Double-CFB (circulating fluidized bed) reaction-regeneration system and method to prepare arenes with synthetic gas

A circulating fluidized bed and regeneration system technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, biological raw materials, etc., can solve problems such as low conversion rate of synthesis gas and regeneration of catalysts, etc., to reduce design difficulty, Reduced back-mixing and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

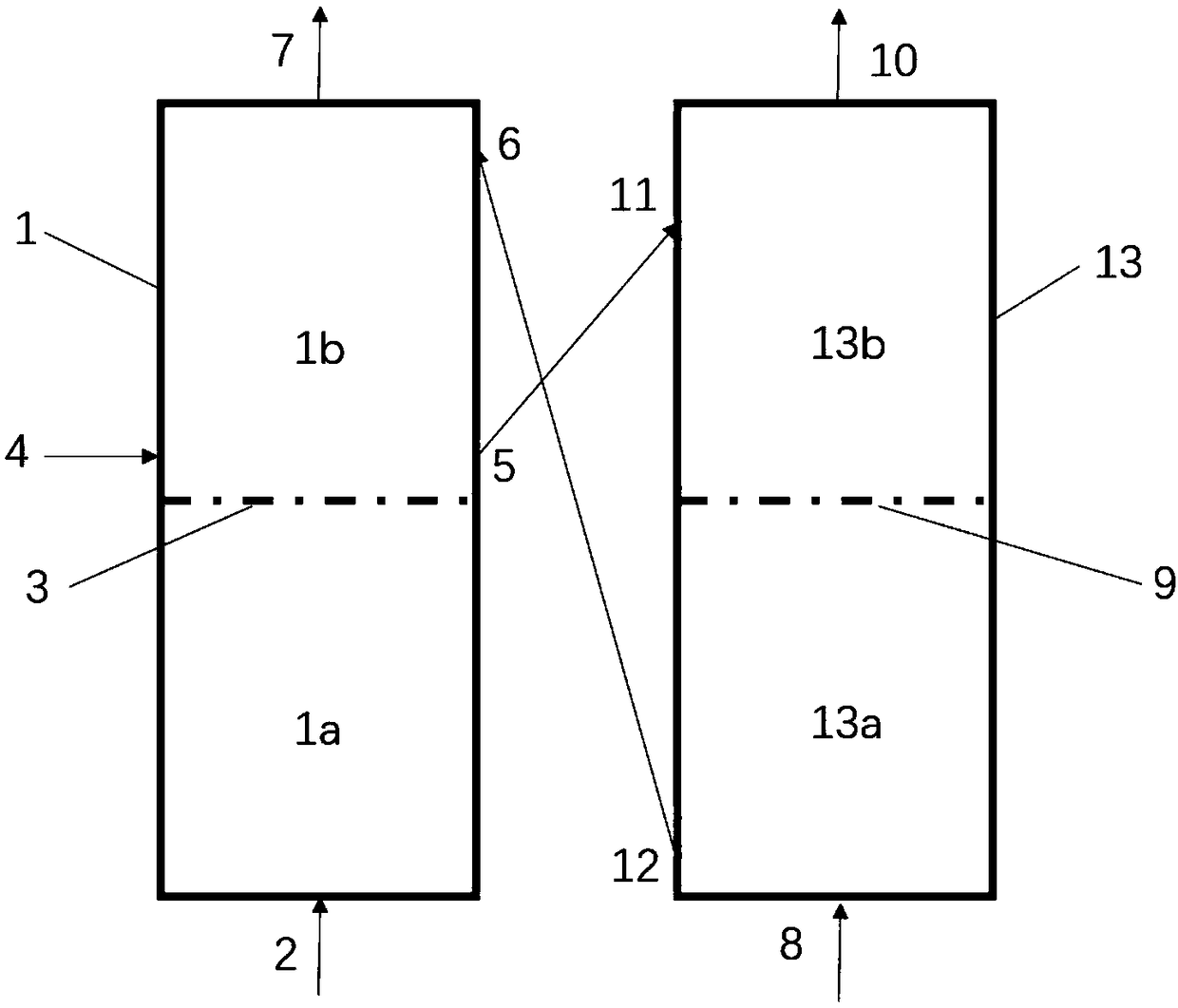

[0032] Hydrocarbon synthesis catalyst (iron nitride / aluminum oxide, iron nitride mass fraction is 50%, the rest is aluminum oxide, the average particle diameter of catalyst is 350 microns) and aromatization catalyst (Ga 2 o 3 / Y molecular sieve / alumina type, in which alumina, Y molecular sieve, Ga2 o 3 The mass fractions are 60%, 30%, and 10%, respectively, and the average particle size of the catalyst is 120 microns) are packed in the first catalyst loading area 1a of the aromatization reactor 1 . Preheat the lower area of the aromatization reactor 1 to 250°C, feed synthesis gas (CO and hydrogen), control the pressure at 3MPa, and blow the aromatization catalyst from the first catalyst loading area 1a to the second catalyst loading area In 1b, the temperature of the second catalyst loading zone 1b is controlled to be 550°C.

[0033] The synthesis gas generates hydrocarbons in the first catalyst loading zone 1a, and the hydrocarbons further react in the second catalyst loa...

Embodiment 2

[0038] Hydrocarbon synthesis catalyst (Fe / Cr / alumina catalyst, alumina, Fe, Cr mass fraction are respectively 5%, 20%, 75%, the average particle diameter of catalyst is 200 microns) and aromatization catalyst (ZnO / Ga 2 o 3 / ZSM-5 / alumina, of which alumina, ZSM-5 molecular sieve, Ga 2 o 3 , ZnO mass fractions are 50%, 35%, 5%, 10% respectively, and the average particle diameter of the catalyst is 40 micrometers) are packed in the first catalyst loading area 1a area in the reactor. The lower area of the reactor was preheated to 380°C, and the synthesis gas (CO and hydrogen) was introduced to control the pressure at 2MPa. The aromatization catalyst is blown from the first catalyst loading area 1a into the second catalyst loading area 1b, and the temperature of the second catalyst loading area 1b is controlled to be 450°C.

[0039] The synthesis gas generates hydrocarbons in the first catalyst loading zone 1a, and the hydrocarbons further react in the second catalyst loadin...

Embodiment 3

[0044] The hydrocarbon synthesis catalyst (Co / Mn / alumina / silicon oxide catalyst (Co, Mn, alumina, silica mass fraction is 0.6%, 0.4%, 70%, 29%, the average particle diameter of catalyst is 270- Micron) and aromatization catalyst (MoO 3 / Fe / β molecular sieve / alumina, of which alumina, β molecular sieve, MoO 3 , Fe mass fractions are 58%, 36%, 3%, 3%, respectively, and the average particle diameter of the catalyst is 80 micrometers) are packed in the first catalyst packing area 1a area in the reactor. The lower area of the reactor was preheated to 280°C, and the synthesis gas (CO and hydrogen) was introduced to control the pressure at 0.1MPa. The aromatization catalyst is blown from the first catalyst loading area 1a into the second catalyst loading area 1b, and the temperature of the second catalyst loading area 1b is controlled to be 480°C.

[0045] The synthesis gas generates hydrocarbons in the first catalyst loading zone 1a, and the hydrocarbons further react in the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com