Patents

Literature

750results about "Liquid degasification by filtration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

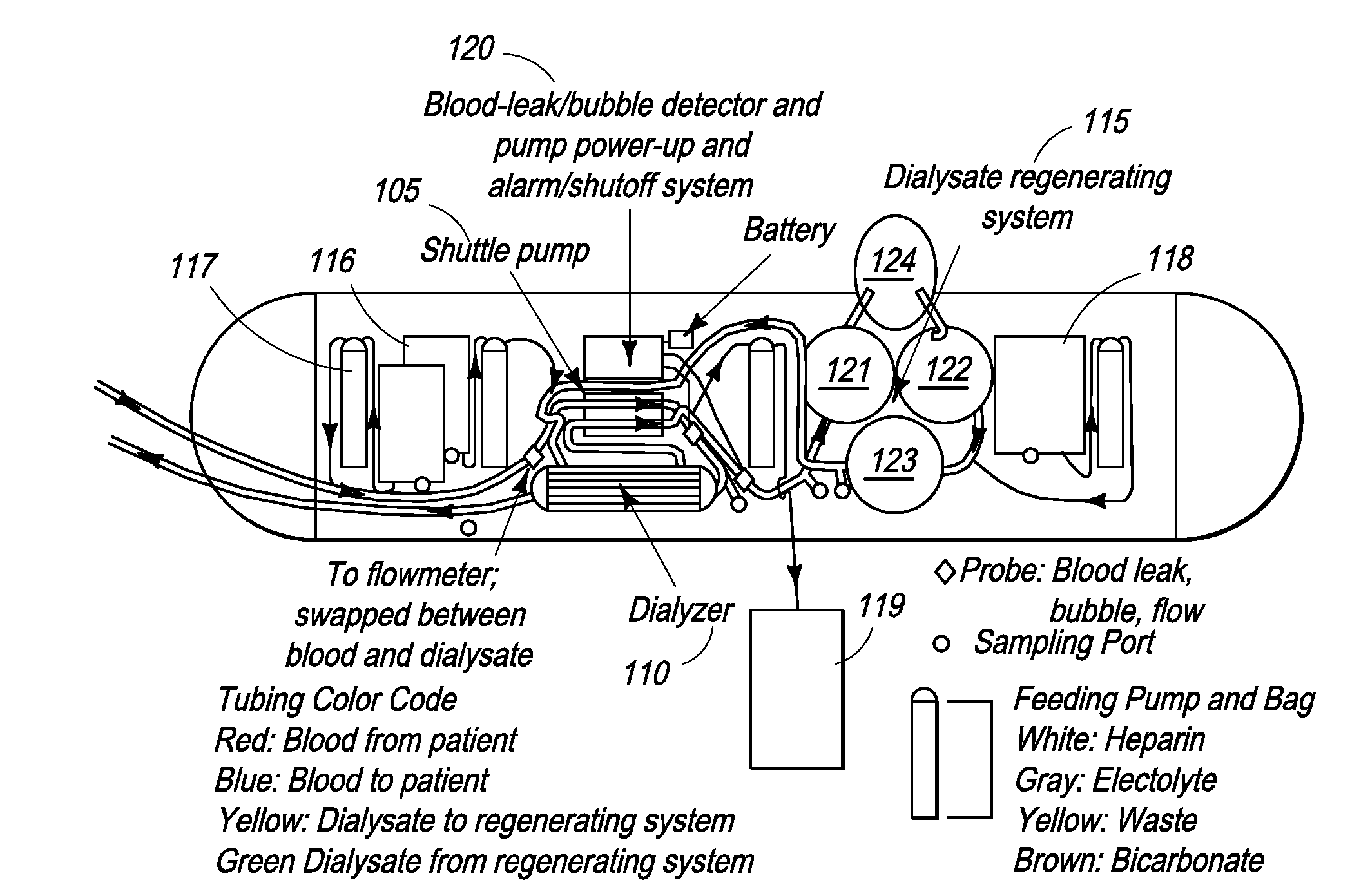

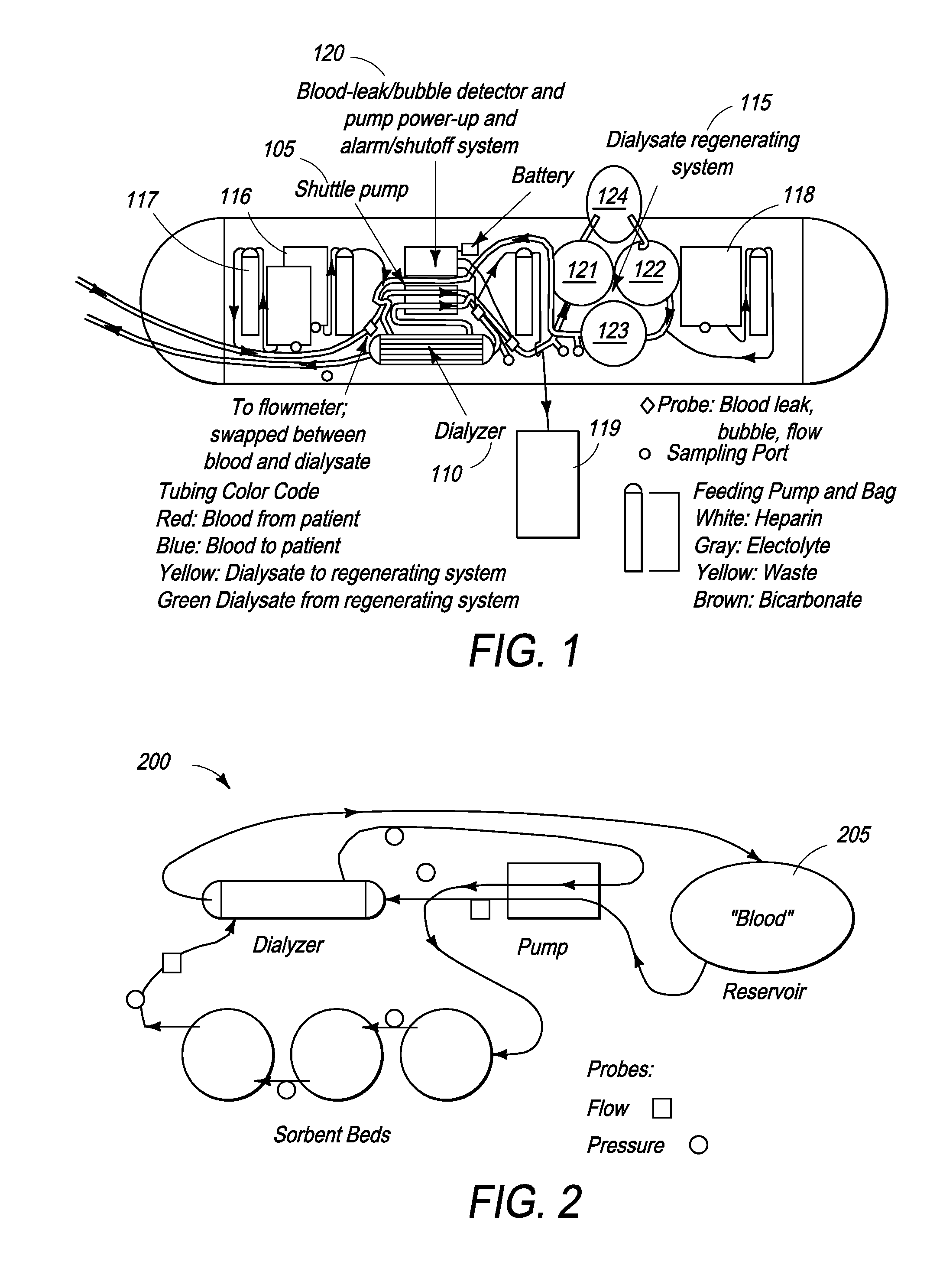

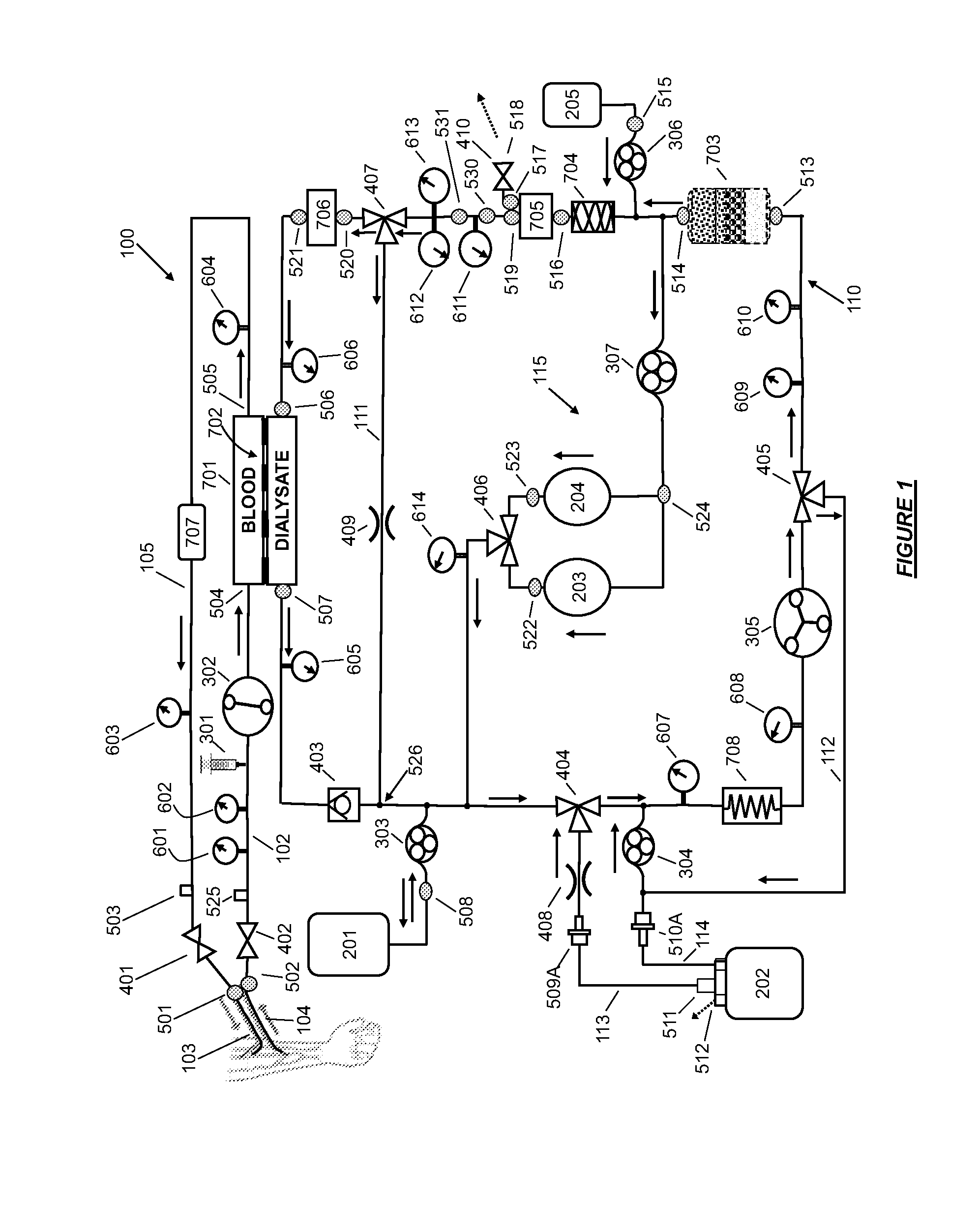

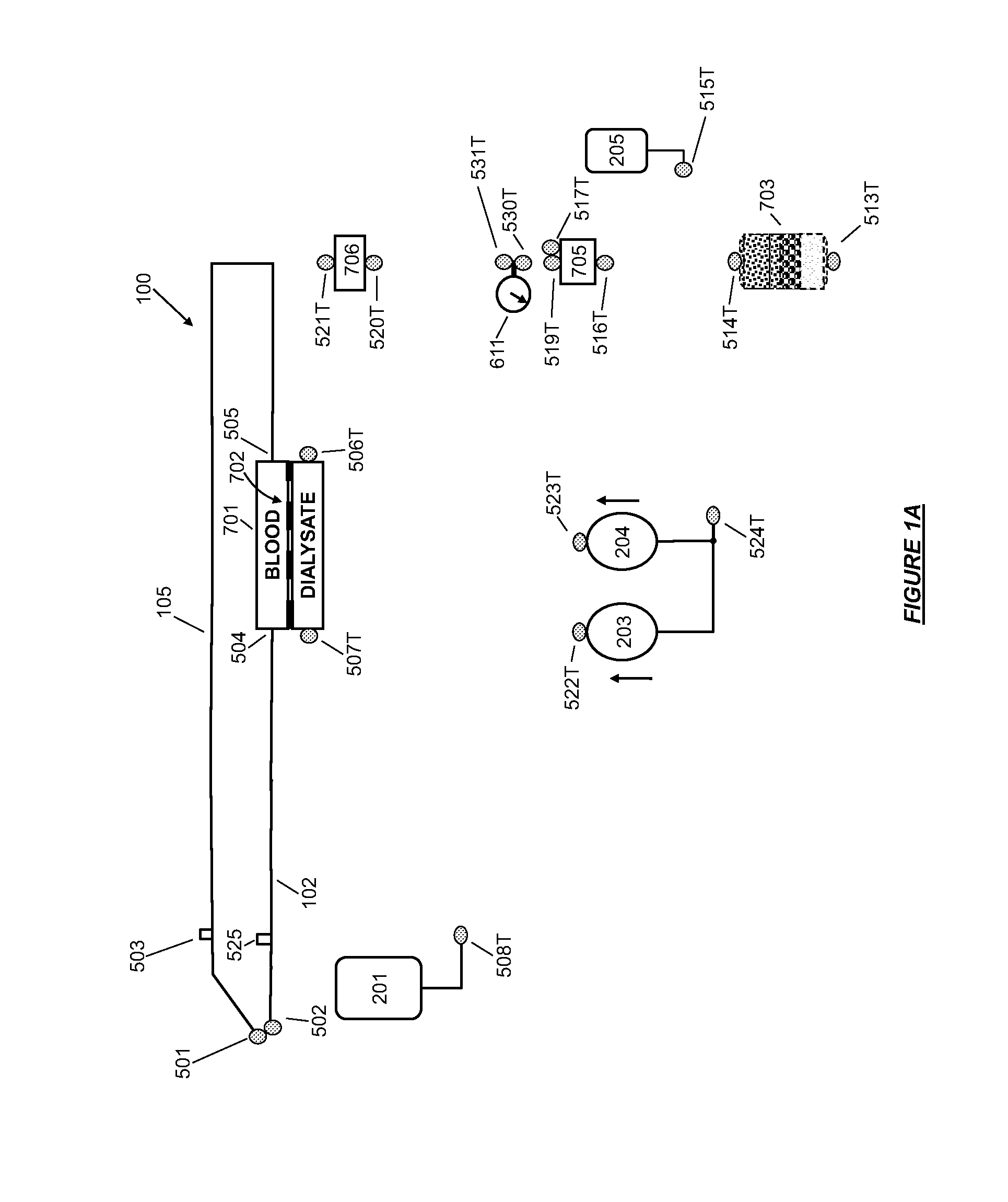

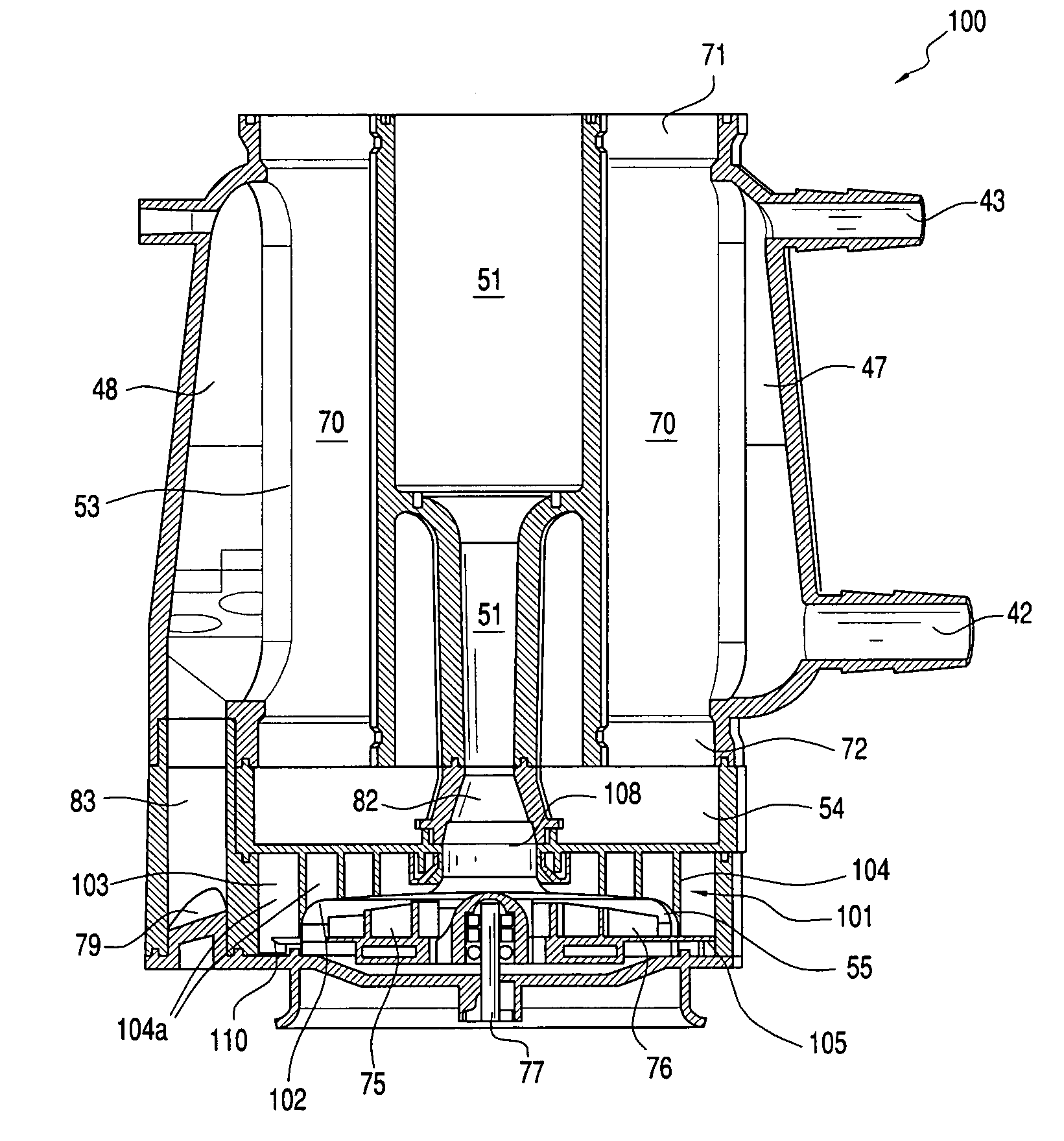

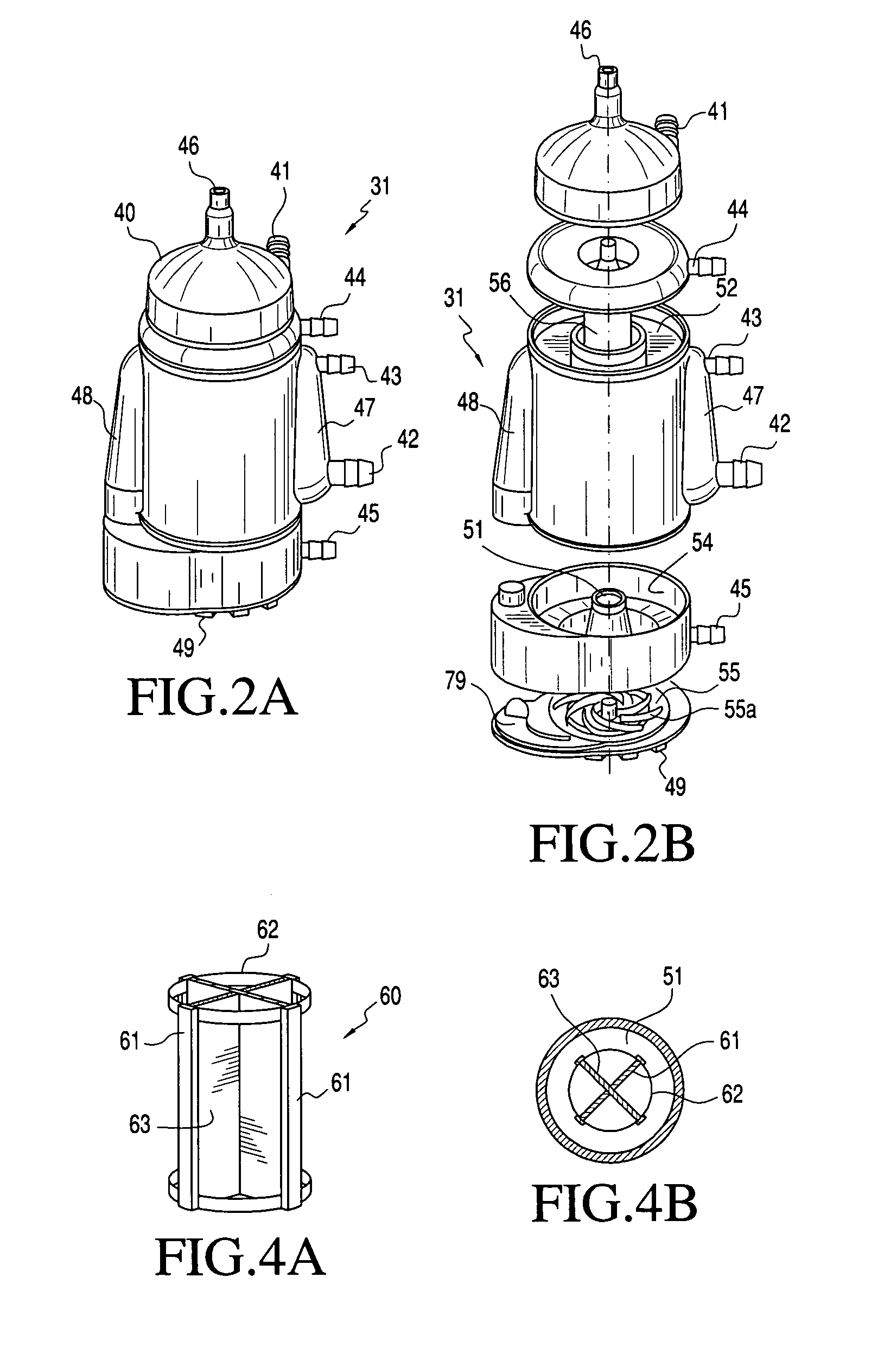

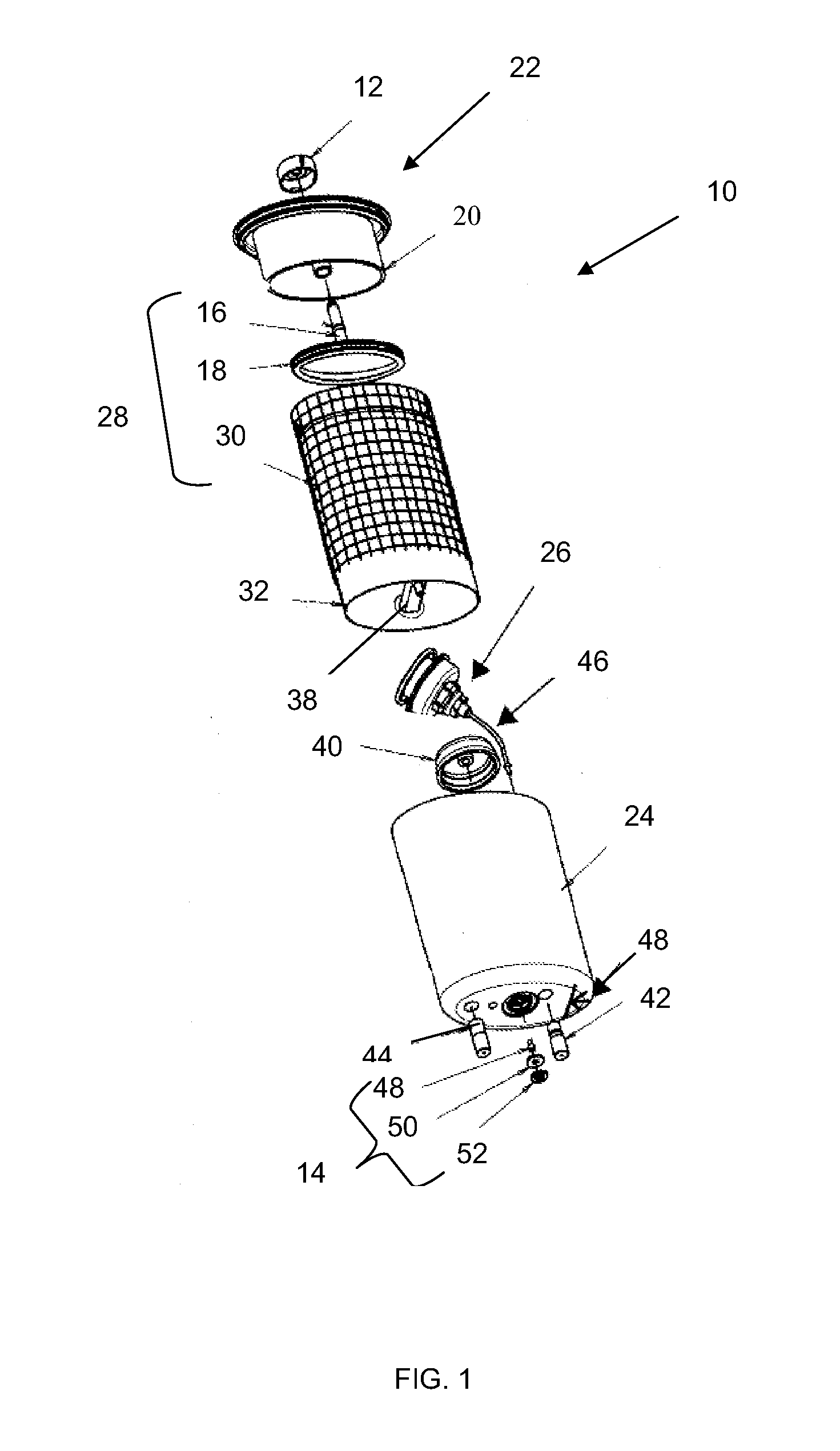

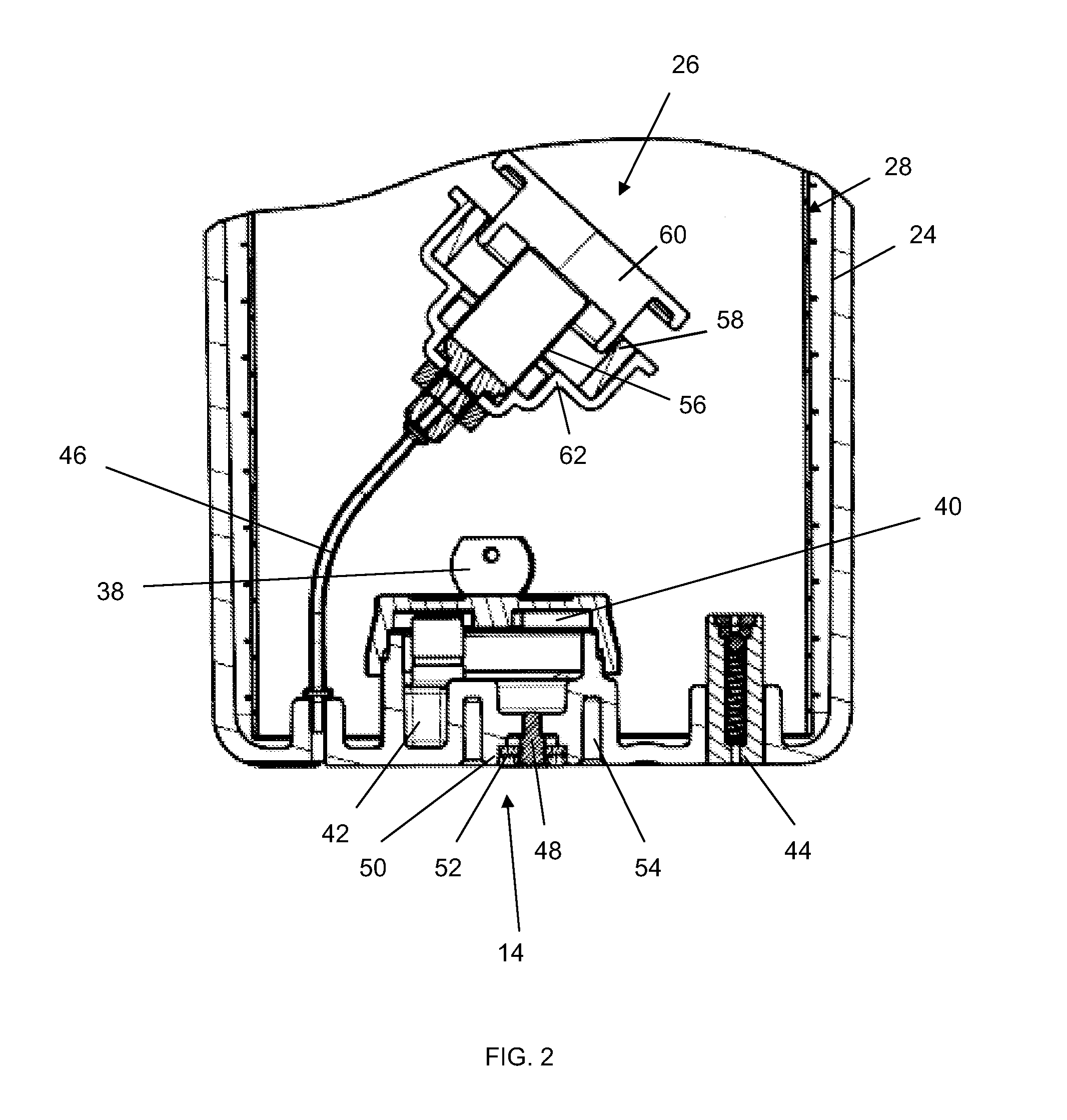

Carbon Dioxide Gas Removal From a Fluid Circuit of a Dialysis Device

ActiveUS20090282980A1Efficient removalSmall sizeMedical devicesIsotope separationEngineeringProduct gas

