Patents

Literature

859 results about "Alloy catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anode catalyst for fuel cells with polymer electrolyte membranes

A platinum / ruthenium alloy catalyst that includes finely dispersed alloy particles on a powdery, electrically conductive carrier material. The catalyst is particularly resistant to carbon monoxide poisoning when the alloy particles display mean crystallite sizes of 0.5 to less than 2 nm.

Owner:EVONIK DEGUSSA GMBH

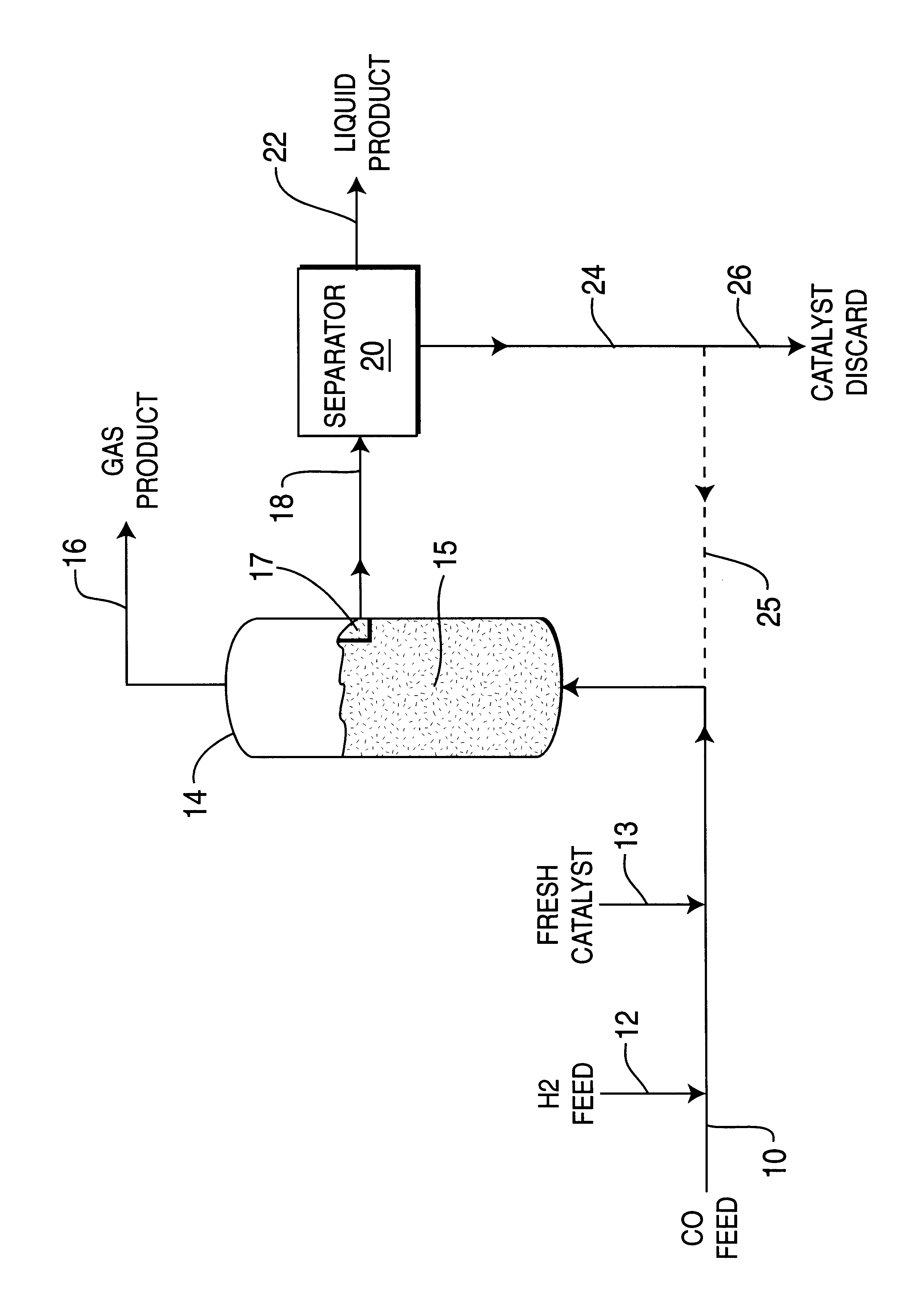

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS6277895B1High particle strengthGood attristion resistanceHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size, 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy pulverized particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen and to provide the smaller size skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-350° C. temperature, 0.5-3.0 mPa pressure and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:INST OF COAL CHEM ICCCHINESE ACADEMY OF SCI +1

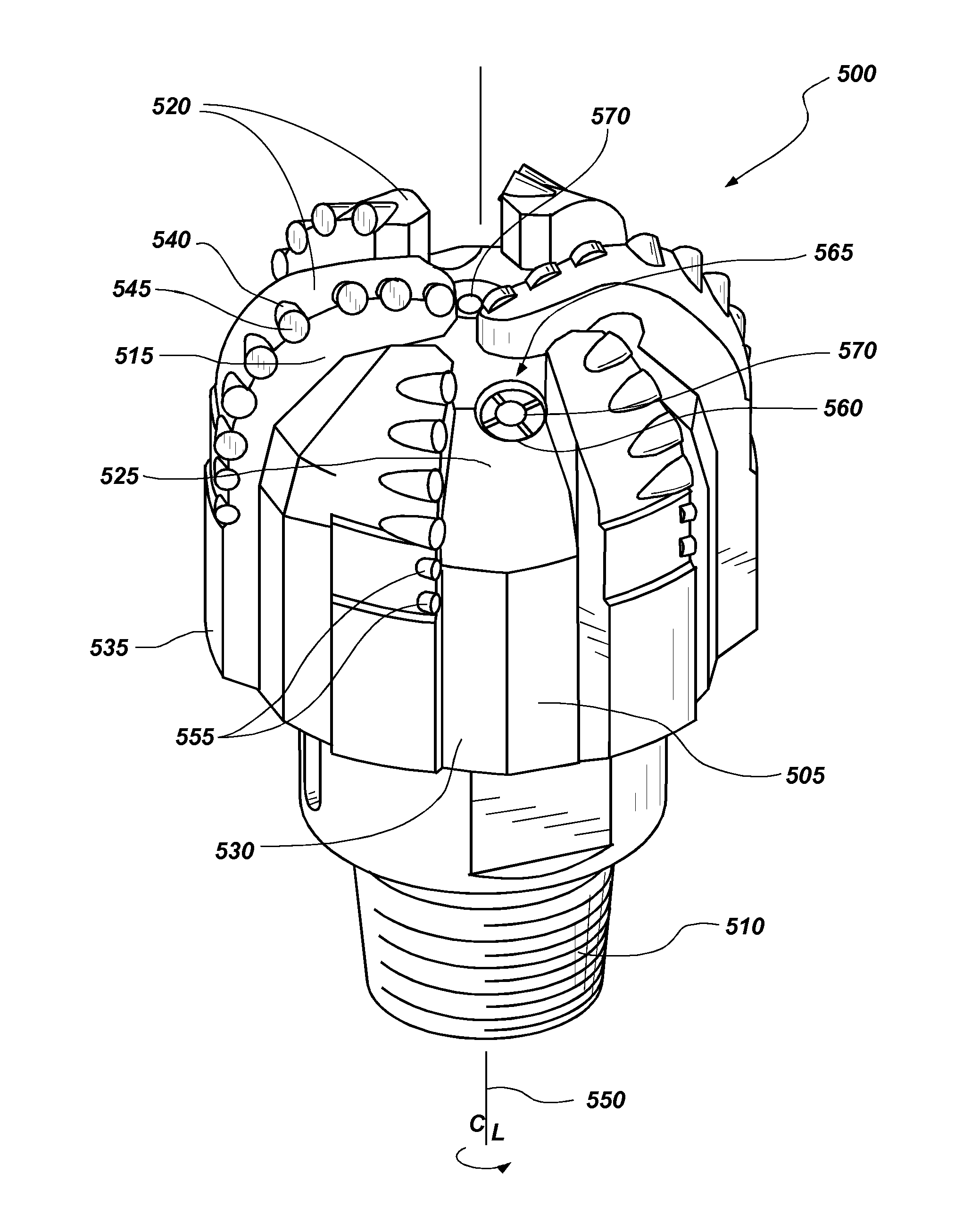

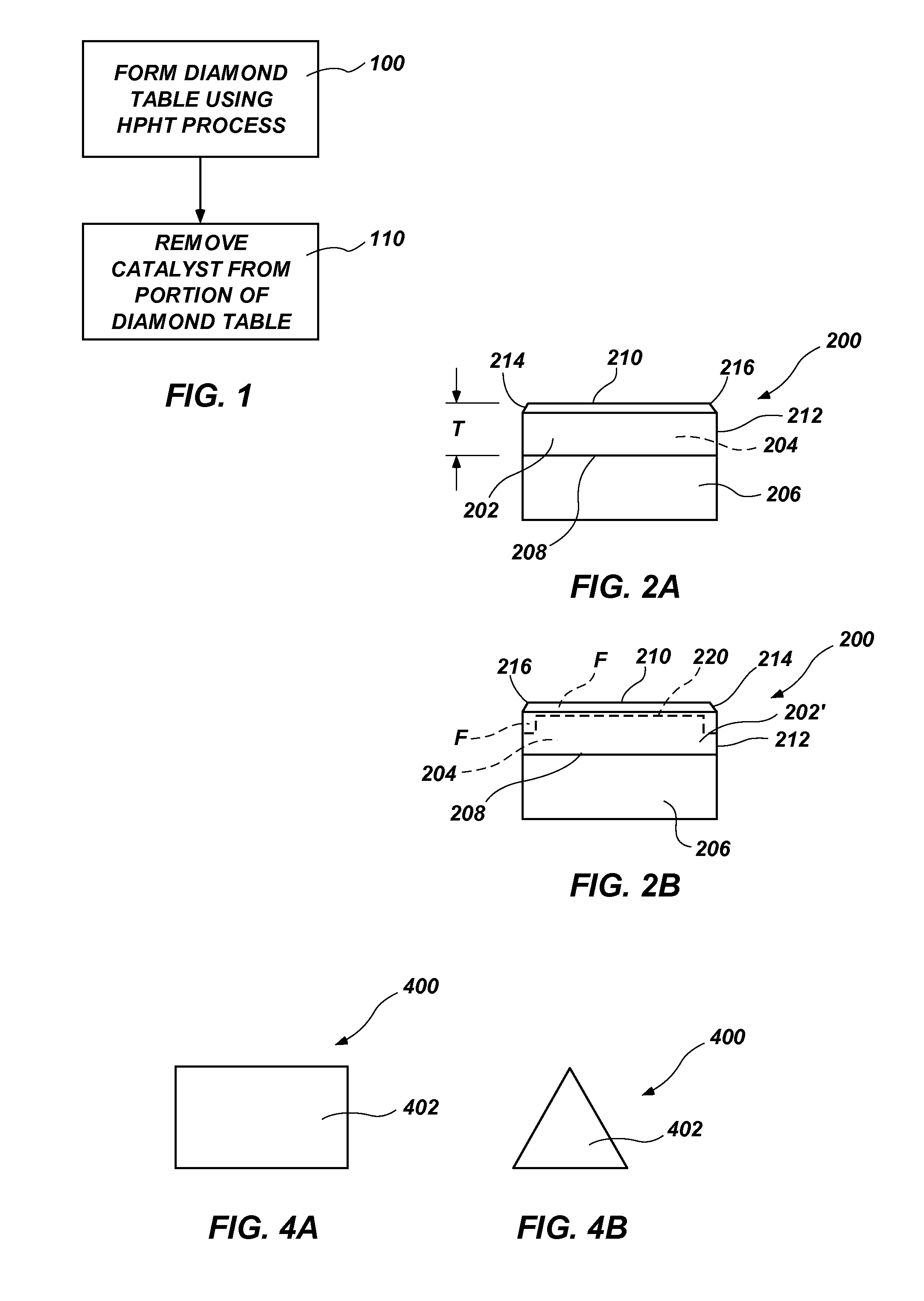

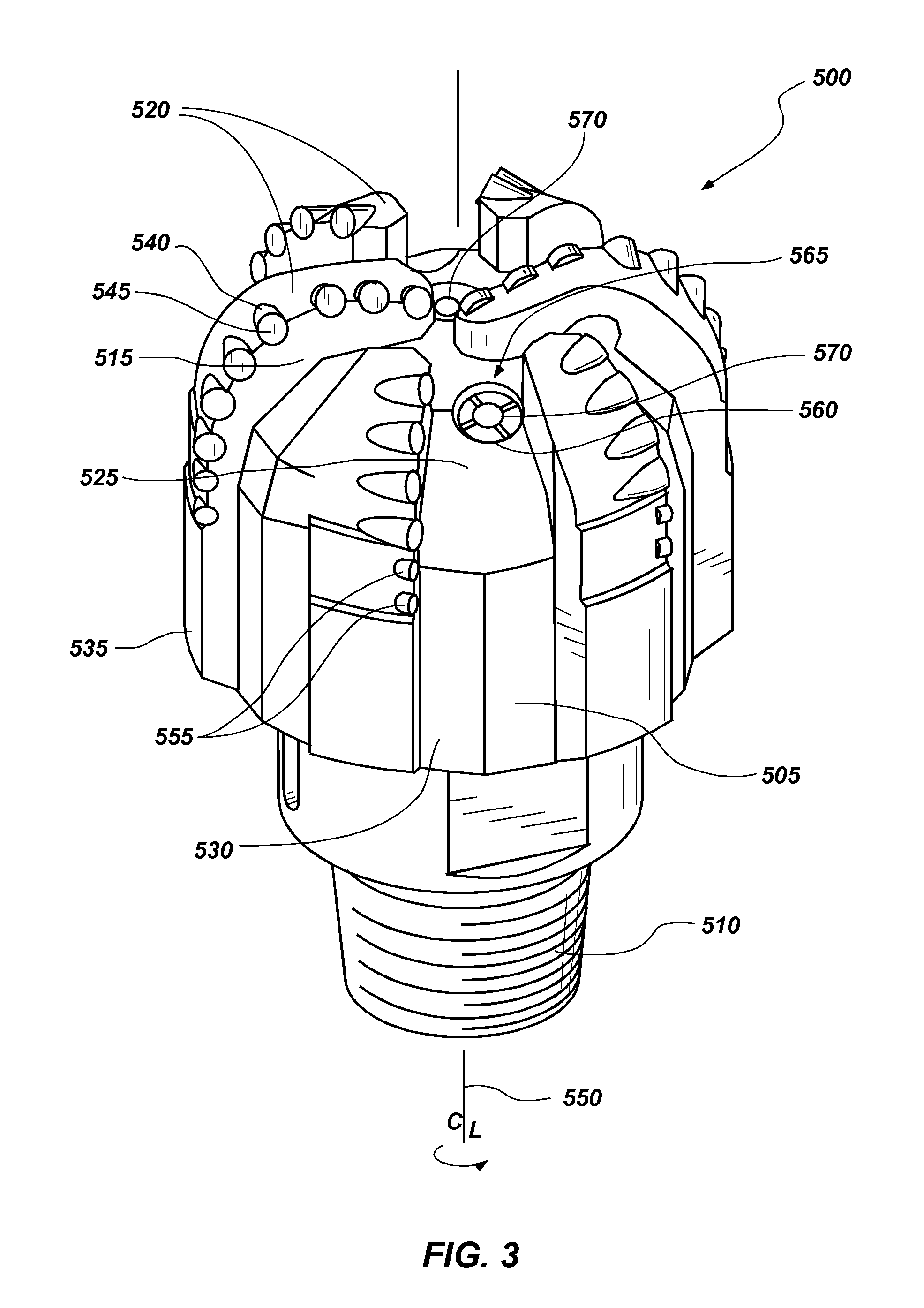

Methods of forming polycrystalline diamond elements, polycrystalline diamond elements, and earth-boring tools carrying such polycrystalline diamond elements

InactiveUS20110042149A1Improves Structural IntegrityImprove thermal stabilityPigmenting treatmentPressurized chemical processAlloy catalystPolycrystalline diamond

Methods of forming polycrystalline diamond elements include forming a polycrystalline diamond element. A Group VIII metal or alloy catalyst is employed to form the polycrystalline diamond compact table at a pressure of at least about 6.5 GPa or greater. The catalyst is then removed from at least a portion of the table to a depth from a working surface thereof, and may be removed from the entirety of the table. Polycrystalline diamond elements include such polycrystalline diamond compact tables. Earth-boring tools include such polycrystalline diamond elements carried thereon and employed as cutting elements.

Owner:BAKER HUGHES INC

Membrane electrode assembly for polymer electrolyte fuel cell

ActiveUS6847518B2Reduce depositionPower generation efficiency deterioratesLiquid electrolytic capacitorsCell electrodesPolymer electrolytesFuel cells

A membrane electrode assembly for a polymer electrolyte fuel cell has a polymer electrolyte membrane, an anode, and a cathode having a catalytic layer and a diffusion layer. The alloy catalyst contains ruthenium in the anode diffusion layer. The assembly has less loss of efficiency, particularly when operated at high potentials.

Owner:HONDA MOTOR CO LTD +1

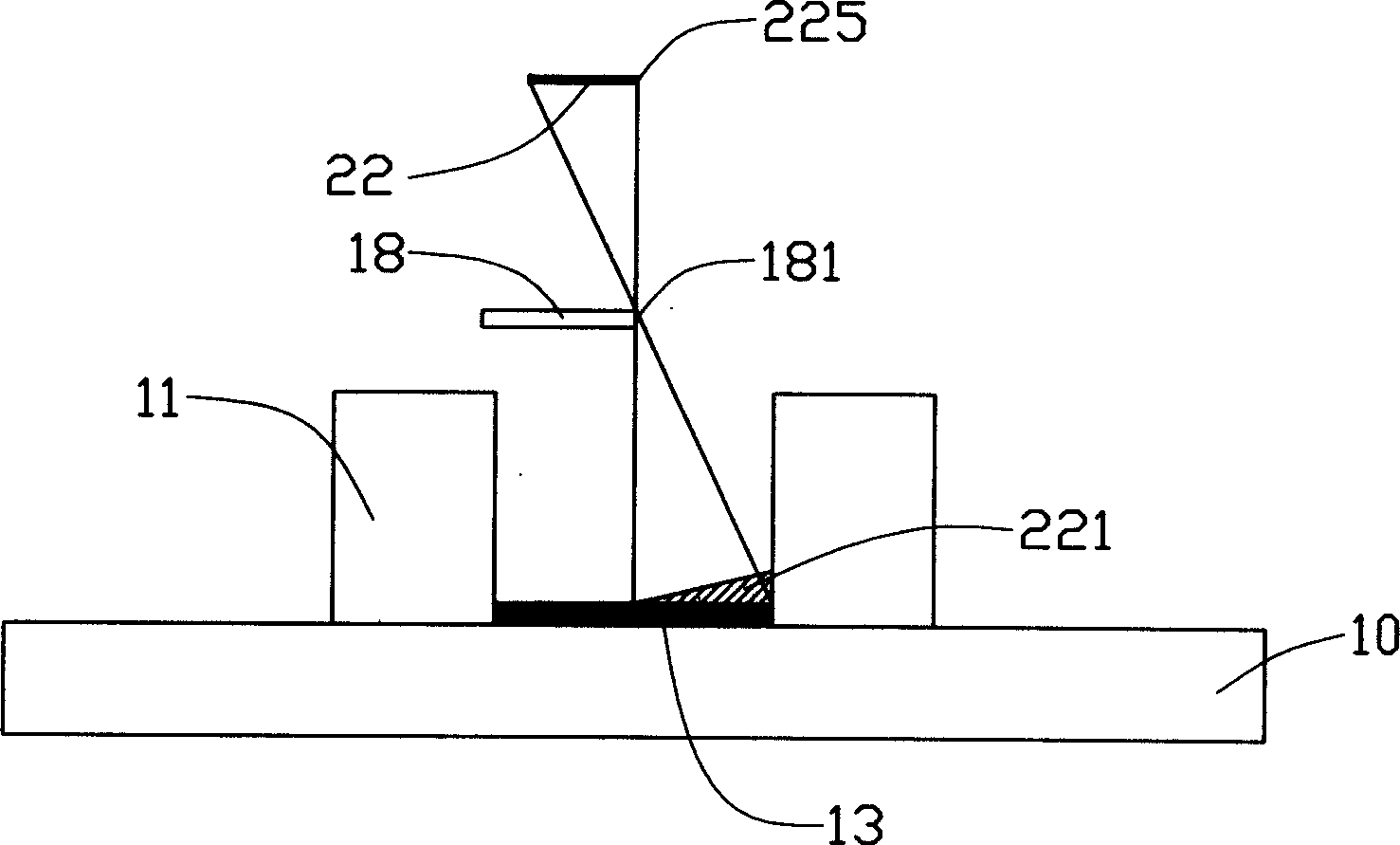

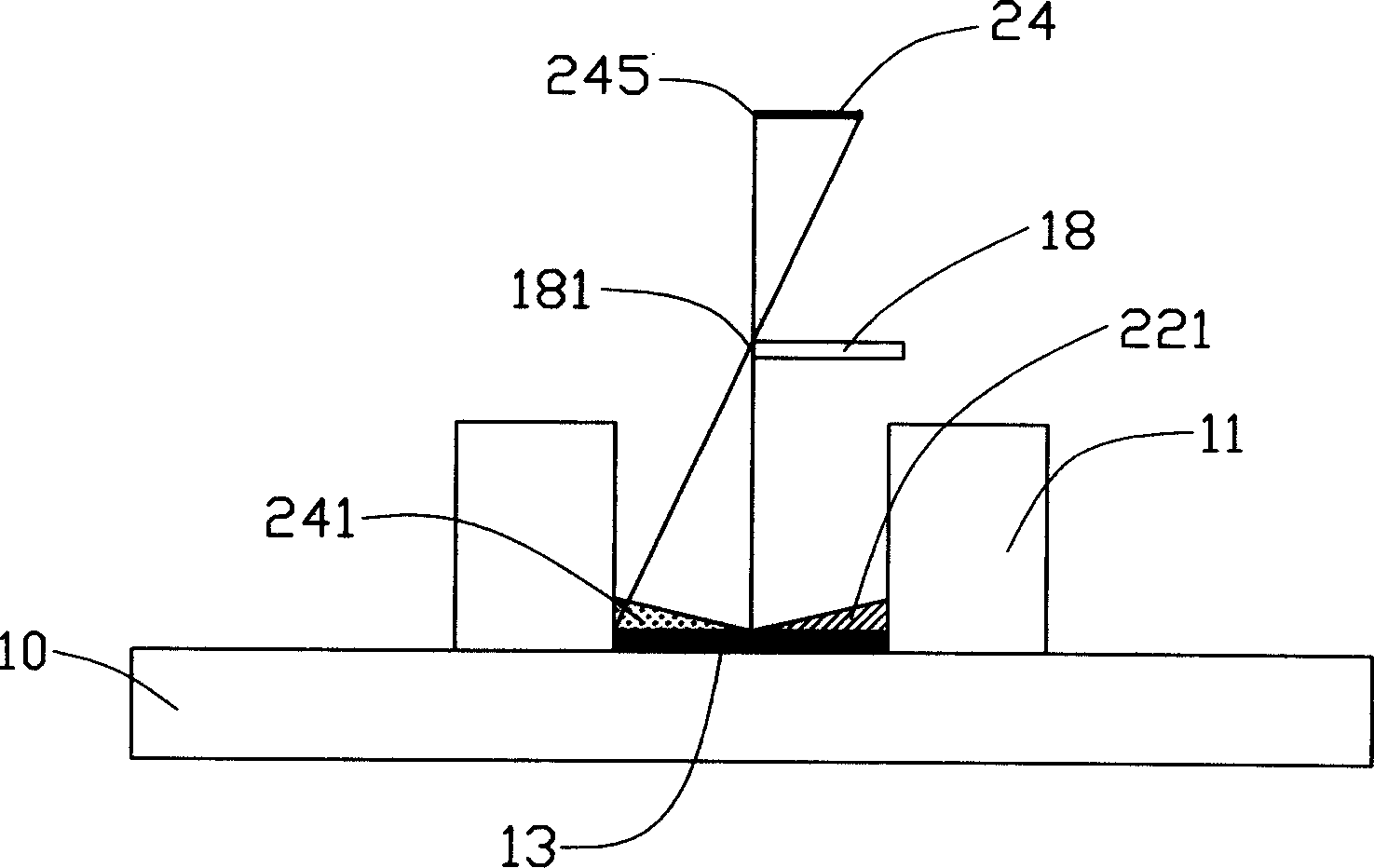

Carbon nanometer tube array structure and growing method thereof

InactiveCN1509982ARich diversityMultiple optionsMaterial nanotechnologyNanoinformaticsAlloy catalystCarbon nanotube

