Raffinade dewatering technology in anthraquinone method production of hydrogen peroxide

A technology of raffinate and hydrogen peroxide, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem that the quality of hydrogen peroxide cannot meet the quality standards of hydrogen peroxide products, the impact, and the whitening of alkaline solution Solve problems such as soil bed damage, achieve the effects of reducing energy consumption, simplifying the operation process, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

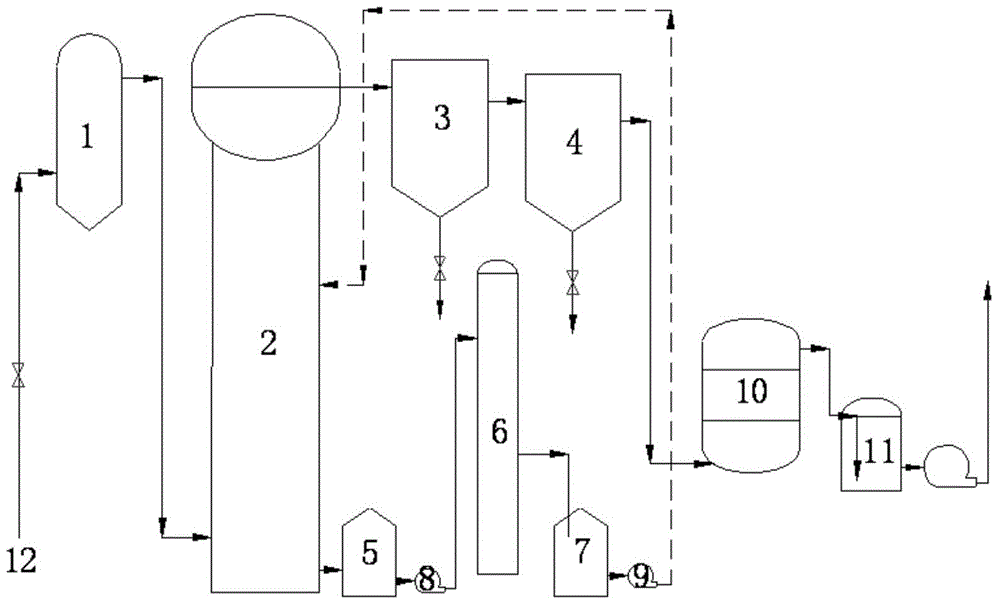

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

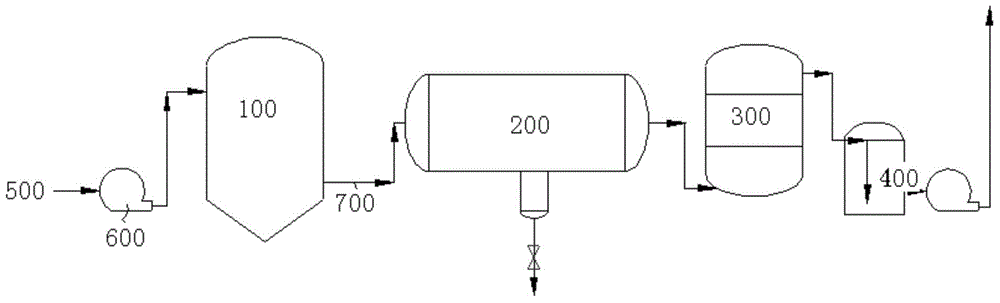

[0019] see figure 2 , the anthraquinone method of the present invention produces the hydrogen peroxide raffinate dewatering process, and it first sends the raffinate 500 to the filter 100 for filtration through a pump 600 to remove particles in the raffinate; then the filtered raffinate 700 is transported to the horizontal oil-water separation device 200. During the water removal process, there is no need to add lye, and the water-containing raffinate passes through the coalescing filter element in the horizontal oil-water separation device 200, where the small water droplets coalesce into large water droplets. Under the action, the large water droplets will settle down and be initially separated from the raffinate, and the raffinate will further pass through the separation filter element, and under the action of the lipophilic and hydrophobic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com