Patents

Literature

39results about How to "Reduce condensation load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

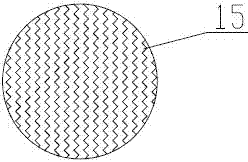

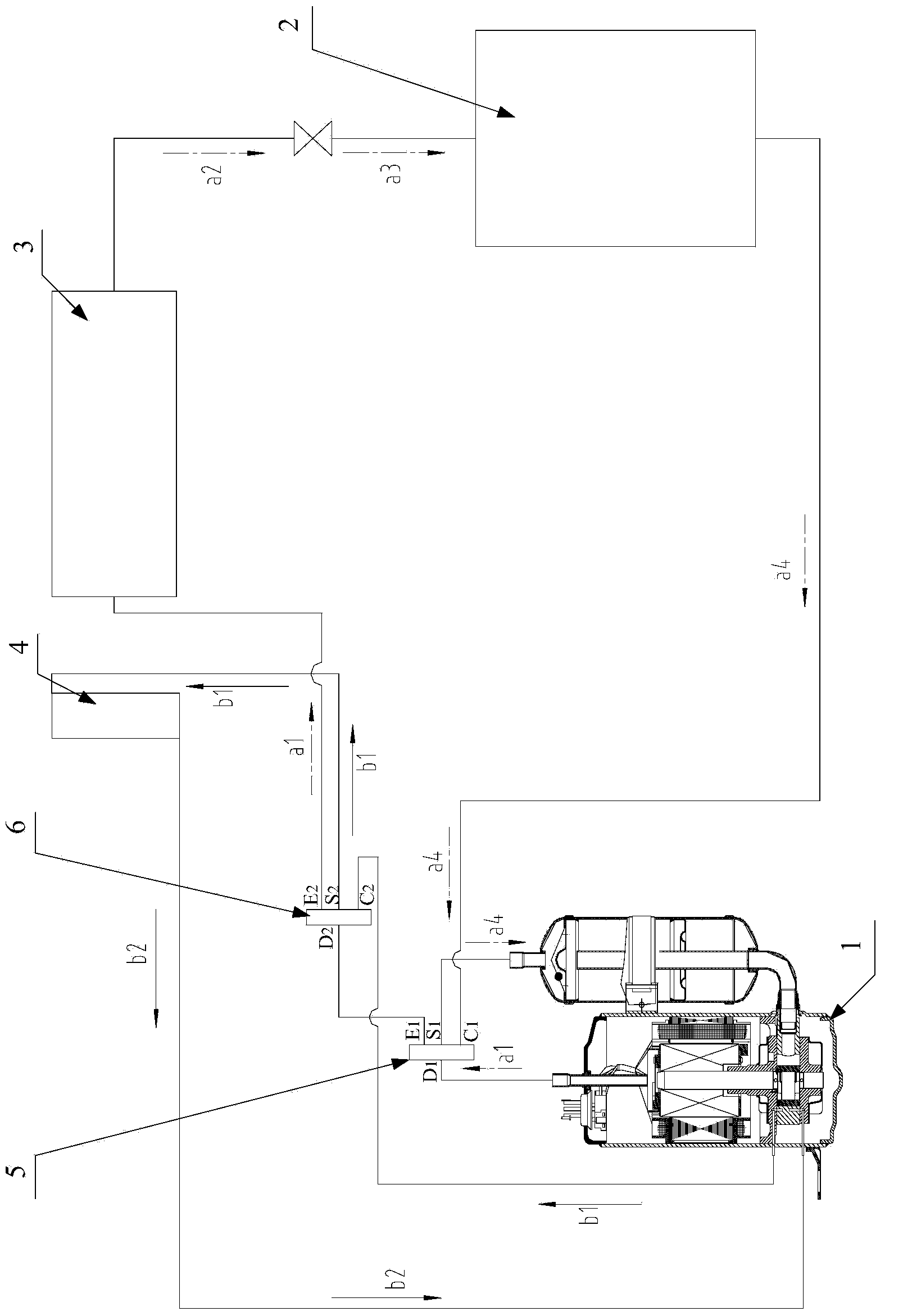

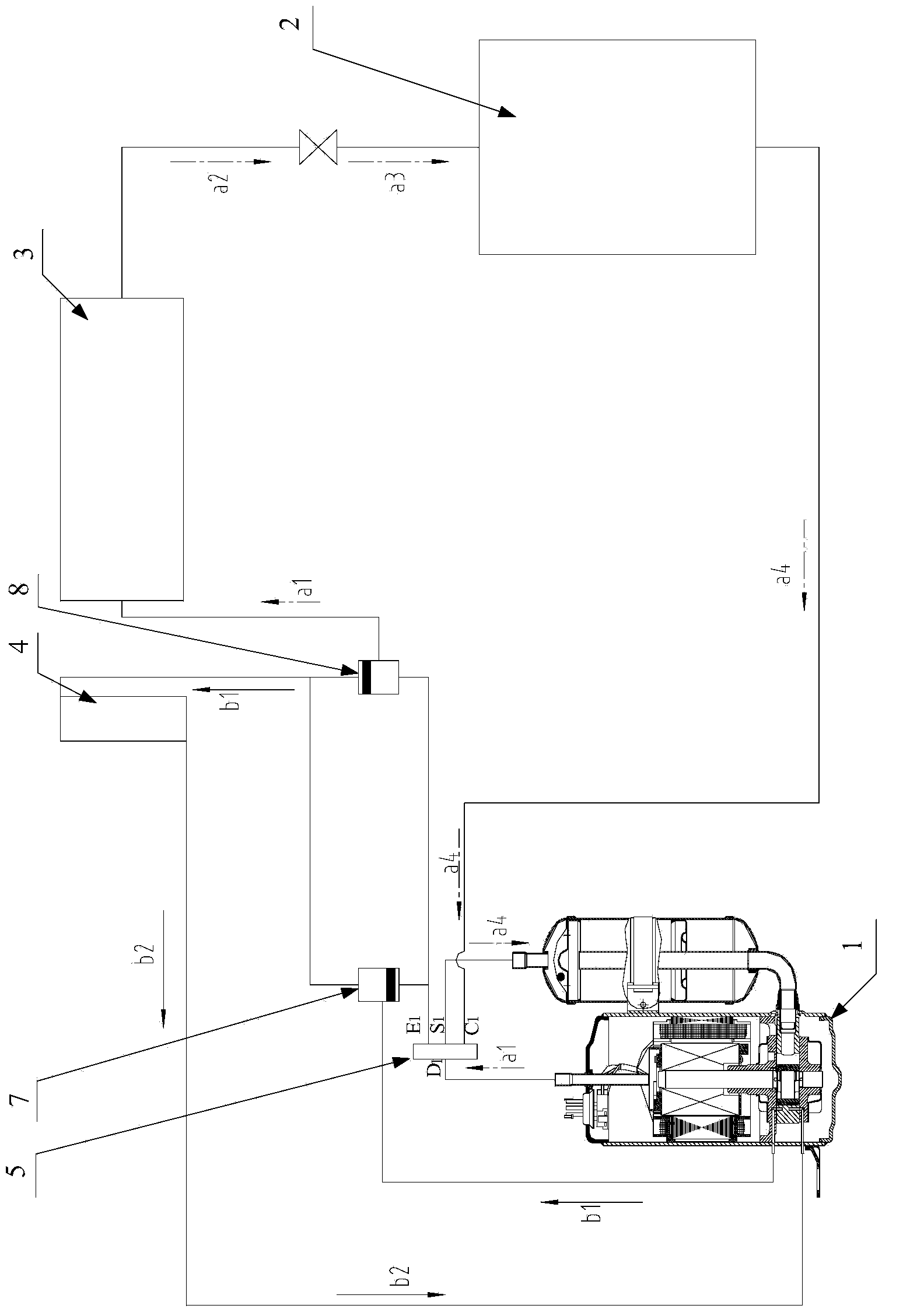

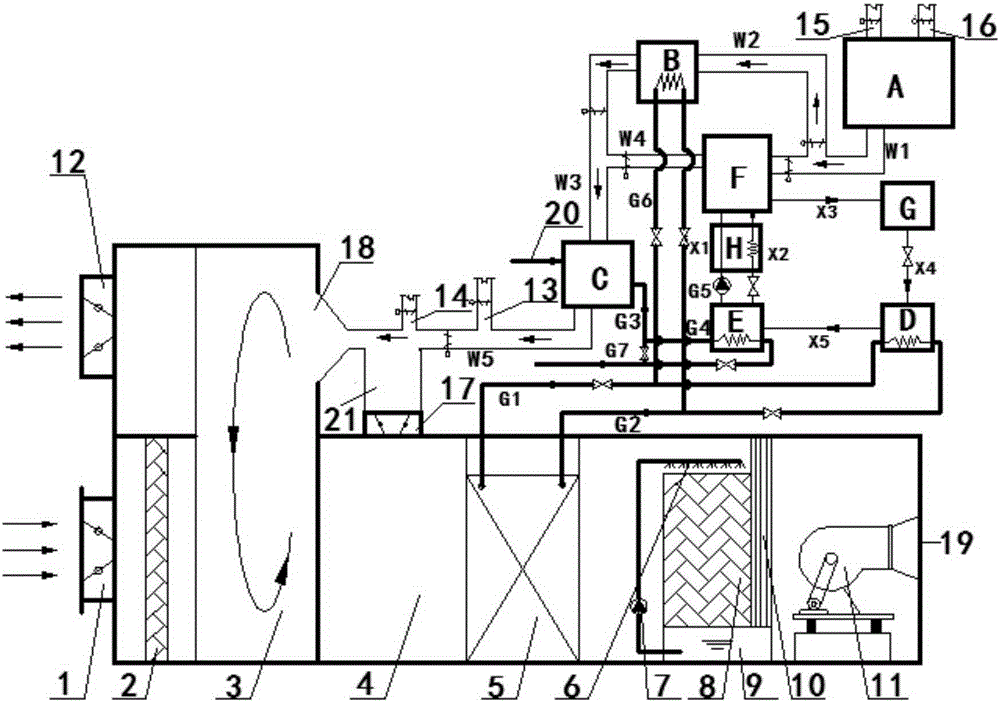

Device for combining power cycle with compression type refrigerating cycle

InactiveCN103075839ASave electricityReduce condensation loadFrom solar energyGeothermal energy generationPower cycleToxic industrial waste

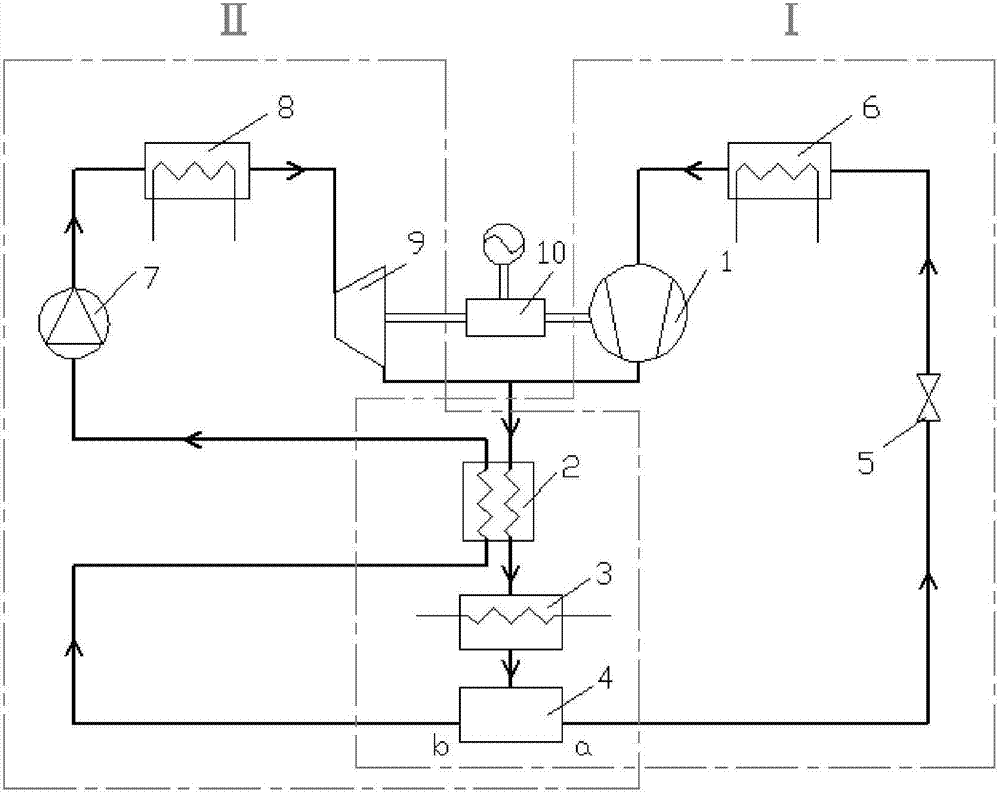

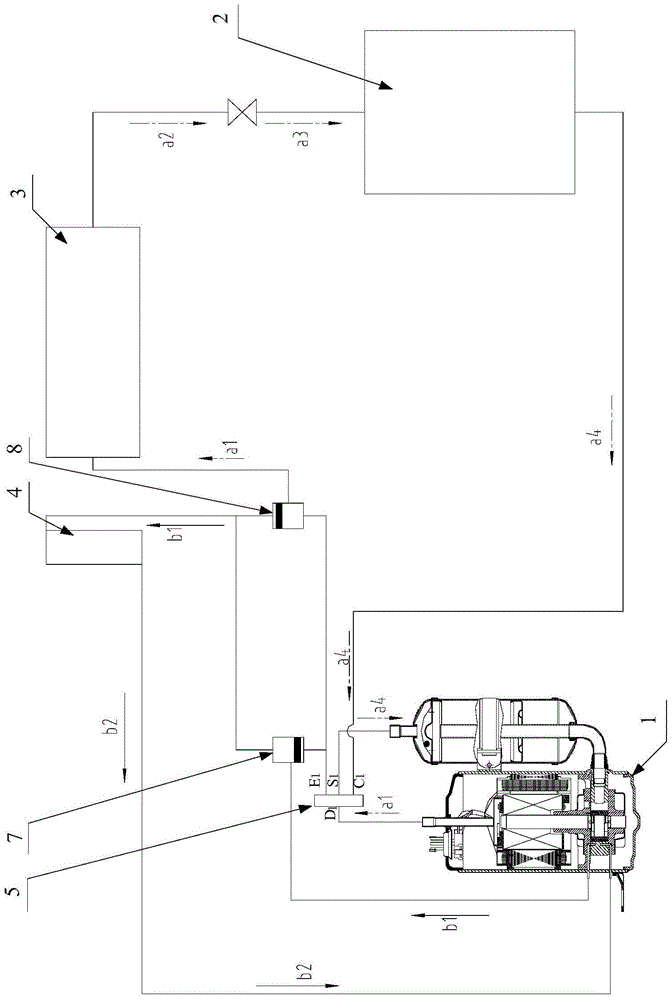

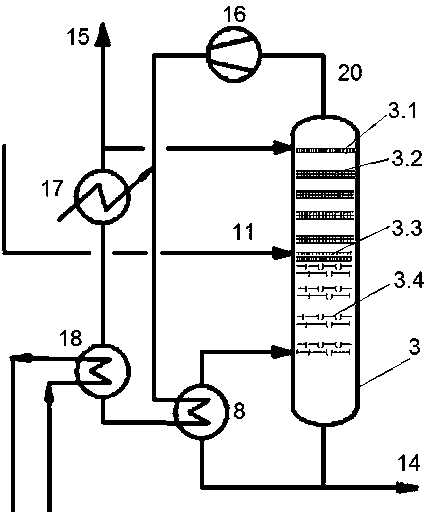

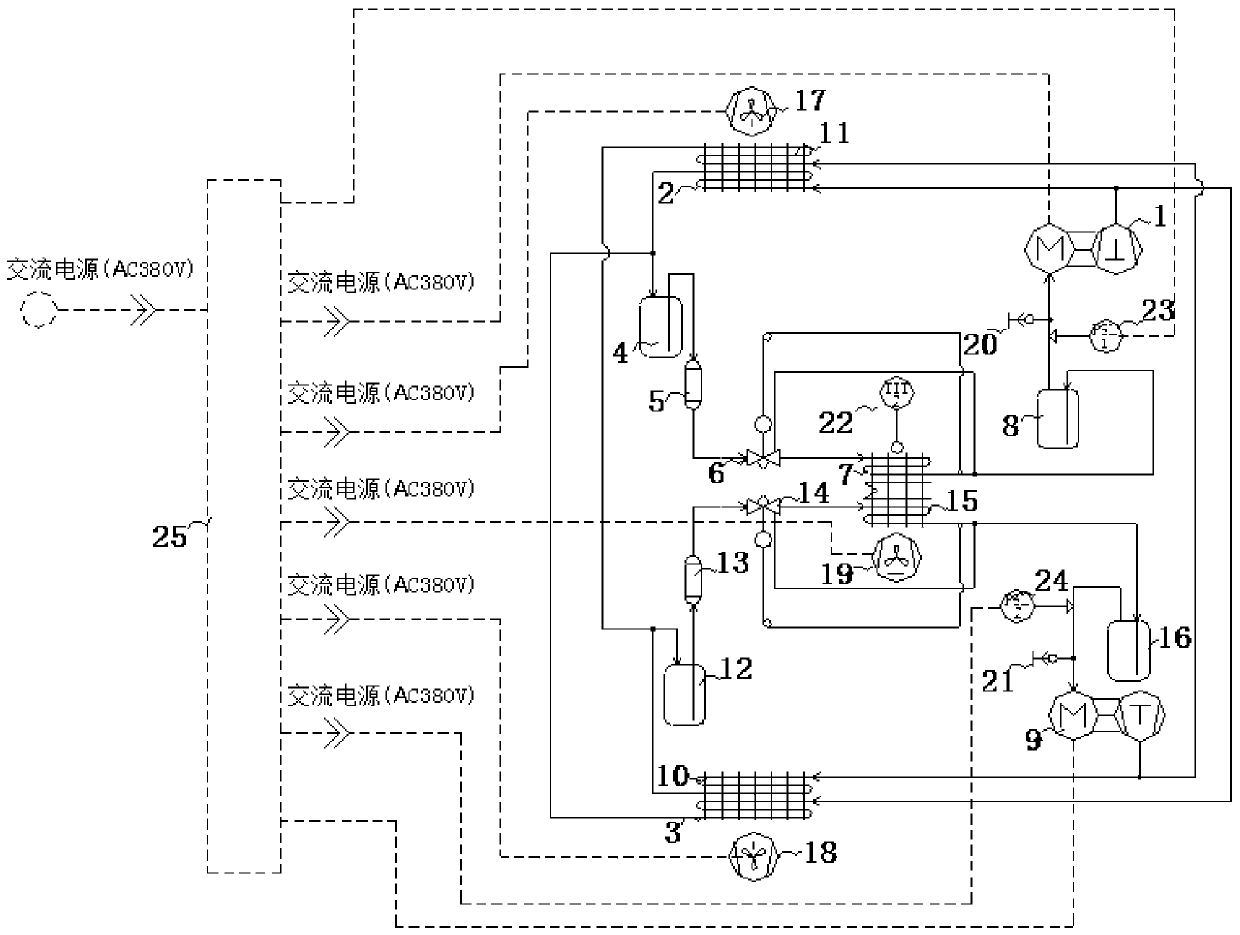

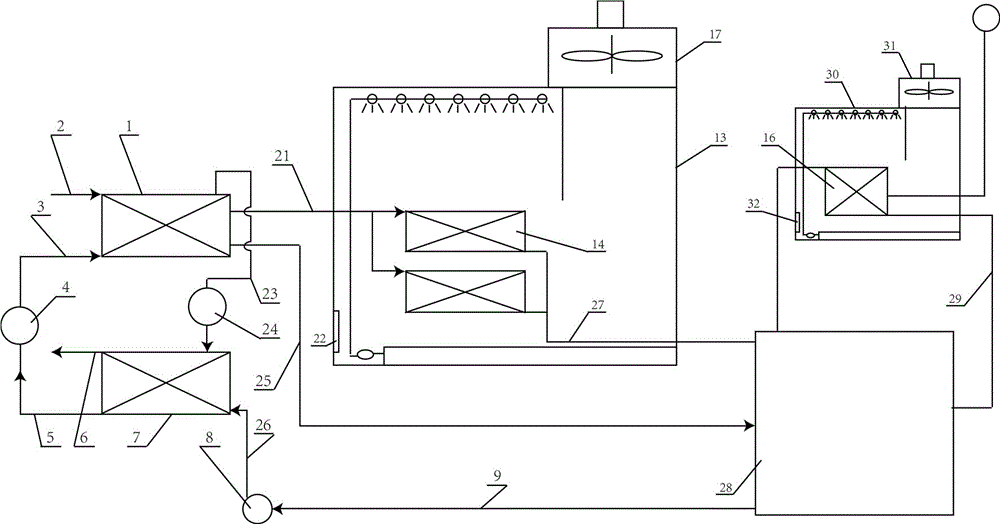

The invention discloses a device for combining power cycle with compression type refrigerating cycle, which can be used for simultaneously completing power cycle and compression type refrigerating cycle. The device comprises a compressor, a heat regenerator, a condenser, a reservoir, a throttle valve, an evaporator I, a working medium pump, an evaporator II, an expander and a transmission device, which are connected according to a rule. According to the device disclosed by the invention, medium-low-grade energy sources such as solar energy, geothermal energy and industrial waste heat can be utilized for driving the expander to apply work, so that the compressor is driven by the output shaft work to operate for achieving the power cycle and the refrigerating cycle. Meanwhile, the device can also be used for generating power when the operation of a refrigerating working condition is not needed. The heat regenerator is additionally arranged in the device, so that the load of the heater is reduced while the load of the condenser is reduced. The reservoir is arranged, so that the two cycles are operated independently, thereby ensuring stable refrigerating to a user. The device disclosed by the invention has a good application prospect in underserved areas of power or small areas or cold supply, and is of significance to energy conservation and emission reduction.

