Patents

Literature

229 results about "Burnup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In nuclear power technology, burnup (also known as fuel utilization) is a measure of how much energy is extracted from a primary nuclear fuel source. It is measured both as the fraction of fuel atoms that underwent fission in %FIMA (fissions per initial metal atom) and as the actual energy released per mass of initial fuel in gigawatt-days/metric ton of heavy metal (GWd/tHM), or similar units.

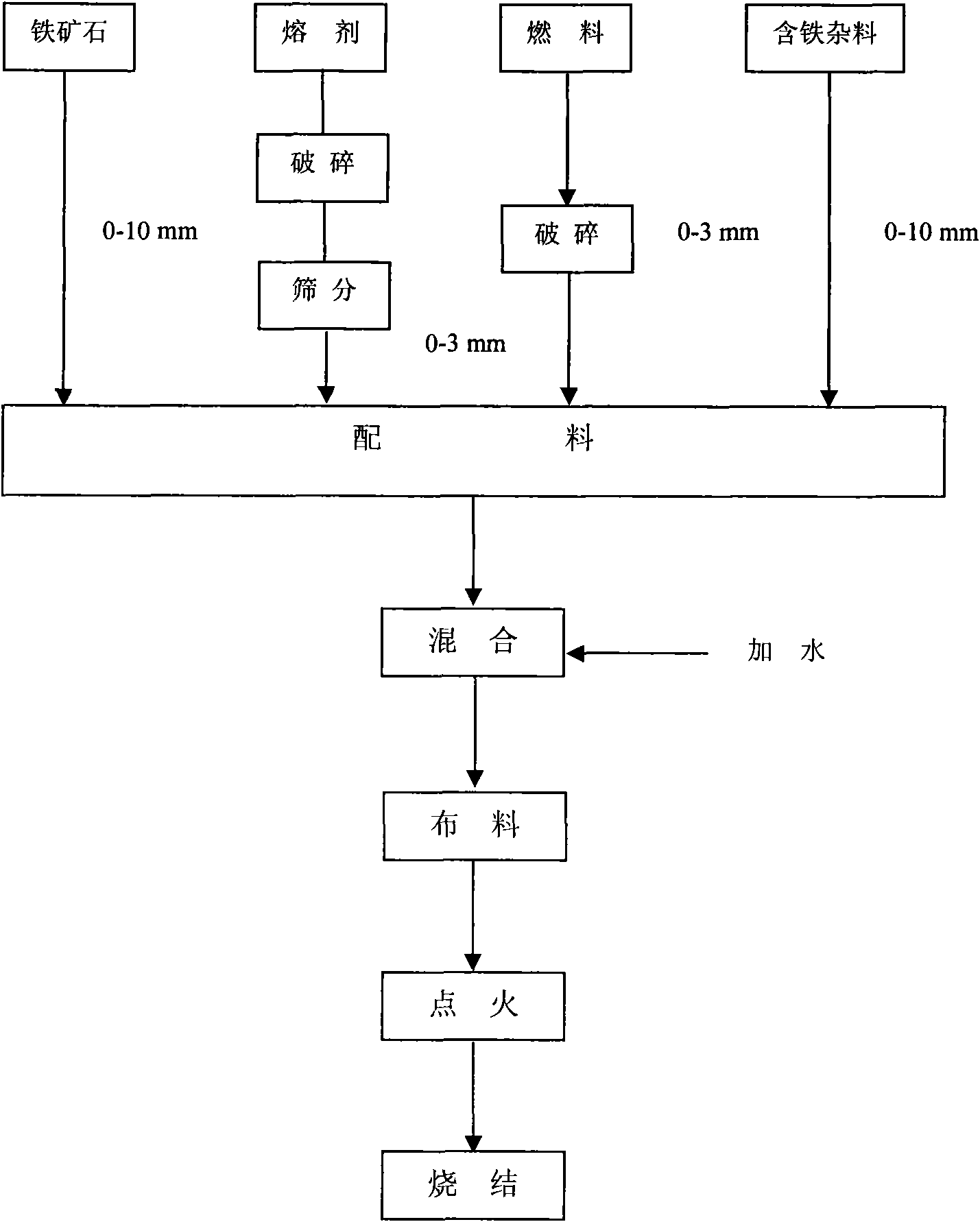

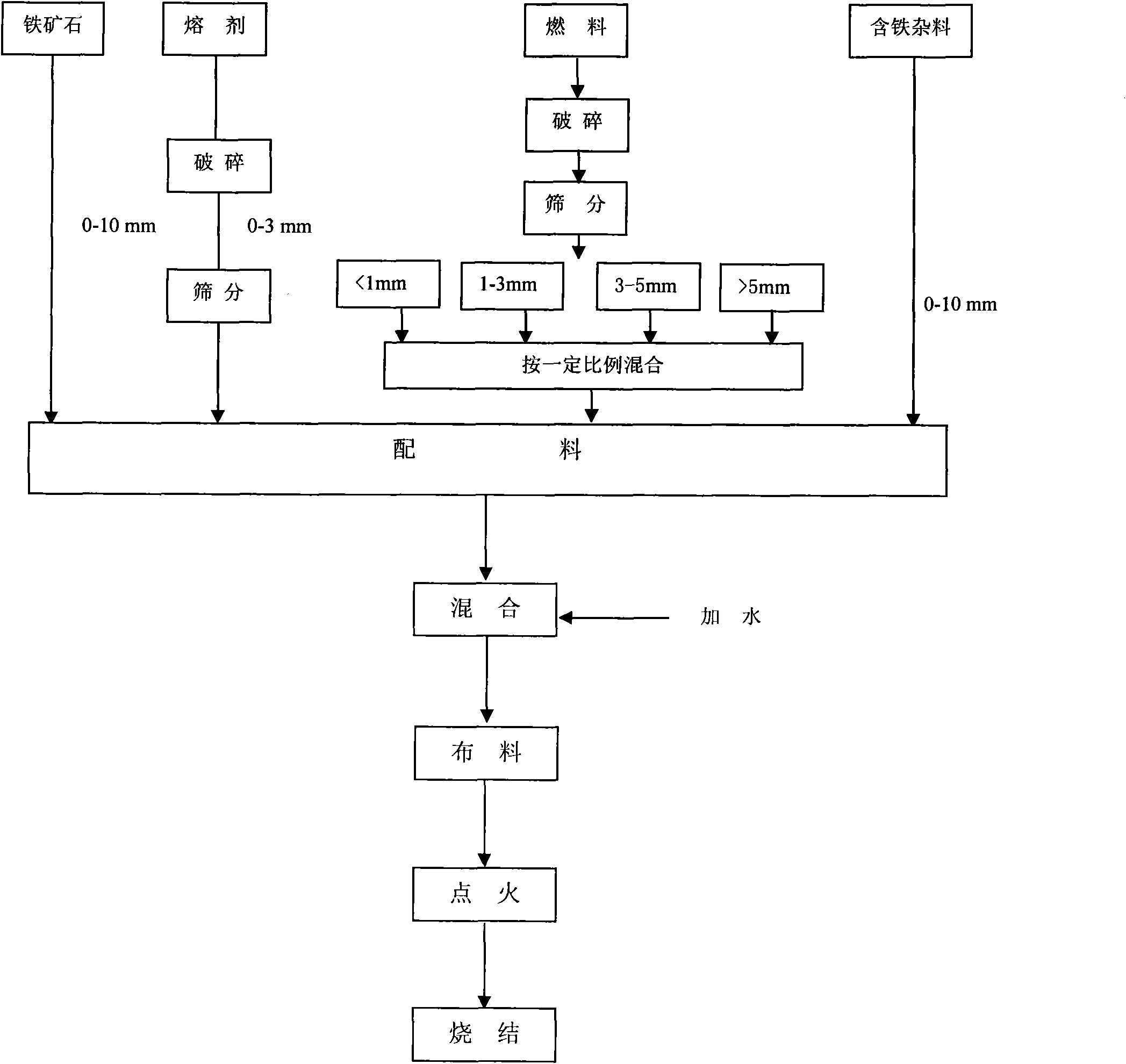

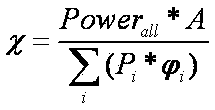

Sinter production method for reducing sintering solid burnup and enhancing intensity

ActiveCN101928824ARational mineralization processReduce fuel consumptionMaterials preparationGranularity

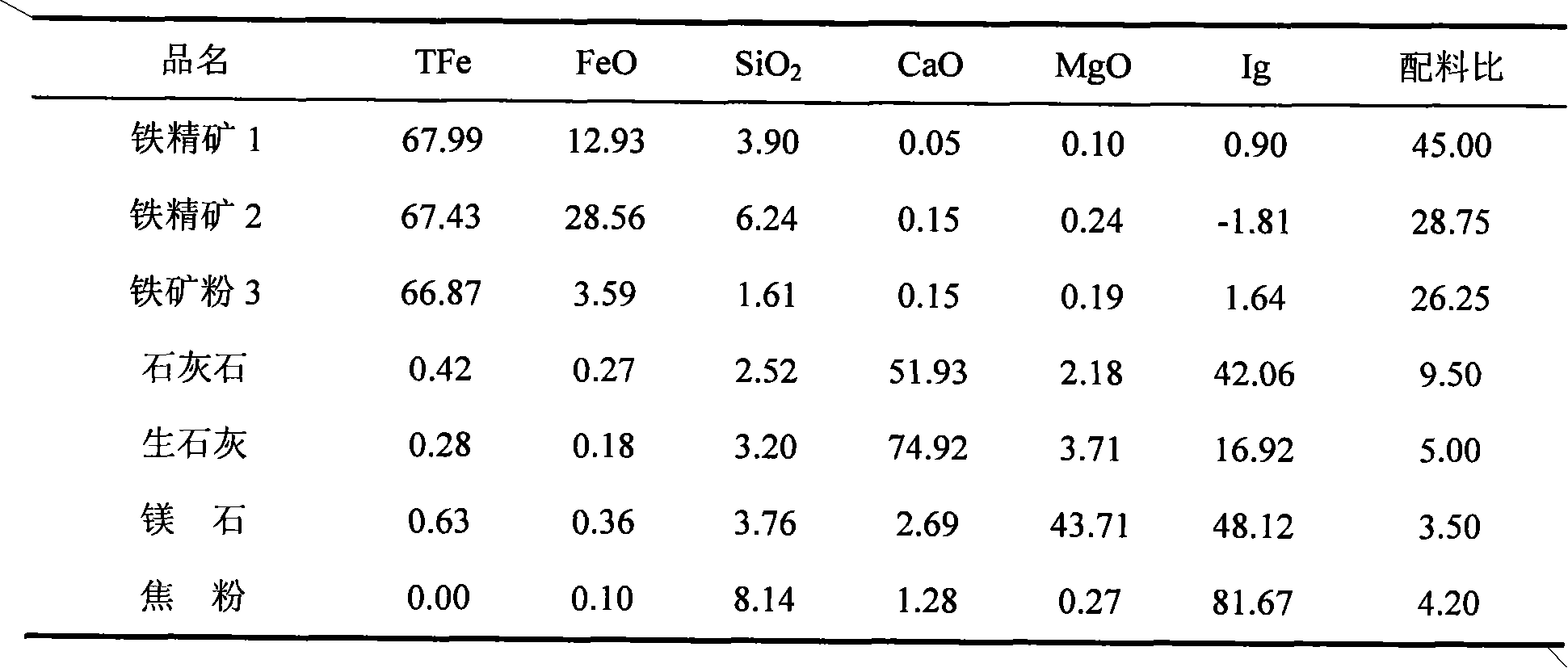

The invention provides a sinter production method for reducing sintering solid burnup and enhancing intensity, which comprises the steps of preparing materials, mixing and pelletizing, distributing materials and sintering. The sinter production method is characterized in that coke powder for sintering is pulverized and prescreened before material preparation; the coke powder is screened into 4 granularity levels: the granularity level less than 1mm, the granularity level of 1 to 3mm, the granularity level of 3 to 5mm and the granularity level larger than 5mm, mixed according to the weight percentages of 55% to 59% of the granularity level less than 1mm, 23% to 27% of the granularity level of 1 to 3mm, 9% to 13% of the granularity level of 3 to 5mm and 4% to 8% of the granularity level larger than 5mm and then prepared with other raw materials. The sinter production method can promote solid fuels to be reasonably burned in the process of sintering; the mineralization processes of iron ores, fusing agents and fuels are reasonable; the sinter intensity is remarkably enhanced; and the sinter solid burnup is obviously reduced. An experiment indicates that the sintering tumbler strengthis enhanced by 1.26%, the solid burnup is reduced by 1.89kg / t and the finished product ratio is enhanced by 4.28% than that of the prior art.

Owner:ANGANG STEEL CO LTD

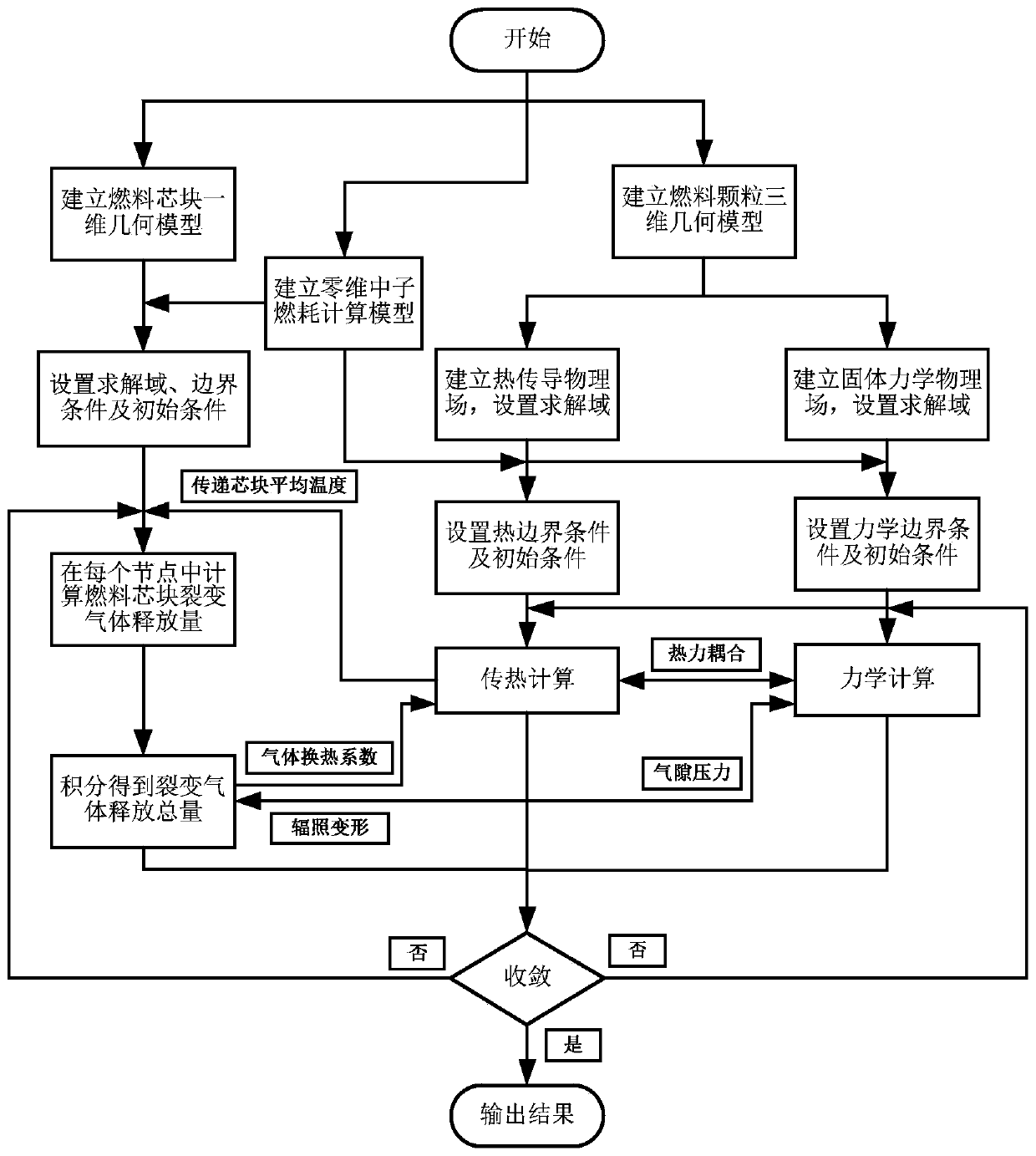

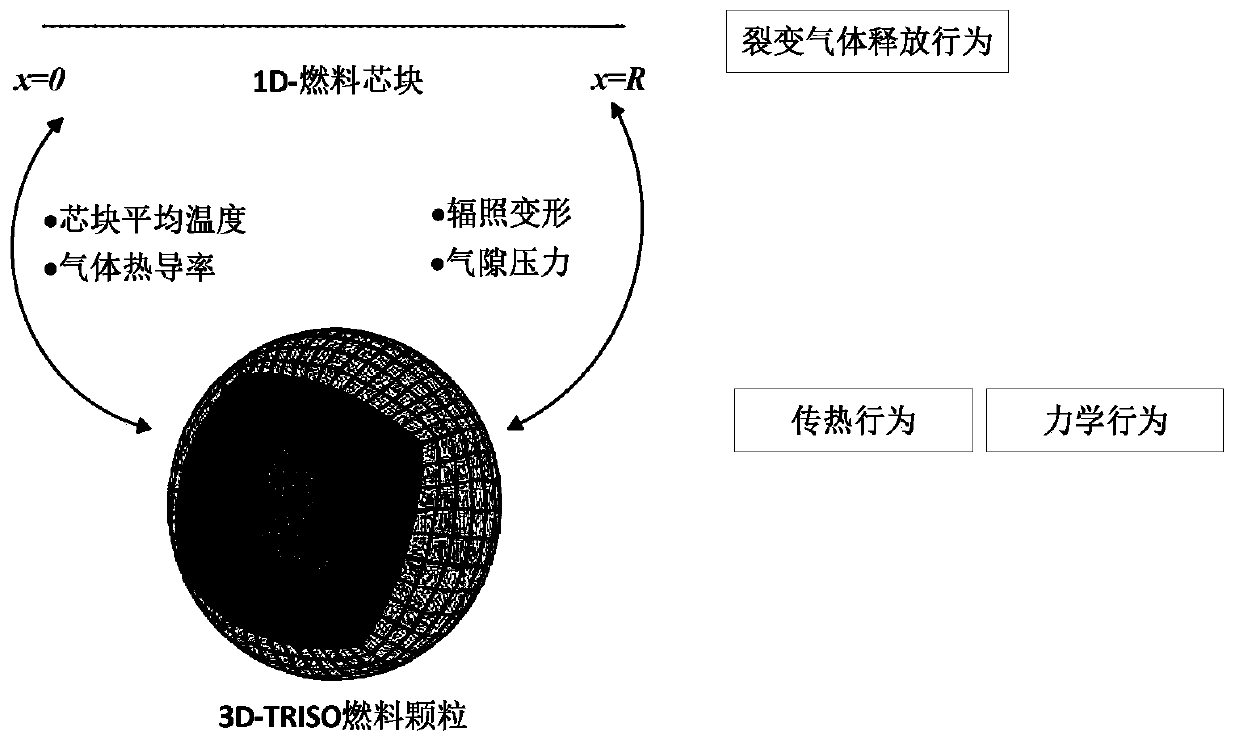

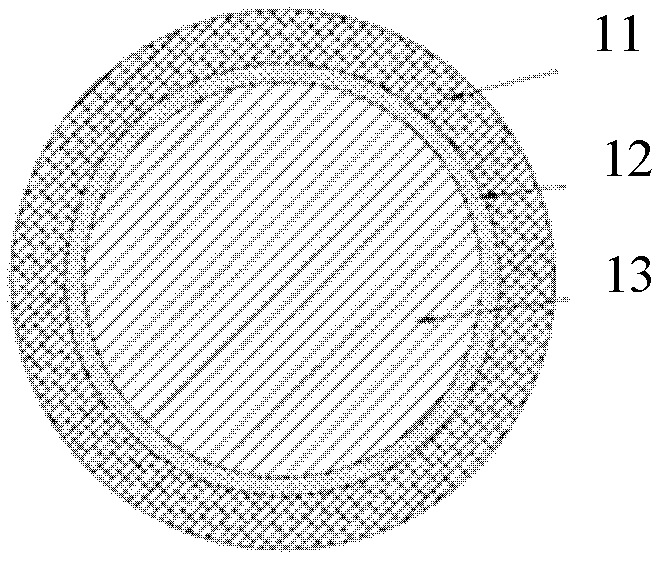

Multi-scale multi-physical field coupling simulation method for nuclear reactor TRISO fuel particles

ActiveCN111291494ARealize one-dimensionalRealize three-dimensional multi-scale couplingDesign optimisation/simulationNuclear reactorGeometric modeling

A multi-scale multi-physical field coupling simulation method for nuclear reactor TRISO fuel particles comprises the following steps of rstablishing 1, a zero-dimensional neutron burnup model, a one-dimensional geometric model and a three-dimensional geometric model; 2, setting a solution domain, an initial condition and a boundary condition at different scales; 3, completing neutron burnup calculation in each time step length, preliminarily calculating fission gas release amount in the fuel pellet one-dimensional geometric model, and completing preliminary calculation of heat transfer and mechanics in the fuel particle three-dimensional geometric model; and 4, taking a calculation result in the one-dimensional geometric model of the fuel pellet in the step 3 as calculation input in the three-dimensional geometric model of the fuel pellet in the next time step length, wherein he calculation result in the fuel particle three-dimensional geometric model in the step 3 is used as calculation input in the fuel pellet one-dimensional geometric model of the next time step, and calculation results of heat transfer and mechanics are mutually transmitted; and 5, repeating the coupling process in the step 4 until the calculation is converged, otherwise, returning to the step 3 until the calculation is converged.

Owner:XI AN JIAOTONG UNIV

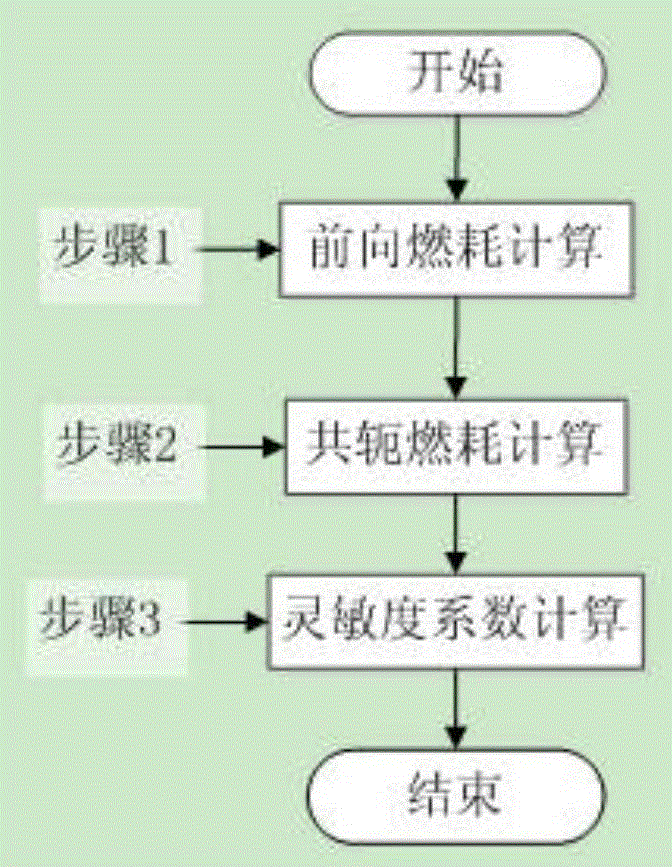

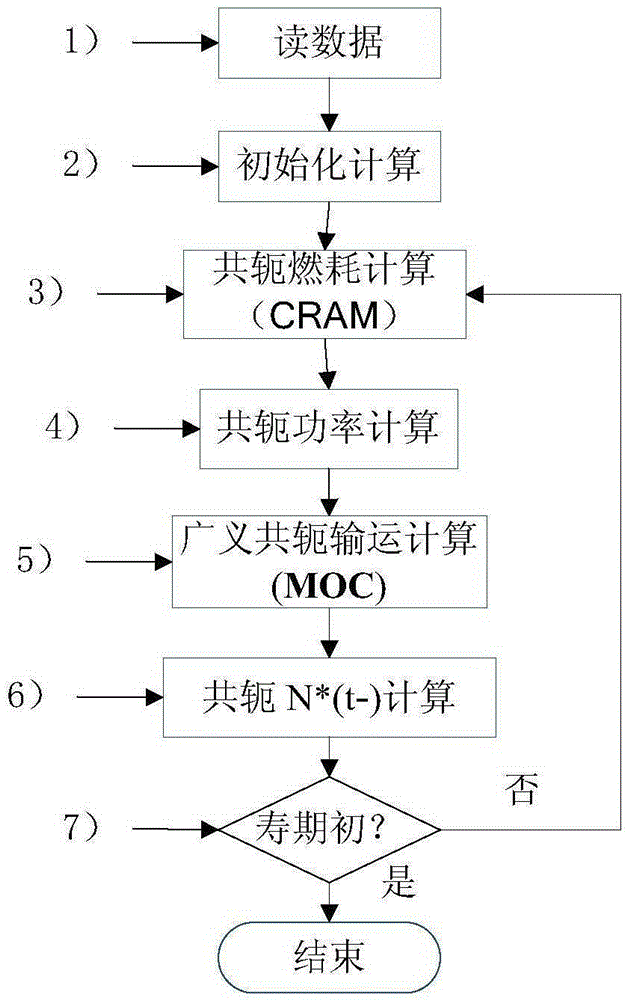

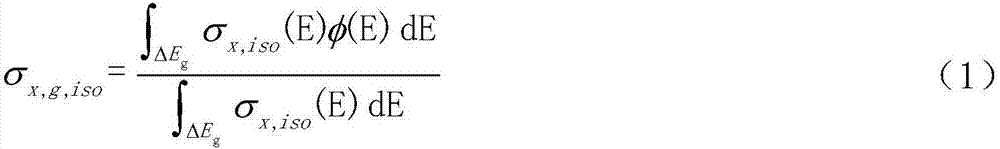

Method for obtaining sensitivity coefficients of effective multiplication factor to section under different burnups

ActiveCN105426659AEffective Proliferation Sensitivity CoefficientInformaticsSpecial data processing applicationsNeutron transportModularity

The present invention discloses a method for obtaining sensitivity coefficients of an effective multiplication factor to a section under different burnups. The method comprises: 1, performing forward burnup calculation: first, using a subgroup method to calculate an effective self-shielding section of each nuclide, second, using a modular characteristic line method to solve a neutron angle flux density and a neutron conjugate angle flux density, and third, using a chebyshev rational approximation method to calculate a nuclear density of each nuclide; 2, performing conjugate burnup calculation: first, using the chebyshev rational approximation method to calculate an initial conjugate nuclear density of each nuclide, and then calculating a conjugate power, second, using the modular characteristic line method to calculate a generalized neutron transport angle flux and a generalized conjugate neutron transport angle flux, and third, calculating a conjugate initial nuclear density of each nuclide of a next step; and 3, calculating sensitivity coefficients of the section of each nuclide to an effective multiplication factor under different burnups. The method provided by the present invention solves a defect of the existing method that sensitivity coefficients of an effective multiplication factor to a nuclear section under different burnups cannot be accurately and effectively calculated.

