System and method for comprehensive utilization of copper mine chats

A technology for copper mines and ores, which is applied in the field of comprehensive utilization of waste rocks in copper mines, and can solve the problems of undisclosed recycling of metals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

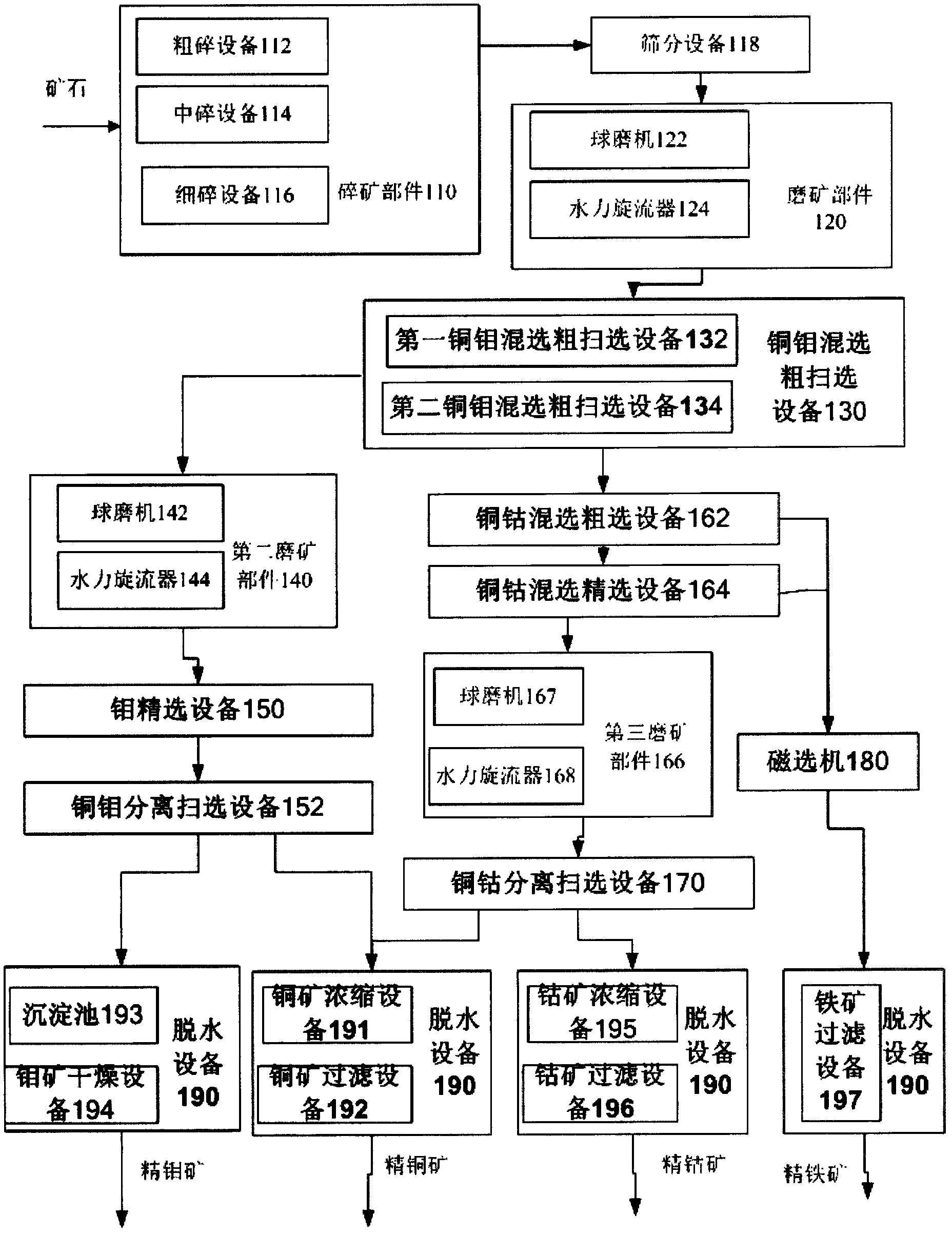

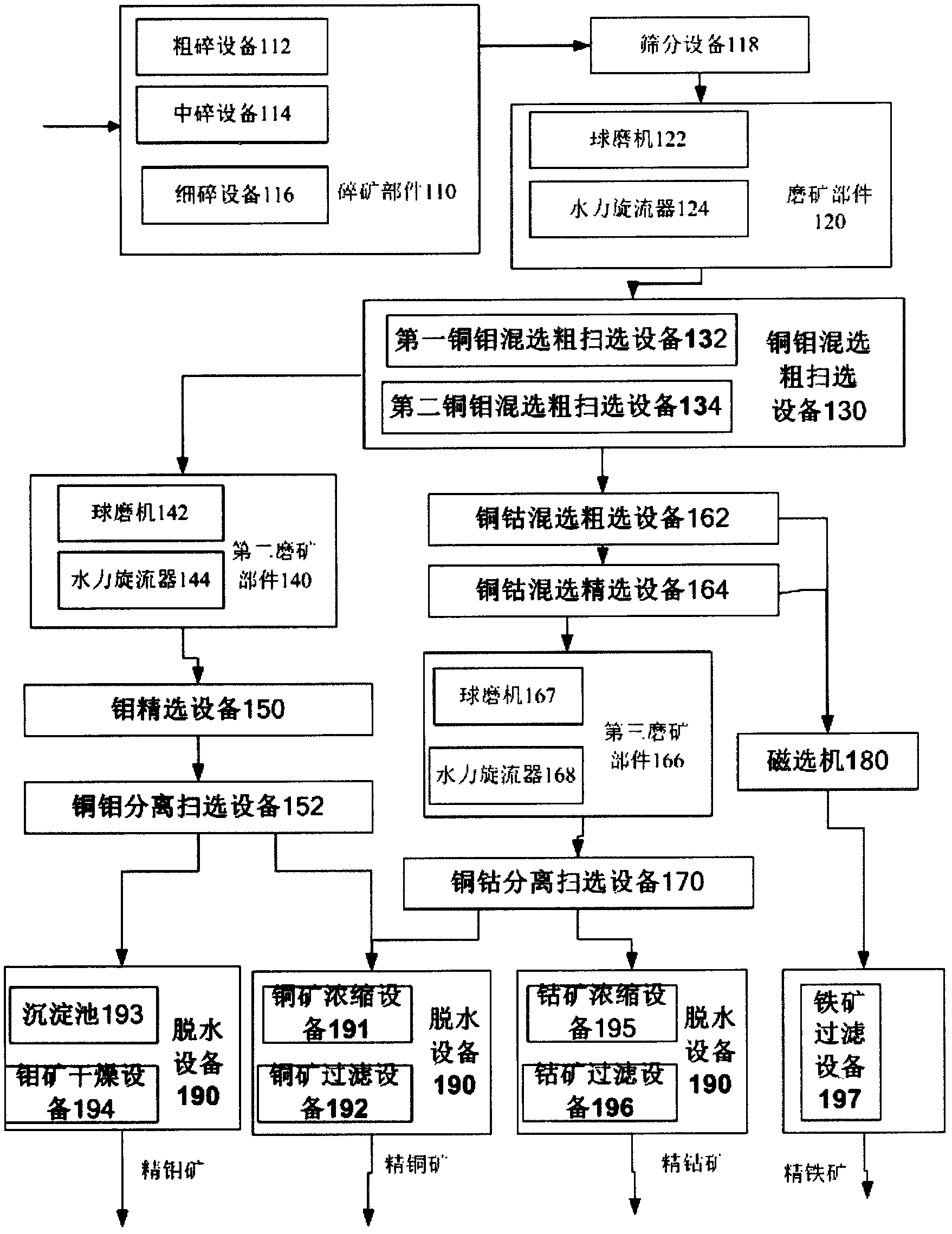

[0018] figure 1 A comprehensive utilization system 100 for low-grade copper mine waste rock according to an embodiment of the present invention is shown. like figure 1 As shown, the waste rock comprehensive utilization system 100 includes an ore crushing component 110 . The ore crushing unit 110 is adapted to crush ore into smaller particles. Since the size of the existing ore is relatively large, the ore crushing unit 110 may include a coarse crushing device 112 , a secondary crushing device 114 and a fine crushing device 116 working in series.

[0019] Available primary crushing equipment includes jaw crushers and gyratory crushers. The structure of the jaw crusher is simple, light in weight, and convenient for maintenance and transportation; the appearance height is small, and the required height difference is small; the work is reliable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com