Patents

Literature

271results about How to "Improve utilization factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

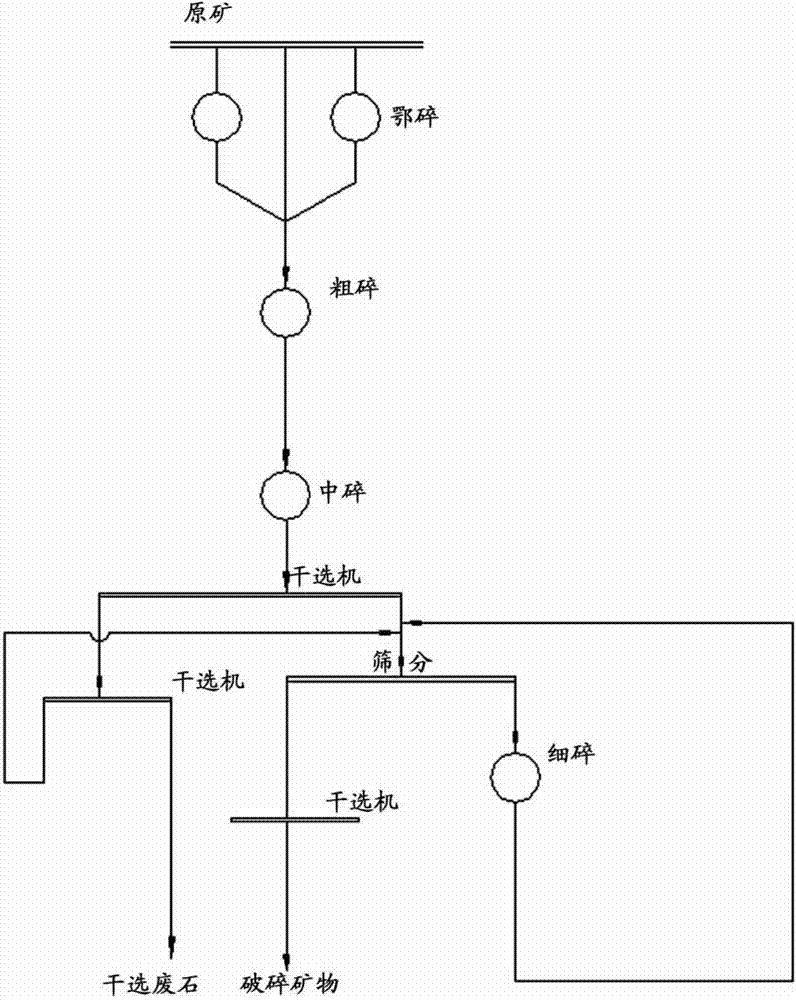

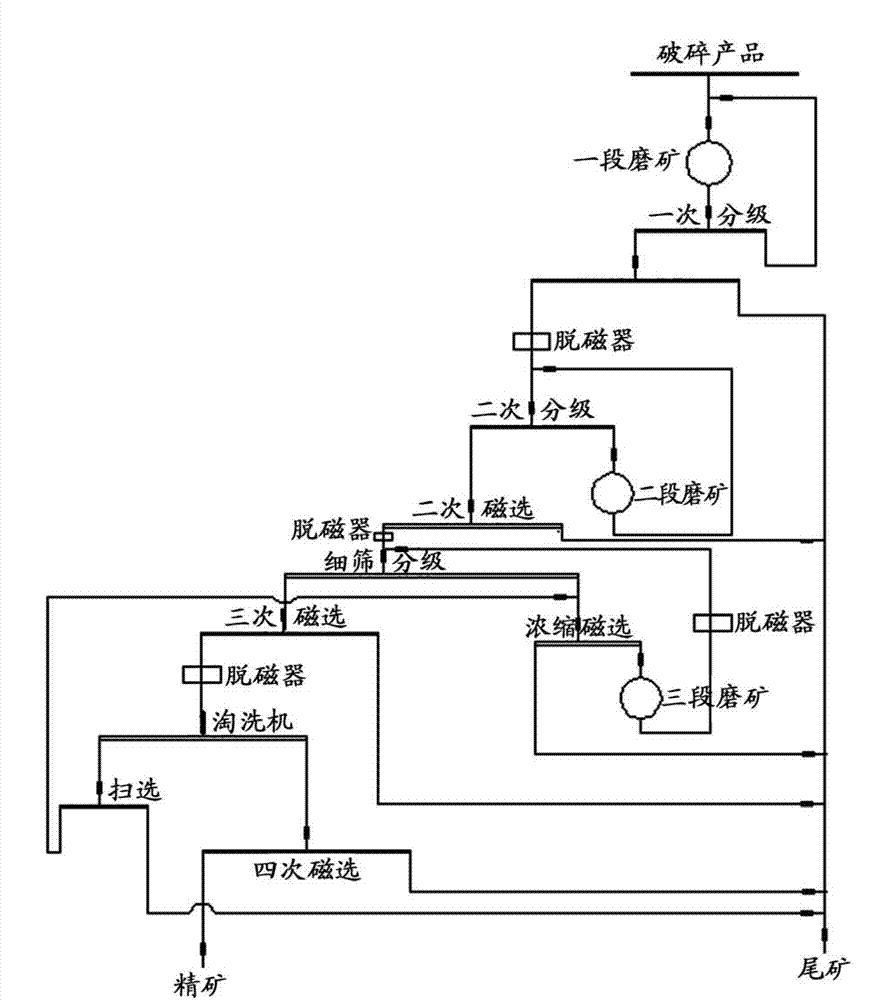

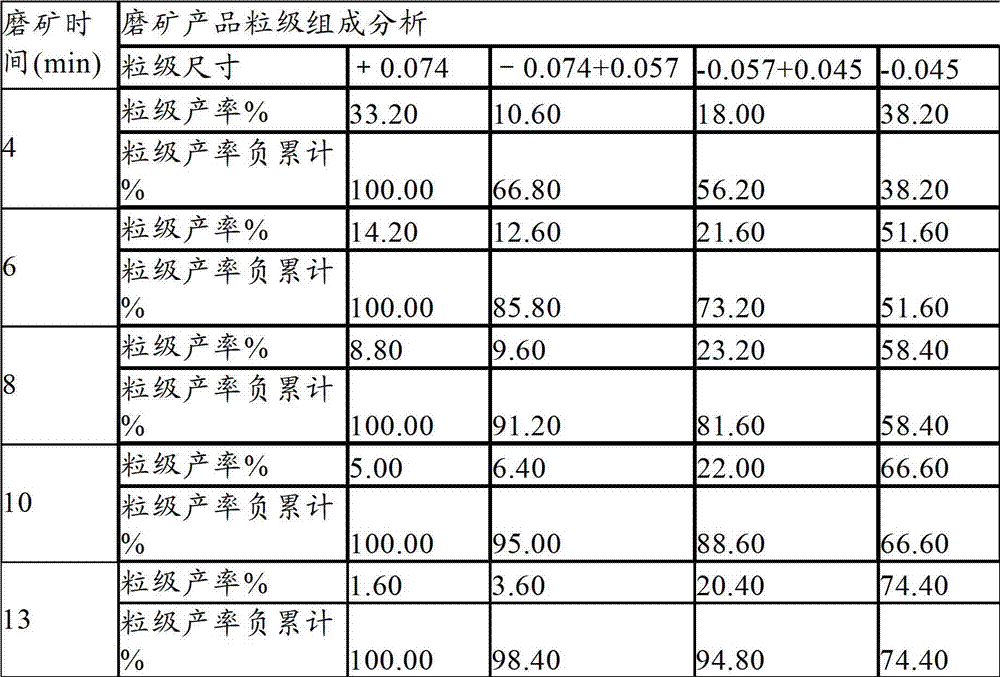

Ore dressing method and ore dressing system suitable for lean magnetite ores

ActiveCN103041920AIncreased throw rateSmall granularityMagnetic separationDressing methodMagnetic separation

The invention relates to an ore dressing method and ore dressing system suitable for lean magnetite ores. The ore dressing method comprises the following steps: (1), four crushing treatments, wherein magnetic separation treatment is carried out on the ores after the last two crushing treatments; and (2), a plurality of staged treatments including grinding, classifying and magnetically separating the ore powder at the plurality of stages in circulation. The invention provides a mixed ore enriching method for lean ores, interlayer ores, recovered ores and the like; therefore, resource waste is reduced, the pressure of a waste-rock yard is reduced, the benefits are increased and purposes of turning waste into wealth, saving energy and reducing emission are achieved.

Owner:TAIYUAN IRON & STEEL GROUP

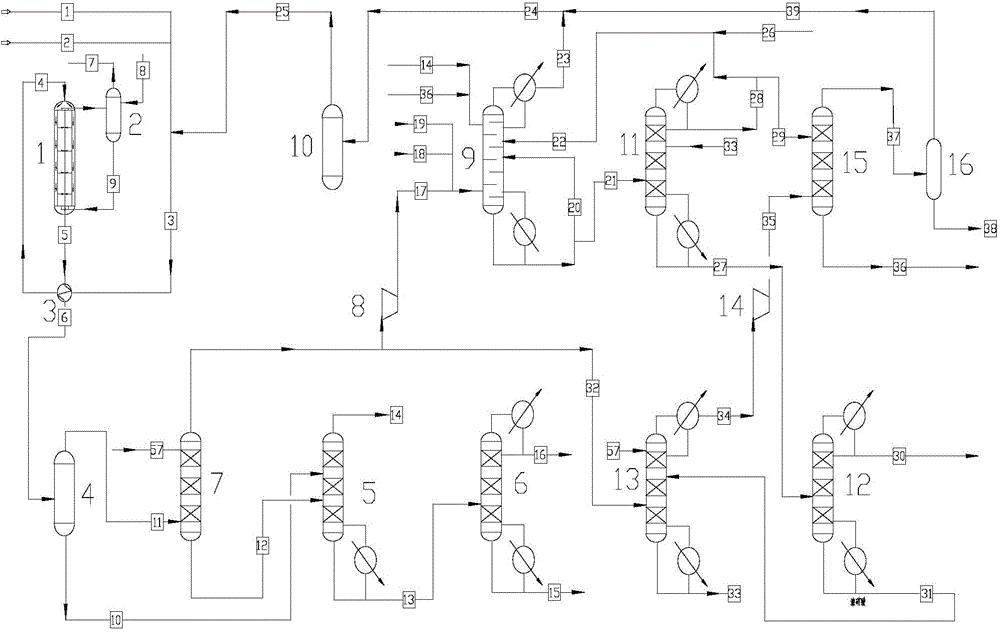

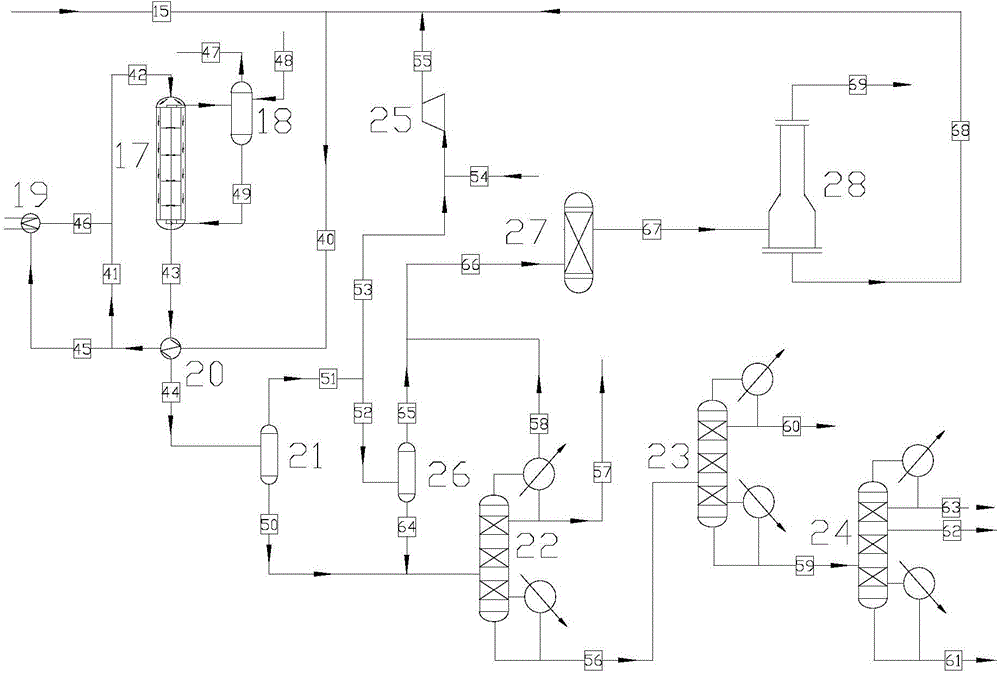

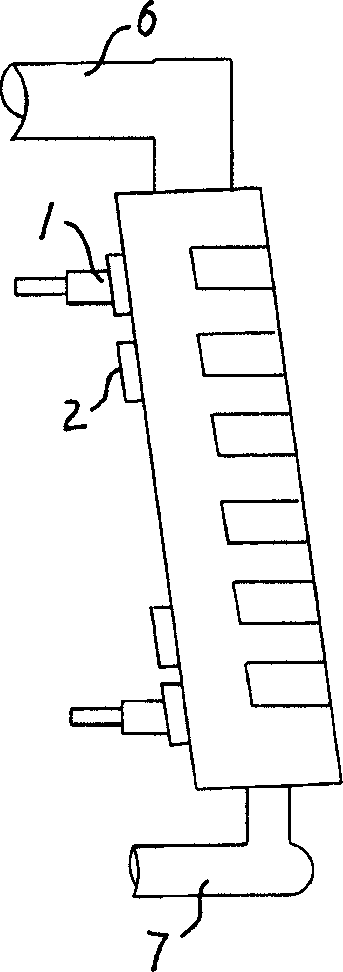

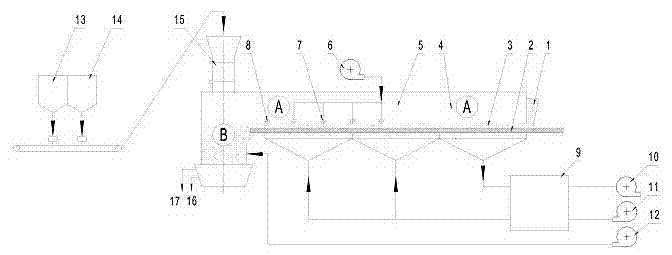

Technology and device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation

ActiveCN104098441AConducive to large-scale productionSmall volume requirementOrganic compound preparationEnergy inputSeparation technologyHigh pressure

The invention relates to a technology and a device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation. The technology comprises the following steps: adopting industrial NO, O2 and methanol as raw materials for an esterification reaction to produce methyl nitrite; adopting industrial CO and methyl nitrite for a carbonylation reaction in a plate reactor to produce carbonylation products, which mainly include dimethyl oxalate and dimethyl carbonate; separating the carbonylation products to obtain dimethyl carbonate products; subsequently adding hydrogen into dimethyl oxalate in the plate reactor to produce ethylene glycol products; conducting the coupling recovery treatment on waste acids in the esterification reaction and purge gases in the carbonylation reaction for recycling. The device system comprises an esterification reaction system, a carbonylation reaction system, a coupling recovery system for purge gases and waste acids and a hydrogenation reaction system. The technology has the characteristic that device consumption is remarkably reduced, and particularly the nitric acid waste liquid recycling and purge gas recycling technologies as well as the separation technologies thereof are highly coupled; recycling of the raw materials in reaction waste gases is realized, and the effect is remarkable.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

High-ore-matching-ratio brown iron ore sintering technology

The invention relates to a high-ore-matching-ratio brown iron ore sintering technology. The weight ratio of brown iron ore and powdered iron in raw material proportion is (5-19):1, the moisture content of the first mixing is controlled to be 7%-8%, the mixing time lasts for 2-3minutes, and the temperature of the mixture is 50-62 DEG C; the moisture content of second mixing pelletizing is controlled to be 7-9%, the pelletizing time lasts for 2-3.5minutes, and the temperature of materials is 52-65 DEG C; the thickness of grate-layer materials in distribution is 20mm, and a sintering material layer is 780-900mm thick; the ignition temperature for sintering is1050-1150 DEG C, and the ignition time lasts for 1.8-2.2minutes; and the negative pressure for sintering is 12-15kpa, the machine speed is 0.9-1.2m / min, the vertical sintering speed is 29-34mm / min, the air leakage rate is no more than 40%, the cooling negative pressure is 11-14kpa, the temperature of a cooling section of a sintering machine is reduced to 250 DEG C below. By using the high-ore-matching-ratio brown iron ore sintering technology, energy is saved, consumption is reduced, cost is decreased and benefit is increased.

Owner:唐山瑞丰钢铁(集团)有限公司

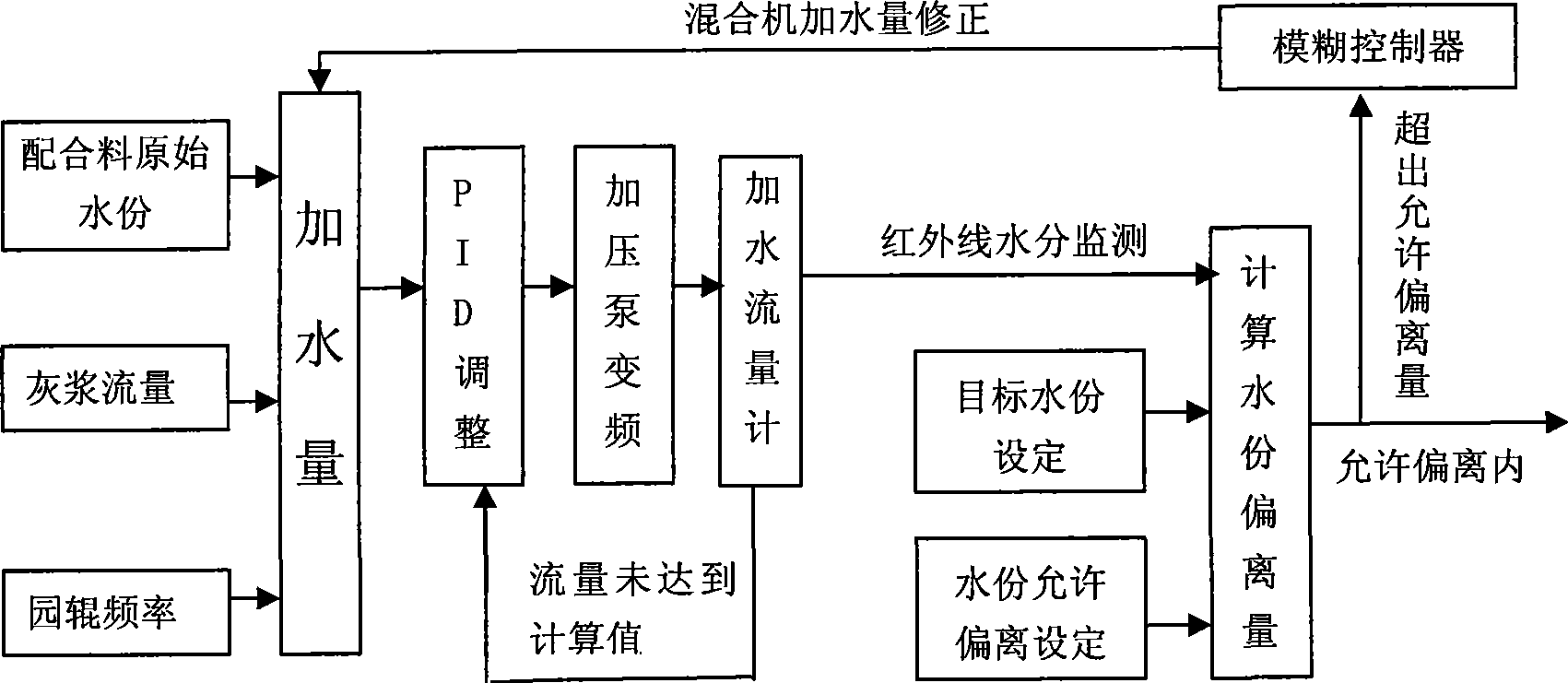

Humidity control method for mixture used in sintering production

ActiveCN101477378AReduce regulatory disturbancesMeet production requirementsControlling ratio of multiple fluid flowsAdaptive controlAutomatic controlData acquisition

The invention relates to a method for controlling moisture of a mixture for sintering production, and belongs to the technical field of automatic monitoring and intelligent control of mixture moisture. The method adopts a PLC system and a development tool. The control process comprises data acquisition, signal display, data processing, manual input of information, model operation and adjustment for fuzzy control, control quantity output, model self-adapting, and judgment and correction of manual intelligent mode. The method achieves automatic dynamic control of water adding amount of the sintered mixture to make the mixture moisture meet sintering production demand, displays data such as real-time moisture, water adding amount and the like of the material in the production process, and displays operation mode and the like. The method has the advantages that the method is suitable for control of the water adding amount in a mixing process using various sintering production process raw materials, can design an independent control system or can be realized by using the PLC control system based on automatic control of the production process, is limited little by field conditions, is suitable for new projects and reformed projects, and has low cost.

