Patents

Literature

184results about How to "Reduce heat transfer temperature difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

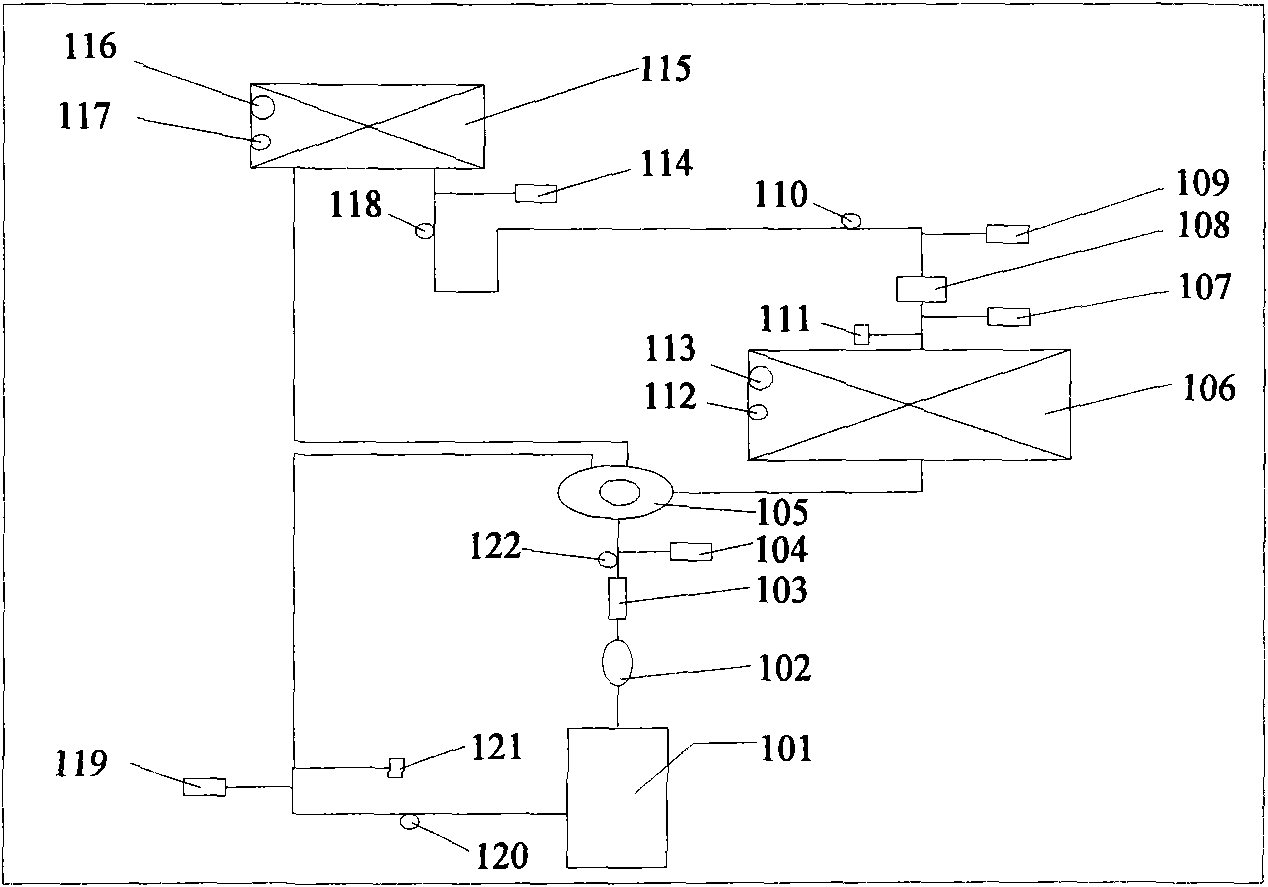

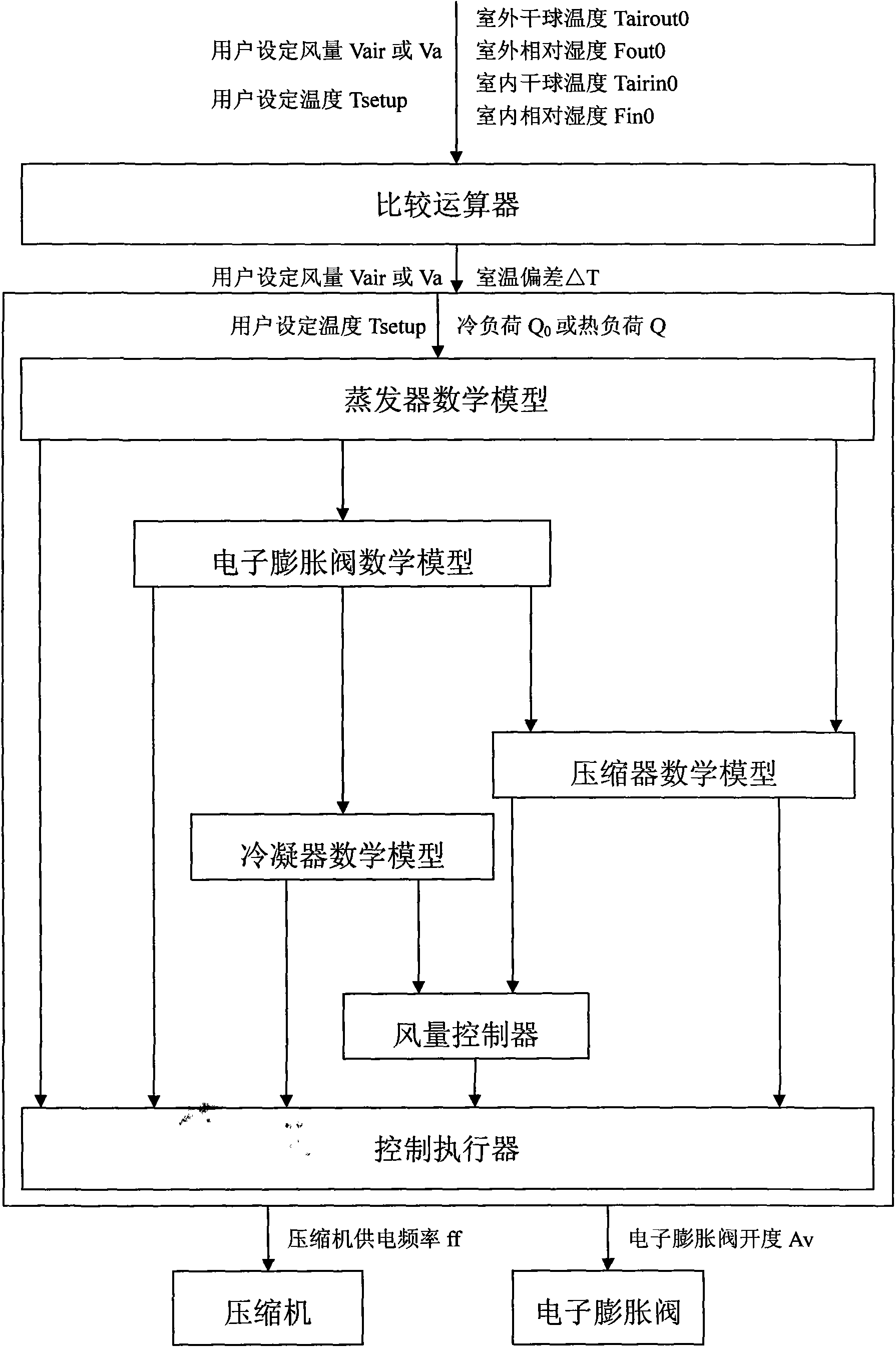

Variable frequency energy-saving control method for refrigeration system

ActiveCN101603751AGive full play to the heat exchange capacityReduce heat transfer temperature differenceSpace heating and ventilation safety systemsSpace heating and ventilation control systemsAir volumeOperating point

The invention belongs to the technical field of energy conservation, and relates to a variable frequency energy-saving control method for a refrigeration system. The control method comprises the steps of: determining the mass flow of a refrigerant according to the change or change trend of cooling load, then determining consumed power of a compressor which satisfies the flow, predicting the minimum condensation pressure which ensures that the thermal load of a condenser satisfies the cooling load and the power change of the compressor through an established energy-saving control mathematical model, and gradually adjusting the power frequency of the compressor to ensure that the rotating speed of the compressor reaches a predicted value; and adjusting the opening degree of an expansion valve to ensure that the condensation pressure reaches to be lowest, realizing the minimum pressure difference operation between the condenser and an evaporator, and ensuring that the operation energy consumption of the refrigeration system is lowest. The method solves the optimizing control problem of the compressor, the expansion valve and a fan in the system, utilizes the energy-saving control mathematical model to perform joint regulation on controllable factors (such as the rotating speed of the compressor, the opening degree of the expansion valve, and the air volume of an outdoor unit) of the operation of the system, ensures that the refrigeration system operates at a best operating point, and realizes the further energy conservation of the refrigeration system based on the variable frequency regulation.

Owner:汉广中药科技(天津)有限公司

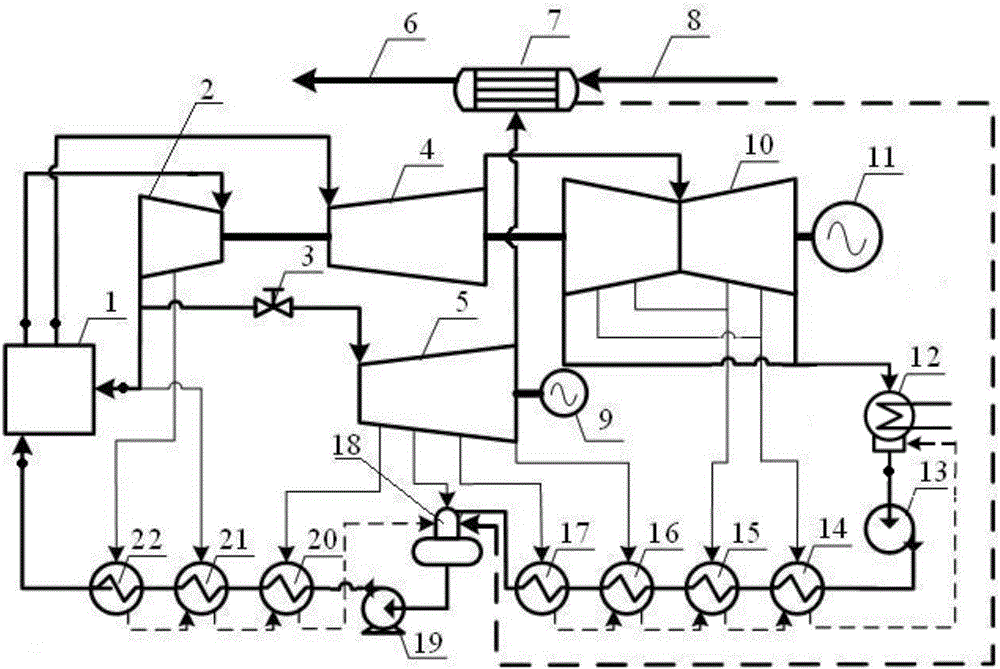

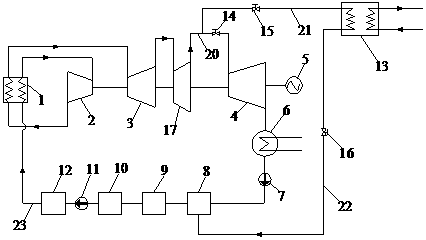

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

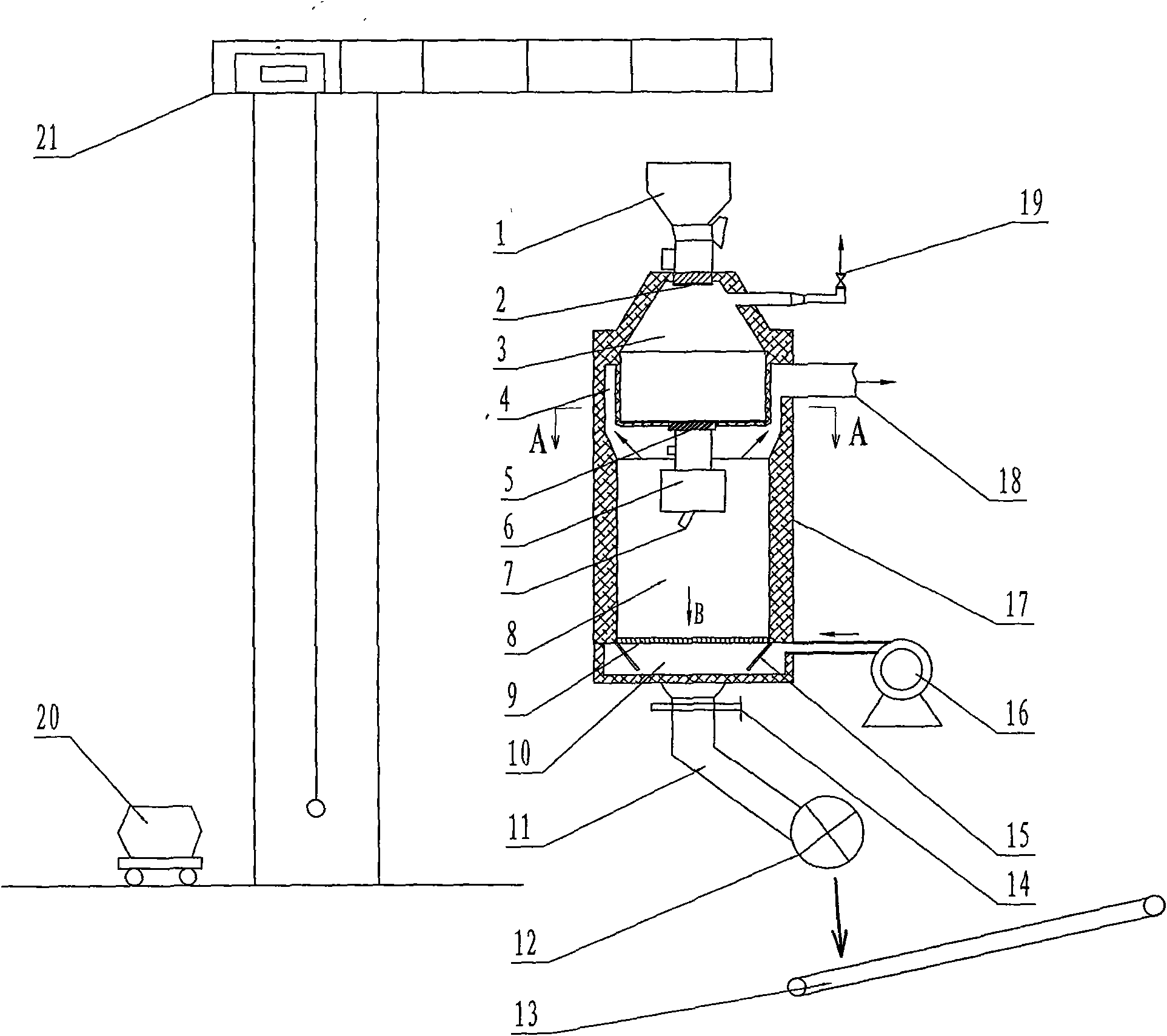

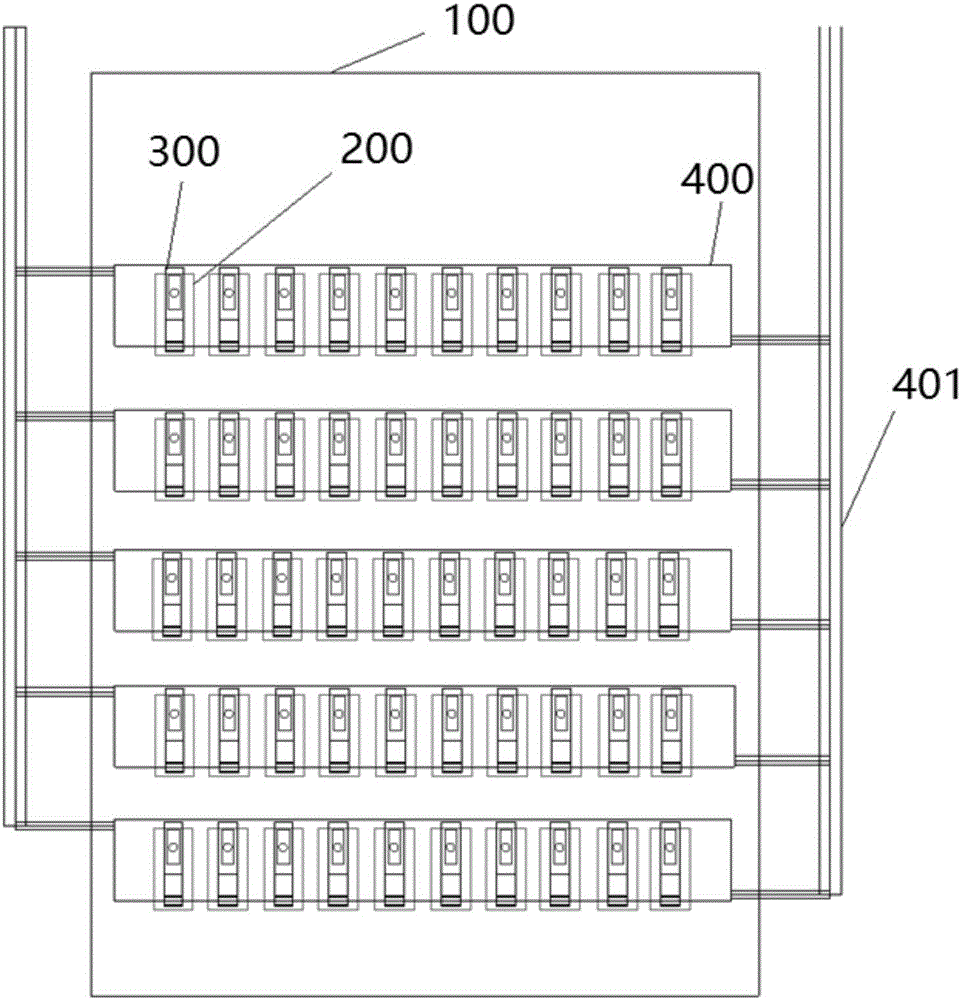

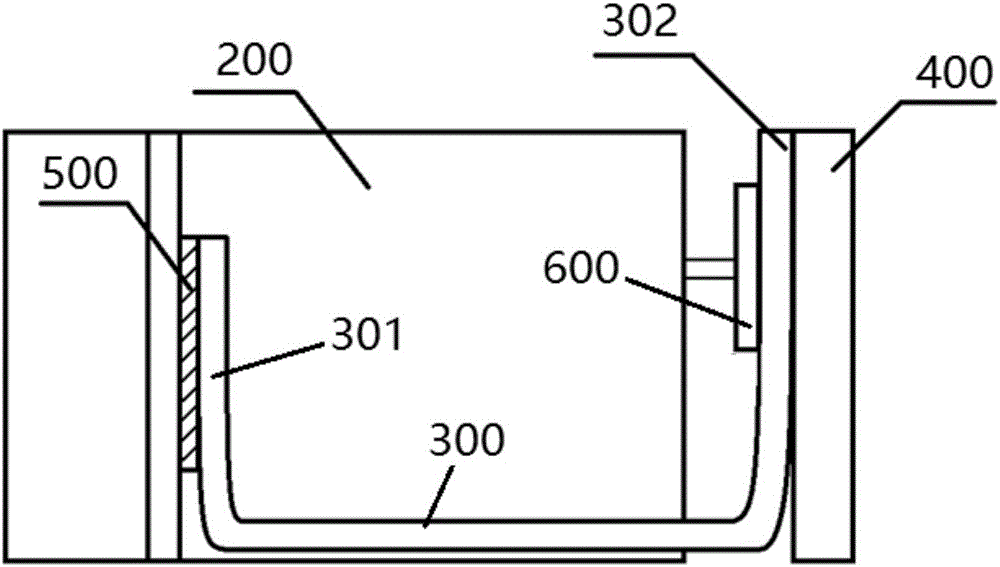

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

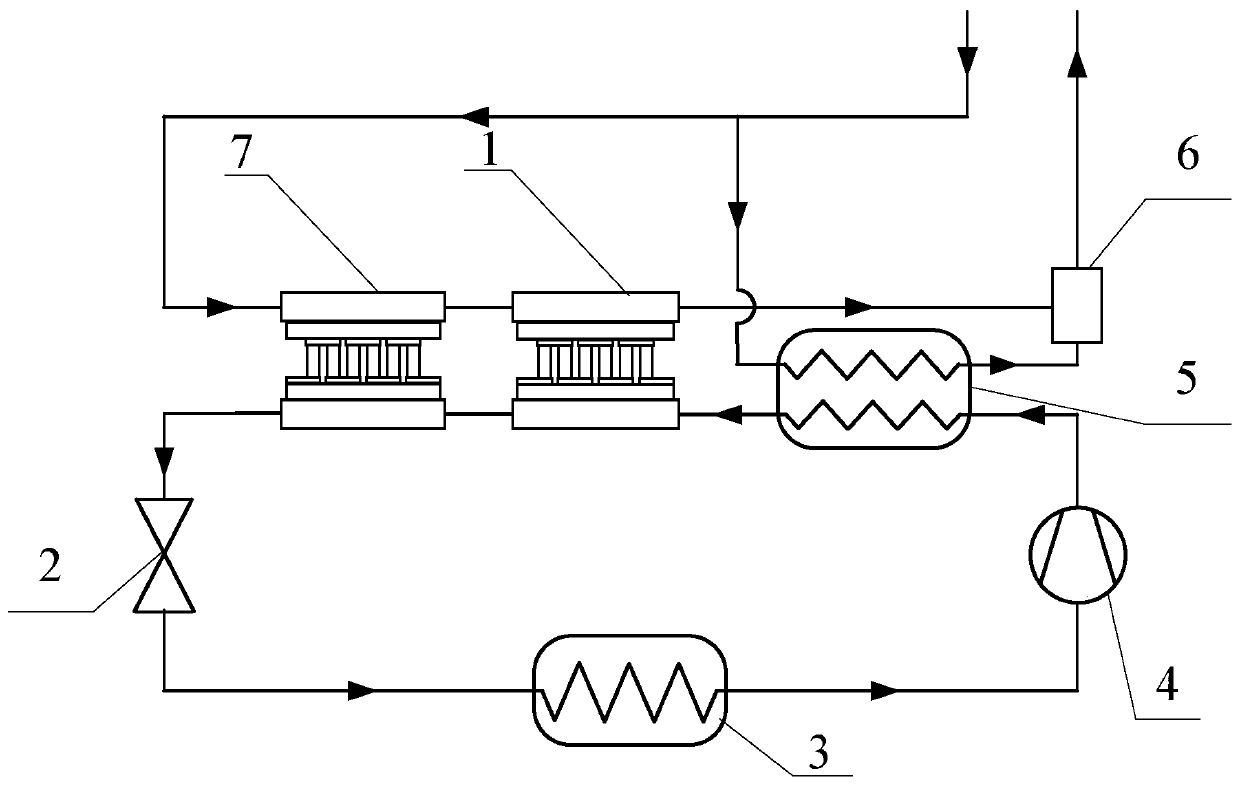

Air-cooling thermotube-type machine room air-conditioning system

ActiveCN101975428ASolve quality processing problemsSolve runnabilitySpace heating and ventilation safety systemsLighting and heating apparatusBusiness efficiencyHigh energy

The invention discloses an air-cooling thermotube-type machine room air-conditioning system which comprises a compressor, a first air cooling condenser, a throttling set, an evaporative condenser, a liquid storage tank, a flow balance valve, a tail end heat exchanger, a bubble pump, a first refrigerant changeover valve, a second refrigerant changeover valve and a second air cooling condenser, wherein the high-pressure exhaust port of the compressor is orderly connected with the first air cooling condenser, the throttling set, the evaporation side of the evaporative condenser, and the low-pressure air suction inlet of the compressor, thereby forming a compression refrigerating cycle loop; the condensing side outlet of the evaporative condenser is orderly connected with the liquid storage tank, the flow balance valve, the tail end heat exchanger, the bubble pump, the first refrigerant changeover valve, and the condensing side inlet of the evaporative condenser; and the outlet of the tail end heat exchanger is orderly connected with the second refrigerant changeover valve, the second air cooling condenser, and the inlet of the liquid storage tank, thereby forming a thermotube refrigerating cycle loop. The system has the advantages of small temperature difference and high energy efficiency ratio during heat exchange.

