Column-machine combined separation method of difficultly-separated low-grade copper-molybdenum ore

A separation method and low-grade technology, applied in solid separation, flotation and other directions, can solve the problems of low recovery rate of molybdenum, high power consumption and long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

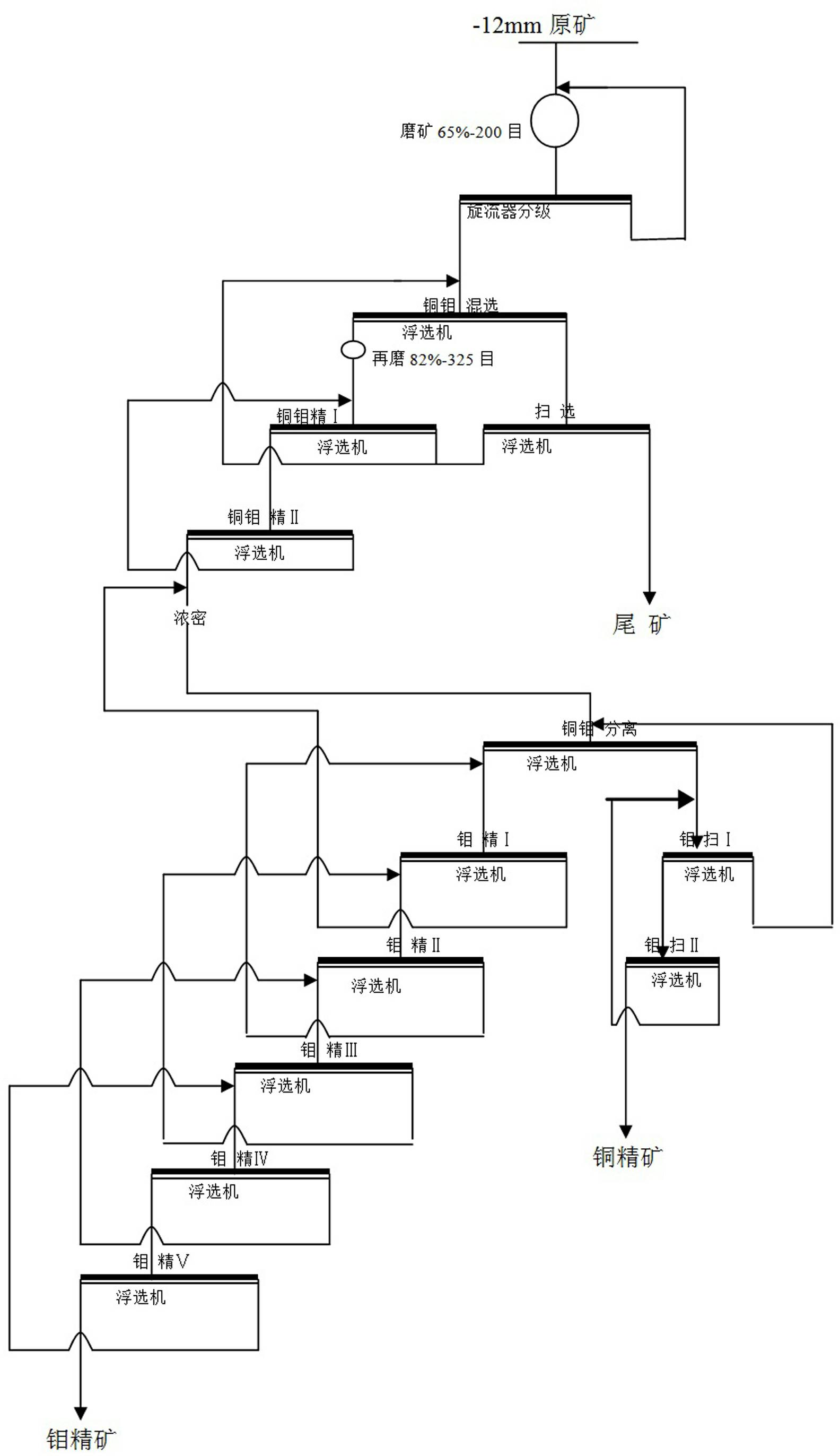

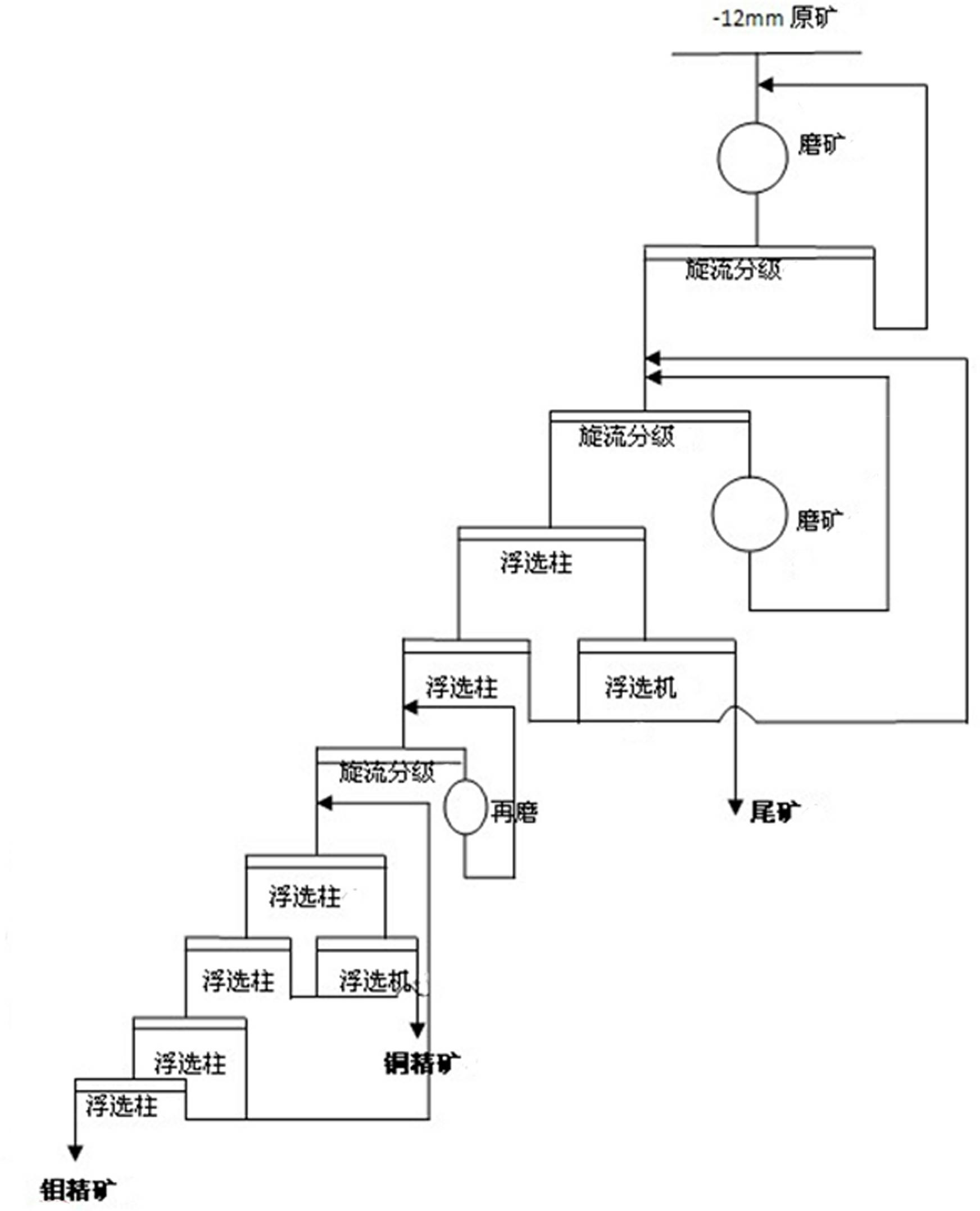

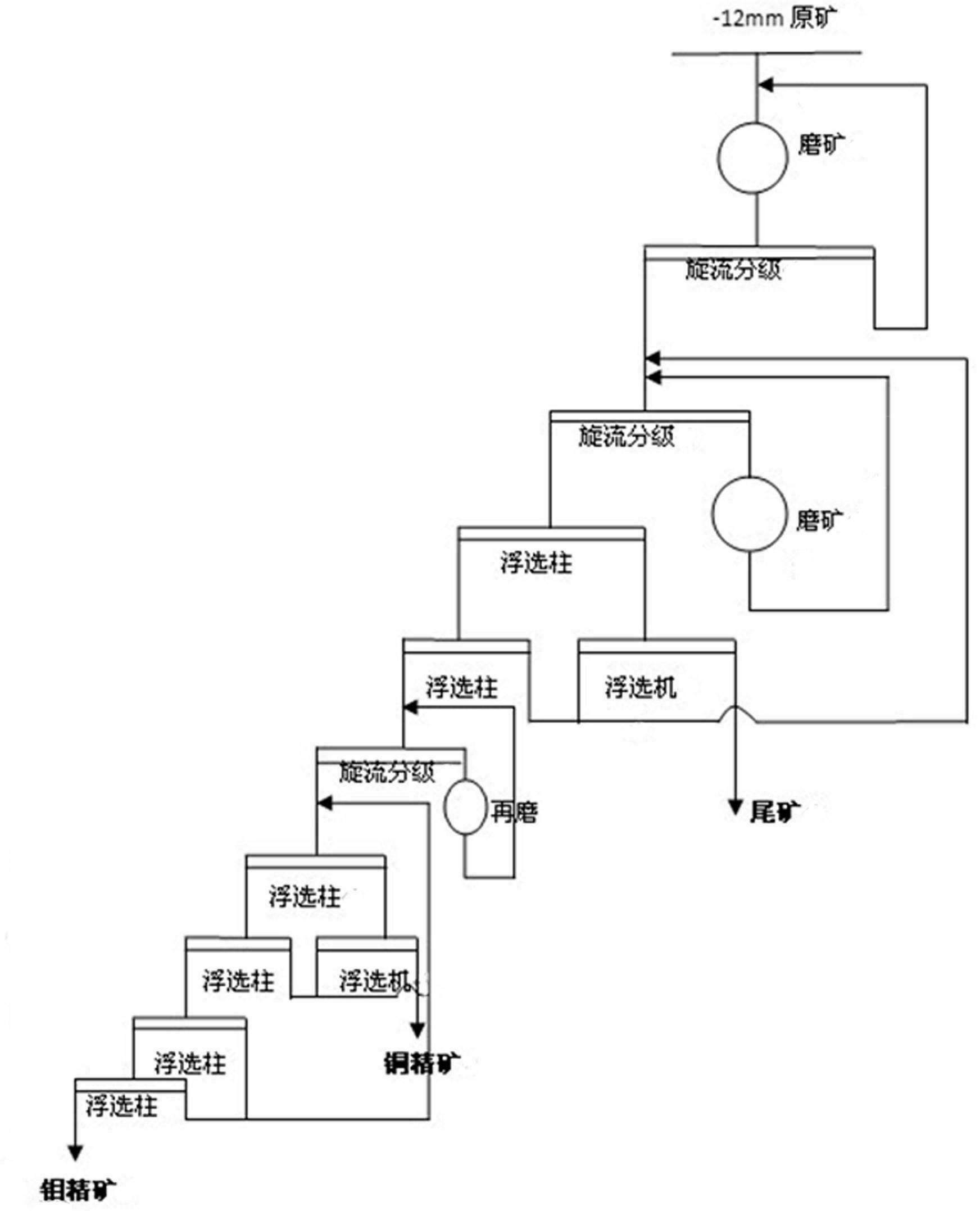

[0037] refer to figure 1 , a column-machine combined separation method for refractory low-grade copper-molybdenum ore. The process of the method is: two closed-circuit grinding-mixed flotation, one roughing, one sweeping, one beneficiation-mixed fine Ore regrinding-separation of copper suppression and floating molybdenum, adopts roughing, one-time sweeping, three times of concentration I, concentration II, and concentration III; during the whole process, the joint operation of flotation column and flotation machine is used; specific steps as follows:

[0038] One or two closed-circuit grinding:

[0039] ①. Grinding to -200 mesh before mixed flotation accounts for 70%, 72%, 74%, 76%, 78% or 80%, adding 500, 600, 700, 800, 900 or 1000 g / ton of water glass; effectively activate the refractory low-grade copper-molybdenum ore and the ore slime in the dispersive mixed flotation process; wherein the grinding overflow concentration is 36%, 38% or 40%;

[0040] ②, add lime 800, 900...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com