Owner:首钢股份公司迁安钢铁公司

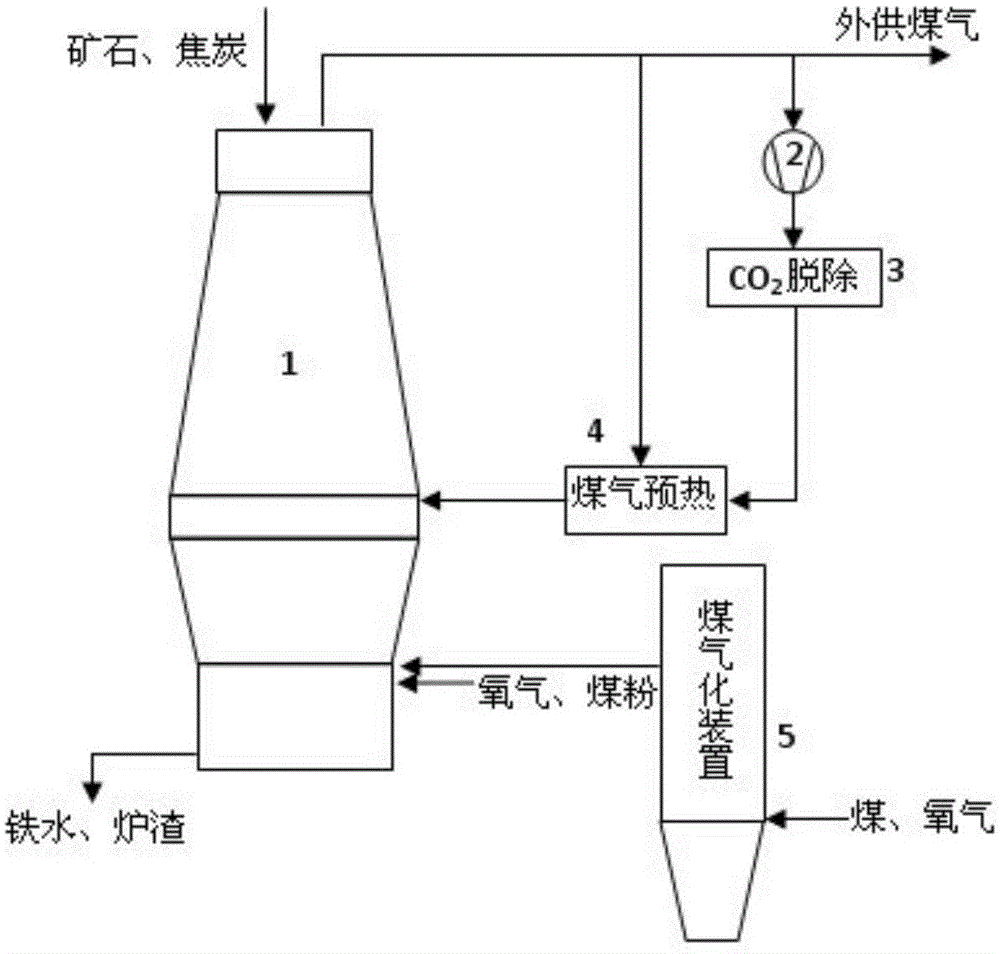

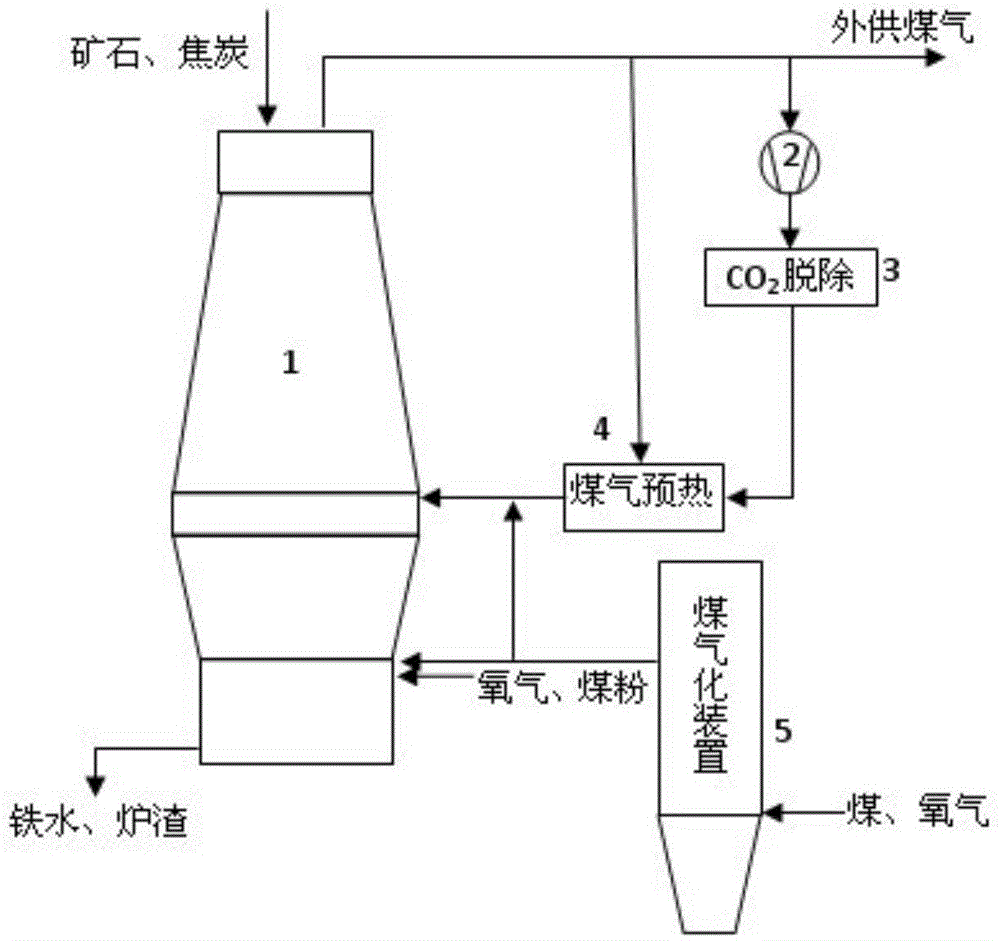

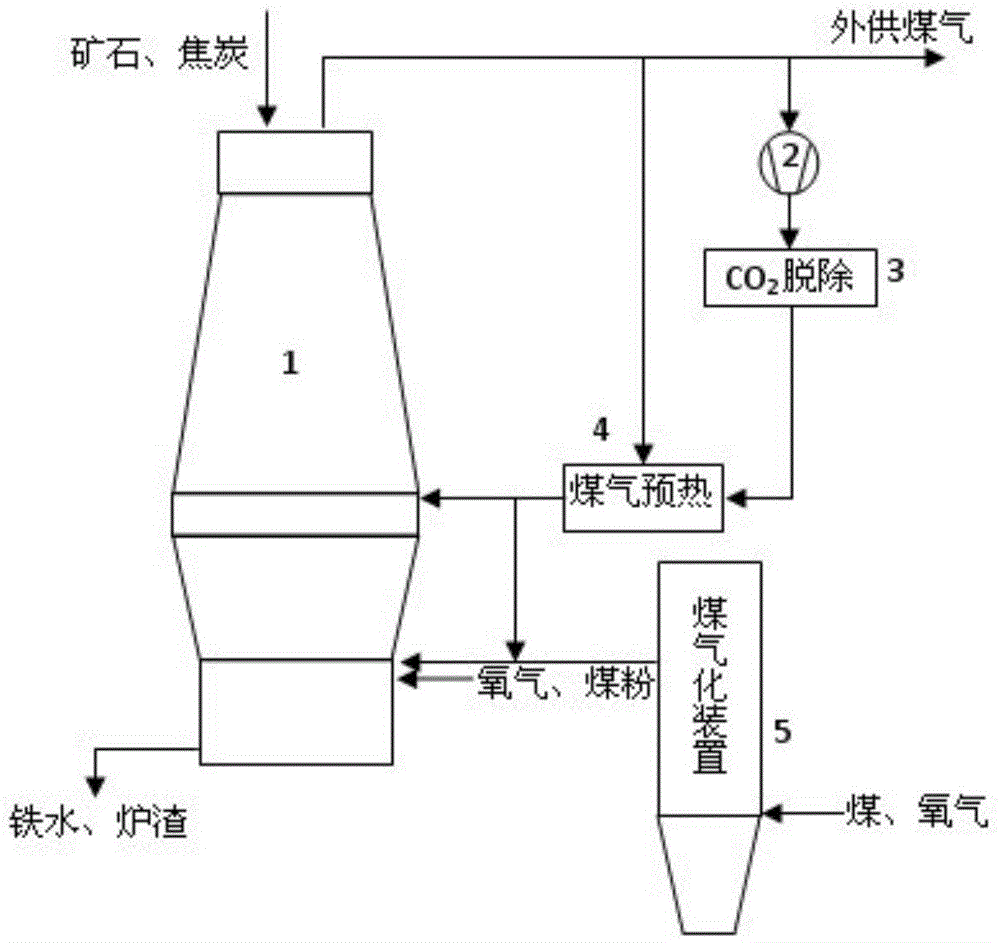

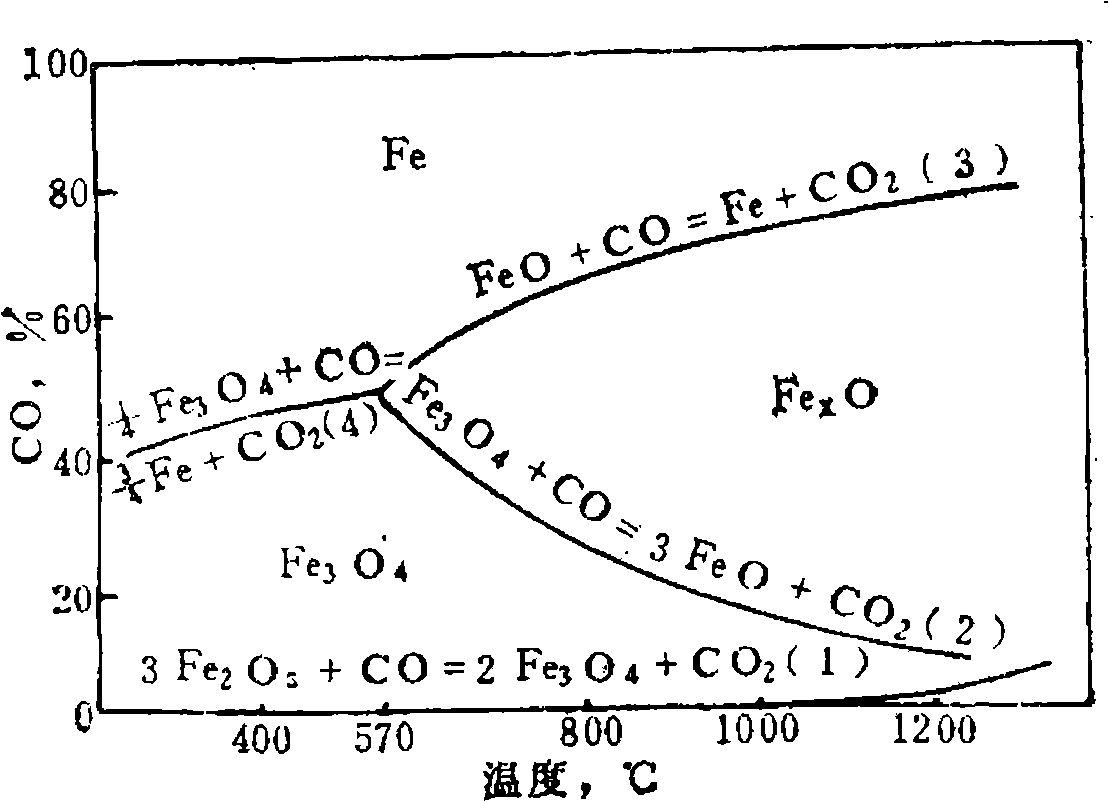

High-temperature gas injection-based iron-making technology

InactiveCN104131122ALower quality requirementsLow priceBlast furnace detailsGas emission reductionCo2 removalCapacity factor

The invention discloses a high-temperature gas injection-based iron-making technology and belongs to the field of black metallurgy. The high-temperature gas injection-based iron-making technology utilizes oxygen-rich normal-temperature air blasting to replace hot air operation, and high-temperature gas produced by a coal gasification device and CO2-free furnace top recycled gas are mixed and are respectively pumped into a blast furnace from the furnace body and the hearth so that furnace top recycled gas CO2 removal is realized. The high-temperature gas injection-based iron-making technology has a coal ratio of 240-350kg / tHM, a coal gasification unit coal-use amount of 50-250kg / tHM and a coke ratio of 180-260kg / tHM and a blast furnace capacity factor of 6.0-7.5, reduces operation costs of oxygen-containing blast furnace top gas CO2 removal and recycled gas pre-heating to a temperature of 900-1300 DEG C, realizes coke reduction and coal use increasing in blast furnace production, improves an iron-making technology energy structure and stabilizes gas balance of a steel enterprise.

Owner:UNIV OF SCI & TECH BEIJING

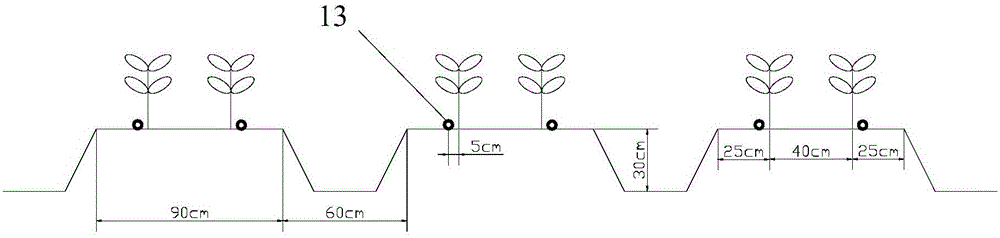

Saline-alkali soil brackish water film mulching drip irrigation processing tomato planting method

ActiveCN105103857AEasy to mineReduce evaporationClimate change adaptationWatering devicesAridAlkali soil

The invention provides a saline-alkali soil brackish water film mulching drip irrigation processing tomato planting method, which comprises the following steps: (1) planting processed tomatoes: planting the processed tomatoes by adopting a manner of wide rows and high ridges, and mulching a white film above plants; (2) laying out a drip irrigation system, wherein an interval b between the drip irrigation systems is 48 to 52 cm; an interval a between drip emitters is 0.25 to 0.35 m; (3) carrying out high-frequency and small fixed amount water irrigation in a growing period of the processed tomatoes: alternatively irrigating brackish water and fresh water, and adopting the fresh water for irrigation in a seedling stage, and no irrigation in a red-mature period. The invention puts forward a cultivation method taking the brackish water and saline-alkali soil as targets in combination with the realities of shortage of fresh water resources, abundant underground brackish water resources and serious soil salinization in an arid region and a semi-arid region, and not only moisture is enabled to be held up within a field microcirculation of soil-and-film, deep seepage losses of the moisture are greatly reduced, but also under-film soil evaporation is remarkably lowered, sources of soil secondary salinization are cut off and the surface accumulation of salt is eliminated.

Owner:CHINA AGRI UNIV

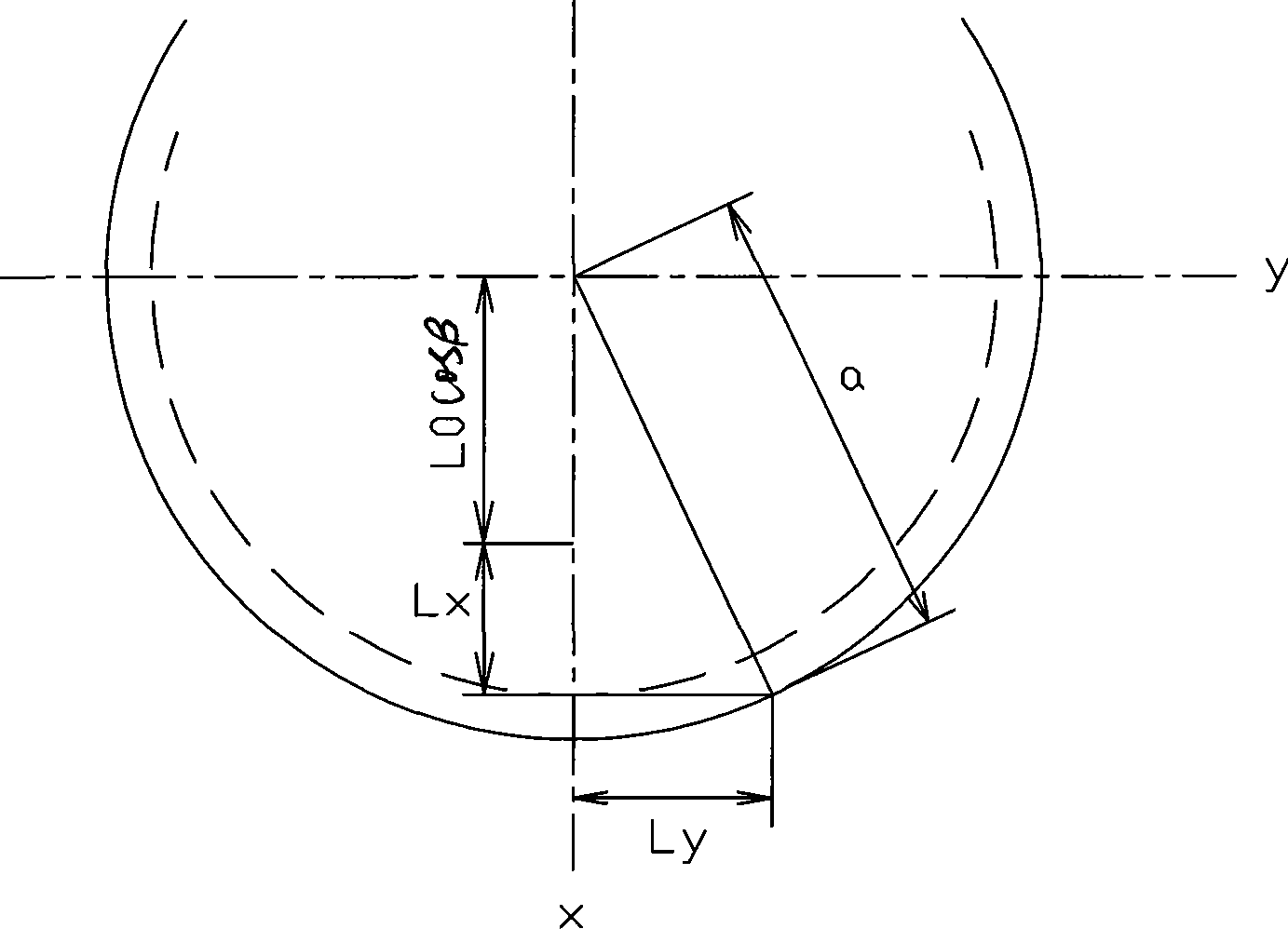

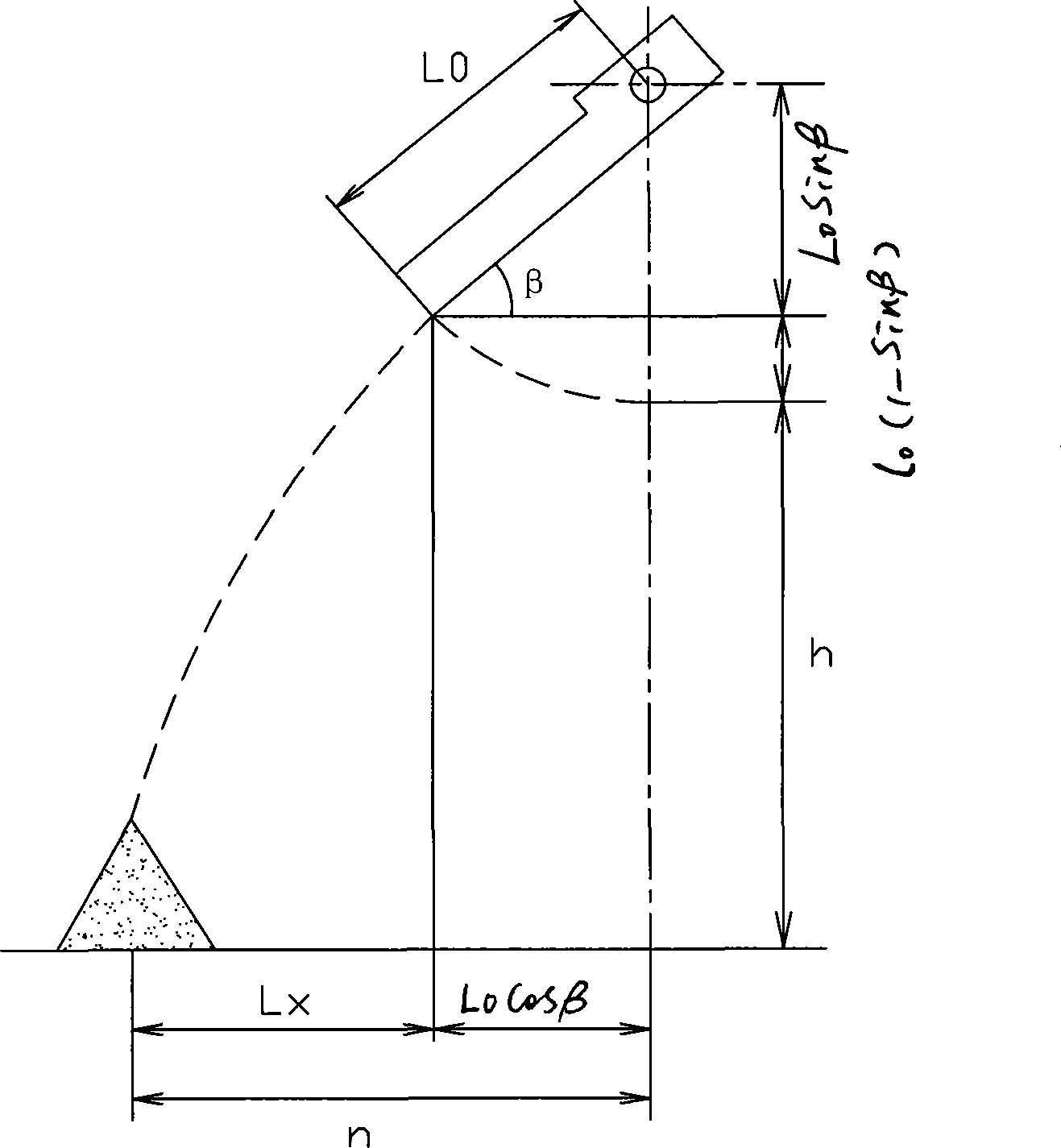

Blast furnace chute polycyclic distributing method

InactiveCN101250602AIncrease production capacityUniform material layerBell-and-hopper arrangementBlast furnace detailsRing numberGravitation

