Patents

Literature

333 results about "Anthraquinone process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

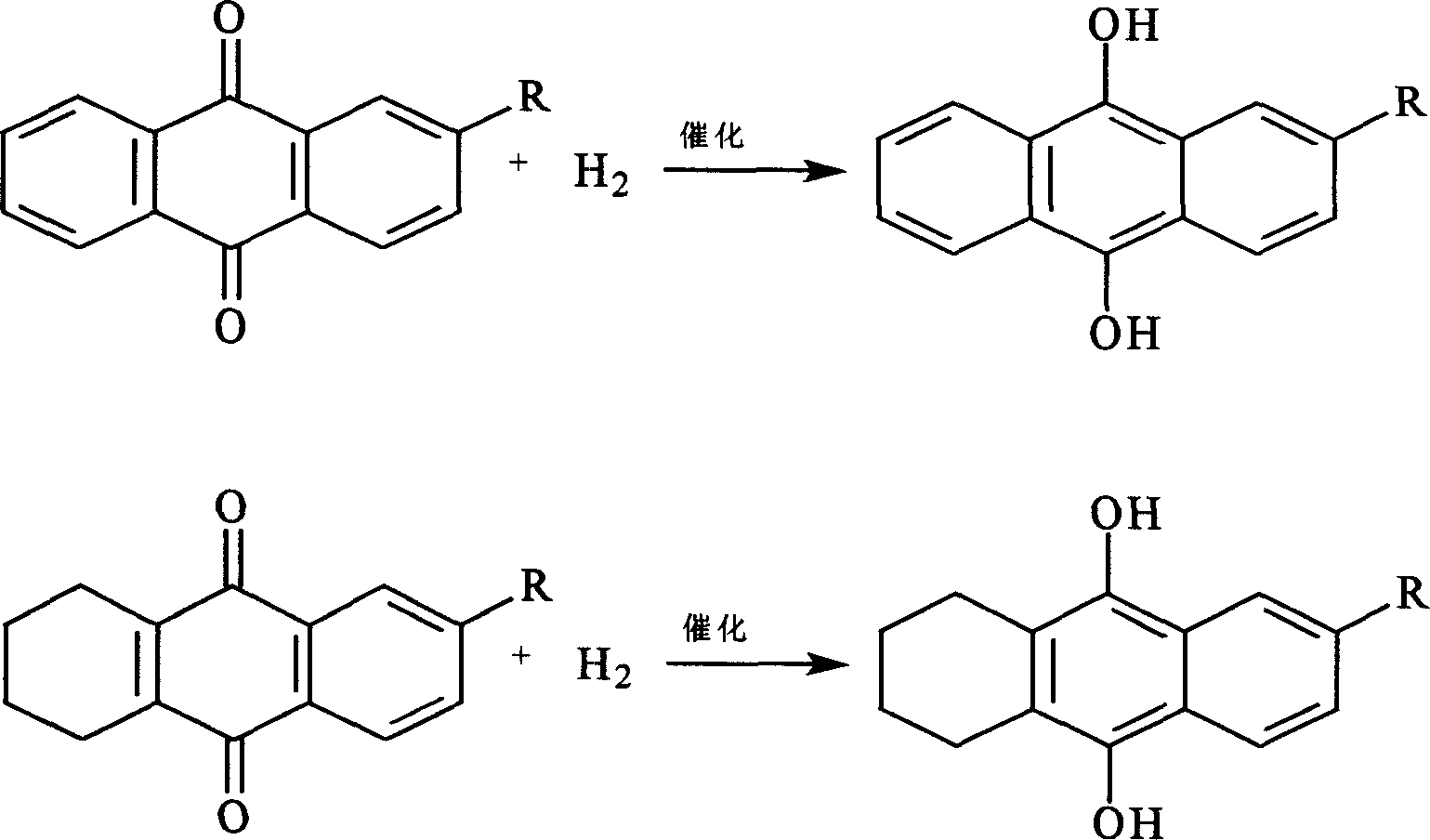

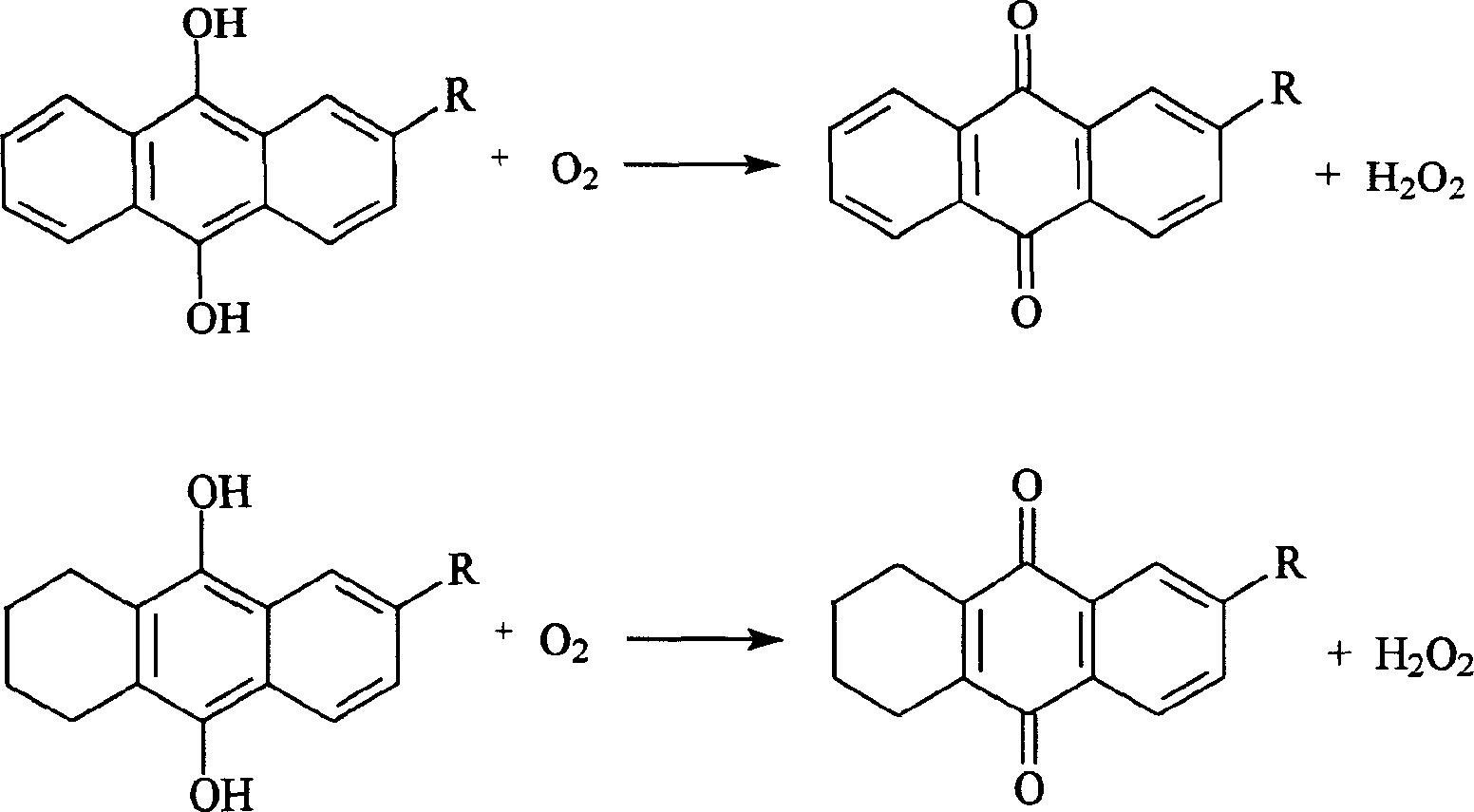

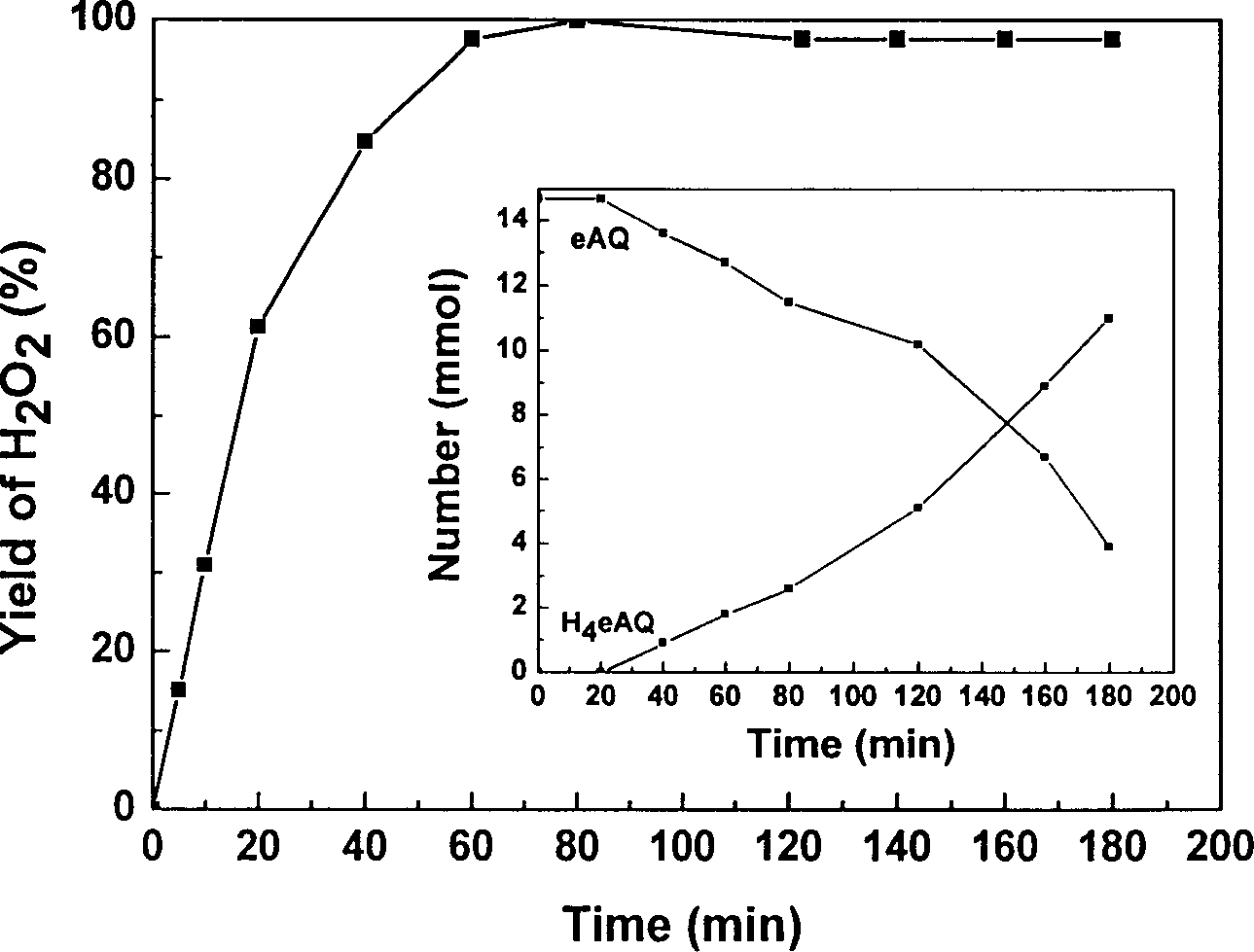

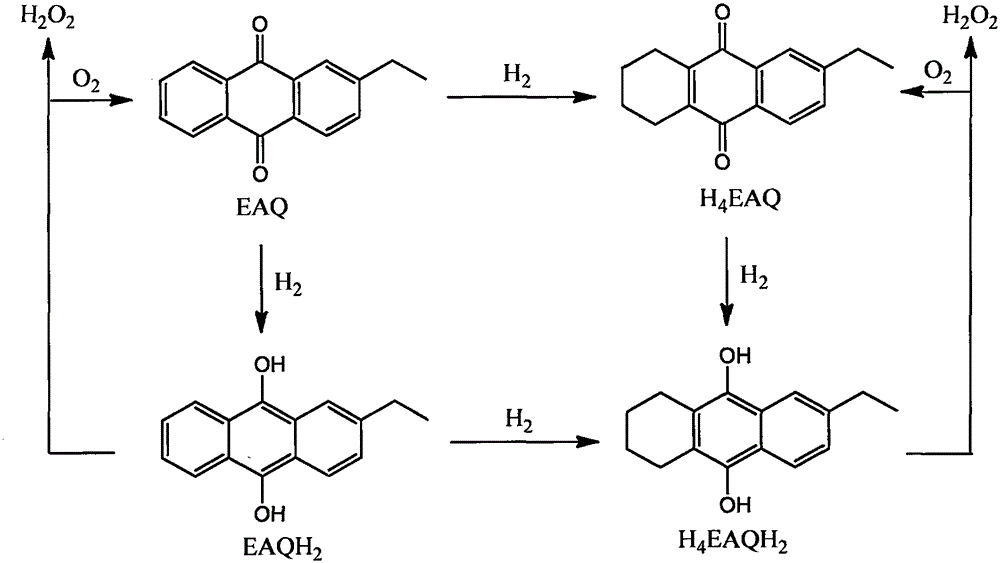

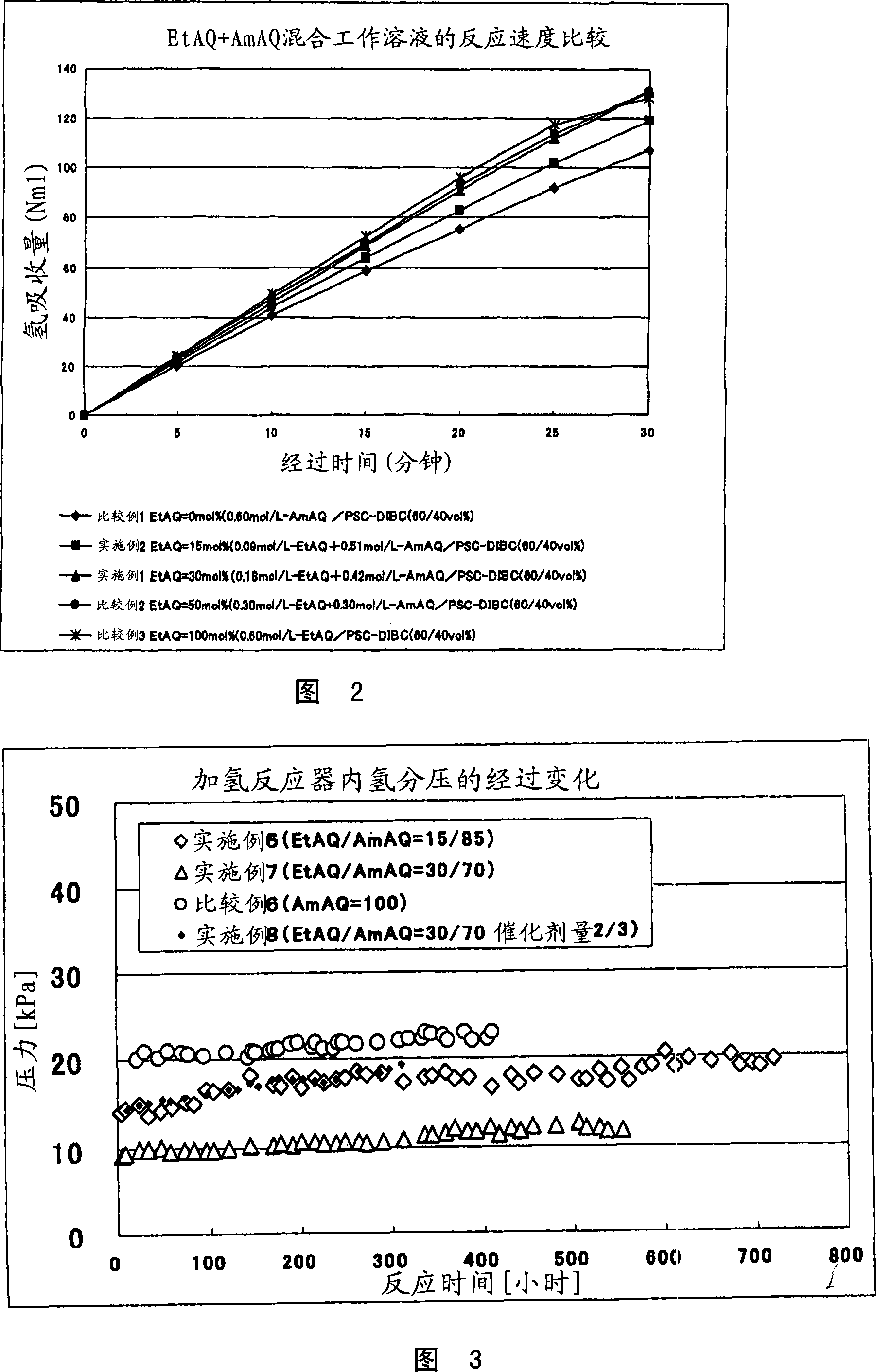

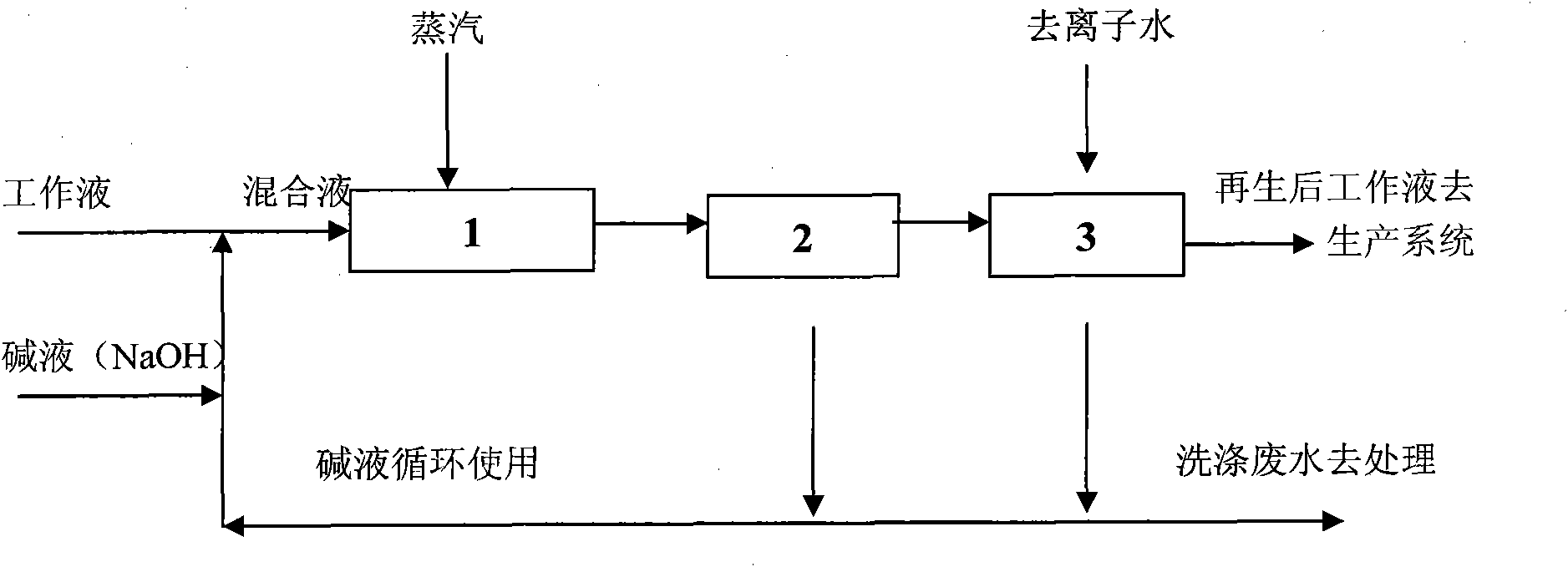

The anthraquinone process is a process for the production of hydrogen peroxide, which was developed by BASF. The industrial production of hydrogen peroxide is based on the reduction of oxygen, as in the direct synthesis from the elements. Instead of hydrogen itself, however, a 2-alkyl-anthrahydroquinone, which is generated before from the corresponding 2-alkyl-anthraquinone by catalytic hydrogenation with palladium. Oxygen and the organic phase react under formation of the anthraquinone and hydrogen peroxide. Among other alkyl groups (R) ethyl- and tert. Butyl are used, e.g., 2-ethylanthraquinone.

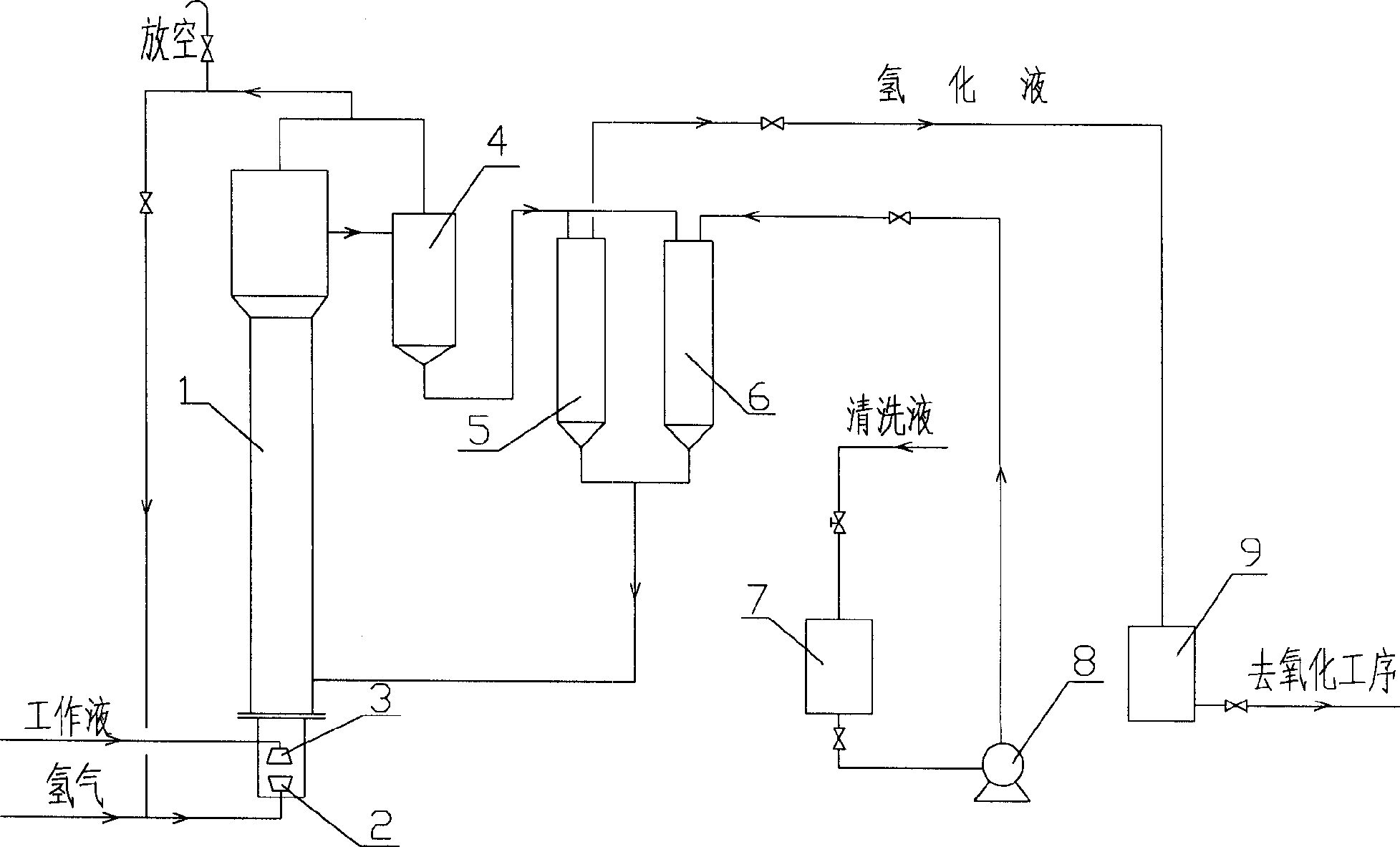

