Patents

Literature

212results about How to "Guaranteed travel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vehicle security risk warning and accident reconstruction system and method of big data processing

InactiveCN106790367AGuaranteed travelEffective information supportTransmission systemsRegistering/indicating working of vehiclesVehicle drivingVideo image

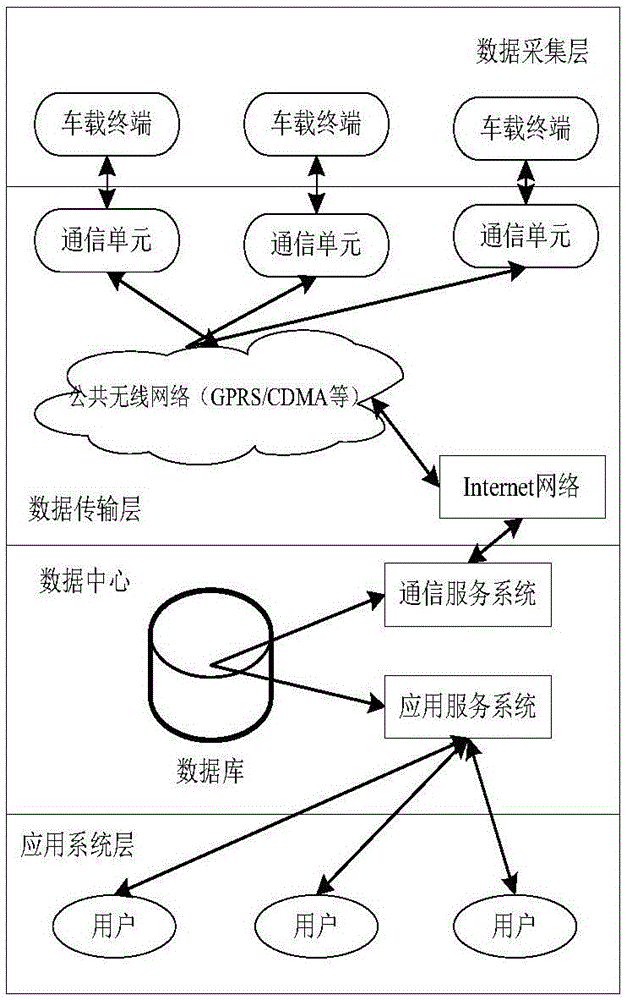

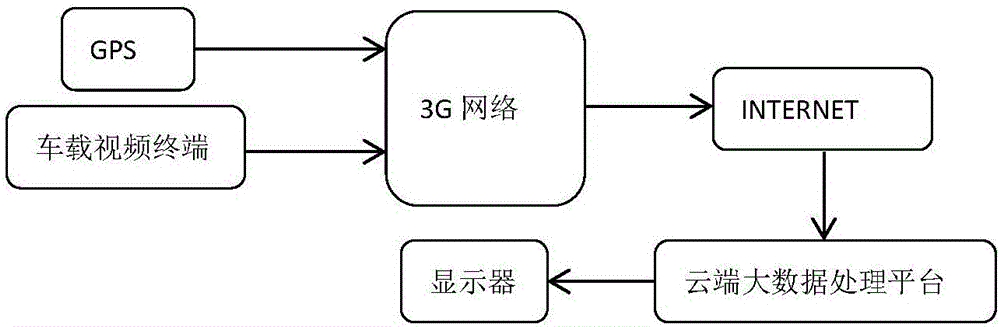

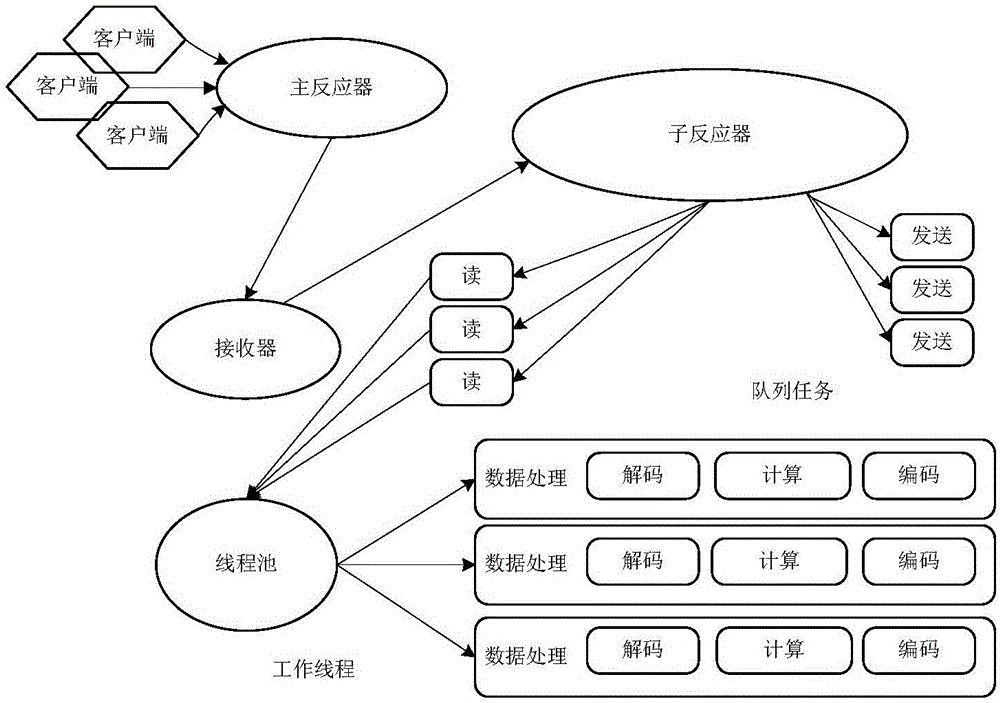

The invention discloses a vehicle security risk warning and accident reconstruction system and method of big data processing. The system comprises a vehicle-mounted video terminal and a cloud big data processing platform, all kinds of parameters, video images, voice information and the like of vehicle operation are analyzed by the big data processing platform in the background to provide effective information for accident authentication, driving behaviors of drivers, vehicle conditions and the like, and provide a novel method for confirmation of responsibility, vehicle improvement, traffic management and the like. The system is a research and development system of a key common technology based on cloud computing, collected videos are encoded in an H.264 manner, stored locally and are circularly covered, and after an abnormal driving behavior is detected, video data within 10-30 seconds before and after the time point are transmitted to a service system for accident analysis and reconstruction. The system solves the vehicle driving security risk problem and provides a vehicle security public service platform.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

Continuous casting process and continuous casting machine for extra-thick plate blank

Owner:WISDRI ENG & RES INC LTD

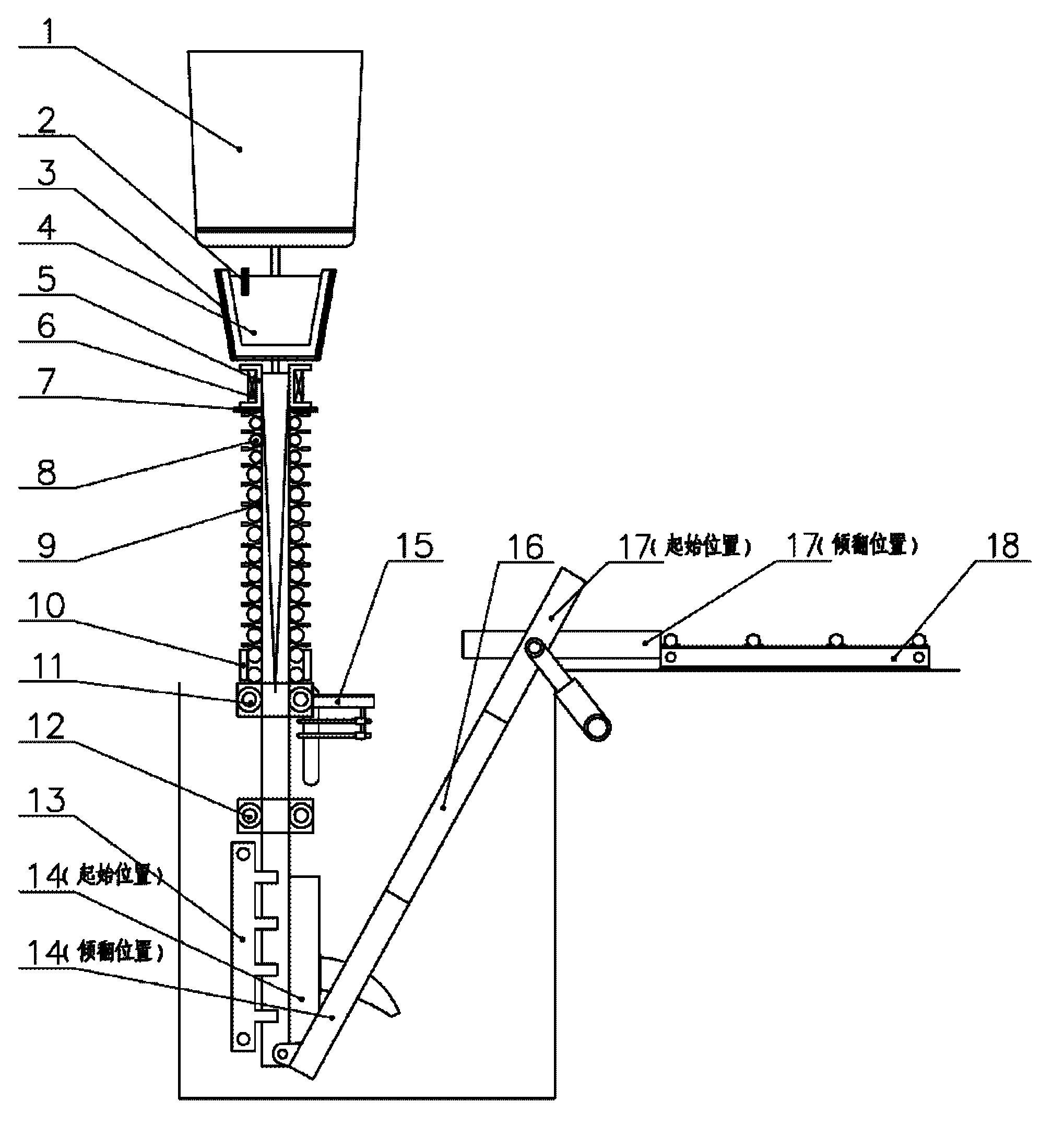

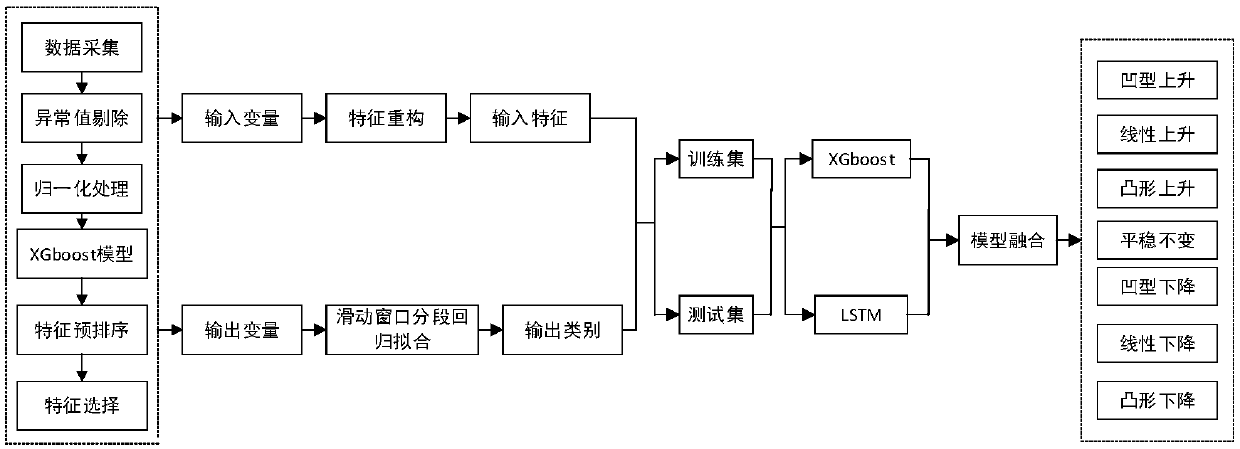

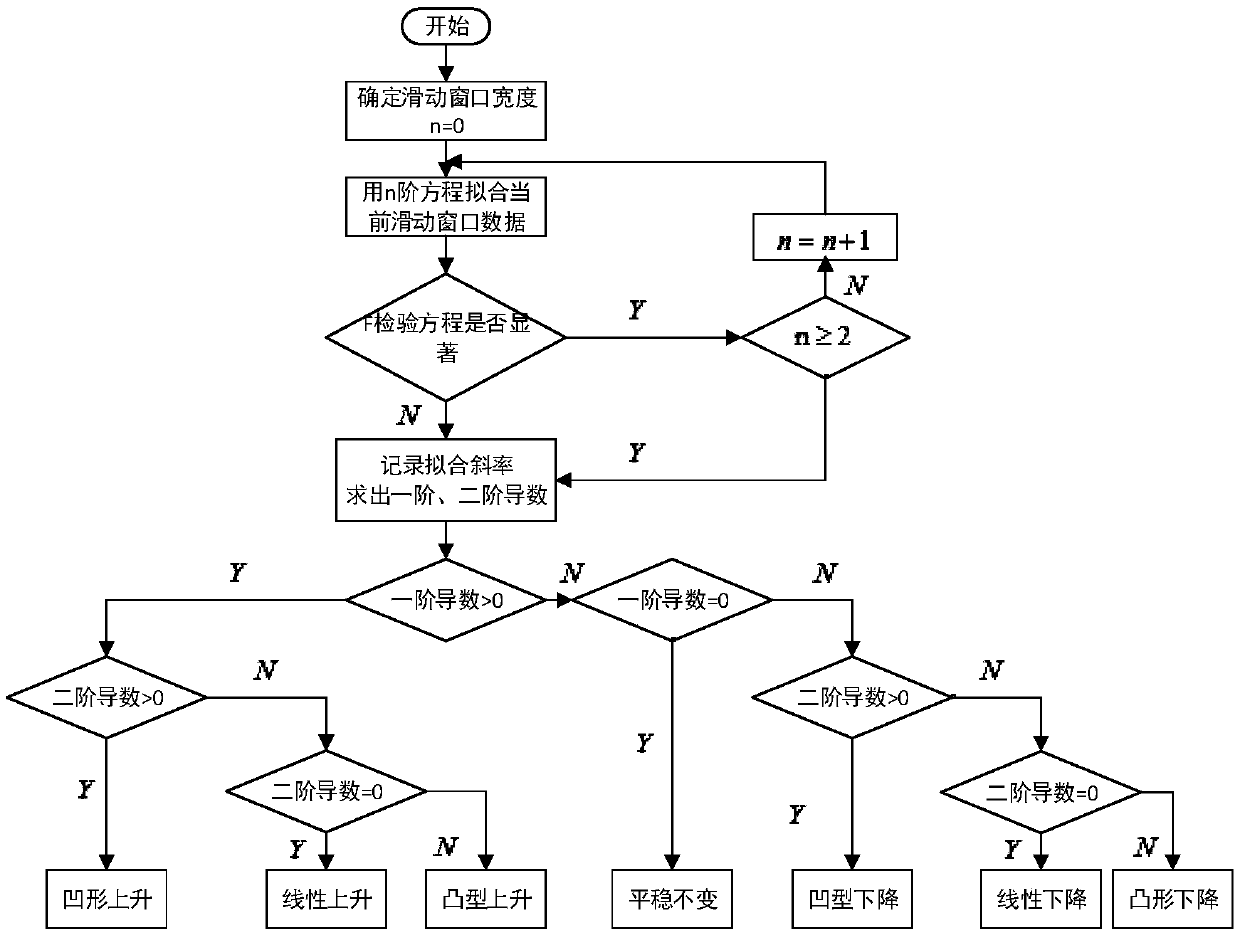

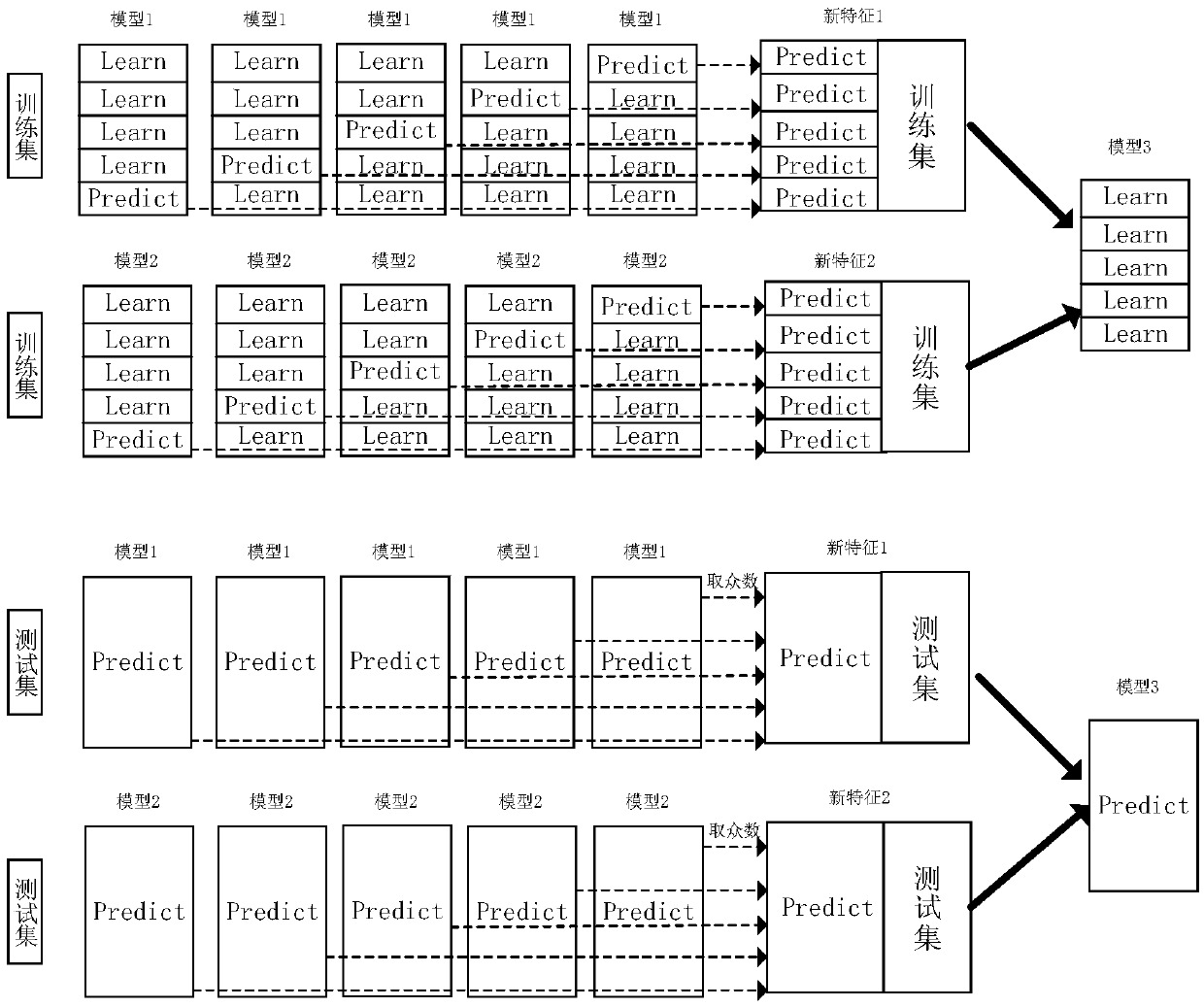

Blast furnace molten iron silicon content change trend prediction method, device and storage medium

ActiveCN108764517AGuaranteed travelGuarantee the quality of hot metalForecastingComplex mathematical operationsShort-term memoryNormal range

The invention provides a blast furnace molten iron silicon content change trend prediction method, a blast furnace molten iron silicon content change trend prediction device and a storage medium. Themethod includes the step that characteristic parameters during an iron making process which are related to silicon content change in blast furnace molten iron are acquired, and a silicon content change trend is predicted on the basis of trained blast furnace molten iron silicon content prediction models, wherein the blast furnace molten iron silicon content prediction models include a first layerprediction model and a second layer prediction model, wherein the first layer prediction model is used for preliminarily predicting the silicon content change trend according to an original sample, and the second layer prediction model predicts the silicon content change trend for the second time according to the prediction result of the first layer prediction model so as to obtain the silicon content change trend. According to the blast furnace molten iron silicon content change trend prediction method, the blast furnace molten iron silicon content change trend prediction device and the storage medium of the invention, a limit gradient enhancement and long-term and short-term memory network fusion model is established to predict the trend of the silicon content in the molten iron, a reference basis is provided for a blast furnace operator to judge the change trend of the condition of the blast furnace and control the amplitude of the blast furnace in advance, and therefore, the smoothness of the iron making process can be ensured, and the quality of the molten iron can be maintained within a normal range.

