Patents

Literature

168 results about "Copper mine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

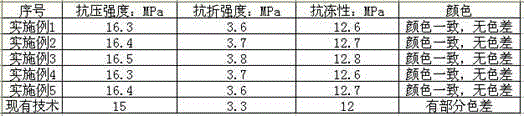

Building hollow brick using industrial tailings and preparation method thereof

InactiveCN102503263AHigh compressive strengthImprove softening effectSolid waste managementBrickAdhesive

The invention relates to the field of building hollow bricks, in particular to a building hollow brick using industrial tailings and a preparation method thereof. The invention especially relates to a burning-free and steaming-free building hollow brick prepared by using industrial iron tailings, copper mine tailings, boric sludge and other industrial wastes and a preparation method thereof. The building hollow brick comprises the following raw materials in percentage by weight: 30-80% of industrial tailings, 5-30% of at least one of cement, fly ash and slag, 0-50% of aggregate, 0-35% of inorganic adhesive and 0-5% of other additives, wherein the water accounts for 3-20% of the total weight of at least one of cement, fly ash and slag and the industrial tailings. The hollow brick is obtained by adding at least one of cement, fly ash and slag to the industrial tailings, vibrating the mixture or molding the mixture under the pressure, releasing the mold after curing the mixture and then continuing to cure the mixture for 28 days or to a strength of more than 5 MPa at room temperature. The hollow brick provided by the invention has the advantages of high strength, good freezing resistance, capability of realizing industrial tailing resources and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

Glaze material for Jun red glaze and process for preparing Jun porcelain from glaze material

The invention discloses a glaze material for Jun red glaze and a process for preparing Jun porcelain from the glaze material. The glaze material consists of the raw materials of melilite, quartzite, calcite, white feldspar, copper ore, ZnO, SnO, GuO, talc, BaO, zirconium silicate and spodumene. The preparation process comprises the following steps: firstly, smashing roughcast raw materials and conducting moulding to fire a plain roughcast, then immersing the plain roughcast into slurry of the glaze material of the Jun red glaze for glazing, and when the slurry adhered on the surface of the plain roughcast is dried, putting the plain roughcast in a kiln for firing, so as to obtain the Jun red glaze Jun porcelain. According to the glaze material for the Jun red glaze and the process for preparing the Jun porcelain by utilizing the glaze material, spodumene and zirconium silicate are added in the glaze material for the Jun red glaze, so that the fired Jun red glaze Jun porcelain is bright in color, mild and smooth in glaze surface, and uniform in cracking, and breaks through the condition that the general Jun red glaze Jun porcelain is dim in color and nonuniform in cracking; the Jun porcelain is taken as the specialty of China, and represents the advanced level of the manufacture process of China, and the social value of the Jun porcelain is improved.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

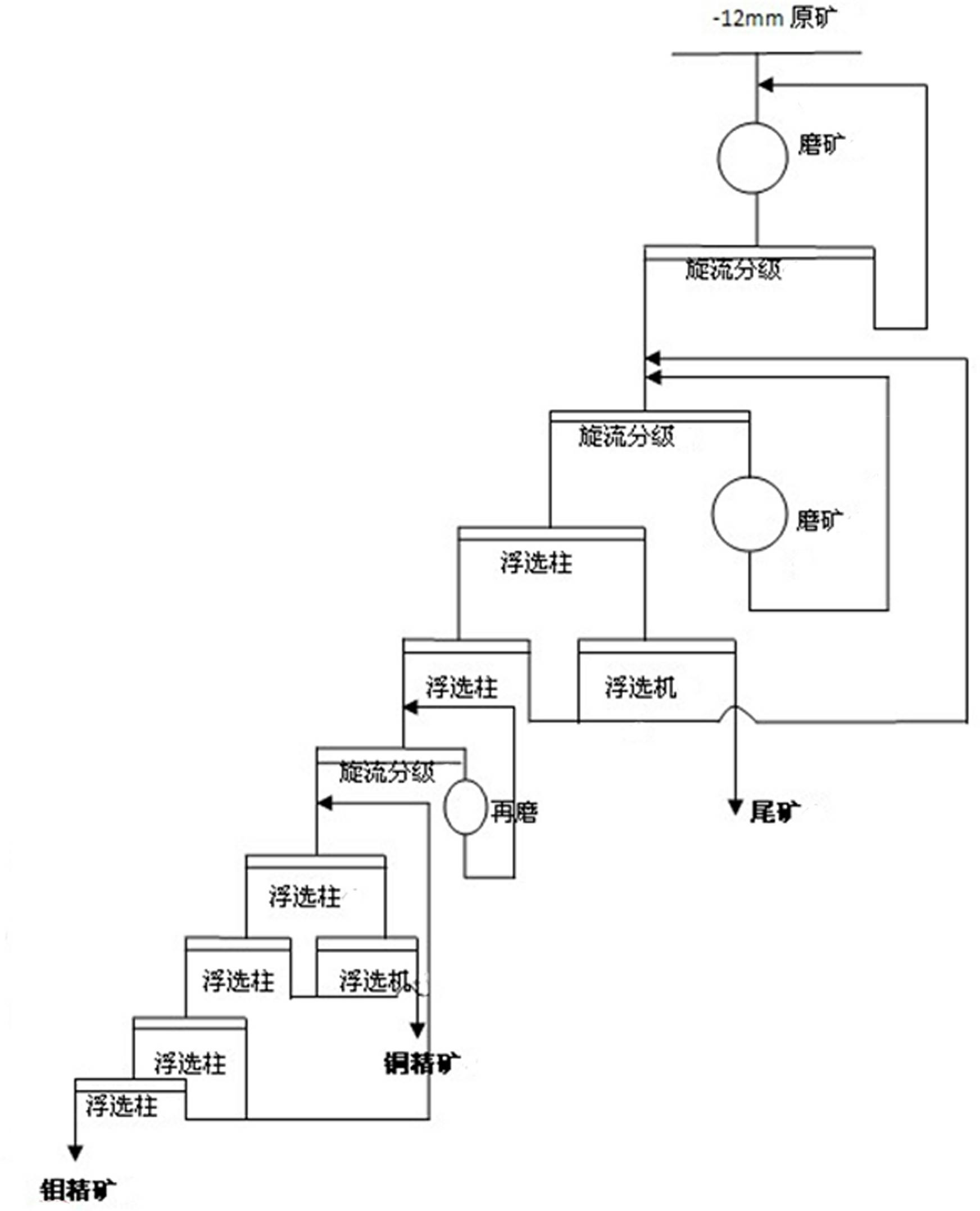

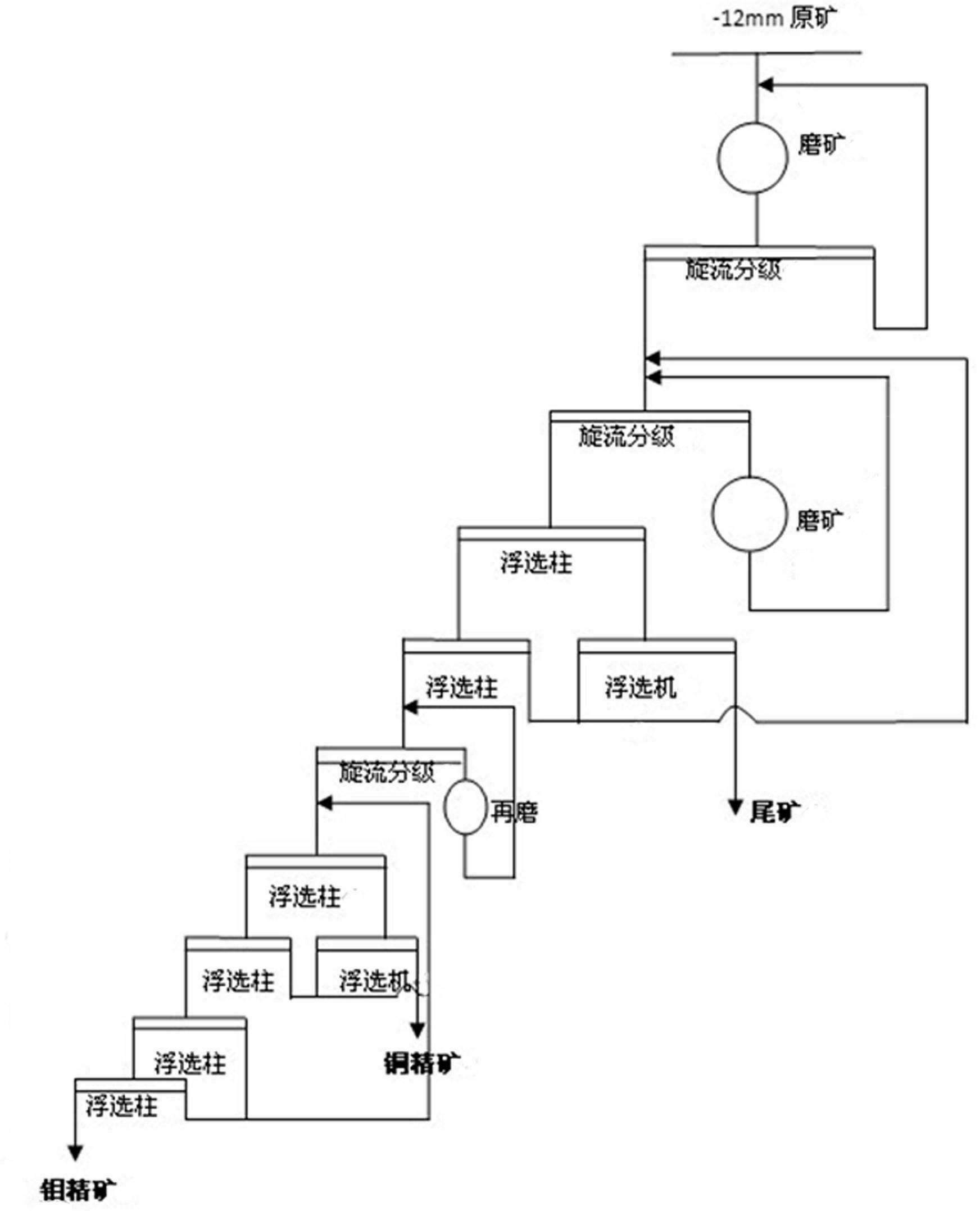

Column-machine combined separation method of difficultly-separated low-grade copper-molybdenum ore

The invention relates to a column-machine combined separation method of difficultly-separated low-grade copper-molybdenum ore. The difficultly-separated low-grade copper-molybdenum ore is skarn-type copper mine of associated molybdenum ore in China. The method comprises the following process flows: twice closed circuit grinding, bulk flotation, primary roughing, secondary scavenging and primary selecting, bulk concentrate regrinding, copper inhibition and float molybdenum separation, wherein roughing, primary scavenging and three-time selecting namely selecting I, selecting II and selecting III are adopted. In the whole process, a flotation column and a flotation machine are used for joint operation. According to the invention, high concentrate product can be obtained, the ore dressing recovery percentage is improved, the process is simple and the cost is relatively low.