A carbon nanotube array structure is composed of a substrate, the alloy catalyst particles on the substrate, which contains the material to affect the growth speed of carbon nanotubes, and the array the carbon nanotubes which is grown from said alloy catalyst particles and bent toward a predefined direction. Its growing process includes such steps as generating a catalyst layer on the substrate, depositing at least two kinds of growth speed regulating material, annealing in oxygen contained gas to change the catalyst layer to catalyst particles, introducing carbon source gas, and growing carbon nanotubes.

Owner:TSINGHUA UNIV +1

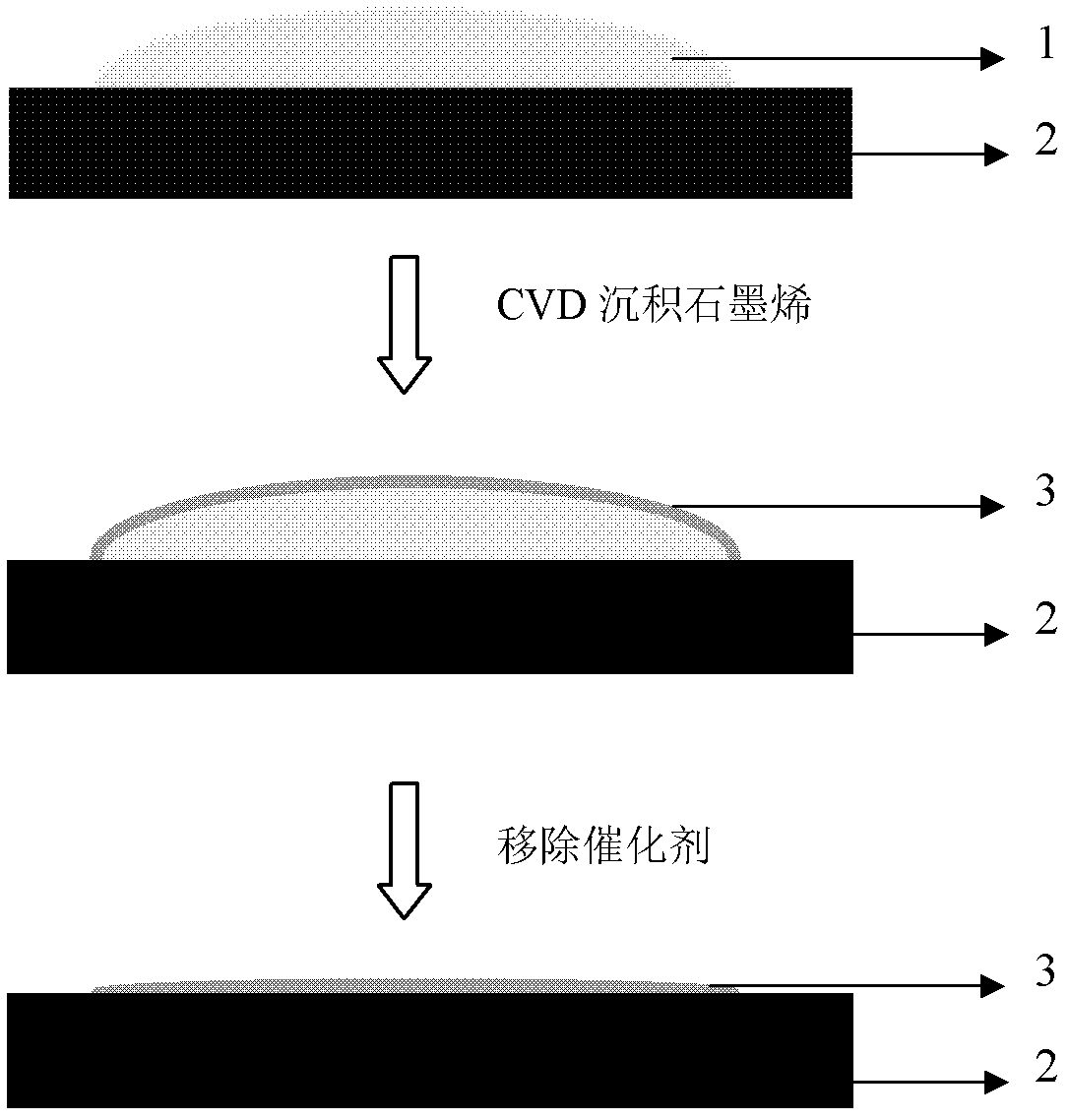

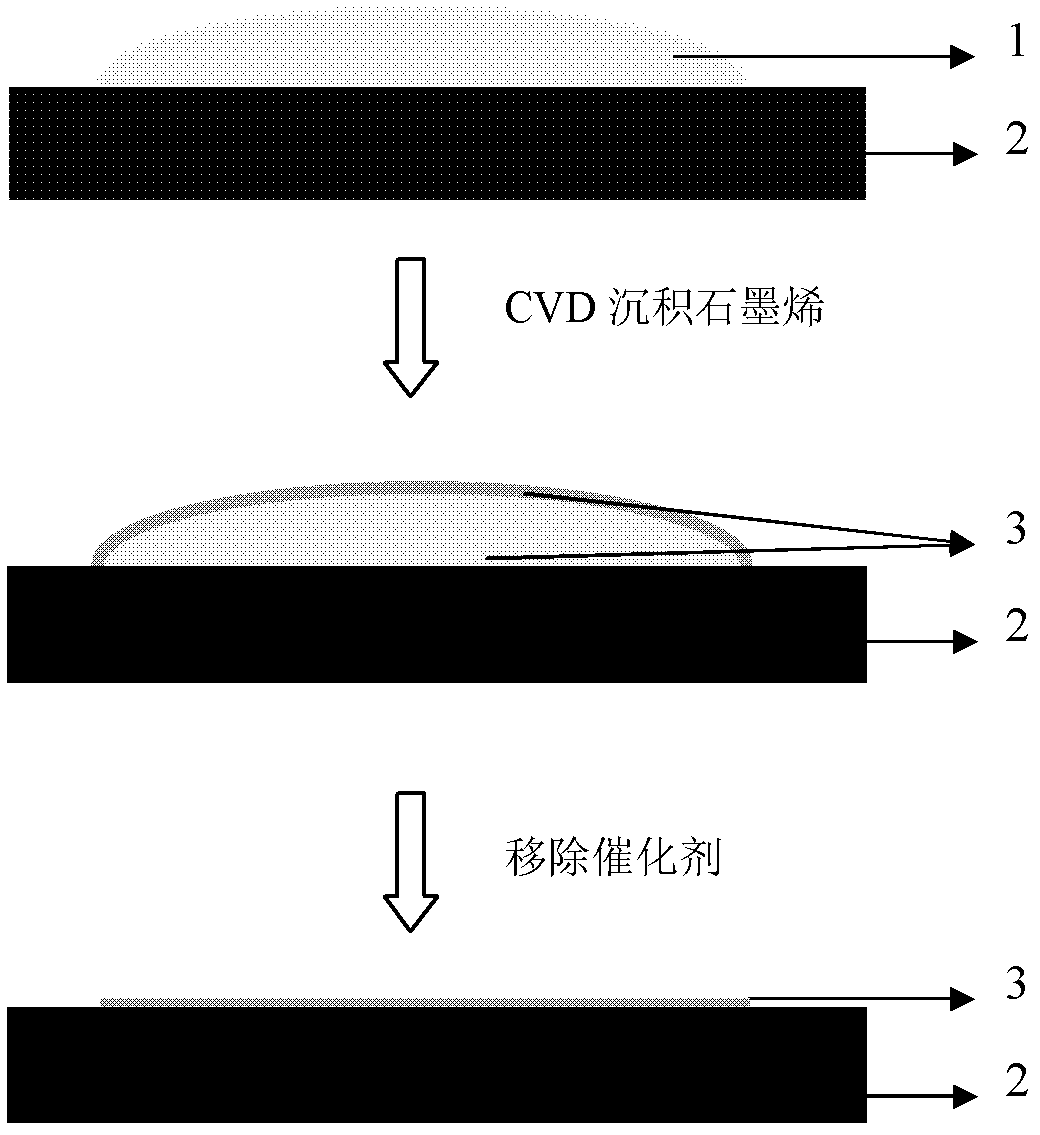

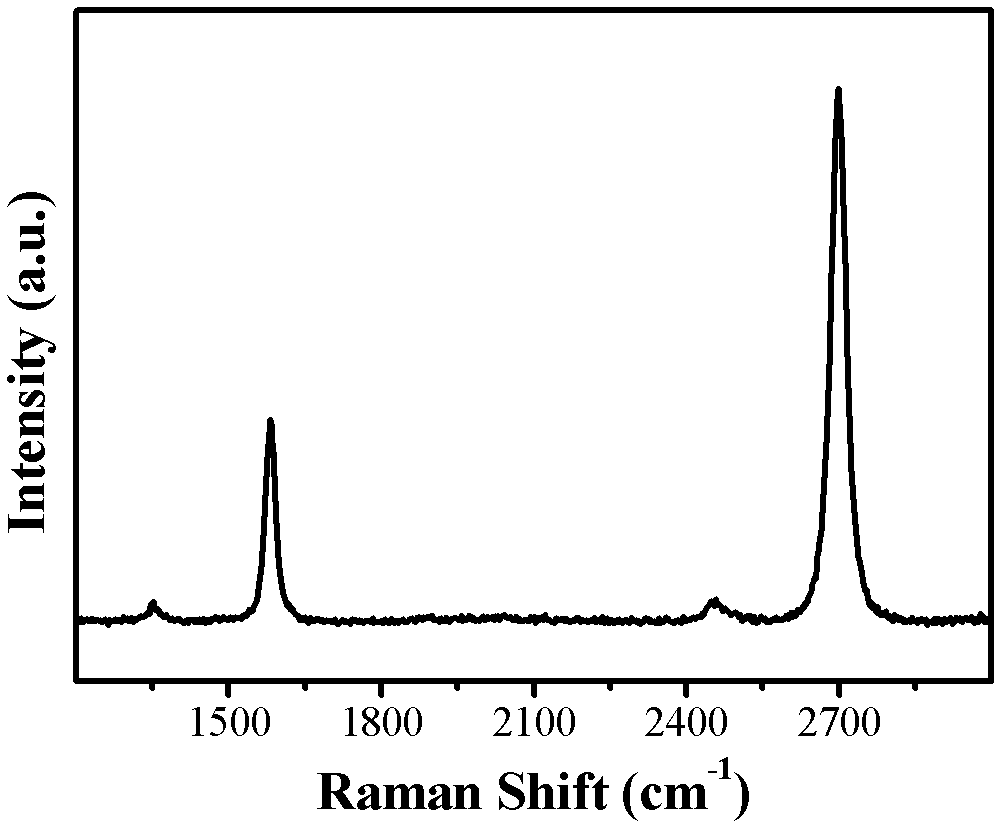

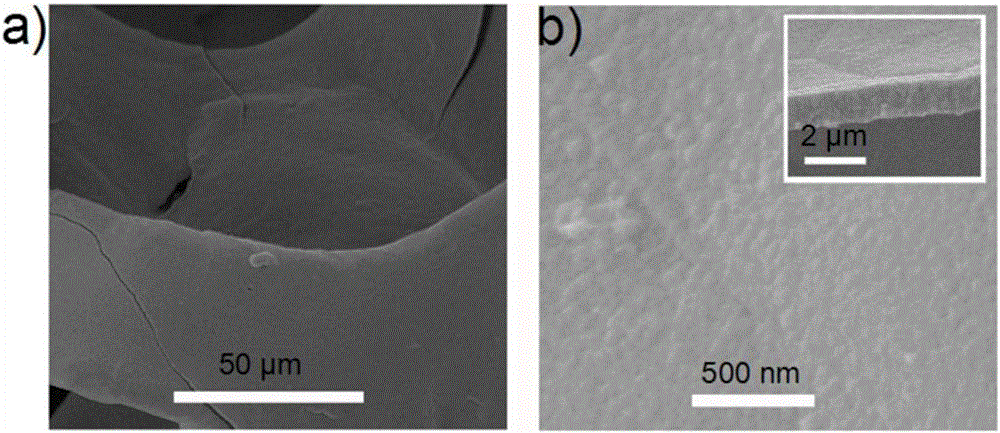

Method for preparing graphene by adopting liquid catalyst aided chemical vapor deposition

ActiveCN102583359ARealize layer controlMolecular activityMaterial nanotechnologyGrapheneIndiumLiquid metal

The invention discloses a method for preparing a graphene film by using a liquid metal or alloy as a catalyst and adopting chemical vapor deposition. The metal with low melting point comprises typical gallium, tin, indium and the like; and the alloy with low melting point comprises gallium-copper, gallium-nickel, indium-copper, indium-nickel, tin-copper, tin-nickel, copper-silver-tin and the like. The chemical vapor deposition is performed above the melting point of the metal or alloy catalyst, so that the continuous graphene film is formed on the surface of the catalyst and the interface of the catalyst and a substrate. Compared with the graphene grown on the surface of a solid catalyst such as copper and nickel, the invention has the advantages that the prepared graphene is controllable in layer number, low in requirement for the micro morphology of the surface of the substrate and suitable for multiple substrate materials, and the catalyst is very easy to remove. The obtained graphene positioned on the surface of the liquid has unique application value.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

