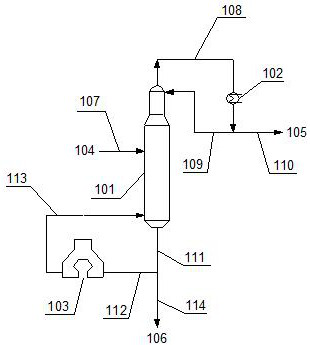

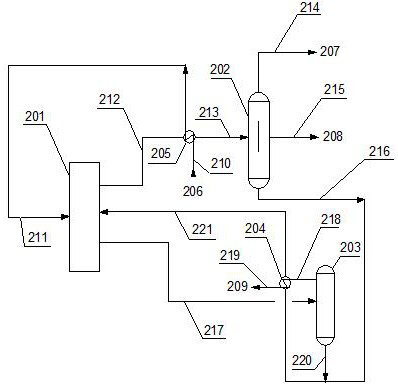

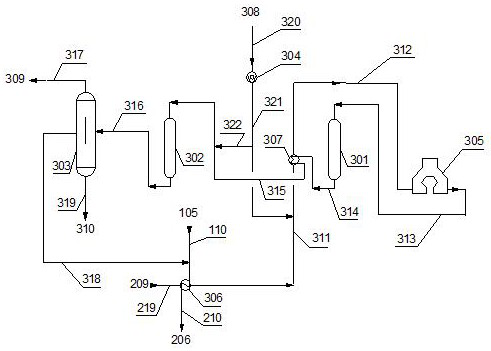

C8 aromatic hydrocarbon separation and conversion process and system

An aromatic hydrocarbon and process technology, which is applied in the field of C8 aromatic hydrocarbon separation and conversion processes and systems, can solve the problems of fast deactivation of white clay, poor adsorption efficiency, and frequent replacement of the environment for waste white clay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] C of the present invention 8 The aromatics separation and conversion process and equipment used in the system are shown in Table 2, and the operating parameters and energy consumption of the device are shown in Table 3.

[0062] Table 2

[0063]

[0064] table 3

[0065]

[0066] As can be seen from Table 1 and Table 2, compared with Comparative Example 1, C provided by the present invention 8 The aromatics separation and conversion process can save equipment investment, reduce the investment of one set of rectification tower, cooler reboiler equipment and one gas-liquid separation tank, air cooler and water cooler, add one reactor, and cancel the clay tower . Adopting the method provided by the invention not only reduces the number of equipment, but also reduces energy consumption by 19.9%. Therefore, equipment investment and floor space are reduced, the operating load of the xylene tower is reduced, and the fuel gas consumption of the xylene reboiler is save...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com