Owner:BAIYIN NONFERROUS GROUP

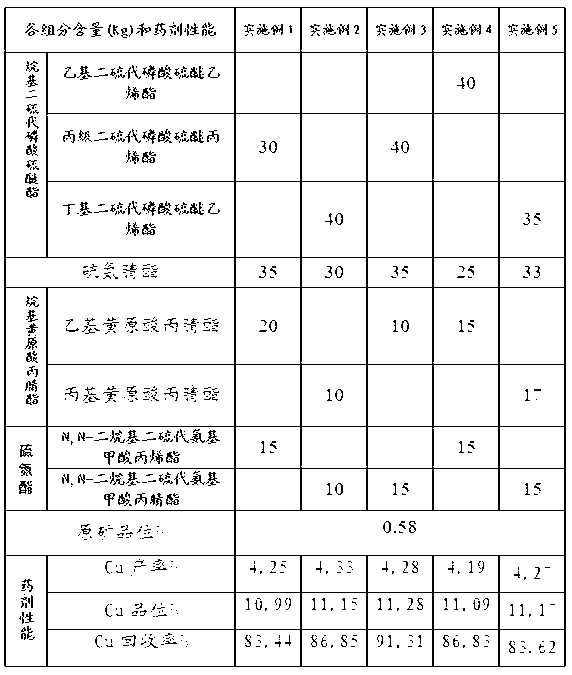

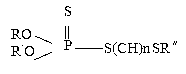

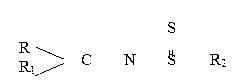

Collecting agent for high-sulfur copper mine

The invention relates to a flotation agent for a copper mine and discloses a high-efficiency collecting agent for a high-sulfur copper mine. The collecting agent comprises the following materials in parts by weight: 30-40 parts of alkyl phosphorodithioic acid thioether ester, 25-35 parts of cyanoethyl diethyl dithionocarbamate, 10-20 parts of alkyl xanthic acid propionitrile ester and 10-15 parts of sulfur-nitrogen ester. The collecting agent for the high-sulfur copper mine has double functions of collecting and foaming, is good in selectivity and high in collecting ability, can realize high-efficiency separation of copper from sulfur in a low pH value (approximately 5) range, can effectively reduce the consumption of lime in the floatation process, can effectively increase the grade and recovery rate of concentrate, and has a wider application scope.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Copper mine waste oxidized ore hillock ecological restoration method

InactiveCN105724016AReduce migration conversionHarm reductionHops/wine cultivationContaminated soil reclamationEnvironmental resource managementEnvironmental engineering

The invention discloses a copper mine waste oxidized ore hillock ecological restoration method. The method comprises the first step of land preparation, the second step of first layer grating laying, the third step of ecological bag slope protection, the fourth step of lime layer spraying, the fifth step of physical isolation layer laying, the sixth step of ecological bar erecting, the seventh step of second layer grating laying, the eighth step of soil matrix improvement layer spraying, the ninth step of seed layer spray-sowing, the tenth step of straw curtain covering and fixing and the eleventh step of water intercepting and drainage facility arranging. By means of the ecological restoration method, acid can be effectively isolated and controlled, and the effect of heavy metal and other pollutants on the surroundings can be controlled from a source.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +2

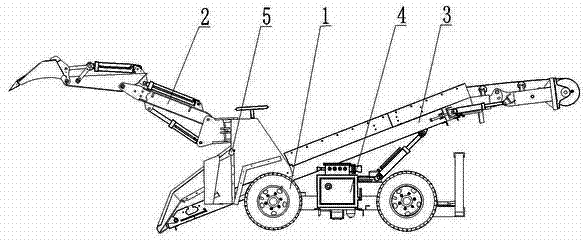

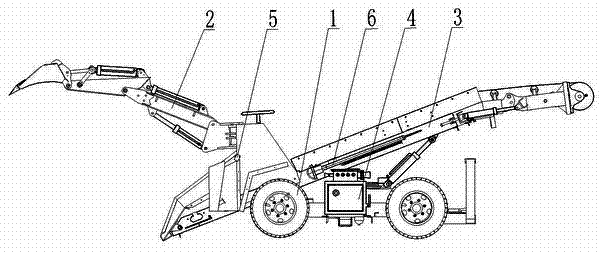

Wheel hoeing machine

ActiveCN103572788AReduce casualtiesCompact structureMechanical machines/dredgersUnderstructuresDiesel engineElectric power

A wheel scrabbling machine relates to the field of mine and engineering machinery and comprises a car chassis, an excavating loading mechanism, a conveying unloading mechanism, an electrical control system, a hydraulic system and an operation mechanism for the hydraulic system; the wheel scrabbling machine adopts a brand new structural design, adopts an external power supply or a self diesel engine as power, and adopts electric, hydraulic and mechanical transmission to realize the continuous hoeing, conveying and loading. The wheel scrabbling machine is compact and reasonable in structure, low in fault rate, simple and convenient in maintenance, flexible in moving and safe and reliable in work and has the characteristics of capability of self walking, stable loading, flexible operation, continuity, efficiency and the like, safety loopholes are reduced and casualty accidents of staff are effectively reduced; the wheel scrabbling machine is suitable for narrow roadways and the construction conditions of an uneven ground, and is mainly suitable for the exploitation and scrabbling operation of a coal mine, a phosphorus ore, an iron mine, a copper mine and a gold mine as well as the collecting and loading of metaling in channel constructions such as a railway, a road, water conservancy and national defense and can also be used in the loading of open-air bulked materials.

Owner:襄阳忠良工程机械有限责任公司

High-sublevel multi-layer mining method of ultrathin copper ore body

InactiveCN102086765ALow cost of industrializationThe pit rate is reducedUnderground miningTunnel/mines ventillationResource protectionCopper mine

The invention discloses a high-sublevel multi-layer mining method of an ultrathin copper mine body. Mining channels are reclaimed to be connected with an upper middle section and a lower middle section based on the high-sublevel that the altitude difference of the middle section of the ore body is 50 meters, wherein, the thickness of the ore body bed is 0.4-1m, and the inclined angle of the ore body is above 25 degrees; the ore blocks between the middle sections are divided into extraction ore blocks with 50 meters square; a layered communication channel with small specification the altitude difference of which is 13-17m is reclaimed between the mining channels; the extraction ore blocks between the mining channel are divided into three extraction units; the ores mined by each extraction unit is centralized to the mining channel uniformly; and the ores are sent out from a trench after being transported to a transportation road. The method disclosed by the invention has the advantages that the copper ore resource mining recovery rate is effectively improved, cost is low, land is saved, unification of the resource protection and the environment protection is realized, and use is safe.

Owner:DAYAO GUIHUA COPPER SMELTING YONGREN ZHIJU BRANCH

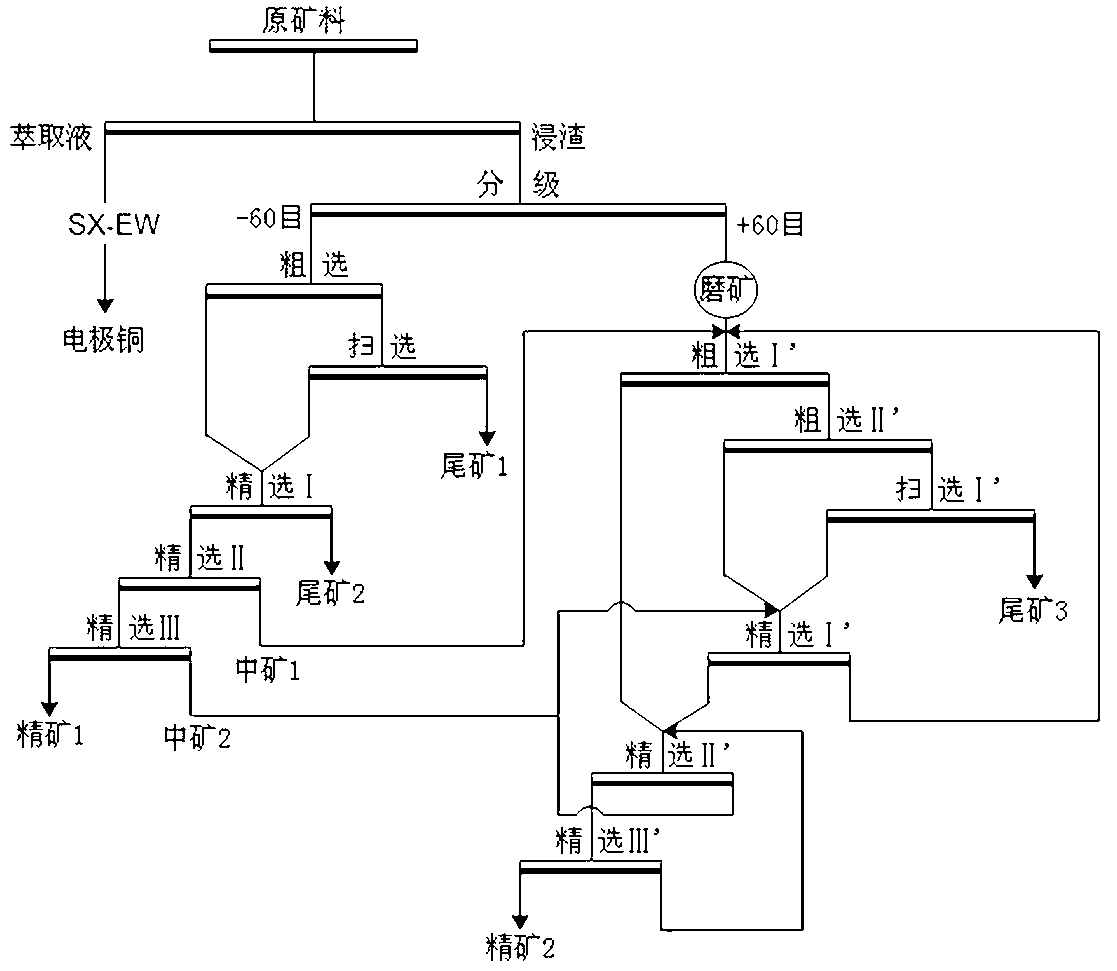

Leaching residue grading and series flotation method for complex copper mine

The invention discloses a leaching residue grading and series flotation method for complex copper mine. The method comprises the working procedures of leaching residue grading, fine flotation and coarse flotation. Particularly, the leaching residue grading comprises the step of dividing leaching residues for hydrometallurgy of copper into fine-grained mine and coarse-grained mine according to a sieve of 60-100 meshes. The fine flotation comprises the step of carrying out series roughing selection, scavenging and fine selection for two to three times on the fine-grained mine to obtain concentrate 1, wherein the fine-grained mine is obtained through grading. The coarse flotation comprises the steps of grinding the coarse-grained mine obtained through grading until the fineness reaches 80% of less than 200 meshes, arranging and connecting the coarse-grained mine in series, carrying out roughing selection for one to two times, scavenging and fine selection for two to three times on mine discharge series to obtain concentrate 2. According to the method, the leaching residues for hydrometallurgy of the low-grade and complex mine with oxygen and sulfur mixed are graded firstly, then the different series flotation and tailing reusing processes are adopted respectively, the mineral recovery rate can be improved to 75-85% of comprehensive recovery from 30-50% of single wet dump leaching, the grade of the leaching residues is reduced to 0.2% or even lower from 0.5% of pre-flotation, the effect of comprehensive recovery is obvious, and meanwhile the pollution to environment by the leaching residues is reduced.

Owner:云南楚雄矿冶有限公司

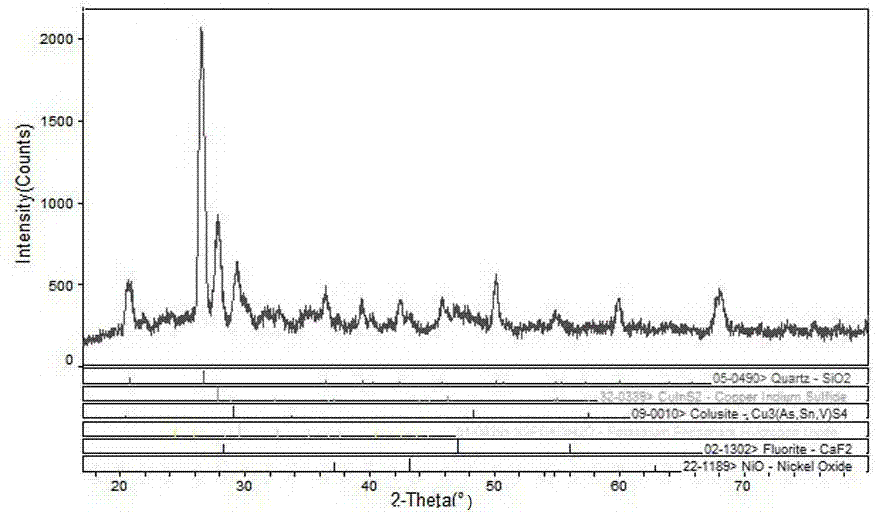

Preparation method of copper mine tailing haydite for landscaping

InactiveCN105669157AConducive to green useHigh strengthSolid waste managementLandscapingPre treatment

The invention discloses a copper mine tailing haydite for landscaping and a preparation method thereof. The preparation method comprises the following steps: carrying out calcination pretreatment and acid waste liquid impregnation on copper mine tailings, reoptimizing raw material composition and contents of the haydite, and regulating the physicochemical properties of the haydite, thereby preparing the copper mine tailing haydite suitable for landscaping.

