Patents

Literature

74results about How to "Flexible processing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Video encoding/decoding method and apparatus

ActiveCN101389021AReduce complexityImprove transmission performanceTelevision systemsDigital video signal modificationVideo transmissionVideo encoding

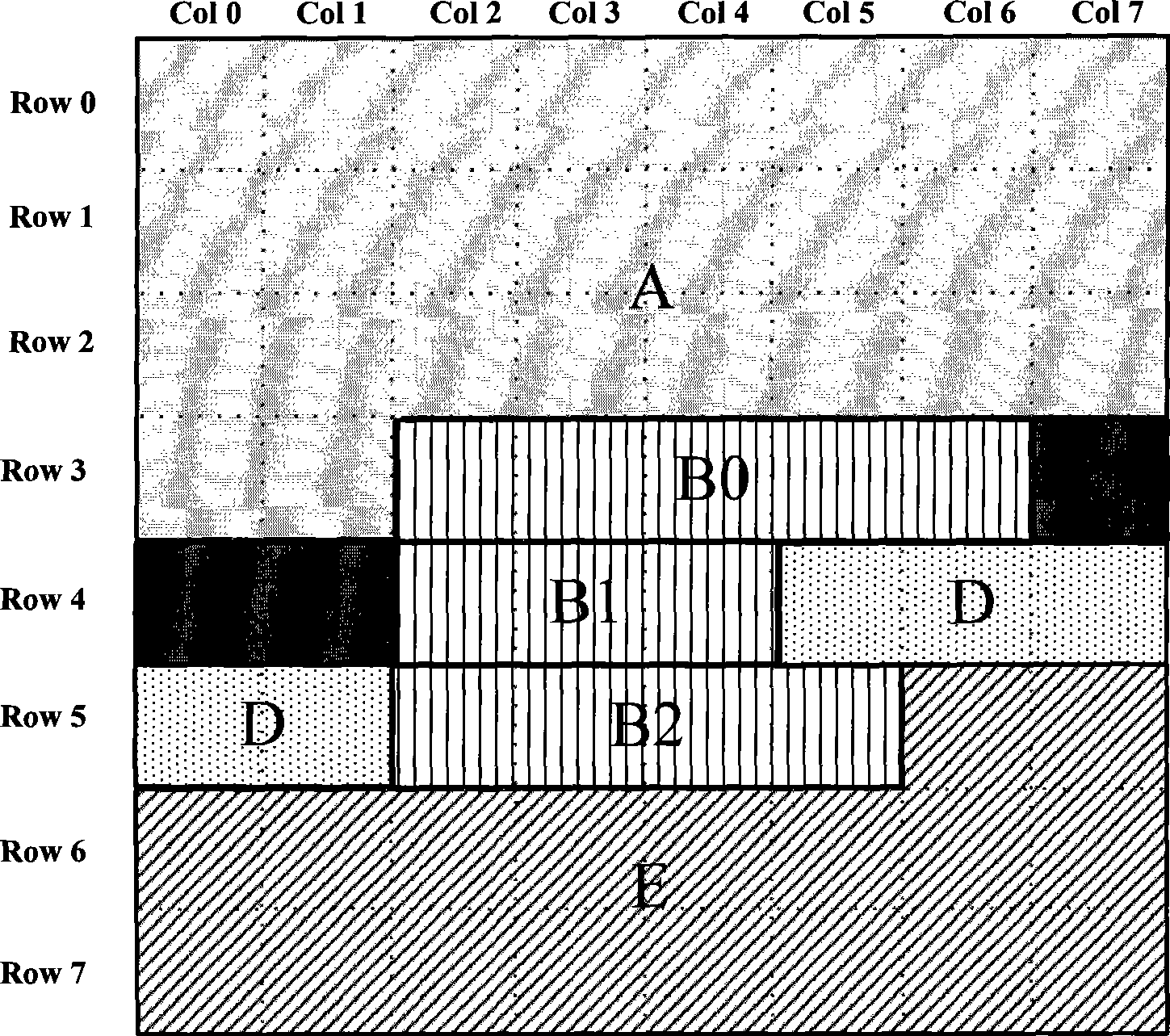

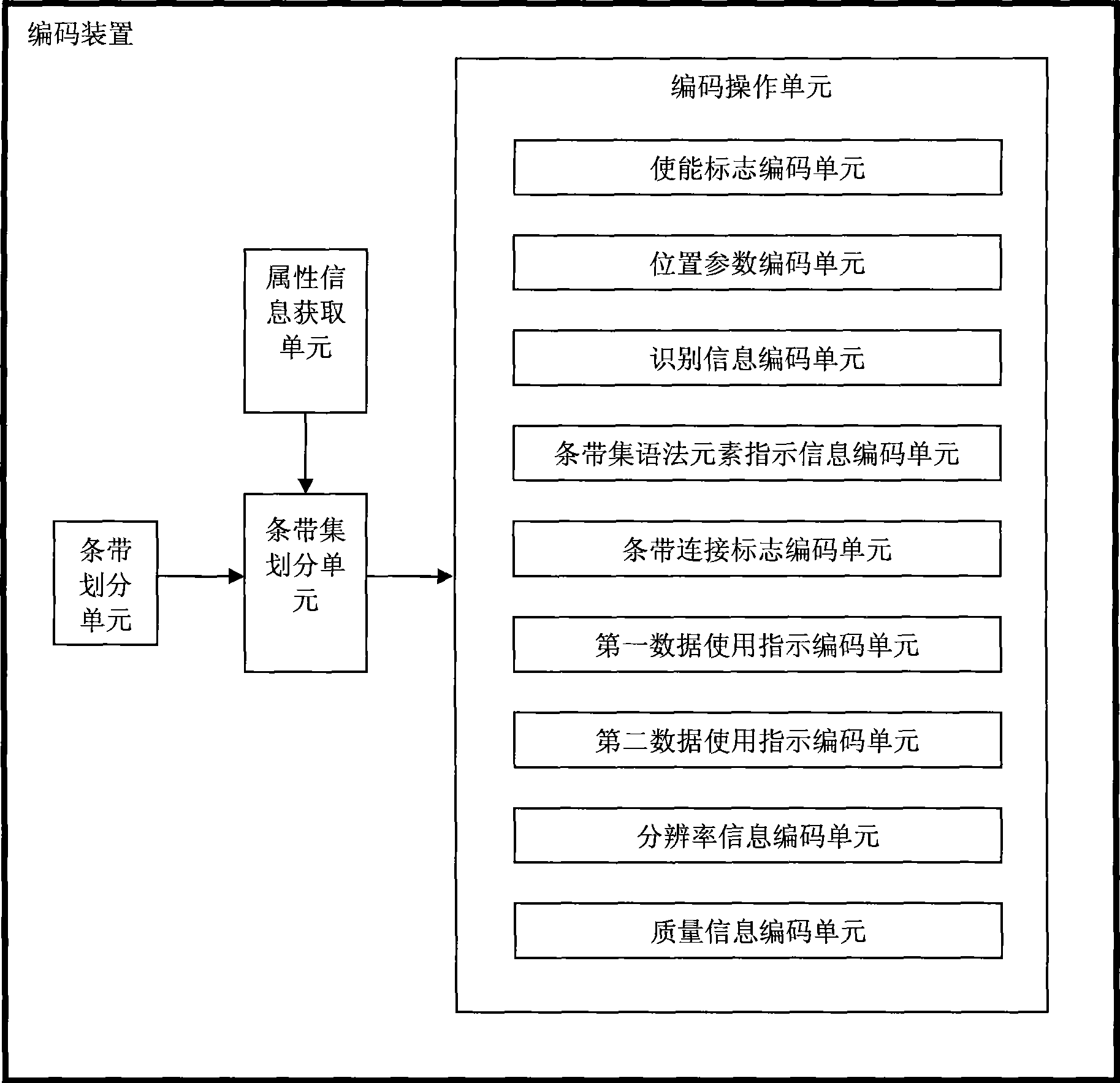

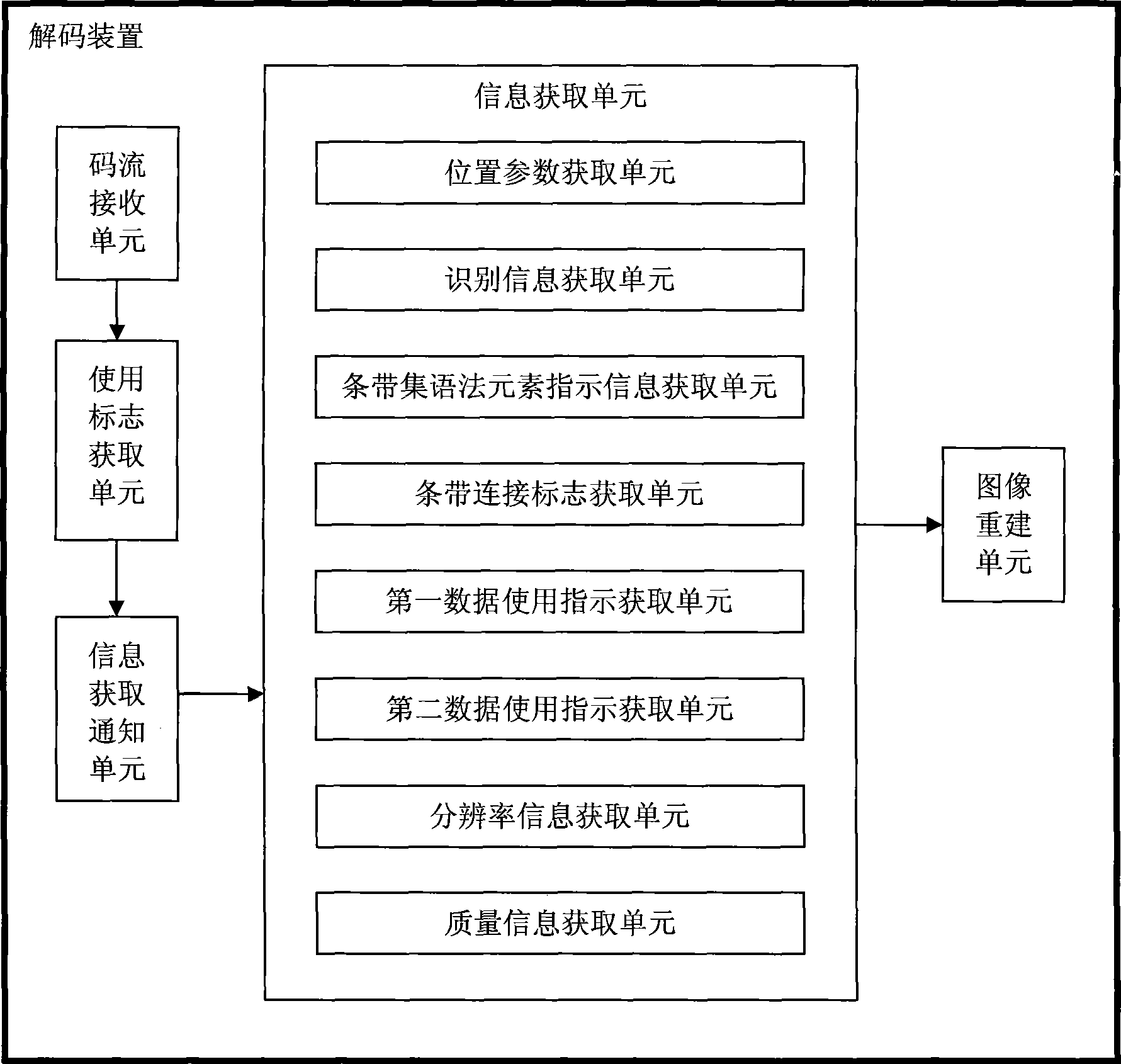

A video coding and decoding method and device, comprising: at the coding end, dividing the to-be-coded picture into several strips; each strip comprising macroblocks sequential according to the appointed scanning sequence in the picture; dividing the strips comprised in the picture into one or more of strip sets according to the attribute information of each strip; each strip set comprising one or more strips; finally, coding the strips in the strip sets according to the dividing information of the strip and the strip sets to obtain the coding bit rate corresponding to the picture; at the decoding end, receiving the coding bit rate, obtaining the dividing information of the strip and the strip set in the bit rate, and decoding the bit rate according to the obtained diving information of the strip and the strip set. The embodiment of the invention is able to effectively improve the video transmission function and is suitable for the coding based on the area; and the realizing process of the whole coding and decoding is simple, thereby reducing the complexity of realizing the coding and decoding system.

Owner:HUAWEI TECH CO LTD +1

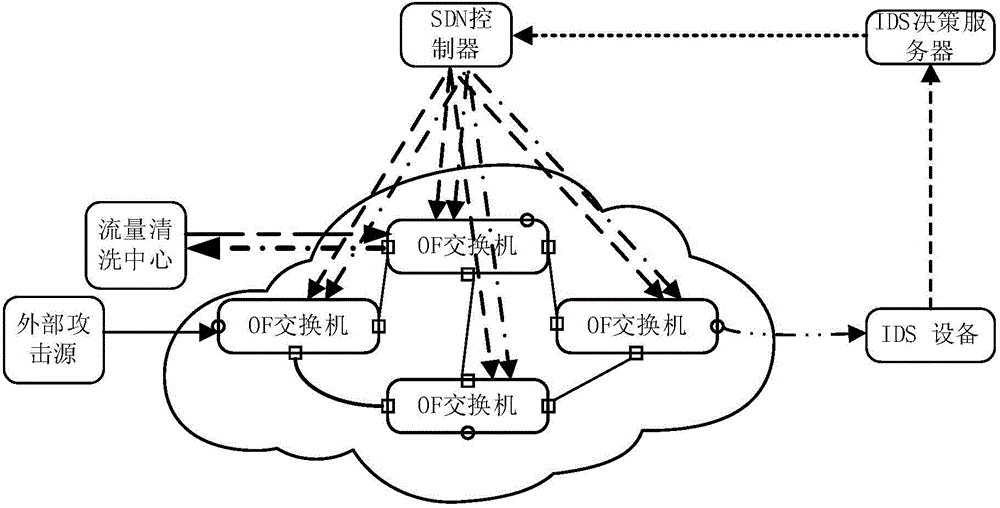

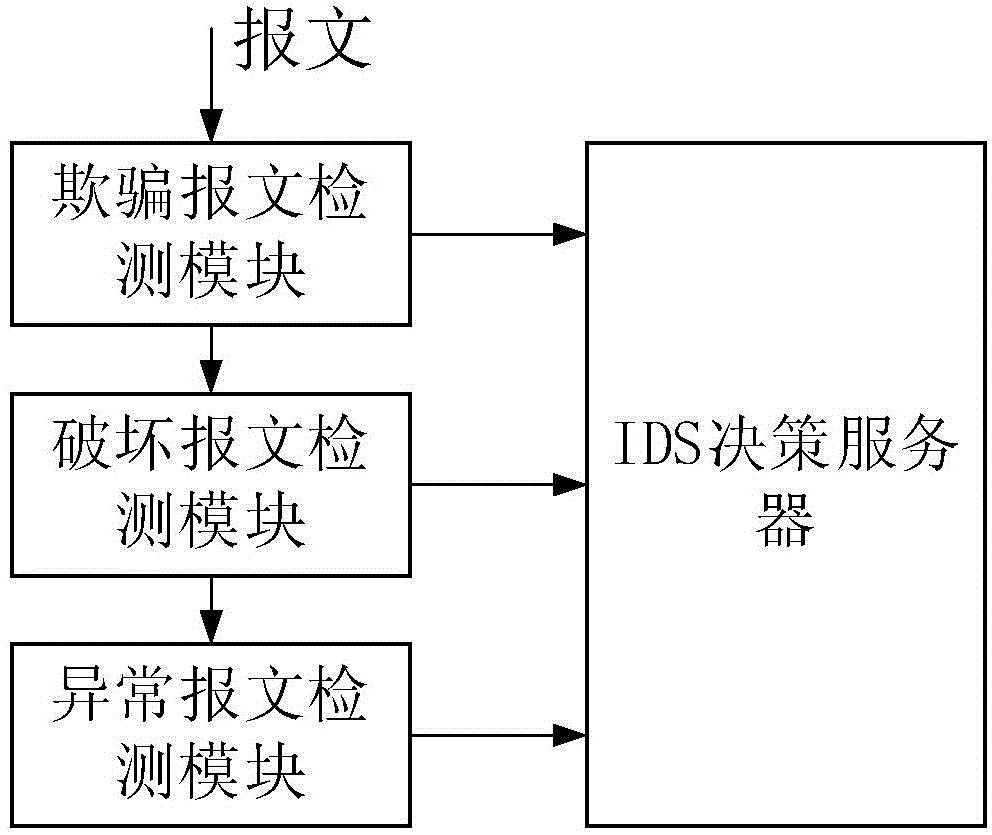

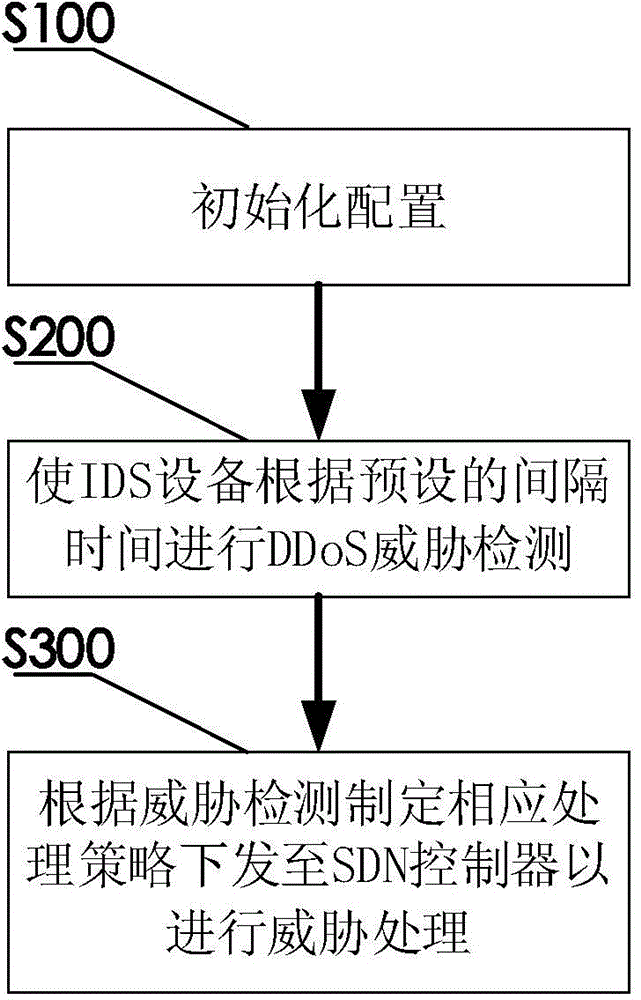

Network security defense system based on software-defined network and working method of network security defense system

The invention discloses a network security defense system based on a software-defined network and a working method of the network security defense system. The network security defense system comprises an SDN controller, an IDS decision making server and an IDS device. The IDS device is suitable for spot-checking messages, and in other words, when the IDS device detects the messages with the DDoS attack characteristics, the messages are reported to the IDS decision making server; the IDS decision making server formulates a processing strategy corresponding to the messages with the DDoS attack characteristics according to reported information, and the processing strategy is issued to the SDN controller for threat processing. The messages are detected in a spot-checking mode, the burden on the SDN controller is greatly reduced, the burden on the server is further reduced in the mode that detection and decision making are separated, and the system is more suitable for network transmission of high-flow data.

Owner:常州麦拉风网络科技有限公司

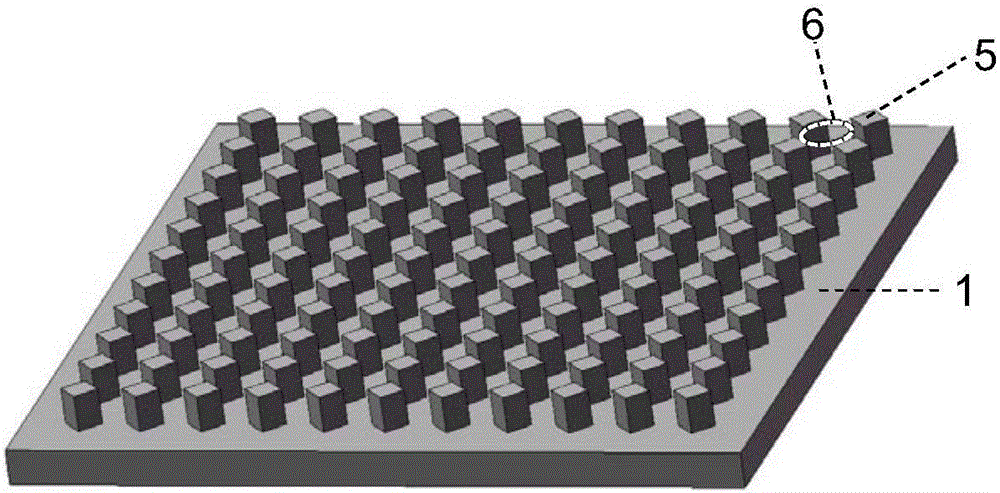

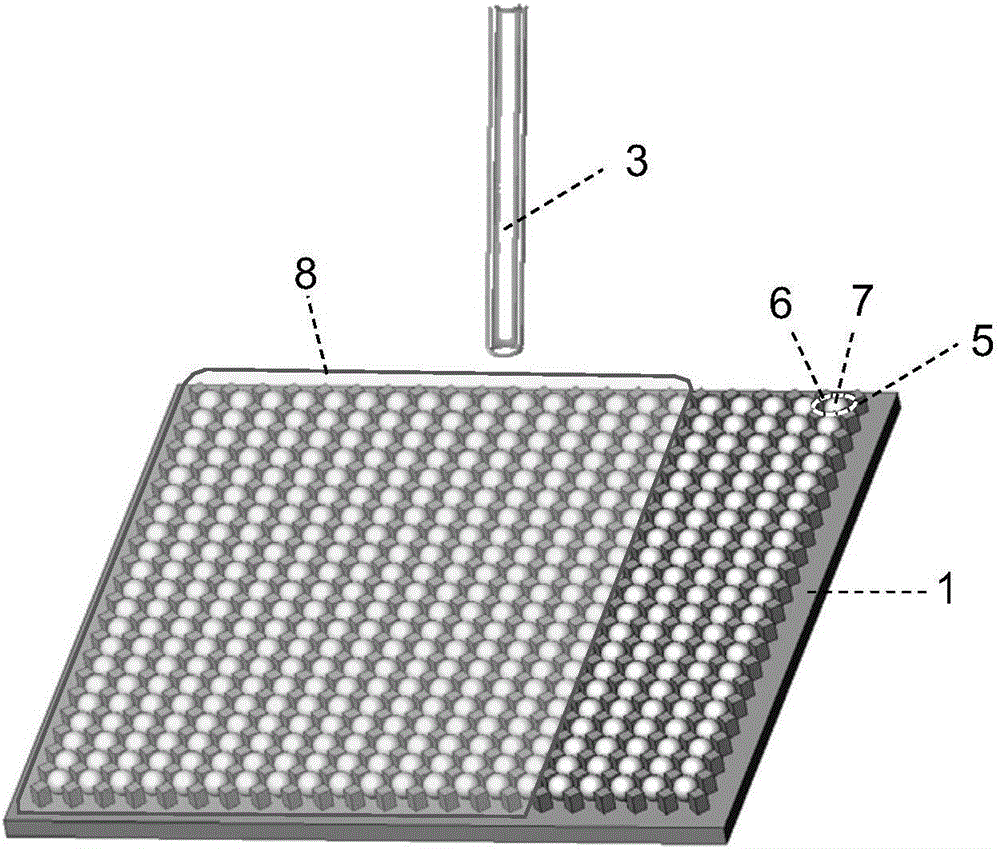

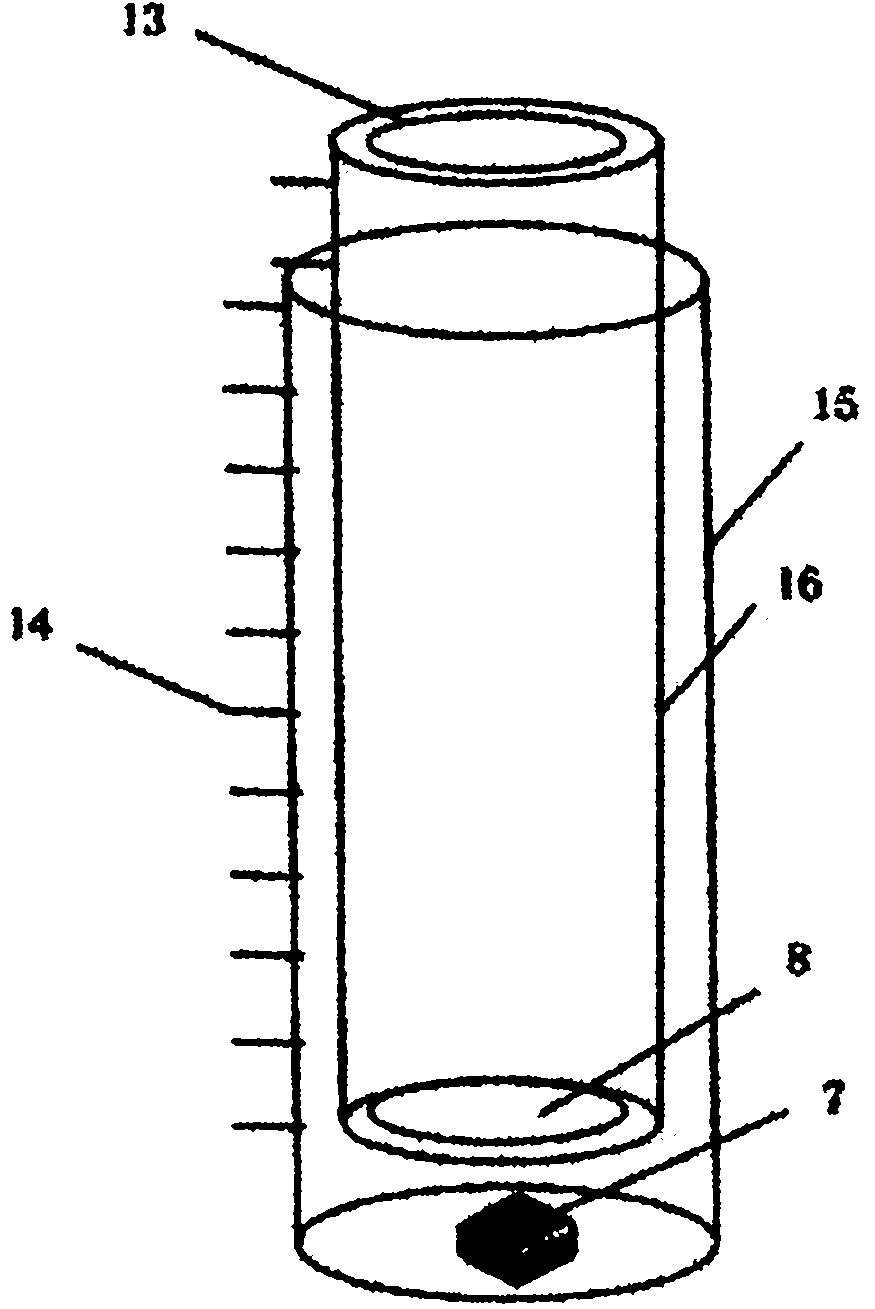

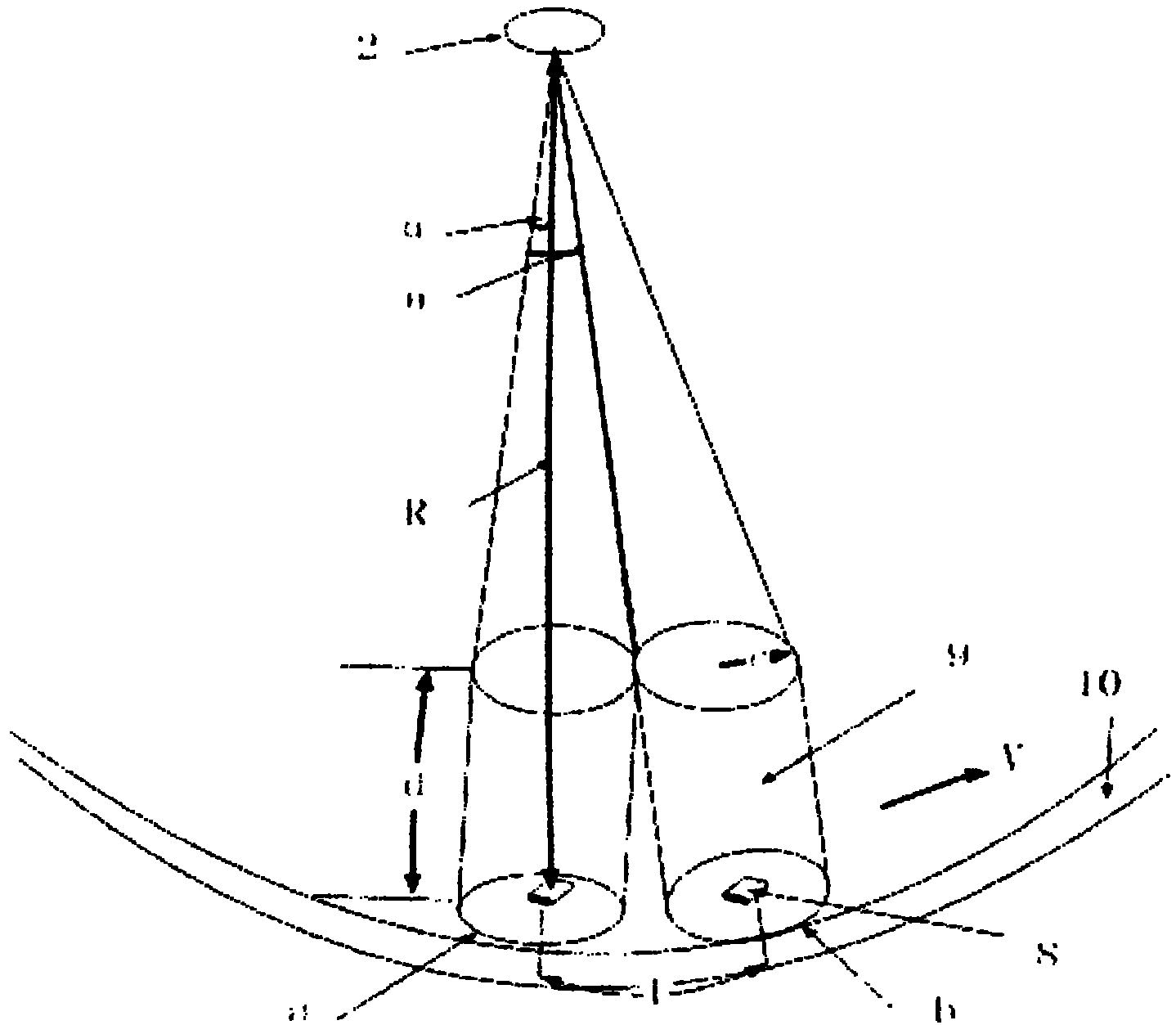

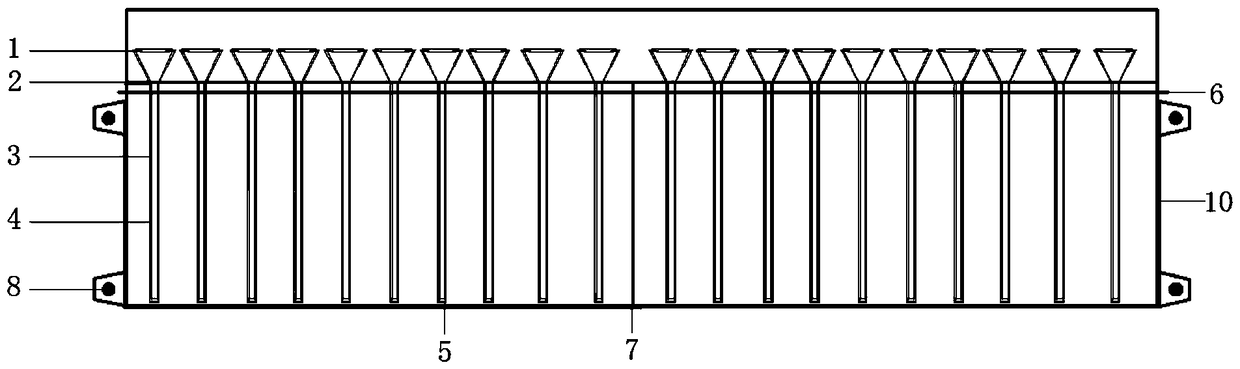

Apparatus for forming and screening two-dimensional liquid droplet array, and use method thereof

The present invention discloses an apparatus for forming and screening a large-scale single-layer two-dimensional liquid droplet array, and a use method thereof. The apparatus comprises a micro-column array chip, a scraping plate for auxiliary spreading of a liquid droplet, a probe for controlling the liquid droplet, a three-dimensional translation table and other components, wherein a micro groove unit for trapping the single liquid droplet is formed by using the gap between micro-columns, and the liquid droplet is spread in the micro groove unit in a single-layer and single manner through gravity effect and capillary effect or through an auxiliary means so as to form the single-layer liquid droplet array. With the apparatus of the present invention, the accurate positioning and detection on the liquid droplet, the sucking on the target liquid droplet and the subsequent treatments can be performed. According to the present invention, the apparatus has characteristics of simple structure and easy operation; and the method has advantages of fast liquid droplet spreading, high flux, high liquid droplet trapping efficiency, liquid droplet position fixing and the like, and is suitable for single cell analysis and screening, single molecule analysis and screening, high-throughput gene screening, protein directed evolution, antibody screening, microbial research, drug screening, and other fields.