Owner:XI AN JIAOTONG UNIV

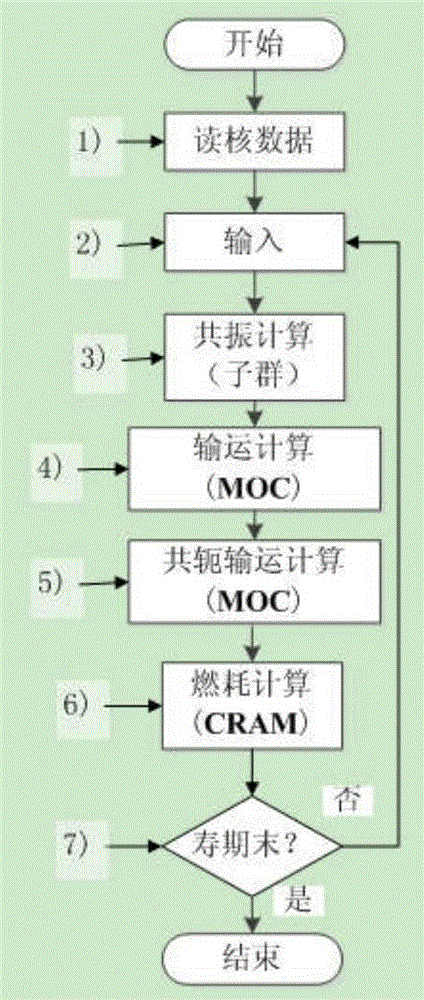

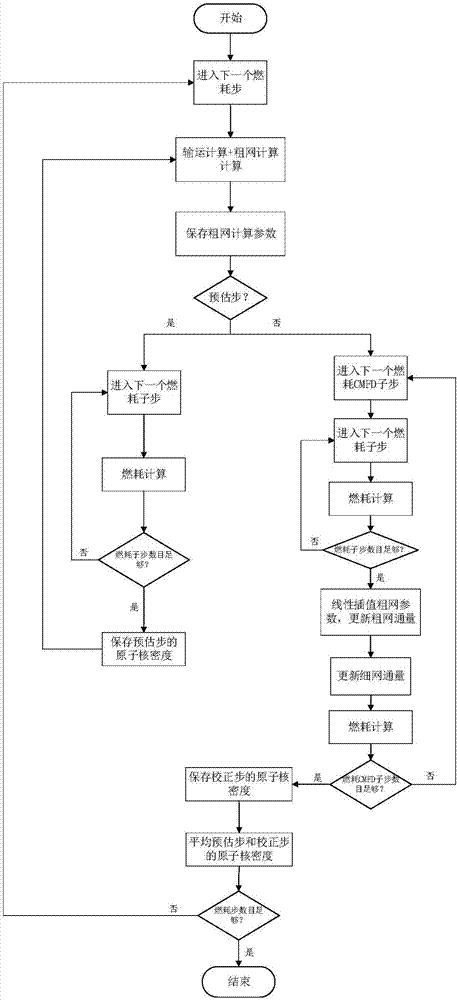

Method suitable for transportation burnup coupling calculation of nuclear reactor

ActiveCN107092784ASpeed up divisionShorten the timeSpecial data processing applicationsInformaticsNuclear reactor coreNuclear reactor

The invention discloses a method suitable for the transportation burnup coupling calculation of a nuclear reactor. The method comprises the following steps that: 1: carrying out transportation calculation on the nucleus concentration of burnup step initiation to obtain a coarse mesh parameter and a microcosmic reaction rate; 2: carrying out burnup calculation by the microcosmic reaction rate and the nucleus concentration to obtain the nucleus concentration estimated by a burnup step end; 3: carrying out the transportation calculation by the estimated nucleus concentration to obtain the coarse mesh parameter and the microcosmic reaction rate; 4: dividing burnup CMFD (Coarse Mesh Finite Difference) substeps in a burnup step, and carrying out linear interpolation on the stored coarse mesh parameter; 5: updating the microcosmic reaction rate of the burnup CMFD substeps by the coarse mesh parameter obtained in the 4 and thin mesh neutron flux in the 3; 6: carrying out the burnup calculation by the microcosmic reaction rate on the burnup CMFD substeps to obtain the accurate nucleus concentration of the burnup step end; and 7: judging whether a burnup step number is consistent with an input value or not to judge whether calculation is finished or not. By use of the method, on a premise that extremely high accuracy is guaranteed, the step length of the burnup calculation is extremely enlarged, and calculation time in the whole service life of the nuclear reactor is shortened.

Owner:XI AN JIAOTONG UNIV

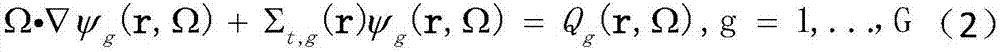

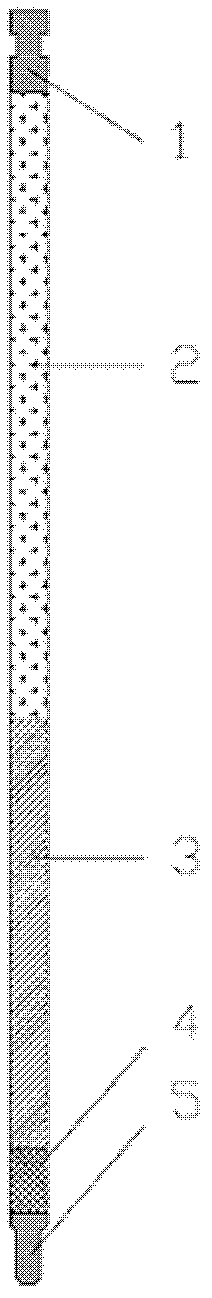

Nuclear fuel rod with ceramic cladding and metallic pellet

ActiveCN103295652AImprove mechanical propertiesReduce breakageOptical rangefindersNuclear energy generationHeat conductingComposite ceramic

The invention aims at providing a nuclear fuel rod with ceramic cladding and metallic pellet. The nuclear fuel rod with ceramic cladding and metallic pellet has the advantages that the heat-conducting property of the nuclear fuel rod can be improved, the central temperature of the fuel pellet is lowered or the fuel power density is effectively improved, the fuel rod cladding mechanical property, corrosion resistance and radiation resistance are greatly improved, the breakage rate of the fuel rod is lowered, the discharge burnup of the fuel rod is remarkably increased and the fuel utilization rate is greatly improved; meanwhile, the fuel rod has good neutronics performance, and can be widely used in a fast reactor or a thermal reactor. The cladding of the nuclear fuel rod provided by the invention is a SiCf / SiC composite ceramic material cladding, the metallic fuel pellet adopts a U-Zr or U-Pu-Zr alloy fuel pellet; a gap between the cladding and the fuel pellet is filled with low-melting-point metal; and a lengthened air cavity is designed at the upper part of the fuel rod.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

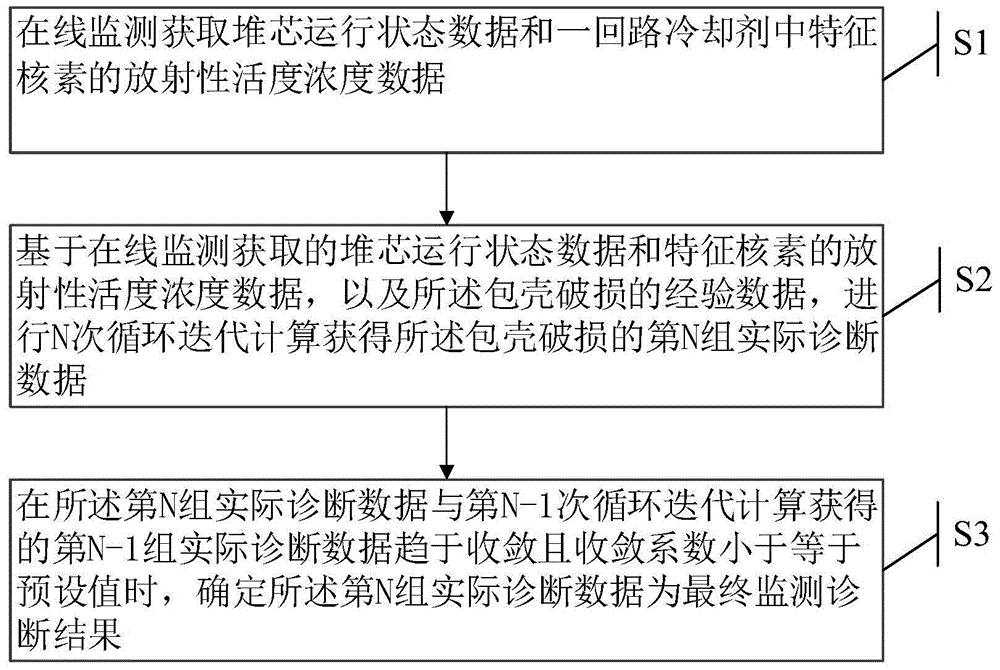

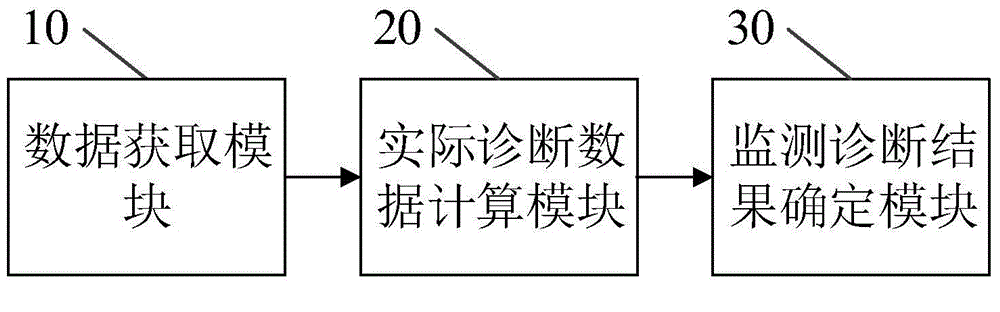

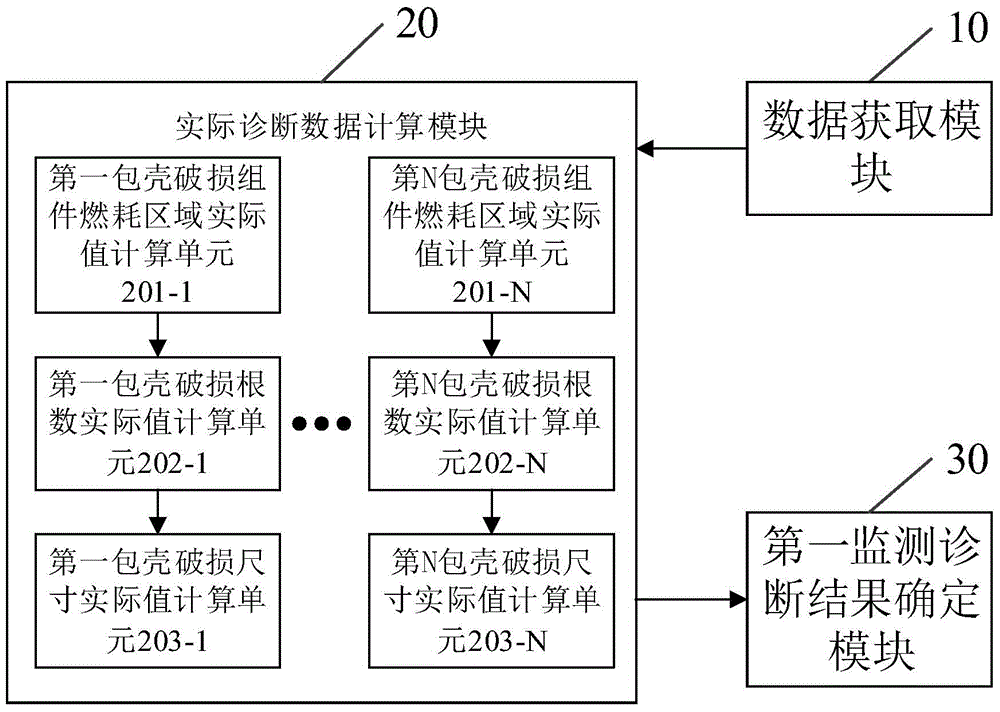

Nuclear power plant fuel element cladding failure monitoring method and system

ActiveCN104934084AImprove securityImprove economyNuclear energy generationNuclear monitoringDiagnostic dataNuclear engineering

The invention discloses a monitoring method and a monitoring system of nuclear power plant fuel element cladding failures. With prior arts, online continuous monitoring is not possible, or defects such as fuel element cladding failure shapes cannot be diagnosed accurately. With the method and the system, the technical problems are solved. The monitoring method comprises the following steps: S1, online monitoring is carried out, such that reactor core operation status data and radioactivity concentration data of a characteristic nuclide in a primary coolant are obtained; S2, N times of loop iteration calculations are carried out based on the reactor core operation status data, the radioactivity concentration data and cladding failure empirical data, such that an Nth set of actual diagnosis data of cladding failure is obtained; S3, when the convergence coefficient of the Nth set of actual diagnosis data and an (N-1)th set of actual diagnosis data obtained by the (N-1)th loop iteration calculation is smaller than or equal to a preset value, the (N-1)th set of actual diagnosis data is determined as a final monitoring diagnosis result. Therefore, online continuous monitoring and diagnosis of fuel element cladding failure existence, failure traits and fuel consumption area location are realized.

Owner:中广核工程有限公司 +1

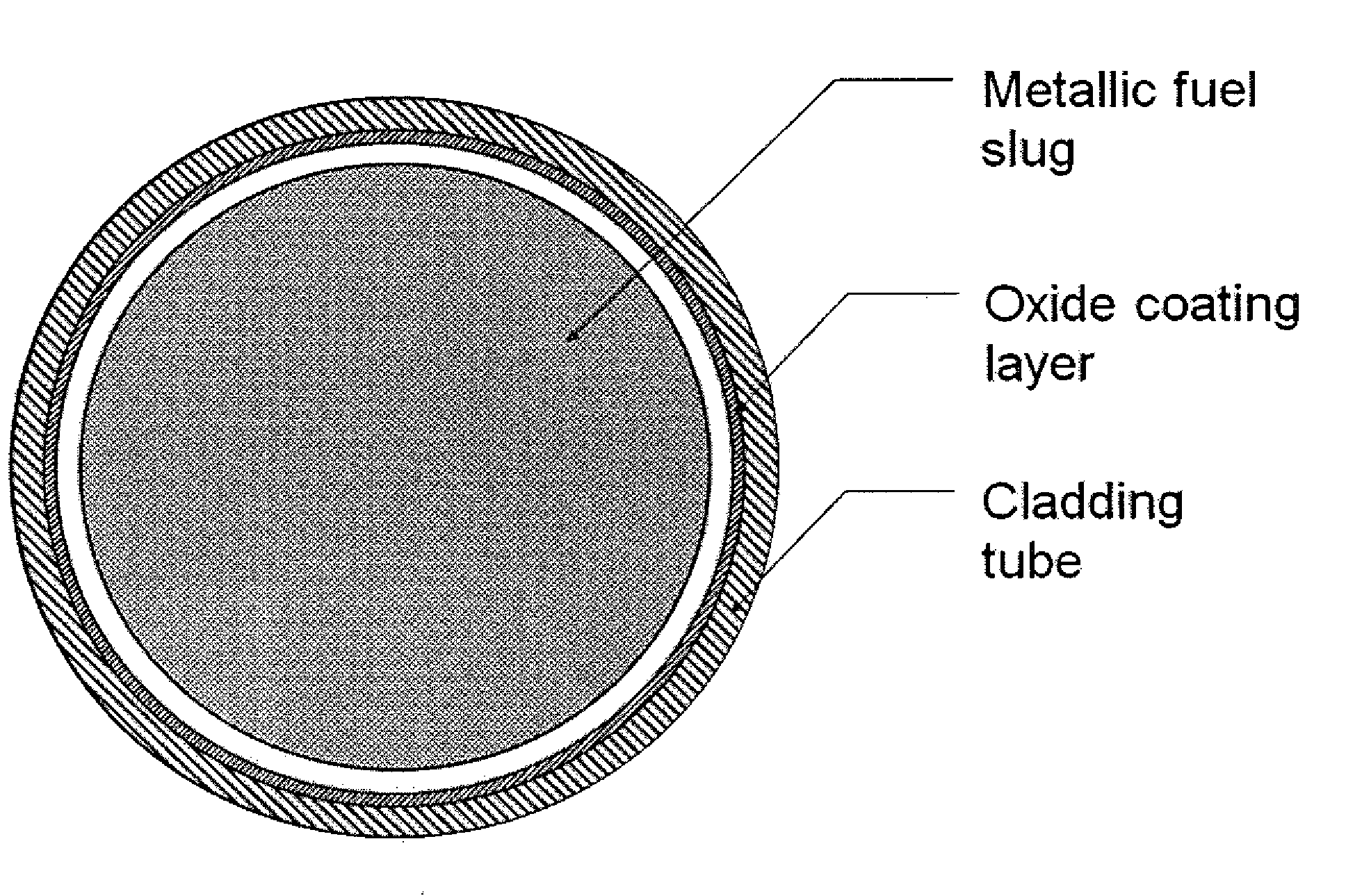

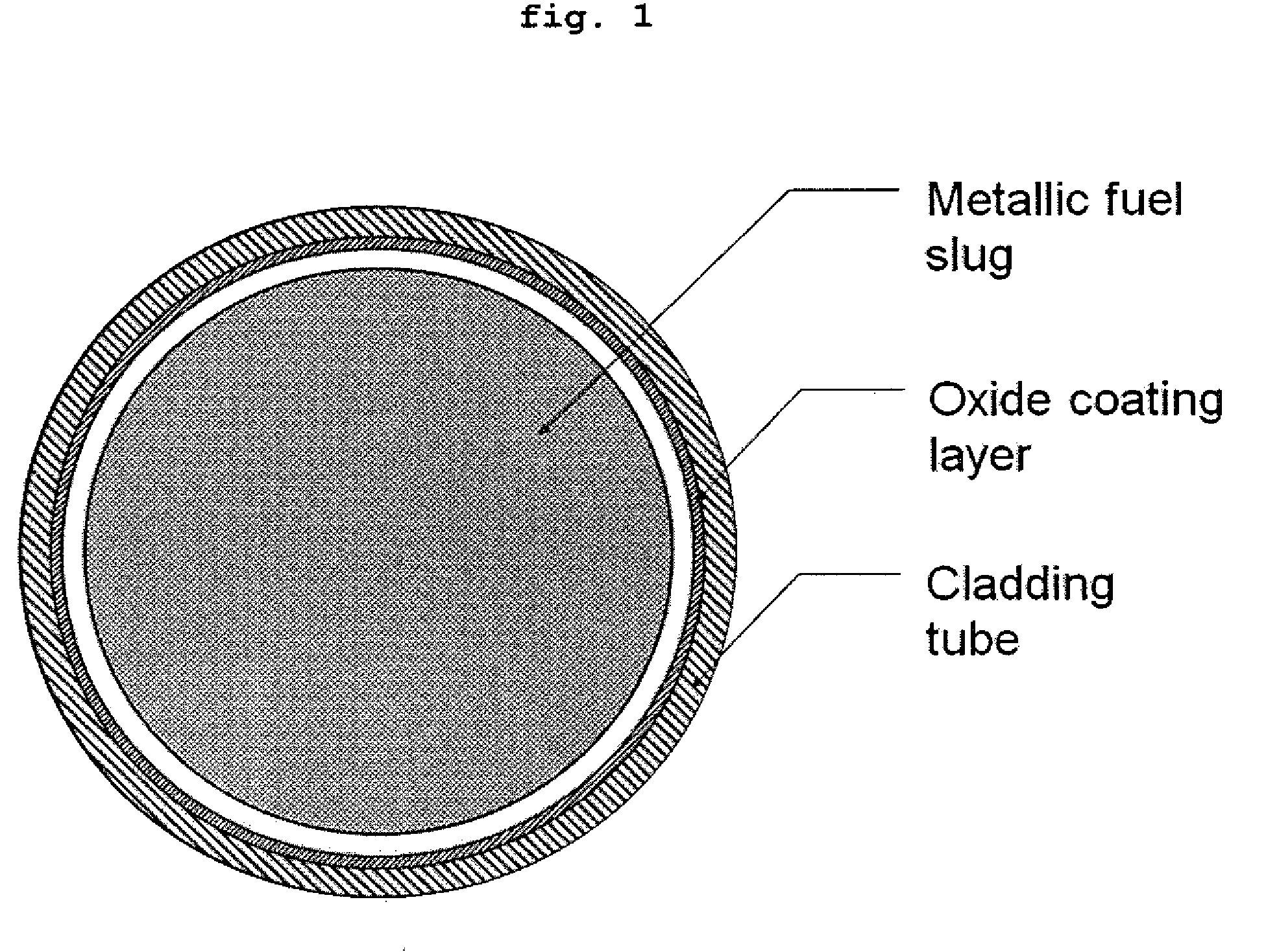

Nuclear fuel rod for fast reactors with oxide coating layer on inner surface of cladding, and manufacturing method thereof

InactiveUS20090141851A1Increase maximum permissible burnupProlonging fuel lifecycleOptical rangefindersFuel elementsEngineeringBurnup

Disclosed herein are a nuclear fuel rod for fast reactors, which includes an oxide coating layer formed on the inner surface of a cladding, and a manufacturing method thereof. The nuclear fuel rod for fast reactors, which includes the oxide coating layer formed on the inner surface of the cladding, can increase the maximum permissible burnup and maximum permissible temperature of the metallic fuel slug for fast reactors so as to prolong the its lifecycle in the fast reactors, thus increasing economic efficiency. Also, the fuel rod is manufactured in a simpler manner compared to the existing method, in which a metal liner is formed, and the disclosed method enables the cladding of the fuel rod to be manufactured in an easy and cost-effective way.

Owner:KOREA ATOMIC ENERGY RES INST +1

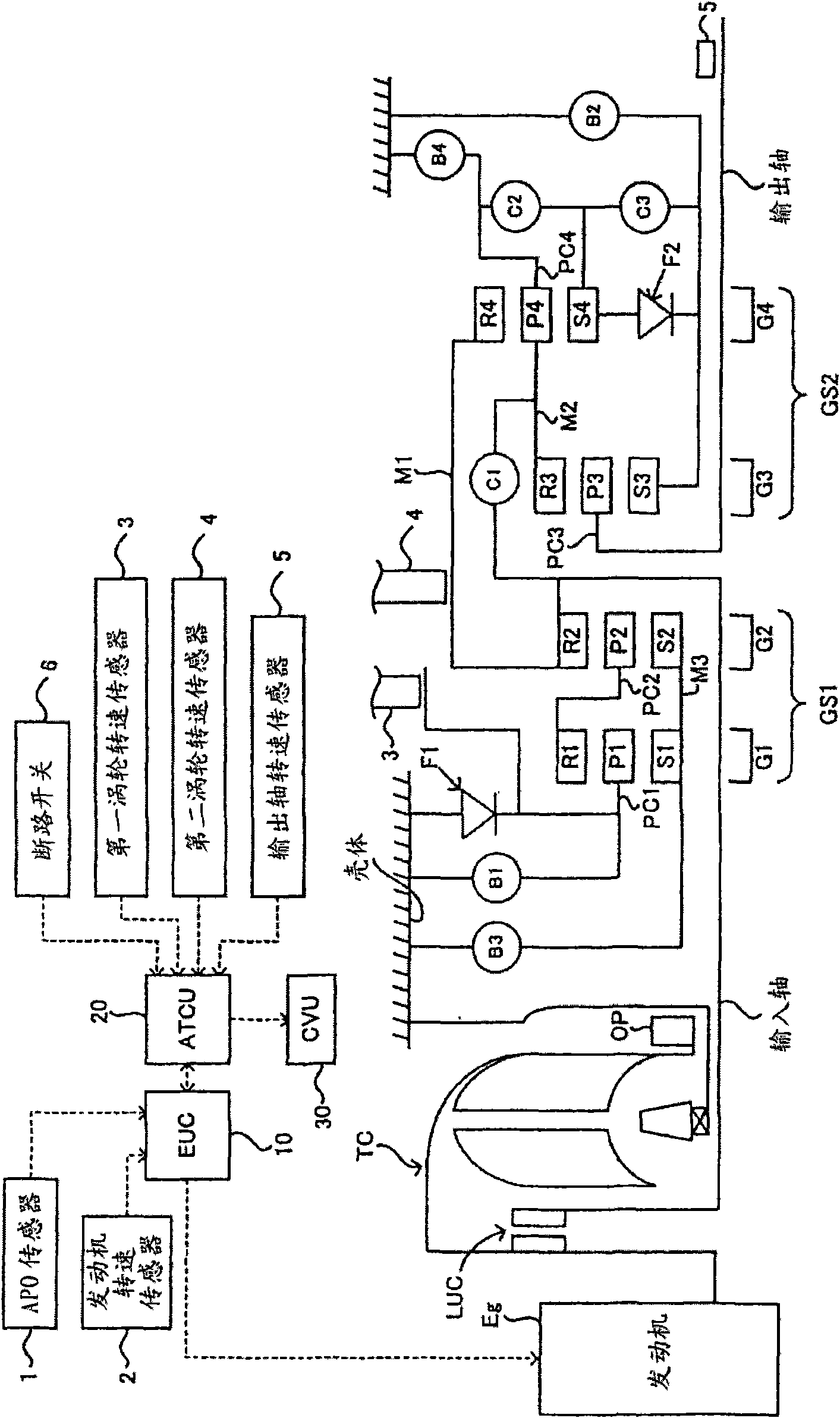

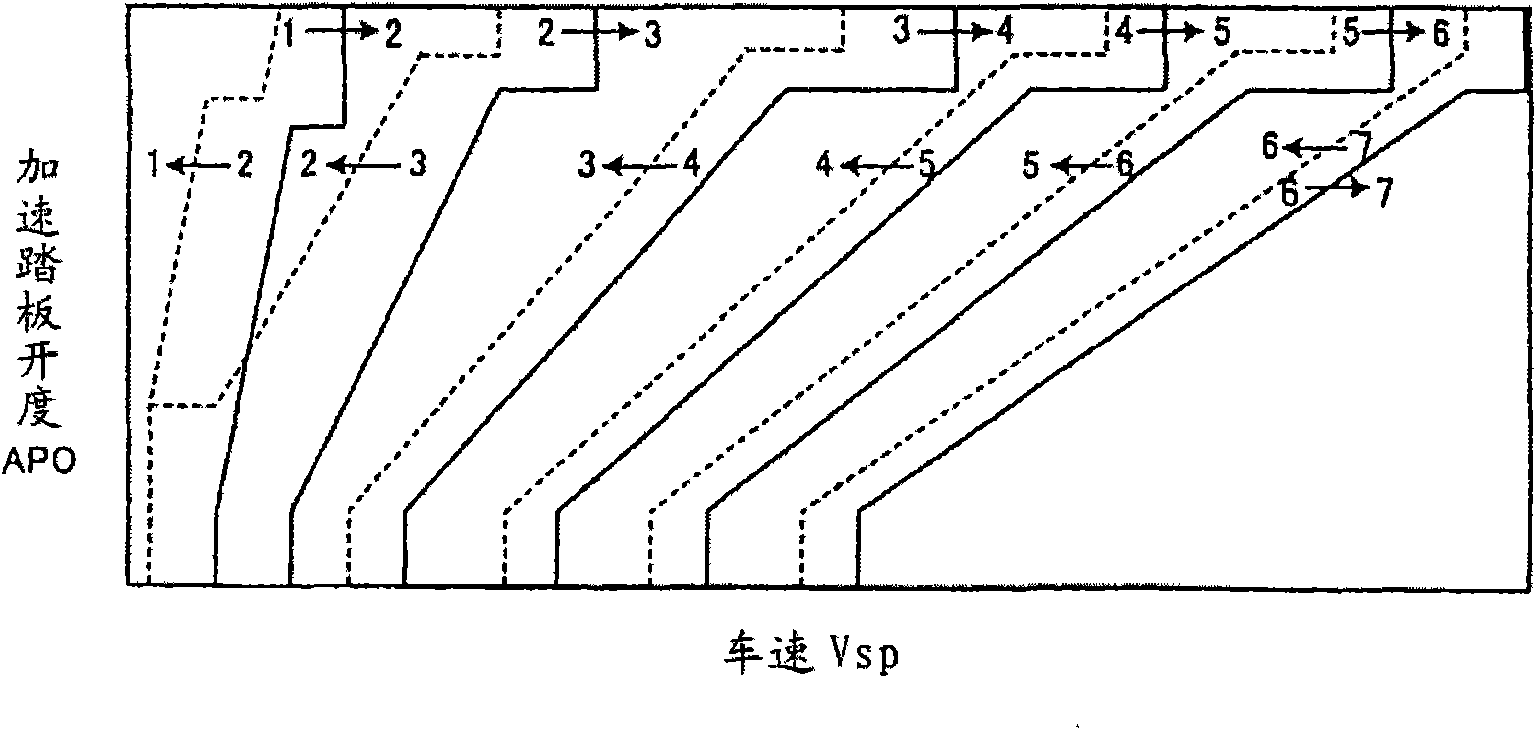

Control device for vehicle and control method thereof

ActiveCN101666380ASuppresses shifting vibrationReduce vibrationElectrical controlRoad transportPre-chargeBurnup

The invention provides a control device for a vehicle which decreases the vibration during shifting and prevents the fuel burnup from worsening. When a downshift is performed while a vehicle travels in a coasting state, a determination is made as to judge whether a fuel cut recovery will be performed. When a fuel cut recovery is performed, an offset oil pressure is set and an initial oil pressureset after raising an oil pressure of an engagement side frictional engagement element to a pre-charge oil pressure is set at an oil pressure obtained by subtracting the offset oil pressure from a reference initial oil pressure.