Owner:CHENGDU YUYA TECH +1

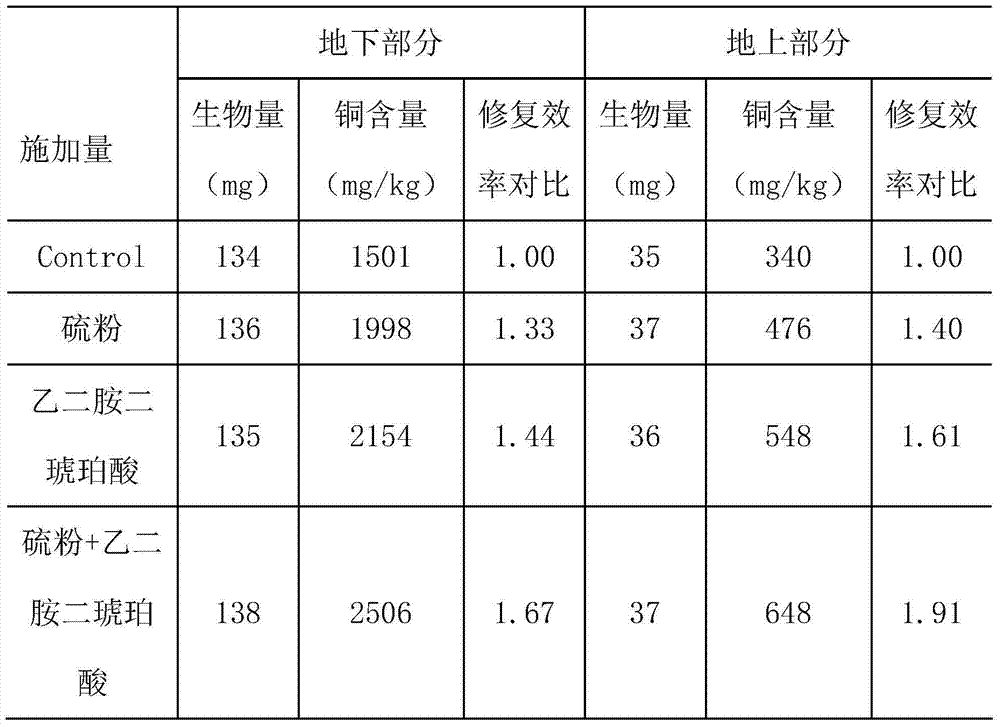

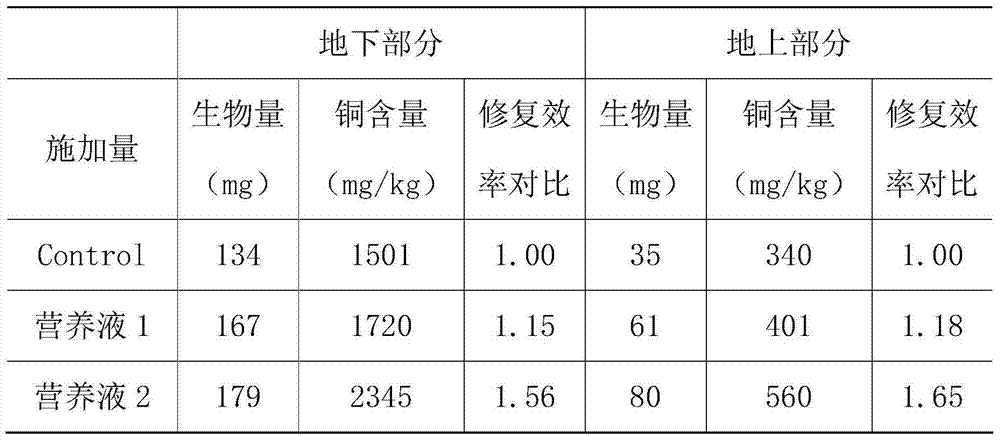

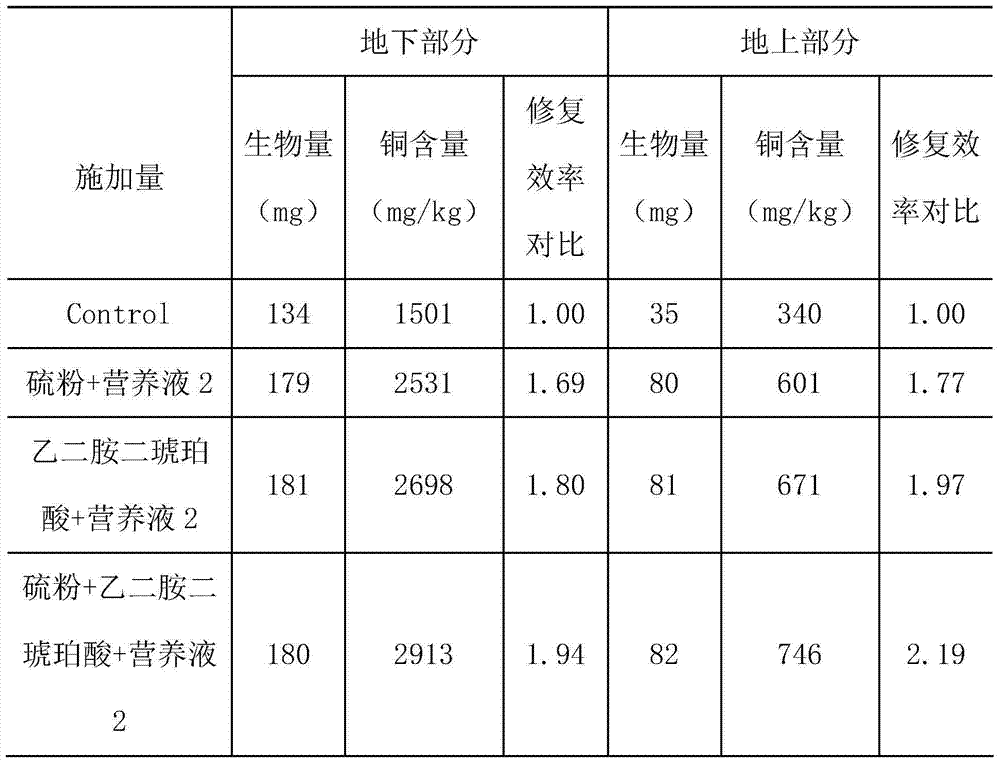

Method for improving phytoremediation efficiency of copper-polluted soil

ActiveCN103785679AIncrease concentrationImprove bioavailabilityContaminated soil reclamationFertilising methodsNutrient solutionGrowing season

The invention belongs to the field of phytoremediation of heavy metal polluted soil, and discloses a method for improving phytoremediation efficiency of copper-polluted soil on the basis of the existing phytoremediation method for the heavy metal polluted soil. The method comprises the following steps: applying a chemical enhancer containing powdered sulfur and ethylenediaminedisuccinic acid to the copper-polluted soil; spraying a nutrient solution containing exogenous plant hormone naming zeatin Z at a fixed period after planting elsholtzia splendens; picking the aboveground parts of elsholtzia splendens after the growing season is finished, so as to reach the purpose of remediating the heavy-metal copper polluted soil. With the adoption of the method, the growth of elsholtzia splendens is promoted, and the problems that high-copper soil represented by soil in a copper mine area inhibits the growth of elsholtzia splendens and causes short plant, small biomass and slow growth can be solved; the method has the advantages of being high in absorbing efficiency, high in degree of enrichment, and obvious in remediation effect.

Owner:JIANGSU SUNTIME ENVIRONMENTAL REMEDIATION

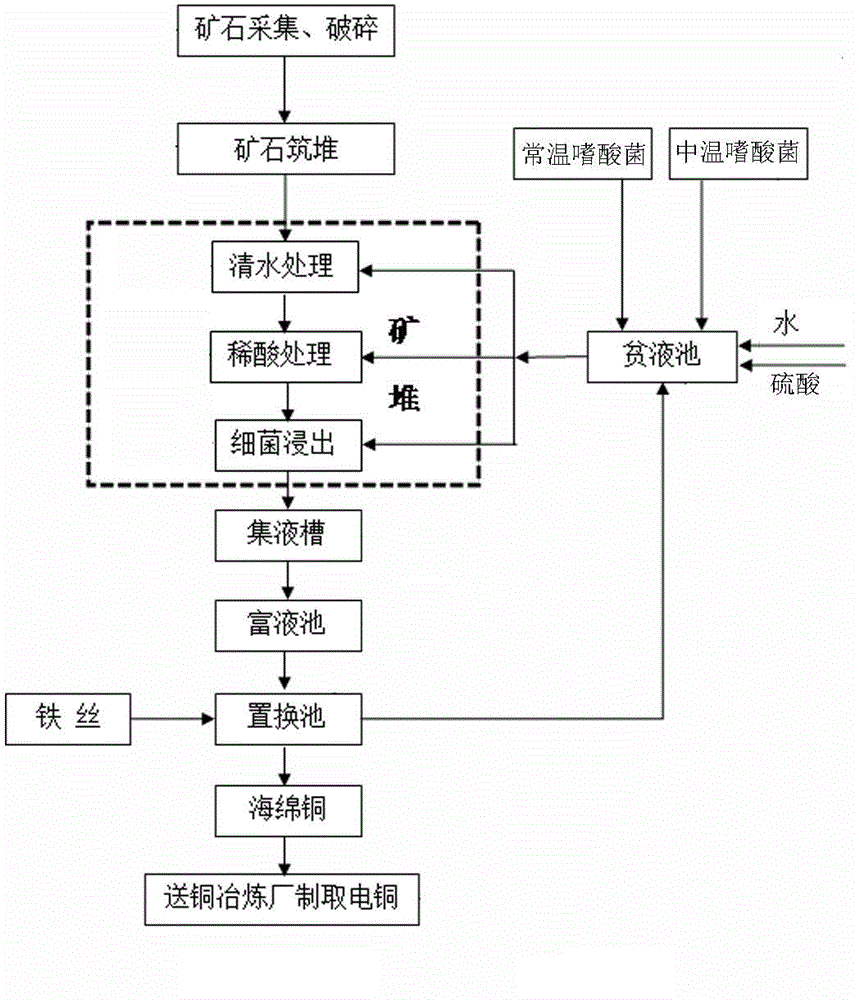

Biological heap leaching technology for stripmining copper sulfide mines

ActiveCN104152691ASimple processShort processProcess efficiency improvementPregnant leach solutionSulfidation

The invention provides a biological heap leaching technology for stripmining copper sulfide mines. The technology comprises the following steps: the copper sulfide mines with a low copper grade and high oxidizability are crushed, sieved and heaped, water and dilute sulphuric acids are dripped and sprinkled successively, a pH value is adjusted, then normal-temperature acidophile and middle-temperature acidophile are dripped and sprinkled successively according to temperature changes, and copper in leach liquor is displaced. The technology has the advantages that the technology is simple, the technological process is short, the pollution is small, the copper sulfide mines with a lower grade can be processed, and the like. Mineral leaching bacteria which are adopted are widely distributed, so that the mineral leaching bacteria are easy to obtain.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

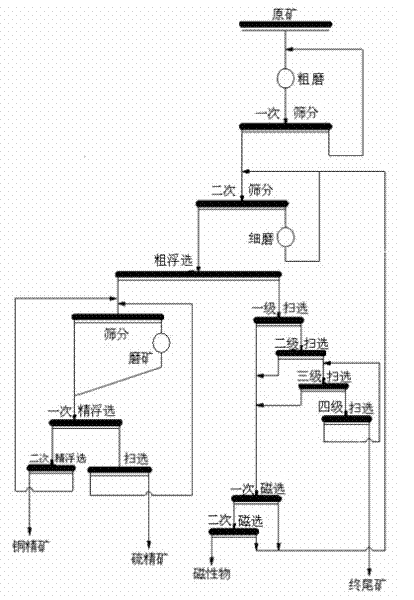

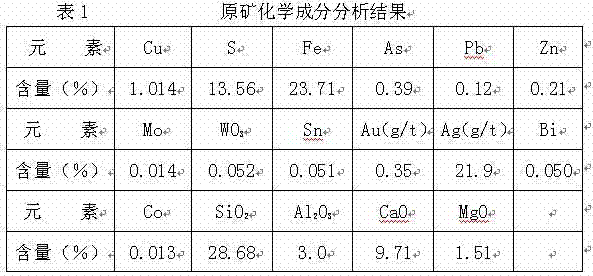

A comprehensive treatment method for mixed copper ore

The invention provides a comprehensive treatment method for mixed copper ore, which successfully separates sulfur concentrate and copper concentrate through the process steps of rough grinding, screening, fine grinding, rough flotation, fine flotation, magnetic separation, and sweeping. , so as to obtain high-quality copper concentrate, and then select a large amount of pyrrhotite from the middling ore through the magnetic separation step, which minimizes the iron and sulfur content of the middling ore, and can make the middling ore a high-quality Good sulfur concentrate can be directly used as raw material for sulfuric acid production, and the tailings after magnetic separation can be returned to the system for circular production, so that valuable resources can be fully recycled, and the tailings are discharged to the tailings dam after multi-stage screening Storage, to overcome the problems of heavy production load caused by the return of tailings, low concentrate grade and low recovery rate, the comprehensive recovery rate of copper is over 80%, the concentrate grade is over 19%, and the gold content of copper concentrate is 6g / t Above, the gold recovery rate is over 45%, the copper concentrate contains more than 418g / t of silver, and the silver recovery rate is over 50%.