Owner:ZHEJIANG UNIV

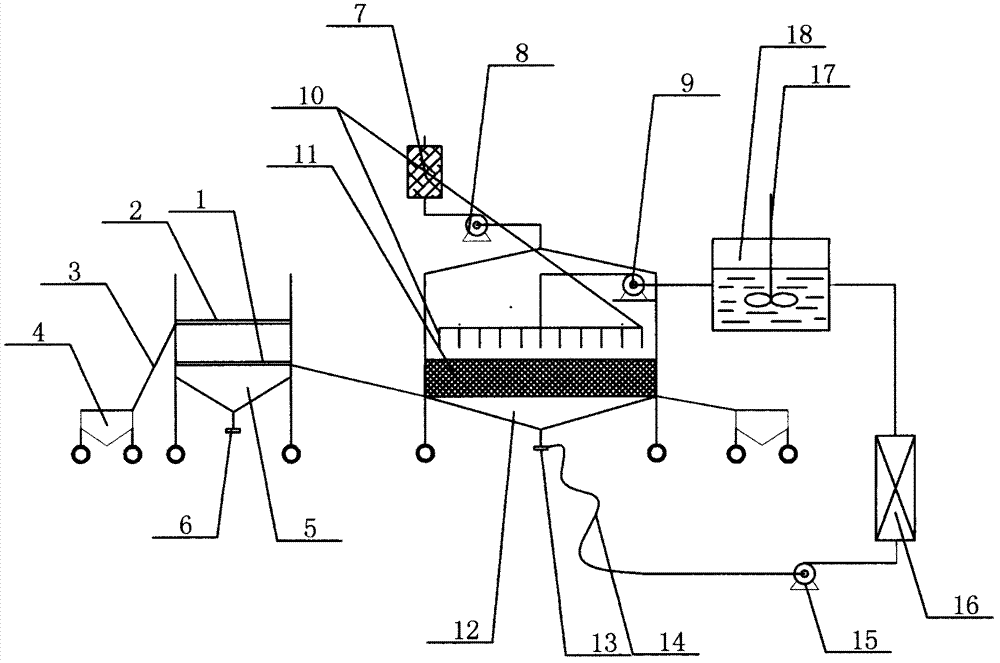

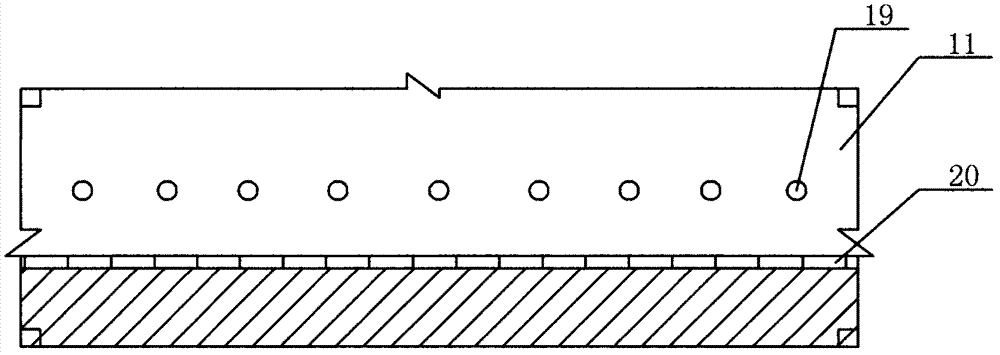

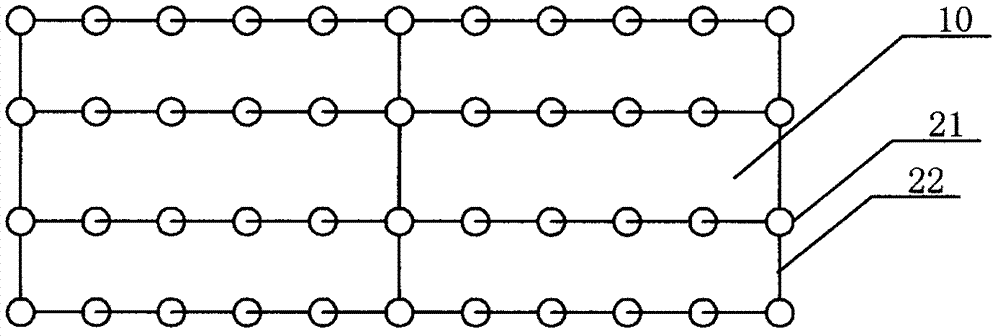

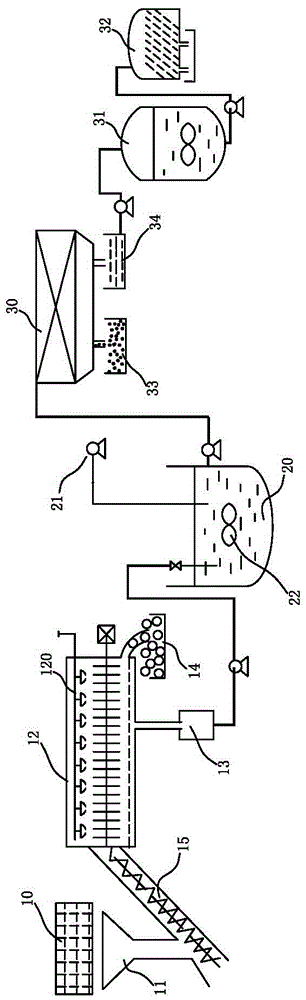

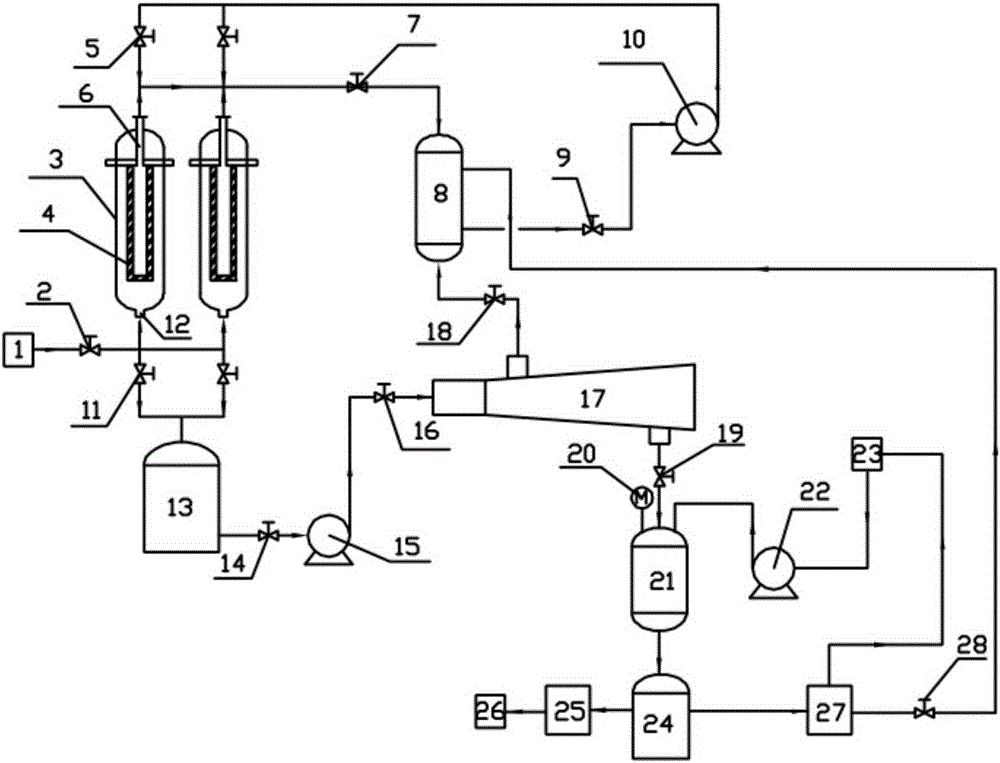

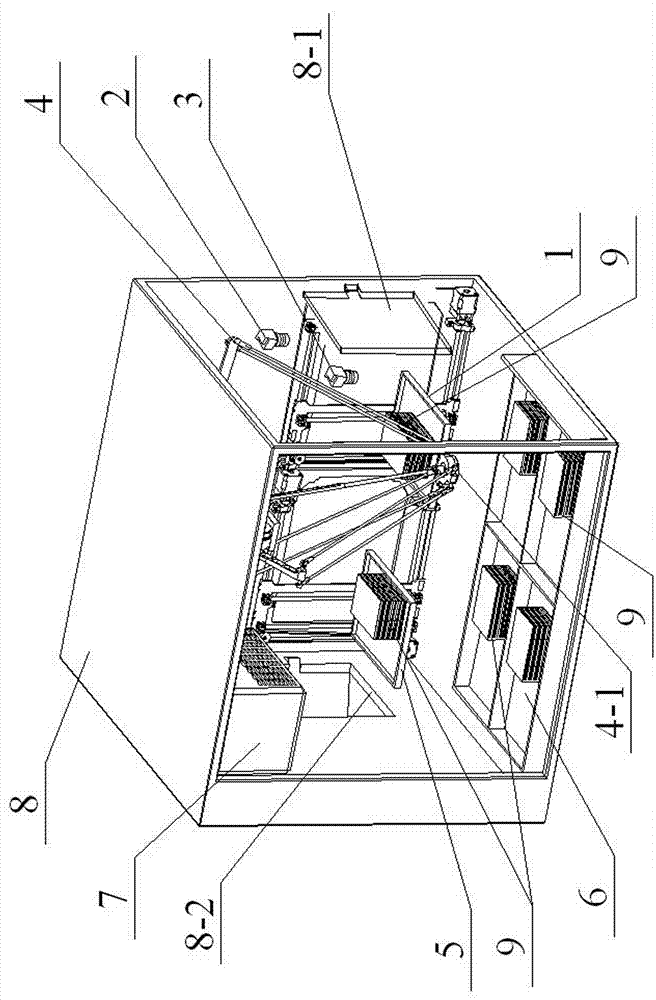

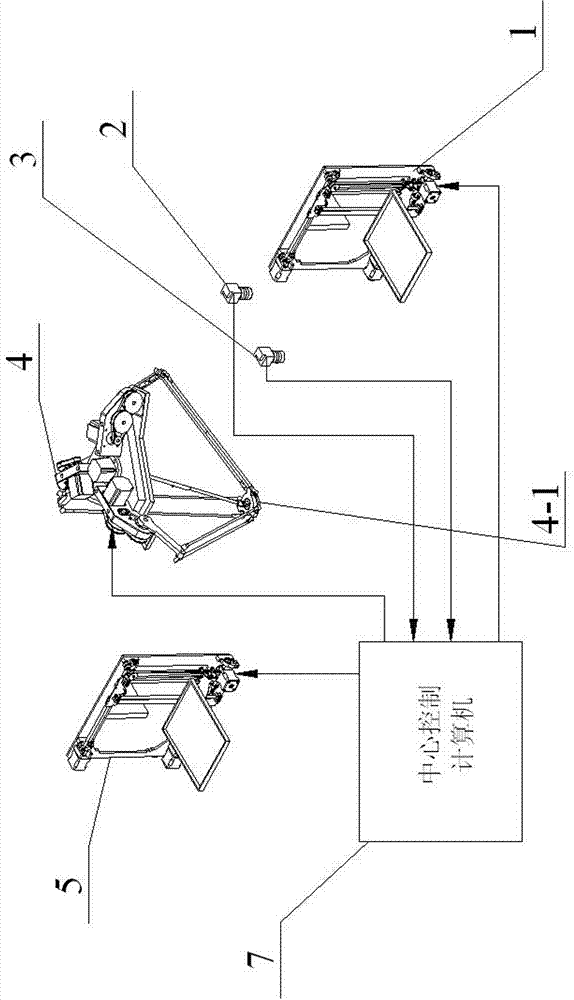

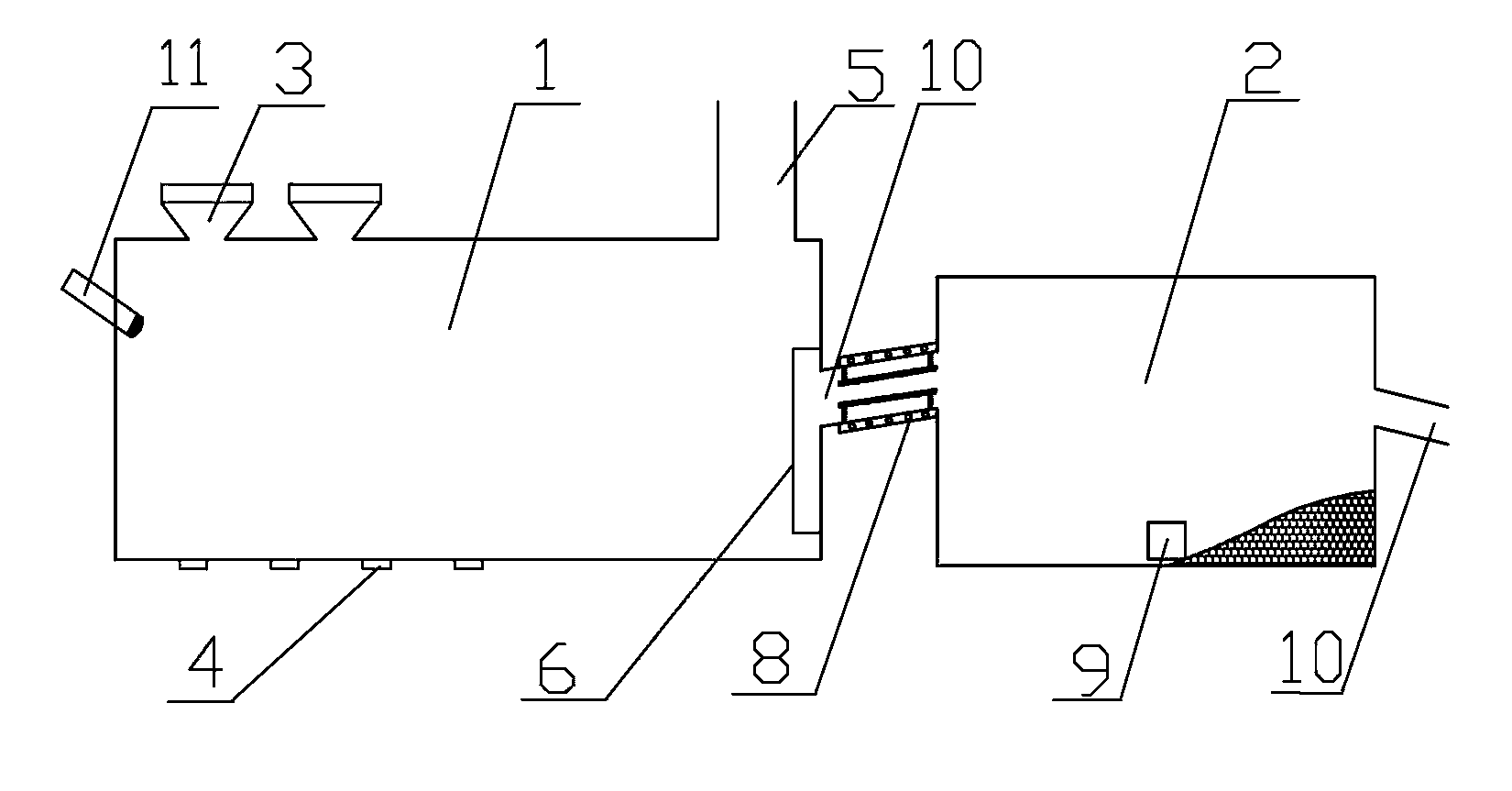

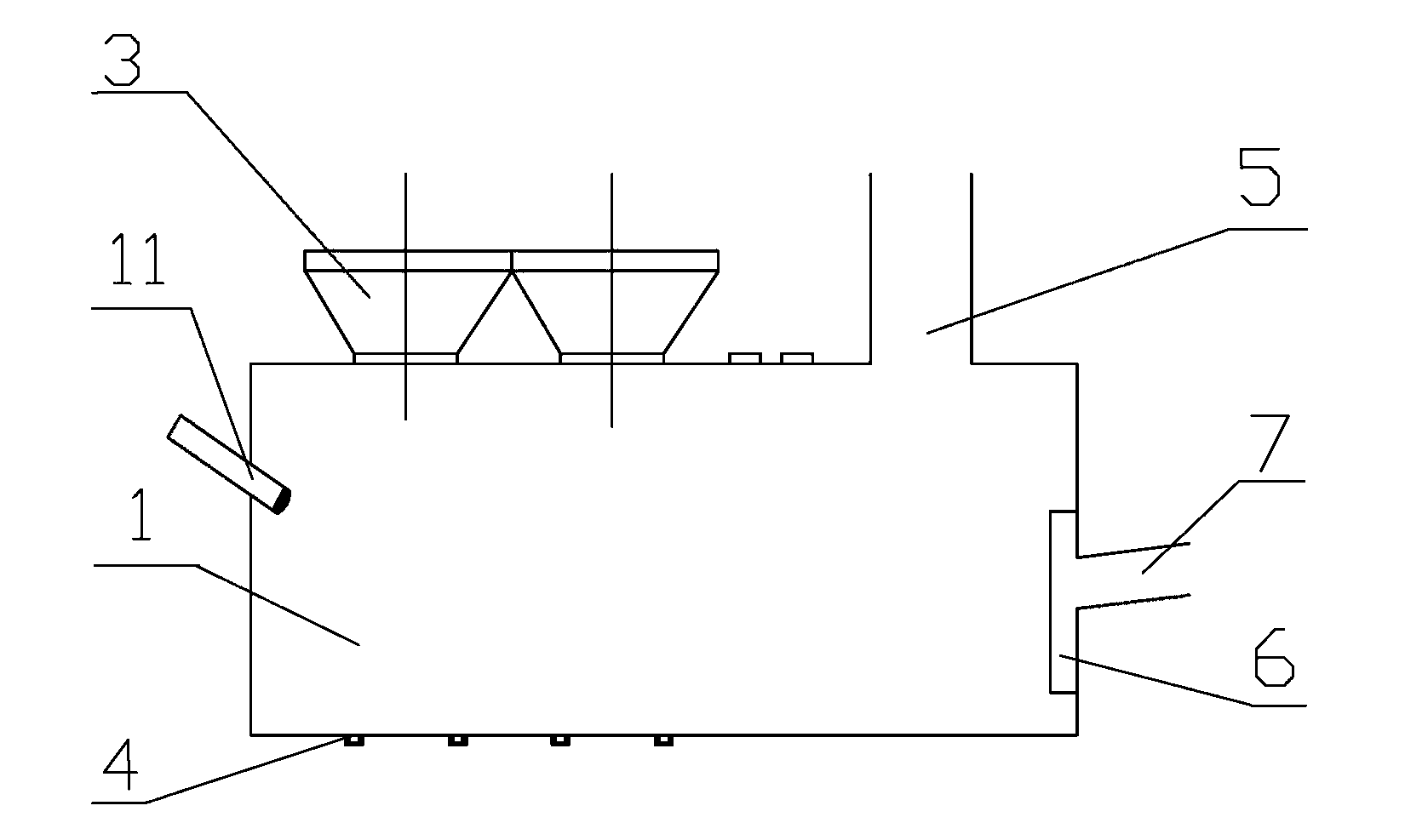

Mobile soil washing apparatus and method thereof

InactiveCN103240266AFlexible assemblyFlexible processing capacityContaminated soil reclamationActivated carbonPollutant

The invention discloses a mobile soil washing apparatus and a method thereof, which relate to the technical field of environment protection. The mobile soil washing apparatus mainly comprises a double-deck vibrating sieve combination device for the purpose of wet type soil sieving, a mobile washing device for washing sieved soil, a mobile wastewater treatment device for treating a washing solution (which can be replaced by a temporary civil sewage treatment facility), and a gas extracting and activated carbon adsorption device for extracting gas generated in a washing process, wherein a small-sized belt conveyor is used for conveying the sieved soil between the vibrating sieve combination device and the washing device. By virtue of the soil washing apparatus, flexible apparatus assembly and washing treatment can be carried out on the soil or bottom mud containing various pollutants in different occasions, and innovative optimization is carried out on a traditional soil washing process from the perspective of resource recovery according to different distributions of the pollutants in soil with different particle size ranges.

Owner:罗春晖

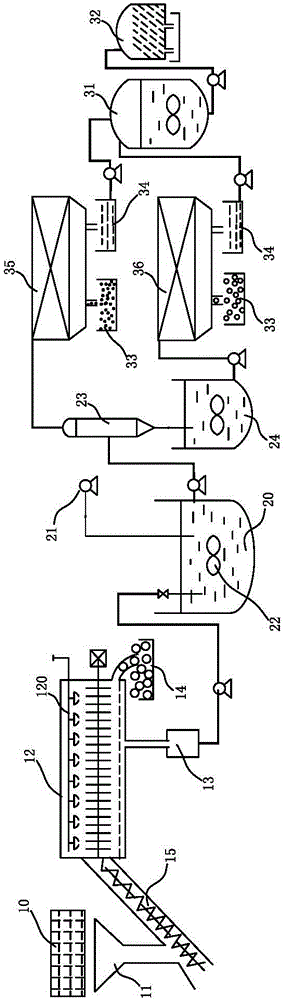

Soil washing device and washing method thereof

The invention discloses a soil washing device and a washing method thereof. The washing device comprises a particle grading unit, a soil washing unit and a sewage treatment unit, wherein the particle grading unit is used for separating soil into particles with different particle sizes, the soil washing unit is used for washing the separated soil particles by adding an agent and clean water, and the sewage treatment unit is used for performing solid liquid separation on washed soil, a separated filter cake is improved, then backfilling is performed, and deep treatment is performed on separated sewage. Particle size grading is performed on polluted soil for multiple times, then soil with a particle size range in which target pollutants exist intensively and a leaching agent are mixed and added into a leaching reactor, multi-stage washing is performed by controlling certain conditions, the washed soil is separated out, then backfilling or deep treatment is performed, and liquid waste gathering the pollutants is treated and then is discharged or reused.

Owner:BEIJING GEOENVIRON ENG & TECH

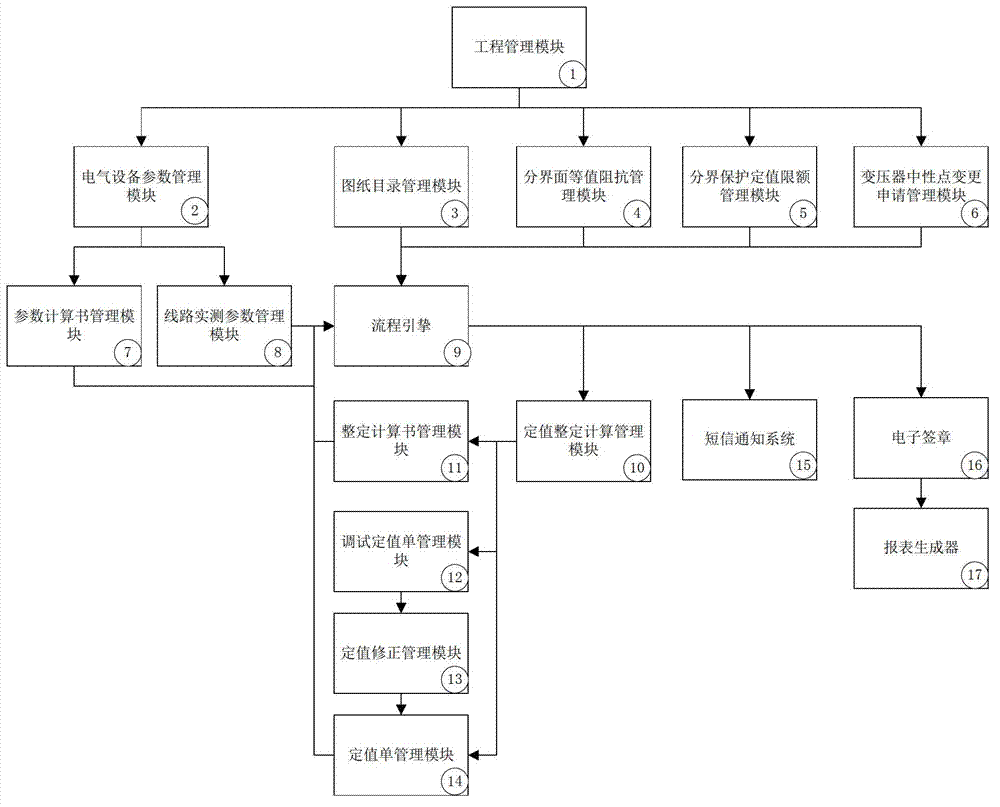

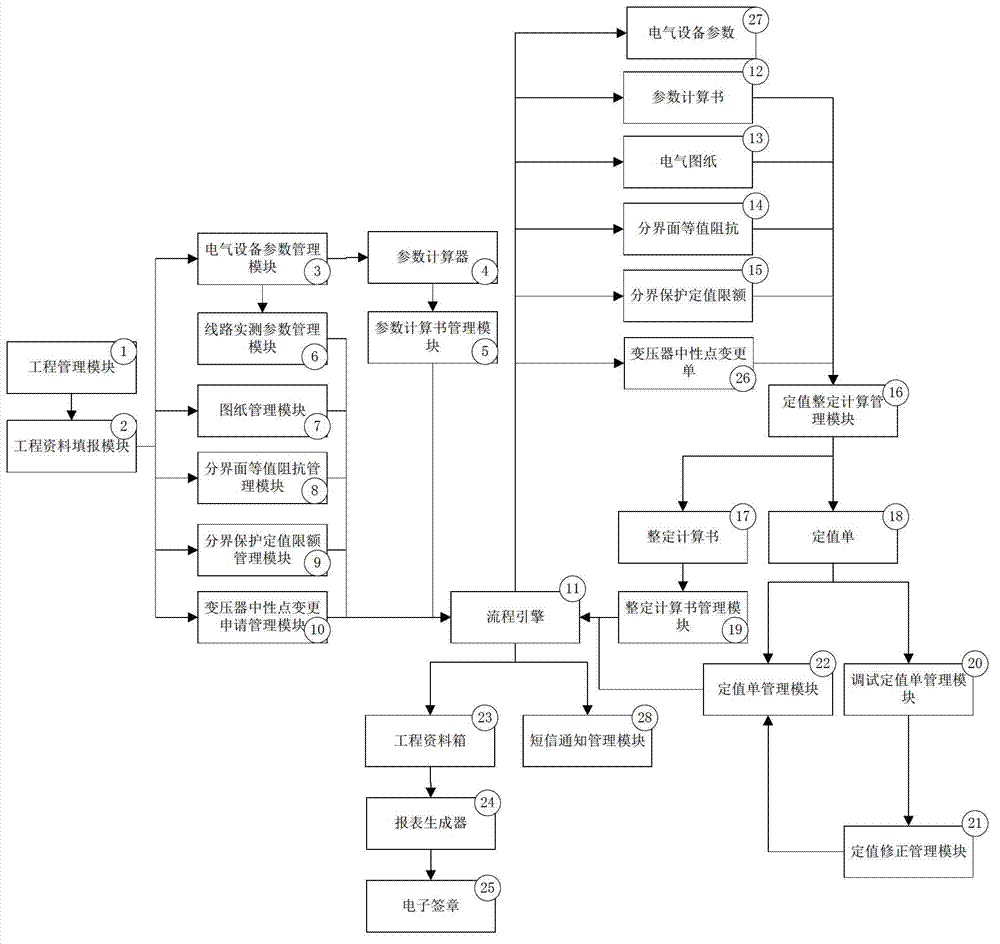

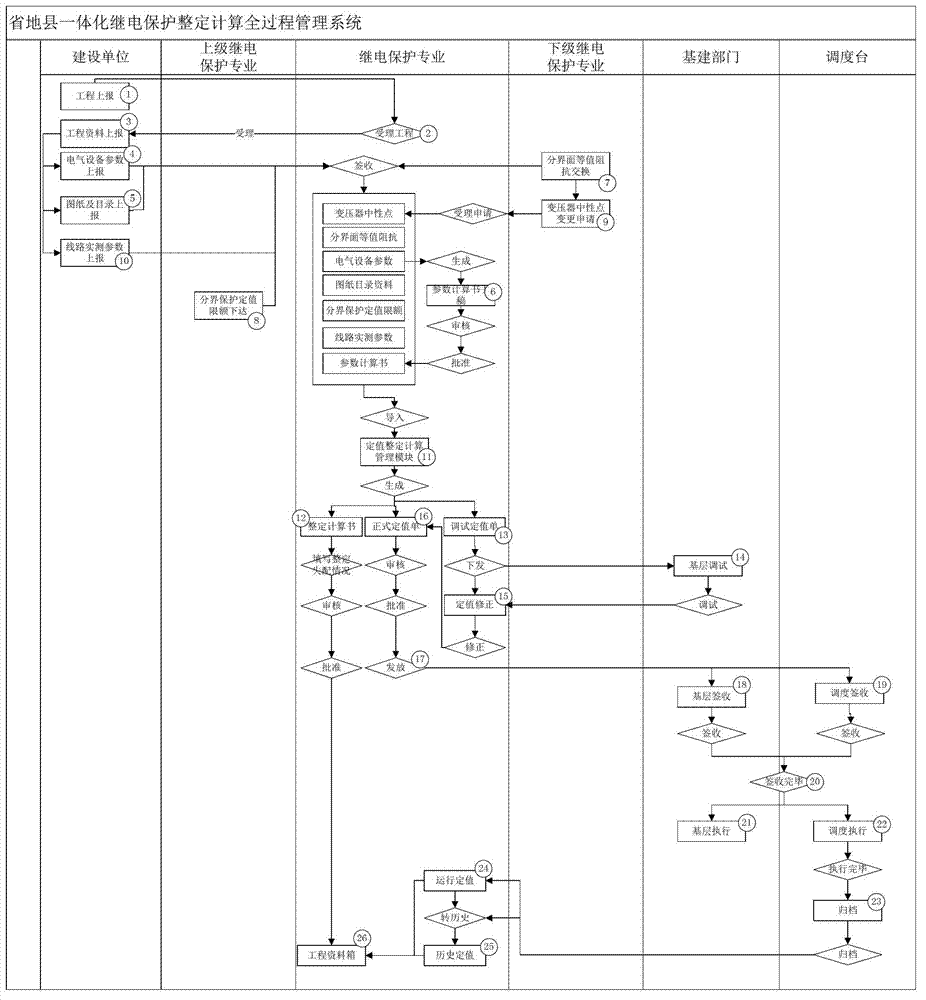

Implementation method of province, city and county integrated relay protection setting calculation overall-process management system

InactiveCN102768750AImprove reliabilityImprove stabilityData processing applicationsValue setElectrical devices

The invention provides an implementation method of a province, city and county integrated relay protection setting calculation overall-process management system. The system comprises an engineering management module (1), an electrical equipment parameter management module (2), a drawing list management module (3), a boundary surface equivalent impedance management module (4), a boundary protection fixed-value quota management module (5), a transformer neutral point management module (6), a parameter calculation sheet management module (7), a circuit actual measurement parameter management module (8), a process engine (9), a fixed-value setting management system (10), a setting calculation sheet management module (11), a debugging report form management module (12), a report form amendment management module (13), a report form management module (14), a short message notification management module (15), an electronic seal (16) and a report form generator (17). The invention provides a richer data showing means; the workloads of full-time staff for setting calculation are greatly reduced; the working efficiency and the economic benefit are increased; and paperless, informationized and standardized process closed-loop management on the whole process of relay protection setting calculation is realized.