Owner:浙江洁普环保科技有限公司

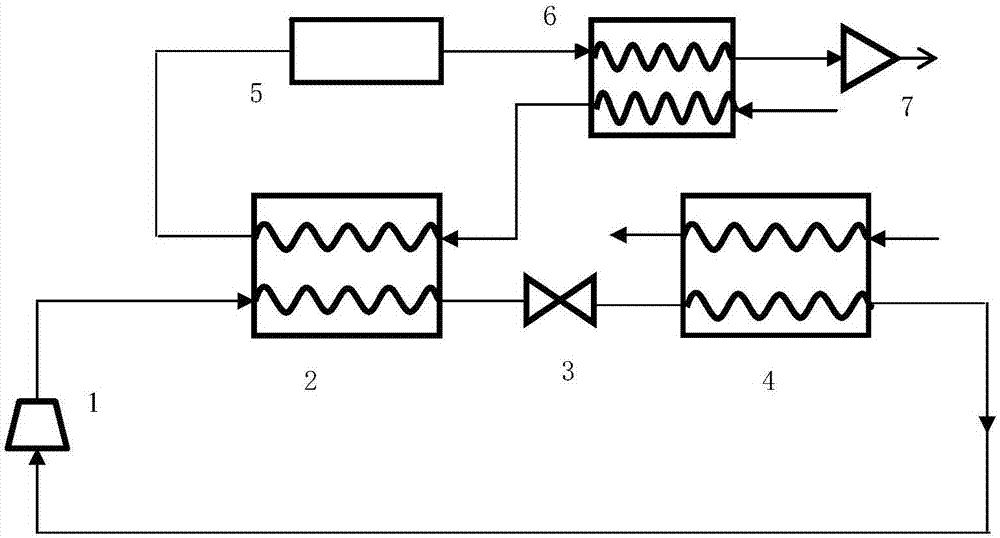

Heat pump drier

InactiveCN101216245AReduce heat transfer temperature differenceImprove drying efficiencyHeat pumpsDrying gas arrangementsWorking fluidEvaporator

The invention discloses a heat pump drying machine with high-efficient and environmentally friendly CO2 as the working fluid. The high-pressure side of a compressor is connected with the working fluid sides of two air source-based gas coolers in series and then connected with an inner heat exchanger, and the high-pressure working fluid side of the inner heat exchanger is connected with the low-pressure working fluid side of the inner heat exchanger via an electronic expansion valve and an evaporator and then connected with the low-pressure side of the compressor, so as to form a working fluid circulating system. The air side of the evaporator is connected with the second air source-based gas cooler in series and then connected with the inlet of a first drying room, the outlet of the first drying room is connected with the first air source-based gas cooler in series and then connected with the inlet of a second drying room, the outlet of the second drying room is connected with an external heat exchanger in series and then connected with the air side inlet of the evaporator, so as to form an air circulating system. The invention takes advantage of the heat exchange characteristics of the heap pump with CO2 as the working fluid with two-stage drying design, and reduces the temperature of the working fluid at the outlet of the gas cooler, so as to reasonably utilize energy, perform continuous drying and shorten drying time.

Owner:TIANJIN UNIV

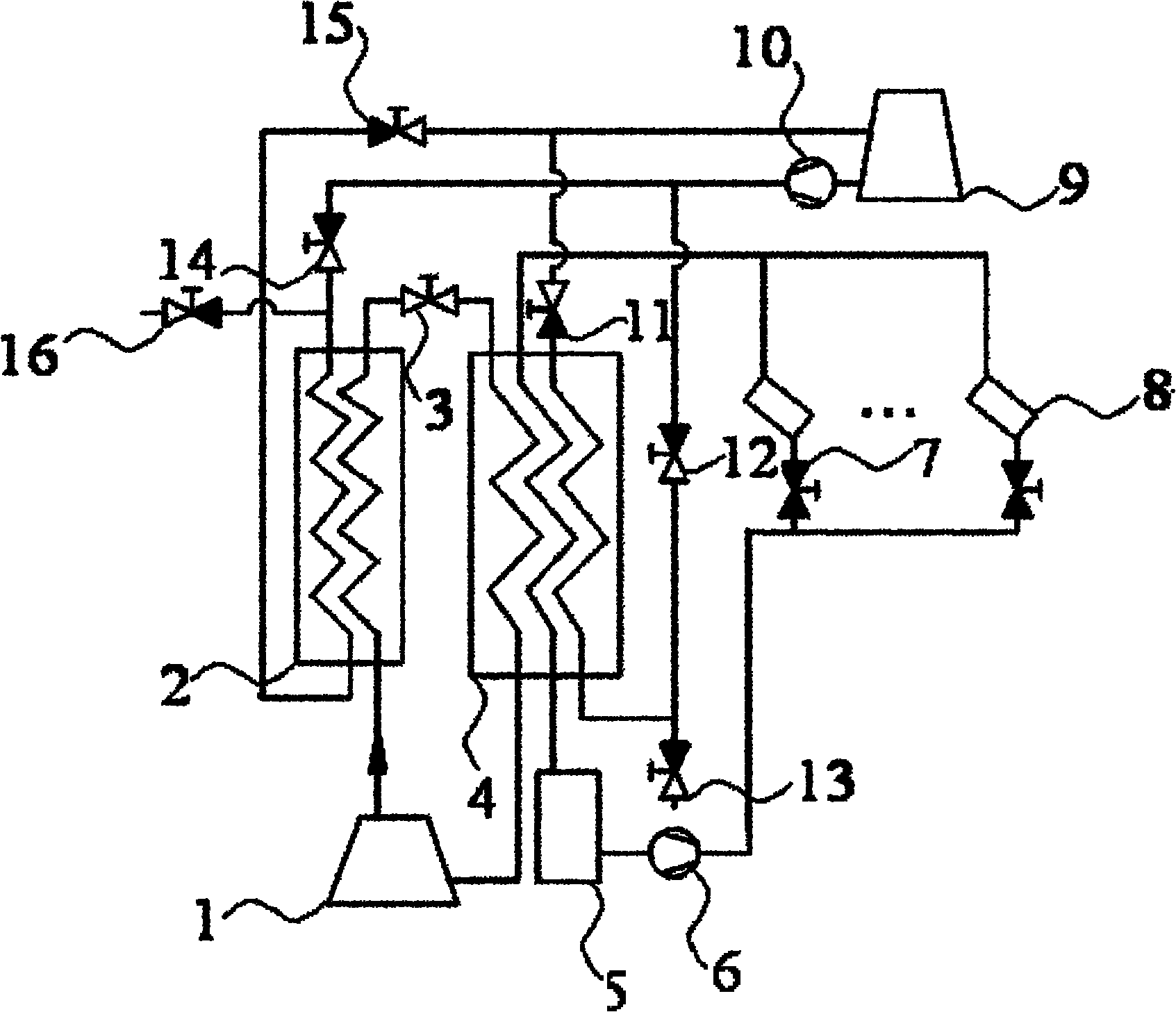

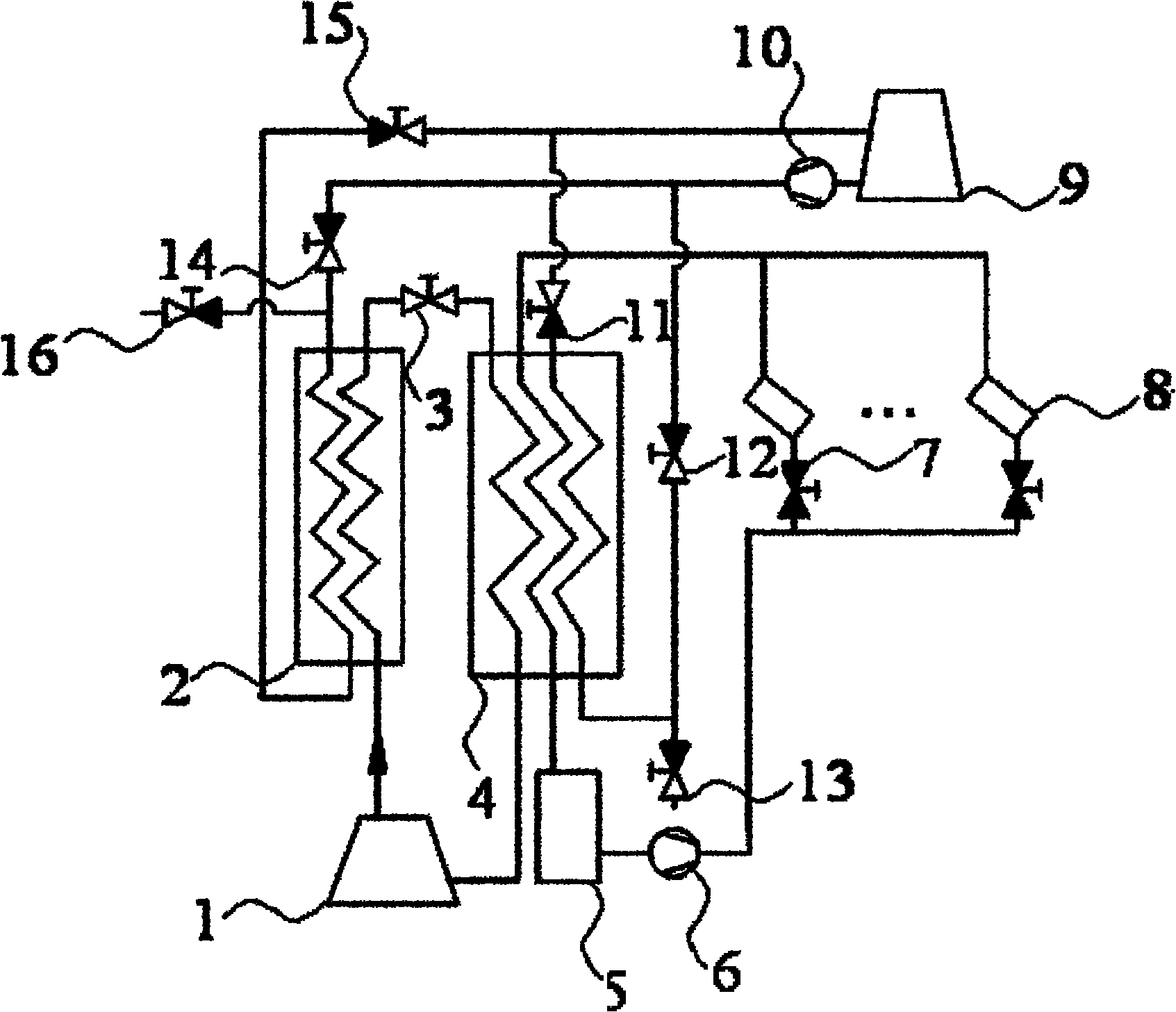

Extraction condensing heat supply system additionally provided with non-reheat medium-pressure steam turbine

InactiveCN105697075AReduce superheatImprove the flow structureLiquid degasificationSteam useEngineeringHeat losses

The invention belongs to the technical field of thermoelectricity, and relates to an extraction condensing heat supply system additionally provided with a non-reheat medium-pressure steam turbine. A part of steam is separated from a steam exhaust port of a high-pressure cylinder of a main steam turbine to enter the added non-reheat medium-pressure steam turbine, and the rest of steam enters a reheater of a boiler and a No.II high-pressure heater; the steam entering the medium-pressure steam turbine does not need to be reheated, an independent generator II is driven, four-stage extraction steam of the medium-pressure steam turbine serves as a heat source for a No.III high-pressure heater, a No.V low-pressure heater, a No.VI low-pressure heater and a deaerator to replace a part of regenerative extraction steam of the main steam turbine, and the extraction steam of the medium-pressure steam turbine is discharged into a heater for heating network to heat heating network water. An effect of additionally installing the medium-pressure steam turbine in the extraction condensing heat supply system disclosed by the invention is to reduce heat exchange exergy loss by reducing heat exchange temperature difference of a part of regenerative heaters and the deaerator; work capability of heat supply steam flow is increased, and therefore heat loss of a high-capacity heat supply unit is caused by a high extraction steam parameter is reduced; and the extraction condensing heat supply system disclosed by the invention is suitable for heat supply and energy conservation transformation on 300 MW (megawatt), 600 MW and above steam turbine units.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

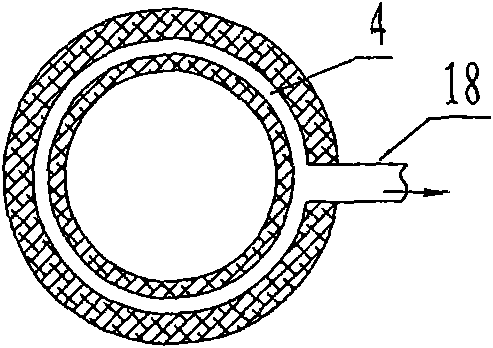

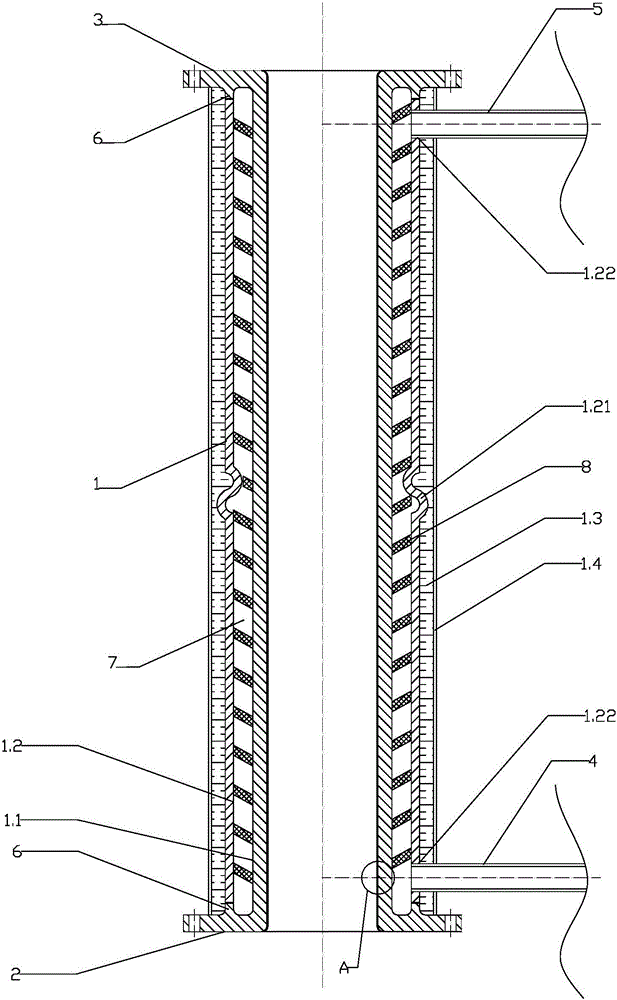

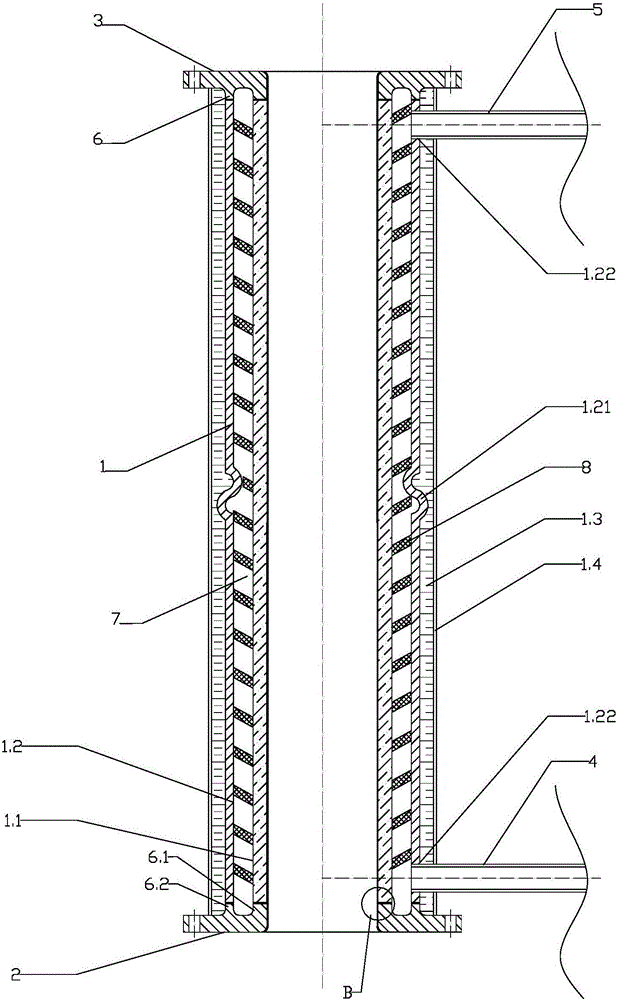

Coke oven ascension pipe raw gas evaporative cooling device and preparation method thereof

InactiveCN105043117APrevent oxidationAvoid carburizationIncreasing energy efficiencyWaste heat treatmentEngineeringCoke oven

The invention discloses a coke oven ascension pipe raw gas evaporative cooling device and a preparation method thereof. The device comprises a cooling pipe, a raw gas inlet flange and a raw gas outlet flange, wherein the raw gas inlet flange and the raw gas outlet flange are connected with the two ends of the cooling pipe respectively. The cooling pipe is sequentially composed of an inner sleeve, an outer sleeve, a heat preservation layer and a protection layer from inside to outside. Through holes are formed in the two ends of the side wall of the outer sleeve respectively. A water inlet steel pipe is installed on the through hole close to the raw gas inlet flange. A vapor outlet steel pipe is installed on the through hole close to the raw gas outlet flange. An annular expansion joint section is arranged at the portion, between the water inlet steel pipe and the vapor outlet steel pipe, of the outer sleeve. The high temperature structural strength and high temperature breakage resistant capacity of the cooling device are remarkably improved, the heat transfer behavior of the pipe wall of the inner sleeve of the cooling device is improved, the radial temperature distribution of the pipe wall is optimized, the efficient function coordination of multiple layers of materials is achieved, and the comprehensive use performance of the inner sleeve is improved; the aim of long-term efficient and stable running of the ascension pipe raw gas evaporative cooling device is finally achieved.

Owner:武汉钢铁有限公司

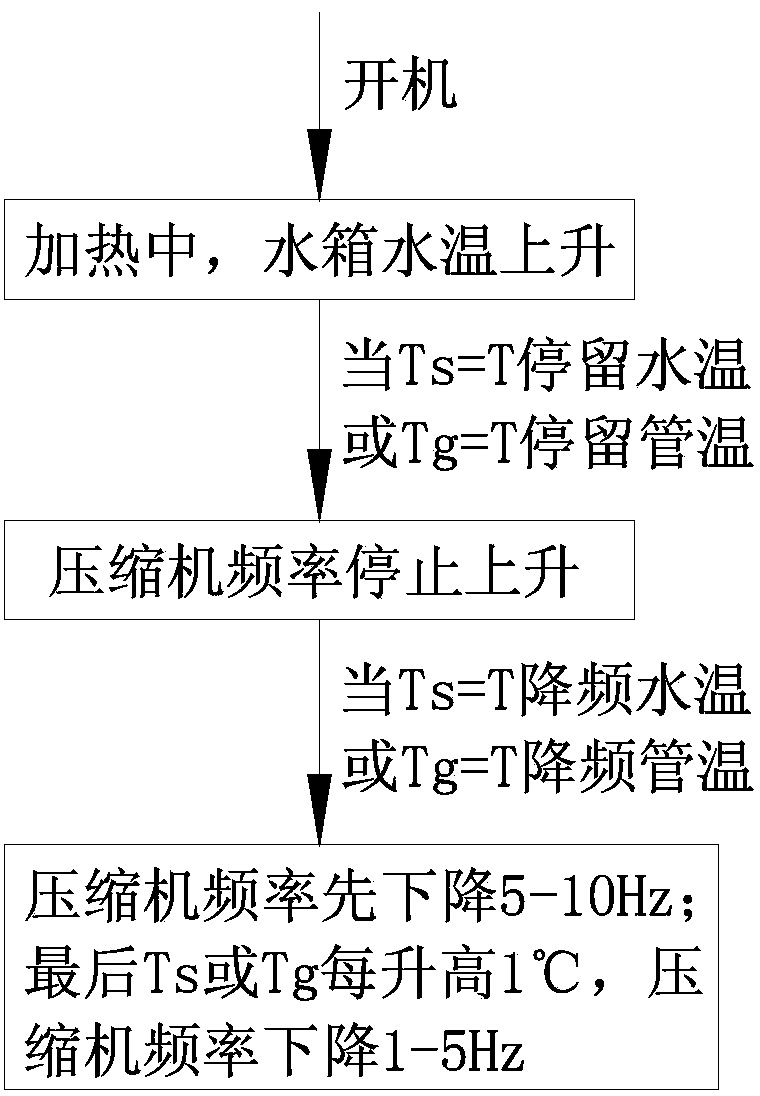

Method for increasing highest outlet water temperature of heat pump water heater

ActiveCN103836789ARaise the water temperatureReduce condensation loadFluid heatersControl systemFrequency reduction

The invention provides a method for increasing the highest outlet water temperature of a heat pump water heater. Due to the fact that a compressor frequency reducing step is included, when a heat pump heat water control system judges that current operating parameters conform to compressor frequency reducing conditions, the compressor frequency reduces, and the circulation volume of coolants is reduced. Consequently, the condensing load of the heat pump water heater is reduced, the heat exchange temperature difference of a condenser is reduced, and the temperature of water in a water tank is further increased. According to the method, judgments are conducted according to the current operating parameters, a method of frequency reduction on a high water temperature section is adopted, and the circulation volume of the system is reduced, namely, the condensing load-heat exchange temperature difference of the system is reduced, and the heat exchange temperature difference is reduced by 5 DEG C, so that the highest water temperature can reach 55 DEG C. On the condition that the cost and the installation space of the whole machine are not increased, the purpose that the highest outlet water temperature of a R410A coolant heat pump water heater reaches 55 DEG C is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

