Ferrochromium fine ore sintering technology

A technology of ferrochrome powder and chromite powder, which is applied in the field of sintering process of chromite powder ore, can solve the problems of increasing the steps of sintering process, high energy consumption of grinding equipment, and increasing process cost, etc., so as to improve the utilization factor, sintering The effect of reducing consumption and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

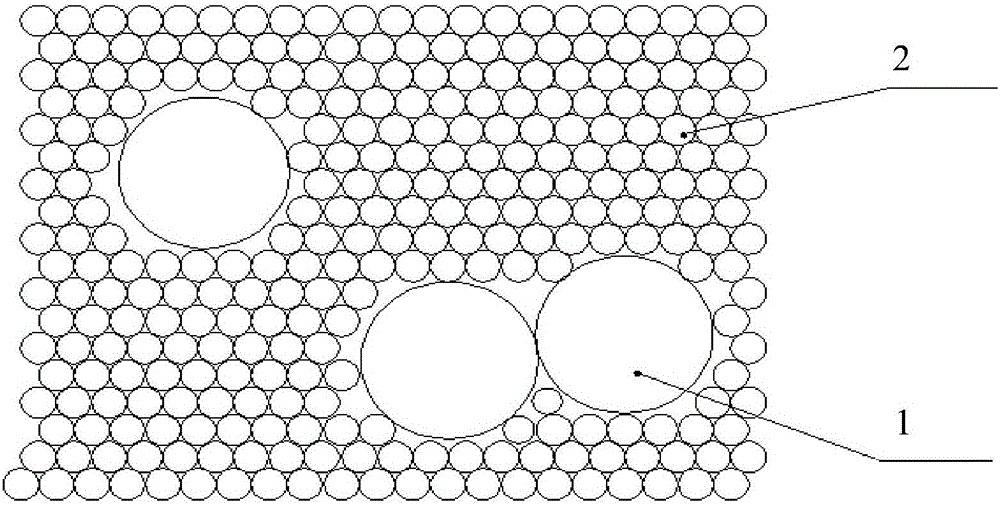

[0016] In order to better understand the sintering process of ferrochrome fine ore in the present invention, a specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings and actual working conditions.

[0017] The following are the different results of one kind of ferrochrome fine ore under different sintering processes:

[0018] The taste of a certain ferrochrome powder ore is 42%Cr 2 o 3 , Moisture content 2 h), the yield rate was 67%.

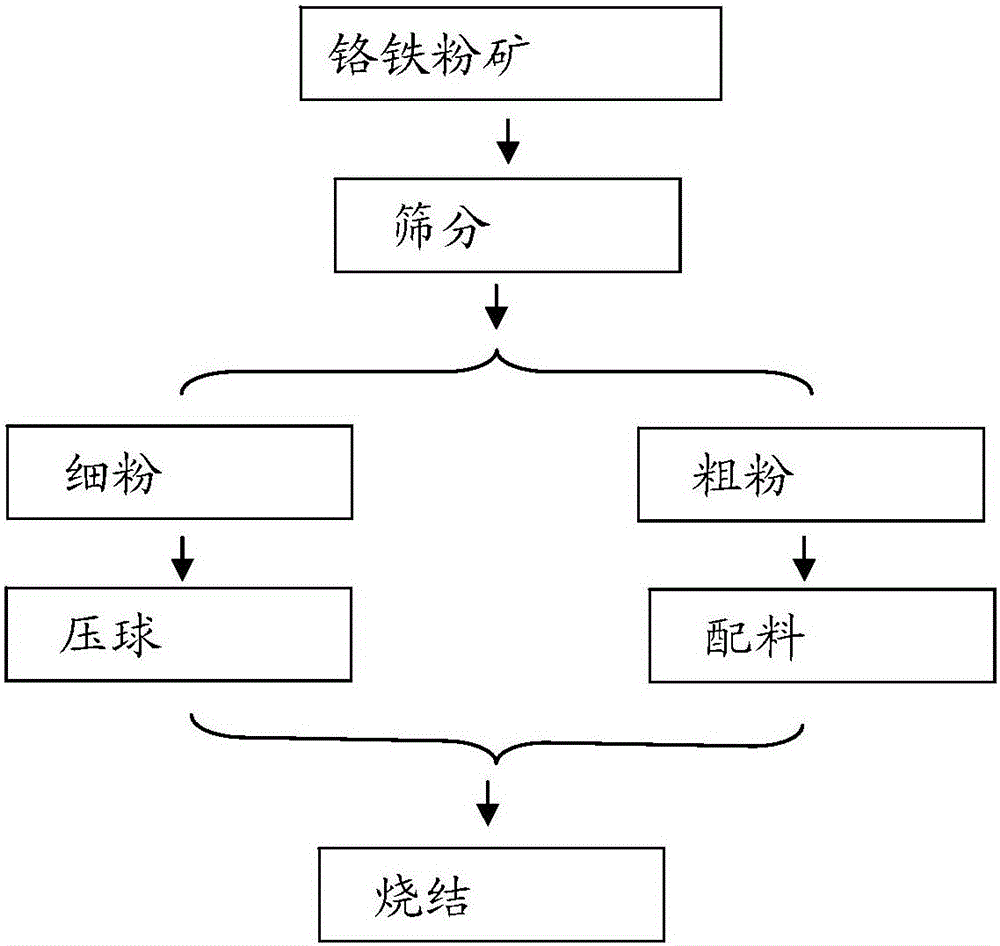

[0019] Adopt sintering process of the present invention, concrete steps are as follows:

[0020] Firstly, the raw materials are sieved to obtain a fine powder with a particle size of -0.125mm (accounting for 20%), and the remaining raw materials are used as coarse powder.

[0021] Then, mix the fine powder, coke powder and binder, wherein the coke powder particle size is less than 0.2mm, and mix them evenly in the wheel mill. While mixing the raw meal, add water to moisten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com