Owner:SOUTHEAST UNIV

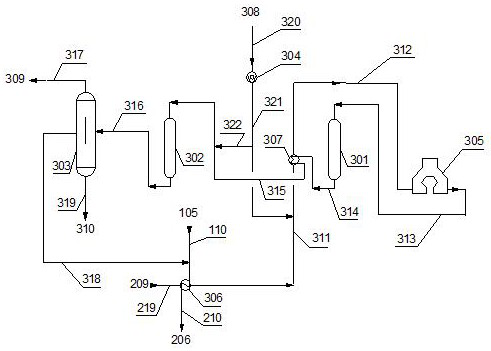

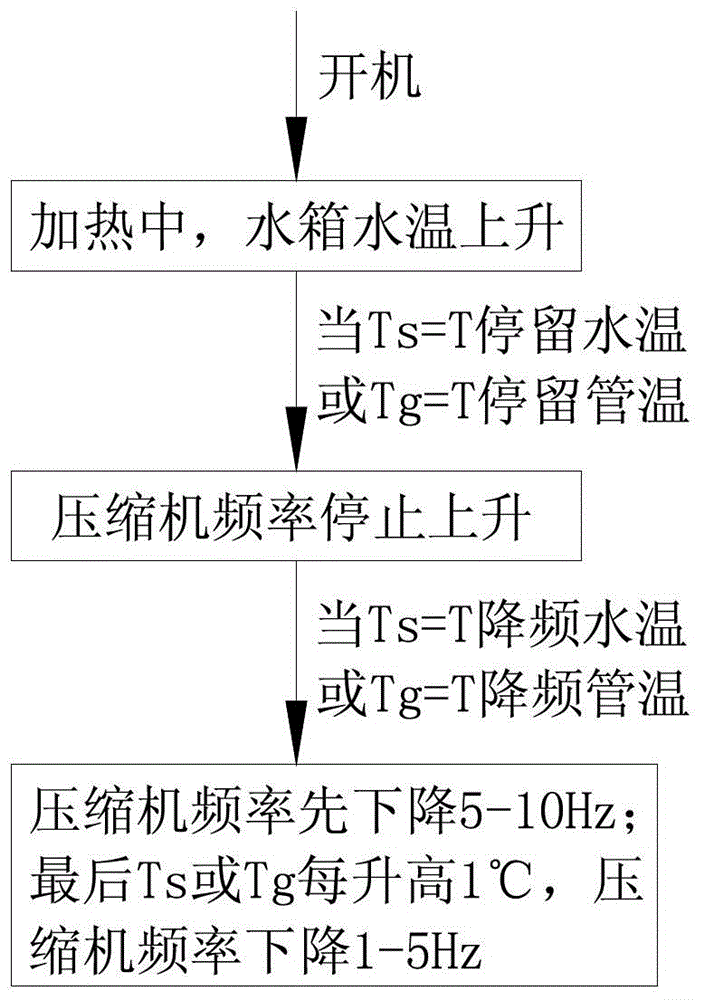

Method for increasing highest outlet water temperature of heat pump water heater

ActiveCN103836789ARaise the water temperatureReduce condensation loadFluid heatersControl systemFrequency reduction

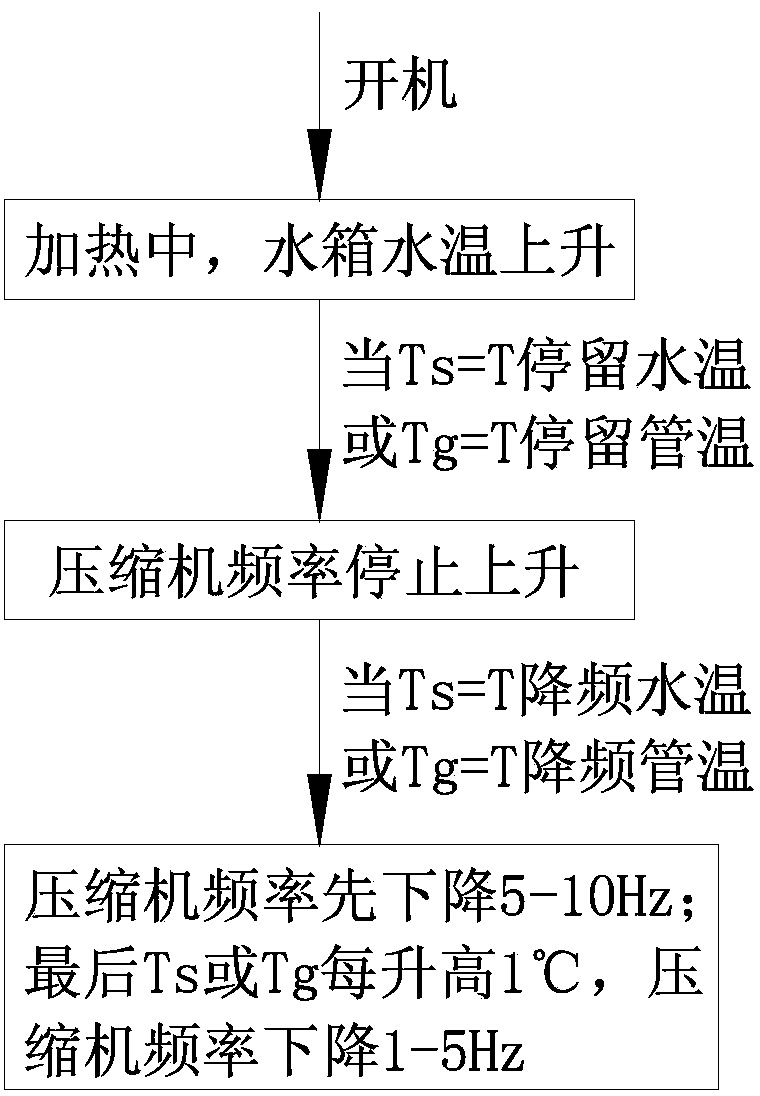

The invention provides a method for increasing the highest outlet water temperature of a heat pump water heater. Due to the fact that a compressor frequency reducing step is included, when a heat pump heat water control system judges that current operating parameters conform to compressor frequency reducing conditions, the compressor frequency reduces, and the circulation volume of coolants is reduced. Consequently, the condensing load of the heat pump water heater is reduced, the heat exchange temperature difference of a condenser is reduced, and the temperature of water in a water tank is further increased. According to the method, judgments are conducted according to the current operating parameters, a method of frequency reduction on a high water temperature section is adopted, and the circulation volume of the system is reduced, namely, the condensing load-heat exchange temperature difference of the system is reduced, and the heat exchange temperature difference is reduced by 5 DEG C, so that the highest water temperature can reach 55 DEG C. On the condition that the cost and the installation space of the whole machine are not increased, the purpose that the highest outlet water temperature of a R410A coolant heat pump water heater reaches 55 DEG C is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