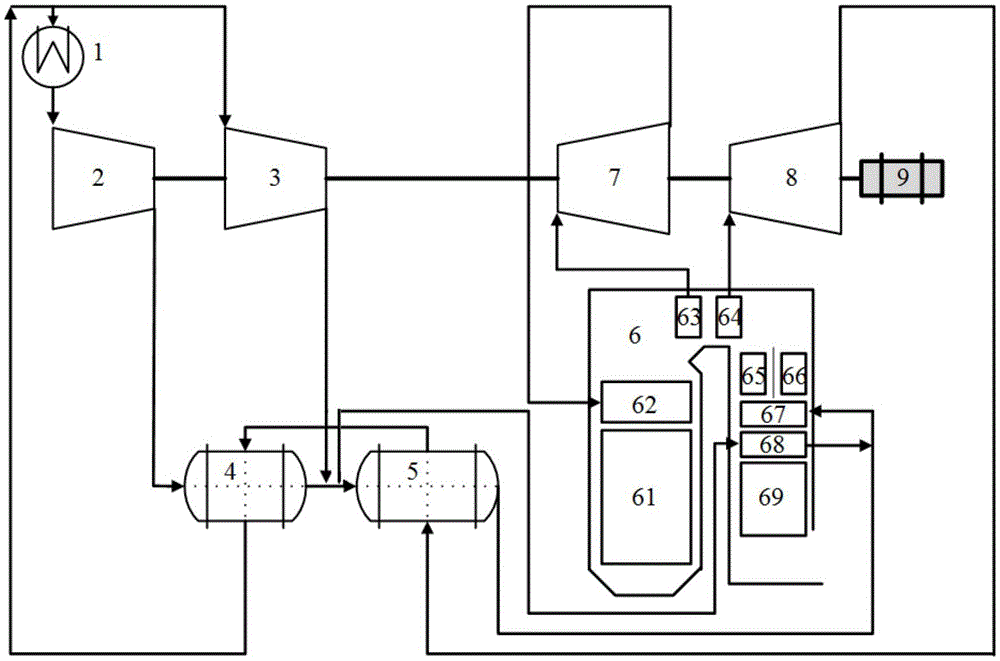

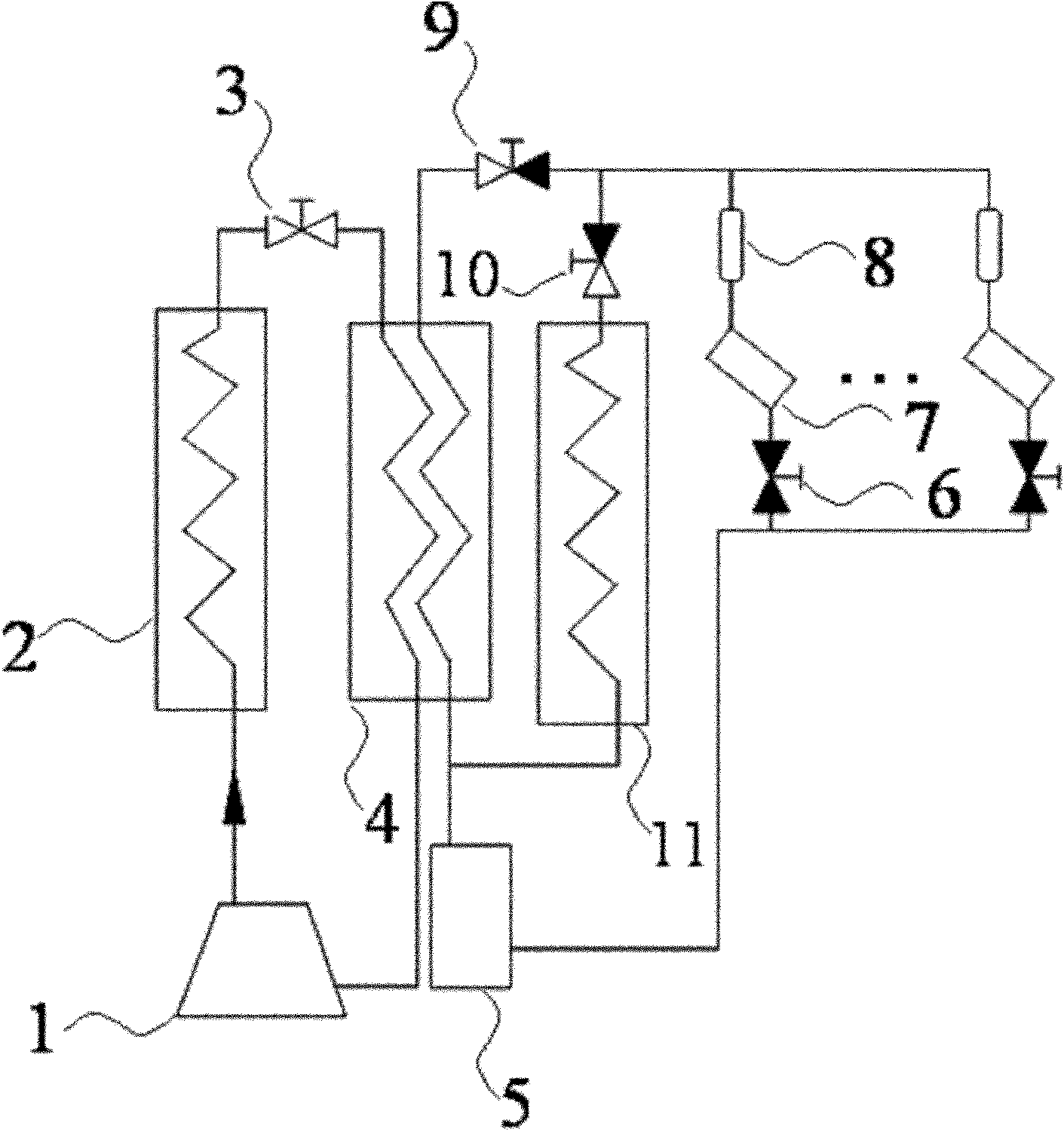

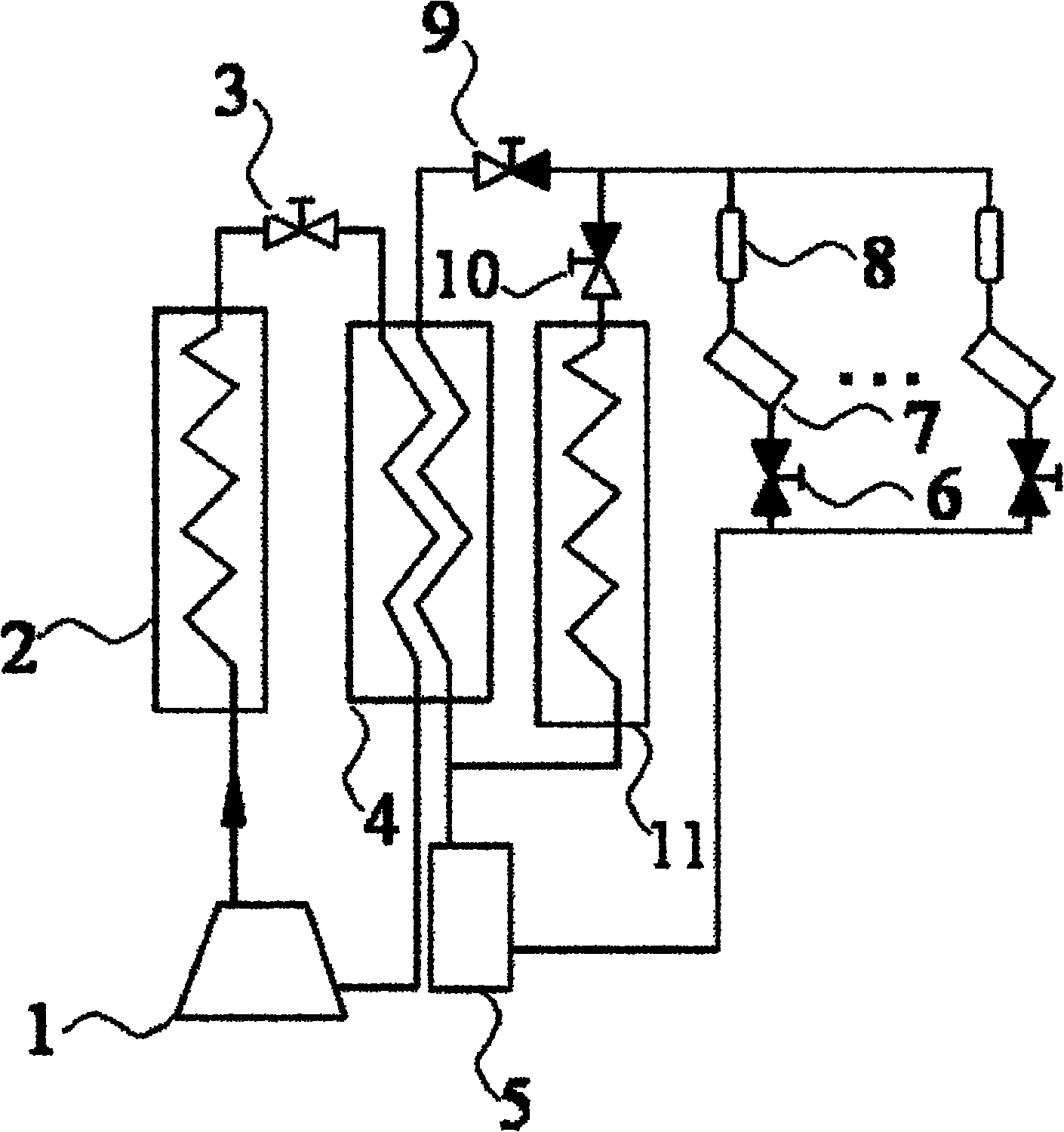

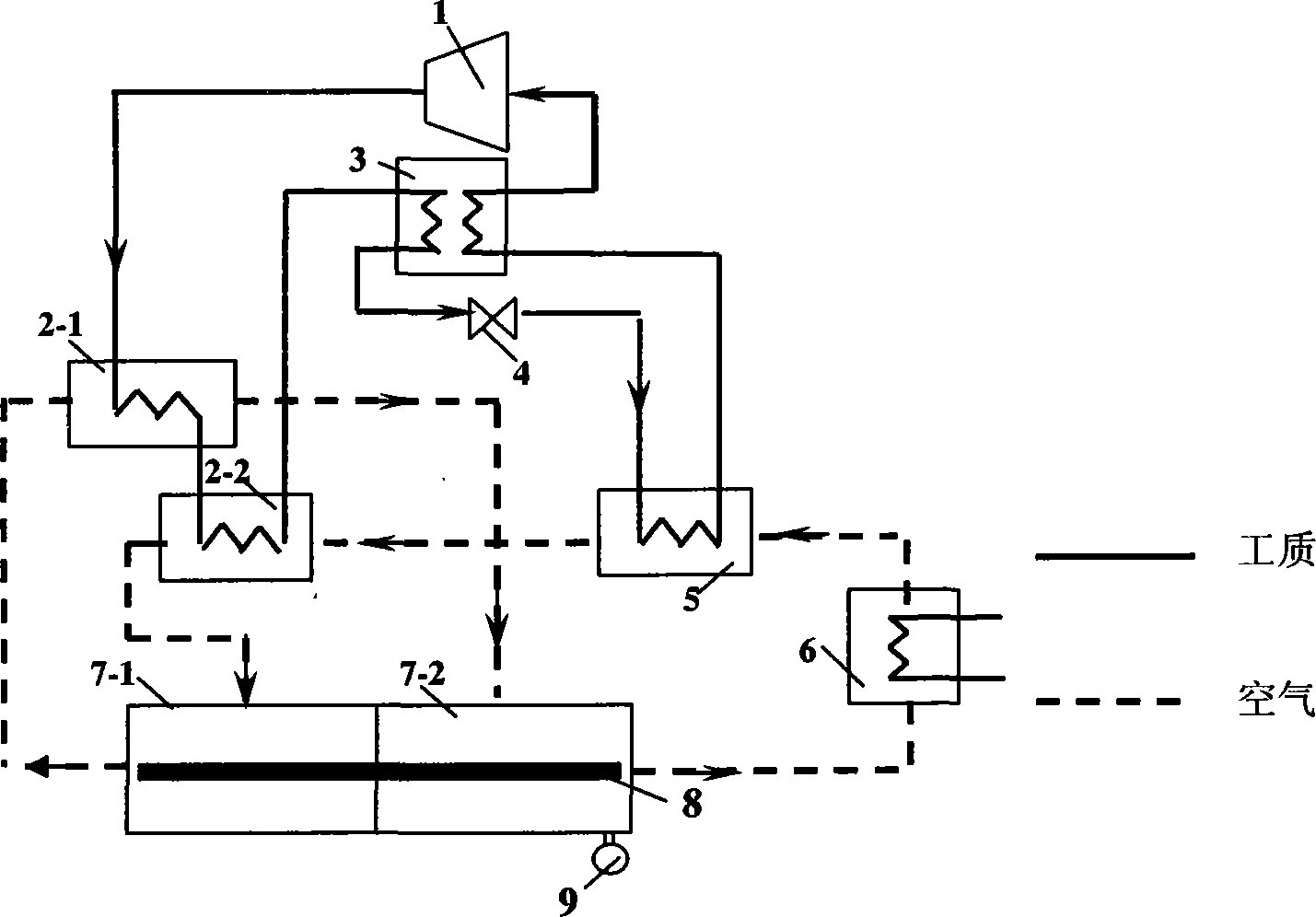

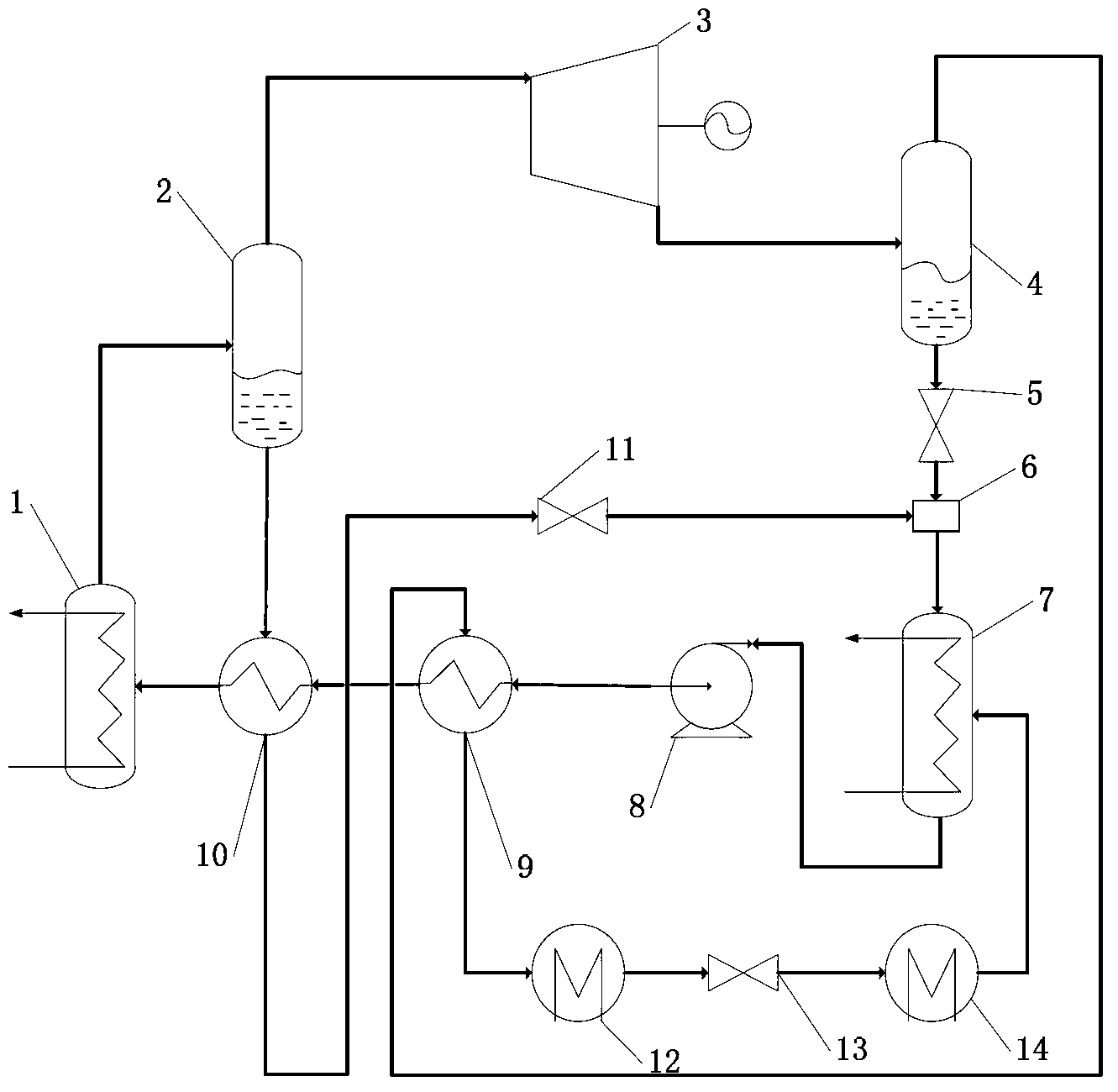

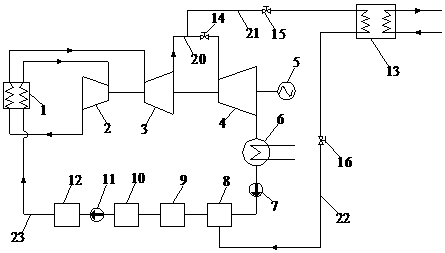

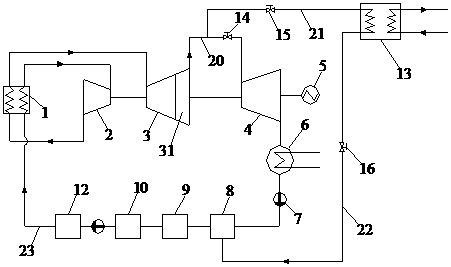

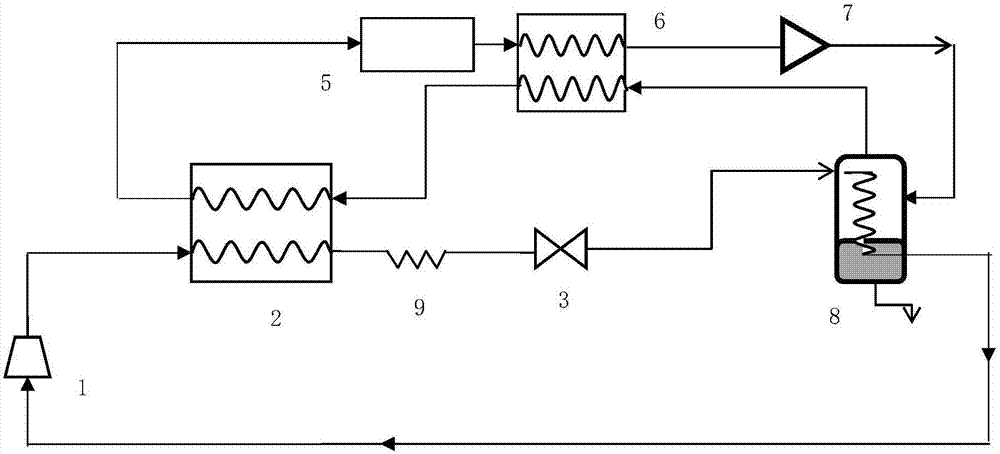

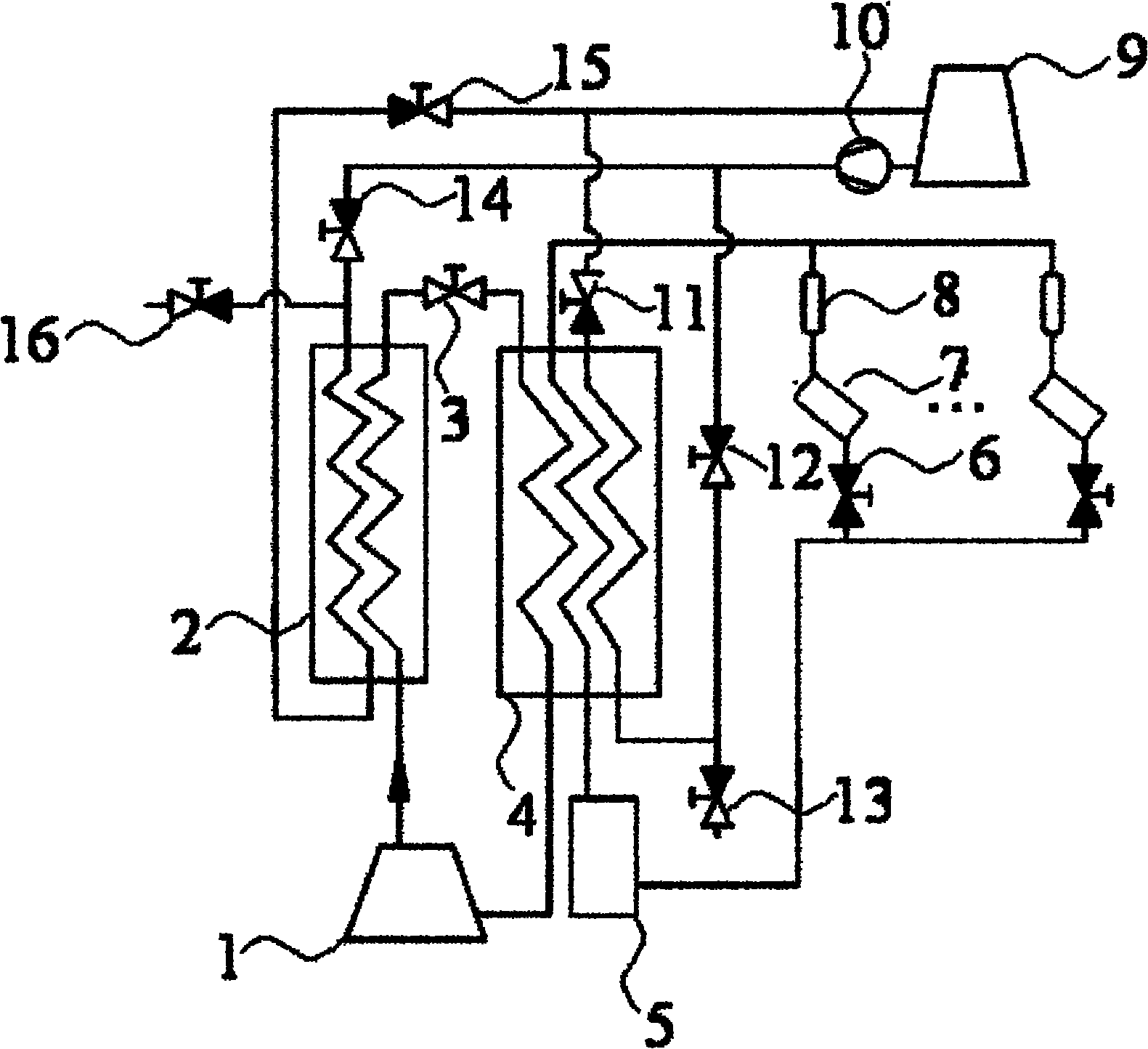

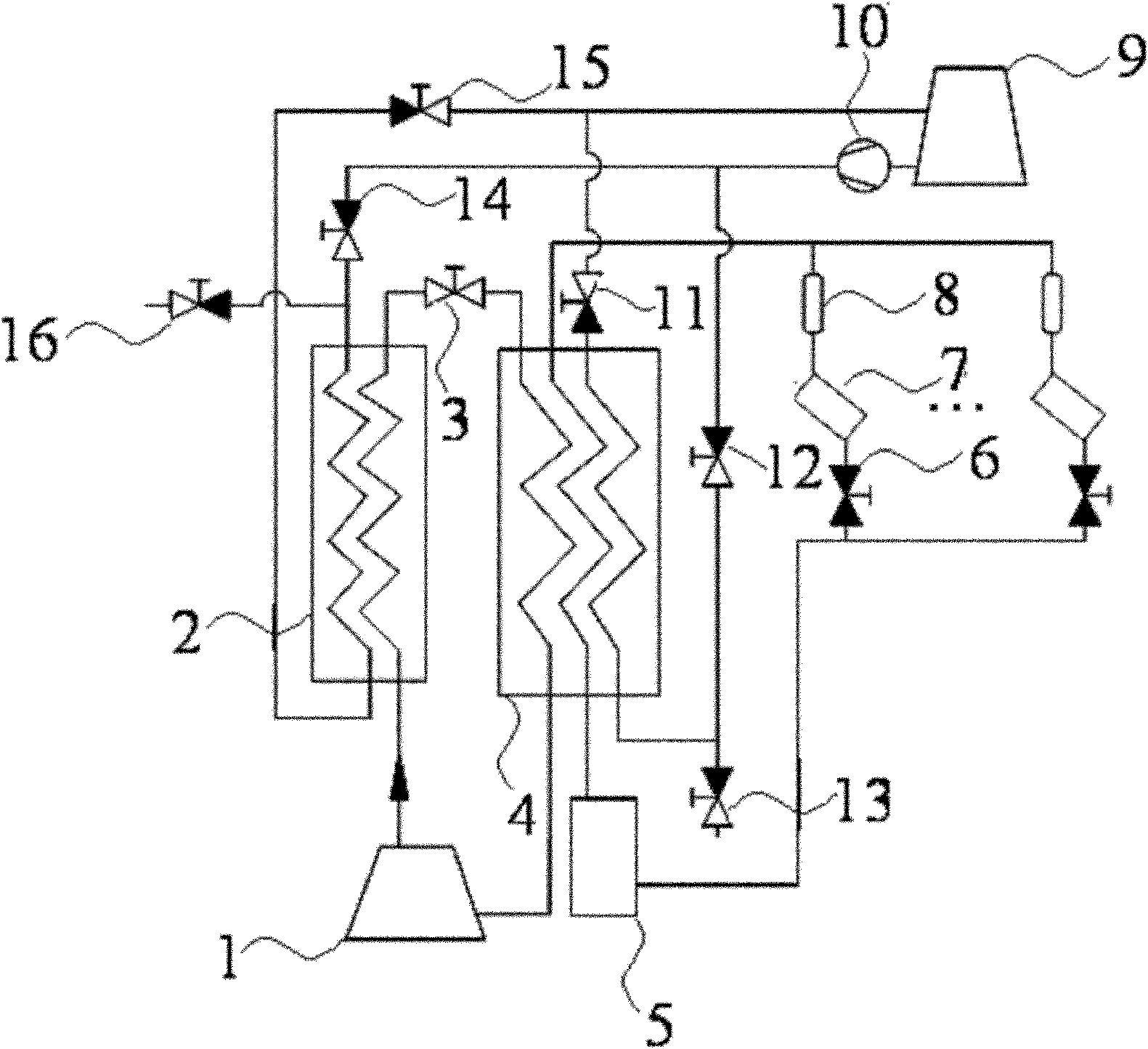

Medium-and-low-temperature waste-heat utilization cooling/power combination system

ActiveCN102797524AReduce energy lossReduce heat transfer temperature differenceEnergy efficient heating/coolingClimate change adaptationVapor generatorProcess engineering

The invention relates to a medium-and-low-temperature waste-heat utilization cooling / power combination system which comprises a steam generator and a first-level steam-liquid separator, wherein the first-level steam-liquid separator is connected with the steam generator, a steam outlet of the first-level steam-liquid separator is communicated with a second-level steam-liquid separator through an expansion machine which is externally connected with an output power work load, a liquid outlet of the second-level steam-liquid separator and a liquid outlet of the first-level steam-liquid separator are respectively connected with a feed inlet of an absorber through pipes, a steam outlet of the second-level steam-liquid separator passes through the heat exchange side of a first heat regenerator, a condenser and an evaporator and then is connected with another feed inlet of the absorber, and a discharge outlet of the absorber is communicated with the steam generator through the other side of the first heat regenerator. The system disclosed by the invention simultaneously provides users with power output and a certain-grade cold flow, thereby realizing the effective utilization of waste heat, improving the energy utilization rate of the system, and meeting various needs of users.

