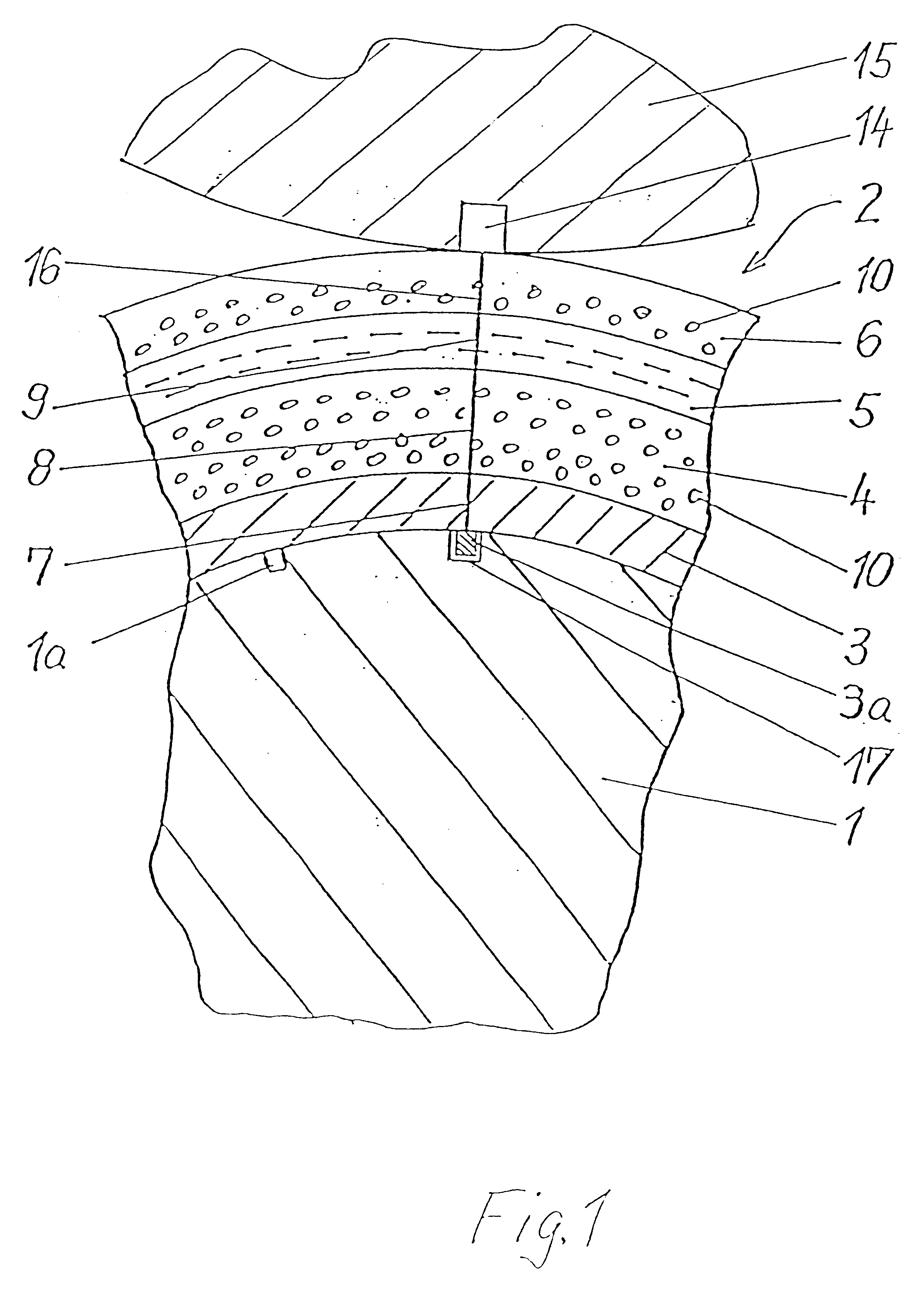

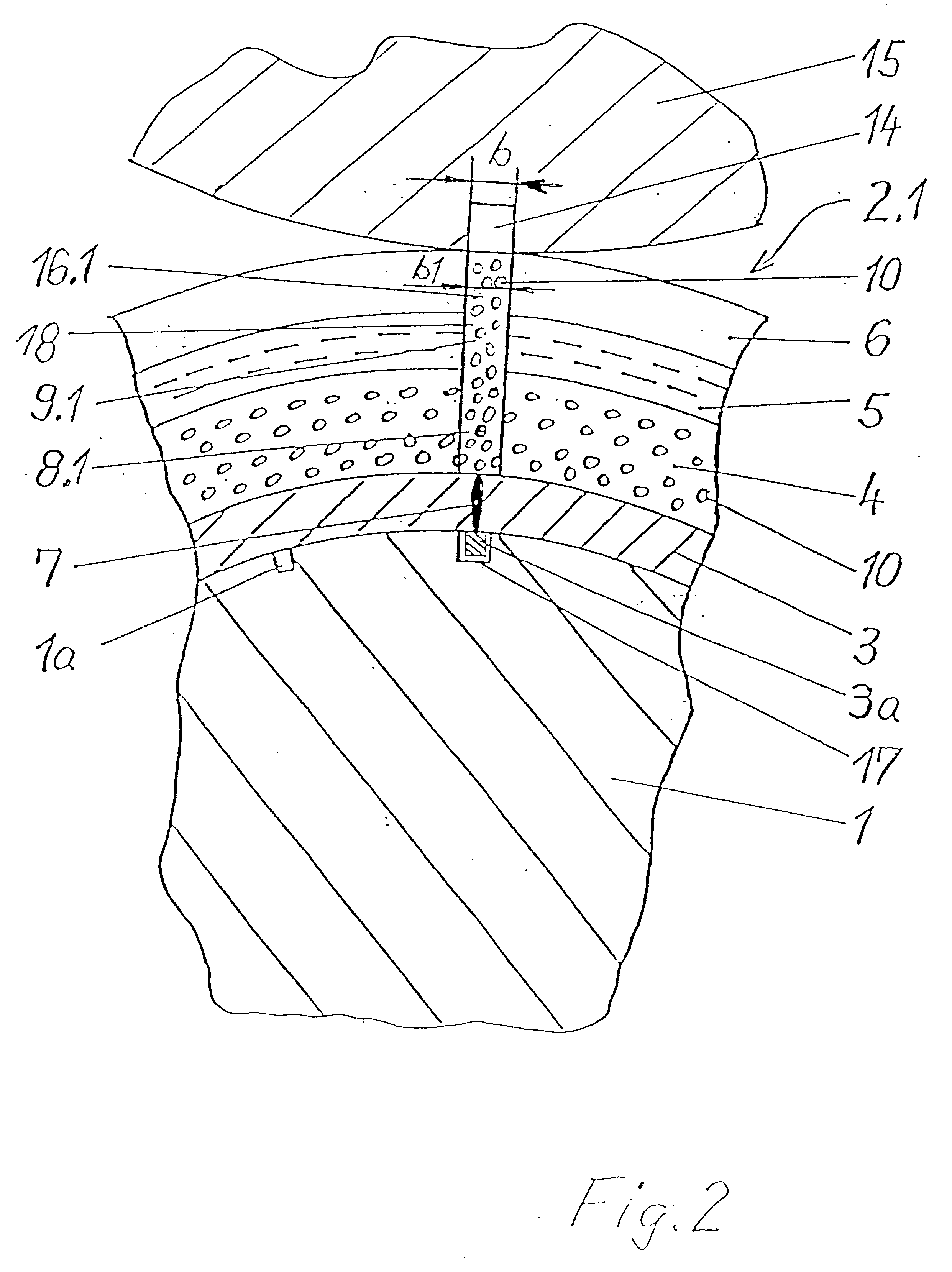

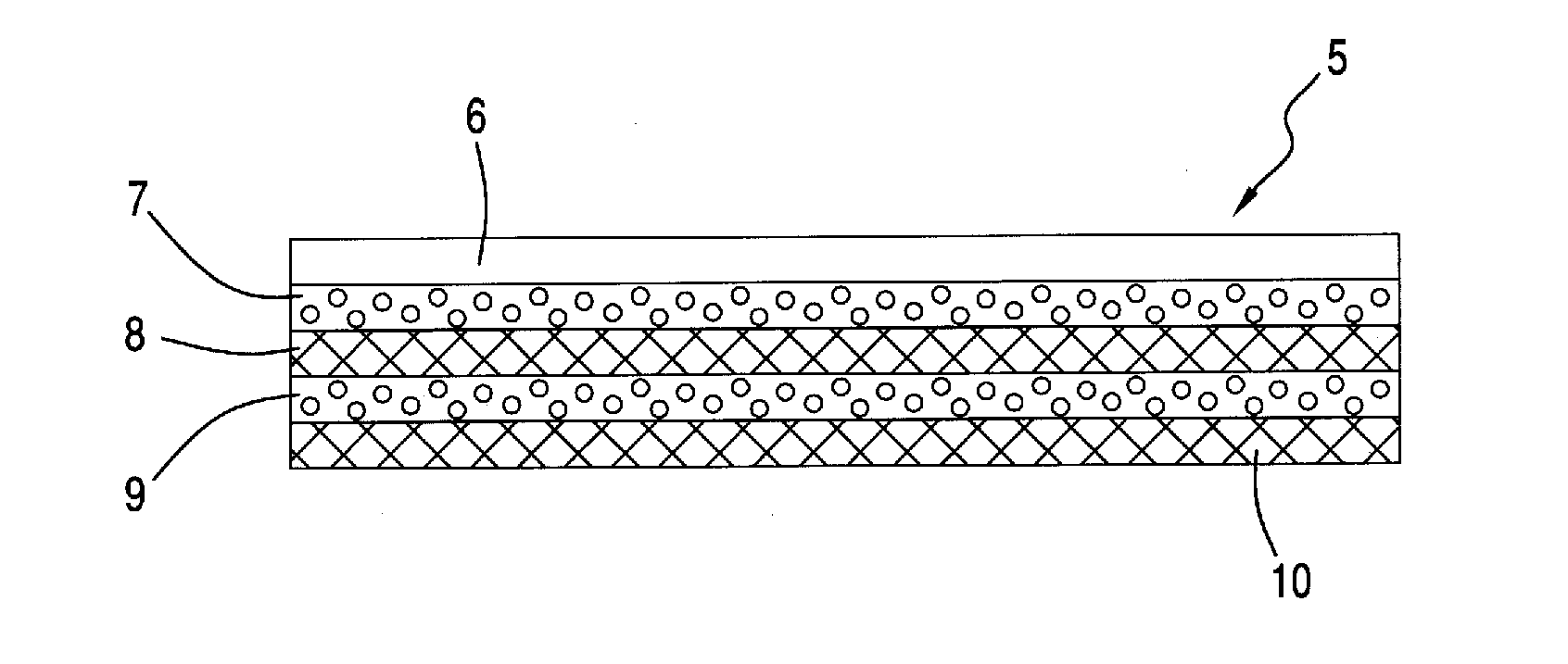

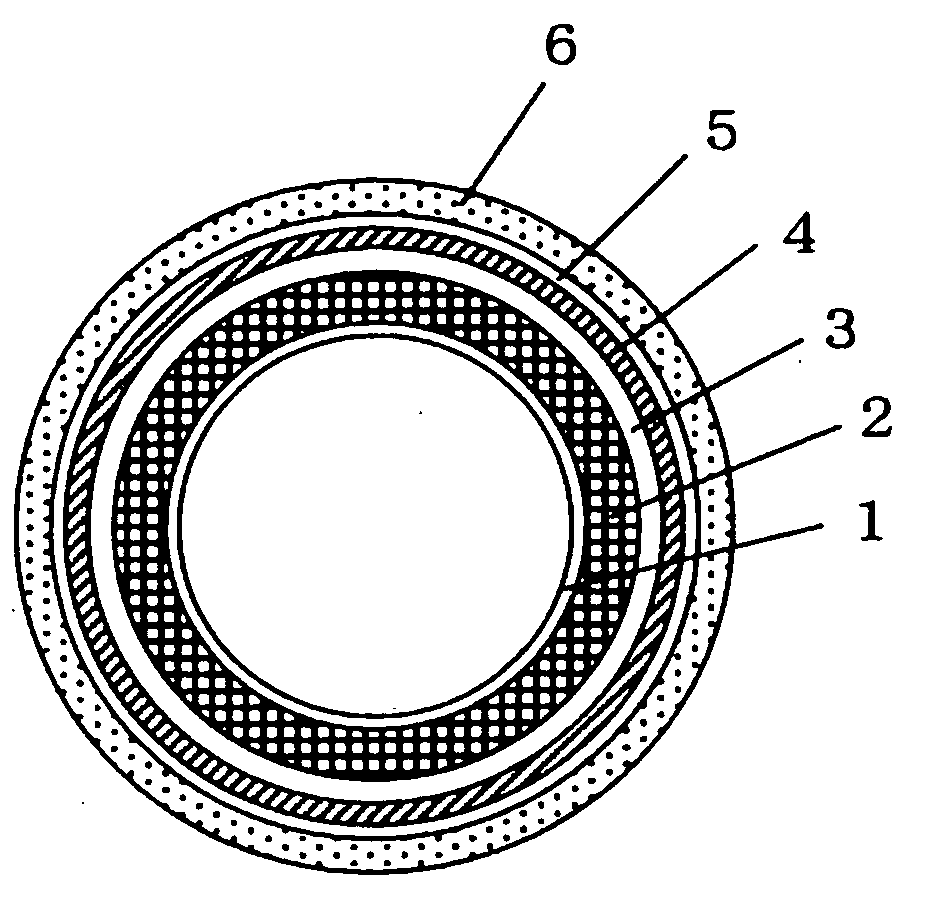

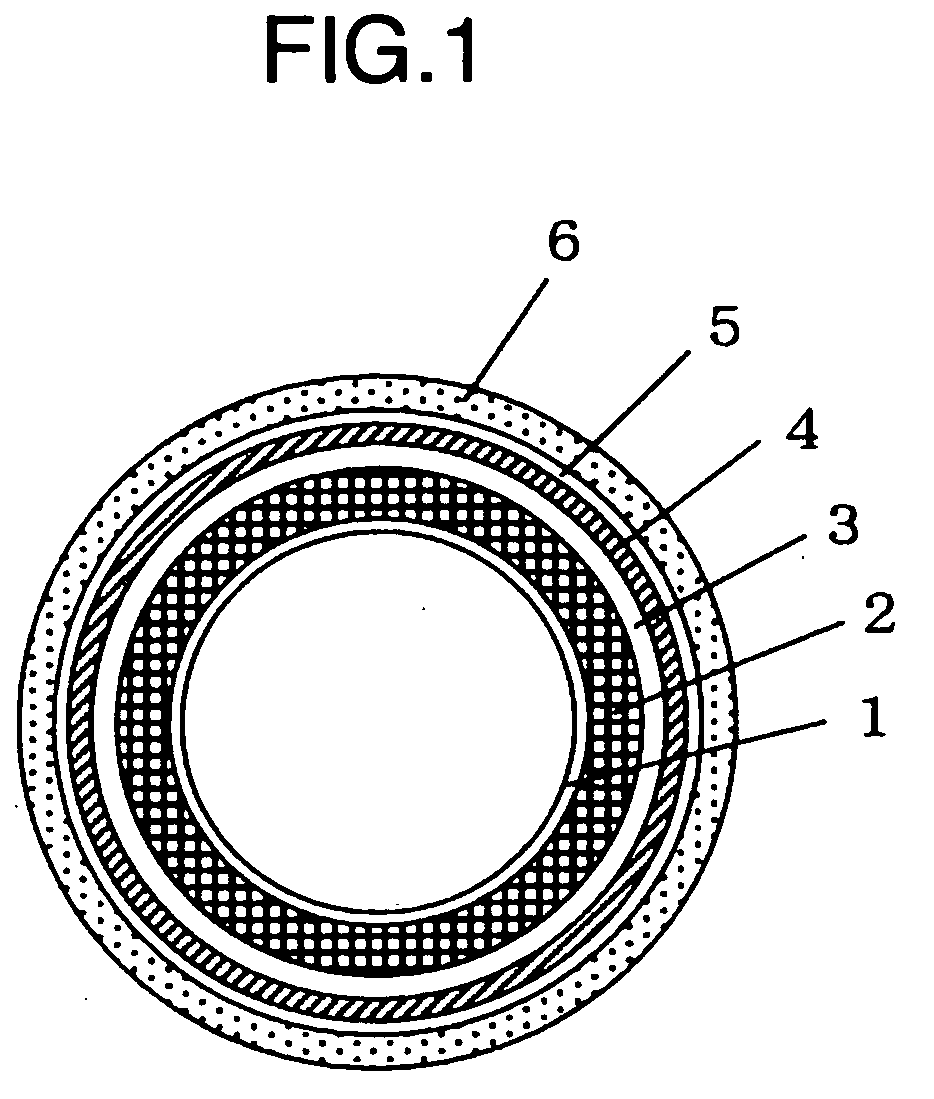

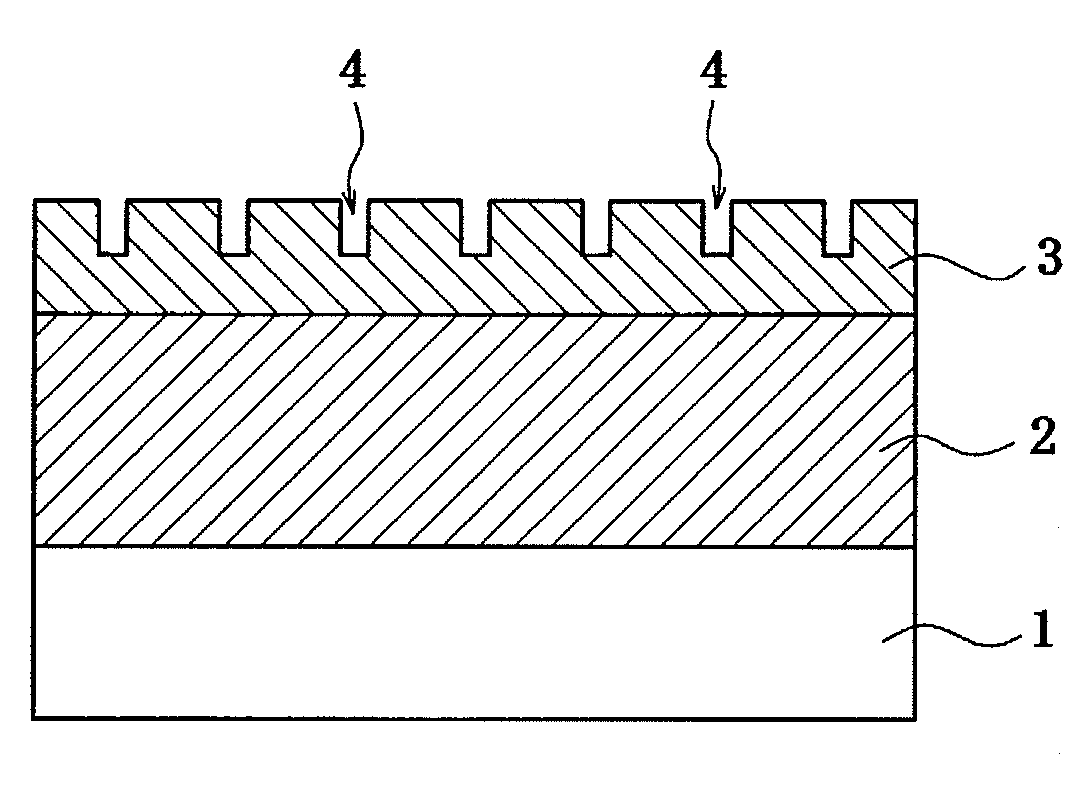

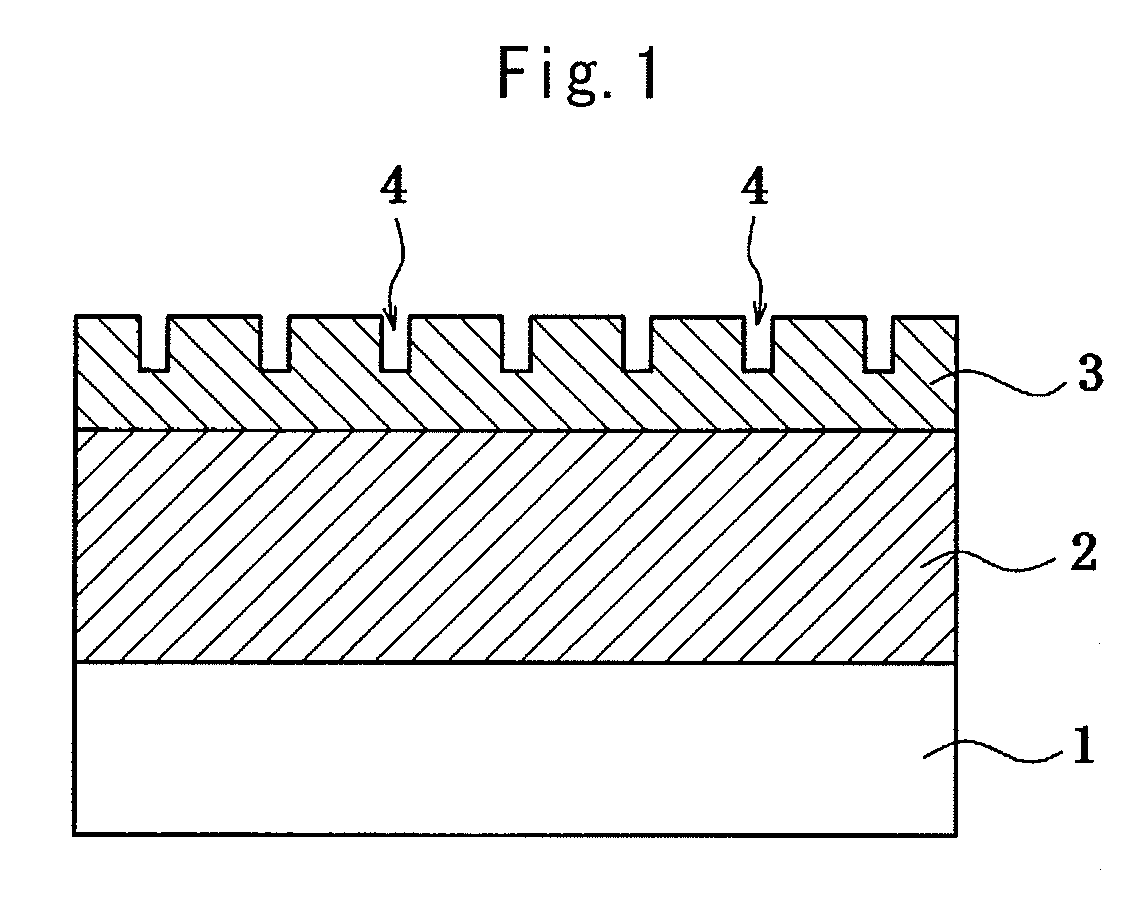

Multiple-layer flat structure in the form of a printing blanket or a printing plate for flexographic and letterpress printing with laser engraving

InactiveUS20120103216A1Quick clean upFast formingMounting boardsPlate printingLetterpress printingLaser engraving

The invention is directed to a multiple-layer flat structure (1) in the form of a printing blanket or a printing plate for flexographic and letterpress printing with: a printing layer (2) which is made from a polymeric material and is provided with laser engraving; at least one compressible layer (3); and, at least one strength-support layer (4); wherein the individual layers form an adhesive connection among one another. The multiple-layer flat structure (1) according to the invention is distinguished by the fact that the polymeric material of the printing layer (2) is a vulcanizate. Advantageous materials are proposed in this regard. The printing layer (2) expediently lies directly on a compressible layer (3). The compressible layer (3) is in turn in direct contact with a strength-support layer (4).

Owner:CONTITECH ELASTOMER BESCHICHTUNGEN

Flexo processor

ActiveUS7237482B2The process is convenient and fastGood flexibilityPlaten pressesMulticolor photographic processingHeat sensitivePost exposure

An improved flexo processor and a method of using the improved flexo processor to increase the flexibility of both the type and the size of the flexographic printing element that may be processed. The novel thermal plate processor system is capable of processing both flat and round photosensitive printing elements with only minimal changes to the system. The thermal plate processor system may also include means for exposure and post-exposure / detack in the same system.

Owner:MACDERMID PRINTING SOLUTIONS

Hollow Cylindrical Printing Element

InactiveUS20080156212A1Good plate thickness accuracy accuracyHigh dimensional accuracyPipe couplingsSynthetic resin layered productsFiberHardness

A hollow cylindrical printing element, comprising a hollow cylindrical core material (A) and a resin layer (B) or a resin layer (C). The hollow cylindrical core material (A) further comprises a photosensitive resin hardened layer (1) of 0.05 to 50 mm in thickness having a fiber-like, cloth-like, or film-like reinforcement material and the shore hardness D of 30 to 100°. The resin layer (B) is laminated on the hollow cylindrical