Owner:CENT SOUTH UNIV

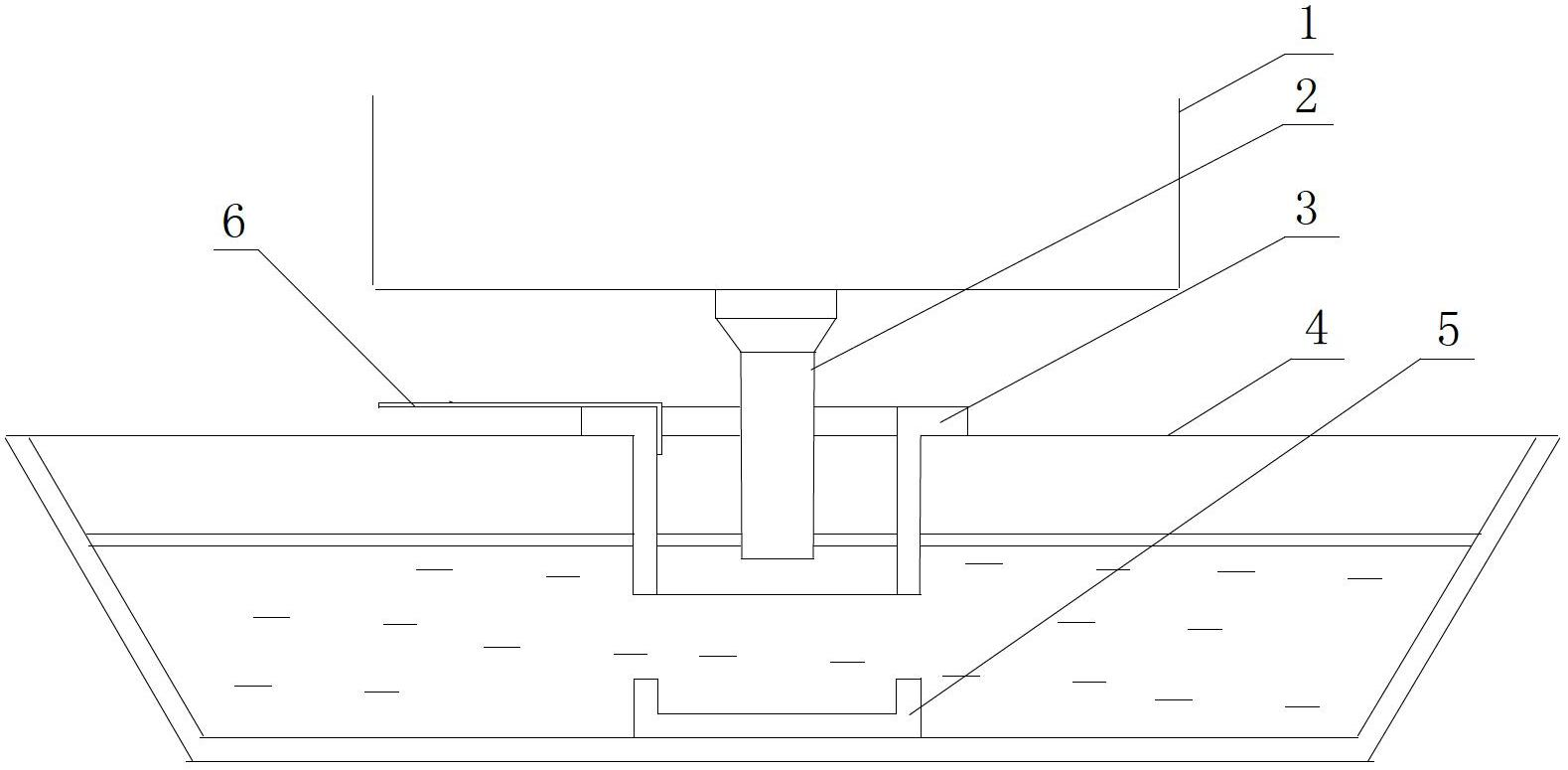

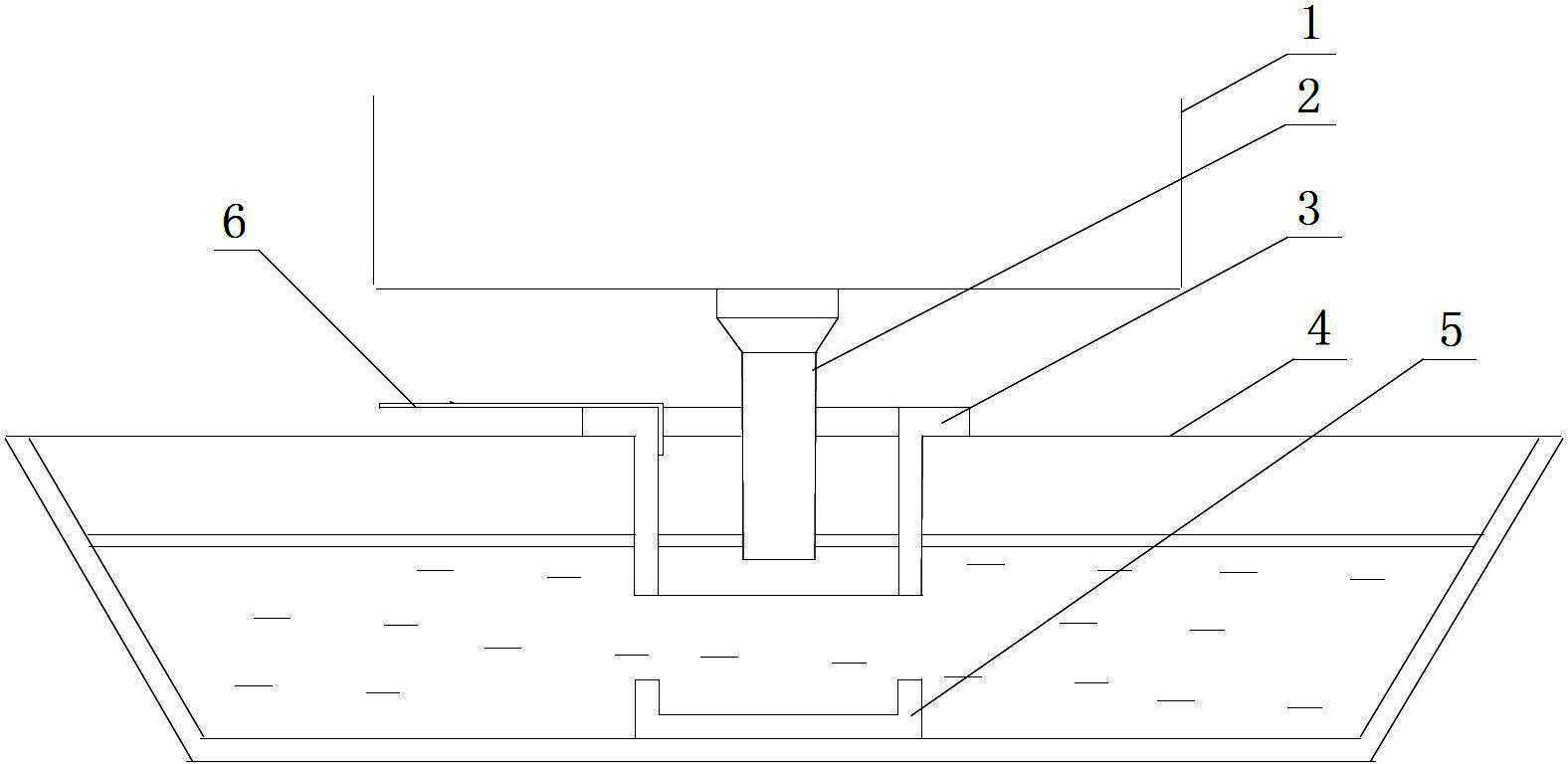

Blast furnace cinder water quenching processing unit

ActiveCN1769498ASimple configurationReasonable configurationRecycling and recovery technologiesCooling towerQuenching

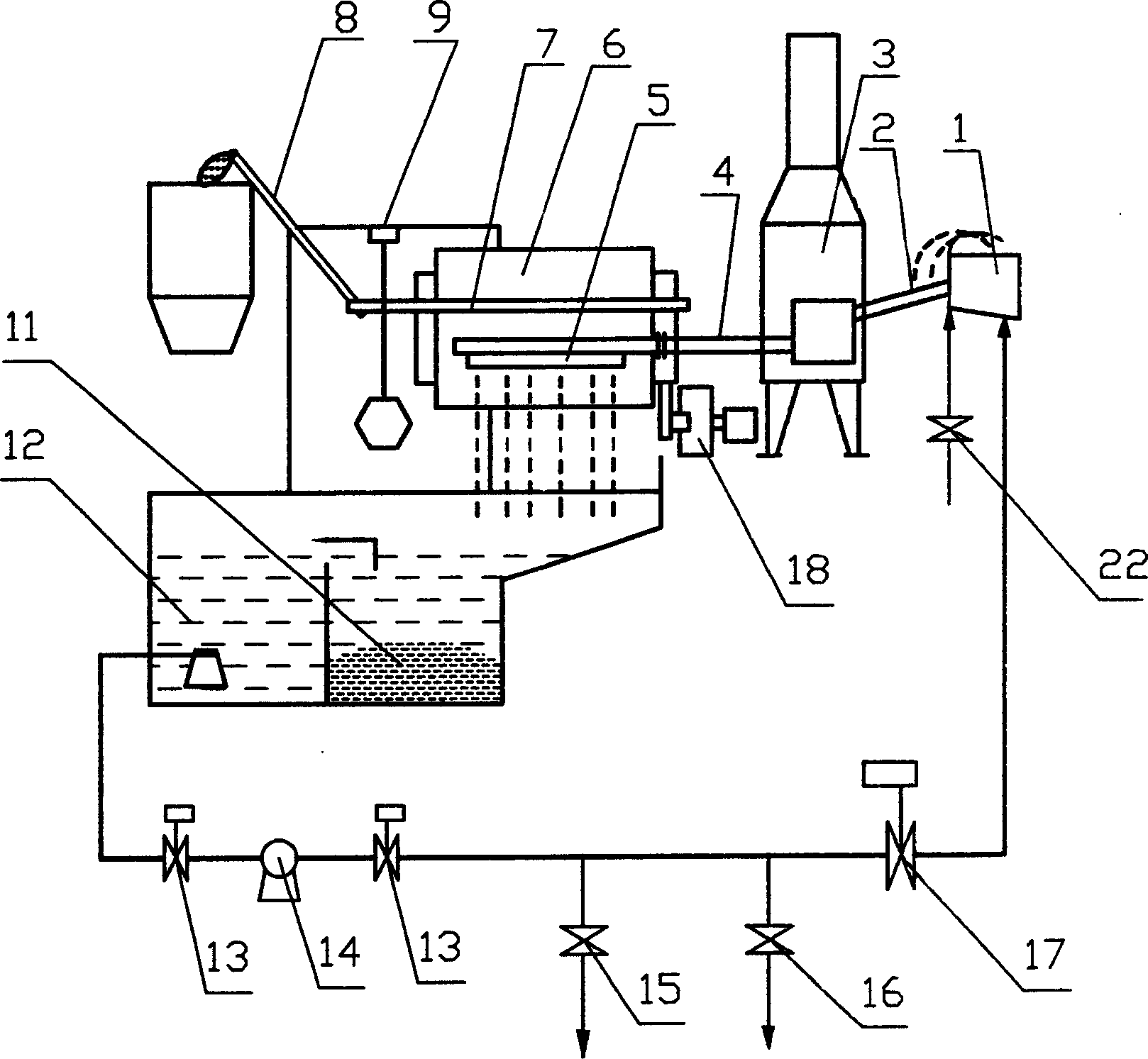

This invention belongs to the molten slag treatment, especially relates to the blast furnace molten slag treating apparatus. The slag ditch connects with the granulating device and slag flume, the down part of the slag flume connects with the communicating pipe, the distributing trough that connects with the communicating pipe extends into the rotating drum filter, the belt device in the canister connects with the rotating belt device to form a finished articles warehouse; the down part of the rotating filter is arranged with the storage cabinet, laying-up basin, which are connected by the overflow on the pool wall, the dregs cleaning device is arranged on the storage cabinet the laying-up basin connects with the granulating device by the tube connector, valve and dregs cleaning pump. The device fault rate is low, the dregs punching out rate reaches up to more than 99úÑ, which is propitious to the operation and steady production of the blast furnace. And the dreg cleaning water and the sewage is used in closed cycle, so it can save a lot of pure water.

Owner:MAANSHAN IRON & STEEL CO LTD

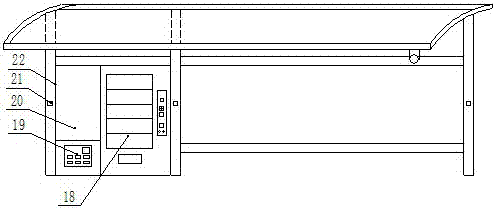

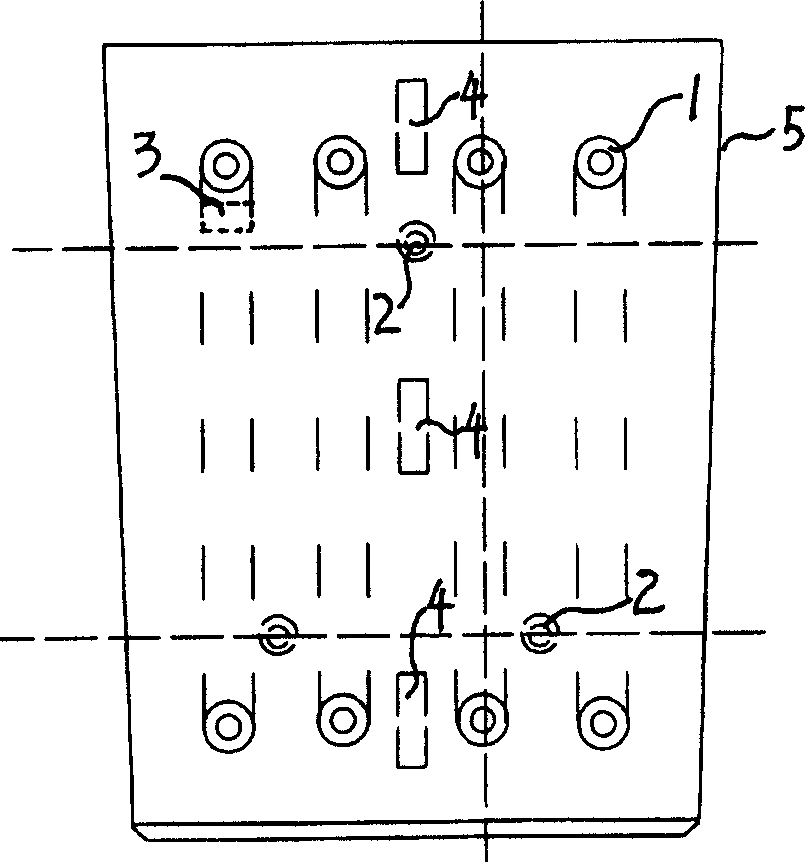

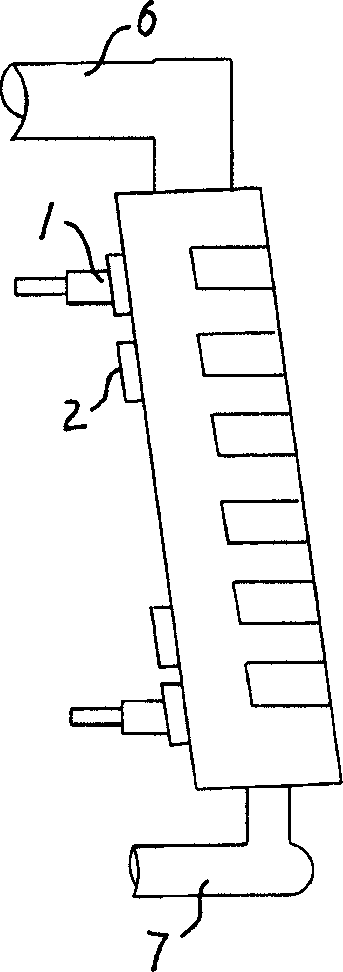

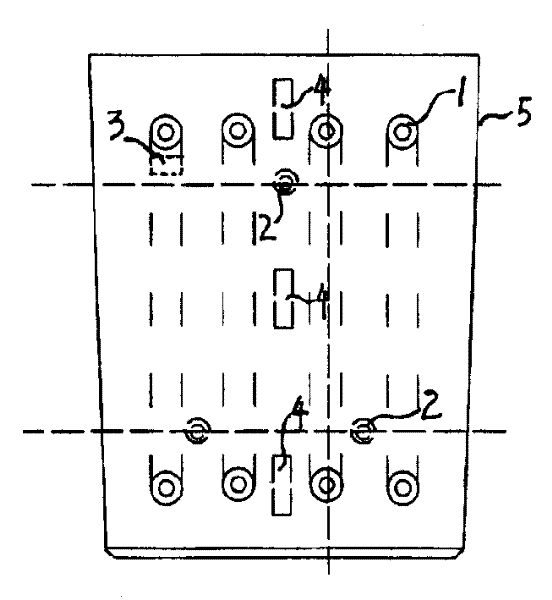

Intelligent multifunctional bus station

PendingCN107170269AEasy accessTravel convenience and intelligenceBatteries circuit arrangementsRoad vehicles traffic controlTime informationUmbrella device

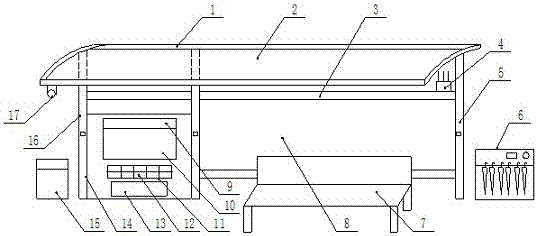

The invention provides an intelligent multifunctional bus station which comprises a station frame, a canopy, columns, and a seat. A bus real-time information query board is installed on the front of the bus station between two adjacent close columns. A convenience board is installed on the back of the bus real-time information query board. A rolling billboard is installed between two adjacent distant columns on the front and back of the station. A shared all-weather umbrella device is installed at one side of the station, and a dustbin is installed at the other side of the station. A camera and shared WIFI equipment are installed on the station frame. A solar panel is installed on the canopy. The columns are provided with a plurality of bus station two-dimensional code scanning areas. The bus station is highly intelligent, informationized, safe and convenient. Convenience and safety are brought to bus passengers, and the multi-page rolling billboard of the bus station can display a lot of useful information. Through use of the solar panel, the running cost of the bus station is reduced. A mobile phone version intelligent bus system greatly enhances the convenience in taking bus.

Owner:XIAMEN DASHA INT ASSET MANAGEMENT CO LTD

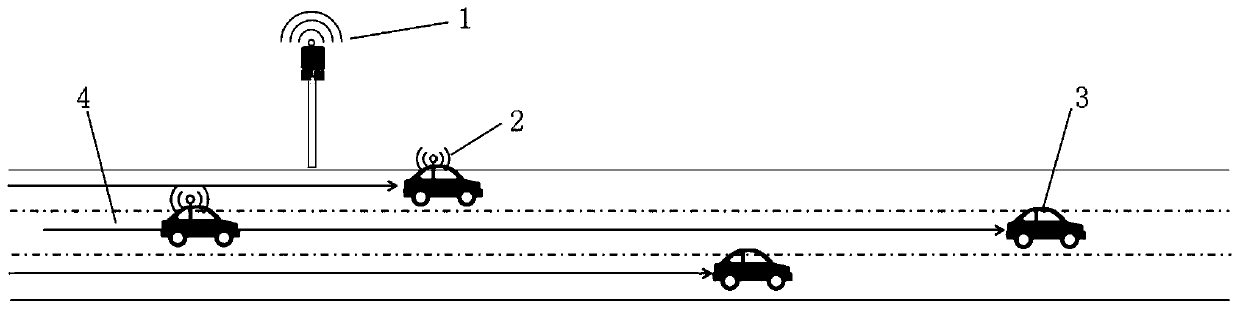

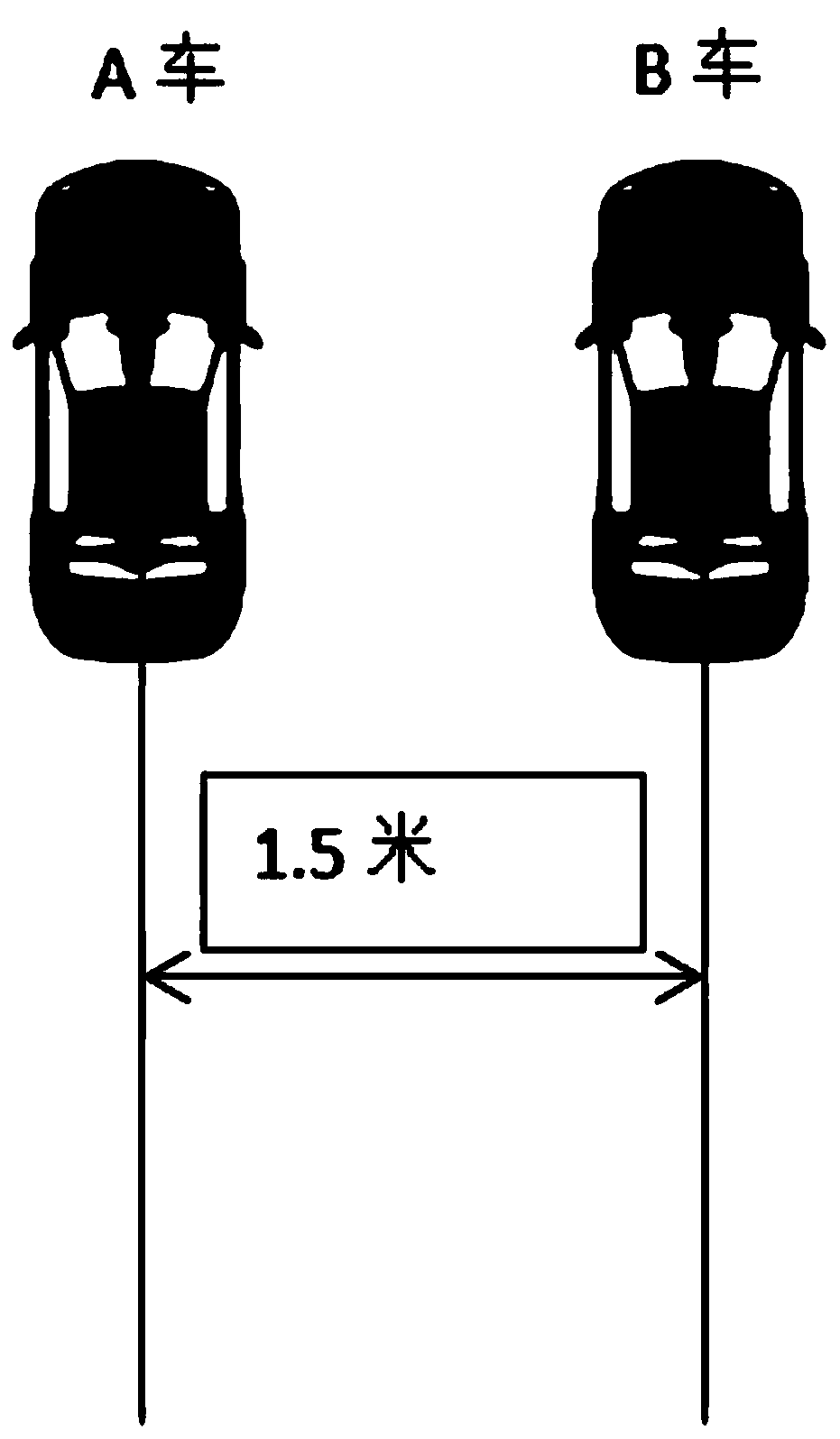

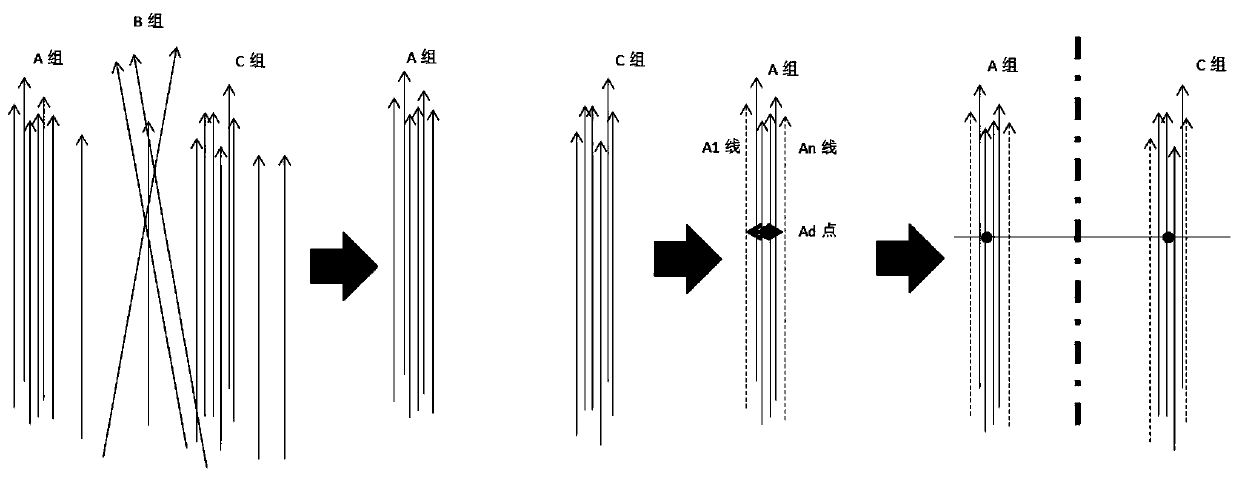

High-precision map road information rapid generation system and method based on space-time trajectory reconstruction