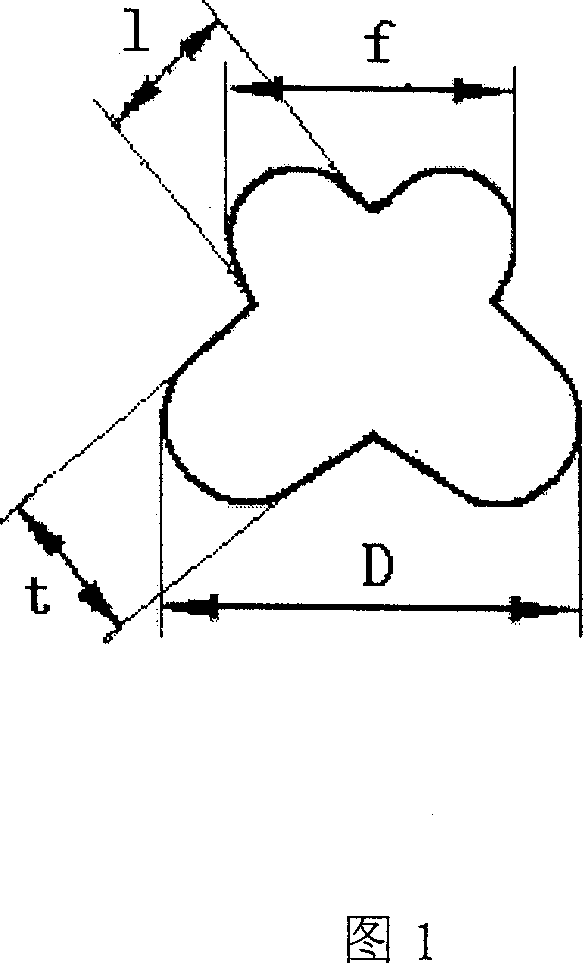

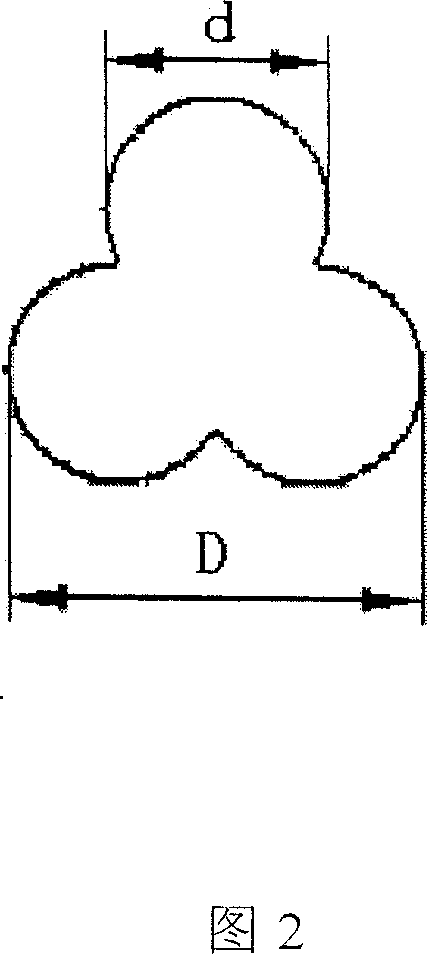

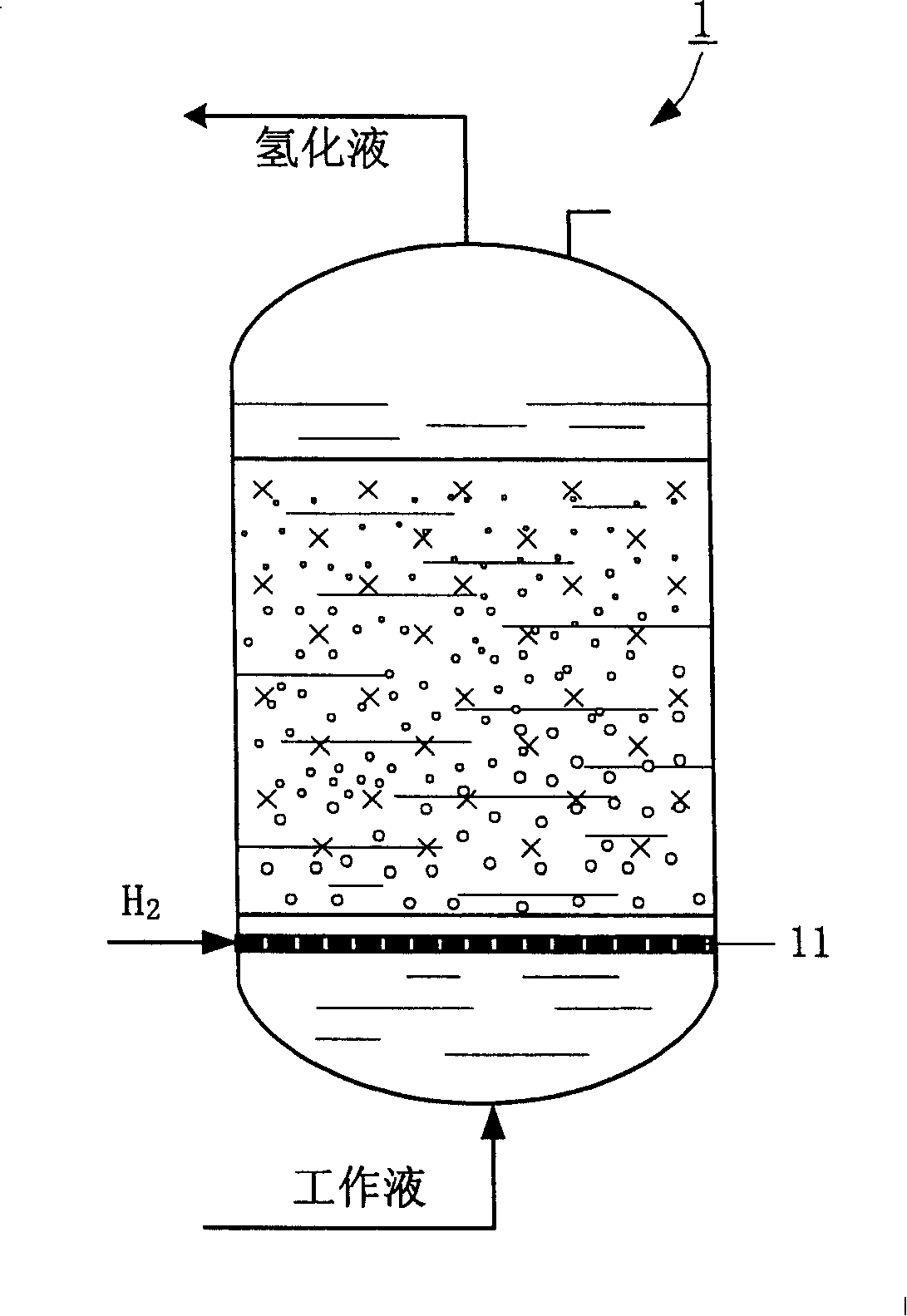

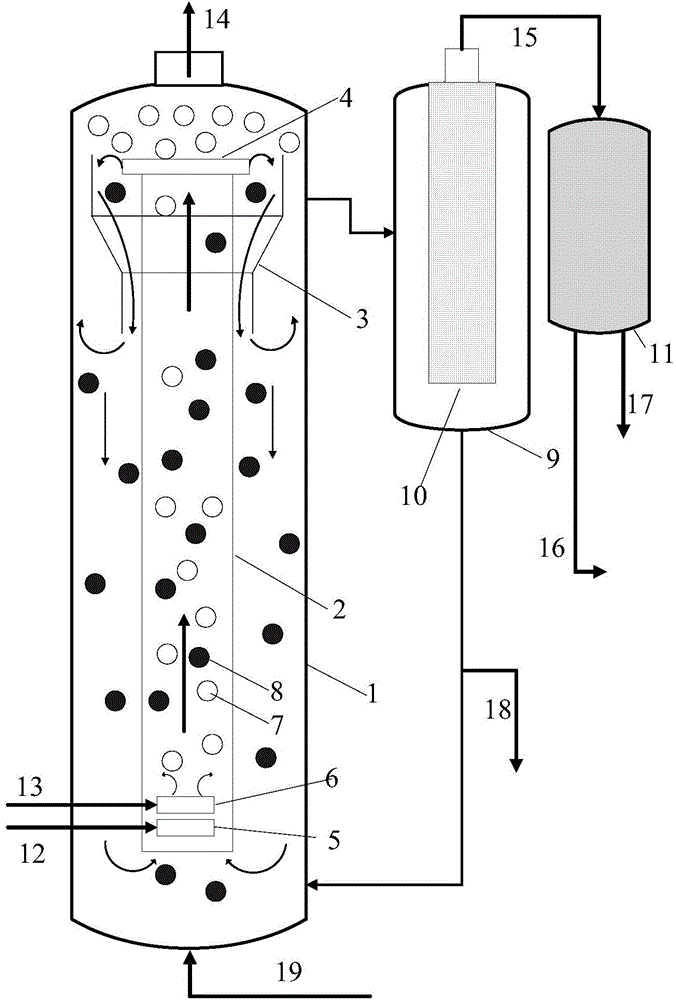

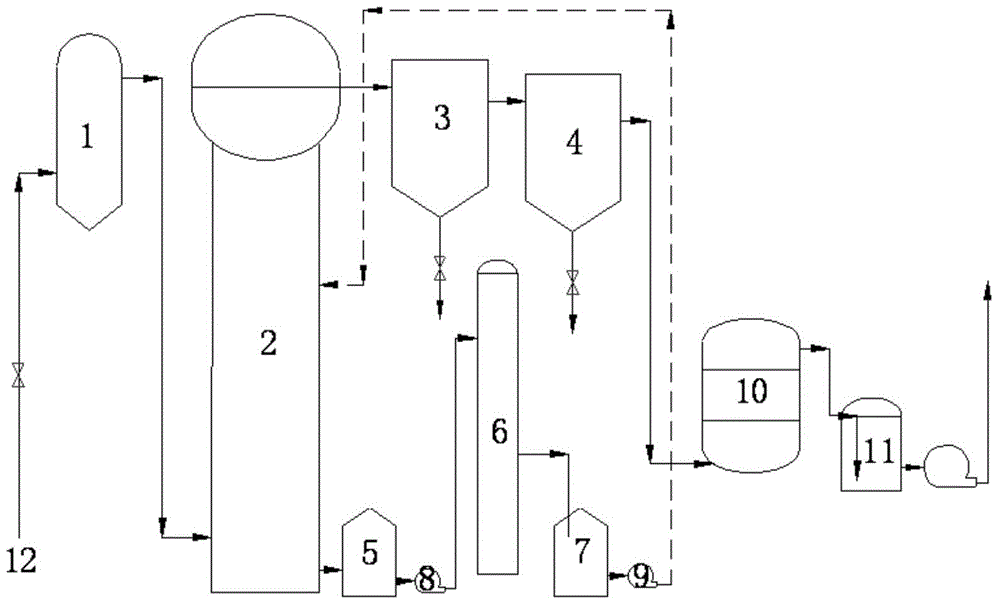

Hydrogenation process of hydrogen peroxide fluidized bed by anthraquinone

InactiveCN1817838AIncrease production capacityReduce differential pressureOrganic chemistryOrganic compound preparationFluidized bedHydrogenation process

A hydrogenation process for producing fluidized bed with hydrogen peroxide by anthraquinone method is carried out by taking empty tower hydrogenation reactor with amplification section on top, moving operating liquid and hydrogen upward at specific speed, floating powdery catalyst in tower body, hydrogenation reacting by free contacting, separating hydrogenated liquid by gas-liquid separating system, filtering by filter system and oxidizing. It has fast hydrogenation speed, low resistance, homogenous distribution and higher utilization rate.

