Patents

Literature

214 results about "Chamber design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

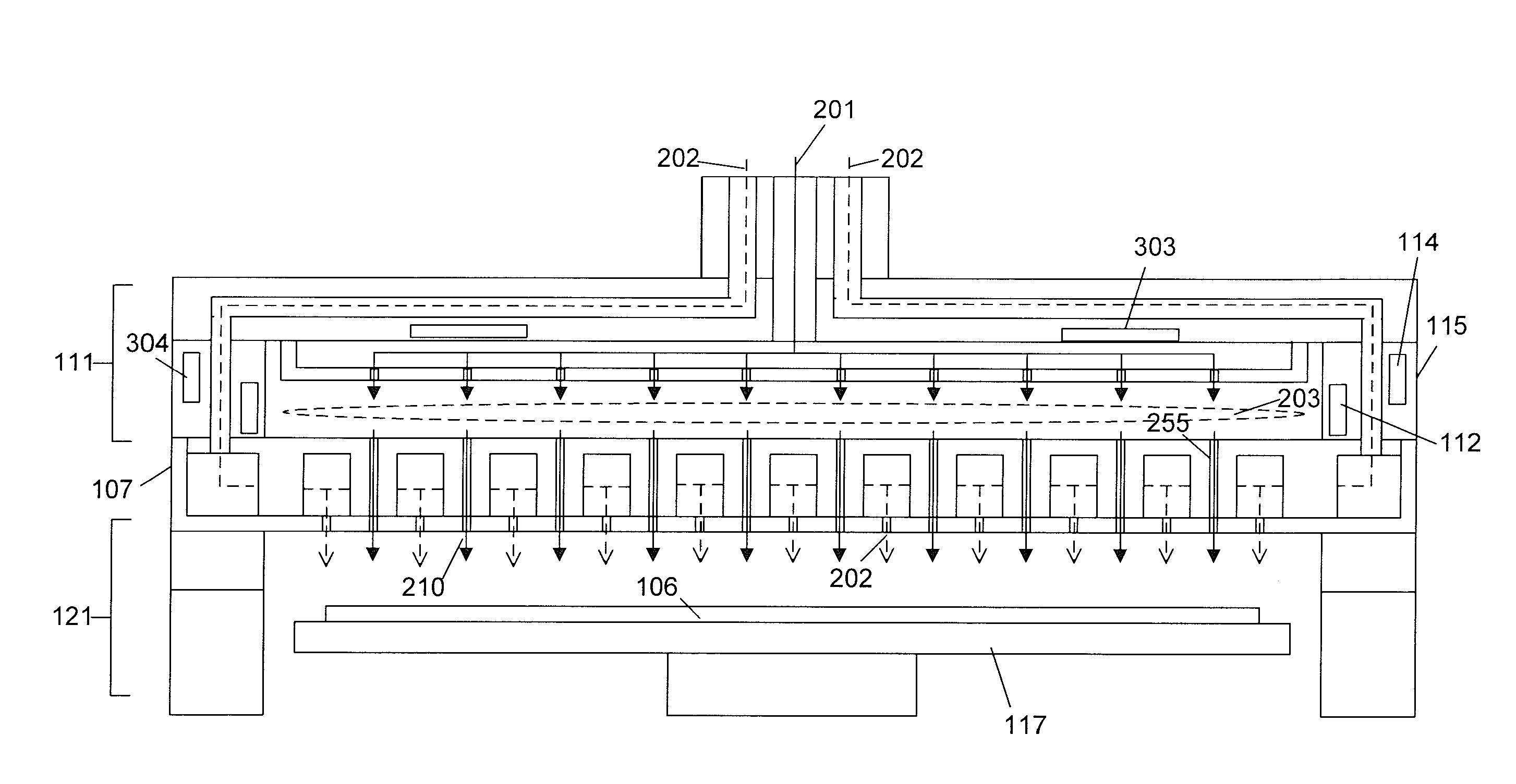

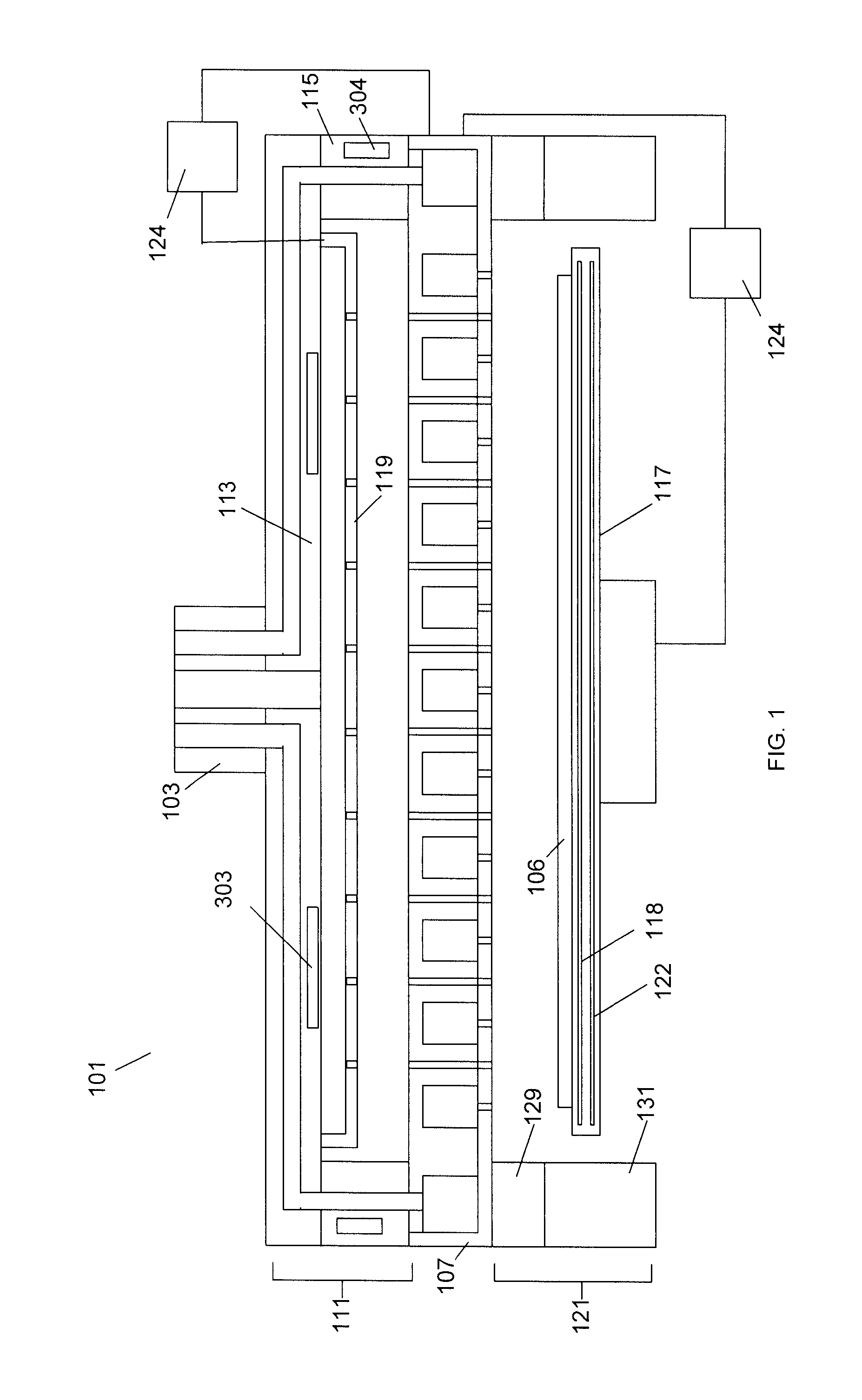

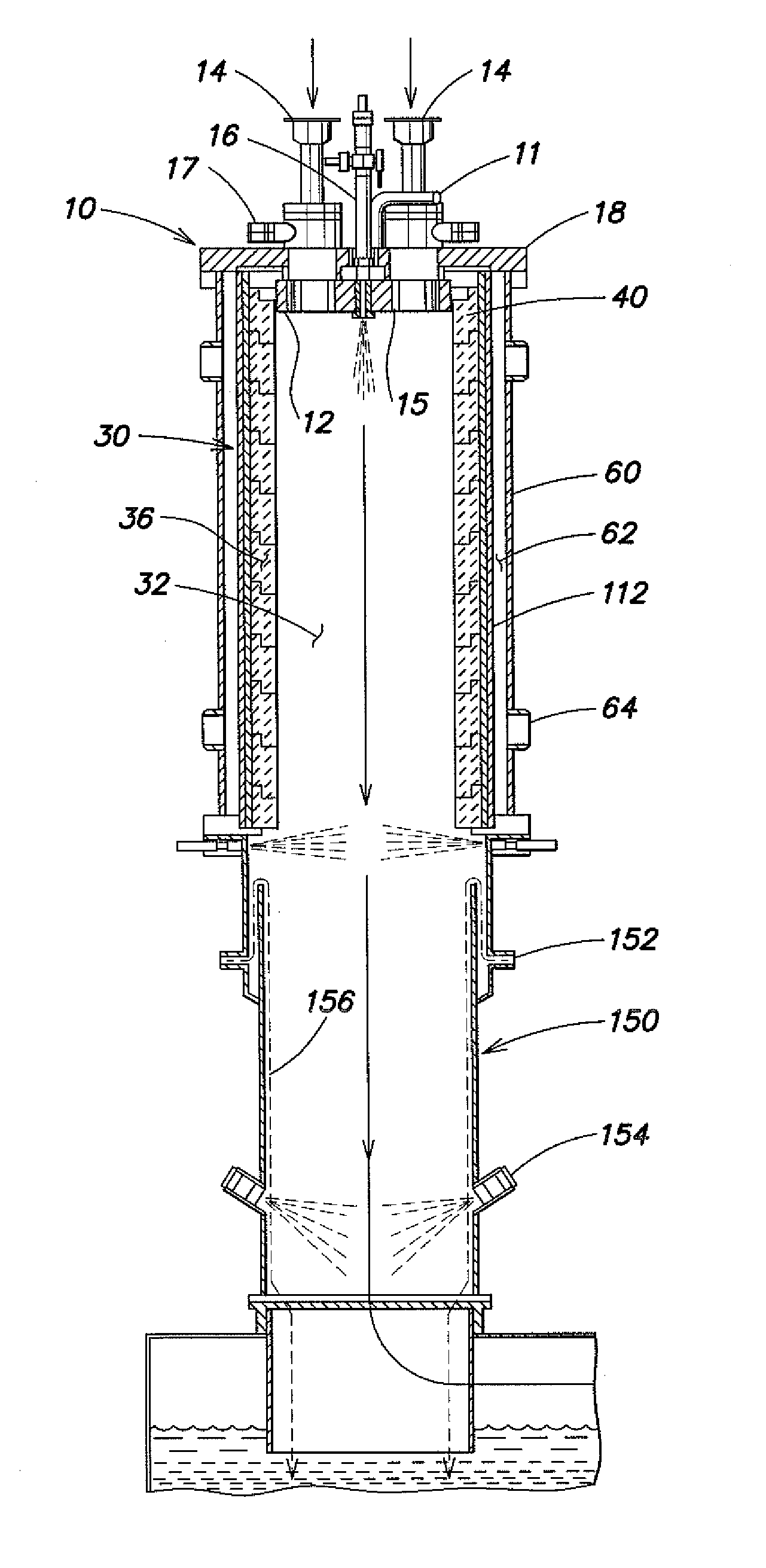

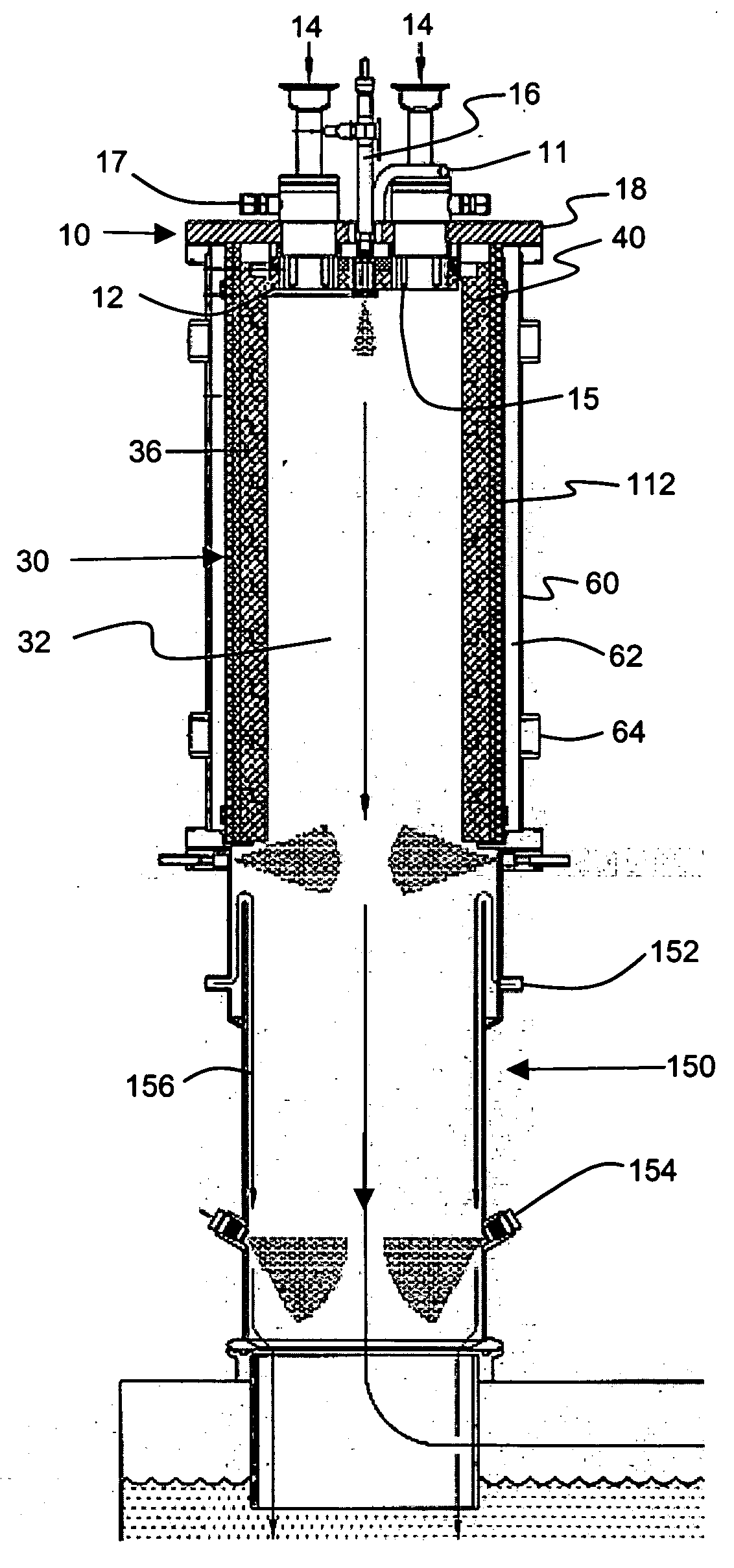

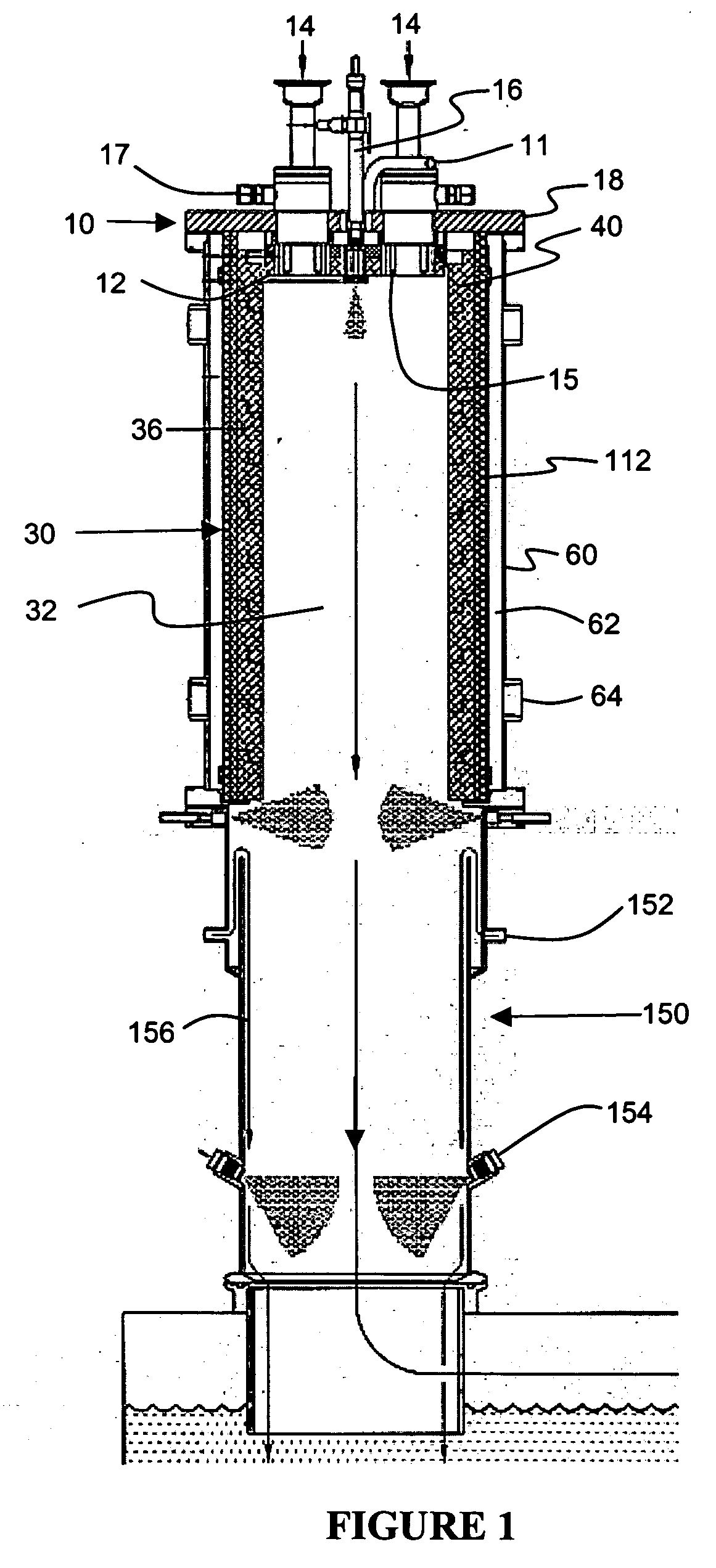

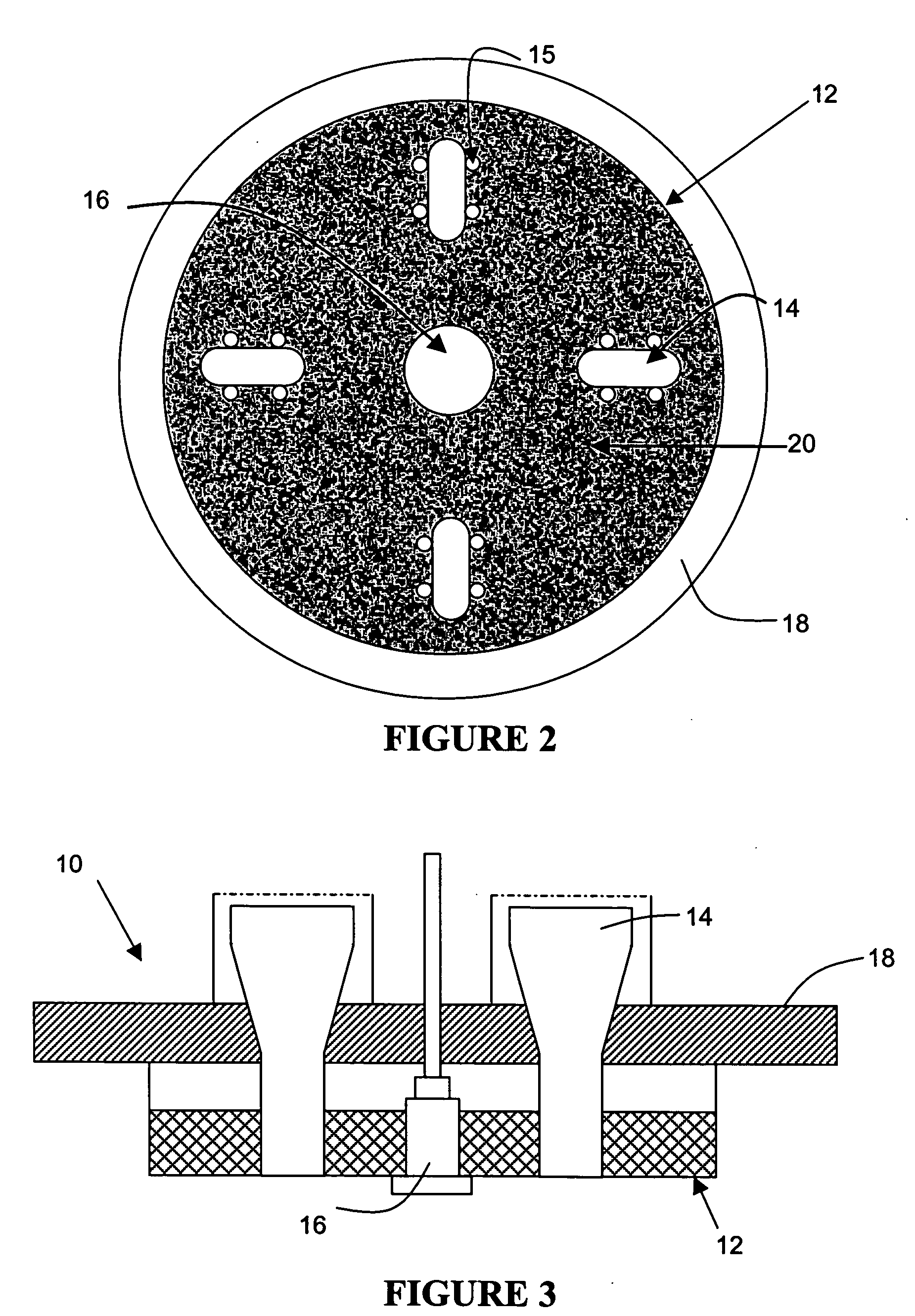

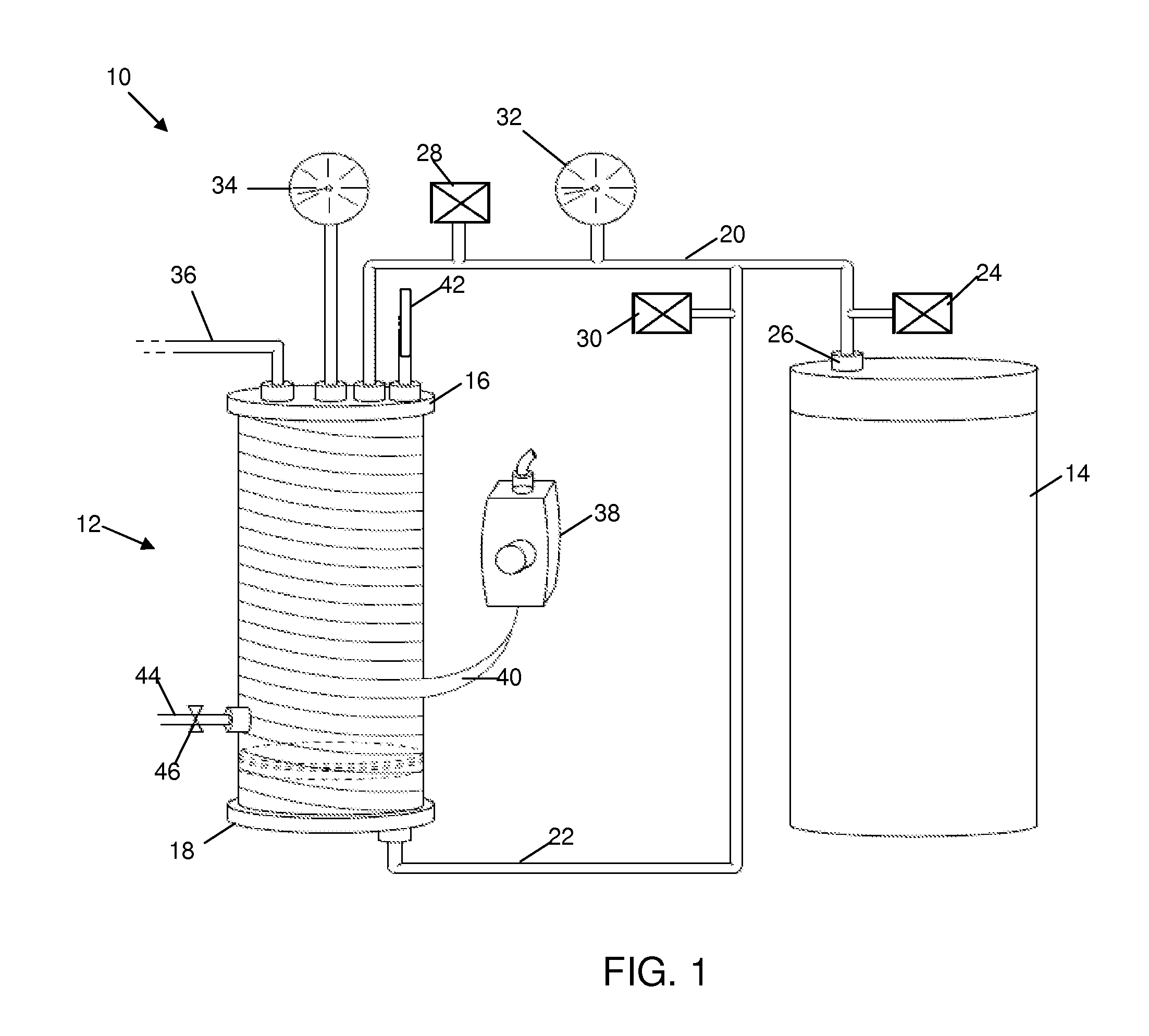

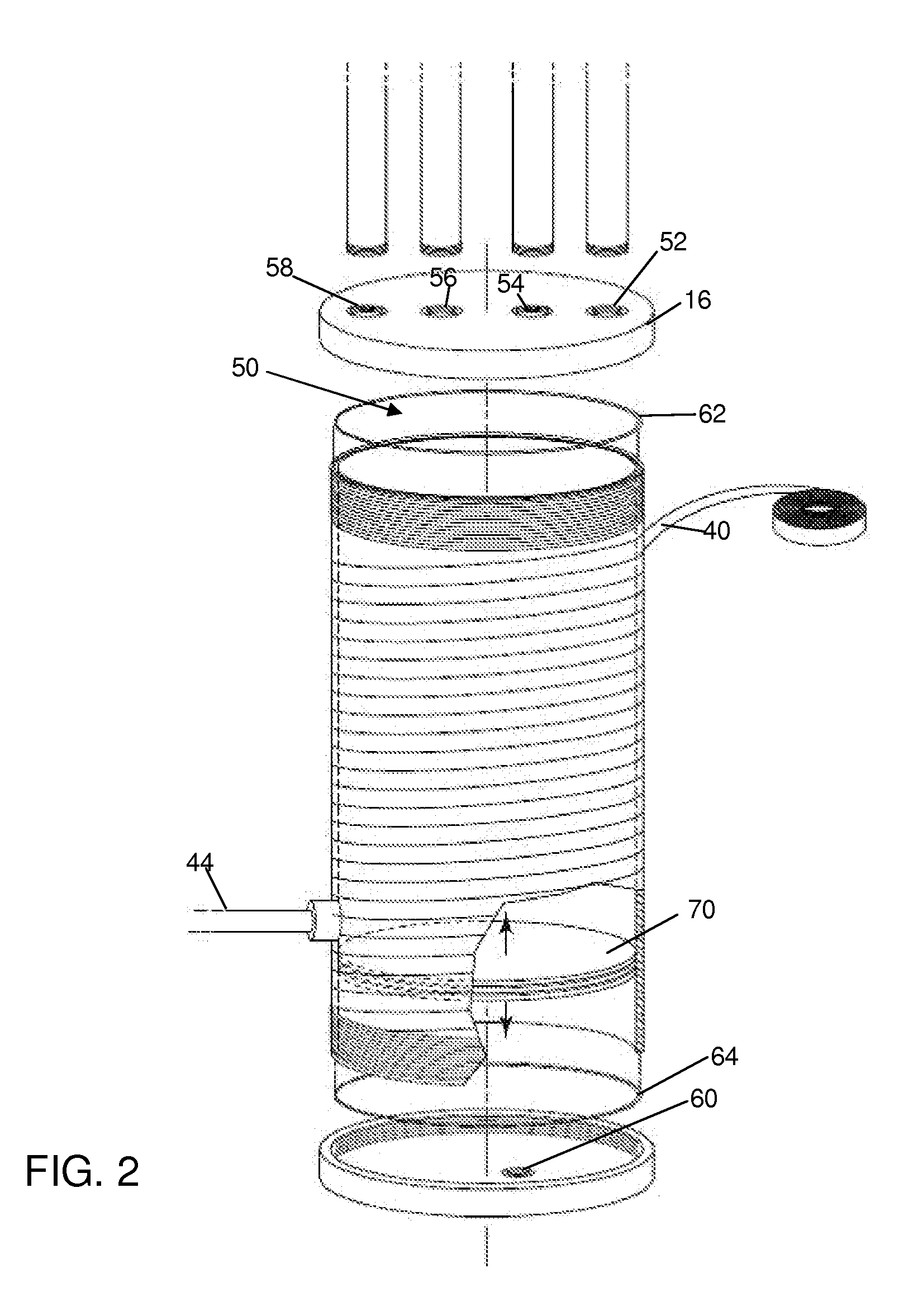

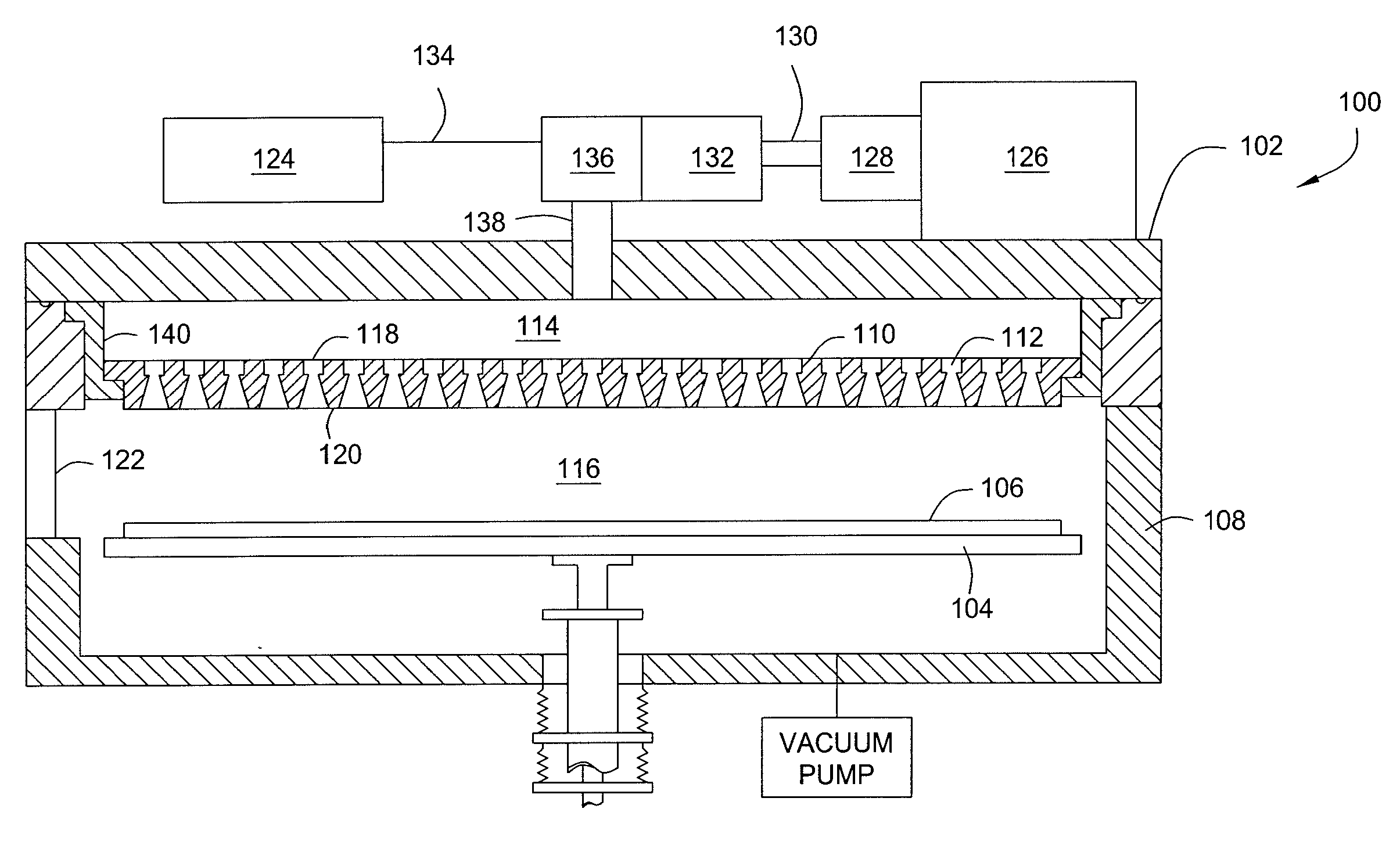

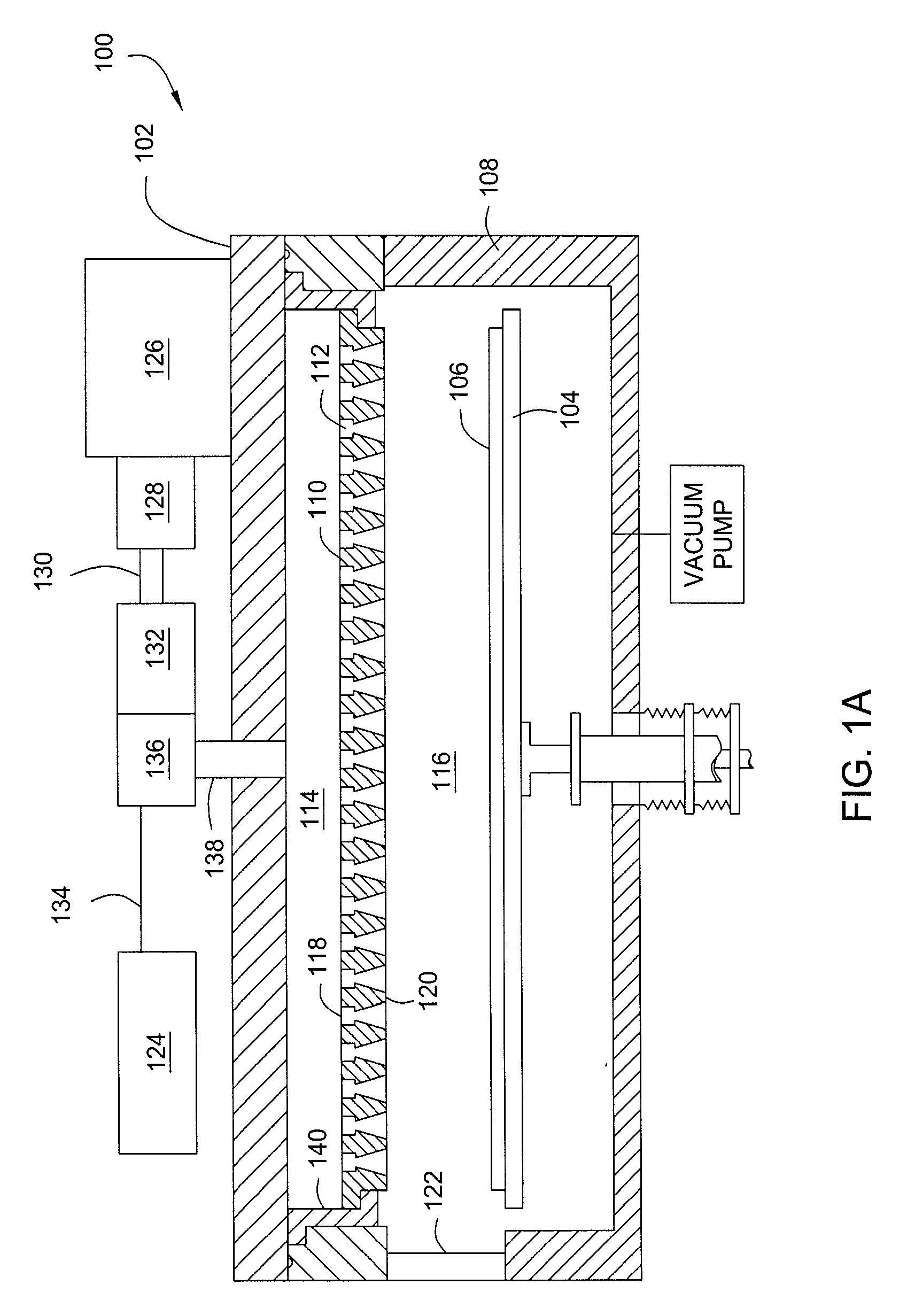

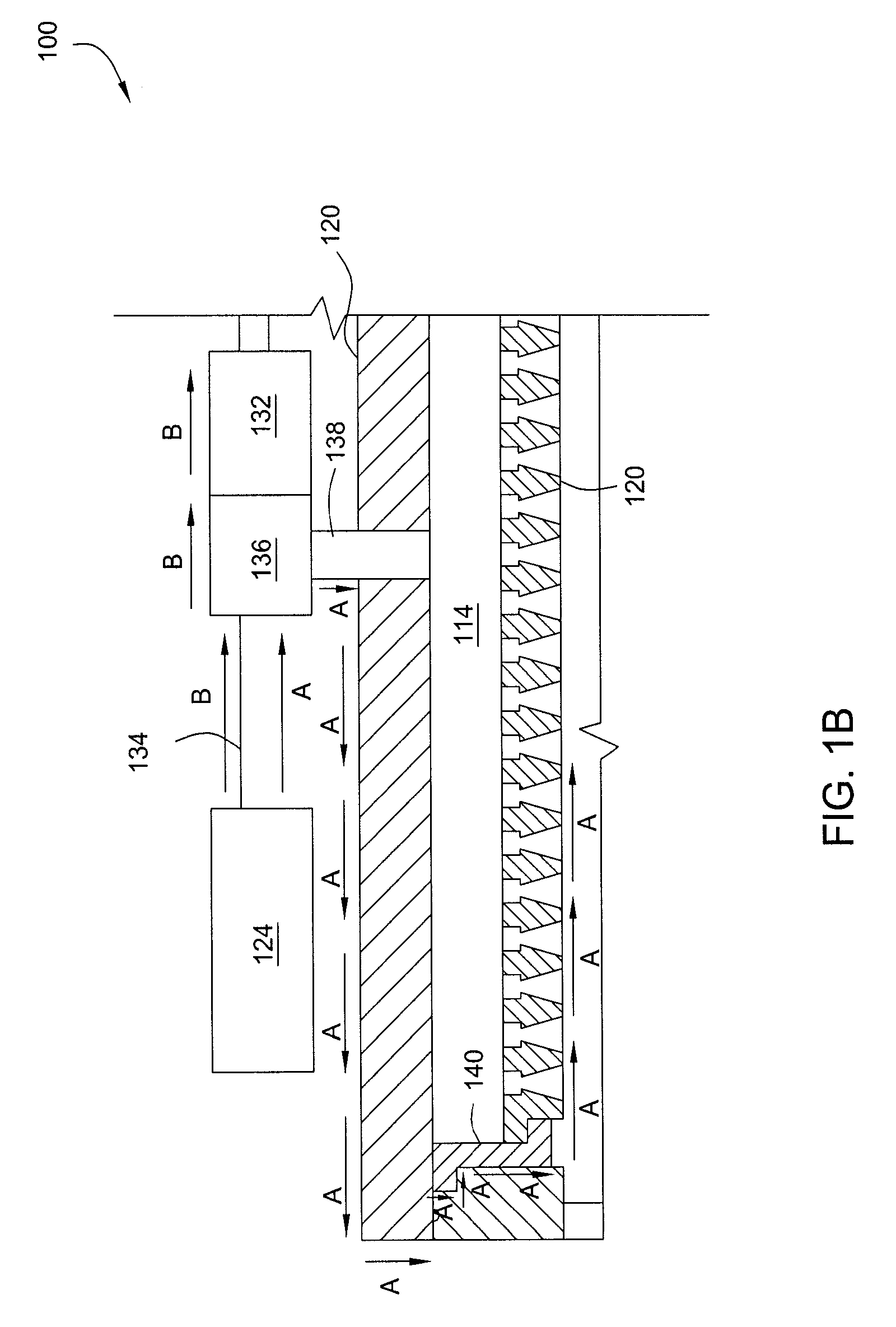

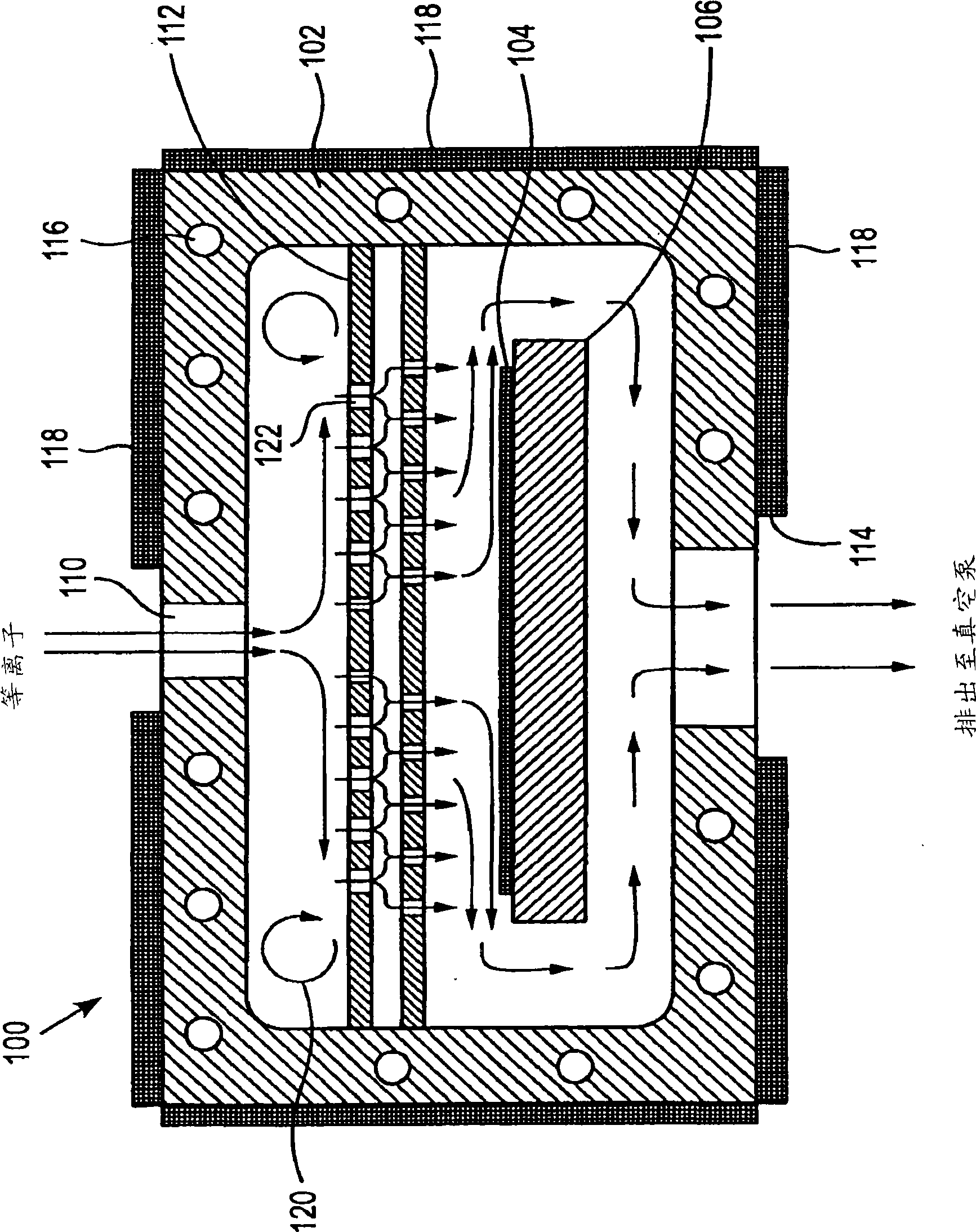

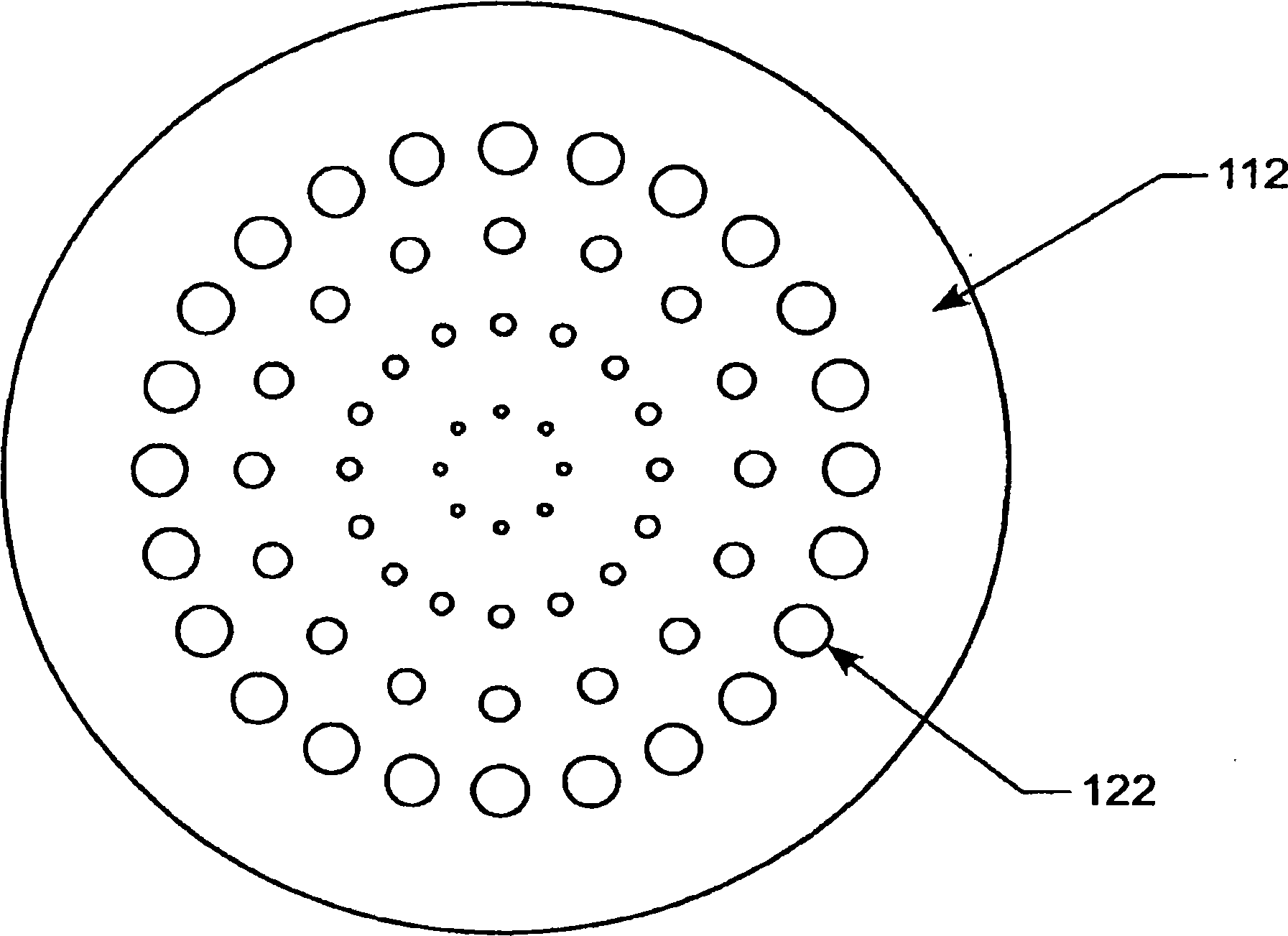

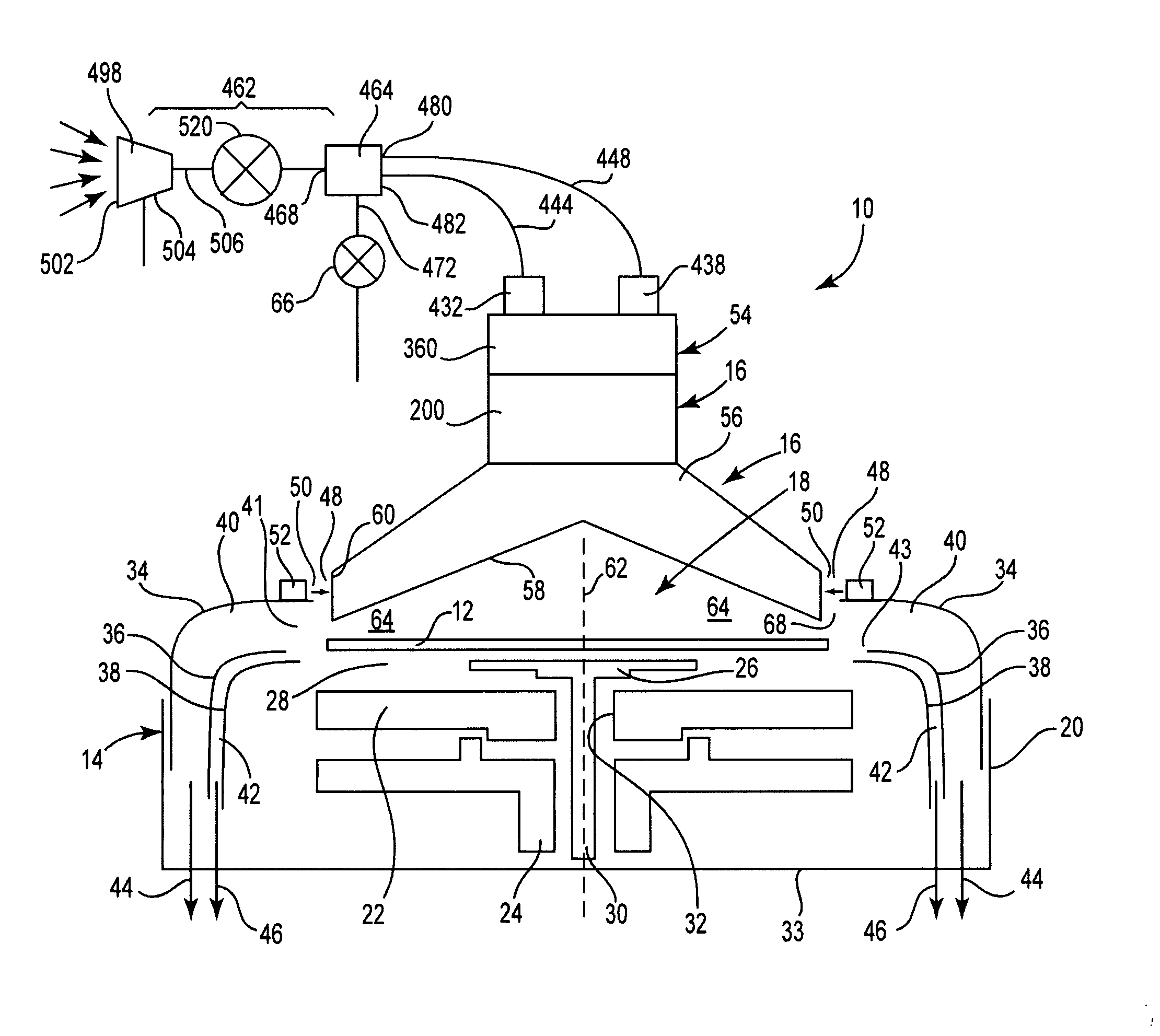

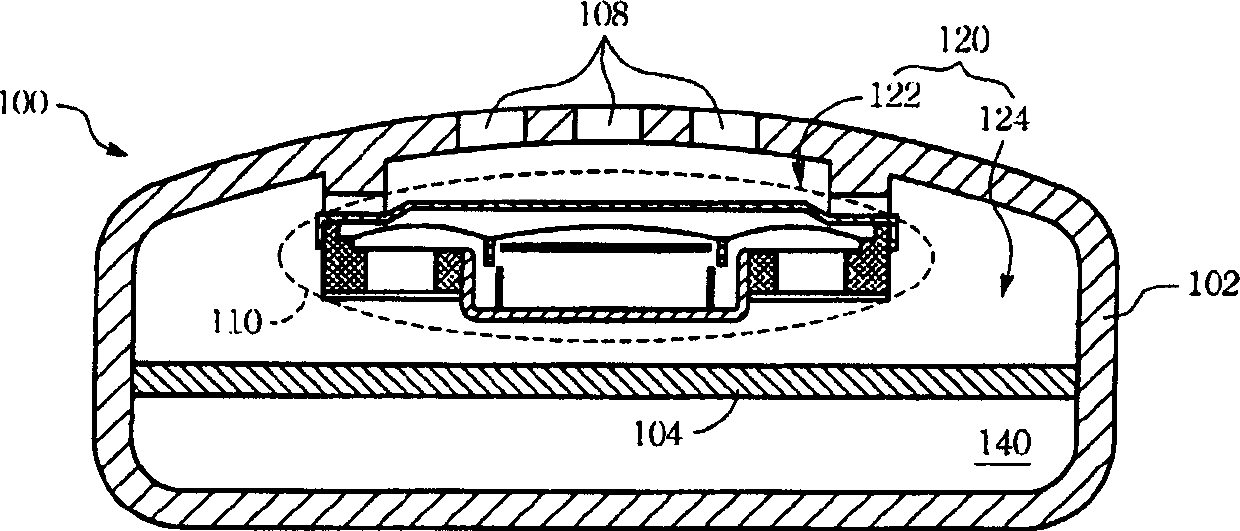

Massively parallel atomic layer deposition/chemical vapor deposition system

InactiveUS20050274323A1Improve generally axi-symmetric gas flowMinimizing vertical heightChemical vapor deposition coatingMassively parallelGas phase

A method and apparatus for the use of individual vertically stacked ALD or CVD reactors. Individual reactors are independently operable and maintainable. The gas inlet and output are vertically configured with respect to the reactor chamber for generally axi-symmetric process control. The chamber design is modular in which cover and base plates forming the reactor have improved flow design.

