A hydrogen peroxide working fluid regenerant in the process of preparing hydrogen peroxide by anthraquinone method and its preparation method

A technology of hydrogen peroxide and anthraquinone method, applied in peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, chemical instruments and methods, chemical recovery, etc. High requirements, easy pulverization and other problems, to achieve the effect of improving activity and selectivity, simple process steps and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

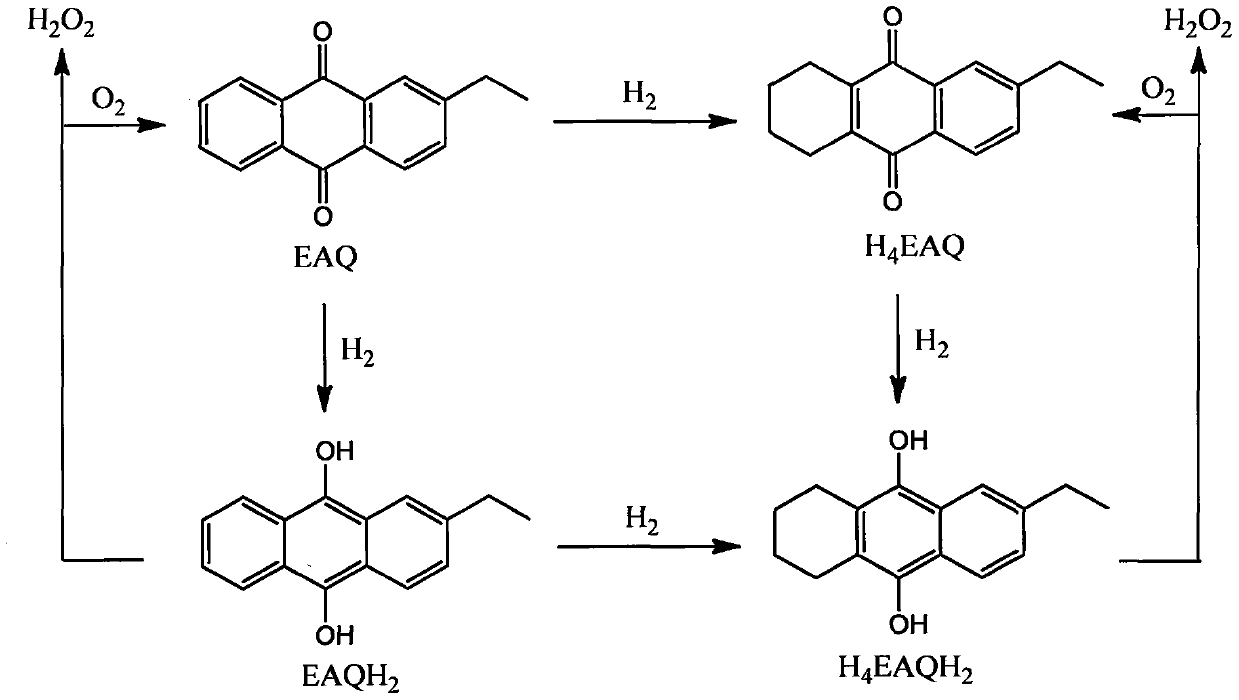

Image

Examples

Embodiment 1

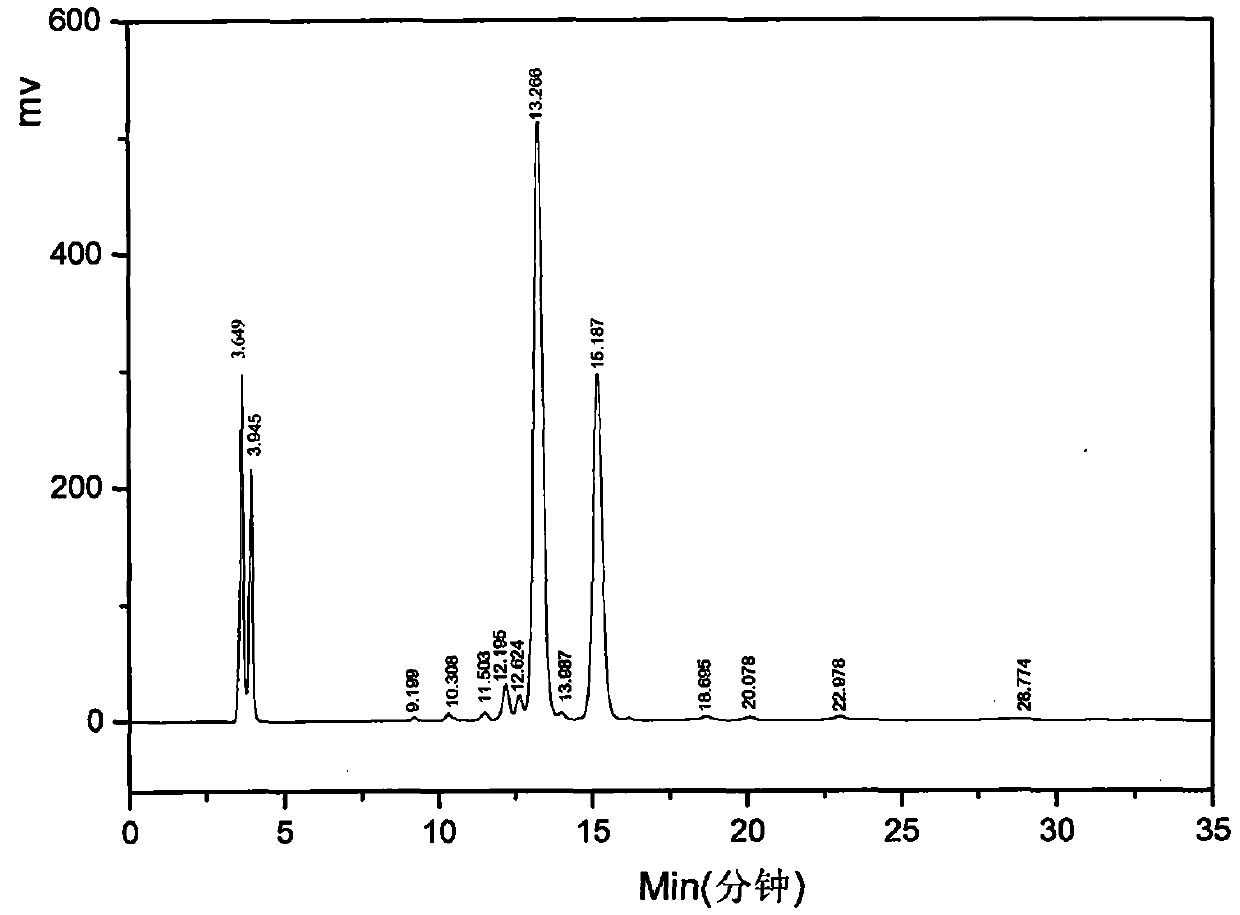

[0035] Take 1mL of the three-water working solution containing anthraquinone degradation products (provided by the hydrogen peroxide unit of Baling Branch of China Petroleum and Chemical Corporation), dilute it 100 times with n-hexane, and use Shimadzu LC-20A high performance liquid chromatography (Japan, Japan, Shimadzu Corporation) to analyze the composition of main substances and degradation products in the working solution (Agilent ZORBAX SIL column; mobile phase: n-hexane-dichloromethane-ethyl acetate (volume ratio is 80:19:0.5); flow rate: 1.0mL / min; column temperature: 30°C; detection wavelength: 280nm; injection volume: 20μL). The analysis method adopts the area normalization method.

[0036] like figure 2 Shown, in the trihydrate working liquid normal phase chromatogram, the retention time of heavy aromatics is 3.649min and 3.945min, H 4 The retention times of EAQ and EAQ are 13.286min and 15.187min respectively, and the rest of the small impurity peaks are degrada...

Embodiment 2

[0041] Weigh 24.00g gamma crystalline alumina powder, 6.00g cubic crystal magnesia powder, 15g deionized water and 1.5g scallop powder, mix well, and then make strip-shaped regeneration with a diameter of 3mm through catalyst molding extrusion device After being dried in the shade at 25°C for 24h, it was dried at 125°C for 10h to obtain the regenerant.

[0042] Take 10g of the regenerant sample prepared above and 50mL of the three-water working solution containing anthraquinone degradation products and put them in a conical flask, put the conical flask in a constant temperature water bath shaker at 60°C for 6 hours, and take the working solution after the regeneration reaction 1mL, analyze the H in the working solution according to the method in Example 1 4 Changes in EAQ and EAQ content.

