Patents

Literature

831 results about "Jet (fluid)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

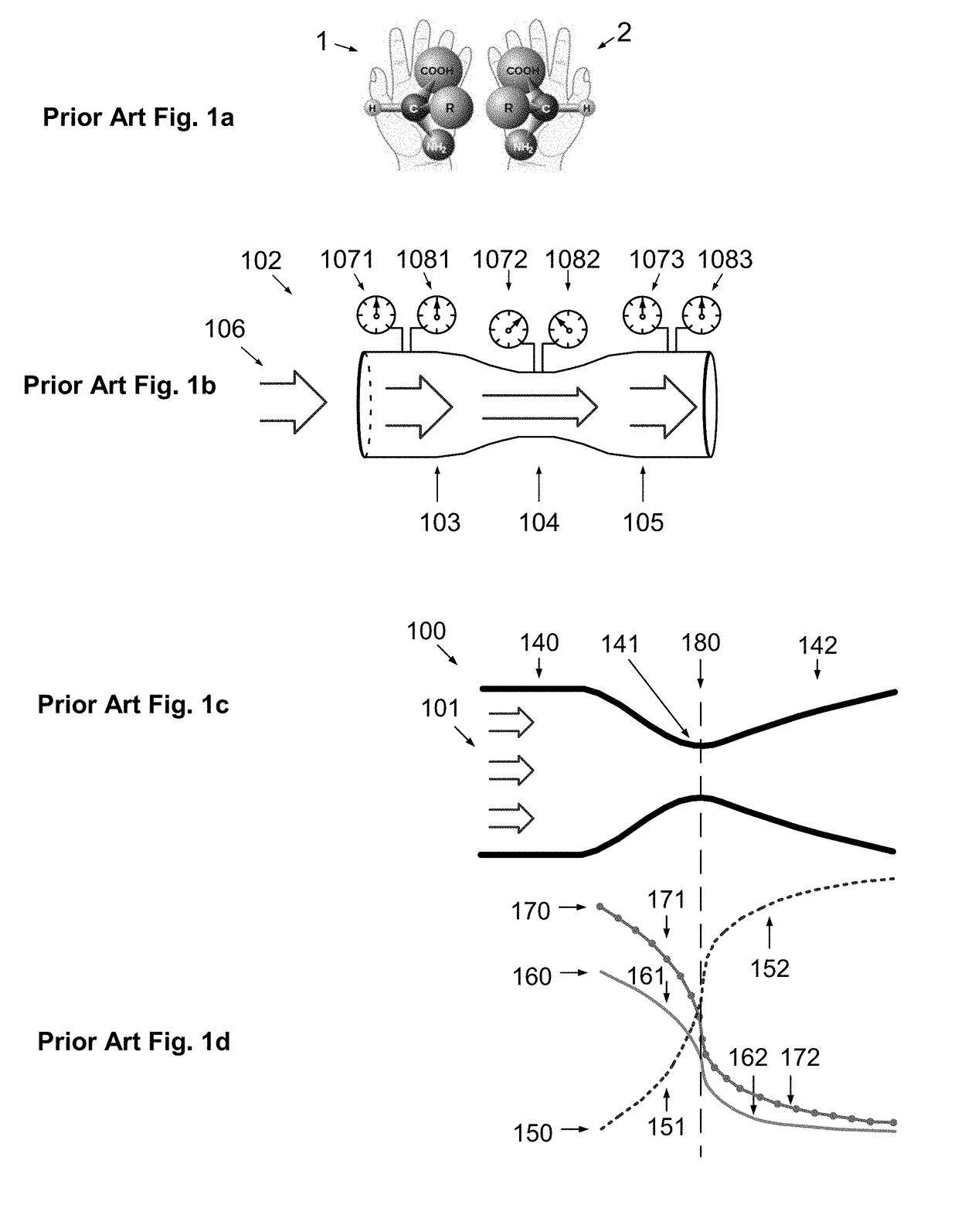

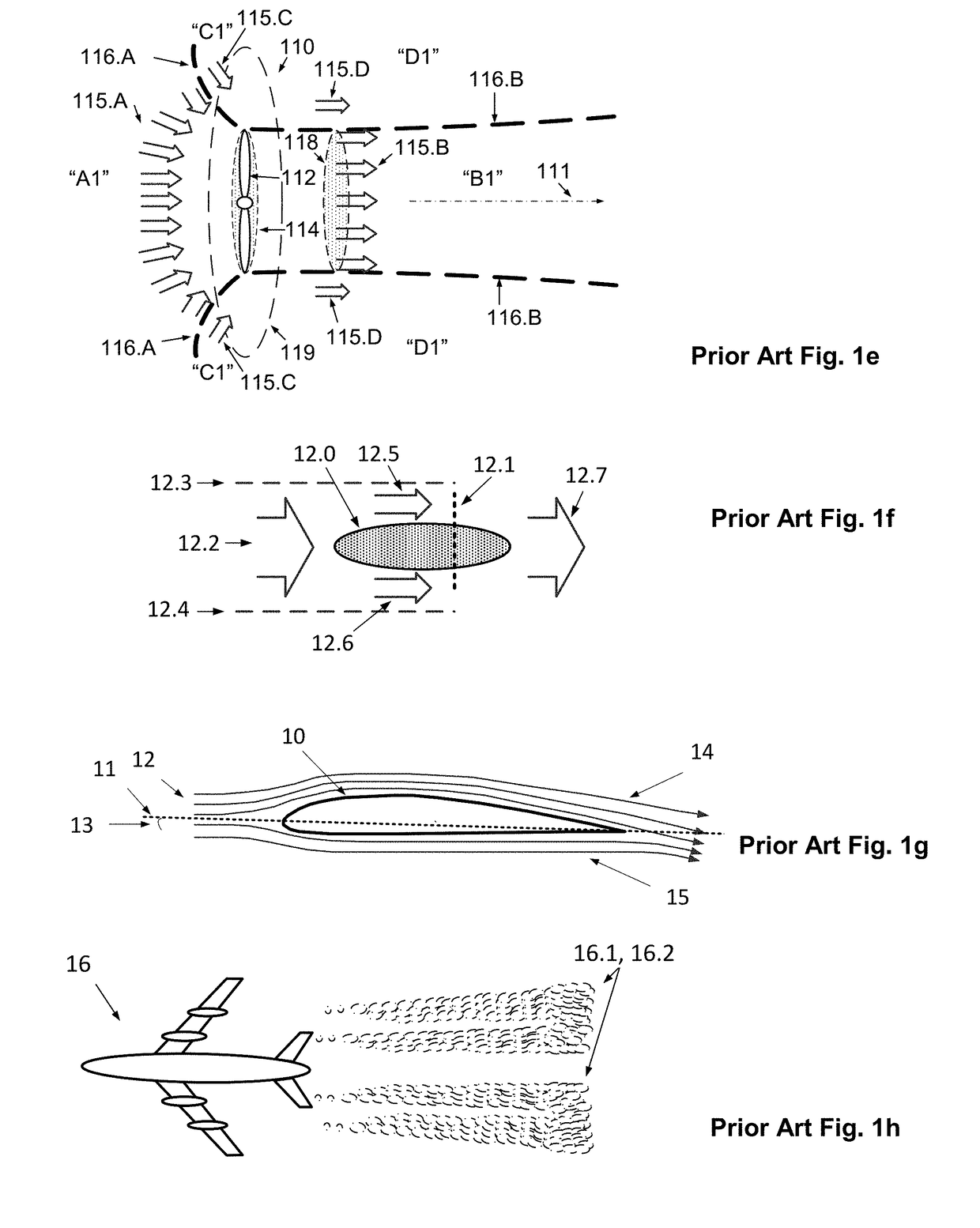

A jet is a stream of fluid that is projected into a surrounding medium, usually from some kind of a nozzle, aperture or orifice. Jets can travel long distances without dissipating. Jet fluid has higher momentum compared to the surrounding fluid medium. In the case that the surrounding medium is assumed to be made up of the same fluid as the jet, and this fluid has a viscosity, the surrounding fluid is carried along with the jet in a process called entrainment.

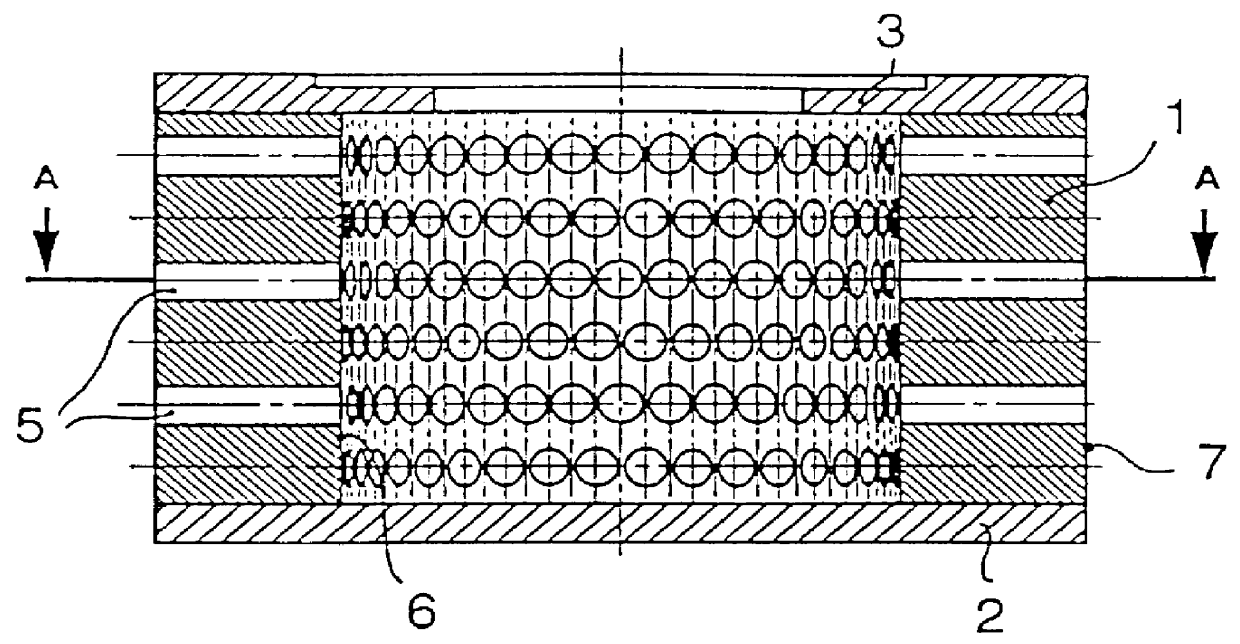

Method for combustion of a fuel

InactiveUS7363756B2Increase speedAccelerated dilutionContinuous combustion chamberGas turbine plantsCombustion chamberFront velocity

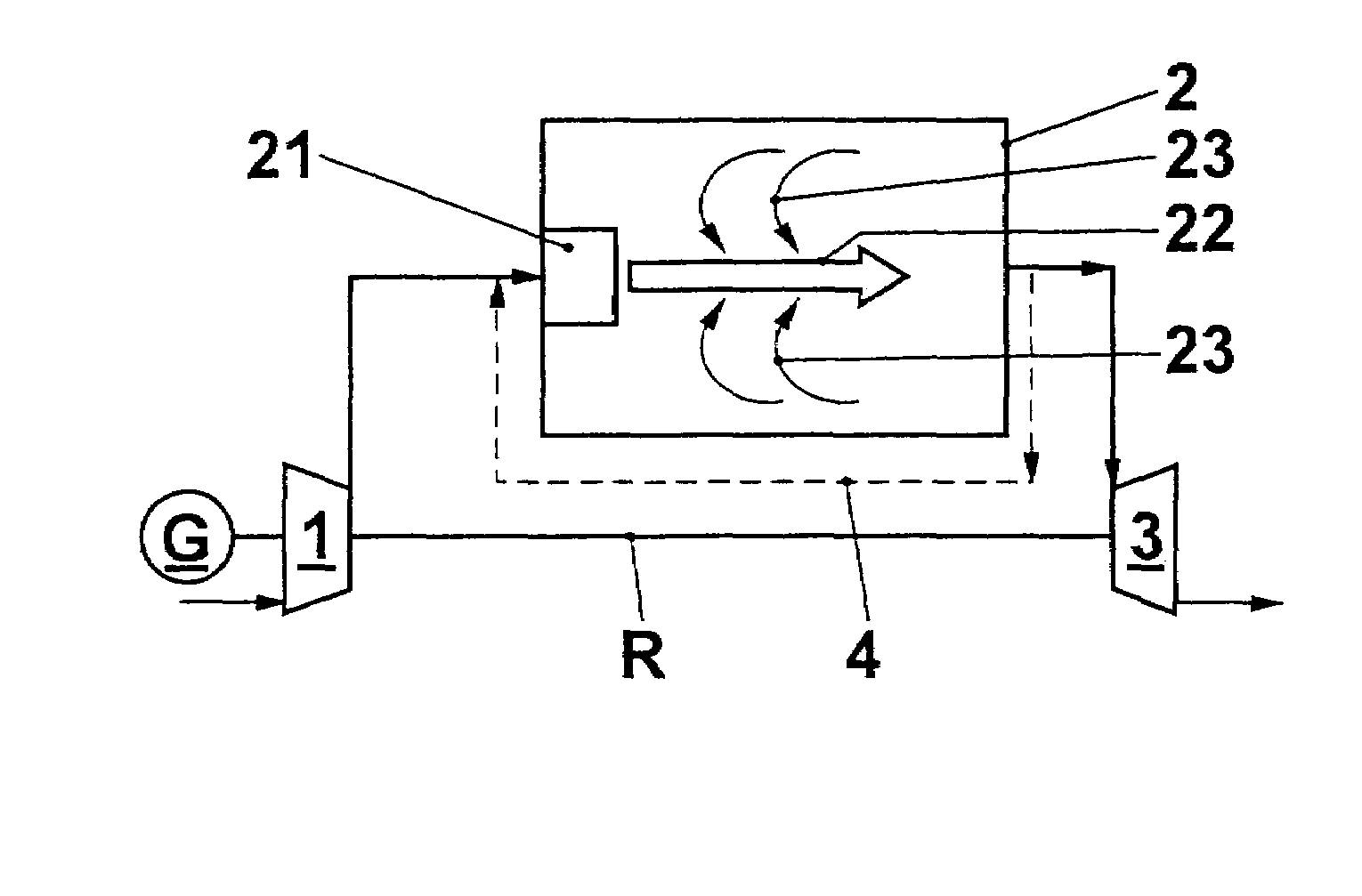

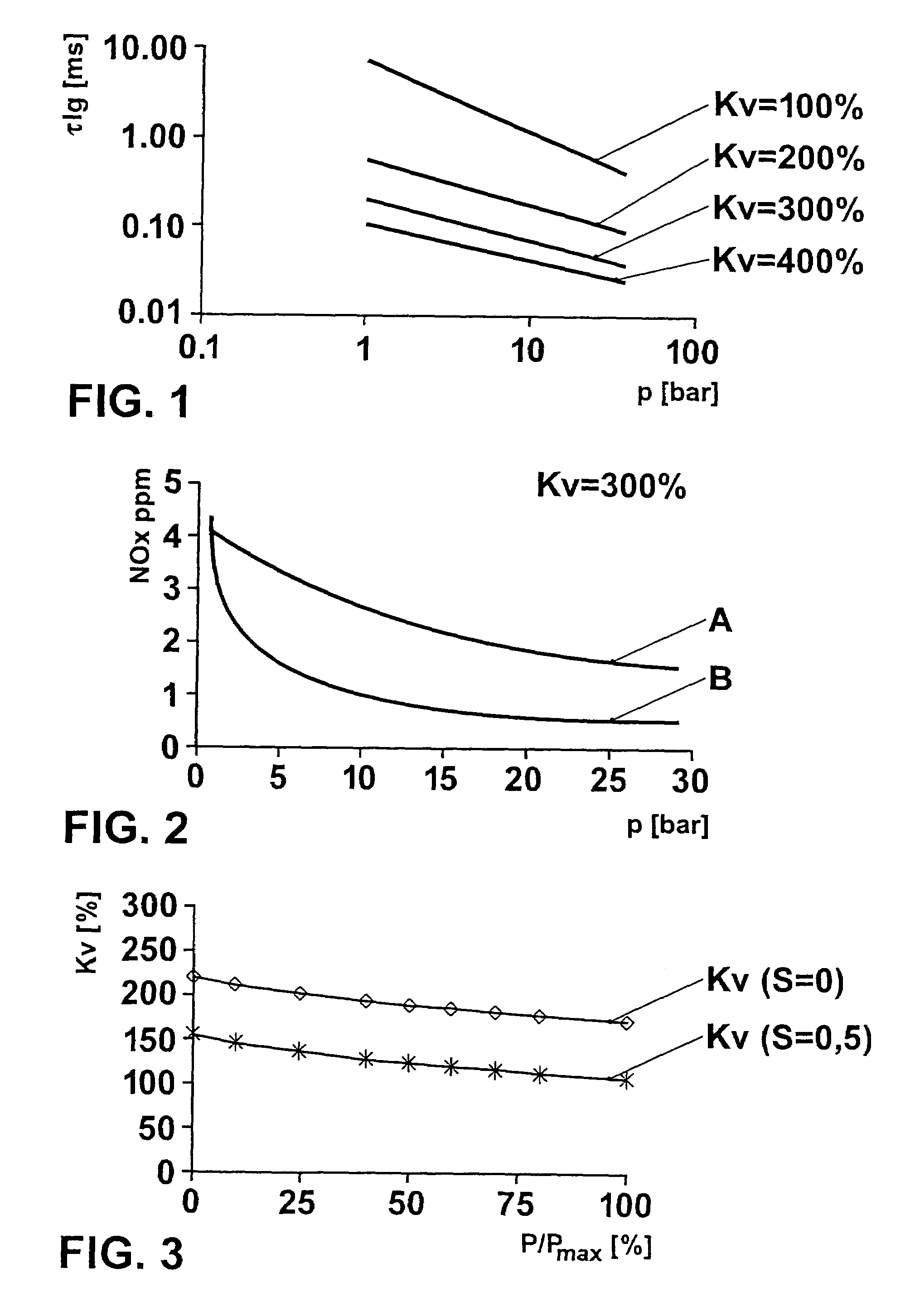

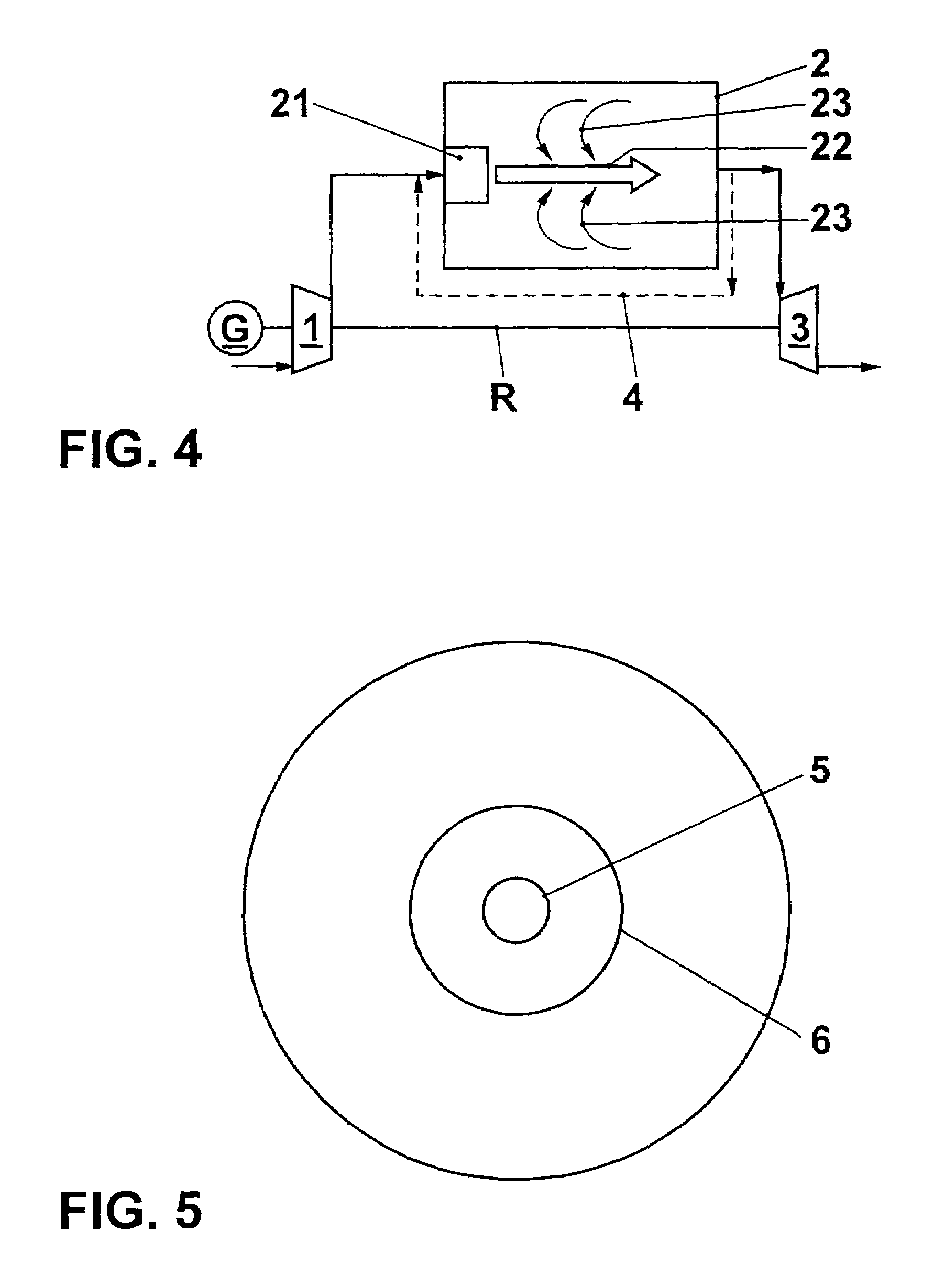

In a method for the combustion of a fuel, a fuel or a premixed combustible mixture is introduced into a combustion space as a combustible fluid open jet. The velocity of the open jet is selected in such a way that it is impossible for a stable flame front to form, i.e. is in any event greater than the flame front velocity, and that, on account of a jet pump effect, flue gas is mixed into the combustible fluid jet from the combustion chamber in a jet-induced recirculation internally within the combustion chamber. The admixed flue gas dilutes and heats the combustible fluid. The heating causes the spontaneous ignition temperature to be exceeded, and a low-pollutant volumetric flame is formed in a highly dilute atmosphere.