ActiveCN111578964ASave on high costsReliable high-precision map informationInstruments for road network navigationDetection of traffic movementIn vehicleSimulation

The invention discloses a high-precision map road information rapid generation system and method based on space-time trajectory reconstruction. The system comprises a track reconstruction module, a lane determination module, a lane separation module, a lane boundary line drawing module and a multi-data synthesis fusion module, wherein the track reconstruction module performs reverse space-time reconstruction of a vehicle driving track by utilizing the vehicle track information acquired by a roadside sensing unit and a vehicle-mounted unit, the lane determination module determines a lane according to a distance between vehicle driving tracks, the lane separation module draws a lane separation line at a midpoint of connecting lines of middle points of the adjacent single lane tracks, the lane boundary line drawing module draws a lane boundary line according to the vehicle driving track direction and the driving speed by taking the lane separation line as the reference and combining the road standard width and various line widths, and the multi-data synthesis fusion module fuses the collected roadside sign information with a map. The system is advantaged in that problems that an existing diversion high-precision map drawing process is complex, and special conditions of a road surface cannot be reflected in time are solved.

Owner:河北德冠隆电子科技有限公司

Casting method of metal substrate cooling wall

InactiveCN1513622AEnhanced feedingImprove feeding capacityFoundry mouldsCooling devicesIron powderChemical reaction

A technology for casting the steel-based cooling wall features that the cooling medium which is the mixture of corundum powder, iron powder and electrode powder is filled in its cooling pipeline. Said cooling medium features strong cooling action, low thermal expansibility, not adhering to pipe wall, and easy removing it.

Owner:MAANSHAN IRON & STEEL CO LTD

Aluminum-containing and sulfur-containing series gear steel smelting process

ActiveCN104611502AControl Si contentInhibit peroxidationProcess efficiency improvementElectric furnaceGranularitySmelting process

The invention discloses an aluminum-containing and sulfur-containing series gear steel smelting process. Liquid iron is required to contain 0.20-0.50% of Si, less than or equal to 0.035% of S, and less than or equal to 0.110% of P, and at a temperature T greater than or equal to 1250 DEG C; lime for an electric furnace and refining is required to contain greater than or equal to 90% of CaO and less than or equal to 1.2% of SiO2, and has the activity degree of greater than or equal to 300 and the granularity of 10-40mm; a low-silicon refining agent is required to contain greater than or equal to 45% and less than or equal to 55% of CaO, less than or equal to 2.0% of SiO2, and greater than or equal to 35% and less than or equal to 40% of Al2O3. The liquid iron hot charge ratio of the electric furnace reaches up to 90%; for LF refining, a first strong and later weak deoxidization manner is adopted; at the middle-late stages, a weak deoxidizer is adopted for furnace slag maintenance to realize further deoxidization. Meanwhile, deoxidization and S removal are performed, and then an S wire is fed to obtain a certain S content; in addition, the S wire is allowed to be fed only in more than 5 minutes after the denaturalization treatment of feeding a calcium-iron wire into VD liquid steel, and therefore, the formation of CaS inclusion in a clogging material at other water gap is prevented; and at last, the castability of the liquid steel is guaranteed while excellent structural properties of the steel product are obtained, and the purity of the liquid steel is improved.

Owner:ZENITH STEEL GROUP CORP +1

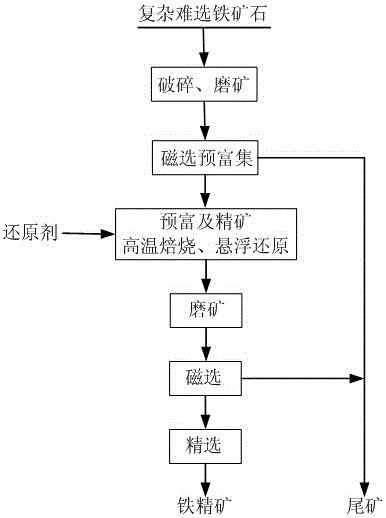

Novel method for producing iron concentrates through complex refractory iron ore

The invention belongs to the technical field of mineral machining and particularly relates to a novel method for producing iron concentrates through complex refractory iron ore. The novel method includes the steps that firstly, the complex refractory iron ore is subjected to ore grinding classifying treatment; classified overflow products are subjected to magnetic separation preconcentration, and powdery preconcentrated concentrates are obtained; the powdery preconcentrated concentrates are fed into a suspension roaster to obtain suspension roasted ore; water is added to the suspension roasted ore, and ore pulp is manufactured, preconcentration is conducted, and obtained magnetic concentrates serve as rough concentrates; and an electromagnetic separator is used for conducting concentration on the rough concentrates, the obtained concentrated concentrates are filtered, moisture is removed, concentrate products with the iron grade ranging from 60% to 68% are obtained, the recovery rate of iron ranges from 80%-90%, the concentrate products with the iron grade ranging from 60%-68% are subjected to reverse floatation desilicication, and concentrate products with the iron grade ranging from 61% to 69% are further obtained. The iron concentrate products with the iron grade larger than 60% are obtained, the recovery rate of iron is larger than 80%, product indexes are stable, the economical efficiency is good, and complex refractory iron ore resources can be efficiently utilized.

Owner:NORTHEASTERN UNIV +1

Method for plugging started head

The invention discloses a method for blocking a dummy bar head; the method mainly adopts a rail head and a cold burden to block the dummy bar head according to the shape of a dovetail groove on the dummy bar head. The method has the advantages that the requirements for an operator are lower, the method is easy to be mastered and can solve the problems of casting failure caused by nonproficiency of operators or minor failure of equipment. By adopting the method, except for the casting failure caused by objective reasons resulting from liquid steel components and temperature, the method can not cause casting failure in other cases, can especially overcome the abnormal phenomenon such as untight closing of a stopper and the like and ensure successful casting. The method can effectively ensure the smooth overall continuous casting production, increase the operating rate of a casting machine and reduce production cost.