Owner:AIXTRON INC

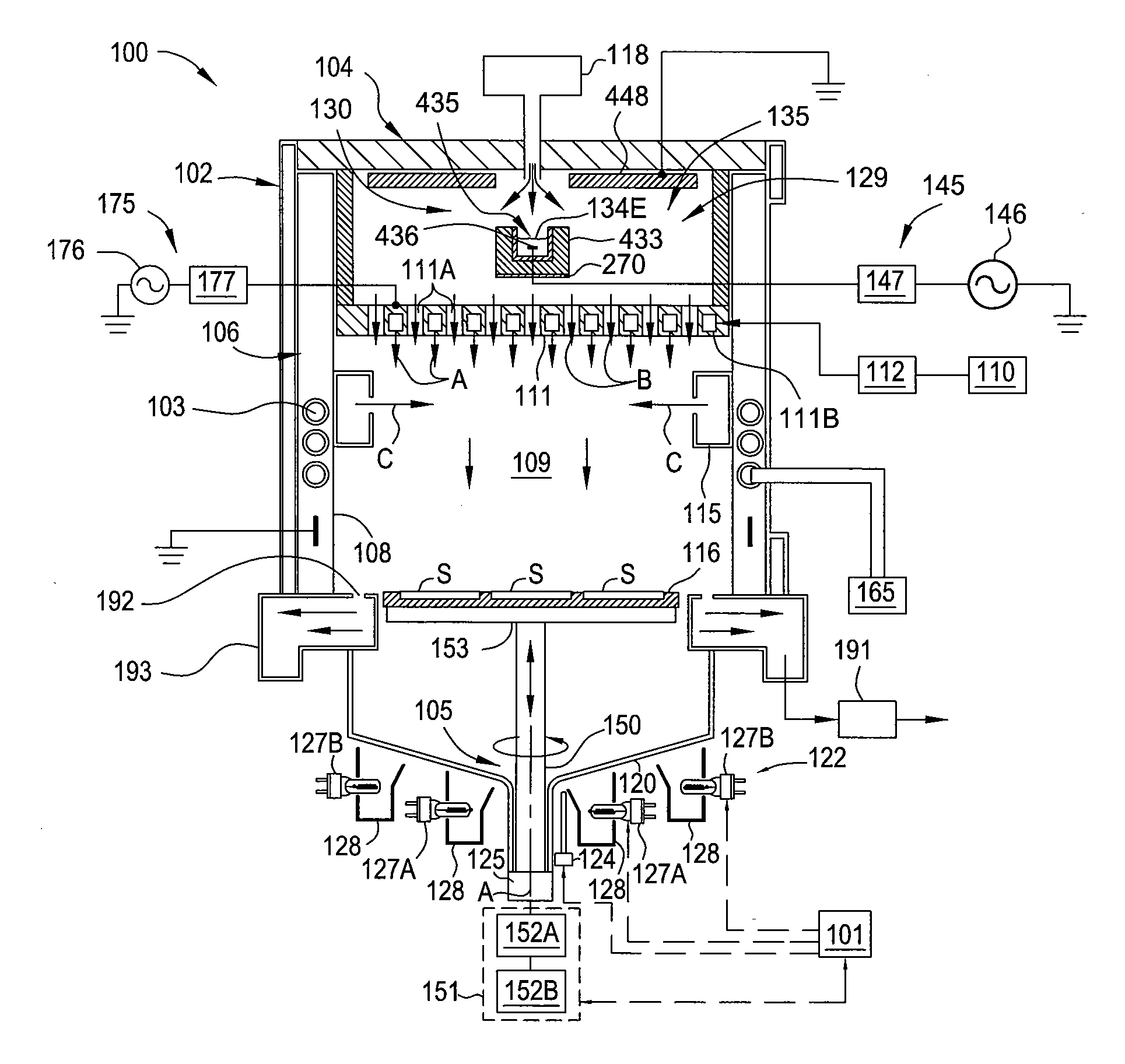

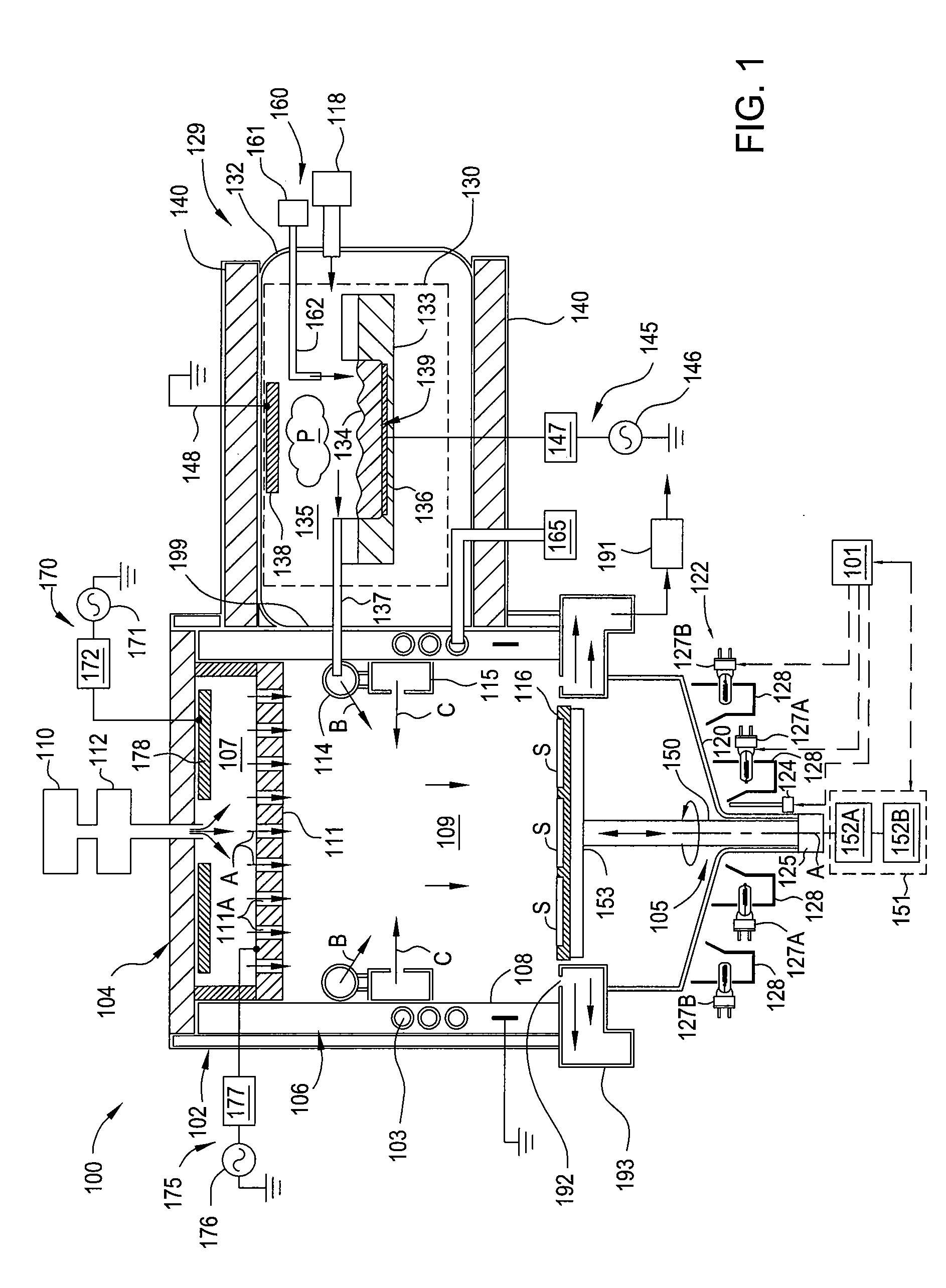

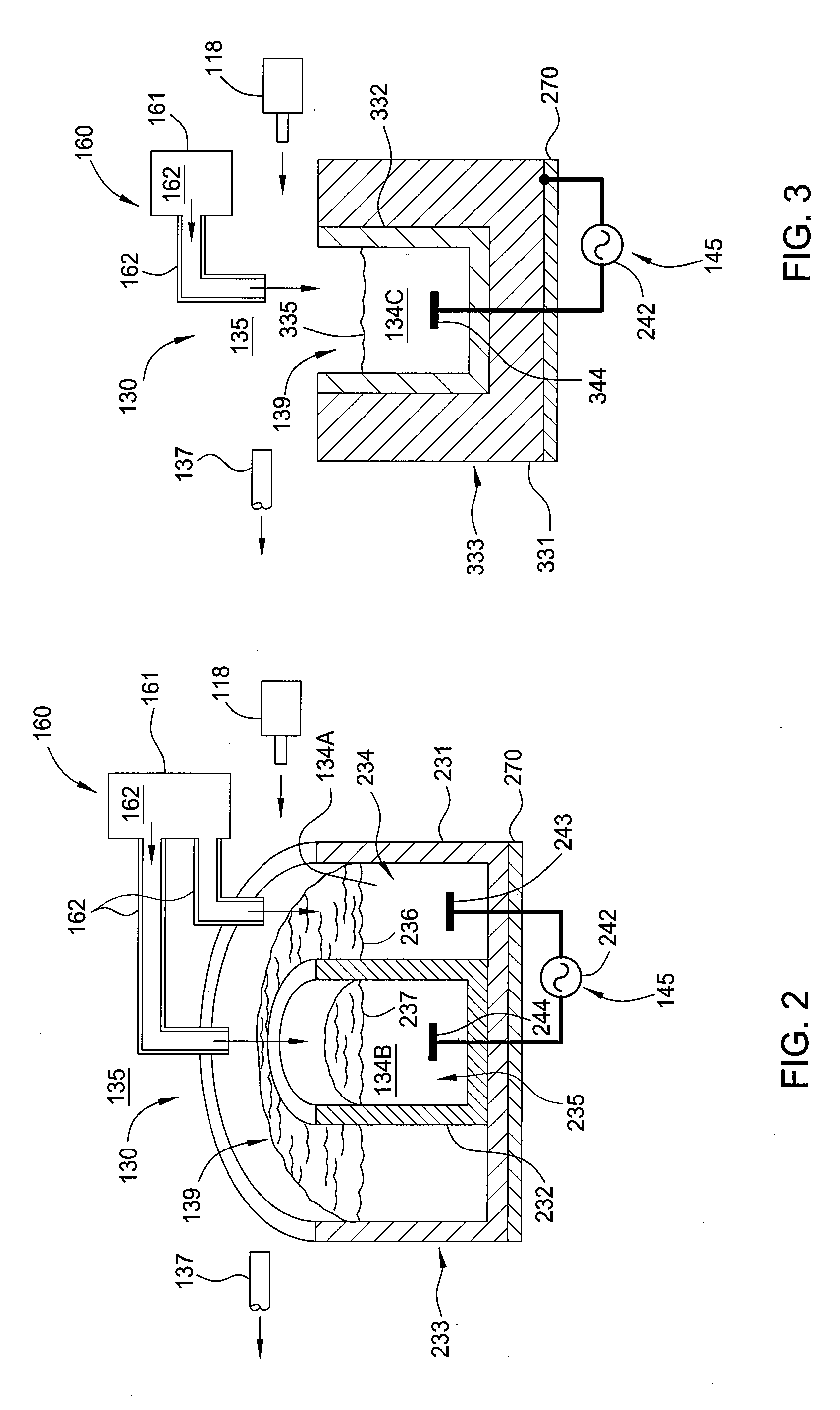

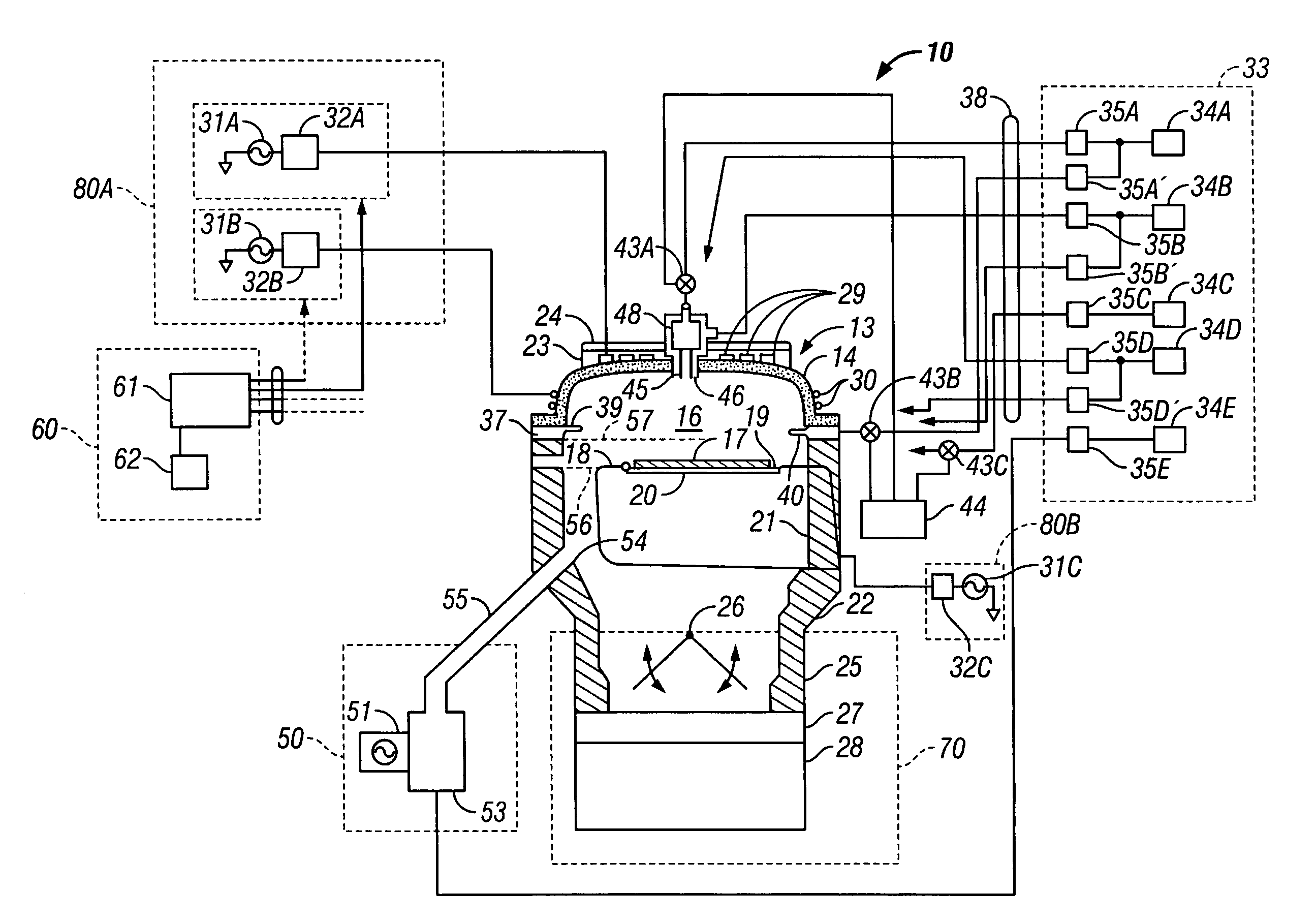

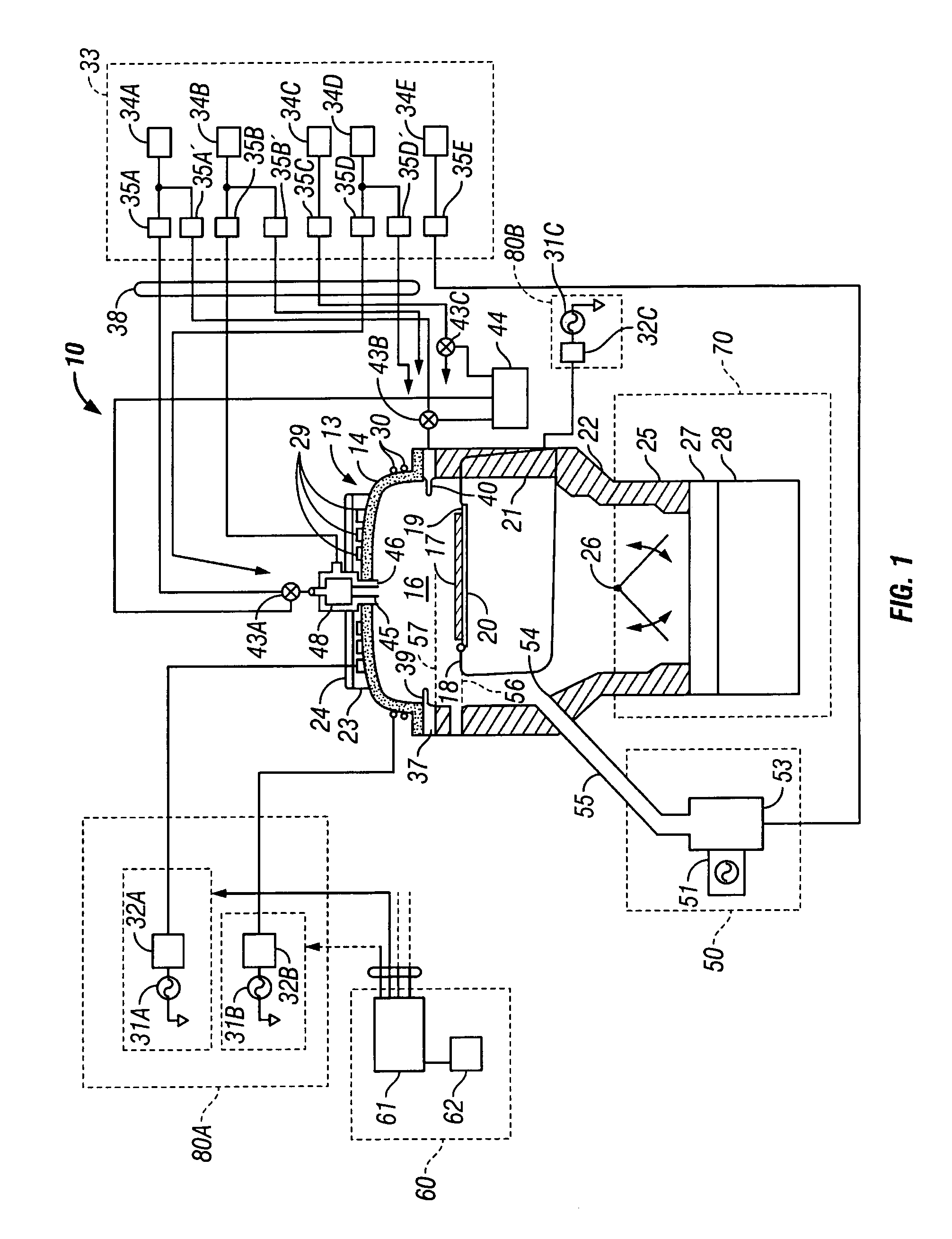

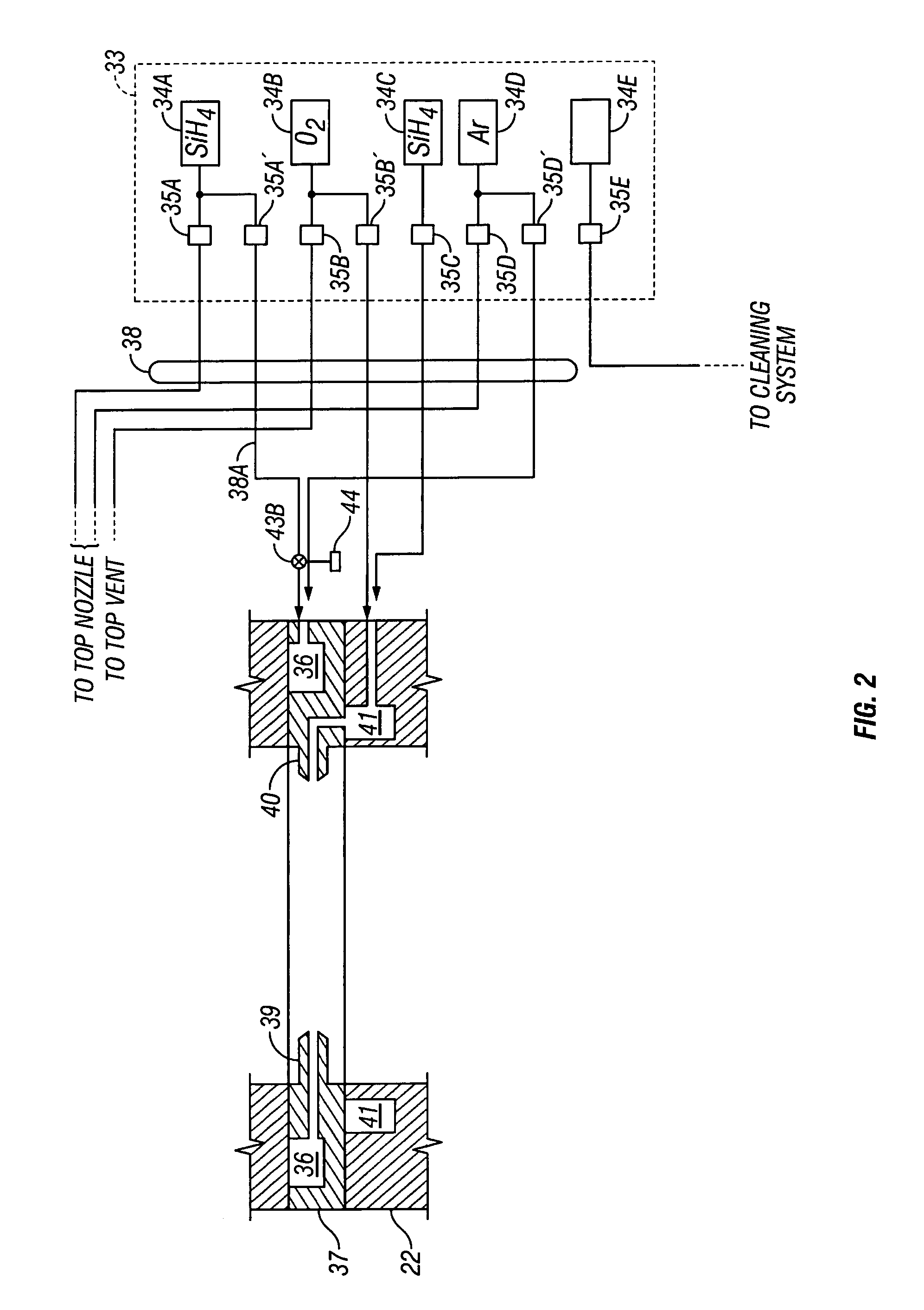

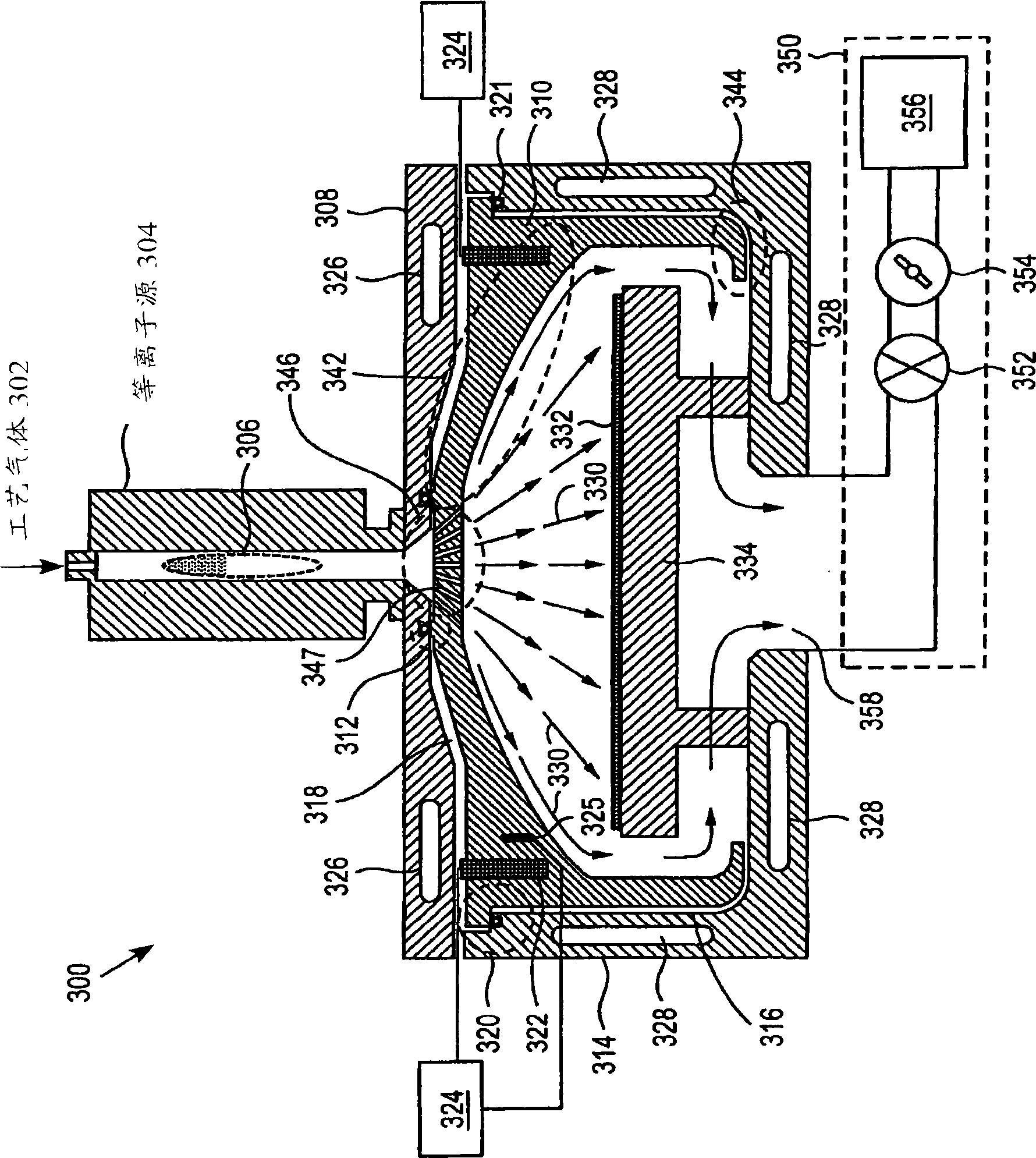

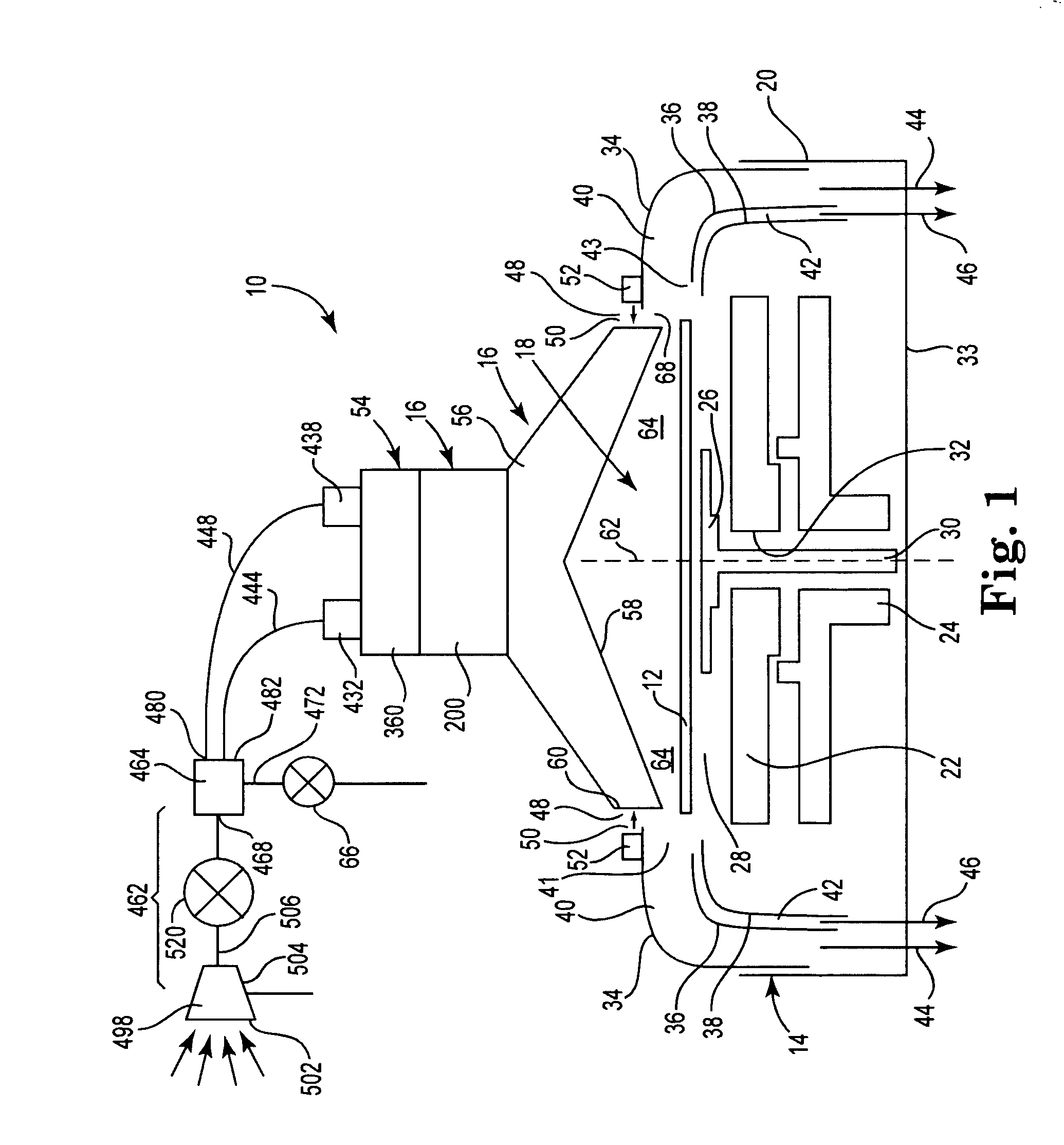

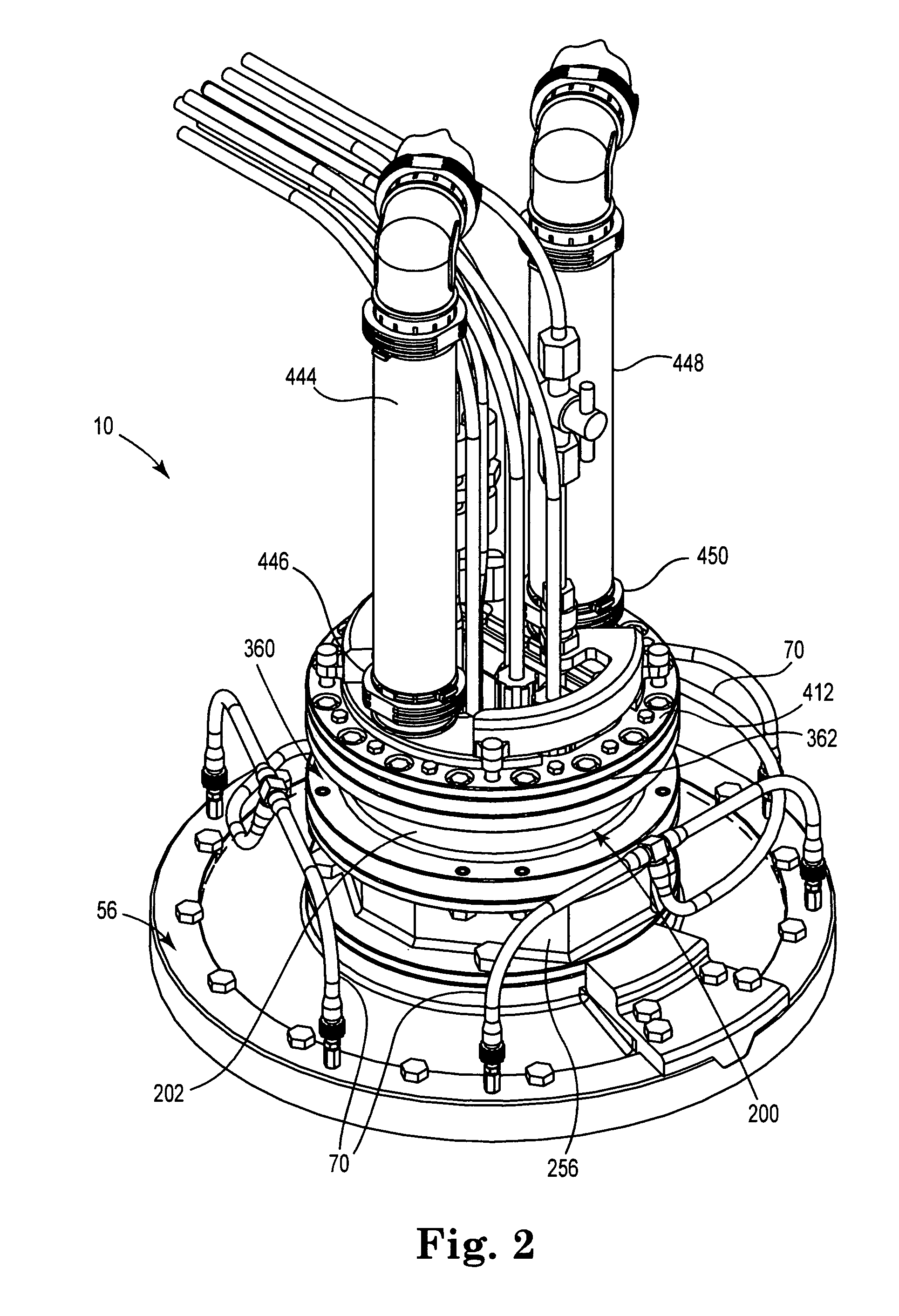

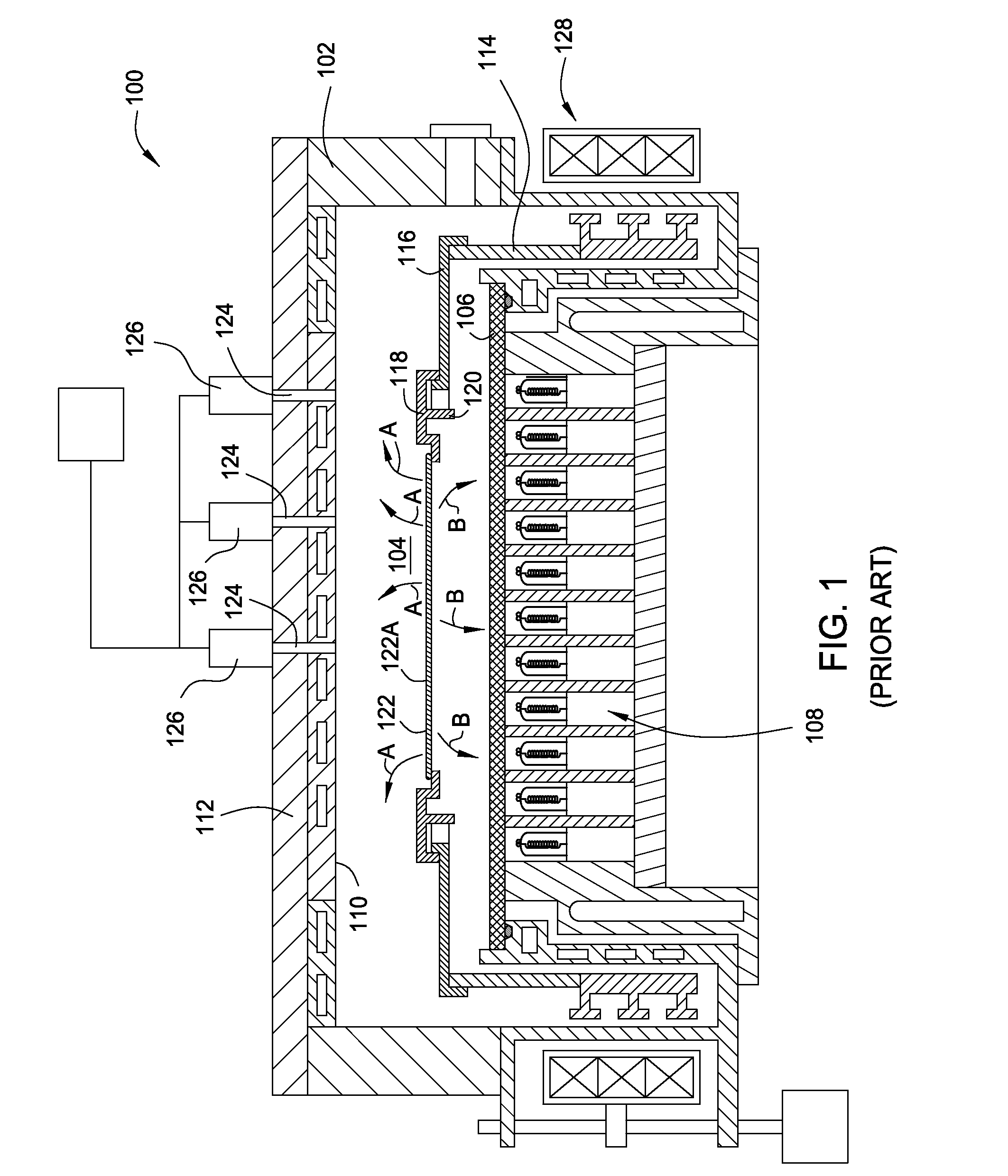

Plasma assisted hvpe chamber design

InactiveUS20130032085A1Enhance deposition reaction kineticsReduce processing timePolycrystalline material growthFrom chemically reactive gasesNitrogenVapor phase

Embodiments of the invention disclosed herein generally relate to a hydride vapor phase epitaxy (HVPE) deposition chamber that utilizes a plasma generation apparatus to form an activated precursor gas that is used to rapidly form a high quality compound nitride layer on a surface of a substrate. In one embodiment, the plasma generation apparatus is used to create a desirable group-III metal halide precursor gas that can enhance the deposition reaction kinetics, and thus reduce the processing time and improve the film quality of a formed group-III metal nitride layer. In addition, the chamber may be equipped with a separate nitrogen containing precursor activated species generator to enhance the activity of the delivered nitrogen precursor gases.

Owner:APPLIED MATERIALS INC

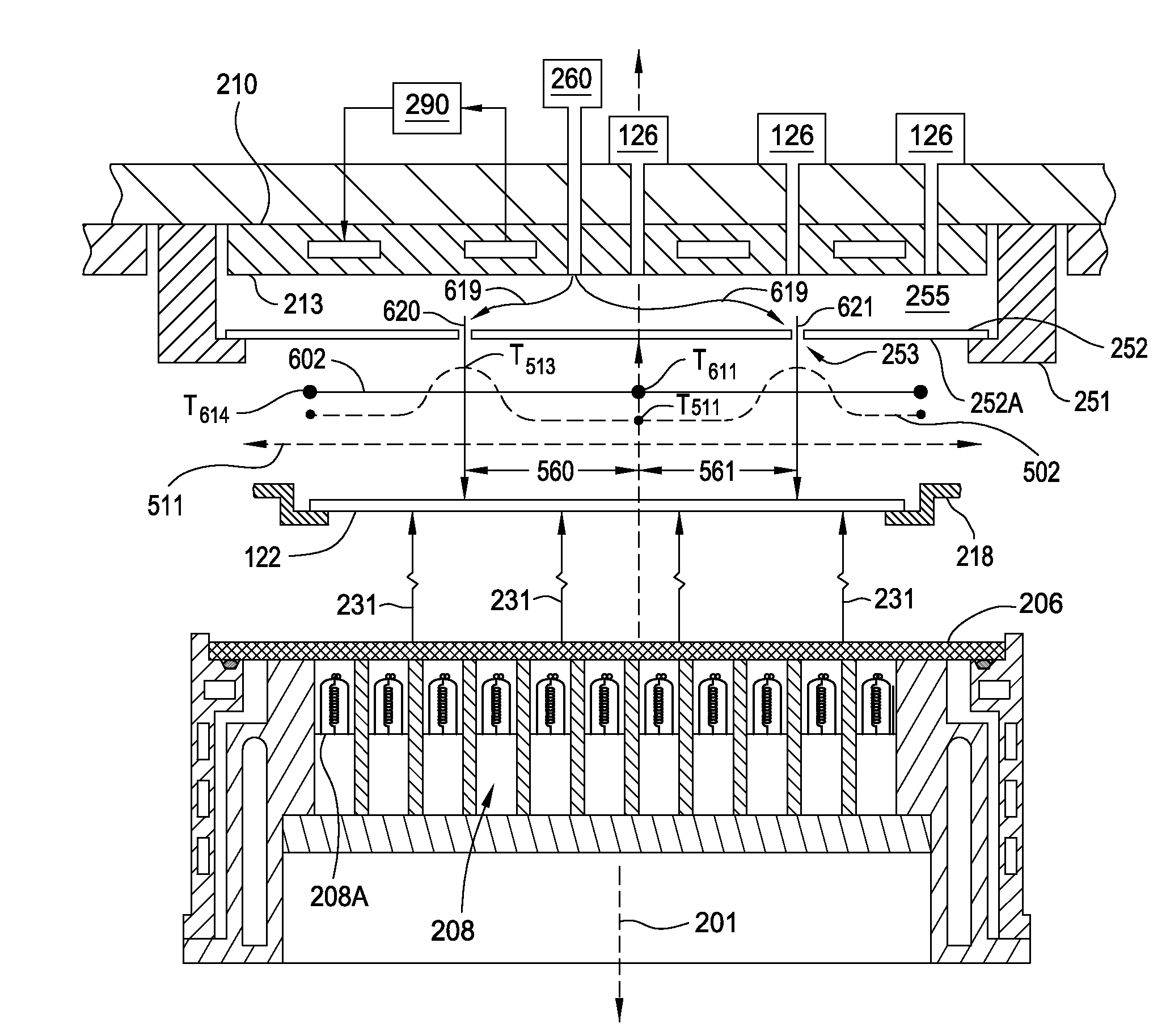

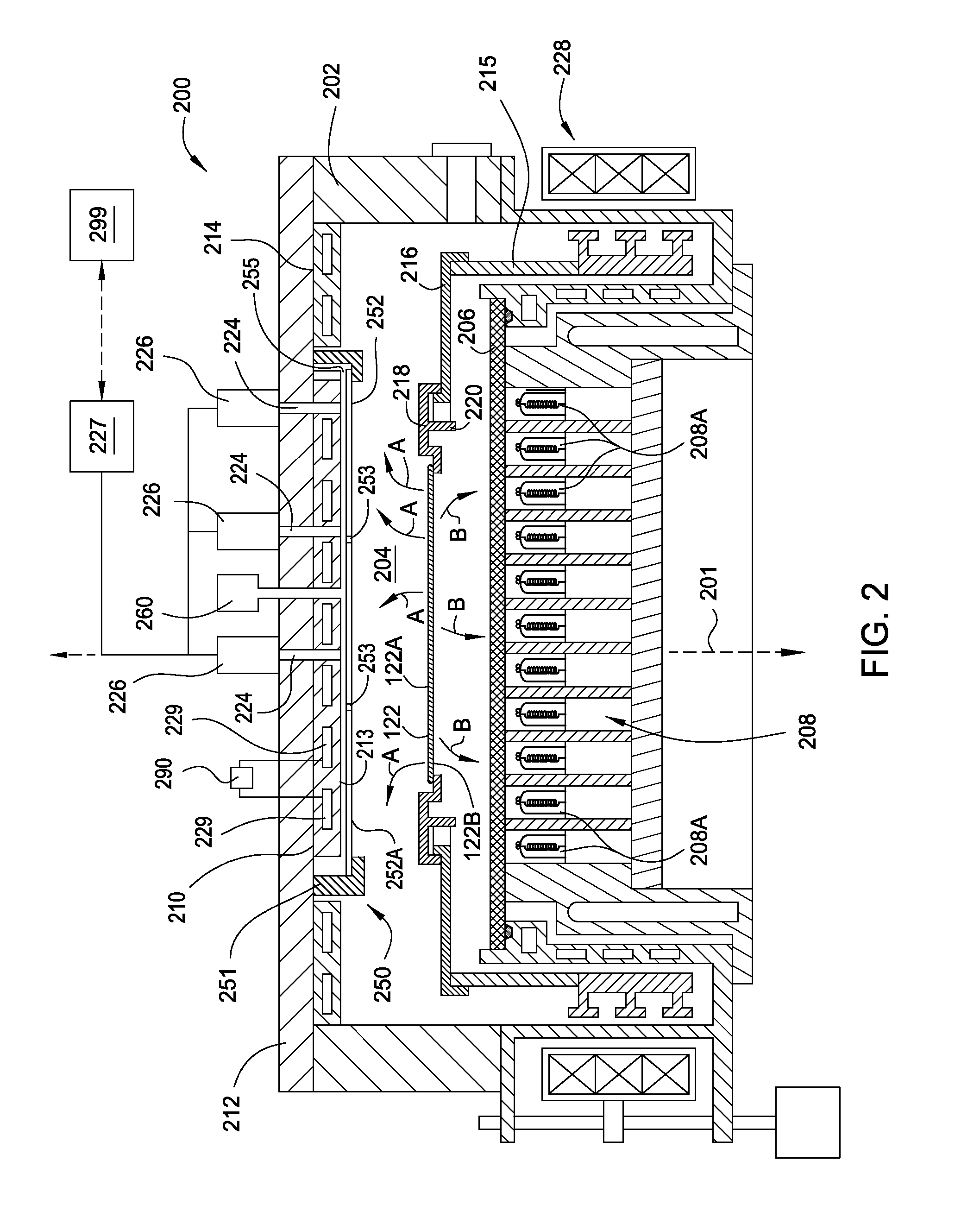

Dual delivery chamber design

InactiveUS20120097330A1Avoid heat damageKeep coolSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDual deliveryPlasma generator

A substrate processing system includes a thermal processor or a plasma generator adjacent to a processing chamber. A first processing gas enters the thermal processor or plasma generator. The first processing gas then flows directly through a showerhead into the processing chamber. A second processing gas flows through a second flow path through the showerhead. The first and second processing gases are mixed below the showerhead and a layer of material is deposited on a substrate under the showerhead.