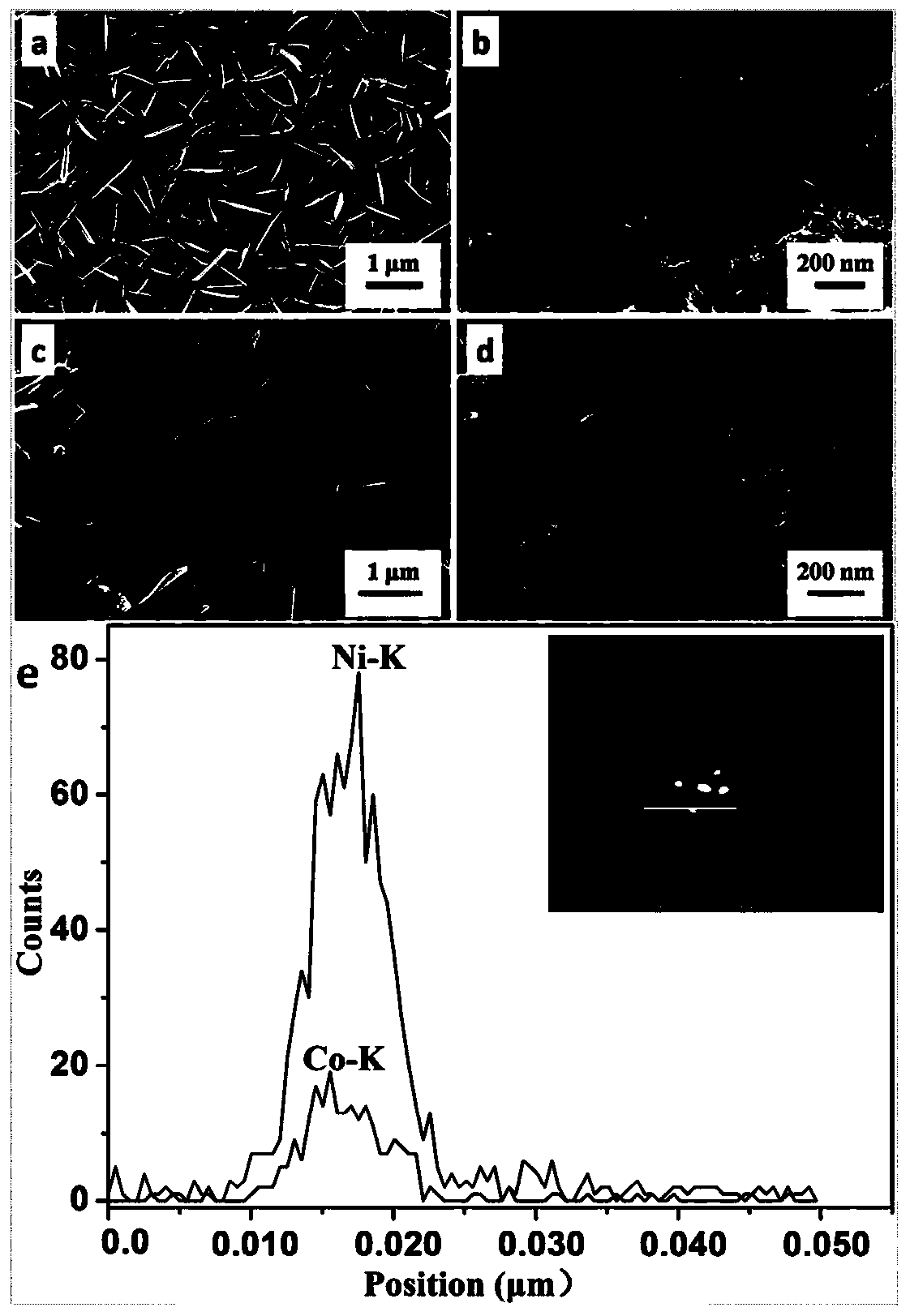

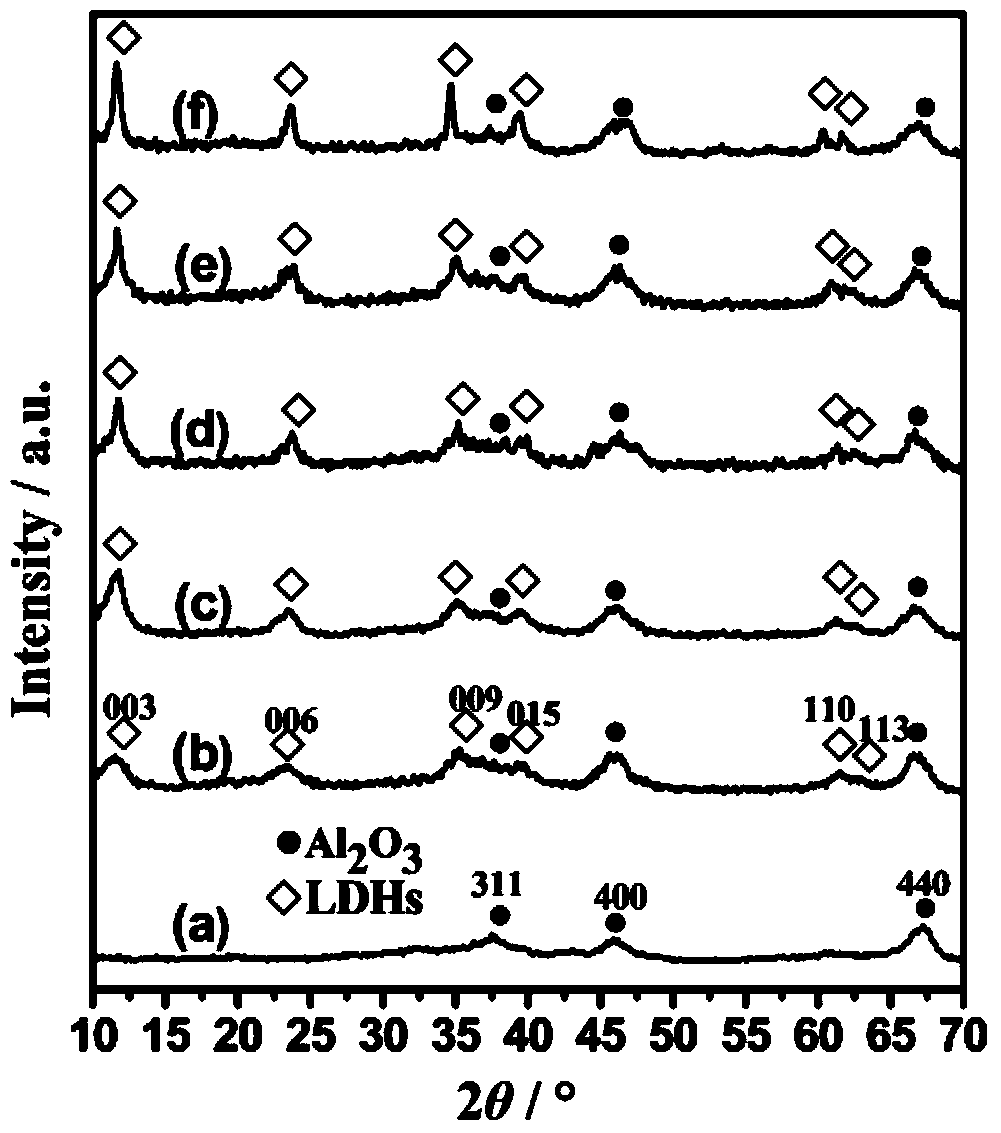

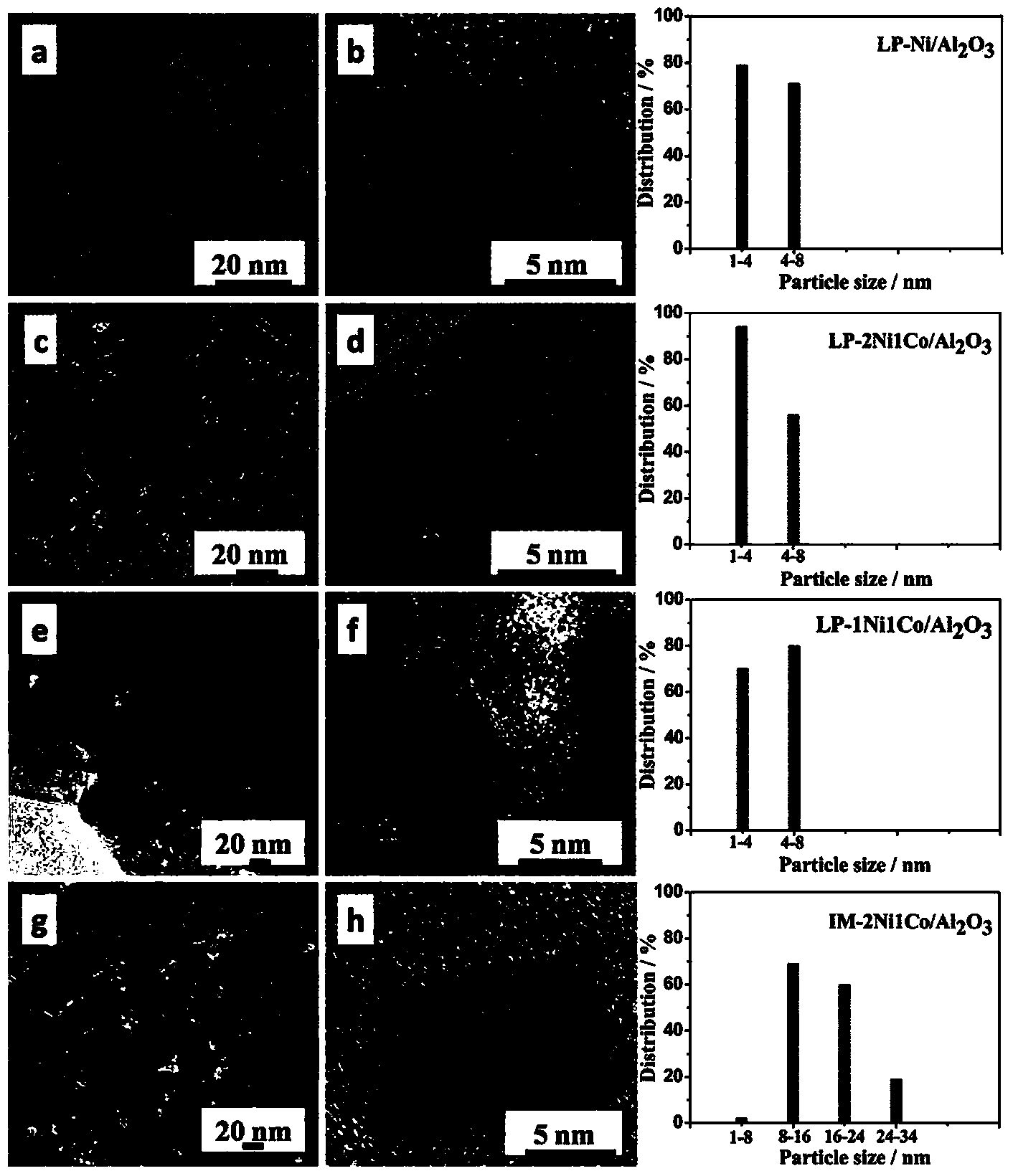

Preparation method and catalytic application of supported type high-dispersion nickel-based alloy catalyst

InactiveCN104368345AImprove conversion rateHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsRefining by aromatic hydrocarbon hydrogenationPtru catalystAlloy catalyst

The invention discloses a preparation method and a catalytic application of a supported type high-dispersion nickel-based alloy catalyst. The preparation method comprises the following steps: by virtue of an in-situ growth method, supporting Ni, M (M=Co, Zn, Cu, Fe, Cr and the like) metal in the form of hydrotalcite on the surface of a microsphere-form gamma-Al2O3 carrier with grain size of 20-40 meshes and in a duct of the microsphere-form gamma-Al2O3 carrier, namely growing lamellar precursor LDHs containing Ni and M metal ions outside and inside a Al2O3 particle to form supported type high-dispersion distribution, converting the lamellar precursor LDHs into a corresponding composite metal oxide by drying and roasting at high temperature, and reducing the composite metal oxide to obtain the supported type high-dispersion nickel-based alloy catalyst with NiM distributed on the outer surface and in the duct of the carrier particle. The supported type high-dispersion nickel-based alloy catalyst is applied to first selective hydrogenation reaction of cracked gasoline, so that the conversion rate, the selectivity and the stability of the catalyst can be effectively improved; and moreover, the supported type high-dispersion nickel-based alloy catalyst can be used for methane reforming, and catalyzing reaction of preparing low-carbon hydrocarbon and alcohol by virtue of CO and CO2 hydrogenation.

Owner:BEIJING UNIV OF CHEM TECH

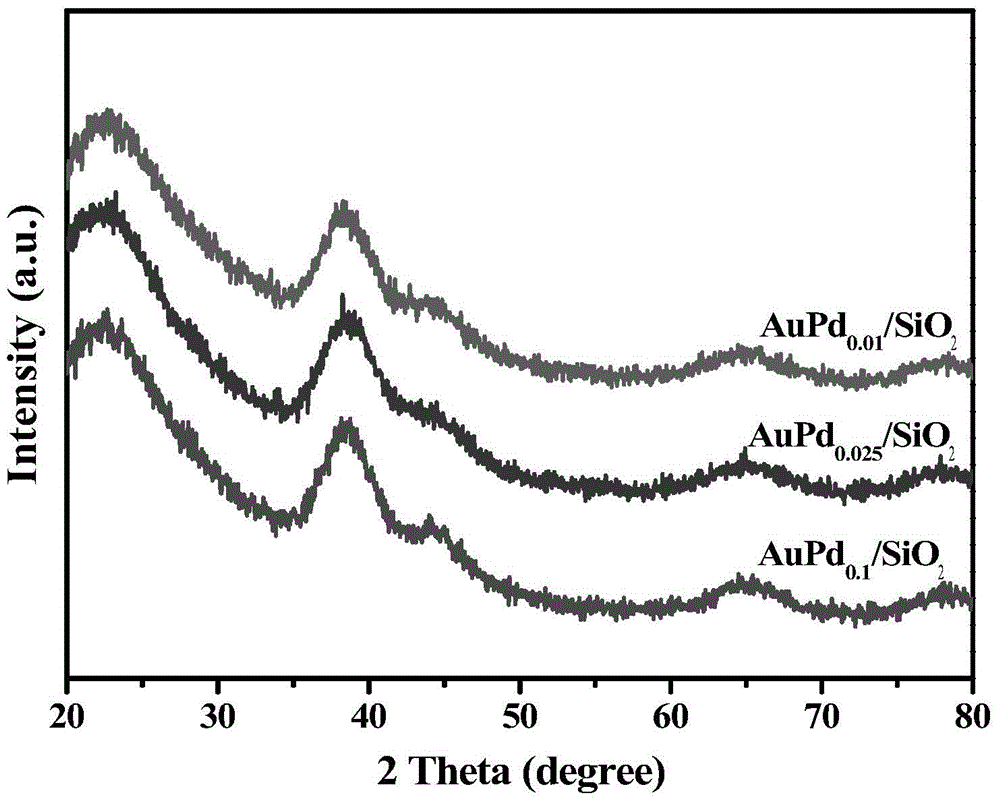

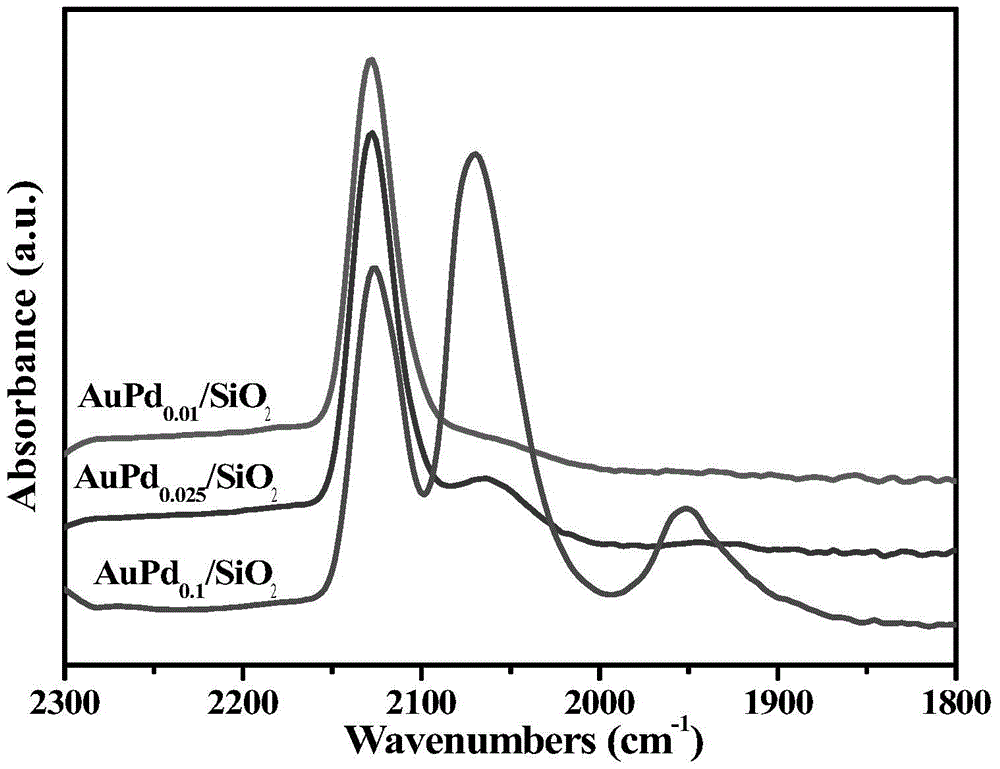

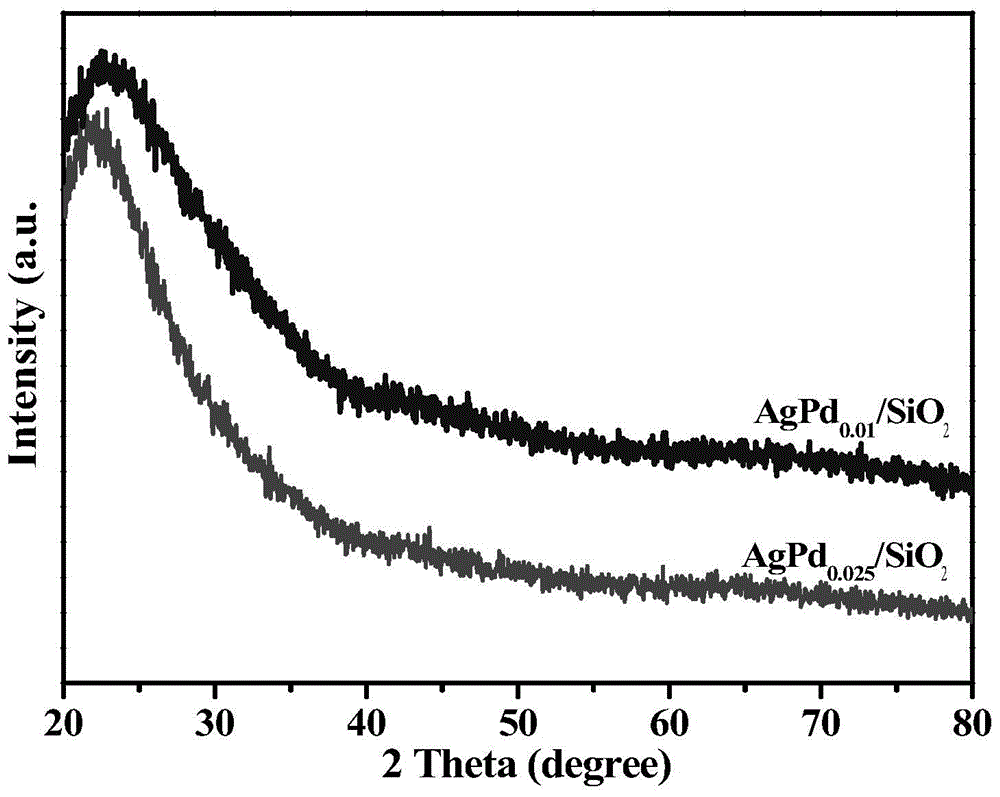

Alloy single atom catalyst for selective hydrogenation of alkyne

ActiveCN104588006AEfficient use ofLess side effectsHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsAlloy catalystAlloy

The present invention relates to a palladium-containing alloy single atom catalyst for selective hydrogenation of alkyne. According to the catalyst, an inert oxide SiO2 is adopted as a carrier, Pd and one or two or more than two materials selected from metal elements in group IB or Group VIII excluding Pd are combined to prepare the supported palladium-containing alloy catalyst so as to make the Pd be in the complete or partial single atom distribution state, wherein the Pd accounts for 0.002-1% of the weight of the carrier, and the content of other metal elements accounts for 0.2-8% of the weight of the carrier. The palladium-containing alloy single atom catalyst has characteristics of high catalytic hydrogenation activity, high ethylene selectivity and the like, and has the good reaction catalysis performance in the reaction for preparing ethylene gas to eliminate trace acetylene through petroleum cracking under the condition close to the industrial condition.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Metal alloy catalyst for formaldehyde purification and preparation method thereof

ActiveCN104646029AReduce dosageSpeed up decompositionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationBULK ACTIVE INGREDIENT

The invention discloses a metal alloy catalyst for formaldehyde purification and a preparation method thereof. The catalyst takes a metal alloy as an active center and takes a metal oxide as a carrier; the metal alloy is formed by compounding a precious metal A and a transition metal B; the precious metal A refers to any one of Pt, Ru, Rh, Pd and Ag; and the transition metal B refers to any one or a mixture of at least two out of Fe, Ni, Mn and Co. The preparation method comprises the following steps: synthesizing composite precious metal alloy nanoparticles by taking a precursor solution of the precious metal and the transition metal as a raw material under the CO atmosphere; loading the nanoparticles serving as active ingredients onto the carrier, reducing by virtue of hydrogen or a reducing solution to obtain the metal alloy catalyst. According to the catalyst disclosed by the invention, the indoor low-concentration harmful gas such as formaldehyde can be subjected to catalytic oxidation so as to prepare nontoxic and harmless CO2 and H2O under the room temperature conditions without light, electricity and other external auxiliary equipment, so that green purification of the formaldehyde is realized, and the catalyst has high stability.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

