Patents

Literature

33 results about "Screen and treat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

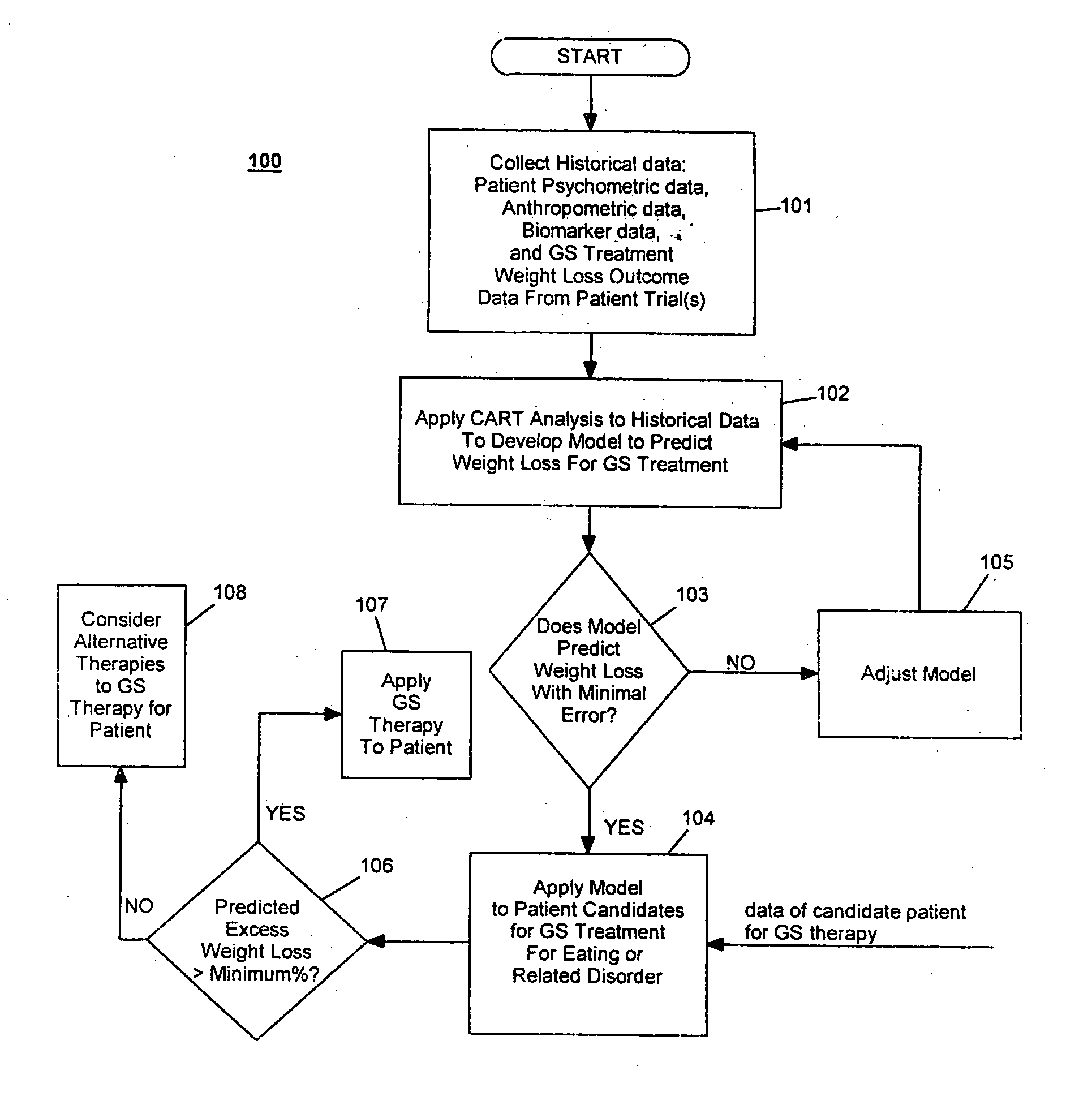

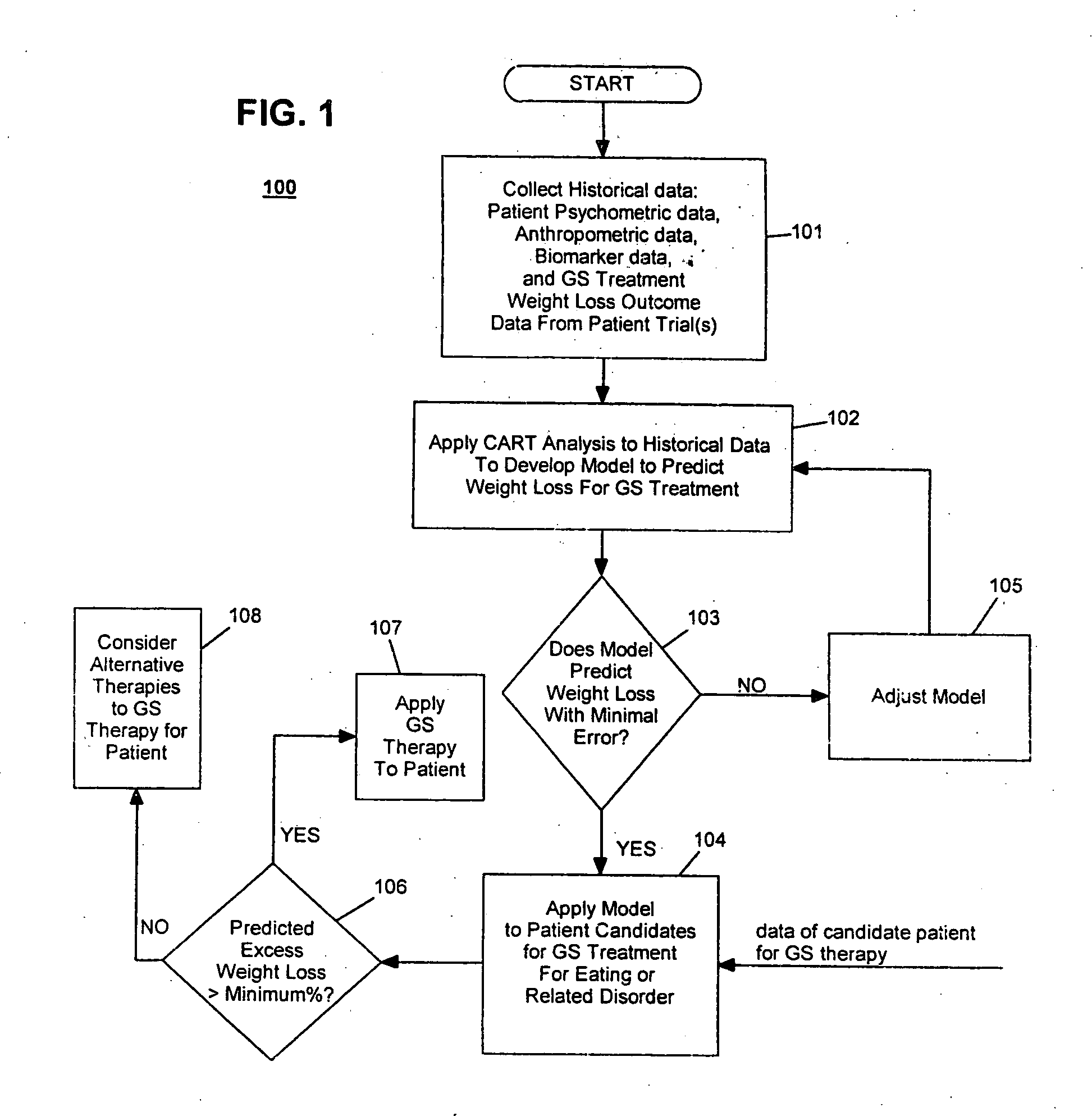

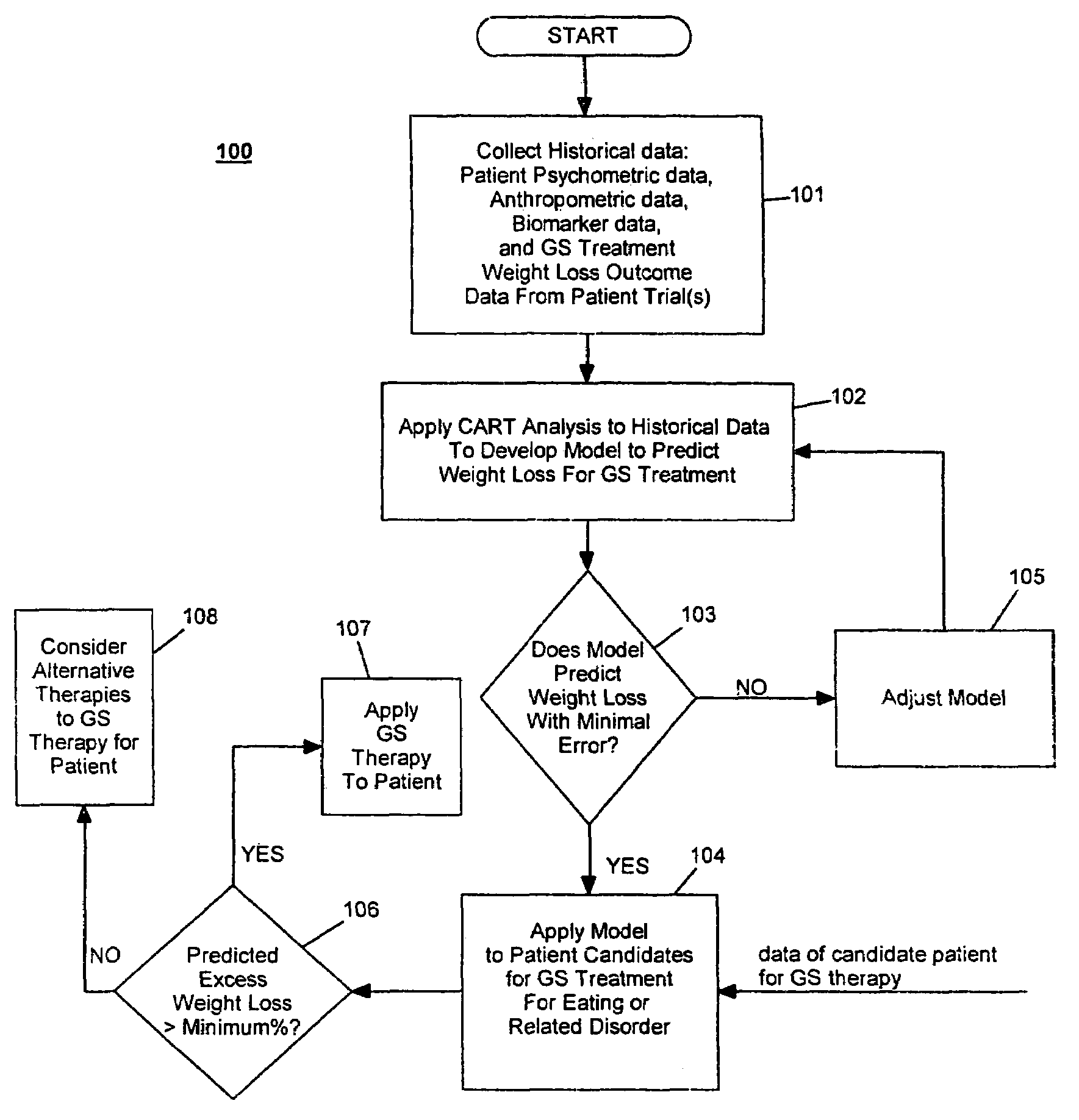

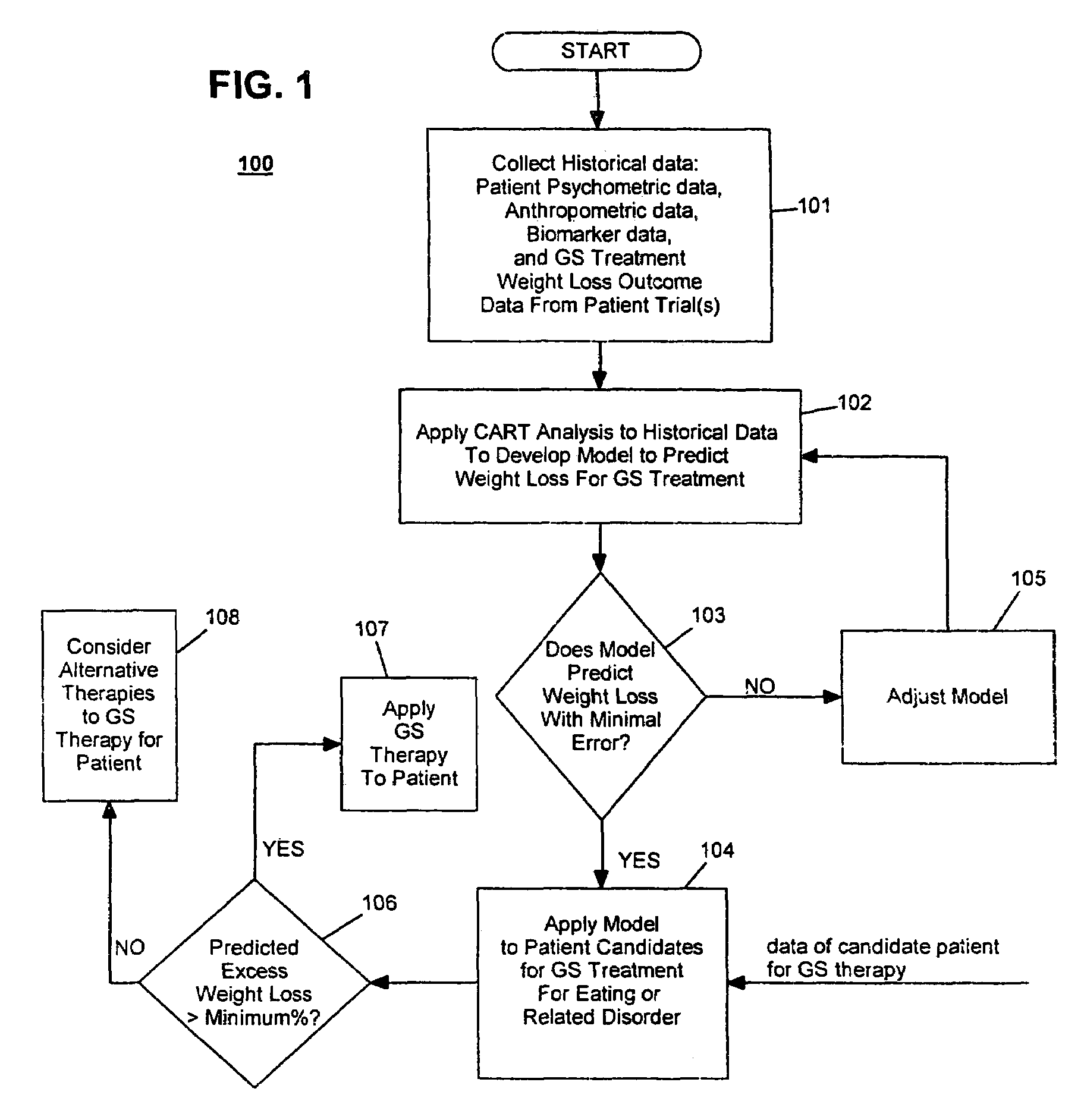

Method for screening and treating patients at risk of medical disorders

InactiveUS20050080462A1Reduced health costAccurate predictionMedical simulationElectrotherapyMedical disorderMorbid obesity

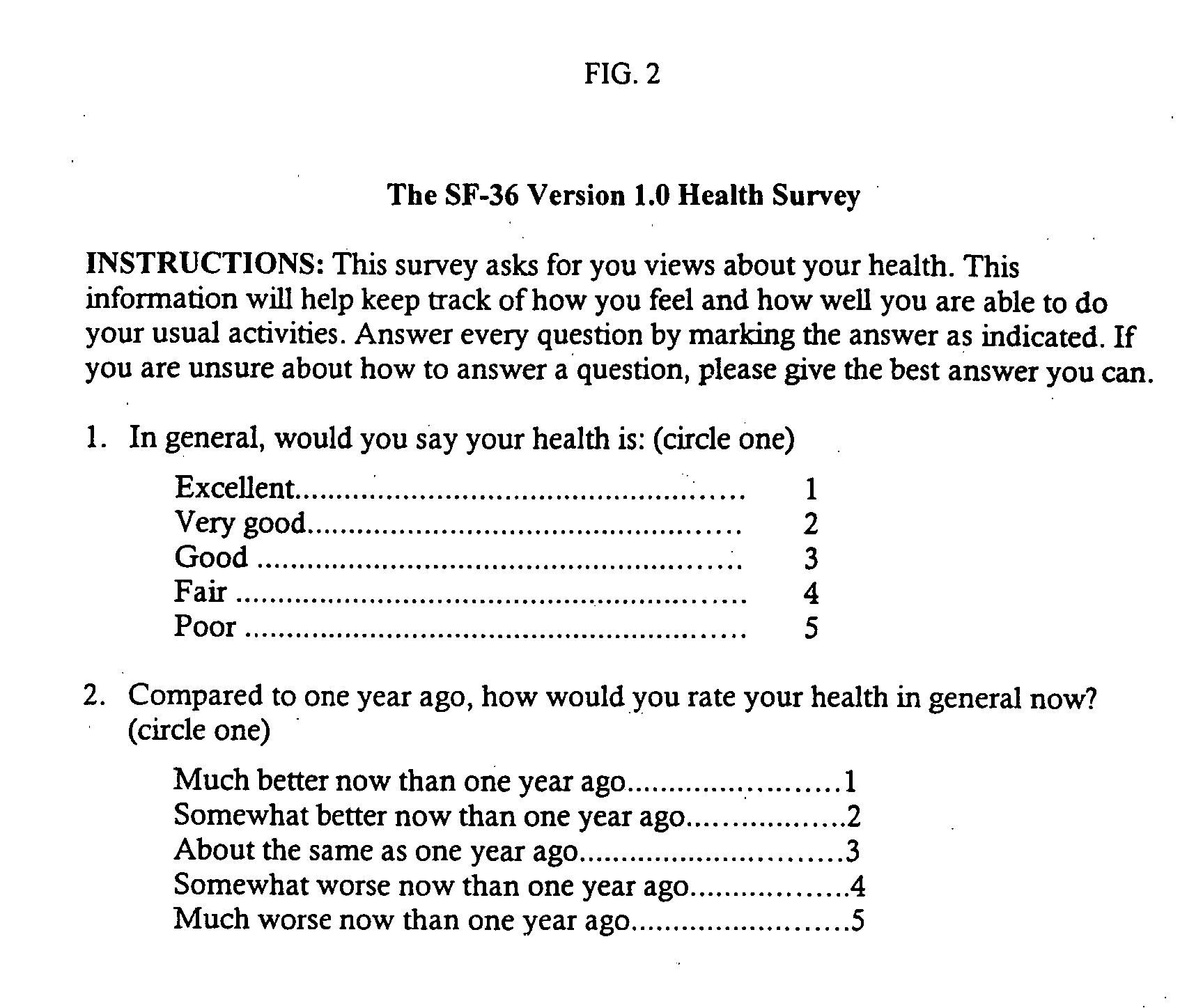

Method for screening patients to predict which patients at risk of a medical disorder, such as morbid obesity, gastrointestinal problems, or gastroesophageal problems, will be responders, and conversely, which patients will not, to achieve a favorable outcome from therapy for that disorder. This method supports an intervention strategy for patients having weight or gastrointestinal problems that will cut health costs. It enables patients and care-givers alike to more efficiently use their time, efforts and resources by enabling an early selection of an appropriate treatment modality for a given patient. Its application also extends to other implantable medical devices and therapies using them.

Owner:TRANSNEURONIX INC

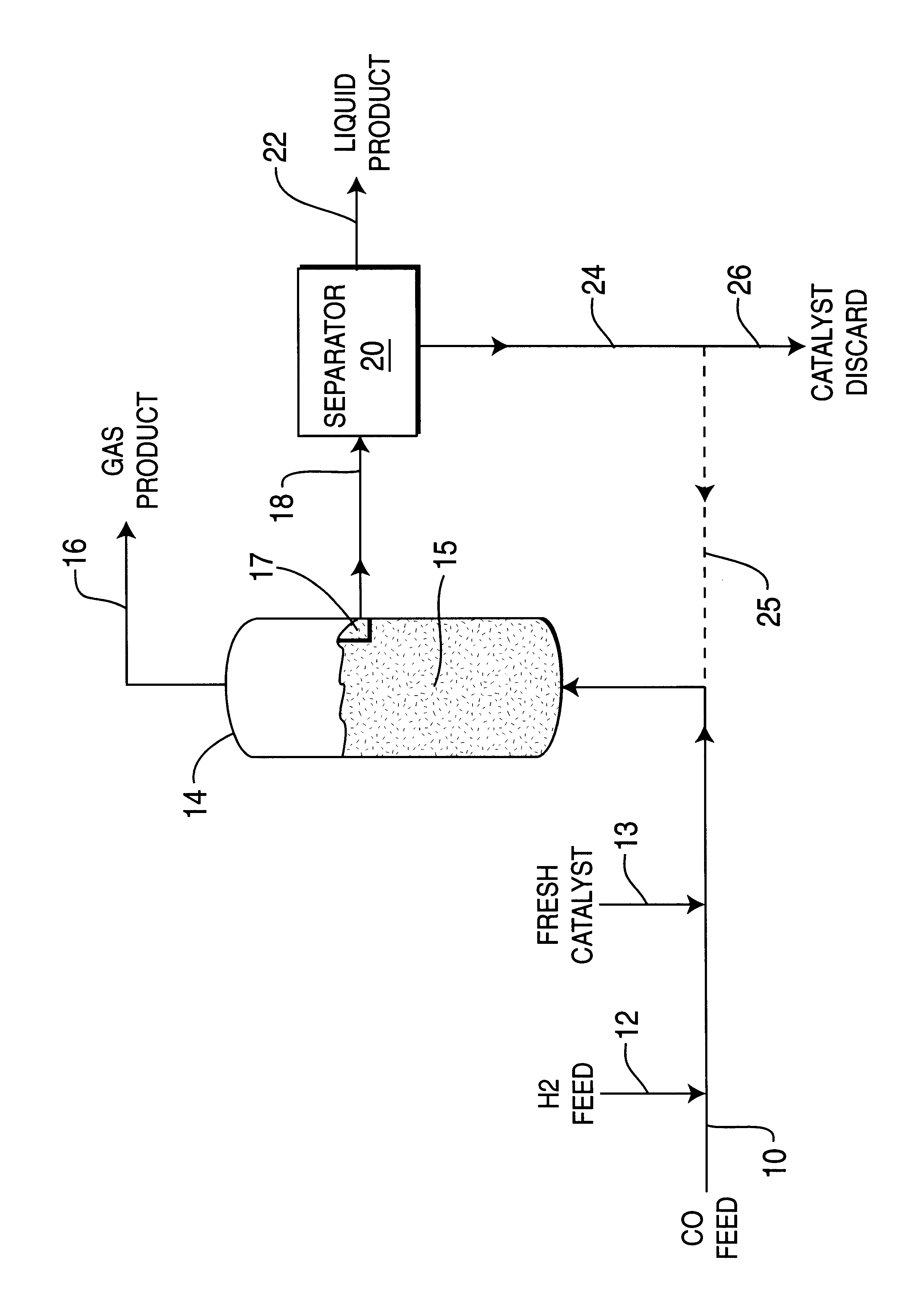

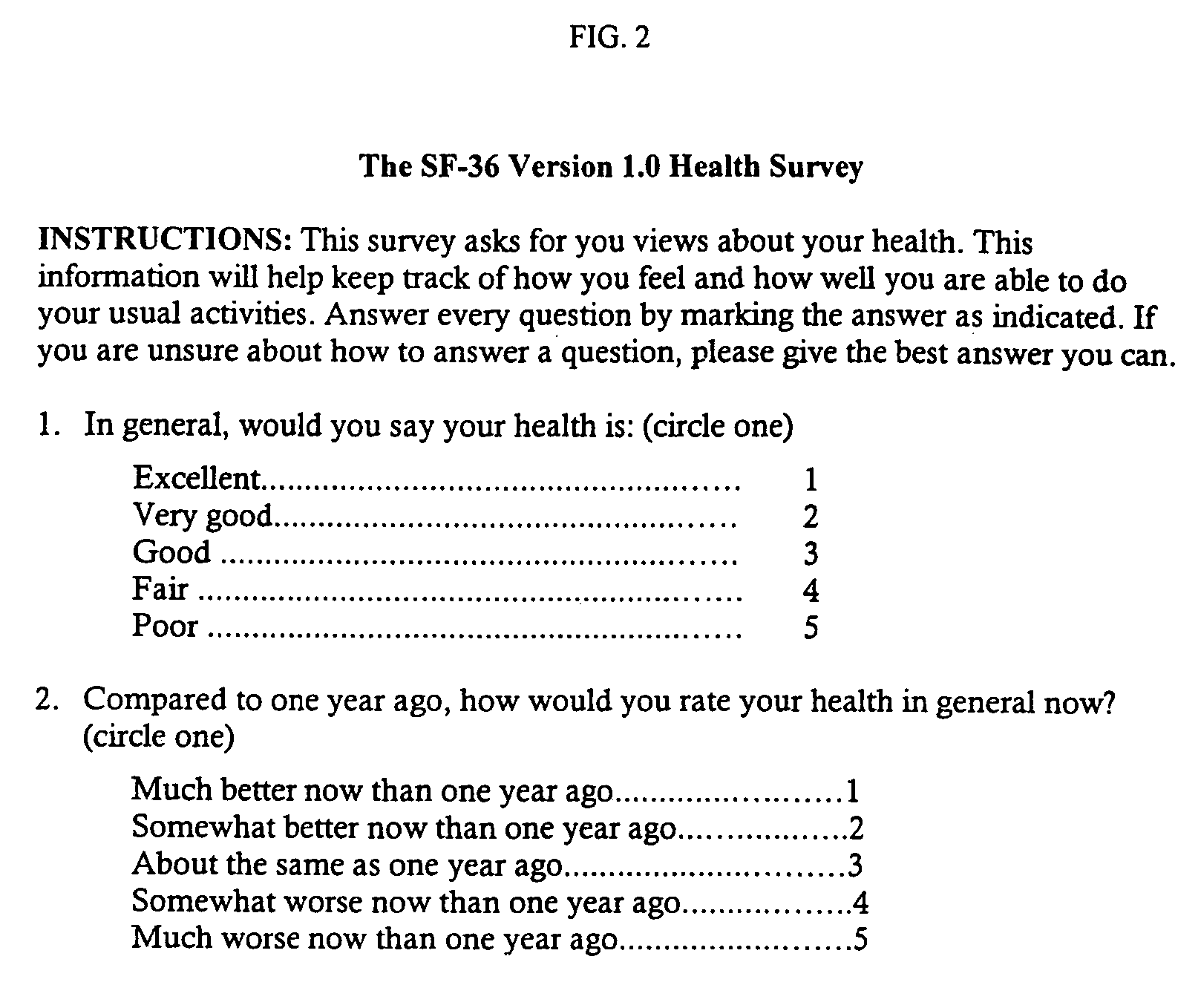

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS6277895B1High particle strengthGood attristion resistanceHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size, 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy pulverized particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen and to provide the smaller size skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-350° C. temperature, 0.5-3.0 mPa pressure and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:INST OF COAL CHEM ICCCHINESE ACADEMY OF SCI +1