Owner:LIMING RES INST OF CHEM IND

Hydrogenation method for production of hydrogen peroxide by anthraquinone process

InactiveCN102009960AUniform distributionIncrease contact areaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical industryHydrogenation process

The invention discloses a hydrogenation method for production of hydrogen peroxide by the anthraquinone process, belonging to the technical field of chemical industry reaction. The method provided by the invention comprises: dispersing the gaseous phase containing hydrogen into the working solution containing the anthraquinone derivatives to obtain the gas-liquid mixing fluid containing micron bubbles, so that the gas-liquid mixing fluid passes through the pipe reactor filled with the hydrogenation catalyst at the space velocity of 3 to 1000h<-1> to finish the hydrogenation process. In the method provided by the invention, the gas-liquid micro-dispersing process and the static bed catalytic hydrogenation process are directly integrated, so that the interphase mass transfer is strengthened, and the contacts between different reactants and between the reactant and the catalyst are more sufficient and more uniform, thereby enhancing the efficiency and the controllability of the hydrogenation process and improving the economical efficiency and the security of the production of the hydrogen peroxide.

Owner:TSINGHUA UNIV

Supported palladium catalyst for producing hydrogen peroxide by anthraquinone process and preparing method thereof

InactiveCN1435277AImprove catalytic performanceImprove overall lifespanPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsPhosphateActive component

A carried Pd-alumina catalyst for preparing hydrogen peroxide by anthraquinone method is prepared from Pd as main active component and Al2O3 as carrier through impregnation. Said Al2O3 has been coated by RE oxide and calcined at 900-1000 deg.C. It has high hydrogenating efficiency of 8-9 gH2O2 / L for 2-ethyl anthraquinone / heavy arene plus trioctyl phosphate or 10-13 gH2O2 / L for (2-tert-butyl anthraquinone plus 2-ethyl anthraquinone) / (heavy arene plus tetrabutyl urea).

Owner:FUZHOU UNIV

Oxidation method for preparing hydrogen peroxide by anthraquinone method

ActiveCN102009961AUniform distributionIncrease contact areaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical reactionAnthraquinone Derivatives

The invention discloses an oxidation method for preparing hydrogen peroxide by an anthraquinone method in the technical field of chemical reaction. The method comprises the following steps of: dispersing an oxygen-containing gaseous phase into hydrogenated anthraquinone derivative-containing working solution to prepare a micron-sized bubble-containing gas-liquid mixed fluid, and finishing oxidation reaction when the gas-liquid mixed fluid flows through a delay pipeline. The method can improve the oxidation efficiency of a hydrogenated anthraquinone derivative, shorten oxidation reaction time, reduce the hold-up of the oxidization working solution in a reaction system and improve the safety of the oxidation process.

Owner:TSINGHUA UNIV

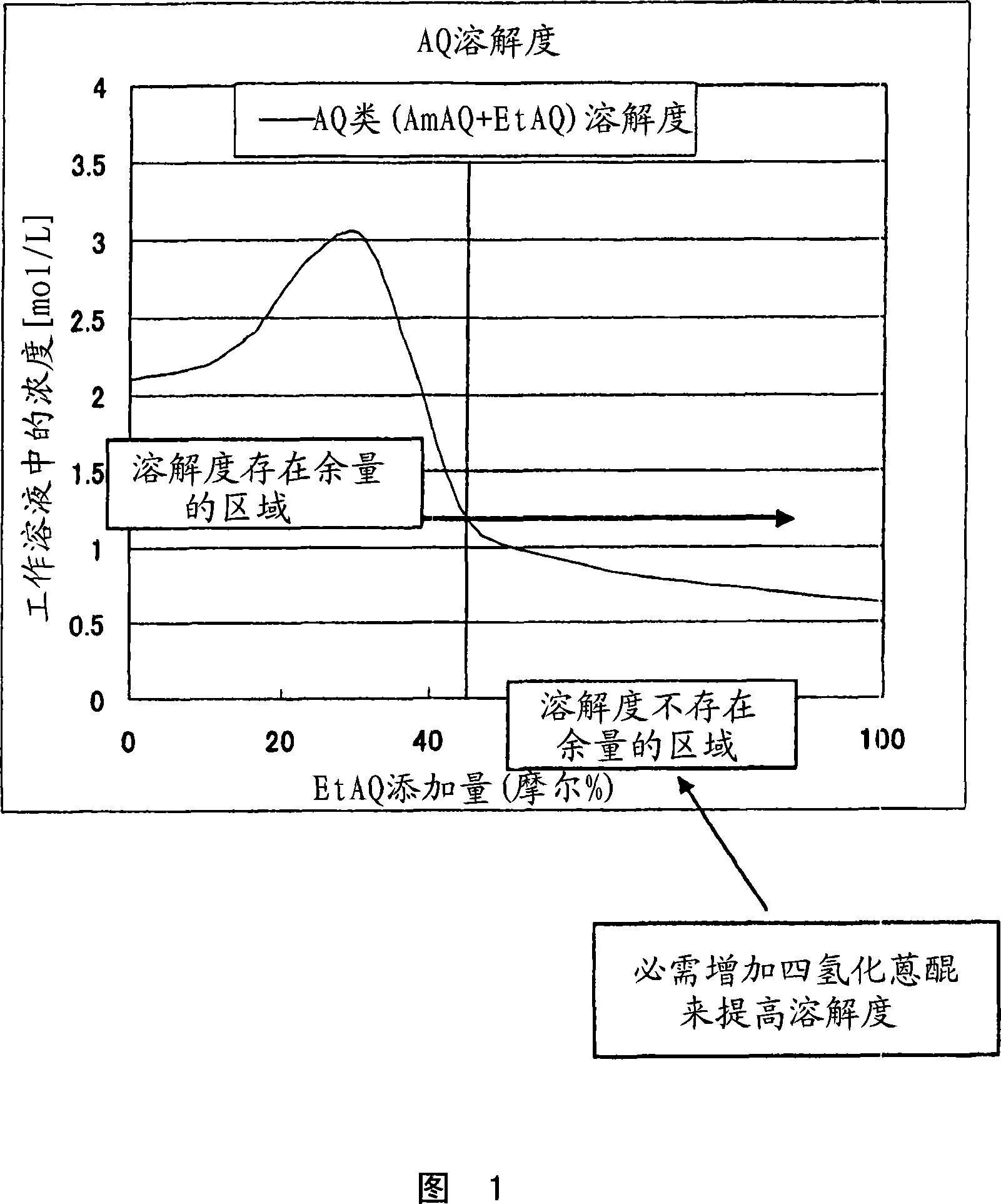

Formula of working liquid for hydrogen peroxide production based on anthraquinone process

InactiveCN101798065AReduce consumptionImprove solubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolubilityBenzene

The invention provides the formula of a working liquid for hydrogen peroxide production based on the anthraquinone process. The working liquid comprises solvent and a working carrier, wherein the solvent comprises the following components by volume percentage: 65% to 80% of alkyl benzene, 5% to 25% of trioctylphosphate (TOP) and 4.5% to 17.8% of N-phenyl-N-ethyl-benzamide; the working carrier is particularly a mixture of alkyl anthraquinone and alkyl tetrahydroanthraquinone with the total content thereof being 130g / L to 200g / L in the working liquid. The working liquid of the invention has the advantages of high working carrier solubility, moderate density and high working load, and reduces the degradation rate of anthraquinone. Therefore, the produced hydrogen peroxide has high yield and low material consumption, and the production process is simple and easy-to-operate.

Owner:江山市双氧水有限公司

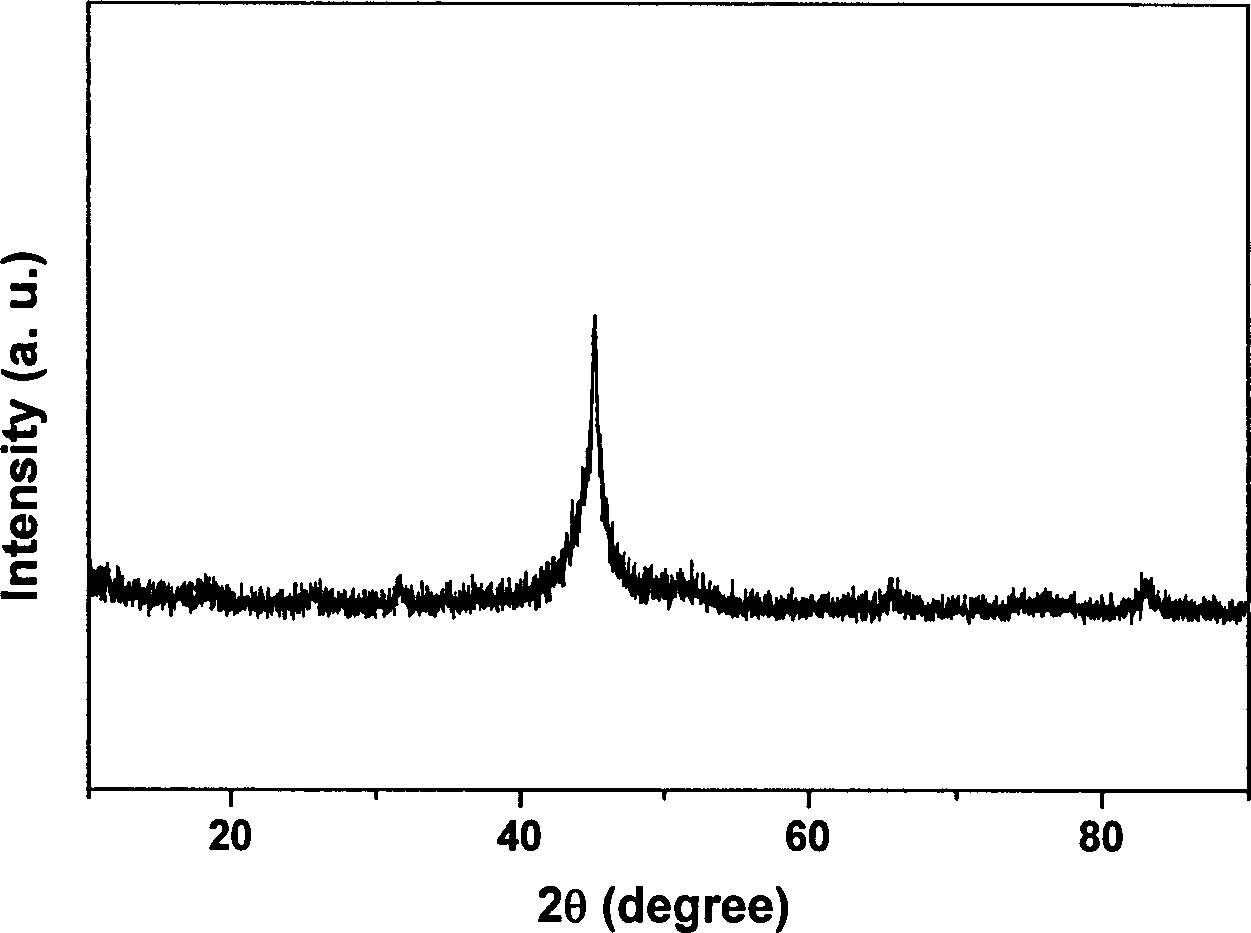

High Dispersing palladium catalyst prepared by lamellar precursor and preparation method thererof

InactiveCN1483512AHigh activityGood choicePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesCatalyst activation/preparationAnthraquinonesPtru catalyst

The present invention provides a new palladium catalyst and its preparation method. Said method includes the following steps: firstly, in situ synthesizing hydrotalcite lamellar precursor body containing palladium in carrier surface layer hole, then roasting at higher temp. to convert the lamellar precursor body into correspondent composite metal oxide, and using hydrogen gas to make reduction treatment so as to obtain the loaded type high-dispersion catalyst in which the palladium is highly dispersed into the surface of internal hole of the carrier. Said catalyst mainly is used in antraquinone hydrogenation process for preparing hydrogen peroxide by means of antraquinone method.

Owner:BEIJING UNIV OF CHEM TECH

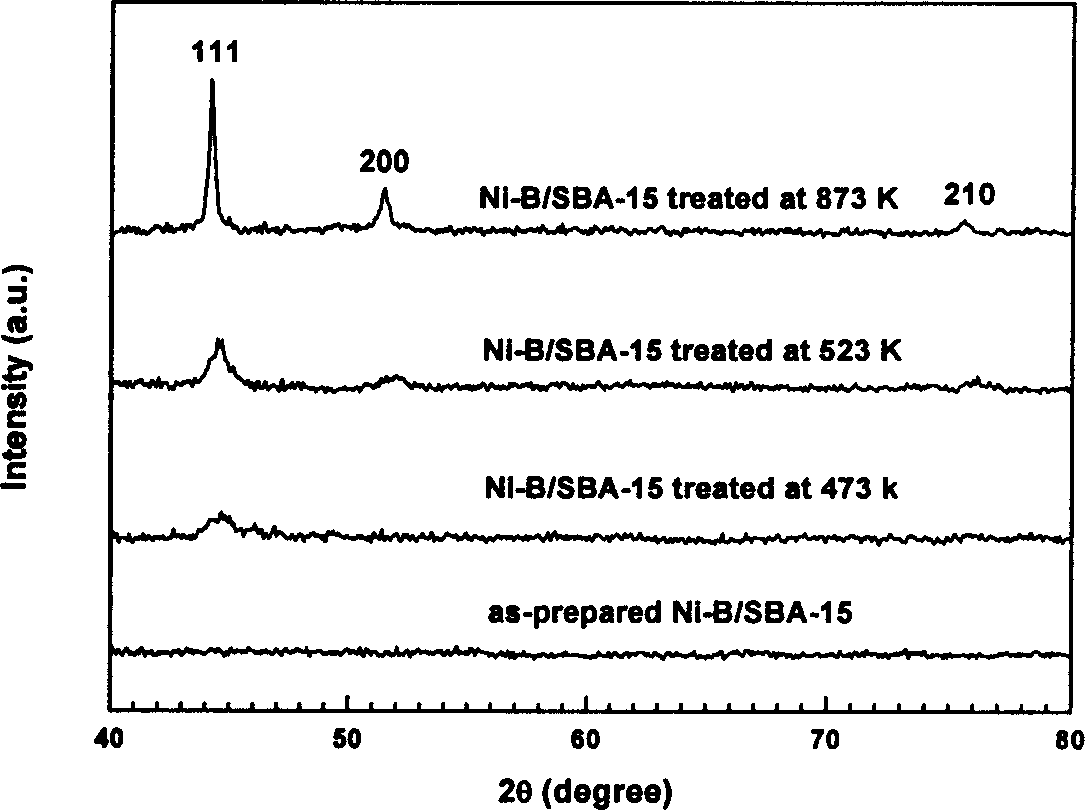

Carrier style palladium amorphous alloy catalyst for hydrogenation of anthraquinone

InactiveCN1424145AHigh activityReduce loadMolecular sieve catalystsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesRare-earth elementIce water

A carried non-crystal Pd alloy catalyst for hydrogenating anthraquinone to prepare H2O2 is prepared from the carrier which is one or two of gamma-Al2O3, alpha-Al2O3, MgO, activated carbon, molecular sieve and mullite, non-crystal PdB alloy and RE element through immersing the carrier in the solution of RE metal's nitrate under ultrasonic condition, calcining at 400-700 deg.C for 2-5 hr, immersing in PdCl2 solution, dropping KBH4 solution in ice water bath, and washing. Its advantages are high catalytic activity and low cost.