Owner:ANSALDO ENERGIA SWITZERLAND AG

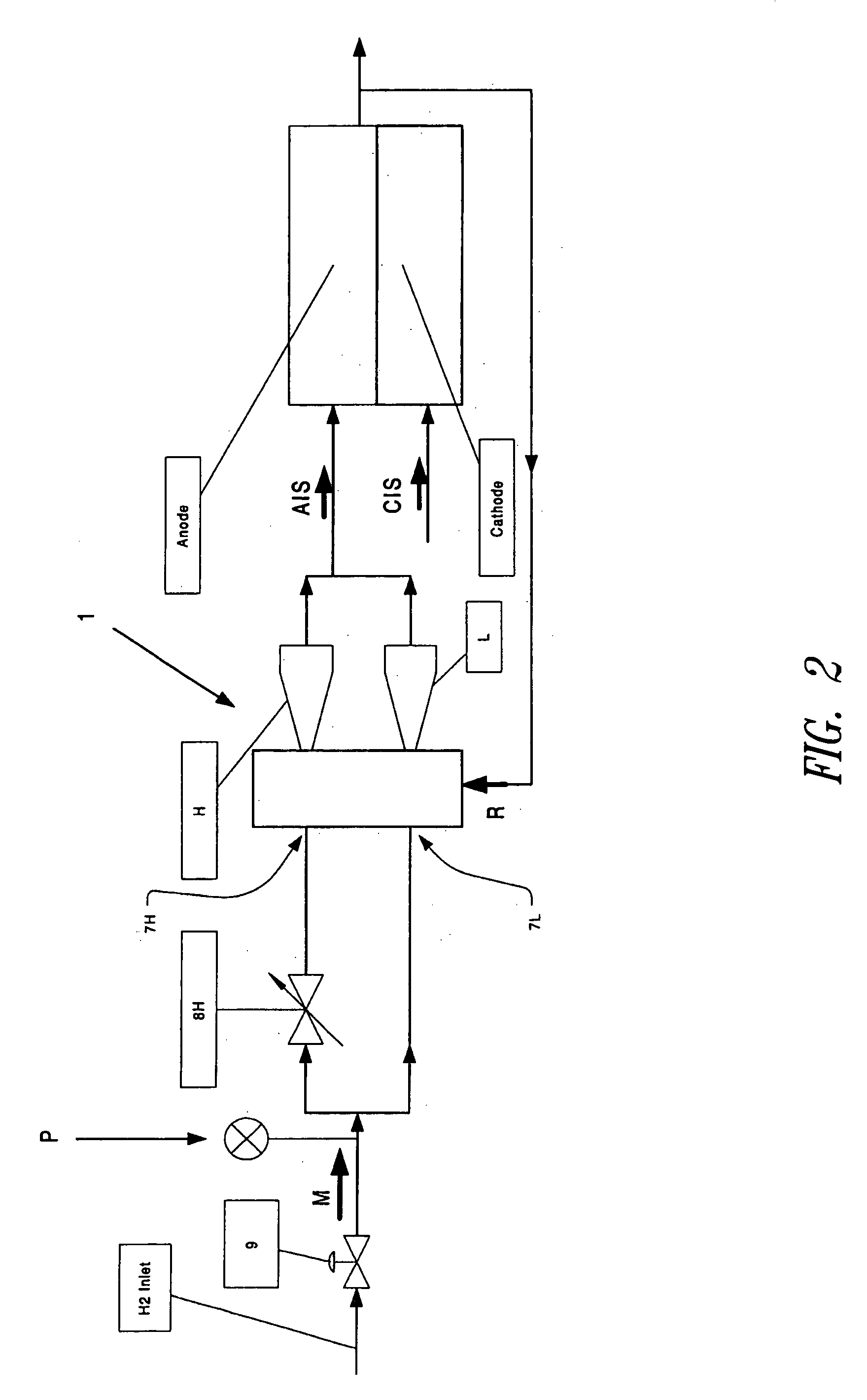

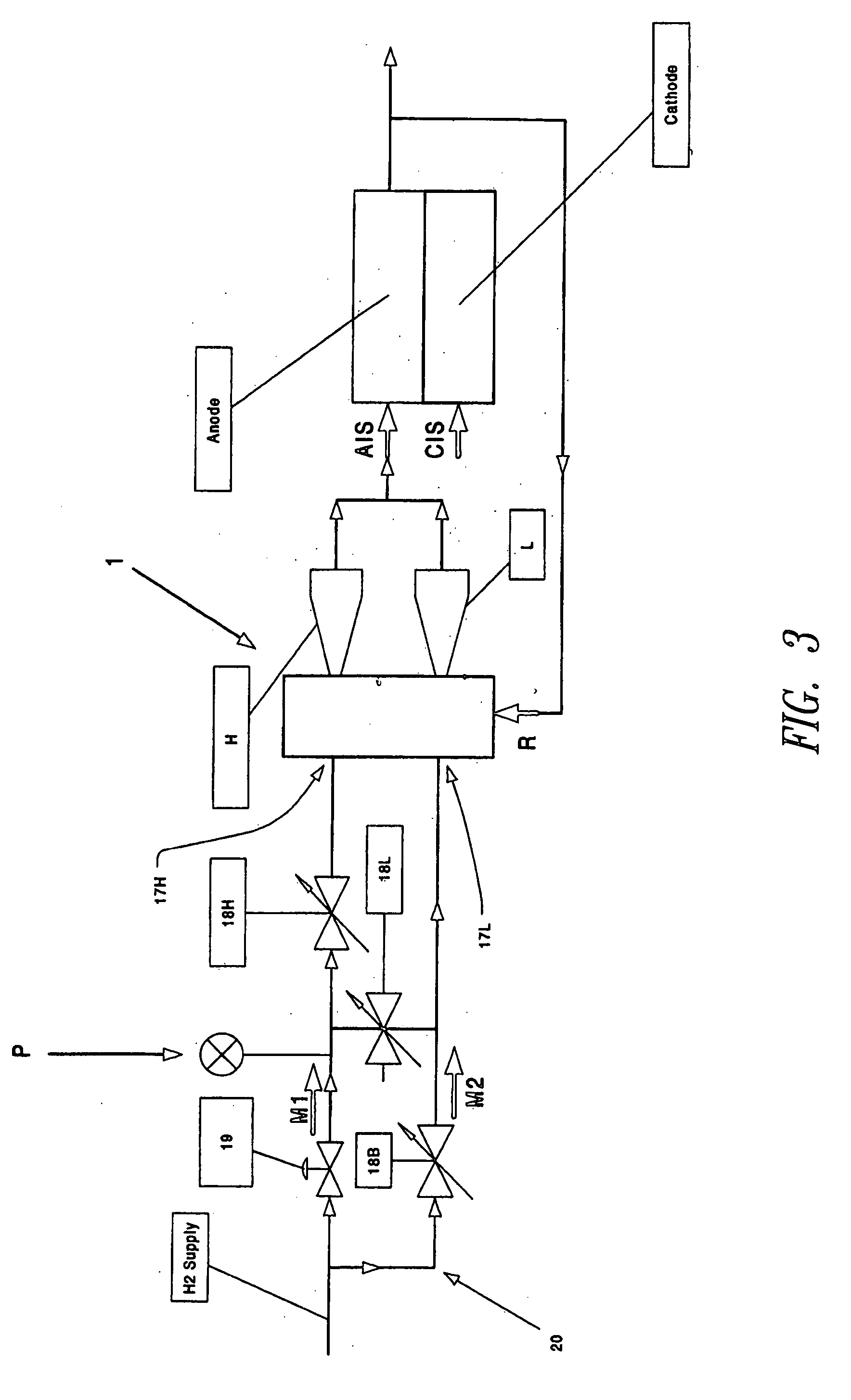

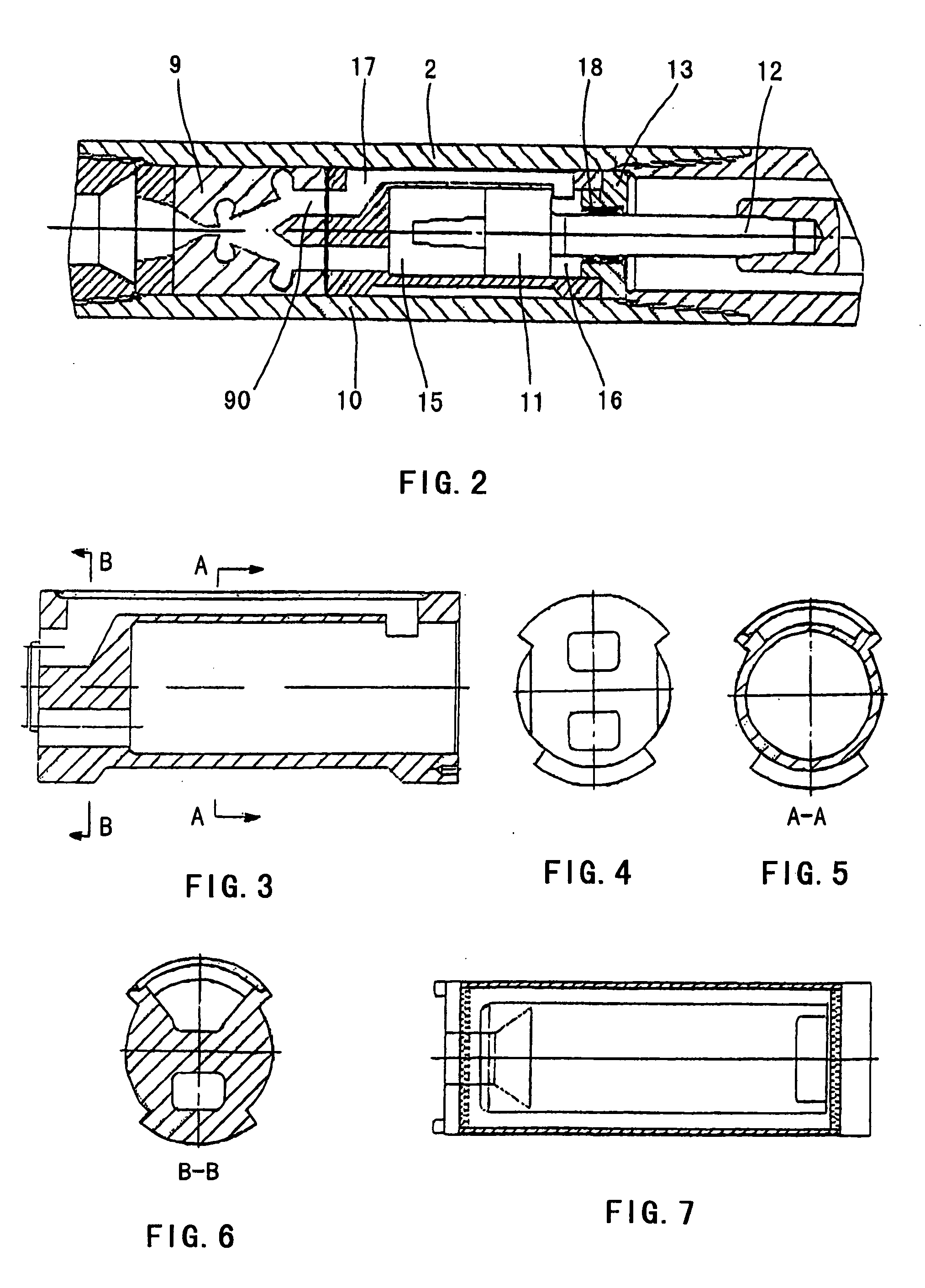

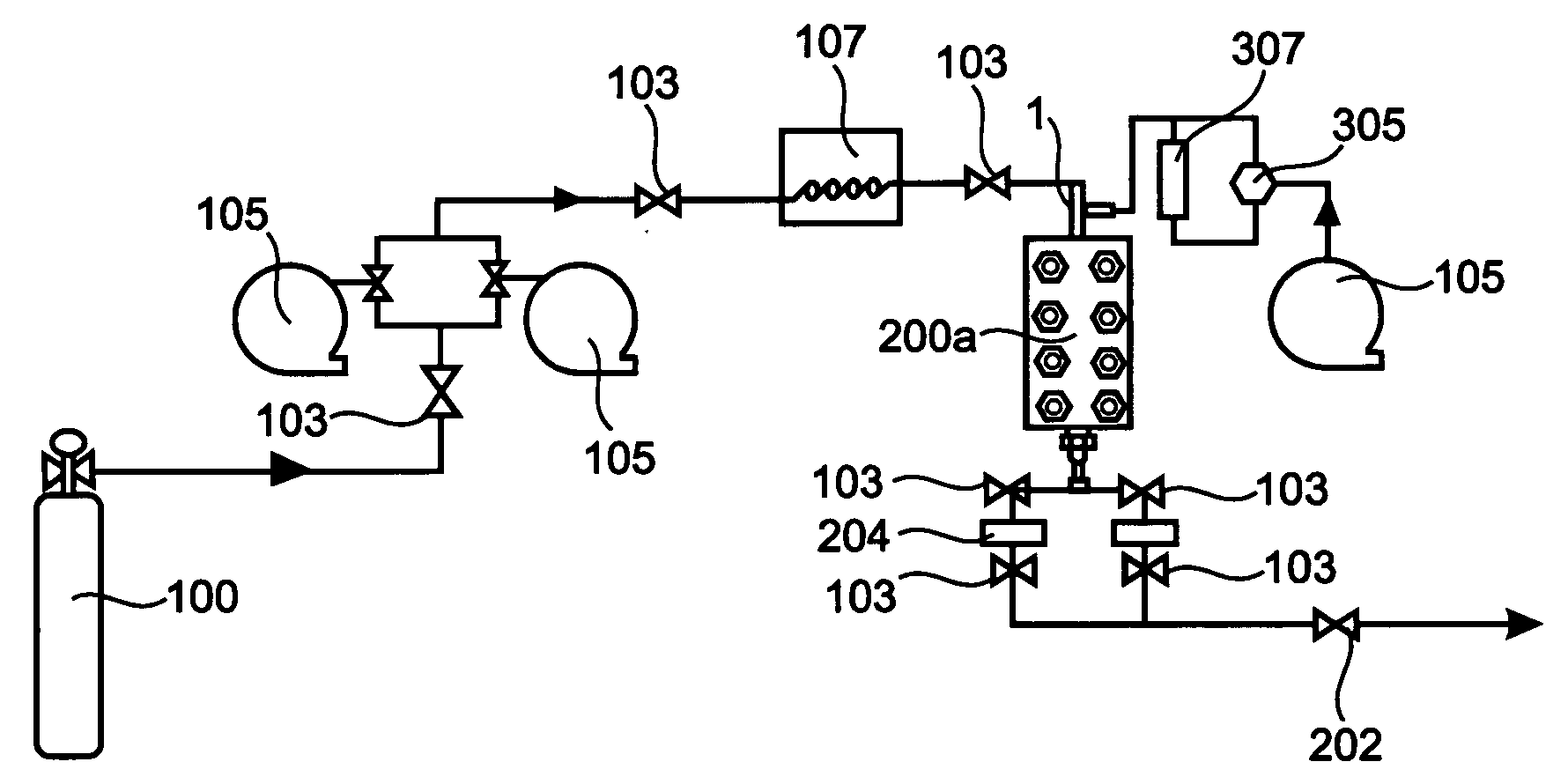

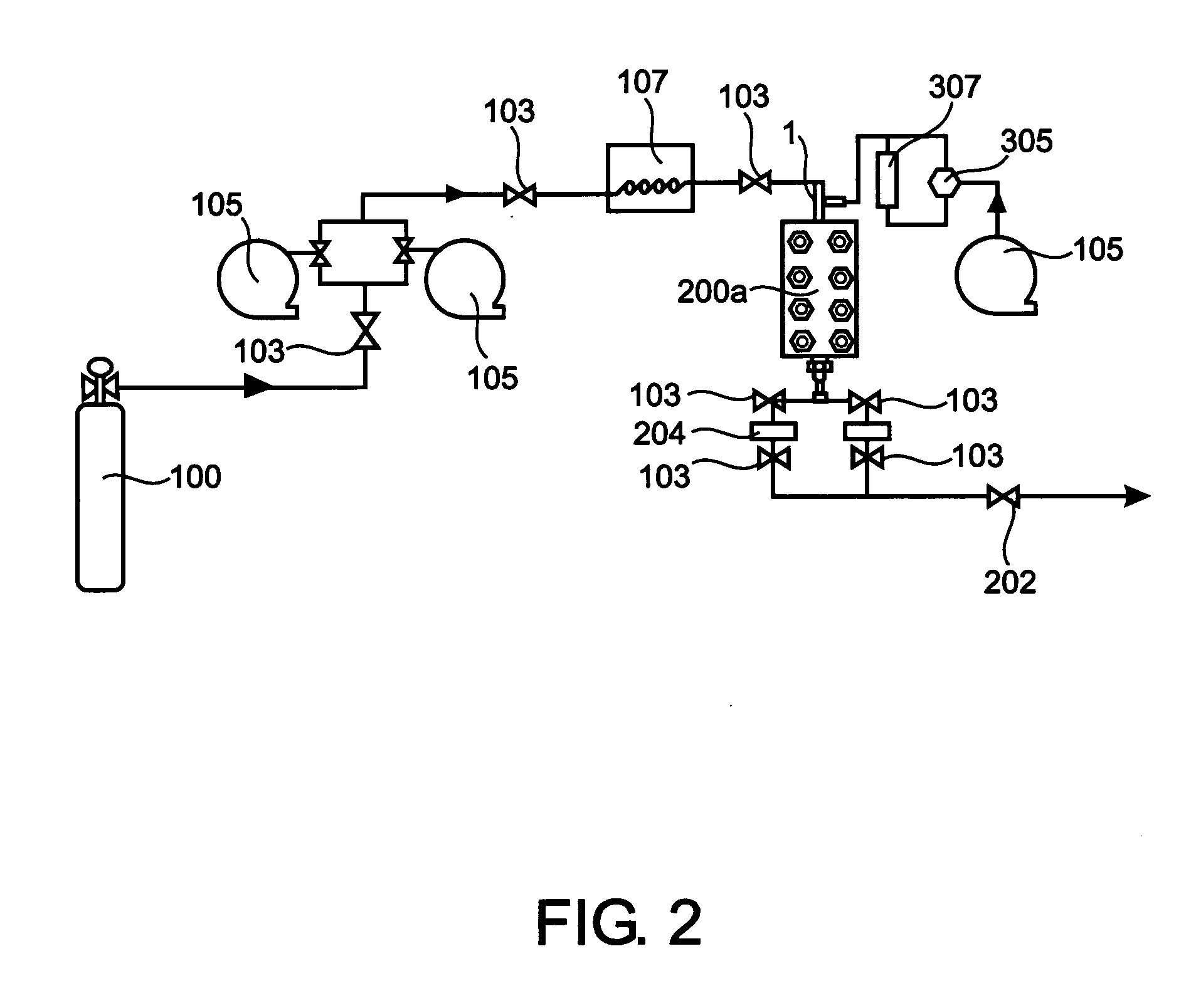

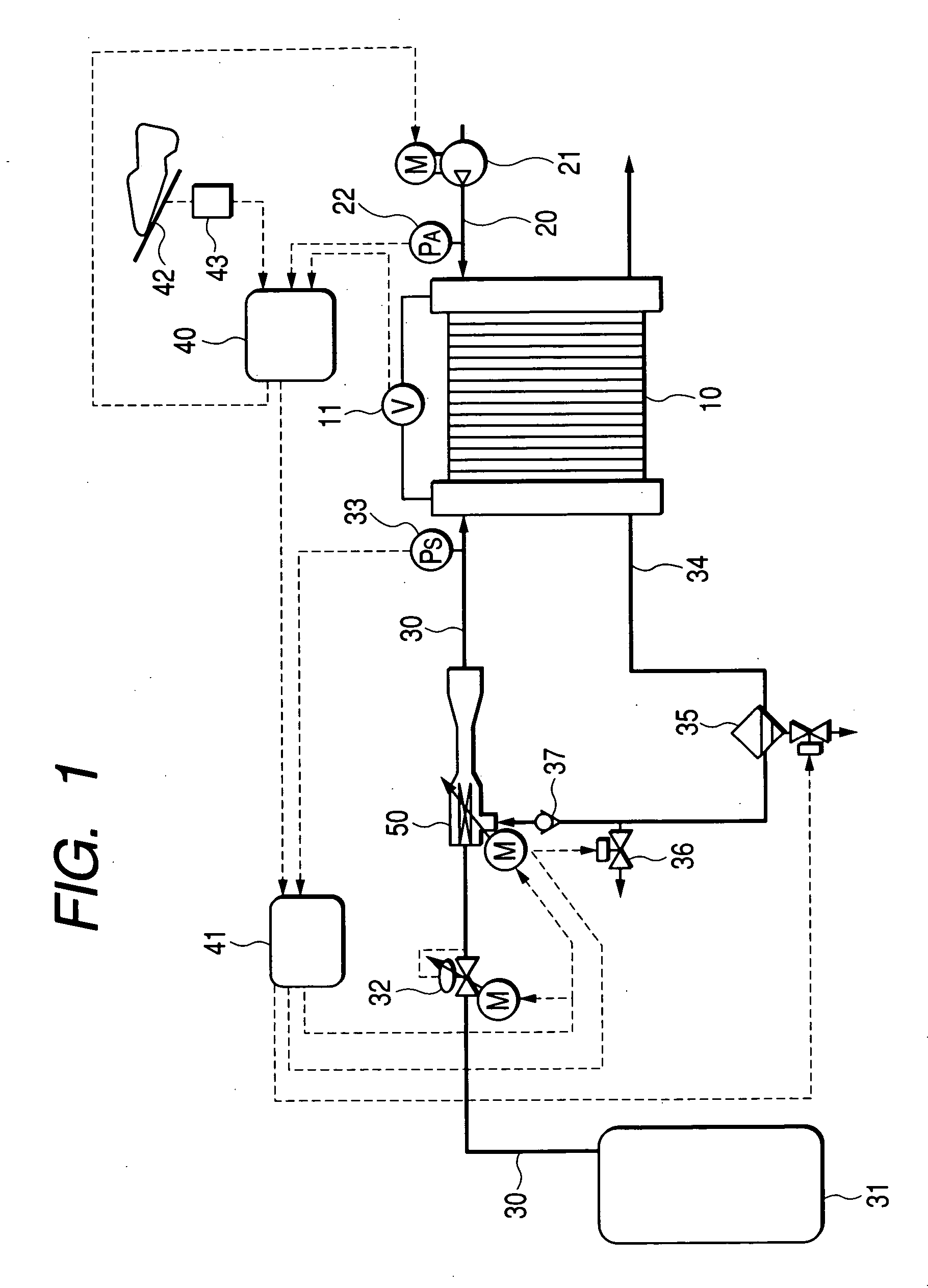

Fuel cell system with fluid stream recirculation

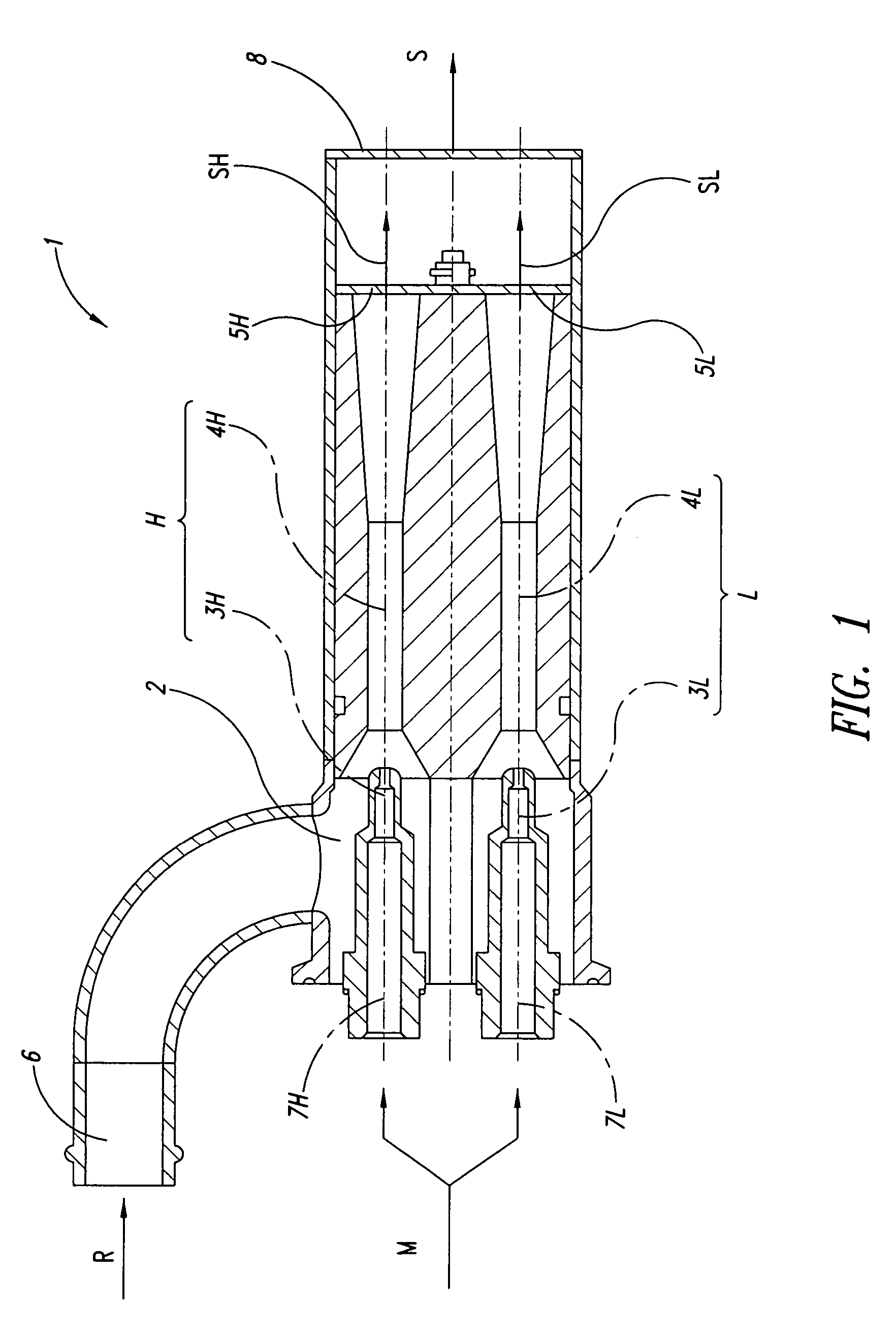

An electric power generation system has a multiple jet ejector assembly for recirculating an exhaust stream. The system includes a fuel cell stack having a reactant stream inlet, a reactant stream outlet and at least one fuel cell. A pressurized reactant supply provides a reactant to the multiple jet ejector assembly. The multiple jet ejector assembly includes two motive flow inlets, one suction inlet, fluidly connected to the reactant stream outlet to receive a recirculated flow from the fuel cell stack, and one discharge outlet, fluidly connected to the reactant stream inlet to provide an inlet stream to the fuel cell stack. A pressure regulator is interposed between the pressurized reactant supply and the two motive flow inlets of the multiple jet ejector assembly. A first solenoid valve is interposed between the first motive flow inlet and the regulator. A second solenoid valve is interposed between the second motive flow inlet and the regulator. A by-pass line connects the pressurized reactant supply to the second motive flow inlet. A by-pass solenoid valve is interposed in the bypass line between the pressurized reactant supply and the second motive flow inlet. During low-load operating conditions, the second solenoid valve is open and the first and by-pass solenoid valves are closed, so that pressurized reactant, controlled by the regulator, is directed to the second motive flow inlet. During high-load operating conditions, the second solenoid valve is closed and the first and by-pass solenoid valves are open, so that pressurized reactant, controlled by the regulator, is directed to the first motive flow inlet and pressurized reactant, not controlled by the regulator, is directed to the second motive flow inlet.

Owner:FORD MOTOR CO +1

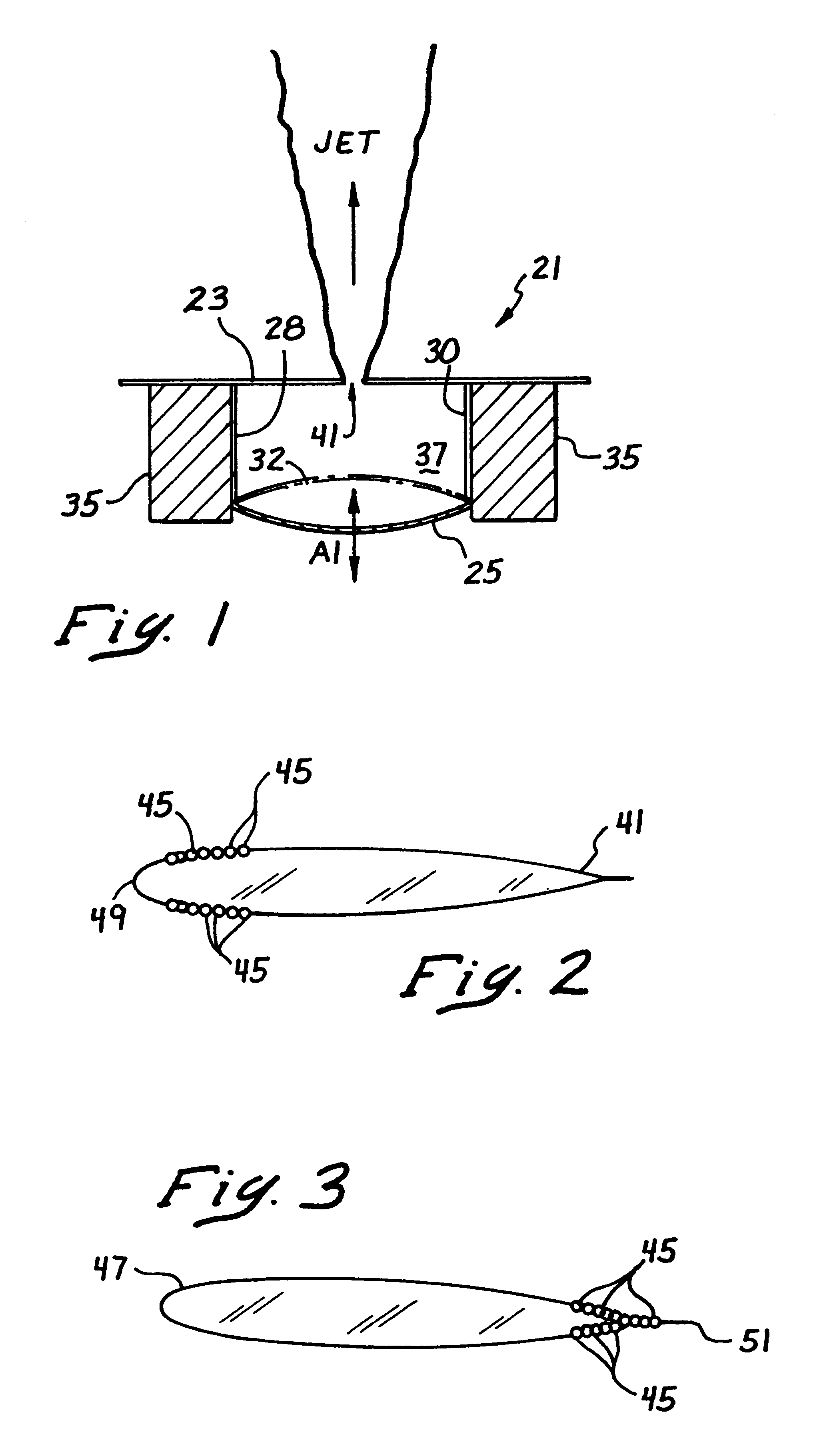

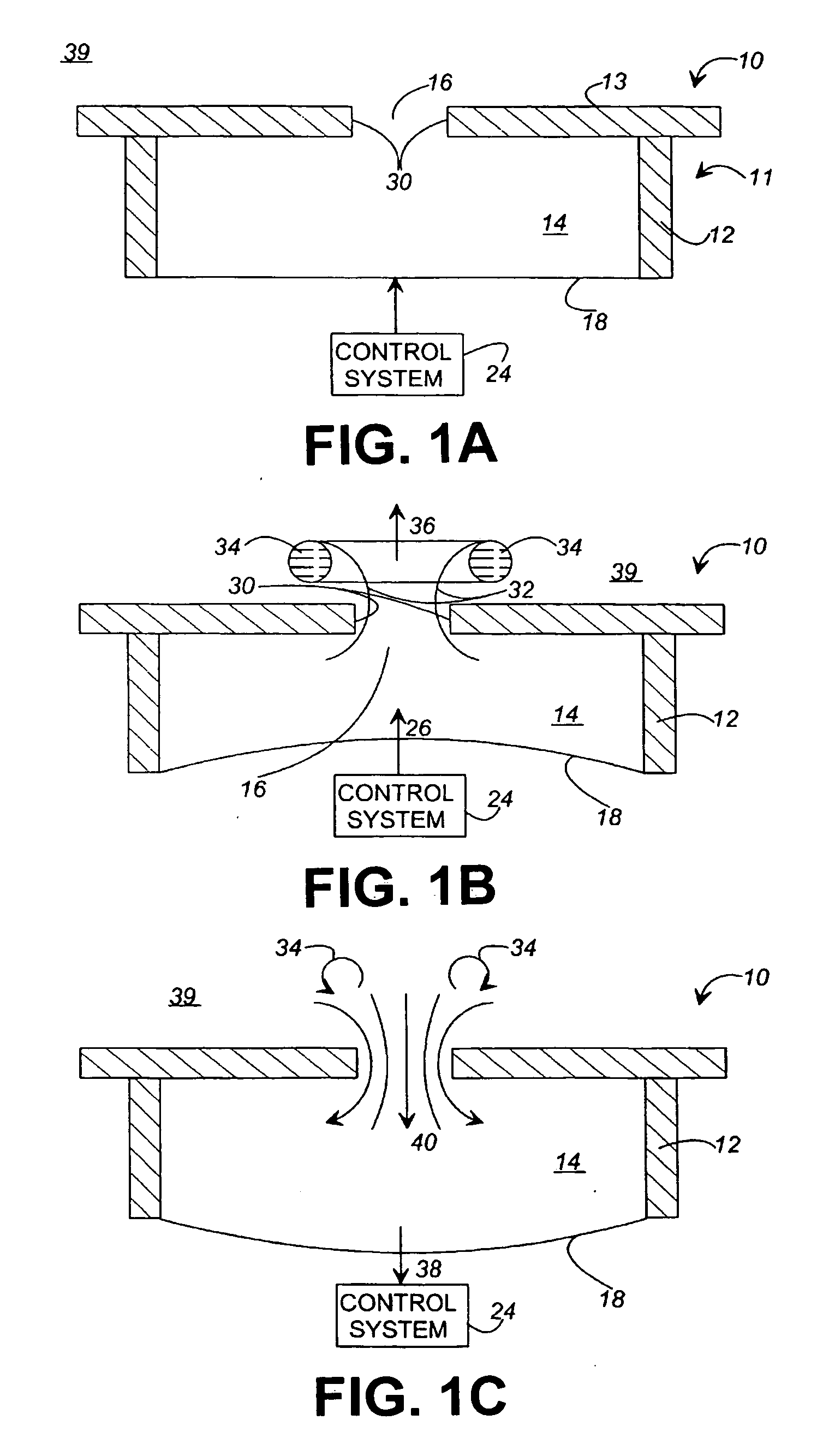

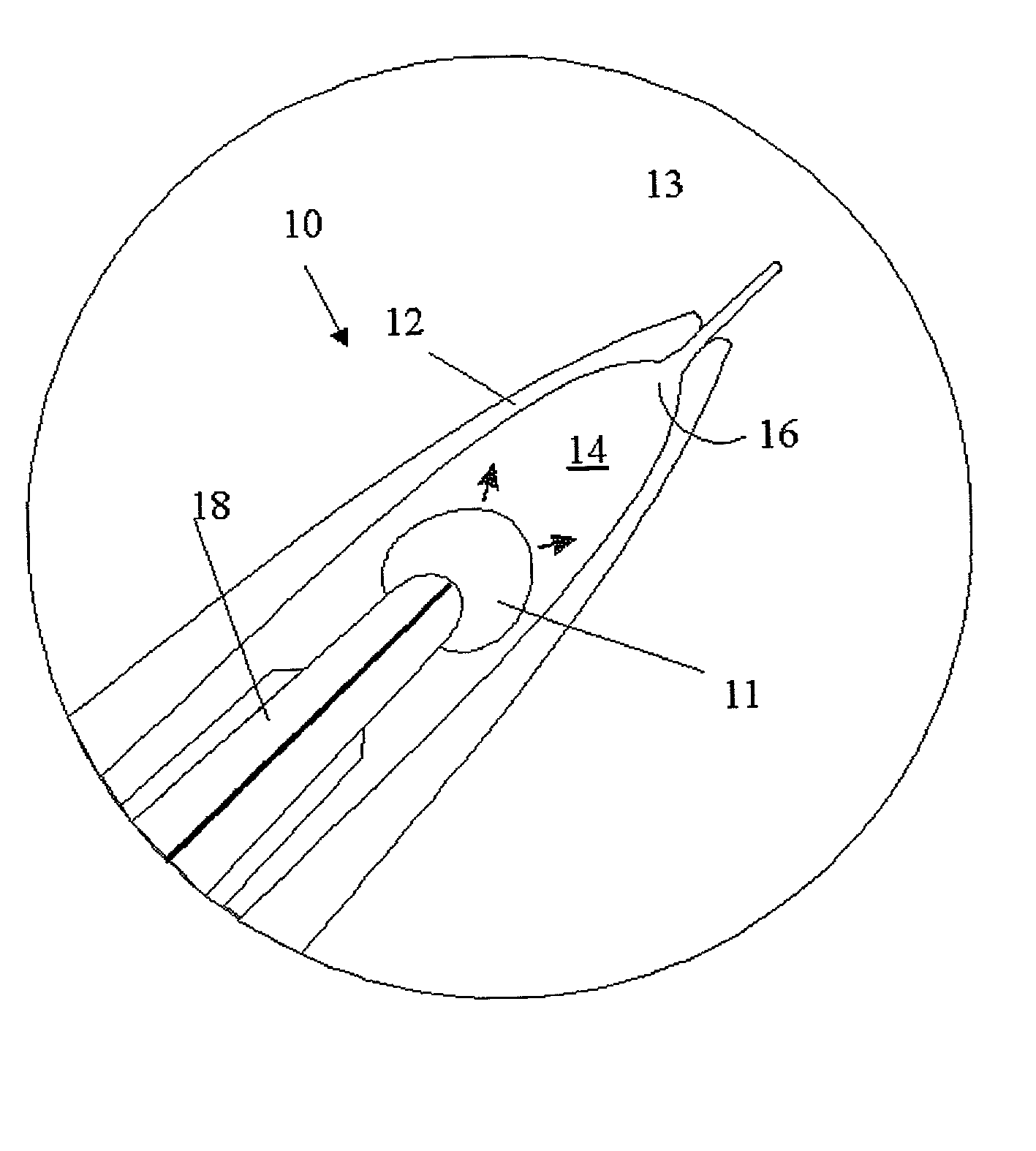

Oscillating air jets for reducing HSI noise

Porous surfaces on an aerodynamic structure driven with positive and negative pressures are used in an active control system for attenuating shock waves responsible for high-speed impulsive (HSI) noise. The control system includes an array of apertures in the outer skin of the structure providing fluid communication between the exterior flow stream and an interior volume of the structure. A movable diaphragm within the structure pushes air out of and pulls air in through the apertures under the action of a drive mechanism within the structure, thus creating oscillating air jets. The drive mechanism may be actuated by a controller based on information supplied by a sensor in the leading edge of the aerodynamic structure. The array of apertures may be spaced apart along the outer skin of the aerodynamic structure so as to span a distance of about 15% of the chord length. The oscillating airjets may be provided on multiple surfaces of the aerodynamic structure, including the upper and lower surfaces.

Owner:MCDONNELL DOUGLAS

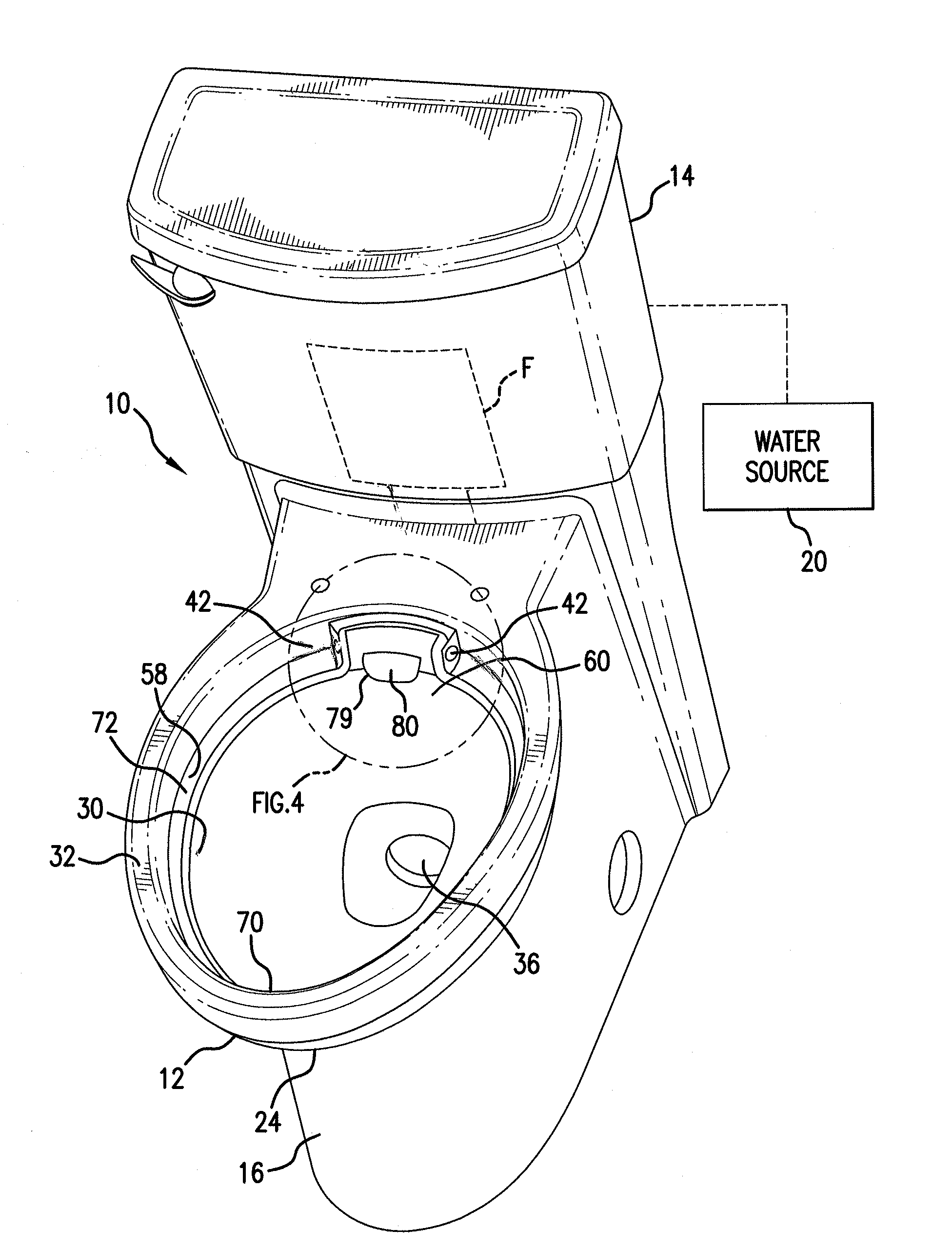

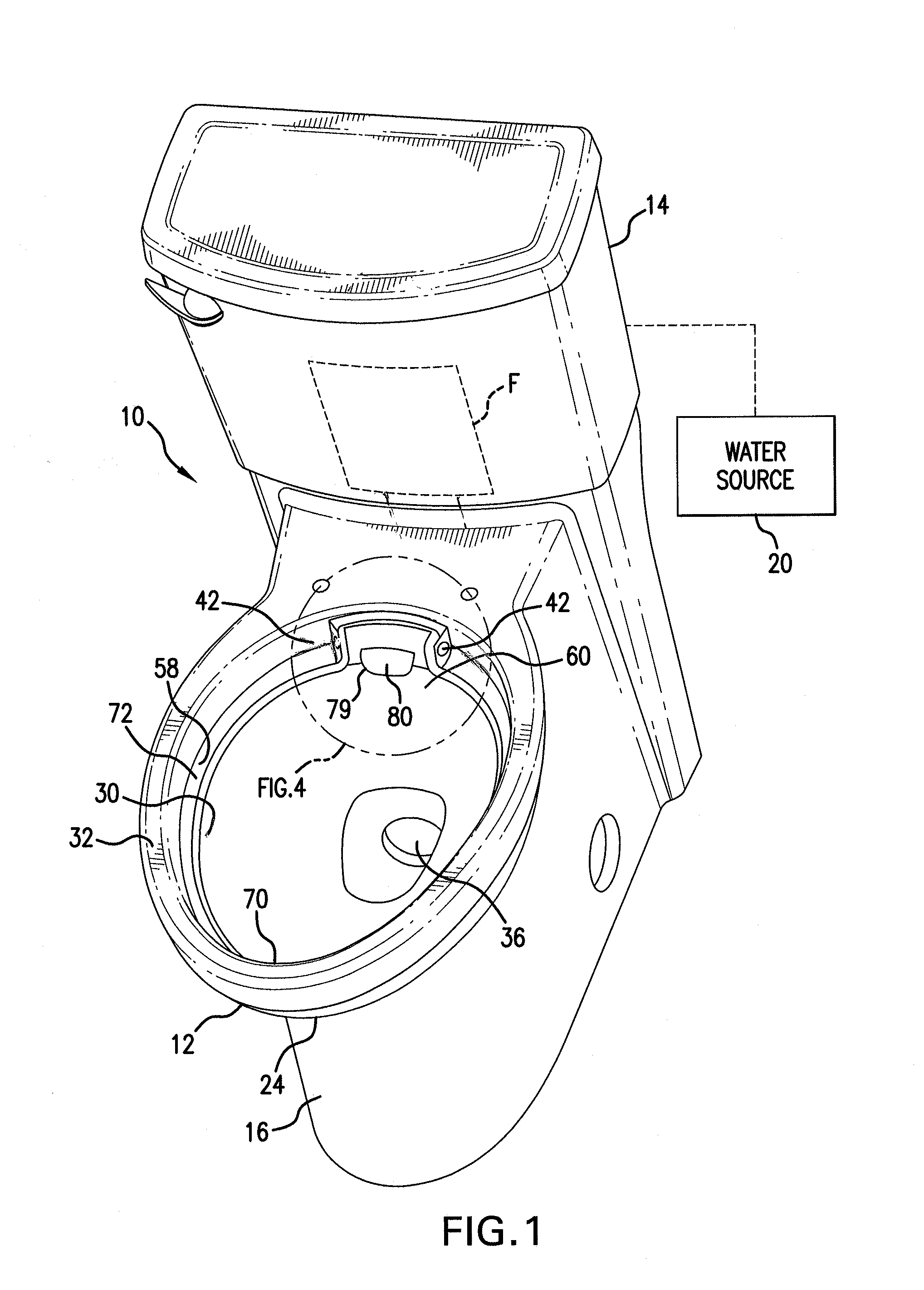

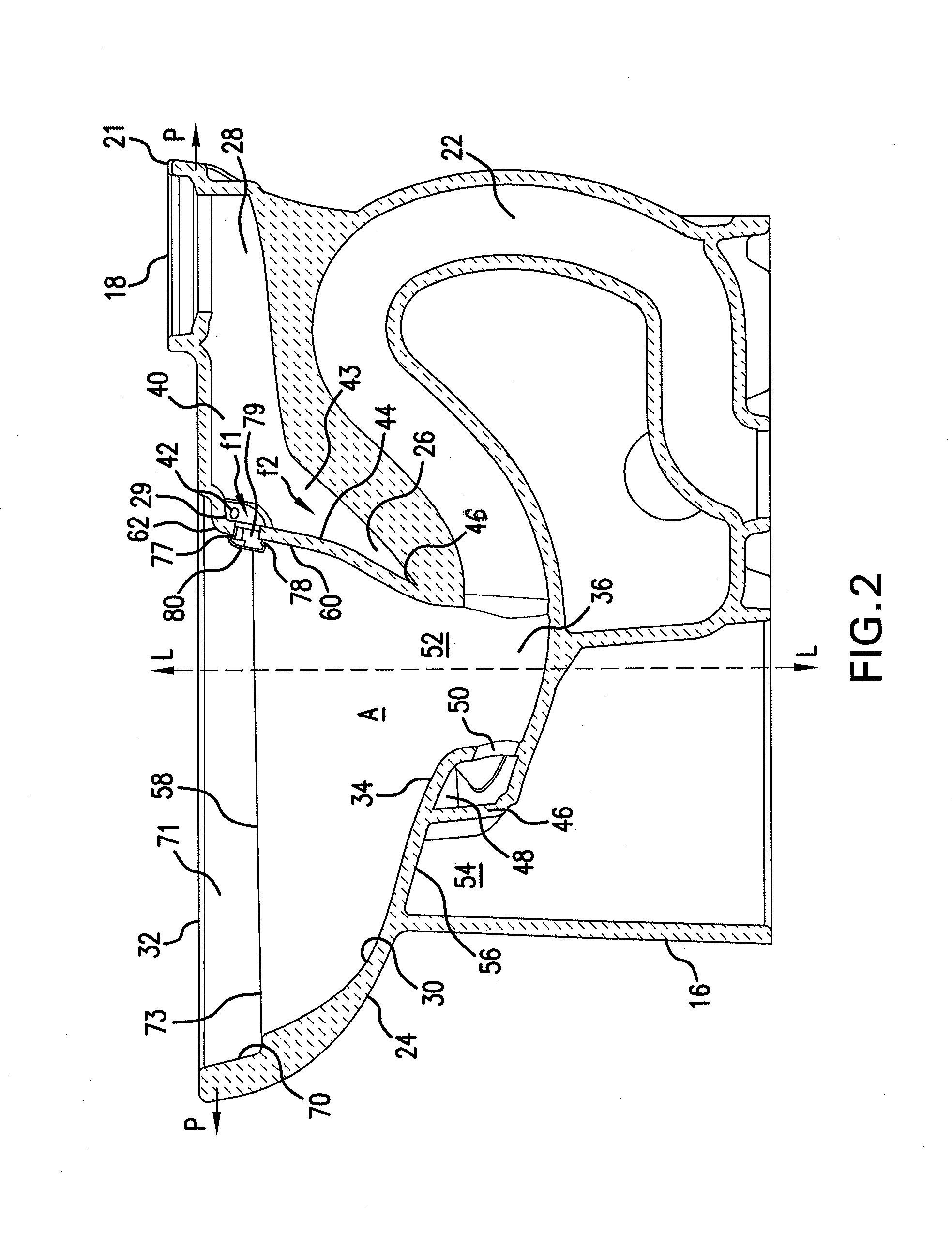

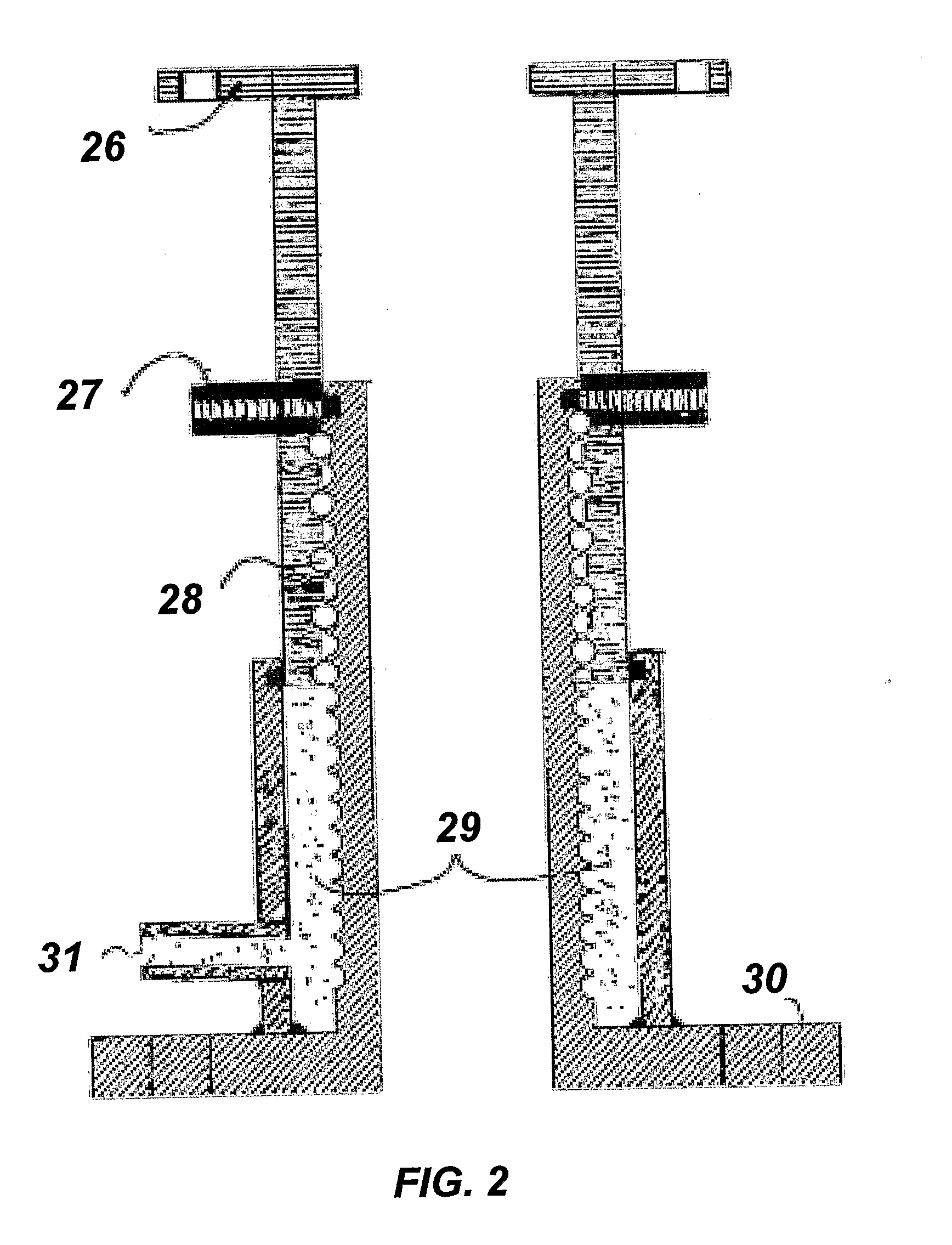

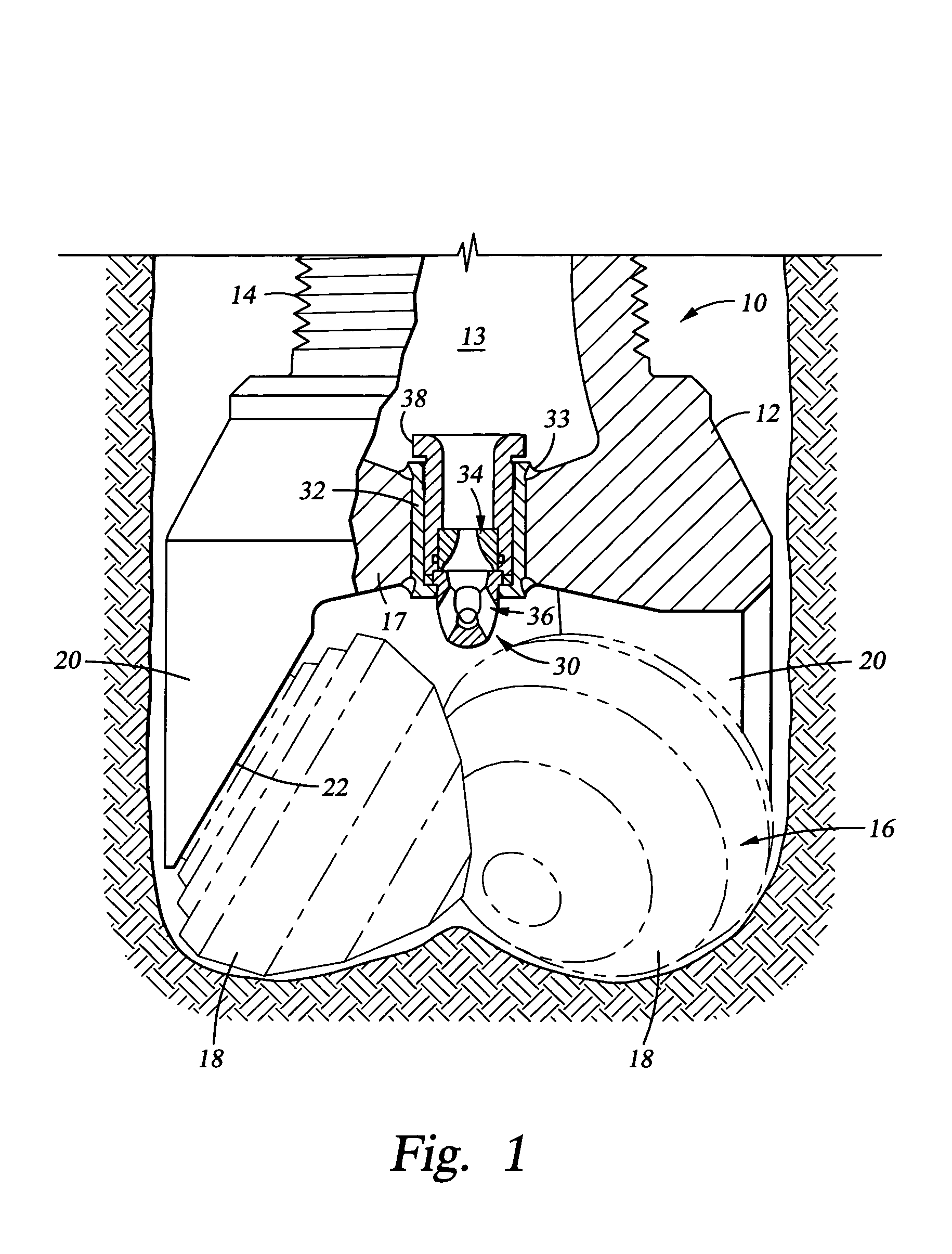

Rimless toilet

A siphonic gravity-powered toilet is provided that is a rimless toilet and includes a toilet bowl assembly having a body and an inlet for receiving fluid. The toilet bowl has an interior bowl surface with an upper peripheral portion configured to have a shelf formed therein below an upper peripheral edge of the toilet bowl. The rimless toilet includes a jet having a jet inlet, an outlet and at least one jet channel. A manifold is included which is configured so that fluid entering an inlet of the toilet bowl assembly divides into a portion that enters the inlet of the direct-fed jet and a portion that enters an interior area of the toilet bowl. At least one toilet bowl inlet port is positioned at an upper rear portion of the toilet bowl. The at least one inlet port is configured to receive fluid from the manifold into the interior area of the toilet bowl such that at least a portion of the fluid travels along the shelf of the toilet bowl prior to passing into a lower portion of the toilet bowl.

Owner:AS IP HOLDCO LLC

Reactor design to reduce particle deposition during process abatement

InactiveUS20060104879A1Reduce accumulationReduce reactor chamber crackingCombination devicesBurnersCombustionDecomposition

The present invention relates to systems and methods for controlled combustion and decomposition of gaseous pollutants while reducing deposition of unwanted reaction products from within the treatment systems. The systems include a novel thermal reaction chamber design having stacked reticulated ceramic rings through which fluid, e.g., gases, may be directed to form a boundary layer along the interior wall of the thermal reaction chamber, thereby reducing particulate matter buildup thereon. The systems further include the introduction of fluids from the center pilot jet to alter the aerodynamics of the interior of the thermal reaction chamber.