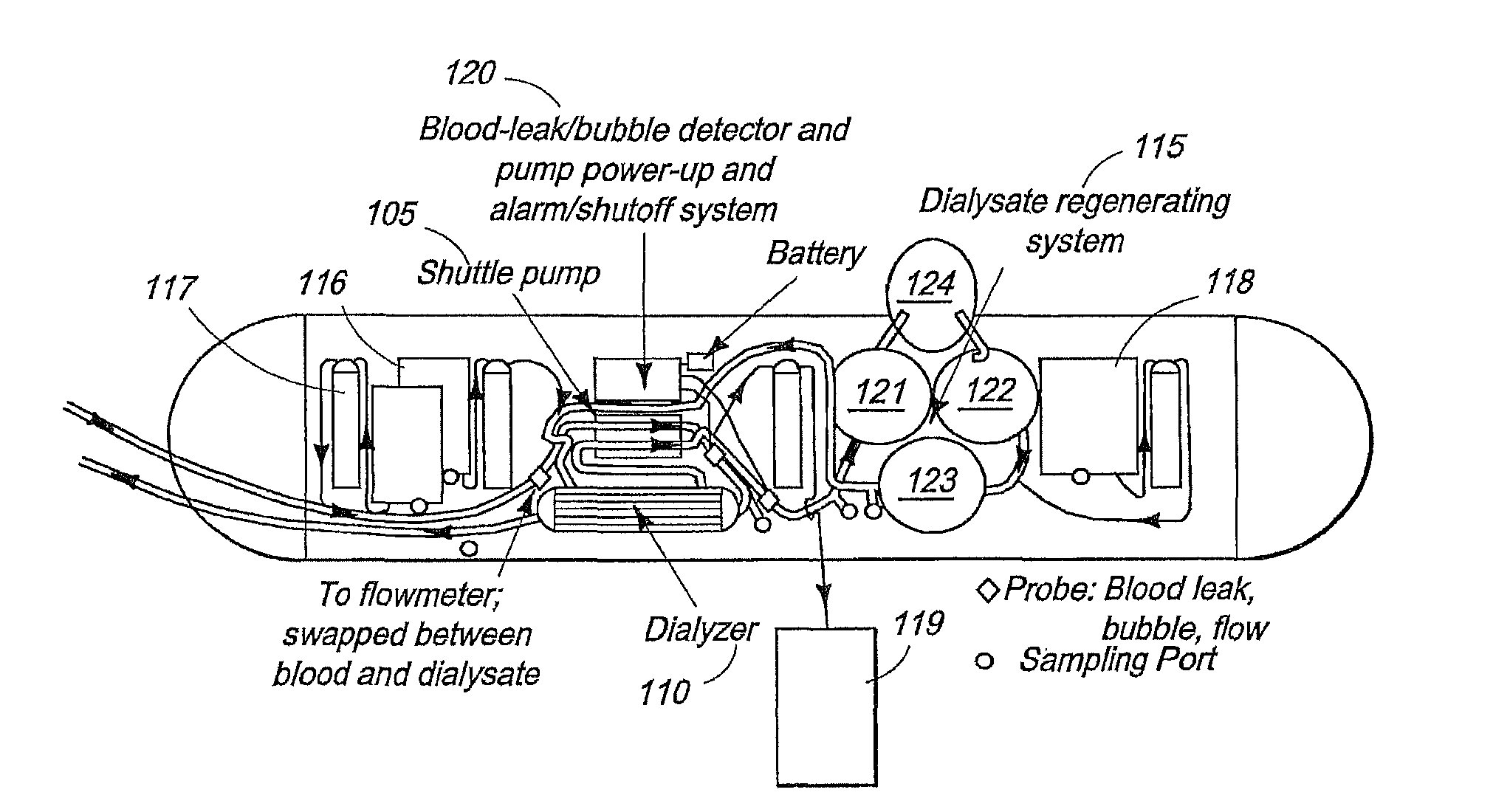

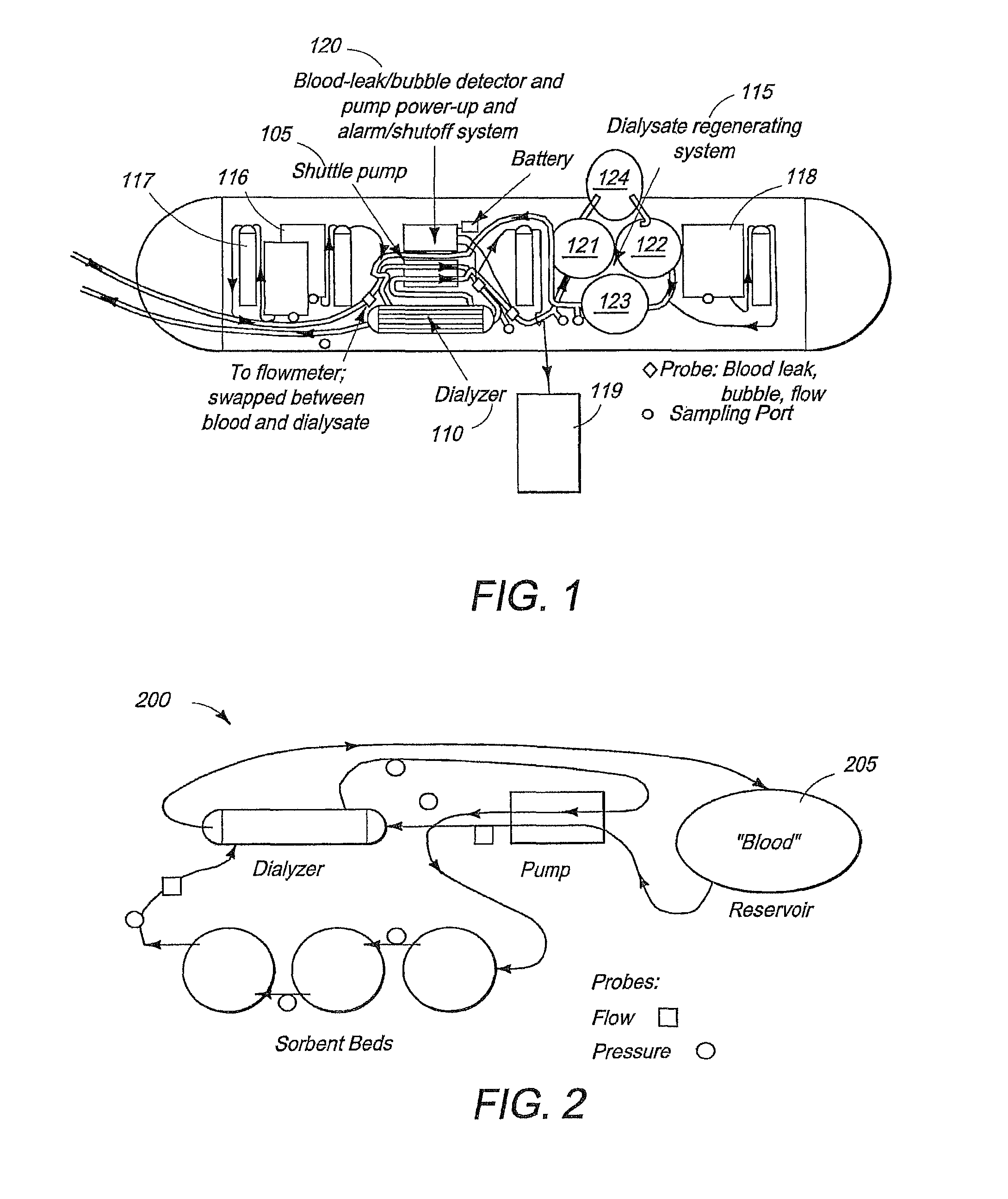

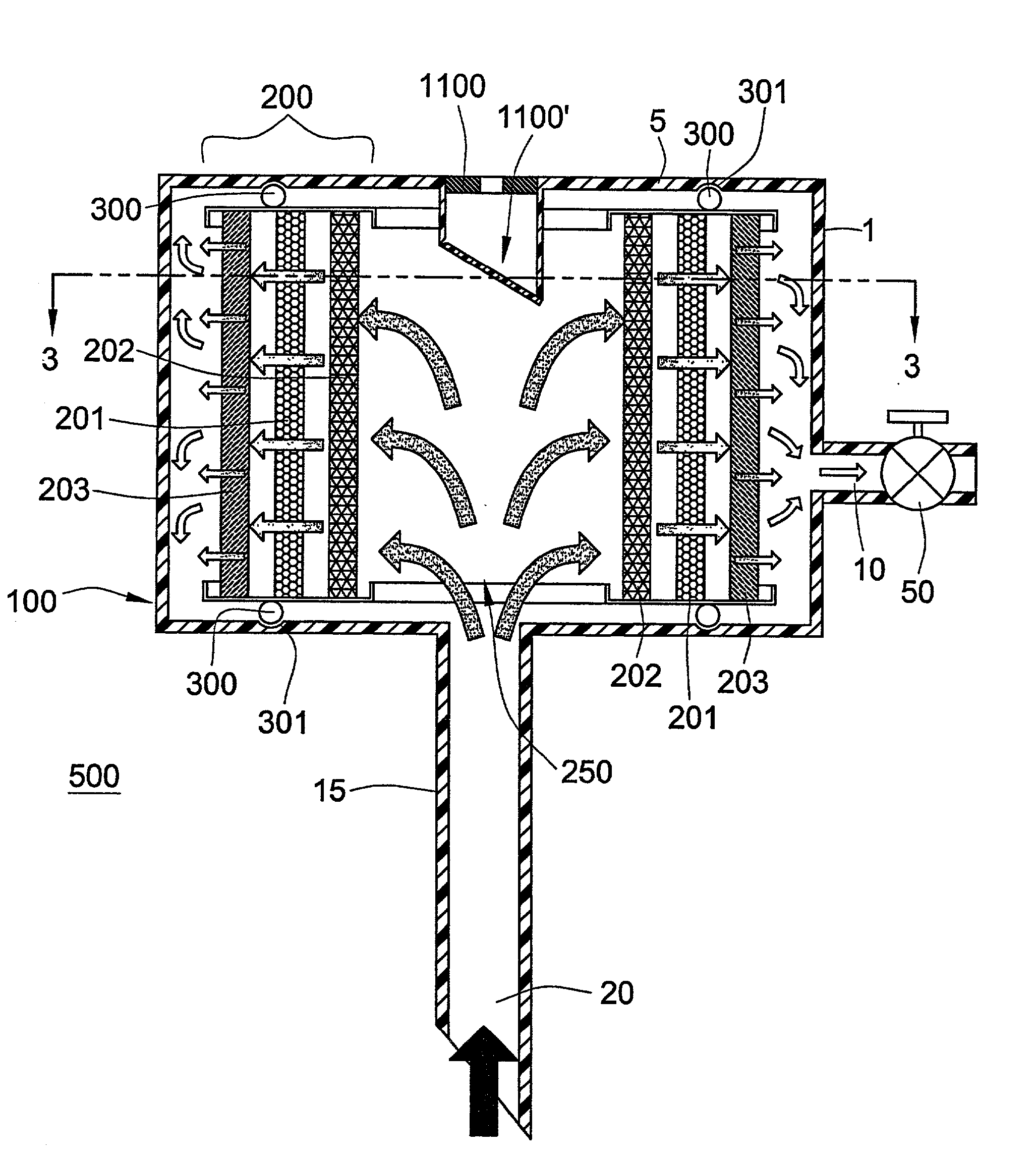

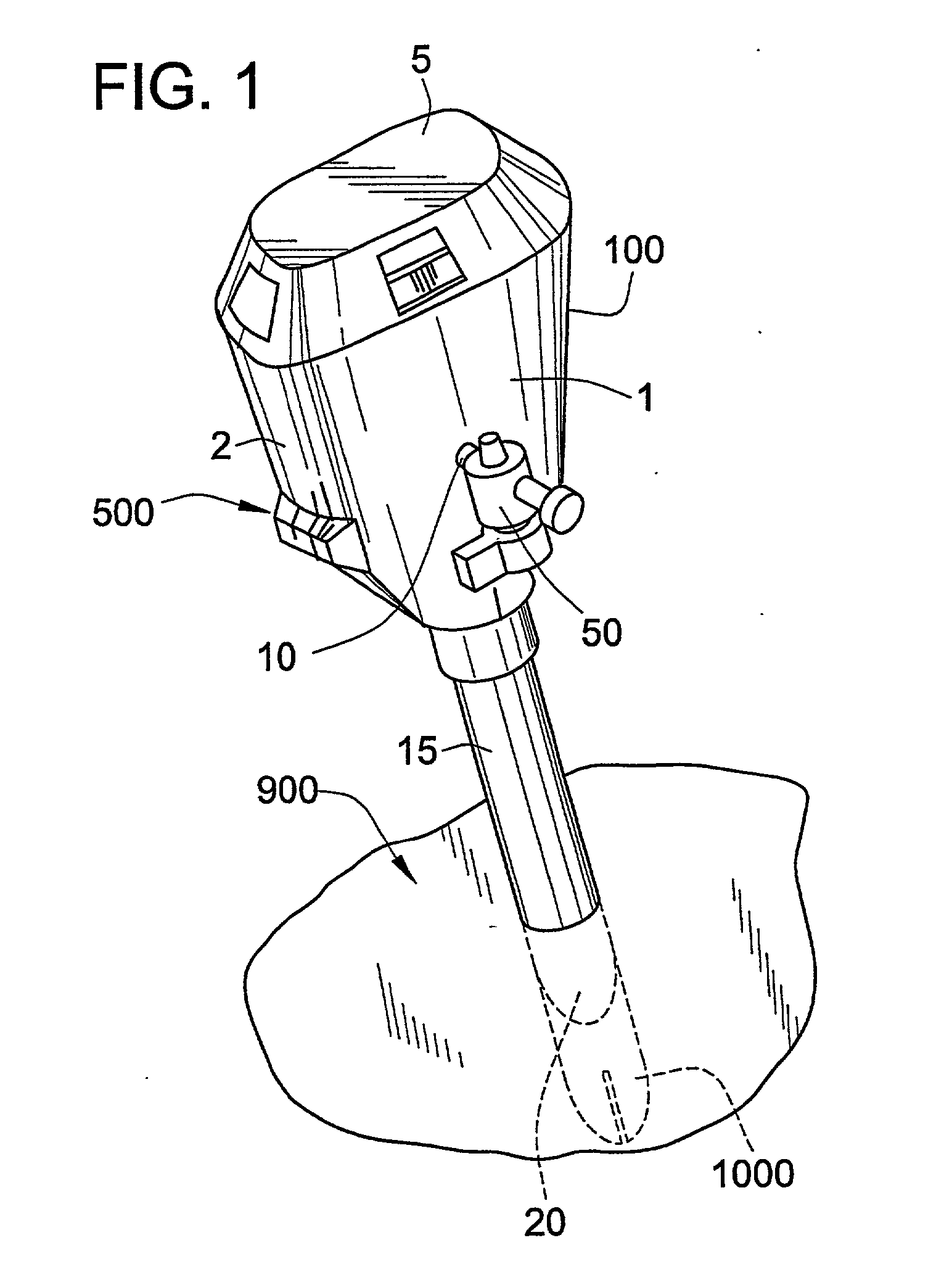

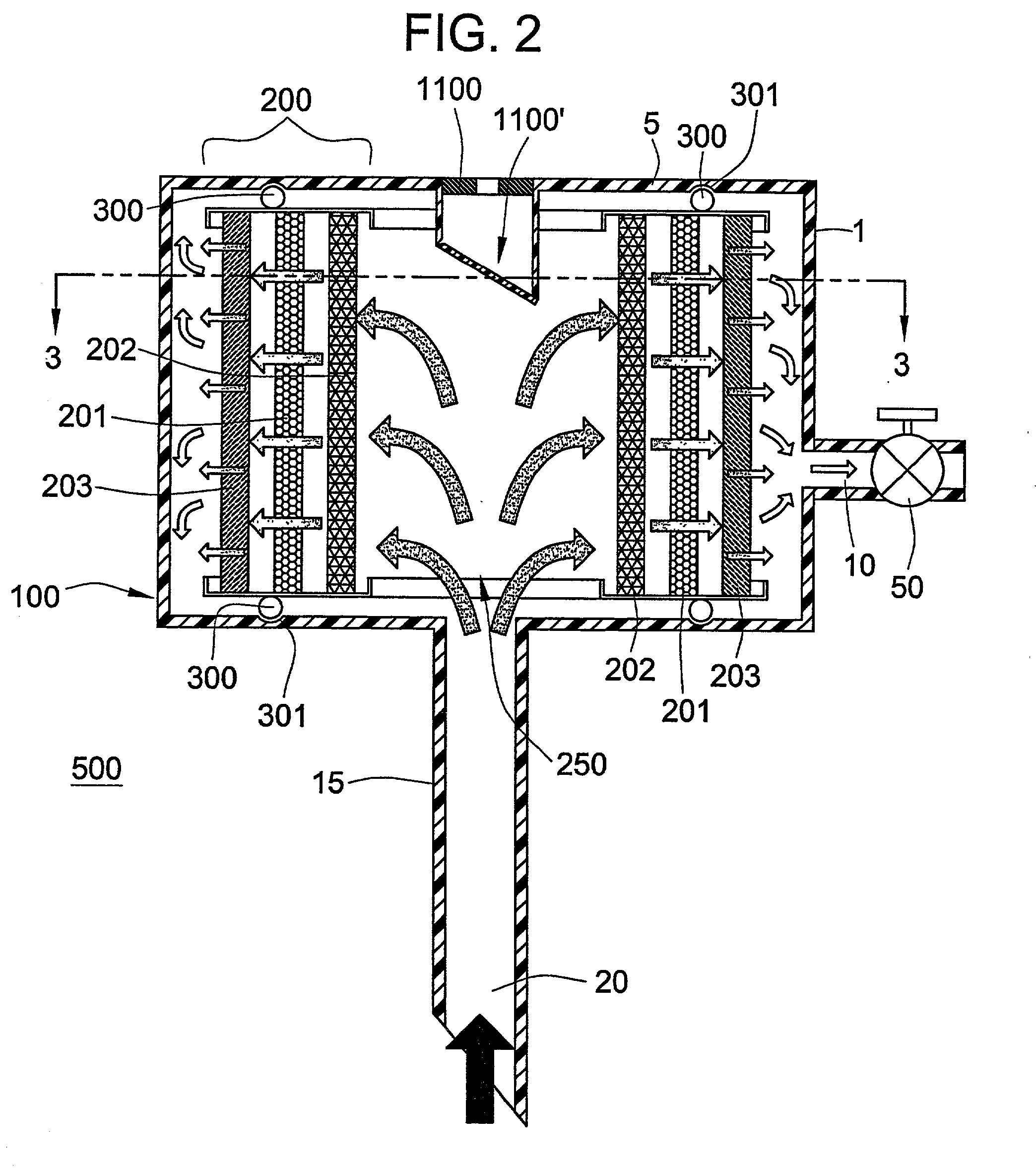

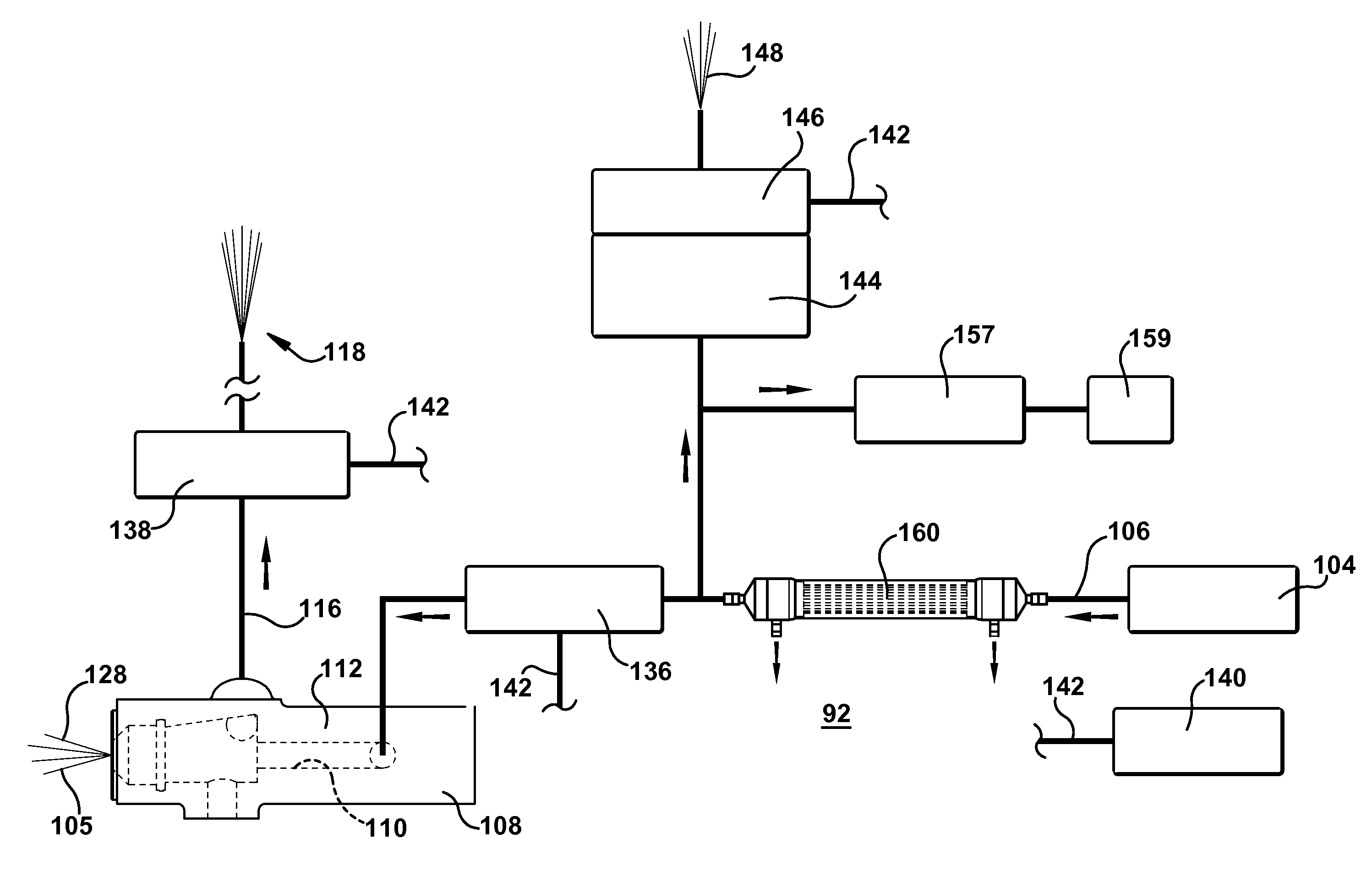

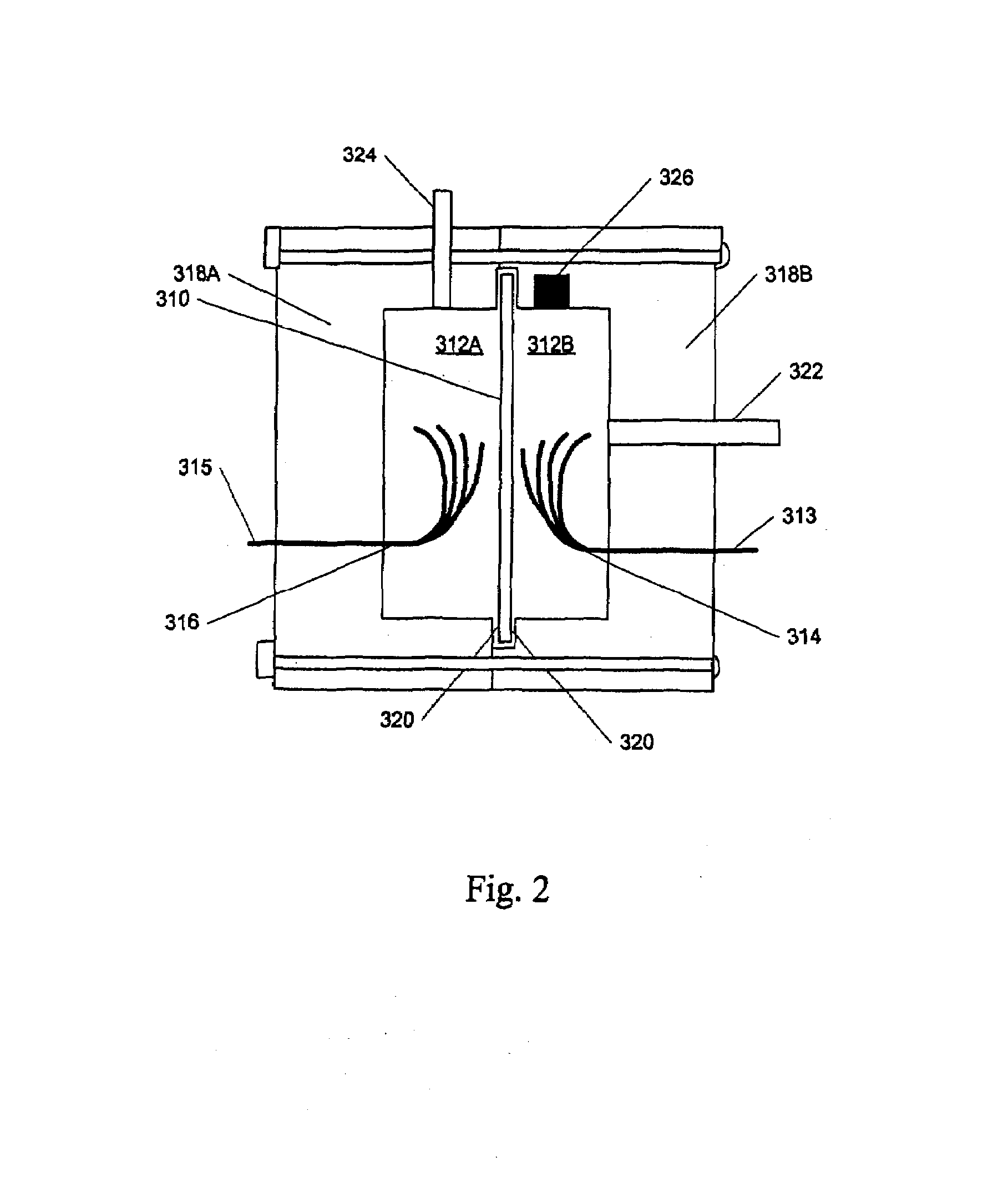

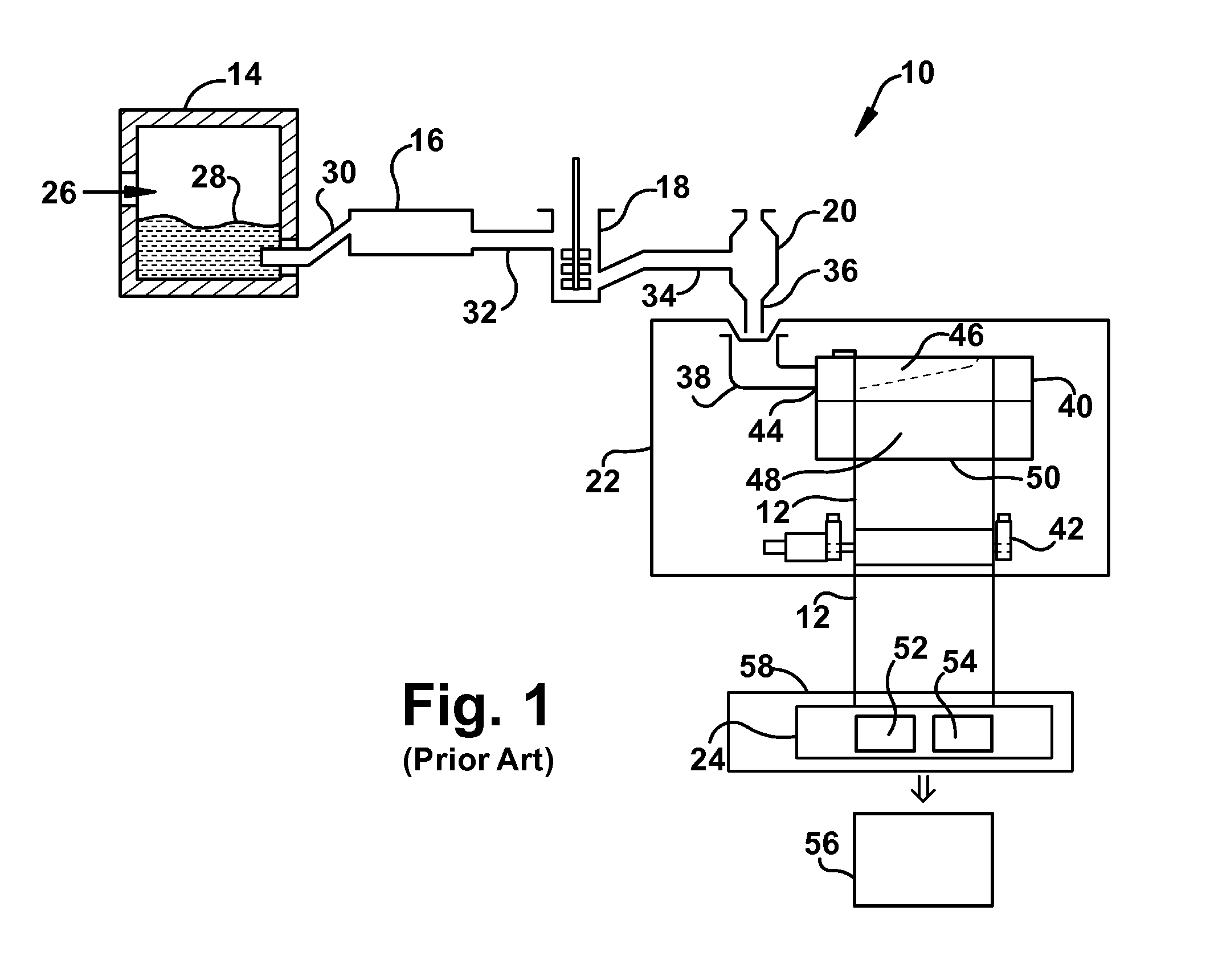

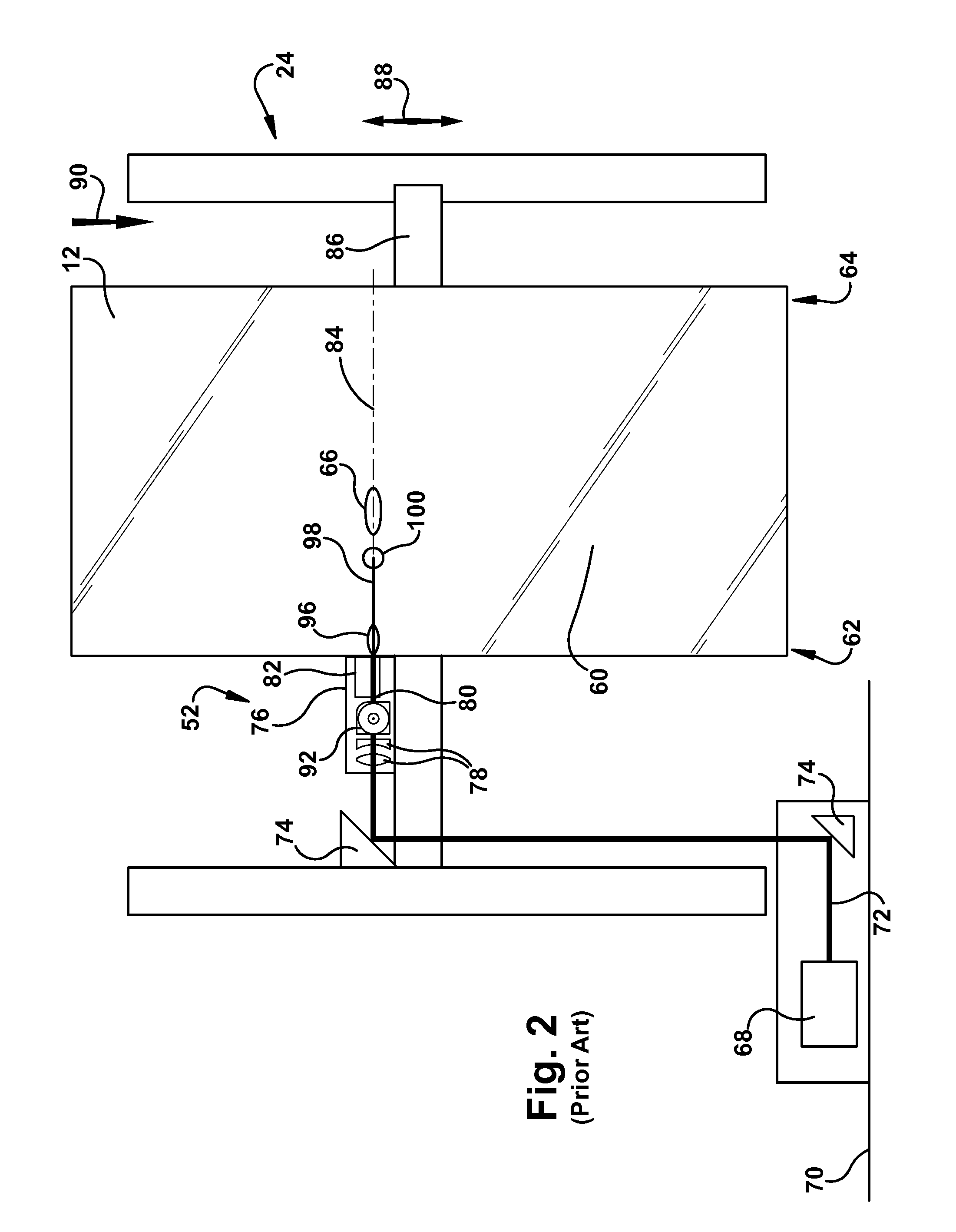

The present invention is directed to degassing devices for dialysate circuits. One embodiment has a first housing and a second housing positioned within the first housing in an annular relationship. A second embodiment comprises a dialysate regeneration system with urease, a dialyzer, and a housing with an external wall, where the external wall is exposed to atmosphere and comprises a material that passes gas but does not pass liquid and where the housing is positioned between the urease and dialyzer.

