Patents

Literature

247results about How to "Reduce chalking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Negative electrode material used for lithium battery and preparation method and application thereof

ActiveCN103474632AStable structureImprove performanceMaterial nanotechnologyCell electrodesPorosityMicro nano

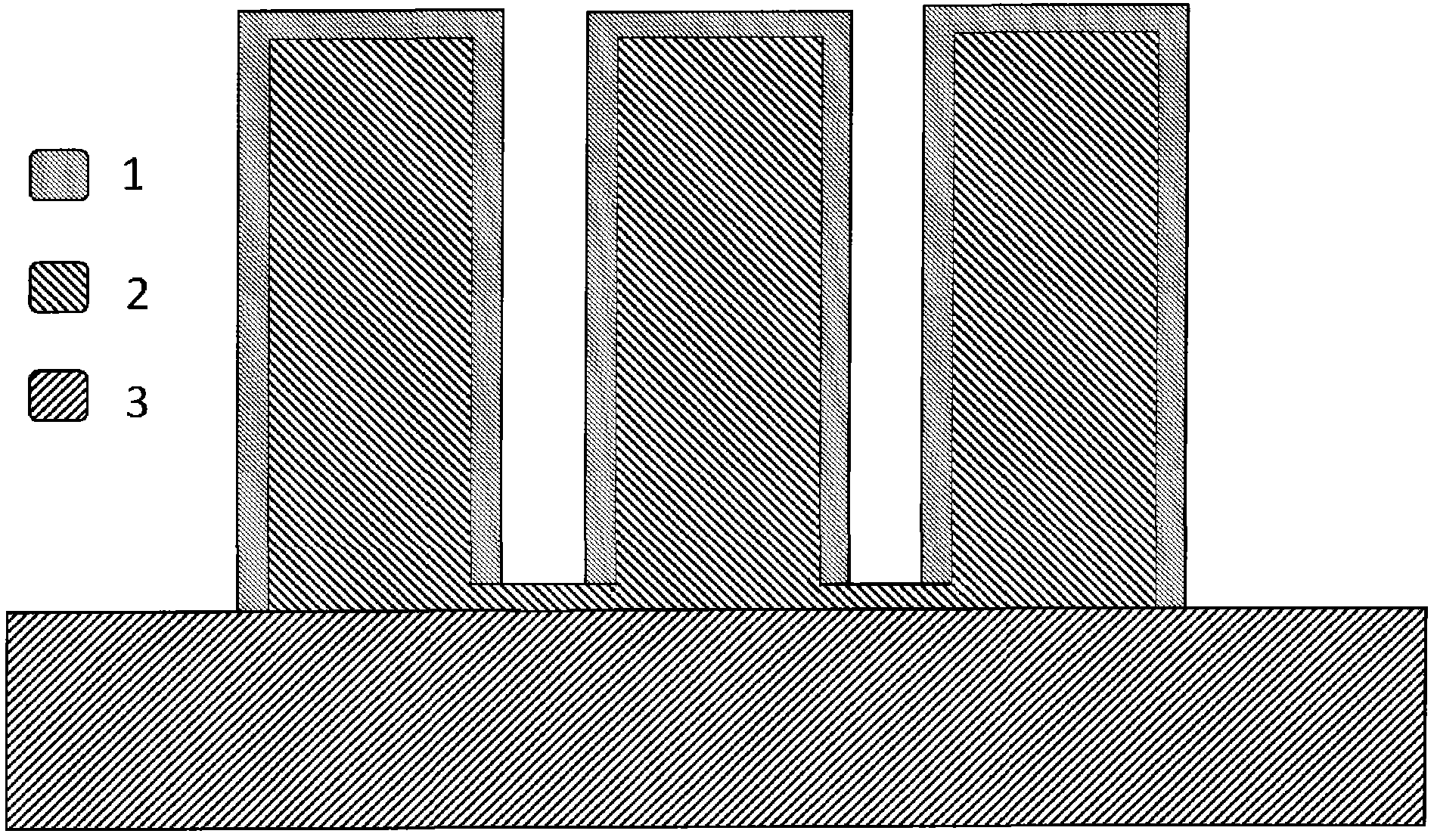

The invention relates to a negative electrode material used for a lithium battery and a preparation method and application thereof, the negative electrode material includes a conductive substrate material layer and a silicon based thin film material layer, the silicon based thin film material layer contains one or more components selected from the group consisting of silicon element, SiOX and silicon alloy, wherein, 0 < X =< 2; in the silicon based thin film material layer, silicon accounts for 10-100% of the weight of the silicon based thin film material layer; the silicon based thin film material layer is a thin film formed by regular and / or irregular columnar and / or fibrous micro nano naps, wherein the micro nano naps are connected with each other by root parts, and the root parts of the micro nano naps are connected with the conductive substrate material layer; gaps are existed among the micro nano naps, and the porosity among the micro nano naps is 2%-98%; the diameter size of the micro nano naps is 1 nm to 10 mum, and the thickness of the silicon based thin film material layer is 50 nm-10 mum.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

Composite film material for lithium battery and preparation method and application thereof

ActiveCN107591511AReduce manufacturing costEasy to operateLi-accumulatorsCell component detailsElectrical conductorComposite film

The invention provides a composite film material for a lithium battery. The composite film material comprises a polymer film and a conductor particle layer coating the surface of the polymer film in one side. The conductor particle layer contains one or more of particles of an ion conductor material, particles of an ion-electron mixed conductor material and particles of an electron conductor material. The invention also provides a preparation method of the composite film material and an application of the composite film material in a rechargeable metal lithium battery. The invention provides aliquid metal lithium battery and solid metal lithium battery containing the composite film material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

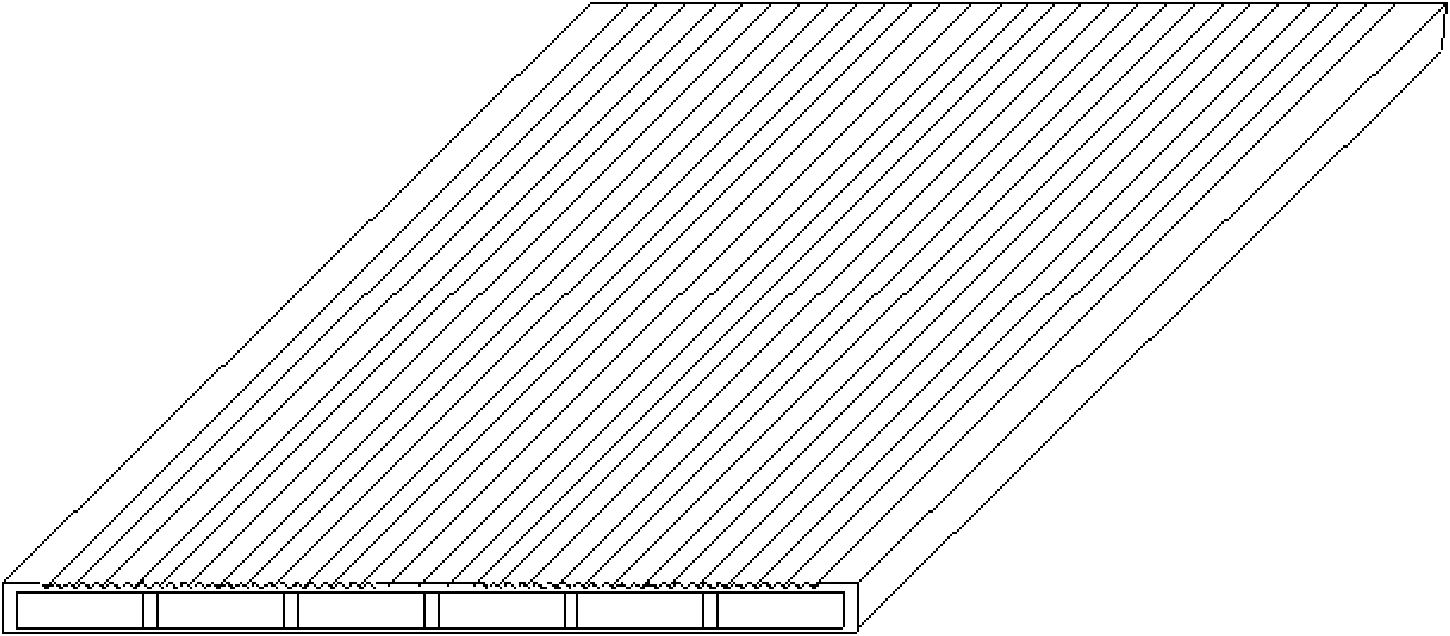

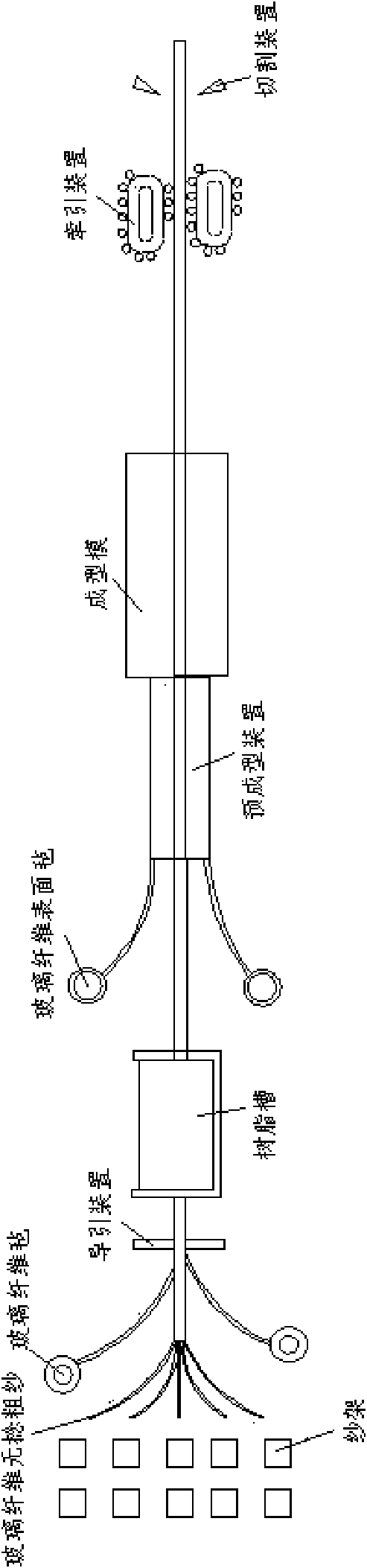

Glass fiber reinforced plastic cable channel cover plate and production method thereof

InactiveCN101672044AImprove corrosion resistanceStrong anti-agingArtificial islandsUnderwater structuresPolyvinyl alcoholEngineering

The invention relates to a glass fiber reinforced plastic cable channel cover plate and a production method thereof. The cover plate is a rectangular hollow belly structure, longitudinal stiffening ribs are arranged in the hollow belly of the cover plate and the upper surface of the cover plate is provided with strip-shaped antiskid grains; the invention comprises the following raw materials: unsaturated polyester resin, curing agent, packing, polyvinyl alcohol solution, pigment, fiberglass roving and fiberglass felt; the invention comprises the following steps: (1) arranging a tooling equipment on an extrusion molding machine; (2) mixing and pouring the raw materials in a resin tank; and (3) inducing the fiberglass roving and the fiberglass felt through immersion, a performing device, a forming device, curing and cutting. The cover plate has high strength, smooth surface, neat and beautiful appearance, corrosion resistance of alkali, acid, petrol and the like, aging resistance, long service life without pulverization, discoloration, crack, deformation and the like. The invention ensures the safe operation of cables and prolongs the service life of the cables.

Owner:醴陵市万通新型材料有限公司

Multifunctional putty for building external walls

The invention discloses multifunctional putty for building external walls, consisting of the following components in percentage by weight: 30% of white cement, 16% of sericite, 20% of talcum powder, 30% of quartz sand, 3.5% of re-dispersible polymer powder, 0.1% of defoaming agent, 0.1% of naphthalene-series water reducer, 0.1% of methylcellulose, 0.1% of waterproof agent and 0.1% of wood fiber. According to the invention, the sericite is used as functional padding so that the putty disclosed by the invention has strong weather ability because the sericite has a trough for absorbing ultraviolet lights as high as 85% and has a strong function for shielding ultraviolet lights. Moreover, through the sheet overlapping and blocking function of the sericite because of high radius-thickness ratio, the reflection and thermal-insulation capability can be effectively improved and the heat-insulating performance of the putty is enhanced. The sericite has active hydroxyl groups and is easy to combine and wrap with molecular chains in the re-dispersible polymer powder so that the comprehensive mechanical property and the penetration resistance of the putty are greatly improved.