Owner:APPLIED MATERIALS INC

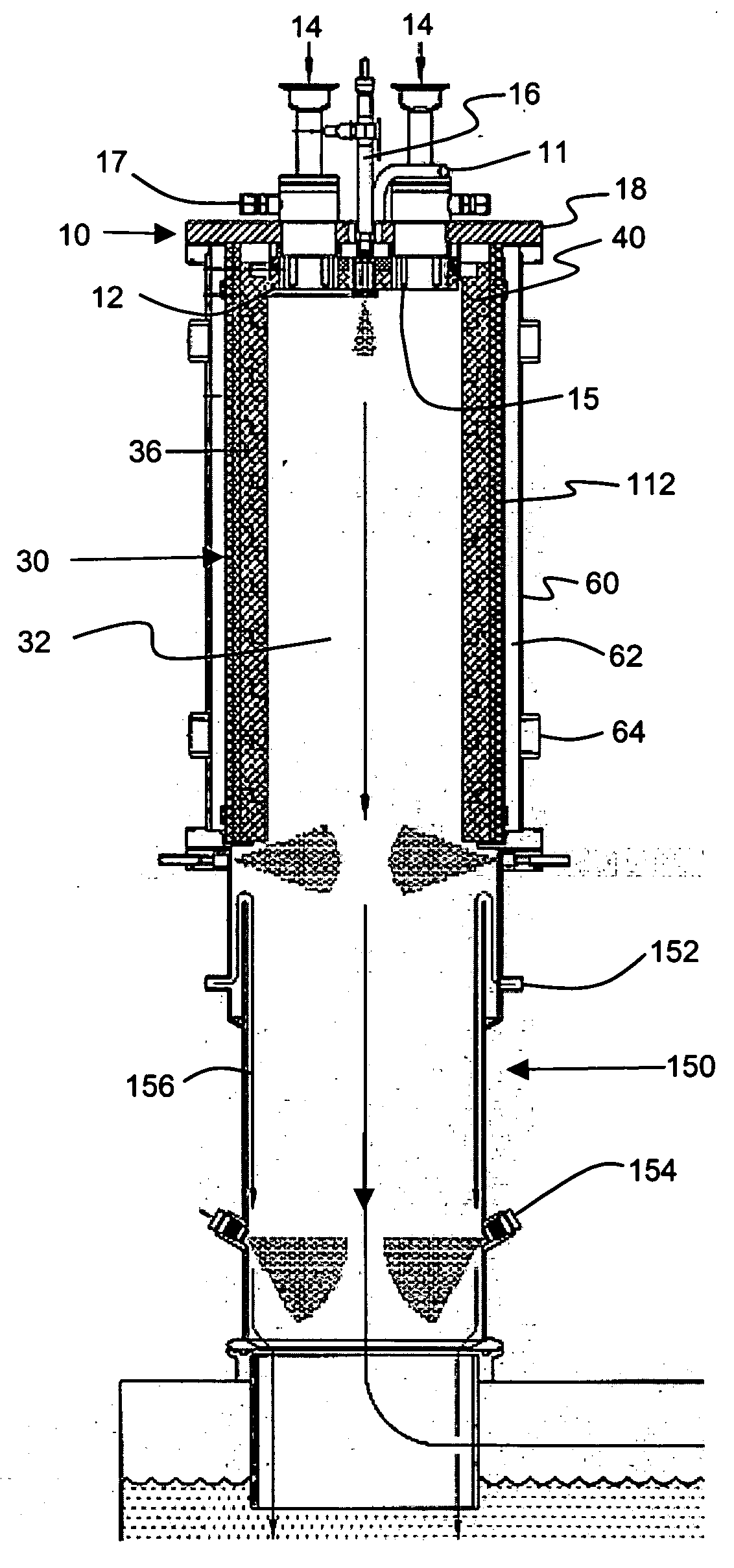

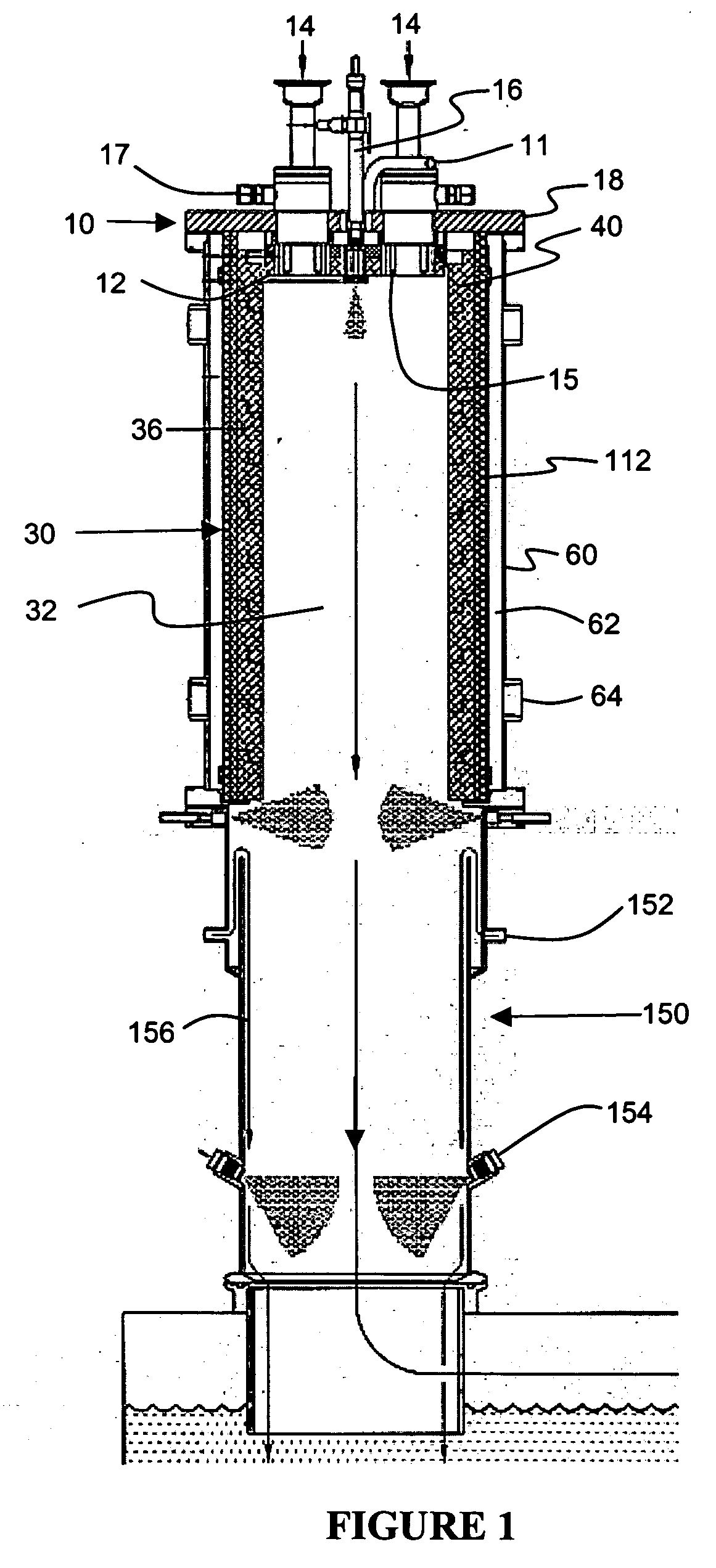

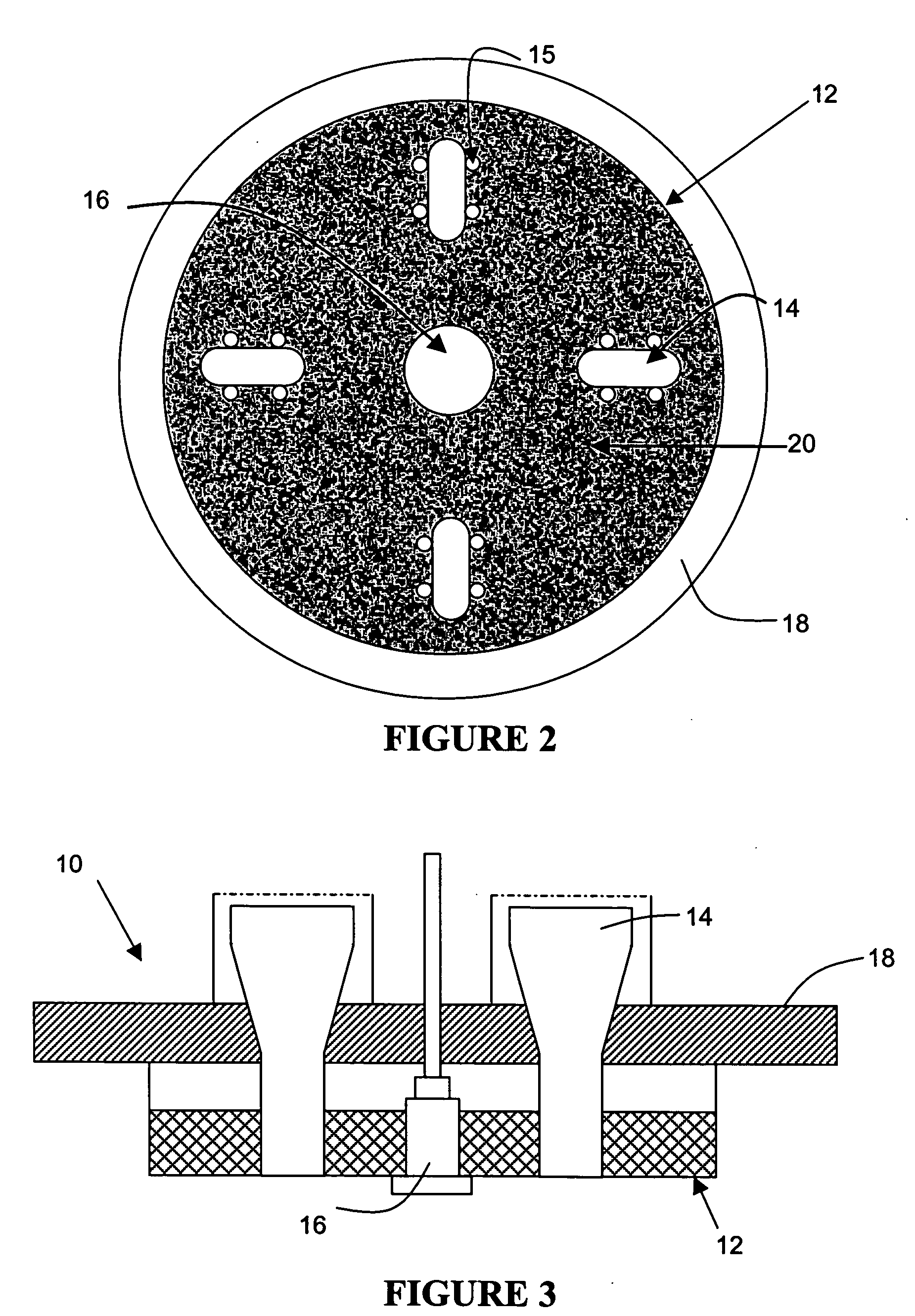

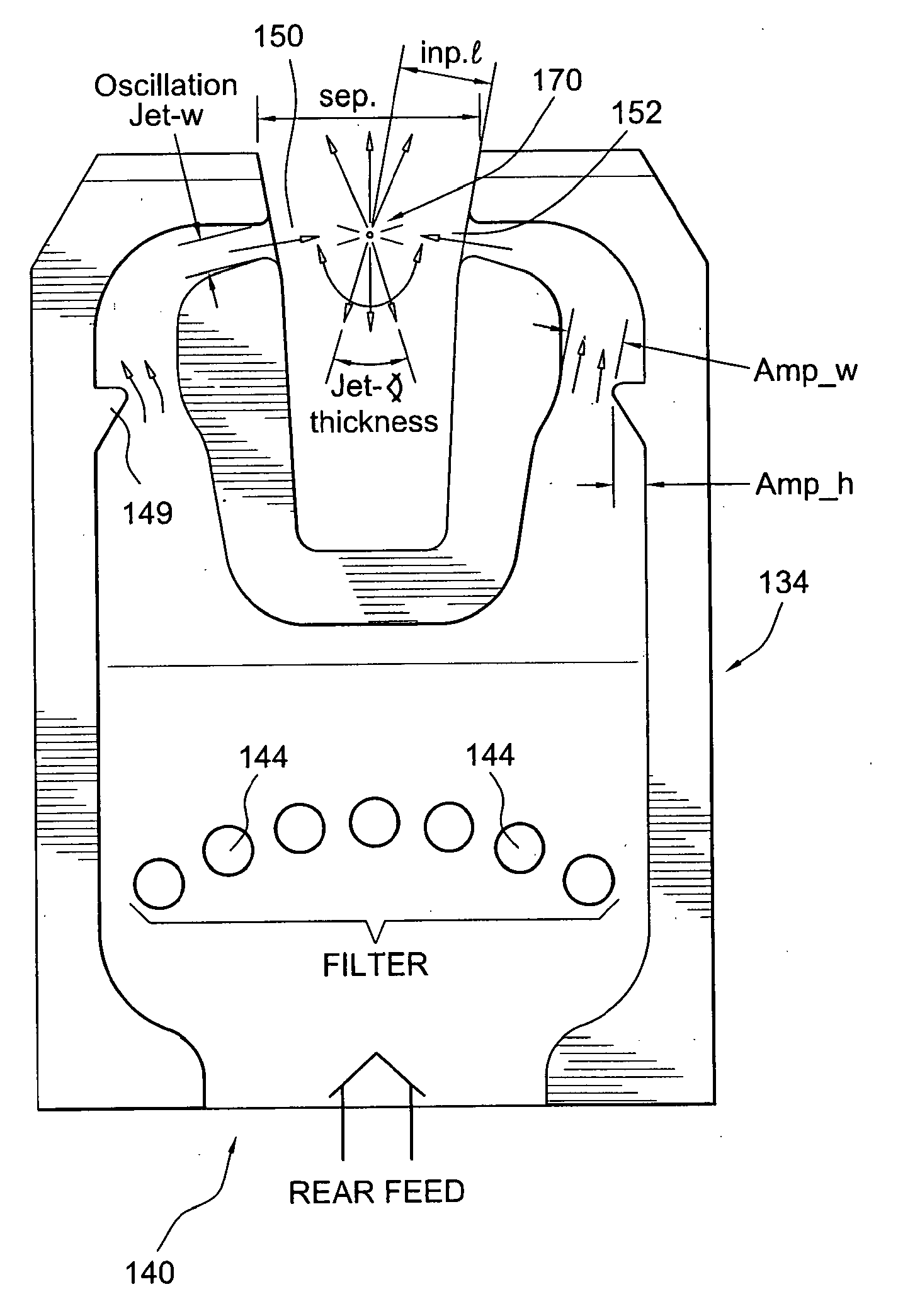

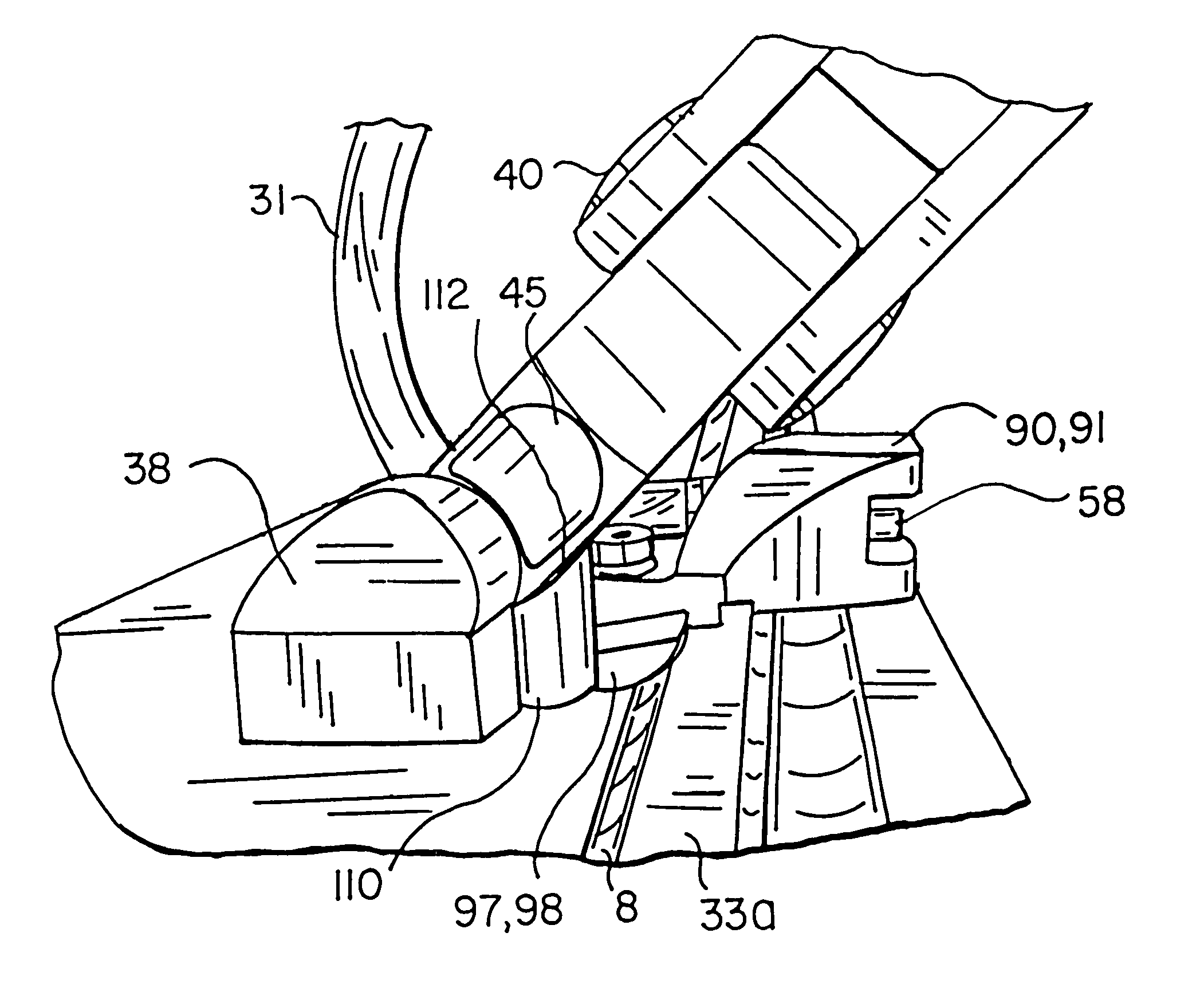

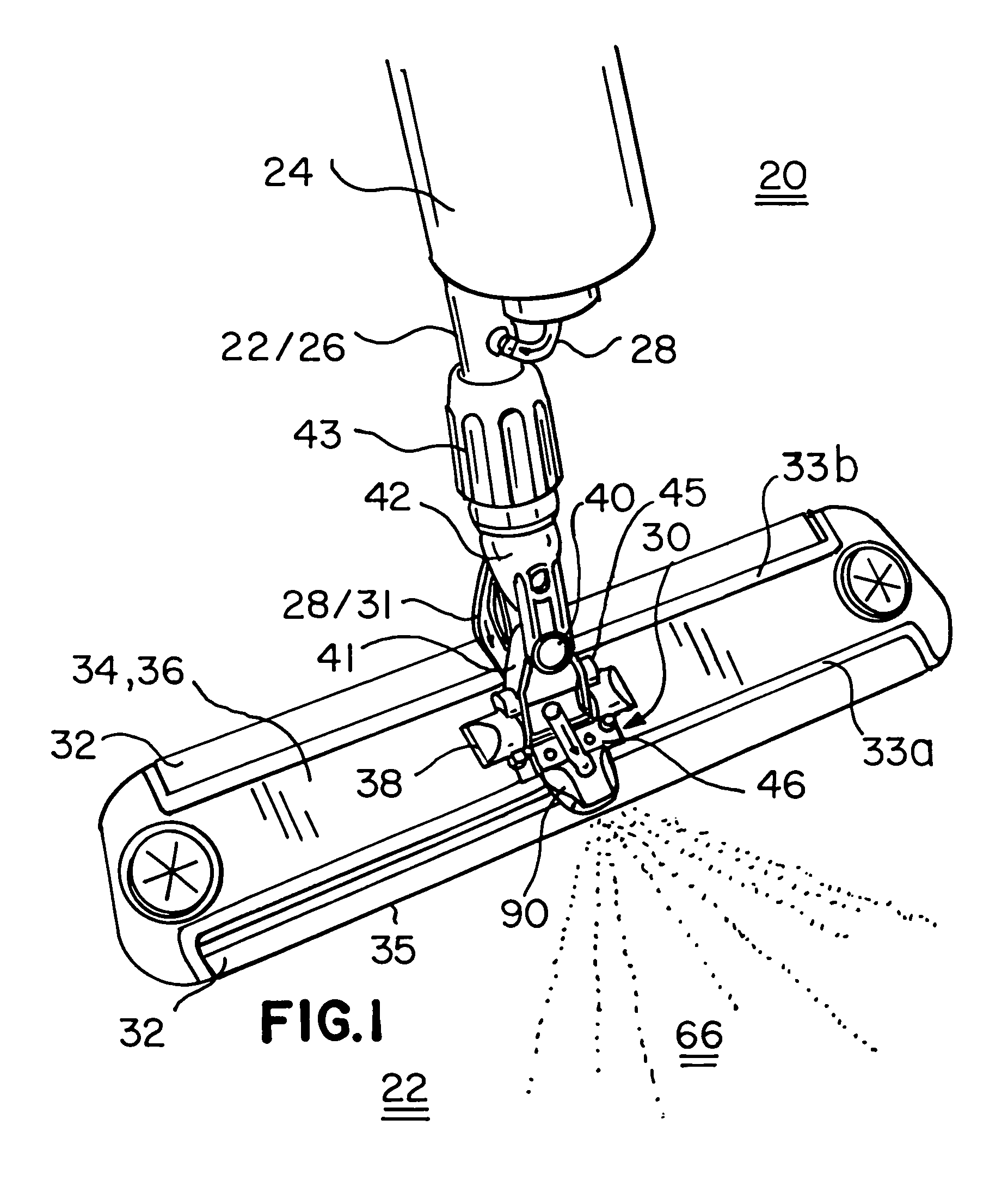

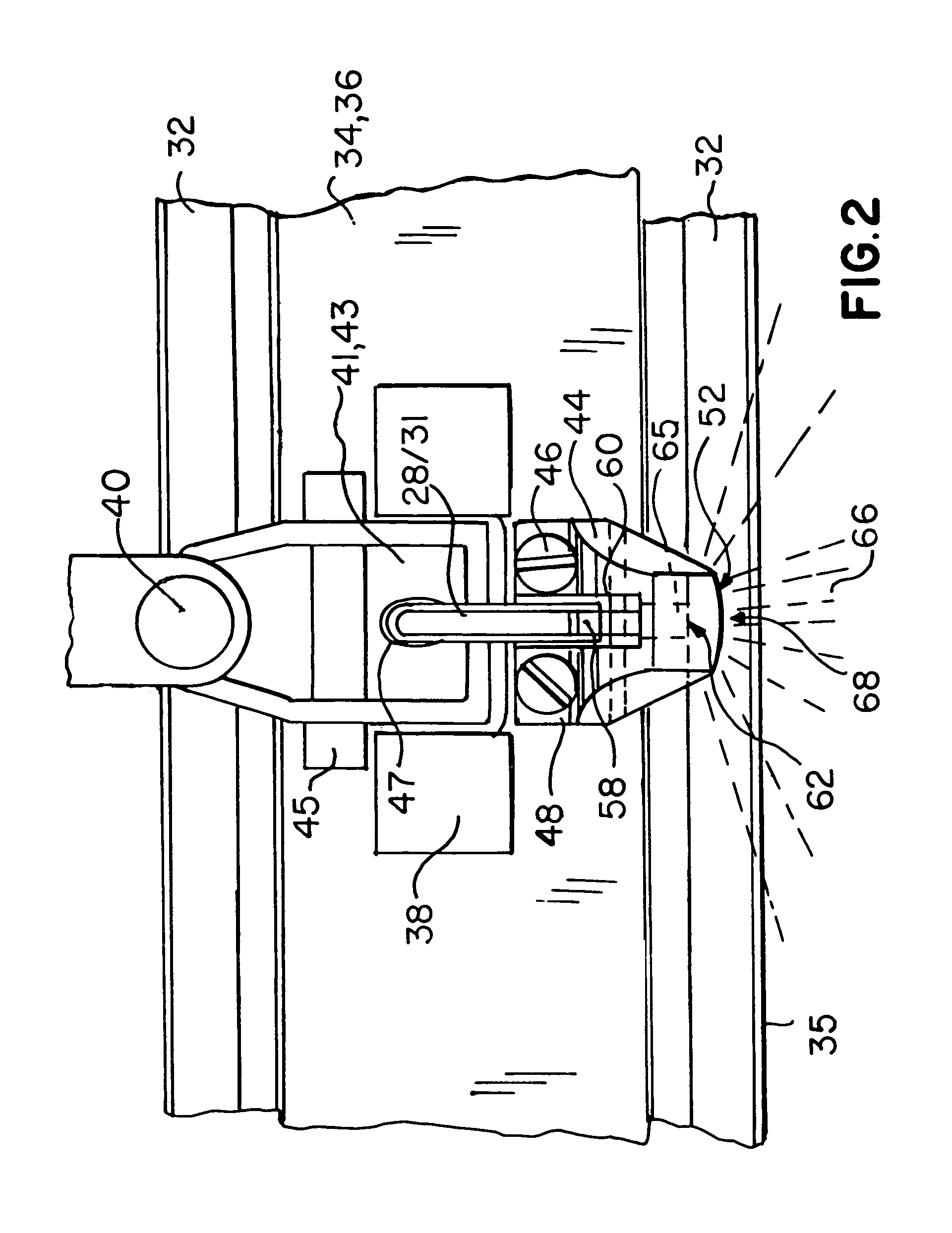

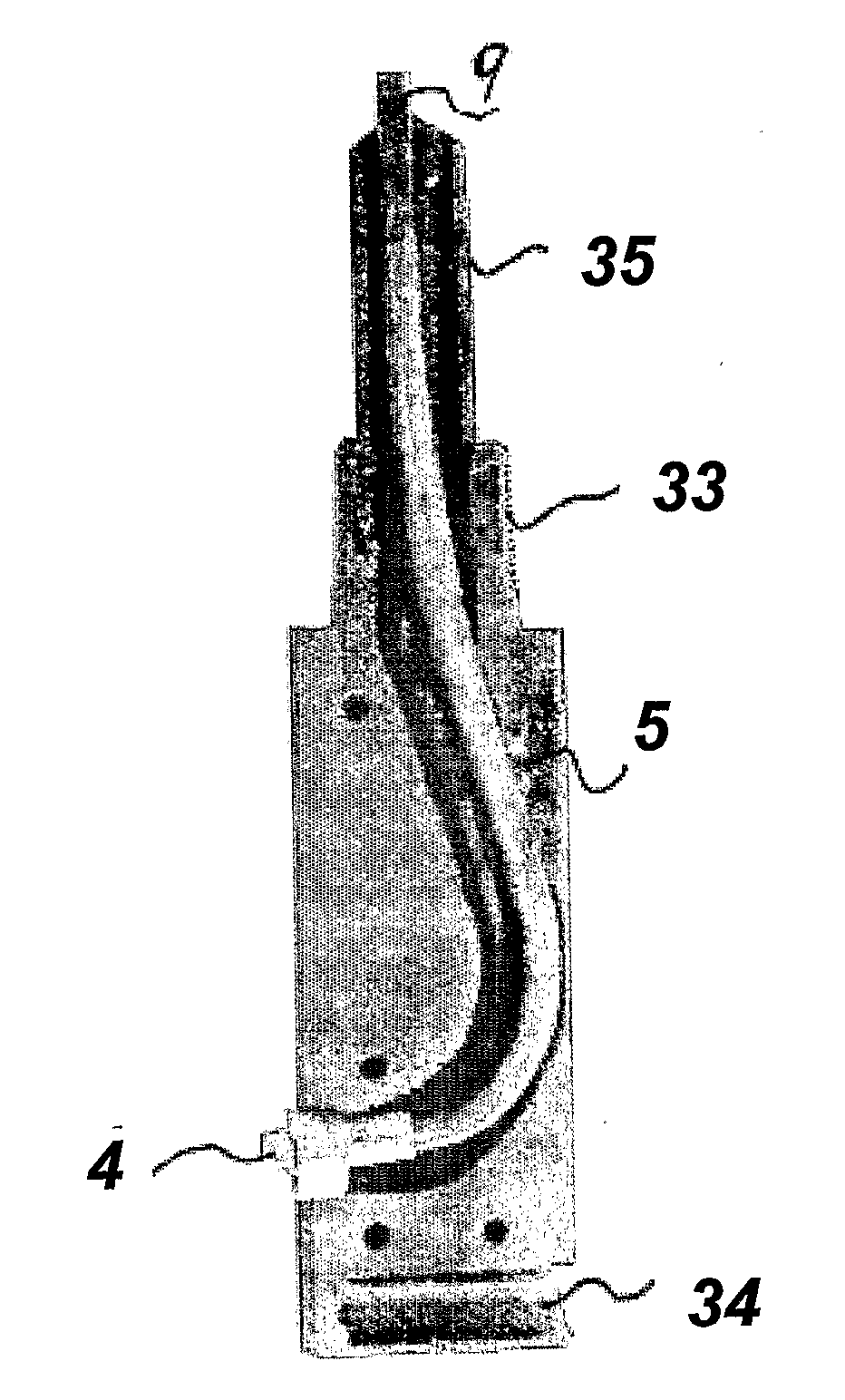

Full coverage fluidic oscillator with automated cleaning system and method

InactiveUS20110061692A1Increase heightImprove spraying effectUrinalsWater closetsAudio power amplifierFluidic oscillator

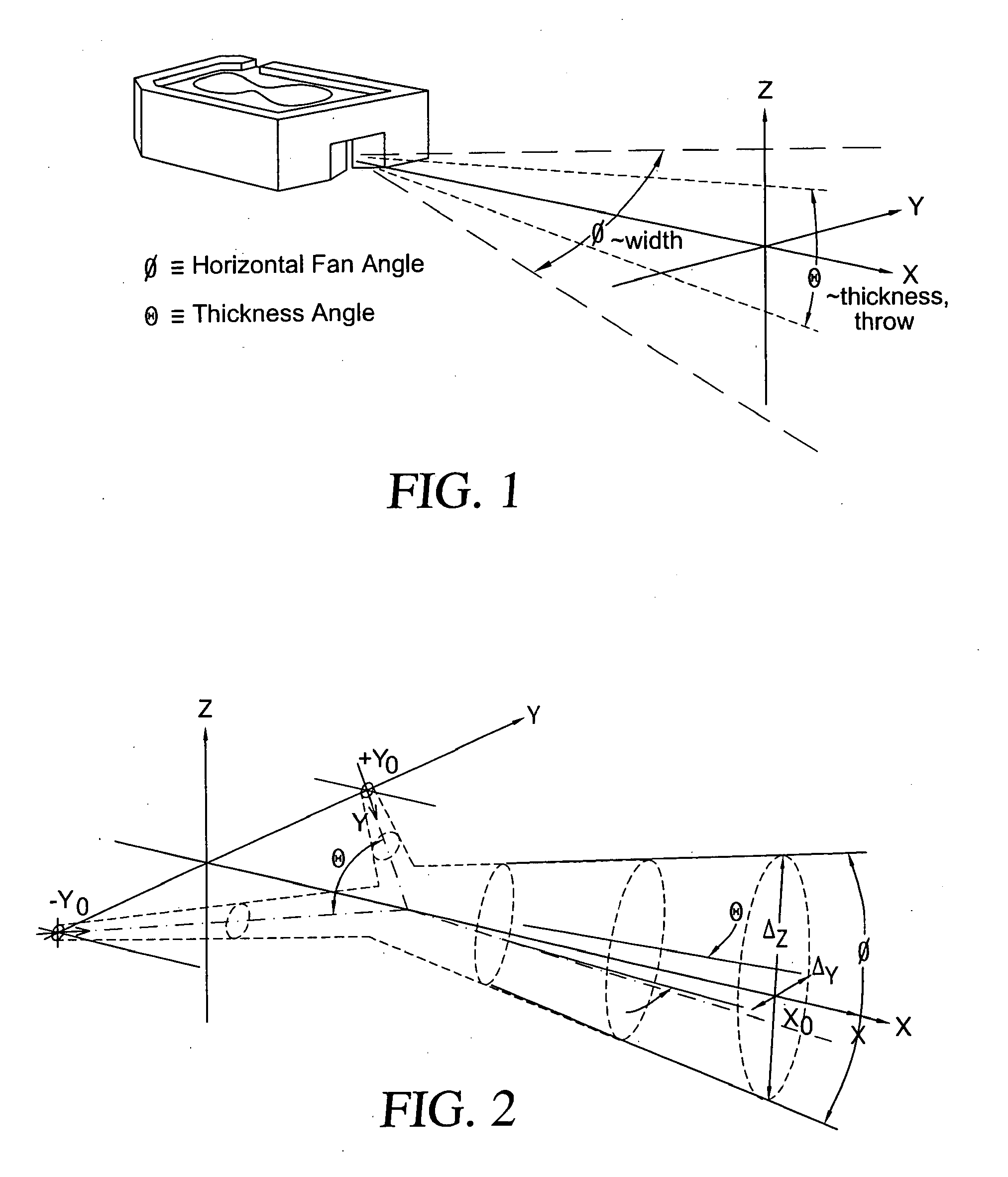

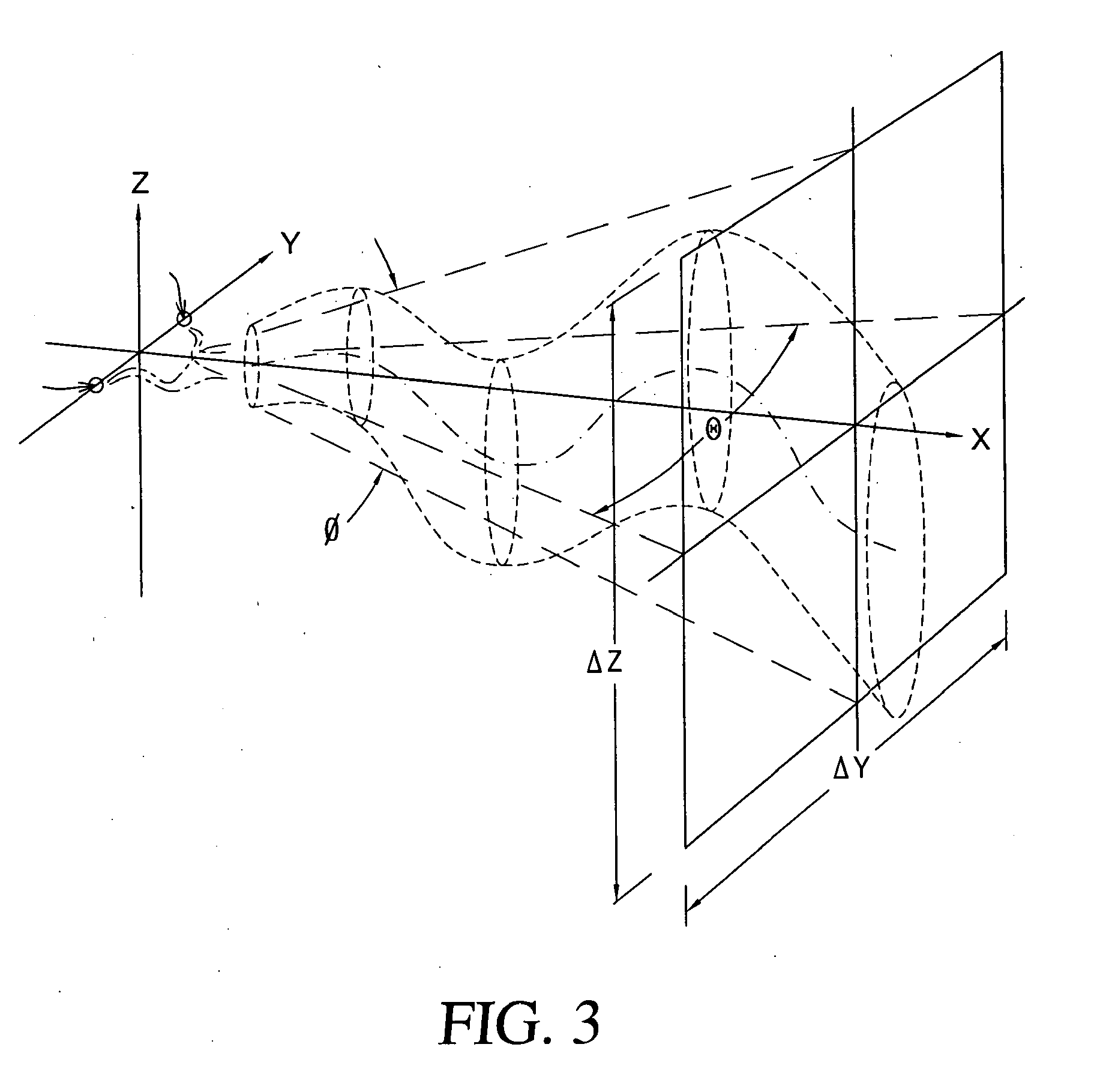

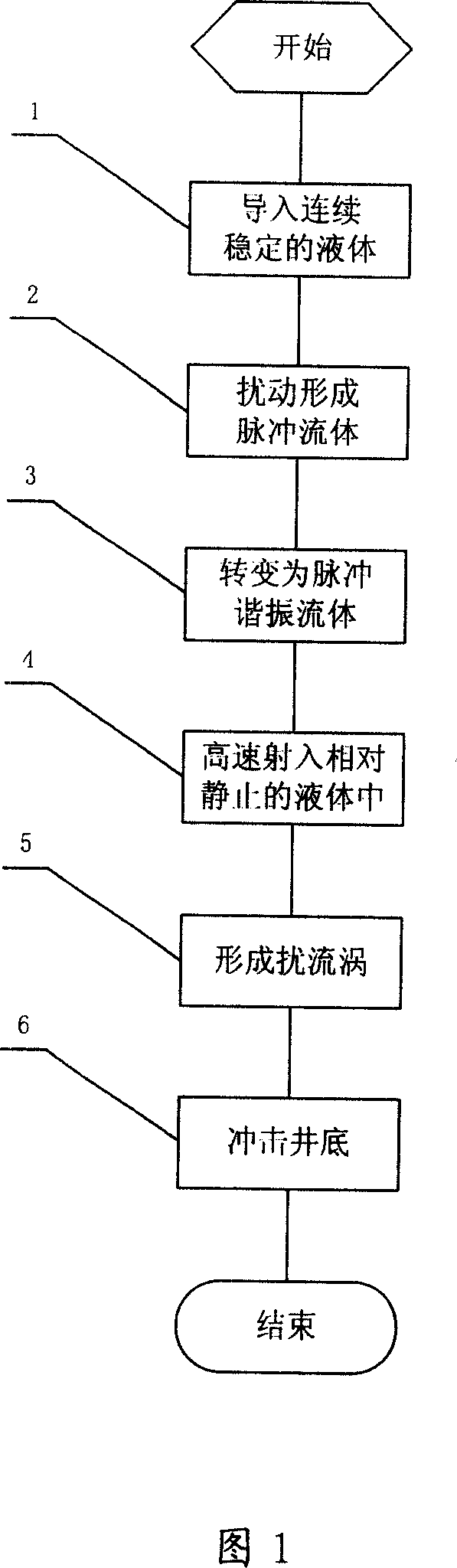

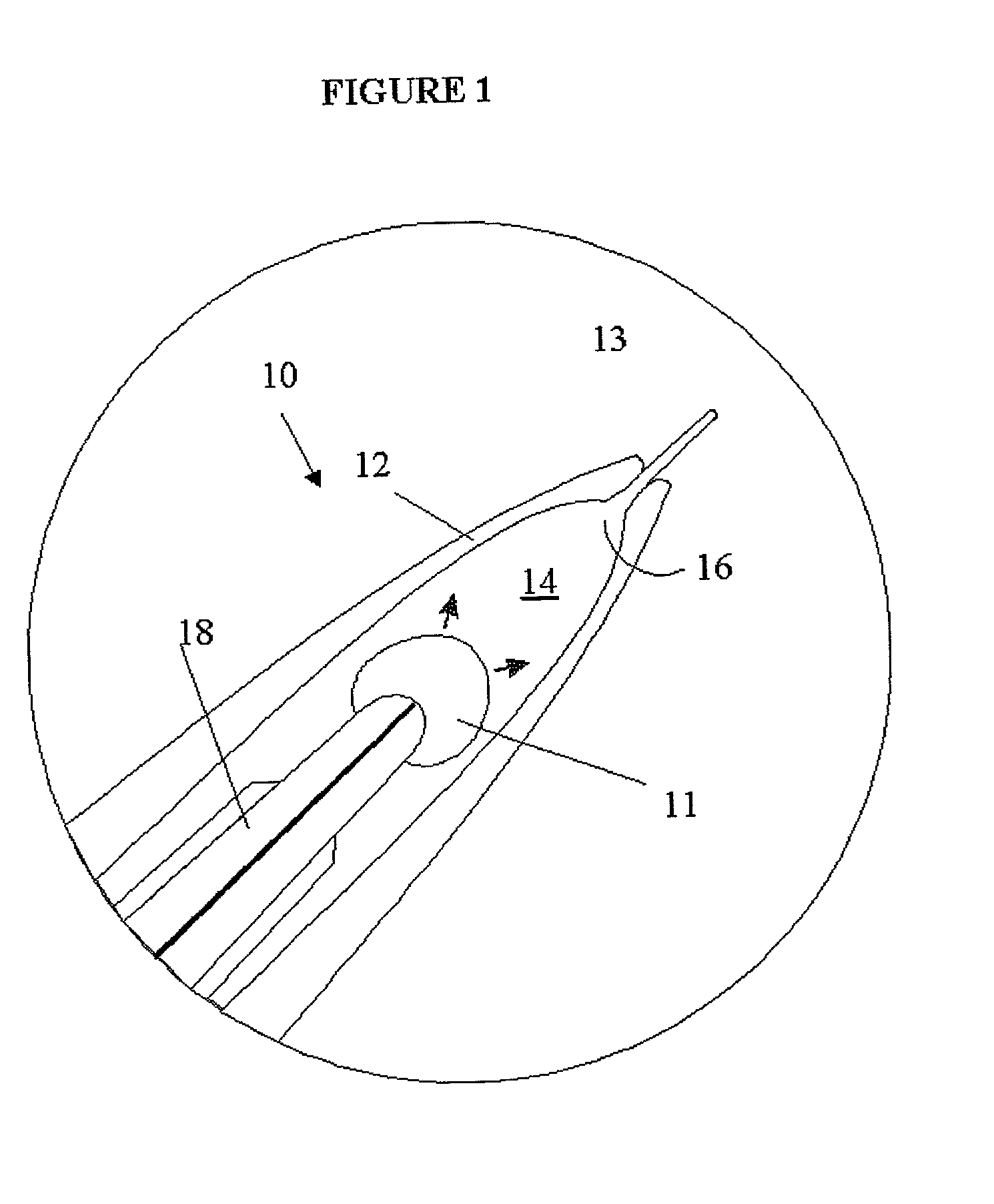

A full coverage fluidic oscillator (2) includes a fluidic circuit member preferably having an oscillation inducing internal chamber, at least one inlet (8) or source of fluid under pressure, at least a pair of output nozzles (14, 16) connected to the source of fluid for projecting at least first and second impinging fluid jets into free space, where the first and second impinging jets collide or impinge upon one another at a selected jet angle to generate a substantially omni-directional sheet jet having selected thickness. The first and second jets are aimed at a pre-selected intersection point in free space where impingement is to occur. The sheet jet's thickness Δy is determined by the time-varying path or oscillation of each of the first and second impinging jets. The first and second impinging jets can be made to oscillate or pulsate by use of vortex generating amplifier structures (68, 70, 72, 149) within the internal chamber's fluid flow paths.