Owner:YUNNAN DIQING MINING DEV

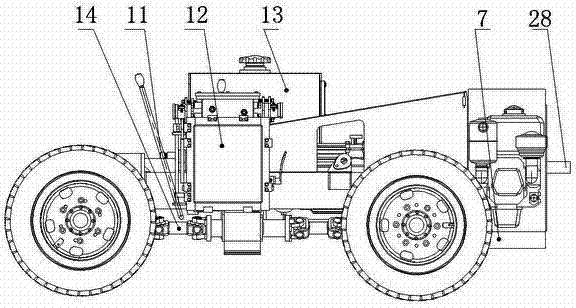

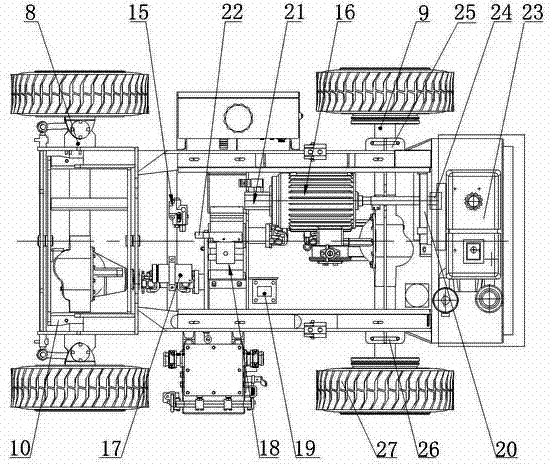

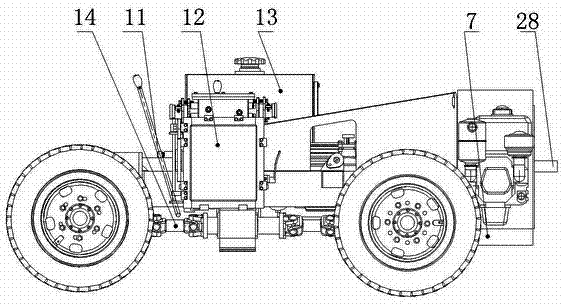

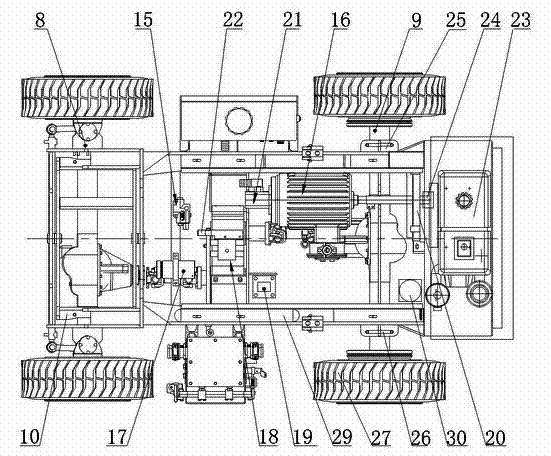

Heading and loading machine for drilling and digging

ActiveCN103590838ACompact structureReasonable structureLoading/unloadingTunnelsFailure rateElectric control

The invention discloses a heading and loading machine for drilling and digging, and relates to the field of mining and engineering machinery. The heading and loading machine comprises a vehicle chassis, a digging and loading mechanism, a conveying and unloading mechanism, a hydraulic drilling rig, an electric control system, a hydraulic system and a control mechanism thereof. According to the brand new design of integrating the vehicle chassis, the digging and loading mechanism, the conveying and unloading mechanism, the hydraulic drilling rig, the electric control system, the hydraulic system and the control mechanism thereof together, continuous digging, heading, conveying, loading and drilling can be realized. The heading and loading machine is compact and reasonable in structure, low in failure rate, simple and convenient to maintain, flexible to move and safe and reliable in working, and has the advantages of automatic travelling, smooth loading, flexibility and convenience in operation, continuity and high efficiency and the like; production efficiency is greatly improved, potential safety hazards are eliminated, casualties can be effectively reduced, equipment investment is saved, equipment transport is reduced, labor intensity is lowered, and energy is saved; the heading and loading machine meets construction conditions of narrow tunnels and sunken ground, and is applicable to exploiting, heading, loading and drilling of coal mines, phosphorous mines, iron mines, copper mines and gold mines.

Owner:襄阳忠良工程机械有限责任公司

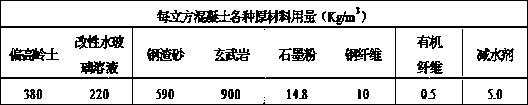

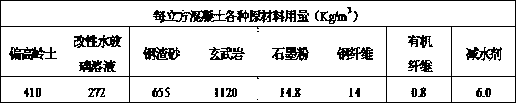

Novel heat accumulation concrete for solar thermal power station and preparation method for novel heat accumulation concrete

The invention belongs to the field of building materials, and in particular relates to a functional concrete material and a preparation method thereof. The invention relates to novel heat accumulation concrete for a solar thermal power station. 1 square meter of heat accumulation concrete is characterized by being prepared from the following raw materials by weight: 380 to 450 kilograms / meter<3> of metakaolin, 220 to 310 kilograms / meter<3> of modified sodium silicate solution, 5 to 10 kilograms / meter<3> of water reducing agent, 900 to 1,200 kilograms / meter<3> of basalt, 590 to 710 kilograms / meter<3> of fine aggregates, 10 to 20 kilograms / meter<3> of steel fibers, 0.5 to 1 kilogram / meter<3> of organic fibers and 10 to 20 kilograms / meter<3> of graphite powder, wherein a liquid-solid ratio of the modified sodium silicate solution to the metakaolin is (0.60-0.70):1; and the fine aggregates comprise ordinary sand, copper ores and steel slag sand. The high-temperature heat accumulation material prepared by the method has the characteristics of low cost, stable performance, high coefficients of heat conductivity, high durability and the like, and is easy to prepare on site.

Owner:WUHAN UNIV OF TECH

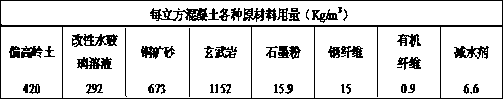

Ore grinding grading method for improving ore grinding processing capacity

The invention relates to mineral processing process improvement in the metallurgical industry, belongs to a process for improving grading efficiency and reducing qualified grade return quantity to increase processing capacity of a ball mill, and particularly relates to an ore grinding grading method for improving ore grinding processing capacity. The ore grinding grading method comprises firstly enabling products after ore crushing to enter the ball mill for ore grinding, sending discharged ore from the ball mill to a hydrocyclone for separation through a slurry pump, returning setting sand in the hydrocyclone to the ball mill, sending fine fraction products which are overflow of the hydrocyclone to a high-frequency vibration sieve for secondary separation through an ore division device, returning products on the sieve to enter the slurry pump, recycling to enter the hydrocyclone for separation, and conducting follow-up grading procedures on products below the sieve. The ore grinding grading method solves a problem that the existing ore grinding grading process is low in grading efficiency, low in platform efficiency of grinding machines, unstable in work and the like. The ore grinding grading method is mainly suitable to mineral separation processing of copper mine and lead and zinc metal ore.