Owner:武汉市丰达建筑节能材料有限公司

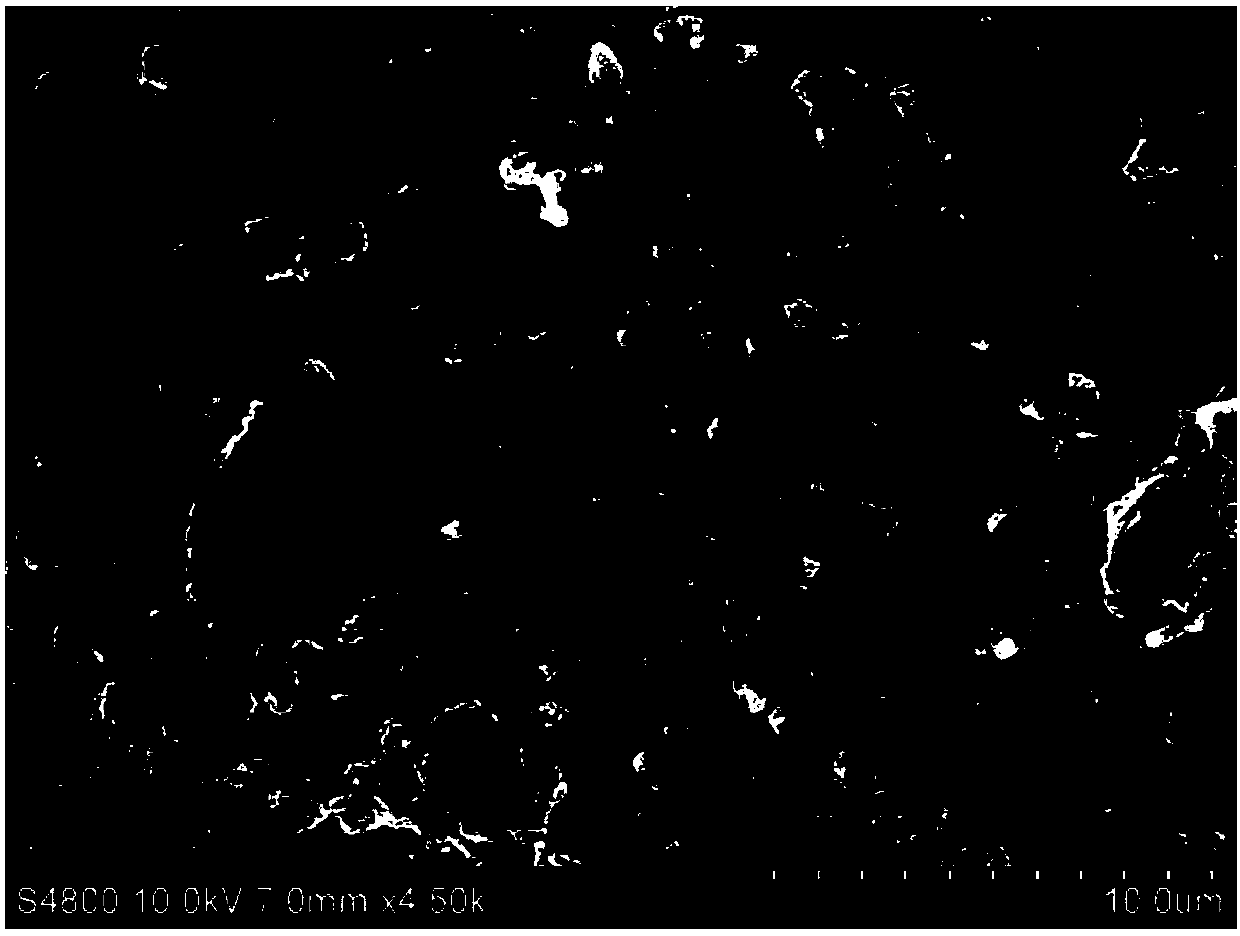

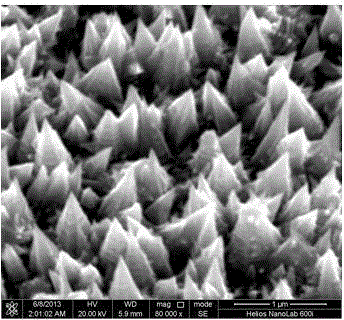

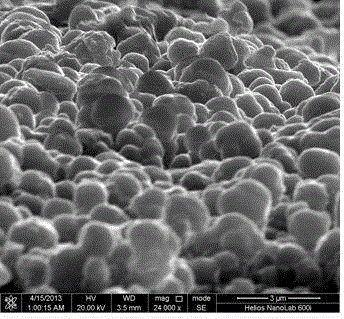

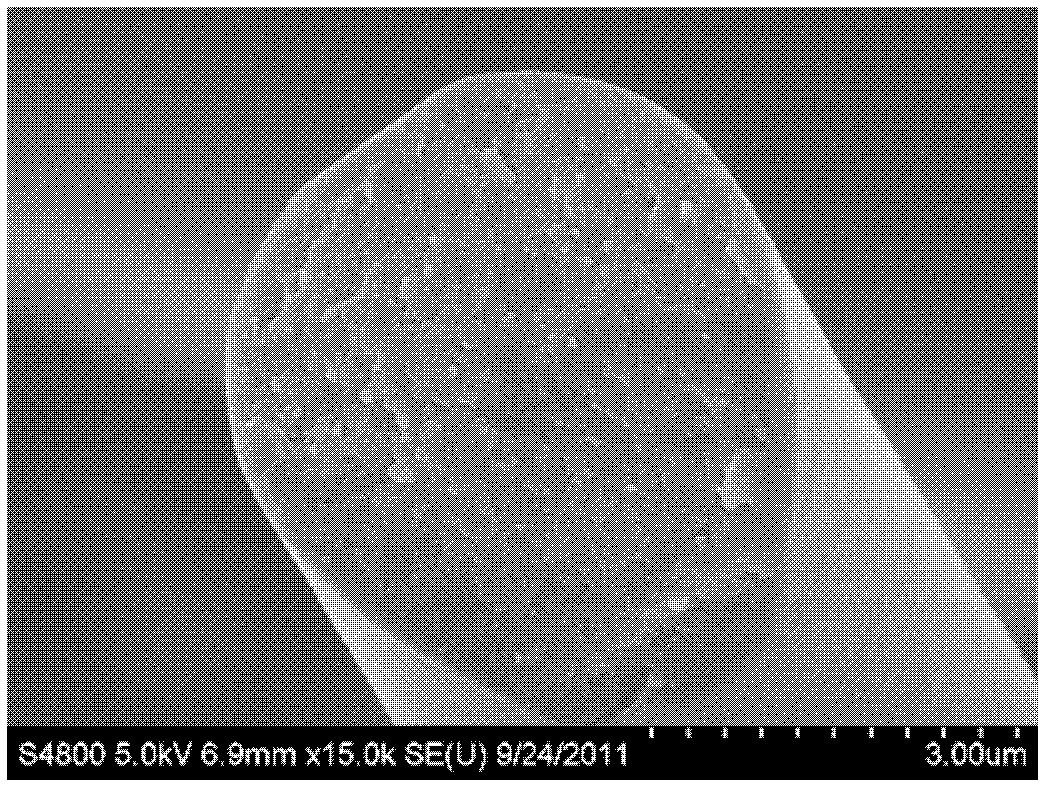

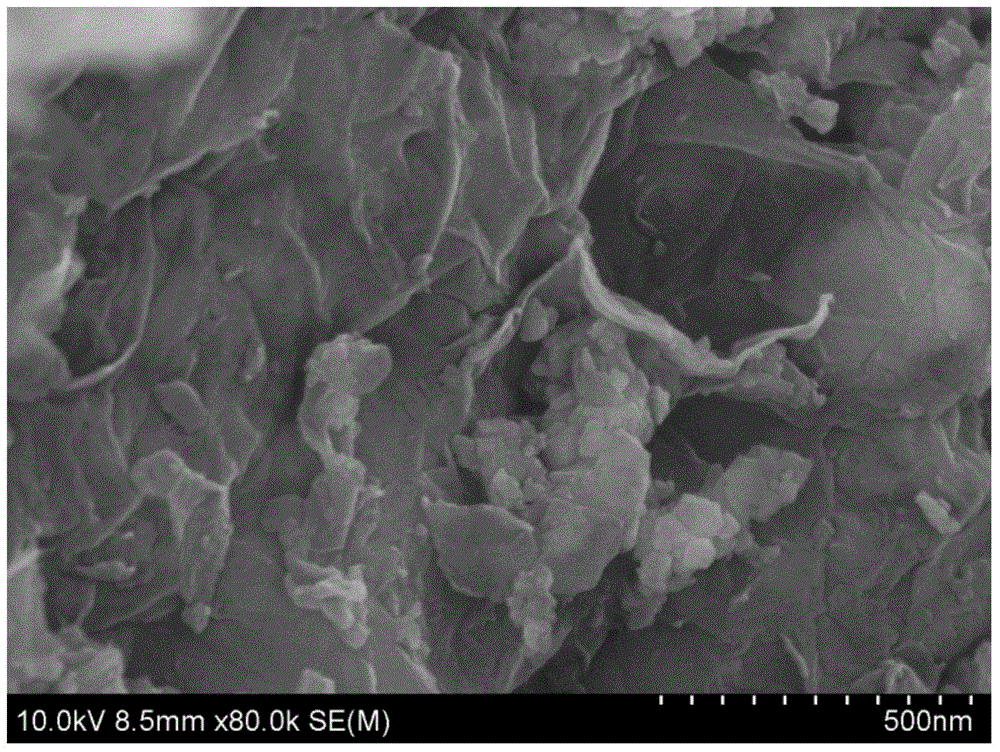

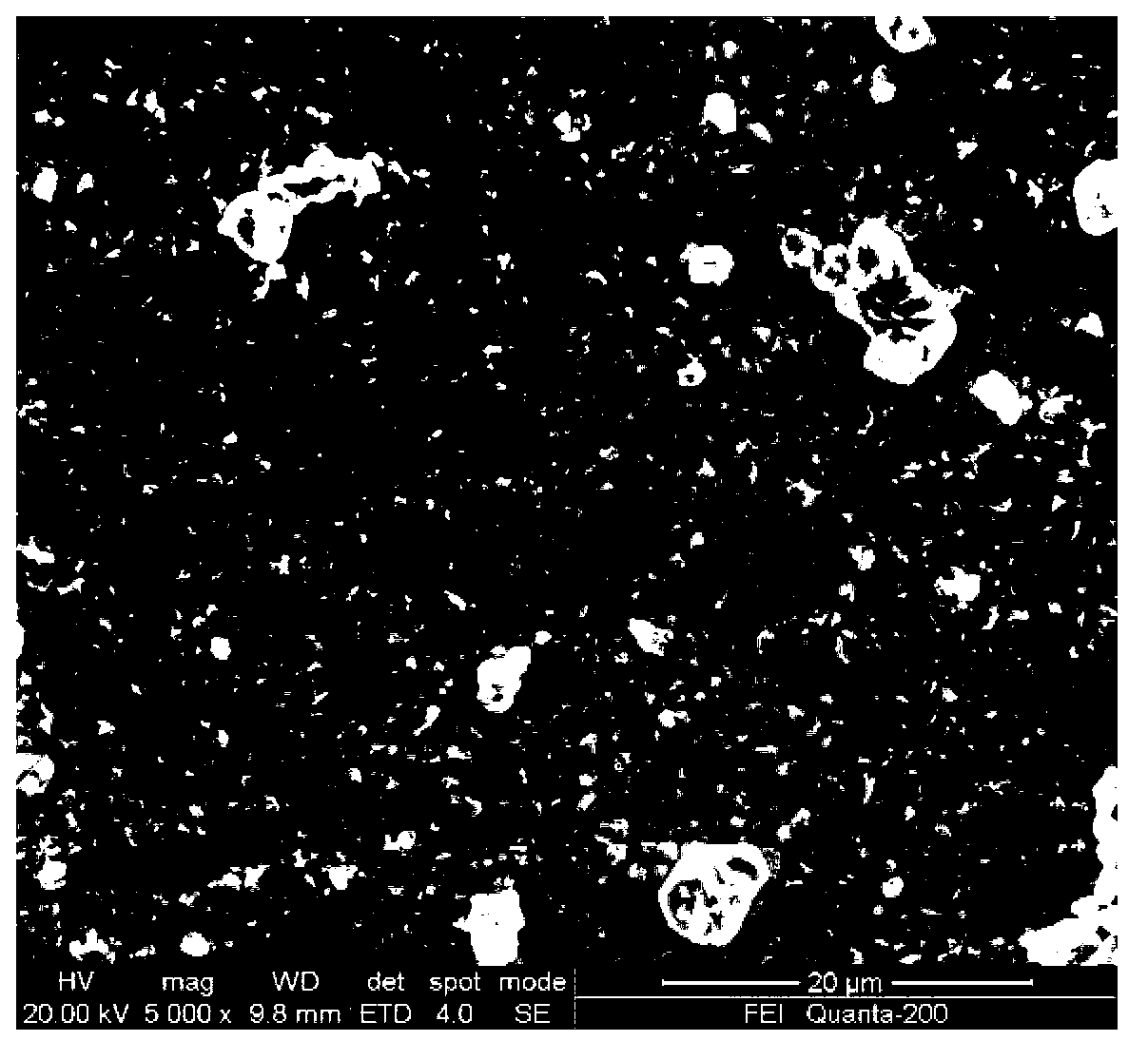

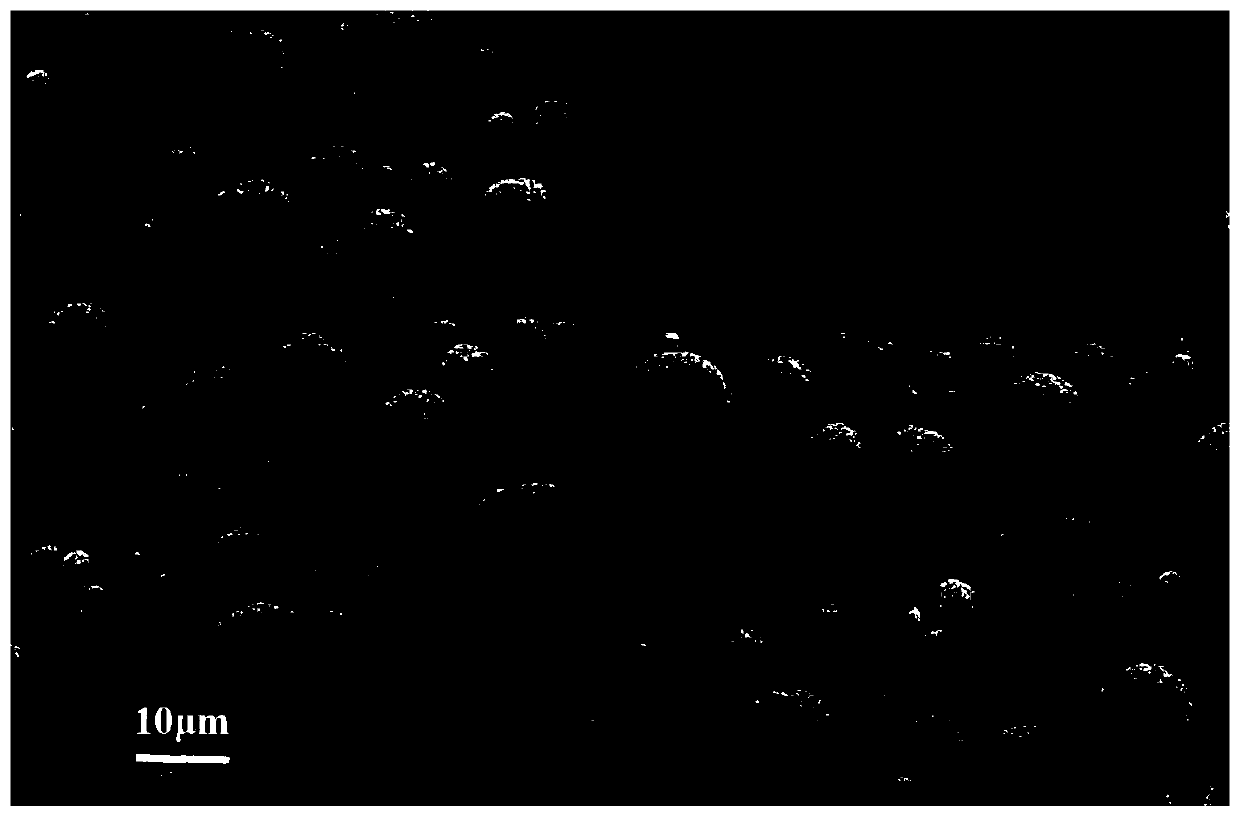

Method for preparing germanium cathode material on nickel nanoneedle conical array

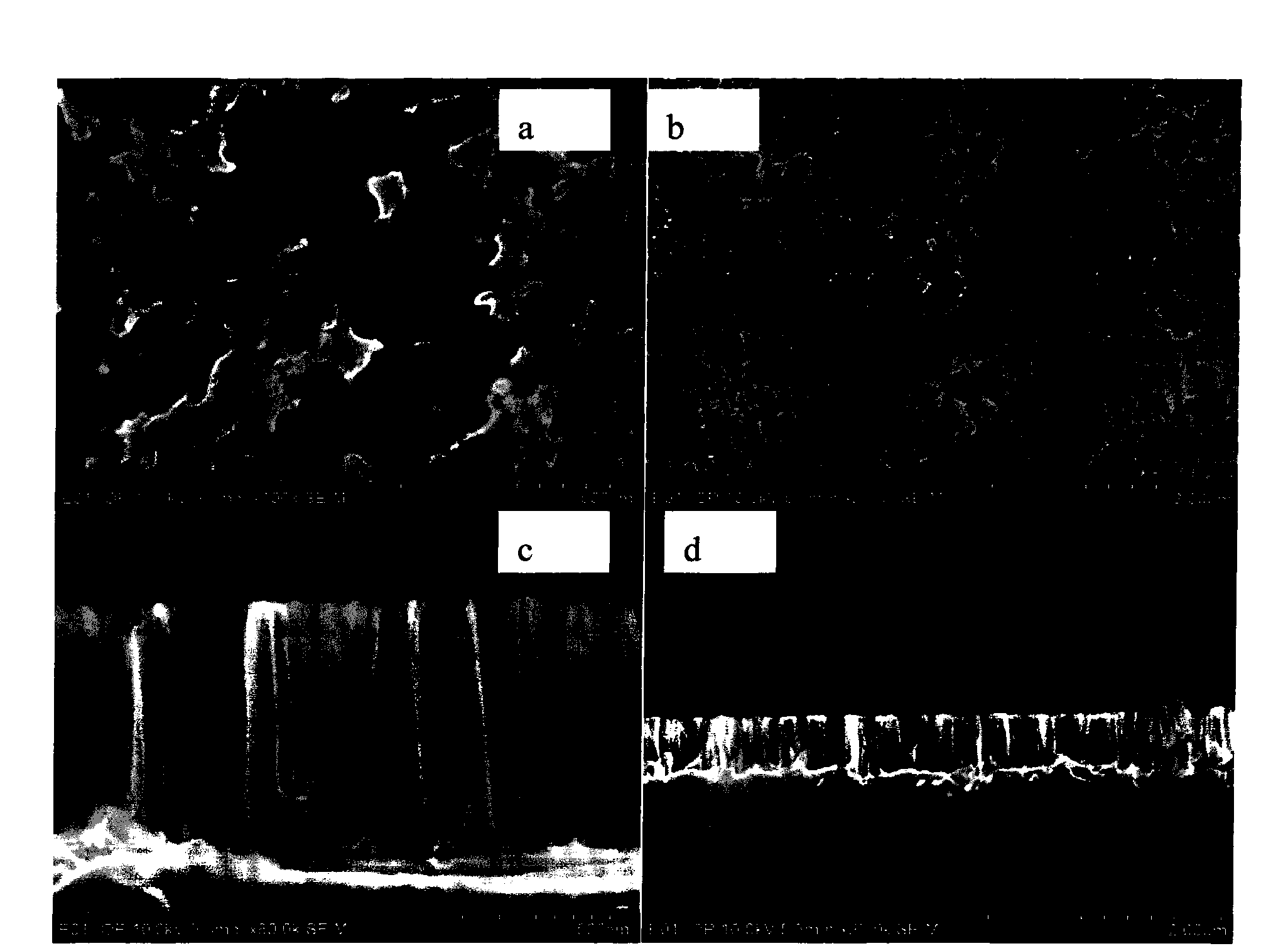

ActiveCN103985836AReduce chalkingIncrease the base areaMaterial nanotechnologyPolycrystalline material growthNickel substrateElectrical battery

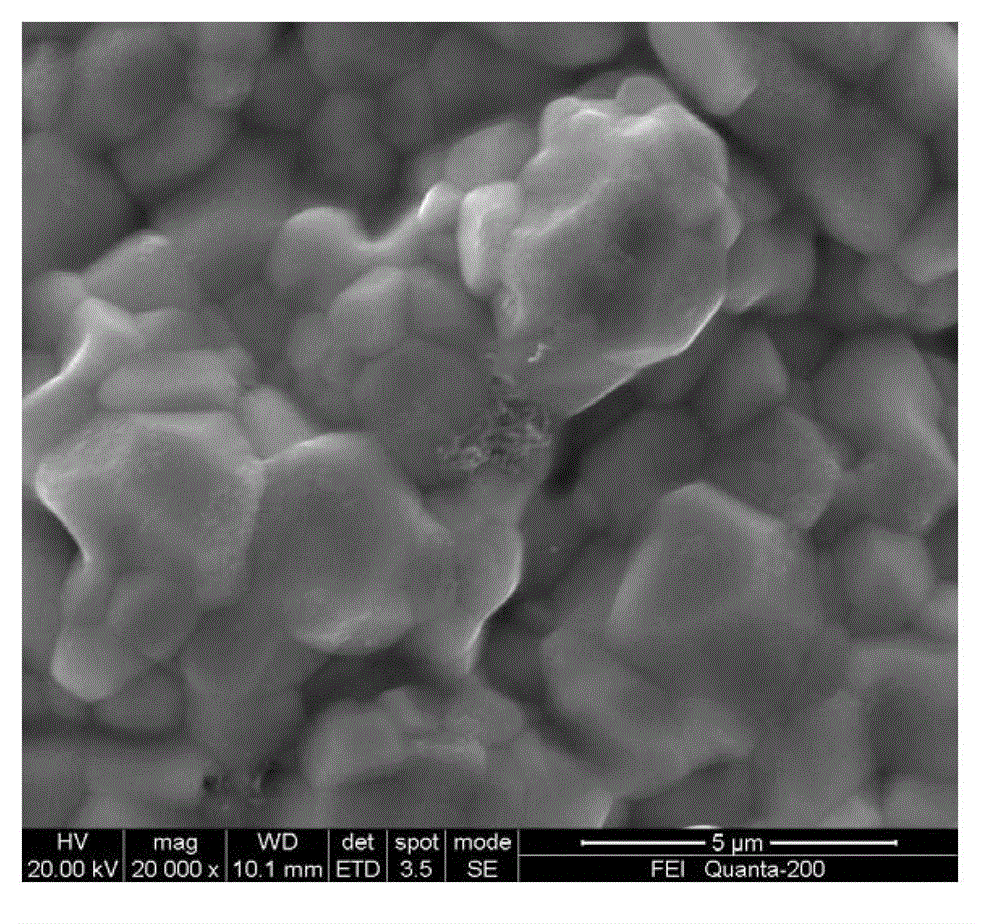

The invention discloses a method for preparing a germanium cathode material on a nickel nanoneedle conical array. The preparation method comprises the following steps: firstly preparing the nickel nanoneedle conical array with a certain height by utilizing a water solution electrodeposition method on a nickel basal body, then preparing a germanium cathode material by utilizing an ionic liquid electrodeposition method in an anaerobic and hydrophobic environment, assembling a battery after carbon spraying treatment, and testing the electrochemical performance of the battery. The ionic liquid electrodeposition method is utilized on the nickel nanoneedle conical array for preparing the germanium cathode material with high specific capacity, long cycle life and high coulombic efficiency; during the ionic liquid electrodeposition process, the current density is low, and prepared germanium films are uniform; moreover, the prepared material comprises nano-sized particles, so that pulverization during the material cyclic process is reduced, the foundation area of the prepared cathode material and the prepared basal body (nickel nanoneedle conical array) is large, the binding force is good, and the preparation method is simple in process and convenient to operate.

Owner:HARBIN INST OF TECH

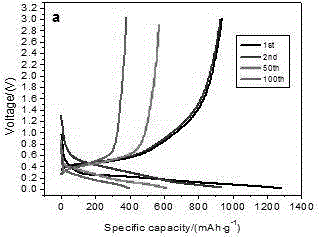

Carbon-Cu6Sn5 alloy negative electrode materials and preparation method thereof

InactiveCN103066252AReduce the likelihood of sheddingIncrease migration rateElectrolytic coatingsCell electrodesCarbon nanotubeAlloy

The invention discloses carbon-Cu6Sn5 alloy negative electrode materials and a preparation method thereof. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof combine carbon nanometer tubes and graphene into electrodes and add a Cu-CNTs connecting layer between active materials and current collectors. Therefore, cyclic perforce of an alloy negative electrode is improved greatly. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof use copper foils as the current collectors (electroplating substrates). The copper foils are plated by a Cu-CNTs composite plating and a composite plating of stannum-carbon nanometer tubes or stannum- graphene or stannum-carbon nanometer tubes- graphenes in sequence, wherein the thickness of the Cu-CNTs composite plating is 1-5 micrometers and the thickness of the composite plating of the stannum-carbon nanometer tubes or the stannum- graphene or the stannum-carbon nanometer tubes- graphene is 1-4 micrometers. The carbon-Cu6Sn5 alloy negative electrode materials can be obtained finally through thermal treatments. First specific discharge capacity of lithium ion battery alloy cathodes prepared by the method can achieve 613 m AH / g and specific capacity attenuation of the lithium ion battery alloy cathodes is only 4%-6% after 100 cycles. The carbon-Cu6Sn5 alloy negative electrode materials and the preparation method thereof are simple in technique, good in prepared alloy cathode performance and suitable for large-scale industrial production.