Owner:DLHBOWLES INC

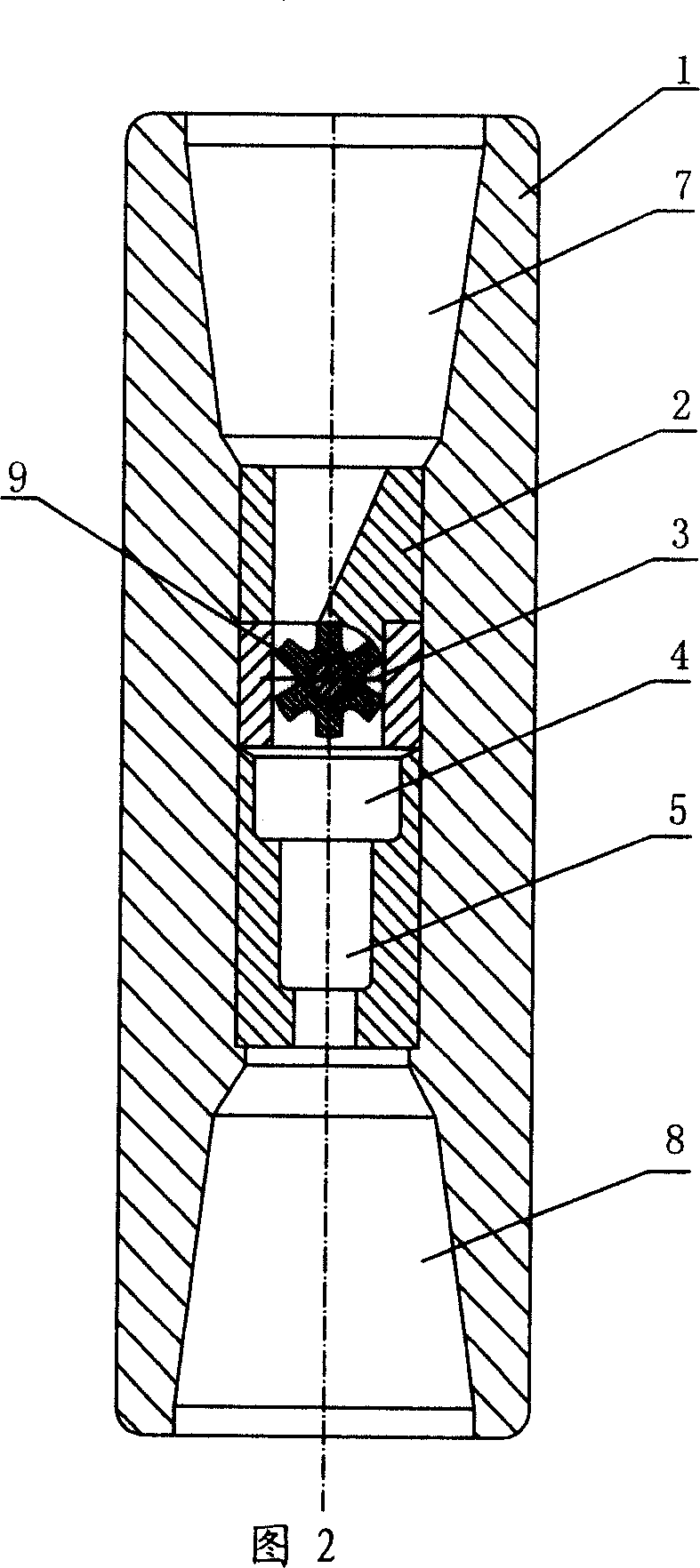

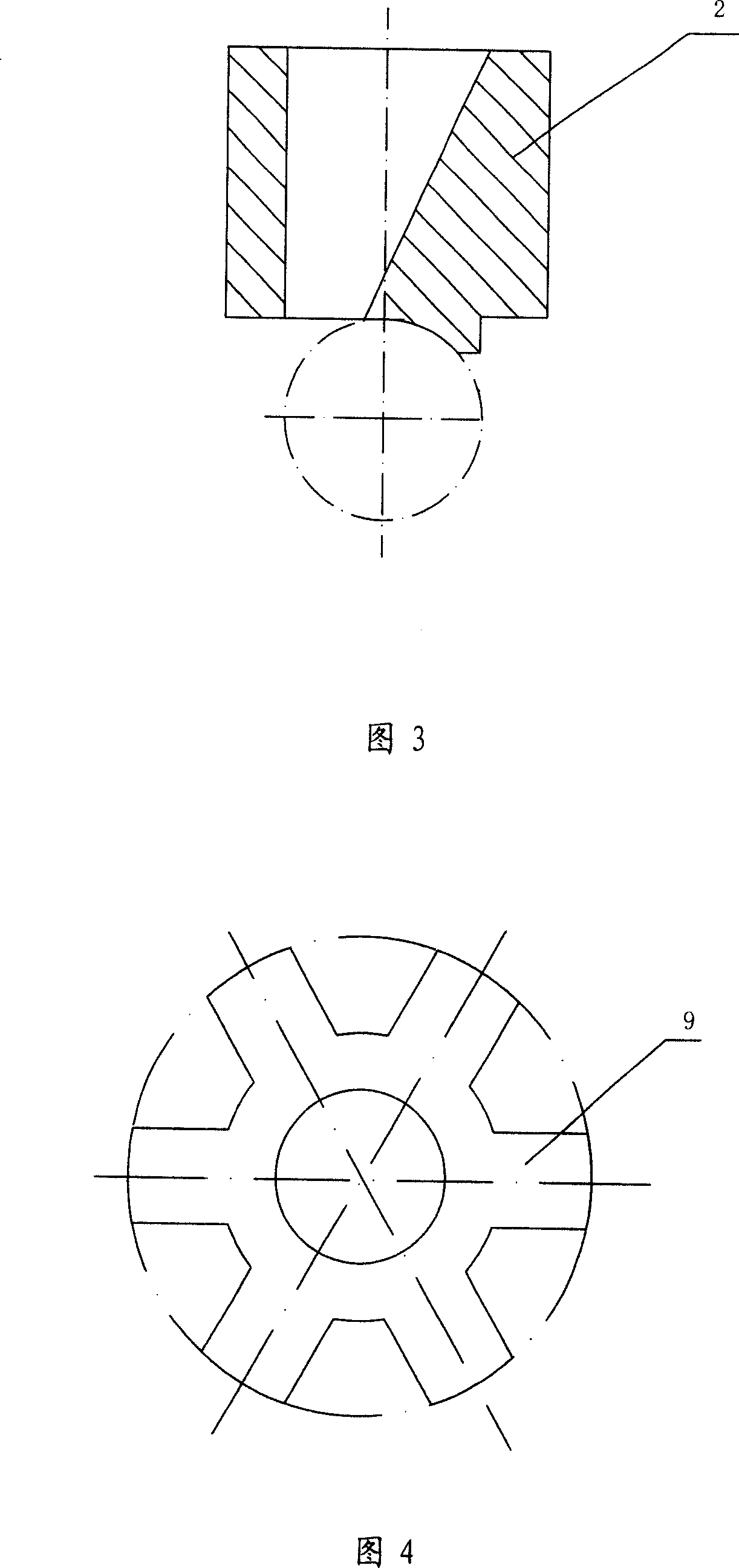

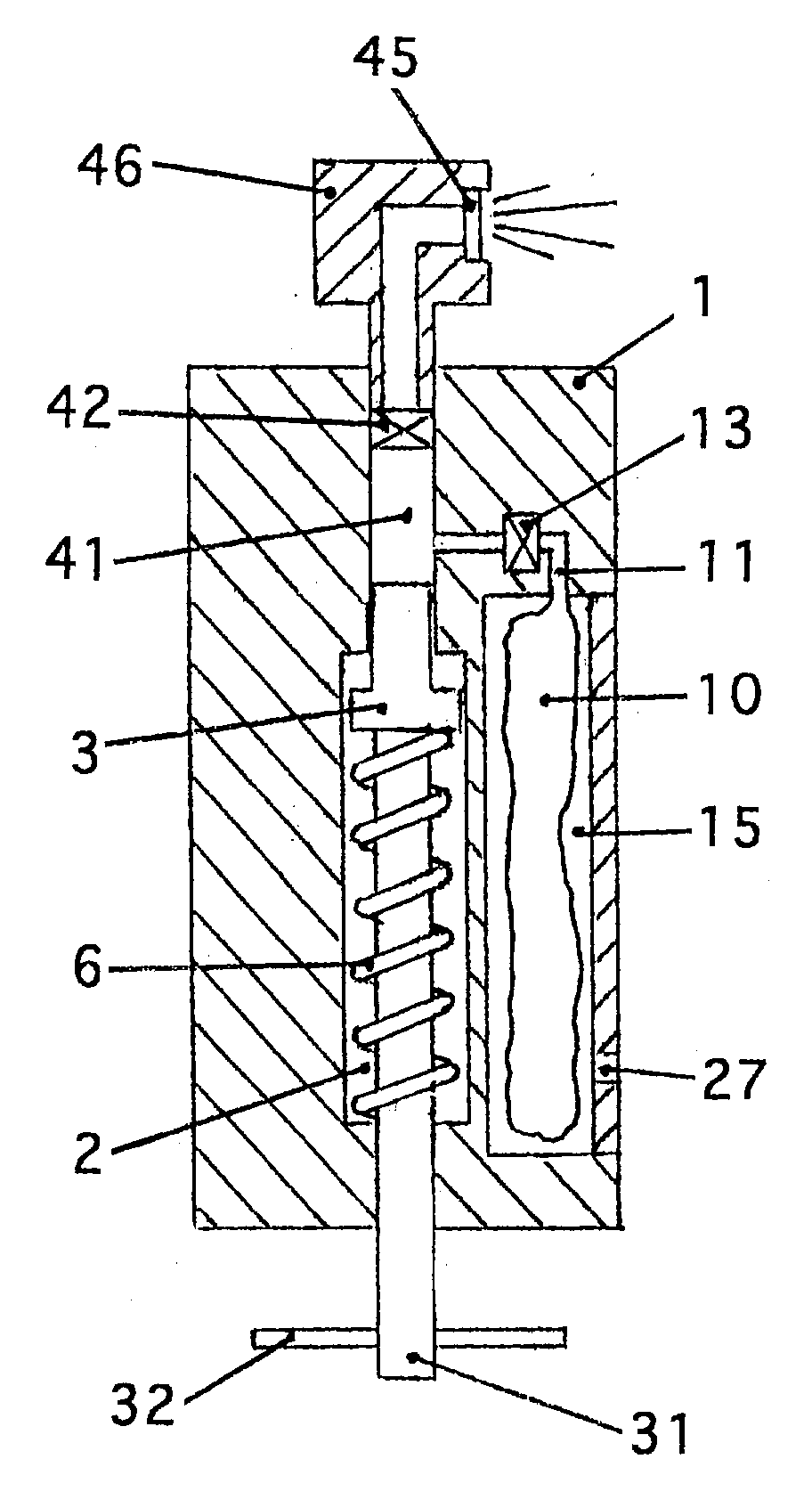

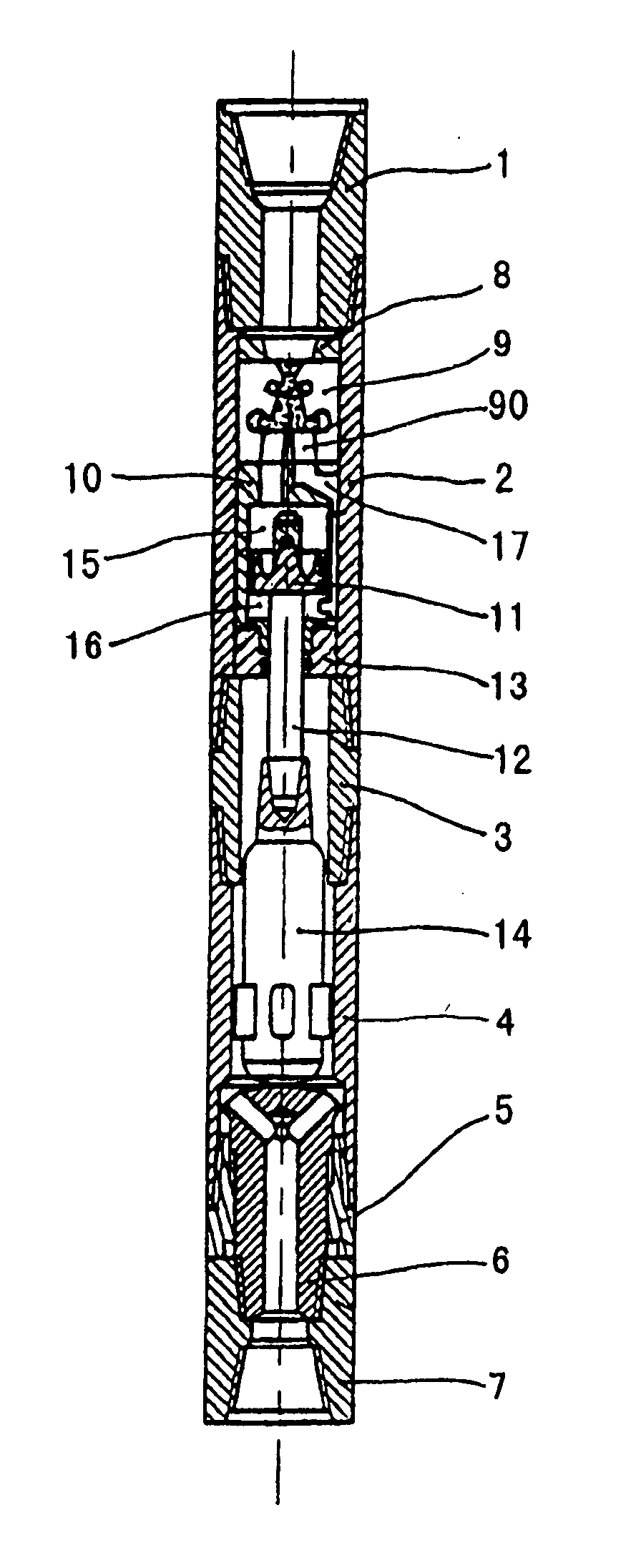

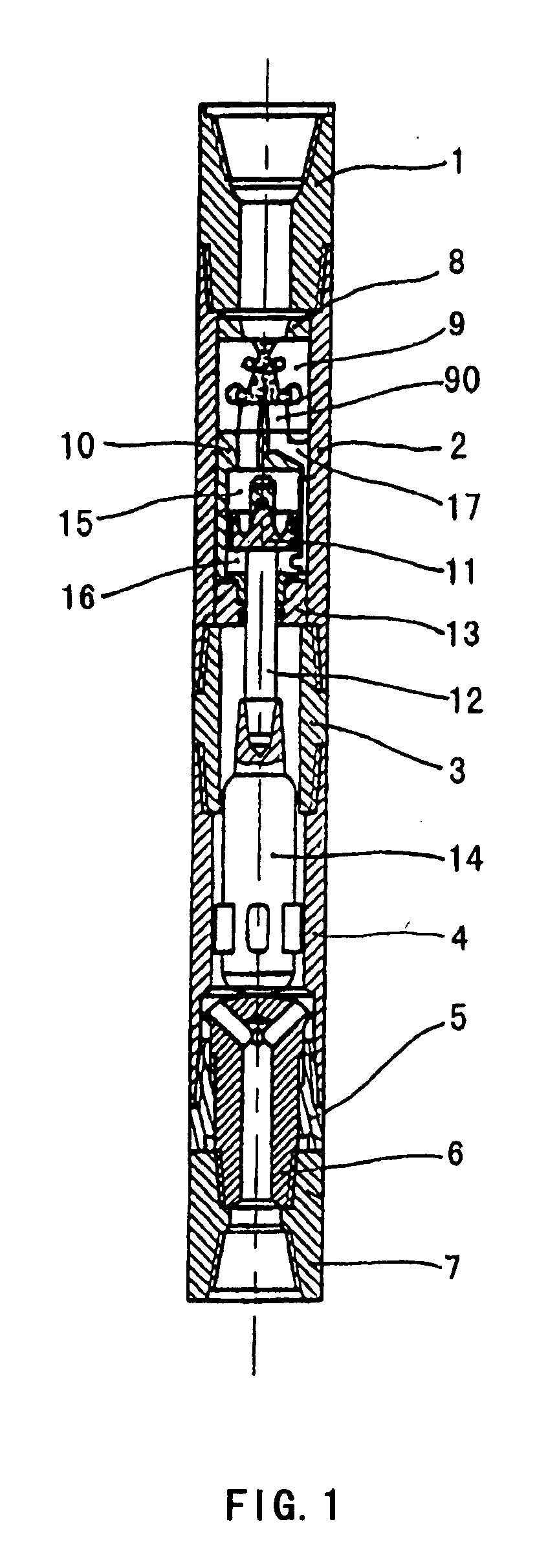

Waterpower pulse cavitation jet well drilling device, method and drill bit

InactiveCN101105115AExtended service lifeSolution to short lifeDrill bitsLiquid/gas jet drillingResonance oscillationCavitation

The invention discloses a hydraulic pulse drilling device with cavitation jet, which comprises a columnar body, wherein a fluid inlet section is provided at one end of the body, a fluid outlet section is provided at the other end of the body, and a fluid diversion portion for deviating the flow direction of the fluid, a pulse generator allowing the continuous fluid to generate pulse and a self-oscillation portion for allowing the fluid with pulse to generate resonance oscillation are sequentially provided between the fluid inlet section and fluid outlet section. The invention also discloses a self-resonating cavitation jet nozzle for drilling head, which improves the rock breaking effect of drilling head and rock cleaning effect at well bottom. The invention also discloses a hydraulic pulse drilling method with cavitation jet, which comprises during drilling work, converting continuous and stable fluid flow for impacting well bottom to pulse resonance flowing fluid; and injecting the pulse resonance flowing fluid into relatively static fluid to generate cavitation phenomena. The impact of well bottom with oscillating pressure reduces clip hold down effect, improves the rock cleaning and rock breaking capacity by jetting, and saves drilling cost.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

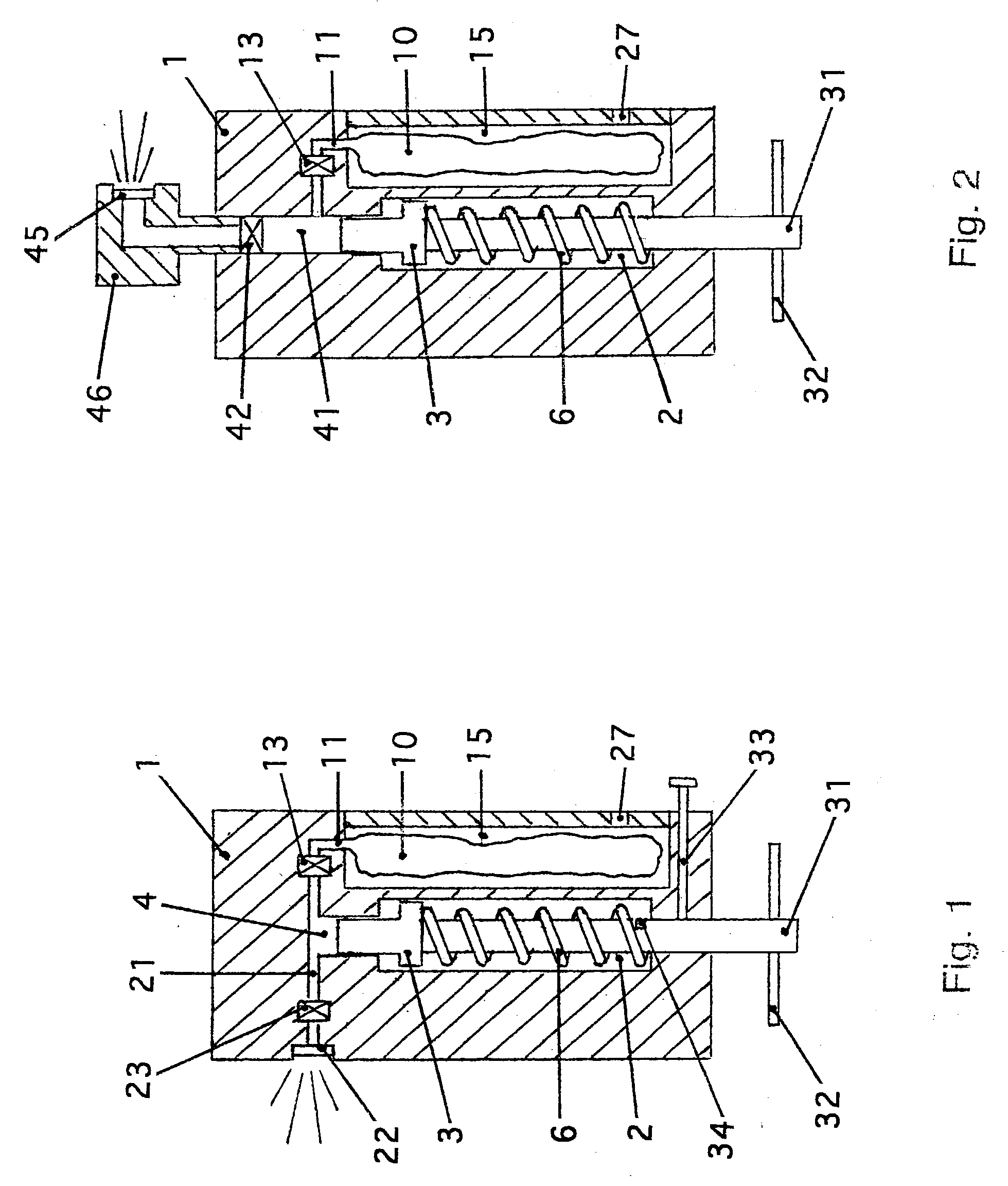

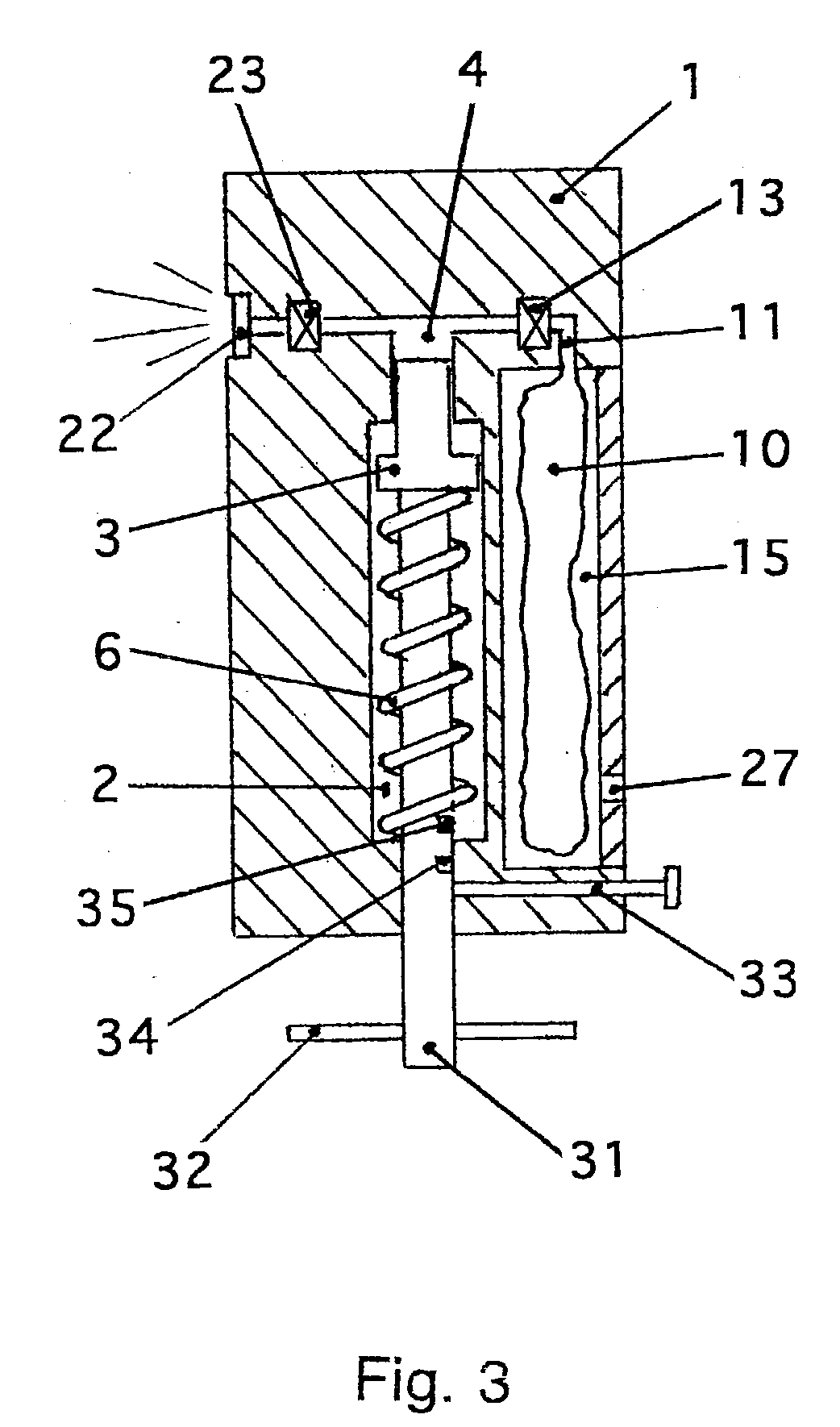

Atomizer for manual actuation

A fluid can be discontinuously atomized with an atomizer of the present invention. The atomizer can include a helical spring, disk spring or gas spring, acting as a pressure spring, as an energy storage device, a cylinder, piston, two ducts and two valves. Atomization can be initiated manually by triggering a locking mechanism. The energy storage device can be disposed outside a storage container for the fluid. The energy storage device can be provided mechanical energy manually. Via the piston, the stored energy can exert pressure onto the fluid in the cylinder, which ranges from 1 MPa to 5 MPa (10 bar to 50 bar). Distribution of the droplet size in the atomized jet can be independent from the level of experience and behavior of the person actuating the atomizer, and can be adjusted in a reproducible manner. The mean droplet diameter can be smaller than about 50 micrometers. The mass flow of the fluid through the nozzle can be less than about 0.4 g / s. The design and function of the atomizer can be adjusted to properties of the fluid, to a planned application, and to a desired manner for handling the atomizer.

Owner:BOEHRINGER INGELHEIM MICROPARTS

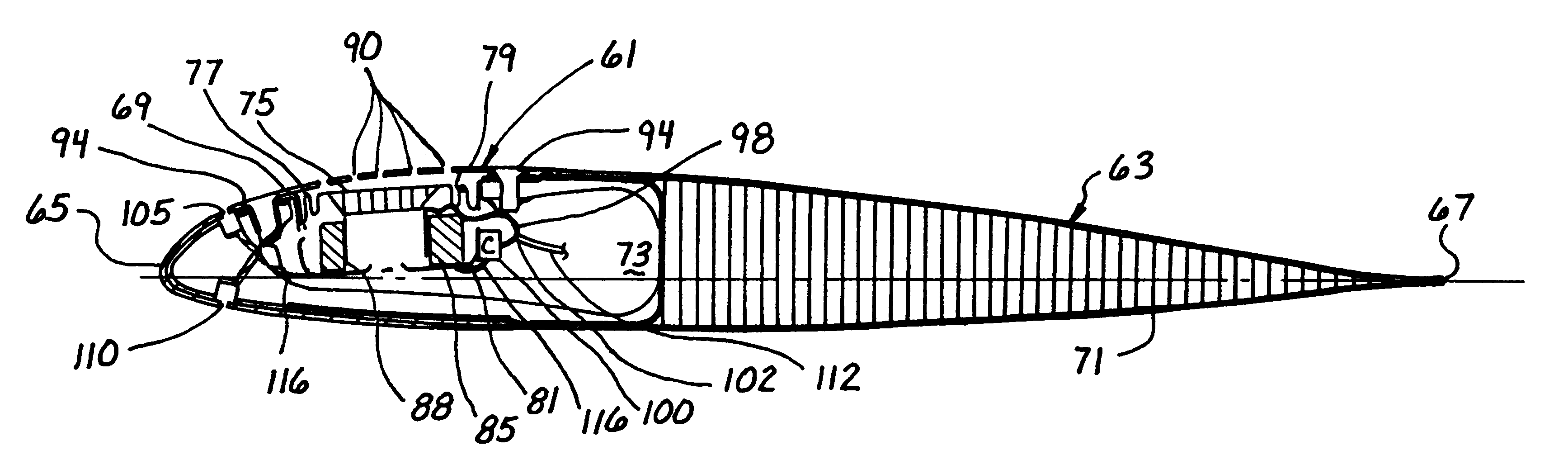

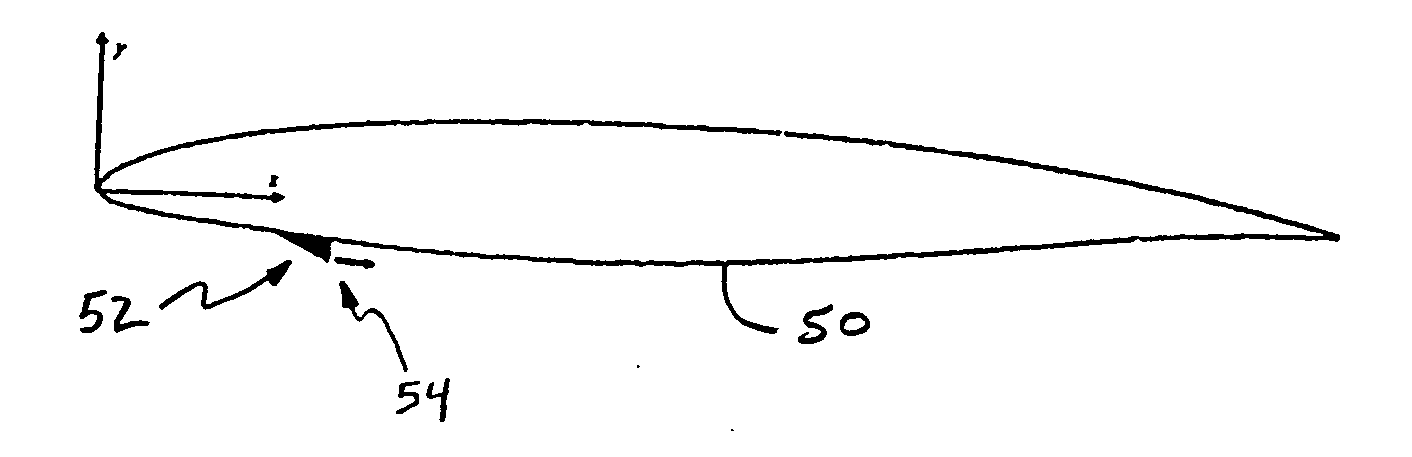

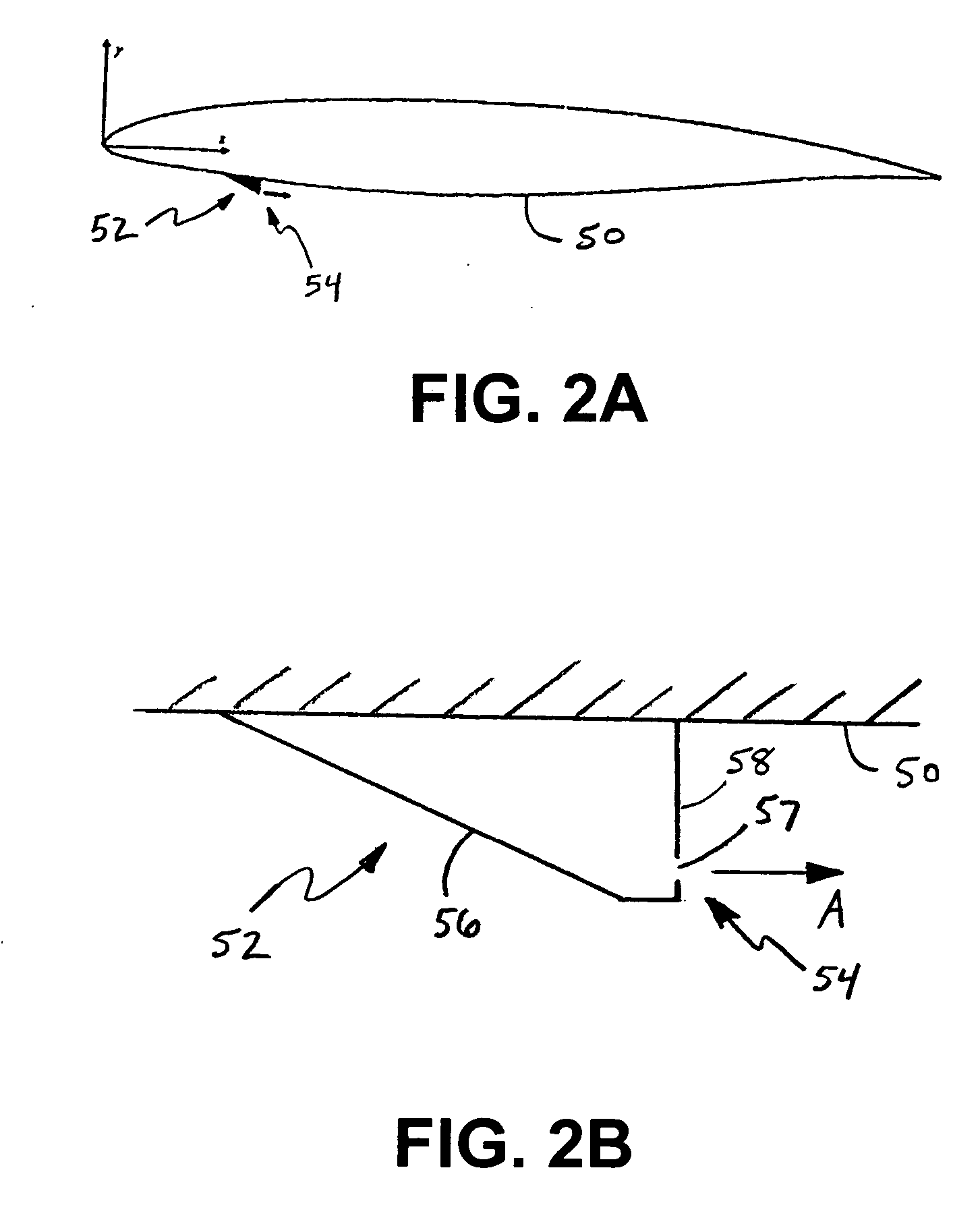

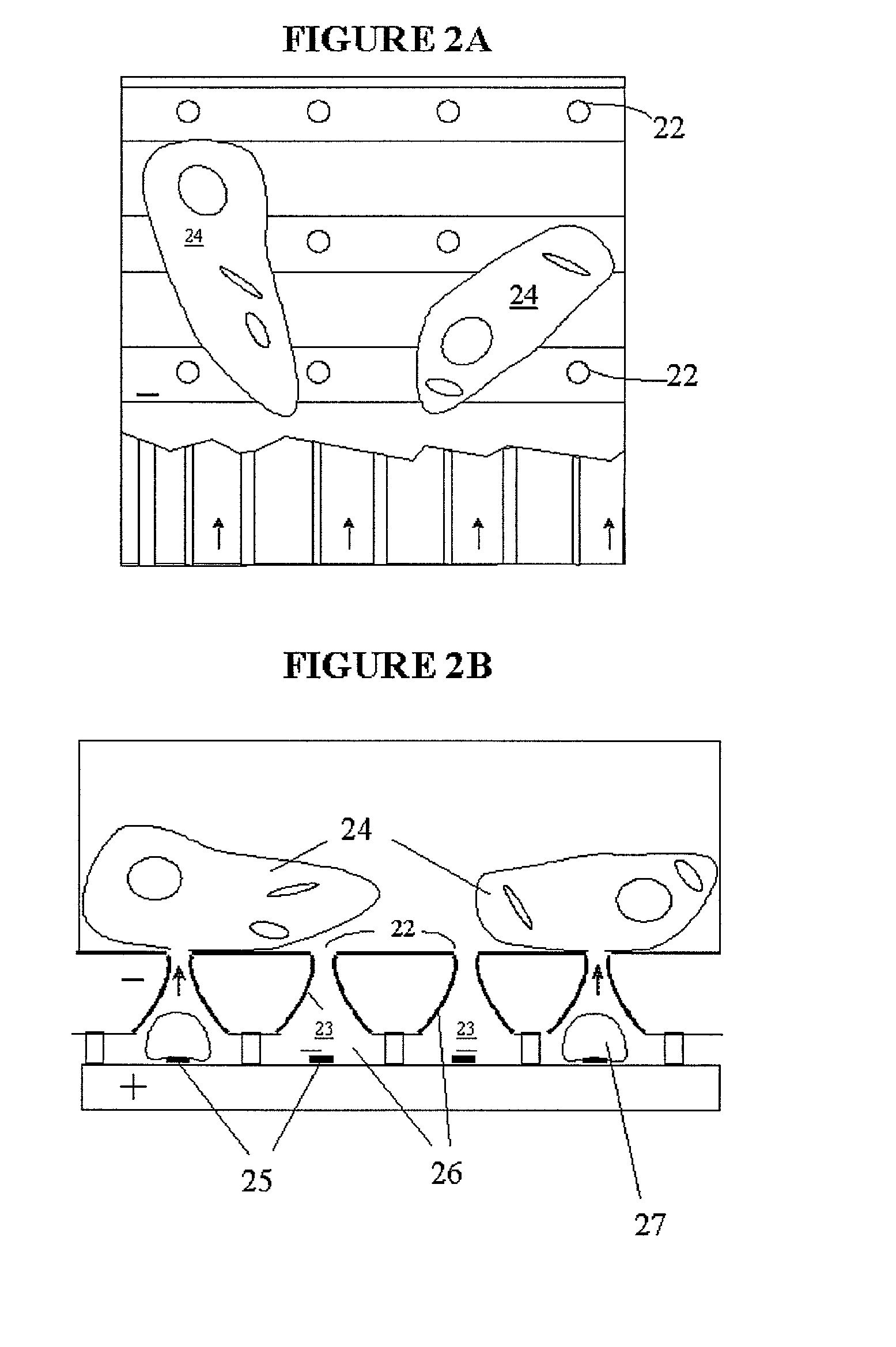

Airfoil performance modification using synthetic jet actuators

ActiveUS20070095987A1Reduce pressure resistanceInfluencers by generating vorticesBoundary layer controlsSolid bodyEngineering

Systems and methods for modifying fluid flowing over solid bodies are provided. A representative system incorporates a vorticity concentration-producing component and a synthetic jet actuator. The vorticity concentration-producing component is disposed on a pressure side of the solid body. The fluid flowing over the solid body remains attached to a surface of the solid body in a vicinity of the vorticity concentration-producing component. The synthetic jet actuator includes a jet housing that incorporates an internal chamber with a volume of fluid and an opening in the jet housing connecting the internal chamber to an external environment having the fluid. The synthetic jet actuator is operative to periodically change the volume within the internal chamber such that a synthetic jet stream comprising a series of fluid vortices is generated and projected in the external environment out from the opening of the jet housing resulting in a reduction in pressure drag of the solid body compared to the pressure drag exhibited by the solid body without operation of the synthetic jet actuator.

Owner:GEORGIA TECH RES CORP

Microfluidic devices and methods for producing pulsed microfluidic jets in a liquid environment

InactiveUS20020045911A1Reduced collateral damageLaser surgerySurgical instrument detailsVapor bubbleEngineering

Microfluidic devices and methods for their use in producing pulsed microfluidic jets in a fluid environment are provided. The subject microfluidic devices are characterized by the presence of a microfluid chamber at their distal ends. The microfluid chamber is bounded by an opening at one end, a vapor producing means opposite the opening, and side walls between the opening and the vapor producing means. The microfluid chambers are further characterized in that the only way fluid can exit the microfluid chambers is through the opening. In using the subject devices to produce a fluid jet in a fluid environment, the chamber is first contacted with the fluid environment. The vapor producing means is then actuated in a manner sufficient to produce a vapor bubble in the chamber which, in turn, produces a microfluidic jet in the fluid environment. The subject devices and methods find use in a variety of different applications, e.g., cutting tissue, introducing fluid into a cell, and the like.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

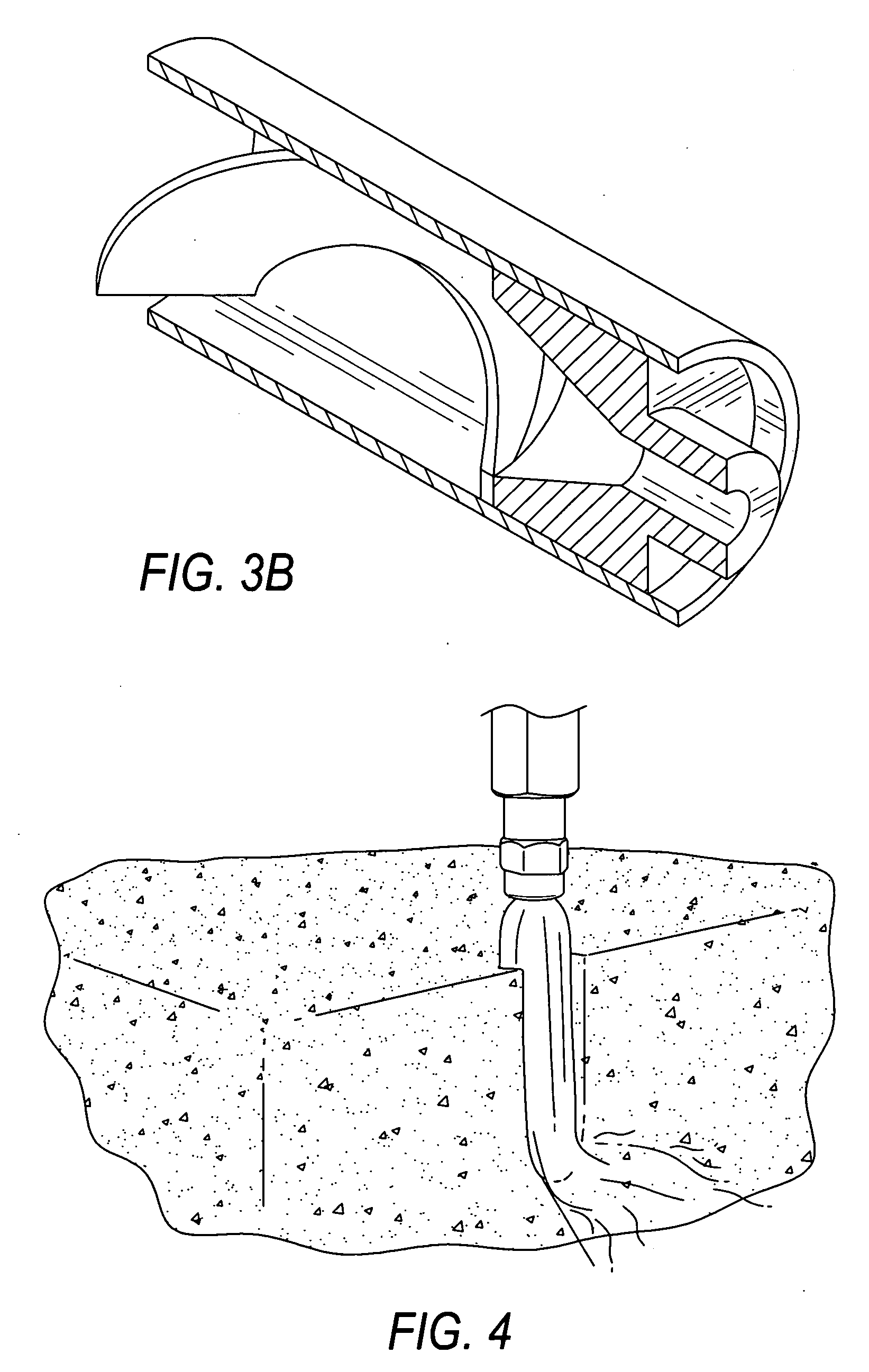

Method and apparatus for jet-assisted drilling or cutting

ActiveUS20090227185A1Lower discharge pressureIncrease efficiency and easeBlast gunsLiquid/gas jet drillingDrilling systemSupercritical fluid

An abrasive cutting or drilling system, apparatus and method, which includes an upstream supercritical fluid and / or liquid carrier fluid, abrasive particles, a nozzle and a gaseous or low-density supercritical fluid exhaust abrasive stream. The nozzle includes a throat section and, optionally, a converging inlet section, a divergent discharge section, and a feed section.