Owner:TIANJIN UNIV

Catalyst support added with hydrogen, peroxide catalyst produced by anthraquinone method and the producing process

ActiveCN101032699AHigh activityImprove stabilityCatalyst carriersPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogenPeroxide

The present invention discloses one kind of oxide containing porous alumina, and oxide of Si, Ti and / or Zr, and the oxide is used as the carrier for hydrogenation catalyst used in an anthraquinone process to produce hydrogen peroxide. The catalyst has Pd supported in the amount of 0.05-10 wt%. The hydrogenation catalyst carrier has stable performance, property specific surface area, pore size and pore volume, and the hydrogenation catalyst has high catalytic activity, high stability and relatively lower noble metal content.

Owner:CHINA PETROLEUM & CHEM CORP

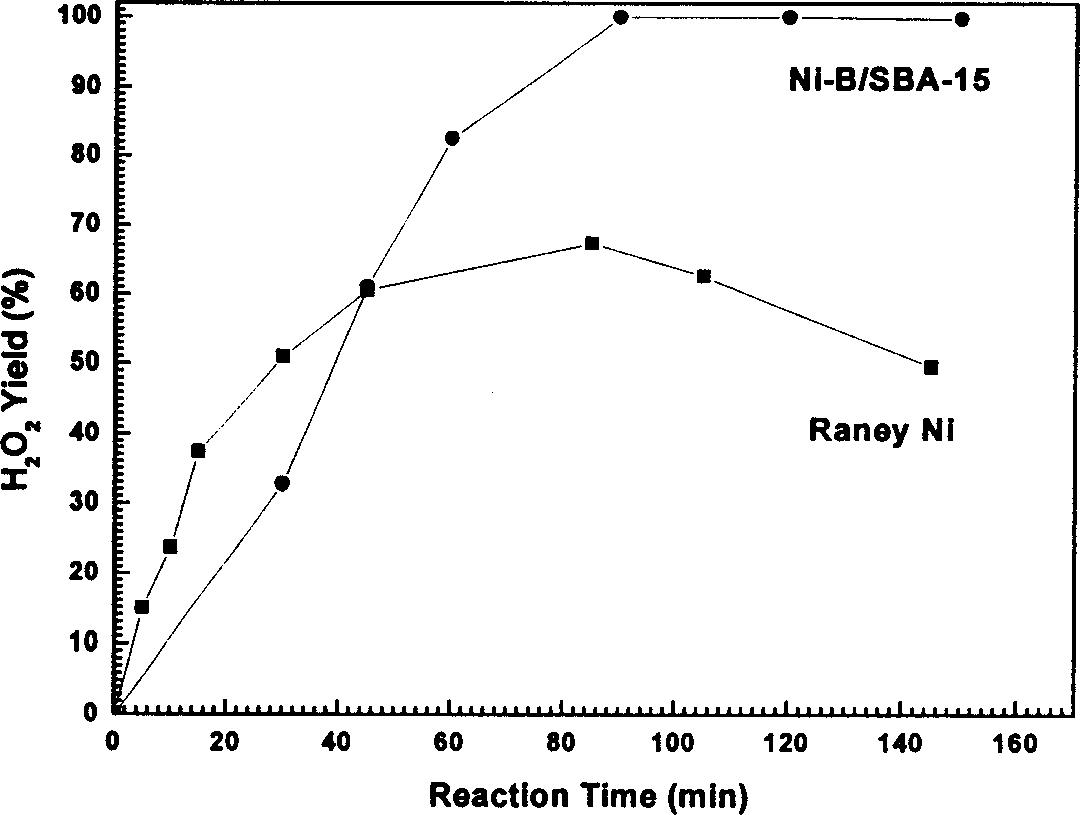

Amorphous skeletal-nickel hydrogenating catalyst for anthraquinone process of preparing hydrogen peroxide and its prepn

InactiveCN1421383AHigh activityHigh selectivityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsAnthranilAlloy catalyst

The present invention belongs to the field of chemical technology and is especially one catalyst for anthraquinone hydrogenation process of preparing hydrogen peroxide and its preparation. The catalyst is obtained with some alloy and through active treatment with alkali solution and the alloy consists of Ni, Al and metal additive including one or several of Cr, Mo, W, Fe, Co, Cu and Zn. The catalyst is one kind of amorphous skeleton alloy catalyst prepared through high temperature melting of metal components, quenching stress to obtain alloy strip or scaly alloy, grinding, sieving and activation in alkali solution. Compared with traditional Raney Ni catalyst, the said catalyst has high anthraquinone hydrogenation activity and high selectivity.

Owner:FUDAN UNIV

Stredford process peroxyl production work liquid post treatment method

InactiveCN1483664ALow costReduce moisturePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesRaffinateSodium nitrate

A process for handling the extraction raffinate of anthraquinone hydrogen peroxide is neutralizing the acidic extraction raffinate with concentrated basic sodium nitrate solution for decomposing the contained hydrogen peroxide, absorbing a part of water to suit to the regeneration of active aluminium oxide, and regenerating a part of degradation matter existed in the extract raffinate to suit to the hydrogenaton .

Owner:中国石油化工股份有限公司巴陵分公司

Method for producing hydrogen peroxide by anthraquinone process

InactiveCN101229915AIncrease production capacityEvenly distributedPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesWorking fluidHydrogenation reaction

The invention provides a process for producing hydrogen peroxide by using an anthraquinone method. The process includes the following steps: hydrogen is added in the anthraquinone to generate anthrahydroquinone which is oxidized to generate the anthraquinone and the hydrogen peroxide. The reaction in which the hydrogen is added in the anthraquinone to generate anthrahydroquinone means that working fluid with the anthraquinone and the hydrogen are led in a fixed bed reactor which is filled with catalyst with the hydrogen so that hydrogenation is generated between the working fluid with the anthraquinone and the hydrogen to generate the anthrahydroquinone under the effect of the catalyst; the obtained hydrogenated working fluid with the anthrahydroquinone is conducted out of an oxidation device, wherein, when the working fluid with the anthrahydroquinone and the hydrogen are conducted in the fixed bed reactor, the working fluid is continuous phase, in which the hydrogen is distributed in the form of bubbles; when the working fluid with the anthrahydroquinone and the hydrogen are conducted in the fixed bed reactor, a feeding inlet is made not higher than a discharging outlet where the hydrogenated liquid is discharged out of the fixed bed reactor. By using the method, utilization efficiency of the catalyst as well as the production capability of the reactor is promoted and bed resistance is reduced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

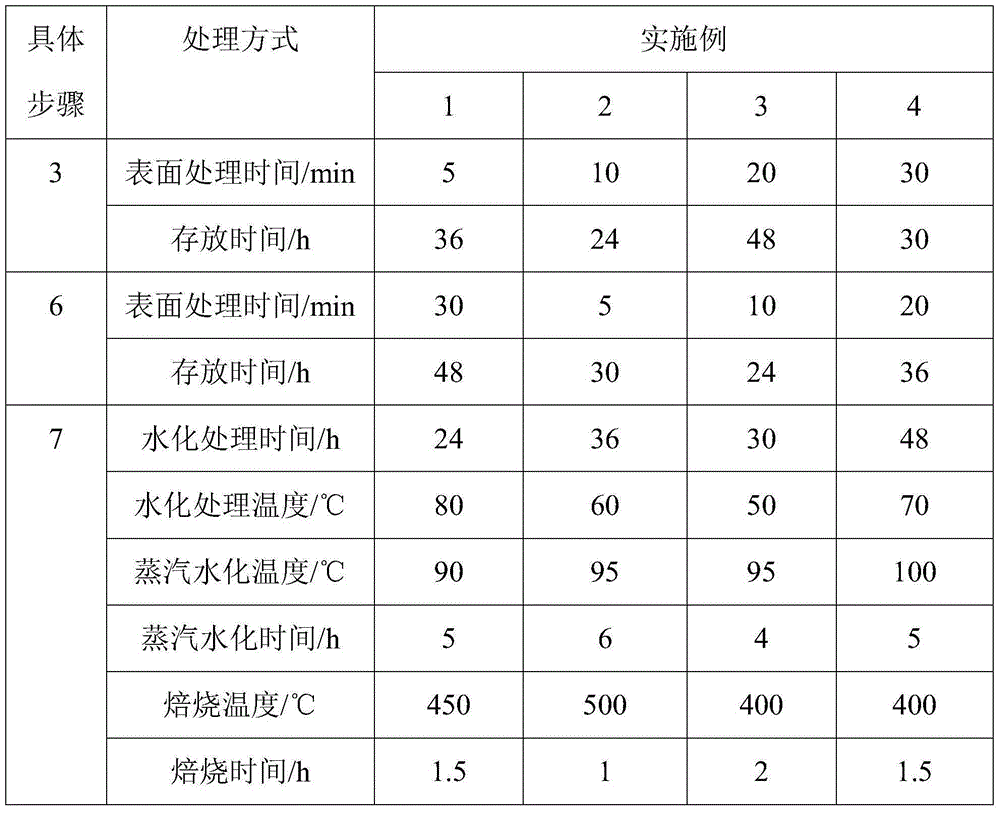

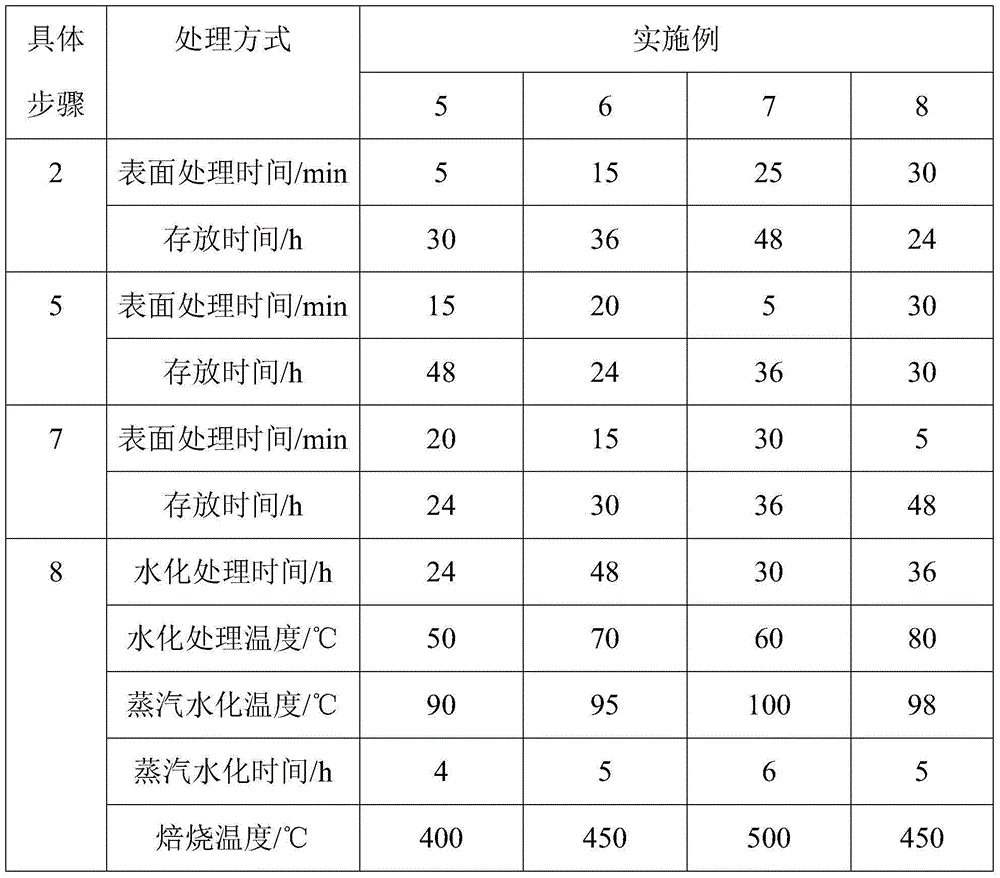

Palladium alumina catalyst for production of hydrogen peroxide by anthraquinone process and its preparation method

ActiveCN102626618AHigh activityHigh compressive strengthPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingPseudoboehmiteAluminium hydroxide