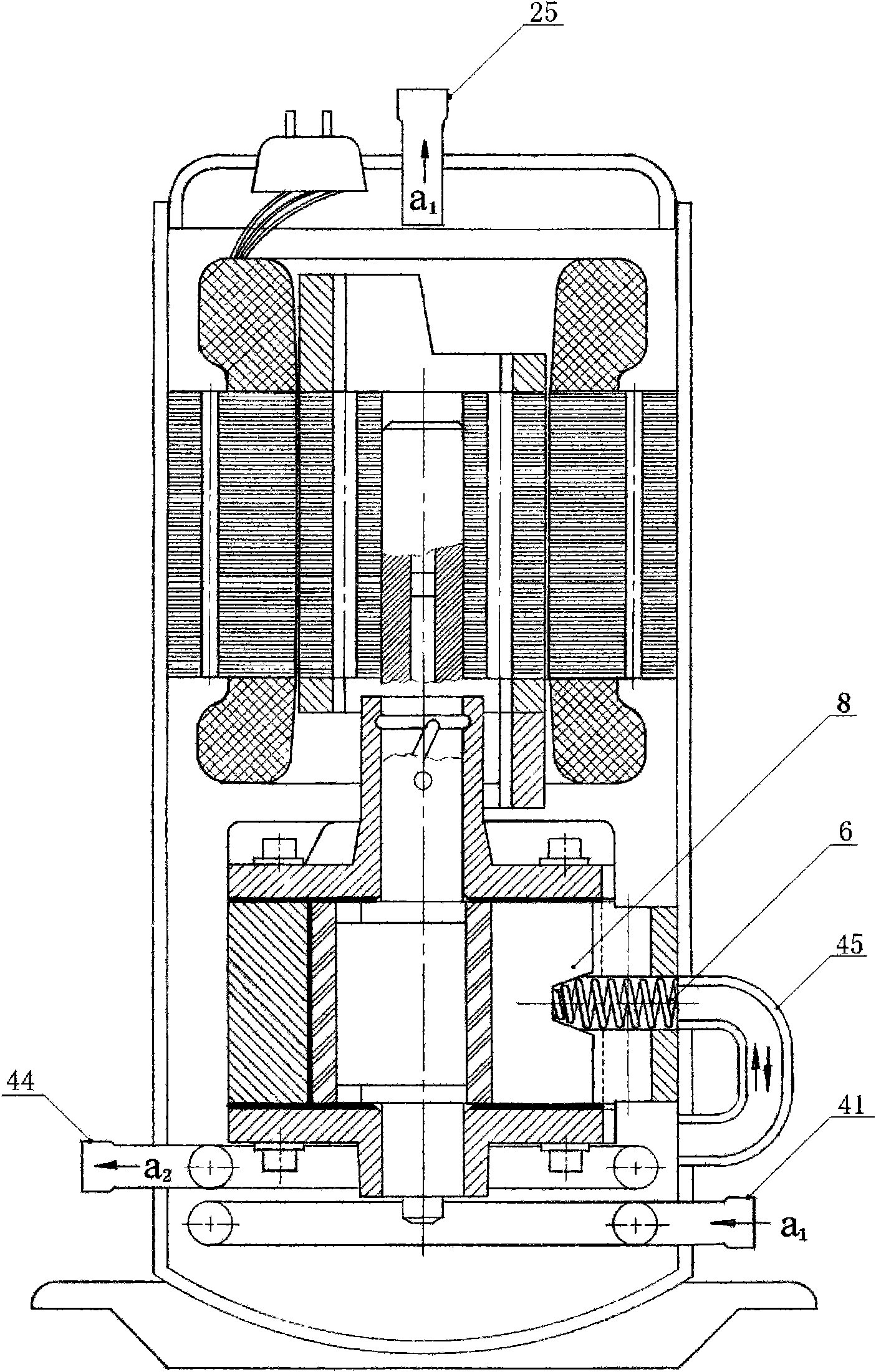

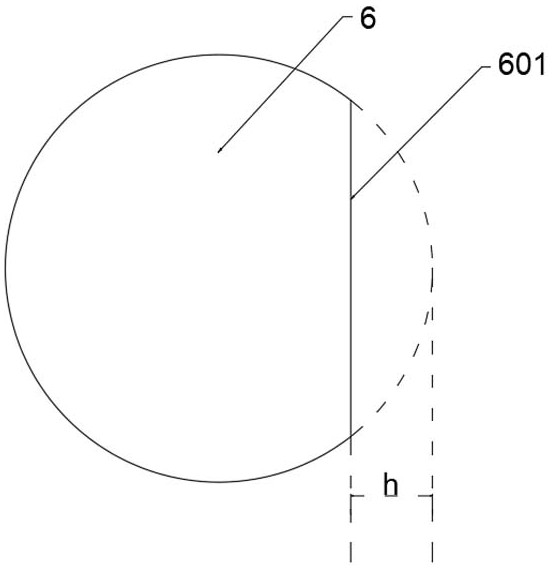

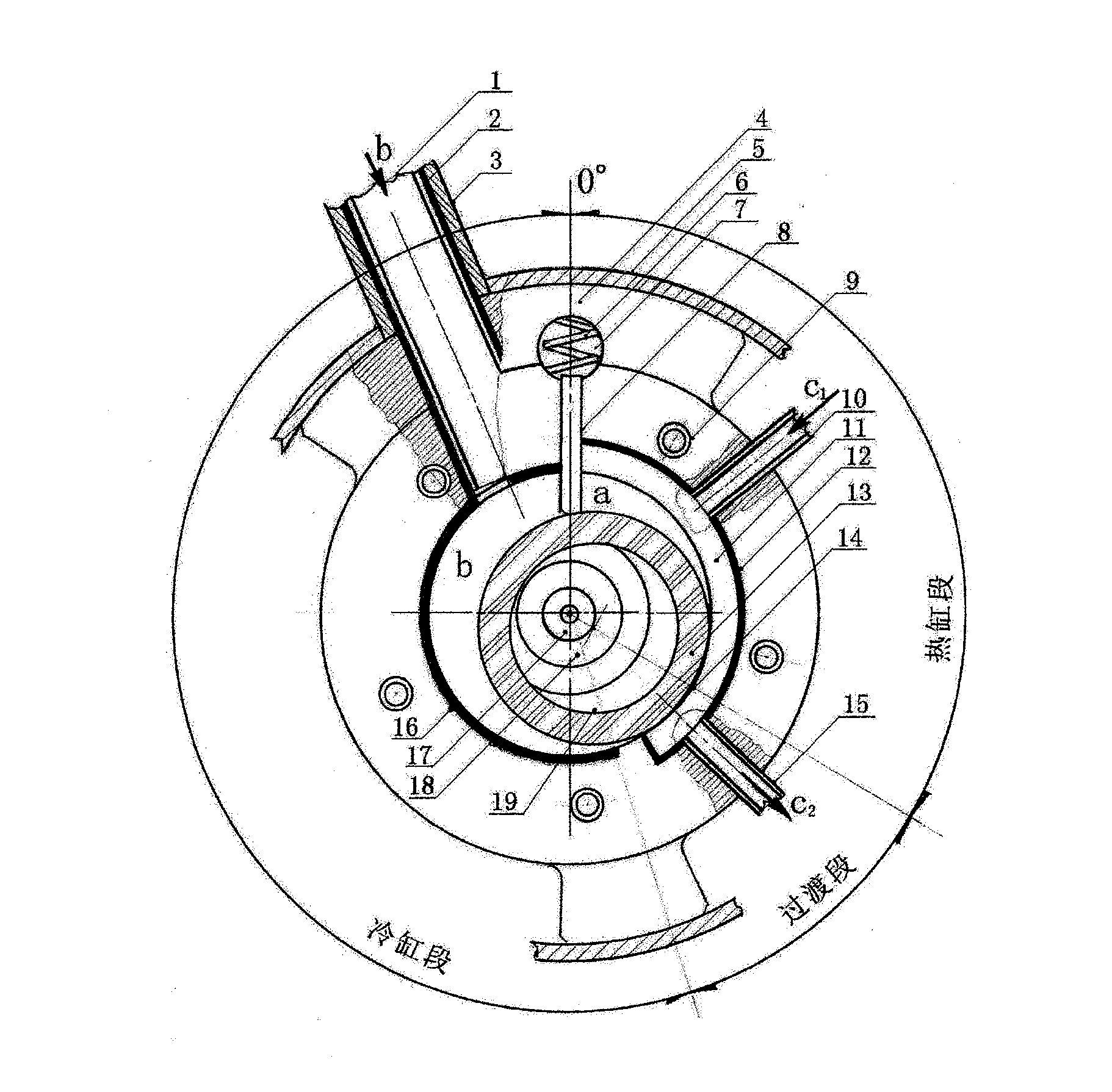

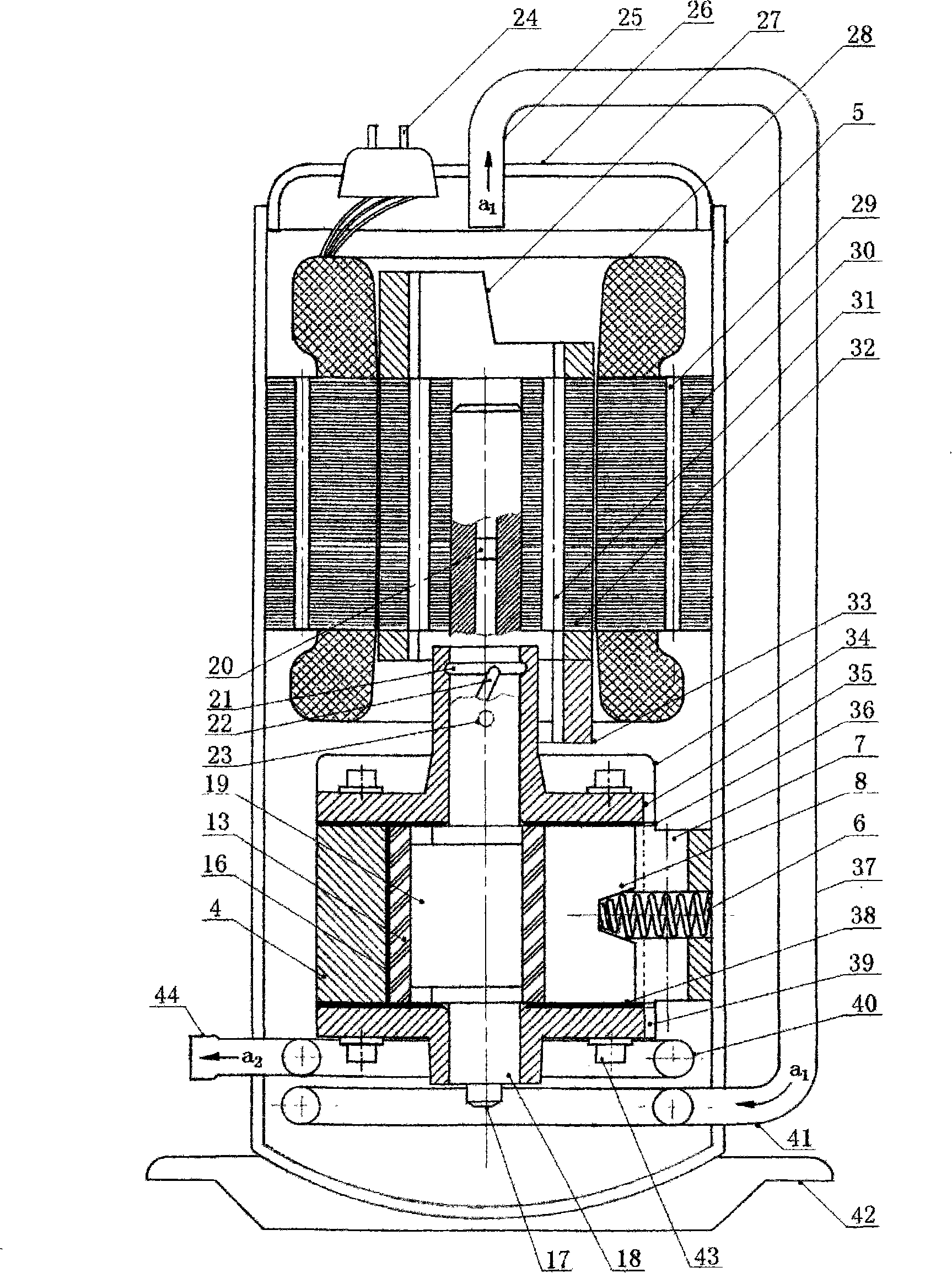

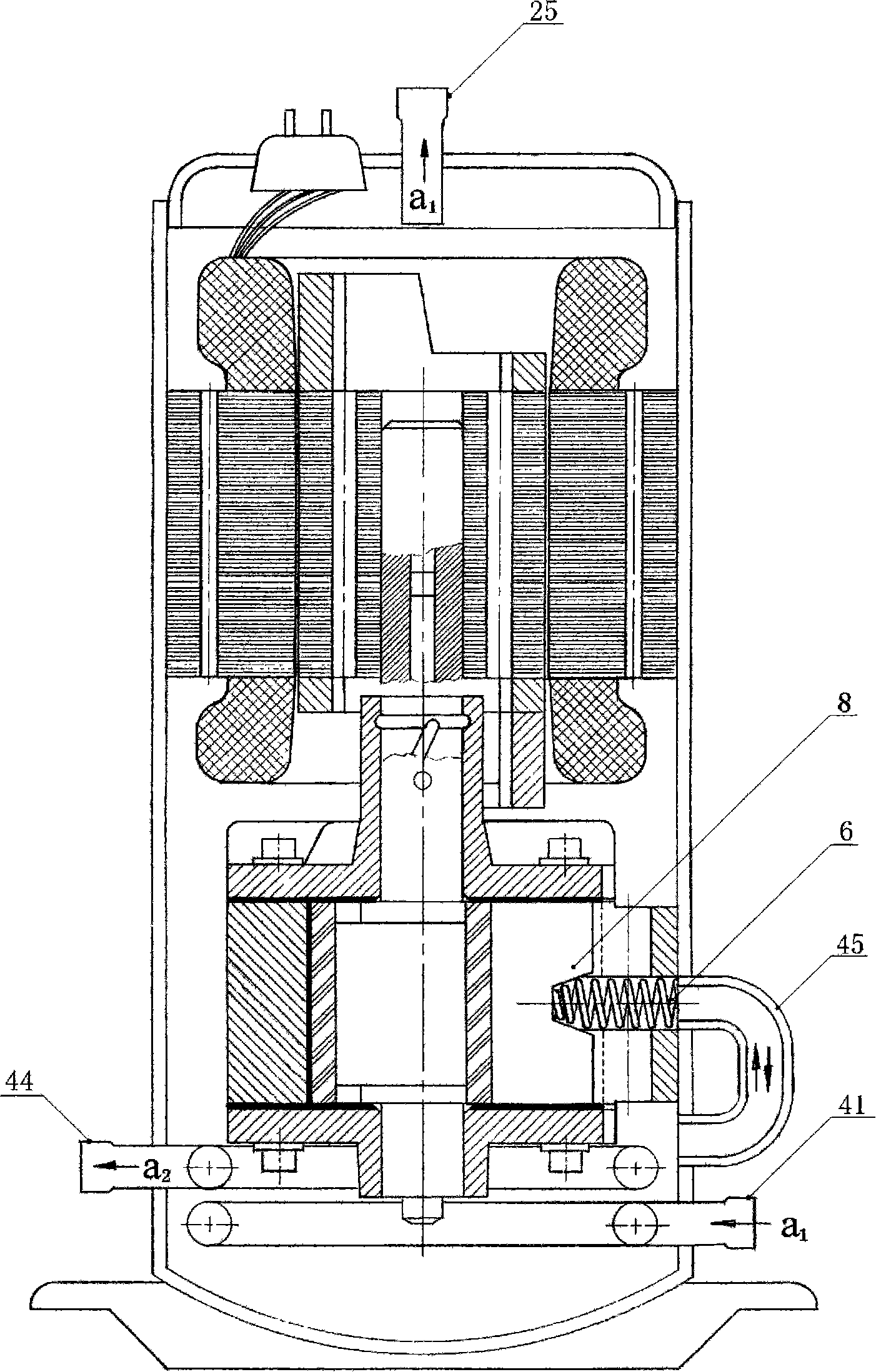

Cooling cylinder compression cycle of rotor-type compressor

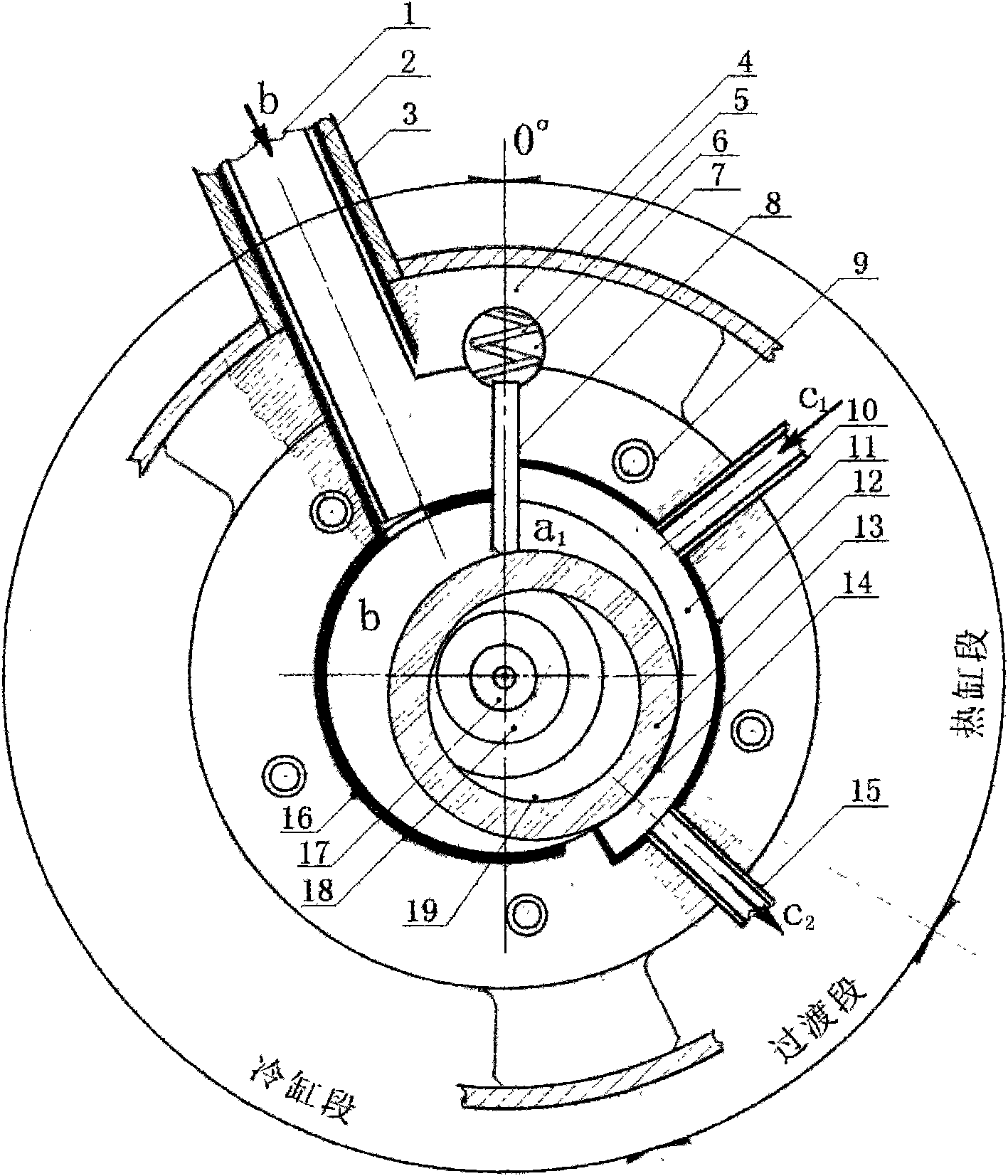

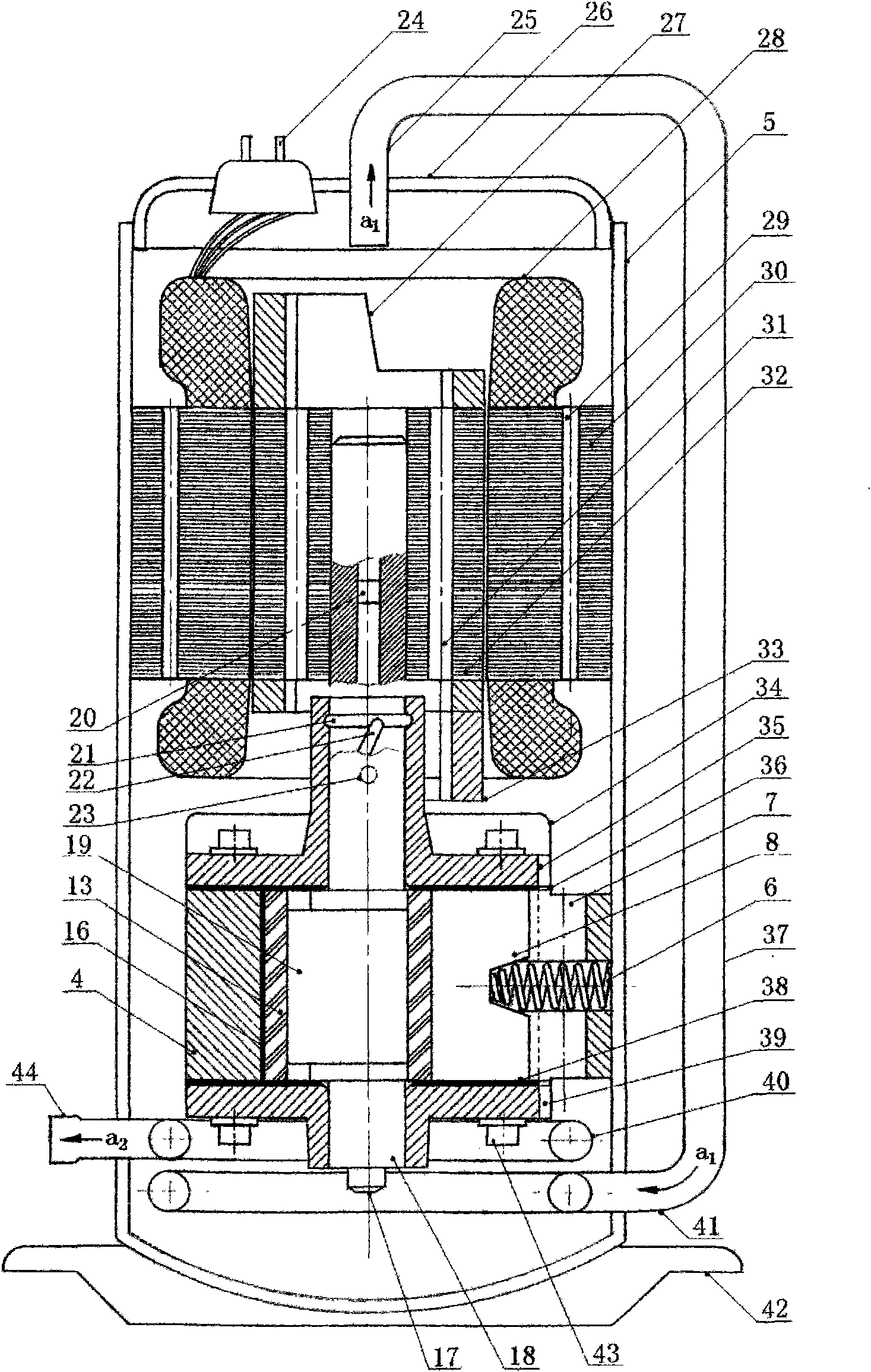

InactiveCN101576083ALower subcooling temperatureReduce condensation loadRotary piston pumpsRotary piston liquid enginesRefrigeration compressorSuction force

The invention relates to a cycling system for improving the efficiency of a cooling compressor, cooling cylinder compression cycle for short. The cooling cylinder compression cycle of a rotor-type compressor is mainly realized in four aspects: a. cooling cylinder compression, i.e. performing low-temperature cooling to a compression strong-heat-release cylinder wall surface (defined as a heat cylinder and others are cooling cylinders), coating heat insulating ceramic on the surfaces of a tongue piece and a rolling rotor, pushing compression heat release to a cooled heat cylinder, and increasing the area of the heat cylinder or reduce the rotational speed so as to fully discharge the compression heat release and prevent the discharged gas from overheating and then to reduce the compression net work and the condensation load; b. cooling cylinder gas suction, i.e. performing the isolation of gas phase from heat insulation to high-pressure gas discharge, the cooling and heat cylinders, upper and lower covers and a gas suction pipe, and ensuring the low-temperature characteristic of a gas suction chamber by means of continuous gas suction and heat cylinder cooling so as to obtain greater cold energy; c. oil way improvement, i.e. increasing the gas-suction force; and d. recovery gas discharge overheating and motor heat releasing, for purposes of heating and compensating absorptive lubricant, wherein an absorbent has low partial pressure and strong absorption capability on the surfaces of the cooling cylinders so that the cold energy is further increased and the compression work is further reduced.

Owner:童夏民

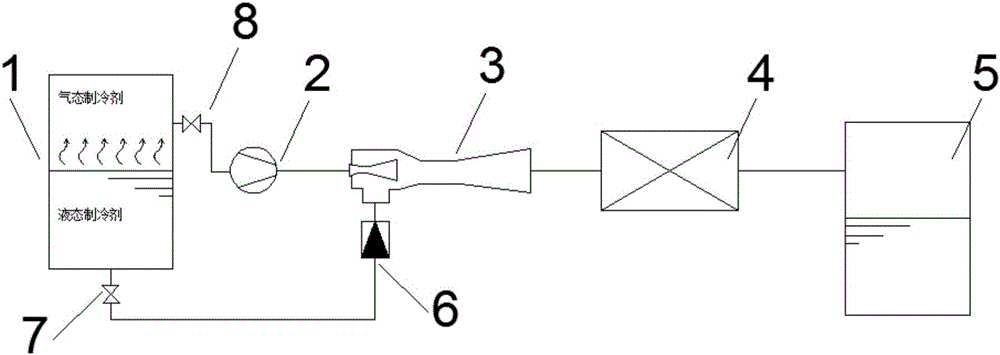

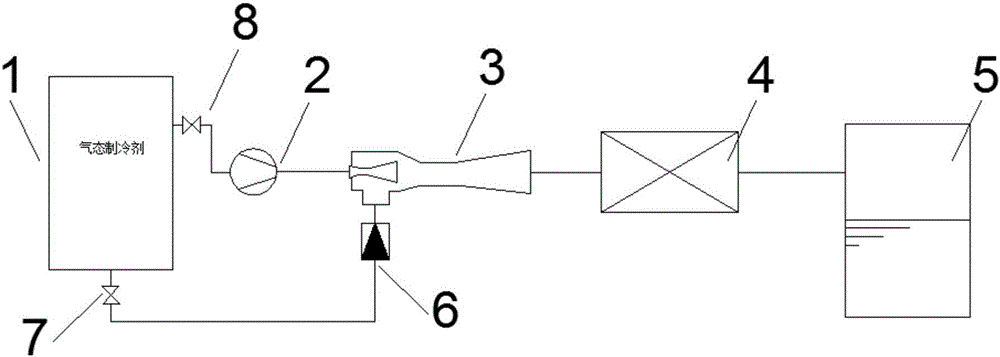

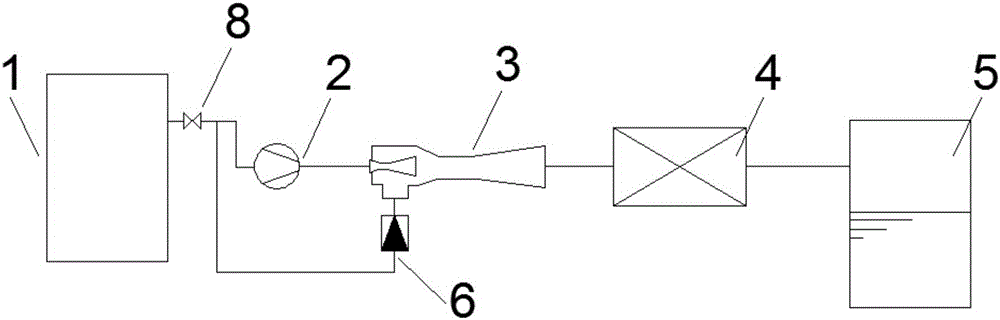

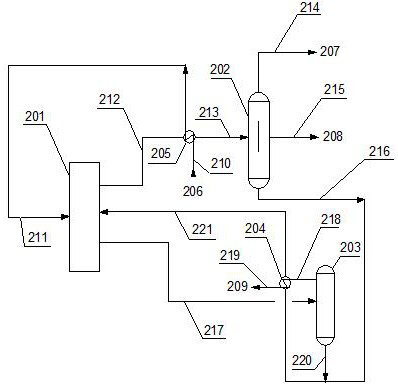

Compression condensation system with ejector

InactiveCN105910318AReduce condensation loadShort runtimeMechanical apparatusCompression machines with non-reversible cycleInjectorRefrigerant