Owner:UNIVERSITY OF MISSOURI

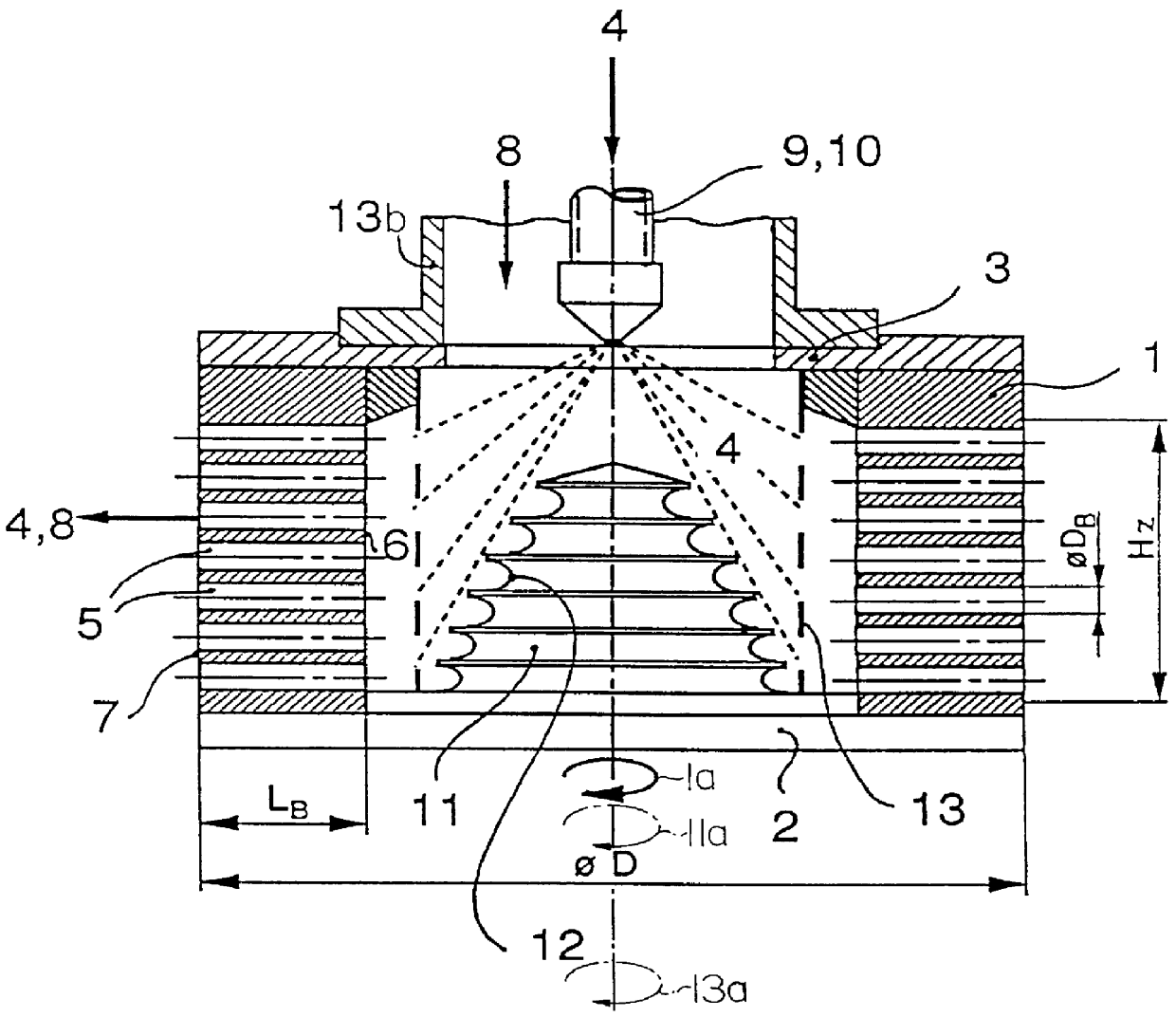

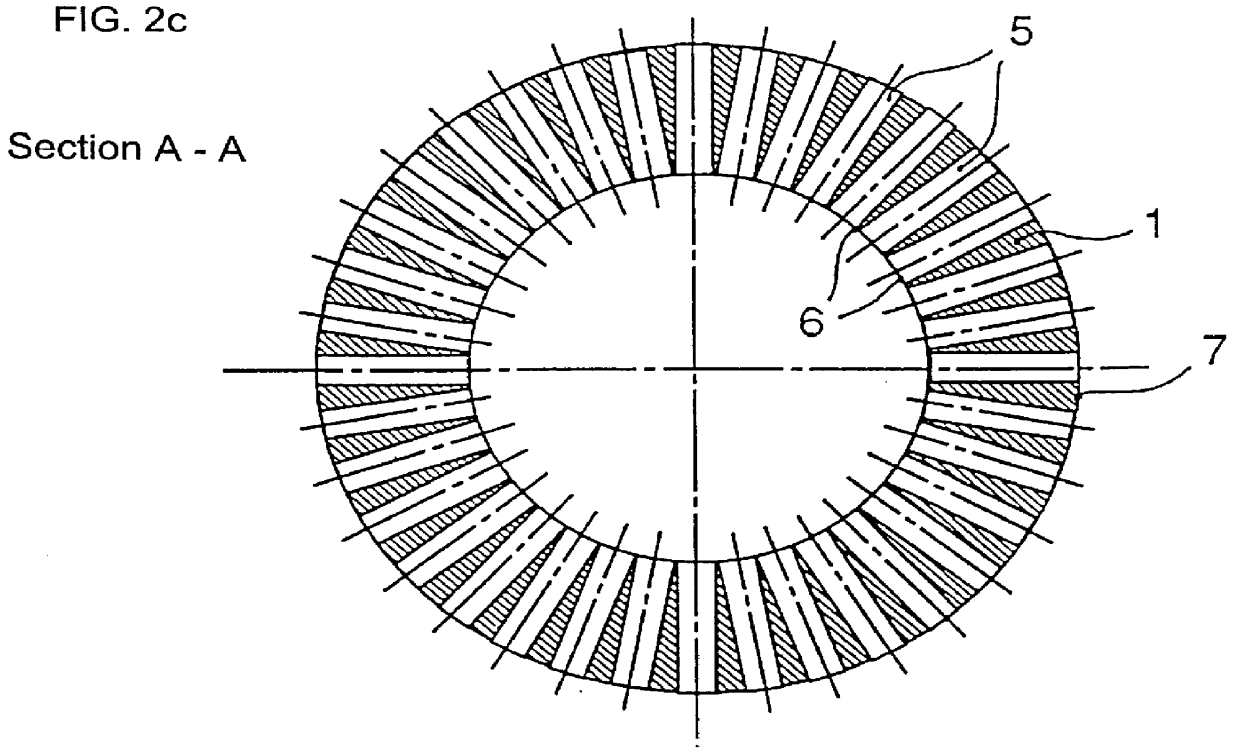

Process and a device for atomizing liquids

InactiveUS6098895ALarge caliberAvoid easy cloggingBurnersMovable spraying apparatusDecompositionEngineering

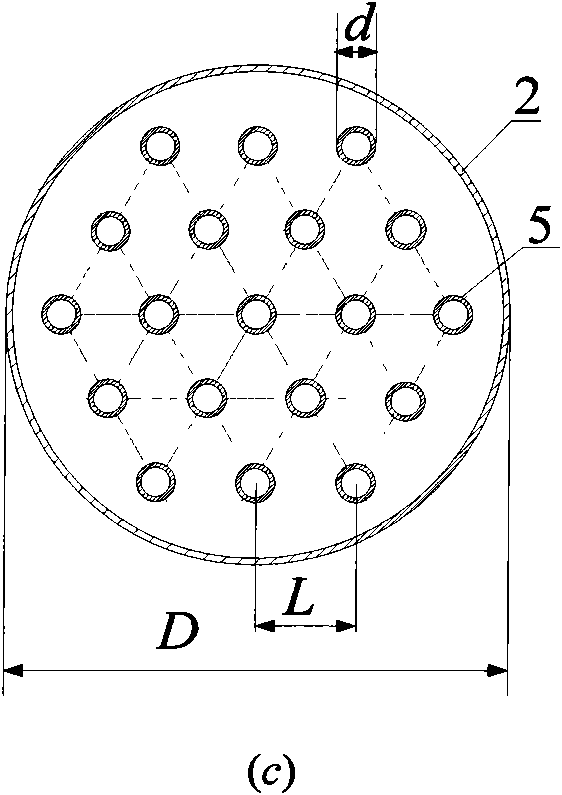

The liquid to be atomized is uniformly sprayed on the inner surface of a hollow rotating cylinder, for example by means of one- or two-fluid-nozzles and is thus distributed on bores provided in the cylinder wall. The rotation of the cylinder causes the liquid to flow outwards through the bores. Droplets are generated when the liquid flows out of the bores by laminary decomposition of the jet. The flow rate in each bore lies in the range 1.0<+E,dot V+EE B (a3 rho 5 / sigma 5)0.25<16 to prevent the droplets from becoming too large and to satisfy the condition of an adequate flow laminarity, i.e. for the value of the Reynolds number for the continuous liquid flow in the boress not to exceed Re delta 400. +E,dot V+EE B represents the flow rate of the liquid in each bore, a represents the centrifugal acceleration at the outer surface of the cylinder, rho represents the density of the liquid and delta indicates the surface tension of the liquid. The large number N>200 of bores having the diameter DB in the cylinder wall causes the flow rate of liquid through each bore to be relatively low, so that a continuous laminary flow in each bore is ensured even at low viscosities and technically useful total flow rates. Preferably cylindrical bores with a minimum length at least three times larger than the bore diameter are provided in the cylinder wall, with a narrow spacing in the range defined by 1.1<t / DB<5, so that a number of bores as large as possible may be arranged in the wall of the cylinder.

Owner:NIRO

Cleaning device

InactiveUS7618206B2Easy to manufactureEasy to installCarpet cleanersFloor cleanersSpray nozzleEngineering

Owner:AVET

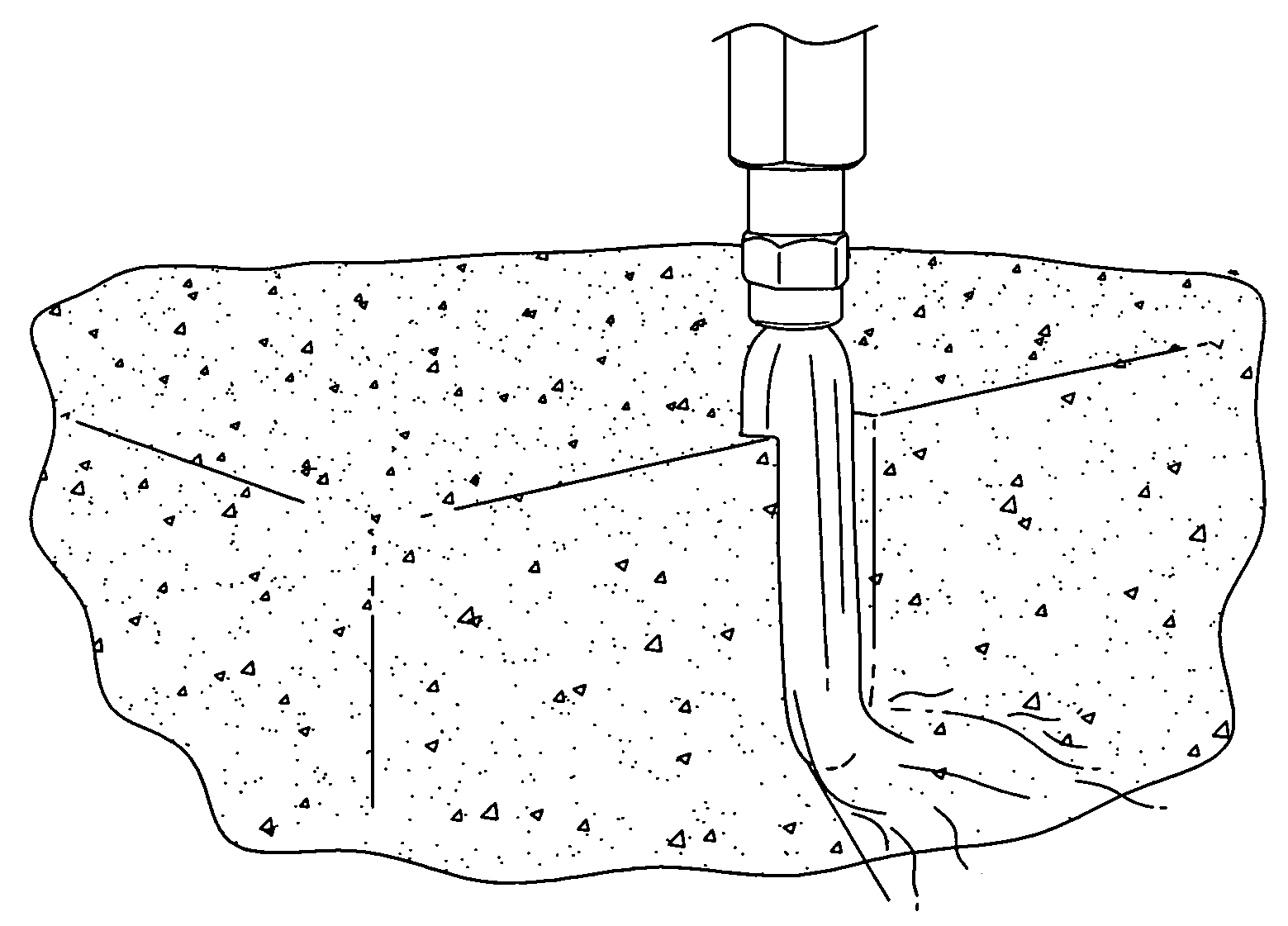

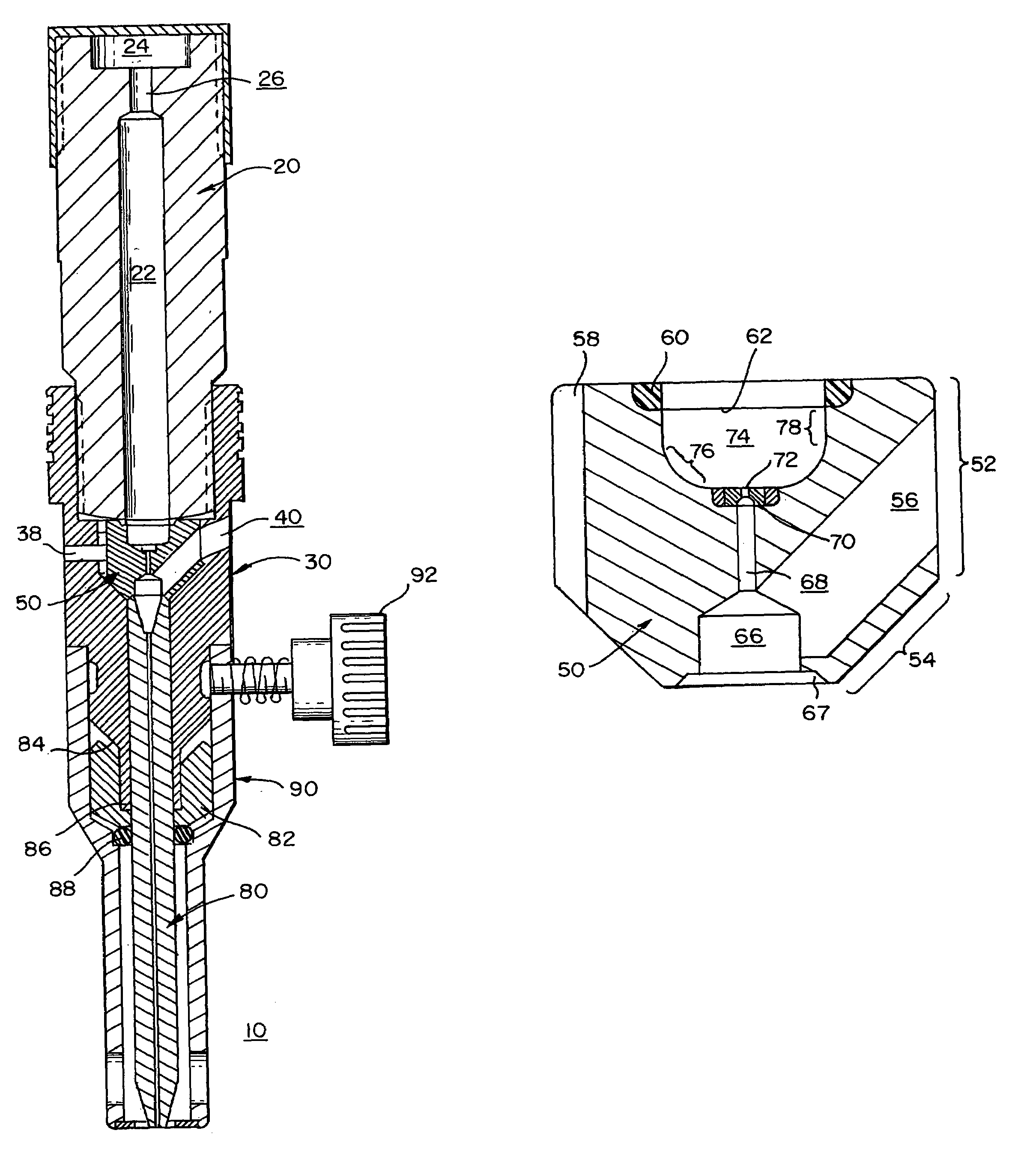

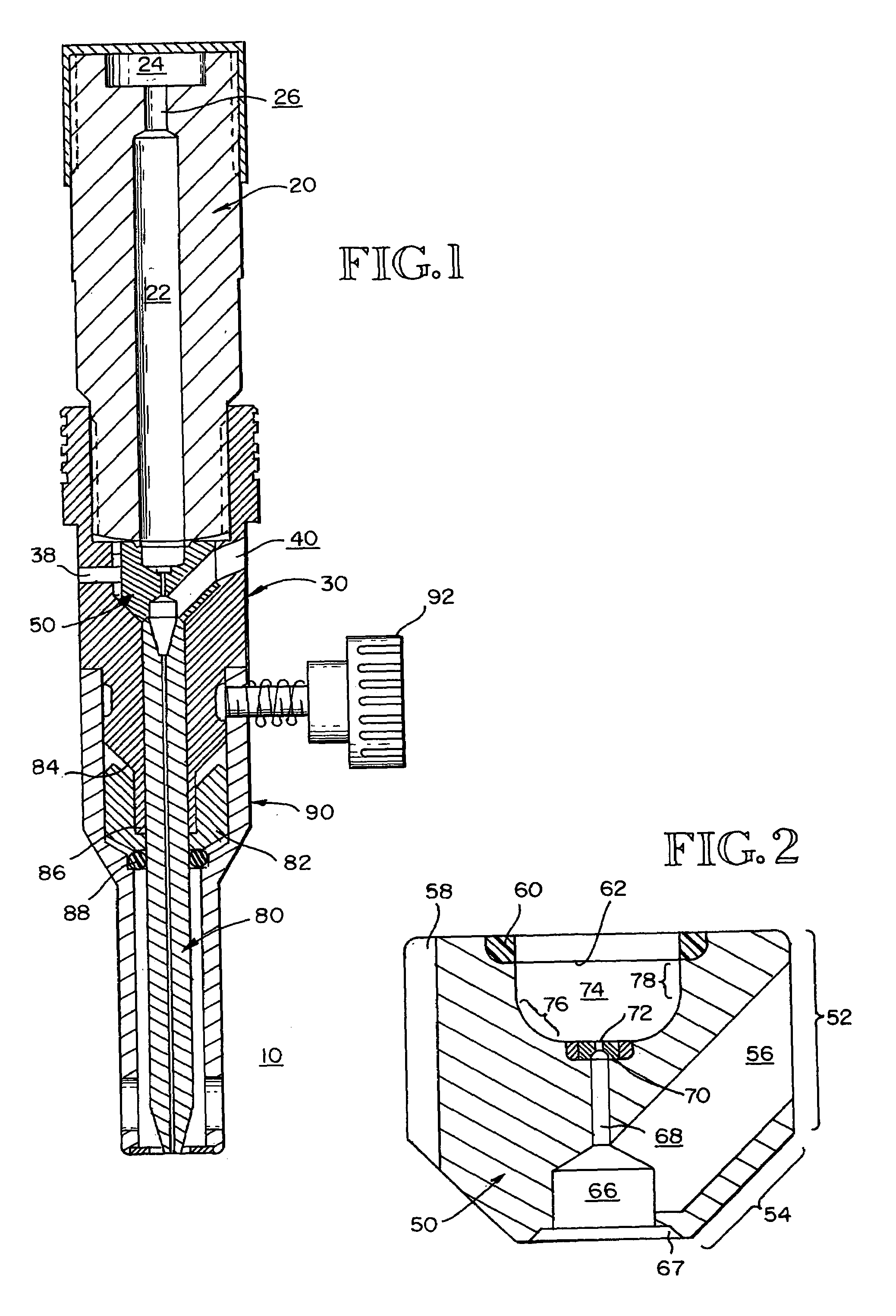

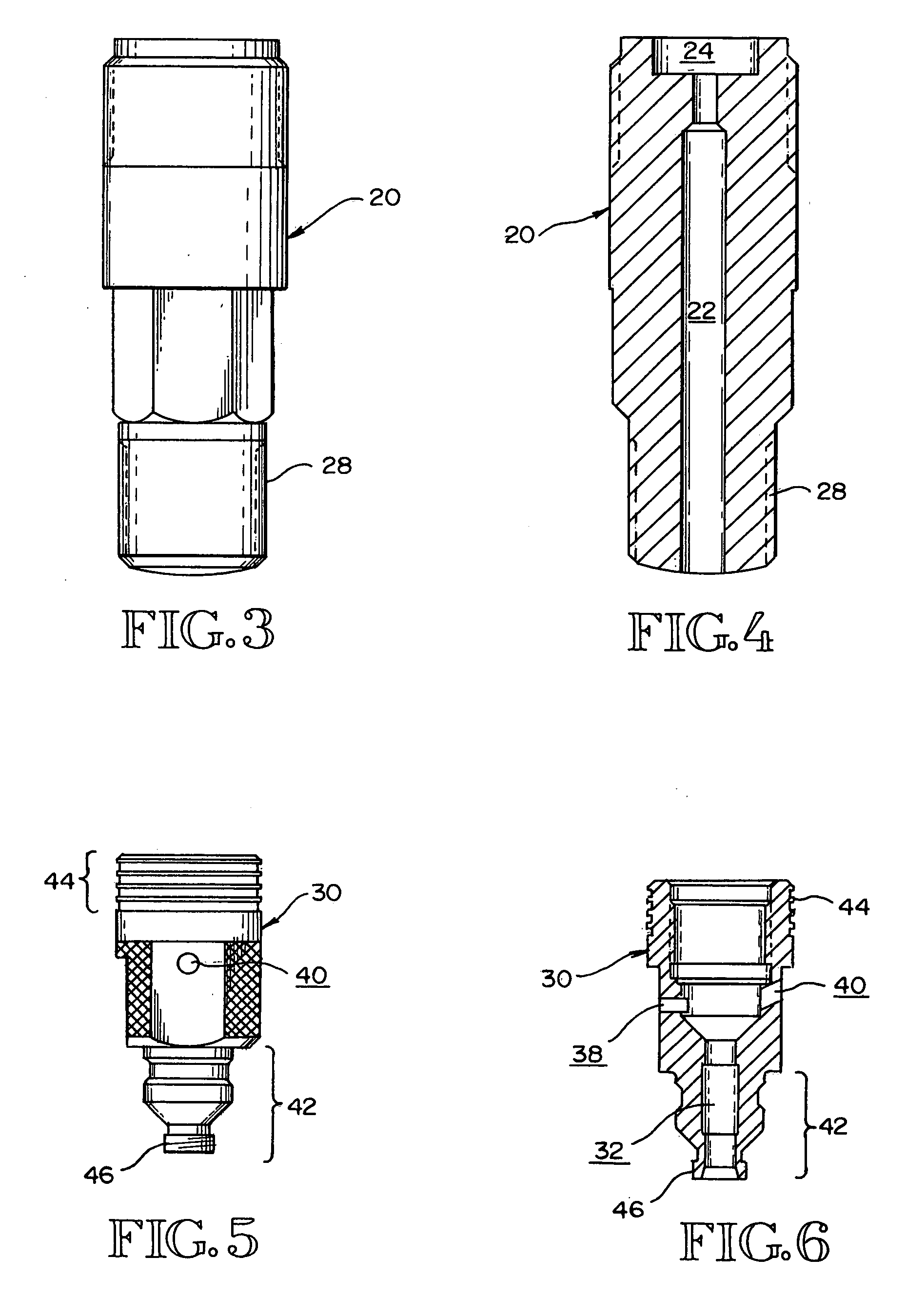

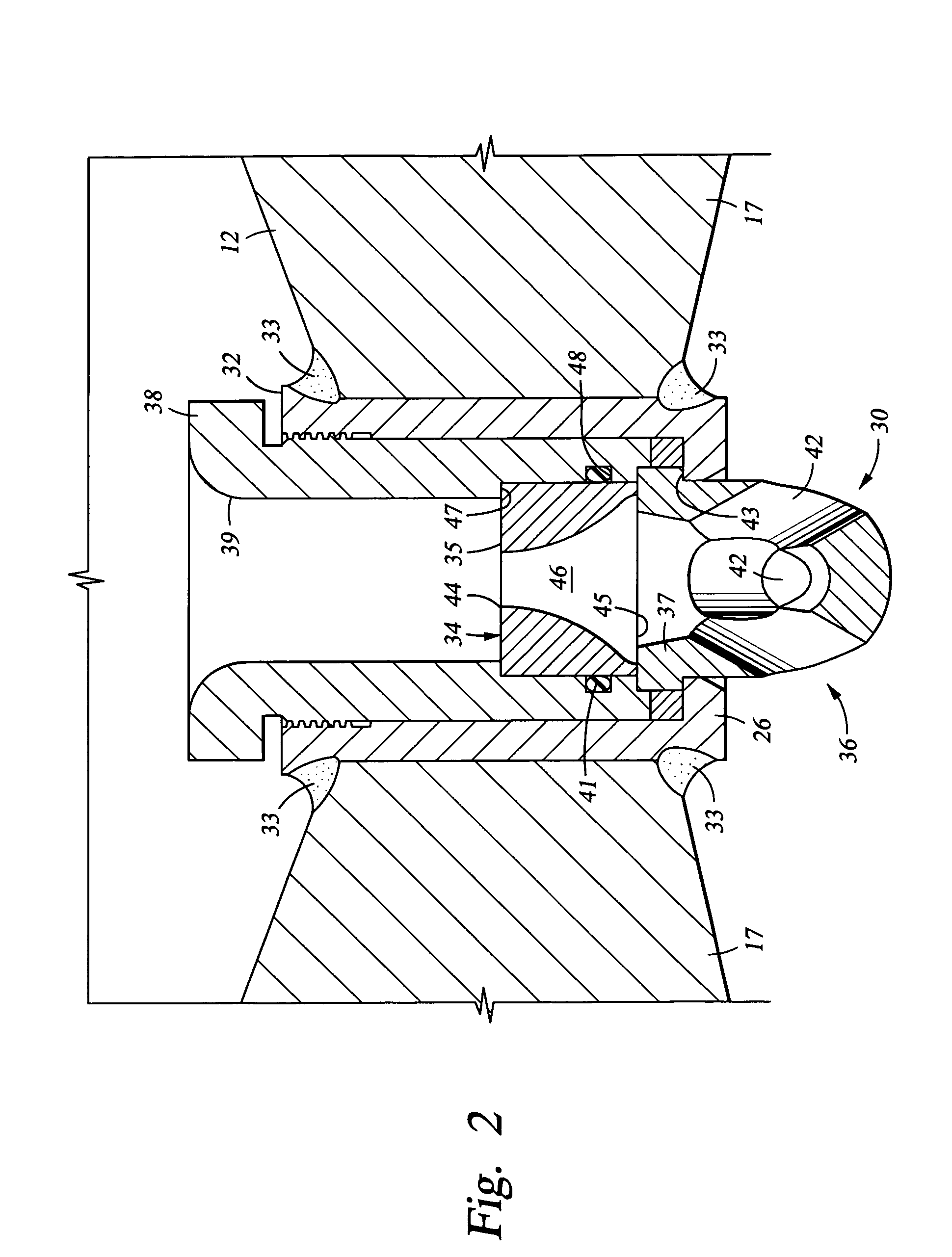

Method and apparatus for jet-fluid abrasive cutting

A method and apparatus for down hole abrasive jet-fluid cutting, the apparatus includes a jet-fluid nozzle and a high pressure pump capable of delivering a high-pressure abrasive fluid mixture to the jet-fluid nozzle, an abrasive fluid mixing unit capable of maintaining and providing a coherent abrasive fluid mixture, a tube to deliver the high pressure coherent abrasive mixture down hole to the jet-fluid nozzle, a jetting shoe adapted to receive the jet-fluid nozzle and directing abrasive jet-fluid mixture towards a work piece, a jetting shoe controlling unit that manipulates the jetting shoe along a vertical and horizontal axis and a central processing unit having a memory unit capable of storing profile generation data for cutting a predefined shape or window profile in the work piece and coordinating the operation of various subsystems.

Owner:ALBERTA ENERGY PARTNERS

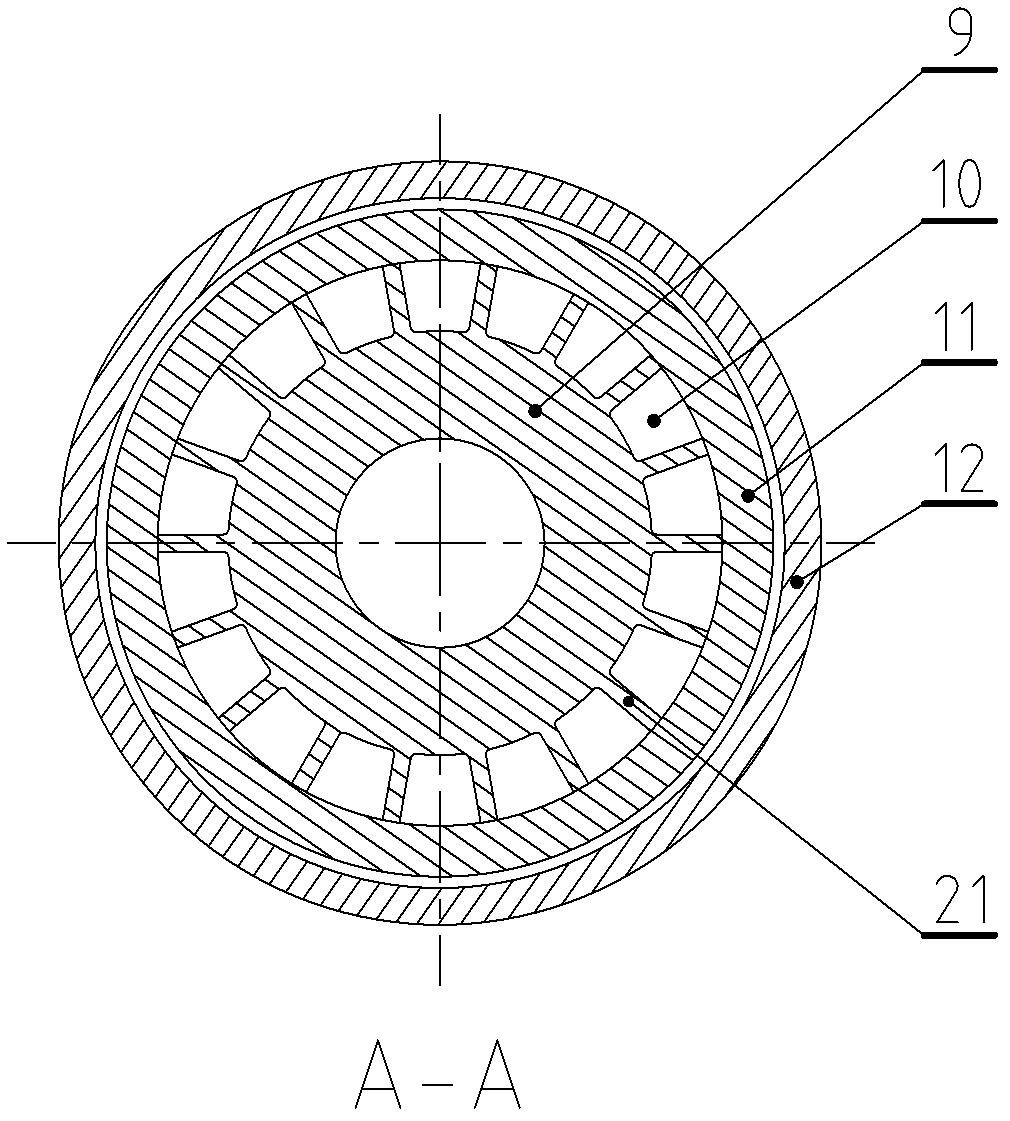

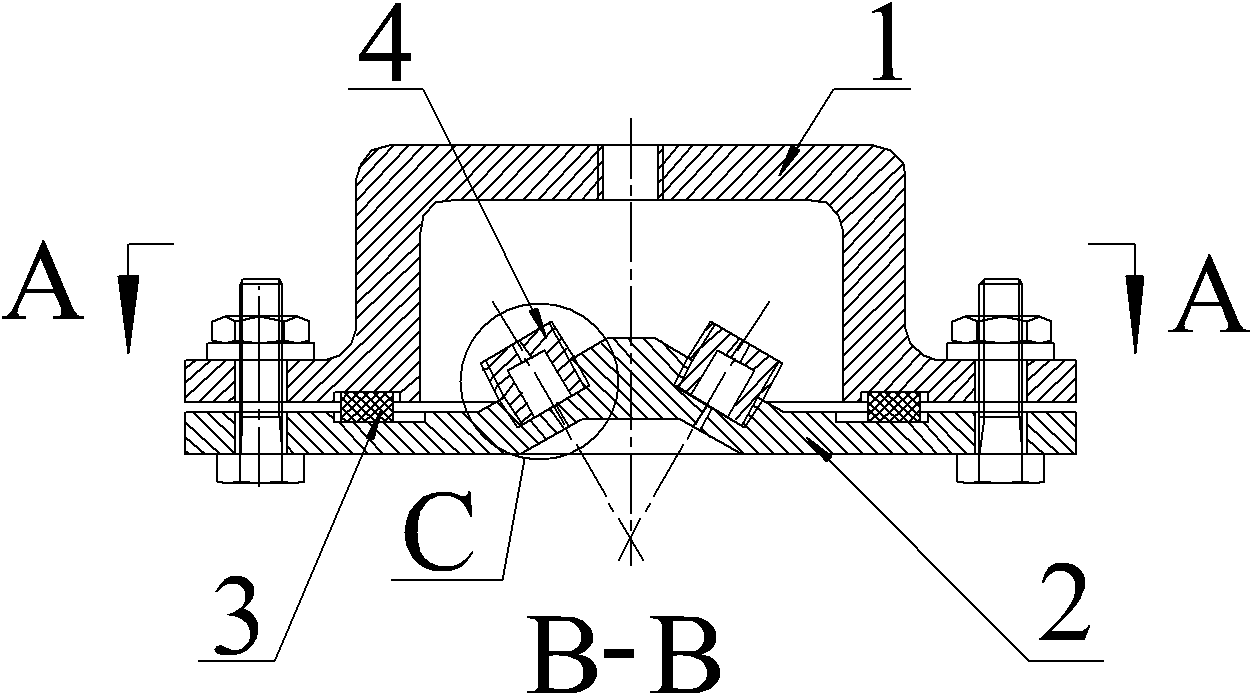

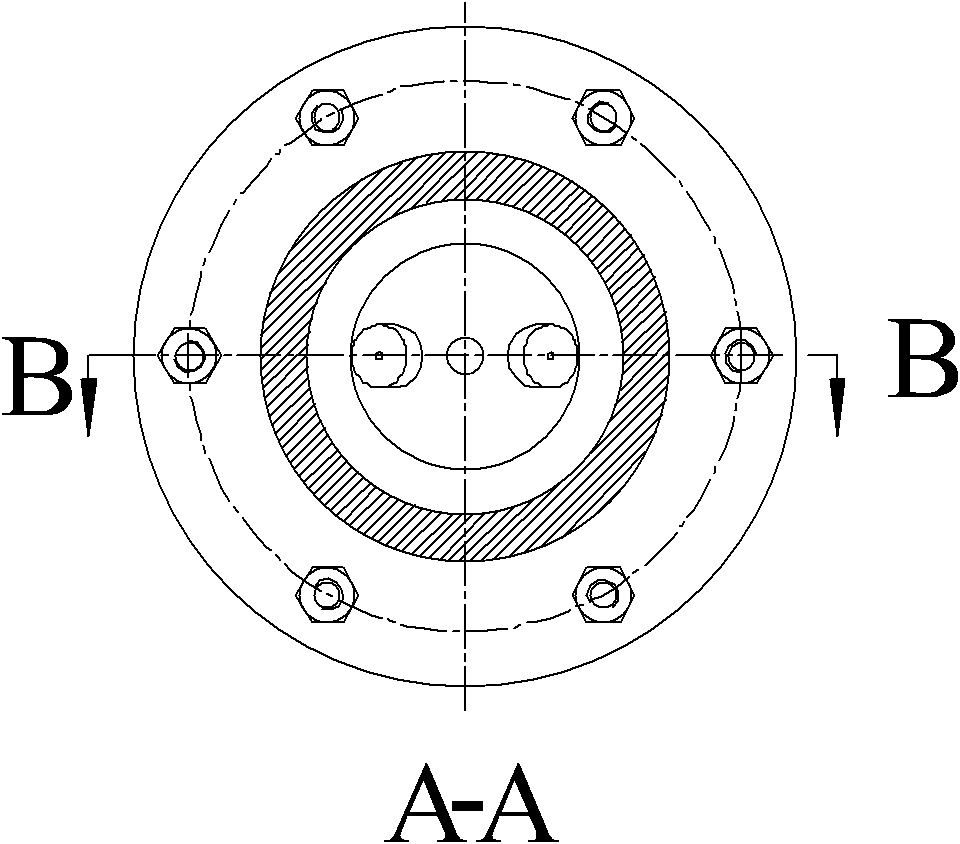

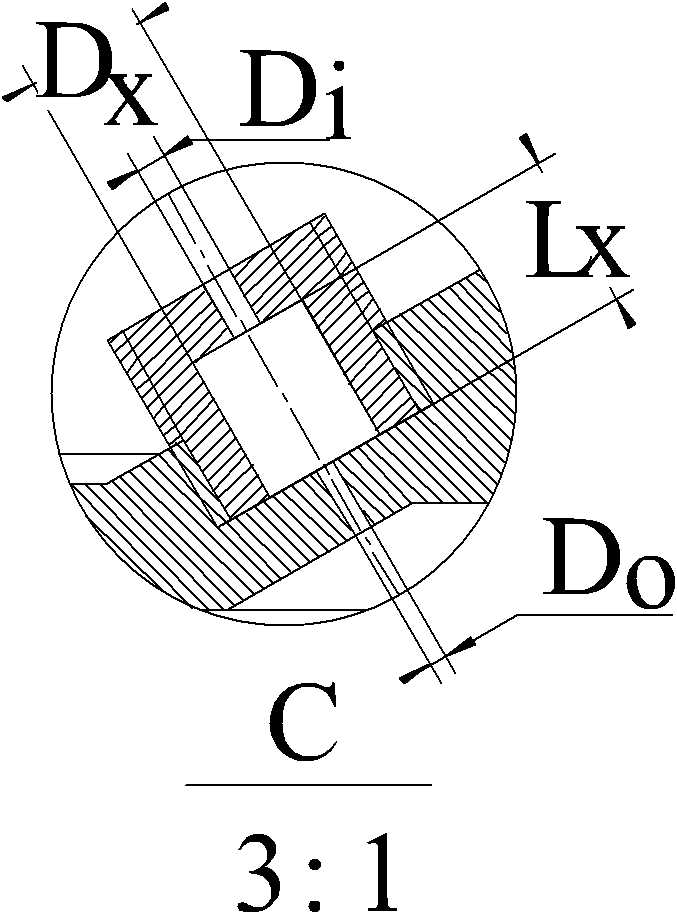

Power transmission unit of an impactor, a hydraulic jet impactor and the application thereof

InactiveUS20060011362A1Improve efficiencyAvoid long workEarth drilling toolsDrill bitsTransmitted powerWorking life

The invention discloses a fluid-driven impactor, a power transmission mechanism for the impactor and the use of the impactor. In the prior art, the working life of the impactor is short, since a rubber primary seal and an upper fluid-diverging lid for the fluid-driven impactor are both liable to erosion and the efficiency in transmitting power is low due to the complexity of the power transmission mechanism. In order to increase the drilling speed and / or extend the life of the impactor, the side cavity passage is formed in such a way that the inner wall of the outer pipe is isolated from the side cavity passage in a watertight manner without the use of the rubber primary seal. The loss in transmitting power is minimized by integrating the anvil of the power transmission mechanism and the lower joint. The problem of abrasion of the fluid-diverging hole is overcome and the nozzle can be used with different fluid flow by mounting a replaceable nozzle in the upper fluid-diverging lid, the nozzle selected from a series of nozzles with various inner diameters and made of a material more wearable than the material for diverging lid the upper fluid.

Owner:CHINA PETROCHEMICAL CORP +1

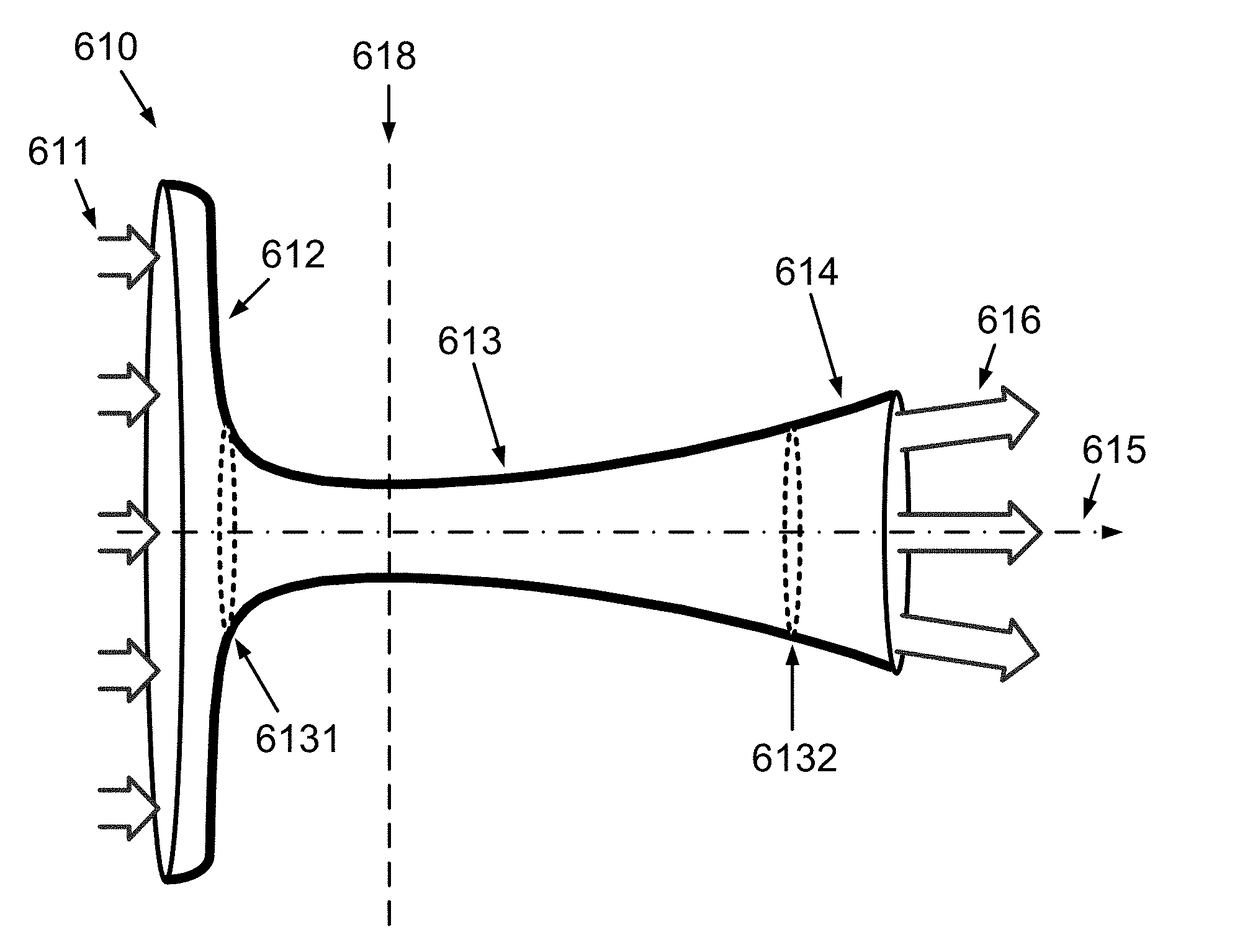

Generalized Jet-Effect

The invention provides a method for computational fluid dynamics and apparatuses making enable an efficient implementation and use of an enhanced jet-effect, either the Coanda-jet-effect, the hydrophobic jet-effect, or the waving-jet-effect, triggered by specifically shaped corpuses and tunnels. The method is based on the approaches of the kinetic theory of matter, thermodynamics, and continuum mechanics, providing generalized equations of fluid motion. The method is applicable for slow-flowing as well as fast-flowing real compressible-extendable fluids and enables optimal design of convergent-divergent nozzles, providing for the most efficient jet-thrust. The method can be applied to airfoil shape optimization for bodies flying separately and in a multi-stage cascaded sequence. The method enables apparatuses for electricity harvesting from the fluid heat-energy, providing a positive net-efficiency. The method enables efficient water-harvesting from air. The method enables generators for practical-expedient power harvesting using constructive interference of waves due to the waving jet-effect.

