Blast-furnace smelting technique of low-sulfur low-manganese high-iron rich-manganese slag

A technology of blast furnace smelting and manganese-rich slag, which is applied in the direction of blast furnace, blast furnace details, process efficiency improvement, etc., can solve the problems of inability to select and utilize, complex mineral composition, and no use value, so as to improve the separation effect of slag and iron, broaden the The scope of use and the effect of improving the separation ability of slag and iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

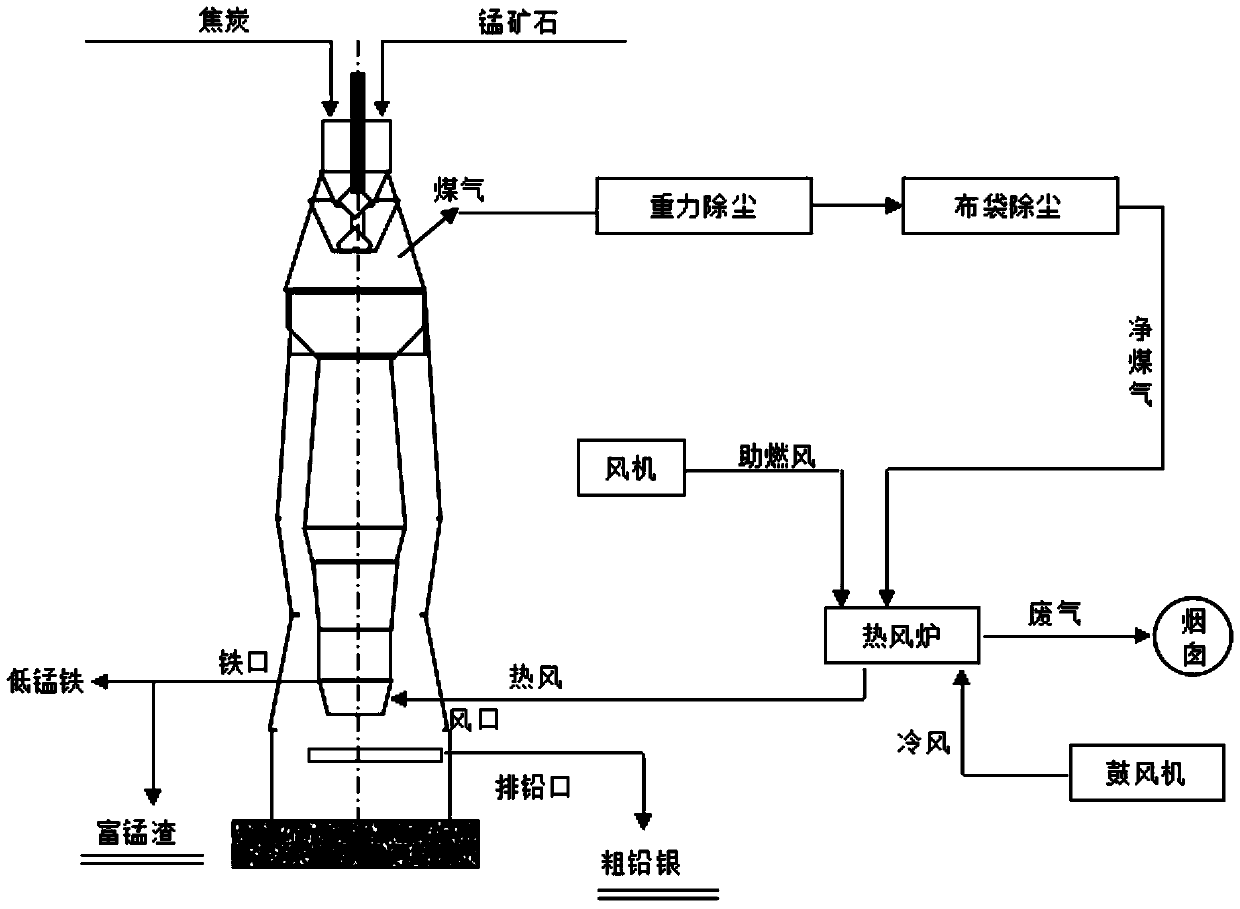

[0024] (1) Mix low-sulfur, low-manganese, high-iron, manganese-rich slag, coke and dolomite in a weight ratio of 78:21:1 and then add them to the blast furnace from the top of the furnace;

