Patents

Literature

124results about How to "Improve radiation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

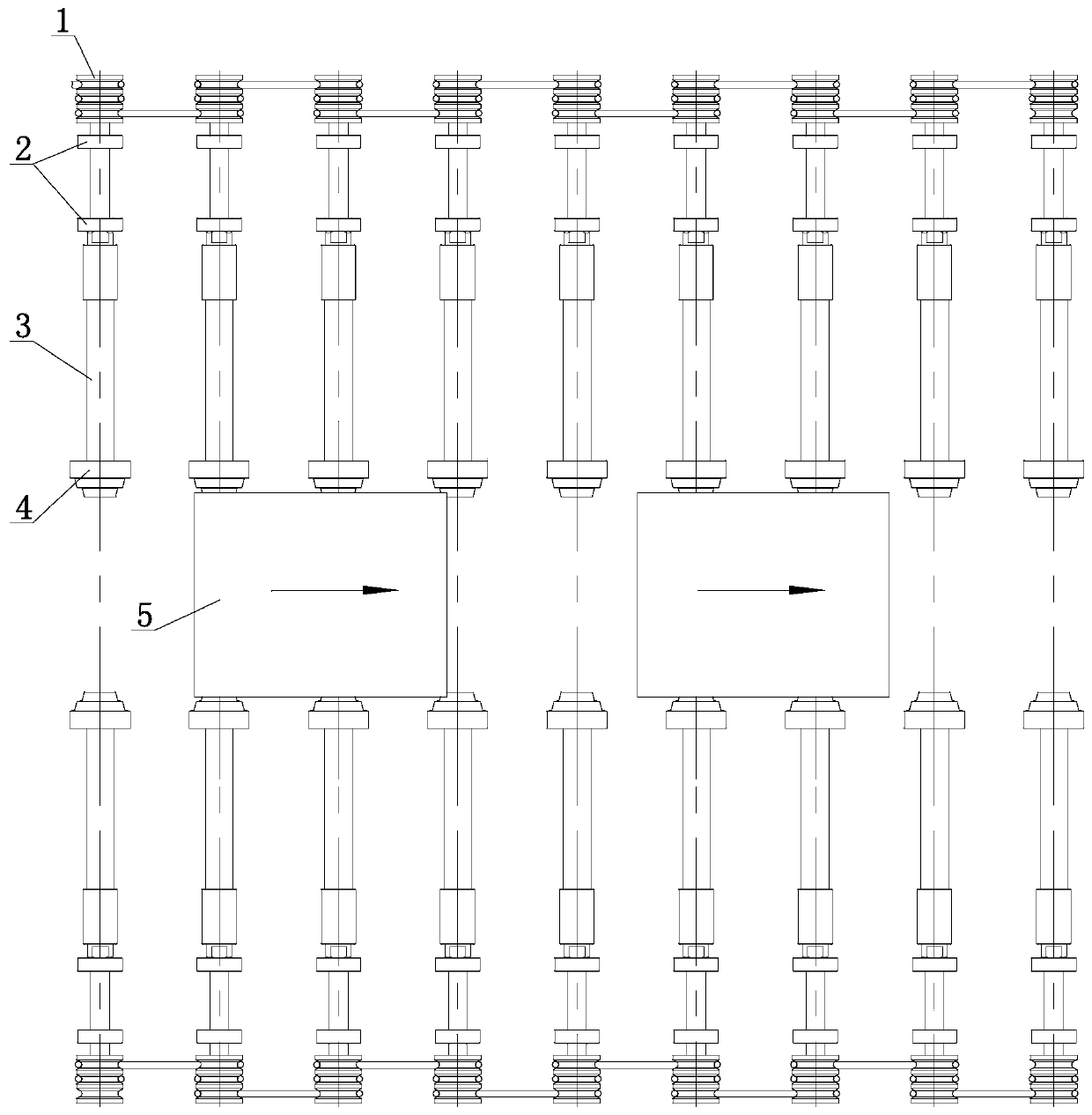

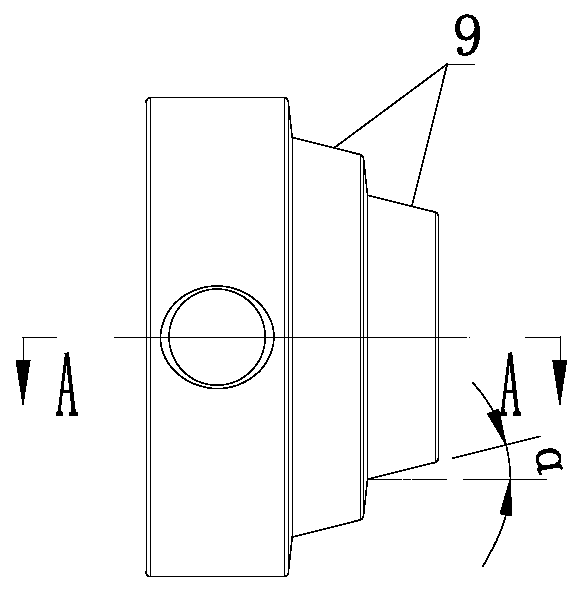

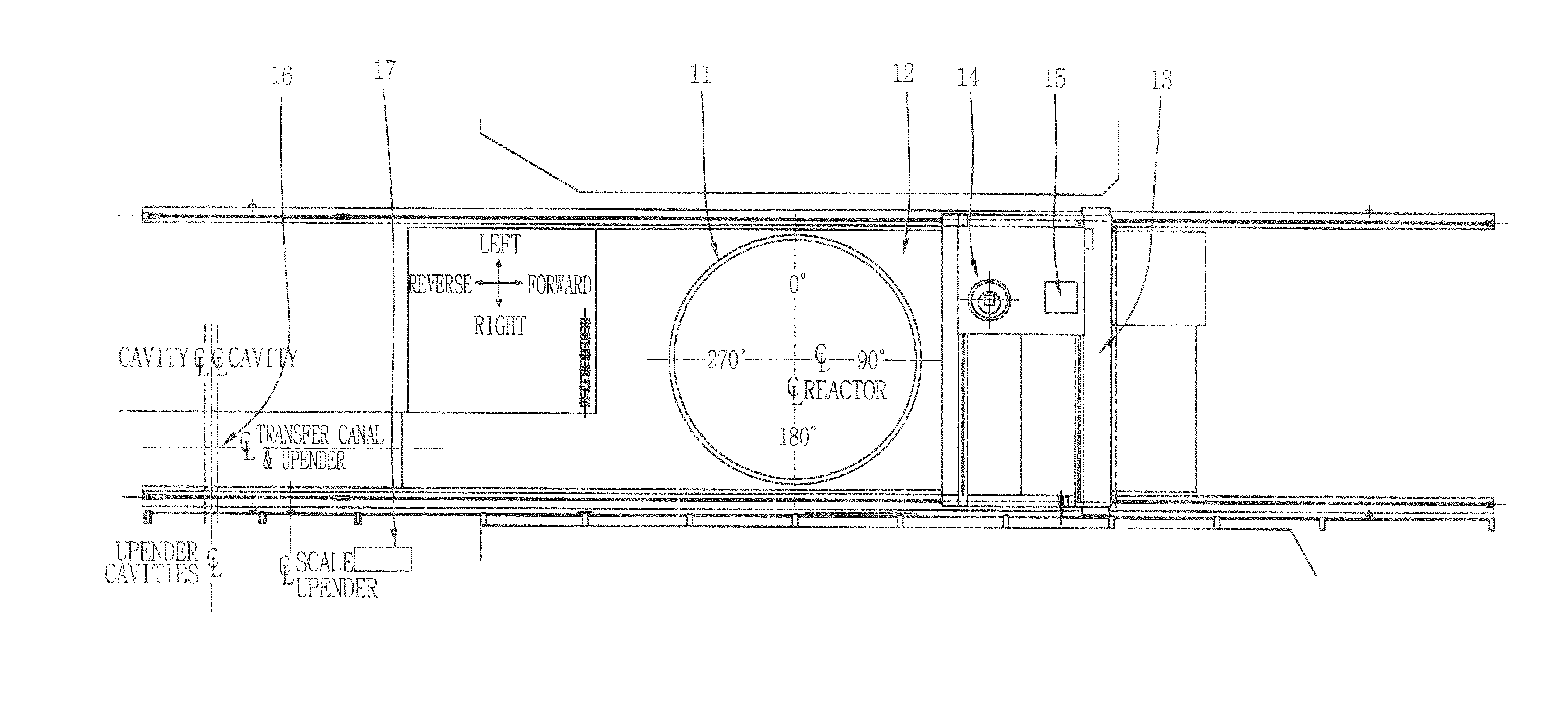

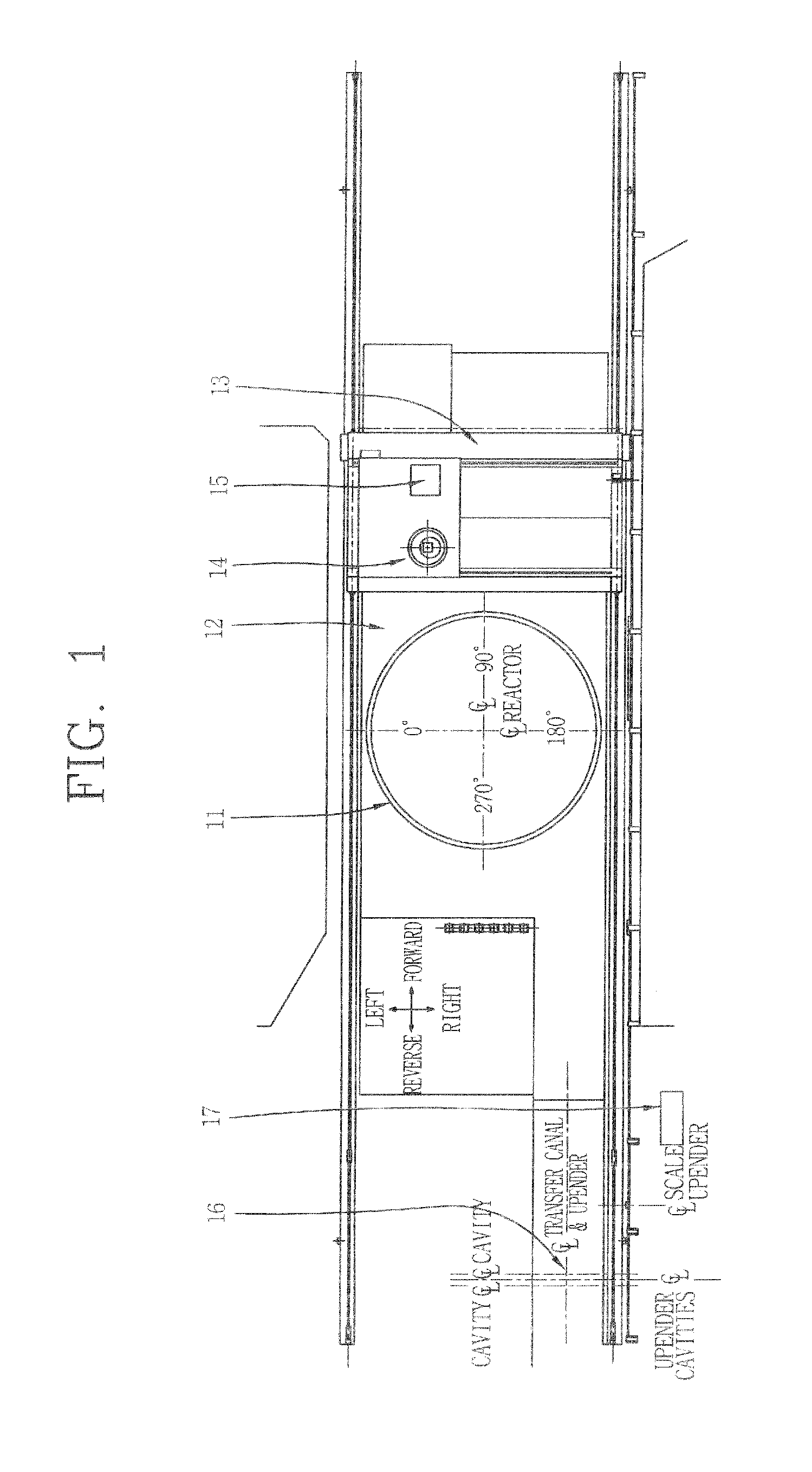

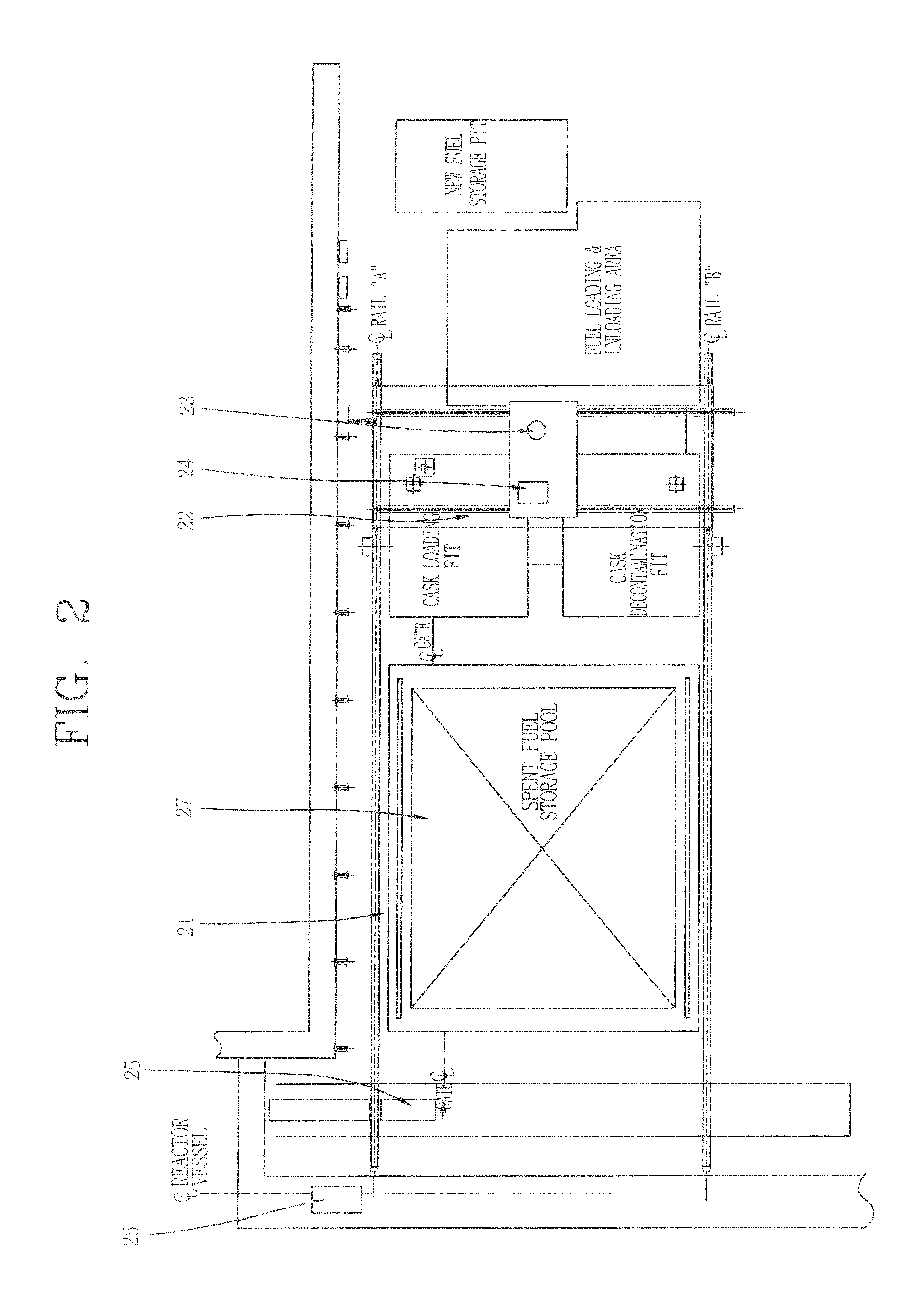

Remote control system for the fuel handling system of nuclear power plant

InactiveUS20120128113A1Reduce exposurePrevent exposure to radioactivity and dropping of foreign substanceMan-machine nuclear interfaceNuclear energy generationHuman–machine interfaceProgrammable logic controller

Disclosed is a remote control system for a fuel handling system of a nuclear power plant, in which the system includes a remote control console; a programmable logic controller (PLC) unit; a servo motor drive; and a human-machine interface (HMI) unit.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

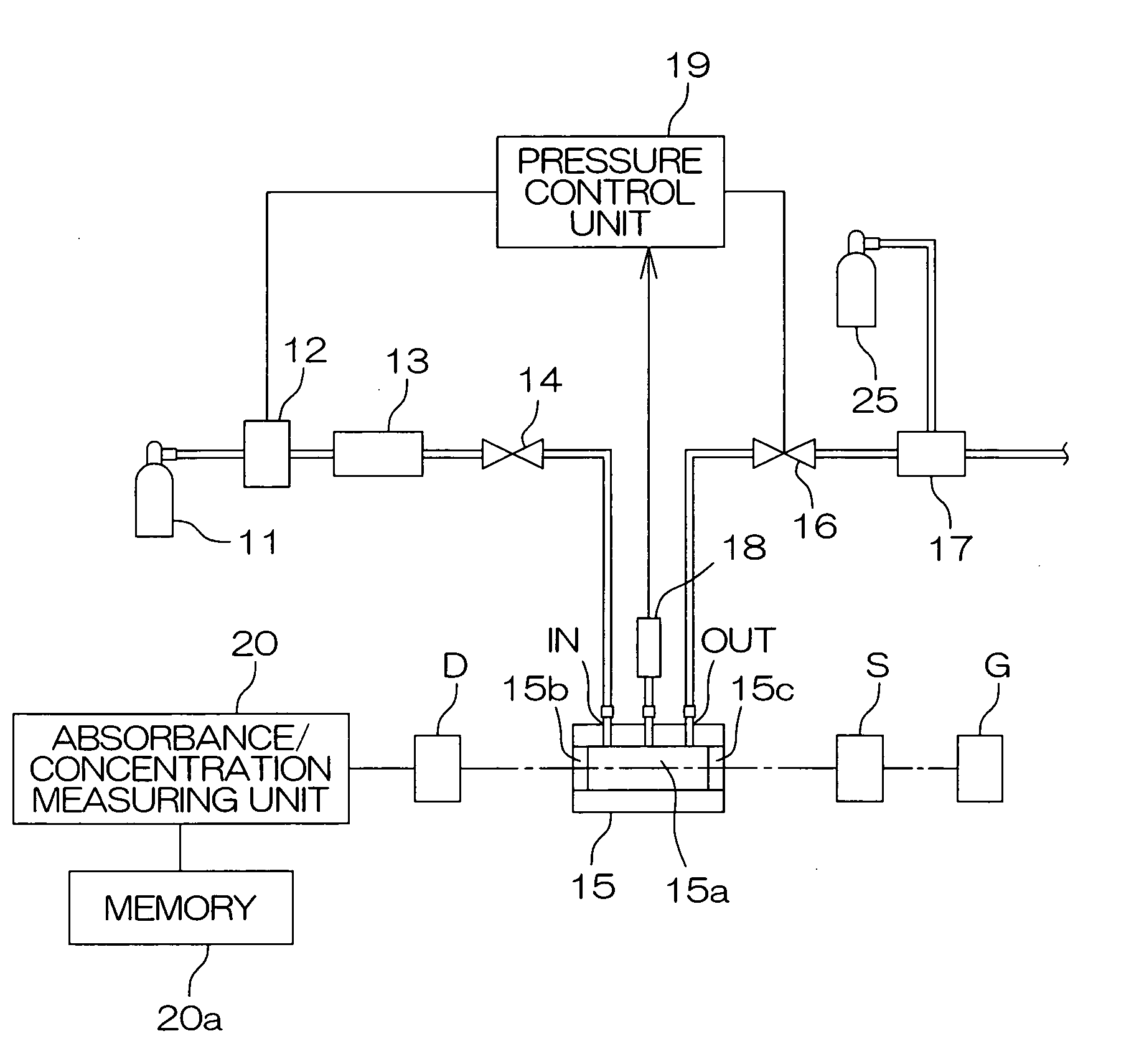

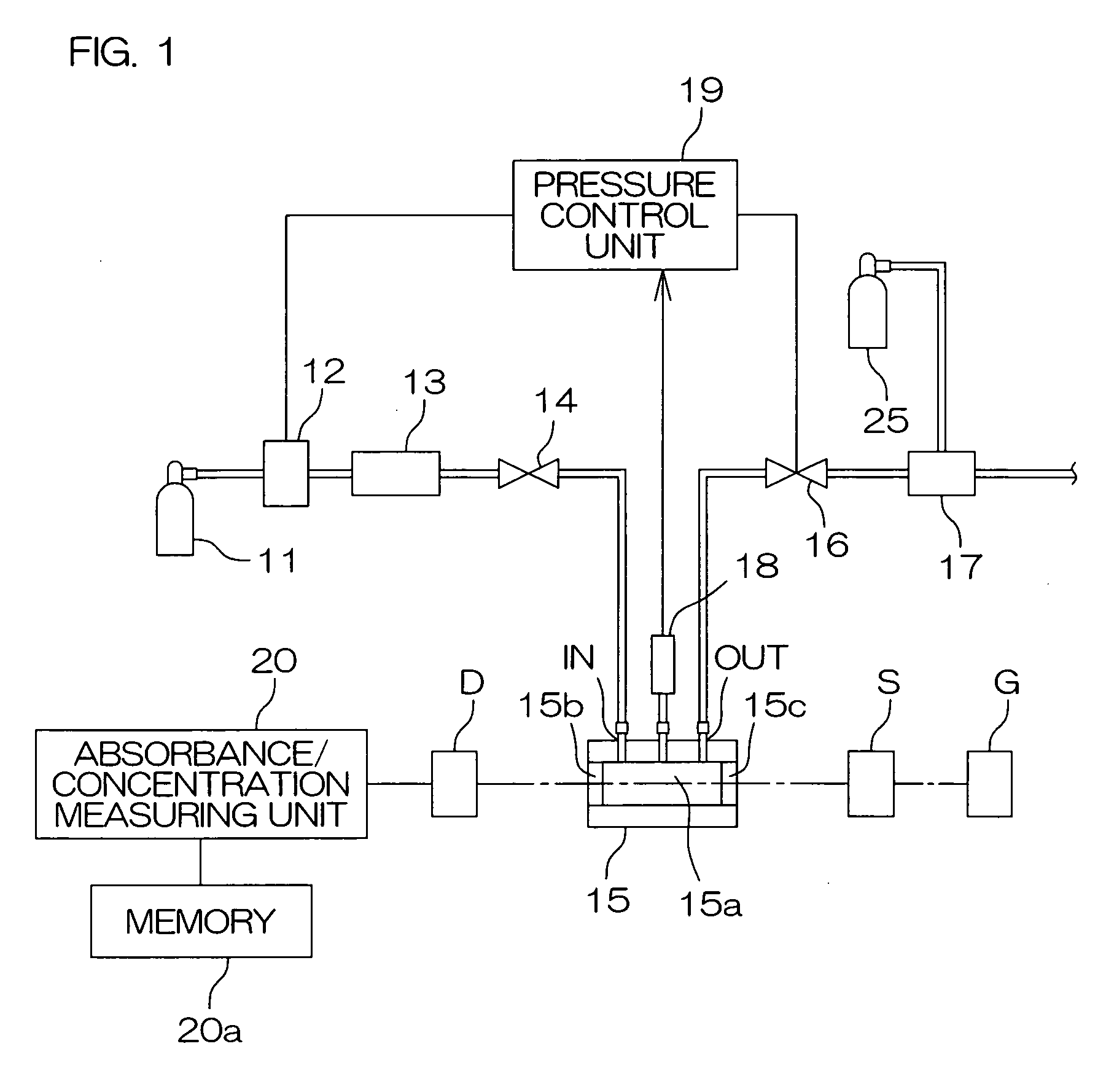

Method of and apparatus for determining the amount of impurity in gas

InactiveUS20060011844A1Accurate measurementEase of evacuationRadiation pyrometryPhase-affecting property measurementsAbsorbanceUltimate tensile strength

Impurity is removed from gas, the resultant gas is introduced into a cell 15, and the intensity of light transmitted through the cell 15 is measured as a reference. Gas containing impurity of which concentration is known, is introduced into the cell 15, and the intensity of light transmitted through the cell 15 is measured with the temperature and pressure maintained at those used at the measurement of the reference light intensity. Then, the absorbance of the impurity is obtained according to the ratio of the two light intensity data obtained by the two measurements above-mentioned. The impurity absorbance thus obtained is stored, in a memory 20a, as a function of an impurity concentration. Gas containing impurity of which concentration is unknown, is introduced into the cell 15, and the intensity of light transmitted through the cell 15 is measured with the temperature and pressure maintained at those used at the measurements above-mentioned. The absorbance of the impurity is obtained according to the last-measured light intensity and the reference light intensity. The absorbance thus obtained is applied to the function, thereby to obtain the impurity concentration.