The invention discloses a blast furnace chute multi-ring burden distribution, which comprises firstly calculating the distance from the center of furnace burden from the center of a blast furnace after furnace burden fell into an xy plane, secondly deciding largest and smallest burden distribution angles in theory, thirdly deciding the actual burden distribution angles of outer ring and inner ring of ores and coke, fourthly deciding the burden distribution ring number of ores and coke, determining the burden distribution angle of middle ring of ores and coke and the angel difference of adjacent rings, and sixthly determining the burden distribution rings of each ring in ores and coke. The process largely enriches the regulating method on the upper portion of the blast furnace, changes coal gas distribution, effectively increases the coal gas usage of the blast furnace, reduces coke ratio, realizes the stable and long term operation of the blast furnace, has strong loading material capacity, can eliminate furnace burden gravity segregation and the existing of pile top, much reasonably distributes furnace burden, is beneficial for strengthening smelting, and improves the press amount relationship and further increases the air quantity of the blast furnace.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

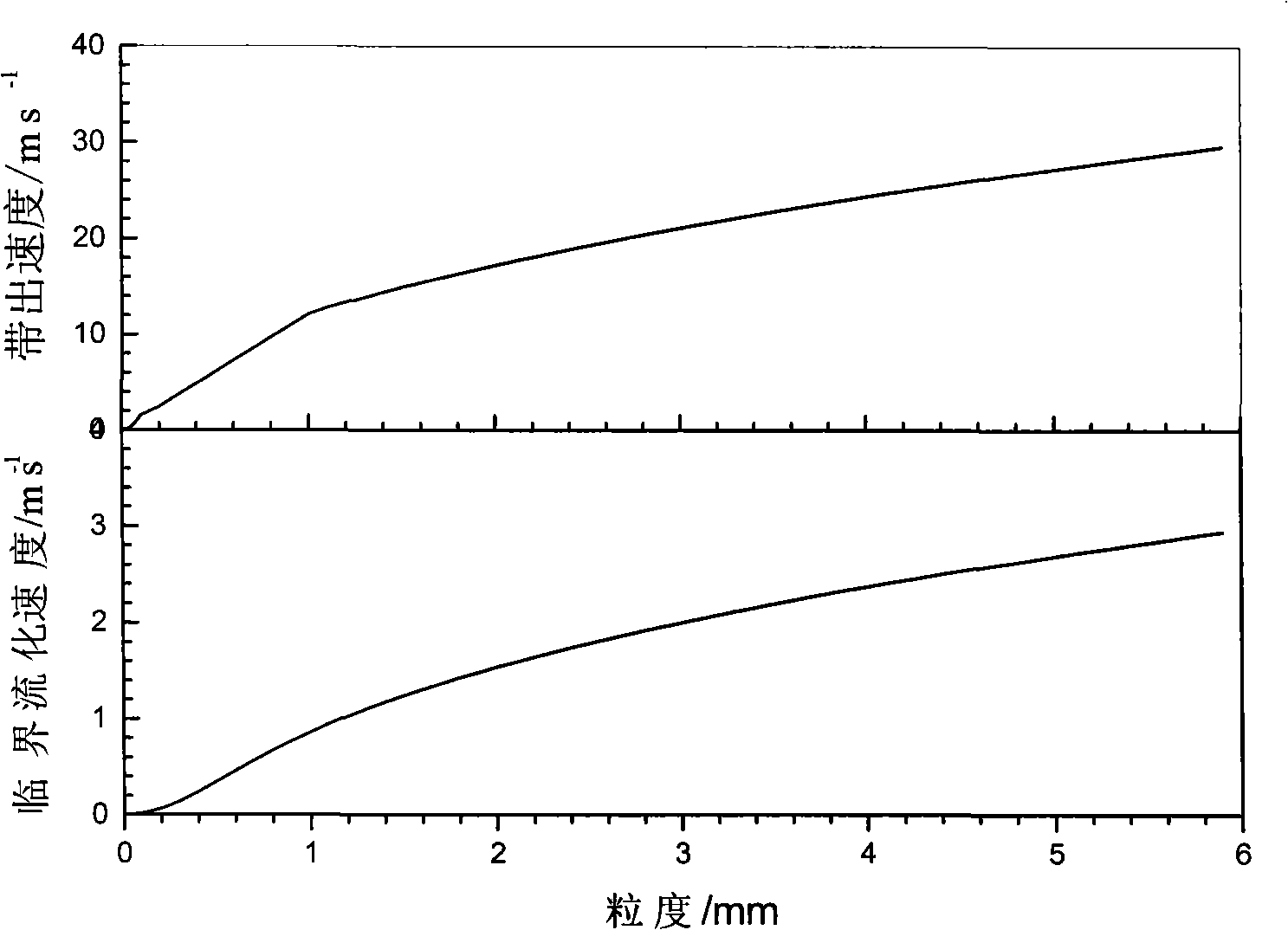

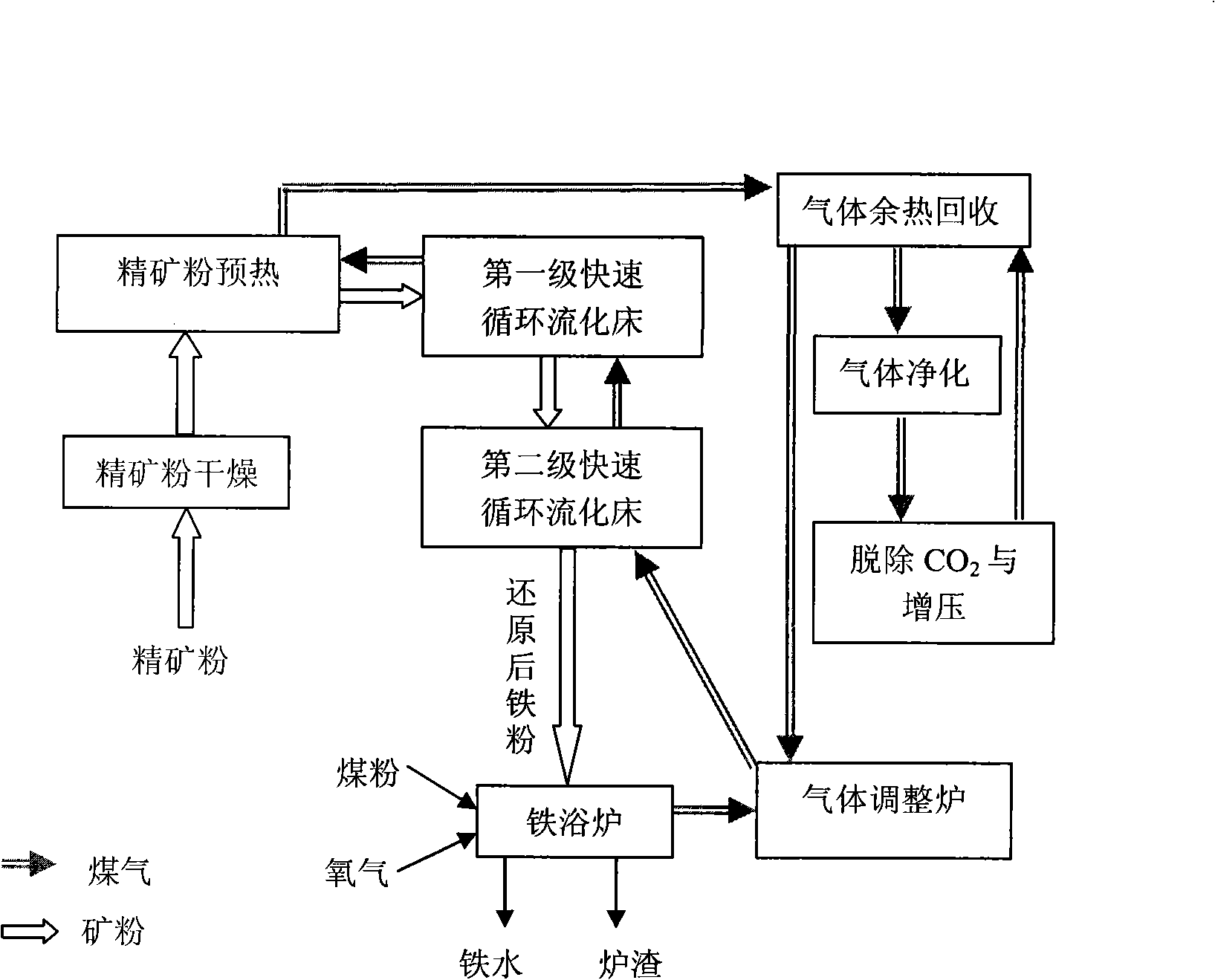

Fusion reduction iron-smelting method for directly using concentrate powder

ActiveCN101260448AHigh calorific valueImprove utilization factorProcess efficiency improvementGas emission reductionProduction lineSteelmaking

The invention belongs to the steelmaking field, and in particular relates to a smelting reduction steelmaking method of using concentrate powder directly. The production line is as follows: the concentrate powder is dried firstly and is pre-heated by the tail gas generated by a secondary rapid circulating fluid bed, the pre-heated concentrate powder enters the rapid circulating fluid bed to be pre-reduced, the metallization rate of the pre-heated iron powder is up to 55 to 80 percent; the pre-reduced iron powder and the coal dust as well as the oxygen are injected into an iron bath furnace to reduce and melt the mineral powder, and the molten iron and slag as well as coal gas are obtained. Compared with the prior art, the smelting reduction steelmaking technique has the advantages of high efficiency, low energy consumption, low pollution and easy implementation.

Owner:CENT IRON & STEEL RES INST +1

Application of limonite as base material in pelletizing agglomerate production method

An application of limonite as grate-layer material in producing spherical agglomerate features that its layer thickness is 30-40 mm and its granularity is 10-25 mm. The raw materials for producing spherical agglomerate include returned ore (10-20 wt.%), calcium lime (2-10), lime stone (0-12), dolomite (0-12), solid fuel (3-7.5) and Fe-contained material (rest).

Owner:新疆钢铁研究所

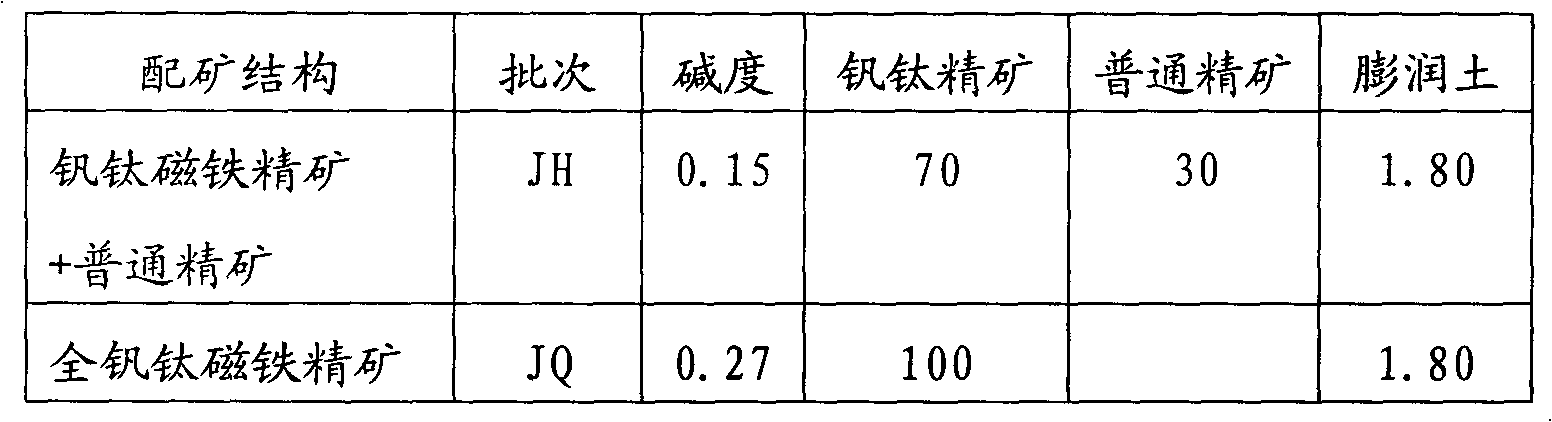

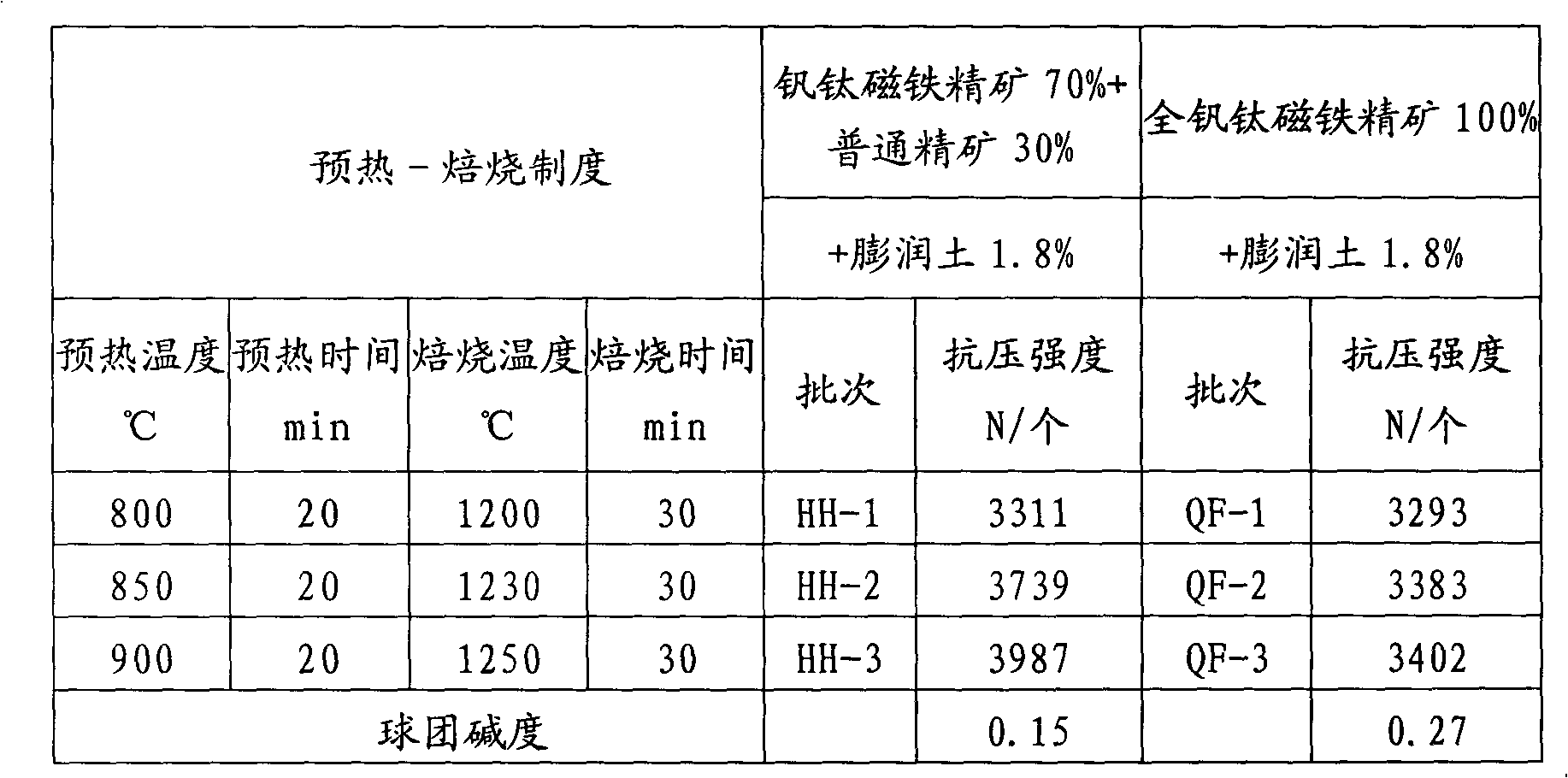

Acidic full-vanadium-titanium pellets and preparation method thereof

Owner:PANZHIHUA IRON AND STEEL +1

Casting method of metal substrate cooling wall

InactiveCN1513622AEnhanced feedingImprove feeding capacityFoundry mouldsCooling devicesIron powderChemical reaction

A technology for casting the steel-based cooling wall features that the cooling medium which is the mixture of corundum powder, iron powder and electrode powder is filled in its cooling pipeline. Said cooling medium features strong cooling action, low thermal expansibility, not adhering to pipe wall, and easy removing it.

