Treatment technology for zinc-containing dust of rotary hearth furnace

A treatment process and rotary hearth furnace technology, which is applied in the field of metallurgy, can solve problems such as high investment cost, zinc ring formation, and low single-time processing capacity, and achieve the effect of reducing investment cost and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below.

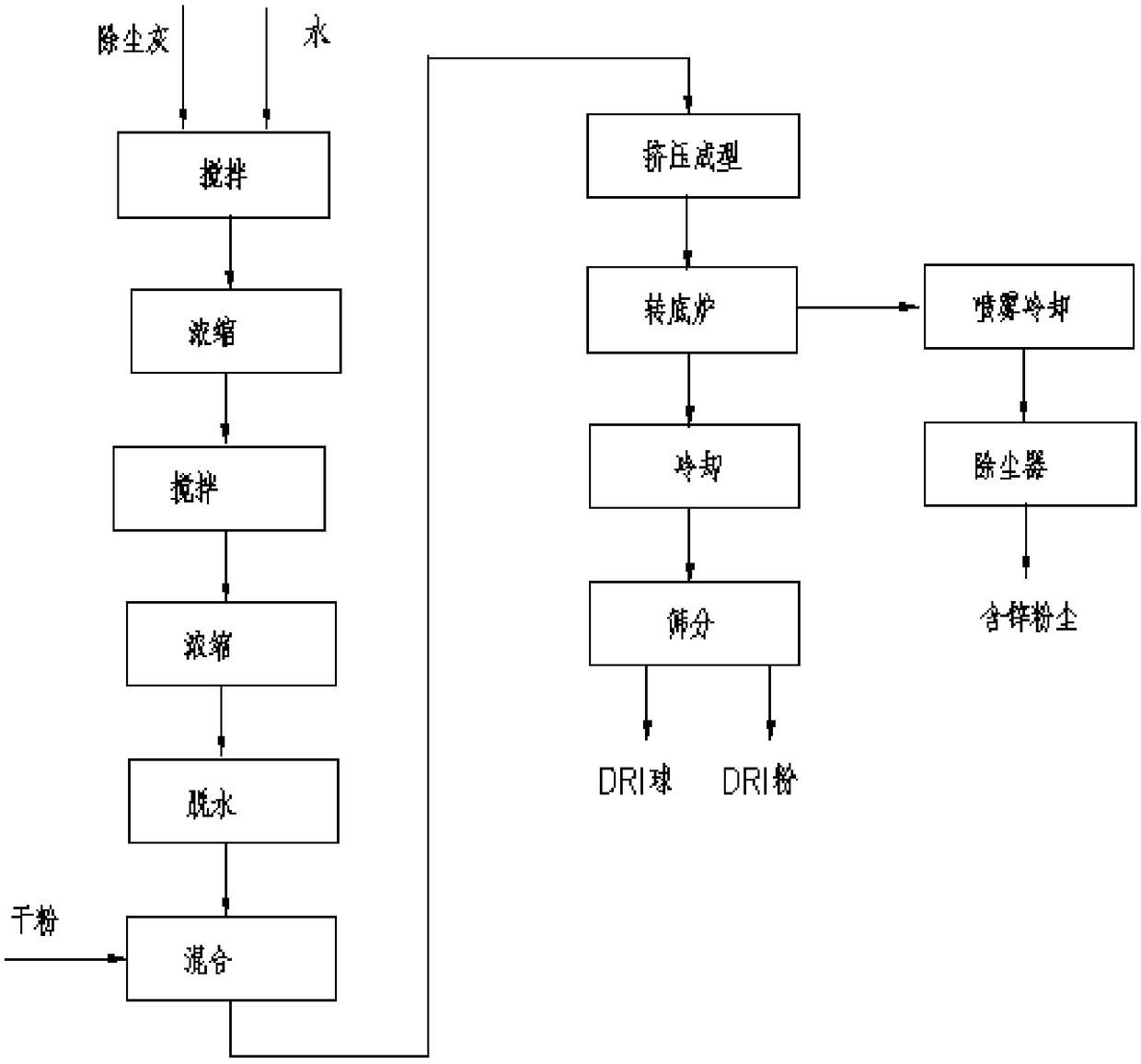

[0023] Such as figure 1 The treatment process for the zinc-containing dust of the rotary hearth furnace shown includes the following steps:

[0024] A. The zinc-containing dust (blast furnace bag dust + converter dust removal dust 50,000 t / a) produced by the steel mill is transported to the batching warehouse by tanker, and is quantitatively fed into the mixing tank through spiral weighing. After adding water, the concentration of zinc-containing dust is 25%, after three times of stirring and concentration, the concentration of zinc-containing dust after stirring and concentration is 50%, and it enters the filter for dehydration to fully remove K, Na, Cl and other elements in the zinc-containing dust. The dehydrated zinc-containing dust sludge is uniformly mixed with dry ash and then pressurized by a coal rod machine. The water content of the extruded mixture is 20%. The mass of the deh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com