Owner:JATCO LTD +1

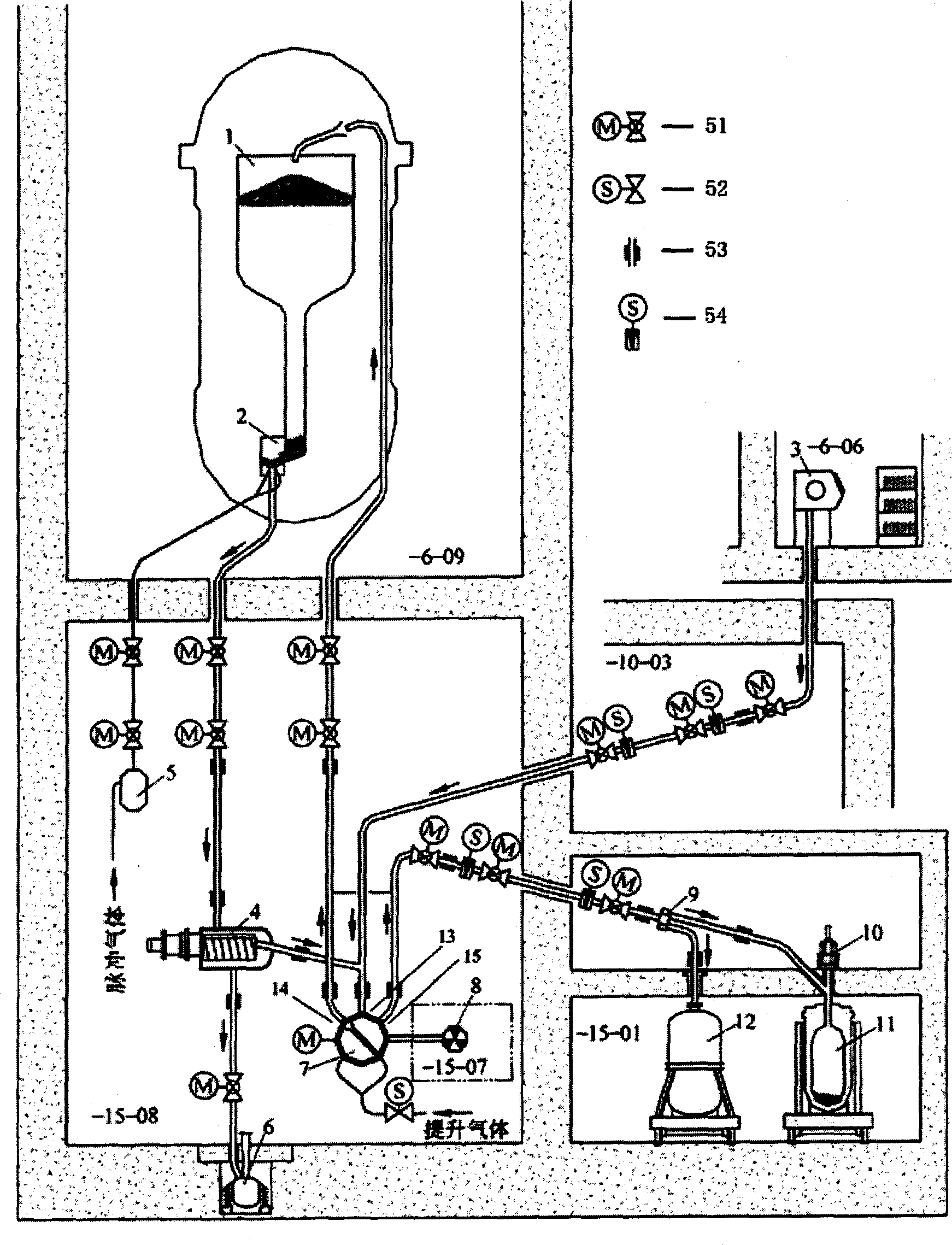

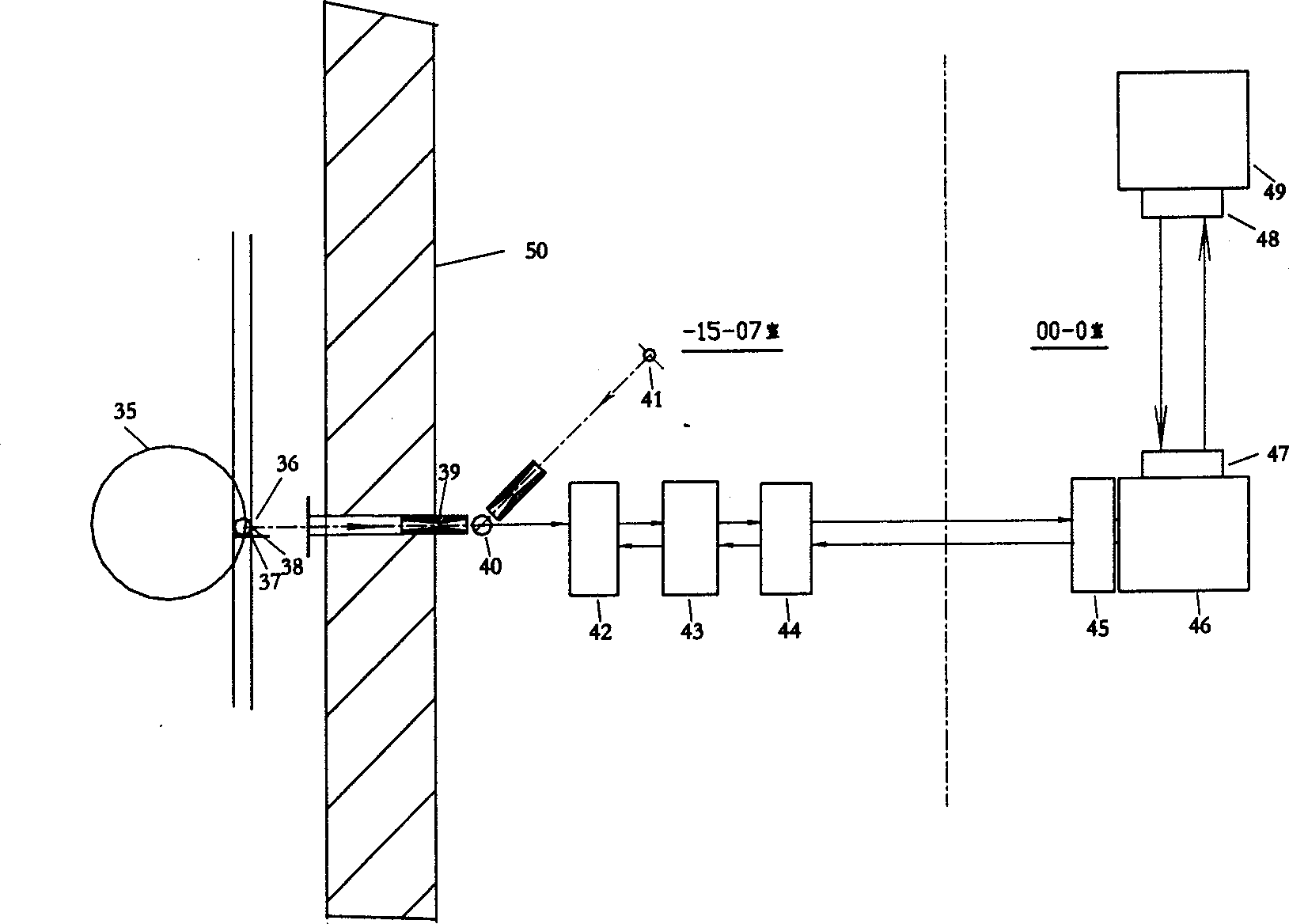

Online measuring method for burn-up level of fuel element of sphere type modular high-temperature gas-cooling reactor

ActiveCN1866408AEasy to separateMode of operation is not affectedNuclear energy generationNuclear monitoringCounting rateNuclear reactor

The related testing technique for nuclear reactor comprises: the upper machine starts up burn-up level measuring program; the fuel element is radiated and cooled; the PLC controls to send the element to lift position with same axis as the collimator and then notify the upper machine for measurement; the high-pure gamma-spectrometer measures the count of 0.661642MeV gamma radioactive ray emitted by 137Cs during decay, and calculates counting rate for the ray to determine whether takes out the core or returns to original core for work, and it sends the measured result to the main control system through a PLC. This invention is not to contact.

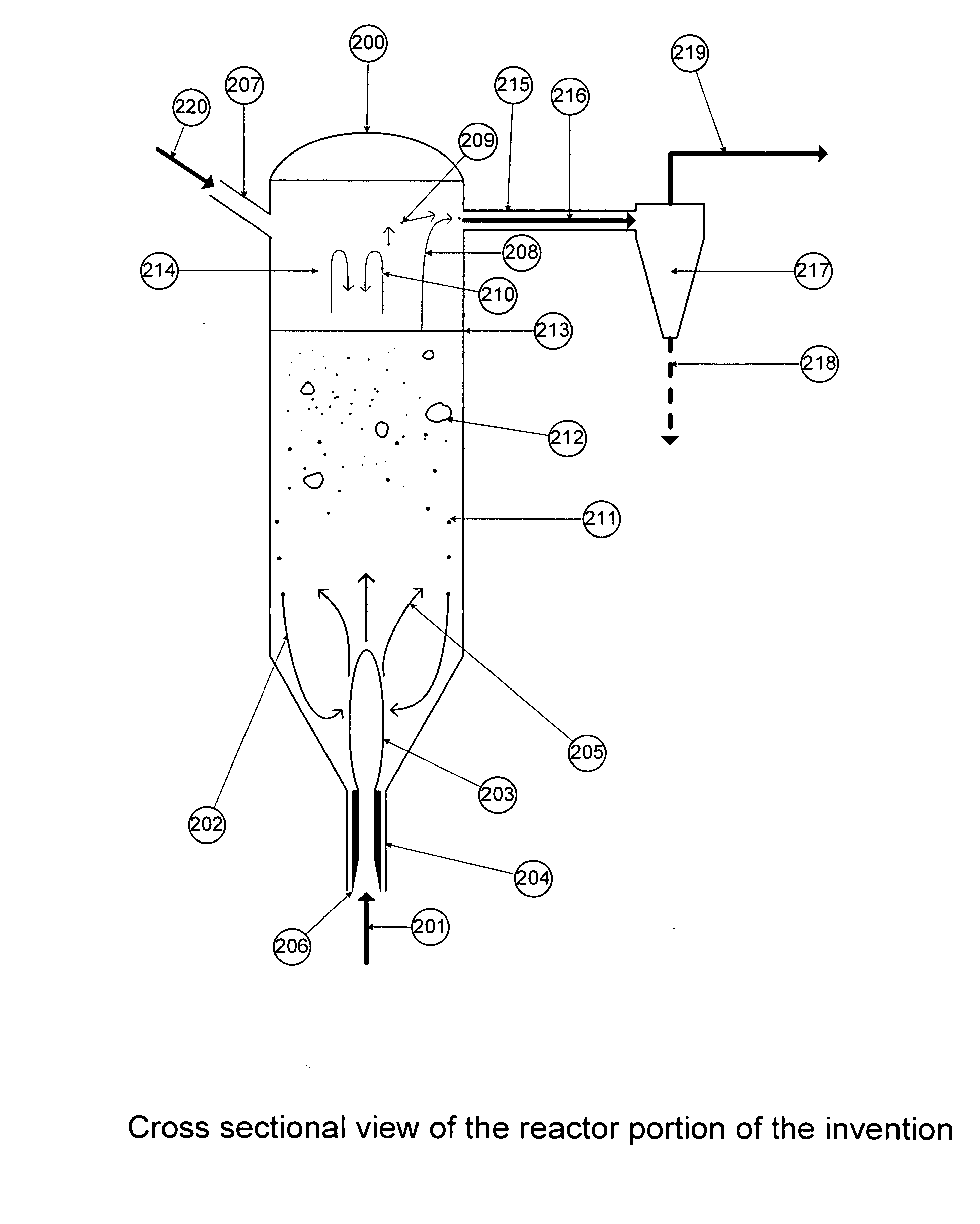

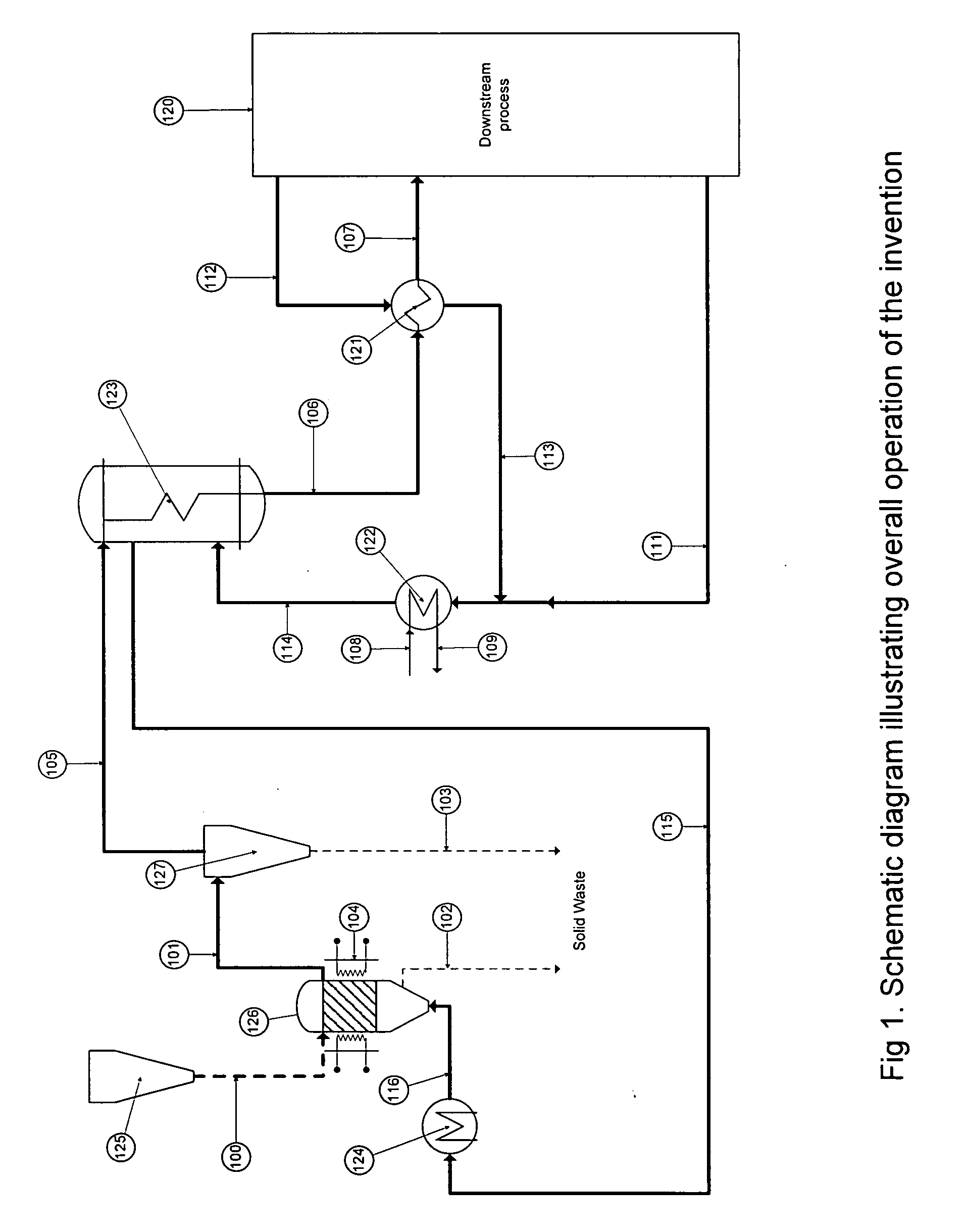

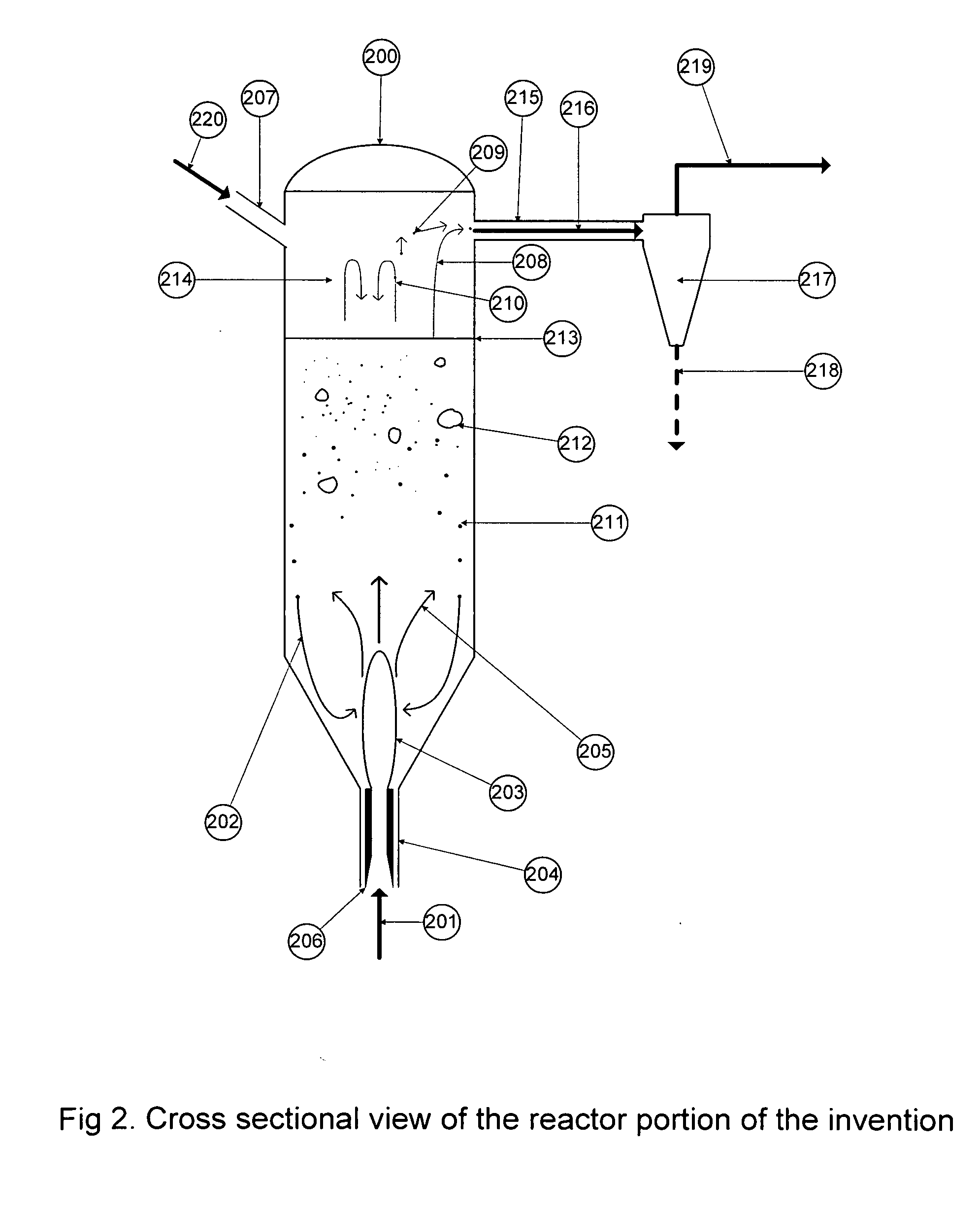

Apparatus and process for hydrogenation of a silicon tetrahalide and silicon to the trihalosilane

ActiveUS20100111804A1High yieldReduce manufacturing costFluidised-bed furnacesPressure vessels for chemical processHydrogenPolysilicon halides

A reactor for hydrogenation of a silicon tetrahalide and metallurgical grade silicon to trihalosilane includes a bed of metallurgical silicon particles, one or more gas entry ports, one or more solids entry ports, one or more solids drains and one or more ports for removing the trihalosilane from the reactor. Fresh surfaces are generated on the bed particles by internal grinding and abrasion as a result of entraining feed silicon particles in a silicon tetrahalide / hydrogen feed stream entering the reactor and impinging that stream on the bed of silicon particles. This has the advantages of higher yield of the trihalosilane, higher burnup rate of the MGS, removal of spent MGS as a fine dust carryover in the trihalosilane effluent leaving the reactor and longer times between shutdowns for bed removal.

Owner:LORD LTD LP

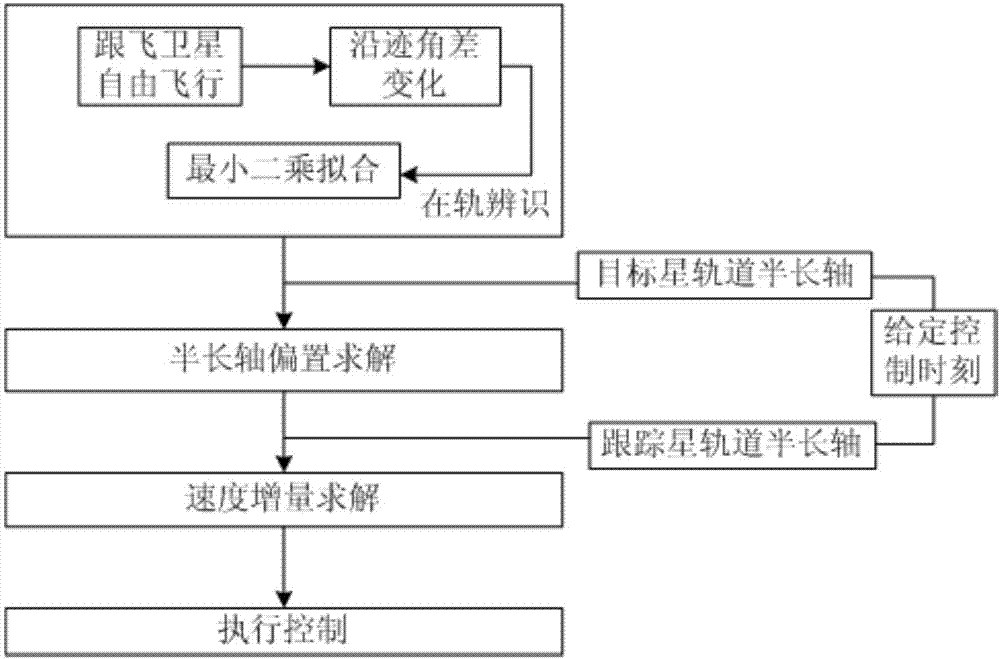

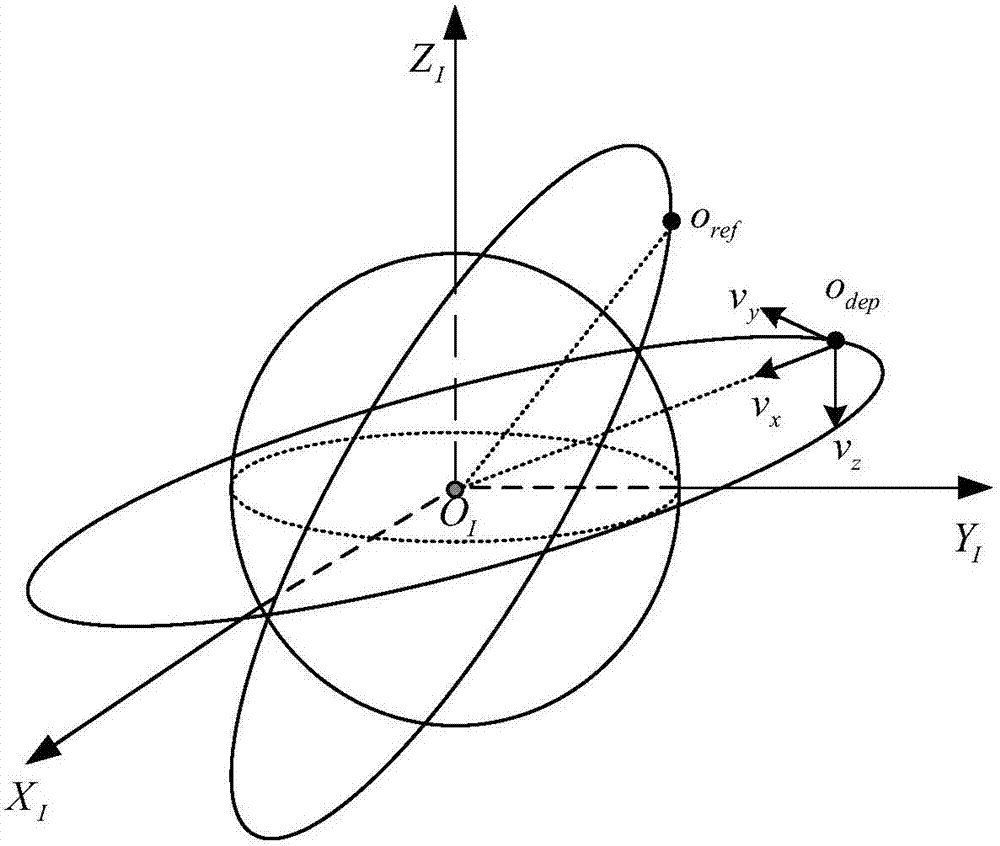

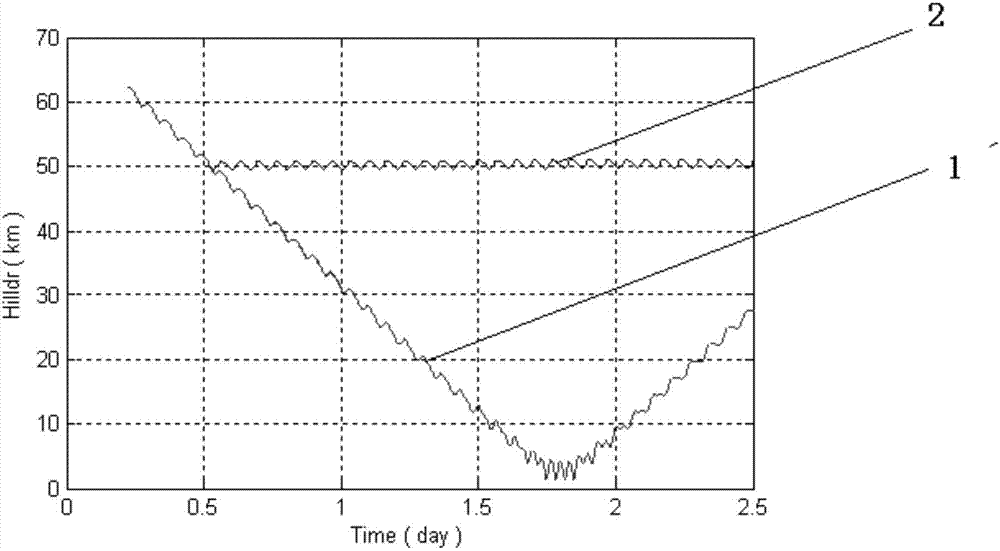

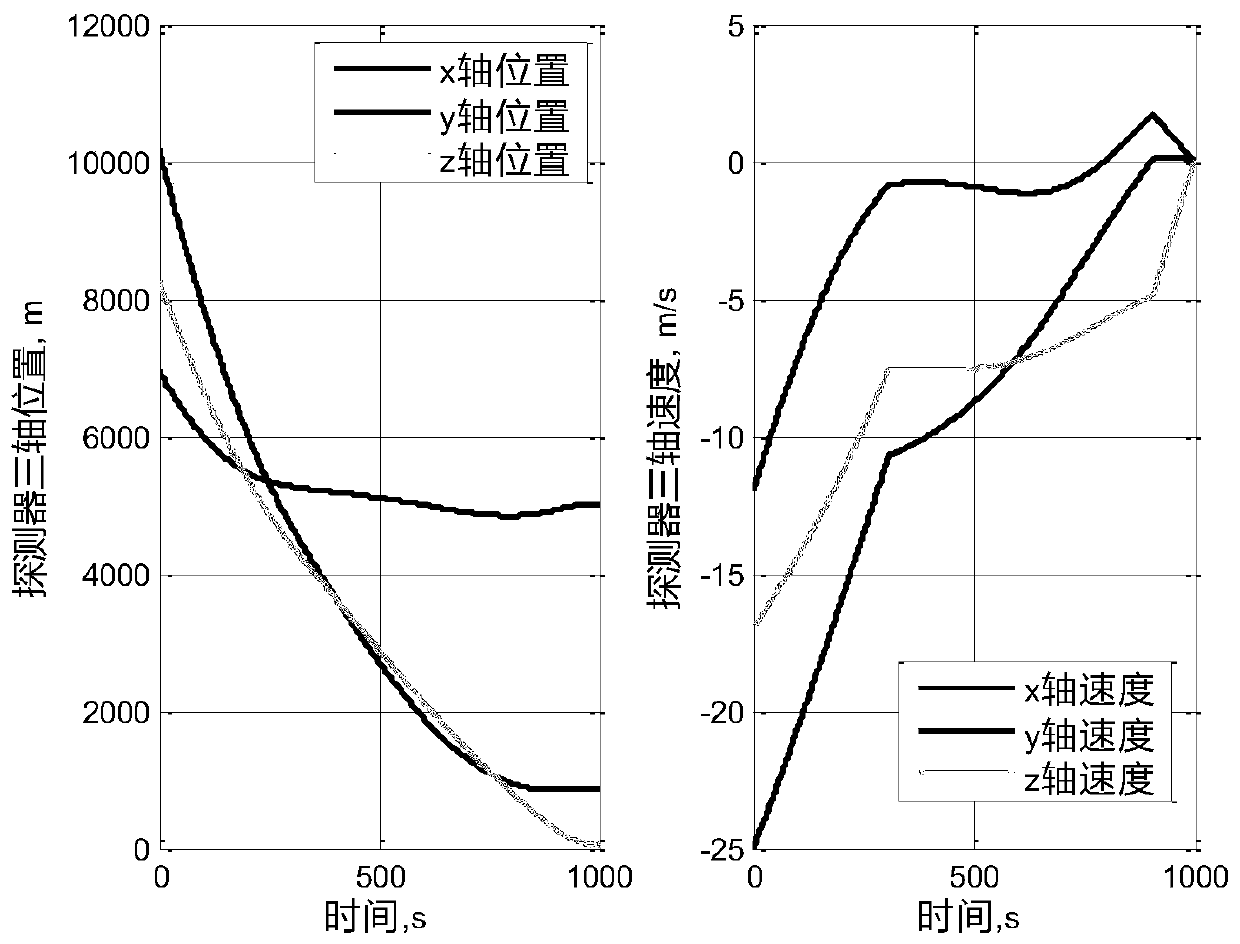

Satellite flight-tracking secular perturbation compensation method based on on-orbit parameter identification and offset

ActiveCN107168372AIncrease flexibilityReduce fuel loadPosition/course control in three dimensionsBurnupOrbit

The invention provides a satellite flight-tracking secular perturbation compensation method based on on-orbit parameter identification and offset, and the method comprises the following steps: 1, carrying out the on-orbit identification of an along-track angle relative drift rate; 2, calculating an orbit semi-major axis offset of a tracking satellite at a given control moment based on the along-track angle relative drift rate obtained at step 1; 3, giving an orbit semi-major axis of the tracking satellite at the control moment, and obtaining the velocity increment, needed by the orbit semi-major axis offset control, of the tracking satellite according to an orbit dynamical model. The method is advantageous in that the (1), the method has no requirements for the control time, and improves the flexibility of formation keeping control; (2), the method is low in control burnup, and effectively reduces the fuel load of a satellite formation; (3), the method can achieve the long-time natural maintaining through one control operation, and reduces the control frequency.