Method for screening and treating patients at risk of medical disorders

InactiveUS7194301B2Timely useAccurate predictionMedical simulationMedical data miningMedical disorderTreatment modality

Owner:TRANSNEURONIX INC

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS20020052423A1Good particle strength and attrition resistanceHigh yieldHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size (62-1000 micron), 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous metal powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % initial iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy precursor particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen so as to provide smaller sized skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-500° C. temperature, 0.5-5.0 mPa pressure, and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:HYDROCARBON TECH

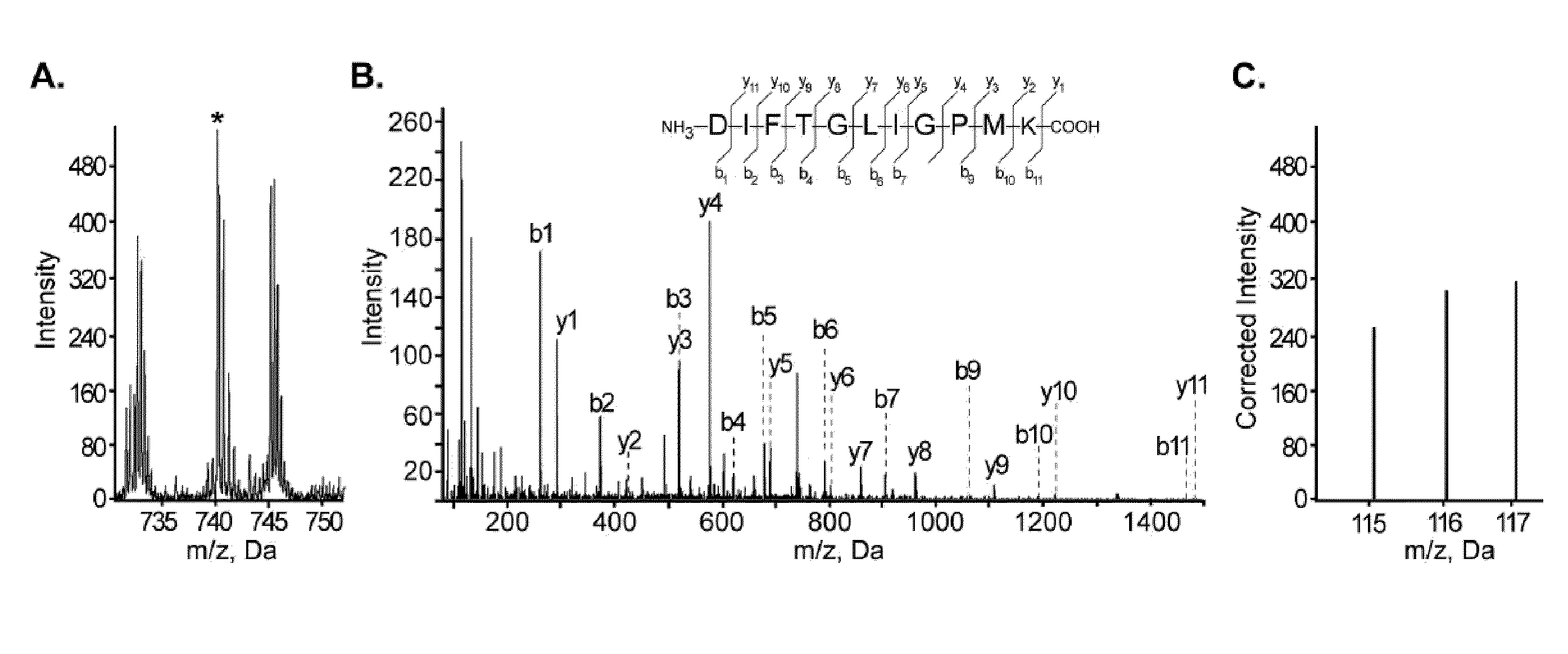

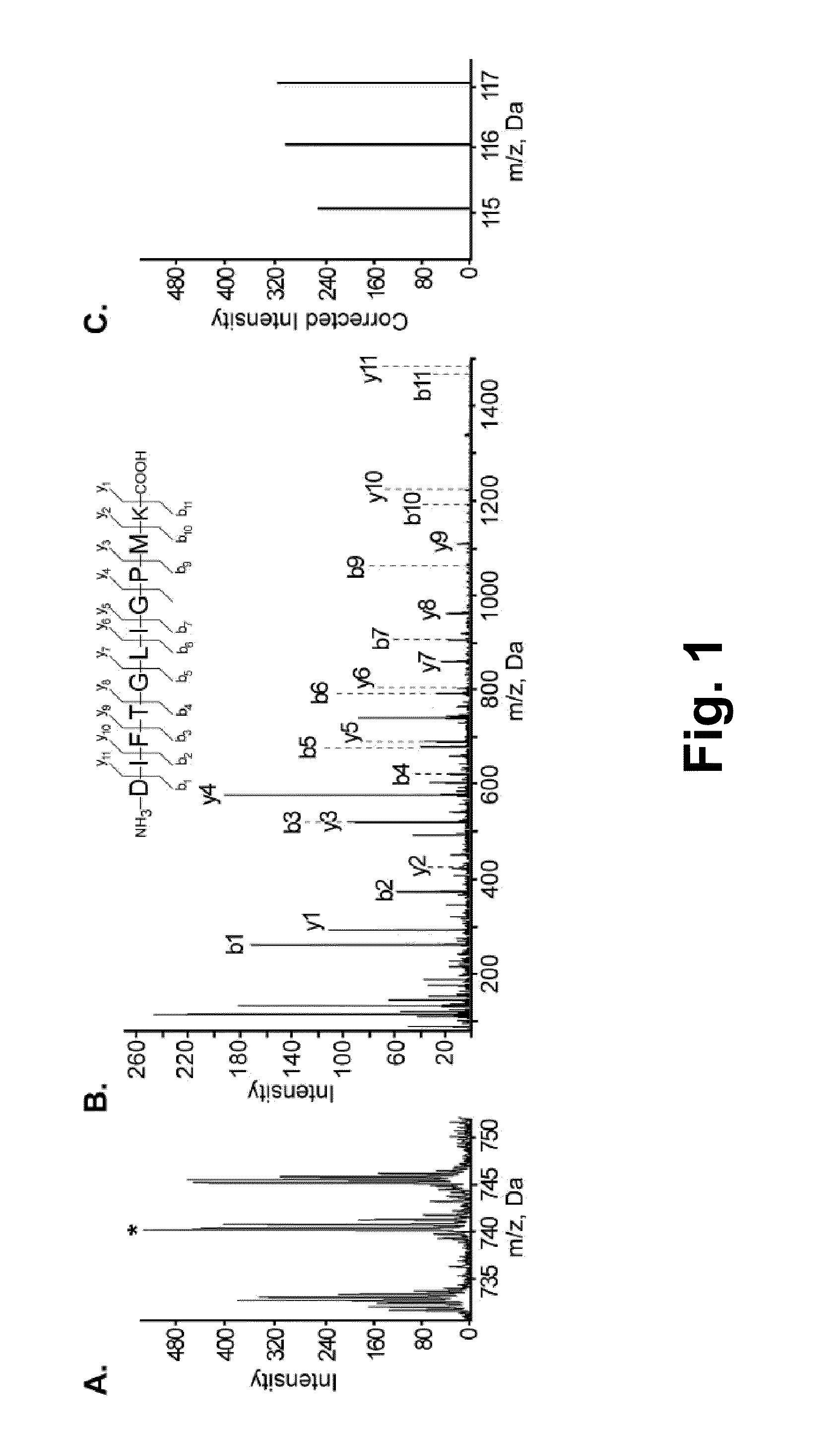

Method for Identifying Mammals at Risk for Elevated intracranial Pressure

InactiveUS20100312139A1Increased riskLower Level RequirementsMicrobiological testing/measurementBiological material analysisMammalSerum ceruloplasmin

Disclosed are methods of diagnosing, screening and treating individuals at risk of elevated intracranial pressure based on detecting a transient decrease in serum ceruloplasmin and / or serum copper levels in the individual soon after occurrence of a head injury. This early drop in ceruloplasmin or copper level indicates an impending, potentially life threatening, elevation in the individual's intracranial pressure. Also disclosed are diagnostic applications and processes for identifying and producing diagnostic and prognostic assays useful for predicting elevated intracranial pressure, and test kits for performing such tests.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

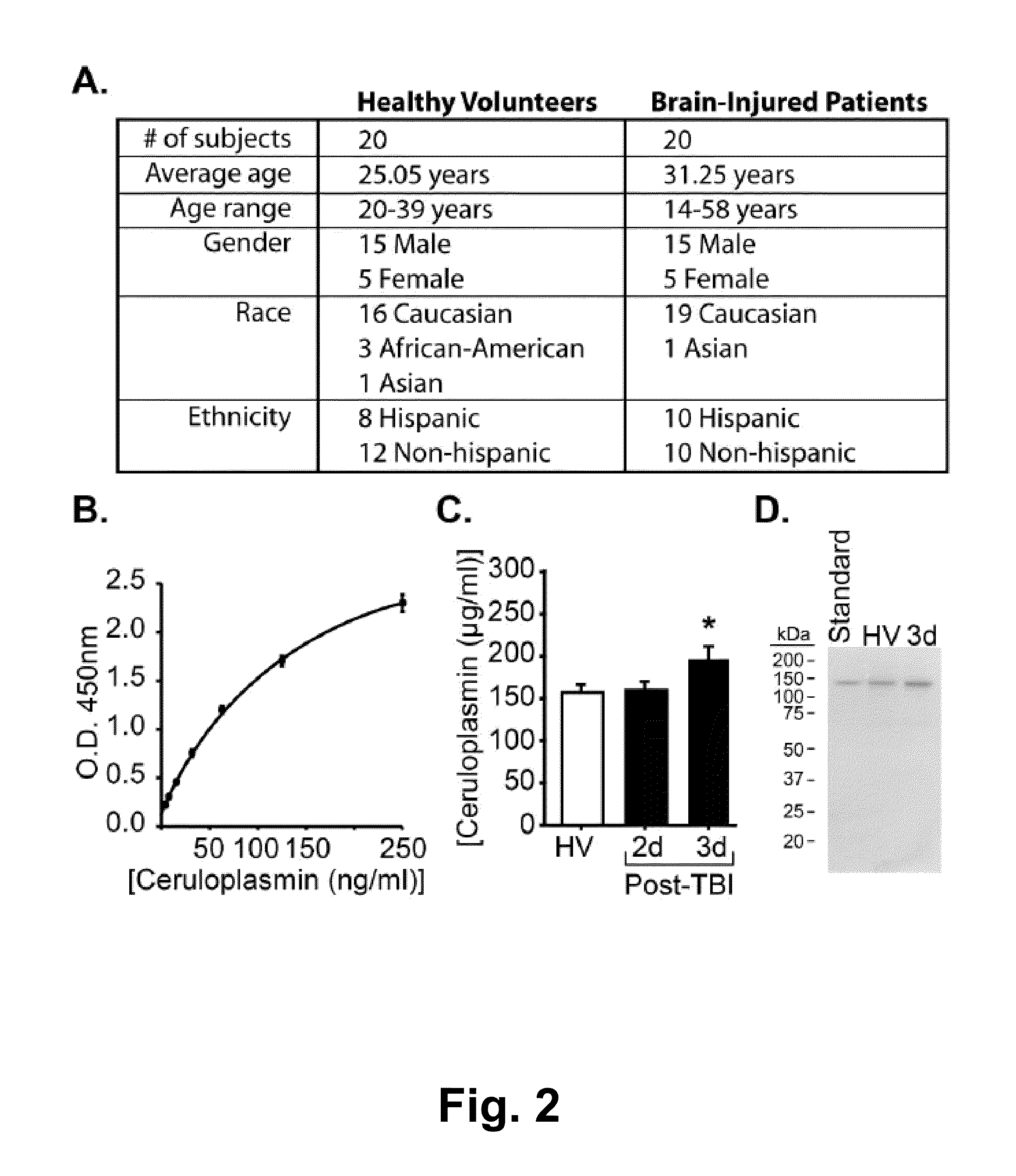

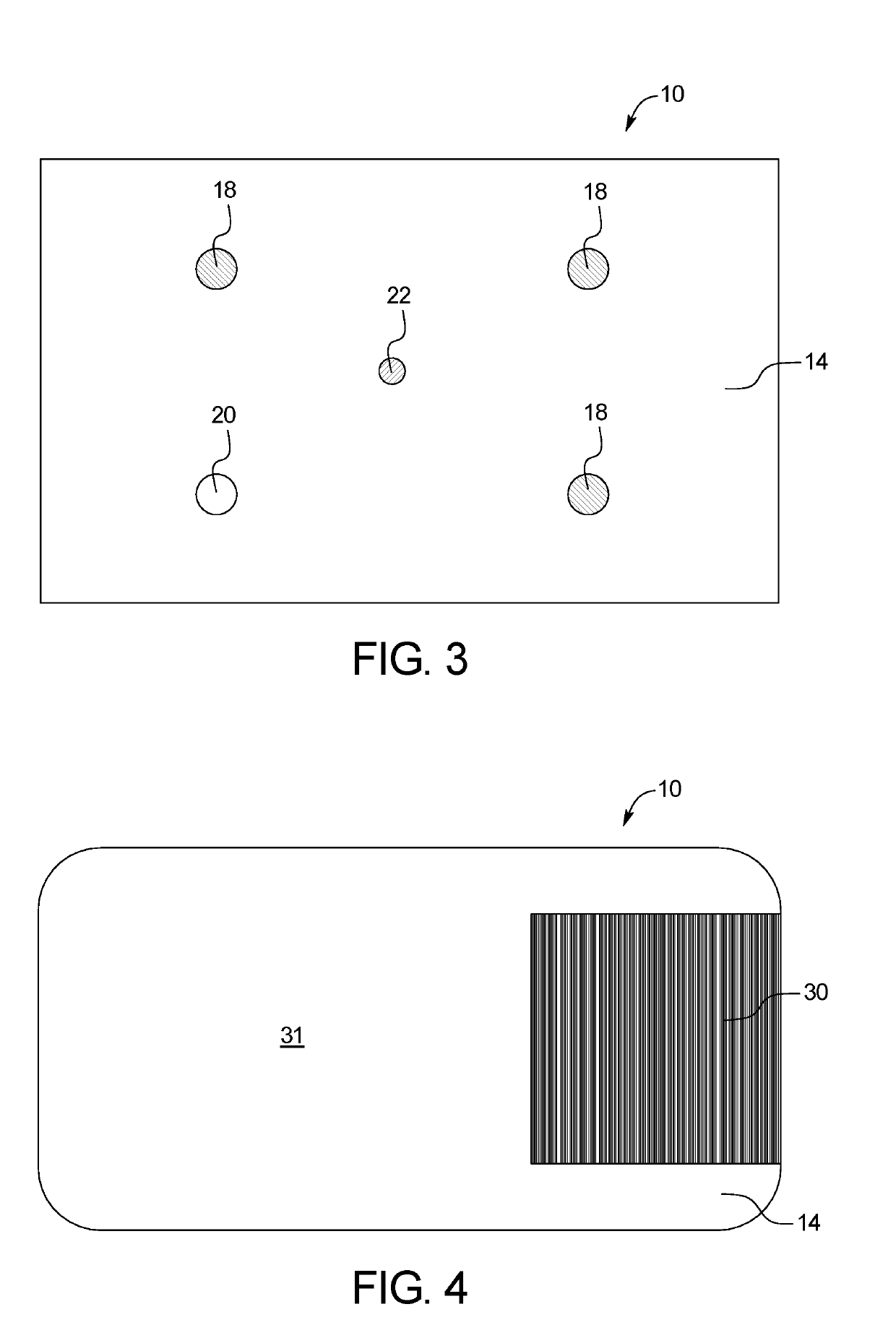

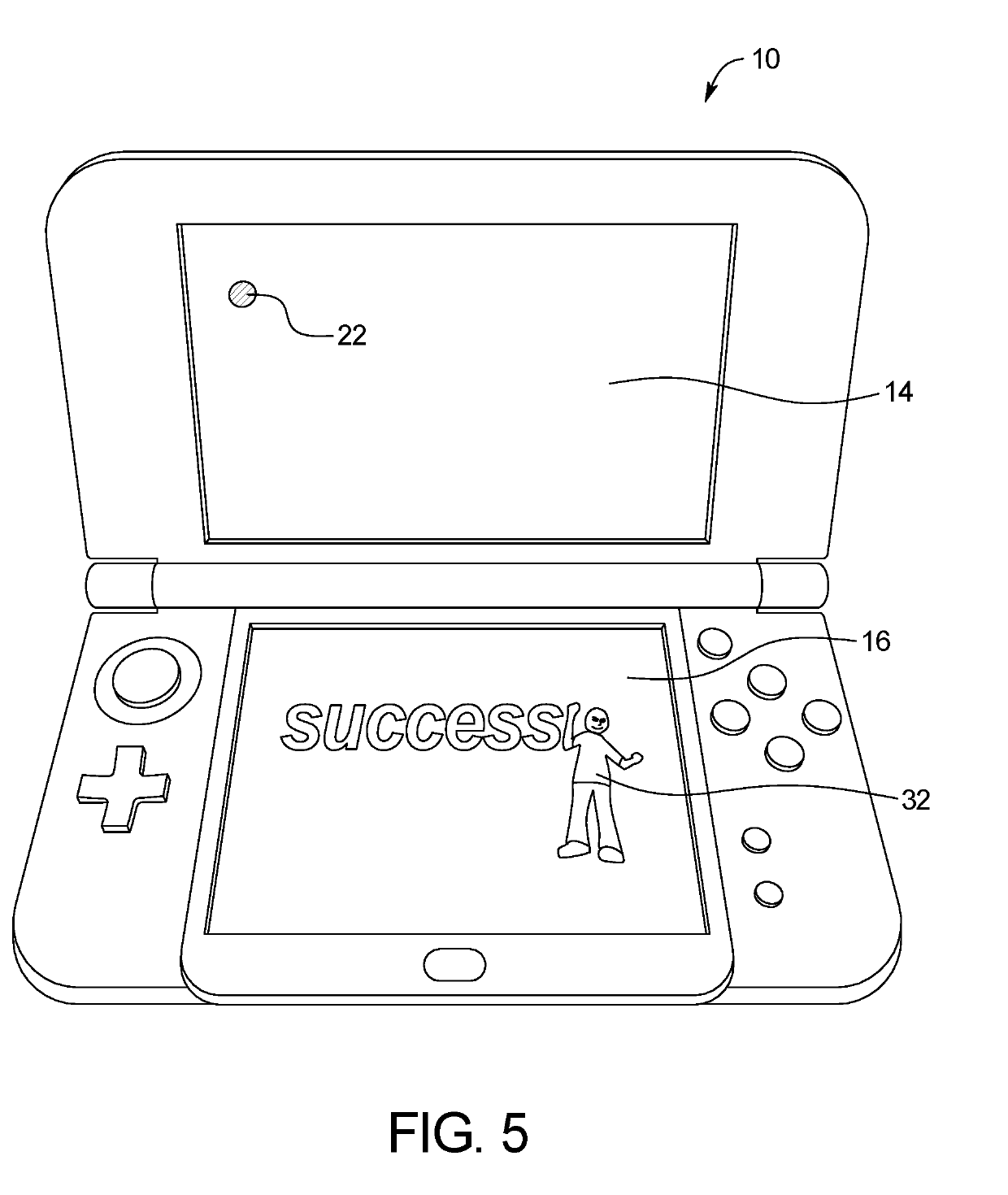

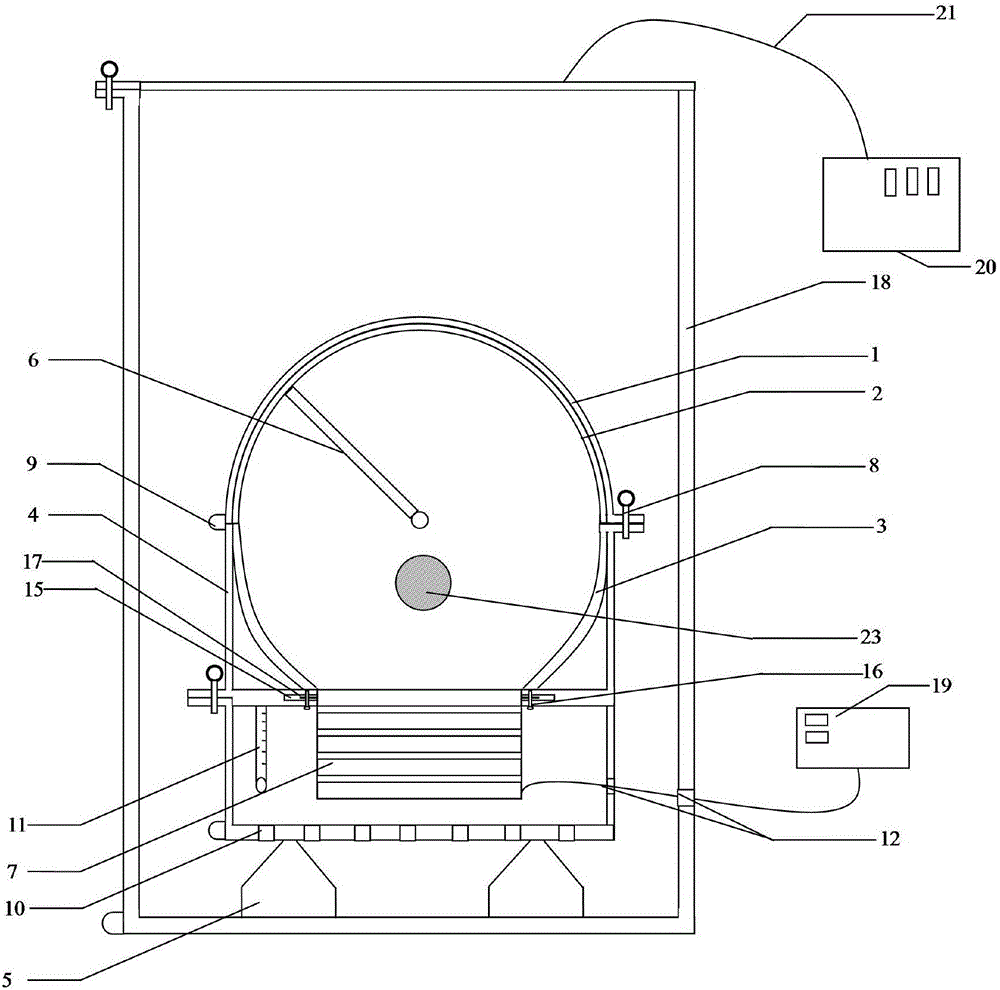

Systems and Methods for Eye Evaluation and Treatment

ActiveUS20190125180A1Diagnosing and treating eye conditionsEye diagnosticsUses eyeglassesTherapy vision

The present disclosure provides a gaming system including an application that can be implemented using a dynamic testing game, wherein the system does not require glasses, goggles, or any other headwear. The system enables a test subject to be screened and treated for vision dysfunctions while engaging with a dynamic video game.