Owner:OTSUKA DENSHI CO LTD

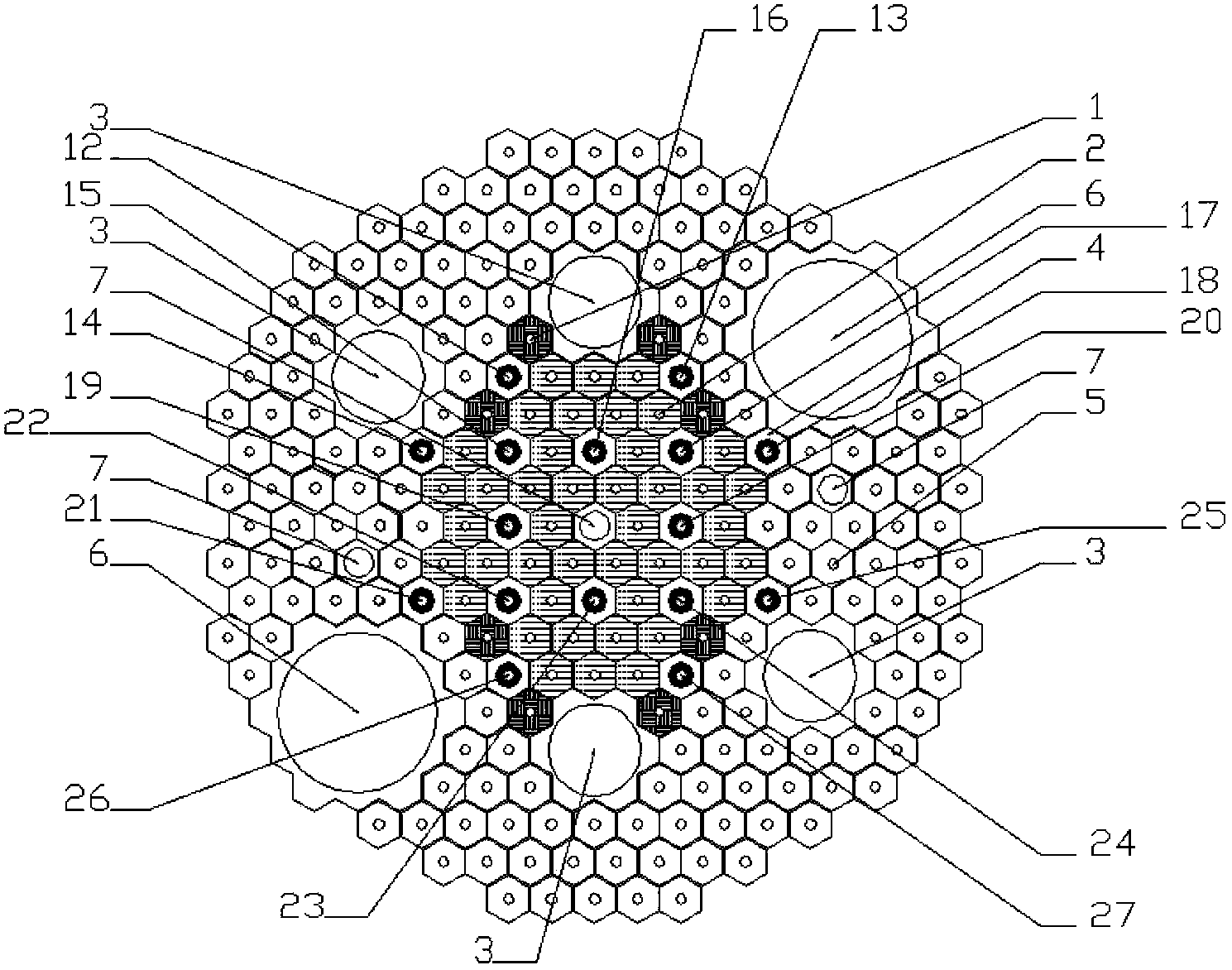

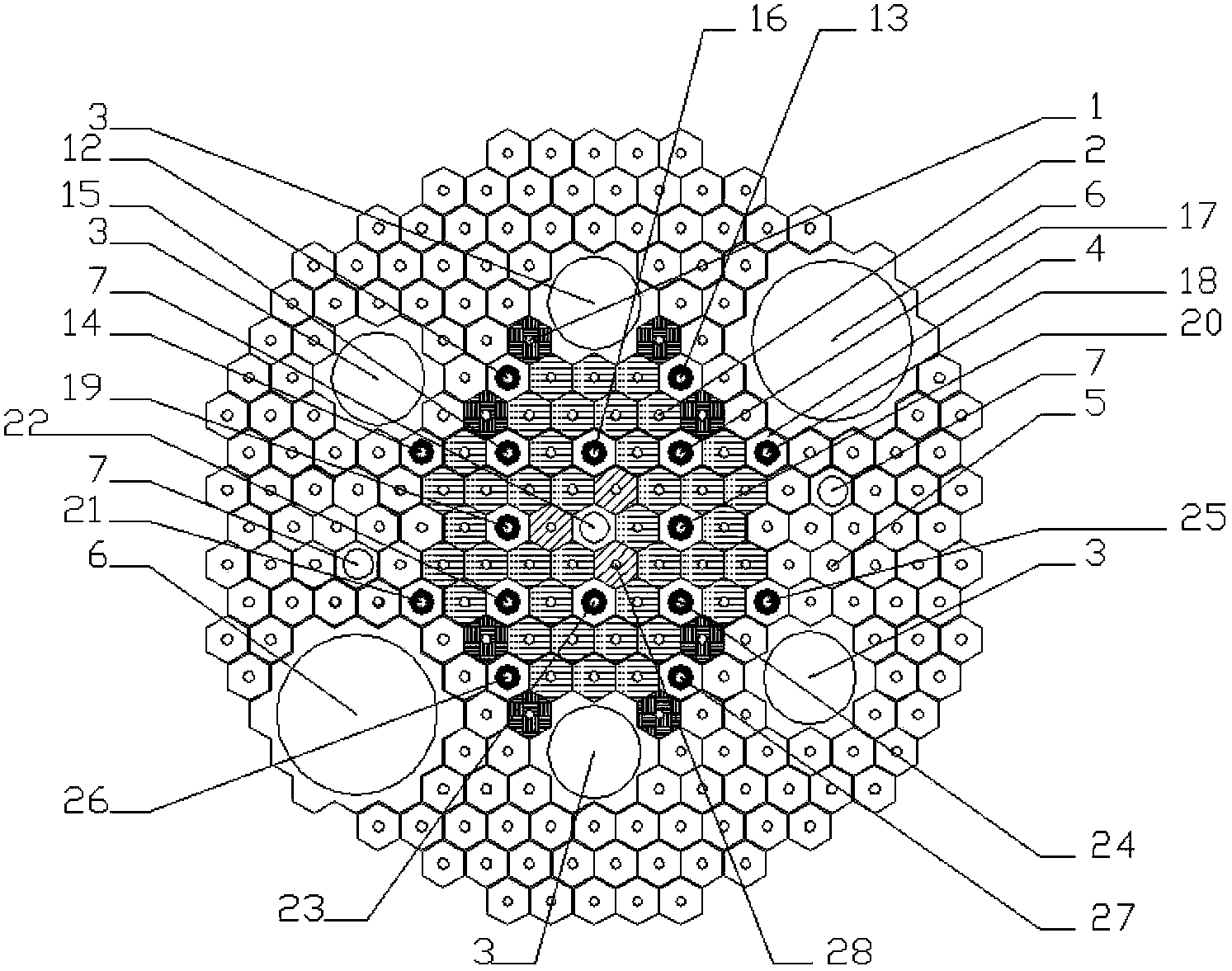

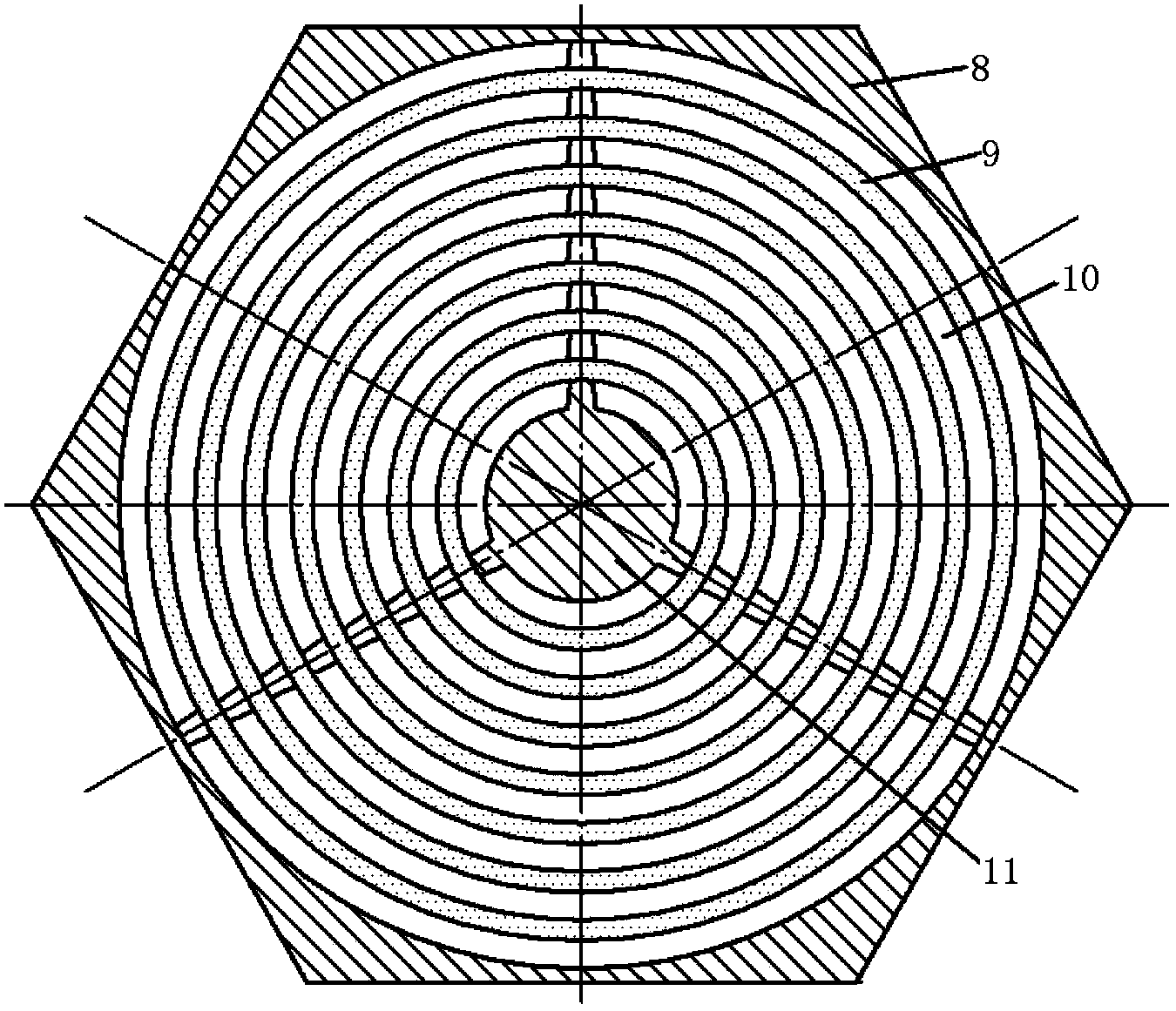

Reactor core with high fast neutron fluence

ActiveCN103474097AEnhanced radiation capability and application rangeBroaden the irradiation capacity and application rangeNuclear energy generationShieldingNuclear reactorCoolant flow

The invention belongs to the technical field of nuclear reactor design, and in particular relates to a reactor core with high fast neutron fluence. The reactor core consists of fuel assemblies, control rod assemblies and beryllium assemblies. The plurality of fuel assemblies are hexagonal sleeve type fuel assemblies and in annular compact arrangement; six fuel assemblies are arranged on an innermost ring to form a fast neutron trap at the center of the annular region; the plurality of hexagonal beryllium assemblies are arranged close to the external side of the annular region of the fuel assemblies to form an inverted neutron trap; and the plurality of control rod assemblies are arranged among the fuel assemblies at intervals and in two rows and two columns in a squared shape. The reactor core with high fast neutron fluence satisfies internationally restricted U-235 enrichment degree and requirements of domestic fuel core production and design of coolant flow velocity, and can obtain high fast neutron fluence level in an irradiation tunnel, and enhance and widen irradiation capability and scope of application of a test reactor.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

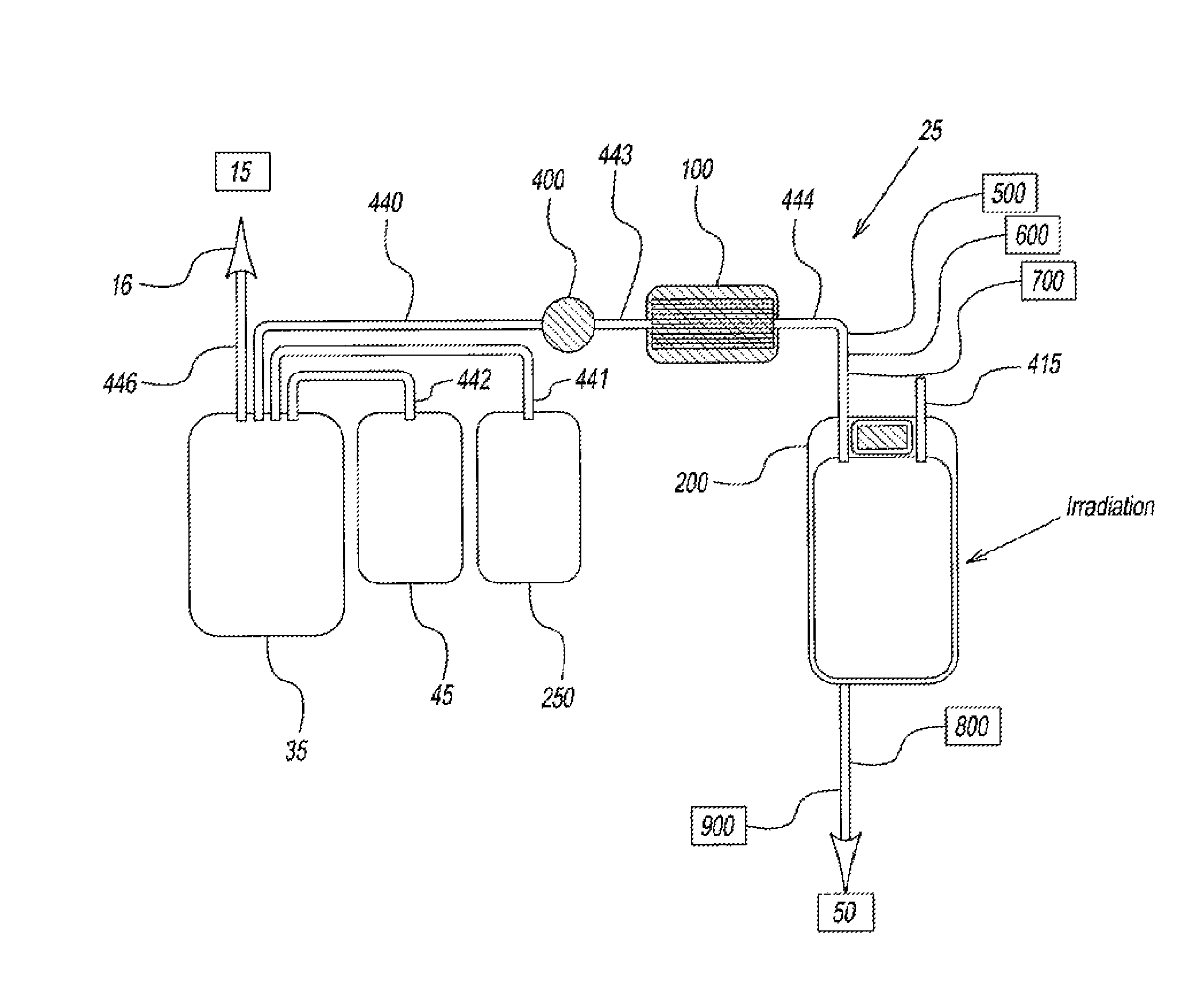

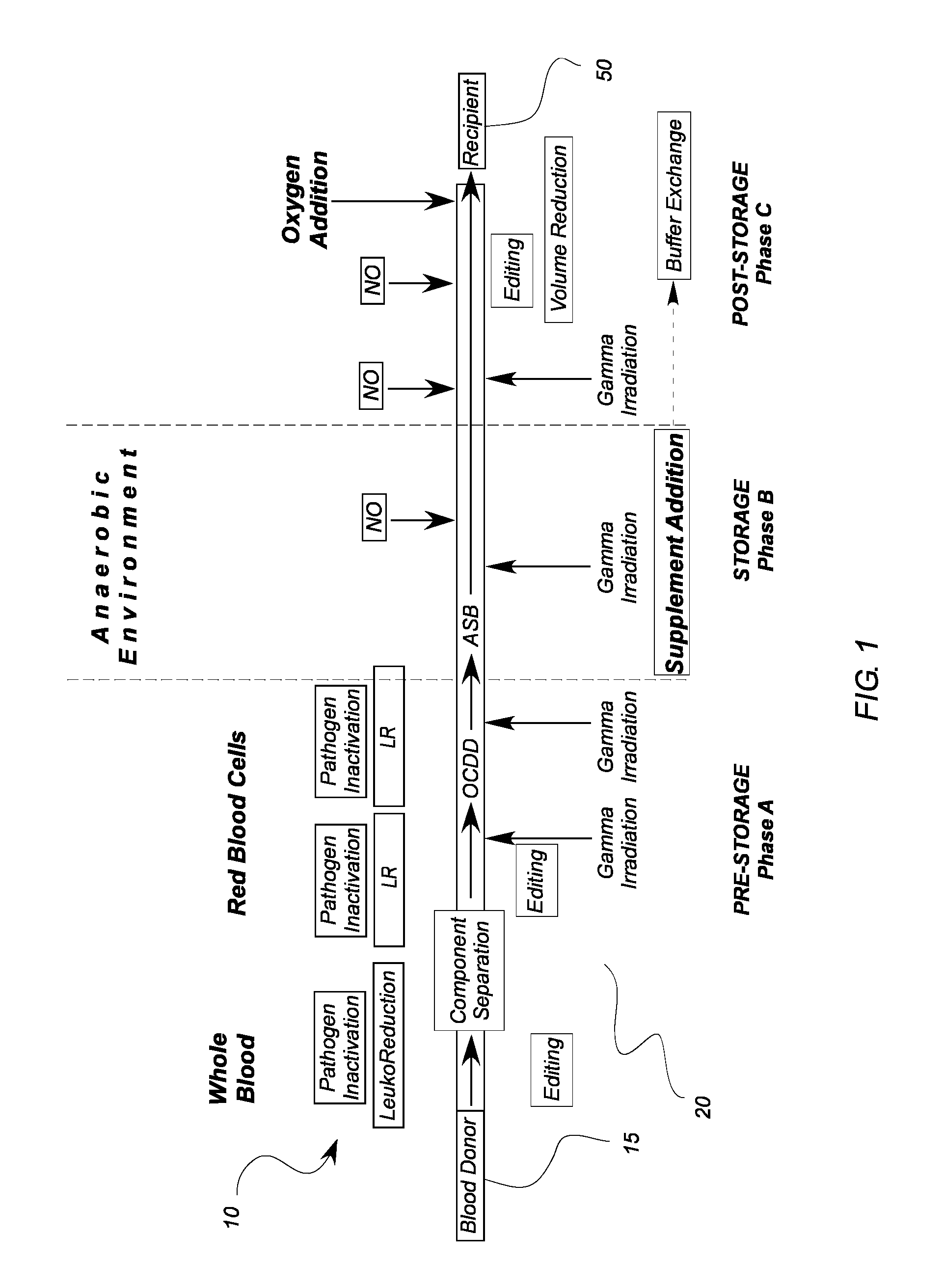

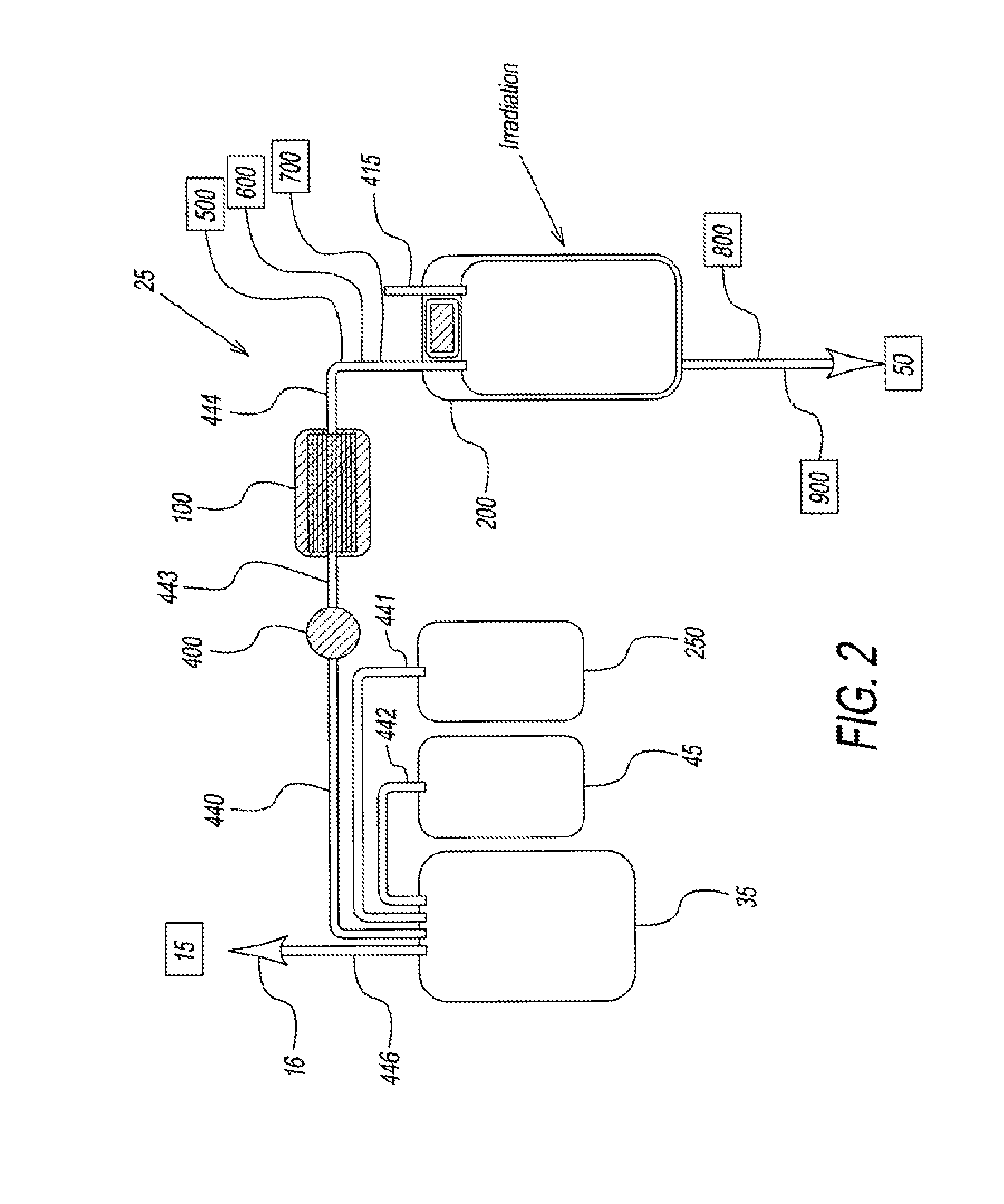

System for extended storage of red blood cells and methods of use

ActiveUS9199016B2Enhanced heterologous transfusion logisticsExtension of timeMedical devicesDead animal preservationRed CellOxygen