Owner:TSINGHUA UNIV

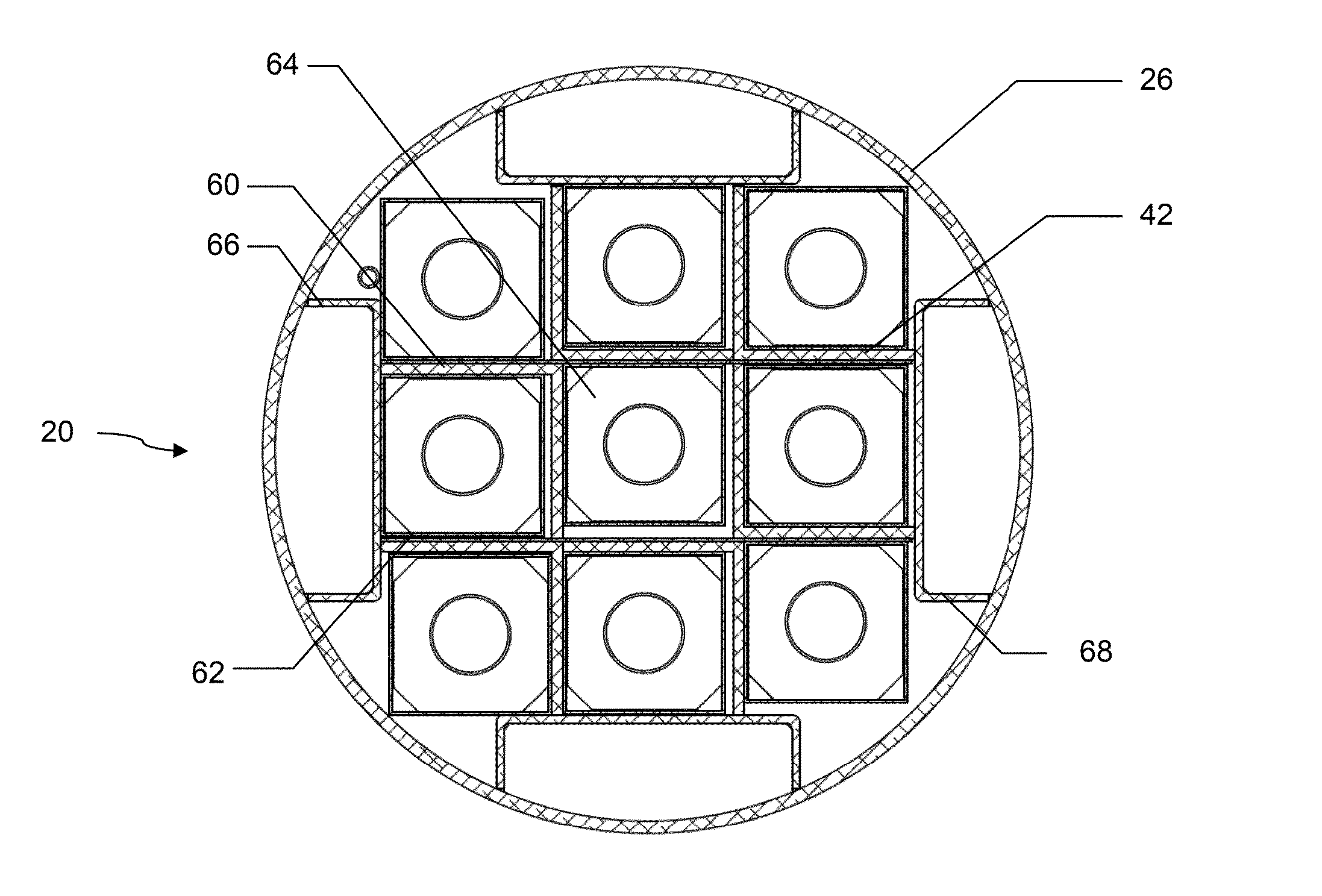

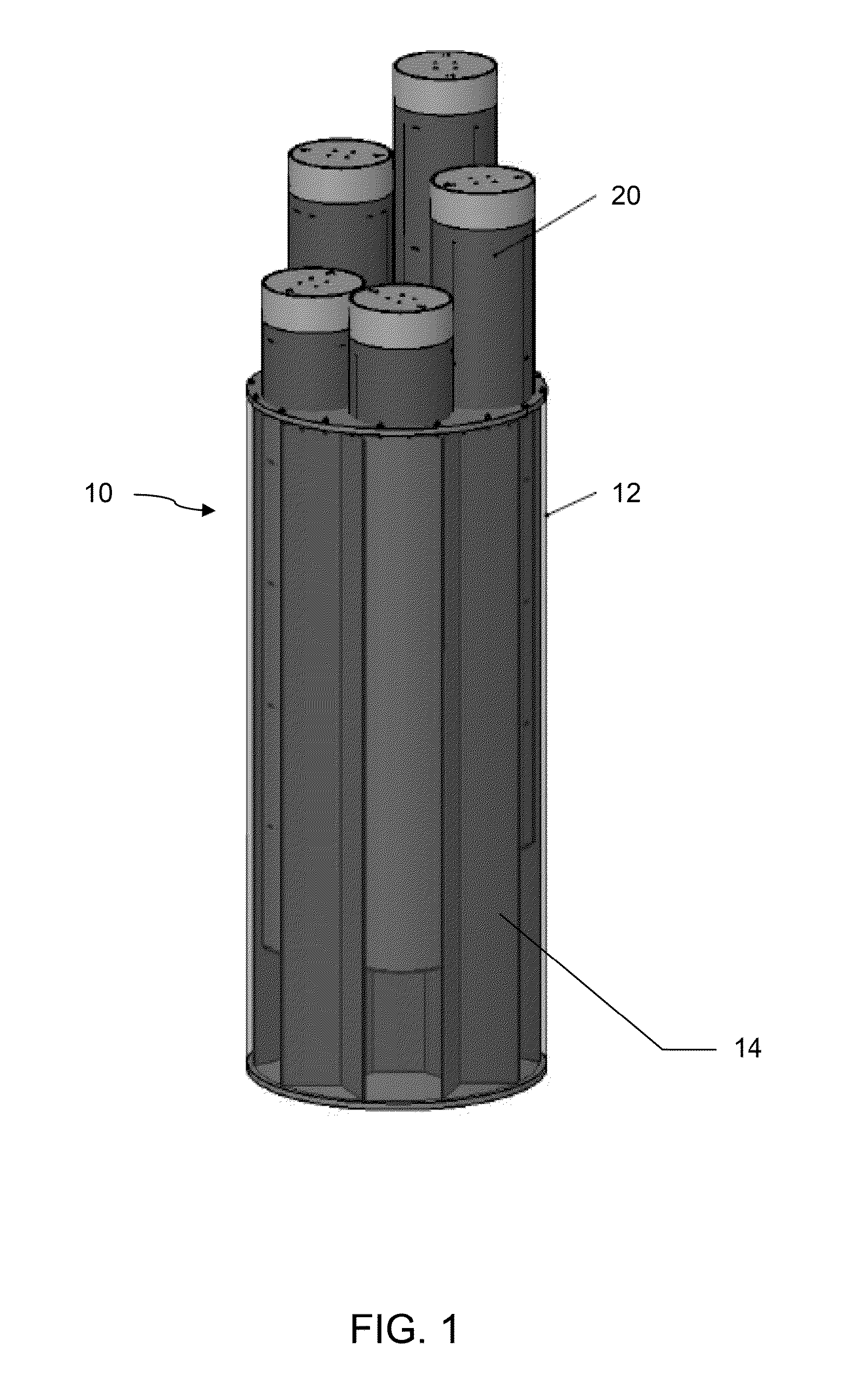

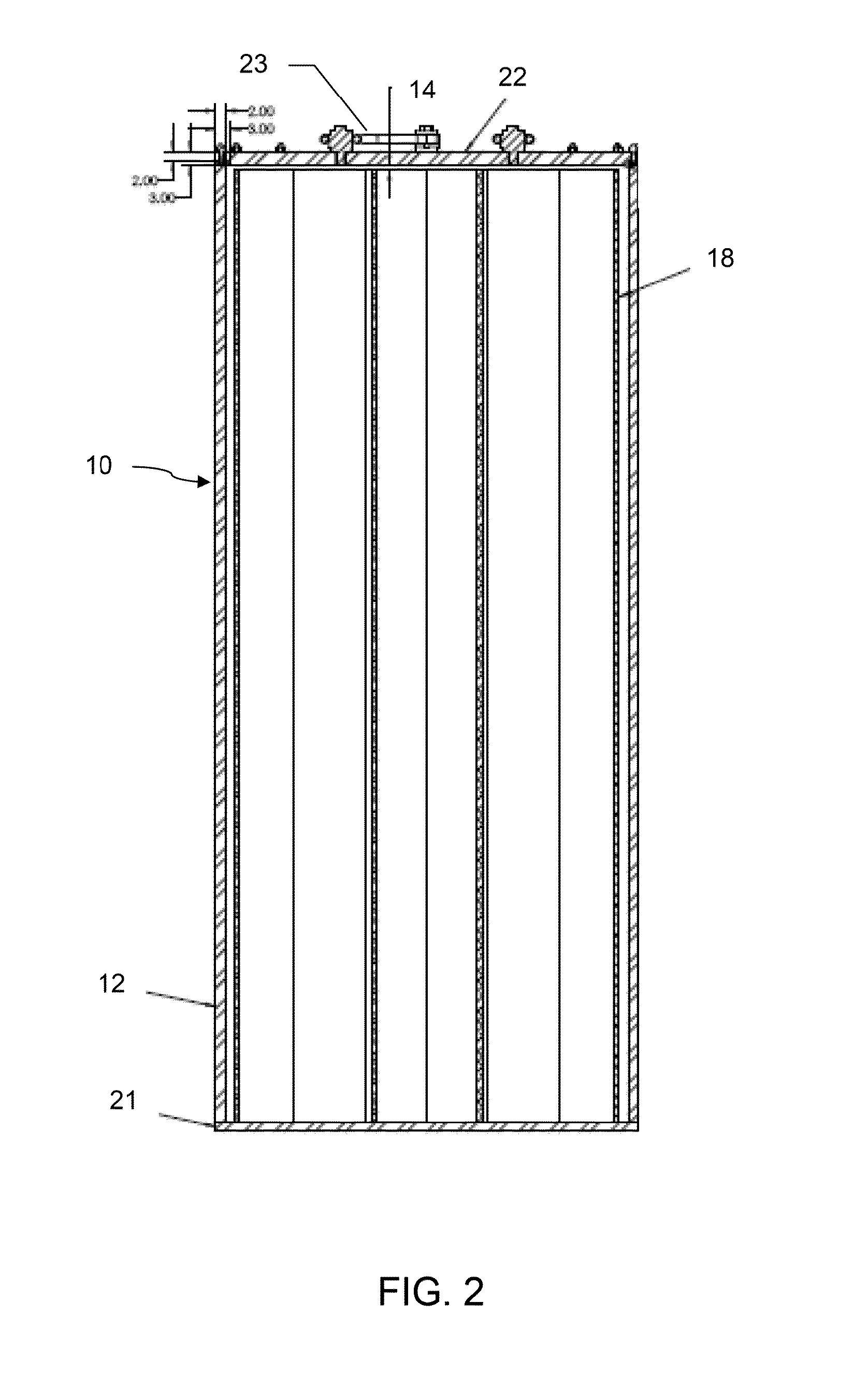

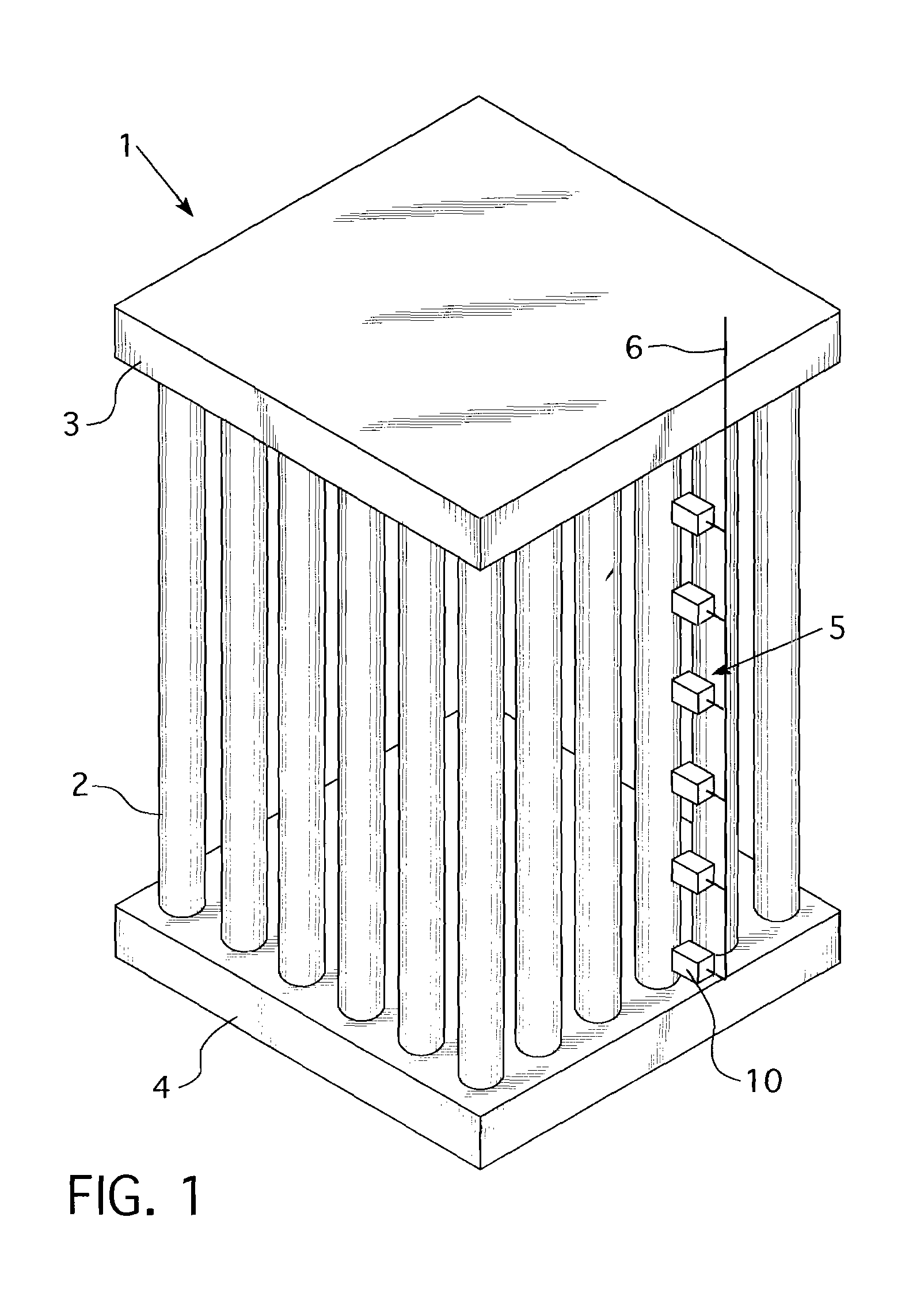

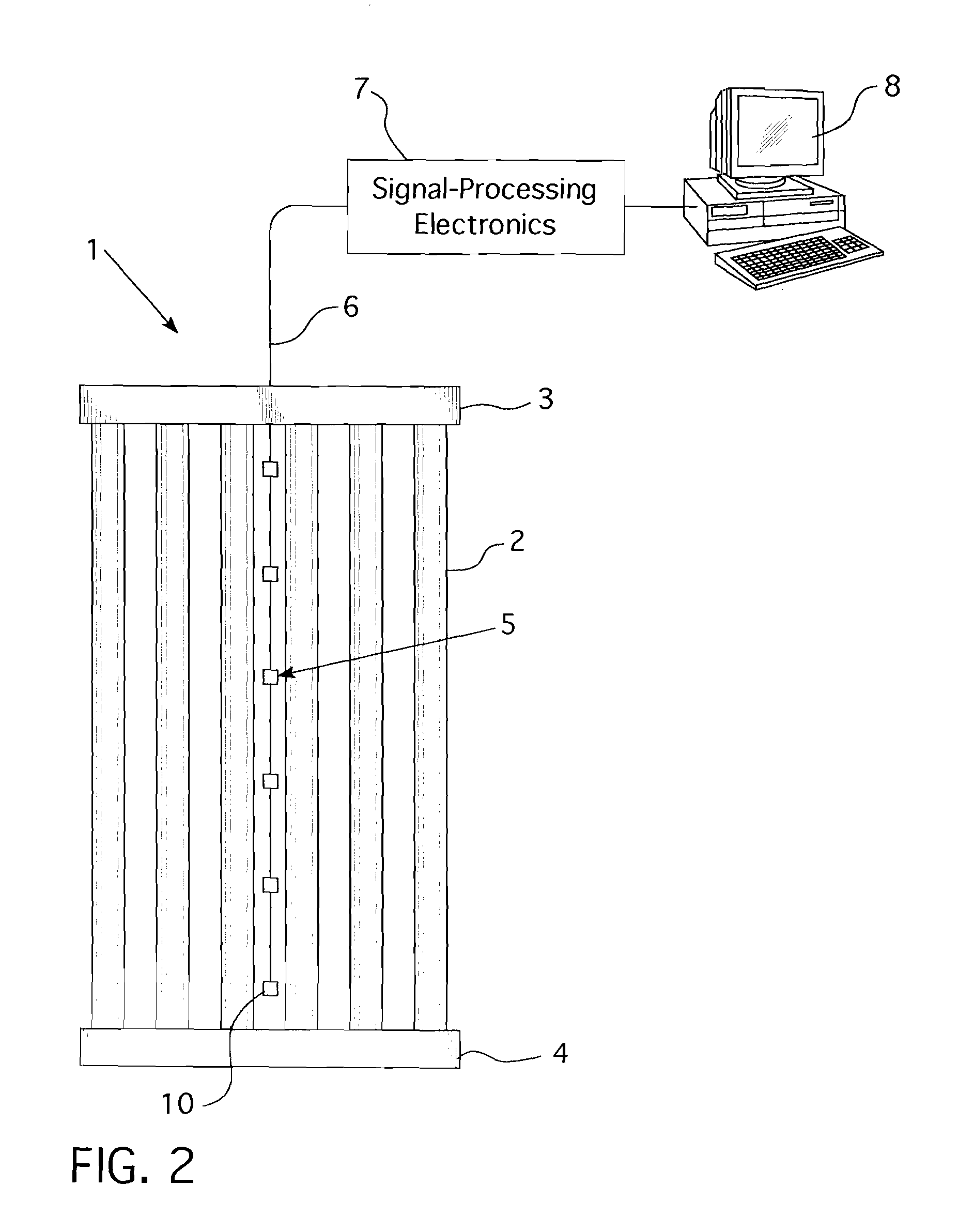

Storage, transportation and disposal system for used nuclear fuel assemblies

ActiveUS20130077728A1Eliminate needMinimize the numberPortable shielded containersReactor fuel elementsHandling systemBurnup

An integrated storage, transportation and disposal system for used fuel assemblies is provided. The system includes a plurality of sealed canisters and a cask sized to receive the sealed canisters in side by side relationship. The plurality of sealed canisters include an internal basket structure to receive a plurality of used fuel assemblies. The internal basket structure includes a plurality of radiation-absorbing panels and a plurality of hemispherical ribs generally perpendicular to the canister sidewall. The sealed canisters are received within the cask for storage and transportation and are removed from the cask for disposal at a designated repository. The system of the present invention allows the handling of sealed canisters separately or collectively, while allowing storage and transportation of high burnup fuel and damaged fuel to the designated repository.

Owner:UT BATTELLE LLC

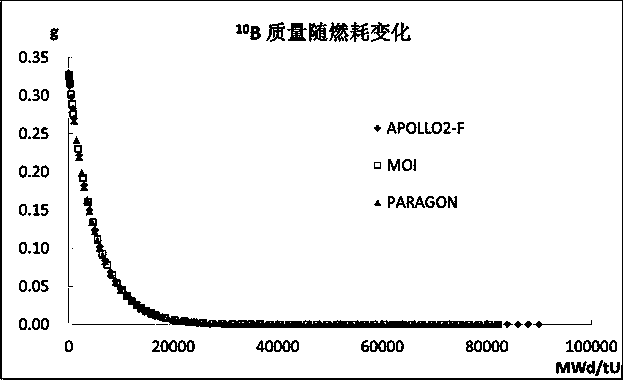

Calculation method for non-fuel burnable poison burn-up in reactor

ActiveCN104021278AReasonable combustion modeRun reasonablySpecial data processing applicationsConstant powerComputer science

The invention discloses a calculation method for non-fuel burnable poison burn-up in a reactor. The calculation method includes the steps that (a), total power is input for burn-up calculation in the reactor; (b), power and flux of all burn-up regions are distributed; (c), constant power burn-up calculation is adopted for a fuel region, and constant-flux burn-up calculation is adopted for a non-fuel burnable poison region. The mixed burn-up calculation mode based on the Monte Carlo method is adopted; for the fuel region, the constant power mode is adopted for burn-up; for the ultra-low power regions of non-fuel burnable poison, thorium-base fuel and others, the constant-flux mode is adopted for burn-up. The application range of burn-up calculation based on the Monte Carlo method is enlarged, and the method can be used for performing processing including burning calculation on the ultra-low power regions of the non-fuel burnable poison, the thorium-base fuel and others. The calculation amount is not added, so that unnecessary approximation is avoided, burn-up calculation is performed directly according to the actual power level, and the confidence coefficient of the burn-up level is guaranteed.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Chemical separation procedure for burnup analysis of spent fuel element

ActiveCN103337265AChemical separation achievedReduce radiation doseNuclear energy generationNuclear monitoringIon exchangeChemical separation

The invention relates to a chemical separation procedure for burnup analysis of a spent fuel element. The chemical separation procedure comprises the following steps of: (I) dissolving a spent fuel element block, namely putting the spent fuel element block into concentrated nitric acid and concentrated hydrochloric acid mixed liquid with the volume ratio of 3:1 to make the spent fuel element block be completely dissolved, and cooling the dissolving liquid to room temperature; (II) diluting the dissolving liquid, namely mixing the dissolving liquid cooled in the step (I) and nitric acid, uniformly stirring the dissolving liquid and the nitric acid to obtain diluted dissolving liquid; and (III) separating uranium, plutonium, molybdenum and neodymium by a column chromatography method through the diluted dissolving liquid obtained in the step (II). The invention establishes a novel chemical separation procedure for measuring the burnup of the spent fuel element; according to the chemical separation procedure, some novel levextrel, ion exchange material and high performance liquid chromatography technologies are adopted, so that chemical separation of the uranium, the plutonium, the molybdenum and the neodymium is realized; the operation procedure is greatly simplified; the operation difficulty is reduced; and the radiation to researchers is reduced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Method for preparing blast furnace ironmaking burden from full-vanadium titanium magnetite concentrate

ActiveCN103103347AImprove granulation effectImprove thermal stabilityBlast furnace detailsAlkalinityMagnetite

The invention discloses a method for preparing blast furnace ironmaking burden from full-vanadium titanium magnetite concentrate, which comprises the following steps of: dividing the full-vanadium titanium magnetite concentrate into two parts according to a proportion of (30-75%):(70-25%) by mass; preparing one part of the vanadium titanium magnetite concentrate into spherical material with the particle size of 3-7.5mm; externally rolling slaked lime accounting for 0.1-0.5% of the spherical material by mass to obtain low-alkalinity spherical material with the alkalinity of 0.29-0.38 and particle size of less than 8mm; dosing the other part of vanadium titanium magnetite concentrate with solid fuel, solvent and return mine, mixing and granulating to obtain a high-alkalinity mixture with alkalinity of 3.3-5.0; uniformly mixing the low-alkalinity spherical material with the high-alkalinity mixture, and applying the mixture to a belt type sintering machine; and igniting and sintering to obtain the finished product of sinter. The method disclosed by the invention can obviously reduce solid burnup and improve the quality index of the sintering product, and is easy to realize large-scale industrial production.