Owner:FRESENIUS MEDICAL CARE HLDG INC

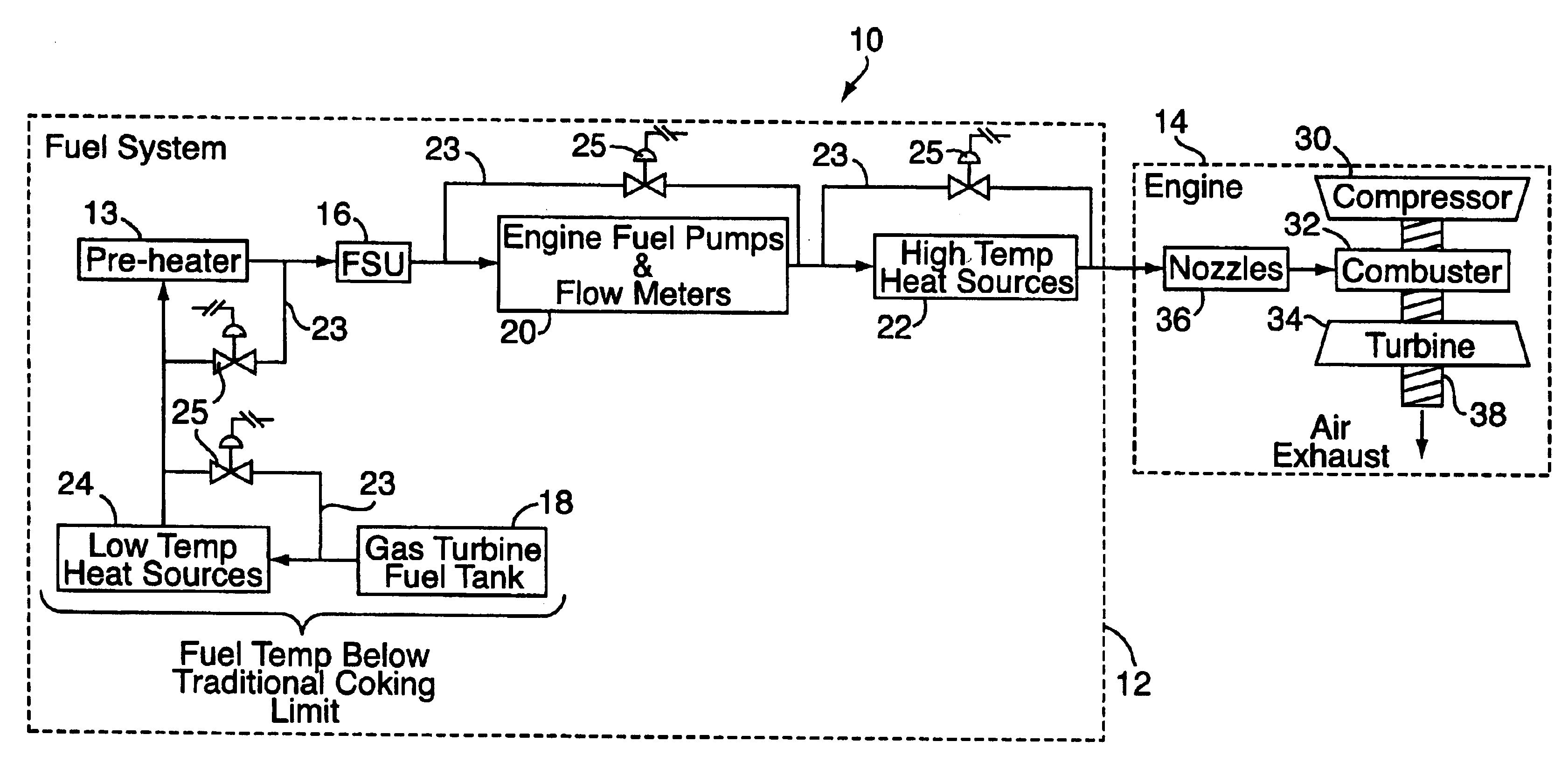

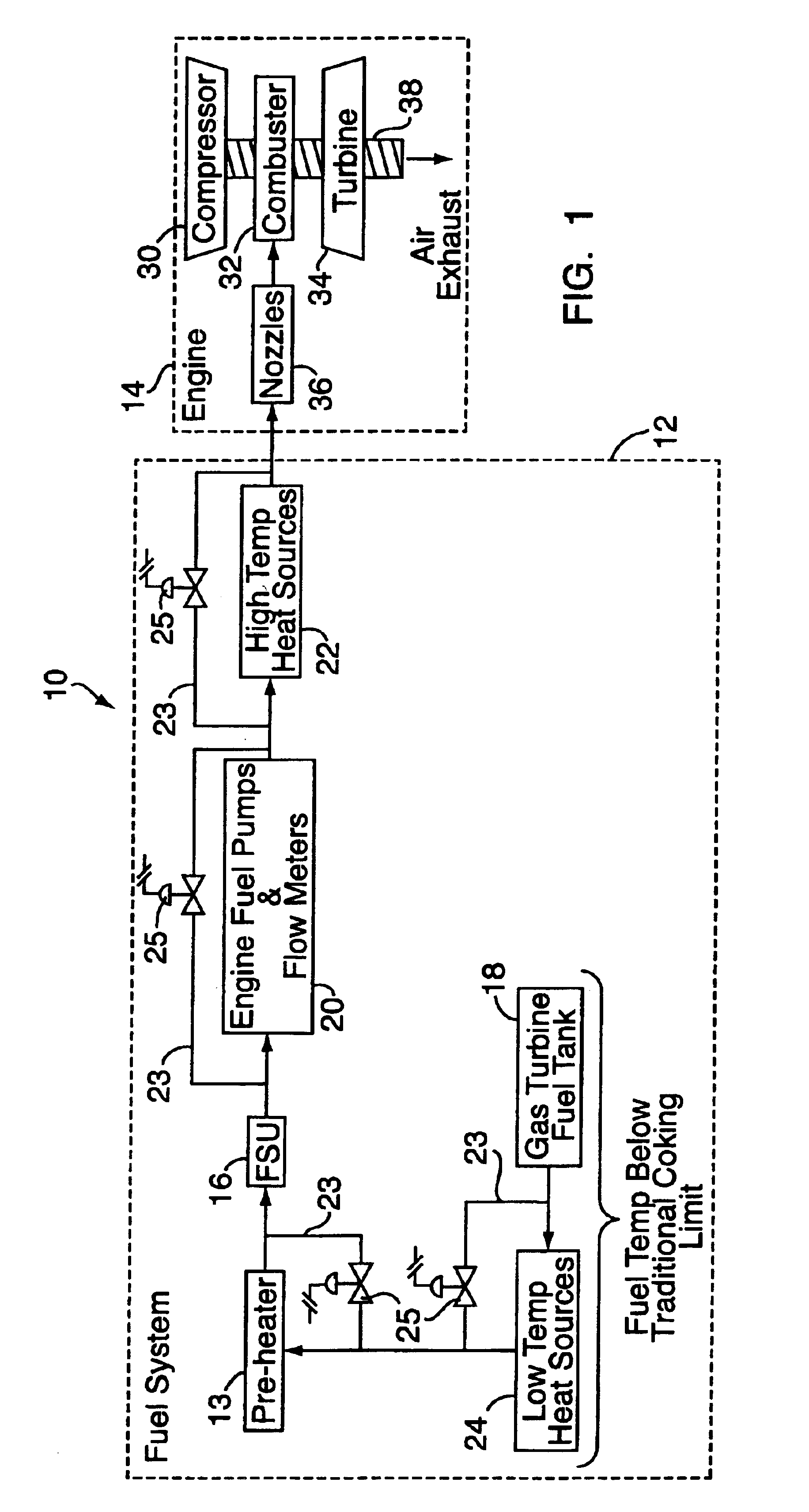

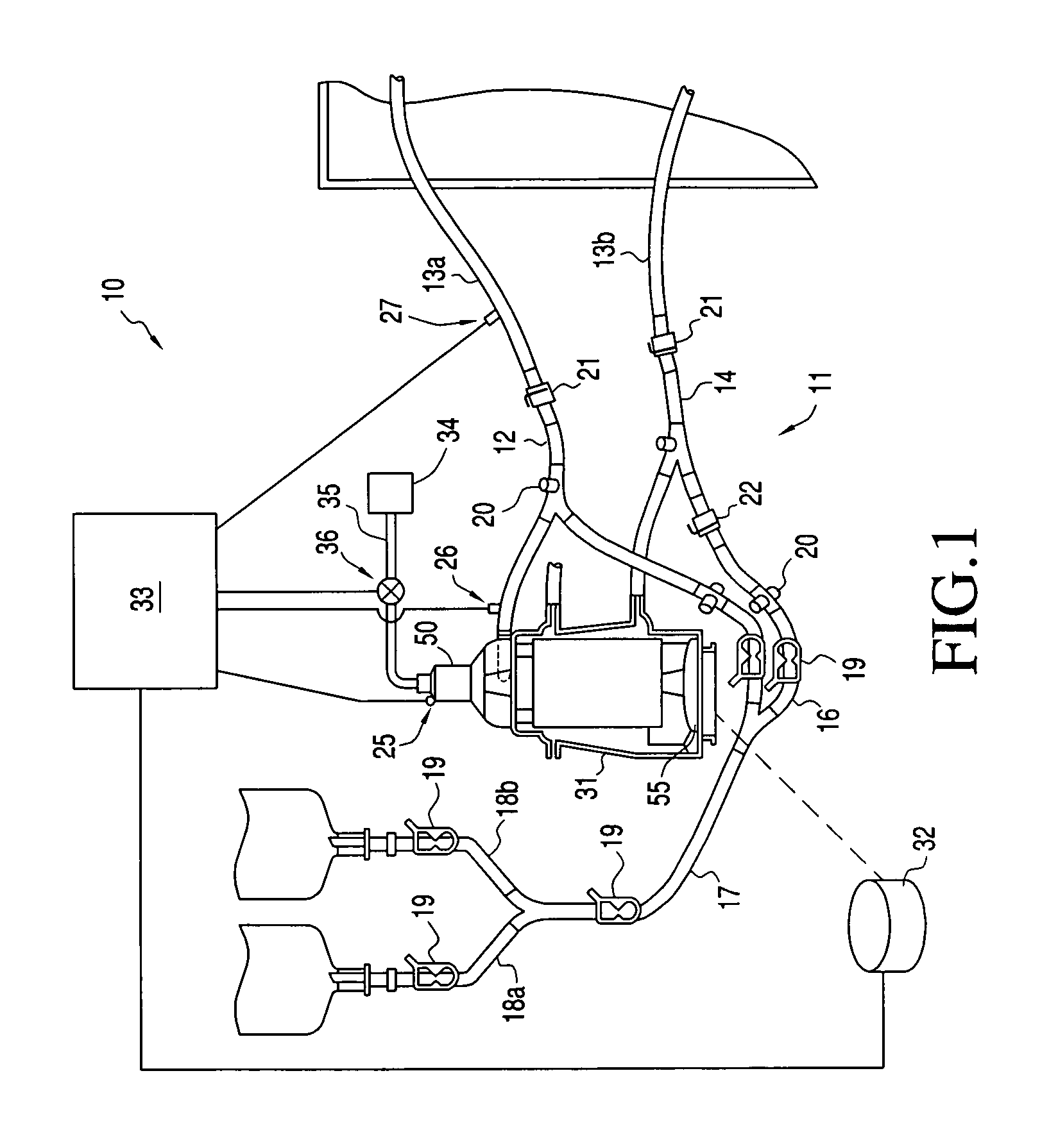

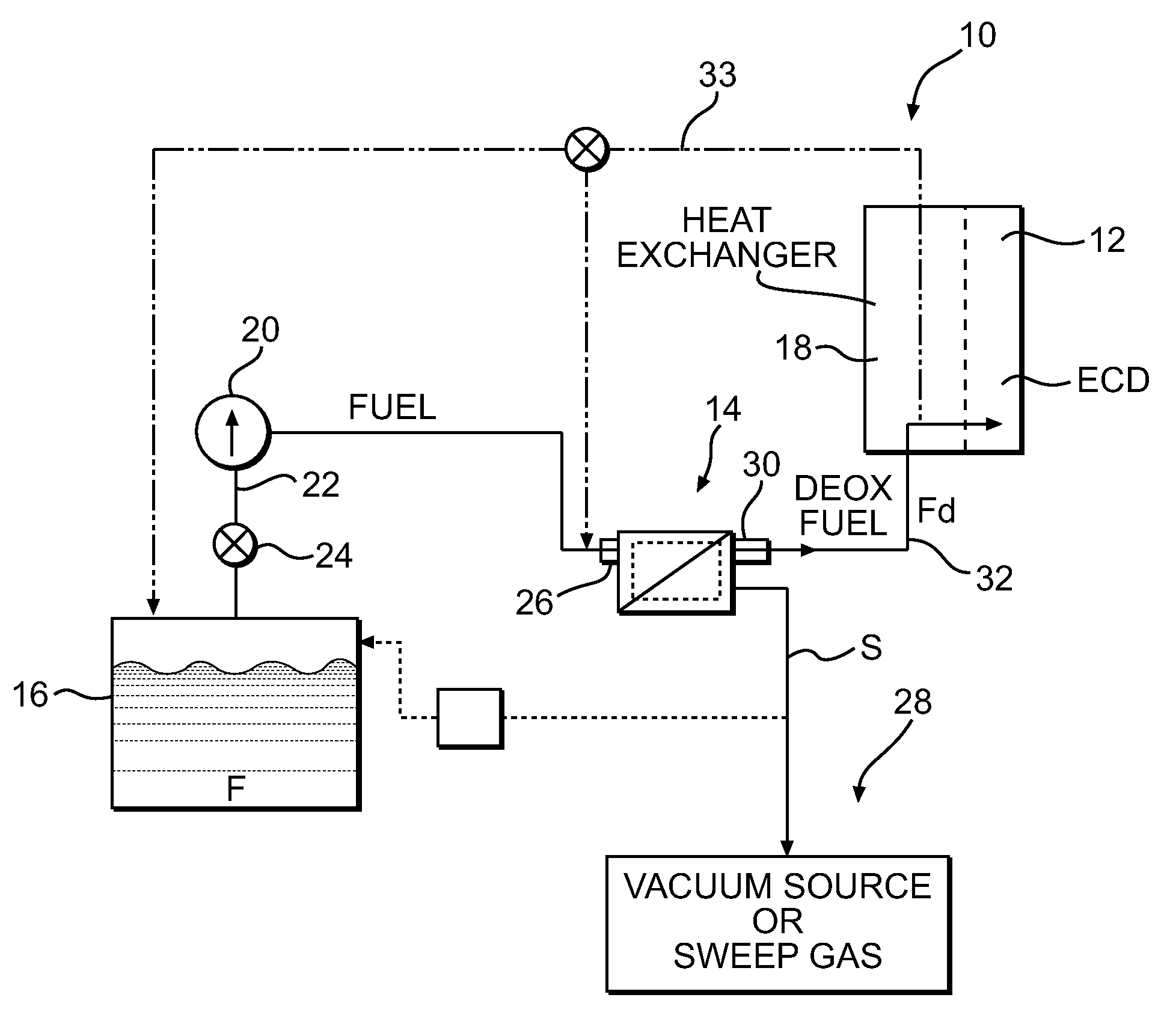

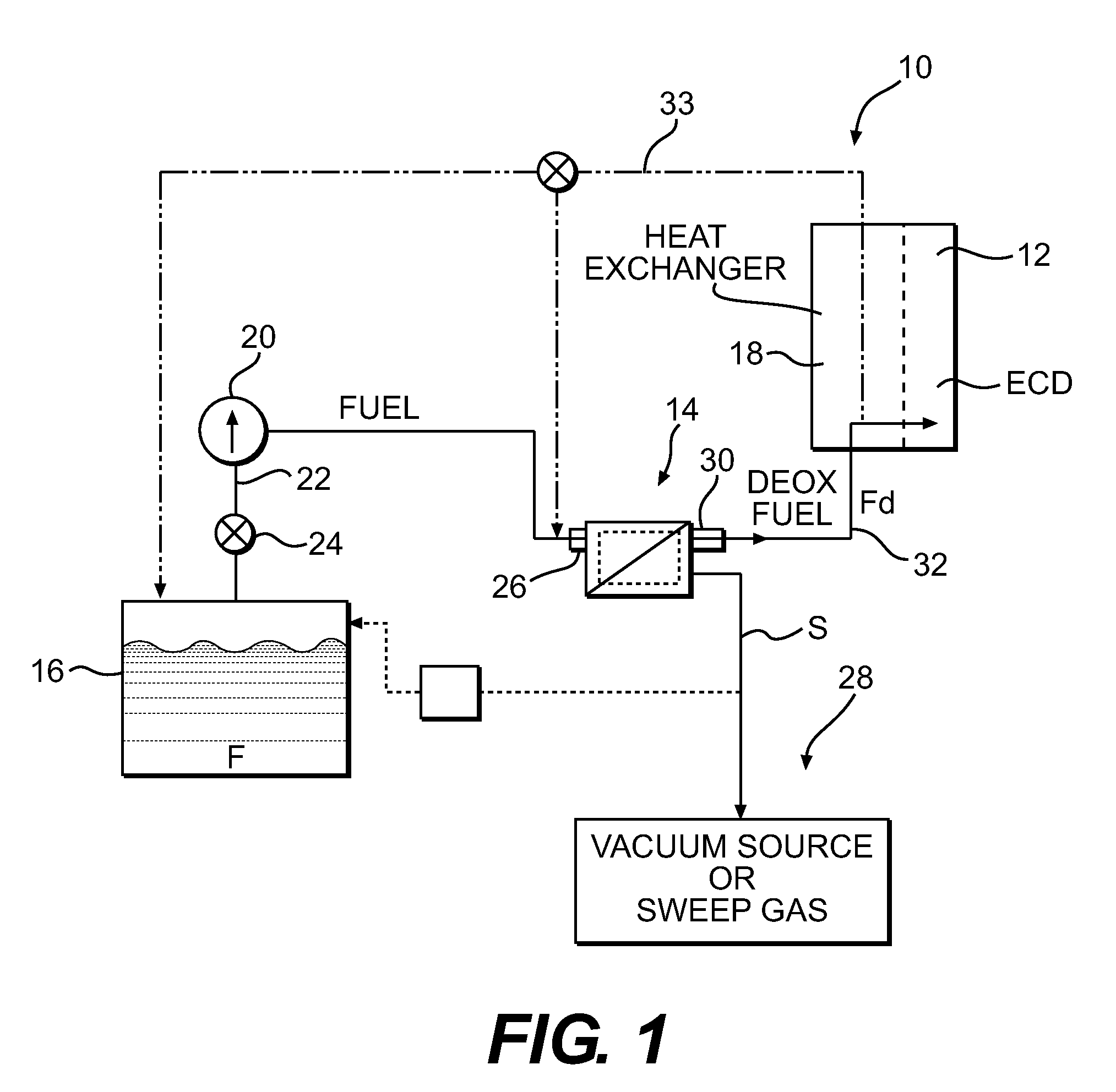

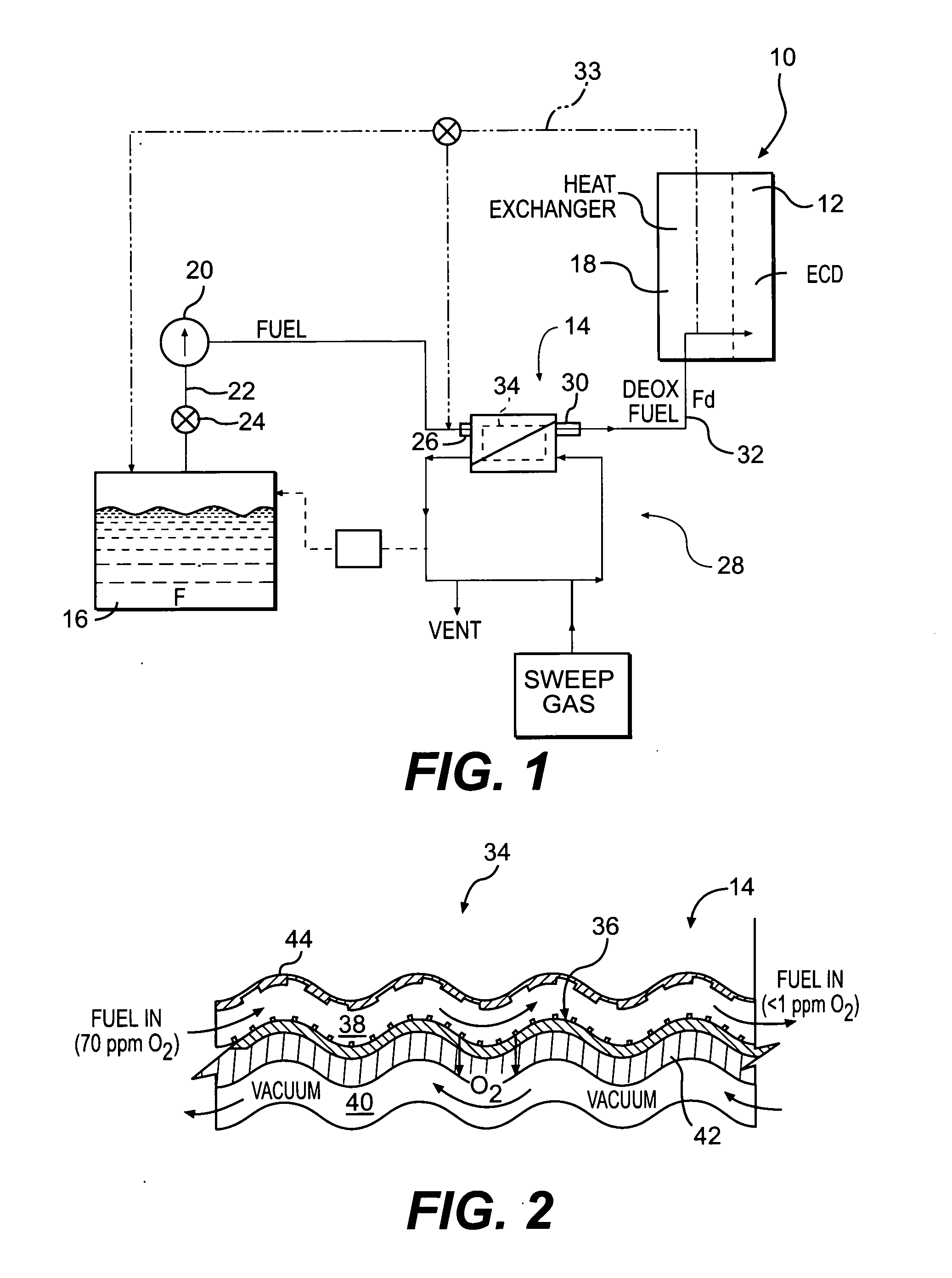

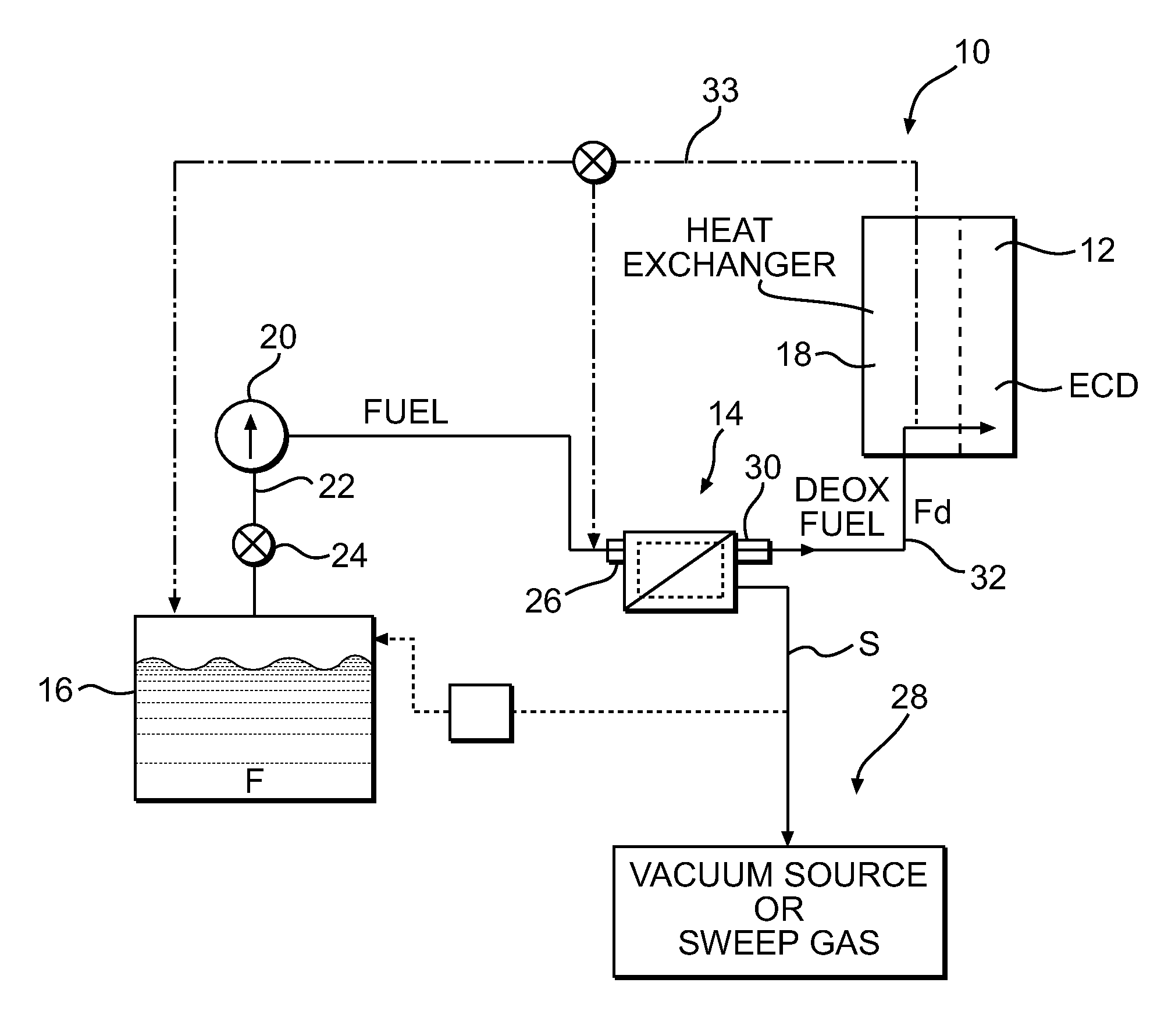

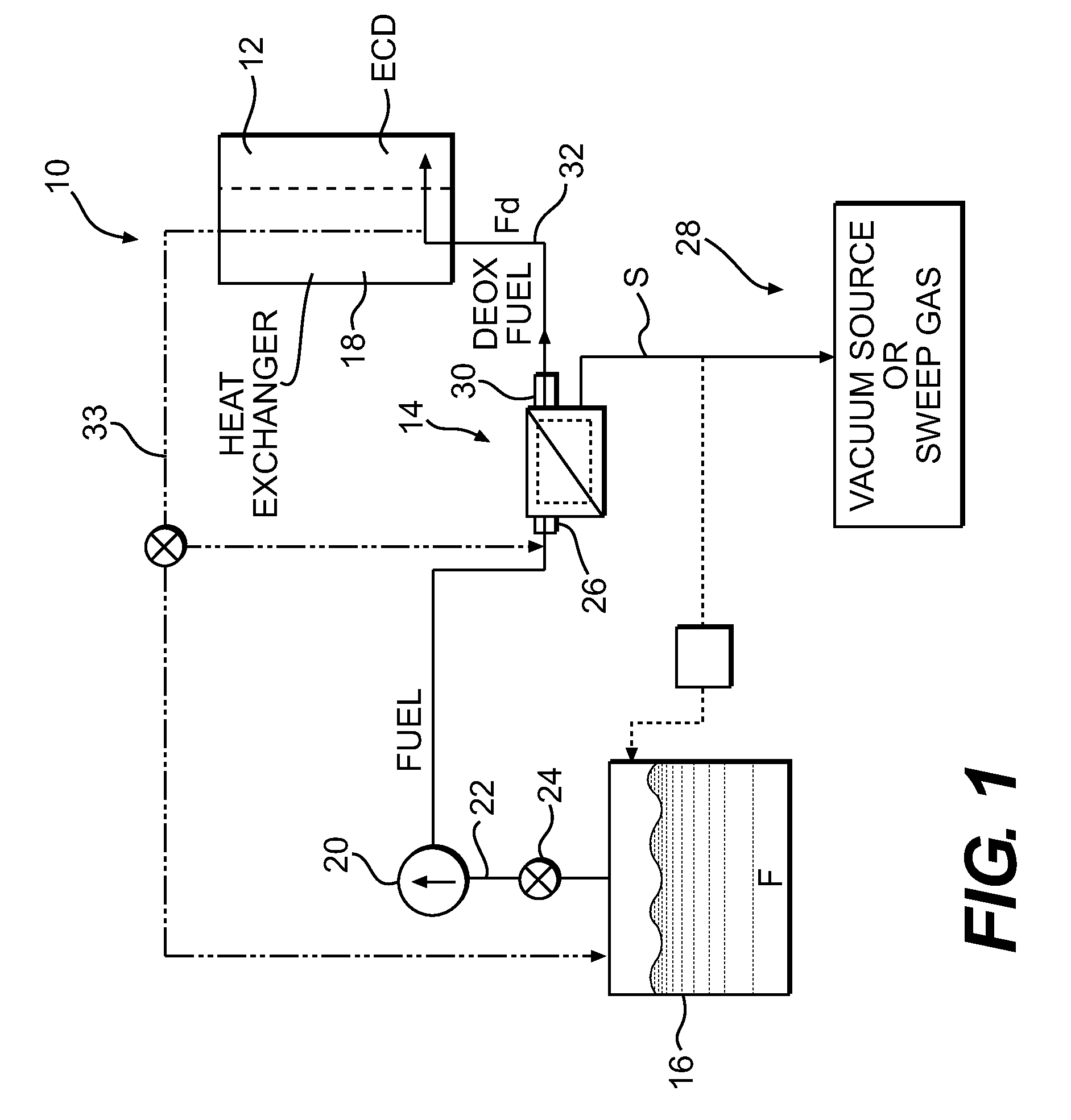

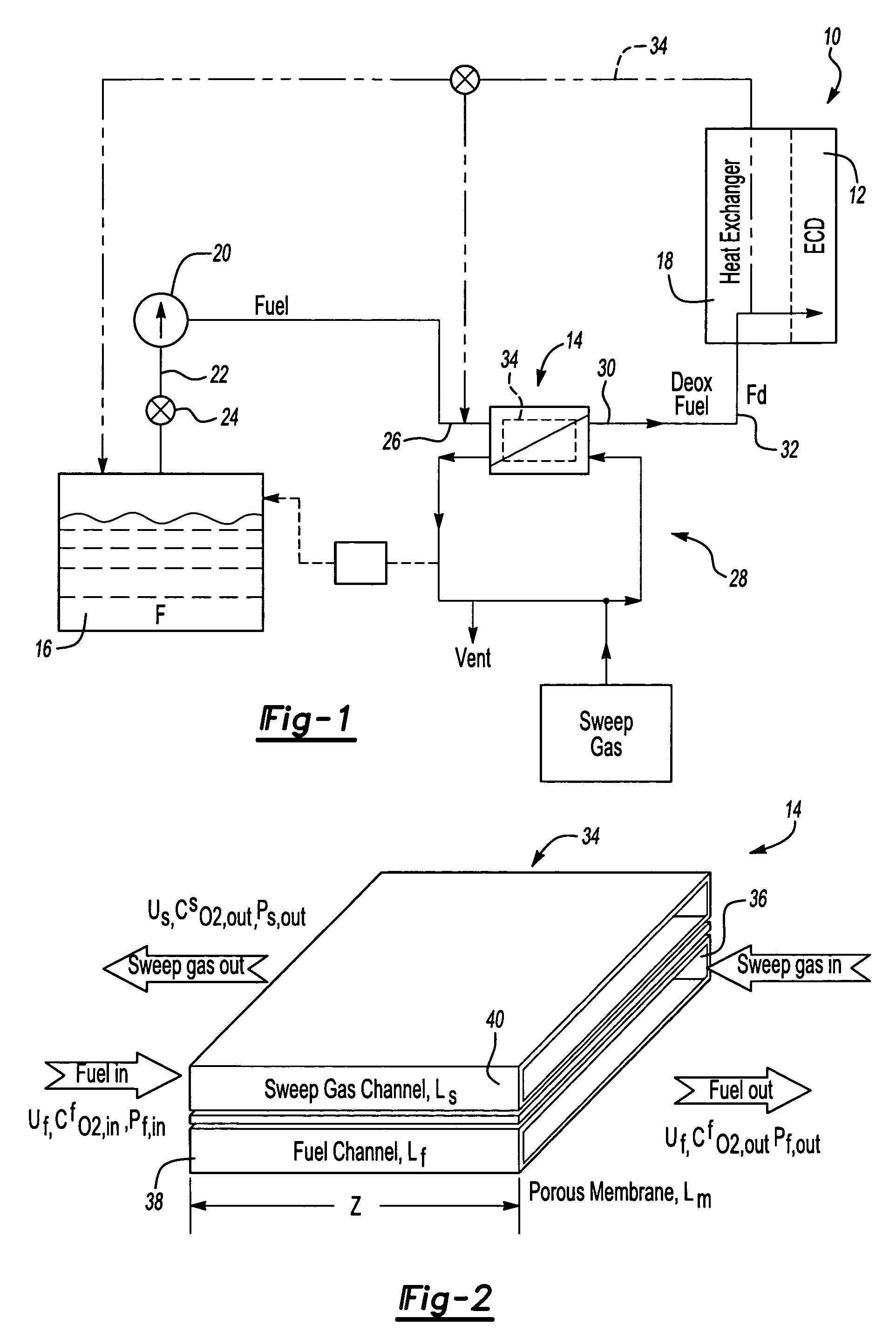

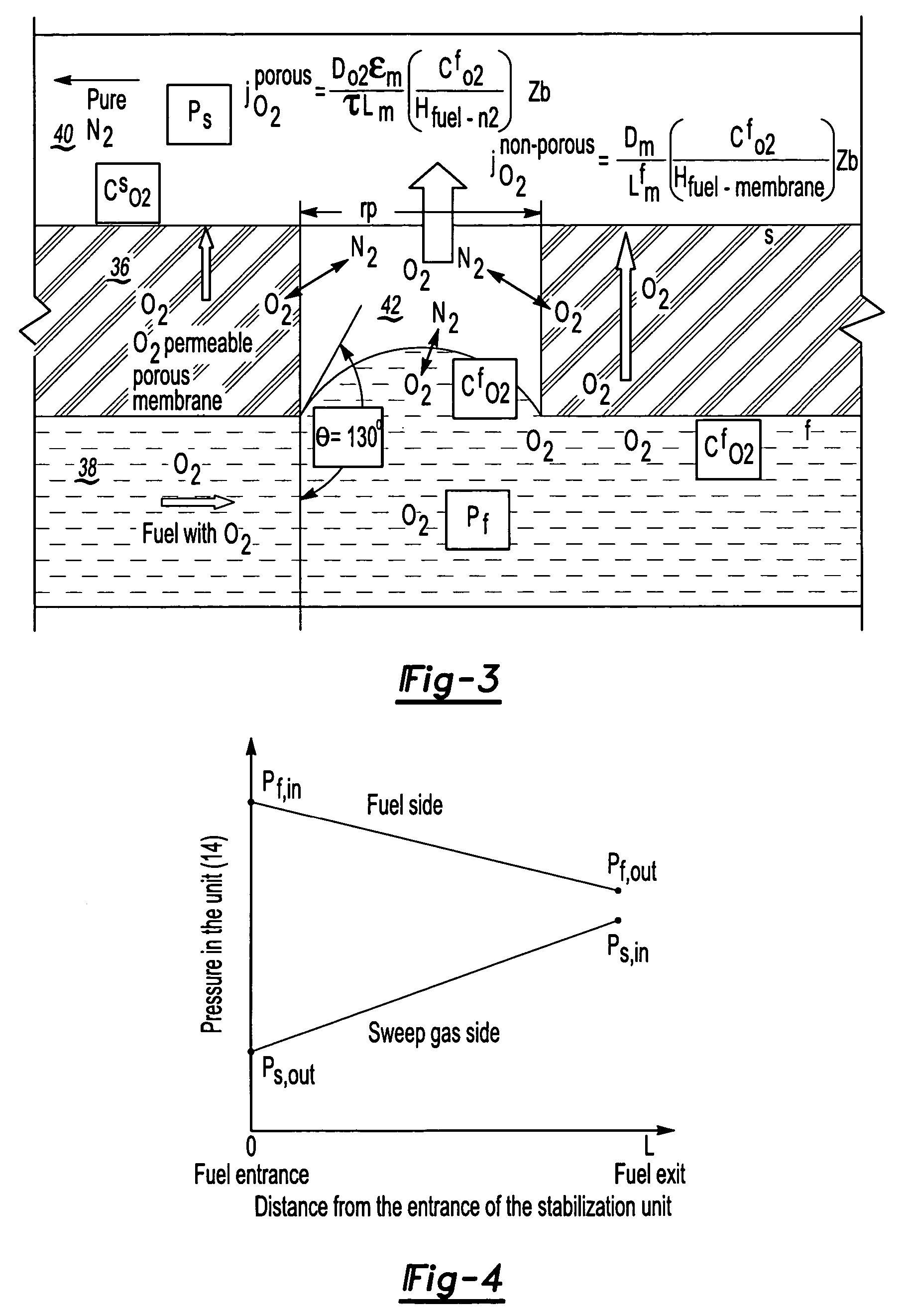

System and method for thermal management

InactiveUS6939392B2Increase in exploitable cooling capacity of fuelImprove cooling effectCombination devicesSemi-permeable membranesOxygenTurbine

A system for the management of thermal transfer in a gas turbine engine includes a heat generating sub-system in operable communication with the engine, a fuel source to supply a fuel, a fuel stabilization unit to receive the fuel from the fuel source and to provide the fuel to the engine, and a heat exchanger in thermal communication with the fuel to transfer heat from the heat generating sub-system to the fuel. A method of managing thermal transfer in an aircraft includes removing oxygen from a stream of a fuel fed to an engine used to drive the aircraft, transferring heat from a heat generating sub-system of the aircraft to the fuel, and combusting the fuel. A system for the thermal management of an aircraft provides for powering the aircraft, supplying a fuel deoxygenating the fuel, and transferring heat between a heat generating sub-system of the aircraft and the fuel.

Owner:RAYTHEON TECH CORP

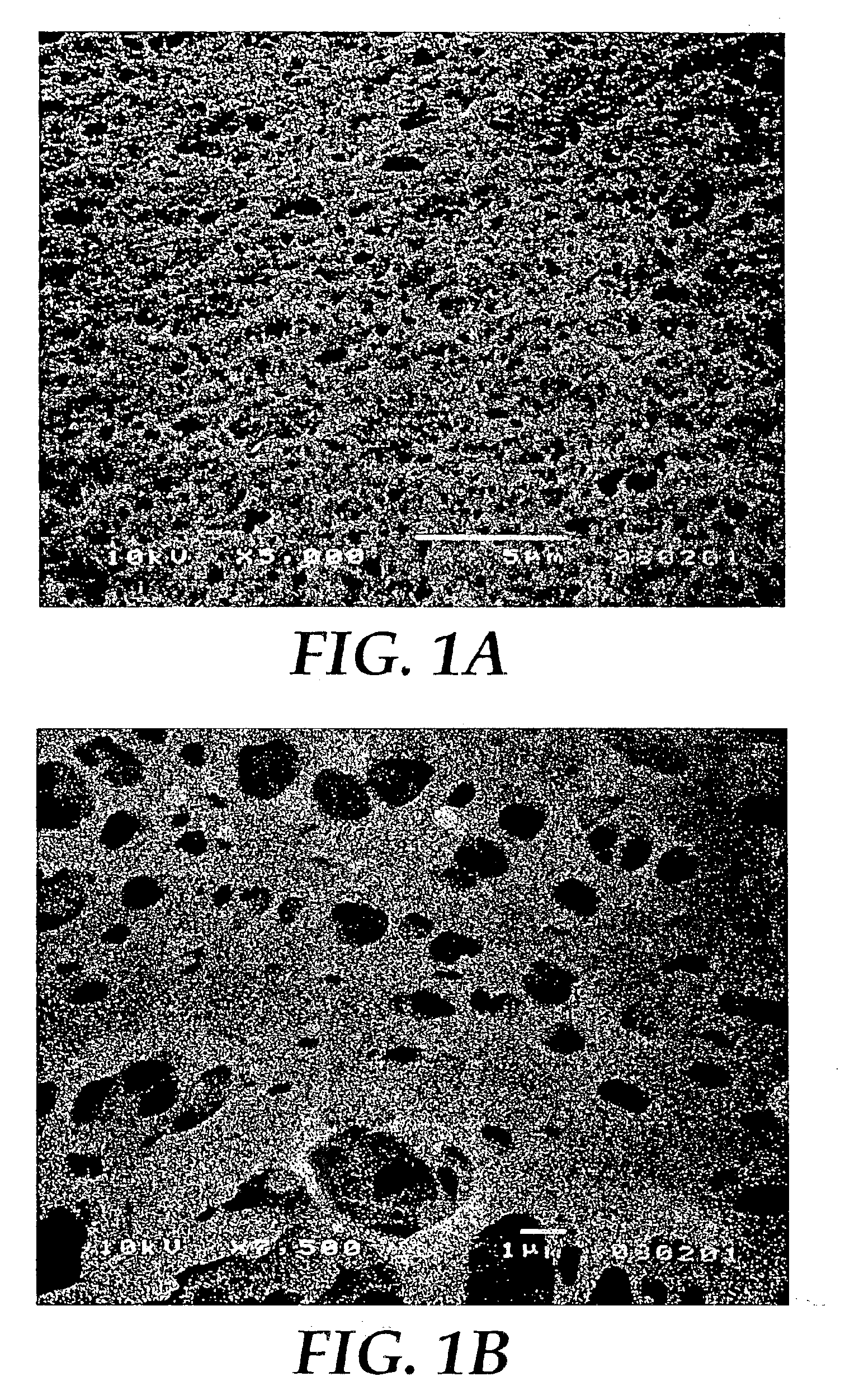

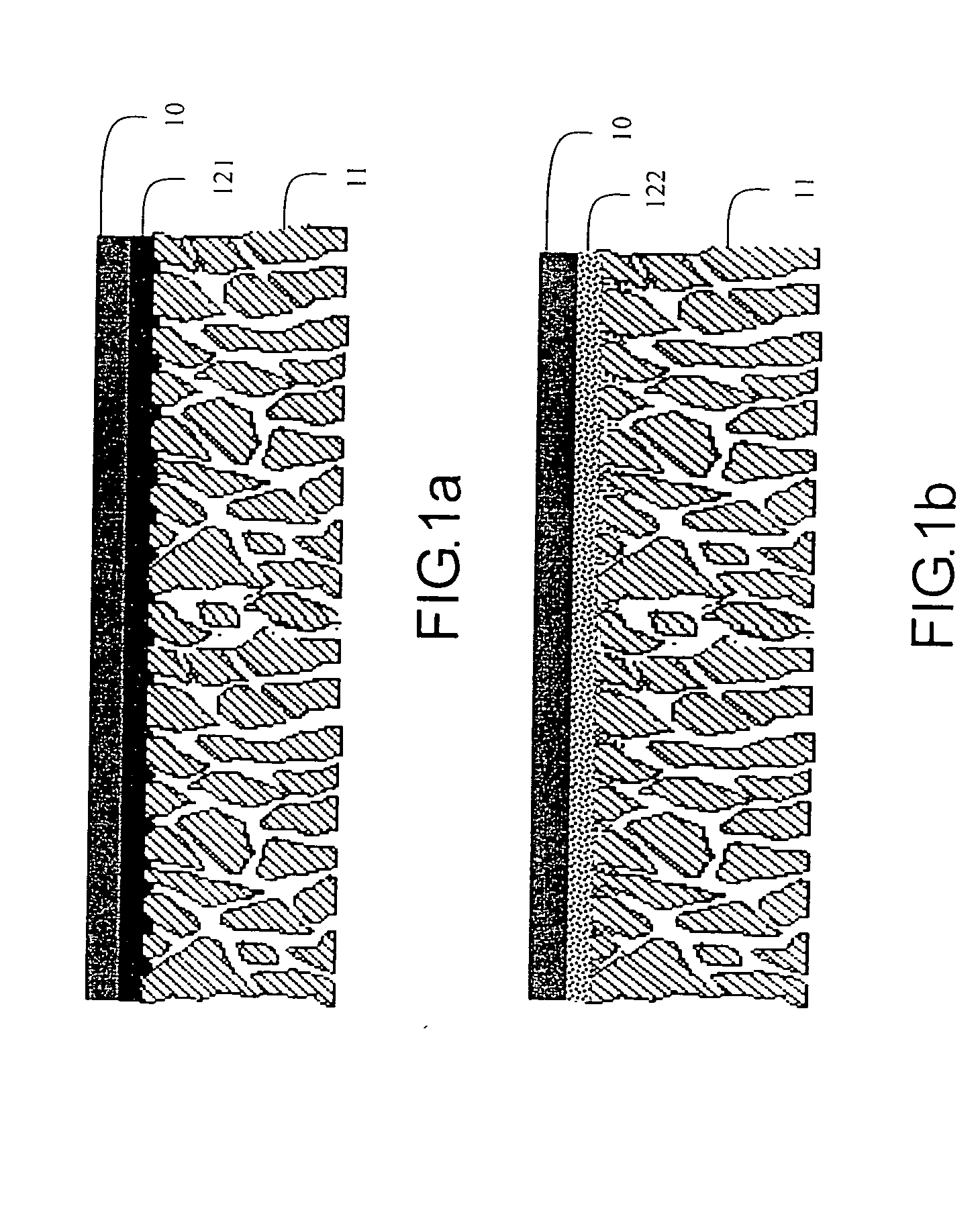

Hydrophobic membrane materials for filter venting applications

The present invention relates to filtration media having both hydrophobic (water-repellent) properties. The filtration media are produced using a fluorothermoplastic material, such as a terpolymer of tetrafluoroethylene, vinylidene fluoride, and hexafluoropropylene. The invention also relates to methods of preparing such filtration media using casting solution phase inversion.

Owner:PALL CORP

Carbon dioxide gas removal from a fluid circuit of a dialysis device

InactiveUS8034161B2Efficient removalSmall sizeSemi-permeable membranesSolvent extractionAtmospheric airProduct gas

The present invention is directed to degassing devices for dialysate circuits. One embodiment has a first housing and a second housing positioned within the first housing in an annular relationship. A second embodiment comprises a dialysate regeneration system with urease, a dialyzer, and a housing with an external wall, where the external wall is exposed to atmosphere and comprises a material that passes gas but does not pass liquid and where the housing is positioned between the urease and dialyzer.

Owner:FRESENIUS MEDICAL CARE HLDG INC

Cannula assembly

Owner:PALL CORP

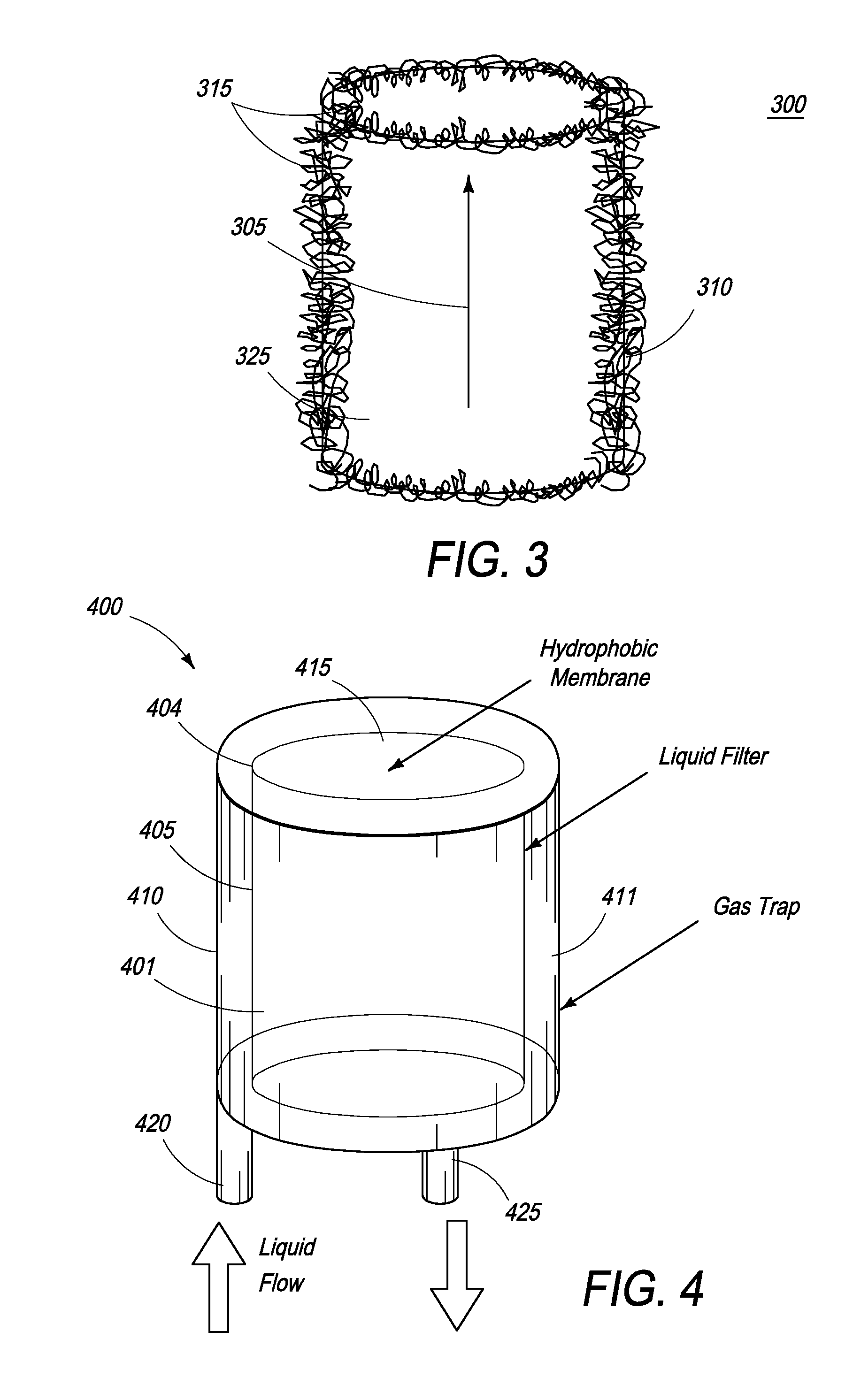

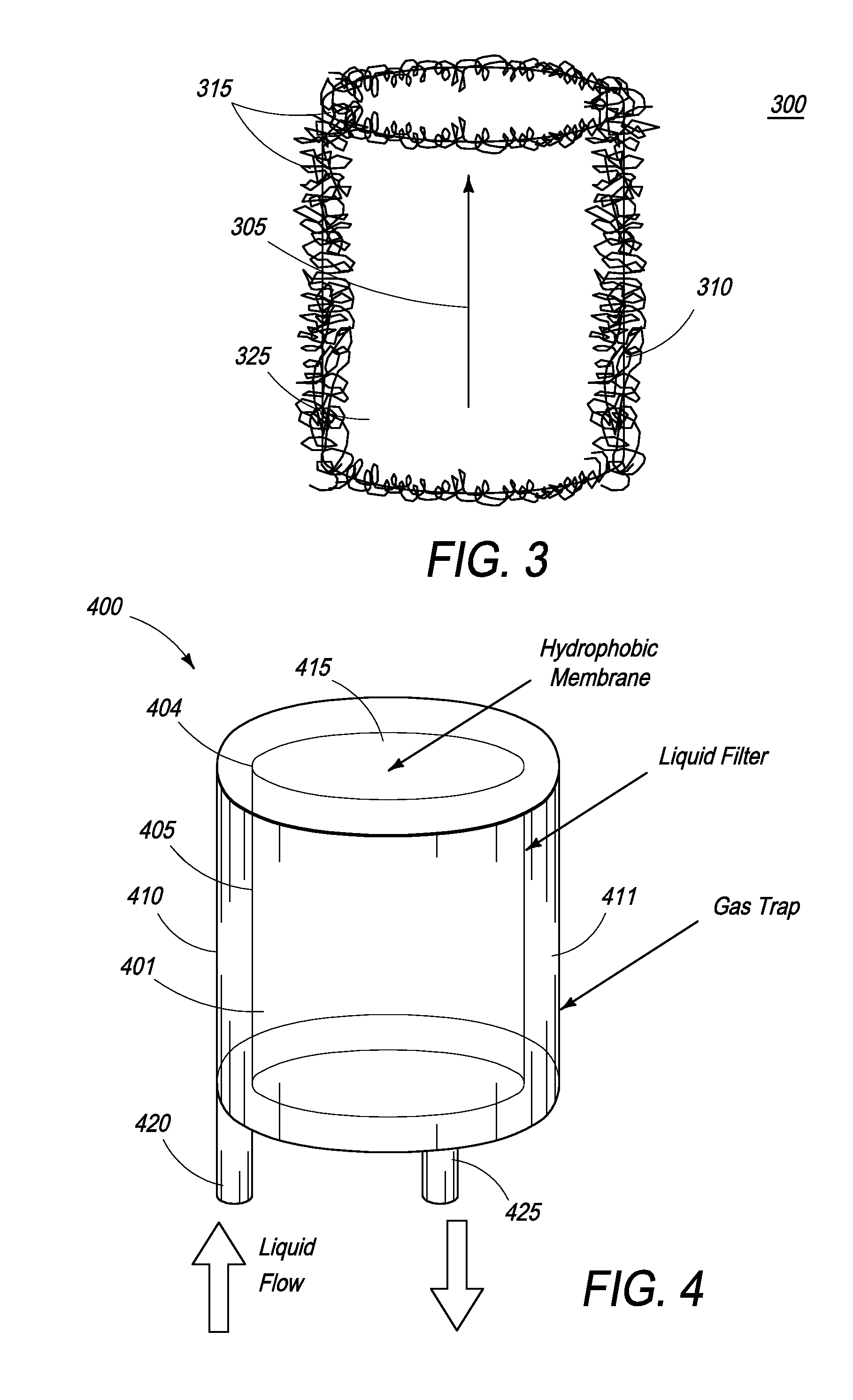

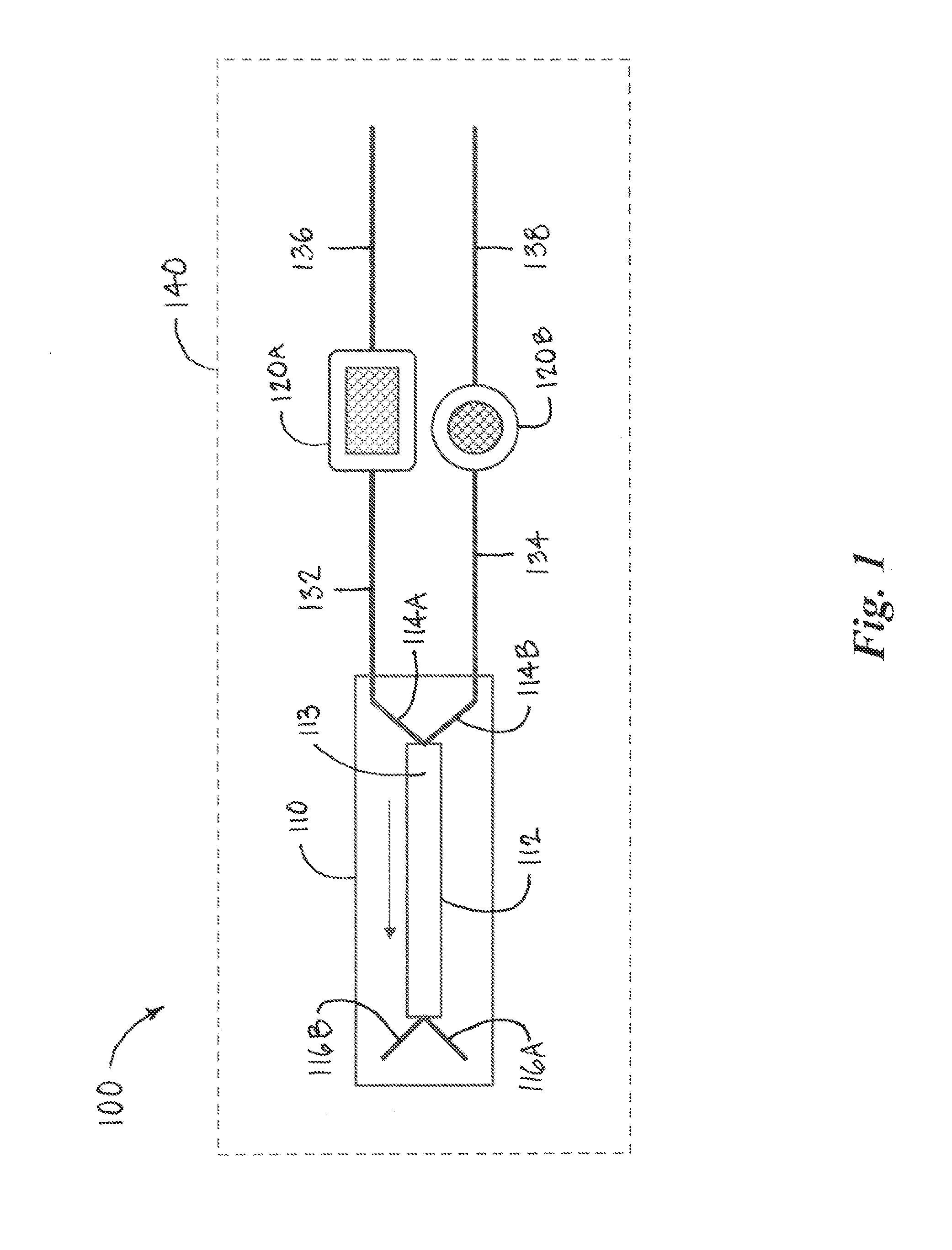

Degassing module for a controlled compliant flow path

ActiveUS20140216250A1Avoid flowDispersed particle filtrationOther blood circulation devicesMedicineHematological test

A degassing module for removal of air and other gases during operation of a medical therapy device that delivers any one of hemodialysis, hemodiafiltration and hemofiltration. The degassing module has a flow-through first chamber that has a hydrophobic vent membrane that has an exterior and interior side forming a portion of the flow-through chamber. The hydrophobic vent membrane is positioned at a higher elevation on the flow-through chamber than a fluid outlet. Fluid flows through the flow-through chamber in a downward direction relative to the hydrophobic vent membrane. A flow-through chamber has a cross sectional area configured to provide for a downward flow velocity of the fluid to be less than the upward rise velocity of a smallest bubble to be removed from the fluid.