Owner:XI AN JIAOTONG UNIV

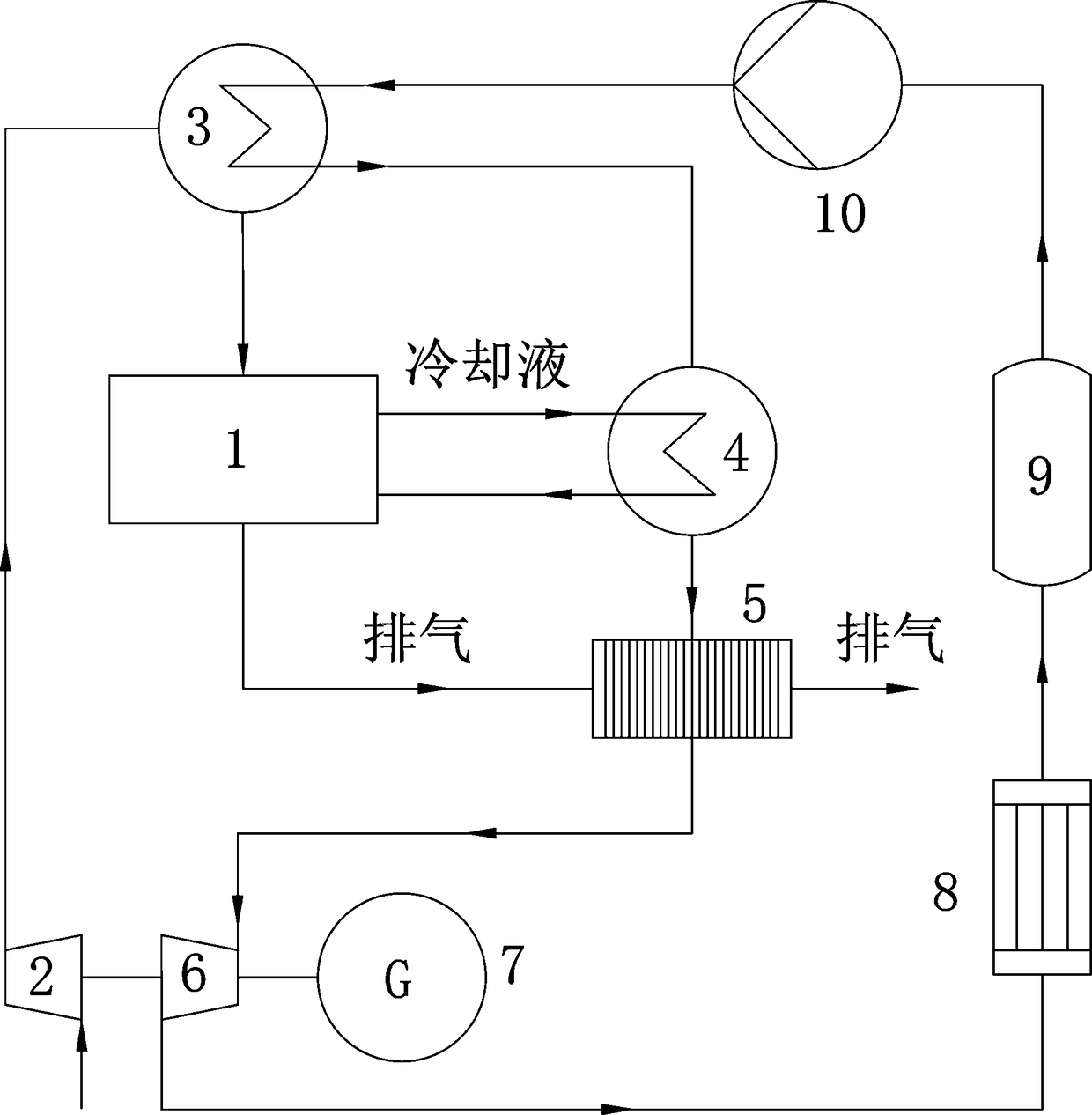

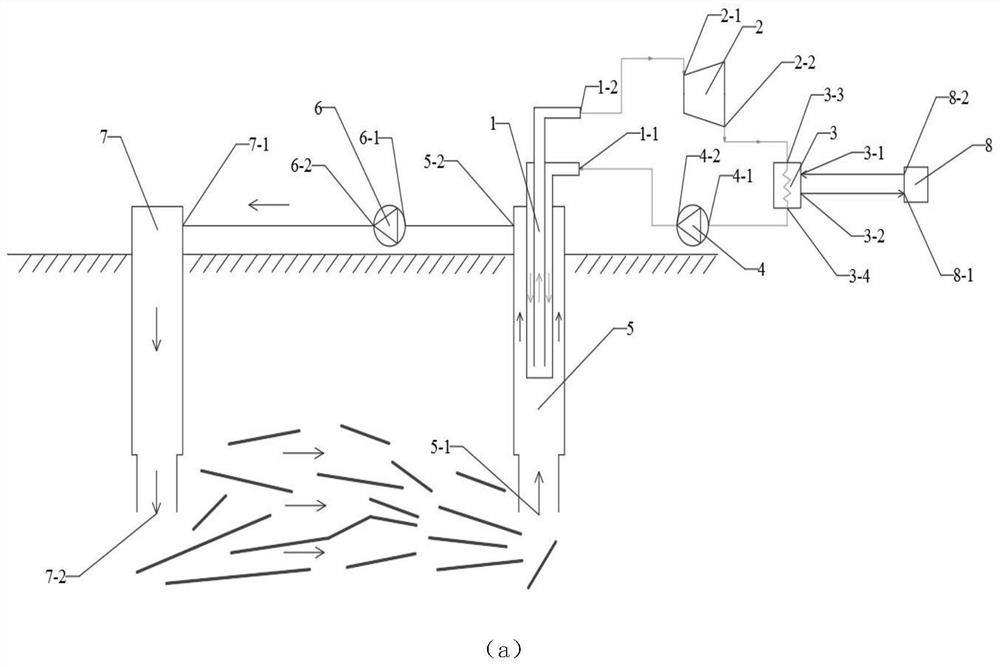

Organic rankine cycle air inflow supercharging internal combustion engine system and method

InactiveCN108374714ASimple equipmentReduce heat transfer temperature differenceInternal combustion piston enginesSteam useIntercoolerBoiling point

The invention provides an organic rankine cycle air inflow supercharging internal combustion engine system and method. The system comprises an internal combustion engine, a gas compressor, an intercooler, a preheater, an evaporator, an expanding agent, an electric generator, a condenser, a liquid storage tank and a working medium pump. According to the organic rankine cycle, low-boiling-point organic matter serves as a working medium, the intercooler, the preheater and the evaporator sequentially absorb compression air heat, cooling liquid heat and engine tail gas waste heat, saturated steam or overheat steam is generated and enters an expanding machine for doing work, the electric generator is driven to generate power, and meanwhile, power is provided for the gas compressor for internal combustion engine air inflow supercharging. According to the system, on the one hand, the ORC expanding machine replaces a turbine in a turbine supercharging internal combustion engine, and equipment can be simplified; on the other hand, the working medium absorbs heat in a stair manner from different devices, the heat exchange temperature difference is small, the work doing energy loss is small, the internal combustion engine waste heat can be used to the maximum degree, the main energy use efficiency is maximum, and the whole system is efficient and environment-friendly.

Owner:CHINA THREE GORGES UNIV

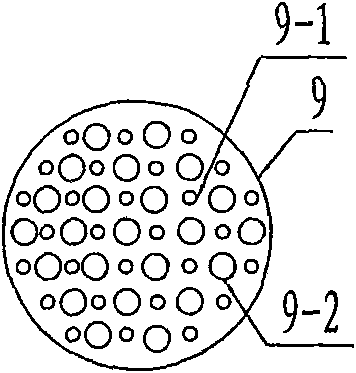

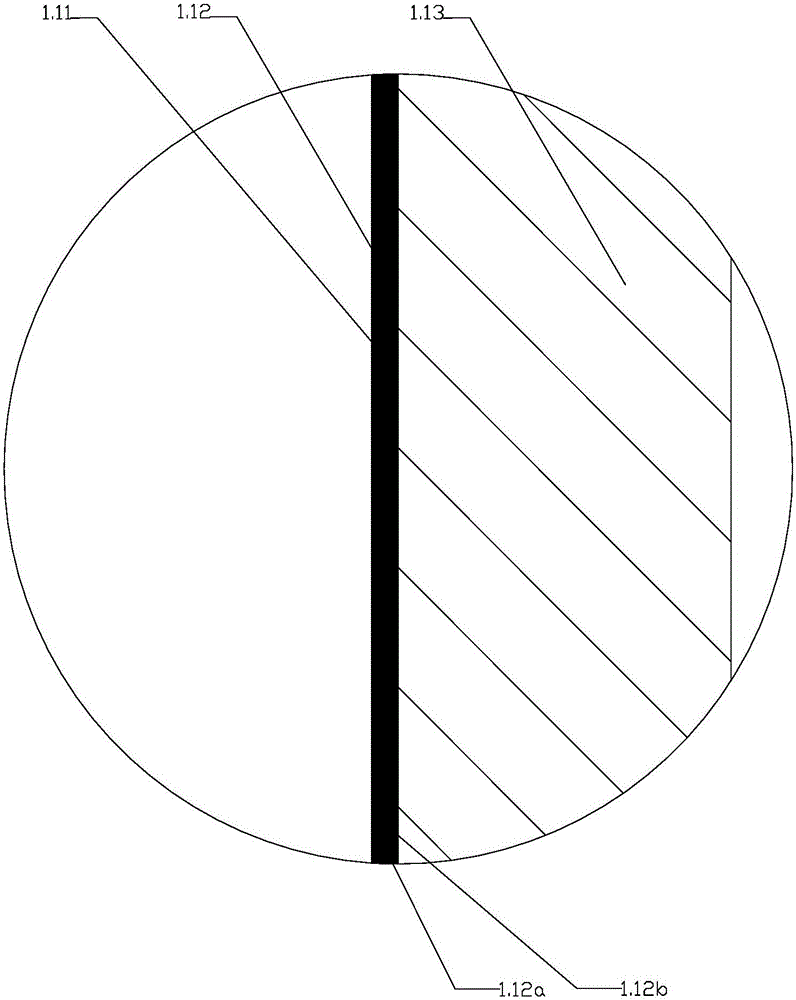

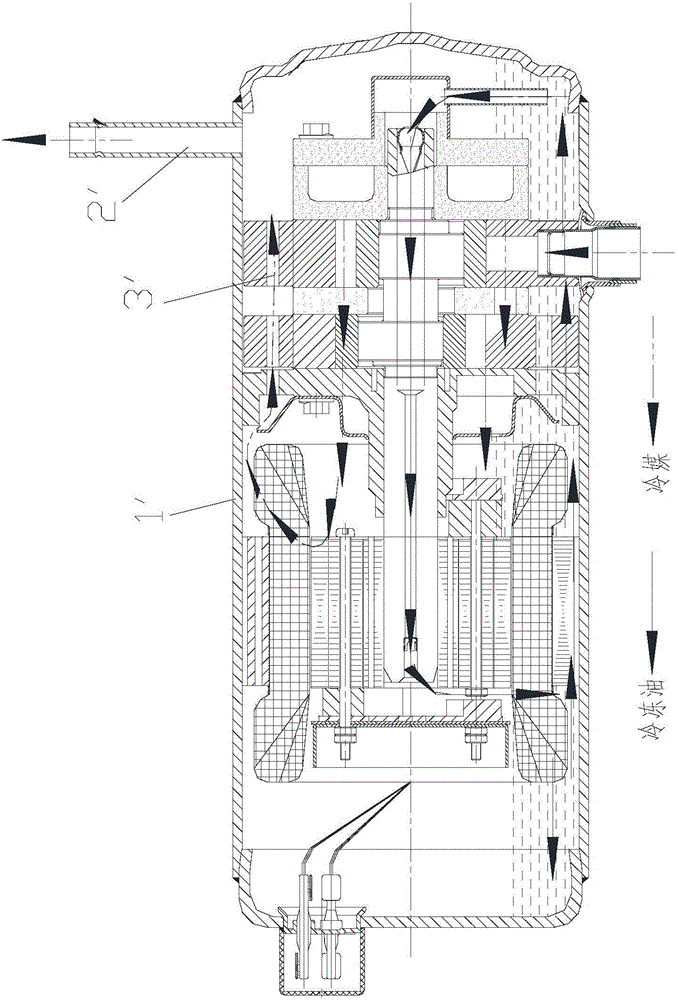

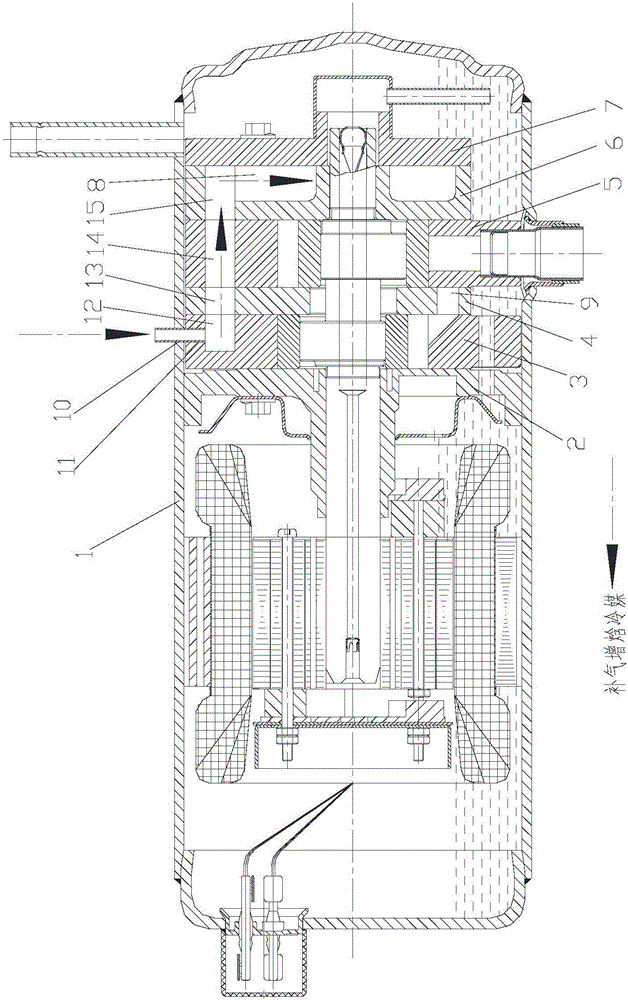

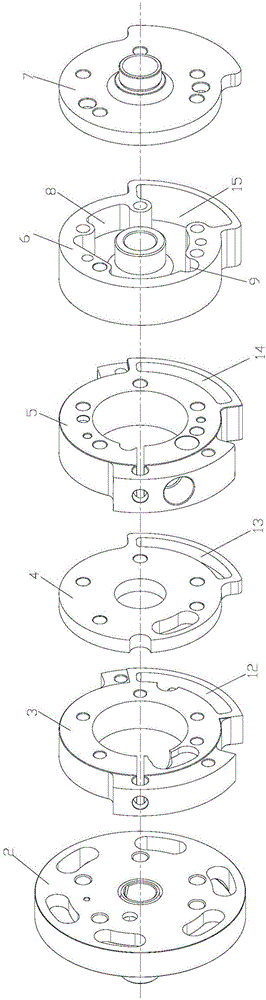

Horizontal rotating two-stage enthalpy increasing compressor

ActiveCN106321436AImprove performanceReduce the temperatureRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsGas cylinderEngineering

The invention discloses a horizontal rotating two-stage enthalpy increasing compressor. The compressor comprises a casing (1) as well as an upper flange (2), an upper gas cylinder (3), a separating plate (4), a lower gas cylinder (5), a lower flange (6) and a lower cover plate (7) which can be arranged in the casing (1) in the axial direction of the casing (1); the lower flange (6) comprises a medium pressure cavity (8) communicating with a gas inlet of the lower gas cylinder (5); through holes (9) for communicating the medium pressure cavity (8) with a compression cavity of the upper gas cylinder (3) are correspondingly formed in the separating plate (4), the lower gas cylinder (5), the lower flange (6) and the lower cover plate (7); and a gas replenishing and enthalpy increasing port (10) communicating with the medium pressure cavity (8) is further formed in the casing (1). With the compressor, the inside temperature of a pump body can be reduced, and the compression efficiency of the compressor can be improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

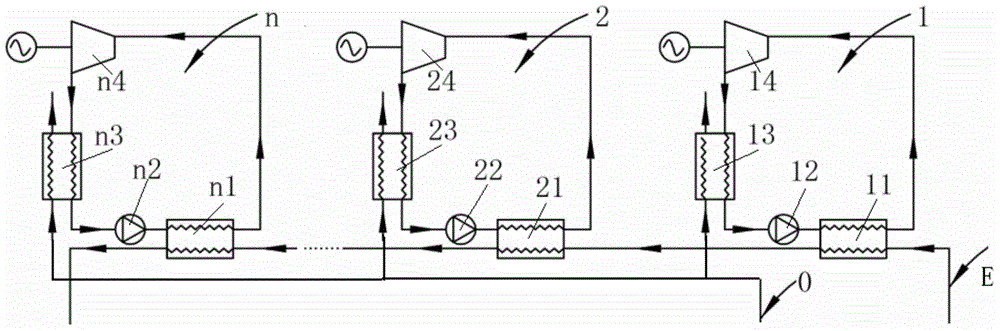

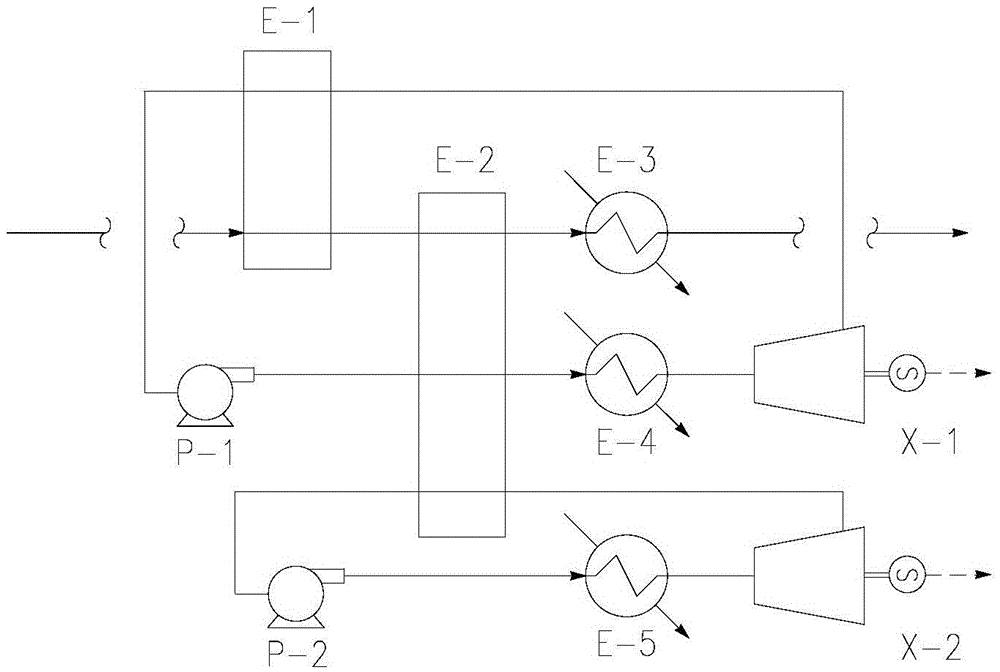

Different evaporation temperature based multistage organic Rankine cycle (ORC) power generation system

InactiveCN104895630AImprove power generation performanceImprove efficiencySteam engine plantsOrganic Rankine cycleSource water

The invention discloses a different evaporation temperature based multistage ORC power generation system. According to the system, n ORC sub-system evaporators are connected in series successively by a heat source water supply system through a hot water pipe. A cooling water supply system is connected in parallel with n ORC sub-system condensers. Working media are subjected to phase change into vapor in respective evaporators to push respective corresponding turbines to be expanded to do work, the liquid media are condensed and return to respective evaporators through respective corresponding work media, and accordingly, the multistage ORC power generation system is formed. The working media used by all the sub-systems are different, so that the different working media can work in optimal evaporation temperature states, and the whole system thermal efficiency is improved. Compared with conventional ORC systems, the heat transmission temperature difference in the evaporator is reduced, irreversible losses are reduced, and the temperature of a heat source discharge system is low, so that the low-grade energy use rate can be improved apparently, and the whole system economy is improved.