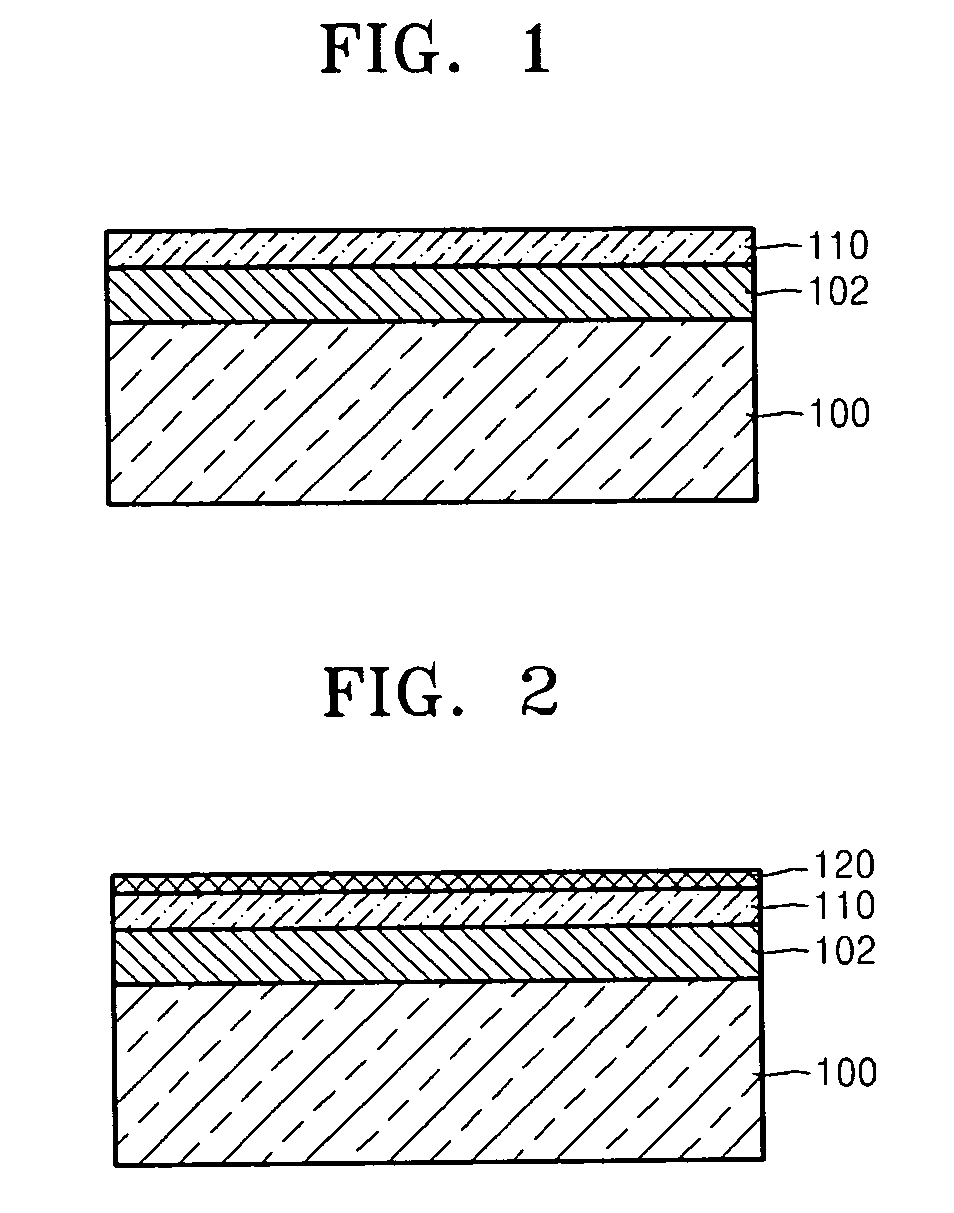

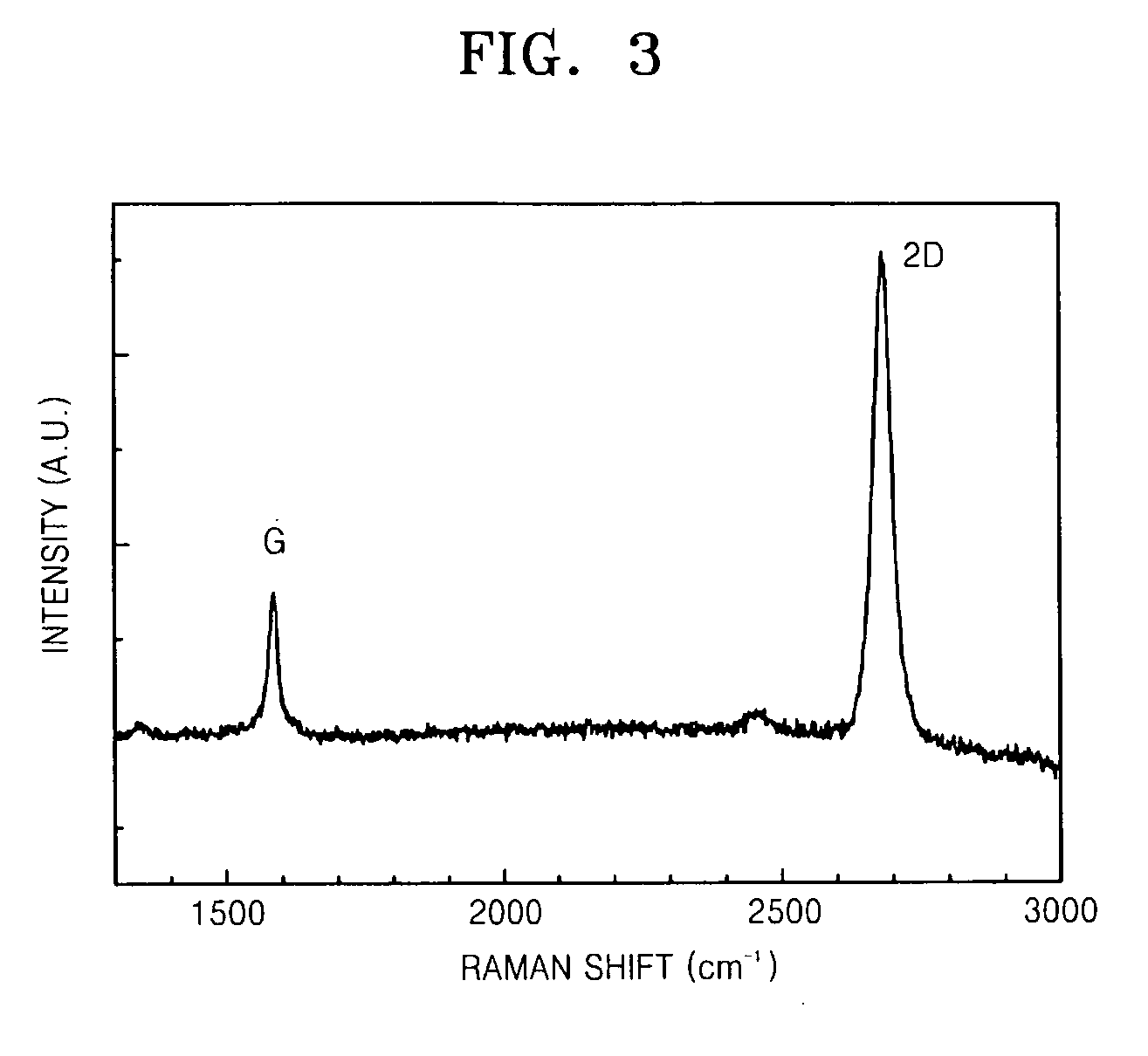

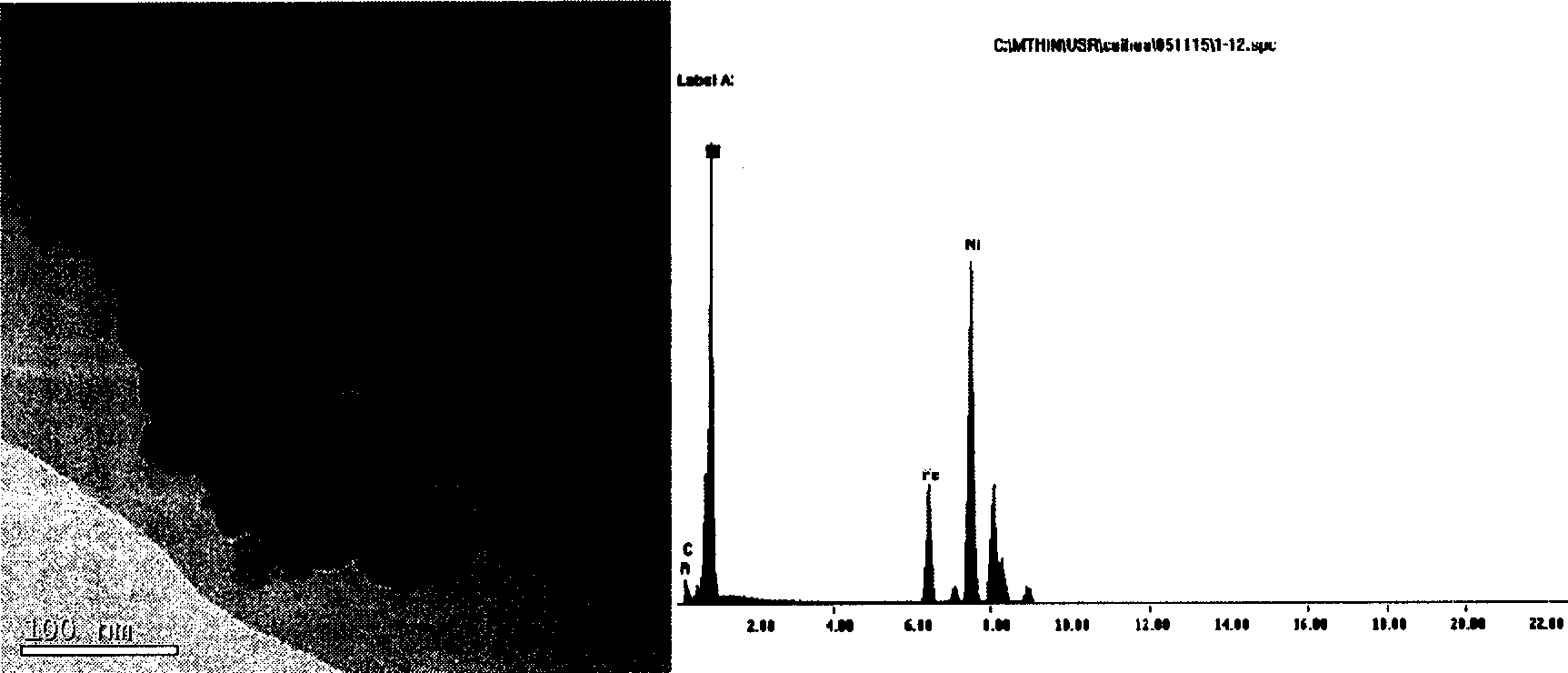

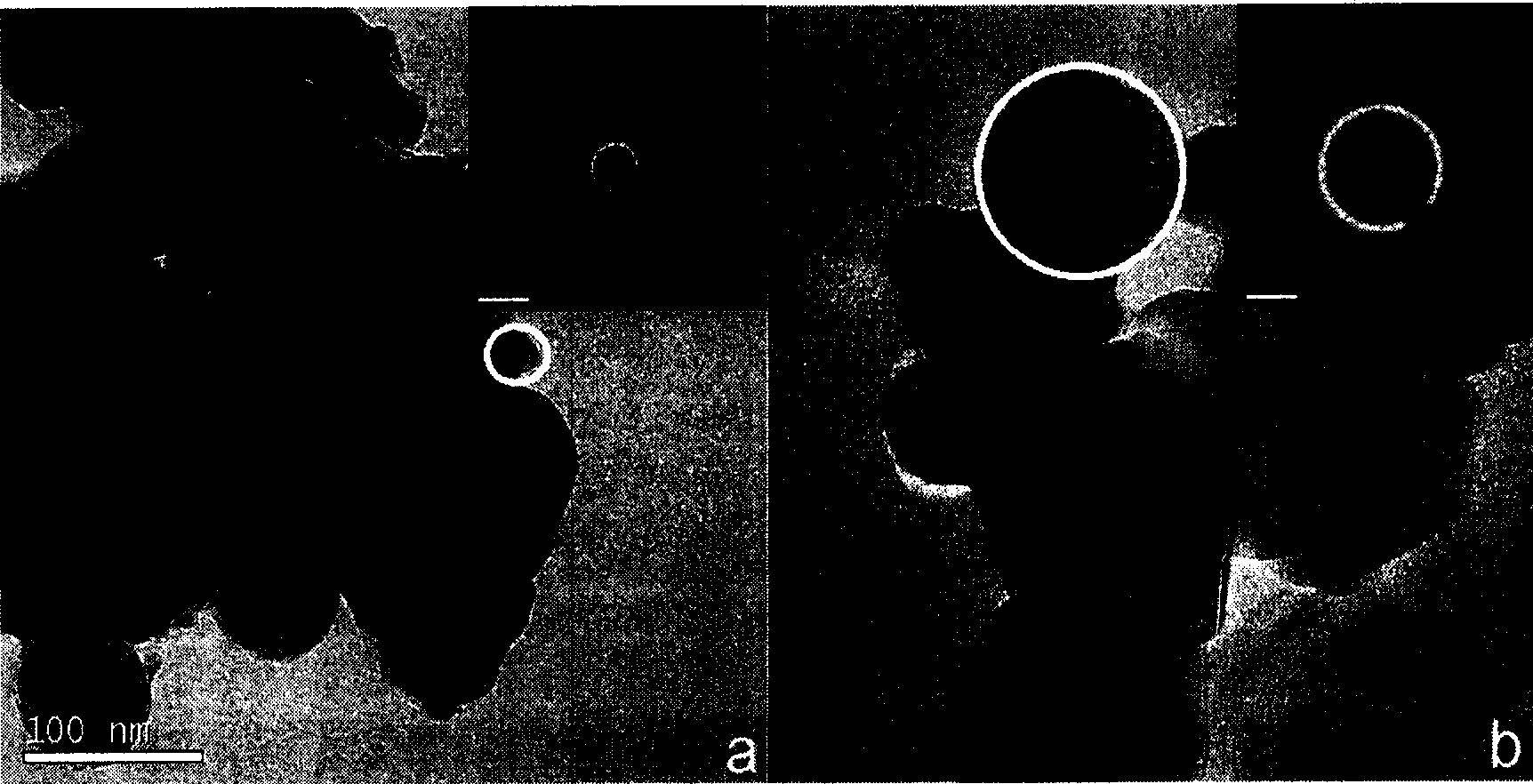

Methods of fabricating graphene using alloy catalyst

Methods of fabricating graphene using an alloy catalyst may include forming an alloy catalyst layer including nickel on a substrate and forming a graphene layer by supplying hydrocarbon gas onto the alloy catalyst layer. The alloy catalyst layer may include nickel and at least one selected from the group consisting of copper, platinum, iron and gold. When the graphene is fabricated, a catalyst metal that reduces solubility of carbon in Ni may be used together with Ni in the alloy catalyst layer. An amount of carbon that is dissolved may be adjusted and a uniform graphene monolayer may be fabricated.

Owner:SAMSUNG ELECTRONICS CO LTD

Alkylation process of alkyl-benzene with olefin using a sodium-and-potassium catalyst

InactiveUS6100437AHigh catalytic activityReduce presenceCatalystsHydrocarbon preparation catalystsPotassiumDouble bond

An alkylbenzene is alkylated with an alkene, in the presence of a sodium / potassium alloy catalyst, on a saturated carbon atom which is alpha to the ring at temperatures which are lower than the temperatures used in a current commercial process. In a pre-alkylation reaction, the catalyst is reacted with a compound which has a saturated carbon atom alpha to a double bond in order to form a catalytic species. Higher amounts of catalyst are used in the pre-alkylation reaction than in the analogous reaction of the current commercial process. Following alkylation, the phase which contains the alkylation product is separated from the phase which contains the catalytic species. The process produces less isomeric and other soluble byproducts, and enables the efficacious production of longer chain alkylbenzenes without the formation of insoluble tars characteristic of the current commercial process.

Owner:ALBEMARLE CORP

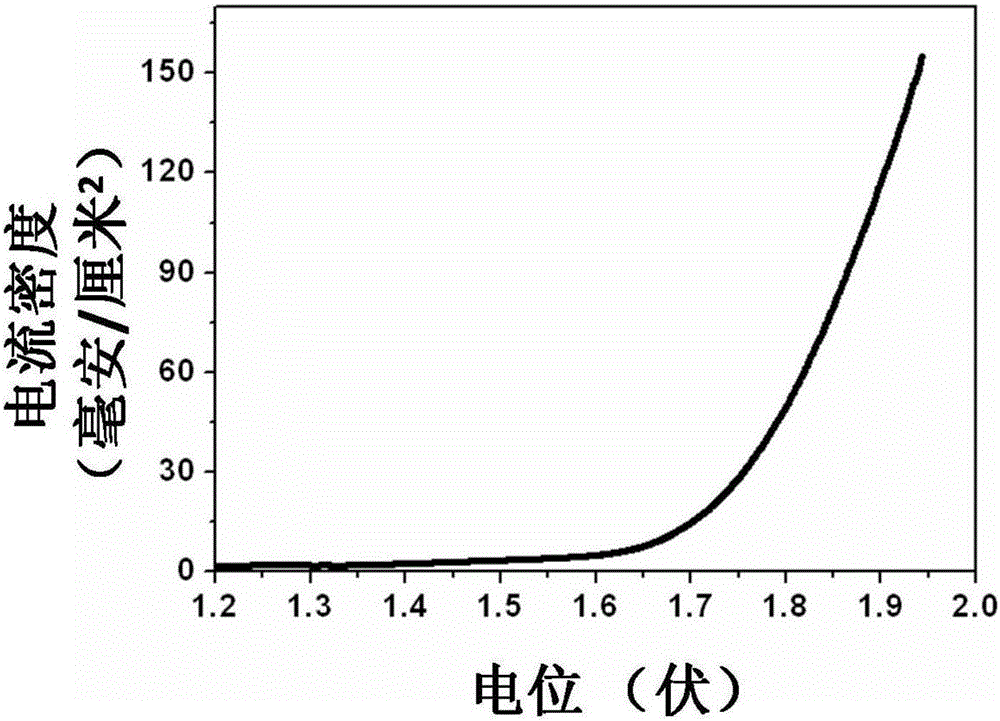

Self-supporting transition metal-phosphorus alloy catalyst, and preparation method and application thereof

InactiveCN105107535AEasy to prepareReduce manufacturing costPhysical/chemical process catalystsElectrodesDecompositionAlloy catalyst

The invention provides a self-supporting transition metal-phosphorus alloy catalyst, and a preparation method and an application thereof, and belongs to the field of alkaline electrolytic bath water decomposition. The preparation method of the catalyst comprises the following steps: mixing the salt of a transition metal element with a phosphorus source, and adding a surfactant or an alkaline solution to obtain an electrolyte; and electrodepositing in the electrolyte with a transition metal conductive substrate as a working electrode in order to obtain the self-supporting transition metal-phosphorus alloy catalyst. The invention also provides the self-supporting transition metal-phosphorus alloy catalyst prepared through the preparation method. The self-supporting transition metal-phosphorus alloy catalyst has excellent electrocatalytic hydrogen evolution and oxygen evolution performances in electrolytic baths.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Load-type non-crystal-state alloy hydogenation catalyst and preparing method

InactiveCN1850330AHigh selectivityIncrease acquisition rateOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsCyclohexanoneAlloy

The present invention discloses a loaded type amorphous alloy catalyst for preparing cyclohexanone by means of phenol catalytic hydrogenation and its preparation method. Said invention utilizes isochoric impregnation KBH4 reduction method to prepare amorphous alloy catalyst, said preparation method includes the following steps: preparing hydrotalcite carrier; making metal salt precursor solution and hydrotalcite carrier undergo the process of isochoric impregnation treatment; drying; roasting; drop-adding reductant KBH4 solution to make reduction; successively using deionized water and absolute ethyl alcohol to wash black solid precipitate obtained by above-mentioned solution reaction to neutrality so as to obtain the invented amorphous alloy catalyst.