Owner:ARNOLD ROBERT WENDELL +1

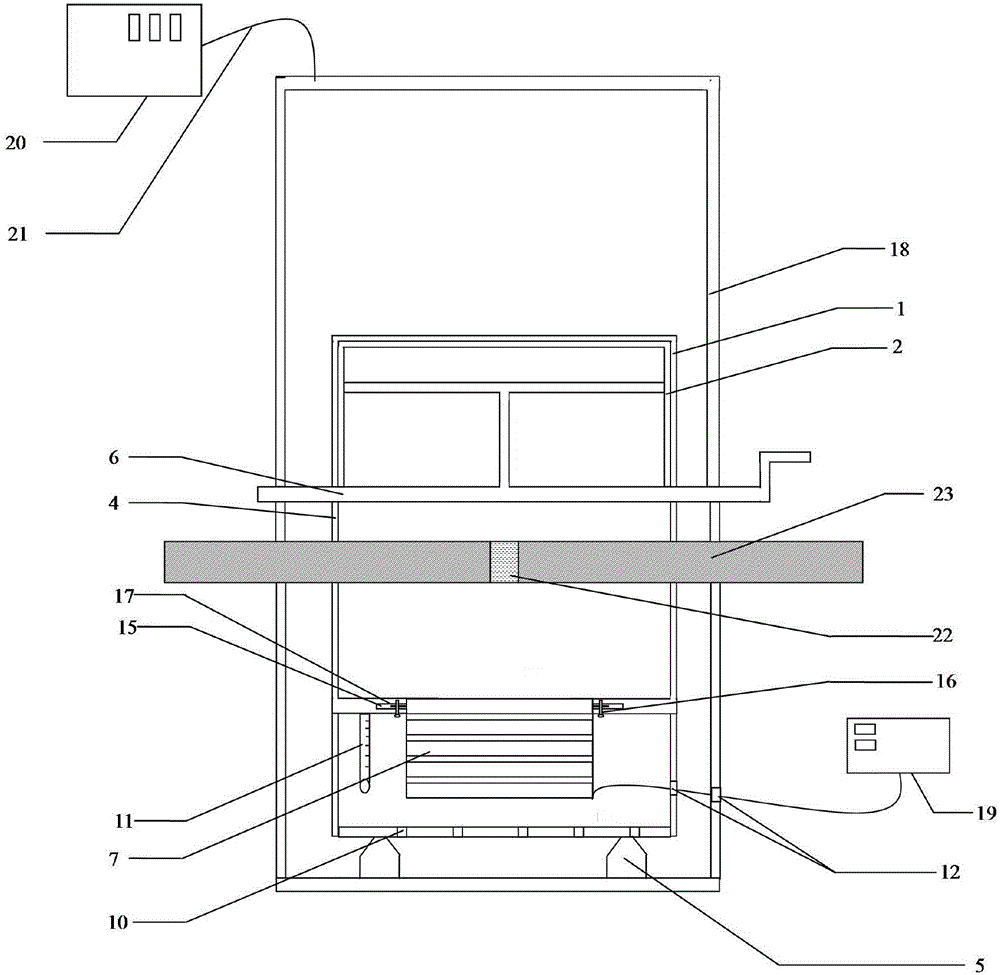

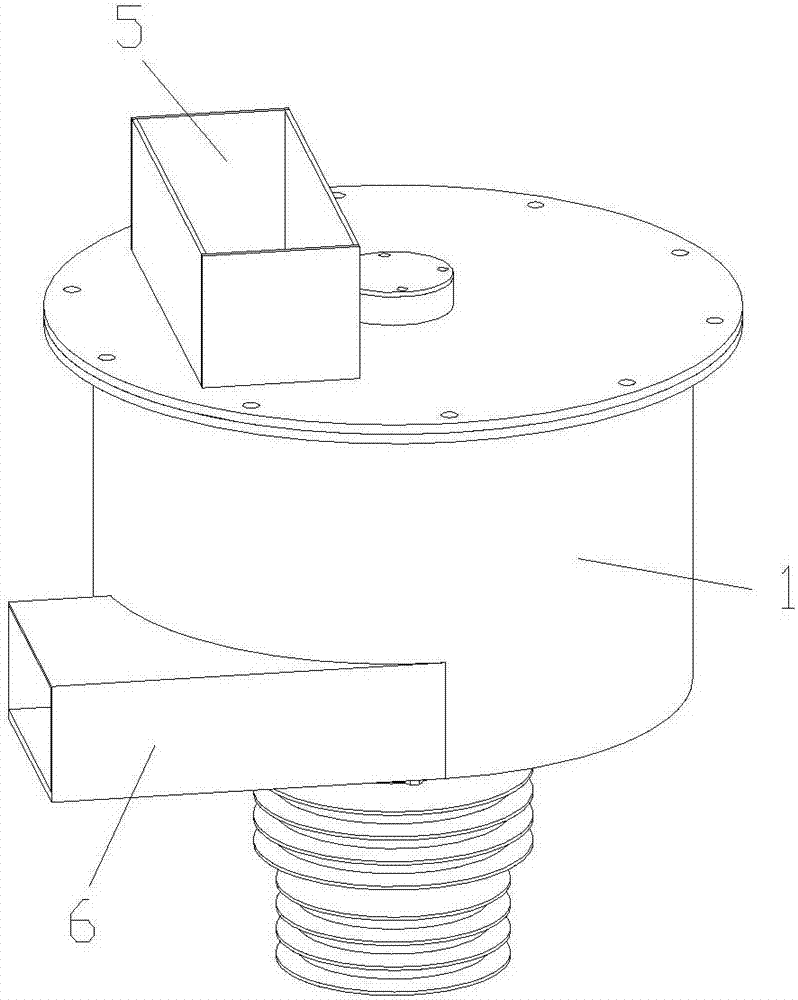

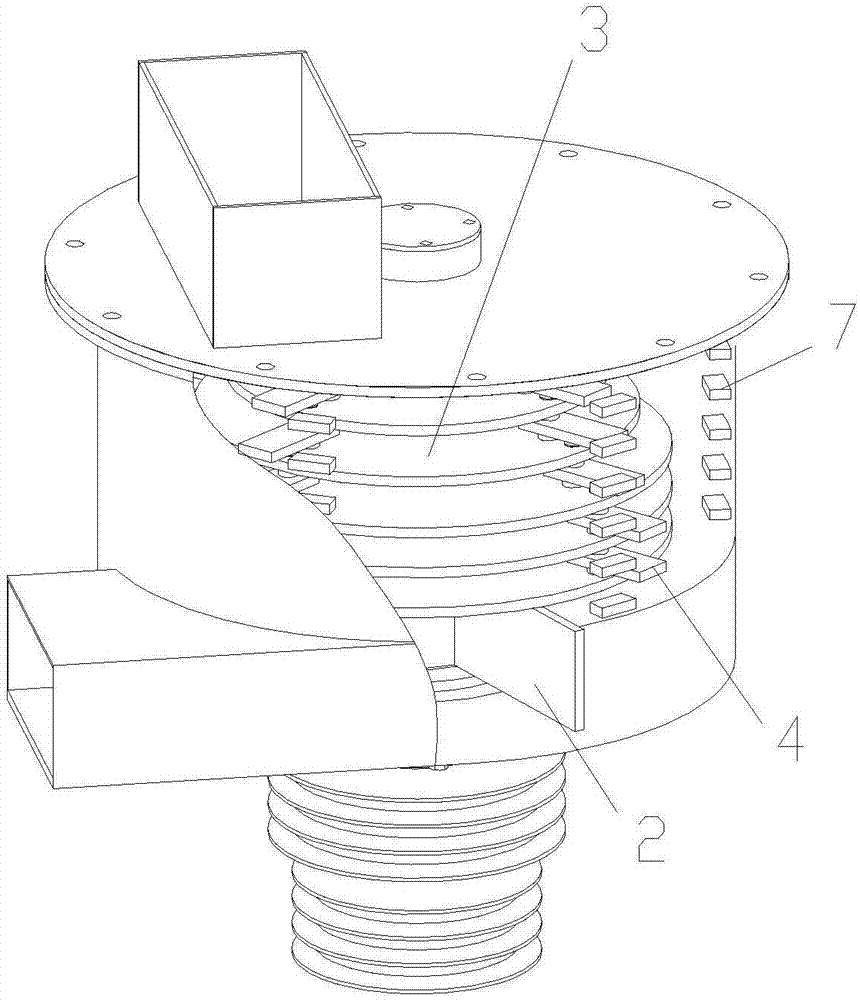

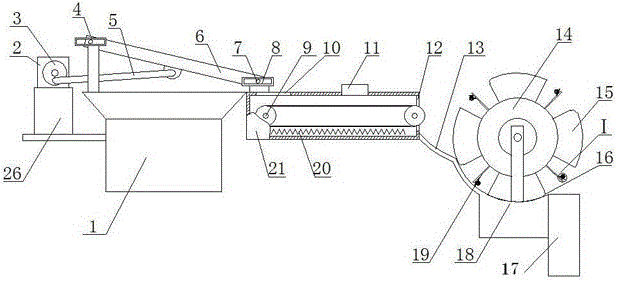

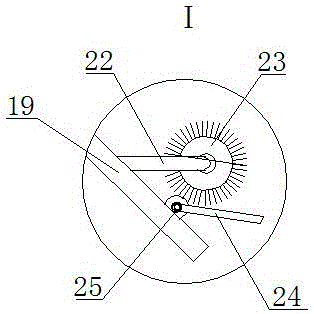

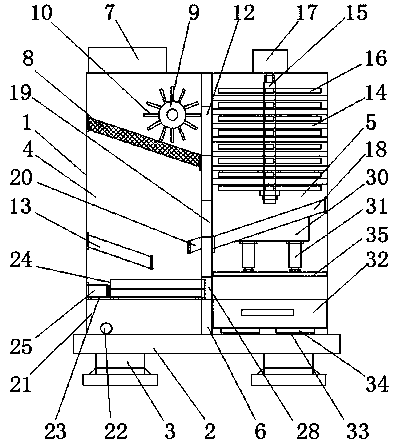

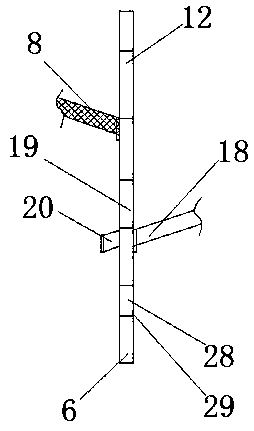

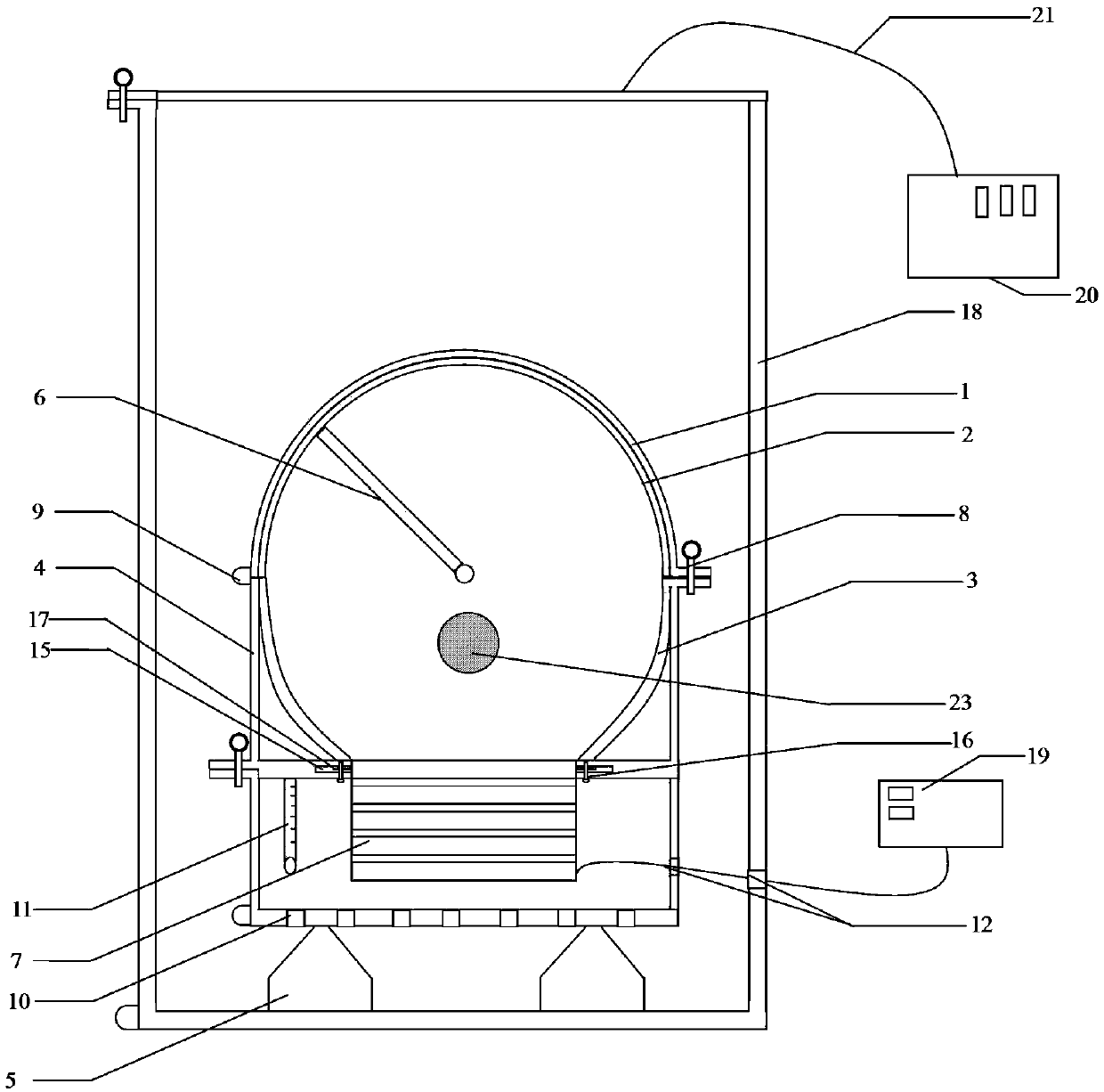

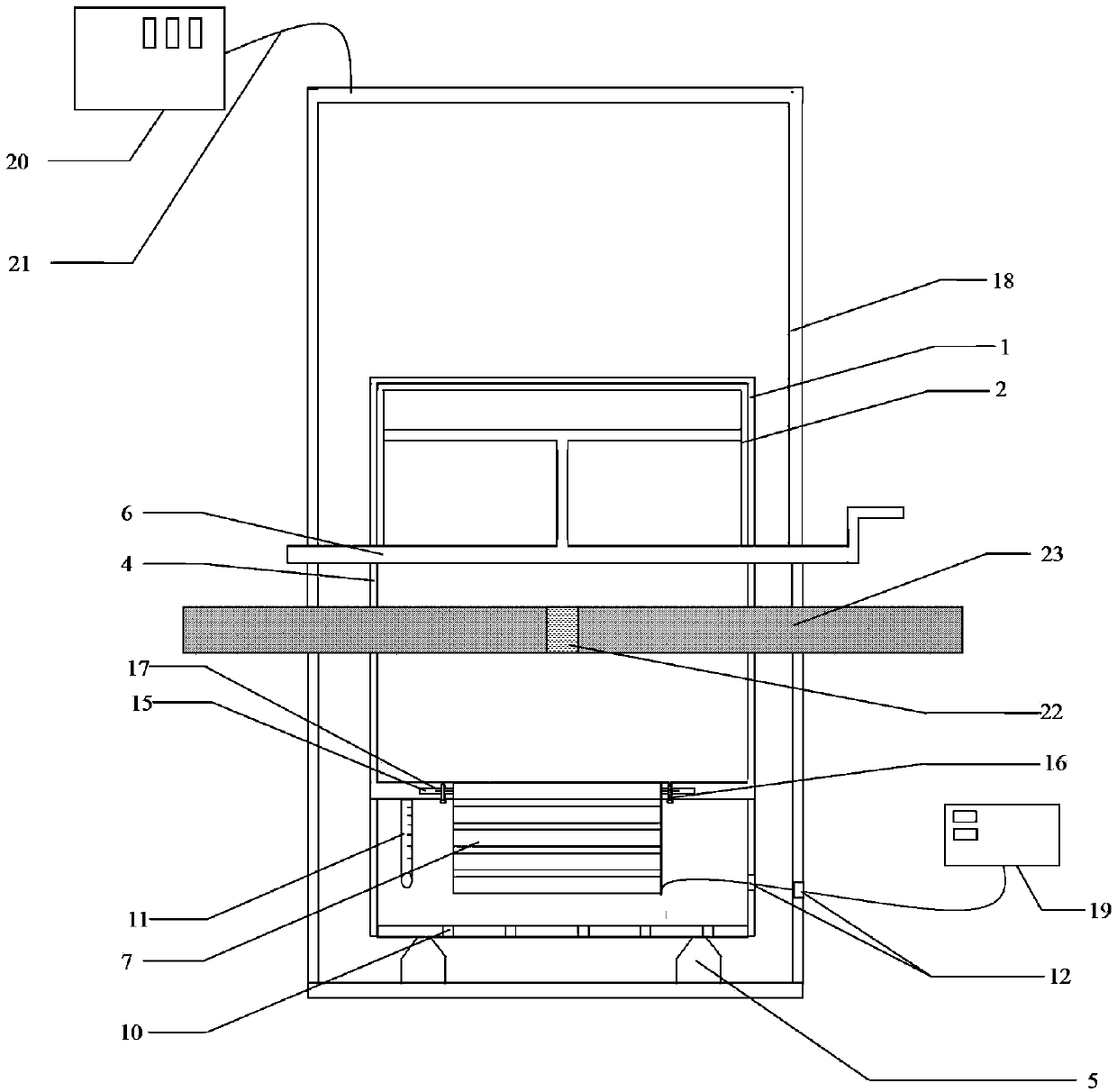

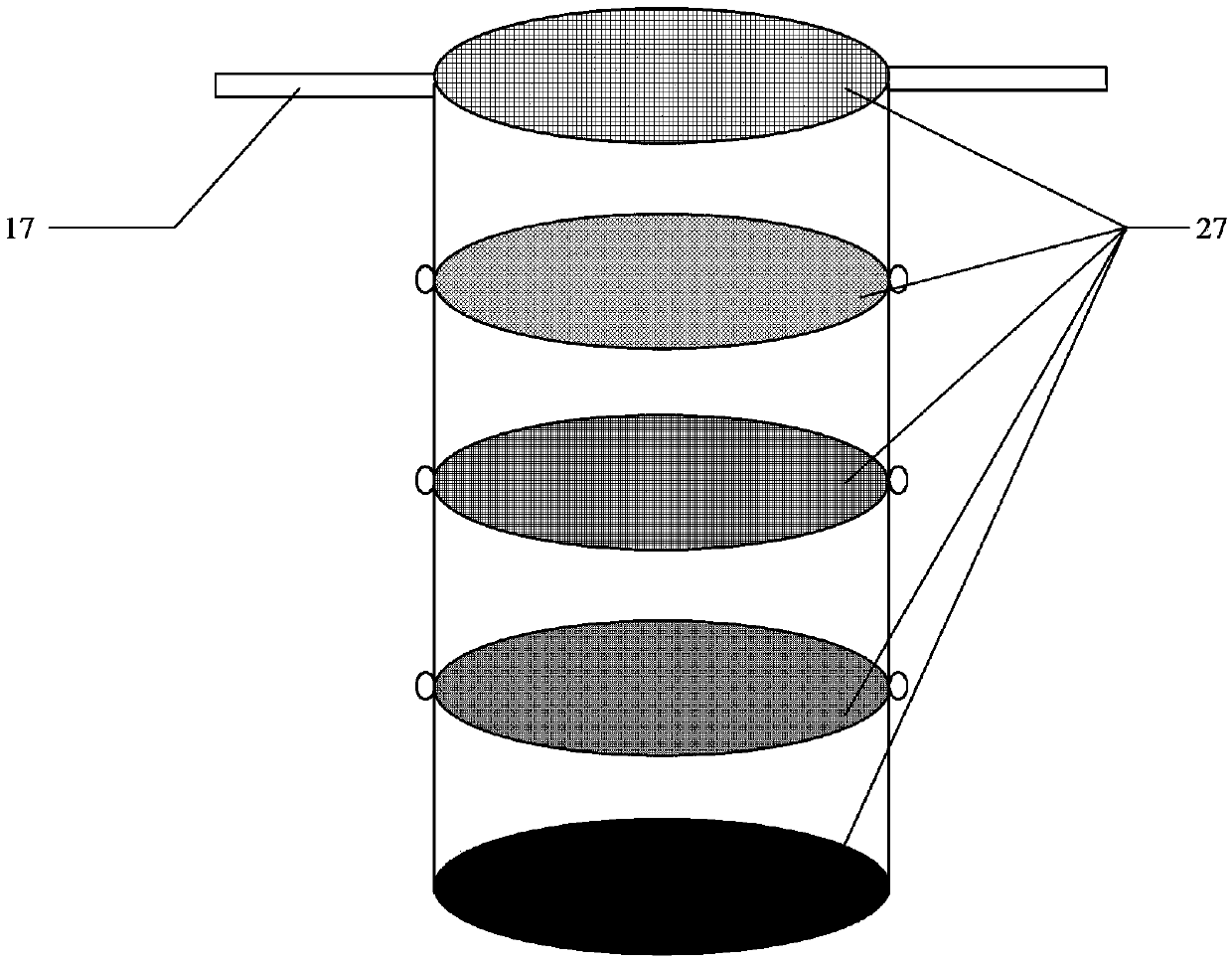

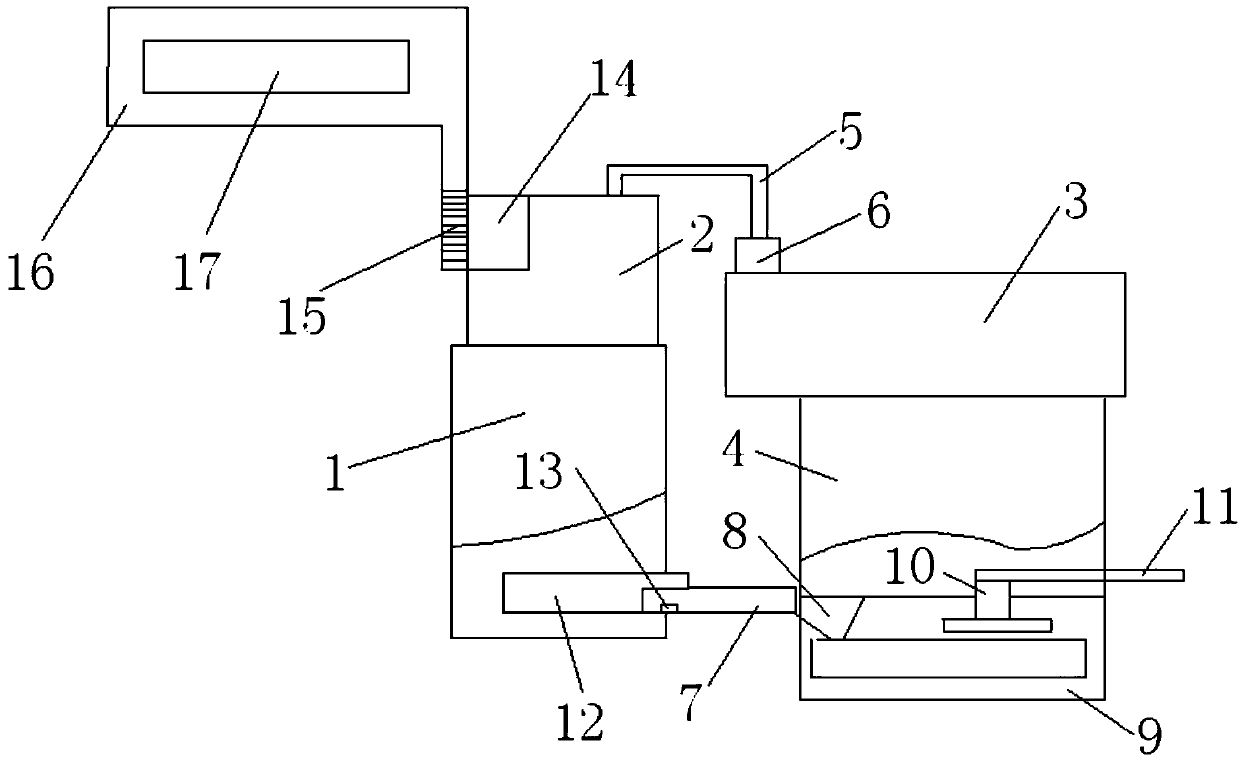

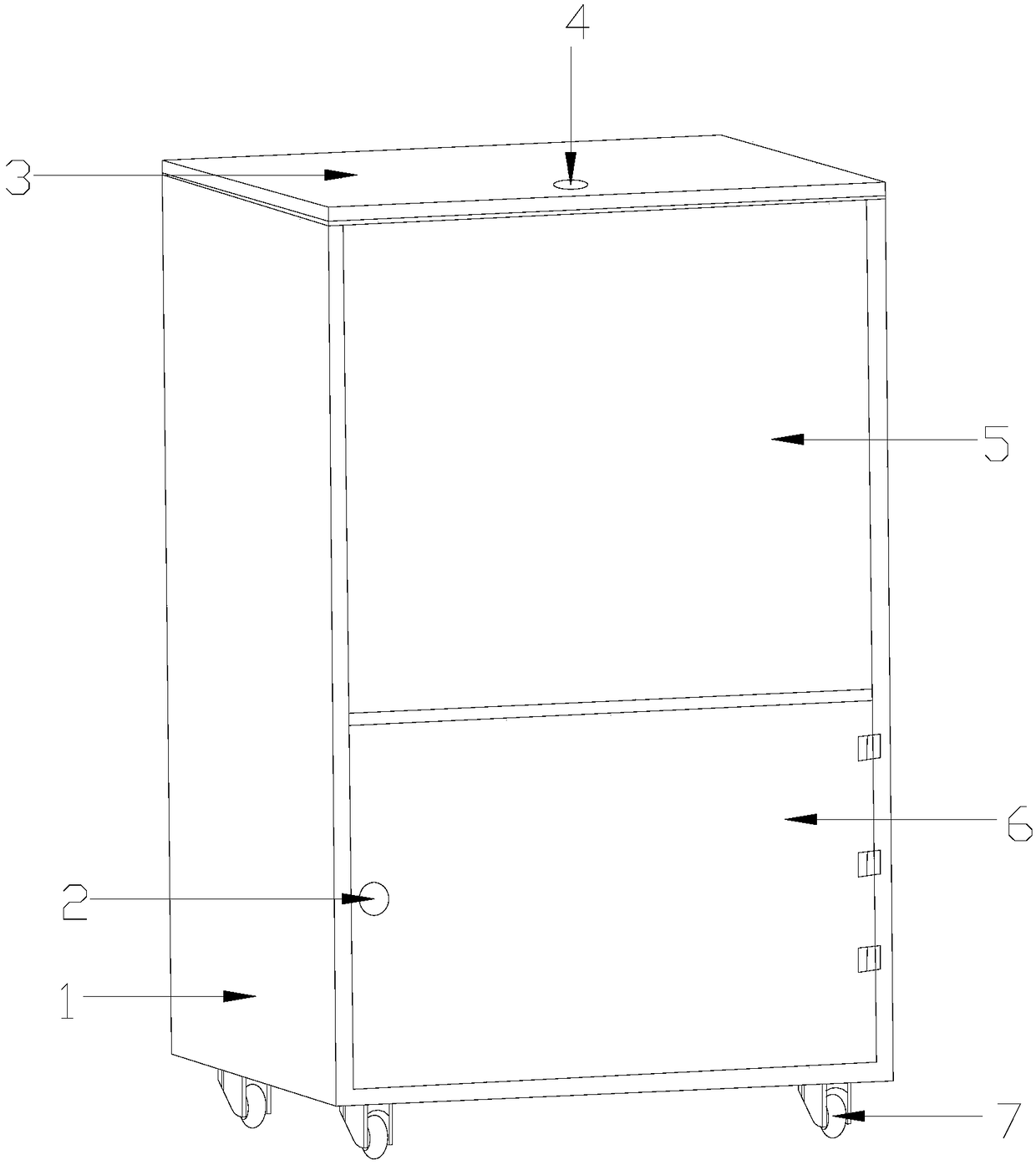

Apparatus for collecting and screening frozen soil fragments in Hopkinson test

ActiveCN106644697AAvoid secondary crushingHelps to movePreparing sample for investigationMaterial strength using single impulsive forceTemperature controlControl power

The invention relates to an apparatus for collecting and screening frozen soil fragments in a Hopkinson test. The apparatus comprises a protective cover which comprises an external layer semicircular protective cover and an internal layer semicircular protective cover by low temperature strong glue bonding; the protective cover is connected to a bracing frame and an internal layer slide plate by a loose-leaf hinge and a positioning pin; air vents are arranged at the lower part of the bracing frame, a channel section is arranged on the bracing frame, and a katathermometer is internally arranged in the bracing frame; a temperature control test box and a protective cover are respectively provided with a pole hole and a rotating wheel hole for a Hopkinson pressure bar and a soil scraping rotating wheel to pass through; the channel, a screw and a support bar are used for connecting the bracing frame and an electric vibrating screen; a control power supply is arranged outside a test box with controllable temperature; a temperature control system is used for controlling the temperature of the test box with controllable temperature. The apparatus can prevent secondary fragmentation of frozen soil fragments, and more frozen soil fragments are collected as possible. The frozen soil fragments are screened and treated at first time after the test, and accuracy of test data is improved.