Owner:CENT SOUTH UNIV

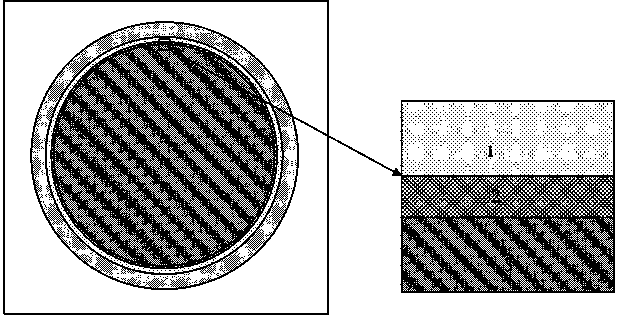

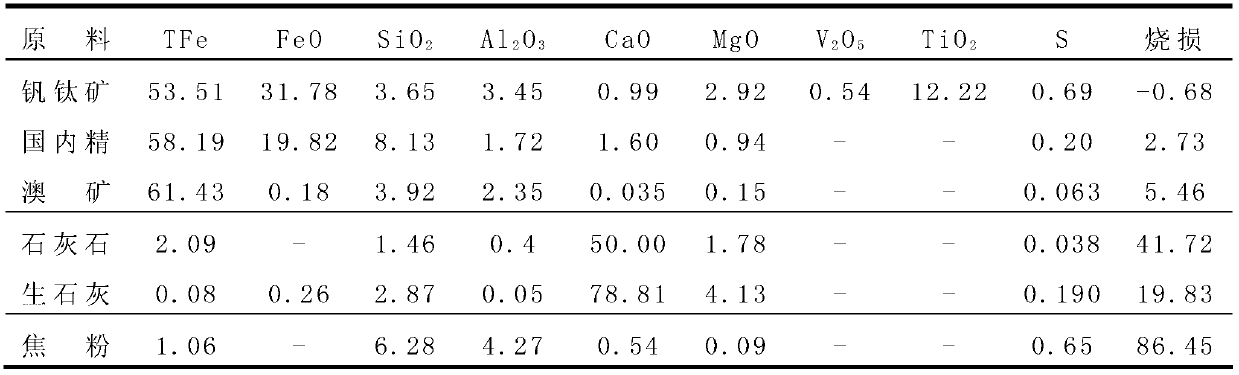

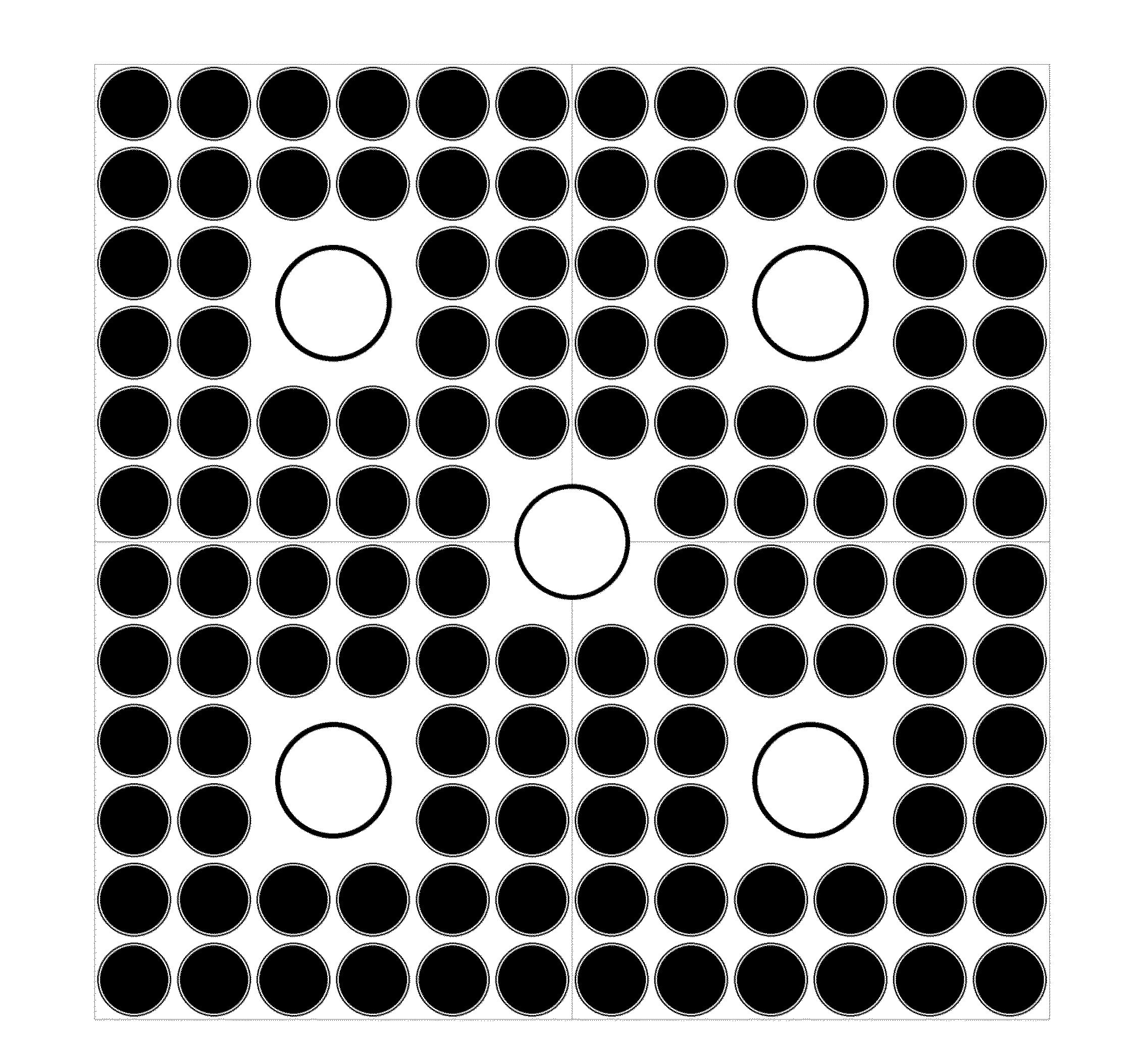

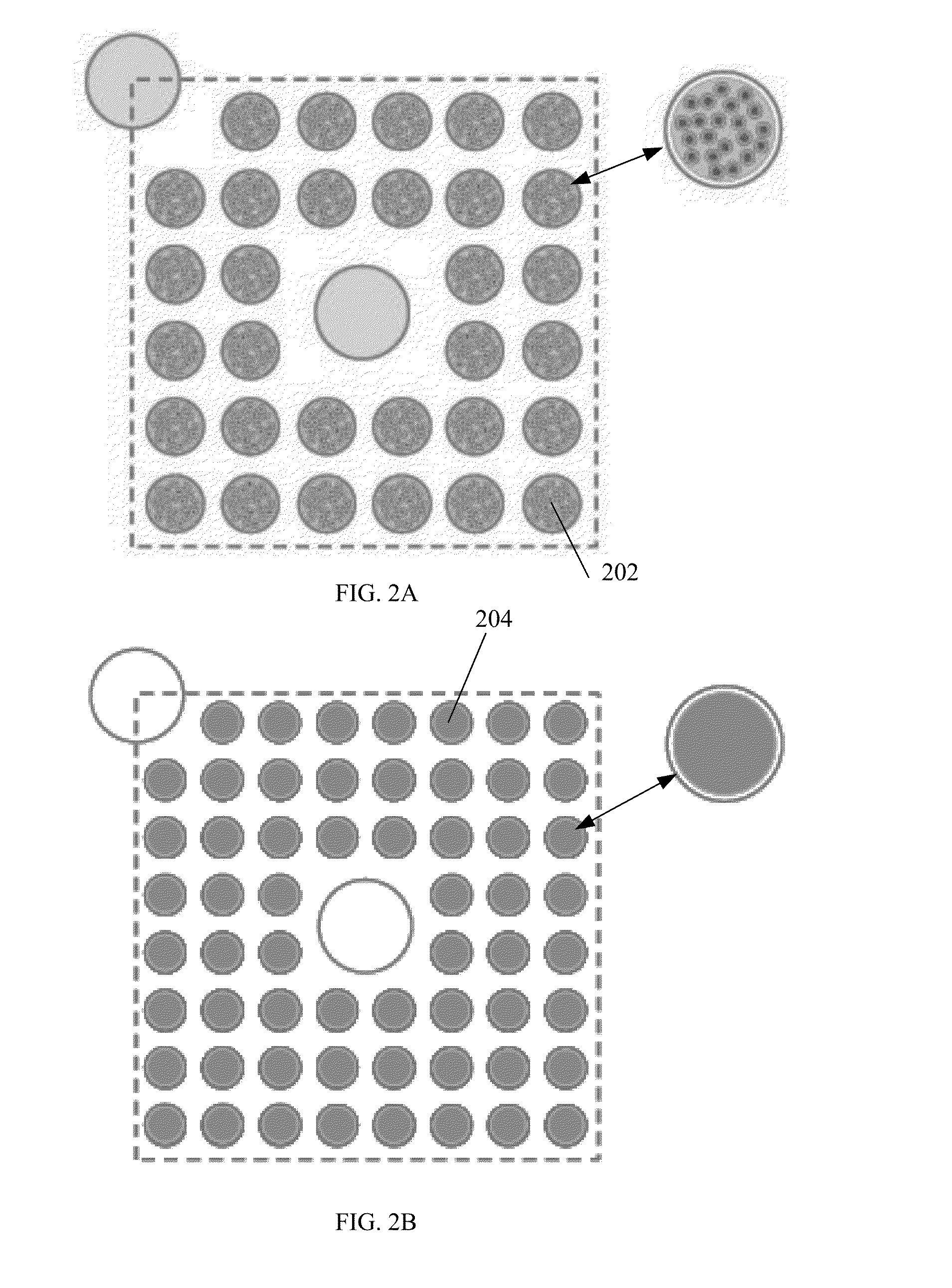

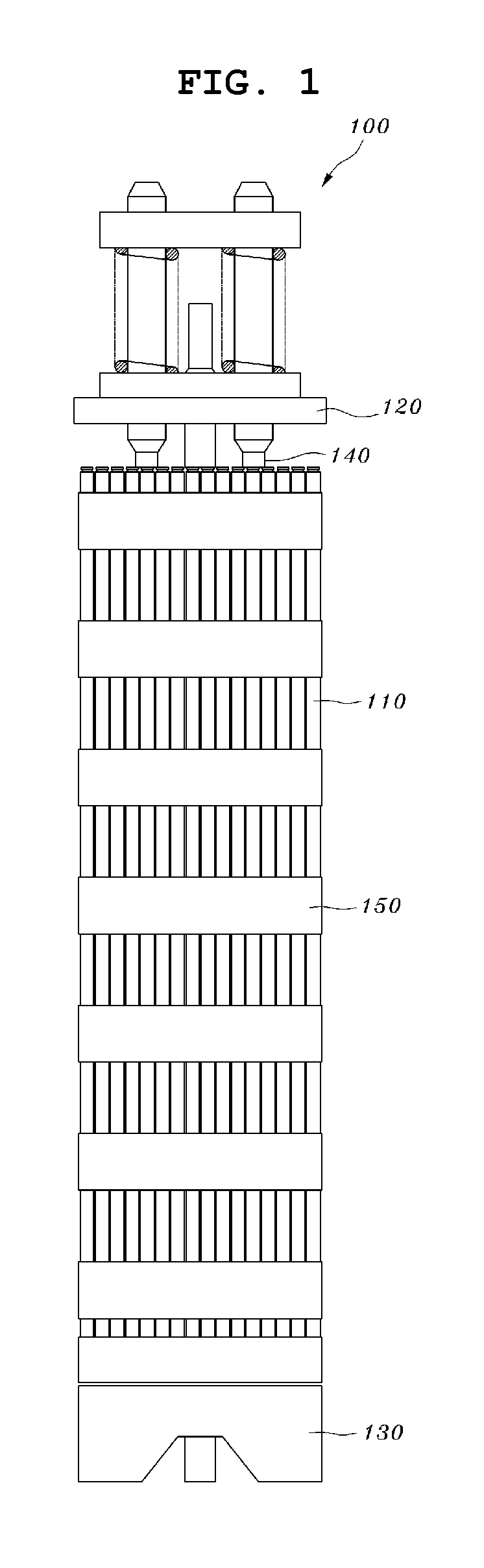

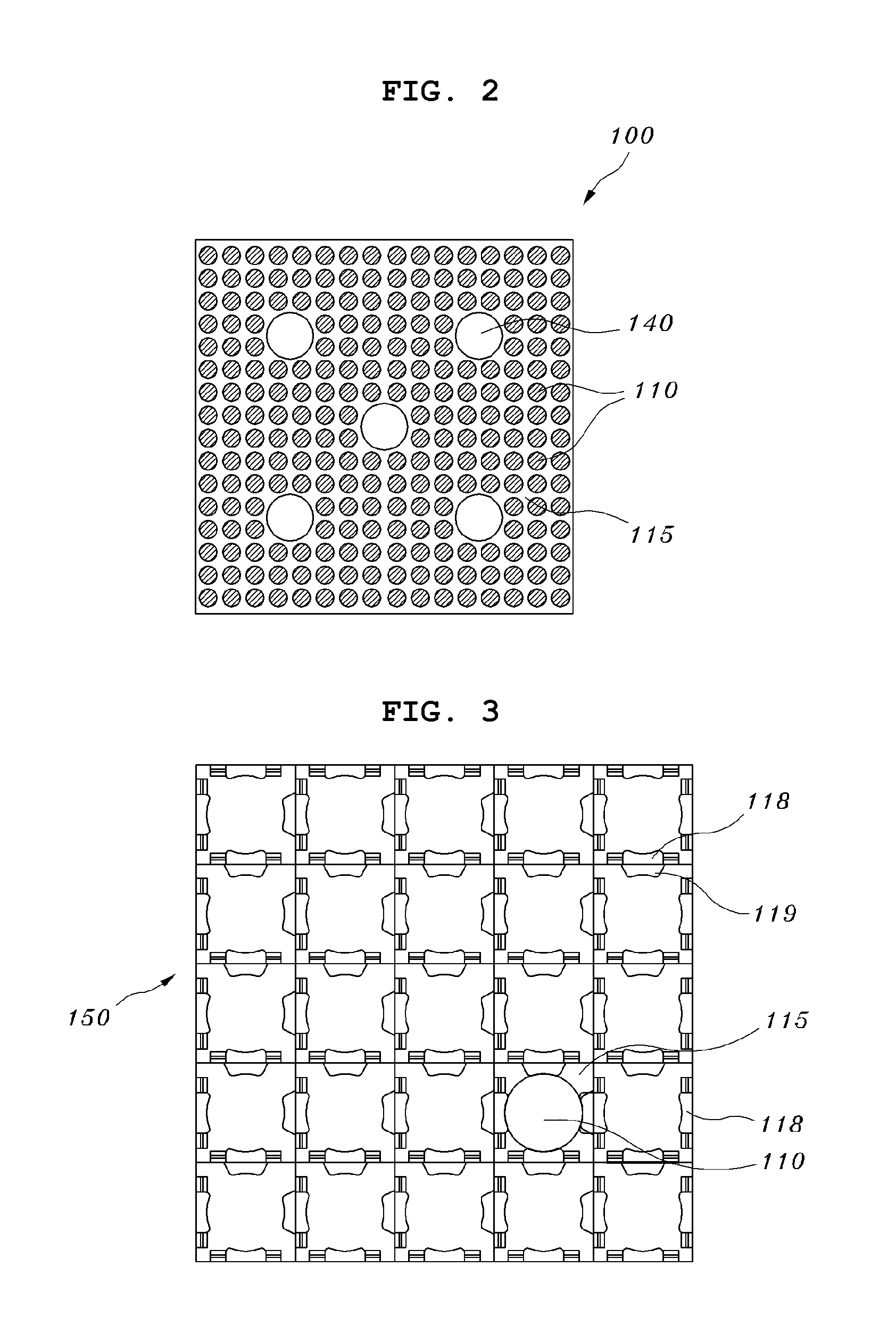

Fully ceramic microencapsulated replacement fuel assemblies for light water reactors

InactiveUS20130114781A1Quality improvementImprove securityOptical rangefindersNuclear energy generationAlternative fuelsBurnup

A fully ceramic micro-encapsulated fuel assembly for a light water nuclear reactor includes a set of FCM fuel rods bundled in a square matrix arrangement. Fully ceramic micro-encapsulated fuel assemblies replace standard reference solid fuel assemblies with smaller number of FCM fuel rods that have a larger diameter than the diameter of the solid standard reference fuel rods, while keeping similar amounts of fissile material in the fuel assembly and maintaining comparable rates of burnup and number of EFPDs, and compatible power production, heat transfer and thermo-hydraulic features. A fully ceramic micro-encapsulated fuel rod includes multiple fully ceramic micro-encapsulated fuel pellets, which are comprised of tristructural-isotropic particles. In order to obtain compatible burnup rates with the standard reference fuel, the tristructural-isotropic particles have preferentially large diameter and packing fraction. Furthermore, Erbium oxide is included in the sintered mix of the SiC compact to serve as a burnable poison.

Owner:KOREA ATOMIC ENERGY RES INST

Pressurized water reactor core and refuelling loading method for new assemblies thereof

ActiveCN103151084ALow enrichmentLow costNuclear energy generationReactor fuel elementsPressurized water reactorBurnup

The invention discloses a pressurized water reactor core and a refuelling loading method for new assemblies thereof. According to the refuelling loading method for the new assemblies, during loading of a batch of new assemblies, a same amount of burnt-up assemblies are discharged; for a same batch of loaded new assemblies, a part of the new assemblies are to be discharged from the pressurized water reactor core after N cycles of burnup in core, and a rest part of the new assemblies are to be discharged from the core after N+1 cycles of burnup in the core, wherein N is a natural number, and during primary loading into the core, the degree of uranium enrichment in the part of the new assemblies is lower than the degree of uranium enrichment in the rest part of the new assemblies. With such a technical scheme provided by the invention, the new assemblies are of two degrees of enrichment, cyclic assemblies with low burnup may employ a low degree of enrichment, so fuel cost is reduced; meanwhile, a residual uranium enrichment degree of the assemblies during discharging of the assemblies can be reduced, and usage efficiency of a fuel can be improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +1

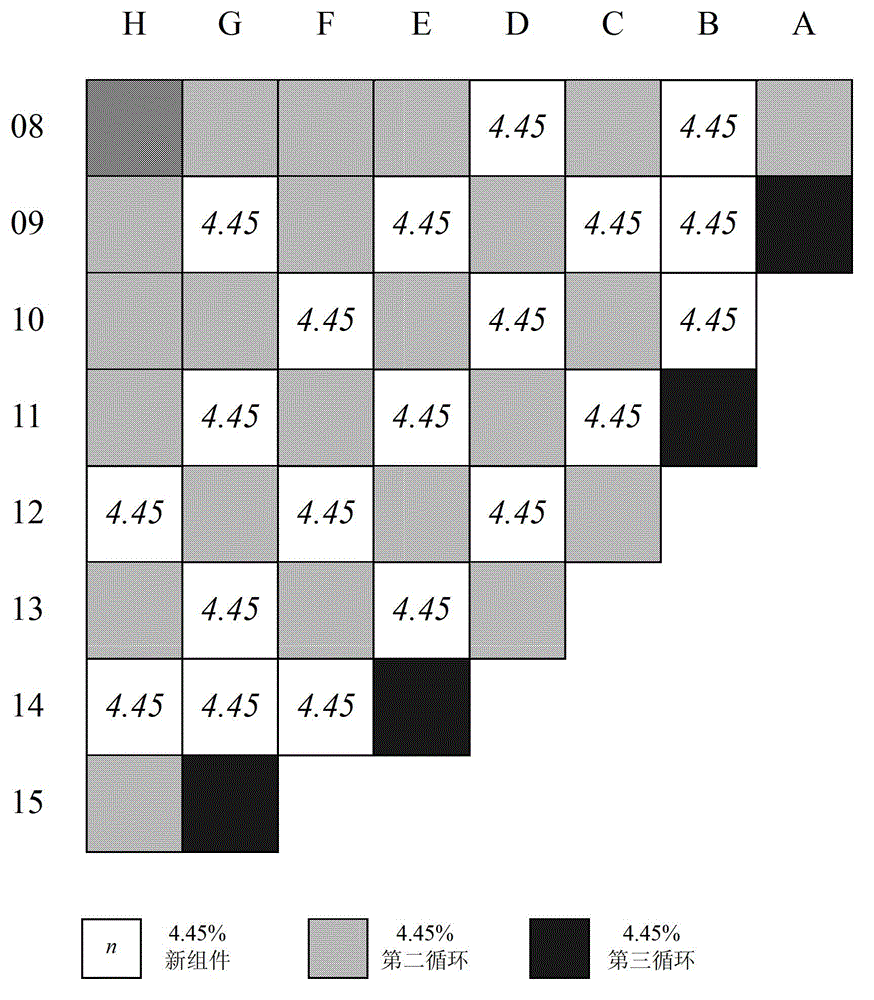

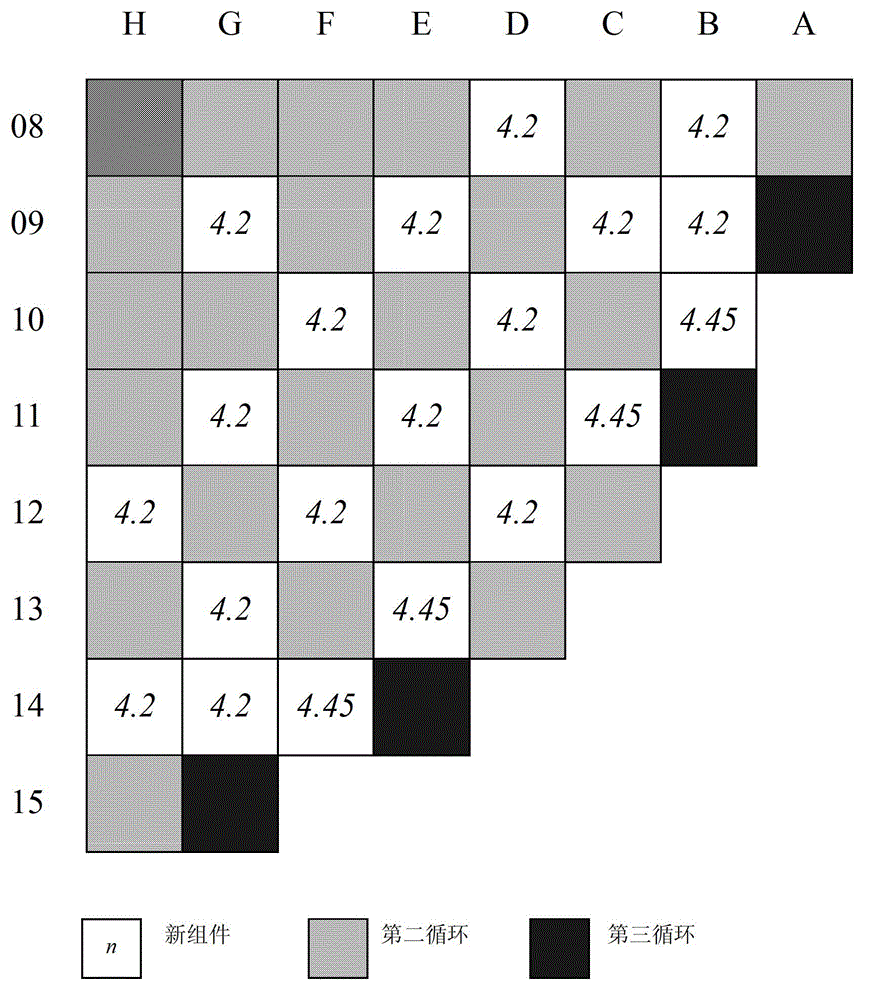

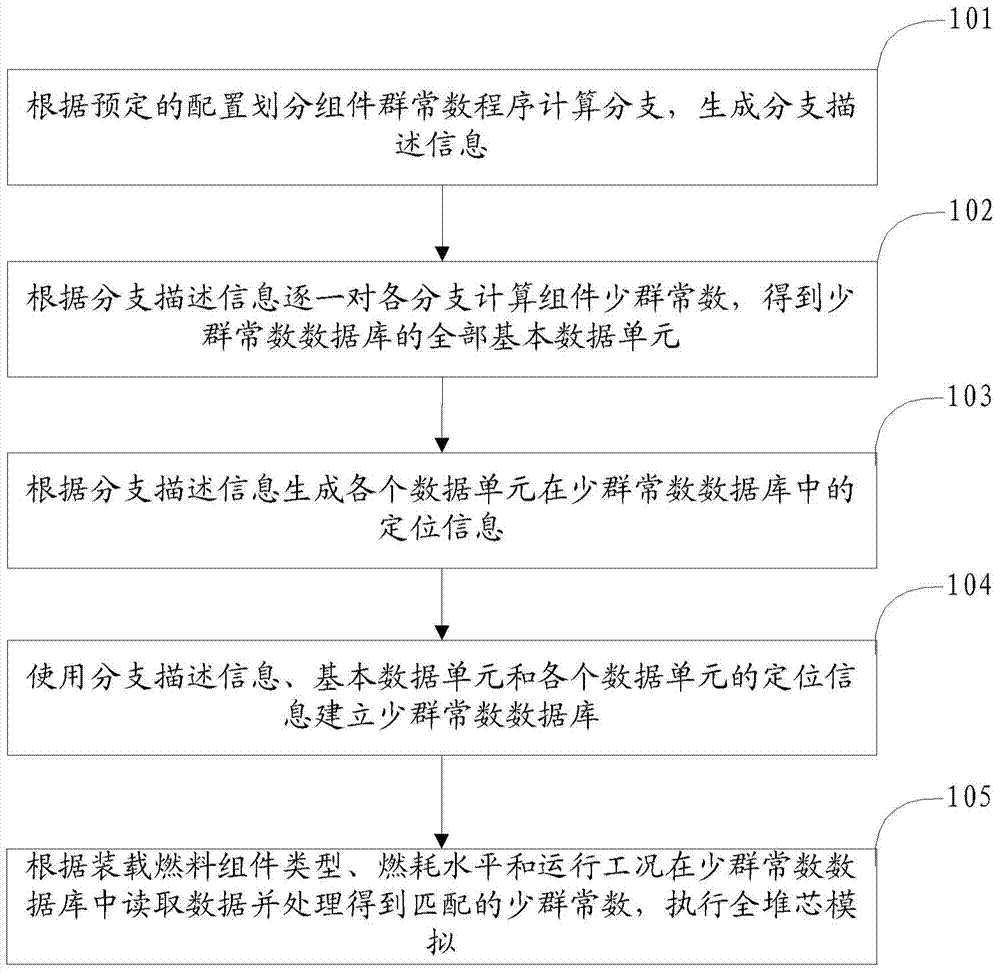

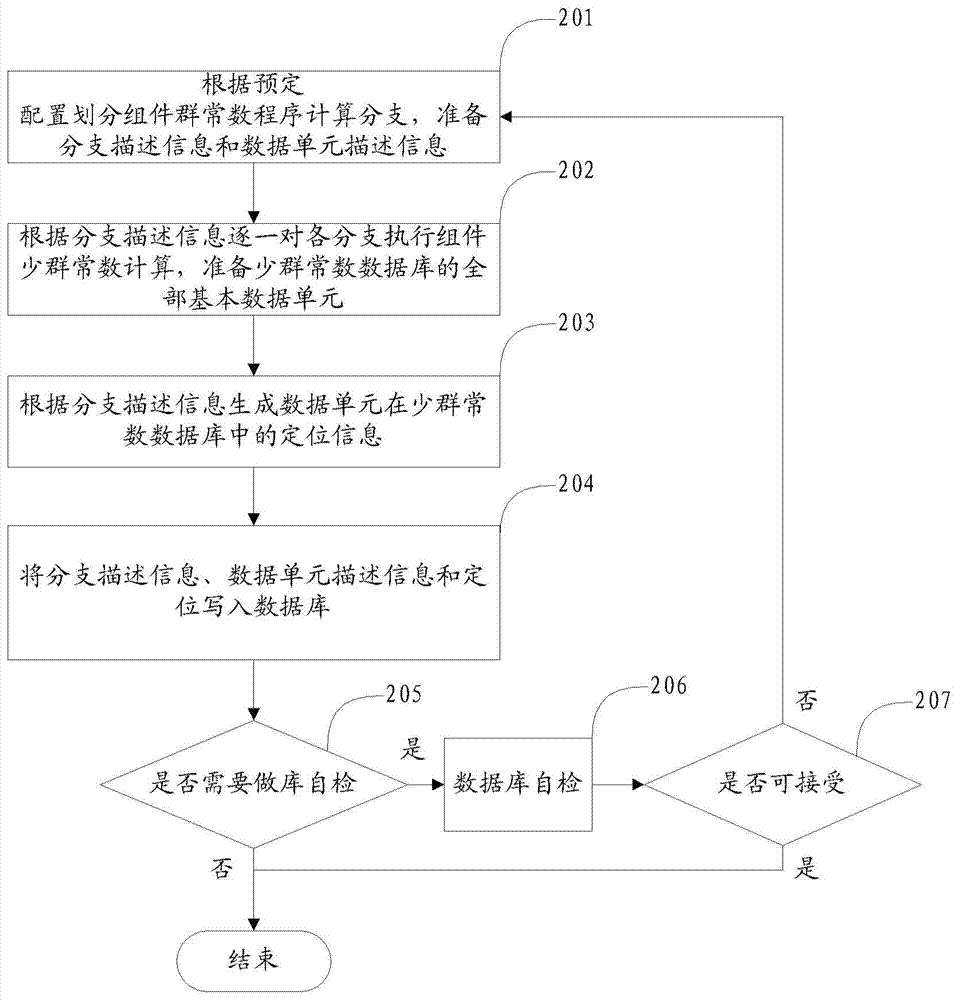

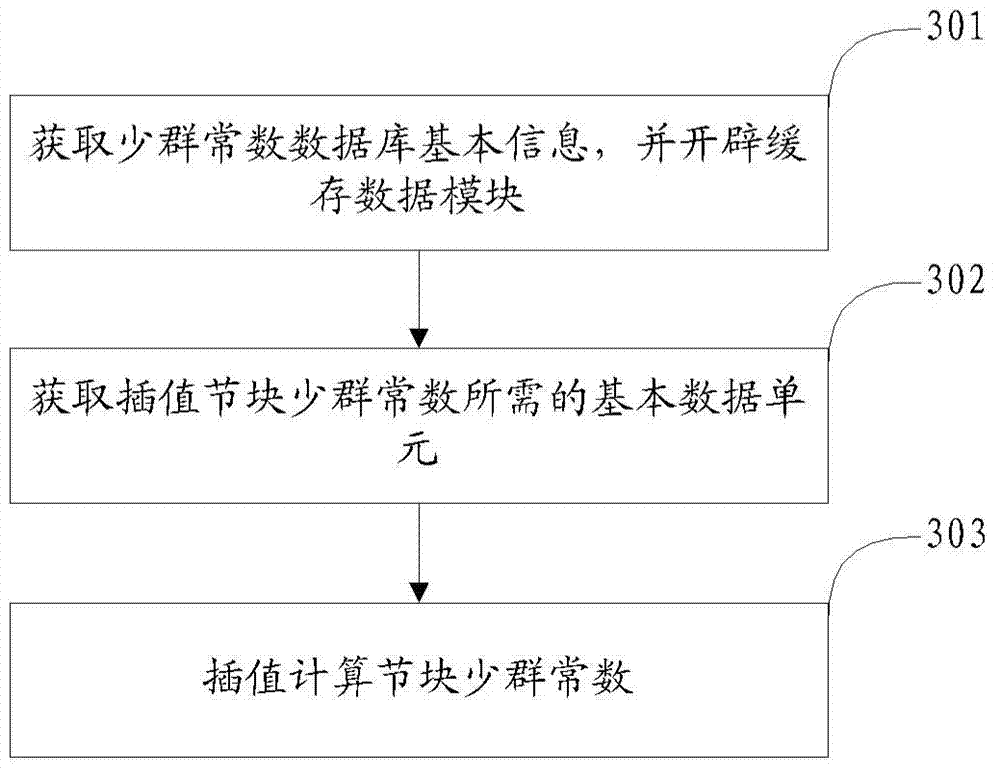

Reactor simulation method, database processing method and reactor simulation system

ActiveCN103617353AImprove efficiencyReduce the number of read operationsSpecial data processing applicationsParallel computingBurnup

The invention discloses a reactor simulation method, a database processing method and a reactor simulation system. The reactor simulation method includes: dividing assembly group constant program computation branches to generate branch description information; according to the branch description information, computing assembly few-group constants for the branches one by one to obtain all basic data units of a few-group constant database; according to the branch description information, generating positioning information of each data unit in the few-group constant database; using the branch description information, the basic data units and the positioning information of each data unit to establish the few-group constant database; according to fuel loading assembly type, burnup level and operating conditions, reading data from the few-group constant database, processing to obtain matched few-group constants, and executing full-reactor-core simulation. By the scheme, efficiency of processing the few-group constant database by reactor core programs is improved and universal applicability to numerical simulation and computation of various nuclear fuel assemblies is guaranteed.