Owner:MAANSHAN IRON & STEEL CO LTD

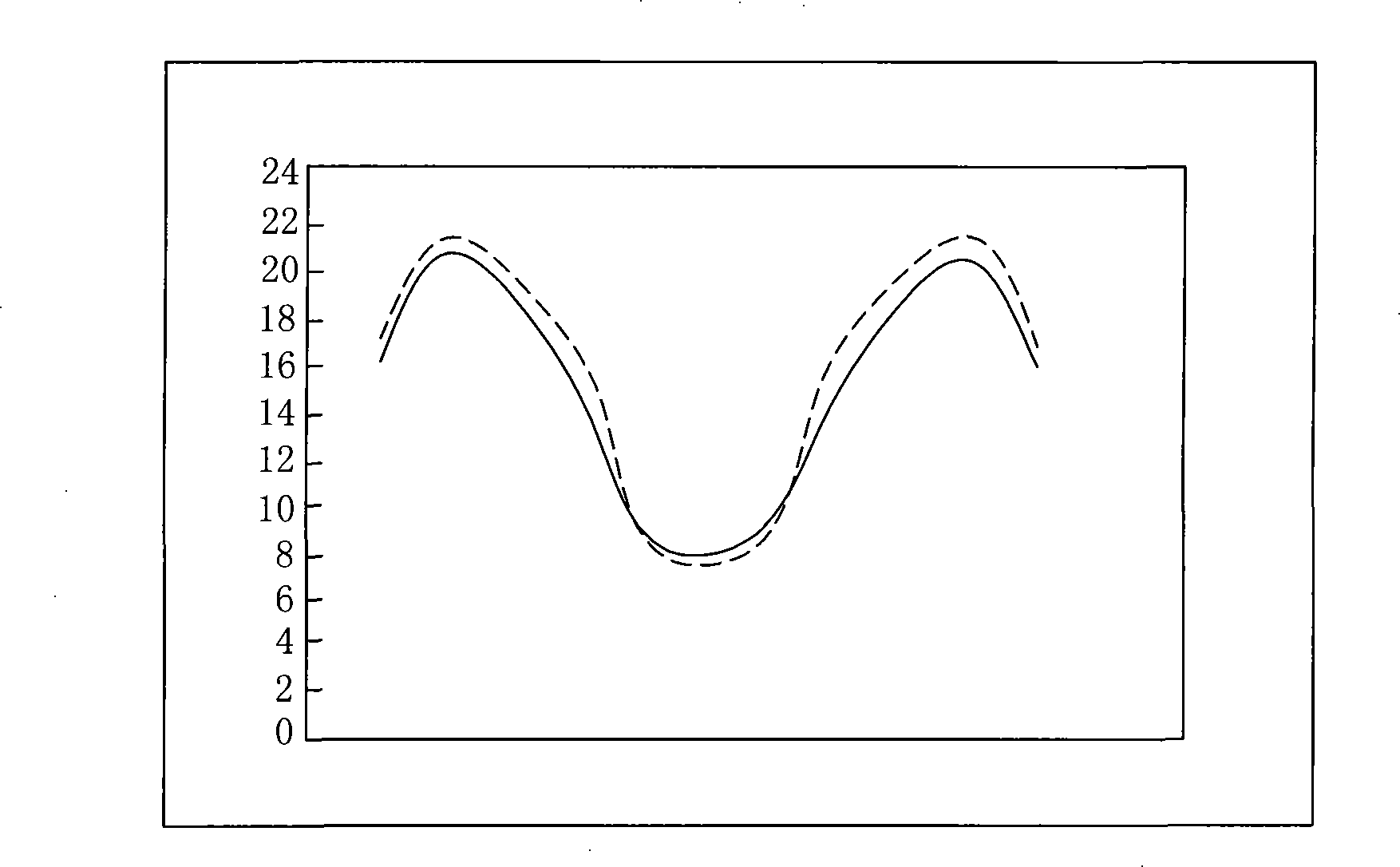

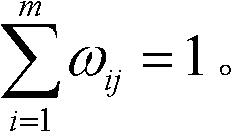

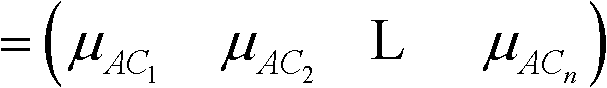

Self-tuning expert control method of burning trough point parameter based on working condition recognition

ActiveCN101907867AImprove anti-interferenceGuaranteed smooth operationAdaptive controlAutomatic controlControl period

The invention provides a self-tuning expert control method of a burning trough point parameter based on working condition recognition, comprising the following steps of: firstly, data collection and fuzzification: collecting and calculating a mixture level, the change rate thereof, a deviation of a burning trough point position, burning trough point temperature, the change rate of a 17-19 air box temperature average value and 6 process variables of sintering waste gas temperature rising point position, and carrying out fuzzification treatment; secondly, fuzzy diagnosis: obtaining the working condition of a current sintering running state according to the 6 fuzzed process variables and based on a diagnosis rule; thirdly, online control: according to the working condition obtained in the fuzzy diagnosis step and based on an established expert rule, realizing automatic control of the burning trough point by online regulating a control period, a control step size as well as an upper limit value and a lower limit value of a sintering machine speed. The invention can efficiently inhibit the phenomenon of unsmooth sintering process caused by instable working condition and enhance the yield and the quality of sintered ores.

Owner:CENT SOUTH UNIV

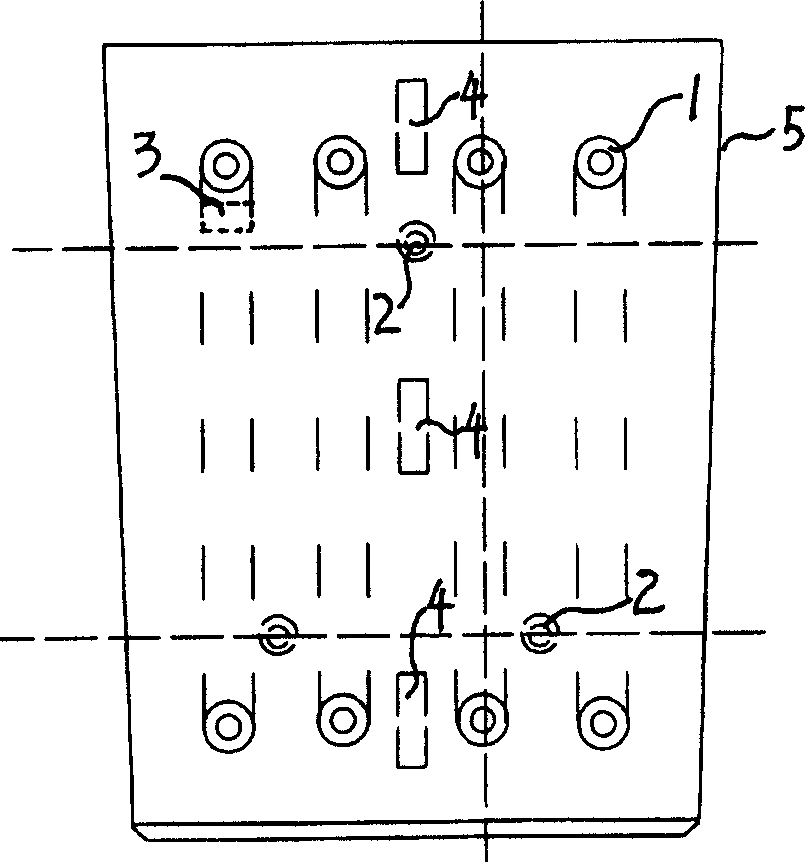

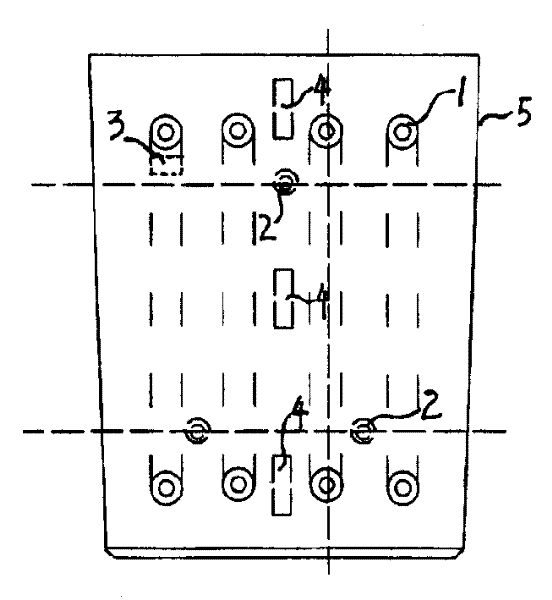

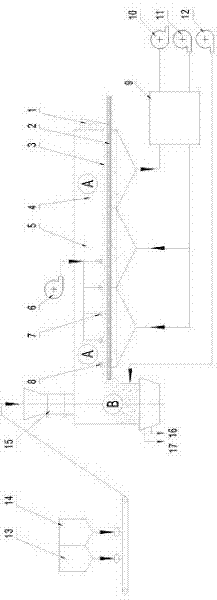

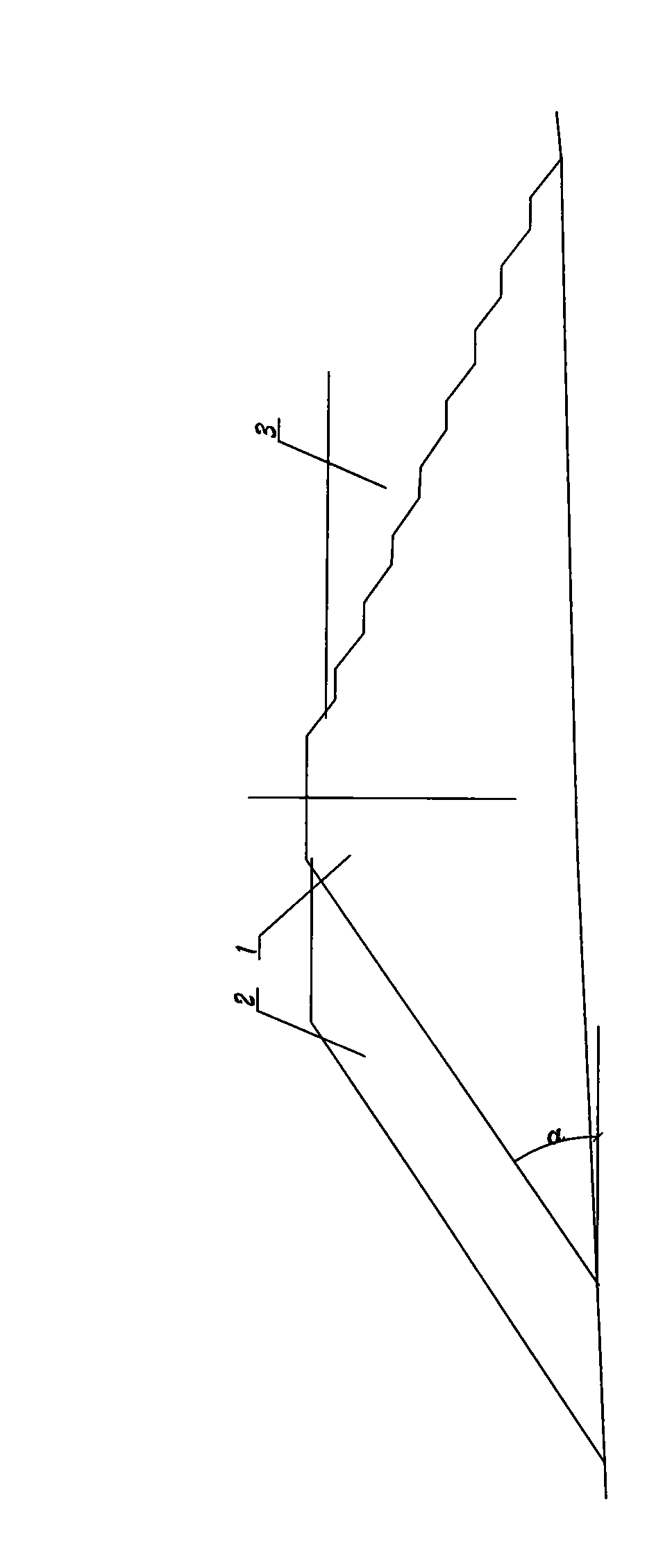

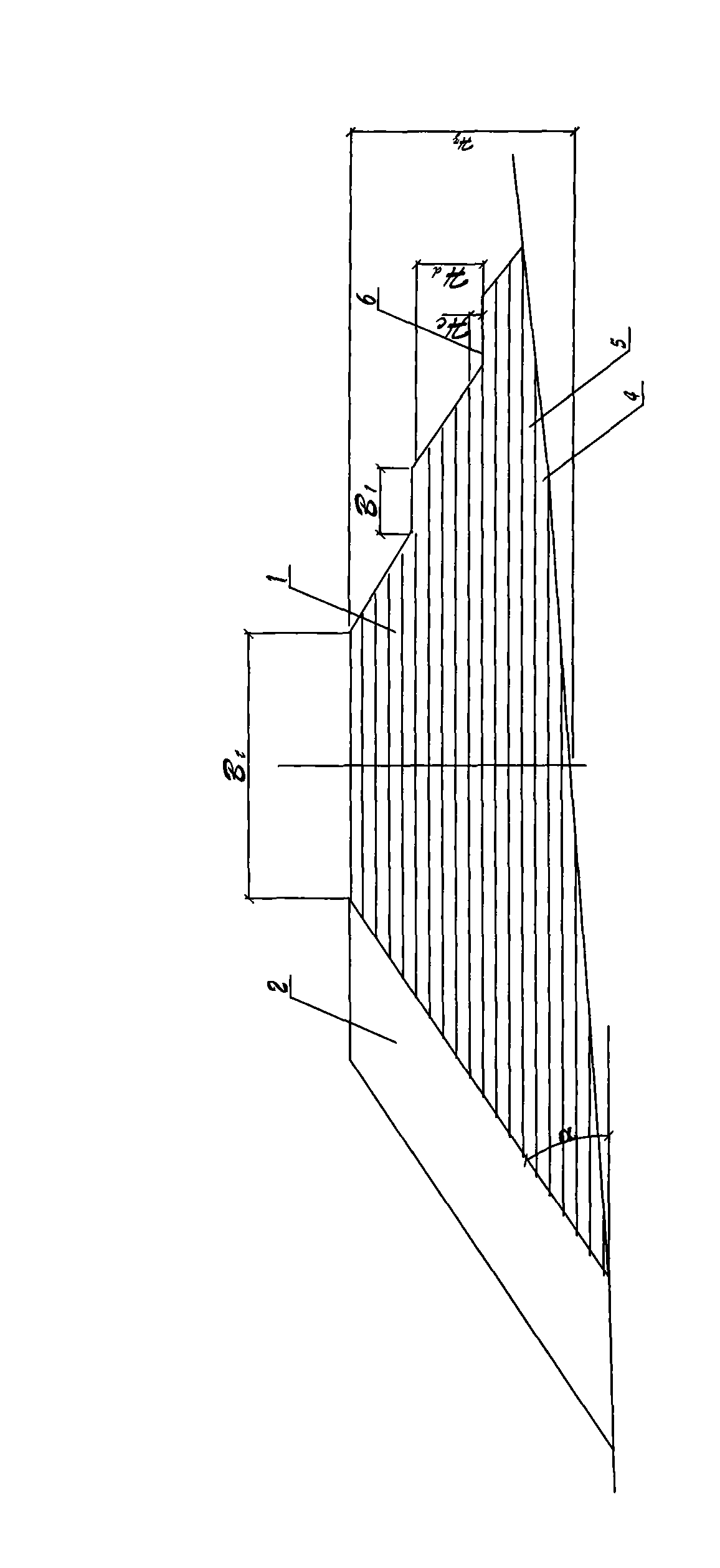

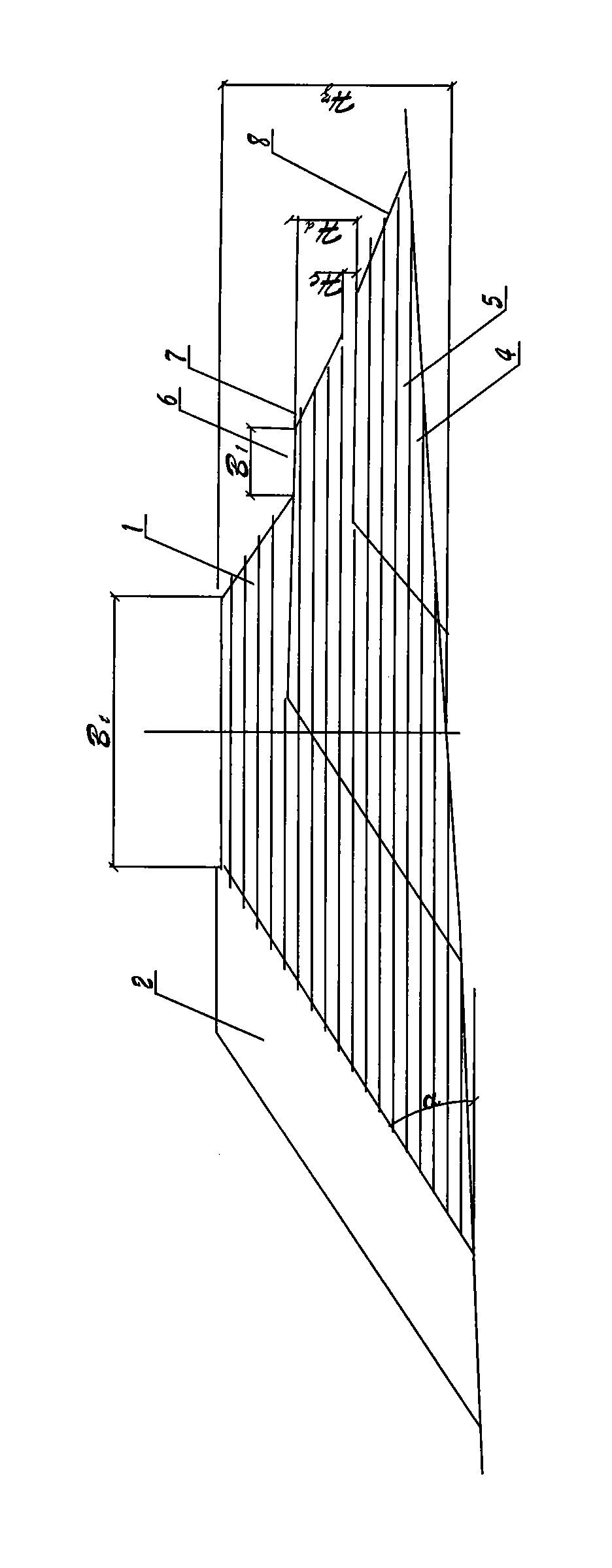

Continued ironmaking device based on melting reduction

The invention relates to a continued ironmaking device based on melting reduction of iron oxide containing carbon iron oxide balling (blocks). In the invention, the device is a continued ironmaking device based on melting reduction and can carry out continual tapping by pre-reducing furnace burden (3) through continually adding the furnace burden (3), extracting air, preheating, blasting and carrying out downstream roasting, and directly conveying the pre-reduced furnace burden (3) into a smelting-separating furnace (B) for continuous smelting-separation; a preheat area (4), a roasting area (5) and the smelting-separation areas behind the preheat area and the roasting area form a connected hearth; a combustion-supporting burner (8) and a secondary tuyere (7) are arranged also; preferably, the high-temperature coat gas generated in the smelting-separation area is subjected to secondary combustion in a pre-reduced furnace (A) for preheating and roasting the furnace burden (3); then the furnace burden (3) is discharged into the smelting-separation area for the further reduction, carburization and melting to separate the slag and iron; in the preheated area (4), the fuse passes through a bed of material to directly heat the furnace burden (3), and then the fuse enters a heat exchanging device (9) and a fuse process system; and a fan blasts the cool air below the bed into a hearth bottom (2) through the heat exchange device (9). The device has the advantages of short flow, reduced energy consumption, low carbon emission, low production cost, simple equipment, less occupied space, less investment and short building period.

Owner:李振洪

Magnesium binder used for pellet and preparation method and addition method thereof

InactiveCN102719662AIncrease the content of MgOImprove metallurgical performance indicatorsPass rateUltimate tensile strength

The invention provides a magnesium binder used for a pellet and a preparation method and an addition method thereof. The preparation method comprises: adding 30-35% of magnesite powder having a passing rate more than 80% through a 320 mesh, 40-55% of bentonite and 12-15% of active lime into a mixer; mixing a mixture above while adding 3-5% of sodium carbonate; and pulling the mixture out and airing the mixture for 7-9h to get a finished product. The addition method comprises adding the binder to a surface of a pellet mixture on a material conveying belt according to a preset weight of the binder that should be conveyed of a unit time and a unit length and based on a ratio by weight from 2.5% to 4.5%. Pellet MgO can be improved by 1-2%, mechanical strength of the pellet can be improved by 1-2%, and an initial softening temperature can be improved by 100-150 DEG C with the magnesium binder added into the pellet mixture. Blast furnace output can be improved by about 5% and coke ratio can be reduced by 10 kg by the pellet using the binder in the invention.

Owner:ANGANG STEEL CO LTD

Method for building tailings dam through adoption of mine dumping

ActiveCN101632993AExtended service lifeImprove utilization factorSolid waste disposalTailings damMining engineering

The invention relates to a method for building a tailings dam, in particular to a method for building a tailings dam through adoption of mine dumping. The method comprises the following steps that: a mine dumping yard and a tailings dam of a concentrating mill are combined; the mine dumping is adopted for directly building the tailings dam; a layered damming method or a strip damming method is implemented; after the tailings dam is formed, the inner side of the tailings dam is a tailings warehouse; and the outer side is a dumping yard. As mine dumping technology and damming technology of the tailings dam of the concentrating mill are combined, the method can greatly reduce the area occupation of the dumping yard, enlarge the utilization coefficient of the tailings warehouse and overcome the disadvantages of the prior damming construction method of the tailings warehouse and the difficult problems of sand lifting of tailings sand and the like; and meanwhile, after a mine stops production, under the condition that the mine dumping cannot be used for building the tailings dam, the concentrating mill can also utilize waste stone of the dumping yard to continue building the tailings dam. The process is suitable for the tailings warehouses of a valley type, mountain-surrounding type, flat type, cut-off river type and other types, is also suitable for building the tailings dam of the concentrating mill of other industries, is also suitable for newly building the tailings dam of the concentrating mill and is also suitable for building the tailings dam of the concentrating mill in course of production.