Owner:ANHUI UNIV OF SCI & TECH

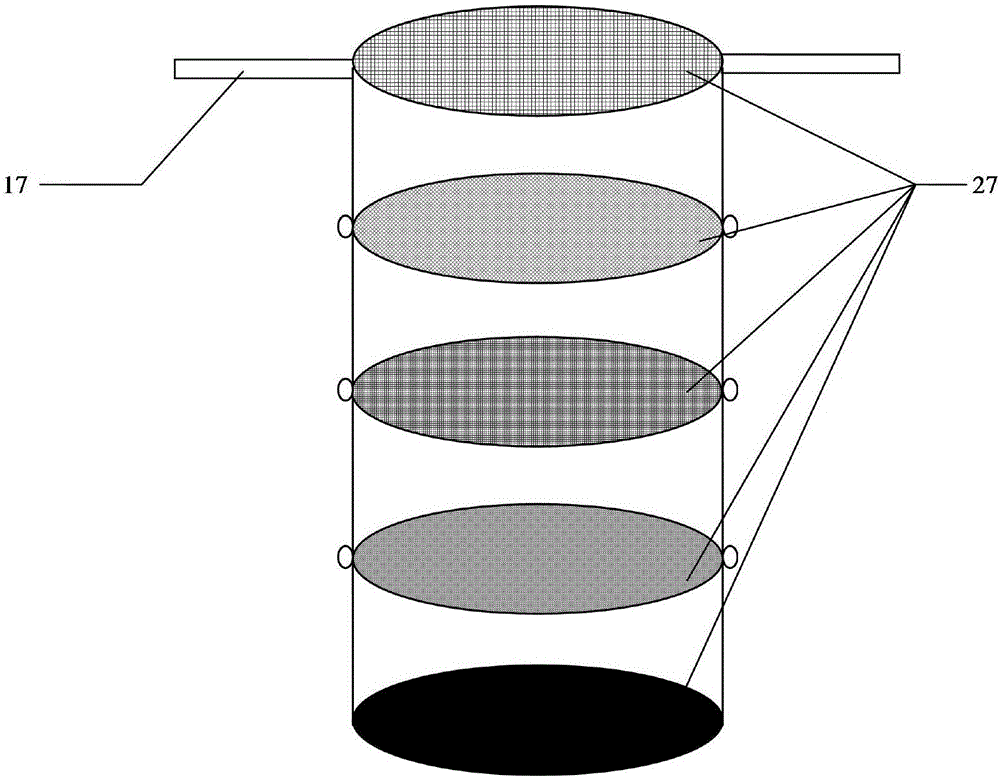

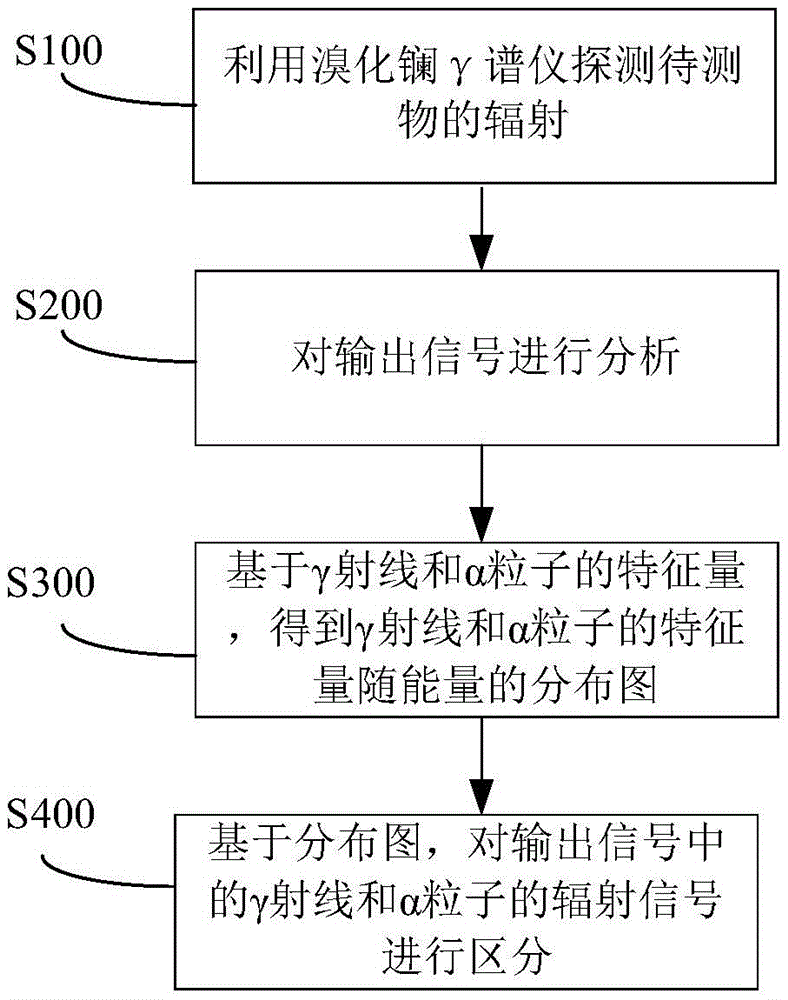

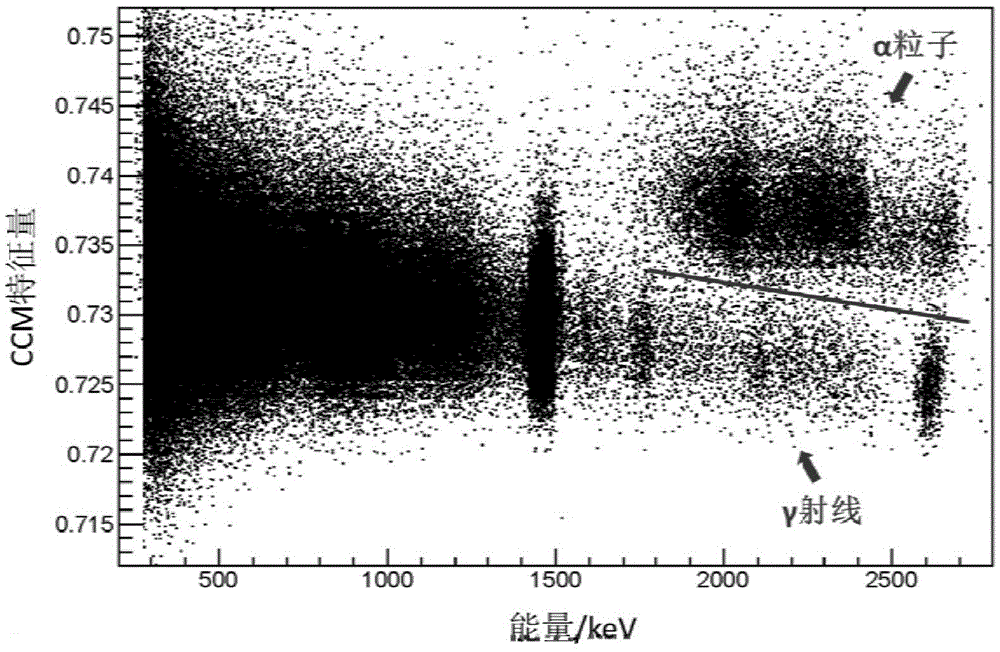

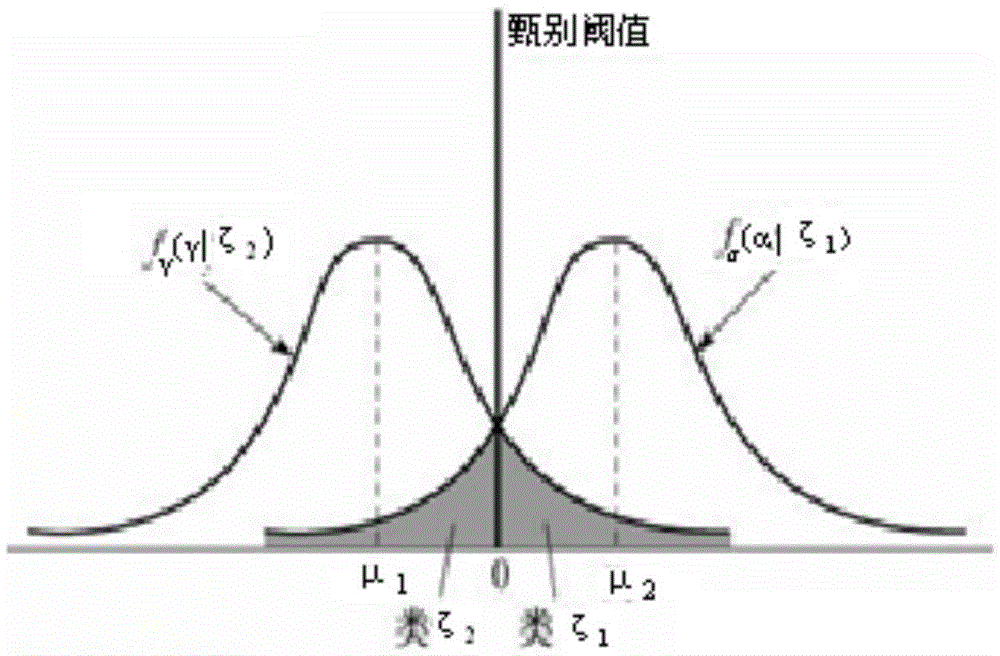

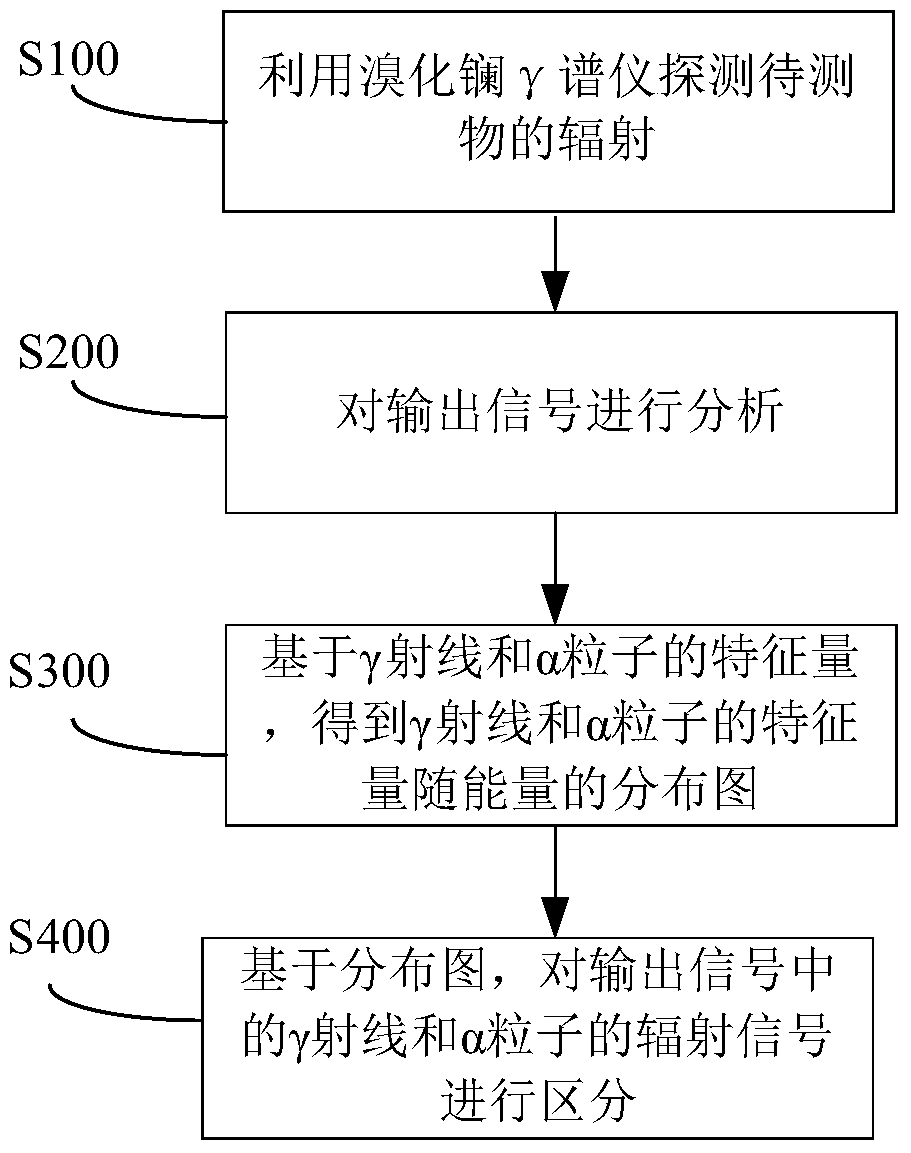

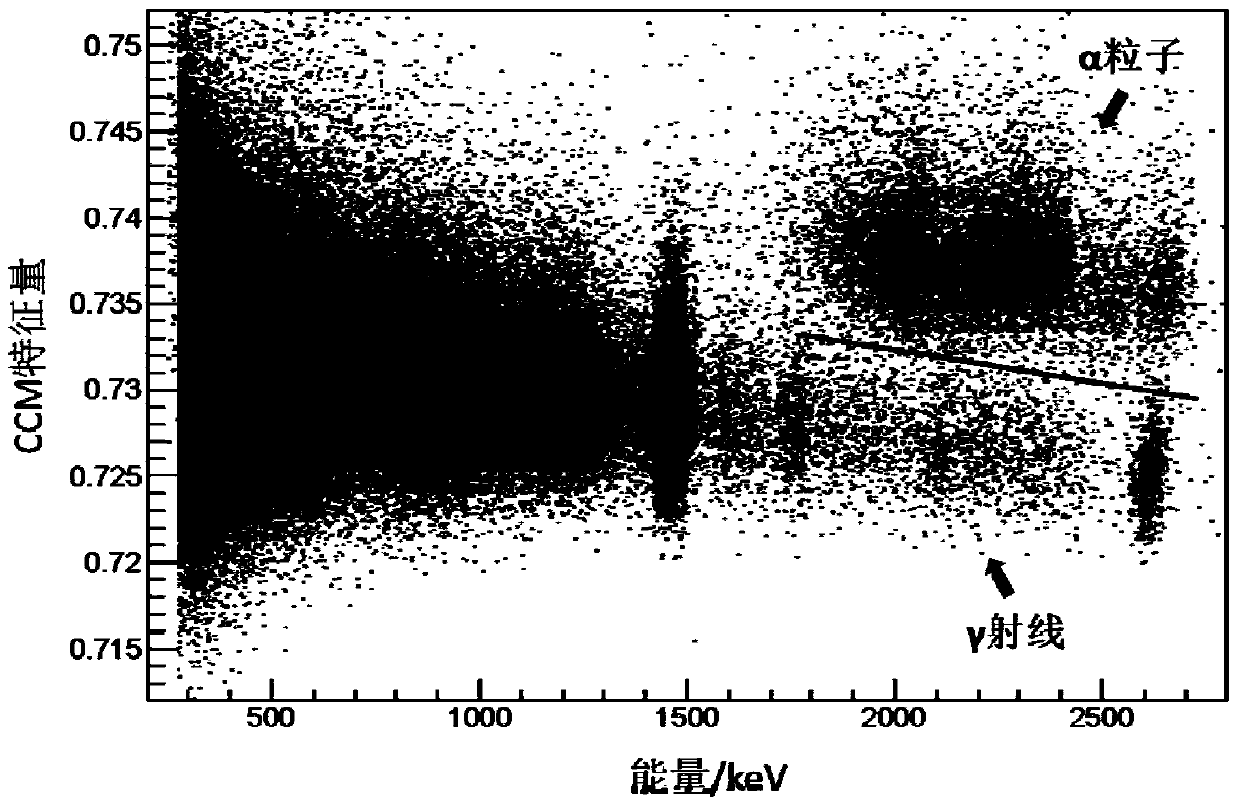

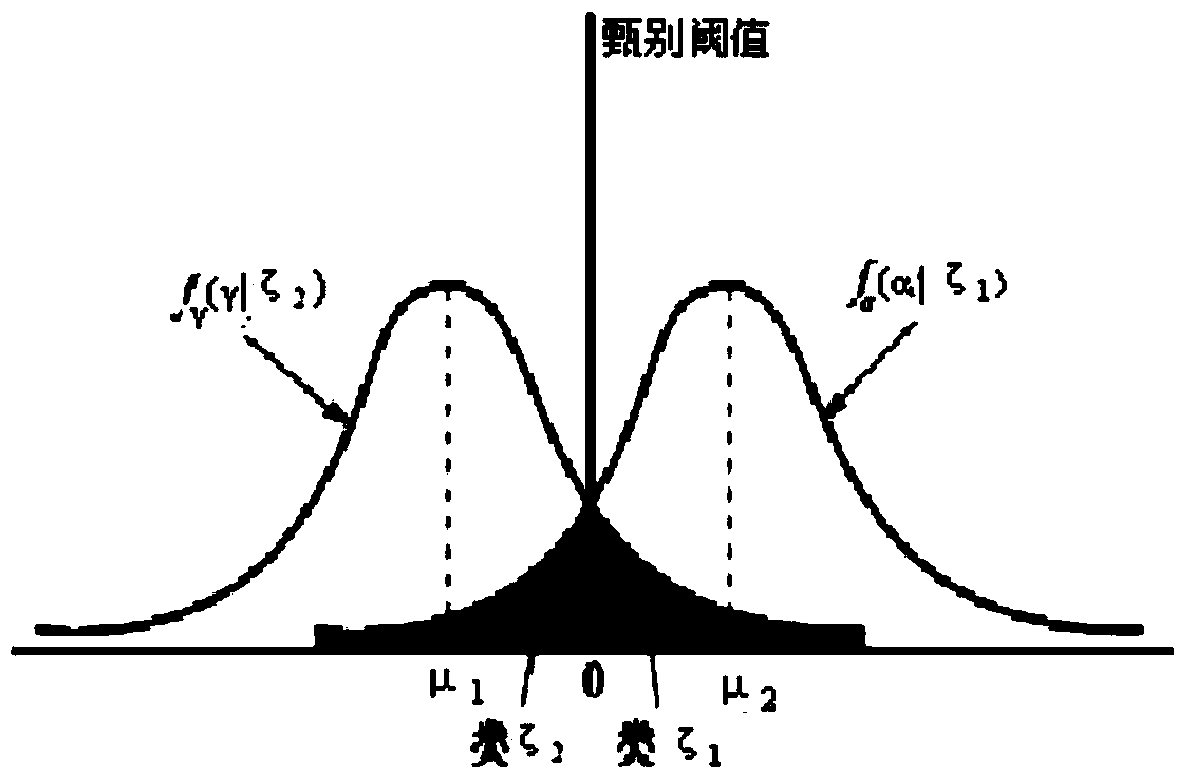

Method for screening and treating output signals of lanthanum bromide gamma spectrometer and application thereof

ActiveCN105629291AEasy to distinguishEfficient distinctionX-ray spectral distribution measurementAlpha particleEnergy based

The invention discloses a method for screening and treating output signals of a lanthanum bromide gamma spectrometer and application thereof, wherein the output signals are radiation signals of gamma ray and alpha particles. The method for screening and treating the output signals of the lanthanum bromide gamma spectrometer includes the steps of: using the lanthanum bromide gamma spectrometer to detect the radiation of an object to be detected so as to obtain the output signals; analyzing the output signals so as to obtain characteristic quantity of the gamma ray and characteristic quantity of the alpha particles; obtaining a distribution diagram of the characteristic quantity of the gamma ray and the characteristic quantity of the alpha particles along with energy based on the characteristic quantity of the gamma ray and the characteristic quantity of the alpha particles; and distinguishing the radiation signals of the gamma ray and the alpha particles in the output signals based on the distribution diagram, and obtaining an energy spectrum measurement value gamma[measurement] of the gamma ray and an energy spectrum measurement value alpha[measurement] of the alpha particles. The method can simply and effectively distinguish the radiation signals of the gamma ray and the alpha particles in the output characteristic quantity signals.

Owner:TSINGHUA UNIV

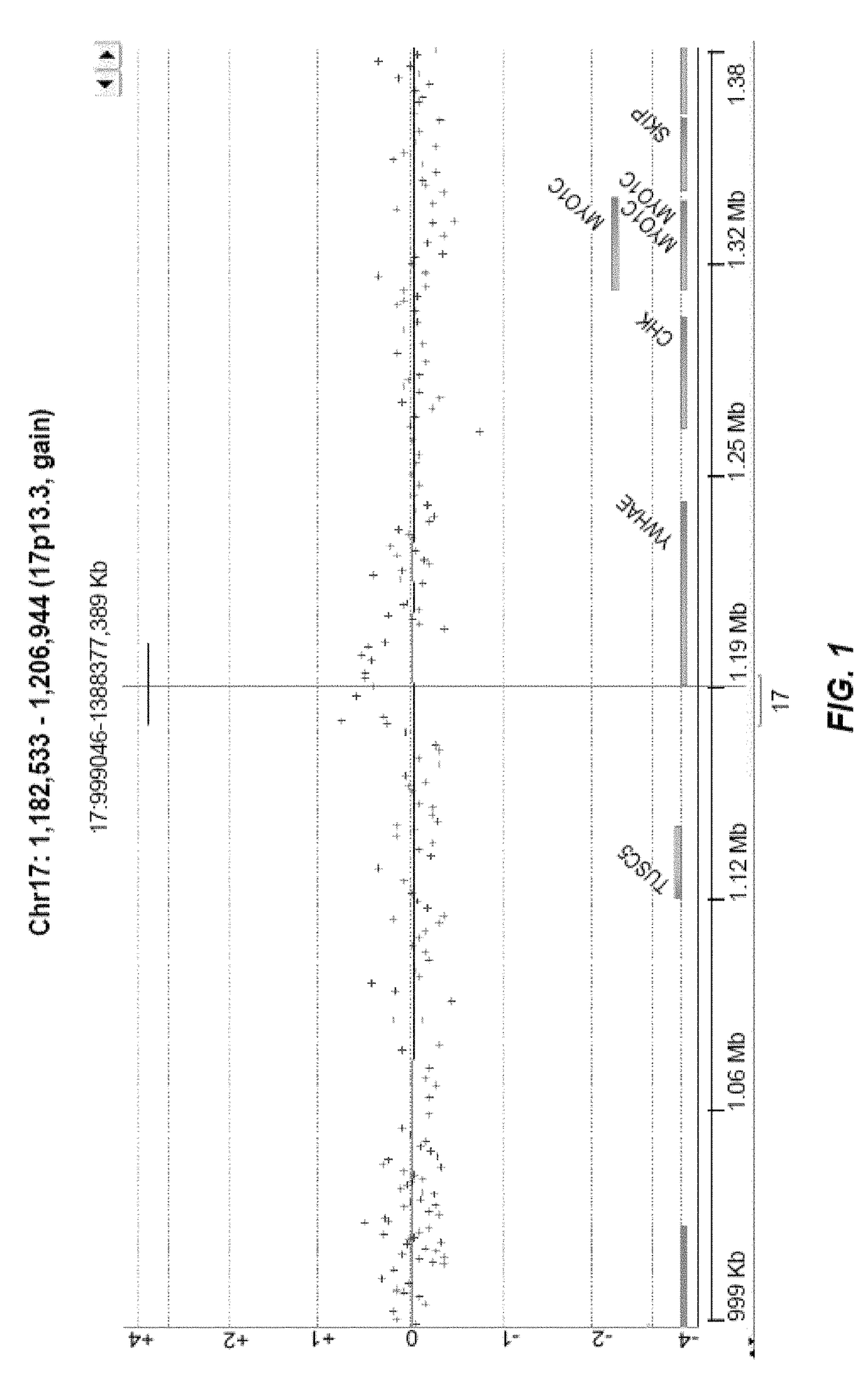

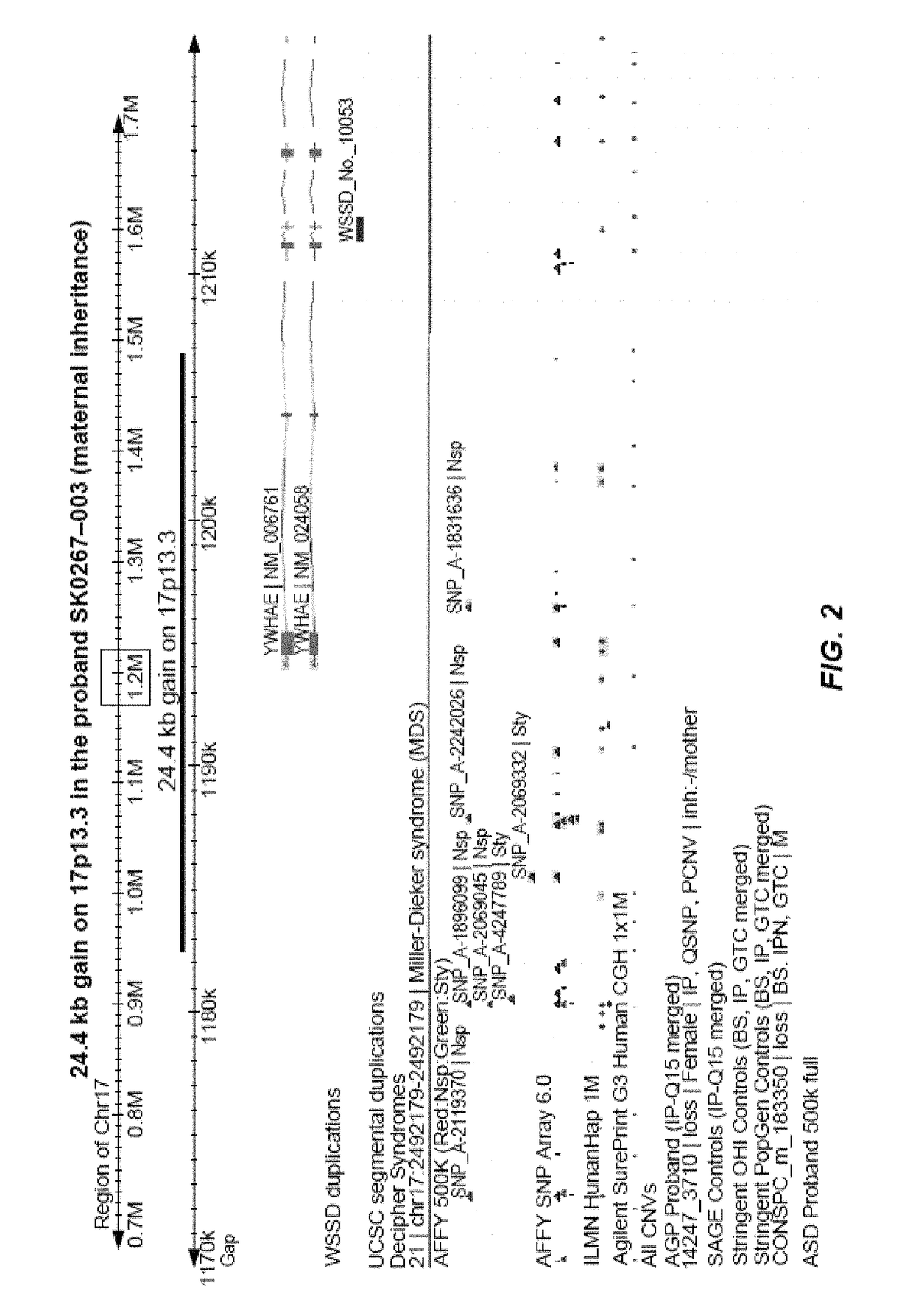

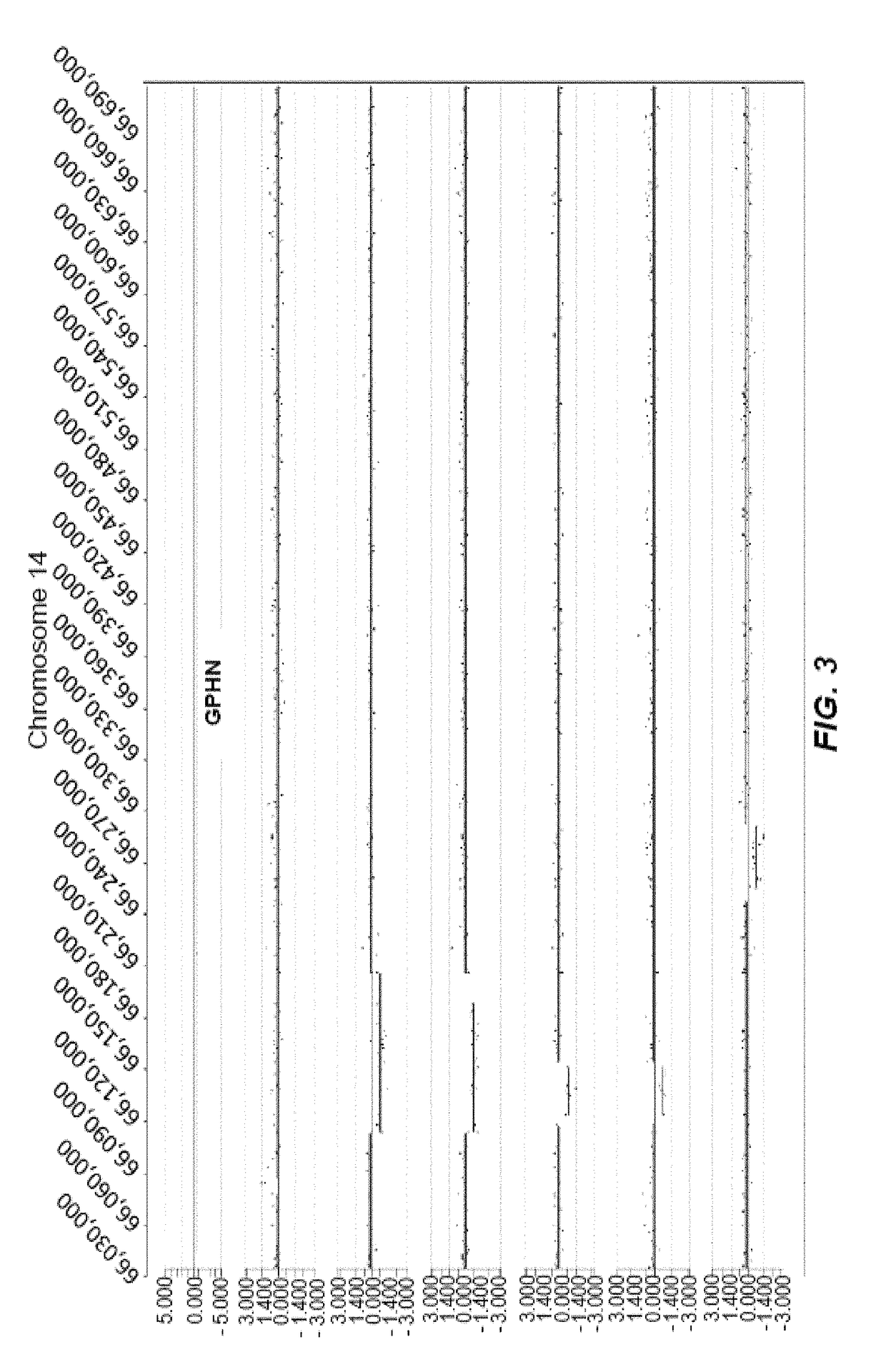

Methods and compositions for screening and treating developmental disorders

ActiveUS10221454B2Compound screeningCell receptors/surface-antigens/surface-determinantsMedicineDevelopmental disorder

This document provides methods and materials related to genetic variations of developmental disorders. For example, this document provides methods for using such genetic variations to assess susceptibility of developing Autism Spectrum Disorder.