Owner:HUBEI XINYING ENVIRONMENTAL TECH +1

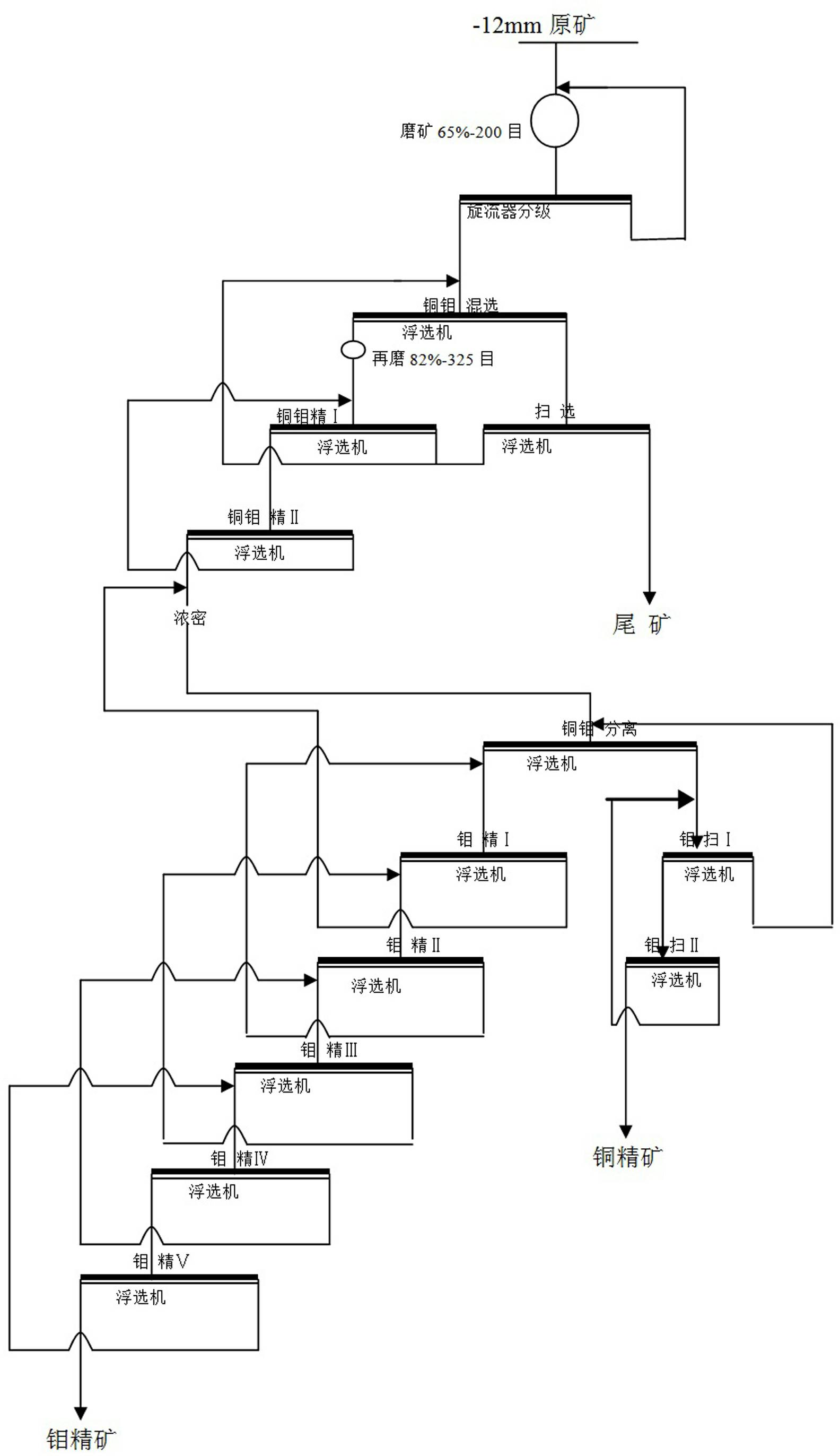

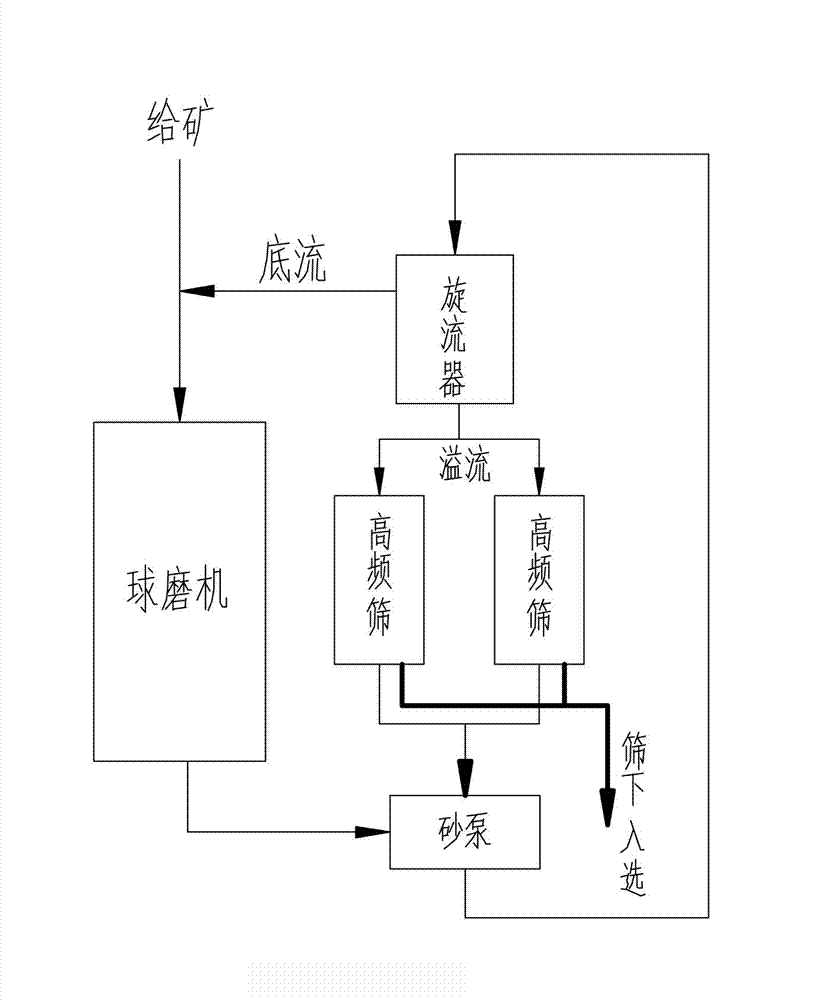

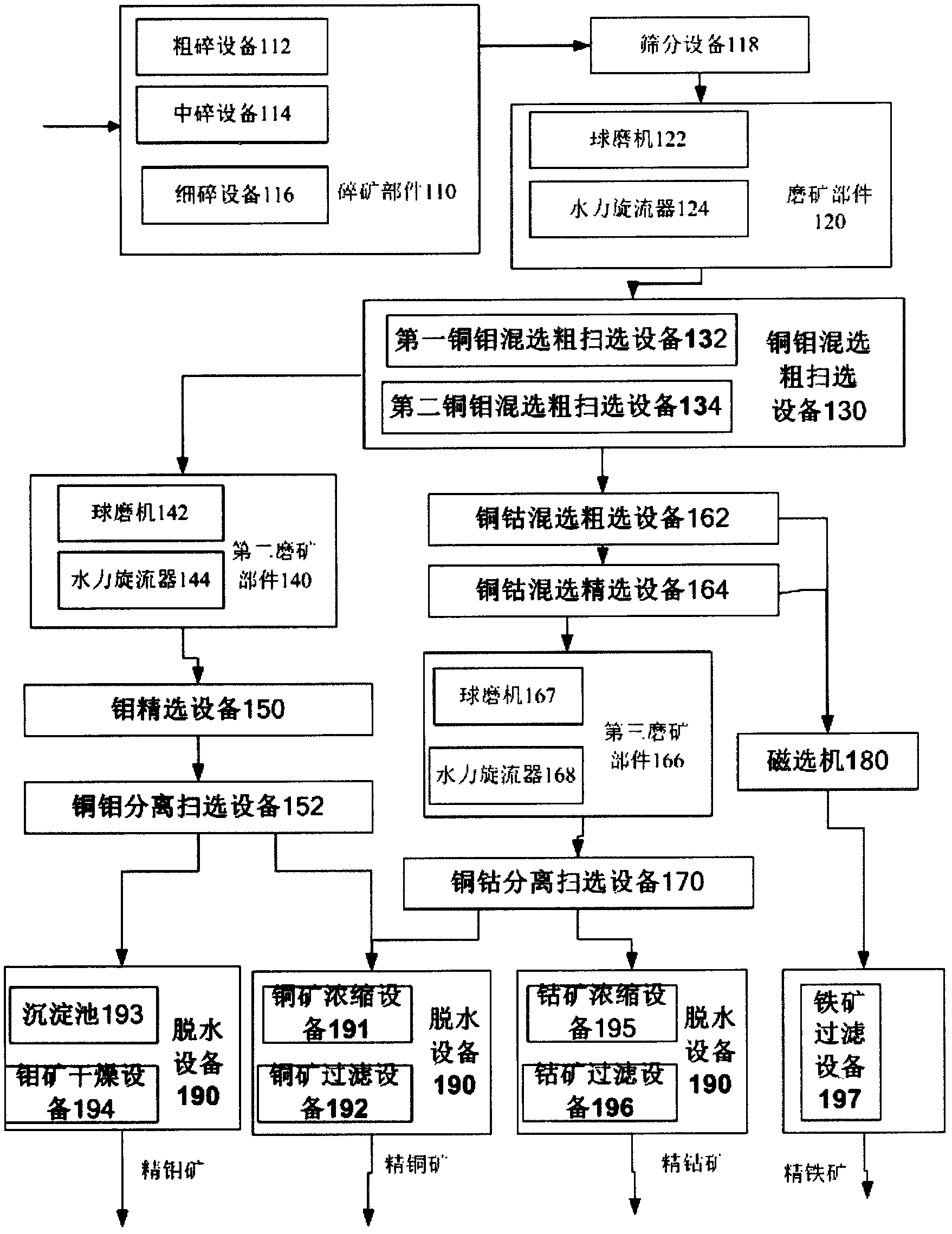

System and method for comprehensive utilization of copper mine chats

The invention discloses a system for comprehensive utilization of copper mine chats. The system comprises an ore crushing part, a first ore grinding part, copper-molybdenum mixing and scavenging dressing equipment, a second ore grinding part, copper-molybdenum concentrating equipment and a copper-molybdenum separating and scavenging equipment, wherein the ore crushing part is suitable for crushing ores, and the granularity of the crushed ores is 1-12mm; the first ore grinding part is suitable for grinding the crushed ores of the ore crushing part so as to obtain the ground ores with the overflow granularity of 60-200 meshes; the copper-molybdenum mixing and scavenging dressing equipment is suitable for selecting crude copper-molybdenum ores from the ores ground by the first ore grinding part; the second ore grinding part is suitable for further grinding the crude copper-molybdenum ores selected by the copper-molybdenum mixing and scavenging dressing equipment; the copper-molybdenum concentrating equipment is suitable for floating copper-molybdenum concentrates in the crude copper-molybdenum ores ground by the second ore grinding part; and the copper-molybdenum separating and scavenging equipment is suitable for further floating the copper-molybdenum concentrates floated by the copper-molybdenum concentrating equipment so as to separate molybdenum concentrates and copper concentrates. The invention further discloses a method for the comprehensive utilization of the copper mine chats.

Owner:会理县马鞍坪矿山废石综合利用有限责任公司

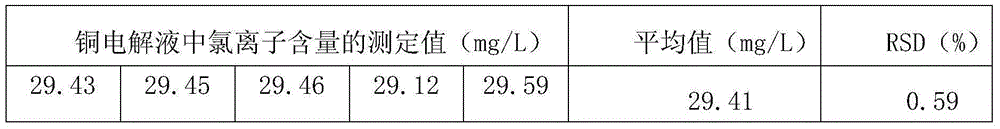

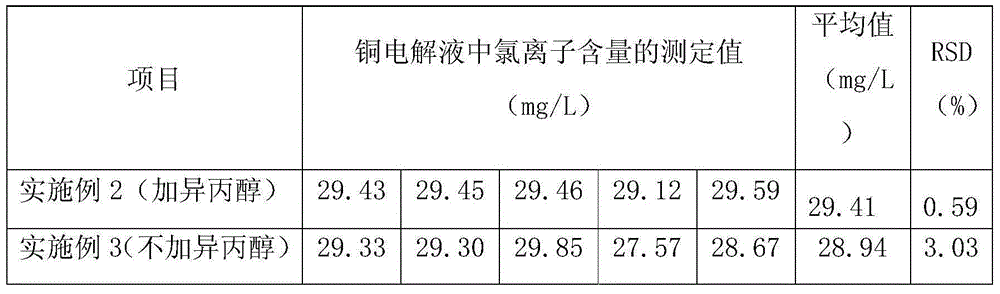

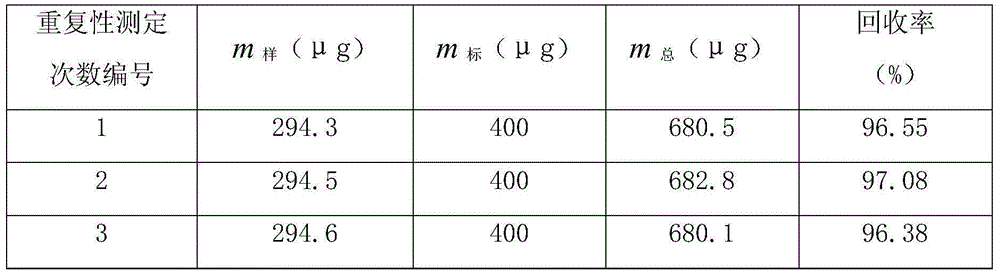

Determination method of chloride ion content of copper electrolyte

ActiveCN105136894AImprove accuracyHigh precisionMaterial electrochemical variablesIon contentElectrolysis

The invention discloses a determination method of chloride ion content of a copper electrolyte. The determination method comprises a, adding a silver nitrate standard solution with a concentration of 0.005-0.01mol / L into a reagent bottle of a potential analyzer, b, orderly adding a copper electrolyte and isopropanol into a beaker according to a volume ratio of 3-7: 1, adding water into the beaker until the mixed solution in the beaker has a volume of 50-60mL, inserting a silver composite electrode and a titrating head into the solution to be detected in the breaker, and controlling a stirring speed in a range of 620-630rpm, and c, dropwisely adding a silver nitrate standard solution into the breaker, recording a silver nitrate standard solution volume corresponding to titration consumption when potential jump is produced, and calculating chloride ion content of the copper electrolyte according to a formula. Through use of isopropanol in the solution to be detected, a potential jump point produced by potentiometric titration is obvious, determined potential is stable and repeatability is good so that accuracy and a precision of the calculated chloride ion content of the copper electrolyte are high, accurate and reliable guide data is provided for practical production for a copper mine enterprise and precious metal reliable recovery and electrolytic copper yield are guaranteed.

Owner:TONGLING NON FERROUS METAL GROUP CORP

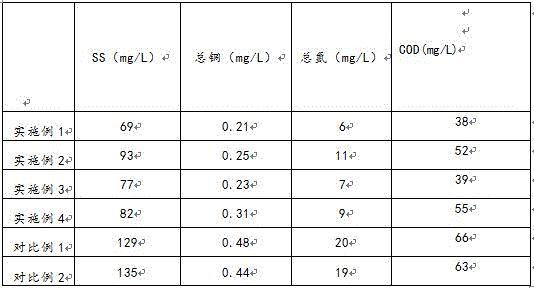

Fast treating method for copper mine waste water

InactiveCN106430754AReduce copper contentReduce organic contentWaste water treatment from quariesWater/sewage treatment with mechanical oscillationsActivated sludgeAluminium chloride

The invention discloses a fast treating method for copper mine waste water. A mixture composed of poly aluminium chloride, potassium ferrate, dimethyl diallyl ammonium chloride, potassium feldspar, bissuccinimide, quartz sand, polyacrylamide, diethylenetriaminepenta acid, urea, citric acid and activated sludge is adopted as a cleaning agent, matched with a flocculating agent with polyferric sulfate, bentonite, zeolite powder, ethoxylated lauryl alcohol sulfate and alum as constituents, and assisted with technologies of deep oxidation, flocculation, ultrasound, resin adsorption, filtration, sterilization, membrane separation and the like, therefore, the copper content and the COD value in the copper mine waste water are effectively reduced, industrial requirements can be met, and the method has a good application prospect.