Owner:MOZARC MEDICAL US LLC

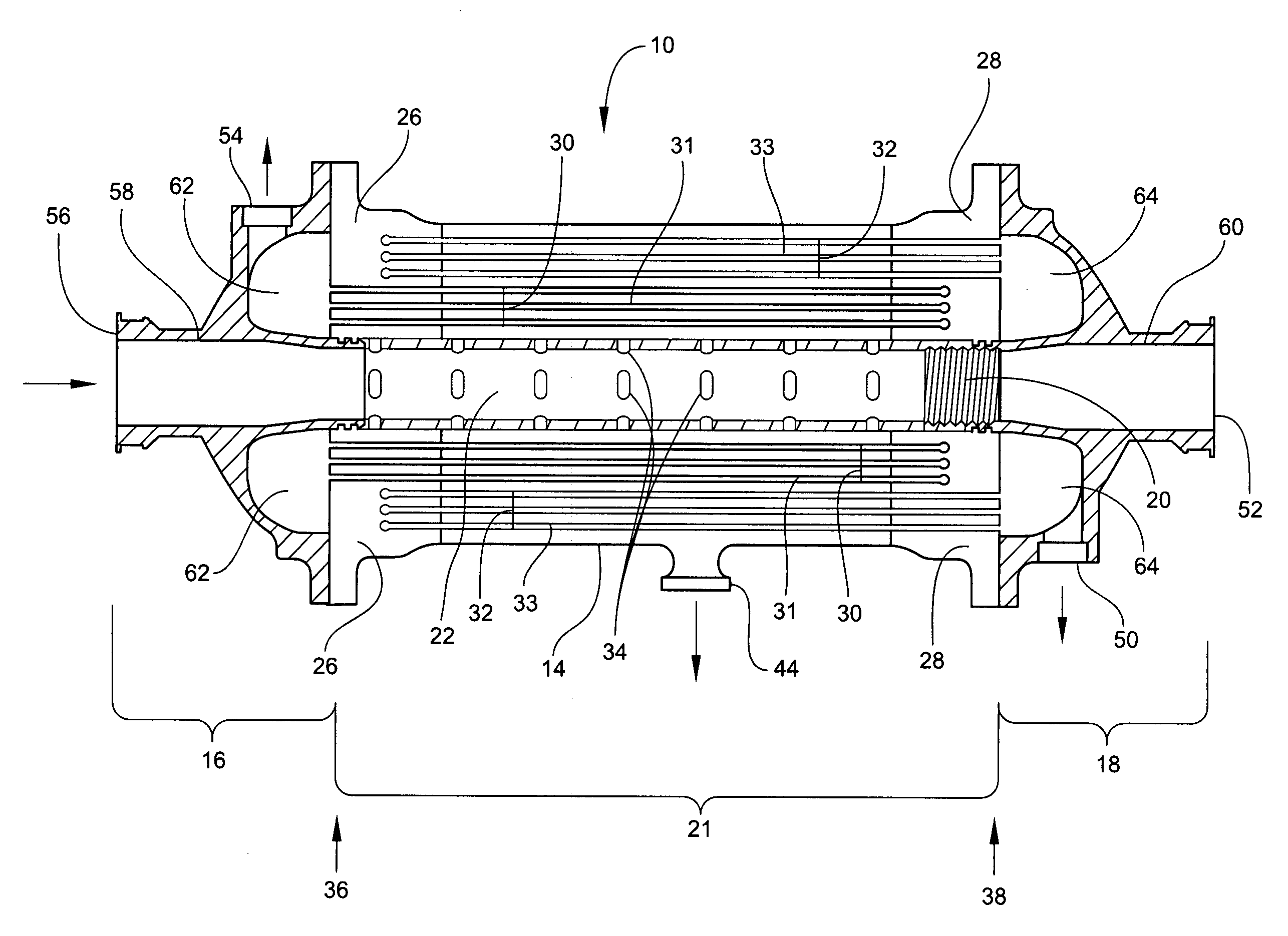

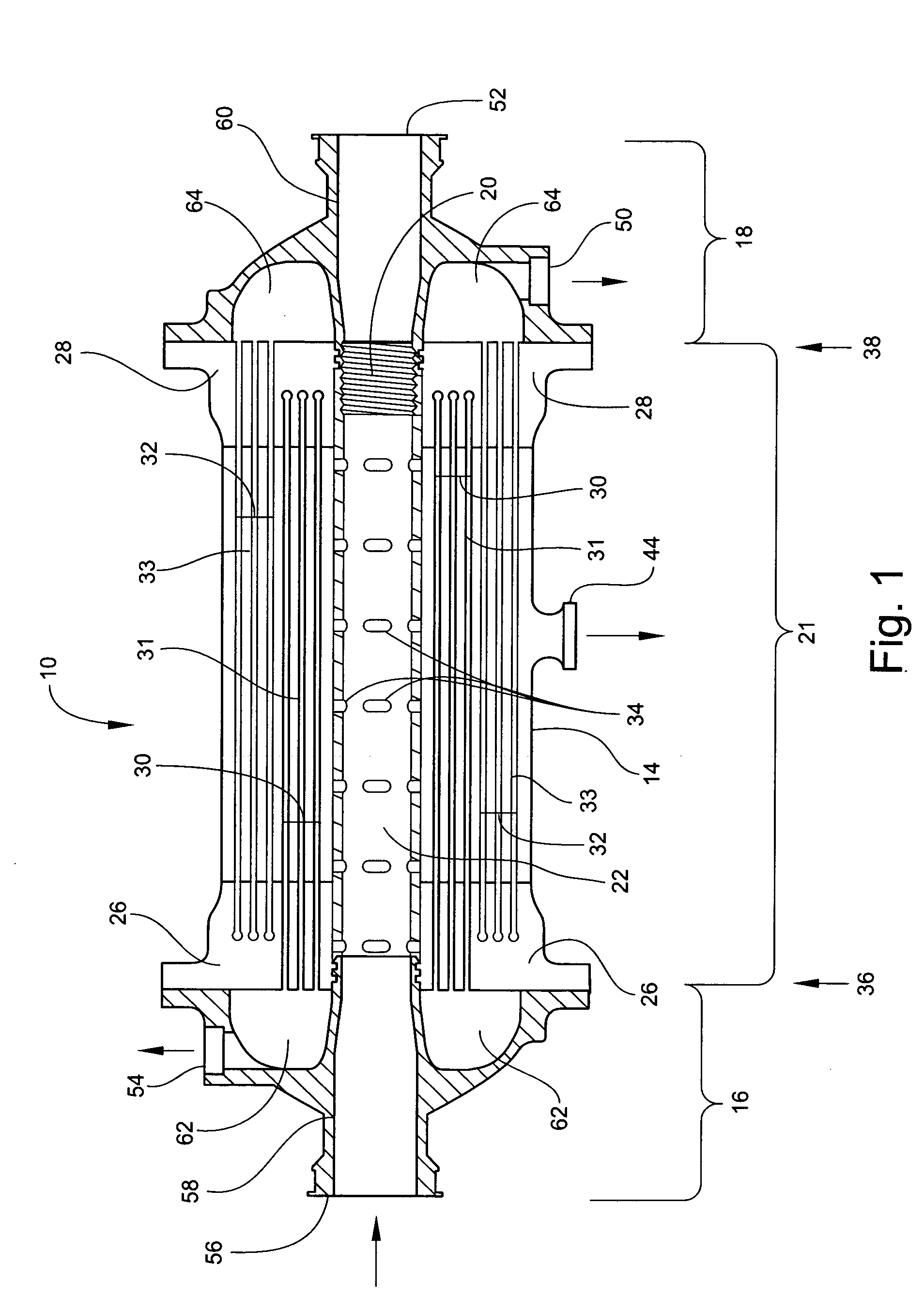

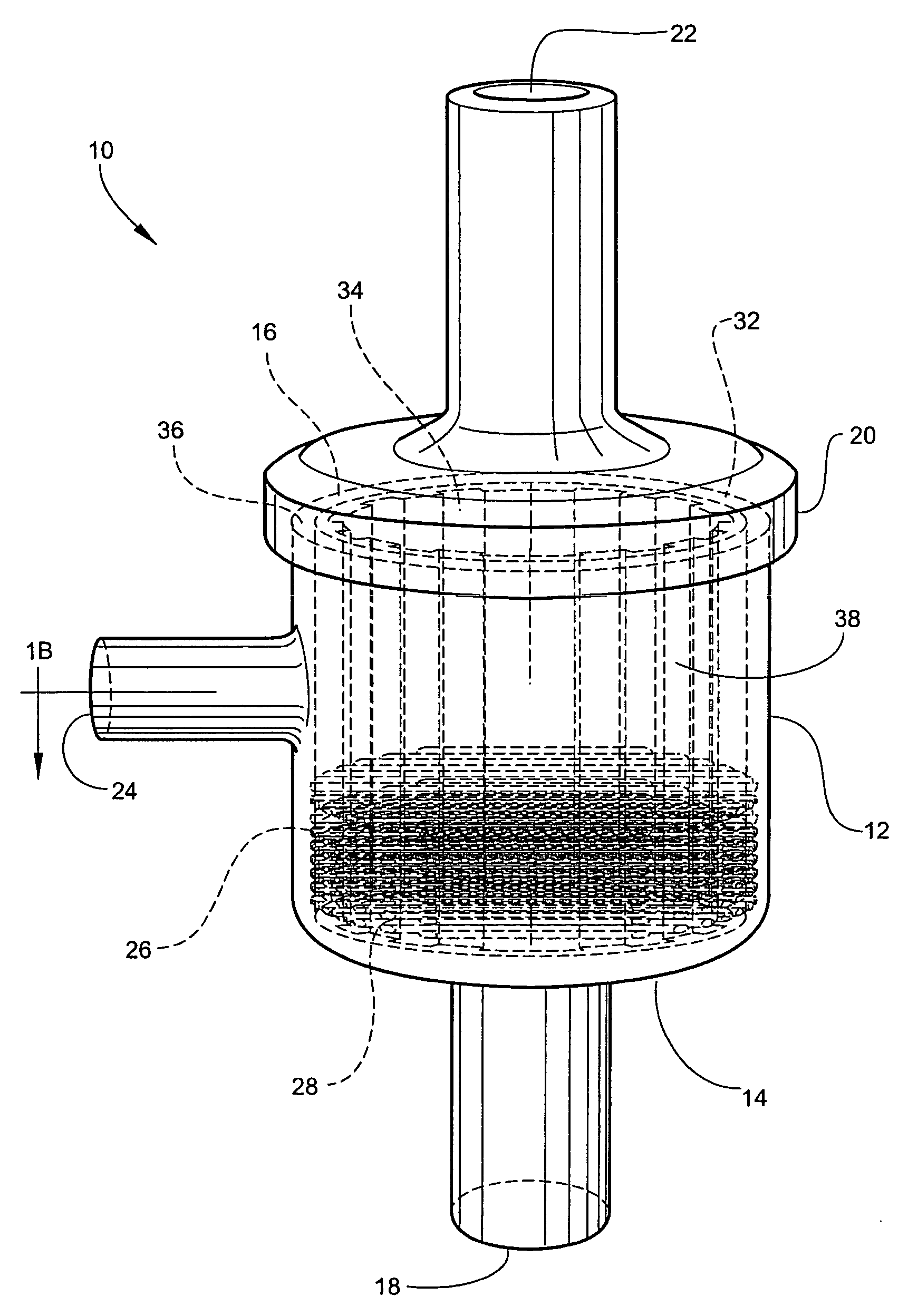

Membrane contactor and method of making the same

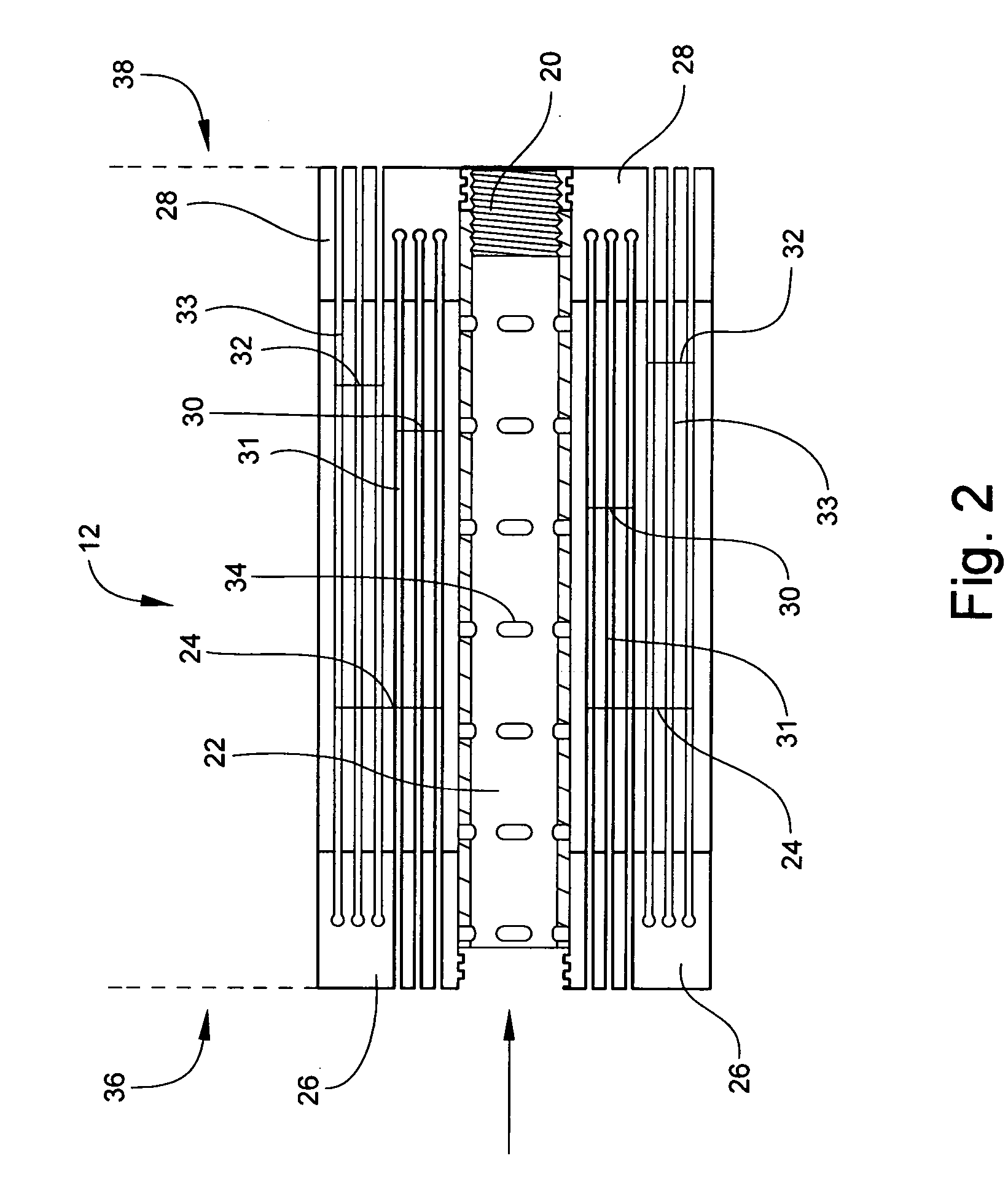

A hollow fiber membrane contactor includes a perforated center tube, a first mat comprising a first hollow fiber membrane, a second mat comprising a second hollow fiber membrane, a first tube sheet, a second tube sheet, a shell, and end caps. The first and second hollow fiber membranes are dissimilar. The first and second mats surround the center tube, and the first and second tube sheets affix the first and second mats to the center tube. The first hollow fiber membrane has a first lumen, and the second hollow fiber membrane has a second lumen. The first lumen may be open at the first tube sheet and closed at the second tube sheet while the second lumen may be open at the second tube sheet and closed at the first tube sheet. The shell surrounds the first and second mats, and it is sealed to the tube sheets. The end caps are affixed to the shell thereby defining headspaces therebetween the tube sheets and the end caps.

Owner:CELGARD LLC

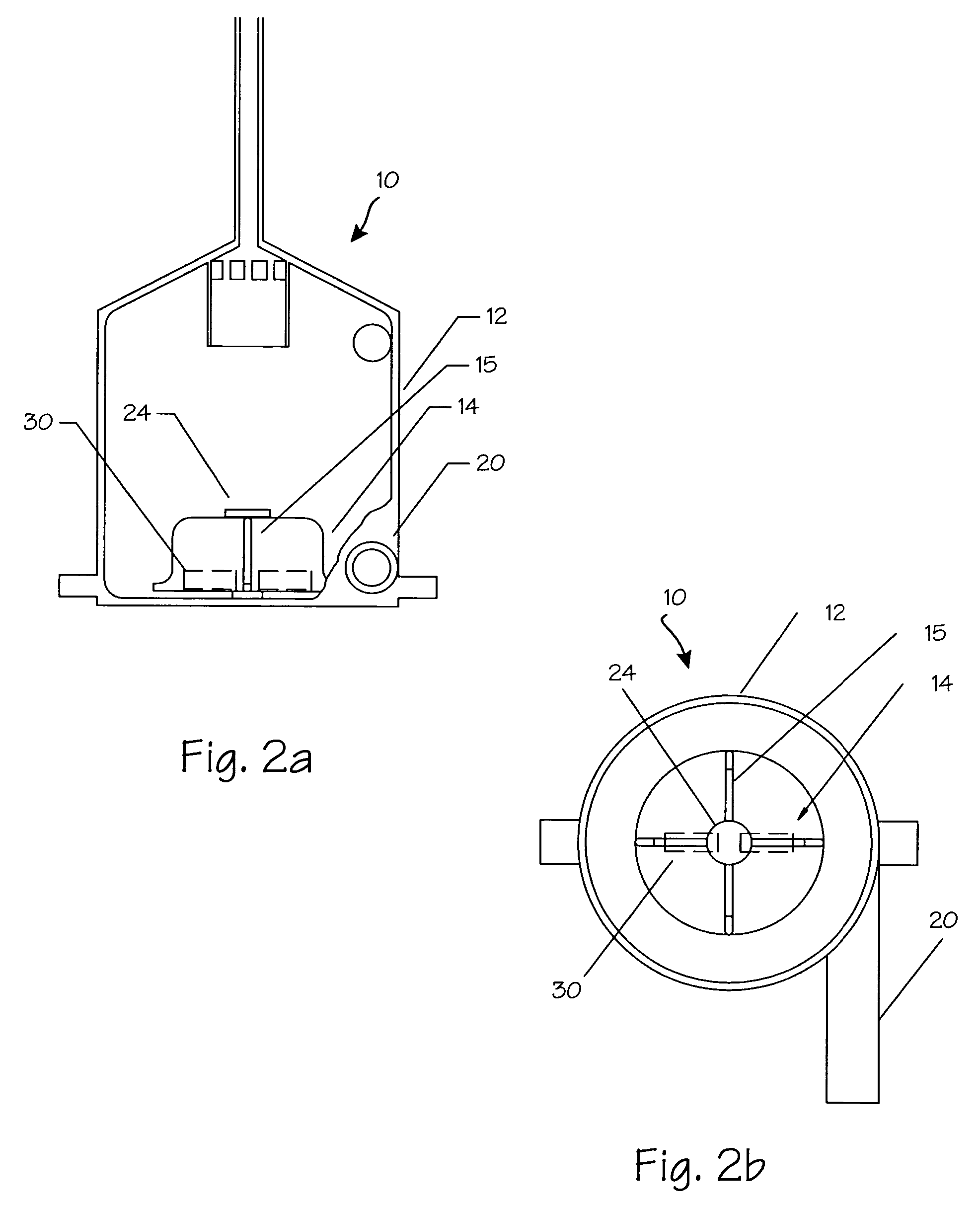

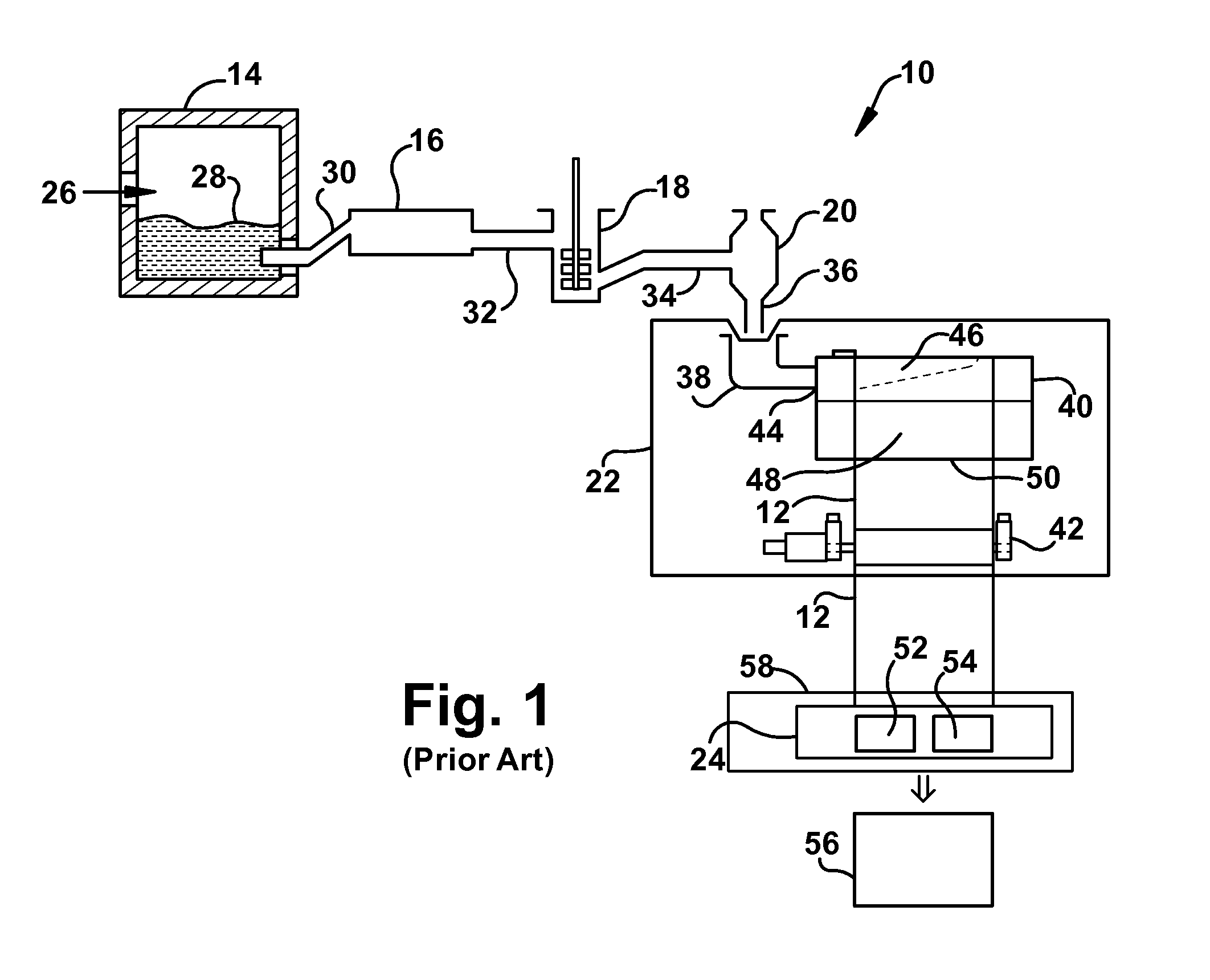

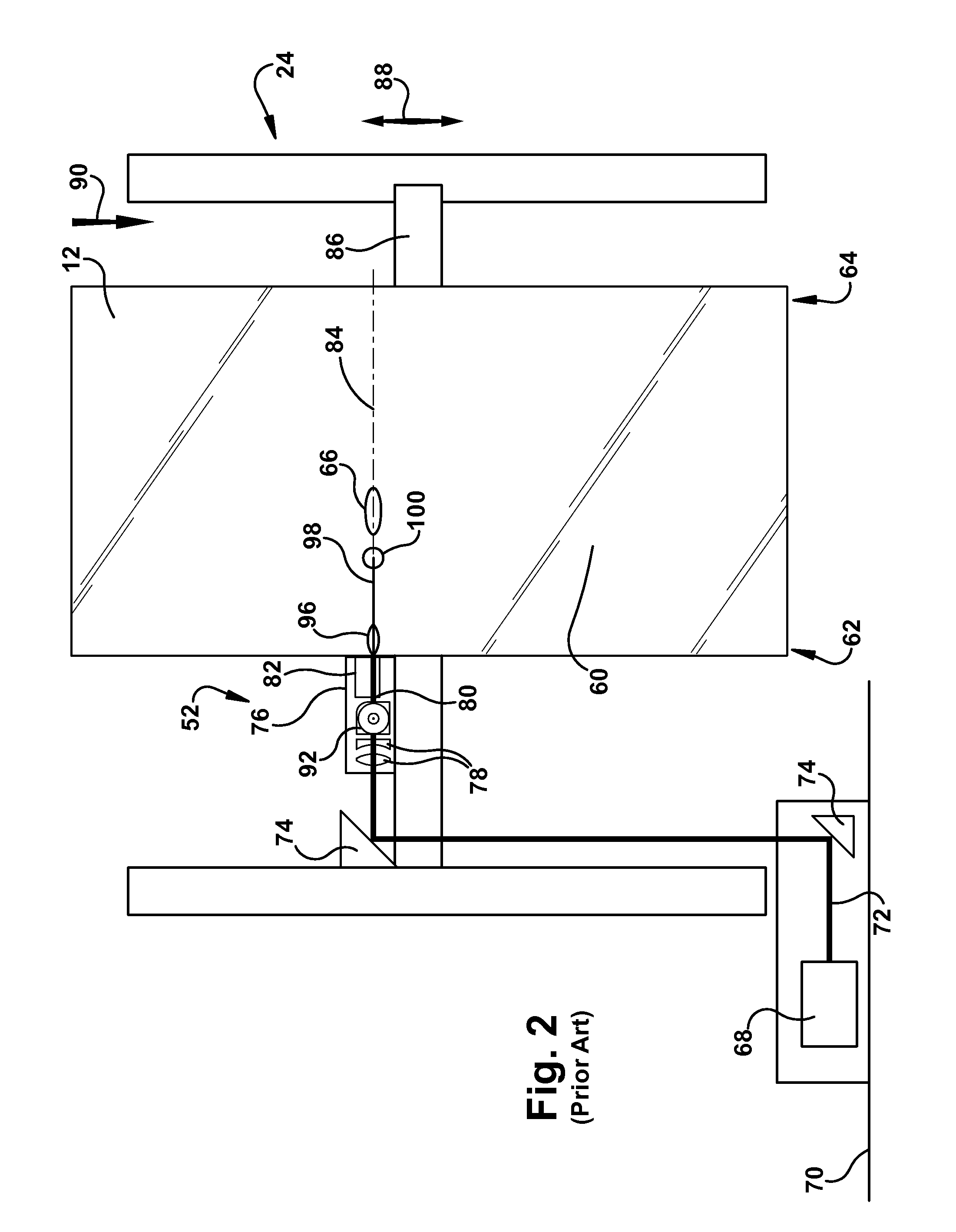

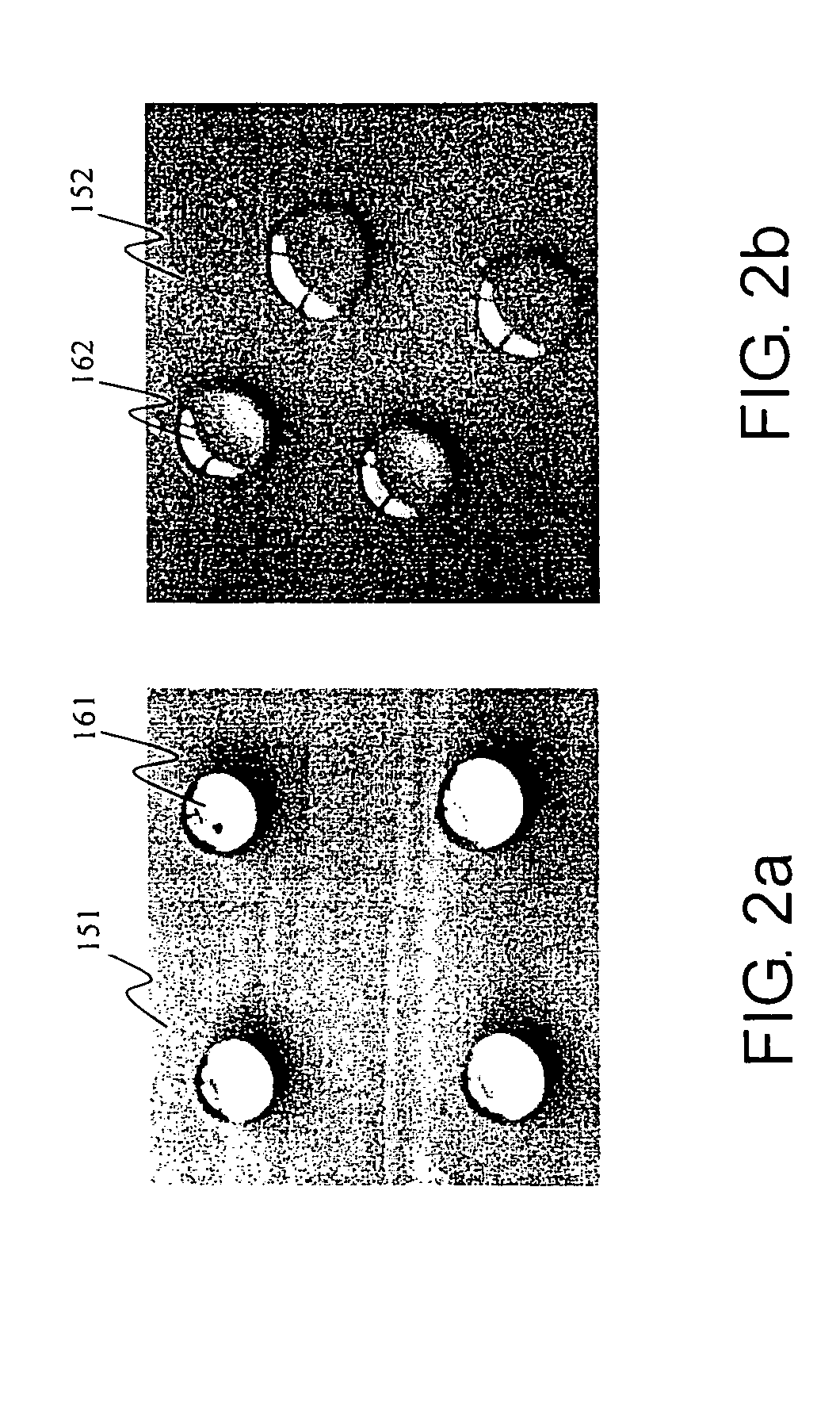

Method and apparatus for removal of gas bubbles from blood

InactiveUS7488448B2Semi-permeable membranesReversed direction vortexAssisting proceduresAssisted procedure

A system for removing gas bubbles from blood during circulatory assist procedures. An active filter apparatus forces the bubbles to the center of the system where they are removed from the blood before the blood exits the filter.

Owner:INDIAN WELLS MEDICAL

Devices, systems and methods for reducing the concentration of a chemical entity in fluids

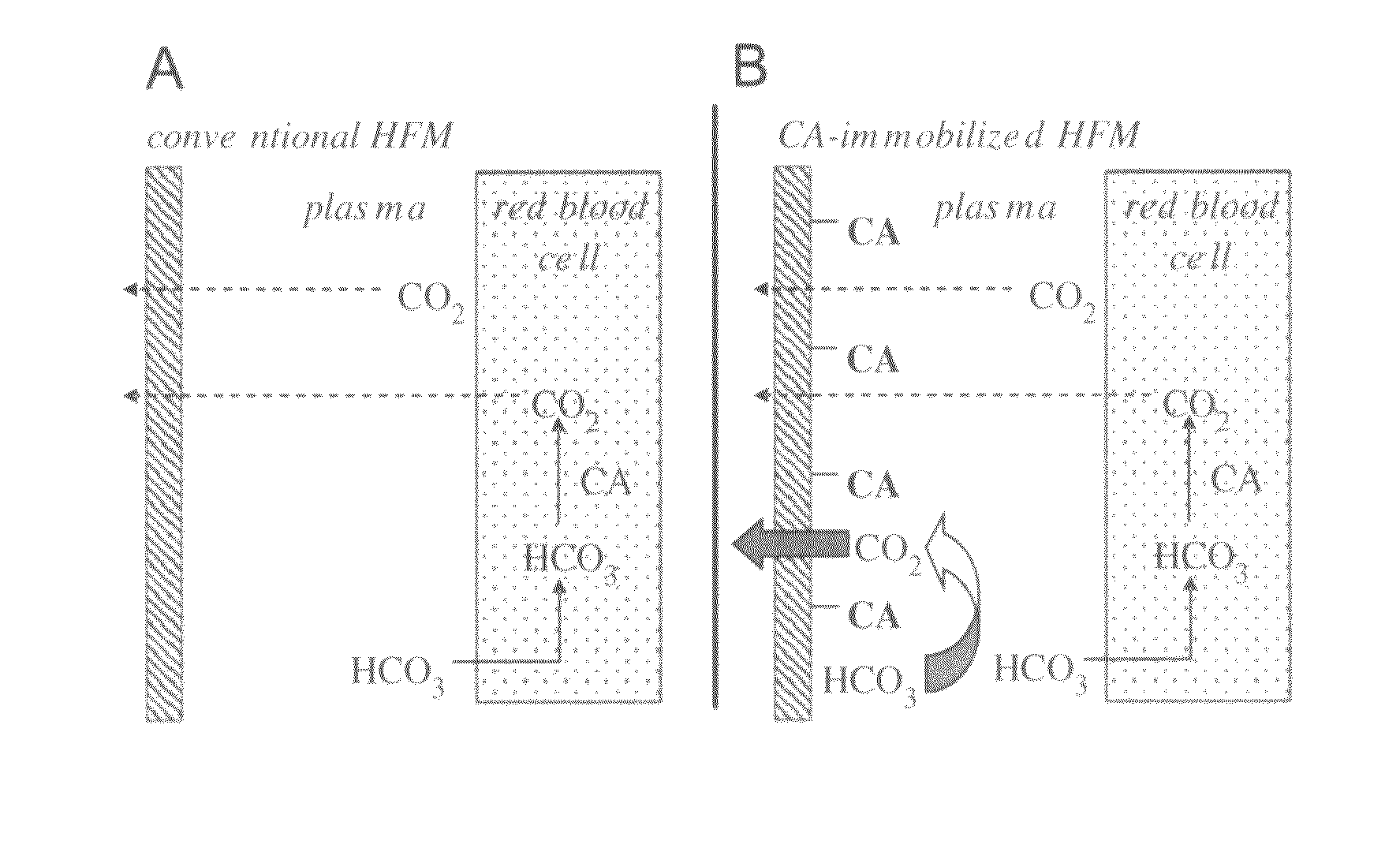

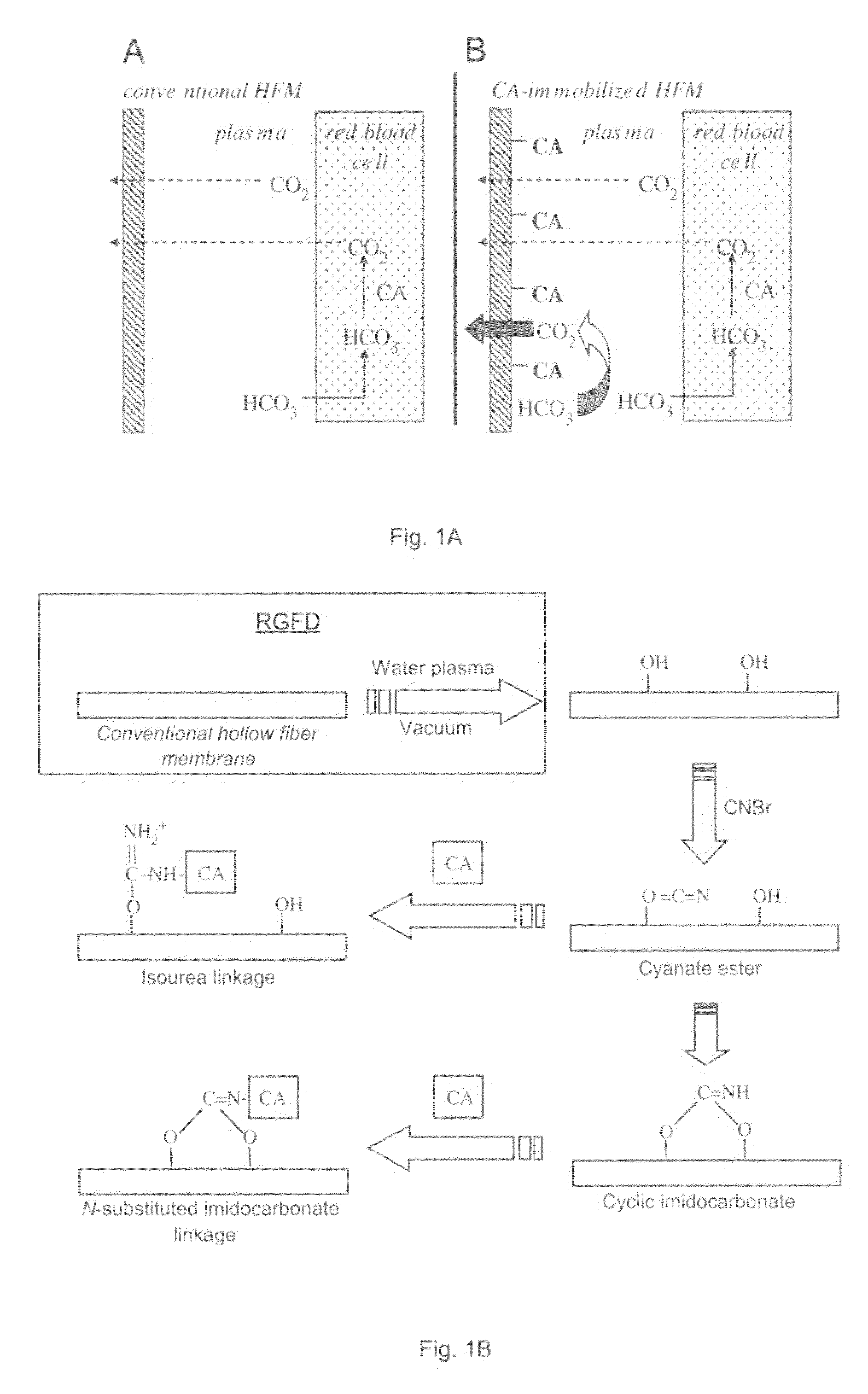

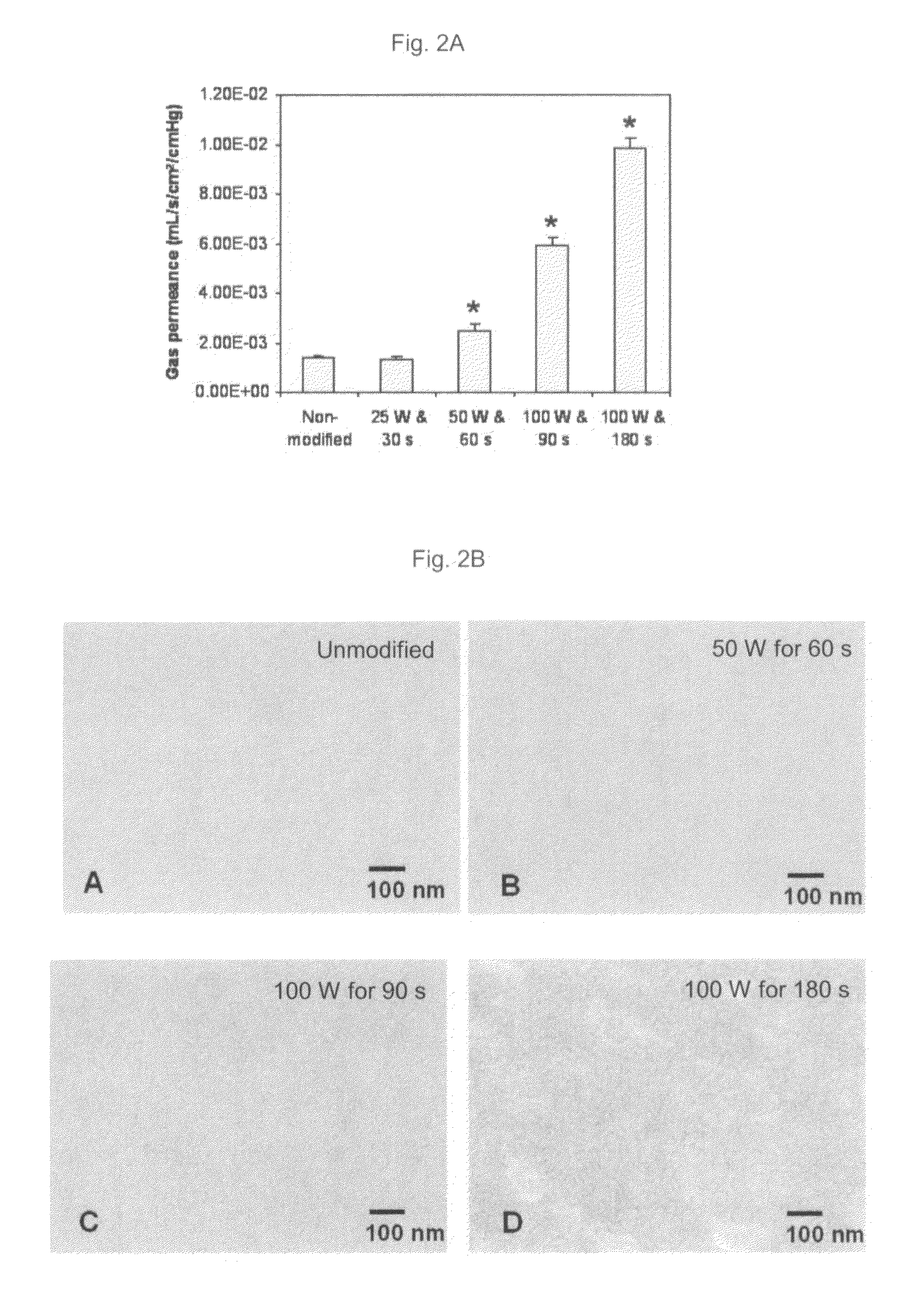

ActiveUS7763097B2Reduce adverse effectsGood removal effectSolid sorbent liquid separationMedical devicesCarbonic anhydrase activityAnalytical chemistry

A device for removal of at least a portion of carbon dioxide from an aqueous fluid includes at least one membrane through which carbon dioxide can pass to be removed from the fluid and immobilized carbonic anhydrase on or in the vicinity of a first surface of the membrane to be contacted with the fluid such that the immobilized carbonic anhydrase comes into contact with the fluid. The first surface exhibits carbonic anhydrase activity of at least 20% of maximum theoretical activity of the first surface of the membrane based on monolayer surface coverage of carbonic anhydrase in the case that the carbonic anhydrase is immobilize on the first surface.

Owner:UNIVERSITY OF PITTSBURGH

Preventing gas from occupying a spray nozzle used in a process of scoring a hot glass sheet

ActiveUS20100287991A1Improve spraying effectImprove performanceGlass drawing apparatusGlass forming apparatusSolubilityHigh energy

A spray nozzle is used in a process of quenching a hot glass sheet during a laser scoring process or other high energy glass heating process. The scoring is conducted by a high energy means such as a laser. The nozzle is located in proximity to the glass sheet, creating gas in liquid used to quench the glass located in the nozzle (e.g., water). The gas (e.g., air bubbles) is removed from the quenching liquid. Then, the spray nozzle is used to spray the quenching liquid onto the sheet at a location trailing laser scoring of the sheet, such as using a traveling anvil machine at the bottom of the draw. The spray nozzle (purge nozzle) has a purge opening and tubing leading to a discharge location. The purge nozzle can have a sloped passageway that pre-stages gas bubbles near the purge opening in the nozzle. The spray nozzle can include a cooling coil passing around the nozzle passageway that enables a coolant to travel along the coil. This cools the quenching liquid passing through the nozzle, and increases the solubility of bubbles in the quenching liquid in the nozzle. A gas filter can receive gas-rich quenching liquid from the pressurized quenching liquid source, remove gas from the liquid, and send gas-depleted quenching liquid to the spray nozzle.

Owner:CORNING INC

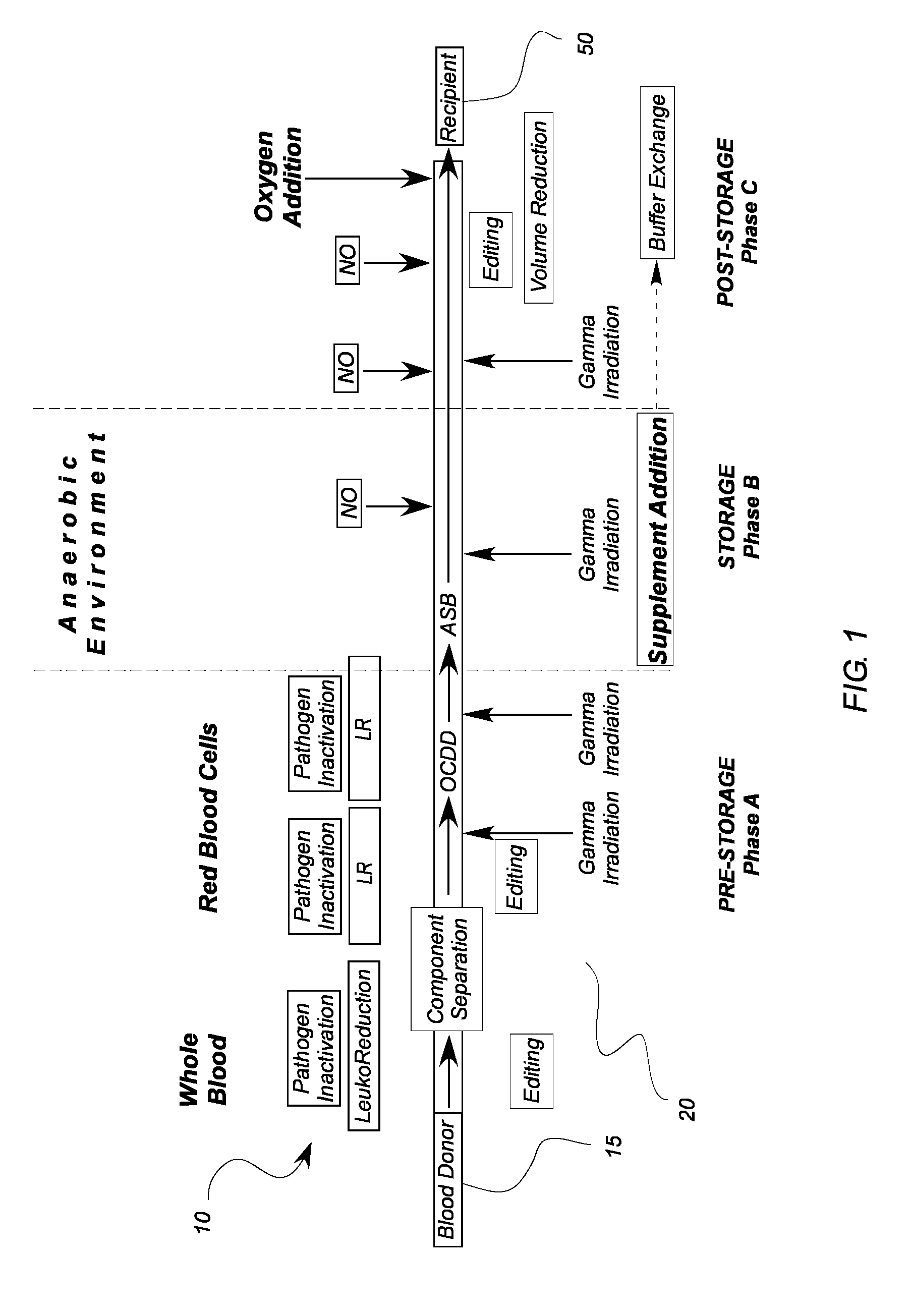

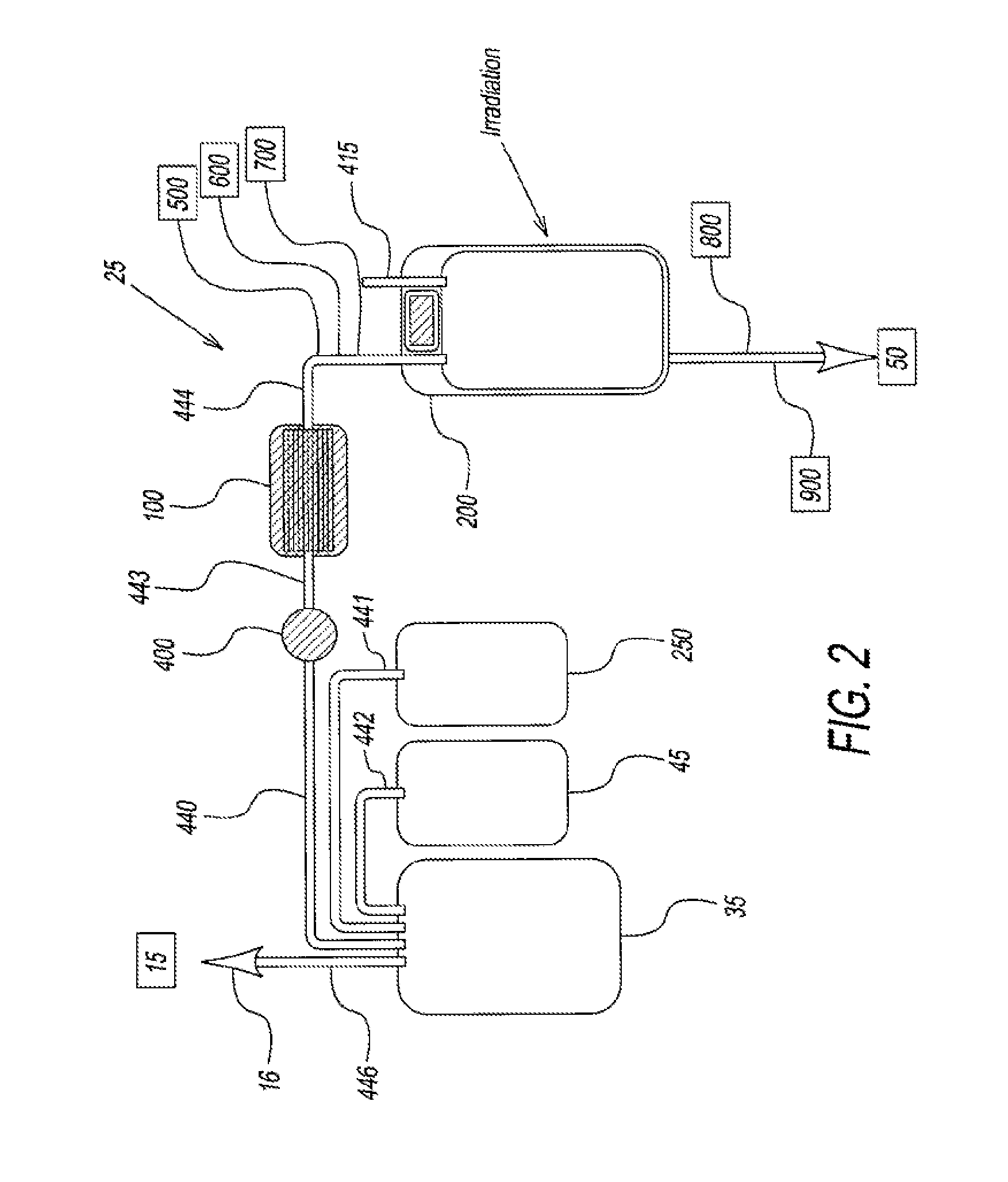

System for extended storage of red blood cells and methods of use

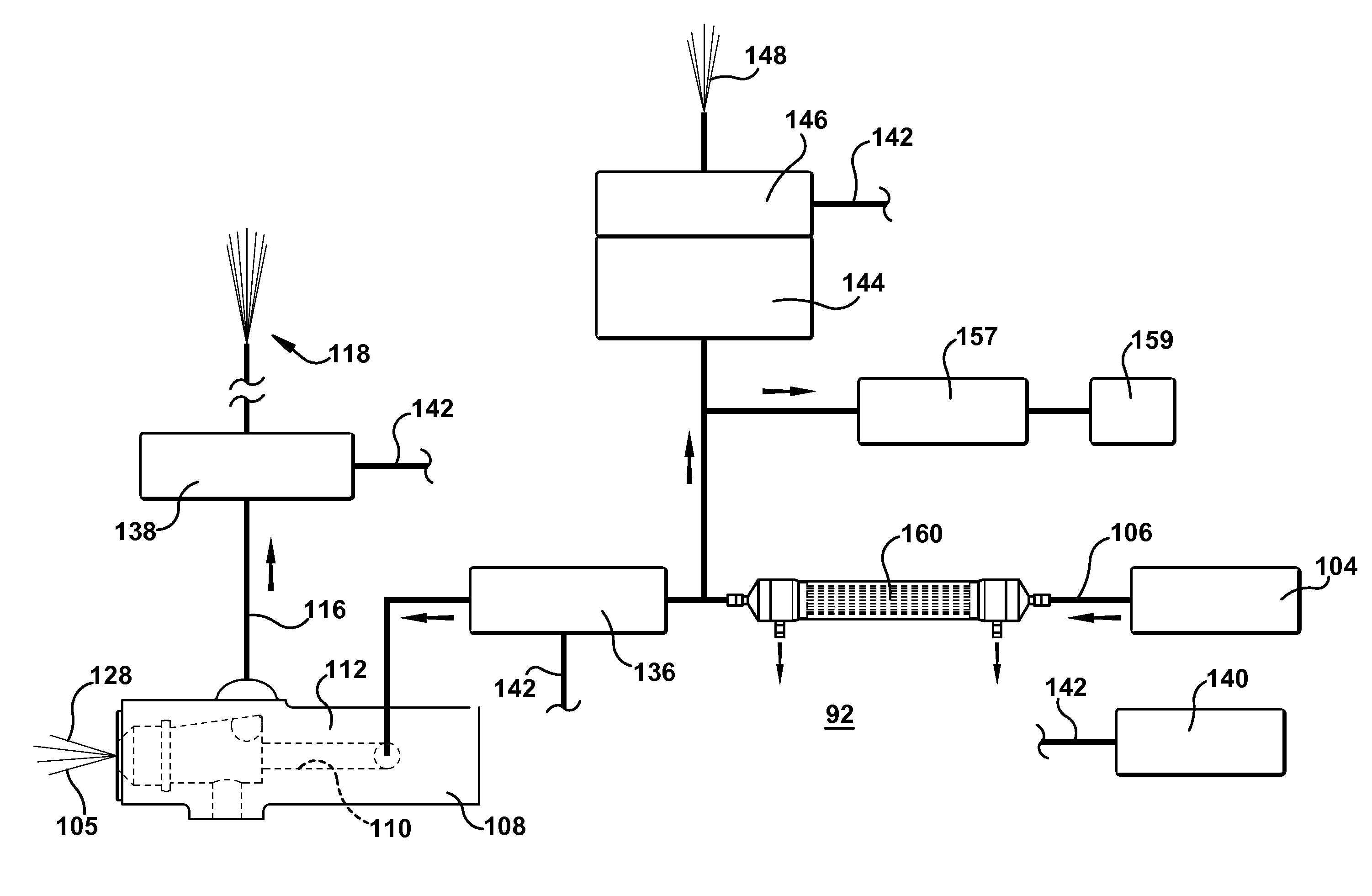

ActiveUS20130004937A1Extension of timeImprove radiation effectMedical devicesDead animal preservationOxygenRed Cell

A system and methodology for the preservation of red blood cells is described in which red blood cells are oxygen or oxygen and carbon dioxide depleted, treated and are stored in an anaerobic environment to optimize preparation for transfusion. More particularly, a system and method for extended storage of red blood cells from collection to transfusion that optimizes red blood cells prior to transfusion is described.