Owner:HOSPITAL FOR SICK CHILDREN

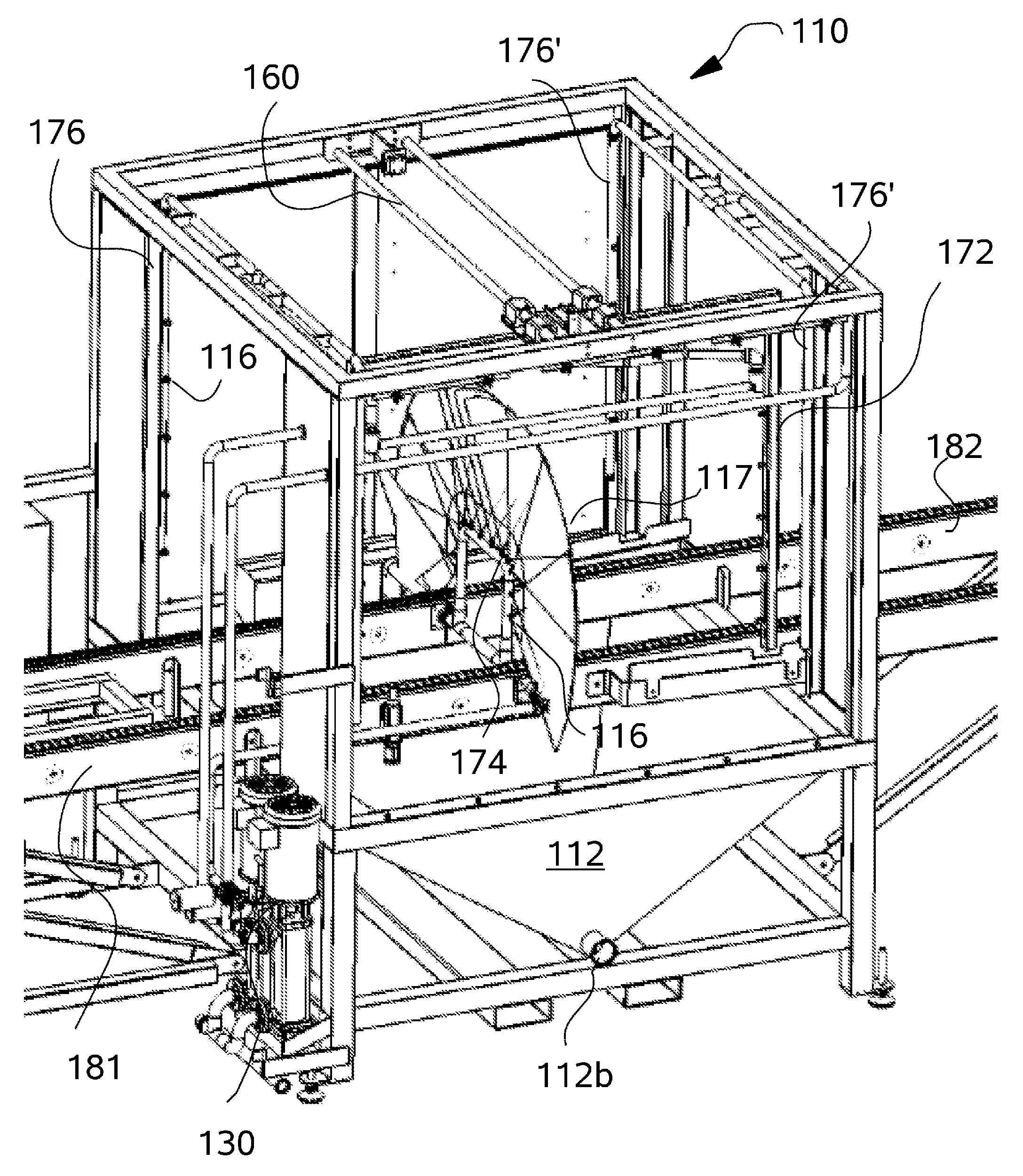

Fruit bin cleaning method and apparatus

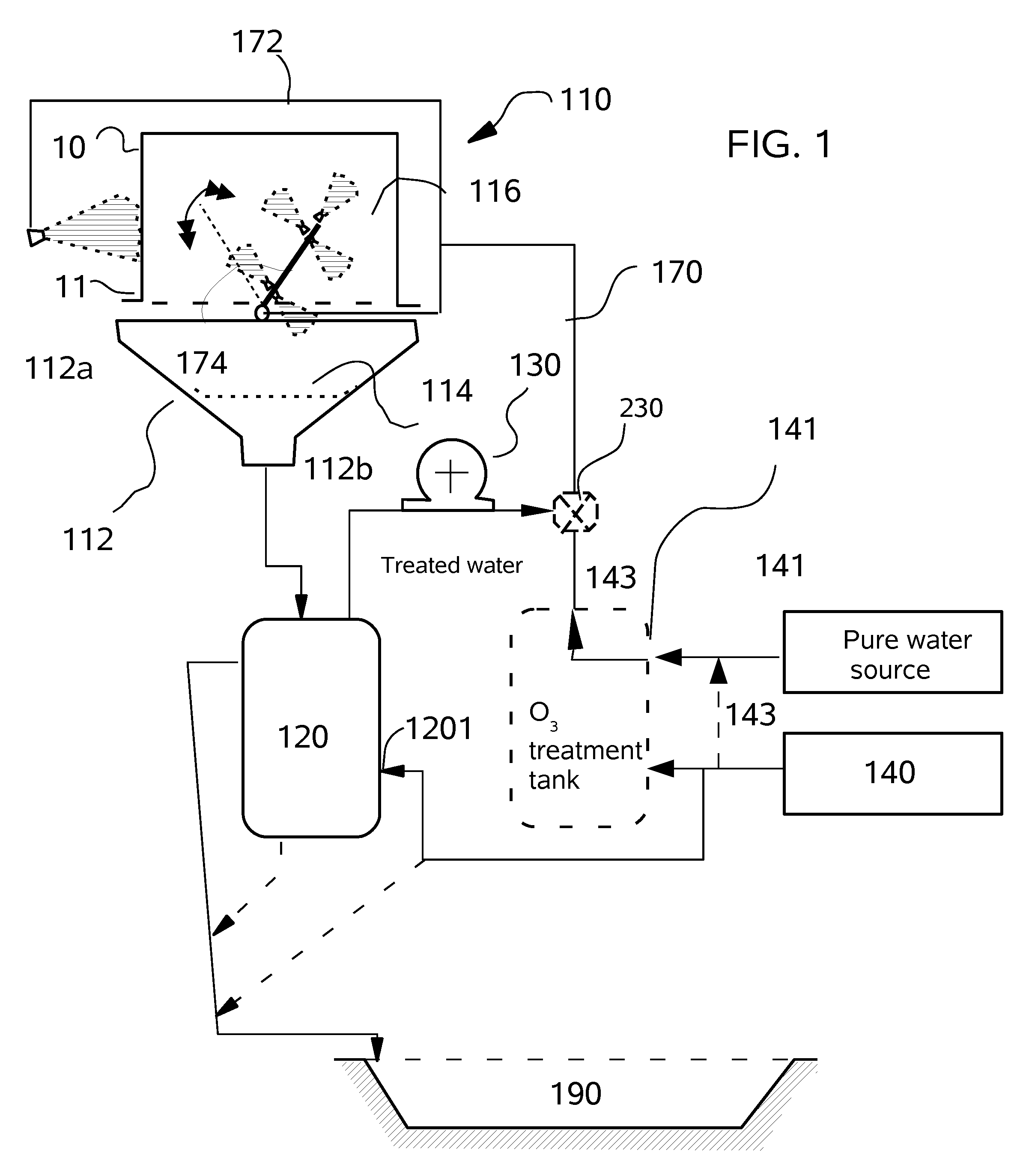

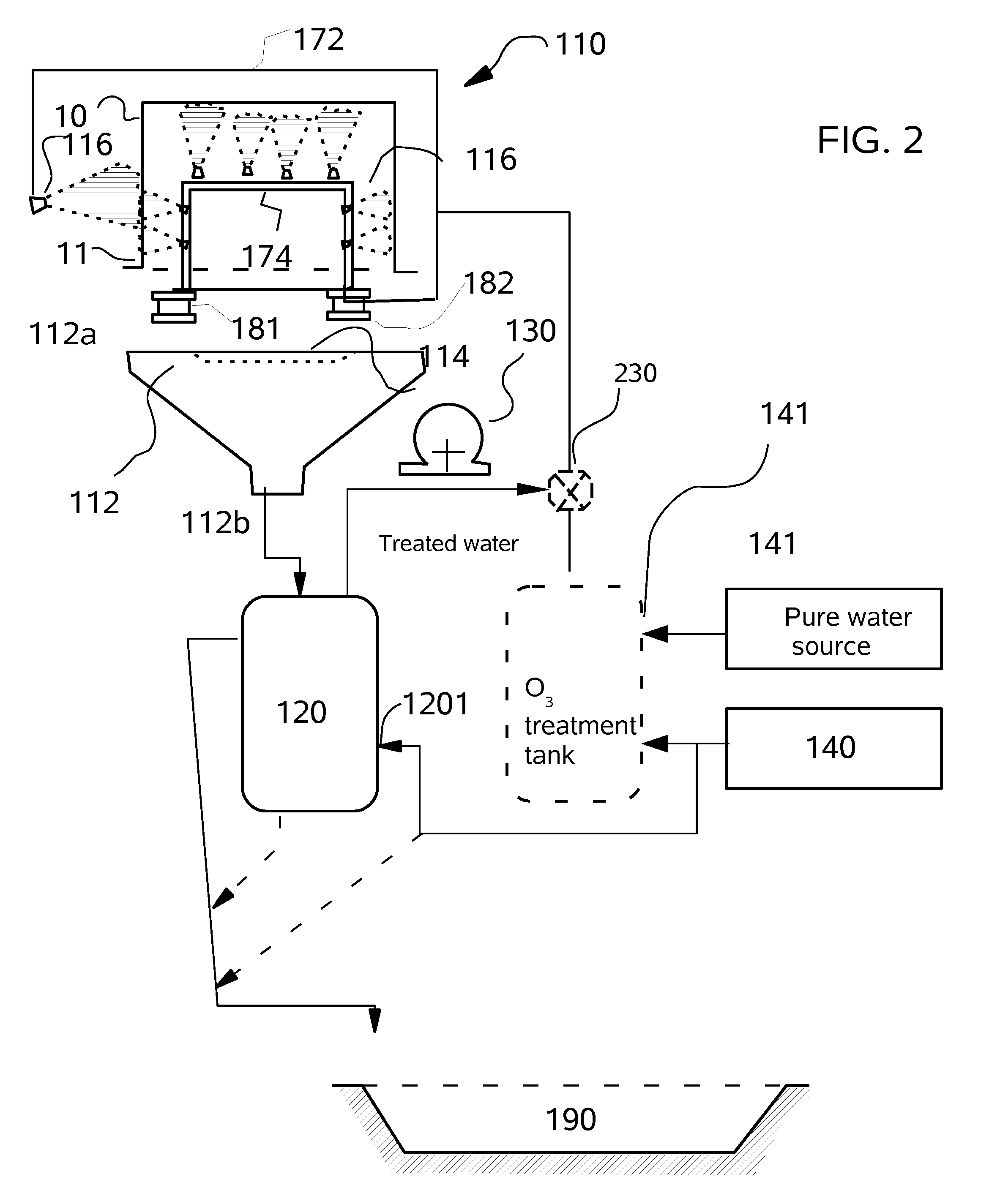

An automated process for cleaning fruit bins, and particularly grape bins, deploys a conveyer system in which bins are simultaneously rinsed on the inside and outside in an inverted position. Two rinse cycles are rapidly completed with the conveyance of the inverted bins through a wash station. The wash station deploys a pivoting V-shaped spray rod inside the bin, below the conveyor track, while the outside is rinsed by a second surrounding inverted V-shaped spray bar that moves transverse to conveyor direction will the bin is stationary inside the wash station. A pivoting L-shaped arm with an integrated conveyor track move the bins on or off the central conveyor, while flipping them 90 degrees. Two such conveyors return the bins to an upright position for use and stacking. The water from a first rinse is optionally screened and treated before its use to rinse subsequent bins.

Owner:ECHO BRAVO

Calcium silicate plate prepared by using waste granite and preparation method thereof

InactiveCN107686313AImprove mechanical propertiesReduce dosageSolid waste managementCalcium silicateFiber

The invention discloses a calcium silicate plate prepared by using waste granite and a preparation method thereof. The calcium silicate plate is characterized by being composed of, by mass, 70-100 parts of Portland cement, 10-30 parts of granite powder, 20-28 parts of superfine quartz sand, 0.5-1.0 part of sodium polyacrylate, 0.2-0.6 part of wood pulp fiber and 15-25 parts of water. Silicon element in waste granite is fully utilized to regulate calcium-silicon ratio of the calcium silicate plate, and mechanical performance of the calcium silicate plate is improved by screening and treating raw materials. Waste granite can be recycled, and consumption of cement and quartz sand can be reduced, so that cost is saved.

Owner:UNIV OF JINAN

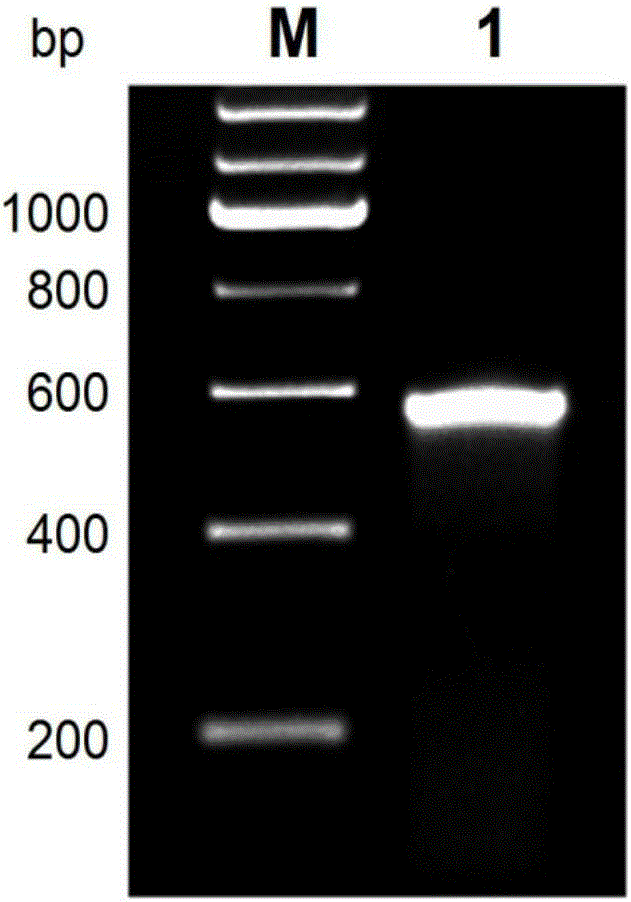

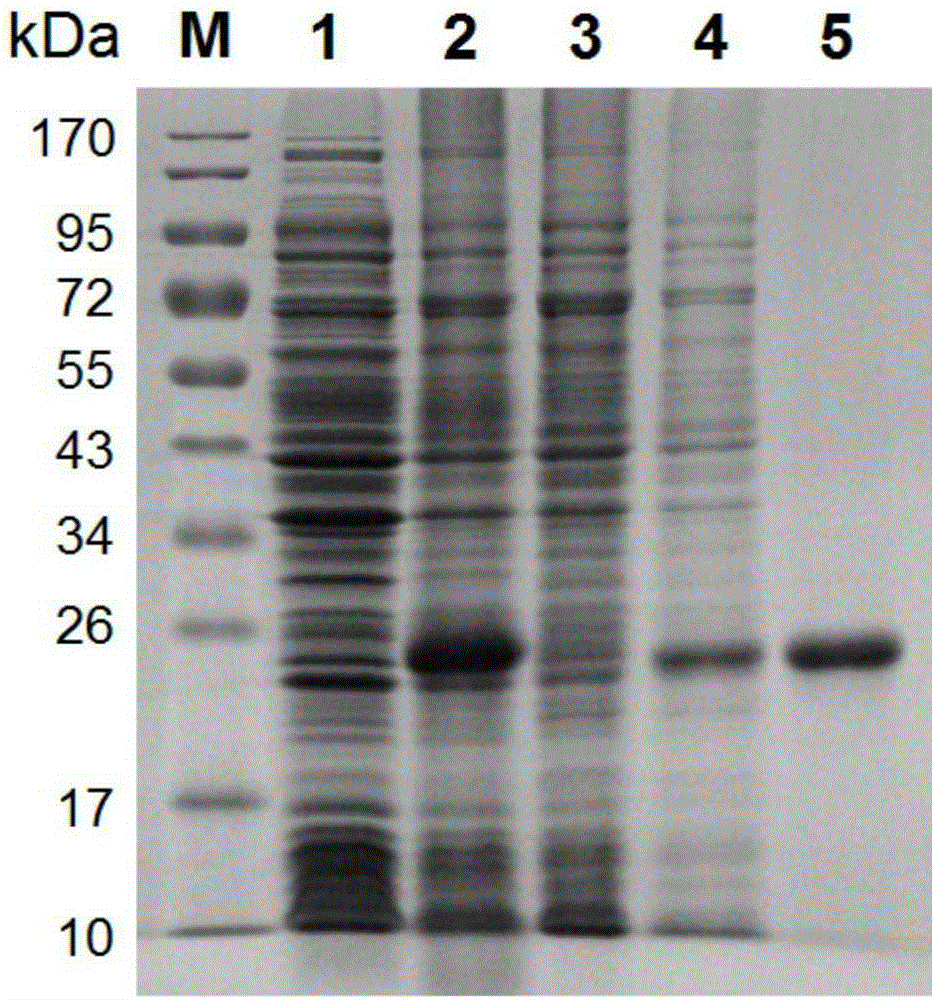

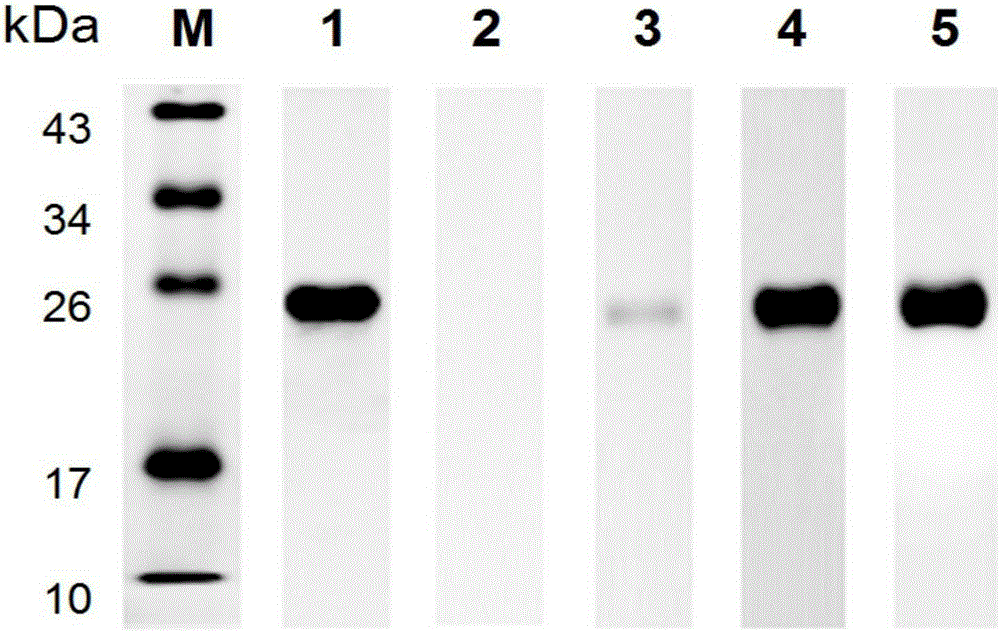

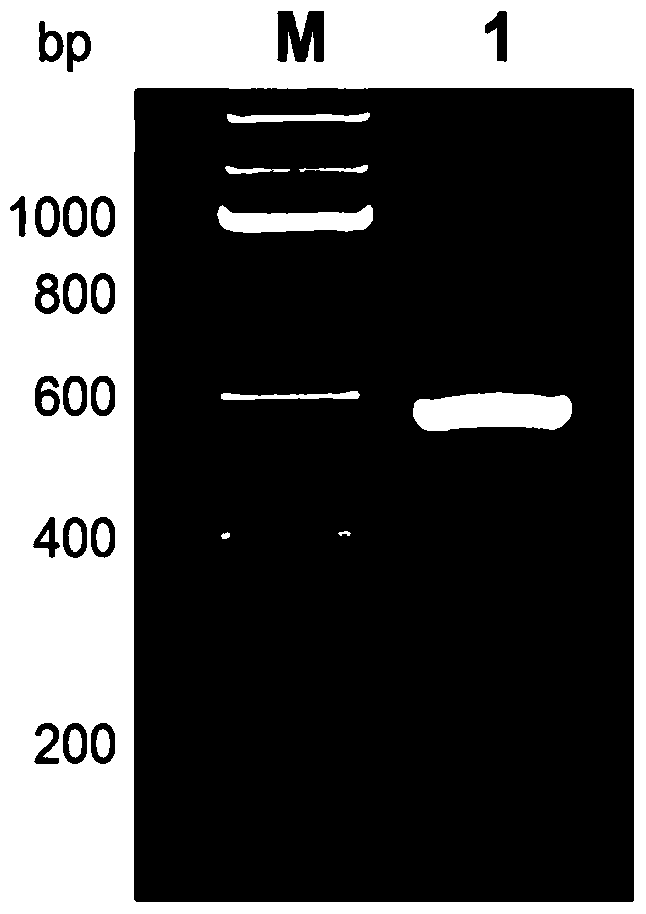

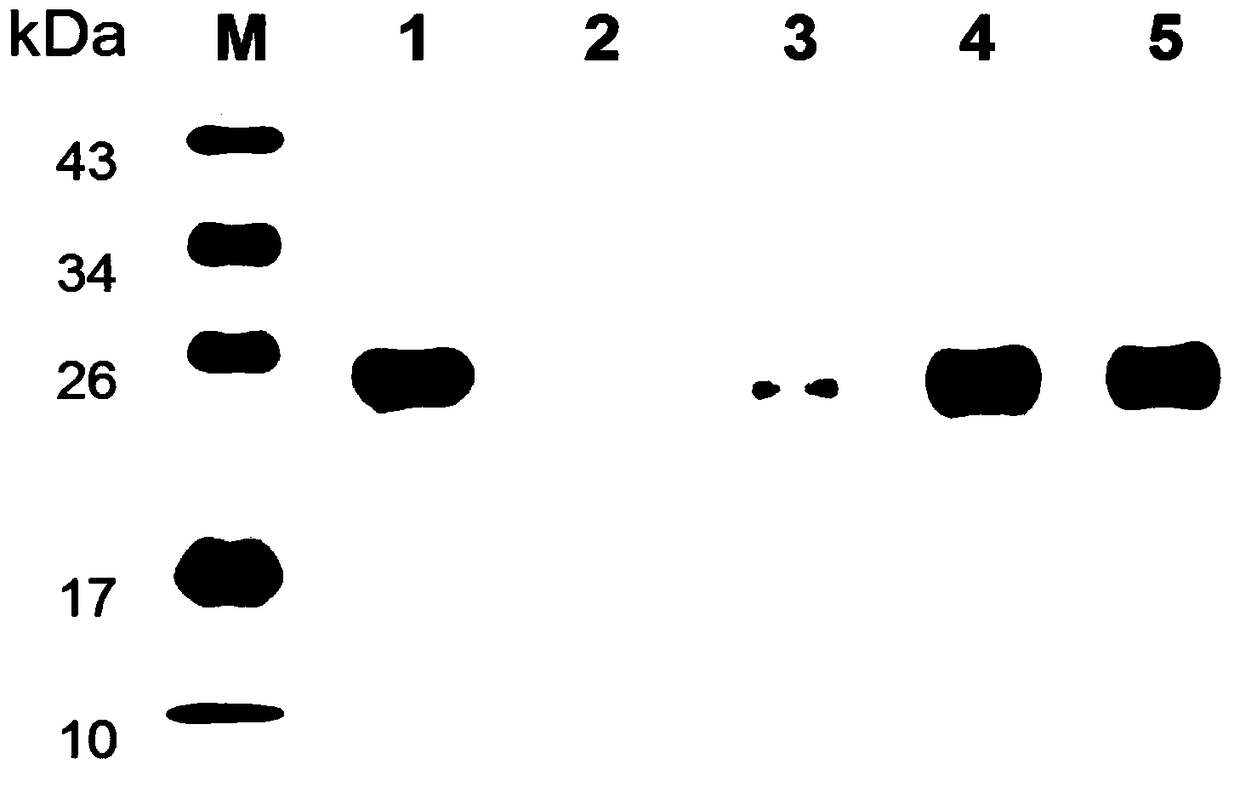

Schistosoma japonicum katsurada recombinant protein SjSAPLP5 as well as encoding gene and application thereof

ActiveCN105254732AImproving immunogenicityGood antigenicityBiological material analysisAntiparasitic agentsAntigenDisease

The invention provides a schistosoma japonicum katsurada recombinant protein SjSAPLP5 as well as an encoding gene and an application thereof. The protein provided by the invention has amino acid sequence as shown in SEQ ID No.2 or has amino acid sequence which is formed by replacement, deletion and / or addition of one or more of amino acid residues and has the same function. The invention also provides the encoding gene for encoding the protein. The recombinant protein SjSAPLP5 provided by the invention is excellent in immunogenicity, can be served as an excellent diagnosis antigen, is used for preparing a schistosoma japonicum katsurada diagnostic kit with high sensitivity and high specificity, and is also used for preparing an anti-schistosome vaccine and the drug served as a potential drug effecting target spot and is used for screening and treating the schistosoma japonicum katsurada diseases.