Owner:WUHAN IRON & STEEL (GROUP) CORP

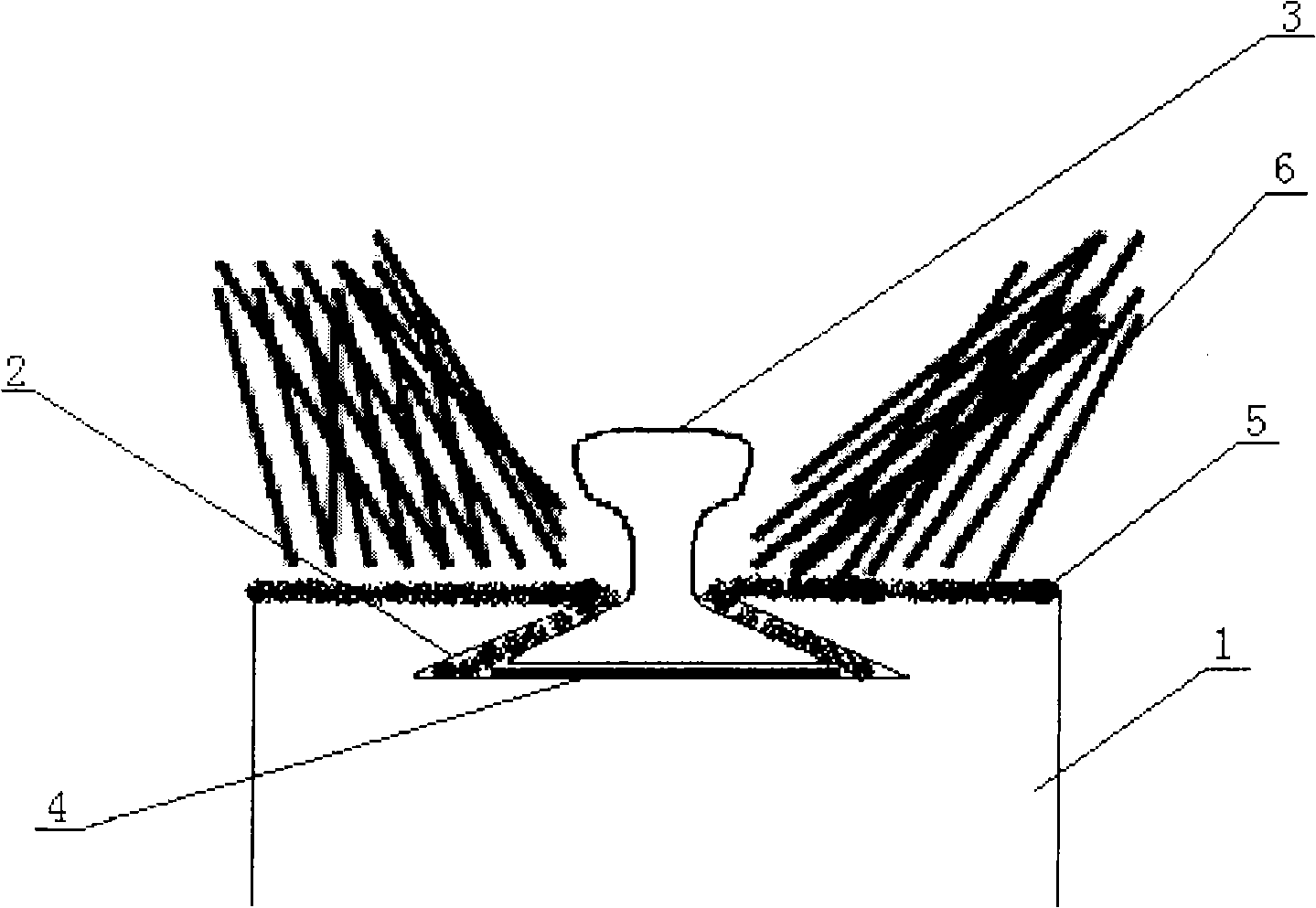

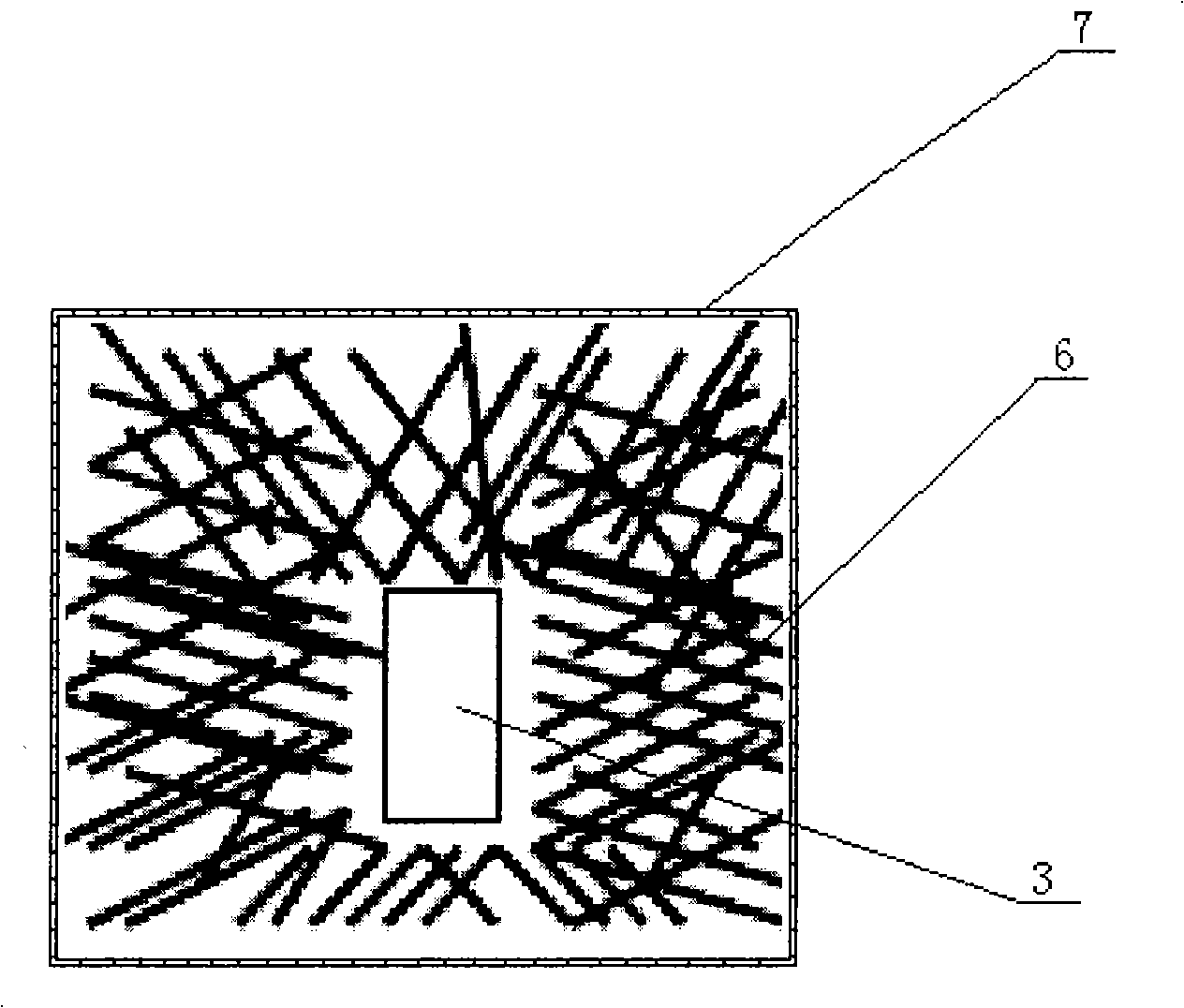

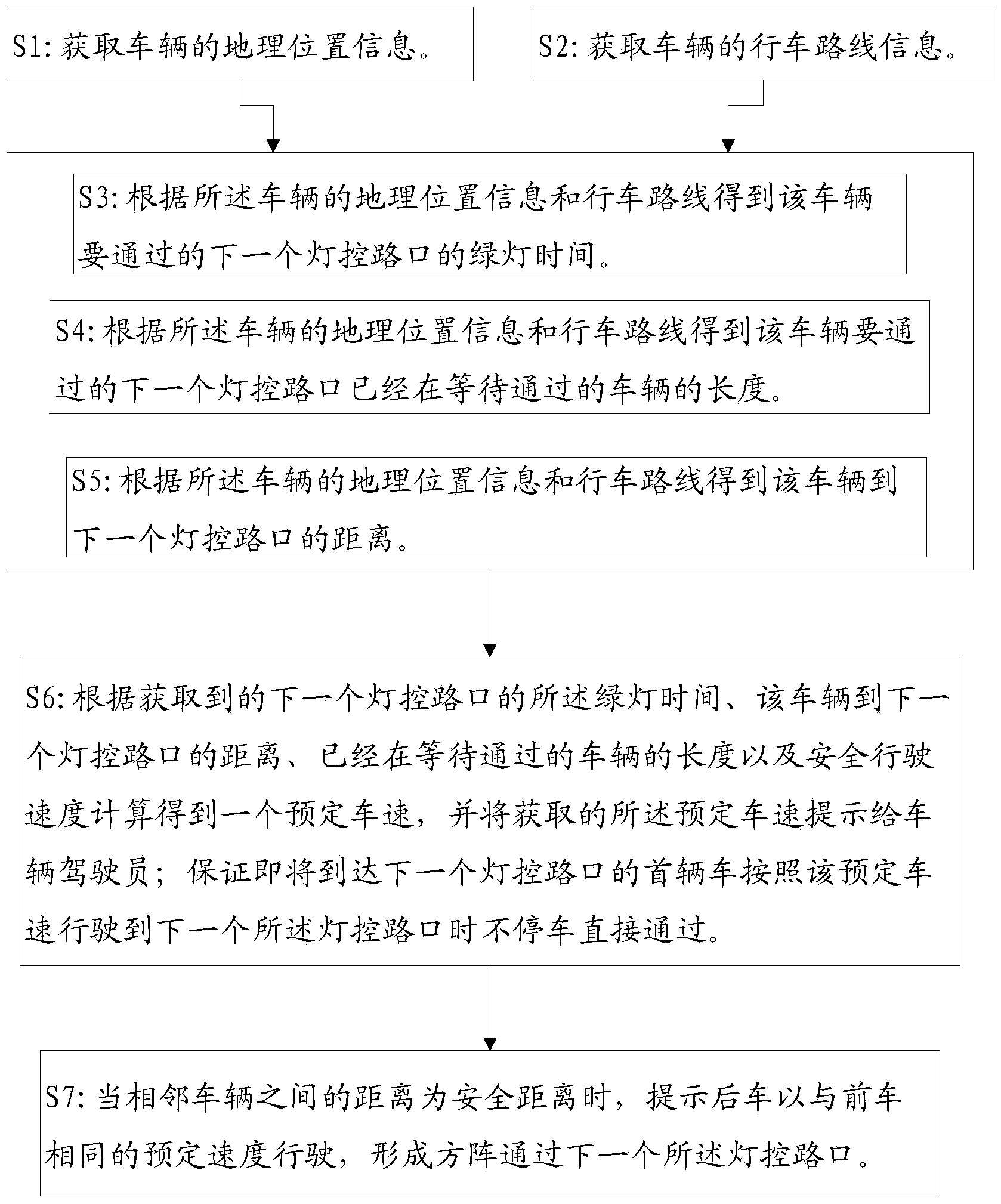

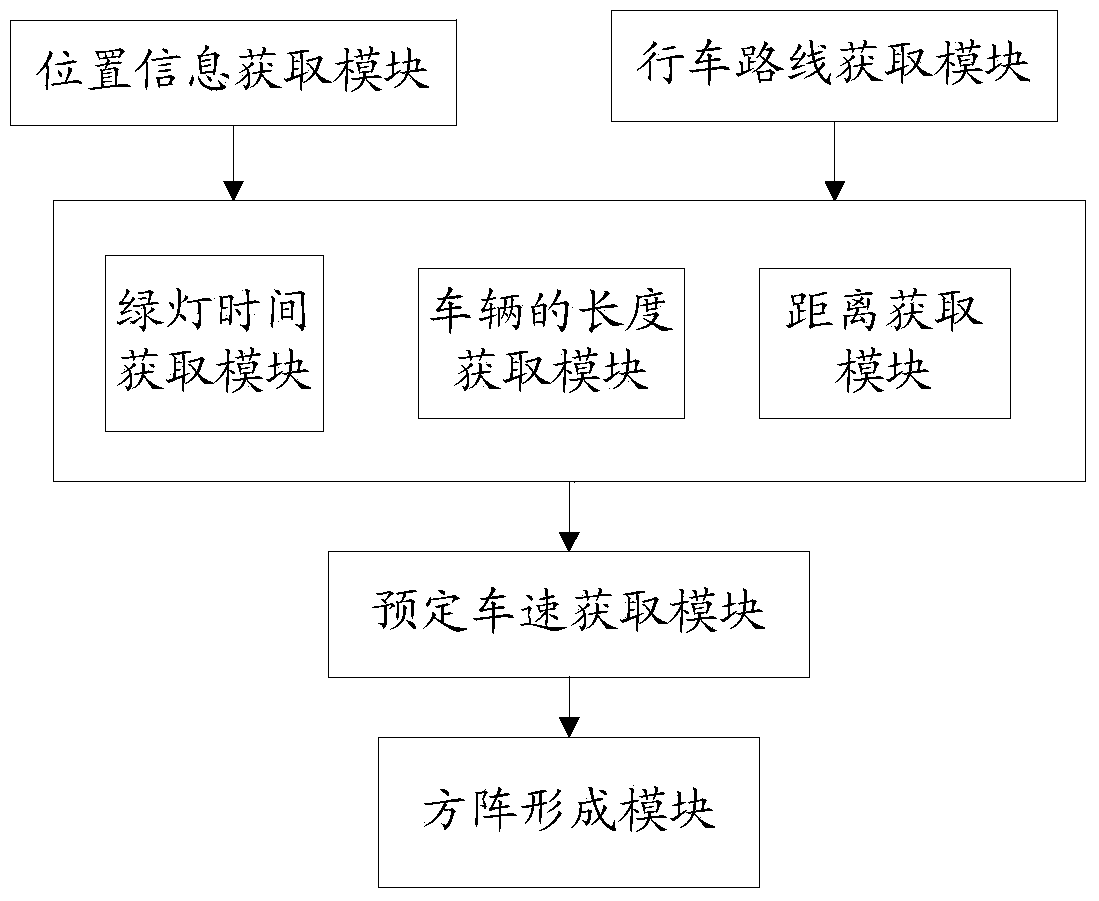

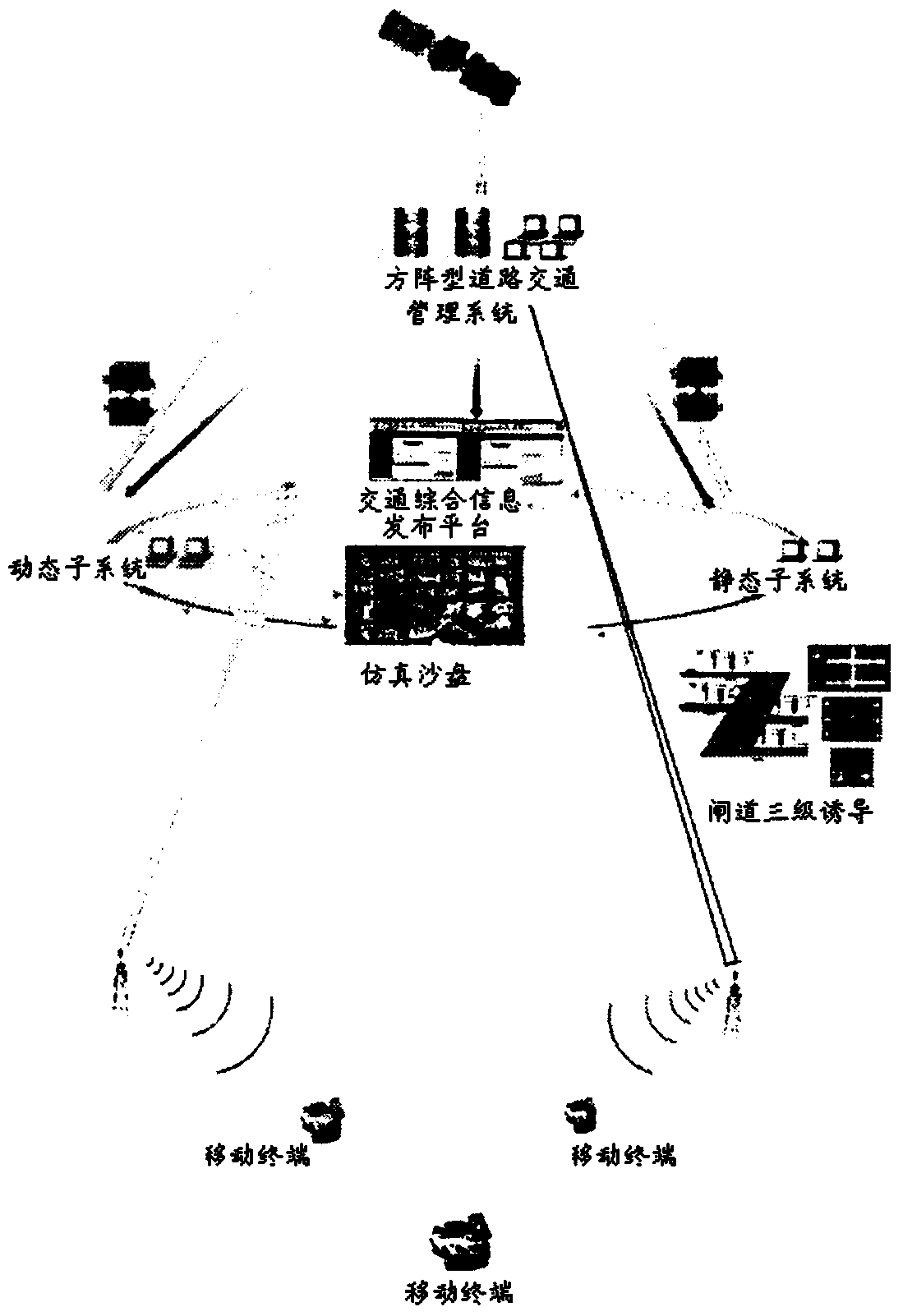

Square matrix type road traffic inducing method and system

ActiveCN103854504AEnergy savingImprove applicabilityIndication of parksing free spacesEngineeringEnergy source

The invention relates to a square matrix type road traffic inducing method and system. The square matrix type road traffic inducing method includes the steps that according to geographical location information and driving route information of a vehicle, the length of vehicles already waiting for passing of a next lamp control intersection which the vehicle is to pass through is obtained; the length of the vehicles already waiting for passing of the next lamp control intersection is taken into account when preset speed is calculated, so that it is ensured that the first vehicle about to reach the next lamp control intersection travels according to the preset speed and directly passes through the next lamp control intersection without stopping. It is fundamentally avoided that because the length of the vehicles already waiting is not taken into account, a motorcade has to stop to wait for a road lamp when reaching the next lamp control intersection according to the preset speed, and therefore energy sources are saved.

Owner:安锐

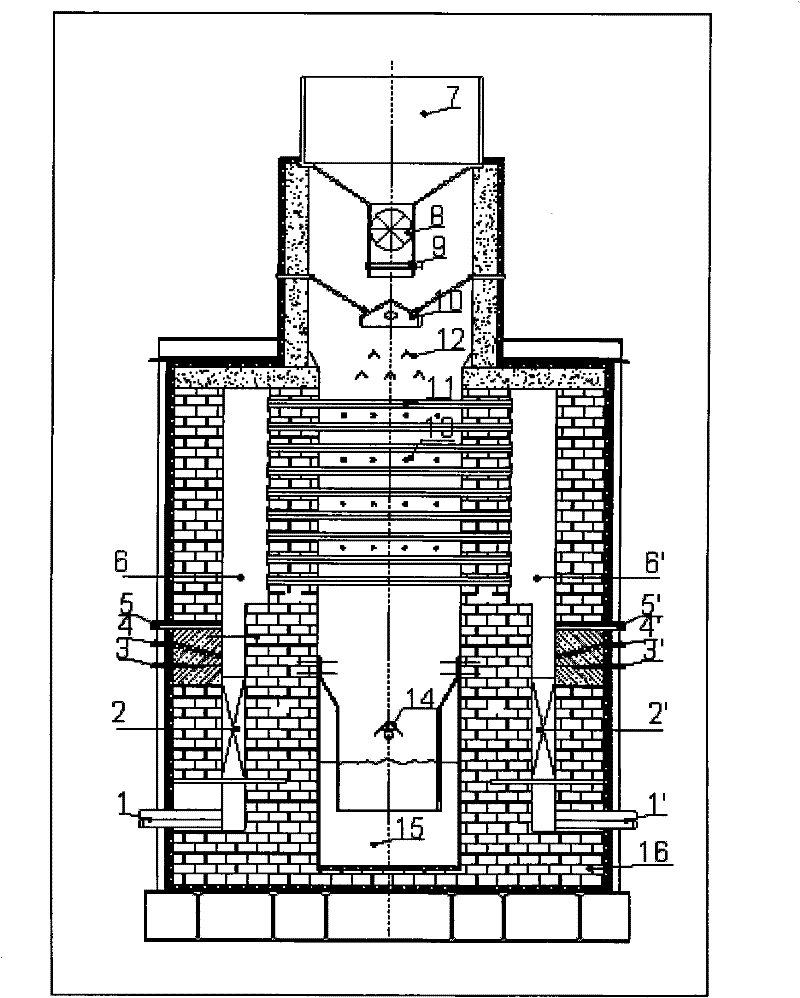

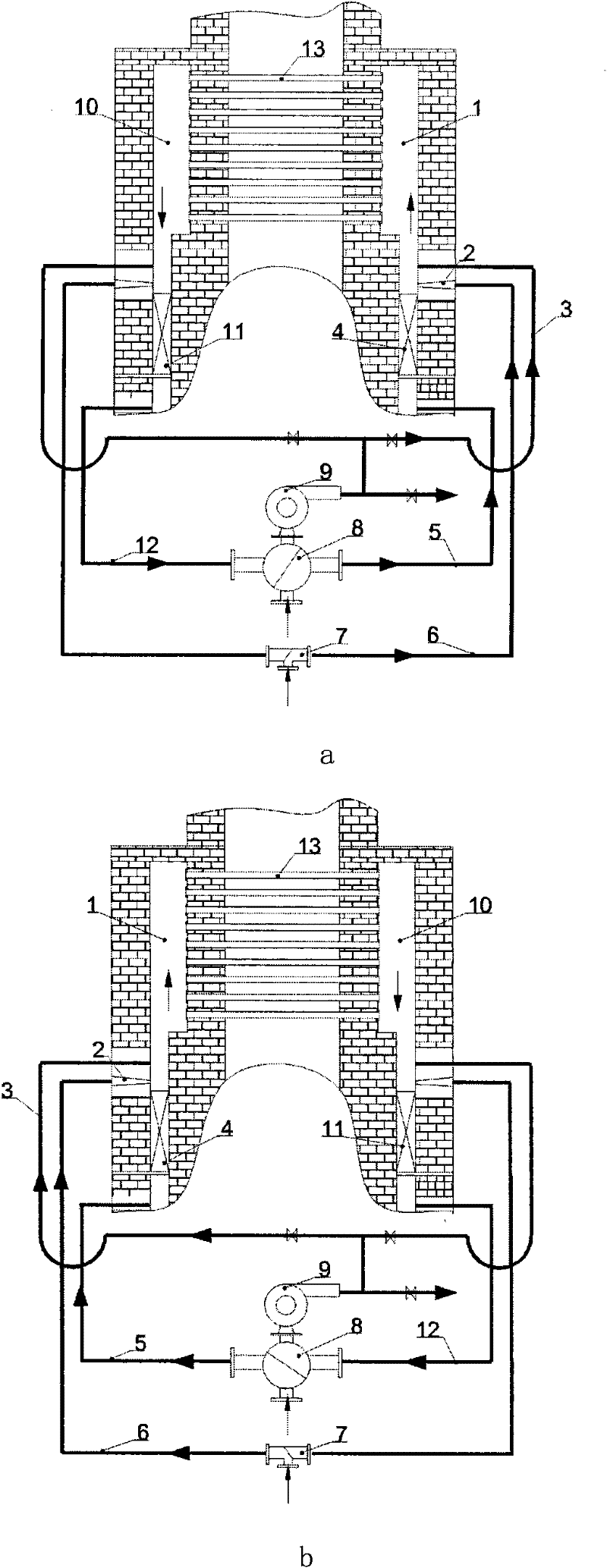

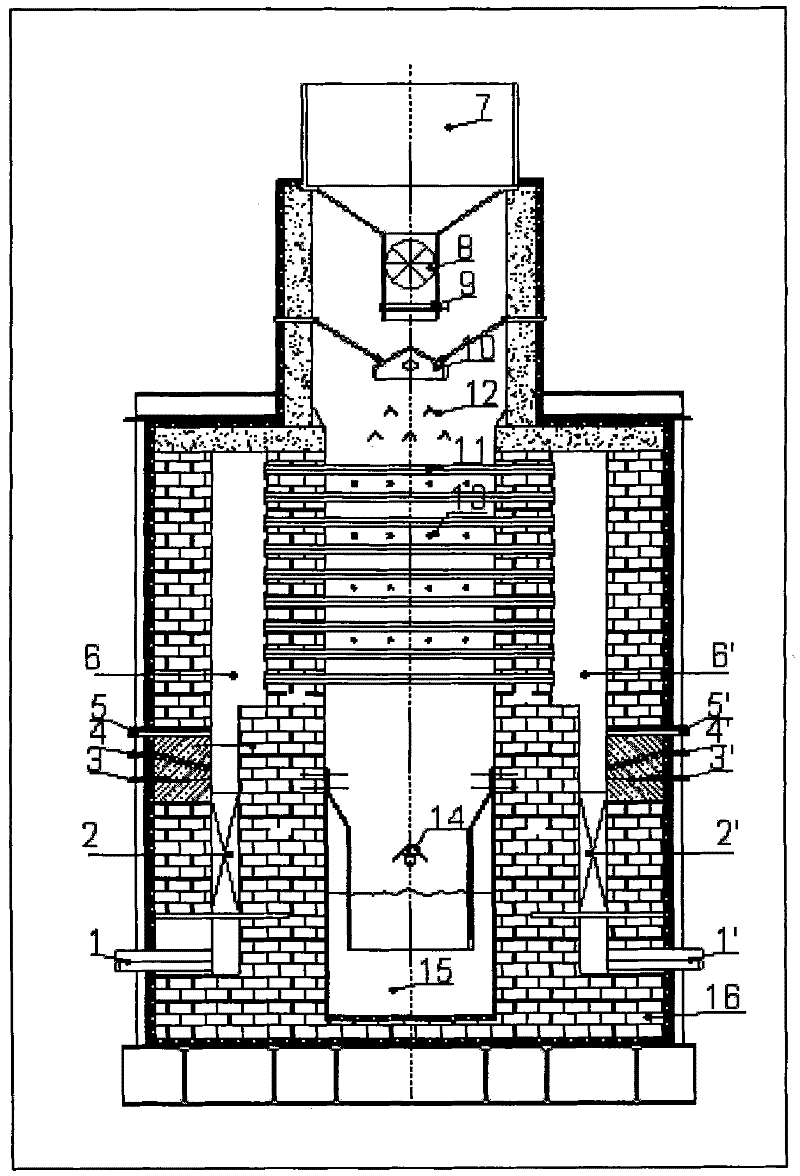

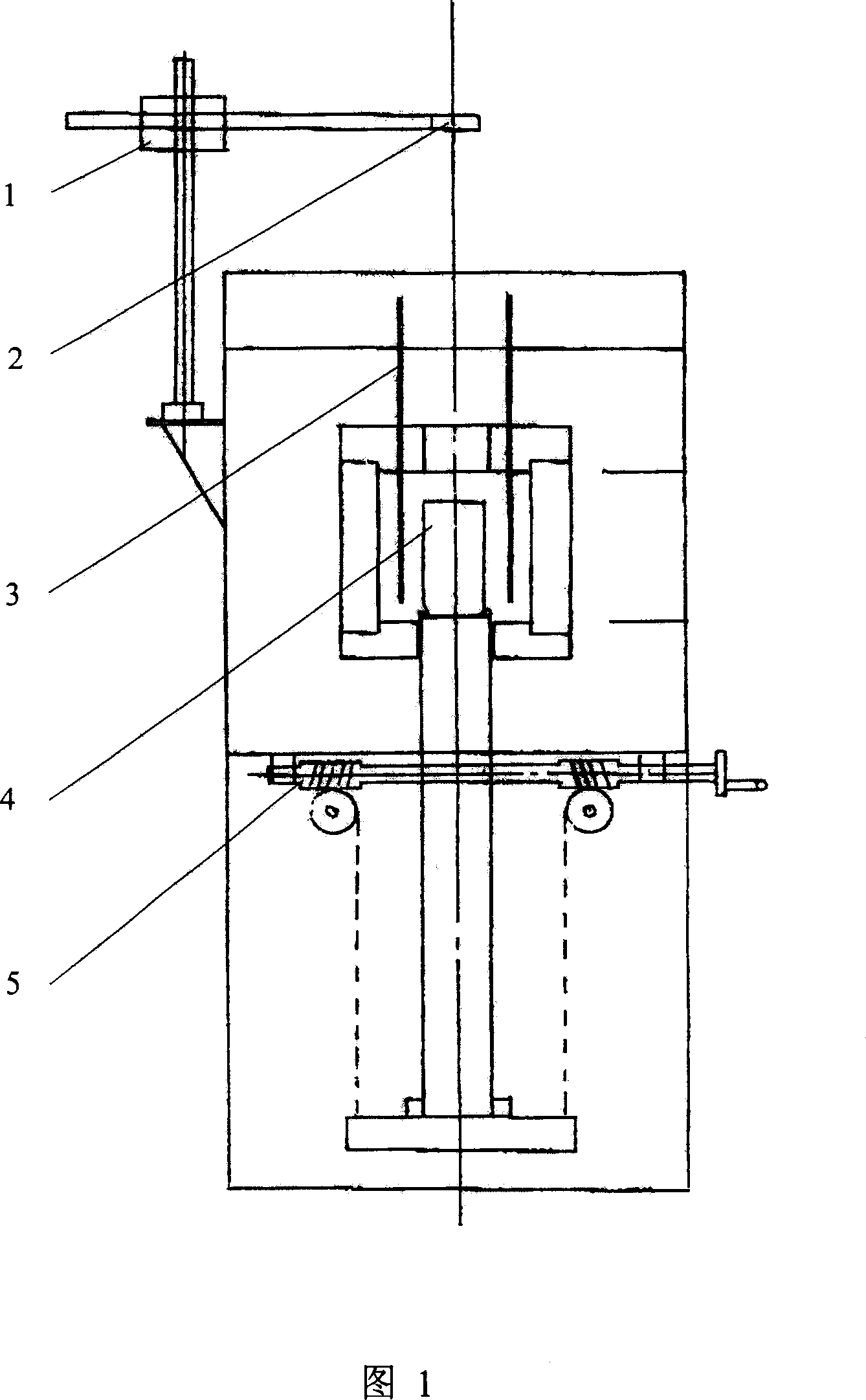

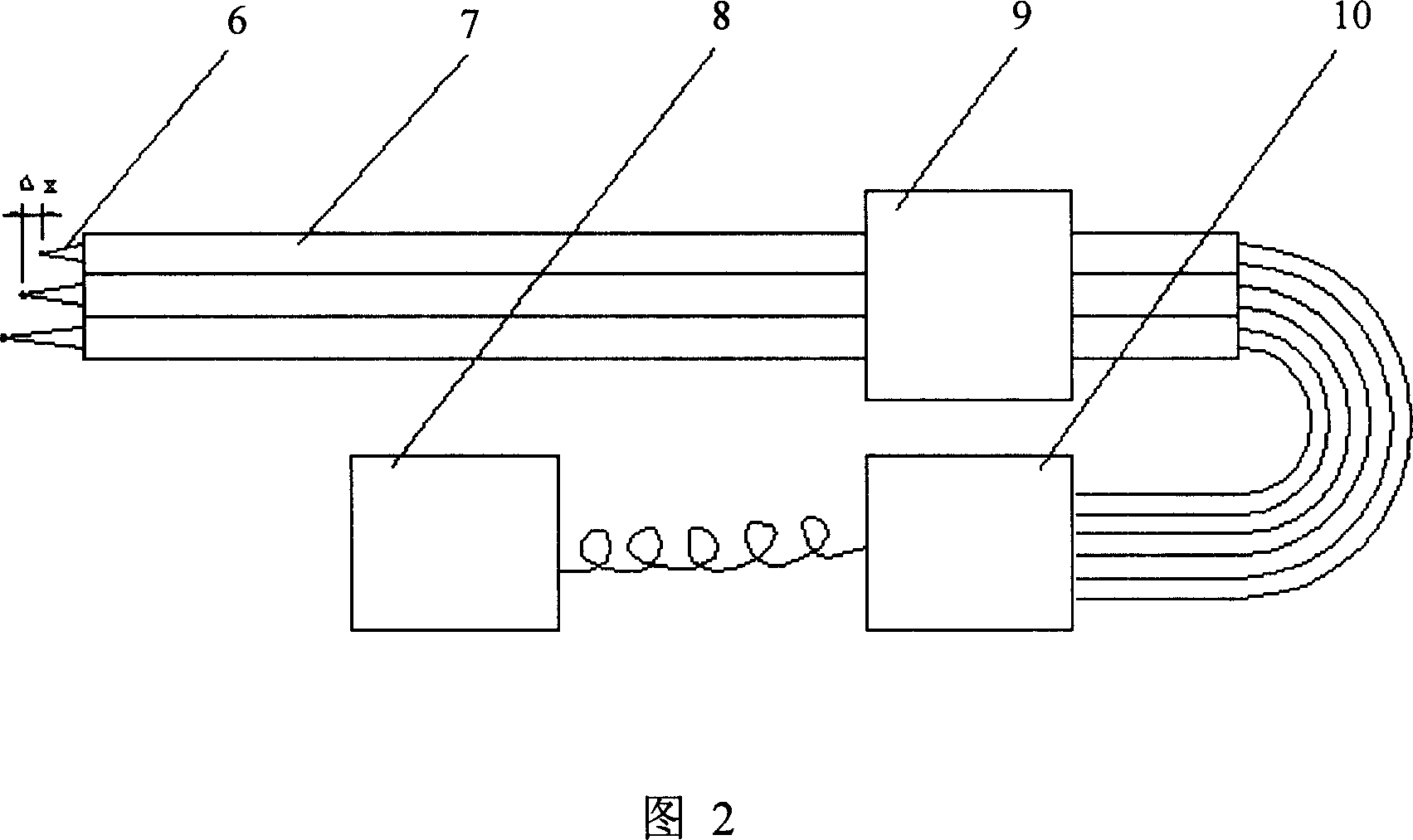

Oil shale dry-wet mixing method dry distillation technology and heat accumulating type external firing shale oven

ActiveCN102363730AReduce lossLess investmentIndirect heating destructive distillationSpecial form destructive distillationCombustion chamberFlue gas