Owner:APPLIED MATERIALS INC

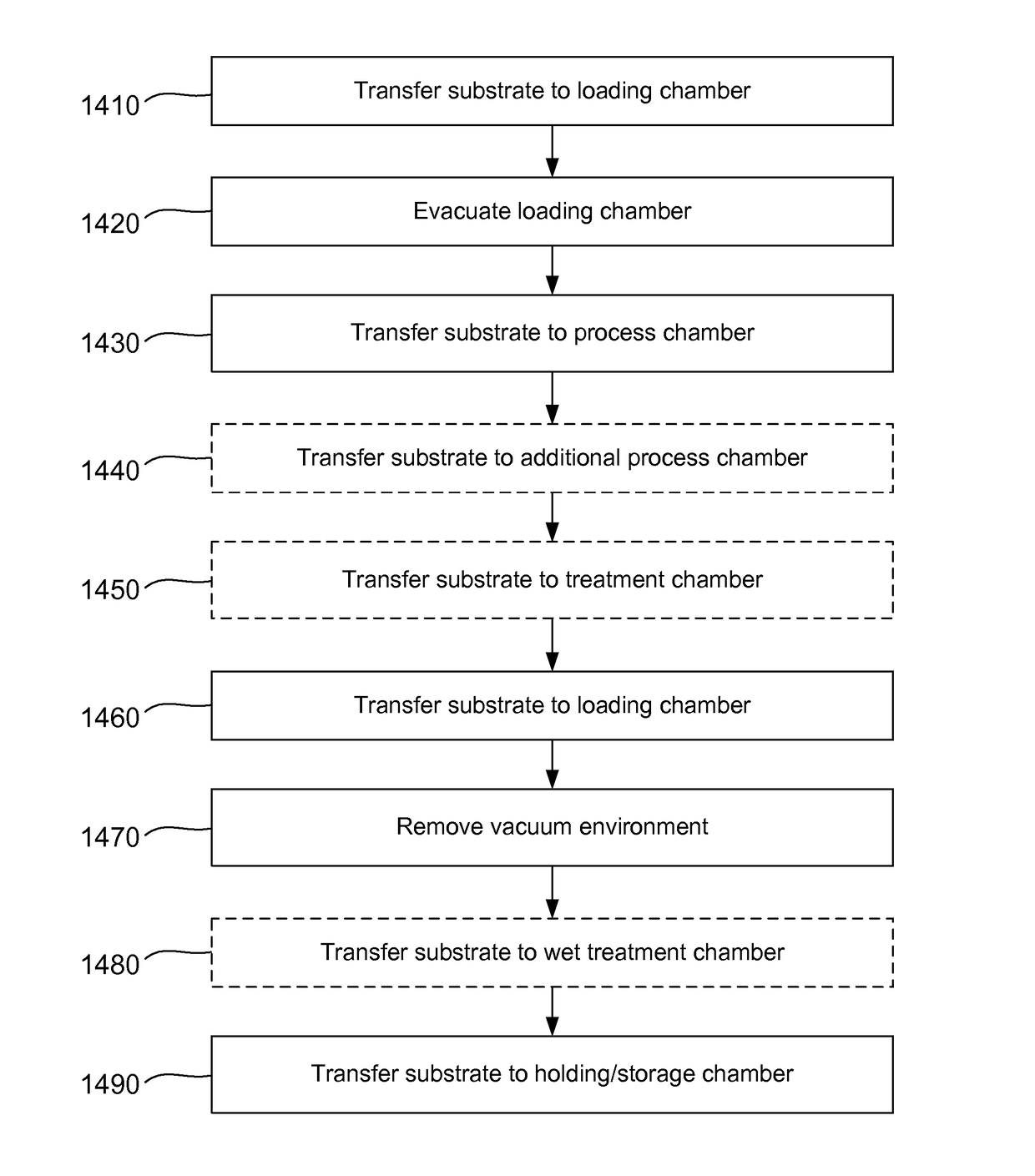

Processing systems and methods for halide scavenging

ActiveUS9704723B2Function increaseKeep the environmentElectric discharge tubesSemiconductor/solid-state device manufacturingProcess engineeringHandling system

Systems, chambers, and processes are provided for controlling process defects caused by moisture contamination. The systems may provide configurations for chambers to perform multiple operations in a vacuum or controlled environment. The chambers may include configurations to provide additional processing capabilities in combination chamber designs. The methods may provide for the limiting, prevention, and correction of aging defects that may be caused as a result of etching processes performed by system tools.

Owner:APPLIED MATERIALS INC

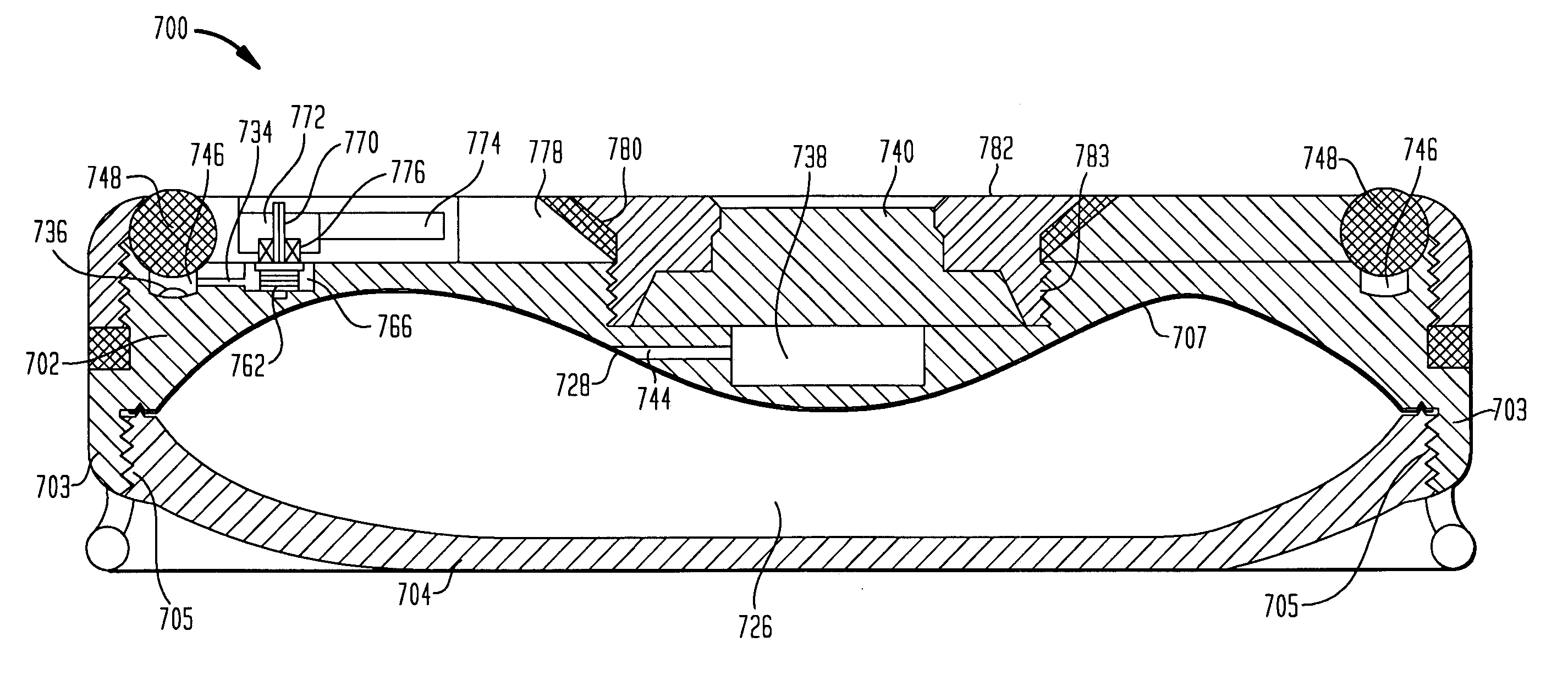

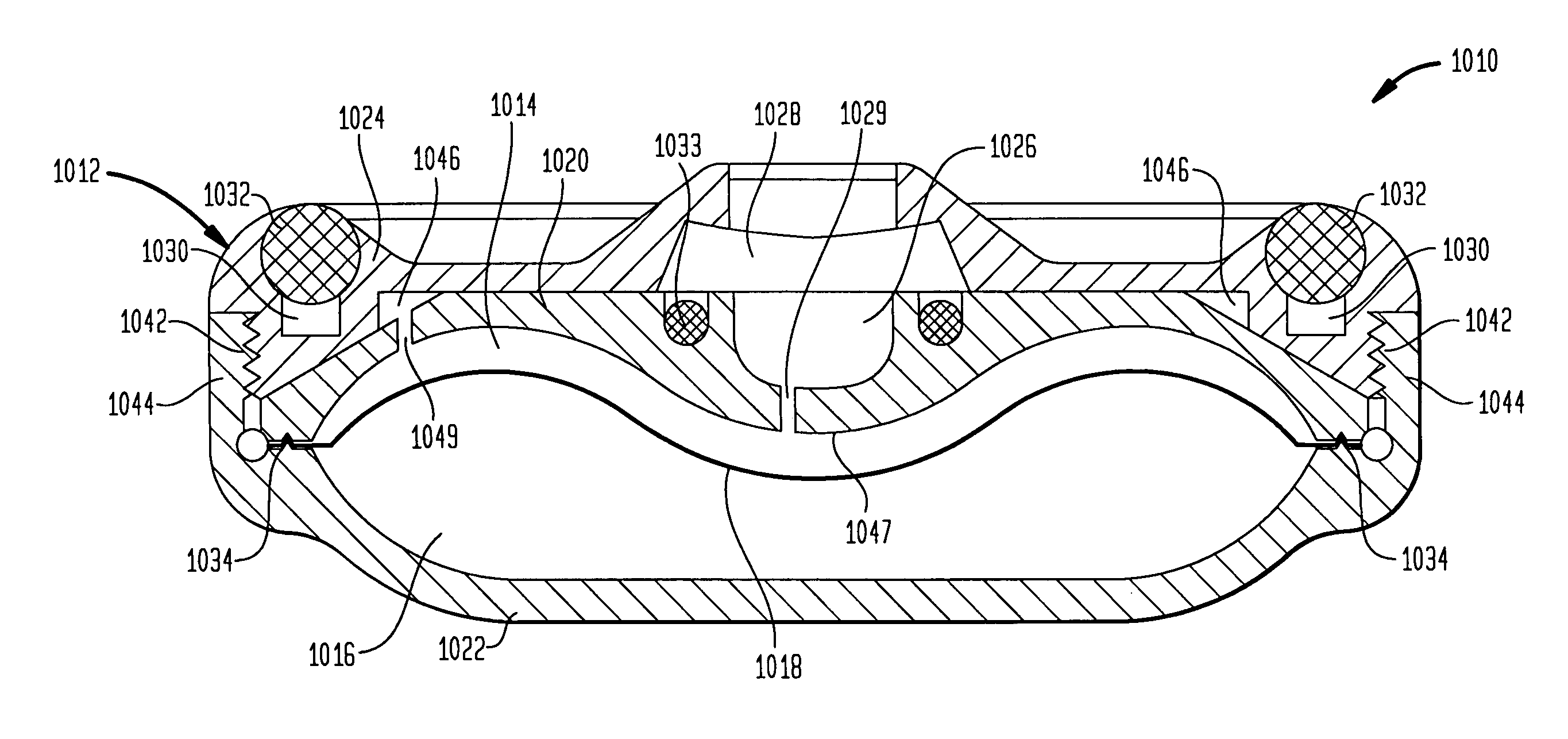

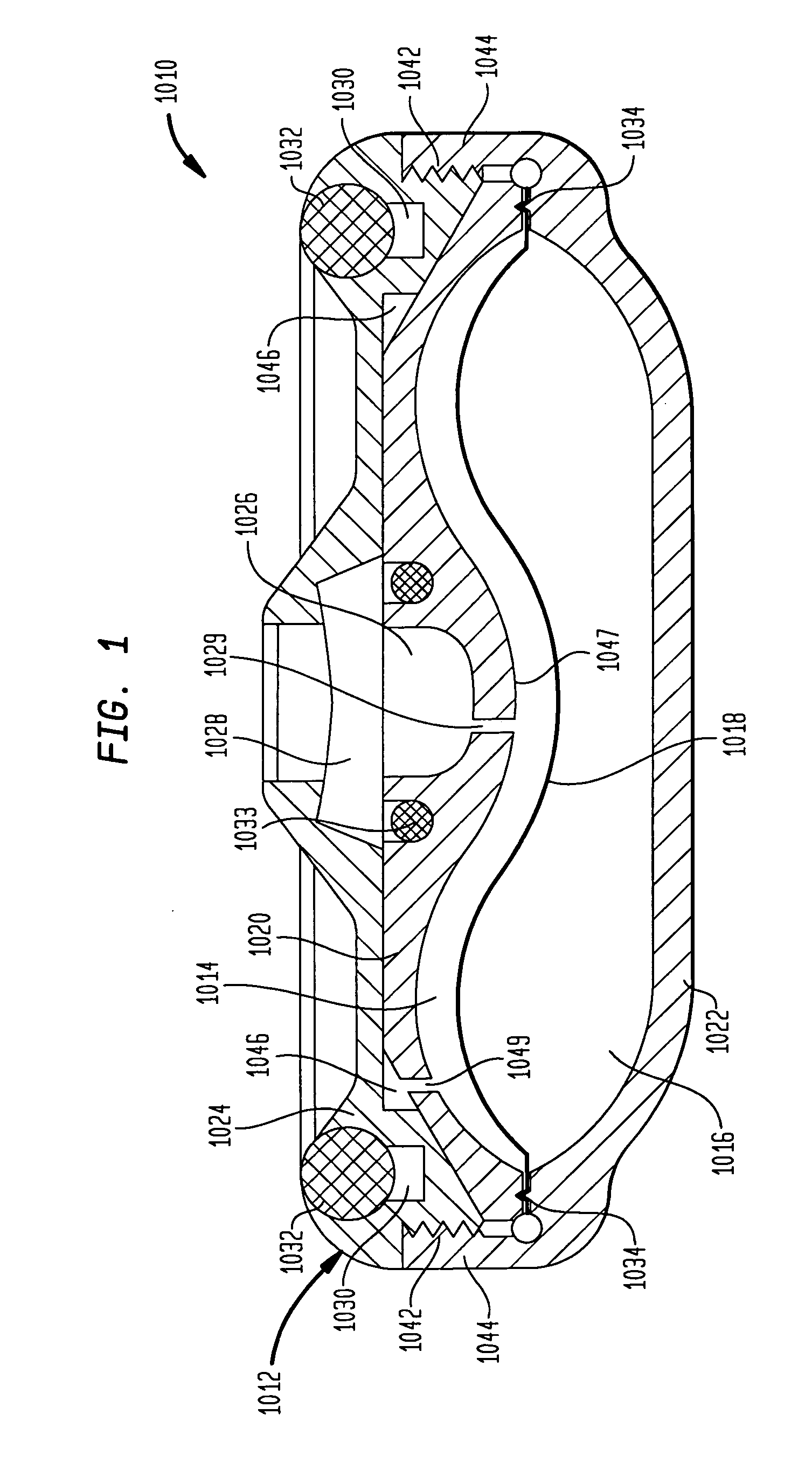

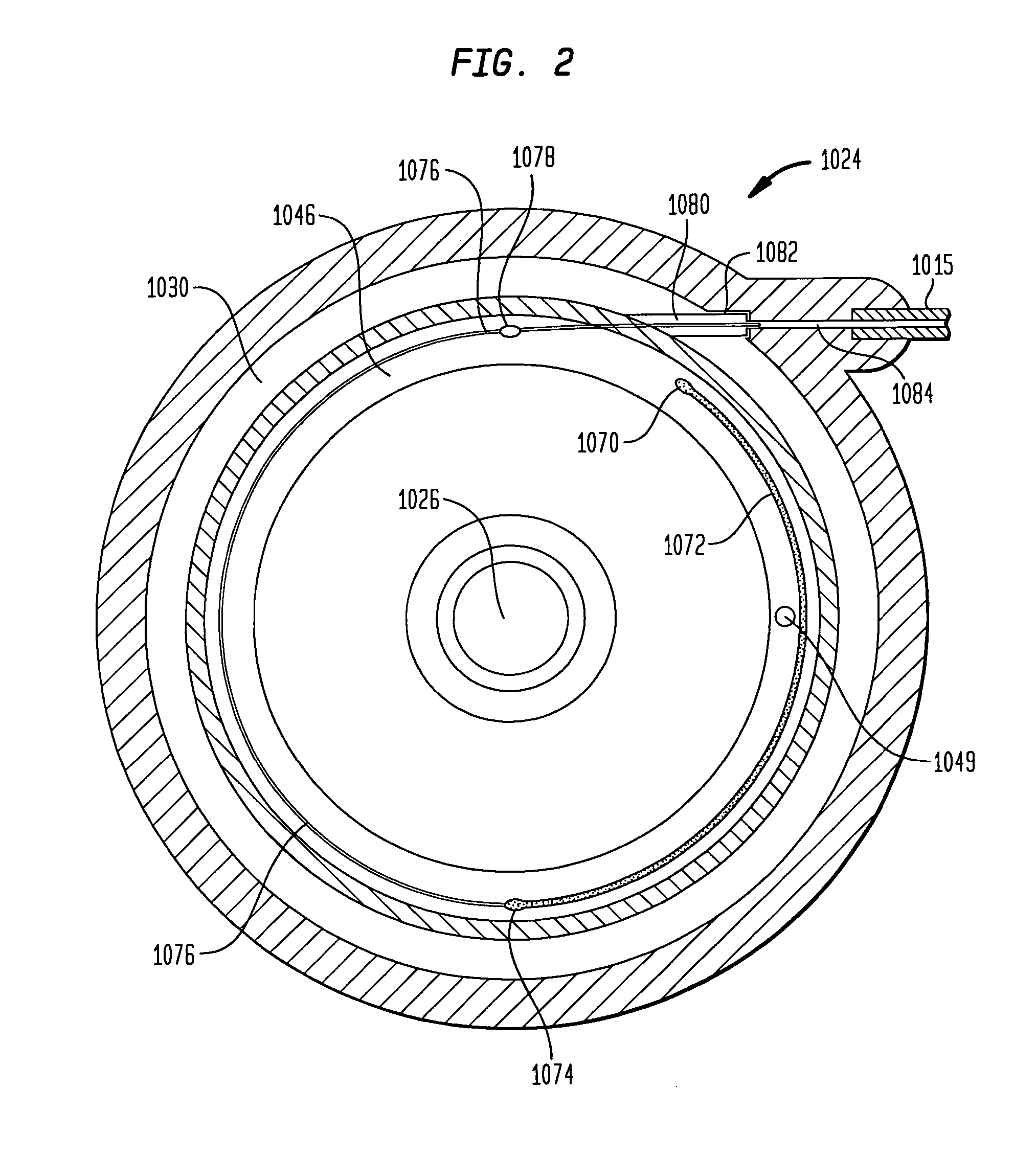

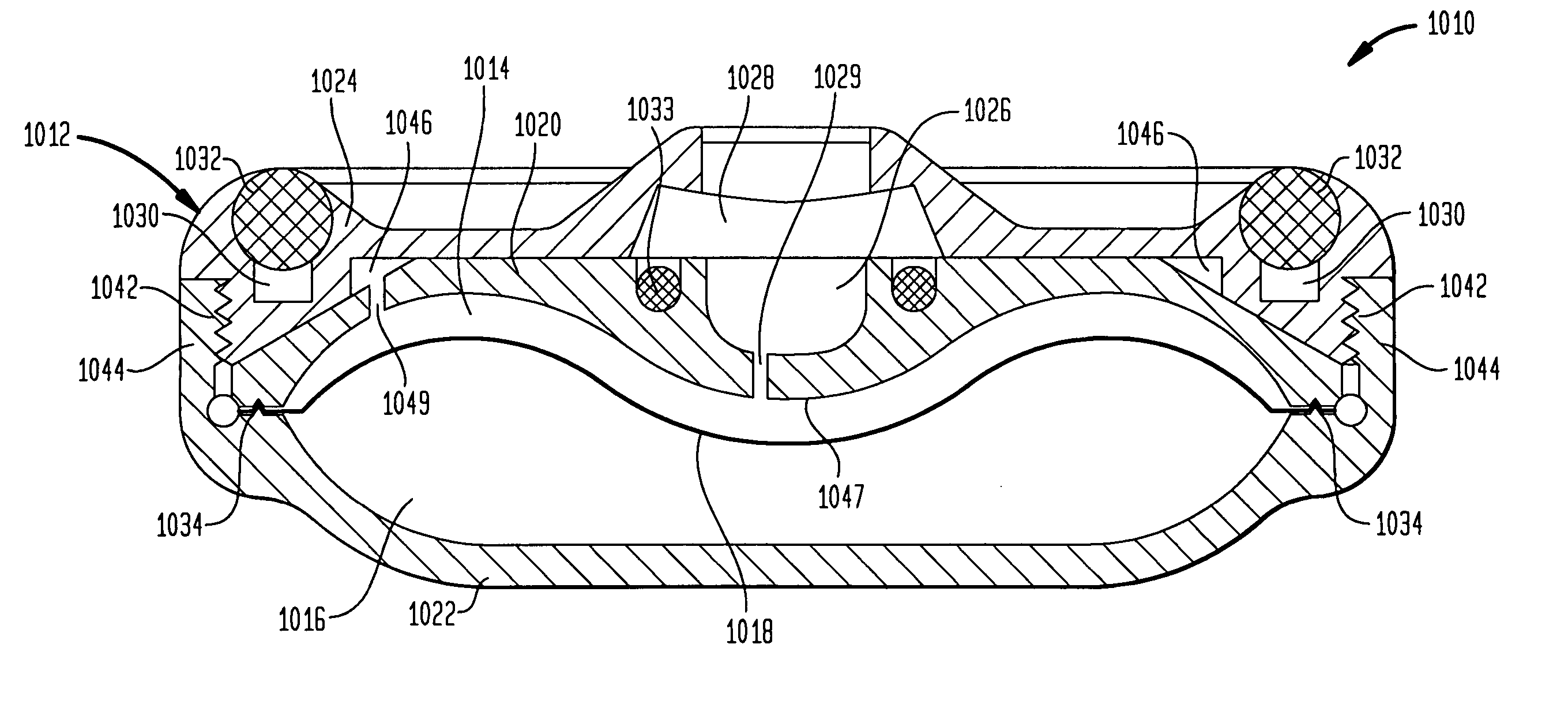

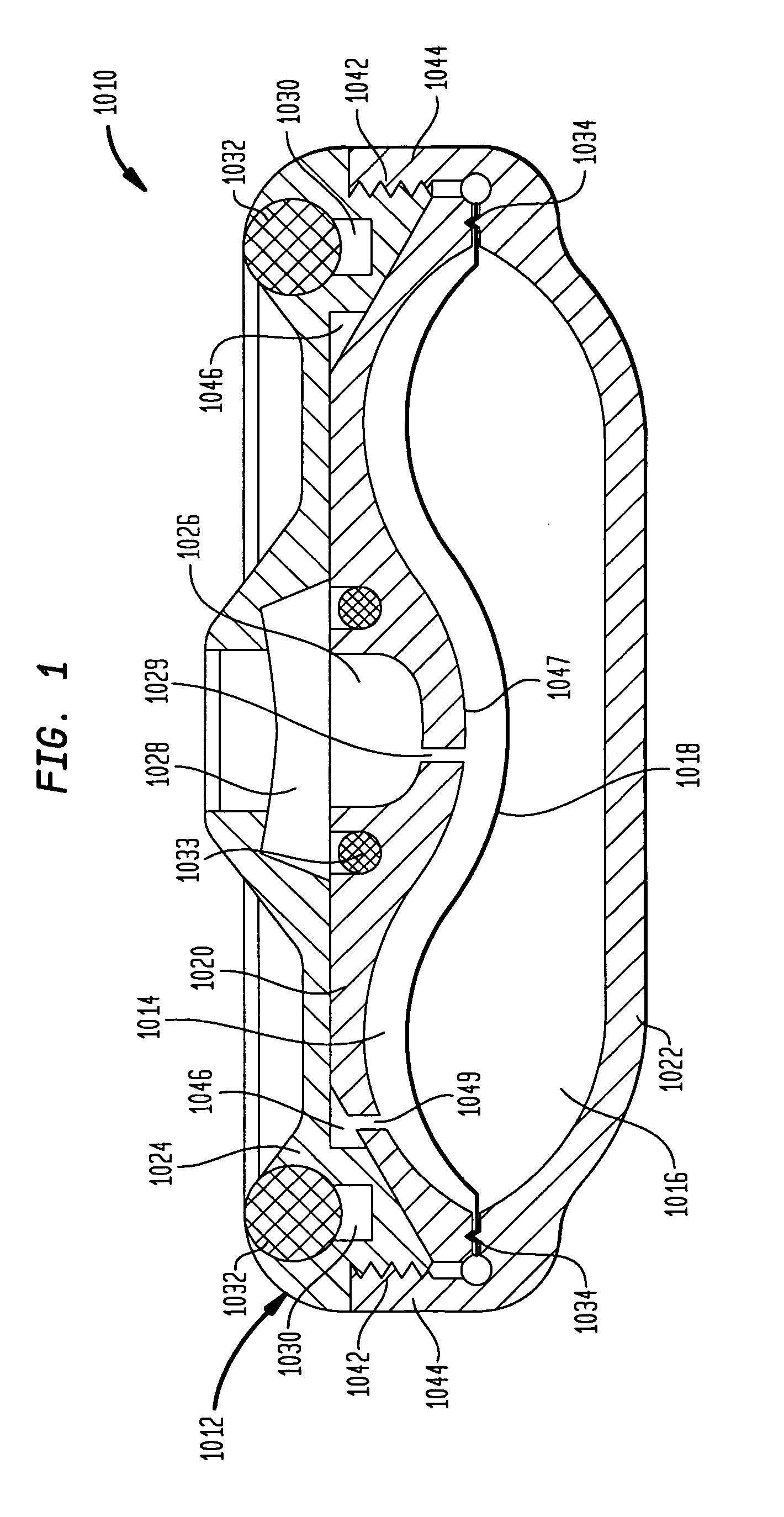

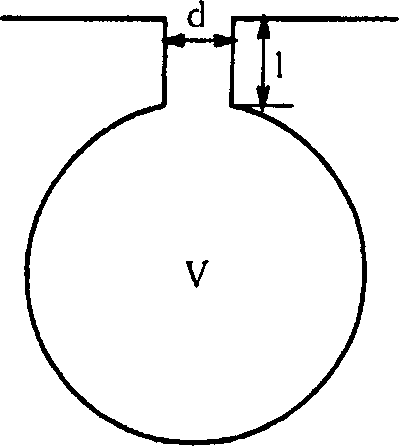

Implantable pump with infinitely variable resistor

InactiveUS20060259015A1Increase and decrease flow rateAlter shapeInfusion devicesPharmaceutical delivery mechanismMembrane configurationResistor

A variable hydraulic resistor for use with implantable pumps is disclosed. The variable hydraulic resistor according to the present invention is particularly useful in varying the flow rate of a medication fluid from an otherwise constant flow implantable pump. An implantable pump is also disclosed, which does not require a complicated clinching system or the like, and which may include an undulating membrane and chamber design to reduce the height of the pump.