Owner:ANSTEEL GRP MINING CO LTD

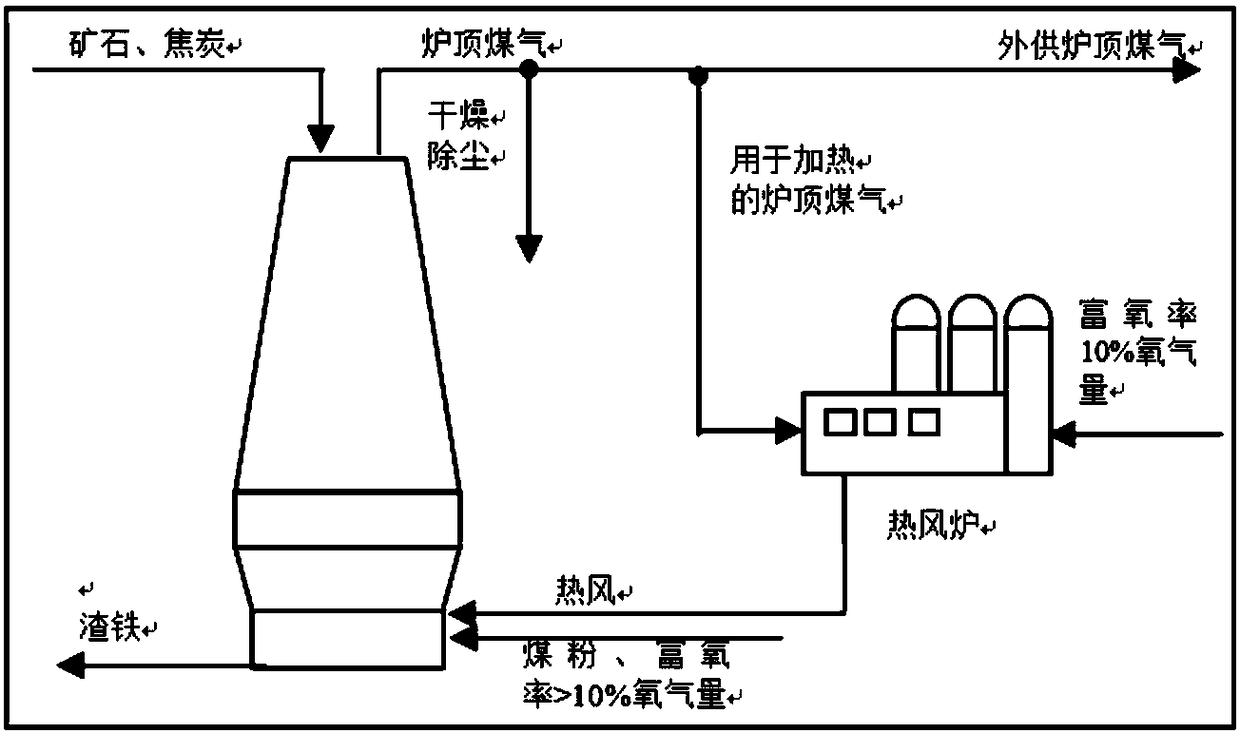

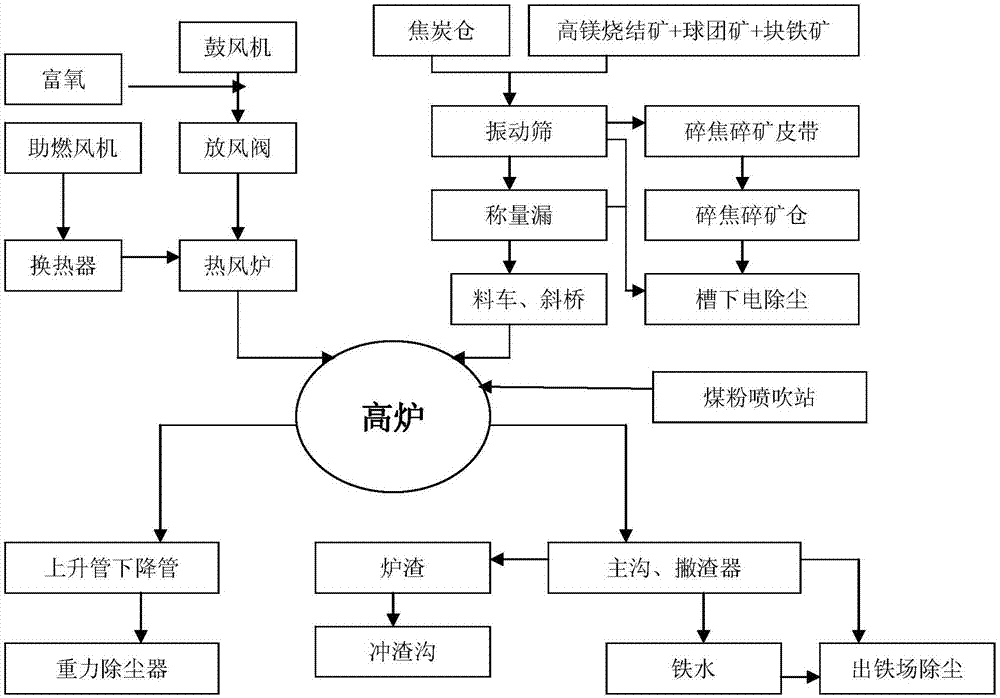

Blast furnace vanadium-titanium magnetite smelting method by utilizing ultra-high oxygen enriching air blasting

ActiveCN108330238AImprove combustion efficiencyIncrease profitBlast furnace detailsBlast furnace smeltingHigh oxygen

The invention relates to the technical field of vanadium-titanium magnetite smelting, and provides a blast furnace vanadium-titanium magnetite smelting method by utilizing ultra-high oxygen enrichingair blasting. The content of oxygen in hot air of a blast furnace is increased to 26-41% level, the corresponding air blasting oxygen enrichment rate is 5-20%, and the combustion rate of coal powder at the front end of a tuyere is increased; the coal gas reducing potential is increased; the reducing, soft melting, dripping and slag forming process of the vanadium-titanium magnetite in the blast furnace is optimized, breathability of the blast furnace is improved, and it is guaranteed that production of the blast furnace is stably and smoothly performed; and the problems that in the process ofsmelting the vanadium-titanium magnetite through the blast furnace process, the coal ratio is low, the energy consumption is high, furnace slag is viscous and thick, breathability is poor and intensified smelting is difficult are solved. According to the method, it is adopted that high-concentration oxygen is extra added in the hot air of the blast furnace, the oxygen content in the hot air is increased, the coal spraying ratio can be increased, the coke ratio is reduced, the iron making energy consumption of the blast furnace is reduced, the smelting strength is improved, production of the blast furnace is stabilized, and the blast furnace smelting cost of the vanadium-titanium magnetite is reduced.

Owner:UNIV OF SCI & TECH BEIJING

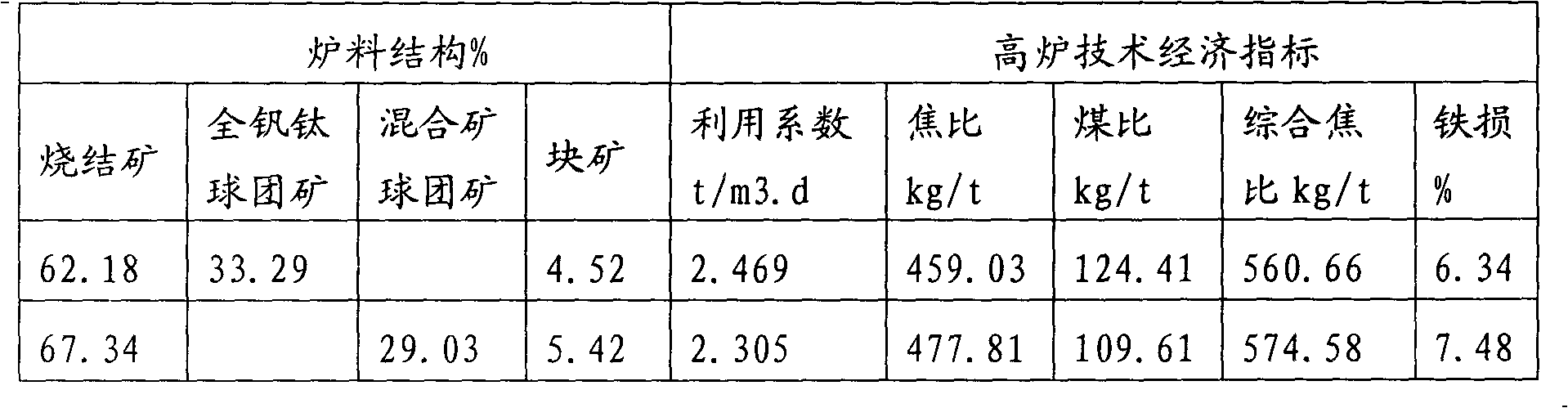

Blast furnace smelting method by using vanadium-titanium two-phase sintering ore

ActiveCN104673951AReduce ironmaking costsImprove utilization factorBlast furnace detailsIronstoneBlast furnace smelting

The invention belongs to the technical field of iron and steel metallurgy, in particular relates to a blast furnace smelting method by using a vanadium-titanium two-phase sintering ore. The blast furnace smelting method by using vanadium-titanium two-phase sintering ore is characterized in that the blast furnace burden structure is as follows: 70-100wt% of vanadium-titanium two-phase sintering ore, 0-30wt% of vanadium titanium magnetite pellet and 0-10wt% of common iron ore, wherein the common iron ore is an iron ore containing no vanadium or titanium. The invention provides the blast furnace smelting method by using vanadium-titanium two-phase sintering ore, and the method is low in cost; vanadium-titanium titanic magnetite for blast furnace smelting is provided by the vanadium-titanium two-phase sintering ore, so as to optimize the blast furnace burden structure, improve the breathability of the blast furnace burden structure and perfect the technical-economic indicator of blast furnace smelting.

Owner:攀钢集团西昌钢钒有限公司

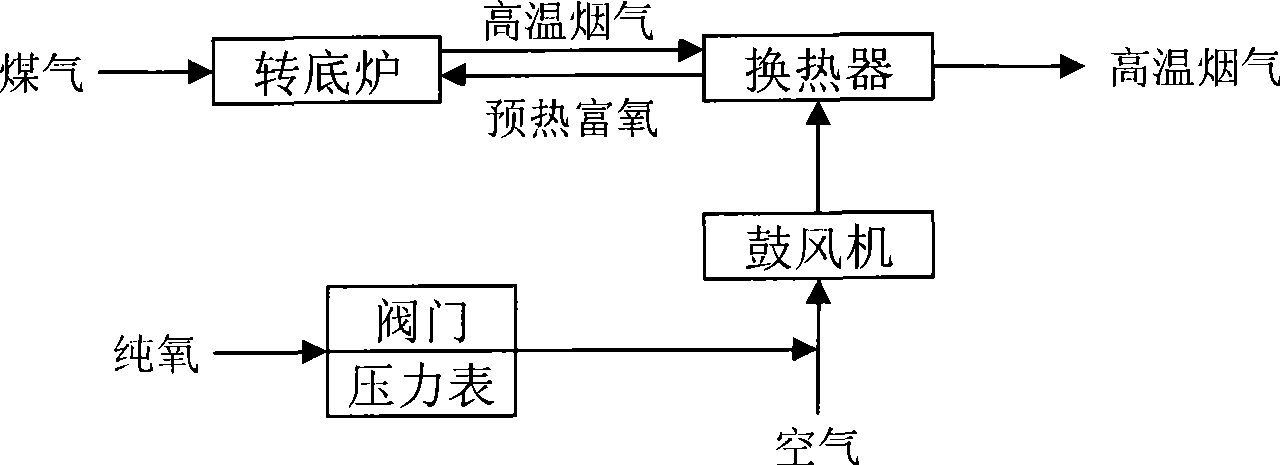

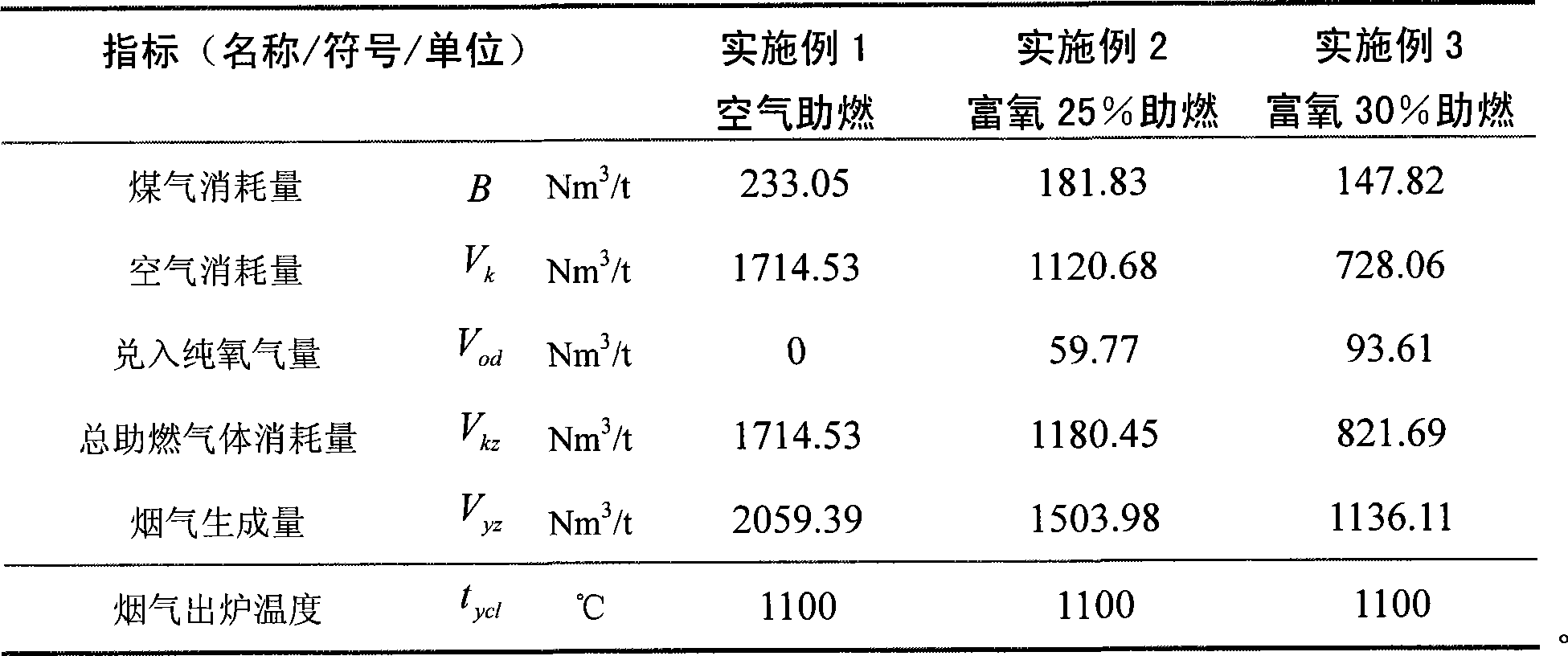

Method for manufacturing metallic pellets by direct reduction of oxygen-enriched combustion in rotary furnace

InactiveCN101445869AReduce consumptionReach the remarkable effect of saving energy and reducing consumptionProcess efficiency improvementAir blowerRotary furnace

The invention provides a method for manufacturing metallic pellets by direct reduction of oxygen-enriched combustion in a rotary furnace, which belongs to the technical field of steel industry for manufacturing metallic pellets (or direct reduction iron). The method is characterized in that oxygen enriched air is adopted as an auxiliary fuel gas; the oxygen enriched air enters a heat exchanger through a blower; and after the heat exchange between the oxygen enriched air and high temperature flue gas is performed, the temperature rises to 400 DEG C to 600 DEG C, and then the oxygen enriched air enters the rotary furnace. The invention breaks through the limitation of the prior air taking as a combustion medium and fixing the oxygen content, realizes the actual demand that the oxygen content in the combustion medium is controllable, further enhances the heat efficiency of the rotary furnace, reduces over 35% of air consumption amount, reduces over 31% of total consumption amount of the auxiliary fuel gas; and the coal gas consumption, the flue gas discharge capacity and the investment cost are reduced, and conforms to the national policy requirements of energy conservation, emission reduction and circulation economy.

Owner:LAIWU IRON & STEEL GRP

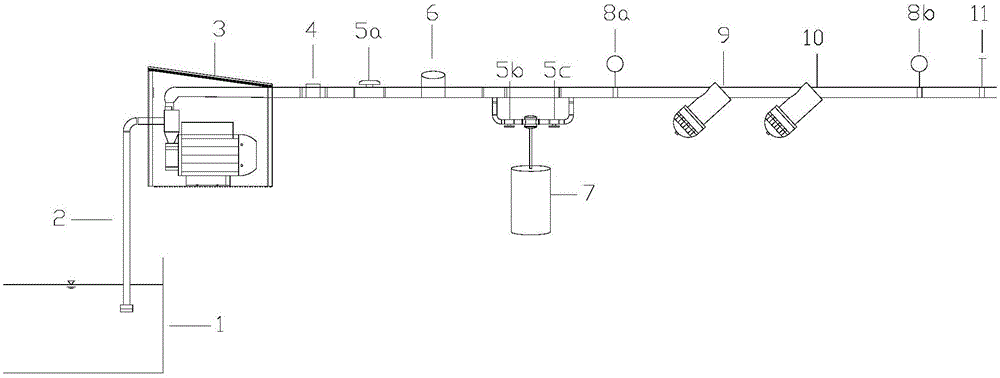

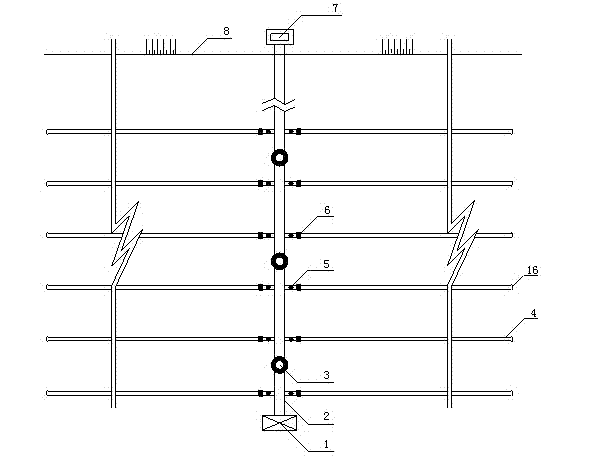

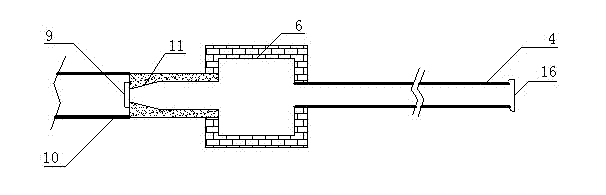

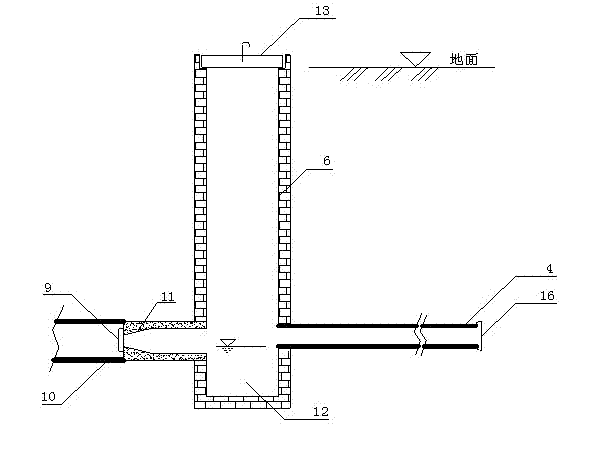

Concealed conduit system for both irrigation and drainage of farmland

The invention relates to the problem of a concealed conduit system for both irrigation and drainage of a farmland and belongs to the technical field of agricultural water soil engineering. The concealed conduit system for both irrigation and drainage of the farmland comprises a water pipe and a seepage pipe, and is characterized in that: the starting end of the water pipe is connected to an irrigation water inlet valve; the terminating end of the water pipe is connected to a drainage control valve; the gradient of the water pipe along a water flow direction is 1 / 500 to 1 / 1000; the water pipe is paved 1.5 to 1.8m under the ground; a water hydrant is upwards arranged on the water pipe every 30 to 50m; a water absorption tube system is arranged along the horizontal and vertical direction of the water pipe every 10 to 20m; the water absorption tube system comprises a backstop, an inspection well and the seepage pipe, which are sequentially communicated; the backstop is communicated with the water pipe; and the gradient of the seepage pipe along the water flow direction is 1 / 300 to 1 / 600. In the concealed conduit system, a low-pressure pipeline irrigation concealed conduit system and a drainage concealed conduit system are combined, so two functions of one set of pipe net are realized, the density of pipe net buried in the farmland can be effectively reduced, and farmland cultivation and mechanical operation are facilitated.