Owner:XIANGTAN UNIV

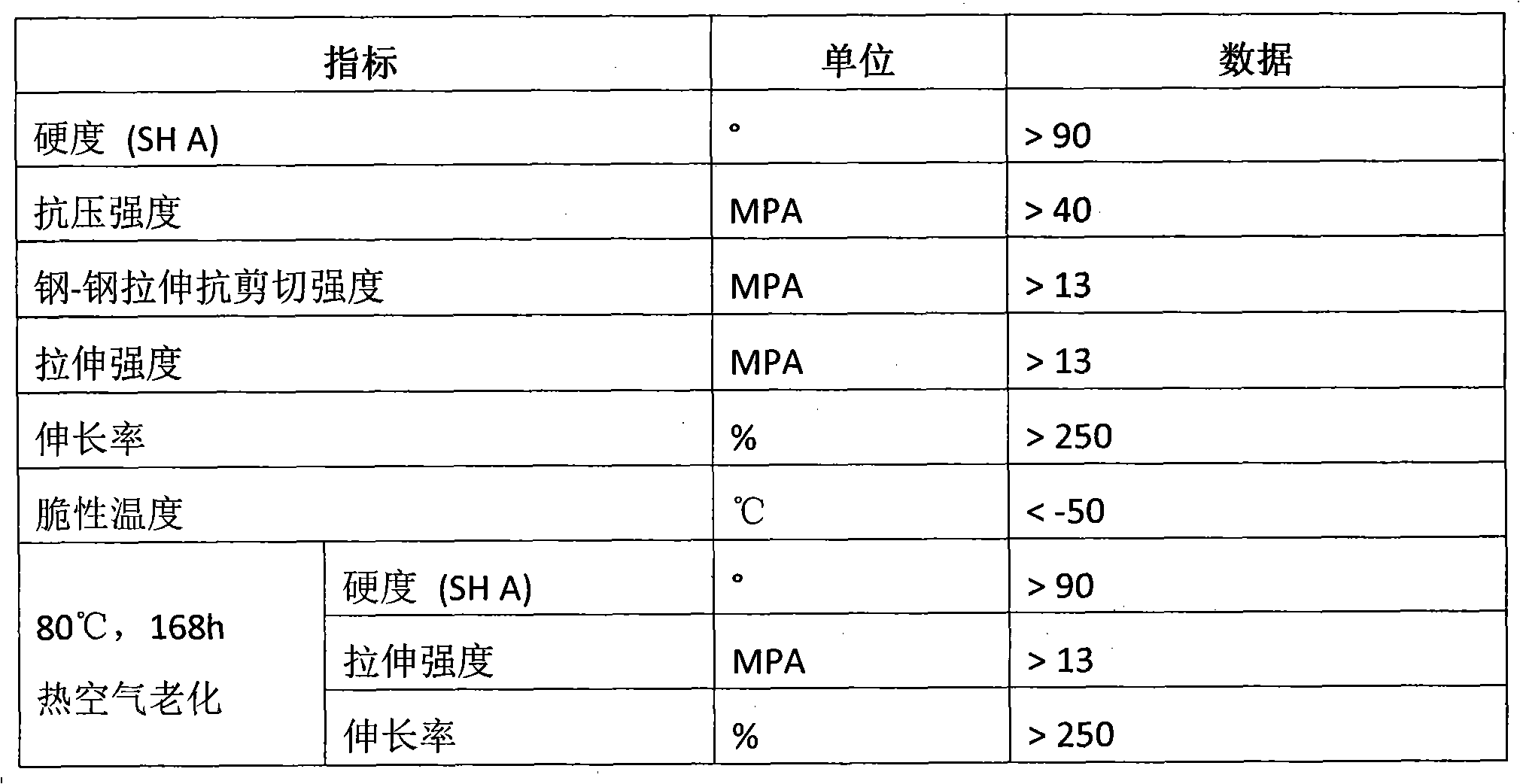

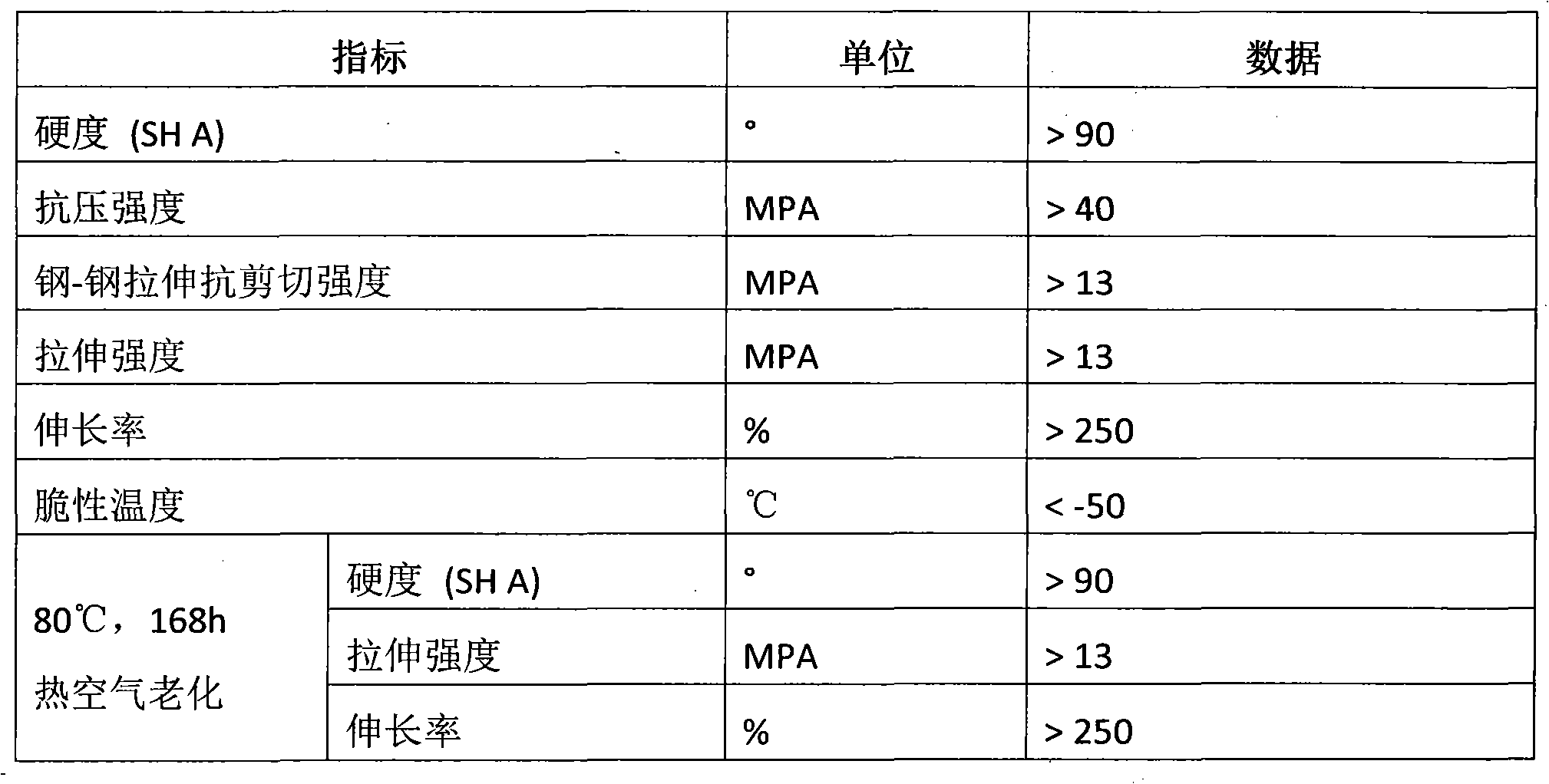

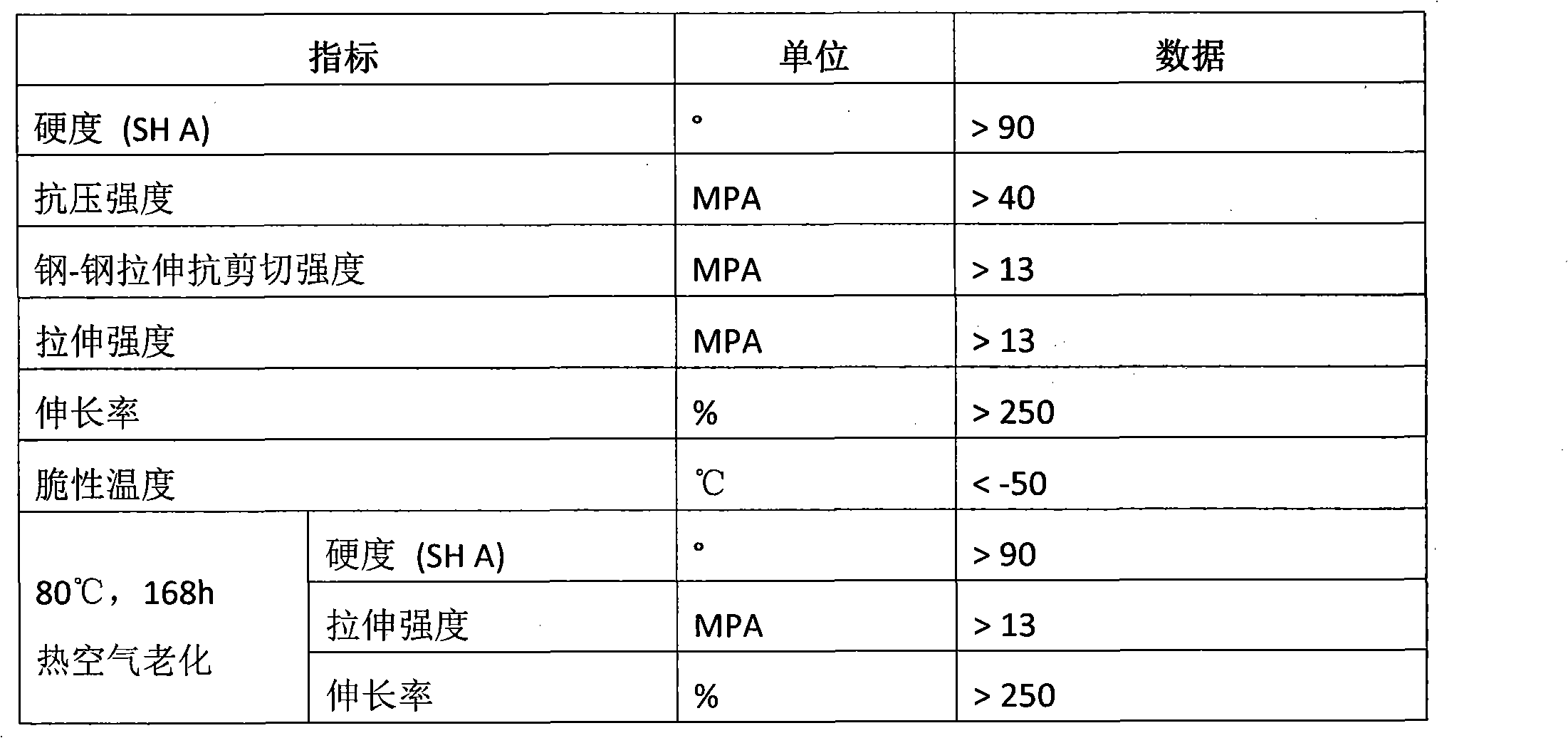

Novel cross-linked polyurethane ballast adhesive for rail transportation

ActiveCN102153982AIncrease resistanceIncrease stiffnessBallastwayPolyureas/polyurethane adhesivesCross-linkVibration attenuation

The invention provides a novel cross-linked polyurethane ballast adhesive for rail transportation, which is characterized in that the ballast adhesive is essentially prepared by mixing a component A and a component B in a weight ratio of (1:0.1)-(1:10) at minus 10 DEG C-100 DEG C, wherein the component A is diisocyanate or a monomer, polymer and derivative of polyisocyanate, or the component A isa prepolymer or semi-prepolymer prepared by reacting a hydroxyl-terminated compound or an amino-terminated compound with isocyanate; and the component B is a mixture of a chain extender and a weather-resistant protective material in a weight ratio of (0.1:1)-(1:5). In the invention, the ballast adhesive using a polyurethane elastic material with good high-low-temperature resistance as the main raw material is substituted for the traditional ballast adhesive in which an epoxy material is used as the main material in foreign countries; and by using the ballast adhesive provided by the invention, the traverse and longitudinal resistances and the ballast bed rigidity of ballast rails (such as linear and curved rails of which ballast shoulders can fall off easily and the like) are improved, and a certain vibration attenuation function is provided for the rail.

Owner:胡小林 +2

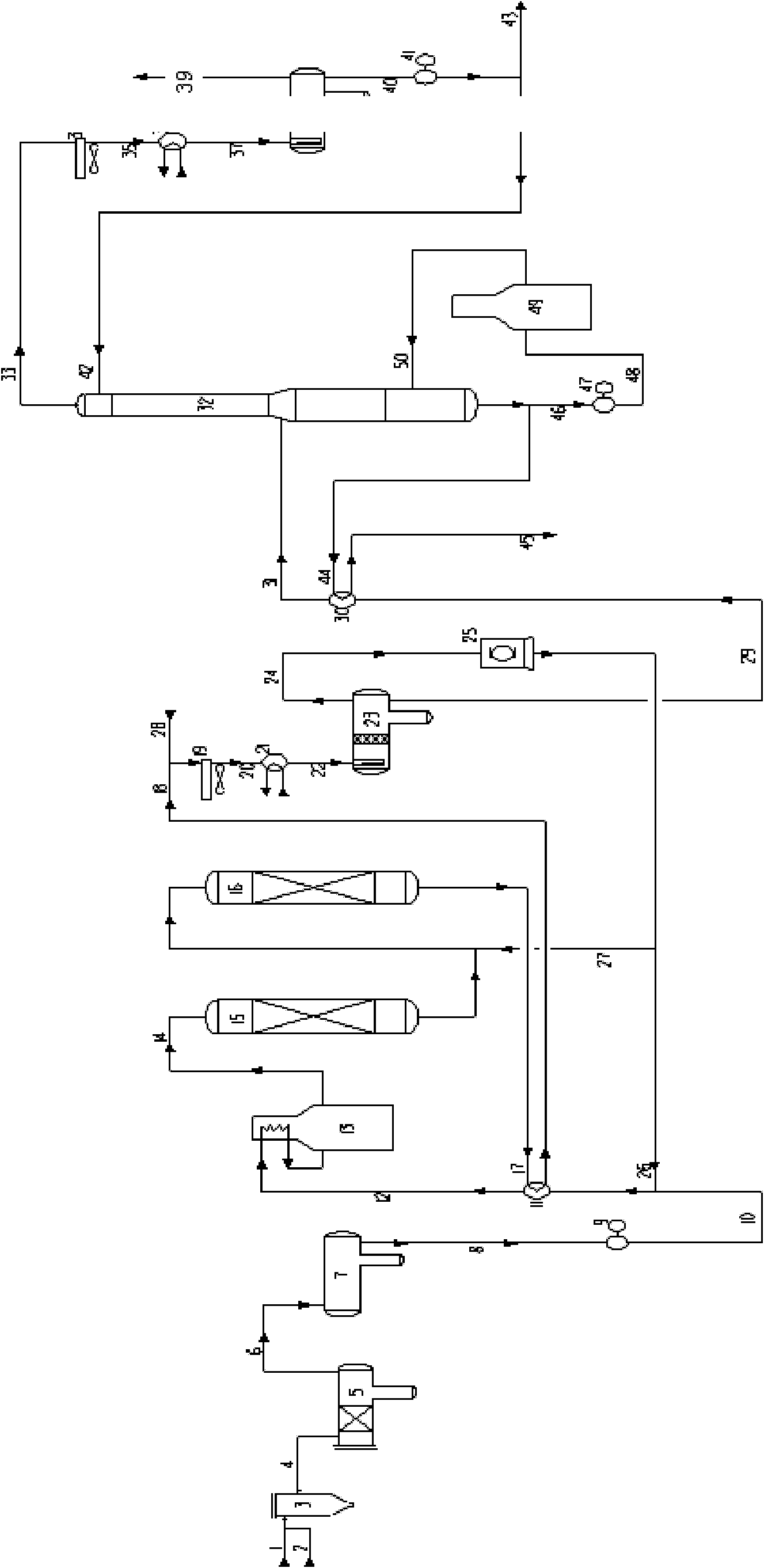

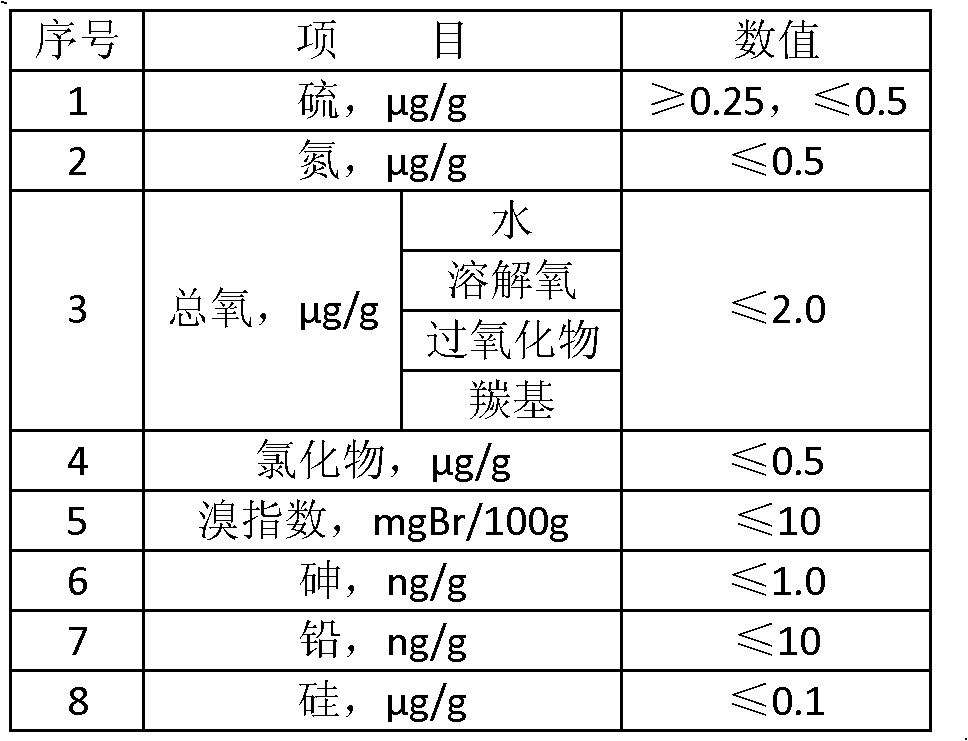

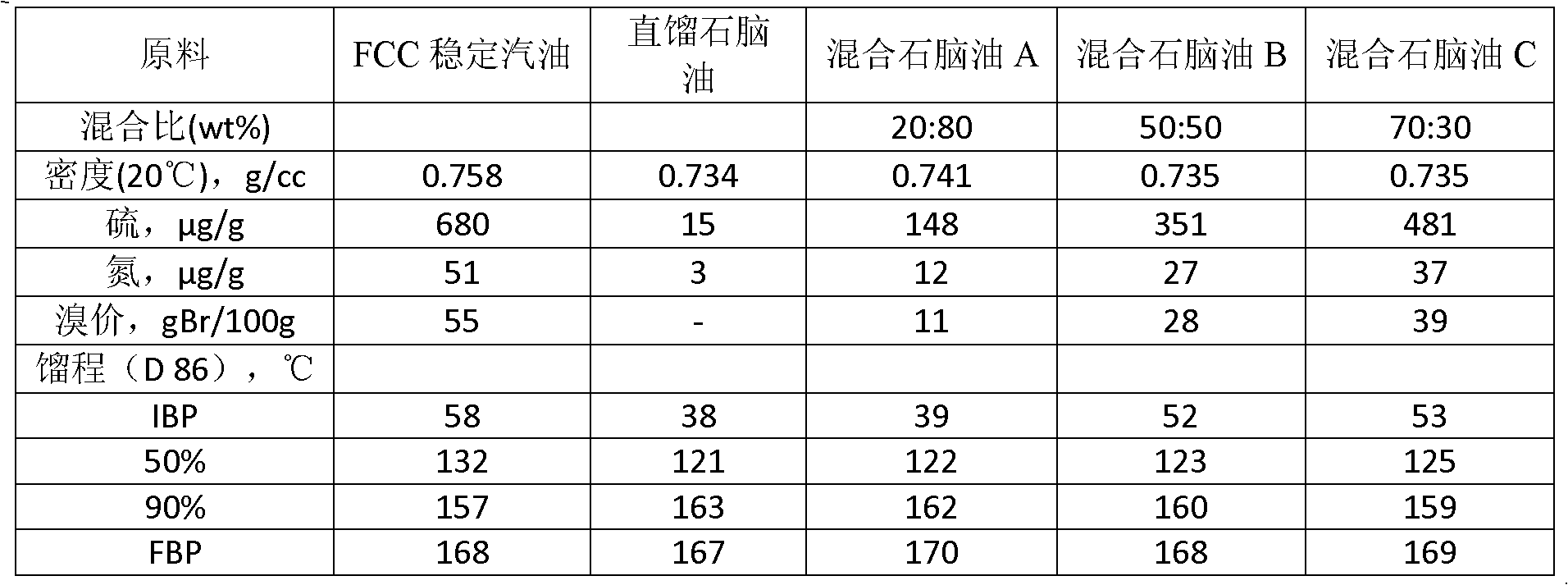

Method for widening catalytic reforming feedstock

ActiveCN102041092AExpand sourceSlow down olefin polymerizationTreatment with hydrotreatment processesChemistryNaphtha

The invention relates to method for widening catalytic reforming feedstock. The comprises the following steps: mixing FCC (fluid catalytic cracking) stabilized gasoline and straight-run naphtha in a ratio of (50:50) to (70:30), filtering the obtained mixture by a feedstock filter so as to remove impurities in the mixture, and then removing the water carried in the mixed naphtha by a coalescer; mixing the mixed naphtha with hydrogen, and heating the obtained mixture to a reaction temperature by a heating furnace, then feeding the obtained mixture into a hydrogenation reactor to contact with a hydrogenation catalyst so as to be subject to olefin saturation, desulphurization and denitrification reactions; and condensating and cooling the obtained hydrogenation effluent, then separating the obtained product so as to obtain hydrogen-rich gas and hydrogenated gasoline, recycling the hydrogen-rich gas, and feeding the hydrogenated gasoline into an evaporation tower to be subject to strippingfractionation, thereby obtaining a refined naphtha meeting the reforming feeding requirements. By utilizing the method provided by the invention, the mixed naphtha containing more than 50 percent of the FCC stabilized gasoline can be subject to hydroprocessing so as to obtain the refined naphtha, wherein the content of the impurities in the refined naphtha satisfies the reforming feeding requirements, thereby solving the shortage problem of the reforming feedstock, and widening the source of the reforming feedstock.

Owner:PETROCHINA CO LTD +1

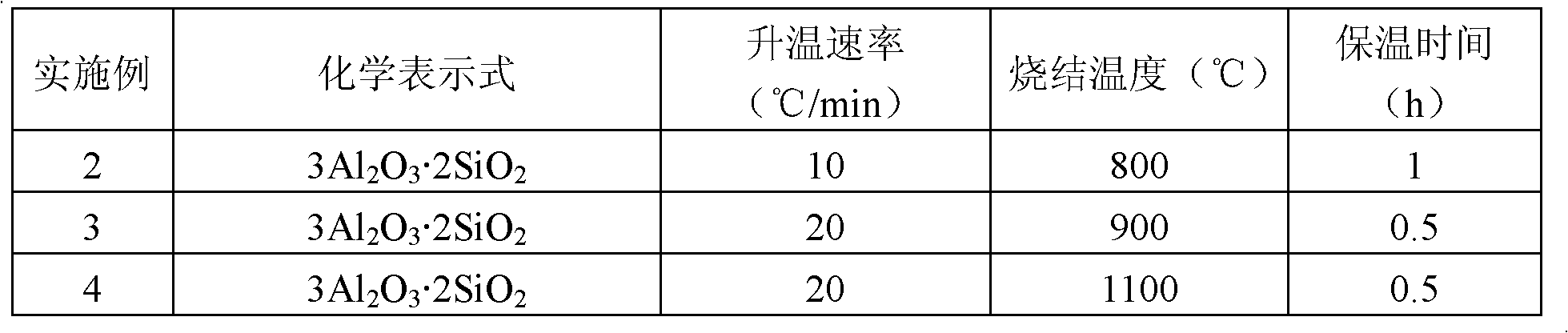

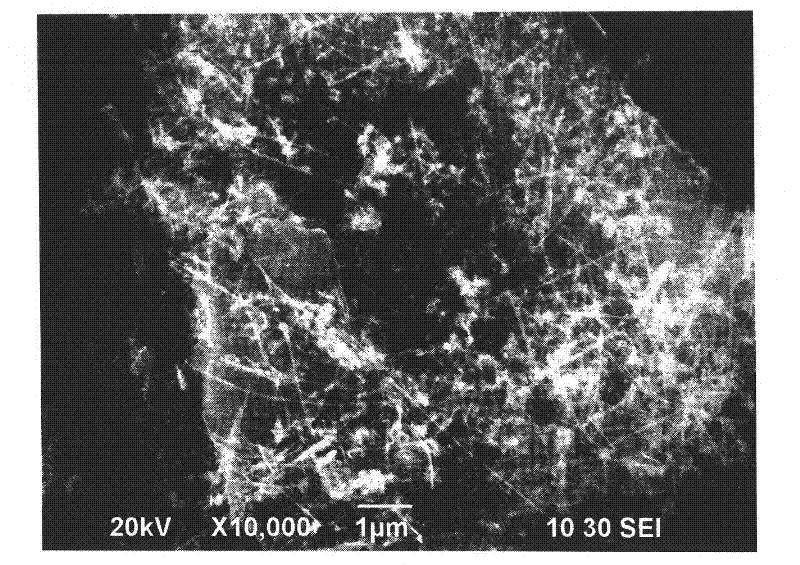

Mullite fiber preparation method

The invention discloses a mullite fiber preparation method which is efficient, rapid, environment-friendly and low in cost. The method includes: taking raw materials according to stoichiometric ratio of elements in the mullite fiber chemical formula, preparing colloid, performing fiber forming and drying for colloid discharging to obtain mullite non-crystal fiber, adding the fiber into a sagger made of wave permeable materials, placing the sagger in a special microwave oven, controlling heating rate by adjusting the microwave power under the air or oxygen atmosphere, heating to a heat treatment temperature, and cooling to the room temperature to obtain the mullite fiber. The mullite fiber prepared by the method is high in impurity and low in porosity, the grain size is about 30nm, and the fiber diameter ranges from 6 micrometers to 10 micrometers. Further, the mullite fiber is excellent in uniformity, brittle fracture and chalking of the fiber are greatly reduced, yield is increased, heat treatment temperature is lowered, heat insulation time is shortened, and production efficiency is greatly improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