Owner:TIANJIN UNIV

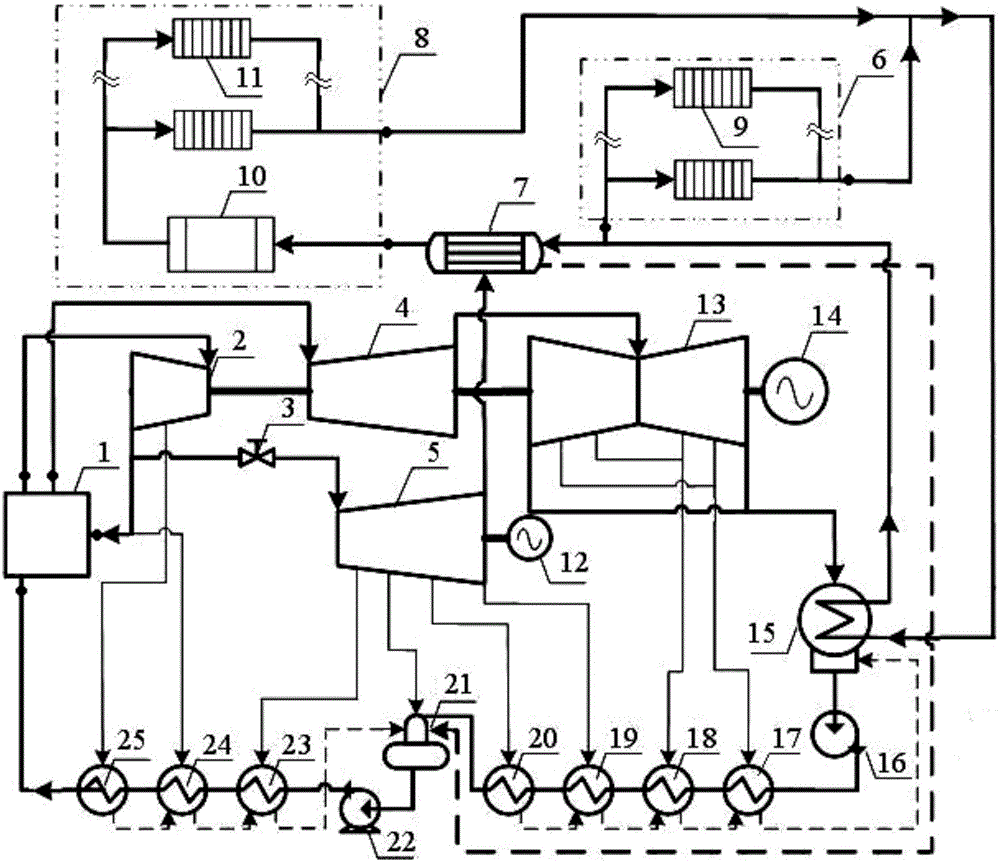

High-back pressure combined heat and power generation system coupled with exhaust steam and supply heat of non-reheat steam turbine

InactiveCN105736068AReduce superheatImprove the flow structureCombination enginesSteam useProcess engineeringDynamo

The invention belongs to the technical field of thermoelectricity, and relates to a high back pressure heat and power cogeneration system coupled with exhaust steam heat supply of a non-reheat steam turbine. A non-reheat medium-pressure steam turbine and generator II are added to the power generation system, and the heating system mainly includes a high backpressure heating condenser, a non-reheat medium-pressure steam turbine, a heat network heater, a remote heat network and a short-range heat network. The exhaust steam from the low-pressure cylinder of the main steam turbine enters the heating condenser to condense and release heat. The circulating water in the condenser absorbs heat and enters the short-distance heating network or heating network heater. The exhaust steam from the steam turbine is further heated and enters the remote heating network, and the return water from the remote and short-range heating networks is mixed and then enters the condenser. The invention utilizes the waste heat of the exhaust steam of the steam turbine to reduce the loss of the cooling source; the return water of the short-range and remote heating network is mixed, so that the temperature of the return water of the heating network entering the condenser is reduced, and the utilization efficiency of waste heat is improved. The invention is suitable for the heat supply transformation of 300MW and above large-capacity units with short-range low-temperature heat demand.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

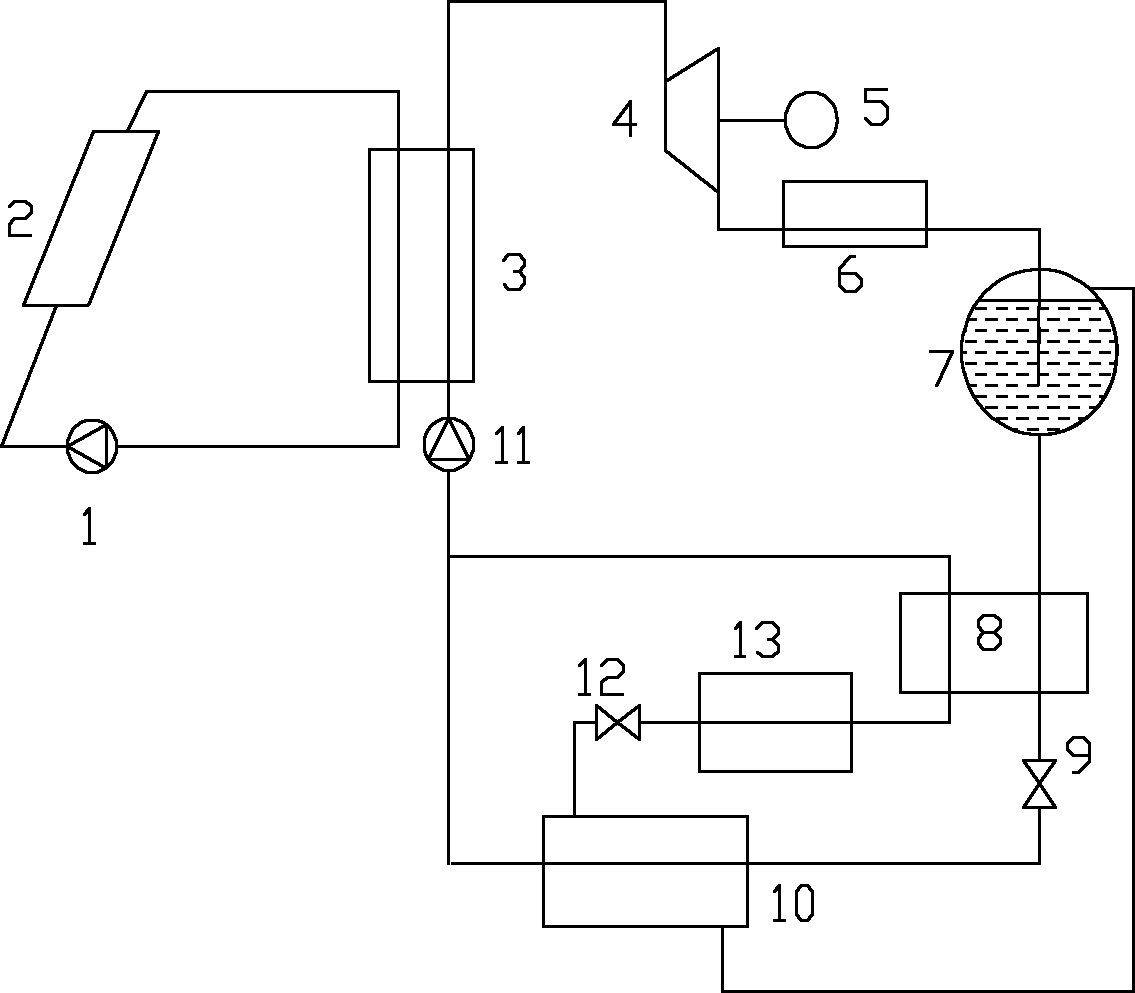

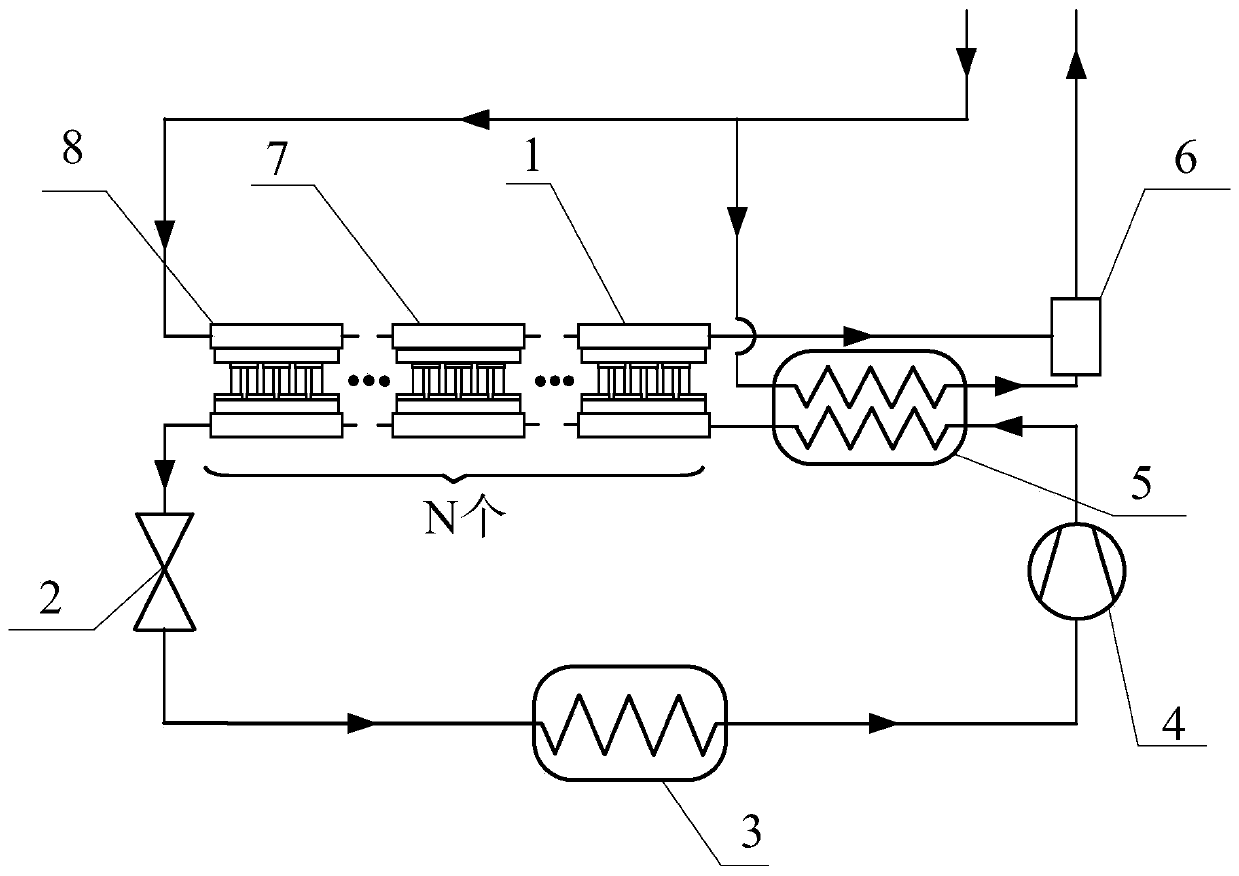

Water-cooled energy-saving machine room air conditioning system

InactiveCN101968245AReduce heat transfer temperature differenceImprove cooling efficiencySpace heating and ventilation detailsFluid circulation arrangementCooling towerHigh energy

The invention discloses a water-cooled energy-saving machine room air conditioning system, which comprises a compressor, a water-cooled condenser, a throttling device, an evaporative cooling condenser, a liquid storage tank, a coolant pump, a flow balancing valve, a terminal heat exchanger, a cooling tower, a cooling water pump, a first water outlet valve, a first water inlet valve, a first drain valve, a second water inlet valve, a second water outlet valve and a second drain valve; the high-pressure exhaust port of the compressor is connected with the refrigerant side of the water-cooled condenser, the throttling device, the evaporation side of the evaporative cooling condenser and the low-pressure air suction port of the compressor in turn to form a compressed refrigerating circulation loop together with a cooing water circulation loop; and the condensation side outlet of the evaporative cooling condenser is connected with the liquid storage tank, the coolant pump, the flow balancing valve, the terminal heat exchanger and the condensation side inlet of the evaporative cooling condenser in turn to form a nearly isobaric evaporation and condensation refrigerating circulation loop together with a cooling water circulation loop. During heat exchange, the system has low temperature difference and high energy efficiency ratio.

Owner:ZHEJIANG UNIV

Secondary heat pipe-based heat-dissipation structure of server cabinet

ActiveCN106028745AGuaranteed independenceCutting costsCooling/ventilation/heating modificationsEvaporationEngineering

The invention discloses a secondary heat pipe-based heat-dissipation structure of a server cabinet. The heat-dissipation structure comprises a primary heat pipe and a secondary heat pipe, wherein a plurality of servers are arranged in the server cabinet; each server comprises at least one main heating element; the primary heat pipe extends into a server case, an evaporation end is tightly attached to the main heating elements of the servers, a condensing end of the primary heat pipe is arranged outside the server case and is pressed and attached to the secondary heat pipe arranged outside the server case, so that heat generated from the inside of the servers is directly conducted by the primary heat pipe for heat exchange with the secondary heat pipe. According to the heat-dissipation structure of the server cabinet, the heat generated by the main heating elements in the server case is directly conducted through the primary heat pipe for heat exchange with the secondary heat pipe, so that the cost required for heat exchange of the server case is reduced; and heat transfer optimization of the server case is achieved.

Owner:BEIJING NYF SCI & TECH DEV CO LTD

Combined heat and power generation system for condensing-extracting-backpressure heat supply and operation method thereof

PendingCN107859538AReasonable designSimple structureSteam engine plantsCombined combustion mitigationCogenerationDeaerator

The invention relates to a combined heat and power generation system for condensing-extracting-backpressure heat supply and an operation method thereof. A traditional centralized heating mode can cause great available energy loss. In the combined heat and power generation system for condensing-extracting-backpressure heat supply provided by the invention, a boiler, a steam turbine high-pressure cylinder, a steam turbine intermediate-pressure cylinder, a steam turbine low-pressure cylinder, an electric generator and a condenser are sequentially connected through a pipeline; a boiler feed pipe is connected between the condenser and the boiler; the condenser, a condensate pump, a low-pressure heater, a feed water heater, a deaerator, a feed pump and a high-pressure heater are sequentially arranged on the boiler feed pipe; a steam inlet of a heat supply network heat exchanger is connected with a communicating pipe between the steam turbine intermediate-pressure cylinder and the steam turbine low-pressure cylinder; and a dewatering outlet is connected with the low-pressure heater. According to the combined heat and power generation system for condensing-extracting-backpressure heat supply and the operation method thereof provided by the invention, the steam turbine intermediate-pressure cylinder is structurally improved, or a secondary intermediate-pressure cylinder is additionallyarranged behind so as to be adapt to switching operation among three working conditions, i.e. pure condensing, steam extracting and backpressure of a turboset. According to the combined heat and powergeneration system for condensing-extracting-backpressure heat supply and the operation method thereof provided by the invention, the original lost energy is converted into high-quality electric energy through the acting of a turbine, so that the gradient utilization of the energy is realized.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

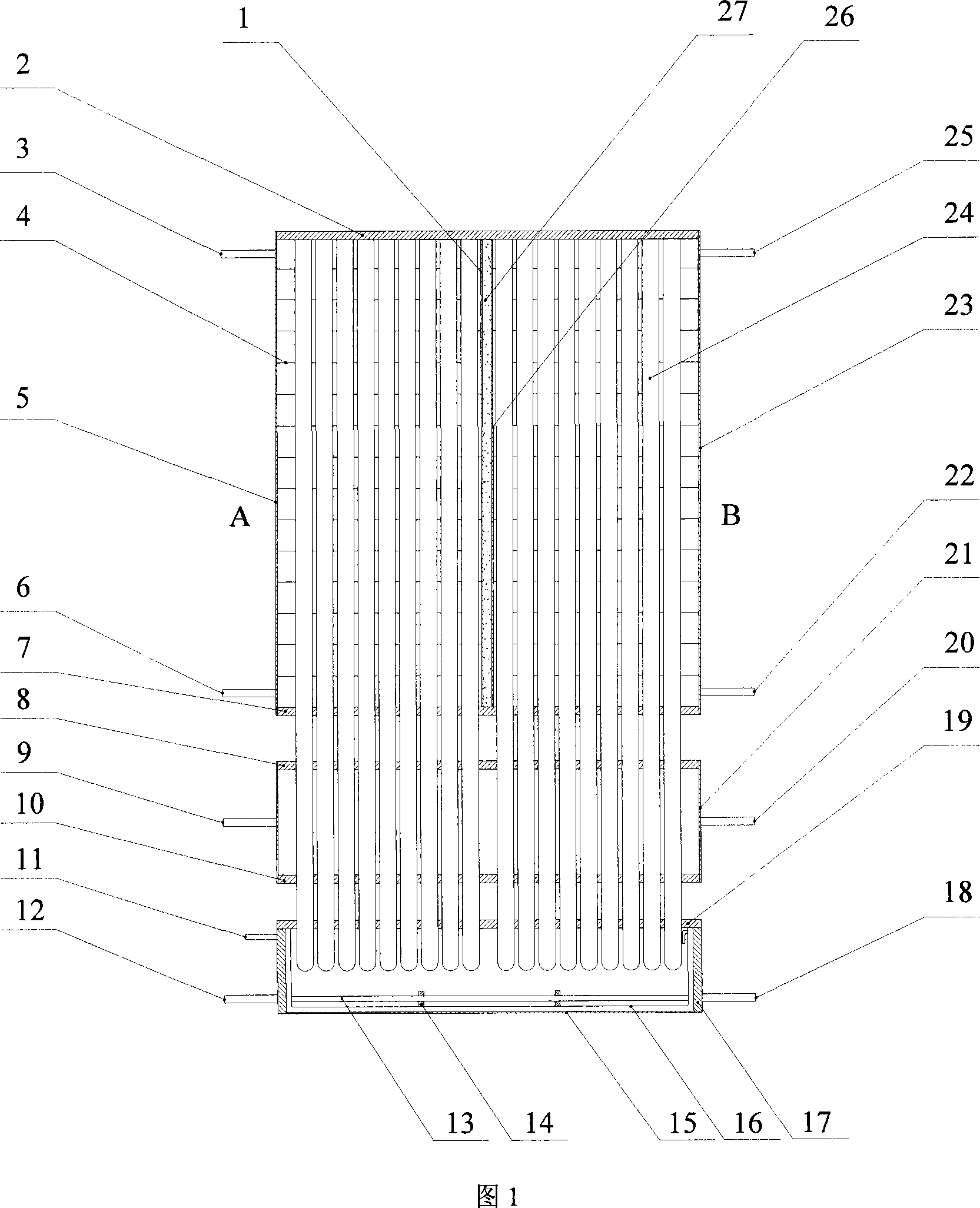

Solid body adsorb unit pipe and combined adsorb refrigerating device thereof

InactiveCN101135508AEasy to achieve vacuumCompact structureClimate change adaptationEnergy efficient heating/coolingAdsorption refrigerationIndependent function

The invention disclosed solid adsorption unit tube and compound adsorption refrigerating apparatus thereof. The adsorption refrigerating apparatus is composed of adsorbent bed A, adsorbent bed B, condenser and evaporator. The whole adsorption refrigerating apparatus is combined with two adsorption -refrigerating units by heat tube evaporator. Every adsorption unit is composed of multi- solid adsorption unit tubes with independent function. Adsorption section, condensation section and evaporation section separately is in the adsorbent bed, the condenser and the evaporator of the whole adsorption refrigerating apparatus, a heat insulating section is set between the evaporator and the condenser and between the condenser and the adsorbent bed.

Owner:QINGDAO UNIV

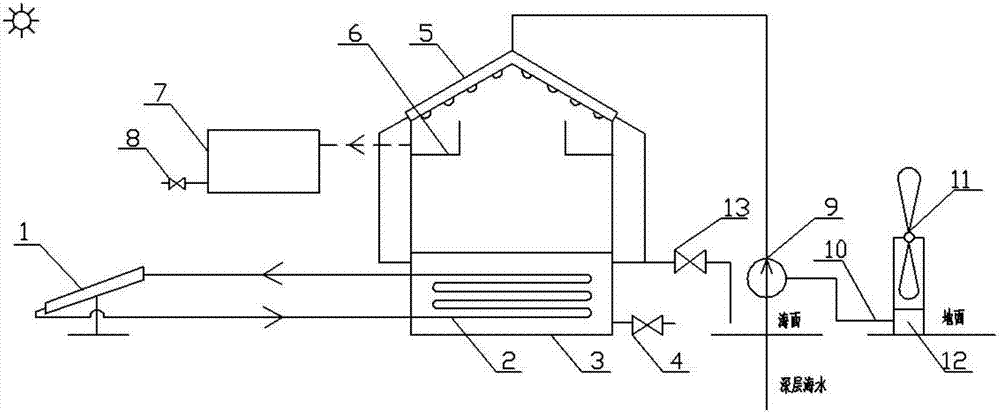

Seawater desalination plant

InactiveCN107188259AIncrease water intake rateImprove compactnessGeneral water supply conservationSeawater treatmentEngineeringWind power system

The invention discloses seawater desalination plant, which includes a solar energy heat storage system, a wind power generation system, a steam generation system, a refrigeration water intake system and a water supply system. The steam generation system is composed of a heat exchange loop and a steam generation chamber, wherein the heat exchange loop is arranged in the steam generation chamber. The refrigeration water intake system comprises a refrigerator, a water collector and a reservoir. Deep seawater is pumped through a water pump and conveyed to a cold source end of the refrigerator through a water supply pipeline. A heat source end of the refrigerator is connected to the inside of the steam generation chamber. The refrigerator is located at an upper-end opening of the steam generation chamber and used for cooling steam generated in the steam generation chamber to a liquid. A biomimetic refrigeration surface of the refrigerator is provided with spherical projections, which include a refrigerator biomimetic refrigeration surface hydrophilic zone and a refrigerator biomimetic refrigeration surface hydrophobic zone. A biomimetic refrigeration surface similar to desert beetles is adopted in the seawater desalination plant. The biomimetic refrigeration surface is good in water collection effect, so that the operation efficiency of the seawater desalination plant is improved.