Owner:HEMANEXT INC

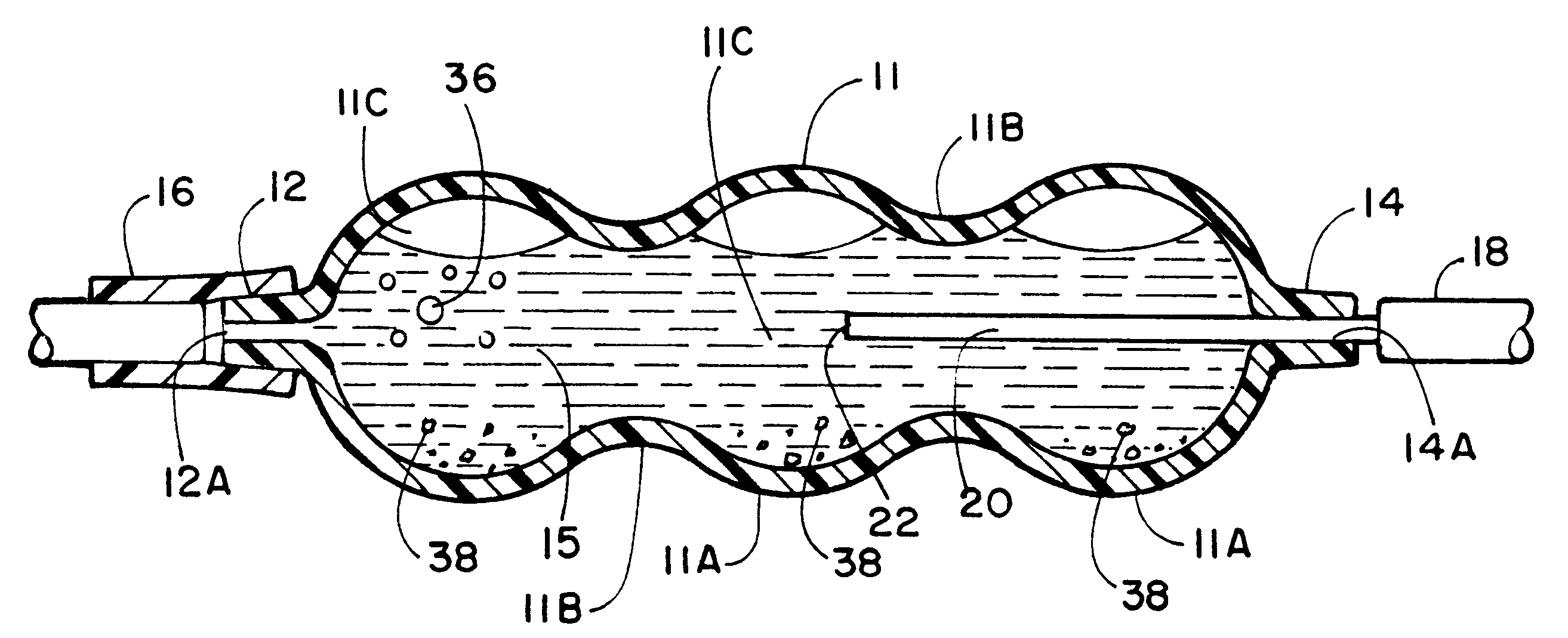

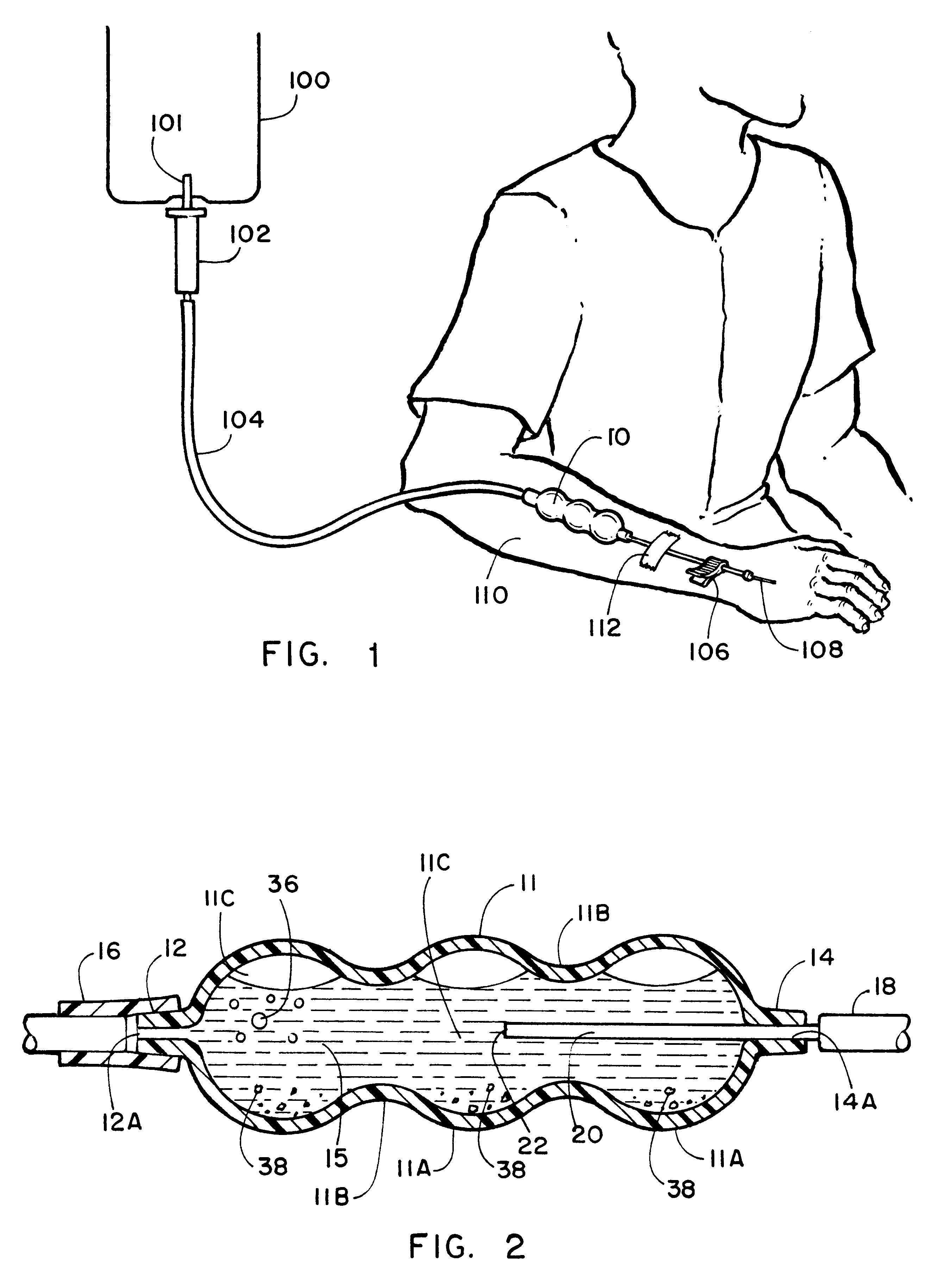

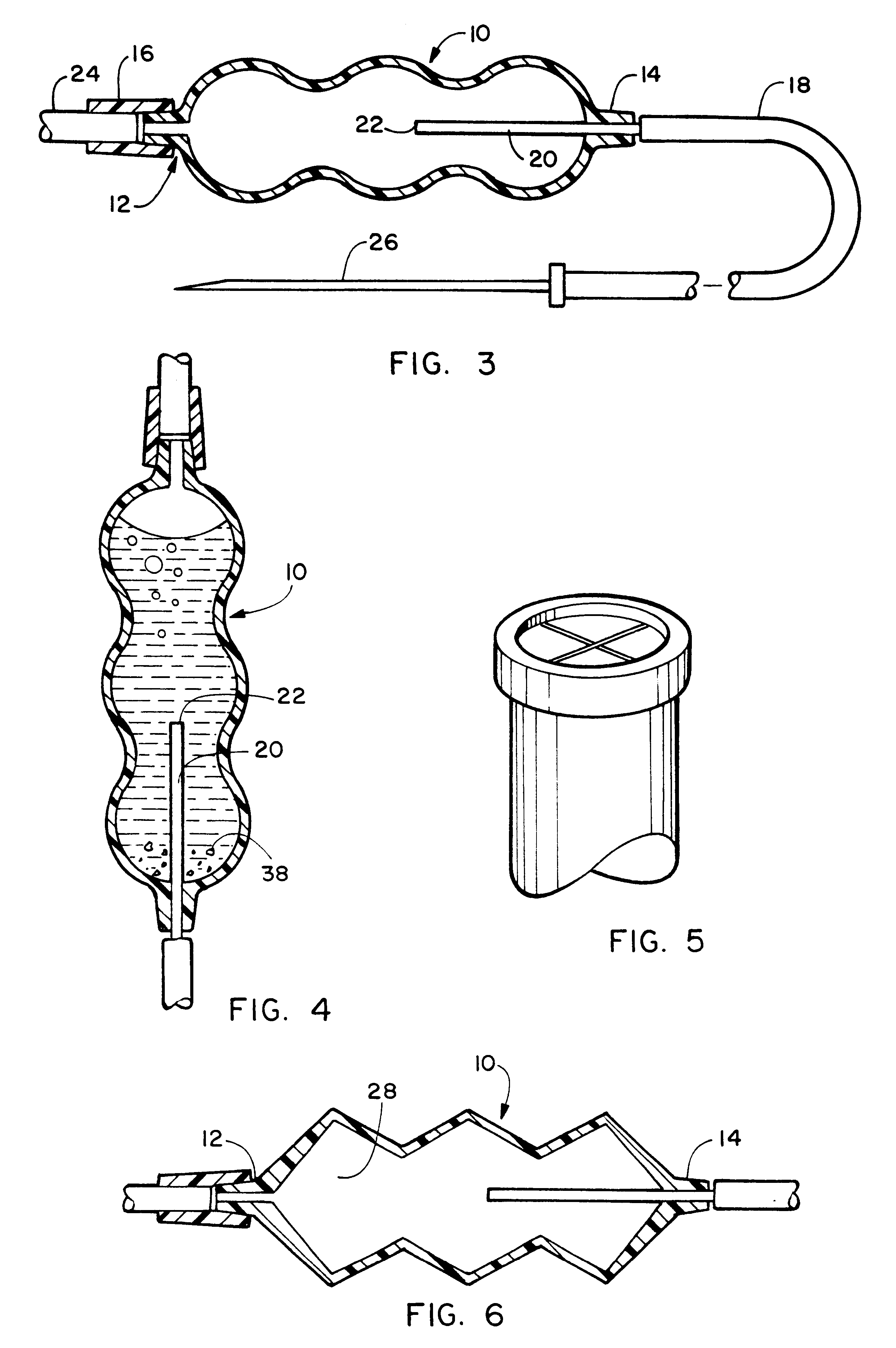

Gas and solid trap for an intravenous line

InactiveUS6537356B1Easy to manufactureEasy to operateMedical devicesLiquid degasification by filtrationStream flowEngineering

A device for trapping of gas and solids in a fluid stream flowing in an intravenous injection mechanism. The trapping device features a longitudinal peanut shaped revolved housing configuration having an outlet nozzle projecting axially inside an internal chamber at approximately the midpoint of a passageway. This allows the outlet nozzle to remain submerged in the fluid under an infinite number of tilt positions and angles. The trap outlet has proximal end with cooperative attachment with conventional intravenous fluid systems and distal end of which may attached to conventional intravenous fluid conduits and devices such as angiocath or plastic needle. Using one or a plurality of chambers having a diameter at bulged cavities that are substantially larger than the diameter of the internal nozzle, gas bubbles and sediment are trapped in the bulging cavity spaces away from centrally located inlet nozzle thus protecting the patient.

Owner:SORIANO NATHANIEL M

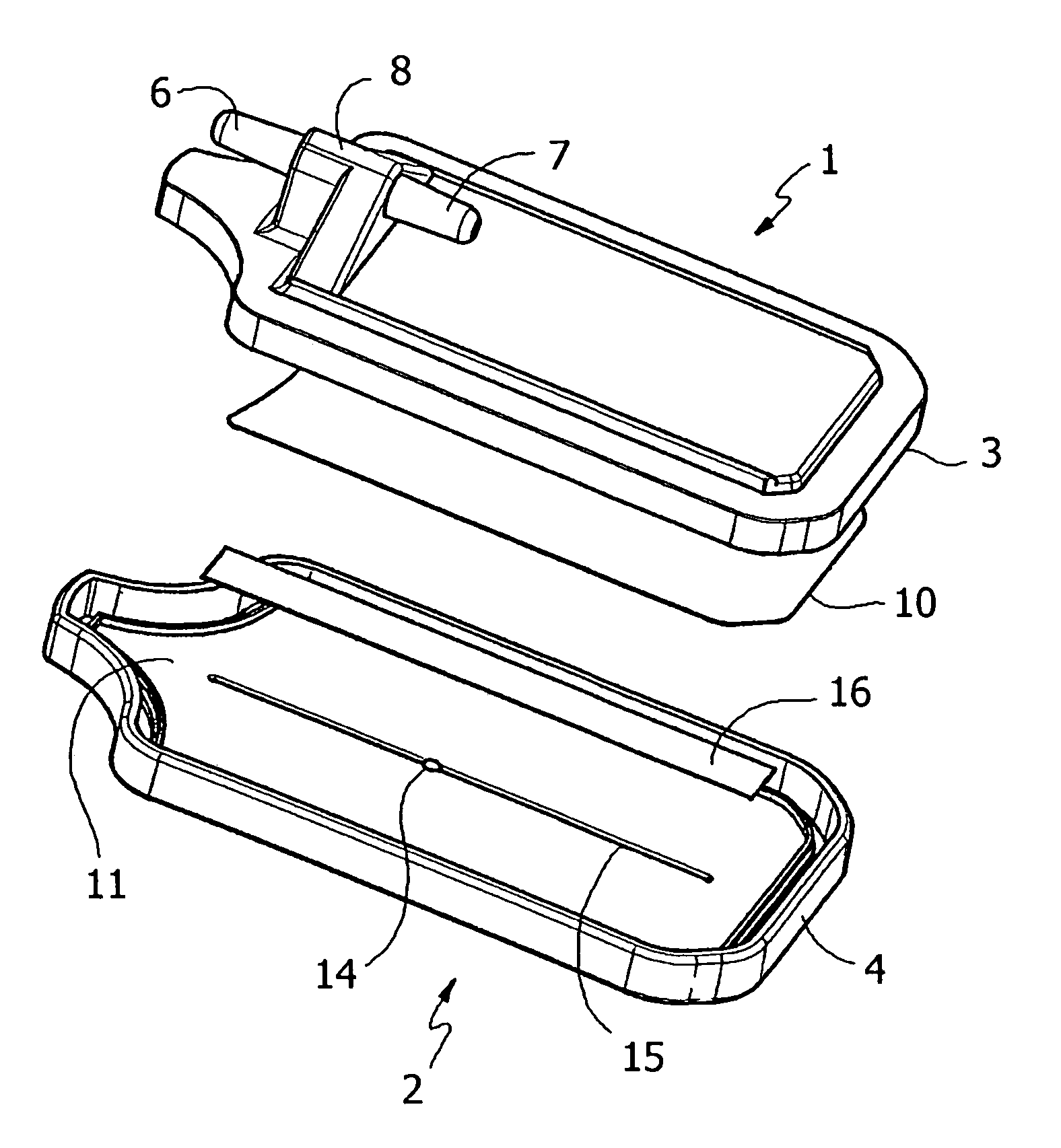

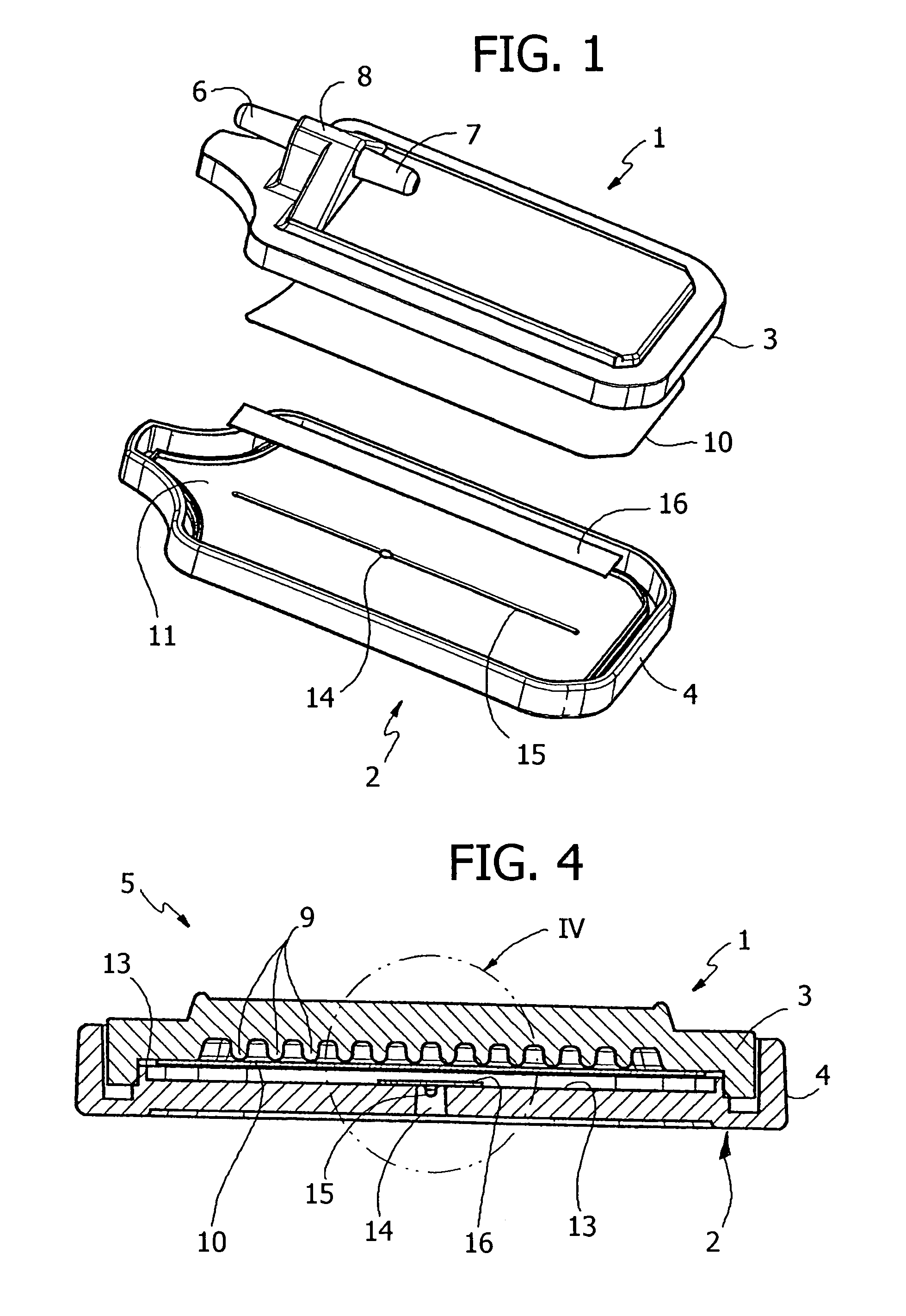

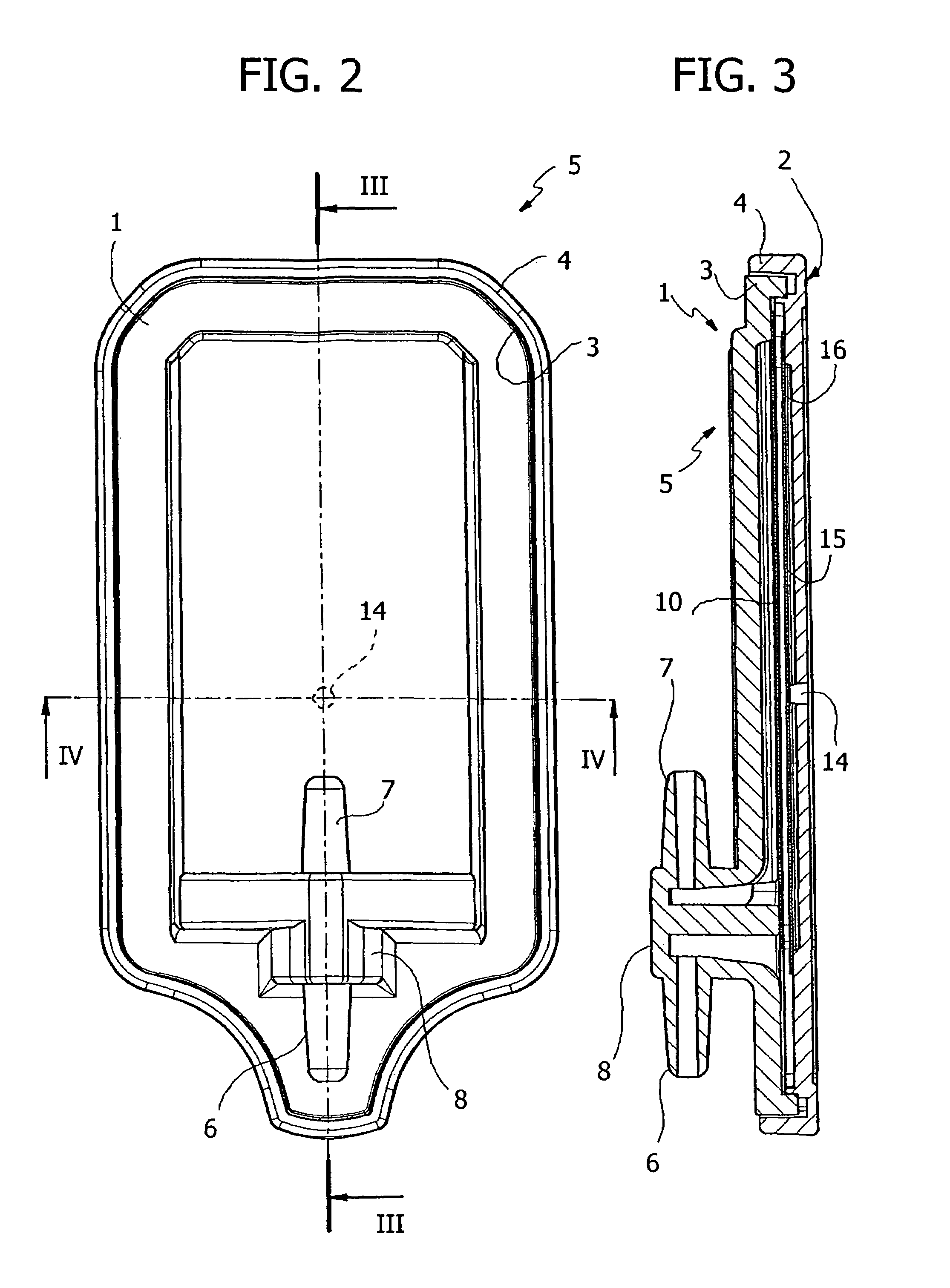

Flat filter for venting gas in intravenous medical lines

Flat filter for venting gas in intravenous medical lines, comprising a case formed by a frontal plate and by a dorsal plate between which a hydrophilic filtering membrane is interposed. The dorsal plate has a single through hole for gas venting in communication with an elongated collecting channel formed on the inner surface of the dorsal plate and along which a hydrophobic membrane of complementary shape is applied.

Owner:IND BORLA

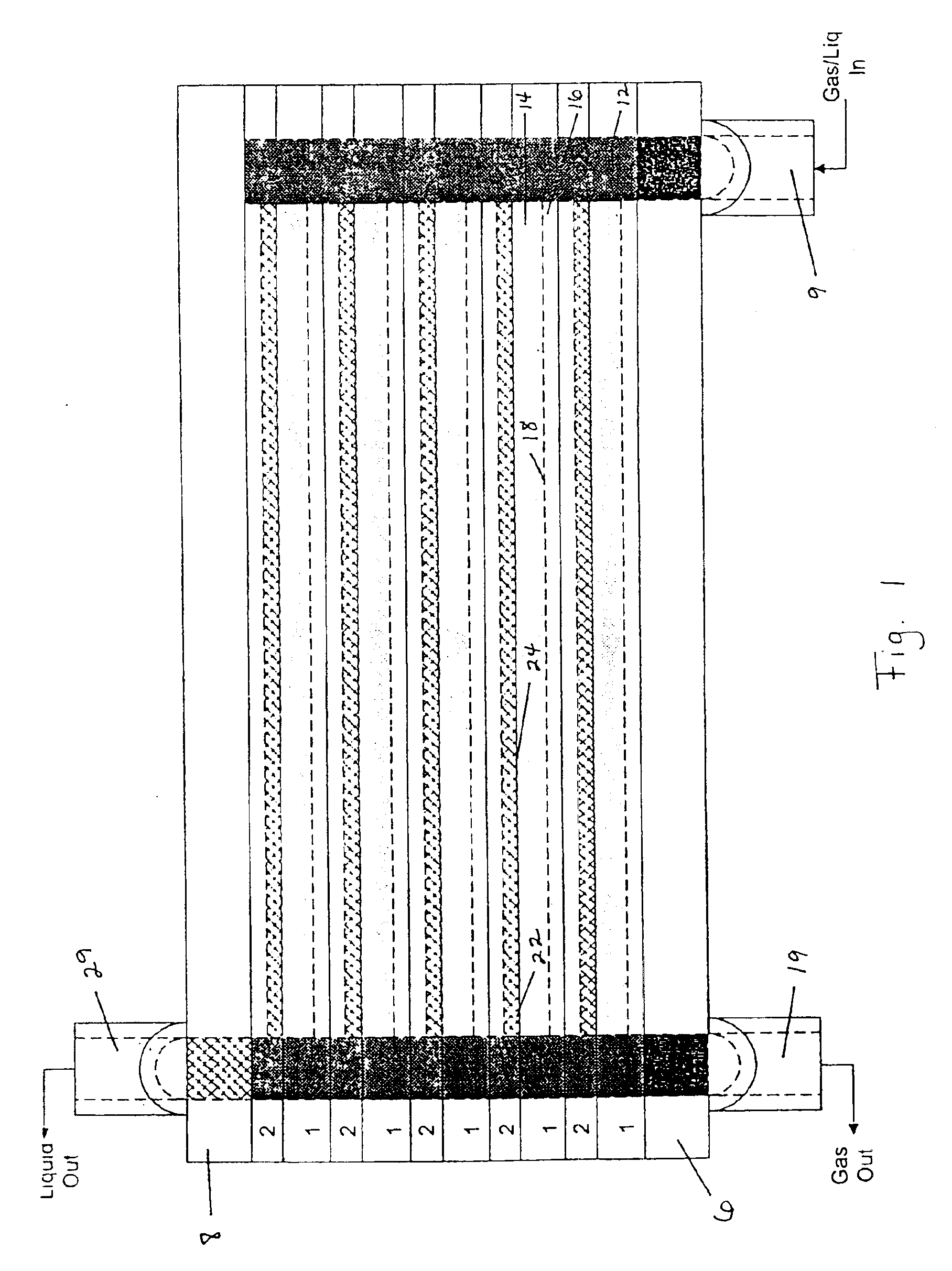

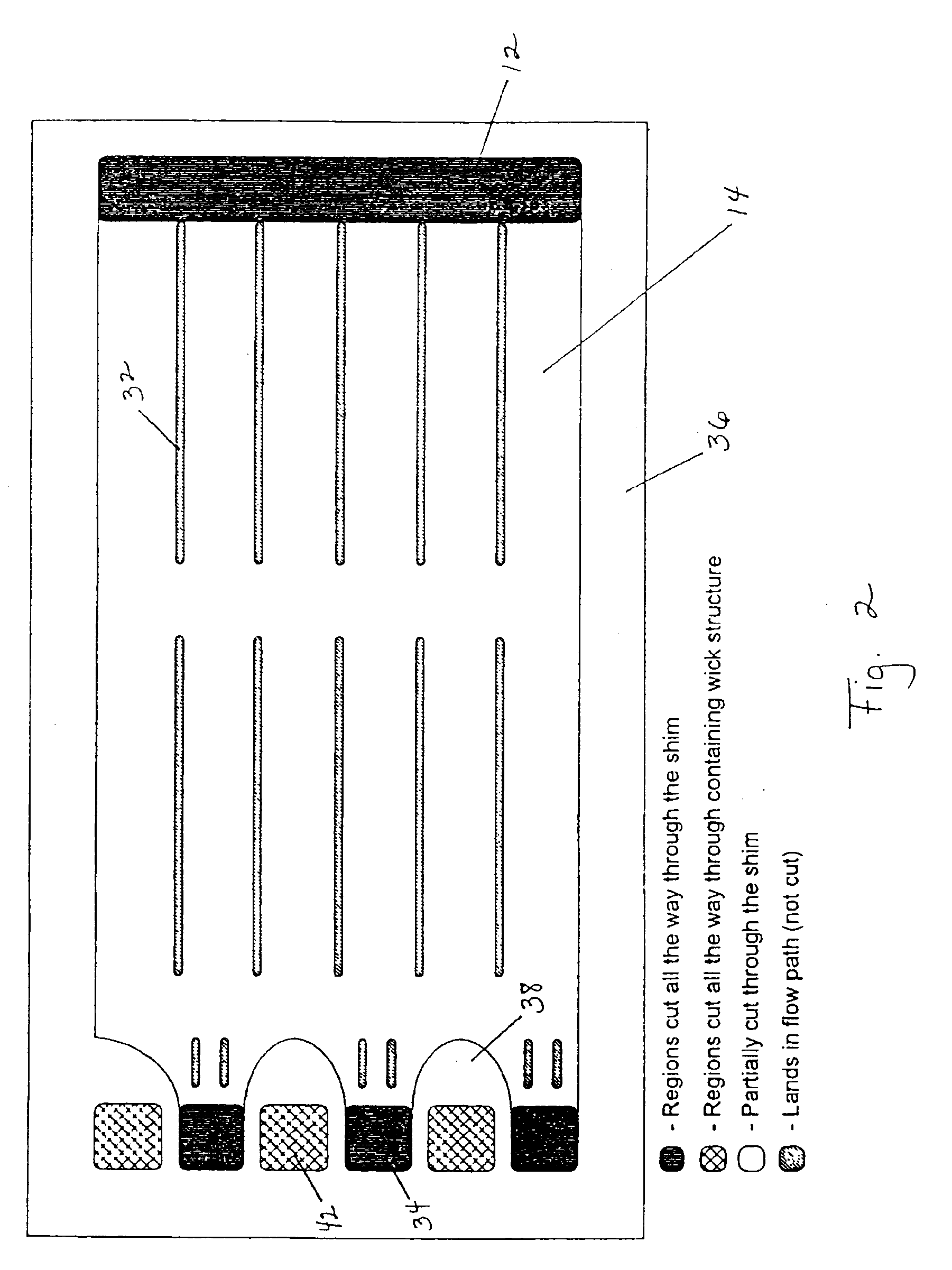

Conditions for fluid separations in microchannels, capillary-driven fluid separations, and laminated devices capable of separating fluids

InactiveUS6875247B2Rapid mass transportImprove heat transfer performanceCombination devicesAuxillary pretreatmentImproved methodChemistry

Owner:BATTELLE MEMORIAL INST

Control of electrolysis gases in electroosmotic pump systems

InactiveUS7134486B2Easy to shapeOptimize distributionFixed microstructural devicesSemiconductor/solid-state device detailsElectricityRe entry

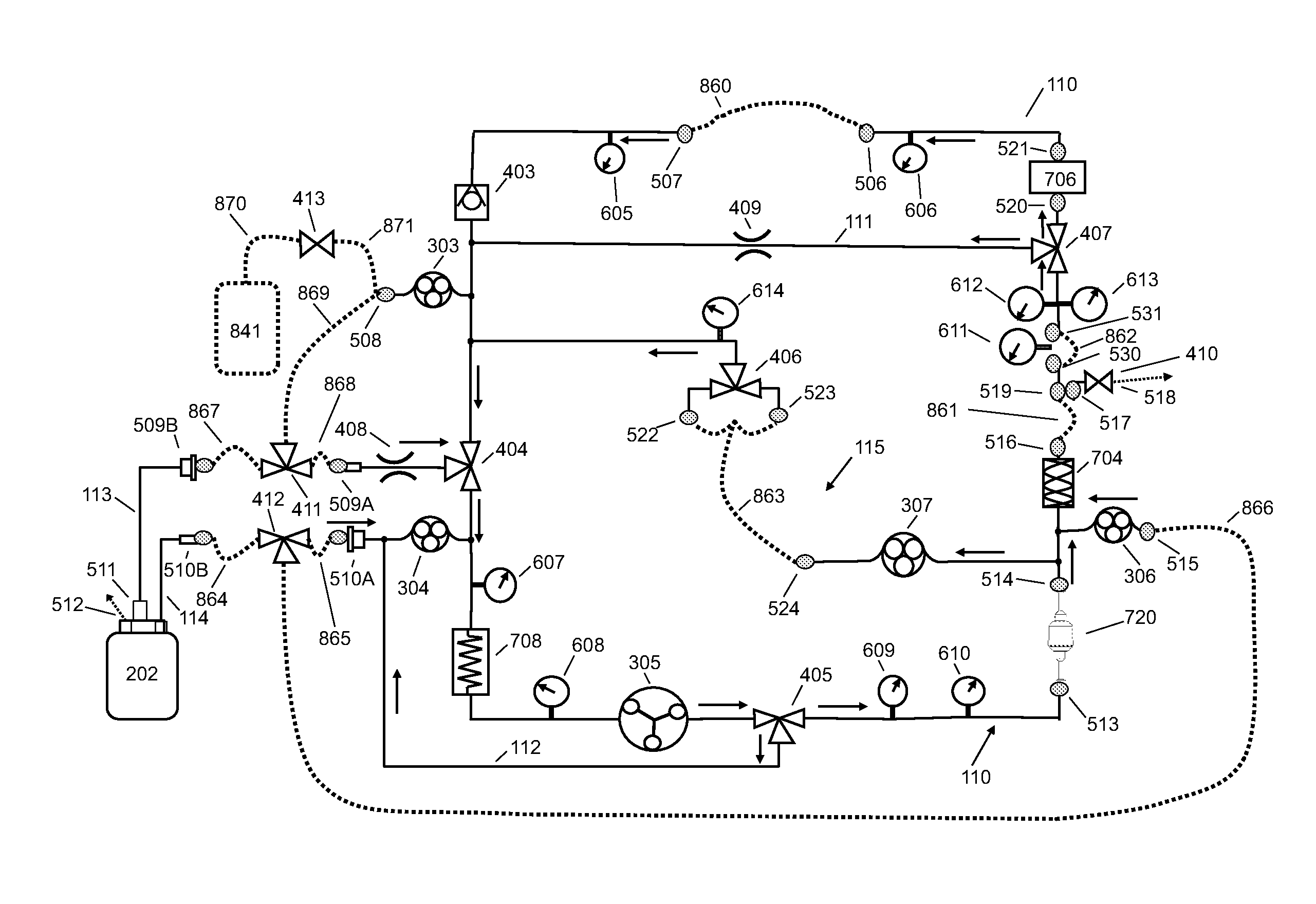

Apparatus and methods according to the present invention preferably utilize electroosmotic pumps that are capable of generating high pressure and flow without moving mechanical parts and the associated generation of unacceptable electrical and acoustic noise, as well as the associated reduction in reliability. These electroosmotic pumps are preferably fabricated with materials and structures that improve performance, efficiency, and reduce weight and manufacturing cost relative to presently available micropumps. These electroosmotic pumps also preferably allow for control including venting or recapture of evolved gases and deposited materials, which may provide for long-term closed-loop operation. A gas permeable membrane removes and vents electrolytic gasses generated within the fluid chamber of the electroosmotic pump to ambient. A catalyst can be used to recombine electrolytic gases to form a vapor product that can be vented or condensed into a liquid state. An osmotic membrane provides for re-entry of condensed fluid to the fluid chamber.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