Owner:吴小慧

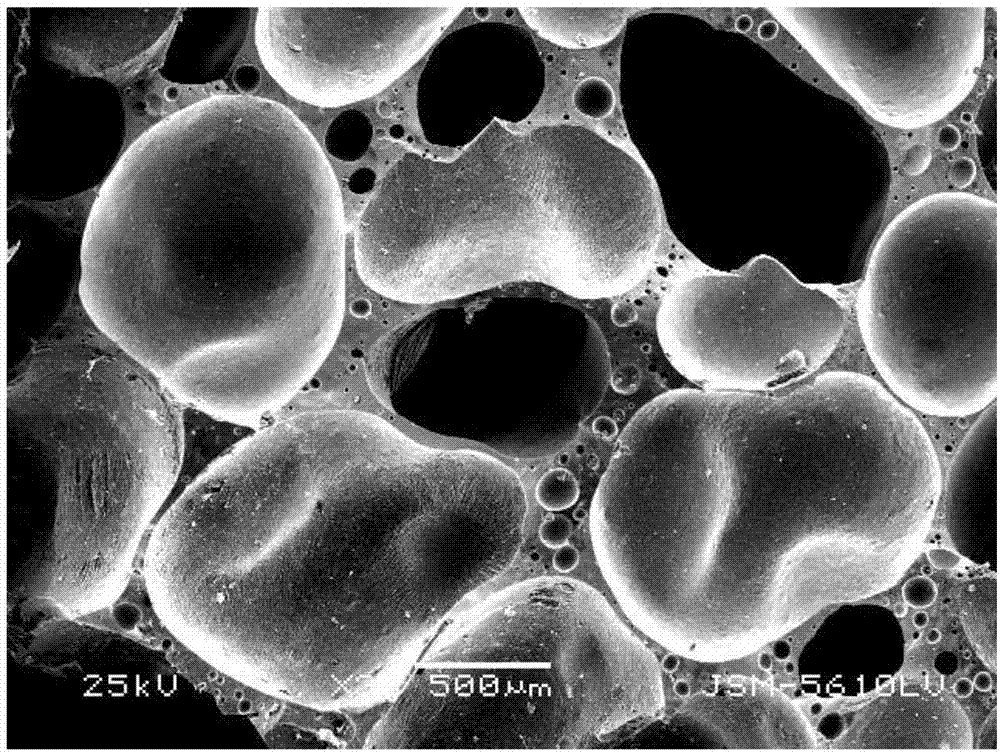

Porous thermal insulation ceramic using gold copper mine tailings as raw material and preparation method thereof

The invention relates to a porous thermal insulation ceramic using gold copper mine tailings as a raw material and a preparation method thereof; the porous thermal insulation ceramic is prepared from the following raw materials by weight: 75-90wt% of gold copper mine tailings, 5-10wt% of float glass powder, 3-8wt% of a foaming agent and 2-8wt% of an additive; the porous thermal insulation ceramic material is prepared by the following processes: proportionally mixing well the gold copper mine tailings, the float glass powder, the foaming agent and the additive, then molding, and sintering; the density of the prepared gold copper mine tailing porous ceramic is in the range of 0.2-0.8g / cm<3>, the pore diameter is 1-6mm, the breaking strength is in the range of 0.5-6.0MPa, ,the thermal conductivity at room temperature is in the range of 0.04-0.12W / (K.m), and the porous thermal insulation ceramic has the advantages of high porosity, low density and high strength, and can be used as a wall thermal insulation material.

Owner:WUHAN UNIV OF TECH

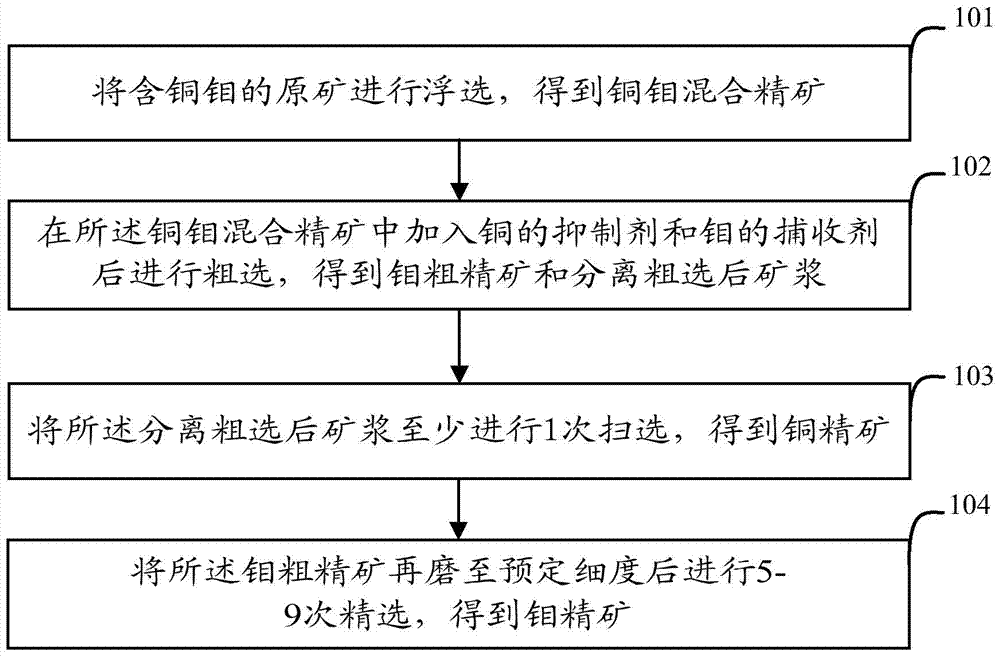

Method for copper-molybdenum bulk concentrate floatation

The invention relates to the field of mineral product exploitation, in particular to a method for copper-molybdenum bulk concentrate floatation. The method for copper-molybdenum bulk concentrate floatation comprises the steps that raw ore containing copper and molybdenum is subjected to floatation, and copper-molybdenum bulk concentrate is obtained; copper inhibitors or molybdenum collectors are added into the copper-molybdenum bulk concentrate, then separation rougher flotation is carried out, and molybdenum rough concentrate and ore pulp after separation rougher flotation are obtained; the ore pulp after separation rougher flotation is subjected to at least one-time scavenging, and copper concentrate is obtained; and the molybdenum rough concentrate is reground to be in preset fineness, then concentration is carried out for 5-9 times, and molybdenum concentrate is obtained. According to the method for copper-molybdenum bulk concentrate floatation, the phenomenon of copper mine overgrinding is avoided, in addition, the good effect of copper-molybdenum separating is achieved, and energy loss during an operation process is lowered.

Owner:TIBET HUATAILONG MINING DEV

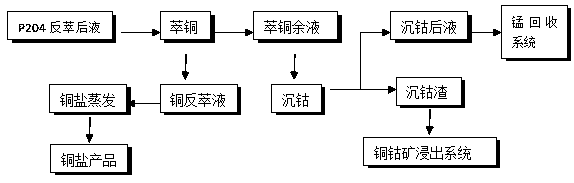

Method for separating and recovering cobalt and copper from P204 reverse extraction liquid in cobalt and copper mine wet method smelting process

PendingCN109487083AHigh recovery rateSolve complexityProcess efficiency improvementCopper sulfatesKeroseneSmelting process

The invention provides a method for separating and recovering cobalt and copper from P204 reverse extraction liquid in a cobalt and copper mine wet method smelting process. The method for separating and recovering the cobalt and the copper from the P204 reverse extraction liquid in the cobalt and copper mine wet method smelting process comprises the following steps that a copper extraction agent and sulfonated kerosene are added into the P204 reverse extraction liquid for extraction, a PH value is controlled between 1.5 and 2.0 in the process, and extracted copper residual liquid and extractedcopper organic load are obtained; sulfuric acid is added into the extracted copper organic load for reverse extraction to form a copper sulphate solution, and the copper sulphate solution is fed intoa copper salt vaporization system for vaporization to obtain a copper salt product; and the extracted copper residual liquid is heated to 30-60 DEG C, a precipitating agent is added for precipitation, a final PH value is controlled between 3.0 and 4.0, filter pressing and solid-liquid separation are carried out finally to obtain cobalt slag and precipitating cobalt liquid, the cobalt slag is fedto a copper and cobalt leaching system, and the cobalt and the copper are effectively separated. According to the method for separating and recovering the cobalt and the copper from the P204 reverse extraction liquid in the cobalt and copper mine wet method smelting process, the operation process is simple, the production cost is low, the production efficiency is high, and the metal recovery rateis effectively improved.

Owner:江苏雄风科技有限公司

High thermal conductive cementing material capable of enhancing heat exchange performance of heat exchange system of floor heating

The invention discloses a high thermal conductive cementing material capable of enhancing the heat exchange performance of the heat exchange system of floor heating. The cementing material is composed of the following components by weight: 100 grams of cement, 50 to 200 grams of steel slag or copper mine slag, 150 to 300 grams of quartz sand, 0.8 to 3.0 grams of antifoaming agent, and 1.2 to 3.6 grams of water reducer. On the construction site, water accounting for 40 to 50% of the total weight of cement and steel slag / copper mine slag is added, and then the mixture is evenly stirred and poured into drill holes. The provided cementing material has the advantages of high thermal conductivity and good workability, can expand slightly, and thus can fully fill the drill holes. So that the heat exchange pipes can be tightly combined with the rock stratum, and the heat exchange performance is enhanced. The high thermal conductive cementing material can effectively protect heat exchange pipes from underground water corrosion, thus the service life of heat exchange pipes is prolonged, and the system operation risk is reduced. Furthermore, the cementing material has the advantages of low price, long service life, easily-available raw materials, and no pollution to environment.

Owner:徐德龙 +3

Underground mining methods of copper mine

InactiveCN101158285AUndamagedAvoid the interference of secondary expansionUnderground miningSurface miningSocial benefitsEconomic benefits

The invention relates to an underground mining plan used for a copper mine, relating to an exploitation and utilization plan of a copper mine. The invention is characterized in that the mine body is divided into an upper part and a lower part, wherein, the lower part adopts a phase ascending mining while the upper part adopts an in-situ crushing-leaching mining. The plan of the invention can improve a stope stressing state and prevent an earth surface sedimentation and sinking, and the plan is also safe and has low cost, and the resource of a copper mine can be fully exploited and a non-waste exploitation can be realized, thus bringing better economic benefits and social benefit to the copper mine enterprises.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Crack-resistant anti-seepage concrete and preparation method thereof

The invention relates to crack-resistant anti-seepage concrete and a preparation method thereof, and mainly solves the problem that the concrete is easy to crack and leak. The crack-resistant anti-seepage concrete comprises 280 to 290 parts of cement, 105 to 115 parts of fly ash, 790 to 800 parts of sand, 1050 to 1060 parts of crushed stone, 1 to 10 parts of a water reducing agent, 2 to 7 parts ofwhite sugar, 20 to 30 parts of a fiber expansion agent, 20 to 30 parts of a crack-resistant anti-seepage agent, 3 to 10 parts of a water repellent, 95 to 105 parts of coal gangue, 73 to 83 parts of metal silicon powder, 40 to 50 parts of iron powder, 65 to 75 parts of copper ore tailings, 10-20 parts of a reactant and 148 to 158 parts of water. The fly ash, the sand, the crushed stone and the copper mine tailings are selected as main raw materials, the production cost of the raw materials is reduced, the anti-wear and anti-erosion ability of the concrete is reduced, the durability of the concrete is improved, and the compactness of the concrete is improved. The crack-resistant anti-seepage concrete has better frost resistance and seepage resistance, and the unique crack-resistant anti-seepage agent is added to the concrete to greatly improve the crack resistance and seepage resistance of the concrete.

Owner:WENZHOU INNOVATION NEW MATERIAL CO LTD

Production method for producing autoclaved sand-lime bricks with copper tailings

The invention relates to a production method for producing autoclaved sand-lime bricks with copper tailings. The method is characterized in that the sand-lime bricks comprise, by mass, 35-45% of the copper tailings sand, 8-12% of calcium carbide slag, 15-20% of stone chips, and 30-35% of fine sand. An effective calcium oxide content of the calcium carbide slag is no lower than 65%. A silicon dioxide content of the copper tailings sand is no lower than 35%. The water content of the stone chips is no higher than 3%. The water content of the fine sand is no higher than 7%. According to the invention, the autoclaved sand-lime bricks are produced with the copper tailings with high water content, such that the copper tailings are fully utilized, and the produced autoclaved sand-lime bricks have high compressive strength and high flexural strength. With the method, enterprise cost is reduced, the environment is effectively protected, safety risk is eliminated, and an effective promotion is provided for the development of the metallurgical industry.