Owner:HOHAI UNIV

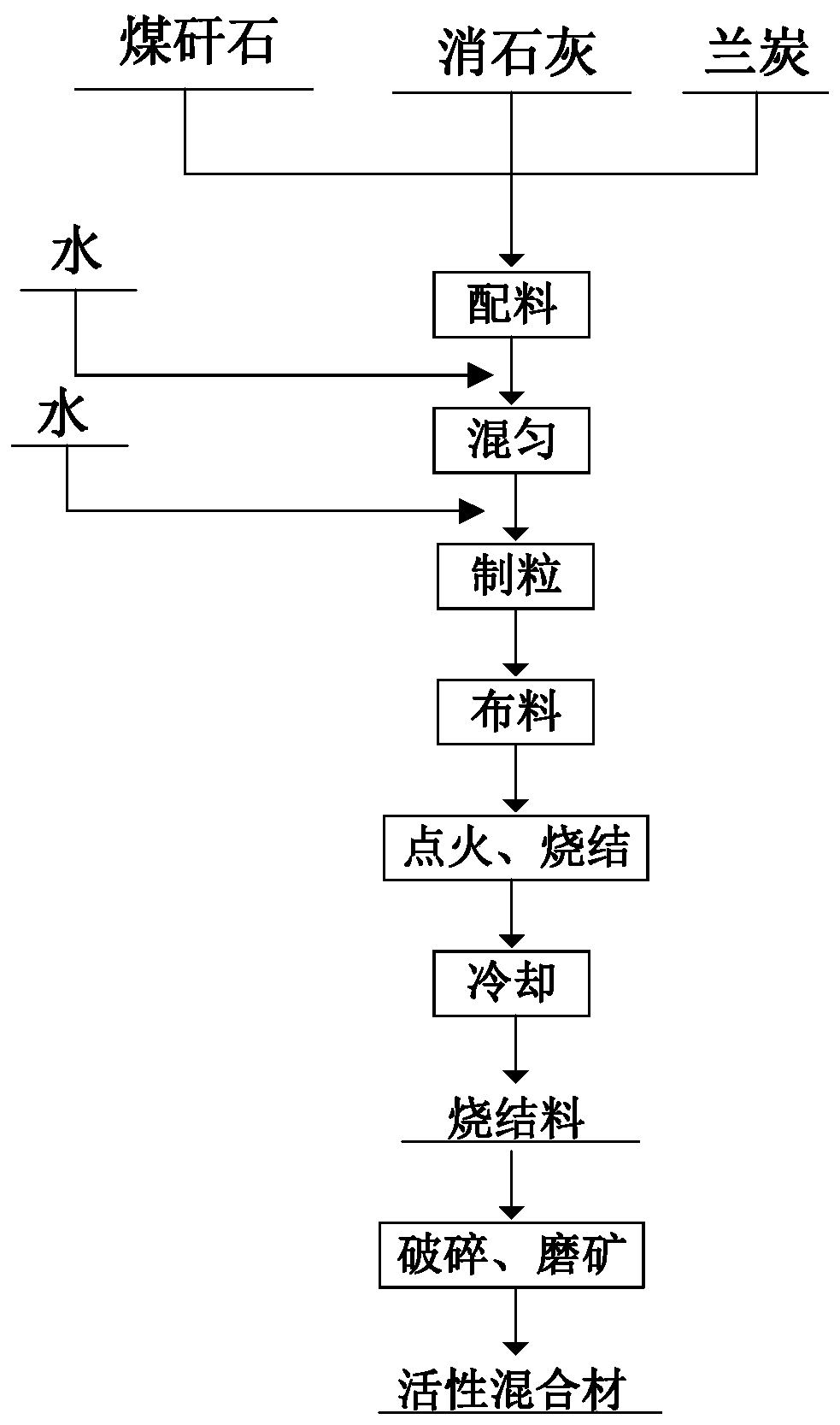

A process for preparing active mixed materials by belt sintering of coal gangue

The invention discloses a process for preparing an activated mixed material through strand sintering of coal gangue. The process comprises the following steps: (1) crushing; (2) preparing materials, and uniformly mixing, namely sufficiently and uniformly mixing crushed coal gangue, quick lime, a carbon fuel and water in a cylinder mixing machine in a set ratio; (3) pelletizing, namely pelletizingthe uniformly mixed minerals into beads of a preset granularity; (4) sintering, namely performing allocation, ignition, air sucking sintering and cooling on the pelletized beads in a strand air sucking sintering machine; (5) crushing and finely grinding, namely crushing the sintered material, and finely grinding till a set specific surface area, thereby obtaining the activated mixed material. Theinvention provides the process for preparing an activated mixed material through strand sintering of coal gangue, by virtue of the properties that a combustion zone is high in temperature and short intime in the sintering process, a vitric phase can be formed, meanwhile, the sintered material mainly contains an oxidation atmosphere, harmful components such as organic matters, residual carbon andsulfur in the coal gangue can be removed at a high temperature, and the cementing property, the freezing resistance and the durability of cement are protected from adverse influence of the harmful components.

Owner:CENT SOUTH UNIV

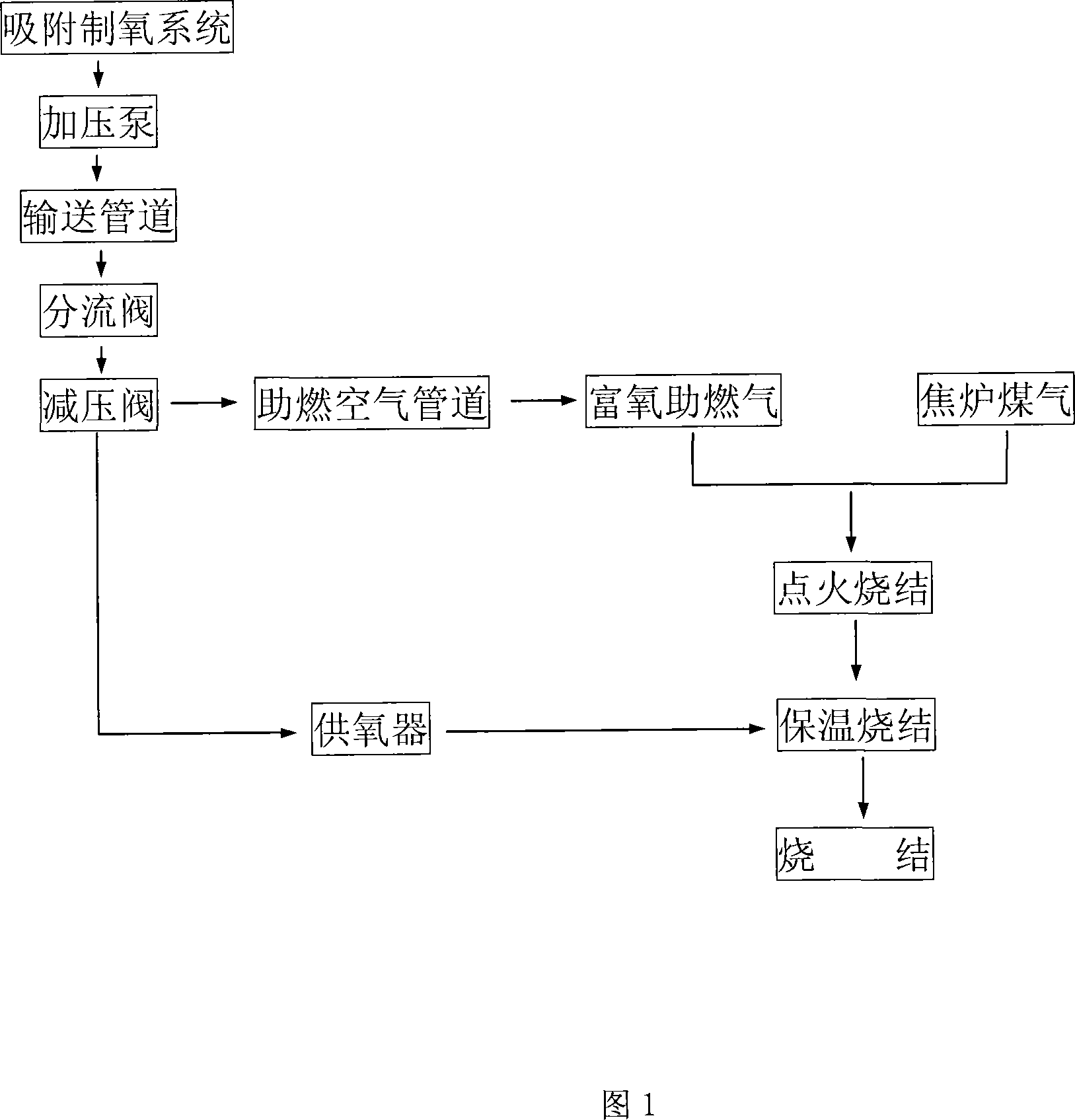

Oxygen-enriched sintering technique

The present invention relates to a rich oxygen sintering technology, which comprises ignition rich oxygen and heat preservation rich oxygen, namely, the rich oxygen sintering is used in both the ignition section and the heat preservation section of a continuous strand sinter machine. The rich oxygen sintering technology has the technical proposal that: first, ignition rich oxygen: oxygen with 93 percent purity produced with an adsorption oxygen producing system is delivered to a combustion-supporting pipeline after passing through a pressurization pump, a transfer pipeline, a flow dividing valve, and a pressure reduction valve, the oxygen and the combustion-supporting air in the combustion-supporting pipeline are mixed, to form the required combustion-supporting air with rich oxygen, and the oxygen content in the combustion-supporting air with rich oxygen is 22 to 25 percent; then ignition is performed after the combustion-supporting air with rich oxygen and coke oven gas is mixed with 2.7: 1 to 4.2:1 proportion of the combustion-supporting air with rich oxygen and the coke oven gas; second, heat preservation rich oxygen: oxygen with 93 percent purity produced with an adsorption oxygen producing system is delivered to an oxygen supply apparatus after passing through a pressurization pump, a transfer pipeline, a flow dividing valve, and a pressure reduction valve, the oxygen supply apparatus adds oxygen to the sintering heat preservation section through the periphery of a heat preservation cover, to lead the oxygen content in the heat preservation atmosphere after being filled with oxygen to achieve 22 to 30 percent, and the rich oxygen is supplied to the sintering material layer through forceful air draught.

Owner:LAIWU IRON & STEEL GRP

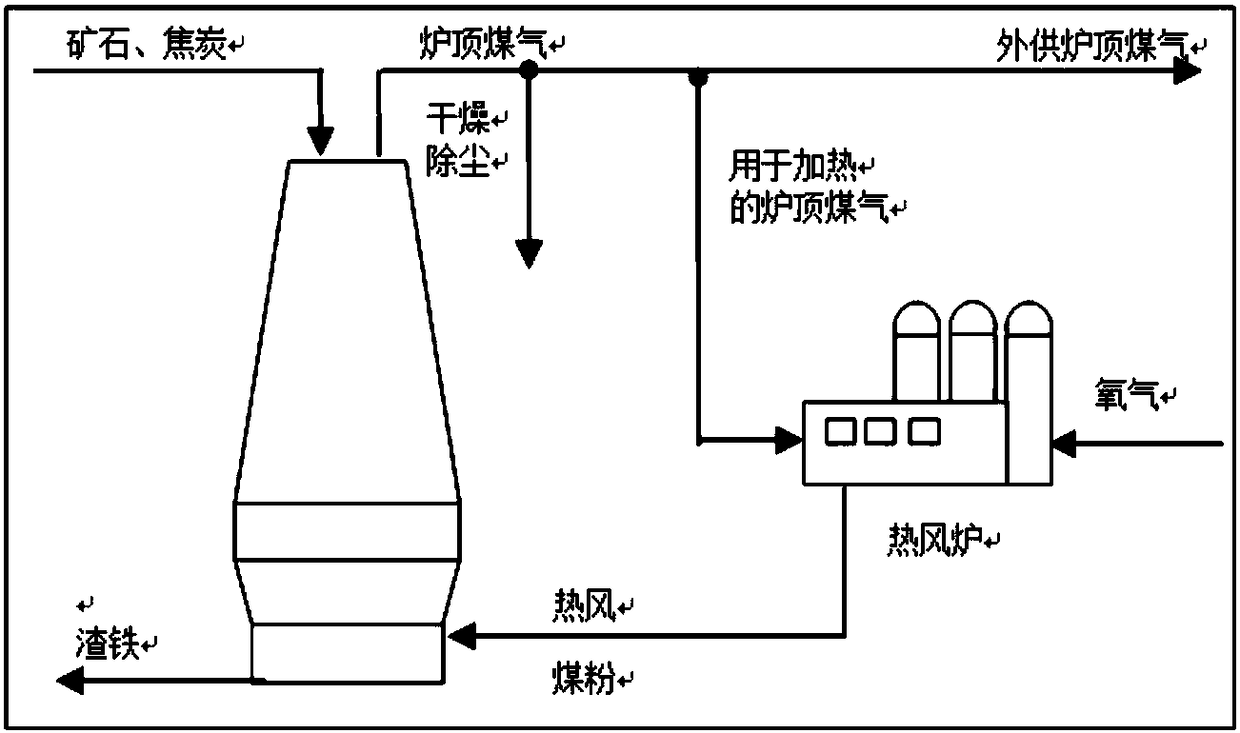

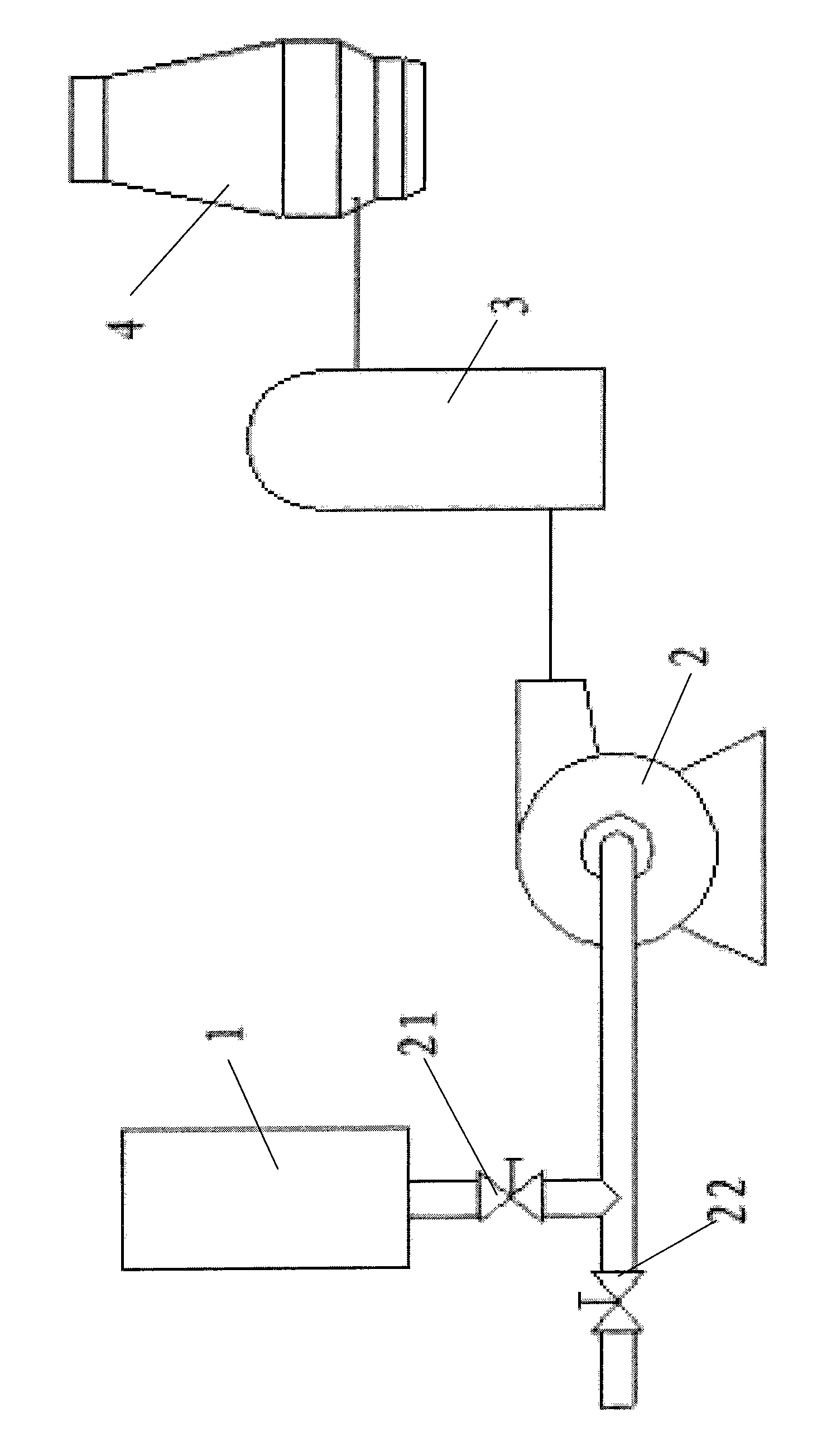

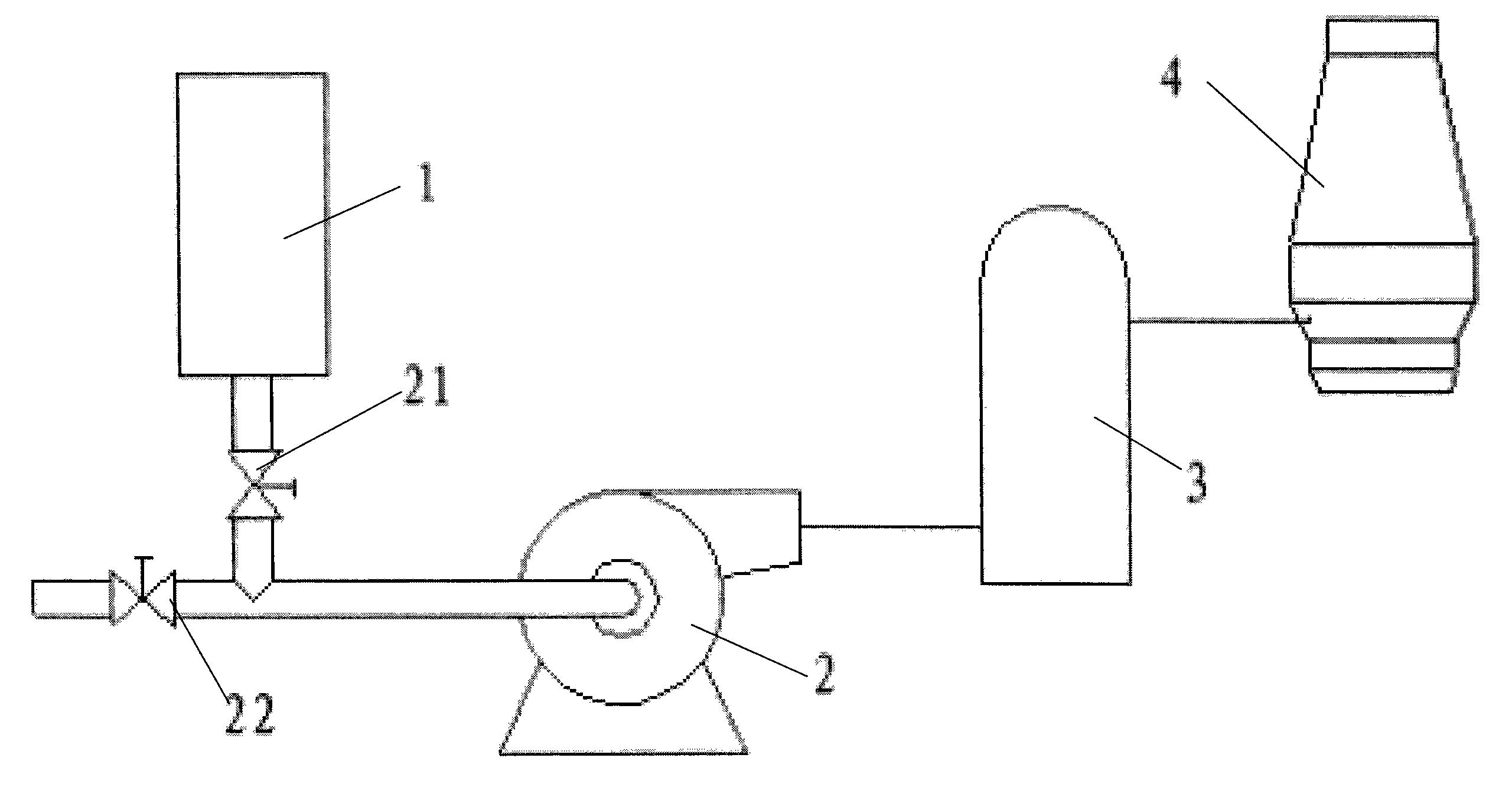

Process for blasting oxygen-enriched hot blast to blast furnace and device applied to same

ActiveCN102010919ACalculation of energy saving effectEmission reductionBlast furnace componentsBlast furnace detailsHigh concentrationCoal

The invention relates to a process for blasting oxygen-enriched hot blast to a blast furnace and a device applied to the same. The process comprises the following steps: producing oxygen-enriched air, preheating the oxygen-enriched air or air mixture of the oxygen-enriched air and the air to obtain oxygen-enriched hot blast and blasting the oxygen-enriched hot blast to the blast furnace. The device comprises an enriched oxygen producing device, a blower and a hot blast furnace, wherein the inlet of the blower is communicated with the outlet of the enriched oxygen producing device and the air respectively via pipelines; the outlet of the blower is communicated with the air inlet of the hot blast furnace; and the air outlet of the hot blast furnace is communicated with the tuyere of the blast furnace. By blasting the oxygen-enriched hot blast with higher concentration to the blast furnace and improving the coal injection ratio, utilization factor and yield of the blast furnace by preheating, the invention has the advantages of reducing the coke ratio, improving the ironmaking efficiency, lowering the ironmaking cost and reducing CO2 exhaust. The invention can also compute the energyconservation effect of oxygen-enriched blast more precisely and provide a good medium for energy performance contracting.