Owner:STATE POWER INVESTMENT CORP RES INST

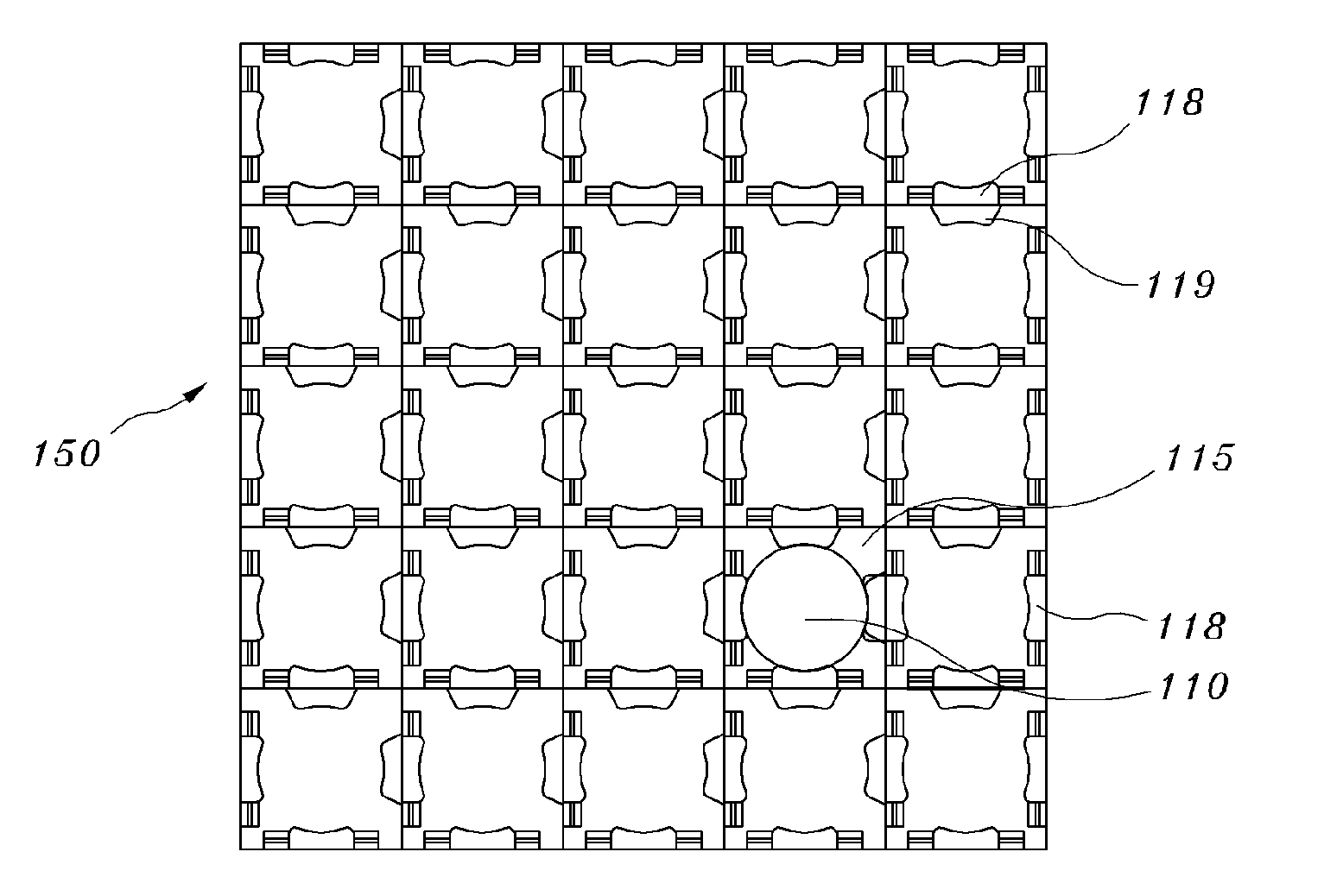

Spacer grid for dual-cooling nuclear fuel rods using intersectional support structures

ActiveUS20100027734A1Maintain compatibilityHigh impact strengthFuel elementsNuclear energy generationCross bracingBurnup

A spacer grid for dual-cooling nuclear fuel rods arranged at a narrow interval. The spacer grid solves the problem in which, since the dual-cooling nuclear fuel rods are used to improve the cooling performance and stability of nuclear fuel and obtain high burnup and output, the outer diameter of each dual-cooling nuclear fuel rod is increased, and thus the gap between each dual-cooling nuclear fuel rod and the grid strap is decreased. The spacer grid includes first grid straps and second grid straps, which are crossed and arranged in transverse and longitudinal directions at regular intervals and have the shape of a flat strip, and support structures, which are fitted into the first and second grid straps around intersections of the first and second grid straps so as to support the dual-cooling nuclear fuel rods.

Owner:KOREA ATOMIC ENERGY RES INST

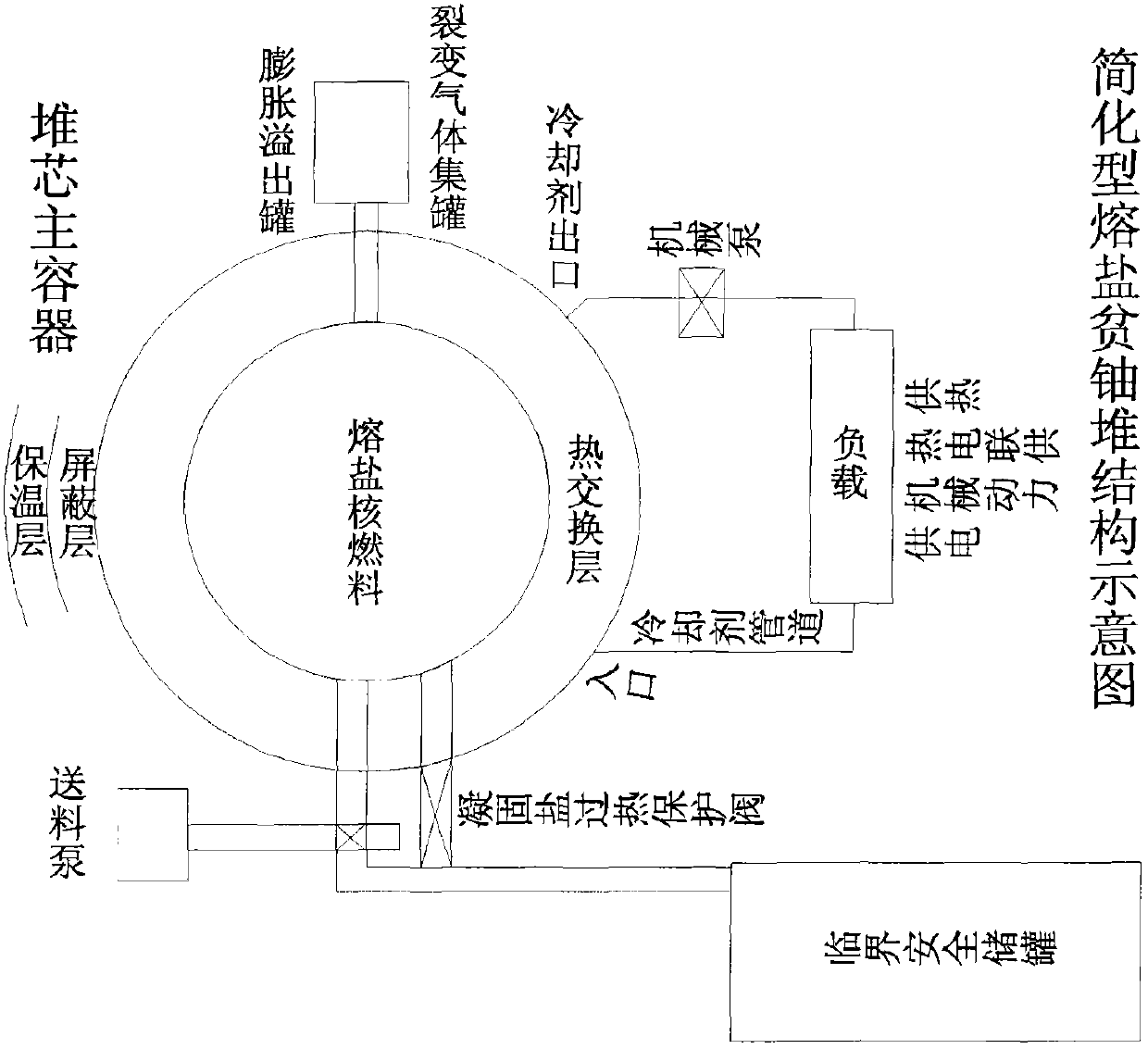

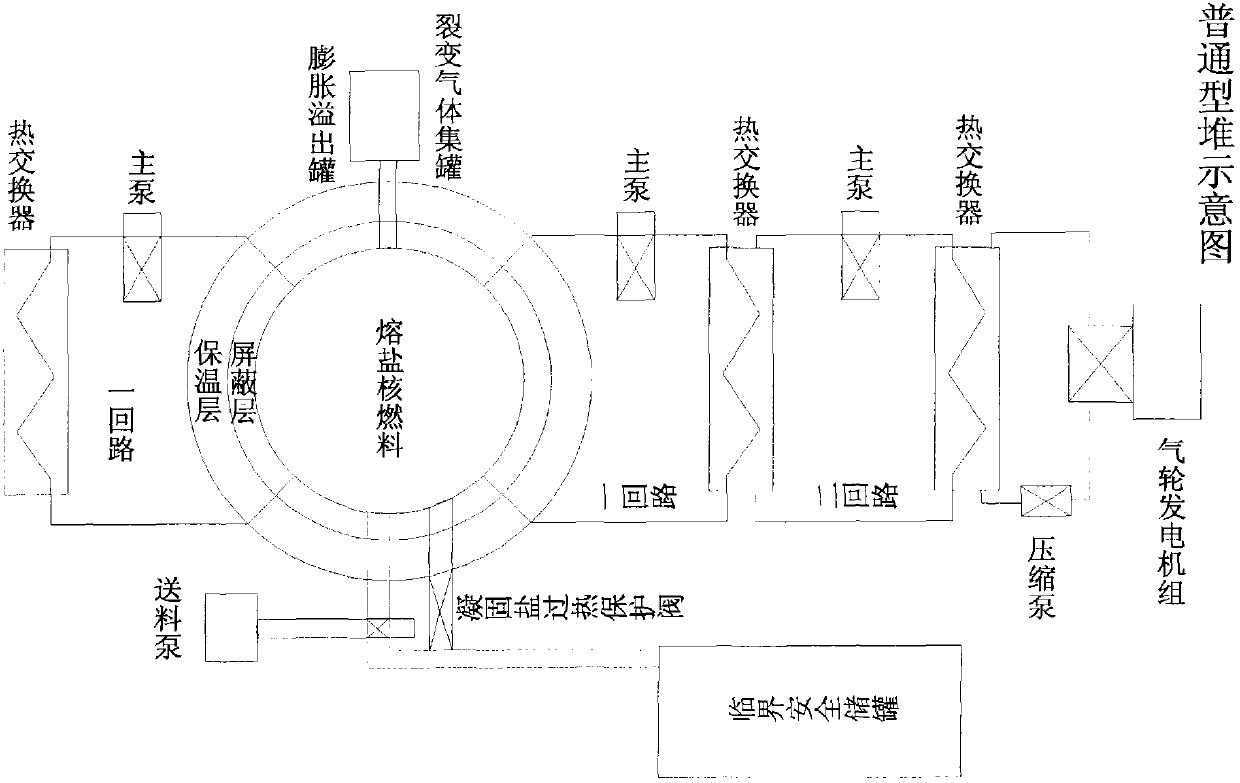

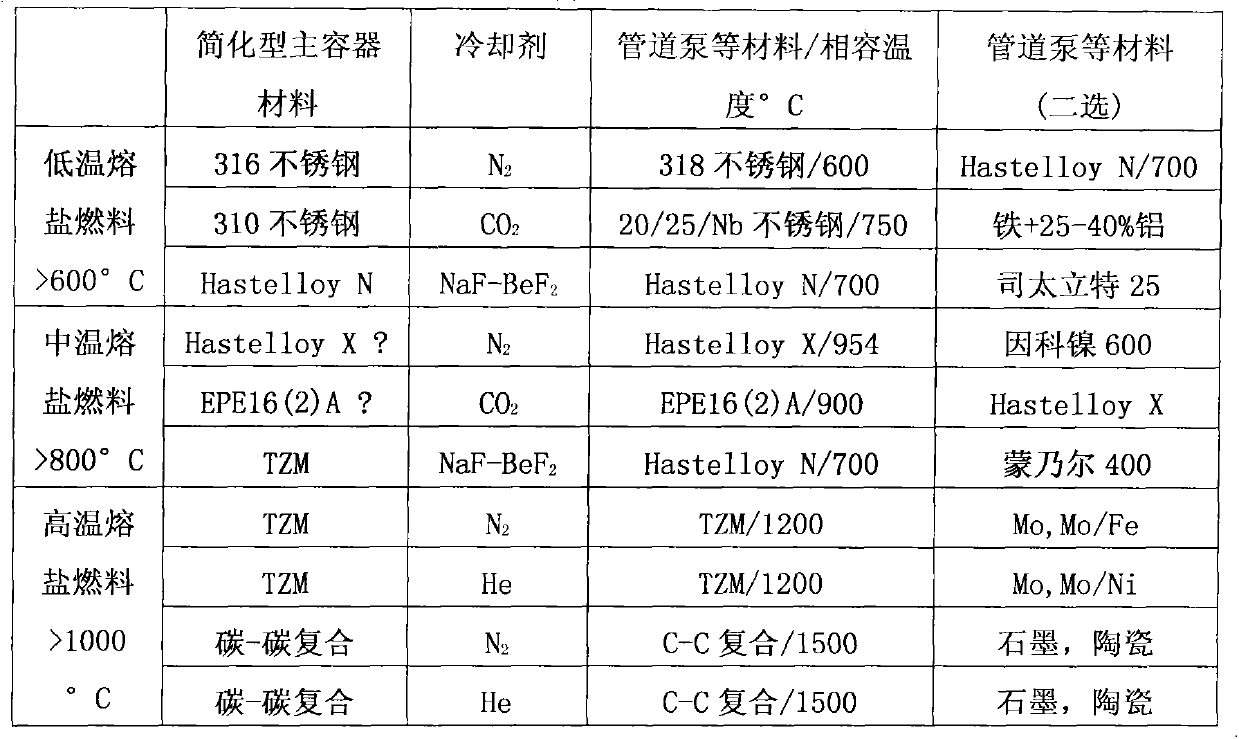

Molten salt depleted uranium reactor

PendingCN104183277AIncrease fuel consumptionSimple structureNuclear energy generationSubcritical reactorsNitrogen gasSteel pipeline

The invention discloses a molten salt depleted uranium reactor, belonging to the technical field of molten salt reactors; fast neutron spectrum, chloride molten salt, uranium plutonium cycle and depleted uranium are used; after start, only by use of a nuclear fuel of self proliferation, long-term stable and safe operation can be achieved, and a supercritical accident may not happen; negative feedback can keep in the critical state; the entire uranium plutonium cycle can be completed in the reactor; normal operation only requires the use of the depleted uranium, the reactor itself does not need uranium enrichment and purification; and high burnup of the depleted uranium can be realized. The reactor has the advantages of simple structure and easy operation, is very suitable for large-scale popularization and application. The reactor is applicable to various types of molten salt formulas and structure materials. The technology, complete set of system technology, engineering and industrialization are feasible. The preferred system is as follows: simplified low temperature IV type + 316 stainless steel main container + nitrogen coolant + 318 stainless steel pipeline pump heat exchanger and the like. Fission nuclear energy can be used to fully meet the national long-term energy needs, at the same time, the problems of the shortage of uranium resources, nuclear criticality safety and low carbon development can be solved, and the reactor is mainly used for heat, electricity or mechanical power supply.

Owner:董保国 +2

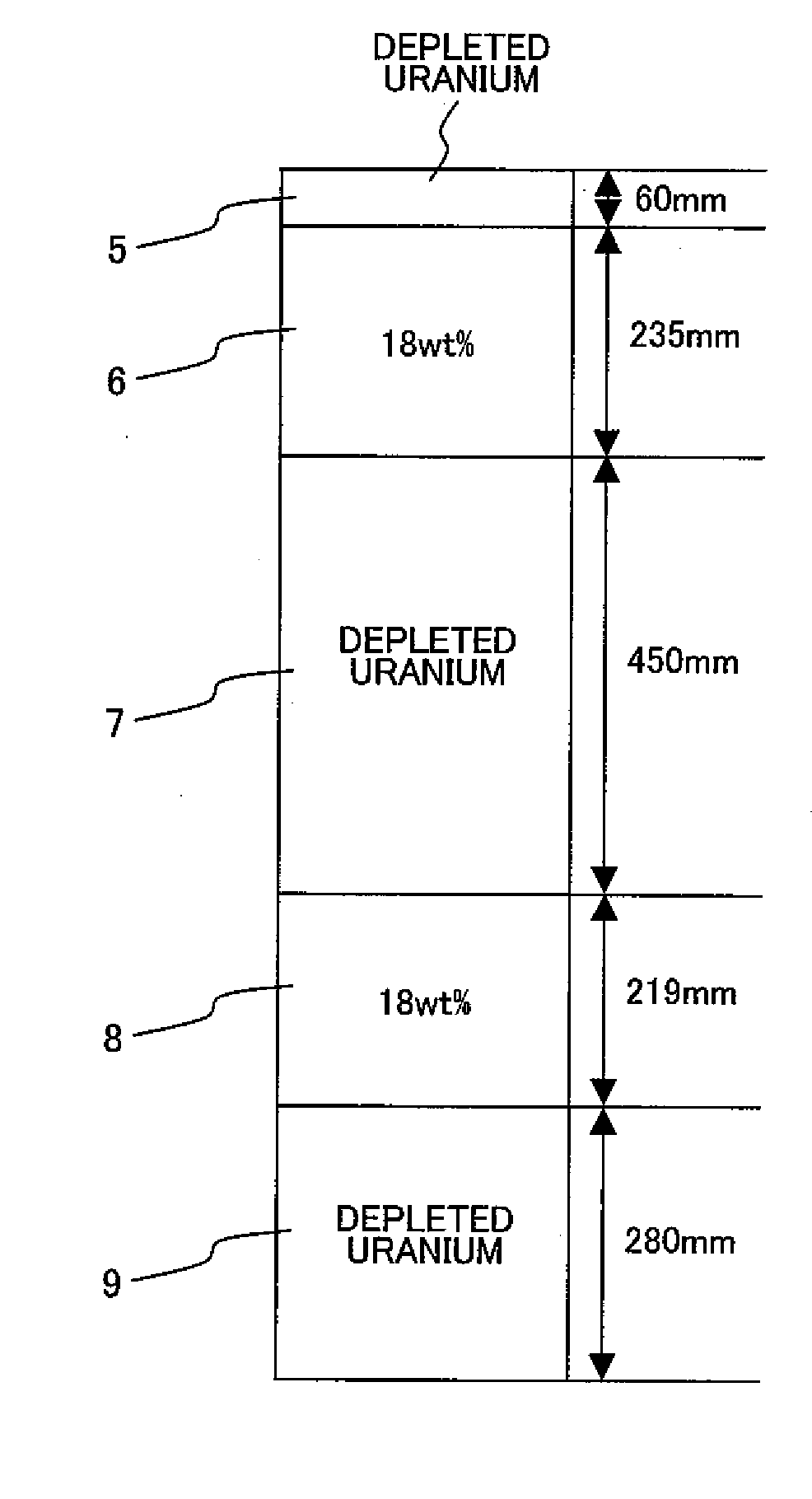

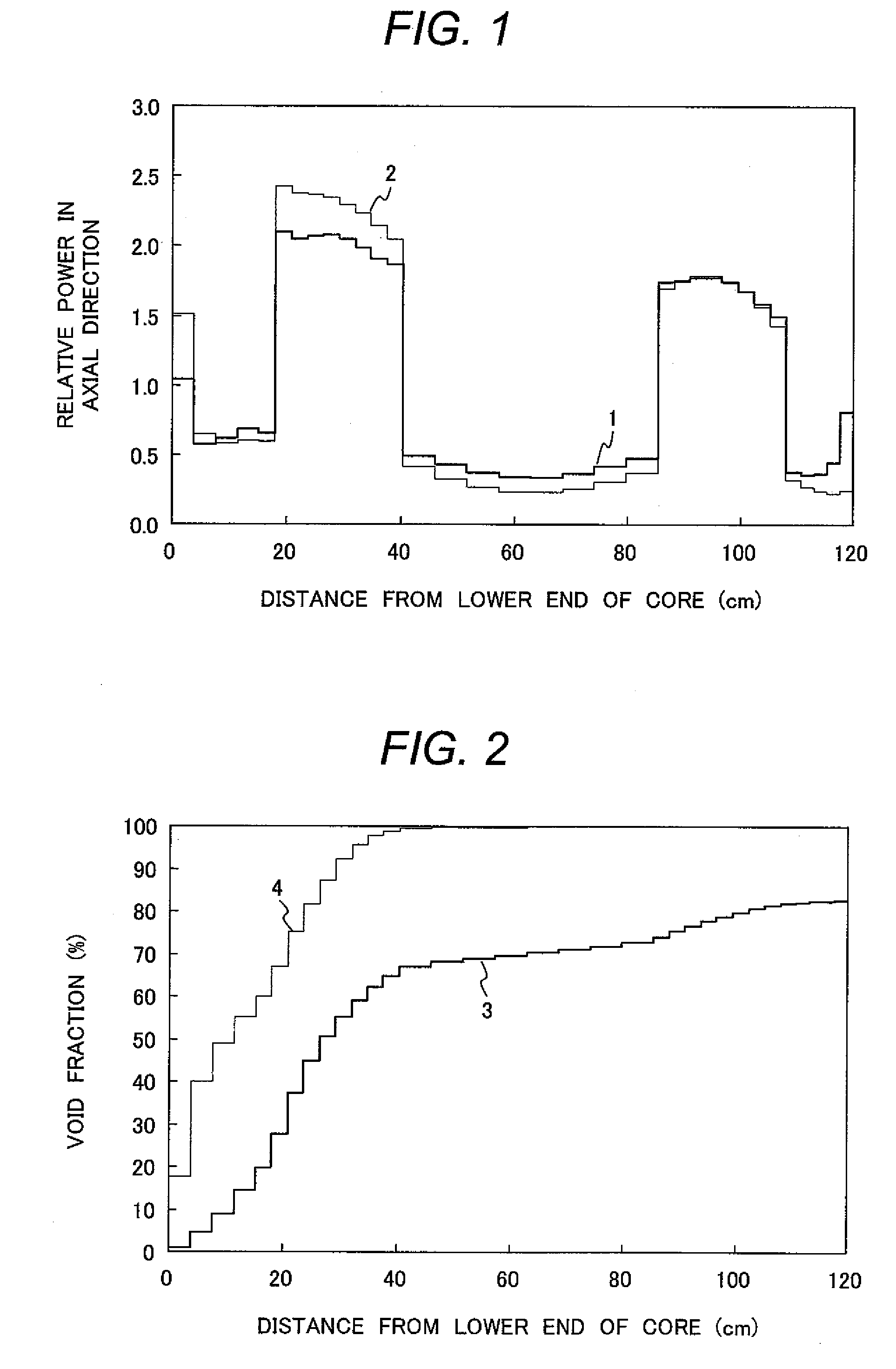

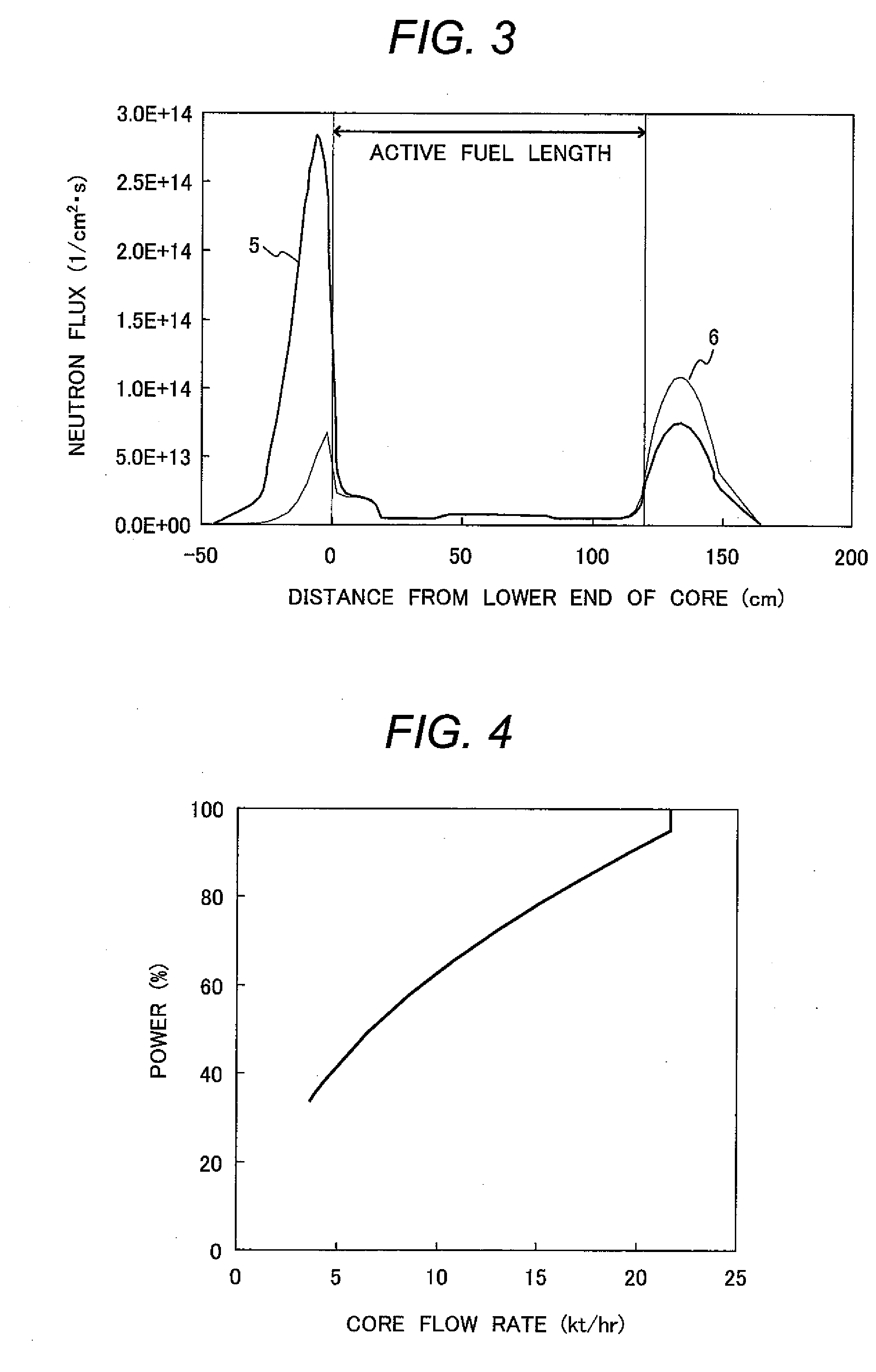

Core of light water reactor and fuel assembly

ActiveUS20100034336A1Economic efficiency of lightIncreased safety marginNuclear energy generationContainmentIsotopeBurnup

A core of a light water reactor having a plurality of fuel assemblies, which are loaded in said core, having nuclear fuel material containing a plurality of isotopes of transuranium nuclides, an upper blanket zone, a lower blanket zone, and a fissile zone, in which the transuranium nuclides are contained, disposed between the upper blanket zone and the lower blanket zone;wherein a ratio of Pu-239 in all the transuranium nuclides contained in the loaded fuel assembly is in a range of 40 to 60% when burnup of the fuel assembly is 0;sum of a height of the lower blanket zone and a height of the upper blanket zone is in a range of 250 to 600 mm; andthe height of said lower blanket zone is in a range of 1.6 to 12 times the height of the upper blanket zone.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

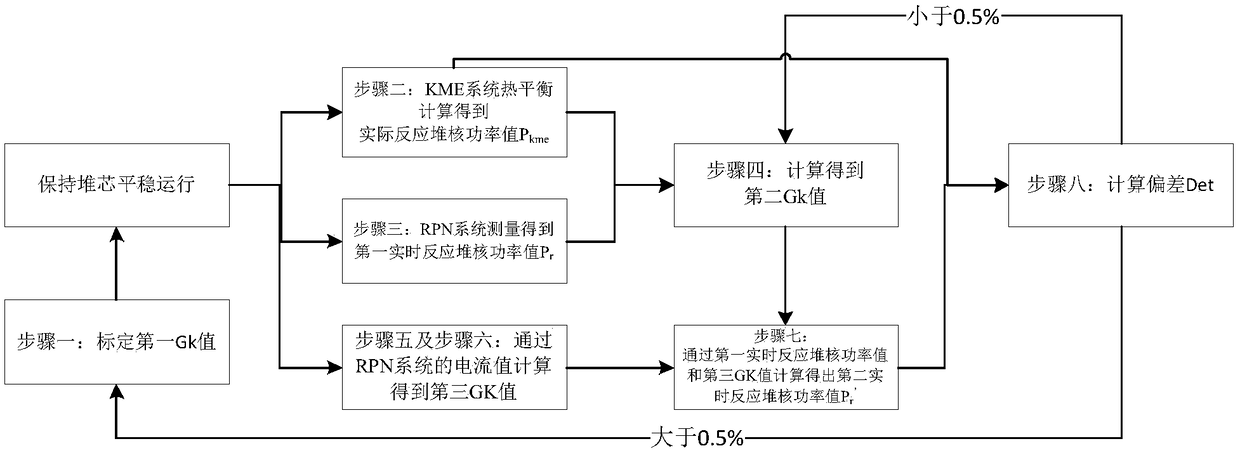

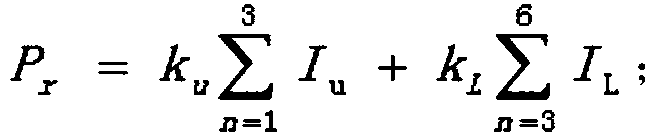

Method for verifying calibration value of power coefficient Gk of power range of nuclear reactor

ActiveCN108986939AImprove operational efficiencyReduce human riskNuclear energy generationNuclear monitoringNuclear reactor coreNuclear reactor

The invention discloses a method for verifying a calibration value of a power coefficient Gk of a power range of a nuclear reactor. According to the method, the coefficient Gk is used for correcting the deviation of a RPN system caused by deepening of burnup of a reactor core of the nuclear reactor and power distribution, the RPN system is provided with four groups of channels, and the power rangeof each group of channels is divided into a plurality of ionization chambers. The method for verifying the calibration value of the power coefficient Gk of the power range of the nuclear reactor comprises the following steps that 1, a first Gk value is calibrated; 2, the actual reactor core power value Pkme is obtained through calculation under the condition that the reactor core operates stably;3, the RPN system measures the nuclear reactor so as to acquire a first real-time reactor nuclear power value Pr; and 4, a second Gk value is obtained through calculation through the actual reactor nuclear power value Pkme and the first real-time reactor nuclear power value Pr. The method for verifying the calibration value of the power coefficient Gk of the power range of the nuclear reactor hasthe advantage that whether the calibration value of the power coefficient Gk of the power range of the reactor is correct or not can be verified.