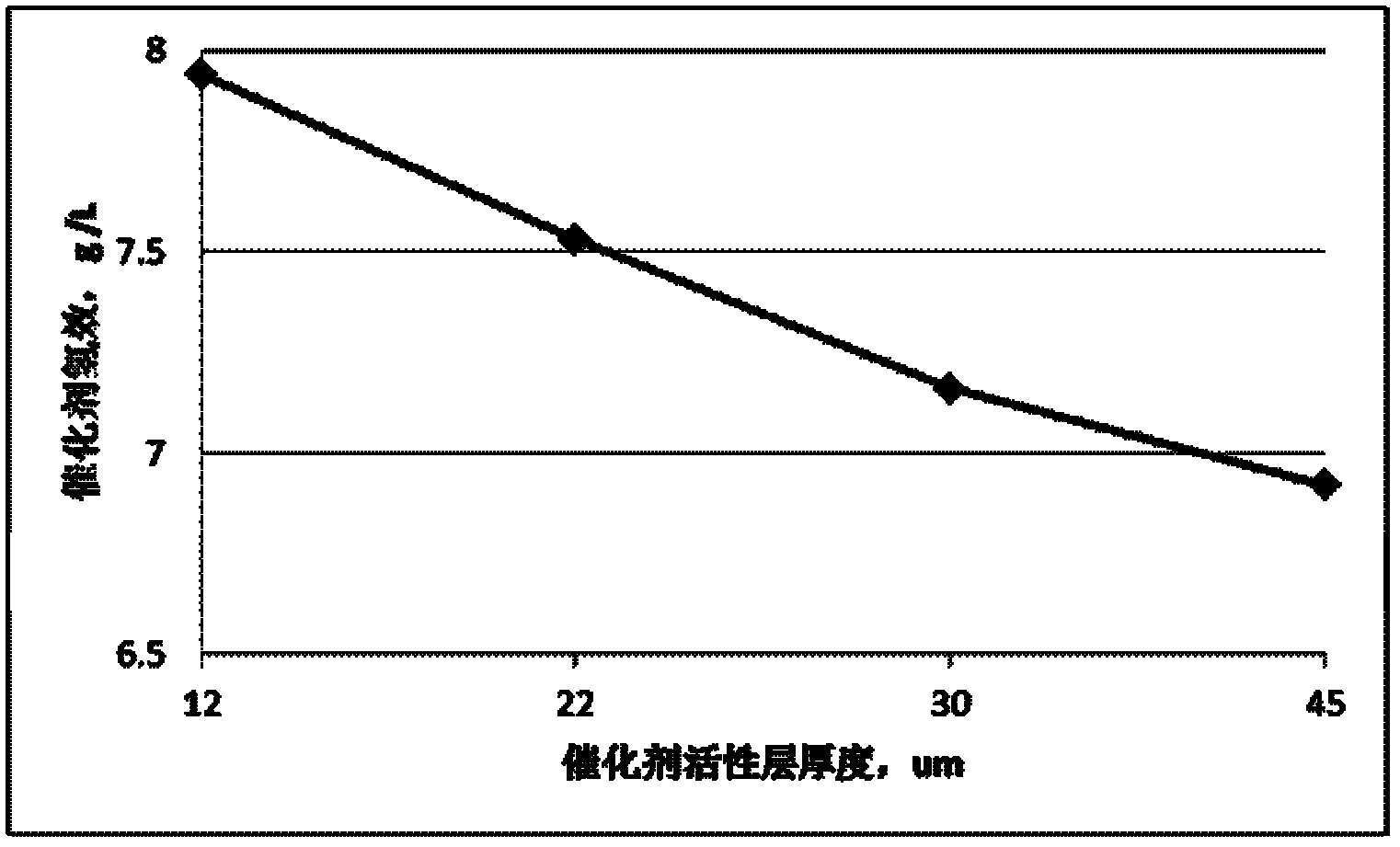

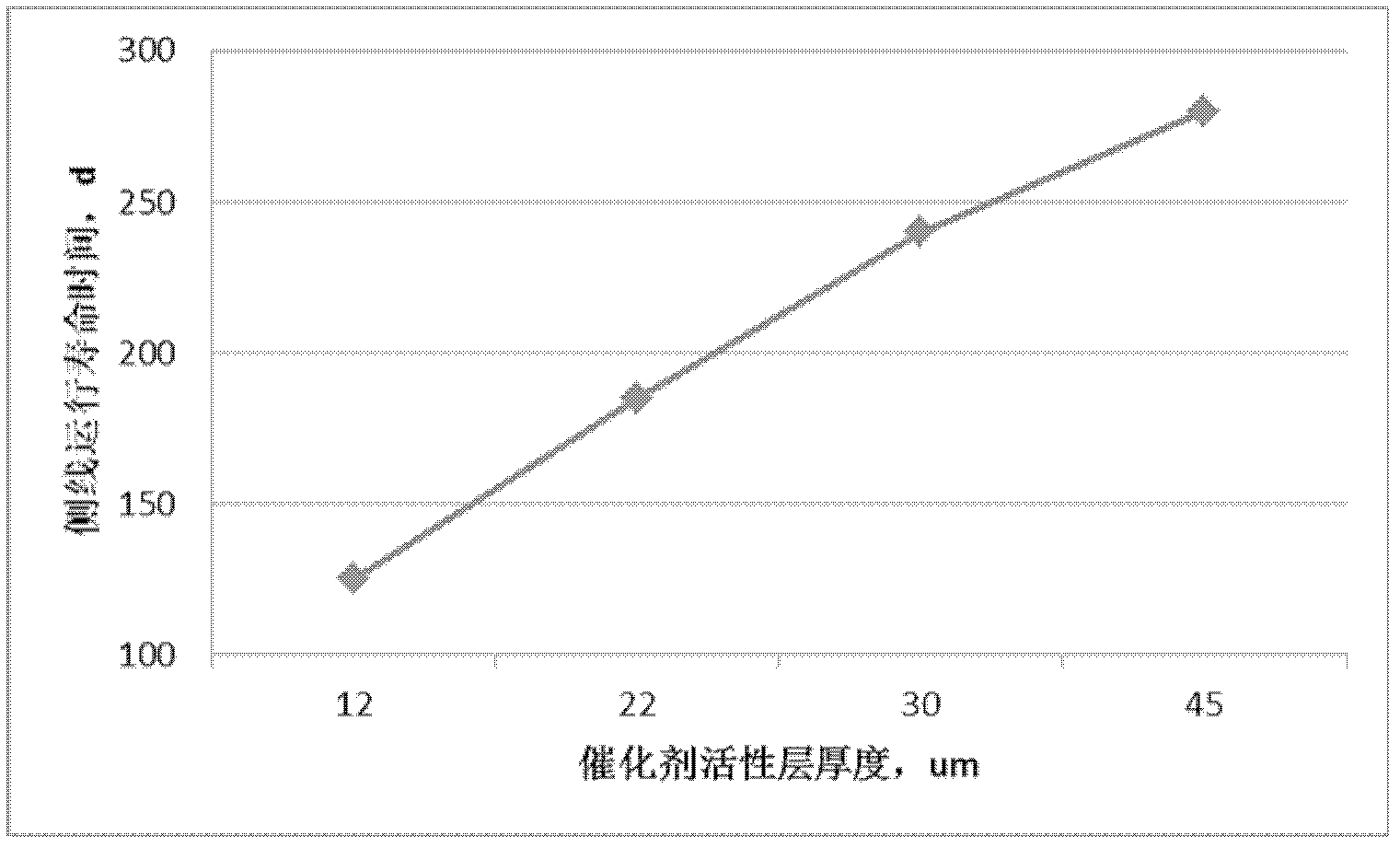

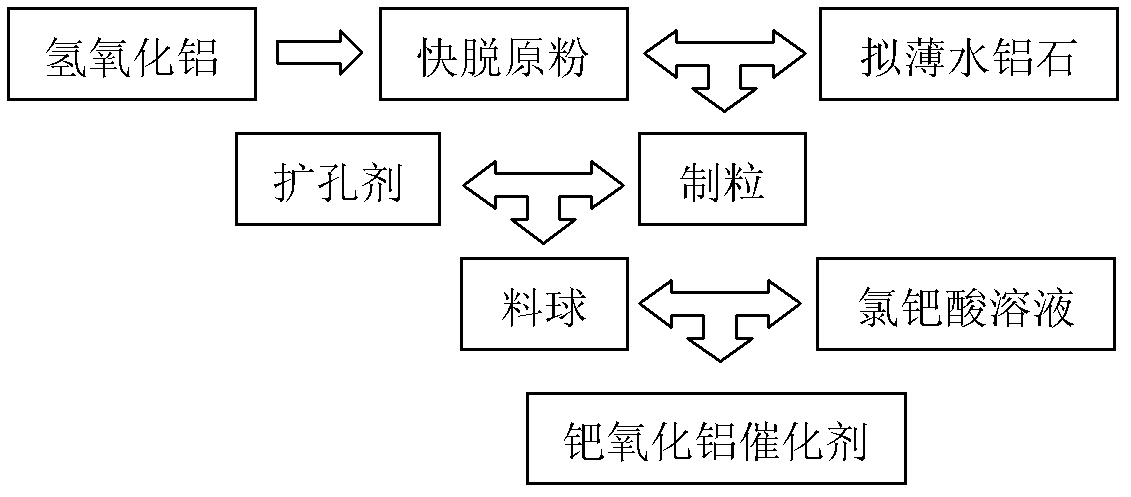

The invention discloses a palladium alumina for production of hydrogen peroxide by an anthraquinone process. The catalyst comprises gamma-Al2O3 as the carrier, the content of which is over 97wt%; and metal palladium as the main active component, the loading of which is 0.1wt%-0.5wt% and the dipping thickness of which is from 10 micrometers to 100 micrometers. The invention also discloses a preparation method of the catalyst, and the method consists of: roasting aluminum hydroxide, mixing the roasted aluminum hydroxide with pseudoboehmite, then adding a pore-expanding agent for molding, conducting surface treatment so as to obtain a catalyst carrier, then performing pre-spraying on the carrier with a locating agent, carrying out drying, and then putting the carrier into a chloropalladate solution for dipping. With appropriate specific surface area, pore volume and pore size distribution, the palladium catalyst provided in the invention is difficult to shed and fragment. In actual production of hydrogen peroxide by an anthraquinone process, the catalyst shows excellent balance between activity and selectivity, as well as good service life and regeneration cycle.

Owner:陕西开达化工有限责任公司

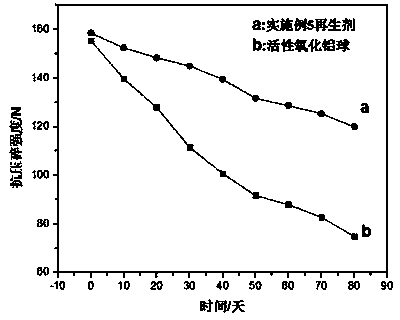

Preparation method of regenerator for preparing hydrogen peroxide by anthraquinone process

ActiveCN103879969AExcellent crush strengthImprove water absorptionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingAnthraquinonesAluminium oxides

The invention provides a preparation method of a regenerator for preparing hydrogen peroxide by an anthraquinone process, which comprises the following steps: adding a dilute acid solution into aluminum oxide powder, uniformly mixing and making a strip; drying at room temperature in the shade, and roasting at 600-900k for 3-5 hours to obtain a strip carrier; and impregnating the strip carrier in a sodium hydroxide solution, taking out, and drying. The regenerator has excellent properties, all indexes achieve or exceed the original active regenerator, and the preparation technique is simple, scientific and reasonable and can satisfy the industrial requirements.

Owner:GUANGXI XINJING TECH

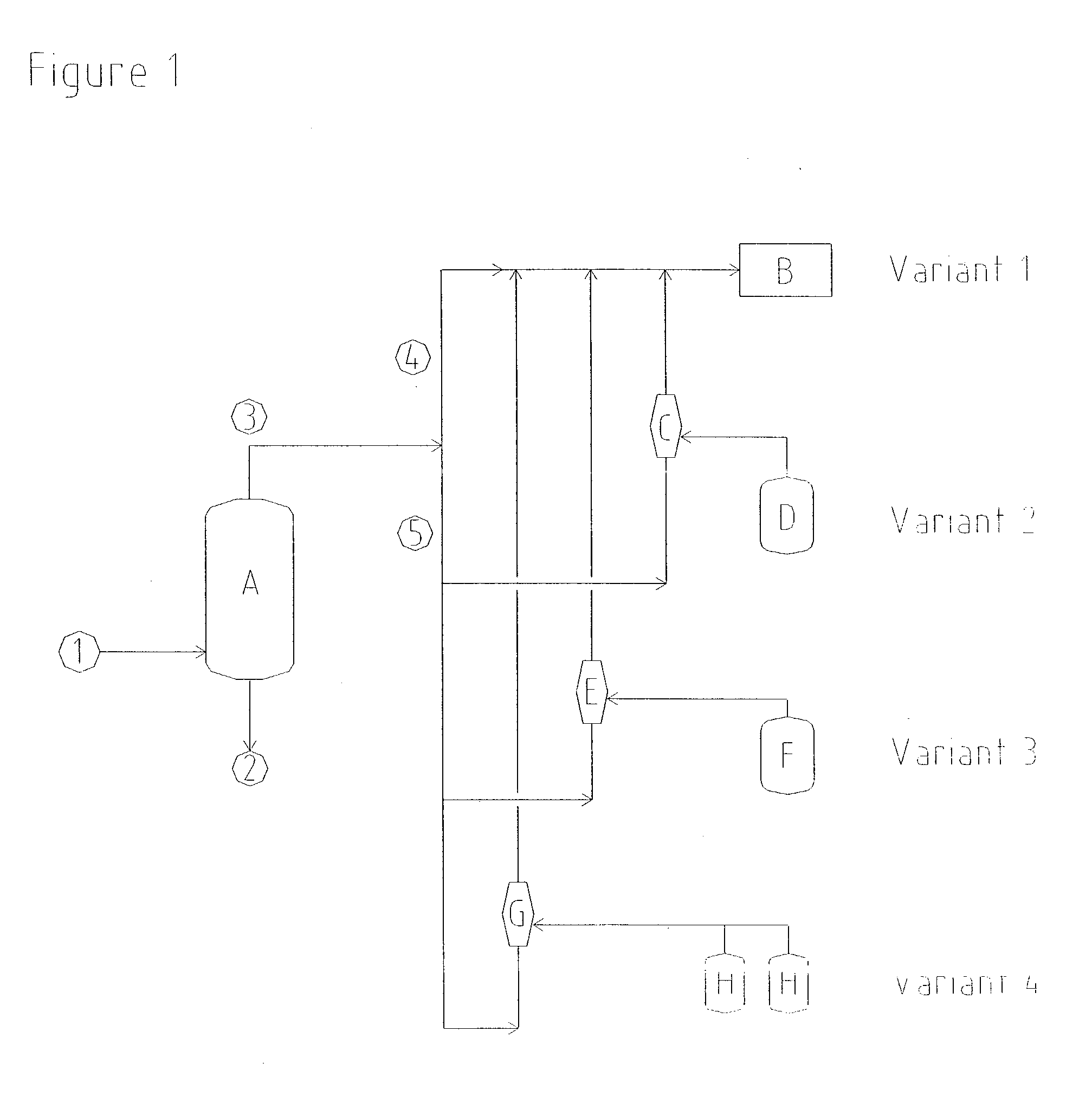

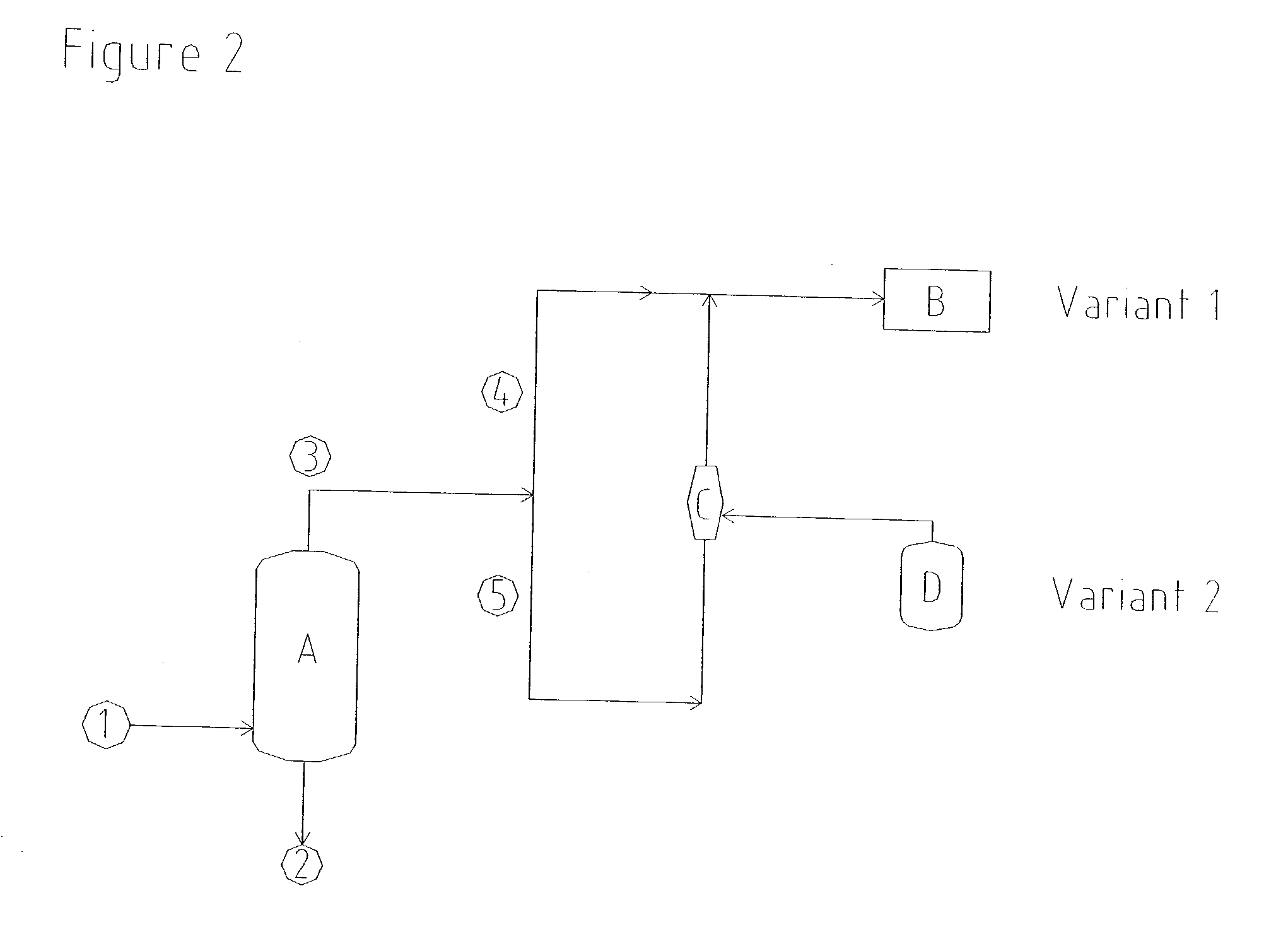

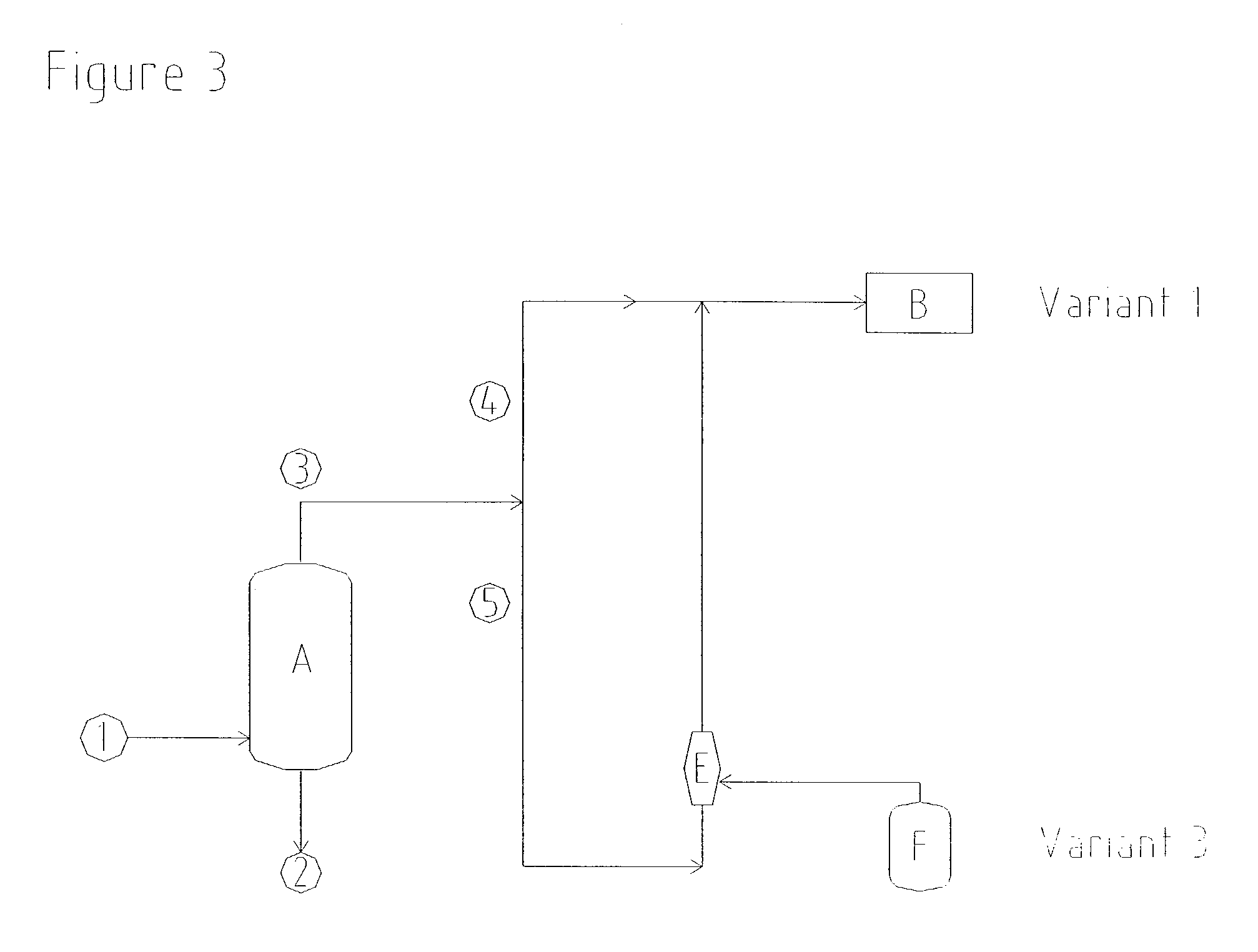

Process for the production of hydrogen peroxide

ActiveUS20030165422A1Reduce investmentPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesDistillationSolvent

The anthraquinone process for producing hydrogen peroxide, including a hydrogenation step, an oxidation step and an extraction step. The oxidation waste gas leaving the oxidation reactor at an excess pressure is passed as a propellant jet to one or more gas jets and whereby a vacuum is produced for auxiliary processes, such as drying of the working solution, distillation of the aqueous hydrogen peroxide solution and drawing off of ventilator gases from solvent storage tanks.