The invention provides a compression condensation system with an ejector. The compression condensation system comprises a recycled container, a refrigeration compressor, the ejector, a condenser and a recycling container. When the compression condensation system is used for a refrigerant recycling system, compressor exhaust drives an ejected refrigerant to enter the condenser together through the ejector, not all liquid refrigerants need to be completely evaporated into gas refrigerants which enter the compressor to be compressed, and temperature rise and pressure rise are avoided, so that condensation loads are few; the gas refrigerants and the liquid refrigerants are recycled at the same time, the running time is short, and the service life of the compressor is prolonged. The invention further provides a refrigeration system with an ejector. The refrigeration system comprises a gas-liquid separator, a refrigeration compressor, the ejector, a condenser, a throttle element and an evaporator. When the refrigeration system with the ejector is used for a refrigeration system, compressor exhaust ejects liquid refrigerants of the gas-liquid separator through the ejector, the air suction and exhaust quantity of the compressor can be reduced at the request that cooling loads are constant, and thus power consumption of the compressor is reduced; and the refrigerants can enter the condenser without completely passing the compressor, so that condensation loads are reduced.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

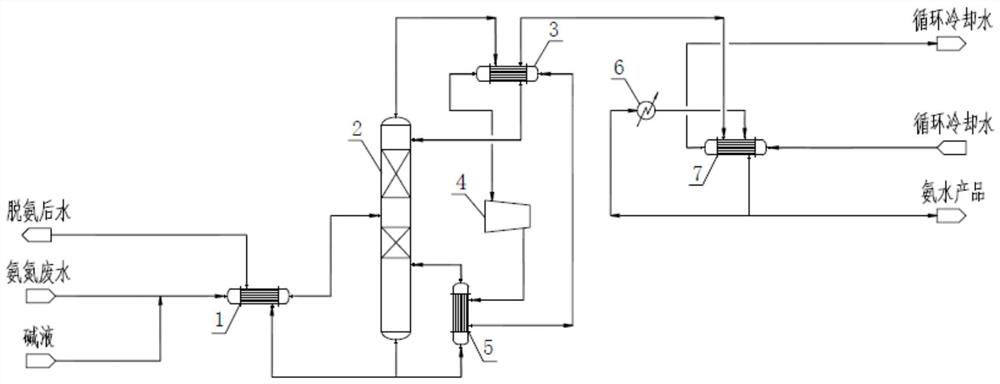

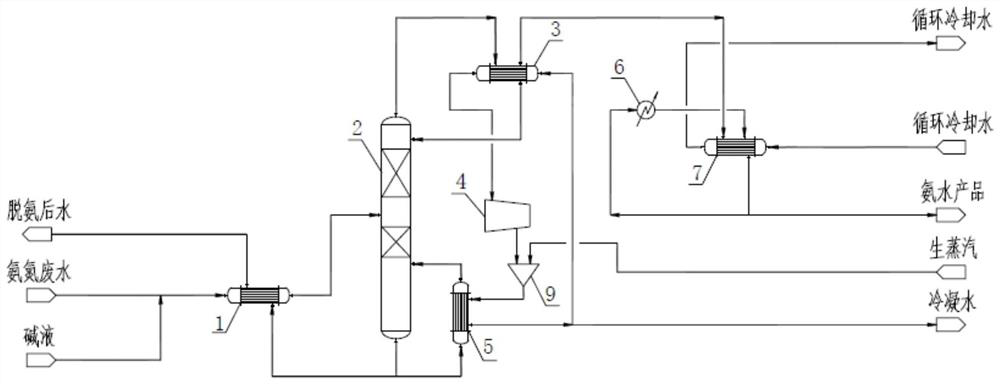

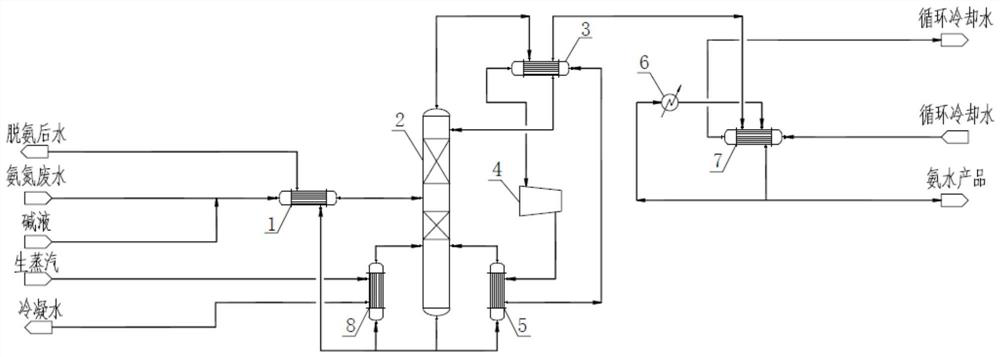

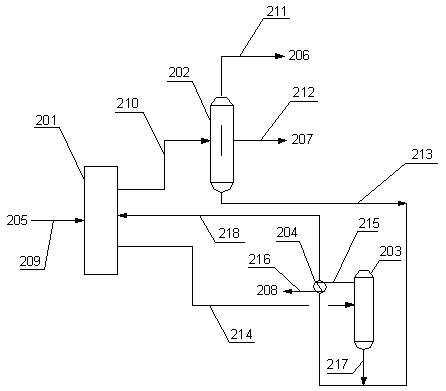

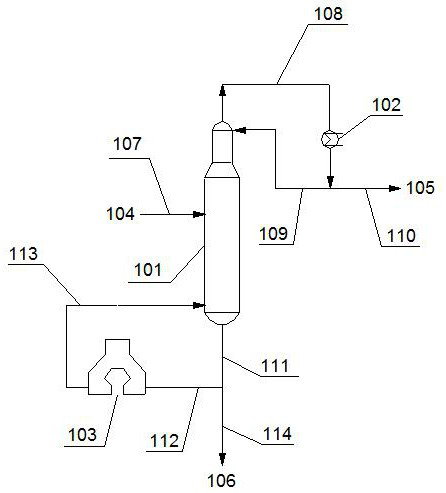

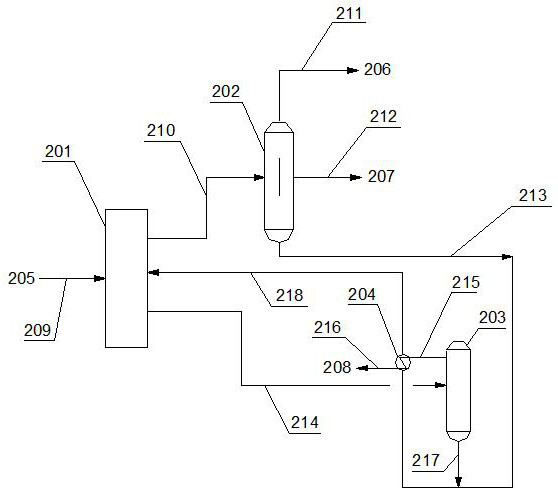

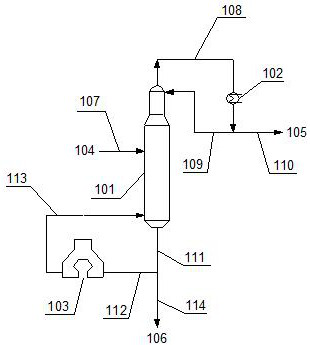

Method and device for treating ammonia-nitrogen wastewater and recovering ammonia

PendingCN111825145AAvoid safety hazardsImprove securityHeat recovery systemsMultiple-effect/fractional condensationAmmoniacal nitrogenIndustrial waste water

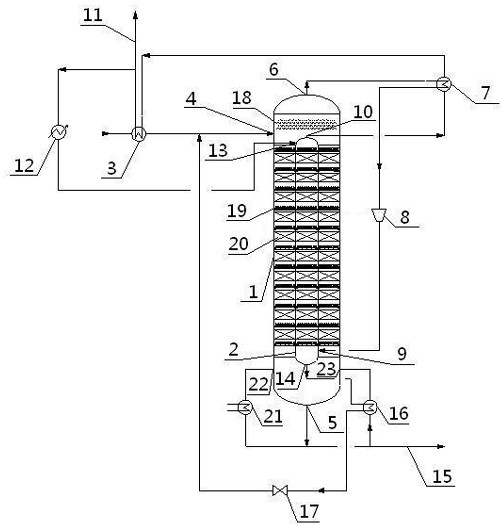

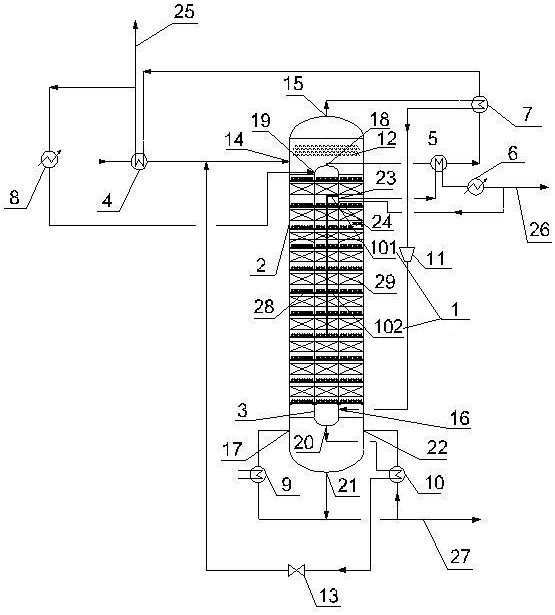

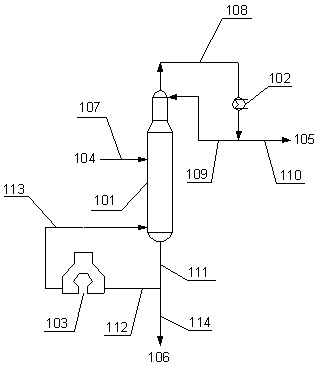

The invention relates to a method and a device for treating ammonia-nitrogen wastewater and recovering ammonia, which belong to the technical field of industrial wastewater treatment and comprise a deamination tower, a heat pump reboiler, a heat pump condenser and a heat pump compressor. An ammonia-nitrogen wastewater feeding hole is formed between a rectifying section and a stripping section of the deamination tower, the rectifying section is provided with an ammonia-containing steam discharging hole and a dilute ammonia water backflow hole, and the stripping section is provided with a deaminated water discharging hole and a stripping steam feeding hole; a heat pump reboiler is circularly communicated between the deaminized water discharging hole and the stripping steam feeding hole; a heat pump condenser is circularly communicated between the ammonia-containing steam discharging hole and the dilute ammonia water backflow hole; and the heat pump condenser and the heat pump reboiler are circularly communicated through a heat pump compressor to form a heat pump cycle. Heat pump working medium steam is used for supplying heat to the heat pump reboiler to replace raw steam, so that energy is saved, and consumption is reduced; non-toxic and harmless heat pump working medium steam is pressurized by the heat pump compressor, so that the problem of potential safety hazards caused by direct pressurization of ammonia-containing steam in the prior art is solved.

Owner:吴嘉

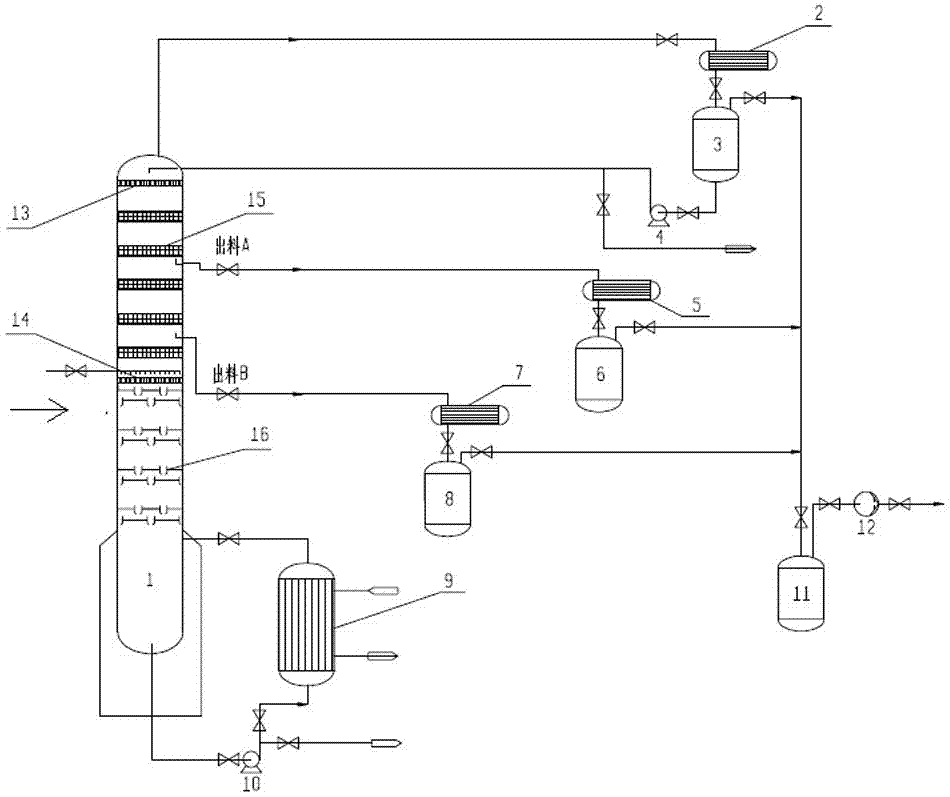

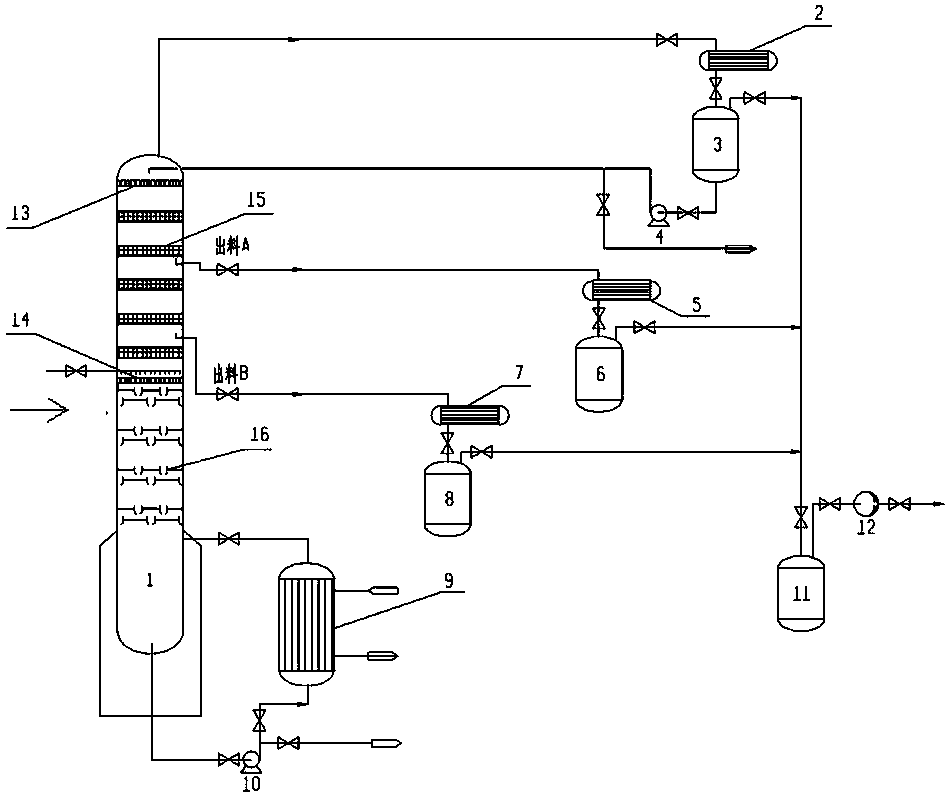

A continuous rectification separation method and equipment for a propylene carbonate crude product

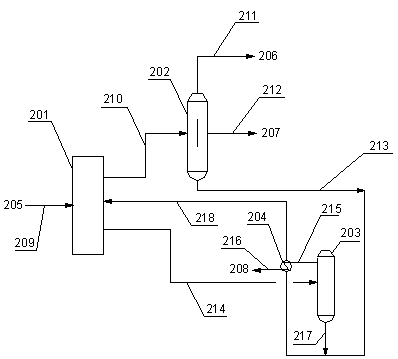

ActiveCN106916135AReasonable distributionReduce distributionOrganic chemistryFractional distillationRefluxFiltration

The invention relates to a continuous rectification separation method and equipment for a propylene carbonate crude product. According to a technical scheme, the propylene carbonate crude product is fed into the middle part of a propylene carbonate rectifying column; the inner cavity of the propylene carbonate rectifying column is provided with a reflux distributor, a plurality of rhombic reaction promoting units, a feed distributor and a plurality of liquid stripping filtration disks from top to bottom; the outside of the propylene carbonate rectifying column is connected to a rectifying column overhead condenser, an A discharging line condenser, a B discharging line condenser and a rectifying column bottom reboiler respectively; the crude product is fed from the middle part of the rectifying column and subjected to sufficient gas-liquid material exchange under negative pressure and heating conditions in the column, thus achieving separation of high-purity propylene carbonate from other impurities; and the high-purity propylene carbonate product is distilled out from a product side line. The method and the equipment are advantageous in that the feeding point is at the middle of the column, amounts of rising gas and descending liquid in rectification and stripping sections are distributed more reasonably, the separating efficiency is increased, operation is simple and stable, product purity is high, and battery-grade purity requirements on the propylene carbonate are met.