Owner:HEMANEXT INC

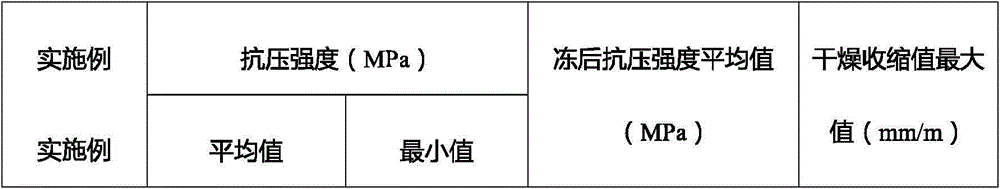

Building thermal insulation dry powder mortar

A building thermal insulation dry powder mortar belongs to a building thermal insulation material. The weight ratio of a dry powder to water is 1: 1.5. The dry powder is prepared by mixing 450 parts by mass of ordinary portland cement, 70 parts by mass of a calcined gypsum powder, 37.5 parts by mass of a redispersible emulsion powder, 15 parts by mass of fine xylem fibers, 13 parts by mass of polypropylene staple fibers, 10 parts by mass of slaked lime, 10 parts by mass of sierozem, 10 parts by mass of heavy calcium carbonate, 3 parts by mass of hydroxypropyl methyl cellulose, 364 parts by mass of a calcined expanded perlite and 17.5 parts by mass of a premixed auxiliary agent. The thermal insulation building dry powder mortar has the advantages of strong thermal insulation, strong bond with walls, high compressive strength, strong drawing force, excellent weather resistance, and environmental protection, and also has the advantages of fire resistance, cracking resistance, leakage resistance, moisture resistance, sliding resistance, earthquake resistance and the like.

Owner:王荣

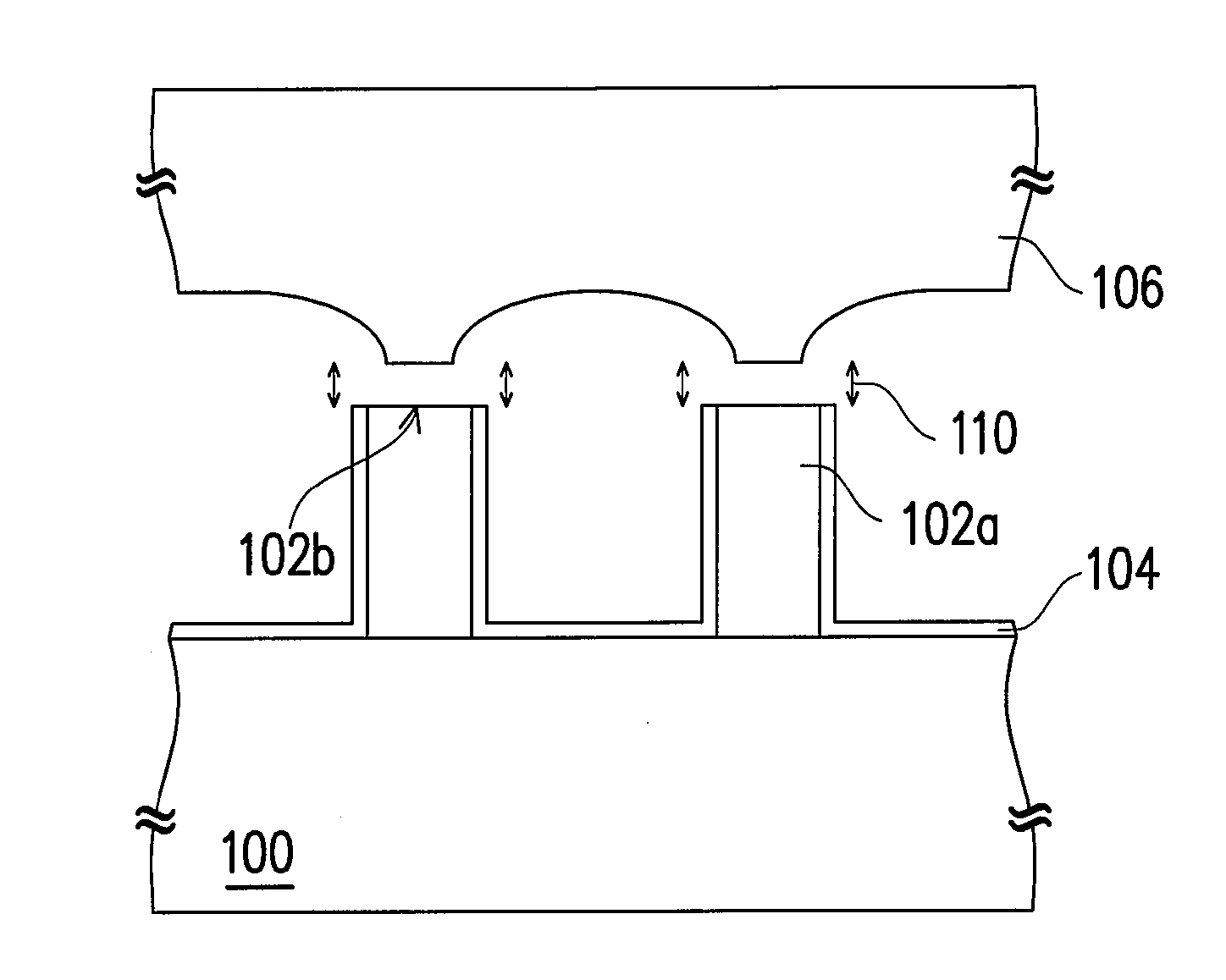

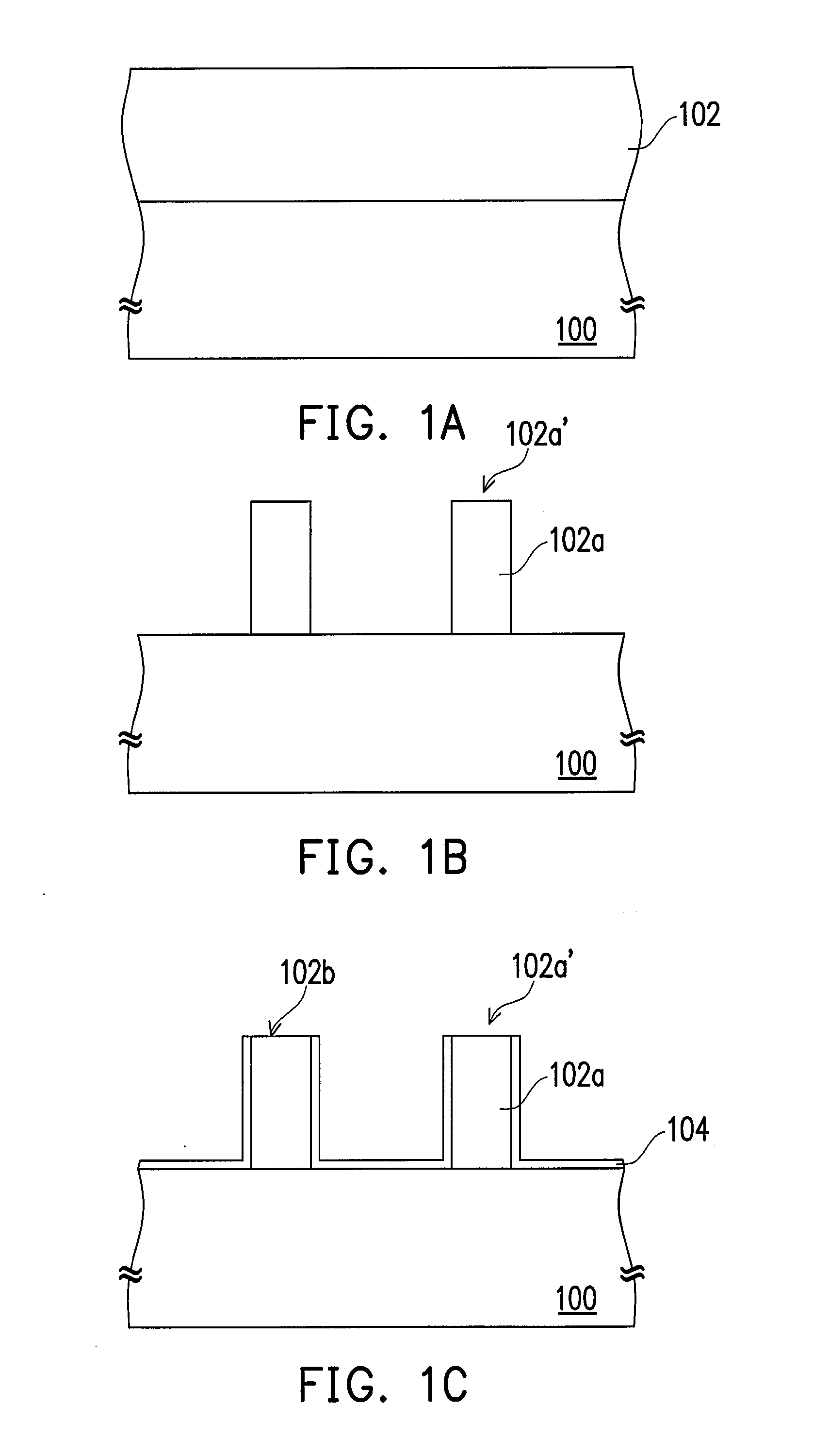

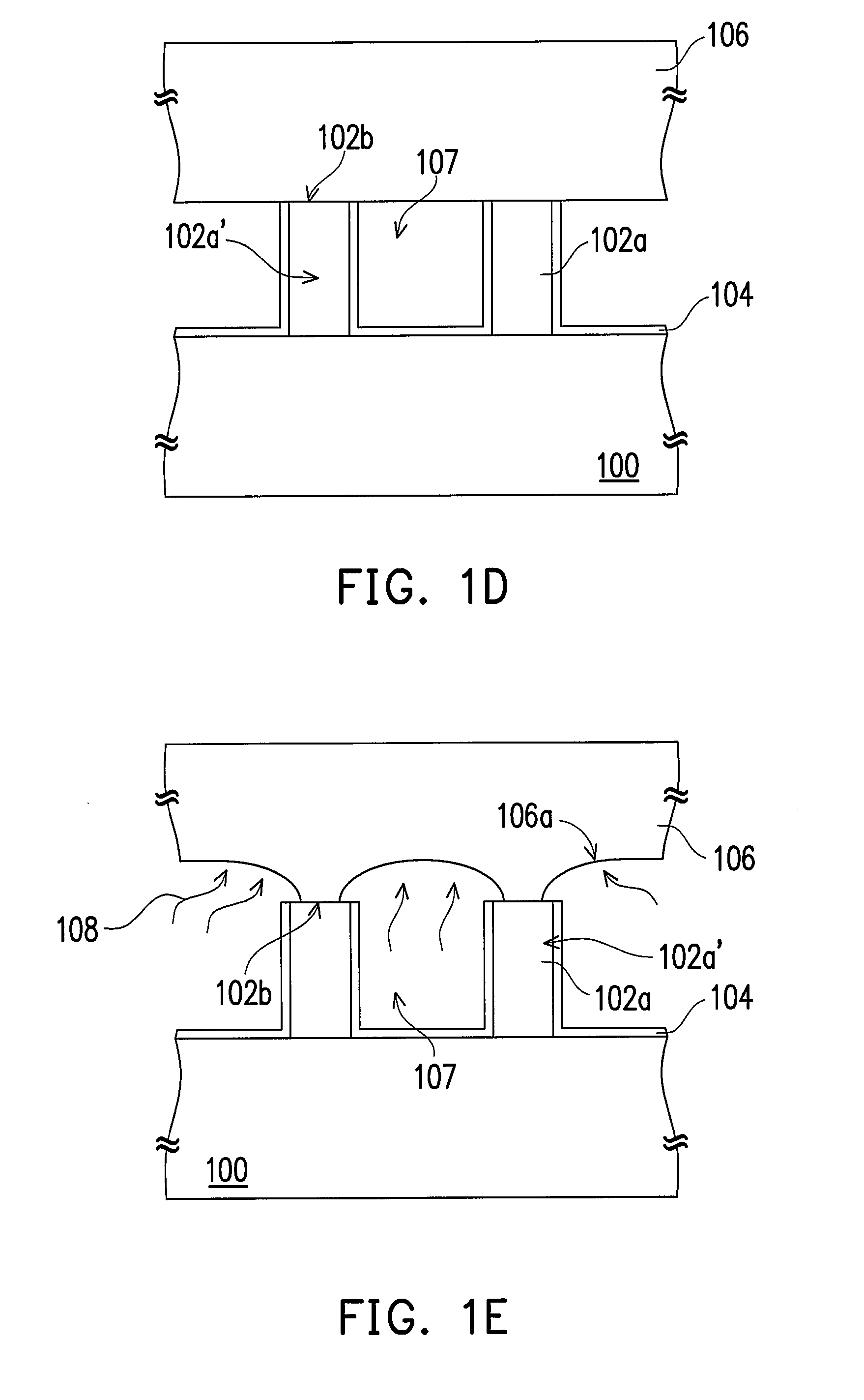

Nitride semiconductor substrate, method for forming a nitride semiconductor layer and method for separating the nitride semiconductor layer from the substrate

InactiveUS20080054292A1Improve radiation effectImprove structural strengthPolycrystalline material growthSolid-state devicesNitride semiconductorsEpitaxy

There is provided a method of forming a nitride semiconductor layer, including the steps of firstly providing a substrate on which a patterned epitaxy layer with a pier structure is formed. A protective layer is then formed on the patterned epitaxy layer, exposing a top surface of the pier structure. Next, a nitride semiconductor layer is formed over the patterned epitaxy layer connected to the nitride semiconductor layer through the pier structure, wherein the nitride semiconductor layer, the pier structure, and the patterned epitaxy layer together form a space exposing a bottom surface of the nitride semiconductor layer. Thereafter, a weakening process is performed to remove a portion of the bottom surface of the nitride semiconductor layer and to weaken a connection point between the top surface of the pier structure and the nitride semiconductor layer. Finally, the substrate is separated from the nitride semiconductor layer through the connection point.

Owner:IND TECH RES INST

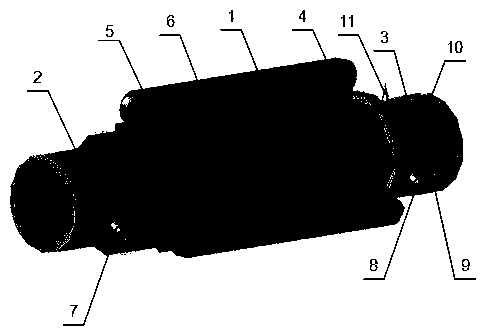

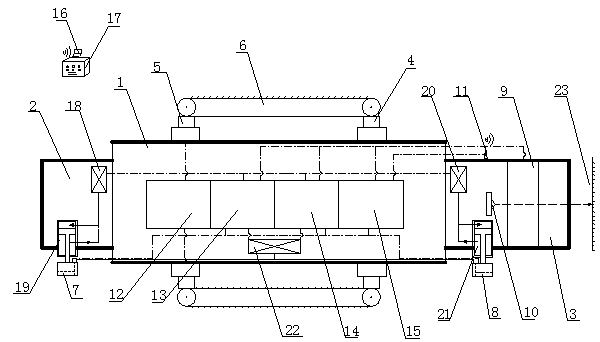

Wireless remote-control comprehensive hole measuring robot used for rock mass engineering

InactiveCN103737589AEliminate the time-consuming and labor-intensive shortcomings of pushing into the drilling holeEliminate the disadvantages of time-consuming and labor-intensiveProgramme-controlled manipulatorMeasurement devicesData acquisitionGeophysics

The invention relates to a wireless remote-control comprehensive hole measuring robot for rock mass engineering and belongs to the technical field of the rock mass engineering.. The wireless remote-control comprehensive hole measuring robot is mainly used for multivariate information measurement like deformation of rock mass engineering and fracture of surrounding rocks. The hole measuring robot is composed of a carrying platform, a front carrying tank, a rear carrying tank, a driving system, a data acquisition system, a sound wave test system, a digital drill hole camera, a control system and the like. The controller controls the hole measuring robot to crawl inside a drill hole by relying on a crawler belt, the digital drill hole camera is used for shooting the wall surface of the drill hole, the sound wave test system is used for acquiring wave speed of a rock mass, and acquired data are wirelessly transmitted to a data receiving platform in a safety zone through a data transmission antenna. By the application of the wireless remote-control comprehensive hole measuring robot, drill hole camera and sound wave test can be simultaneously completed; by the adoption of wireless remote control which is timesaving and laborsaving, the comprehensive hole measuring robot is applicable to monitoring of the multivariate information measurement of deformation of ordinary rock mass engineering, fracture of the rock masses and the like and also applicable to the rock mass engineering environment unsuitable for long-term stay for human beings and having strong power impact and highly-radioactive dangers.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Total absorption superlaser energy meter