Owner:EVONIK OPERATIONS GMBH

Anthraquinone hydrogenation catalyzer of anthraquinone method oxydol preparation process and its preparation method

InactiveCN1544312AHigh catalytic efficiencyGood reaction selectivityMolecular sieve catalystsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMolecular sieveAnthranil

The invention discloses a novel catalyst and process of preparation for anthraquinone hydrogenation in hydrogen dioxide solution preparation, wherein the catalyst comprises nickel, boron, metallic additive M and carrying agent S, the specific surface is 200-1200 m2g-1, the active specific surface is 0.1-50 m2g-1. The catalyst preparing process comprises the steps of charging surface activator in the nickel-boron alloy preparation, producing mixture of mesopore or micropore molecular sieve and nickel-boron alloy, the conventional immersion or reducing agent immersion method can be employed to load the nickel-boron alloy onto the common carrying agent or mesopore and microporous molecular sieve.

Owner:FUDAN UNIV

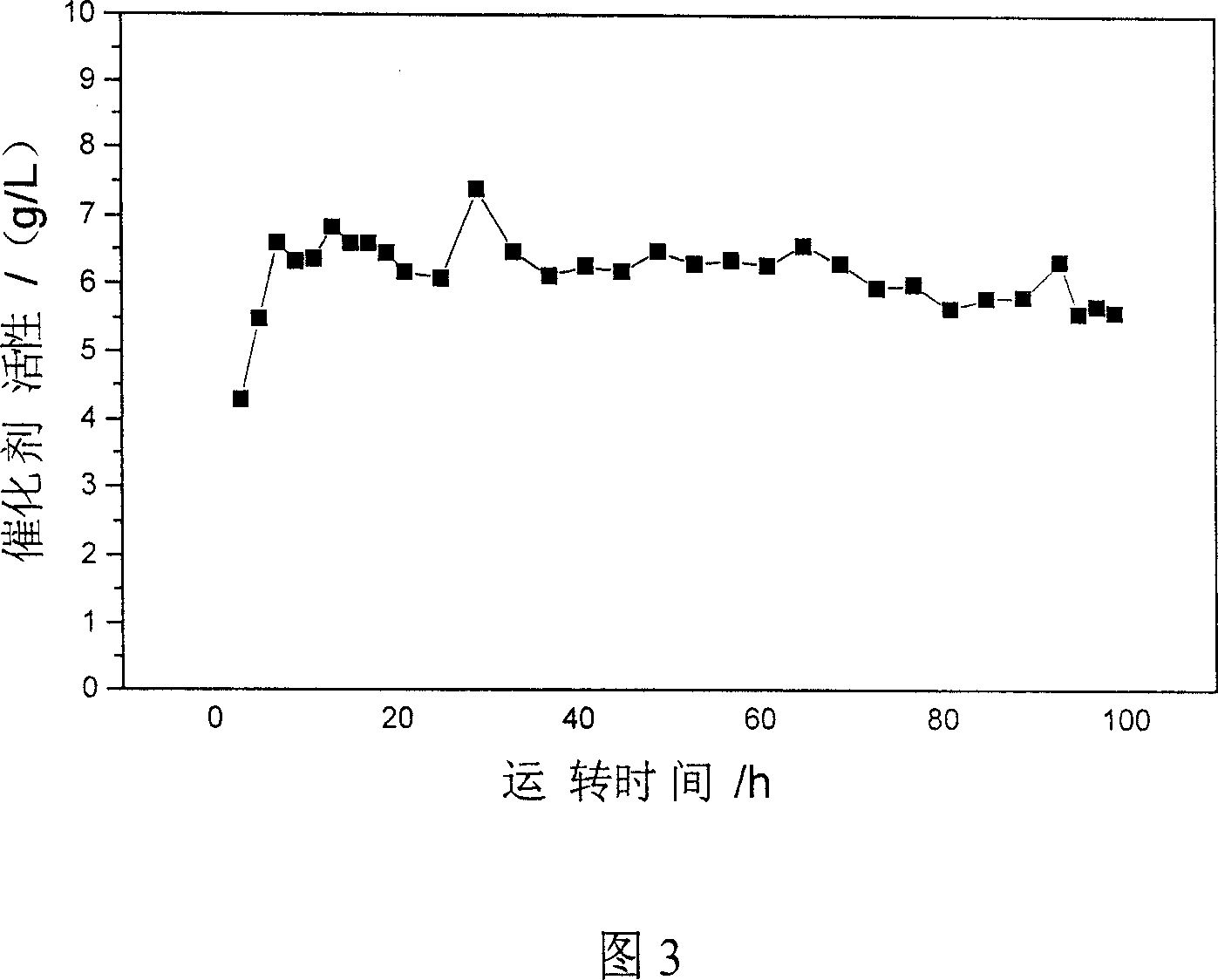

Catalyst for producing auricome by anthraquinone method and preparation method thereof

InactiveCN101462052AHigh activityHigh selectivityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsHydrogen pressureReaction temperature

The invention discloses a catalyst for producing hydrogen peroxide by an anthraquinone method and a preparation method thereof. The composition of the catalyst is represented by Pd-MOx / gamma-Al2O3, and M represents a metal element Cr, Zr or Mn. The catalyst can be prepared by adopting an incipient co-impregnation method and a two-step impregnation method, and the hydrogenation activity test of 2-ethyl anthraquinone is performed under the condition that the liquid space velocity is 28.6h<-1>, the hydrogen pressure is 0.18MPa, and the reaction temperature is 45 DEG C. The catalyst has the advantages that the catalyst has high catalytic activity, and the hydrogenation efficiency can reach between 8.0 and 10.0g (H2O2) / L; the catalyst has good selectivity which is more than 99 percent; the catalyst has the simple preparation method; and the catalyst has mild reaction conditions, still keeps high activity at high liquid space velocity, and is suitable for industrial scale-up production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

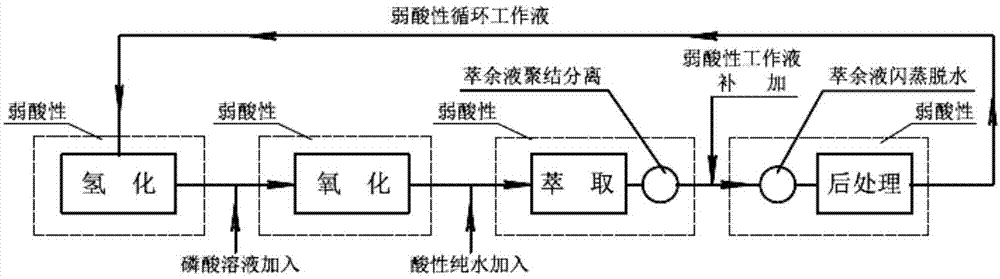

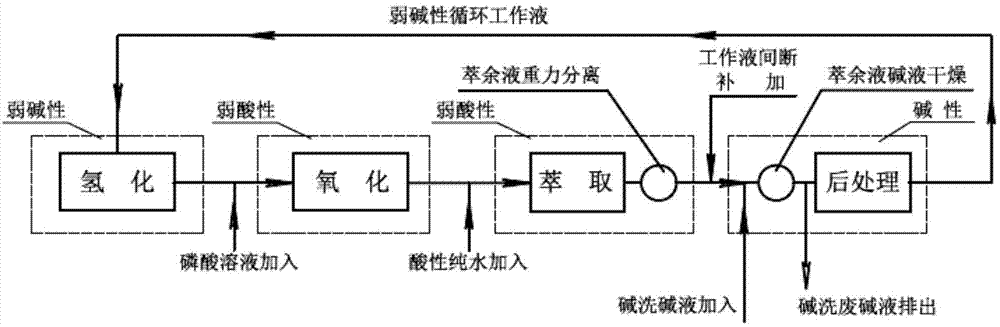

Method of preparing hydrogen peroxide from all-acid working solution system by anthraquinone process

ActiveCN103496674AGuaranteed outputQuality assurancePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOperational costsPurified water

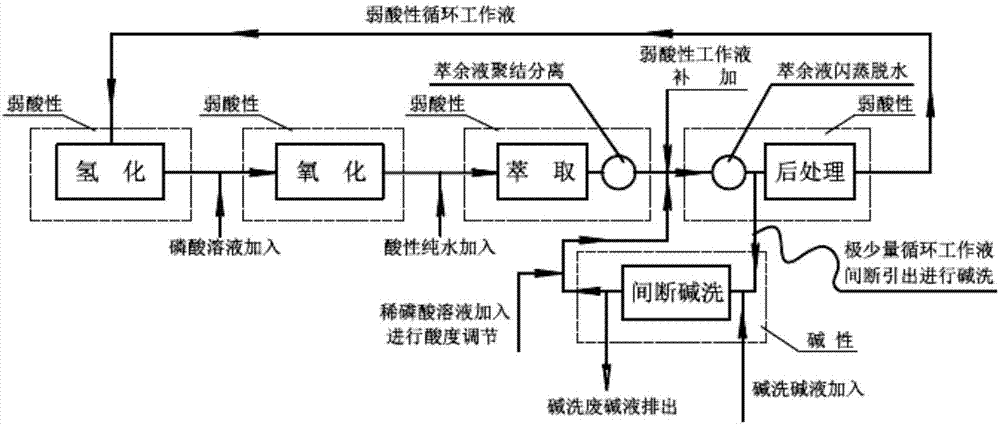

The invention discloses a method of preparing hydrogen peroxide from an all-acid working solution system by the anthraquinone process. The method includes hydrogenation, oxidization, extraction and post-treatment of working solution. During the method, the whole working solution system is faintly acid constantly. The method includes: hydrogenating prepared faintly acidic working solution to obtain hydrogenated solution; mixing the hydrogenated solution with acid, and performing air oxygenation to obtain oxidized liquid; extracting the oxidized liquid with purified water; purifying extract to obtain finished hydrogen peroxide; removing free water and free hydrogen peroxide from the extract, performing vacuum flashing to remove dissolved water and dissolved hydrogen peroxide, and using vacuum-flashed residual extract as circulating working solution. Very little circulating working solution can further be intermittently guided out of a main process for alkali washing by the method. The method has the advantages that safety and reliability of the production process of hydrogen peroxide can be improved effectively and fixed capital input and production operational cost can be reduced.