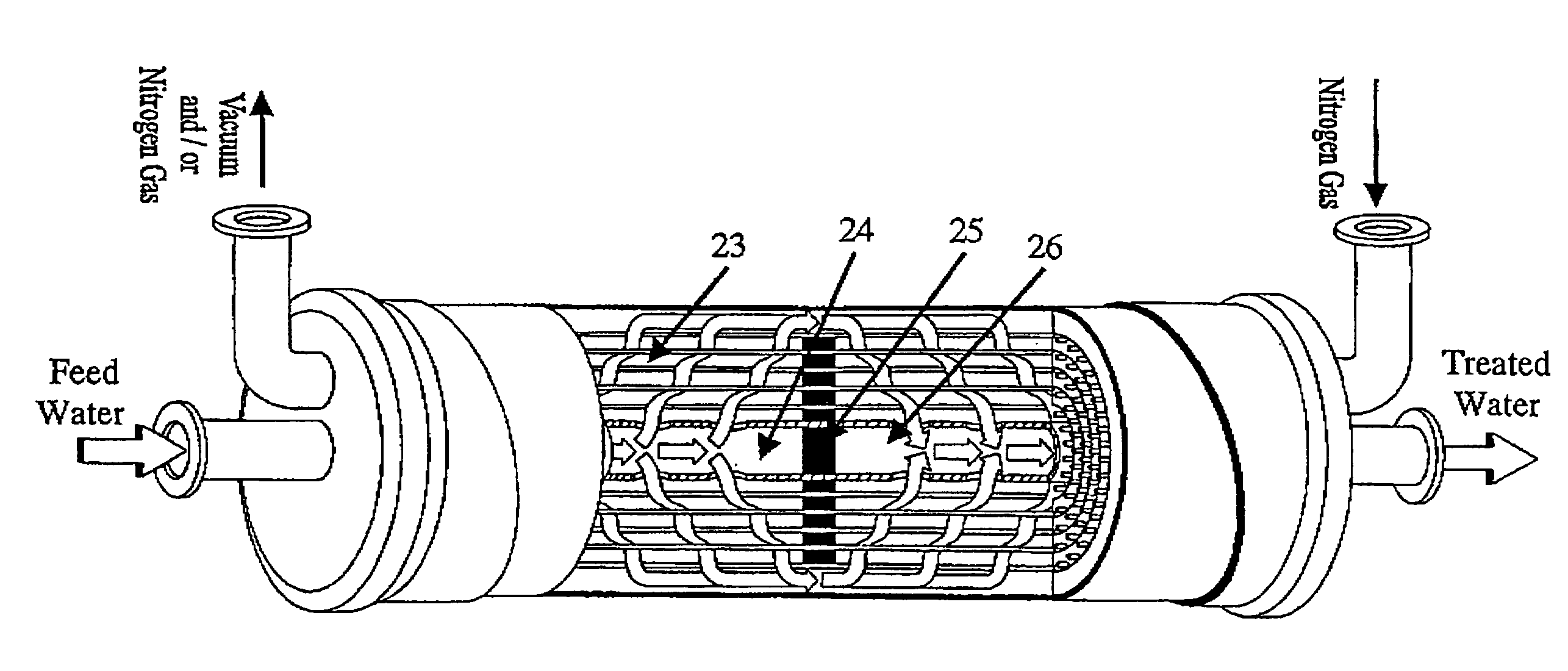

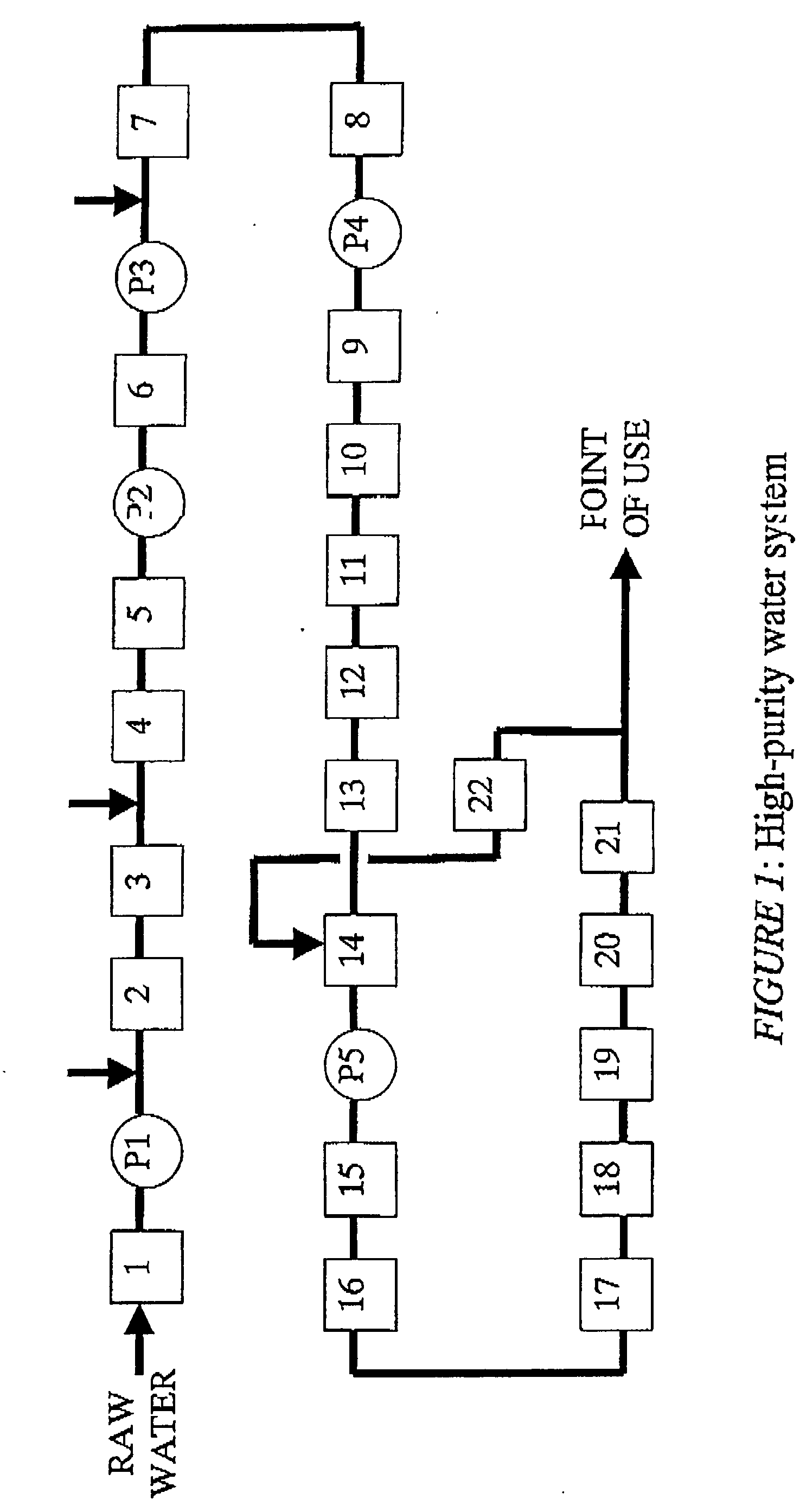

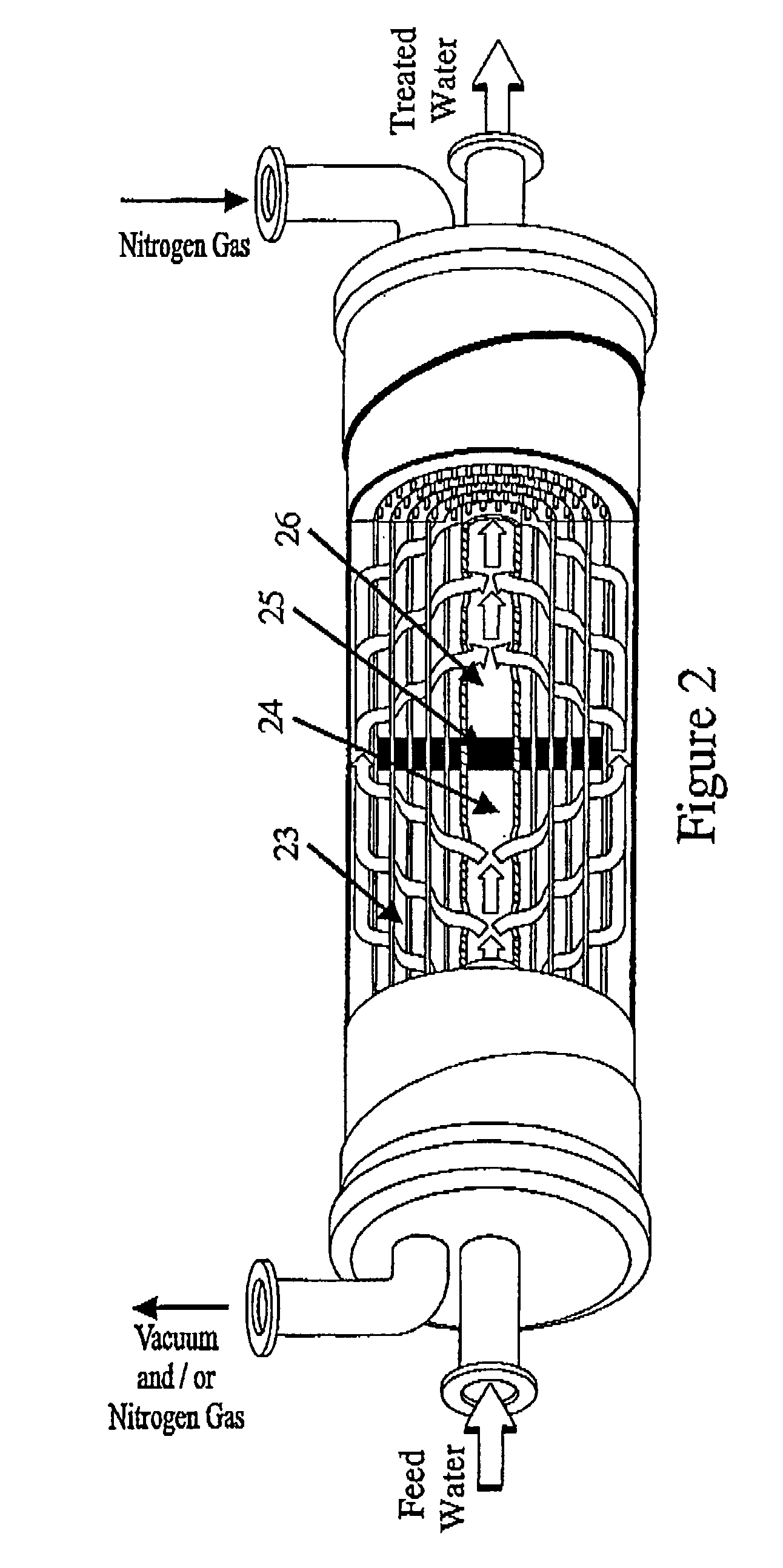

Method of removing organic impurities from water

InactiveUS20040050786A1Improves organic removal efficiencyLow flux rateTreatment involving filtrationSolid sorbent liquid separationWater useElectronic industry

In addition to health implications, trihalomethanes (THMs) poses a challenge to the electronic industry where such impurities cannot be tolerated. A process is provided for removing THMs from high-purity water used in the electronic industry. The method of the invention comprises contacting the high-purity water with a membrane degassifier, preferably operating at a temperature exceeding 45° C.

Owner:EVOQUA WATER TECH PTE LTD

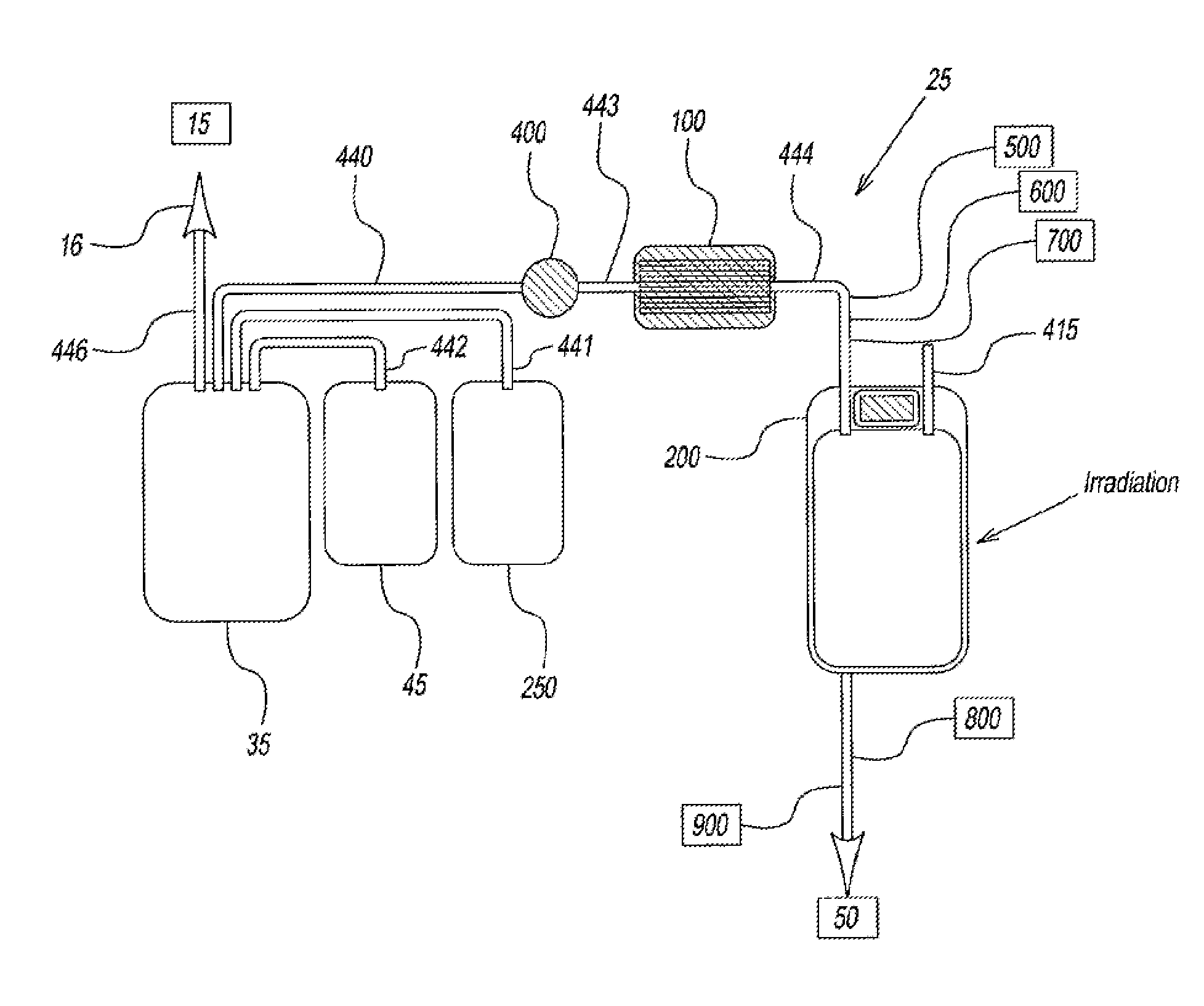

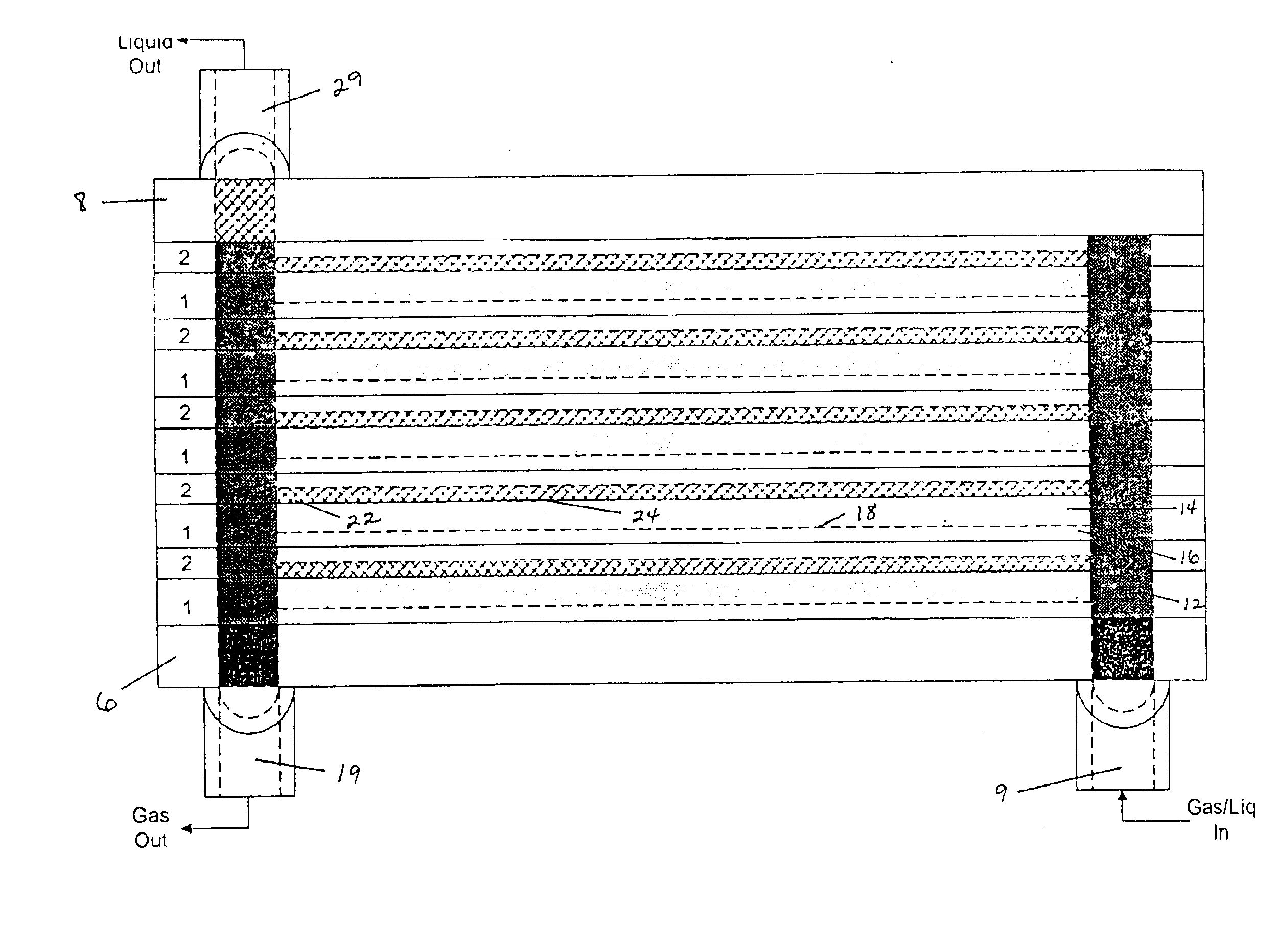

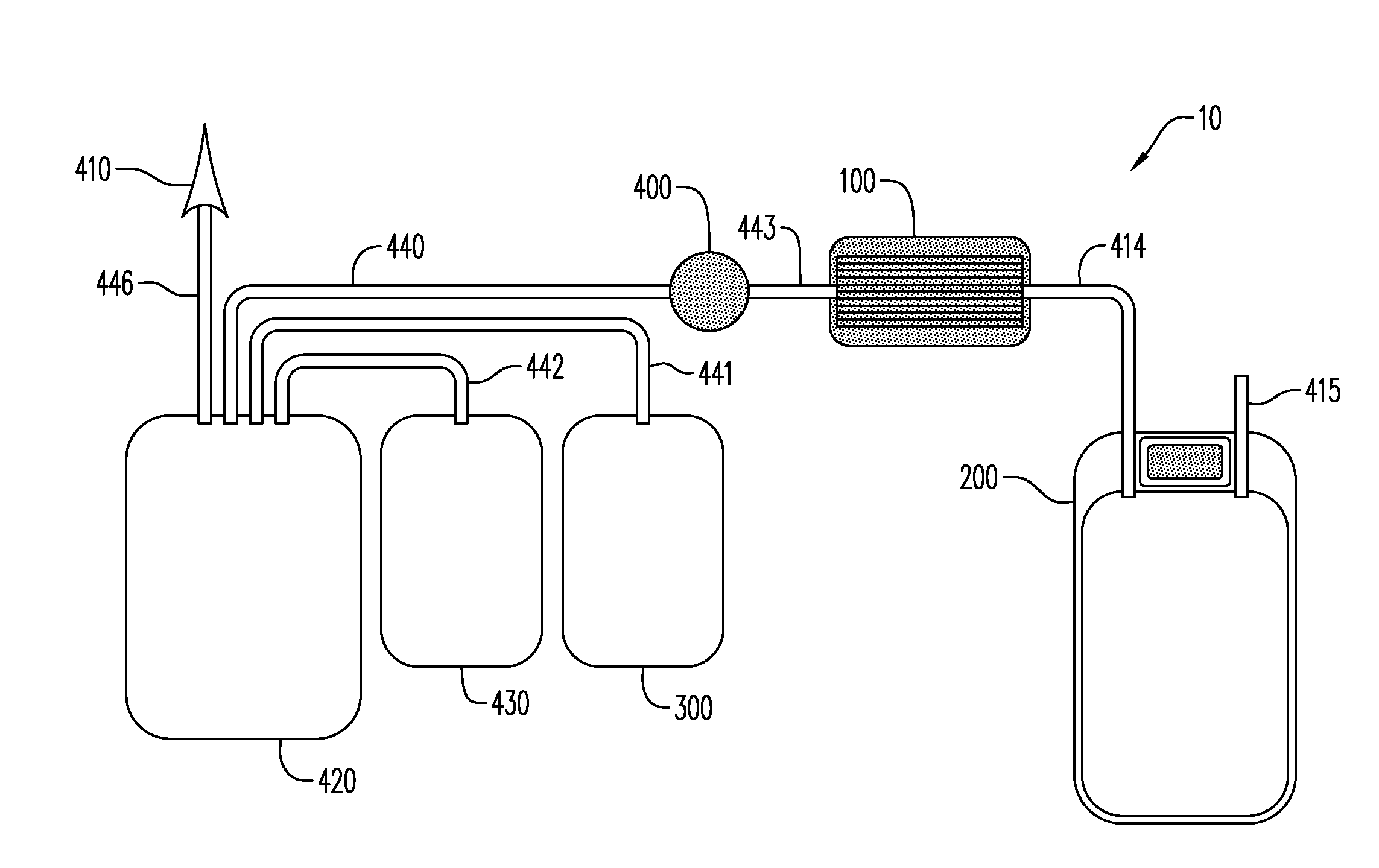

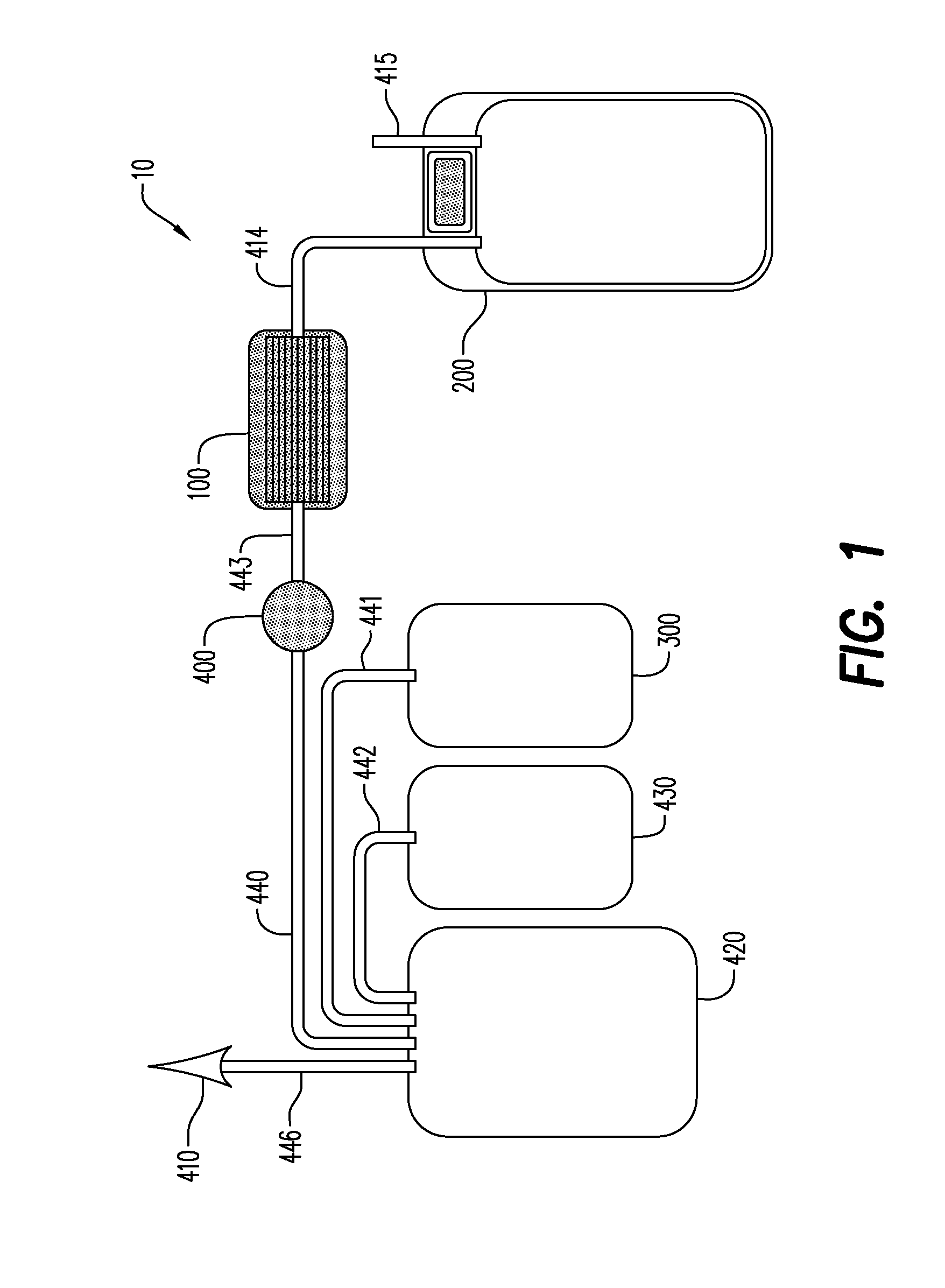

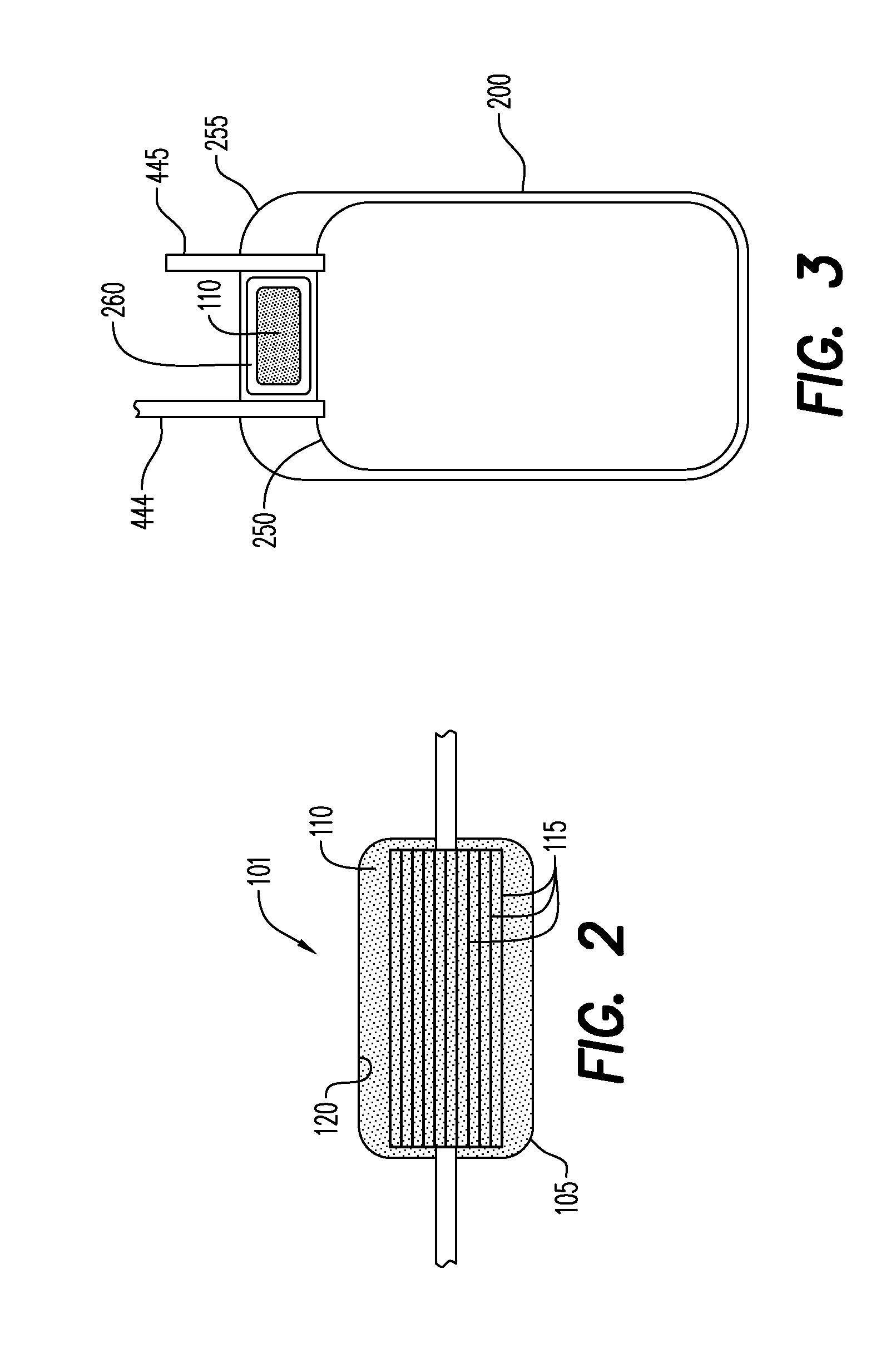

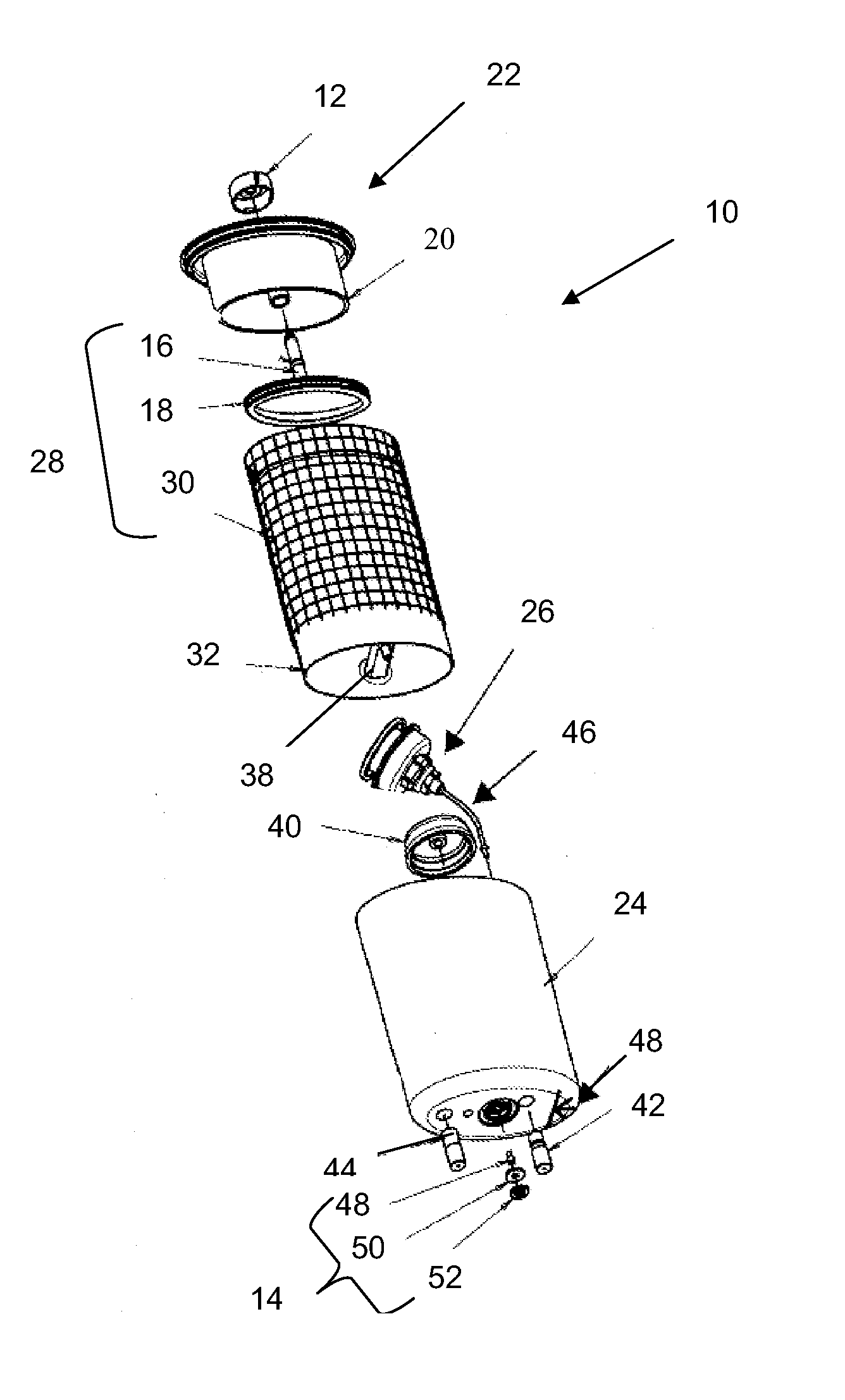

Blood storage bag system and depletion devices with oxygen and carbon dioxide depletion capabilities

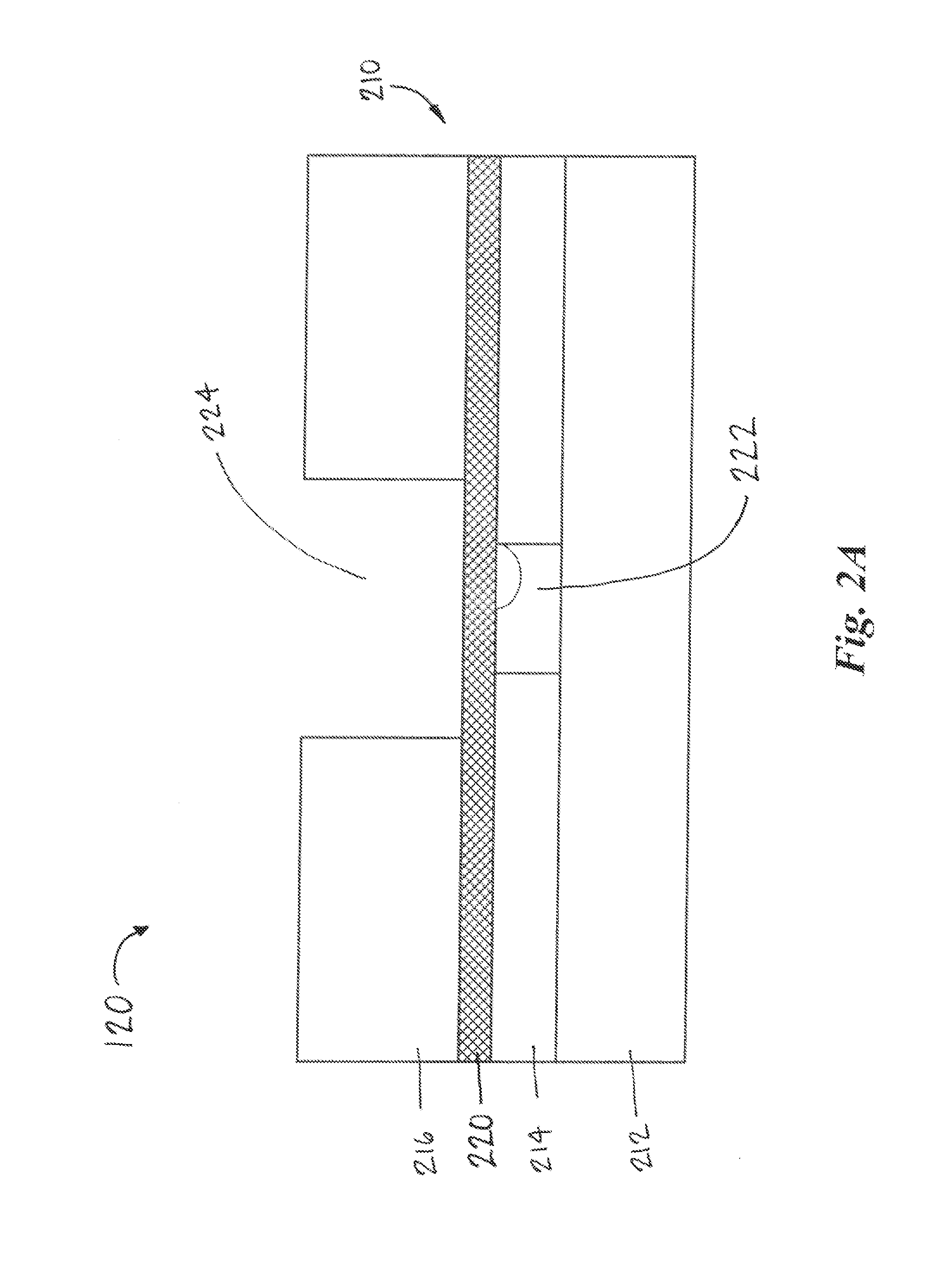

ActiveUS20120024156A1Facilitate transmissionLower Level RequirementsPharmaceutical containersMedical devicesHollow fibreEnvironmental engineering

A blood storage system. The system has a collection bag for red blood cells; an oxygen / carbon dioxide depletion device; a storage bag for red blood cells; and tubing connecting the collection bag to the depletion device and the depletion device to the storage bag. The depletion device includes a receptacle of a solid material having an inlet and an outlet adapted to receiving and expelling a flushing gas; a plurality of hollow fibers or gas-permeable films extending within the receptacle from an entrance to an exit thereof. The hollow fibers or gas-permeable films are adapted to receiving and conveying red blood cells.

Owner:NEW HEALTH SCI

Extracorporeal blood handling system with integrated heat exchanger

InactiveUS7022284B2Improve heat transfer efficiencyMinimized in sizeOther blood circulation devicesHaemofiltrationPlate heat exchangerBlood oxygenation

Apparatus for oxygenating and pumping blood includes a housing defining a blood flow path including, in series, a gas collection plenum, a pump space and a blood oxygenation element. A pump disposed in the pump space is configured to draw blood from the gas collection plenum and propel blood from the pump space through a heat exchanger and the blood oxygenation element. The heat exchanger includes a heat exchange plate and a coolant space.