Owner:DONGGUAN UPC IND & TRADE +1

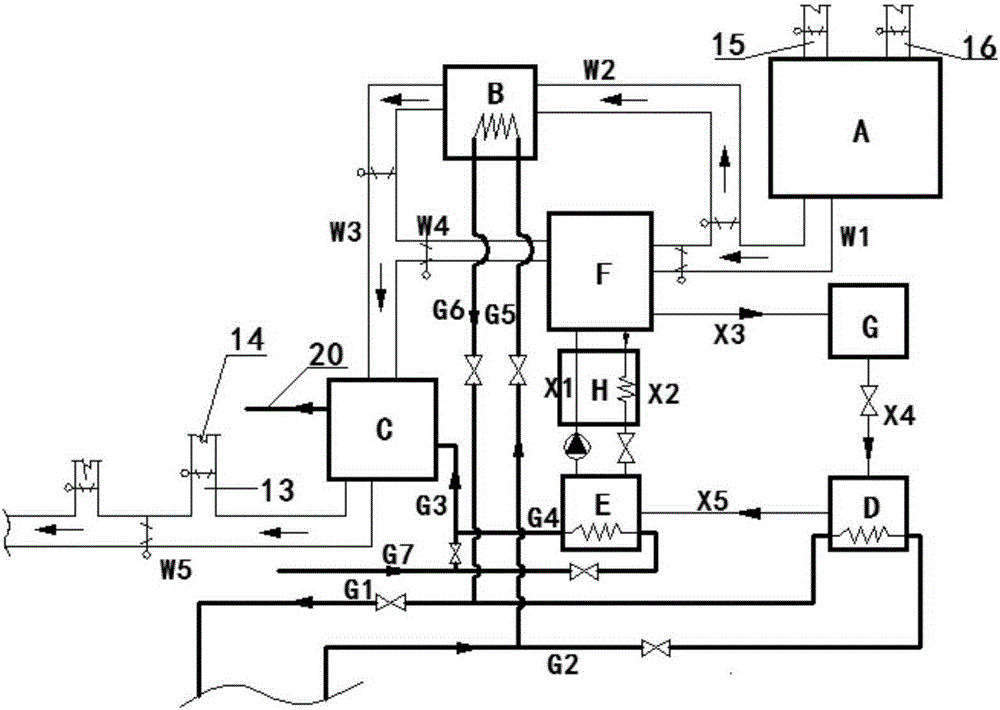

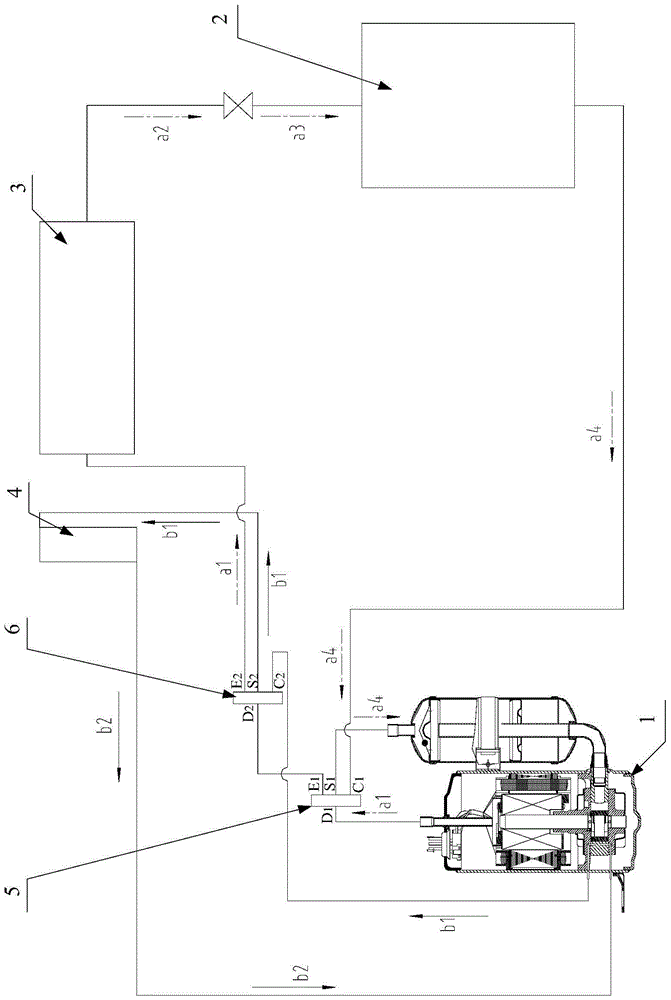

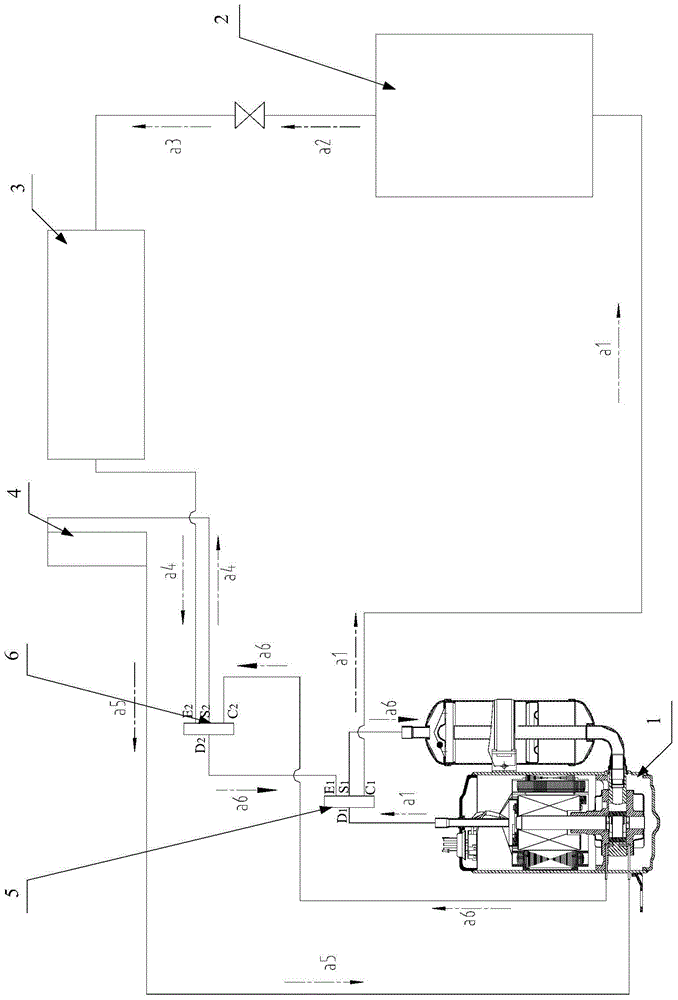

Air conditioning system

ActiveCN104344595AImprove cooling effectImprove heating effectMechanical apparatusFluid circulation arrangementAir conditioningRefrigeration

The invention discloses an air conditioning system. The air conditioning system comprises a compressor (1) and an evaporator (2) and further comprises a refrigerating condenser (3) for indoor refrigeration and a pump body condenser (4) which is used for cooling a pump body of the compressor (1); the compressor (1), the refrigerating condenser (3) and the evaporator (2) form a main circulation loop for indoor cooling; one opening of the refrigerating condenser (3) is communicated with the evaporator (2); the outlet of the pump body condenser (4) is communicated with a pump body cooling inlet of the compressor (1) and the inlet of the pump body condenser (4) is communicated with a pump body cooling outlet of the compressor (1) to form a pump body cooling circulation loop for cooling the pump body; the system further comprises a switching module used for controlling simultaneous connections and disconnections between the other opening of the refrigerating condenser (3) and the inlet of the pump body condenser (4) and between the pump body cooling outlet and the inlet of the compressor (1). Through adoption of the air conditioning system disclosed by the invention, the refrigerating and heating performances are improved.

Owner:GREE ELECTRIC APPLIANCES INC

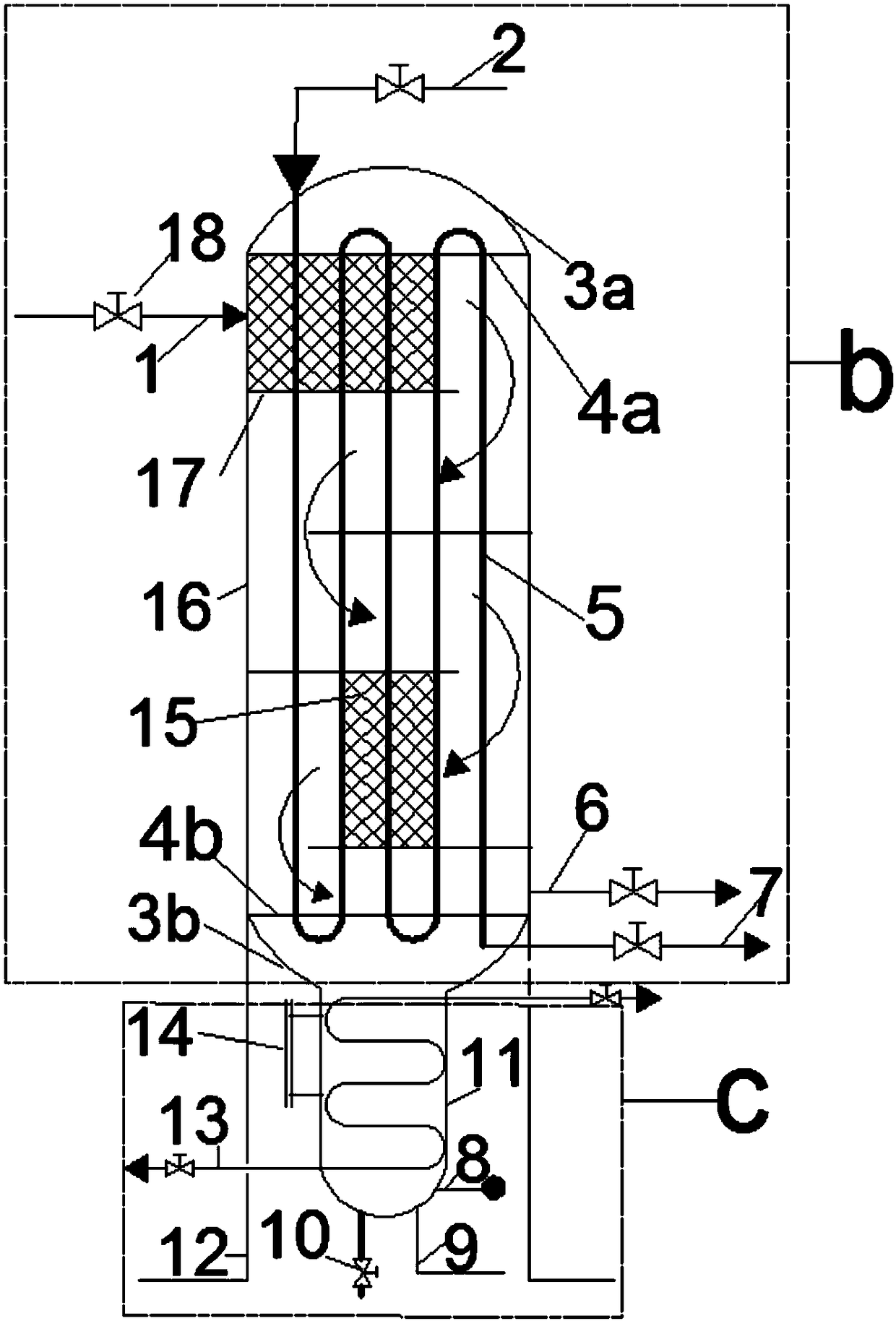

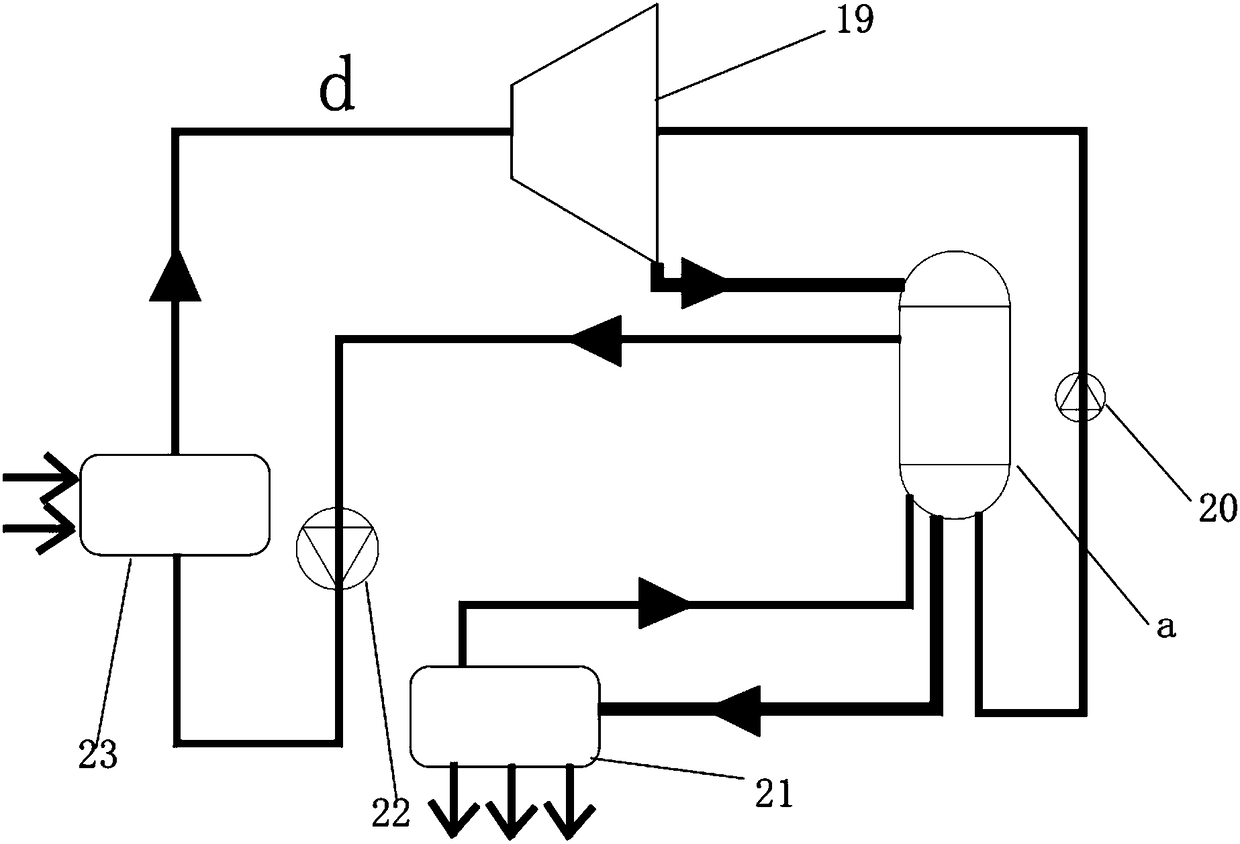

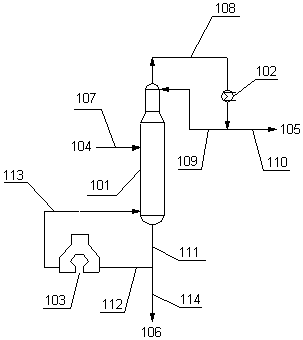

Circulating working medium heat exchanger with oil separation function and application thereof

InactiveCN108468576AImprove heat recovery efficiencySave crafting materialsSteam engine plantsOrganic Rankine cycleGas phase

The invention discloses a circulating working medium heat exchanger with an oil separation function and application thereof. The circulating working medium heat exchanger with the oil separation function comprises an oil separation heat exchange device (b) and a heat exchange oil storage device (c) placed below the oil separation heat exchange device (b), and the oil separation heat exchange device and the heat exchange oil storage device communicate with each other; a screen filter element assembly (15) is arranged inside the oil separation heat exchange device (b) to integrate the oil separation and the heat exchanger functions together, and materials of equipment and the occupied space are saved; and liquid phase working medium is used for recycling waste heat from gas phase working medium, lubricating oil is separated from the gas phase working medium at the same time, the separated lubricating oil is stored in a cylinder body of the heat exchange oil storage device, and a heat exchange tube in the cylinder body is used for heating and cooling the lubricating oil. The heat exchanger is applied to an organic Rankine circulatory system (d) to reduce the temperature of the gas phase working medium at an outlet of a volumetric-type expansion machine (19), and the oil separation effect is improved while the thermal efficiency of the system is improved.

Owner:SOUTHEAST UNIV

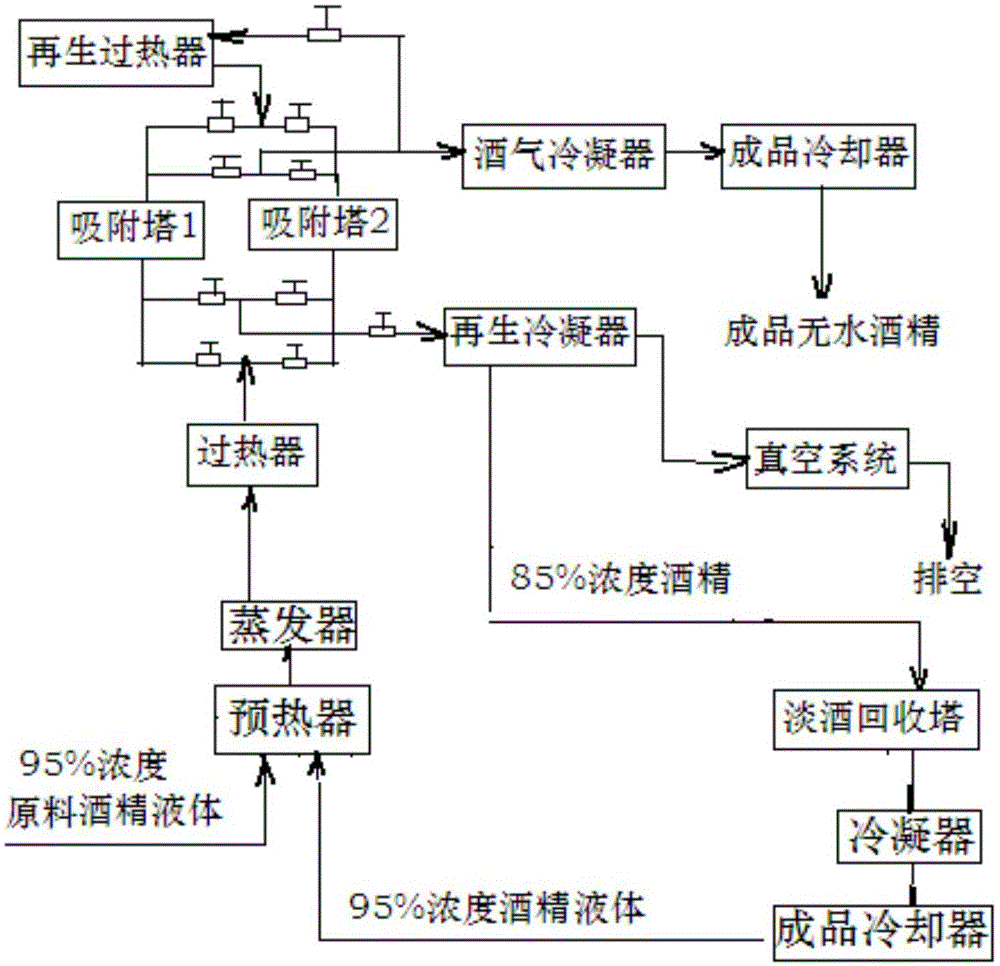

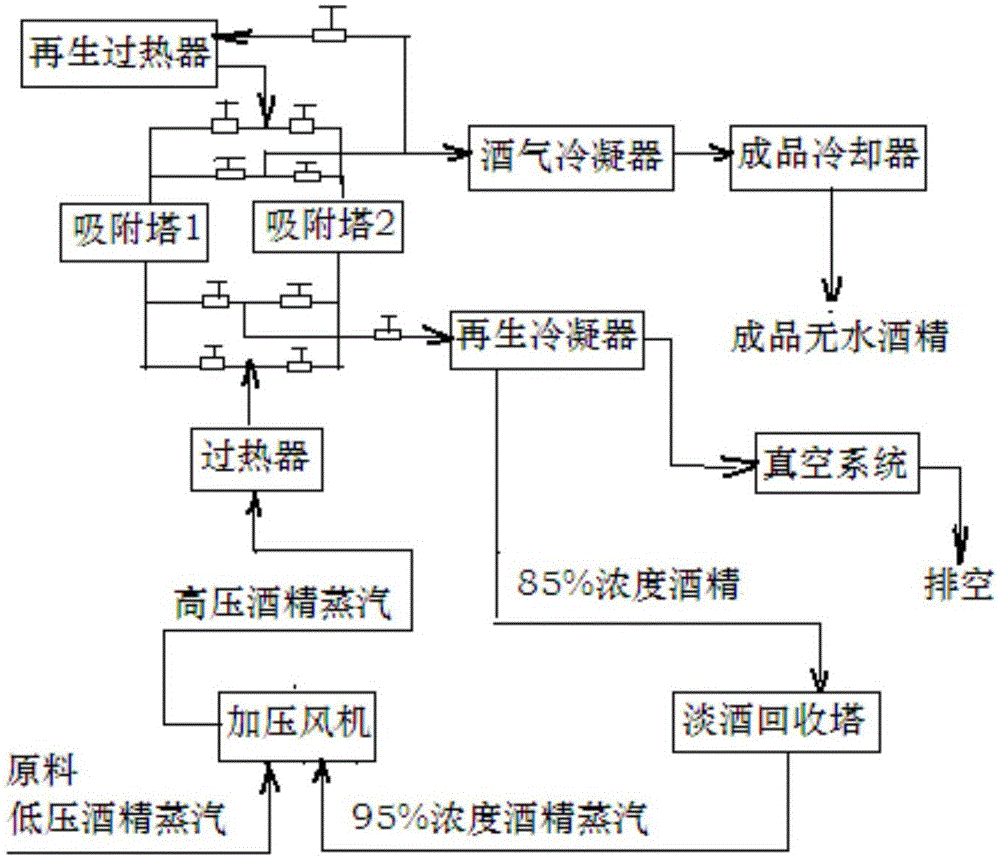

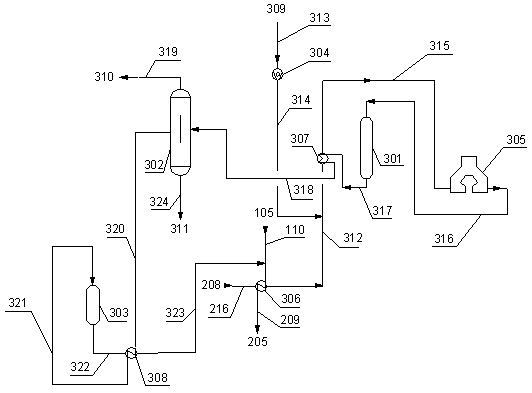

Vapor phase feeding process for production of anhydrous alcohol with concentration of 99.9%

InactiveCN105001054AIncrease adsorption pressureImprove adsorption capacityHydroxy compound separation/purificationAlcoholSorbent

The invention discloses a vapor phase feeding process for production of anhydrous alcohol with its concentration of 99.9%. Alcohol steam with its concentration of 95% from a thin alcohol recovery distillation column in an alcohol plant and a raw material low pressure alcohol steam are pressurized by a pressurization fan to generate high-pressure alcohol steam; the high-pressure alcohol steam is adsorbed by an adsorption column, and vaporous water molecules in the alcohol steam are adsorbed by an adsorbent of the adsorption column; and the alcohol steam after the adsorption is condensed by an alcohol condenser and cooled by a product cooler so as to generate the finished product anhydrous alcohol. Thin alcohol with its concentration of 85% at the bottom of the adsorption column enters a thin alcohol recovery tower so as to obtain alcohol steam with its concentration of 95%; the alcohol steam directly enters the pressurization fan to be pressurized; and after pressurization, the alcohol steam is heated by a steam superheater to 130-145 DEG C and then directly enters the adsorption column for circulating production. Energy consumption of the process is obviously lower than energy consumption of a liquid phase alcohol vaporization and adsorption tower dehydration process.