Owner:SOLITON HLDG CORP DELAWARE CORP

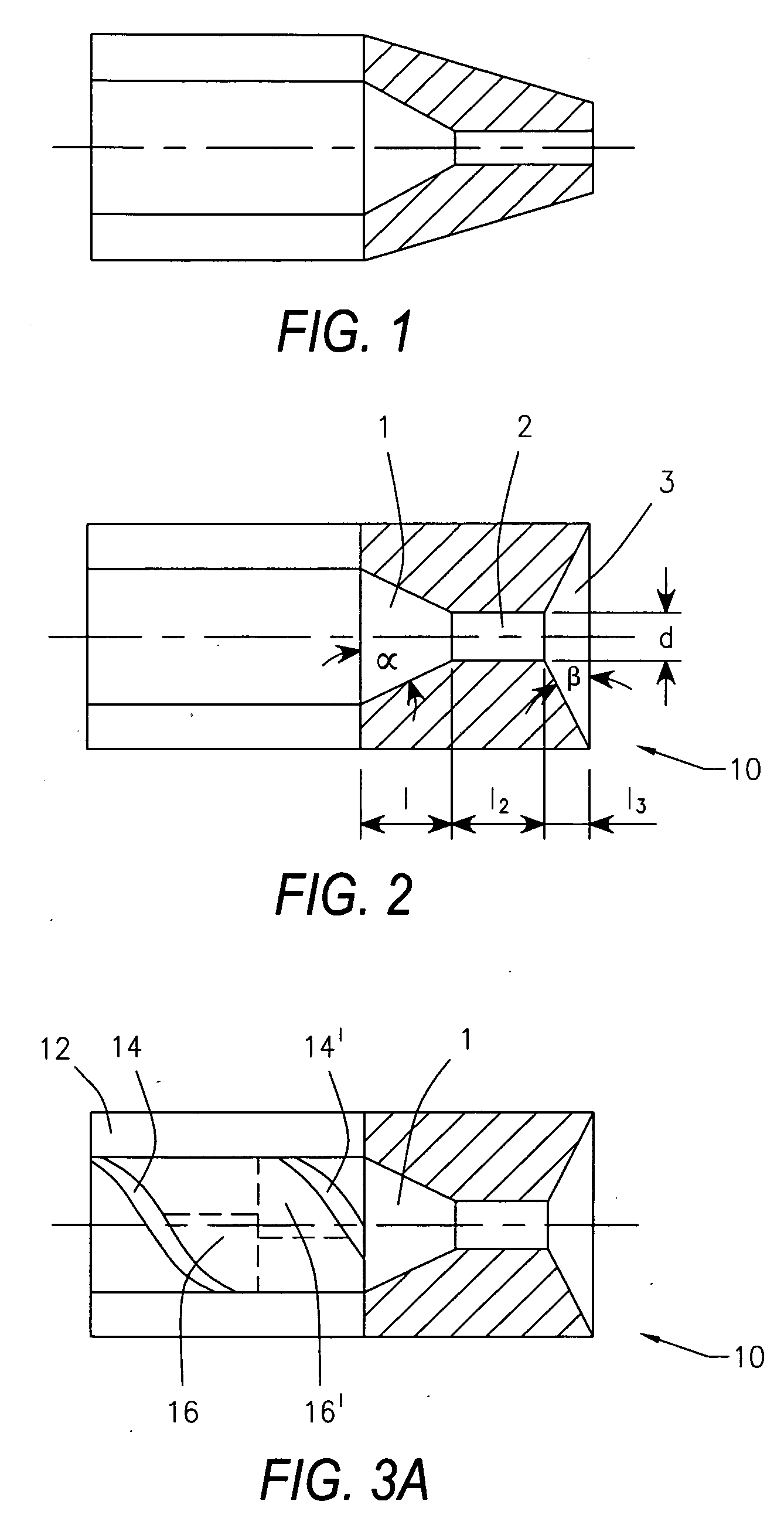

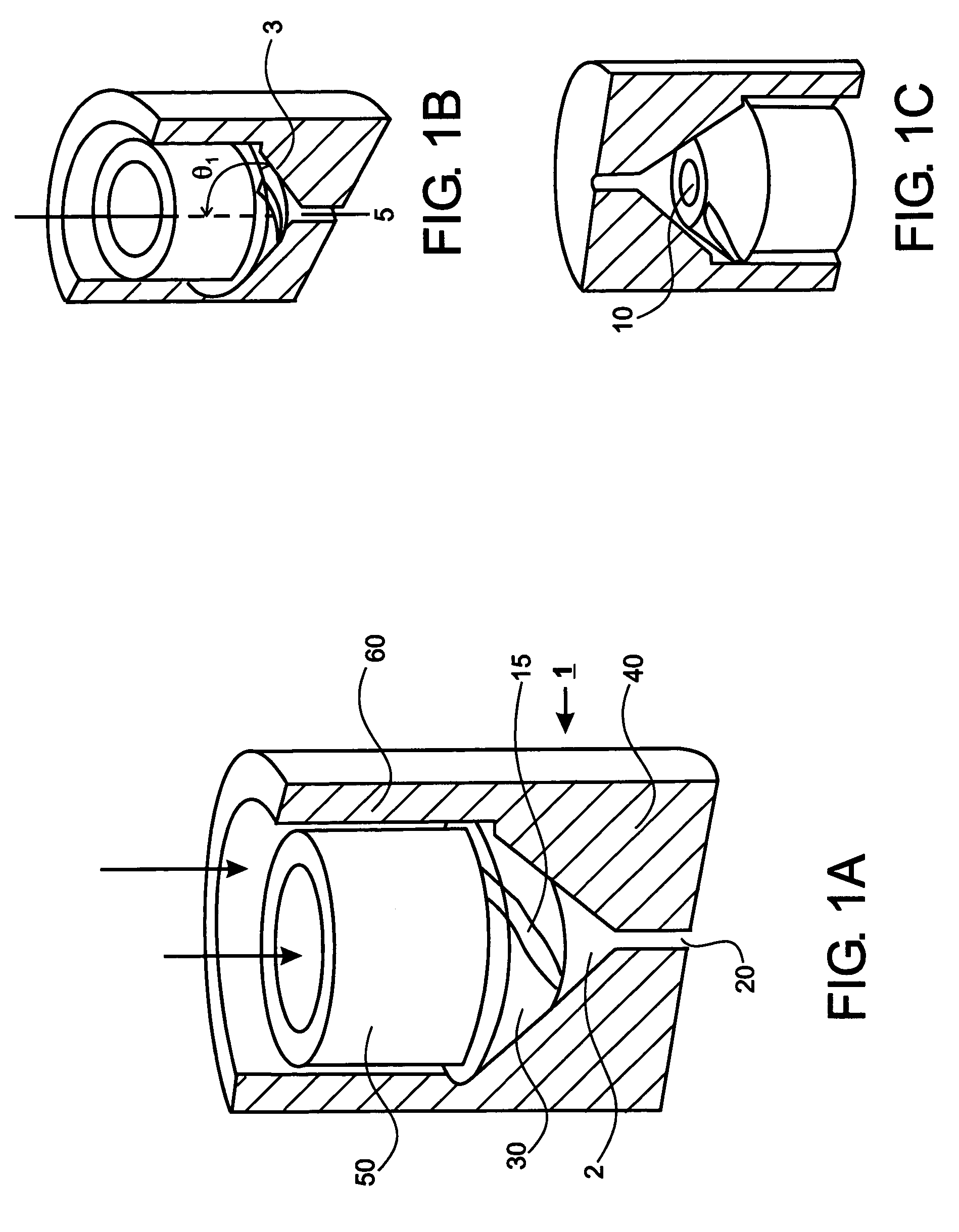

Orifice body with mixing chamber for abrasive water jet cutting

InactiveUS6932285B1Simple designImprove operationDrill bitsBlast gunsUltra high pressureHigh pressure

An improved orifice assembly for use with an ultra high pressure fluid jet cutting apparatus is disclosed. The improved orifice assembly generally includes an orifice body defining a central bore, a high pressure inlet cavity located at an upstream portion of the body, a mixing cavity located at a downstream portion of the body, and an abrasive material inlet bore that is in direct communication with the mixing cavity. The inlet or high pressure cavity preferably has a cylindrical cross section at the side wall portion and a generally flat bottom wall, with a constant radius transition portion between the side and bottom walls. A jeweled orifice is preferably located at the bottom wall and forms a portion thereof. A chamfer at the downstream portion of the mixing chamber permits appropriate coaxial alignment of a mixing tube with the jeweled orifice so as to preserve proper fluid flow characteristics. In addition, the incorporation of a soft seal between the mating surfaces of the inlet body and the orifice assembly permit easy user removal of these components from a cutting jet system.

Owner:SILICON VALLEY BANK

Devices and methods for the production of particles

The present invention provides methods and devices for producing particles with an average diameter less than about 15 μm using the precipitation with compressed fluid-antisolvent (PCA) process and the carbon-dioxide assisted nebulization with a bubble dryer (CAN-BD) process. In the methods and nozzles of the invention, at least one jet of supercritical or near-supercritical fluid and at least one jet of solution interact to mix the supercritical or near-supercritical fluid and the solution within a chamber. The solution contains at least one solvent and at least one solute. At least one of the jets is a swirling jet. To form particles, the solvent and supercritical or near-supercritical fluid are then injected into a PCA or a CAN-BD process chamber. The degree of mixing depends in part on the power input into the mixing chamber. Power inputs of about 6.5×109 W / m3 enhance the degree of mixing and allow production of nanoscale particles with the PCA process. The nanoscale particles have a size distribution so that polydispersity is less than about 1.75.

Owner:UNIV OF COLORADO THE REGENTS OF

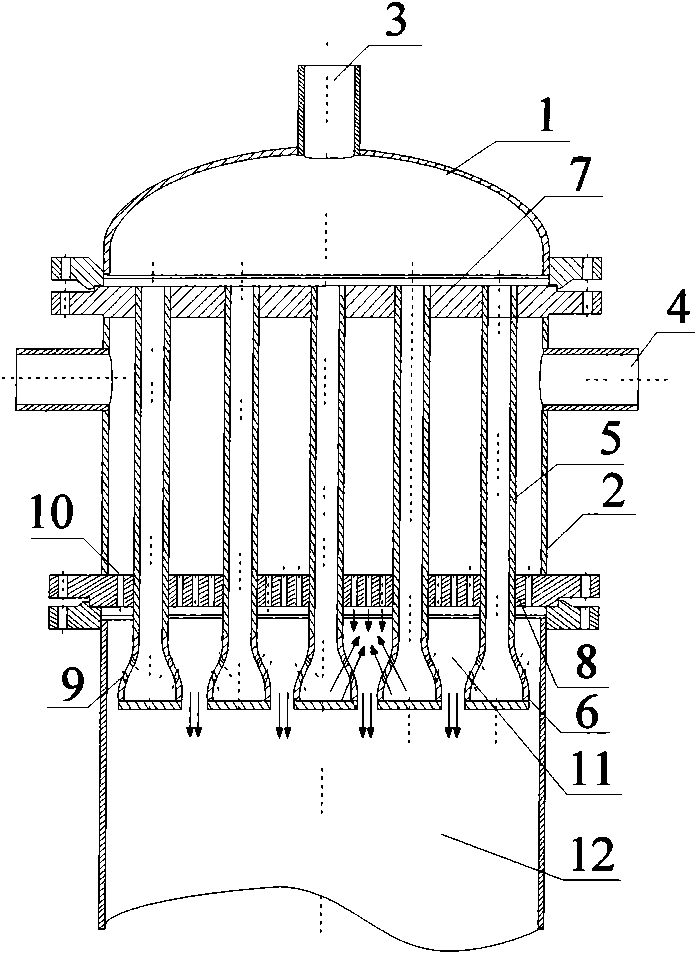

Column tube type impinging stream reactor and operating system for producing toluene diisocynate

ActiveCN101612547ASmall amplification effectReduce generationIsocyanic acid derivatives preparationOrganic compound preparationJet flowReaction zone

The invention relates to a column tube type impinging stream reactor and an operating system for producing toluene diisocynate. The upper head of the column tube type impinging stream reactor is connected with a barrel body on which a barrel body feeding hole (4) is arranged, the column tubes pass through the barrel body and are evenly distributed on the upper tube-plate and the lower tube-plate in the barrel body, jet orifices (10) of the lower tube-plate are evenly distributed on the lower tube-plate; the lower end of the column tube is connected with an expanding section of the column tube; and the jet orifices (9) of the column tubes are arranged on the lower ends of the column tubes and the expanding sections of the column tubes. A stream of material is injected by the jet orifices (10) of the lower tube-plate in a jet current mode; around the jet orifices of the lower tube-plate, the column tubes and column tube expanding sections are arranged in parallel and are vertical to the lower tube-plate; the other stream of fluid is injected into an impinging mixed zone with a certain angle in a jet current mode by the jet orifices (9) of the column tubes arranged on the column tubes and the column tube expanding sections and is impacted with the first stream of material and then is quickly mixed; and the reaction material enters into a second reaction zone (12) for further reaction. The size of the impinging mixed zone can be flexibly changed by adjusting the structure parameters of the mixed zone, therefore, the reactor has strong adaptability.

Owner:SEDIN ENG +1

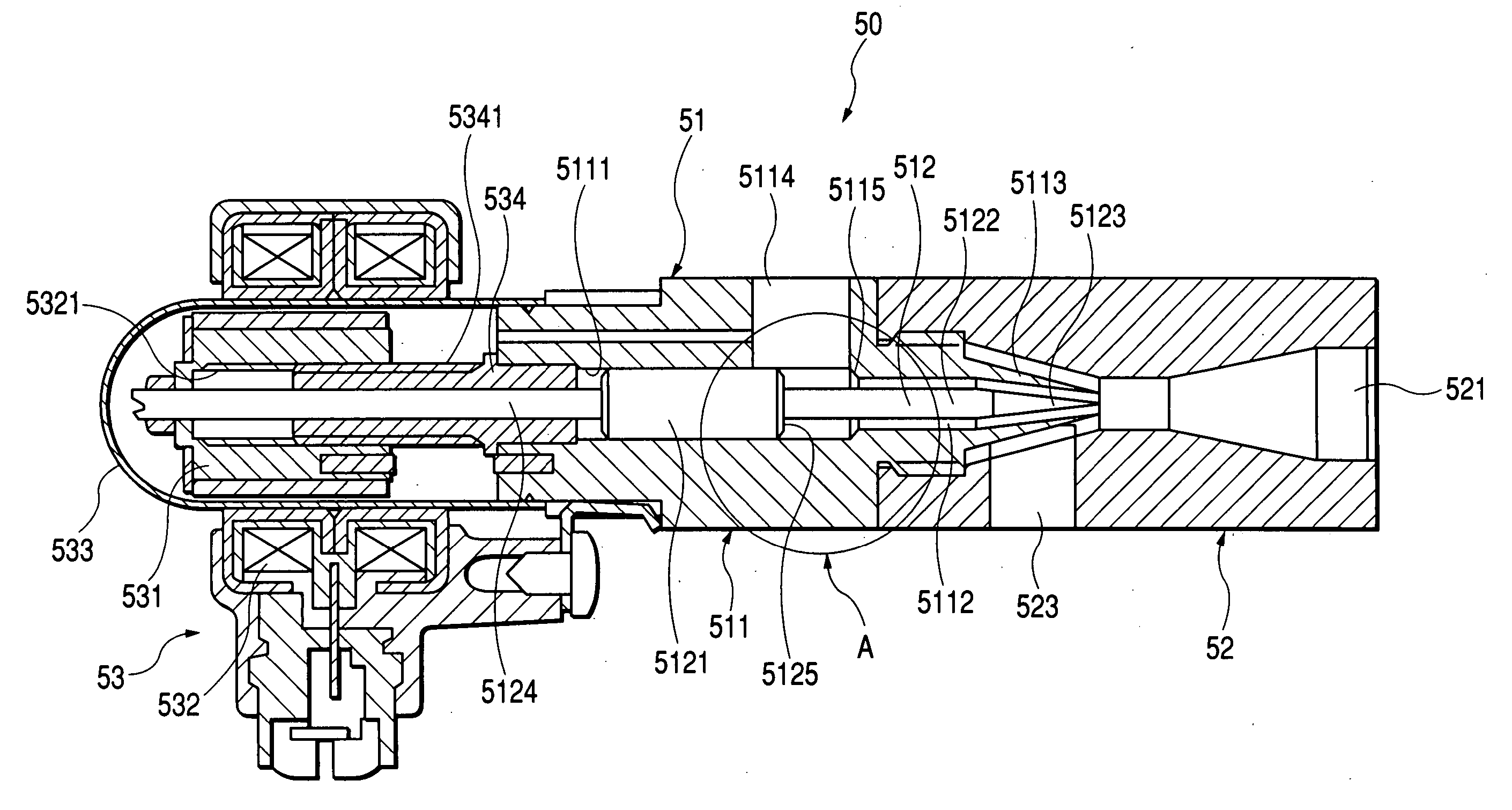

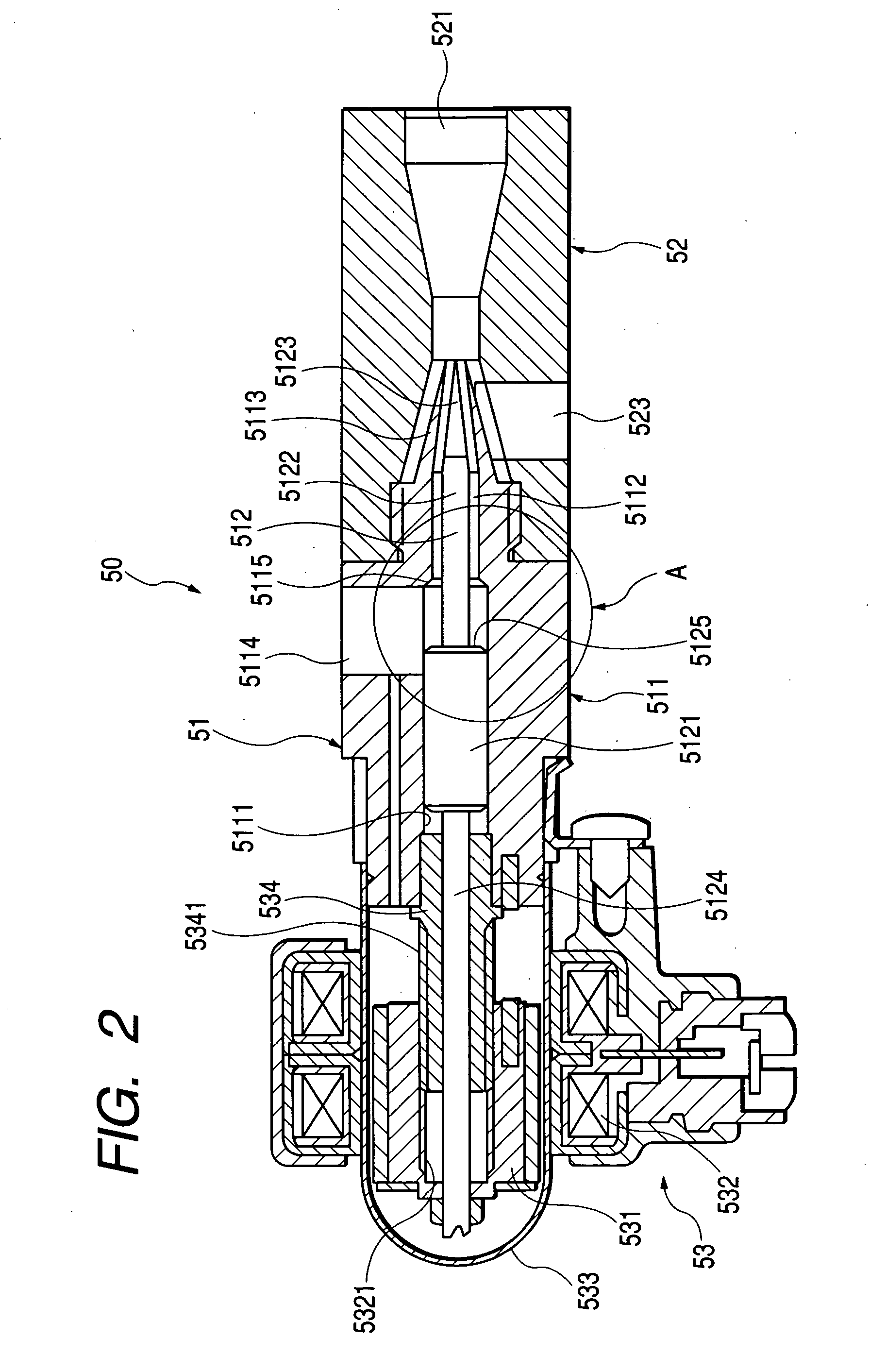

Structure of ejector pump

ActiveUS20050002797A1Increase kinetic energySuction is requiredFuel cell auxillariesJet pumpsAbutmentBiomedical engineering

An ejector pump is provided which works to use dynamic energy of a jet of a main fluid emitted from a nozzle to suck a sub-fluid therein. When it is required to stop the ejector pump, the needle is moved to bring a sealing surface formed on a head thereof into abutment with a sealing surface formed around a main fluid flow path extending inside the ejector pump to close the main fluid flow path, thereby inhibiting the fluid pressure from acting on any downstream device. Upon the abutment, the needle is kept away from a nozzle, thereby avoiding undesirable wear or deformation of the needle and nozzle.

Owner:DENSO CORP

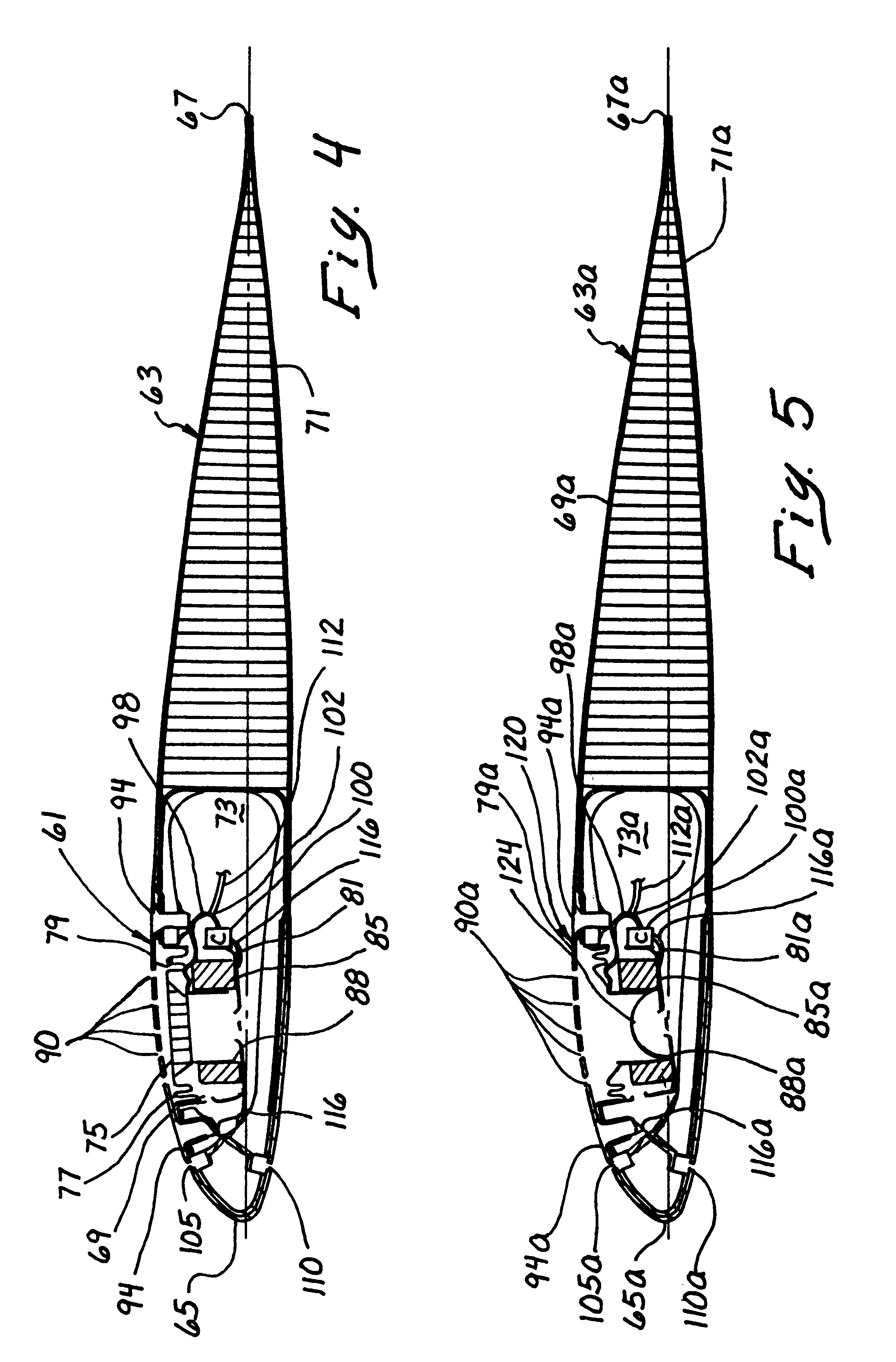

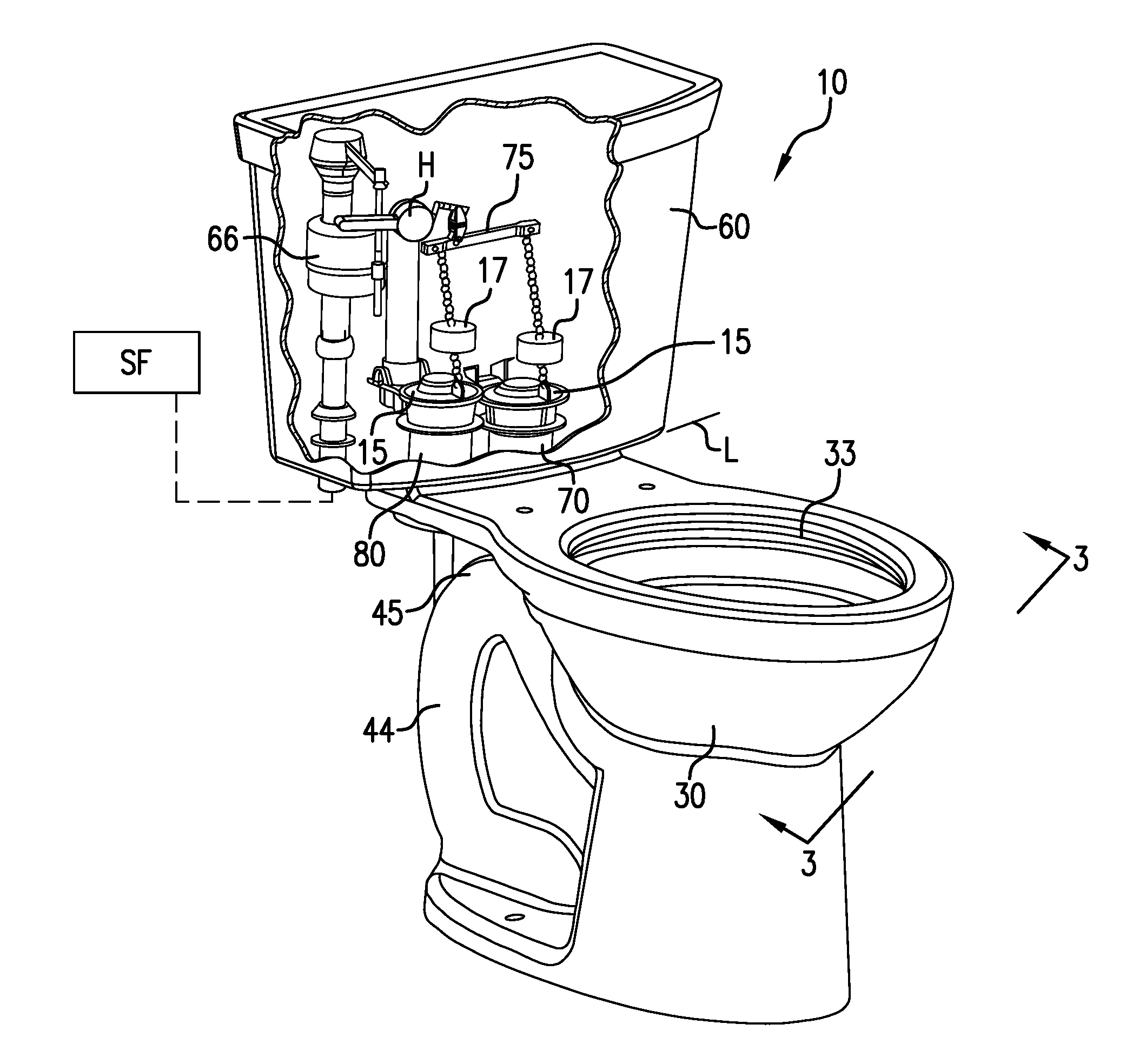

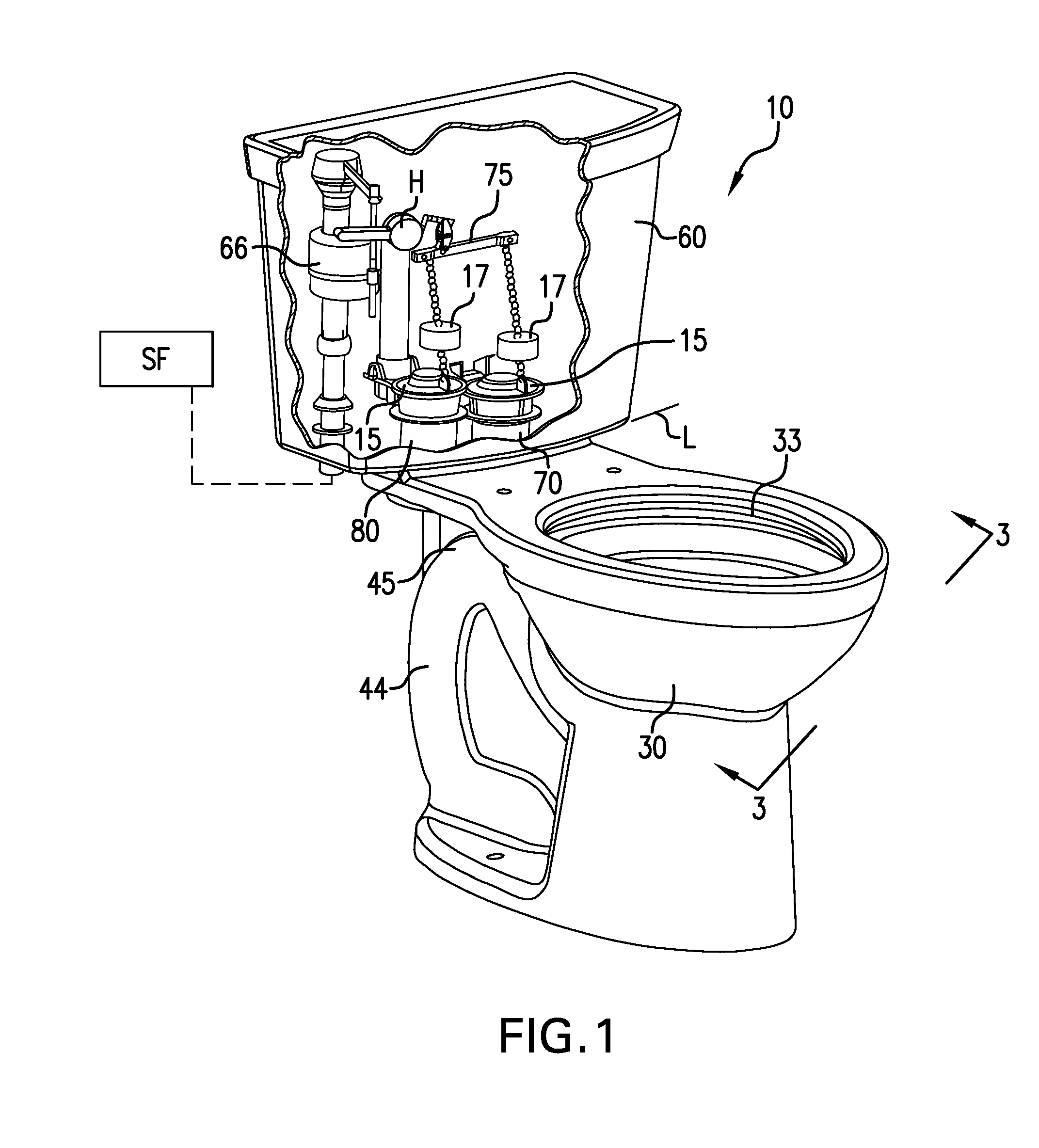

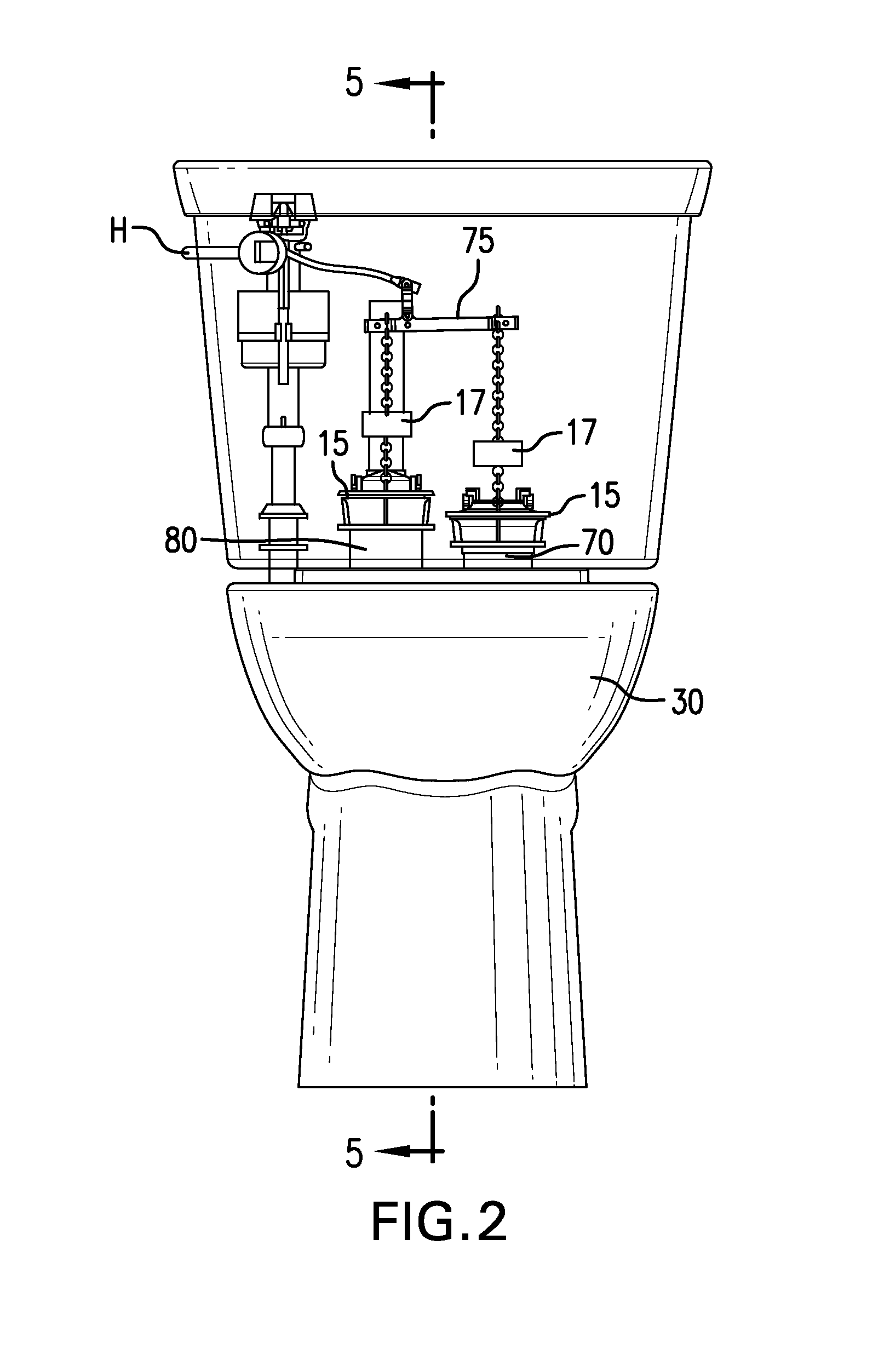

Primed Siphonic Flush Toilet

A siphonic flush toilet system and method of priming the same having a toilet bowl assembly comprising at least one jet flush valve assembly and at least one rim valve; and bowl having a rim and a jet defining at least one jet channel, the at least one jet channel having an inlet port and a jet outlet port configured for discharging fluid to a sump area, wherein the sump area is in fluid communication with a trapway. The bowl has a closed jet pathway including the jet channel and extending from the jet flush valve assembly outlet to the jet channel outlet port to maintain the jet channel in a primed state with fluid from the jet flush valve assembly so as to assist in preventing air from entering the closed jet pathway. Flush valves are also disclosed having back-flow preventer mechanisms and / or at least partly flexible valve covers for use with the toilet systems and methods herein