[0025] (2) Send the hot gas and hot air sent from the hot blast stove into the blast furnace from the bottom of the furnace to burn the coke to generate gas and release heat;

[0026] (3) Control the furnace temperature at 1250-1350°C, carry out selective reduction reaction in the blast furnace, and then collect the slag on the upper part of the hearth as manganese-rich slag.

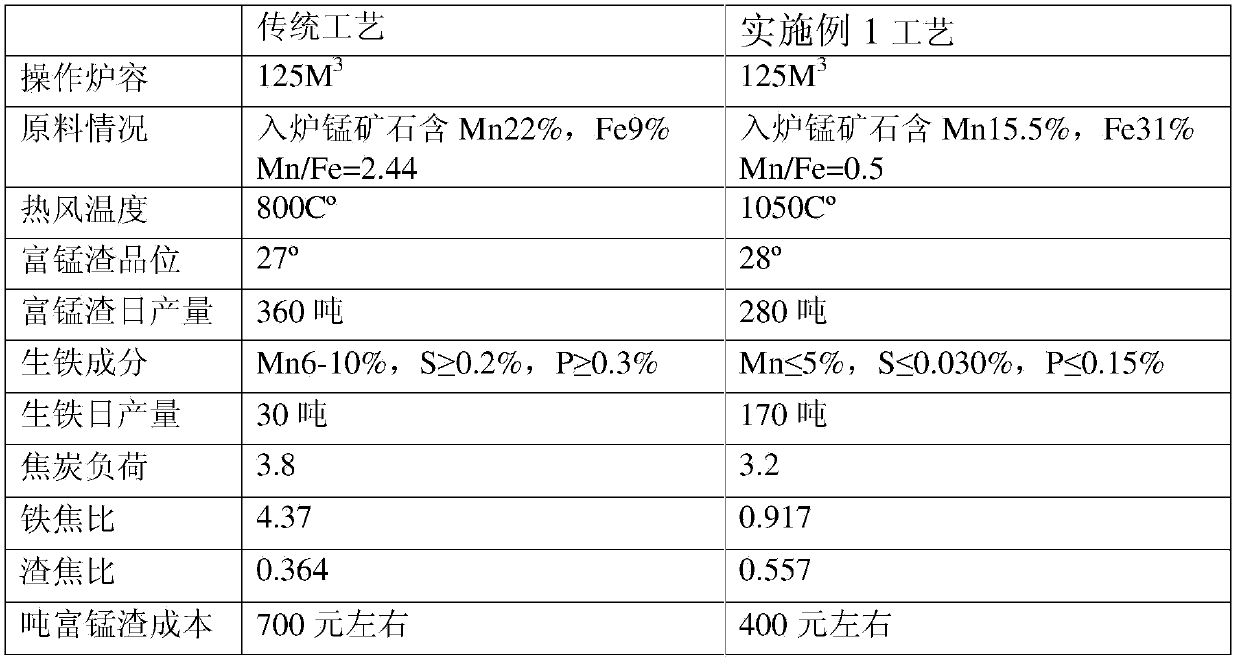

[0027] Traditional technology compares with present embodiment 1 operation:

[0028]

[0029] The process of smelting manganese-rich slag in blast furnace is the enrichment process of manganese in slag. Its basic principle is selective reduction, that is, selective reduction is carried out according to the different reduction properties of manganese, iron, phosphorus, etc., that is, while ensuring the full reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com