Owner:GUANGXI FANGCHENGGANG NUCLEAR POWER +1

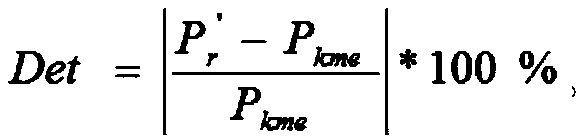

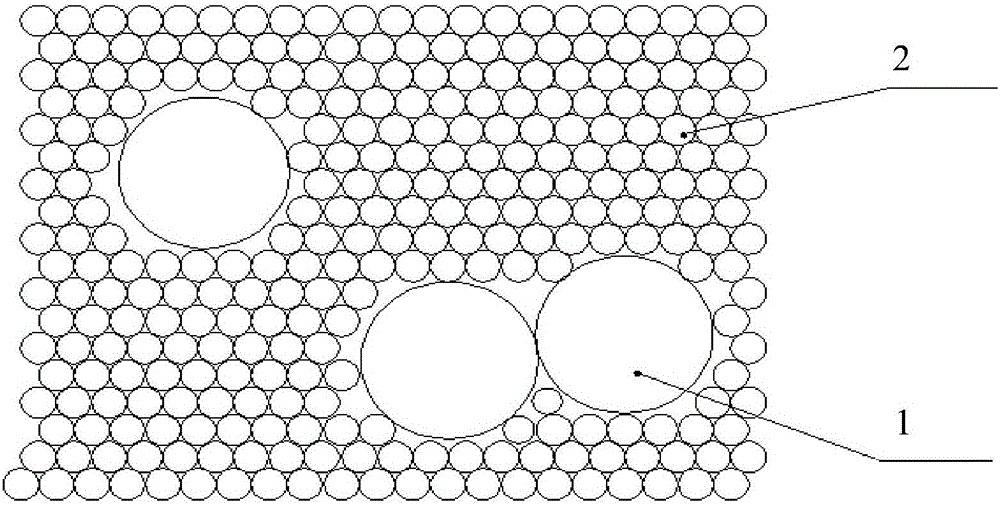

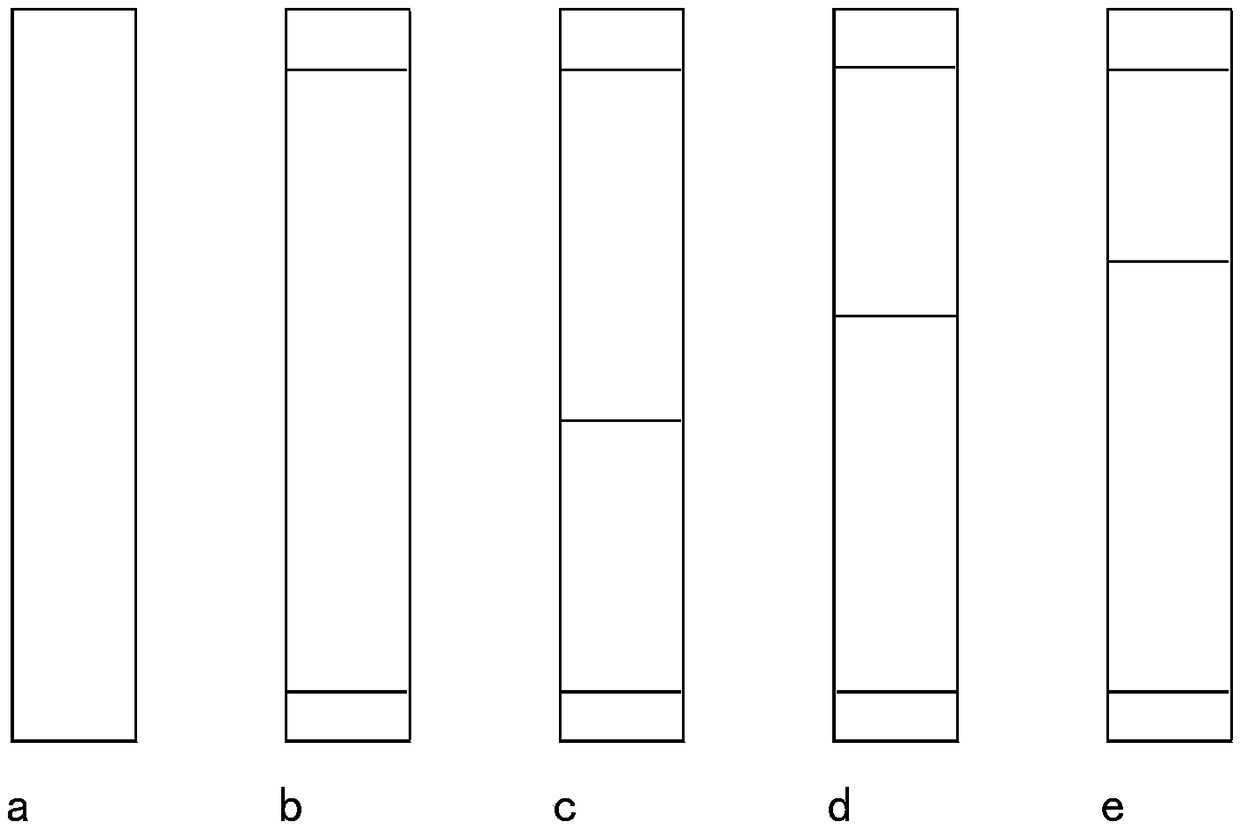

Method for reducing burnup of iron ore powder composite agglomerated solid

The invention discloses a method for reducing burnup of an iron ore powder composite agglomerated solid. An iron ore powder composite agglomeration material comprises a pellet material and a matrix material, wherein the pellet material does not contain fuel, and the matrix material contains solid fuel; the distribution of the matrix material along a material layer is regulated to be matched with a distribution rule of utilizable heat storage capacity at different heights of the material layer, and the content of the solid fuel in the matrix material is controlled, so that the matrix material has sufficient heat for liquid phase solidification, and the pellet material is adequately subjected to solid phase solidification by virtue of stored heat of the material layer. According to the method, the stored heat of the composite agglomeration material layer is adequately utilized, so that the consumption of the solid fuel is reduced, and the rate of finished products and the product quality of the composite agglomeration are improved. Compared with a normal composite agglomeration process, the method has the advantages that the consumption of the solid fuel is reduced by 6.2%-12.6%, the yield is increased by more than or equal to 2%-5%, and the drum strength of the product is improved by 3%-5%; by further producing blast furnace materials by virtue of operation regulations of high material layer and low negative pressure, the yield of the composite agglomeration is increased by 10%-20%, and the electricity consumption of an exhaust fan is decreased by 10% or more.

Owner:CENT SOUTH UNIV

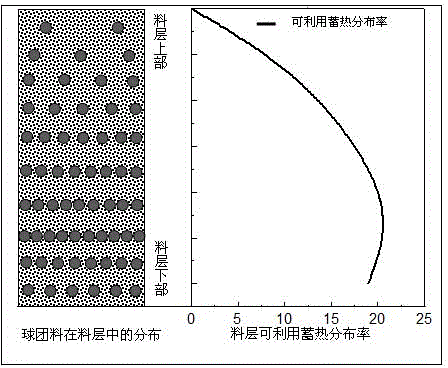

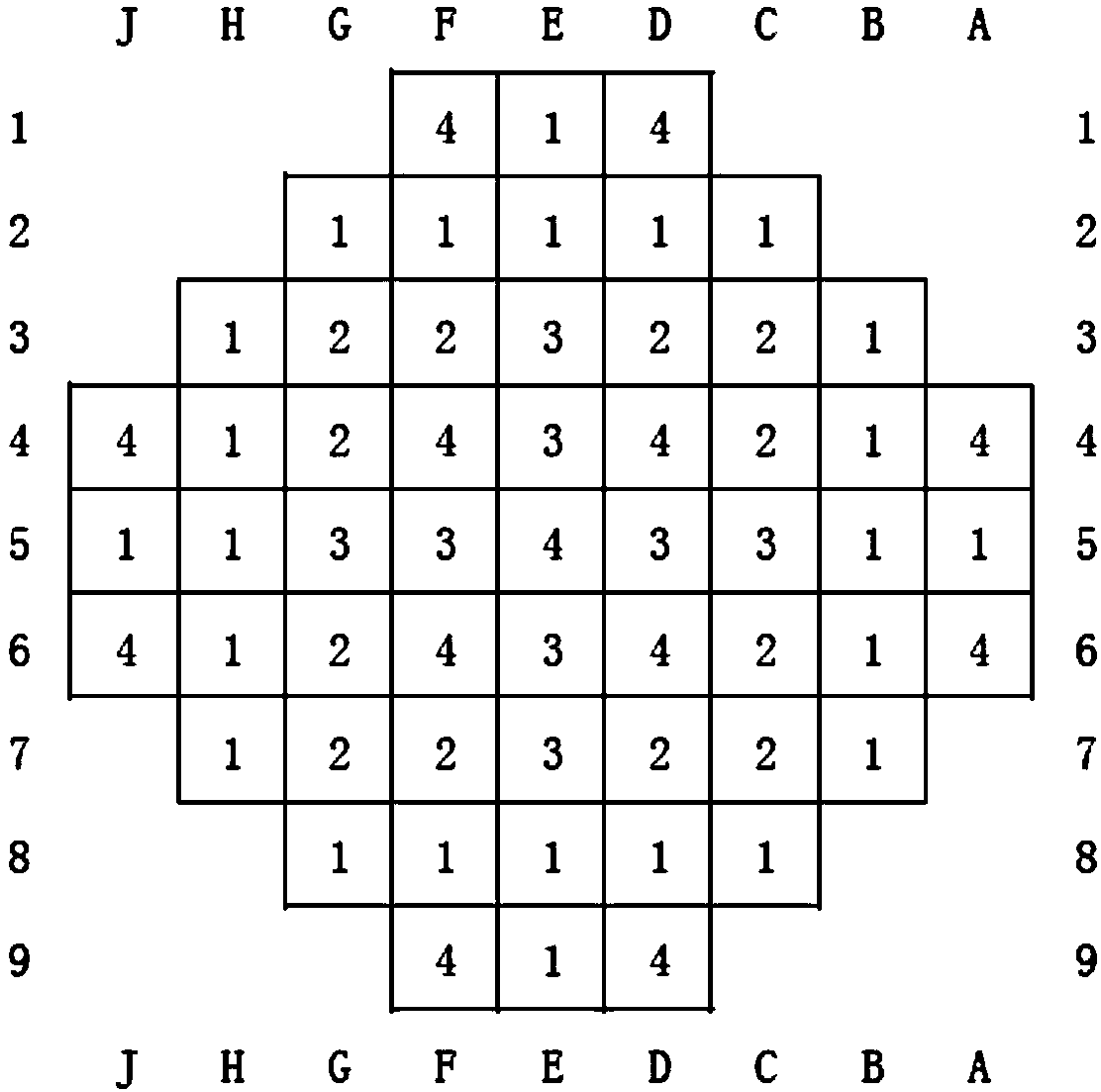

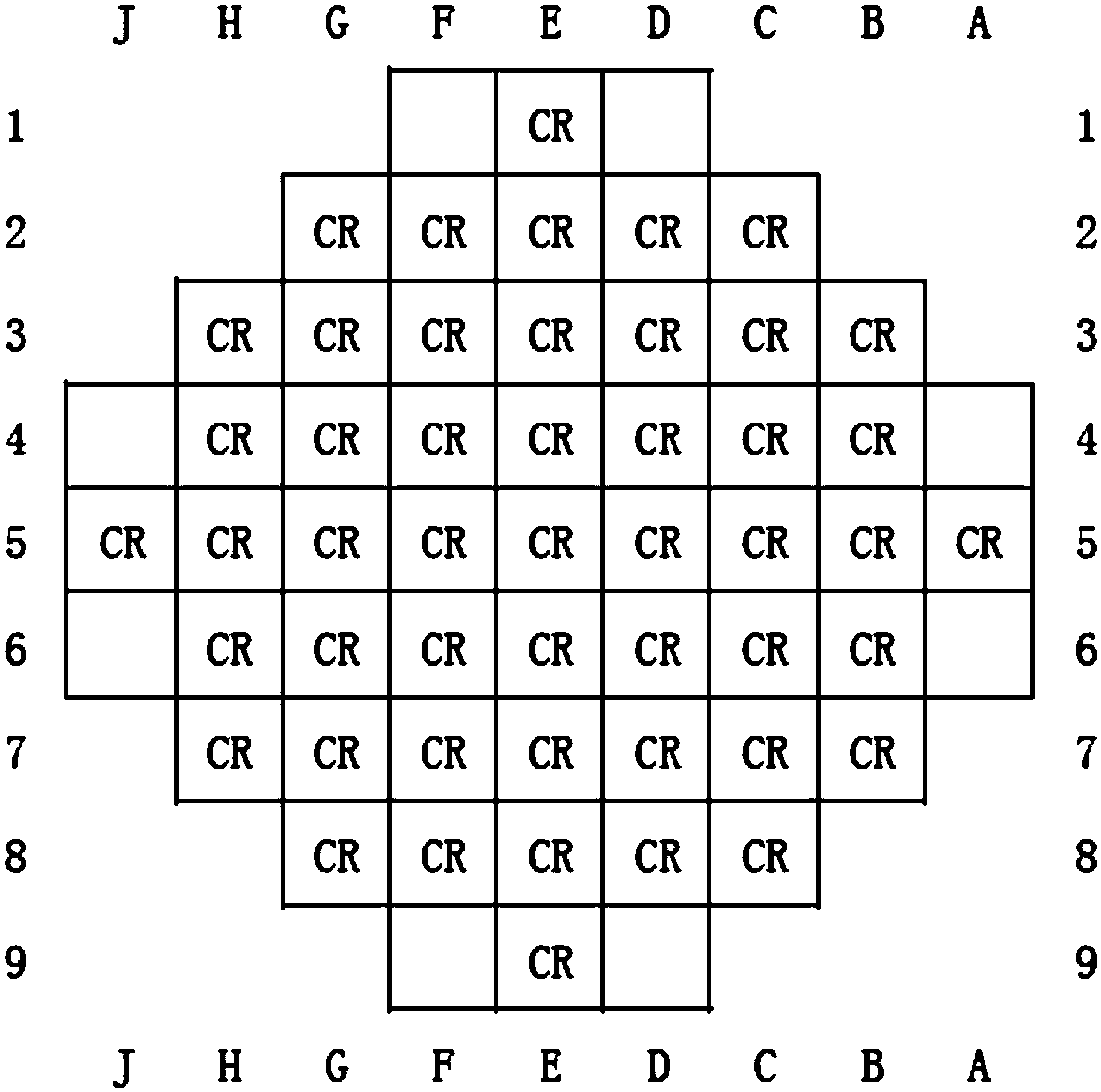

Method of improving the spent nuclear fuel burnup credit

A dimensional reactivity management system that takes into account the axial burnup shape data of a nuclear fuel assembly to determine the acceptability of placement of the assembly relative to other assemblies in a storage container.

Owner:WESTINGHOUSE ELECTRIC CORP

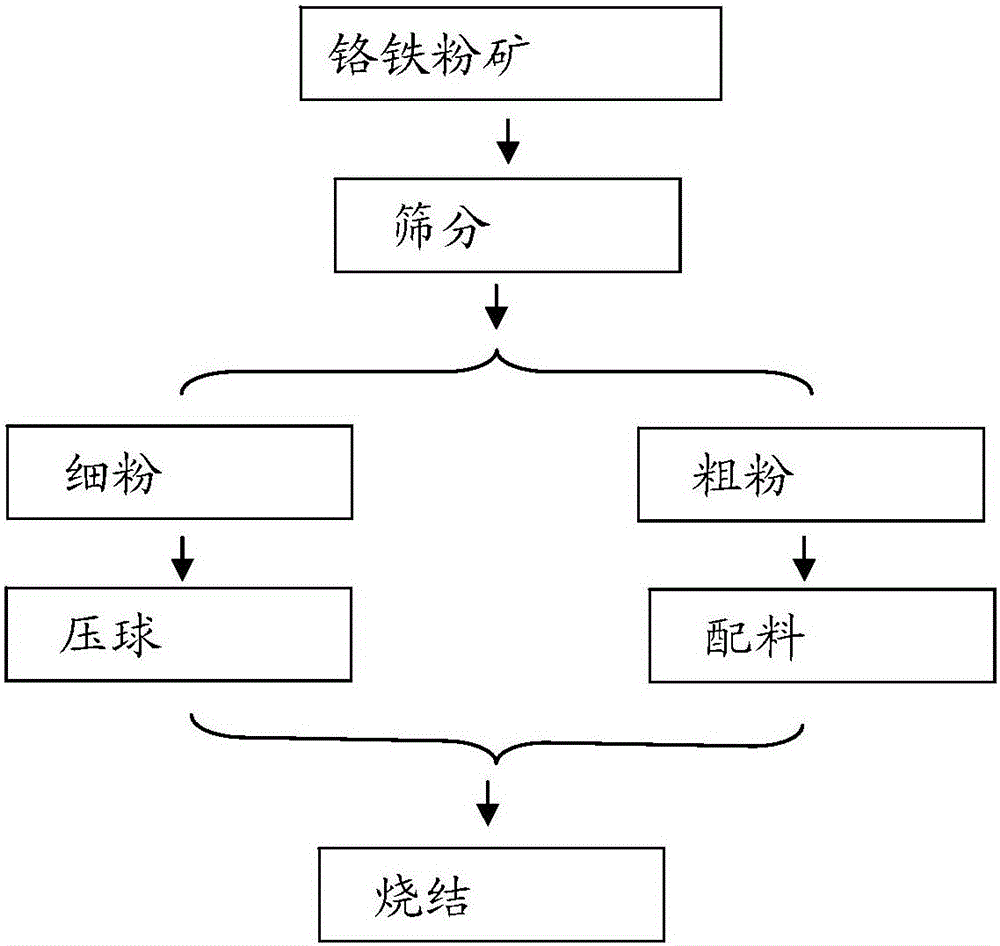

Ferrochromium fine ore sintering technology

The invention provides a ferrochromium fine ore sintering technology. The work process includes the steps that coarse powder and fine powder are screened, cold pressing is carried out on the fine powder to obtain balls, the coarse powder is mixed, then, the coarse powder and the fine powder are mixed to be jointly sintered and screened, and the oxygen enrichment sintering technology is adopted. After the sintering technology method is adopted, ferrochromium fine ore does not need to be finely ground. Compared with a pelletizing method, the technological process is simple, and according to the scheme, the overall water consumption is small, and the sintering burnup is correspondingly reduced; and the sintering capacity and sinter yield are increased.

Owner:BERIS ENG & RES CORP

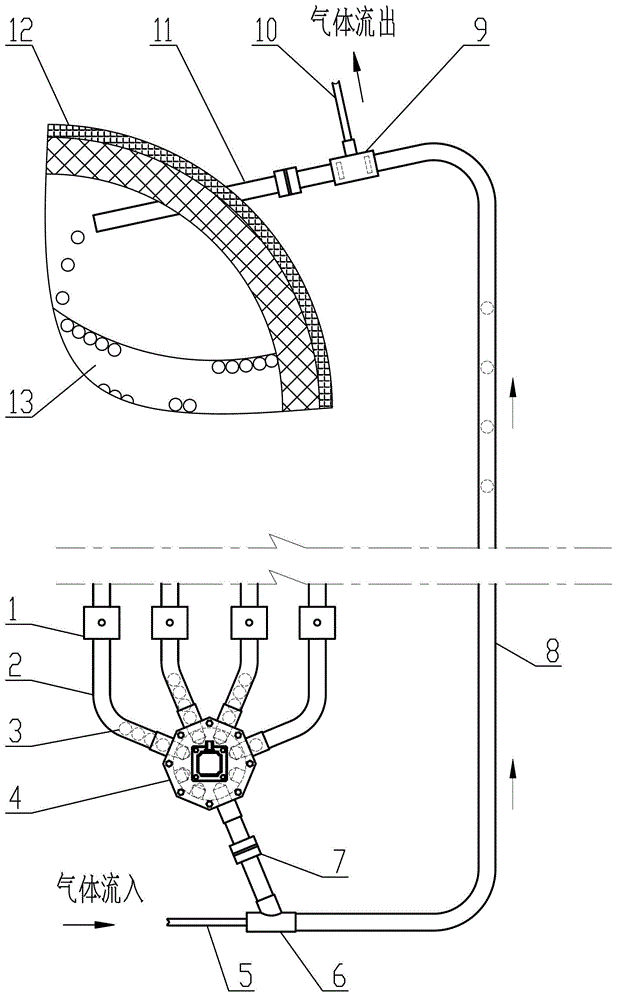

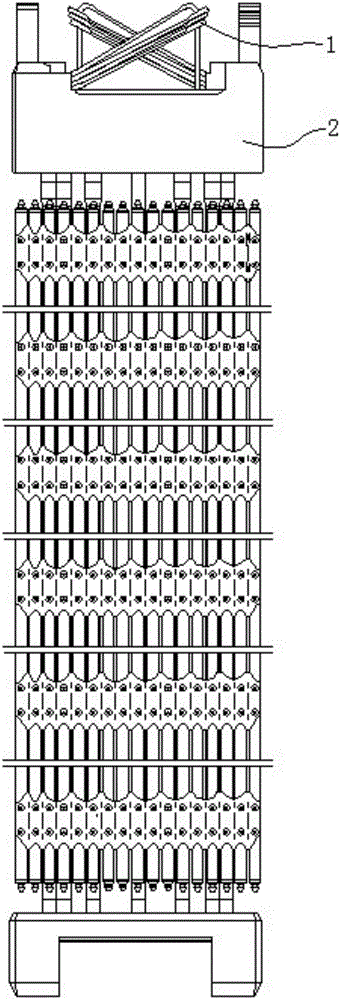

Grouped pneumatic lifting system and method for pebble-bed reactor fuel elements

ActiveCN102750996AImprove abilitiesImprove delivery efficiencyNuclear energy generationReactor fuel elementsSystem structureBurnup

The invention provides a grouped pneumatic lifting system and method for pebble-bed reactor fuel elements. The system comprises a plurality of groups of burnup detection assemblies, a feeder, a lifting pipeline, a gas diverter and a fluid power plant. The number of inlets of the feeder is identical to the number of the burnup detection assemblies; the feeder has an outlet, a fuel element is let out from the outlet of the feeder at a preset time interval, and at least two fuel elements are allowed to form a queue in the lifting pipeline and to be lifted at the same time. The grouped pneumatic lifting system and method can realize grouped lifting of fuel elements into a reactor core; the number of fuel elements in each group and spacing among the fuel elements are controllable, and under different working conditions, lifting capability can be optimized, conveying efficiency can be improved and energy consumption can be reduced; the grouped pneumatic lifting system and method only employs one lifting pipeline and has the advantages of a simple structure, low cost for manufacture, maintenance and utilization and applicability to construction and operation of pebble-bed reactors.

Owner:TSINGHUA UNIV

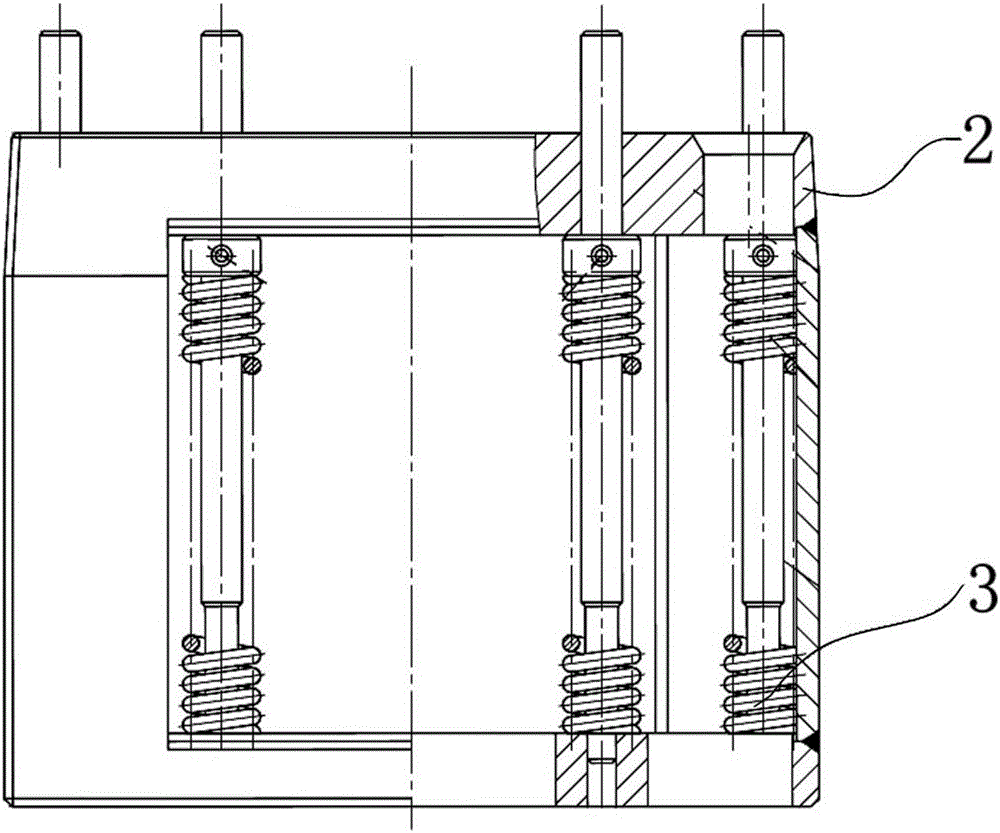

High stability fuel assembly compacting system with variable rigidity and low radiation slack

ActiveCN106531230AChange the stiffnessGuaranteed axial compressionNuclear energy generationFuel element assembliesThermal stateNatural state

The invention discloses a high stability fuel assembly compacting system with variable rigidity and low radiation slack. The system solves the problem that the existing compacting system has large stress in a spring in operation so that radiation slack is easy and a spring pressing force is reduced and is insufficient in the middle and late stages of the life of the fuel assembly. The system comprises a plurality of spring assemblies mounted on a tube socket (2) and is characterized in that a preset spring is arranged in the spring assembly, in a thermal state normal operation of the fuel assembly, the preset spring is in a natural state, and when the fuel assembly jumps under the transient external load or the burnup of the fuel assembly is increased, the preset spring is in a compacting state. The system reduces bending deformation during the operation of the fuel assembly and improves the fuel assembly running stability and the service life.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

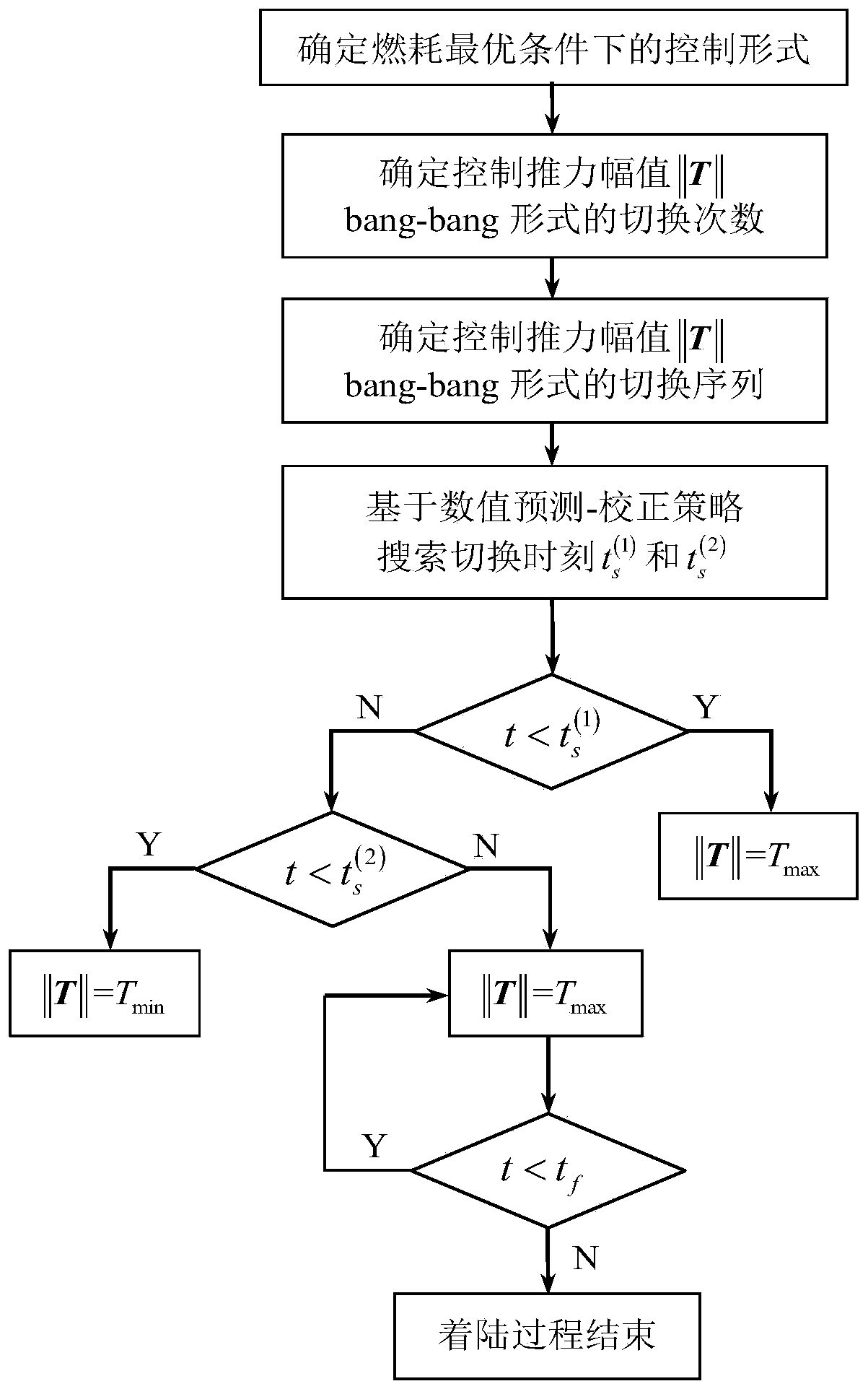

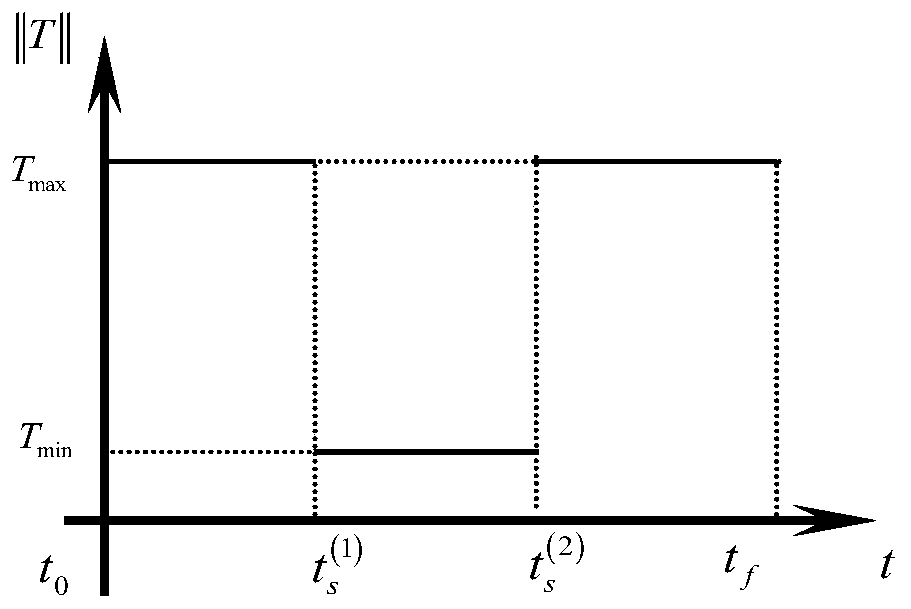

Rapid on-line planning method for soft landing burnup optimal trajectory of small celestial body