Owner:AQULINX MEDICAL

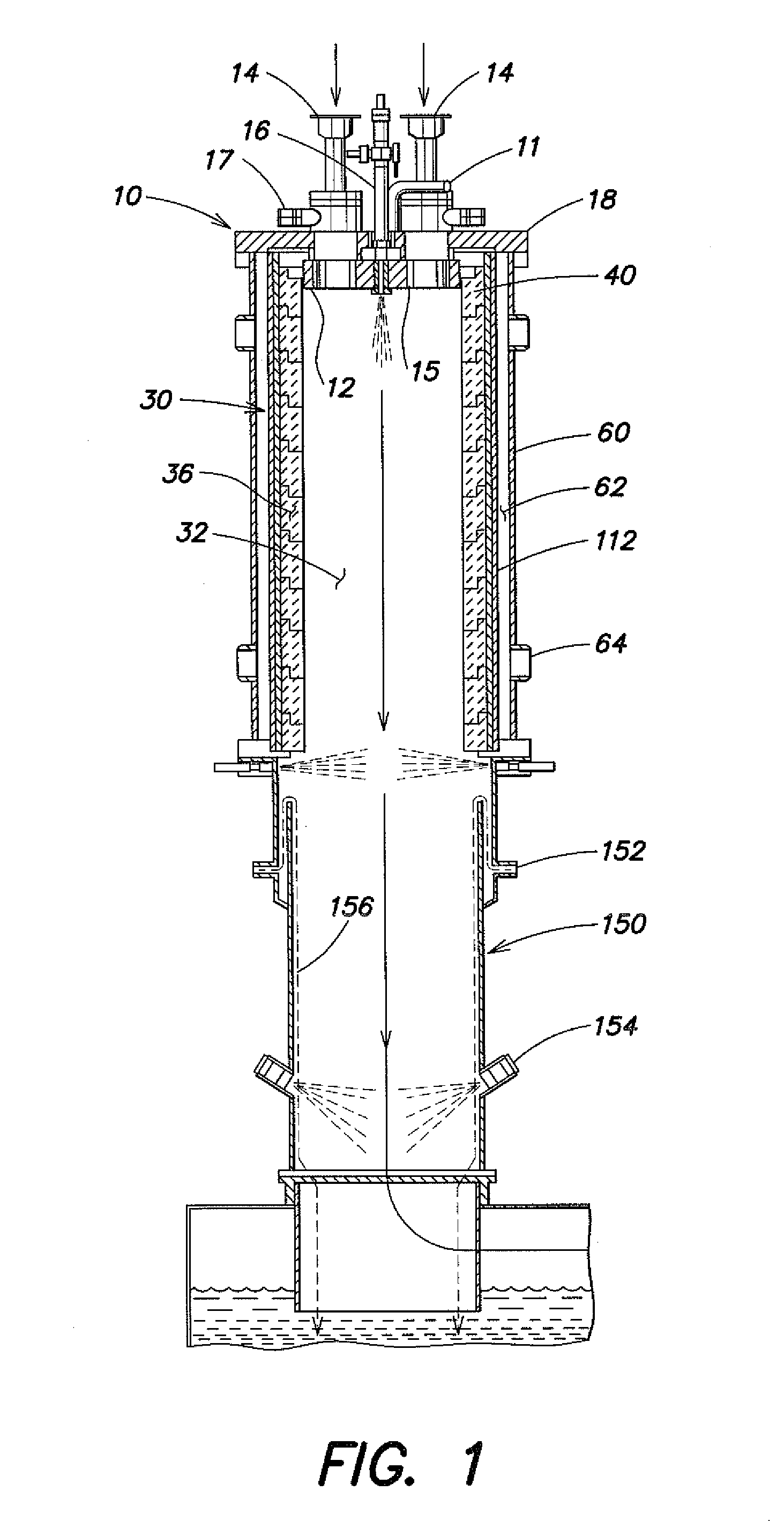

Reactor design to reduce particle deposition during process abatement

InactiveUS20070274876A1Reduce accumulationReduce crackingCombination devicesBurnersCombustionDecomposition

The present invention relates to systems and methods for controlled combustion and decomposition of gaseous pollutants while reducing deposition of unwanted reaction products from within the treatment systems. The systems include a novel thermal reaction chamber design having stacked reticulated ceramic rings through which fluid, e.g., gases, may be directed to form a boundary layer along the interior wall of the thermal reaction chamber, thereby reducing particulate matter buildup thereon. The systems further include the introduction of fluids from the center pilot jet to alter the aerodynamics of the interior of the thermal reaction chamber.

Owner:APPLIED MATERIALS INC

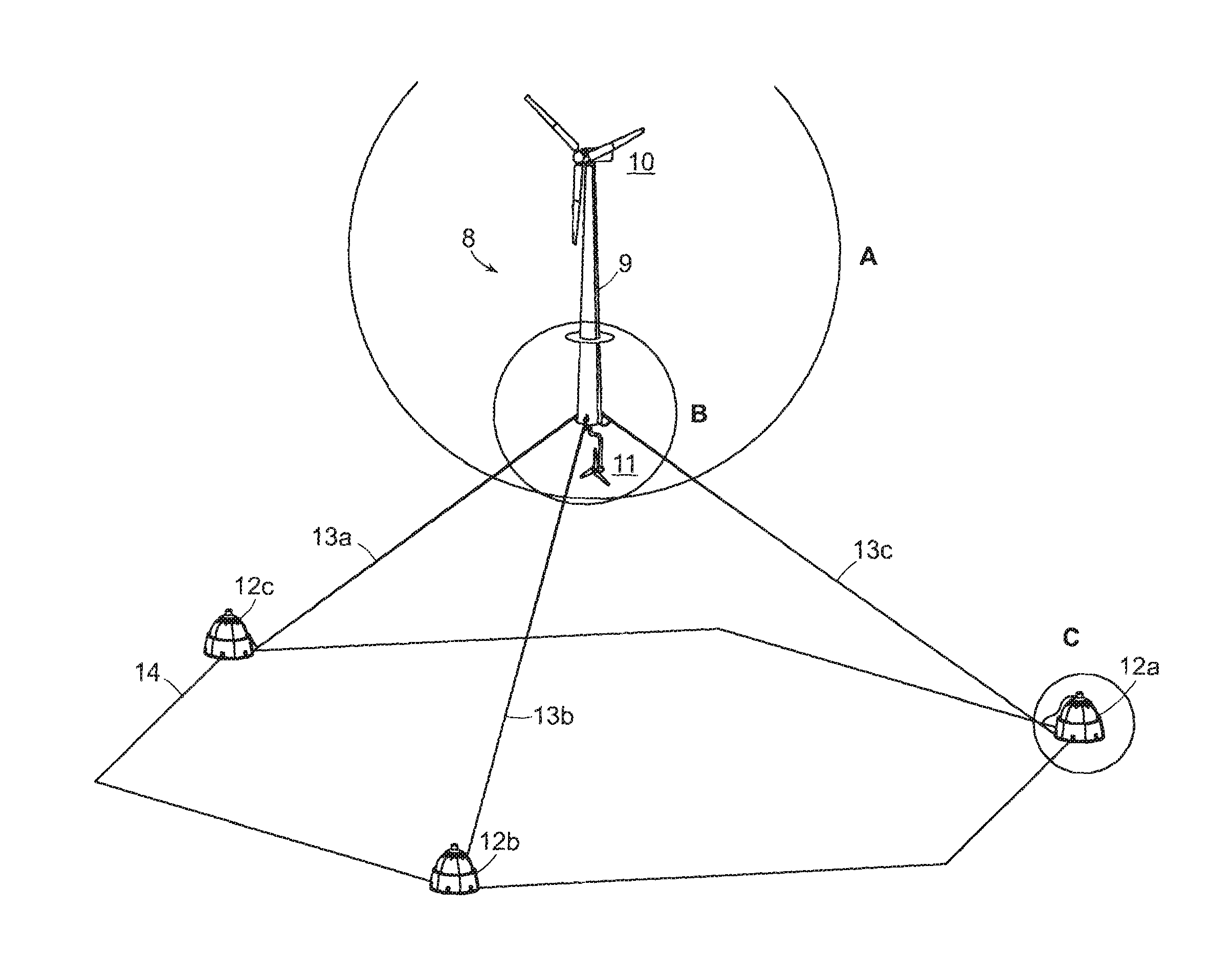

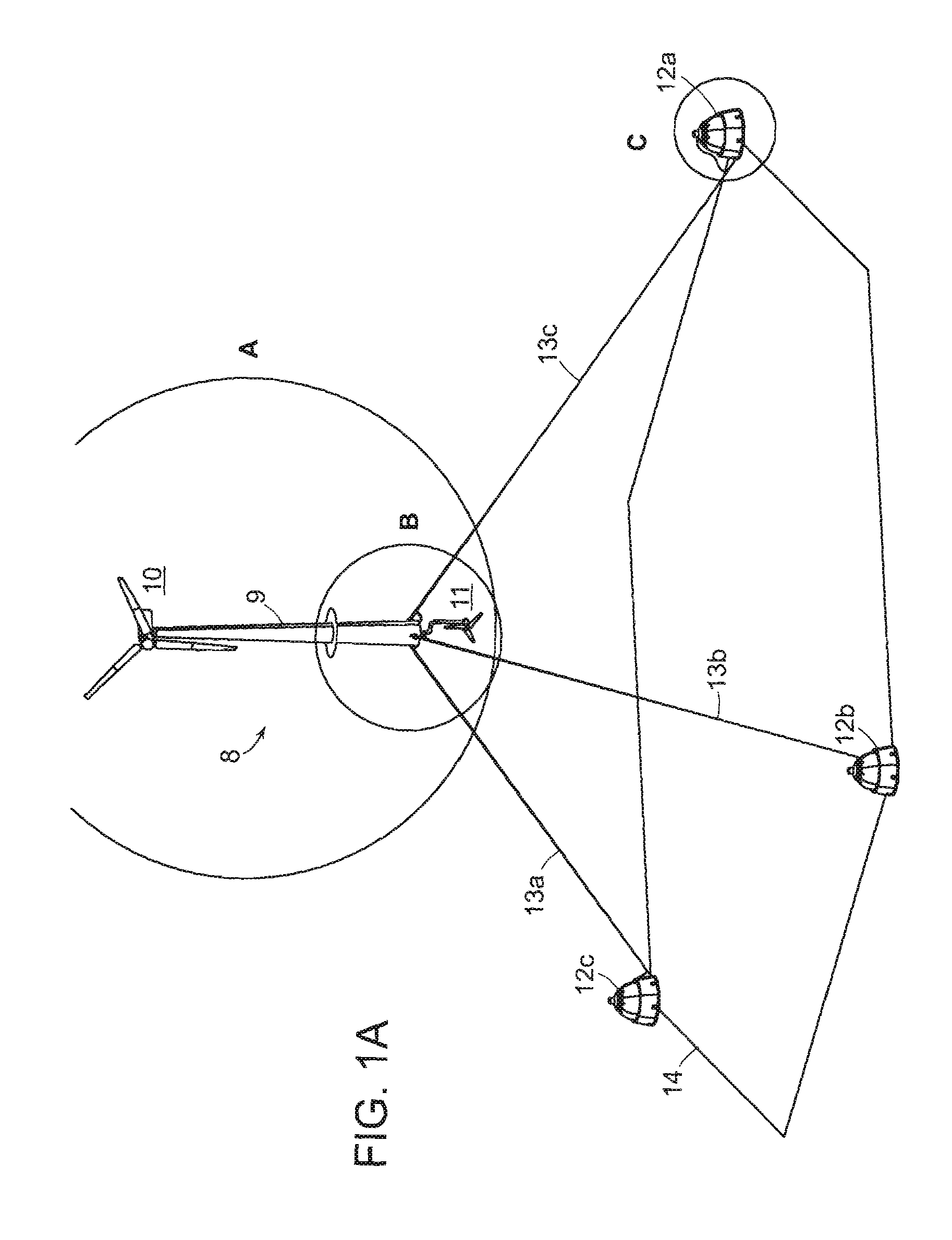

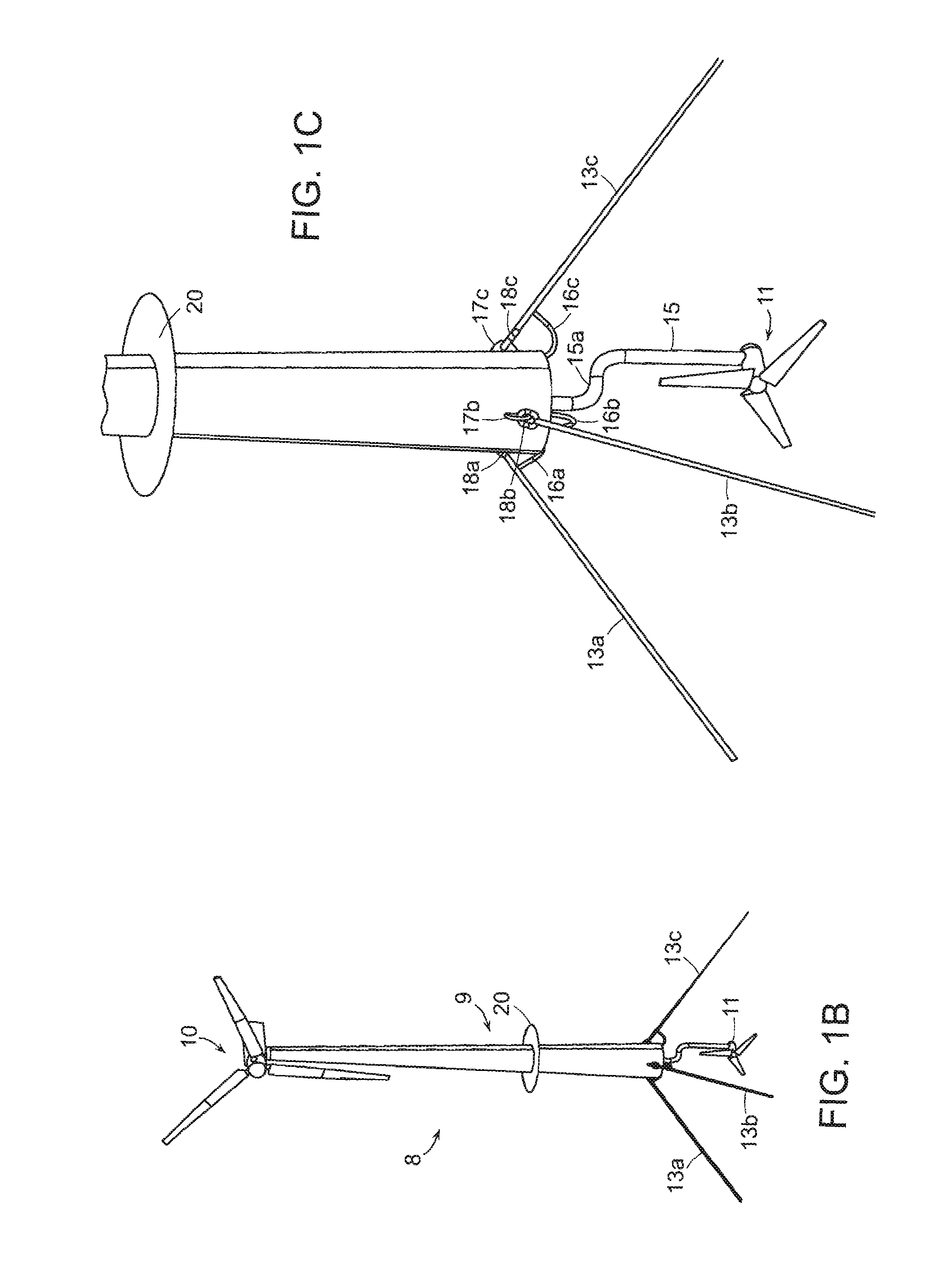

Offshore energy harvesting, storage, and power generation system

ActiveUS20110215650A1Improve efficiencyEmission reductionLarge containersWind motor supports/mountsOcean bottomExcess energy

A system for harvesting, storing, and generating energy, that includes floating structure supporting machinery to extract energy from wind, waves, surface generators, or currents. At least one energy storage and power generating unit is anchored to the seafloor and adapted to tether the floating structure to the unit. The unit includes an internal chamber into which water flows through a hydroelectric turbine to generate electrical energy. A pump is provided, powered by energy from the floating structure machinery, to evacuate water from the unit and a control system directs power from the machinery to pump water out of the unit during periods of excess energy extraction by the machinery and to allow water to flow into the chamber through the hydroelectric turbine to generate electrical energy during periods of lower energy extraction by the machinery. The same internal chamber design can be utilized to store hydrocarbons in the vicinity of undersea wellheads during “shut-in” procedures when the wellhead would otherwise be secured.

Owner:MASSACHUSETTS INST OF TECH

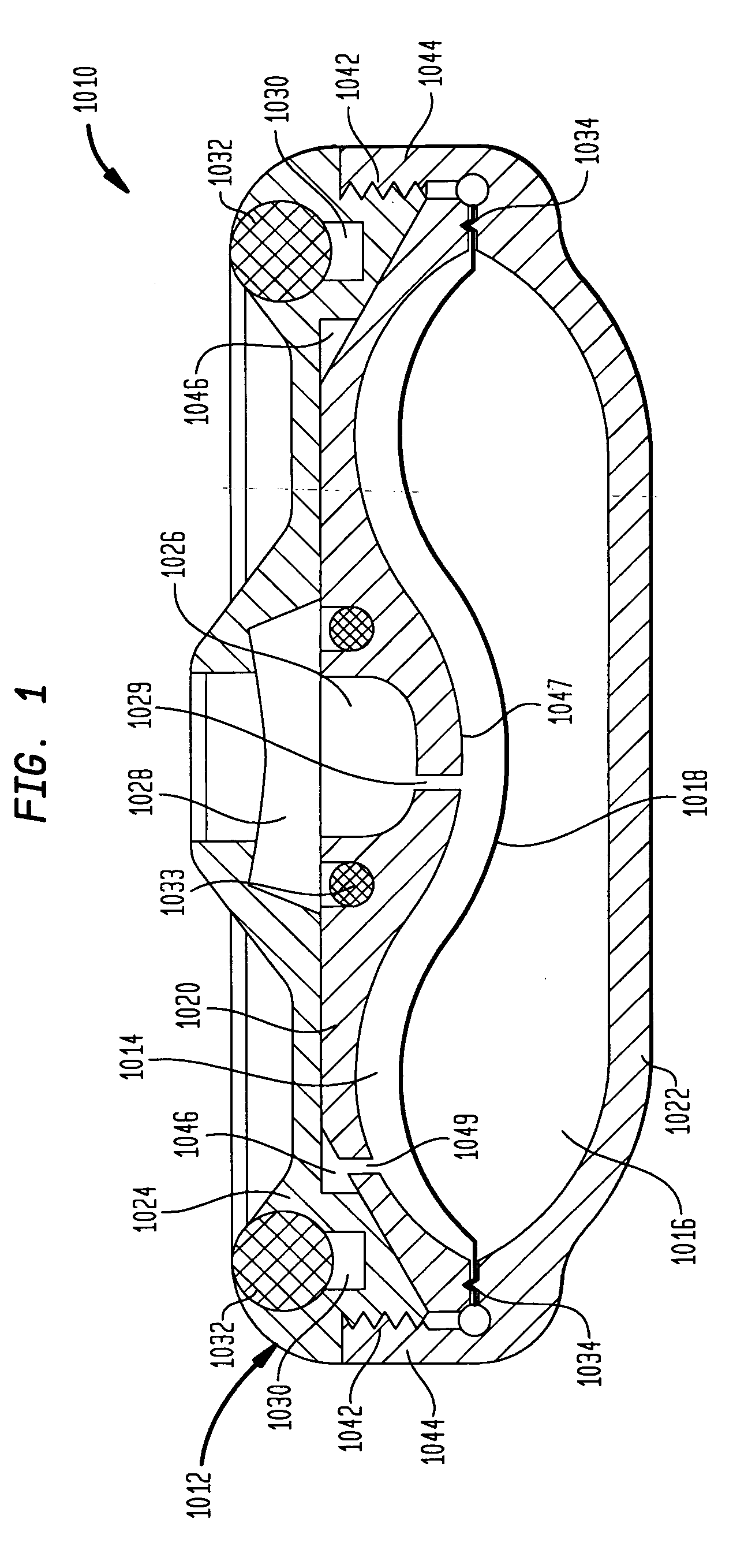

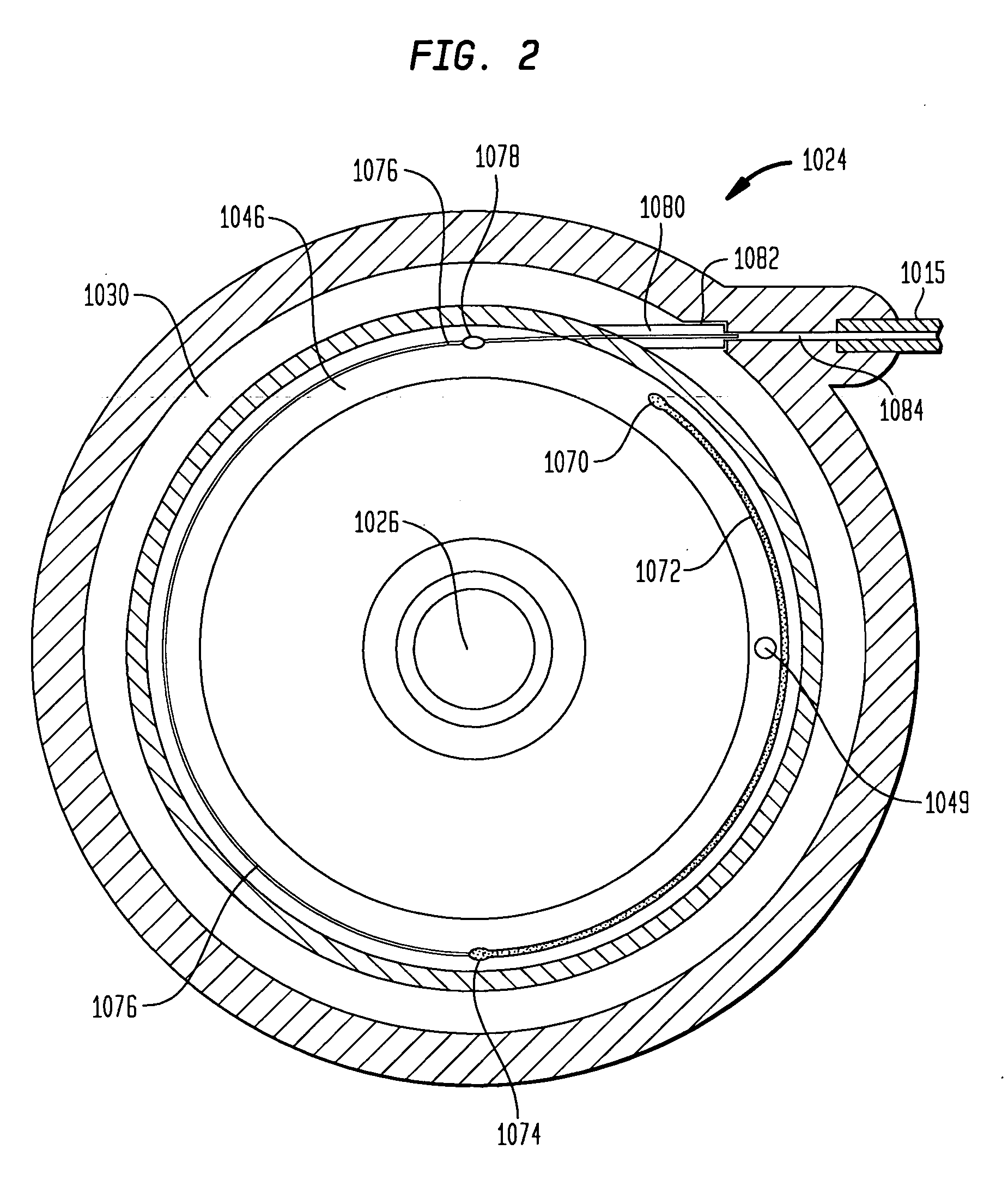

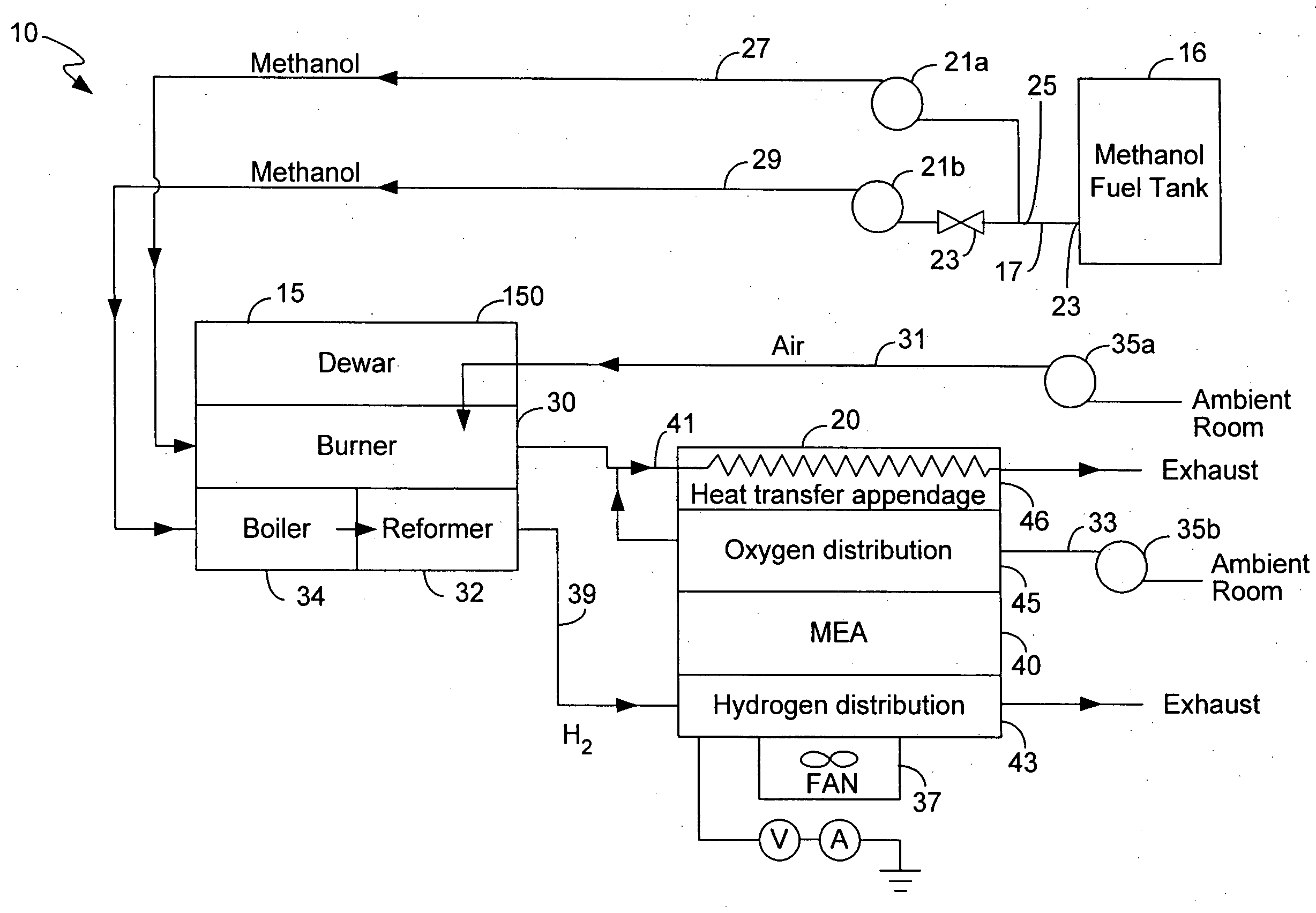

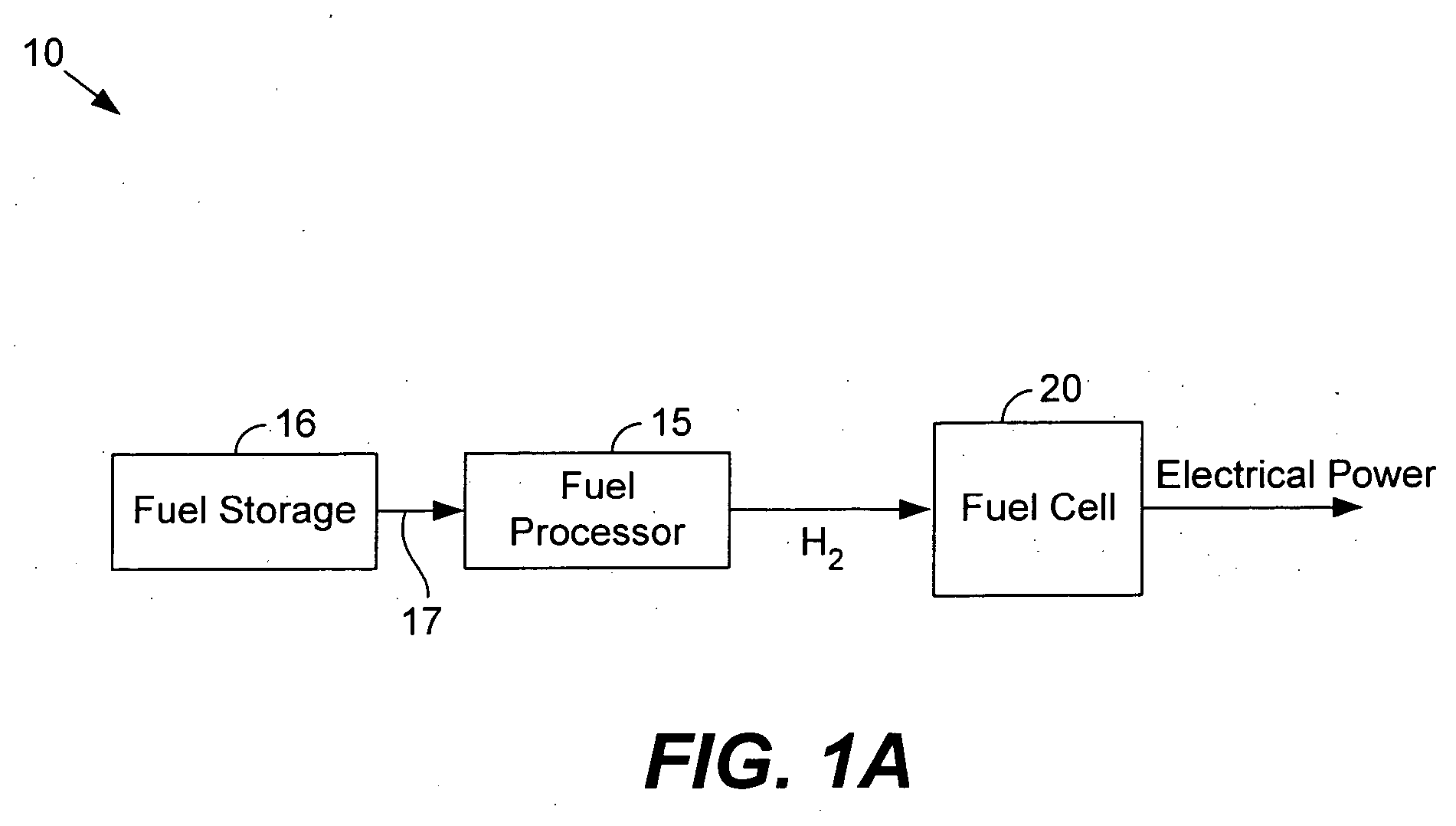

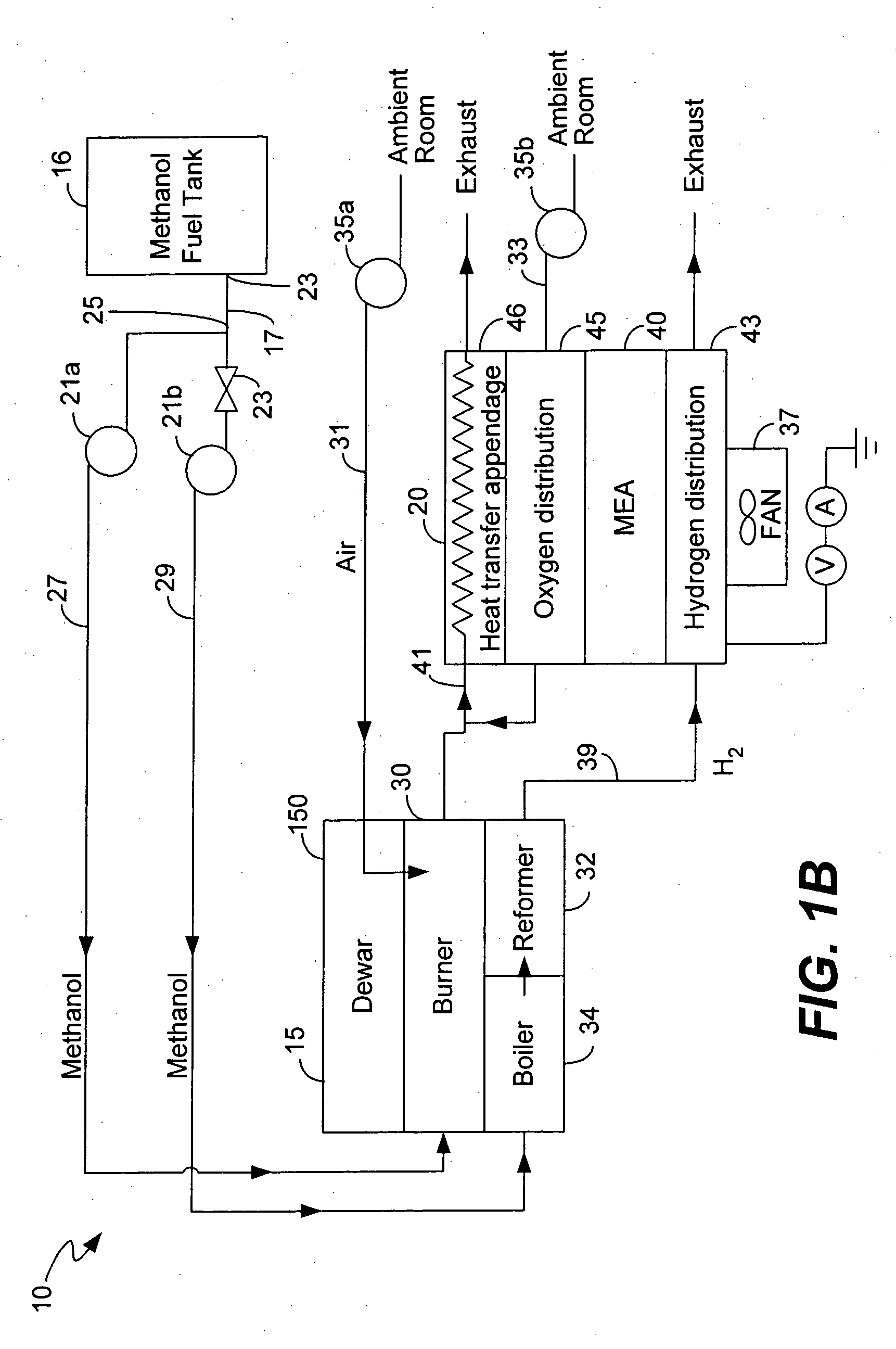

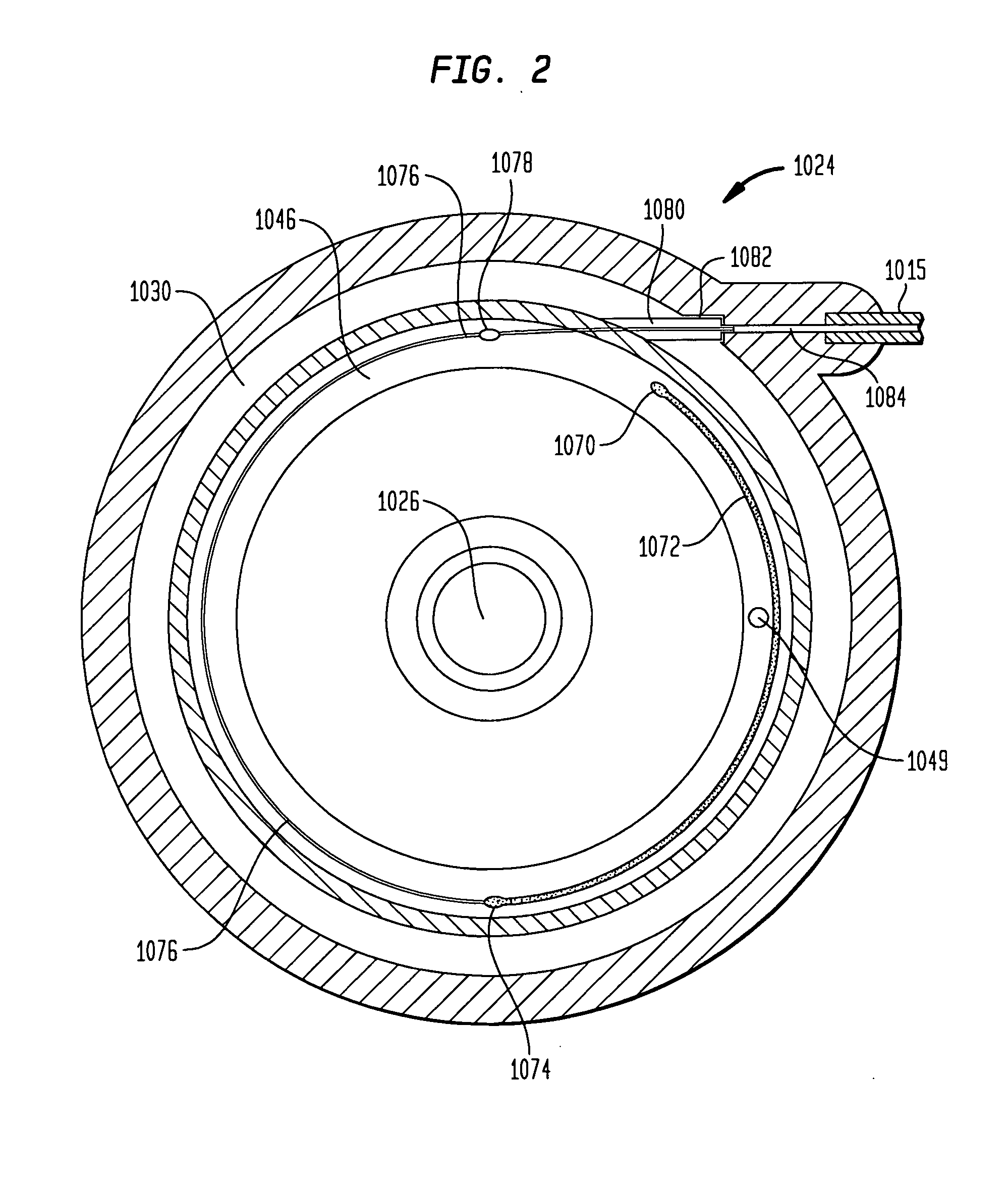

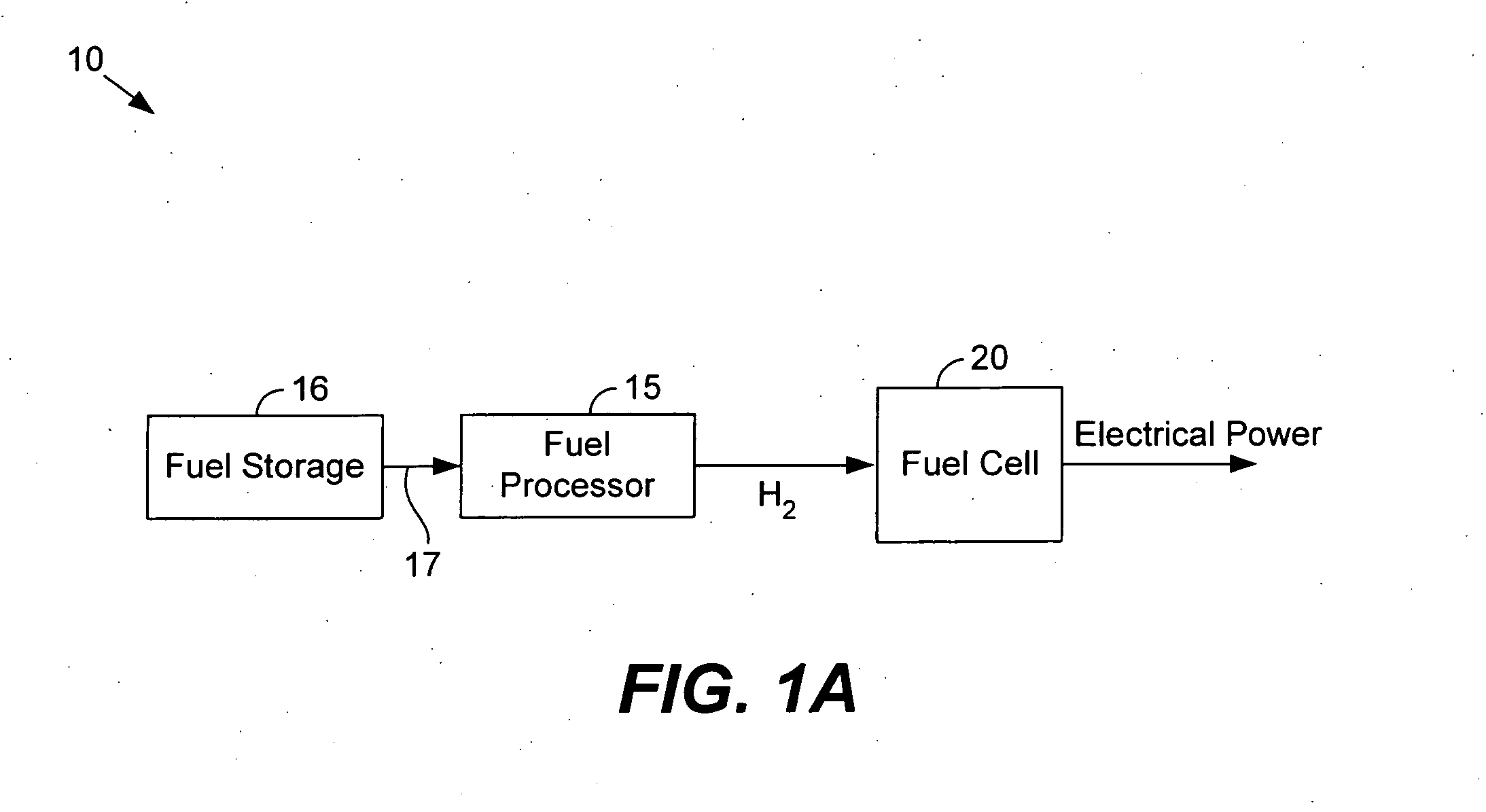

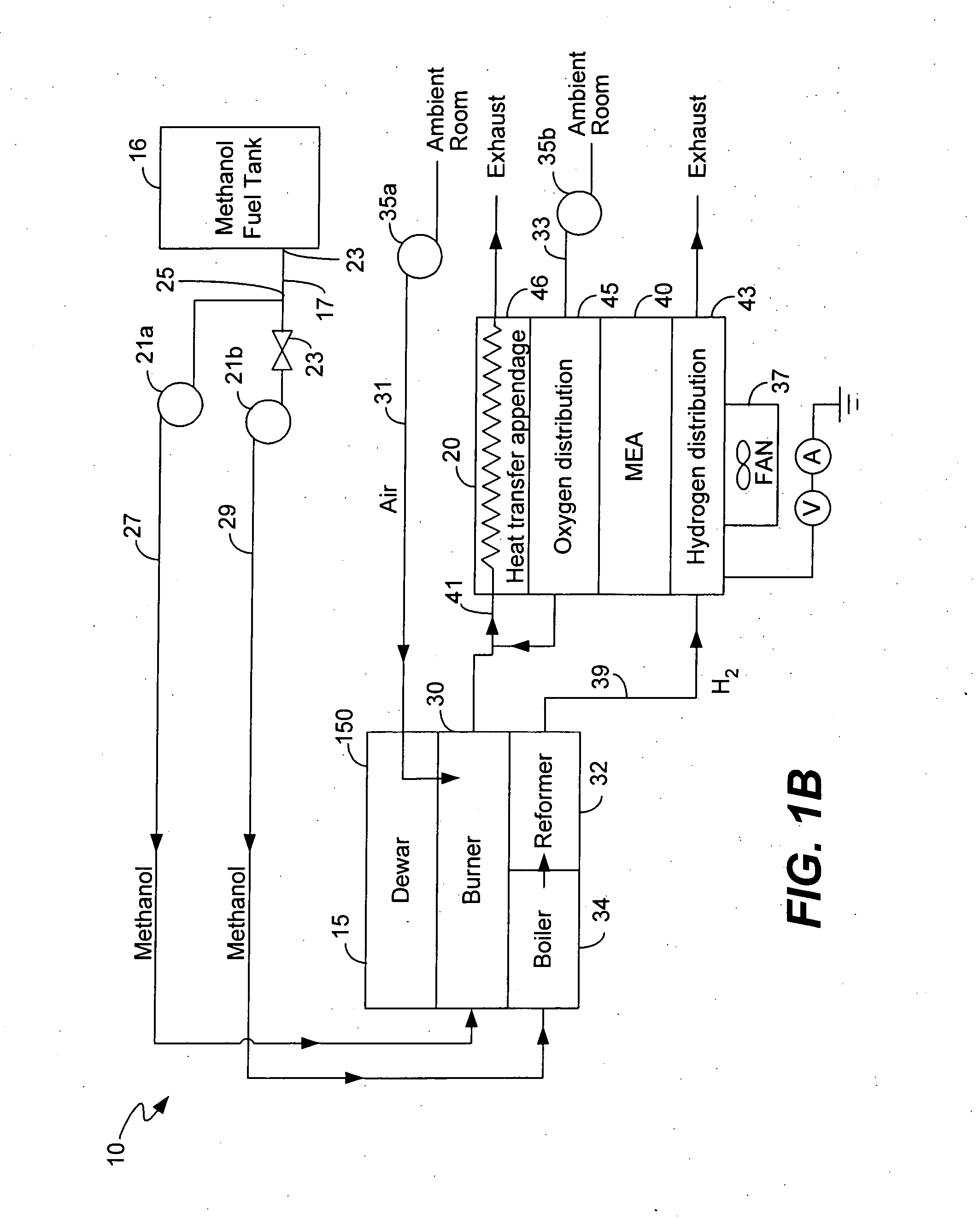

Annular fuel processor and methods

ActiveUS20050011125A1Promote productionIncreased hydrogen productionPressurized chemical processLevel controlCombustorHydrogen

Described herein is a fuel processor that produces hydrogen from a fuel source. The fuel processor comprises a reformer and burner. The reformer includes a catalyst that facilitates the production of hydrogen from the fuel source. Voluminous reformer chamber designs are provided that increase the amount of catalyst that can be used in a reformer and increase hydrogen output for a given fuel processor size. The burner provides heat to the reformer. One or more burners may be configured to surround a reformer on multiple sides to increase thermal transfer to the reformer. Dewars are also described that increase thermal management of a fuel processor and increase burner efficiency. A dewar includes one or more dewar chambers that receive inlet air before a burner receives the air. The dewar is arranged such that air passing through the dewar chamber intercepts heat generated in the burner before the heat escapes the fuel processor.