Owner:SOUTHEAST UNIV

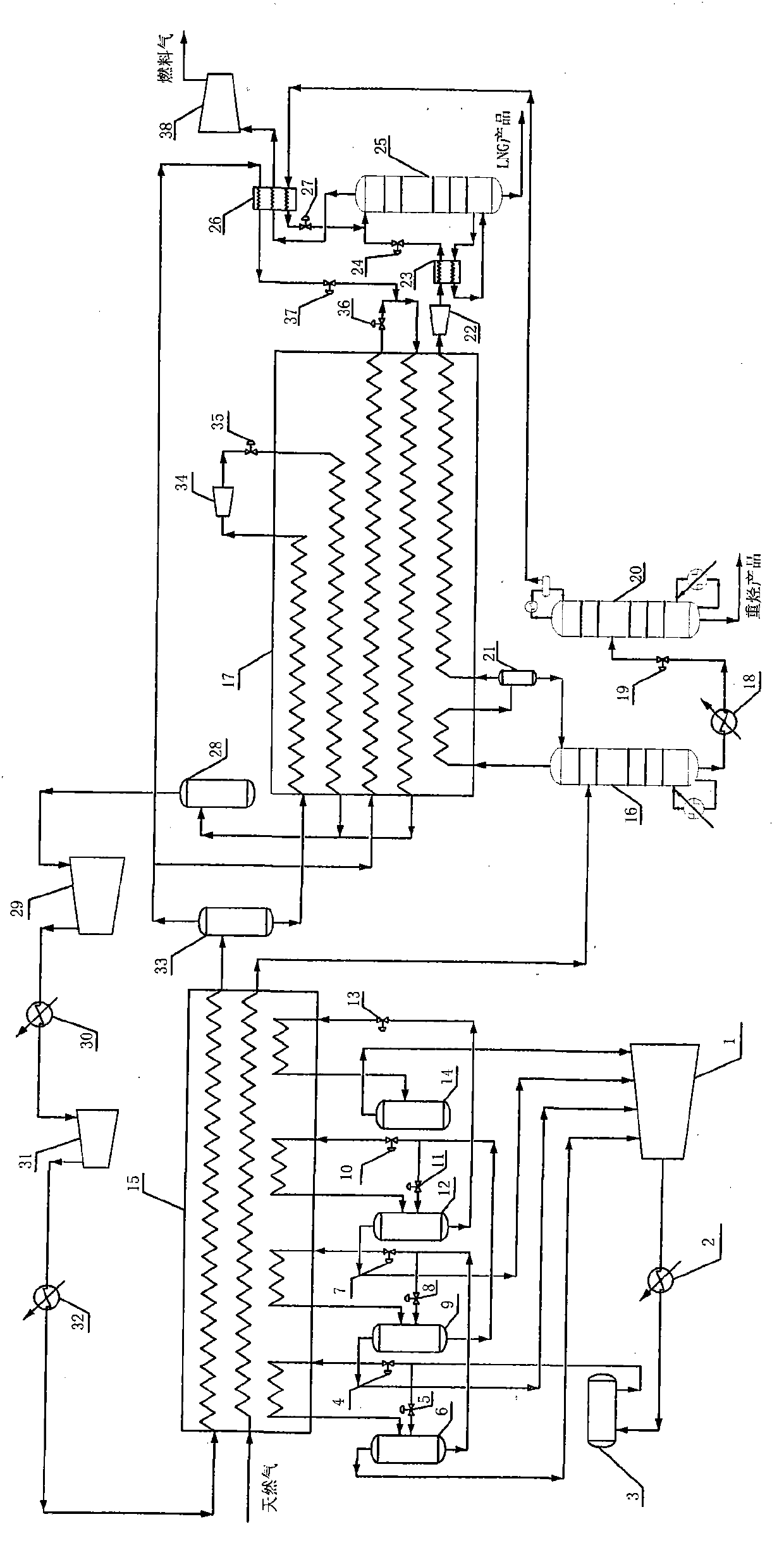

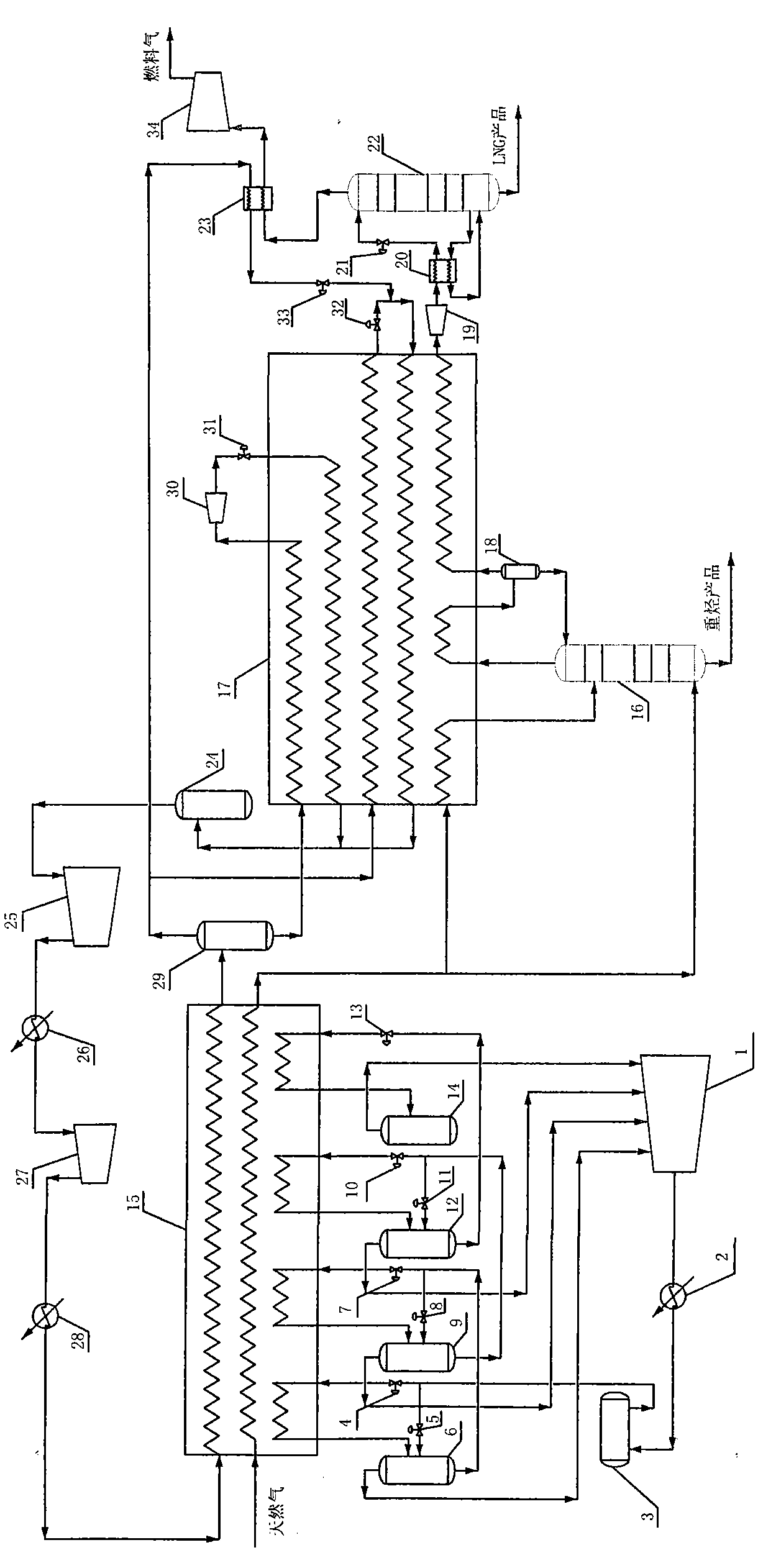

Novel low-energy-consumption natural gas liquefaction technology

InactiveCN103438661ARecoverable energyReduce energy consumptionSolidificationLiquefactionSeparation technologyCurrent technology

The invention discloses a novel low-energy-consumption natural gas liquefaction technology. The novel low-energy-consumption natural gas liquefaction technology comprises a high-efficiency natural gas precooling heat exchanger, a natural gas liquefaction cryogenic heat exchanger, a heavy-hydrocarbon separation system, a liquid expansion machine, a BOG knockout tower, namely a knockout tower of non-condensable gas in the process of natural gas liquefaction, a BOG recuperative heating cooling box, a BOG supercharger, a propylene refrigerating system and an optimized mixed refrigerant refrigerating system. According to the novel low-energy-consumption natural gas liquefaction technology, the liquid expansion machine is added to the novel low-energy-consumption natural gas liquefaction technology, and is used for recycling energy of high-pressure liquid; innovation is carried out on a heavy-hydrocarbon separation technology, the temperature of heavy-hydrocarbon separation operation is increased, and refrigerant consumption and equipment investment are reduced; a BOG separation technology is optimized, the total quantity of the BOG is reduced, and the power of a BOG compressor is reduced; recycling of BOG refrigerants is improved, and BOG high-level refrigerants are recycled. According to the novel low-energy-consumption natural gas liquefaction technology, compared with the current technology of China, the energy consumption can be reduced by 10% or so, equipment investment is small, the capacity of adapting to working conditions is good, and localized production of key equipment can be achieved.

Owner:北京麦科直通工程技术有限公司

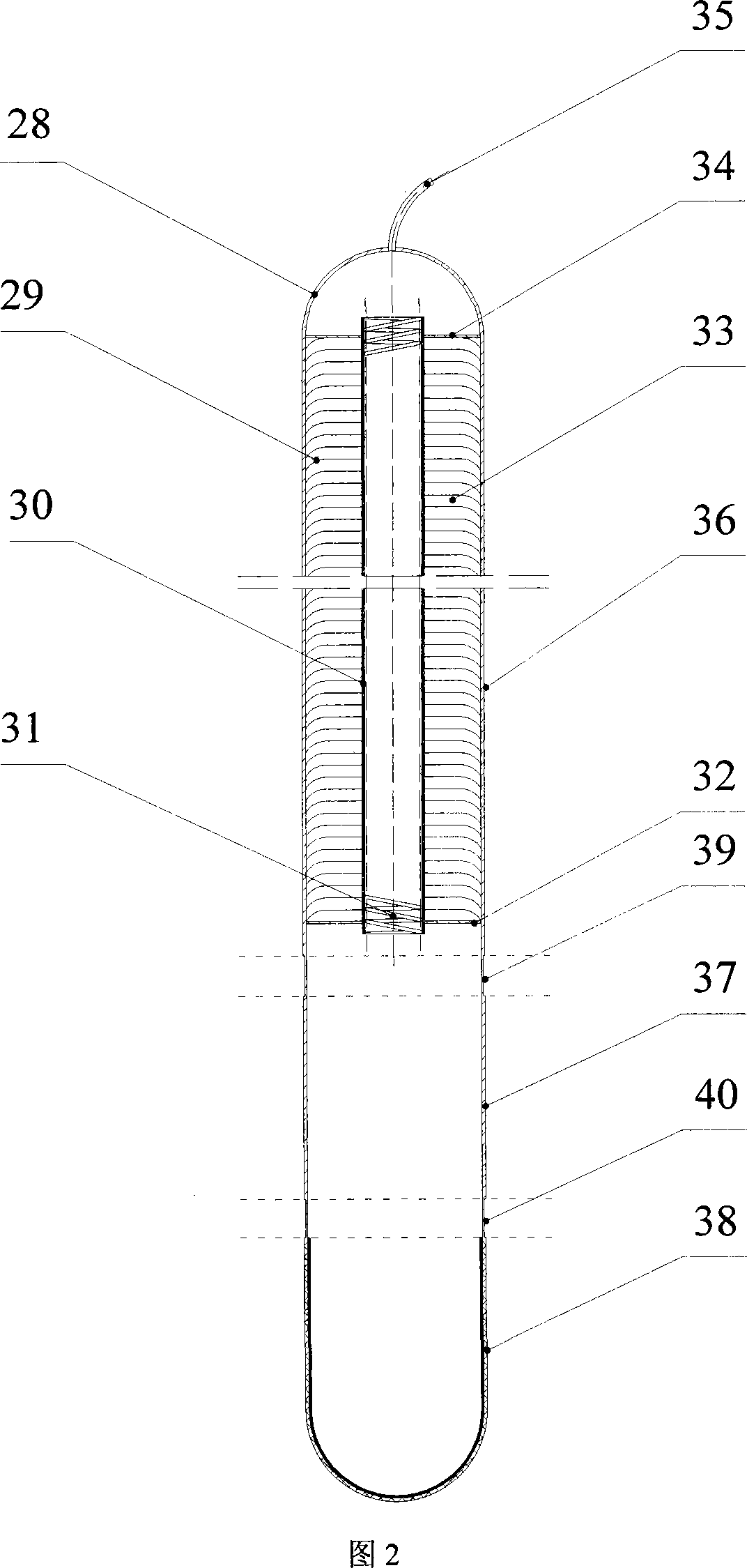

Solar energy-driven cogeneration device

InactiveCN102094772AIncrease profitReduce areaFrom solar energySteam engine plantsVapor–liquid separatorCogeneration

The invention discloses a solar energy-driven cogeneration device. The device mainly comprises a solar heat collecting device, a steam turbine or an expander, a generator, a condenser, a gas-liquid separator, a regenerator, a condensation evaporator, an evaporator and a working medium pump, wherein the outlet of the solar heat collecting device is connected with the steam turbine or the expander;the steam turbine or the expander is connected with an engine; the steam outlet of the steam turbine or the expander is connected with the condenser and the gas-liquid separator in turn; the liquid outlet of the gas-liquid separator is connected with the regenerator, the condensation evaporator and the working medium pump in turn; the steam outlet of the gas-liquid separator is connected with thecondensation evaporator, the evaporator, the regenerator and the working medium pump in turn; and the outlet of the working medium pump is connected with the inlet of the solar heat collecting deviceto form a cycle. By the device, the utilization rate of the collected solar energy can be greatly improved, comprehensive efficiency is improved, and the area of a heat collector can be effectively reduced.

Owner:SOUTHEAST UNIV

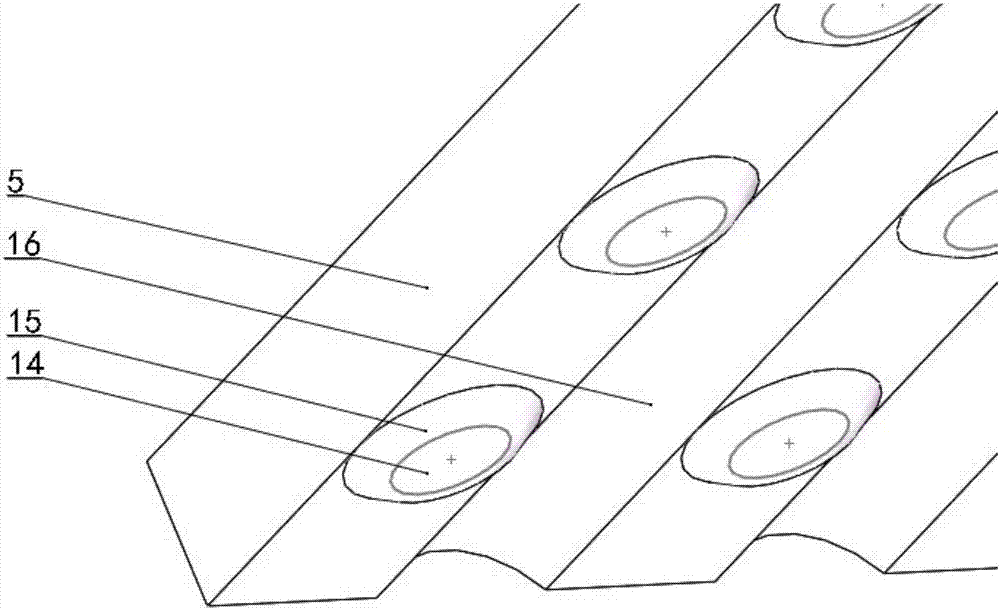

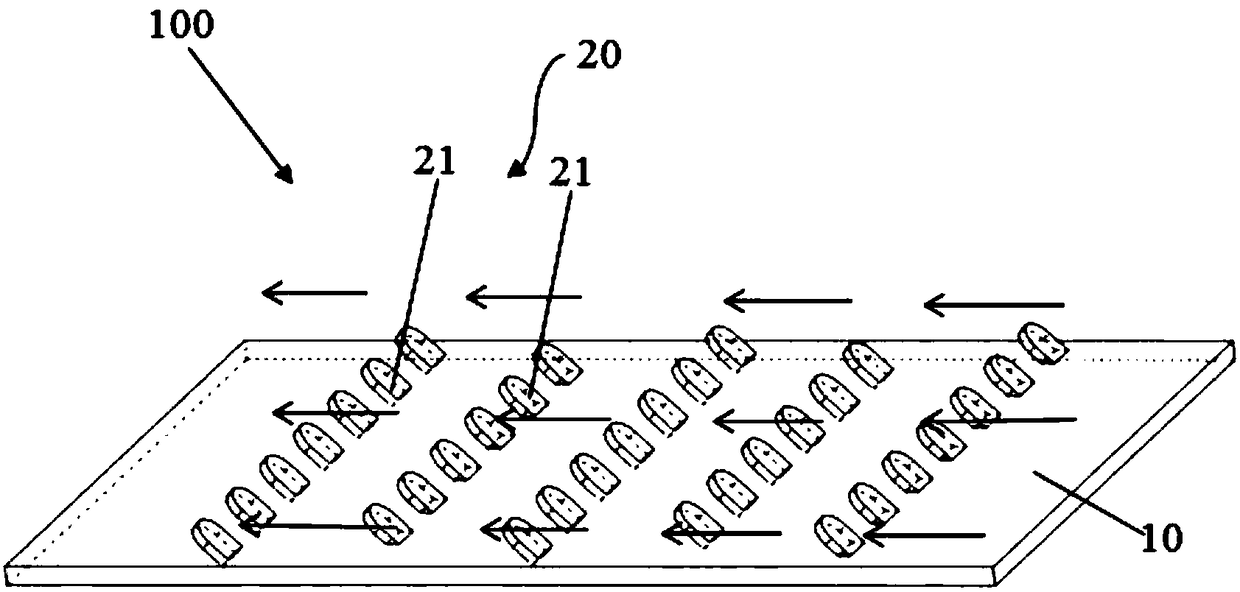

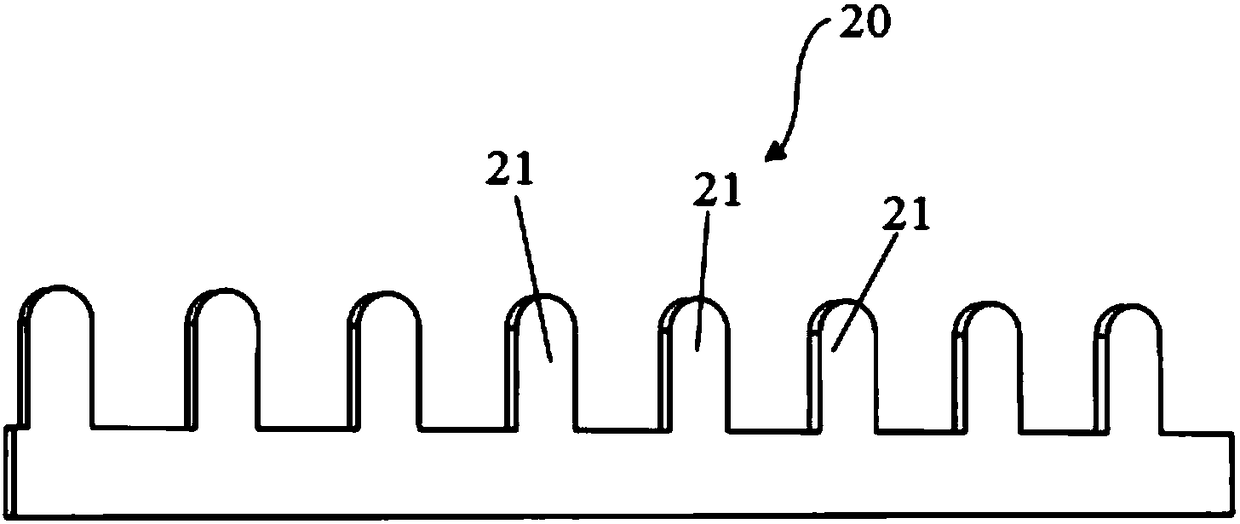

Heat exchange device

InactiveCN108344323AAchieving Bionic Heat DissipationImprove heat transfer efficiencyHeat transfer modificationHeat exchanger fasteningEngineeringTemperature difference

The invention provides a heat exchange device. The heat exchange device comprises a heat exchanger body and heat exchange assemblies, hot fluid and cold fluid used for exchanging heat with the hot fluid are arranged on the two sides of the heat exchanger body in a communicating mode, the heat exchange assemblies are arranged on at least one side of the heat exchanger body and each are provided with a plurality of heat exchange component s arranged at predetermined intervals, the heat exchange efficiency is adjusted according to the temperature difference between the cold fluid and the hot fluid, and one end of each heat exchange component is fixed to the heat exchanger body, wherein, the heat exchange components are made of memory metal or composite materials containing the memory metal. The heat exchange device has the advantages that when the heat exchange amount is relatively large or the heat exchange temperature difference is relatively large, the other ends of the heat exchange components are erected at larger angles, so that the heat exchange area of the heat exchange device is increased, and then the heat exchange amount is increased; and when the heat exchange amount or the heat exchange temperature difference is decreased, the other ends of the heat exchange components are erected at smaller angle or are attached to the heat exchanger body, so that the heat exchange area of the heat exchange device is decreased, then the heat exchange amount is decreased, and therefore biomimetic heat dissipation can be realized, the heat exchange efficiency of the heat exchange device can be effectively improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

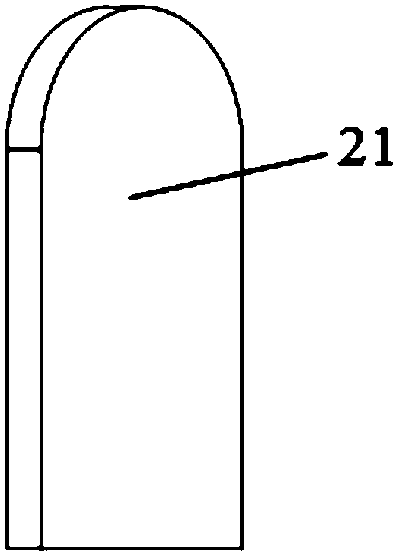

Transcritical carbon dioxide energy storage coupling steam turbine power generation peak shaving system and operation method

PendingCN113914952AImprove economyReduce difficulty of liquefactionSteam engine plantsPhysicsChemistry

The invention discloses a transcritical carbon dioxide energy storage coupling steam turbine power generation peak shaving system and an operation method. The transcritical carbon dioxide energy storage coupling steam turbine power generation peak shaving system comprises a steam turbine steam cycle power generation system and a transcritical carbon dioxide energy storage system, energy storage compression heat in the transcritical carbon dioxide energy storage system is used for heating condensed water, high-temperature and high-pressure steam is used for heating high-pressure and low-temperature carbon dioxide in the energy release stage, the situation that a heat accumulator is used for collecting compression heat to heat the carbon dioxide in the energy release stage is avoided, and the economical efficiency of a unit is improved. According to the system, air is replaced with the carbon dioxide, the critical temperature of the carbon dioxide is 31.1 DEG C, liquid storage can be achieved at the normal temperature, the liquefaction difficulty is greatly reduced, meanwhile, the density of supercritical carbon dioxide is close to that of liquid, the viscosity of supercritical carbon dioxide is close to that of gas, and the supercritical carbon dioxide has good fluidity and transmission characteristics; and the supercritical carbon dioxide is used for replacing air as an energy storage medium, the energy storage density is greatly improved, the scale of a storage system is remarkably reduced, and the cost is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

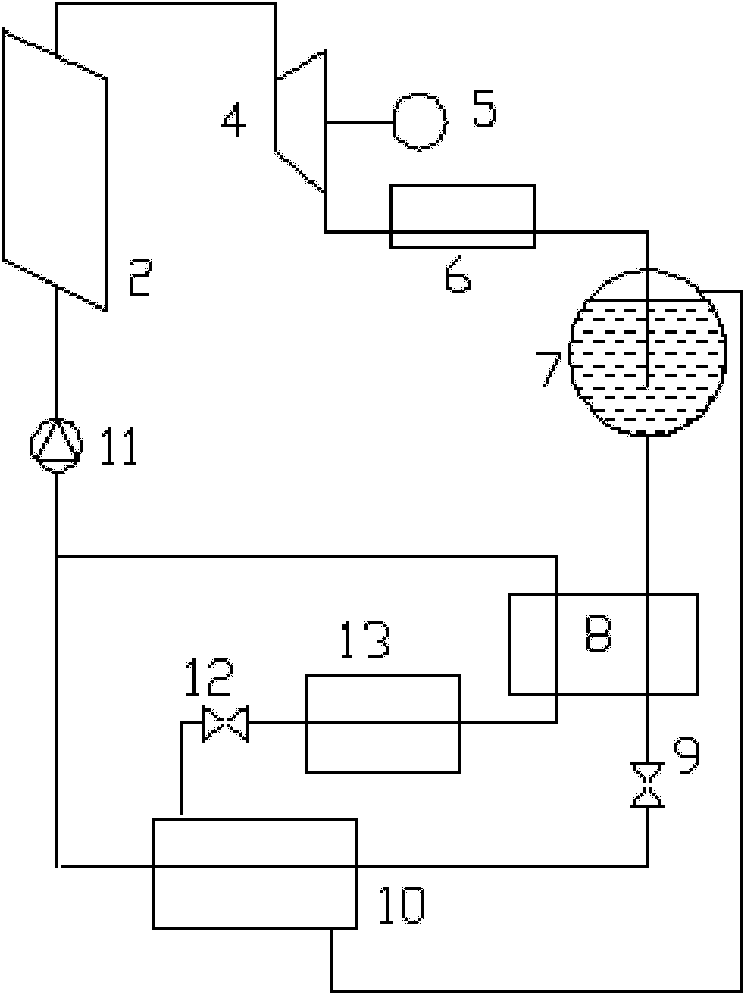

Heat pump drying system

InactiveCN107966009ARaise the gas temperatureReduce heat transfer temperature differenceMechanical apparatusHeat pumpsEvaporatorEngineering

The invention provides a heat pump drying system which comprises a compressor, a condenser, a throttling component, an evaporator, a drying chamber, a backheating heat exchanger and a draught fan. Anoutlet of the compressor is connected with a hot end inlet of the condenser, a hot end outlet of the condenser is connected with a cold end inlet of the evaporator through the throttling component, and a cold end outlet of the evaporator is connected with an inlet of the compressor; a cold end inlet of the backheating heat exchanger inputs air acted by the draught fan, a cold end outlet of the backheating heat exchanger is connected with a cold end inlet of the condenser, a cold end outlet of the condenser is connected with an inlet of the drying chamber, an outlet of the drying chamber is connected with a hot end inlet of the backheating heat exchanger, a hot end outlet of the backheating heat exchanger is connected with an inlet of the draught fan, and an outlet of the draught fan is communicated with the outside. By means of the heat pump drying system, the backheating heat exchanger is used for achieving temperature recovering of air discharged from the drying chamber, the temperature of air entering the cold end evaporator is decreased, the temperature of air entering the hot end condenser is increased, the heat exchange temperature difference can be effectively reduced, coldand heat end heat exchange is improved, and the system efficiency is improved.