Owner:SHANTOU XIJIA BUILDING MATERIALS

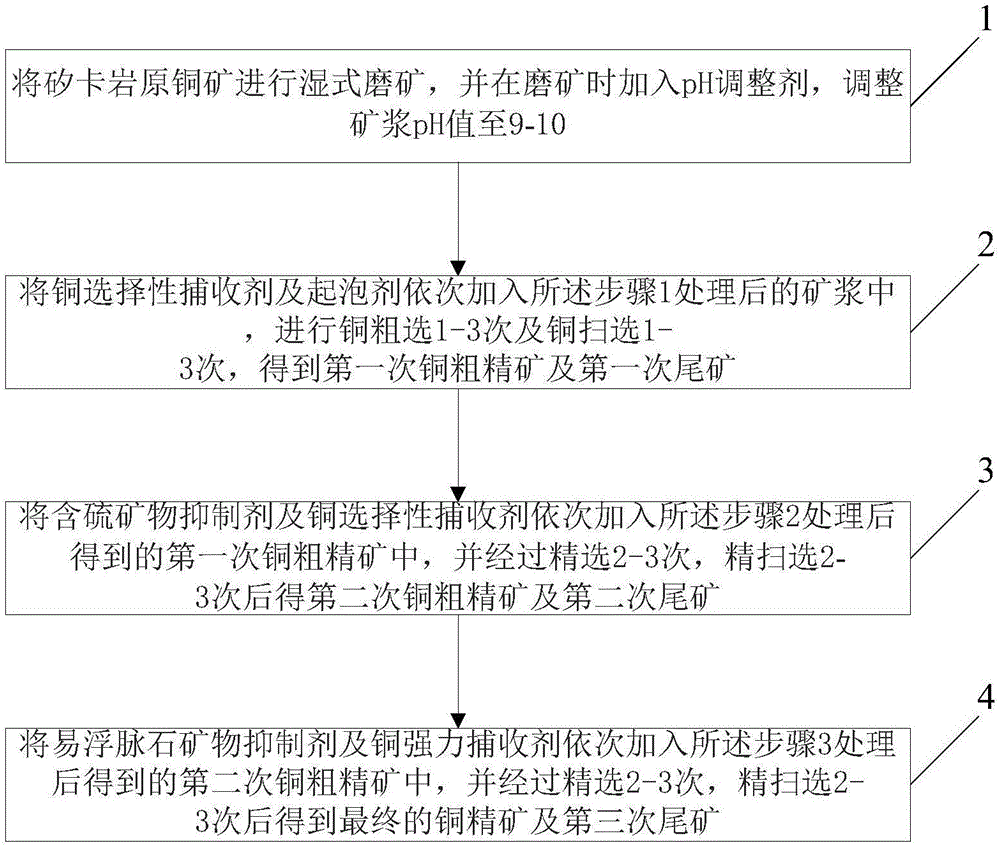

Skarn copper mine beneficiation method

The invention discloses a skarn copper mine beneficiation method. Firstly, raw skarn copper mine is subject to wet type ore grinding, a pH regulator is added during ore grinding, and the pH of ore pulp is adjusted to be 9 to 10; a copper selectivity collector and a foaming agent are sequentially added into ore pulp treated in the step (1), copper roughing is carried out 1 time to 3 times, copper scavenging is carried out 1 time to 3 times, and first-time copper rough concentrate and first-time tailings are obtained; a sulfur-containing mineral inhibitor and a copper selectivity collector are sequentially added into the first-time copper rough concentrate obtained by treatment in the step (2), fine selection is carried out 2 times to 3 times, refined scavenging is carried out 2 times to 3 times, and second-time copper rough concentrate and second-time tailings are obtained; a floatable gangue mineral inhibitor and a copper strong collector are added into the second-time copper rough concentrate obtained through treatment in the step (3), fine selection is carried out 2 times to 3 times, refined scavenging is carried out 2 times to 3 times, and final copper concentrate and third-time tailings are obtained. By means of the method, the using amount of the inhibitors can be effectively reduced, and the copper recovery rate is improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

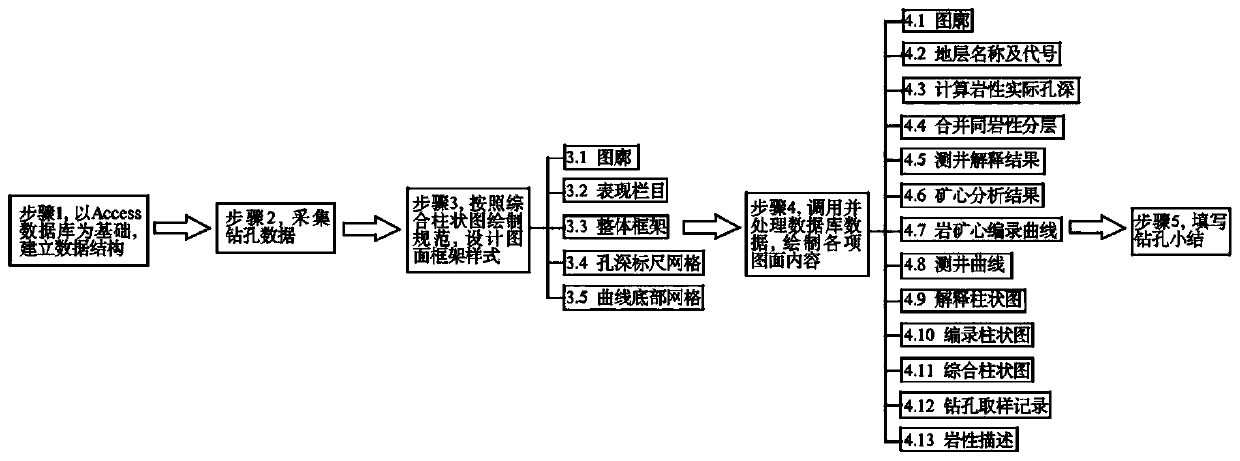

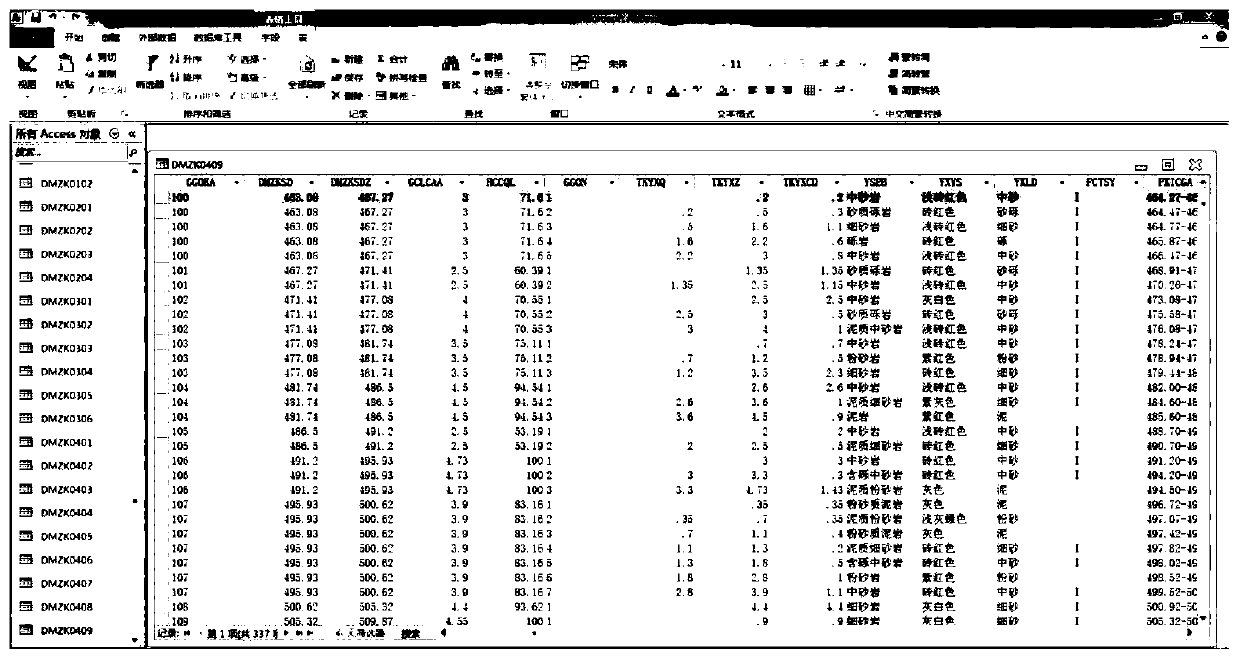

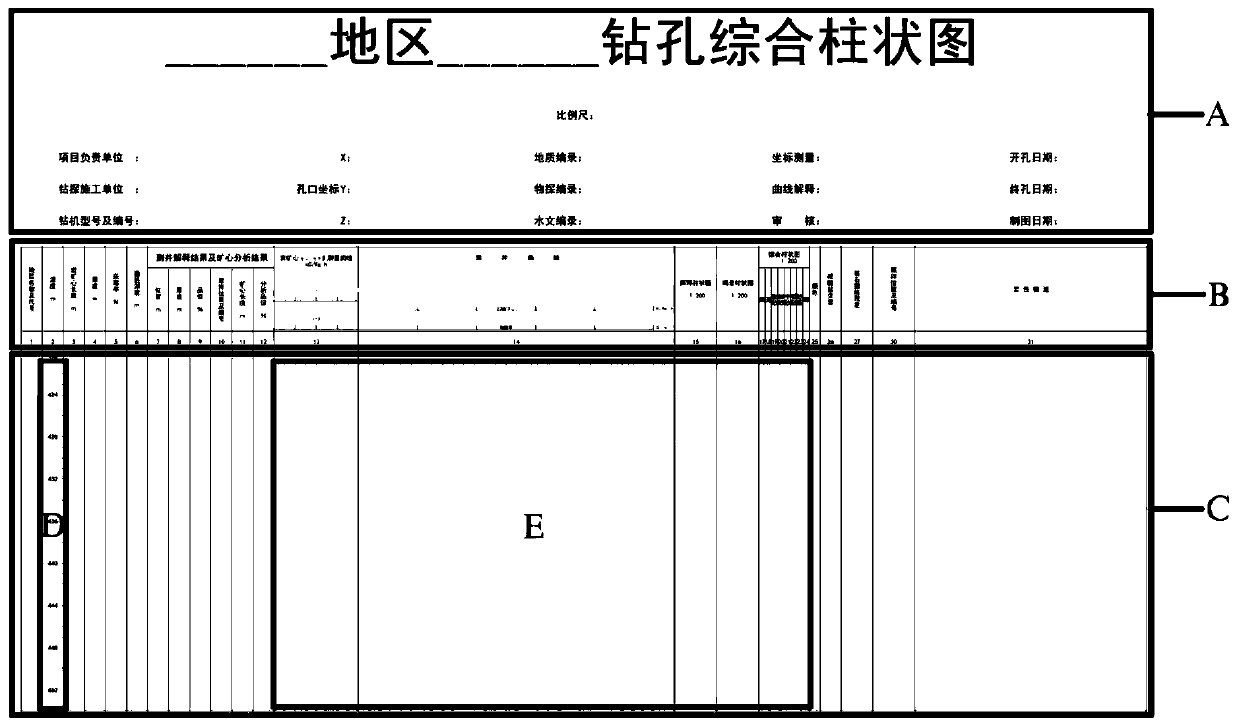

Electronized compilation method of copper mine drilling comprehensive histogram

InactiveCN110647528AUniform styleStyle specificationData processing applicationsDrawing from basic elementsMining engineeringCopper mine

The invention discloses an electronic compiling method for a copper mine drilling comprehensive histogram, which comprises the following steps of: establishing a data structure on the basis of an Access database; acquiring drilling data; designing a drawing surface frame style according to a comprehensive histogram drawing specification; calling and processing database data, and drawing various drawing contents; filling borehole knots. The method has the advantages that 1, the operation is simple and convenient; 2, pattern styles are unified and standardized; 3, computer mapping is carried out, and the working efficiency is improved; 4, data is digitalized, and modification is convenient; and 5, the electronic map is convenient to store and search and utilize in the later period. The method is suitable for compiling the copper mine drilling comprehensive histogram, and the working efficiency is greatly improved by establishing the drilling database and utilizing a computer to form thediagram.