core material (A), has a thickness of 0.1 to 100 mm, and allows a pattern to be formed on the surface thereof. The resin layer (C) has a pattern formed on the surface thereof.

Owner:ASAHI KASEI CHEM CORP

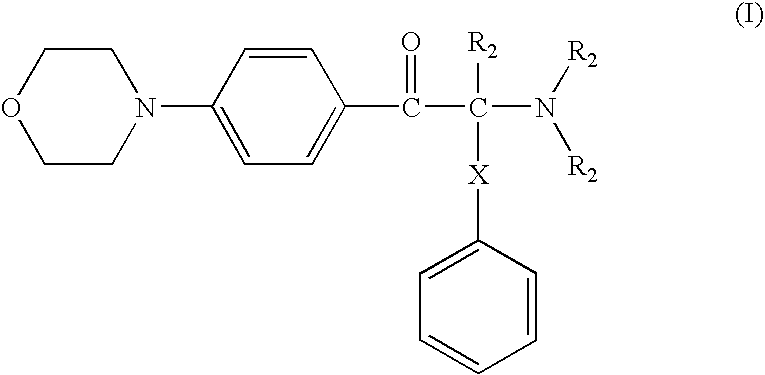

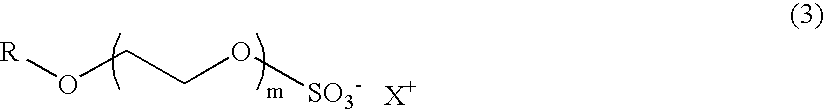

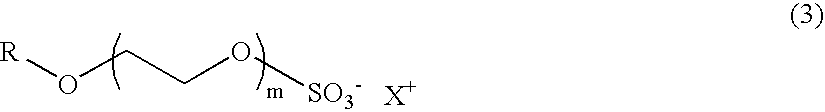

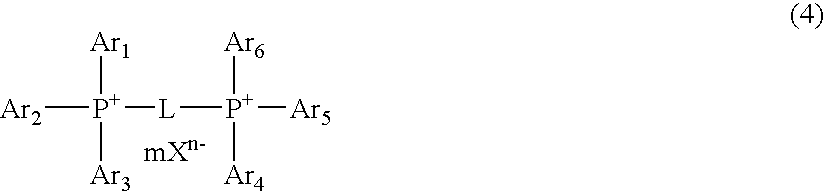

Lithographic printing plate precursor

ActiveUS20070214987A1Good on-press development propertySufficient printing durabilityPlaten pressesPhotosensitive materialsImage recordingPrinting ink

A lithographic printing plate precursor which is capable of undergoing on-press development by supplying at least one of printing ink and dampening water and includes a support and an image-recording layer, wherein the image-recording layer contains at least one of compounds represented by the formulae (1) to (3) as defined herein.