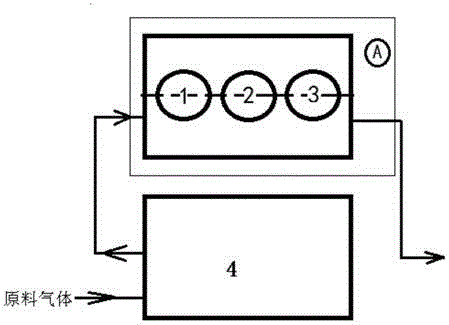

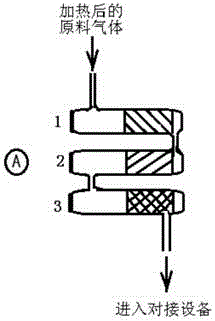

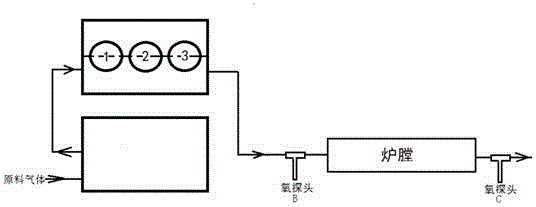

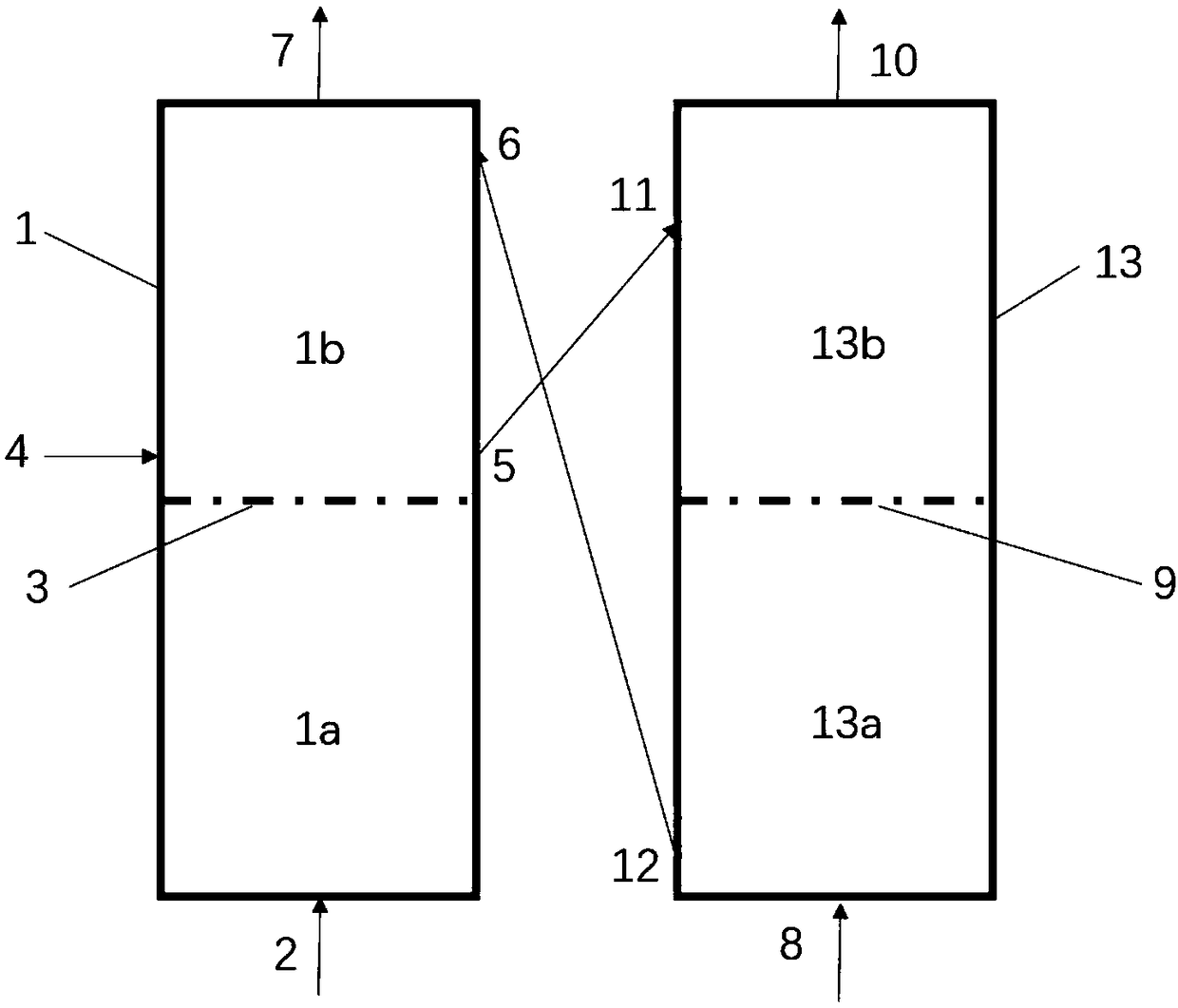

Deep deoxidizing apparatus and application thereof

The invention relates to a deep deoxidizing apparatus and an application thereof, and belongs to the technical field of chemical reaction deoxidization. The deep deoxidizing apparatus designed by the invention comprises a gas heating device (4), a No.1 deoxidizing channel (1), a No.2 deoxidizing channel (2) and a No.3 deoxidizing channel (3) which are sequentially communicated, wherein a No.1 deoxidizing agent is contained inside the No.1 deoxidizing passage (1), and the No.1 deoxidizing agent is selected from one of elemental metallic copper and copper-based alloy; a No.2 deoxidizing agent is contained inside the No.2 deoxidizing channel (2), and the No.2 deoxidizing agent is selected from one of elemental metallic titanium, sponge titanium and titanium-based alloy; a No.3 deoxidizing agent is contained inside the No.3 deoxidizing passage (3), and the No.3 deoxidizing agent is selected from one of elemental magnesium and magnesium-based alloy. The apparatus disclosed by the invention, when applied to deoxidizing treatment on Ar gas which is 99.999% in purity, can achieve a deoxidizing precision of 10-21ppm. The apparatus designed by the invention can carry out efficient deep deoxidization under normal pressure, and has the advantages of simple equipment, recycling use of the deoxidizing agents and the like.

Owner:CENT SOUTH UNIV

Lithium ion battery and negative electrode active material thereof

InactiveCN102332569ASi content controllableStable structureCell electrodesSecondary cellsCarbon layerNano silicon

The invention which belongs to the technical field of lithium ion batteries especially relates to a lithium ion battery and a negative electrode active material thereof. The negative electrode active material comprises graphite, silicon nanometer wires growing on graphite, and an amorphous carbon layer coated on the silicon nanometer wires. The lithium ion battery prepared with the negative electrode active material has the characteristics of high first efficiency, high capacity, low expansion, excellent cycle performance and the like. The invention also provides the lithium ion battery with the negative electrode active material.

Owner:DONGGUAN AMPEREX TECH +2

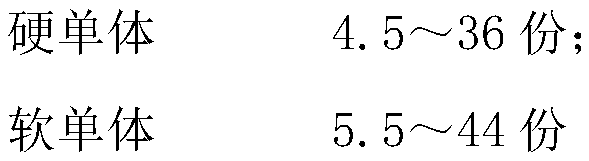

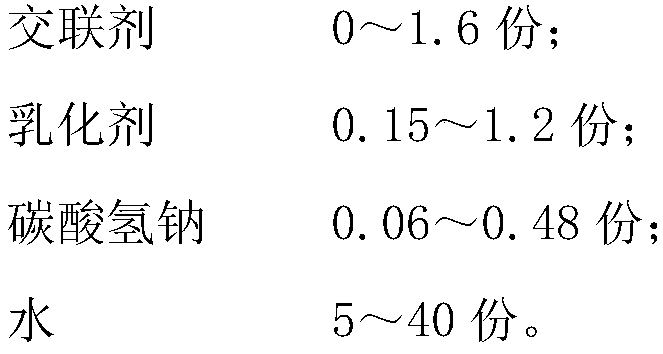

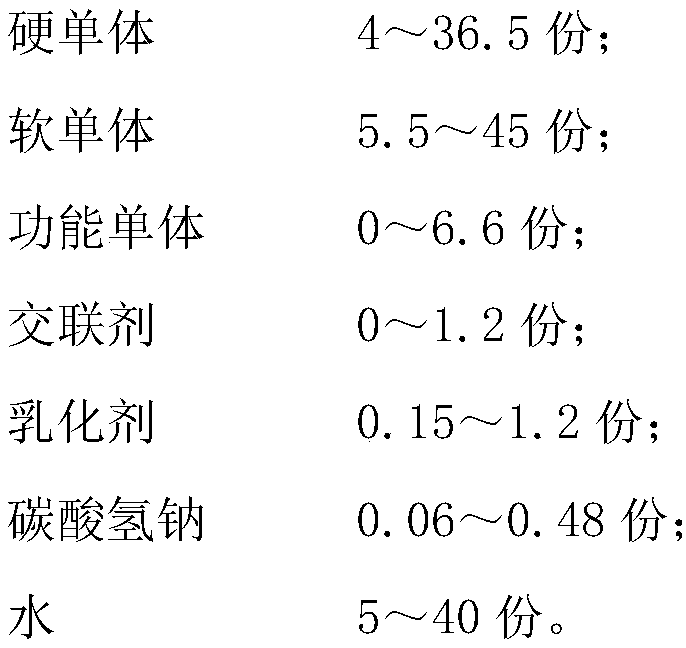

Silicon negative electrode adhesive for lithium battery and preparation method of adhesive

The invention relates to a silicon negative electrode adhesive for a lithium battery. The adhesive is obtained by performing polymerization on a core emulsion and a shell emulsion, wherein the core emulsion is obtained by performing polymerization on a core pre-emulsion and a core initiator solution, and the shell emulsion is obtained by performing polymerization on a shell pre-emulsion and a shell initiator solution. The adhesive provided by the invention has good adhesion force and toughness, significantly reduces particle pulverization of a silicon-based material, well protects a conductivenetwork in an electrode, improves quality of the lithium battery, and has very good economic benefits.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD

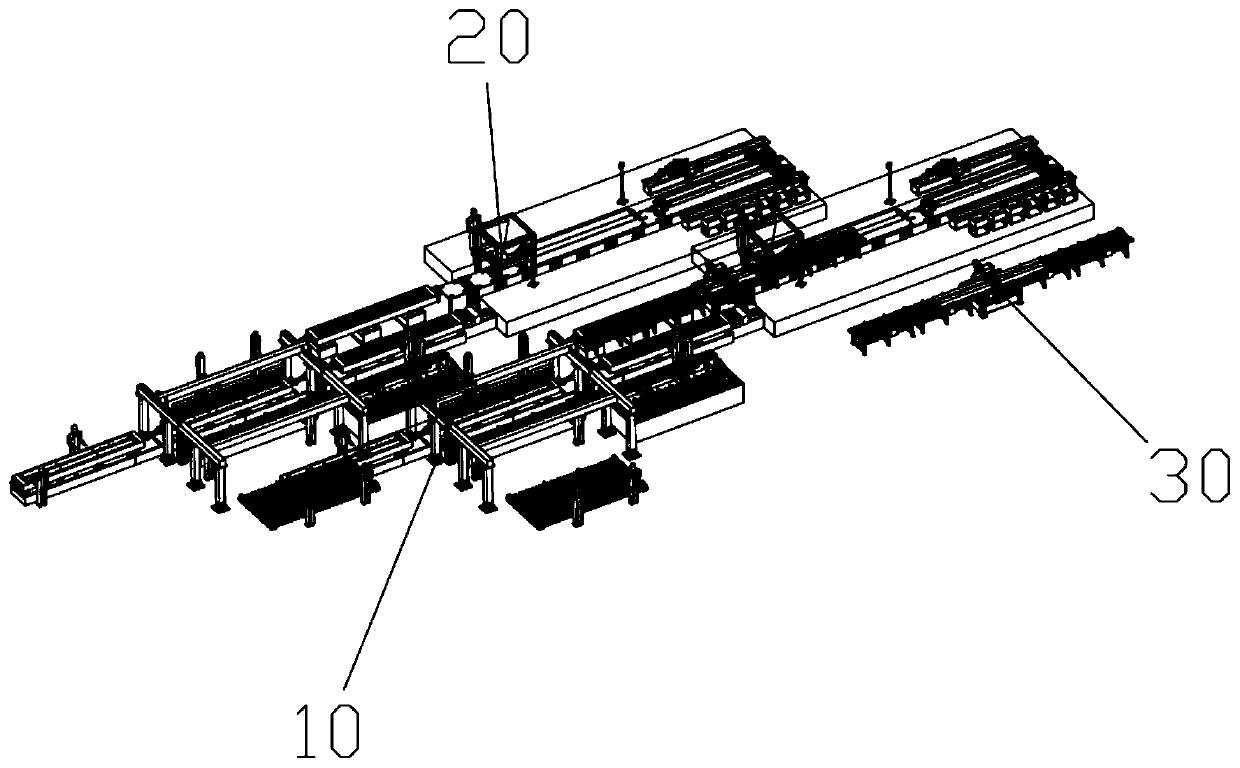

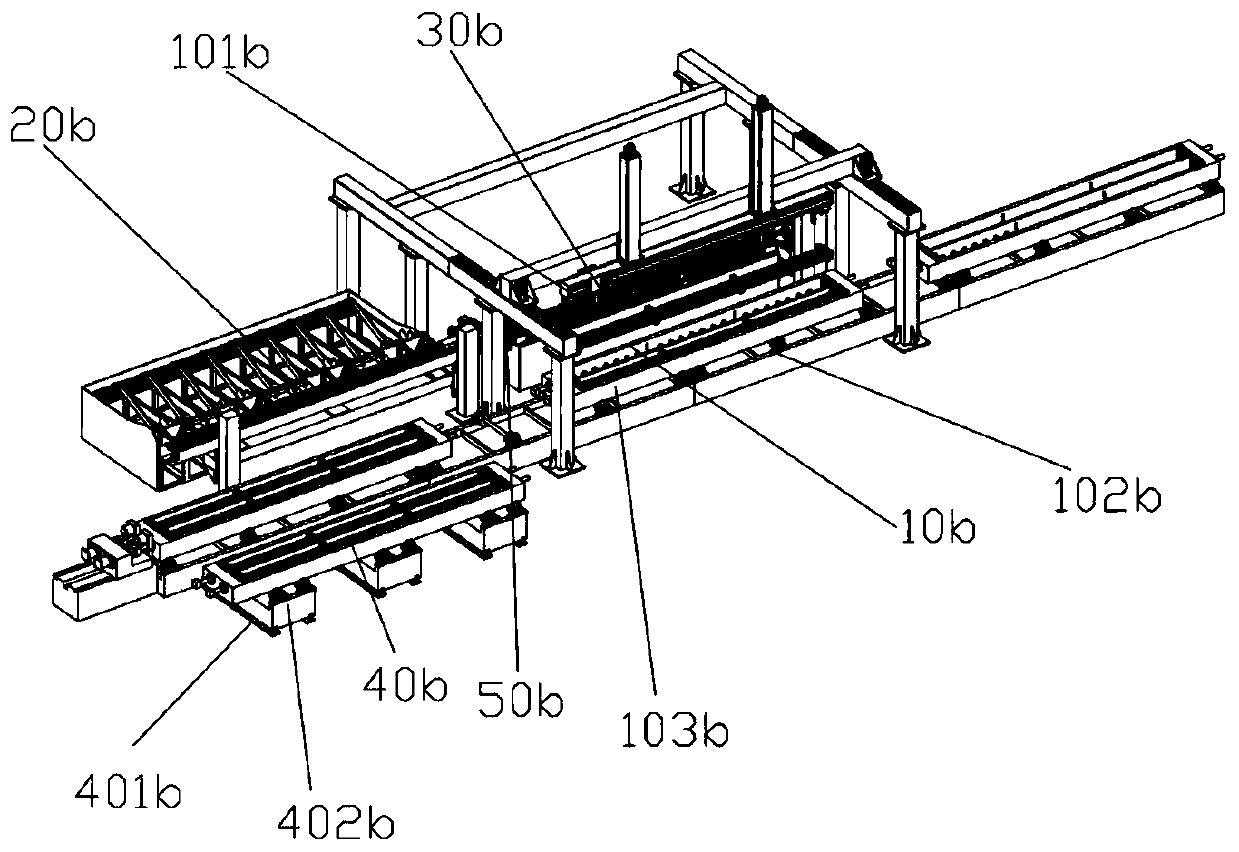

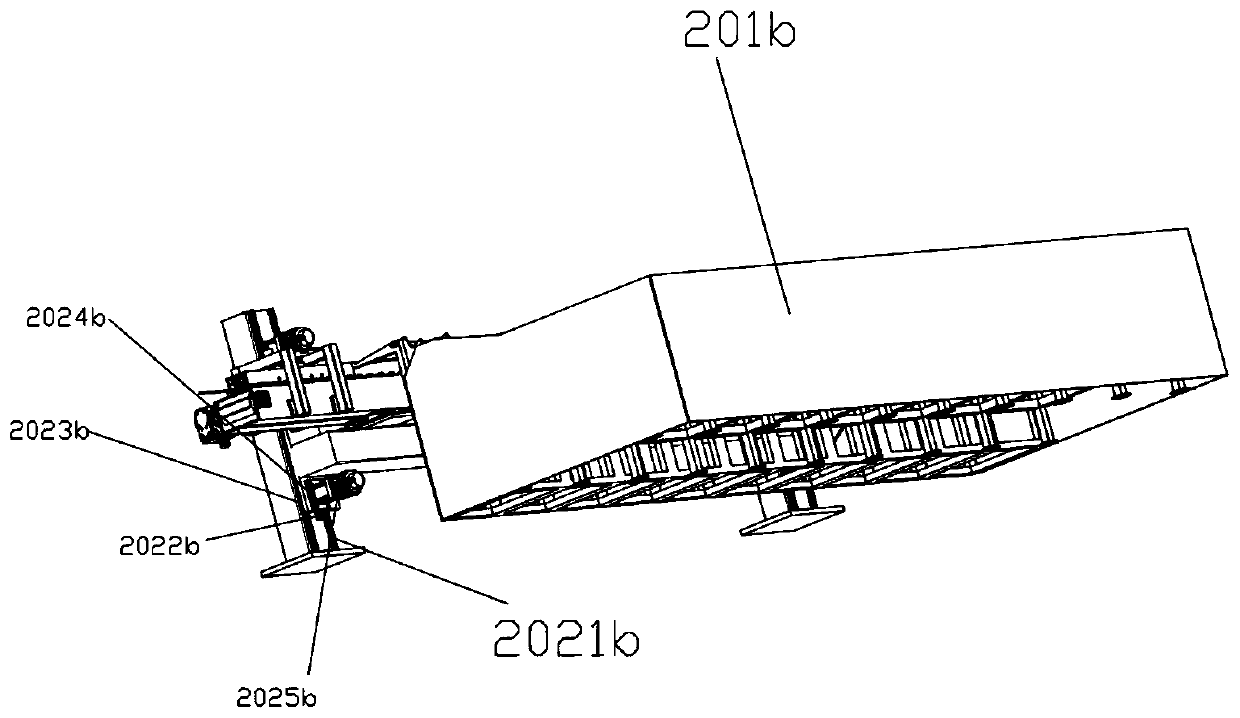

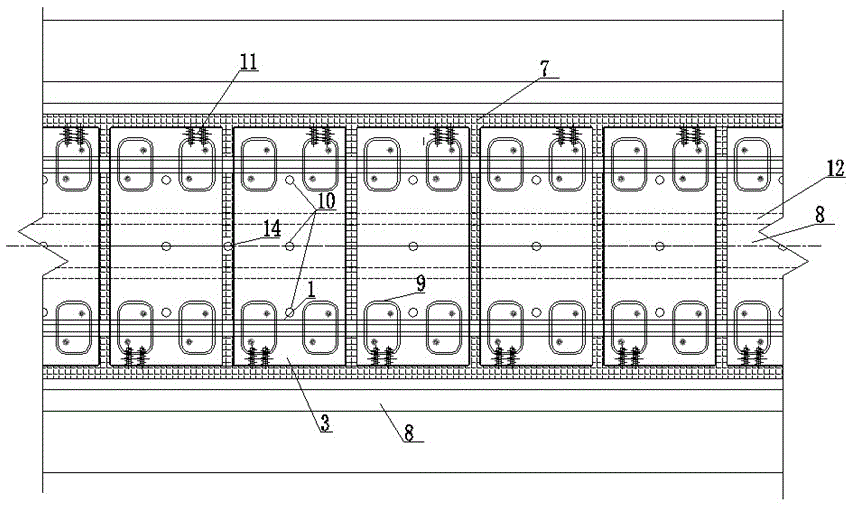

Automatic sleeper production line and working method thereof

ActiveCN110450277AReal-time monitoring of actual statusIncrease stiffnessCeramic shaping plantsFeeding arrangmentsProduction lineAir bubble

The invention discloses an automatic sleeper production line and a working method thereof. The automatic sleeper production line comprises a framework forming device, a distributing device and a watercutting device; and a vibration conveying mechanism is arranged in the middle of a groove in the distributing device and comprises a plurality of rectangular supports, a certain gap is formed betweeneach two rectangular supports, and a rail wheel set is arranged in the gap between every two rectangular supports. When the automatic sleeper production line runs, air bubbles are reduced through vibration between gaps; and meanwhile, a pin shaft material disc is arranged on a pedal assembly, the pin shaft is inserted into concrete, rigidity of the sleeper is improved, track pulverization is reduced, and bearing force of a track structure is increased.

