Casting method of metal substrate cooling wall

A metal matrix and cooling wall technology, applied in cooling devices, casting and forming equipment, metal processing equipment, etc., can solve the problems of easy deformation and melt-through of cooling pipes, reduce overhaul costs, eliminate thermal resistance, and improve blast furnace life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4-8

[0014] Get embodiment 4-8 and pour cast steel cooling stave by following casting pouring process:

[0015] The pouring process is as follows: firstly make the wooden mold, and at the same time, according to the design requirements, 20 # The low-carbon steel hot-rolled seamless steel pipe is cold-bent to form a serpentine cooling water pipe, which is sandblasted and derusted. After being assembled into a whole, the box is then filled. The cooling water pipe is filled with cooling medium. # The low-carbon steel molten steel is poured and formed, and the sand is cleaned after completion, and finally heat-treated.

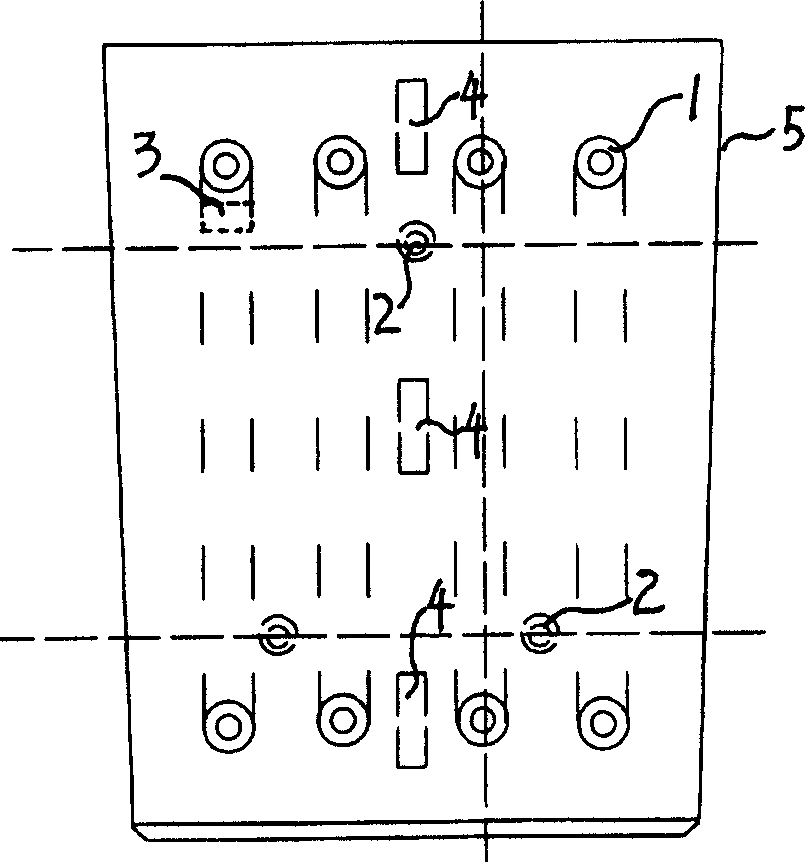

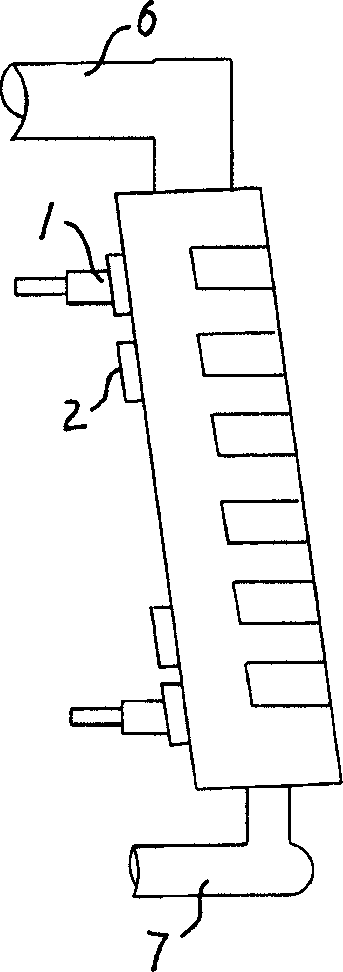

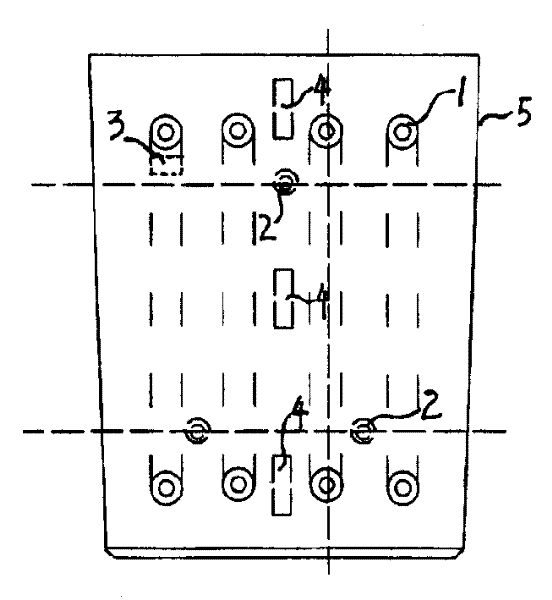

[0016] In the above process, if figure 2 The open gating system 7 with bottom injection is shown in the figure. The gate of the gating system 7 is placed between the cooling water pipes 1 to prevent the high-temperature molten steel from directly rinsing the cooling water pipe 1. An insulation riser 6 is provided at the opposite end of the gate. The thermal insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com