Owner:肥城金威机械有限公司

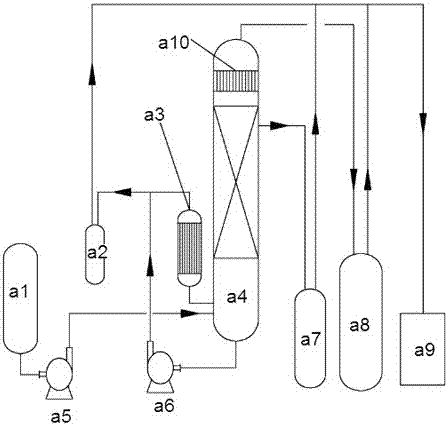

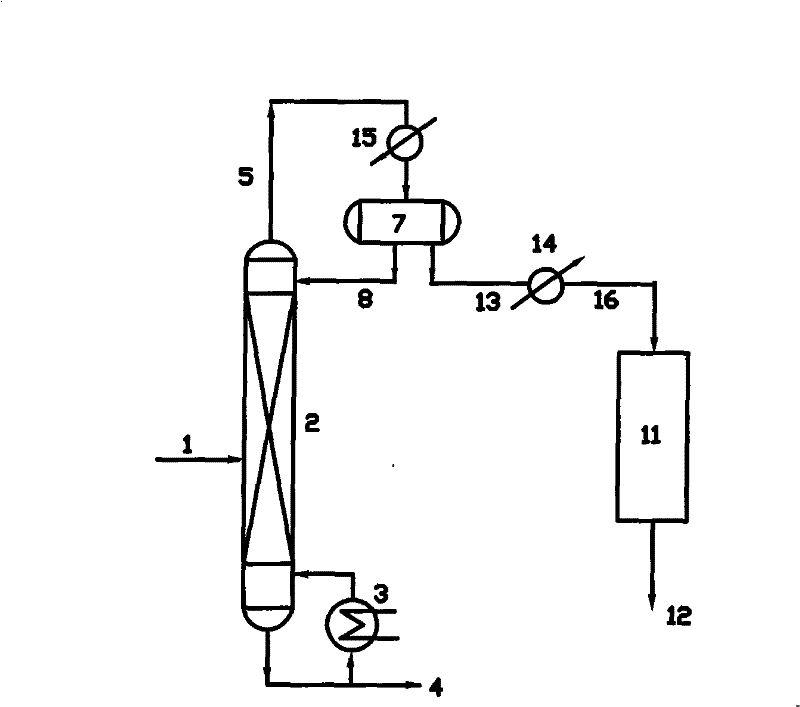

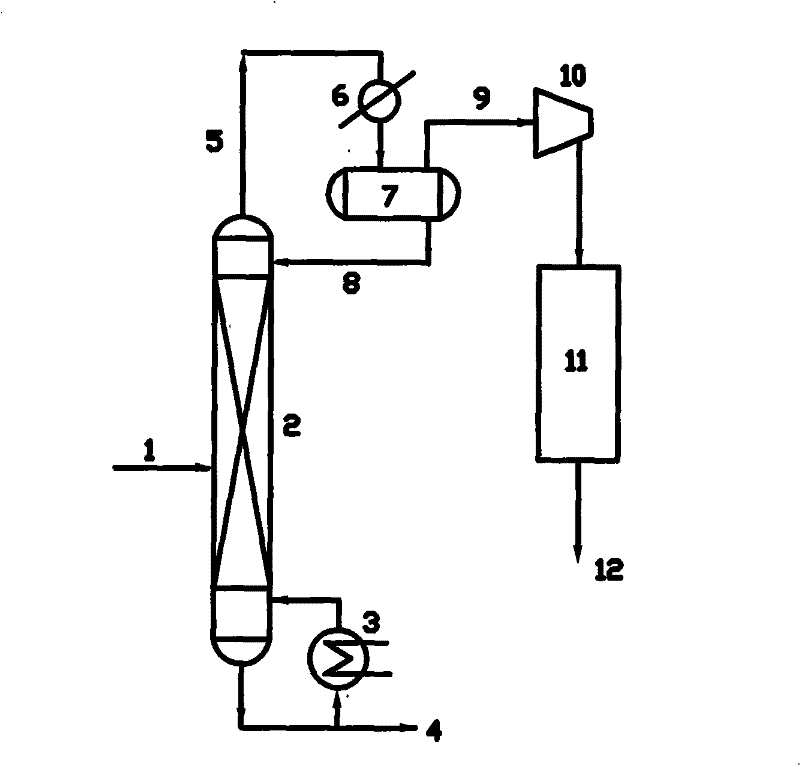

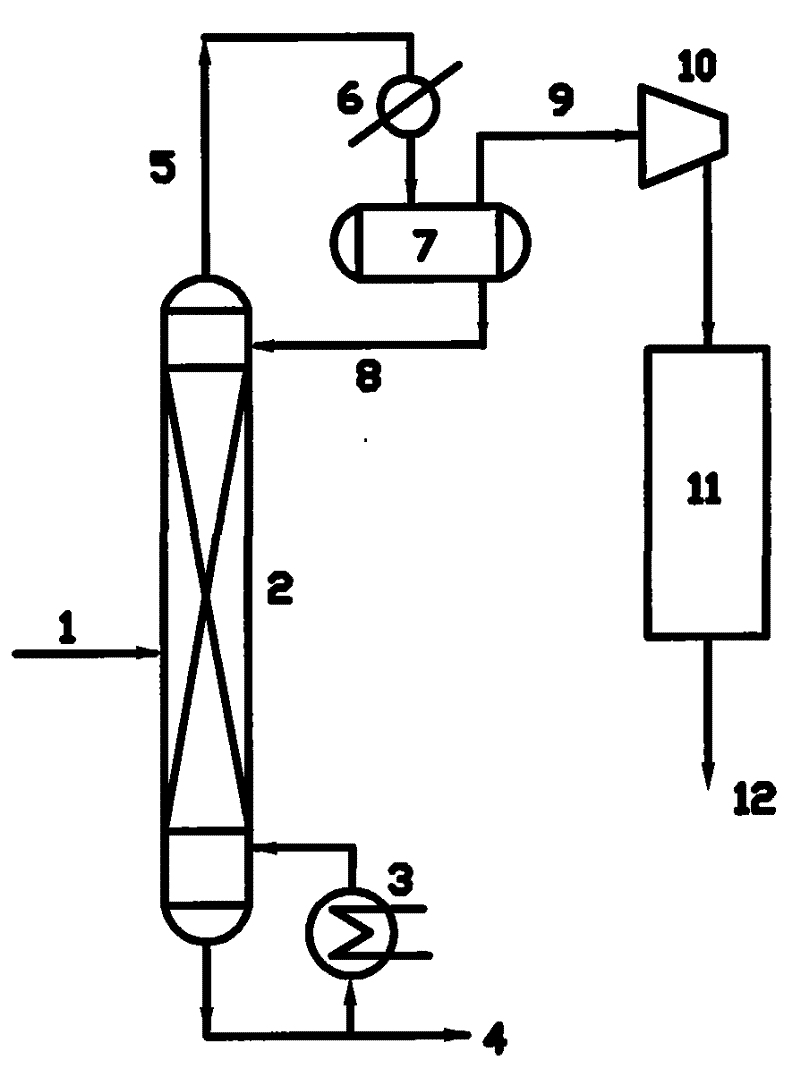

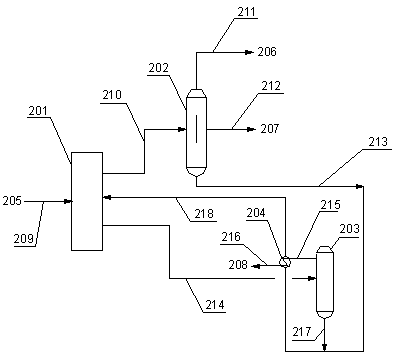

Ethanol distillation dehydration energy saving technique and device

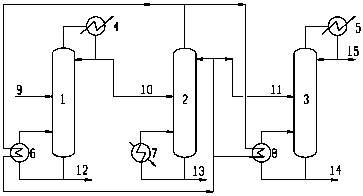

ActiveCN101525272BReduce condensation loadReduce manufacturing costOrganic compound preparationChemical industryThermal energyHigh concentration

The invention relates to an ethanol distillation dehydration energy saving technique and a device thereof, the technical proposal of which is that (a) part of gas phase at the tower top of an ethanol rectifying tower is condensed; (b) part of condensed gas phase enters into a compressor to be pressured; (c) the compressed gas phase directly enters into an adsorption unit. Overhead gas phase obtained after ethanol raw material passes through the ethanol rectifying tower enters into a partial condenser, the obtained mixing material enters into a reflux storage tank; wherein, liquid phase material as circulating liquor returns to the ethanol rectifying tower, the gas phase material enters into the compressor, and then enters into the adsorption unit after being pressured, after absorption, the needed high concentration ethanoal product is obtained. The invention can effectively reduce heat exhaustion in the production course of high concentration ethanol and the condensation loading of the tower top of the rectifying tower, reduces the manufacturing cost of the ethanol and has good application prospect.

Owner:TIANJIN UNIV

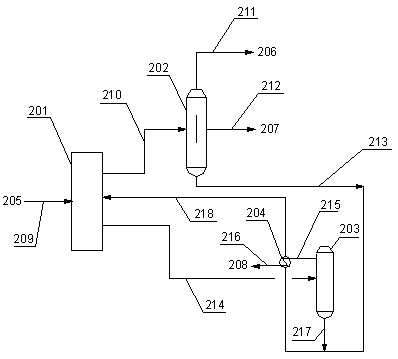

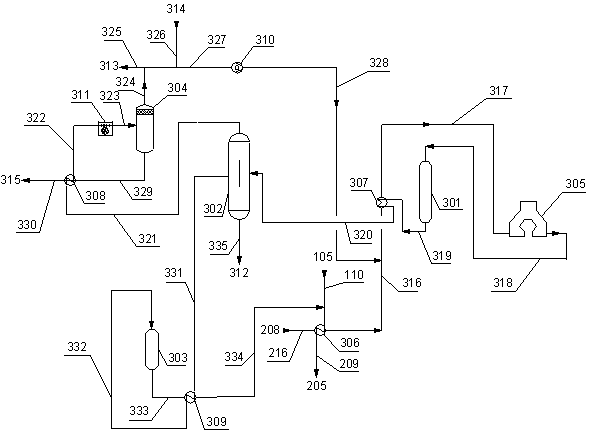

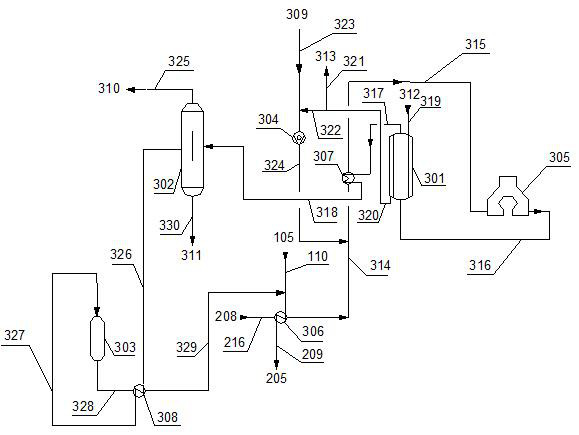

Device and process for producing p-xylene

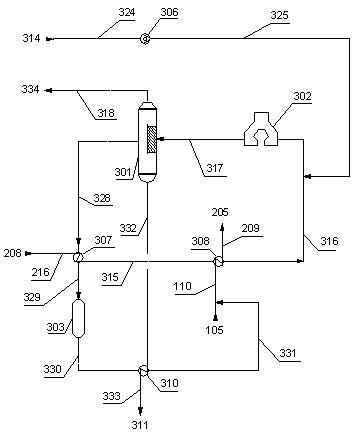

ActiveCN110937969AReduce operating loadSave gas consumptionHydrocarbon by isomerisationChemical industryChemistryReboiler

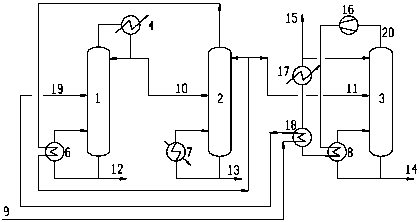

The invention discloses a device and a process for producing p-xylene. The device comprises a xylene fractionation unit, an adsorption separation unit and an isomerization reaction unit, wherein the adsorption separation unit comprises an adsorption separation tower, an extraction liquid fractionating tower, a raffinate tower and a heat exchanger II, and the isomerization reaction unit comprises an isomerization reactor, an isomerization product fractionating tower, a white clay tower, an isomerization reaction heating furnace, a heat exchanger III, a heat exchanger IV, a heat exchanger V anda compressor. The invention also provides a process for producing p-xylene. According to the invention, with the device and the process, the equipment investment and the occupied area are reduced, theoperation load of the xylene tower is reduced, the fuel gas consumption of the xylene reboiler and the isomerization reaction heating furnace is saved, the heat exchange network is optimized, the energy consumption is greatly reduced, and the economic benefit and the social benefit are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and process for producing p-xylene

ActiveCN110937973AReduce backmixingReduce irrational useHydrocarbon by isomerisationChemical industryXylyleneSocial benefits

The invention discloses a device and a process for producing p-xylene. The device comprises a xylene fractionation unit, an adsorption separation unit and an isomerization reaction unit, wherein the adsorption separation unit comprises an adsorption separation tower, an extraction liquid fractionating tower, a raffinate tower and a heat exchanger II, and the isomerization reaction unit comprises an isomerization reactor, an isomerization product fractionating tower, a white clay tower, a gas-liquid separation tank, an isomerization reaction heating furnace, a heat exchanger III, a heat exchanger IV, a heat exchanger V, a heat exchanger VI, a compressor and an air cooler. The invention also provides a process for producing p-xylene. According to the invention, the equipment investment and the occupied area are reduced, the operation load of the xylene tower is reduced, the fuel gas consumption of the xylene reboiler and the isomerization reaction heating furnace is saved, the heat exchange network is optimized, the energy consumption is greatly reduced, and the economic benefit and the social benefit are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

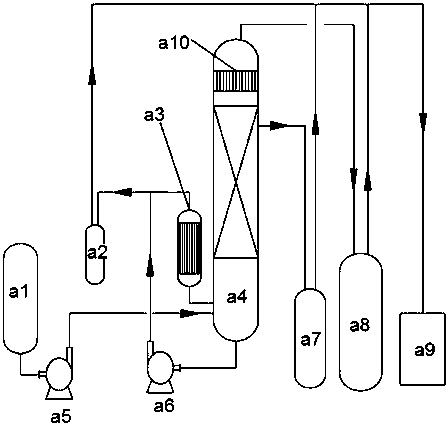

Vacuum wet meal desolventizing system

InactiveCN103468395AReduce protein denaturationReduce residual solvent contentFatty-oils/fats productionEconomic benefitsEngineering

The invention provides a vacuum wet meal desolventizing system. By utilizing a steam jet pressurizer, a drying layer of an evapo-separated machine is designed by utilizing a steam jet pressurizer, and factors such as the material layer height, drying temperature, vacuum degree and drying time in the vacuum wet meal desolventizing and drying process are further optimized, so that the residual content of bean pulp is about 78ppm at the best condition; the steam jet pressurizer performs vacuumization on the drying layer of the evapo-separated machine, a pumped mixed gas is pressurized into direct steam to be pumped into a desolventizing layer for desolventizing the wet meal, thus the residual content of the bean pulp can be effectively reduced, the denaturation of protein in the bean pulp is weakened so that the produced bean pulp is golden yellow, the steam consumption is reduced, condensation load of the whole wet meal desolventizing system is lowered, and the continuity of wet meal desolventizing production and the quality of finished bean pulp are ensured. Thus, with the adoption of the vacuum wet meal desolventizing system, the quality of the finished bean pulp is effectively improved, and the economic benefits of an enterprise are also improved.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Double-purpose air conditioner system combining absorption refrigeration and evaporative cooling and used in winter and summer

InactiveCN105202670ATake advantage ofRealize cascade utilizationEnergy recovery in ventilation and heatingHeat recovery systemsEvaporative coolerAdsorption refrigeration

The invention discloses a double-purpose air conditioner system combining absorption refrigeration and evaporative cooling and used in winter and summer. The system comprises an evaporation cooling air conditioner unit and an adsorption refrigeration system which are connected through a pipeline network. The double-purpose air conditioner system used in winter and summer solves the problems that an existing evaporation cooling air conditioner unit can not be used for heating in winter, and direct-burning type absorption refrigeration wastes a lot of energy.