Owner:北京凯迪森科技有限公司

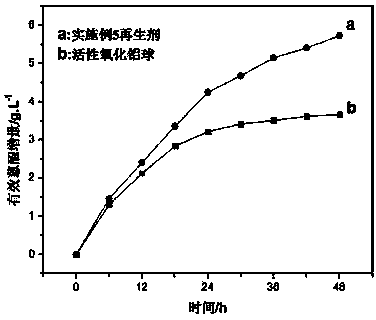

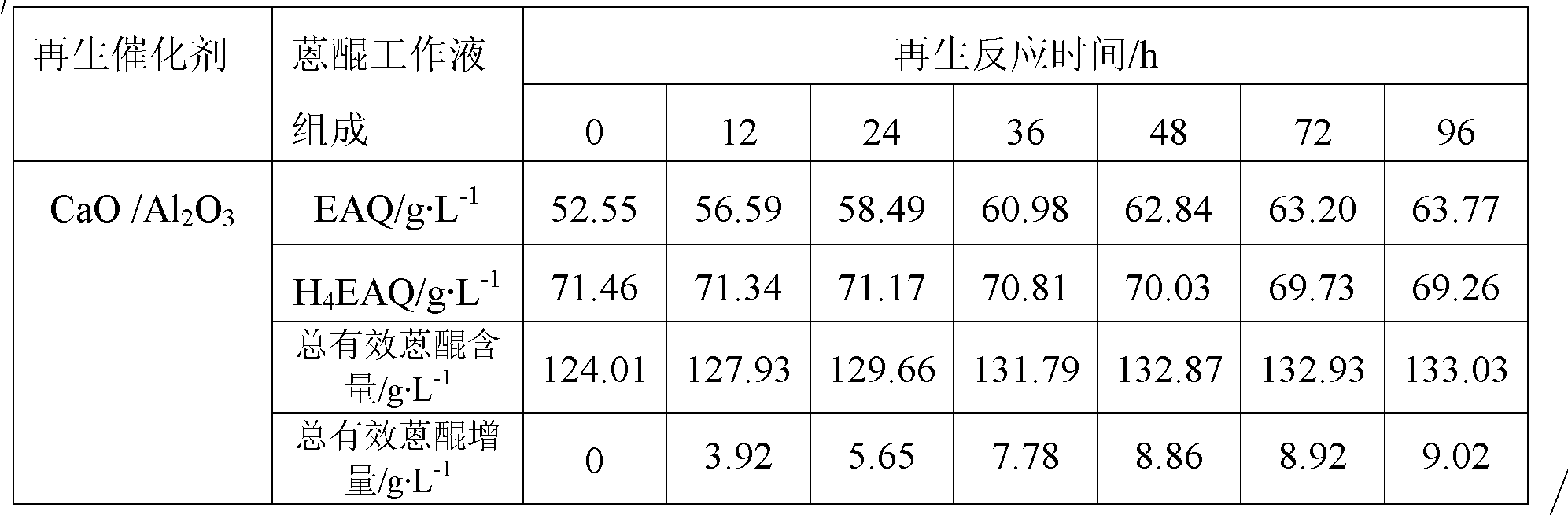

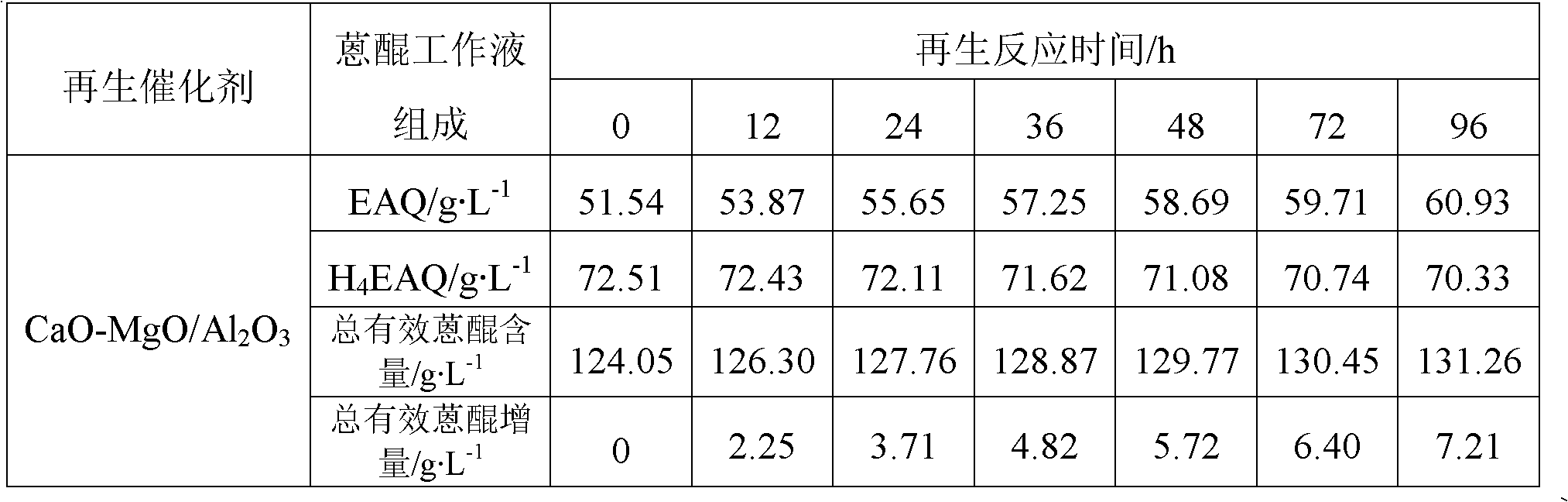

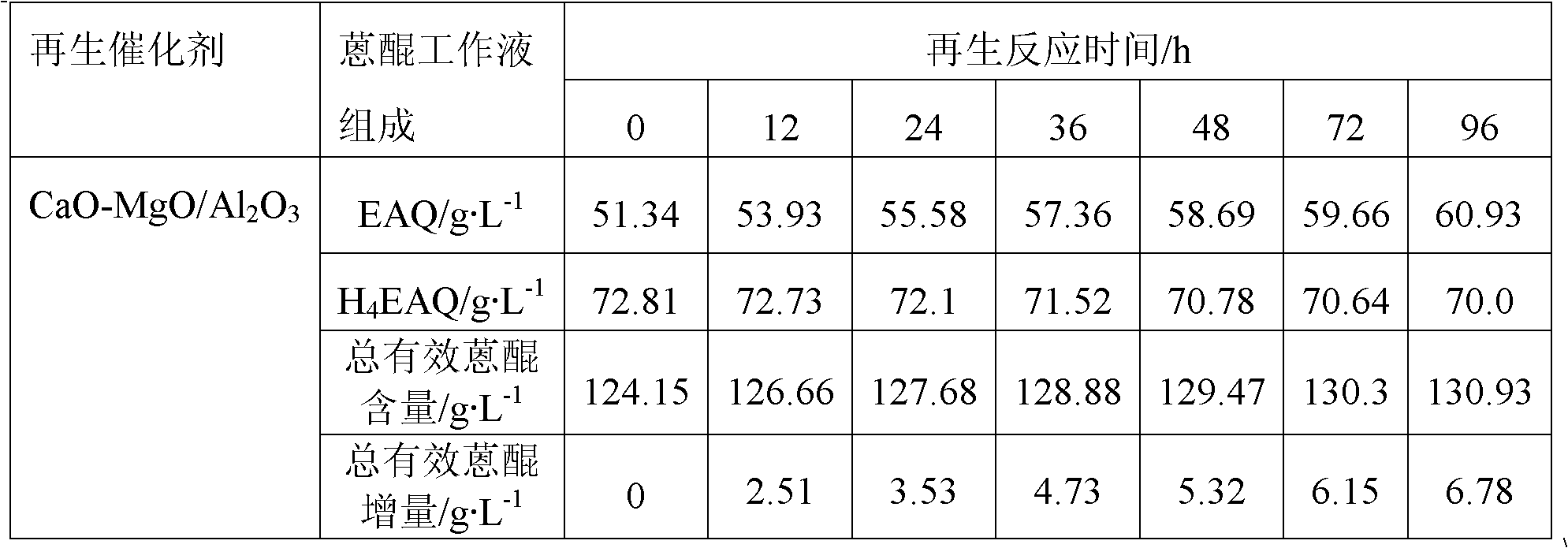

Hydrogen peroxide working solution regenerant used in preparation of hydrogen peroxide process according to anthraquinone method and preparation method of hydrogen peroxide working solution regenerant

InactiveCN105152137APromote regenerationImprove stabilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingMagnesiumAnthraquinone process

The invention discloses a hydrogen peroxide working solution regenerant used in preparation of a hydrogen peroxide process according to an anthraquinone method and a preparation method of the hydrogen peroxide working solution regenerant. The regeneration effect of the hydrogen peroxide working solution regenerant is better than that of the conventional activated aluminum oxide anthraquinone degradation product regenerant used in the industry. Compared with the conventional regenerant, after regeneration, the quantity of effective anthraquinone is increased by 0.8 to 2.1 percent. During the preparation process, the reaction between magnesium oxide and water is very slow, the reaction product magnesium hydroxide is hard to dissolve in water, covers magnesium oxide to inhibit further reaction between magnesium oxide and water, and can properly improve the alkalinity of a working solution, while slight alkalinity provides convenience for improving the activity and the selectivity of a palladium catalyst, accelerating the speed of the hydrogenation, and avoiding a great amount of degradation. Meanwhile, the regenerant provided by the invention has favorable stability, is less susceptible to pulverization in the working solution, and low in adsorption of effective anthraquinone in the working solution; the preparation method is simple in process step, can be suitable for large-scale industrial production, and has a relatively high economical effect.

Owner:XIANGTAN UNIV

Anthraquinone degradation product regeneration catalyst and preparation method thereof

InactiveCN102728338AReduce manufacturing costSolution to short lifeOrganic compound preparationQuinone preparationHydrotalciteCompressive strength

The invention provides an anthraquinone degradation product regeneration catalyst and a preparation method thereof. MeO / Al2O3 represents the anthraquinone degradation product regeneration catalyst, wherein MeO represents an alkaline oxide; a crystal form of Al2O3 is a gamma form; Al2O3 crystals are in shapes of balls, strips and whitetip clover; a mass percent of MeO is in a range of 1 to 60wt%; a specific surface area of MeO / Al2O3 is in a range of 100 to 300m<2>.g<-1>; a pore volume is in a range of 0.3 to 1.5cm<3>.g<-1>; and compressive strength is in a range of 50 to 150N / particle. The preparation method comprises the following steps of synthesizing a hydrotalcite MeAlCO3-LDH / Al2O3 precursor on surfaces of Al2O3 carriers and in channels of the Al2O3 carriers and carrying out calcination at a temperature of 500 to 600 DEG C to obtain the anthraquinone degradation product regeneration catalyst. The anthraquinone degradation product regeneration catalyst which is an alkaline composite oxide can be used for regeneration of an anthraquinone working solution used in an anthraquinone process-based hydrogen peroxide preparation industry and has a stable regeneration period of 6 to 20 months. Compared with the existing regeneration catalyst used industrially, the anthraquinone degradation product regeneration catalyst has a service life prolonged by 2-3times and higher regeneration efficiency.

Owner:BEIJING UNIV OF CHEM TECH

Method for generating palladium catalyst for producing hydrogen peroxide by using anthraquinone process

InactiveCN104475175AActive recovery is goodExtend the life cycleCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsPalladium catalystNitrogen

The invention discloses a method for generating a palladium catalyst for producing hydrogen peroxide by using an anthraquinone process. The method comprises the following comprehensive regeneration steps: soaking or circularly washing a catalyst to be regenerated by using aromatic hydrocarbon with temperature of 30-70 DEG C, treating by using saturated steam with temperature of 100-120 DEG C, soaking or circularly washing by using hot water with temperature of 30-95 DEG C, displacing with nitrogen, activating with nitrogen, and the like. The regenerated catalyst is thorough in regeneration degree, good in activity recovery, and long in regeneration period and service life.

Owner:YANTAI BAICHUAN HUITONG TECH CO LTD

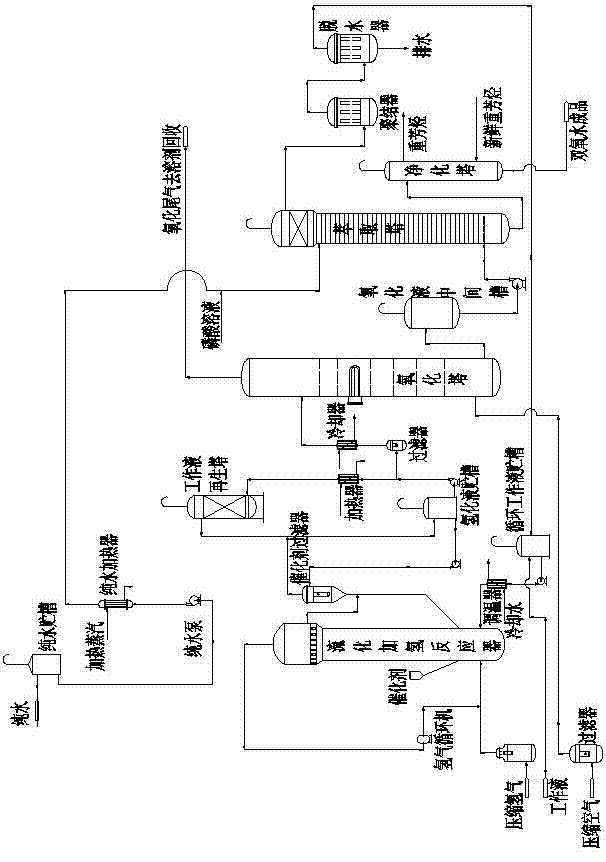

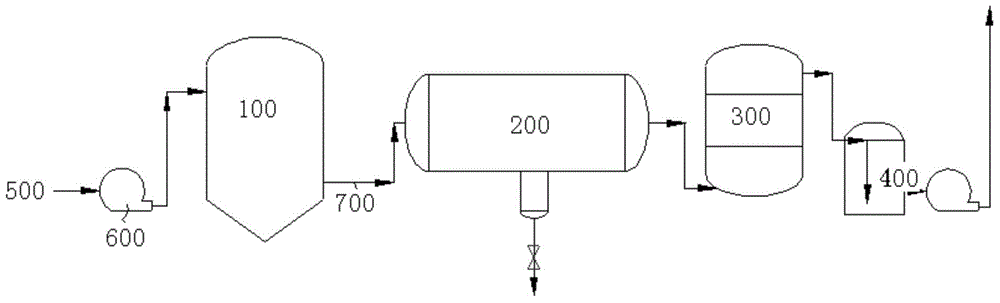

Production method of hydrogen peroxide

InactiveCN103588176ALow investment costImprove hydrogenation efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHigh concentrationPhosphate

Relating to the technical field of large-scale high concentration hydrogen peroxide production technologies, particularly to hydrogen peroxide production technologies by an anthraquinone process, the invention provides a production method of hydrogen peroxide. The method includes: taking heavy aromatics, tetrabutylurea and trioctyl phosphate as solvents, adopting 2-ethylanthraquinone as a reaction material, adding a well prepared working solution into a circulating working solution storage tank, making use of a circulating working solution pump to send the working solution into a working solution thermoregulator, using circulating cooling water to lower the temperature of the working solution to about 35DEG C, then bringing the working solution to the bottom of a fluidization hydrogenation reactor, adding a hydrogenation catalyst into the fluidization hydrogenation reactor in advance through a catalyst adding groove, at the same time, passing compressed hydrogen through a hydrogen buffer filter to filter out impurities, then letting the compressed hydrogen enter the bottom of the fluidization hydrogenation reactor, using the compressed hydrogen to blow and stir the catalyst and the working solution so as to undergo hydrogenation reaction at a temperature of about 50DEG C, under a pressure of about 0.26mPa, and at hydrogenation efficiency of about 13g / L.

Owner:YANGZHOU RONGXIANG CHEM TECH DEV DESIGN

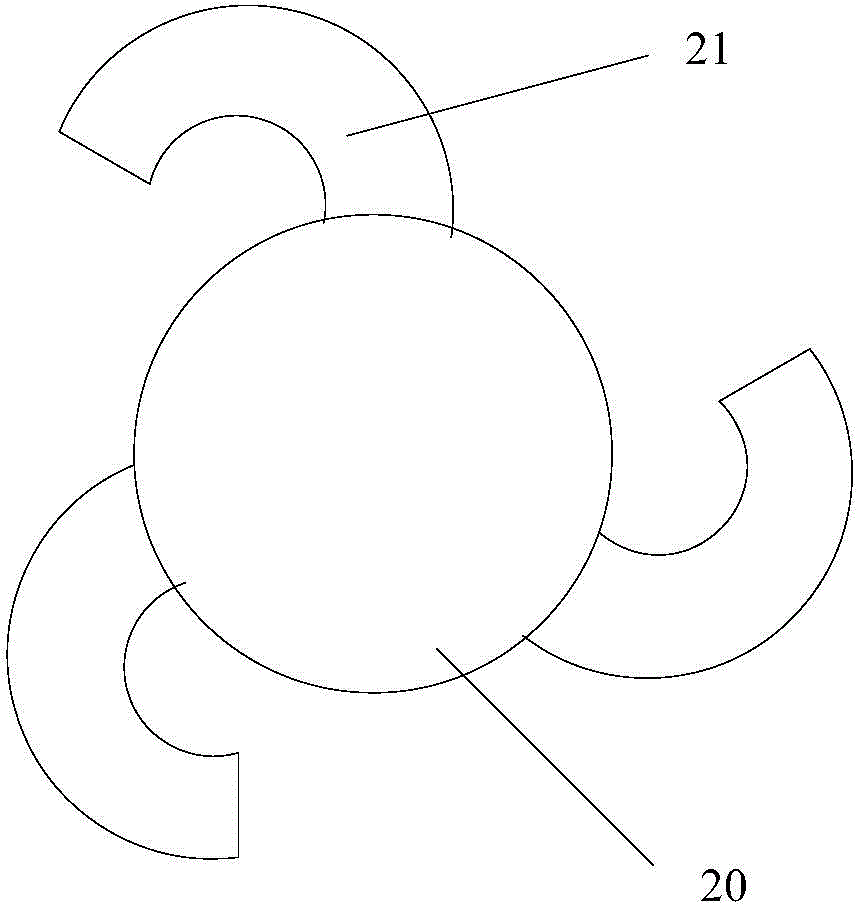

Loop reaction device in slurry bed, application and method for producing hydrogen peroxide

ActiveCN104549066AExtended operating cycleIncrease profitPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