Owner:YUNNAN POWER GRID CORP TONGFANG TECHCO

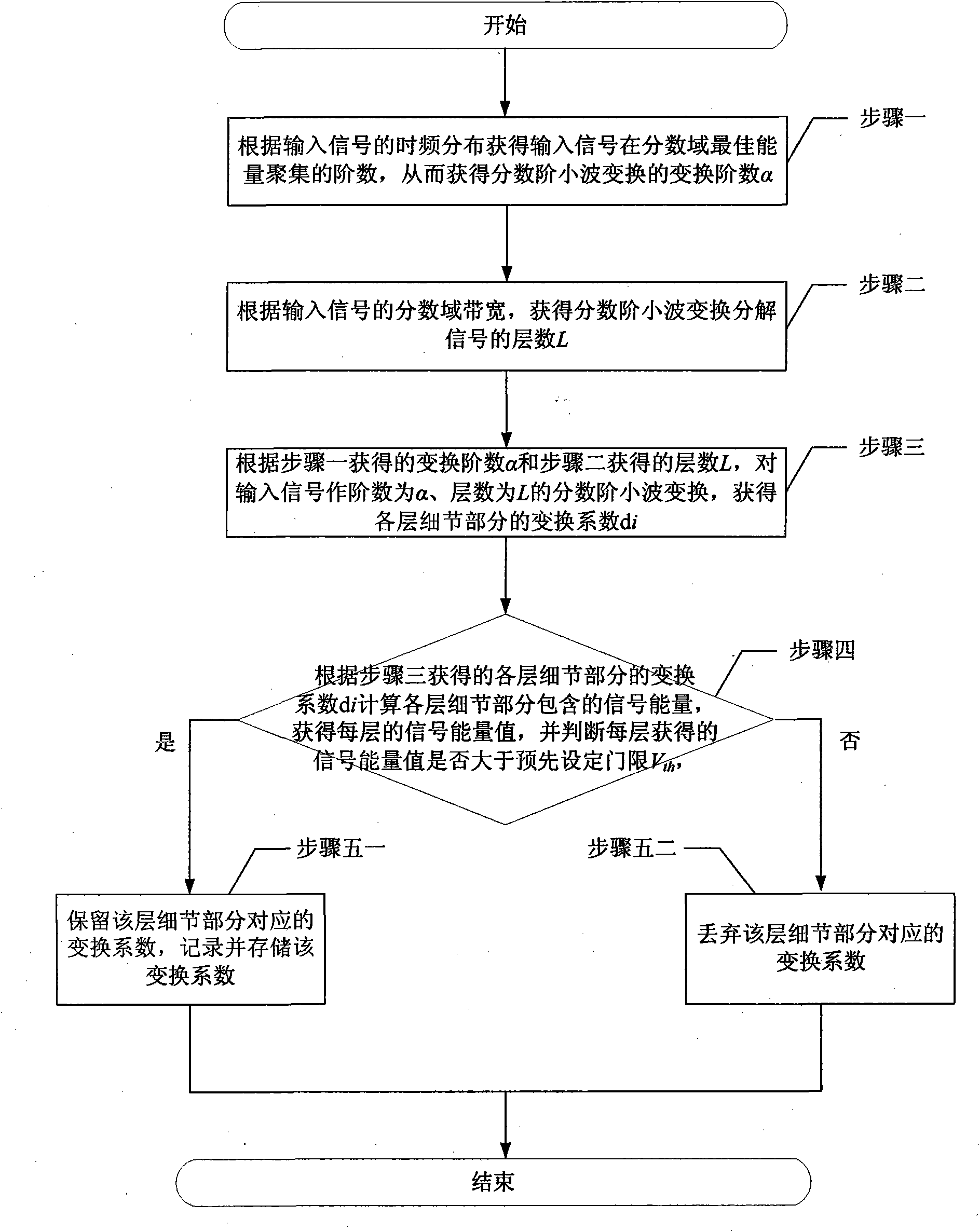

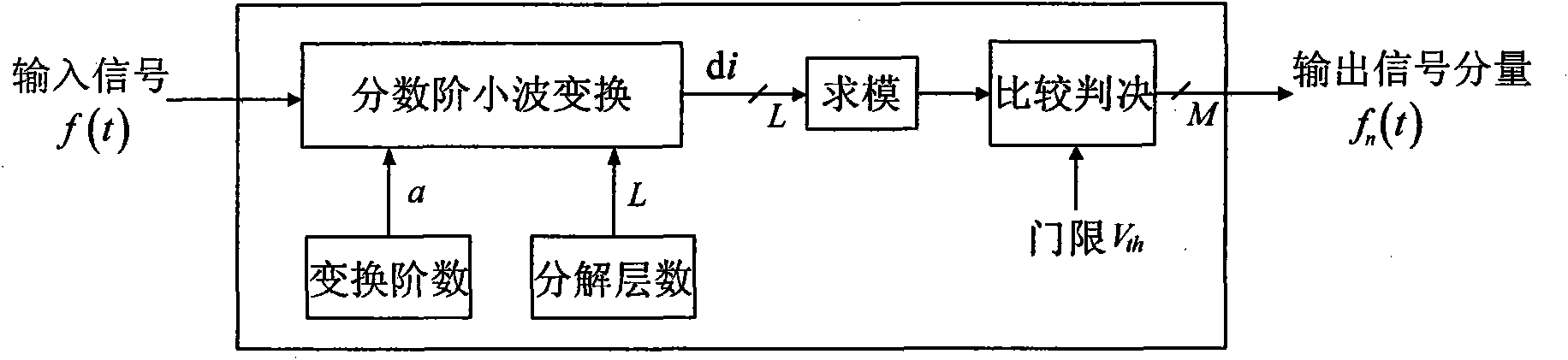

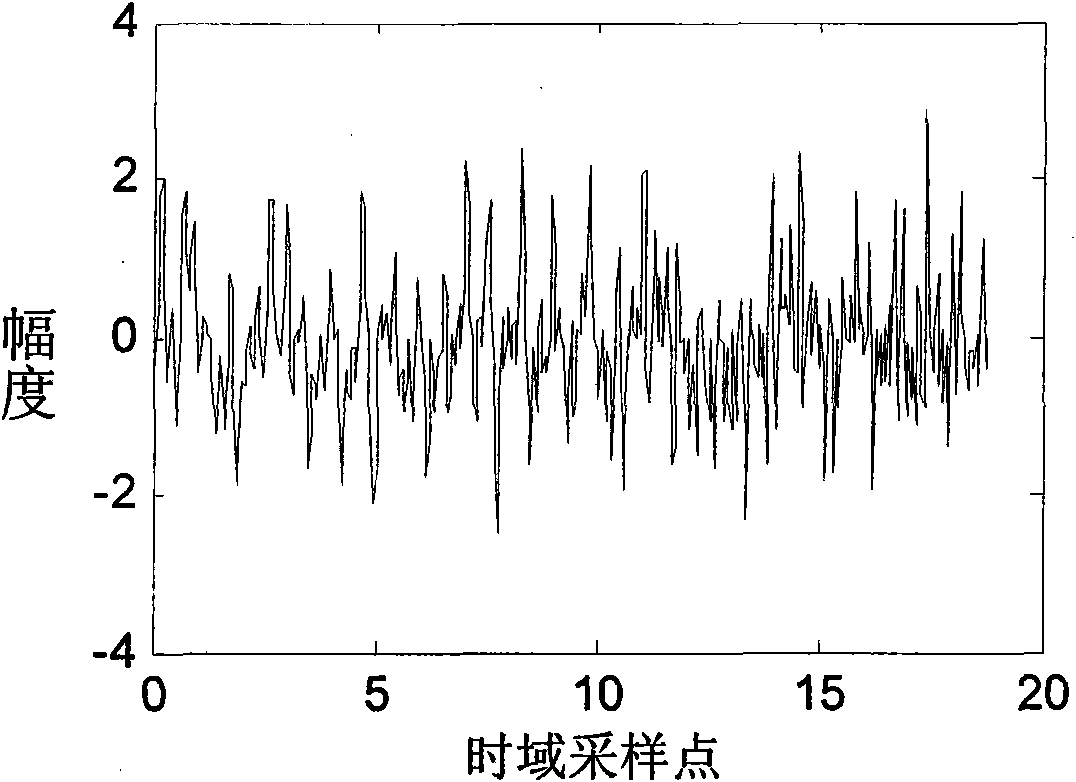

Signal separation method based on fractional wavelet transform

InactiveCN101655834AFlexible processing capacityFlexible analysisComplex mathematical operationsComputer scienceWavelet transform

The invention relates to a signal separation method based on fractional wavelet transform. The signal separation method solves the problem that the traditional wavelet transform method has poor effects on non-stationary signal analysis and treatment. The signal separation method comprises the following steps: determining the order and the layer number of the fractional wavelet transform accordingto parameters of input signals, calculating a transform coefficient of the detailed part of each layer by fractional wavelet transform, calculating signal energy which corresponds to the detailed partof each layer according to the transform coefficient, comparing the signal energy with a set threshold value, retaining the transform coefficient which corresponds to the detailed part of the layer and recording and storing the retained detailed part if the signal energy is larger than the set threshold, and abandoning the transform coefficient which corresponds to the detailed part of the layerif the signal energy is smaller than the set threshold. The signal separation method is applicable to the treatment and analysis occasions of non-stationary signals.

Owner:HARBIN INST OF TECH

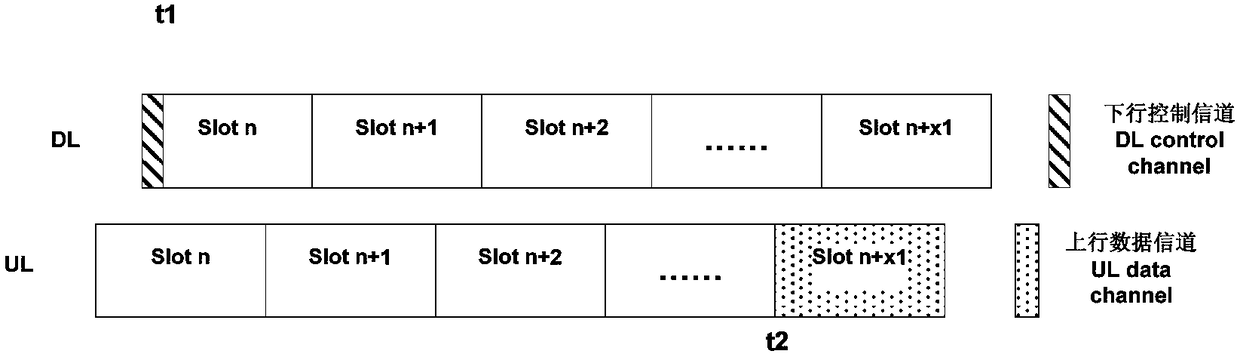

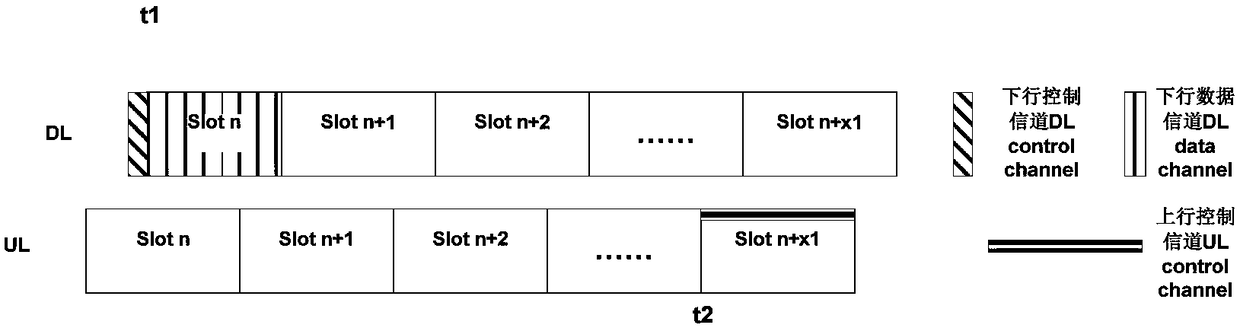

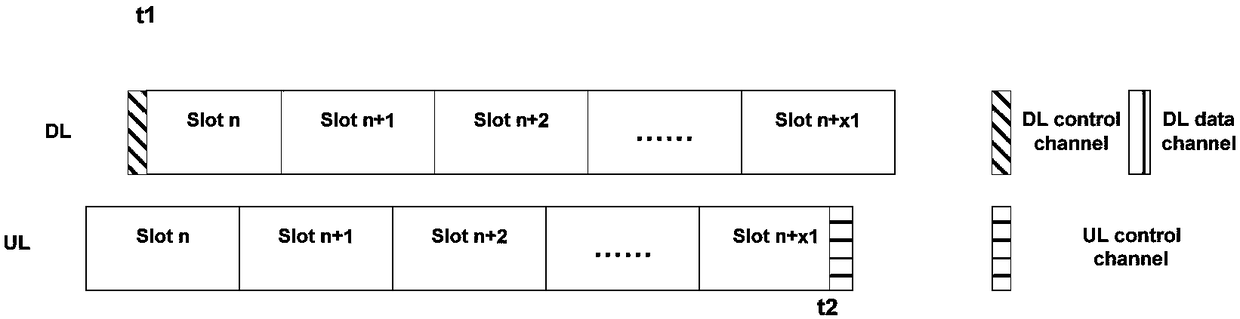

Configuration method and device of start symbol position of uplink data channel, and storage medium

ActiveCN108112078AFlexible processing capacityLow costSynchronisation arrangementSpatial transmit diversityAlgorithmProcessing cost

The invention provides a configuration method and a configuration device of a start symbol position of an uplink data channel, and a storage medium. The method comprises the steps of determining a configuration value of a first kind of parameter sets, wherein the first kind of parameter sets is sets of uplink data parameters; determining a configuration range of the start symbol position of the uplink data channel according to the configuration value of the first kind of parameter sets; and selecting the start symbol position of the uplink data channel within the configuration range of the start symbol position of the uplink data channel, and informing a receiving terminal of the selected start symbol position of the uplink data channel. Therefore, the problem that in related technologies,the terminal processing service is high in cost and inflexible in time can be solved, and the effects of reducing the service processing cost and flexibly performing service processing are achieved.

Owner:ZTE CORP

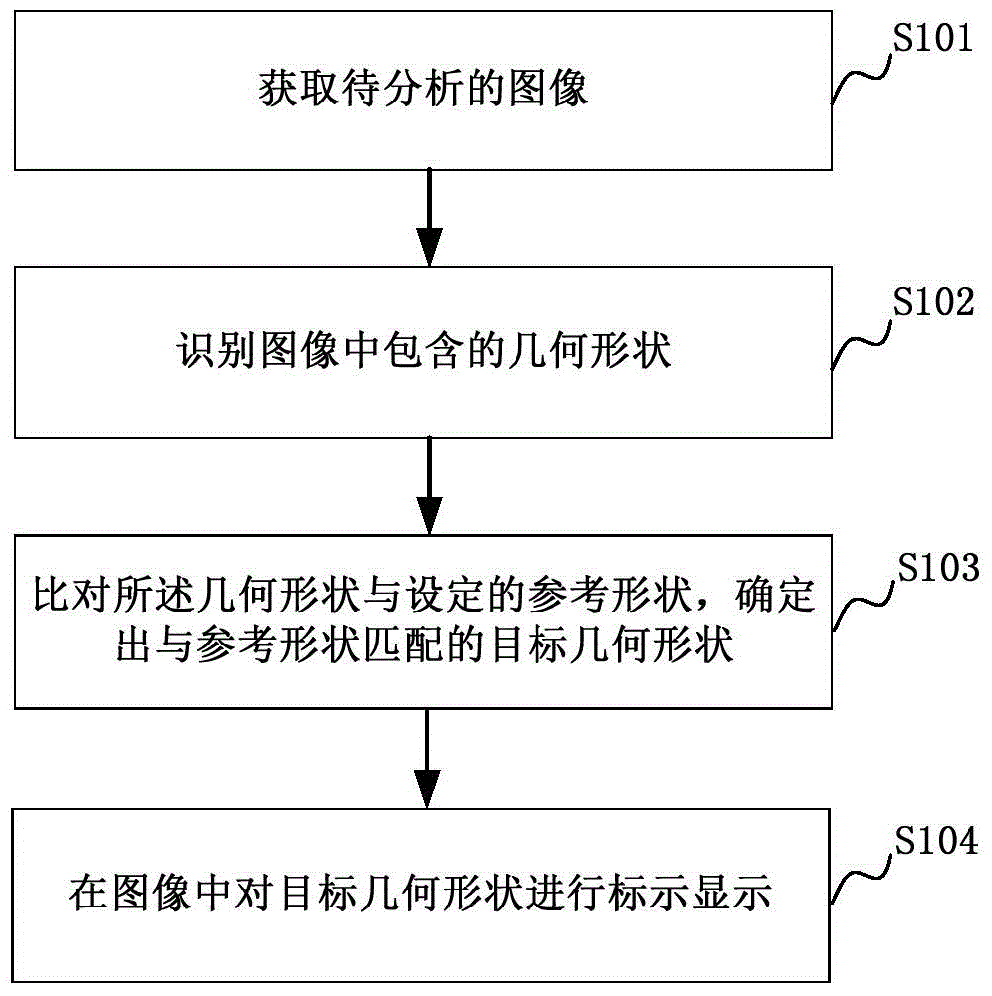

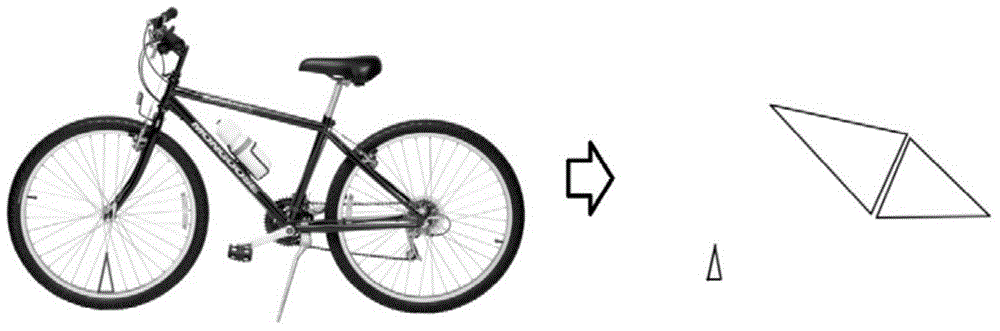

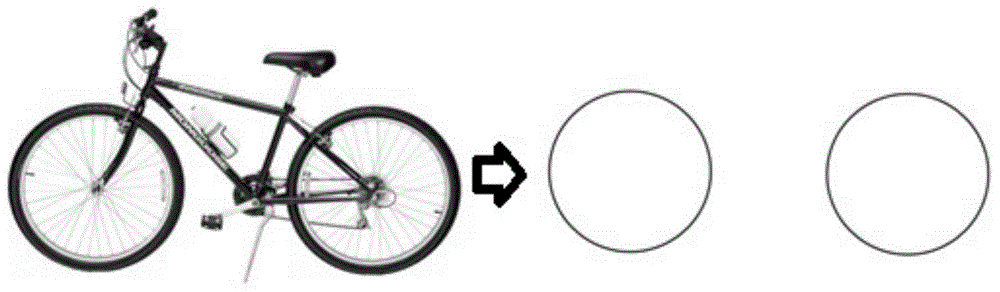

Image identification method and apparatus

InactiveCN105069454AFlexible abstractionFlexible processing capacityCharacter and pattern recognitionGraphicsShape matching

The invention relates to an image identification method and apparatus. The method comprises: obtaining a to-be-analyzed image; identifying a geometrical shape contained in the image; comparing the geometrical shape with a set reference shape and determining a target geometrical shape matching the reference shape; and marking and displaying the target geometrical shape. According to the invention, different geometrical shapes in an image can be identified based on different reference shapes; abstraction and simplification can be carried out on an object in the image flexibly; and students can understand geometric figures in natural life visually.

Owner:GUANGZHOU SHIRUI ELECTRONICS

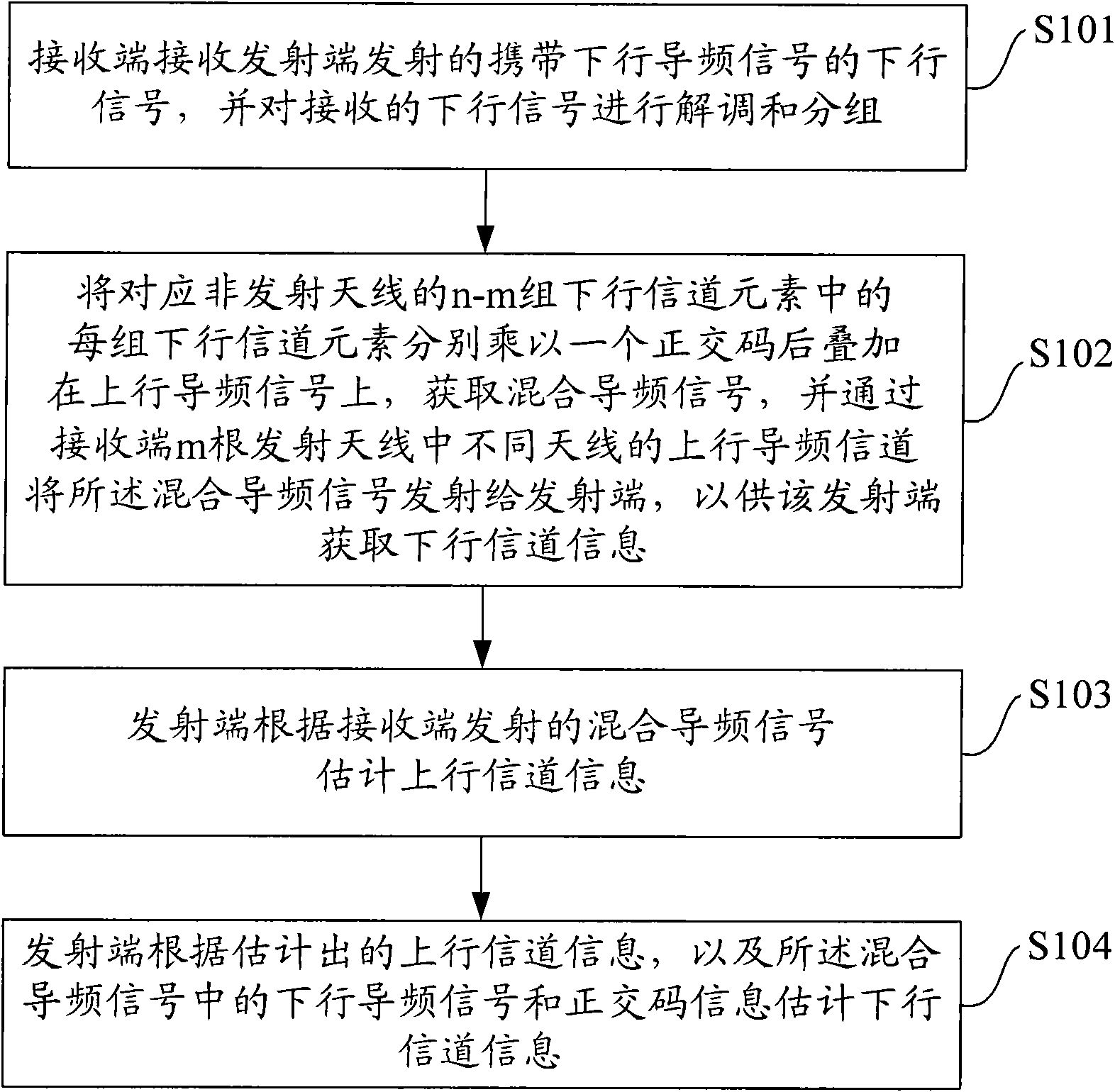

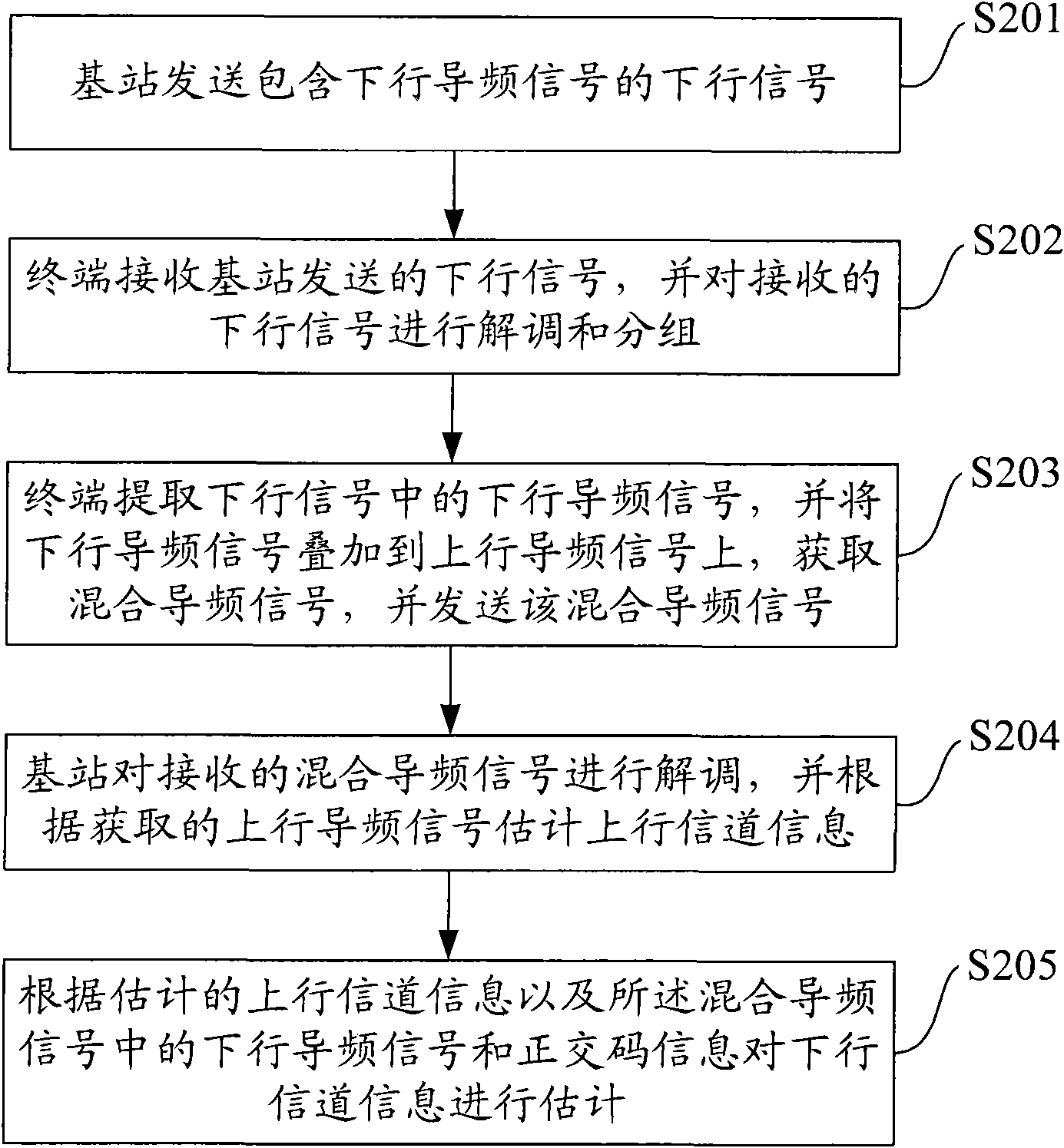

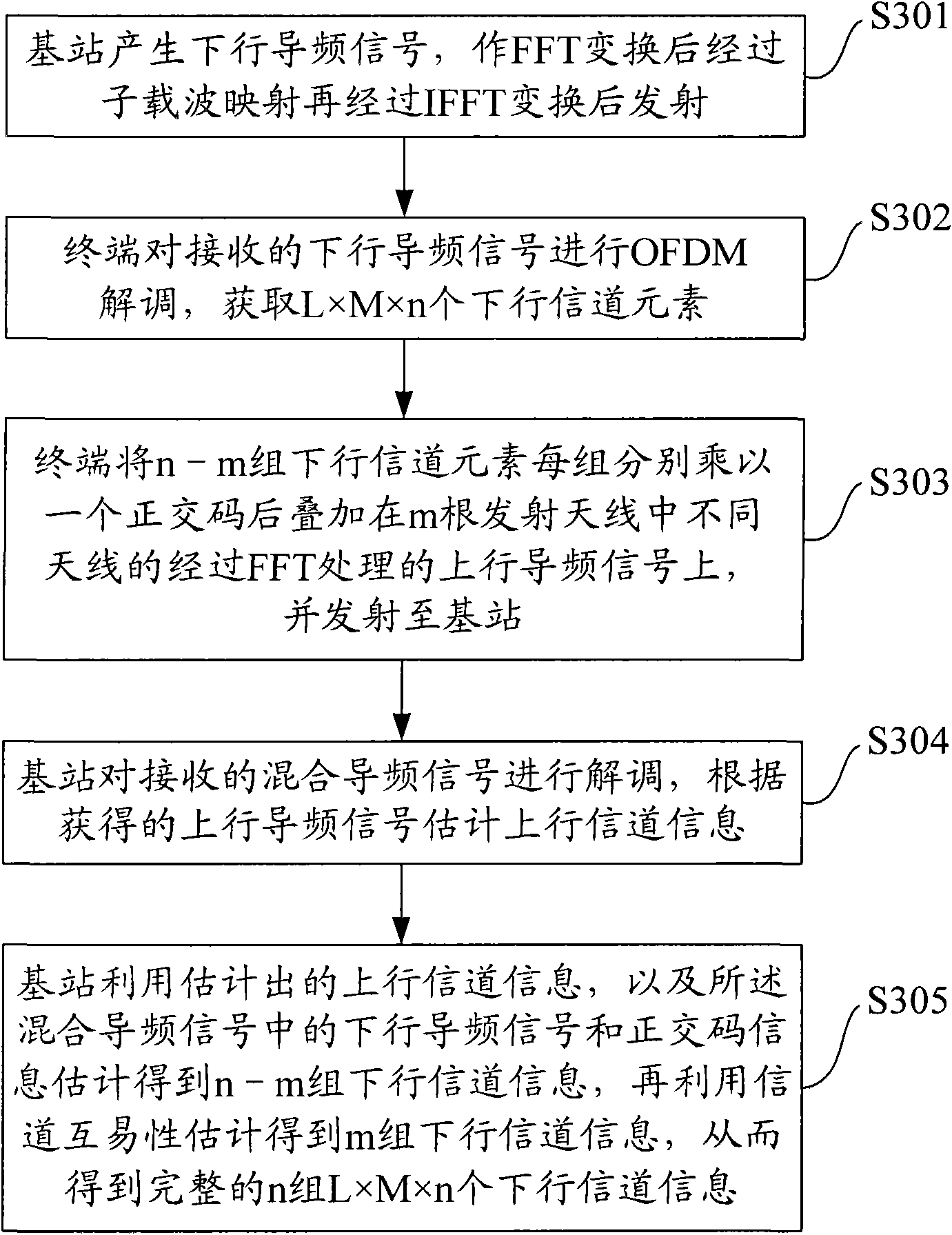

Method, system and device for obtaining descending channel information

ActiveCN101577968AReduce signaling overheadAvoid delivery errorsModulated-carrier systemsSignal allocationTelecommunicationsPilot signal

The embodiment of the invention discloses a method, a system and a device for obtaining descending channel information. The method for obtaining descending channel information comprises the following steps: receiving a descending signal which is transmitted by a transmitting terminal and carries a descending pilot signal by a receiving terminal; demodulating the received descending signal, obtaining descending channel elements at the descending pilot signal, grouping the obtained descending channel elements according to the receiving antenna number of the receiving terminal and dividing the descending channel elements after grouping into a first subgroup of descending channel elements and a second subgroup of descending channel elements; and superimposing every group of descending channel elements in the first subgroup of descending channel elements on an ascending pilot signal after respectively multiplying by one orthogonal code, obtaining a mixed pilot signal and transmitting the mixed pilot signal to the transmitting terminal by an ascending pilot channel of the receiving terminal so as to enable the transmitting terminal to obtain the descending channel information. The embodiment of the invention enables the transmitting terminal to obtain the complete descending channel information.