Owner:CARDIOVENTION

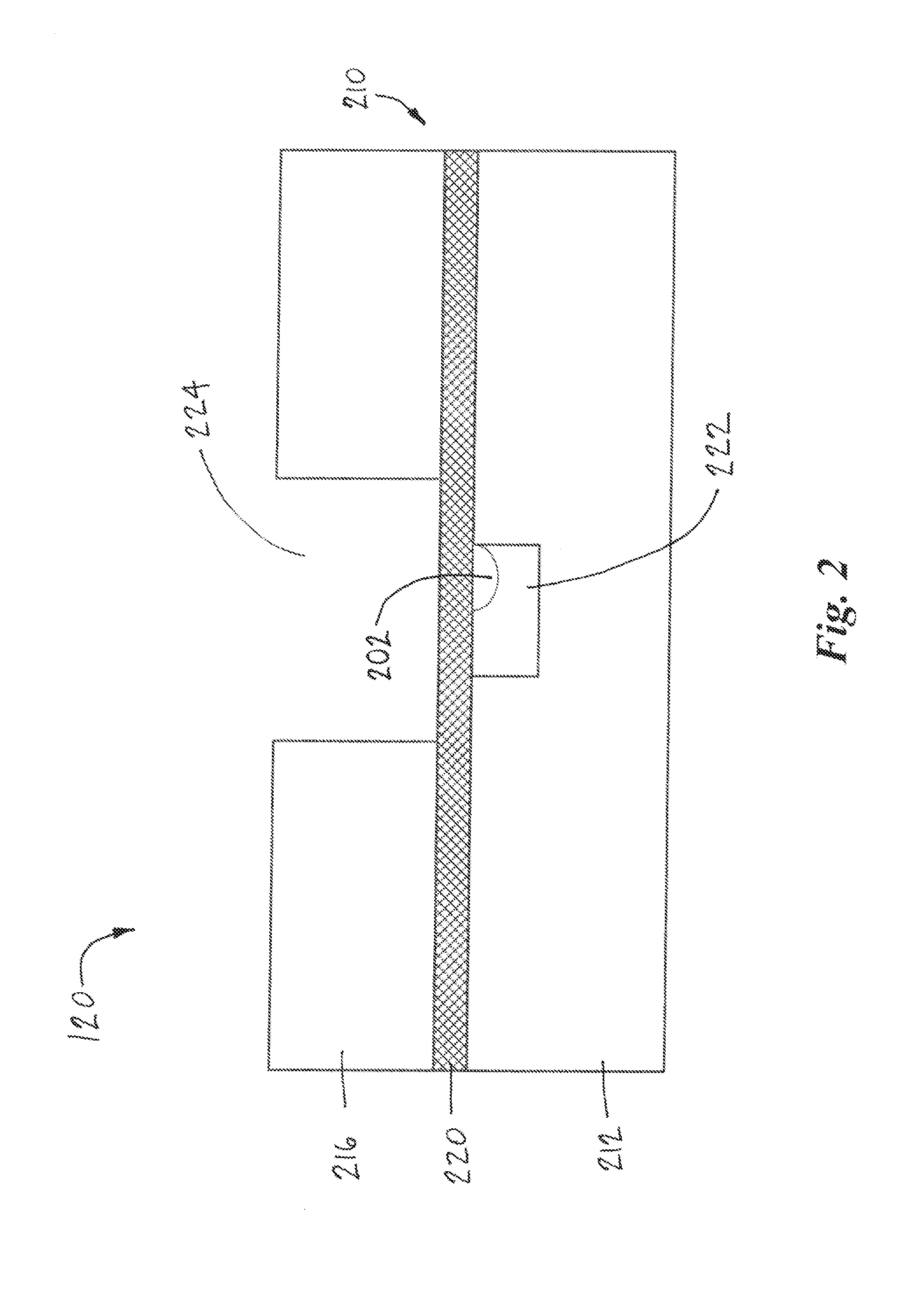

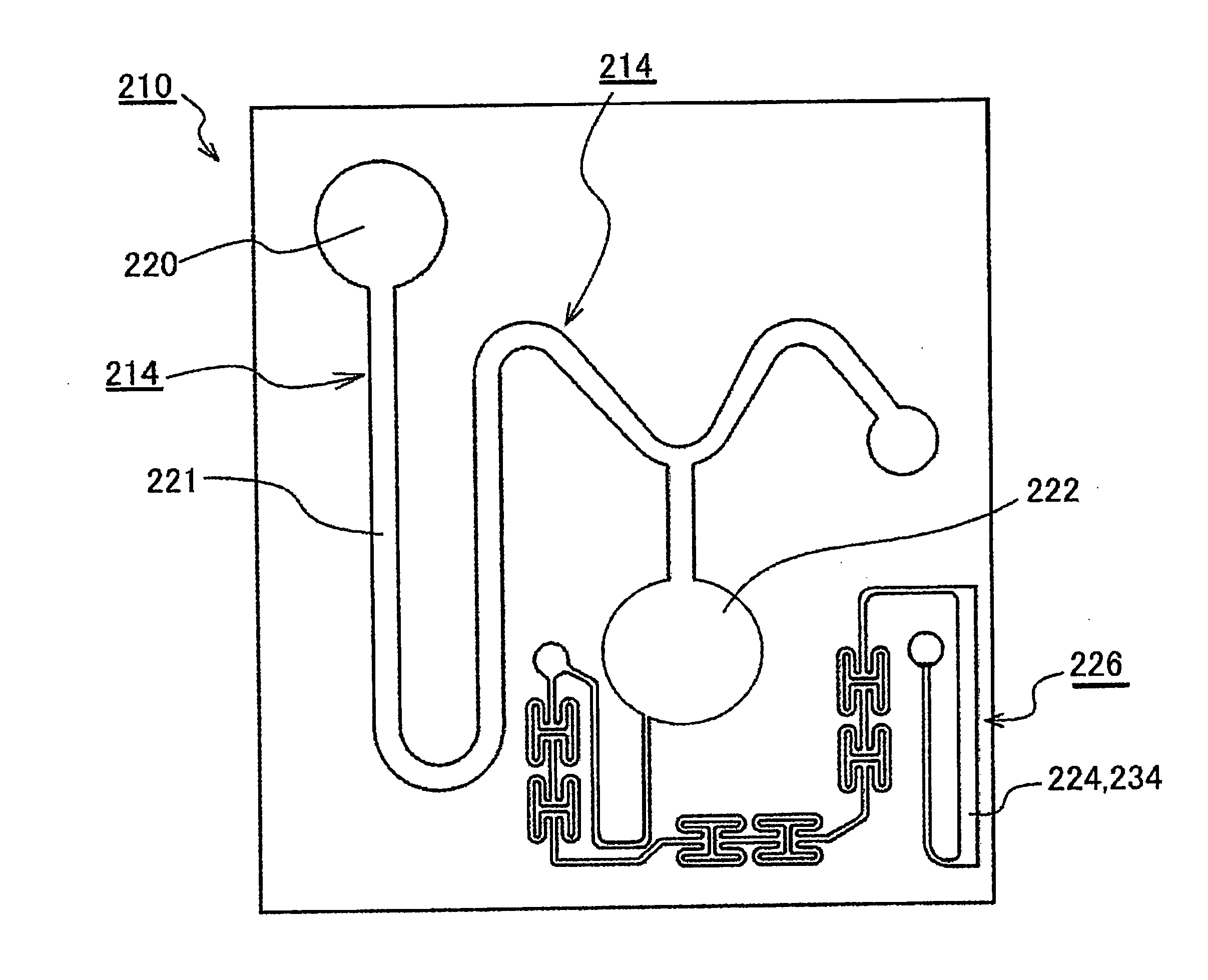

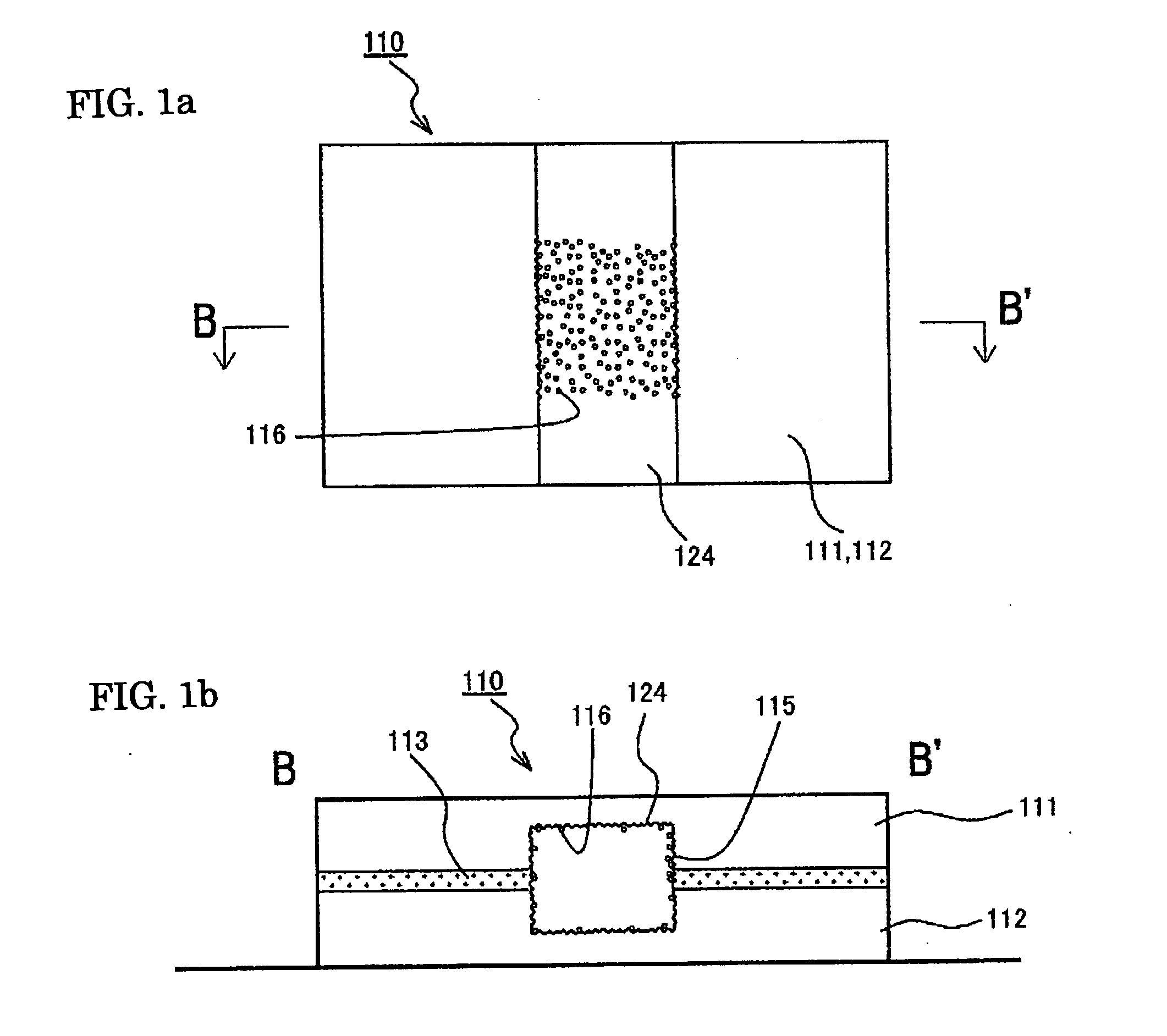

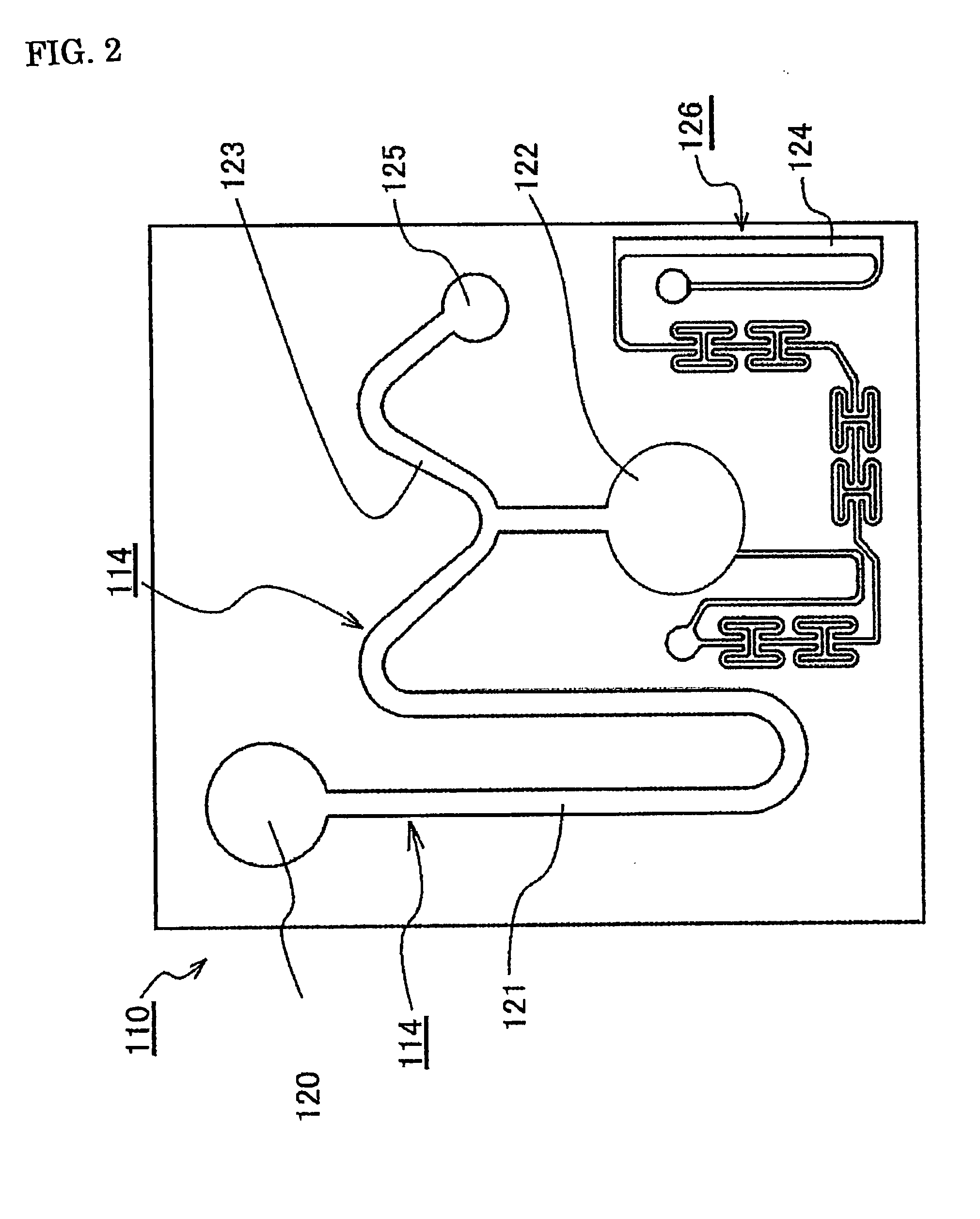

Removing bubbles in microfluidic systems

ActiveUS20150209783A1Avoid problemsReduce evaporation lossBioreactor/fermenter combinationsBiological substance pretreatmentsPorous membraneEvaporation

A microfluidic system includes a microfluidic device connected to a bubble trap device whereby fluid flowing to the microfluidic device passes through the bubble trap device to remove gas bubbles prior to entering the microfluidic device. The bubble trap can include a separation chamber and an exhaust chamber separated by a hydrophobic porous membrane and gas bubbles in the fluid entering the separation chamber pass through the hydrophobic porous membrane into the exhaust chamber while the fluid remains in the separation chamber. The bubble trap can be formed by bonding a first body portion to a first side of the hydrophobic porous membrane and bonding a second body portion to a second side of the hydrophobic porous membrane. The exhaust chamber can be connected to an elongated exhaust channel that limits the evaporation losses of the fluid through the hydrophobic porous membrane.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Preventing gas from occupying a spray nozzle used in a process of scoring a hot glass sheet

ActiveUS8132427B2Reduce solubilityAvoid occupyingGlass drawing apparatusGlass forming apparatusSolubilityHigh energy

A spray nozzle is used in a process of quenching a hot glass sheet during a laser scoring process or other high energy glass heating process. The scoring is conducted by a high energy means such as a laser. The nozzle is located in proximity to the glass sheet, creating gas in liquid used to quench the glass located in the nozzle (e.g., water). The gas (e.g., air bubbles) is removed from the quenching liquid. Then, the spray nozzle is used to spray the quenching liquid onto the sheet at a location trailing laser scoring of the sheet, such as using a traveling anvil machine at the bottom of the draw. The spray nozzle (purge nozzle) has a purge opening and tubing leading to a discharge location. The purge nozzle can have a sloped passageway that pre-stages gas bubbles near the purge opening in the nozzle. The spray nozzle can include a cooling coil passing around the nozzle passageway that enables a coolant to travel along the coil. This cools the quenching liquid passing through the nozzle, and increases the solubility of bubbles in the quenching liquid in the nozzle. A gas filter can receive gas-rich quenching liquid from the pressurized quenching liquid source, remove gas from the liquid, and send gas-depleted quenching liquid to the spray nozzle.

Owner:CORNING INC

Oil/gas separation membrane, its use in gas sensor and process for producing the same

InactiveUS20050086998A1Losing mechanical propertyLosing permeation efficiencyPreparing sample for investigationFuel testingAdhesiveHexafluoropropylene

An oil gas separation membrane combines a gas permeable yet oil and temperature resistant bulk polymer membrane such as poly(tetrafluoroethylene) and poly(tetrafluoroethylene-co-hexafluoropropylene); a porous metal support such as sintered metal frit disk made with stainless steel, bronze or nickel; and an highly gas permeable adhesive that bonds firmly the bulk polymer membrane and the metal frit surface together. The adhesive is either a homogenous polymer that has desirable gas permeability, or a coalescent porous polymer particulates network. A gas sensor employing the oil gas separation membrane for detecting and monitoring fault gases of oil filled electrical equipment requires no mechanical wearing or moving part such as pump and valve and the gas sensor is operated normally under various temperature and pressure conditions.

Owner:ASENSOR TECH

Hydrogen Membrane Separator

ActiveUS20110104021A1Improve hydrophobicityReactant parameters controlLiquid degasification by filtrationHydrogenProduct gas

The present application is directed to a hydrophobic membrane assembly (28) used within a gas-generating apparatus. Hydrogen is separated from the reaction solution by passing through a hydrophobic membrane assembly (28) having a hydrophobic lattice like member (36) disposed within a hydrogen output composite (32) further enhancing the ability of the hydrogen output composite's ability to separate out hydrogen gas and prolonging its useful life.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

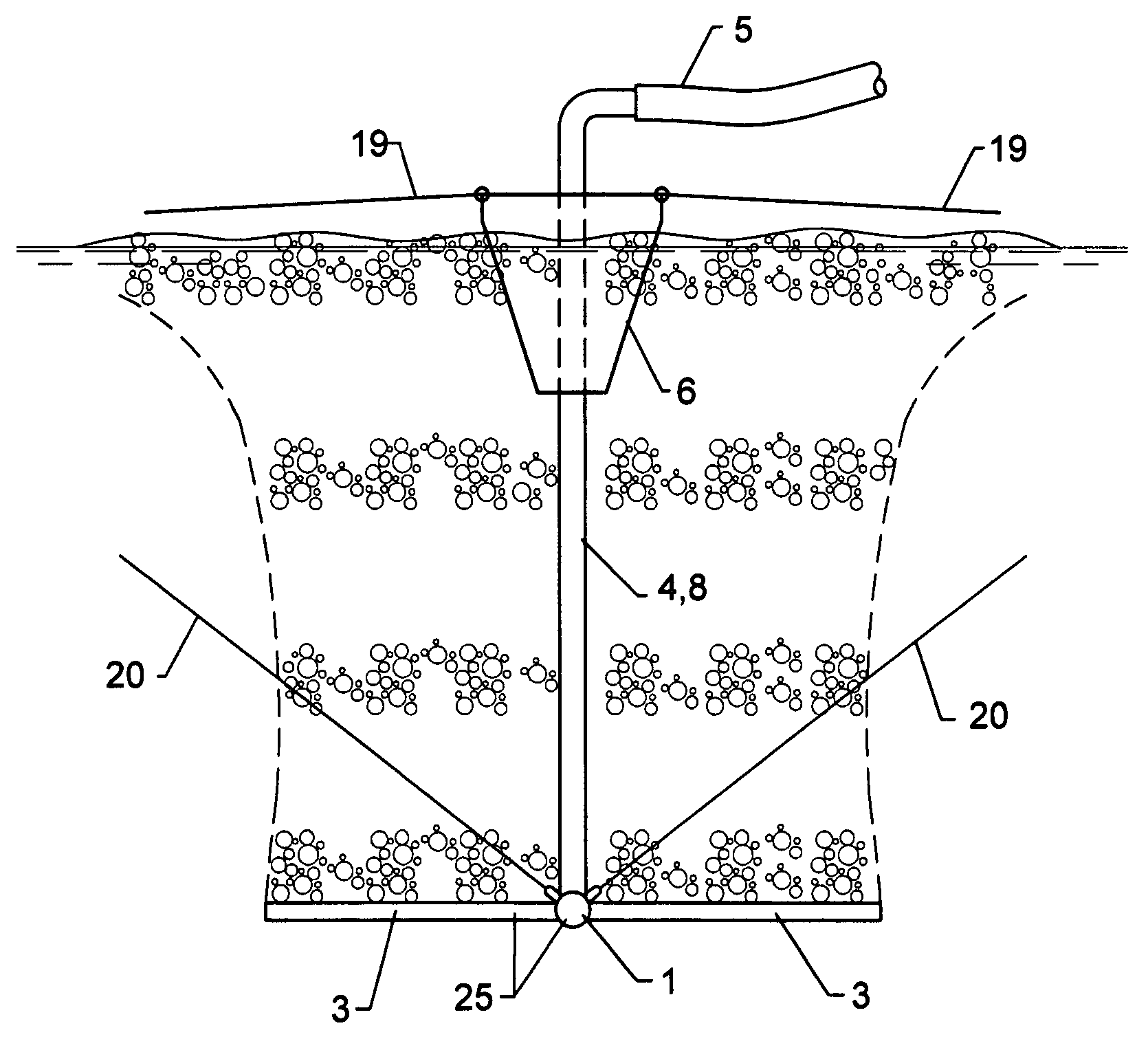

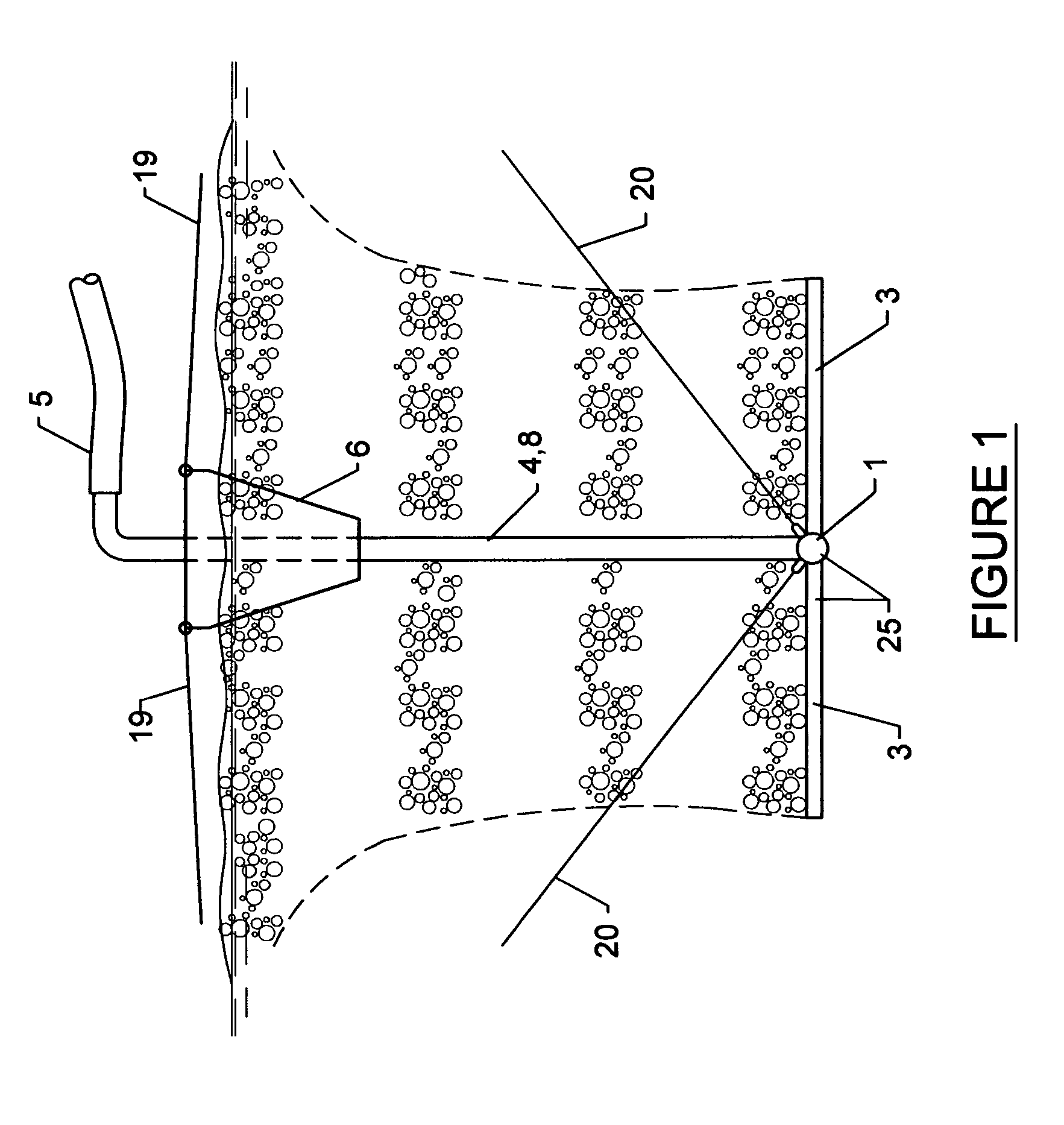

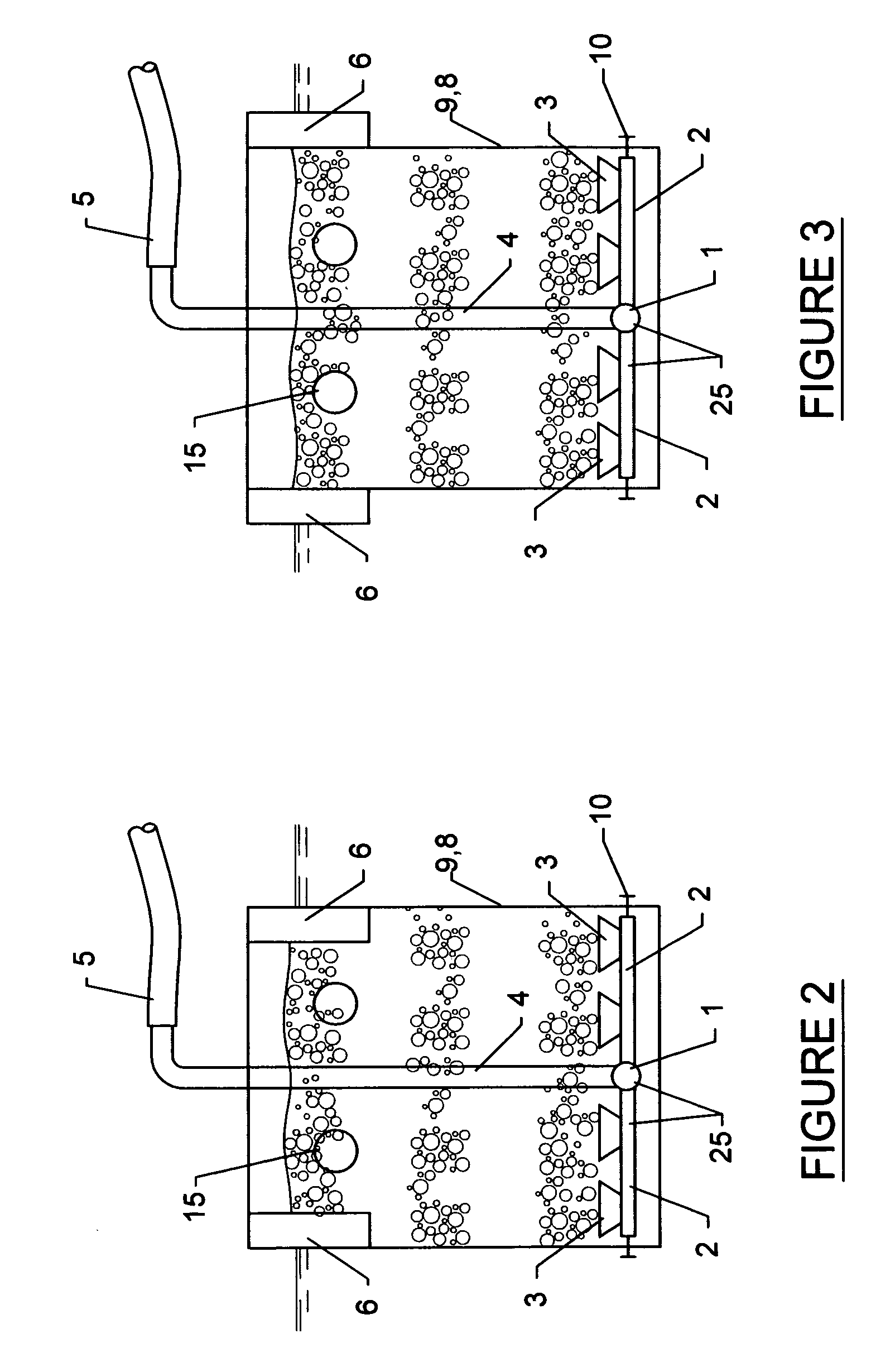

Pulsating reactors

InactiveUS20050098497A1High densityTreatment using aerobic processesTransportation and packagingFlocculationLiquid medium

This is a method and apparatus for treatment of liquid media making use of at least one float positioned at the top of the liquid and at least one gas diffuser placed under the float and connected to this float by at least one brace, the diffuser is connected to a gas source by at least one flexible conduit. The gas emitted from the diffuser produces a mixture with liquid having density lower than the liquid and the float partially sinks in the liquid thus increasing the submergence of the diffuser and lowering the gas flow through the diffuser. At increased submergence, the gas flow is reduced, the mixture density increases, and the float rises. A repeatable motion up and down of the float-diffuser is established producing pulsations in the liquid. The method and apparatus can be used in a multitude of chemical, pharmaceutical, petrochemical, environmental and other industries for carrying out mass transfer, chemical and biological transformations, phase separations, thickening of suspensions, mixing, suspending of particles, washing, coagulation-flocculation, membrane filtration, filtration across particulate media, filtration across floating media, mass transfer across membrane, and other processes.