Owner:AS AMERICA

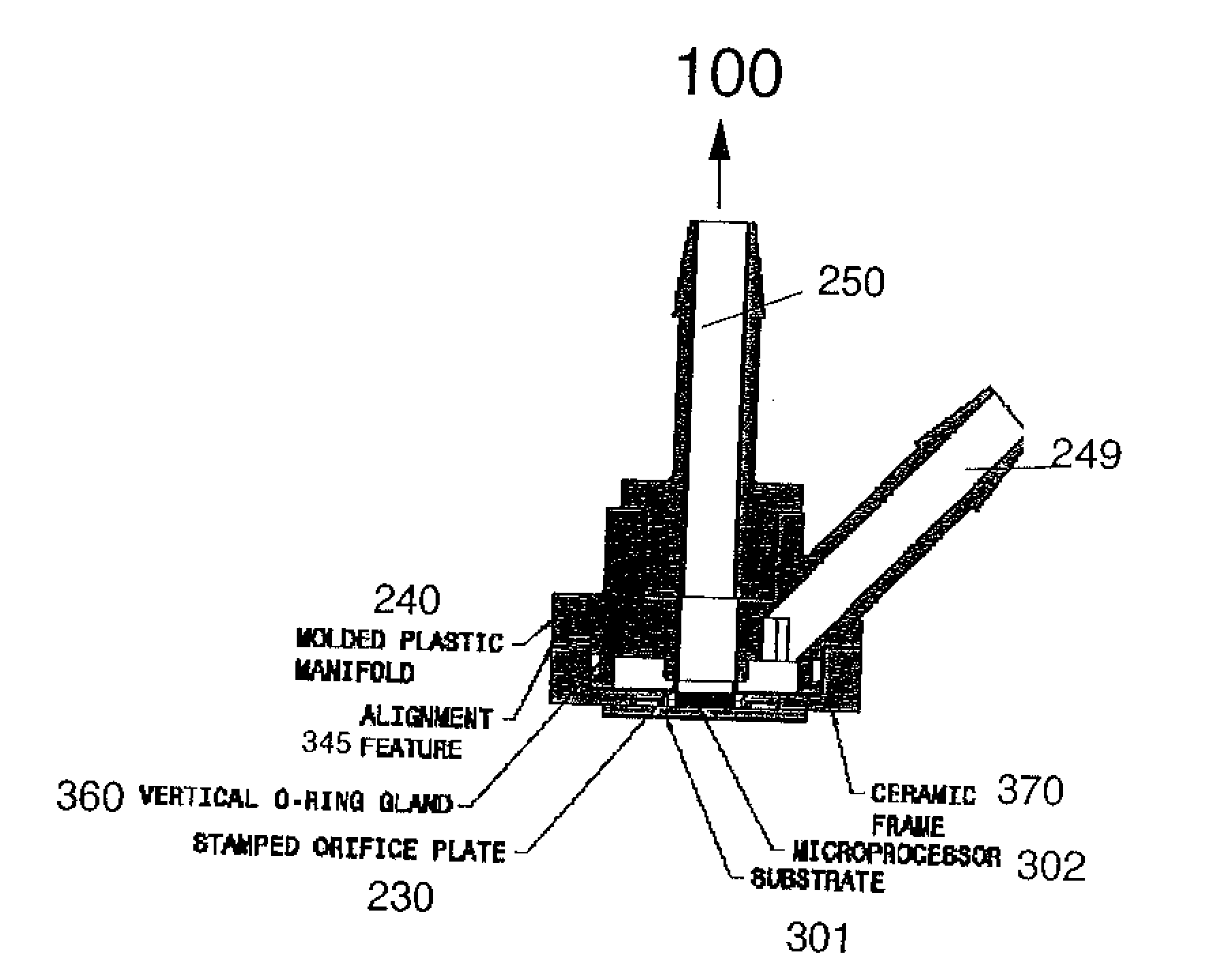

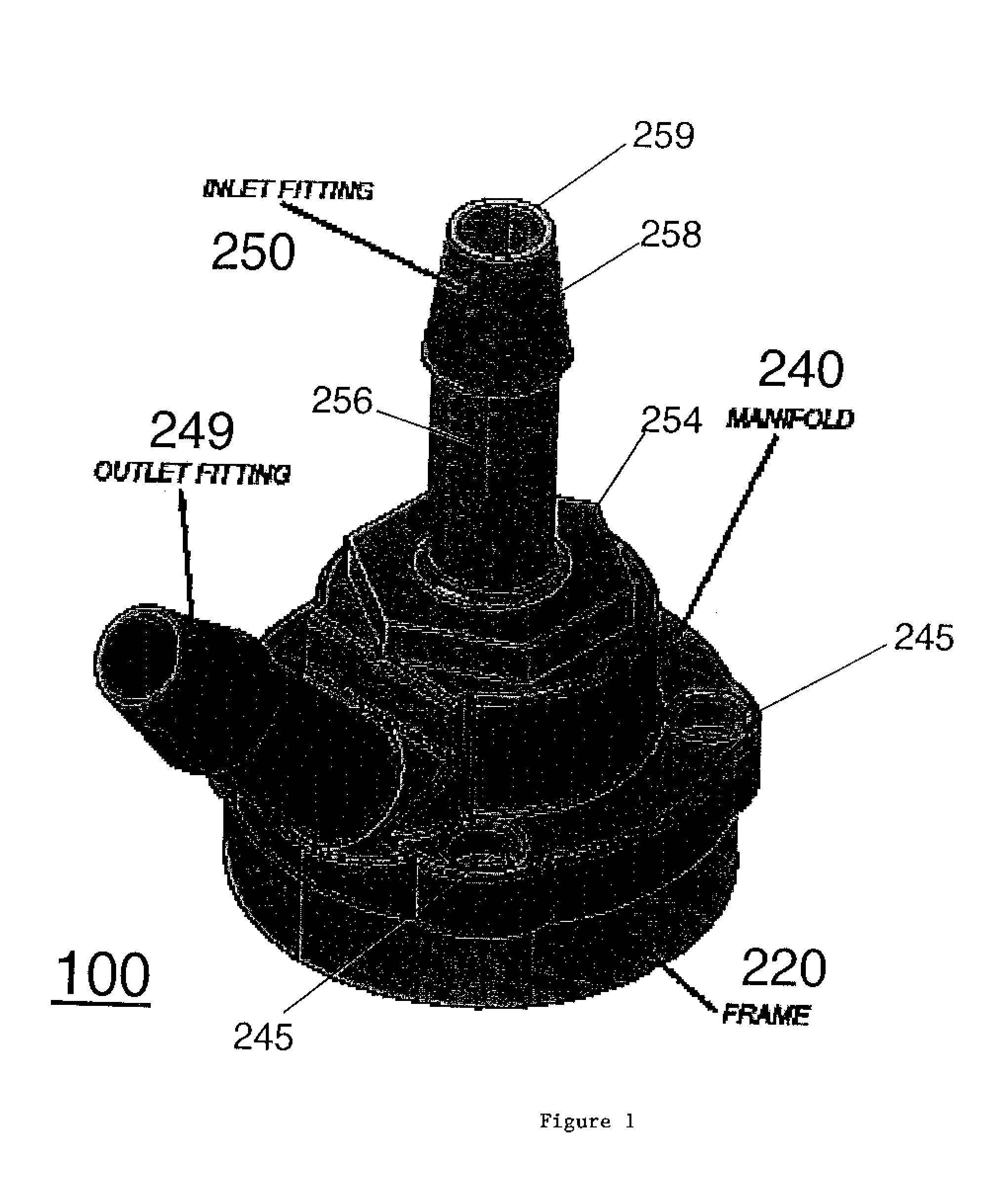

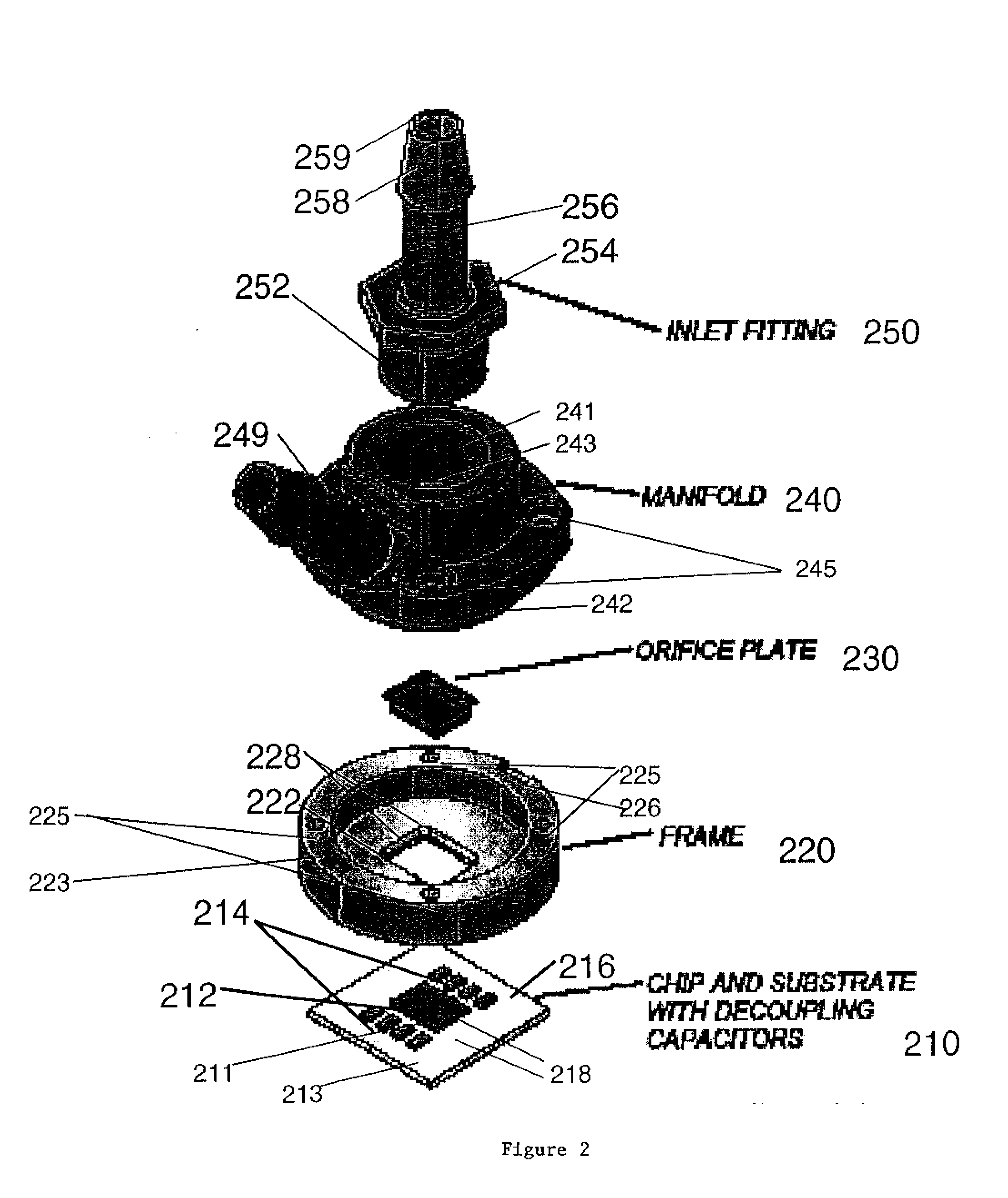

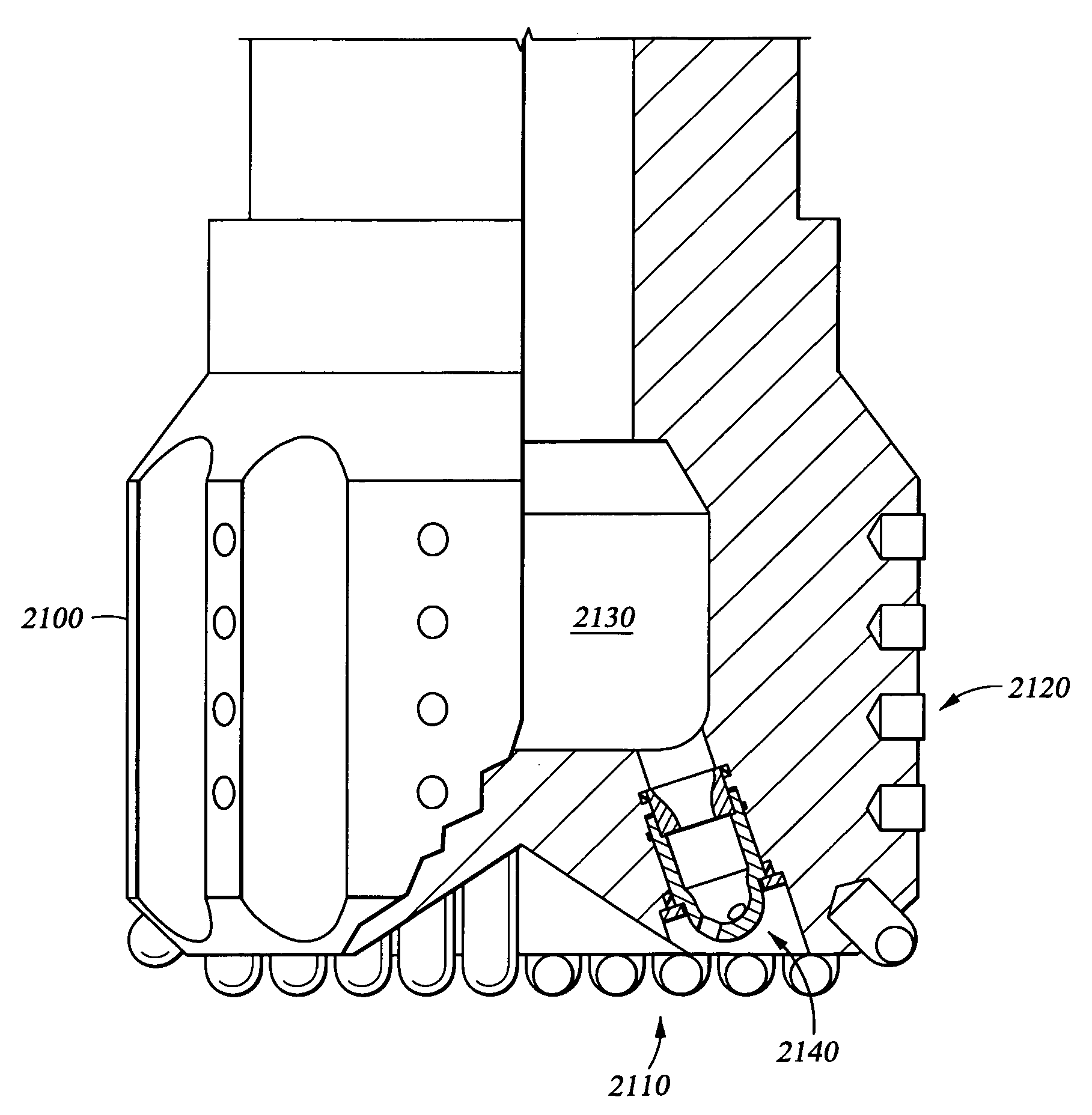

Direct liquid jet impingement module for high heat flux electronics packages

InactiveUS20080002363A1Semiconductor/solid-state device detailsSolid-state devicesLiquid jetJet flow

A direct liquid jet impingement module and associated method of providing such used in cooling of electronic components housed in an electronic package is provided. The module comprises a frame having an orifice to be placed over to-be-cooled components. A manifold is then disposed over the frame, such that the manifold opening is aligned with the frame orifice to ultimately enable fluid impingement on the to-be-cooled components. The manifold is formed to receive an inlet for the flow of coolants and an outlet fitting for removal of dissipated heat. A jet orifice plate is also provided inside the manifold opening, aligned with the frame orifice for directing fluid coolant flow over to-be-cooled components.

Owner:IBM CORP

Multi-stage diffuser nozzle

InactiveUS7188682B2Improve permeabilityEasy to cleanDrill bitsConstructionsEngineeringPlenum chamber

A multi-stage diffuser nozzle for use as a drill bit nozzle jet includes a flow restriction portion upstream of a fluidic distributor portion, and also preferably includes a transition region between these two. The flow restrictor communicates with the interior fluid plenum of a drill bit and is used to limit or restrict the total flow of drilling fluid by having a relatively small cross-sectional area for fluid flow. The fluidic distributor communicates with the flow restrictor and reduces the exit flow velocities of the drilling fluid as the drilling fluid is ejected from the nozzle by providing a relatively larger cross-sectional area for fluid flow. The fluidic distributor also directs the flow paths of the drilling fluid to locations such as cone surfaces that are prone to bit balling. The transition region is an area that dampens fluid pressure oscillations in the drilling fluid.

Owner:SMITH INT INC

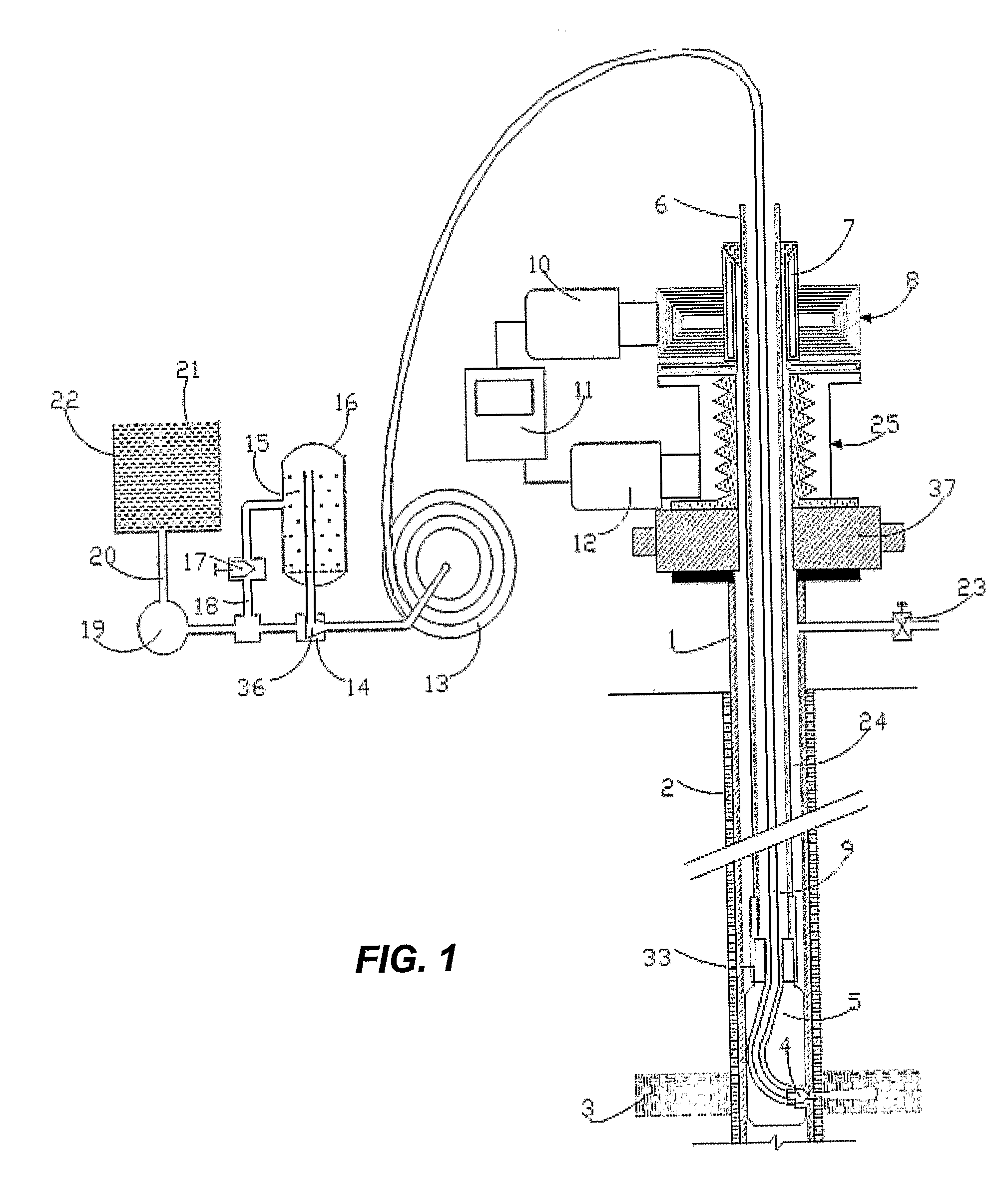

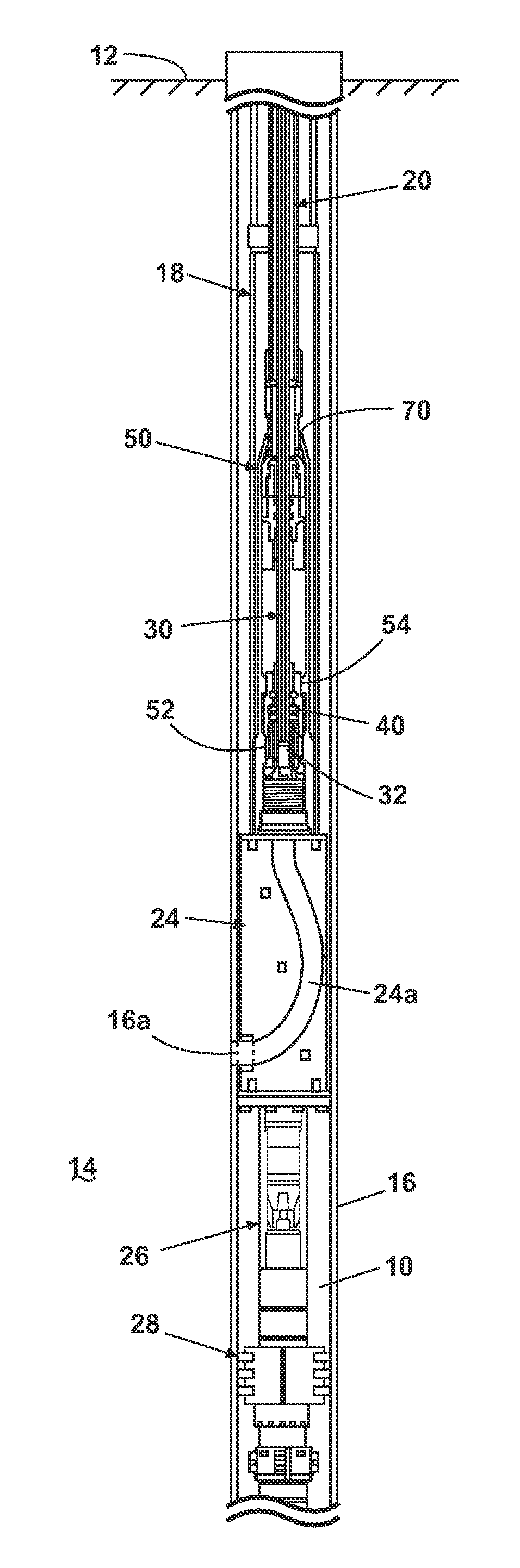

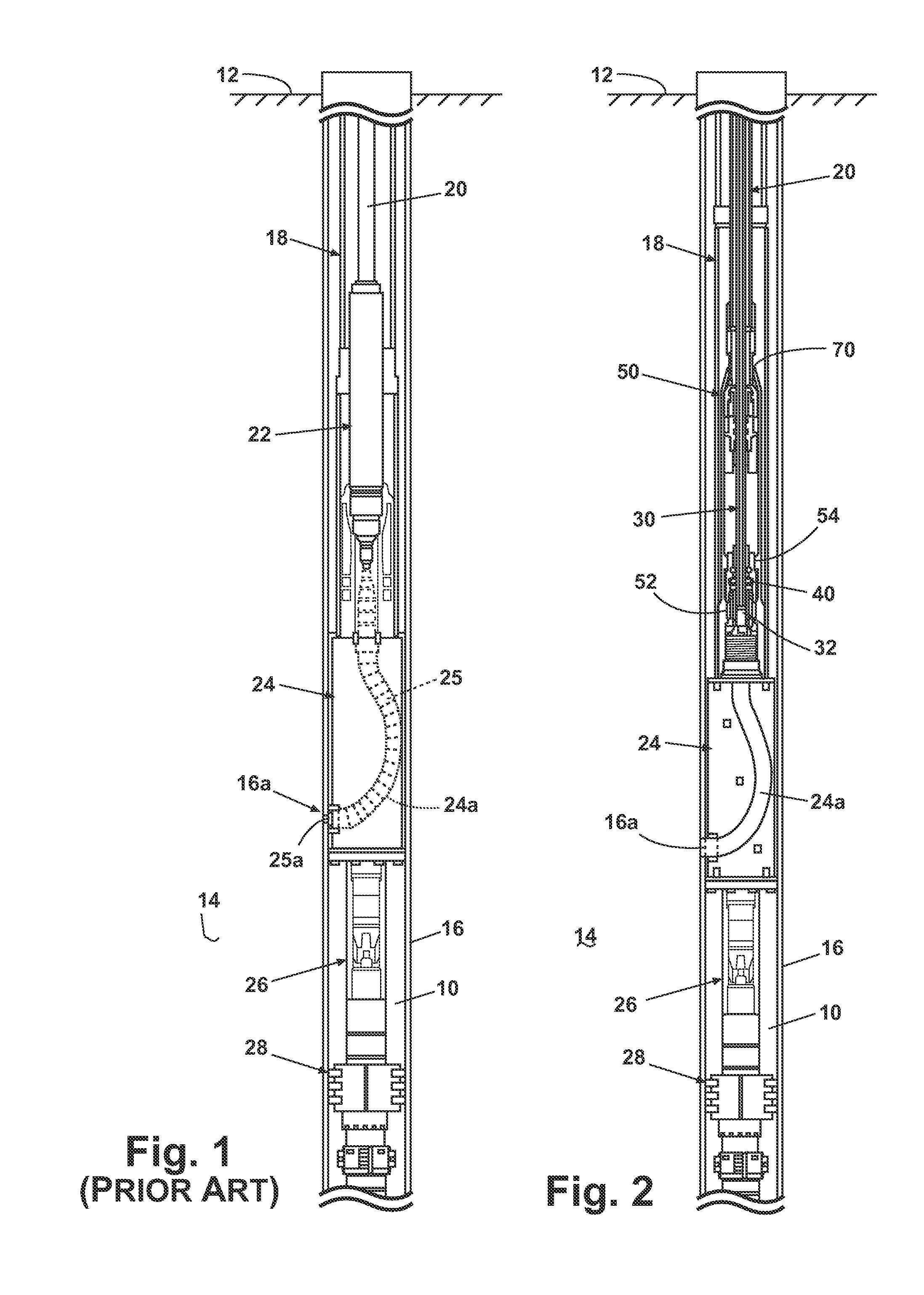

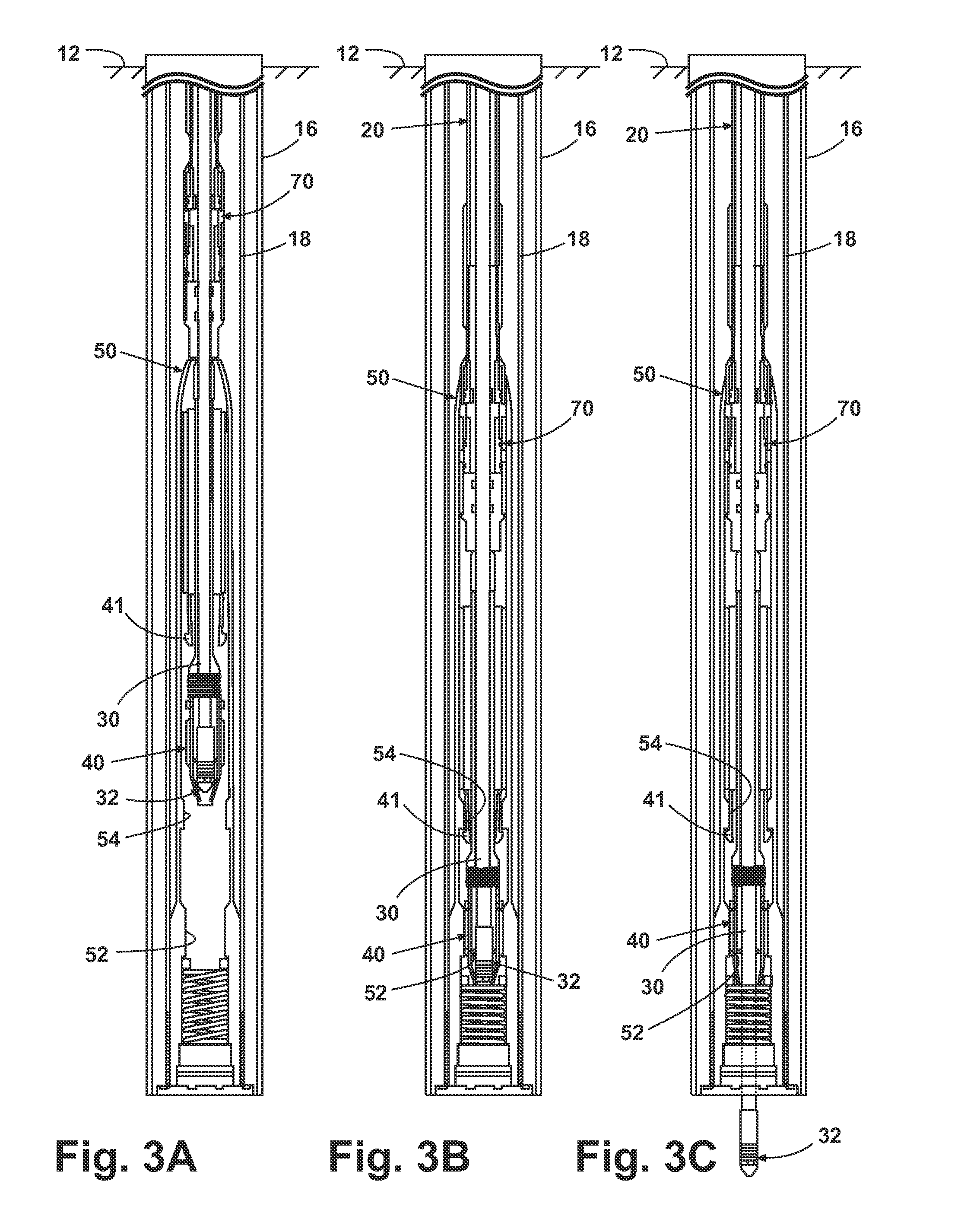

Apparatus and Method for Conveyance and Control of a High Pressure Hose in Jet Drilling Operations

InactiveUS20090101414A1Easy to adjust its sizeEliminate needArtificial islandsLiquid/gas jet drillingWell drillingEngineering

A jetting hose is conveyed downhole retracted within a tubing string for jetting lateral boreholes from a main wellbore, is released at the jetting depth and pumped from the tubing string and into a lateral borehole with jetting fluid. A piston is secured to the upper end of the jetting hose, and the pumped jetting fluid drives the piston. A speed control regulates the penetration rate of the jetting hose into the formation independent of the tubing string weight.

Owner:FUTURE TECH LTD

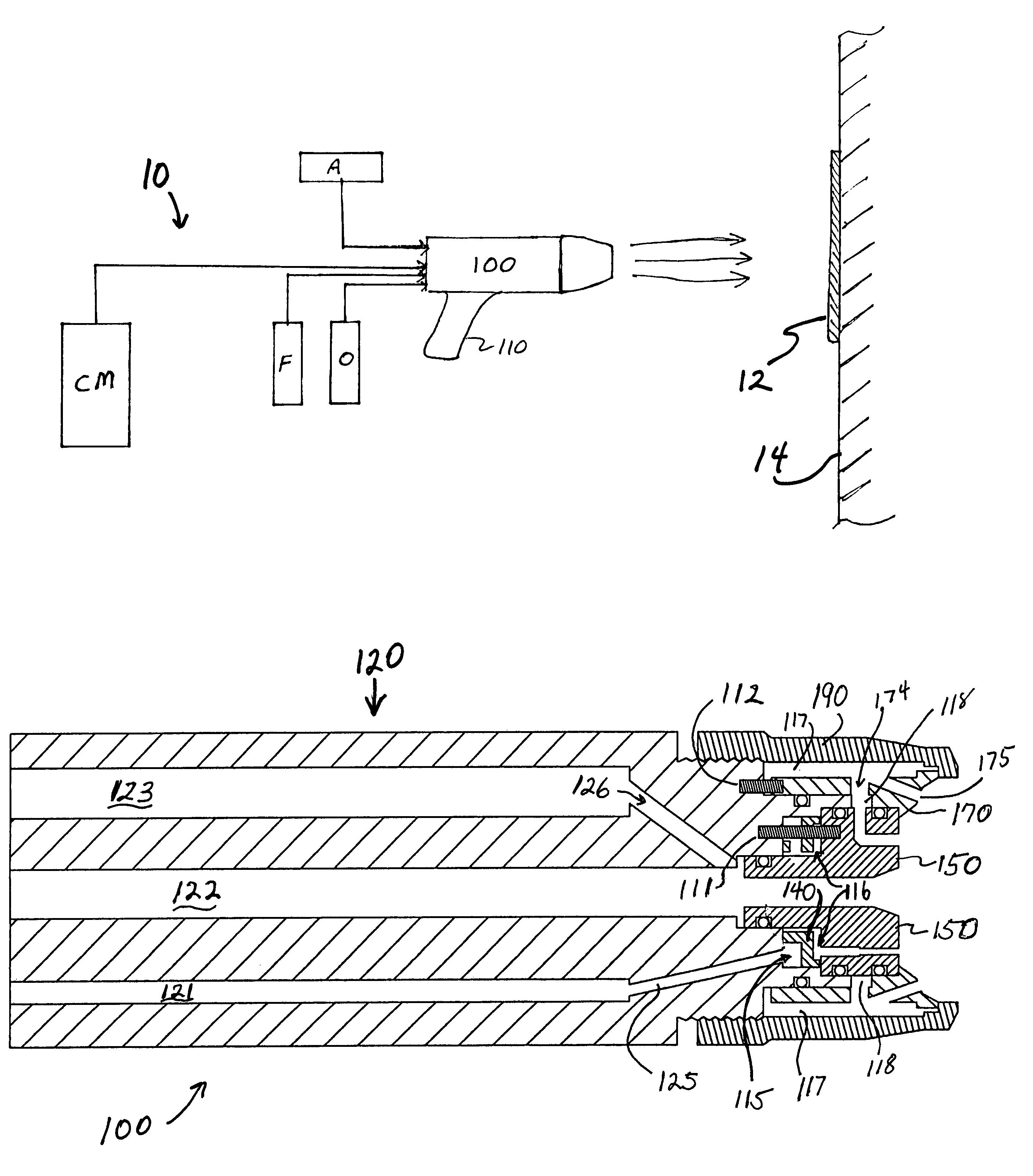

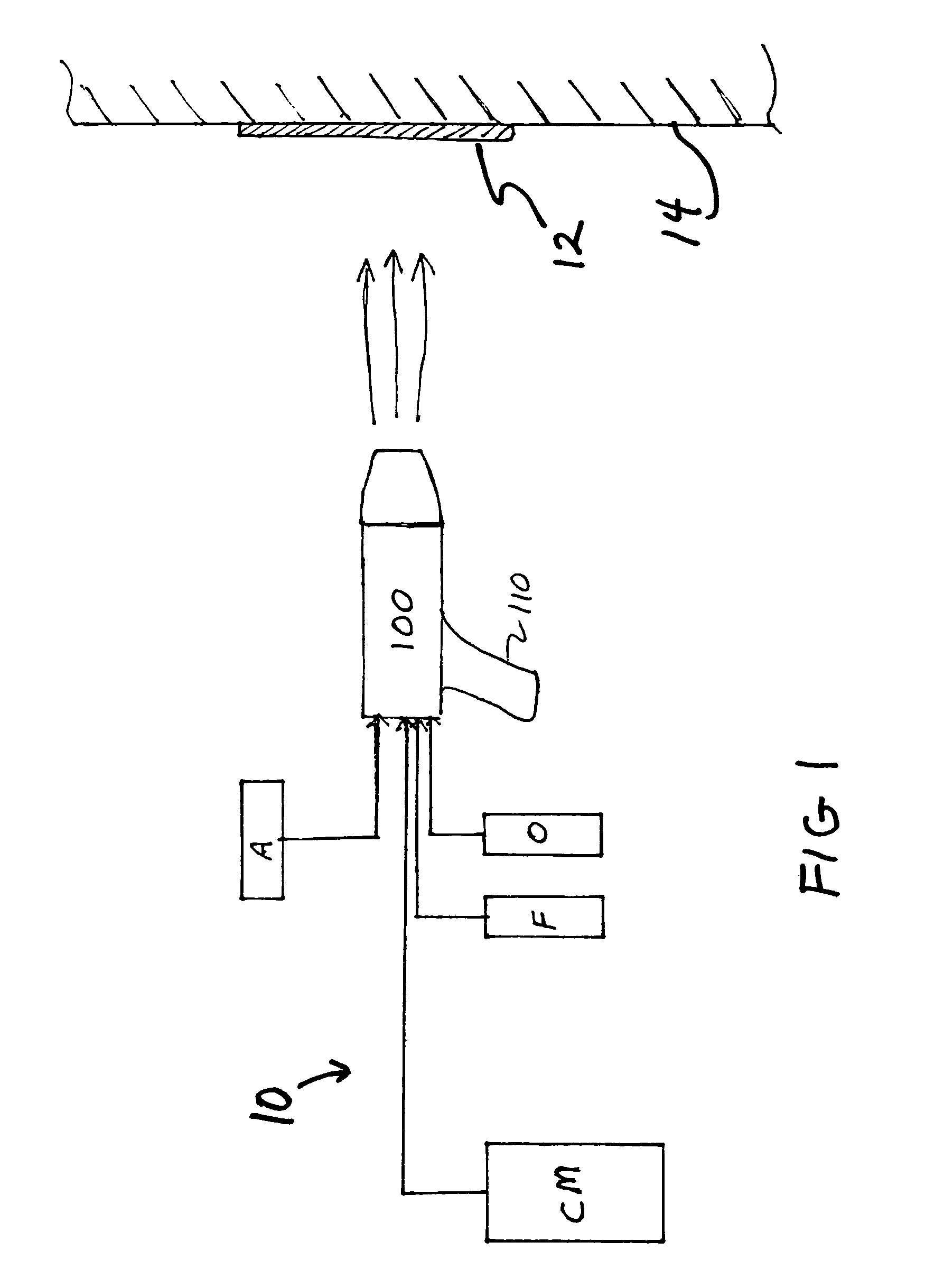

Apparatus for thermal spray coating

A system for thermal spray coating of a particulate material onto a substrate includes a spray gun apparatus having dual vortex chambers for the mixing of fuel gas and oxygen. The apparatus provides a jet flame resulting from a compression wave formed by compressed air. Dual venturis control the flow of fluidized coating material particles to provide smooth and controlled delivery of coating material to the spray gun.

Owner:XIOM CORPORATION

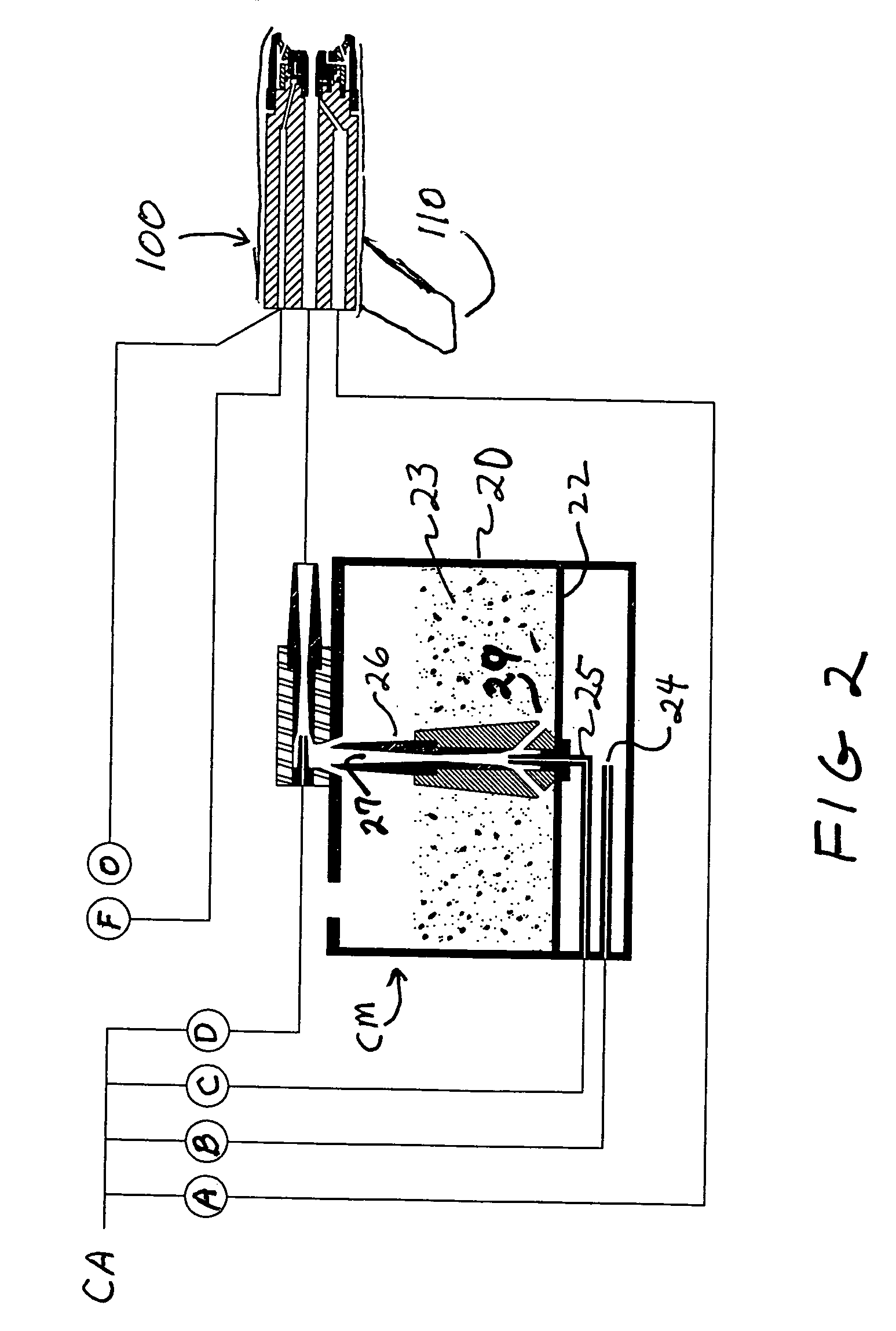

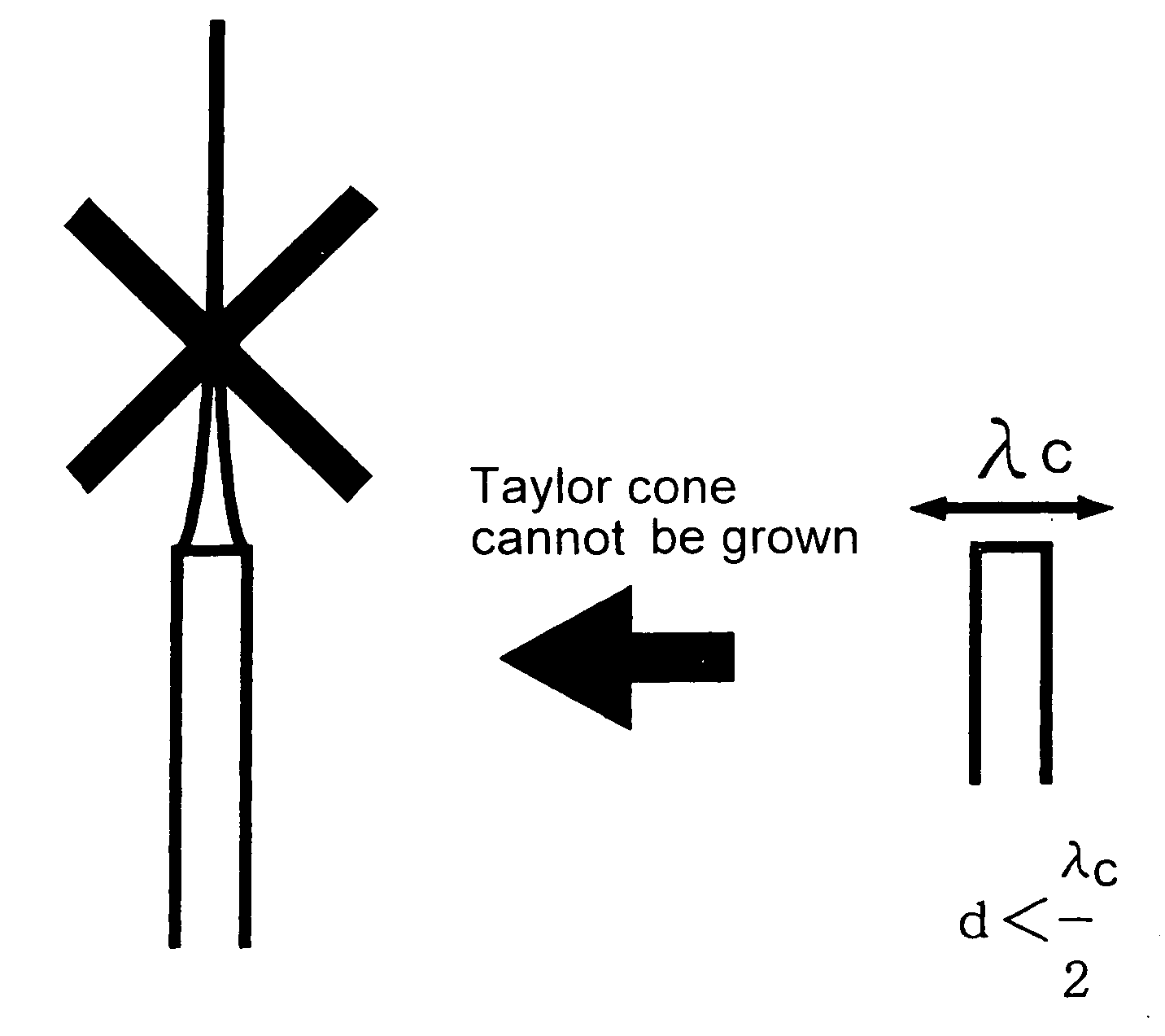

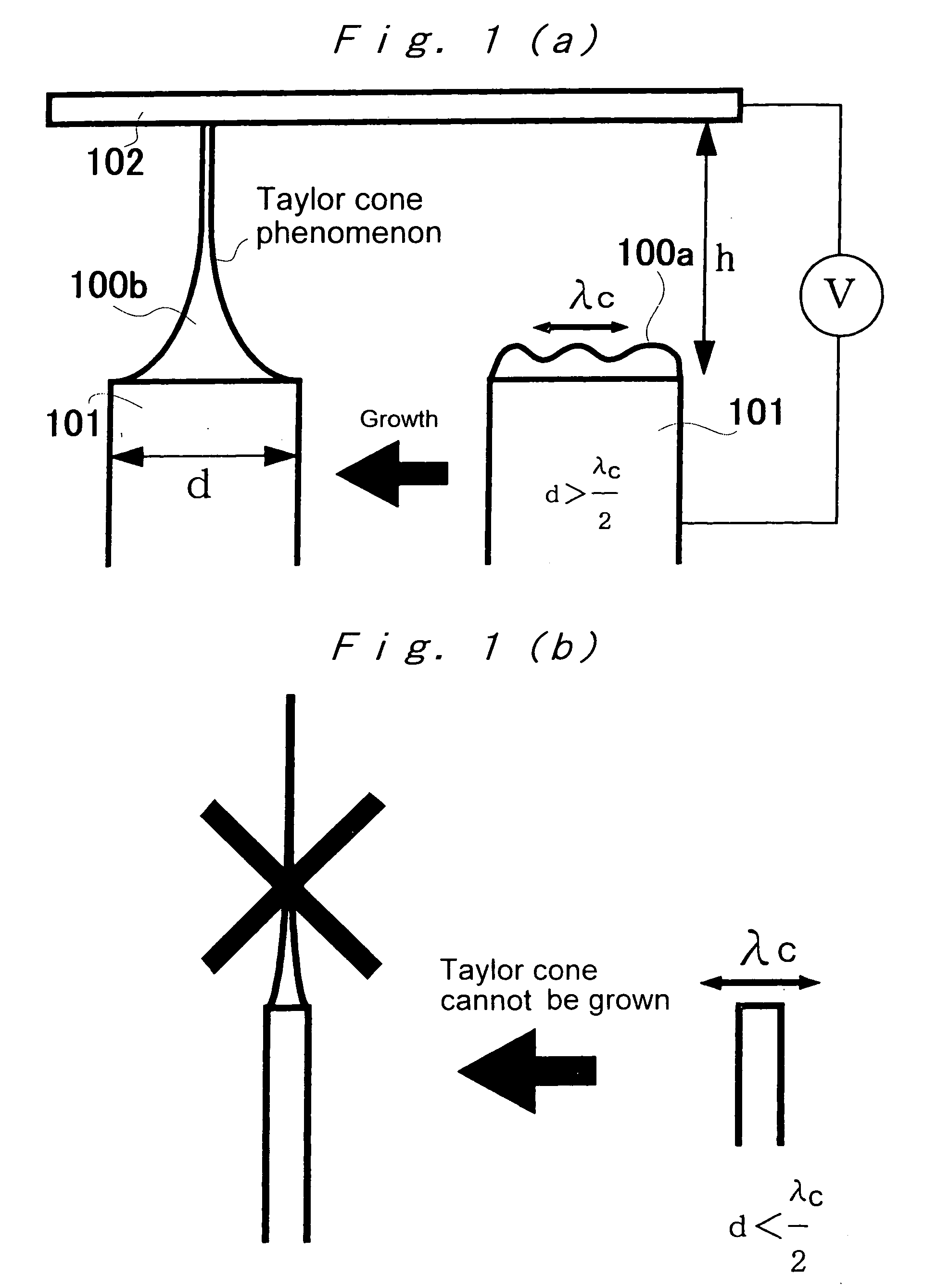

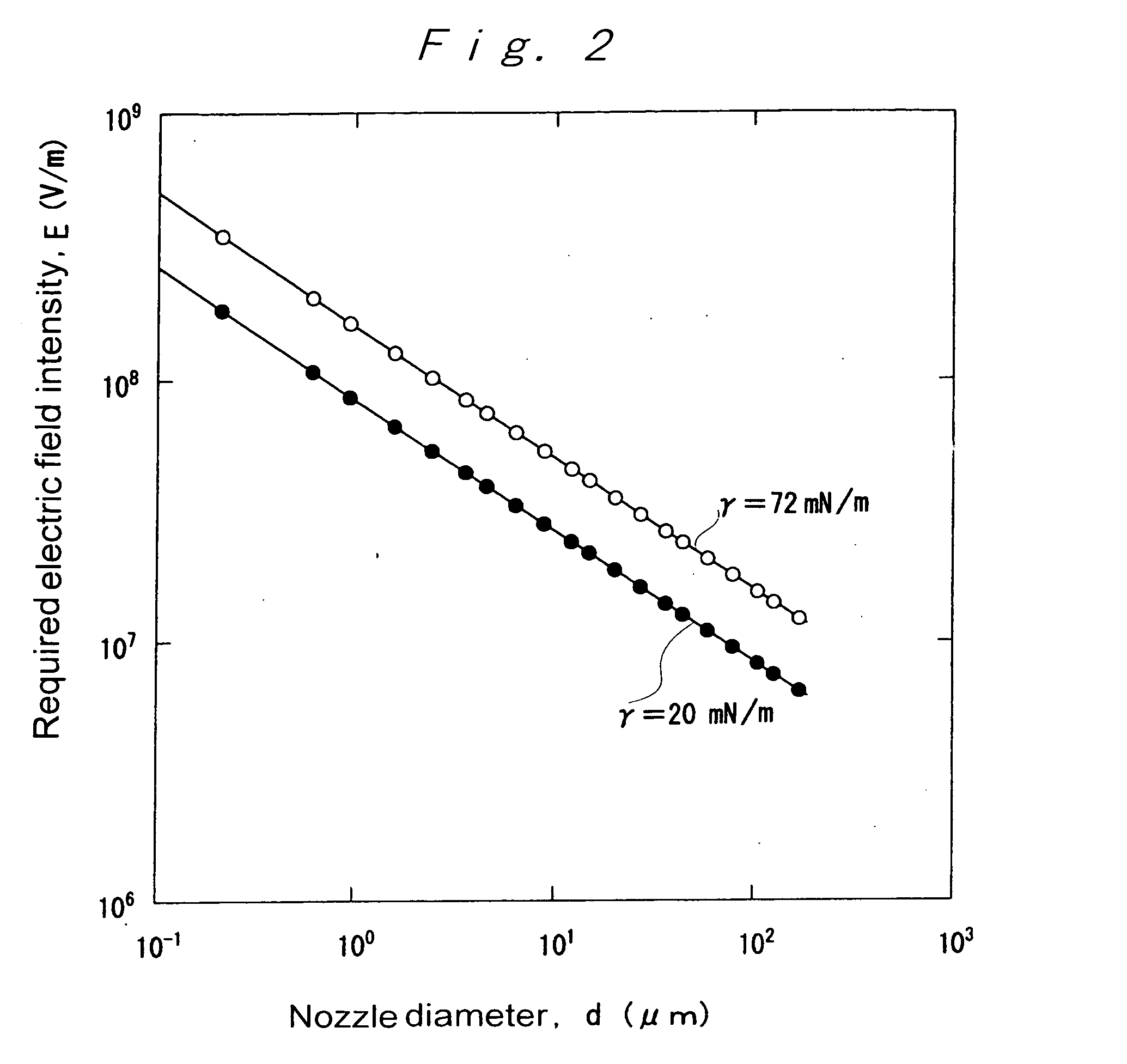

Ultrafine fluid jet apparatus

ActiveUS20050116069A1Improve the immunityReduce the overall diameterBurnersLiquid spraying plantsElectrical field strengthEvaporation