Owner:HUAWEI TECH CO LTD

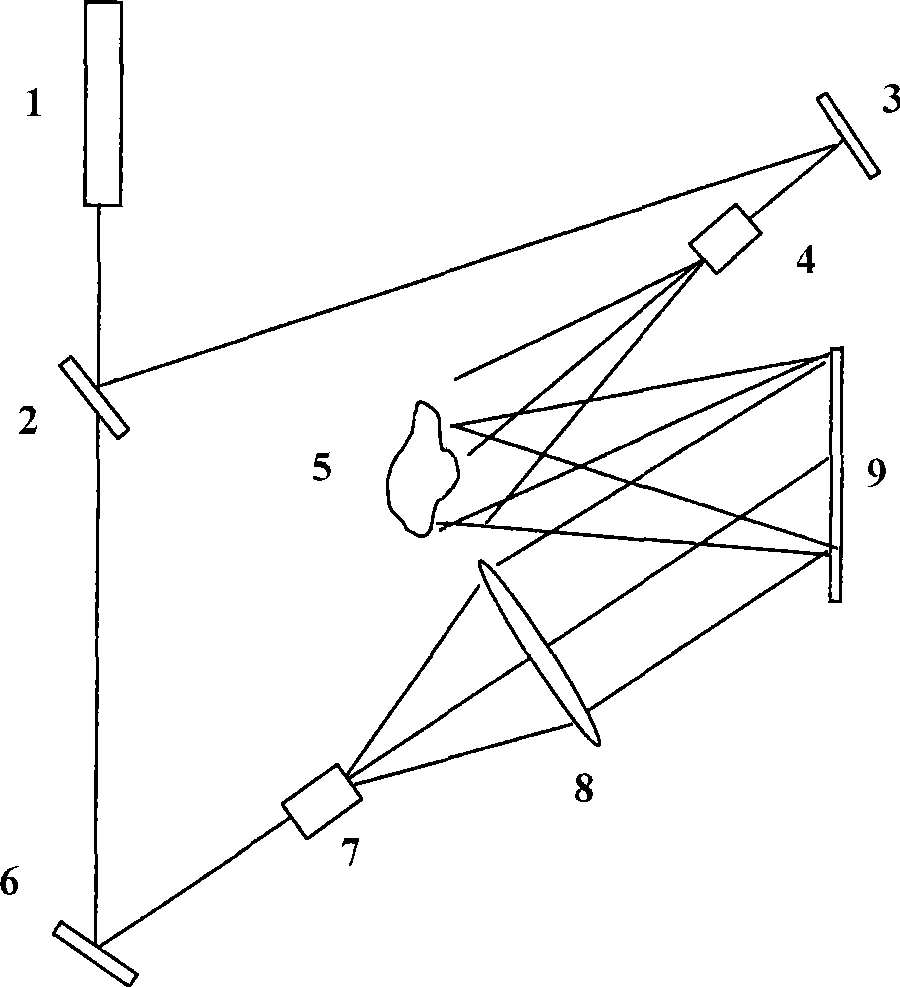

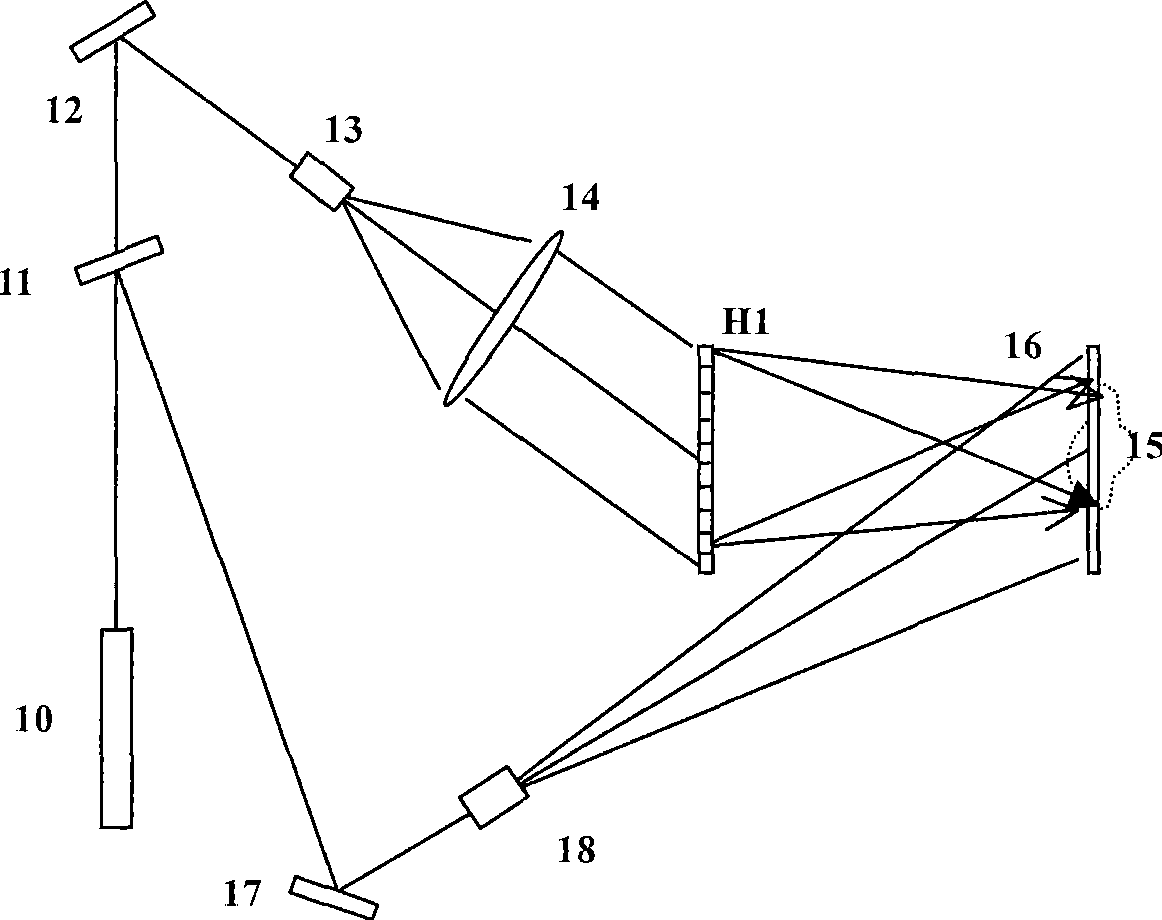

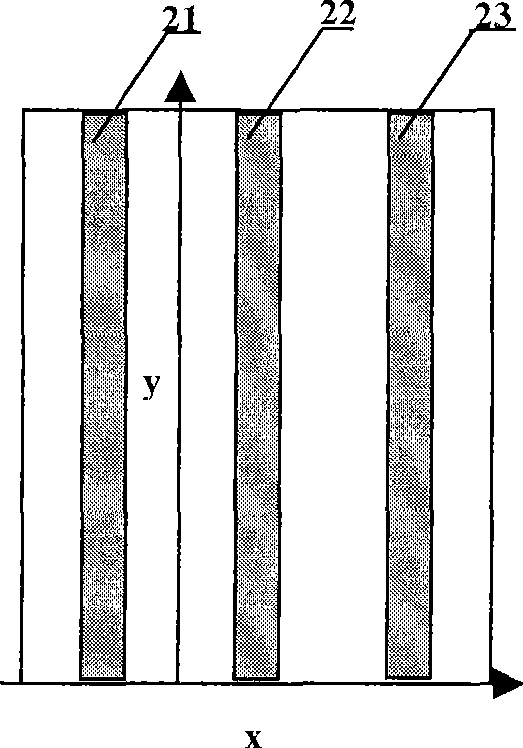

Three-dimension graphics direct-writing method with multi-vision angle graphical input

ActiveCN101477326ASolving limitations that are difficult to scaleFlexible Image InputInstrumentsSpatial light modulatorDirect writing

The invention discloses a three-dimensional graph direct writing method for multi-visual angle graphic input, which comprises the following steps: firstly, acquiring sub-visual angle planar digital images of a three-dimensional object; secondly, performing color separation on each image, splitting the image into subgraphs, and forming subgraphs with same corresponding positions in various images into a group; thirdly, acquiring a group of subgraphs, respectively adopting an iterative Fourier transform principle to calculate light field distribution of each subgraph in a far field, extracting phase information, arranging the phase information according to the visual angle, and encoding the phase information into H1; fourthly, using a spatial light modulator to display the H1, laying the H1 on a front focal plane of a lens, forming multi-visual angle image reproduction on a rear focal plane of the lens, introducing interference light, and recording reproduced images on recording materials through an interference light path; fifthly, moving the position of the recording materials corresponding to the position of the next group of subgraphs; and sixthly, repeatedly executing the steps until all the subgraphs are recorded, and realizing recording of a three-dimensional graph. The three-dimensional graph direct writing method uses a mode of laser direct writing to manufacture the three-dimensional graph which has rich information expression characteristic.

Owner:SVG TECH GRP CO LTD +1

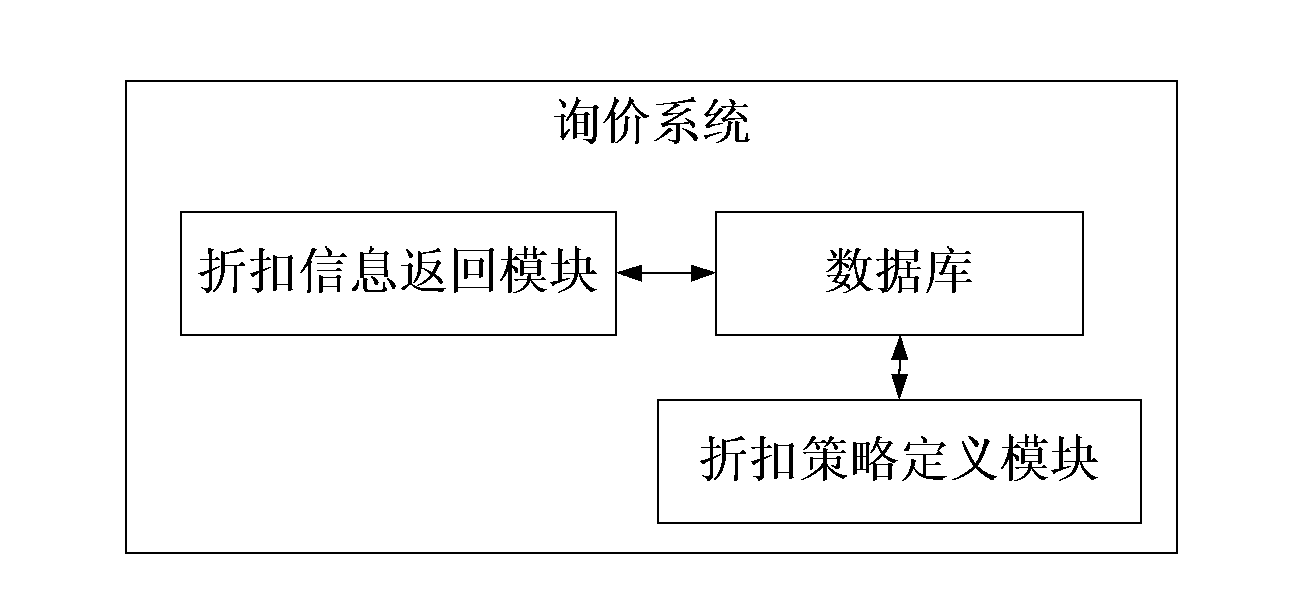

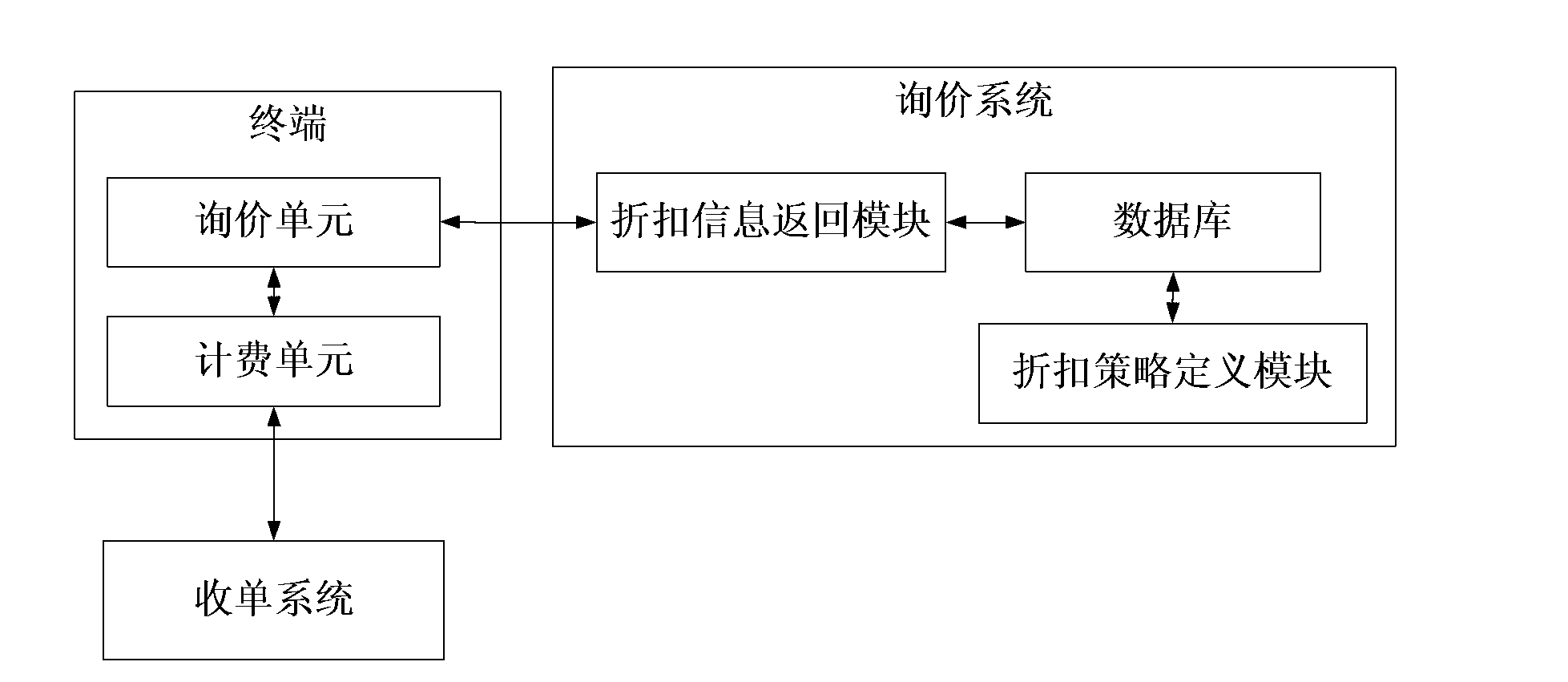

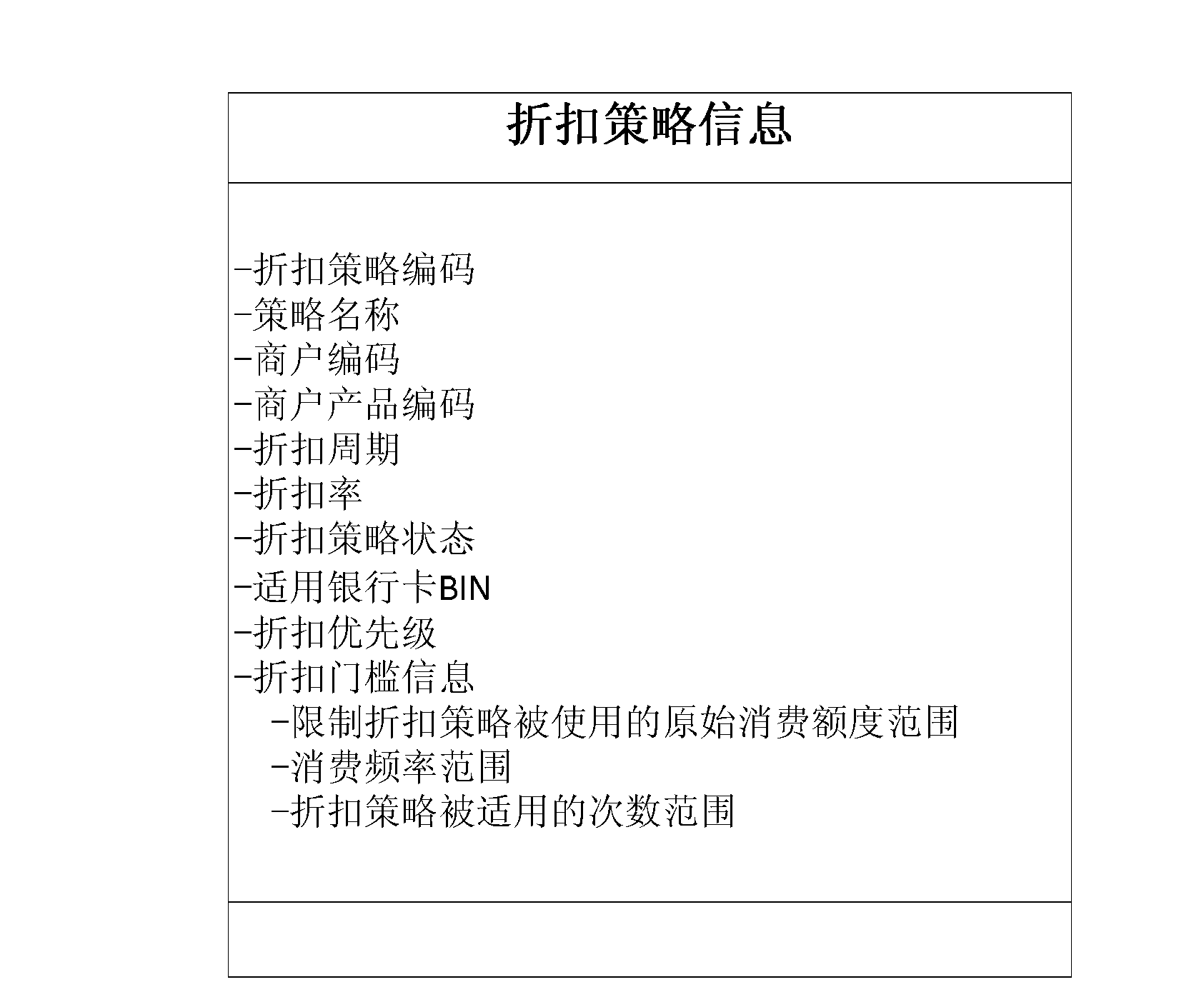

Method, system, price enquiring system, terminal and checking system for realizing discount consumption

InactiveCN103246996AFlexible controlFlexible processing capacityCash registersBuying/selling/leasing transactionsIssuing bankComputer terminal

The invention discloses a method, a system, a server, a terminal and a checking system for realizing discount consumption. The method comprises the steps that the terminal or the checking system sends a request report toward the price enquiring system according to the happened service transaction, wherein the request report comprises bank card information and consumption information of the service transaction; the price enquiring system enquires the previously saved discount strategy information related to the bank card according to the bank card information and the consumption information of the service transaction, and sends the consumption information subjected to discount processing and contained in a price enquiring responding report back to the terminal or the checking system after performing discount processing on the consumption information of the service transaction according to the enquired discount strategy information; and the terminal or the checking system finishes the billing processing of the service transaction according to the received consumption information subjected to the discount processing. After the scheme disclosed by the invention is adopted, different consumption discount and privilege requirements of each card issuing bank can be flexibly and accurately controlled and processed.

Owner:北京首惠开桌科技有限公司

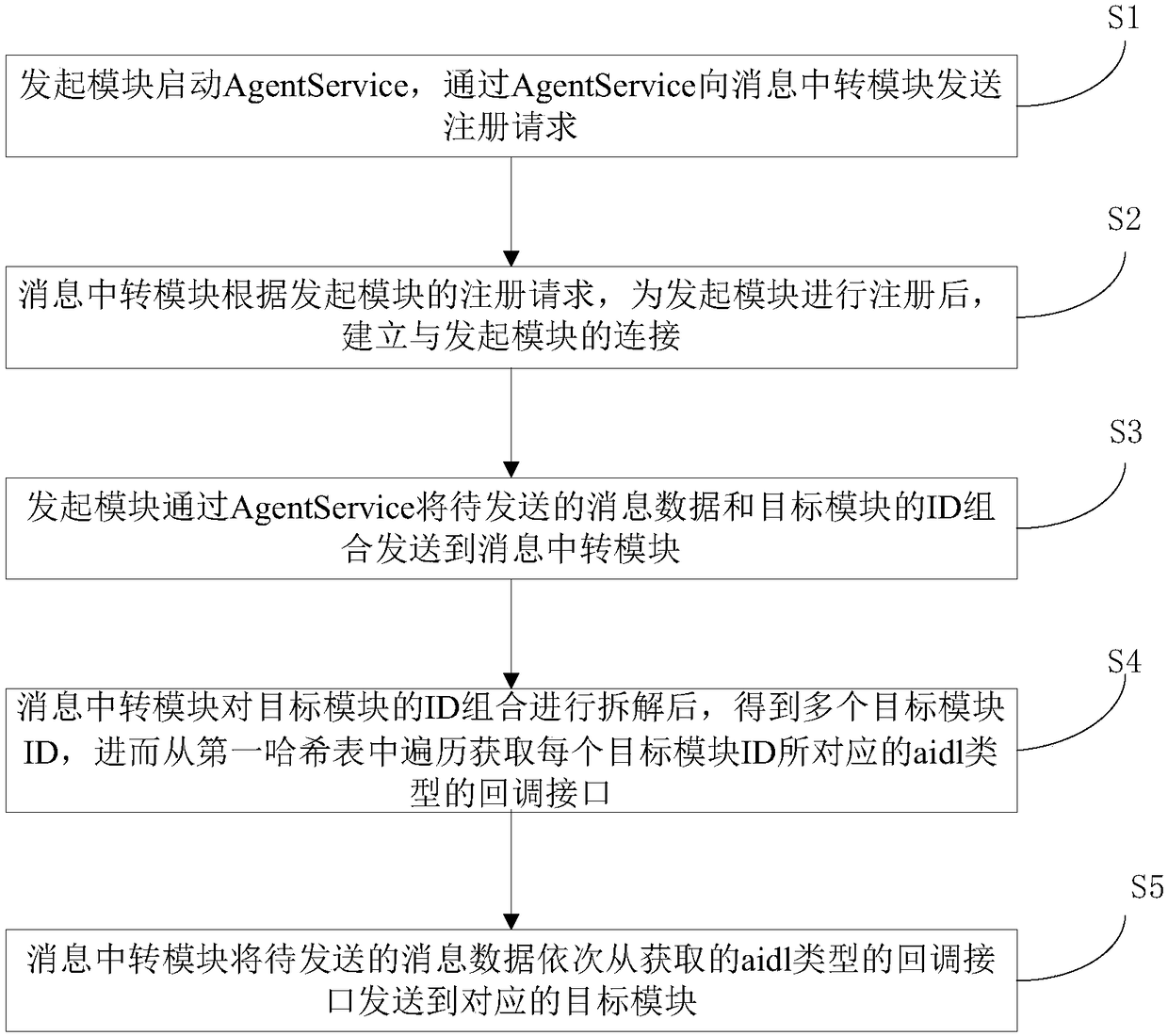

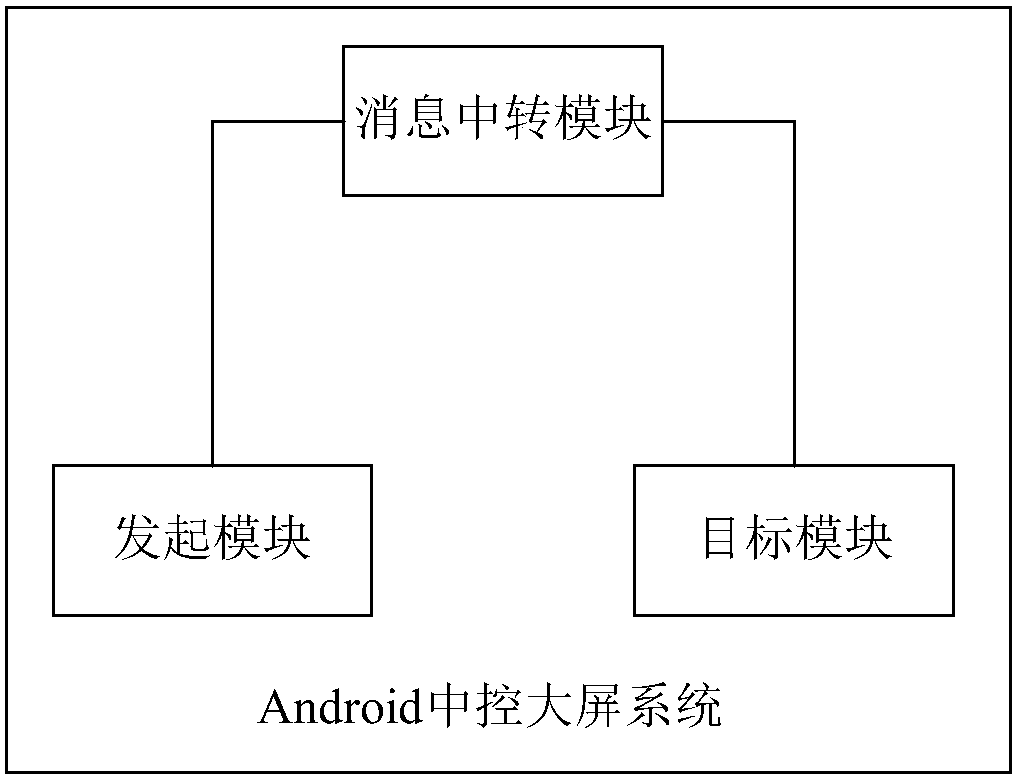

Method and system for communication between modules of Android central control large screen system

ActiveCN108182121AFlexible processing capacityFlexible deliveryInterprogram communicationLarge screenEmbedded system

The invention discloses a method and system for communication between modules of an Android central control large screen system. The method comprises the steps that a starting module initiates AgentService, registering requests are transmitted to a message transferring module through the AgentService, and after registration is conducted for the starting module by the message transferring module, the connection with the starting module is established; to-be-transmitted message data and the ID combination of target modules are transmitted to the message transferring module through the AgentService; after disassembly of the ID combination of the target modules is conducted by the message transferring module, the ID of multiple target modules is obtained, and corresponding aidl type callback interfaces of the ID of each target module are obtained; the to-be-transmitted message data is sequentially transmitted to the corresponding target modules from the obtained aidl type callback interfaces. According to the method, message data can be processed and transmitted more flexibly, the use is convenient, the stability is good and the safety is high, and the method is more intelligent and can be extensively applied to industries of automobile communication.

Owner:GUANGZHOU XIAOPENG MOTORS TECH CO LTD

Dust removal purification device and method for crude coal tar

InactiveCN105327550AGuaranteed uptimeEasy to handleFiltration circuitsTar working-up by solvent extractionDistillationTar

The invention discloses a dust removal purification device and method for crude coal tar. The dust removal purification device comprises a backwashing filter, a horizontal decanter centrifuge, a residual oil buffer tank, a purified tar tank, a factice tank, a vacuum filter, a dryer and a distillation apparatus, wherein a filter element is arranged in a cavity of the backwashing filter, and dust-containing coal tar is purified continuously through filtering and backwashing of the filter element; residual oil after backwashing enters the horizontal decanter centrifuge for liquid-solid separation, and purified tar and factice are obtained. In order to increase the recovery rate of the purified tar sufficiently, the factice is extracted with a recycling solvent, and final products of a system comprise purified coal tar and dry cinders. The backwashing filter and the horizontal decanter centrifuge are adopted to cooperate with the solvent extraction system for dust removal purification of the crude coal tar, through graded and stepped treatment, the treating capacity of the system is improved sufficiently while the coal tar is recovered to the greatest extent, besides, the solvent is recycled, and energy saving and environmental protection are realized.

