Method for plugging started head

A technology of dummy head and steel rail, which is applied in the field of continuous casting production, can solve problems such as failure, unskilled operators, small faults of equipment, etc., and achieve the effect of reducing requirements, high reliability and improving operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

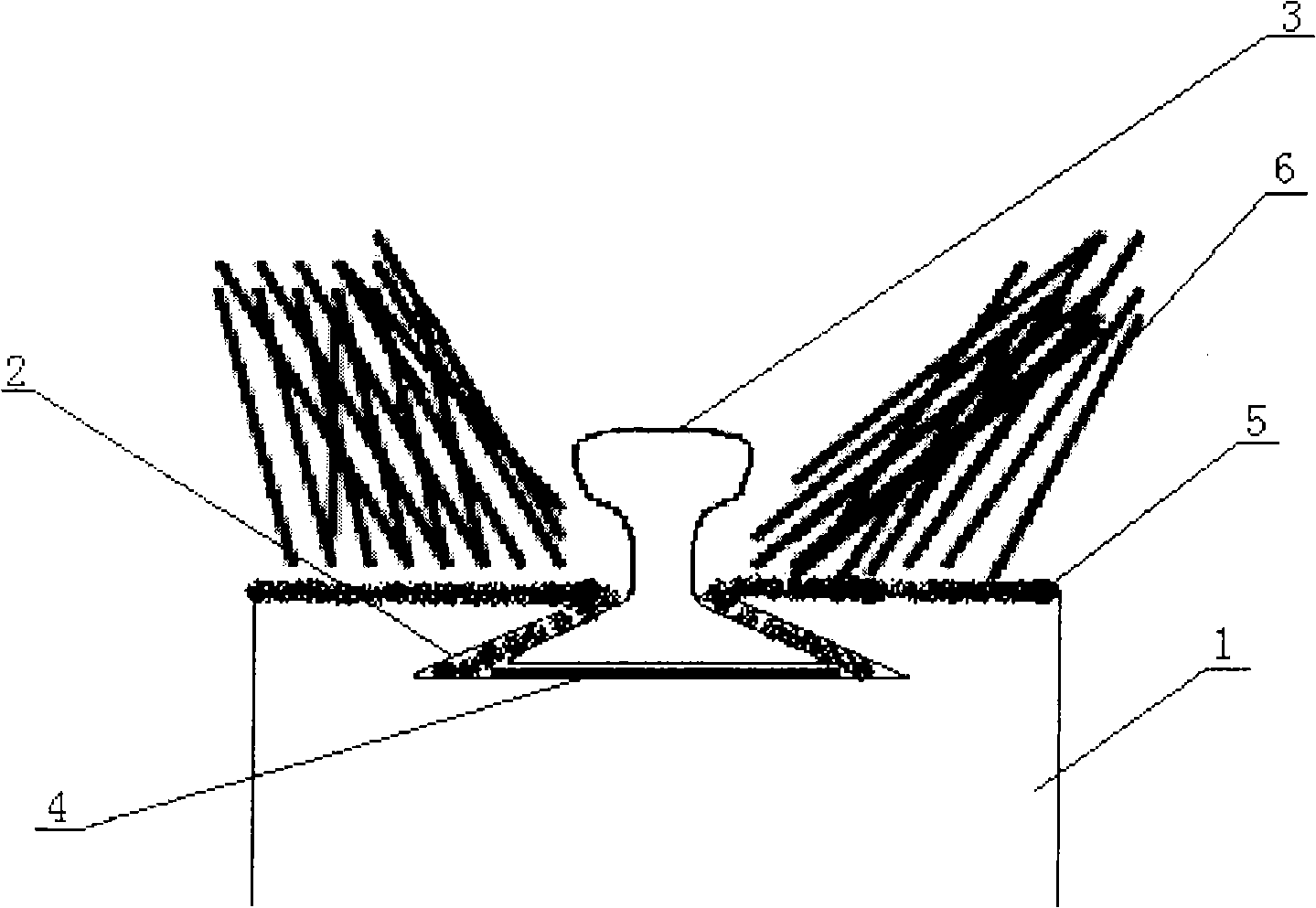

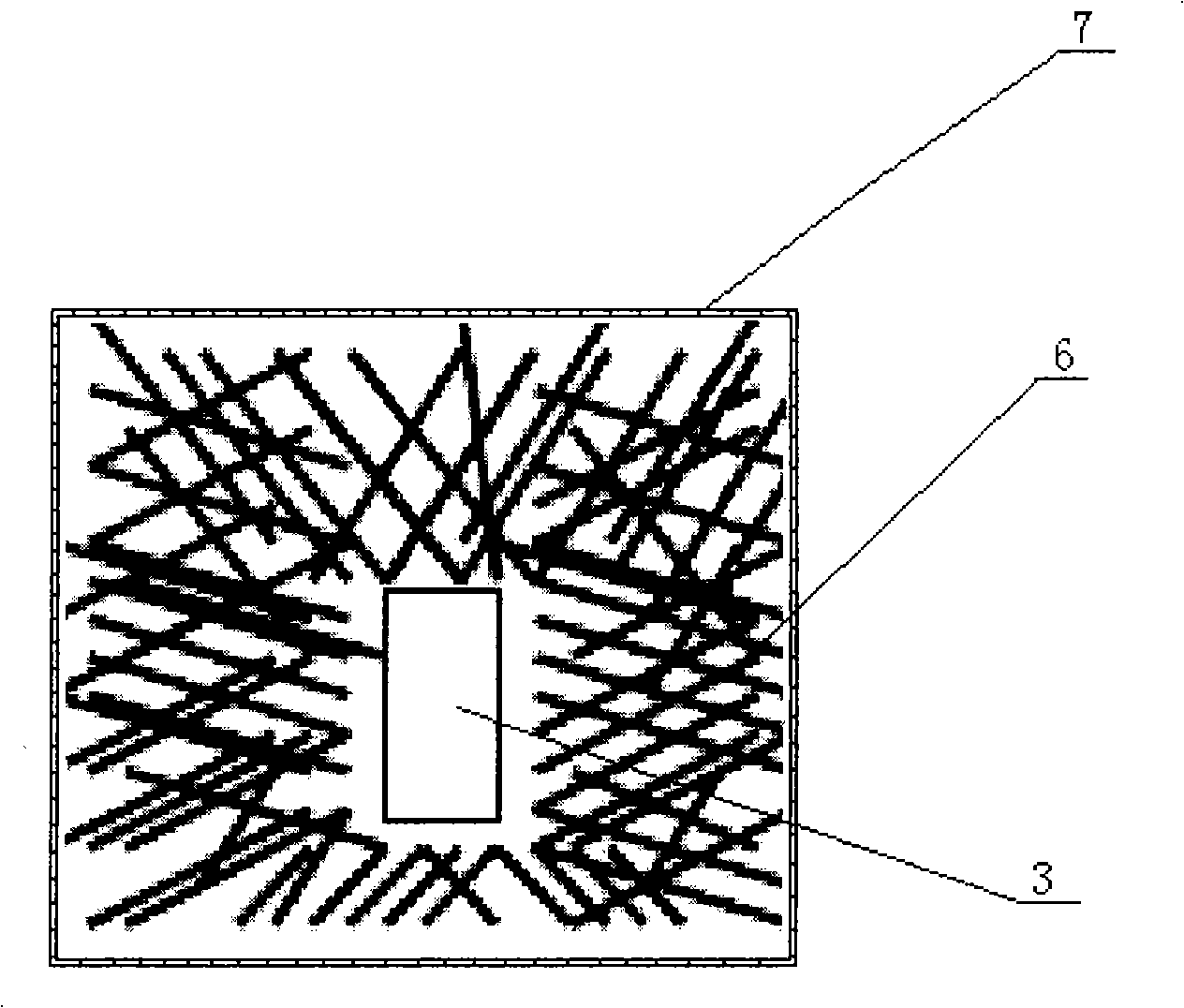

[0016] Below in conjunction with accompanying drawing, the present invention will be further described:

[0017] Such as figure 1 , 2 Shown, a kind of method for plugging dummy head, this method comprises the following steps successively:

[0018] 1) Use a paper rope to block the gap between the dummy head and the crystallizer;

[0019] 2) Lay a layer of heat insulation cloth on the bottom of the dovetail groove of the dummy head;

[0020] 3) Insert a section of rail head at the center of the dovetail groove body;

[0021] 4) Evenly spread a layer of iron filings on the surface of the dummy head including the inside of the dovetail groove;

[0022] 5) Thin flat steel about 200mm long is evenly arranged radially around the rail head.

[0023] The thermal insulation cloth described in step 2) of the above-mentioned method is to facilitate the separation of the dummy head when taking off the dummy ingot.

[0024] The rail head described in the above method step 3) can be cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com