Vapor phase feeding process for production of anhydrous alcohol with concentration of 99.9%

An anhydrous alcohol and process method technology, applied in the separation/purification of hydroxyl compounds, etc., can solve the problems of low alcohol vapor pressure, high steam energy consumption, and low concentration of anhydrous alcohol, and achieve reduced condensation load and low energy consumption , the effect of reducing steam consumption

Inactive Publication Date: 2015-10-28

肥城金威机械有限公司

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

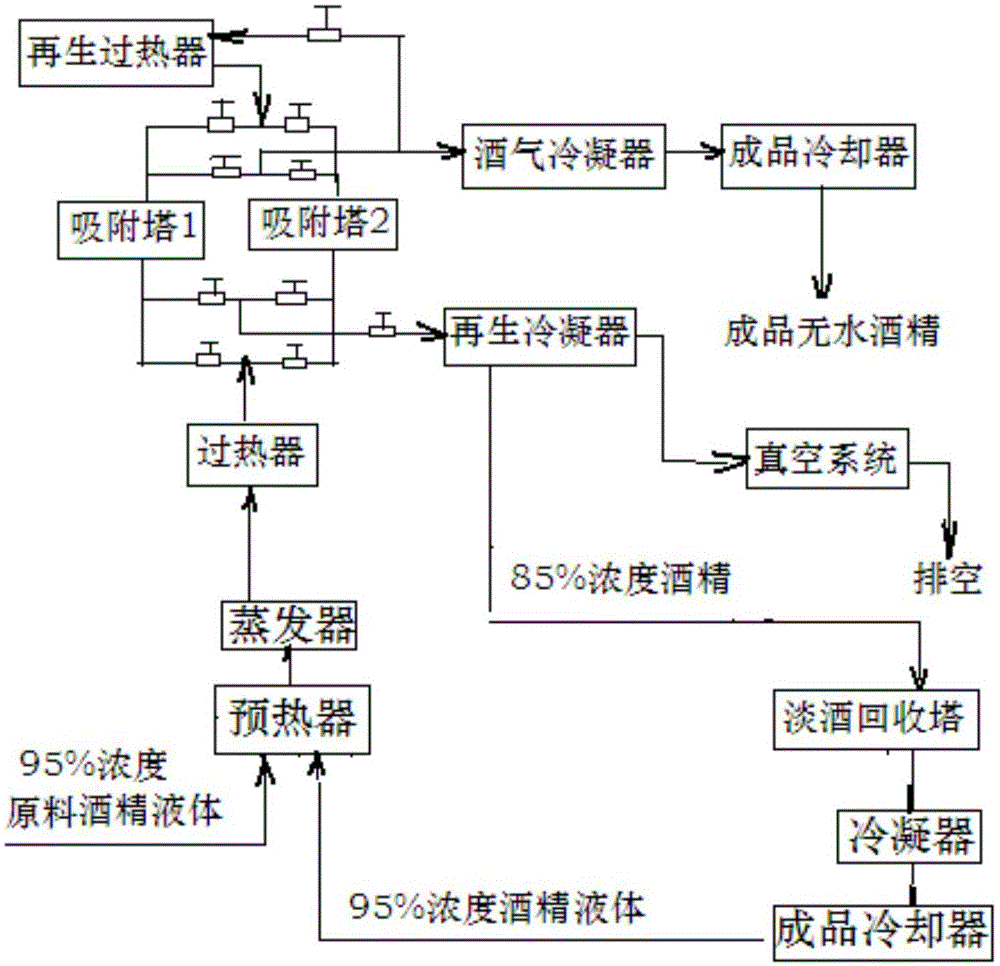

[0006] Since the production process of the above-mentioned molecular sieve method is a liquid-phase feed, it needs to be heated by a preheater, alcohol vapor is generated by an evaporator, and then heated by a superheater to a superheated state of 130-145°C and enters the adsorption tower, resulting in more equipment and complicated processes. Moreover, the alcohol vapor pressure is low, which affects the adsorption capacity of the adsorbent, and the concentration of the obtained anhydrous alcohol is low, which cannot reach the concentration of 99.9%. Moreover, the energy consumption of steam is large, and the consumption of circulating water and primary cooling water is large.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