Owner:SHAANXI YANCHANG PETROLEUM GRP

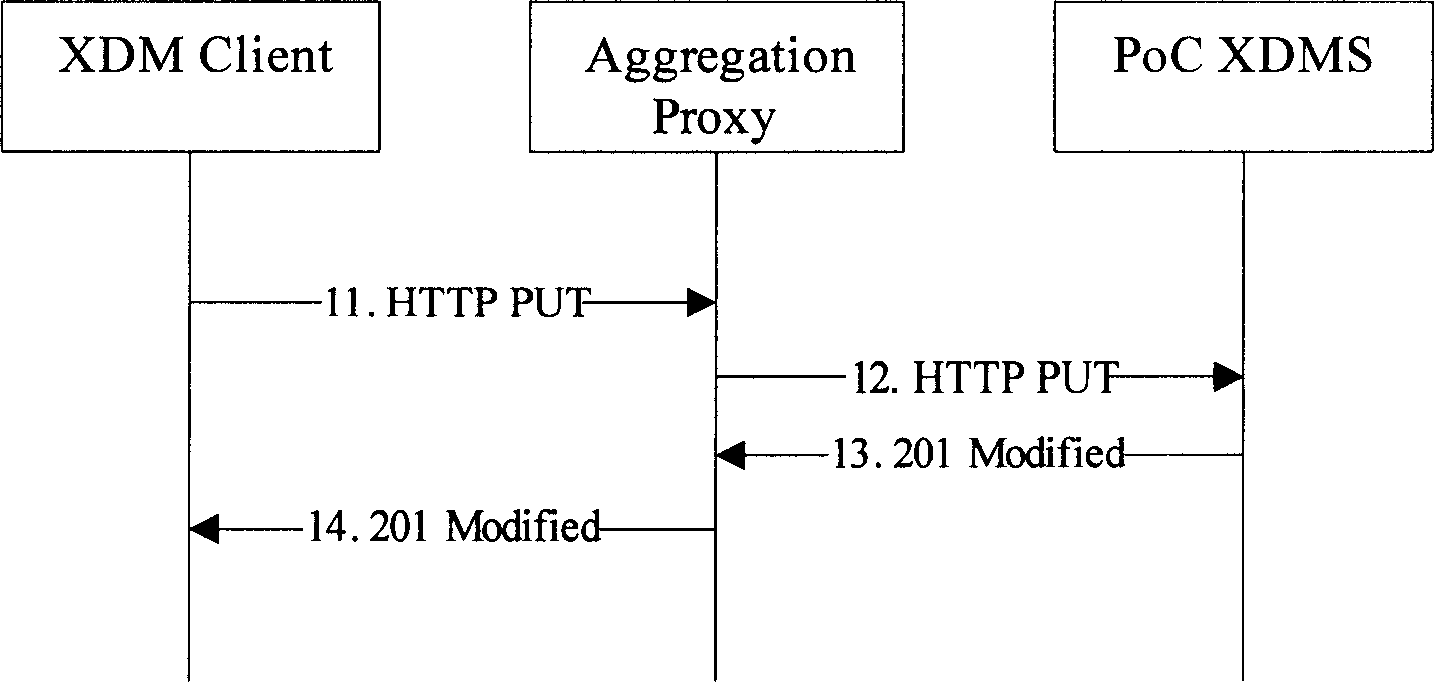

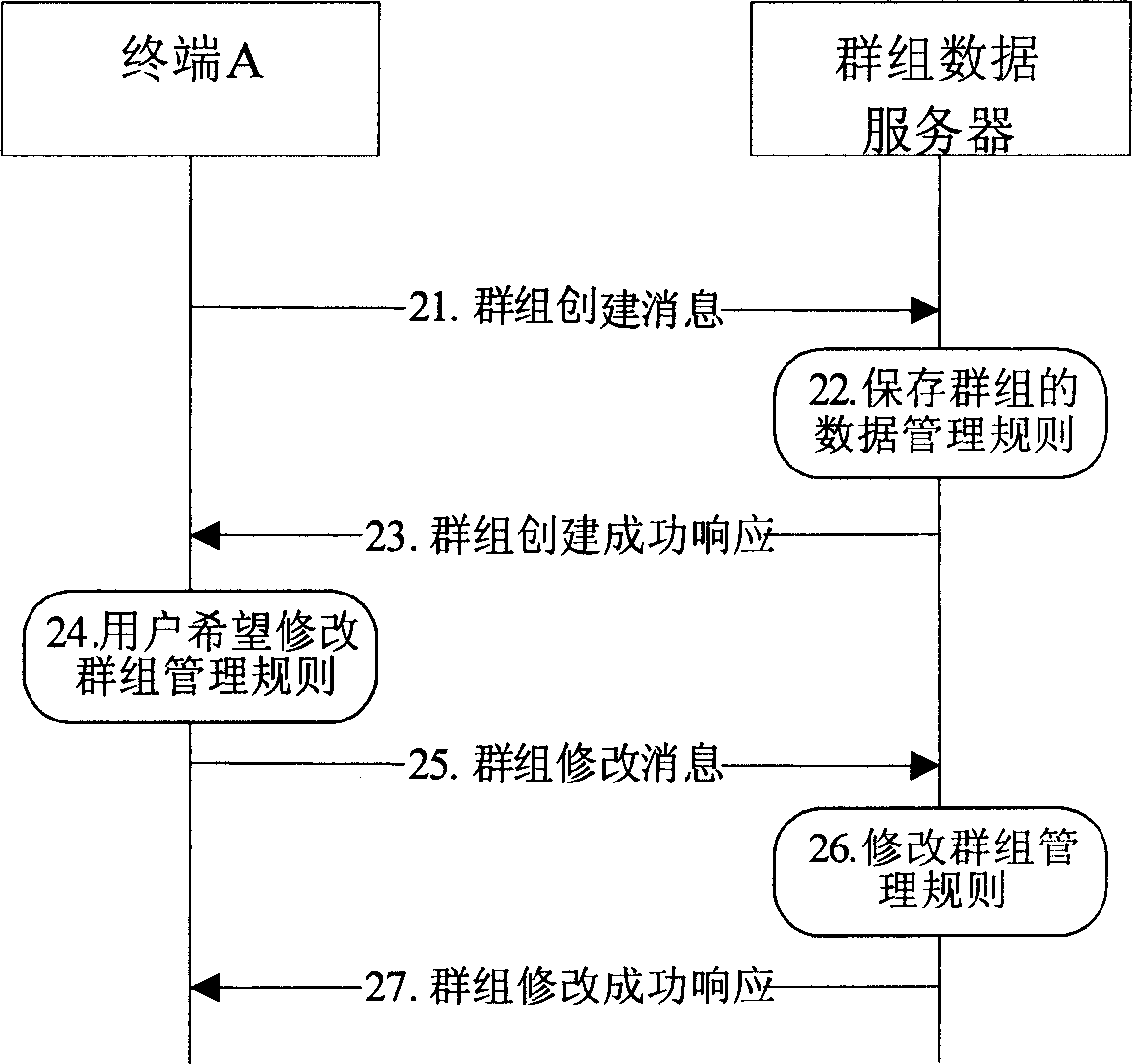

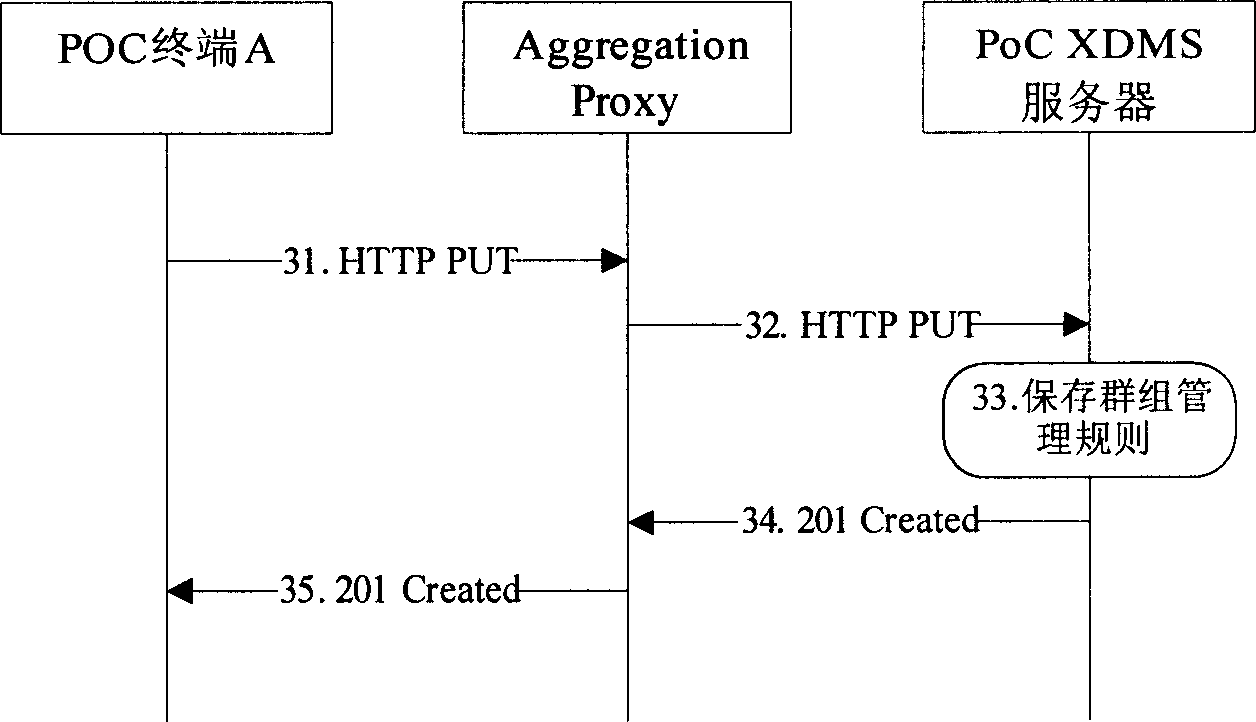

Group data managing method and system based on PoC

InactiveCN1867109AImplement join or leave groupJoin flexibleRadio/inductive link selection arrangementsKnowledge managementData messages

The invention relates to a group data managing method based on PoC and relative system. Wherein, it mainly comprises: first, storing the data management rule of said group in the group data server, while said rule records the priority information of user terminal that modifying the group data; then, when the user terminal sends information that operating on the group data of group data server, the group data server, according to the data management rule and the operation sent by user terminal, operates the group data. With said invention, the group data management rule can be defined by the Owner of group, to be stored in group data server; then other common members can modify the group character limited by said rule, to realize the operation that adding or leaving the group.

Owner:GLOBAL INNOVATION AGGREGATORS LLC

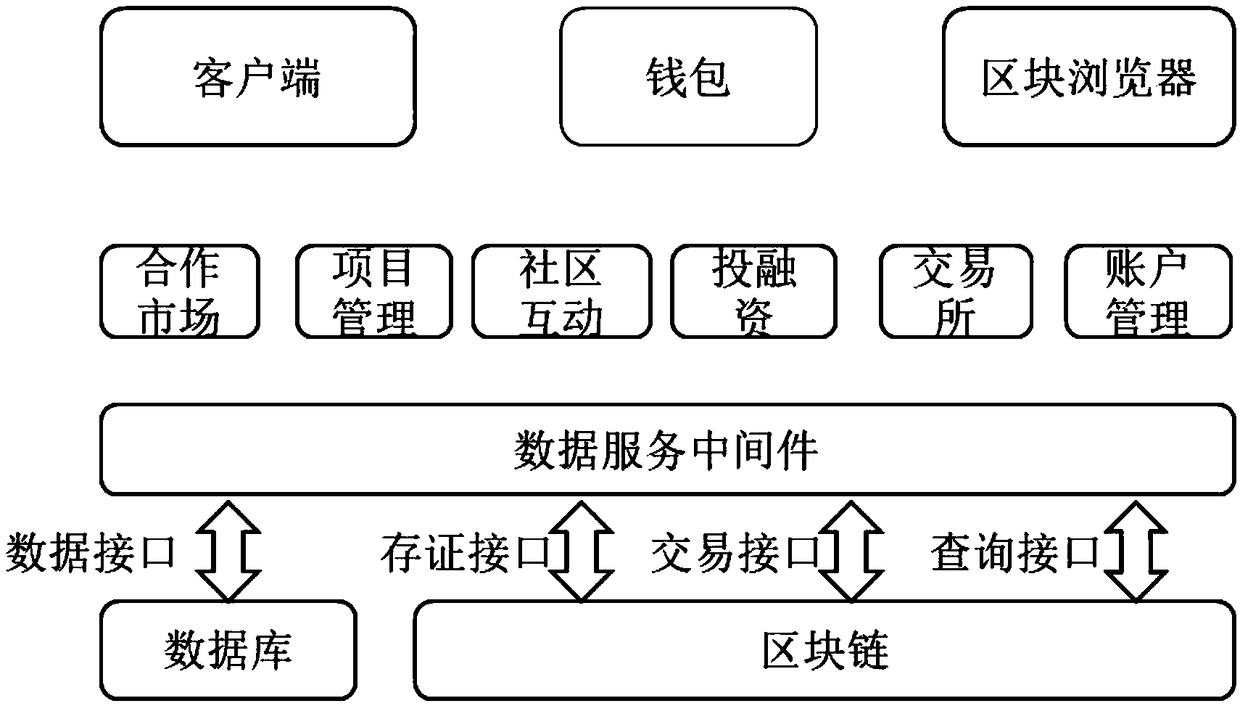

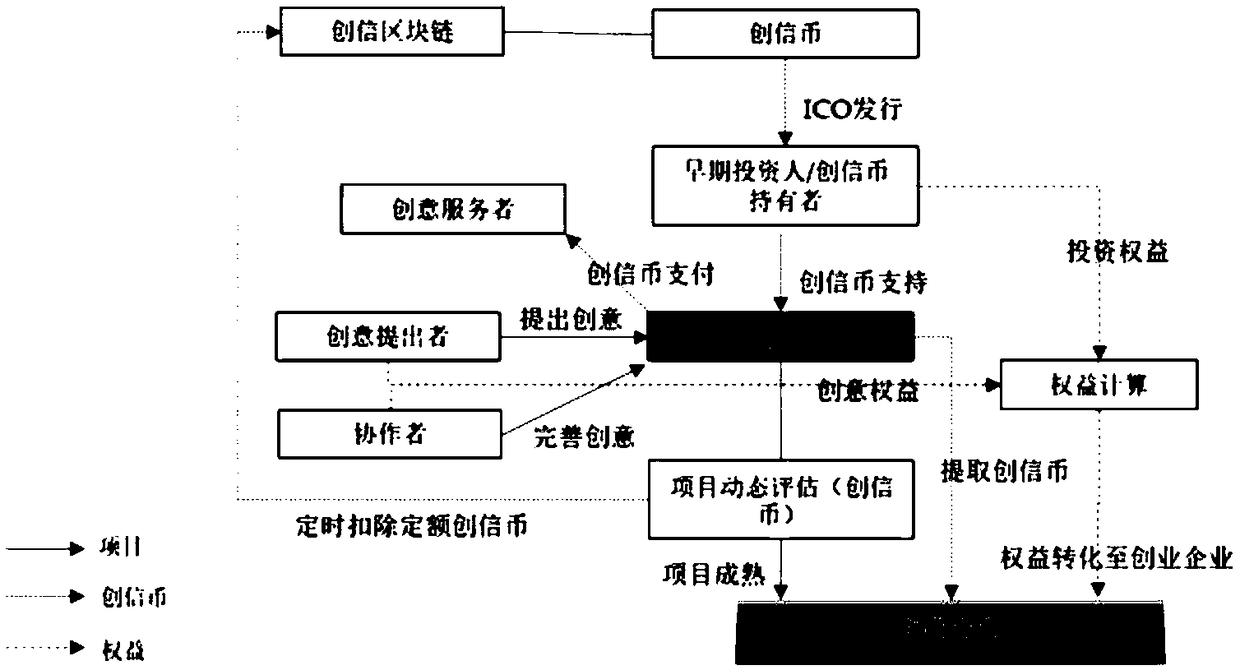

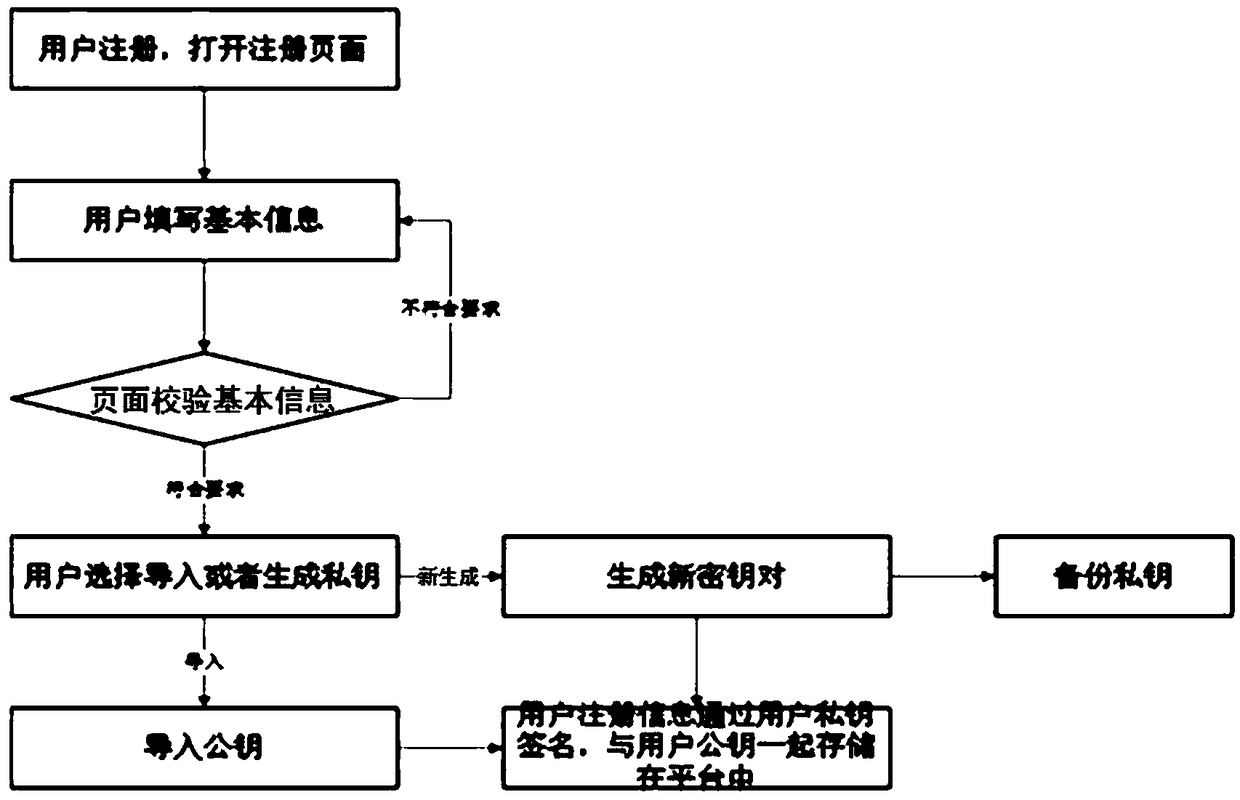

An innovation and entrepreneurship incubation system and method based on a block chain

InactiveCN109359933AAvoid demandEfficient use of processing powerFinanceOffice automationThe InternetBody function

The invention provides an innovation and entrepreneurship incubation system and method based on a block chain. The system comprises an incubator website module; a client; a wallet module for managingassets of a user in the incubation system; the block chain browser module is used for understanding the operation situation of the block chain at the bottom of the system and querying and verifying various flow processing information; a main body function module, configured to realize the main body function of the system; a block chain module is used for providing the underlying data and communication services of the system. The invention constructs a novel on-line incubation mechanism of the Internet. Through the combination of value transfer and community interaction, this new incubation mechanism can effectively solve the needs of human, financial, material and other resources in the incubation process, and effectively utilize the flexible processing capacity provided by the block chainintelligent contract, and the inherent value transfer capacity of the block chain.

Owner:周开宇 +1

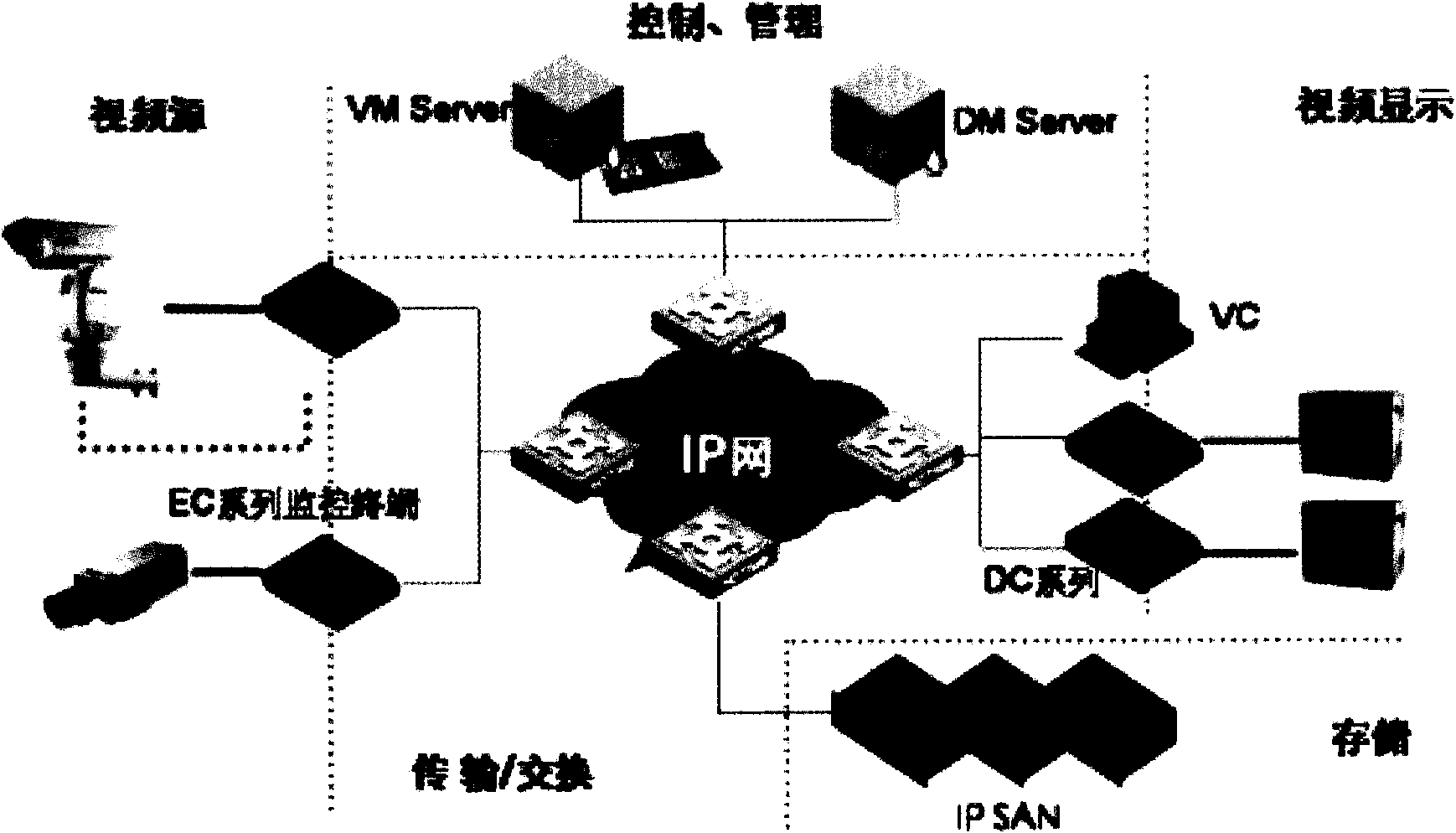

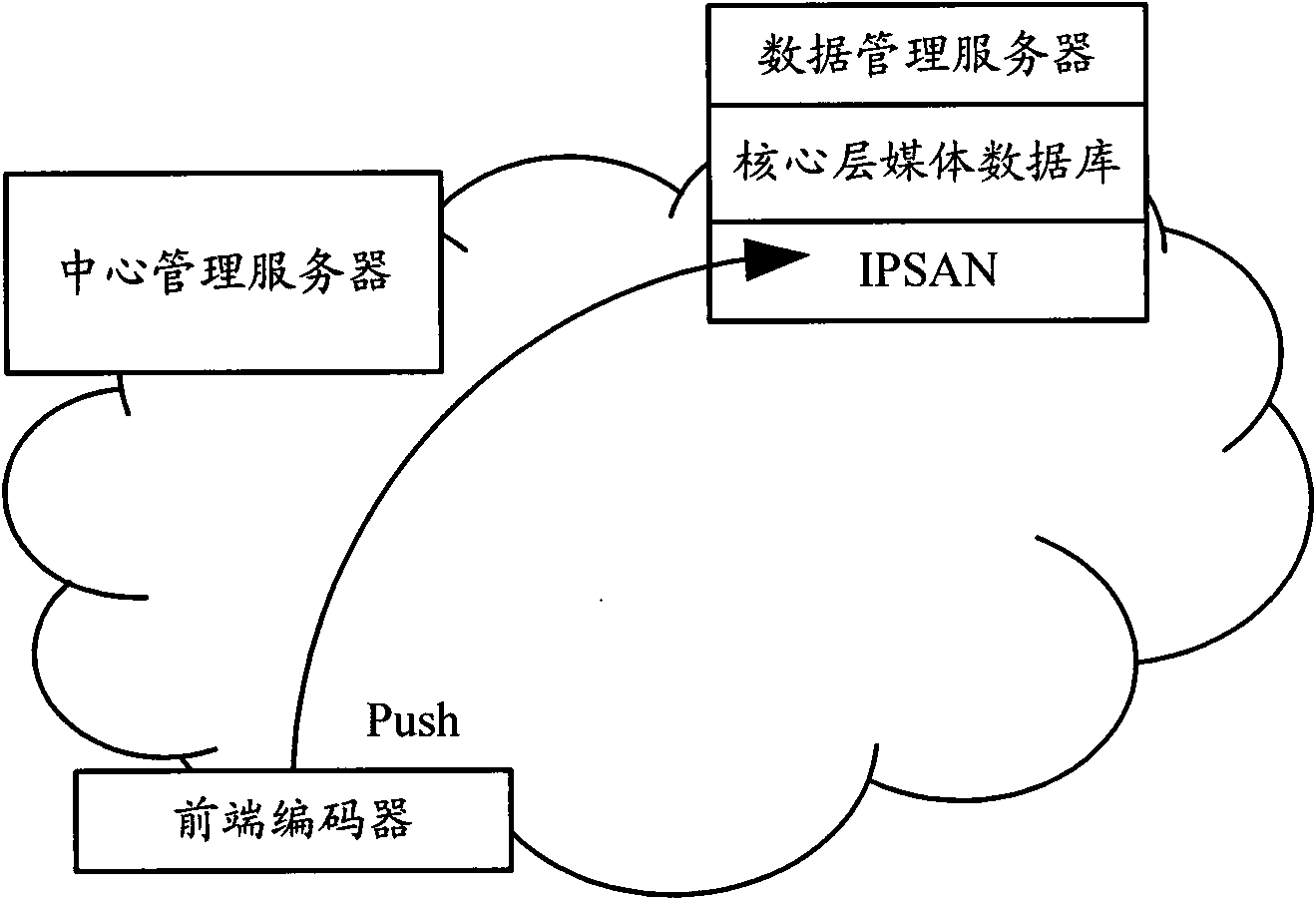

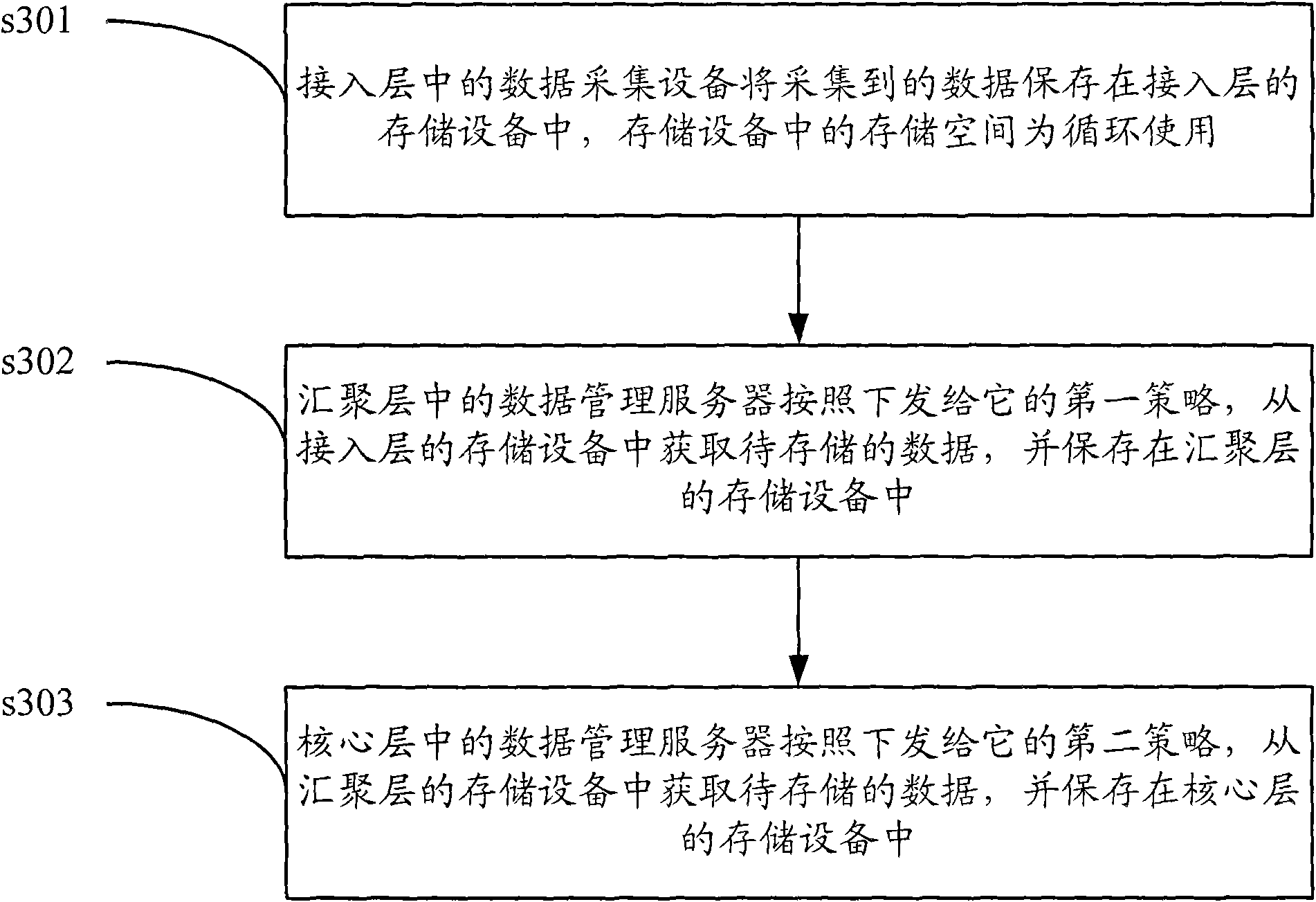

Data storage method and data storage system

ActiveCN101626499AAcquisition and processing flexibilityFlexible accessClosed circuit television systemsData storage systemData store

The invention discloses a data storage method and a data storage system. The method is applied to the data storage system which comprises an access layer, a distribution layer and a core layer. In the method and the system provided by the invention, an upper-layer server obtains storage data from lower-layer storage equipment in an active obtainment mode according to a preset policy, can firstly scan the storage data according to the preset policy and then stores the storage data so that the acquiring and the processing of the stored data become more flexible.

Owner:NEW H3C TECH CO LTD

Method for efficiently concentrating precious metal from difficultly-treated palladium-containing waste catalyst

The invention discloses a method for efficiently concentrating precious metal from a difficultly-treated palladium-containing waste catalyst. The method includes the steps that the palladium-containing waste catalyst, copper mud pressurizing slag, a reducing agent and a fluxing agent are heated and subjected to heat insulation; slag and a precious lead alloy are subjected to cooling separation, grinding is conduced, and sampling analysis of the content is conducted; vacuum melting distillation separation is conducted on the precious lead alloy, a vacuum furnace rare and precious alloy and a lead bismuth alloy are obtained, and the precious metal is separated from lead and bismuth. By means of the method, a melting low-temperature alkaline concentration smelting method is used for treatingthe high silicon and aluminum carrier type high and low grade palladium-containing waste catalyst and the copper anode mud pressurizing slag, gradient comprehensive utilization of gold, silver and platinum family precious metal, lead, bismuth and dissipated, rare and precious metal elements is achieved, the process is the shortest, the cost is the lowest, and efficiency is the highest. The palladium-containing waste catalyst rate can be large and can be small, the treatment capability is flexible, concentration smelting treatment is achieved, and concentration smelting of the palladium familyprecious metal is not affected; and a melting low-temperature alkaline smelting technology is adopted, the smelting temperature is far lower than that of matte smelting, energy consumption is greatlyreduced, and therefore the machining cost of the difficultly-treated waste catalyst is reduced.