Owner:SHANGHAI NORMAL UNIVERSITY

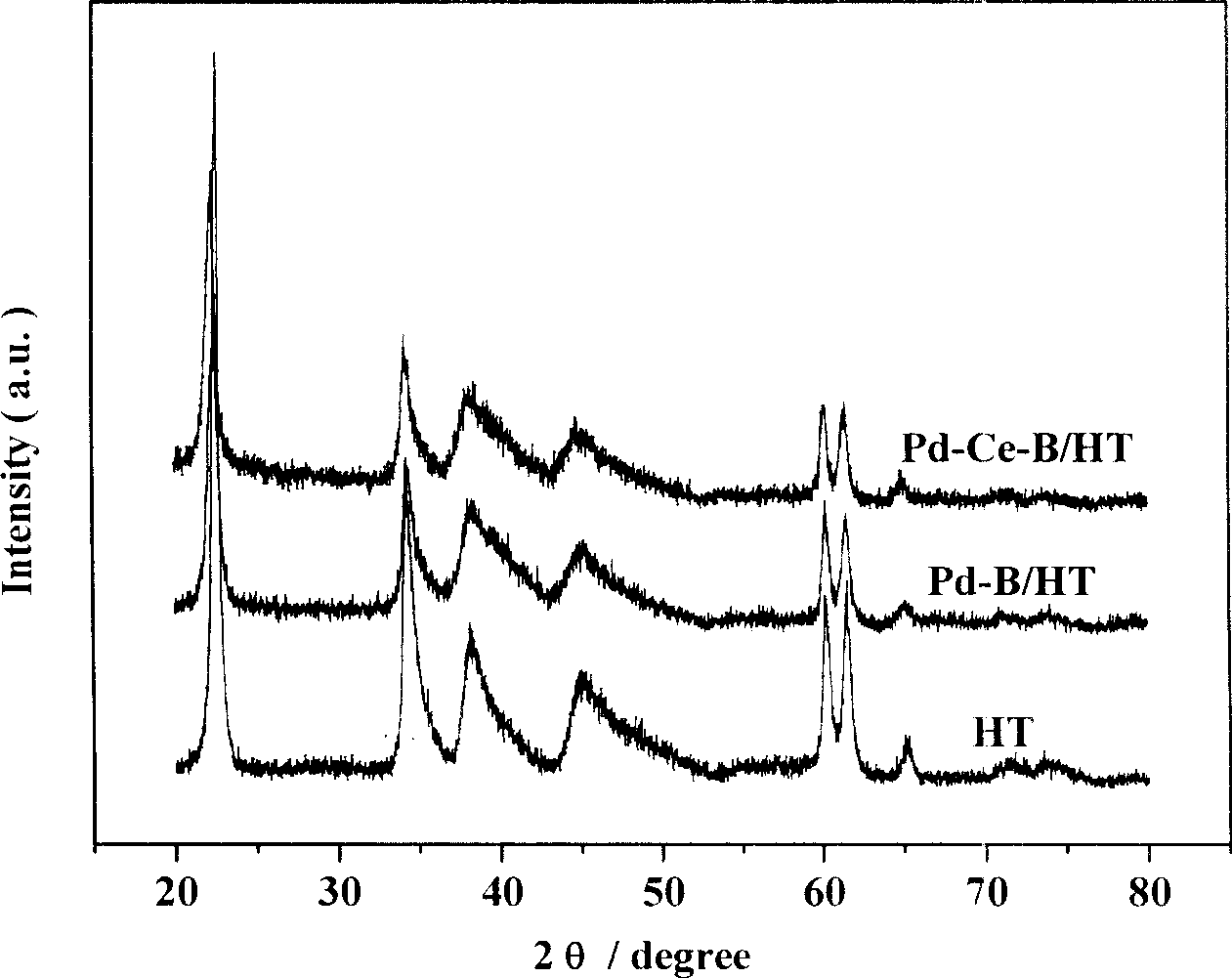

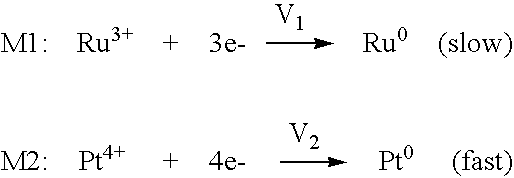

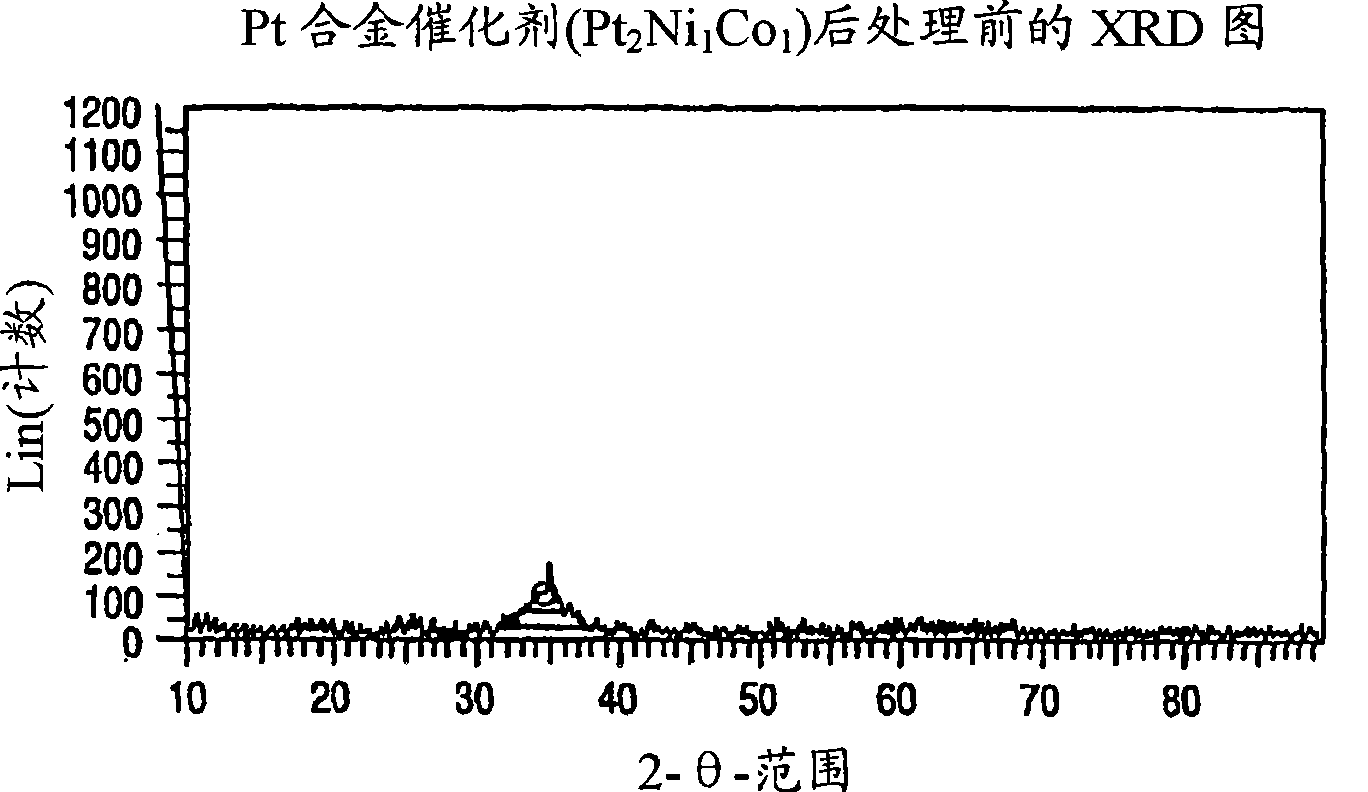

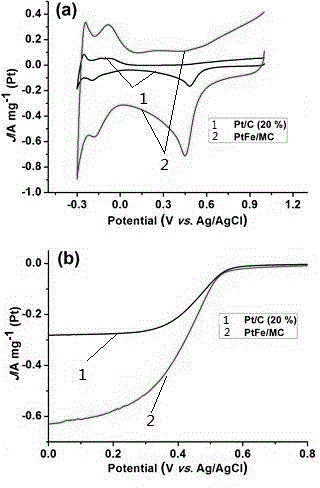

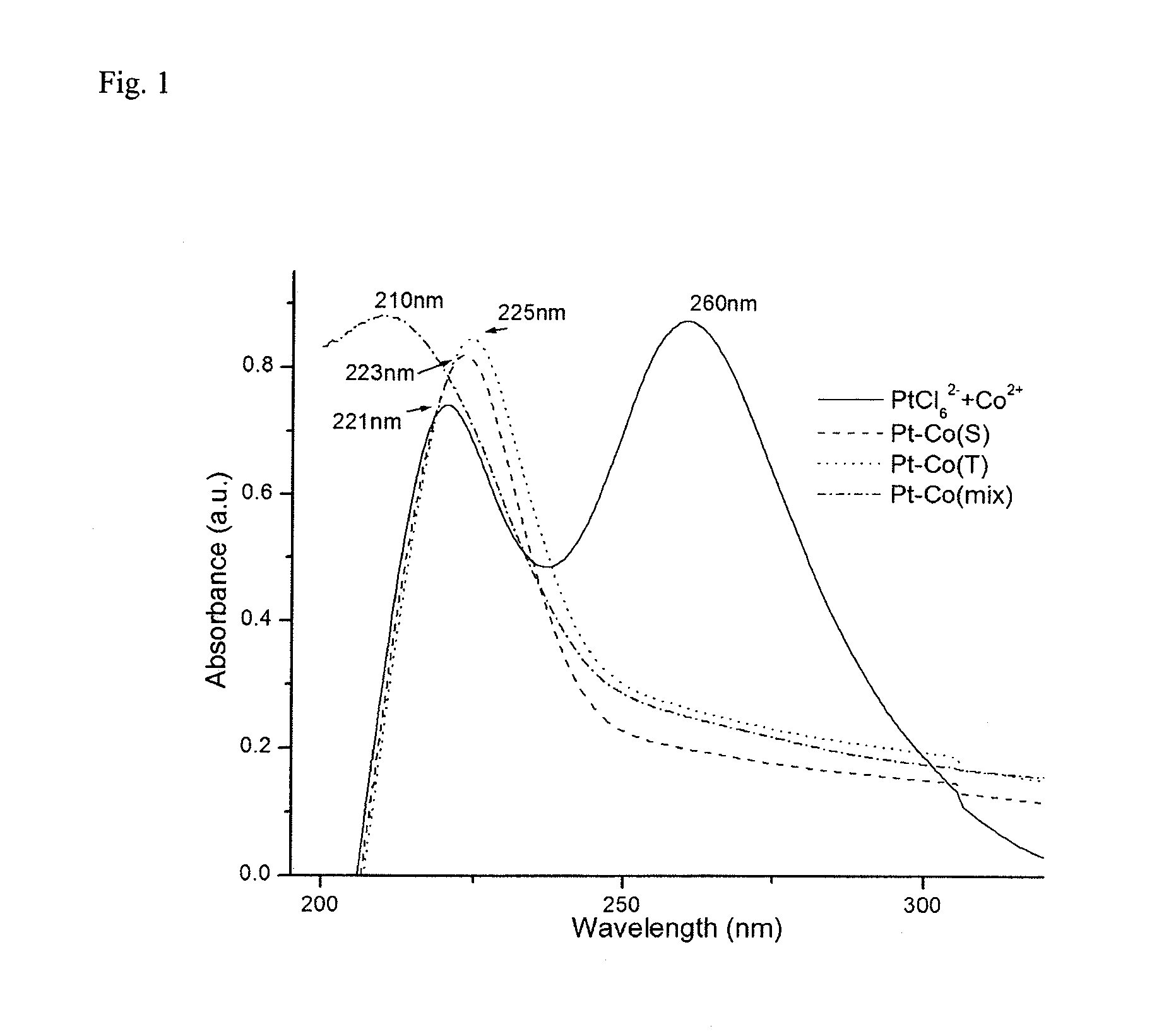

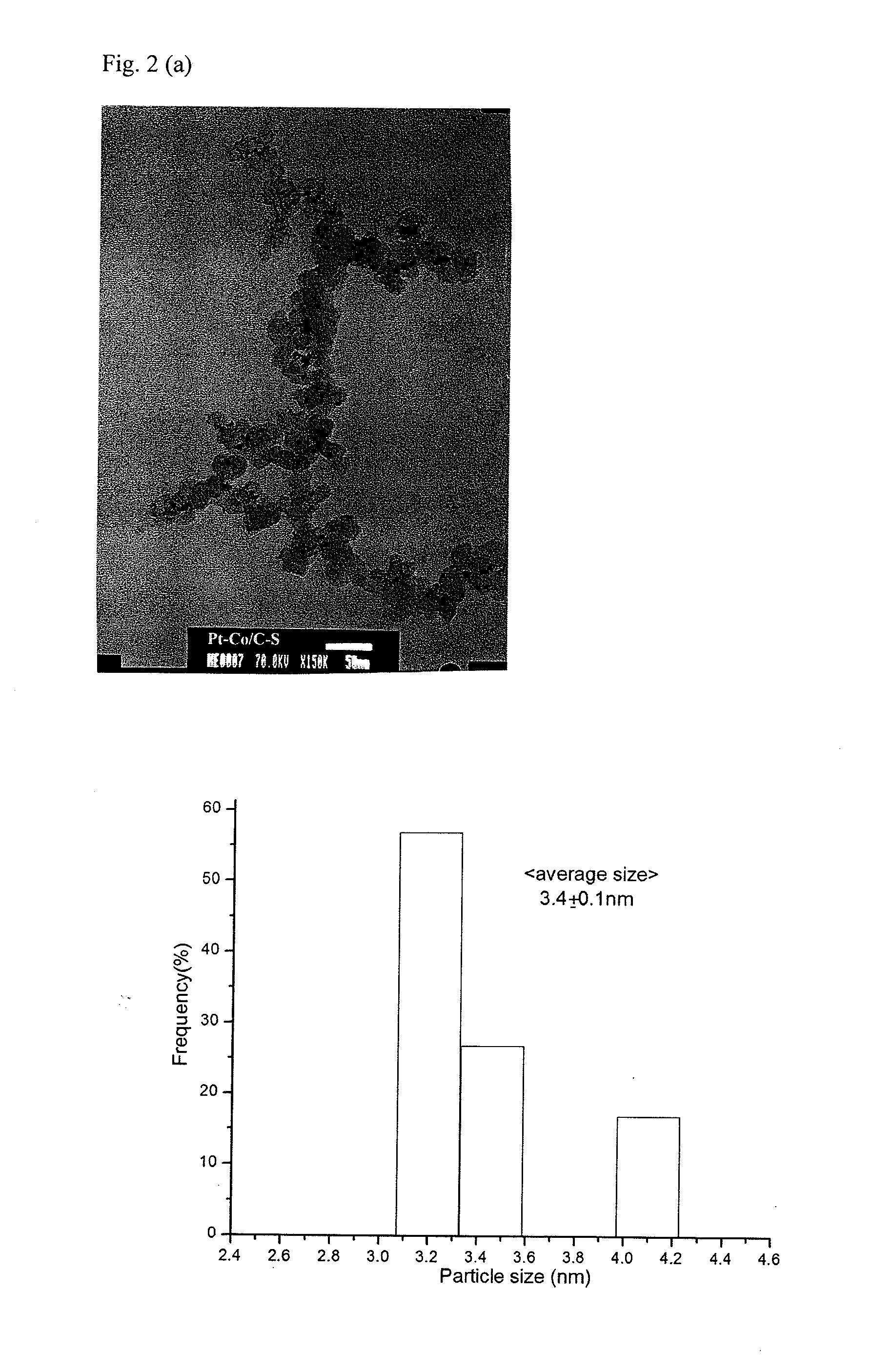

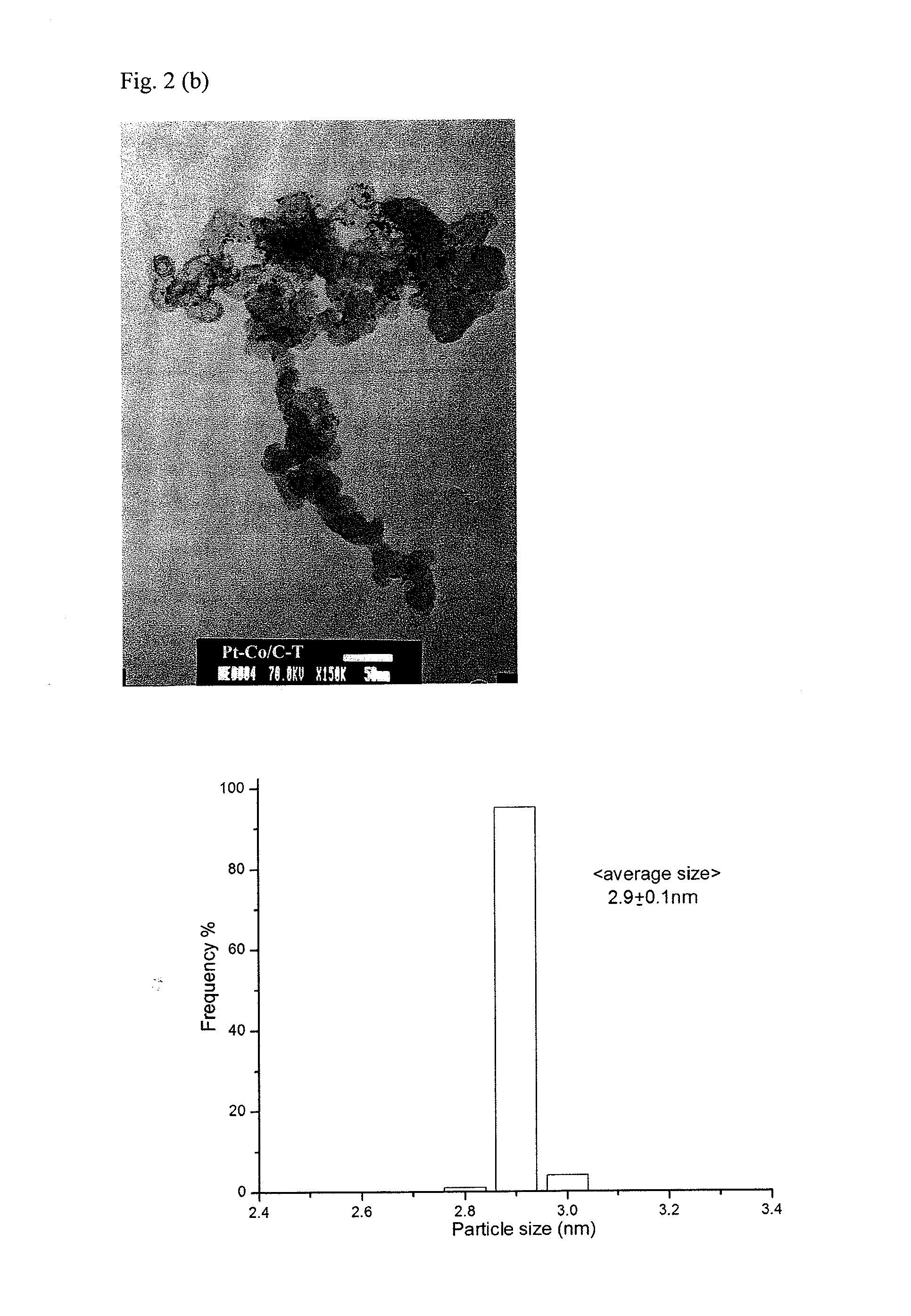

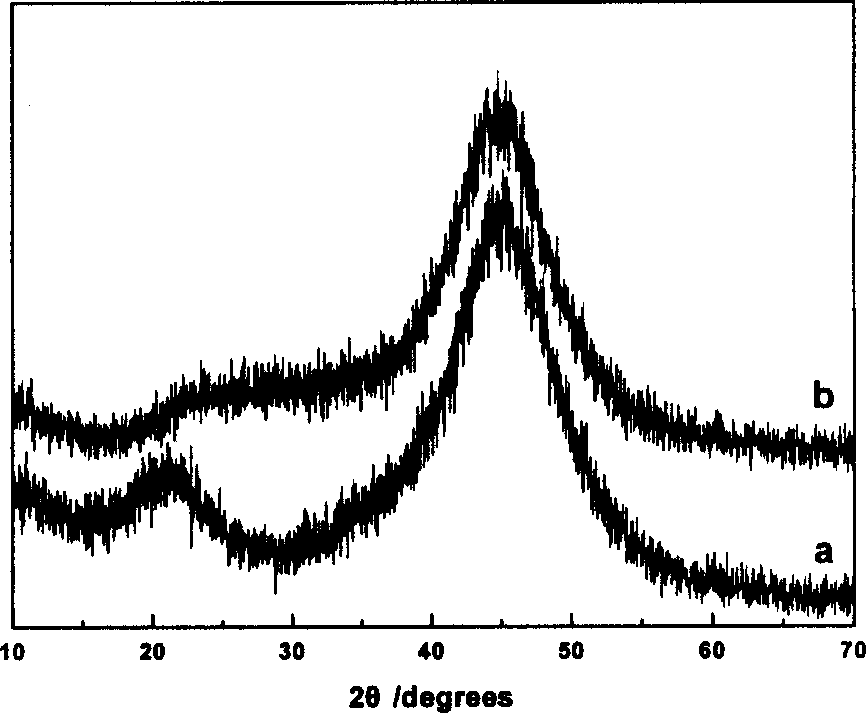

Method for manufacture of noble metal alloy catalysts and catalysts prepared therewith

ActiveUS20060094597A1High degreeEasy to manufactureMaterial nanotechnologyGas treatmentGas phaseReaction temperature

The present invention provides a method for manufacture of supported noble metal based alloy catalysts with a high degree of alloying and a small crystallite size. The method is based on the use of polyol solvents as reaction medium and comprises of a two-step reduction process in the presence of a support material. In the first step, the first metal (M1=transition metal; e.g. Co, Cr, Ru) is activated by increasing the reaction temperature to 80 to 160° C. In the second step, the second metal (M2=noble metal; e.g. Pt, Pd, Au and mixtures thereof) is added and the slurry is heated to the boiling point of the polyol solvent in a range of 160 to 300° C. Due to this two-step method, an uniform reduction occurs, resulting in noble metal based catalysts with a high degree of alloying and a small crystallite size of less than 3 nm. Due to the high degree of alloying, the lattice constants are lowered. The catalysts manufactured according to the method are used as electrocatalysts for polymer electrolyte membrane fuel cells (PEMFC), direct-methanol fuel cells (DMFC) or as gas phase catalysts for CO oxidation or exhaust gas purification.

Owner:UMICORE AG & CO KG

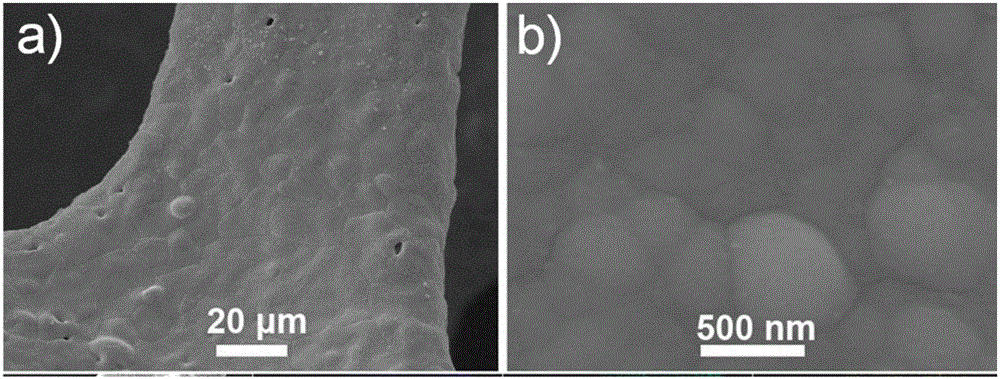

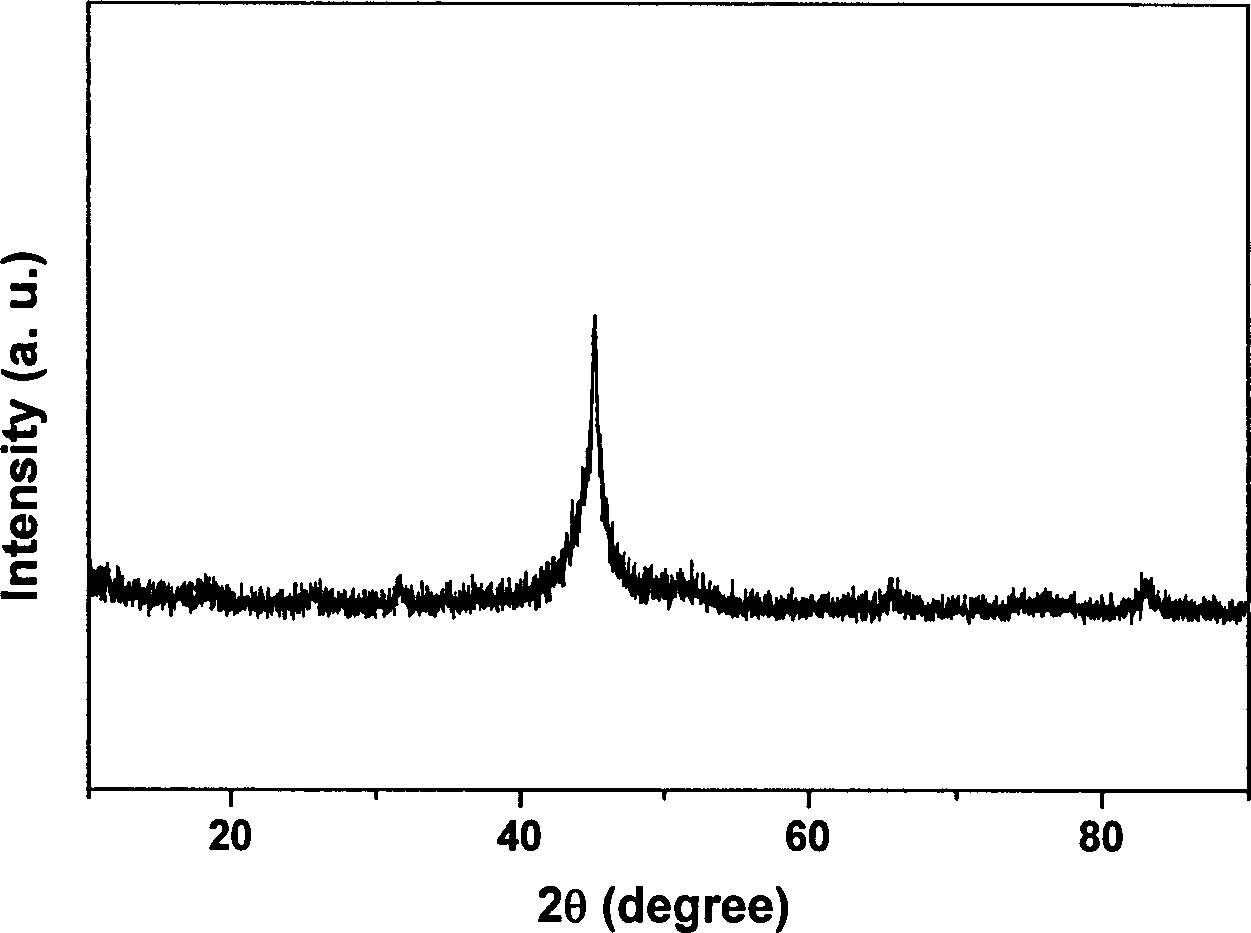

Carrier style palladium amorphous alloy catalyst for hydrogenation of anthraquinone

InactiveCN1424145AHigh activityReduce loadMolecular sieve catalystsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesRare-earth elementIce water

A carried non-crystal Pd alloy catalyst for hydrogenating anthraquinone to prepare H2O2 is prepared from the carrier which is one or two of gamma-Al2O3, alpha-Al2O3, MgO, activated carbon, molecular sieve and mullite, non-crystal PdB alloy and RE element through immersing the carrier in the solution of RE metal's nitrate under ultrasonic condition, calcining at 400-700 deg.C for 2-5 hr, immersing in PdCl2 solution, dropping KBH4 solution in ice water bath, and washing. Its advantages are high catalytic activity and low cost.