Owner:ADVENT TECH LLC

Reactor design to reduce particle deposition during process abatement

InactiveUS20060104879A1Reduce accumulationReduce reactor chamber crackingCombination devicesBurnersCombustionDecomposition

The present invention relates to systems and methods for controlled combustion and decomposition of gaseous pollutants while reducing deposition of unwanted reaction products from within the treatment systems. The systems include a novel thermal reaction chamber design having stacked reticulated ceramic rings through which fluid, e.g., gases, may be directed to form a boundary layer along the interior wall of the thermal reaction chamber, thereby reducing particulate matter buildup thereon. The systems further include the introduction of fluids from the center pilot jet to alter the aerodynamics of the interior of the thermal reaction chamber.

Owner:APPLIED MATERIALS INC

Pressurized and heated testing chamber

ActiveUS20110232368A1Quickly and conveniently be subjectedSurveySamplingQuality assuranceFracturing fluid

An apparatus and process for testing a sample of a hydraulic fracturing fluid is provided. A small quantity of a fracturing fluid sample to be observed and / or tested is placed in a chamber designed with suitable heat and pressure simulation apparatus. With the sample chamber, the efficacy of the fracturing fluid can be ascertained, improper fracturing fluid compositions and / or mixtures, e.g., caused by human error, can be detected, and contamination of the frac-tank can be determined. The overall apparatus is portable and can be transported to the site of the fracturing fluid tank, thereby allowing testing immediately prior to introduction into the well. The samples in the test chamber can be observed for quality control and quality assurance prior to, or during stimulation and water shutoff treatments in the field.

Owner:SAUDI ARABIAN OIL CO

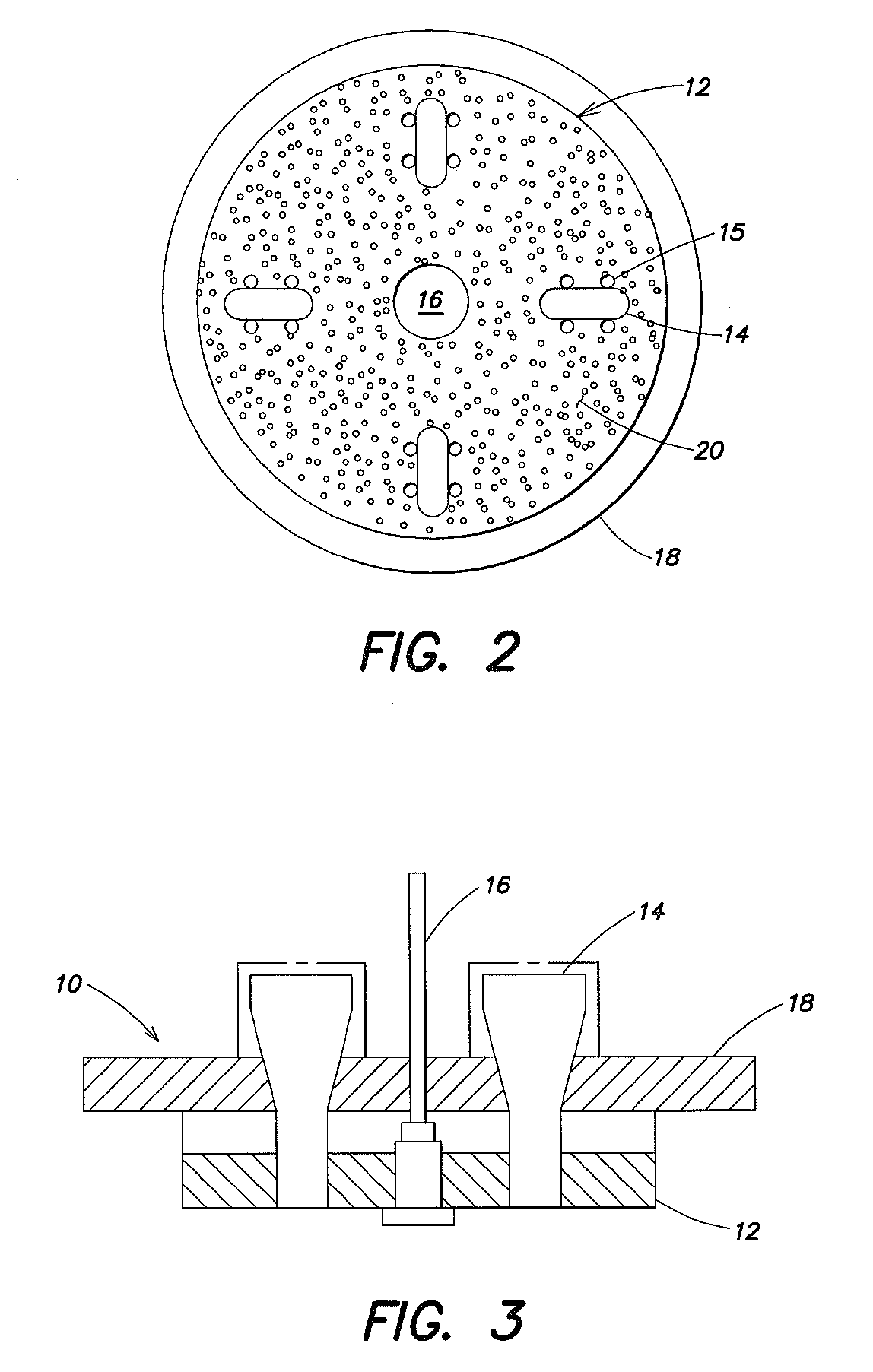

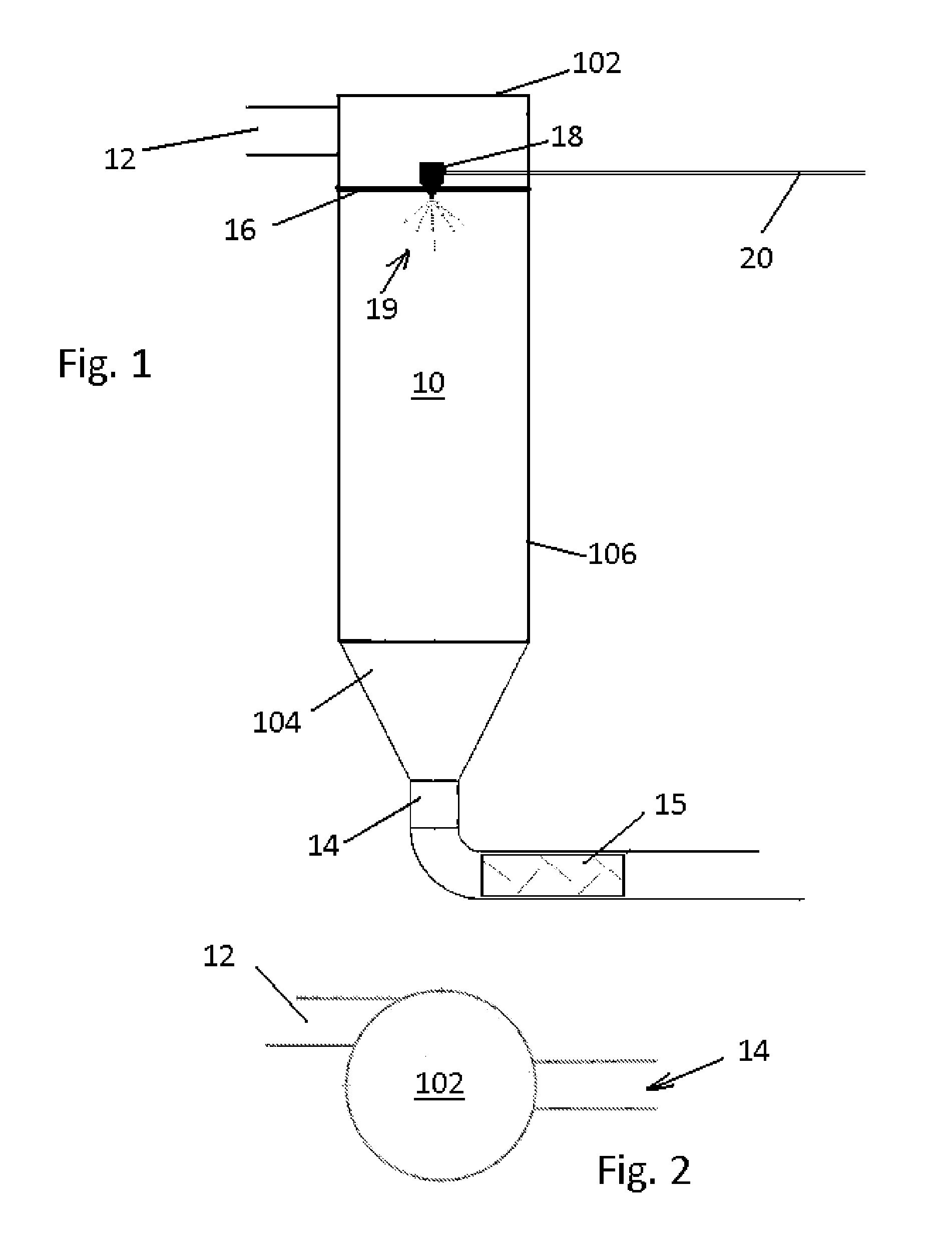

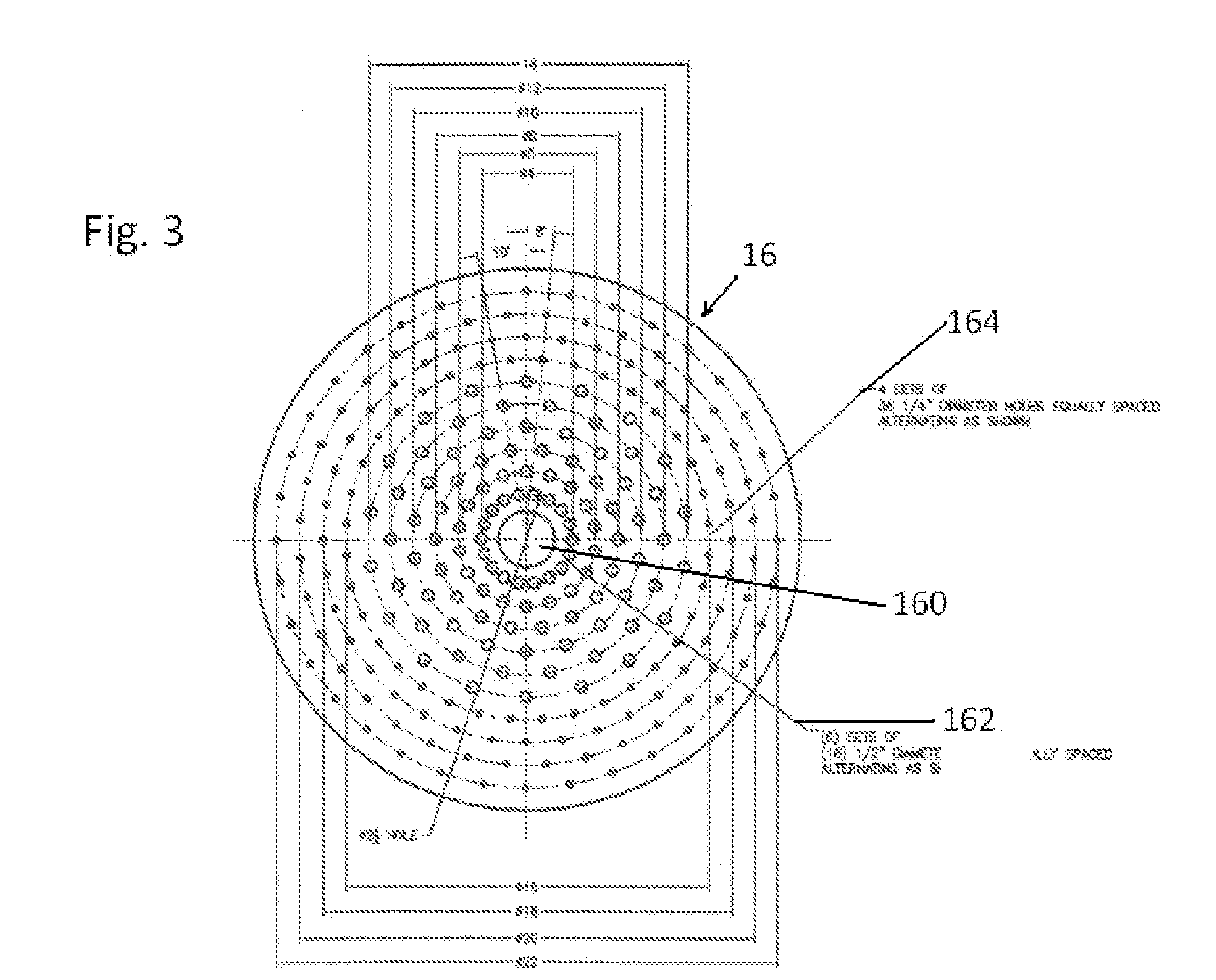

SELECTIVE CATALYTIC NOx REDUCTION PROCESS AND APPARATUS PROVIDING IMPROVED GASSIFICATION OF UREA TO FORM AMMONIA-CONTAINING GAS

ActiveUS20090297417A1Reduce concentrationHigh gas velocityGas treatmentOrganic chemistryProduct gasAmmonia

Disclosed are methods and apparatus enabling the efficient utilization of urea for purposes such as selective catalytic reduction (SCR) of NOx, which enable feeding urea to a chamber designed to efficiently and completely gasify the urea to enable ammonia feed. Preferably, aqueous urea is fed to a gasification chamber, which is also fed with heated gases. An injector means, capable of distributing the aqueous urea as fine droplets, is positioned centrally of a gas distribution plate in the chamber. An arrangement of spaced holes in the gas distribution plate provides higher gas velocity in the vicinity of the injector means than near the walls of the chamber. Uniform gas distribution without equipment fouling is achieved.

Owner:FUEL TECH

Upper chamber for high density plasma CVD

InactiveUS7354501B2Easy temperature controlImprove particle performanceElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlHigh density

The present invention is directed to an upper chamber design of a plasma CVD chamber which provides more uniform conditions for forming thin CVD films on a substrate. Embodiments of the invention improve temperature control of the upper chamber and improve particle performance by reducing or minimizing the temperature fluctuations on the dome between the deposition and non-deposition cycles. In accordance with an aspect of the present invention, an apparatus for processing semiconductor substrates comprises a chamber defining a plasma processing region therein. The chamber includes a bottom, a side wall, and a dome disposed on top of the side wall. The dome has a substantially flat dome top. A top RF coil is disposed above the dome top, and has an outer loop which is larger in size than the substrates to be processed in the chamber. A cold plate is disposed above the top RF coil, and is larger in size than the substrates to be processed in the chamber.