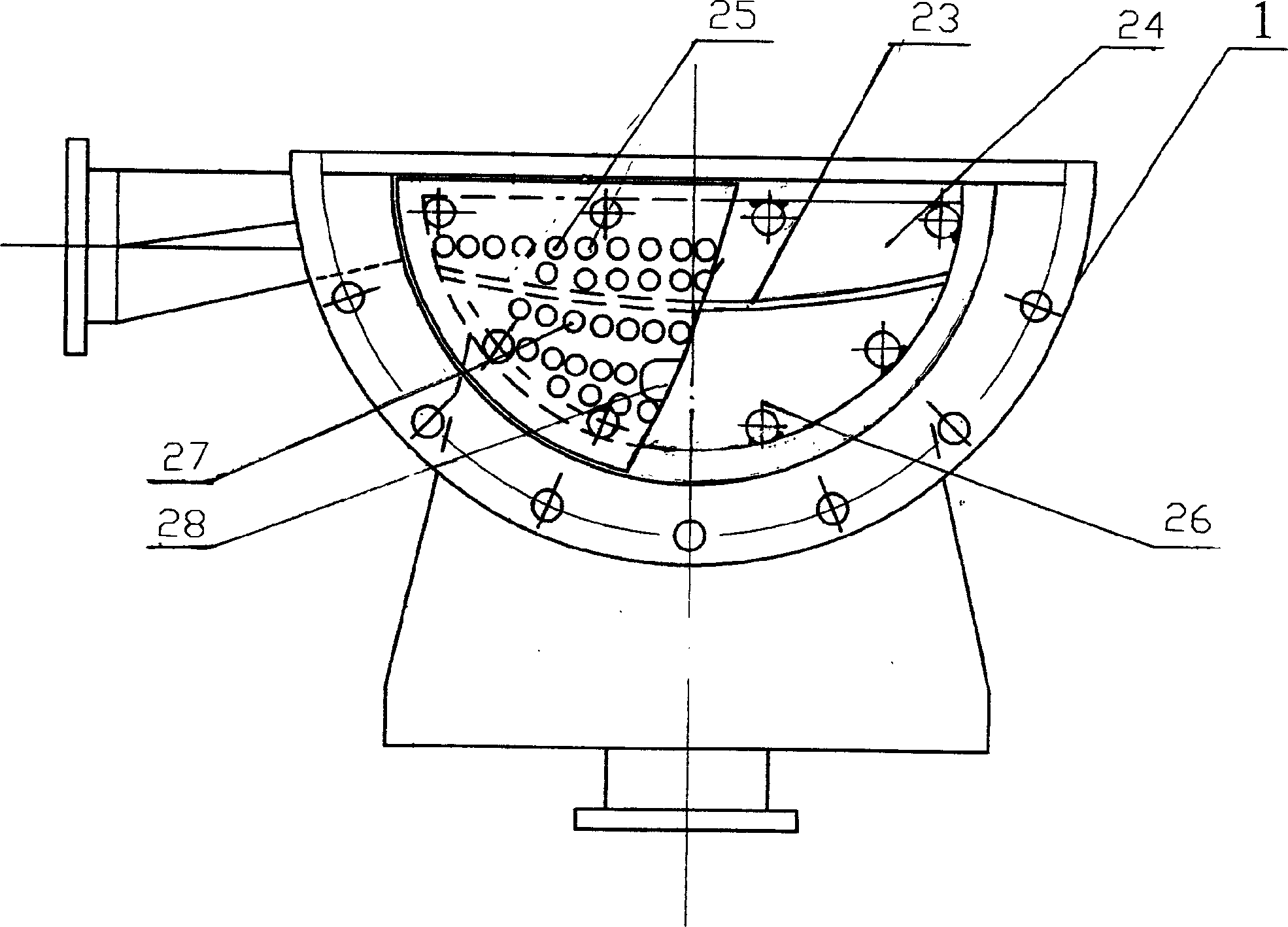

An oil shale dry-wet mixing method dry distillation technology and a heat accumulating type external firing shale oven are respectively a technology and a device for obtaining shale oil and high heating value gas via low-temperature dry distillation. In a new dry distillation technology, a group of heat transmission tube bundle is arranged in the shale oven, high-temperature combustion products, which are mixed well, flow in the tubes, and the external side of each tube directly exchanges heat with the shale to produce oil vapor. A new shale oven is of a shaft-furnace structure, and materials moves from top to bottom under the action of gravity and a drop guide. Combustion chambers are arranged at two sides of the shale oven, and a heat accumulating type combustion technology and a flue gas flow-back exchange mode are used for producing high-temperature flue gas flowing through a heat exchange tube bundle in the shale oven, so as to provide a heat source for the shale oven.

Owner:SHENYANG DONGDA IND FURNACE

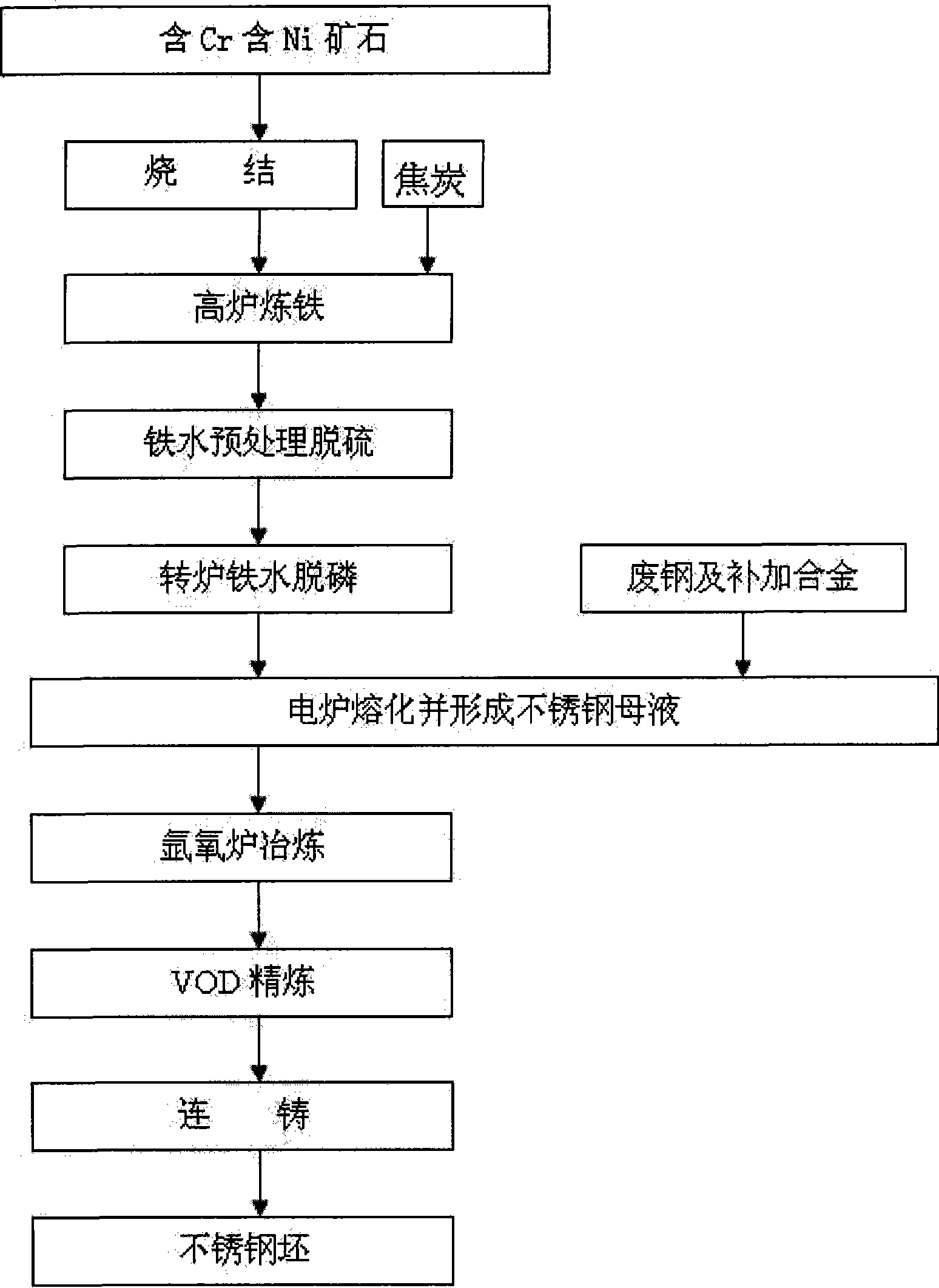

Ni-containing stainless steel smelting method

The invention discloses a method for smelting stainless steel containing Ni, which is characterized in that the method mainly comprises the following steps: low-grade nickel-containing chromium-containing ore is dried and then is sintered; the sintered ore is smelted into molten iron containing the Ni in a blast furnace; the molten iron is subject to pretreatment desulfurization and dephosphorization to form a stainless steel mother solution; iron alloy is melted in an electric furnace; the refining is performed in a stainless steel smelting furnace and a VOD furnace; and a stainless steel billet is obtained by continuous casting. The low-grade nickel-containing chromium-containing ore is used to substitute for chromium and nickel alloy to smelt the stainless steel, so the cost for the stainless steel is reduced greatly. At the same time, the method can fully utilize the low-grade ore, ensure that the idle scarce resource is fully utilized, and can reduce cost.

Owner:SHEN KAN QINHUANGDAO GENERAL ENG DESIGN & RES INST CORP MCC

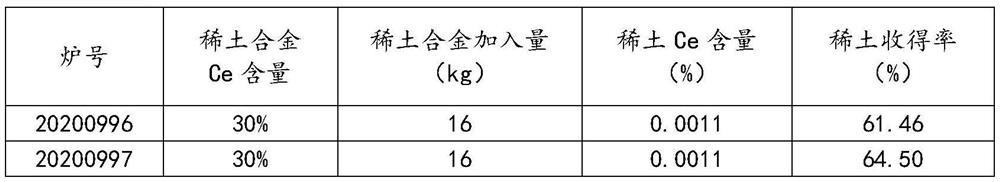

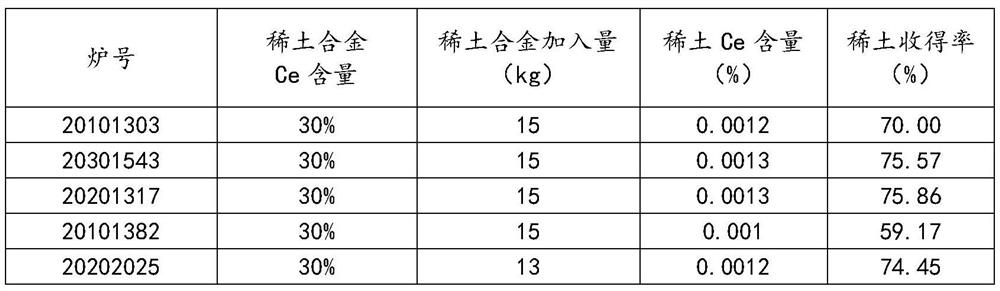

Rare earth adding control method for high-strength rare earth girder steel

InactiveCN112226578AImprove cleanlinessEvenly distributedManufacturing convertersSteelmakingMetallurgy

The invention discloses a rare earth adding control method for high-strength rare earth girder steel. The cleanliness of molten steel of rare earth high-strength girder steel and the yield of rare earth in the steel is improved by optimizing the steel-making process. In early-stage rare earth steel research, due to the fact that the key control processes such as a rare earth adding mode, adding time and the like are not completely mastered, the yield of rare earth is low and is about 35%; and meanwhile, the number of rare earth composite inclusions in steel is large, and the continuous castingpourability of a casting machine is poor. In order to increase the yield of the rare earth, the cleanliness of molten steel is guaranteed before the rare earth is added, and the component uniformityof the rare earth in the molten steel is guaranteed after the rare earth is added. Meanwhile, protective pouring is conducted in the casting process of a casting machine, secondary oxidation of the molten steel is prevented, and the yield of the rare earth in the steel can be remarkably increased.

Owner:BAOTOU IRON & STEEL GRP

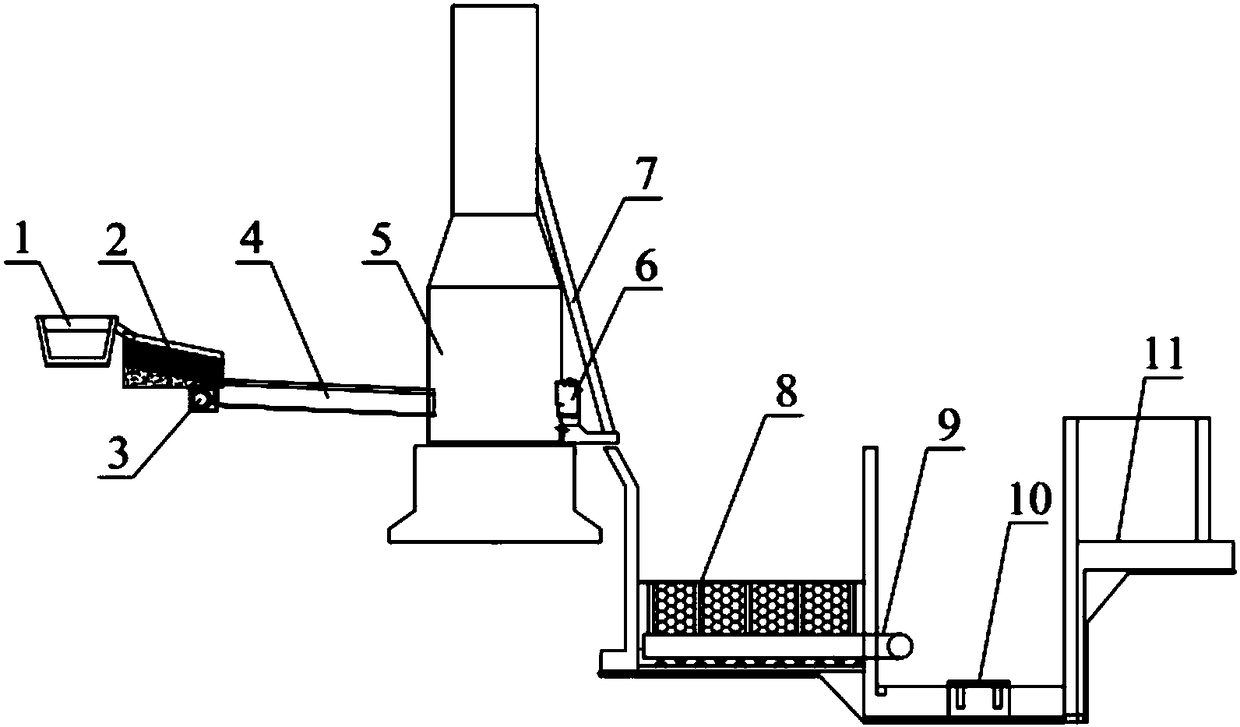

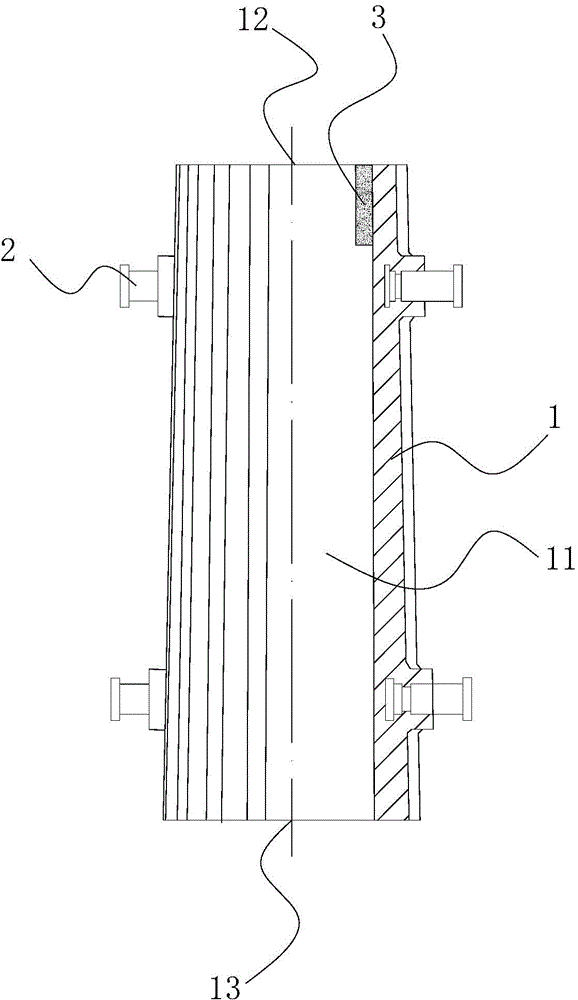

Bottom-filtration-process slag treatment method for ferroalloy submerged arc furnace

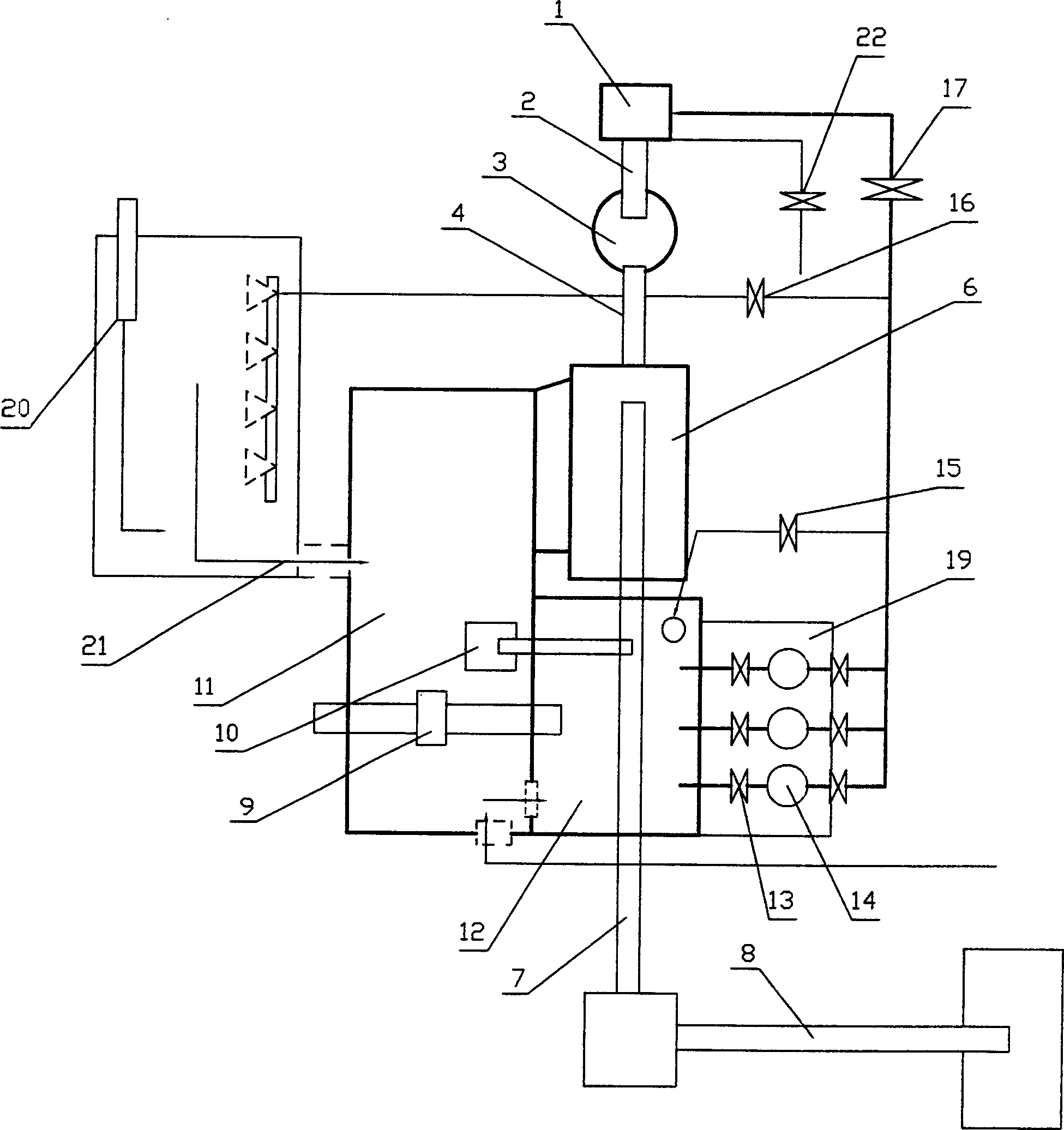

ActiveCN108220511AImprove granulation effectReduce generationRecycling and recovery technologiesPunchingFiltration

The invention discloses a bottom-filtration-process slag treatment method for a ferroalloy submerged arc furnace and belongs to the technical field of ferroalloy submerged arc furnace. The method comprises the following steps of making molten slag overflow into a molten slag ditch via a slag tank; performing crushing, water quenching and pelletizing on the slag which flows from the molten slag ditch into a waste slag ditch by high-speed water flow sprayed out of a punching box; making a slag and water mixture flow from the water granulated slag ditch into a buffer tower and continuing to coolthe slag and water mixture; making the slag and water mixture inside the buffer tower directly flow into a filter tank via an outlet device; filtering the water inside the filter tank by using a filter pipe, and conveying the water to a slag treatment water pool by using a water pump; conveying the water inside the water pool to the punching box in order to realize slag punching and cyclic utilization; and grabbing out the water granulated slag from the filter tank by using a water granulated slag grabbing hopper. The method disclosed by the invention is simple in process and reasonable in procedures, commendably guarantees the granulation degree of the slag, realizes more complete slag and water separation, greatly reduces emission of steam, reduces environmental pollution and realizes simple industrial implementation.