Owner:TIANJIN UNIV

Catalytic oxidation catalyst for methyl acetate in organic waste gas and preparation method thereof

ActiveCN102247867AEasy to makeSuitable for large-scale productionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationManganese

The invention discloses a catalytic oxidation catalyst for methyl acetate in organic waste gas and a preparation method thereof. The catalyst is a supported noble metal alloy catalyst, wherein the noble metal alloy is an arbitrary metal combination of two or more of Pd, Pt, Rh, Au and Ag; the vector is activated alumina and / or titanium dioxide, as well as at least one transition metal oxide whichcomprises metal oxide of manganese, cerium, nickel, lanthanum, copper, vanadium, tungsten, iron, cobalt or chrome; and the weight ratio of the noble metal alloy to the vector is (1:2,000)-(1:5). The catalyst provided by the invention can be used for treating organic waste gas containing methyl acetate, especially for treating waste gas of a PTA (purified terephthalic acid) device, by a catalytic oxidation method; and the catalyst has the advantages of simple preparation, high catalytic oxidation activity, good stability, excellent halogenated hydrocarbon poisoning resistance and high practical application value.

Owner:CHINA PETROLEUM & CHEM CORP +1

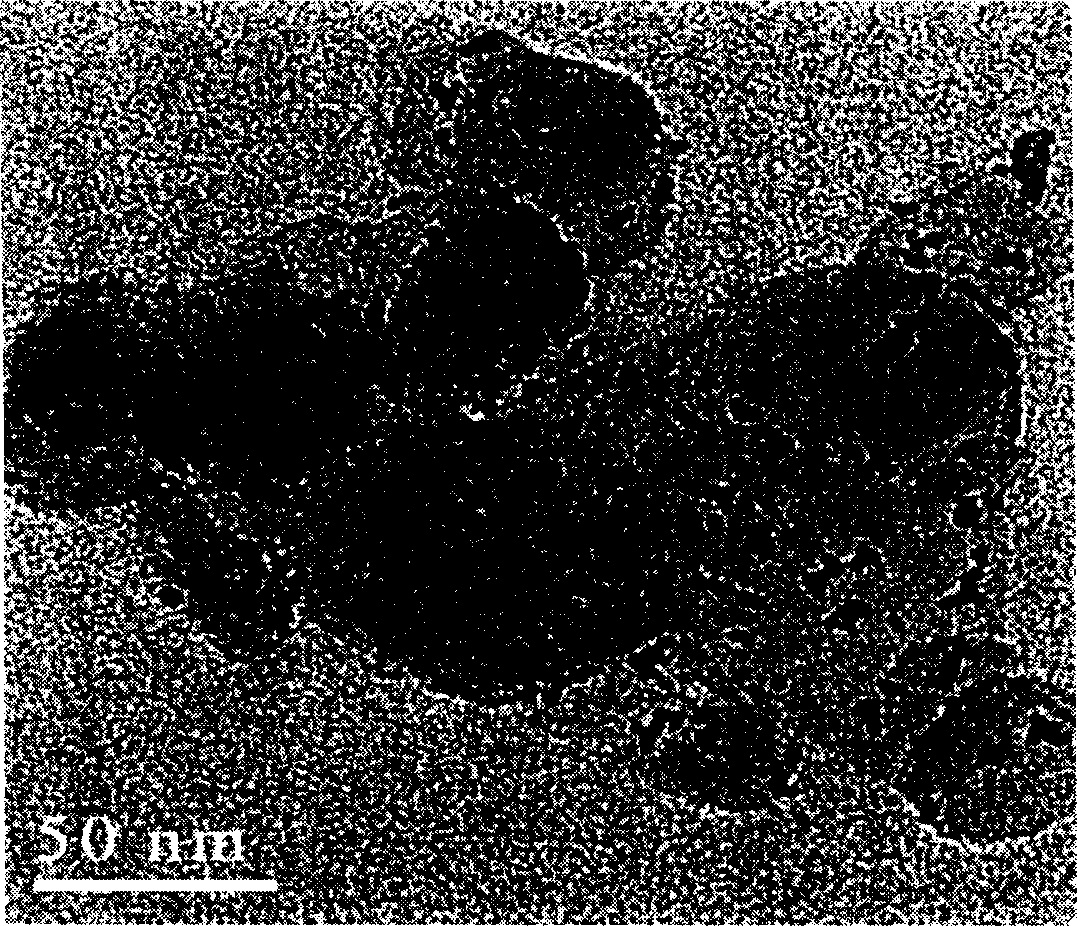

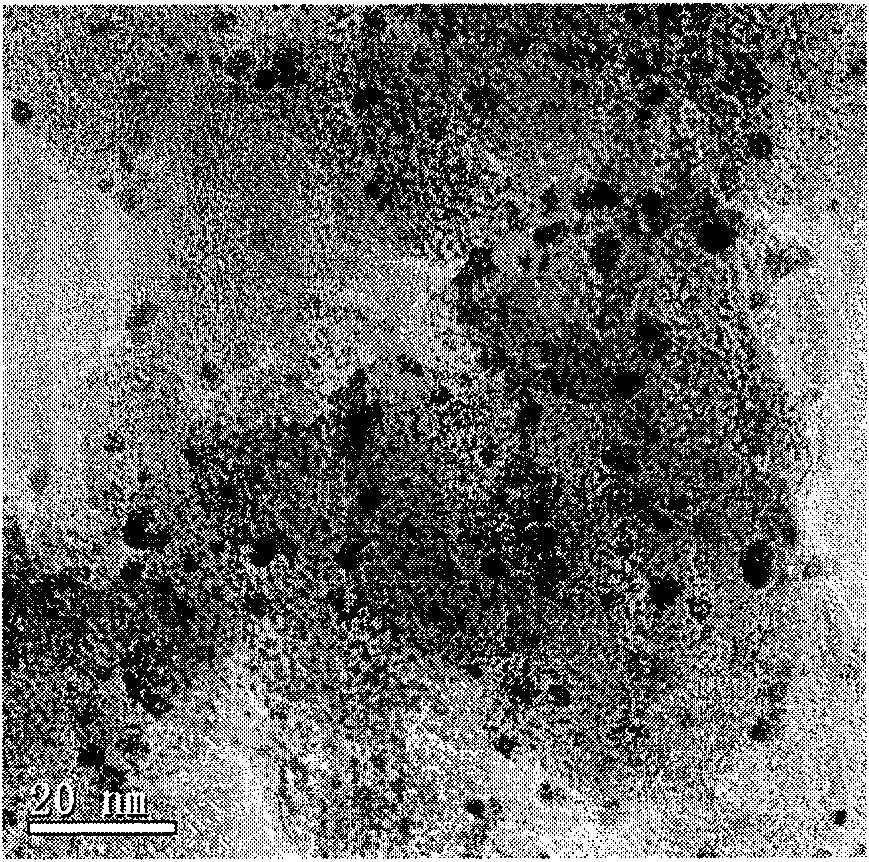

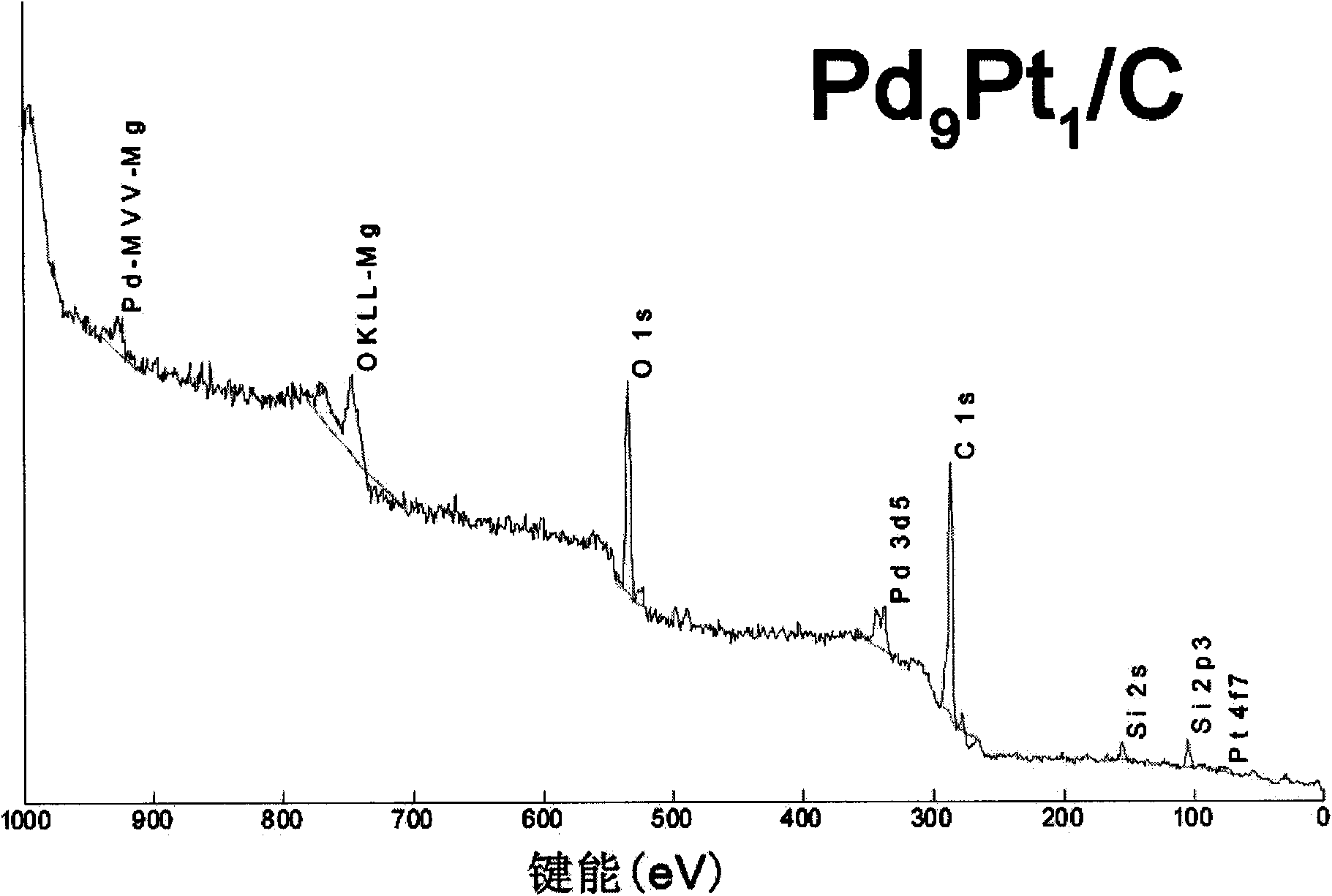

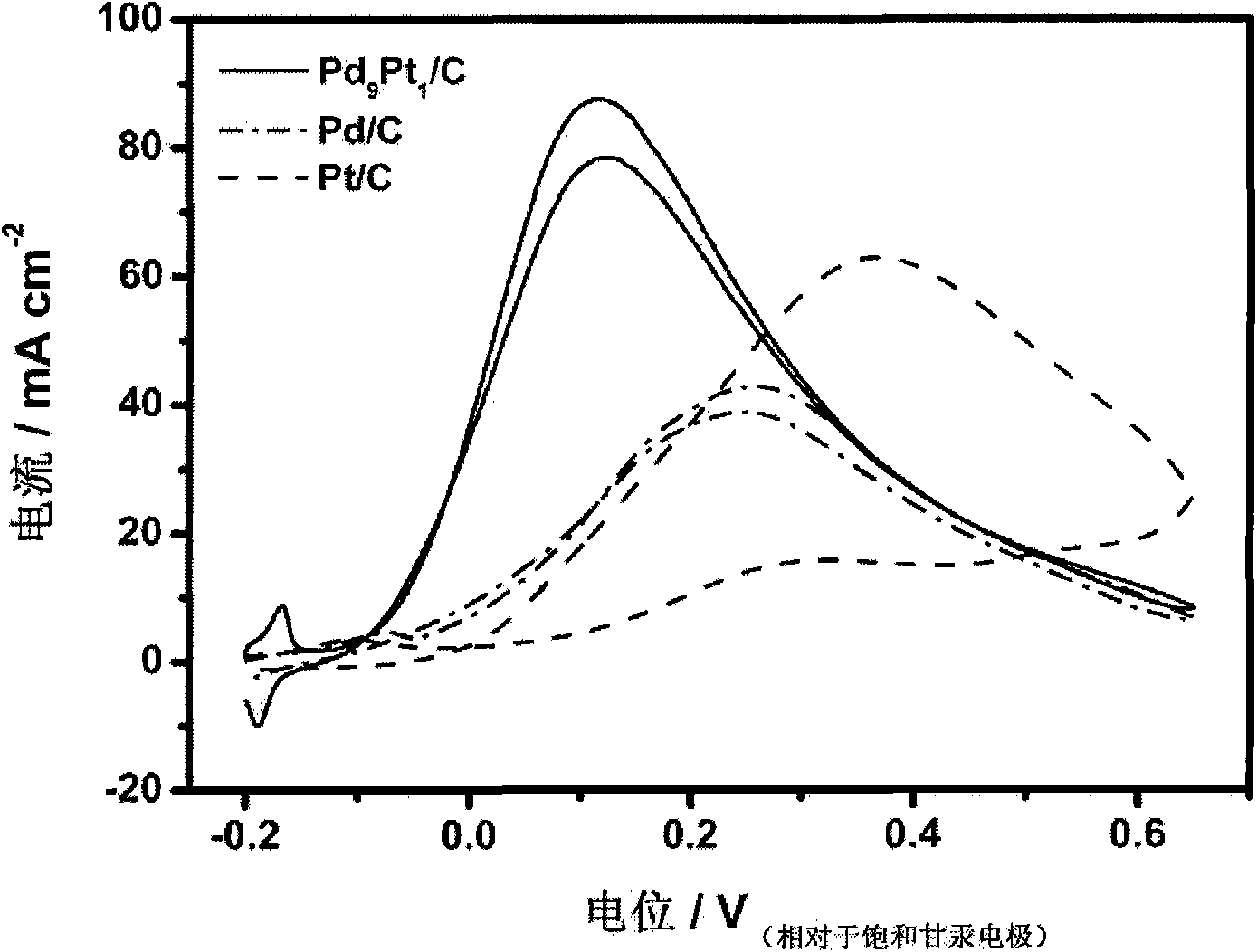

Low-platinum carbon-supported nanometer Pd-Pt alloy catalyst, and preparation method and application thereof

InactiveCN101612566AImprove catalytic performanceImprove performanceCell electrodesCatalyst activation/preparationAlloy catalystAlloy

The invention belongs to the technical field of electrochemical energy, in particular to a low-platinum carbon-supported nanometer Pd-Pt alloy catalyst, and a preparation method and an application thereof. The invention provides the low-platinum carbon-supported nanometer Pd-Pt alloy catalyst; wherein, the Pd-Pt alloy catalyst particles are supported by carbon carrier, the content of Pd-Pt alloy in the carbon-supported nanometer Pd-Pt alloy catalyst is 1-60wt%, the molar ratio of Pd to Pt is 10:0.01-5 and the central particle size of the Pd-Pt alloy catalyst particles is 1.5-50nm. Compared with the traditional Pd / C and Pt / C catalyst, the low-platinum carbon-supported nanometer Pd-Pt alloy catalyst provided by the invention has better catalytic performance to the oxidation of formic acid and longer catalytic stability.

Owner:FUDAN UNIV

Catalyst used in the catalytic hydrogenation of p-nitrophenol and its preparation method

ActiveCN101007275AHigh activityReduce loadCatalyst carriersOrganic compound preparationFiltrationUltrasonic radiation

The invention involves a load palladium amorphous alloy catalyst used for nitrophenol hydrogenation and preparation method and belongs to catalyst technology field. Said catalyst uses NaY, MCM-41, molecular screen, Al2O3, TiO2, SiO2 or MgO as carrier, and is loaded with Pd-B amorphous alloy, the quality of Pd is 0.1-0.5% of toatl quality of catalyst. The preparation process includes ultrasonic dispersion, vacuum impregnation, KBH4 chemical reduction under vacuum conditions, filtration and washing of carriers; it is characterized by introducing vacuum and ultrasonic radiation conditions. The advantages of the invention lies in its high activity of catalyst, low preparation cost and simple preparation process, it could widely apply to the preparation of p-aminophenol through nitrophenol catalysis and hydrogenation.

Owner:NANJING UNIV OF TECH

Method for preparing 1,3-propylene glycol

InactiveCN1431183ALow priceImprove securityPhysical/chemical process catalystsPreparation by oxygen reductionHigh activityPropanediol

A process for preparing 1,3-propanediol from formaldehyde and acetaldehyde includes such steps as under existance of alkali and organic solvent, reacting at 10-40 deg.C for 2-10 hr to obtain 3-hydroxypropanol, making the 3-hydroxypropanal in contact with catalyst, and hydrogenation reaction at 50-100 deg.c and 3-9 MPa. The said catalyst contains Ni (70-90 wt.%), Fe or Mo (0-9), P (1-5) and Al (rest). Its advantages are high output rate, high safety, and high activity and selectivity of said catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