Owner:APPLIED MATERIALS INC

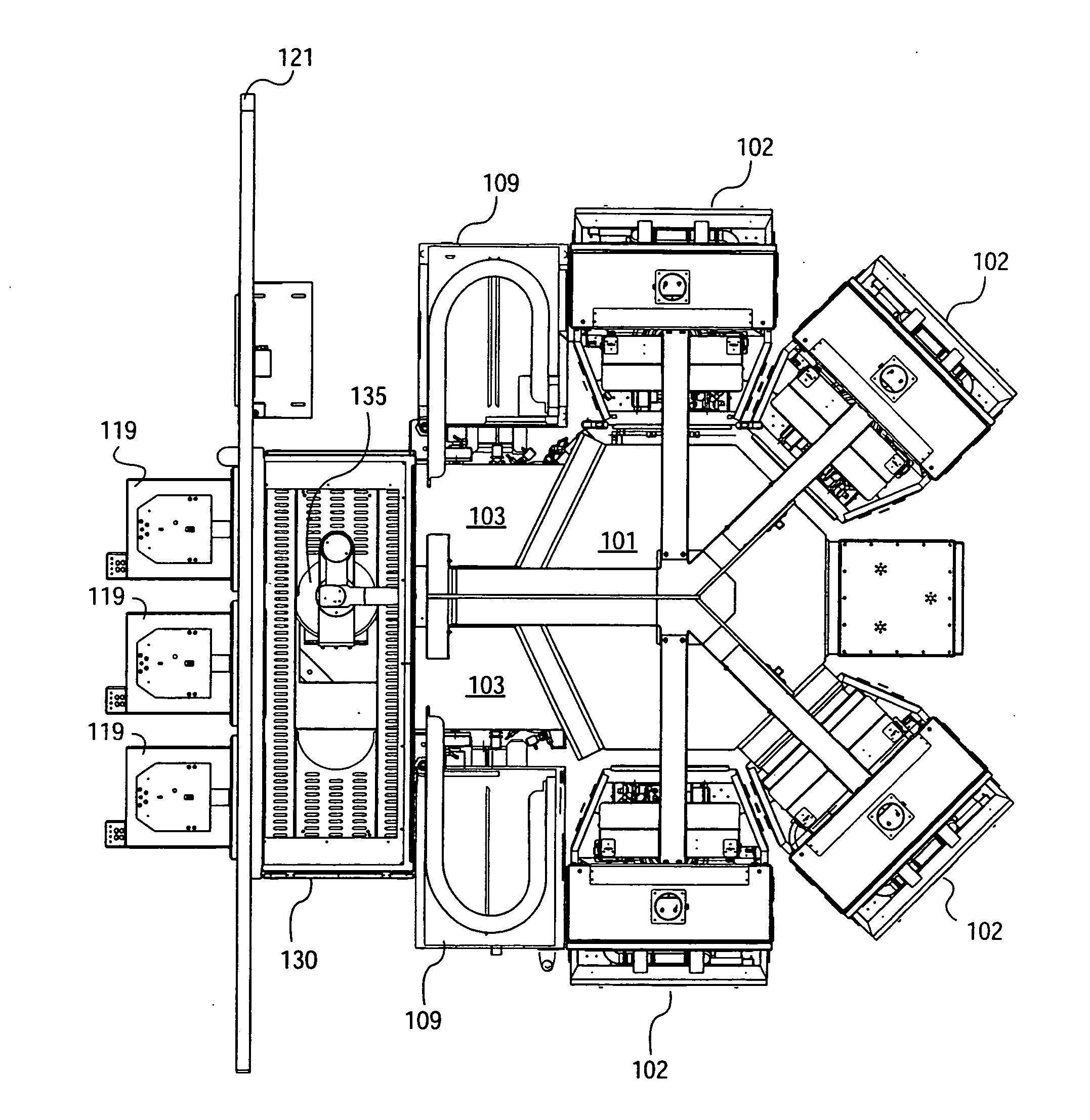

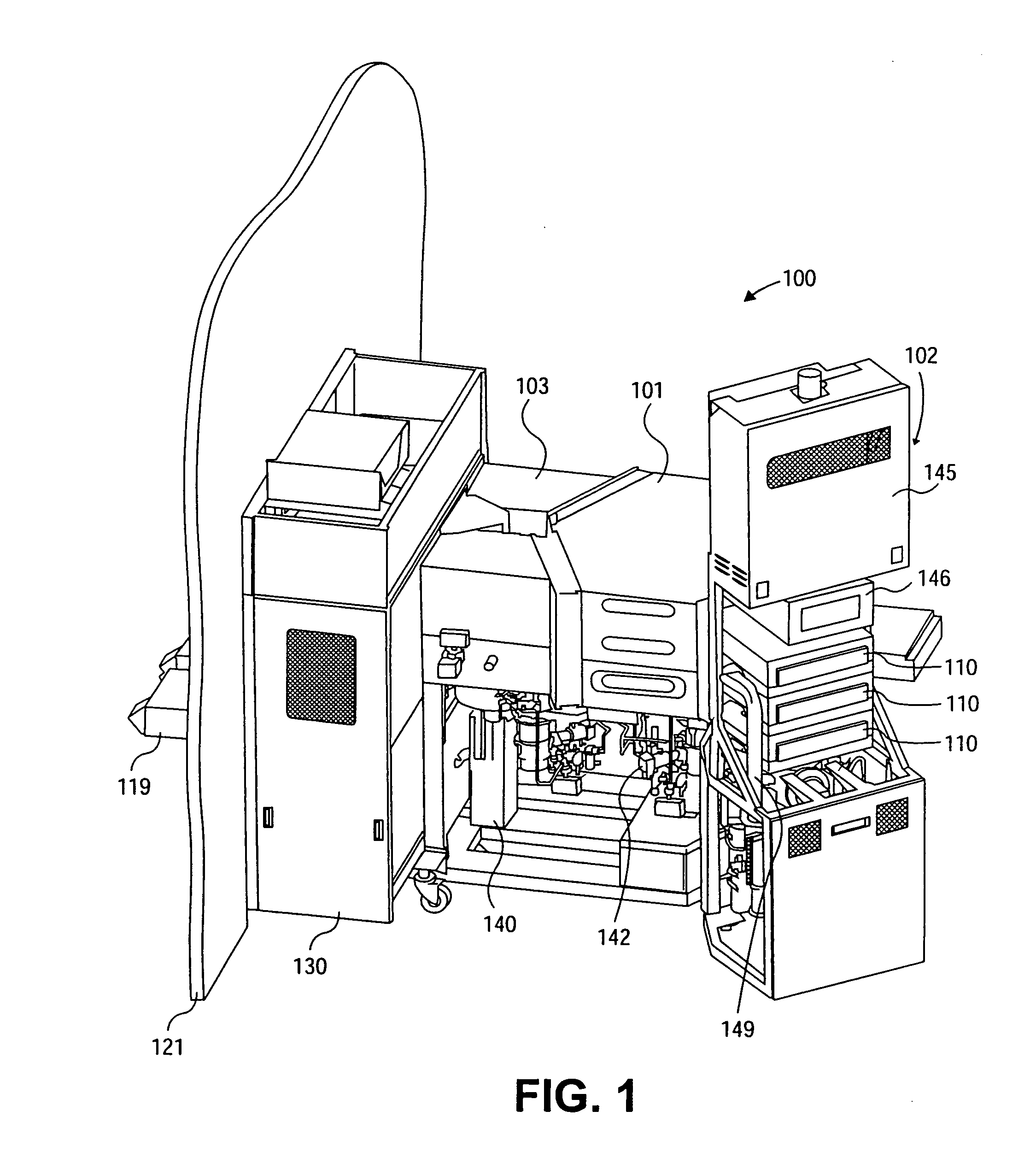

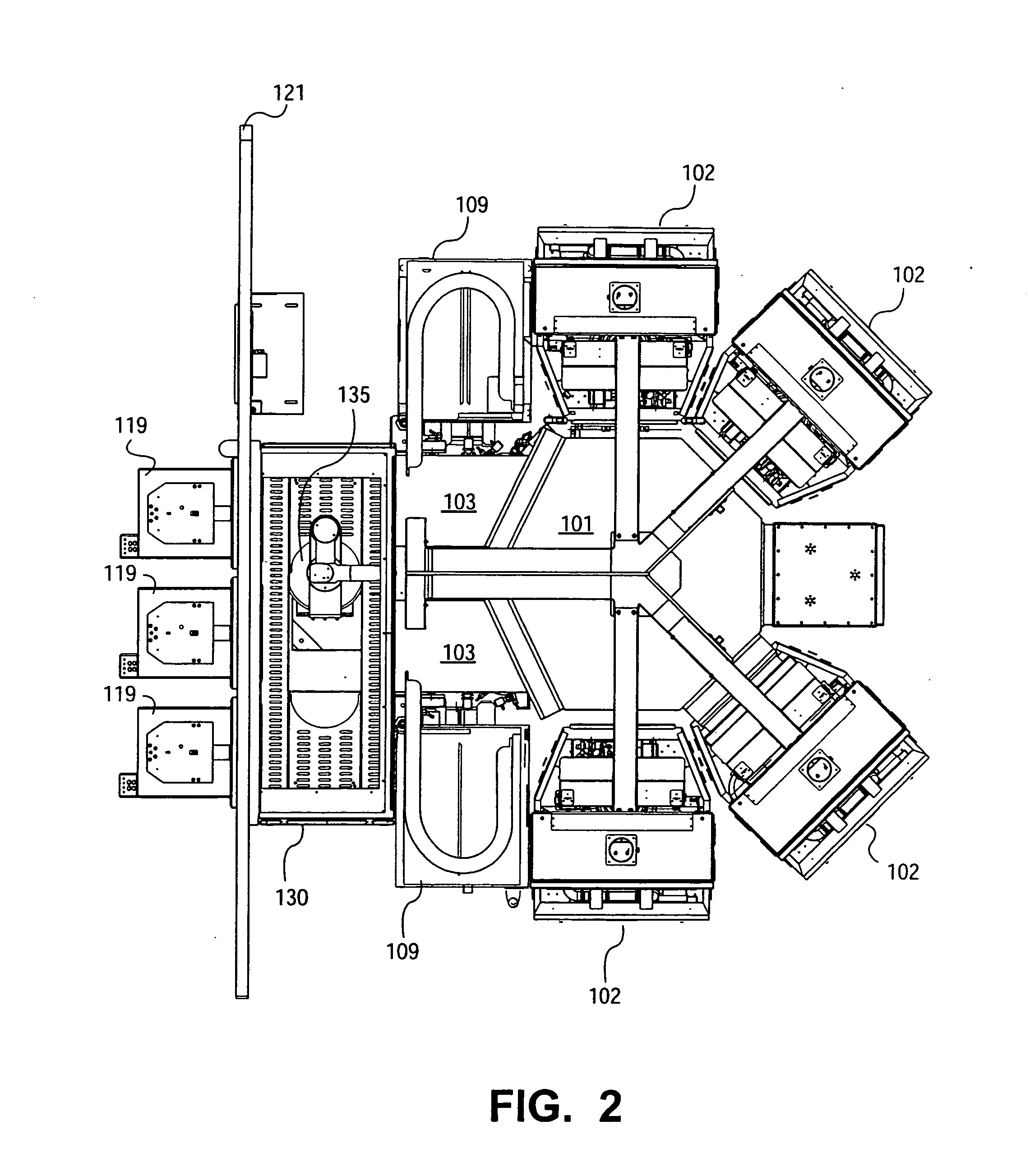

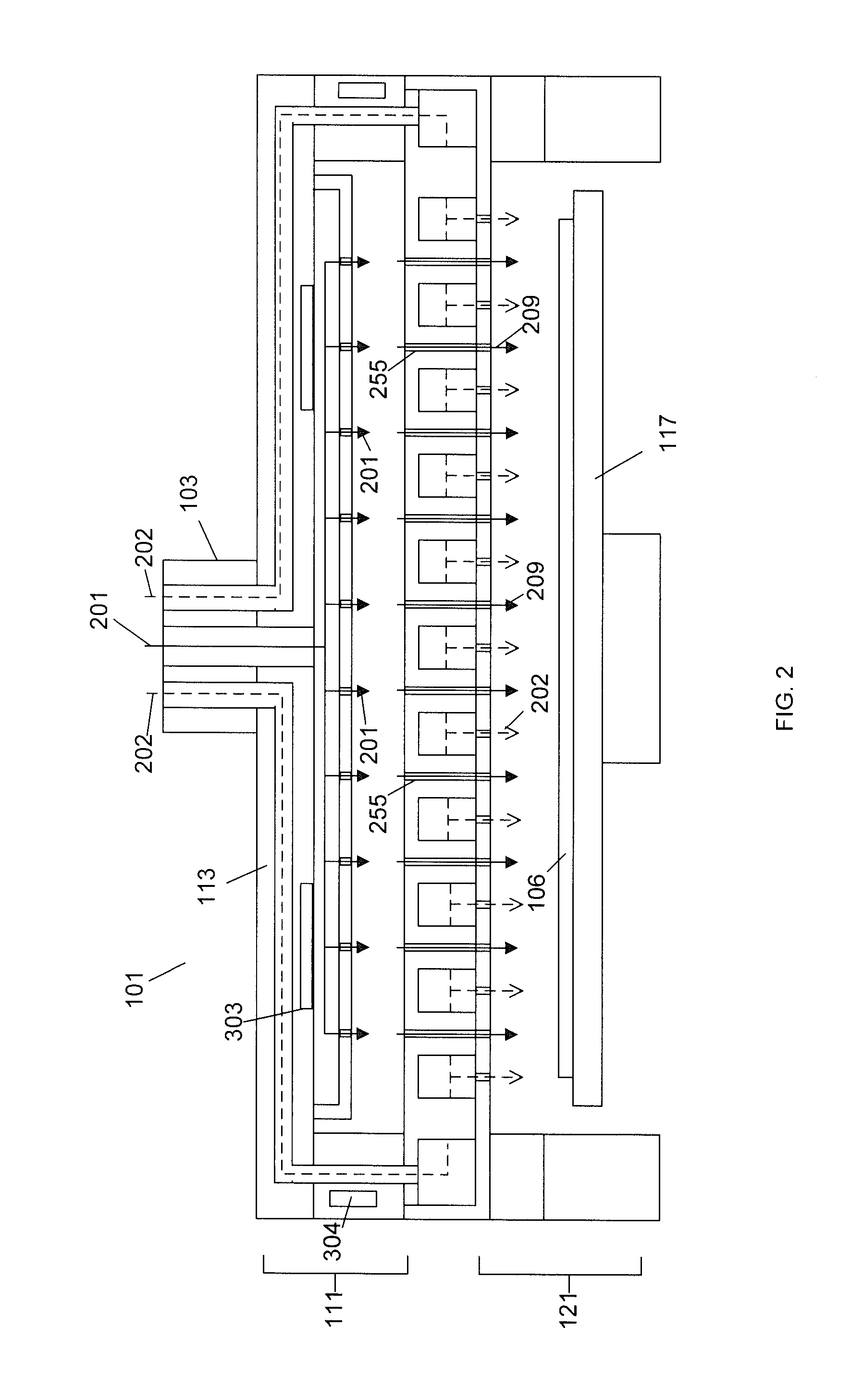

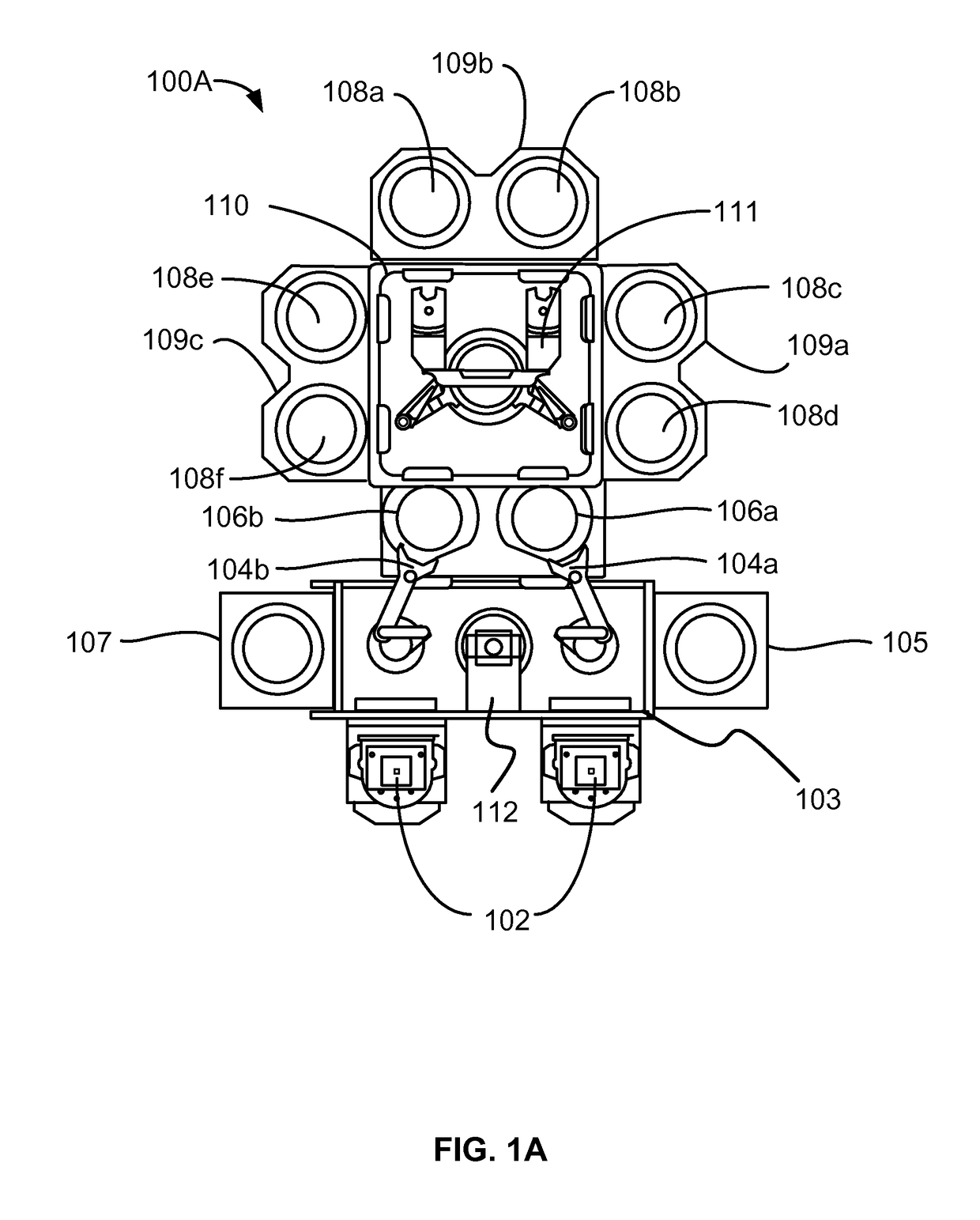

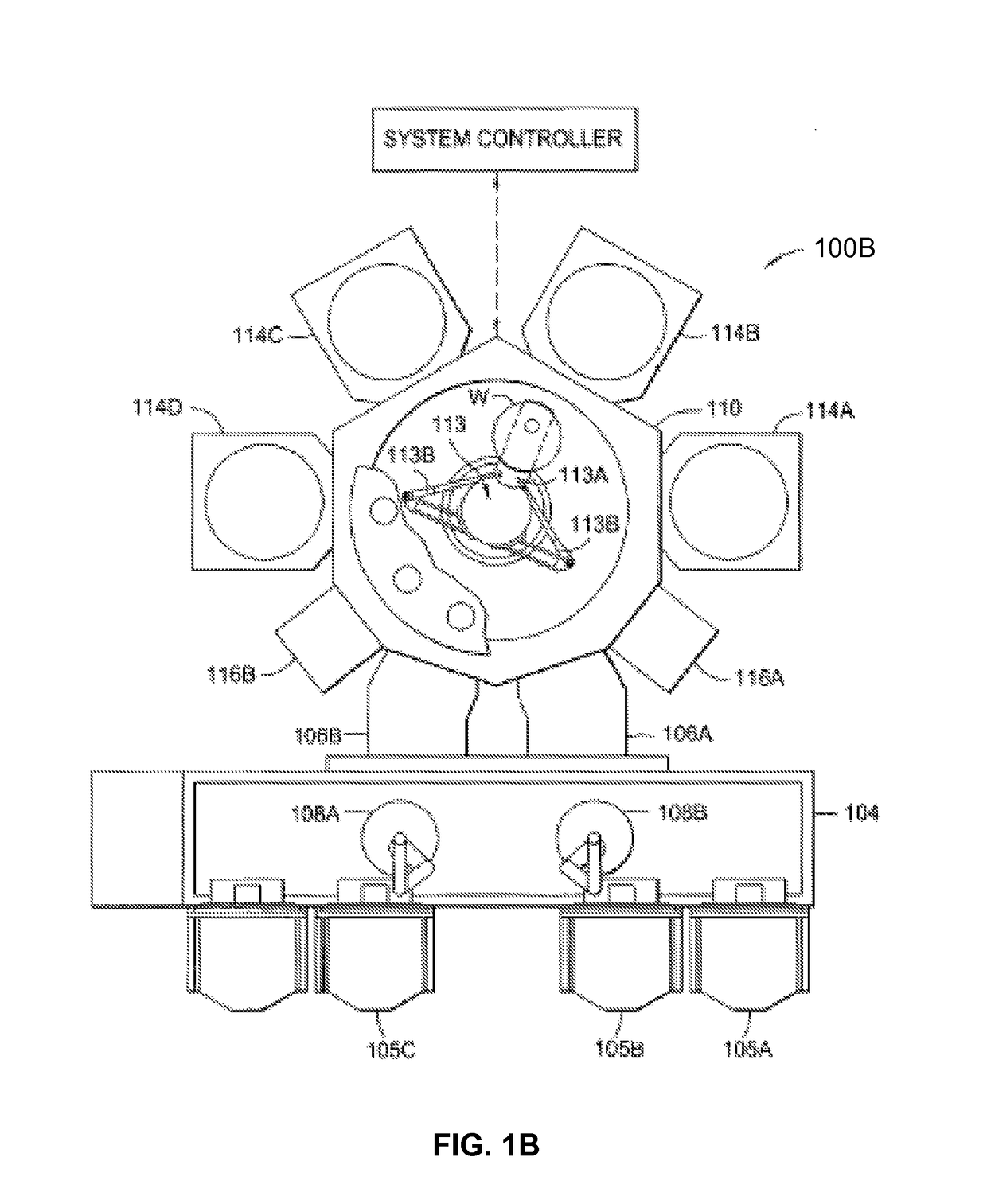

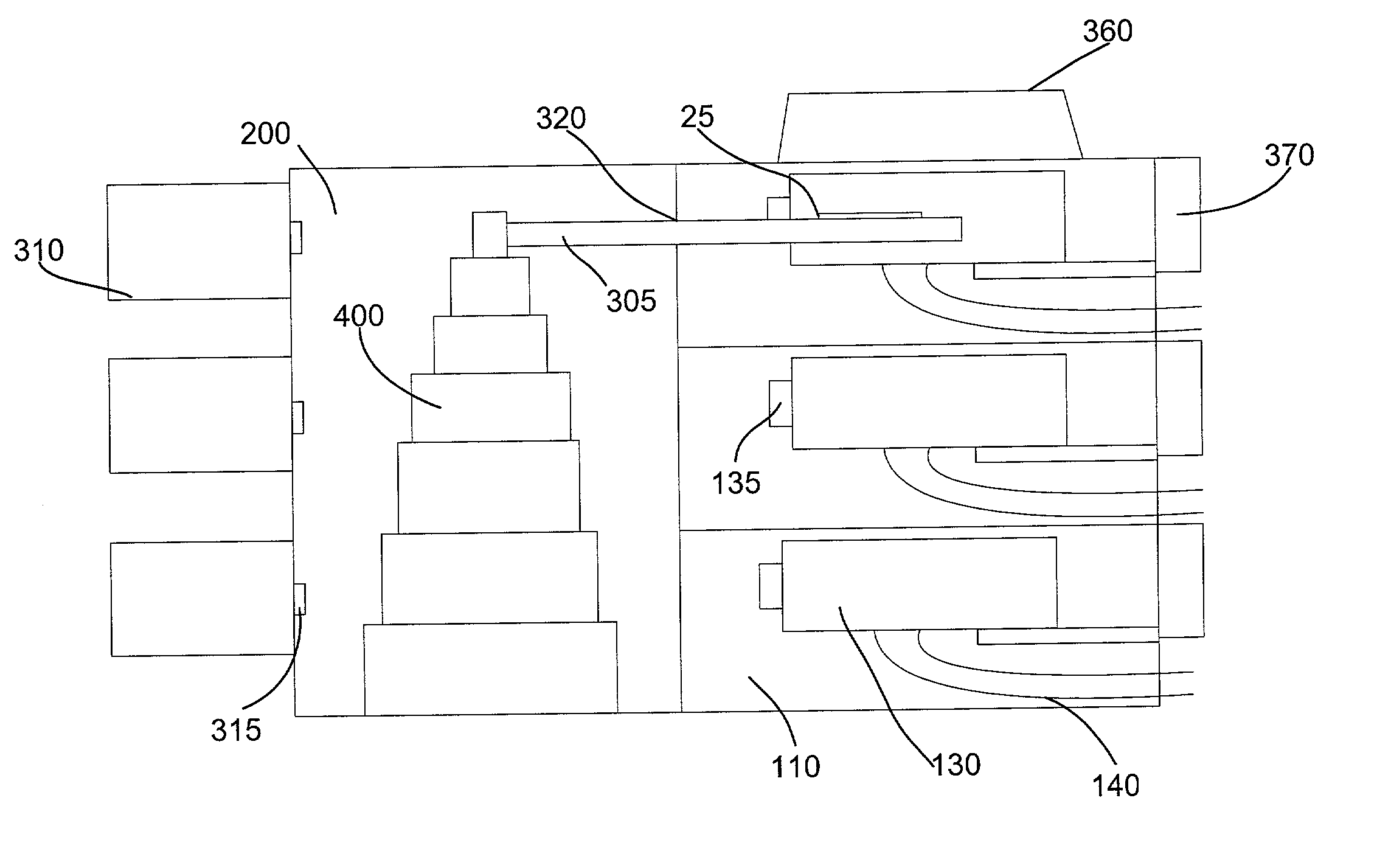

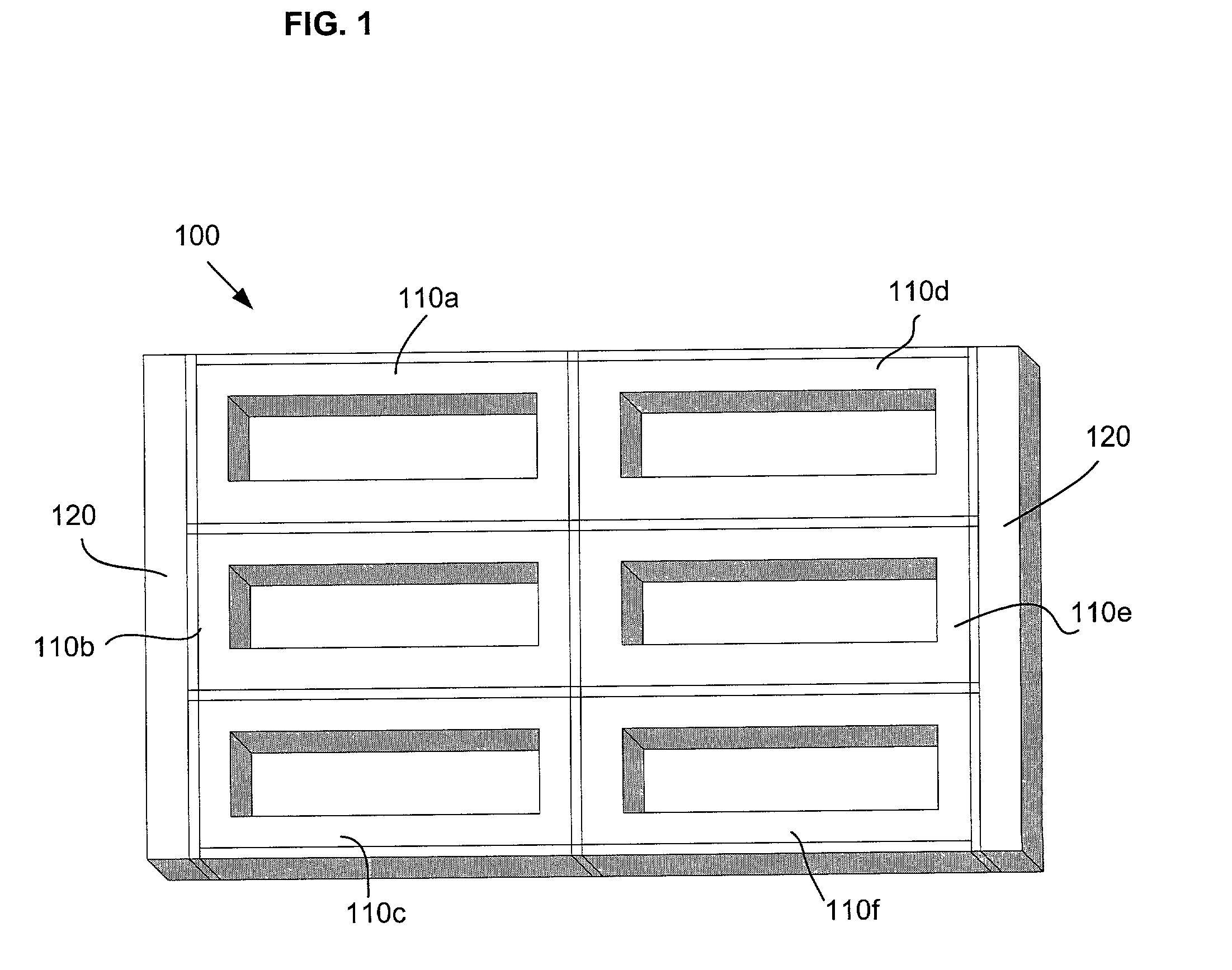

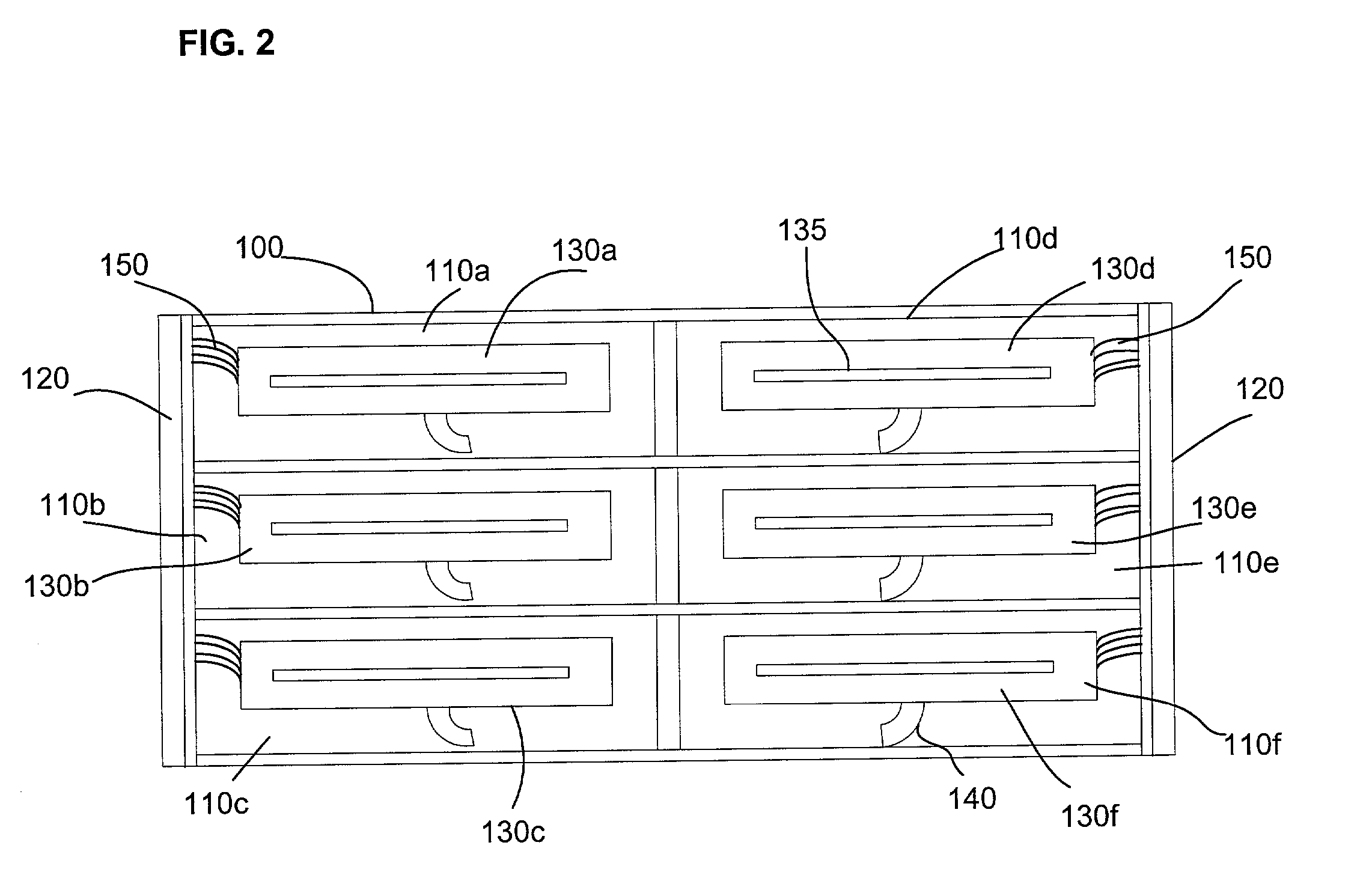

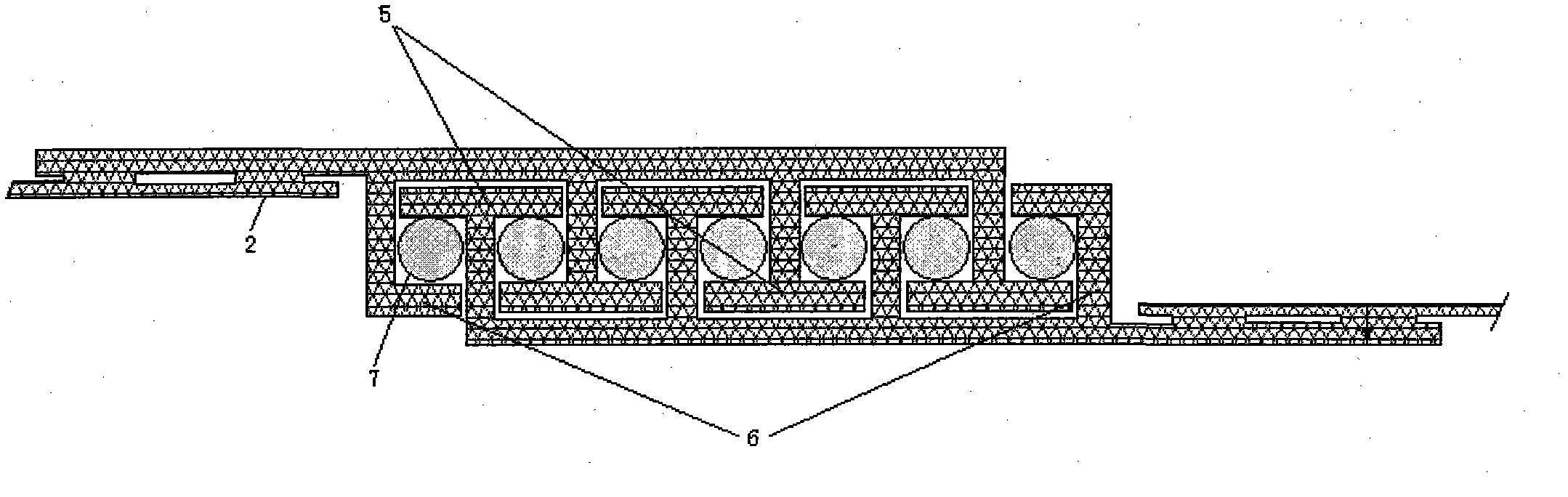

Workpiece distribution and processing in a high throughput stacked frame

InactiveUS20020137346A1Semiconductor/solid-state device manufacturingSpecial data processing applicationsEngineeringSemiconductor

An integrated workpiece vacuum processing system for processing semiconductor workpieces is provided using a stacked chamber design. The processing system comprises a multiple chamber support unit having a plurality of processing chamber support bays arranged in rows and columns wherein a vacuum processing chamber module is received in each support bay and a transfer chamber is coupled to the plurality of processing chamber modules.

Owner:APPLIED MATERIALS INC

RF choke for gas delivery to an RF driven electrode in a plasma processing apparatus

ActiveUS20090022905A1Simplify chamber designSimple designTransformers/inductances coolingElectric discharge tubesRemote plasmaProduct gas

In large area plasma processing systems, process gases may be introduced to the chamber via the showerhead assembly which may be driven as an RF electrode. The gas feed tube, which is grounded, is electrically isolated from the showerhead. The gas feed tube may provide not only process gases, but also cleaning gases from a remote plasma source to the process chamber. The inside of the gas feed tube may remain at either a low RF field or a zero RF field to avoid premature gas breakdown within the gas feed tube that may lead to parasitic plasma formation between the gas source and the showerhead. By feeding the gas through an RF choke, the RF field and the processing gas may be introduced to the processing chamber through a common location and thus simplify the chamber design.

Owner:APPLIED MATERIALS INC

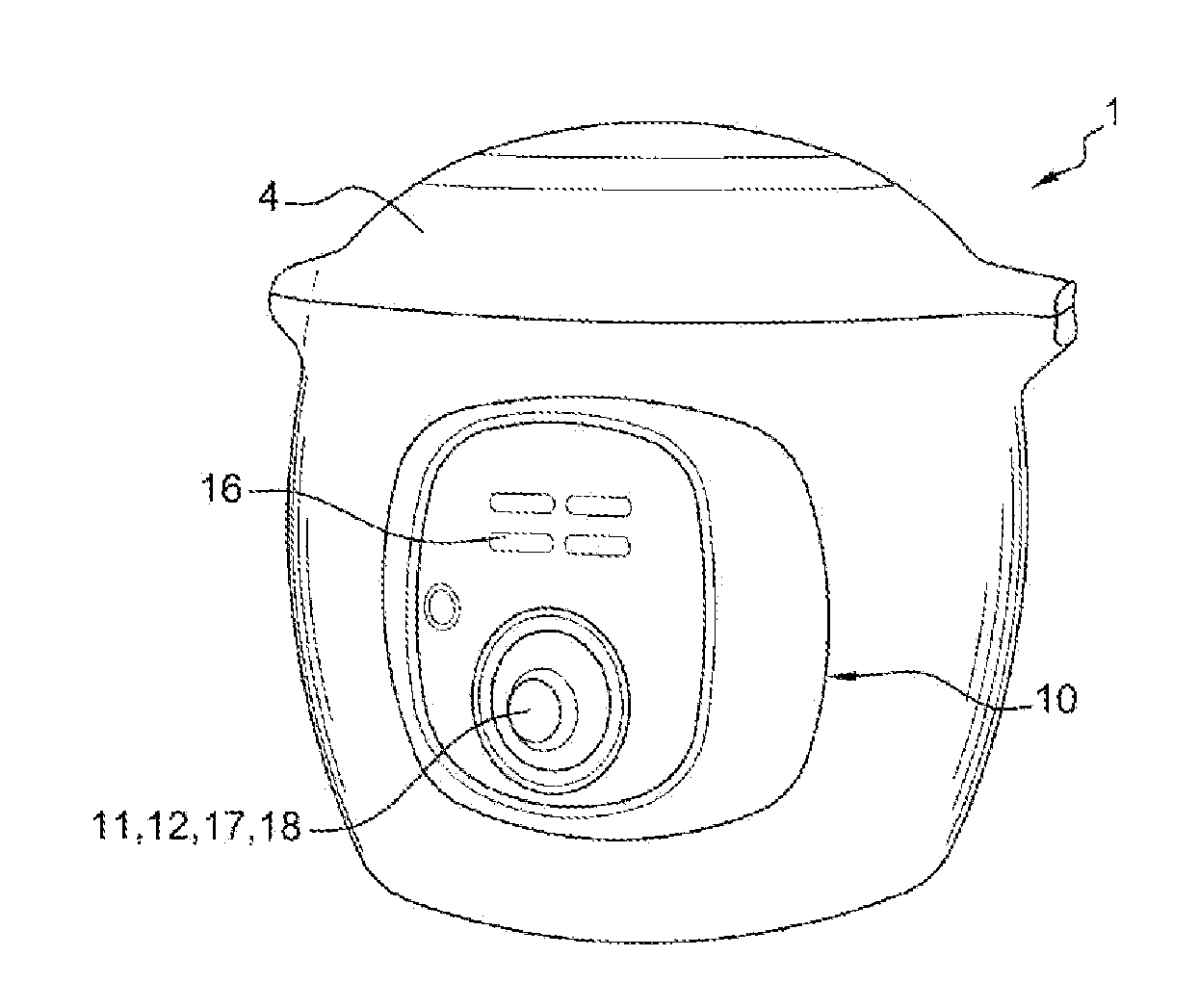

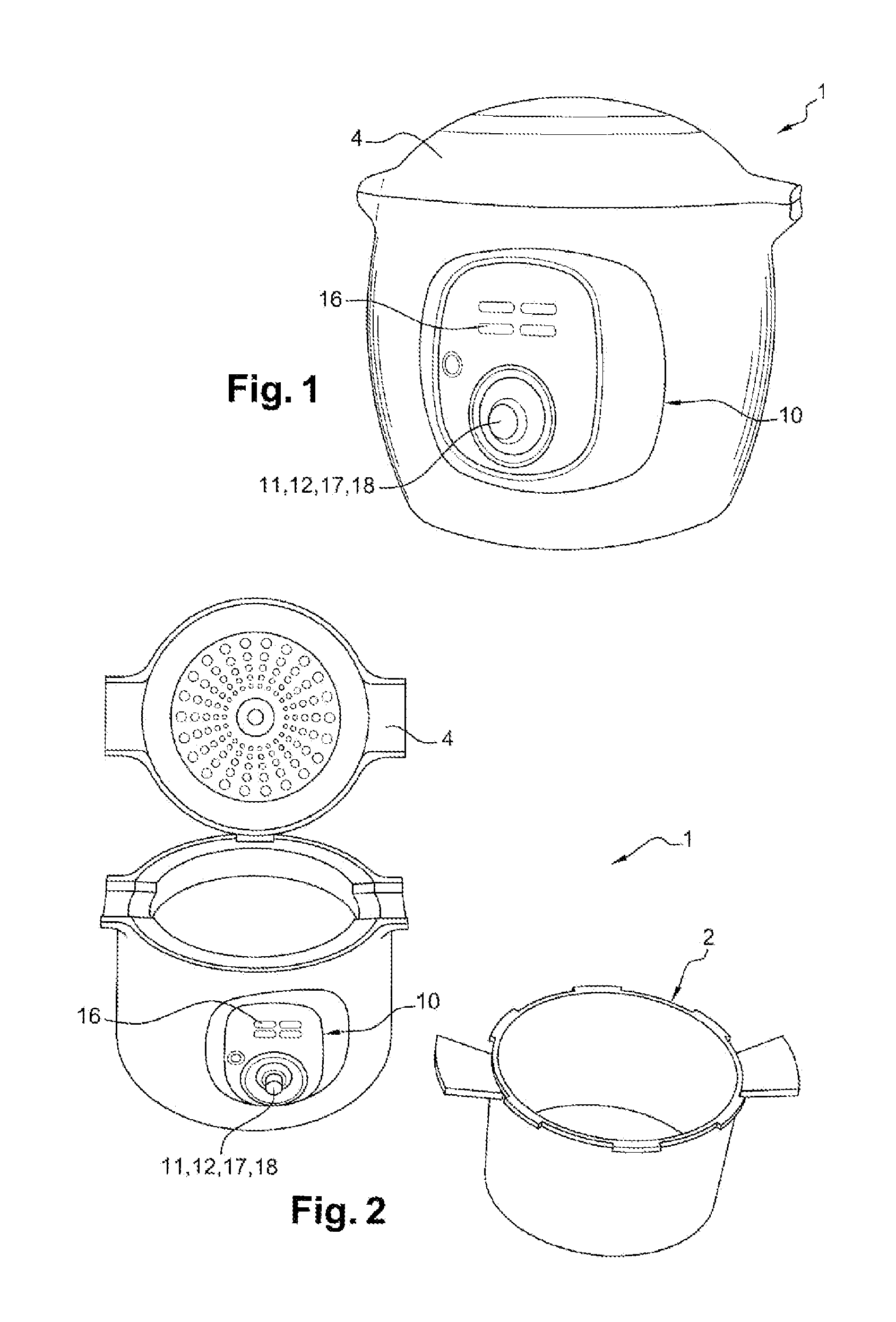

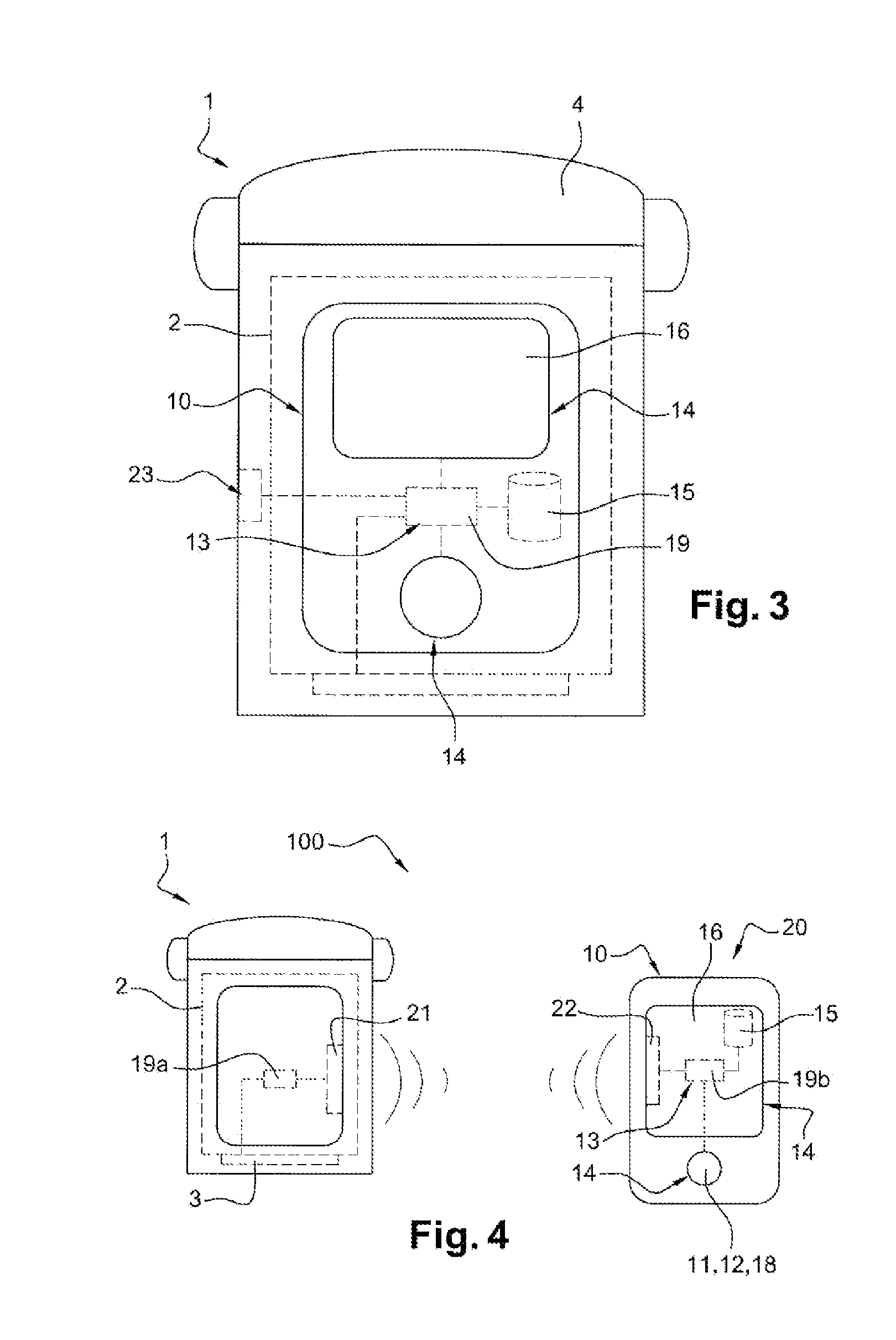

Cooking device

ActiveUS20130125763A1Optimize its cookingAccurate representationDomestic stoves or rangesBoiling over preventionAdditive ingredientProcess engineering

A control device for a cooking appliance, the cooking appliance including a cooking chamber designed to receive at least one predetermined food or a plurality of ingredients of a predetermined recipe, a heating component for heating the cooking chamber, the control device including a control unit arranged to determine at least one combination of predetermined cooking parameters as a function at least of the specific surface area of the at least one unitary element of the at least one predetermined food or the at least one ingredient of the plurality of ingredients of the predetermined recipe inserted into the cooking chamber of the cooking appliance, the specific surface area being estimated from descriptive parameters of the at least one unitary element of the predetermined food or the at least one ingredient from among the plurality of ingredients of the predetermined recipe.

Owner:SEB SA

High chamber temperature process and chamber design for photo-resist stripping and post-metal etch passivation

ActiveCN101523592AElectric discharge tubesSemiconductor/solid-state device manufacturingResistVacuum chamber

A vacuum chamber for passivation and / or stripping a photoresist layer formed on a semiconductor substrate. The chamber includes an internal chamber body that forms a cavity to surround the substrate and has a plurality of gas passages extending therethrough to the cavity and one or more heaters to heat the internal chamber body. The internal chamber body is slidably mounted on an external chamber body that surrounds a side of the internal chamber with a gap therebetween. The device also includes: an exhaust unit operative to pump the gas from the cavity; a chamber top mounted on the internal chamber body to cover a top surface of the internal chamber body with a gap therebetween and having an opening in fluid communication with the gas passages; and a plasma source operative to energize the gas into a plasma state and coupled to the opening for fluid communication with the cavity.

Owner:LAM RES CORP

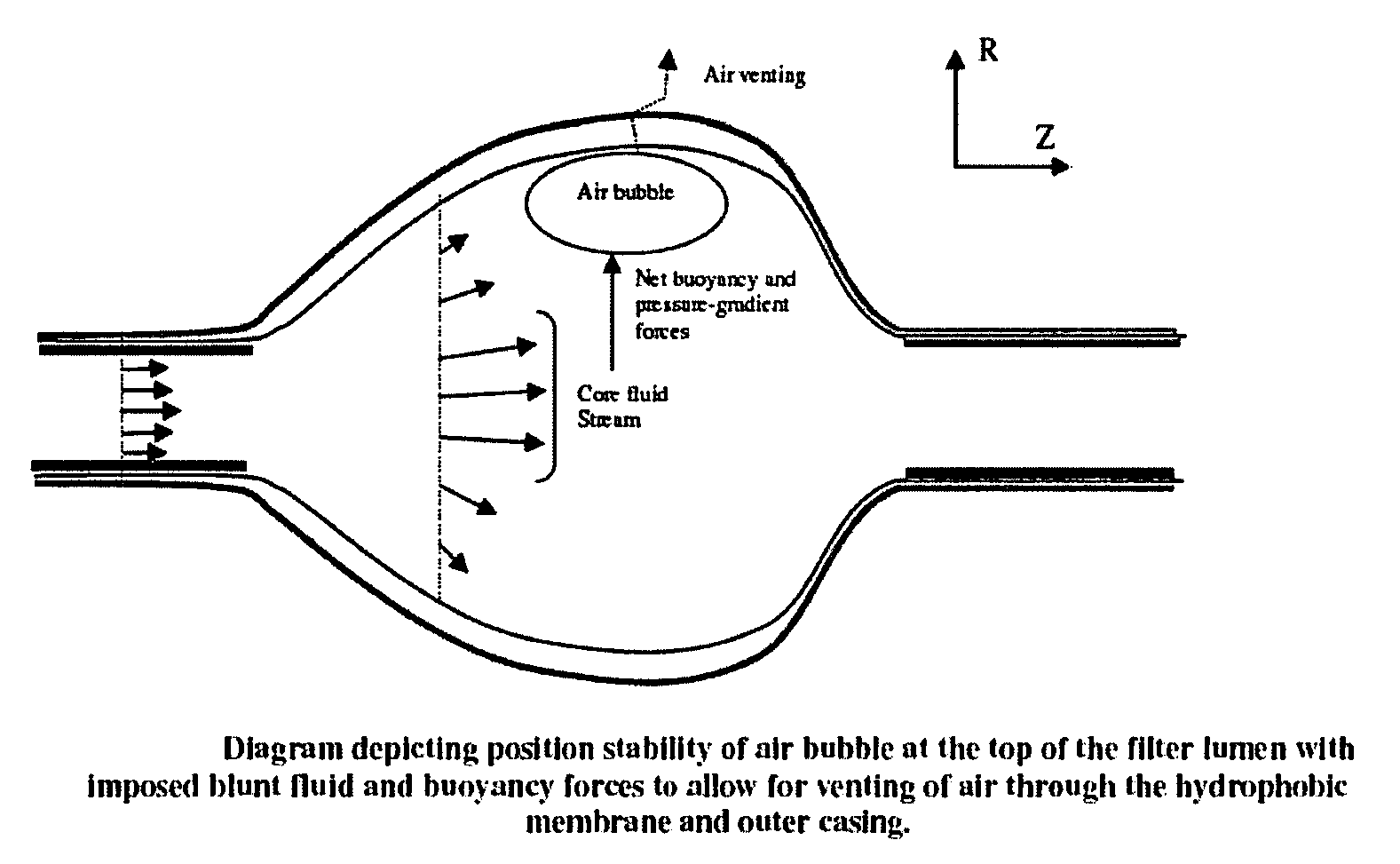

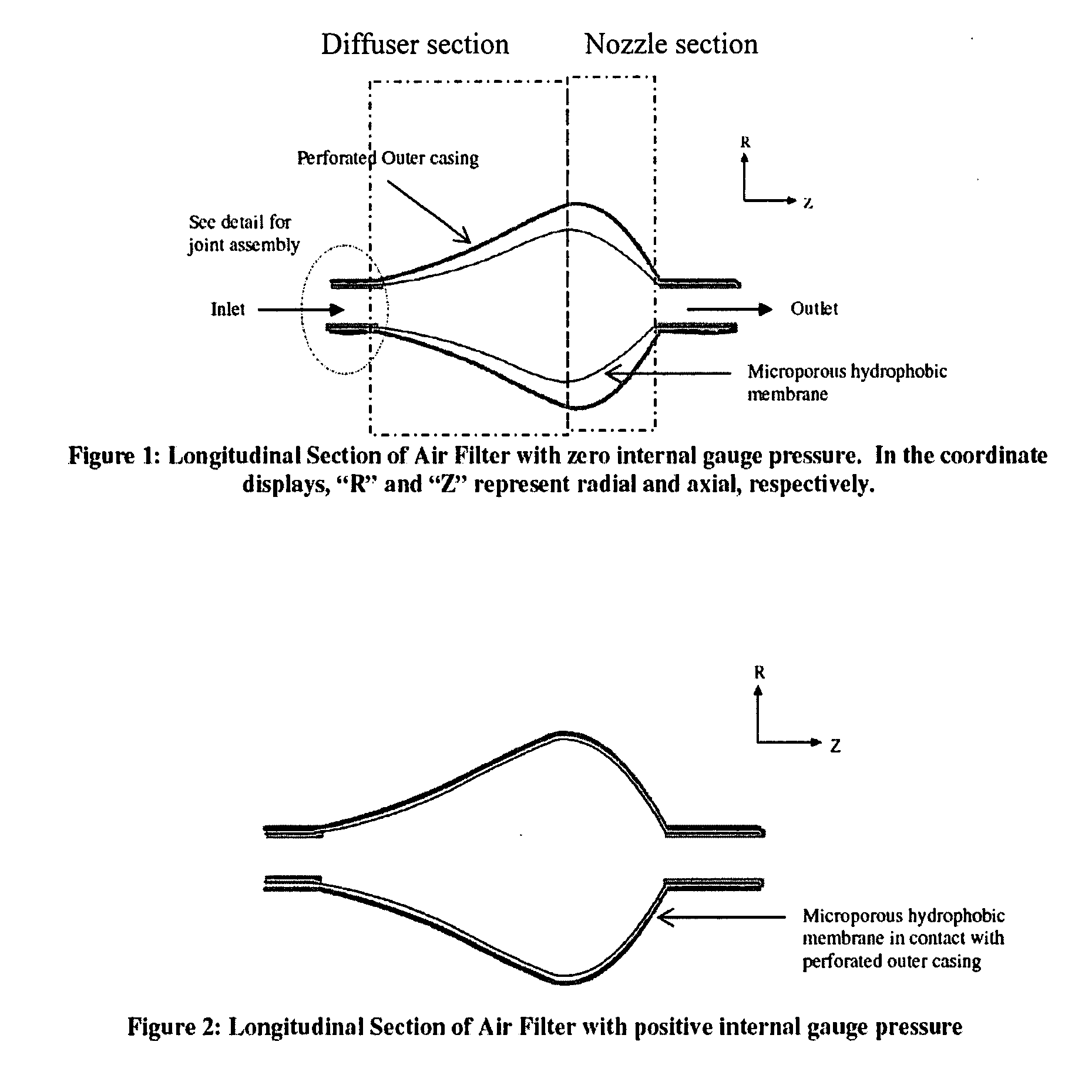

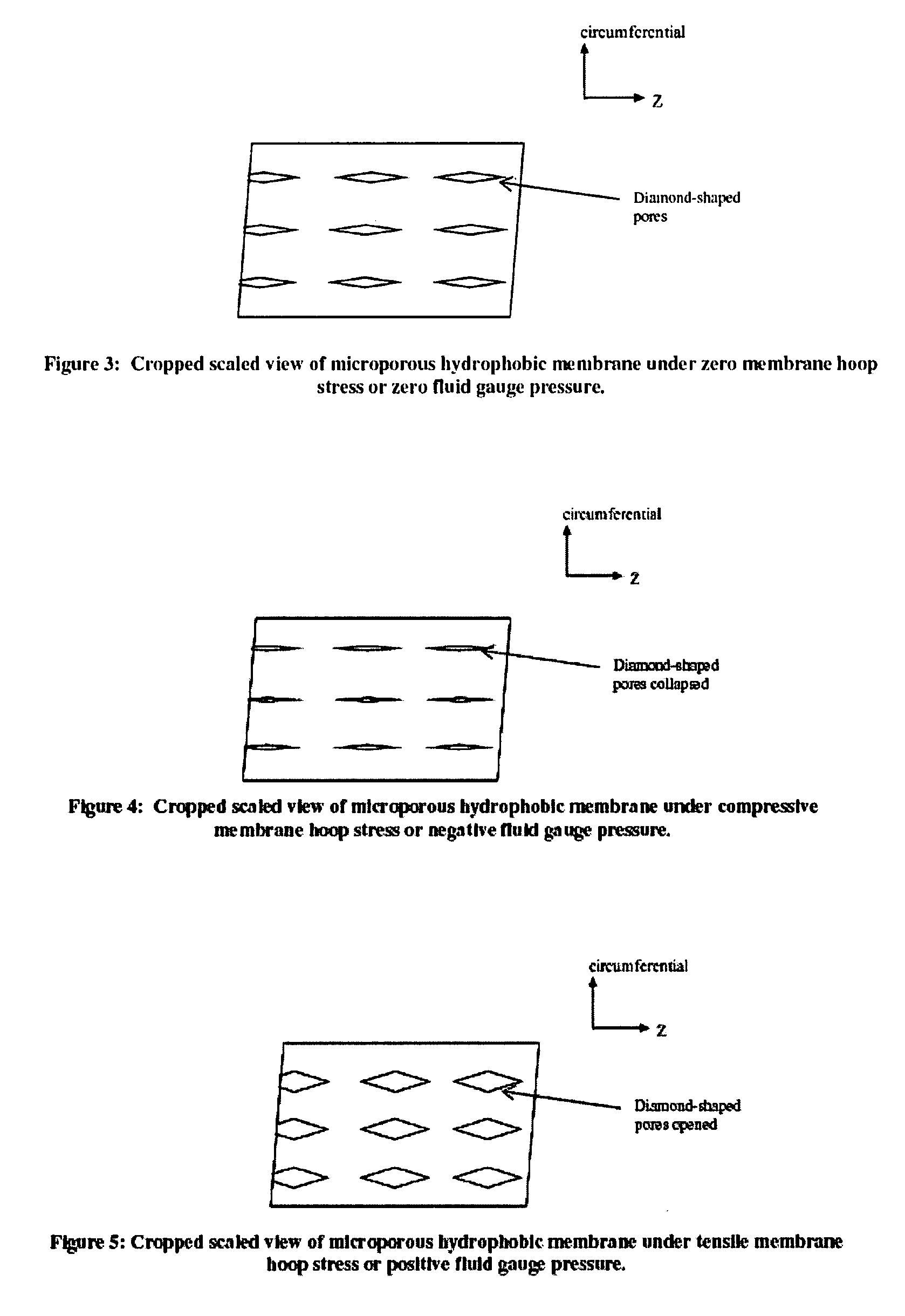

Open lumen air filtration for liquid lines

ActiveUS20100218679A1Improve filtering effectLow flow resistanceIsotope separationLiquid degasification by filtrationLiquid lineAir filtration

Devices and systems for capturing and removing accumulated gas bubbles in a liquid-carrying line wherein the device is an expanded double-layered chamber designed and adapted to be integrally placed within the flow pathway of a liquid-carrying line. The device allows insertion of tubes and wires through the device while in use without occlusion of the fluid flow path and without interruption of the bubble-removing function. The efficiency of the air venting and bubble-removing process is not dependent on the fluid flow rate under stable flow conditions, and the device works to remove air bubbles under a range of orientations.