Owner:JINCHUAN GROUP LIMITED

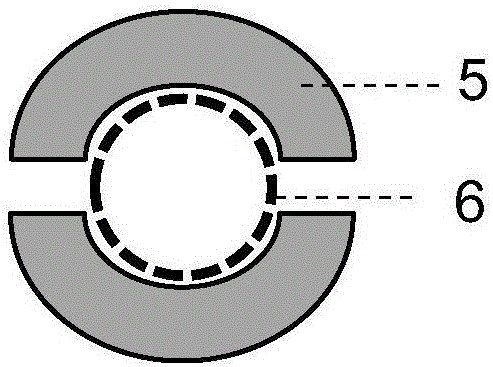

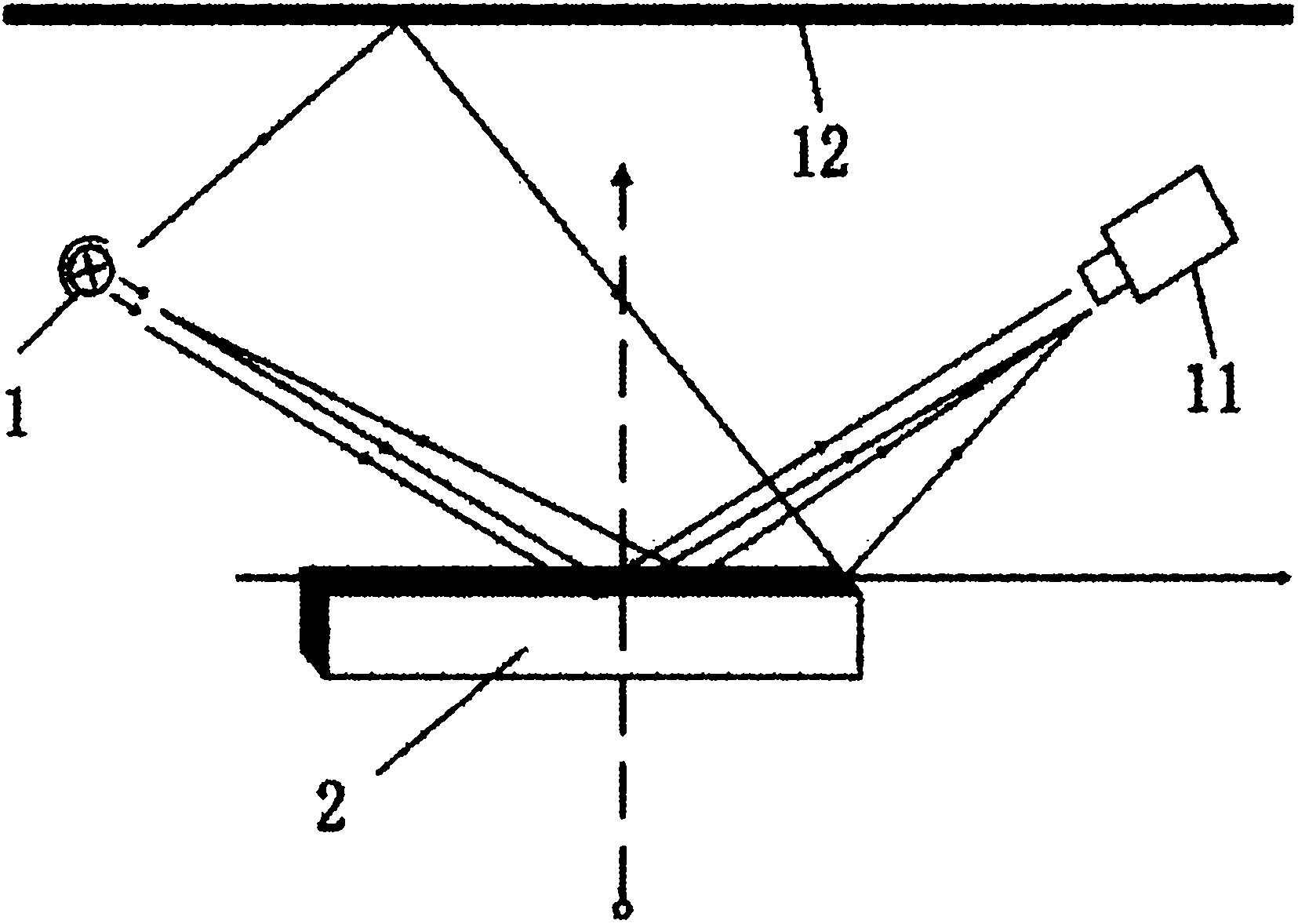

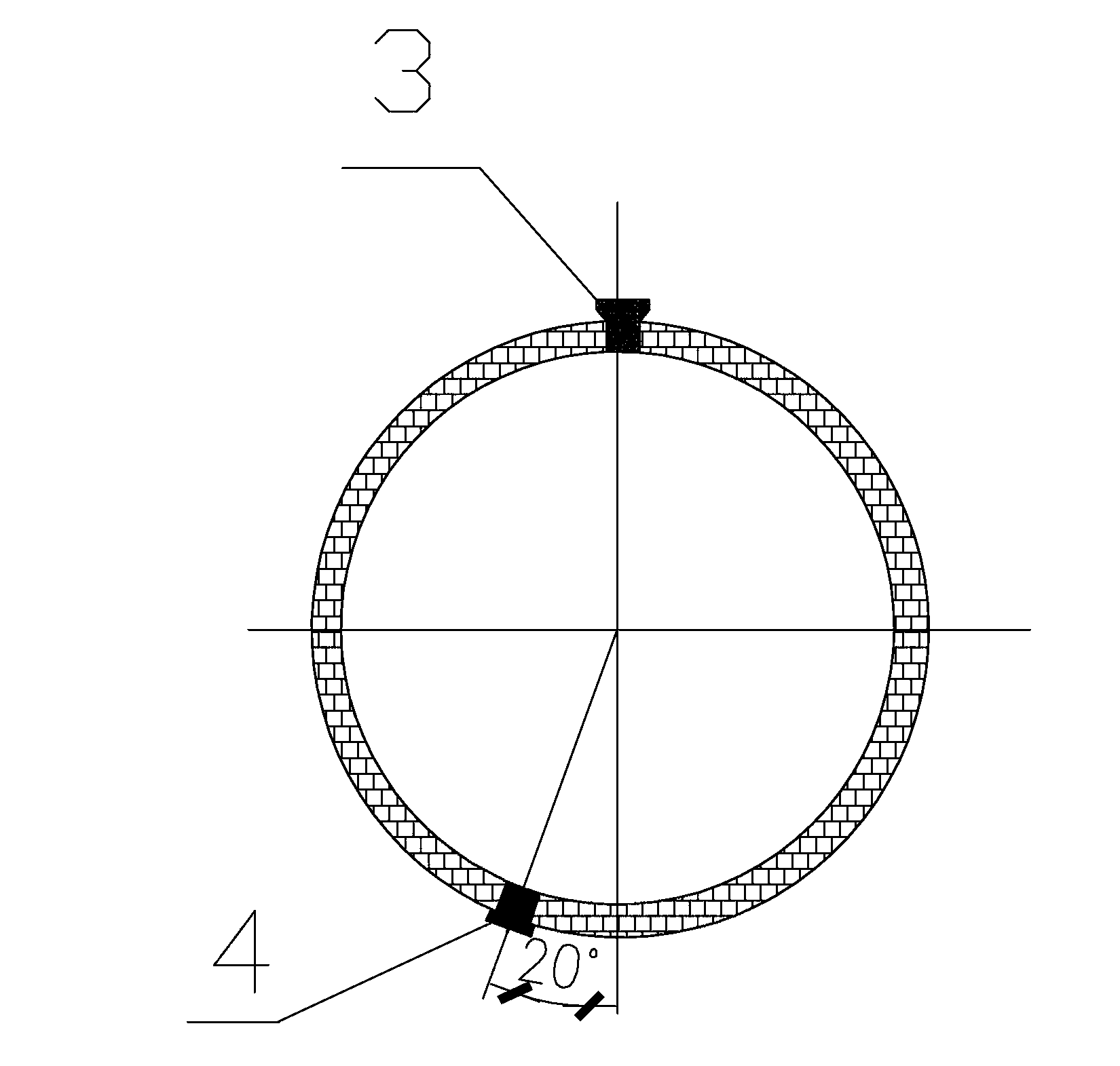

Detection device and method of reflected light

InactiveCN102023052AAvoid errorsAvoid difficult situations that cannot be handled in real timePhotometryPulleyLight intensity

The invention discloses detection device and method of reflected light. The device comprises a probe and a detection rack, wherein the probe comprises a probe tube, a sensor and an embedded processor; the probe tube is a telescopic internal and external nested casing; a light-absorbing coating material is coated on the inner wall of the probe tube; a variable aperture is arranged at a probe tube opening; the sensor and the embedded processor are arranged at the bottom of the casing; the detection rack comprises a base plate, a support sliding rod, a connecting rod and semicircular sliding rails; and movable sliding wheels are arranged at the bottom of the base plate. The invention can effectively avoid the errors brought by detection data which are manually recorded and acquisition data processed at low efficiency in the prior art; and in the invention, by using the embedded processor to control the telescopic sensor probe, the intensity of the synthesized reflected light on the periphery of a reflecting body for one or more times from different angles and different distances can be acquired and the measured angle and distance can be recorded simultaneously.

Owner:大连金冠霖科技股份有限公司

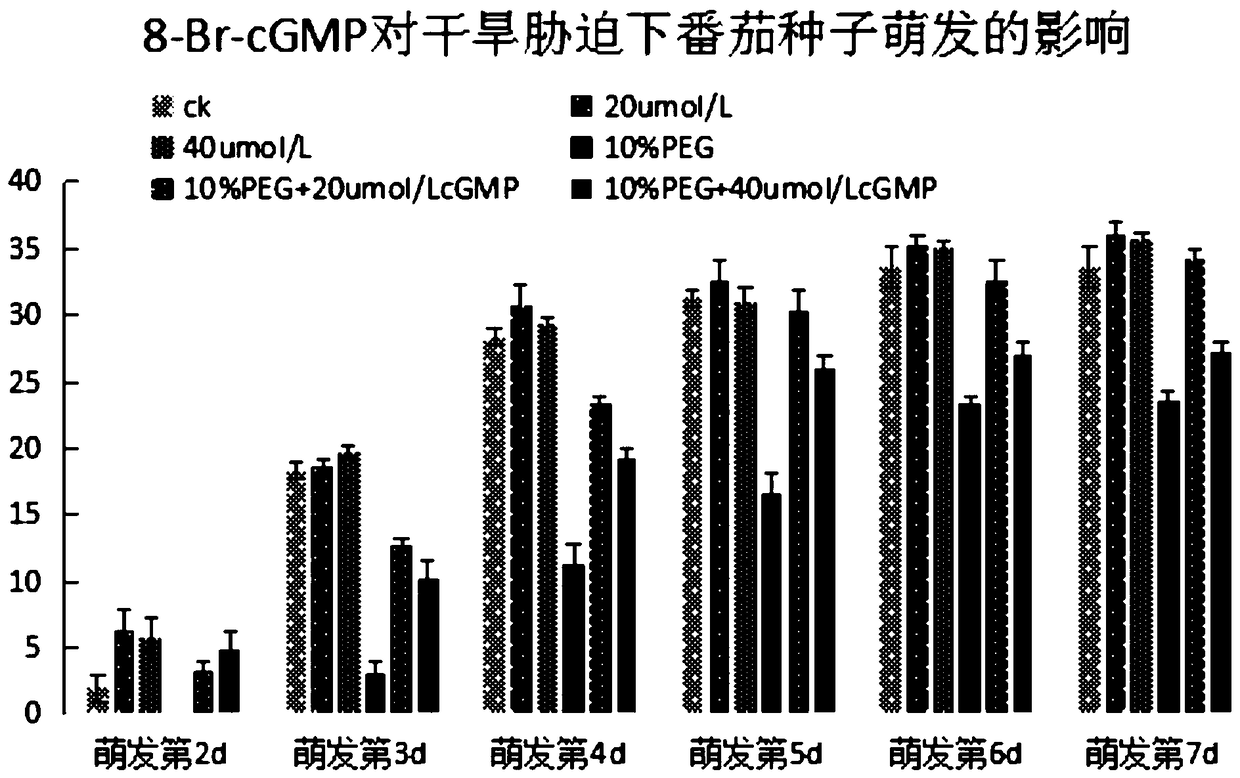

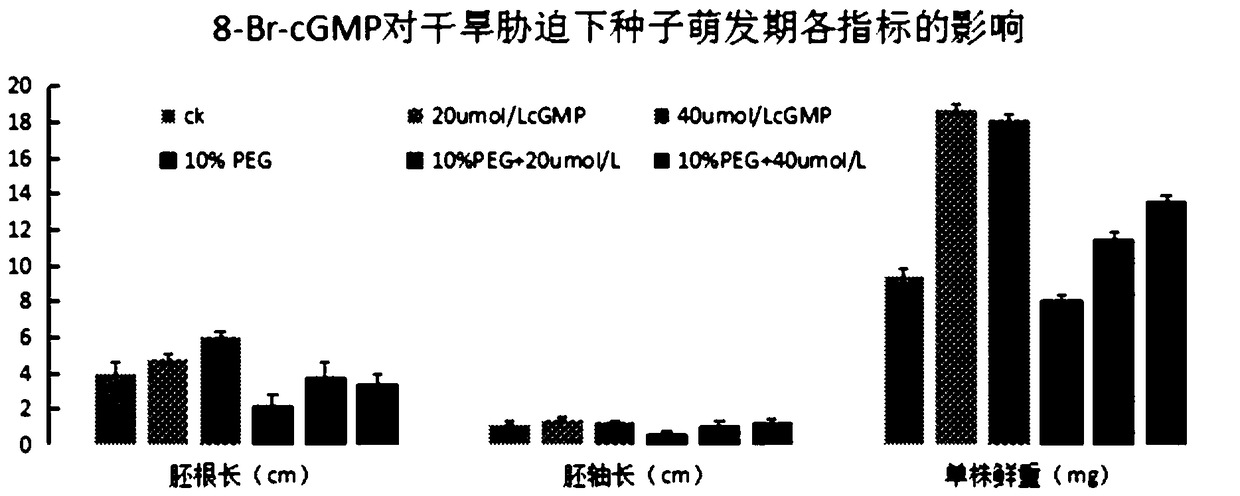

Method for increasing tomato seed germination rate under drought stress and observation device

ActiveCN108207167AImprove germination ratePromote germinationSeed and root treatmentMembrane permeabilityRepeatability

The invention provides a method for increasing a tomato seed germination rate under drought stress. According to the invention, 8-Br-cGMP with appropriate concentration is used for processing tomato seeds, and the germination rate of the tomato seeds under drought stress can be increased. In addition, the invention also provides a seed germination observation device by simulating natural light induction condition, and comparison and form observation of the seeds in a tomato seed germination test are realized. The used 8-Br-cGMP has membrane permeability and high utilization rate, the low-concentration membrane 8-Br-cGMP can obviously increase the tomato seed germination rate under drought stress. The used device has the advantages of simple structure, simple operation and strong repeatability, and can be used for real-time observation of different seed germination conditions, in addition, the processing and repetition of the device are more flexible.

Owner:GANSU AGRI UNIV

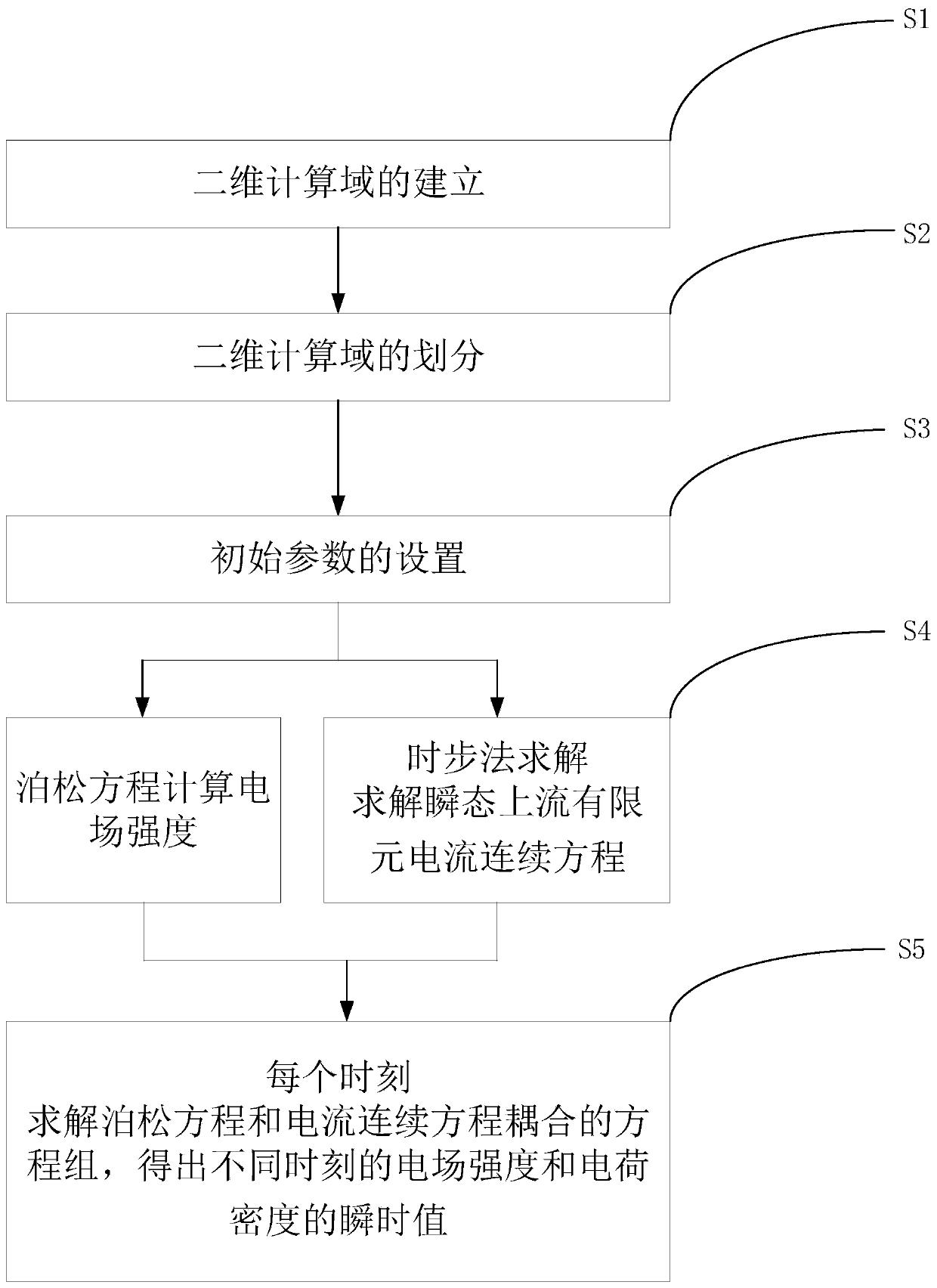

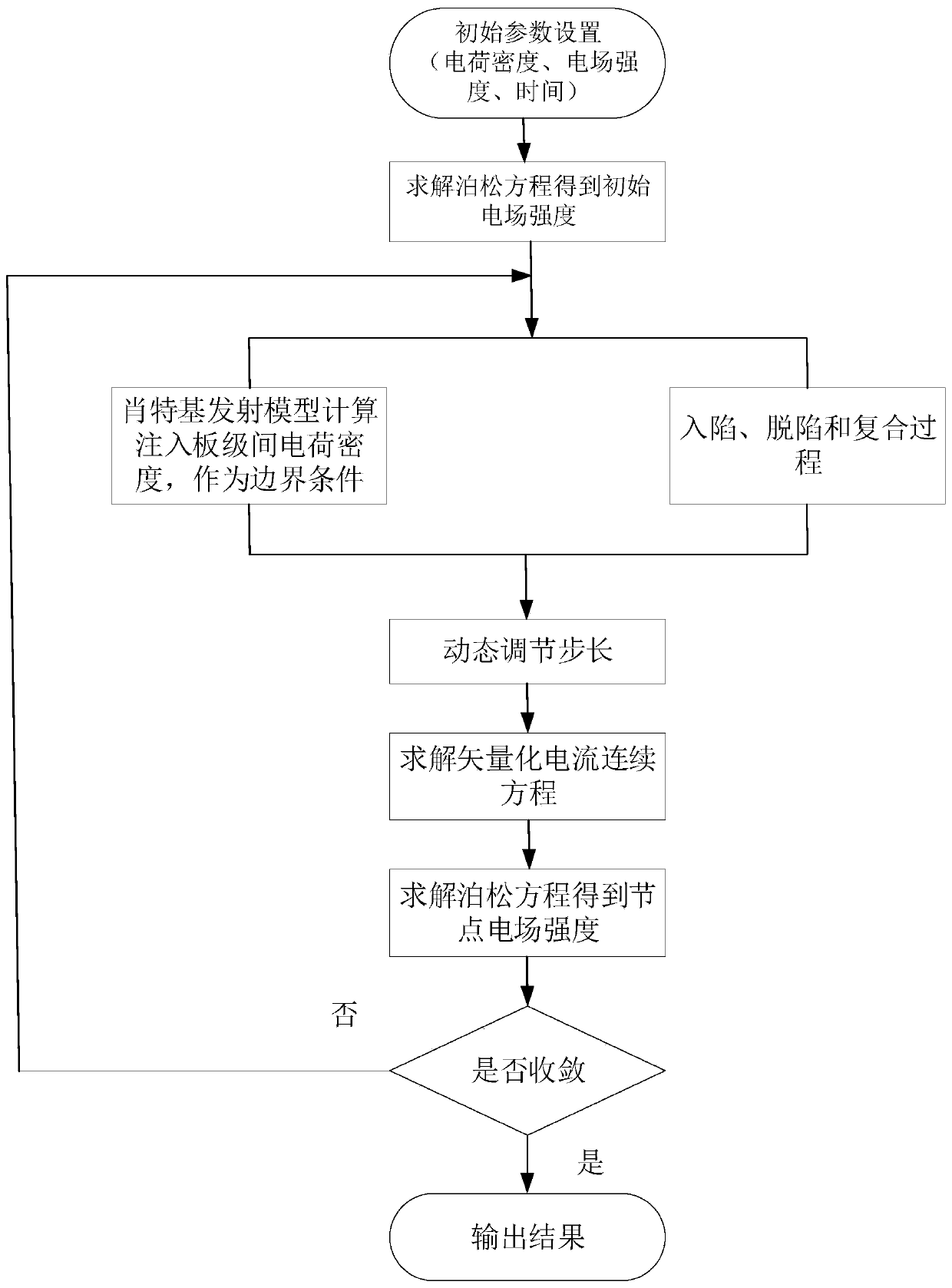

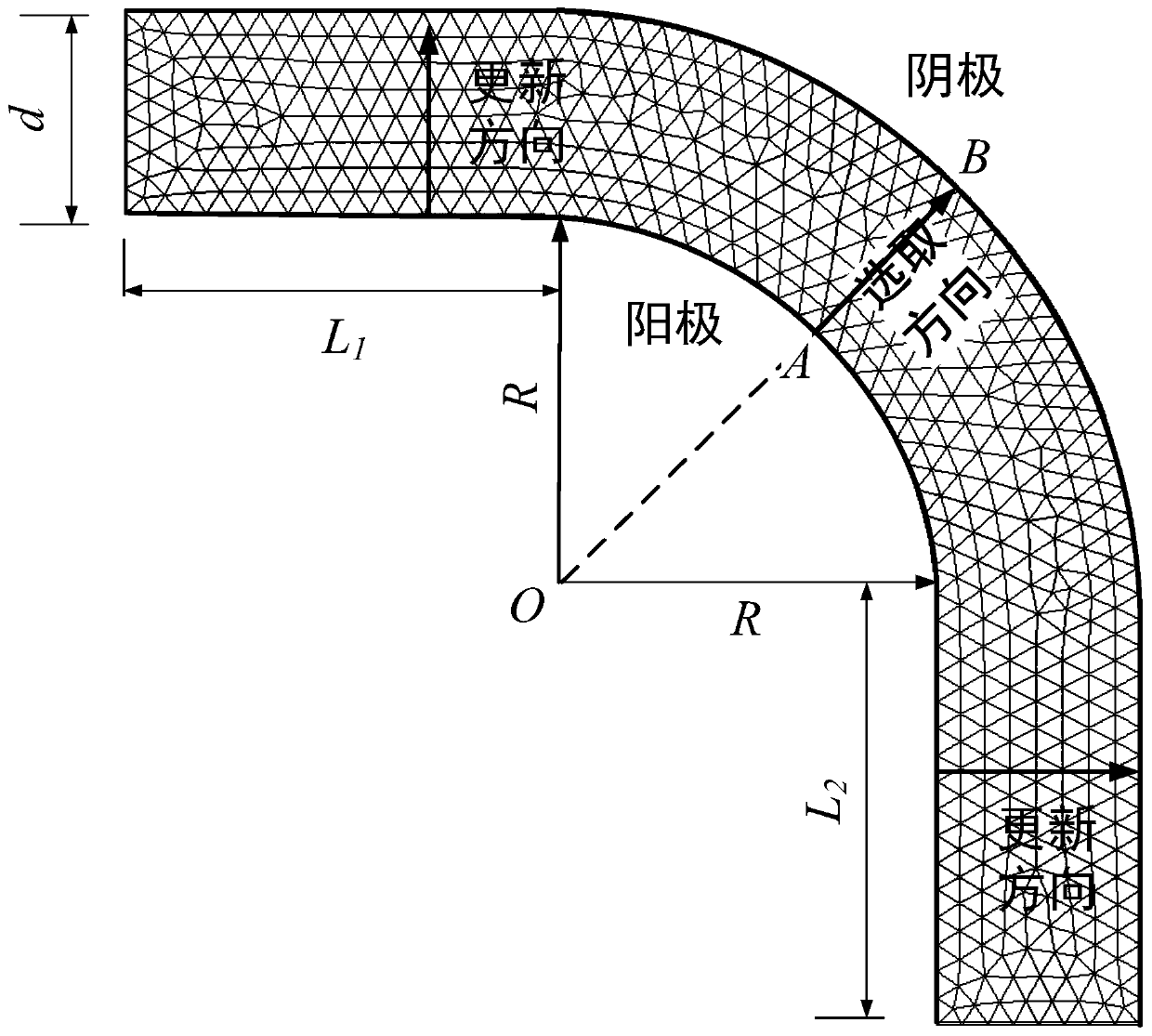

Oil-paper insulation space charge calculation method and system based on time-step transient up-flow finite element

PendingCN111400954AEasy to calculateAccurate calculationDesign optimisation/simulationElectrical field strengthTransformer

The invention relates to the field of internal insulation design and optimization calculation of a high-voltage DC converter transformer, and specifically discloses an oil-paper insulation space charge calculation method and system based on a time-step transient up-flow finite element. The oil-paper insulation space charge calculation method comprises the following steps: (1) establishing an oil-paper insulation space charge two-dimensional calculation domain; (2) solving a Poisson equation by adopting a finite element method to obtain electric field intensity; (3) discretizing the current continuous equation to construct a finite element form; (4) adding the influence of the temperature gradient on the carrier mobility; (5) solving a current continuous equation based on a time-step transient up-flow finite element method; (6) continuously performing iterating, and solving a solution of an equation formed by coupling a Poisson equation and a current continuous equation in each instantaneous value. According to the method, the time-step method is introduced into transient finite element calculation, so space charge numerical calculation is more accurate, convergence is better, and the method can be applied to internal insulation calculation and optimization design of the high-voltage DC converter transformer.

Owner:GUANGXI UNIV

Intelligent note filing equipment

InactiveCN104777820AFlexible processing capacityFlexible transmissionTotal factory controlCoin/paper handlersComputer scienceIntelligent sensor

Owner:YANCHENG HARLEY POWER DRIVE & INTELLIGENT EQUIP IND RES INST CO LTD

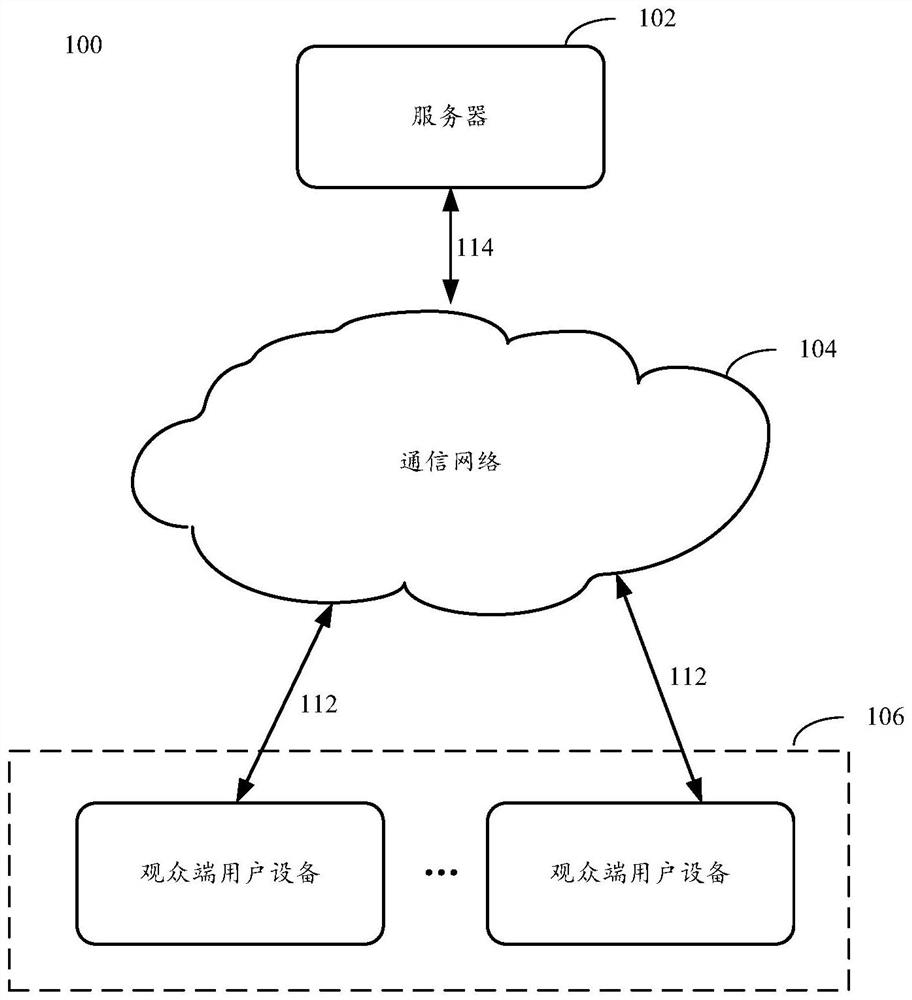

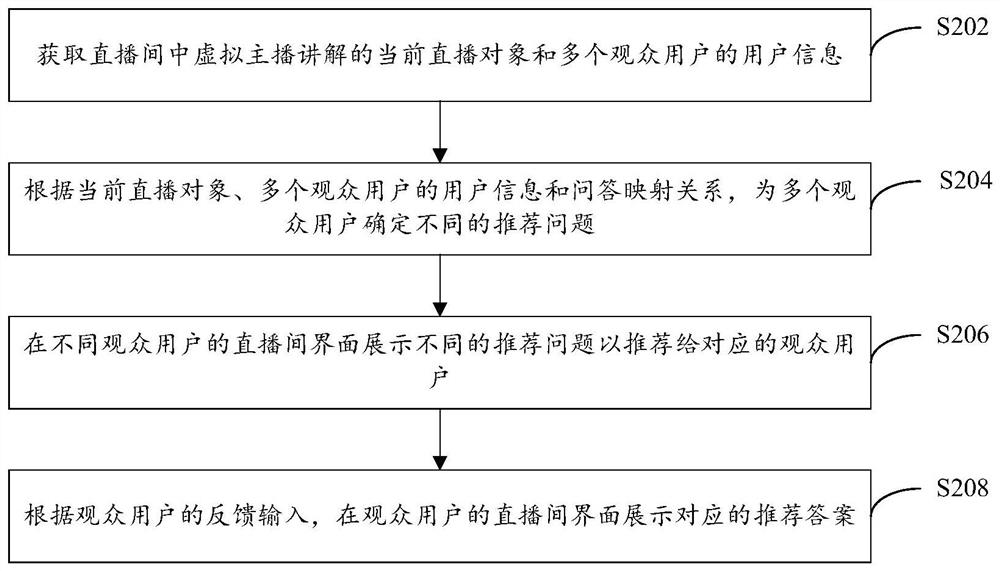

Live broadcast question and answer and interface display method and computer storage medium

PendingCN114430490AImprove the efficiency of asking questionsImprove experienceSelective content distributionEngineeringQuestions and answers

The embodiment of the invention provides a live broadcast question and answer method, a live broadcast interface display method and a computer storage medium, the live broadcast question and answer method is suitable for a live broadcast room using a virtual anchor to perform live broadcast, and the method comprises the following steps: obtaining a current live broadcast object explained by the virtual anchor in the live broadcast room and user information of a plurality of audience users, the user information comprises attribute information and / or user preference information of the audience user; according to the current live broadcast object, the user information and a question and answer mapping relationship, determining different recommendation questions for the plurality of audience users, the question and answer mapping relationship representing a corresponding relationship between a plurality of live broadcast objects and a plurality of question and answer pairs; displaying different recommendation questions on live broadcast room interfaces of different audience users so as to recommend the different recommendation questions to the corresponding audience users; and according to feedback input of the audience user, displaying a corresponding recommendation answer on a live broadcast room interface of the audience user.