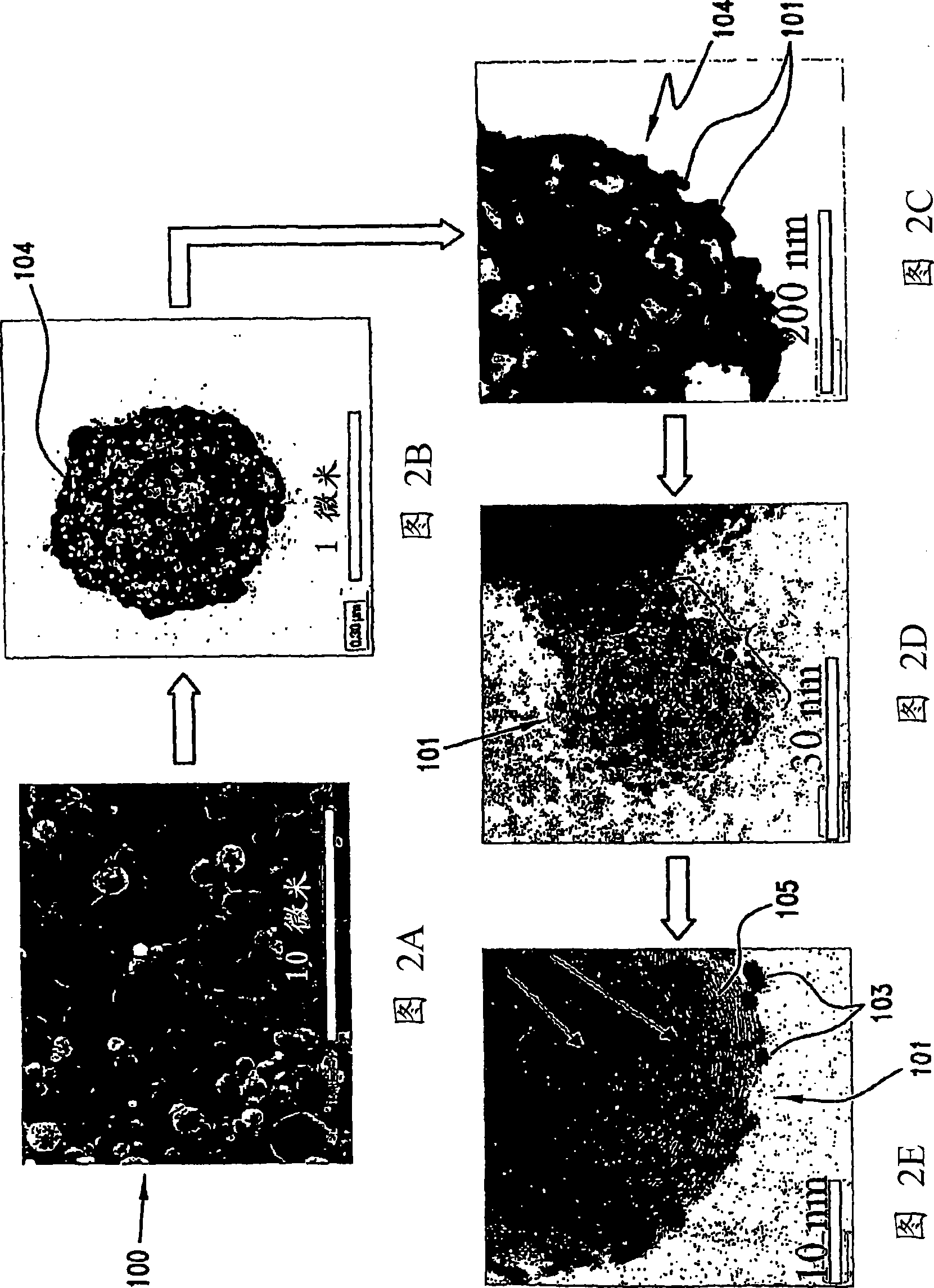

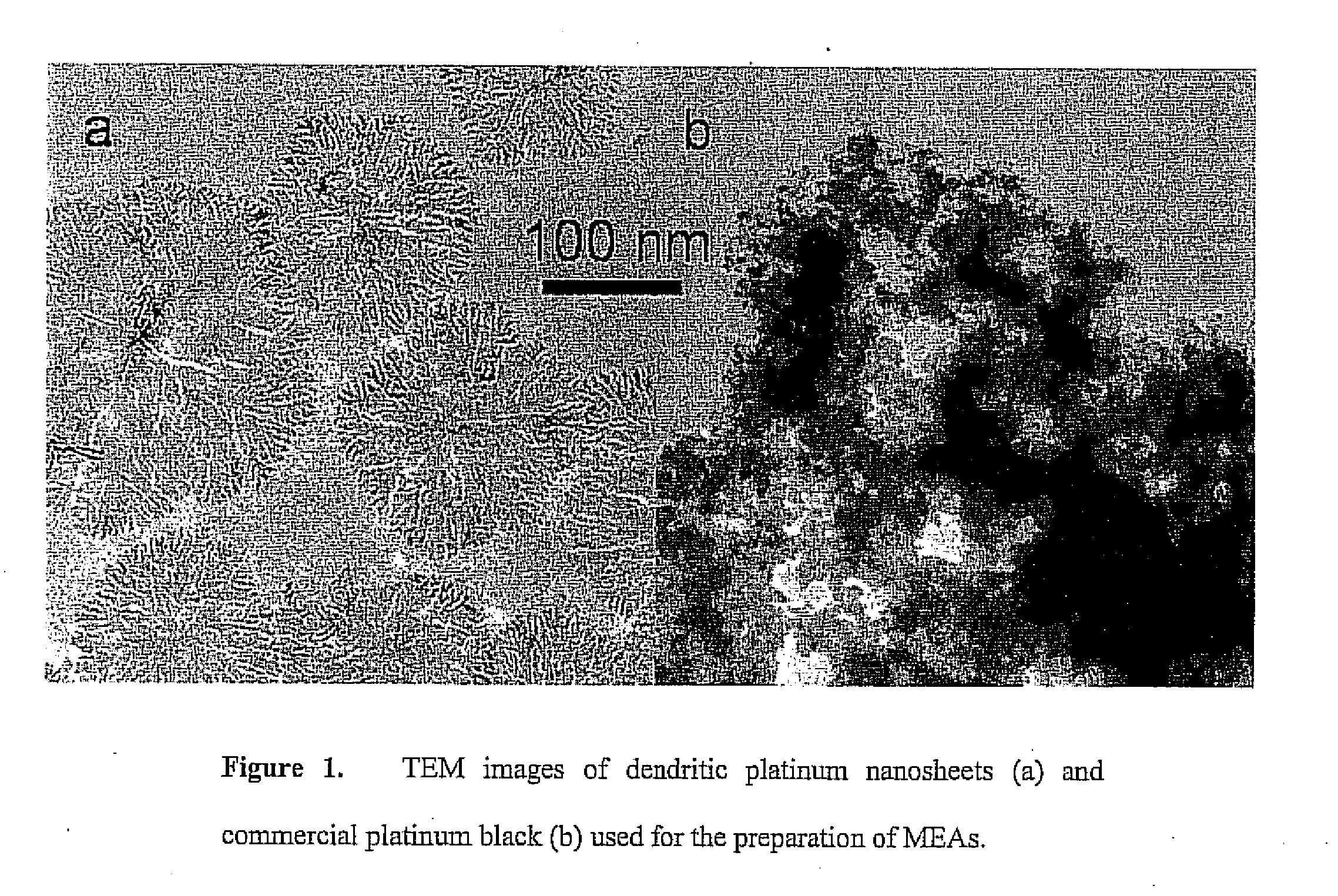

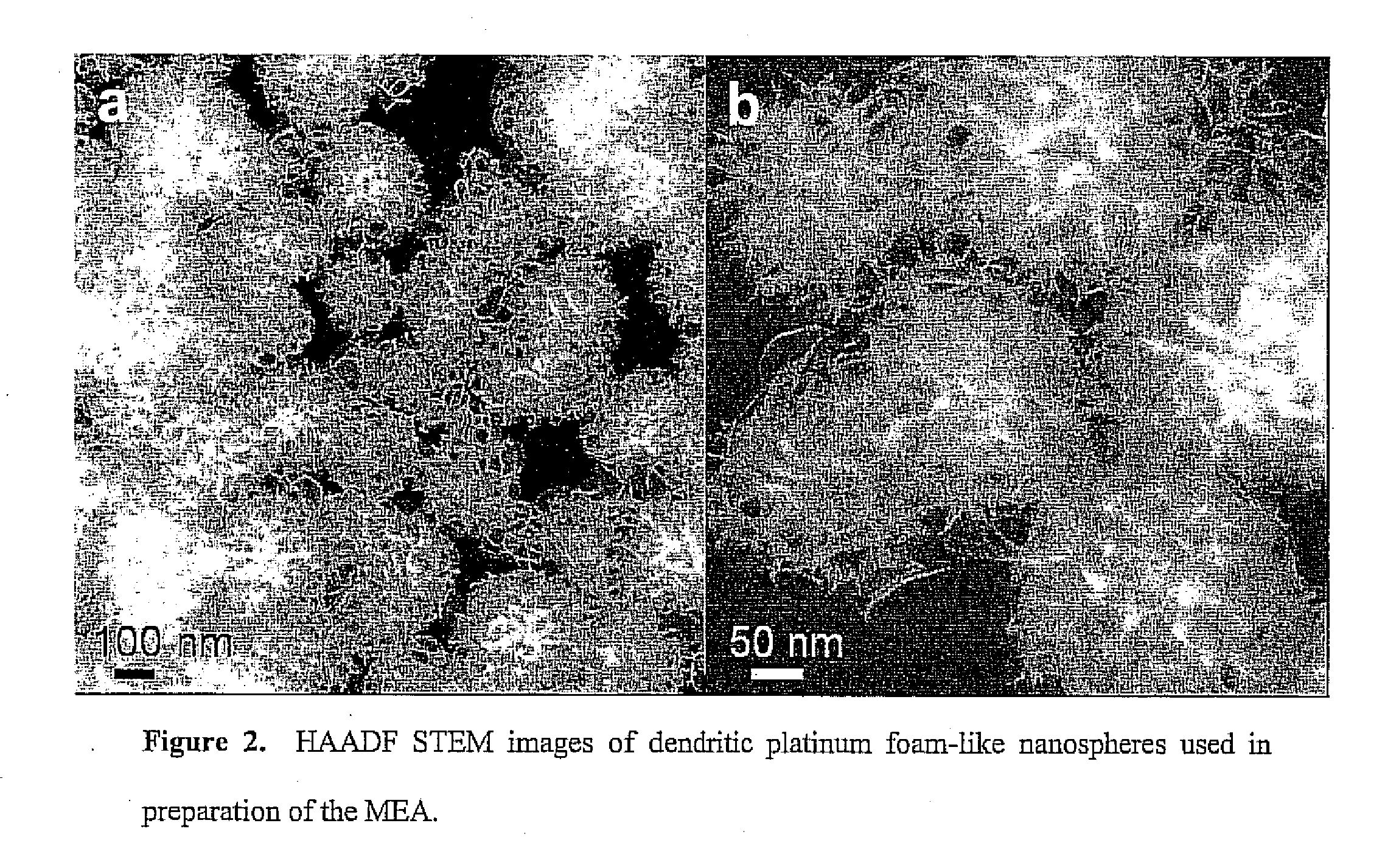

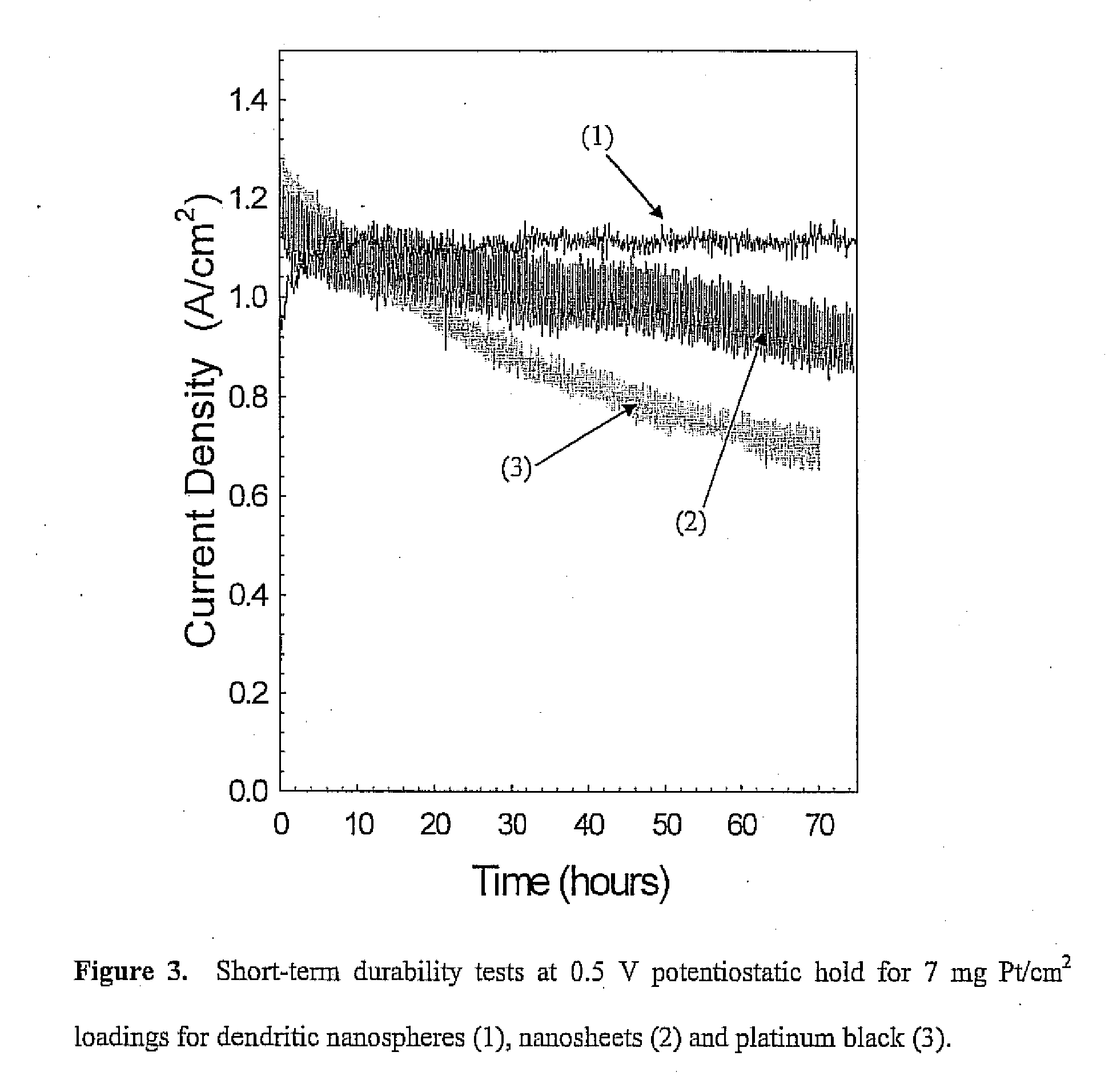

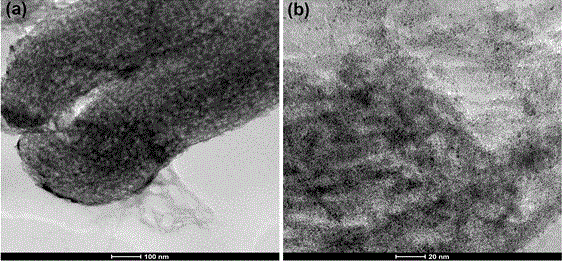

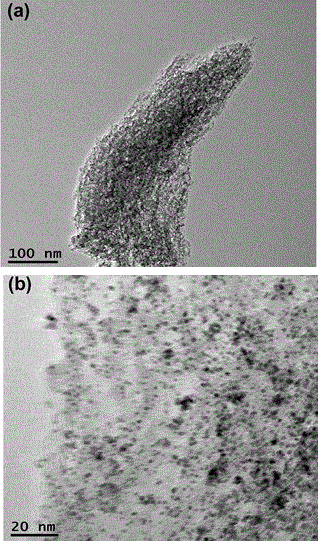

Dendritic metal nanostructures for fuel cells and other applications

InactiveUS20070231674A1Reduce the amount requiredPromote growthMaterial nanotechnologyActive material electrodesDendrimerPolymer electrolytes

Embodiment of the present invention relate to dendrimers useful for application as catalysts, in particular as improved electrocatalysts for polymer electrolyte membrane fuel cells (PEM-FCs). Methods of preparing such catalysts are described. Examples include dendritic nanostructured metal catalysts, such as platinum and platinum-alloy catalysts.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC +1

Porous material supported nano alloy catalyst as well as preparation method and application thereof

ActiveCN104549555AHigh catalytic activityImprove stabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMetallurgy

The invention relates to a porous material supported nano alloy catalyst as well as a preparation method and application thereof and belongs to the technical field of nano material application and catalysis. The preparation method for the porous material supported nano alloy catalyst is characterized comprising the step of reaction through taking a metallic compound as a precursor, a porous material as a carrier and a borane substance as a reducing agent under the action of supercritical carbon dioxide used as a fluid medium; in the catalyst, the types of nano alloy are selected from Pt, Au, Ag, Pd, Ru, Rh, Pb, Fe, Co, Ni, Ir, Cu and the like and can be arbitrarily matched and proportioned; the size of each of nano alloy particles is about 1-2 nm. The nano particles not only can be distributed on the surface of the carrier, but also can be distributed in holes, even mesopores; therefore, the catalyst has higher catalytic activity and stability.

Owner:JIANGSU UNIV

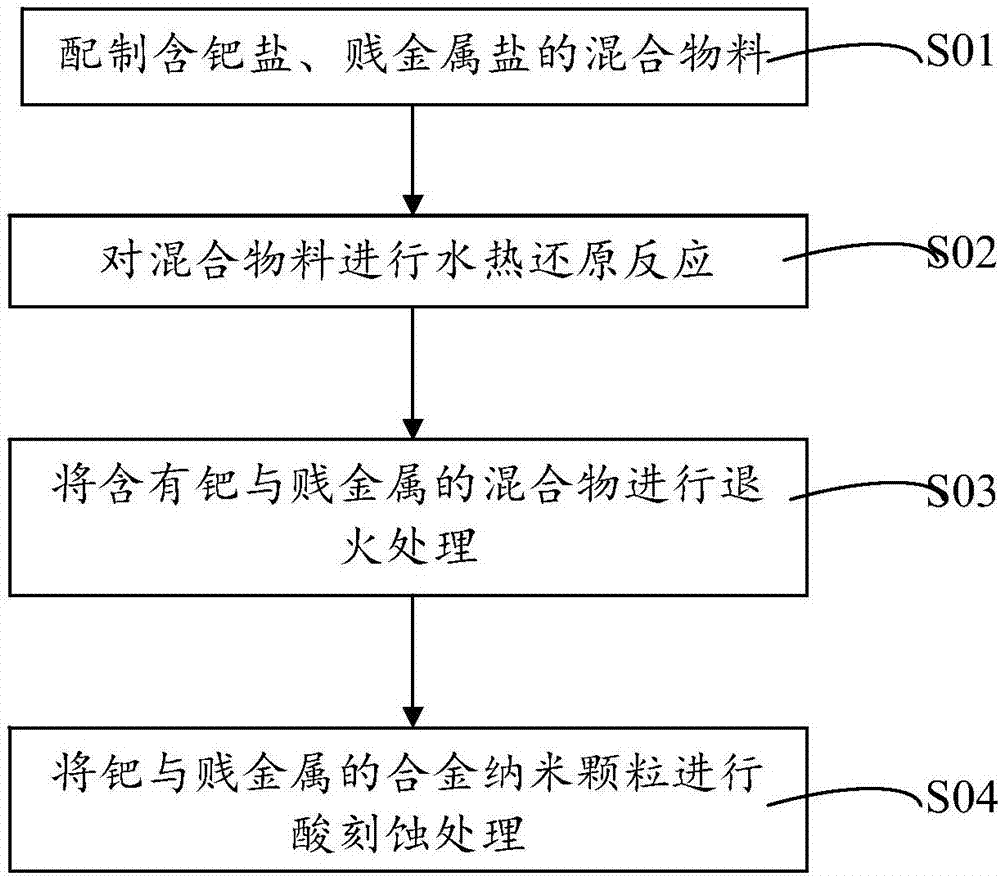

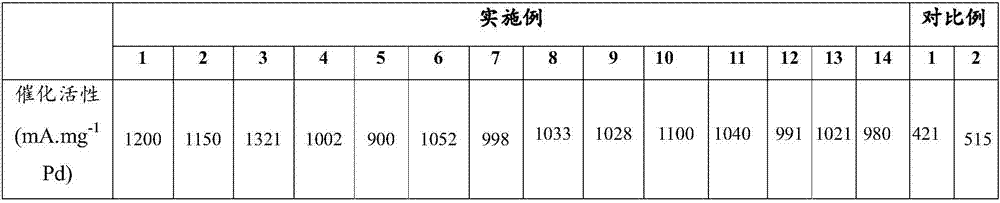

Palladium alloy catalyst, preparation method and applications thereof

InactiveCN106992300AReduce economic costsHigh catalytic activityCell electrodesMetalMaterials science

The present invention discloses a palladium alloy catalyst, a preparation method and applications thereof, wherein the palladium alloy catalyst is alloy nanoparticles formed from a palladium element and a base metal element, and the surface of the alloy nanoparticles has a porous structure. According to the present invention, by introducing the base metal into the palladium metal, the palladium metal content is effectively reduced, the economic cost of the palladium alloy catalyst is effectively reduced, the palladium metal provides the synergistic effect with the base metal, and the palladium alloy catalyst can have high catalytic activity and high stability through the porous structure on the surface; and with the method, the advantages of effectively-reduced catalyst production cost, energy source saving, environment protection and mass-production can be provided.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