Owner:北京恒泰盈创科技发展有限公司

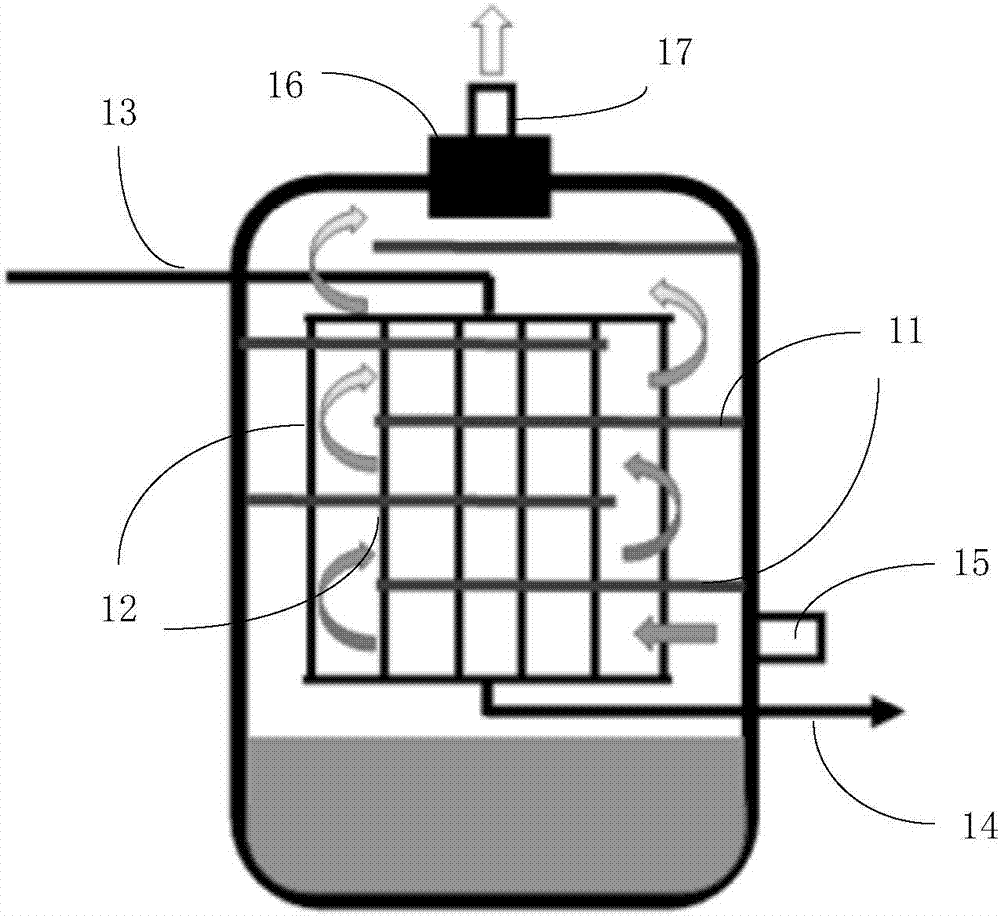

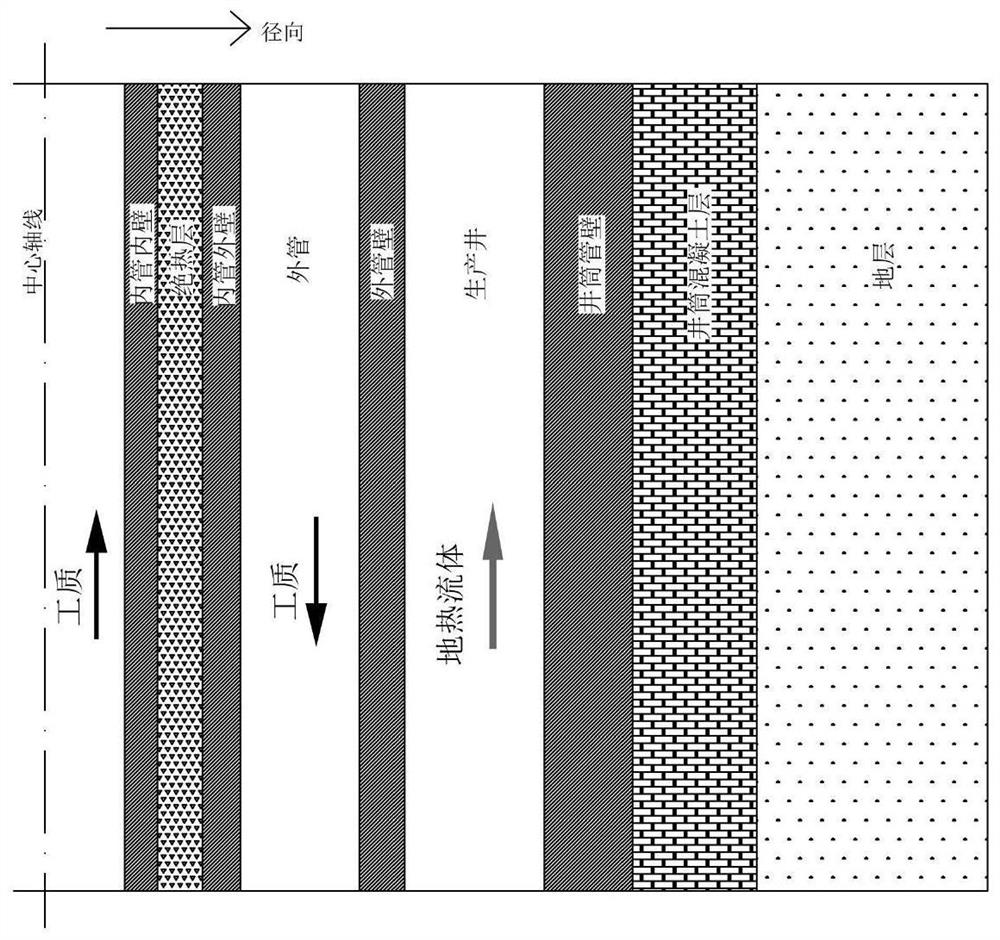

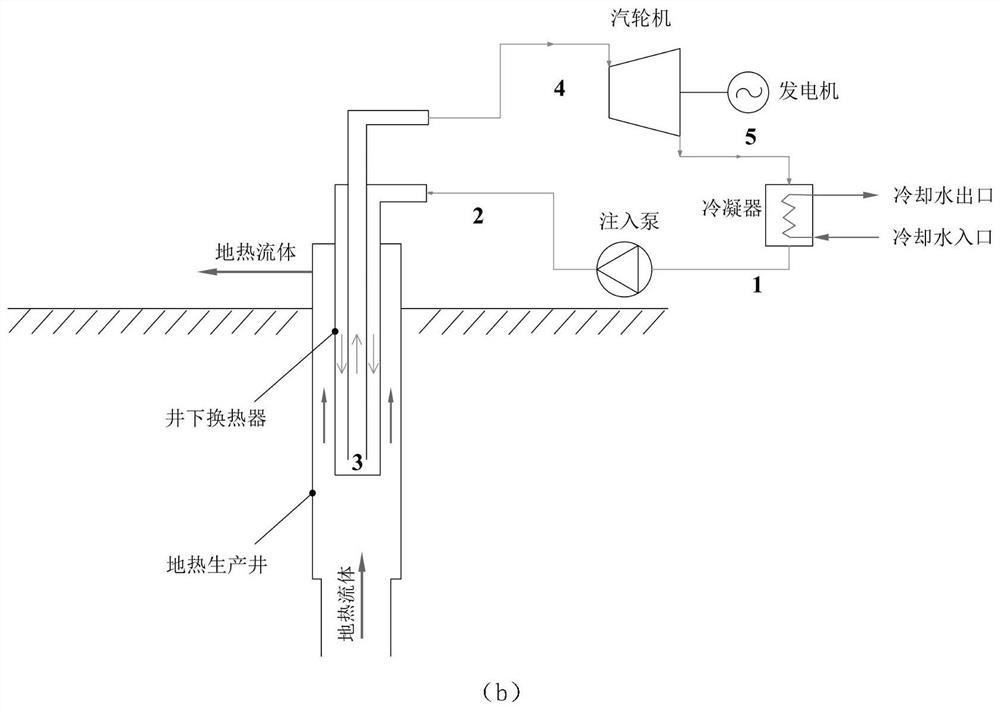

Pressurization and heat absorption transcritical cycle hot dry rock geothermal power generation model based on CO2 mixed working medium

InactiveCN112065521AConsider thermal propertiesTaking into account stabilityGeothermal energy generationSteam generationTranscritical cycleBinary cycle

The invention relates to a pressurization and heat absorption transcritical cycle hot dry rock geothermal power generation model based on a CO2 mixed working medium, which comprises a geothermal watercycle, a mixed working medium cycle and a cooling water cycle; and an underground coaxial sleeve heat exchanger is arranged in the mixed working medium cycle. The innovation is reflected in that a pressurization and heat absorption process is realized by utilizing a gravity field, so that the cycle heat absorption capacity is increased, and the cycle power generation is increased. A binary mixedworking medium composed of CO2 and an organic working medium is adopted; and therefore, a transcritical cycle with pressurization heat absorption and temperature reduction heat release can be achieved, irreversibility of heat exchange of a heat source and a cold source can be effectively reduced, and the cycle efficiency is improved. The mixed working medium adopted by the cycle comprises (but notlimited to) CO2 / R32, CO2 / R161, CO2 / R1270, CO2 / R1234yf, CO2 / R134a, CO2 / R152a and CO2 / R1234ze. The pressurization and heat absorption transcritical circulation hot dry rock geothermal power generationmodel based on the CO2 mixed working medium mainly aims at hot dry rock geothermal resources, but is not limited to the hot dry rock geothermal resources; and the power generation system is also suitable for application occasions of other binary cycle geothermal power generation systems.

Owner:TIANJIN UNIV

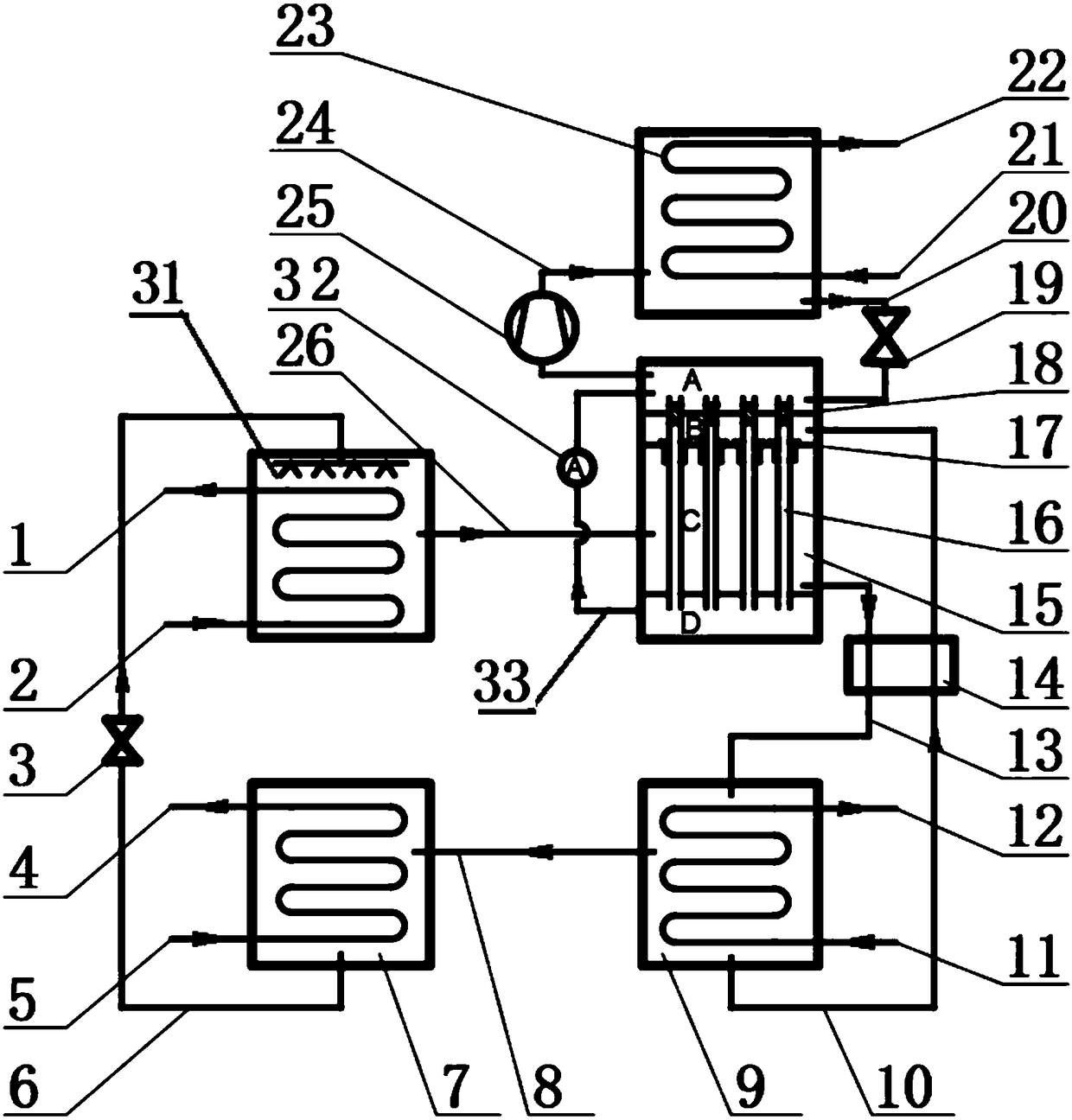

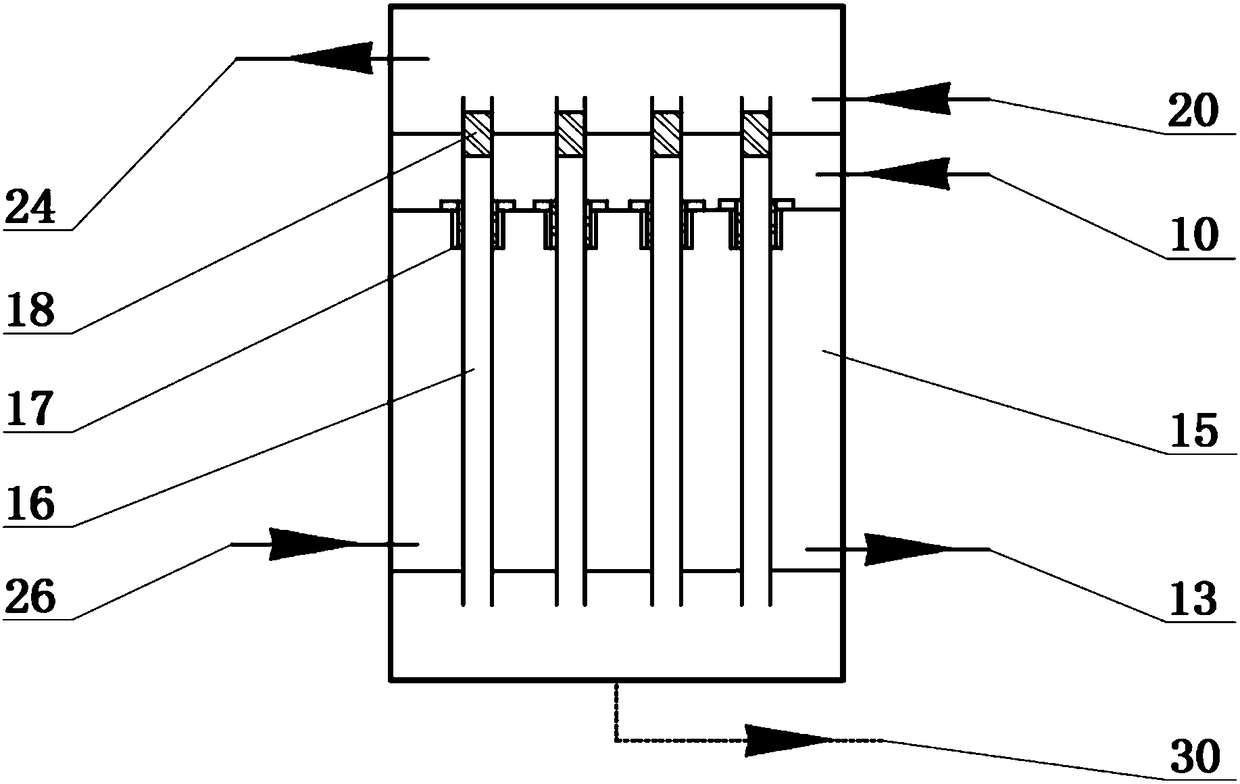

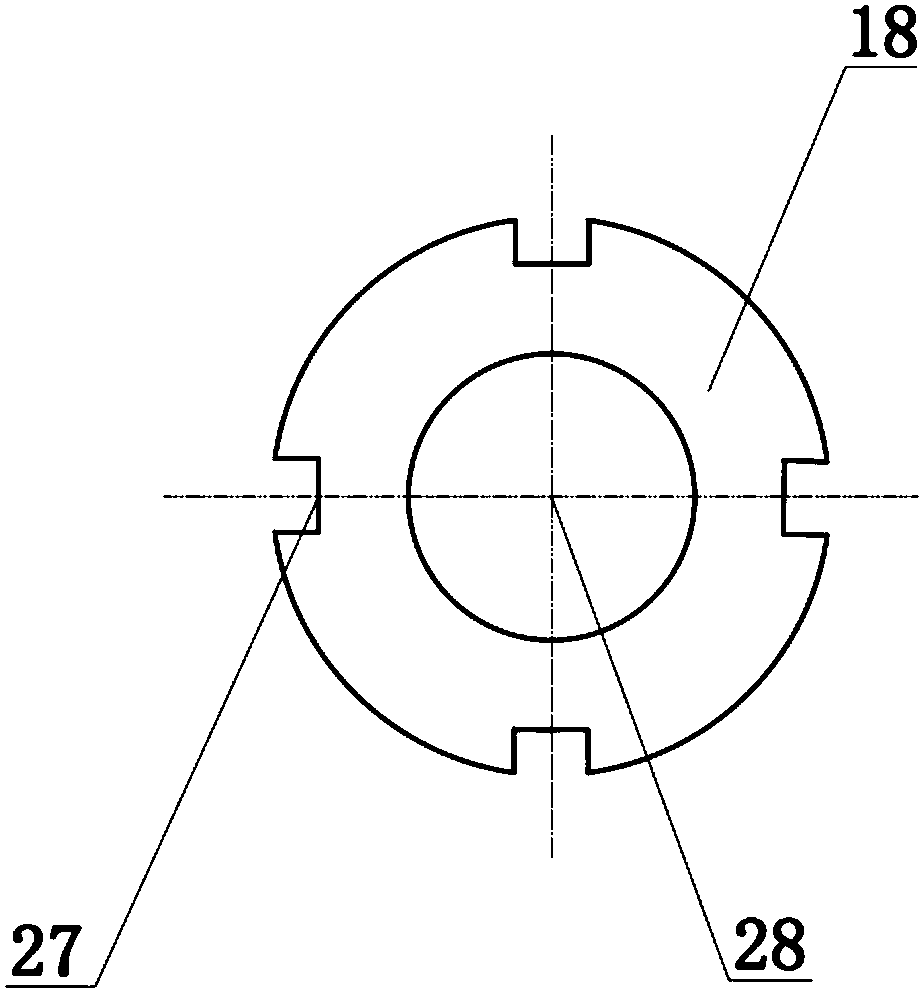

Combined heat exchanger unit with electric heat pump and absorption heat pump

PendingCN108592444AReduce irreversible lossReduce heat transfer temperature differenceHeat pumpsEnergy efficient heating/coolingLower gradeLow graded

The invention provides a combined heat exchanger unit with an electric heat pump and an absorption heat pump. The heat exchanger unit comprises an electric heat pump condenser, a bilateral phase change heat exchanger, an absorption heat pump generator, an absorption heat pump condenser, an absorption heat pump evaporator and a pipeline and can be widely applied to various low-grade waste heat recovery occasions. The heat exchanger unit adopts the combined structure of the absorber of the absorption heat pump and an electric heat pump evaporator and can greatly raise the outlet temperature of aheated medium. Compared with the technology only adopting the absorption heat pump, the heat exchanger unit releases the maximum outlet temperature limit caused by the heat pump process and a workingmedium. Compared with the technology only adopting the electric heat pump, the heat exchanger unit greatly reduces powder consumption and significantly reduces the operating cost of equipment. The novel unit has a certain application prospect in the field of energy conservation and environmental protection.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