Owner:NANJING NIEBO INTERNET OF THINGS TECH CO LTD

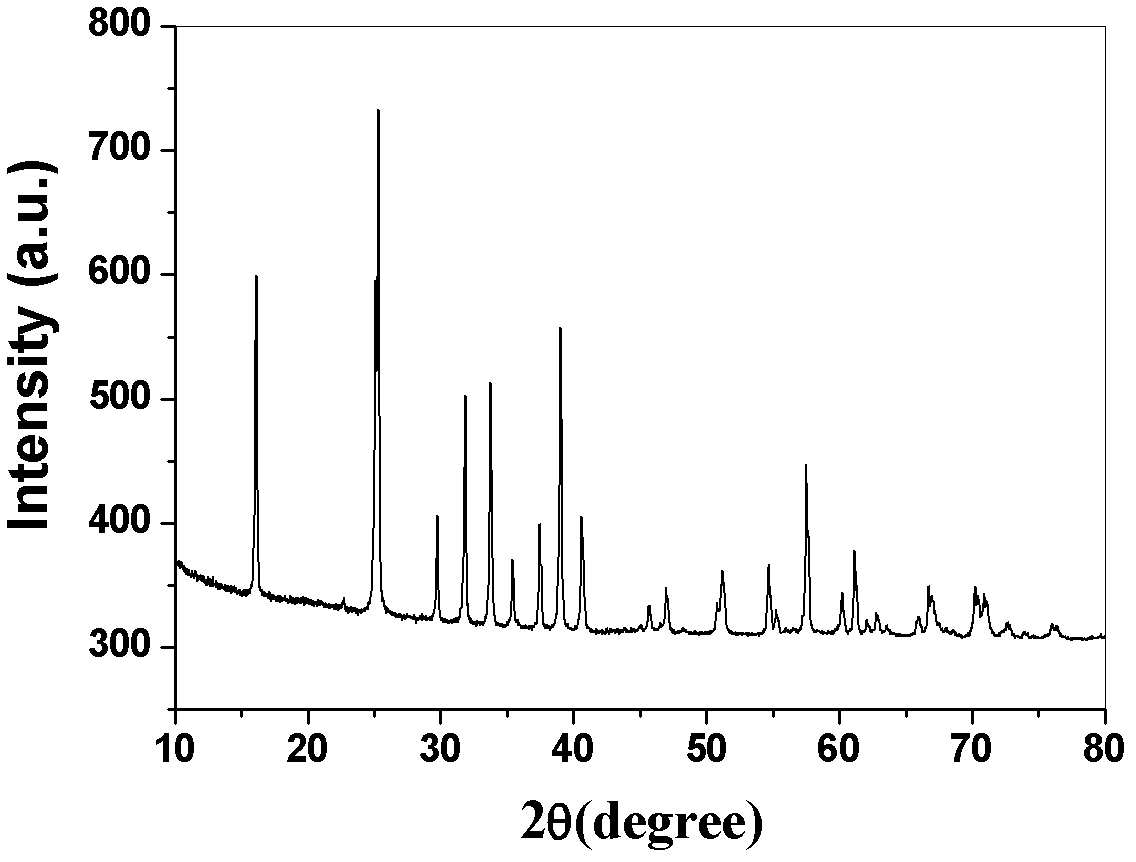

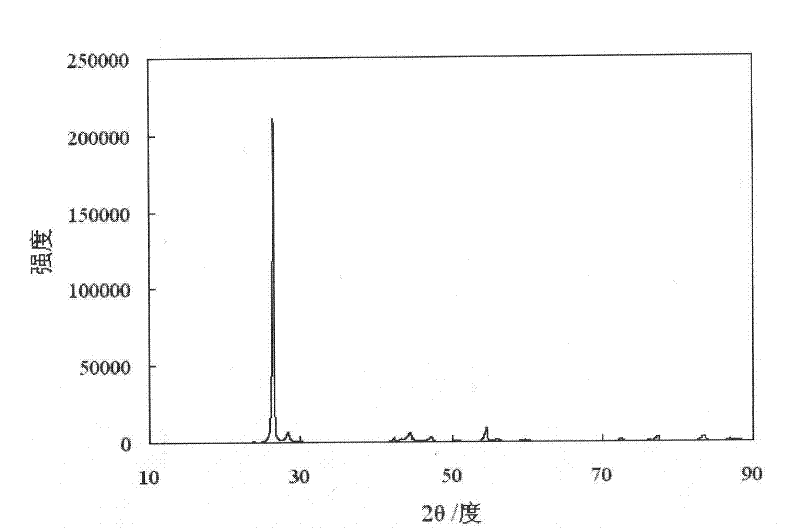

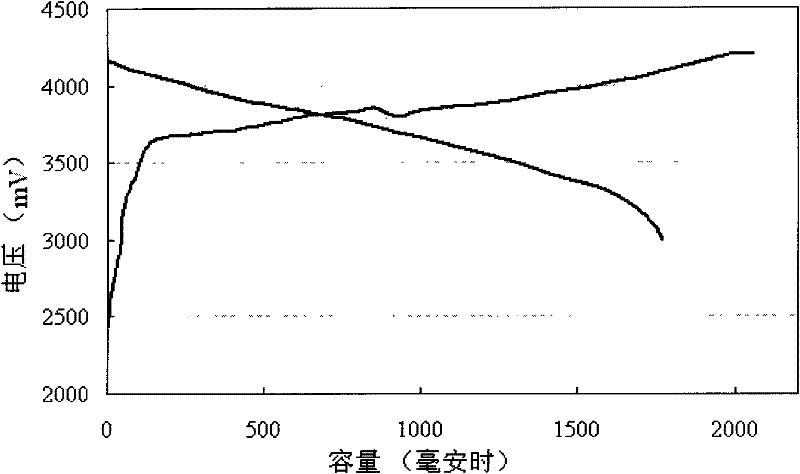

Preparation method of porous metal doped lithium manganate/graphene lithium battery positive electrode material

InactiveCN105206799AImprove conductivityAvoid reunionMaterial nanotechnologyCell electrodesCvd grapheneMuffle furnace

The invention relates to a preparation method of a porous metal doped lithium manganate / graphene lithium battery positive electrode material. The method includes the steps that 1, a sol-gel method is adopted for preparing a precursor of porous LiM0.2Mn1.8O4, and the precursor is put into a muffle furnace to be calcined at constant temperature to obtain porous LiM0.2Mn1.8O4; 2, graphene oxide is taken and added into deionized water to prepare a graphene oxide solution with the mass concentration of 0.05-0.1 g / mL; 3, porous LiM0.2Mn1.8O4 is put into the graphene oxide solution, the mixture is subjected to magnetic stirring, ultrasonic dispersion and drying and then transferred into a tube furnace to be calcined at constant temperature, and the porous metal doped lithium manganate / graphene lithium battery positive electrode material is obtained. Compared with the prior art, the preparation method is simple, and the raw materials are easy to get; the prepared material is good in crystallinity and uniform in particle size, and the size is about 30 nm; serving as a lithium battery positive electrode material, the prepared material is good in electrochemical stability, high in specific discharge capacity and good in rate performance and cycle performance.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method for MOF derived oxide coated NCA high nickel ternary cathode material

InactiveCN110061224AEasy to operateInnovative designCell electrodesSecondary cellsMass ratioMetal-organic framework

The invention discloses a preparation method for an MOF derived oxide coated NCA high nickel ternary cathode material and belongs to the technical field of a lithium ion battery. The preparation method comprises the steps of (1), preparing corresponding metal organic frameworks (MOFs) containing specific metal elements; (2), mixing an NCA high nickel ternary cathode material with the specific MOFsaccording to a mass ratio, and carrying out ball milling, thereby enabling the MOFs to be attached to the surface of the NCA high nickel ternary cathode material uniformly; and (3), calcining the material in air, thereby changing a coating material from the MOFs to MOF derived oxides, and obtaining a final product. According to the method, through utilization of features of the nano-material MOFs, a coating layer is kept at a nano-level, so the surface of the material is protected, side reaction due to direct contact with electrolyte is reduced, and battery performance of the cathode materialis improved. The method is novel and convenient and is obvious in effect.

Owner:TIANNENG SAFT ENERGY JOINT CO

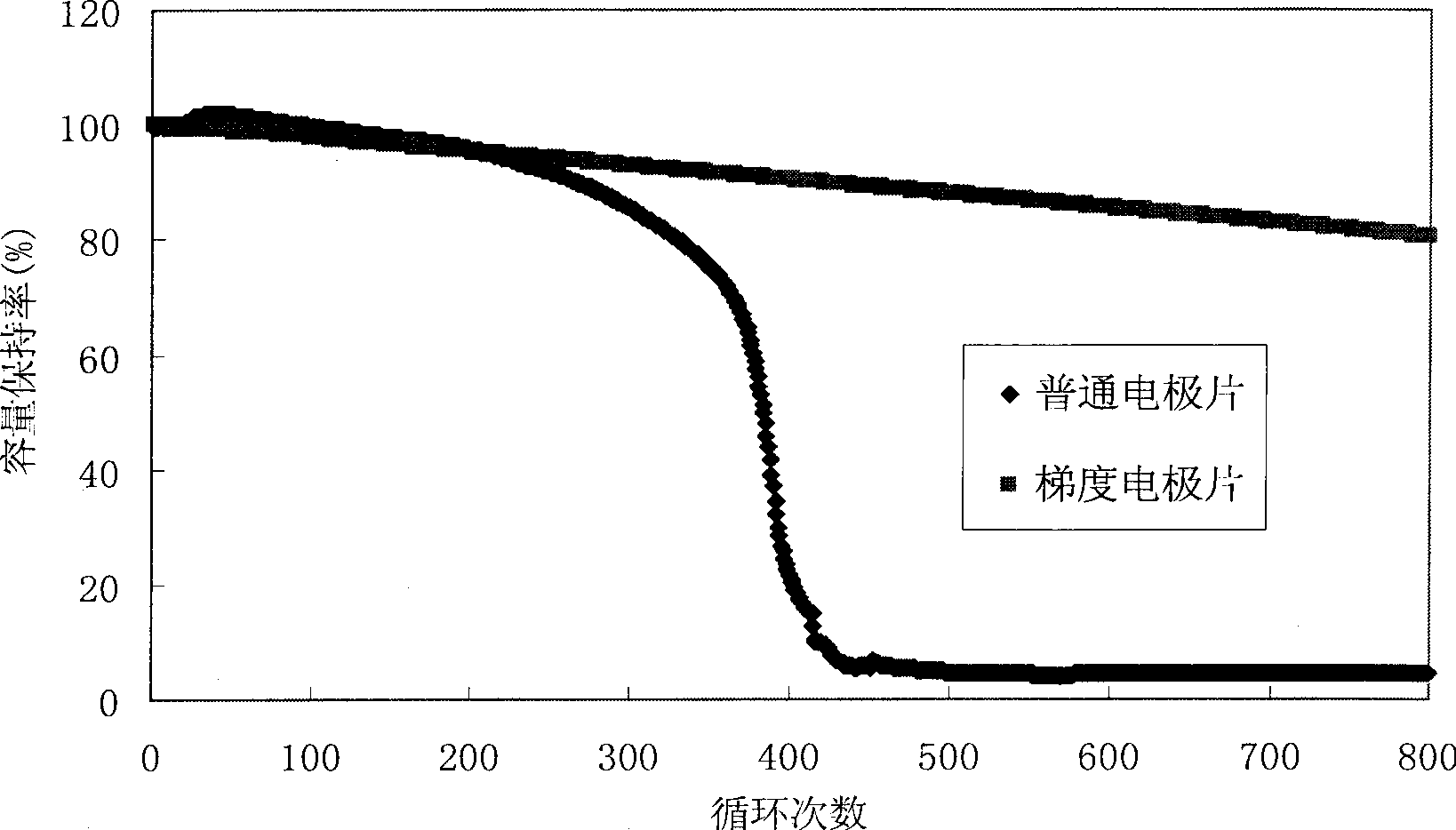

Battery electrode splice, preparation thereof, and battery prepared by the electrode splice

InactiveCN101483235AGood mechanical propertiesGood toughnessElectrode manufacturing processesActive material electrodesElectrochemistryBattery electrode

The invention relates to a lithium ion battery and its preparing method, especially to a battery slice with good mechanical property, smooth electrochemistry process and good cycling stability and a preparation method thereof and a battery made thereby. The battery electrode slice comprises an afflux medium and a coating layer containing an electrode active matter and an auxiliary material, wherein the electrode active matter is distributed in a state that the granularity and the content are gradually decreasing from the afflux medium to outside in the coating layer. The preparation method comprises: (1) preparing a mixture of the electrode active matter and the auxiliary; (2) adding an adhesive, mixing uniformly and pulping; (3) coating the obtained slurry on the afflux medium to form the coating layer, enabling the coating layer internal to form the active matter gradient distribution through sedimentation and drying; (4) pressing the obtained electrode slice by a roller press. The invention also relates to the battery made by the battery slice from the invention.

Owner:SHENZHEN CAPCHEM TECH

Double-CFB (circulating fluidized bed) reaction-regeneration system and method to prepare arenes with synthetic gas

ActiveCN108654527AReduce design difficultyReduce backmixingLiquid hydrocarbon mixture productionBio-feedstockFluidized bedAromatization

A double-CFB (circulating fluidized bed) reaction-regeneration system and method to prepare arenes with synthetic gas are provided. The system herein comprises an aromatization reactor and a catalystregeneration reactor which are connected with each other through a pipeline; the aromatization reactor comprises a first catalyst filling area and a second catalyst filling area; the catalyst regeneration reactor includes a fourth catalyst filling area and a third catalyst filling area; the aromatization reactor is filled with a hydrocarbon synthetic catalyst and an aromatization catalyst; under the action of a flow of gas, the hydrocarbon synthetic catalyst stays mainly in the area below, and the aromatization catalyst stays mainly in the area above. A regeneration method is also disclosed, including: after the aromatization catalyst is inactive, allowing the aromatization catalyst to enter a low-temperature hypoxic area of the catalyst regeneration reactor and then enter a high-temperature hyperoxic area of the catalyst regeneration reactor. The system and method herein have the advantages that controlling at different temperatures is achieved and catalyst design is less difficult.

Owner:TSINGHUA UNIV

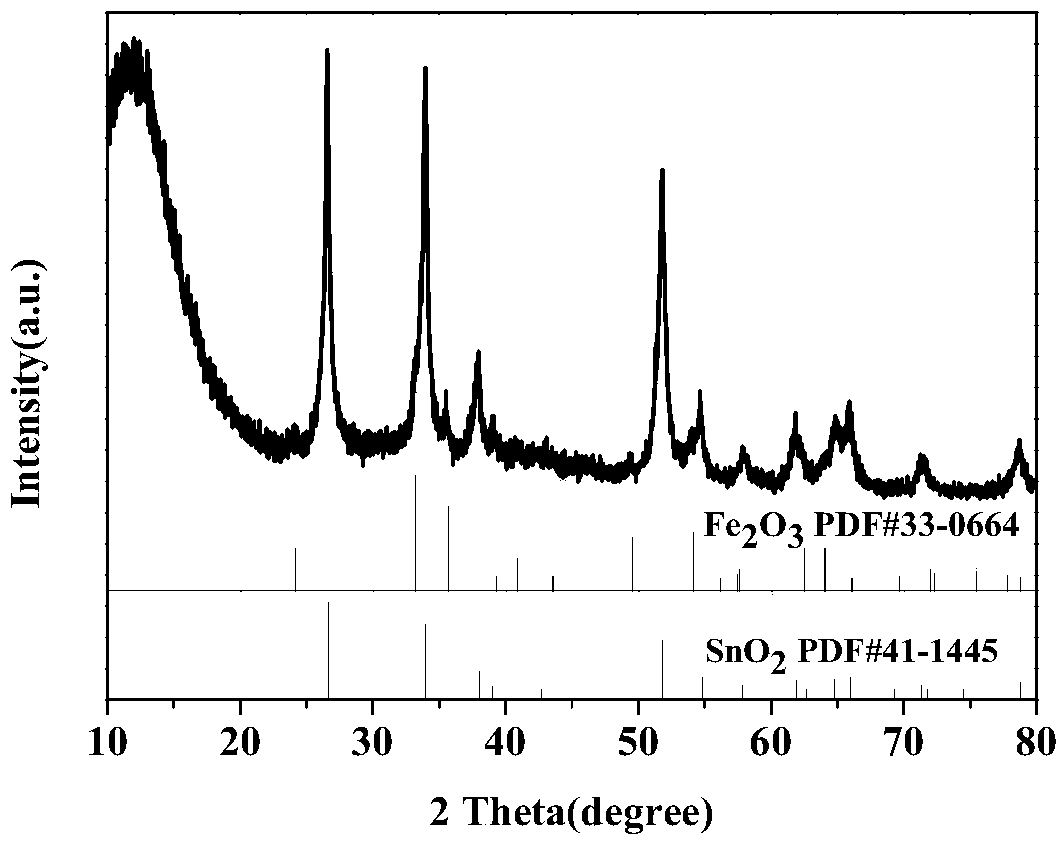

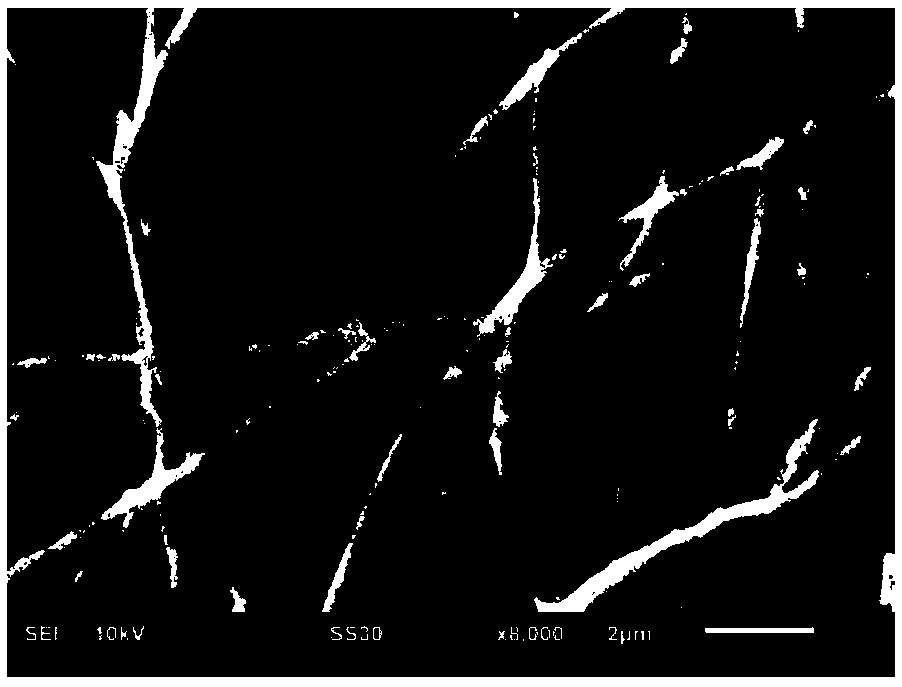

Fe2O3/SnO2 composite material and preparation method and application thereof and lithium-ion battery

InactiveCN108767243AImproved magnification performanceImprove performanceCell electrodesSecondary cellsFiberAir atmosphere

The invention discloses a Fe2O3 / SnO2 composite material and a preparation method and application thereof and a lithium-ion battery and relates to the technical field of preparation of electrode materials for lithium-ion batteries. The Fe2O3 / SnO2 composite material has a fibrous microstructure. The preparation method of the Fe2O3 / SnO2 composite material comprises the following steps of adding a tinsalt and a ferric salt to an electrospinning solution, mixing evenly and then carrying out electrostatic spinning to obtain a head product; and drying the head product and carrying out thermal treatment in air atmosphere to obtain the Fe2O3 / SnO2 composite material. The Fe2O3 / SnO2 composite material disclosed by the invention has the advantages of being small in grain size, uniform in granularity,high in charge-discharge specific capacity, good in cycle performance and excellent in rate capability. The preparation method of the Fe2O3 / SnO2 composite material disclosed by the invention has theadvantages of relatively low cost and relatively high output rate, and microscopic fiber shape and form, size and arrangement of the material can be well controlled.