Owner:ALIBABA (CHINA) CO LTD

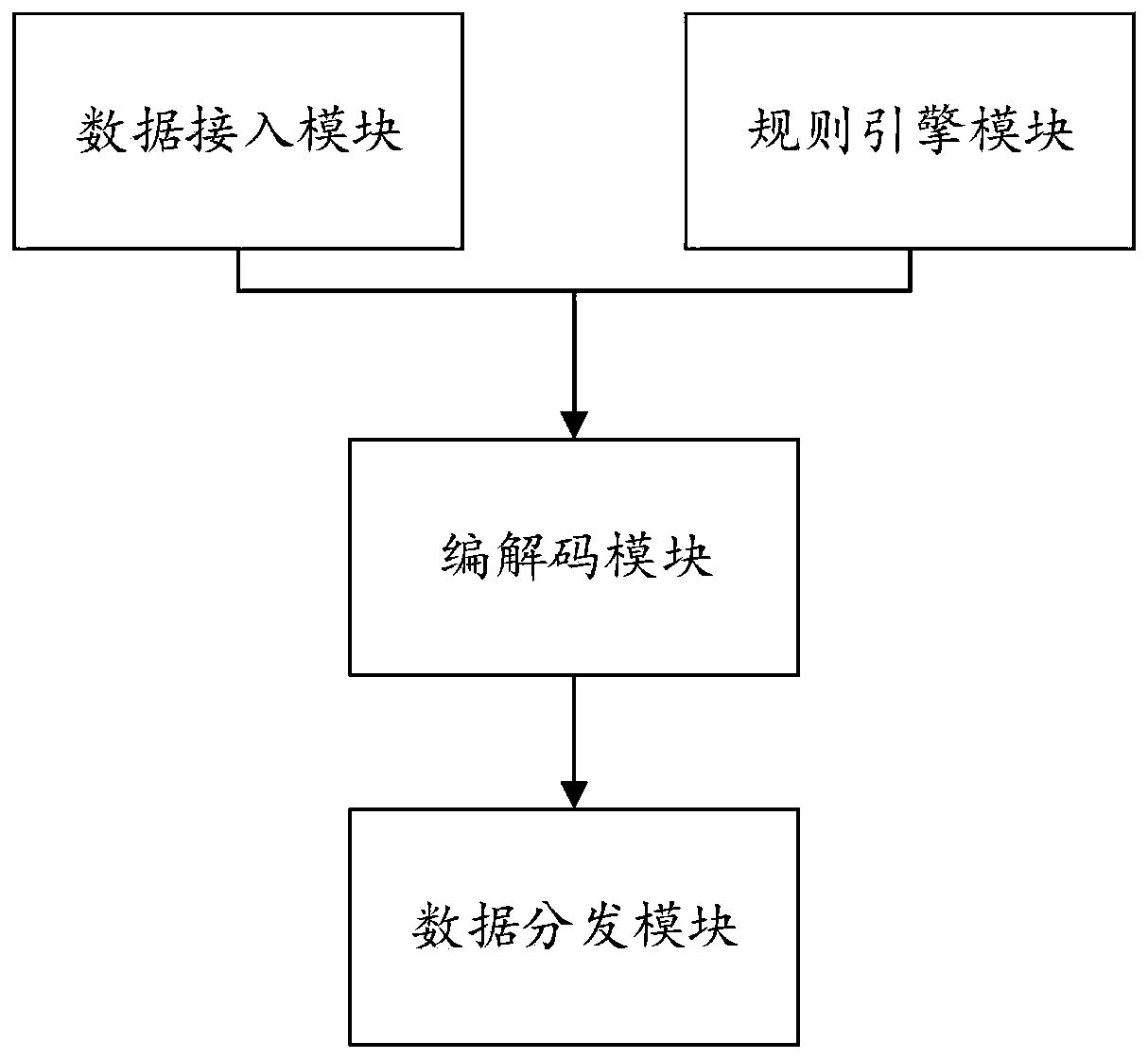

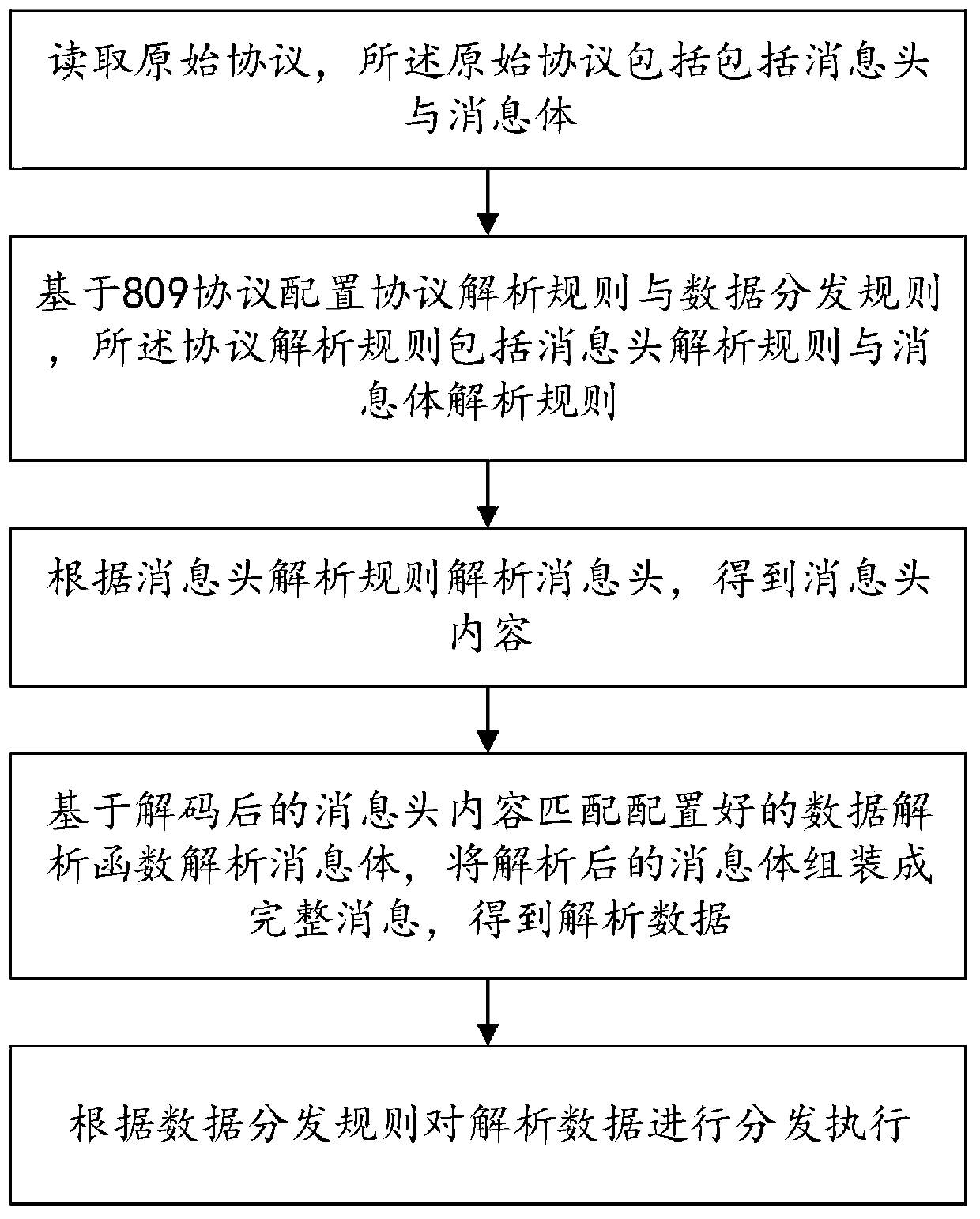

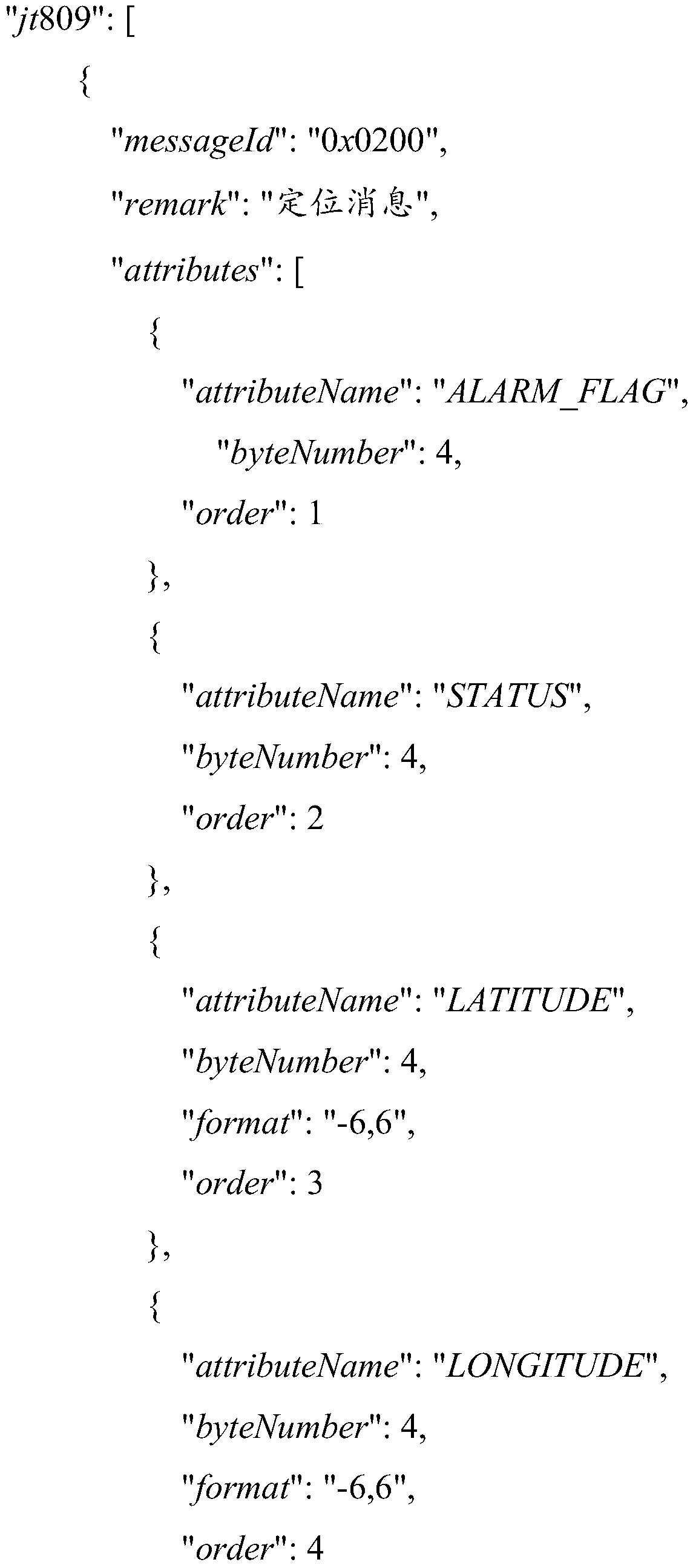

Data analysis and distribution system and method based on 809 protocol

PendingCN111212056AReduce development costsReduce maintenance costsTransmissionAnalysis dataTheoretical computer science

The invention discloses a data analysis and distribution system and method based on an 809 protocol, and the system comprises a data access module which is used for the access of to-be-analyzed and to-be-distributed original protocol data, a rule engine module which is used for configuring a protocol analysis rule and a data distribution rule based on the 809 protocol, an encoding and decoding module which is used for reading the protocol analysis rule in the rule engine module and carrying out primary analysis and secondary analysis on the original protocol data to obtain analysis data, and adata distribution module which is used for reading the data distribution rule in the rule engine module and distributing and executing the analysis data. Enterprises can develop superior and subordinate management platforms through an 809 protocol, various protocol versions in the 809 protocol can be flexibly adapted and paired, according to the method, the data is analyzed in a configuration rule mode according to different protocol versions and message types, the analyzed data can be flexibly processed and distributed, the 809 protocol system development and maintenance cost of manufacturers is reduced, the production efficiency is improved, services are rapidly adjusted, and protocol upgrading is adapted.

Owner:CHINA POWER IND INTERNET CO LTD

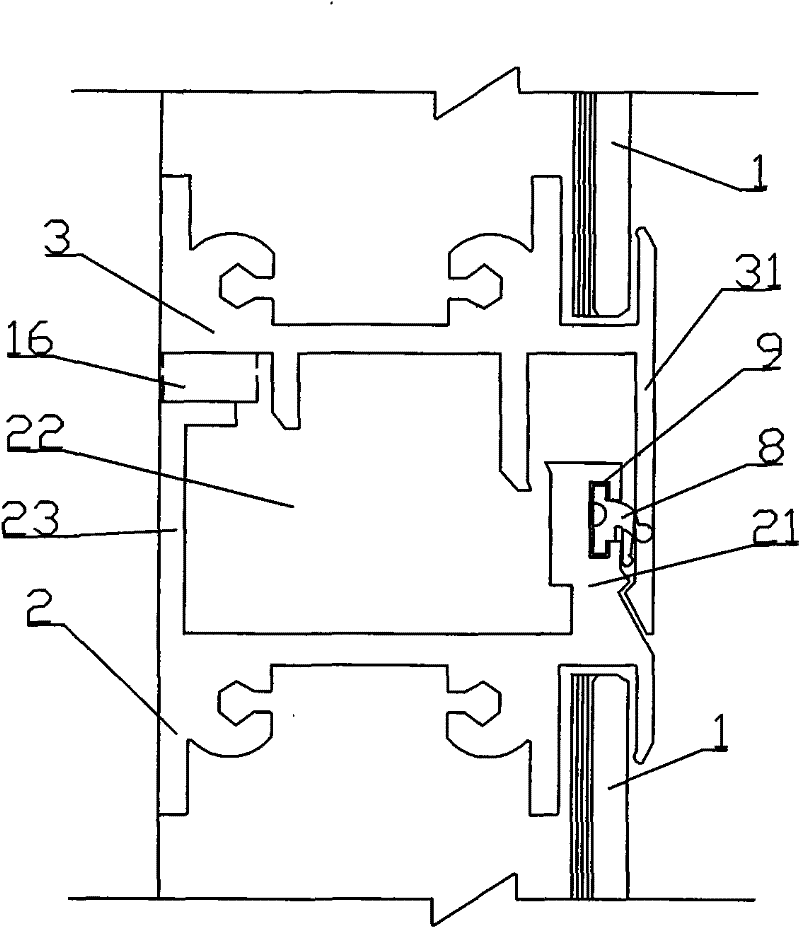

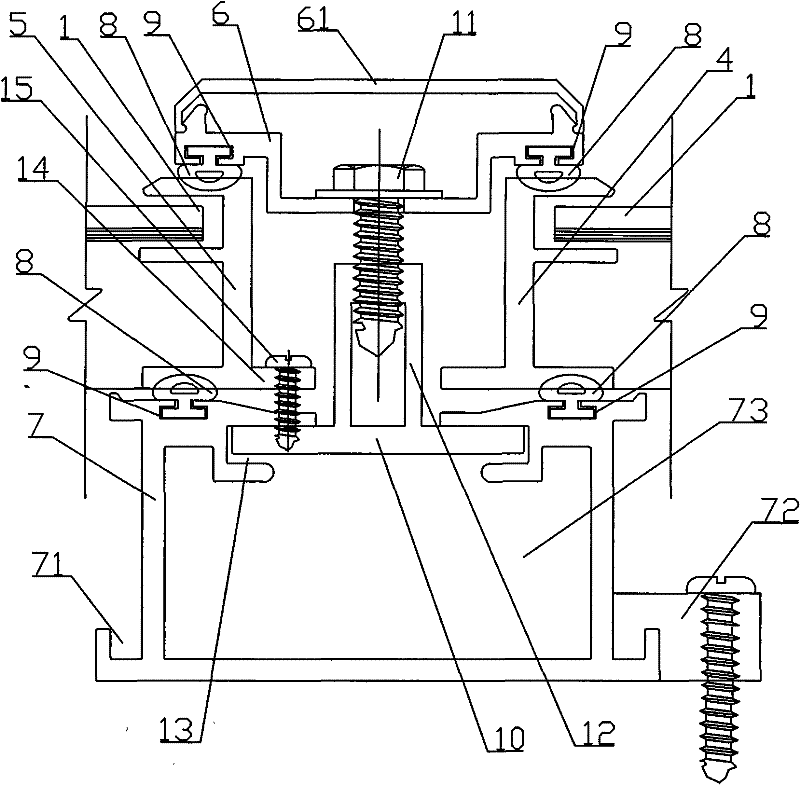

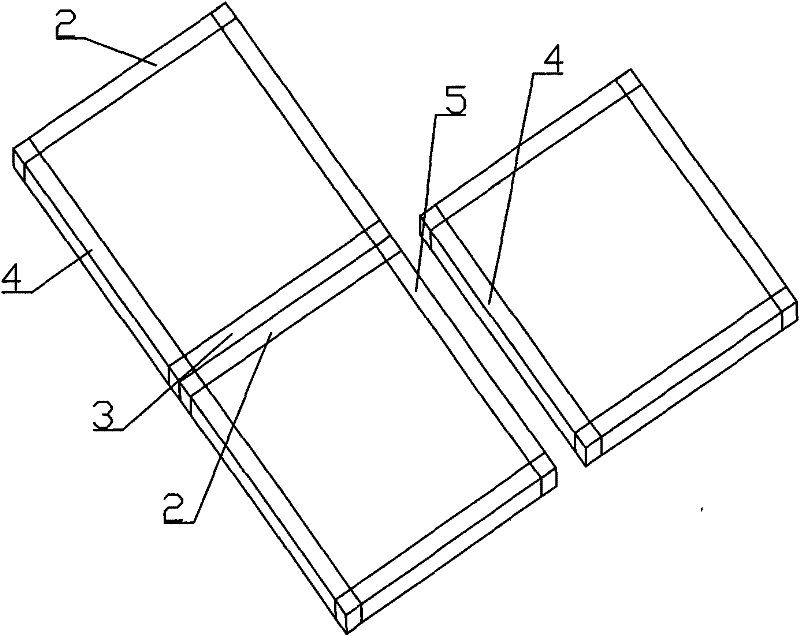

Roofing photovoltaic installation system

ActiveCN101614058BLess frame typesSimple structurePhotovoltaic supportsRoof covering using slabs/sheetsPhotovoltaic mounting systemMarine engineering

The invention relates to the technical filed of photovoltaic system installation combined with the building into a whole, in particular to a roofing photovoltaic installation system, which comprises upper frames, lower frames, left frames and right frames of photovoltaic components, and keels arranged below longitudinal gaps between the photovoltaic components; the external lateral surfaces of the lower frames are provided with extended lower frame panels; the external lateral surfaces of the corresponding upper frames are provided with extended upper frame panels; the lower frame panels of the photovoltaic components cover the upper frame panels of the adjacent photovoltaic components; the left frames and the right frames of the photovoltaic components are erected on the keels; and longitudinal pressure plates are arranged in the gaps between the left frames and the right frames of the adjacent photovoltaic components, cover the gaps and are compressed by pressure plate connecting pieces and the left frame and the right frame of the adjacent photovoltaic components. The whole system reduces the required types; the left frame and the right frame can be consistent; in addition, thestructure is relatively simplified, the installation and the replacement are more convenient, and the connection and side retracting treatment with different types of buildings are more flexible.

Owner:TRINA SOLAR CO LTD

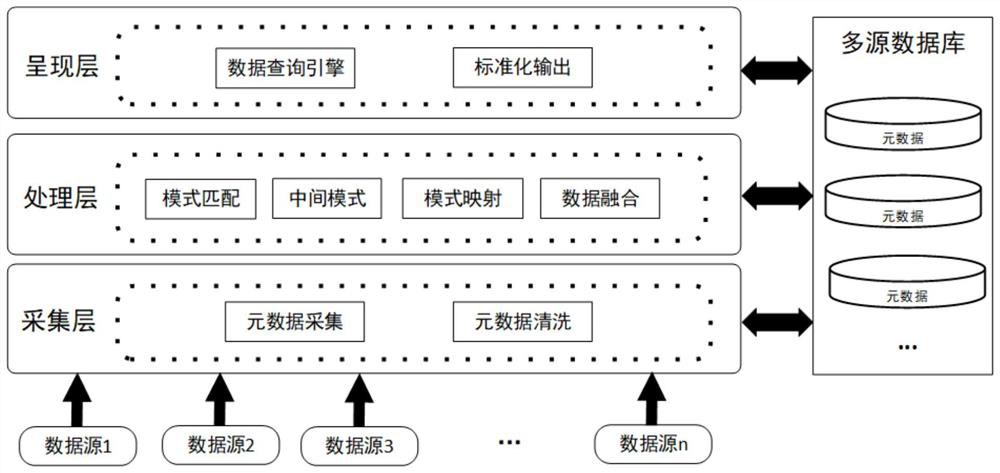

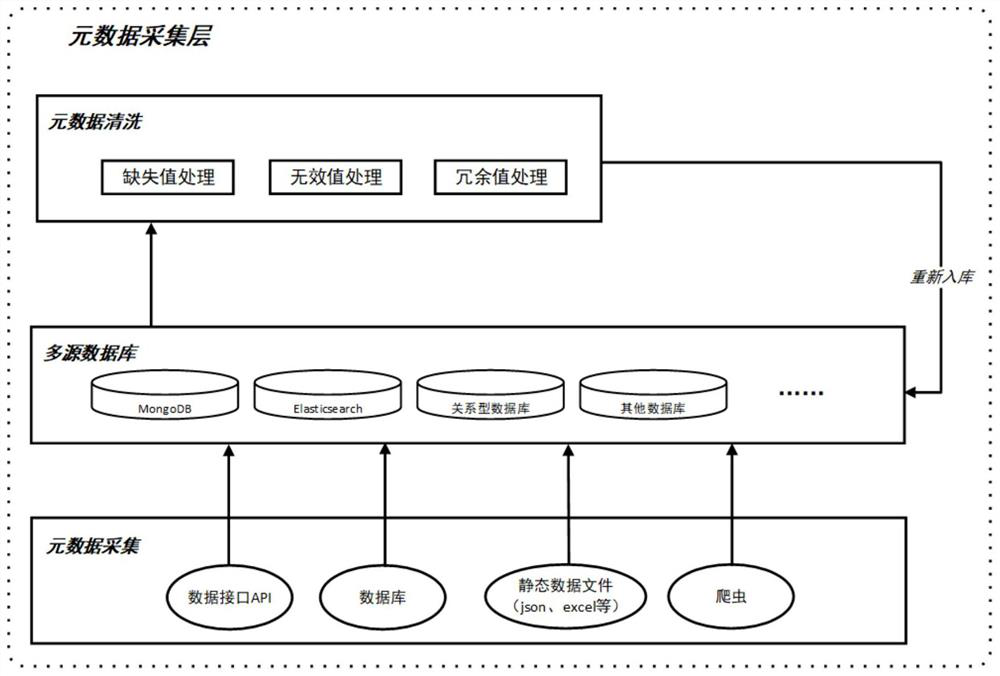

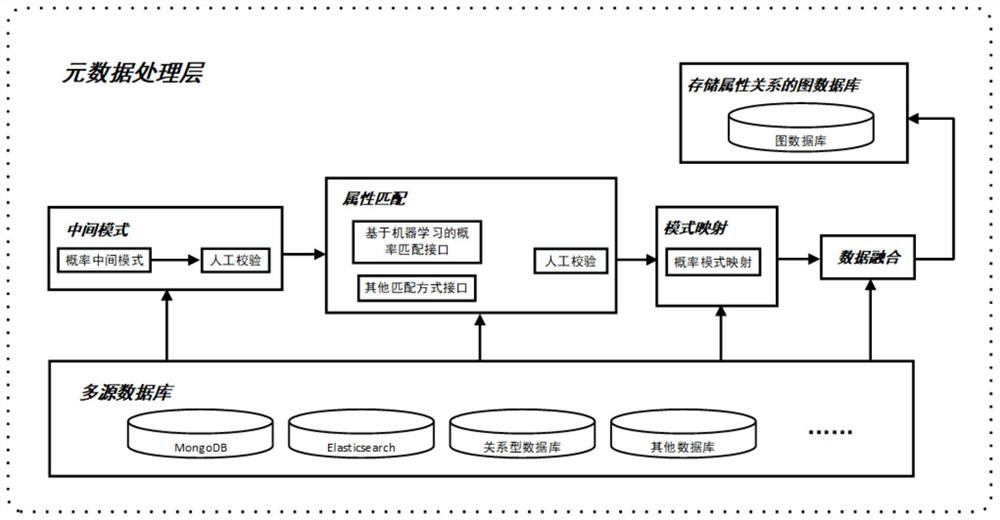

Scientific and technological resource integration system based on multi-source database

PendingCN113312342AFlexibility and adaptabilityTroubleshoot integration issuesDatabase queryingDatabase management systemsData querySource data

The invention discloses a scientific and technological resource integration system based on a multi-source database. The system comprises an acquisition layer, a processing layer, a presentation layer and the multi-source database. The acquisition layer comprises a metadata acquisition module and a metadata cleaning module and is used for receiving scientific and technological resource metadata of a plurality of data sources, storing the multi-source heterogeneous scientific and technological resource metadata into a unified storage format and cleaning the data; the processing layer comprises an intermediate mode module, a mode matching module, a mode mapping module and a data fusion module, and is used for mapping the heterogeneous scientific and technological resource metadata into a unified semantic structure; the presentation layer comprises a data query engine and a standardized output module and is used for outputting the scientific and technological resource metadata into a specific standard form; and the multi-source database comprises multiple databases for storing the scientific and technological resource metadata, is connected with the acquisition layer, the processing layer and the presentation layer, and is used for centrally storing scientific and technological resources from different sources.