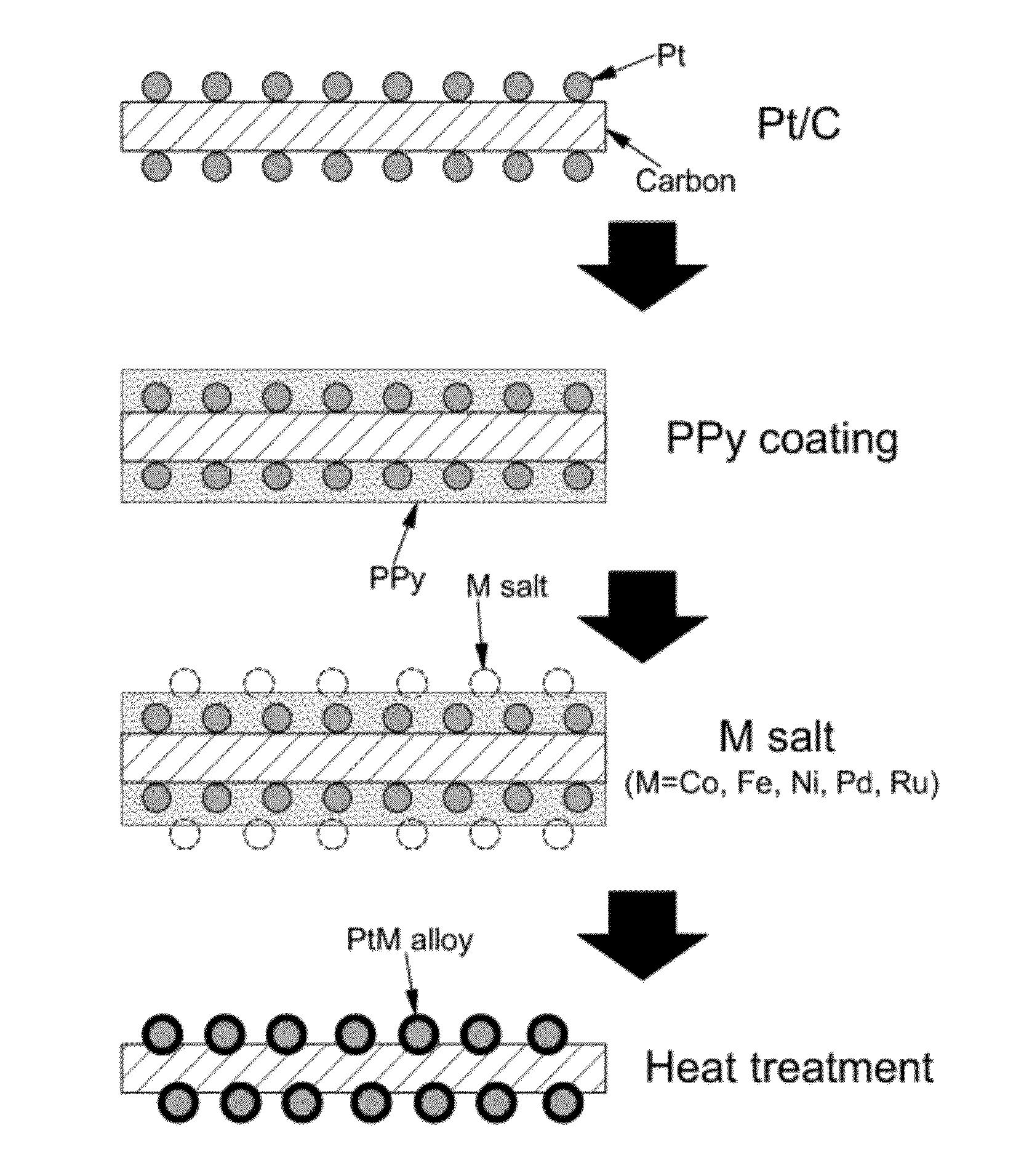

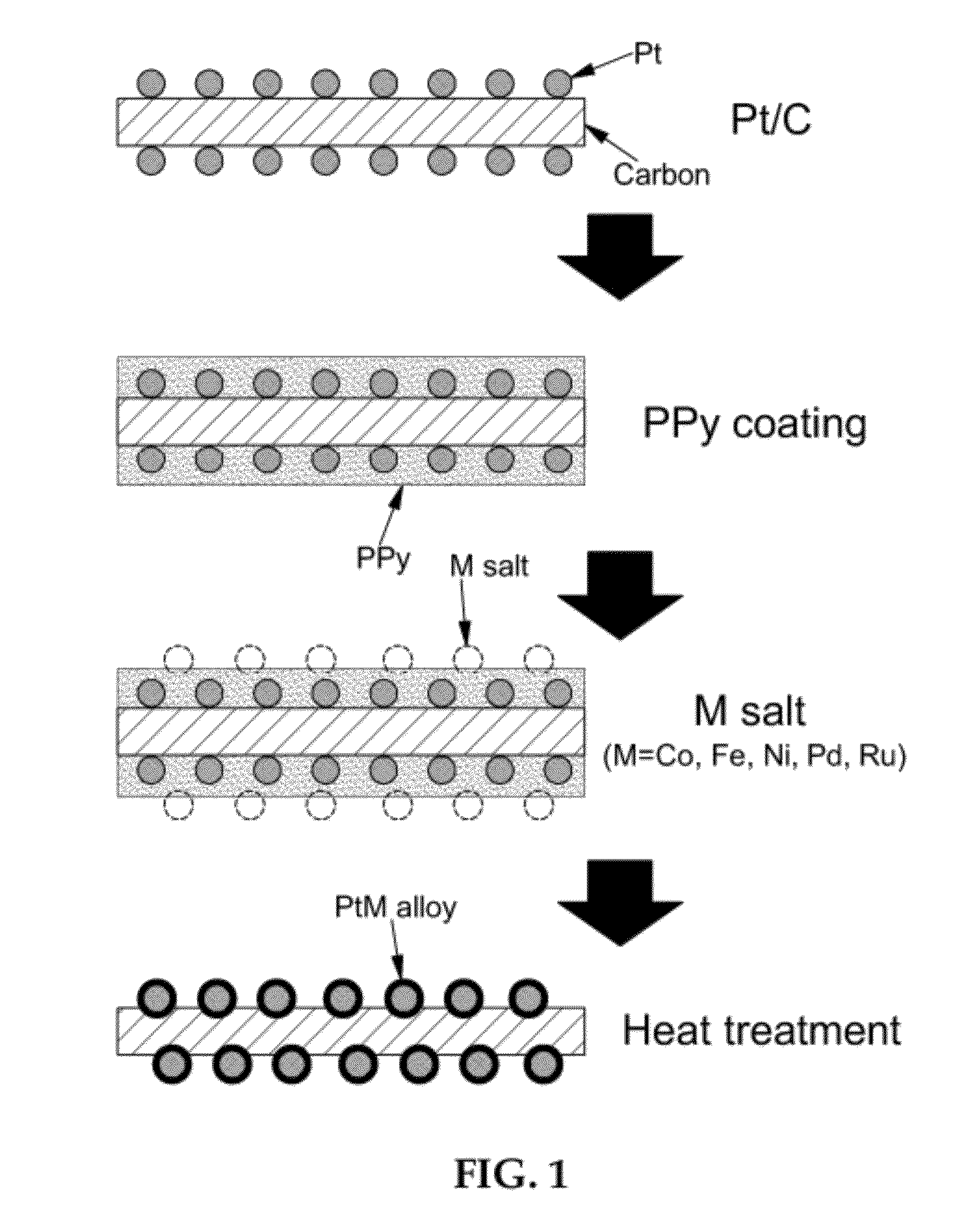

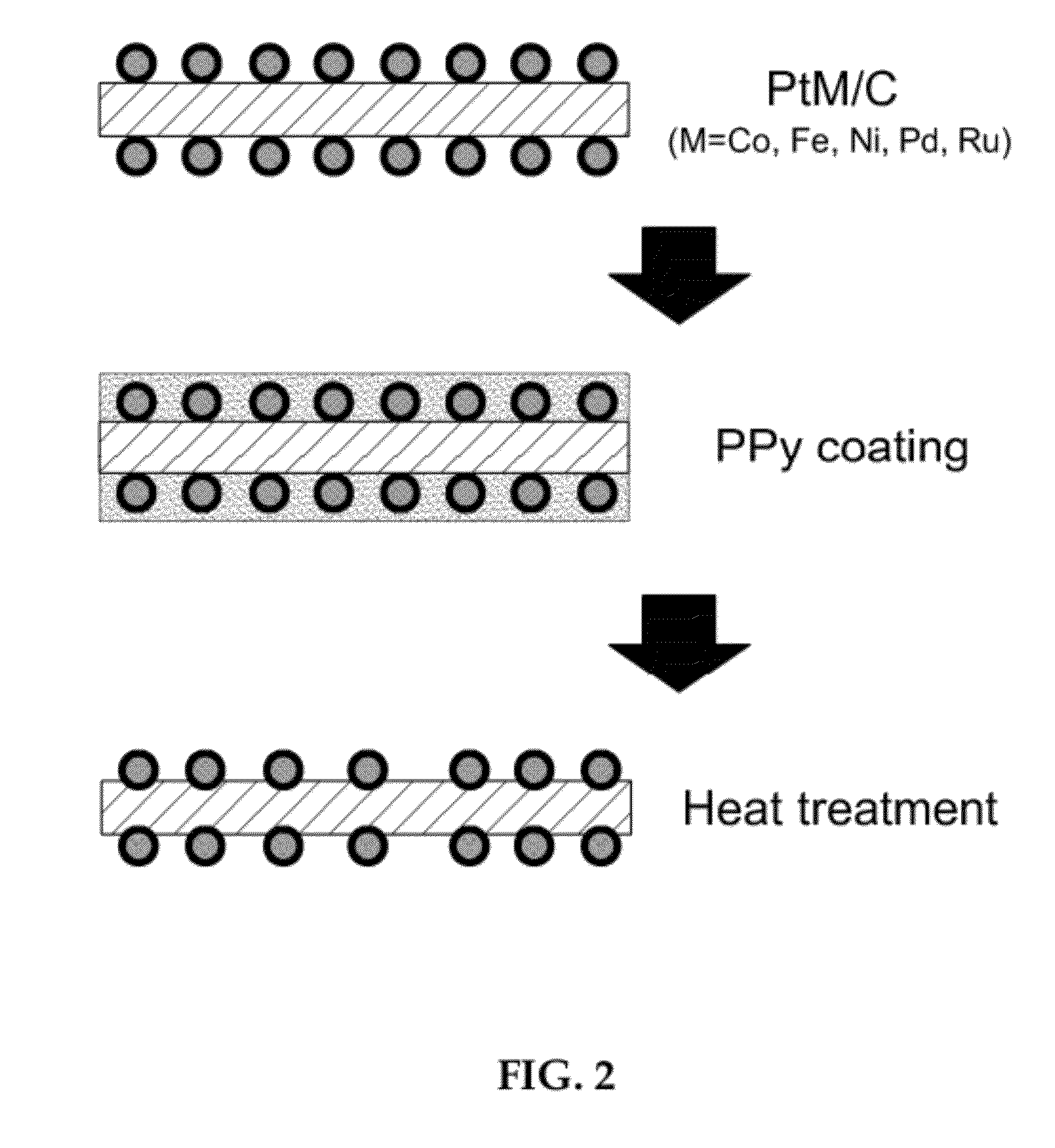

Preparing an alloy catalyst using conductive polymer coating

ActiveUS20120135137A1Improve concentrationReduced dissolving out of transition metalMaterial nanotechnologyCell electrodesDispersityConductive polymer

Techniques herein prepare an alloy catalyst using a protective conductive polymer coating. More particularly, an alloy catalyst is prepared by: preparing a platinum catalyst supported on carbon; coating the surface of the platinum catalyst with a conductive polymer; supporting a transition metal salt on the coated catalyst; and heat treating the catalyst on which the transition metal salt is supported. Also, an alloy catalyst may be prepared by: preparing a platinum-transition metal catalyst supported on carbon; coating the surface of the platinum-transition metal catalyst with a conductive polymer; and heat treating the coated catalyst. Accordingly an alloy catalyst with superior dispersity can be prepared by increasing the degree of alloying of the catalyst through heat treatment while preventing the increase of catalyst particle size through carbonization of the conductive polymer. The prepared catalyst may be useful, for example, for a fuel cell electrode.

Owner:HYUNDAI MOTOR CO LTD +2

Process for preparing modified amorphous nickel alloy catalyst

ActiveCN101199934AAvoid dissolution lossPrevent embeddingOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsAlloy catalystRare earth

Disclosed is a preparation method for modified noncrystalline nickel alloy catalyst, comprising processes of heating up the metallic nickel and the metallic aluminium into a melting state, preparing the nickel aluminium alloy by rapid quenching, and extraction and dealuminizing; the utility model is characterized in that the alloy got from the extraction and dealuminizing is washed to a PH value of 7 to 13 by the deionized water; and then the alloy is contacted with the salt solution of one or a plurality of metal promoters selected from the rare earth metal or the IIB,VIB,VIIB,VIII group metal; and calculated based on the weight of the metal nickel, the weight of the promoter metal used in the contact is less than 10 percent by weight. The metallic modified noncrystalline alloy prepared by the method has the advantages of high retention rate of the metal promoters, high hydrogenation activity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

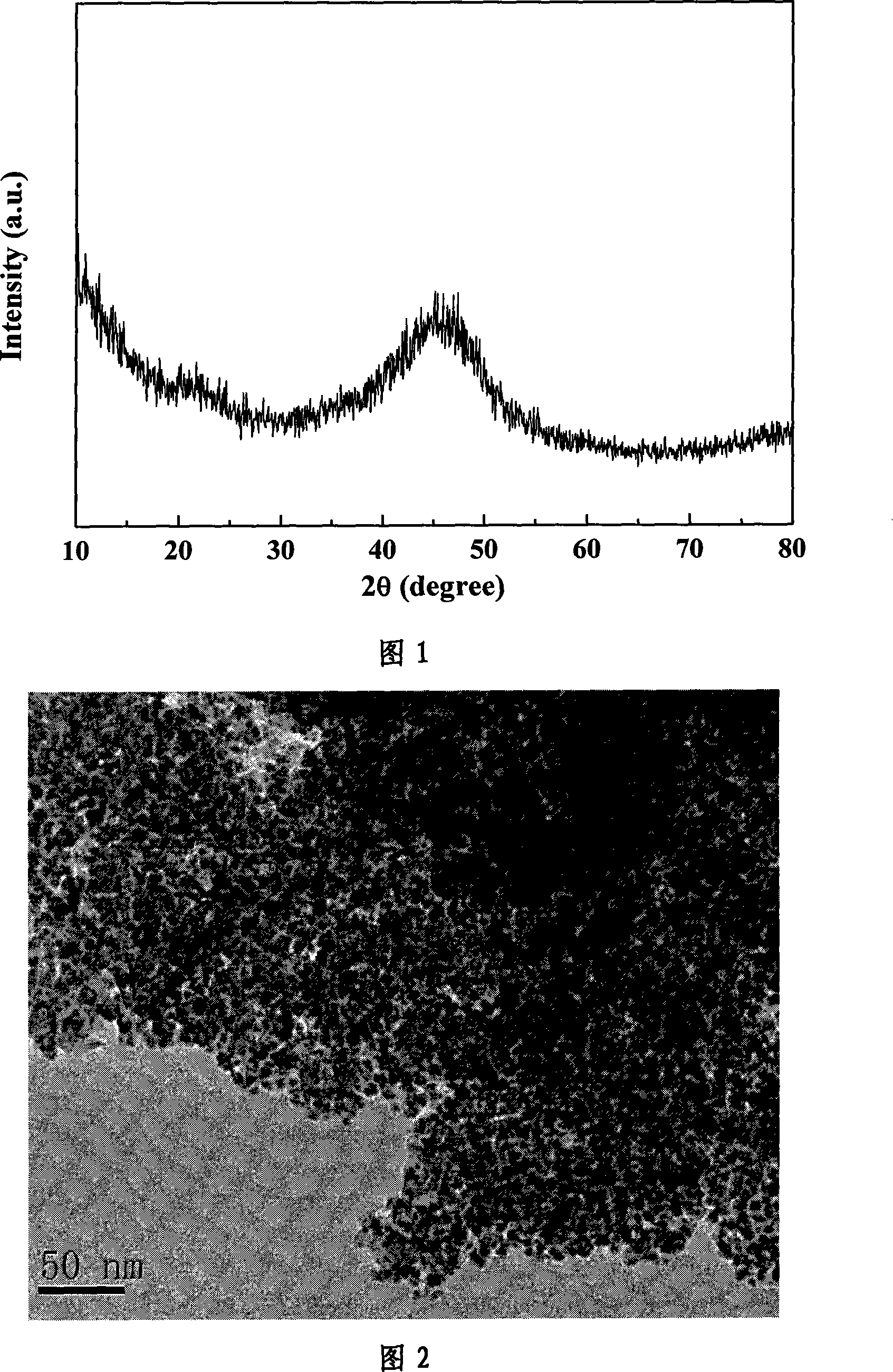

Aluminum oxide loaded PtCu monatomic alloy catalyst and preparation method and application thereof

ActiveCN108620092AHigh activityPt content decreasedHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDehydrogenation

The invention discloses an aluminum oxide loaded PtCu monatomic alloy catalyst and a preparation method and application thereof. The catalyst takes Al2O3 as a carrier, takes Cu as an auxiliary, and loads a small amount of active components Pt; the mass percent of Pt is 0.025%-0.15%, and the mass percent of Cu is 5%-20%; and during preparation, a co-impregnation method is used, the Al2O3 carrier isimpregnated in an aqueous solution of chloroplatinic acid and copper nitrate, the PtCu / Al2O3 catalyst is obtained after drying and roasting and high-temperature reduction, and the catalyst has high activity and high stability, and is low in price and low in toxicity. The catalyst is suitable for reaction for producing olefin by dehydrogenation through low alkane, and is particularly suitable forreaction for producing propylene by dehydrogenation through propane in a hydrogenation atmosphere, the dehydrogenation activity is quite high under the condition of high temperature, the selectivity of the propylene can reach 90% or above, the stability is good, the use amount of Pt is small, the utilization rate is high, and compared with an industrial Pt series catalyst, the aluminum oxide loaded PtCu monatomic alloy catalyst is cheaper.

Owner:TIANJIN UNIV

Amorphous skeletal-nickel hydrogenating catalyst for anthraquinone process of preparing hydrogen peroxide and its prepn

InactiveCN1421383AHigh activityHigh selectivityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsAnthranilAlloy catalyst

The present invention belongs to the field of chemical technology and is especially one catalyst for anthraquinone hydrogenation process of preparing hydrogen peroxide and its preparation. The catalyst is obtained with some alloy and through active treatment with alkali solution and the alloy consists of Ni, Al and metal additive including one or several of Cr, Mo, W, Fe, Co, Cu and Zn. The catalyst is one kind of amorphous skeleton alloy catalyst prepared through high temperature melting of metal components, quenching stress to obtain alloy strip or scaly alloy, grinding, sieving and activation in alkali solution. Compared with traditional Raney Ni catalyst, the said catalyst has high anthraquinone hydrogenation activity and high selectivity.

Owner:FUDAN UNIV

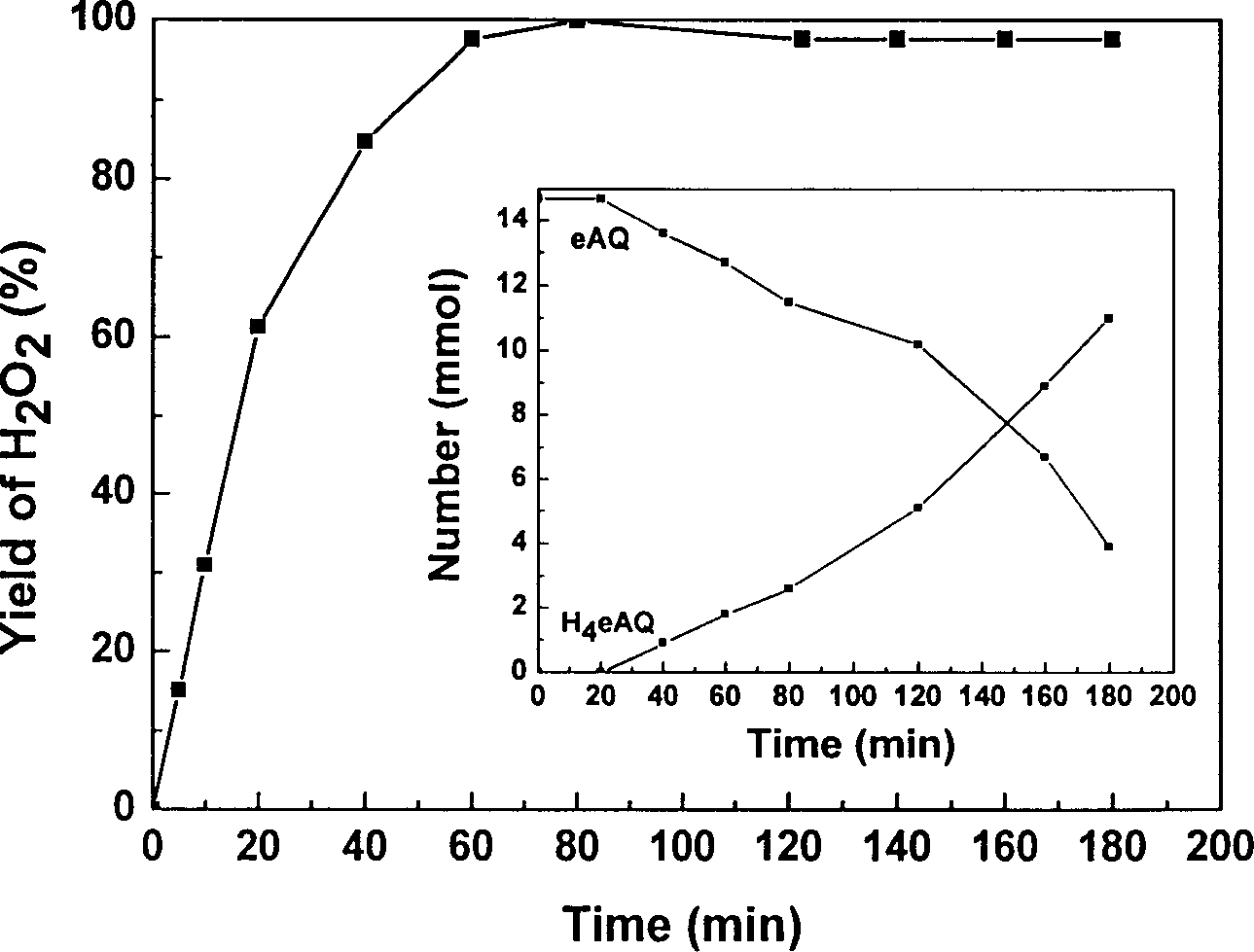

A non-crystal alloy catalyst as well as its preparing method and purpose

InactiveCN101157034AGood catalyticParticle size controllableOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsNitro compoundReaction rate

The invention discloses amorphous alloy catalyst with controllable grain size being smaller than 50 nm and uniform grain size distribution, and adds a new variety for the prior amorphous alloy catalyst field. The activity ratio surface area of the amorphous alloy catalyst is 10 to 50 m<2> / g, the particle diameter can be controlled in the range of 2 to 50 nm, and the grain size distribution is uniform. The invention realizes the amorphous alloy catalyst with the grain size being smaller than 50 nm and achieves the controllable grain size and the uniform grain size distribution through the preparation method for controlling the reduction reaction rate by oil in water microemulsion. The amorphous alloy catalyst of the invention can be taken as hydrogenation catalyst containing unsaturated functional group compounds such as alkene, alkyne, arene, nitrile, nitro compound, carbonyl compound, etc., not only the catalytic performance is superior to the catalytic performance of the ordinary amorphous alloy catalyst, but also the catalytic performance can be controlled; the life of the catalyst is longer than the life of the ordinary amorphous alloy catalyst, and the catalyst can be recovered and reused time after time.

Owner:SHANGHAI NORMAL UNIVERSITY

Platinum alloy electrocatalyst with enhanced resistance to anion poisoning for low and medium temperature fuel cells

ActiveUS20110207019A1Improve electrochemical performanceMaterial nanotechnologyActive material electrodesFuel cellsAlloy catalyst

A platinum alloy catalyst is made by a microemulsion method. The resulting catalyst has superior properties for use in low and medium temperature fuel cells.

Owner:NORTHEASTERN UNIV

Method for preparing NiB non-crystalline alloy catalyst with the aid of microwave

InactiveCN1792440ACluster size controllableGood dispersionCatalyst carriersHydrocarbon by hydrogenationChemical platingIron(II) chloride

A microwave aided process for preparing the catalyst of non-crystalline NiB alloy suitable for catalytic hydro-reaction with high catalytic active features that the chemical reduction and chemical plating in microwave field is used, KBH4 is used as reducer, its primary salt is chosen from nickel sulfate, nickel acetate, etc, its secondary salt is chosen from cobalt chloride, iron chloride, etc, its carrier is chosen from oxide, molecular sieve, etc, its solvent is chosen from water, tetrahydrofuran, etc and the complex agent, stabilizer and additive is used.

Owner:NANKAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com