Owner:HUBEI ENG UNIV

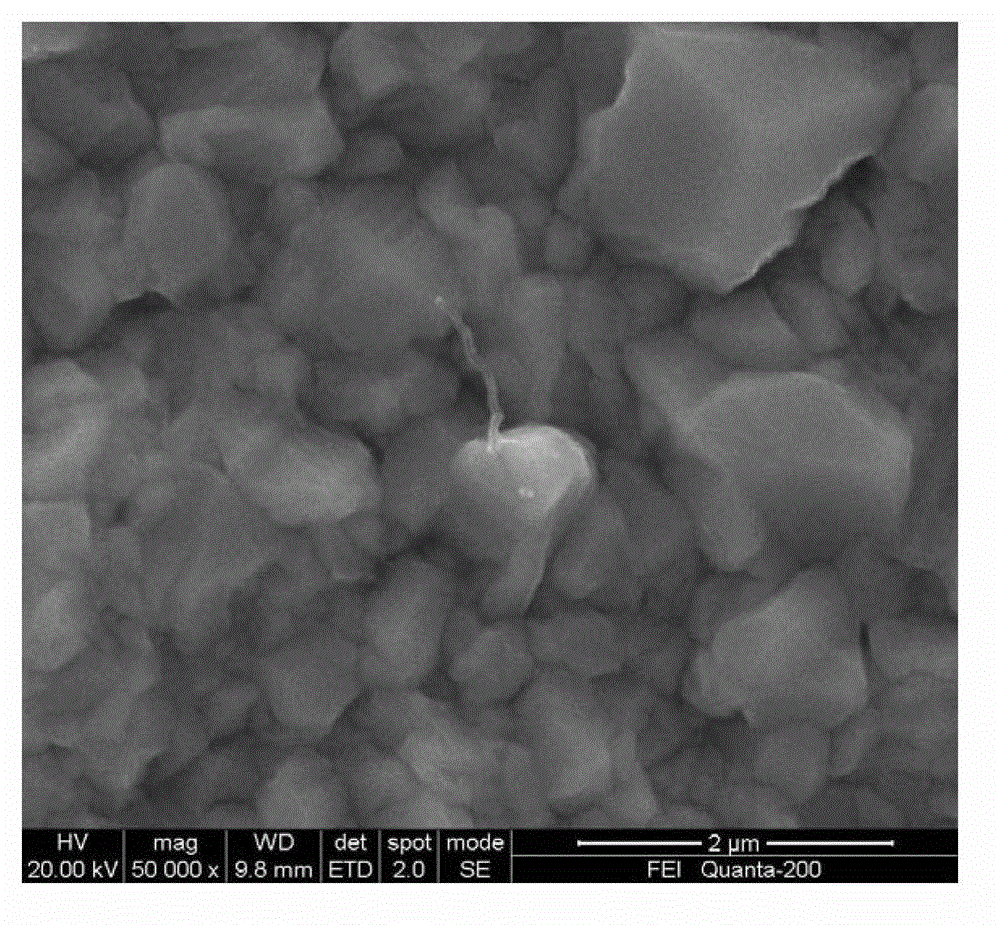

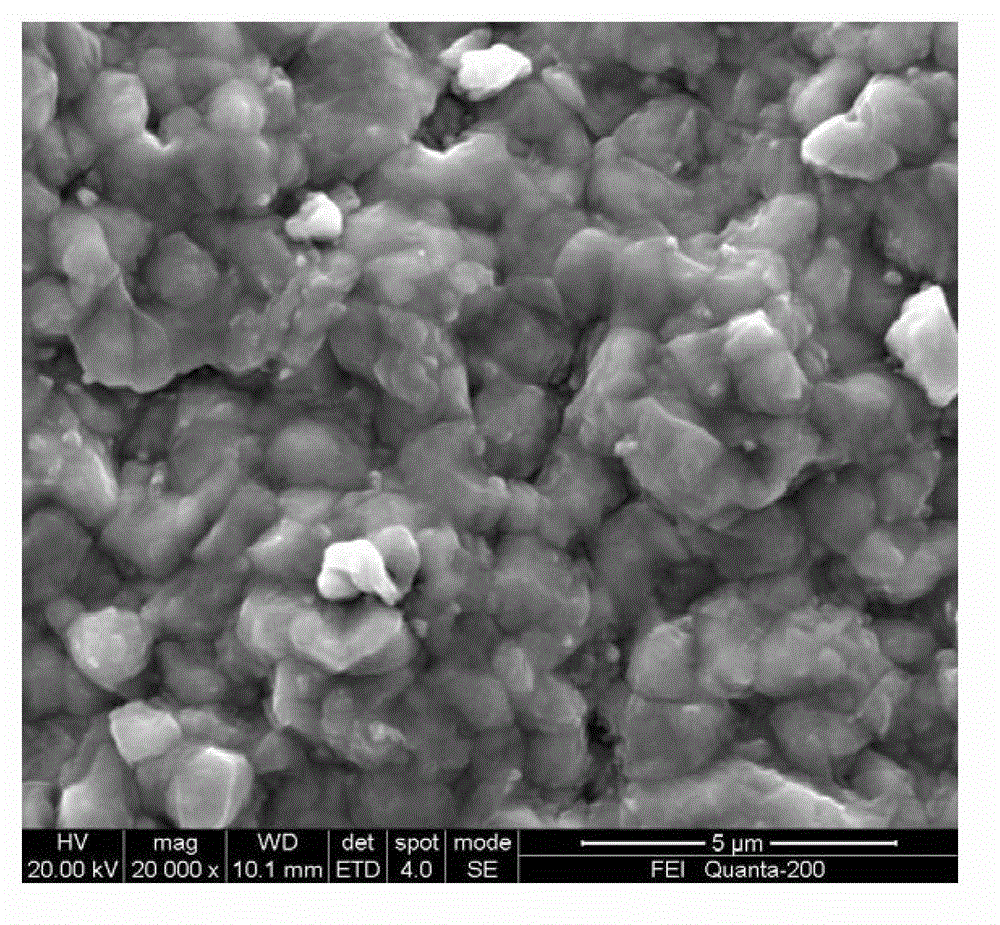

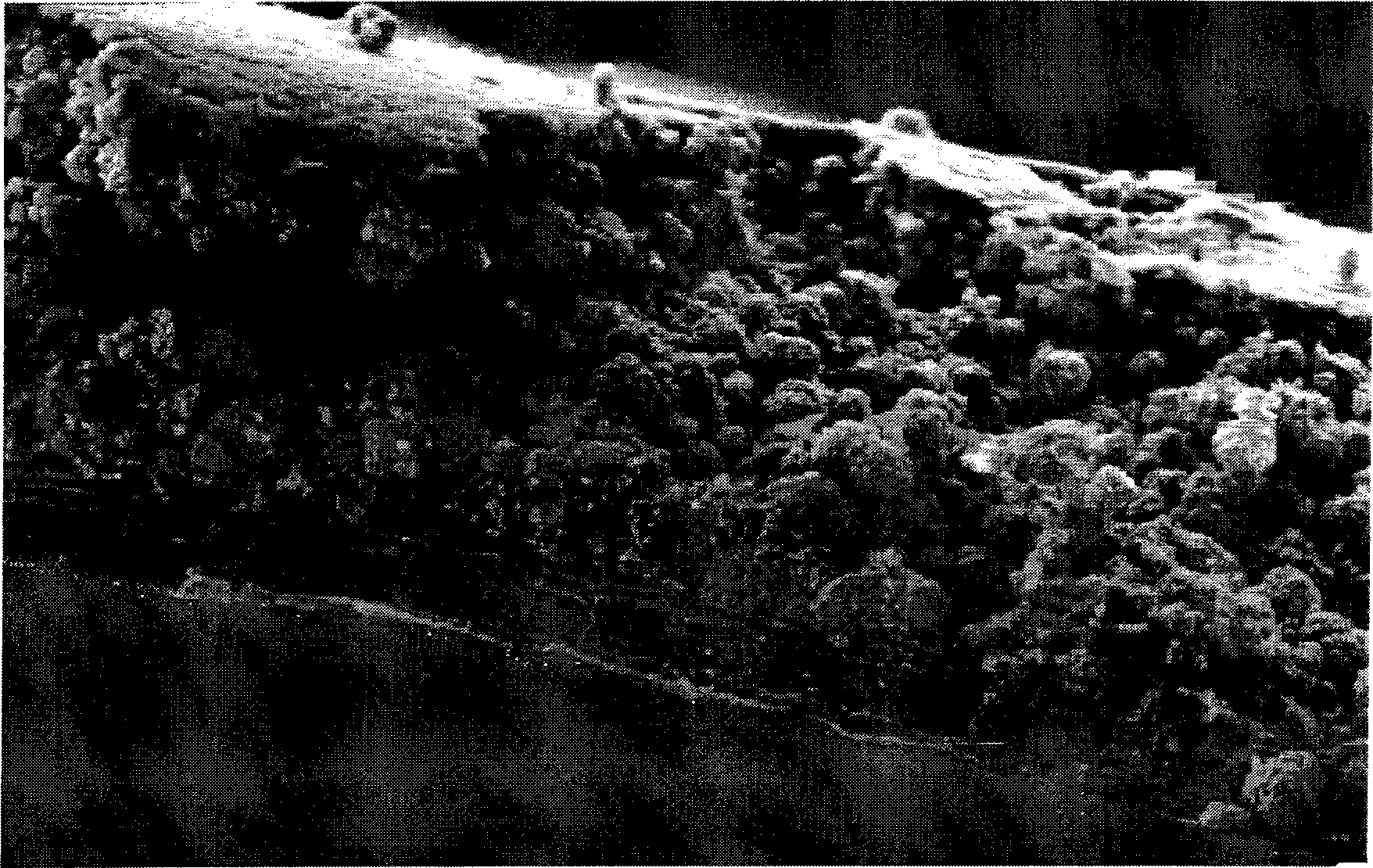

Carbon nano tube-Sn-M alloy cathode material and preparation method thereof

InactiveCN103022449AComplete structureResidue reductionElectrolytic coatingsCell electrodesCarbon nanotubeAlloy

The invention discloses a carbon nano tube-Sn-M alloy cathode material and a preparation method of the carbon nano tube-Sn-M alloy cathode material. According to the invention, carbon nano tubes (CNTs) are composited into an electrode; a CNTs-Cu connection layer is added between the active material and a current collector; and the advantages of multicomponent alloy are combined, so that the circulation property of the alloy cathode is greatly improved. According to the invention, copper foil is used as a current collector (electroplate substrate) to composite and electroplate a CNTs-Cu composite coating with the thickness of 1-5 micro and a thin tin (or tin alloy) film with a thickness of 1-4 micro in sequence; and finally the CNTs-Sn-M alloy cathode material is obtained by heat treatment. The lithium ion battery alloy cathode prepared by adopting the method has a specific discharge capacity of 500-800 mAh / g for the first time, and the specific capacity is only decayed by 2-5 percent after 100 times of circulation. According to the invention, the process is simple, the performance of the prepared alloy cathode is good, and the alloy cathode is suitable for performing large-scale industrialized production.

Owner:XIANGTAN UNIV

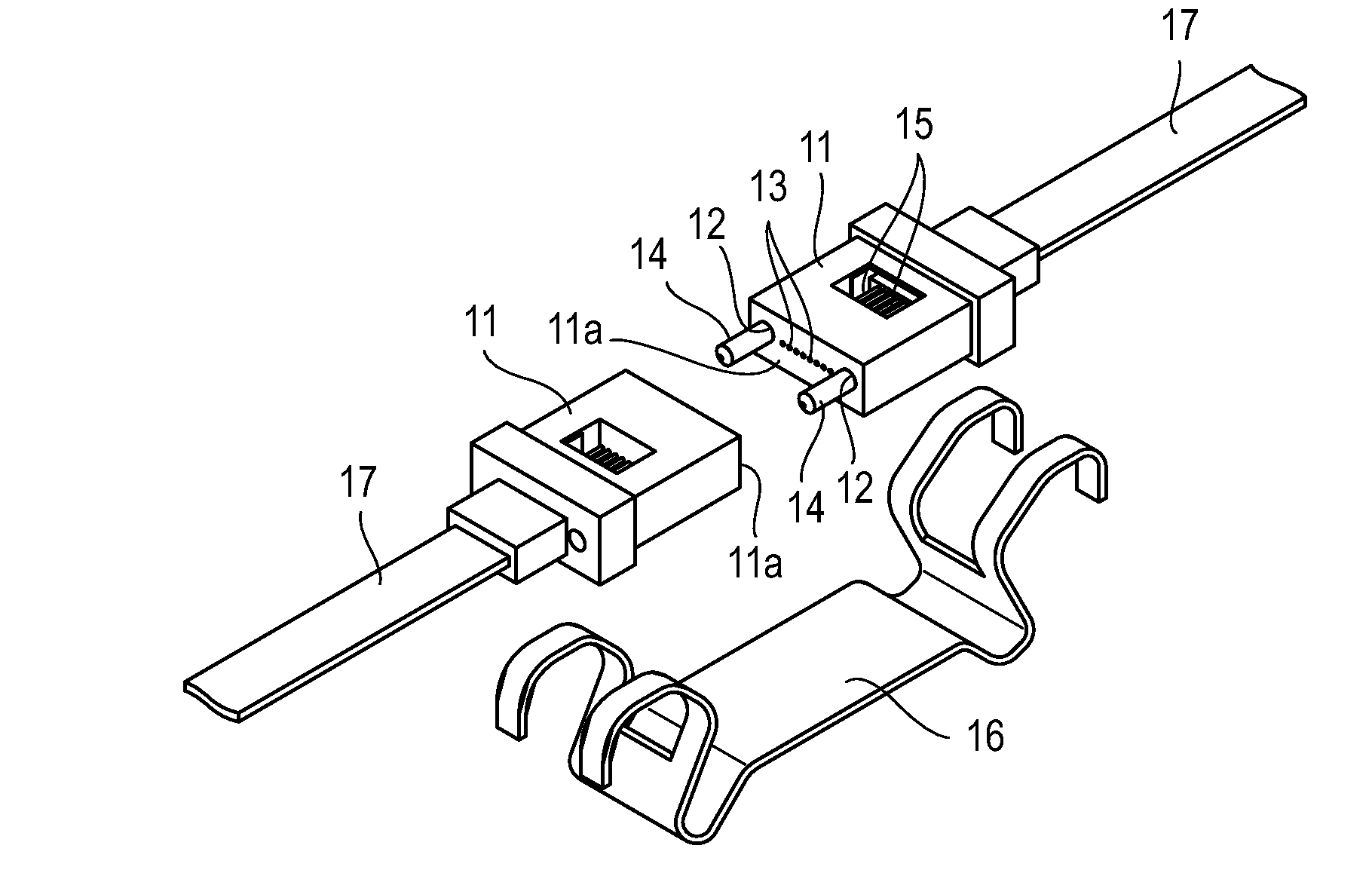

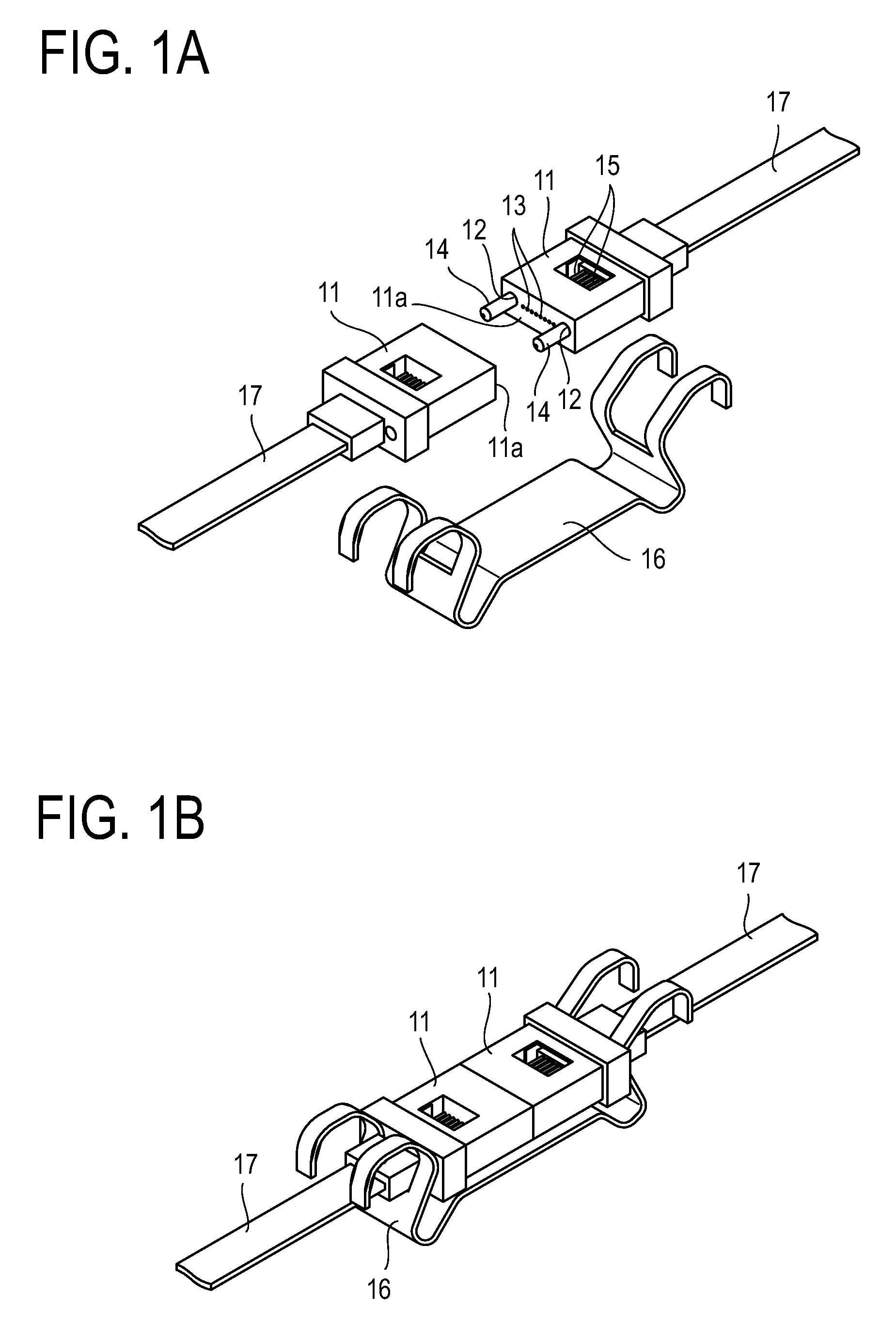

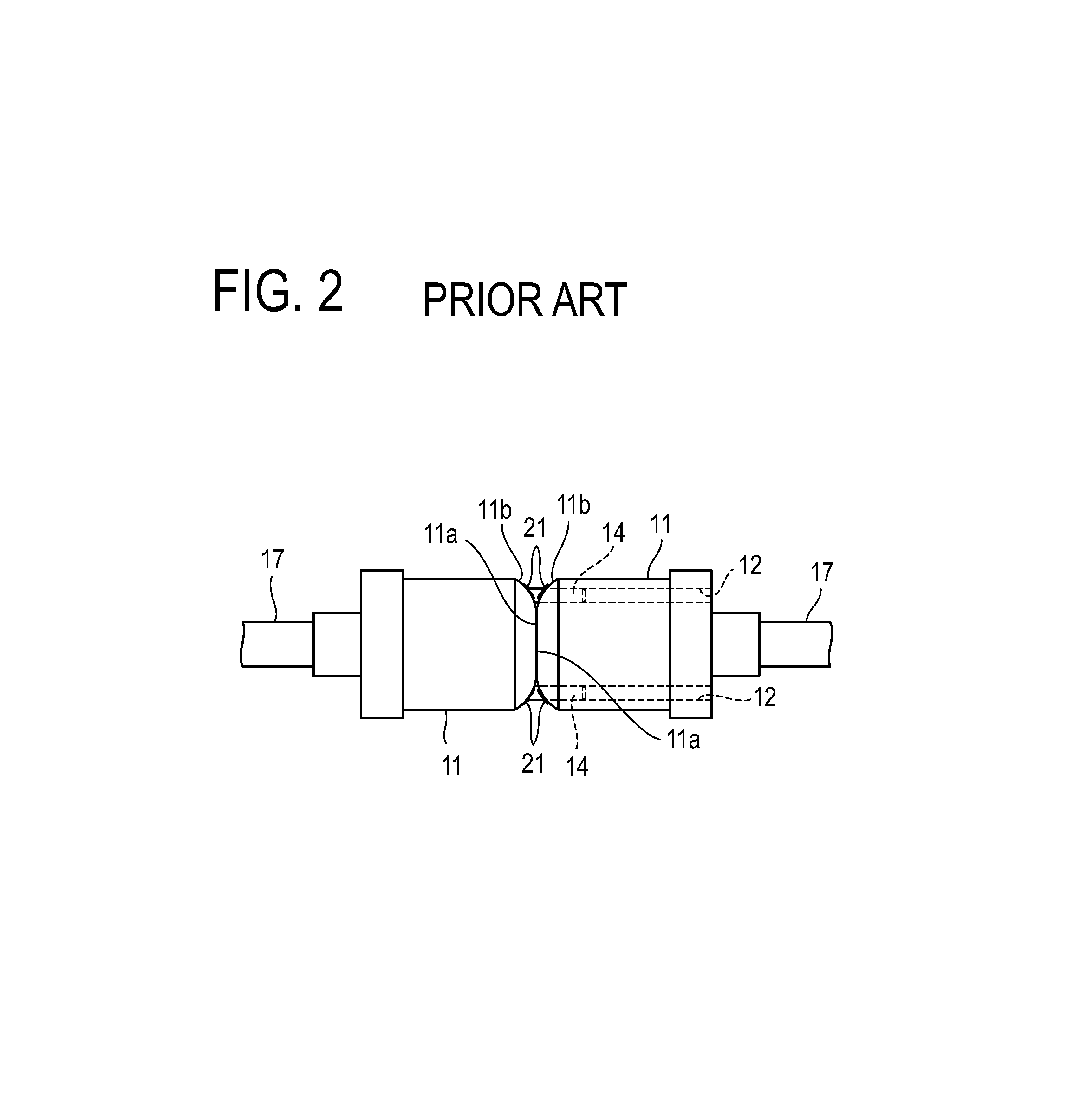

Optical connector

ActiveUS8678667B2Reduce chalkingAvoid connectionCoupling light guidesMechanical engineeringOptical connectors

In an optical connector, end faces of a pair of ferrules that hold multiple optical fibers are positioned with two guide pins and butted against each other to connect the optical fibers in the pair of ferrules. The optical connector is provided with an urging member for pushing the end faces against each other. The end faces are ground at an angle. The gap between the guide pins and guide holes, which open at the end faces and into which the guide pins are fitted, is larger than 0.004 mm and smaller than or equal to 0.008 mm. Powder caused by the friction generated when the guide pins are inserted and fitted into the guide holes is greatly reduced. Connection loss does not increase even when frequent connection and disconnection are performed, and cleaning the connector becomes unnecessary.