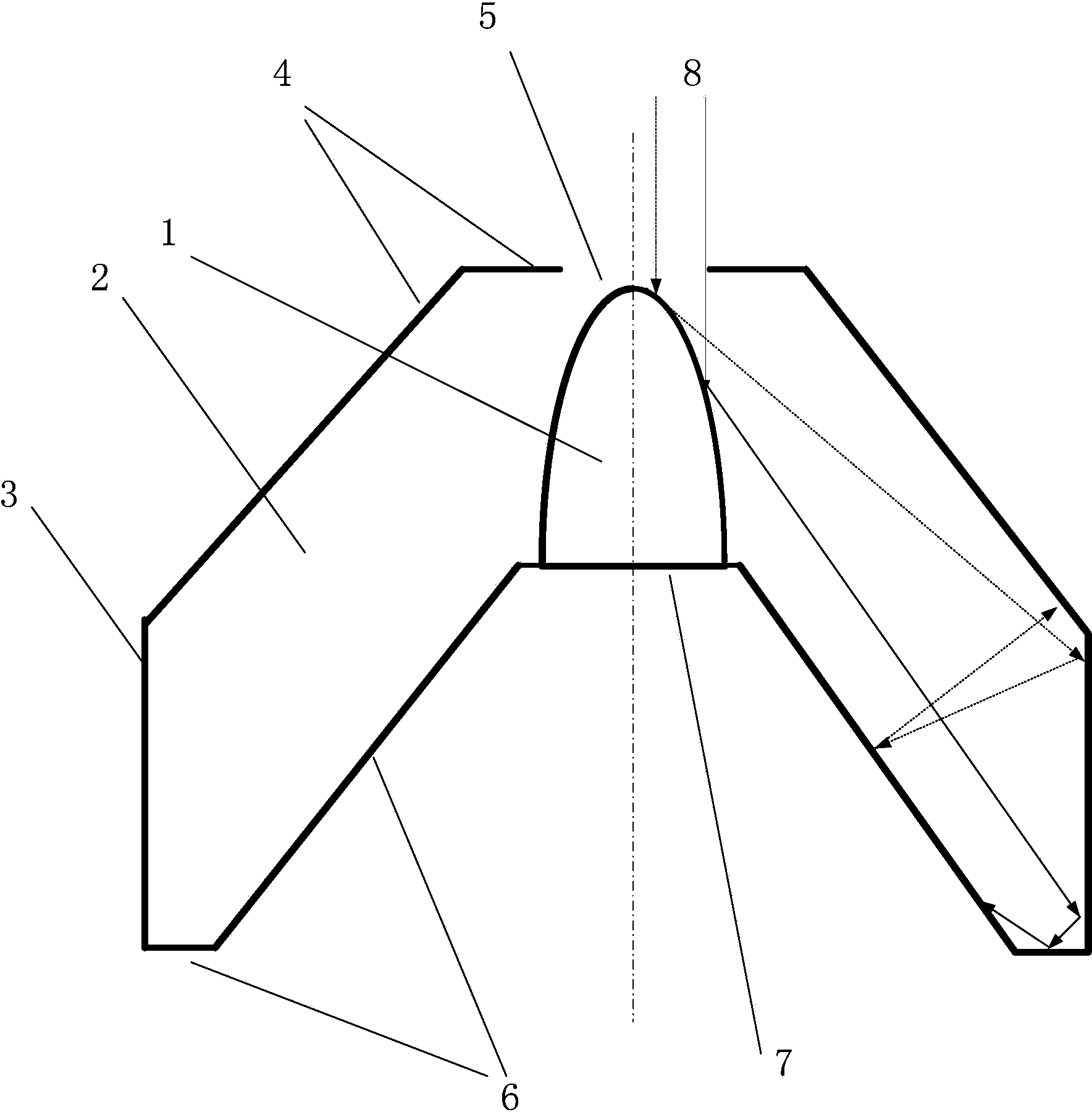

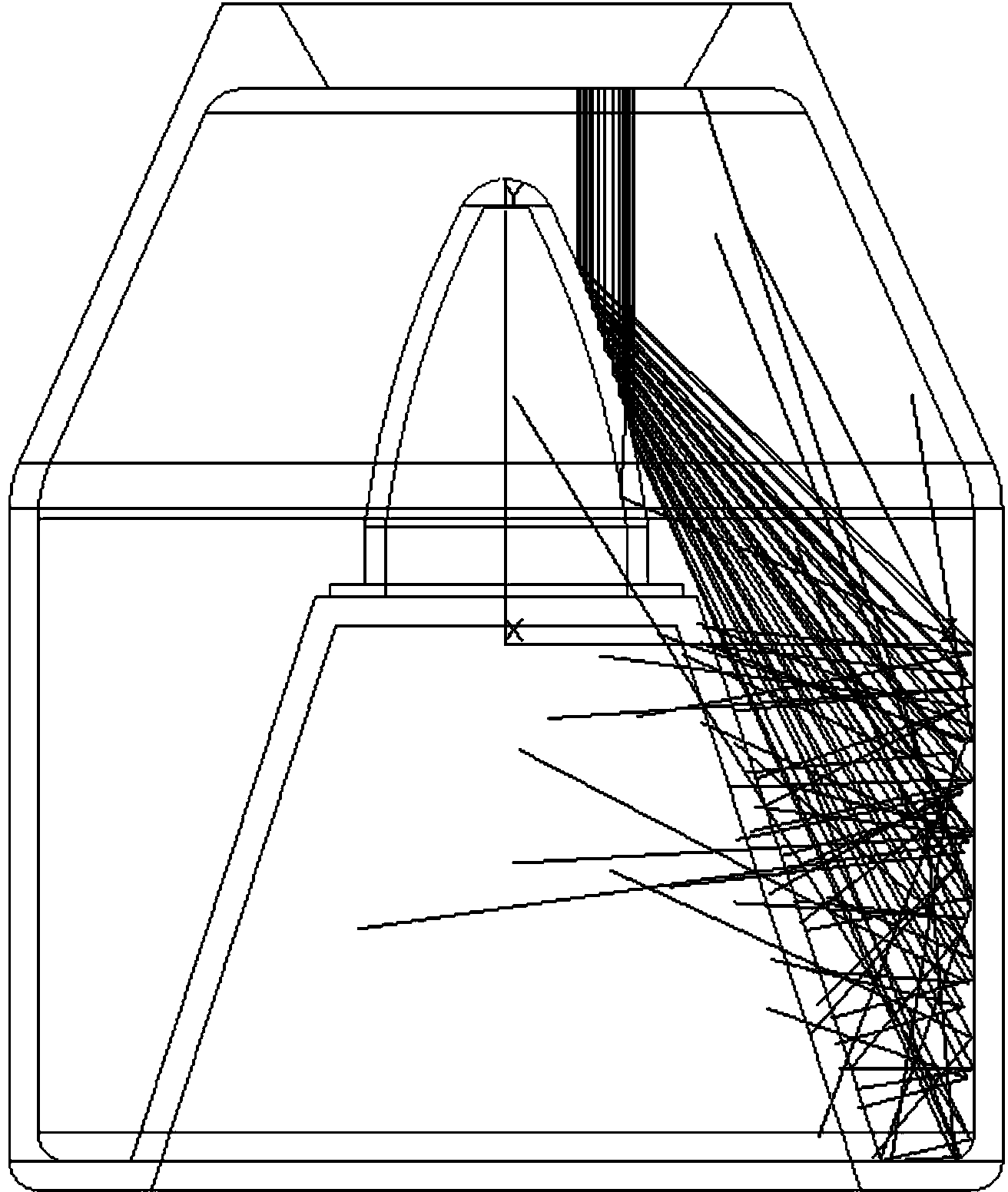

ActiveCN104048755AReduce laser power densityIncrease light receiving areaPhotometryLaser power densityCollimated light

The invention disclose a total absorption superlaser energy meter which comprises a reflection cone and an absorption cavity, wherein the generatrix of the reflection cone is arc-shaped, the absorption cavity is formed by sealed connection of a base plate, an inner lateral plate, an absorption cylinder and a cover plate, the whole structure of the absorption cavity is concave, the wall of the absorption cylinder is arranged on the light path of a superlaser beam after the superlaser beam is reflected through the reflection cone, and the absorption cylinder is located behind the reflection cone in the front and back direction. According to the total absorption superlaser energy meter, the incident collimated light beam is reflected onto the wall of the absorption cylinder in an axial and circumferential two-dimensional beam expansion mode, the power density of laser irradiating on the wall of the absorption cylinder is reduced greatly, the light receiving area of the reflection cone is increased at the same time, and the laser irradiation bearing capacity of the reflection cone is improved; furthermore, due to the adoption of the cavity structure, the probability that the reflection cone is polluted by dust is effectively reduced, and meanwhile, the exit escape rate of laser is reduced and measurement accuracy of the energy meter is improved.

Owner:NORTHWEST INST OF NUCLEAR TECH

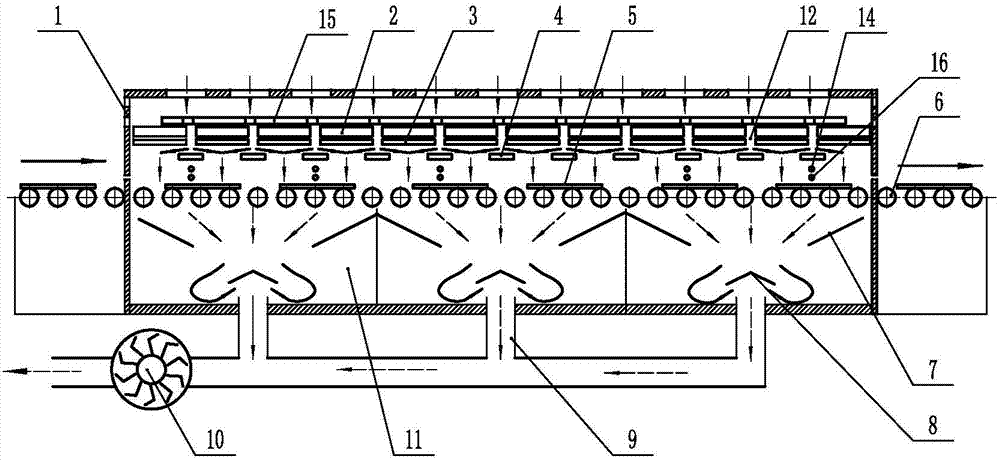

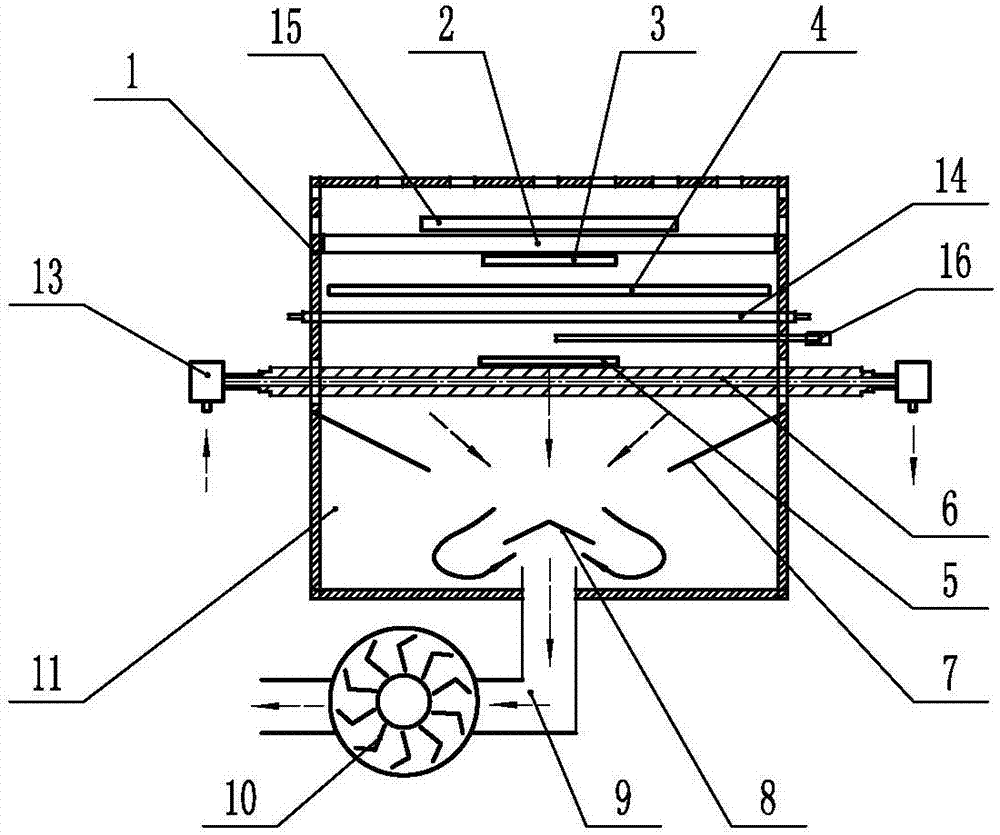

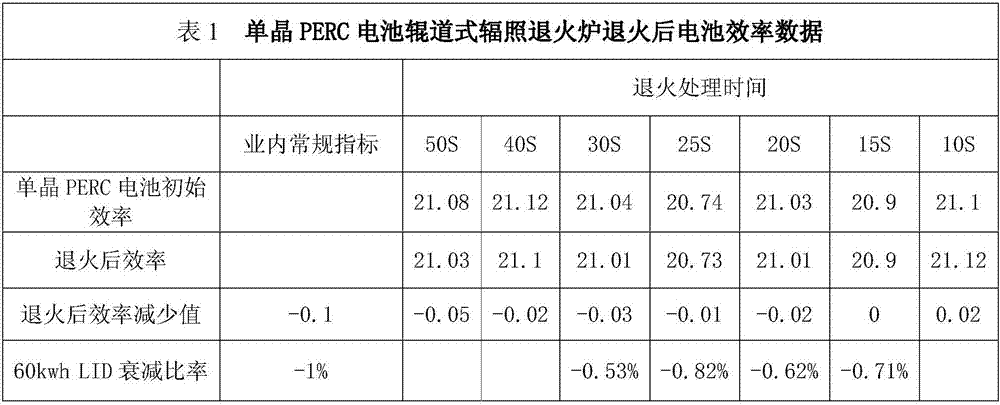

Solar cell irradiation annealing furnace capable of uniformly and efficiently annealing

ActiveCN107146828AUniform temperature controlSame cooling effectFinal product manufacturePhotovoltaic energy generationMetallurgySolar cell

The invention relates to a solar cell irradiation annealing furnace capable of uniformly and efficiently annealing. The solar cell irradiation annealing furnace comprises a furnace body, wherein the furnace body comprises an upper furnace body and a lower furnace body, at least one group of light sources are arranged in the upper furnace body, an air inlet is arranged between two adjacent groups of light sources or between the light sources and an upper furnace body framework, a diversion plate is arranged below the corresponding air inlet, a battery piece transmission device is arranged in the lower furnace body, a battery piece is horizontally transmitted in the battery piece transmission device and receives irradiation of the light sources, an air outlet is arranged in the lower furnace body below the battery piece and is externally connected with an air suction device, a temperature sensor is arranged in the furnace body, and the light sources, the battery piece transmission device, the air suction device and the temperature sensor are connected with a controller. The solar cell irradiation annealing furnace is simple in structure and reasonable in design, the processing temperature of the battery piece can be uniformly controlled, the problem of a non-uniform irradiation processing effect is solved, the irradiation annealing processing can be completed within 30 seconds, moreover, an LID is controlled within 1%, the processing time is shortened, and the annealing effect and the production efficiency are improved.

Owner:BEIJING SOLARRAY TECHNOIOGY CO LTD +1

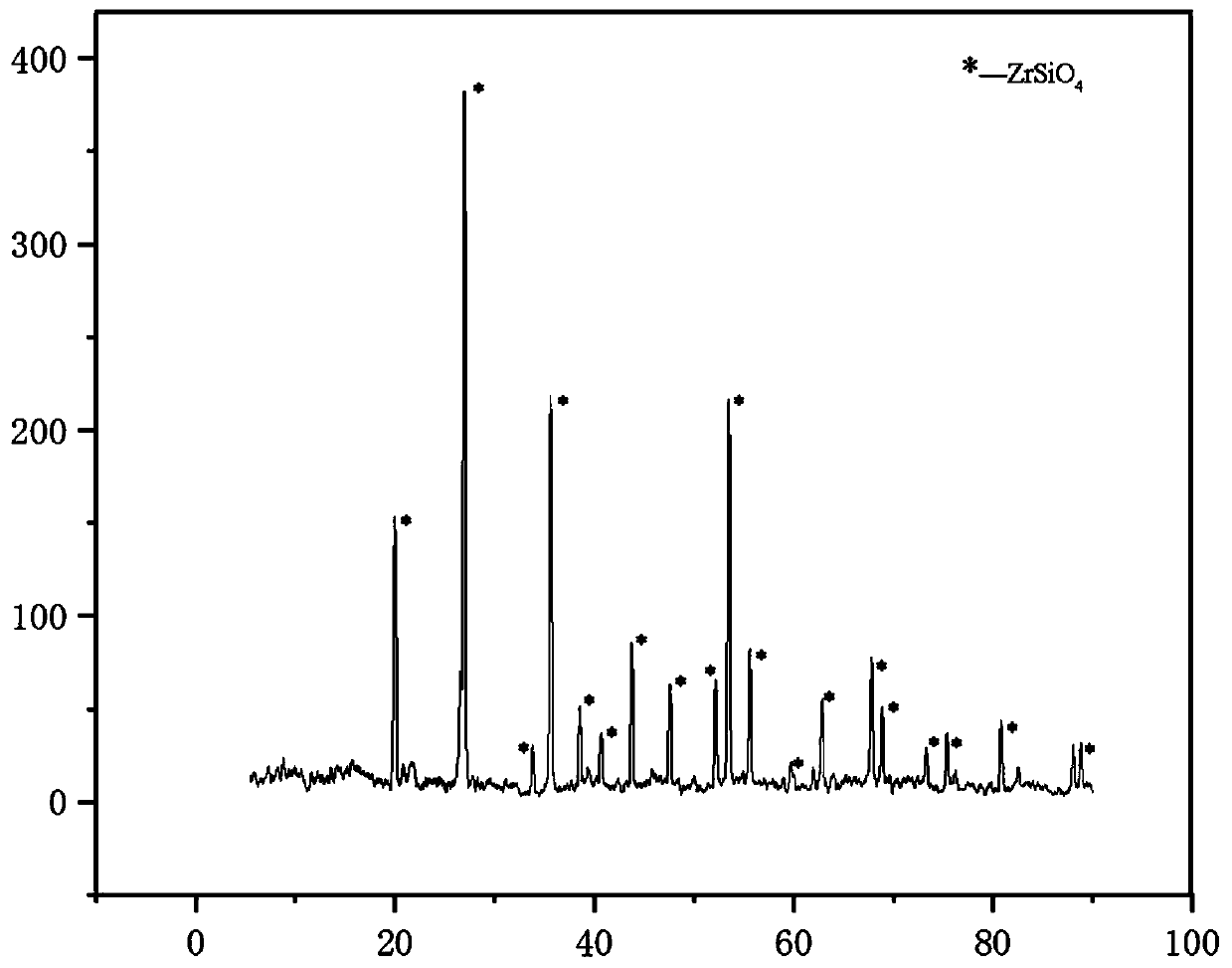

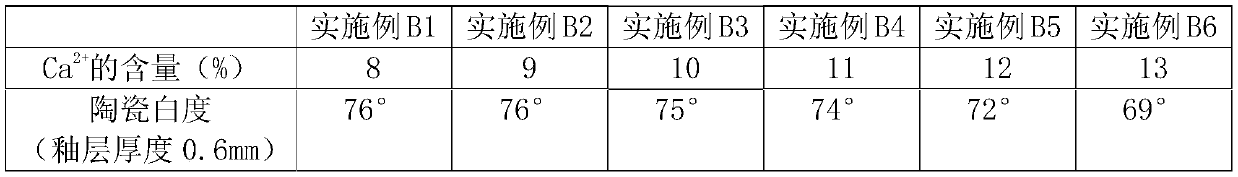

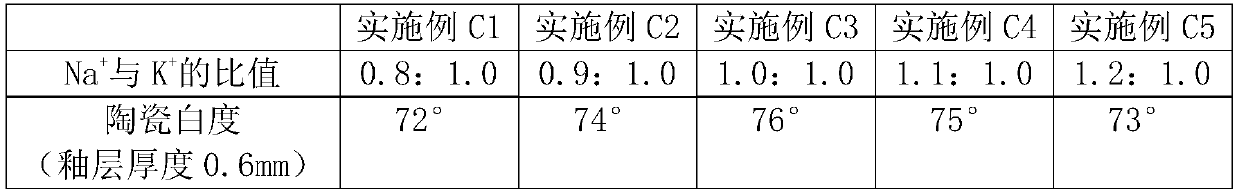

Low-zirconium white glaze for sanitary ceramic and preparation process of low-zirconium white glaze

The invention discloses a low-zirconium white glaze for a sanitary ceramic. The low-zirconium white glaze comprises the following raw materials in percentage by mass: 6.5-7.5% of zirconium silicate, 24-27% of quartz, 5-7% of kaolin, 2.5-3.5% of aluminum oxide, 12-18% of potassium feldspar, 9-15% of albite, 6-8.5% of calcite, 9-13% of wollastonite, 2-5% of dolomite, 2-3.5% of sintered talc, 2-3.5%of zinc oxide and 1.5-4% of frit. The low-zirconium white glaze is prepared by using a preparation process through operation of steps (1)-(3). Under a condition of a low zirconium silicate content, high glossiness, high ceramic whiteness, good high-temperature flowability and low radioactivity of the low-zirconium white glaze can be still maintained, and the low-zirconium white glaze has the effects of high glossiness, high ceramic whiteness, good high-temperature flowability and low radioactivity.

Owner:FOSHAN DONGPENG CERAMIC +3

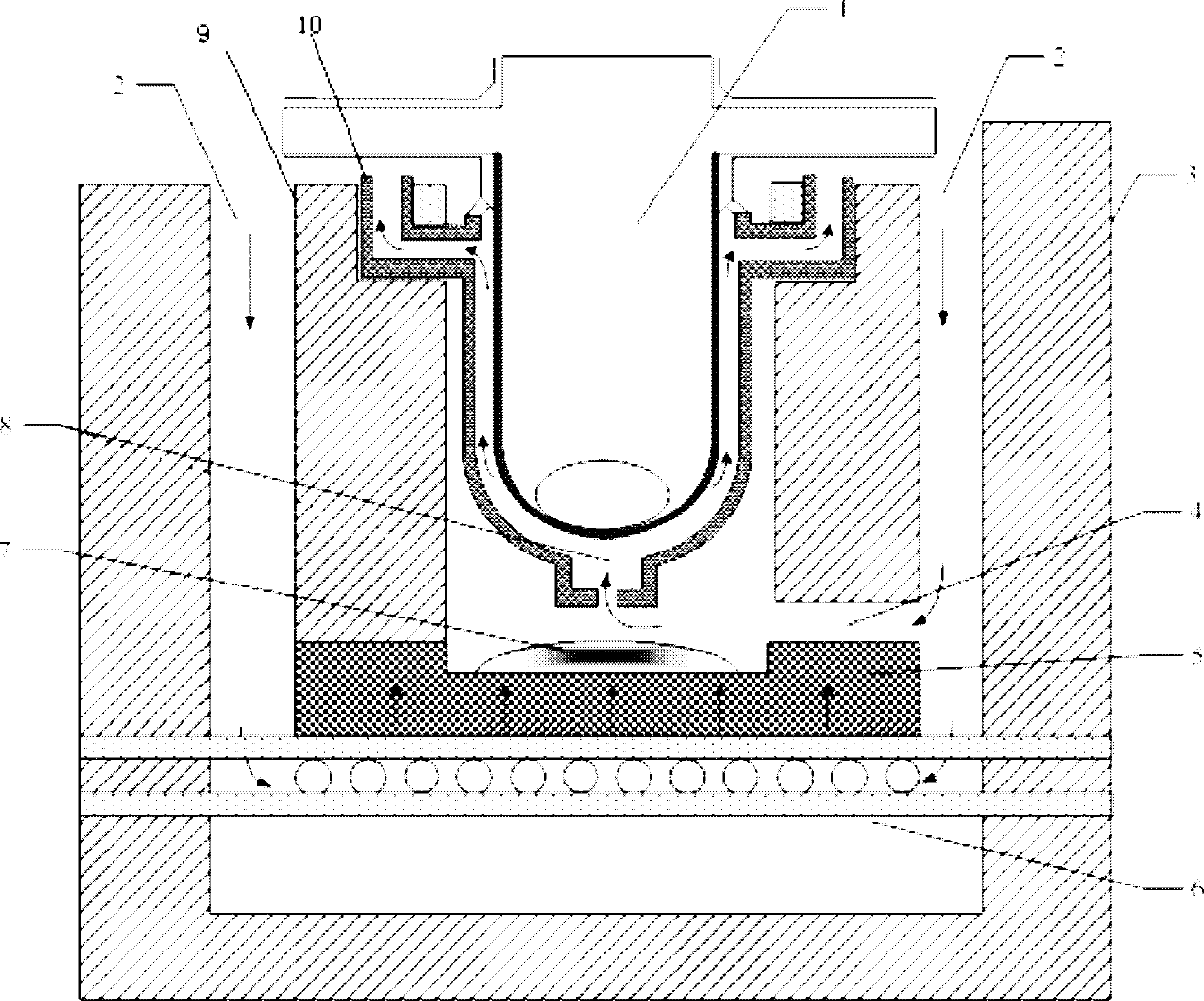

V-shaped reactor external melt retention device used after nuclear power plant accident

ActiveCN103377722AThe decay heat is exported in timeIntegrity guaranteedNuclear energy generationEmergency protection arrangementsNuclear engineeringRefractory

The invention relates to a V-shaped reactor external melt retention device used after a nuclear power plant accident. The V-shaped reactor external melt retention device comprises an inner wall, a steam channel wall fixed at an opening in the bottom of the inner side of the inner wall, a pressure container arranged in the steam channel wall, an outer wall surrounding the inner wall, a reactor core melt retention device fixed at the bottom of the inner wall and a reactor core melt cooling device which is in tight contact with the bottom of the reactor core melt retention device, wherein a coolant descending channel is formed between the inner wall and the outer wall; a coolant channel is formed between the inner wall and the reactor core melt retention device; a reactor core melt retention groove is formed in the upper surface of the reactor core melt retention device under the pressure container; the lower surface of the reactor core melt retention device is a plane; the reactor core melt retention device is made of an inorganic non-metal fireproof material. By adopting a melt retention design outside a reactor, melts are accommodated by different materials and are cooled by a coolant loop and the reactor core melt cooling device, and therefore, the safety of a nuclear power plant.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Quartz tailings heat-insulating building block and preparation method thereof

ActiveCN105294017AMeet the technical requirements for sand useImprove qualityRadioactive agentFilling materials

The invention relates to the technical field of quartz tailings applied to building materials and especially relates to a quartz tailings heat-insulating building block and a preparation method thereof. The heat-insulating building block is prepared by combining a hollow block with a filling material; the raw materials of the hollow block and the filling material both comprise quartz tailings powder; the quartz tailings powder is formed by grinding the quartz tailings into fine powder, wherein the fineness is subjected to the screening treatment by adopting a square hole sieve with the size of aperture being 45mu m and the weight of screen residue is 10%; the content of silicon dioxide in the quartz tailings is 70%; the limitation of the raw material ingredients in the hollow block and the filling material is adopted, so that all the raw materials are interacted, especially, the synergic effect between the quartz tailings and the quick lime, the aluminum powder or cement is achieved; the content of the radioactive substance in the raw materials is reduced, so that the radioactivity is reduced and the quality of the heat-insulating building block is increased.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +2

Soil heavy mental absorbing agent

InactiveCN106345431ALow costImprove water absorptionOther chemical processesContaminated soil reclamationAluminateSorbent

The invention provides a soil heavy mental absorbing agent. The soil heavy mental absorbing agent comprises, by weight, 12-15 parts of peats, 2-6 parts of natural humus, 13-17 parts of lignin, 1-3 parts of chitin, 1-5 parts of zeolite, 3-8 parts of tetrabutyl titanate, 5-12 parts of silica solution, 6-8 parts of calcium aluminate, 3-7 parts of volcanic, 6-9 parts of polyamide 6 (PA6) powder, 1-3 parts of gelatin, 2-4 parts of ammonium hydrogen carbonate and 3-45 parts of inorganic minerals. Compared with the prior art, the soil heavy mental absorbing agent has the advantages that the soil heavy mental absorbing agent is low in cost, convenient in raw material obtaining and suitable for being popularized and applied widely in development of green and pollution-free agricultural product industries; due to high chitin molecular weight, the soil heavy mental absorbing agent is strong in absorbing ability and suitable for being applied in the manufacturing industry and the environmental protection field; in addition, the chitin has a natural anti-bacteria effect, so that the soil heavy mental absorbing agent is high in broad-spectrum antibacterial rate.