ActiveCN110532724ARealize online generationGuaranteed speedSpecial data processing applicationsSearch problemEngineering

The invention discloses a rapid on-line planning method for a soft landing optimal trajectory of a small celestial body, and belongs to the technical field of deep space exploration. The implementation method comprises the following steps: determining an optimal trace control form of small celestial body fuel consumption as a bank-bank control form, determining the switching times of controlling athrust amplitude bank-bank form, and determining a switching sequence of the bank-bank form for controlling the thrust amplitude on the basis of the switching times. Therefore, the optimal path planning problem of small celestial body fuel consumption is converted into the online search problem of the bang-bang control switching moment. Through a numerical prediction-correction strategy, on-linesearch is carried out on switching time, a two-variable search problem is converted into a sequence single-variable search problem of an inner loop and an outer loop, on-line generation of a small celestial body soft landing fuel consumption optimal trajectory is achieved, and rapidity and convergence of the landing trajectory planning method are guaranteed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Design method of one-hundred-thousand-kilowatt-class reactor core

ActiveCN108320820AImprove economyFlexible operationNuclear energy generationReactors manufactureNuclear reactor coreBurnup

The invention discloses a design method of a one-hundred-thousand-kilowatt-class reactor core. The one-hundred-thousand-kilowatt-class reactor core comprises 57 fuel assemblies; the height of an active section is 2-15cm; a refueling cycle is about 24 months; integrated burnable poisons are used; through reasonable mass percentages of a plurality of burnable poisons, reasonable partitioned usage ofa plurality of burnable poison rods, cooperative usage of a plurality of axial partitioning forms, combination of multiple fuel enrichment mixing and loading strategies, arrangement of a large amountof control rods and adoption of optimized grouping and rod withdrawing sequence, the reactivity control and the power flattening are achieved, so that the reactor core can meet the requirements on relevant safety analysis; a 1 / 3 reactor core shuffling strategy is used; the average discharging burnup of the fuel assemblies is improved; the flexibility of the small reactor in use is further improved; meanwhile, the fuel economy of the small reactor is improved; the design of the reactor core is more in line with the multipurpose orientation of the small reactor.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

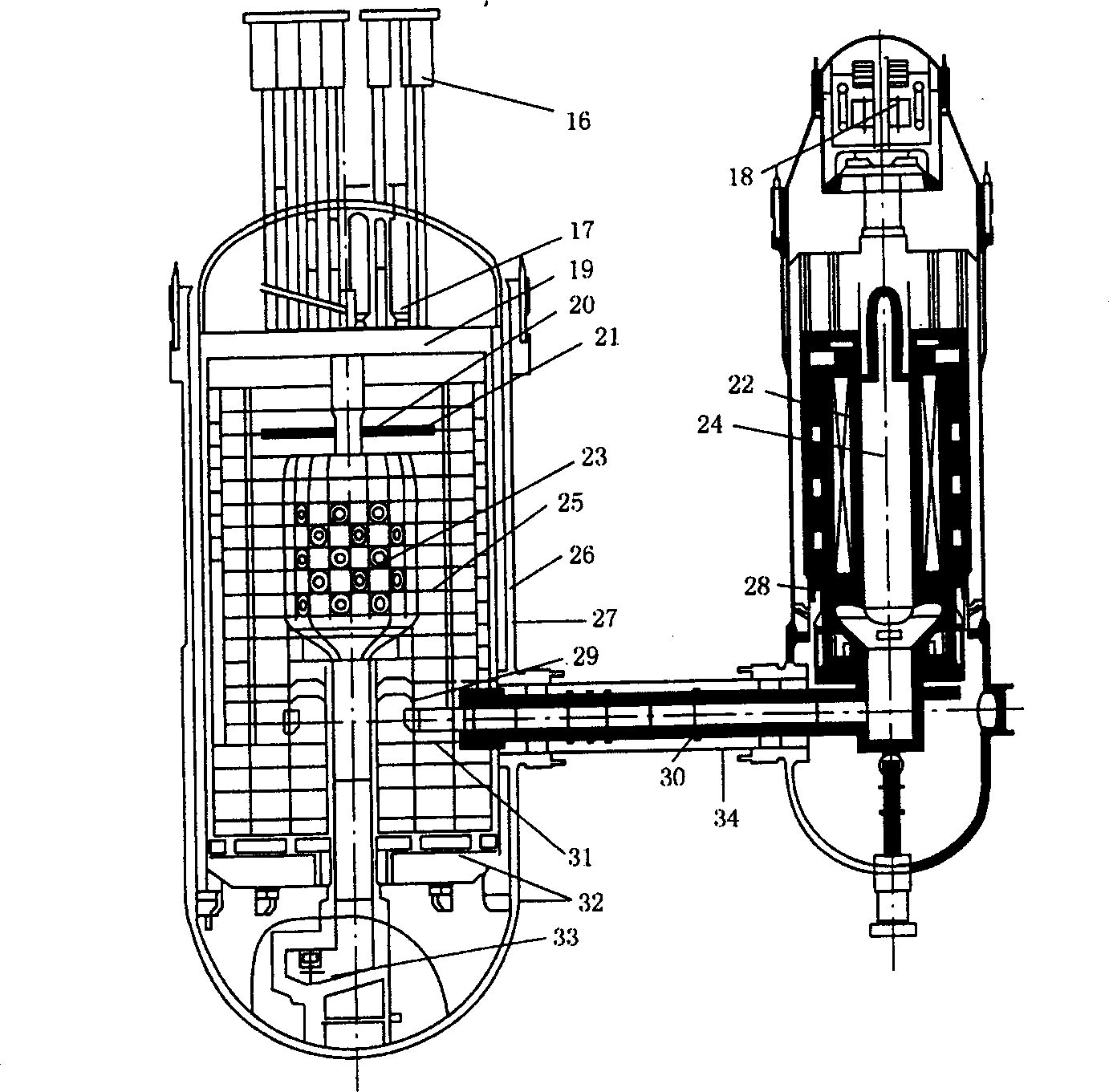

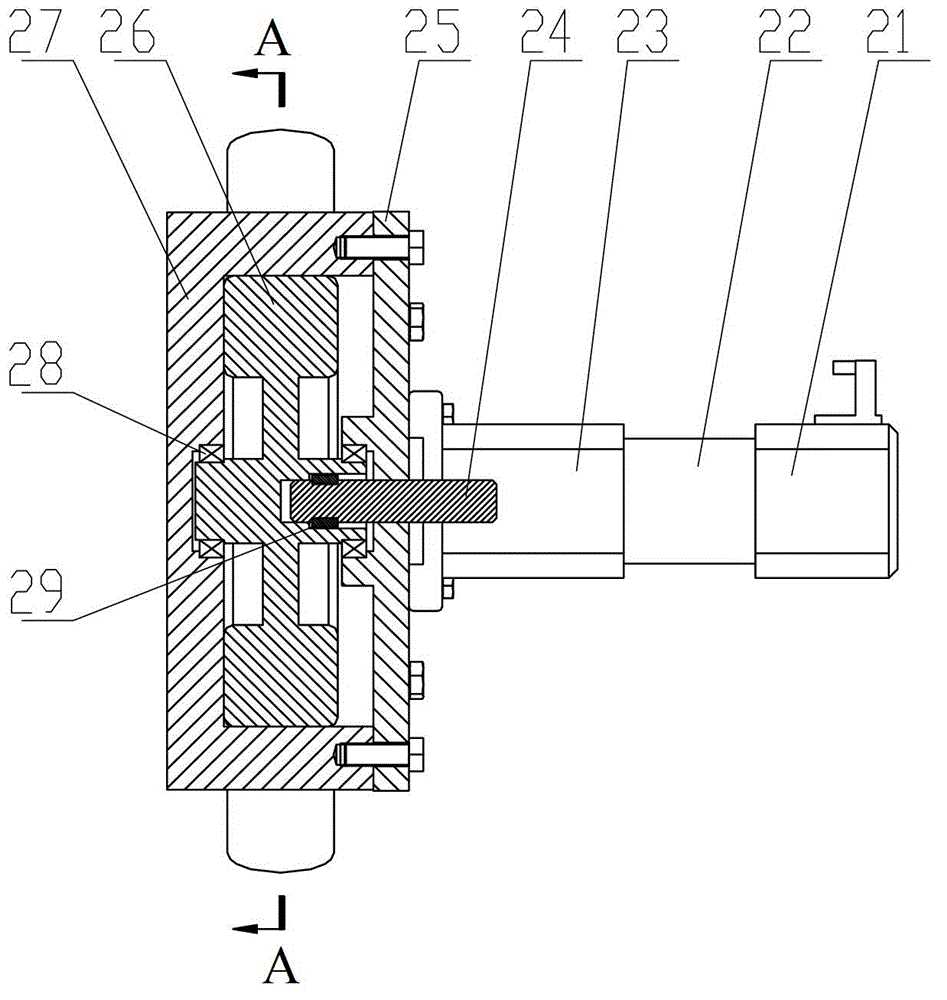

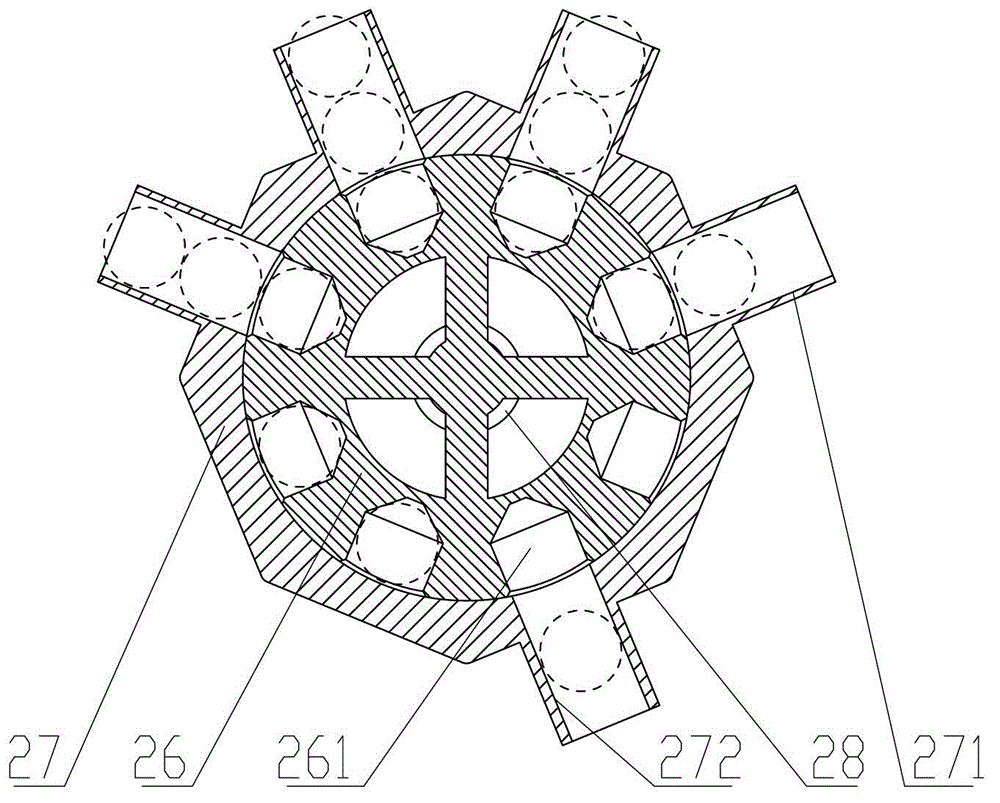

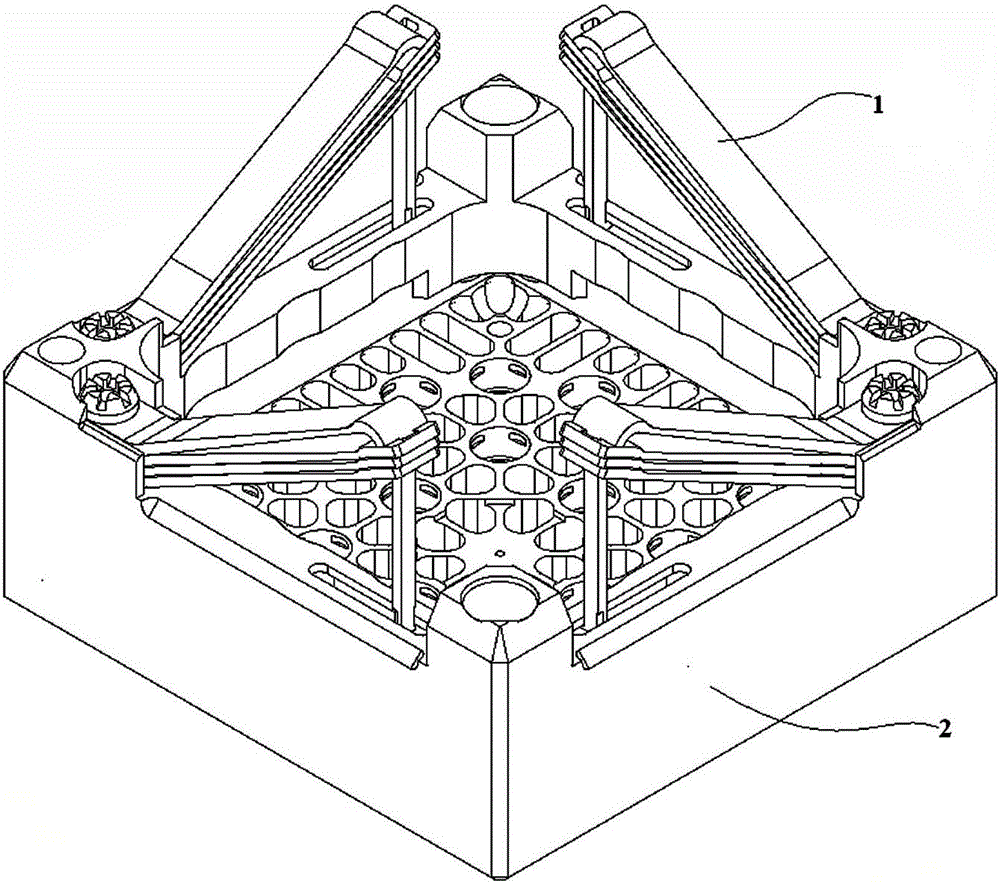

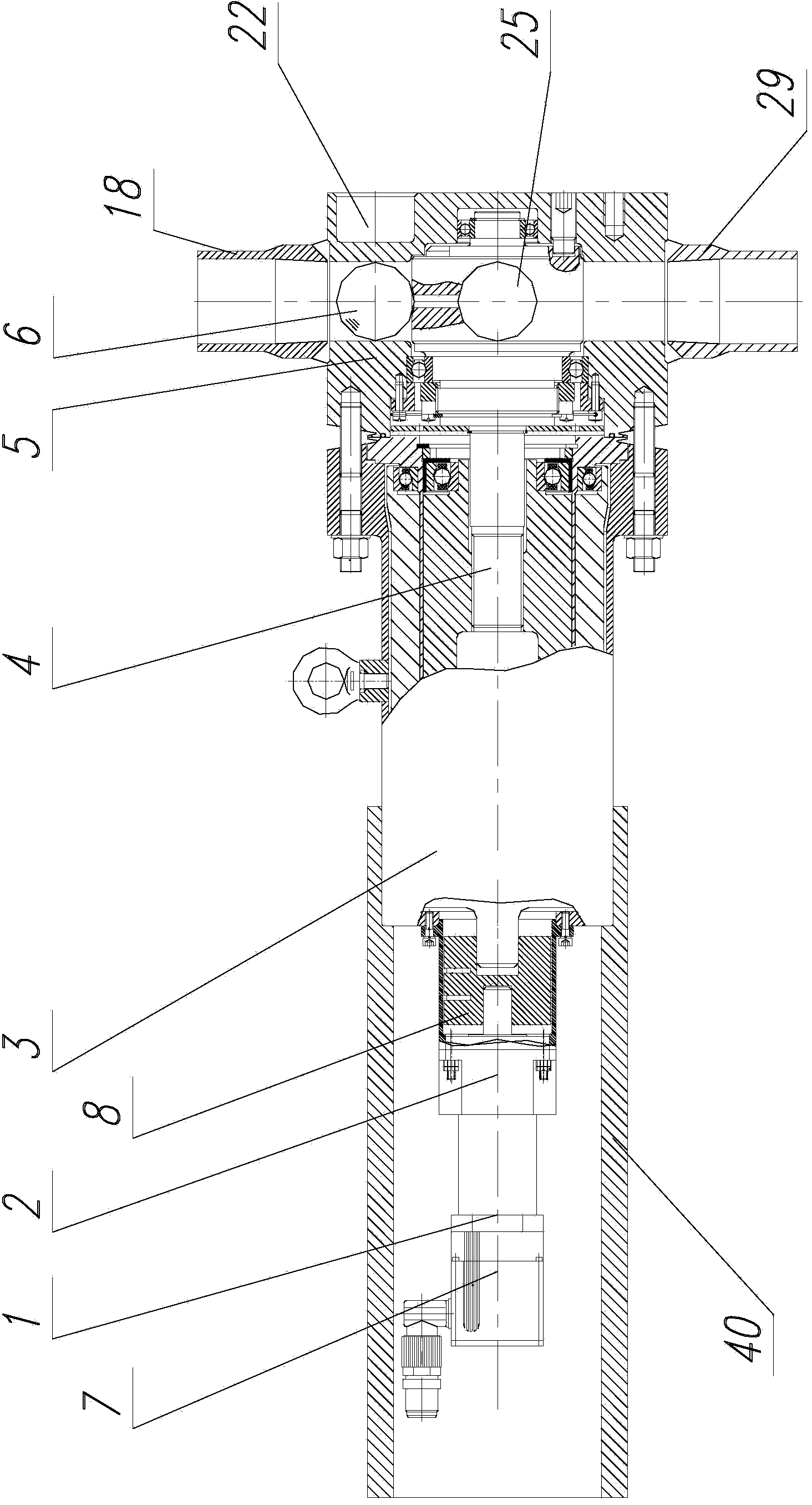

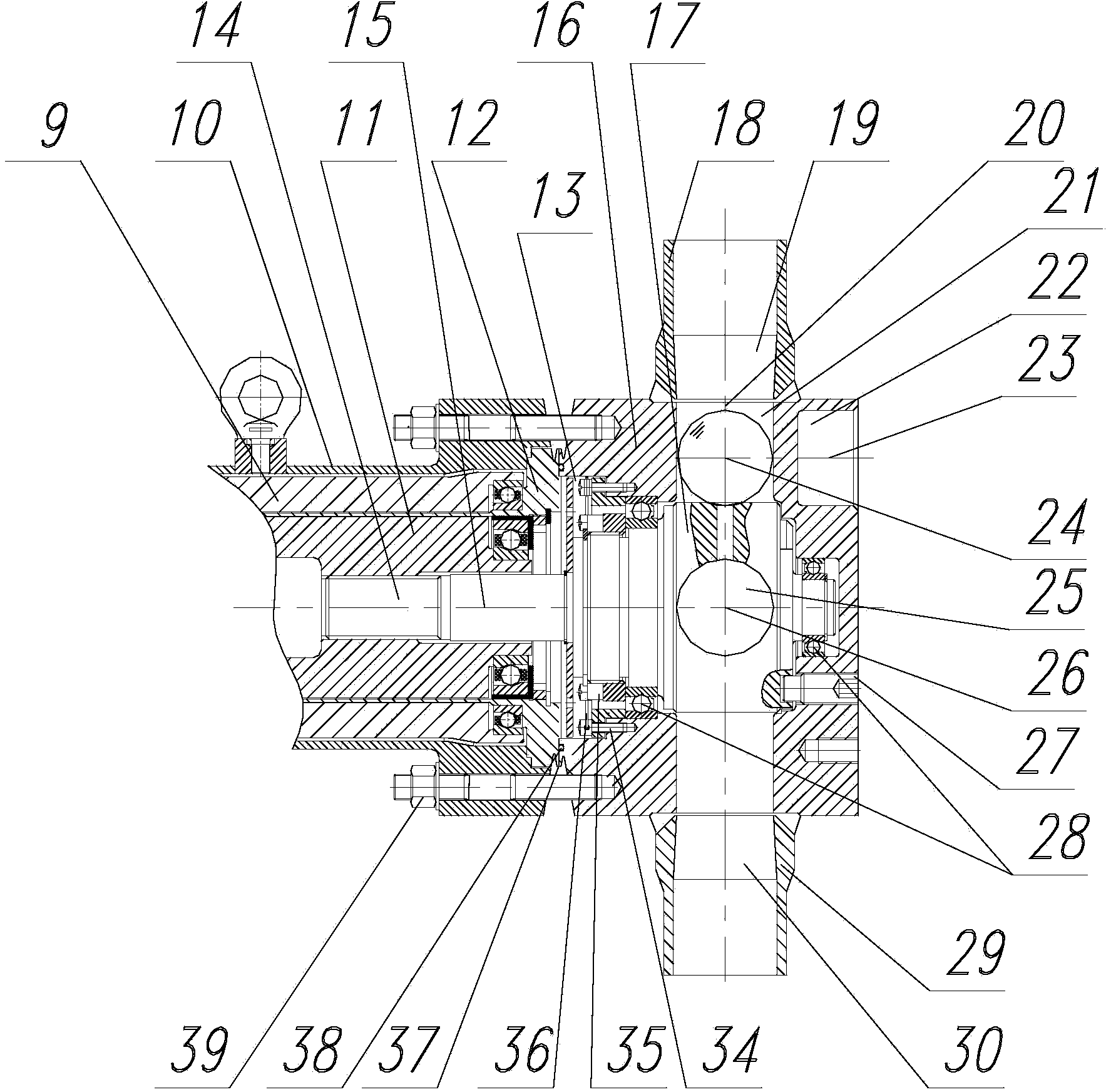

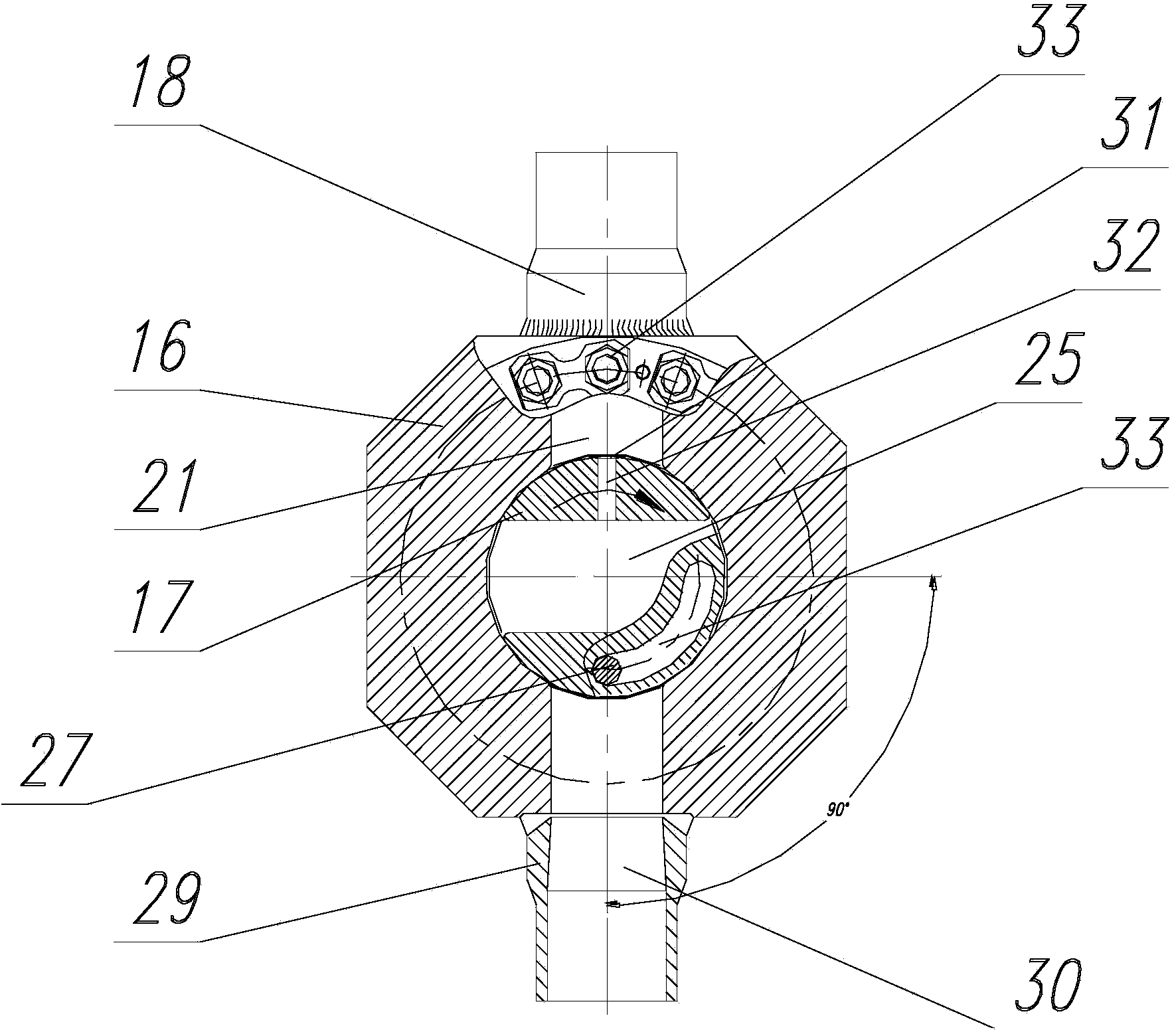

Burnup measuring and positioning device applied to high-temperature gas cooled reactor

ActiveCN103778981AMeet operating life requirementsGuaranteed fuel consumption measurement accuracyNuclear energy generationNuclear monitoringMagnetic tension forceAlloy

The invention provides a burnup measuring and positioning device applied to a high-temperature gas cooled reactor. The burnup measuring and positioning device applied to a high-temperature gas cooled reactor comprises a power component, a magnetic driver, a box body component, a rotor component and a shield, wherein the box body component consists of a box body as well as a ball charge pipe and a ball discharge pipe which are welded on the box body and are coaxial and equal in diameter; the box body is provided with a ball passing through hole, a rotor counter bore and a collimation counter bore; the ball passing through hole has the diameter of 61mm; one ends, which are communicated with the ball passing through hole, of the ball charge pipe and the ball discharge pipe are reducing sections; the rotor component comprises a rotor and bearings; a rotary drum of the rotor is provided with a ball passing through hole and a ventilation hole; the top of the ventilation hole is provided with a conical surface ball stop socket, and the bearings are made by heat-resistant and abrasion-resistant alloy; the power component consists of an alternating-current servo motor with a rotary transformer and a planetary gear speed reducer. The burnup measuring and positioning device provided by the invention can start and stop frequently and perform receiving, ball stopping, positioning and measurement and transmitting rapidly, stably and accurately, is compact in structure, and can guarantee the reliability requirement of long-time running.

Owner:CHINERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com