Owner:JAPAN AVIATION ELECTRONICS IND LTD

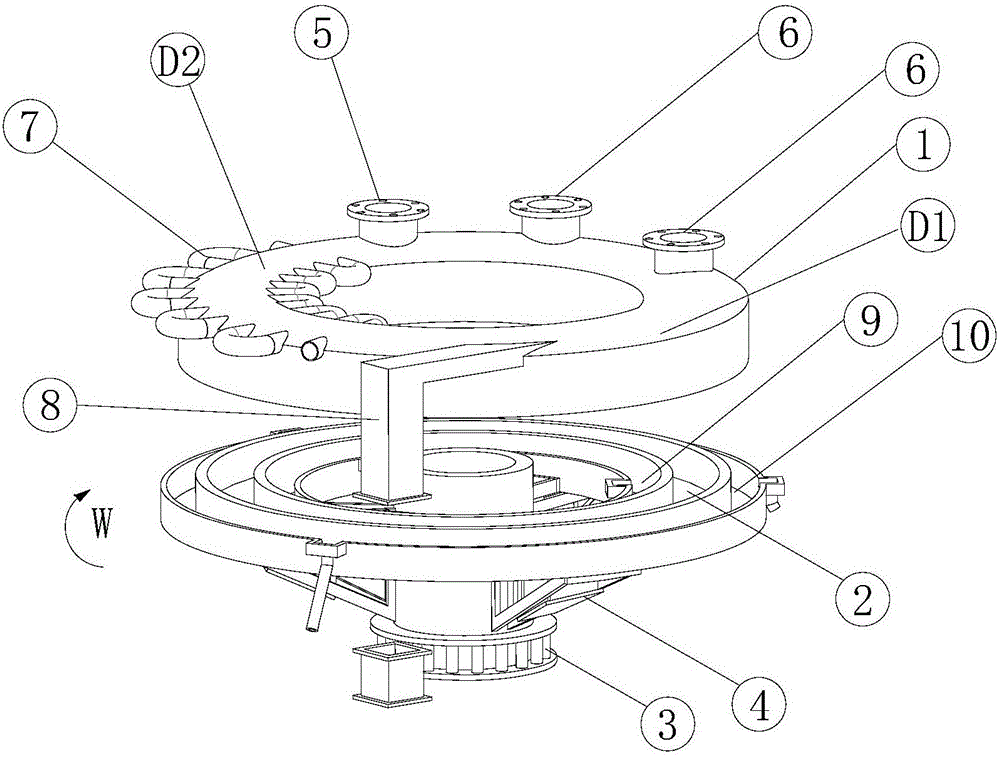

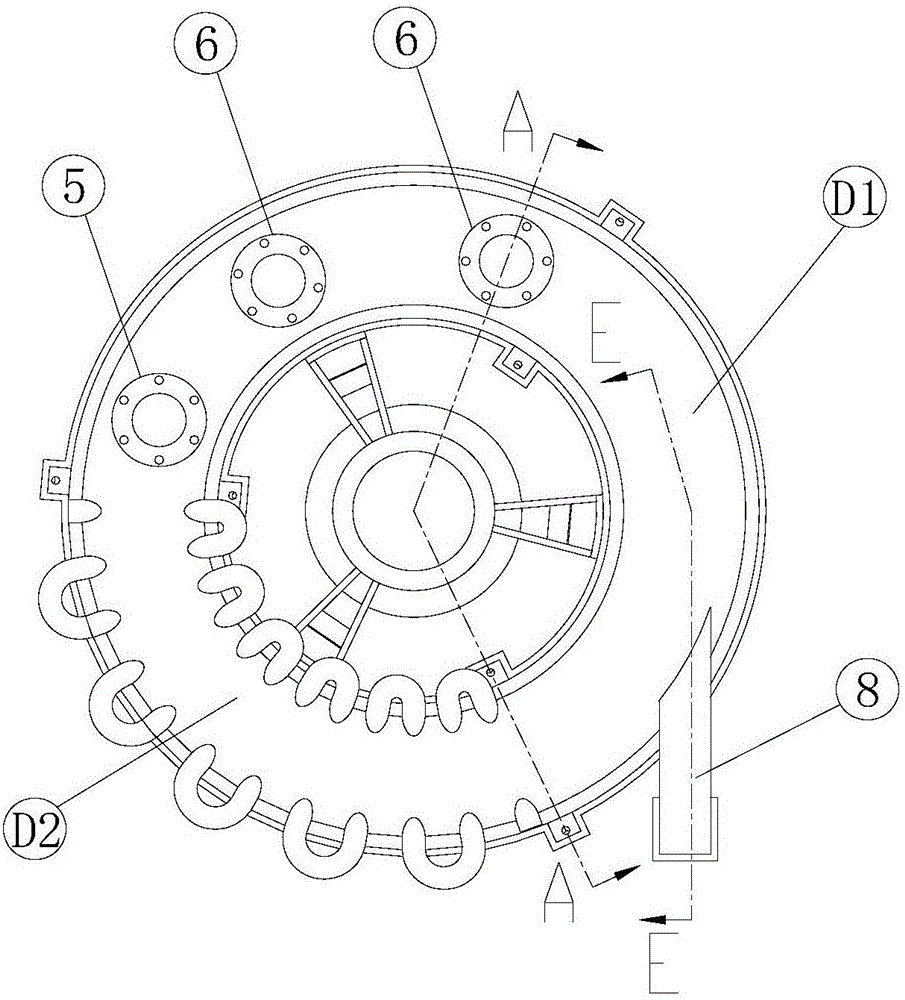

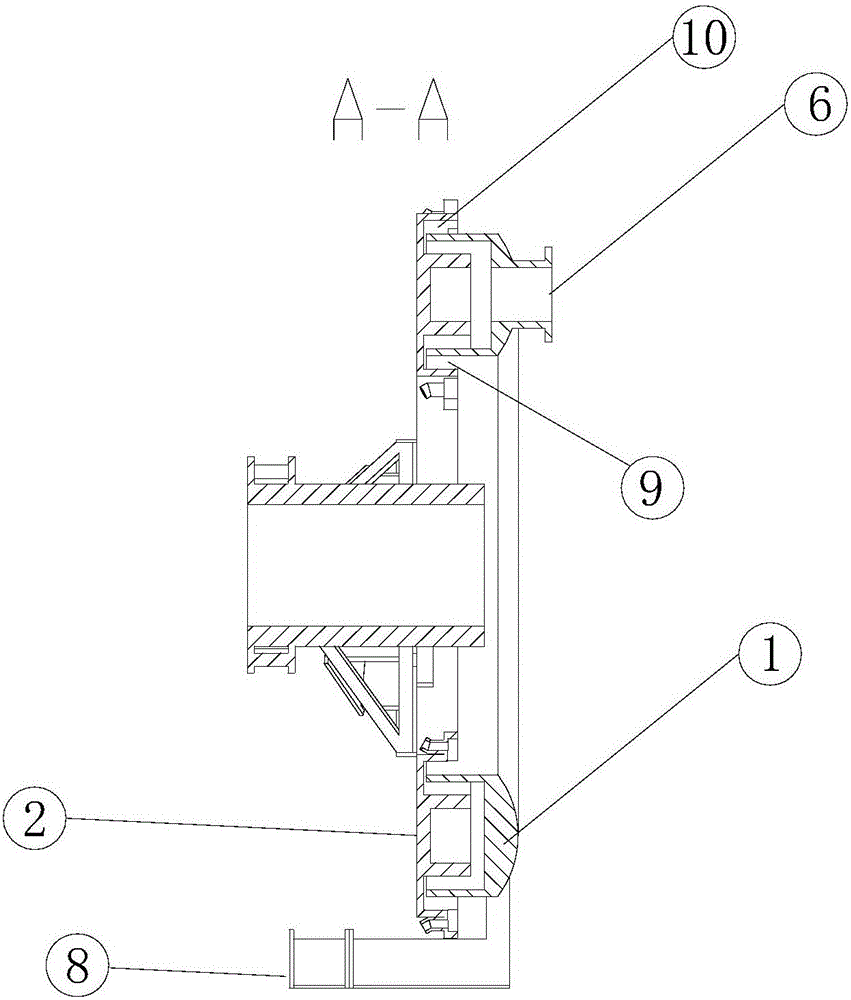

Solid heat carrier pyrolyzer

ActiveCN106190206AReduce the overall heightReduce chalkingDirect heating destructive distillationSpecial form destructive distillationHeat carrierPyrolysis

The invention discloses a solid heat carrier pyrolyzer which comprises a top cover (1), a bed (2) and a rotary mechanism. An annular pyrolysis tank is arranged on the top face of the bed, the top cover covers the pyrolysis tank from the upper side, and a feed inlet (5), a pyrolysis gas outlet (6) and a discharge point communicated with the pyrolysis tank are sequentially arranged in the circumferential direction of the sealed annular area, corresponding to the pyrolysis tank, in the top cover in a spaced mode; in the sealed annular area, one side sector ring area between the discharge point and the feed inlet is a pyrolysis area (D1), and the other side sector ring area is a reheating area (D2) provided with heating air pipes (7). Solid heat carriers in the pyrolysis tank rotate along with the bed and are reheated by a heating device, enter the pyrolysis area after being heated, and are mixed with pyrolysis raw materials and pyrolysized, one part of pyrolysis products serve as pyrolysis finished product and are discharged through the discharge point, and the other part of the pyrolysis products circularly flow back to the reheating area. The pyrolyzer is novel and compact in structure and small in occupied space, and integrates pyrolysis, discharging and solid heat carrier heating and circulation functions.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

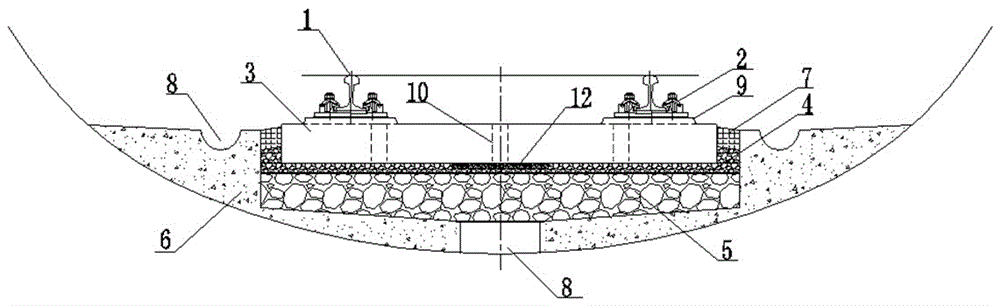

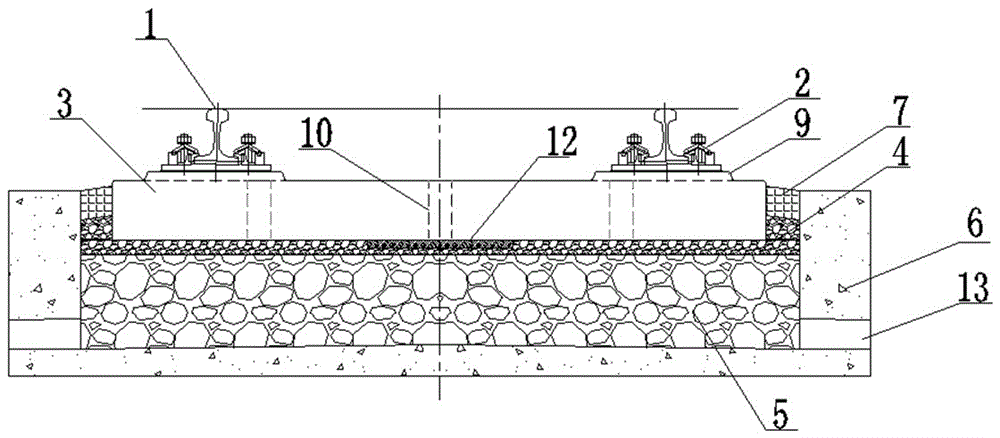

Wide sleeper plate sticking type ballast track

InactiveCN106436495AIncrease elasticityIdeal matchBallastwayMolecular materialsStructural engineering

The invention relates to a wide sleeper plate sticking type ballast track. After the line foundation of a ballastless track structure of an existing rail transit is deformed, the track repairing work is extremely high in workload, high in time consumption and high in difficulty; a ballast track is easy to repair, but the geometric state of the track is not liable to retain, and the daily maintenance work is high in workload and frequent. The wide sleeper plate sticking type ballast track comprises a railway ballast trough arranged in the line direction and a track structure arranged in the railway ballast, wherein the track structure comprises a macro-molecular material cured railway track, macro-molecular material cured small-granular chicken girt and wide sleeper plates from bottom to top; the macro-molecular material cured railway track is flatly paved at the bottom of the railway track trough; the macro-molecular material cured small-granular chicken girt is located on the macro-molecular material cured railway track; lower grooves are formed in the upper surface of the macro-molecular material cured small-granular chicken girt; the wide sleeper plates are located in the lower grooves. The wide sleeper plate sticking type ballast track has the advantages that the geometric position of the ballast track is liable to retain, the maintenance workload is low in an operation period, and the ballast track can be quickly and conveniently repaired after the foundation is greatly deformed in the space.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Lightweight heat-insulating fire brick and preparation method thereof

InactiveCN103693974AReduce consumptionGood air-cooled thermal shock resistanceCeramicwareSodium BentoniteDecomposition

The invention discloses a lightweight heat-insulating fire brick comprising the following raw materials in percentage by weight: 3%-15% of plastic hollow balls or floating beads in fly ash, 3%-90% of clay powder, 0-90% of bauxite powder, 3%-8% of kyanite powder, 1%-4% of bentonite, 0-5% of aluminum dihydrogen phosphate and 0.01%-0.5% of sodium tripolyphosphate. The preparation method of the lightweight heat-insulating fire brick comprises the steps of firstly, mixing the plastic hollow balls or the floating beads in fly ash with the aluminum dihydrogen phosphate and the bentonite, and standing; then, adding the clay powder, the bauxite powder, the kyanite powder and the sodium tripolyphosphate, mixing and performing decomposition; adding lignosulfonate the weight of which accounts for 0.1%-2% of the total weight of the total raw material mixture and water the weight of which accounts for 5%-9% of the total weight of the total raw material mixture, and mixing; performing compression molding; and drying and firing. The strength of the lightweight heat-insulating fire brick disclosed by the invention is not lower than 4MPa after the brick is dried at 110 DEG C for 24 hours, the air-cooled thermal shock resistance stability of the brick is good at 1000 DEG C, the lightweight heat-insulating fire brick does not generate large cracks and damages for at least 5 times, the probability of chalking in use is reduced, and the brick is favorable for reducing energy consumption.

Owner:武汉钢铁有限公司

Preparation method of silicon carbon negative electrode precursor

ActiveCN110350161AAvoid reunionGuaranteed dispersion effectNegative electrodesSecondary cellsPelletizingNanometre

The invention discloses a preparation method of a silicon carbon negative electrode precursor. The preparation method comprises the steps of adding nanometer silicon powder and carbon micro powder into an organic solvent, and performing grinding and dispersion to form paste A; adding a nanometer carbon material into the organic solvent, and performing uniform dispersion to form paste B; adding a binding agent into the organic solvent, and performing uniform dispersion to form paste C; mixing and uniformly dispersing the paste A, the paste B and the paste C to form paste D; and performing spraydrying granulation on the paste D to obtain the silicon carbon negative electrode precursor. Multi-step dispersion is employed, the dispersion performance and the stability of the mixed paste are improved, the dispersion process time is reduced, the dispersion efficiency is improved, a relevant risk such as granulation plug is reduced, and subsequent application and mass production are facilitated; meanwhile, the carbon micro powder and the nanometer carbon material are introduced, on one hand, the problem of silicon conductivity is solved, the internal resistance is reduced, and the initialcoulombic efficiency and the rate performance are improved; and on the other hand, the volume expansion during the charge-discharge process of silicon is solved, the integral expansion rate of the material is reduced, the material pulverization is prevented, and the cycle property is improved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