Owner:夏百庆

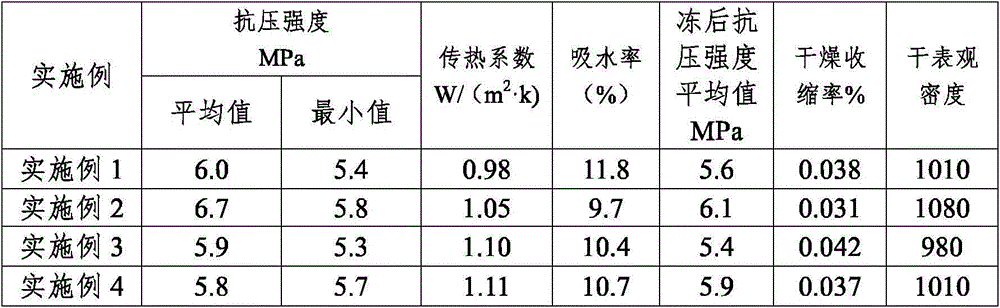

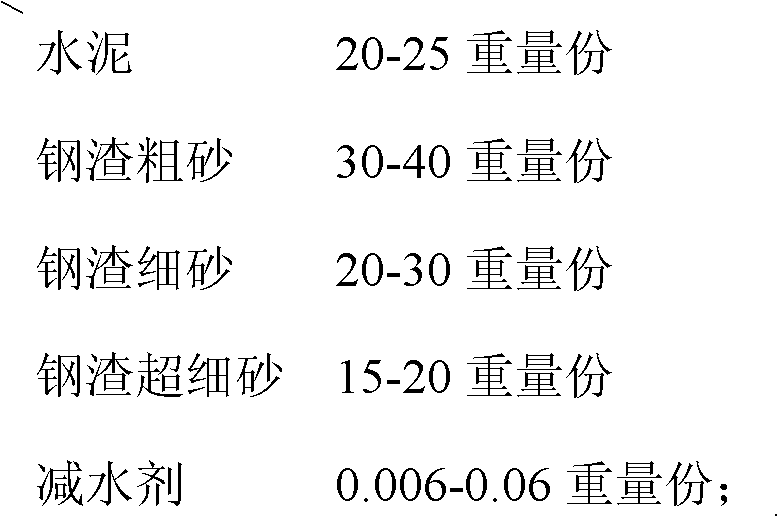

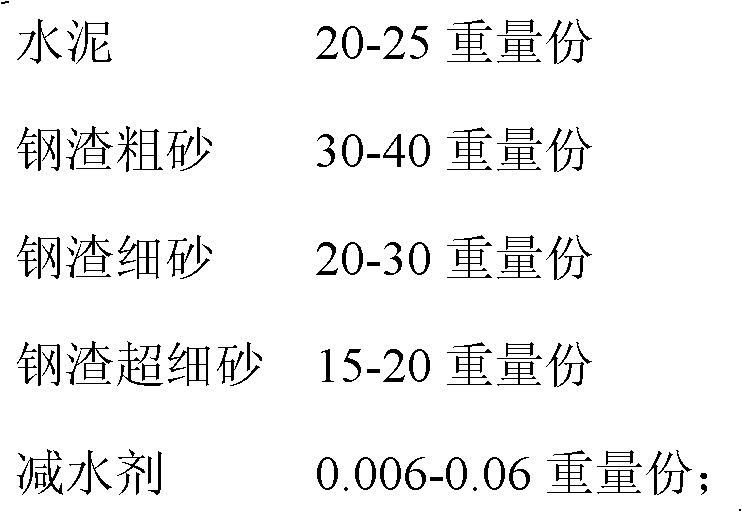

Cement-based steel slag granite product and preparation method thereof

ActiveCN102701645AImprove surface wear resistanceImprove flexural strengthSolid waste managementPolyesterSlag

The invention provides a cement-based steel slag granite product which comprises the following raw material components of cement, steel slag coarse sand, steel slag fine sand, steel slag ultrafine sand, a water reducer and water, wherein the weight ratios of the cement, steel slag coarse sand, steel slag fine sand, steel slag ultrafine sand, and the water reducer are that: 20-25 parts by weight of cement, 30-40 parts by weight of steel slag coarse sand, 20-30 parts by weight of steel slag fine sand, 15-20 parts by weight of steel slag ultrafine sand, and 0.006-0.06 parts by weight of water reducers; the weight ratio of water and cement is 0.20-0.35:1; the cement-based steel slag granite product has dry-state compression strength of more than 130 MPa, and abradability of more than 5*10<-3> g / cm2. The product of the invention greatly improves surface wear resistance and mechanical properties of cement-type artificial marble, overcomes the disadvantage of poor weatherability of polyester-type steel slag artificial marble, and further improves the added value of steel slag solid wastes.

Owner:MCC BAOSTEEL TECH SERVICE +1

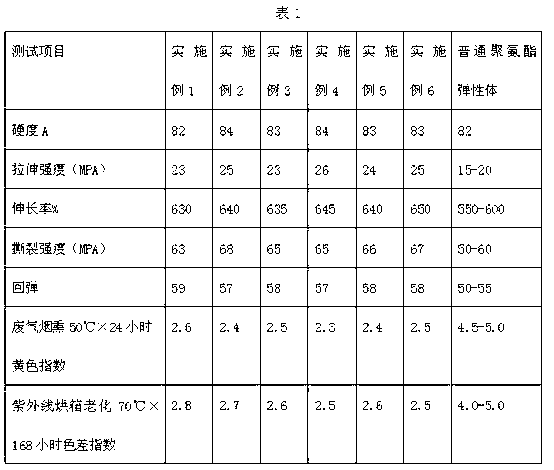

Yellowing-resistant and uvioresistant polyurethane elastomer and preparation method thereof

InactiveCN103275300AOvercome adverse effects on physical and mechanical propertiesPromote absorption and transformationPolymer sciencePropanoic acid

The invention discloses a yellowing-resistant and uvioresistant polyurethane elastomer and a preparation method thereof. The yellowing-resistant and uvioresistant polyurethane elastomer is prepared from a component A and a component B, wherein the component A comprises 60-70% of polyether polyol, 20-35% of toluene diisocyanate and 1-2% of (bi[beta(3-tert-butyl-5-methyl-4-hydroxylphenyl)]propanoyl) as an antioxidant; and the component B comprises 65-80% of polyether polyol, 12-30% of diethyl methyl benzene diamine as a curing agent, 0.05-1% of triethylene diamine dipropylene glycol solution as a catalyst and 1-2% of {2-(2'-hydroxyl-3',5'-bi[1,1-dimethylphenyl])-benzotriazole)-5-chloridized benzotriazole} as an anti-aging agent. The yellowing-resistant and uvioresistant polyurethane elastomer can be used for intensely absorbing ultraviolet rays with the wavelength of 270-400nm and has favorable absorption, conversion, reflection and radiation functions for the ultraviolet rays, so that the ultraviolet ray shielding property and the efficient anti-aging and yellowing resistance of a polyurethane product are improved.

Owner:DONGGUAN JINGLUN IND

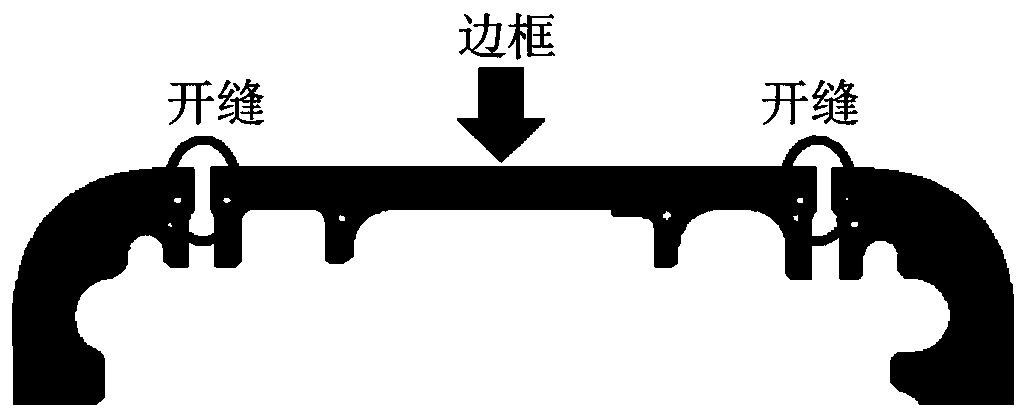

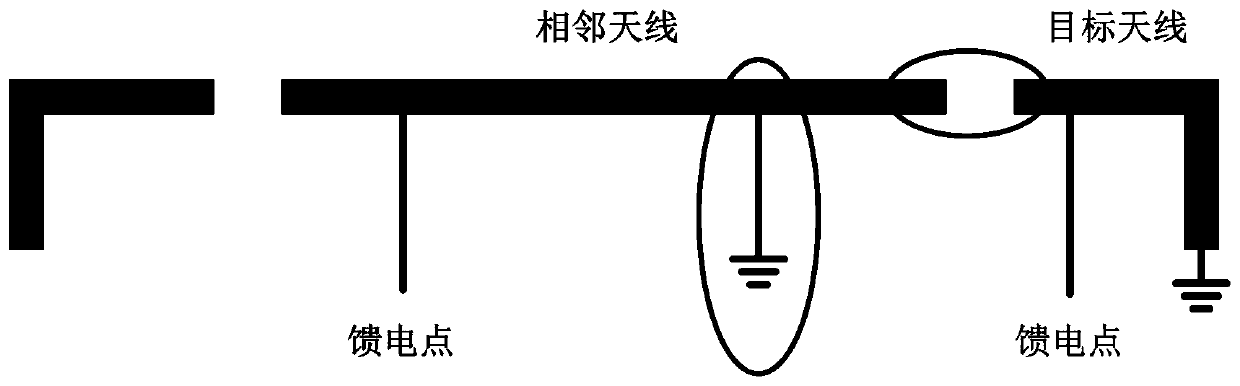

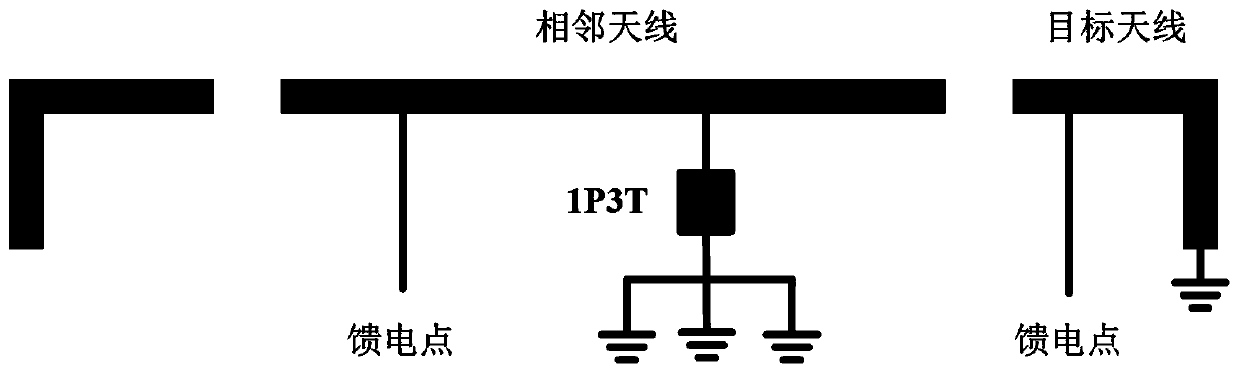

Antenna filtering circuit in electronic terminal, antenna filtering method and electronic terminal

ActiveCN110380236AImprove isolationImprove radiation effectAntenna supports/mountingsRadiating elements structural formsCoupling effectFilter methods

The invention provides an antenna filtering circuit in an electronic terminal, an antenna filtering method and an electronic terminal. A metal frame of the electronic terminal is divided into at leasttwo parts through at least one slit. Each of the at least two parts is made into an independent antenna, so that at least two antennas are formed. Any one of the at least two antennas is determined as a target antenna. The antenna filtering circuit includes a multi-channel changeover switch and a plurality of filters, wherein a first connection end of the multi-channel changeover switch is connected to a first predetermined position of an antenna adjacent to the target antenna, a second connection end of the multi-channel changeover switch can be connected to first ends of the different filters, and a second end of each filter is grounded. By adopting the antenna filter circuit in an electronic terminal, the antenna filtering method and the electronic terminal in the exemplary embodimentof the invention, the isolation degree between adjacent antennas can be increased, the mutual coupling effect between adjacent antennas can be reduced, and the overall radiation performance of antennas can be improved.

Owner:SAMSUNG GUANGZHOU MOBILE R&D CENT +1

Health care putty powder

The invention relates to health-care lacquer putty powder, which is characterized in that the health-care lacquer putty powder is prepared from the following raw materials in portion by weight: 60 to 65 portions of heavy calcium carbonate powder, 16 to 30 portions of calcium hydroxide powder, 10 to 15 portions of talc powder, 0.5 to 1 portion of methyl cellulose powder, 1 to 2.5 portions of bentonite powder, 0.5 to 1 portion of titanium pigment powder, 3 to 4 portions of vegetable gum tragacanth powder, 2 to 3 portions of sandalwood powder, 1 to 2 portions of honeysuckle flower dry powder, 1 to 2 portions of chrysanthemum flower dry powder, 2 to 3 portions of keel powder and 1 to 2 portions of green bean powder. The health-care lacquer putty powder has the advantages of being nontoxic and harmless, having fresh and clean flavor, strong adhesion, good leveling property, scrubbing resistance, grinding resistance, good weathering resistance and ultraviolet penetration resistance, being favorable for the human health and improving work efficiency, being incapable of coiling the skin, chipping off and fracturing, having no radioactivity, having no influence on the human body, and being capable of effectively protecting the wall body.