Owner:马钢集团设计研究院有限责任公司

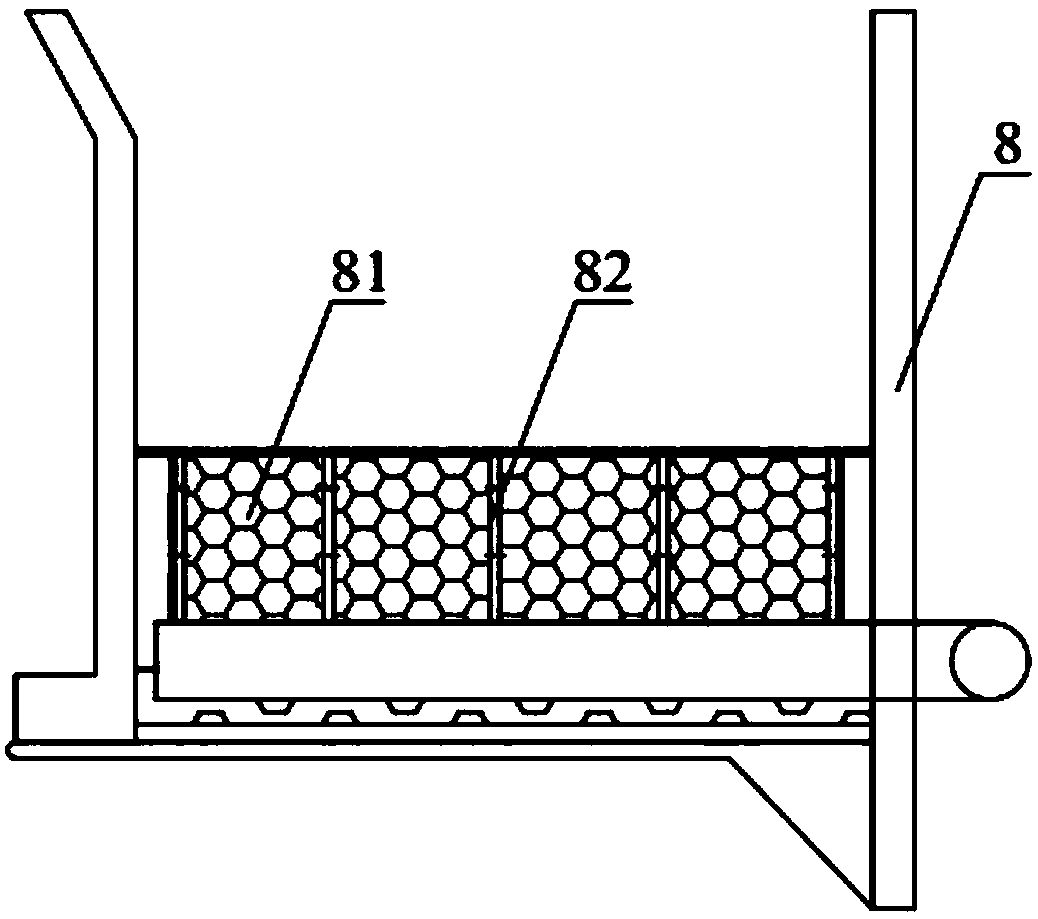

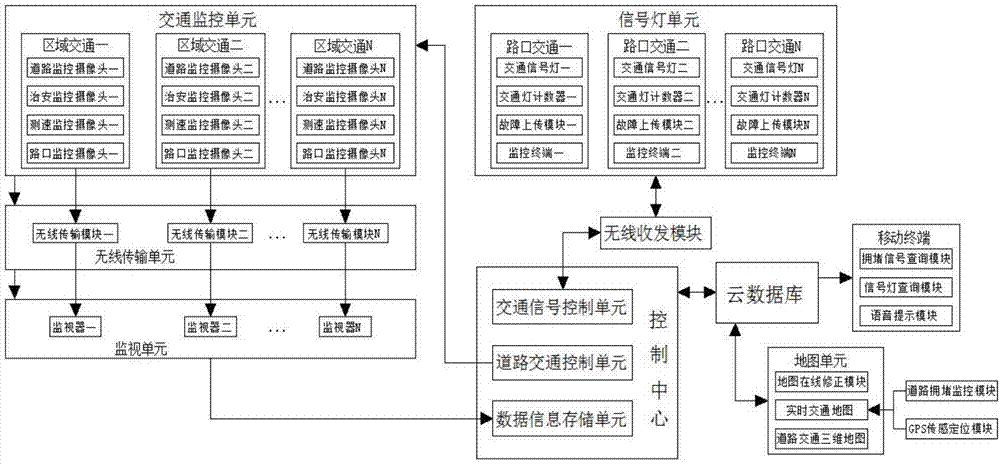

Urban traffic and cloud data management platform based on Internet of things technology

InactiveCN107516416AEasy to manageGuaranteed to be organizedControlling traffic signalsArrangements for variable traffic instructionsElectricityCloud data management

The invention discloses an urban traffic and cloud data management platform based on Internet of Things technology, which includes a control center, which is electrically connected to a cloud database bidirectionally, and an output end of the cloud database is electrically connected to an input end of a mobile terminal. The urban traffic and cloud data management platform based on the Internet of Things technology can manage and monitor the urban road system and signal light system in different regions, effectively ensuring the orderliness of urban traffic management, more targeted, and more convenient management. Real-time monitoring and feedback can reasonably comprehensively manage and store road information and signal light information, effectively improve the urban traffic management system, and meet the requirements of modern urban traffic. Citizens can monitor road live information and signal light information through mobile terminals. Accurate query makes it more convenient to use, effectively avoids the occurrence of traffic jams, and effectively guarantees the normal travel of citizens.

Owner:ZHAOQING SHENGSHANG INTPROP SERVICE CO LTD

Round ingot die and round ingot manufacturing method

The invention relates to the technical field of casting of ingots, and provides a round ingot die. The round ingot die comprises a die body, a lug and an insulation board; an inner cavity is formed in the die body; the cross section of the outer side surface of the die body is polygonal wave shaped. According to the round ingot die, the radiating area of the side surface of the ingot is increased; hot melt at the outermost layer can be quickly cooled to form a chilling layer; the thickness increase of the chilling layer is sped up; therefore, static pressure in pouring of hot melt can be borne; crack can be prevented; the difficulty at pouring of the round ingot can be greatly reduced; meanwhile, the size precision of the outer side surface of the round ingot die cannot influence the size precision of the round ingot, so that the requirement on the processing precision of the outer side surface of the round ingot die is reduced, the process and working houses are decreased, and the cost can be saved. The invention further provides a round ingot manufacturing method. The method is that the degree of superheat of hot melt is 40 to 55 DEG C; the linear speed of pouring of an ingot body is 80 to 220mm / min; the linear speed of filling and pouring of a dead head of the insulation board is 35 to 90mm / min. The method can properly reduce the casting temperature and speed; the round ingot can be quickly radiated; therefore, the surface cracks can be decreased.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

High-alkalinity high-lubricity continuous casting crystallizer casting powder and method for performing continuous casting on peritectic steel slab

InactiveCN103990770AImprove the lubrication effectReduce longitudinal crack defectsAlkalinityMetallurgy

The invention discloses high-alkalinity high-lubricity continuous casting crystallizer casting powder. The casting powder comprises CaO, SiO2, Al2O3, MgO, Na2O, K2O, Li2O, F- and C. The alkalinity of the casting powder is 1.40-1.90. The viscosity of the casting powder is 0.02 Pa.S-0.15 Pa.S at 1300 DEG C. The fusion point of the casting powder is 1020 DEG C-1150 DEG C. The invention further provides a method for performing continuous casting on a peritectic steel slab under the condition that the high-alkalinity high-lubricity continuous casting crystallizer casting powder exists. In this way, not only is the crystallinity of the casting powder improved, but also the lubricity of the casting powder is improved. In addition, the defect of longitudinal cracks on the surface of the peritectic steel slab is remarkably overcome in the continuous casting process of the peritectic steel slab, and the problem of steel sticking and break-out of the crystallizer due to casting powder does not happen.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Ore blending method for improving heat-state intensity index of sintering ore

The invention provides an ore blending method for improving a heat-state intensity index of a sintering ore. The ore is prepared from the following raw materials in percentage by weight: 66-88 percent of hematite powder, 5-15 percent of magnet ore powder, 3-12 percent of ludwigite concentrate fines, and 4-7 percent of mixed material; the ludwigite concentrate fines comprise the main components in percentage by weight: 52-54 percent of TFe, 20-24 percent of FeO, 4-6 percent of SiO, 0.5-1.0 percent of CaO, 10-13 percent of MgO, 0.2-0.4 percent of Al2O3, 3-5 percent of B2O3, 0.3-0.5 percent of S, 3-5 percent of burning loss Ig and 1.0-1.5 percent of crystal water. According to the ore blending method, the heat-state intensity index of the sintering ore can be obviously improved, and low-temperature reduction degradation ratio of the sintering ore is reduced on the premise that the requirements of a blast furnace on the grade of the sintering ore and the alkalinity can be completely met. The low-temperature reduction degradation index RDI+3.15mm of the sintering ore reaches an average of 62.92 percent, and the low-temperature reduction degradation index RDI-0.5mm reaches 7.11 percent, so that the smooth operation of the production of the blast furnace can be guaranteed, the yield of the blast furnace is improved, and the coke ratio is reduced.

Owner:ANGANG STEEL CO LTD

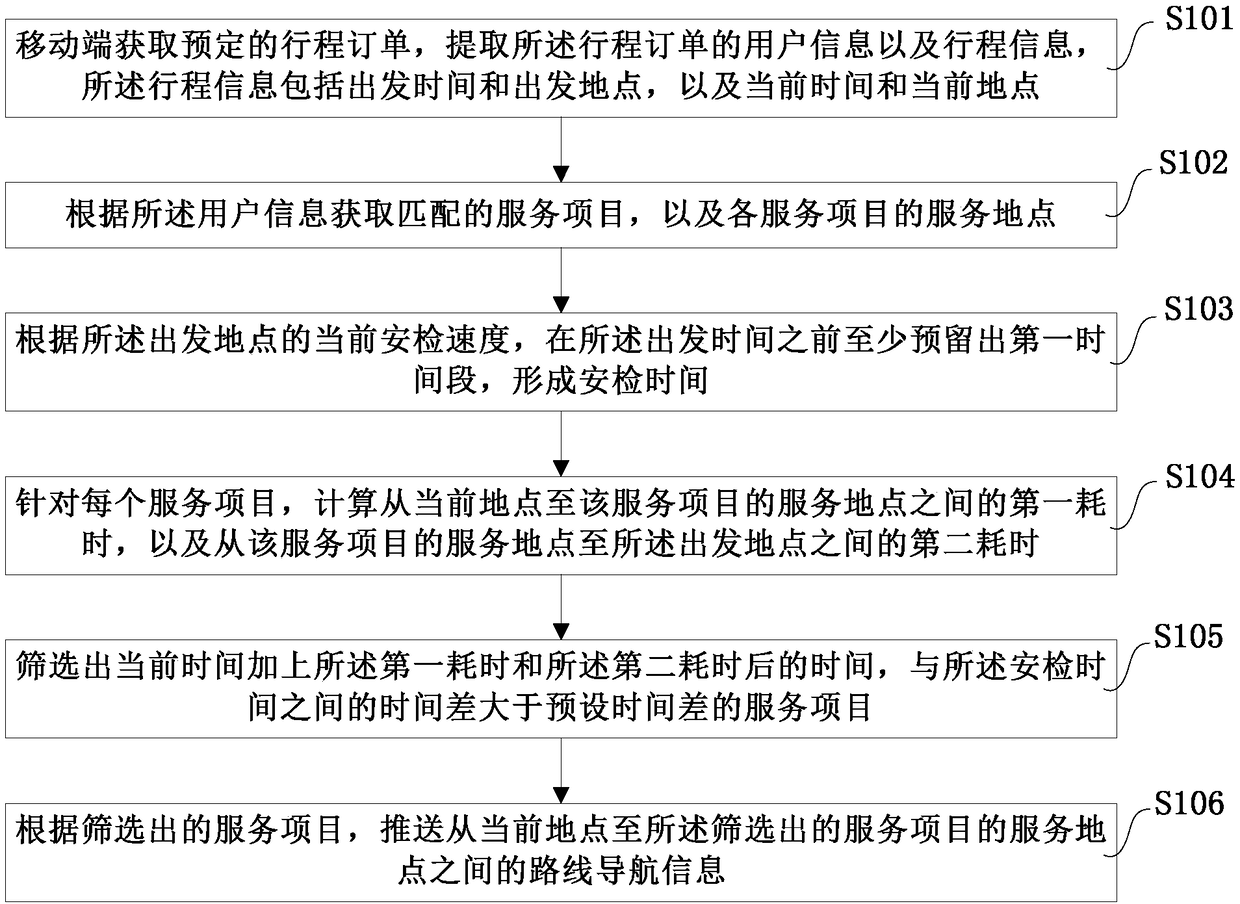

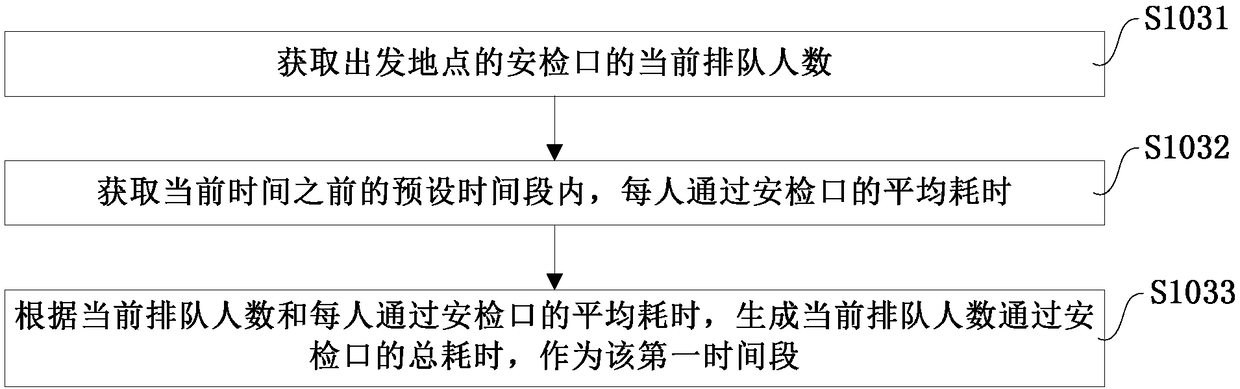

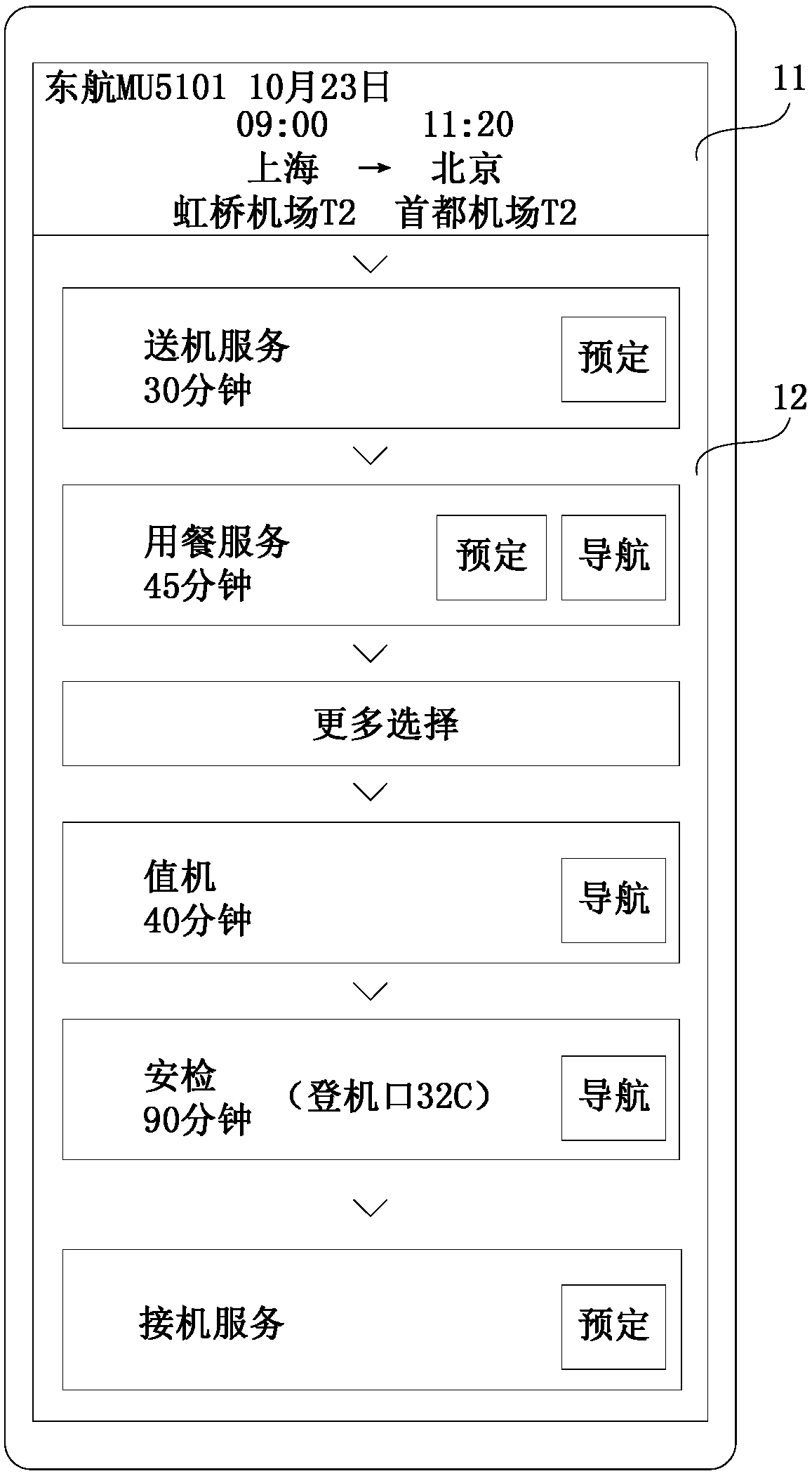

Related service pushing method, system and device of itinerary order and storage medium

ActiveCN108256050AGuaranteed travelTravel delayReservationsSpecial data processing applicationsPersonalizationGeolocation

The invention provides a related service pushing method, system and device of an itinerary order and a storage medium. The related service pushing method of the itinerary order includes the steps of obtaining the scheduled itinerary order, and extracting user information and itinerary information of the itinerary order; according to the user information, obtaining matched service items; accordingto the current security check speed of a departure place, reserving at least a first duration before departure time, and forming security check time; regarding each service item, calculating first consumed time from a current place to a service place of the service item, and calculating second consumed time from the service place of the service item to the departure place; screening out the service item meeting the condition that the time difference between calculated time and the security check time is greater than a preset time difference, wherein the calculated time is obtained by adding the first consumed time and second consumed time of the service item to current time; according to the service item which is screened out, pushing route navigation information between the current placeand the service place of the service item. According to the related service pushing method, system and device of the itinerary order and the storage medium, security check waiting time is fully considered; on the basis of the real-time geographic location of a user, the service item matched with the user information is pushed individually, and the travel experience of the user is improved.

Owner:CTRIP TRAVEL NETWORK TECH SHANGHAI0

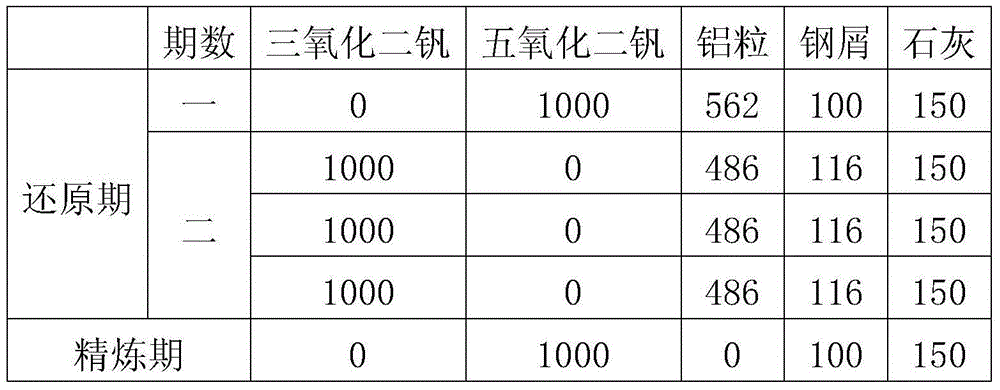

High vanadium ferroalloy smelting method

ActiveCN103757171BReduce coolingOvercoming difficult follow-up problemsMetal recyclingProcess efficiency improvementReduction treatmentElectric arc furnace

The invention discloses a high vanadium ferroalloy smelting method. The method comprises the steps of adding cold-state vanadium-rich slag and limestone to the bottom of an electric arc furnace, adding a phase-I mixture consisting of vanadium pentoxide, aluminum particles, limestone and steel cuttings and smelting; returning heat-state vanadium-enriched slag of last batch into the electric arc furnace and discharging slag when vanadium content in smelting slag is less than 0.5%; adding a phase-II mixture consisting of vanadium trioxide, aluminum particles, limestone and steel cuttings, smelting, discharging slag when vanadium content in smelting slag is less than 0.5%, and before discharging the slag, adding aluminum or aluminum-magnesium alloy for reduction treatment; adding a refining mixture consisting of vanadium pentoxide and limestone or iron scale and limestone, smelting, controlling temperature of vanadium-iron alloy liquid in the furnace to be above 1900 DEG C, discharging the vanadium-iron alloy liquid and the vanadium-enriched slag when vanadium content is 78-82% and aluminum content is less than 1.5% in the vanadium-iron alloy liquid, pouring the vanadium-iron alloy liquid into an ingot mould which is preheated to be above 500 DEG C, and cooling, demoulding and breaking to obtain high vanadium ferroalloy which contains more than 80% of vanadium.

Owner:攀钢集团西昌钒制品科技有限公司

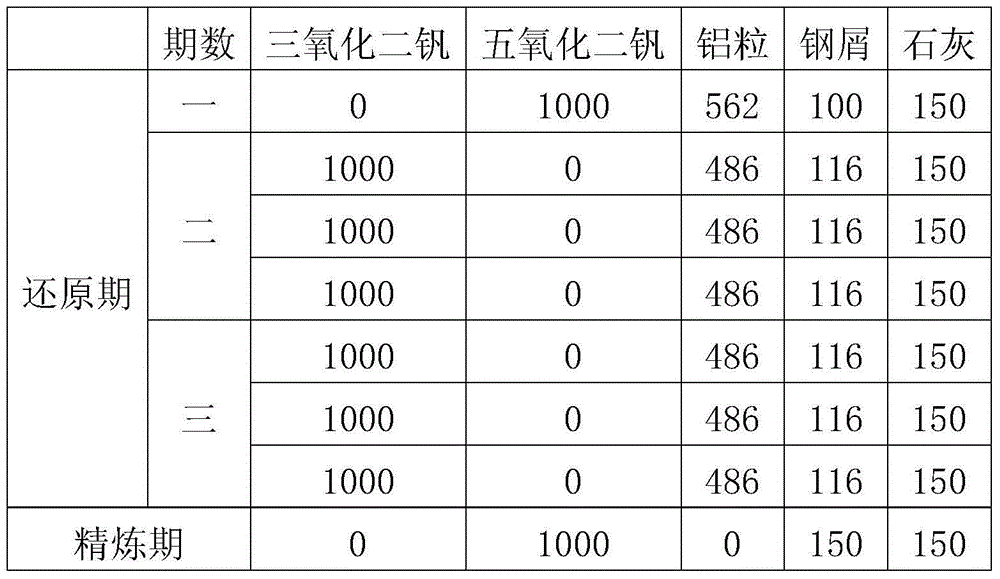

Treatment technology for zinc-containing dust of rotary hearth furnace

InactiveCN109055726ALow investment costSo as not to damageCombination devicesProcess efficiency improvementHearthSpray cooling

The invention belongs to the technical field of metallurgy, and relates to a treatment technology for zinc-containing dust of a rotary hearth furnace. K, Na, Cl and other elements in the zinc-containing dust are fully removed by adopting a wet way technology, wherein the wet way technology is to make the zinc-containing dust of a steel and iron mill to be mixed with water and subjected to multiplestirring, concentration and then dehydration; a mode of coal rod machine extrusion is adopted to make raw materials form at a moisture content of 15-20%, meanwhile, drying, preheating, heating and reducing roasting of the raw materials are completed in the rotary hearth furnace, thus raw material drying does not need to be configured with a dryer, drying is directly carried out in the rotary hearth furnace, and the cost is saved; and meanwhile, flue gas of the rotary hearth furnace is cooled by adopting a mode of spray cooling, no boiler or heat exchanger is required to be configured, the investment cost of flue gas treatment of the rotary hearth furnace is reduced, the flue gas of the whole rotary hearth furnace can meet the treatment requirements of the zinc-containing dust of medium and small steel mills, and the production cost is saved.