Owner:INST OF PATHOGEN BIOLOGY CHINESE ACADEMY OF MEDICAL SCI

Conductive heat-conduction liquid silicone rubber for OA rubber roller and preparation method of liquid silicone rubber

InactiveCN109535733ALow compression setReduce deformation rateHeat-exchange elementsPolymer scienceSilanes

The invention discloses conductive heat-conduction liquid silicone rubber for an OA rubber roller and the preparation method of the liquid silicone rubber. The liquid silicone rubber comprises the following raw materials in parts by mass: 40-60 parts of vinyl silicone oil (with a vinyl molar content of 0.2-0.5% and viscosity of 10000-50000 mPa*s), 2-5 parts of multi-walled carbon nanotubes, 0.1-1part of hydroxyl silicone oil (with viscosity of 30-50 mPa*s, and a hydroxyl molar content of 5.0-10.0%), 40-60 parts of metal aluminum powder (with a particle size of 1-30 microns), 1-2 parts of vinyl triethoxy silane, 1-3 parts of hydrogen-containing silicone oil (with a hydrogen molar content of 0.4-0.8%), 5-10 ppm of a platinum catalyst and 200-400 ppm of ethynyl cyclohexanol. According to theinvention, the structure and the molecular weight of vinyl silicone oil are adjusted, and filler is screened and treated, so that extremely low compression deformation rate and excellent ageing resistance are achieved. The overall deformation rate is low, aging resistance is good, and heat conduction performance is good.

Owner:XINAN TIANYU SILICONE CO LTD

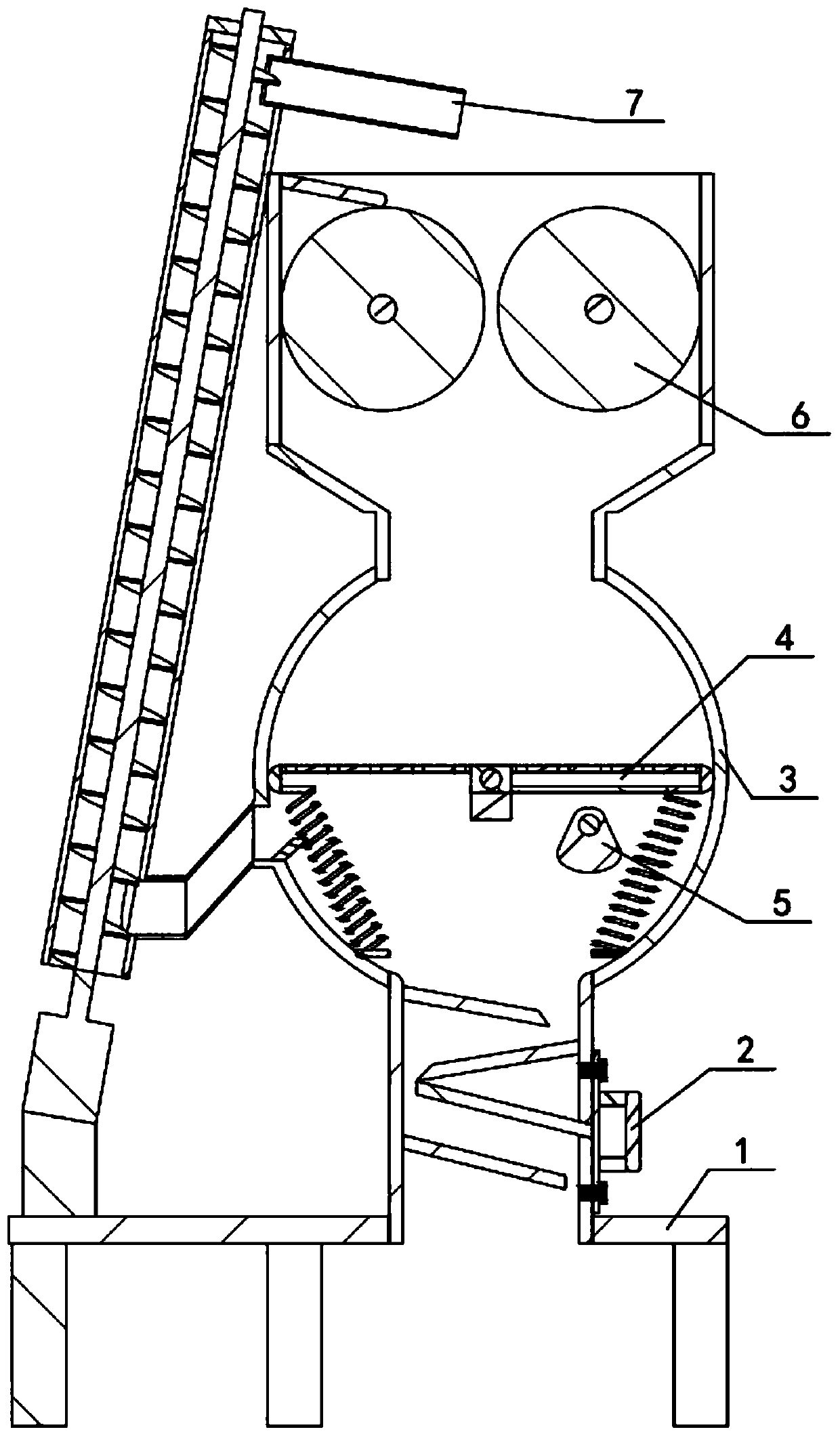

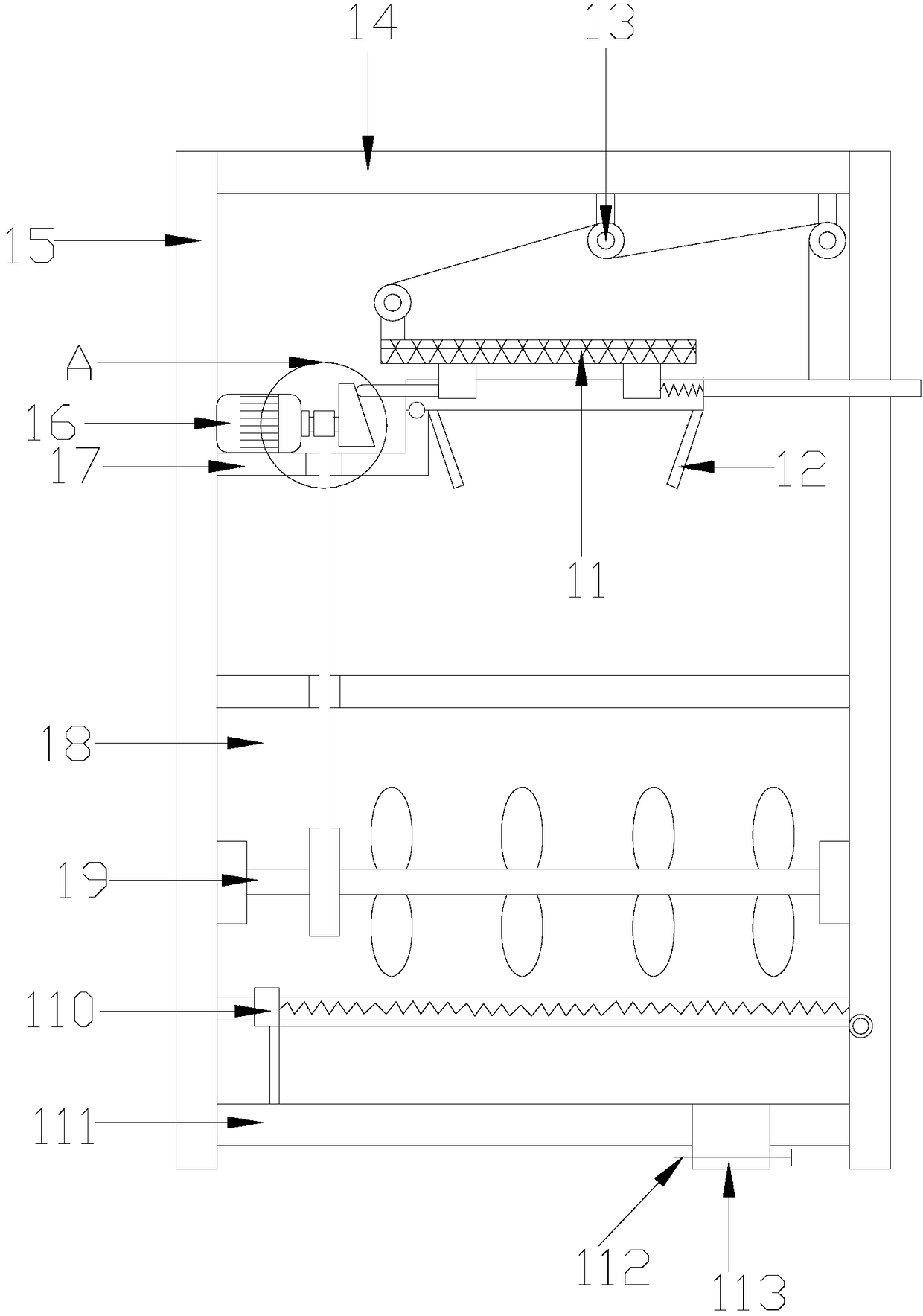

Vertical garbage pulverizer

InactiveCN106964439AIt has the effect of cushioning and crushingGrain treatmentsStructural engineeringEngineering

The invention relates to a vertical garbage pulverizer, which relates to the field of garbage pulverization equipment, and comprises a pulverization cavity, a layered cutter set and a scraper; the layered cutter set is installed in the pulverization cavity, and the inner wall of the pulverization cavity is provided with There is a protruding cutter head; the layered cutterhead group includes multi-layer cutterheads arranged coaxially, and blades are hinged on each layer of cutterheads; the blades rotate around their hinge points; the outer edge track of the blade extends out The outer edge of the cutterhead; the cutterheads on the adjacent next layer are arranged vertically according to the law of the increasing outer diameter of the cutterhead, and the track line of the outer edge of the blade on the layer-by-layer cutterhead is also gradually increasing; the blades on the two adjacent layers of cutterheads The positions in between correspond to a layer of cutter heads on the inner wall of the crushing chamber; the scraper is coaxially installed on the lower side of the layered cutter head group. The vertical garbage shredder adopts cutterheads with variable sizes to crush garbage. Based on partial cutterheads of different sizes, the garbage can be automatically screened and processed during the crushing process, which can achieve the effect of garbage crushing.