Owner:XI'AN POLYTECHNIC UNIVERSITY

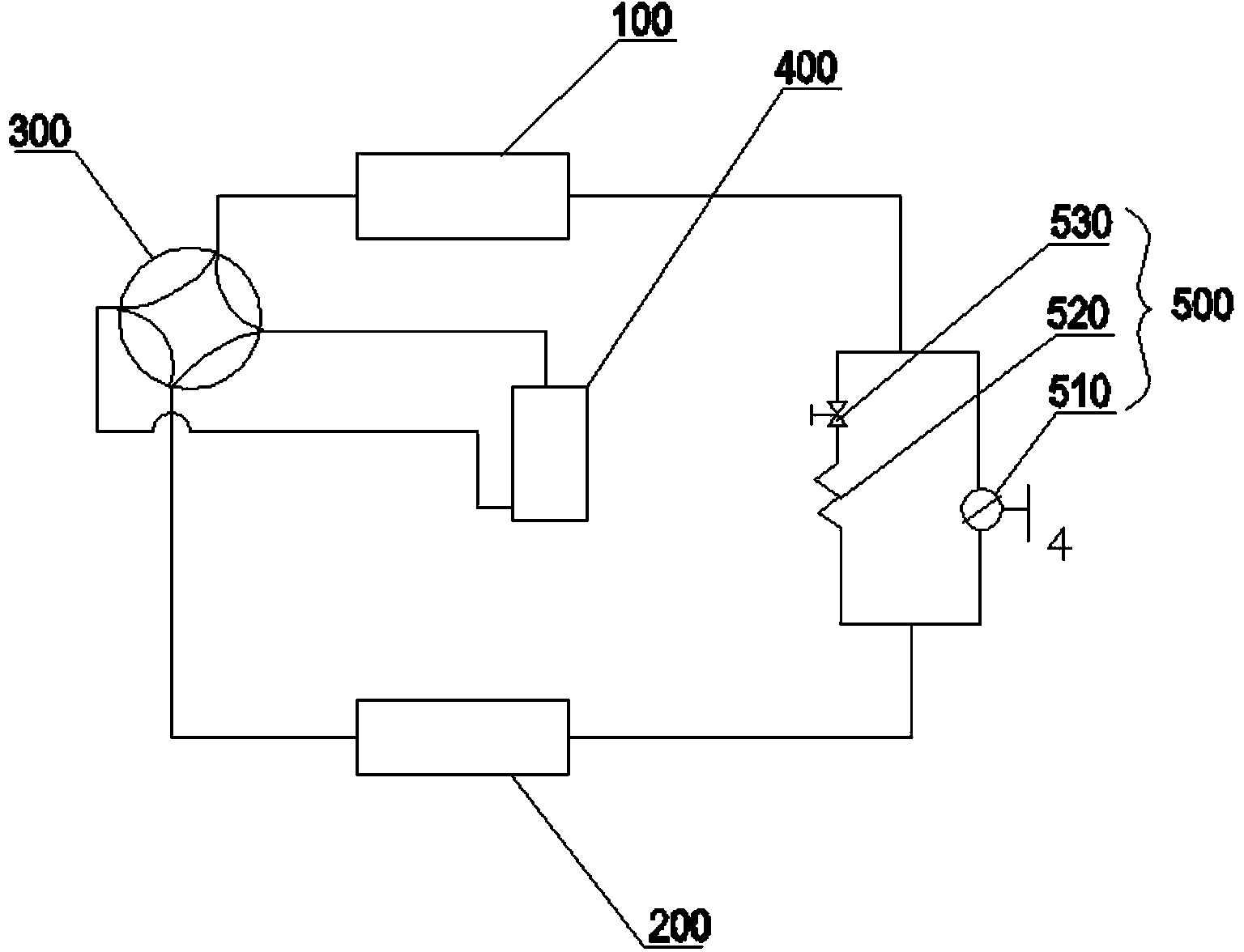

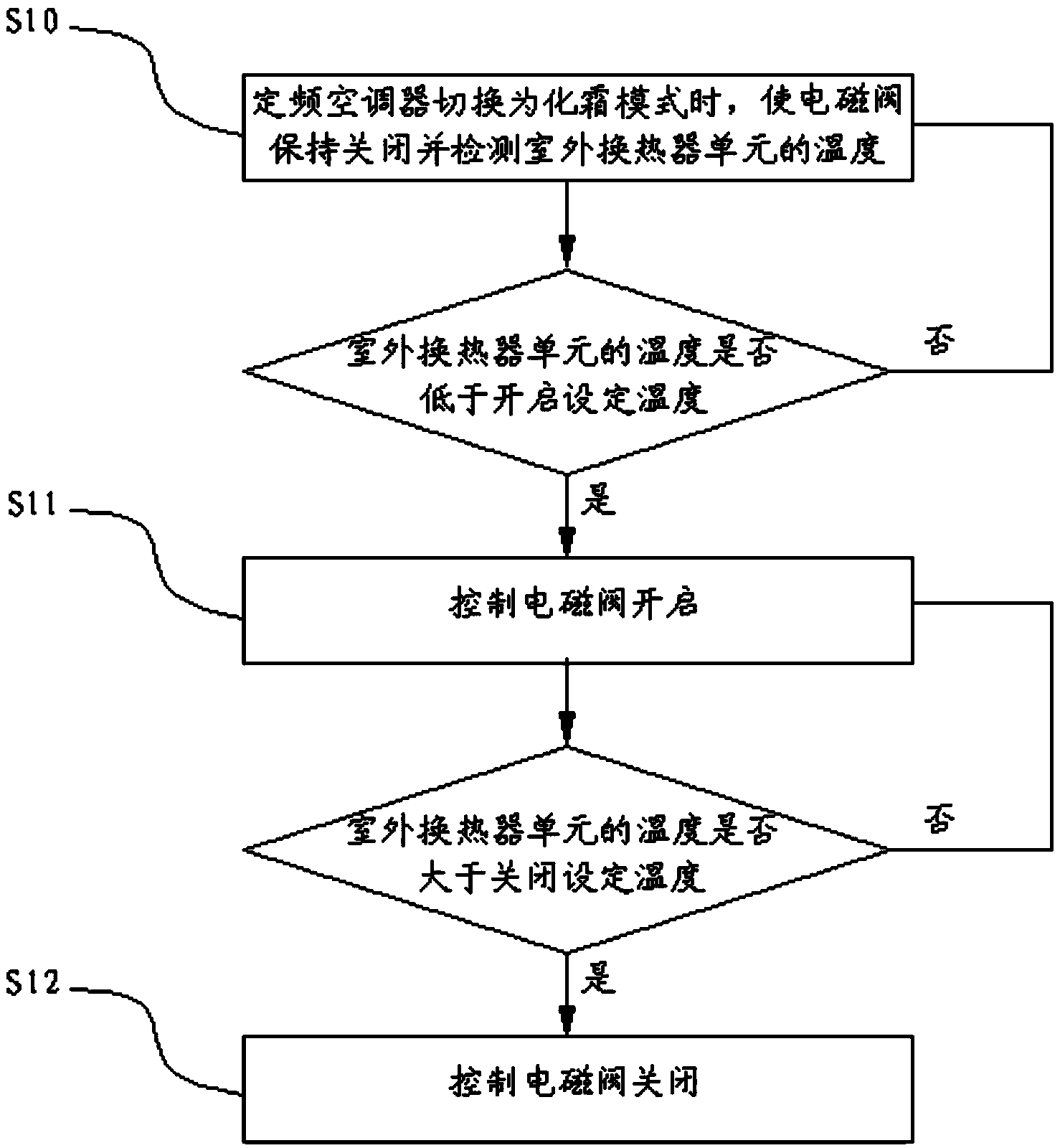

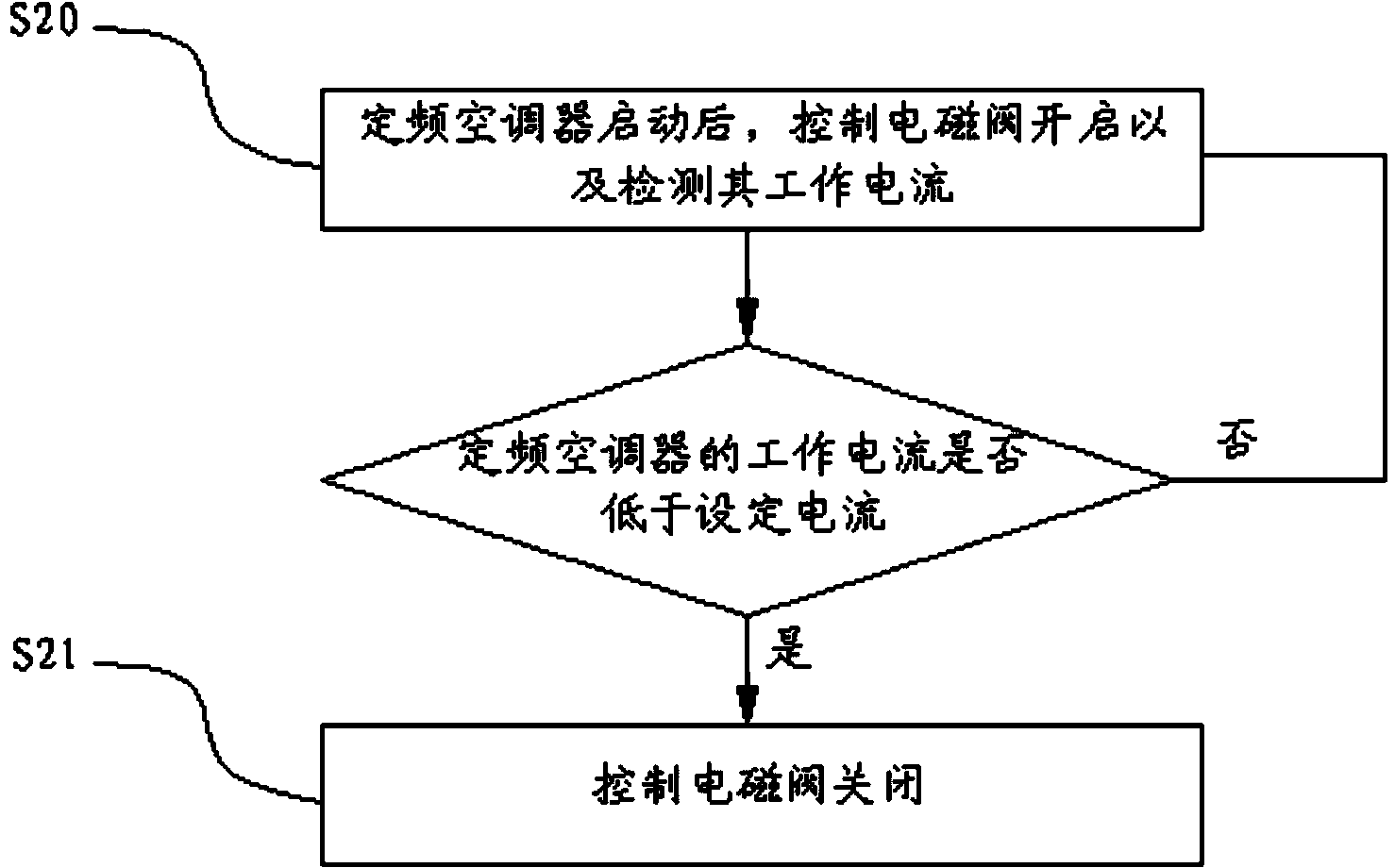

Fixed-frequency air conditioner and control method of fixed-frequency air conditioner

ActiveCN103884127AGuaranteed uptimeImprove comfortMechanical apparatusFluid circulation arrangementFour-way valveEngineering

The invention discloses a fixed-frequency air conditioner which comprises an outdoor heat exchanger unit, an indoor heat exchanger unit, a four-way valve, a compressor unit and a throttling unit. The throttling unit comprises a first throttling element, a second throttling element and an electromagnetic valve, the first throttling element is connected between the outdoor heat exchanger unit and the indoor heat exchanger unit, the second throttling element and the electromagnetic valve are connected in series to be connected between the outdoor heat exchanger unit and the indoor heat exchanger unit, and the electromagnetic valve is switched on or off to control whether the second throttling element participates in throttling or not. According to the fixed-frequency air conditioner, due to the fact that the electromagnetic valve is switched on or off to control whether the second throttling element carries out throttling on refrigerants or not, the electromagnetic valve is switched on to control the second throttling element to carry out throttling on the refrigerants when defrosting occurs or the power supply voltage is low, in this way, the defrosting time is shortened when defrosting occurs, or condensation loads are released when the power supply voltage is low, and therefore the comfort of the fixed-frequency air conditioner is improved.

Owner:MIDEA GRP CO LTD

Production device and process of aromatic hydrocarbon product

ActiveCN112441870AReduce backmixingReduce irrational useChemical industryDistillation purification/separationXylyleneSocial benefits

The invention discloses a production device and process of an aromatic hydrocarbon product. The device comprises a xylene fractionation unit, an adsorption separation unit and an isomerization reaction unit; the adsorption separation unit comprises an adsorption separation tower, an extract fractionating tower, a raffinate tower and a heat exchanger II; and the isomerization reaction unit comprises an isomerization membrane reactor, an isomerization product fractionating tower, a carclazyte tower, an isomerization reaction heating furnace, a heat exchanger III, a heat exchanger IV, a heat exchanger V and a compressor. The invention also provides a production process of the aromatic hydrocarbon product. According to the invention, the equipment investment is reduced, the operation load of the xylene tower is reduced, the fuel gas consumption of the xylene reboiler is saved, the phenomenon of unreasonable energy consumption of cooling and then heating materials is avoided, meanwhile, theheat exchange network is optimized, the fuel gas consumption of the isomerization reaction heating furnace is reduced, the energy consumption is greatly reduced, and the economic benefit and the social benefit are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Air Conditioning System

ActiveCN104344595BImprove cooling effectImprove heating effectMechanical apparatusFluid circulation arrangementEngineeringAir conditioning

The invention discloses an air-conditioning system, comprising a compressor (1) and an evaporator (2), and further comprising: a refrigeration condenser (3) used for indoor refrigeration and a pump body used for cooling the pump body of the compressor (1) Condenser (4); compressor (1), refrigerating condenser (3) and evaporator (2) form the main circulation circuit for indoor cooling, an opening of refrigerating condenser (3) and evaporator (2) ) is communicated; the outlet of the pump body condenser (4) is communicated with the pump body cooling inlet of the compressor (1), and the inlet of the pump body condenser (4) is communicated with the pump body cooling outlet of the compressor (1), forming a The pump body cooling circulation circuit for cooling the pump body; also includes the control between another opening of the refrigeration condenser (3) and the inlet of the pump body condenser (4) and between the cooling outlet of the pump body and the inlet of the compressor (1) Switching components that are switched on and off at the same time. The air conditioning system provided by the invention improves the cooling and heating performance.

Owner:GREE ELECTRIC APPLIANCES INC

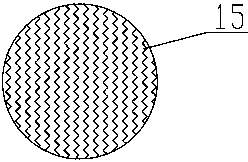

Internal energy integrated rectification device and rectification method using same

PendingCN112742057AReduce exergy lossReduce separation energy consumptionFractional distillationReboilerSuperheater

An internal energy integrated rectification device comprises a rectification tower with an inner layer tower body and an outer layer tower body, the outer layer tower body is a stripping section, the inner layer tower body is a rectification section, a feed inlet I formed in the upper portion of the outer layer tower body is externally connected with a feed preheater, a liquid outlet I is formed in the bottom of the outer layer tower body, and the liquid outlet I is connected with a tower bottom discharge pipe and connected with a feed inlet V after passing through a reboiler; a gas outlet I is formed in the top of the outer layer tower body, is externally connected with a compressor inlet superheater and a compressor in sequence, and is connected with a feeding hole II in the bottom of the inner layer tower body; a gas outlet II is formed in the top of the inner layer tower body, is externally connected with a compressor inlet superheater and a feeding preheater in sequence and then is connected with a tower top discharging pipe and a feeding hole III in the top of the inner layer tower body; a liquid outlet II is formed in the bottom of the inner layer tower body and is connected with a feeding hole I after passing through a reboiler and a throttling valve in sequence; a silk screen condensation plate is arranged below the top gas outlet I in the outer layer tower body; and liquid distribution devices and packing layers which are distributed at intervals are arranged in the outer layer tower body and the inner layer tower body. When the device is used for rectification, the effective energy loss in the rectification process is reduced, and the separation energy consumption is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A device and method for energy saving and consumption reduction of dimethyl carbonate plant

ActiveCN106699565BReduce energy consumptionReasonable distributionComponent separationOrganic compound preparationGas phaseReboiler

The invention relates to a device and method for energy saving and consumption reduction of a dimethyl carbonate device. The method comprises the following steps that (a) a mixed material of propylene carbonate, methanol and methanol base catalysts passes through a heat exchanger and then enters a reaction rectifying tower for primary reaction and fractionation; a generated azeotrope of dimethyl carbonate and the methanol enters a pressurization rectifying tower after being condensed by a tower top condenser; (b) after the separation by the pressurization rectifying tower, light ingredients enter a methanol rectifying tower to be rectified; (c) an azeotropic composition at the tower top of the methanol rectifying tower is subjected to temperature rise and pressurization through a rectifying heat pump, and is then used as a heat source of a reboiler of the methanol rectifying tower; the azeotrope discharged from the reboiler respectively enters a feeding preheater and a condenser to be cooled through the reaction rectifying tower. The device and method provided by the invention have the beneficial effects that the energy consumption is reduced by 20.2 percent; the distribution of gas phase materials in the tower is more reasonable; the mass transfer separation efficiency of the rectifying tower is improved; in addition, the continuous and regular collection of liquid samples is realized; the product monitoring frequency is greatly improved; the device can be favorably regulated in time.

Owner:DONGGUAN UPC IND & TRADE +1

Internal energy integrated rectifying device for three-component separation and rectification method using same

ActiveCN112742056AReduce exergy lossReduce separation energy consumptionFractional distillationFluid phaseReboiler

An internal energy integrated rectifying device for three-component separation comprises a rectifying tower with an inner tower body and an outer tower body, the outer tower body is a stripping section, the inner tower body is a rectifying section, and the inner tower body is provided with a partition plate; and through the arrangement of tower top gas phase and tower bottom liquid phase discharging and feeding paths in all tower bodies, heat exchangers, condensers, reboilers, compressors, throttling valves and the like and the arrangement of liquid distribution devices and silk screen condensation plates in the towers, heat and cold of the rectifying tower are fully utilized, and heat integration is achieved. When the device is used for rectification, the separation of three components can be realized in one tower body, meanwhile, the effective energy loss in the rectification process is reduced, and the condensation load and the reboiling load are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

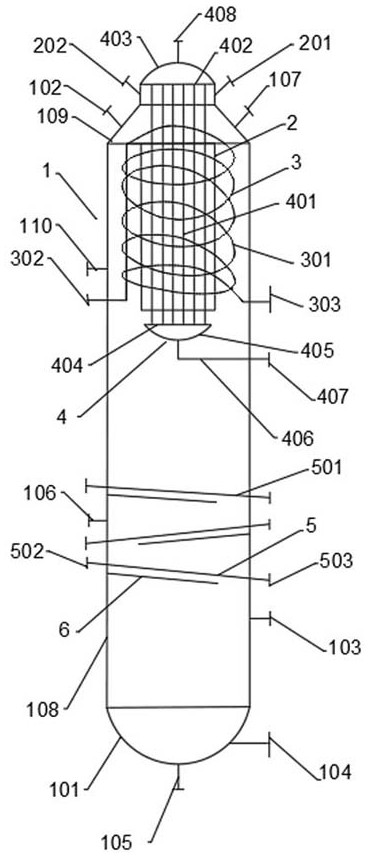

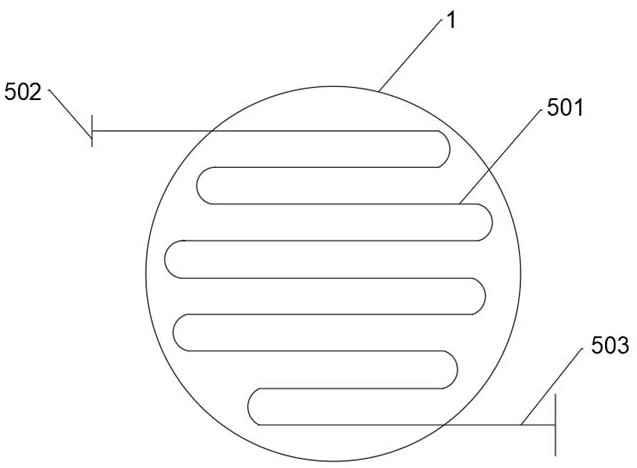

A kind of chemical condenser and method for using it to condense and separate gas phase products

ActiveCN113996080BReduce condensation loadImprove condensation efficiencyMultiple-effect/fractional condensationGas phaseGlycol synthesis

The invention provides a chemical condenser and a method for condensing and separating gas phase products using it, and relates to the field of chemical condensers. The chemical condenser includes an outer cylinder, an inner isolation cylinder, a coil condenser, an exposed tube condenser, and a coil A heater and a film-forming plate; the outer cylinder is composed of an outer cylinder body, an outer cylinder upper head and an outer cylinder lower head, the upper part of the outer cylinder body is a condensation area, and the lower part is a separation area. The present invention utilizes part of the urea and ethylene glycol reaction to prepare the mixed gas discharged from the ethylene carbonate reactor as the heat source of the coil heater, which avoids the use of additional heating medium and plays an energy-saving role; Part of the high-boiling point substances in the gas condense and liquefy, and make them leave the initial cooling zone in time and fall into the heating zone, so that the high-boiling point substances in the mixed gas entering the cryogenic zone are reduced, reducing the condensation load in the cryogenic zone , which improves the condensation efficiency in the cryogenic zone.

