Preparation method of ferrite martensite steel ladle shell pipe

A martensitic steel and cladding tube technology, applied in the field of fourth-generation lead-bismuth cooling fast reactor structural materials, can solve problems such as high fuel consumption and insufficient ductility, and achieve improved corrosion performance, high temperature performance and medium resistance. Effects of sub-irradiation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0065] A method for preparing a ferritic martensitic steel cladding pipe, comprising the following steps:

[0066] (1) Determine the alloy composition of ferritic martensitic steel cladding pipe

[0067] The composition of the alloy includes:

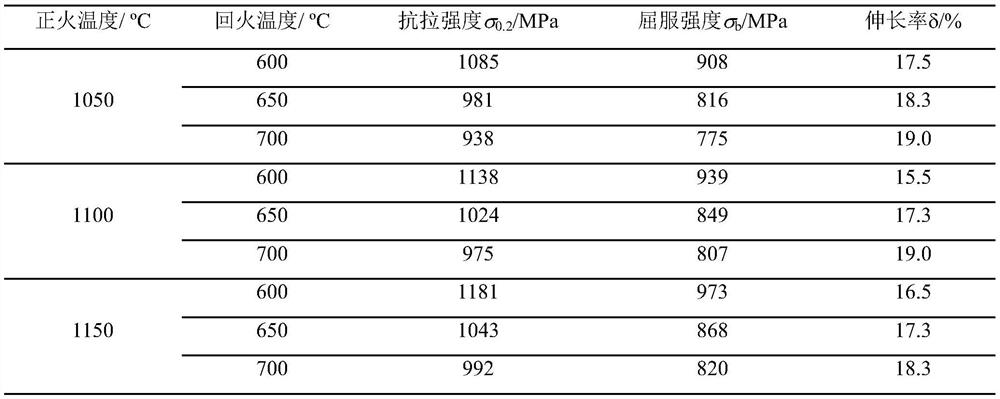

[0068] C: 0.15-0.25%, Mn: 0.30-0.8%, Si: 0.40-1.20%, Cr: 10.5-12.5%, W: 1.0-2.5%, V: 0.10-0.40%, Ta: 0.10-0.40%, Zr : 0.005~0.08%, La: 0.005~0.05%, N: 0.008~0.04%; the rest is Fe and impurities;

[0069] The C, N content in the alloy has a special relationship with the Ta, V, Zr content, 1 times (C+N) content ≤ (Ta+V+Zr) content ≤ 3 times (C+N) content; impurities in the alloy The content control thereof satisfies the following conditions: S<0.003wt%, P<0.008wt%, B<0.01wt%, O<0.002wt%, H<0.001wt%.

[0070] As a preferred technical solution, the main component of the alloy is Fe-12Cr-1.5W-0.5Mn-0.20C-0.15Ta-0.2V-0.02N-0.01Zr-0.03La-0.5Si except for impurities.

[0071] (2) Melting

[0072] (2.1) Carry out the batching of smelting al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com