Owner:ANSHAN PUBEIDA TECH

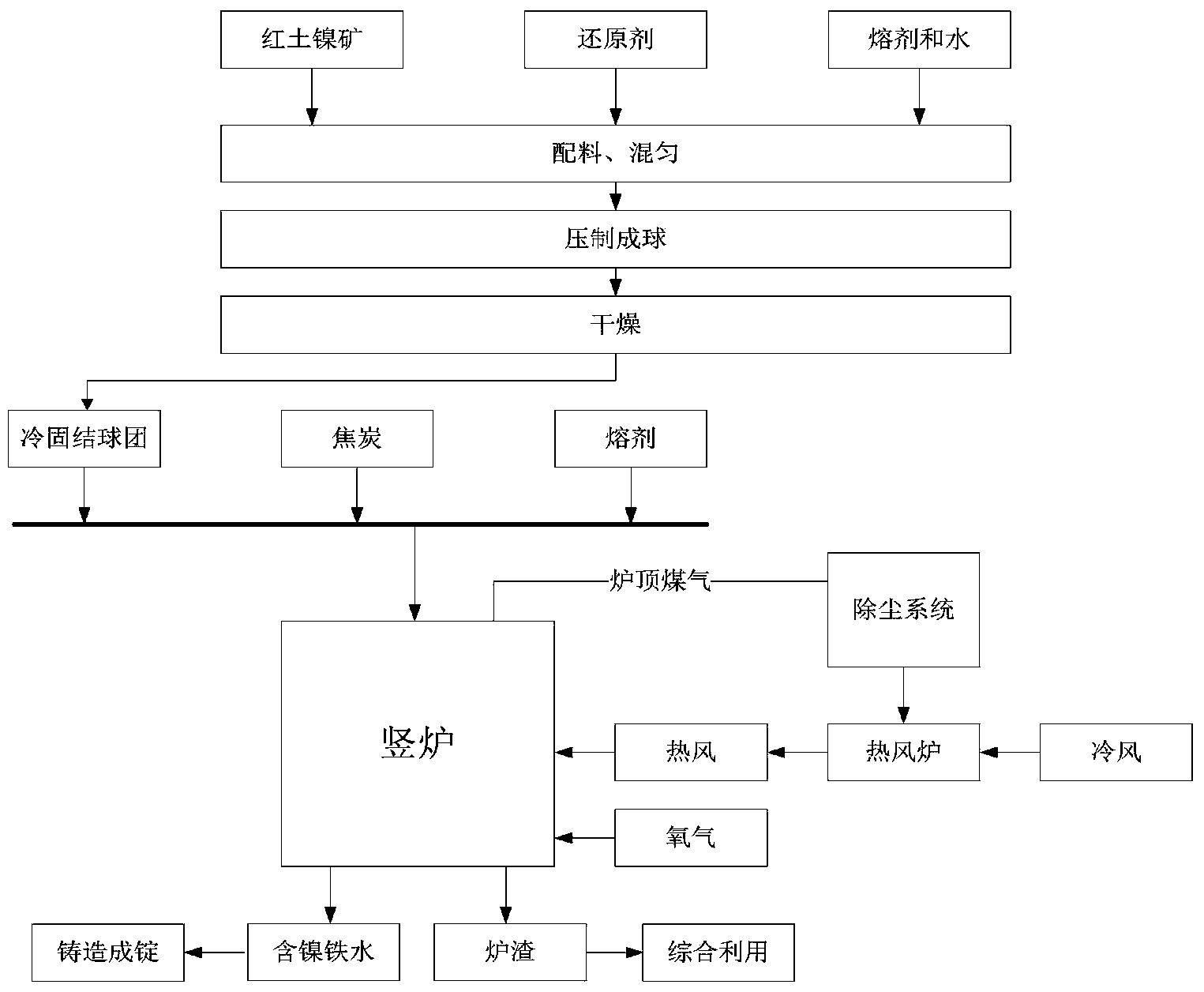

Ferro-nickel alloy production technology with laterite nickel ore processed through oxygen enrichment hot air shaft furnace

InactiveCN103451451AImprove utilization factorImprove nickel gradeShaft furnaceResource utilizationSmelting process

The invention discloses a ferro-nickel alloy production technology with laterite nickel ore processed through an oxygen enrichment hot air shaft furnace and belongs to the field of laterite nickel ore production. The technology is characterized in that the laterite nickel ore is main raw materials, a certain quantity of reducing agents, fusion agents and water are added, after complete mixing, a ball is formed by pressing through a ball press machine, after drying, the ball is sent into the oxygen enrichment hot air shaft furnace for smelting, finally nickeliferous molten iron, high-heat-value gas and slag are obtained, the nickeliferous molten iron is cast to form an ingot, ferro-nickel alloy is obtained, and the high-heat-value gas and the slag are cycled and used. The production technology has the advantages of being simple and easy to operate, raw material adaptability is strong, processing efficiency is high, different kinds of laterite nickel ore can be processed efficiently, the ferro-nickel alloy is produced, and meanwhile the high-heat-value gas generated in the smelting process can be used in a physical heat and chemical heat mode, the generated slag can be in resource utilization, and obvious economic benefit and environmental benefit are achieved.

Owner:UNIV OF SCI & TECH BEIJING

Coke passivator and preparation method thereof

ActiveCN101186853AReduce washoutReduced responseSolid fuelsHigh magnesiumCoke strength after reaction

The invention belongs to the technical field of ironmaking, in particular relating to a coke passivator and process for preparation. The coke passivator is produced by the raw materials at different part by weight, including 15-30 parts of boracic acid, 15-30 parts of borax, 30-50 parts of high magnesium powder, 5-15 parts of aluminum silicon powder, and 5-20 parts of calcium silicon powder. The coke passivator can uniformly form a layer of protective coating, which can reduce the erosion of the coke caused by CO2, decrease the reactivity of the coke, increase the coke strength after reaction, improve the utilization coefficient and the service life of the blast fumace and reduce the coke ratio. Utilizing the concentration of 0.3kg / t can reduce the reactivity of the coke by 5%, increase the coke strength after reaction by 7% and improve the production of the blast furnace by more than 3%-5%. The invention is an ideal product for blast furnace ironmaking which has the advantages of saving energy, reducing consumption, increasing production, improving benefits and protecting environment.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

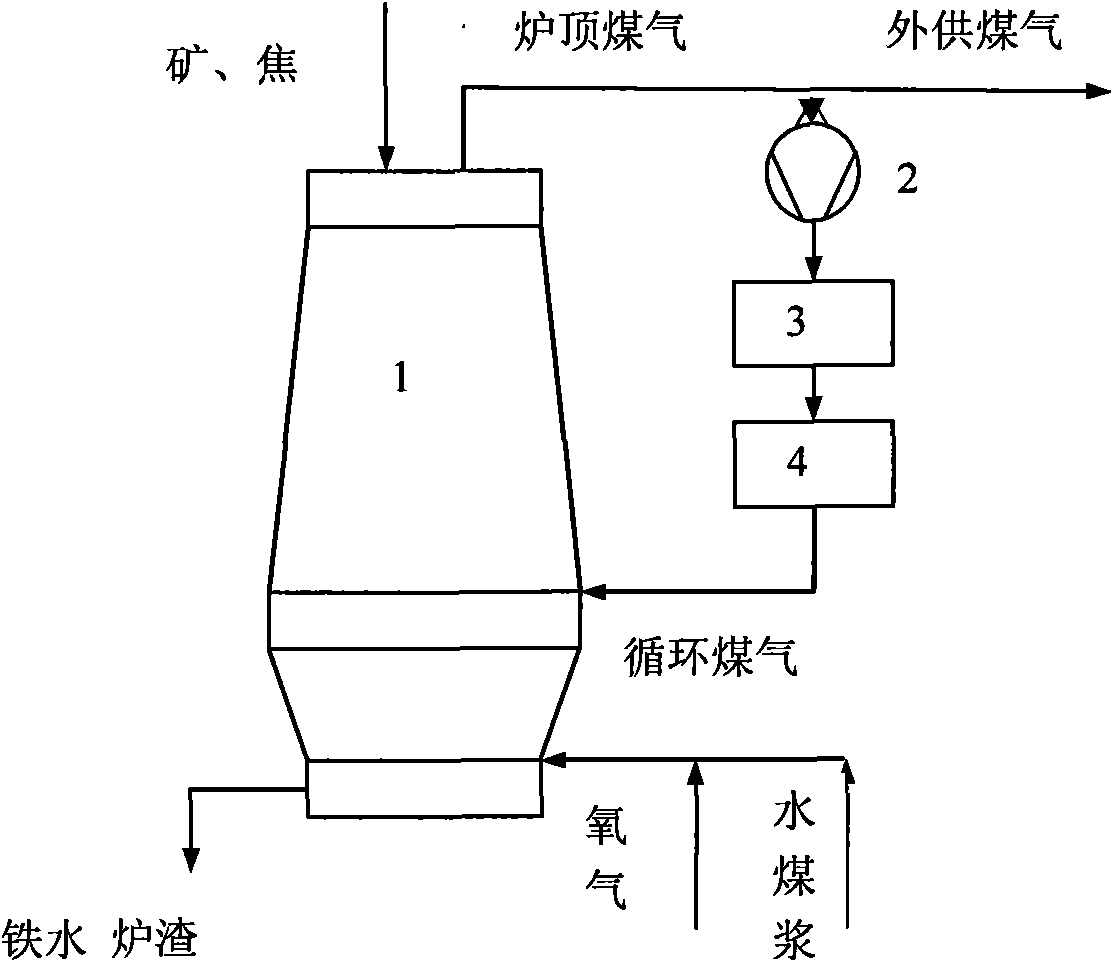

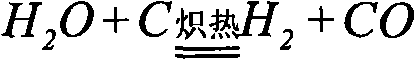

Oxygen blast furnace iron-making process adopting water-coal-slurry as fuel

InactiveCN101555533AImprove productivityReduce adverse effectsBlast furnace detailsDecompositionCoal dust

The invention belongs to the field of ferrous metallurgy and relates to a blast furnace iron-making process using water-coal-slurry as fuel and reducer for iron-making. The process using water-coal-slurry is simple and safe, and the injecting process of water-coal-slurry provides convenience for accurate control and precise measurement. A water-coal-slurry oxygen blast furnace utilizes normal-temperature oxygen and water-coal-slurry as fuel which is injected into the blast furnace so as to partially displace coke and coal dust; the injected amount of oxygen is 200 to 500 Nmt HM, the injected amount of water-coal-slurry is 200 to 400 Nm / t HM, the required weight ratio between coal and water in the water-coal-slurry is 7:3, and the required thermal value of the water-coal-slurry is larger than 20 MJ / kg. The water-coal-slurry is decomposed and burnt to generate water-gas reaction in a circulation zone of a blast-furnace tuyere, the absorbed heat can be adopted to solve the problem of 'lower hot' caused by smelting with prior oxygen blast furnaces, and a large amount of gas generated by the decomposition and burning of the water-coal-slurry raises and can relieve the problem of 'upper cold' caused by the full-oxygen injection of the blast furnace; and the water-coal-slurry oxygen blast furnace contains rich H2 so as to enhance the penetrating power and reduction performance of blast-furnace coal gas, raise the indirect reduction degree of the blast furnace and reduce the emission amount of CO2 by 200 to 500 Nm / t HM. The process reduces both manufacturing cost and pollution to environment.

Owner:UNIV OF SCI & TECH BEIJING

Brackish-water ecological cultivation technology for Yangtze-river two-year-old coilia ectenes fingerlings and exopalaemon carinicauda

ActiveCN103960173AIncrease specificationHigh outputClimate change adaptationPisciculture and aquariaExopalaemon carinicaudaGram

The invention discloses a brackish-water ecological cultivation technology for Yangtze-river two-year-old coilia ectenes fingerlings and exopalaemon carinicauda. The technology is characterized by comprising the following steps: firstly, an estuary-area earth pond and natural brackish water with an inflow salinity of 0.5-1.5% are chosen, and food organism is inoculated in the pond; secondly, an aerator is opened before fingerlings are put in the pond in winter or in early spring, wherein the stocking size of the fingerling is a total length of 10 to 20 cm, and the stocking density of the fingerlings is 500 to 600 fishes per mu; thirdly, putting the exopalaemon carinicauda into the pond, wherein the stocking density of the exopalaemon carinicauda is 6 to 12 jin per mu, and the stocking size is 200 to 280 fishes per jin; after the fingerlings and exopalaemon carinicauda are put in the pond, 1 / 3 of water is changed each month from January to June, 1 / 3 of water is changed each half month from July to September, and 1 / 3 of water is changed each month from October to December; fourthly, prawn artificial pellet feed which is adopted as exopalaemon carinicauda feed is fed 1 time per day, wherein the feeding amount is 1 to 3 percent of the weight of the exopalaemon carinicauda; finally, the fingerlings and exopalaemon carinicauda are captured with nets in winter at the temperature of 6 to 8 DEG C, wherein the specification of the captured coilia ectenes is 16 to 20 gram per fish while the specification of the exopalaemon carinicauda is 100 to 150 fishes per jin.

Owner:上海市水产研究所(上海市水产技术推广站)

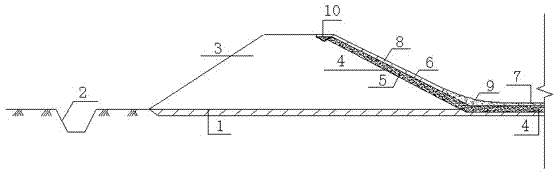

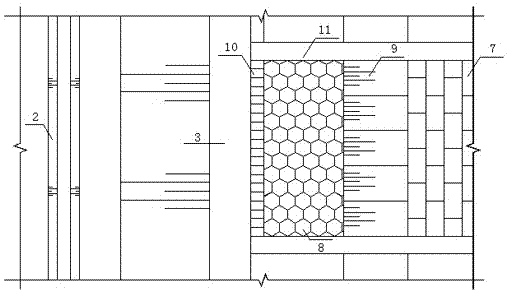

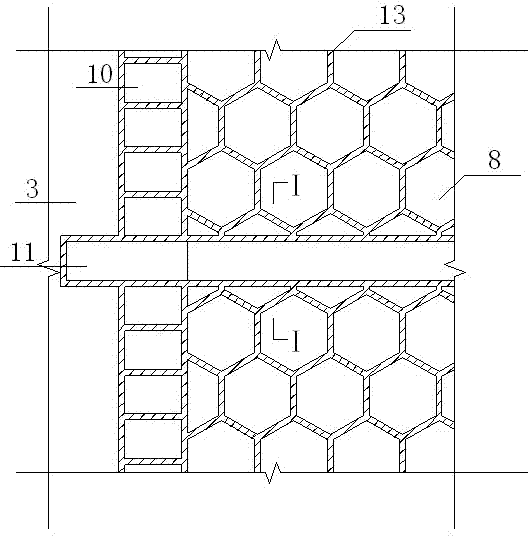

Fill channel anti-frost heaving and anti-seepage structure and construction method

ActiveCN104514216AGuaranteed compactnessGuaranteed StrengthIrrigation ditchesMarine site engineeringStress concentrationStress conditions

The invention discloses a fill channel anti-frost heaving and anti-seepage structure and a construction method. The structure is characterized in that drainage channels are arranged on the two sides of the channel; a wind-blown sand layer is arranged on the bottom and two sides of an embankment of the channel; a plastic film is arranged on the wind-blown sand layer; a slope toe on a connection position of the bottom and the embankment of the channel is cast-in-place concrete; prefabricated concrete blocks are laid on the plastic film; and a capping concrete board is arranged on the top of the embankment of the channel. The construction method comprises the following steps: digging a drainage open channel; clearing channel base earth; carrying out filling to form the embankment of the channel; laying wind-blown sand; laying the plastic film; casting the arc channel-bottom concrete in place; laying the prefabricated concrete blocks; and laying the capping concrete board. The problems of the common channel design such as seepage, frost heaving and destruction, and not stable quality are eliminated, the wind-blown sand layer is arranged on the bottom and the two sides of the embankment of the channel, the foundation bearing force is increased, the frost heaving is lightened; the polyethylene plastic film is laid on the wind-blown sand layer to prevent seepage of the channel; concrete is arranged on the film to prevent water flow from scouring and seeping; the concrete arc channel bottom is cast in place, the stress condition is good and the stress concentration is prevented; and the drainage open channel prevents underground water retention and eliminates frost heaving.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