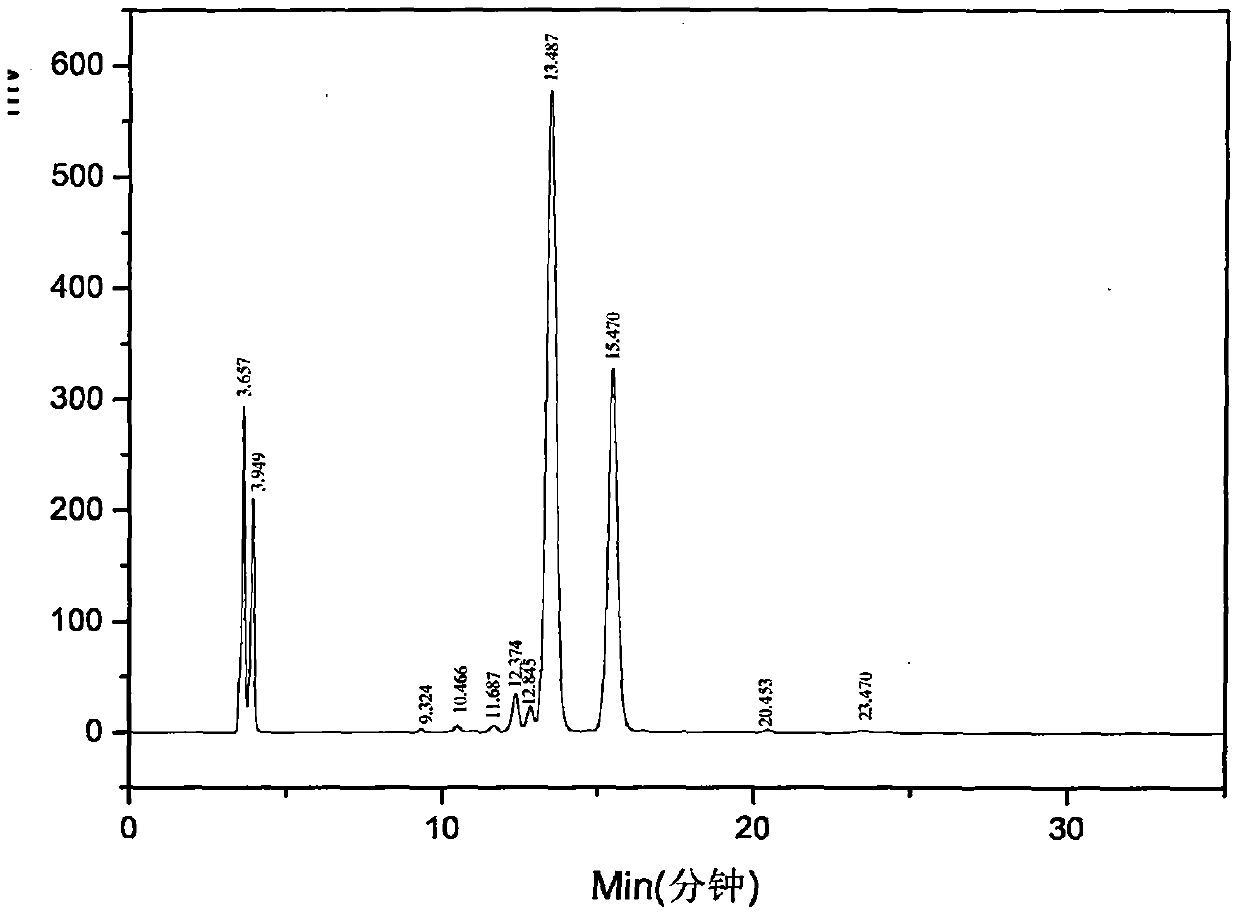

[0043] Check the regeneration performance of the regenerated catalyst in the anthraquinone working solution according to the above method, as image 3 As shown in the normal phase chromat...

Embodiment 3

[0048] Weigh 21.00g gamma crystalline alumina powder, 9.00g cubic crystal magnesia powder, 15g deionized water and 1.5g scallop powder, mix well, and then make strip-shaped regeneration with a diameter of 3mm through catalyst molding extrusion device After drying in the shade at 25°C for 24h, dry it at 125°C for 10h.

[0049] According to the method examination of embodiment 2, the regeneration performance of this regenerated catalyst in the anthraquinone working solution, as Figure 4 As shown in the normal phase chromatogram after the regeneration of hydrogen peroxide working solution, the results of the area normalization method of each component are shown in the table below, and the effective anthraquinone (H 4 EAQ+EAQ) content increased by 3.0511%.

[0050] Composition of main substances and degradation products in the working fluid after embodiment 3 regeneration

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com