Owner:核工业二四三大队

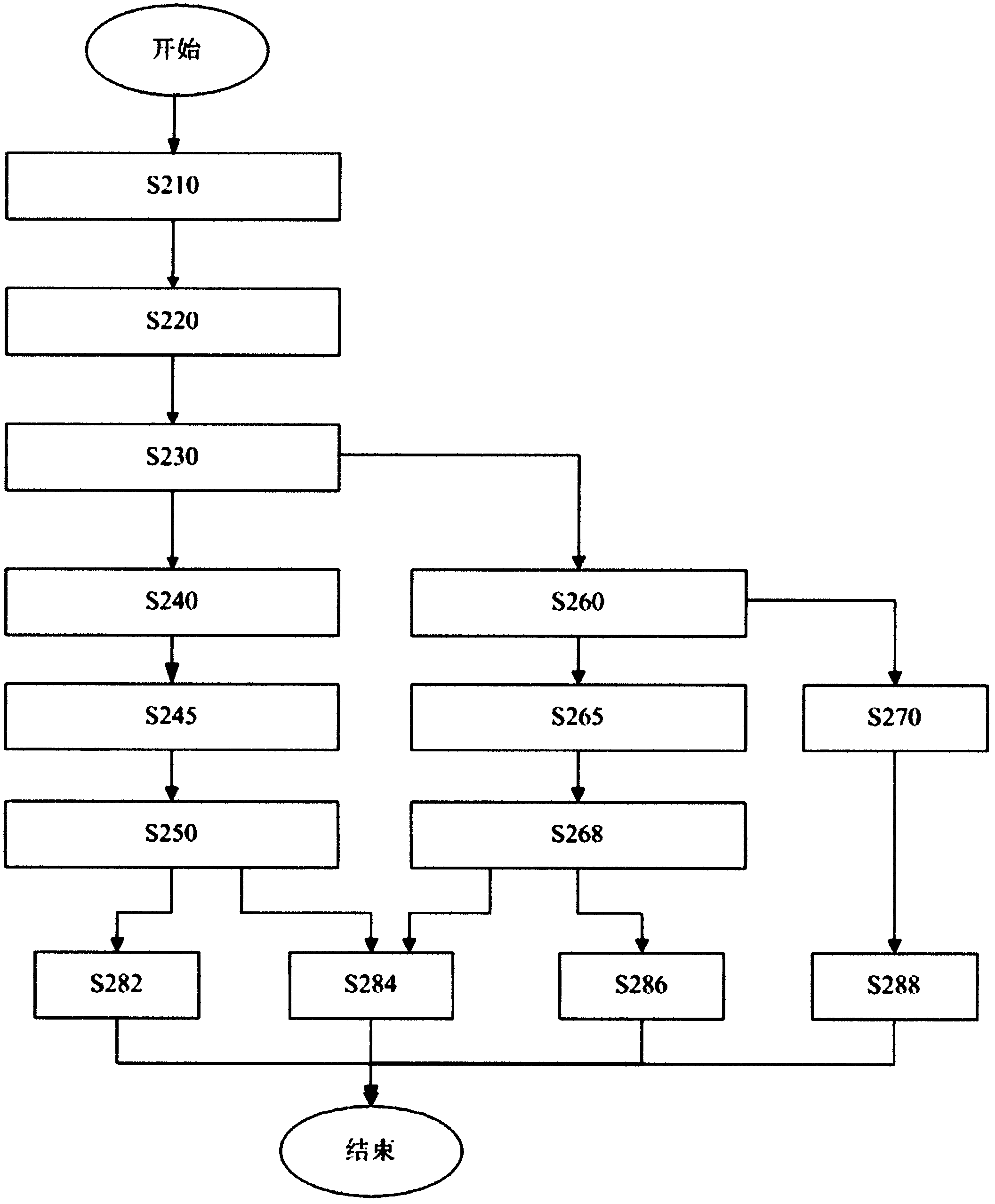

Method for vegetation restoration in copper mine abandoned land

ActiveCN109287182AMaintain diversityImprove the ecological environmentCultivating equipmentsSoil-working methodsRevegetationChemical treatment

The invention provides a method for vegetation restoration in copper mine abandoned land, and belongs to the technical field of ecological restoration and ecological engineering of degraded land. Themethod comprises the steps of S1, land consolidation and soil improvement, wherein the land is leveled, and soil improvement is conducted by means of soil fertilizer and chemical treatment; S2, plantconfiguration, wherein plant materials suitable for local growth are selected, and evergreen tree species and deciduous tree species are reasonably matched according to seasonal variation characteristics; S3, vegetation construction, wherein high-quality nursery stocks growing robustly are selected for planting; S4, cultivating management. Through the steps, a complete vegetation restoration and self-sustaining system is formed for the copper mine abandoned land from improvement to vegetation construction, and the ecological environment of the metal mine abandoned land is effectively improved.According to the method, based on the concept of natural restoration, the vegetation coverage is high, the energy is saved, the environment is protected, the operation method is simple, the construction is convenient, and the method has high application and popularization value.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY +1

Artificial soil based on copper tailing modification and preparation method thereof

PendingCN113173763AReduce pollutionMeet physical and chemical propertiesOther chemical processesSolid waste managementFiberEcological environment

The invention discloses artificial soil based on copper tailing modification and a preparation method thereof. The artificial soil is prepared from the following components in parts by mass: 100 parts of copper tailings, 10 to 20 parts of bagasse fiber, 4 to 8 parts of low-alkali cement, 0.2 to 0.4 part of aggregate accelerant, 0.06 to 0.10 part of drought-resistant water-retaining agent, 0.4 to 0.8 part of acidity regulator and 5 to 10 parts of microbial fertilizer. According to the invention, the copper tailings are used as a main raw material, and other components are doped to modify the copper tailings, so that the copper tailings have physicochemical properties and nutritional components required by plant growth, the artificial soil for ecological restoration can be produced by using local materials on mines, precious natural soil resources are not consumed, the purpose of treating wastes with wastes is realized, the cost of copper mine ecological environment restoration and treatment is reduced, pollution caused by tailing stockpiling is reduced, and the ecological environment of a mining area and the surrounding of the mining area is improved.

Owner:KUNMING PROSPECTING DESIGN INST OF CHINA NONFERROUS METALS IND

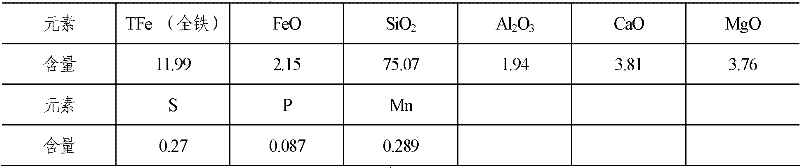

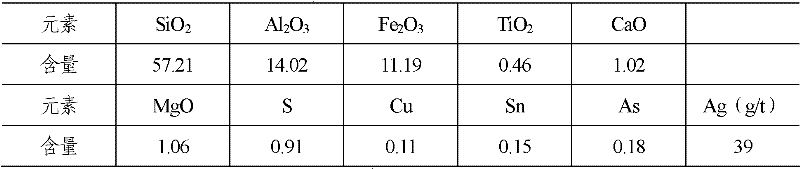

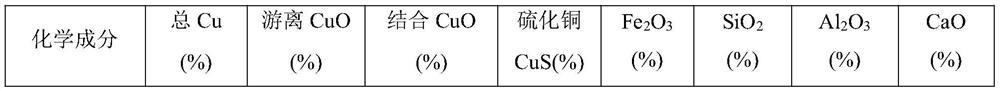

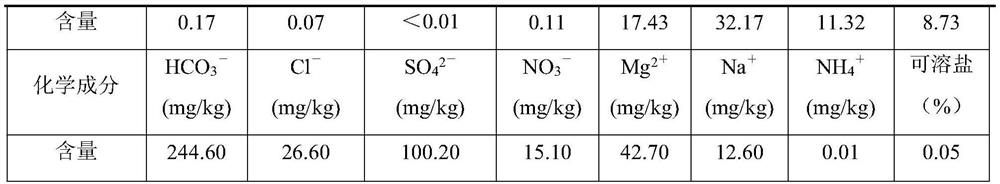

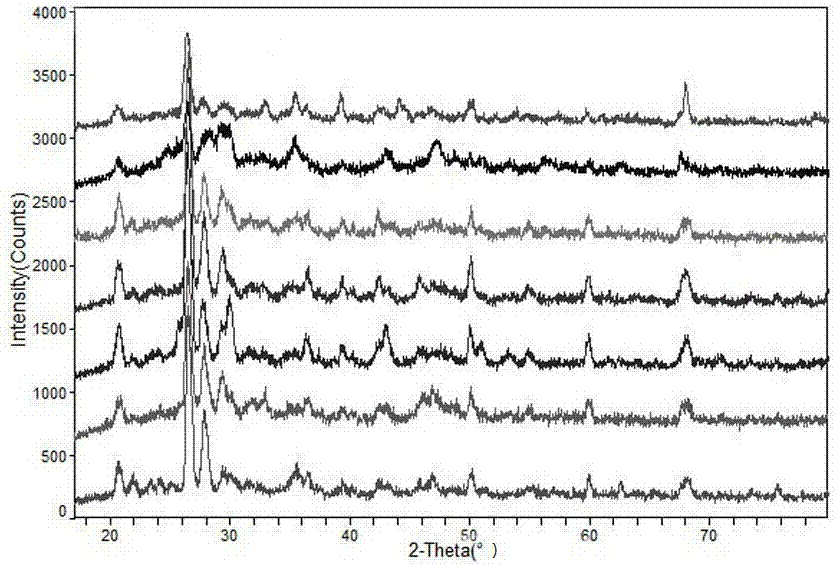

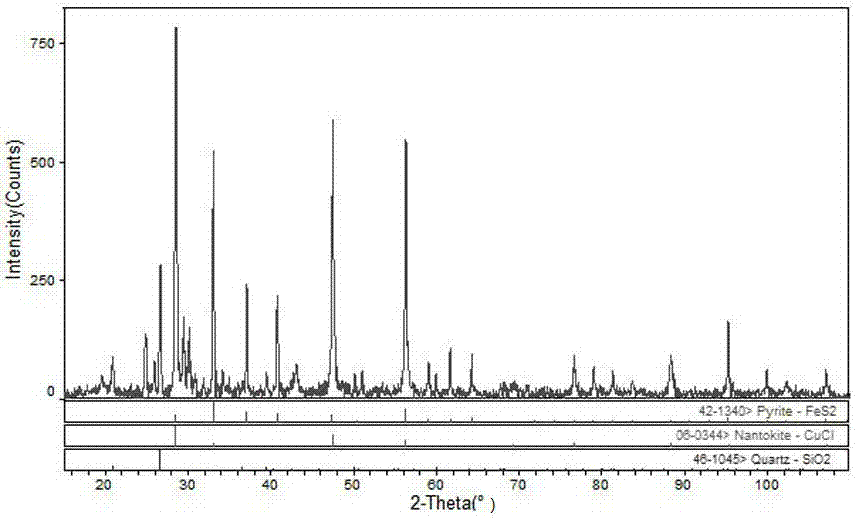

Identification of property of copper mine or copper-containing primary smelting or sintering material

InactiveCN106885814AScientific identification dataMaterial analysis using wave/particle radiationSpectroscopyX-ray

The invention discloses identification of the property of a copper mine or copper-containing primary smelting or sintering material. The property of the copper mine or copper-containing primary smelting or sintering material is identified by X-ray fluorescence spectroscopy and X-ray diffraction spectroscopy; quantitative semi-qualitative detection is performed on elements through the X-ray fluorescence spectroscopy; the spectrum peak characteristic of the copper mine or copper-containing primary smelting or sintering material is identified by the X-ray diffraction spectroscopy in order to judge the property of a sample. The identification has the advantages of rapidness, easiness and convenience, faster customs clearance of port commodities is facilitated, environmentally hazardous and false and concealed commodities are forbidden to enter the country immediately and accurately, the aim of preventing the false and concealed commodities from entering the country is fulfilled during imported goods inspection, technical support is provided for inspection and quarantine and China customs, and scientific identification data are provided for import and export trade enterprises.

Owner:阿拉山口出入境检验检疫局综合技术服务中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com