Owner:SUZHOU MEISHENG ENVIRONMENTAL PROTECTION TECH

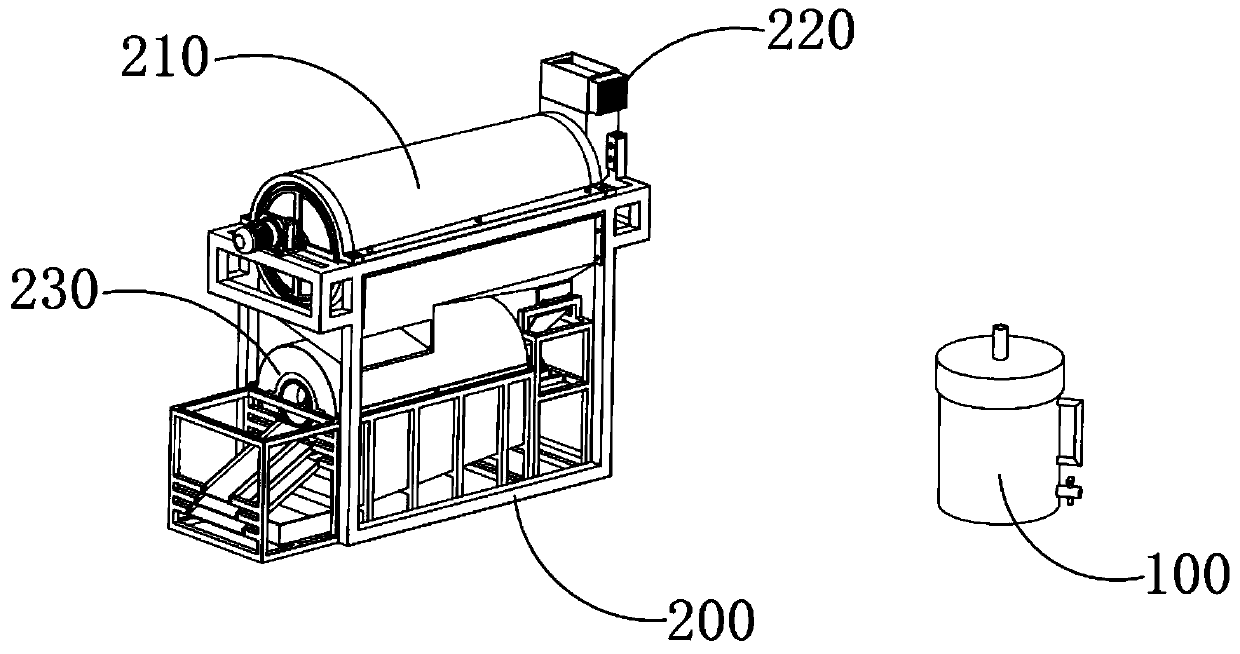

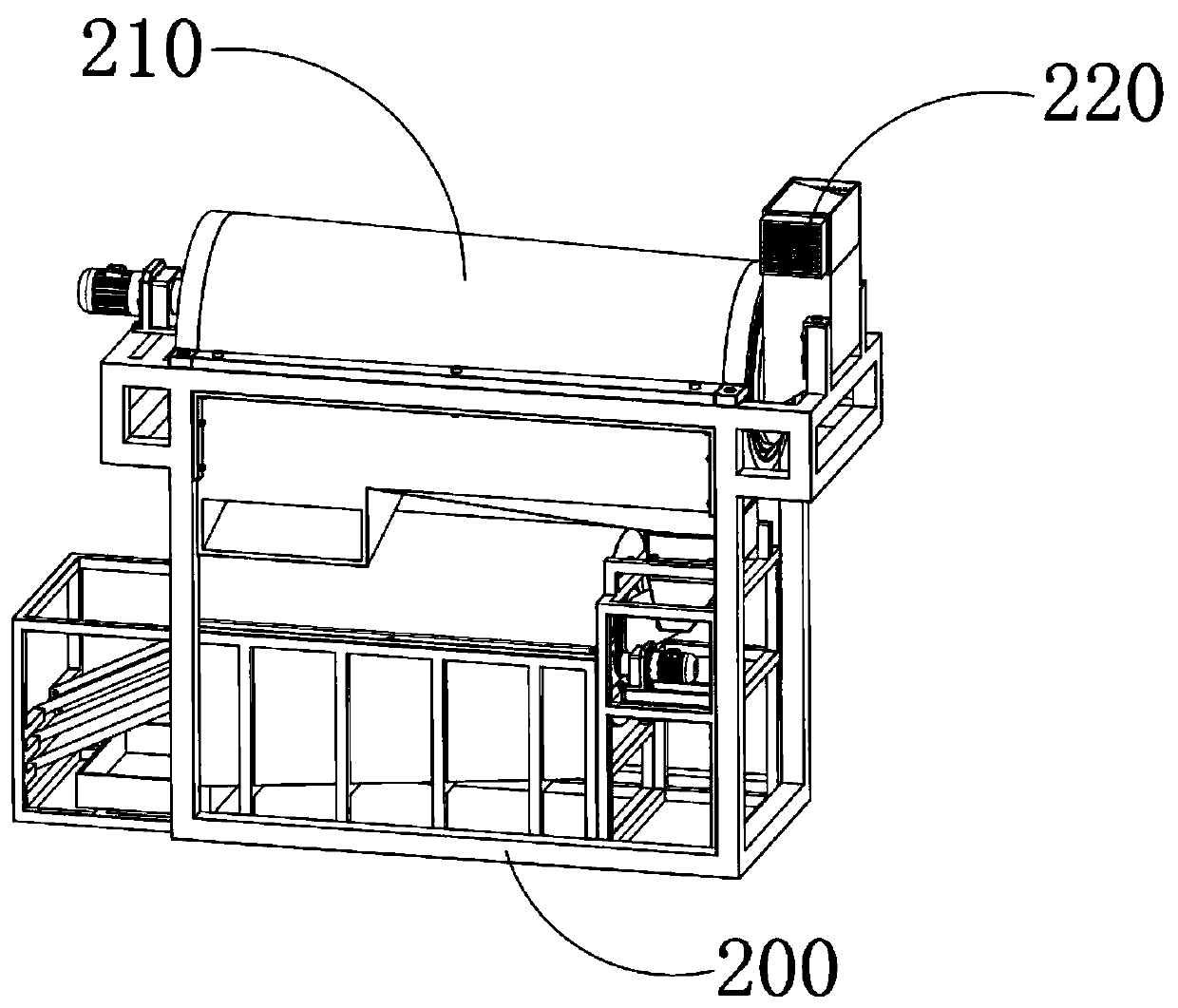

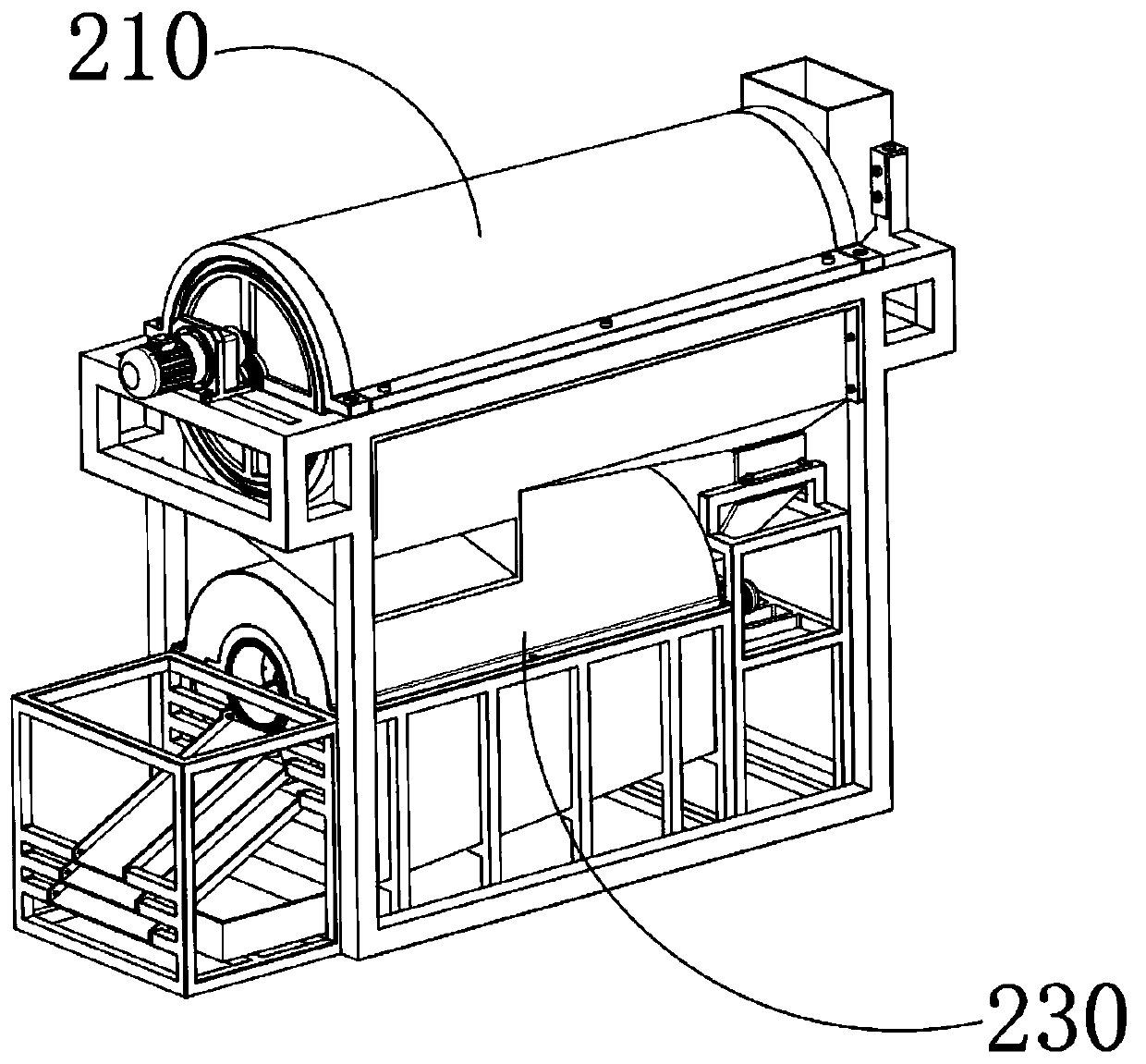

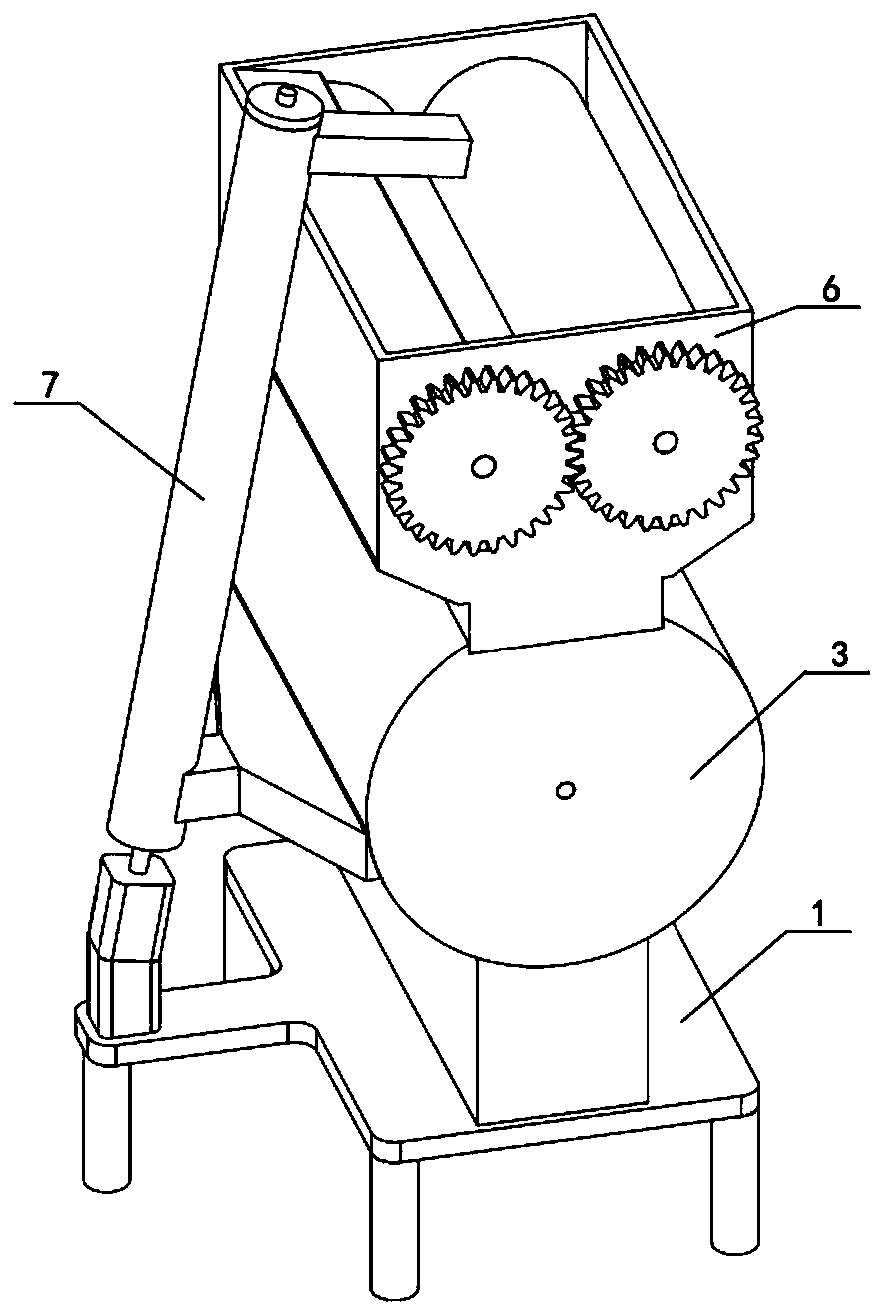

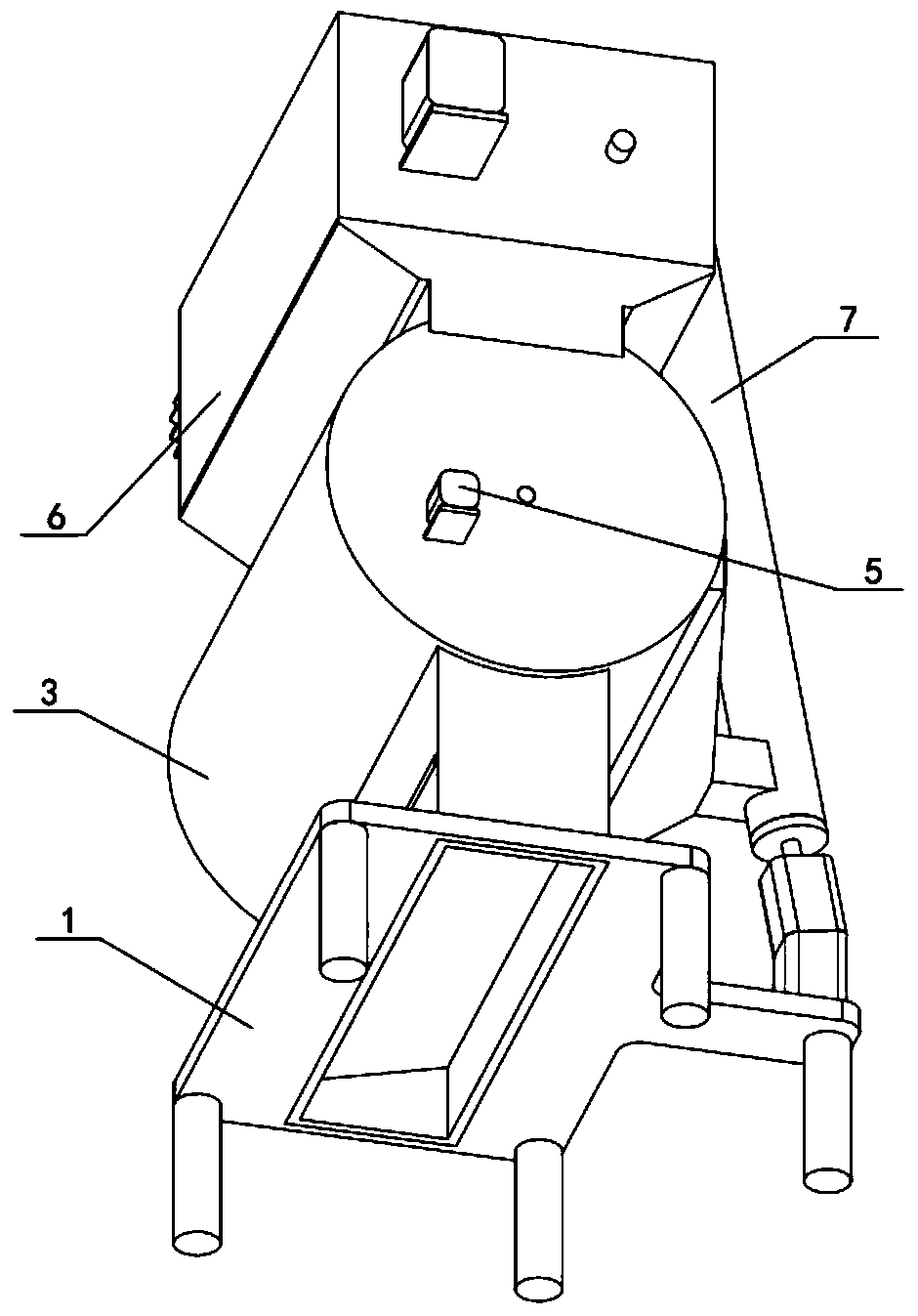

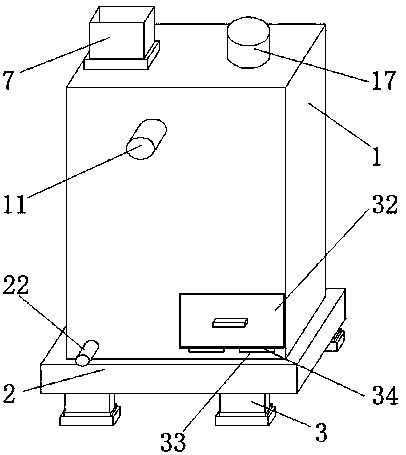

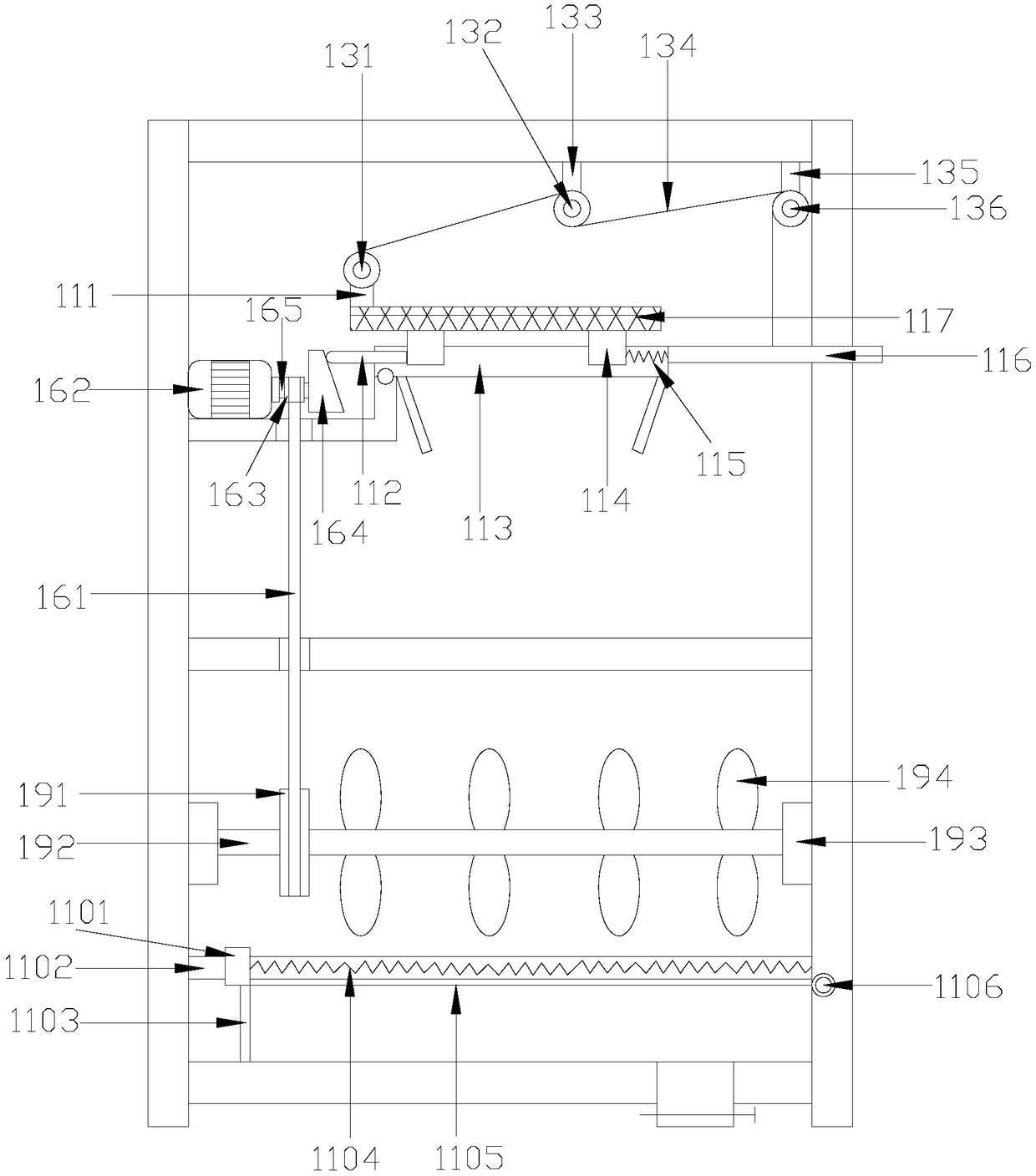

Automatic screening and packaging process of granular traditional Chinese medicinal materials

InactiveCN109834085AImprove classification and screening efficiencyReduce labor intensityGas current separationDrying gas arrangementsEngineeringSewage

The invention provides an automatic screening and packaging process of granular traditional Chinese medicinal materials. The automatic screening and packaging process comprises the following steps: 1,traditional Chinese medicinal materials are placed in a rinsing component for washing, sewage in the rinsing component is drained after washing is completed, and the rinsing component is opened to the input end of an air drying component; 2, the air drying component is used for receiving the clean traditional Chinese medicinal materials poured by a leaching bucket and carrying out rapid air drying on the clean traditional Chinese medicinal materials, an impurity removal component is used for receiving the air-dried traditional Chinese medicinal materials of the air drying component, removingimpurities on the air-dried traditional Chinese medicinal materials and discharging the impurities, and the impurity removing processed traditional Chinese medicinal materials fall into the input endof the screening part from the output end of the impurity removing part; and 3, a screening part accepts the impurity removing traditional Chinese medicinal materials, and the granular traditional Chinese medicinal materials are automatically screened and treated, and the four traditional Chinese medicinal materials with different sizes are screened and classified; and 4, the screened traditionalChinese medicinal materials are output by an output guide plate, the granular traditional Chinese medicinal materials with different specifications are separately output, and a user can carry out bagging on the classified granular traditional Chinese medicinal materials at the output end.

Owner:王和勤

Liquid organic fertilizer, liquid organic fertilizer preparation device and liquid organic fertilizer preparation method

The invention relates to the field of fertilizer making, in particular to a liquid organic fertilizer, a liquid organic fertilizer preparation device and a liquid organic fertilizer preparation method. The liquid organic fertilizer preparation device comprises a magnetic adsorption treatment base, a magnetic adsorber, a screening chamber, a screening device, a deflection oscillator, a crushing chamber and a loop conveyor, wherein a screening device body is in a balanced state through a tension spring, and waste furnace slag in production of alloy steel is screened by using a vibration exciterand a 50-mesh filter screen; the furnace slag which is less than 50 meshes can be further screened and treated through magnetic separation; and the furnace slag which is larger than 50 meshes can enter the crushing chamber for being re-crushed due to starting of the deflection oscillator and transportation of the loop conveyor.

Owner:QINGDAO HUIJUN ENVIRONMENTAL ENERGY ENG

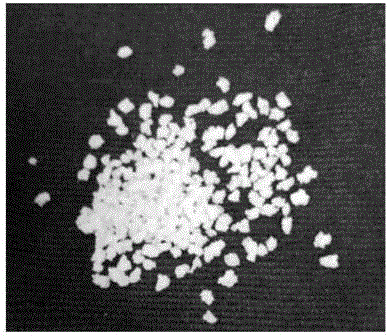

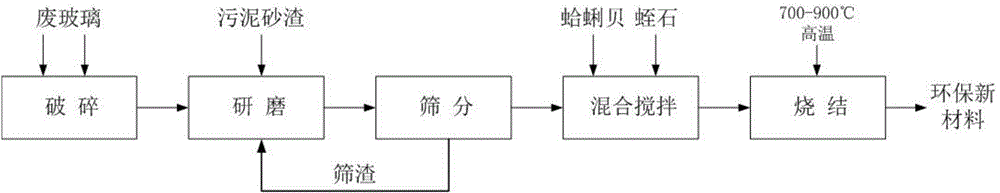

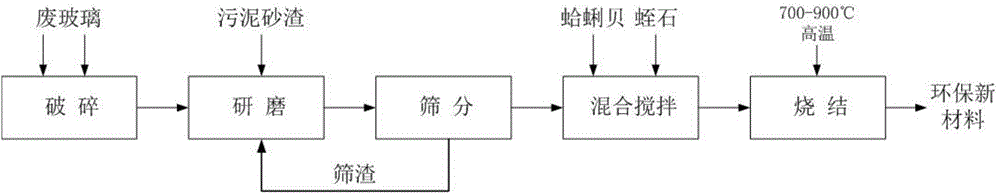

Porous environment-friendly material

InactiveCN105601312ATurn waste into treasureAchieve water retentionSolid waste disposalCeramicwareEnvironmental resistancePowder mixture

The invention discloses a porous environment-friendly material. The specific gravity of the porous environment-friendly material is 0.6-1.1, and the hydroscopicity is below 15%; the porous environment-friendly material is prepared by the following steps: glass powder as well as sludge sand and sediment which are produced by dehydration, desiccation and burning from a sewage treatment plant are mixed according to a proportion of 35-80:1-10 in parts by weight, grinding is carried out, and a primary powder mixture is obtained; the primary powder mixture is screened and treated, and the screened primary powder mixture composed of glass powder as well as sludge sand and sediment is added into a mixing and stirring device; 5-20 parts of clam shells and 1-15 parts of vermiculite powder are added into the mixing and stirring device in the step 4, mixing and stirring are carried out for the clam shells, the vermiculite powder, the glass powder, and the sludge sand and sediment, and mixed power is formed; the mixed power is added into a sintering furnace, and the porous environment-friendly material is manufactured at a high temperature condition. Recycle of waste glass and regeneration of sludge sand and sediment are organically combined with breakthrough, bubbles are enclosed, independent and discontinuous, and the environment-friendly material can be used as building light-weight frame material, construction foundation material, and water quality purifying material.

Owner:苏州希克曼物联技术有限公司 +1

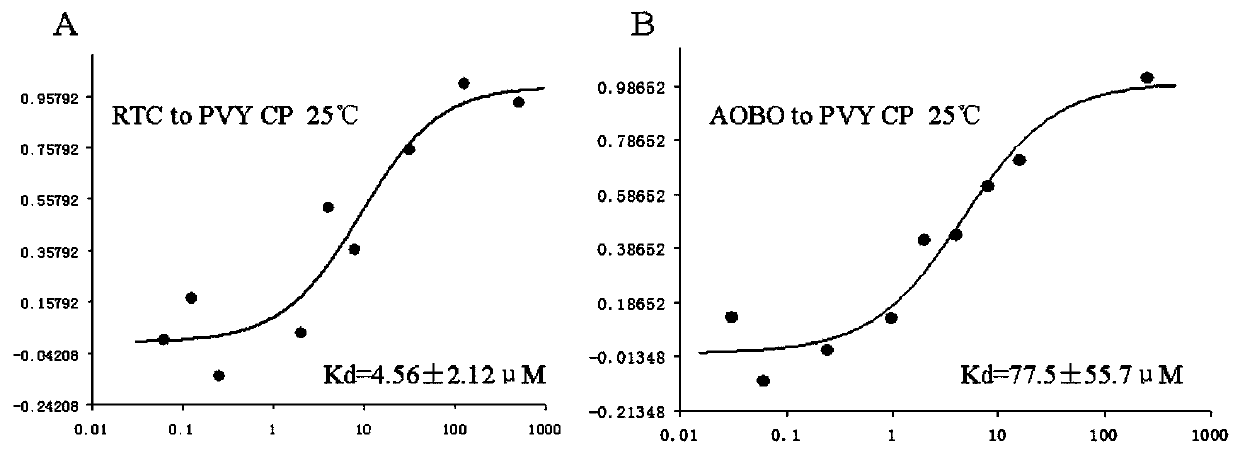

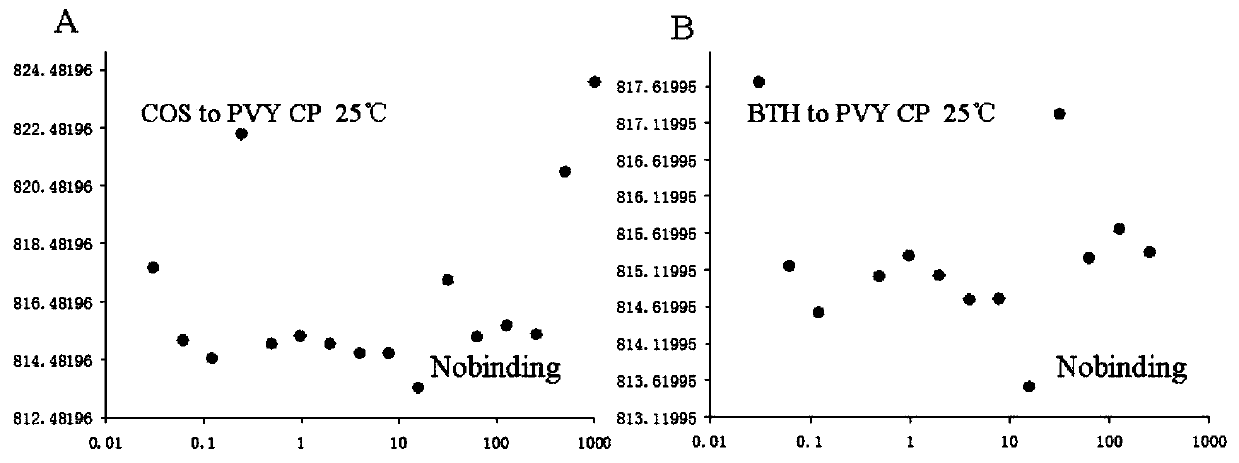

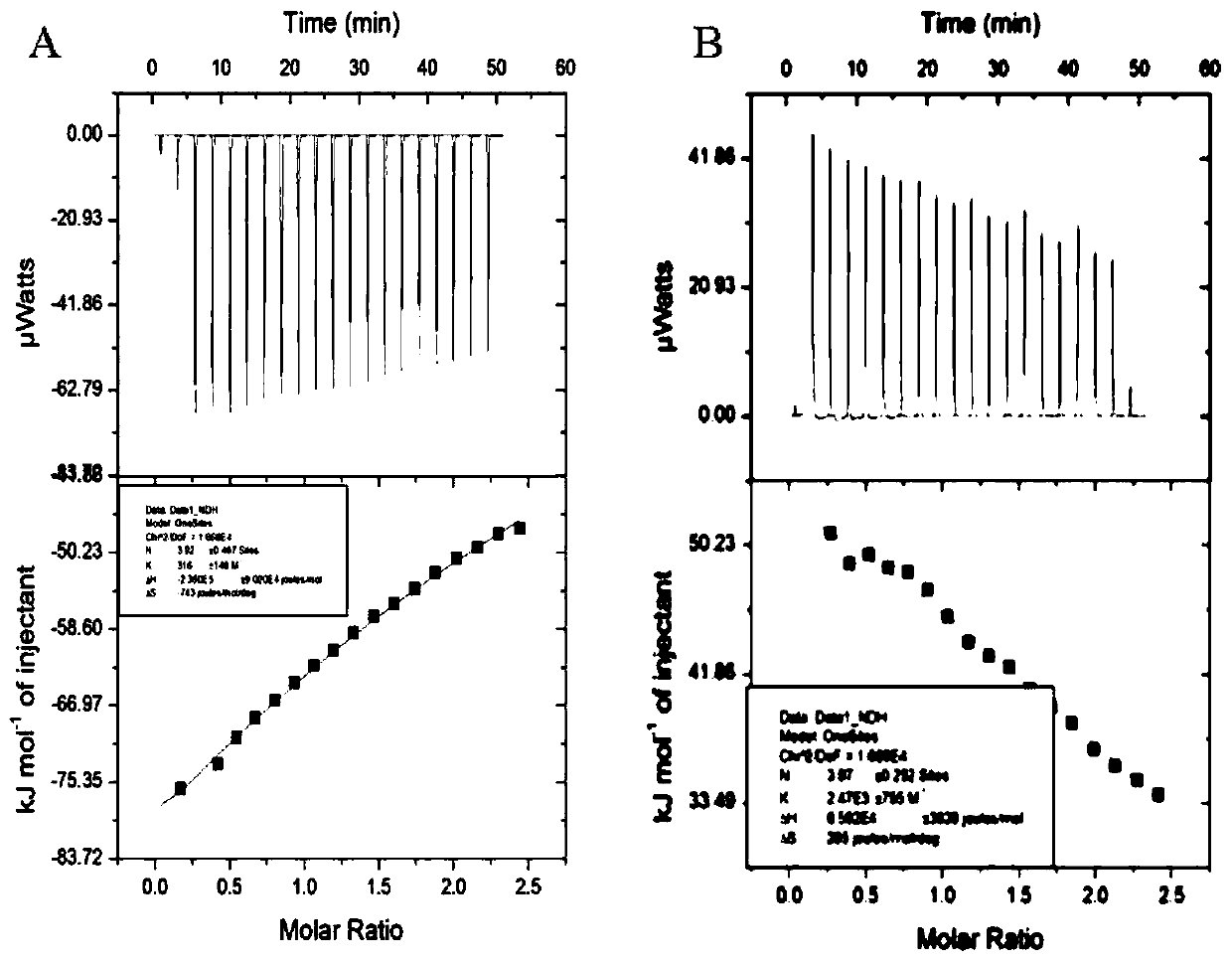

PVY-CP serving as target of drug for screening and treating potato Y virus and application thereof

The invention belongs to the field of gene function and application and relates to PVY-CP serving as a target of a drug for screening and treating potato Y virus and an application thereof. The invention provides the target of the drug for screening and treating the potato Y virus, wherein the target is potato Y virus coat protein, that is, PVY-CP. The invention also provides an application of thepotato Y virus coat protein, that is, the PVY-CP, serving as the target of the drug for screening and treating the potato Y virus. The invention further provides the drug for screening and treating the potato Y virus, wherein the drug takes the potato Y virus coat protein, that is, PVY-CP, as the target. For the action mechanism of the PVY-CP in the virus transmission process, the PVY-CP is usedas the target of potential antiviral agents for the first time; in vitro screening of drug active small molecules is conducted, and activity detection of small pharmaceutical molecules in live tobaccoplants is carried out; and a binding protein immunoblotting proves that the PVY-CP can serve as the target of the drug for screening and treating the potato Y virus.