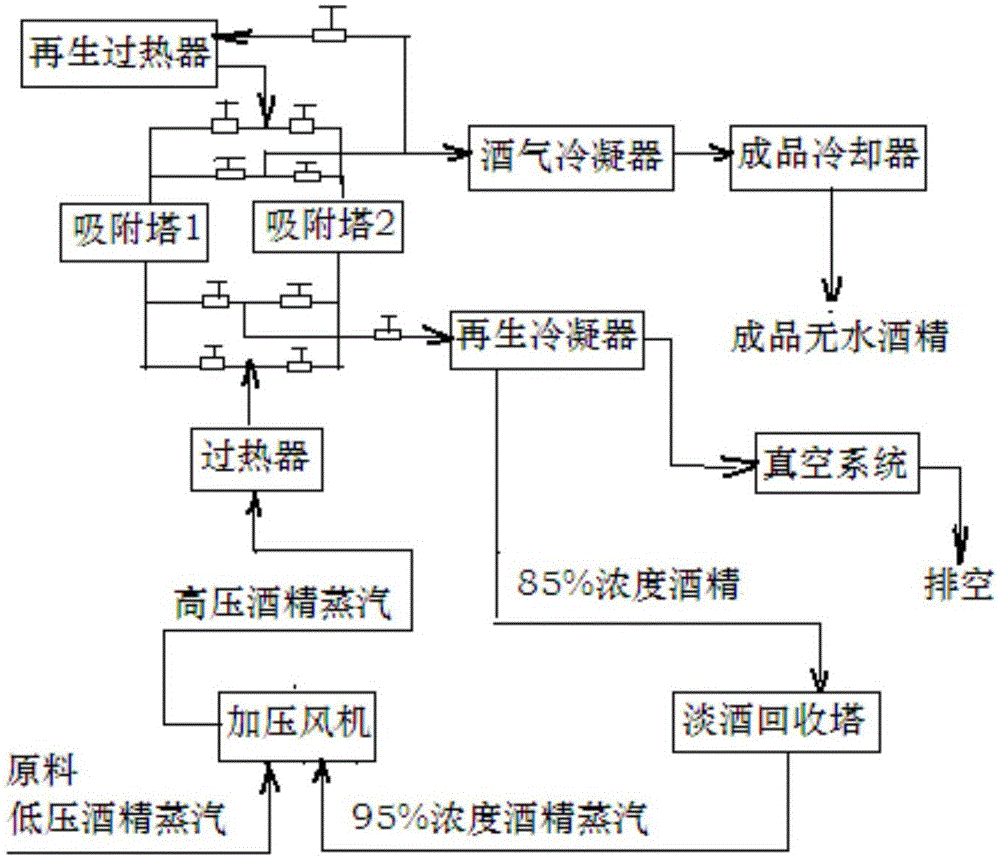

[0016] Those skilled in the art according to the content of the invention and the appended figure 2 The schematic diagram of the technological process of the production of anhydrous alcohol with vapor-phase feedstock shown can be fully implemented, and will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a vapor phase feeding process for production of anhydrous alcohol with its concentration of 99.9%. Alcohol steam with its concentration of 95% from a thin alcohol recovery distillation column in an alcohol plant and a raw material low pressure alcohol steam are pressurized by a pressurization fan to generate high-pressure alcohol steam; the high-pressure alcohol steam is adsorbed by an adsorption column, and vaporous water molecules in the alcohol steam are adsorbed by an adsorbent of the adsorption column; and the alcohol steam after the adsorption is condensed by an alcohol condenser and cooled by a product cooler so as to generate the finished product anhydrous alcohol. Thin alcohol with its concentration of 85% at the bottom of the adsorption column enters a thin alcohol recovery tower so as to obtain alcohol steam with its concentration of 95%; the alcohol steam directly enters the pressurization fan to be pressurized; and after pressurization, the alcohol steam is heated by a steam superheater to 130-145 DEG C and then directly enters the adsorption column for circulating production. Energy consumption of the process is obviously lower than energy consumption of a liquid phase alcohol vaporization and adsorption tower dehydration process.

Description

technical field [0001] The present invention relates to the production method of anhydrous alcohol. Background technique [0002] Anhydrous alcohol is a basic chemical raw material, which is widely used in chemical industry, medicine, pesticide, dye, ink, adhesive, paint, spice, cosmetic, detergent, rubber and other industries. In recent years, with the world's energy crisis and increasing oil shortages, the demand for anhydrous alcohol has grown rapidly. The largest consumer market for anhydrous alcohol abroad is as fuel, especially automobile fuel. When used as a vehicle fuel, anhydrous alcohol is added to a denaturant to form denatured fuel ethanol. As a kind of renewable energy, fuel ethanol has been paid attention to by countries all over the world. Therefore, the production and development of anhydrous alcohol has become a very urgent task. [0003] The traditional production process of anhydrous alcohol mainly adopts the ternary azeotropic distillation method, that...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C31/08C07C29/76

CPCC07C29/76C07C31/08

Inventor 黄建军袁峰王琴孙建尹秀梅马春霞王新

Owner 肥城金威机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com