Owner:CISDI RES & DEV CO LTD

Method for displaying multi-item alarm information at single position of operation screen

InactiveCN101727082ASimplify workSimplified accuracyComputer controlSimulator controlDirect observationComputer science

The invention relates to a method for displaying multi-item alarm information at a single position of an operation screen. The method for displaying multi-alarm information in a single position of the operation screen comprises the following steps: using HMI system software in GE Company to organize the order of the multi-item alarm information of each device in real time according to the importance; expressing all the chains of the alarm information in a program; and manufacturing the abnormal chain information at a screen position, and selecting the display mode and content according to need. The method for displaying the multi-item alarm information at the single position of the operation screen has the advantages of wide information contents and complete scheme, ensures that an operator directly observes and knows the information contents through the frequently used screen and knows a dispelling method, saves complicated calculation process of searching the program, shortens the accident handling time, improves the equipment operation rate, and guarantees the device safety and smooth operation of the production; and the method is simple, the program is concise, the display screen is clear, and the operating method is easy to grasp.

Owner:ANGANG STEEL CO LTD

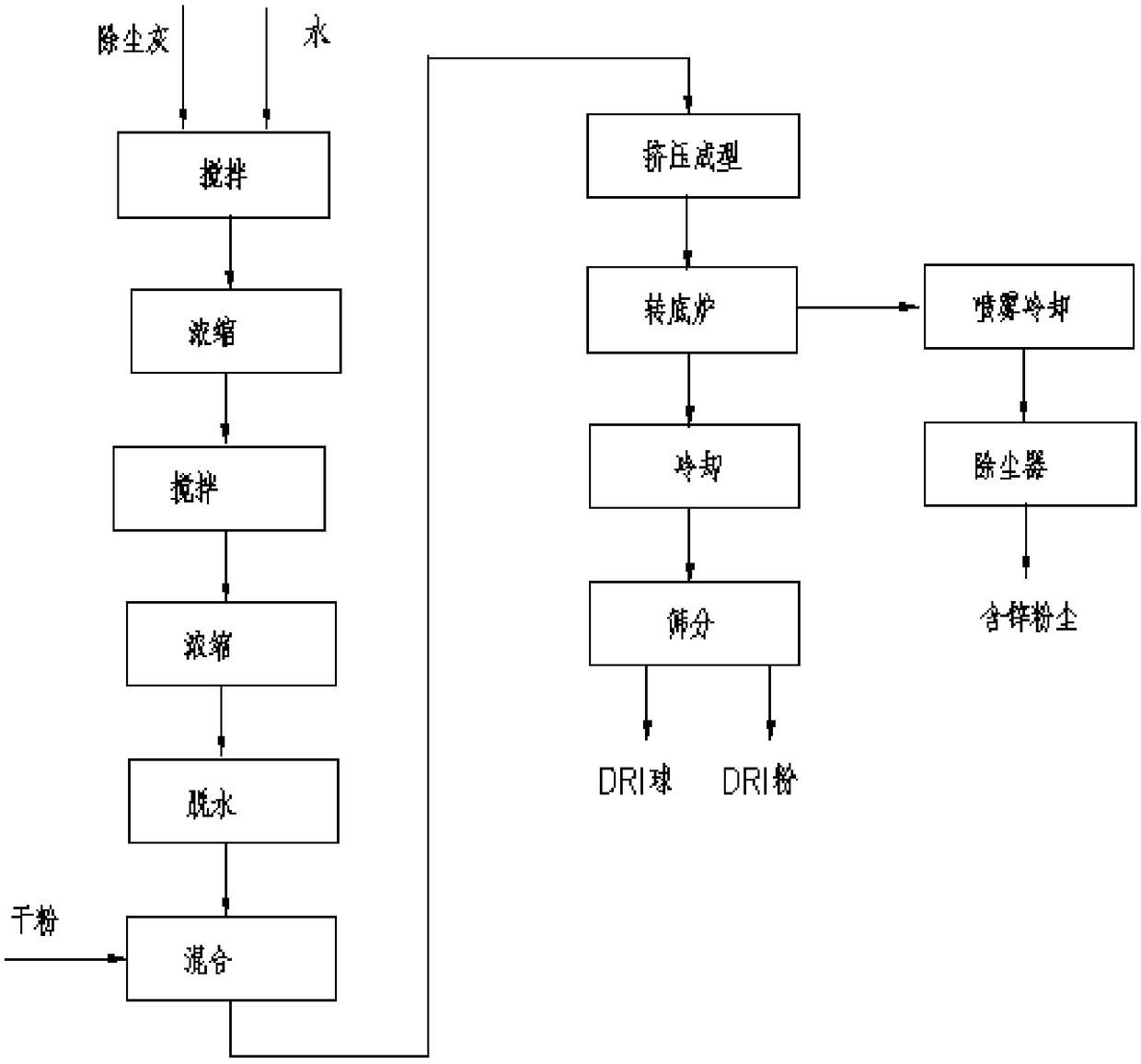

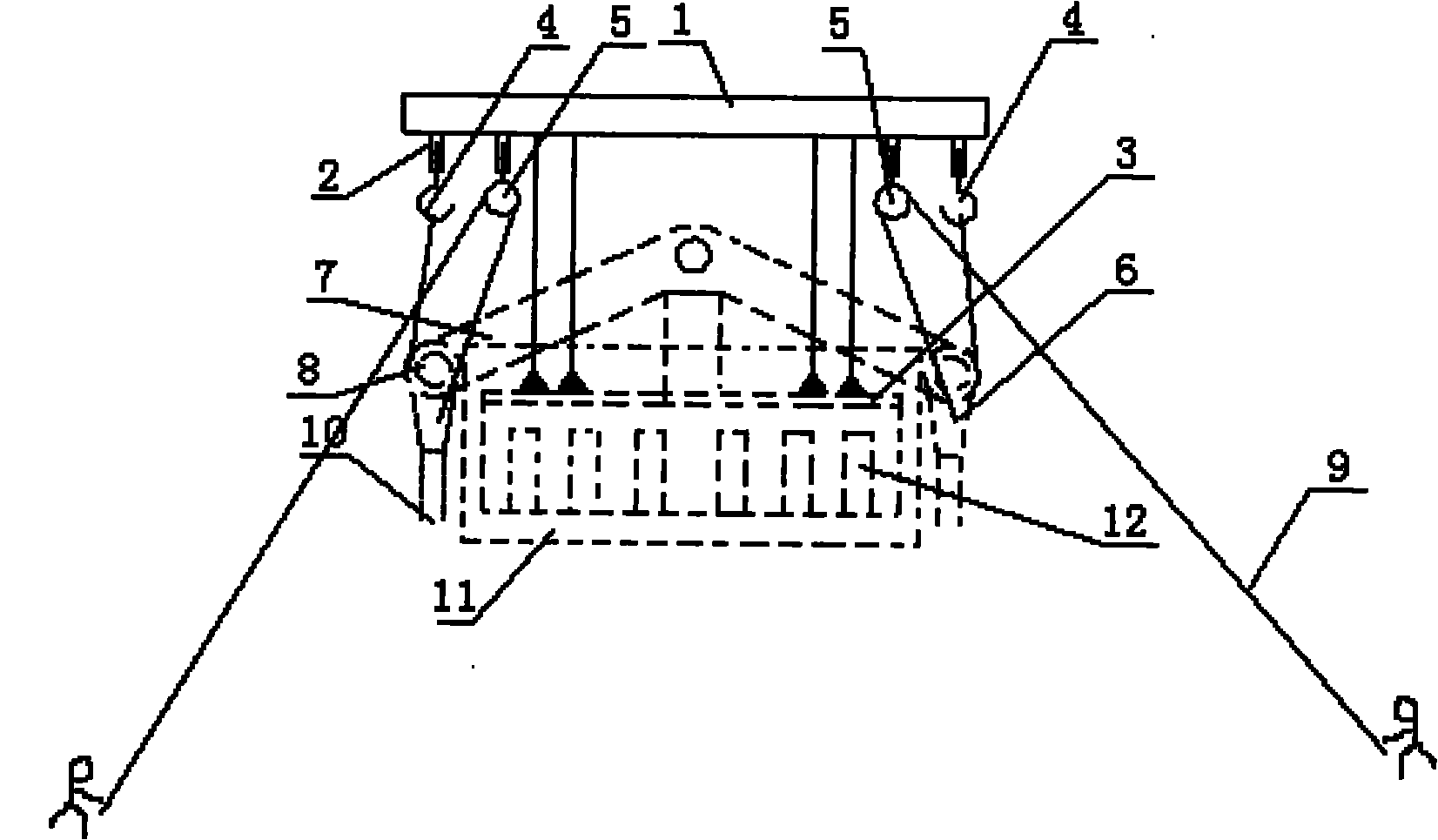

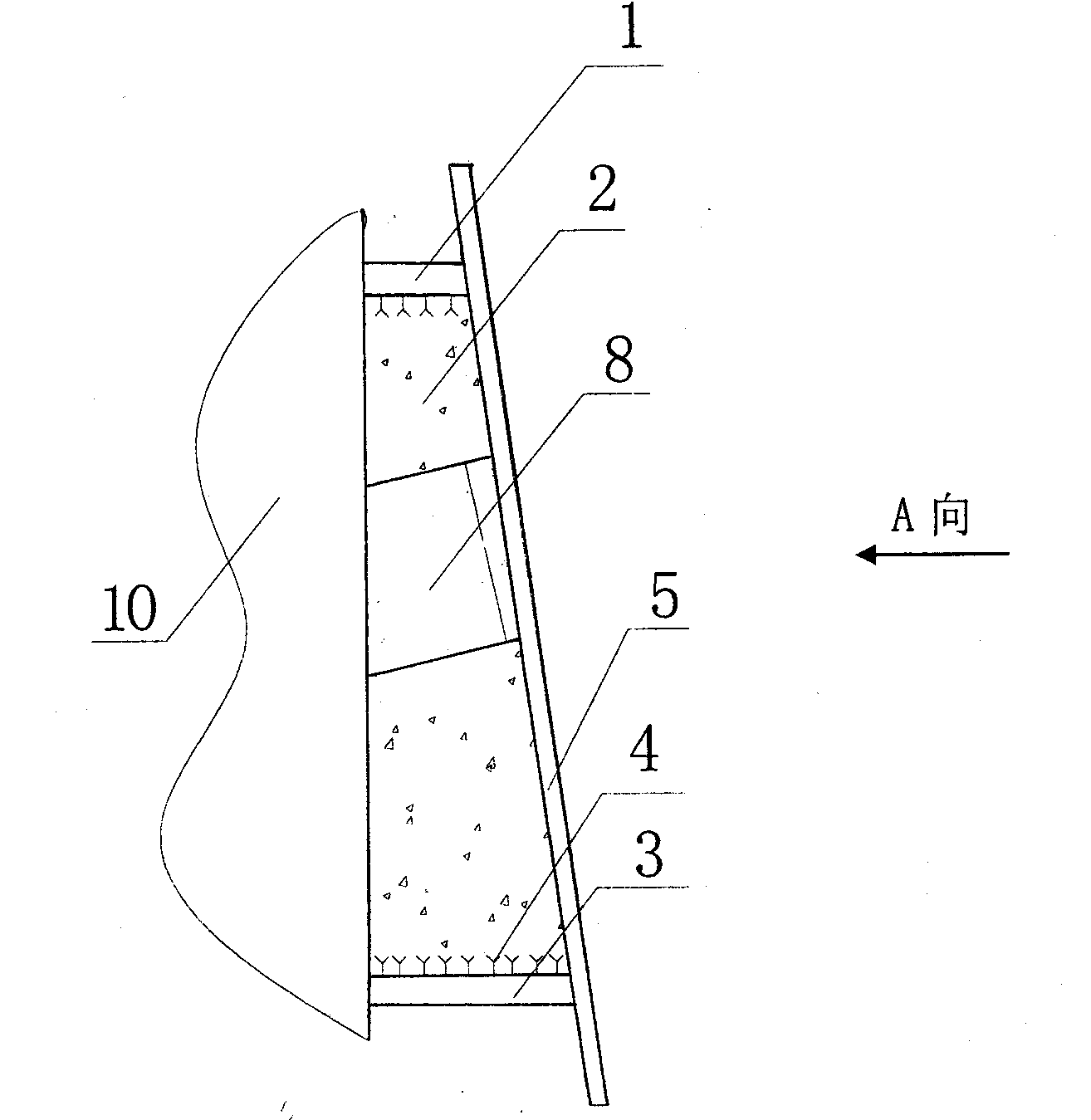

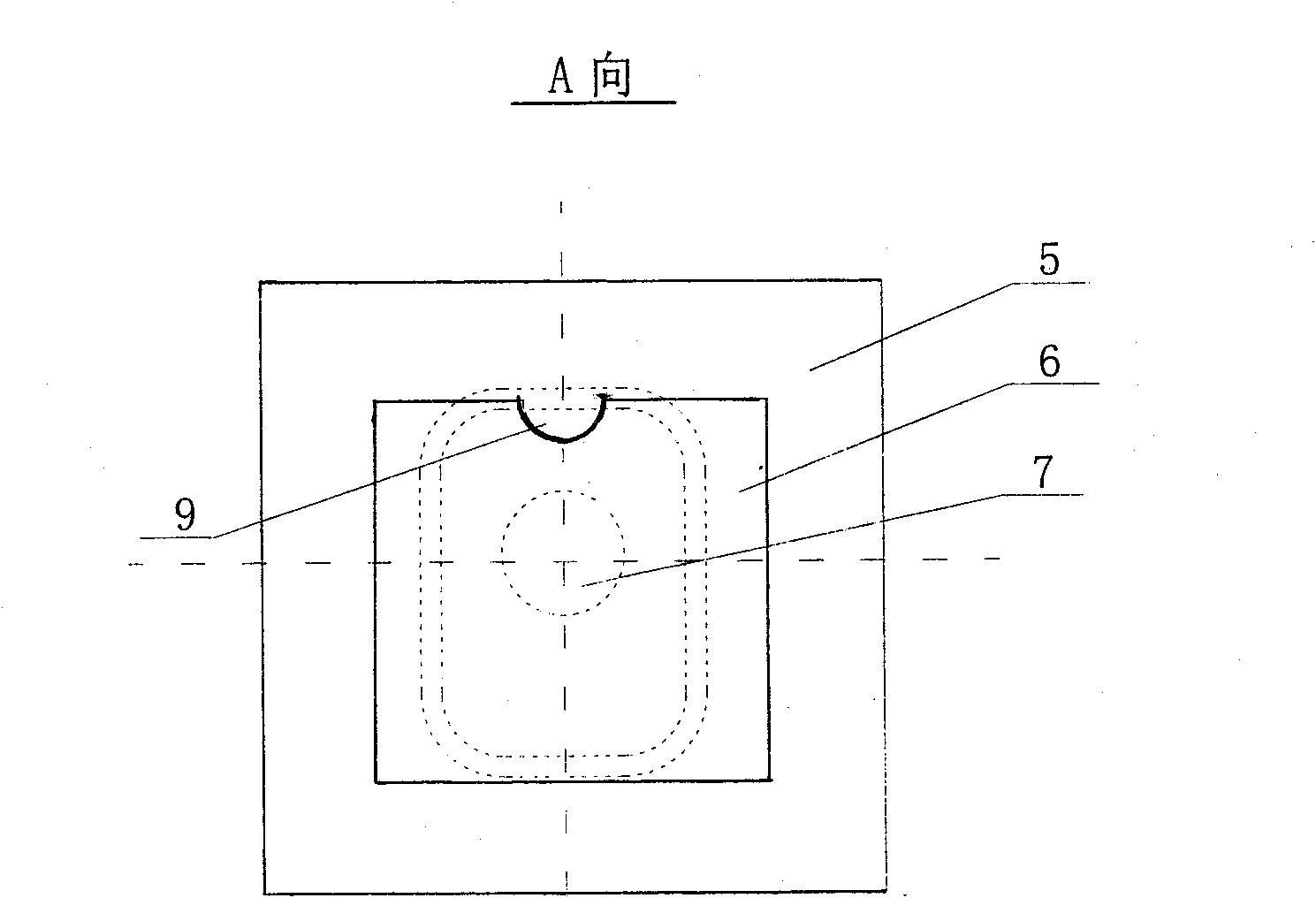

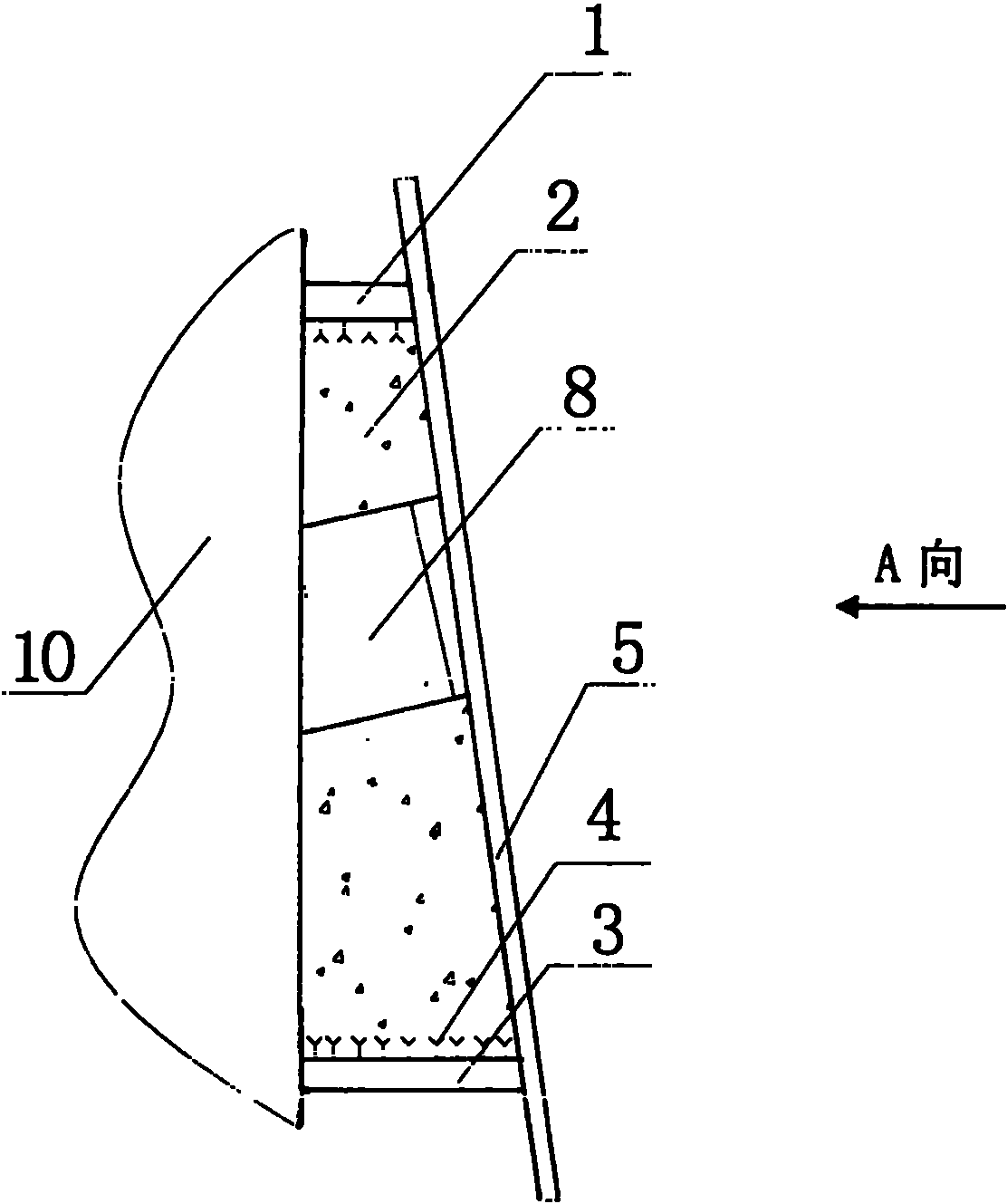

Auxiliary tool and method for replacing wire rope of bridge crane

ActiveCN102030270AEnsure personal safetyReduce labor intensityTravelling cranesOverhead craneIndustrial engineering

The invention relates to an auxiliary tool and a method for replacing a wire rope of a bridge crane. A gantry frame is manufactured on a cover plate on the upper part of a fixed pulley block of a drum of a bridge crane trolley; lifting rings are arranged on the two sides of the gantry frame; a chain hoist and a fixed pulley are arranged on the lifting rings on the two sides respectively; thus the old wire rope is replaced by a new one. Compared with the prior art, the auxiliary tool and the method have the advantages that: after the device is used, the time for replacing the wire rope is greatly shortened each time, the personal safety of construction personnel is guaranteed, the labor intensity of workers is relieved, the labor productivity is improved, and smooth running of workshop production is guaranteed.