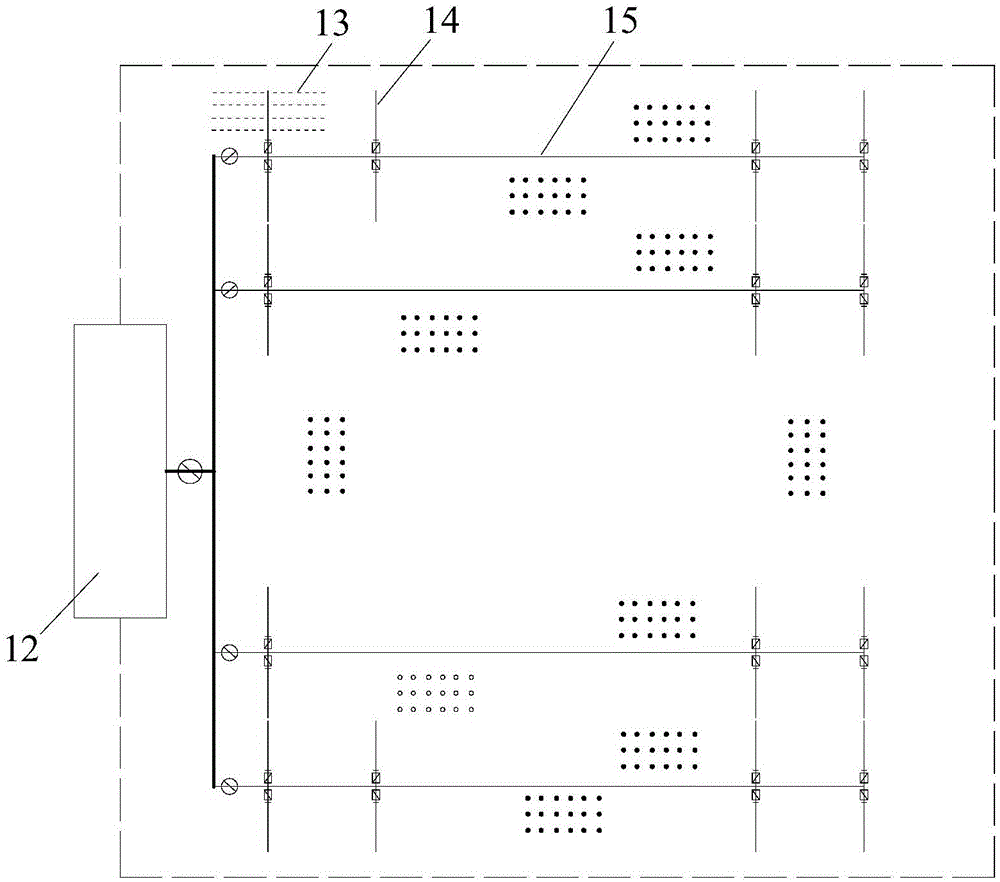

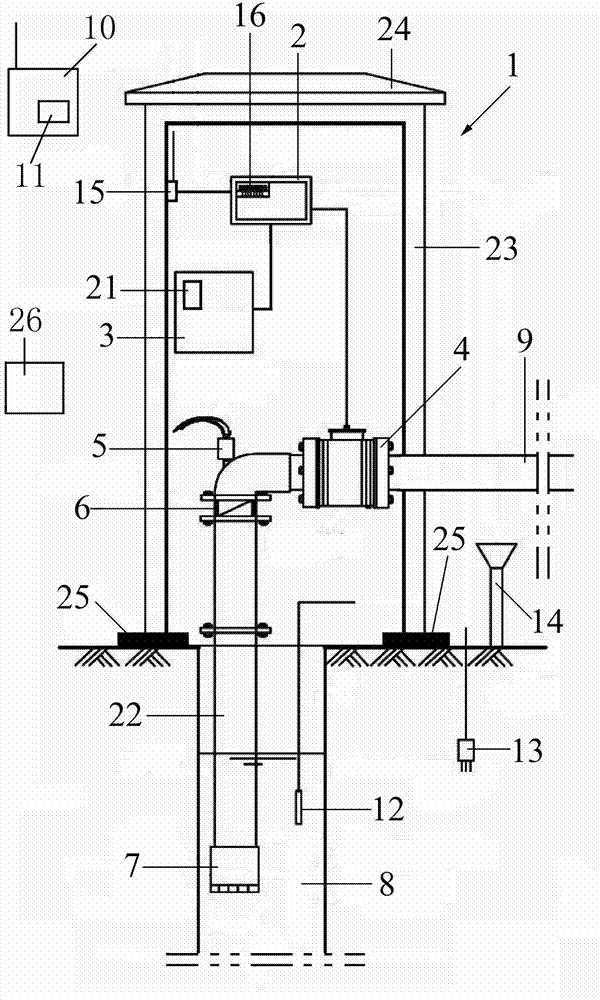

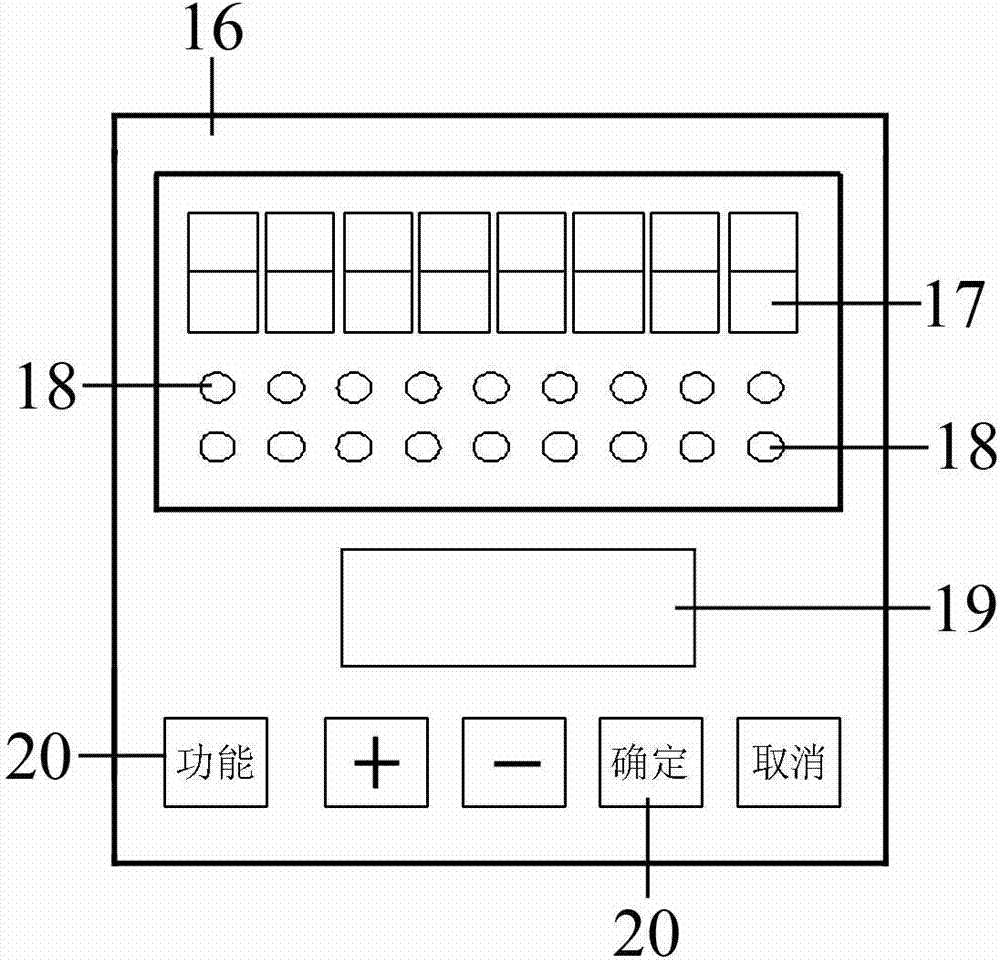

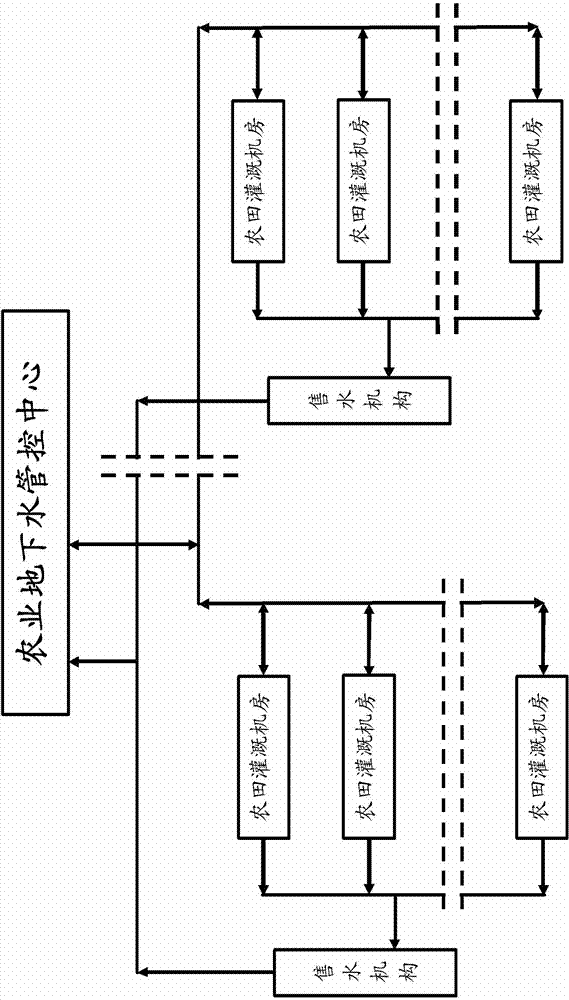

Agricultural underground water management and control system, manufacturing method and agricultural underground water management and control method

ActiveCN104299322ACorrosion resistantHas acid and alkali resistanceData processing applicationsWatering devicesExhaust valveEcological environment

The invention provides an agricultural underground water management and control system, a manufacturing method and an agricultural underground water management and control method. The system is composed of an agricultural water management and control center, water sale mechanisms and farm irrigation machine rooms. The agricultural water management and control center is built according to an agricultural irrigation plan of one region and used for managing and controlling the whole underground water resources of one region, only one water sale mechanism is arranged for every administrative village, the farm irrigation machine rooms are built according to the agricultural irrigation plan of one region, are set according to the farm irrigation area and are connected with the agricultural underground water management and control center through GPRS communication antennas. Each farm irrigation machine room is composed of a water resource controller, a distribution board, the GPRS communication antenna, a flow meter, an exhaust valve, a check valve, a submerged pump, an underground water source well, a water taking pipeline, a water conveying pipeline, a water level sensor, a soil moisture sensor and a rainfall sensor. The agricultural underground water management and control system is scientific in design, reasonable in structure, low in cost and easy to manufacture, water resources are saved, land subsidence is inhibited, the ecological environment is improved, the ability to withstand natural disasters is improved for the agriculture, and the agriculture comprehensive production capacity is improved.

Owner:TIANJIN WATER RESOURCES RES INST

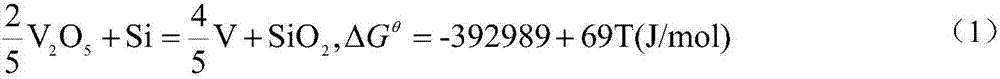

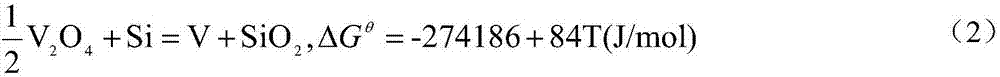

Blast furnace smelting method of high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrates

A blast furnace smelting method of high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrates comprises the following steps that (1) high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrate fines, iron ore concentrate powder, magnesite, lime, return mines and fuel are mixed, and high-magnesium sintered ore is made; (2) high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrate fines, bentonite and fuel are compacted to be pellets; (3) the high-magnesium sintered ore and the pellets are mixed, lump iron is added, and blast furnace burden materials are made; (4) blast furnace smelting is started, and blast furnace smelting comprises a charging system, an air blowing system, a thermal system and a slag forming system; the wind-warm syndrome is 1100-1200 DEG C, the coke ratio is 330-380 kg / t, and the coal ratio is 160-200 kg / t; and (5) tapping is conducted on molten iron every 70-90 min, and the temperature of the molten iron is 1430-1500 DEG C. According to the blast furnace smelting method of the high-grade high-vanadium chromium-contained type vanadium-titanium iron ore concentrates, the proportion of the high-vanadium chromium-contained type vanadium-titanium iron ore concentrates in blast furnace smelting raw materials is improved, and the ironmaking cost is reduced; and the blast furnace utilization factor is improved, the comprehensive coke ratio is greatly reduced, and meanwhile the metal yield is kept at a high level.

Owner:NORTHEASTERN UNIV

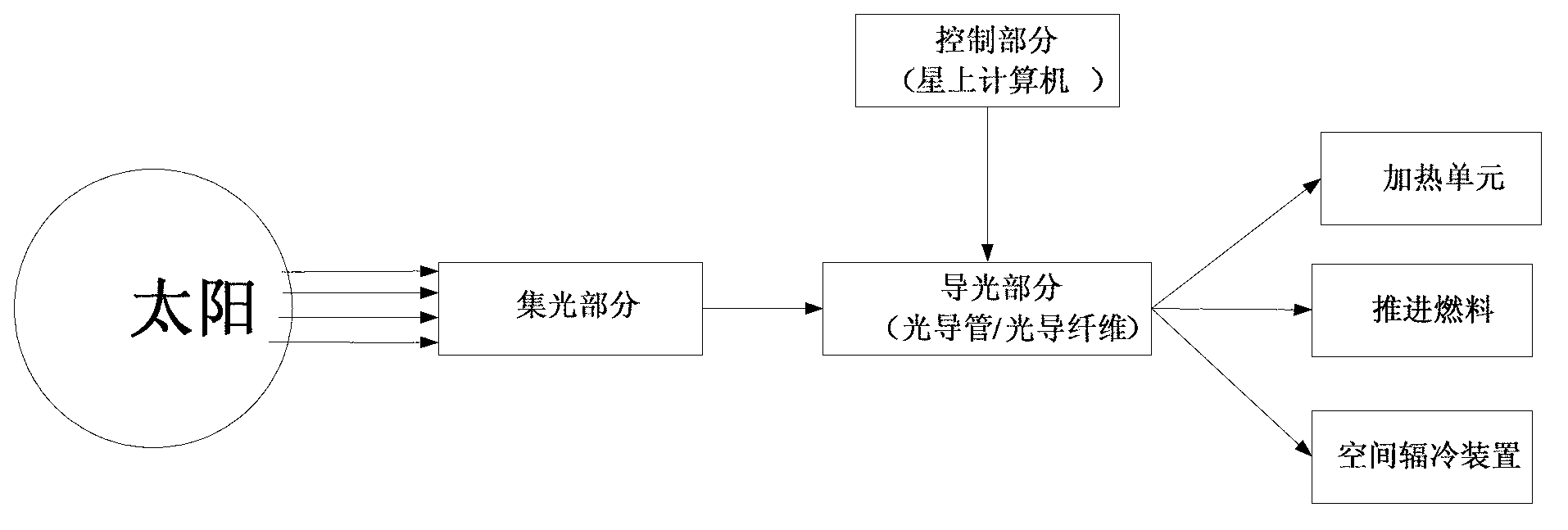

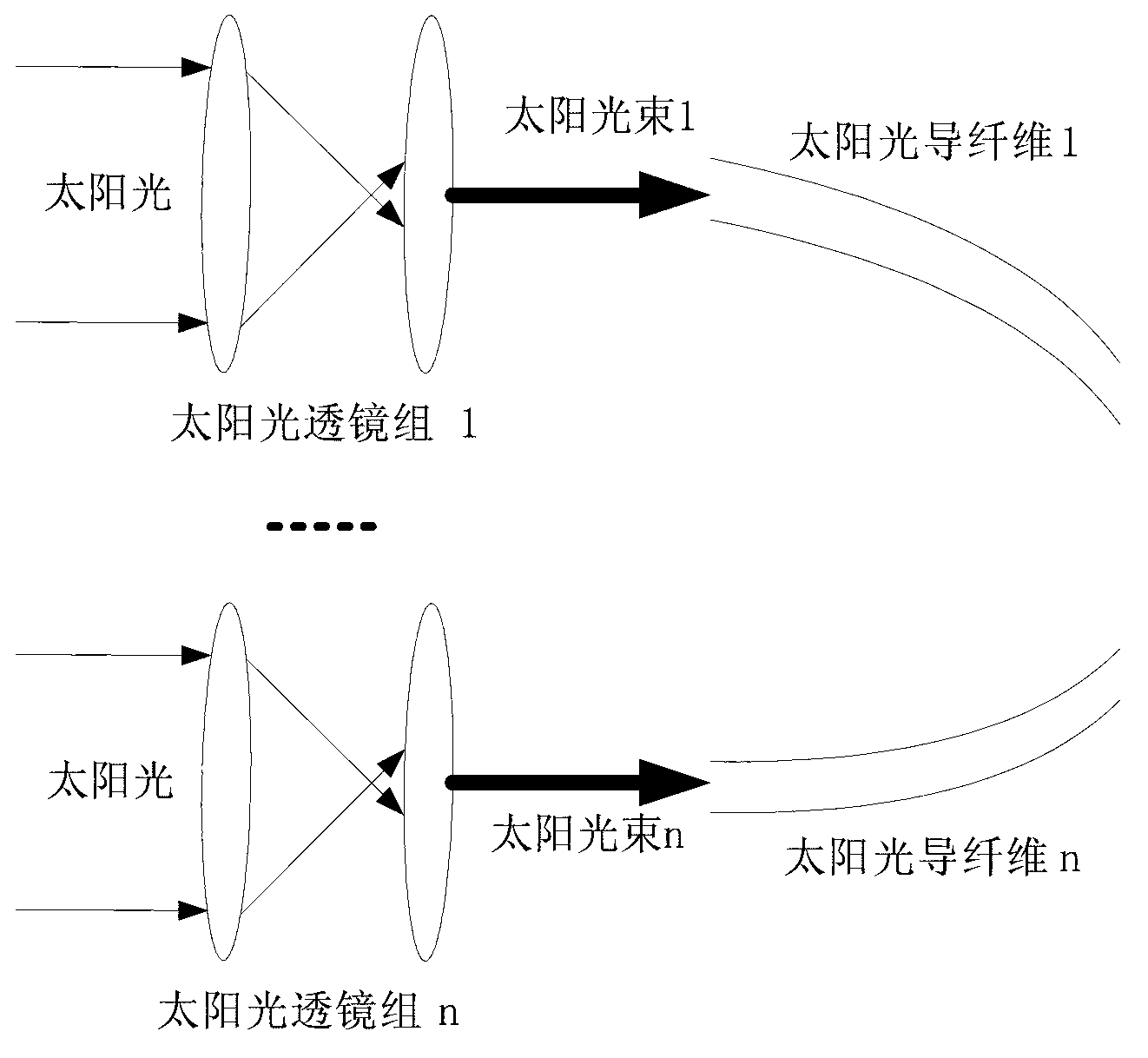

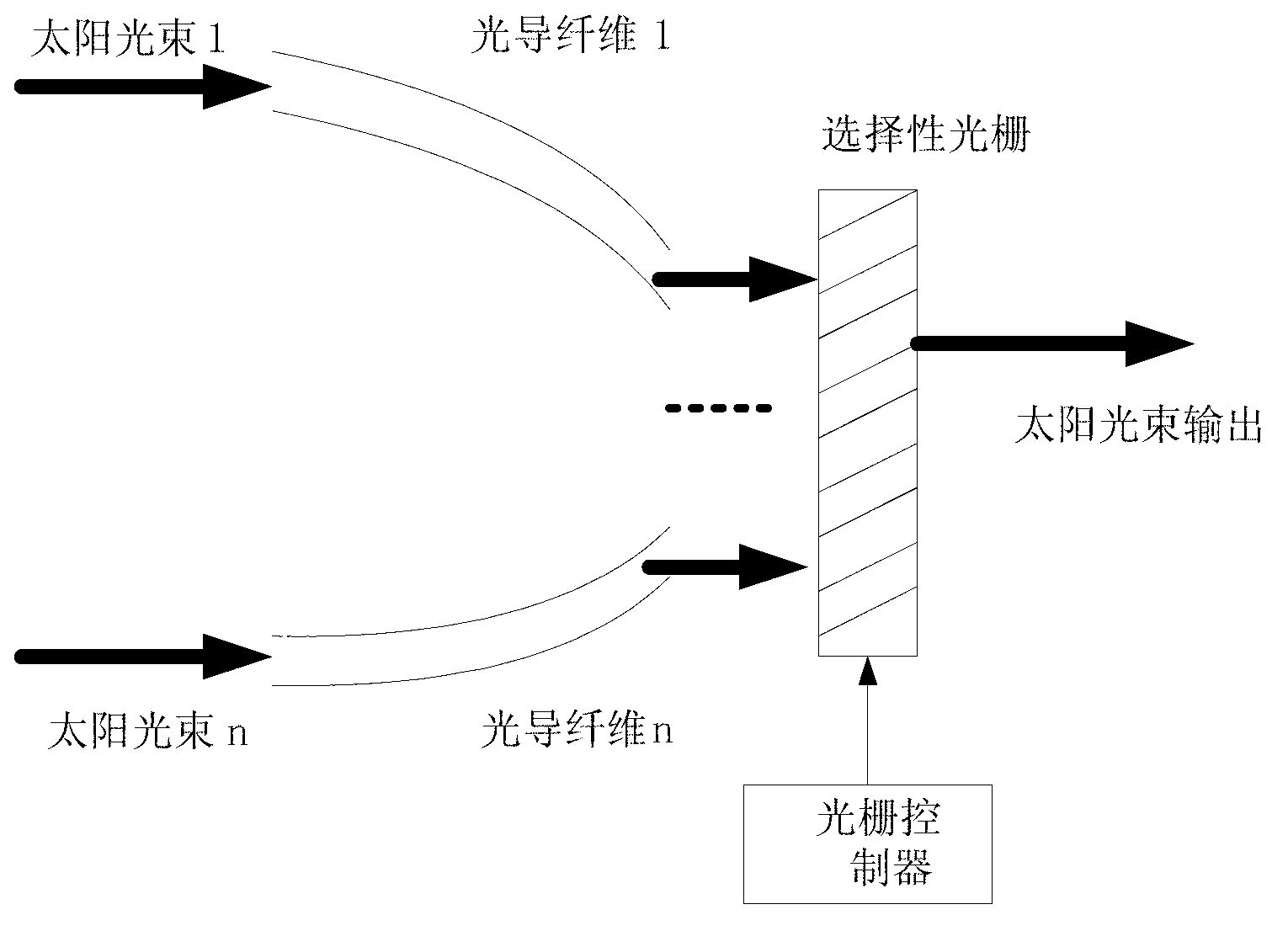

Spacecraft thermal control system directly utilizing sunlight

ActiveCN103231811ARealize solar heat control functionMeet temperature control needsCosmonautic environmental control arrangementFiberSystems design

The invention discloses a spacecraft thermal control system directly utilizing sunlight, which comprises a sunlight buncher, a sunlight branching device, a light-guide fiber, a heating unit and a space radiant cooling device. The spacecraft thermal control system directly converges sunlight on the sunward side of spacecraft to be served as thermal control energy of the spacecraft, utilizes light energy produced by converged sunlight to heat a spacecraft light heating device or a single machine, simultaneously reduces the increased temperature caused by sun radiation on the sunward side, solves the problem of low power consumption space thermal control, reduces the thermal control electric power of the spacecraft, also reduces corresponding solar battery array area and accumulator capacity, improves the energy utilization of sunlight, and reduces the design difficulty of spacecraft thermal control and energy equal division systems. The spacecraft thermal control system solves the technical difficulty of thermal control required by navigation of the spacecraft in the solar system, and has certain effects on improving the thermal control efficiency of the spacecraft and the space exploration range, and reducing the resource cost for navigation.

Owner:SHANGHAI SATELLITE ENG INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com