Owner:HEKMAT NEEMA +1

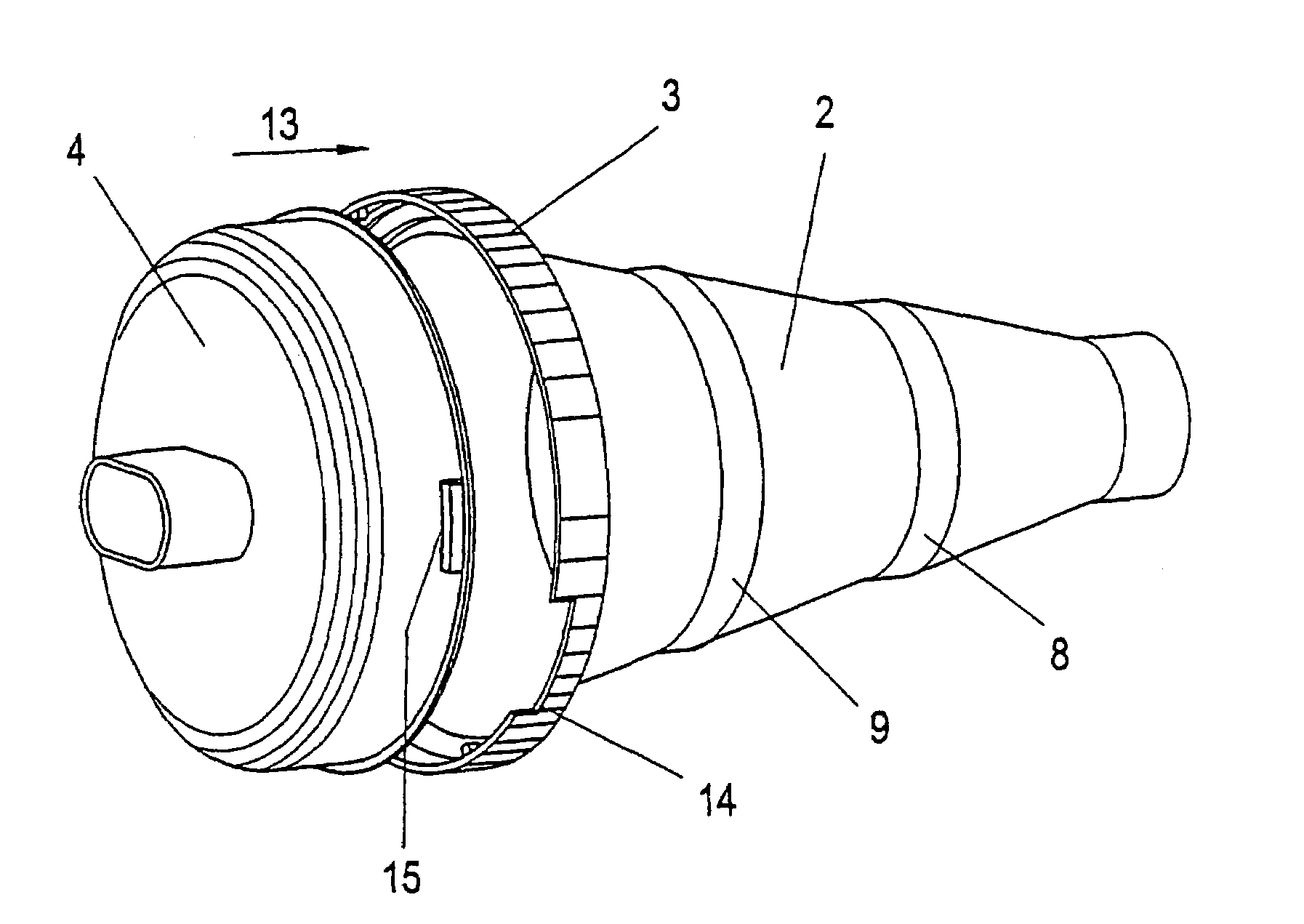

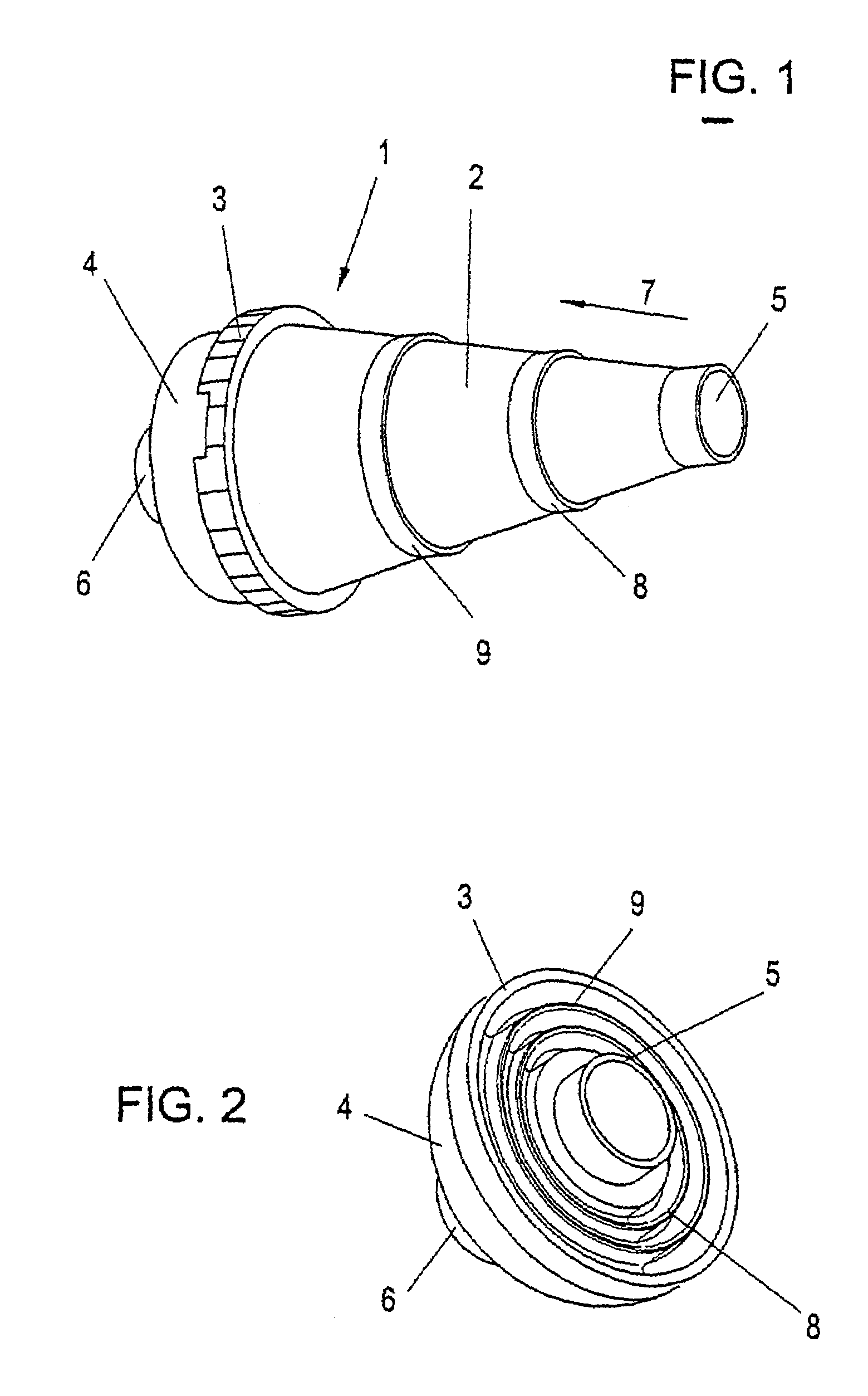

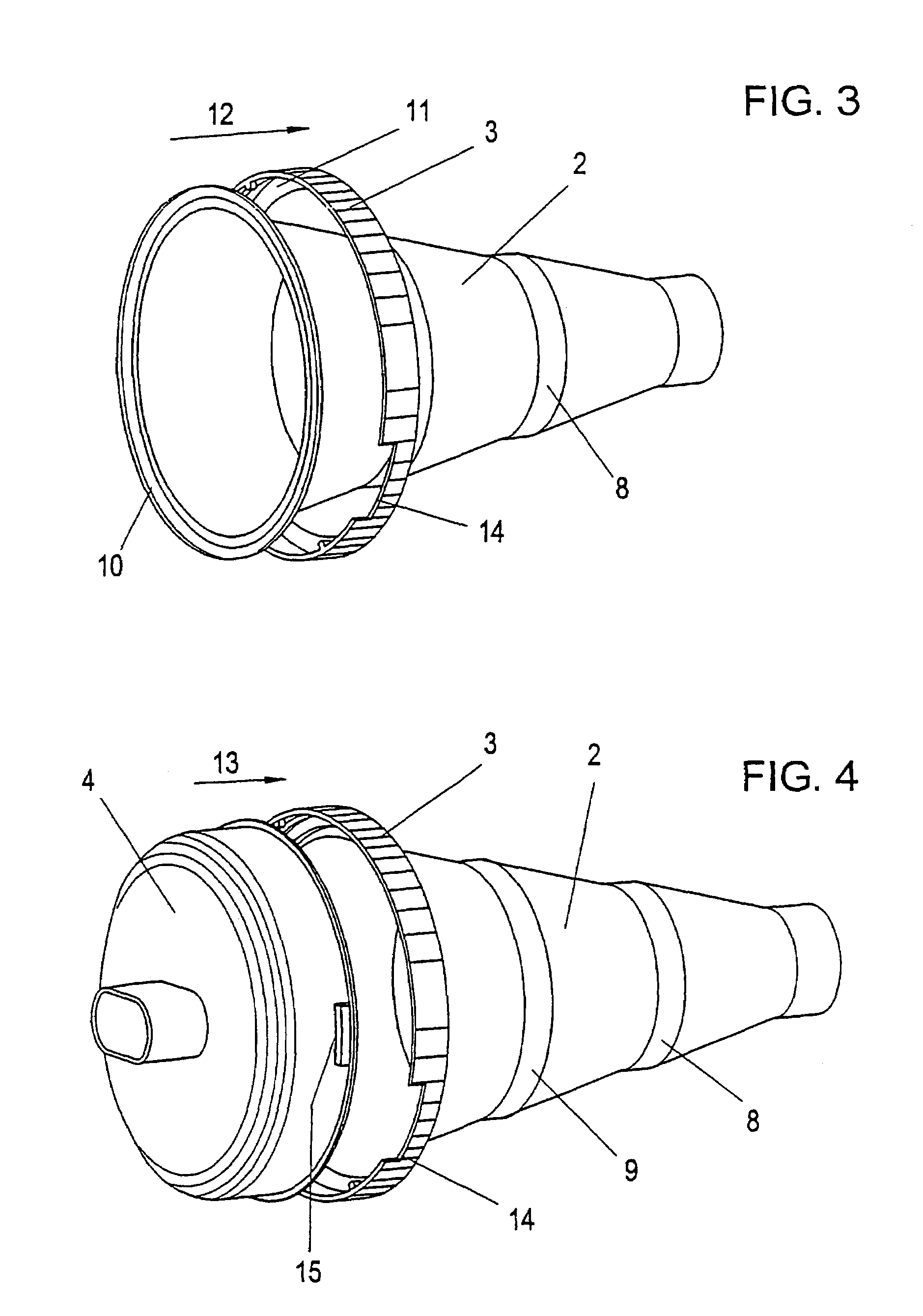

Inhalation aid

InactiveUS7556037B2Increase in sizeUniform materialRespiratorsLiquid surface applicatorsMedicineInhalation

Owner:INT PROD & SERVICES GRP

Implantable pump with infinitely variable resistor

InactiveUS20070005044A1Increase and decrease flow rateInfusion devicesPharmaceutical delivery mechanismMembrane configurationResistor

A variable hydraulic resistor for use with implantable pumps is disclosed. The variable hydraulic resistor according to the present invention is particularly useful in varying the flow rate of a medication fluid from an otherwise constant flow implantable pump. An implantable pump is also disclosed, which does not require a complicated clinching system or the like, and which may include an undulating membrane and chamber design to reduce the height of the pump.

Owner:PALYON MEDICAL BVI

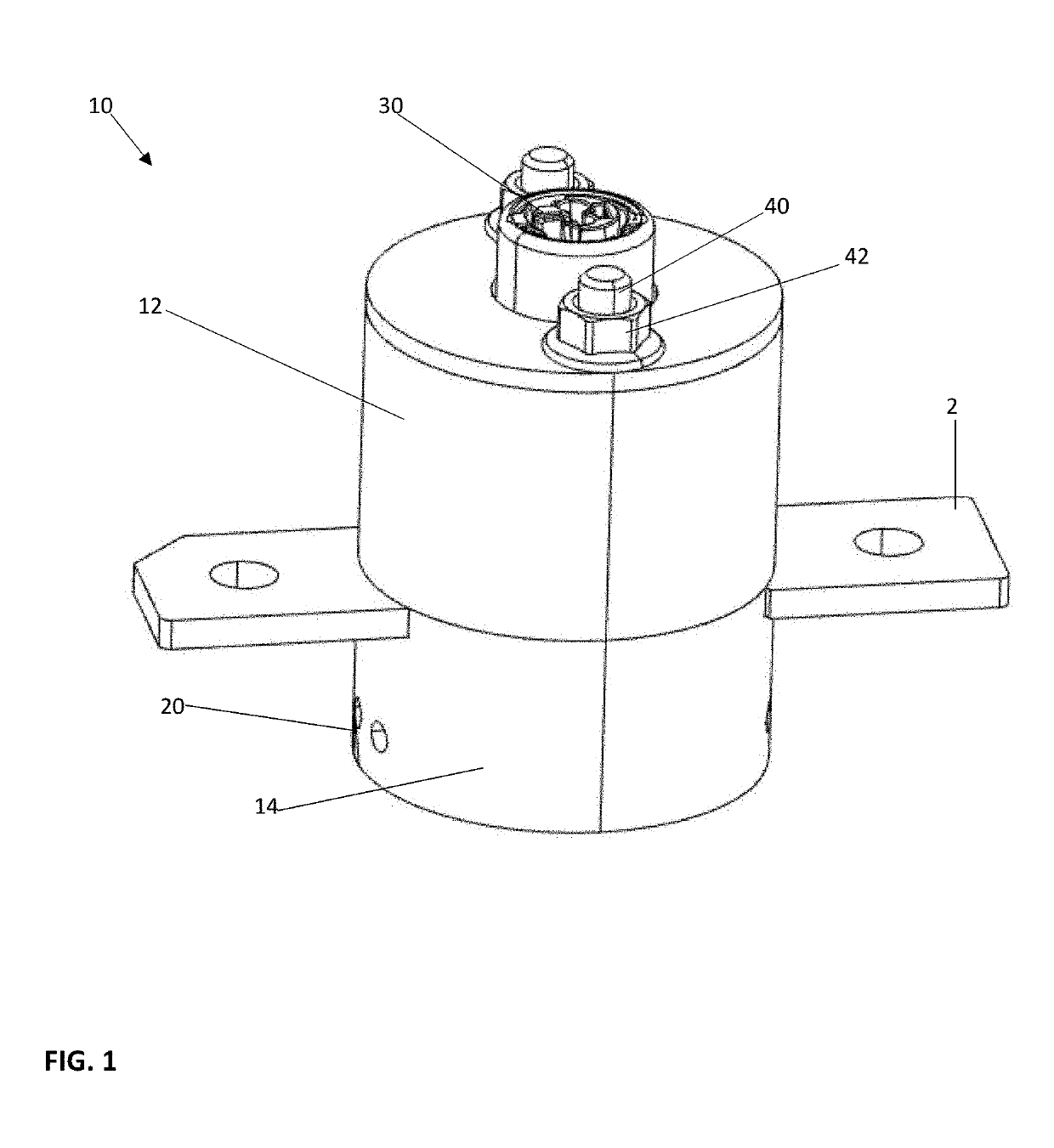

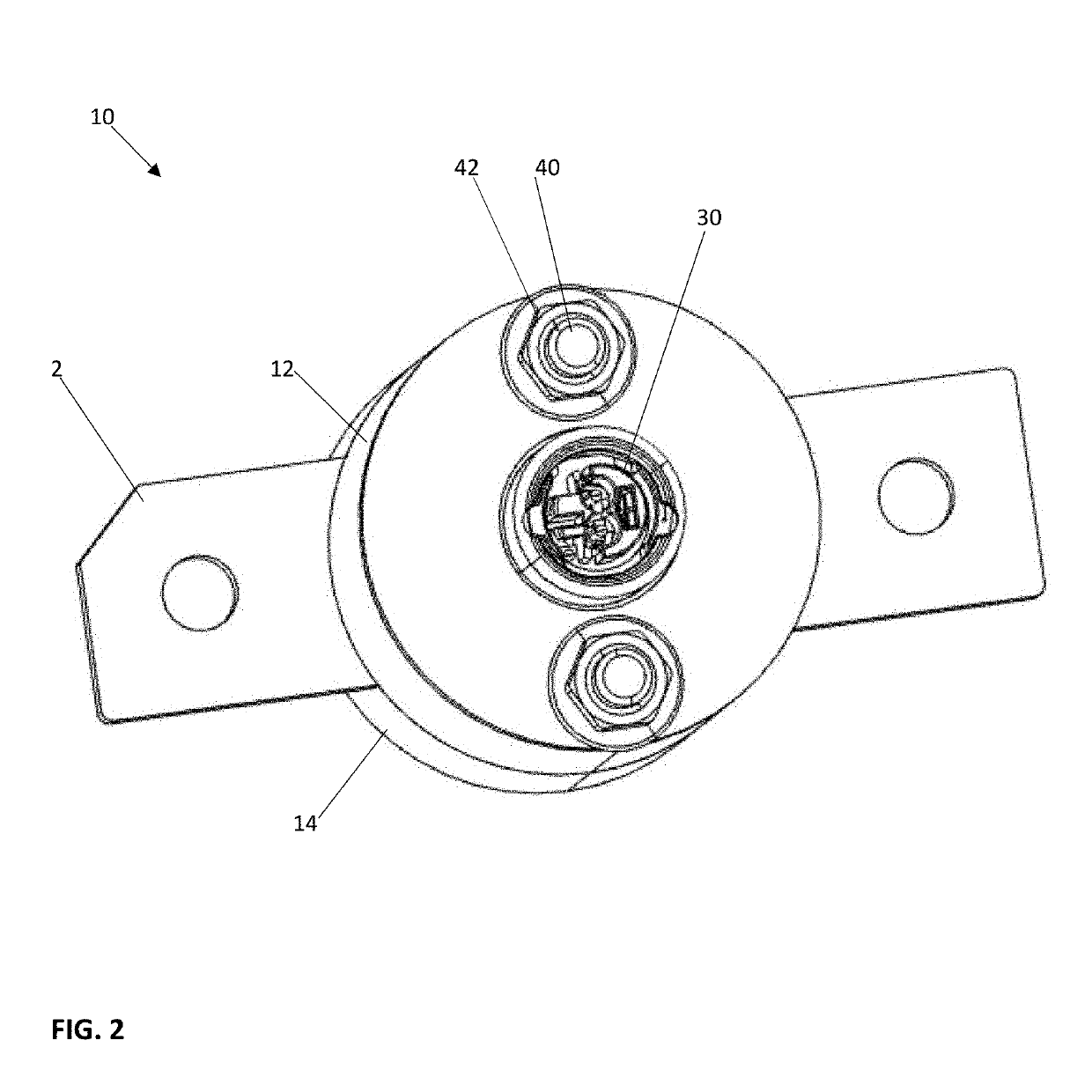

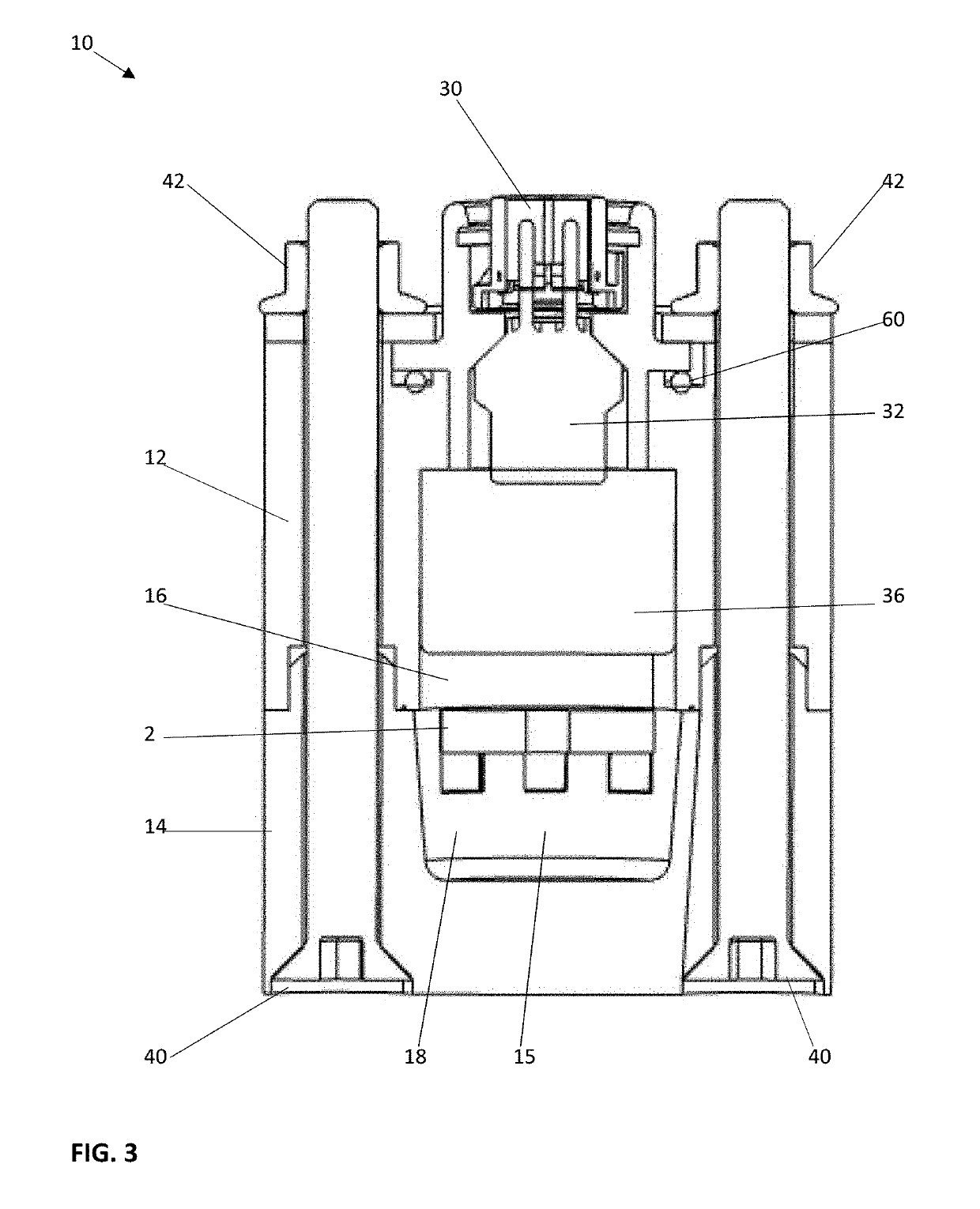

High voltage electric line cutter device

ActiveUS20190108957A1High voltage be generateHigh voltageProtective switch detailsBus-bar/wiring layoutsElectric dischargeBusbar

An electric line cutter device for high voltage busbars has a two-part housing, a piston, an igniter and a busbar. The upper housing includes a cylinder, cuboid or prism chamber. The lower housing also includes a cylinder, cuboid or prism chamber. The piston is contained inside one of either the upper housing chamber or the lower housing chamber. Upon igniting the igniter, the piston breaks a portion of the busbar moving the piston and the portion of the busbar into the opposite chamber thereby stopping the electric current flow. The piston is at least partially formed as an insulator to prevent electric discharge. The piston design together with chamber design includes integrated “squeeze areas” and “blow channels” for the appearing arc. A channel system outside or from inside the piston allow the pyro gases to push the arc plasma into a filter system to cool down the gases.

Owner:KEY SAFETY SYST

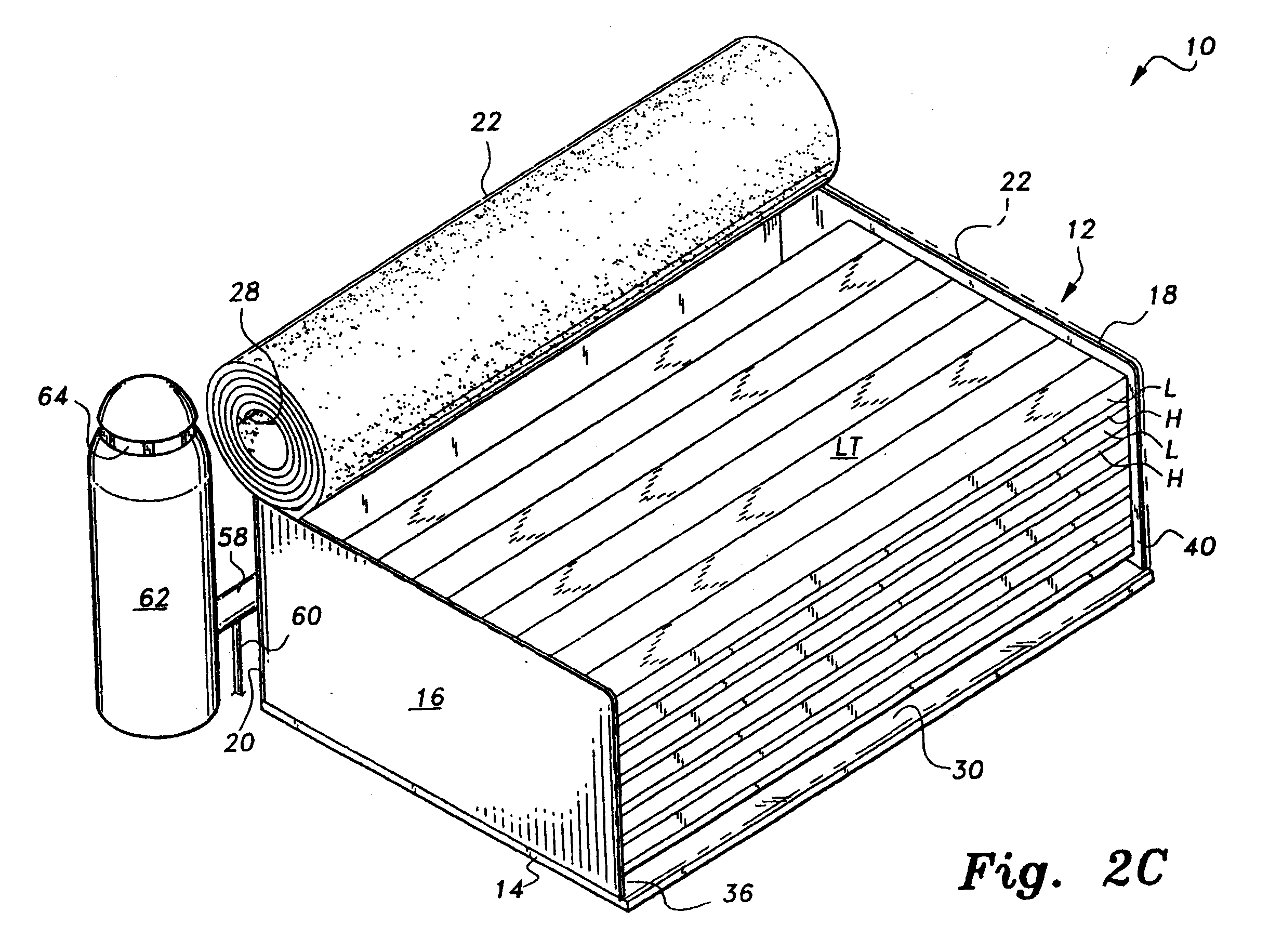

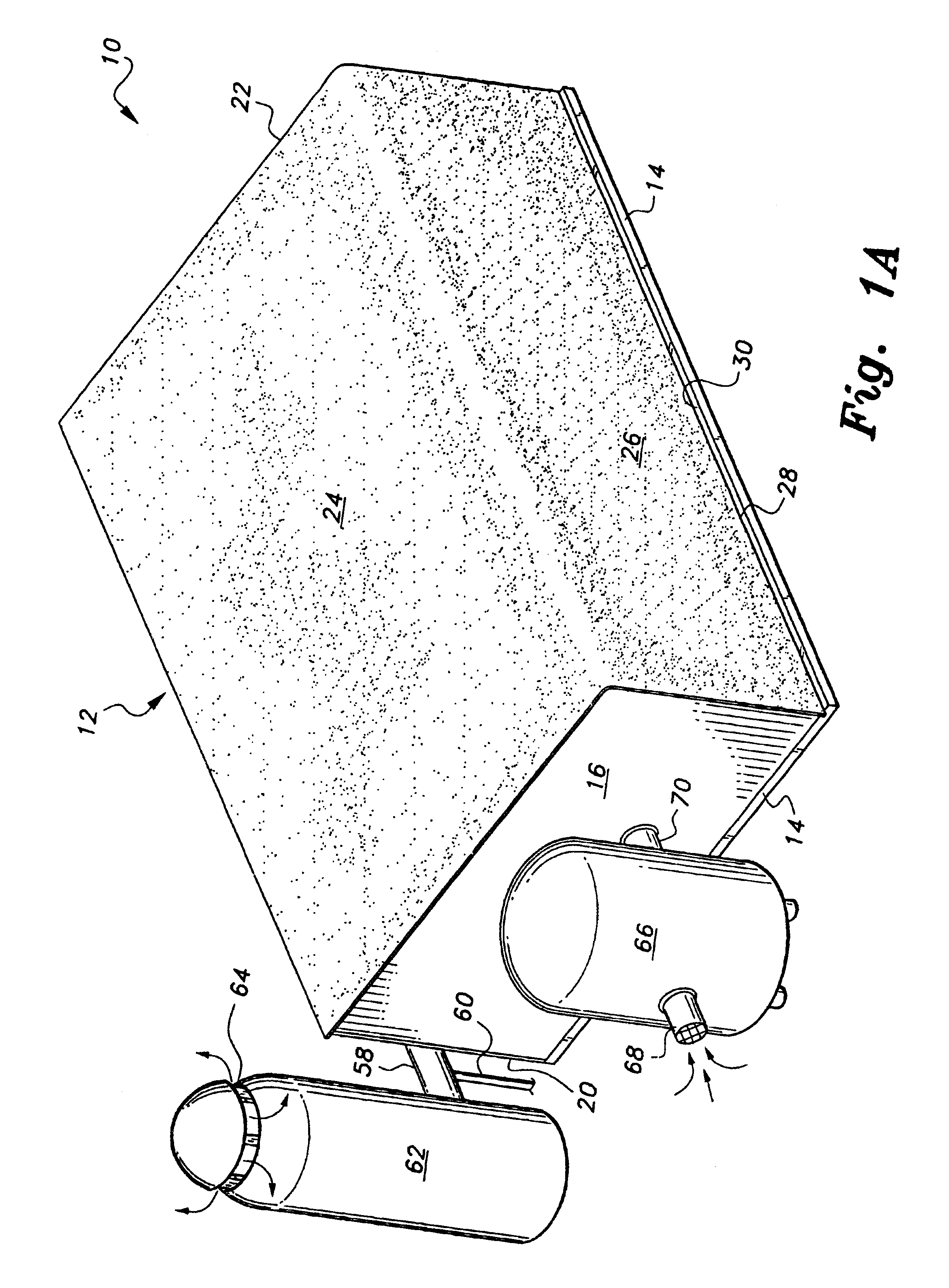

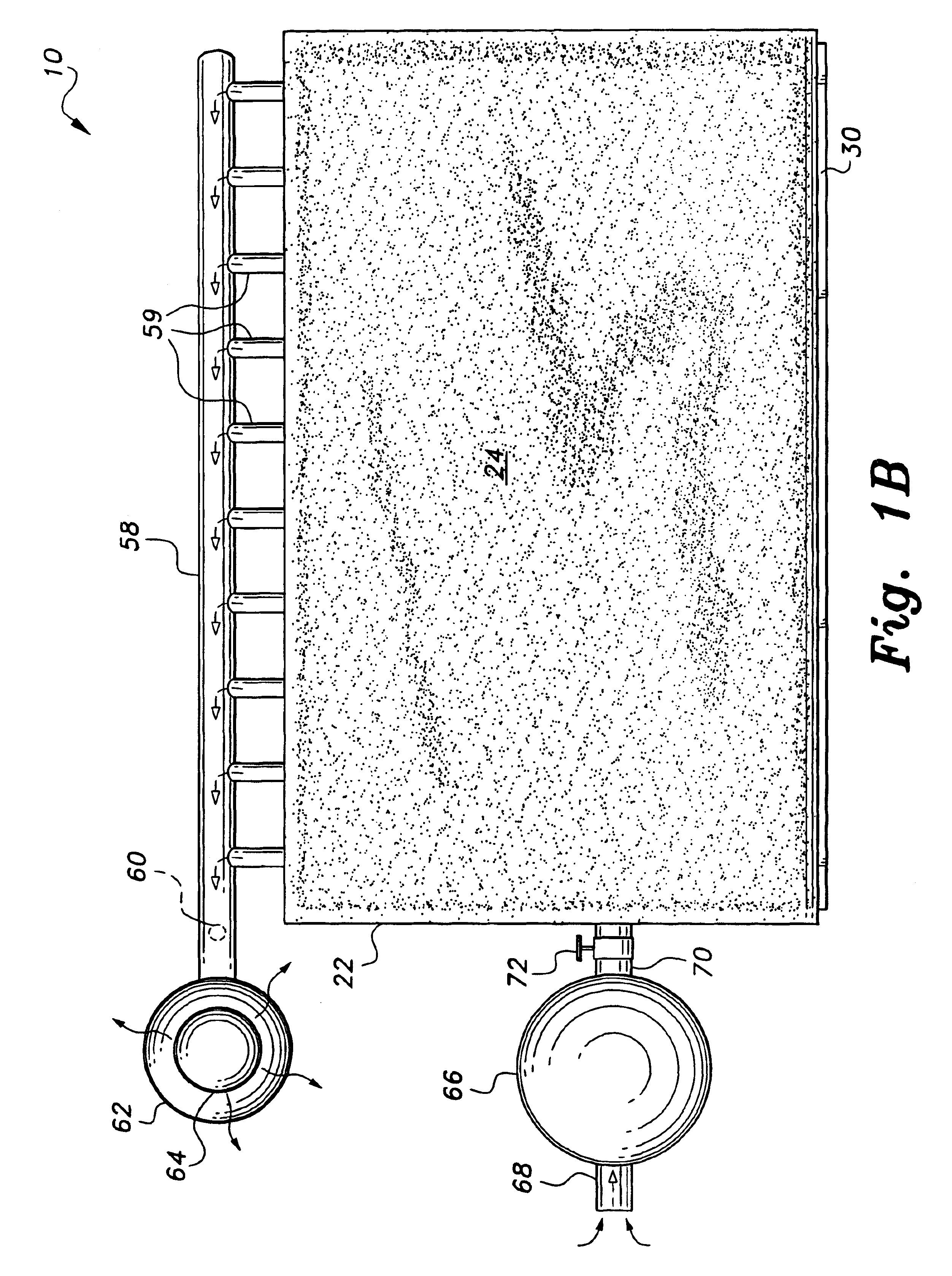

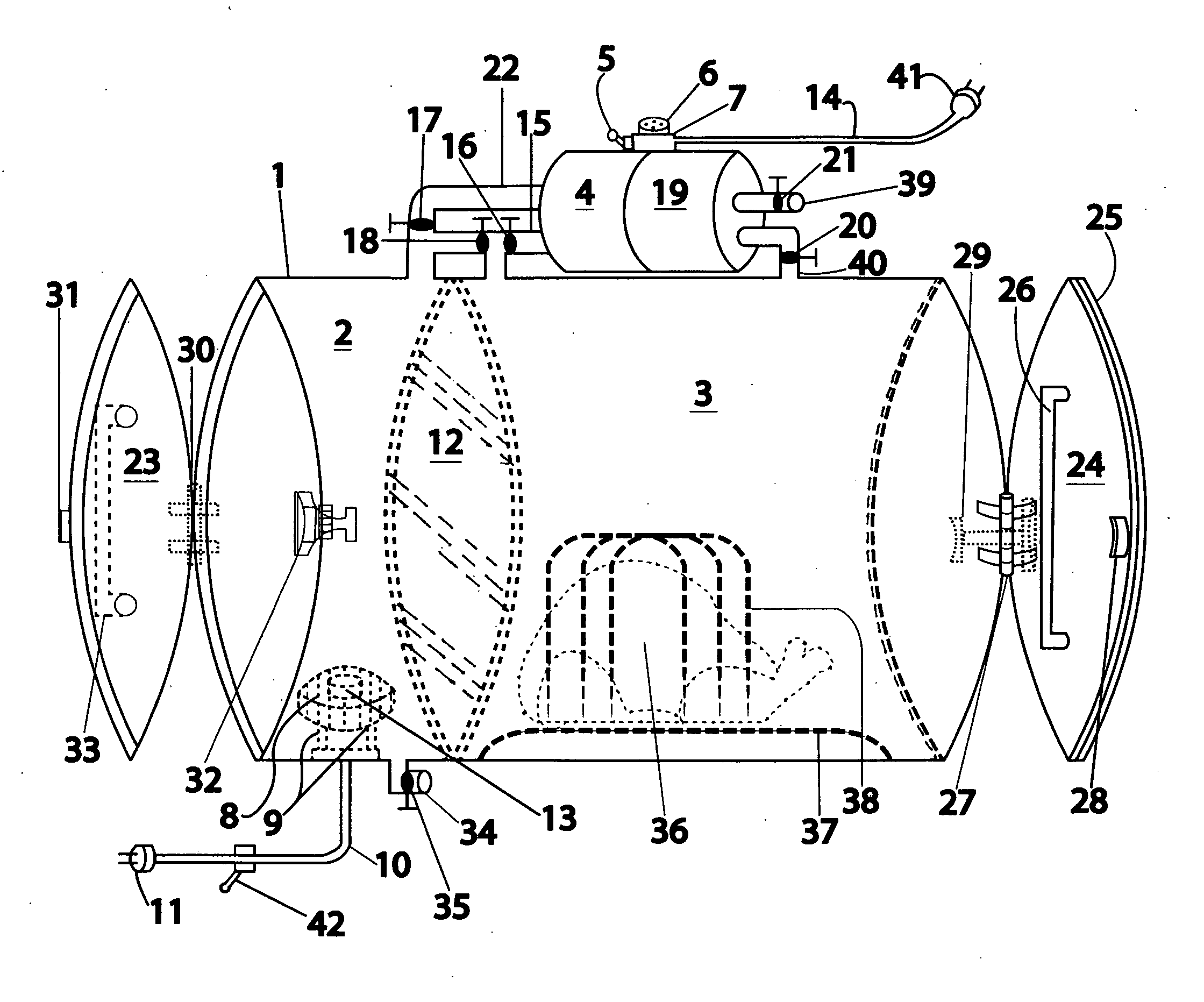

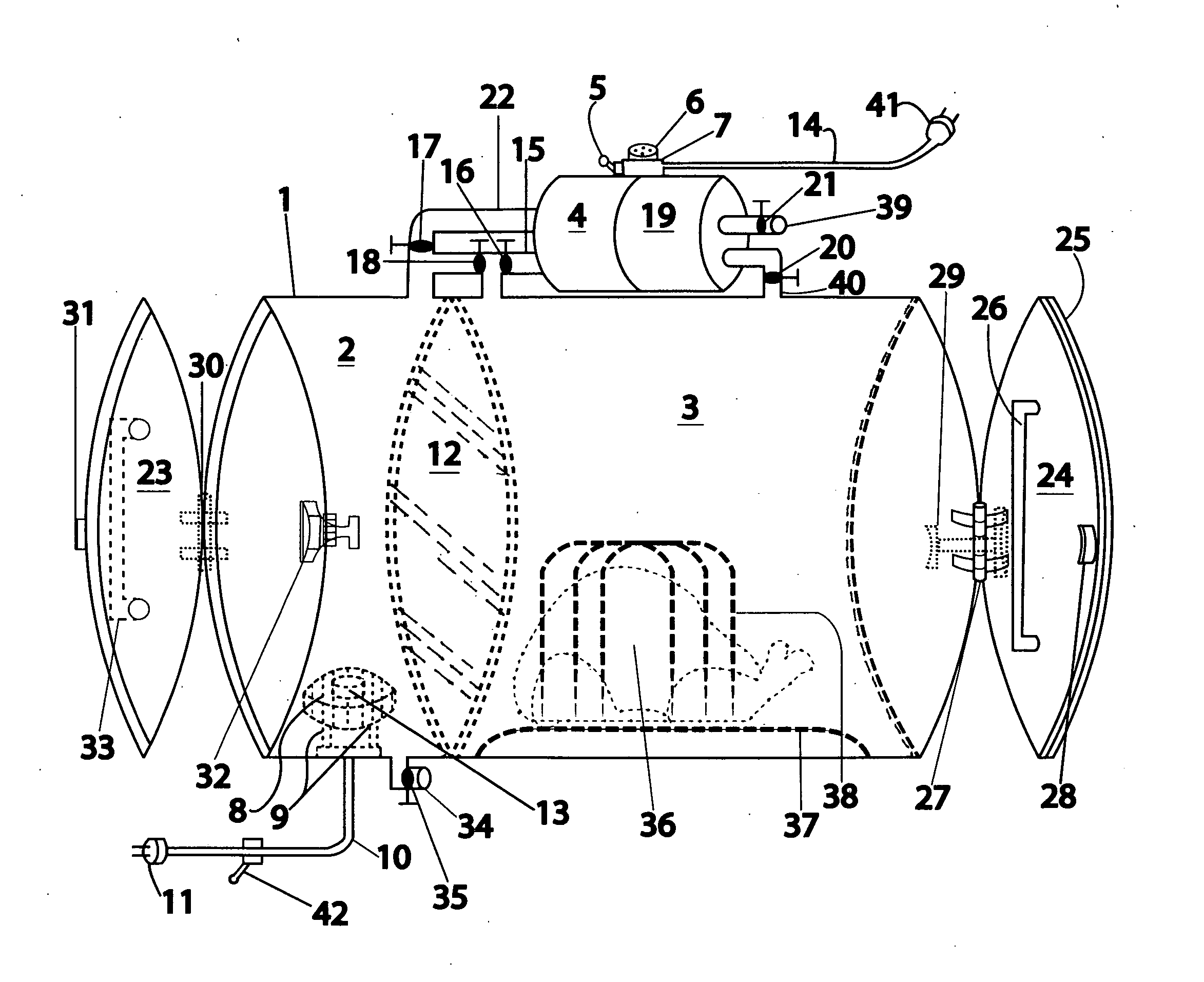

Vacuum lumber drying kiln with collapsing cover and method of use

InactiveUS6865821B2Low costFlexible in of operationDrying using combination processesDrying solid materials with heatEngineeringReinforced rubber

A lumber drying kiln employs outside air pressure uses a flexible collapsing bag or cover alone or in combination with walls. The collapsing bag seals against a base to maintain the vacuum. The air pressure against the flexible top keeps the lumber layers from warping or cupping during drying. The lumber stack has alternating layers of hot plates or stickers separating layers of lumber. A bag having an open bottom and made of nylon-reinforced rubber or other strong flexible material is placed over the wood and sealed to the stainless steel platform. A vacuum pump is connected with the bag by means of a manifold and operated to remove air from the enclosed lumber stack, the vacuum strengthening the seal between the base and the bottom of the bag. This chamber design is easily scaled up or down to provide a desired drying capacity.