Owner:ANSHAN IRON & STEEL GROUP CORPORATION

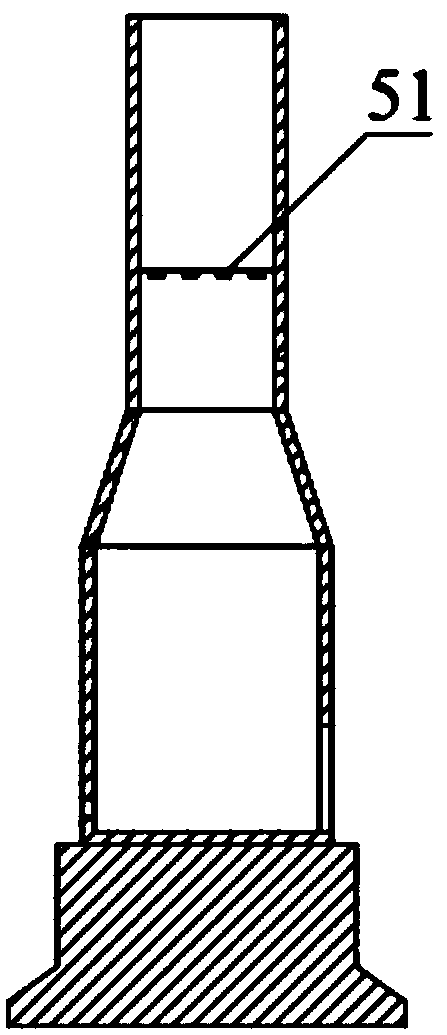

Tap hole integral pouring mud sleeve for blast furnace and manufacturing method thereof

ActiveCN101781693AReduce production workloadSave consumption and costBlast furnace componentsBlast furnace detailsSlagRefractory

The invention relates to a tap hole integral pouring mud sleeve, which belongs to fittings for an ironmaking blast furnace tap hole and particularly relates to a mud sleeve for opening or blocking a tap hole. The mud sleeve is made of a refractory material arranged in a mud sleeve frame, and is characterized in that the refractory material is a pouring material and is compactly filled in the mud sleeve frame. The mud sleeve frame is a box-shaped body, and a consolidated hanger is arranged at the inner side of a frame plate; the rear end of the mud sleeve frame is connected with a blast furnace shell, a door frame is arranged at the front end of the mud sleeve frame, and a template is embedded in the door frame; a pouring hole is arranged at the upper side of the template, a module is fixed on the template and is opposite to the center of the tap hole, and an iron pipe provided with a tapping channel is arranged between the module and the tap hole; and compared with the prior art, the invention has the advantages that the tap hole mud sleeve is durable, the service life is markedly prolonged, the manufacturing workload of the mud sleeve is reduced, the usage quantity and the expense of the refractory material are saved, the gas leakage is reduced, and the casthouse operation is safe; the operation under pressure can be carried out, thereby avoiding damping down due to the manufacture of the tap hole mud sleeve, ensuring the timely slag iron tapping of the blast furnace and ensuring blast furnace successful operation, energy saving, consumption reduction and yield increase.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for synthetic slag washing of tundish

The invention provides a method for the synthetic slag washing of a tundish. The method comprises the following steps of: manufacturing a slag washing tube with a small upper opening, a large lower opening and an upturned edge, wherein an argon blowing hole is reserved in the slag washing tube; before the pouring of a large tank, seating the slag washing tube on a tundish cover of the tundish, and inserting a long nozzle in the lower part of the large tank into the slag washing tube for pouring; and in the initial pouring stage, medium pouring stage and final pouring stage of the large tank, adding a certain amount of pre-molten slag into the slag washing tube respectively, and performing argon blowing, wherein the alkalinity of the pre-molten slag in the slag washing tube is controlled to be 2.5 to 3.2 in the pouring process. Tiny impurities with sizes of 5 to 100 mu m can be effectively removed from molten steel, the removal of tiny aluminum oxide impurities from the molten steel is facilitated, and the impurity removal efficiency and effects of the tundish are remarkably enhanced. The cleanliness of the molten steel is greatly improved, and the quality of steel is improved. In addition, the metallurgical functions of the tundish are completed, and the phenomenon that a submerged nozzle of the tundish is jammed is effectively reduced to ensure smooth production.

Owner:ANGANG STEEL CO LTD

Anhydrous stemming for submerged-arc furnace, and preparation method of anhydrous stemming

The invention belongs to the technical field of metallurgical materials, and in particular relates to anhydrous stemming for a submerged-arc furnace, and a preparation method of the anhydrous stemming. The anhydrous stemming for the submerged-arc furnace is prepared from the following components in parts by weight: 20-30 parts of refractory adhesive medium powder, 15-25 parts of aggregate, 8-16 parts of silicon nitride, 15-20 parts of a plasticizer, 2-5 parts of an adhesive agent, 2-5 parts of coal ash and 40-50 parts of metallurgical solid waste. The anhydrous stemming for the submerged-arc furnace can greatly increase the service cycle of a single furnace hole and prolong the service life of the single furnace hole. Furthermore, the anhydrous stemming for the submerged-arc furnace can guarantee the long-term smooth operation of the furnace condition, enables the furnace to normally discharge slag and carbon, and can indirectly increase the production indexes.

Owner:方文成

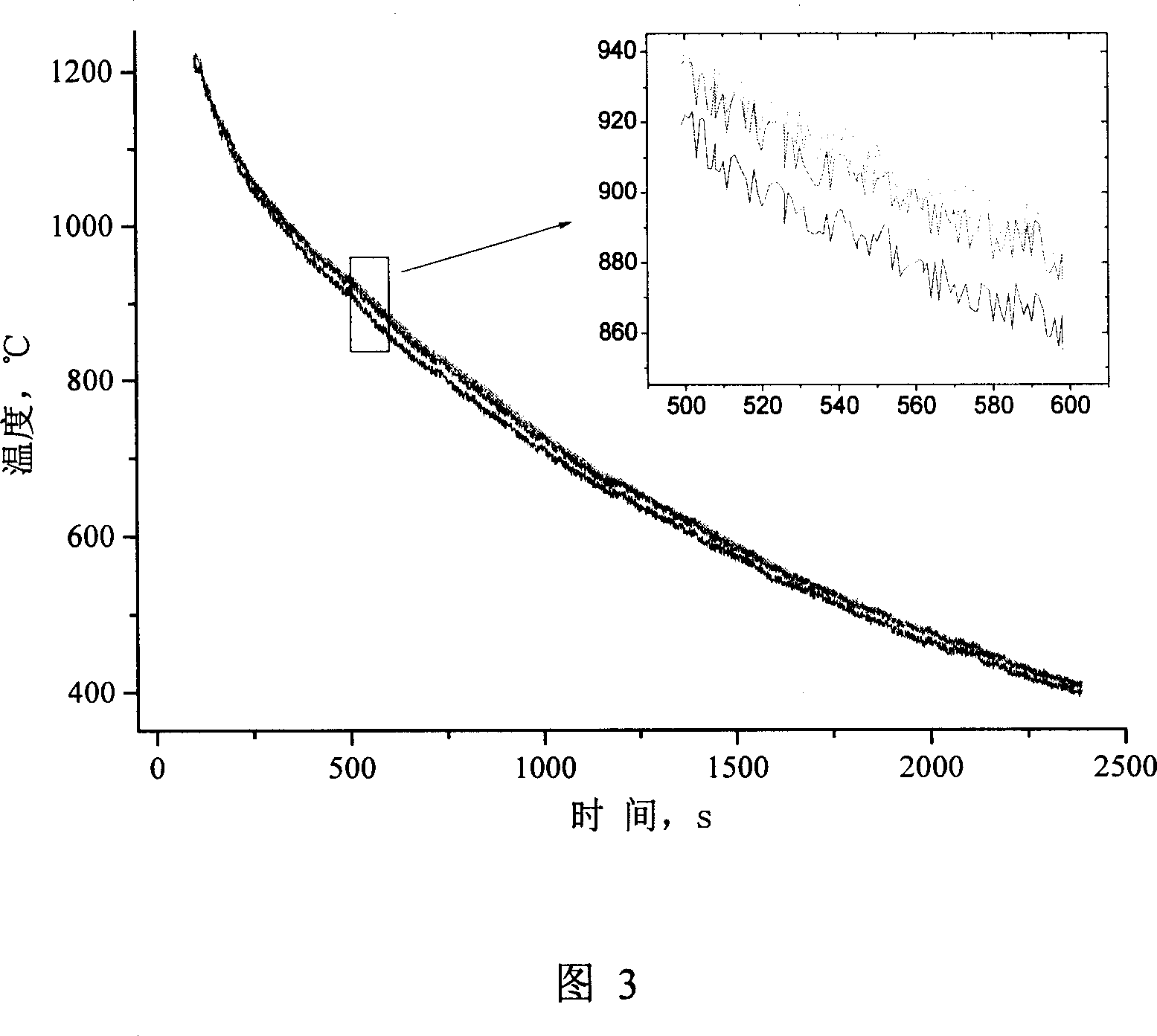

Process of detecting heat conductivity coefficient of protecting slag

InactiveCN101046456AGuaranteed travelMaterial thermal conductivityMaterial heat developmentSlagHeat transmission

The present invention relates to detection of protecting slag for steel casting, and is especially process of detecting heat conductivity coefficient of protecting slag. The present invention detects the heat conductivity coefficient of protecting slag with several thermocouples arranged in certain intervals to measure the temperature in the sample period. The present invention can measure the heat conductivity coefficient of protecting slag and its changing trend and heat transmission controlling capacity.

Owner:BAOSHAN IRON & STEEL CO LTD

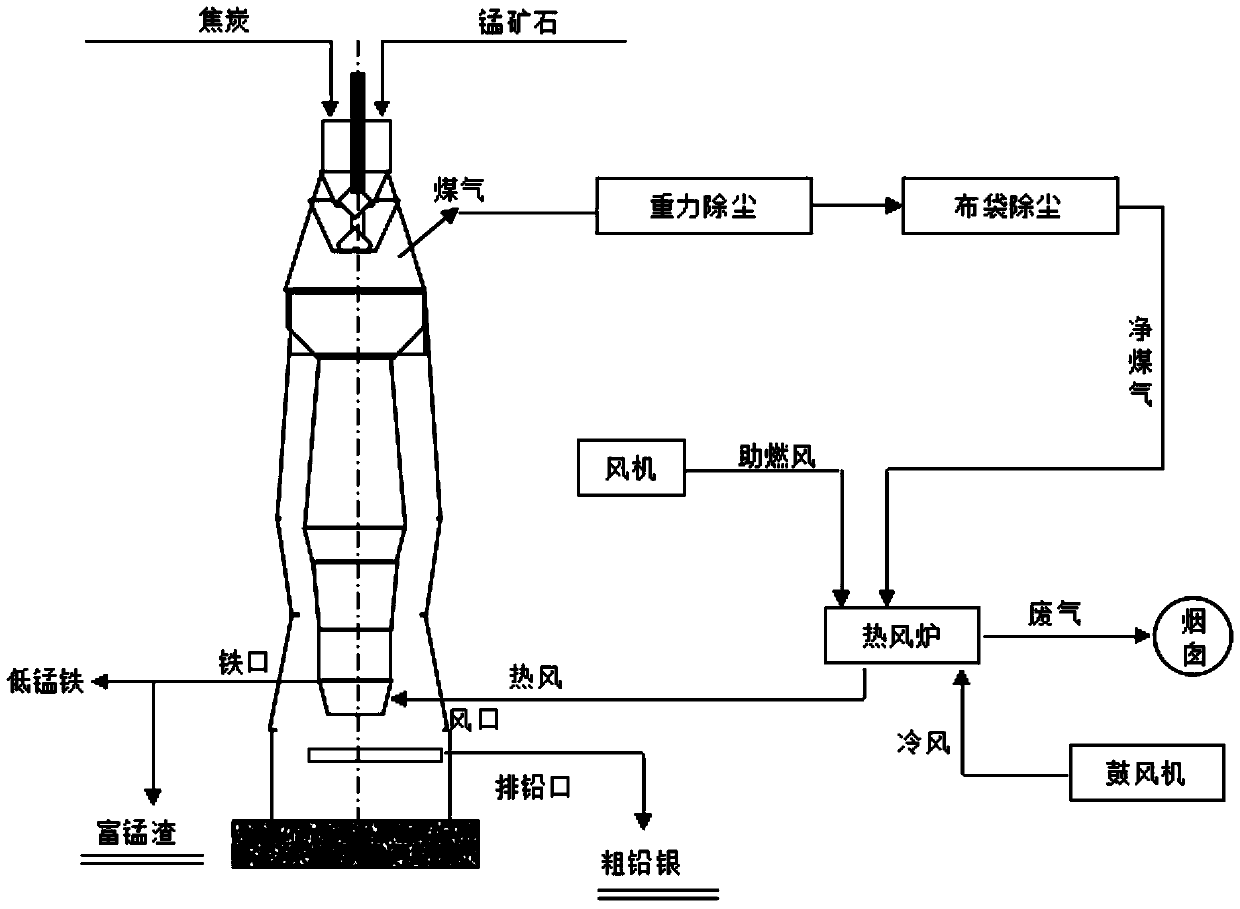

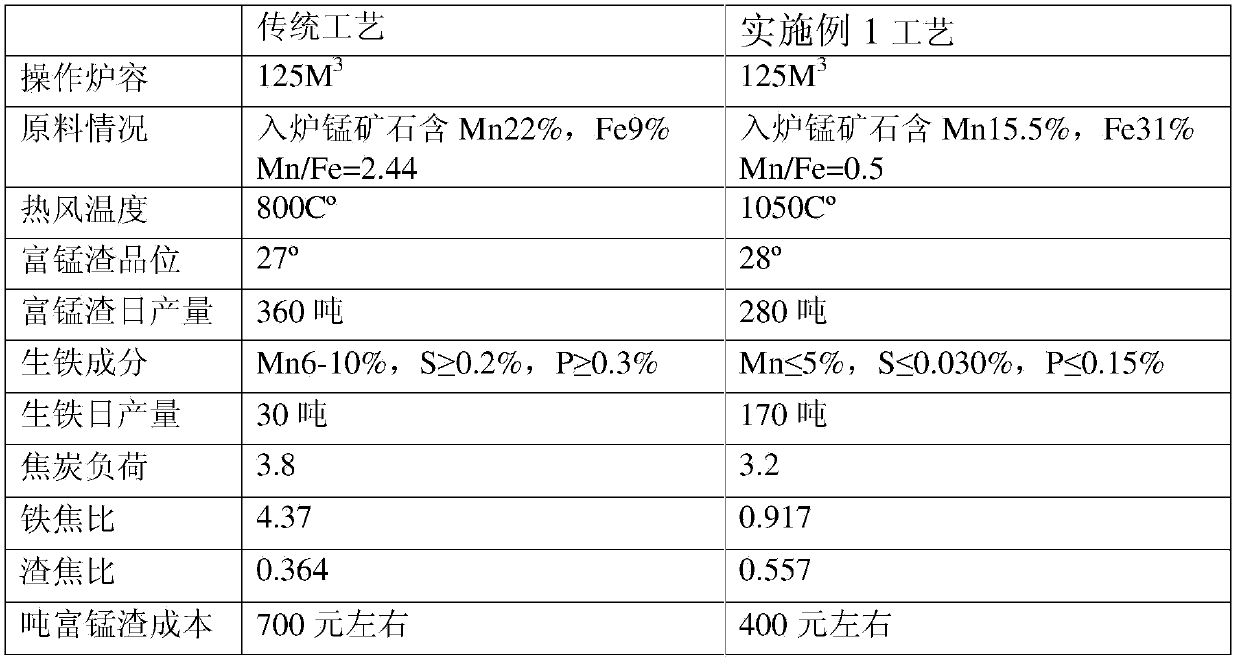

Blast-furnace smelting technique of low-sulfur low-manganese high-iron rich-manganese slag

InactiveCN104046780AReduce manufacturing costLow costBlast furnace detailsProcess efficiency improvementSulfurManganese

The invention relates to a smelting technique of high-iron high-phosphorus refractory deficient-manganese ores, particularly a blast-furnace smelting technique of low-sulfur low-manganese high-iron rich-manganese slag. The technique is characterized by comprising the following steps: (1) mixing low-sulfur low-manganese high-iron rich-manganese slag, coke and dolomite in a weight ratio of 78:21:1, and adding the mixture into the blast furnace via the furnace roof; (2) sending hot coal gas and hot air from a hot-blast furnace into the blast furnace via the furnace bottom to combust coke, thereby generating coal gas and releasing heat; and (3) while controlling the furnace temperature at 1250-1350 DEG C, carrying out selective reduction reaction in the blast furnace, and collecting the slag on the upper part of the furnace hearth, thereby obtaining the rich-manganese slag. The technique uses national abundant idle deficient-manganese ores and a certain proportion of imported high-manganese high-iron ores as raw materials, and regulates the operating parameters, operating system and operating means on the basis of the traditional rich-manganese slag smelting technique and pig iron smelting technique to form a novel smelting production technique of rich-manganese slag.

Owner:宁夏晟晏实业集团能源循环经济有限公司

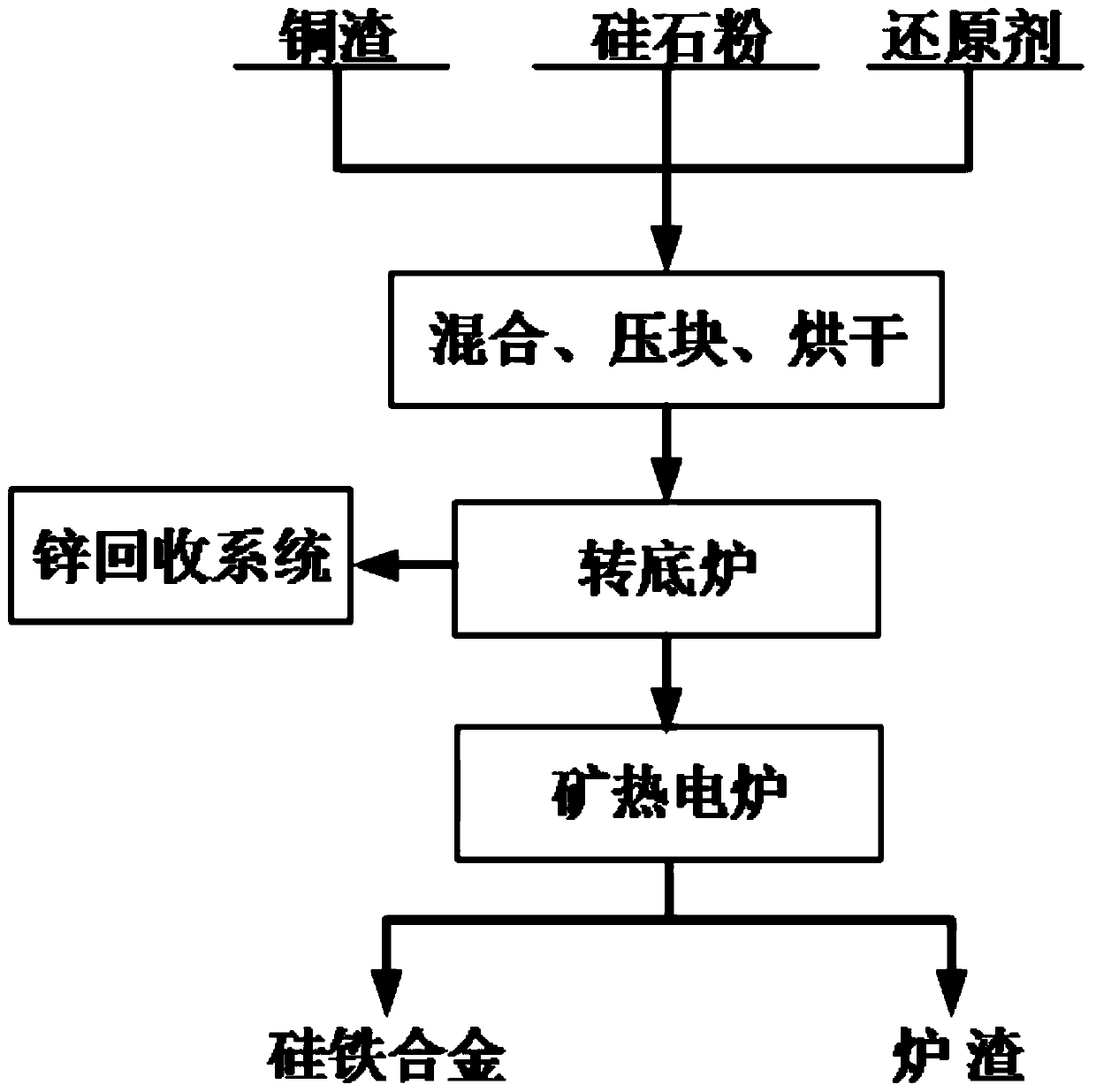

Copper slag treatment method by utilizing rotary hearth furnace direct reduction and ore-smelting electric furnace smelting reduction

ActiveCN110669945ARealize resource utilizationReduce energy consumptionProcess efficiency improvementFerrosiliconIron alloys

The invention discloses a copper slag treatment method by utilizing rotary hearth furnace direct reduction and ore-smelting electric furnace smelting reduction. The method comprises the following steps that 1) raw materials are treated, specifically, copper slag, silica powder, a reducing agent and a binder are prepared and mixed, then are prepared into copper slag carbon-containing pellets through a pelletizing process, and the copper slag carbon-containing pellets are dried for later use; 2) rotary hearth furnace reduction and pellet coking enhancing are conducted, specifically, the copper slag carbon-containing pellets are fed into the rotary hearth furnace for reduction to obtain zinc oxide powder and metalized pellets; and 3) ferrosilicon smelting is conducted, specifically, the high-temperature metalized pellets discharged from the rotary hearth furnace are directly fed into the ore-smelting electric furnace for smelting to obtain a ferrosilicon iron alloy and the slag. Accordingto the method, an innovative process of the rotary hearth furnace reduction and ore-smelting electric furnace smelting combination is adopted, a zinc element is recycled in the rotary hearth furnaceto obtain high-value-added zinc oxide powder, the high-temperature metalized pellets discharged from the rotary hearth furnace are directly hot-loaded into the ore-smelting electric furnace for smelting, the process that traditional cold burden inlet into the furnace needs to consume electric energy for heating is omitted, and the power consumption and the raw material cost are greatly saved.

Owner:宝武集团环境资源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com