Owner:GUIZHOU UNIV

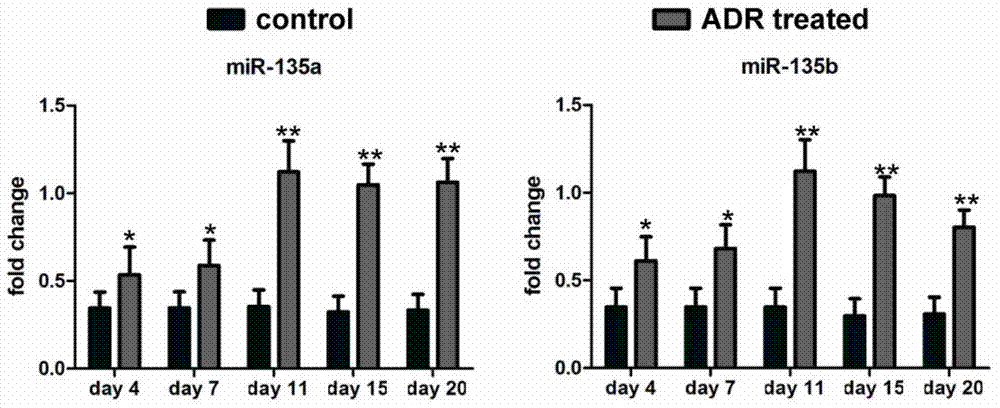

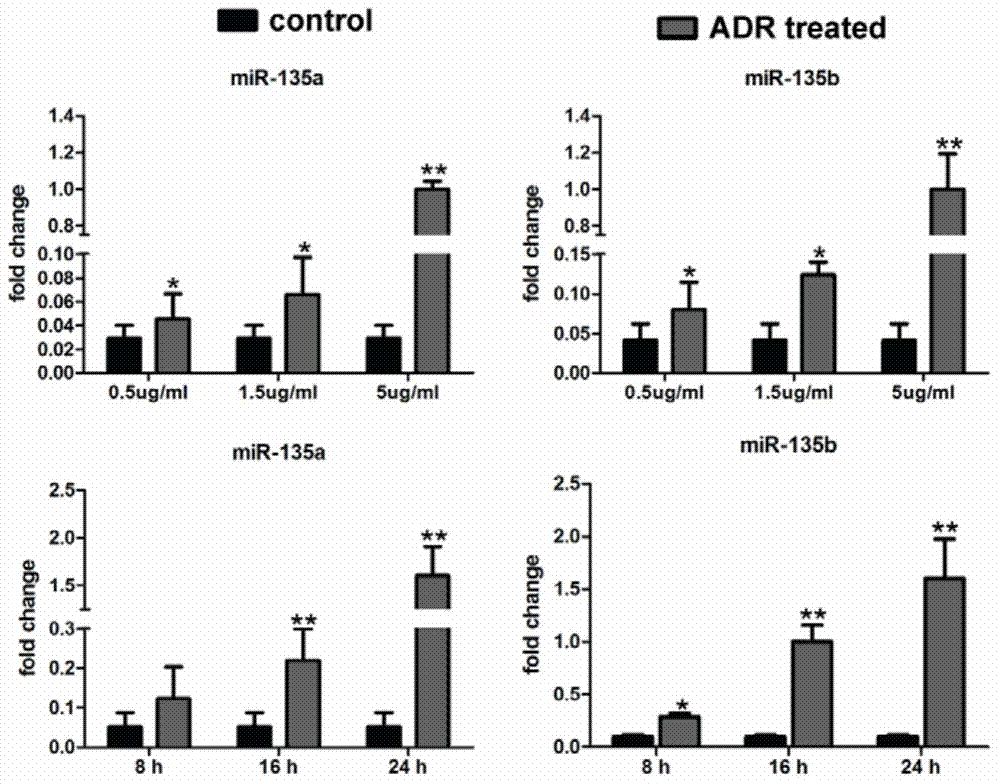

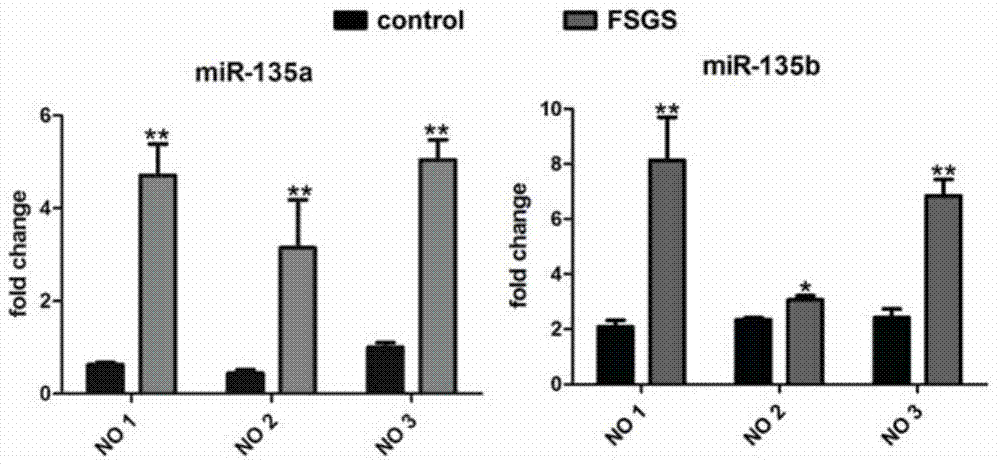

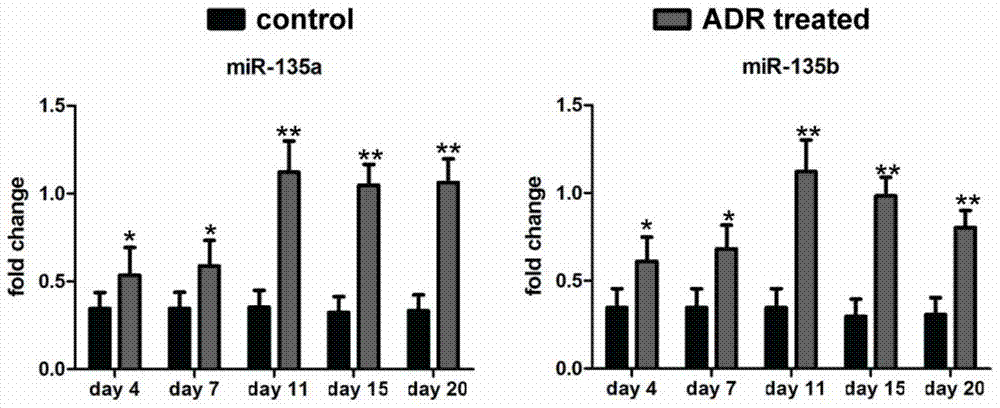

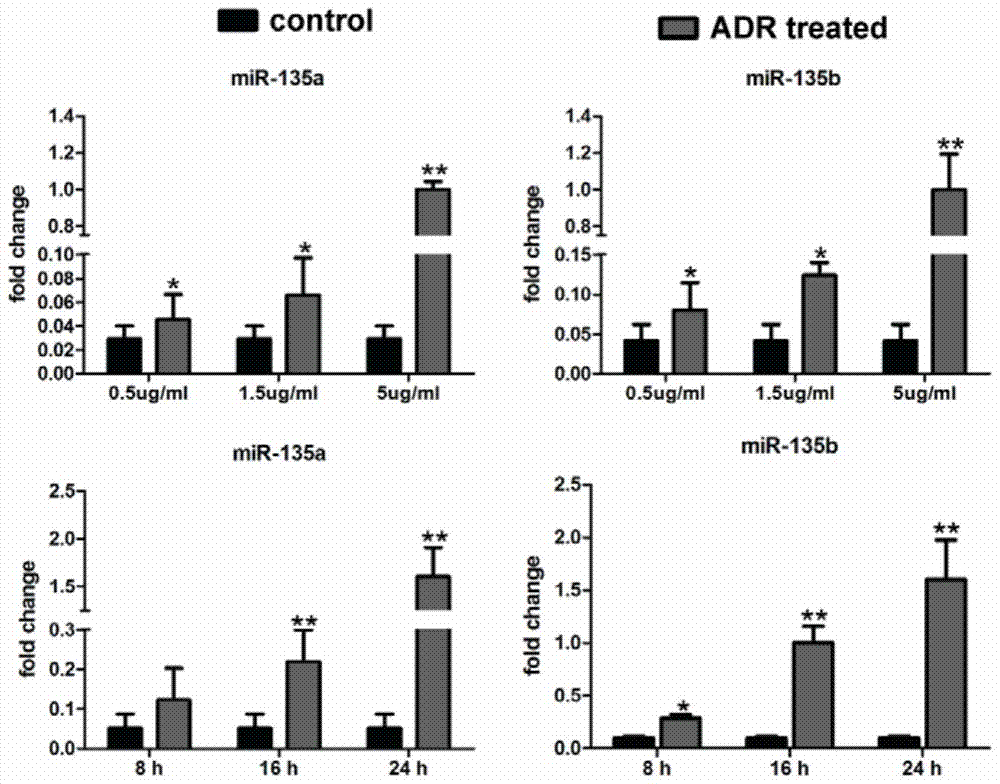

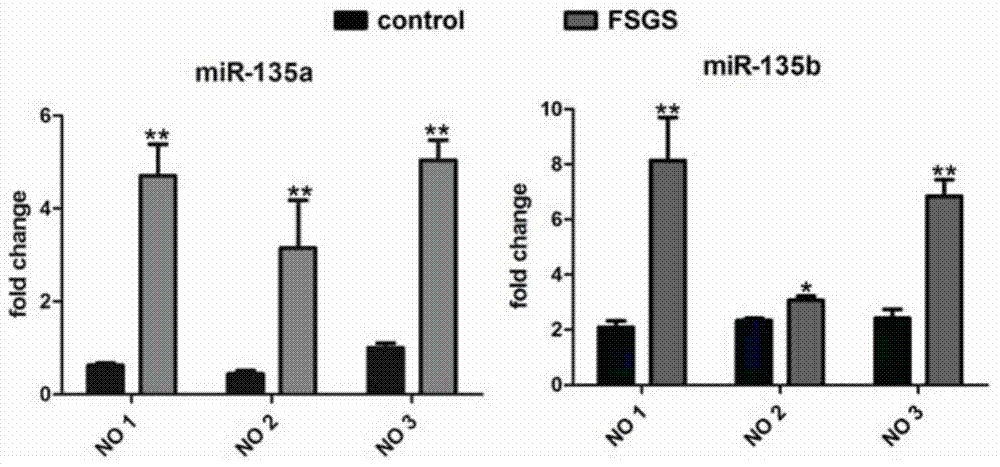

Purpose and relevant medicine of miR-135

InactiveCN104846102APrecise screeningImprove efficiencyOrganic active ingredientsGenetic material ingredientsScreen and treatCell injury

The invention relates to the field of biotechnology, in particular to a purpose and relevant medicine of miR-135. The invention discloses the dependency of the miR-135 and the foot cell injury for the first time, and discloses the capability of overexpression miR-135 to cause foot cell injury for the first time, and the process is more similar to the human disease causing process. A foot cell injury model has the sufficient foot cell injury typical features, can well simulate the occurrence and the development of foot cells in the body, and belongs to an ideal model of foot cell injury base and clinic application study, so that the miR-135 can be well applied to the medicine for screening and treating the foot cell injury.

Owner:CHONGQING MEDICAL UNIVERSITY

Contaminated soil stabilizing treatment device

InactiveCN106077059AImprove processing efficiencyEasy to handleContaminated soil reclamationSoil treatmentPollution soil

The invention relates to a contaminated soil stabilizing treatment device, which comprises a fine particle storage box with an upper opening, a conveyer shell and a coarse particle storage box with an upper opening sequentially arranged from left to right. A left guide frame is fixedly arranged on the left side of the upper part of the fine particle storage box; a right guide frame is arranged on the left side of the upper part of the conveyer shell; the height of the left guide frame is larger than the height of the right guide frame; a screening plate is arranged on the upper part of the fine particle storage box; matching shafts are arranged on two ends of the screening plate, and are respectively matched with the left guide frame and the right guide frame; a motor support frame is arranged on the left side of the fine particle storage box; a motor is arranged on the motor support frame; and an output shaft of the motor is connected to the center of a disk. The contaminated soil stabilizing treatment device provided by the invention can be used for screening and pre-treating contaminated soil, so that large caked soil is screened and treated, soil with smaller particles enters the next treatment process, and the soil treatment efficiency is improved.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

Fish farming pond garbage cleaning device

InactiveCN110140686ARealize solid-liquid separationEasy feedingPisciculture and aquariaEngineeringFish farming

The invention discloses a fish farming pond garbage cleaning device which can realize solid-liquid separation and can screen and treat garbage conveniently and rapidly. Larger garbage can be conveyedinto a second treatment cavity and treated, and the conveyed garbage can be crushed conveniently and rapidly. The device is provided with a conveying frame, a first servo electric cylinder, sliding rails, a discharging plate, a first limit plate and a second limit plate, the first servo electric cylinder is adjusted to extend and retract, the conveying frame can be conveyed into the second treatment cavity, the second limit plate limits the discharging plate, and the garbage falls into a receiving hopper from the conveying frame and can be conveyed conveniently and rapidly. By the aid of a second servo electric cylinder and a pressing plate, when the garbage is conveyed into the receiving hopper, the second servo electric cylinder is adjusted to be pushed downwards, the pressing plate canbe pushed to move downwards, and the garbage inside the receiving hopper is tightly pressed. By the aid of the receiving hopper in movable connection, the compacted garbage can be pulled out of a boxconveniently and rapidly.

Owner:徐海连

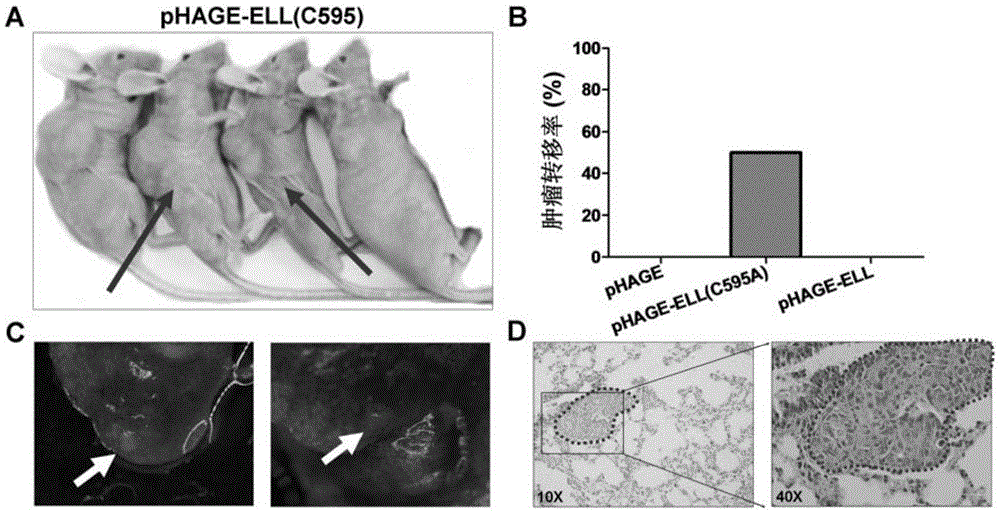

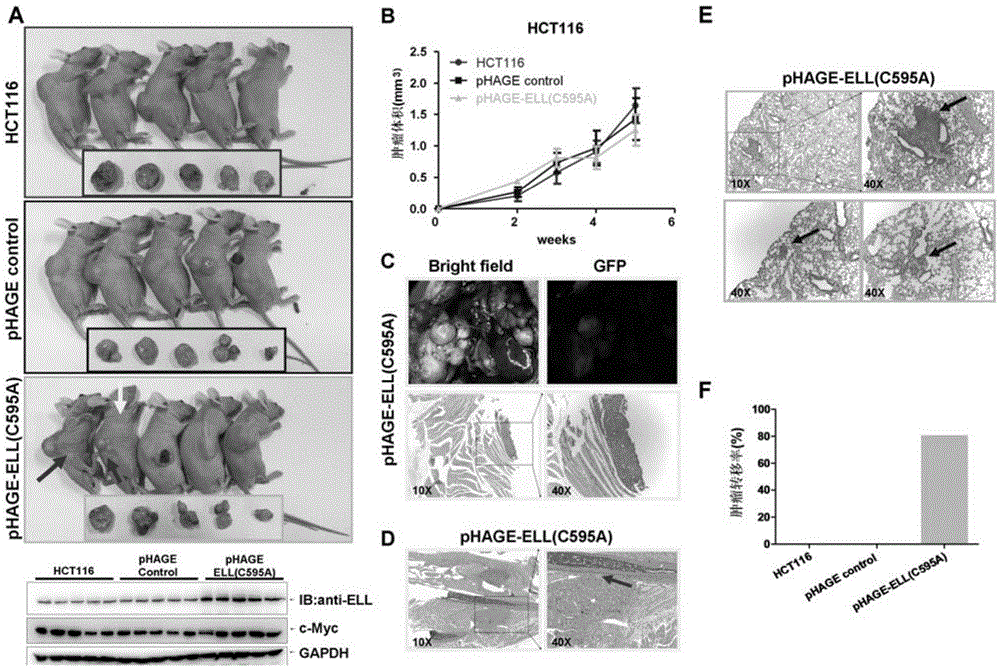

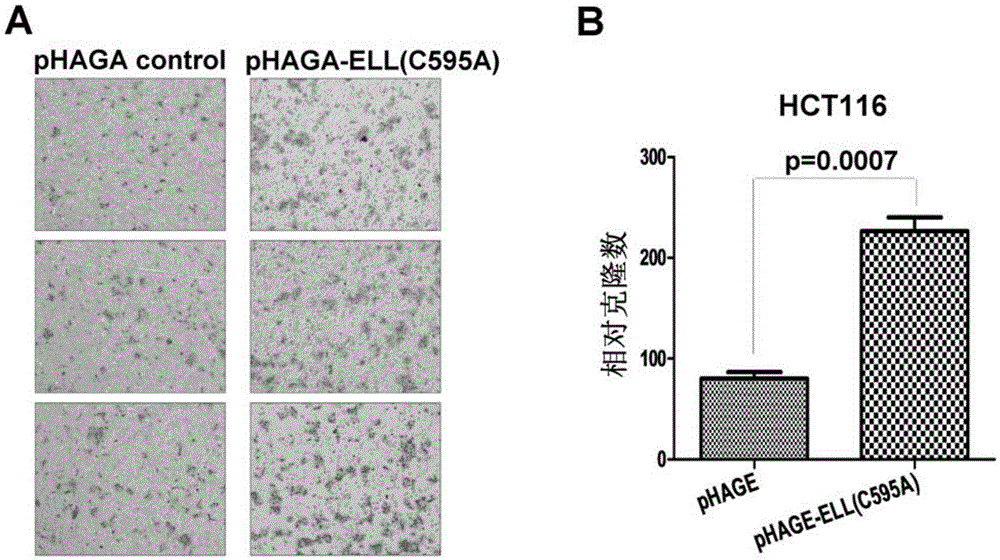

Application of ELL(C595A) mutant in promotion of tumor metastasis

ActiveCN105566487AIncrease aggressivenessPromote migrationAnimals/human peptidesLymphatic SpreadMutant

The invention discloses an application of an ELL(C595A) mutant in the promotion of tumor metastasis. The invention provides at least one applications of ELL(C595A) protein of (1) to (6): (1) preparing products that promote tumor metastasis; (2) preparing products that promote tumor cell migration; (3) preparing products that can improve the performance on resisting tumor cell invasion; (4) preparing products that can increase the gene expression related with tumor metastasis; (5) preparing animal models that are used to screen and treat tumor metastasis; (6) preparing animal models that are applied to researches on tumor metastasis mechanism. The inventor finds that ELL mutant namely ELL(C595A) protein can promote tumor metastasis and improve the performance on resisting tumor cell invasion; and moreover, the ELL(C595A) protein can be used to prepare animal models that are used to screen and treat tumor metastasis and animal models that are applied to researches on tumor metastasis mechanism.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Uses of mir‑135 and its related drugs

InactiveCN104846102BHigh sensitivityImprove accuracyOrganic active ingredientsMicrobiological testing/measurementScreen and treatCell injury

Owner:CHONGQING MEDICAL UNIVERSITY

A device for collecting and sieving frozen soil fragments in the Hopkinson test

ActiveCN106644697BAvoid secondary crushingHelps to movePreparing sample for investigationMaterial strength using single impulsive forceTemperature controlControl power

The invention relates to an apparatus for collecting and screening frozen soil fragments in a Hopkinson test. The apparatus comprises a protective cover which comprises an external layer semicircular protective cover and an internal layer semicircular protective cover by low temperature strong glue bonding; the protective cover is connected to a bracing frame and an internal layer slide plate by a loose-leaf hinge and a positioning pin; air vents are arranged at the lower part of the bracing frame, a channel section is arranged on the bracing frame, and a katathermometer is internally arranged in the bracing frame; a temperature control test box and a protective cover are respectively provided with a pole hole and a rotating wheel hole for a Hopkinson pressure bar and a soil scraping rotating wheel to pass through; the channel, a screw and a support bar are used for connecting the bracing frame and an electric vibrating screen; a control power supply is arranged outside a test box with controllable temperature; a temperature control system is used for controlling the temperature of the test box with controllable temperature. The apparatus can prevent secondary fragmentation of frozen soil fragments, and more frozen soil fragments are collected as possible. The frozen soil fragments are screened and treated at first time after the test, and accuracy of test data is improved.

Owner:ANHUI UNIV OF SCI & TECH

A kind of Schistosoma japonicum recombinant protein sjsaplp5 and its coding gene and application

ActiveCN105254732BImproving immunogenicityGood antigenicityBiological material analysisAntiparasitic agentsDrug effectImmunogenicity

The invention provides a schistosoma japonicum katsurada recombinant protein SjSAPLP5 as well as an encoding gene and an application thereof. The protein provided by the invention has amino acid sequence as shown in SEQ ID No.2 or has amino acid sequence which is formed by replacement, deletion and / or addition of one or more of amino acid residues and has the same function. The invention also provides the encoding gene for encoding the protein. The recombinant protein SjSAPLP5 provided by the invention is excellent in immunogenicity, can be served as an excellent diagnosis antigen, is used for preparing a schistosoma japonicum katsurada diagnostic kit with high sensitivity and high specificity, and is also used for preparing an anti-schistosome vaccine and the drug served as a potential drug effecting target spot and is used for screening and treating the schistosoma japonicum katsurada diseases.

Owner:INST OF PATHOGEN BIOLOGY CHINESE ACADEMY OF MEDICAL SCI

Construction waste disposal device

InactiveCN109909260ALow running costGood coordination of power supply and demandSteam generation heating methodsConstruction waste recoveryHigh pressureWaste treatment

The invention relates to a construction waste disposal device. The construction waste disposal device comprises an incineration box, wherein a steam storage tank and an incineration waste treatment box are arranged on the right side of the incineration box, the steam storage tank is connected with a steam preparation tank of the incineration box through a high-pressure pipeline, an L-shaped solardevice is arranged on the left side of the steam preparation tank, a photovoltaic panel is arranged on the upper end surface of the L-shaped solar device, an energy storage battery connected with thephotovoltaic panel is arranged in the bottom end of the L-shaped solar device, and a controller is arranged in the steam preparation tank. According to the construction waste disposal device, the steam storage tank, an one-way input port and the incineration waste treatment box are arranged, so that steam storage and steam one-way input are facilitated, and incineration wastes are screened and treated; the L-shaped solar device is adopted for power supply, the photovoltaic panel converts solar energy into electric energy which is then stored in the energy storage battery, and the energy storage battery supplies power to the construction waste disposal device through the controller; and the construction waste disposal device has the advantages of being low in operation cost, good in power supply and demand coordination performance, convenient to operate and the like.

Owner:张强

Treatment device for alcohol production waste liquid

InactiveCN108499217AThe operation process is simple and convenientGood processing effectFiltration circuitsLiquid wasteRotational axis

The invention discloses a treatment device for alcohol production waste liquid. The treatment device structurally comprises a convenient and fast waste liquid treatment mechanism, a linking lock, an upper end cover, a built-in lock, a first sealing plate, a second sealing plate and castors. Waste liquid is screened and treated by virtue of mutual cooperation of a screening mechanism and a pulley connecting mechanism, meanwhile, suspended solids in waste clear liquid are further separated by virtue of an optimal stirring mechanism and an optimal cleaning mechanism, finally the waste liquid is settled by virtue of a settling tank and can be utilized after reaching the standard, so that the operation process is simple and convenient, equipment is safe and reliable, and the treatment effect isgood; by starting a motor is to work, a first rotating shaft is driven to rotate, a disc-shaped cam is driven to rotate by virtue of the first rotating shaft, a contact rod is driven to move left andright during the rotation of the disc-shaped cam, a first sliding block is driven to move left and right during the left-right movement of the contact rod, a net plate can be driven to move left andright during the left-right movement of the first sliding block, and the waste liquid can be adequately screened by virtue of the left-right movement of the net plate.

Owner:FOSHAN GUANGXIE ENVIRONMENTAL PROTECTION TECH CO LTD

Process method for refining sand by recycling sludge

InactiveCN105601060AAchieve water retentionImprove breathabilitySludge treatmentGlass shaping apparatusPowder mixtureSludge

The invention discloses a process method for refining sand by recycling sludge. The method comprises the following steps: glass fragments are grinded and treated, in order to manufacture glass powder of micron particle size; glass powder as well as sludge sand and sediment which are produced by dehydration, desiccation and burning from a sewage treatment plant are mixed according to a proportion of 35-80:1-10 in parts by weight, grinding is carried out, and a primary powder mixture is obtained; the primary powder mixture is screened and treated, and the screened primary powder mixture composed of glass powder as well as sludge sand and sediment is added into a mixing and stirring device; 5-20 parts of clam shells and 1-15 parts of vermiculite powder are added into the mixing and stirring device in the step 4, mixing and stirring are carried out for the clam shells, the vermiculite powder, the glass powder, and the sludge sand and sediment, and mixed power is formed; the mixed power is added into a sintering furnace, and the porous environment-friendly material is manufactured at a high temperature condition of 600-900 DEG C. Recycle of waste glass and regeneration of sludge are organically combined with breakthrough, and the environment-friendly material can be used as building light-weight frame material, construction foundation material, water quality purifying material, and artificial floating island.

Owner:TIANHE AUTOMATION TECH SUZHOU +1

Method and Application of Discriminating and Processing the Output Signal of Lanthanum Bromide Gamma Spectrometer

The invention discloses a method for screening and treating output signals of a lanthanum bromide gamma spectrometer and application thereof, wherein the output signals are radiation signals of gamma ray and alpha particles. The method for screening and treating the output signals of the lanthanum bromide gamma spectrometer includes the steps of: using the lanthanum bromide gamma spectrometer to detect the radiation of an object to be detected so as to obtain the output signals; analyzing the output signals so as to obtain characteristic quantity of the gamma ray and characteristic quantity of the alpha particles; obtaining a distribution diagram of the characteristic quantity of the gamma ray and the characteristic quantity of the alpha particles along with energy based on the characteristic quantity of the gamma ray and the characteristic quantity of the alpha particles; and distinguishing the radiation signals of the gamma ray and the alpha particles in the output signals based on the distribution diagram, and obtaining an energy spectrum measurement value gamma[measurement] of the gamma ray and an energy spectrum measurement value alpha[measurement] of the alpha particles. The method can simply and effectively distinguish the radiation signals of the gamma ray and the alpha particles in the output characteristic quantity signals.

Owner:TSINGHUA UNIV

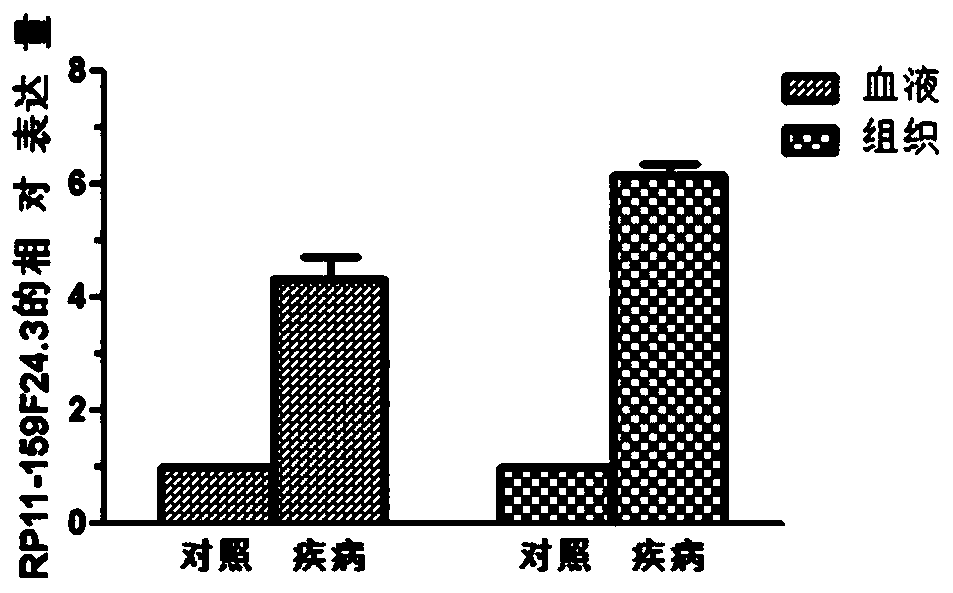

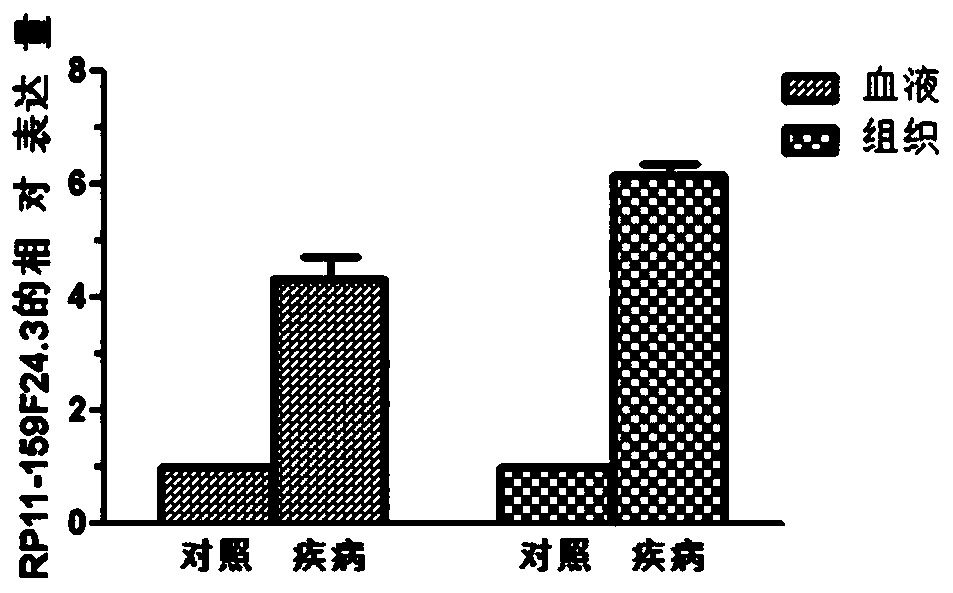

Application of lncRNA to preparation of products for diagnosing and/or treating osteoarthritis

ActiveCN111154863AOrganic active ingredientsGenetic material ingredientsScreen and treatCancer research

The invention provides an application of lncRNA to preparation of products for diagnosing and / or treating osteoarthritis, specifically provides an application of lncRNA RP11-159F24.3 to preparation ofproducts for diagnosing and / or treating osteoarthritis, and further provides an application of the lncRNA RP11-159F24.3 to candidate medicines for screening and treating the osteoarthritis.

Owner:XIAN HONGHUI HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com