Owner:CHINA PETROLEUM & CHEM CORP +1

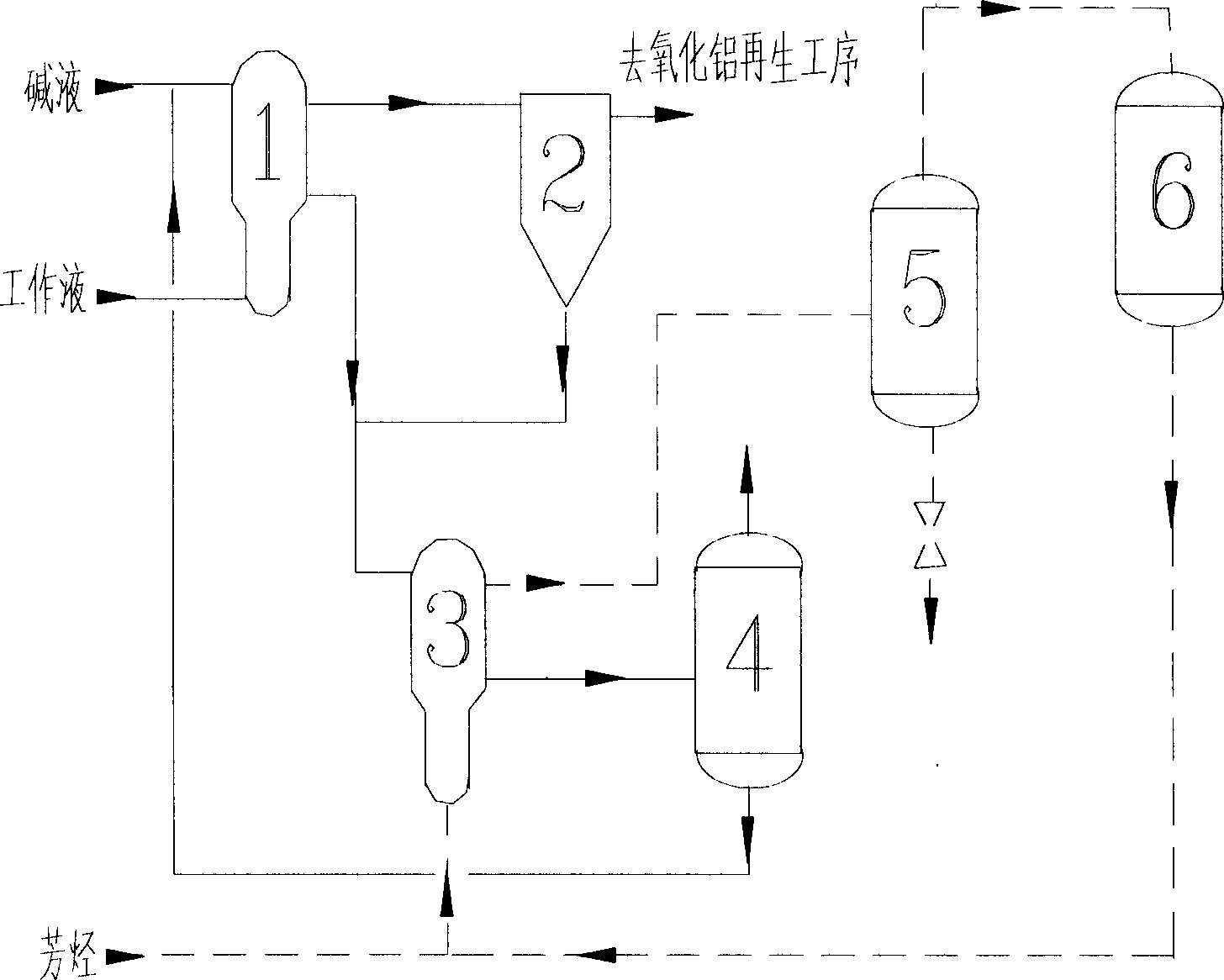

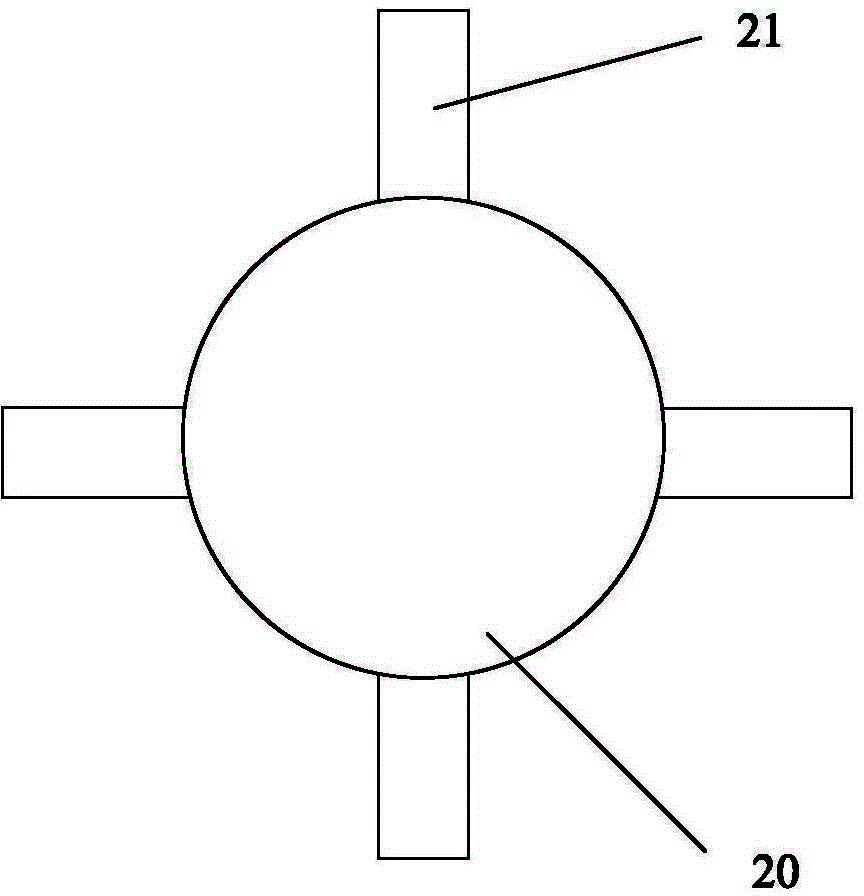

Method and device for processing oxidized tail gas of anthraquinone process-based hydrogen peroxide production

InactiveCN103372357AHigh recovery rateEfficient use ofCombination devicesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthraquinonesActivated carbon

The invention discloses a method and a device for processing oxidized tail gas of anthraquinone process-based hydrogen peroxide production. The device comprises a heat exchanger (1), a first gas-liquid separation tank (2), a second gas-liquid separation tank (3), a turbo-expander (4) and an activated carbon adsorption apparatus (5), wherein the second gas-liquid separation tank (3), the turbo-expander (4) and the activated carbon adsorption apparatus (5) are interconnected through a pipeline; the oxidized tail gas firstly performs heat exchange through the heat exchanger (1); the cooled oxidized tail gas enters into the first gas-liquid separation tank (2), then the non-condensed gas exhausted from the first gas-liquid separation tank (2) enters into an expansion cavity of the turbo-expander (4), after being cooled under expansion work, the gas enters into the second gas-liquid separation tank (3), and the non-condensed gas exhausted from the second gas-liquid separation tank (3) enters into the heat exchanger (1) to perform heat exchange; after being heated up, the gas enters into the turbo-expander (4) to be compressed and pressurized, then, the gas enters into the activated carbon adsorption apparatus (5); the arene separated from the liquid-gas separation tanks and the activated carbon adsorption apparatus (5) is recycled.

Owner:湖南双阳高科化工有限公司

Composite activated regenerant for hydrogen peroxide working fluid of anthraquinone process and preparation method thereof

ActiveCN105174229APrevent from being too alkalineInhibitory activityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesWorking fluidAlkali metal oxide

The invention discloses a composite activated regenerant for hydrogen peroxide working fluid of anthraquinone process and a preparation method thereof. The regenerant comprises a two-layer or three-layer structure, wherein the two-layer structure is as follows: an outer-surface layer comprises 50 to 95% of activated aluminium oxide, with the balance being calcium oxide, and a core-part layer comprises 50% of calcium oxide and 50% of silicon dioxide; and the three-layer structure is as follows: the outer-surface layer comprises 50 to 99% of the activated aluminium oxide, 0 to 2.5% of alkali metal oxide, with the balance being the calcium oxide; a centripetal-part layer comprises 50 to 90% of the calcium oxide, 0 to 2.5% of the alkali metal oxide, with the balance being the silicon dioxide; and the core-part layer comprises 50 to 99% of the silicon oxide, with the balance being the calcium oxide. The activated regenerant provided by the invention solves the problems of over strong alkalinity, uncontrollability and instability of the working fluid due to long-term use of conventional hydrogen peroxide working fluid; a composite layering structure is adopted, so regeneration activity is high, and system load and anthraquinone consumption are effectively reduced; meanwhile, a large number of costs are saved.

Owner:陕西开达化工有限责任公司

Method for producing regeneration catalyst for working solution usable for hydrogen peroxide production

ActiveCN101342492AInhibit deteriorationRemarkable effect during regenerative reactionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHeterogenous catalyst chemical elementsMagnesium saltAmmonia

The present invention is directed to a method for producing a regeneration catalyst for a working solution usable for producing hydrogen peroxide by an anthraquinone method, wherein active alumina is treated with a 20% by weight to saturated aqueous solution of a magnesium salt, treated with ammonia and then burned.

Owner:MITSUBISHI GAS CHEM CO INC

Method for producing oxydol by dihydrodiketoanthracene method

InactiveCN101177246AIncreased effective anthraquinone contentPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsCounter flowHydrogen

The invention discloses an anthraquinone preparation method for producing hydrogen peroxide, which is characterized in that the catalyst palladium is put into the hydrogenation tower to activate hydrogen; the hydrogen replacement with nitrogen is performed and then the prepared operating fluid is sent to the hydrogenation tower. Under the catalysis of the palladium, the hydrogenation takes place with hydrogen and the corresponding hydrogenated fluid is obtained. Then the hydrogenated fluid is sent to the oxidation tower, and oxidation takes place; the oxidized fluid is counter-flow extracted with pure water and the hydrogen peroxide is obtained. After the purification, the finished product is obtained and the disposed extraction raffinate can be calculatedly as operating fluid with a characteristic of quenching and softening the catalyst palladium. The invention has the advantages that the degradation of anthraquinone caused by the high activity of the catalyst palladium at the beginning of the process effectively is reduced; the activity of the catalyst is made full use, and the stability for the system is increased.

Owner:YANTAI BAICHUAN HUITONG TECH CO LTD

Straw cutting-free method for preparing straw pulp by spherical digester alkali digestion

InactiveCN102400404AImprove the environmentImprove qualityPulping with inorganic basesNon-woody plant/crop pulpAnthraquinonesBlack liquor

The invention provides a straw cutting-free method for preparing straw pulp by spherical digester alkali digestion. The method comprises the following steps of: washing a straw raw material; adding a hot alkali solution, adding water, mixing uniformly, and heating; performing digestion by adopting a conventional sulfate method or a caustic soda anthraquinone method; stopping the digestion when the lignin discharged from the straw raw material by the digestion reaches 75 to 90 percent, discharging a black liquor I, and thus obtaining straw pulp; and adding the hot alkali solution into the straw pulp, performing digestion and conventional washing and thus obtaining unbleached pulp, wherein the thin black liquor discharged during washing is a black liquor II, the black liquor II and water are added into the new straw raw material together, and the unbleached pulp is continuously obtained by repeating. The straw cutting process is eliminated in the method, so that the flow for preparing the pulp by using the straw is simplified; and on the premise of ensuring the digestion effect, the concentration of the solid matter of the black liquor can be improved to over 13 percent, the stock loss of the raw material is reduced by about 5 percent, the single-pot digestion capacity is improved by 10 to 15 percent, and the yield and the viscosity of the formed pulp are raised with different degrees.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

Method for producing hydrogen peroxide

Owner:MITSUBISHI GAS CHEM CO INC

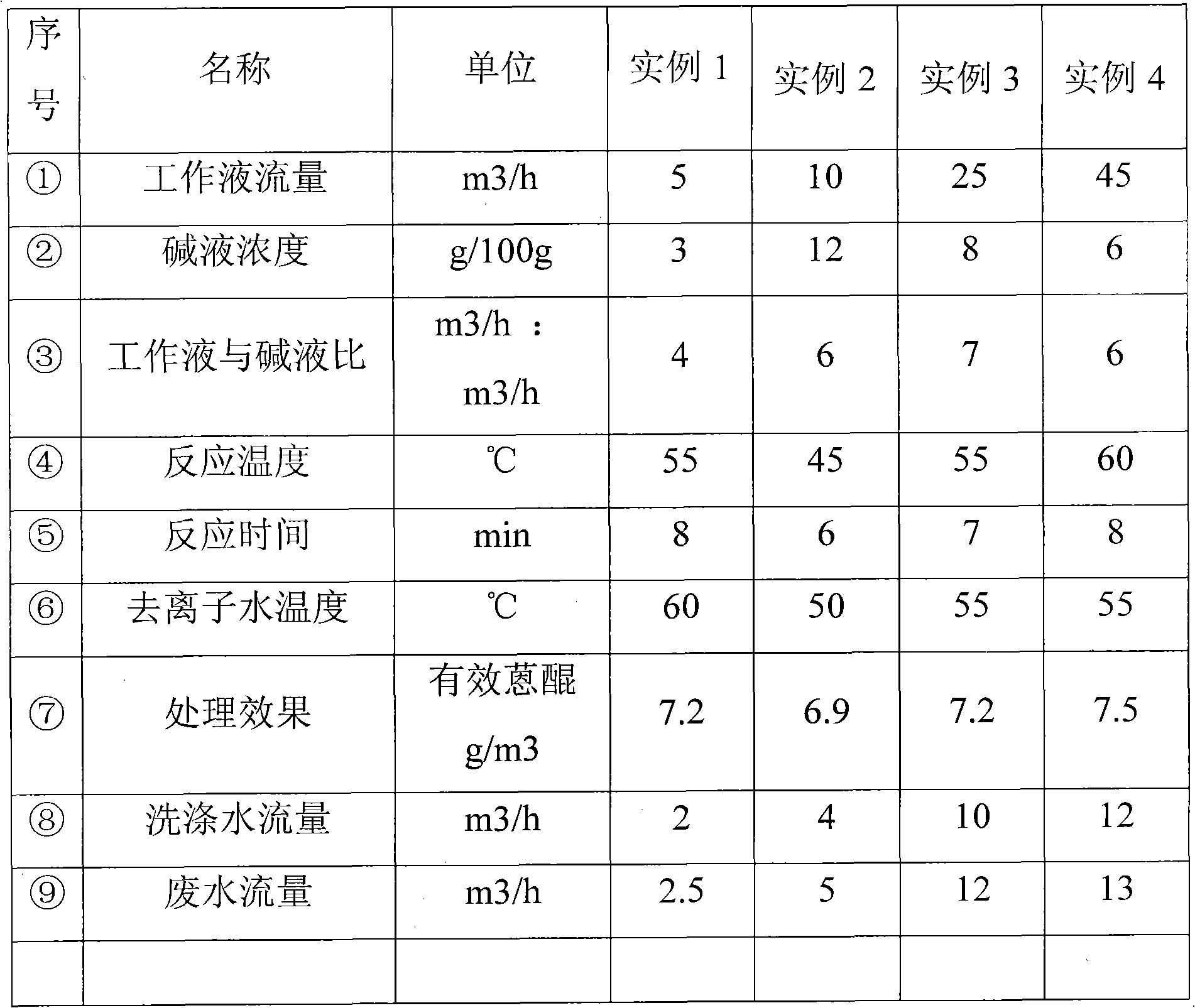

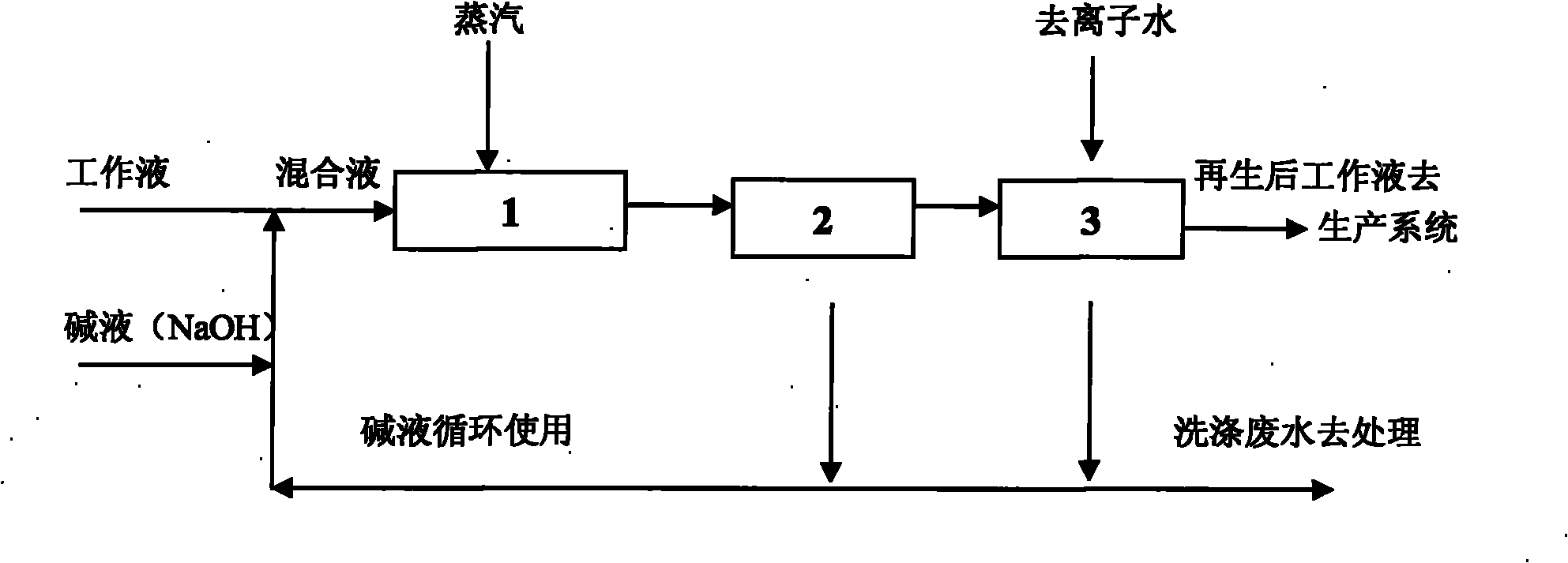

Treatment method for continuous regeneration of hydrogen peroxide working solution produced by anthraquinone process

InactiveCN101891158ALow viscosityIncreased content of 2-ethylanthraquinonePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesTreatment effectWastewater

The invention provides a treatment method for continuous regeneration of hydrogen peroxide working solution produced by an anthraquinone process. The method comprises the following steps of: mixing the working solution and alkaline liquor according to a ratio, making the mixture enter a tubular reactor for reaction, and separating the working solution from the reacted mixed solution by using a separator; washing the separated working solution by using heated deionized water, and making the working solution washed by the deionized water enter a production system. The alkaline liquor separated by the separator and the washing solution washed out by the deionized water are used for replacing partial alkaline liquor for recycling. The method realizes continuous alkaline washing regeneration treatment of the hydrogen peroxide working solution by the anthraquinone process, and has the advantages of good alkaline washing treatment effect on the working solution, high treatment capability, low consumption of raw materials, low wastewater amount, low labor intensity, and the like.

Owner:江山市双氧水有限公司

Raffinade dewatering technology in anthraquinone method production of hydrogen peroxide

ActiveCN104370331AEliminate destructionImprove qualityFatty/oily/floating substances removal devicesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogenation processOil water

The invention discloses a raffinade dewatering technology in anthraquinone method production of hydrogen peroxide. The technology comprises the following steps: conveying raffinade from an extraction tower to a filter through a pump, filtering to remove particles in the raffinate; allowing the obtained filtrate to go through an oil-water separation device to dewater the filtrate in order to eliminate the destroys of an alkali solution to a carclazyte bed; and regenerating the dewatered raffinate through the clay bed, and circulating to enter a hydrogenation process. The dewatering technology using the oil-water separation device to remove water in the raffinate substitutes traditional alkali solution dewatering technologies, so the destroys of the alkali solution to the carclazyte bed are eliminated, thereby a circulating working fluid cannot be polluted by alkali metal ions, and the content of water not dissolved in the circulating working fluid is reduced reduces to several to dozens of ppm.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com