Owner:袁显兰

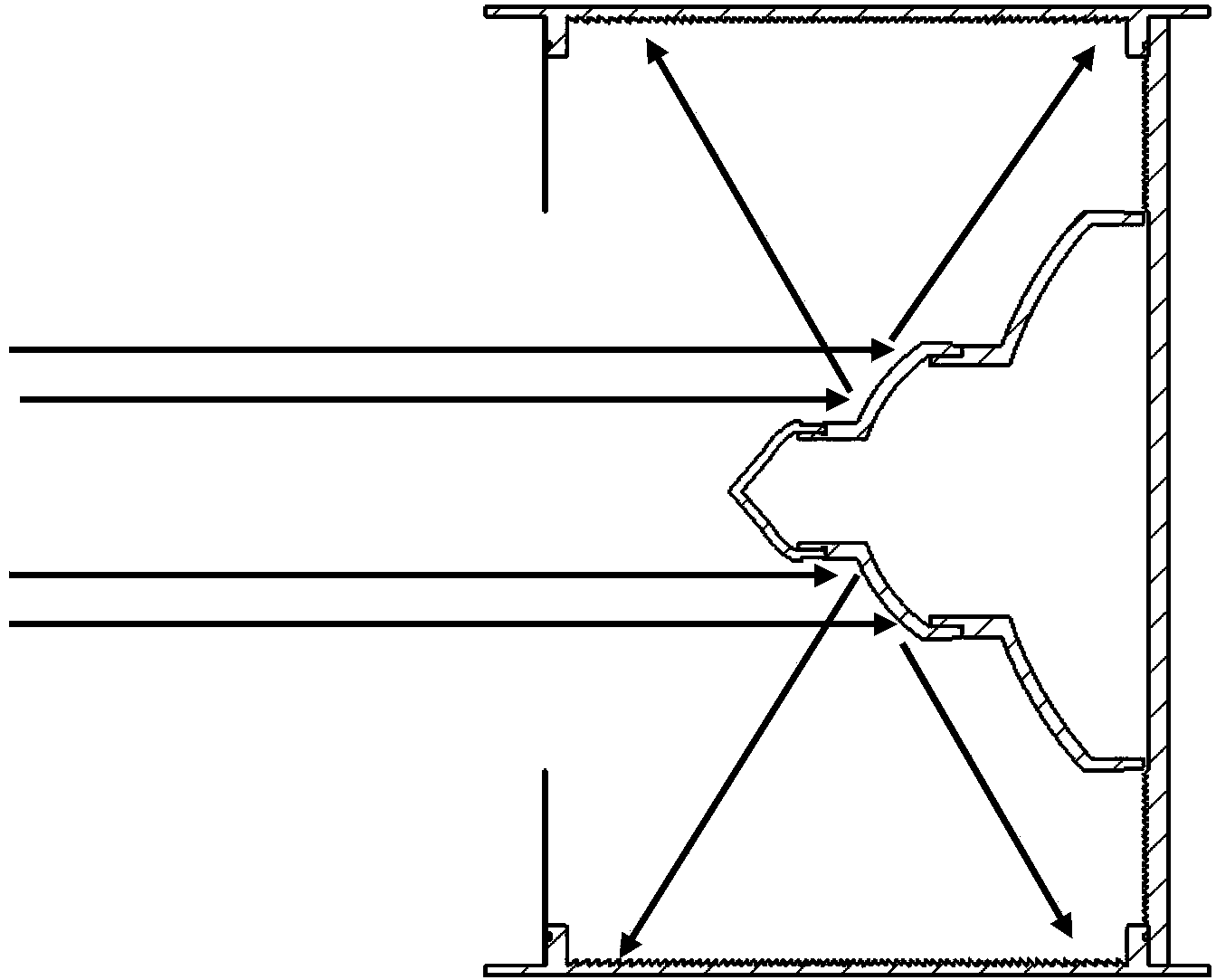

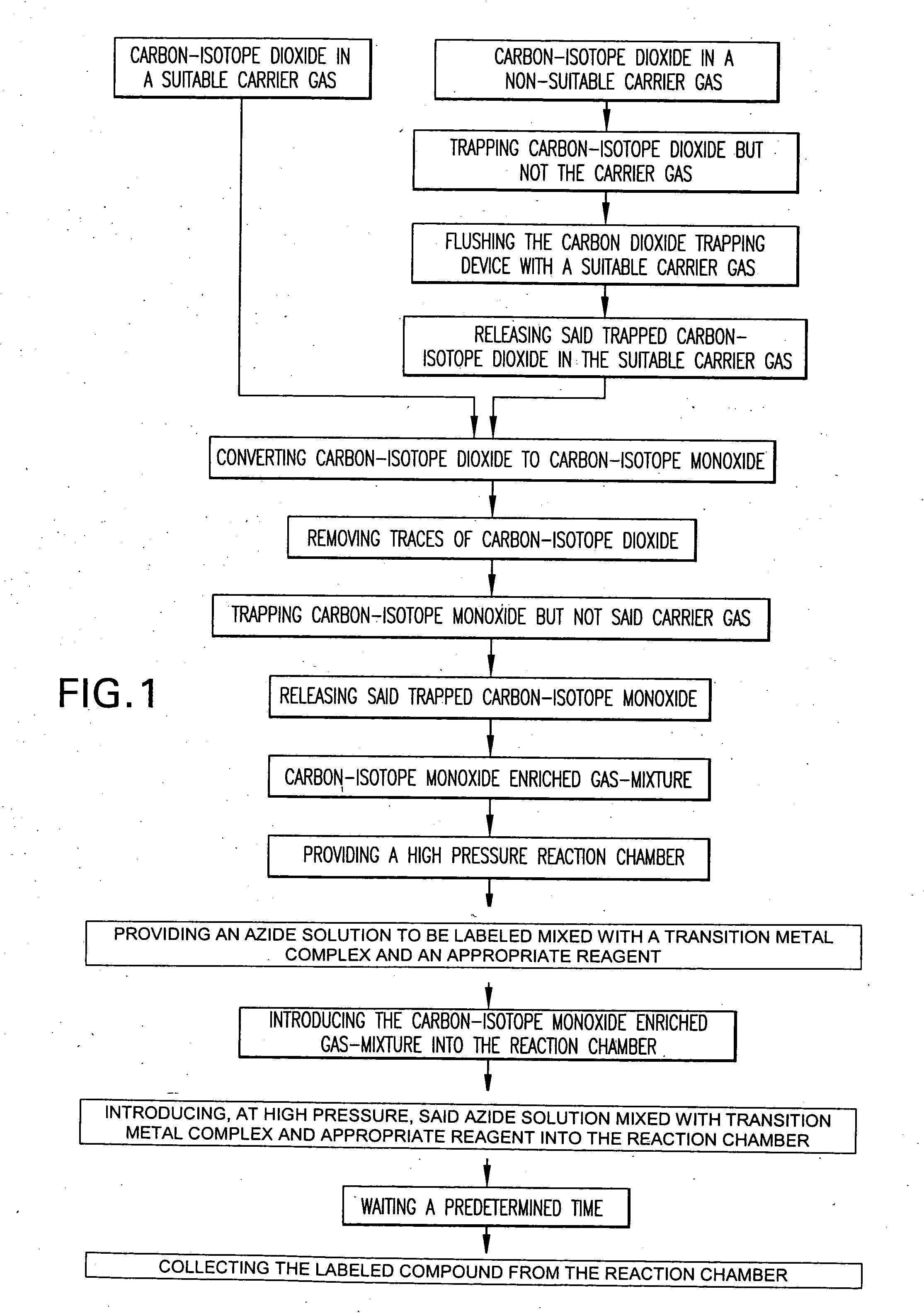

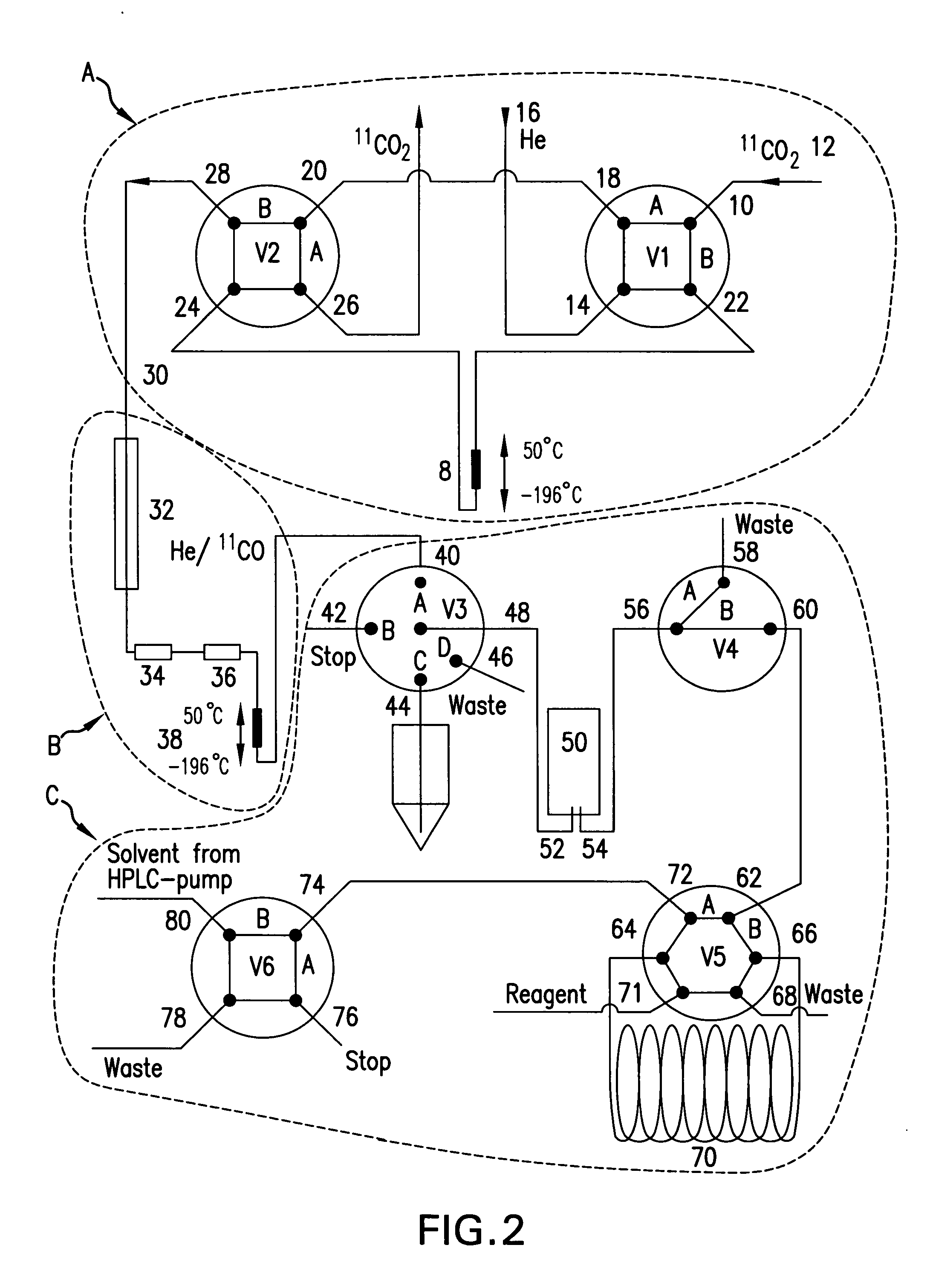

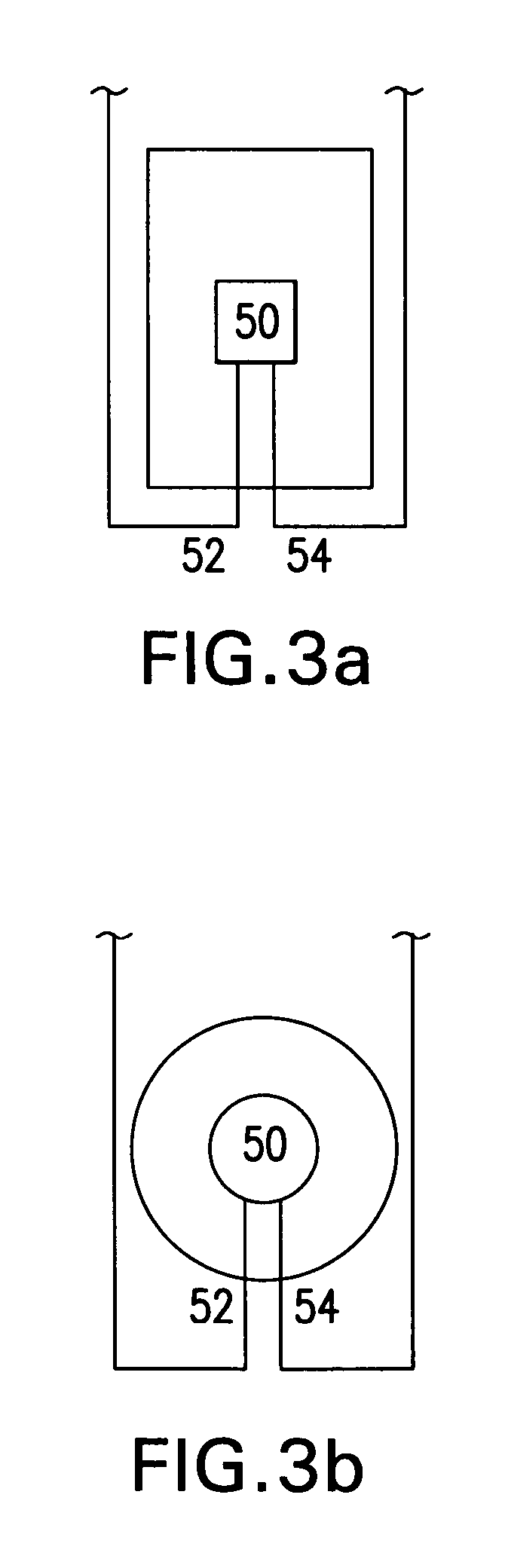

Methods for carbon isotope labeling synthesis by transition metal-promoted carbonylation via isocyanate using azides and carbon-isotope monoxide

InactiveUS20060002851A1Improve radiation effectOvercome limitationsUrea derivatives preparationCarbamic acid derivatives preparationIsotopic labelingIsotope

Methods and reagents for transition metal-promoted carbonylation via isocyanate using carbon-isotope labeled carbon monoxide are provided. The resultant carbon-isotope labeled compounds are useful as radiopharmaceuticals, especially for use in Positron Emission Tomography (PET). Associated kits for PET studies are also provided.

Owner:GE HEALTHCARE LTD

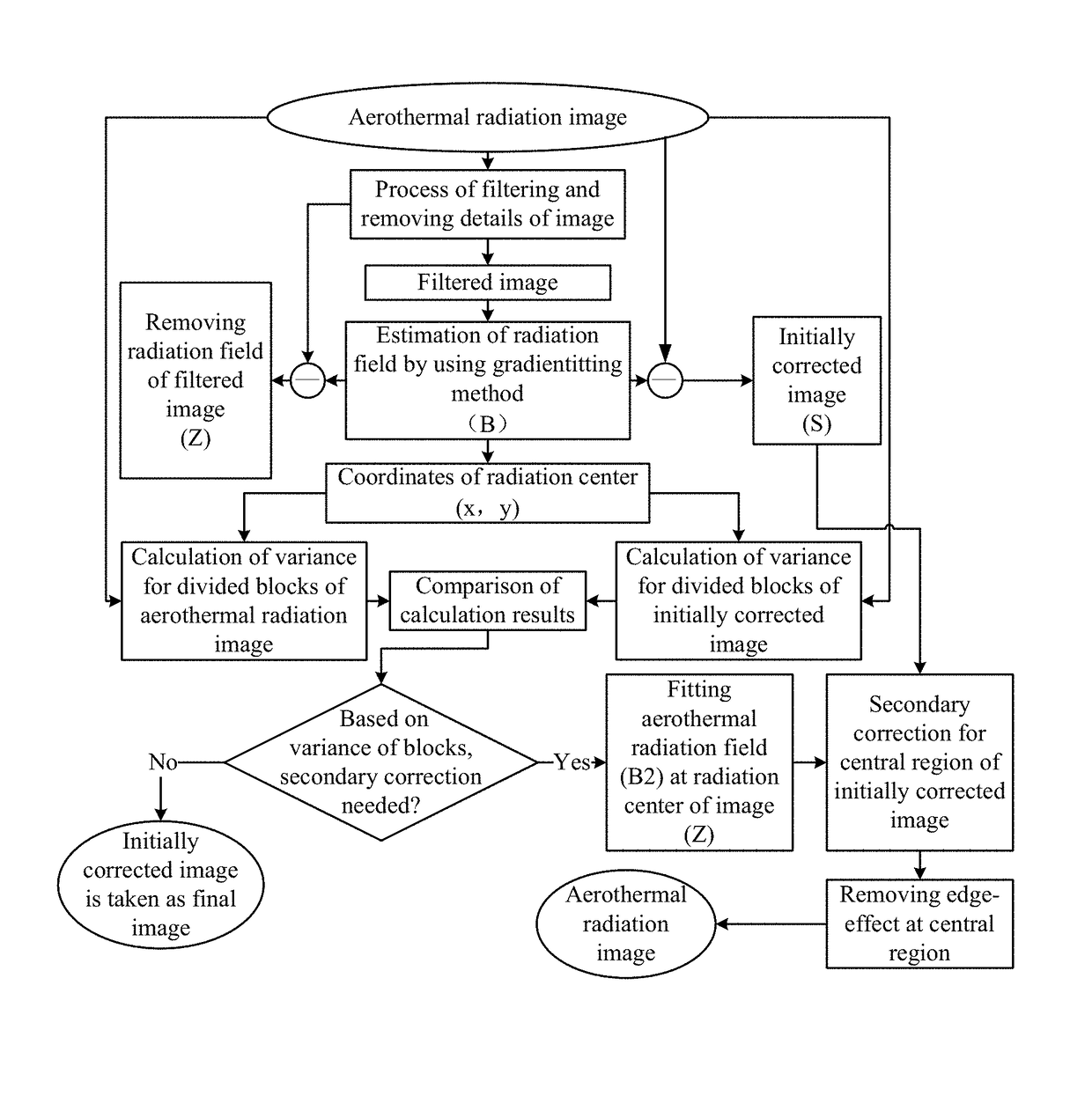

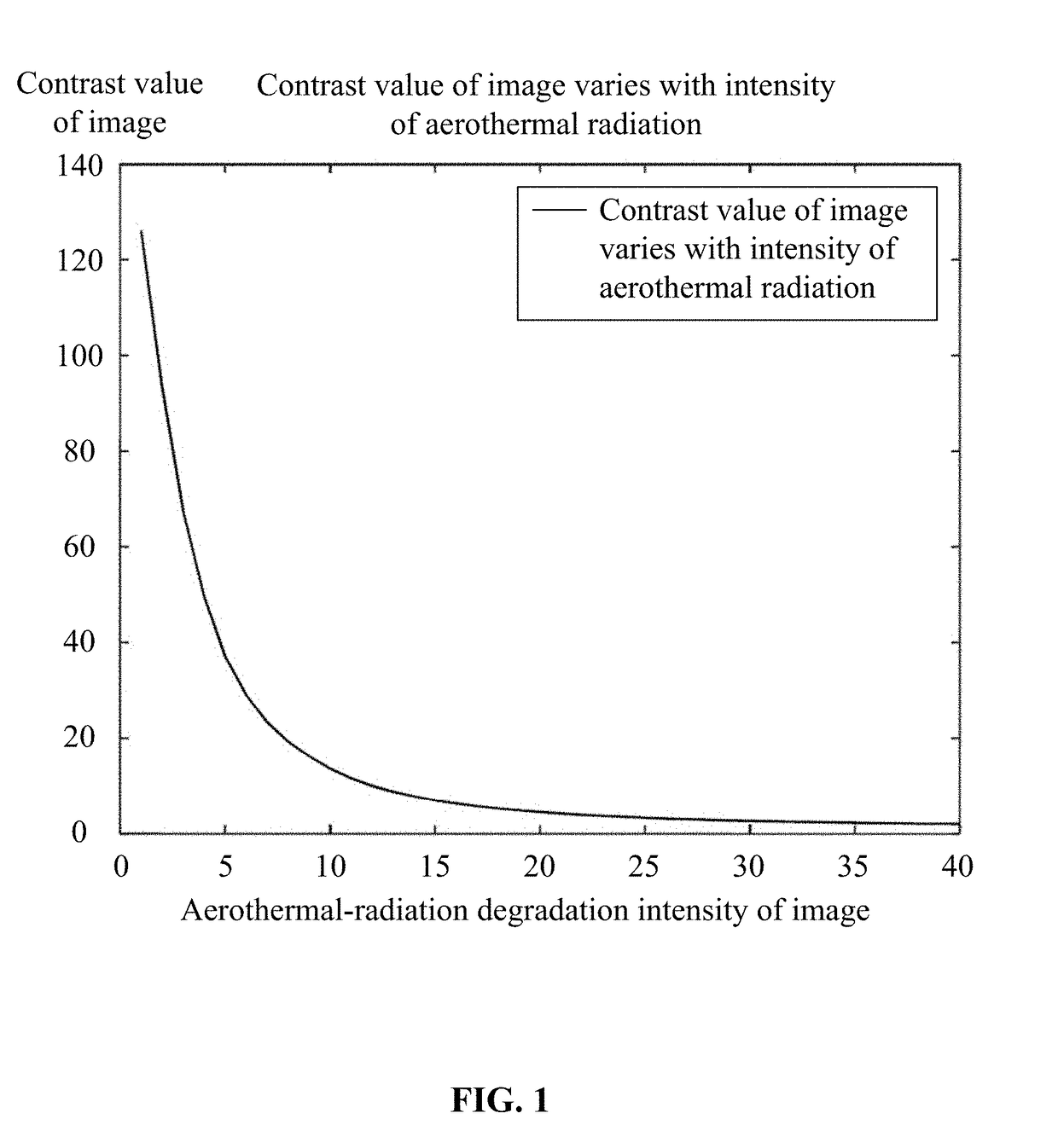

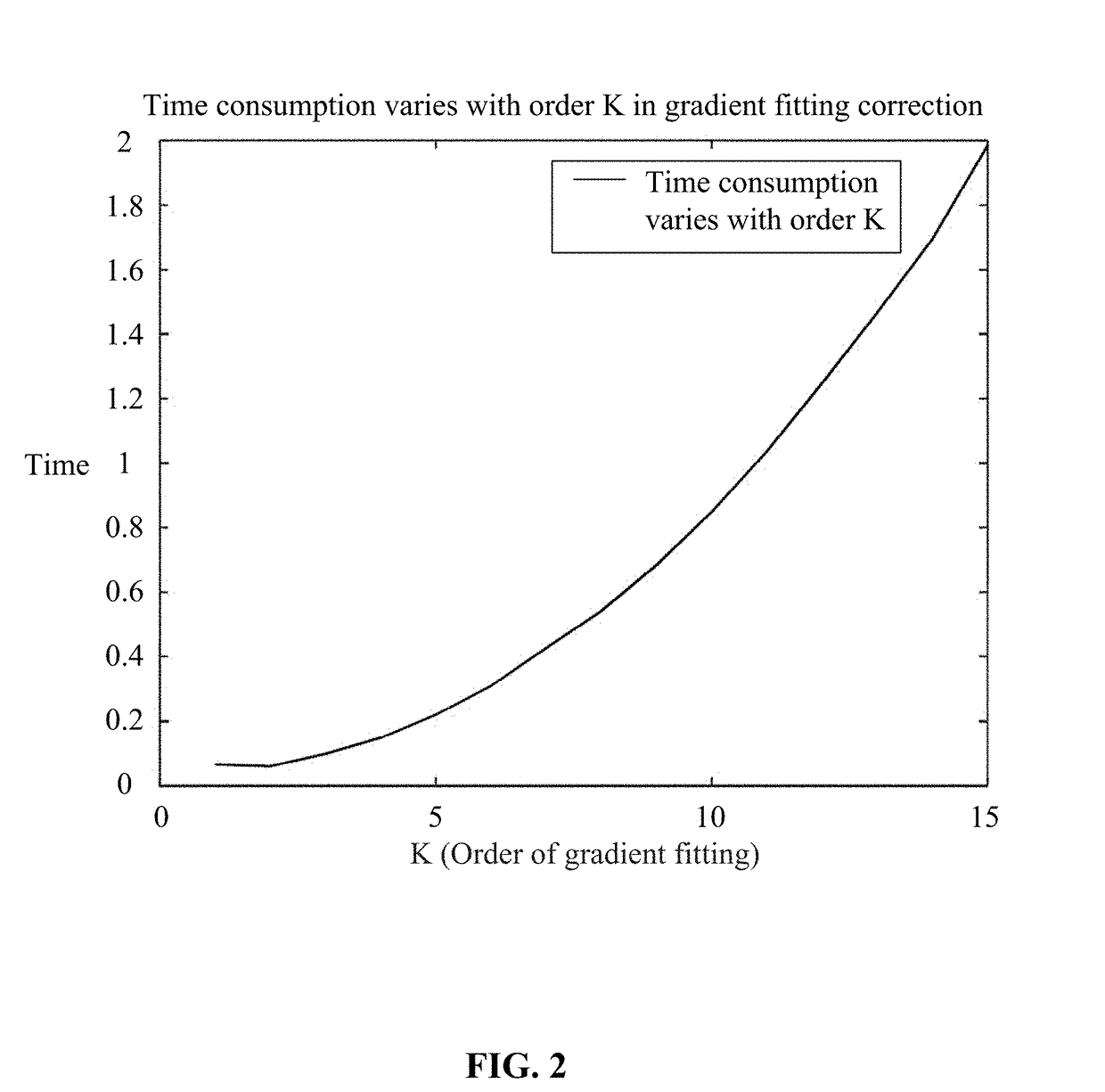

Contrast constrained aerothermal radiation correction method

ActiveUS20180286017A1Quality improvementRaise the ratioImage enhancementImage analysisSignal-to-noise ratio (imaging)Image contrast

Disclosed in the present invention is a contrast constrained aerothermal radiation correction method. By analyzing features of images at different intensities of aerothermal radiation, it has been discovered that the stronger the aerothermal radiation effect is, the smaller the image contrast becomes, and when thermal radiation correction is performed using a gradient fitting algorithm, it has been discovered that time consumption thereof grows exponentially with an increase in a degree of a fitting surface and with an increase in an image size. The present invention can rapidly and effectively restore an aerothermal radiation image, remarkably improving a signal to noise ratio and quality of the image.

Owner:HUAZHONG UNIV OF SCI & TECH

Detection, localization and staging of tumors using labeled activated lymphocytes directed to a tumor specific epitope

InactiveUS20060171883A1Bind more effectivelyGood effectDisease diagnosisRadioactive preparation formsAbnormal tissue growthCell specific

A Disclosed are methods for detecting and localizing a cell-specific antigen in a mammal, such as a human subject, comprising exposing peripheral blood mononuclear cells (PBMCs) of the mammal to an immunogenic peptide epitope of the antigen, under conditions for antigen-specific activation of T lymphocytes in the PBMCs, thereby producing antigen-specific T lymphocytes that at least bind to the cell-specific antigen. Labeled antigen-specific T lymphocytes are administered to the mammal, typically with-out IL-2, either intraperitoneally or intravenously. The distribution of these cells in the mammal is determined by imaging, thereby detecting and localizing cell-specific antigen in the mammal. Exposing PBMCs to the immunogenic peptide typically involves a cell-free peptide preparation and interleukin-2 (IL-2), but no additional cells such as antigen presenting cells (APC) separately pulsed with antigen. The antigen-specific T lymphocytes typically are cytolytic for cells expressing the cell-specific antigen and may comprise CD4+, CD8+, and / or CD45RO+ memory T cells.