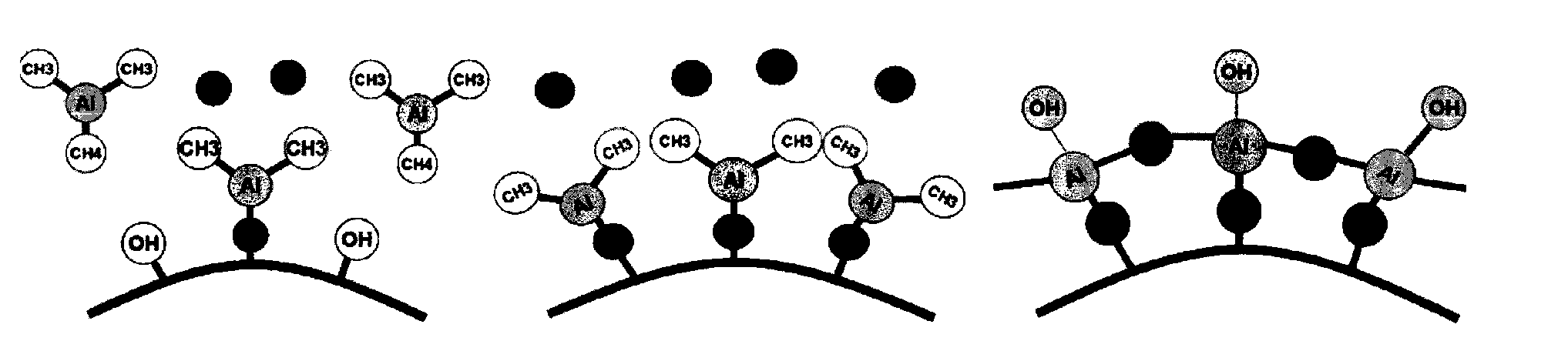

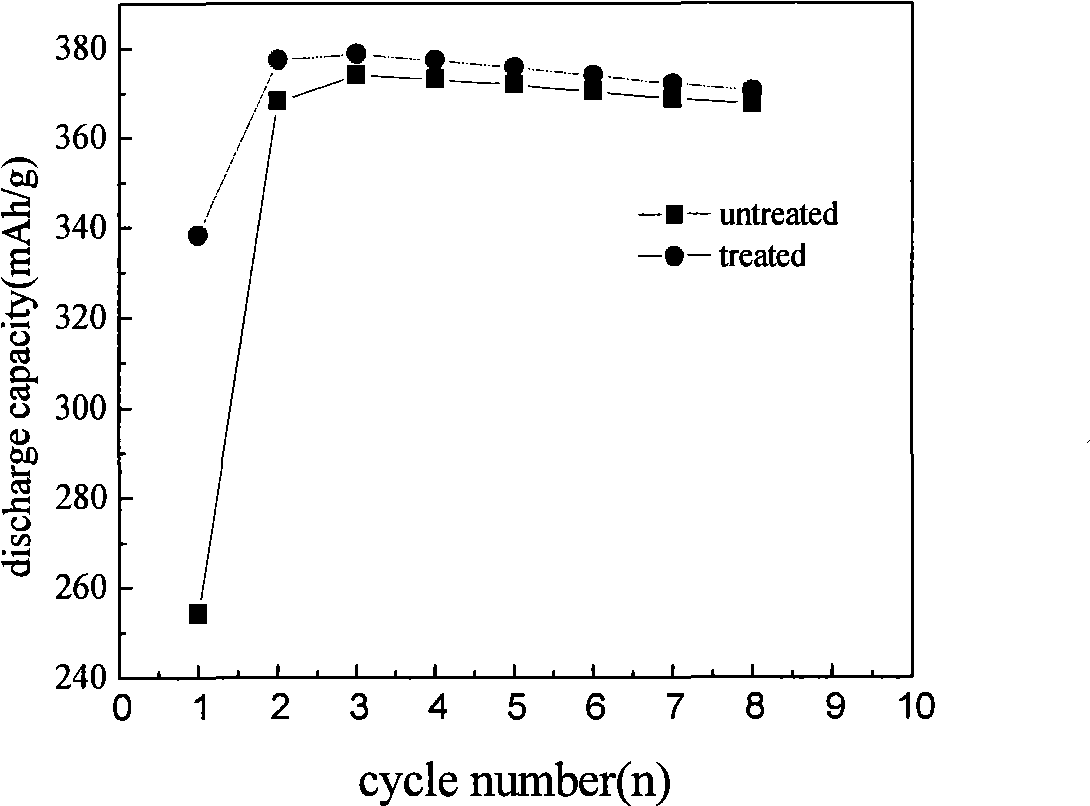

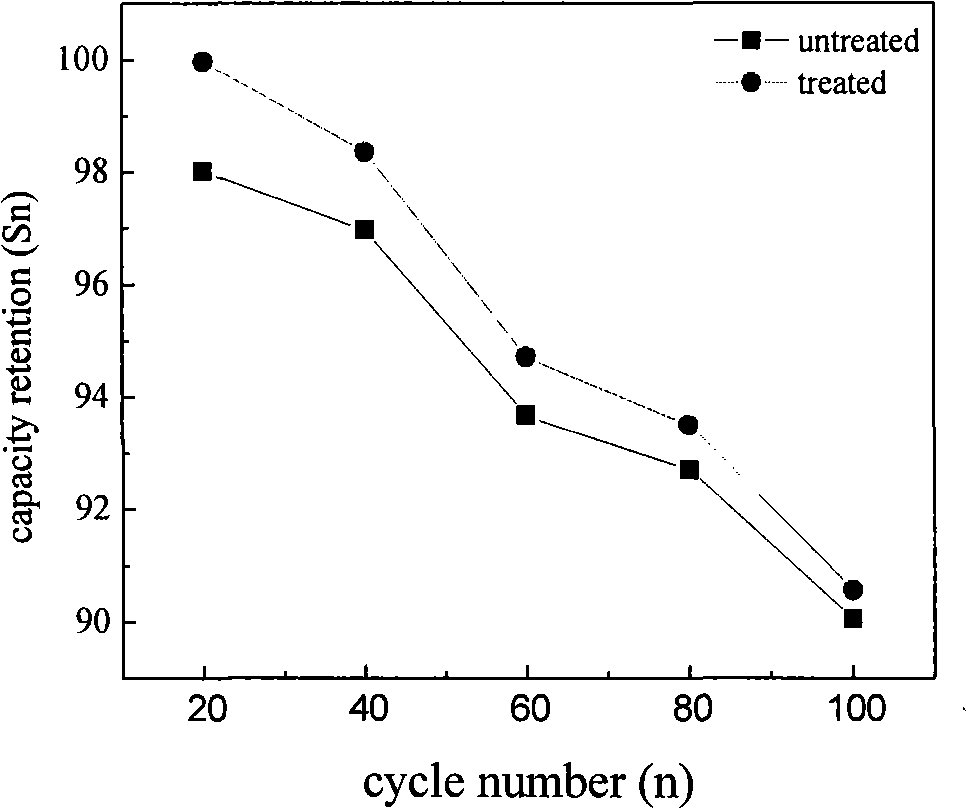

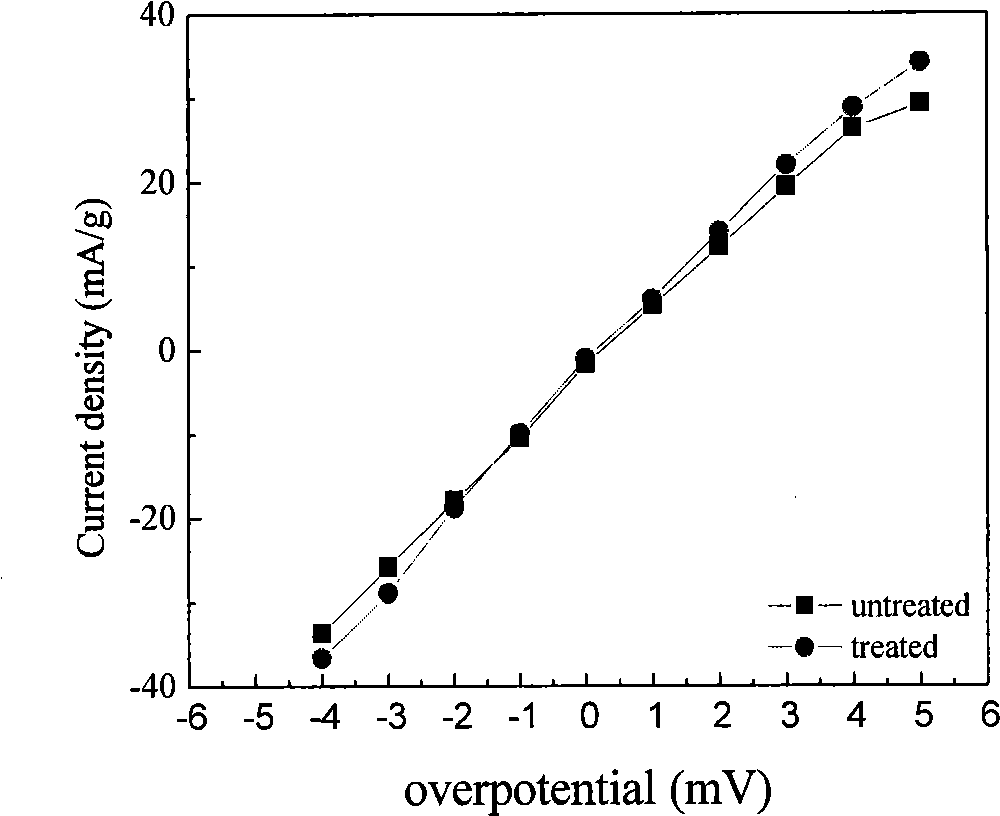

Surface recombination processing method for rare earth-magnesium-nickel based AB3 type hydrogen storage alloy

InactiveCN101476127AReduce pressure on environmental protectionEasy to operateLiquid/solution decomposition chemical coatingEtchingMagnesium

The invention relates to a surface complex treating method for a rare-earth - magnesium - nickel base AB3 type hydrogen storage alloy which belongs to the chemical surface treating of metal material field. The method is a surface complex treating technique for the rare-earth - magnesium - nickel base AB3 type hydrogen storage alloy powder processed in a treating solution by surface chemical etching and chemical nickel plating. The hydrogen storage alloy powder is added into the etching solution contained with fluoride for treating, then nickel salt is added for processing surface nickel plating treating. The chemical etching treating is processed by combined action of fluorinion solution, buffer solution, reducing agent and deionized water; the surface nickel plating treating is processed by added nickel ion reduction action with the reducing agent in the treating solution and generated hydrogen directly for depositing on the alloy powder surface. Activation performance, cycle life and dynamic performance of the hydrogen storage alloy are obviously increased after being treated by the method provided by the invention.

Owner:YANSHAN UNIV

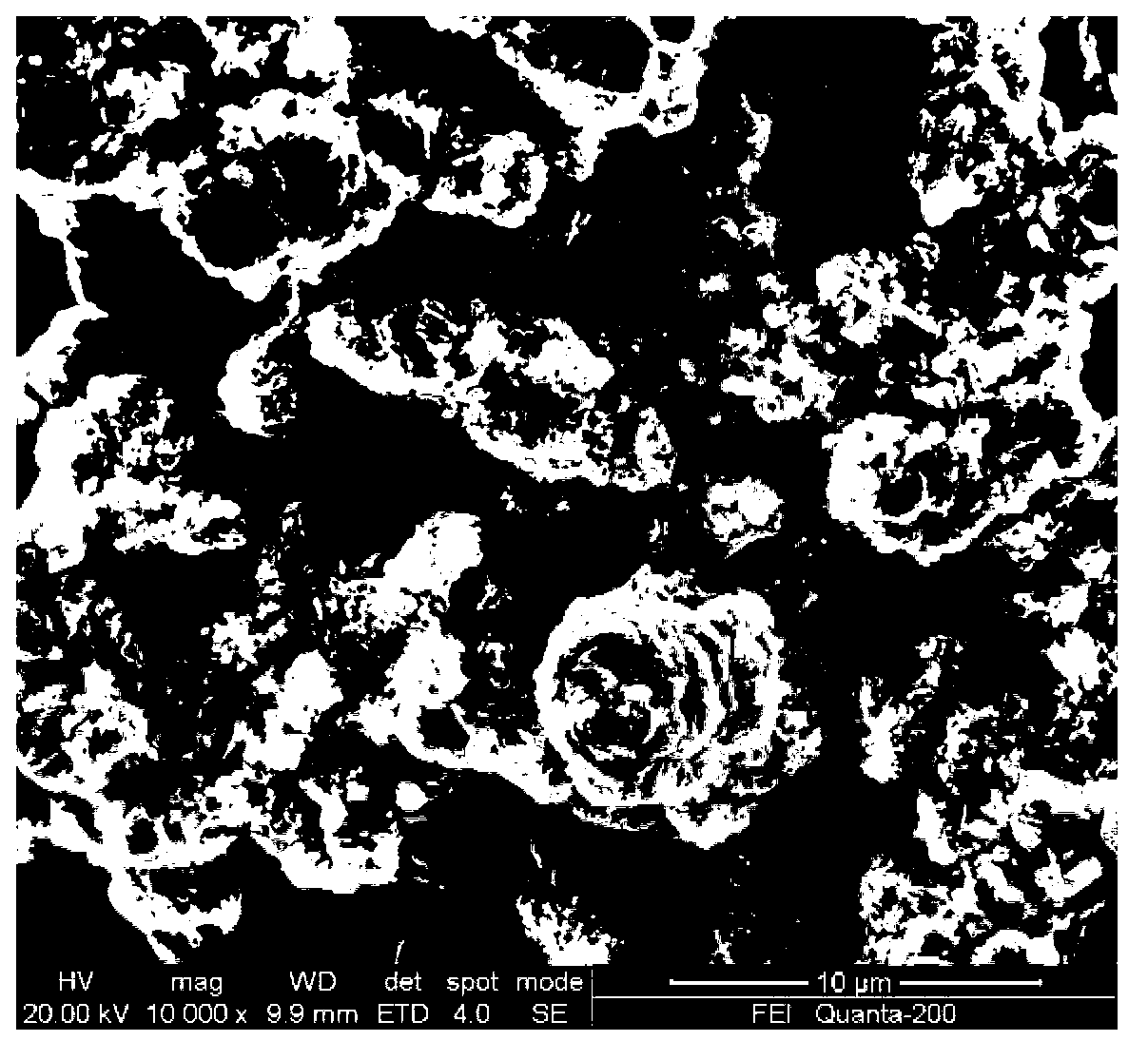

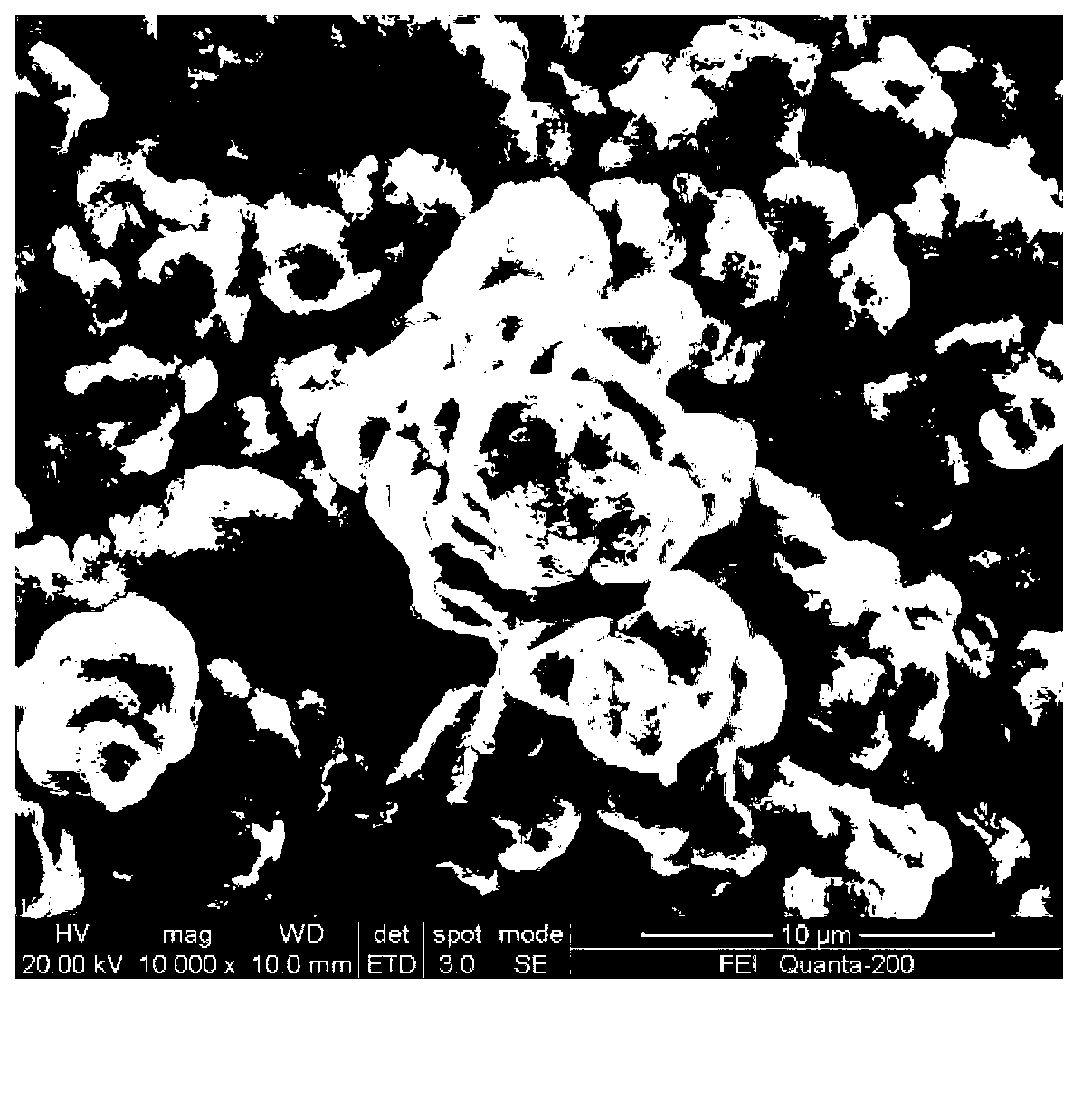

High-radial and high-tap density nickel cobalt lithium aluminate precursor and preparation method thereof

ActiveCN110611098AHigh radial arrangementPromote migrationCell electrodesPhysical chemistryLithium aluminate

The invention discloses a high-radial and high-tap density nickel cobalt lithium aluminate precursor and a preparation method thereof. The nickel cobalt lithium aluminate precursor is nickel cobalt aluminum hydroxide, the planed surface is radial from inside to outside, aluminum elements in the material are uniformly distributed from inside to outside, primary particles are laminary, and high tapdensity and high sphericity are achieved. The preparation method disclosed by the invention comprises the processes of seed crystal preparation and crystal growth, and uniform directional growth of the precursor is realized by strictly controlling reaction conditions of nucleation and growth. The method is simple in process, easy in process stable control, excellent in product performance and suitable for large-scale industrial production.

Owner:SHAANXI COAL & CHEM TECH INST

Rich magnesium dust strengthen sintering additive agent

The invention relates to magnesium powder strengthening sintering additive which is made by taking magnesite and limestone as the main raw materials, and adding ascharite through scientific proportion that the magnesite is 65 to 70 shares, dolomite is 25 to 30 shares and the ascharite is 3 to 5 shares. The invention has the advantages of low decomposition temperature (426 DEG C), small needing decomposition heat, long duration of high temperature in sintering process, favorable effect of forming liquid phase, good concretion performance of sintering mine, improved finished product rate of sintering mine and good benefit for reducing the consumption of the solid fuel.

Owner:辽宁华盛矿业集团有限公司

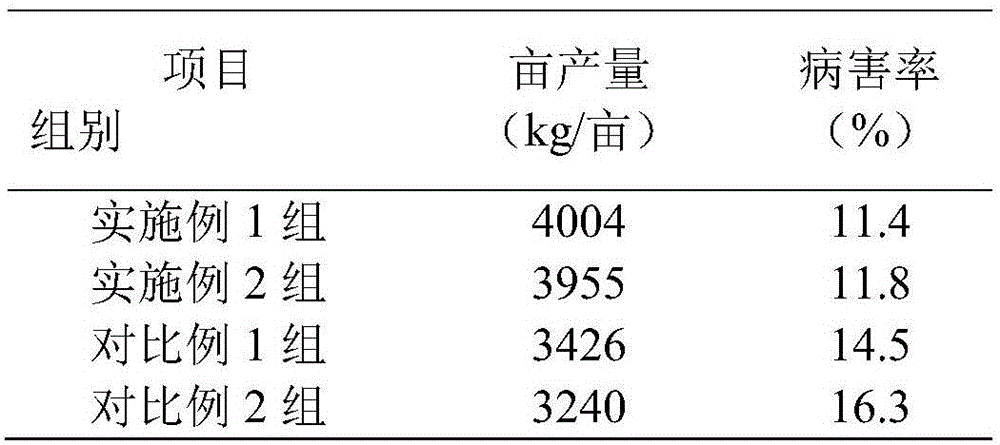

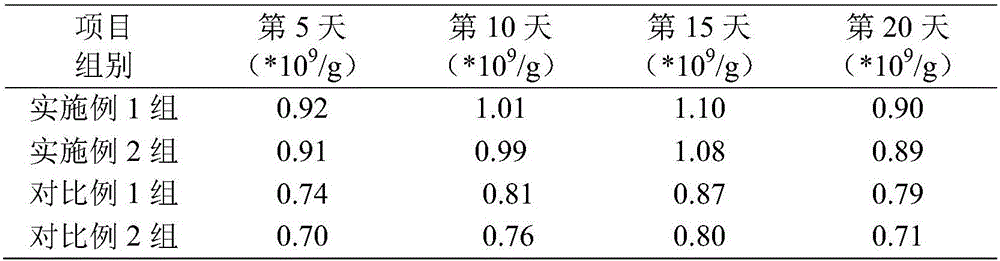

Microbial compound fertilizer containing double-layer envelopes

InactiveCN106116804AImprove the growing environmentPromote reproductionOrganic fertilisersLayered/coated fertilisersMicroorganismSalinity

The invention provides a microbial compound fertilizer containing double-layer envelopes. The microbial compound fertilizer comprises a core layer, a first envelope layer and a second envelope layer; the core layer comprises compound fertilizer, the first envelope layer is organic carbon coated on the surface of the compound fertilizer, and the second envelope layer is microorganism coated on the surface of the organic carbon, wherein the mass ratio of the core layer to the first envelope layer to the second envelope layer is 10-5000:1-5:0.01-110. The microbial compound fertilizer containing double-layer envelopes enables microorganism to survive in high salinity environment in the early growth stage, increases the survival rate of microorganism entering the soil, prolongs reproduction time and achieves coordinative synergism of microorganism and the compound fertilizer.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

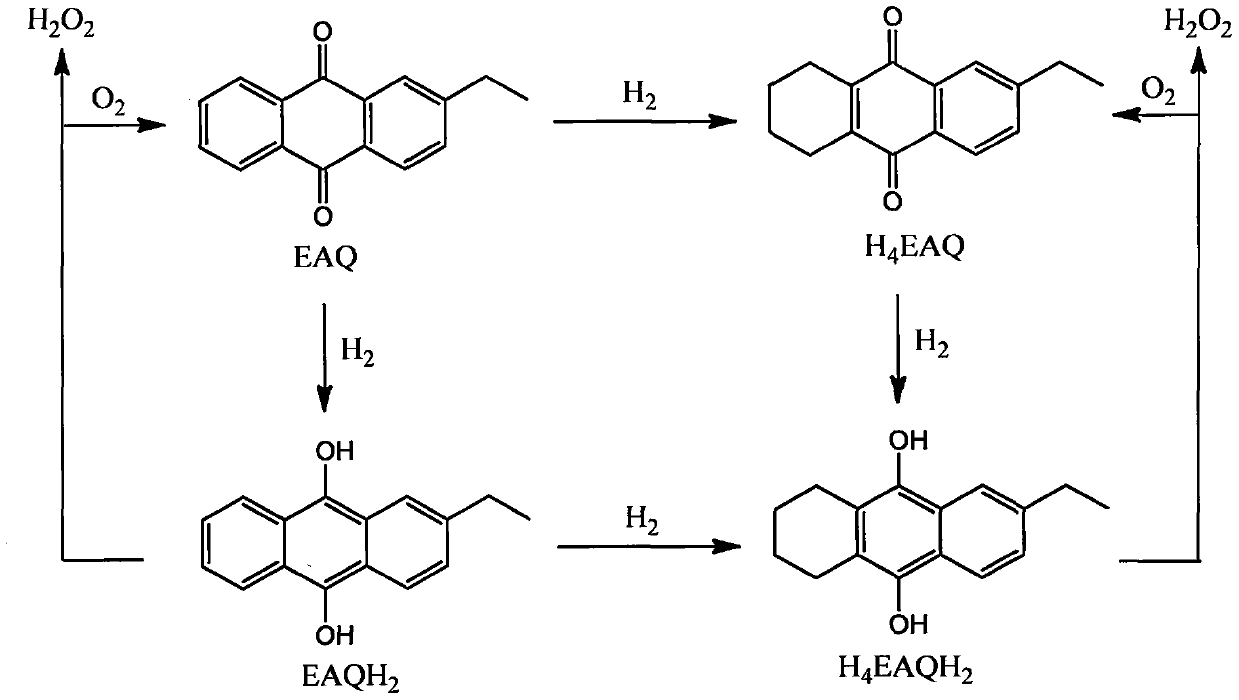

A hydrogen peroxide working fluid regenerant in the process of preparing hydrogen peroxide by anthraquinone method and its preparation method

InactiveCN105152137BPromote regenerationImprove stabilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingWorking fluidMetal working fluid

Owner:XIANGTAN UNIV

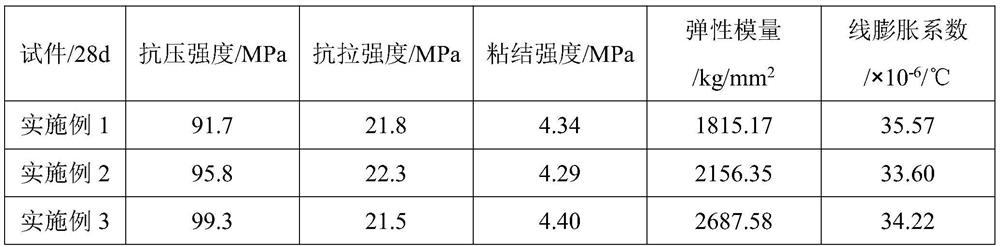

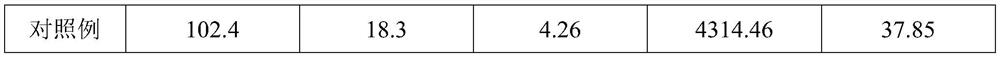

Toughened abrasion-resistant epoxy resin cement gum and preparation method thereof

ActiveCN111607312AImprove fracture toughnessMake up for loss of strengthEpoxy resin coatingsBridge engineeringPolymer science

The invention provides toughened abrasion-resistant epoxy resin cement gum which is composed of a component A and a component B. The component A comprises epoxy resin, a diluent, an active diluent AGE, a silane coupling agent, fumed silica and brominated nano light calcium carbonate. The component B is prepared from a curing agent, a DMP-30 accelerant, brominated nano light calcium carbonate and graphene oxide nanosheets. The epoxy resin is composed of a bonding body and a modifying body, wherein the bonding body is bisphenol A type epoxy resin or bisphenol F type epoxy resin, and the modifying body is epoxy-terminated polysiloxane with epoxy equivalent weight of 400-900g / mol. The epoxy cement gum prepared by the preparation method has relatively high strength, toughness, impact resistanceand abrasion resistance, is good in comprehensive performance, and can be applied to hydroelectric and hydraulic engineering, bridge engineering, high-speed rail traffic engineering, constructional engineering and the like.

Owner:杭州每步材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com