Owner:FUJIFILM CORP

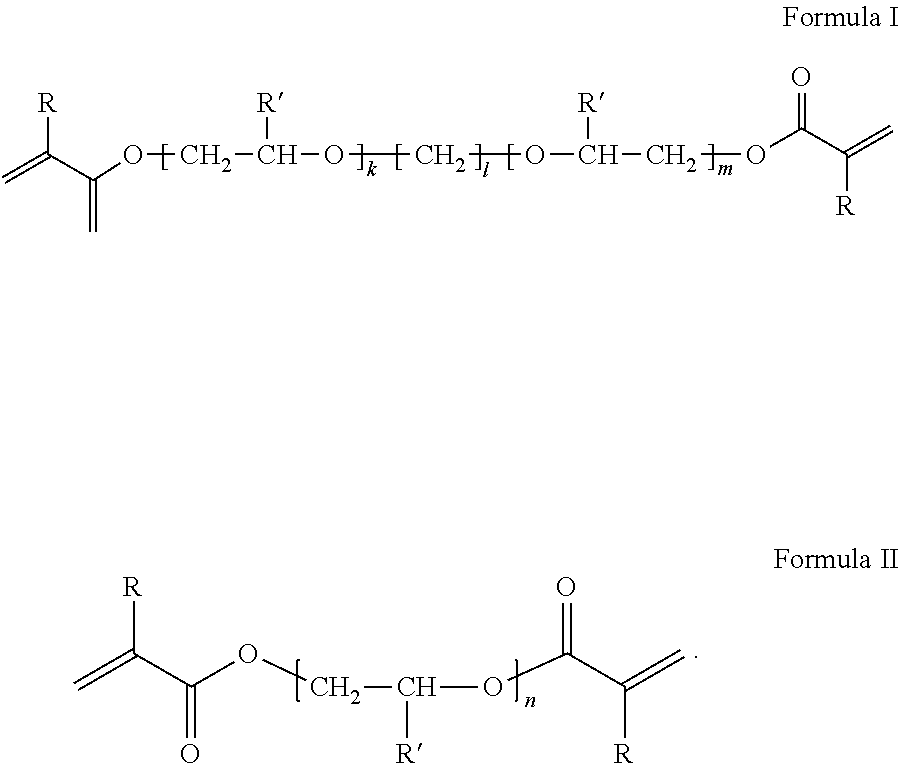

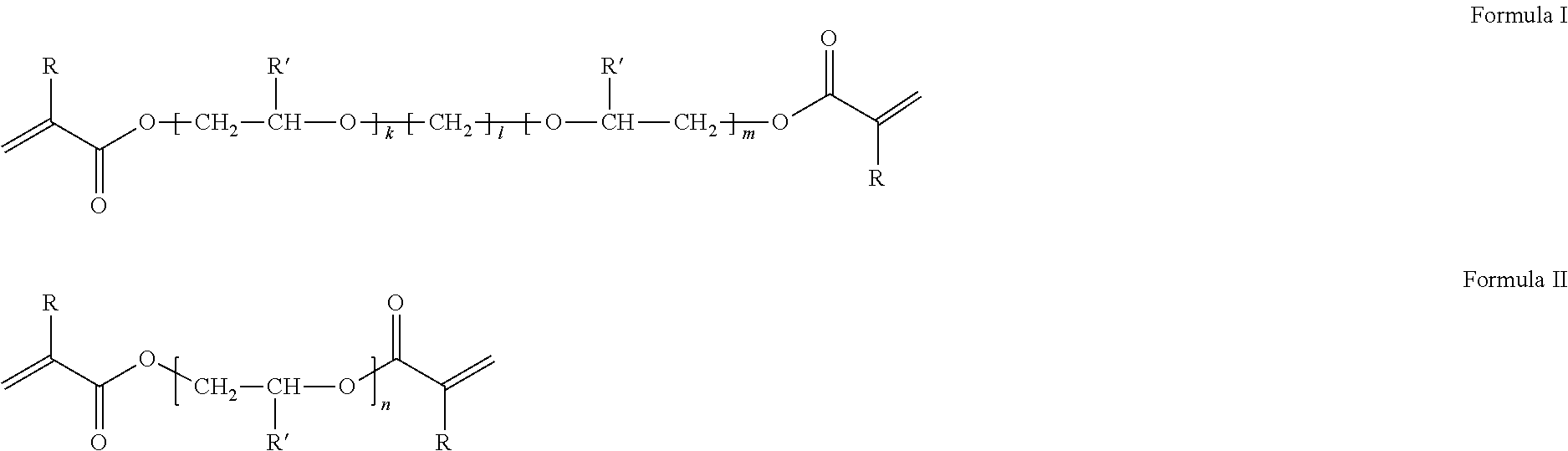

Curable jettable fluid for making a flexographic printing master

The present invention relates to a curable jettable fluid for making a flexographic printing master characterized in that the jettable fluid comprises a monofunctional (meth)acrylate monomer, a polyalkylene glycol di(meth)acrylate monomer of which the polyalkylene glycol chain has a MW of at least 300 and at least 1 wt. % of a difunctional (meth)acrylate monomer according to Formula I) or (II), wherein k and m in Formula (I) is an integer ranging from 0 to 5, l in Formula (I) is an integer ranging from 1 to 20, n in Formula (II) is 1, 2, 3 or 4, R in Formula (I) and (II) is H or CH3, and R′ in Formula (II) is H or an alkyl group.

Owner:AGFA NV

Method for producing a flexographic printing plate formed by inkjetted fluid

InactiveUS7036430B2Rapid and inexpensive mannerDuplicating/marking methodsMulticolor photographic processingEngineeringElectrical and Electronics engineering