Owner:BEIHANG UNIV

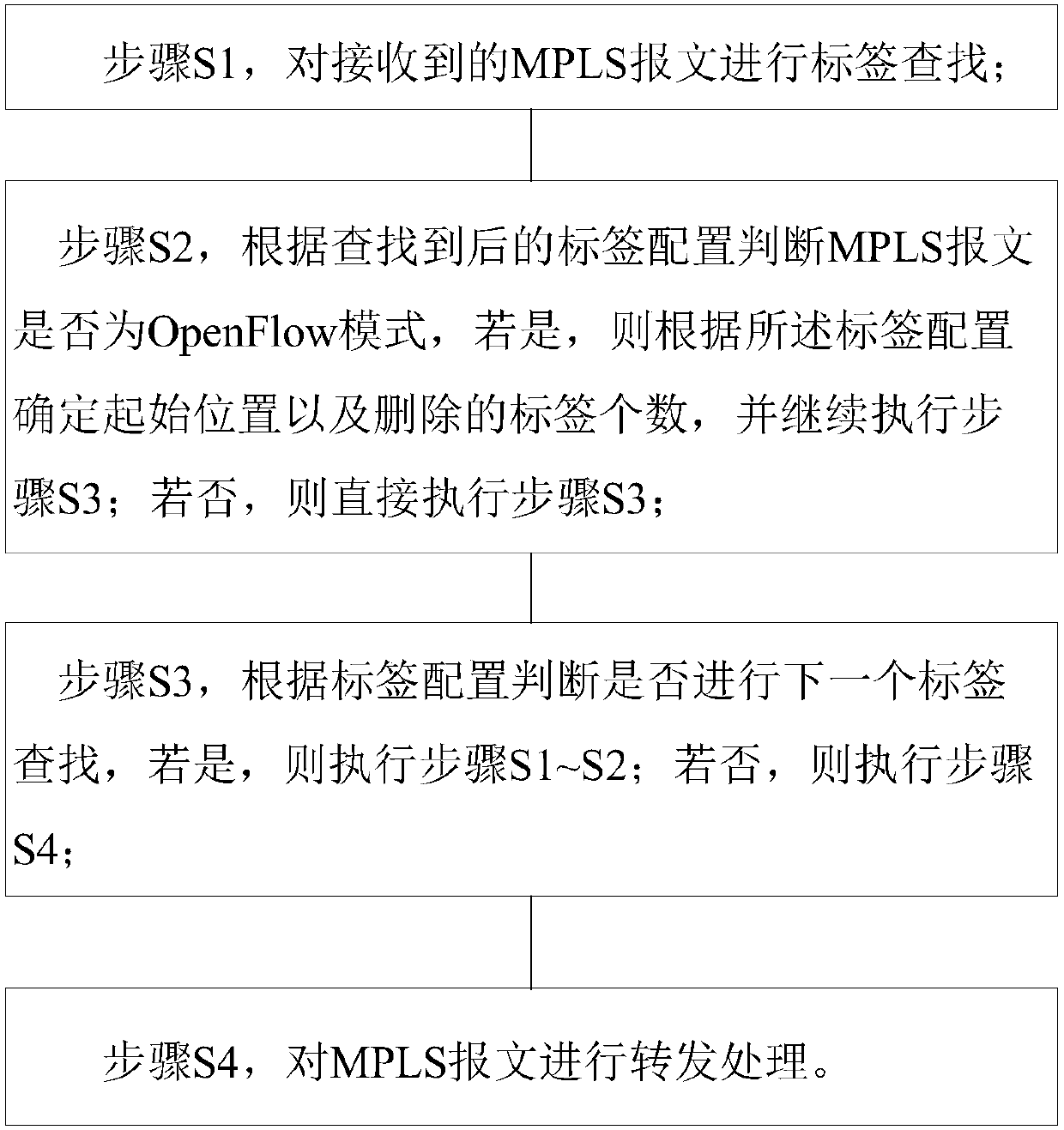

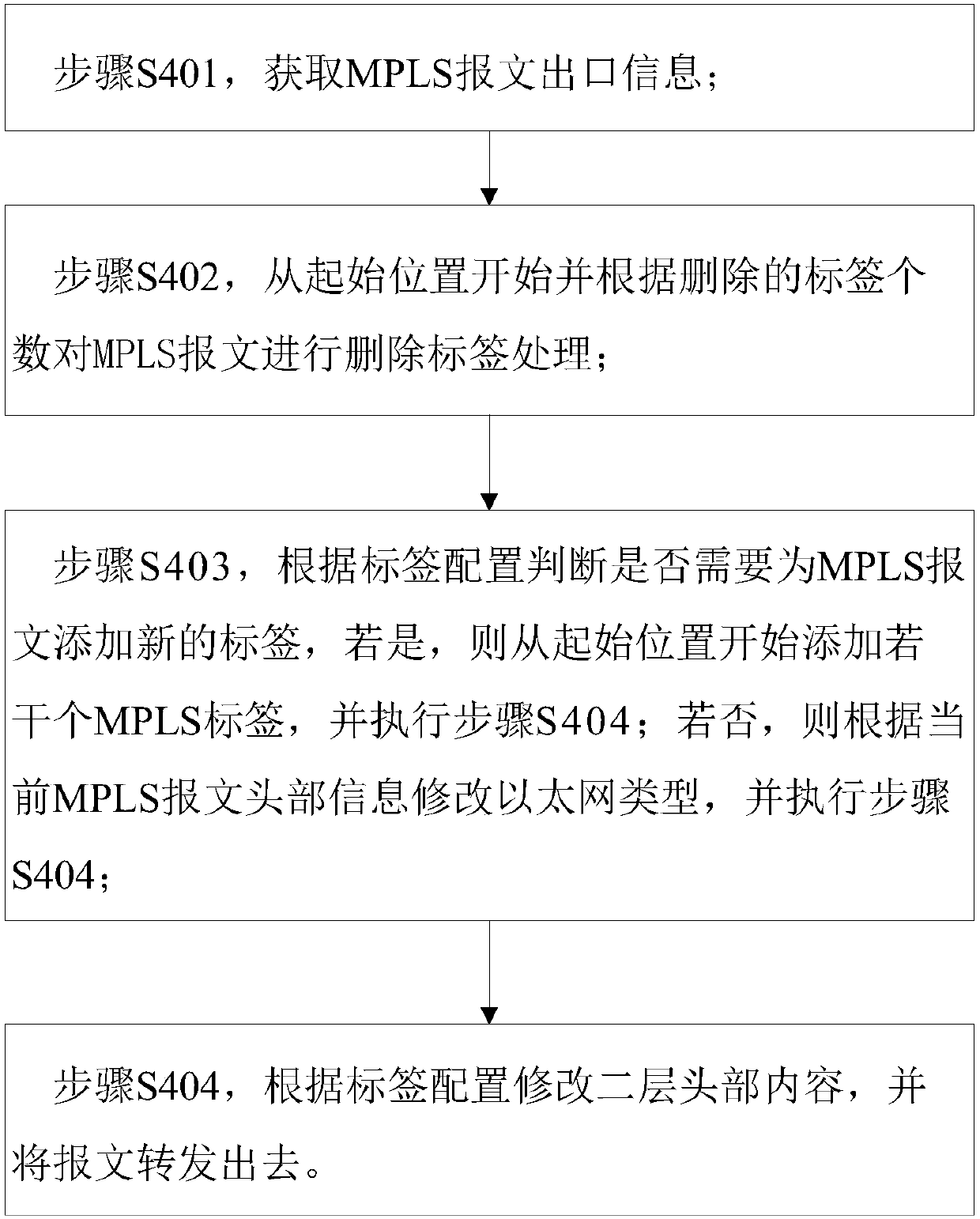

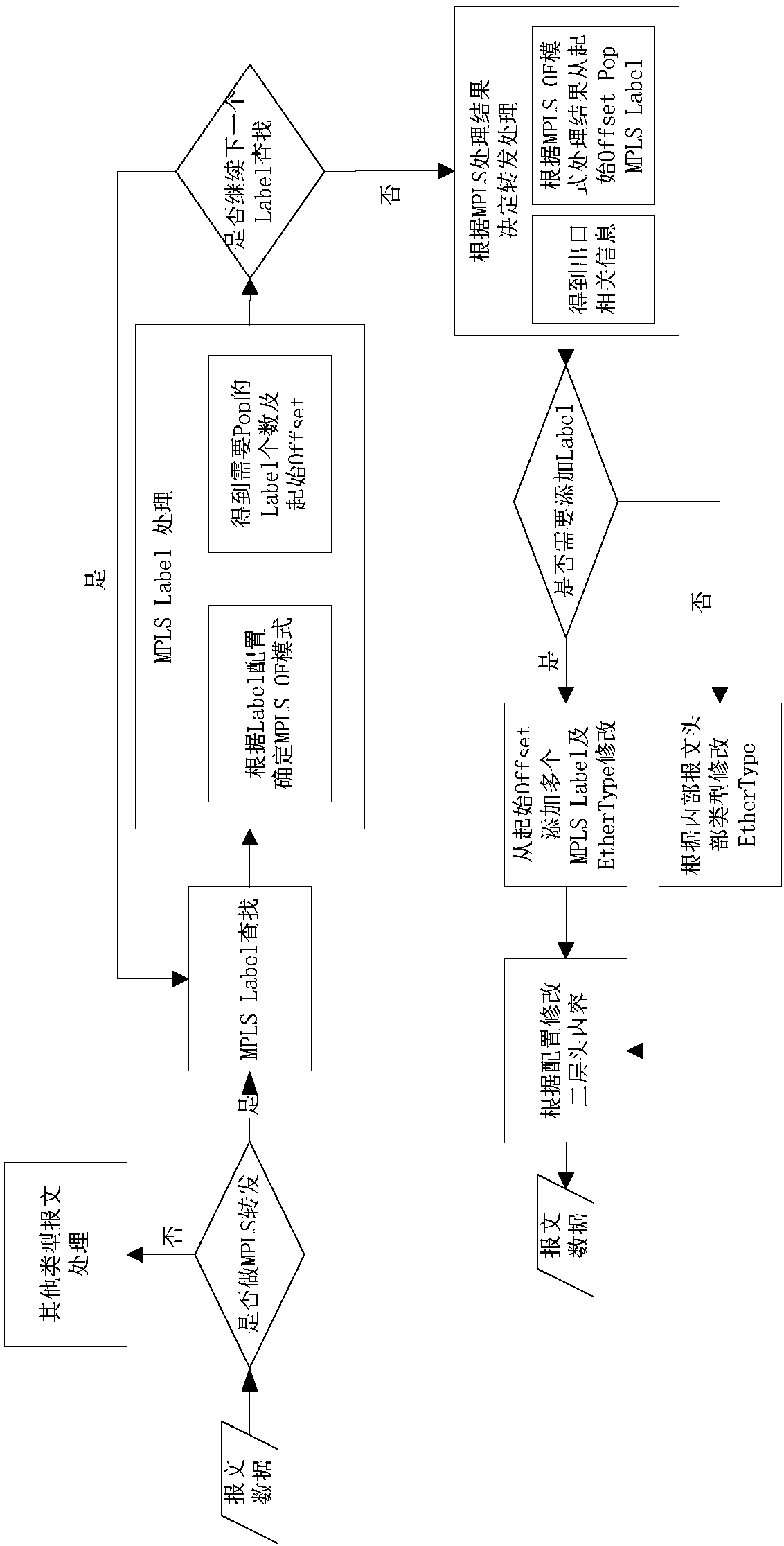

OpenFlow-based MPLS message processing method and device

ActiveCN107770071AFlexible editingFlexible processing capacityData switching networksUser needsOpenFlow

The invention discloses an OpenFlow-based MPLS message forwarding method and device. The method includes the following steps: performing tag lookup for a received MPLS message, judging whether the MPLS message is in an OpenFlow mode based on the configuration of the found tag, if yes, determining a starting location and the number of deleted tags according to the tag configuration, and determiningwhether to perform the next tag lookup according to the tag configuration; if not, directly determining whether to perform the next tag lookup according to the tag configuration; if the tag lookup isneeded, performing the next tag lookup; and finally forwarding the MPLS message. According to the scheme of the invention, the operation of adding or deleting tags of an MPLS message tag stack can beflexibly carried out, and more changeable user needs can be met.

Owner:SUZHOU CENTEC COMM CO LTD

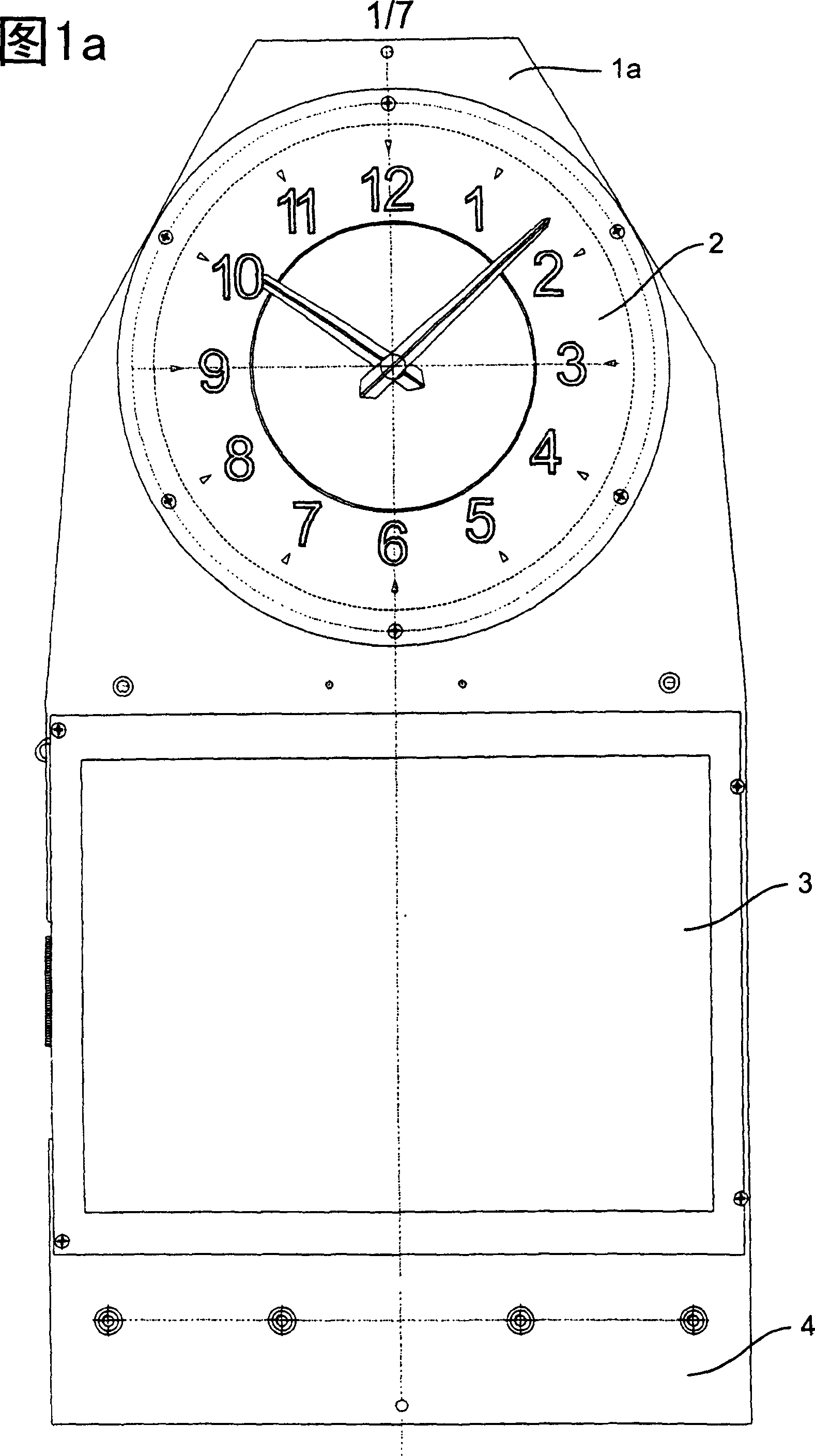

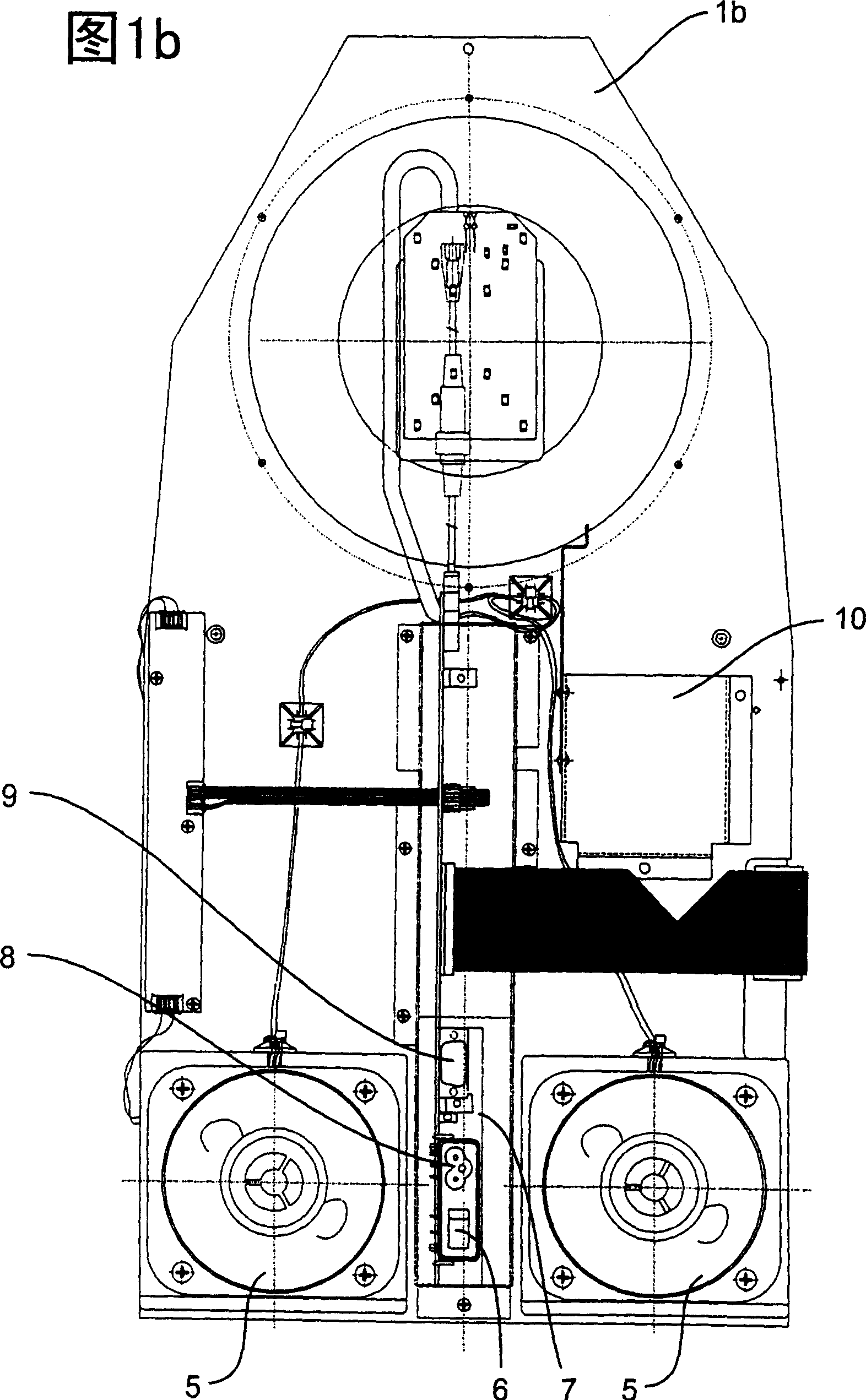

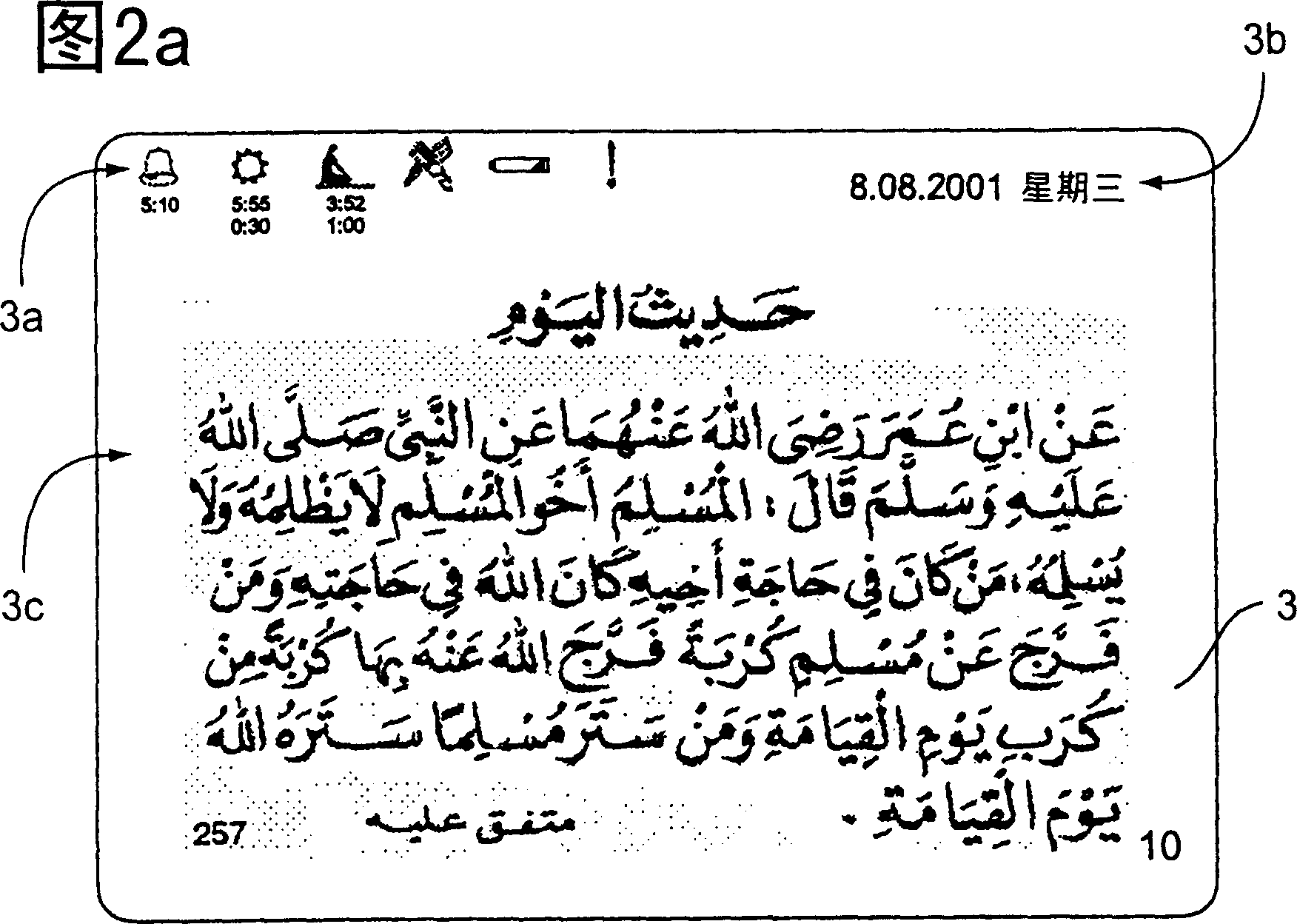

Pray clock

InactiveCN1444119AFlexible processing capacityMechanical clocksVisual indicationsComputer scienceOccurrence time

Owner:阿里・阿布加塞姆・优素福・舍巴尼

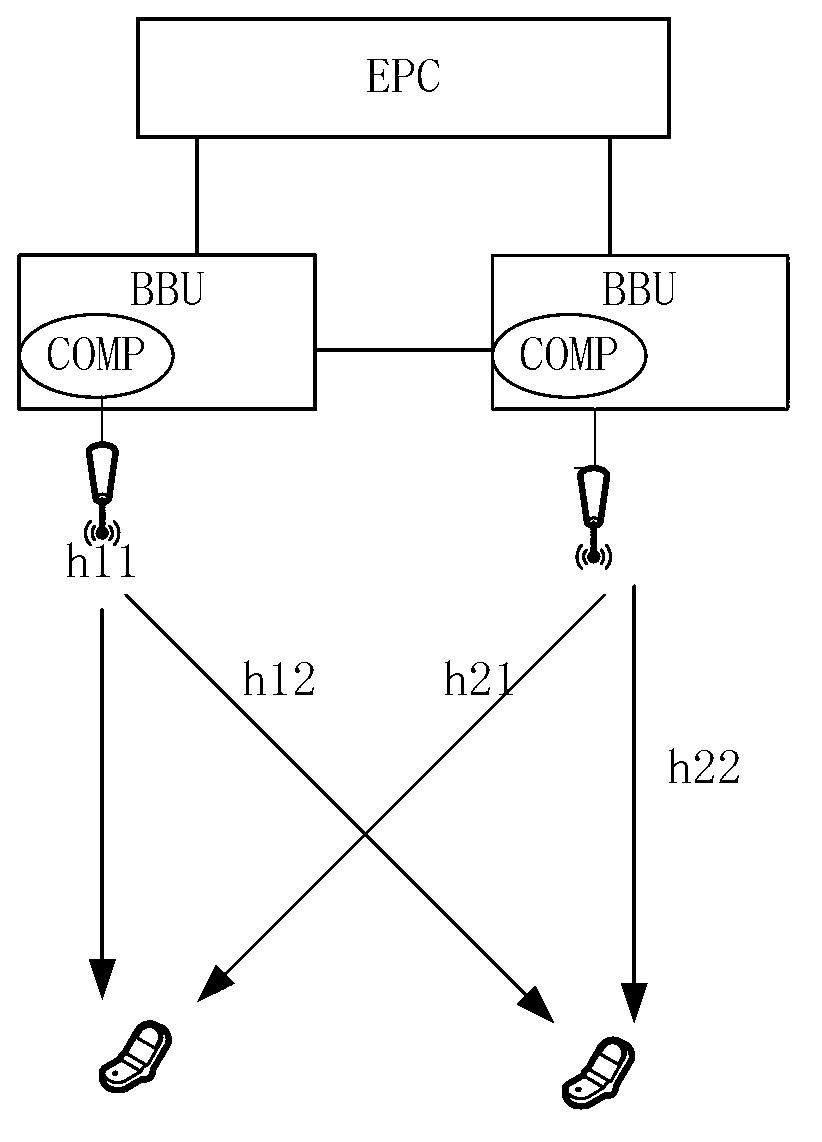

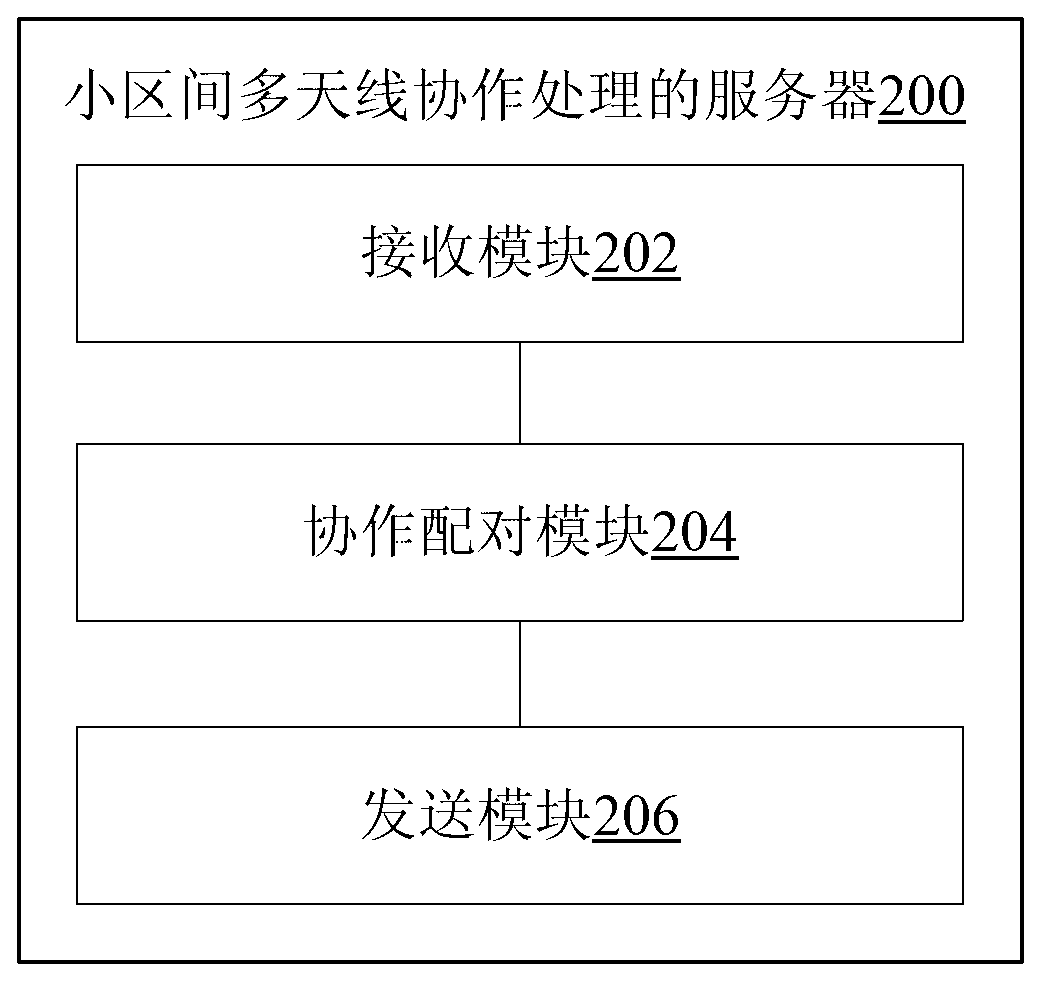

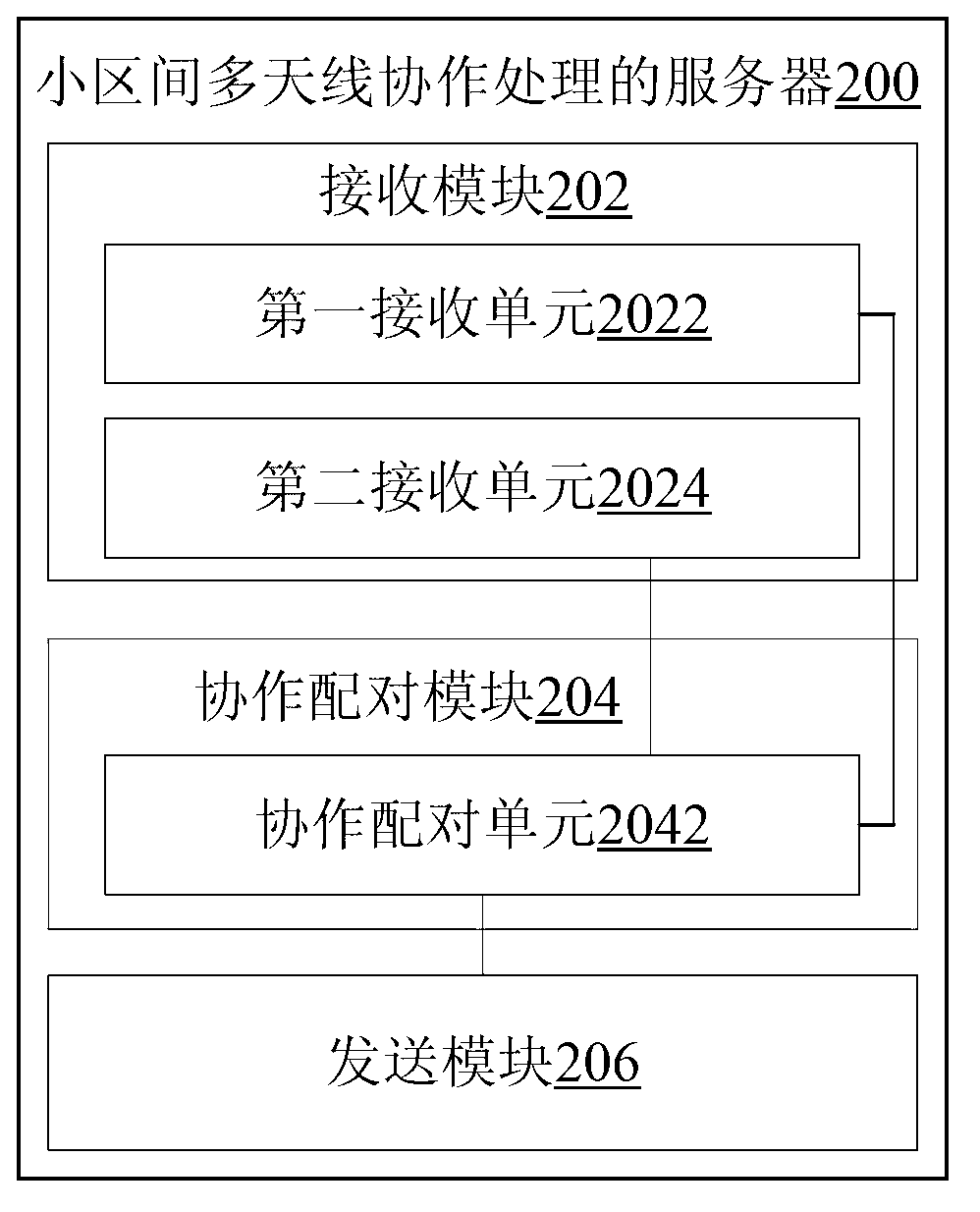

Server for inter-cell multi-antenna cooperative processing, system and method

InactiveCN102711189AFlexible processing capacityIncrease flexibilityError preventionNetwork traffic/resource managementStructure of Management InformationMultiple point

The invention provides a server for inter-cell multi-antenna cooperative processing, a system and a method. The method comprises the steps that the server receives information from a base station, and the information is used for performing coordinated multiple point transmission COMP processing to terminals; the server performs COMP coordinated pairing to the terminals according to the information; and the server sends coordination result information to a base station requiring COMP coordination. The server, the system and the method solve the problem in related technologies that as a base station accomplishes inter-terminal COMP coordinated pairing algorithm, a base station with proper processing capability to meet processing requirements of different scenes can not be designed, thereby improving the flexibility of processing capability of a system of COMP collaborative technology, and enriching the system structure of the collaborative technology.

Owner:ZTE CORP

Horizontal type molten pool smelting process outside furnace and dedicated device thereof

InactiveCN103031447AAdaptableFlexible processing capacityRotary drum furnacesCrucible furnacesElectric heatingSmelting process

The invention discloses a horizontal type molten pool smelting process outside a furnace and a dedicated device thereof. The process comprises the following steps: uniformly mixing copper concentrate, quartz stone, limestone and cold materials; continuously adding the copper concentrate, the quartz stone, the limestone and the cold materials into a molten pool smelting furnace; blowing enrichment oxygen and compressed air by an oxygen lance inserted into the bottom of the molten pool smelting furnace to strongly stir a smelting body; rapidly finishing mass transfer and heat transfer processes in the molten pool, so as to generate copper sulfonium, smelting slag and high temperature flue gas. The process is characterized in that the copper sulfonium and the smelting slag continuously flow into an electric heating front bed through a smelting body chute; the copper sulfonium and the smelting slag are stilled, settled and separated in the electric heating front bed to obtain the copper sulfonium and the furnace slag; the copper sulfonium enters a converting furnace through a copper sulfonium outlet; the furnace slag is discharged through a furnace slag chute; the dedicated device comprises a main body of the horizontal type molten pool smelting furnace outside the furnace and the electric heating front bed; and the devices are connected through the chutes. With the adoption of the horizontal type molten pool smelting process outside the furnace and the dedicated device thereof, the copper sulfonium is separated from the smelting slag outside the furnace; the amount of copper contained in the slag is smaller than 0.5%, the slag can be directly discarded; and various low-grade copper mine such as gold concentrate and high arsenic ore can be processed.

Owner:申殿邦 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com