Owner:PHILLIPS CATHERINE A DR +1

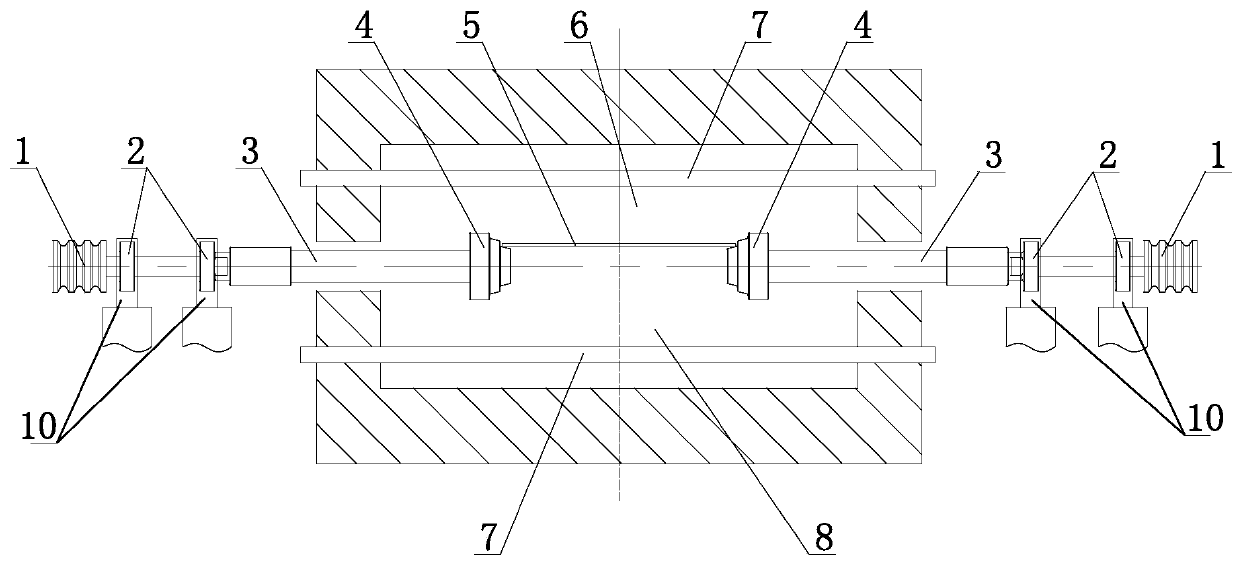

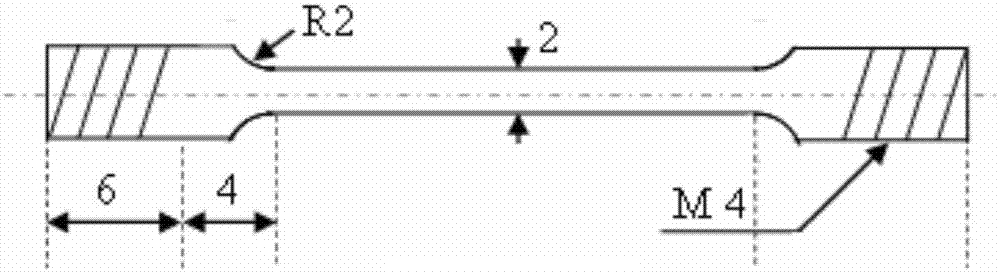

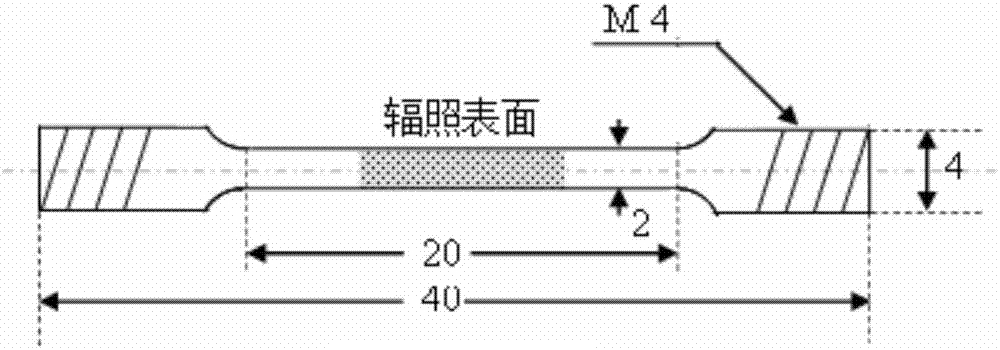

Stress corrosion tensile sample adopting ion irradiation to simulate neutron irradiation and preparation method of stress corrosion tensile sample

PendingCN107462451AUniform exposure to ion irradiationHighlight the effects of radiationPreparing sample for investigationMaterial strength using tensile/compressive forcesNeutron irradiationChemical composition

The invention belongs to the field of the preparation of stress corrosion tensile samples, and particularly relates to a stress corrosion tensile sample adopting ion irradiation to simulate neutron irradiation and a preparation method, which is used for studying stress corrosion sensitivity of an irradiated material so as to evaluate the service performance of the material in a high-temperature high-pressure water environment of a nuclear power plant. The tensile sample comprises parallel portion scale distance section with a rectangular cross section, a tangential transitional arc portion and a threaded connection clamping portion. The preparation method comprises the following steps: (a) preparing a sample unit body; (b) grinding by using abrasive paper; (c) manually polishing; (d) ultrasonically cleaning; (e) pre-observing; and (f) performing EBSD detection. The stress corrosion tensile sample provided by the invention can uniformly receive the ion irradiation, and can effectively enable the influence of the irradiation to be prominent; the preparation method is simple, the practicability is high, and the cost is low; and the preparation method can effectively avoid the change of chemical components on the surface of the sample.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

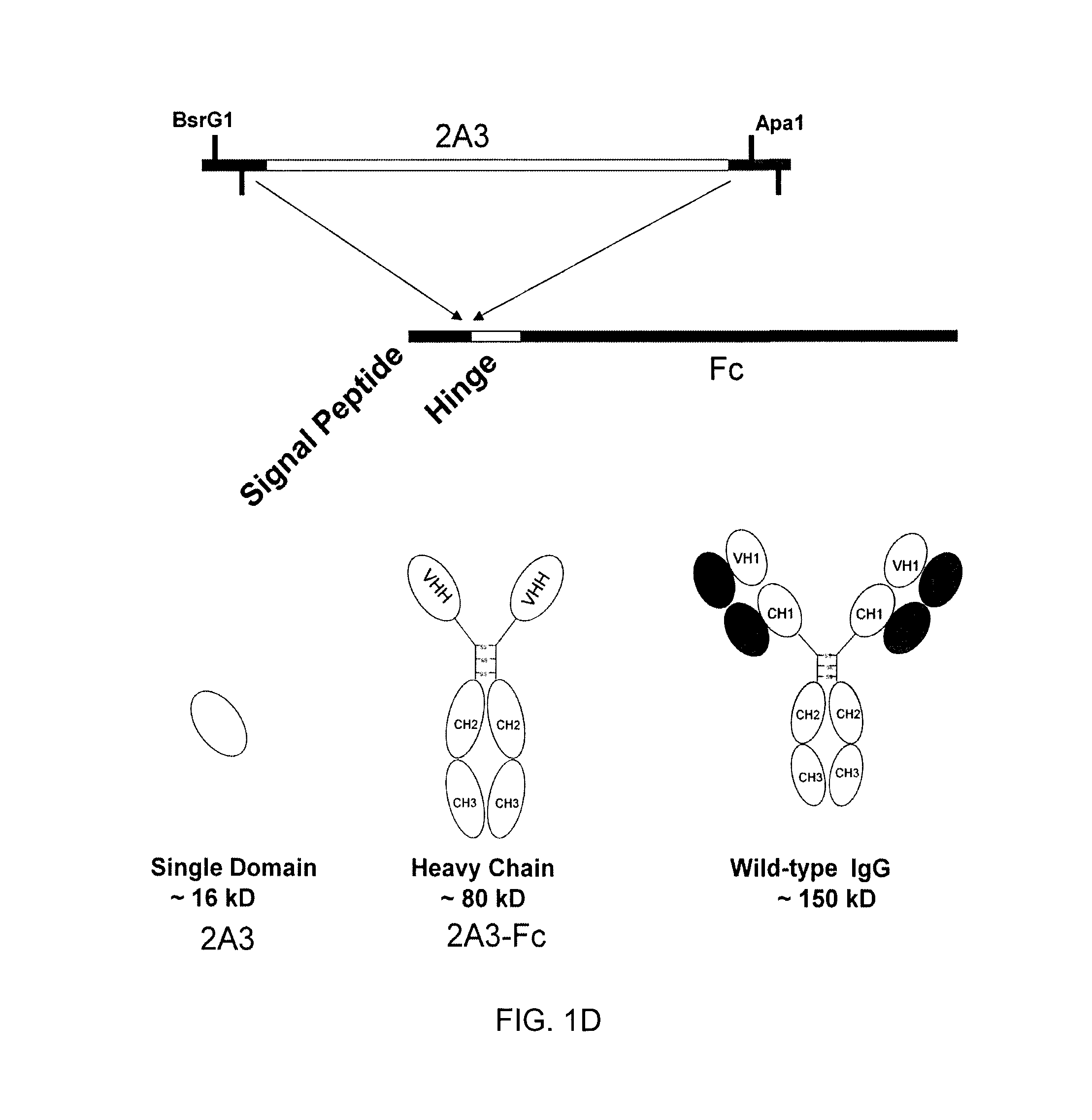

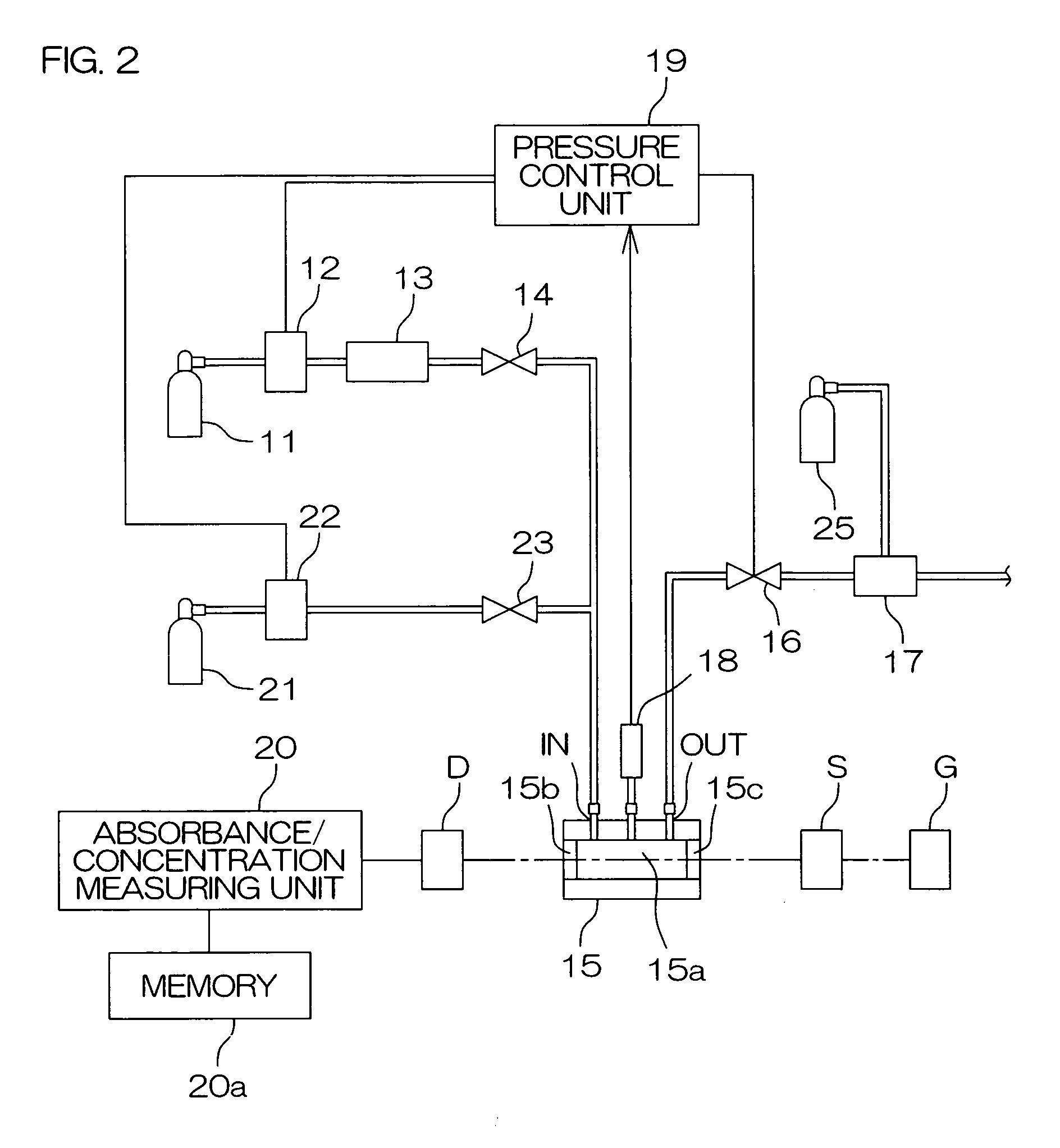

Method for the use of [11C] carbon monoxide in labeling synthesis of 11C-labelled amides using metal amides and photo-induced free radical carbonylation

InactiveUS7553942B2Improve radiation effectOvercome limitationsIsotope introduction to heterocyclic compoundsIn-vivo radioactive preparationsArylIsotopic labeling

Owner:GE HEALTHCARE LTD

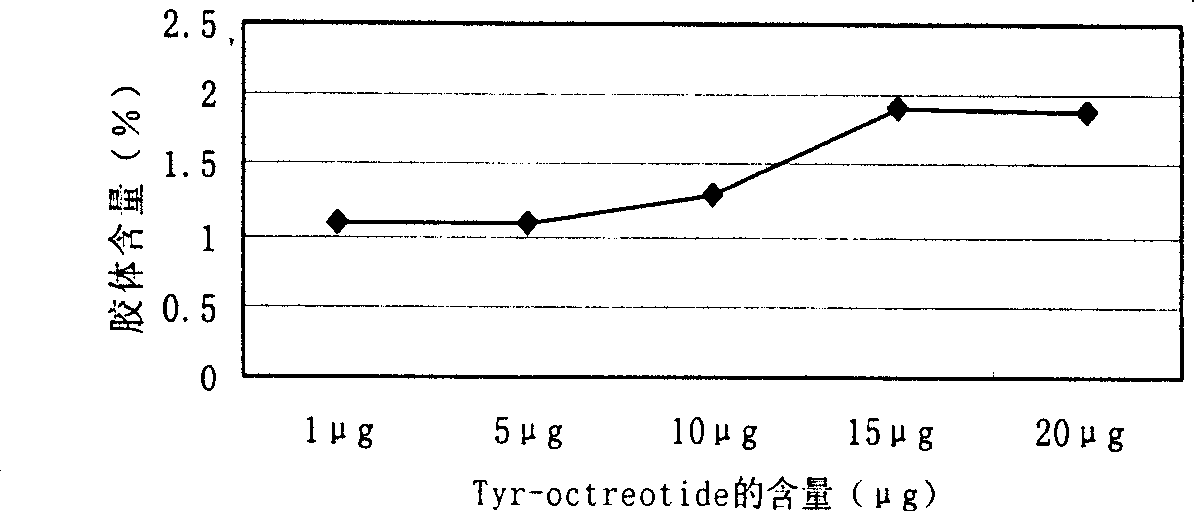

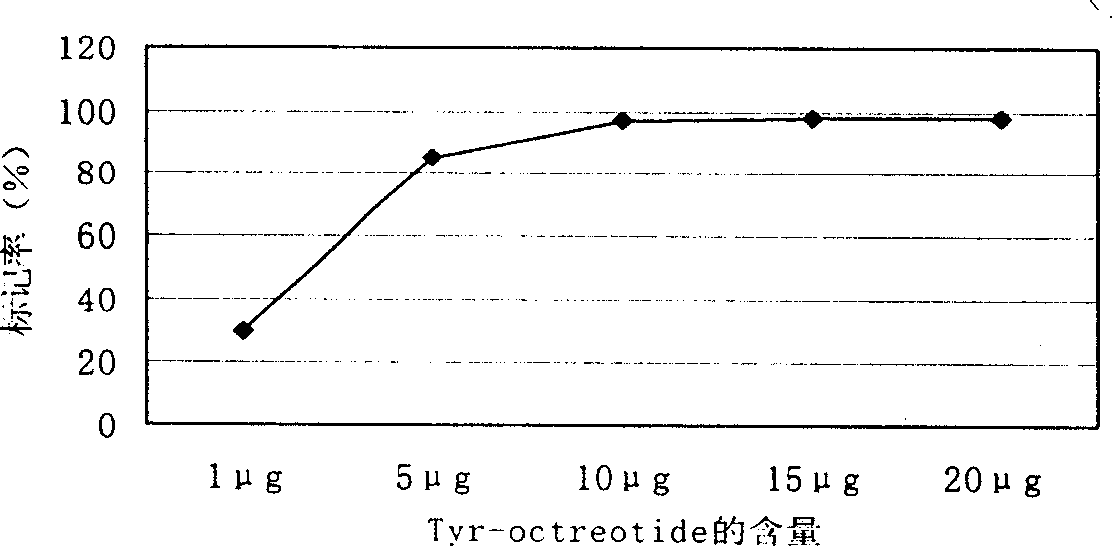

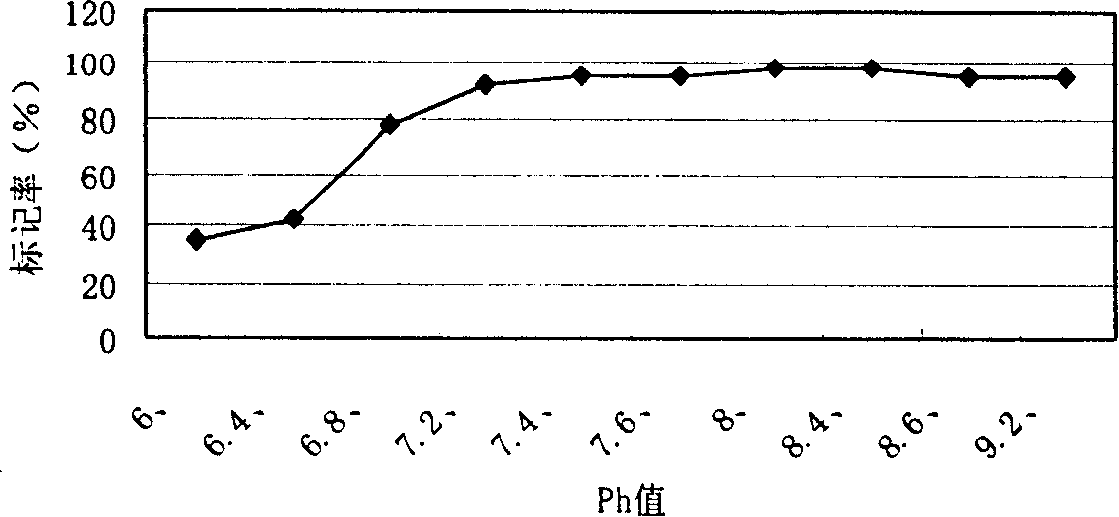

Recombinant octreotide and uses thereof

InactiveCN101182349AQuick clearHigh affinitySugar derivativesPeptide/protein ingredientsAnti-Tumor DrugsIsotope

The invention belongs to the biological engineering field and discloses a recombinant octreotide and an application thereof. Aiming at the problems that the prior octreotide can not realize targeting short-distance irradiation towards tumour cells and can not be applied to the preparation of targeting curative drug, the invention provides a recombinant octreotide, the amino acid sequence of which is shown as SEQ ID NO.2. The recombinant octreotide is in favor of radioactive isotope <131>I marking and can be applied to the preparations of antitumor drug or targeting diagnosis reagent.

Owner:王自正 +4

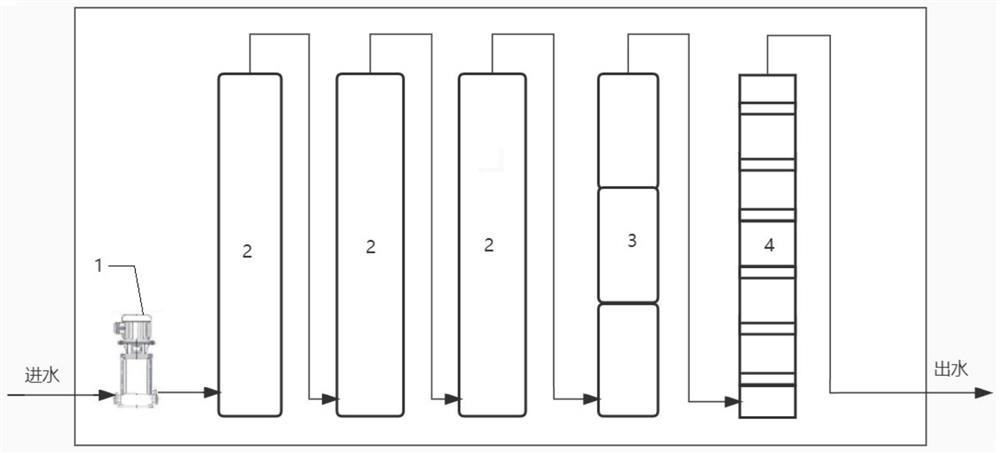

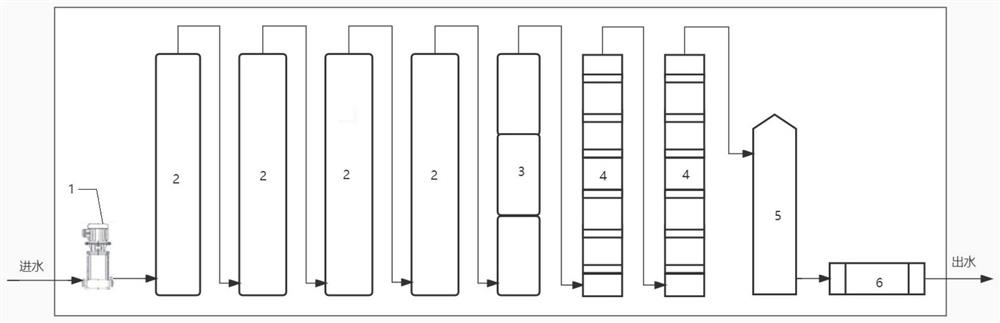

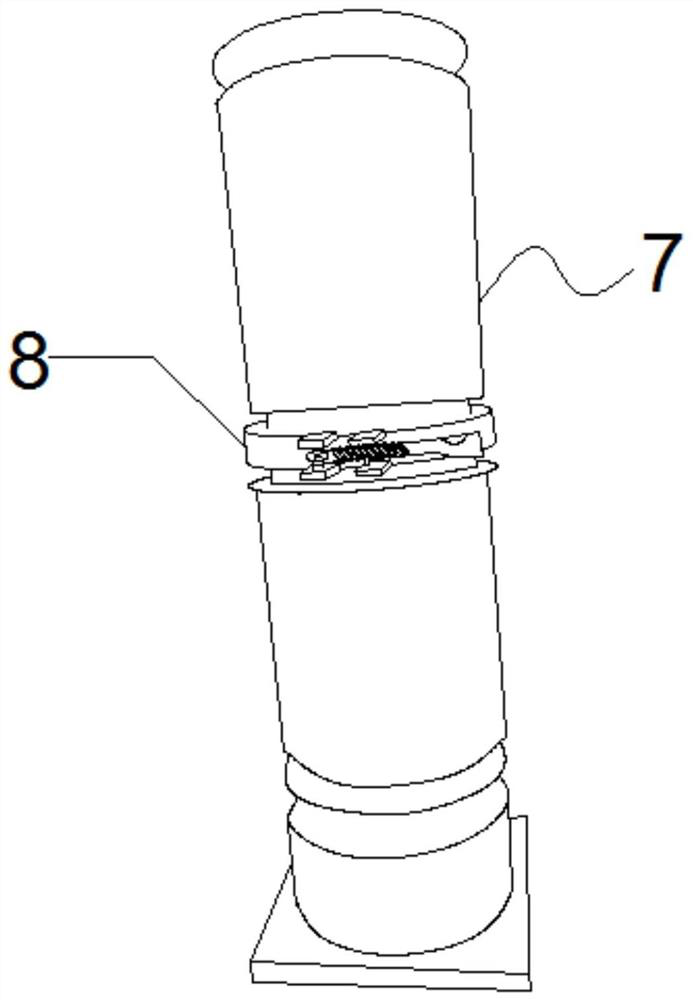

Active hydrogen generator

ActiveCN114315000APreparation highSafe preparationMultistage water/sewage treatmentData displayCeramic

The invention relates to an active hydrogen generator which is provided with a supercharging device, a water activating device, a hydrogen enriching device and an electron releasing device, and the supercharging device, the water activating device, the hydrogen enriching device and the electron releasing device are sequentially connected through a water supply pipe. The water activating device comprises a first filter cartridge, and energy spar and projectile natural ore are arranged in the first filter cartridge; the hydrogen-enriching device comprises a second filter cartridge; a combined multifunctional health-preserving hydrogen-enriching water sheet and a composite medical stone ceramic ball are arranged in the second filter cartridge; the electron release device comprises an inner ribbed tube, and a combined material composed of a composite tourmaline ceramic ball and an electrode metal band is placed in the inner ribbed tube. The active hydrogen generator can prepare a large amount of active hydrogen in a lasting, safe and environment-friendly manner, and third-party detection data shows that the content of the active hydrogen in water treated by the active hydrogen generator reaches 5-8 PPm.