Owner:KODAK IL

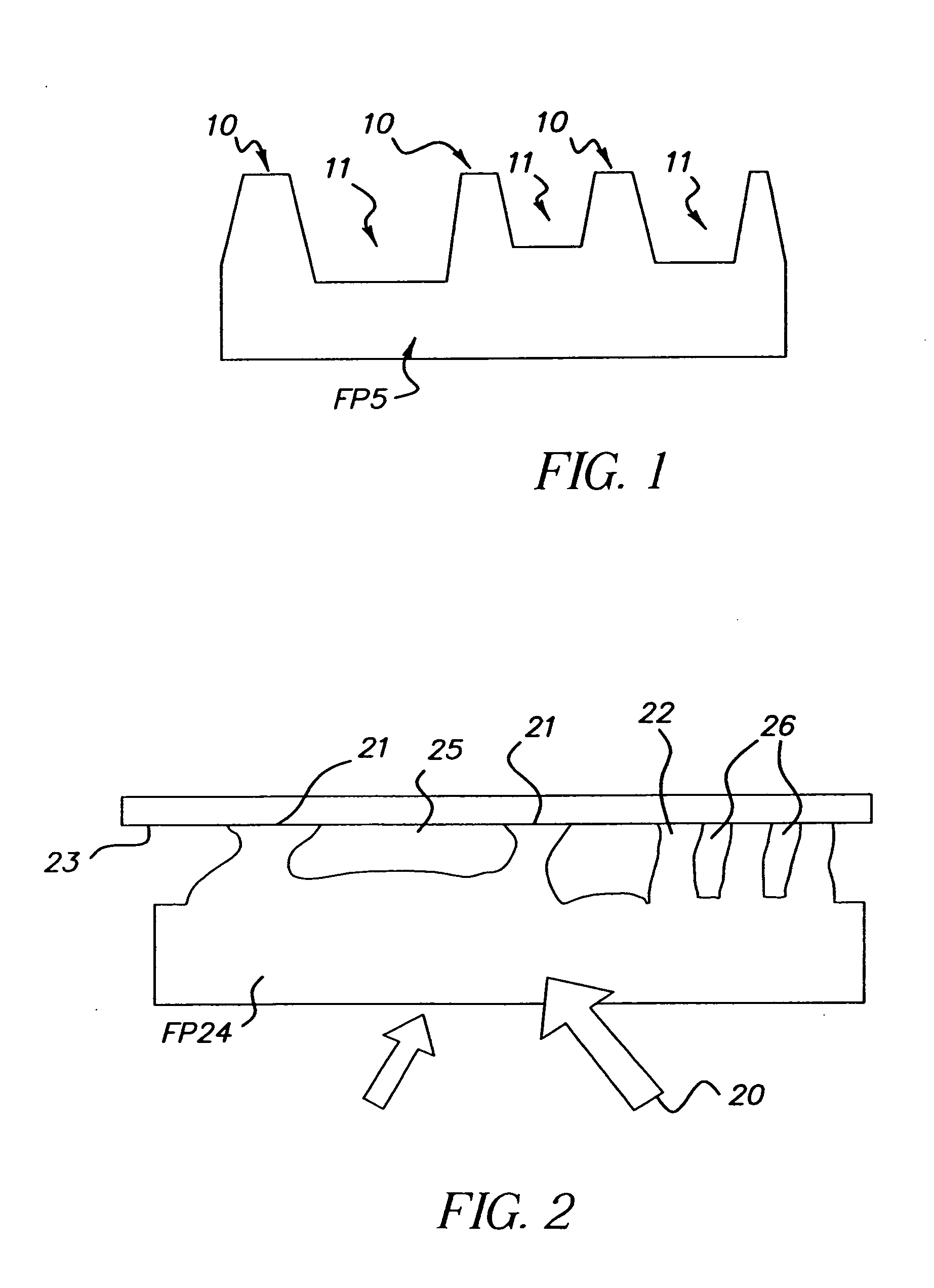

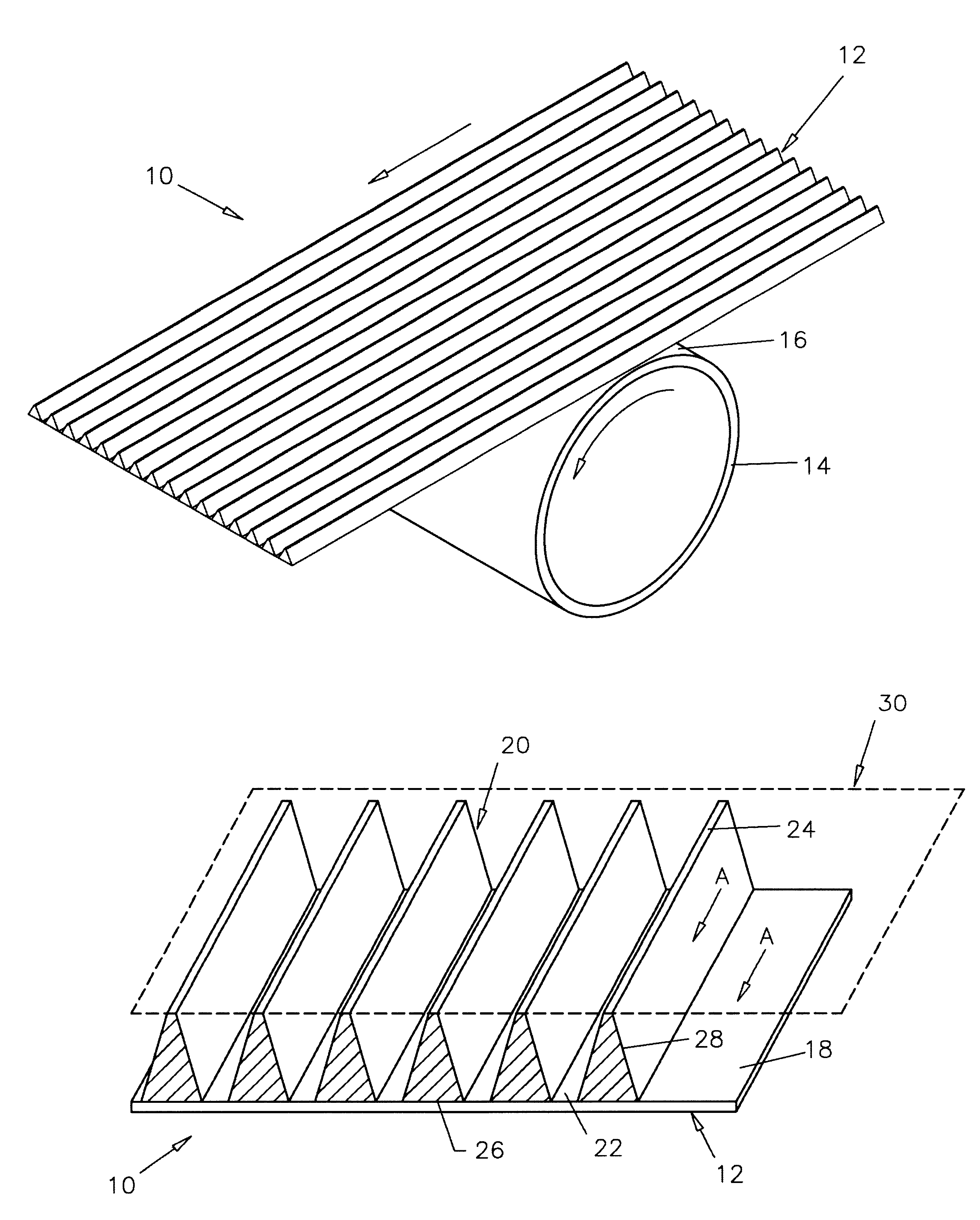

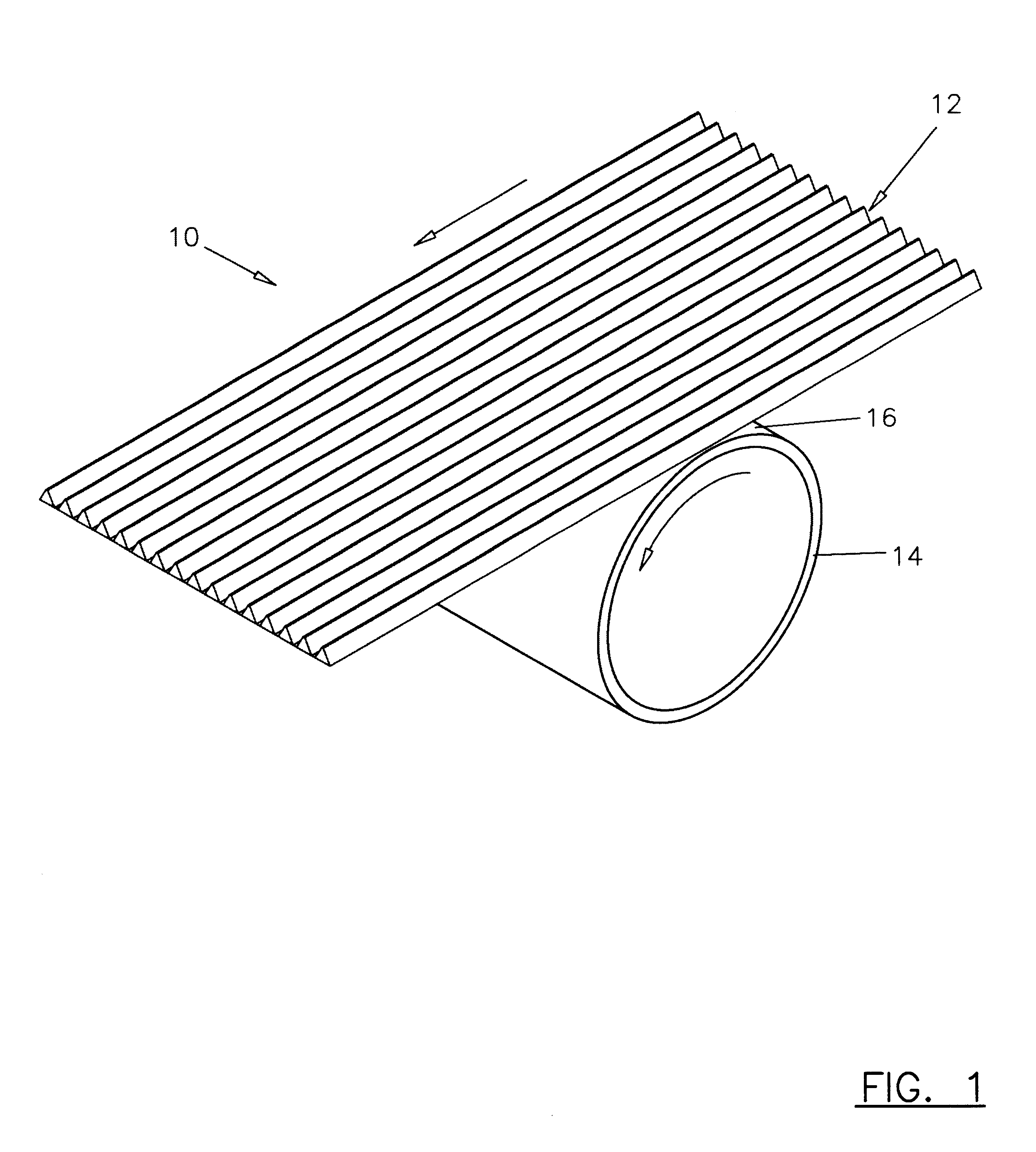

Shock absorber cushion for flexographic printing plate and method of use

InactiveUS6247403B1Increase pressureImprove efficiencyMounting boardsPlate printingElastomerEngineering

