Porous thermal insulation ceramic using gold copper mine tailings as raw material and preparation method thereof

A technology of gold-copper tailings and thermal insulation ceramics, which is applied in the direction of ceramic products, other household utensils, household utensils, etc. It can solve the problems that the quantity and quality cannot meet the needs of the rapid development of the construction industry, high quality requirements, and low development and utilization rates. , to achieve the effect of high strength, simple production process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

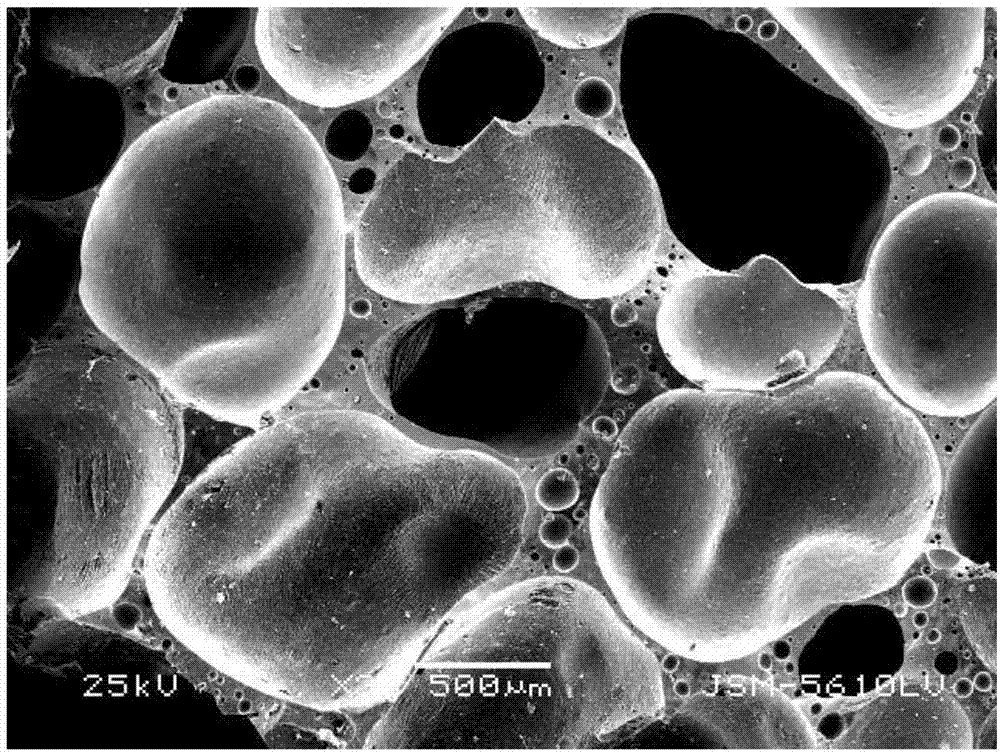

Image

Examples

Embodiment 1

[0029] A kind of porous thermal insulation ceramics with gold-copper tailings as the main raw material, its preparation method is as follows:

[0030] 1) Grind the gold-copper tailings, float glass powder, foaming agent, and additives respectively to pass through a 300-mesh sieve, and the sieve residue is controlled at 0.5wt%, and the weight percentage of each component is 75wt% of the gold-copper tailings, 10wt% float glass powder, 2wt% silicon carbide, 4.5wt% calcium carbonate, 0.5wt% activated carbon, 5wt% borax, and 3wt% soda ash are weighed and prepared, and the weighed raw material components are loaded into a ball mill Grinding and mixing were carried out in the tank, and the mixing time was 5 hours;

[0031] 2) The mixed material obtained in step 1) is molded with a molding pressure of 8 MPa to make a porous ceramic body (shaped into a plate);

[0032] 3) Put the formed green body on the refractory shed plate coated with aluminum hydroxide coating, put the two togethe...

Embodiment 2

[0036] A kind of porous thermal insulation ceramics with gold-copper tailings as the main raw material, its preparation method is as follows:

[0037] 1) Grind gold-copper tailings, float glass powder, foaming agent, additives, etc. to pass through a 250-mesh sieve, and control the sieve residue at 0.5wt%, according to the weight percentage of each component, it is 80.0wt% gold-copper tailings Ore, 10.0wt% float glass powder, 2.0wt% silicon carbide, 2.0wt% calcium carbonate, 1.0wt% activated carbon, 3.0wt% borax, 2.0wt% soda ash are weighed and prepared, and the weighed The raw material components are put into a ball mill tank for grinding and mixing, and the mixing time is 4 hours;

[0038] 2) Mold the mixture obtained in step 1) with a molding pressure of 14 MPa to make a porous ceramic body (molded into a block);

[0039] 3) Put the formed green body on the refractory shed plate coated with aluminum hydroxide coating, put the two together on the transmission roller of the ...

Embodiment 3

[0042] A kind of porous thermal insulation ceramics with gold-copper tailings as the main raw material, its preparation method is as follows:

[0043] 1) Grind gold-copper tailings, float glass powder, foaming agent, additives, etc. to pass through a 300-mesh sieve, and control the sieve residue at 0.5wt%, and the weight percentage of each component is 85.0wt% gold-copper tailings Mine, 8.0wt% float glass powder, 1.0wt% silicon carbide, 1.0wt% calcium carbonate, 1.0wt% activated carbon, 2.0wt% borax, 1.0wt% soda ash is weighed and prepared, and the weighed The raw material components are put into a ball mill tank for grinding and mixing, and the mixing time is 3 hours;

[0044] 2) Molding the mixture obtained in step 1) with a molding pressure of 18MPa to make a porous ceramic body;

[0045] 3) Put the formed green body on the refractory shed plate coated with aluminum hydroxide coating, put the two together on the transmission roller of the roller kiln of the firing equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com