Owner:DONGYING HI TECH SPRING CHEM IND +1

Cooling cylinder compression cycle of rotor-type compressor

InactiveCN101576083BLower subcooling temperatureReduce condensation loadRotary piston pumpsRotary piston liquid enginesRefrigeration compressorThermodynamics

The invention relates to a cycling system for improving the efficiency of a cooling compressor, cooling cylinder compression cycle for short. The cooling cylinder compression cycle of a rotor-type compressor is mainly realized in four aspects: a. cooling cylinder compression, i.e. performing low-temperature cooling to a compression strong-heat-release cylinder wall surface (defined as a heat cylinder and others are cooling cylinders), coating heat insulating ceramic on the surfaces of a tongue piece and a rolling rotor, pushing compression heat release to a cooled heat cylinder, and increasing the area of the heat cylinder or reduce the rotational speed so as to fully discharge the compression heat release and prevent the discharged gas from overheating and then to reduce the compression net work and the condensation load; b. cooling cylinder gas suction, i.e. performing the isolation of gas phase from heat insulation to high-pressure gas discharge, the cooling and heat cylinders, upper and lower covers and a gas suction pipe, and ensuring the low-temperature characteristic of a gas suction chamber by means of continuous gas suction and heat cylinder cooling so as to obtain greater cold energy; c. oil way improvement, i.e. increasing the gas-suction force; and d. recovery gas discharge overheating and motor heat releasing, for purposes of heating and compensating absorptive lubricant, wherein an absorbent has low partial pressure and strong absorption capability on the surfaces of the cooling cylinders so that the cold energy is further increased and the compression work is further reduced.

Owner:童夏民

Double-condenser air conditioning device

PendingCN111284299AEasy to useStable controlAir-treating devicesVehicle heating/cooling devicesVapor–liquid separatorElectric control

The invention discloses a double-condenser air conditioning device. The air conditioning device comprises a refrigerating system A, a refrigerating system B, a ventilating system and an electric control system, wherein the compressor A, the condenser AI, the condenser AII, the liquid accumulator A, the filter A, the thermostatic expansion valve A, the evaporator A and the gas-liquid separator A form a refrigerating system A; the compressor B, the condenser BI, the condenser BII, the liquid accumulator B, the filter B, the thermostatic expansion valve B, the evaporator B and the gas-liquid separator B form a refrigerating system B; the condenser AI and the condenser BII are coupled together to share an axial flow fan A; the condenser AII and the condenser BI are coupled together to share anaxial flow fan B; and the evaporator A and the evaporator B are coupled together to share a centrifugal fan. The air conditioner can efficiently achieve air conditioning. In addition, a refrigeratingsystem can be effectively protected, safety and reliability are achieved, and energy is saved.

Owner:合肥天鹅制冷科技有限公司

Device and process for producing aromatic hydrocarbon products

ActiveCN110937968AReduce operating loadSave gas consumptionHydrocarbon by isomerisationDistillation purification/separationXylyleneIsomerization

The invention discloses a device and a process for producing aromatic hydrocarbon products. The device comprises a xylene fractionation unit, an adsorption separation unit and an isomerization reaction unit, wherein the adsorption separation unit comprises an adsorption separation tower, an extraction liquid fractionating tower, a raffinate tower and a heat exchanger II, and the isomerization reaction unit comprises an isomerization reaction rectifying tower, a white clay tower, an isomerization reaction heating furnace, a heat exchanger III, a heat exchanger IV, a heat exchanger VI and a compressor. The invention also provides a process for producing aromatic hydrocarbon products. With the device and the process of the invention, the equipment investment is reduced, the operation load ofthe xylene tower is reduced, the fuel gas consumption of the xylene reboiler is saved, the isomerization reaction and the product separation are carried out at the same time so as to achieve the coupling utilization of energy, the heat exchange network is optimized, the consumption of fuel gas of the isomerization reaction heating furnace is reduced, the energy consumption is greatly reduced, andthe economic benefit and the social benefit are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

C8 aromatic hydrocarbon separation and conversion process and system

ActiveCN112624894AReduce backmixingReduce irrational useHydrocarbon by isomerisationChemical industryChemistryAdsorption separation

The invention discloses a C8 aromatic hydrocarbon separation and conversion process and system. The process comprises the following steps: enabling a C8 aromatic hydrocarbon raw material to enter a xylene tower for fractionation, sending a tower top material flow to an adsorption separation tower through heat exchange, making an obtained p-xylene-rich extract liquid enter an extract liquid fractionating tower through a heat exchanger, letting p-xylene-poor raffinate enter a raffinate tower, and subjecting an upper side material to heat exchange, performing heating by an isomerization reaction heating furnace, carrying out isomerization reaction, carrying out heat exchange on the reaction product, removing olefin in a hydrogenation reactor, and introducing the reaction product into an isomerization product fractionating tower which is in the form of a dividing wall tower; wherein tower top materials are C7 or below light hydrocarbon and hydrogen, side line materials are mixed with adsorption separation feed, and the tower bottom discharged material is C9<+> aromatic hydrocarbon. Directed at the defects of the prior art, a heat exchange network is optimized, the energy consumption is greatly reduced, meanwhile, the problems of poor adsorption efficiency, frequent replacement of spent bleaching clay, environmental pollution and the like caused by quick deactivation of the bleaching clay and limited adsorption capacity are solved, and the social and economic benefits are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

How to increase the maximum outlet water temperature of heat pump water heater

ActiveCN103836789BRaise the water temperatureReduce condensation loadFluid heatersHeat pumpsControl systemTemperature difference

The invention provides a method for increasing the highest outlet water temperature of a heat pump water heater. Due to the fact that a compressor frequency reducing step is included, when a heat pump heat water control system judges that current operating parameters conform to compressor frequency reducing conditions, the compressor frequency reduces, and the circulation volume of coolants is reduced. Consequently, the condensing load of the heat pump water heater is reduced, the heat exchange temperature difference of a condenser is reduced, and the temperature of water in a water tank is further increased. According to the method, judgments are conducted according to the current operating parameters, a method of frequency reduction on a high water temperature section is adopted, and the circulation volume of the system is reduced, namely, the condensing load-heat exchange temperature difference of the system is reduced, and the heat exchange temperature difference is reduced by 5 DEG C, so that the highest water temperature can reach 55 DEG C. On the condition that the cost and the installation space of the whole machine are not increased, the purpose that the highest outlet water temperature of a R410A coolant heat pump water heater reaches 55 DEG C is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

A kind of continuous rectification separation method and device of propylene carbonate crude product

ActiveCN106916135BReasonable distributionReduce distributionOrganic chemistryFractional distillationRefluxReboiler

Owner:DONGGUAN UPC IND & TRADE +1

Comprehensive water-saving and energy-saving system for generator sets

ActiveCN105091403BReduce condensation loadHighlight energy-saving effectClimate change adaptationMachines using waste heatWater savingGas phase

Owner:李永堂 +1

Reaction kettle, reaction system and reaction method

PendingCN112263980AReduce condensation loadReduce the possibility of implosionChemical/physical/physico-chemical stationary reactorsStationary tubular conduit assembliesMechanical engineeringCooling pipe

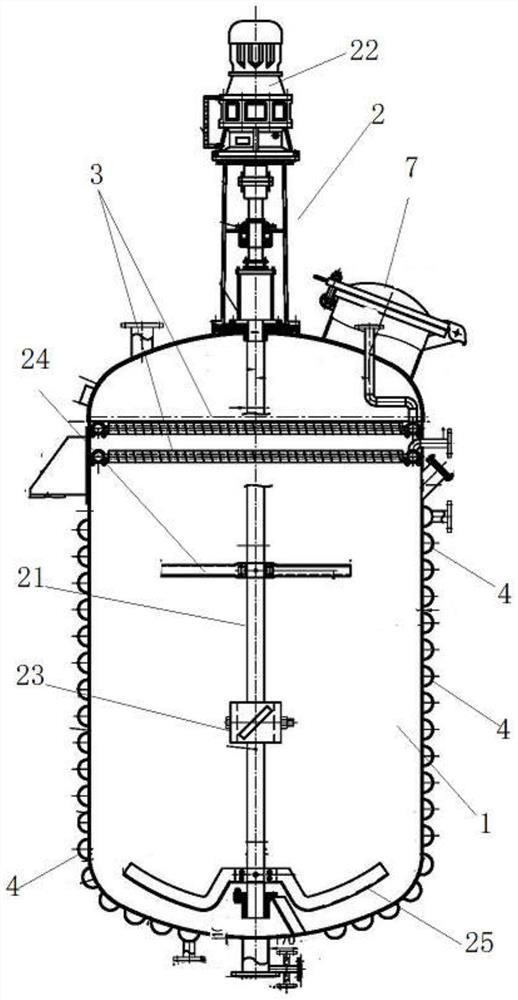

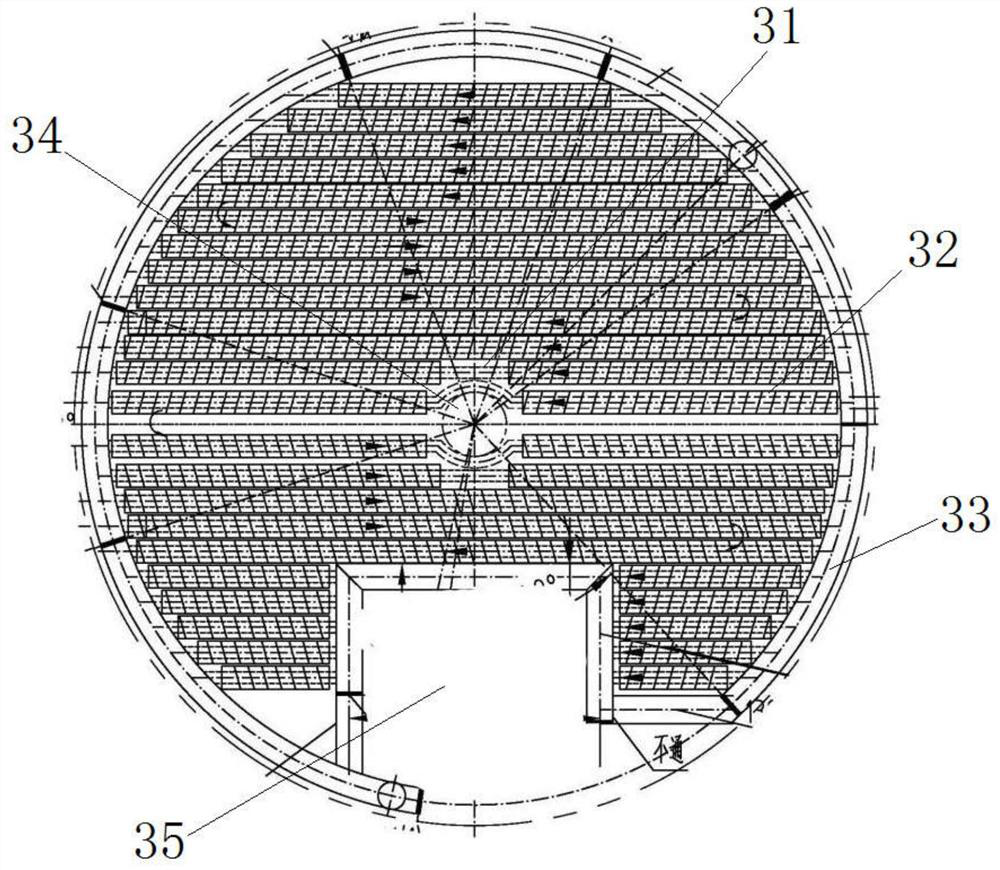

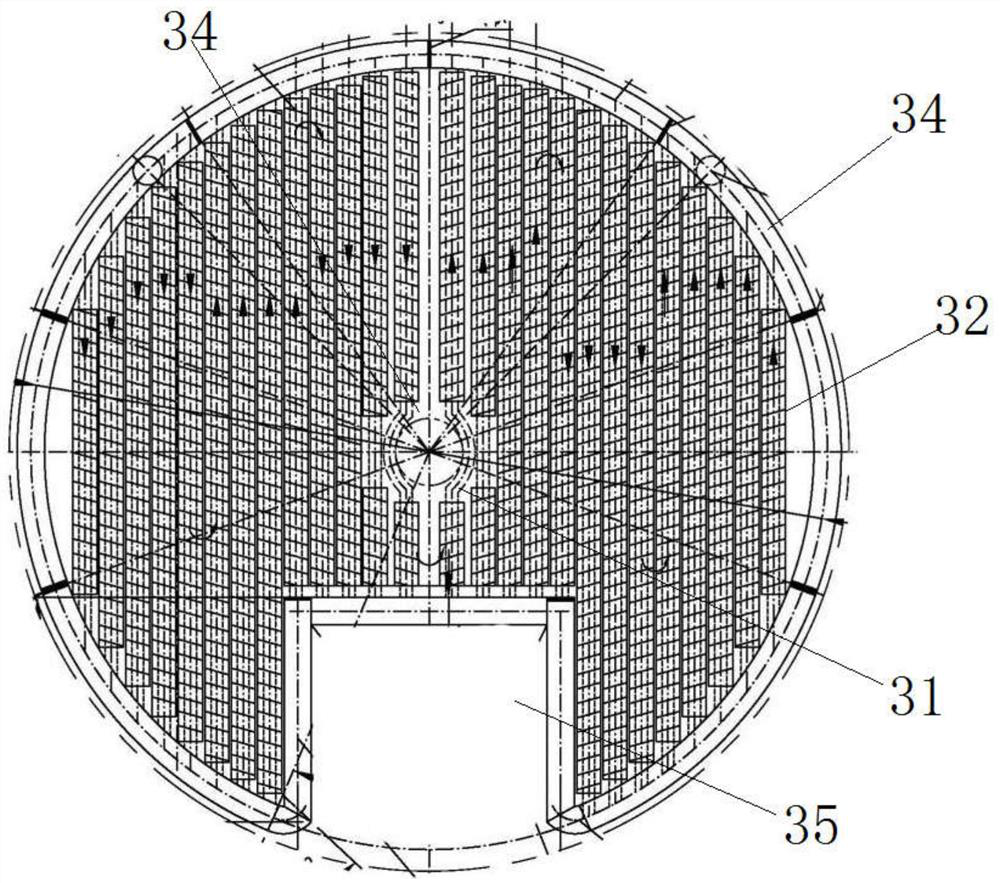

The invention belongs to the field of chemical engineering, and discloses a reaction kettle which comprises a kettle body and a stirrer extending into the kettle body, and a cooling layer is arrangedat the upper part of an inner cavity of the kettle body; the cooling layer is at least one fin layer; and the fin layer is composed of a plurality of cooling pipes side by side, and fins are arrangedon the cooling pipes. According to the reaction kettle, the cooling layer with the fins is additionally arranged, so that a gasified solvent can be repeatedly liquefied in the kettle, the condensationload of an external cooler is reduced, the possibility of implosion of polymerization reaction is reduced, and the consistency of reaction products is improved. Meanwhile, the invention also providesa reaction system and a reaction method.

Owner:贵州省欣紫鸿药用辅料有限公司

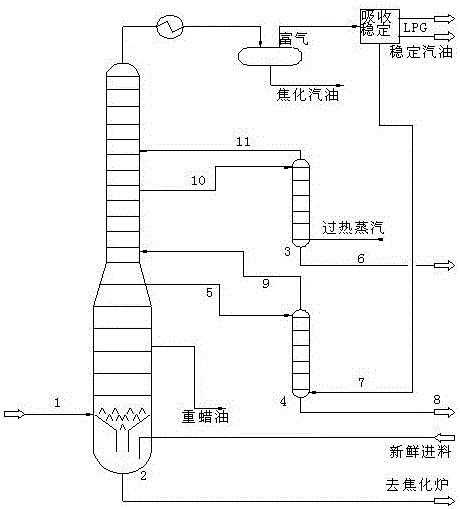

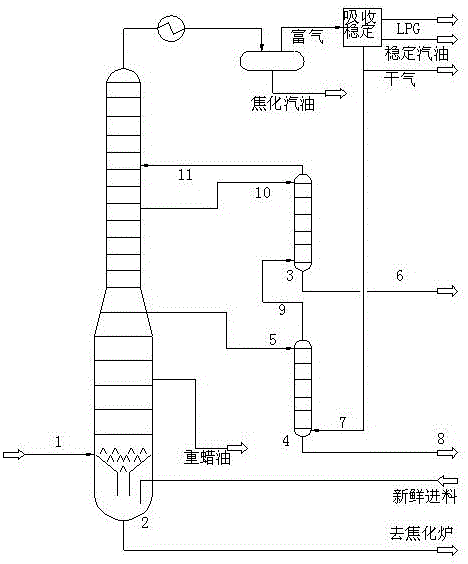

A process for increasing the production of coked diesel oil

ActiveCN104611005BHigh yieldLess investmentHydrocarbon oils treatment productsWaxDifferential pressure

The present invention discloses a process method for increasing the coking diesel fuel yield. The method comprises that: a wax oil steam stripping tower is arranged on the coking main fractionation tower light wax oil side-draw portion; and dry gas from the re-absorption tower top of a coking apparatus absorbing stabilizing unit is introduced into the wax oil steam stripping tower, the oil gas differential pressure of the coking wax oil is reduced, the relatively light diesel fuel distillate is subjected to steam stripping by using the self-heat of the coking wax oil and returns to the coking main fractionation tower from the coking main fractionation tower top or passes through a diesel fuel steam stripping tower and then returns to the coking main fractionation tower, and finally the diesel fuel distillate is extracted from the diesel fuel steam stripping tower. With the method of the present invention, the diesel fuel yield of the delayed coking apparatus can be significantly improved, the coking diesel fuel yield increase purpose can be achieved, the energy consumption of the apparatus can be reduced, the economic benefit of the apparatus can be increased, and the equipment investment can be saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com