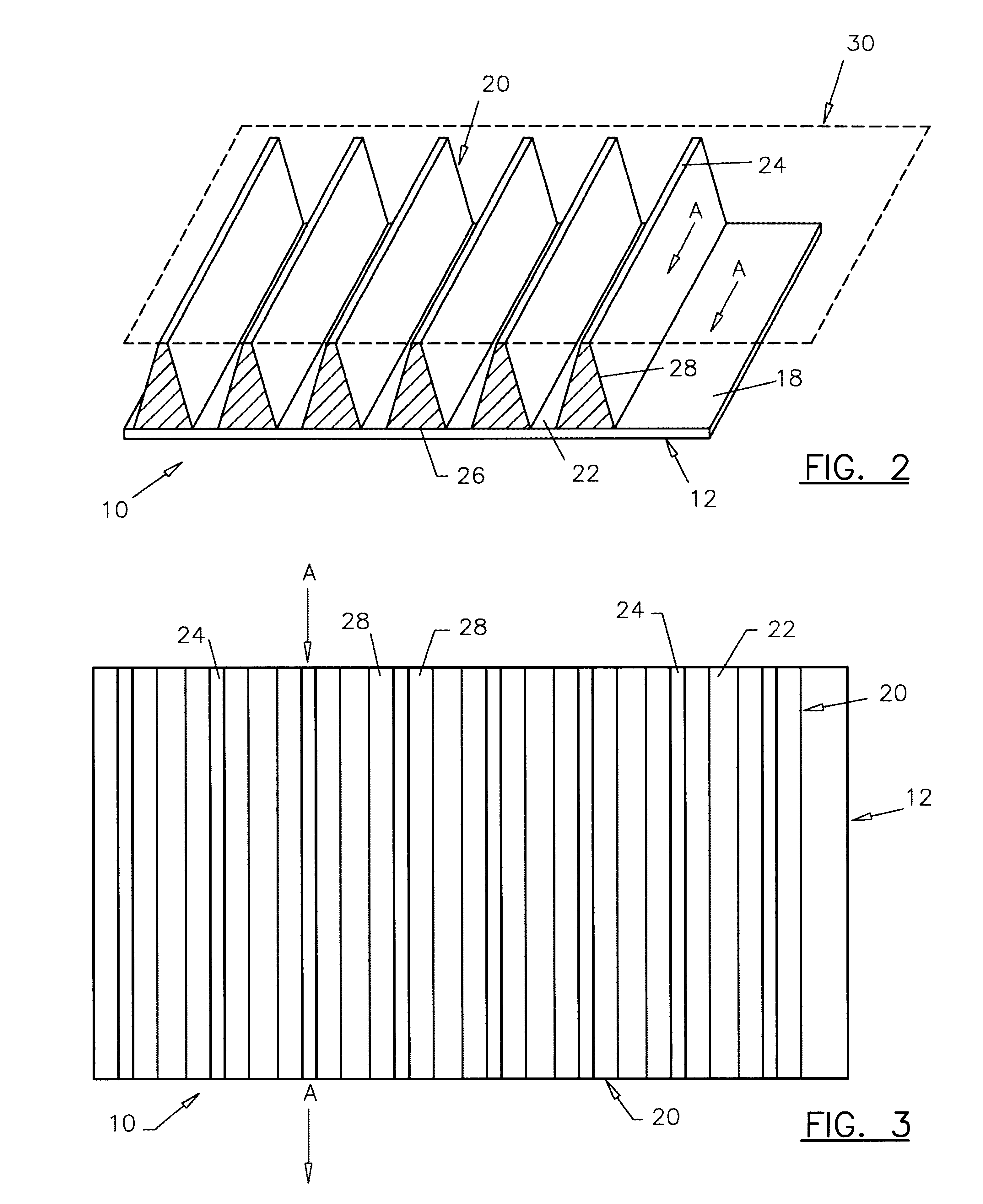

A sheet of elastomeric material that serves as a shock absorber and cushion for use between a flexographic printing plate and a printing cylinder during printing for compensating for variations in thickness, height and centricity of the printing cylinder and flexographic printing plate to prevent distortions in the image being printed that includes providing an elastomeric sheet having a longitudinal direction in the direction of circumferential travel of the cylinder circumference that includes a plurality or array of protrusions formed of the elastomeric material of predetermined cross-sectional shape and area and the material having a durometer to cushion the flexographic plate in such a way to provide the necessary compensation to ensure a high quality printed image at high speed. The cross-sectional shapes and the array of the longitudinal protrusions provide for material displacement zones that allows the elastomeric material to be compressed and return relatively instantaneously to its original height or near original height in sharing high quality printing compensating for tolerance errors between the drum size and the flexographic plate thicknesses.

Owner:RANDAZZO JEFFREY A

Lithographic printing system with reusable support surfaces and lithographic constructions for use therewith

InactiveUS6024019AEasy to disassembleResidue reductionAddressographsPlaten pressesMetal sheetEngineering

Lithographic printing constructions are removable from a permanent support, which may be a metal sheet affixable (usually by clamps) to a plate cylinder, or may instead be the permanent surface of such a cylinder. In this way, the traditional "plate" is replaced with a thin, easily manufactured printing member, which is separated from the support following its use.

Owner:PRESSTEK

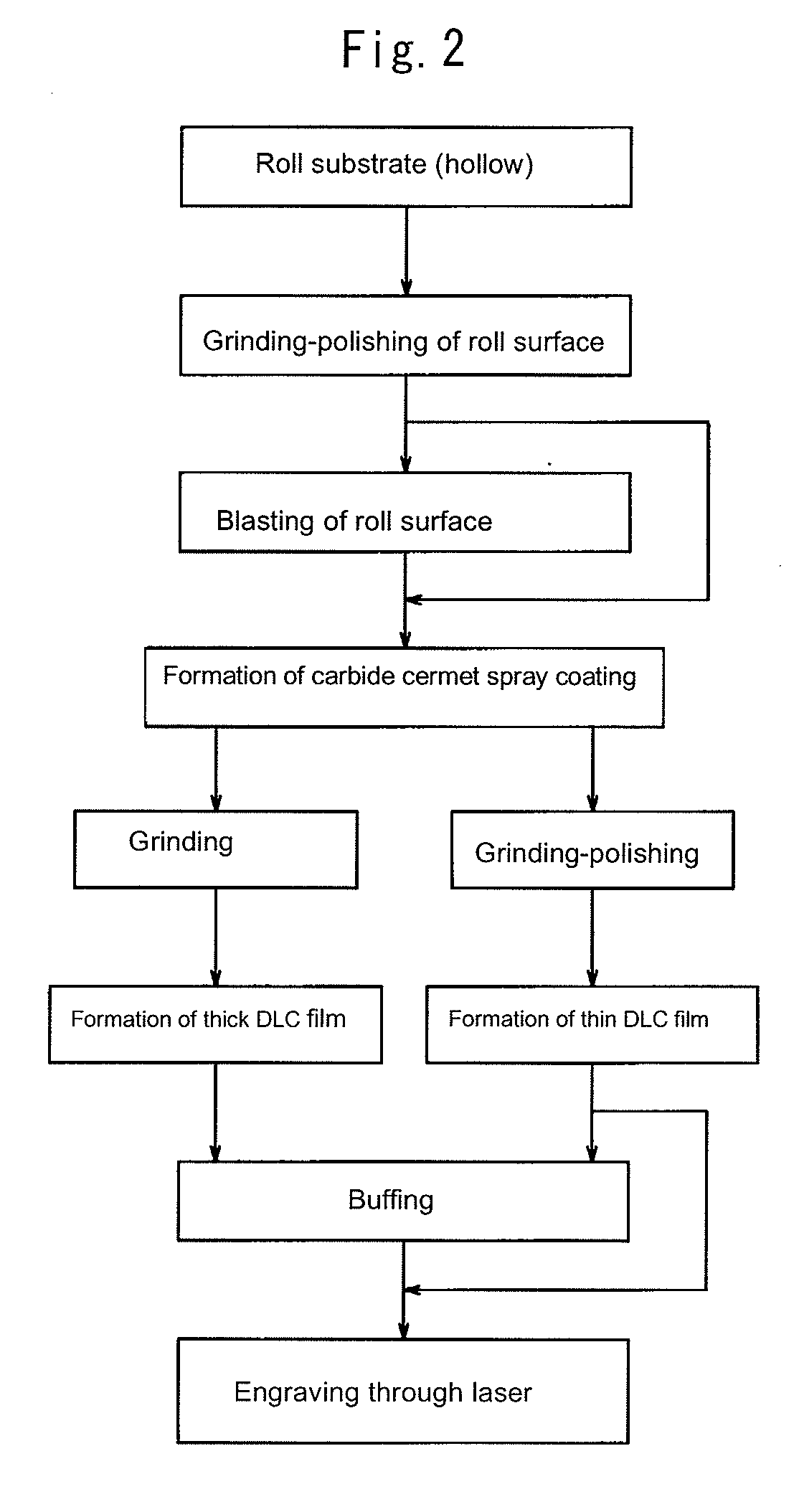

Printing roll and method of producing the same

InactiveUS20110203468A1Improve wear resistanceSmall contact resistanceMounting boardsPlate printingCermetEngineering

In order to propose a dry process technique of producing a printing roll having safe and beauty concave portions for printing image area without discharging environmental contaminating substance and a new technique for improving quality of printed matters, this invention is to provide a printing roll with DLC film layer in which laser beam-engraved grooves as concave portions for printing image area are formed on a carbide cermet spray coating formed on a surface of a roll substrate, and a method wherein a carbide cermet spray coating is formed on a surface of a roll substrate roughened by a blast treatment, the surface of the carbide cermet spray coating is ground or ground-polished, then a DLC film is formed on the ground or ground-polished surface and thereafter laser beam-engraved grooves are formed on the surface of the DLC film as a concave portion for printing image area.

Owner:TOCALO CO LTD

Combined ablation and exposure system and method

Owner:ESKO GRAPHICS IMAGING +1

Flexo processor

ActiveUS20050211121A1Good flexibilityThe process is convenient and fastPlaten pressesMulticolor photographic processingPost exposureEmbedded system

An improved flexo processor and a method of using the improved flexo processor to increase the flexibility of both the type and the size of the flexographic printing element that may be processed. The novel thermal plate processor system is capable of processing both flat and round photosensitive printing elements with only minimal changes to the system. The thermal plate processor system may also include means for exposure and post-exposure / detack in the same system.

Owner:MACDERMID PRINTING SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com