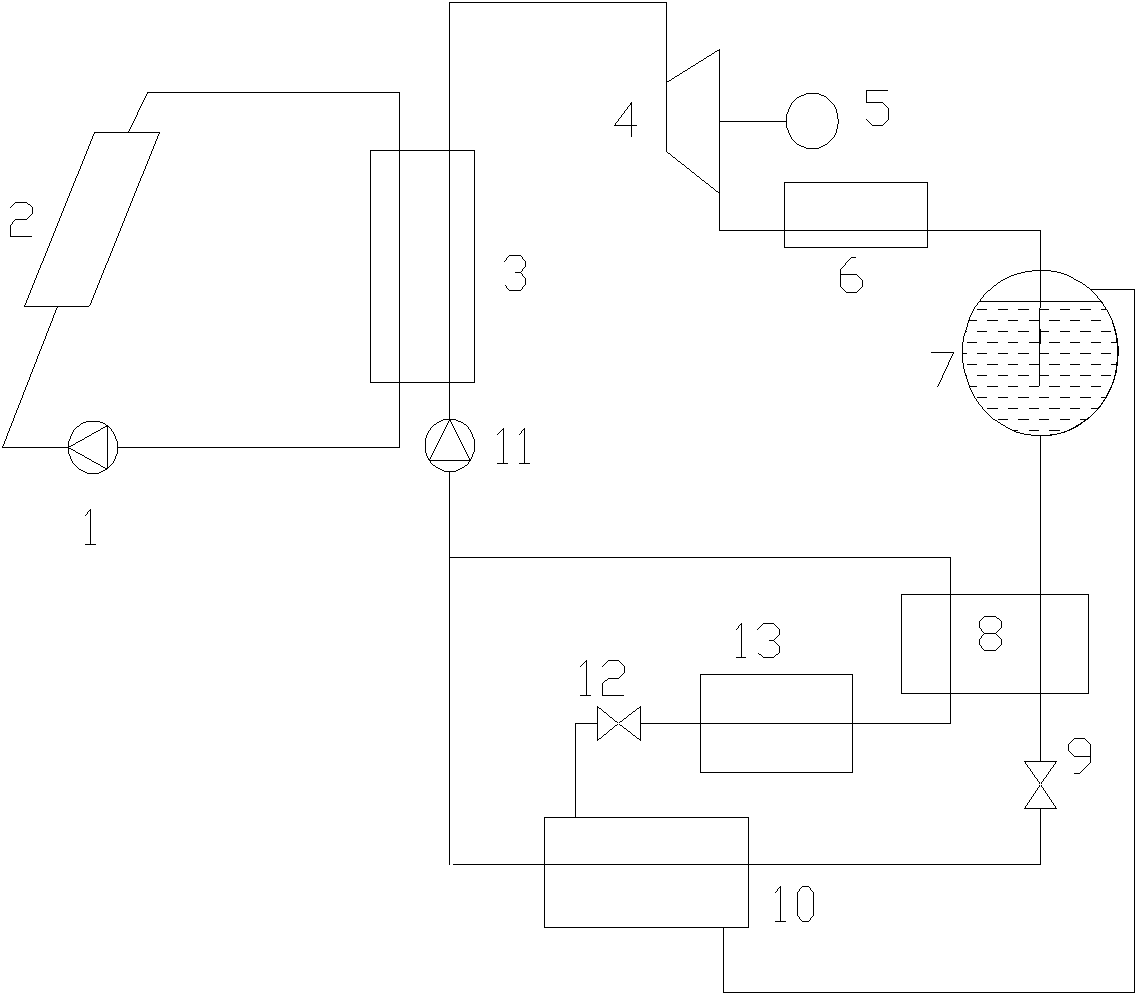

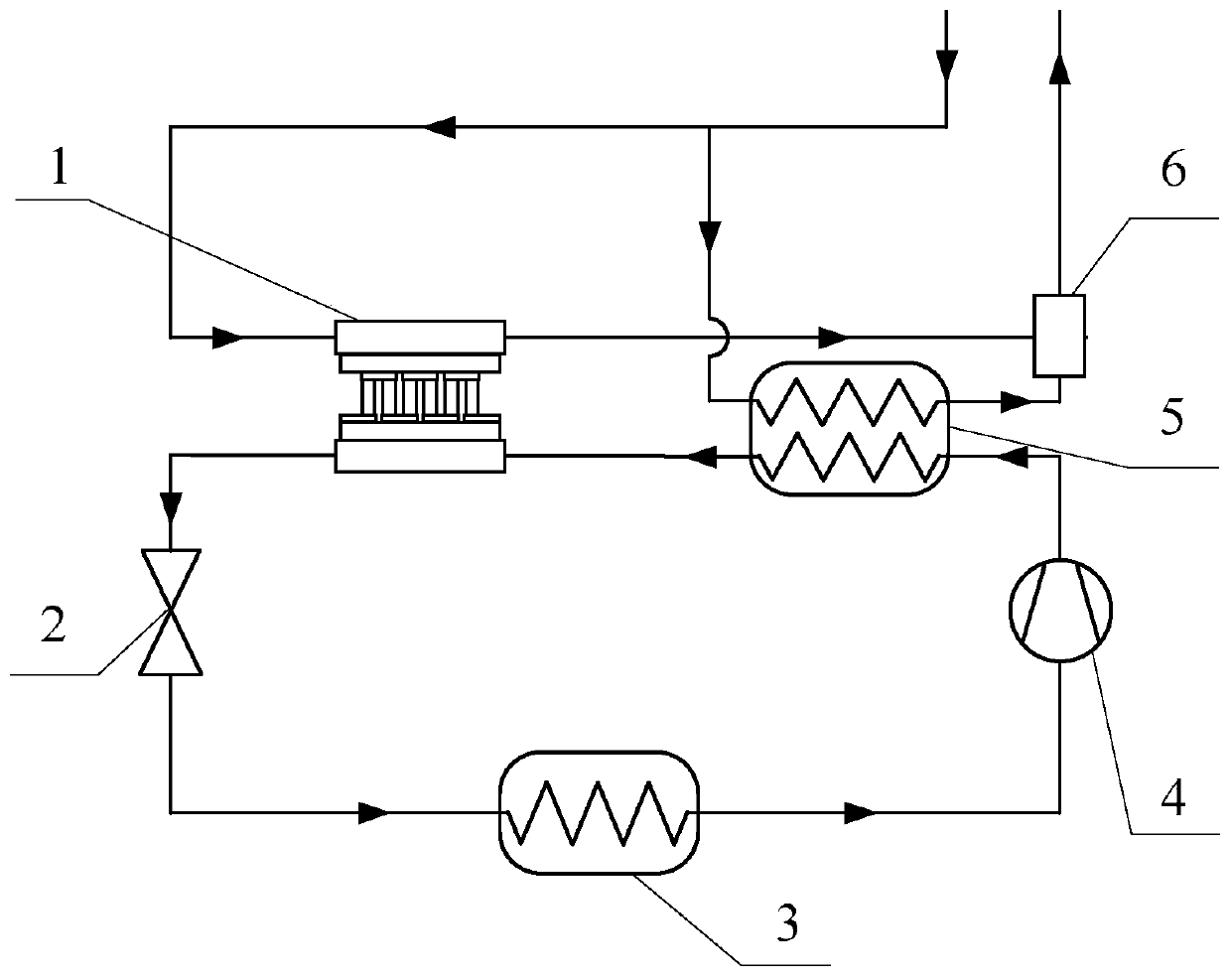

Water-cooled heat pipe-type machine room air-conditioning system

ActiveCN101979928AReduce heat transfer temperature differenceImprove cooling efficiencySpace heating and ventilation safety systemsLighting and heating apparatusCooling towerHigh energy

The invention discloses a water-cooled heat pipe-type machine room air-conditioning system. The system comprises a compressor, a water-cooled condenser, a throttling device, an evaporative cooling condenser, a liquid storage pot, a flow equilibrium valve, a terminal heat exchanger, an air bubble pump, a cooling tower, a cooling water pump, a first water outlet valve, a first water inlet valve, a first drain valve, a second water inlet valve, a second water outlet valve and a second drain valve, wherein the high-pressure exhaust port of the compressor is connected with the refrigerant side of the water-cooled condenser, the throttling device, the evaporation side of the evaporative cooling condenser, and the low-pressure air suction port of the compressor in turn, so as to form a compressing refrigeration circulation loop with a cooling water circulation loop together; and the outlet on the condensing side of the evaporative cooling condenser is connected with the liquid storage pot, the flow equilibrium valve, the terminal heat exchanger, the air bubble pump and the inlet on the condensing side of the evaporative cooling condenser in turn, so as to form a heat pipe refrigeration circulation loop with the cooling water circulation loop together. The system has a smaller temperature difference and a high energy efficiency ratio when performs heat exchange.

Owner:浙江洁普智汇能源科技有限公司

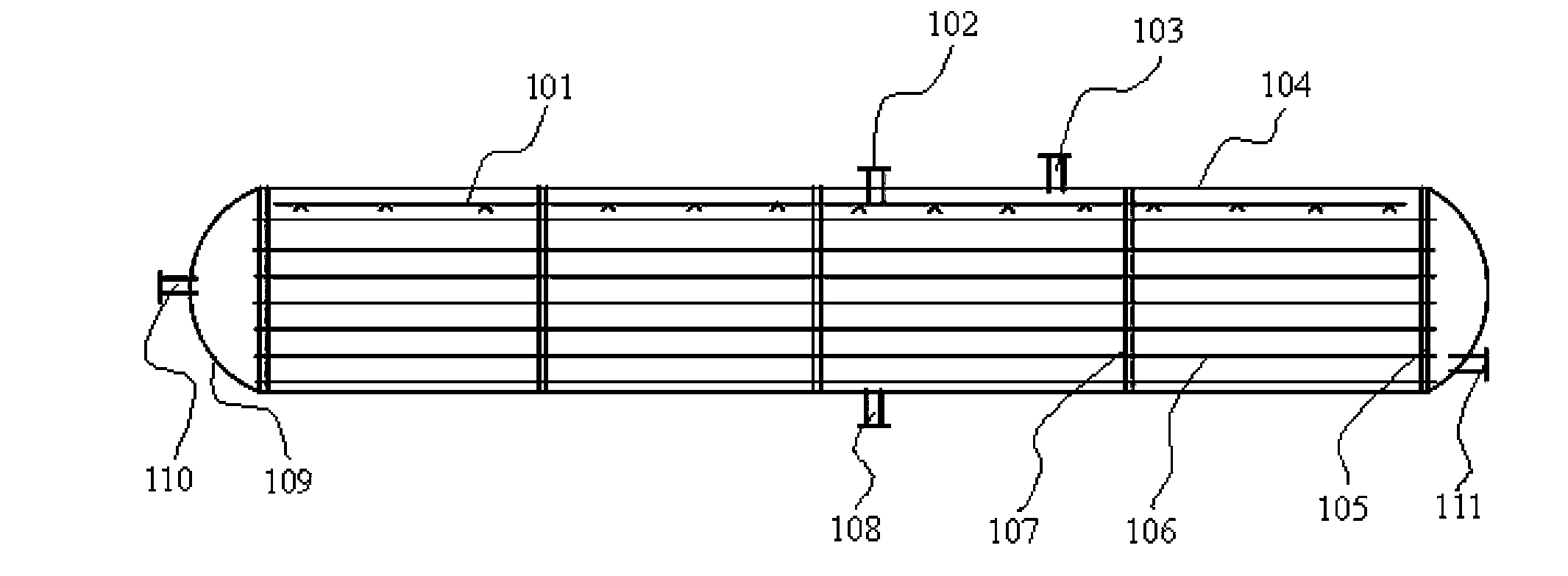

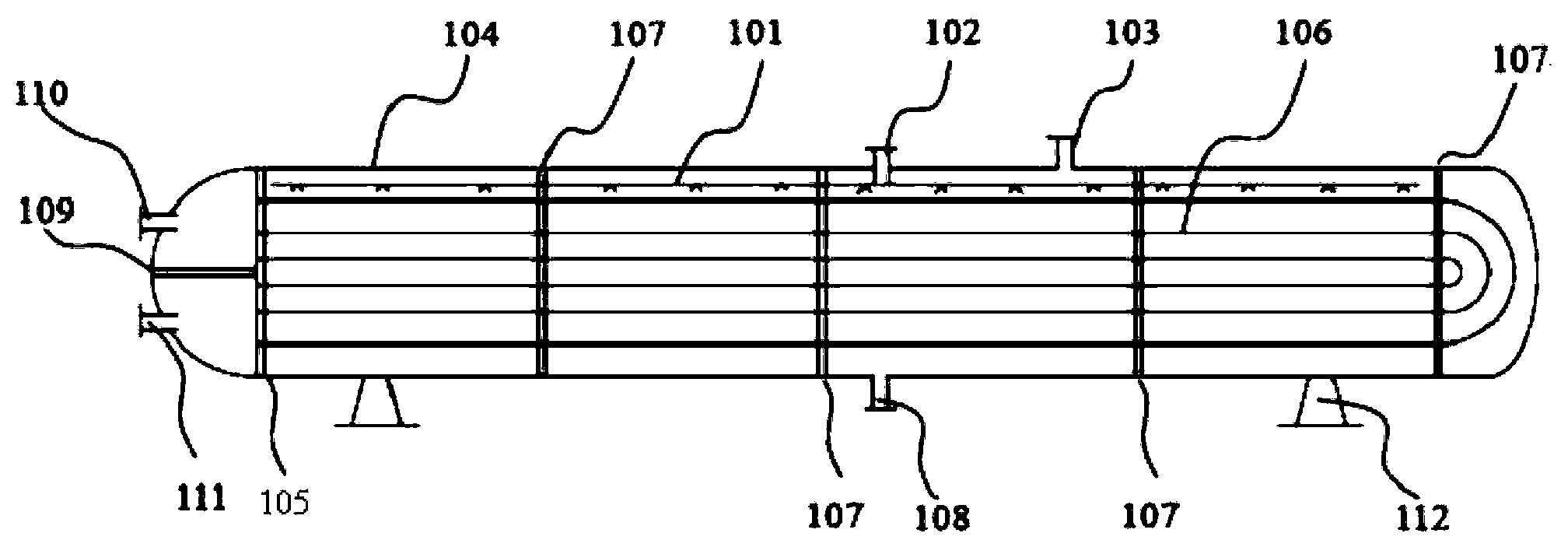

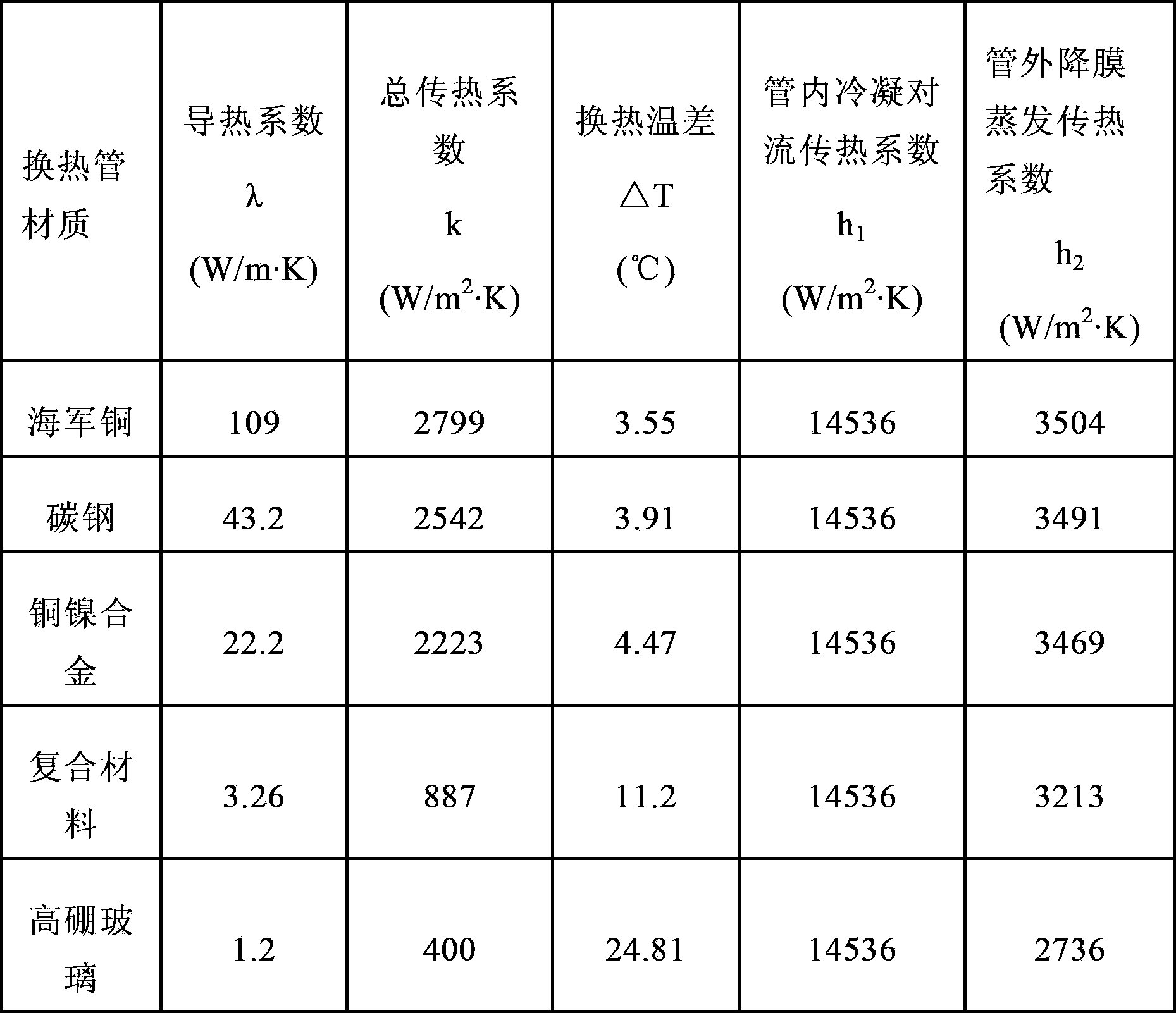

Spray type shell-and-tube heat exchanger adopting nonmetal heat exchange tubes

InactiveCN103837015ASmall diameterMeet heat transfer requirementsStationary conduit assembliesHeat exchange apparatusShell and tube heat exchangerDistillation

The invention relates to the technical field of shell-and-tube heat exchange, and discloses a spray type shell-and-tube heat exchanger adopting nonmetal heat exchange tubes. The heat exchanger comprises a shell, a sprayer, the heat exchange tubes arranged in parallel in the shell, a supporting plate for supporting the heat exchange tubes and a tube plate connected with the heat exchange tubes, wherein the heat exchange tubes are made of nonmetal material with the heat conductivity coefficient of 0.5 W / m*K-10 W / m*K, and the outer diameter of the heat exchange tubes is 5 mm-15mm. The corrosion prevention problem of heat exchange tubes in low-temperature multi-effect distillation sea water desalting equipment and a lithium bromide absorption refrigerator can be solved, and the spray type shell-and-tube heat exchanger has the advantages of being low in heat transfer temperature difference and cost and the like.

Owner:BLUELAGOON TECH

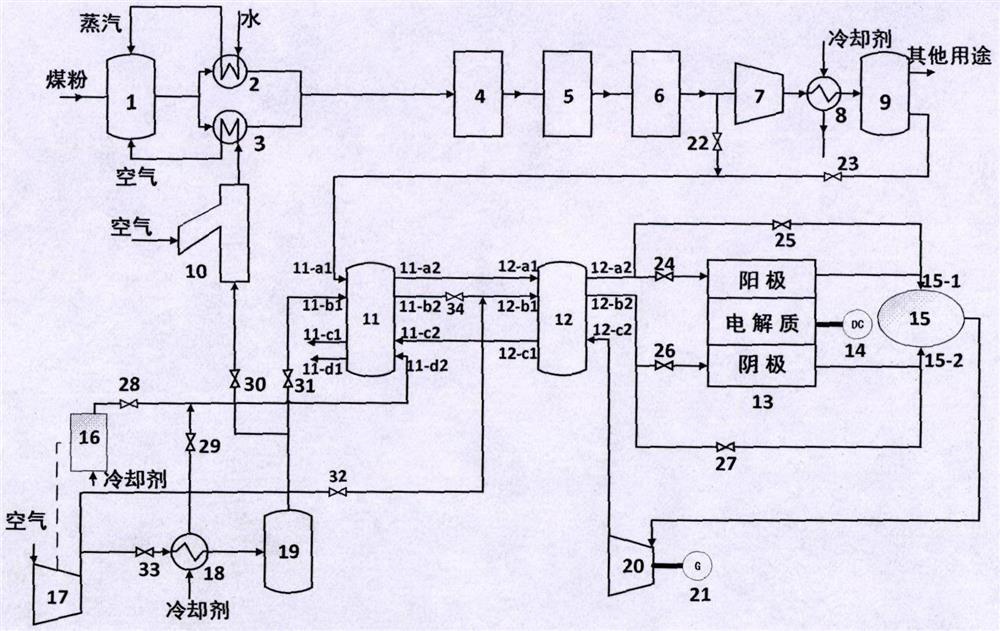

Coal gasification solid oxide fuel cell hybrid energy storage power generation system

ActiveCN111799819ASmooth load fluctuationFlexible operating modeEnergy storageAc network load balancingHeat energyLoad following power plant

The invention discloses a coal gasification solid oxide fuel cell hybrid energy storage power generation system, and belongs to the technical field of energy storage power generation. The system comprises a coal gasification subsystem, a gas storage subsystem, a heat storage subsystem, a solid oxide fuel cell power generation subsystem and a gas turbine power generation subsystem. In the energy storage stage, the coal-to-gas process is completed by utilizing off-peak electric energy of a power grid load or electric energy generated by intermittent renewable energy sources, and air and synthesis gas are compressed and then stored in a compressed air storage tank and a synthesis gas storage tank. In the energy release stage, compressed air in the compressed air storage tank and compressed synthesis gas in the synthesis gas storage tank are released and supplied to the solid oxide fuel cell power generation subsystem and the gas turbine power generation subsystem. And the heat storage subsystem can carry out gradient storage and gradient utilization on heat energy of different tastes. The system can flexibly operate in different operation modes, is a novel energy storage power generation system, can perform clean utilization on coal, and has the characteristics of high fuel utilization rate, low pollutant discharge and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Thermoelectric supercooling cross-critical CO2 heat pump combined heating system

PendingCN110454851AReduce heat transfer temperature differenceReduce the irreversible loss of heat exchangeHeat pumpsCompression machinesEngineeringGas cooler

The invention discloses a thermoelectric supercooling cross-critical CO2 heat pump combined heating system. An outlet of an evaporator is connected with an inlet of a compressor; an outlet of the compressor is connected with an inlet of the working medium side of a gas cooler; an outlet of the working medium side of the gas cooler is connected with an inlet of the cold end of a thermoelectric supercooling device; an outlet of the cold end of the thermoelectric supercooling device is connected with an inlet of a throttling valve; an outlet of the throttling valve is connected with an inlet of the evaporator; a heating water return outlet is connected with an inlet of the thermal end of the thermoelectric supercooling device; an outlet of the thermal end of the thermoelectric supercooling device is connected with an inlet of the heat exchange fluid side of the gas cooler; an outlet of the heat exchange fluid side of the gas cooler is connected with an inlet of a mixing tank; and an outlet of the mixing tank is connected with a heating water return inlet. According to the system, the throttling loss is reduced to a greater extent, the high pressure of CO2 operation is further reduced,the overall system efficiency of a CO2 heat pump is improved, the compression ratio of the compressor is reduced, the isentropic efficiency is improved, and the service life of the compressor is prolonged.

Owner:TIANJIN UNIV OF COMMERCE

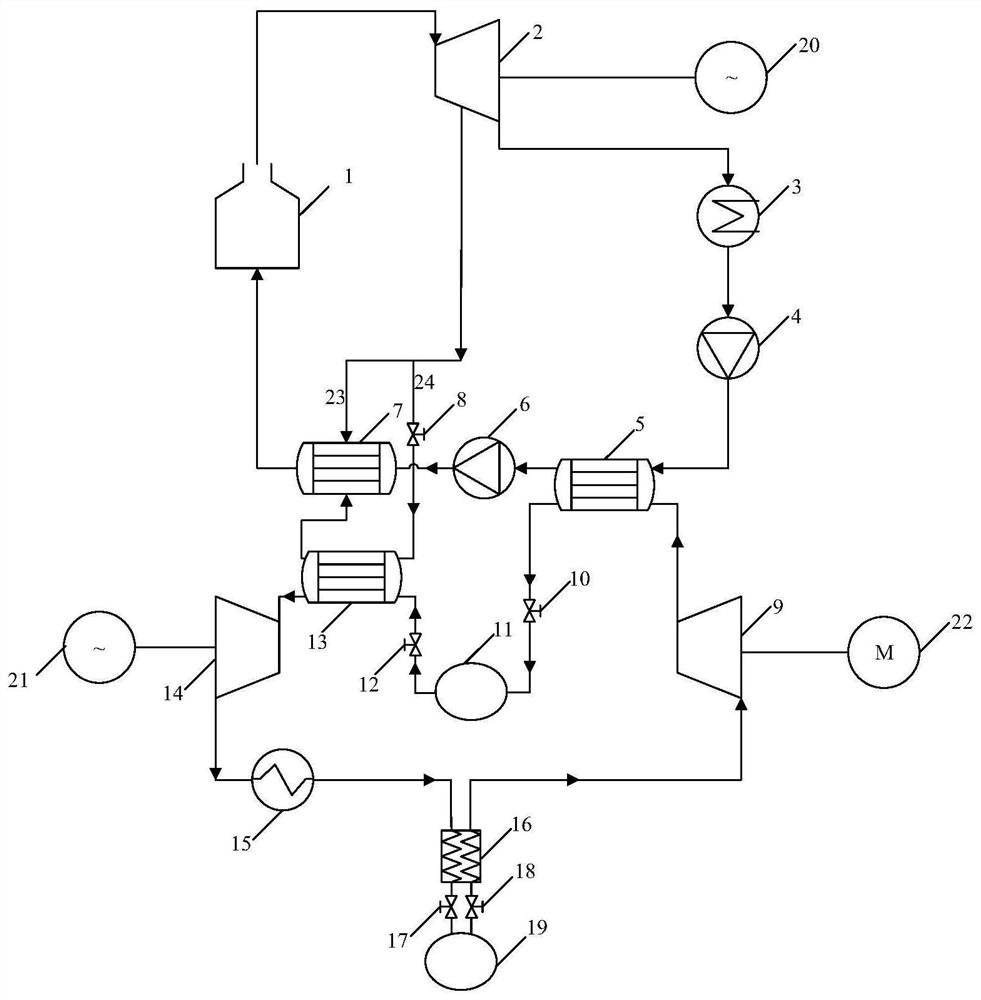

Process and device for generating electricity by using LNG cold energy

ActiveCN105569752AImprove utilization efficiencyReduce heat transfer temperature differenceSteam engine plantsElectricityEconomic benefits

The invention relates to a process and device for generating electricity by using LNG cold energy. A lot of cold energy is released in the process of supplying vaporized LNG to a downstream pipe network; and the process uses two independent cycles to recover the cold energy for generating electricity, so that the loss of the cold energy is prevented, the economic benefit of enterprises is promoted, the pollution problem caused by power generation of a power plant is prevented in power generation, and the requirements of energy conservation and environmental protection are accorded with.

Owner:XINDI ENERGY ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com