Owner:KHUDENKO BORIS MIKHAILOVICH

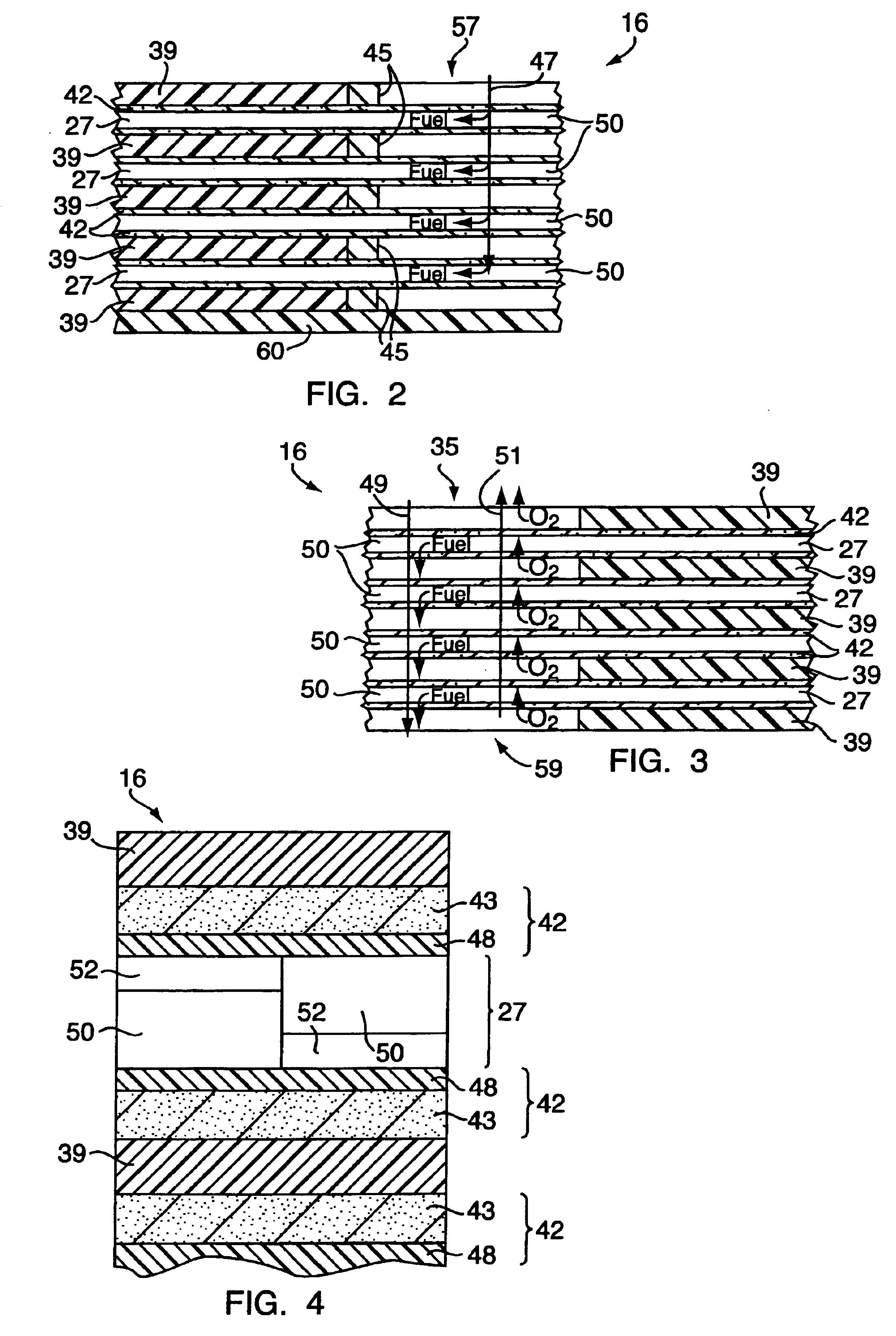

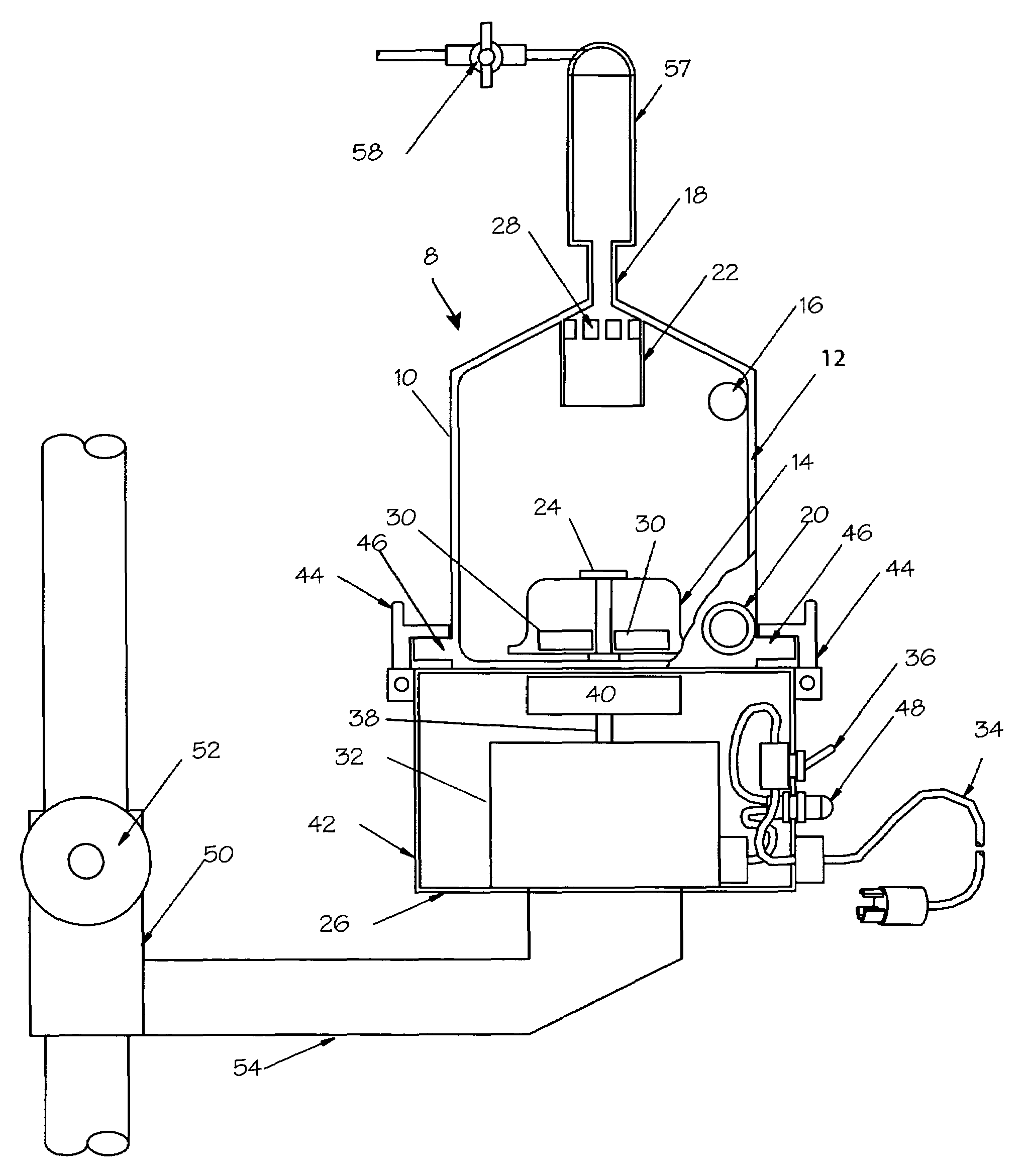

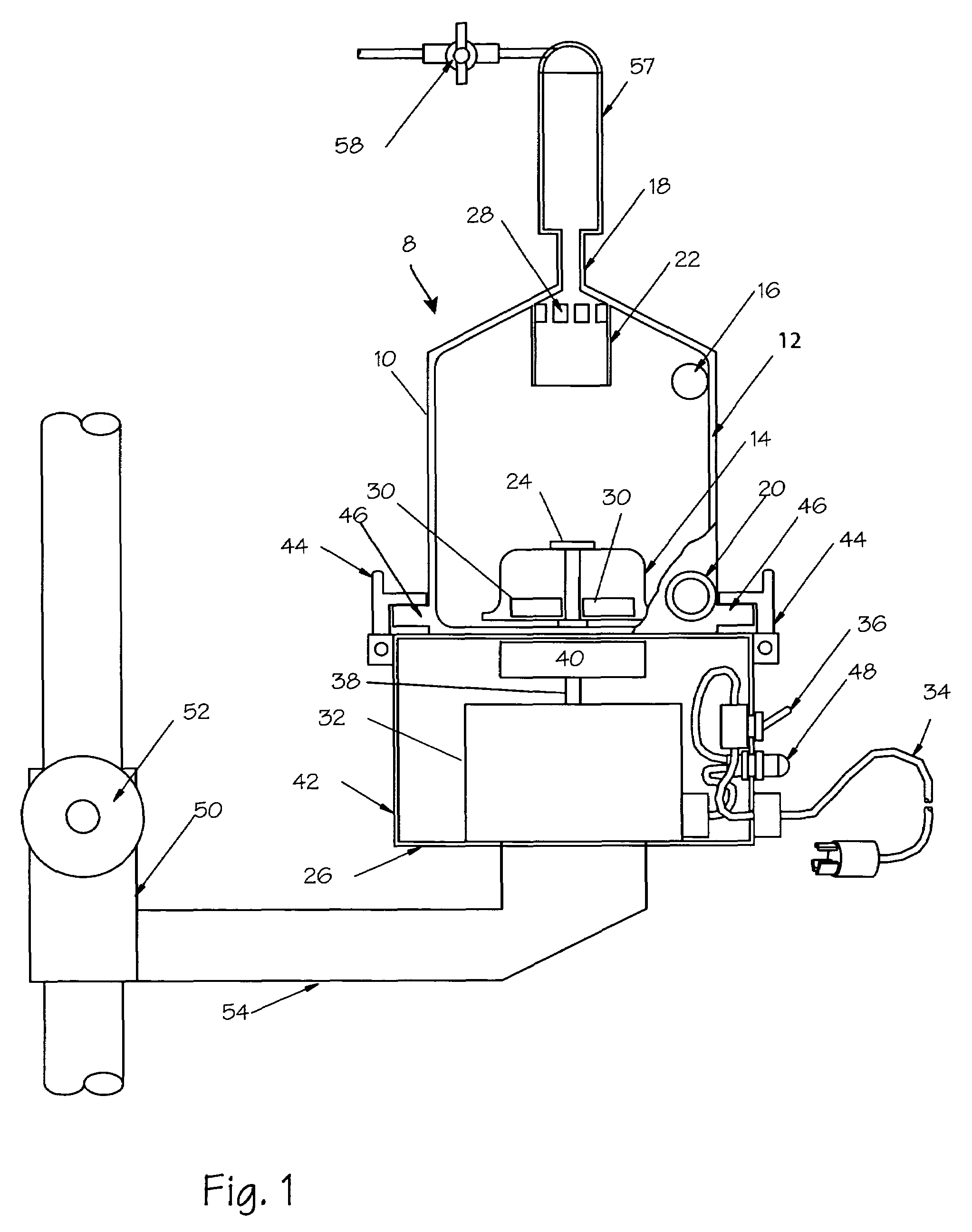

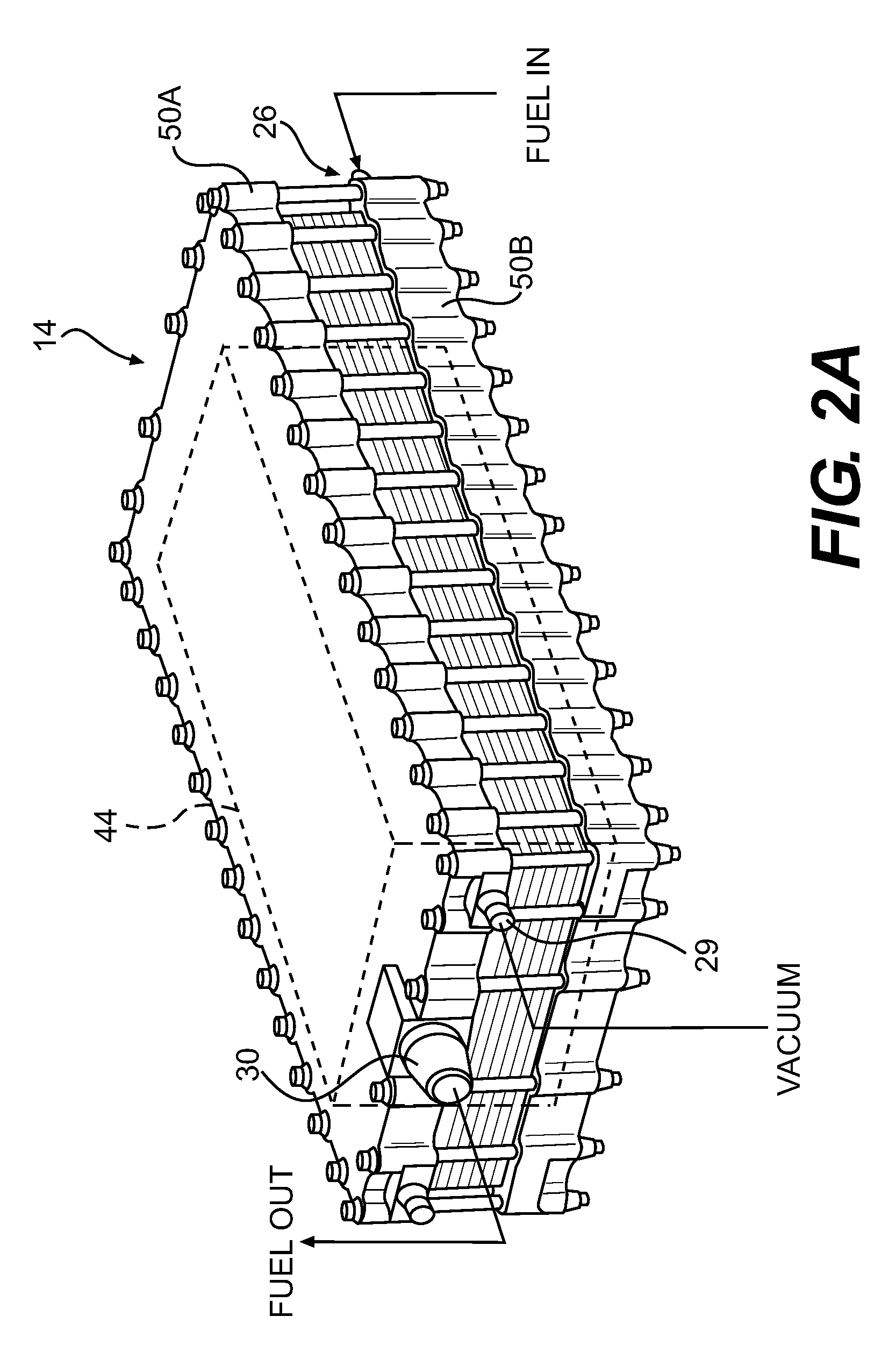

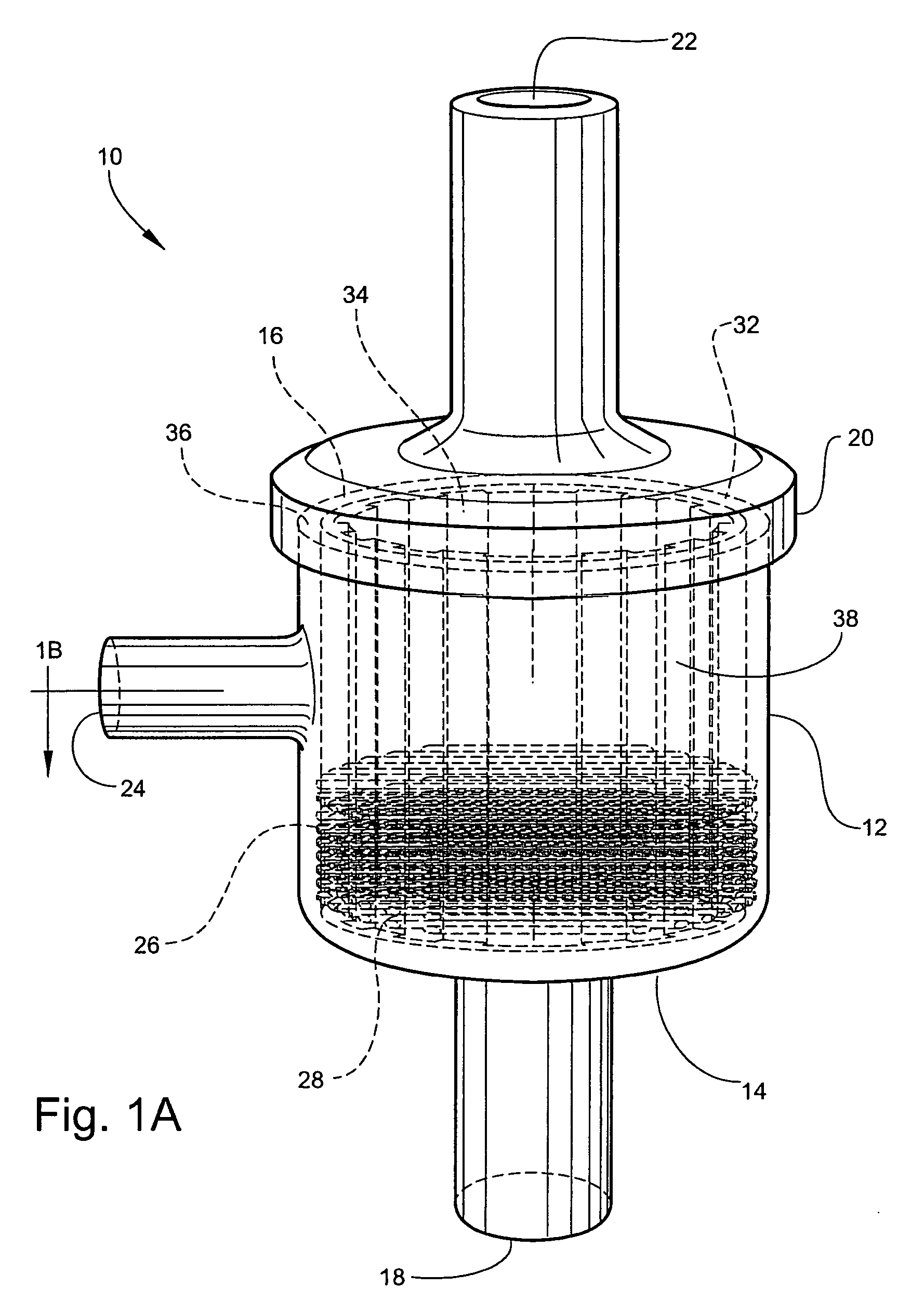

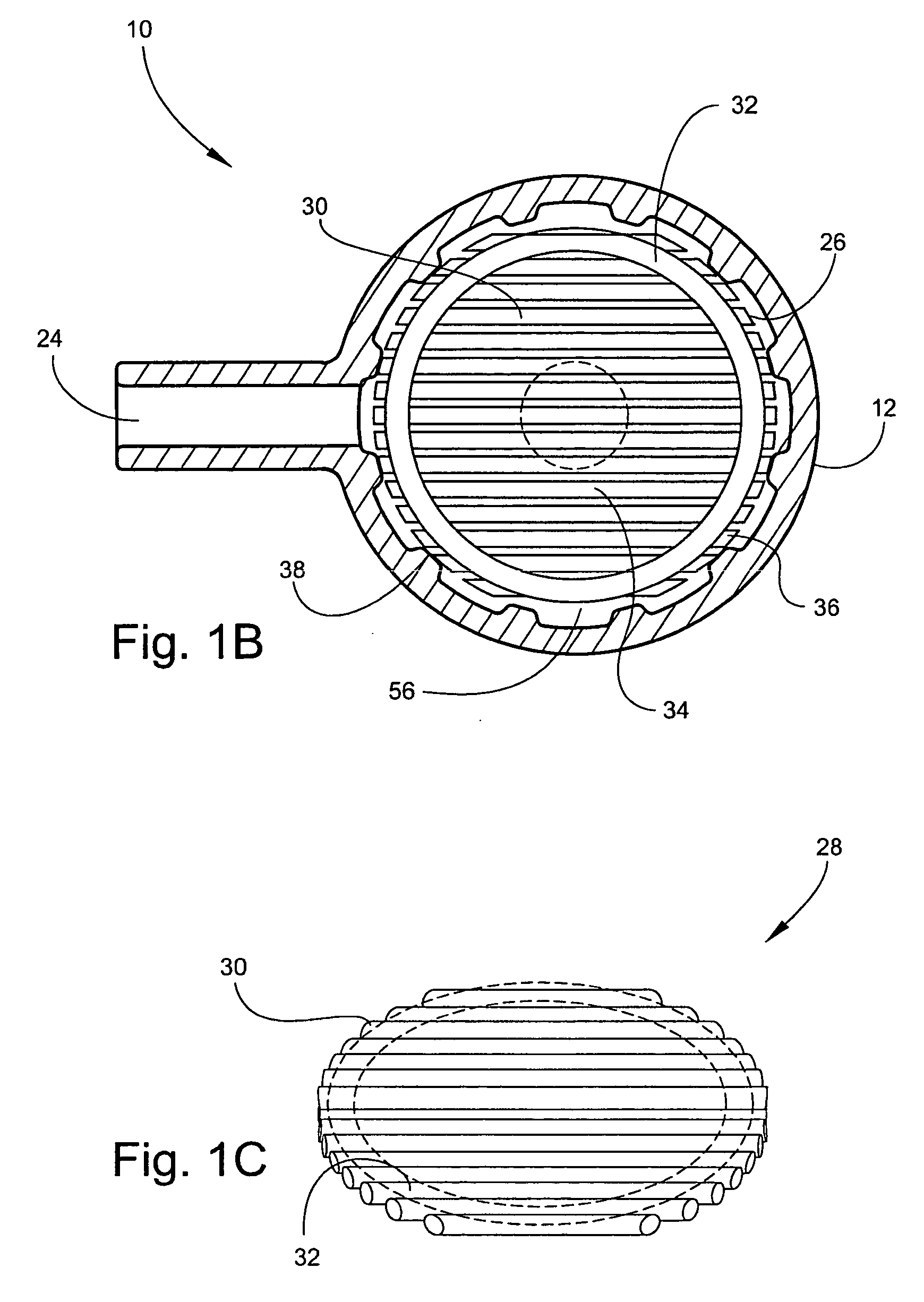

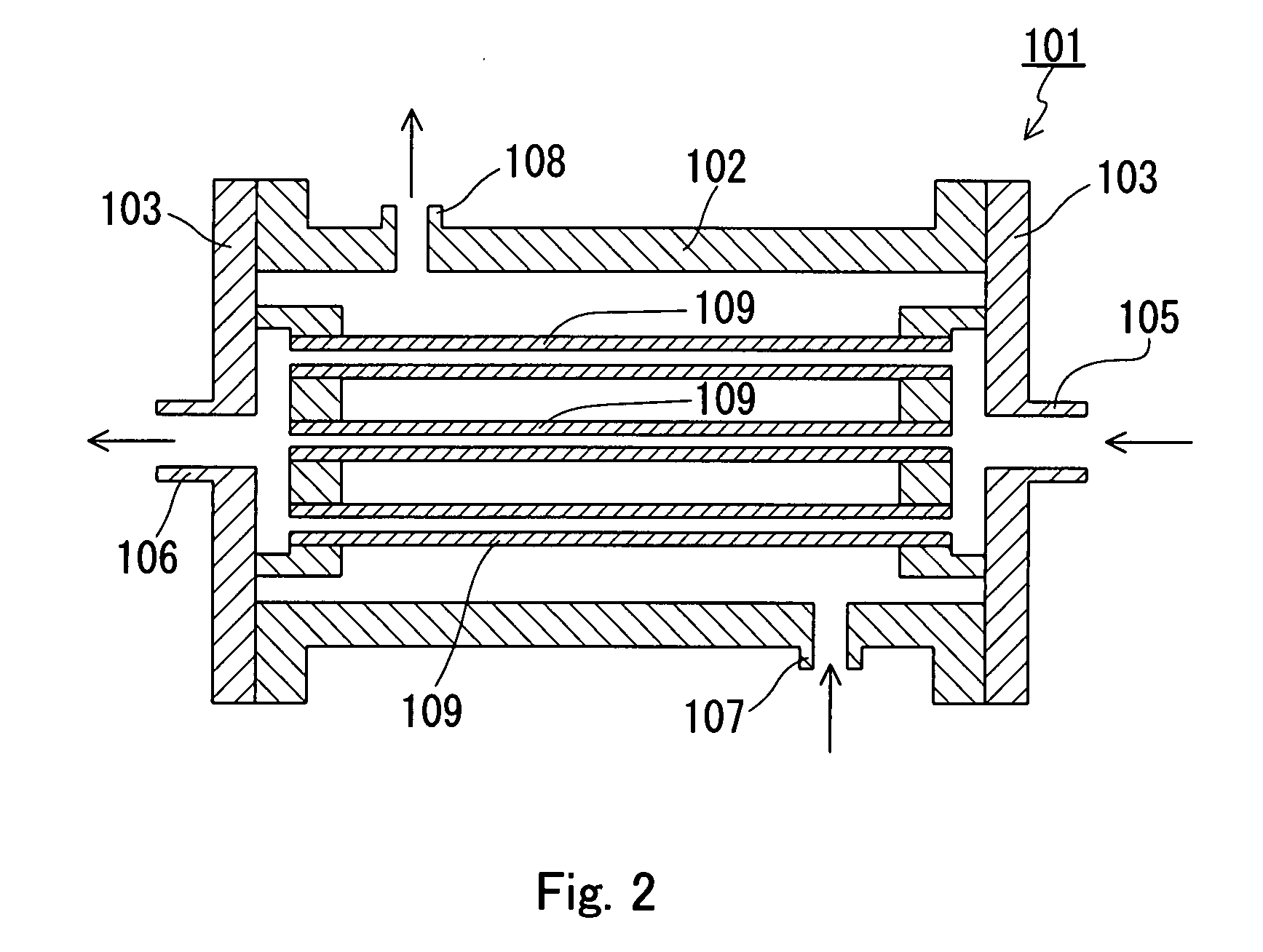

Fuel deoxygenator with porous support plate

A device for use in a fluid system includes a fuel channel for receiving fuel having dissolved gas therein. A gas permeable membrane supported by a porous support, the gas permeable membrane in communication with the fuel channel. A gas-removal channel adjacent the gas permeable membrane for receiving the dissolved gas from the fuel through the gas permeable membrane and the porous support.

Owner:RAYTHEON TECH CORP

Microchannel and Microfluid Chip

InactiveUS20080317632A1Quickly and accurately and detectedMeasure quickly and accuratelyAnalysis using chemical indicatorsLaboratory glasswaresTrappingAnalytical chemistry

Owner:ROHM CO LTD

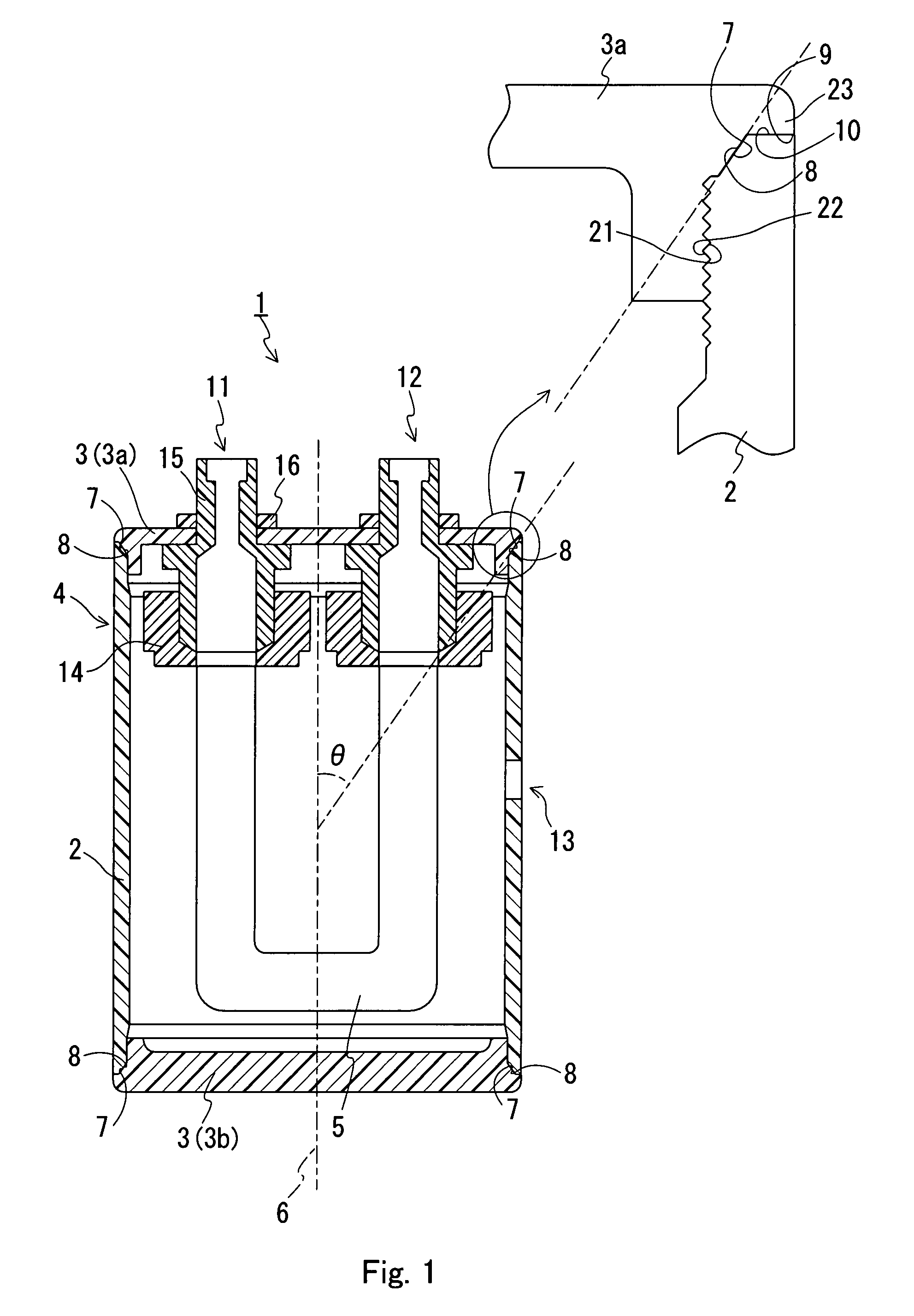

Membrane contactor

A membrane contactor includes a housing, a stack of membrane mats, and a cap. The housing has a closed end and an open end. The closed end includes an outlet port. The cap is united to the open end and includes an inlet port. A stack of membrane mats is within the housing stacked substantially perpendicular to the longitudinal axis of the housing. Each membrane mat has a plurality of hollow fiber members. A potting material bonds the membrane mats to each other and simultaneously bonds one end of the stack to the closed end and bonds the other end of the stack to the cap. The potting material forms an internal chamber and at least one external chamber within the housing. The hollow fiber members extend through the potting material from the internal chamber into the external chambers. The inlet port and the outlet port are in communication with the internal chamber. At least one side port is in communication with the external chambers.

Owner:3M INNOVATIVE PROPERTIES CO

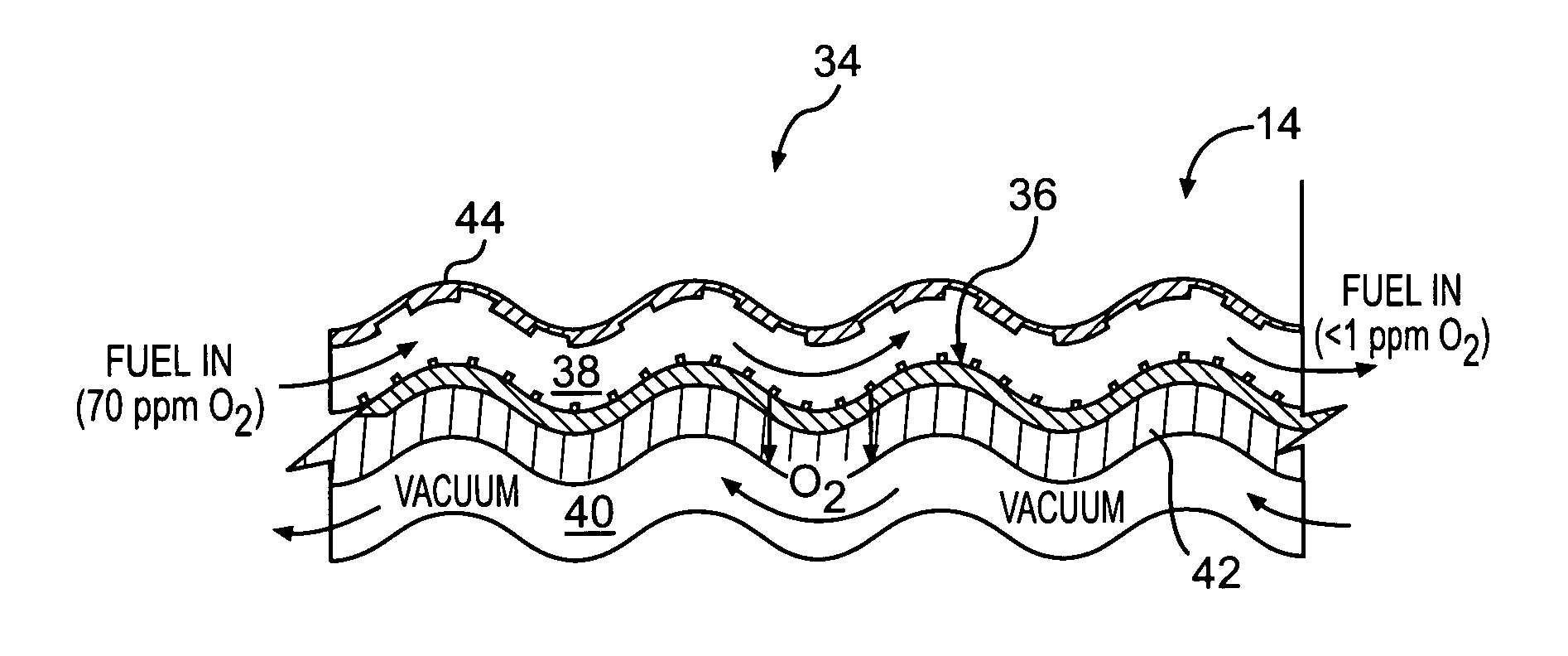

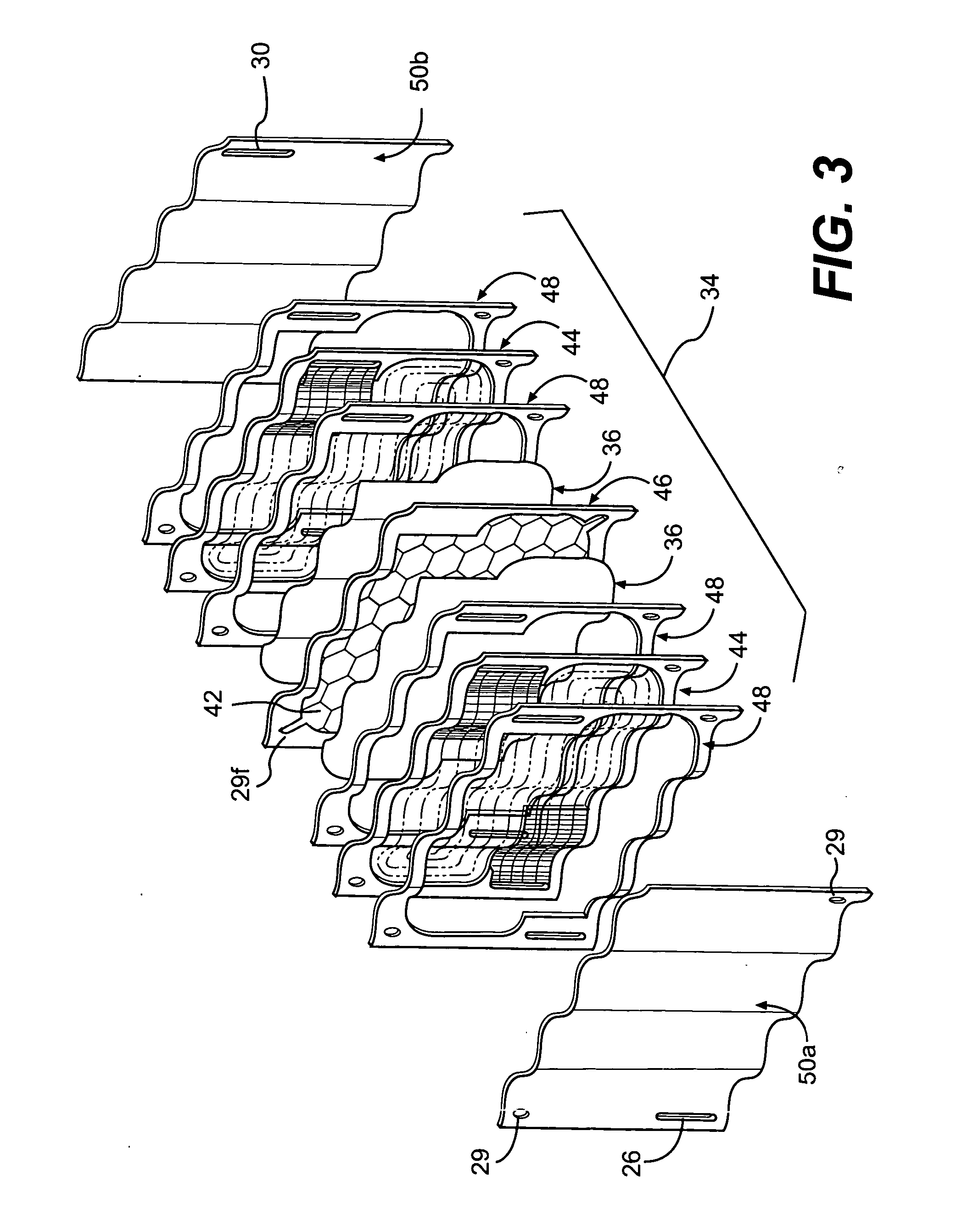

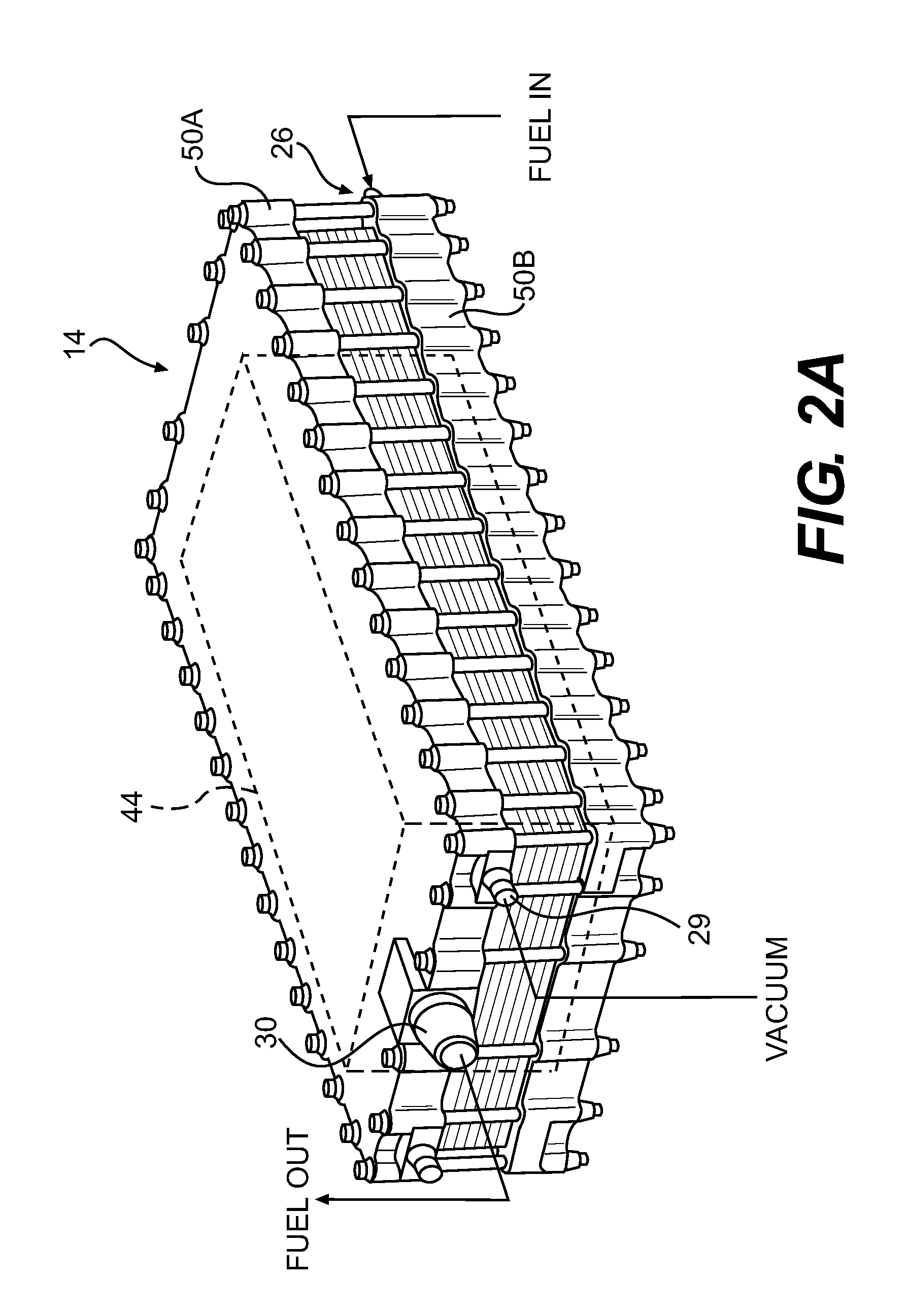

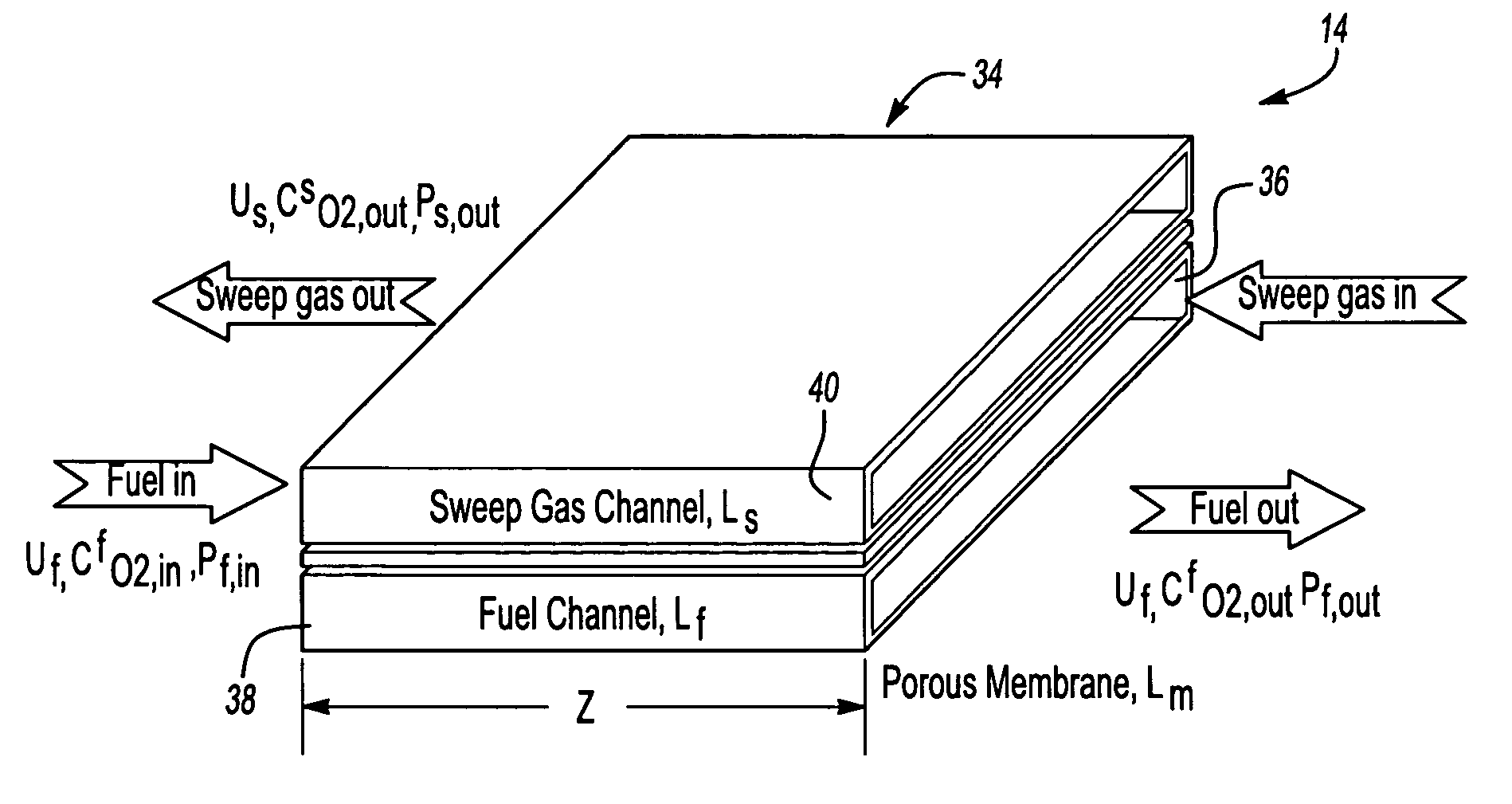

Fuel deoxygenation system with non-planar plate members

ActiveUS20060278073A1Enhances deoxygenationImprove efficiencyPower plant fuel tanksIsotope separationPorous substrateEngineering

A fuel system for an energy conversion device includes a multiple of fuel plates, oxygen permeable membranes, porous substrate plates, and vacuum frame plates which define a wave pattern configuration. The wave configuration enhances deoxygenation by increasing the efficiency and integrality due to higher surface volume ration, increase of flow turbulence, and minimal sharp edges which may otherwise damage the oxygen permeable membranes compared to other configurations.

Owner:RAYTHEON TECH CORP

Fuel deoxygenator with porous support plate

A device for use in a fluid system includes a fuel channel for receiving fuel having dissolved gas therein. A gas permeable membrane supported by a porous support, the gas permeable membrane in communication with the fuel channel. A gas-removal channel adjacent the gas permeable membrane for receiving the dissolved gas from the fuel through the gas permeable membrane and the porous support.

Owner:RTX CORP

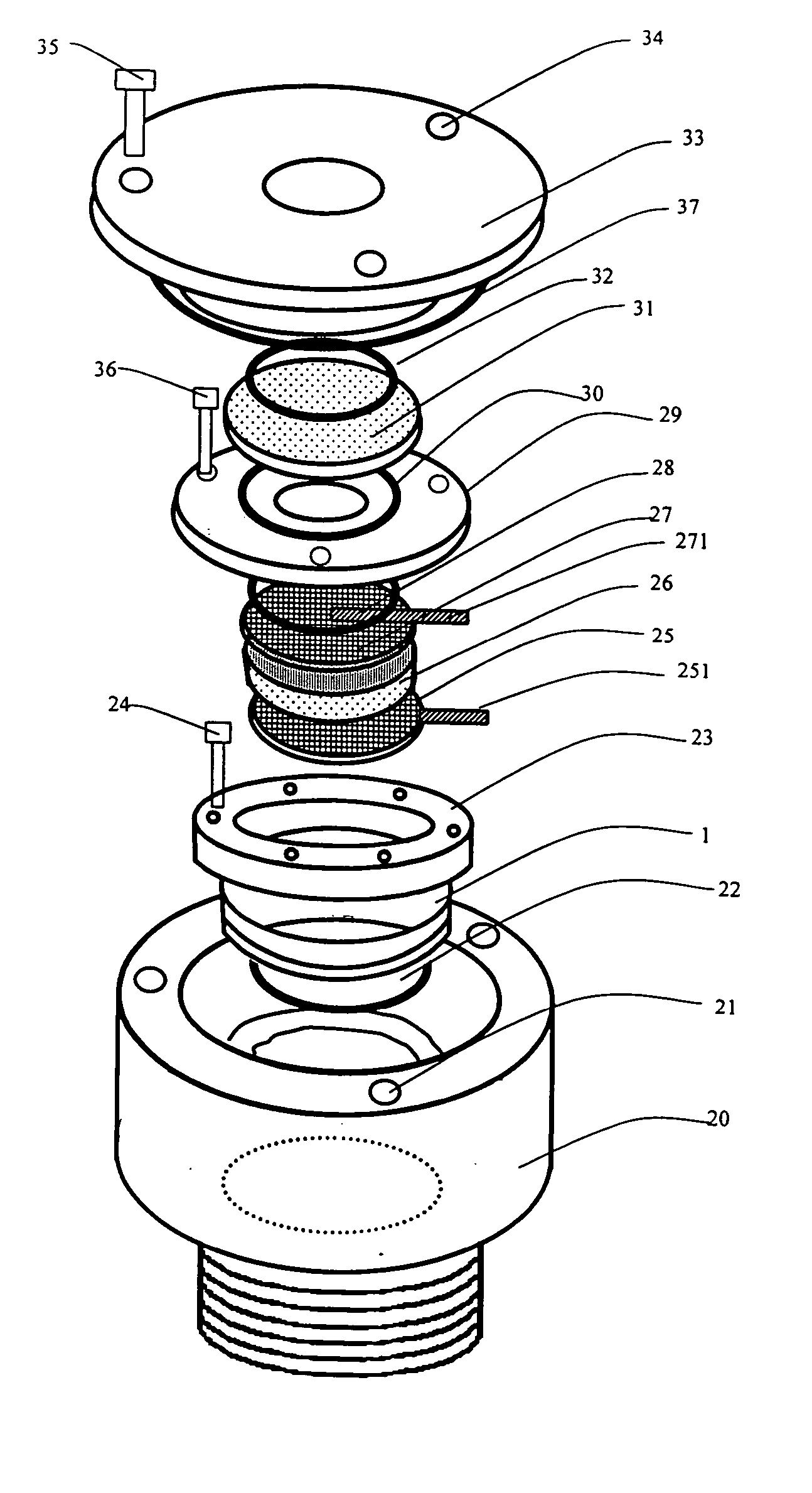

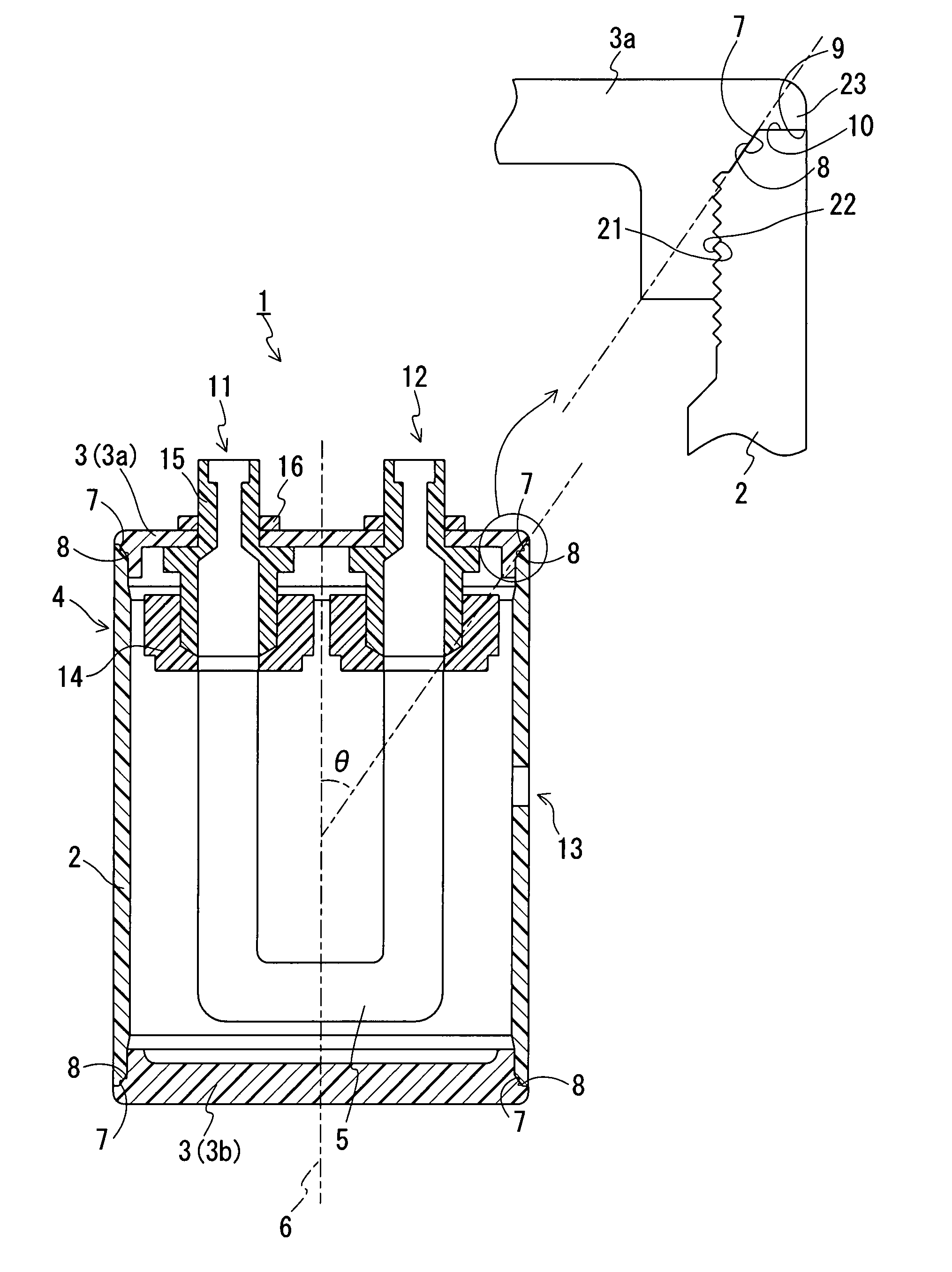

Degasifier

InactiveUS20070240569A1Prevents deterioration in sealing propertySemi-permeable membranesDispersed particle filtrationDecompression chamberEngineering

A degasifier is provided in which the deterioration in sealing property (deterioration in airtightness) is prevented while sealing members to be placed between a container and covers that compose a decompression chamber can be omitted. A degasifier includes a decompression chamber provided with a container and covers, and a gas-permeable tube. The container is a tubular body extending along the central axis. The covers seal the openings of the ends of the tubular body. The gas-permeable tube is contained in the decompression chamber in such a manner that a liquid to be degassed that has entered from the outside of the decompression chamber flows therethrough and the liquid to be degassed that has flowed therethrough flows out of the decompression chamber. The inner circumference surfaces in the vicinities of the openings of the container each are provided with a first slope that is formed to be tilted at a predetermined angle θ with respect to the central axis and to extend away from the central axis toward the opening side of the container. A portion of each of the covers that is in contact with the container is provided with a second slope that is formed to be tilted at the angle θ with respect to the central axis and to extend to approach the central axis toward the inner side of the decompression chamber, with the openings being sealed. The openings are sealed with the container and the covers being joined to each other in the state where the first slopes and the second slopes are in contact with each other, respectively.

Owner:NITTO DENKO CORP

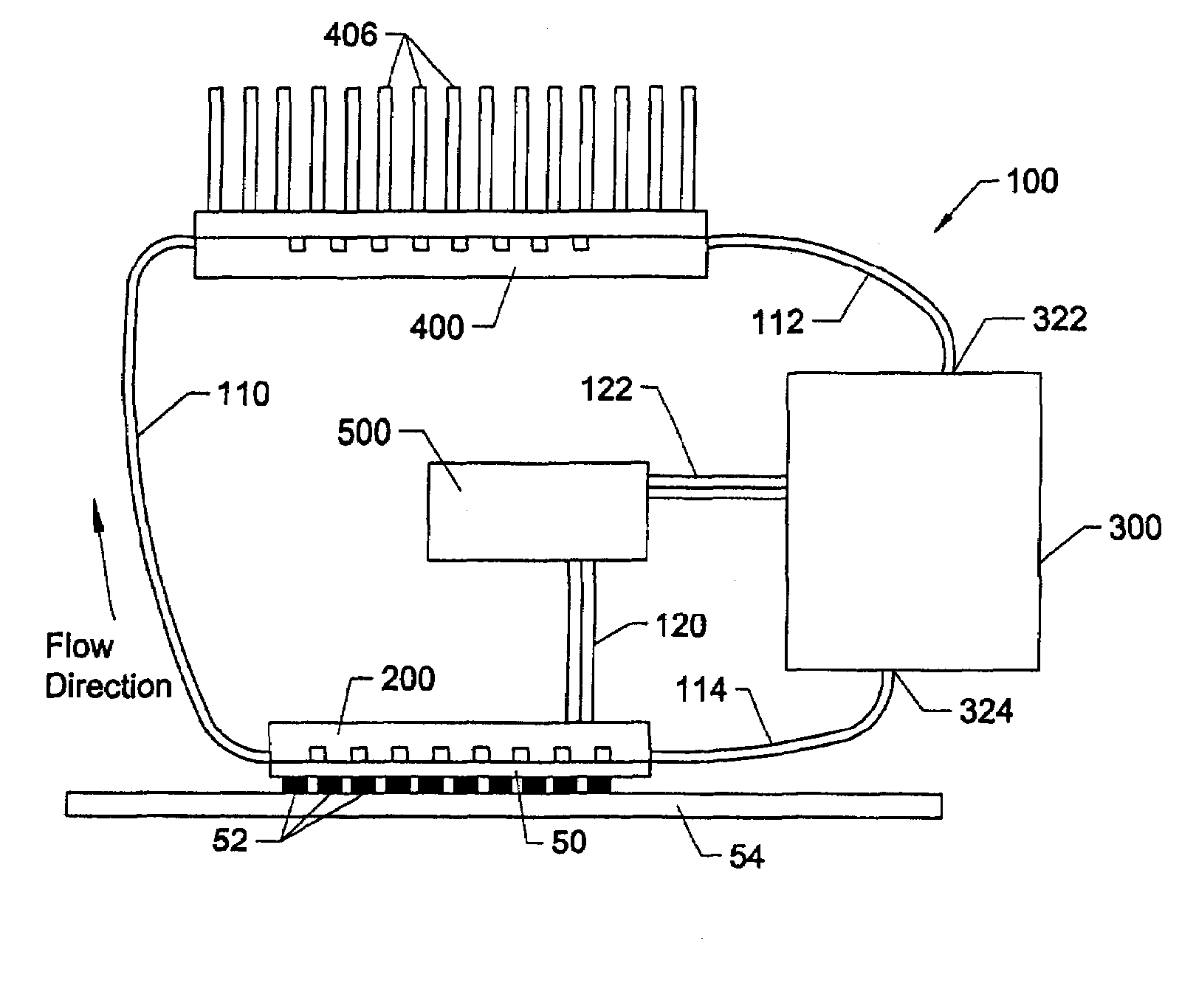

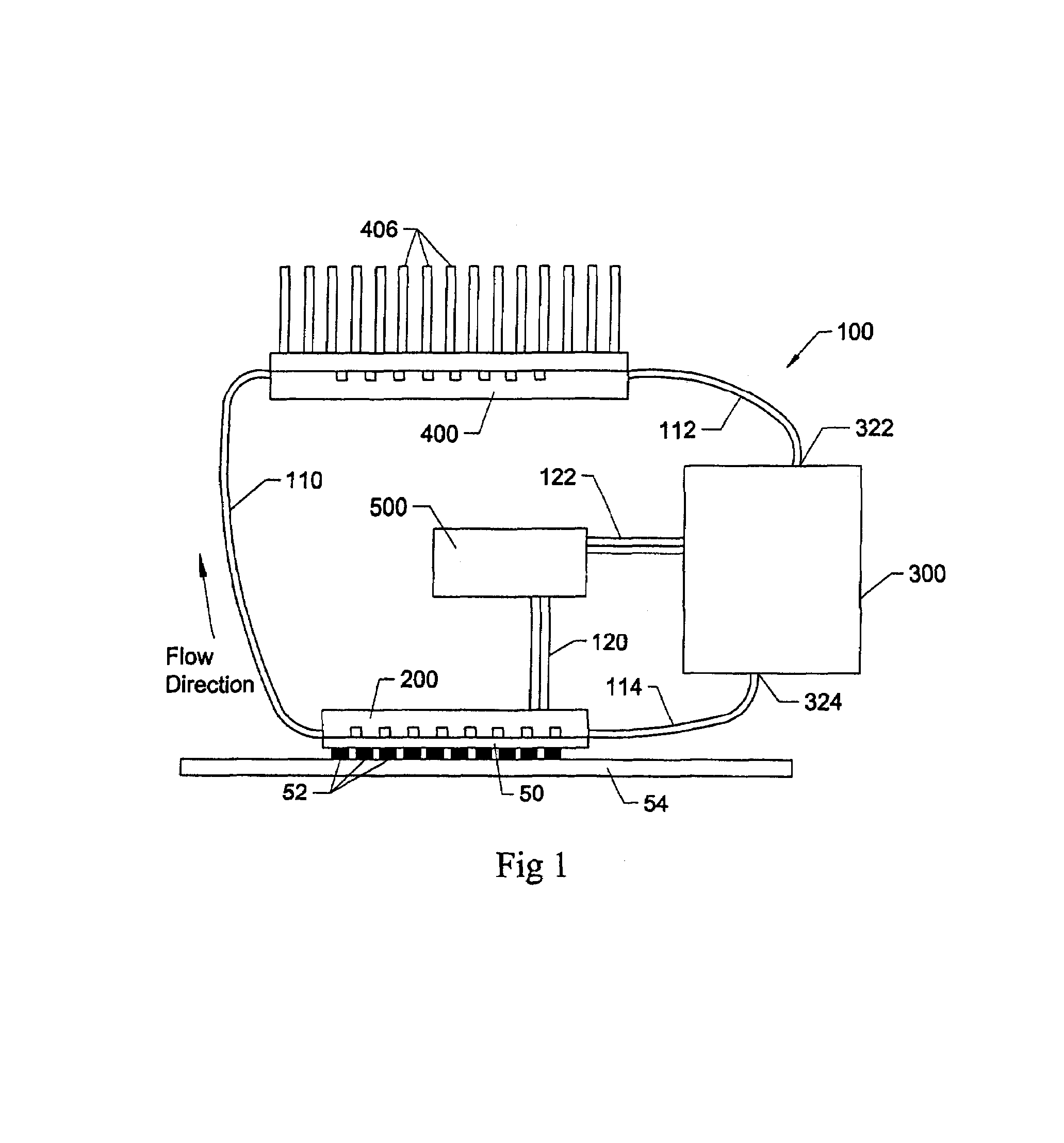

Fuel deoxygenation system

ActiveUS7153343B2Inexpensive sizeInexpensive weightLiquid fuel feeder/distributionSemi-permeable membranesPorous membraneEngineering

A fuel system for an energy conversion device includes a deoxygenator system with a porous membrane. The deoxygenator includes an oxygen receiving channel separated from the fuel channel by the porous membrane. The capillary forces counteract the pressure differential across the membrane, preventing any leakage of the fuel, while the oxygen concentration differential across the membrane allows for deoxygenation of the fuel through the porous membrane.

Owner:RTX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com