An ultrafine fluid jet apparatus comprising a substrate arranged near a distal end of an ultrafine-diameter nozzle to which a solution is supplied, and an optional-waveform voltage is applied to the solution in the nozzle to eject an ultrafine-diameter fluid droplet onto a surface of the substrate; wherein an electric field intensity near the distal end of the nozzle according to a diameter reduction of the nozzle is sufficiently larger than an electric field acting between the nozzle and the substrate; and wherein Maxwell stress and an electro-wetting effect being utilized, a conductance is decreased by a reduction in the nozzle diameter or the like, and controllability of an ejection rate by a voltage is improved; and wherein landing accuracy is exponentially improved by moderation of evaporation by a charged droplet and acceleration of the droplet by an electric field.

Owner:SIJTECH +1

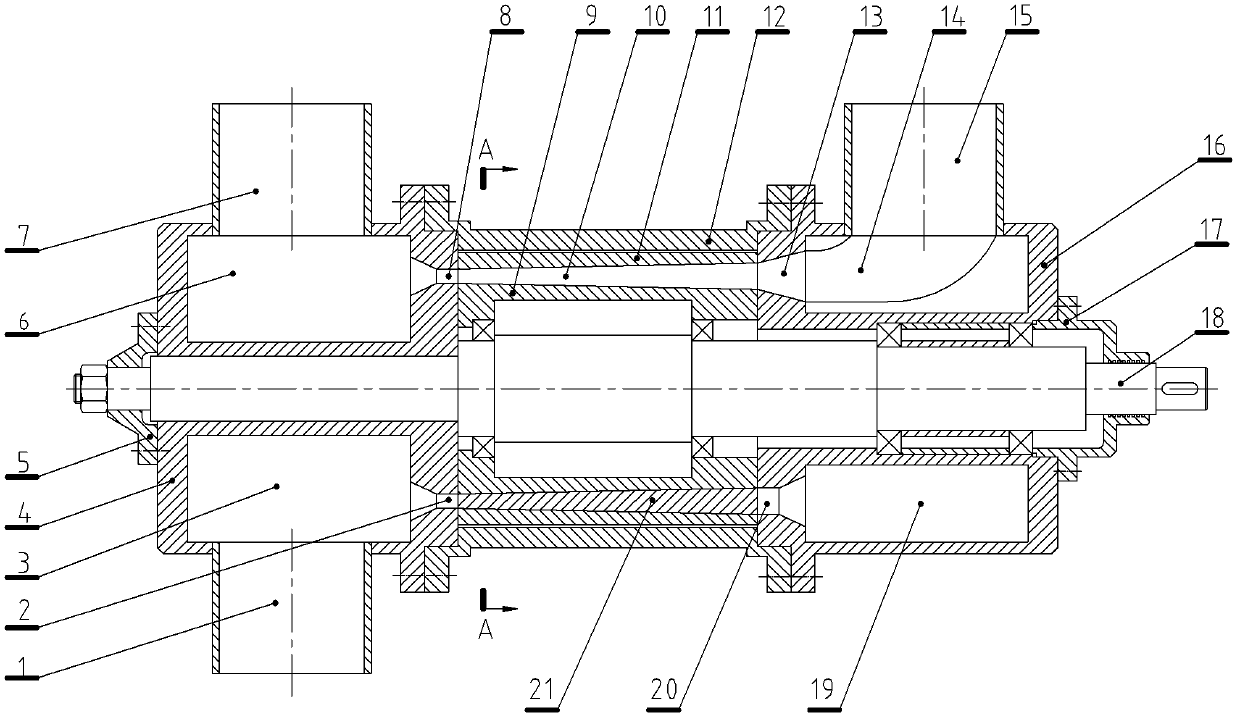

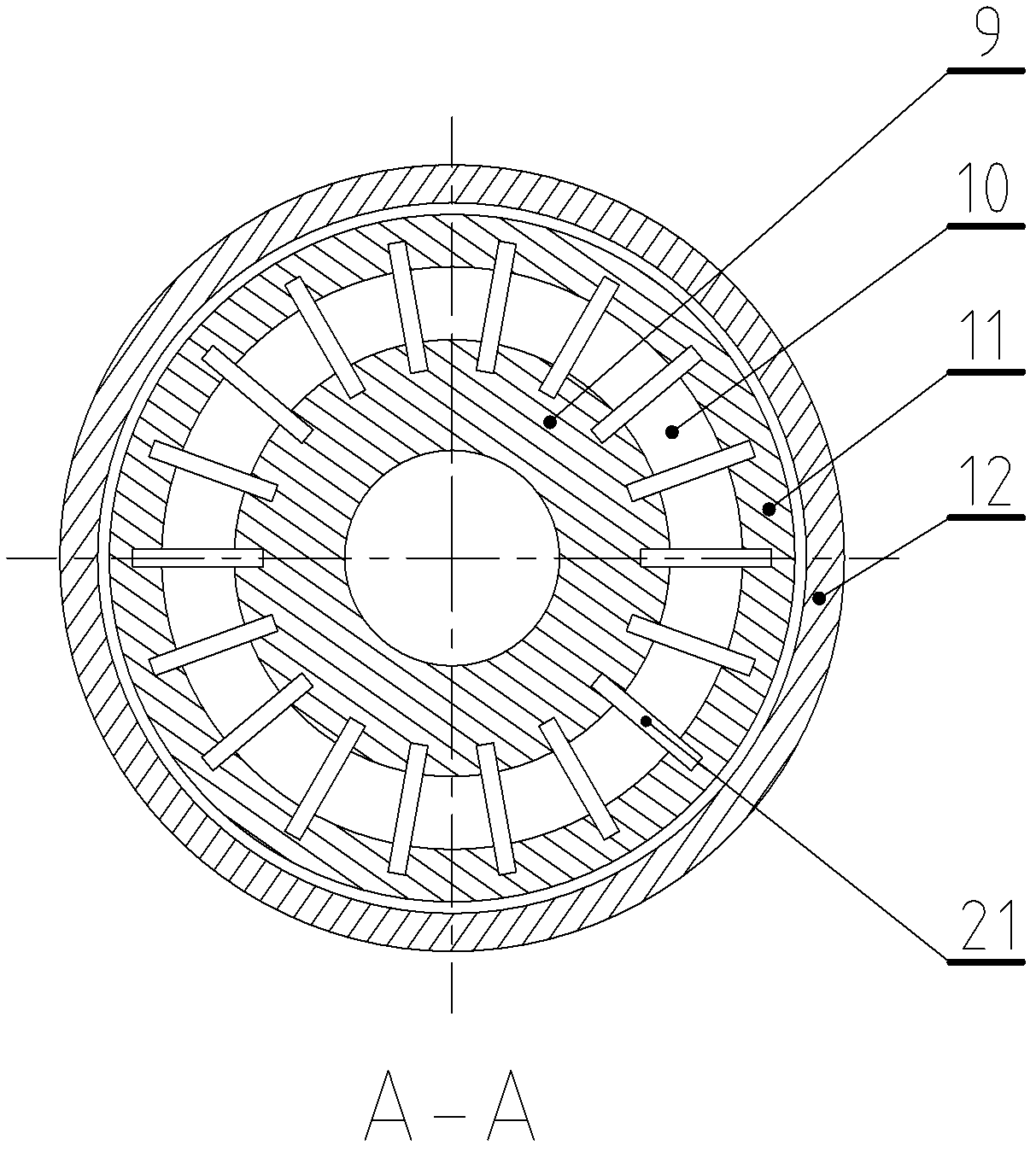

Axial-flow type jet flow gas wave pressure supercharger

InactiveCN102606547ARealize pressure exchangeHigh pressure levelFluid-pressure convertersJet flowEnergy exchange

An axial-flow type jet flow gas wave pressure supercharger relies on operation of pressure wave to achieve energy exchange between high-pressure gas and low-pressure gas, avoids mixed diffusion energy loss and has the advantages of being high in isentropic efficiency, low in rotation speed, capable of working with fluid and the like. A pressure oscillation tube channel with variable rectangular cross section is adopted to reduce incident loss and flow loss of jet flows. A pressure equalizing port is arranged in the pressure supercharger so that performance of different pressure ratios is balanced. A pressure expansion fluid director is arranged at the position of a compression fluid outlet to effectively convert air flow kinetic energy. The axial-flow type jet flow gas wave pressure supercharger can fully utilize pressure energy in the production process and stratal pressure energy such as natural gas and can serve as an efficient device for effectively utilizing the pressure energy.

Owner:DALIAN UNIV OF TECH

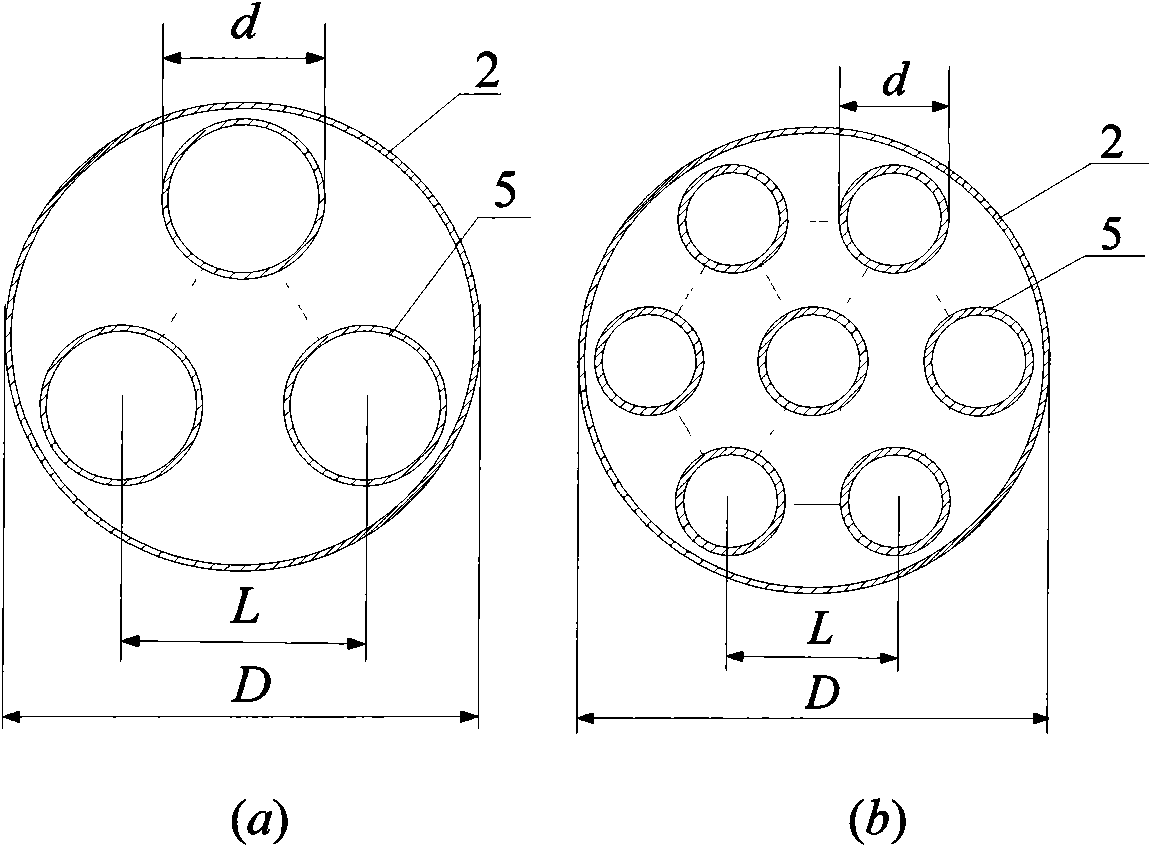

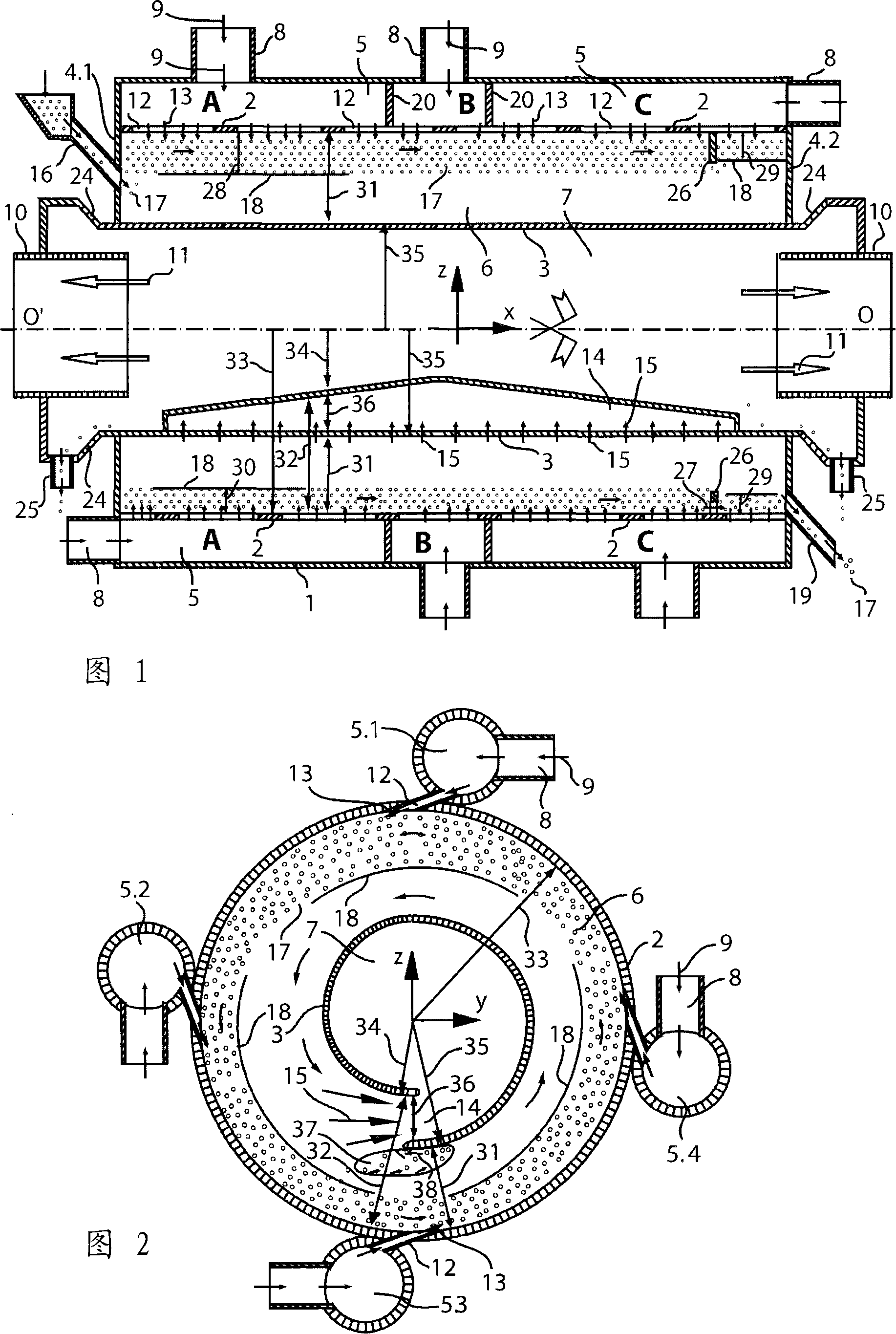

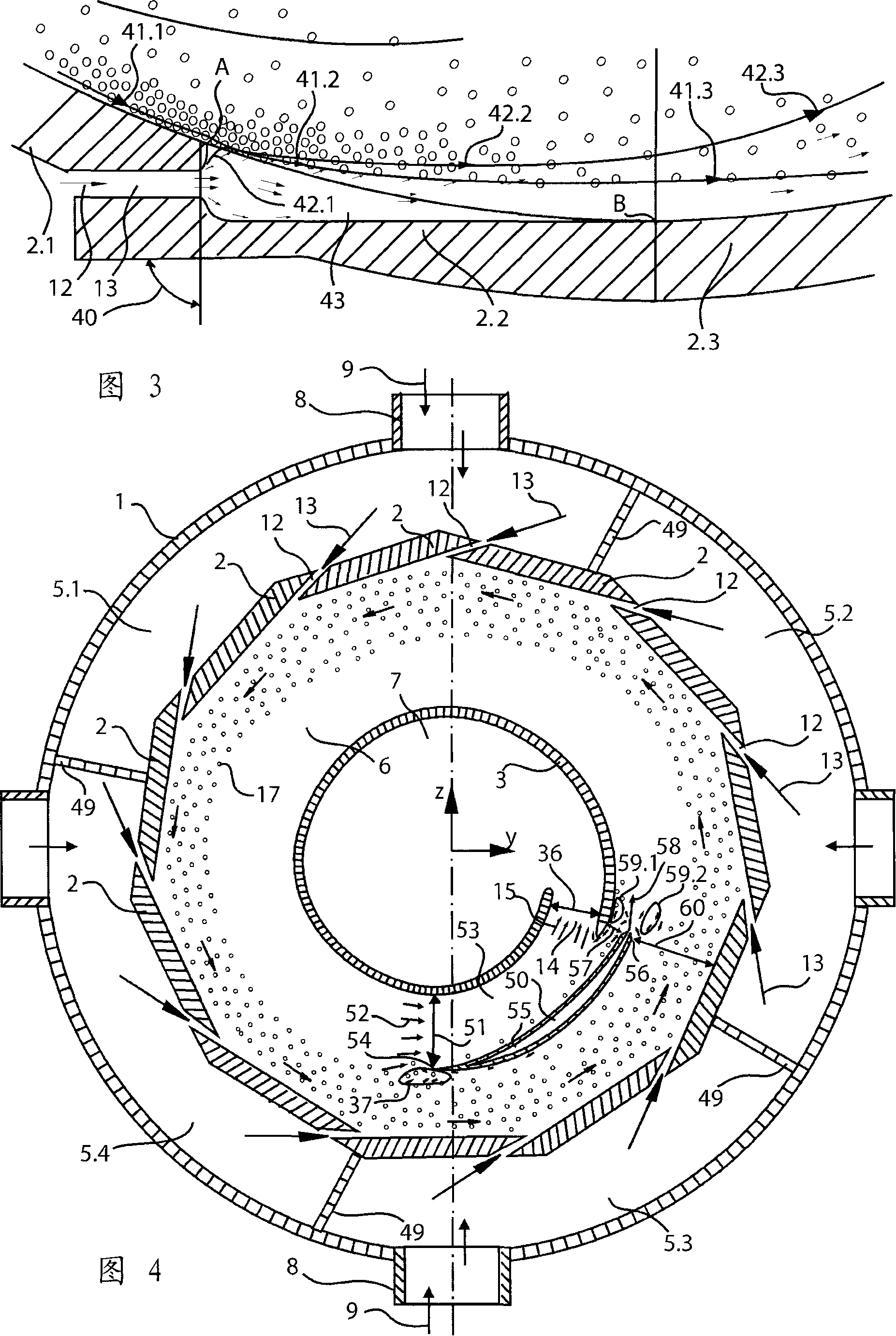

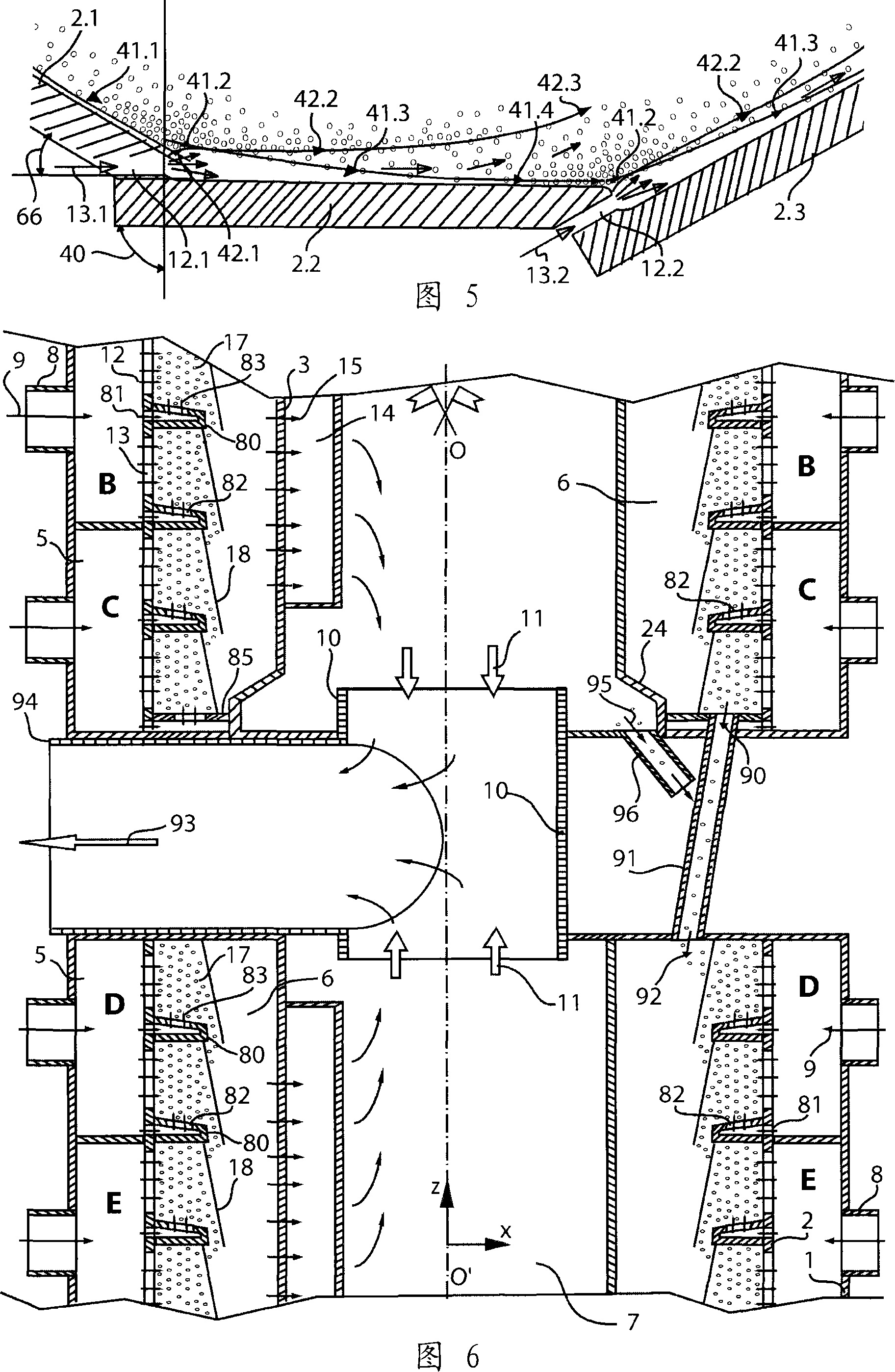

Rotary fluidized bed device and using method thereof

InactiveCN101124039AIncrease flow rateIncrease in sizeDrying solid materials with heatChemical/physical processesSuspended particlesFluidized bed

The invention concerns a device for injecting fluids inside a rotary fluidized bed wherein the fluid jets are oriented in the rotational direction of the fluidized bed and surrounded with at least one deflector delimiting around said jets a space generally convergent then divergent and upstream of said jet passages through which suspended particles in the rotary fluidized bed can penetrate so as to be mixed with the fluid jets which transfer to them part of their kinetic energy before leaving said space.

Owner:阿克塞尔·德布罗克维尔

Self-oscillation jet impact-type nozzle for atomizing complex fluids

ActiveCN102019236AImprove atomization effectSimple structureSpray nozzlesLiquid spraying apparatusResonant cavityEngineering

The invention relates to a self-oscillation jet impact-type nozzle for atomizing complex fluids, comprising a fluid collection cavity shell, an injection panel and a resonant cavity shell, wherein the center of the upper part of the fluid collection cavity shell is connected with a supply pipeline through a threaded hole; the fluid collection cavity shell and the injection panel are connected through a flange and are sealed by using a sealing gasket; a cavity between the fluid collection cavity shell and the injection panel is a fluid collection cavity; the center of the bottom of the injection panel is provided with a truncated cone-shaped indent space; two or more spray orifices are symmetrically arranged on the side surface vertical to the truncated cone-shaped indent space; the axes of the spray orifices form certain angle with the central axis of the injection panel, and the axes of all the spray orifices are intersected at one point on the central axis of the injection panel; the side surface of a central truncated cone at the upper part of the injection panel is provided with spray orifice inlets; the spray orifice inlets are provided with internal threads; the resonant cavity shell is provided with resonant cavity inlets; the outer surface of the resonant cavity shell is provided with an external thread; the resonant cavity shell is connected with the injection panel through the internal threads of the spray orifice inlets; and two or more resonant cavities are formed between the resonant cavity shell and the injection panel.

Owner:BEIHANG UNIV

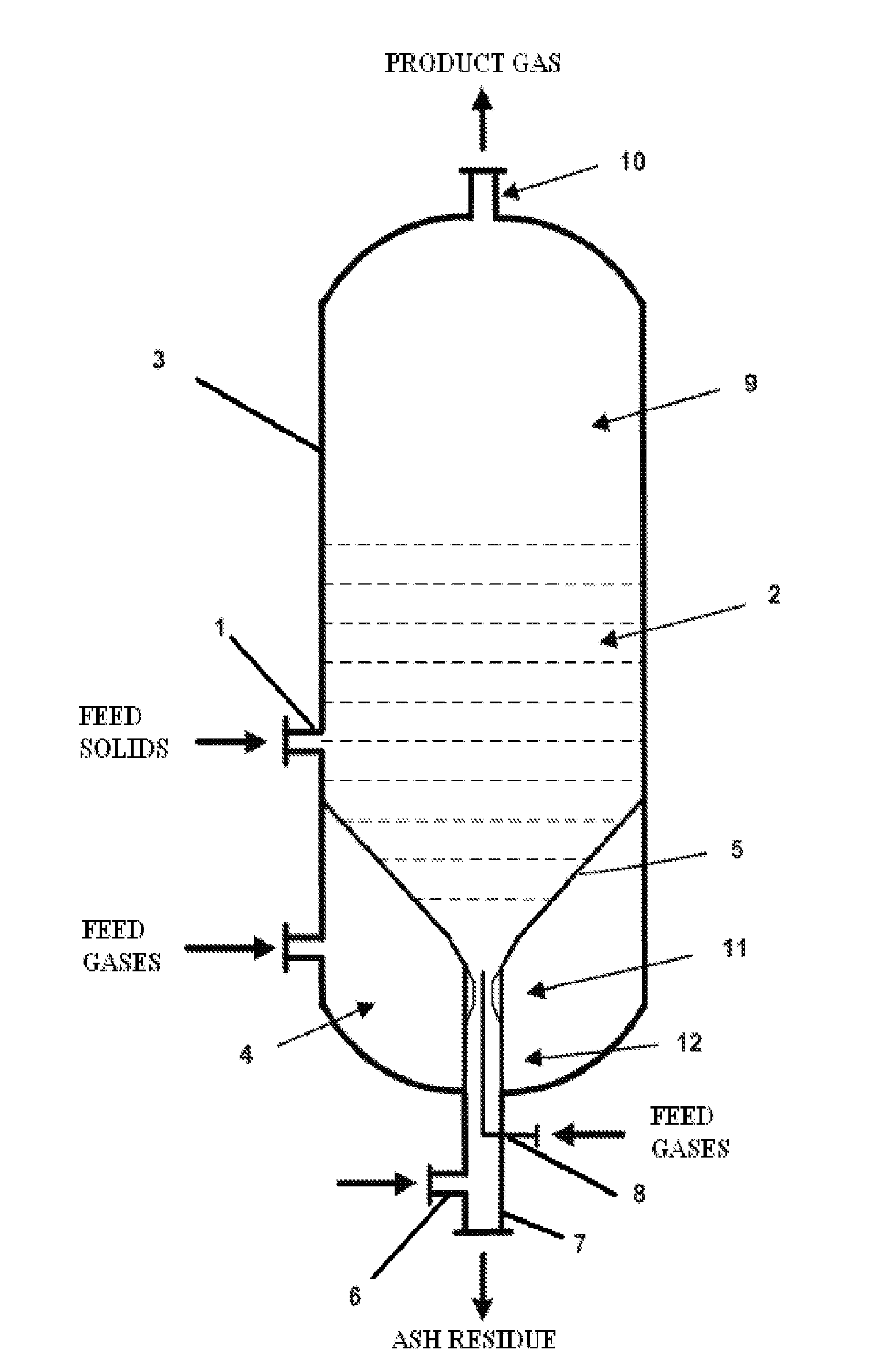

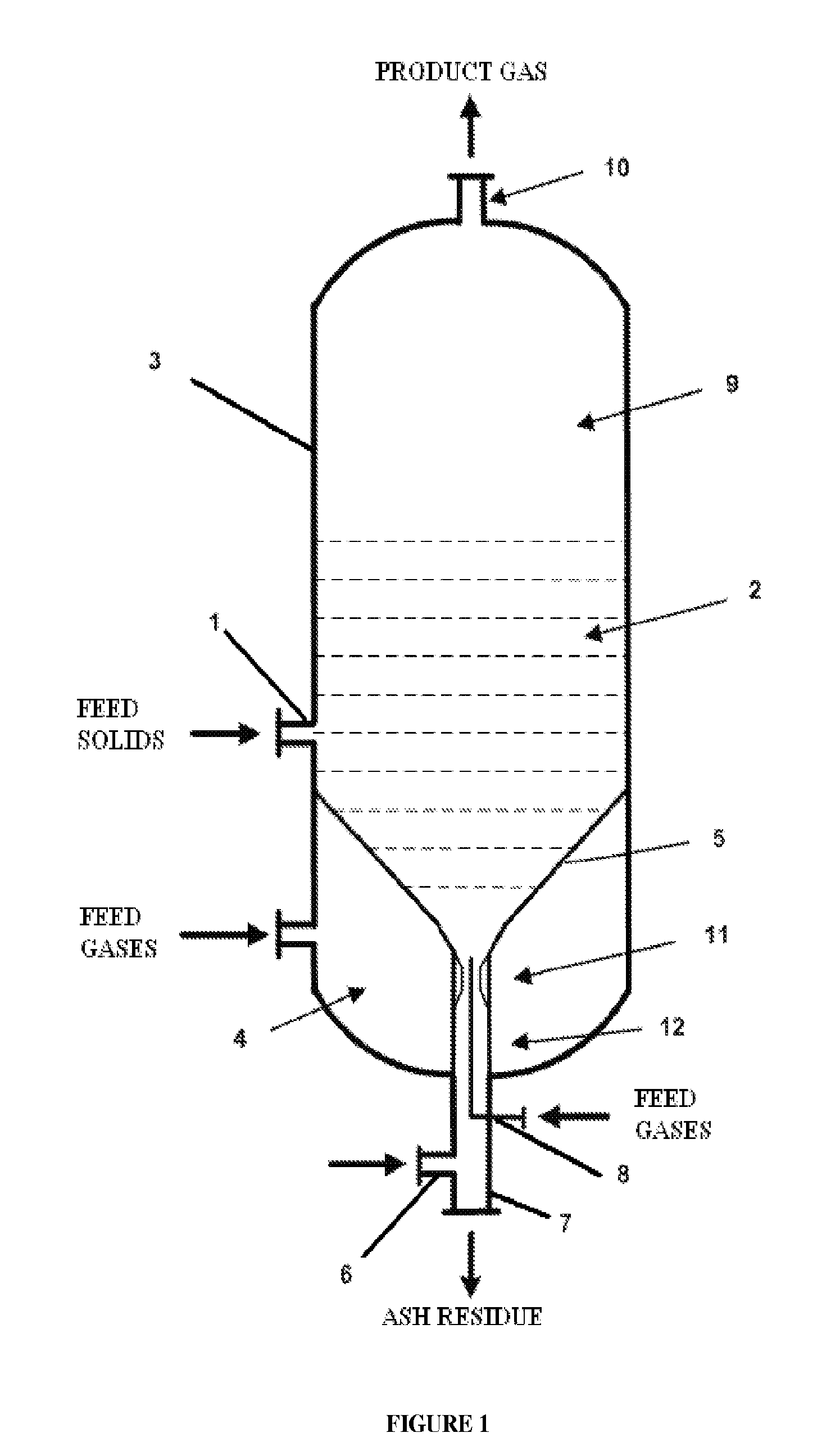

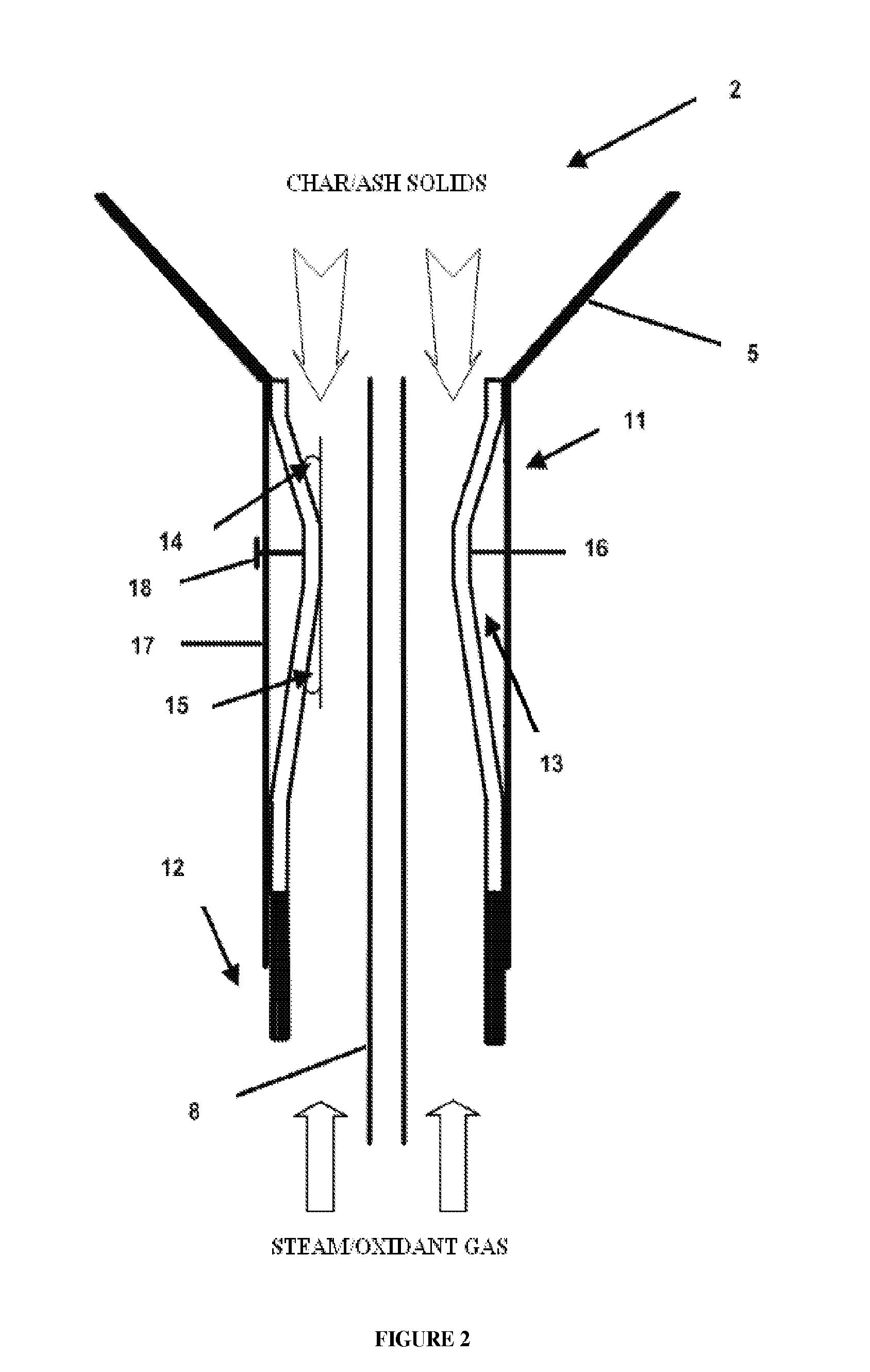

Fluidized bed gasifier with solids discharge and classification device

InactiveUS20110189054A1Speed up the conversion processKeep for a long timeGasifier feeding meansGasifier mechanical detailsFluidized bed gasifierFluidized bed

An apparatus for withdrawing solids from a fluidized bed reactor comprises a venturi tube connected to the stem end of a funnel-shaped distribution plate, and a center jet pipe enclosed within the venturi, wherein a jet stream of feed gas is delivered above the venturi throat. Preferably, the distribution plate is equipped with multiple horizontally- or downwardly-oriented grid holes through which the feed gases flow and enter the fluidized bed, which holes may be covered by metal plates to prevent solids from weeping through grid holes and falling into the plenum below the distribution plate. The venturi is preferably engineered to be readily removable from the rest of the gasifier reactor for repair or replacement. Also provided is a fluidized bed reactor comprising the above apparatus.

Owner:SYNTHESIS ENERGY SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com