Owner:北京氢润科技有限公司

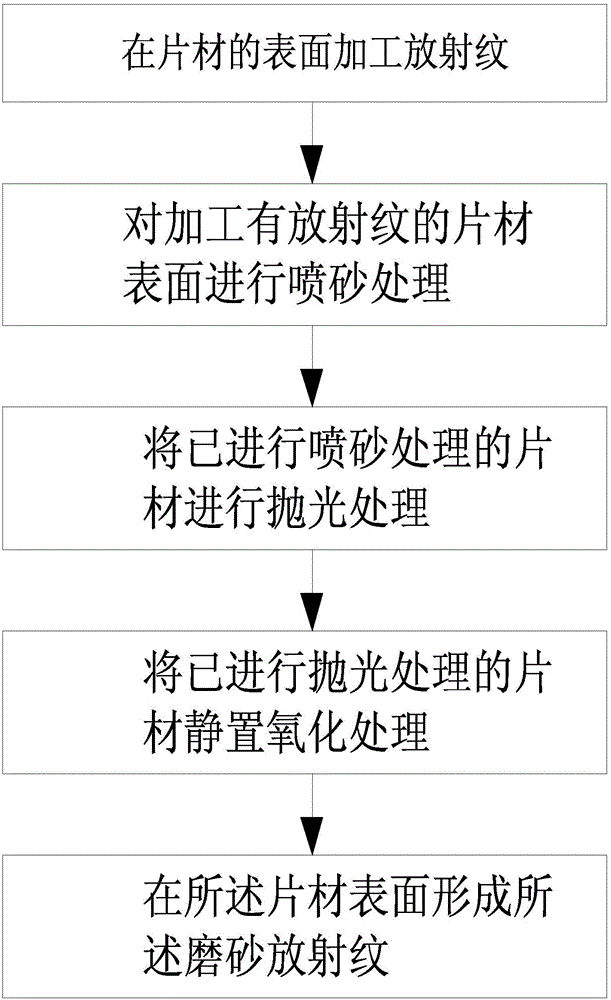

Dull polish radiation grain manufacturing technology and shell of terminal equipment

InactiveCN106364251AEliminate grainImprove appearance decoration effect and yield rateCasings/cabinets/drawers detailsSpecial ornamental structuresEngineeringRadiation

The embodiment of the invention provides a dull polish radiation grain manufacturing technology. Radiation grains are machined on the surface of a sheet; the surface of the sheet with the radiation grains is subject to sand blasting treatment; the sheet subject to sand blasting treatment is polished; the polished sheet is subject to standing oxidation treatment; dull polish radiation grains are formed on the surface of the sheet; the embodiment of the invention further provides a shell of terminal equipment. In conclusion, the grain effect that the radiation grains and dull polish are overlapped is formed, the decoration effect is novel and unique, and the texture decoration can be effectively improved; the dull polish radiation grains are good in vision effect and soft in reflected light, the grains have the regularity and smooth hand feeling, and use experience of a user is effectively improved; particularly, the grains manufactured through the manufacturing technology are applied to the metal shell of a terminal, and the use effect of the grains is more prominent; meanwhile, the technology is simple in step and short in manufacturing procedure, and the production efficiency is effectively improved.

Owner:VIVO MOBILE COMM CO LTD

Anti-ceacam6 antibodies and uses thereof

ActiveUS20130272958A1Reduced activityReduce invasionImmunoglobulin superfamilySugar derivativesLinear epitopeIn vivo

The present invention relates to isolated or purified antibodies or fragments thereof specific for CEACAM6 and their use as therapeutic or diagnostic tools. Specifically, the present invention is directed to antibodies or fragments thereof specific for a linear epitope of CEACAM6. In vivo and in vitro methods of diagnosis as well as therapeutic methods are also described.

Owner:NAT RES COUNCIL OF CANADA

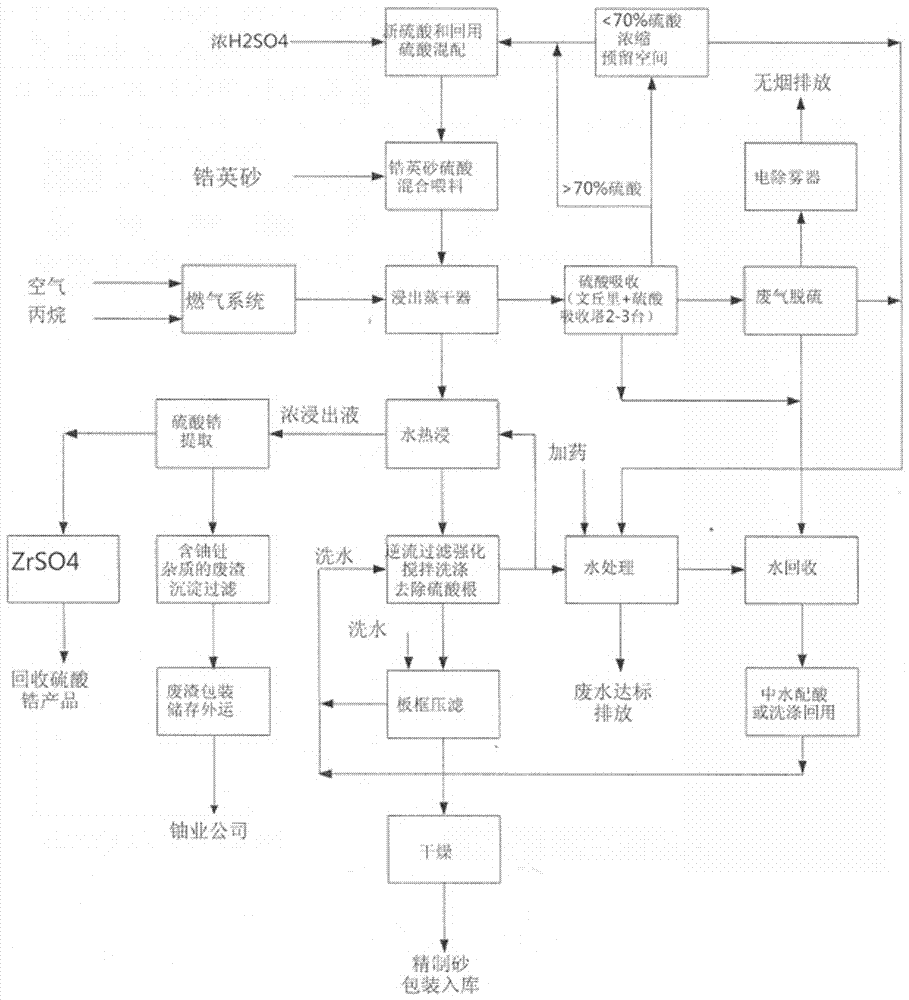

A method for reducing impurities of uranium, thorium, titanium, iron and aluminum in zircon sand

ActiveCN105217641BIncreased total leaching rateReduce the amount requiredSilicon compoundsWater floodingEvaporation

A method for reducing uranium, thorium, and titanium impurities in zircon sand. Zircon sand with a particle size of ≤200 mesh accounting for 96-96.2% is fully processed by adding 70% sulfuric acid at a mass ratio of zircon sand to 70% sulfuric acid of 1:0.6. After mixing, it is sent to the leaching evaporator. The leaching temperature is 200-300 degrees Celsius. The leaching time is 1-2 hours. The evaporation-drying temperature is less than 500 degrees Celsius. The evaporating-drying time is 30 minutes. The free sulfuric acid in the solid zircon sand after evaporation is Less than 0.5%, the solid zircon sand is stirred and water-soaked at 80-100 degrees Celsius. The water-soaked solid zircon sand is washed with water 3-5 times the mass of the zircon sand until neutral, and dried at 105 degrees Celsius. That’s it. The invention can increase the total leaching rate of uranium and thorium to 50-70%, reduce the total amount of uranium and thorium in the zircon sand to less than 500 ppm, and reduce the titanium oxide to less than 0.2%. Thus, the highly radioactive and high-titanium zircon sand reaches the standard of high-grade products.

Owner:阿斯创钛业(营口)有限公司

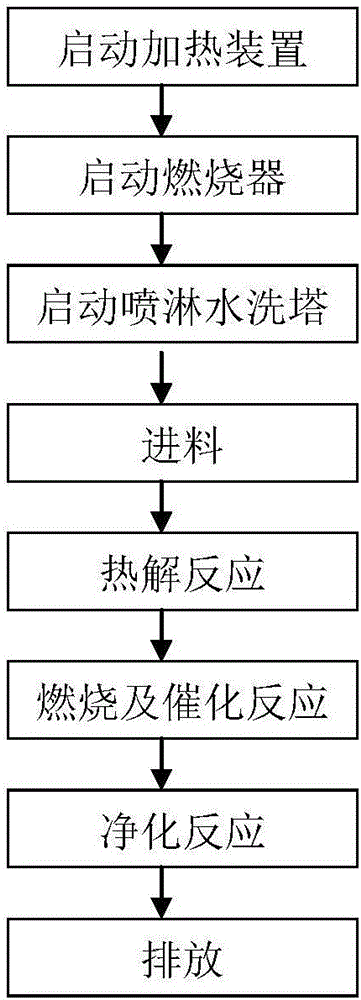

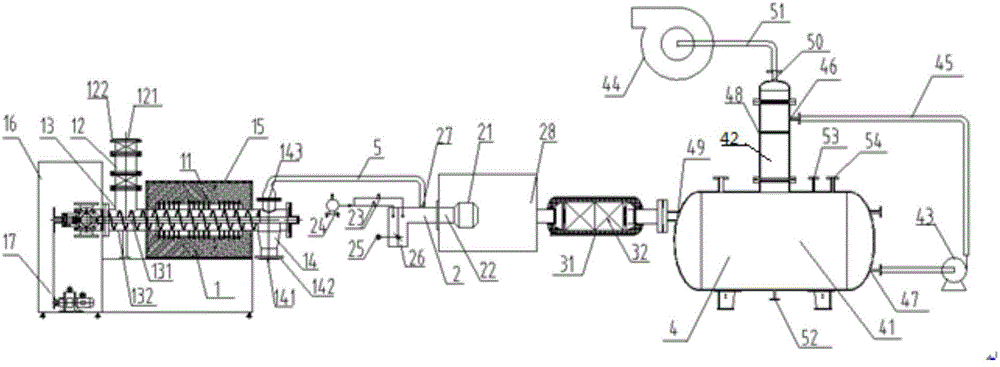

Intermediate- and low-level radioactive waste treatment method

ActiveCN106782734AEliminate pollutionEasy to storeRadioactive decontaminationOperational costsCombustor

The invention belongs to the technical field of intermediate- and low-level radioactive waste treatment and relates to an intermediate- and low-level radioactive waste treatment method. The intermediate- and low-level radioactive waste treatment method is achieved in an intermediate- and low-level radioactive waste treatment device and is used for treating organic combustible waste which contains radioactive substances and is generated by hospitals, factories, research institutions and nuclear power plants. The sludge volume reduction and the harmless treatment of the intermediate- and low-level radioactive waste are achieved. The sludge volume reduction rate is more than 95%. The difficulties of big deposit volume and difficult storage of the intermediate- and low-level radioactive waste are solved. Firstly, heating equipment is started, then a burner is started, then a spray water scrubber is started to carry out pre-treatment, then feedstock is carried out, the waste is pyrolyzed, burned, and experiences catalytic reaction, and finally, is purified and discharged. The process is simple in method, reliable in principle, high in sludge volume reduction rate, good in curing effect, environmentally friendly in application, low in investment and operation costs, energy-saving and environmentally friendly, and has a good economic benefit and a wide market prospect.

Owner:青岛天和清原科技有限公司

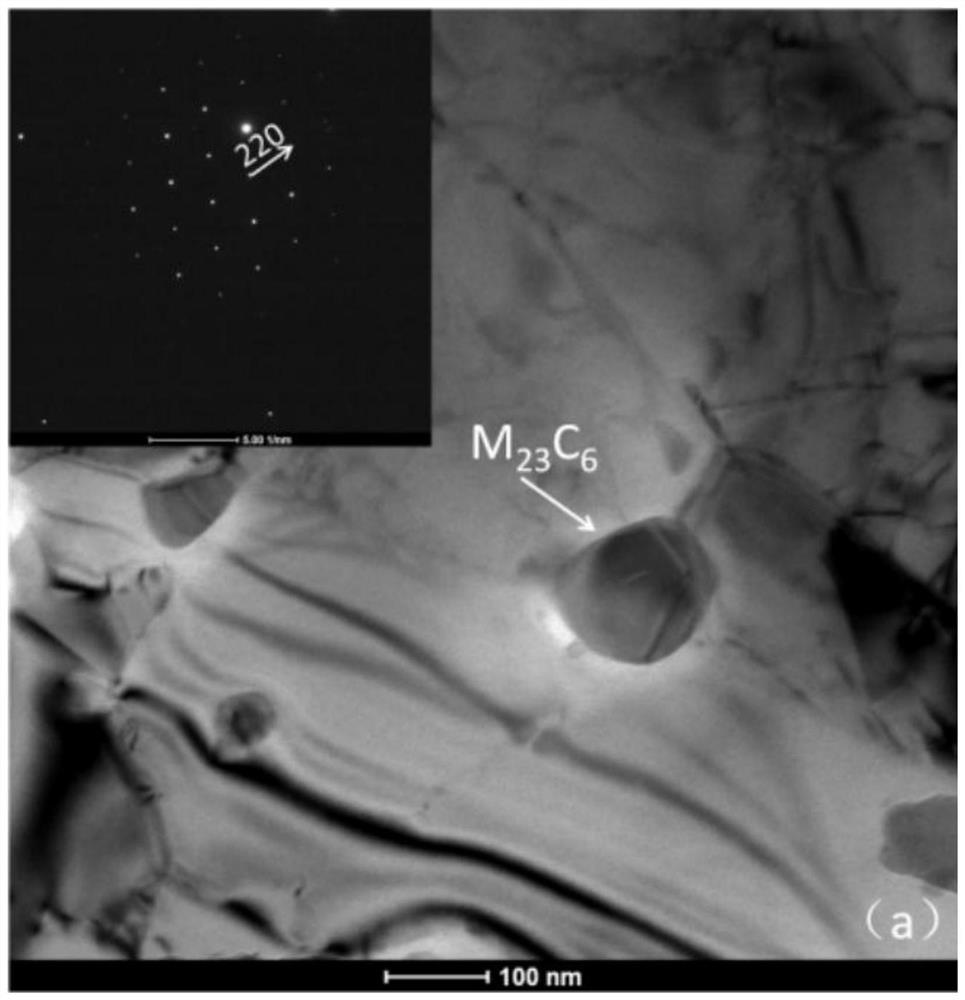

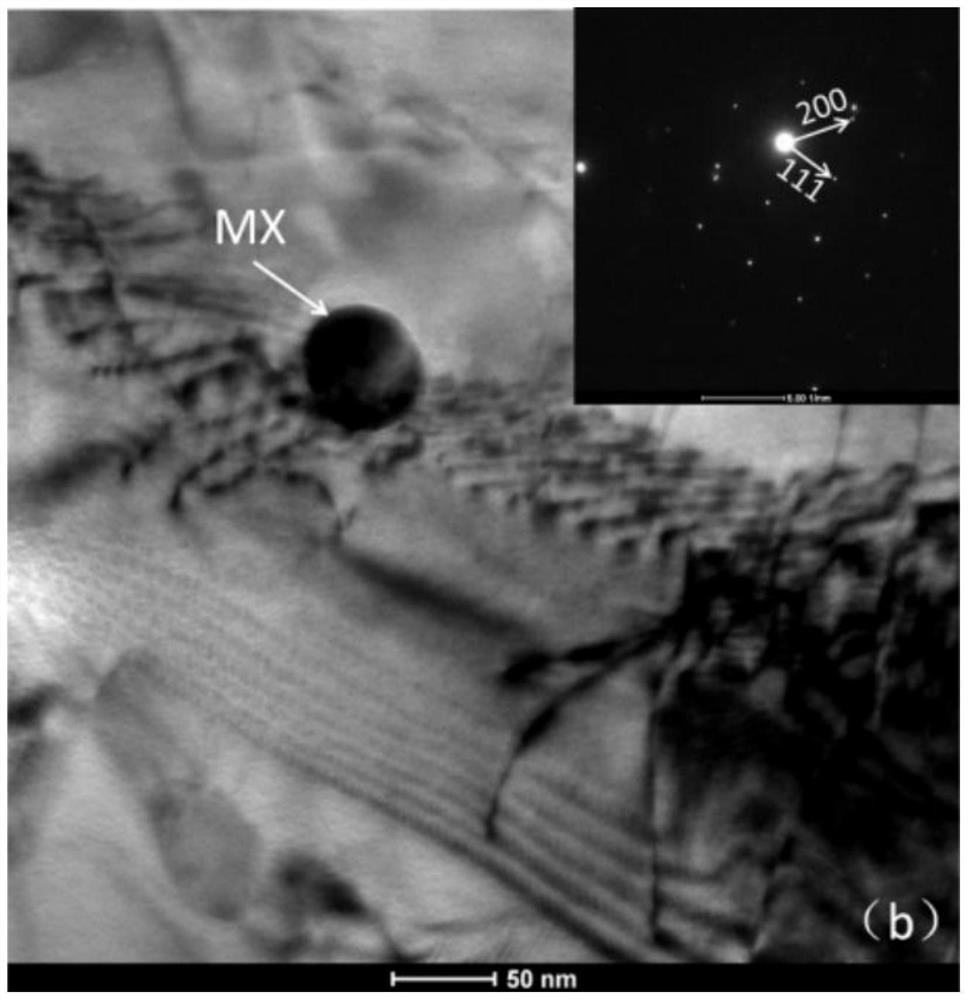

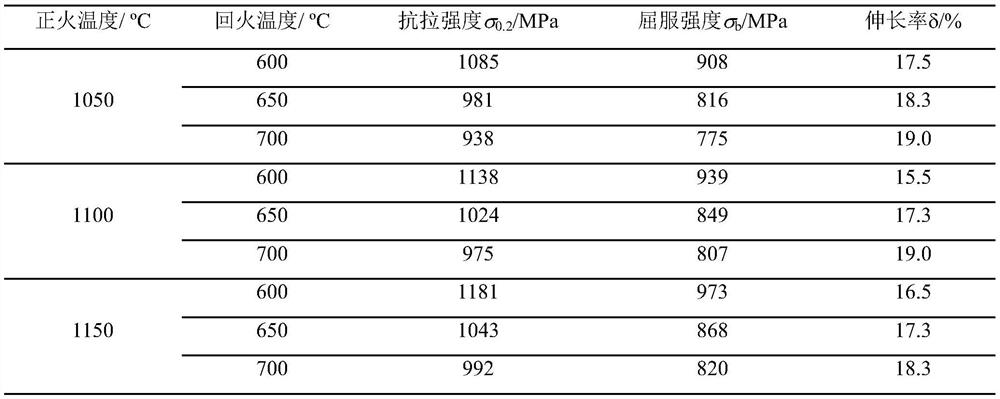

Preparation method of ferrite martensite steel ladle shell pipe

ActiveCN112695255AImprove high temperature performanceImprove neutron radiation resistance performanceNuclear energy generationFurnace typesLead bismuthMachining deformation

The invention belongs to the technical field of fourth-generation lead bismuth cooling fast reactor structural materials, and particularly relates to a preparation method of a ferrite martensite steel ladle shell pipe. The ferrite martensite steel ladle shell pipe comprises the components of 0.15%-0.25% of C, 0.30%-0.8% of Mn, 0.40%-1.20% of Si, 10.5%- 12.5% of Cr, 1.0%-2.5% of W, 0.10%-0.40% of V, 0.10%-0.40% of Ta, 0.005%-0.08% of Zr, 0.005%-0.05% of La, 0.008%-0.04% of N, and balance Fe and impurities. The preparation method of the ferrite martensite steel ladle shell material comprises the following process steps of (1) determining the alloy components; (2) smelting; (3) casting; (4) forging; (5) extruding; (6) pipe blank machining and heat treatment; (7) multi-pass cold rolling and intermediate heat treatment of the alloy; and (8) final heat treatment of the pipe. According to the preparation method of the ferrite martensite steel ladle shell pipe, through the innovative component design, the optimized pipe machining deformation process and the heat treatment technology, the microstructure of the material is improved, grains are refined, and therefore the comprehensive performance of the alloy is improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Novel roller way transmission structure of solar cell roller way furnace

PendingCN111383978AReasonable designEliminate occlusionFinal product manufactureSemiconductor/solid-state device manufacturingElectrical batteryMechanical engineering

The invention belongs to the technical field of photovoltaic solar cells, and particularly relates to a novel roller way transmission structure of a solar cell roller way furnace. A plurality of roller ways are arranged in a furnace body, the roller ways are arranged on two sides of the furnace body, a gap is arranged between the roller ways on two sides, and the size of the gap is matched with the size of a battery piece. The novel roller way transmission structure of the solar cell roller way furnace is reasonable in design, eliminates the shielding effect of an original roller way on radiation of a heating lamp tube or an LED light source from the lower portion, improves the sintering or irradiation effect of the back face of a cell piece, eliminates the sintering or irradiation difference of the front face and the back face, and therefore, the product quality is integrally improved. Furthermore, when the battery pieces incline or are broken in the conveying process, the battery pieces can fall into the lower hearth from the intervals in time, and rear-end collision or lamination accidents of the battery pieces are prevented.

Owner:BEIJING SOLARRAY TECHNOIOGY CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for the use of [<sup>11</sup>C] carbon monoxide in labeling synthesis of <sup>11</sup>C-labelled amides using metal amides and photo-induced free radical carbonylation Method for the use of [<sup>11</sup>C] carbon monoxide in labeling synthesis of <sup>11</sup>C-labelled amides using metal amides and photo-induced free radical carbonylation](https://images-eureka.patsnap.com/patent_img/3717ade3-a1b7-4e46-8fdf-e70161e646e0/US07553942-20090630-D00001.png)

![Method for the use of [<sup>11</sup>C] carbon monoxide in labeling synthesis of <sup>11</sup>C-labelled amides using metal amides and photo-induced free radical carbonylation Method for the use of [<sup>11</sup>C] carbon monoxide in labeling synthesis of <sup>11</sup>C-labelled amides using metal amides and photo-induced free radical carbonylation](https://images-eureka.patsnap.com/patent_img/3717ade3-a1b7-4e46-8fdf-e70161e646e0/US07553942-20090630-D00002.png)

![Method for the use of [<sup>11</sup>C] carbon monoxide in labeling synthesis of <sup>11</sup>C-labelled amides using metal amides and photo-induced free radical carbonylation Method for the use of [<sup>11</sup>C] carbon monoxide in labeling synthesis of <sup>11</sup>C-labelled amides using metal amides and photo-induced free radical carbonylation](https://images-eureka.patsnap.com/patent_img/3717ade3-a1b7-4e46-8fdf-e70161e646e0/US07553942-20090630-D00003.png)