Owner:MERSCHAT JOHN R

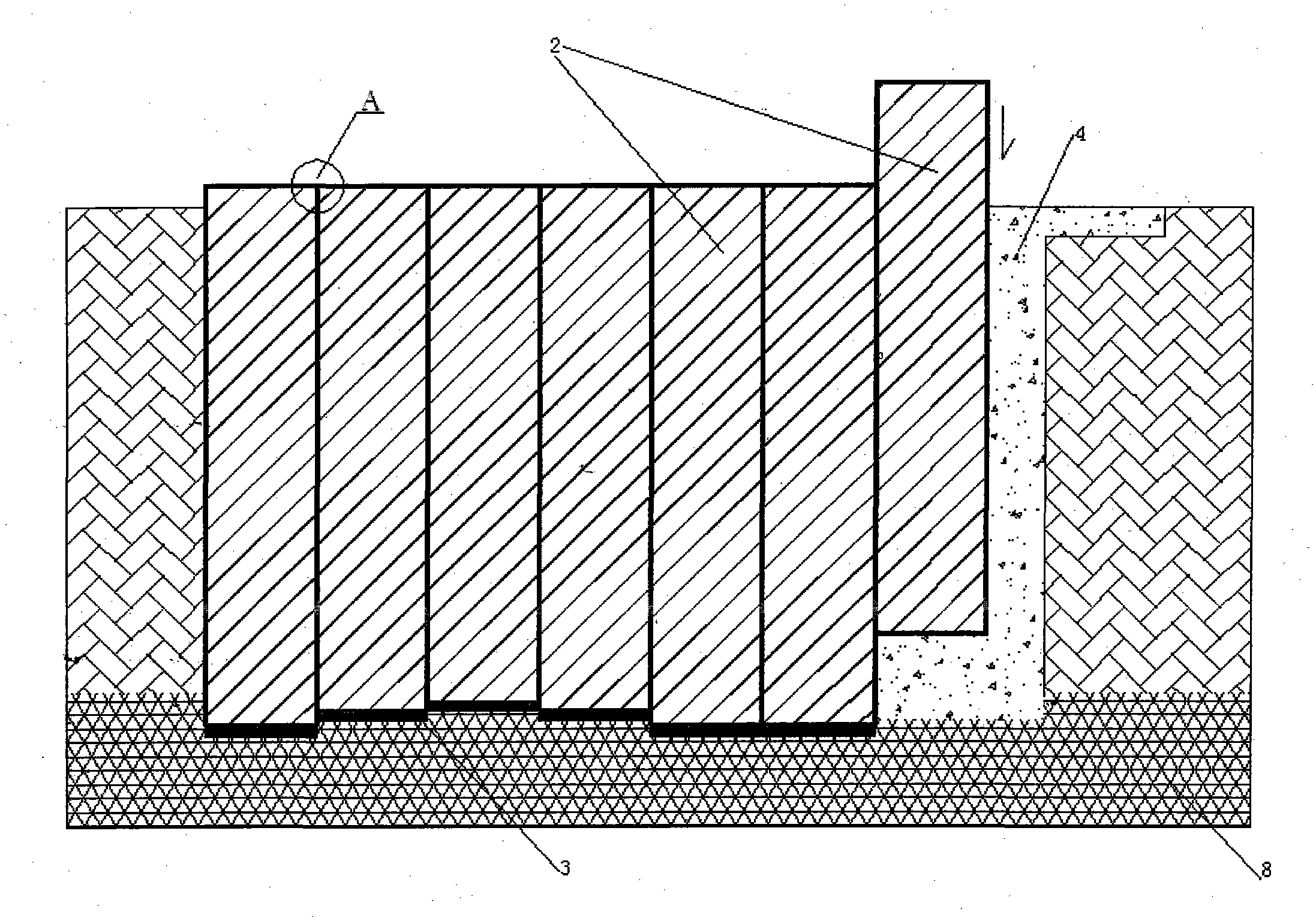

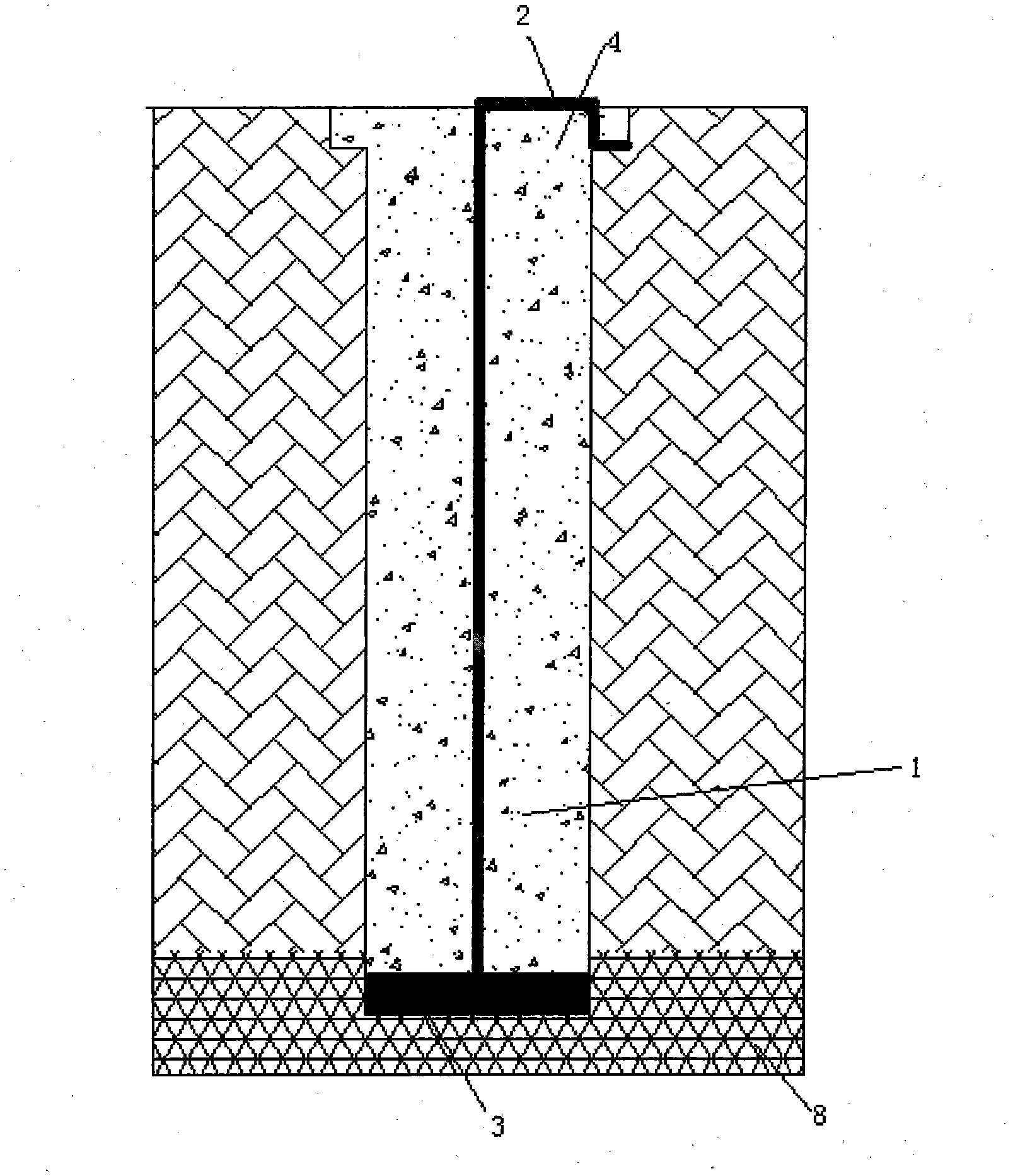

Method for installing vertical soft barrier system based on soil-stone foundation

InactiveCN102367672ADoes not affect the anti-seepage functionStop the spreadArtificial islandsProtective foundationGeomembraneChemical grouting

The invention discloses a method for installing a vertical soft barrier system based on a soil-stone foundation. The method comprises the following steps of: digging a ditch for installing the vertical soft barrier system; refilling anti-seepage slurry into the ditch to form a retaining wall protection layer; installing an HDPE (High-Density Polyethylene) geomembrane in the ditch by using a support tool to form an HDPE geomembrane wall; chemically grouting and sealing the bottom of the HDPE geomembrane wall to form a bottom sealing layer; and withdrawing the support tool to form the vertical soft barrier system. Due to the adoption of the method, an anti-seepage function is ensured, seepage at a joint is prevented, and isolated liquid is effectively prevented from being dispersed; the horizontal dispersion of pollutants can be prevented and blocked for a long time; a connecting lock piece has a reversely-rotatable HDPE structure of which the positive and negative surfaces can be replaced by each other, is provided with a plurality of sealing chambers, can be used for accommodating a plurality of sealing materials and joint seepage detection systems, and is easy to install and operate; an expansion water blocking gasket can expand after contacting water, so that liquid is prevented from flowing through a porous sealing device, and persistent sealing is ensured; and a large installation depth is realized.

Owner:BEIJING GEOENVIRON ENG & TECH

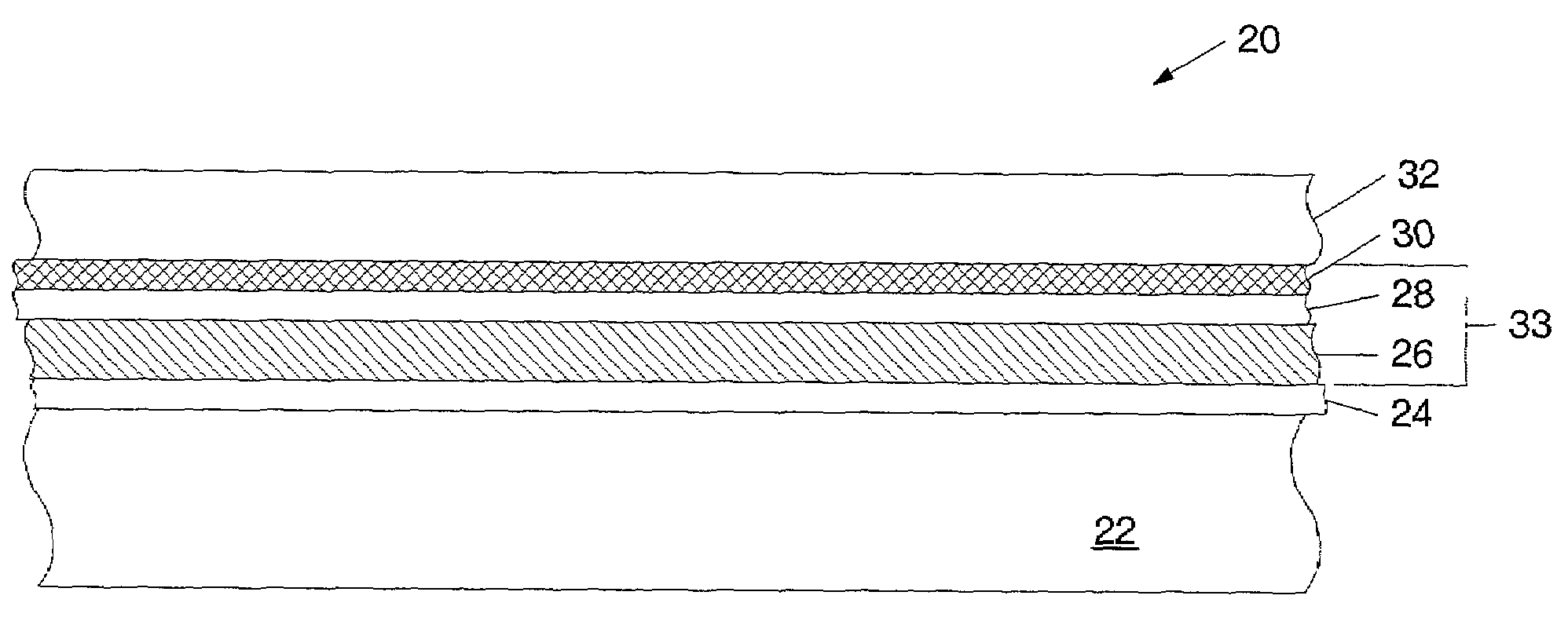

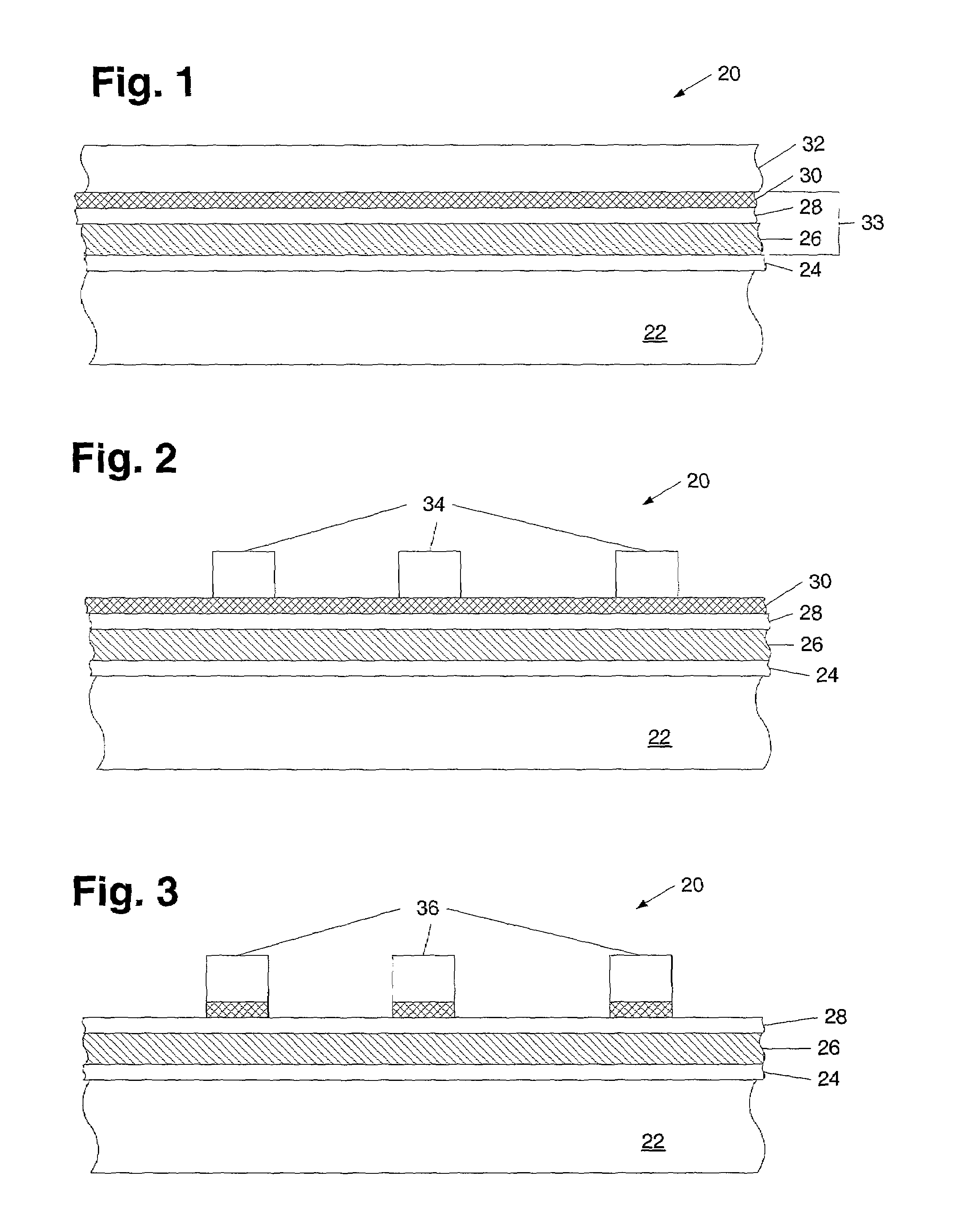

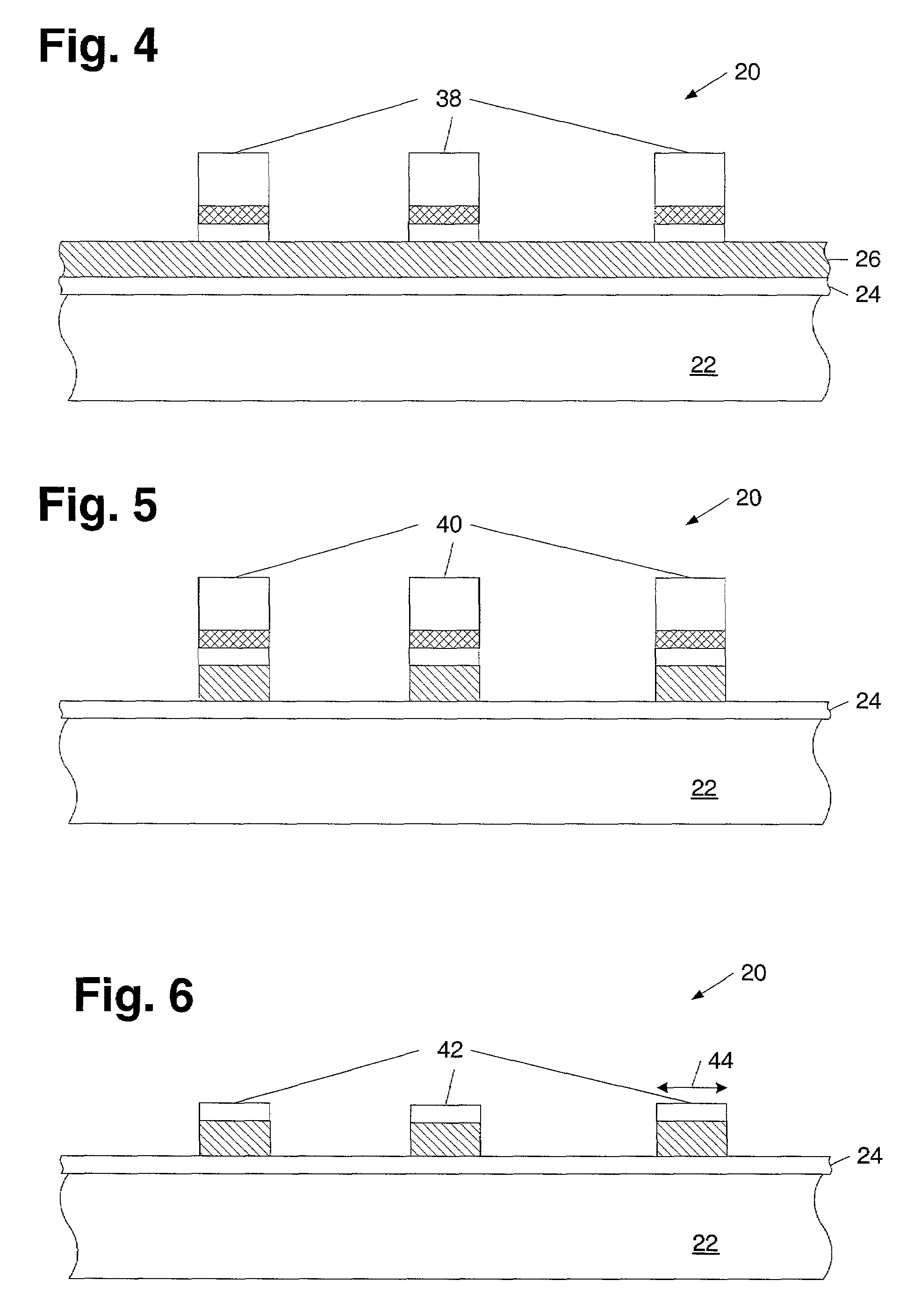

Reducing defect formation within an etched semiconductor topography

InactiveUS7129178B1Reduce formationReduce removalSemiconductor/solid-state device manufacturingNoble gasTopography

A method is provided which includes etching one or more layers in an etch chamber while introducing a noble gas heavier than helium into the etch chamber. In a preferred embodiment, the introduction of such a noble gas may reduce the formation of defects within an etched portion of the semiconductor topography. Such defects may include bilayer mounds of nitride and a material comprising silicon, for example. In some embodiments, the method may include etching a stack of layers within a single etch chamber. The stack of layers may include, for example, a nitride layer interposed between an anti-reflective layer and an underlying layer. In addition, the single etch chamber may be a plasma etch chamber designed to etch materials comprising silicon. As such, the method may include etching an anti-reflective layer in a plasma etch chamber designed to etch materials comprising silicon.

Owner:MONTEREY RES LLC

Reduced size implantable pump

InactiveUS20060259016A1Increase and decrease flow rateAlter shapeInfusion devicesMedical devicesReduced sizeMembrane configuration

A variable hydraulic resistor for use with implantable pumps is disclosed. The variable hydraulic resistor according to the present invention is particularly useful in varying the flow rate of a medication fluid from an otherwise constant flow implantable pump. An implantable pump is also disclosed, which does not require a complicated clinching system or the like, and which may include an undulating membrane and chamber design to reduce the height of the pump.

Owner:AQULINX MEDICAL

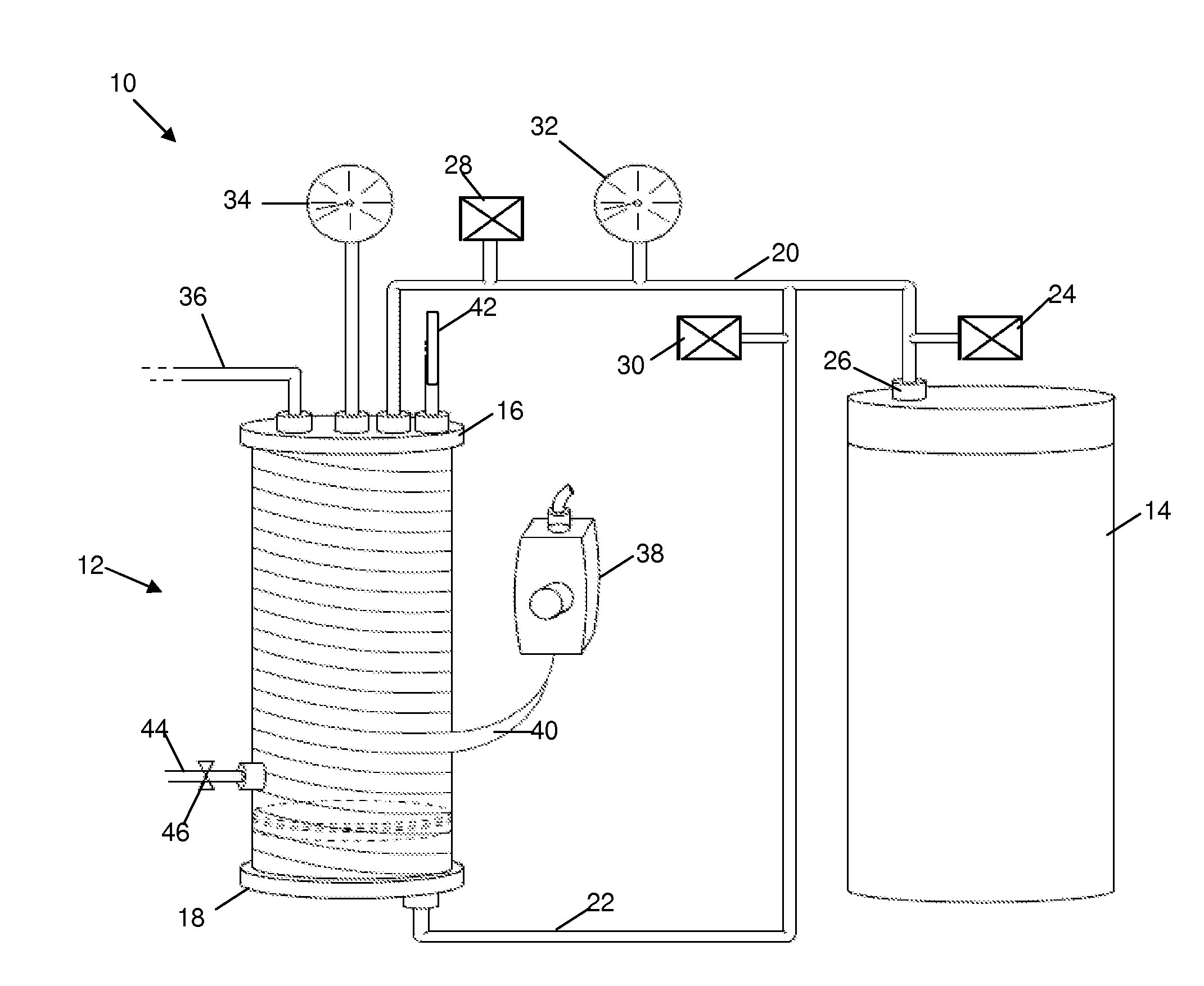

Fuel processor dewar and methods

ActiveUS20050005521A1Promote hydrogen productionIncreased hydrogen productionPressurized chemical processLevel controlCombustorHydrogen

Described herein is a fuel processor that produces hydrogen from a fuel source. The fuel processor comprises a reformer and burner. The reformer includes a catalyst that facilitates the production of hydrogen from the fuel source. Voluminous reformer chamber designs are provided that increase the amount of catalyst that can be used in a reformer and increase hydrogen output for a given fuel processor size. The burner provides heat to the reformer. One or more burners may be configured to surround a reformer on multiple sides to increase thermal transfer to the reformer. Dewars are also described that increase thermal management of a fuel processor and increase burner efficiency. A dewar includes one or more dewar chambers that receive inlet process gas or liquid before a burner receives the process gas or liquid. The dewar is arranged such that process gas or liquid passing through the dewar chamber intercepts heat generated in the burner before the heat escapes the fuel processor.

Owner:ADVENT TECH LLC

Food smoker apparatus

ActiveUS20110247505A1Short timeAdd flavorMeat/fish preservationClimate change adaptationFlavorEngineering

This invention comprises a new process for imparting the flavor of smoke to food and consists of a vacuum / compression chamber designed for the placement of meat or other food product within; and which can be sealed to create an airtight condition within; and which is connected by an adjustable valve or valves to a smoke producing chamber capable of producing smoke saturated air which can be sucked into said vacuum / compression chamber by an attached vacuum pump, causing said smoke saturated air to be pulled deeper into said meat or other food product than would occur under normal exposure conditions; and subsequently pushed further into said meat or other food product by compression of said smoke saturated air within said vacuum / compression chamber; and this process can be enhanced by piercing meat or other food product with a skewer device which creates more exposed surface within the meat or other food item.

Owner:DAVIS GEORGE MICHAEL

Tools and methods for processing microelectronic workpieces using process chamber designs that easily transition between open and closed modes of operation

ActiveUS8235062B2Easy to closeEasy transitionSpraying apparatusVacuum evaporation coatingProcess engineeringAmbient air

Strategies for tool designs and their uses wherein the tools can operate in either closed or open modes of operation. The tools easily transition between open and closed modes on demand. According to one general strategy, environmentally controlled pathway(s) couple the ambient to one or more process chambers. Air amplification capabilities upstream from the process chamber(s) allow substantial flows of air to be introduced into the process chamber(s) on demand. Alternatively, the fluid pathways are easily closed, such as by simple valve actuation, to block egress to the ambient through these pathways. Alternative flows of nonambient fluids can then be introduced into the process chamber(s) via pathways that are at least partially in common with the pathways used for ambient air introduction. In other strategies, gap(s) between moveable components are sealed at least with flowing gas curtains rather than by relying only upon direct physical contact for sealing.

Owner:TEL EPION

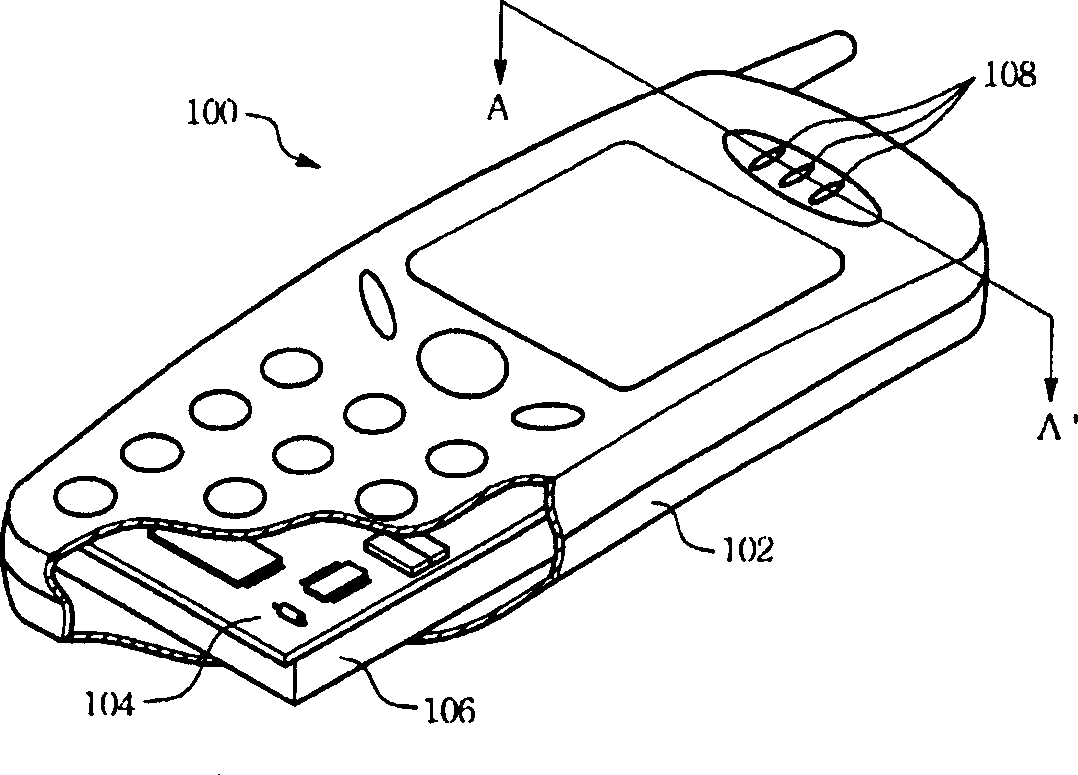

Design of sound chamber of mobile phone

InactiveCN1658622AIncrease cavity volumeGood low frequency response performanceSubstation speech amplifiersTelephone set constructionsSound qualityEngineering

A sound chamber design of cell phones. The shell of the cell phone has a front sound hole, and a circuit board is in the internal space of the shell and divides the internal space into the first and the second sound chambers. A sounding device is in the first sound chamber and electrically connects the circuit board. The circuit plate has at least a sound through hole to link the first and the second sound chambers, to increase the volume of the resonance chamber of this sounding device and improve its low frequency response effect. In addition, the shell also has an attuning hole to link the first and the second sound chambers to the outside. The flattening of the resonance frequency curve of the whole cell phone improves the sound quality.

Owner:BENQ CORP

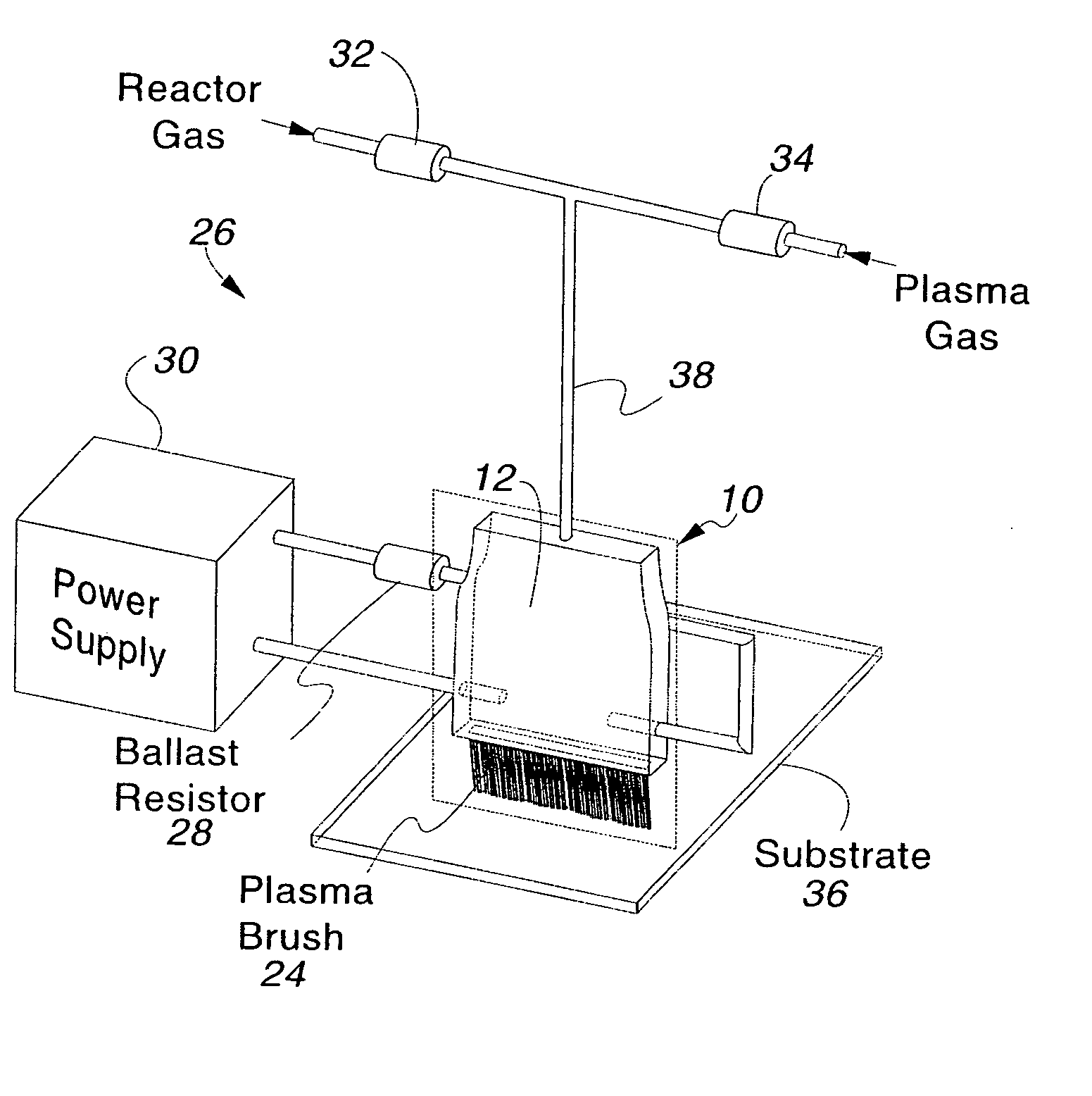

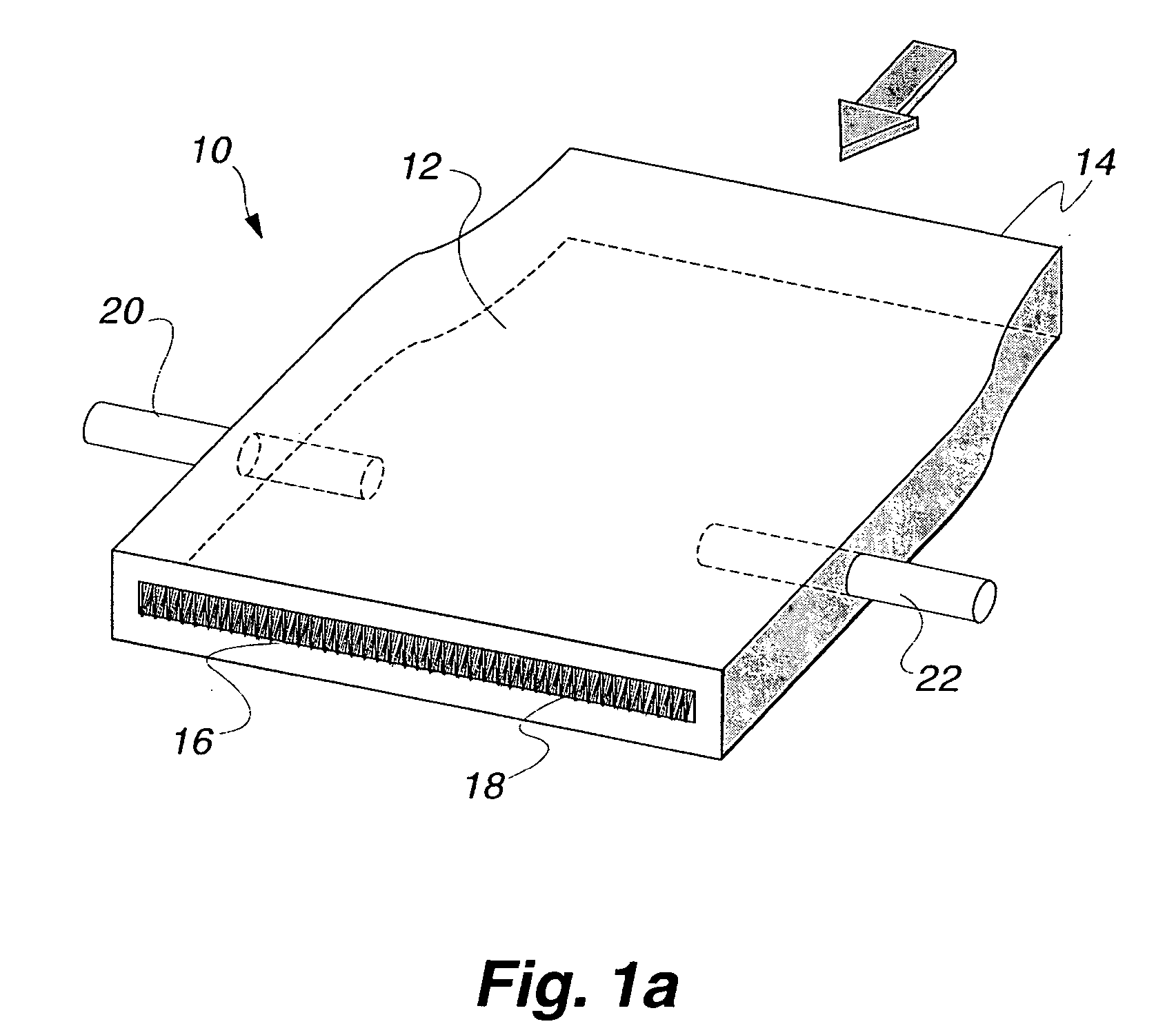

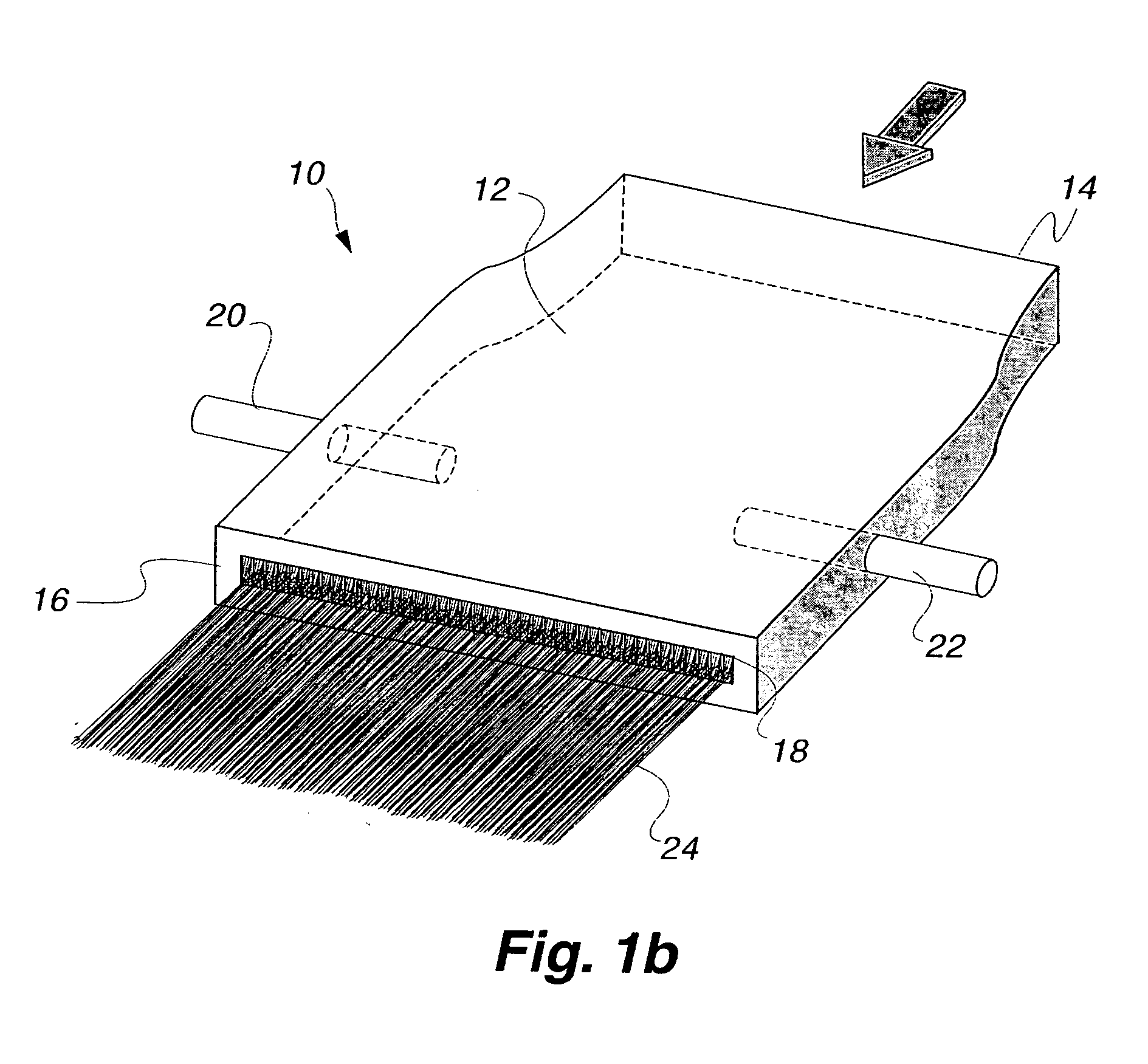

Plasma brush apparatus and method

InactiveUS20070116891A1Pretreated surfacesChemical vapor deposition coatingPlasma jetPlasma deposition

An apparatus with a narrow slit chamber generates plasma having non-equilibrium characteristics and a brush-like shape at a temperature near room temperature and at a pressure of about one atmosphere. Plasma gas enters the narrow slit chamber. An external power source provides power to electrodes near the exit that excite the plasma gas and produce a plasma jet having a brush-like shape that exits the chamber. The apparatus operates with low power consumption, and the temperature of the plasma is low. Glow-to-arc transitions are prevented using a ballast resistor and appropriate plasma gases with the narrow slit chamber design. The brush-like shaped plasma extends beyond the exit of the chamber, and possesses the reactive features of low-pressure or non-equilibrium plasmas. The plasma brush apparatus can be used for plasma treatment, plasma cleaning, plasma deposition, plasma sterilization, and plasma decontamination of chemical and biological warfare agents.

Owner:LOS ALAMOS NATIONAL SECURITY

Apparatus for reducing the effect of contamination on a rapid thermal process

ActiveUS20150155190A1Improve temperature uniformityReduced chamber down timeSemiconductor/solid-state device testing/measurementBaking ovenEngineeringContamination

Embodiments of the present disclosure provide a cover assembly that includes a cover disposed between a device side surface of a substrate and a reflector plate, which are disposed within a thermal processing chamber. The presence of the cover between the device side surface of a substrate and a reflector plate has many advantages over conventional thermal processing chamber designs, which include an improved temperature uniformity during processing, a reduced chamber down time and an improved cost-of-ownership of the processes performed in the thermal processing chamber. In some configurations, the cover includes two or more ports that are formed therein and are positioned to deliver a gas, from a space formed between the reflector plate and the cover, to desired regions of the substrate during processing to reduce the temperature variation across the substrate.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com